Technical method for treating silicon carbide acidic wastewater

A technology of acid wastewater and process methods, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to reduce construction investment and renovation funds, reduce resource loss rate, and reduce treatment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

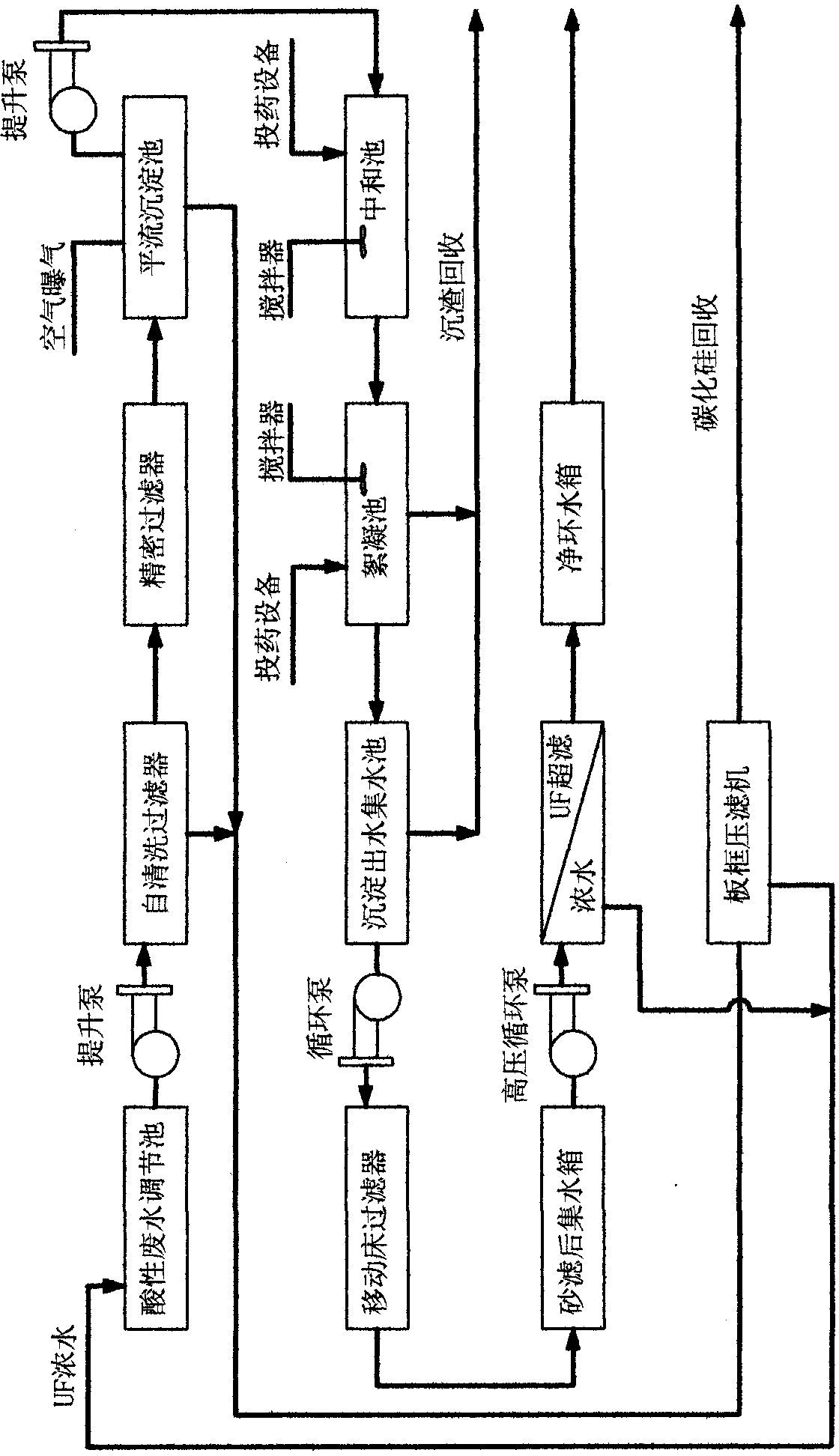

[0017] See figure 1 , the process method of the present invention for treating silicon carbide acidic wastewater, adopts high-concentration suspended matter pretreatment to reduce suspended matter; neutralizes flocculation and sedimentation; sand filtration primary advanced treatment; ultrafiltration secondary advanced treatment four parts, realized according to the following process steps:

[0018] (1) Pretreatment of high-concentration suspended solids to reduce suspended solids: In the stage of high-concentration suspended solids ss pretreatment to reduce turbidity, the acidic wastewater generated during the production of silicon carbide is mixed with the iron removal cleaning water after ball milling and other equipment cleaning water Send them together to the acidic wastewater regulating tank. After the pH value is naturally adjusted, the incoming water is homogeneous, and the water volume is stabilized in the acidic wastewater regulating tank, the water in the acidic was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com