Feeding system for blast furnace ore and coke channel system

A coke trough and blast furnace technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of large overall floor area, low top surface height, and re-crushing of materials, so as to reduce floor space and effective volume Reduce, optimize the effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

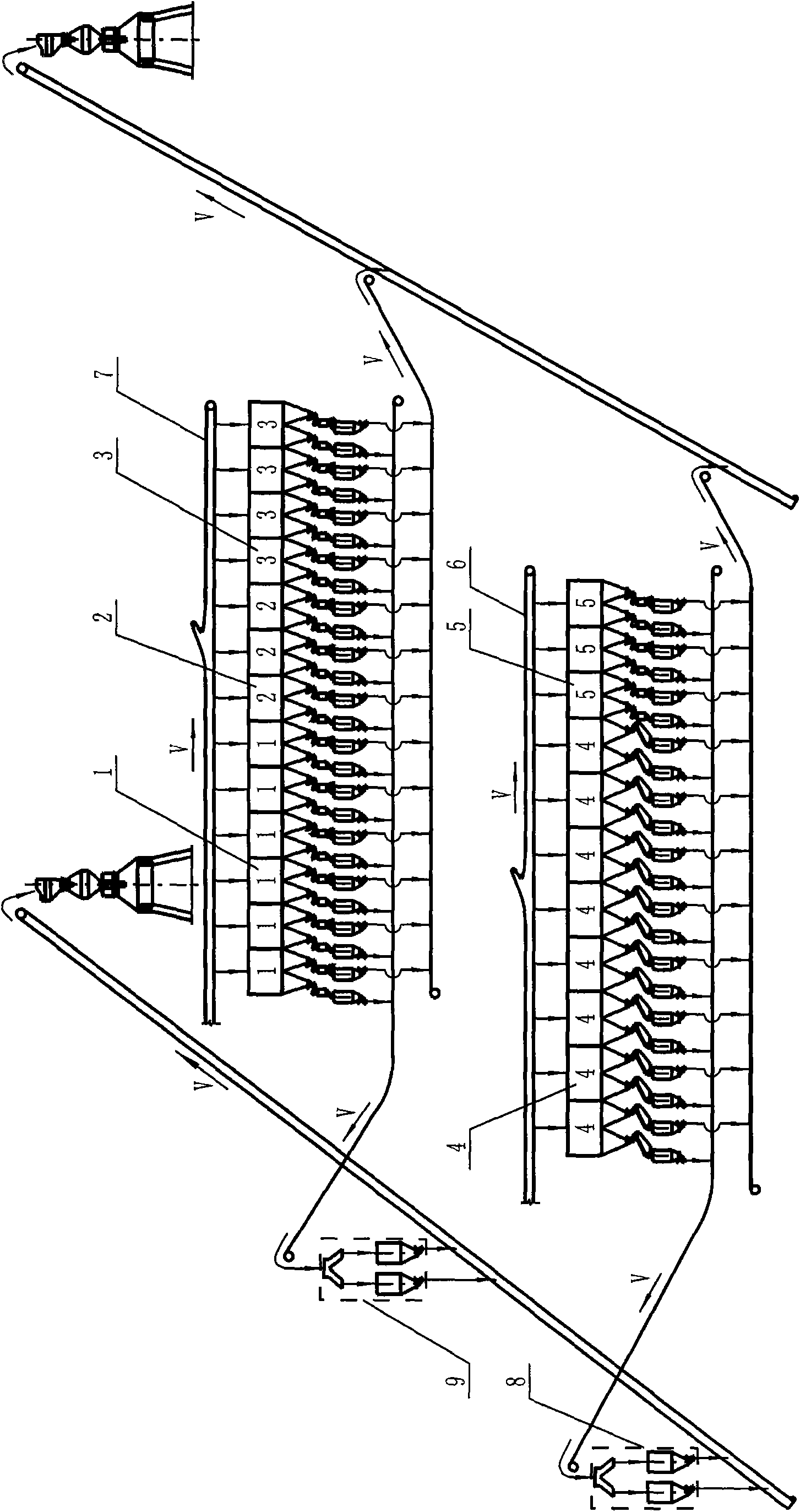

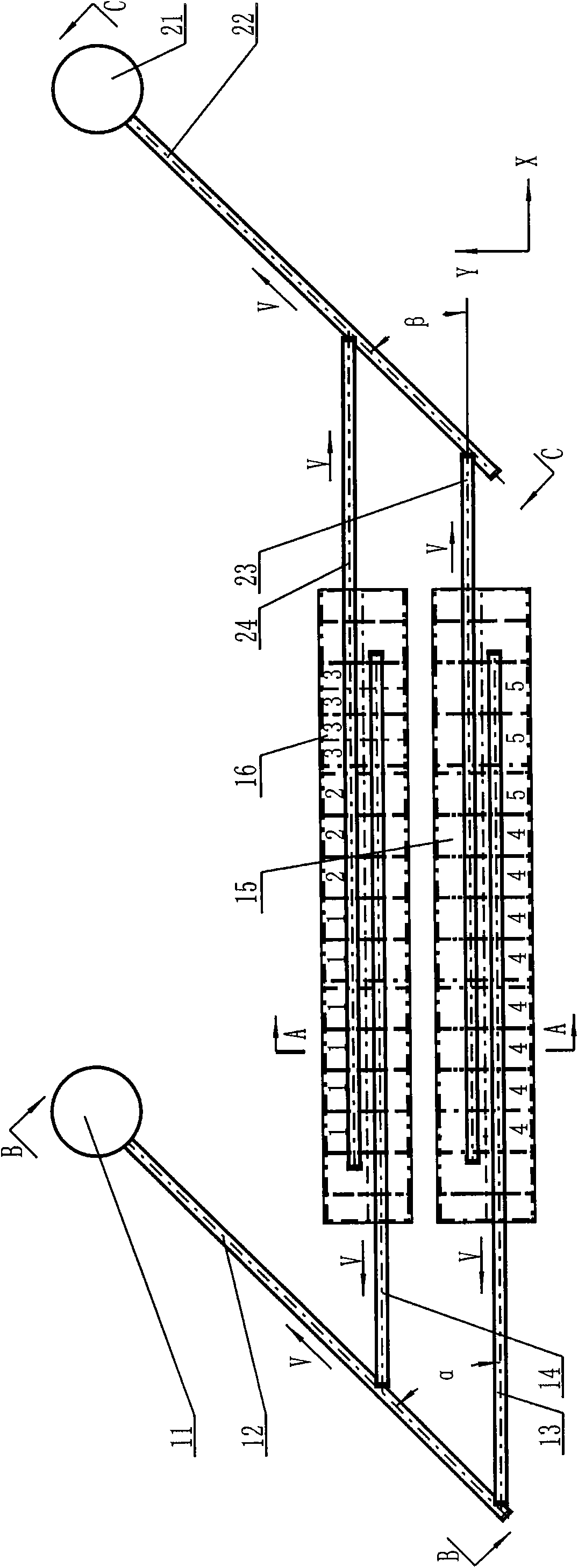

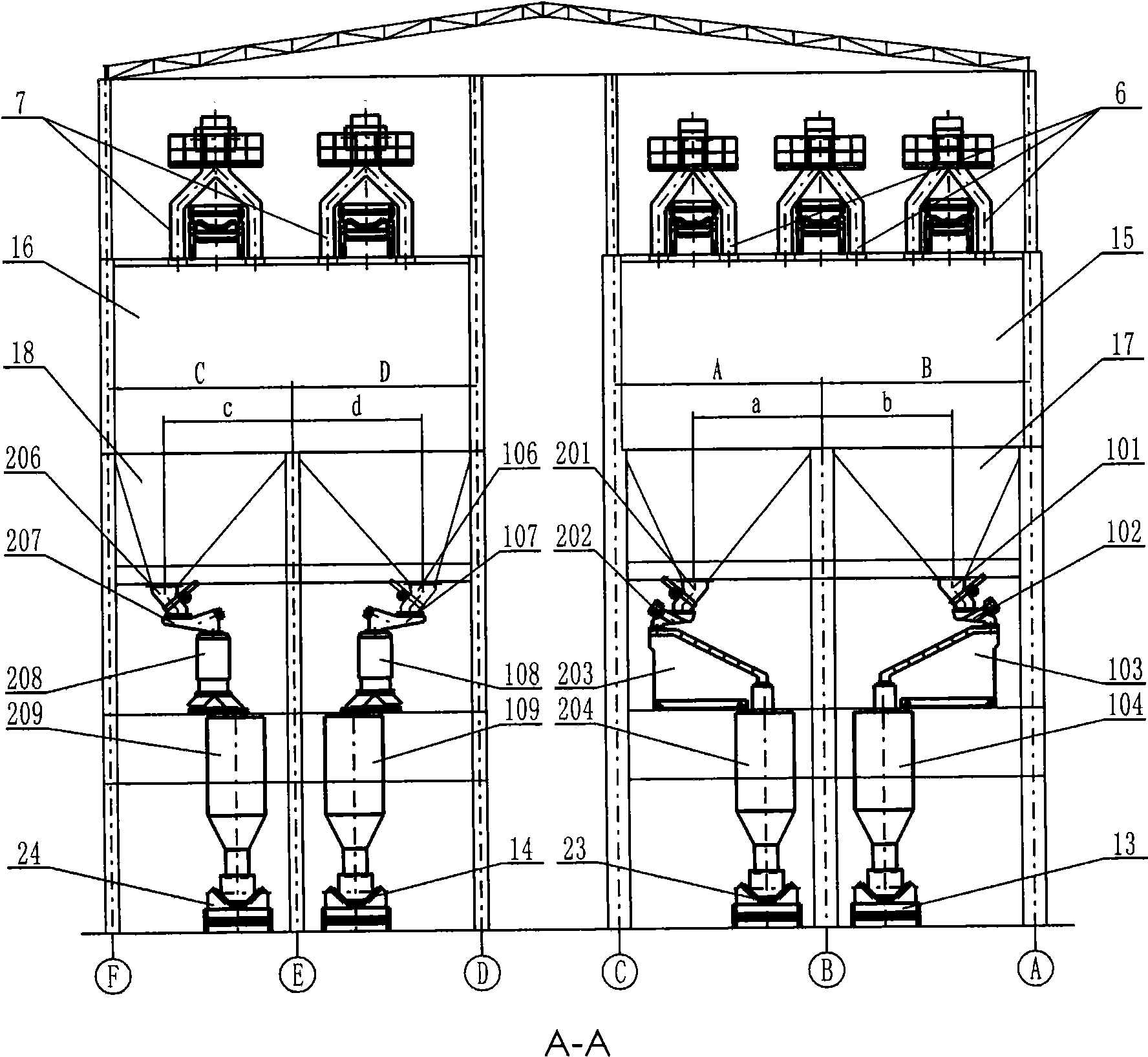

[0057] Figure 1 to Figure 5 It is a specific embodiment of the present invention. As can be seen from the figure, this embodiment provides a feeding system for blast furnace ore and coke trough, which can serve two blast furnaces, including: 1# blast furnace 11, 1# blast furnace main belt conveyor 12, 1# blast furnace ore chute Lower feeding belt machine 13, 1# blast furnace coke groove lower feeding belt machine 14, mine side tank body 15, coke side tank body 16, 2# blast furnace 21, 2# blast furnace main belt machine 22, 2# blast furnace mine tank Feeding belt machine 23 under the trough, 24 feeding belt machine 24 under the coke trough of the 2# blast furnace, the hopper 17 under the mine side trough body, and the hopper 18 under the coke side trough body.

[0058]The raw materials and fuels required by the two blast furnaces are transported to the top surface of the ore and coke tanks of the blast furnace through the mechanized transportation system (the previous process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com