Patents

Literature

72results about How to "Delay in construction investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

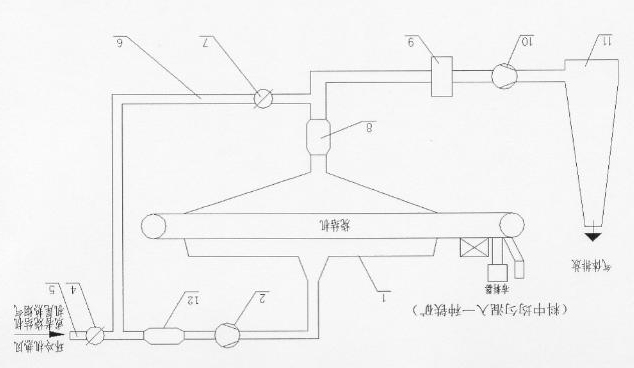

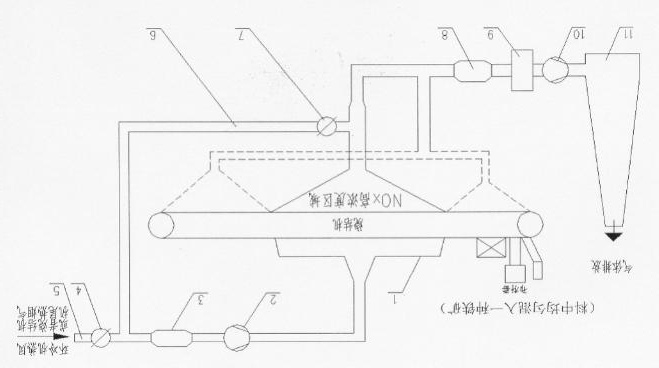

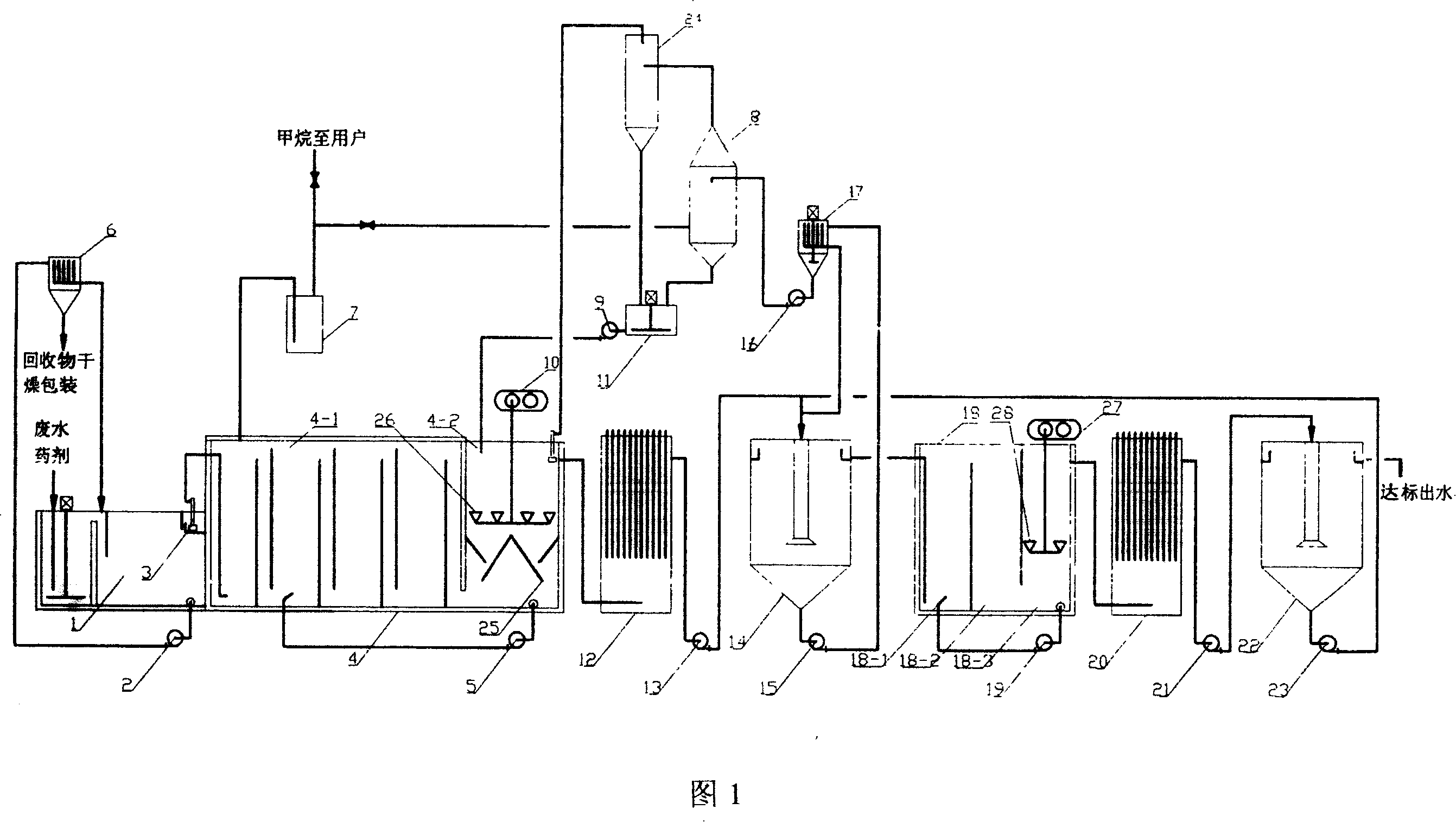

Emission reduction system of sintered fume nitric oxide with low energy consumption and method thereof

InactiveCN101829481ASimple systemSimple operation management and maintenanceDispersed particle separationNitric oxideHigh concentration

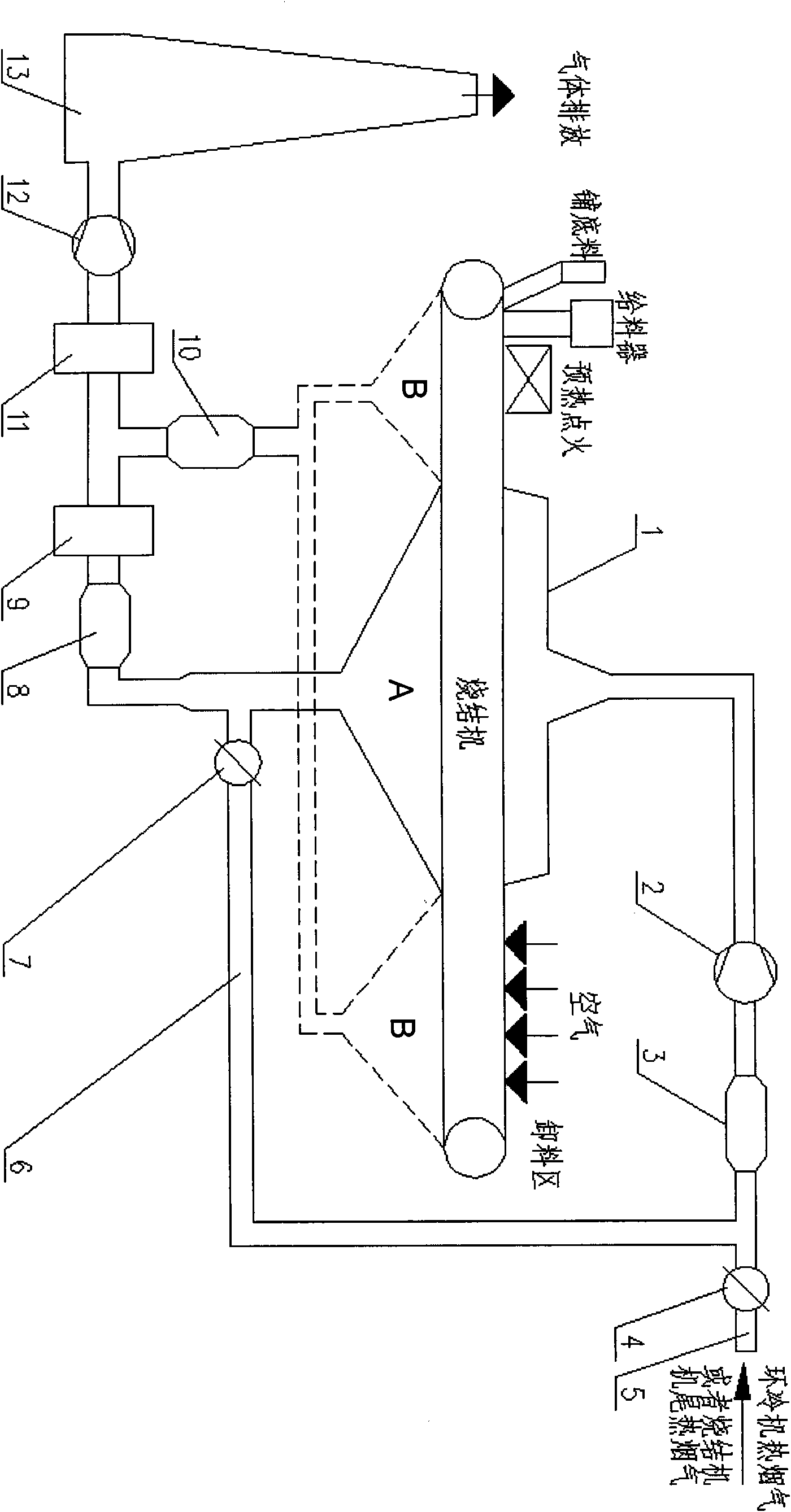

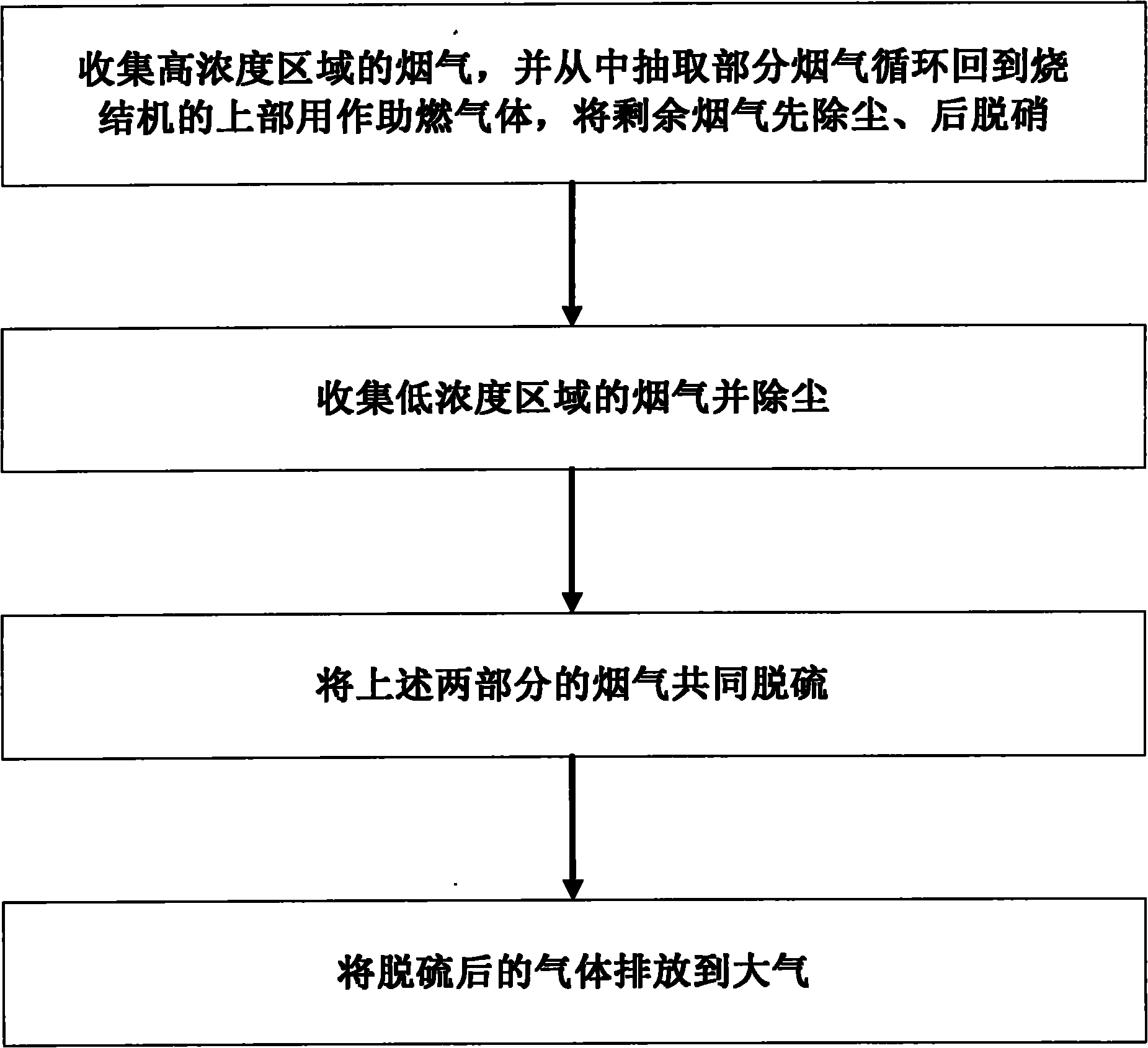

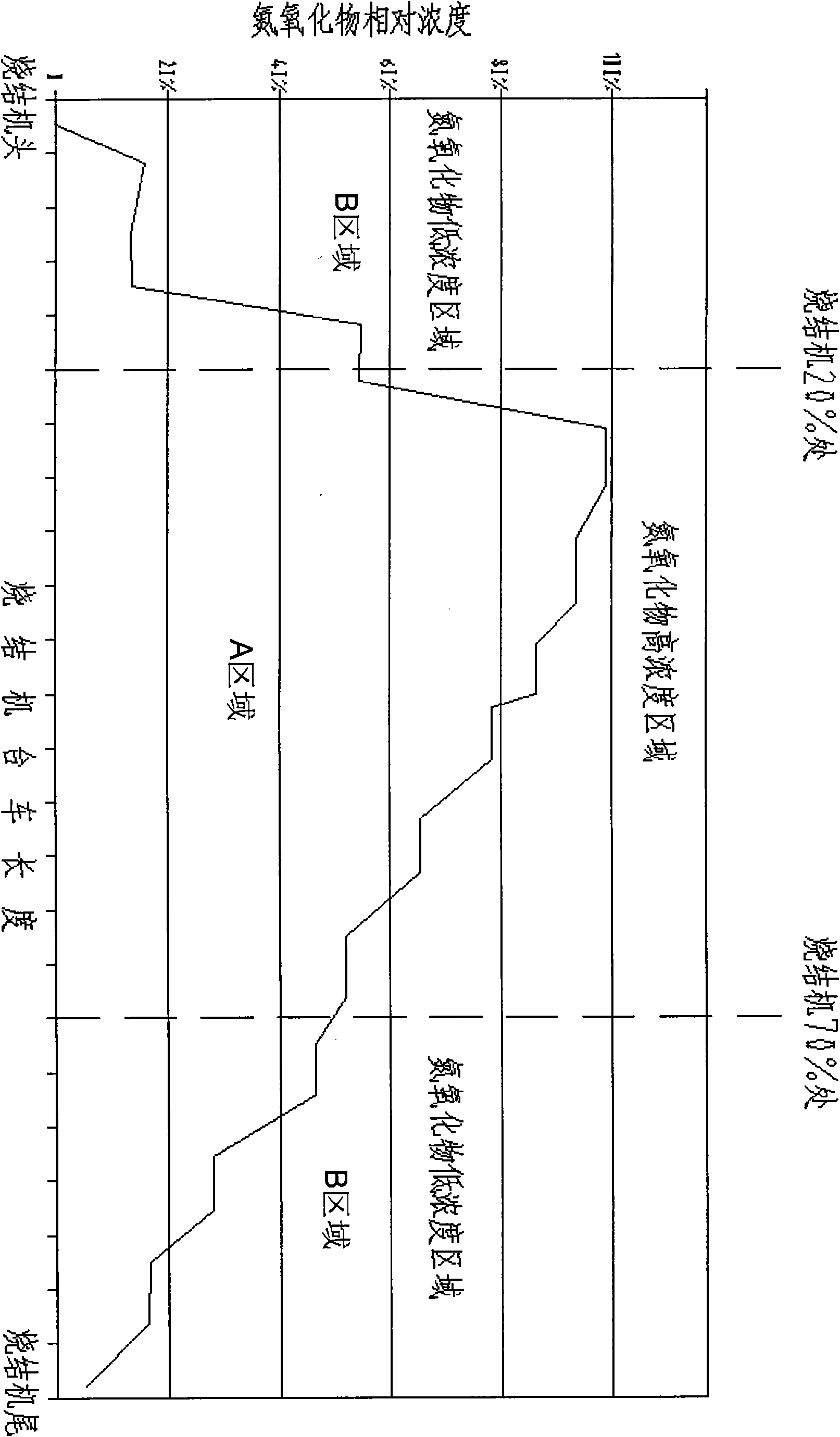

The invention relates to an emission reduction system of sintered fume nitric oxide with low energy consumption and a method thereof. The system comprises a nitric oxide high-concentration region air bellow A, a nitric oxide low-concentration region air bellow B, a denitration dust remover, a denitration device, a dust remover, a desulfuration device, a main exhaust fan, an emission chimney and a circulation loop. The denitration dust remover is connected with the air bellow A to collect the fume in the air bellow; the denitration dust remover is sequentially connected with the denitration device and the desulfuration device; and the fume subjected to dust removal and denitration is guided into the desulfuration device. The dust remover is connected with the nitric oxide low-concentration region air bellow B to collect the fume; the dust remover is connected with the desulfuration device; and the fume subjected to dust removal is guided into the desulfuration device. The desulfuration device is sequentially connected with the main exhaust fan and the emission chimney so as to desulfur the fume and discharge into the atmosphere. The circulation loop at least comprises a circulation fume hood, a circulation blower, a circulation fume dust remover and a circulation pipeline. The method comprises the following steps of collecting fume, removing dust, denitrating, desulfuring, discharging fume into the atmosphere and the like. The whole system is relatively simple and has obvious effects of energy saving and emission reduction.

Owner:BAOSTEEL ENG & TECH GRP

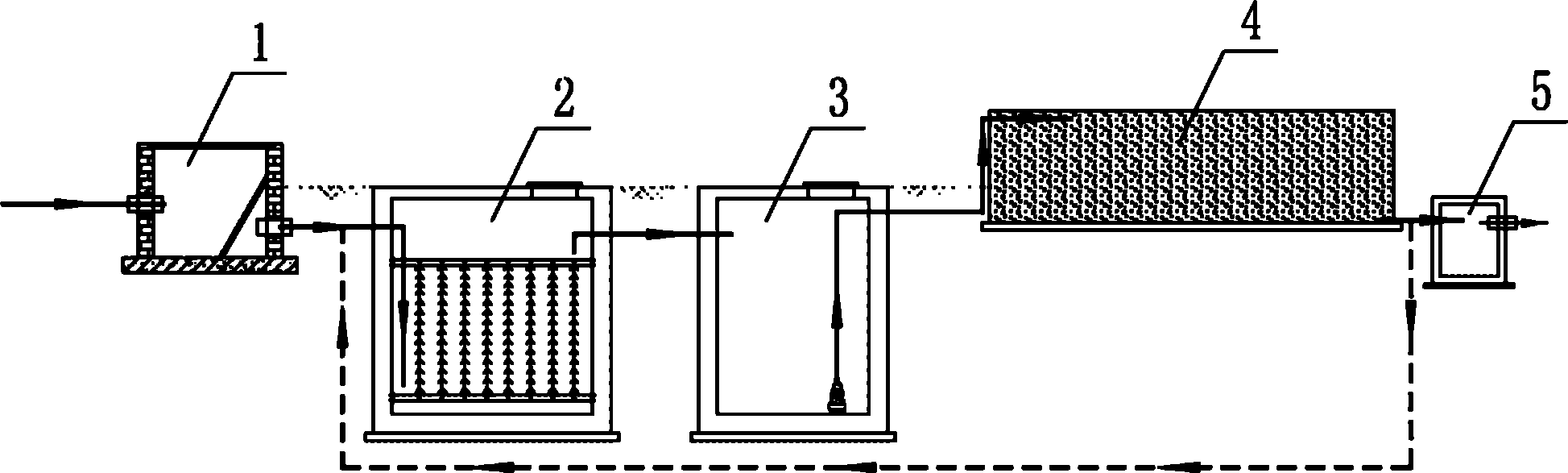

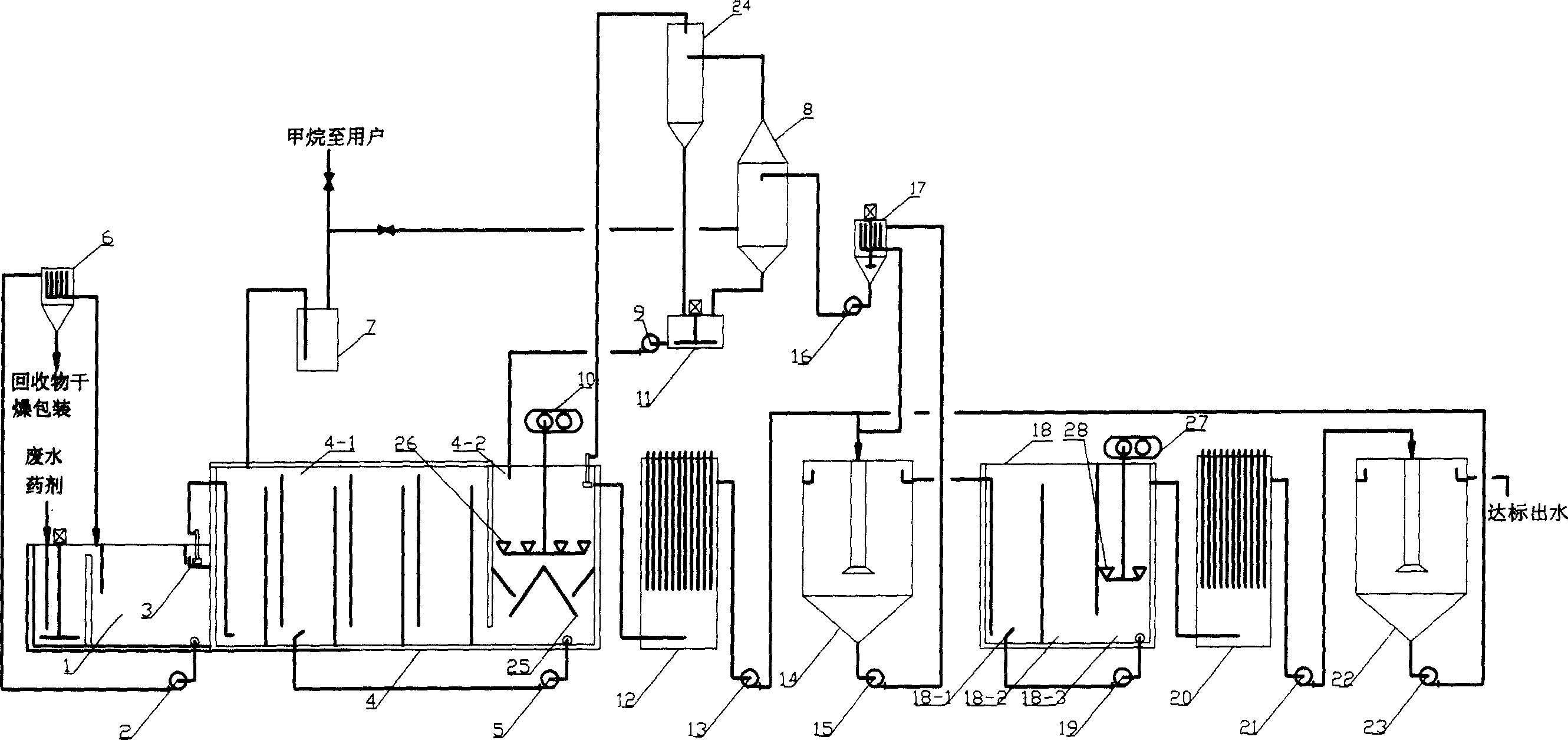

Method for controlling oil-bearing waste water

InactiveCN1367146AIncreased chance of collisionLow costMultistage water/sewage treatmentFlocculationDemulsifier

A technological process for treating oily waste water in oil field does not adopt the biological technology with harsh requirement, and directly utilizes the intensified demulsifier to make intensified demulsification of waste water in which the oil must be intercepted and sand must be removed, then adopts the air-float process to directly make oxidation reduction reaction and flocculation adsorption action, then utilizes several filtering media to make complete filtration so as to implement waste water discharge reaching the standard.

Owner:吴振庭

On-line assembling entirety on-position assembling method of edge mill

ActiveCN101391267ADelay in construction investmentReduce installation costsMetal rolling stand detailsMetal rolling arrangementsEngineeringBuilding design

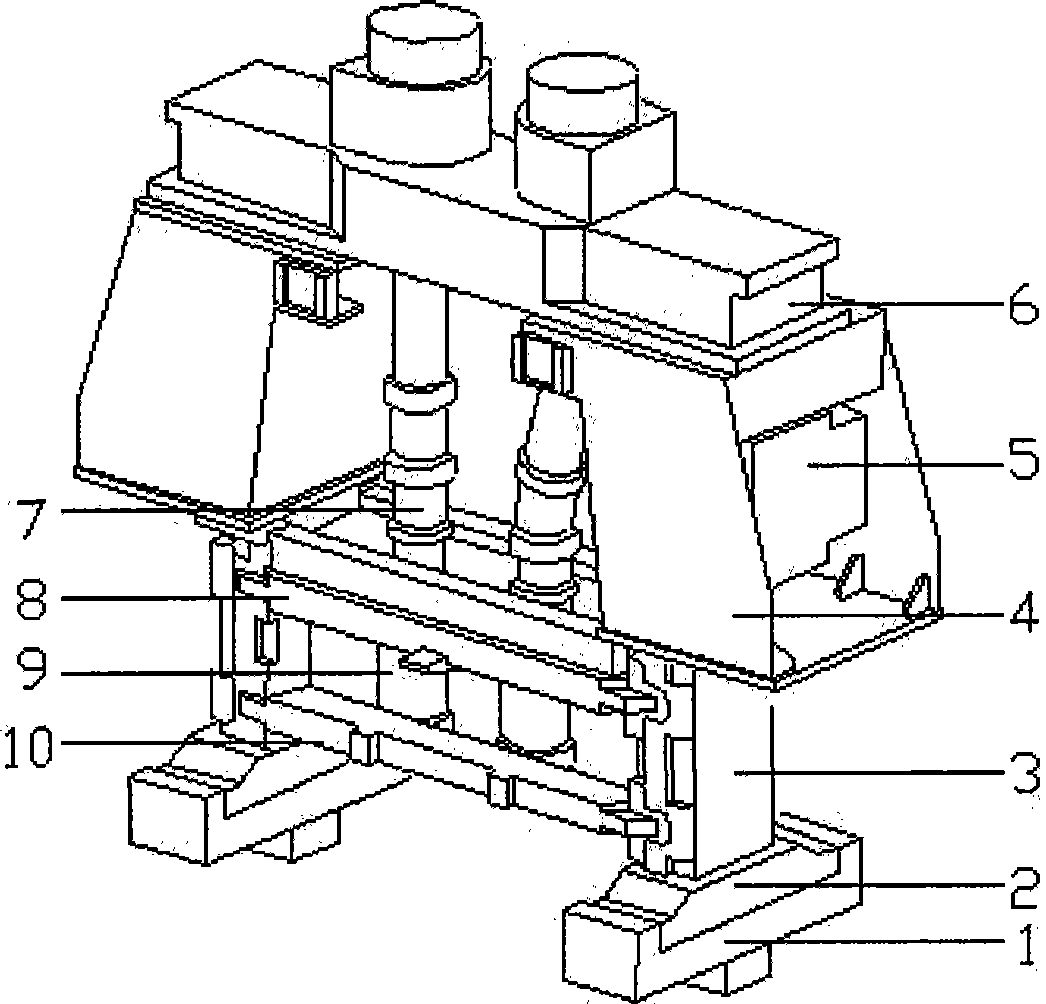

The invention relates to a method for the integral falling installation of on-line assembly of a vertical miller, belonging to the technical field of installation of large-sale equipment. The installing steps comprise the installation and transverse alignment of the soleplate of the vertical miller, the arrangement of an assembling and falling device, the assembly of an upper beam and a lower beam of a stander outlet, the slippage of a stander torii, the assembly and fixation of an upper beam and a lower beam of a stander inlet; the integral falling installation position of the stander and the installation of a rolling mill transmission device. The invention has the advantages that a special lifting device is not needed to be manufactured; the architecture design of workshops is not needed; the constructing investment is not increased; a field for building a precision assembly platform is not needed to be reserved in a main workshop; the time for the vertical miller equipment to enter the arena is not limited, so the installation cost can be greatly reduced, the labor intensity is lightened, and the time limit for the installation is shortened; and the invention is applied to the projects of installation and repairing of vertical millers attached to hot plate or band roughing mills.

Owner:BEIJING SHOUGANG CONSTR GROUP +1

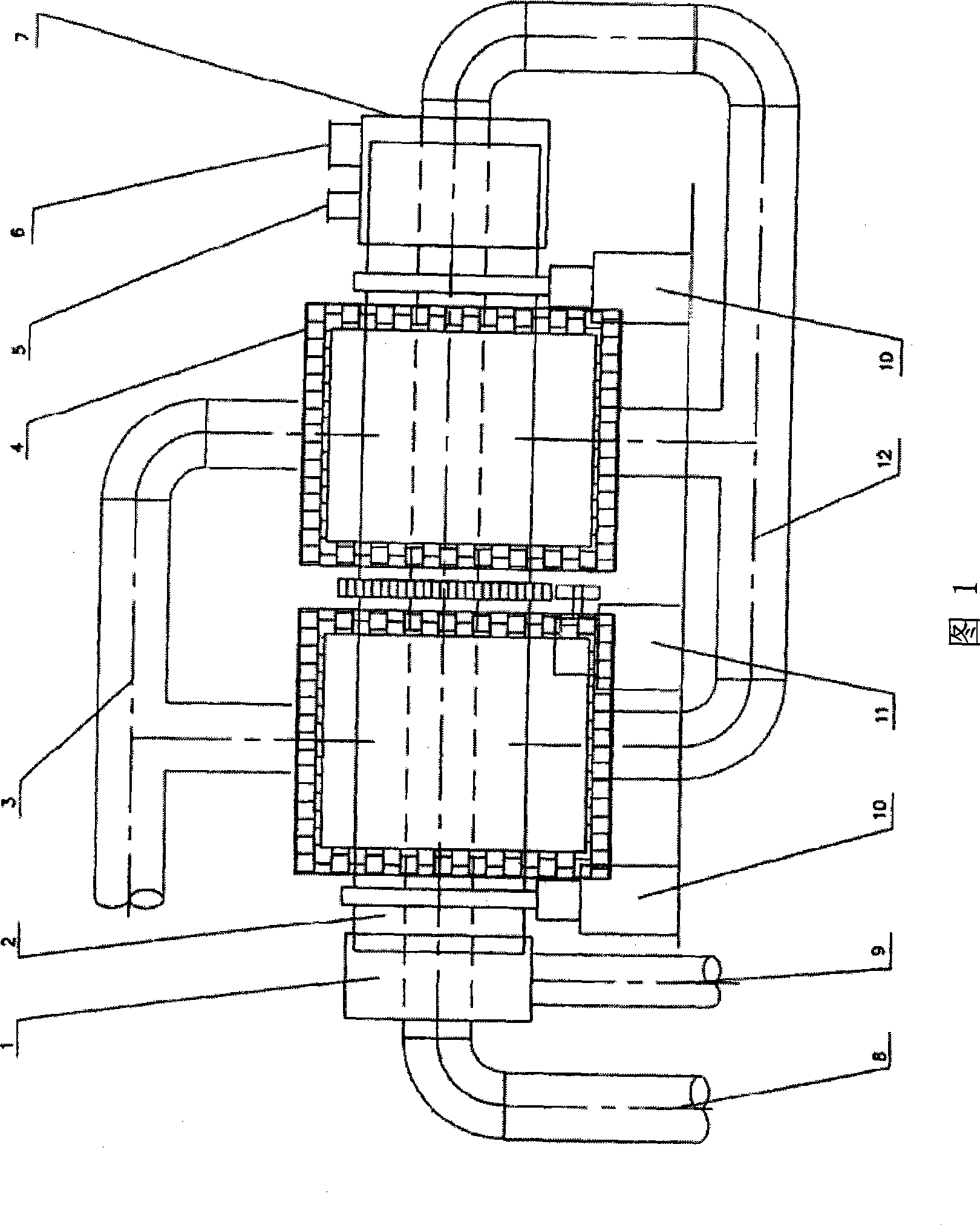

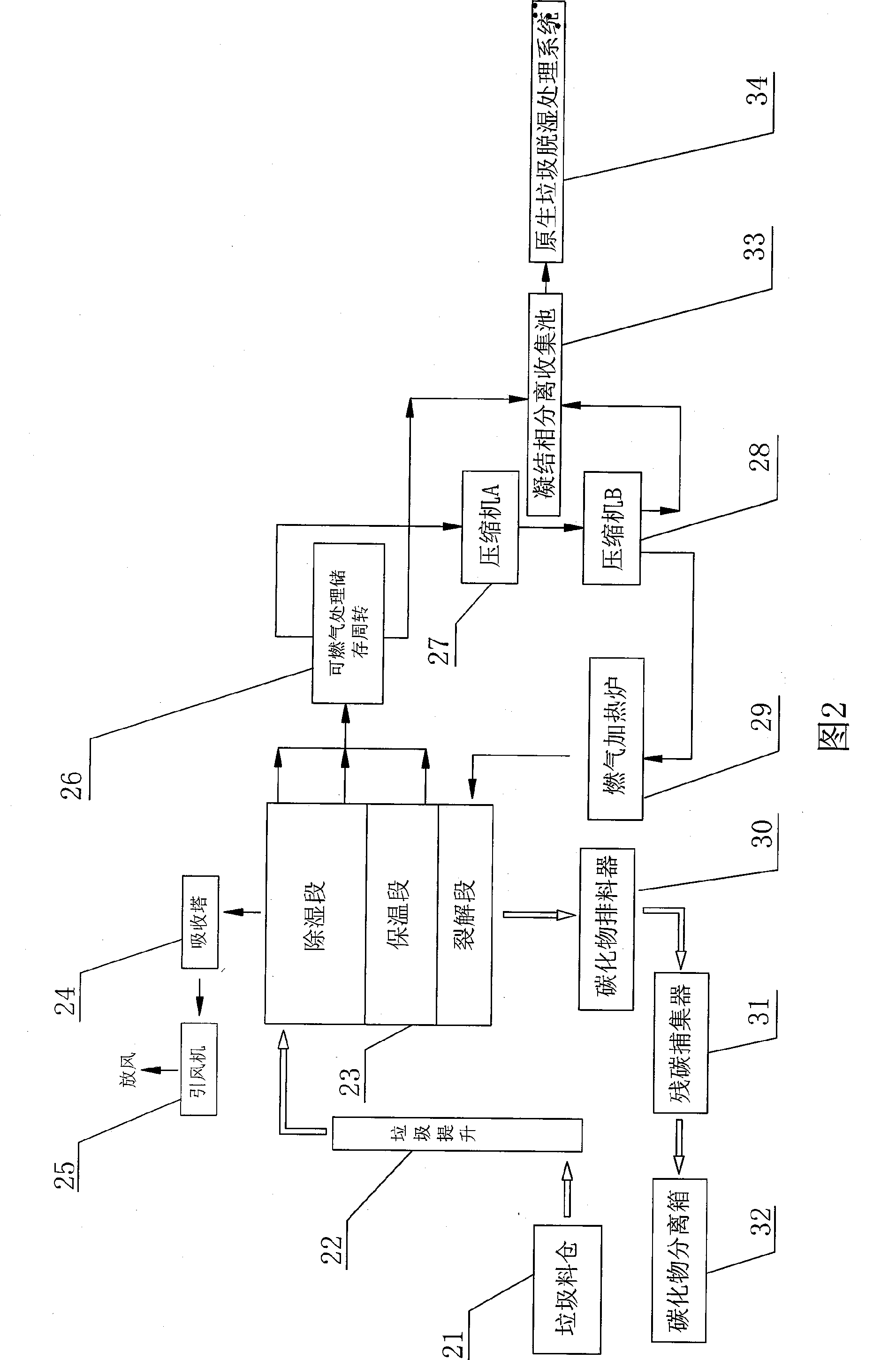

No-oxygen pyrolysis gasification processing device of urban domestic garbage and technique thereof

The present invention discloses a city domestic rubbish anaerobic schizolysis gasification processing apparatus and technical skill thereof, wherein the apparatus is composed by a rubbish storage hopper, a converting kiln, a compressor, an organic matter converting kiln and a sewage disposal system etc. The technical skill includes no exogenous source low energy consumption dispose and system secondary pollution control technique etc. Technical problems like system oxygen exhaust technology, domestic rubbish dehumidifying technology, flowing technology of solid material inside the system, heating technology during the process etc. are solved through the invention. Harmlessness and zero discharge, energy self-supply and basic energy source and substance recirculation in the process of production, social low cost input and facilitating operation of rubbish treatment, and every saving, exhaust reducing and material cycle in natural world can be realized.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

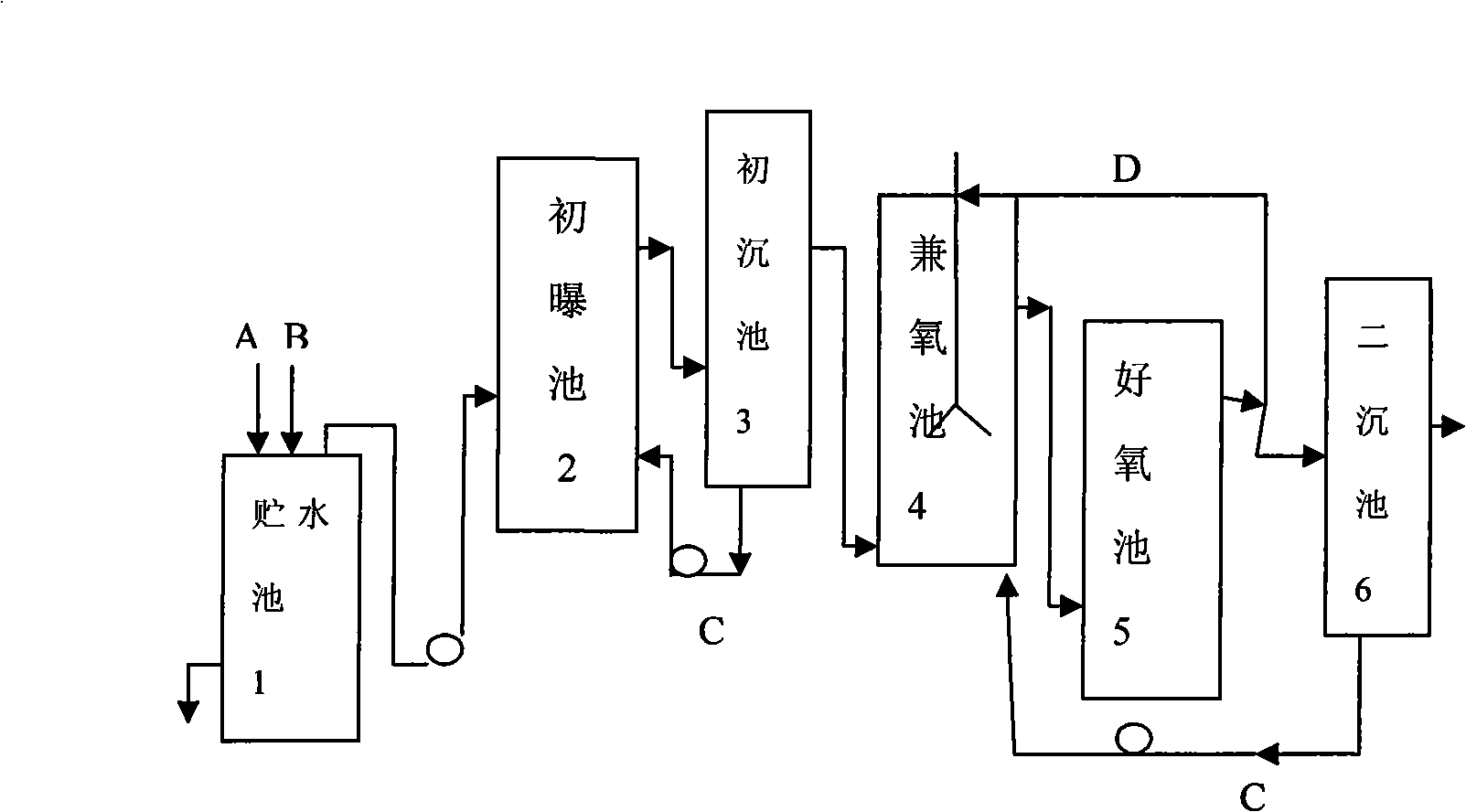

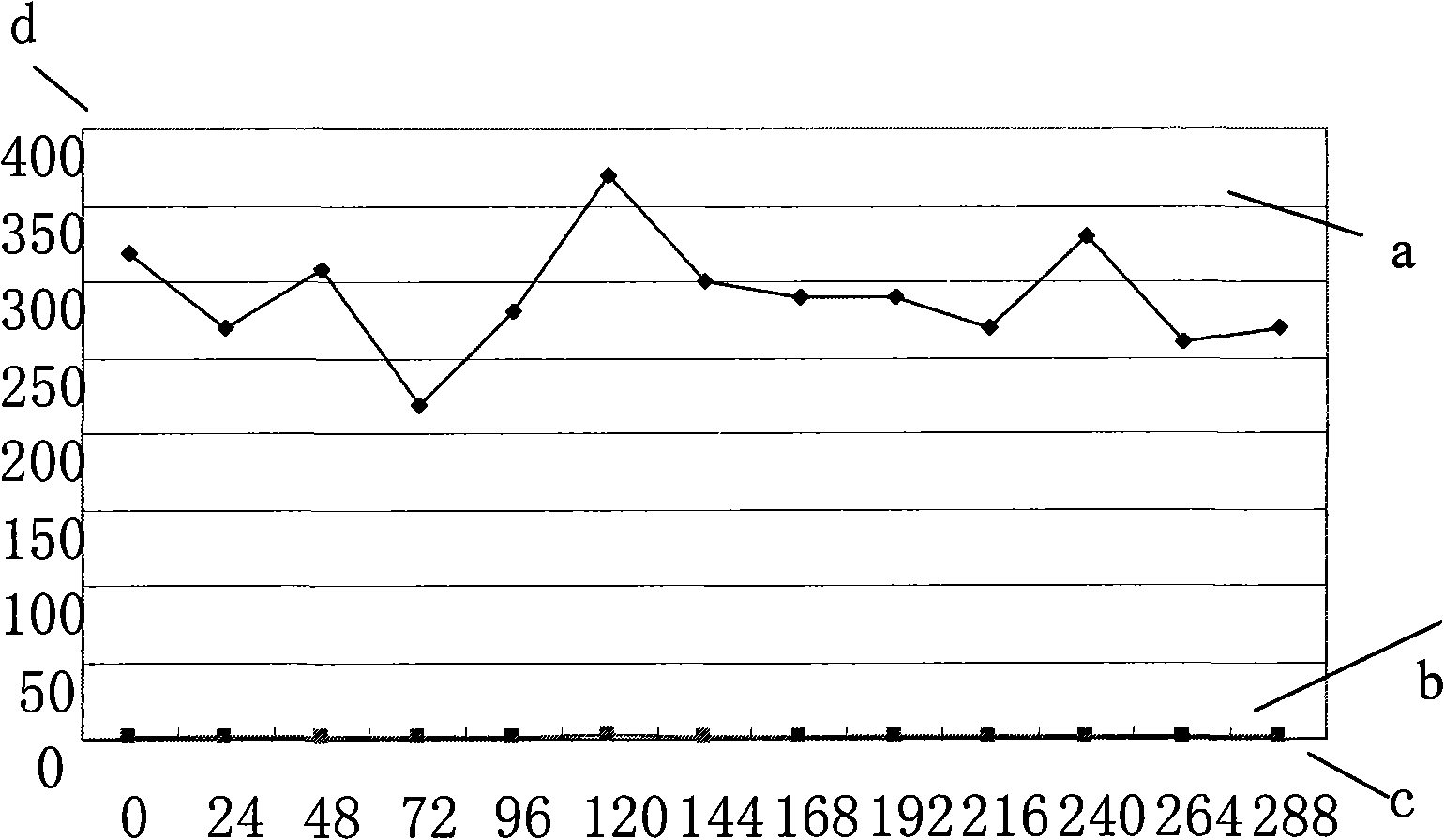

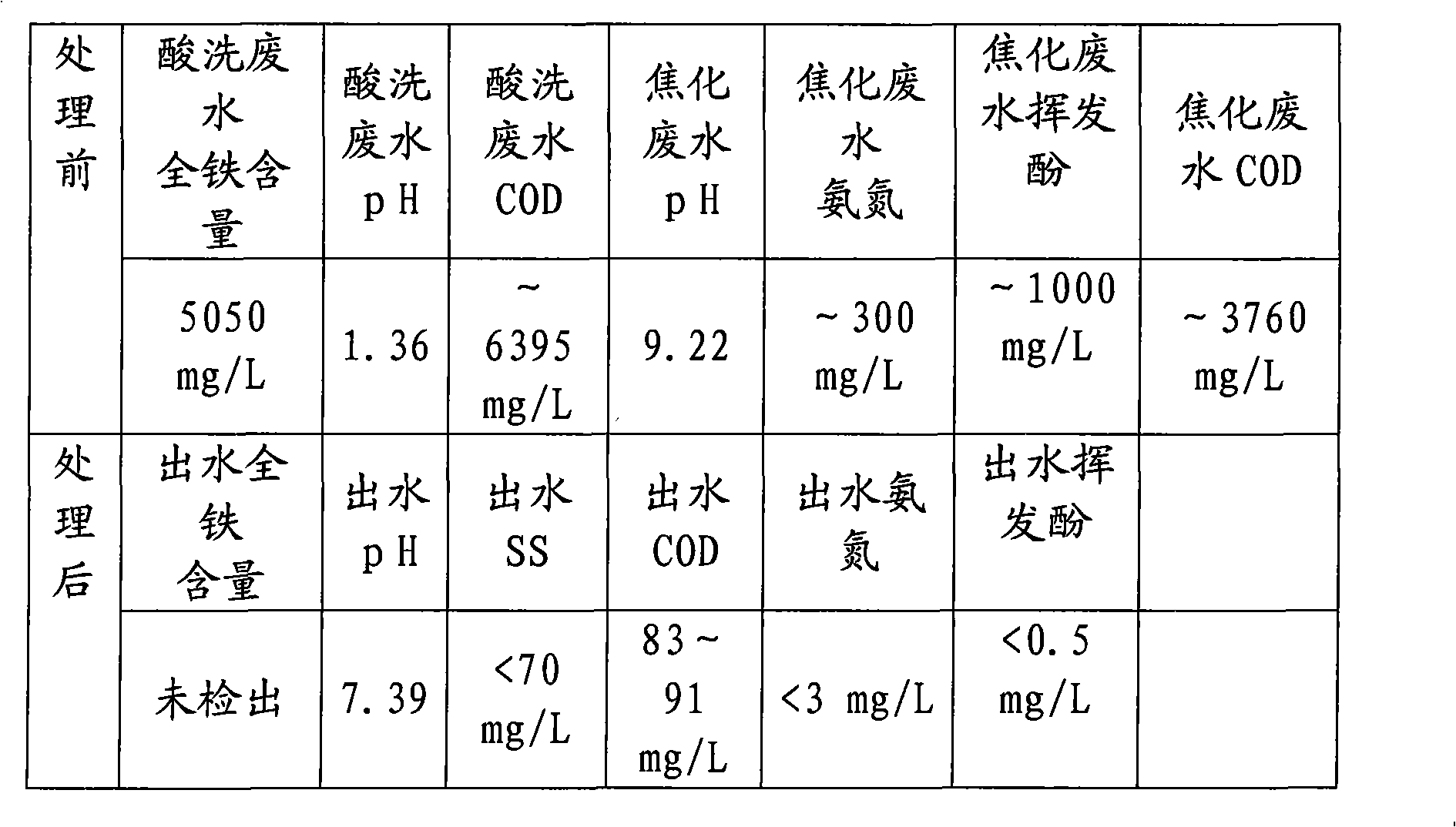

Method and device for synchronously treating steel pickling waste water and coking waste water

ActiveCN101259978AReduce investmentSimple processWaste water treatment from metallurgical processMultistage water/sewage treatmentCoking wastewaterCoke wastewater

The invention relates to a method for processing pickling wastewater and coking wastewater in steel industry synchronously and a device to carry out the method. The method comprises the following steps of: mixing pickling wastewater and coking wastewater in a cistern at a certain ratio with PH value of the mixture controlled between 7 and 9, selecting supernate after sedimentation for purifying treatment in the next stage of a biochemical system. The biochemical system comprises a primary aerator pool, a primary sedimentation pool, a facultative tank, an aerobic pool and a secondary sedimentation pool, the wastewater passes the primary aerator pool, the primary sedimentation pool, the facultative tank, the aerobic pool and the secondary sedimentation pool in the biochemical system in sequence, wherein the primary aerator pool, the facultative tank and the aerobic pool are added with microorganism bacterium flora and microorganism carriers. The device comprises the primary aerator pool, the primary settling pool, the facultative tank, the aerobic pool and the secondary sedimentation pool, and is characterized in comprising a cistern which is arranged ahead of the primary aerator pool and is provided with a stirring device and a spatula device inside. The invention is simple in technology procedures and is a method of 'treating waste with waste' and can treat the pickling wastewater and the coking waste water comprehensively.

Owner:浙江汉蓝环境科技有限公司

Refuse leachate treatment technology

InactiveCN1978346ASolve total nitrogenSolve the problem of high ammonia nitrogenWater/sewage treatment by electrochemical methodsTreatment with aerobic and anaerobic processesLitterFluidized bed

This invention relates to a process technology for rubbish seep filtrates including 1, blowing and stripping off, 2, internal circulation anaerobic sludge fluidized bed process, 3, active biofilm process, 4, electric catalysation and oxidation.

Owner:昆明市环境科学研究所

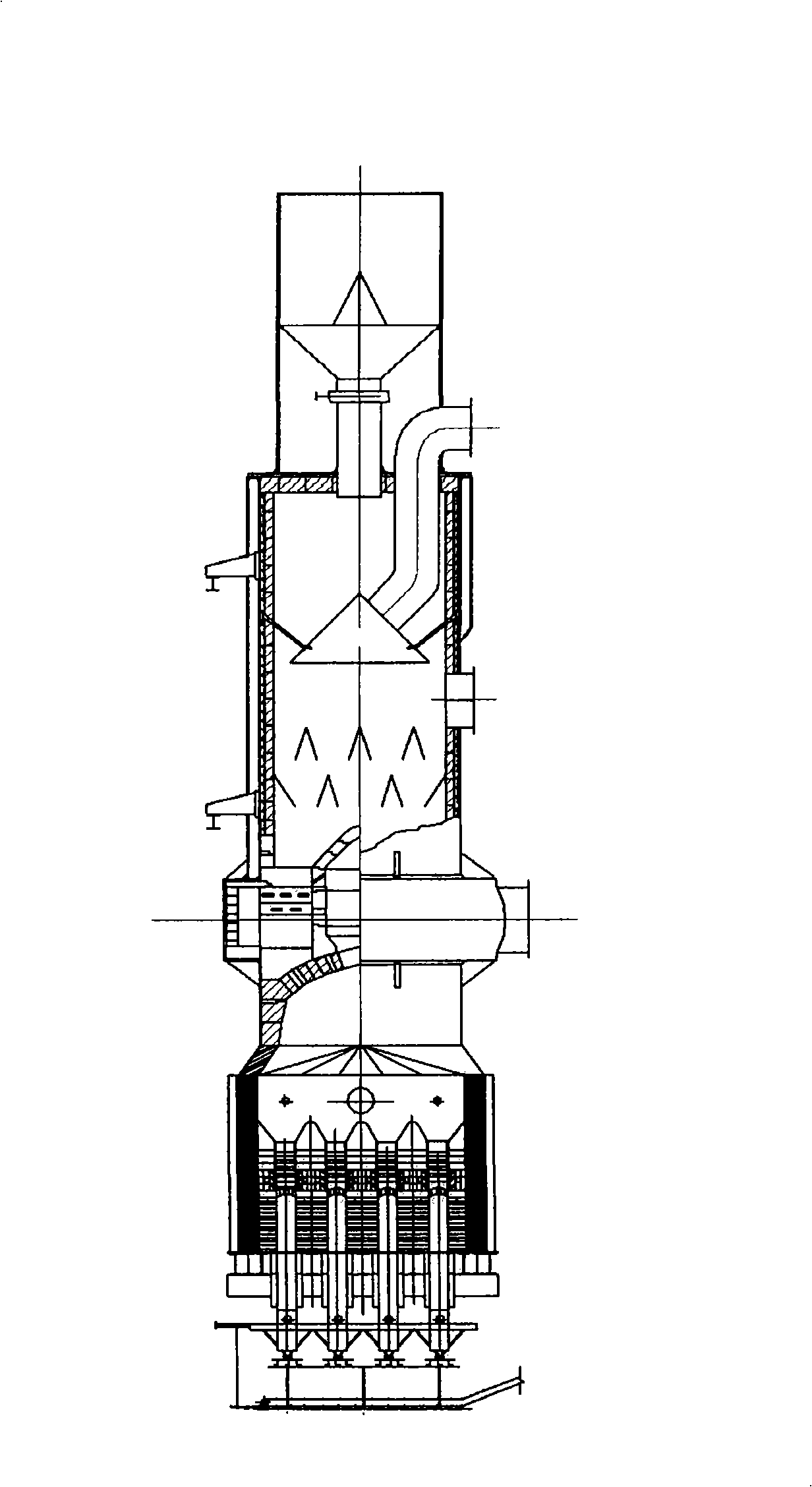

Complete alternation gas retort for treating 300 tons of wax shale mash gas a day

ActiveCN101402870AHigh recovery rateExtend life timeSpecial form destructive distillationWaxHeat carrier

The invention discloses equipment for carrying out carbonization on oil shale by utilizing gas as a heat carrier under the state of full circulation, which is suitable for processing the oil shale of 6 to 50mm; the daily processing capacity of the equipment is 300 tons and the oil yield is more than 90 percent. No gas engine is arranged in a carbonization furnace and no gas enters the carbonization furnace; all the heat needed by carbonization can be completely supplied by circulation gas. The oil shale through pre-heating carbonization enters the carbonization furnace from the upper part. A cloth tracery wall and a gas distribution structure the sizes of which are corresponding to that of the grains of the oil shale are arranged in the carbonization furnace. The thermal circulation gas of 700 DEG C is evenly and continuously fed into the middle part of the carbonization furnace. The cold circulation gas enters the carbonization furnace from the lower part to cool the semi-cokes after carbonization to 250 DEG C and the semi-cokes are discharged into a water-sealed semi-coke pool to be cooled to 80 DEG C and discharged outside the furnace by a drawing template. The highest temperature in the carbonization furnace is controlled below 550 DEG C, thus not only ensuring the complete carbonization of the oil shale, but also avoiding the problems like over-heating and caking.

Owner:辽宁成大能源科技有限公司

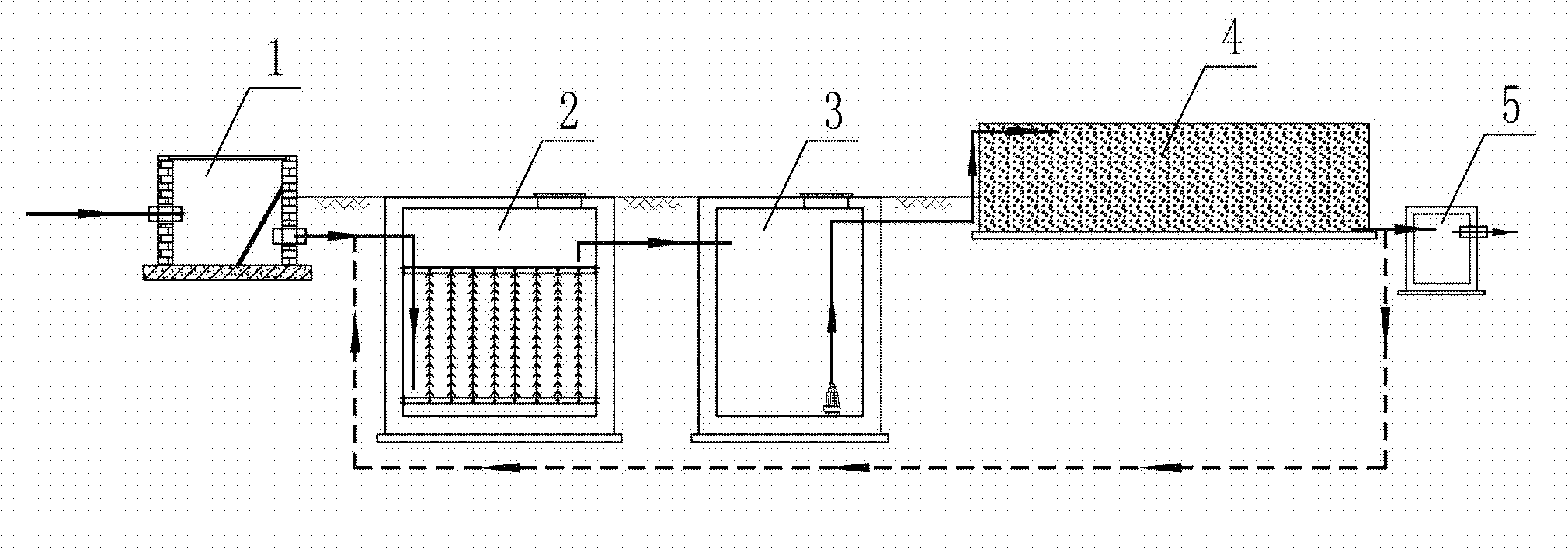

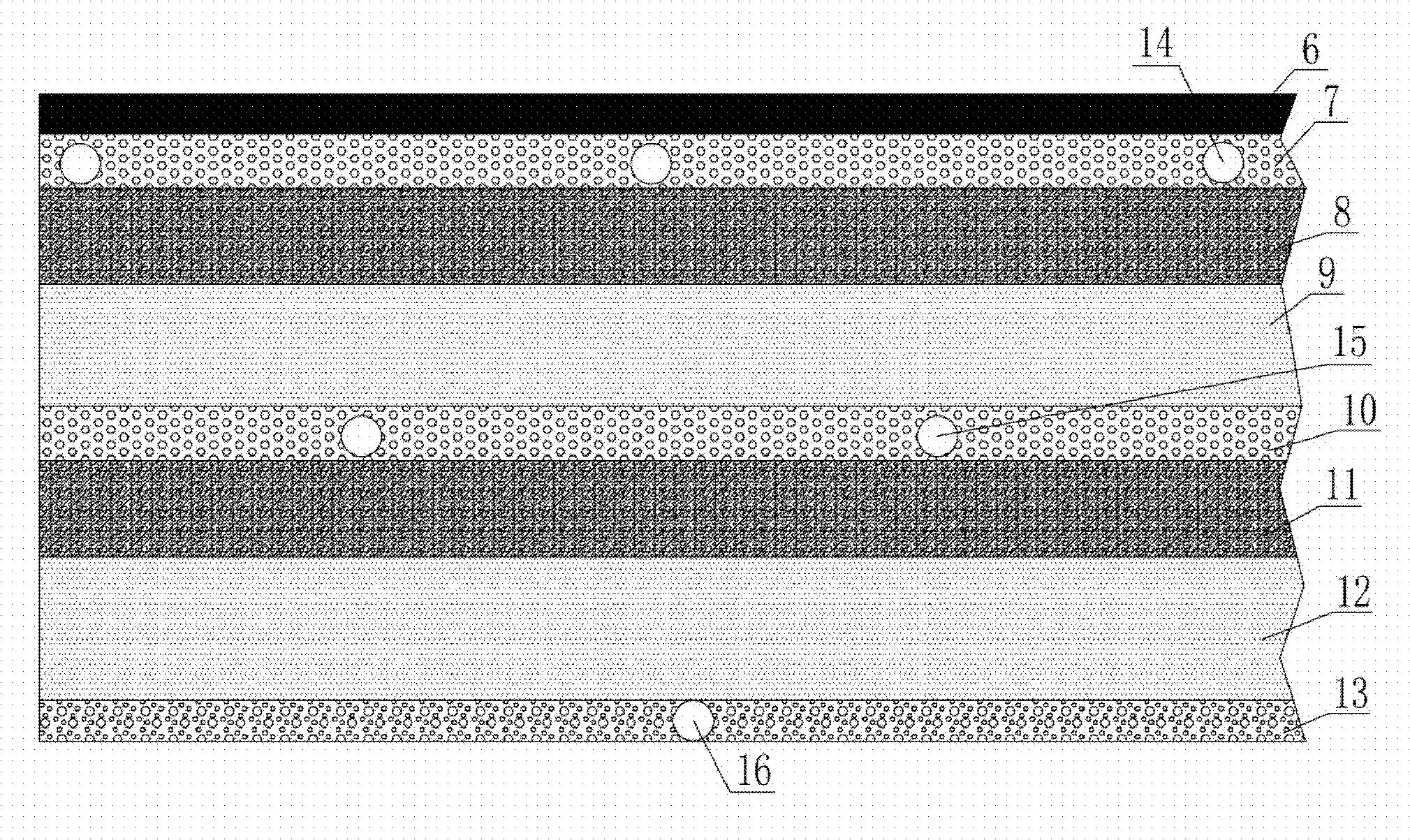

High-efficiency denitrification artificial soil subsurface infiltration sewage treatment composite system and method

ActiveCN102503036AHigh activityTo achieve the purpose of removing total nitrogenMultistage water/sewage treatmentGratingSludge

The invention discloses a high-efficiency denitrification artificial soil subsurface infiltration sewage treatment composite system and a high-efficiency denitrification artificial soil subsurface infiltration sewage treatment composite method. The system comprises a grating tank, an anaerobic sedimentation tank, an adjustment tank and an artificial soil subsurface infiltration unit which are connected with each other sequentially; the water inlet of the grating tank is a domestic sewage inlet; the water outlet of the artificial soil subsurface infiltration unit is connected with the water inlet of the anaerobic sedimentation tank and a sampling tank respectively; and the bottom of the adjustment tank is provided with a submersible sewage pump which is connected with the artificial soil subsurface infiltration unit through a pipeline. The method comprises the following steps of: feeding domestic sewage into the grating tank to remove floating garbage, mixing the obtained raw sewage and backswater, feeding into the anaerobic sedimentation tank, performing anaerobic denitrification, and removing sludge particles and floating oil simultaneously; and feeding a mixed solution into the adjustment tank, pumping the mixed solution to the artificial soil subsurface infiltration unit by the submersible sewage pump and performing multi-stage filtering to obtain backswater and discharge water, and then discharging. High-efficiency denitrification is realized under the condition of guaranteeing that other indexes reach the standard, and the increasingly environment-friendly requirementis met.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

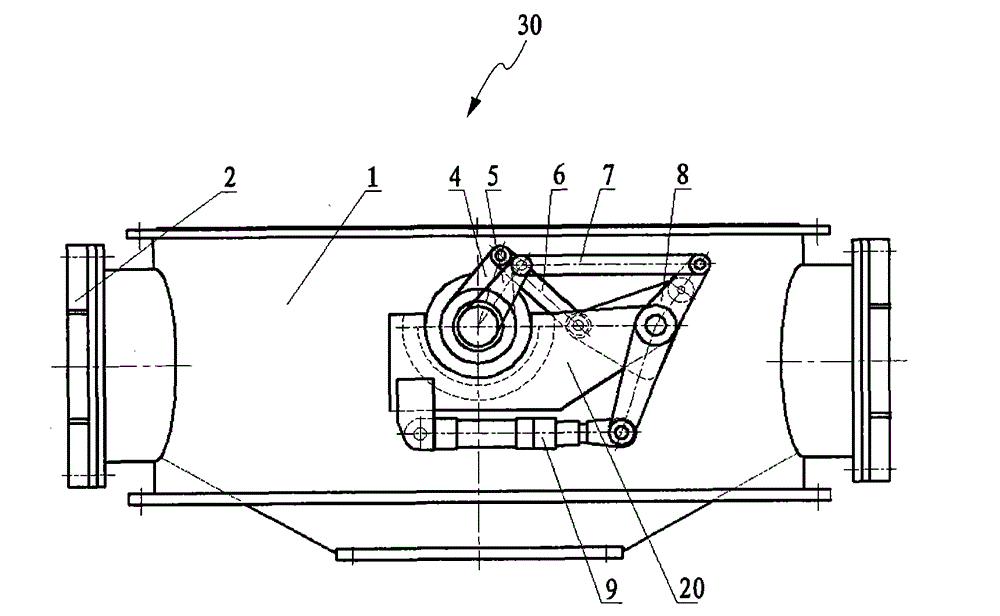

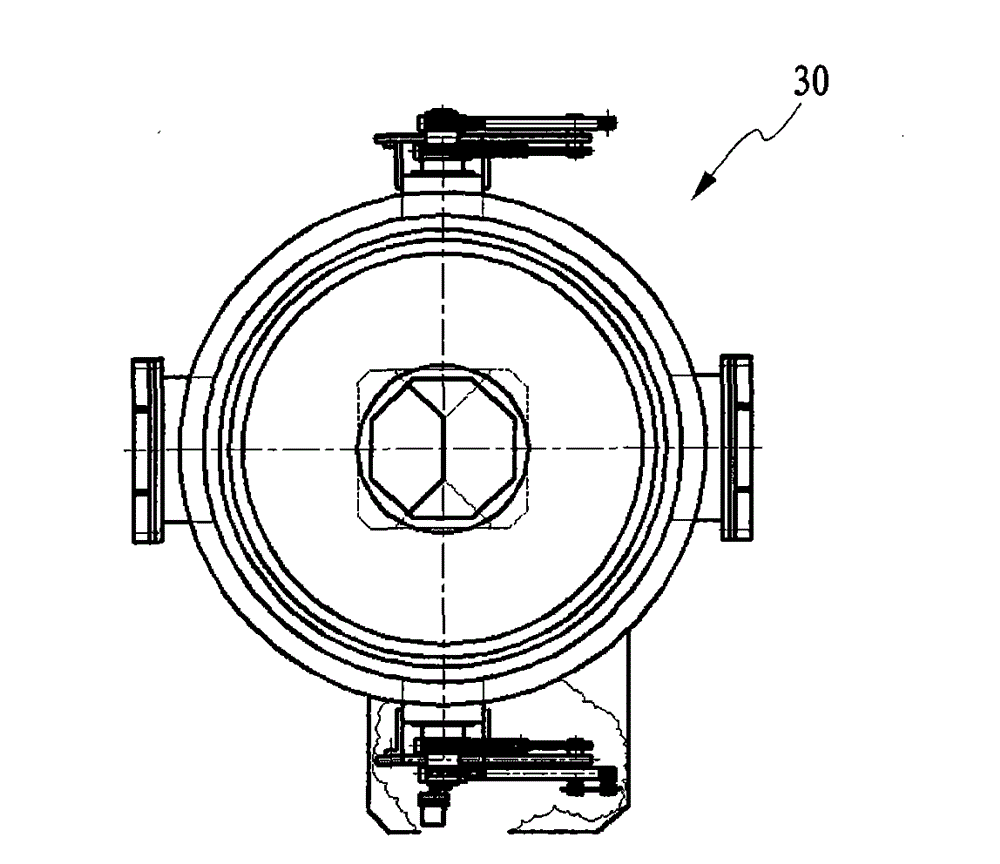

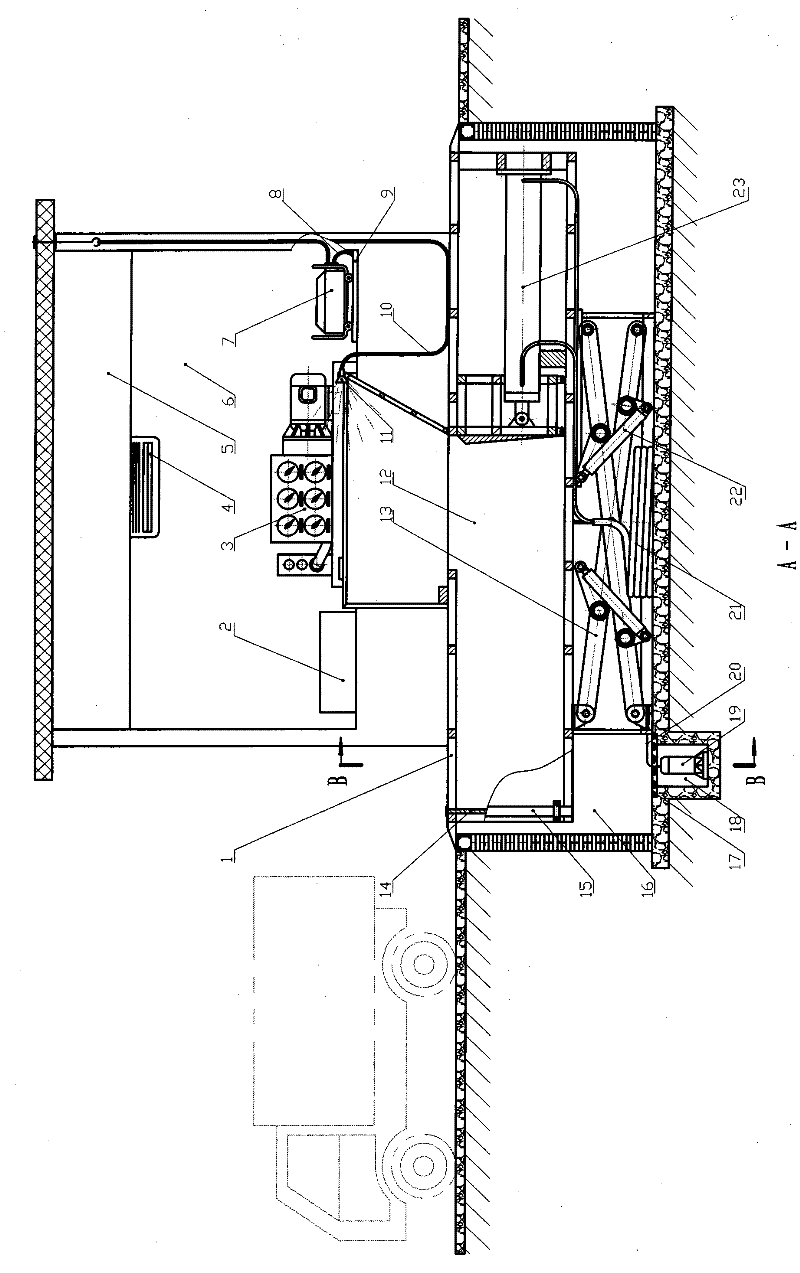

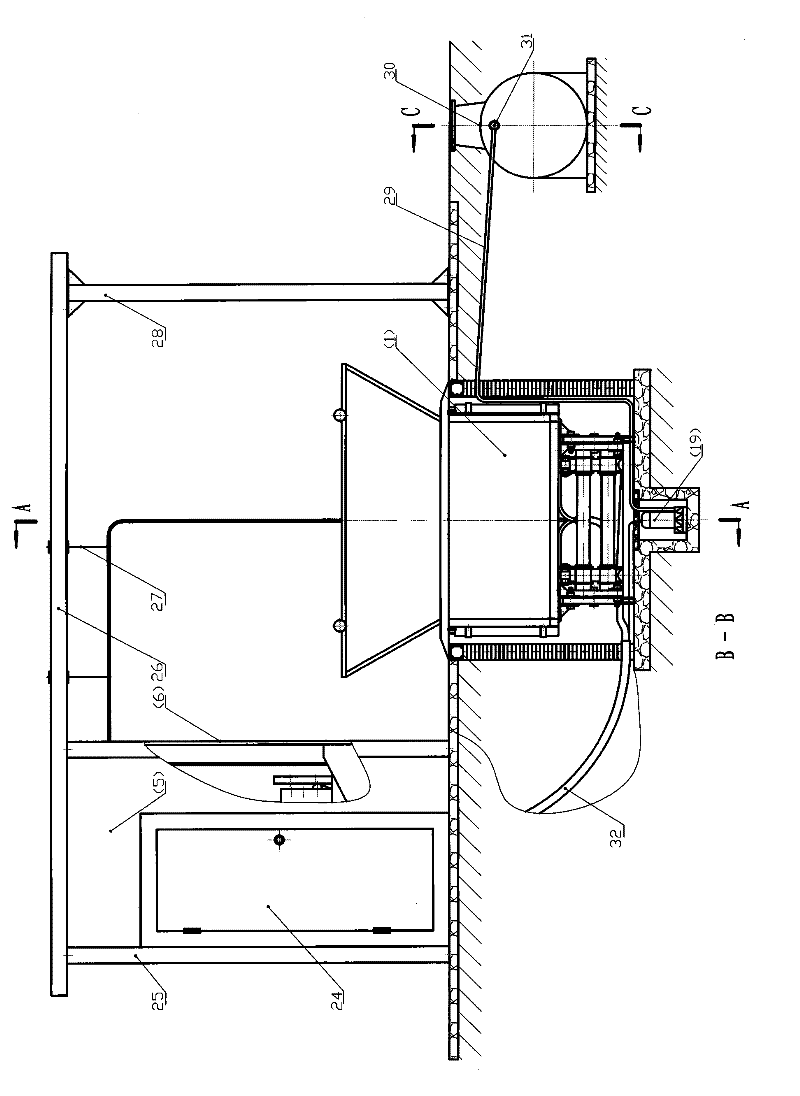

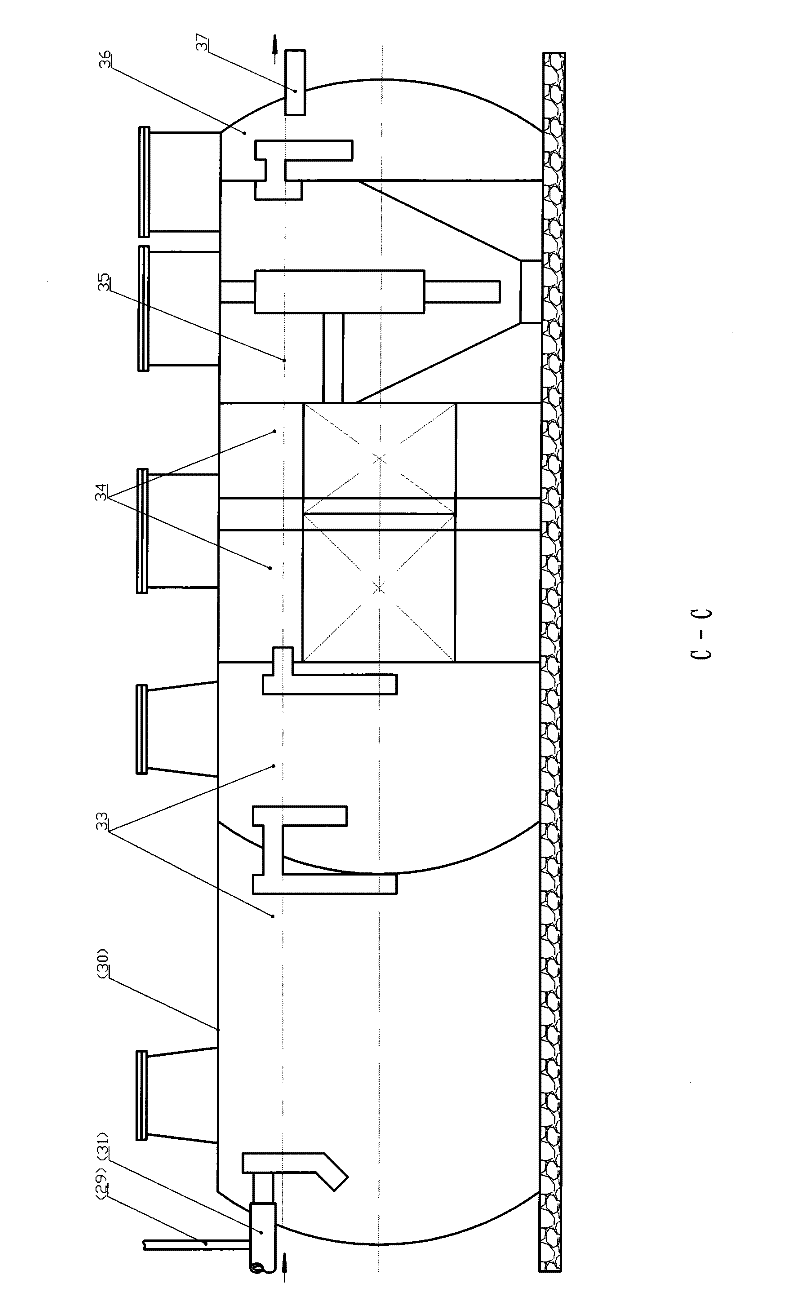

Compact material flow adjusting valve

ActiveCN102748486AHigh control precisionReduce wearOperating means/releasing devices for valvesBlast furnace componentsEngineeringTransmitted power

The invention discloses a compact material flow adjusting valve, which comprises a valve body, a manhole door, a tapered sleeve and a liner barrel, wherein the manhole door is correspondingly arranged at the side part of the valve body; the tapered sleeve is supported inside the valve body; the liner barrel is supported inside the tapered sleeve; the compact material flow adjusting valve further comprises a first valve plate, a second valve plate and an executing mechanism, wherein the first valve plate and the second valve plate are correspondingly arranged below the liner barrel; the first valve plate and the second valve plate move relatively and are used for controlling the velocity or the time of material flow; and the executing mechanism are used for driving the first valve plate and the second valve plate so as to transmit power to the first valve plate and the second valve plate in a linkage way. With the adoption of the compact material flow adjusting valve, the stable and smooth operation of a blast furnace is ensured, the furnace burden segregation is prevented, the structure is compact, the height is relatively low, and the production cost is reduced effectively.

Owner:BERIS ENG & RES CORP

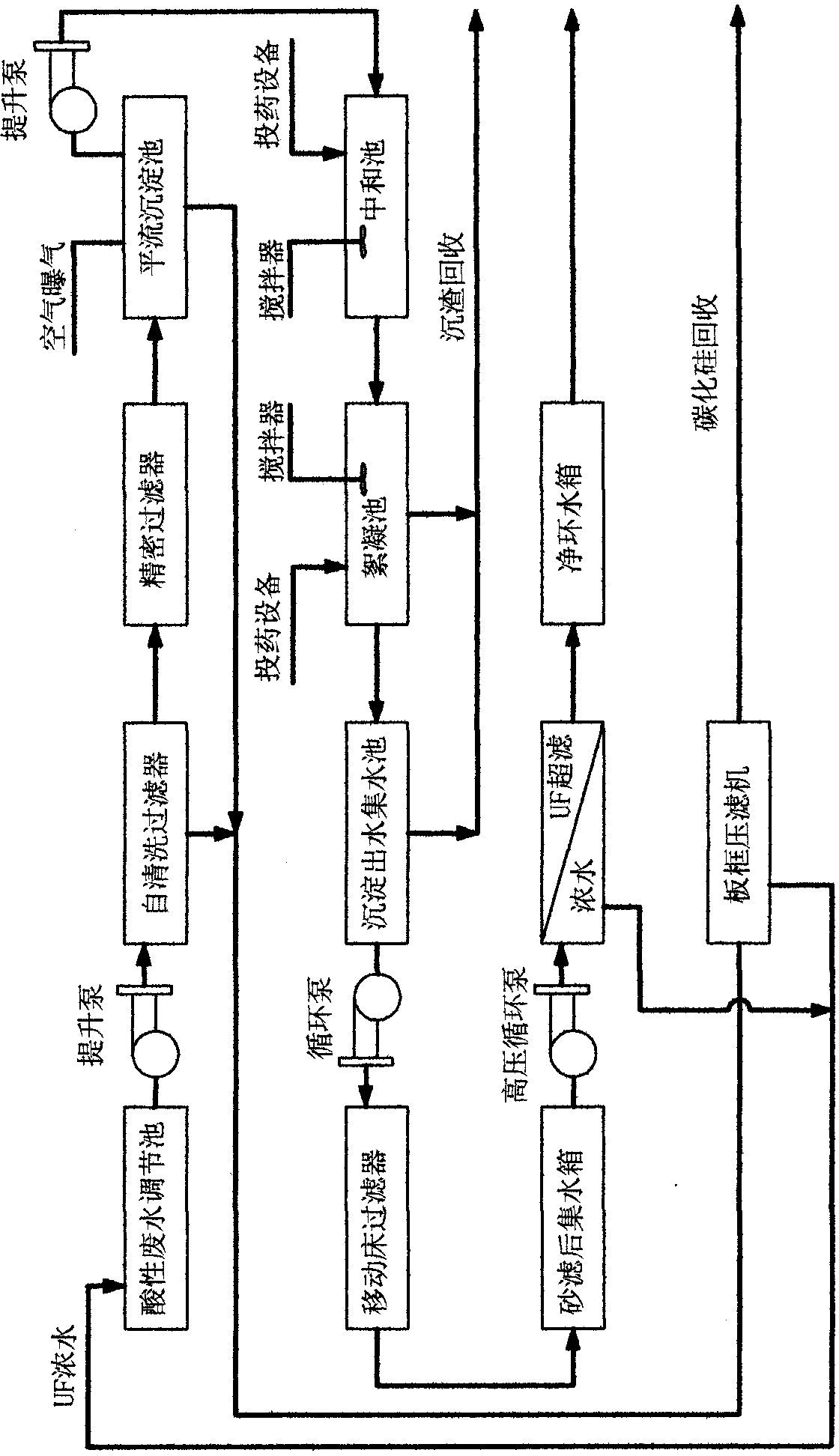

Technical method for treating silicon carbide acidic wastewater

ActiveCN103755075AGuaranteed purityImprove qualityMultistage water/sewage treatmentWater useUltrafiltration

The invention belongs to the technical field of environment protection, and relates to a technical method for treating acidic wastewater generated during the production of silicon carbide. The technical method is characterized by comprising the technical steps of pretreatment and descending of high-concentration suspended matters, neutralization, flocculation and precipitation, sand filtration and primary advanced treatment, and ultrafiltration and secondary advanced treatment; water after ultrafiltration treatment with a UF is 6-9 in pH value, less than 10 mg / L in SS, and less than 10 mg / L in COD; the water is delivered to a clean circulation water tank to substitute new water and use as reuse water; water production rate is above 95%; concentrated water during the ultrafiltration is returned to an acidic wastewater adjusting tank. According to the invention, waste water with high-concentration suspended matters, of which the SS is more than 20000 mg / L can be treated; silicon carbide resource can be recycled directly; silicon carbide purity is guaranteed; reuse water with high quality is produced; construction investment and capital for upgrading are reduced; running cost is reduced; reuse of reclaimed water and sediment as resource is guaranteed; the sediment can be used as construction materials, decorative materials, environment-friendly materials and agricultural fertilizer improving soil.

Owner:鞍山宏源环能科技有限公司 +1

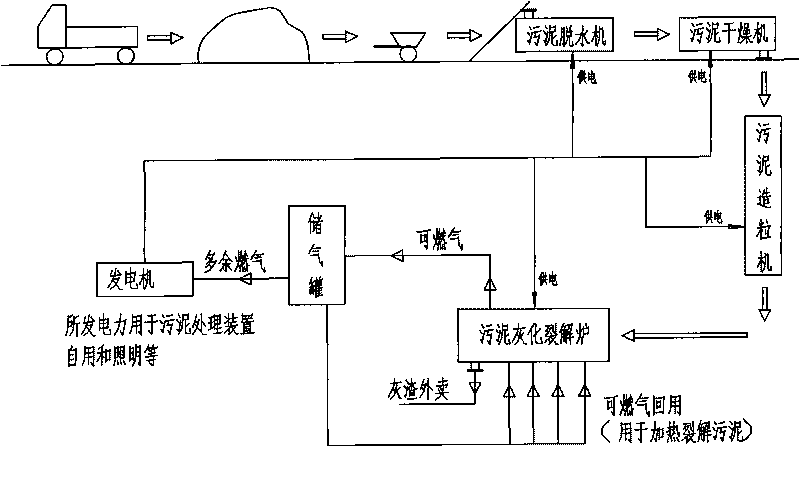

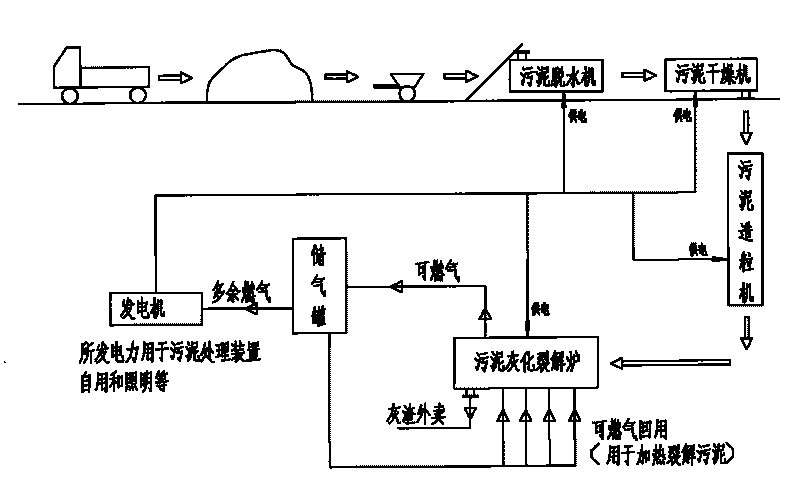

Harmless domestic sludge pyrolysis and carbonization treatment technique

InactiveCN101746939AHarmlessZero emissionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeCarbonization

The invention discloses a harmless domestic sludge pyrolysis and carbonization treatment technique. The technique includes pre-stage domestic sludge premixing and standing treatment, pre-dehydration, shaping, dehumidification, granulation, pre-reaction, pre-pyrolysis reaction, full carbonization reaction and other treatment processes, the completely reacted solid carbonized matter is discharged out of a system by a discharger, and is then collected and stored, the gas generated in sludge pyrolysis is separated by a gas condensation and separation system, the uncondensed flammable gas is guided into a gas holder and stored as heat source for the system, and the condensed gas is centrally treated by a reclaimed water system. The invention realizes purposes such as harmless and zero discharge in the process of production, energy self-sufficiency and low consumption in the process of production, resource and basic energy substance recycling, energy saving, discharge reduction and natural substance recycling, and has the advantages of easy operation, low investment cost, remarkable economic benefit, significant discharge reduction effect for the environment and the like.

Owner:SHANGHAI LOTUS ENVIRONMENTAL PROTECTION TECH

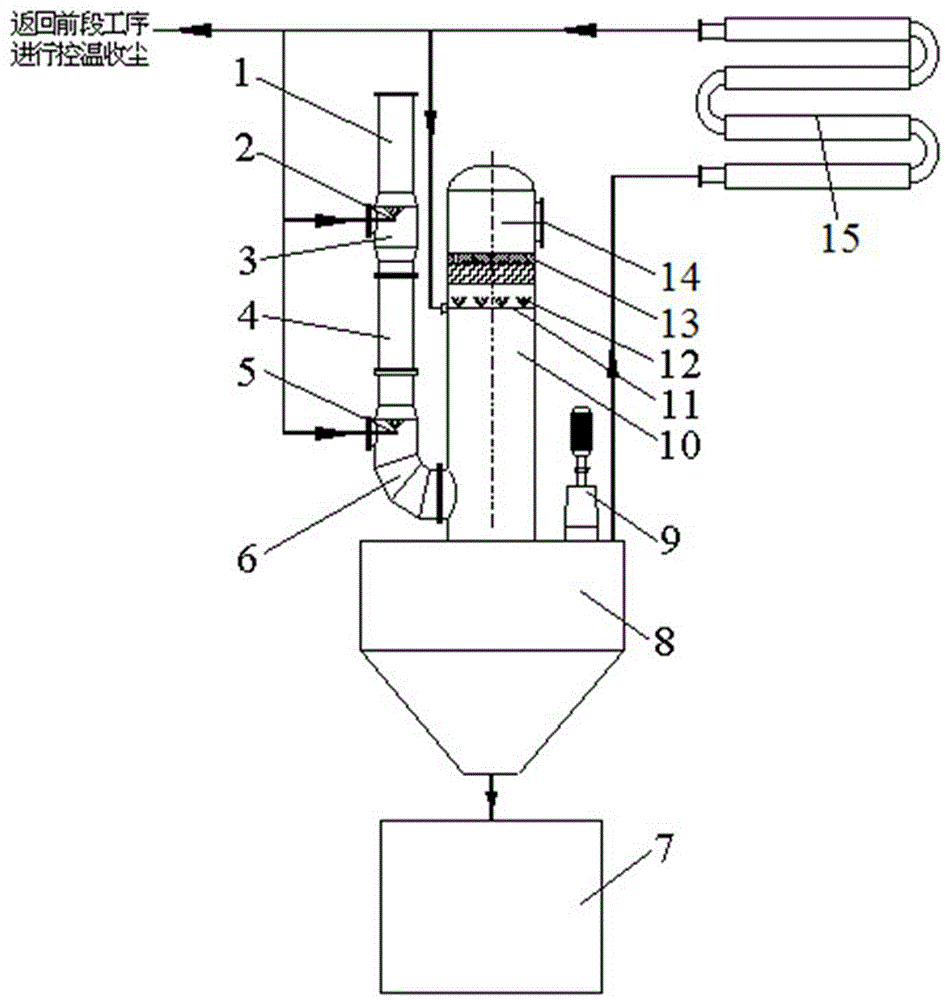

Wet dust removal device and technique for titanium tetrachloride smoke

ActiveCN103143220AHigh yieldReduce dust contentUsing liquid separation agentTitanium halidesFilter systemTower

The invention provides a wet dust removal device and a wet dust removal technique for titanium tetrachloride smoke. The device comprises a circulation slot and a bottom flow slot, wherein a separation tower and a circulation pump with an outlet connected to an inlet of a sleeve heat exchanger are mounted on the circulation slot; an air outlet is formed in the side wall of the separation tower; a mist eliminator and a plurality of cleaning blow heads with upward nozzles are arranged in the separation tower; the lower part of the side wall of the separation tower is fixedly connected with a turbulent inverse nozzle with an upward opening, wherein a two-stage blow head is arranged in the turbulent inverse nozzle; and an outlet and a liquid inlet of the sleeve heat exchanger are communicated with a liquid inlet tube and the two-stage blow head. A smoke inlet is connected with a chlorination furnace smoke outlet, the air outlet is connected with a washing and condensing process, and the outlet of the sleeve heat exchanger is connected with a front-end solid phase dust collection process; after heat exchange in the sleeve heat exchanger, circulation liquid is sent to the two-stage blow head, the liquid inlet tube and the front-end solid phase dust collection process; and after entering the turbulent inverse nozzle, chlorination furnace smoke is inversely crashed with the liquid blown from the two-stage blow head and then is washed and led to the separation tower for secondary washing. In the device, a thickener and a filter are abandoned, so that the energy consumption in production is reduced and the investment and maintenance costs of a settling and filtering system are saved.

Owner:JINCHUAN GROUP LIMITED

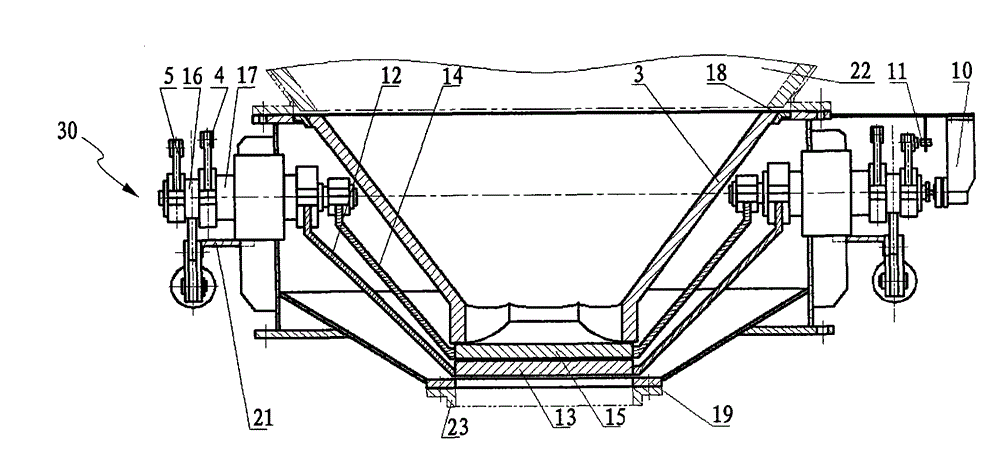

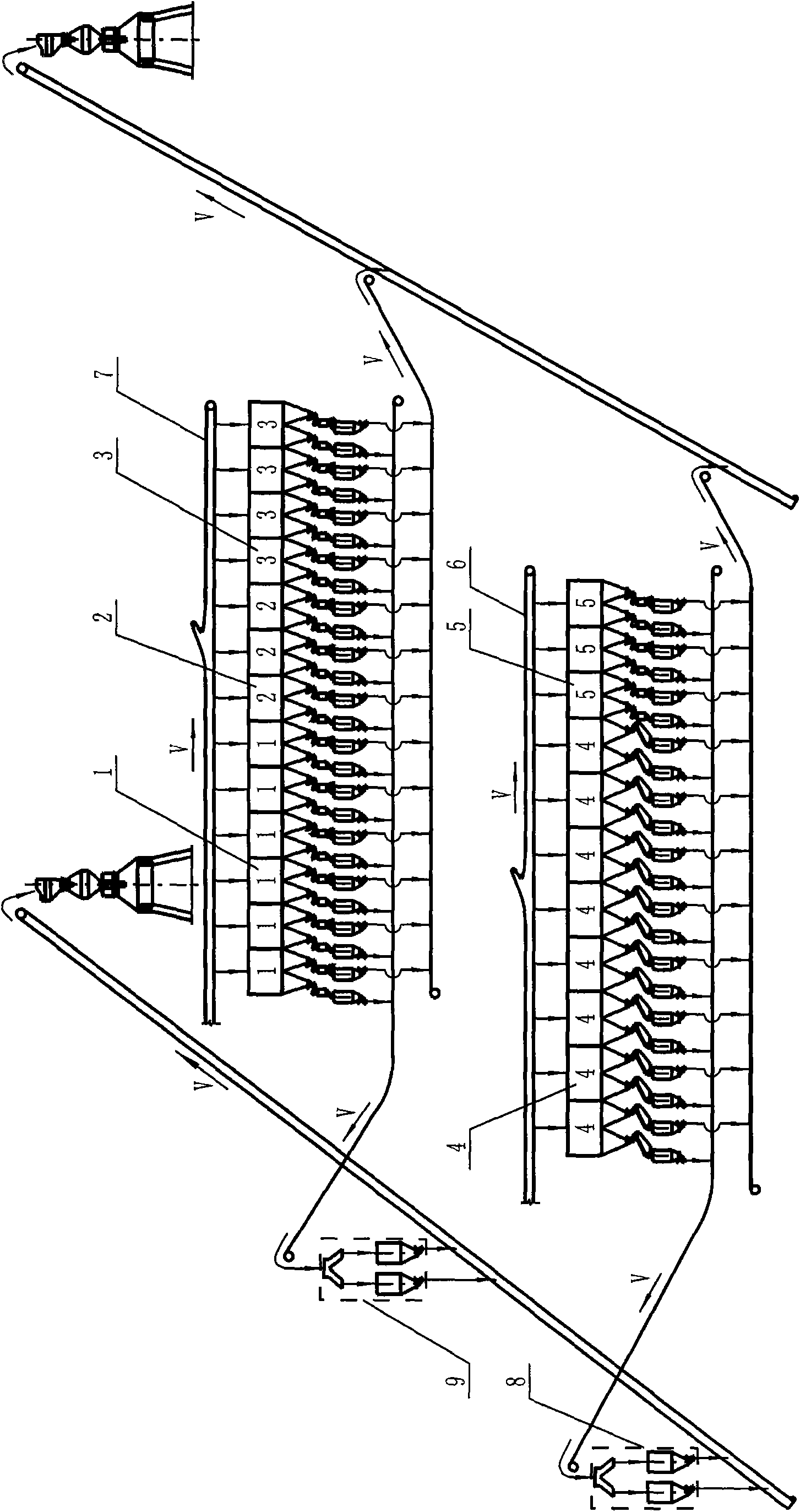

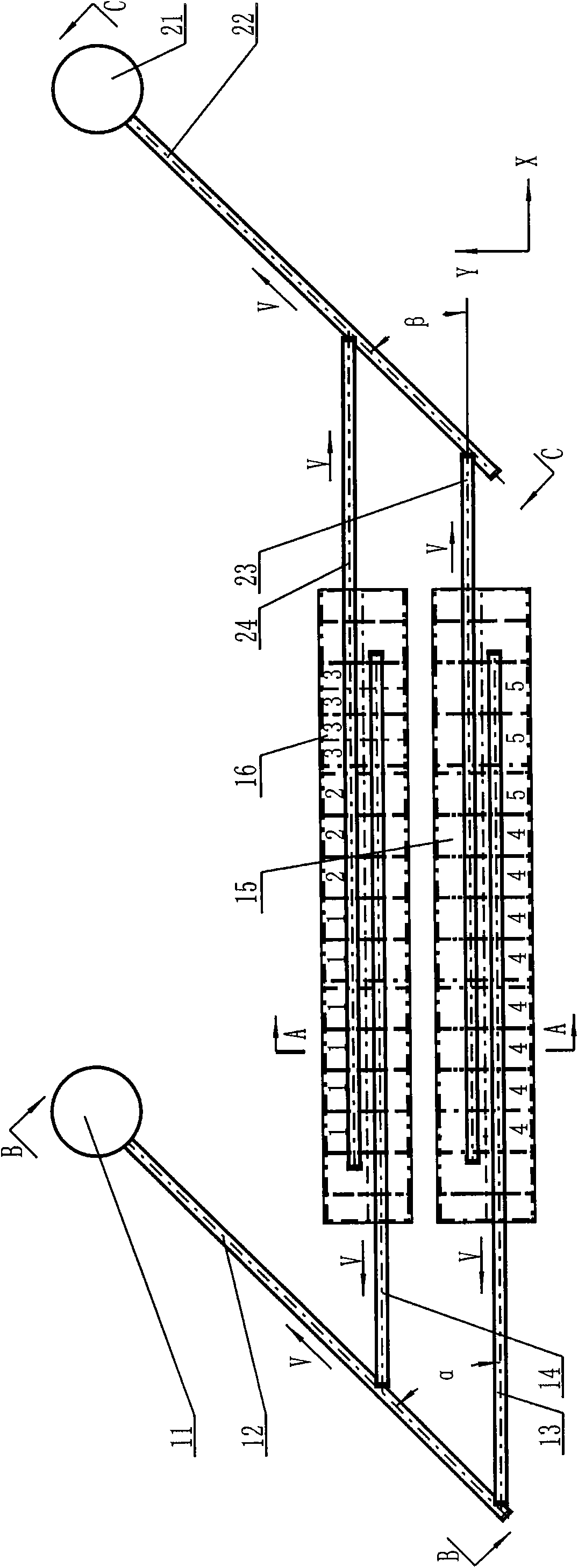

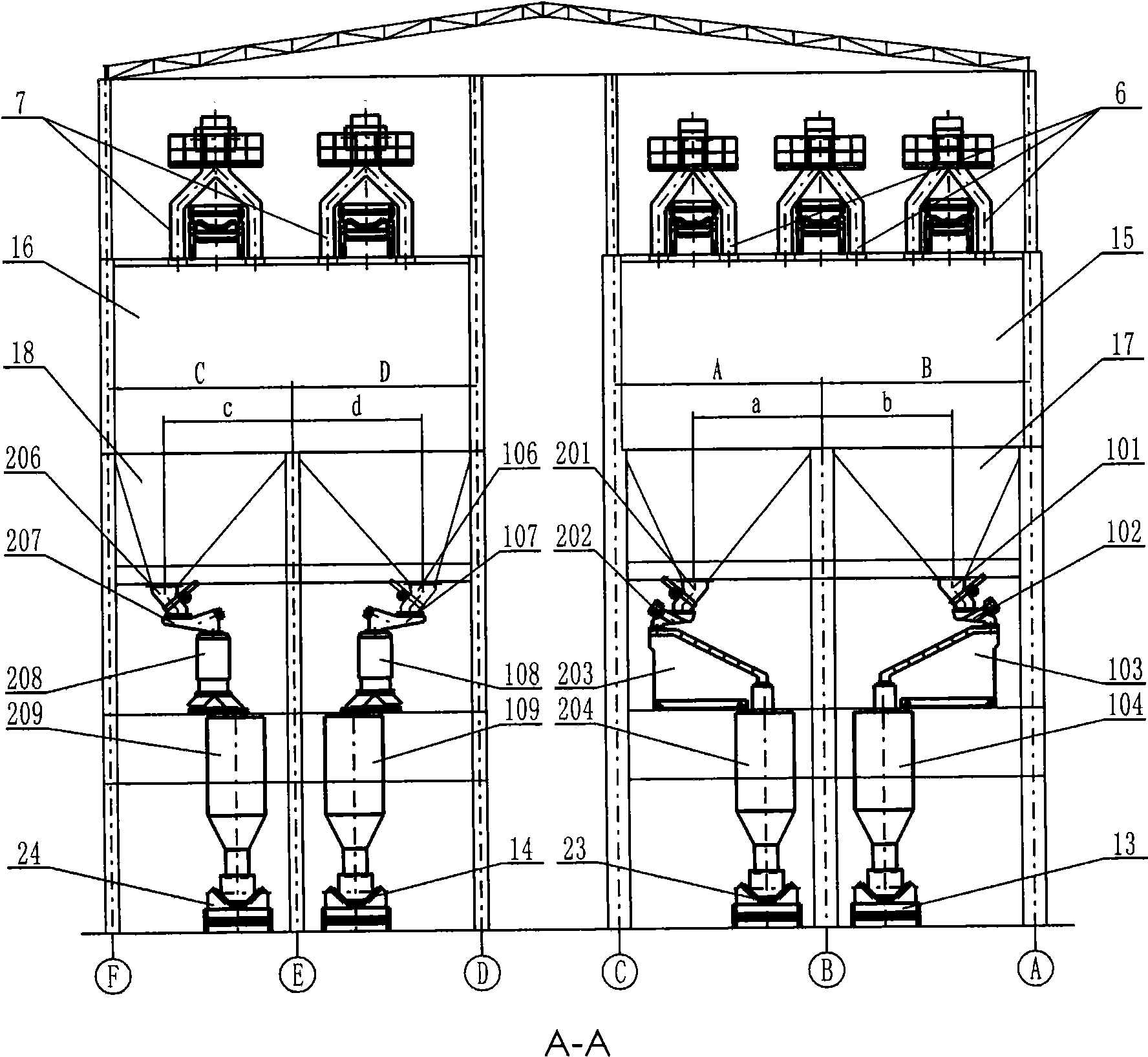

Feeding system for blast furnace ore and coke channel system

ActiveCN101792835ASmall footprintSave construction investmentBlast furnace componentsBlast furnace detailsBelt conveyorMaterials science

The invention relates to a feeding system for a blast furnace ore and coke channel system, belonging to the technical field of the iron making and producing in the metallurgy industry. The feeding system comprises a blast furnace ore and coke channel system and a feeding system; the blast furnace ore and coke channel system comprises a blast furnace ore and coke channel and equipment arranged on the blast furnace ore and coke channel; the feeding system comprises equipment arranged below the blast furnace ore and coke channel and loading equipment; the equipment arranged on the blast furnace ore and coke channel comprises auxiliary equipment and belt conveyor with a storehouse, wherein the auxiliary equipment and the belt conveyor with a storehouse are arranged on the top surface of the blast furnace ore and coke channel, and the belt conveyor with a storehouse is connected with the top surface of the blast furnace ore and coke channel; each equipment arranged below the blast furnace ore and coke channel comprises a feeding port gate, a feeder, a vibrating screen, a weighing can and an unloading gate; the feeding port gate corresponds to the hopper of the blast furnace ore and coke channel and the outlet thereof one by one; the number of the equipment arranged below the blast furnace ore and coke channel, the number of the hoppers of the blast furnace ore and coke channel and the number of the outlets of the hoppers of the blast furnace ore and coke channel are equal and are 2 or 3 or 4 along the width direction; and the equipment arranged below the blast furnace ore and coke channel corresponds to the hoppers blow the body of the blast furnace ore and coke channel and the outlets of the hoppers along the length direction. The feeding system can serve 3 or 4 blast furnaces and can be used in various forms.

Owner:BEIJING SHOUGANG INT ENG TECH

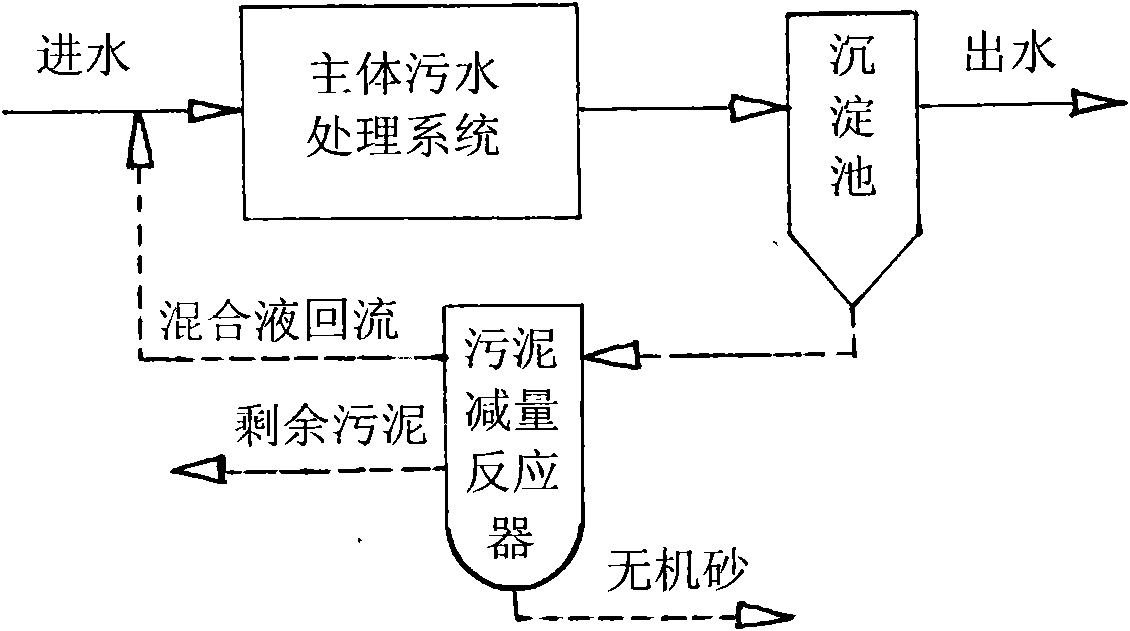

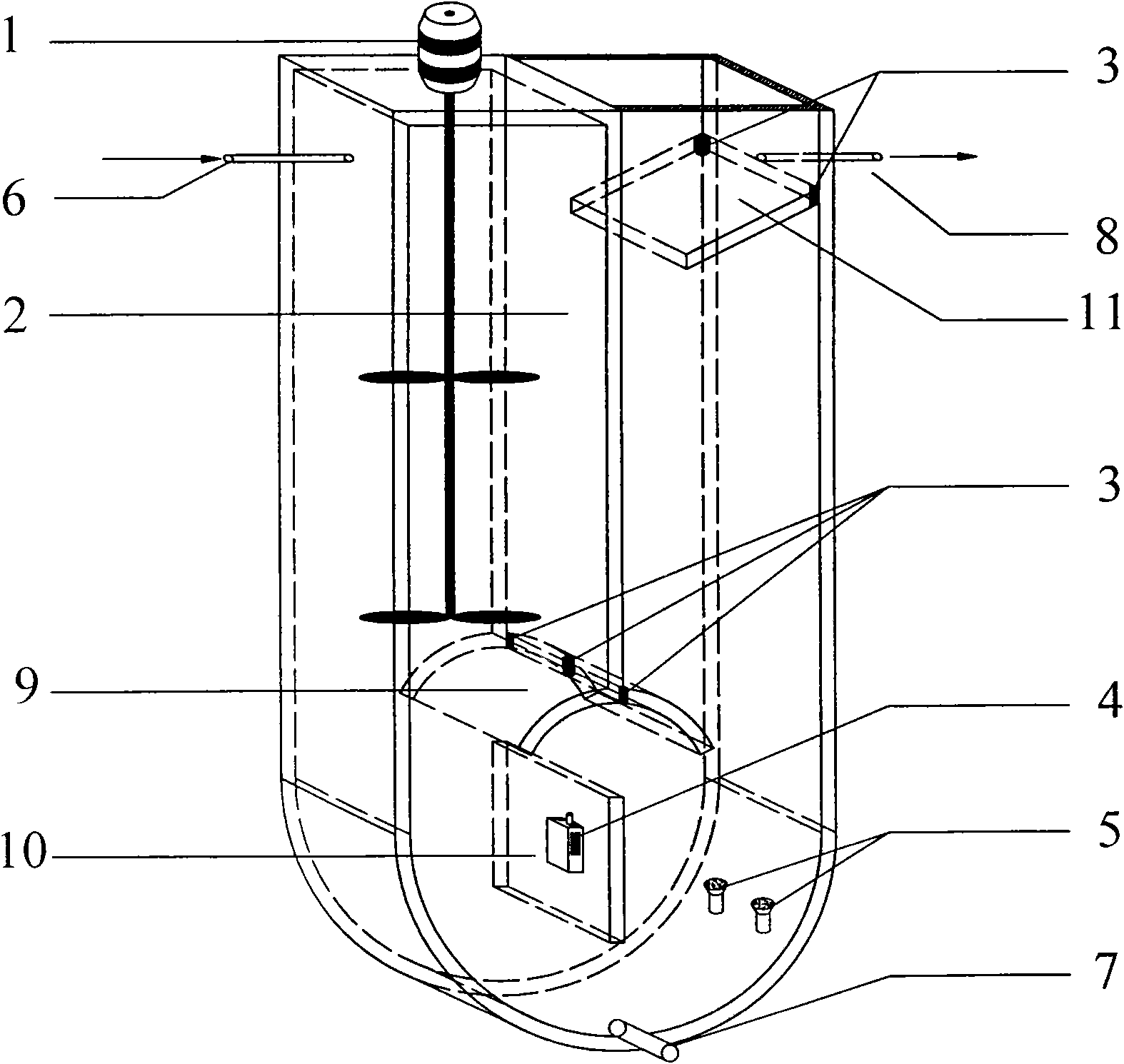

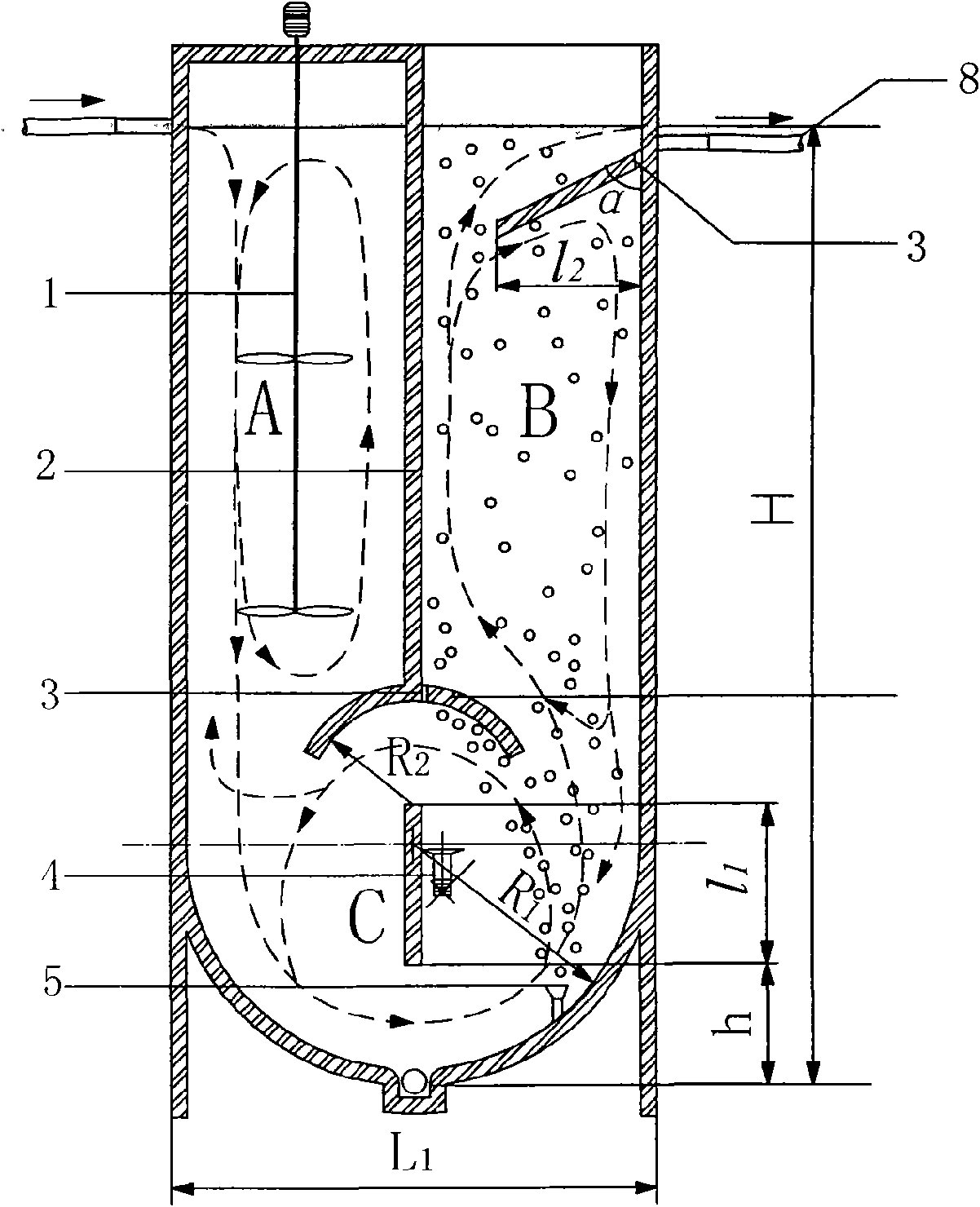

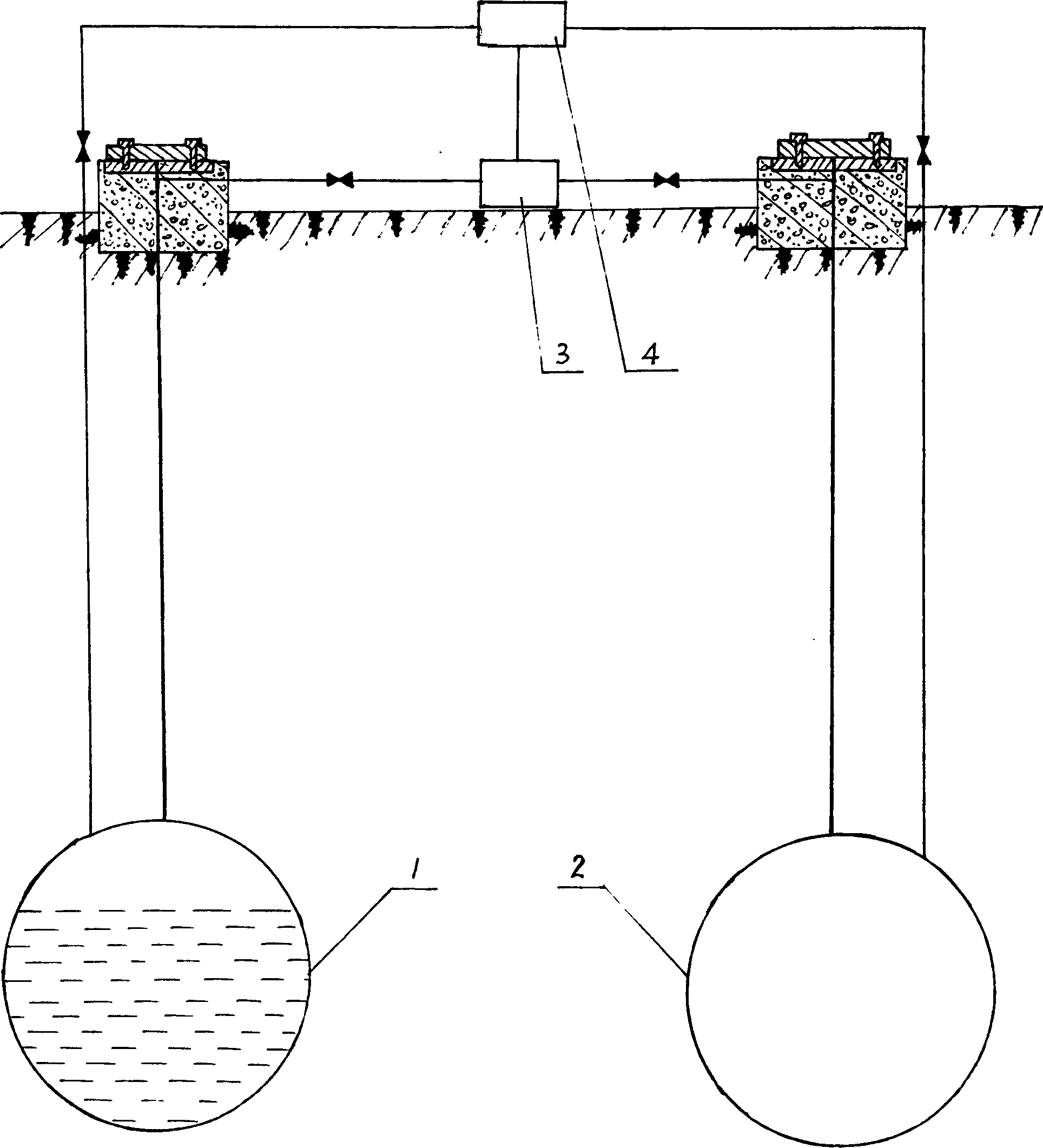

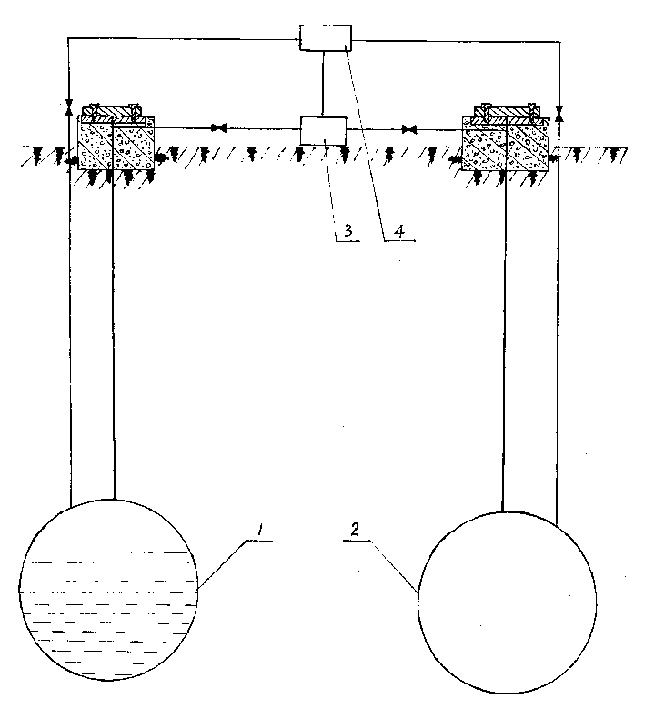

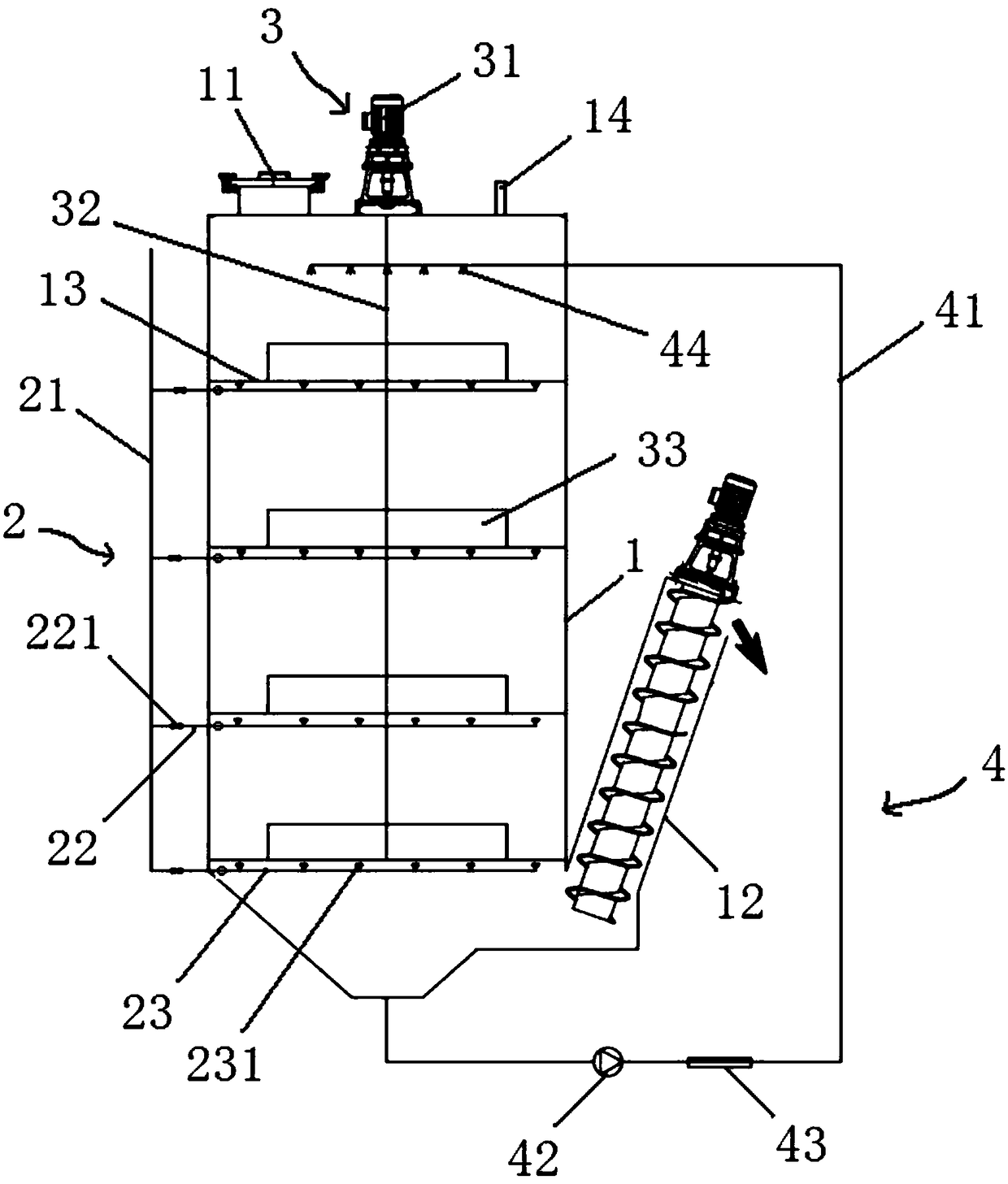

Method for controlling residual sludge reduction in activated sludge-sewage treatment system and reactor

InactiveCN101602548AFacilitate the hydrolysis effectIncrease consumptionTreatment with aerobic and anaerobic processesActivated sludgeWater treatment system

The invention provides a method for controlling residual sludge reduction in an activated sludge-sewage treatment system. The method sets three zones, namely an anaerobic zone, a circulating zone and a limited oxygen zone which are connected in turn from a sludge inlet to a sludge outlet in a sludge reduction reactor; the sludge enters the anaerobic zone from the sludge inlet at the upper part, is evenly mixed by stirring, and then downwards flows to the circulating zone; and the sludge circularly flows in the circulating zone under the action of an underwater mixer, then upwards enters the limited oxygen zone, and finally is discharged from the sludge outlet at the upper part of the limited oxygen zone. The invention further provides a reactor for realizing the method for anaerobic / limited oxygen hemicyclic sludge reduction with an arc guide plate. The residence time of the whole reactor is 6 hours, the dissolved oxygen concentration of the limited oxygen zone is 0.5 to 1.1 milligrams per liter, and the ratio of the practical anaerobic / limited oxygen residence time in the reactor is 1.10-1.25:1.0. The radius R1 of the circulating zone of the reactor is 0.5 L1, and the effective height H of the reactor is 4R1. The method has the advantages of good activated sludge reduction effect, low energy consumption, occupied place economy and the like, and can effectively separate inorganic granules in the activated sludge, ensure the effluent effect of the sewage treatment system, well improve the settling performance of the activated sludge, and the like.

Owner:CHONGQING UNIV

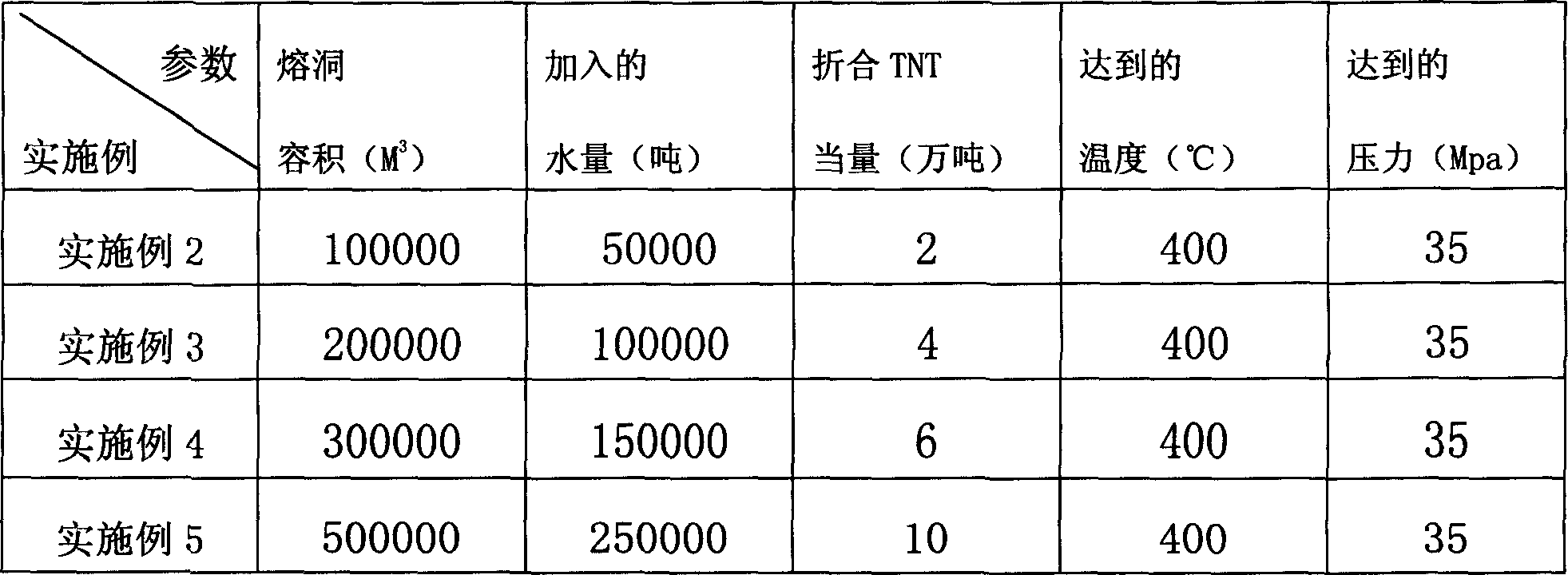

Method for electric power generation using thermonuclear fusion energy

InactiveCN1489157AEndless sourcesLow priceNuclear energy generationNuclear explosivesElectricityNuclear fusion

Water is filled into 1 / 3-2 / 3 of underground solution cave, and light type nuclear fusion body is put into the cave. Igniting the nuclear fusion body make water reach water vapour state in high temperature and high pressure 300-400 deg.C and 30-40Mpa, which drives rotation of turbo generator to generate electricity. With power being done, exhaust steam is condensed in condensator. Then, igniting the nuclear fusion body is carried out in another solution cave. Alternant igniting nuclear fusion bodies in two solution caves realizes cycling generating electricity. The method uses not exhausted very clean energy source of burning deuterium so as to have value for commerce development.

Owner:化建华

Method for treating high concentration organic waste water

InactiveCN1821128AImprove degradation rateReduced footprintWaste based fuelTreatment with anaerobic digestion processesHigh concentrationSlag

The method of treating high concentration organic waste water includes eliminating sand and slag, and flocculating deposition to separate, as well as microbial degradation and catalytic oxidizing degradation in an integrated degrading tank, and electrolyzing oxidation degradation. After depositing separation, the sludge is incinerated and the catalytic oxidant is regenerated for reuse. The treated waste water is drained or reused. The present invention integrates various water treating modes, physical, biological, chemical, electrochemical, etc. and has high waste water purifying effect.

Owner:绵阳馨源环保科技有限公司

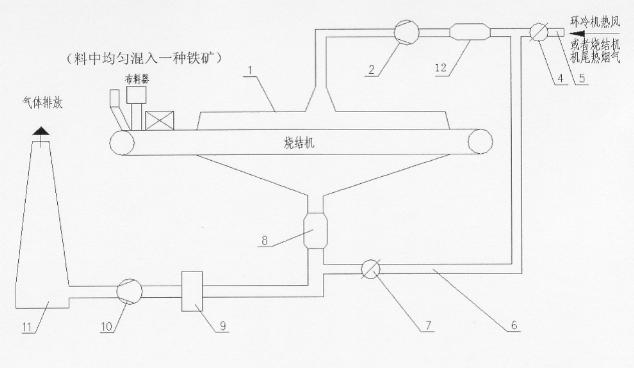

Low-carbon method for improving emission reduction efficiency of oxynitride in circulated flue gas from sintering machine

InactiveCN102188905AImprove catalytic emission reduction efficiencyNo need for additional facilitiesDispersed particle separationFurnace typesFlue gasOxygen

The invention relates to a low-carbon method for improving the emission reduction efficiency of oxynitride in circulated flue gas from a sintering machine, and the method comprises the following steps: (1) taking the flue gas in the middle of the total flue gas from a main flue, circulating the taken flue gas, wherein the flue gas is specifically taken from the area 20-70% from the head of the sintering machine to the bottom of the sintering machine, and the content of the oxygen in the flue gas in the upper circulating hood of a sintering pallet is no less than 18%; and (2) uniformly allocating an iron ore into sintering auxiliaries to serve as a catalyst. The invention provides a technical method for improving the circular denitration for the flue gas from the sintering machine with lowcost and low energy consumption. The technical method is characterized in that the iron ore is uniformly added into the sintering auxiliaries based on the flue gas circulation of the sintering machine, so as to improve the efficiency for denitration of the oxynitride. The technology provided by the invention is implemented based on the flue gas circulation of the sintering machine, the efficiencyfor denitrating the oxynitride from the circulated flue gas can be increased to 80-90% on the premise of not increasing the investment on equipment and construction, and the cost for energy consumption and operation.

Owner:BAOSTEEL ENG & TECH GRP

Energy-saving and environmentally-friendly complete equipment for garbage compaction transfer station

InactiveCN102190146APollution suppressionHigh compression transfer efficiencyGlass recyclingRefuse receptaclesHigh pressureSimple machine

The invention discloses energy-saving and environmentally-friendly complete equipment for a garbage compaction transfer station, which consists of garbage compaction equipment, dust-removing and deodorizing equipment, sewage treatment equipment and a simple machine room, wherein the garbage treatment equipment adopts a buried horizontal garbage compactor; in the dust-removing and deodorizing equipment, the water inlet end of a high-pressure cleaning machine is connected with a water tank and a spraying nozzle is additionally arranged at the water outlet end of the high-pressure cleaning machine; the sewage treatment equipment is formed by combining a submerged pump with a glass fiber reinforced plastic sewage tank; the simple machine room has a semi-closed structure; one half of the simple machine room is a closed control chamber and the other half of the simple machine room is a pavilion for supporting a room top plate by upright posts; the buried horizontal garbage compactor has low energy consumption and high efficiency; during high-pressure spraying, a disinfection deodorant is added to inhibit air pollution; the glass fiber reinforced plastic sewage tank shared with a toilet is discretionarily selected for carrying out innocent treatment on sewage and draining the sewage after reaching the standard; and by using the semi-closed simple machine room, the construction investment and the resource consumption are better reduced, and thereby the energy-saving and environmentally-friendly requirements of the garbage compaction transfer station are comprehensively met.

Owner:YANCHENG ZHONGYE HYDRAULIC COMPONENT

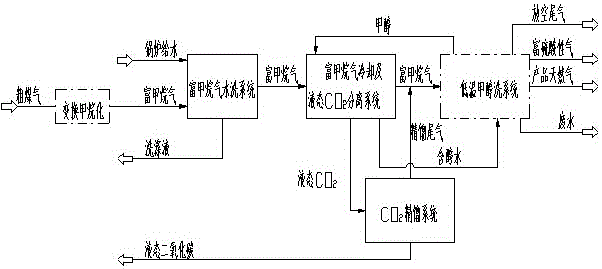

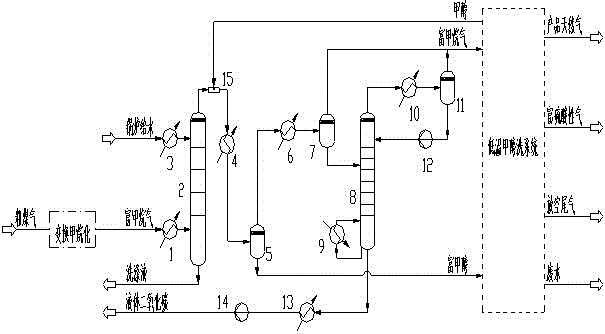

Low-carbon acid gas removal technique and system for high methane gas

ActiveCN106010700AReduce air emissionsGood environmental benefitsGaseous fuelsEnvironmental chemistryCarbonic acid

The invention provides a low-carbon acid gas removal technique and system for high methane gas. After raw gas is subjected to a transformation methanation reaction, the high methane gas which is rich in CH4 and CO2 is generated, and the content of CO2 exceeds 60%. The high methane gas is treated by the low-carbon acid gas removal technique provided by the invention, obtain natural gas as a product meets requirements of a kind of natural gas to the content of CO2 and the content of sulfur in the national standard GB 17,820-2012, and obtained liquid CO2 meets requirements of geological storage. The technique comprises the following steps: firstly, washing the high methane gas with water to purify the high methane gas; then cooling the high methane gas; carrying out liquid separation on most of CO2; after rectifying, super-cooling and pressurizing the separated liquid CO2, geologically storing the separated liquid CO2; carrying out low-temperature methanol washing treatment on the high methane gas after most of CO2 is separated from the high methane gas. Most of CO2 in the high methane gas is geologically stored, emission of CO2 to the atmosphere is greatly reduced, and low-carbon production is realized.

Owner:重庆化工设计研究院有限公司

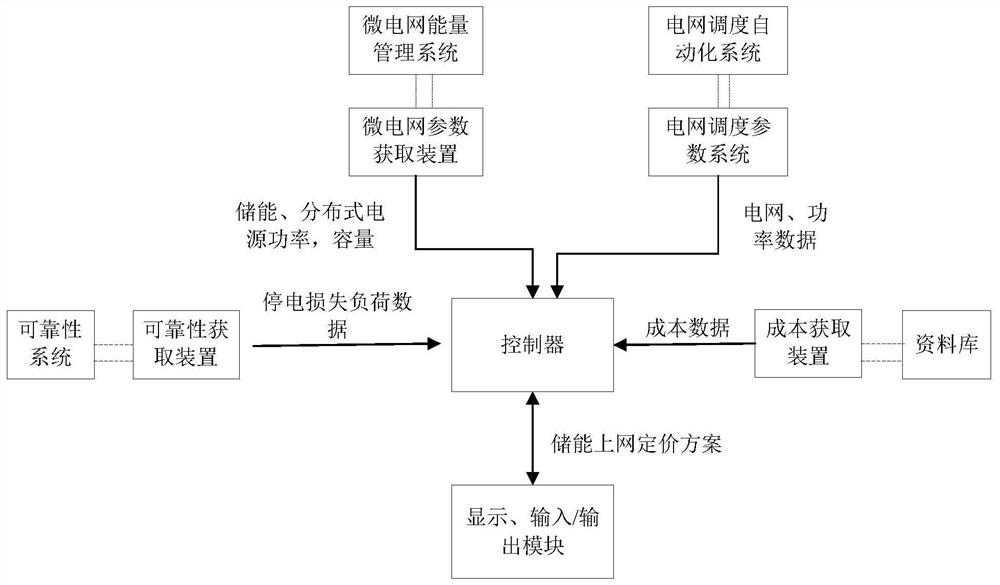

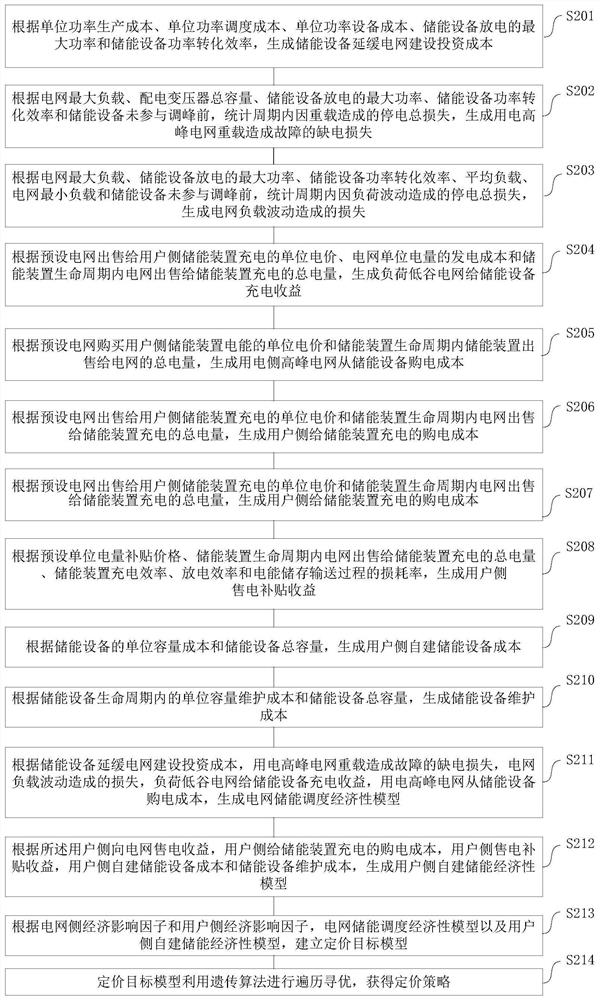

Energy storage online pricing system and method

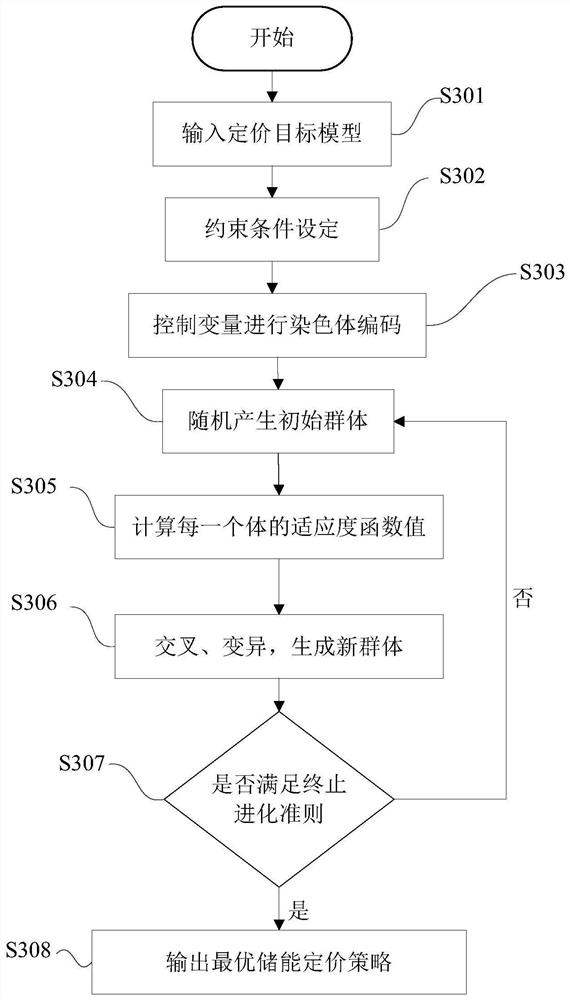

PendingCN112132638ADelay in construction investmentImprove economyDiscounts/incentivesForecastingBuilding energyGenetics algorithms

The invention relates to the technical field of micro-grids, and provides an energy storage online pricing system and method. The pricing system comprises a micro-grid parameter acquisition device, apower grid dispatching parameter acquisition device, a reliability acquisition device, a cost acquisition device, and a controller connected with the microgrid parameter acquisition device, the powergrid dispatching parameter acquisition device, the reliability acquisition device and the cost acquisition device. The controller is configured to generate a pricing target model, and the pricing target model performs traversal optimization by using a genetic algorithm to obtain a pricing strategy. The energy storage scheduling economy of a power grid and the self-built energy storage economy of auser side are maximized, so that self-built energy storage equipment of the user side is excited, the construction investment of the power grid is delayed, the power shortage loss and the load fluctuation are reduced, and the economy and reliability of power grid operation are improved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Bauxite ore dressed and ore cleaned tailings piling method

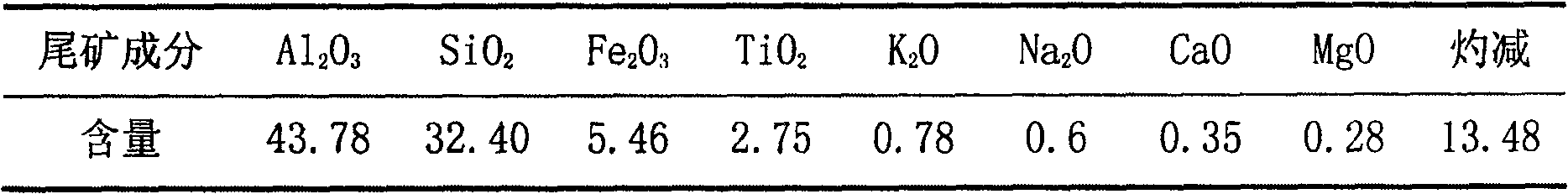

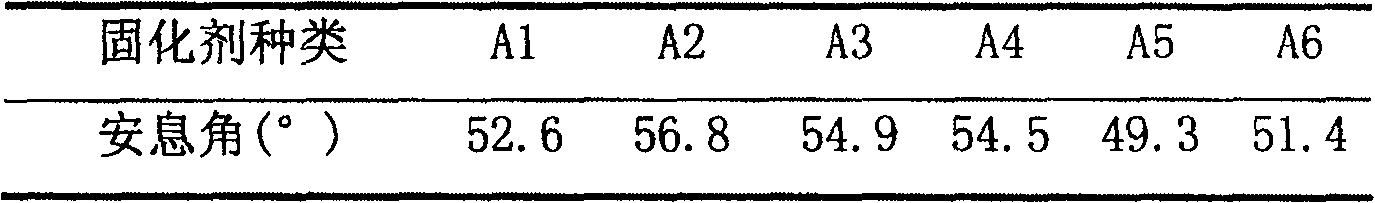

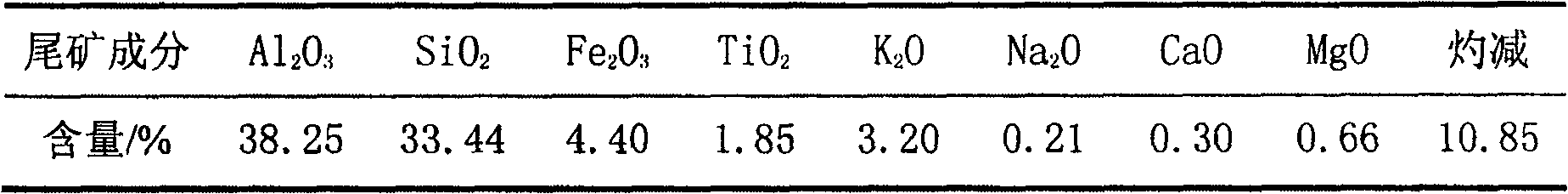

ActiveCN100593441CDelay in construction investmentHarm reductionOther chemical processesSolid waste disposalSulfateSlag

The invention relates to a method for selecting, washing, and stacking the alumyte, wherein it uses concentrate machine, high-effect deep taper concentrate machine, and tail mineral house to treat thealumyte into bottom flow or deposited sand; or dewater the bottom flow and deposited sand until the solid content of tail mineral is higher than 600g / l, adds lime dust and one or several of anhedritite, coal ash, mineral slag and sulfate to be mixed and transferred into stack site, to be compressed and solidified. The invention can realize dry stack, to reduce the area and effect on around condition.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Stage air-blowing composting device

PendingCN108147858AQuality improvementImprove efficiencyBio-organic fraction processingBiological combination treatmentOxygen utilization rateHigh energy

The invention belongs to the technical field of composting devices, and particularly relates to a stage air-blowing composting device. The stage air-blowing composting device aims at solving the problems of long composting period and high energy consumption when existing composting devices are adopted for conducting aerobic composting treatment on organic solid waste. The stage air-blowing composting device comprises a reaction tank, an air blowing unit and a stirring unit; the reaction tank is internally provided with four clapboards which divide the interior of the reaction tank into five regions, and each clapboard is provided with a discharge hole; the air blowing unit is provided with a main pipe, a plurality of branch pipes and a plurality of air distribution pipes, and the air distribution pipes are arranged in different regions in the tank body respectively and communicated with the main pipe through the independent branch pipes; the stirring unit includes blades connected to arotating shaft, and at least one set of blades are arranged on each clapboard. By means of the stage air-blowing composting device, oxygen can be accurately supplied according to the demand amount ofoxygen in different stages of aerobic composting fermentation, the oxygen utilization rate is increased, the composting period is shortened, and the energy consumption is reduced.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

Method for treating high concentration organic waste water

InactiveCN100368324CImprove degradation rateReduced footprintWaste based fuelTreatment with anaerobic digestion processesHigh concentrationSlag

Owner:绵阳馨源环保科技有限公司

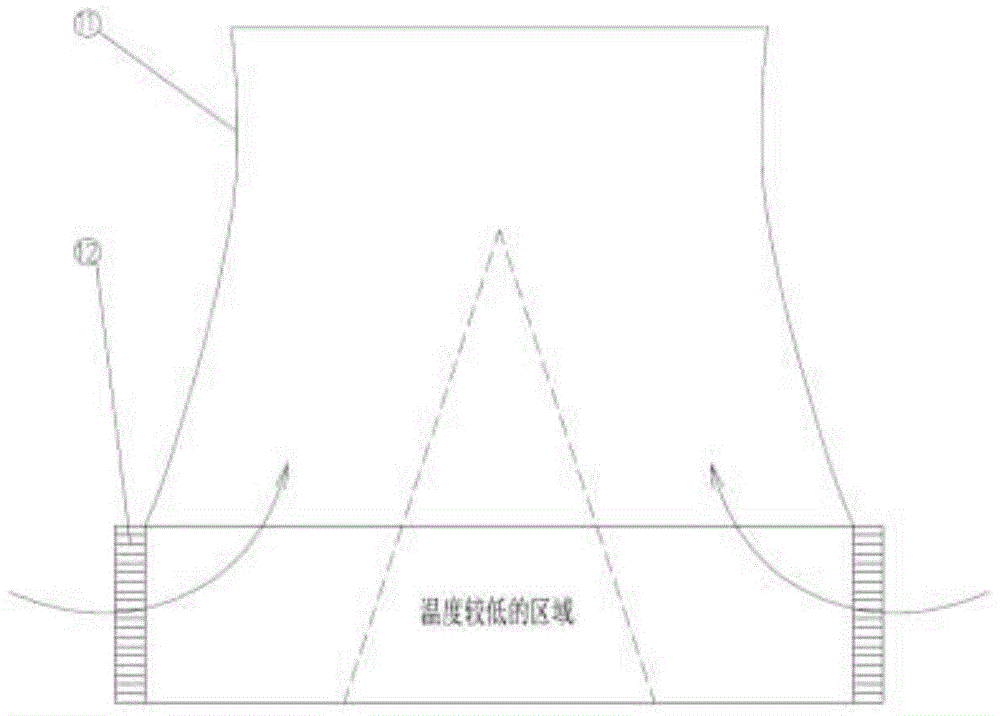

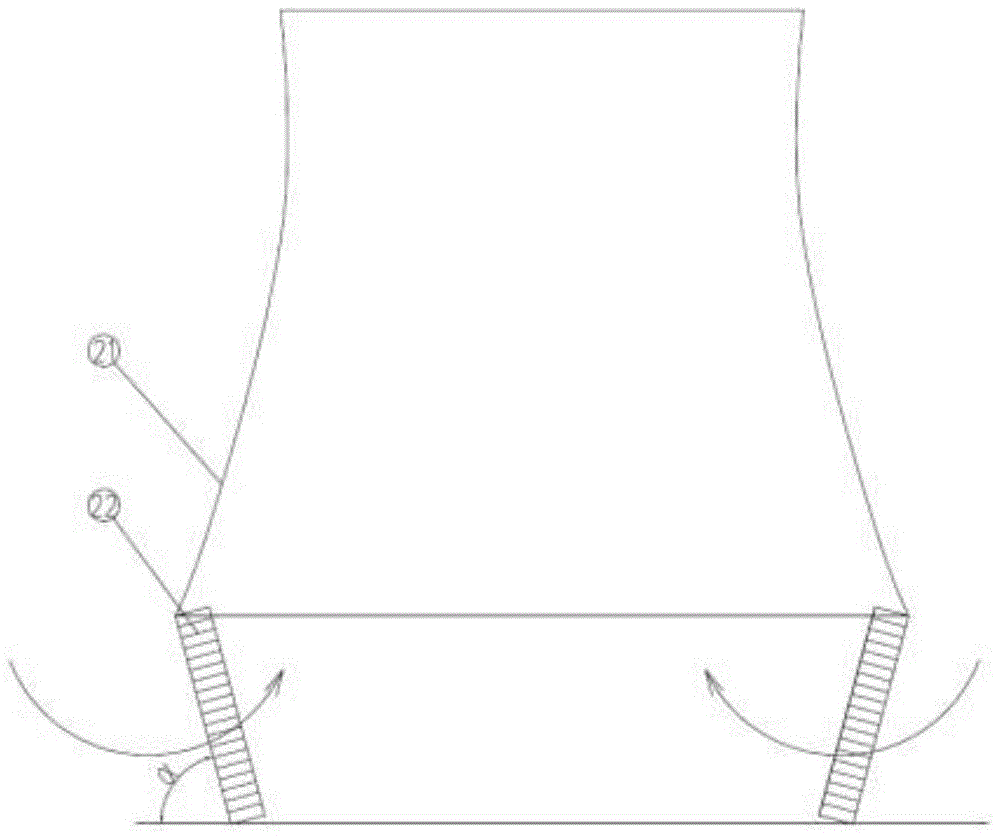

Indirect cooling tower with cooling triangles arranged obliquely

InactiveCN104697356AReduce water temperatureReduce coal consumption for power supplyTrickle coolersCooling towerEngineering

The invention discloses an indirect cooling tower with cooling triangles arranged obliquely, and particularly relates to an indirect cooling tower with cooling triangles arranged obliquely and segmented cooling triangles arranged obliquely. The indirect cooling tower comprises an indirect cooling tower drum and the cooling triangles arranged obliquely. After the structure is adopted, the indirect cooling tower has the following advantages that under the condition of the same diameter of the tower drum, the heat dissipation area can be increased; on the premise of ensuring the same heat dissipation area, the diameter of the tower drum of the cooling tower can be greatly reduced, occupied area and construction investment can be reduced, and the natural circulation power of the cooling tower can be increased; it can be effectively avoided that cross ventilation occurs in a crosswind environment to reduce the cooling efficiency; a temperature field and a flow field in the tower are more uniform.

Owner:SHANDONG UNIV

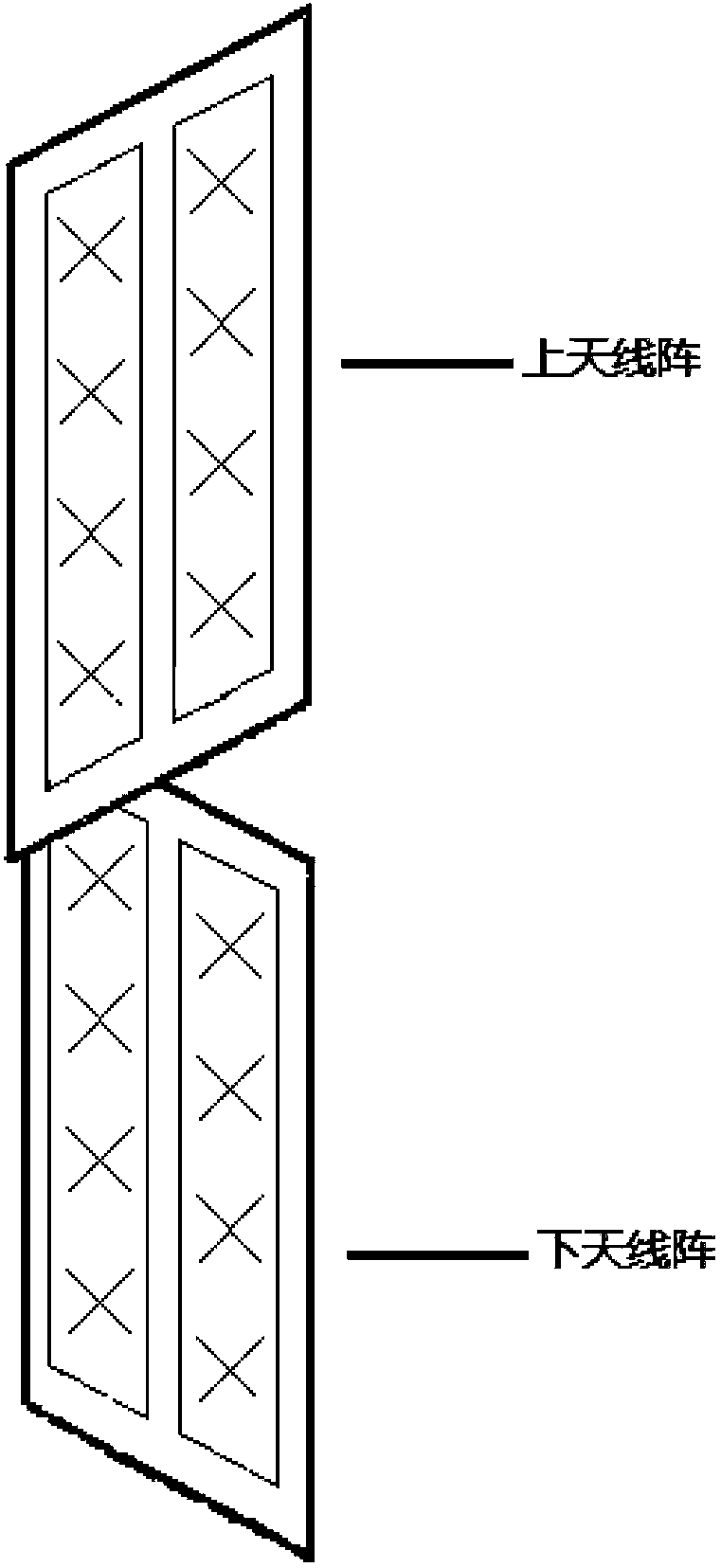

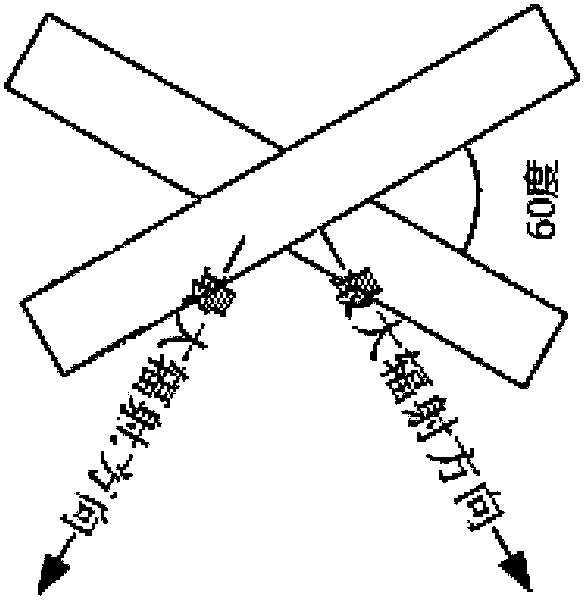

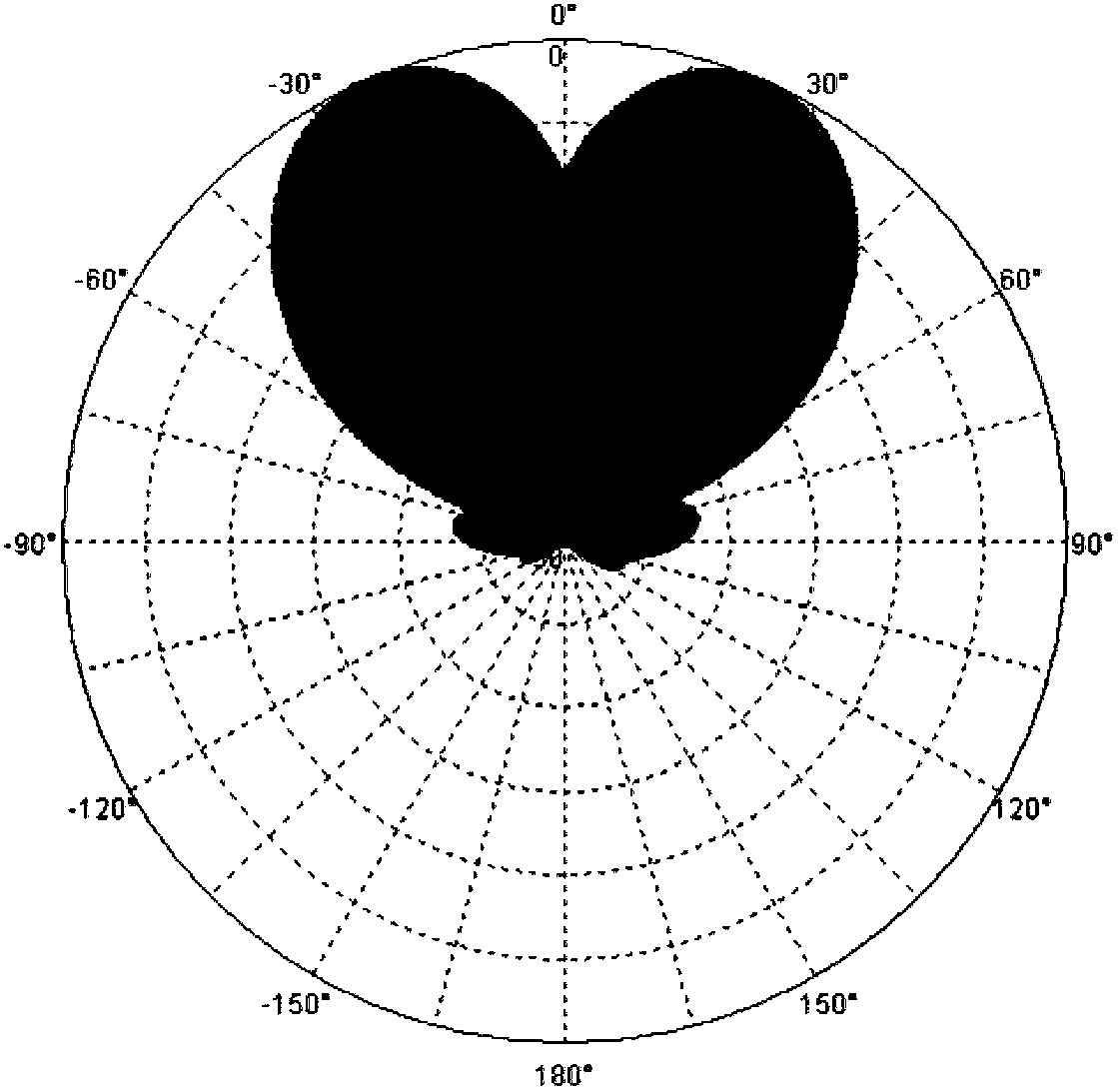

Multiple-input-multiple-output eight antennae and base station

ActiveCN104051864AWork lessDelay in construction investmentPolarised antenna unit combinationsAntenna designBeam direction

The invention discloses multiple-input-multiple-output (MIMO) eight antennae and a base station and relates to the field of mobile communication. The MIMO eight antennae include an upper antenna array and a lower antenna array. Two dual-polarization antennae are arranged in each of the upper and lower antenna arrays. The upper and lower antenna arrays adopt an up-down vertical isolation mode. The inclined angle of normal directions of the upper and lower antenna arrays is 60 degrees. The two dual-polarization antennae in the upper / lower antenna array are capable of forming 33-degree horizontal width wave beams at two different polarization directions. The 33-degree horizontal width wave beams formed by the upper / lower antenna array are vertical to the plane of the upper / lower antenna array and the wave beam direction is the normal direction of the plane of the upper / lower antenna array. The invention proposes an MIM-eight-antenna design scheme which is based on the vertical isolation mode and compatible with three-sector and six-sector configurations so that an antenna device can be used under both of a three-sector configuration and a six-sector configuration and thus the antenna device does not need to be replaced.

Owner:CHINA TELECOM CORP LTD

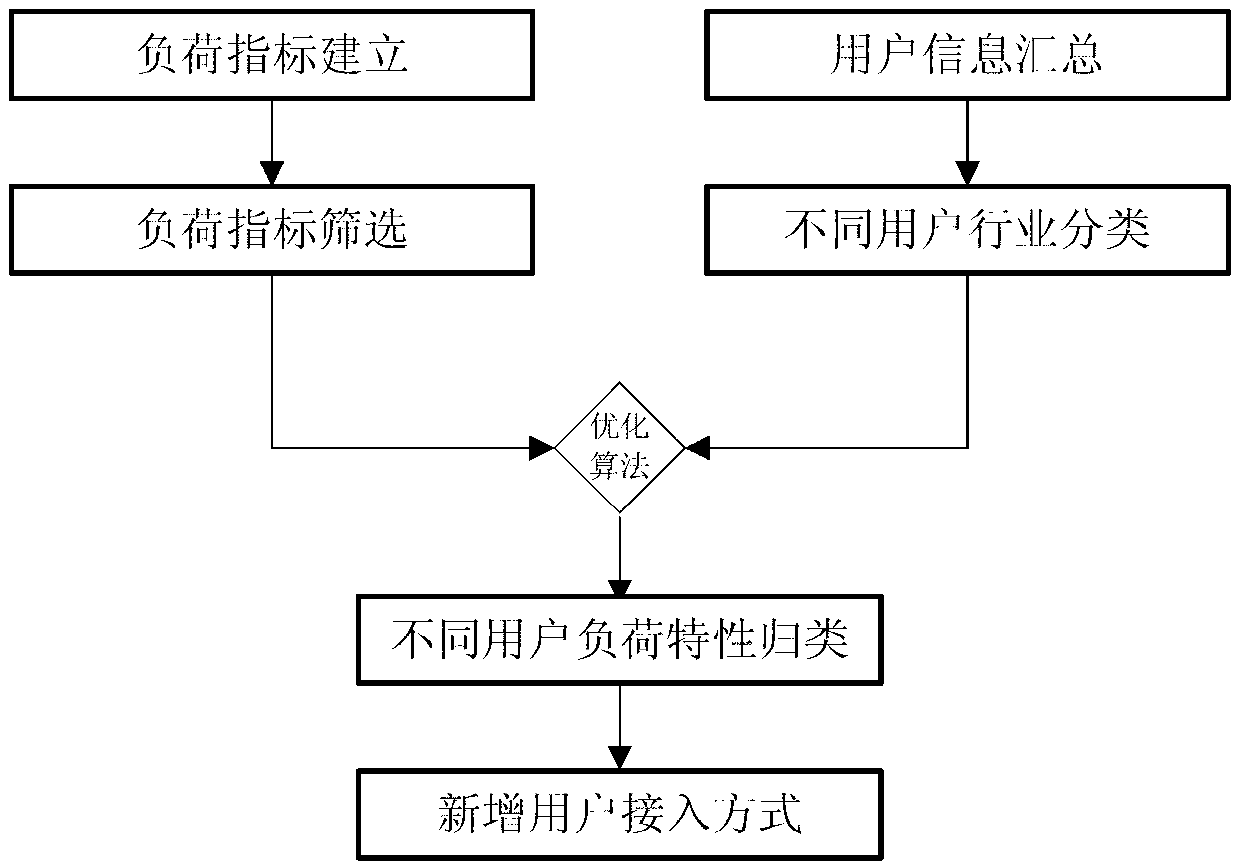

Processing method for optimizing connecting information of new consumers of power distribution network

ActiveCN103345659AReduce lossImprove operational efficiencyForecastingOperational costsElectric power system

The invention relates to a processing method for optimizing connecting information of new consumers of a power distribution network. The processing method for the optimizing connecting information of the new consumers of the power distribution network comprises the following steps of (1) carrying out industry classification on the new power consumers , meanwhile, carrying out analysis on the connected power distribution network, (2) carrying out matching on the new consumers and the power distribution network according to a different consumer combination optimization algorithm, and (3) obtaining the optimizing connecting information of the new consumers. Compared with the prior art, the processing method for the optimizing connecting information of the new consumers of the power distribution network has the advantages of improving operating efficiency of power generation and supply devices, reducing operating cost of a power system, reducing consumption of resources, being beneficial to environmental protection and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

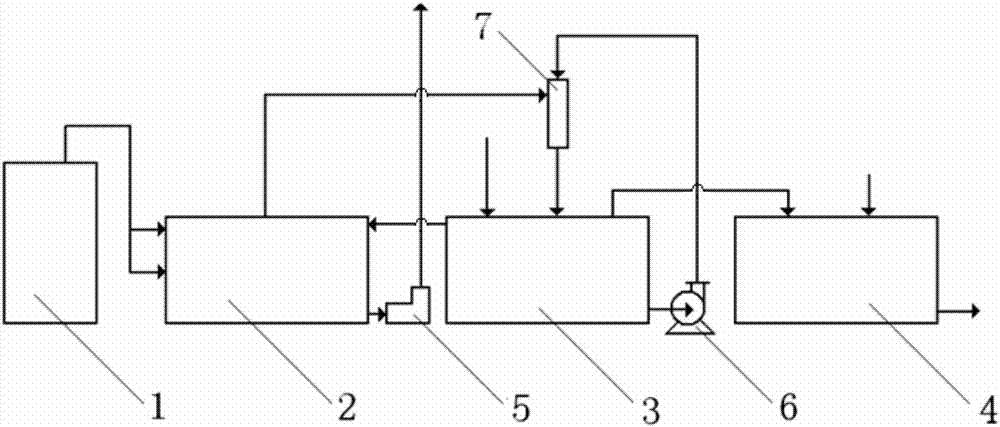

Active chlorine dioxide disinfectant production method and apparatus

ActiveCN107509742AIncrease concentrationImprove absorption efficiencyBiocideDisinfectantsHigh concentrationChlorine dioxide

The invention discloses an active chlorine dioxide disinfectant production method. The active chlorine dioxide disinfectant production method comprises the following steps: (1) pumping high-purity ClO2 gas prepared by a high-purity chlorine dioxide generator into a middle part and an upper part of an absorption trough under the negative pressure, performing the forced bubbling absorption, preparing a high-concentration active ClO2 solution, and directly sending a finished product into an application field by virtue of a metering pump; (2) absorbing, by the absorption trough, tail gas, enabling circulating liquid of a circulating trough to pass through a circulating pump, pumping by virtue of a water injector, re-introducing the tail gas absorbed by the circulating trough into a tail gas treatment trough, and regularly discharging the treated neutralization solution; and (3) enabling the circulating liquid of the circulating trough to overflow into the absorption trough, and supplementing the circulating liquid of the circulating trough by virtue of tap water. The invention also discloses an apparatus for the method of the invention. By adopting the method, the investment is reduced, the absorption rate is increased, and the effect for absorbing ClO2 is ideal.

Owner:SHENZHEN OUTAIHUA ENG EQUIP

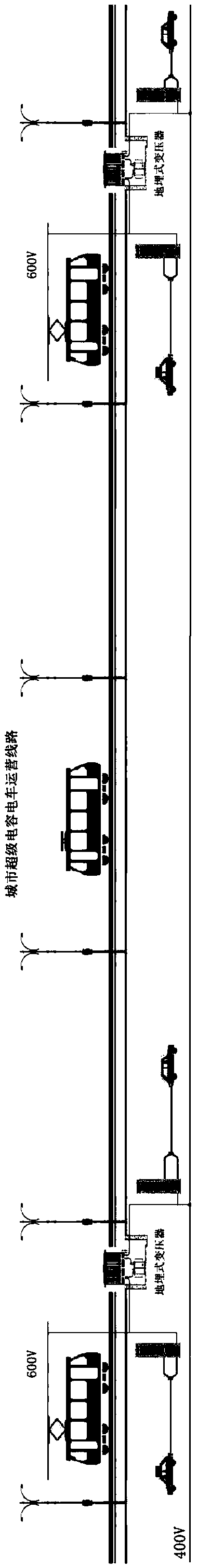

Electric vehicle charging management method and system based on urban infrastructure

ActiveCN105244931BSolve the load pressureImprove power supply flexibilityBatteries circuit arrangementsCharging stationsFast chargingElectric cars

The invention discloses and provides an electric vehicle charging management method based on urban infrastructure, which can realize high efficiency, less space, and low investment, and can solve the bottleneck of large-scale popularization of electric vehicles to supplement electric energy and hinder the development of electric vehicles. and system. The power supply dispatching software management system receives in real time the power values of several substations in the city and the power storage conditions sent by the energy storage batteries in the substations, and sends the real-time power distribution command to the substations or the energy storage batteries; the substation Or the energy storage battery selects the electric vehicle to be charged and the charging and discharging power after receiving the command power value of the power dispatching software management system, and sends an instruction to the substation fast charging device to charge the electric vehicle; the substation quickly The charging device performs charging of the electric vehicle. The invention can be widely used in the charging field of electric vehicles.

Owner:ZHUHAI TITANS TECH

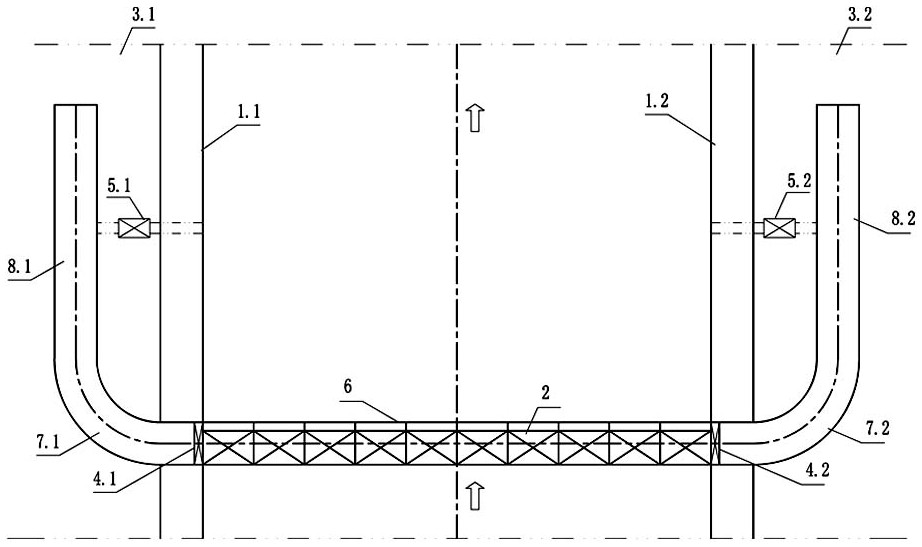

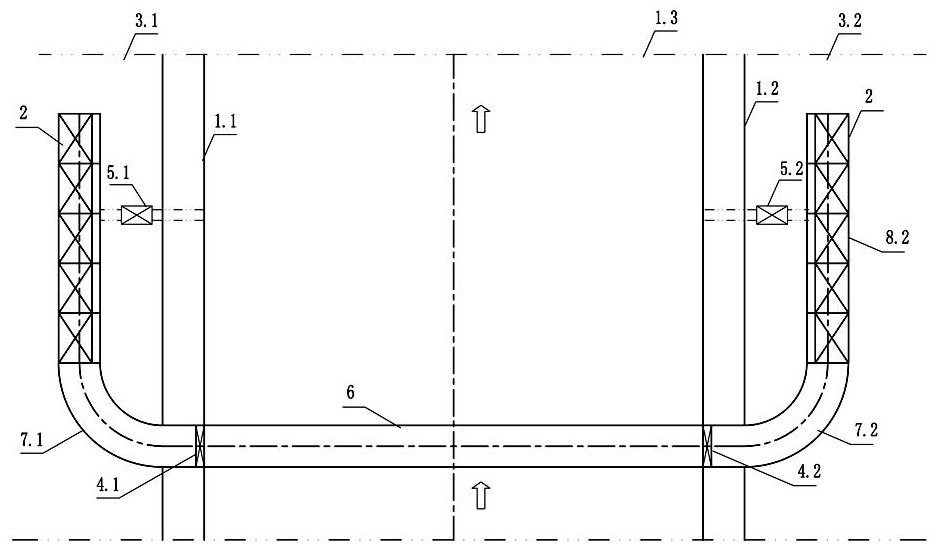

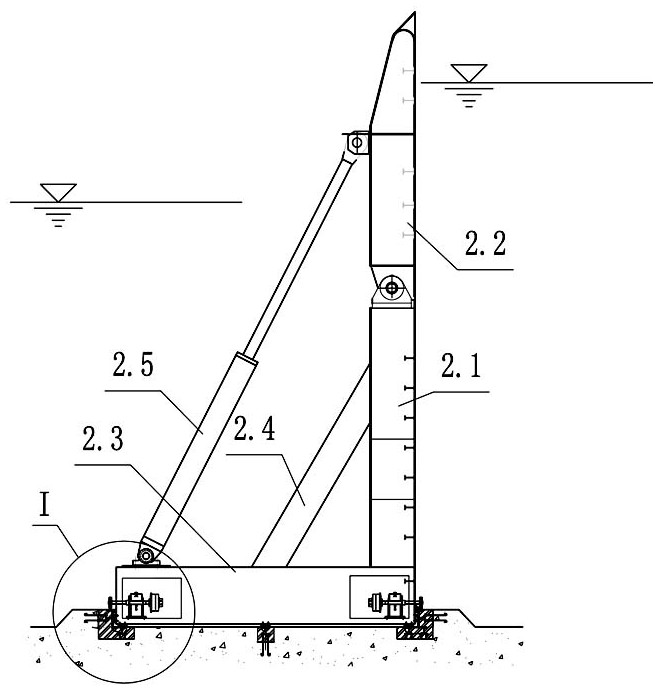

Multi-unit driven translation gate with tongue flaps

PendingCN113931142ASolve the strength problemSolve the requestBarrages/weirsStructural engineeringMechanical engineering

The invention discloses a multi-unit driven translation gate with tongue flaps. The translation gate comprises a gate chamber consisting of left and right gate piers and a gate baseplate, and a gate arranged between the left and right gate piers; left and right gate warehouses are respectively arranged on the outer sides of the left and right gate piers; access doors communicated with the left and right gate warehouses are formed in the left and right gate piers; a gate rail is transversely paved in the gate baseplate; two ends of the gate rail extend into the corresponding left and right gate warehouses, and are joined with access rails in baseplates of the left and right gate warehouses through arc rails; and the gate consists of multiple gate units with independent driving devices. The translation gate solves the problem of difficult satisfaction of the strength and the rigidity of a large-span gate, is more reasonable in stress structure, greatly reduces the engineering quantity and the construction investment compared with an integral large-span gate, meanwhile, solves the problems of no-water maintenance and difficult operation of the gate, and reduces the resistance in the gate opening and closing process.

Owner:YELLOW RIVER ENG CONSULTING

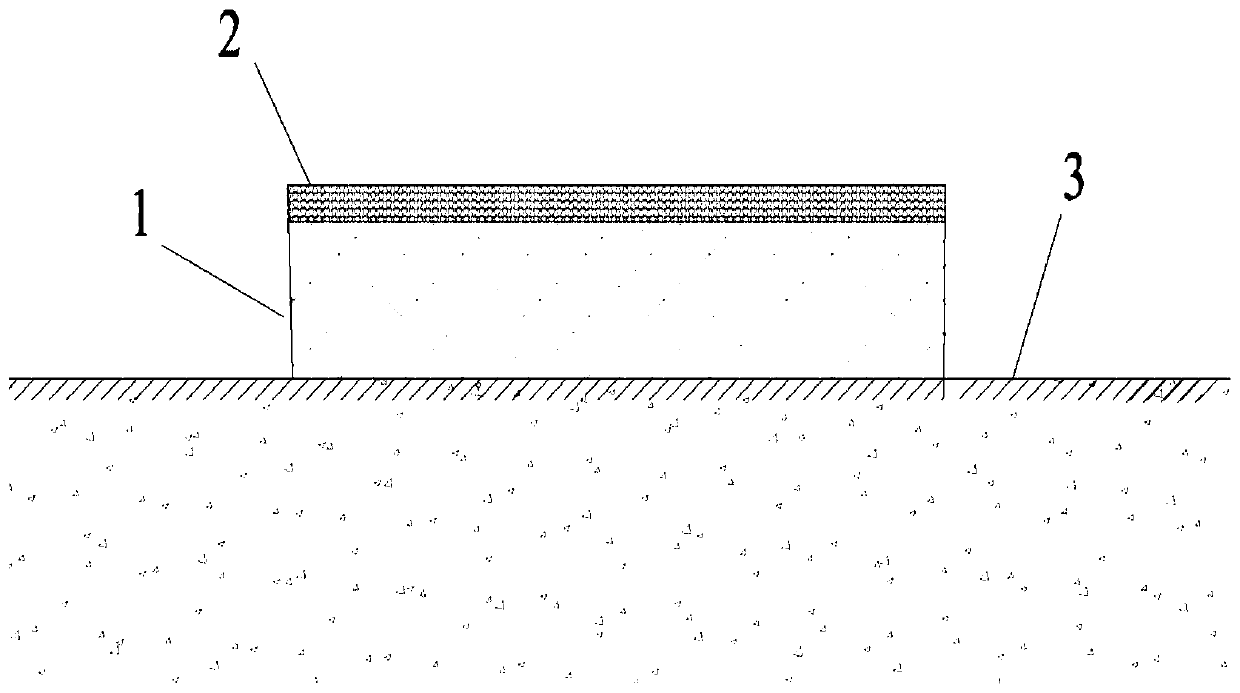

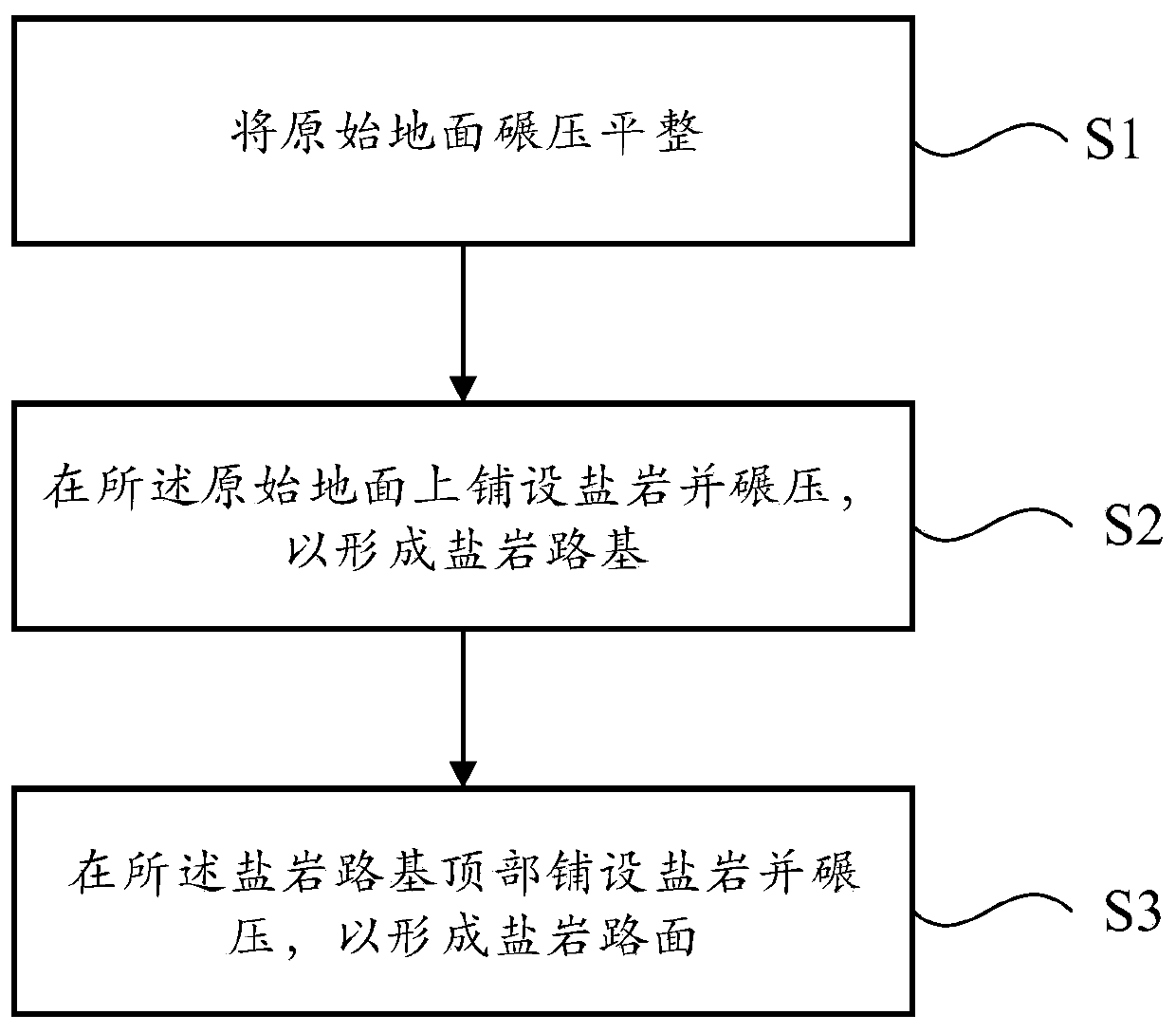

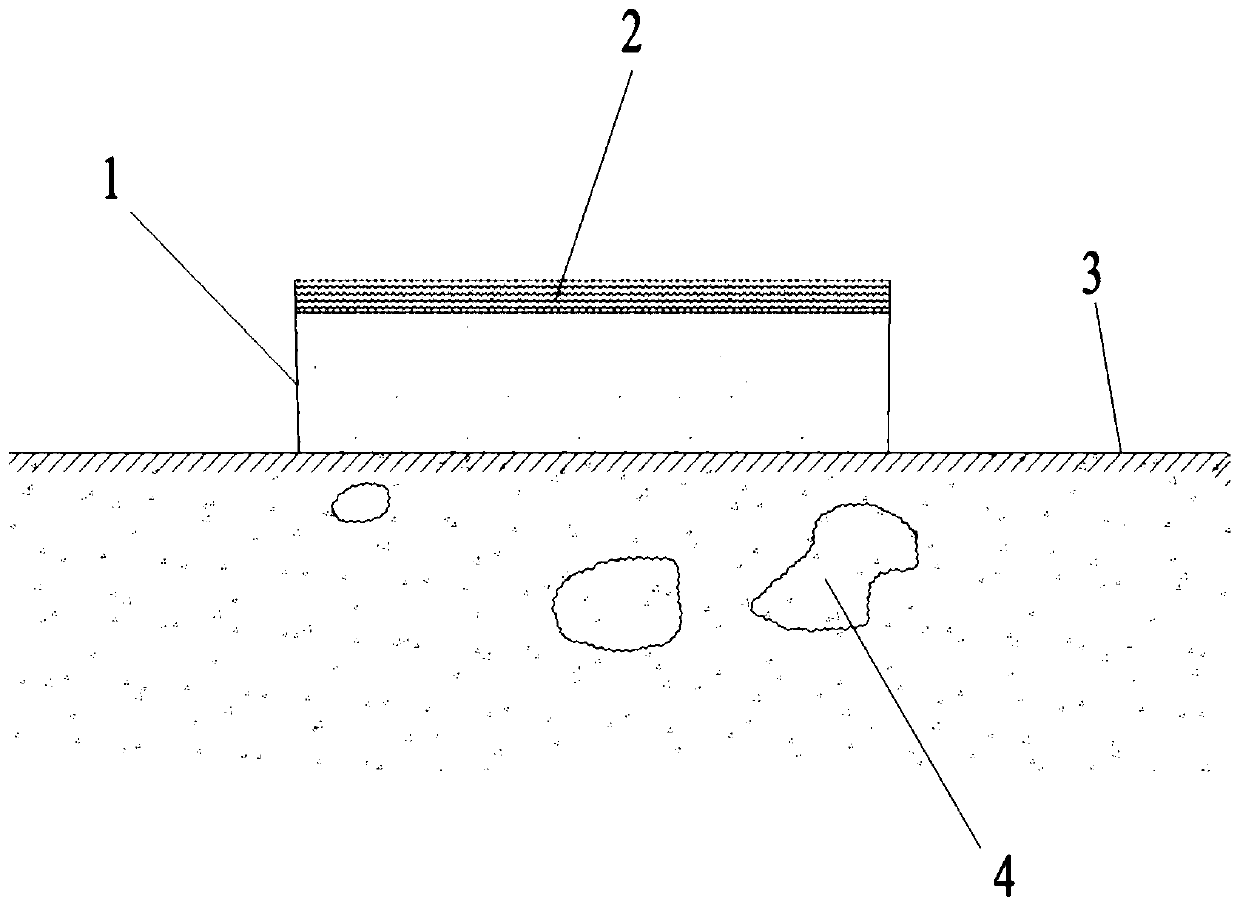

Factory and mine salt rock road and construction method thereof

InactiveCN109736175ADelay in construction investmentLow costIn situ pavingsClimate change adaptationSubgradeEnvironmental geology

The invention provides a factory and mine salt rock road and a construction method thereof. The construction method comprises the steps that S1, the original ground is rolled and leveled; S2, salt rock is paved on the original ground and rolled to form a salt rock subgrade; and S3, the salt rock is laid on the top of the salt rock subgrade and ground to form a salt rock pavement. According to thetechnical scheme, the salt rock is used for constructing the road, local materials are used, and road construction and raw material investment and cost are reduced; the built salt rock road is stablein performance, not prone to collapse, good in safety and easy to maintain; the constructed salt rock road meets the construction standard, the application effect is good, and the actual transportation requirement is met.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com