Preparation method of high-purity cannabidiol

A high-purity technology of cannabidiol, applied in the field of preparation of high-purity cannabidiol, can solve the problems of complex phenolic components and affecting the safety of CBD products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

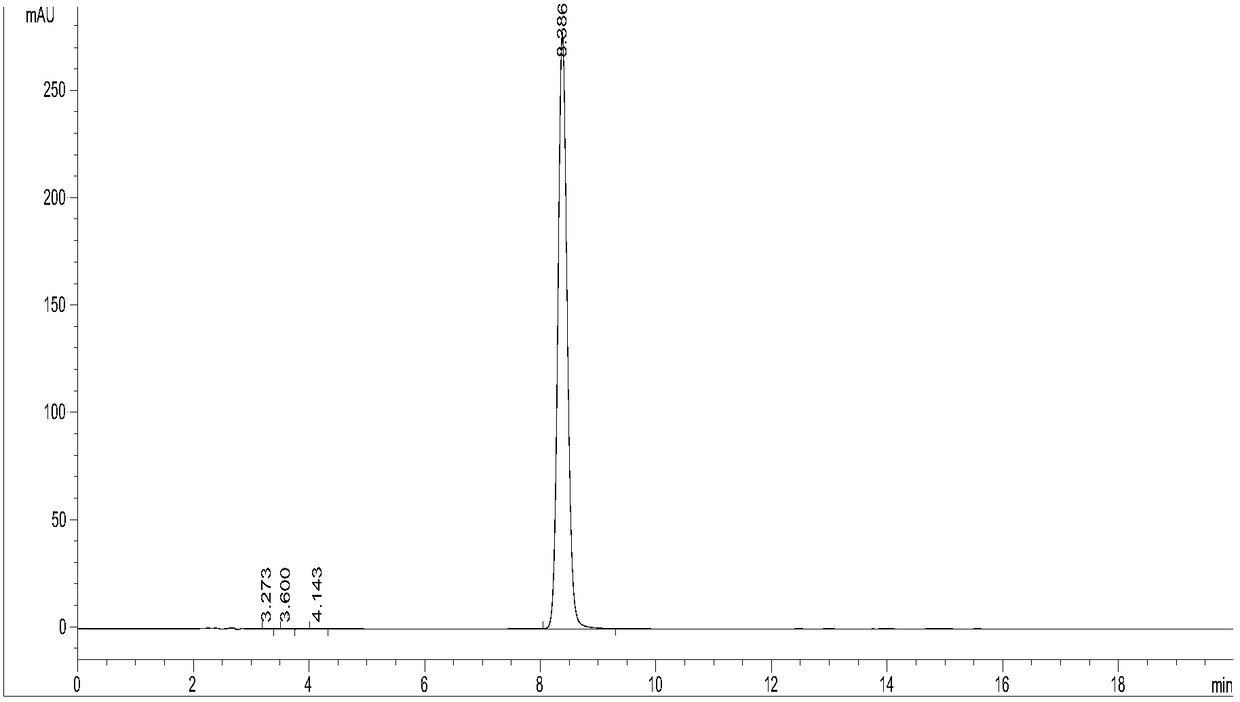

Image

Examples

Embodiment 1

[0022] Embodiment 1. Preparation of high-purity CBD

[0023] ①Solvent extraction: take the top part of the hemp which accounts for about one-fifth of the whole plant, dry it and crush it into the coarsest powder, extract it three times with 95% ethanol as the solvent, and use 10 times the amount of solvent each time. The extracts were combined and filtered, dealcoholized under reduced pressure at 50°C until the solution was slightly cloudy, and cooled to room temperature.

[0024] ② Two-step column chromatography:

[0025] The first step of column chromatography: HPD-417 macroporous adsorption resin is used as the chromatography medium, and the column load is 5g medicinal material / mL resin. First eluted with 45% ethanol for 7 column volumes to wash away most of the polar impurities, and then eluted with 85% ethanol for 5 column volumes to elute the target components. Collect the eluate rich in target components, dealcoholize under reduced pressure at 50°C until the solution ...

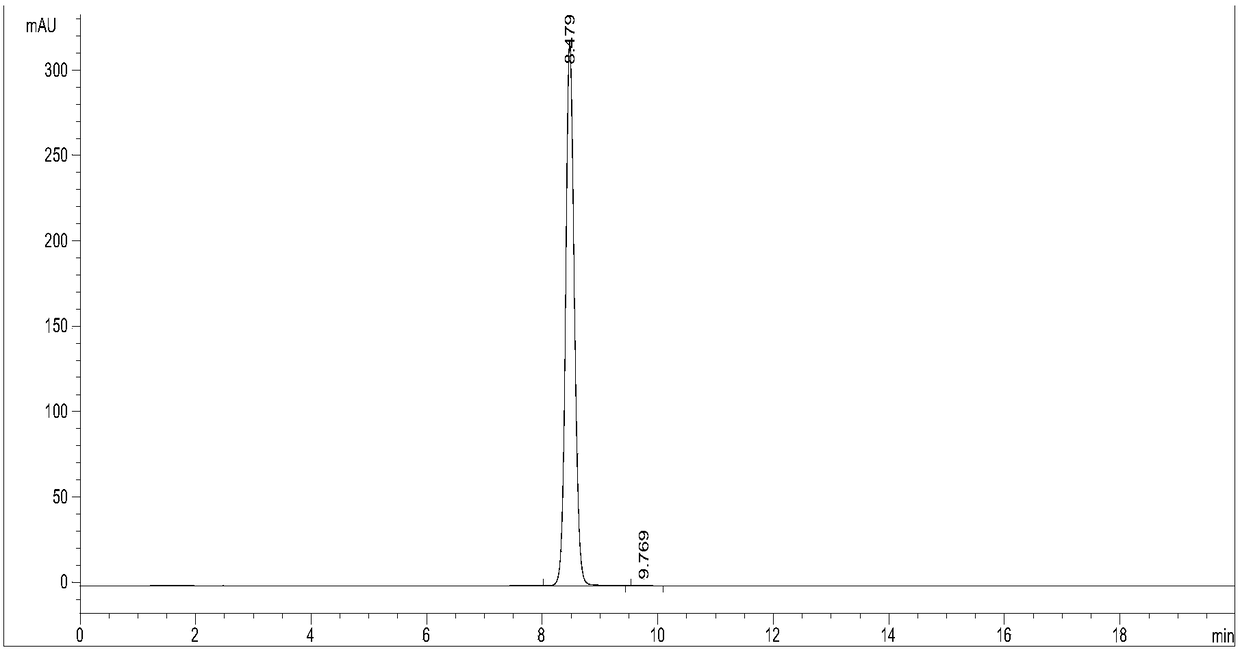

Embodiment 2

[0028] Embodiment 2. Preparation of high-purity CBD

[0029] ①Solvent extraction: Take the top part of the hemp which accounts for about one-fifth of the whole plant, dry it and crush it into the coarsest powder, extract it three times with 95% ethanol as the solvent, and use 15 times the amount of solvent each time. The extracts were combined and filtered, dealcoholized under reduced pressure at 60°C until the solution was slightly cloudy, and cooled to room temperature.

[0030] ② Two-step column chromatography:

[0031] The first step of column chromatography: HPD-450 macroporous adsorption resin is used as the chromatography medium, and the column load is 3g medicinal material / mL resin. First eluted with 55% ethanol for 5 column volumes to wash away most of the polar impurities, and then eluted with 95% ethanol for 3 column volumes to elute the target components. Collect the eluate rich in target components, dealcoholize under reduced pressure at 60°C until the solution ...

Embodiment 3

[0034] Embodiment 3. Preparation of high-purity CBD

[0035] ①Solvent extraction: take the top part of the hemp which accounts for about one-fifth of the whole plant, dry it and crush it into the coarsest powder, extract it three times with 95% ethanol as the solvent, and use 20 times the amount of solvent each time. The extracts were combined and filtered, dealcoholized under reduced pressure at 70°C until the solution was slightly cloudy, and cooled to room temperature.

[0036] ② Two-step column chromatography:

[0037] The first step of column chromatography: AB-8 type macroporous adsorption resin is used as the chromatography medium, and the column load is 8g medicinal material / mL resin. First elute with 55% ethanol for 3 column volumes to wash away most of the polar impurities, and then use 95% ethanol for 3 column volumes to elute the target components. Collect the eluate rich in target components, dealcoholize under reduced pressure at 70°C until the solution is slig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com