Energy-saving and environmentally-friendly complete equipment for garbage compaction transfer station

A technology for garbage compression and complete sets of equipment, applied in the field of environmental sanitation equipment, can solve the problems of substandard environmental protection, large investment and high energy consumption, reduce construction investment and resource consumption, meet energy saving and environmental protection requirements, and maximize the efficiency of compression and transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

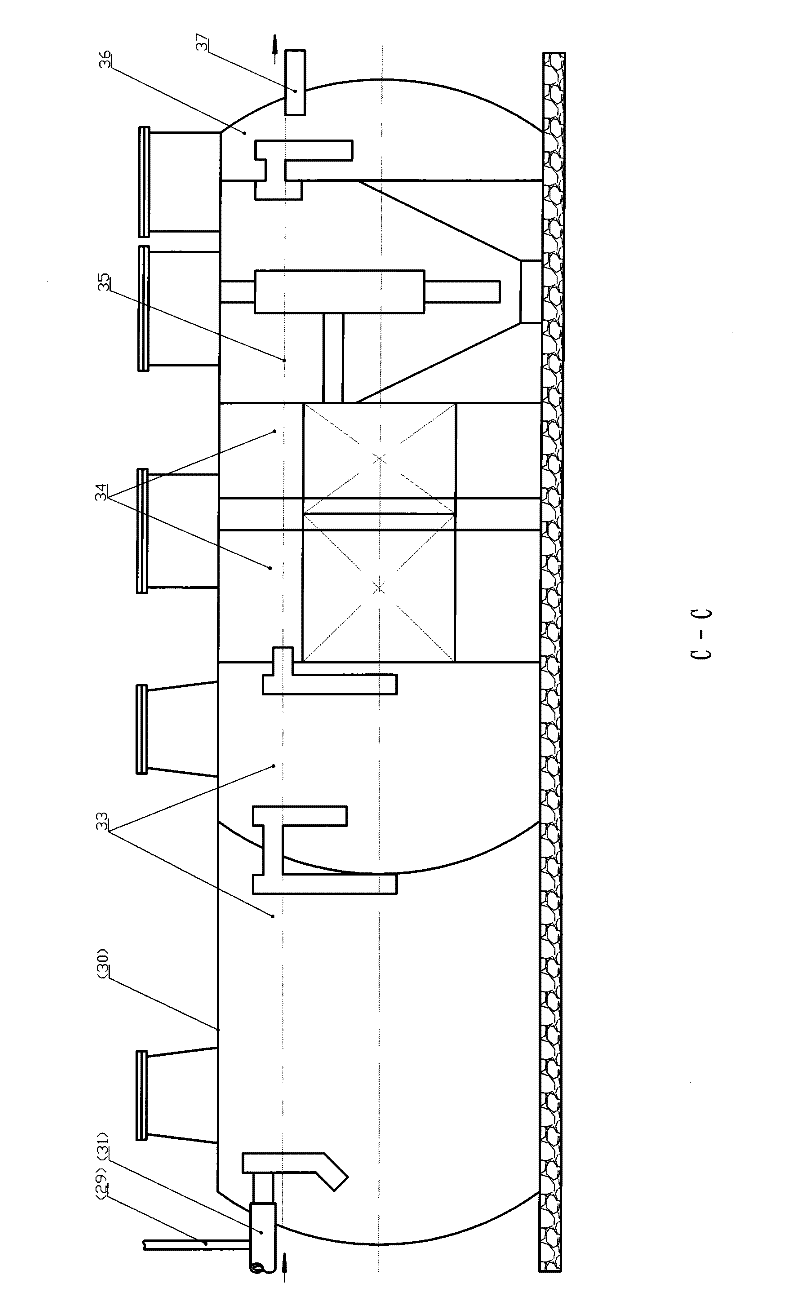

[0013] In order to meet the basic functions and environmental protection requirements of the garbage compression transfer station, garbage compression equipment, dust reduction and deodorization equipment, sewage treatment equipment and machine rooms must be completely matched; Auxiliary facilities such as green belts to further improve the working conditions and working environment of the garbage compression transfer station.

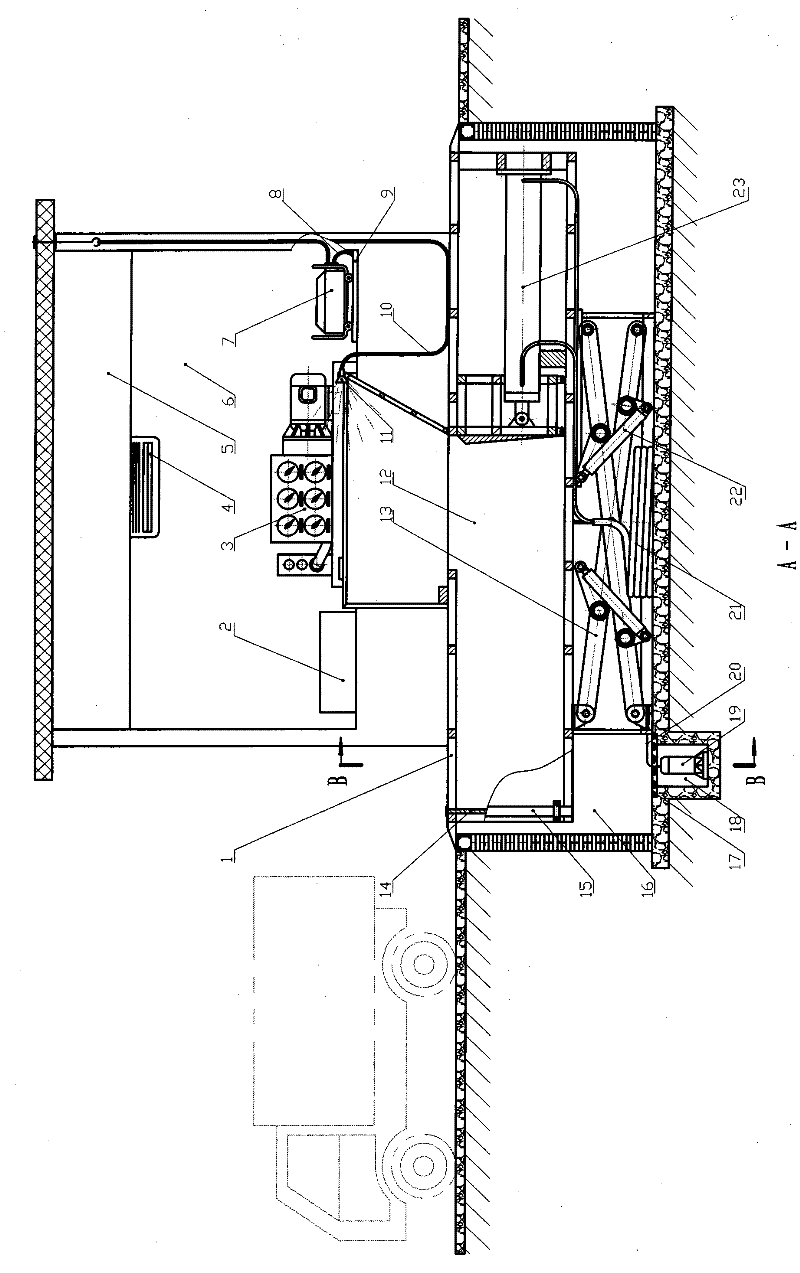

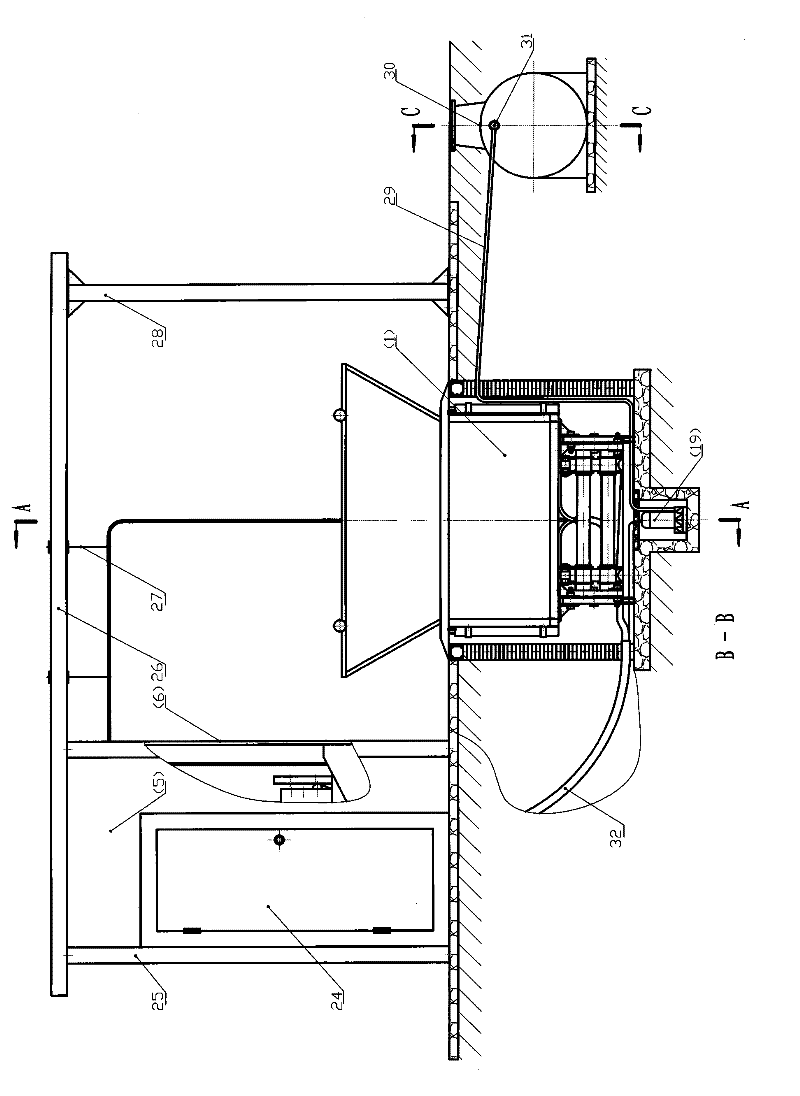

[0014] figure 1 and figure 2 Among them, the garbage compression equipment of the present invention adopts a buried horizontal garbage compressor (1) with compact structure, simple operation, less energy consumption and high efficiency, its operating console (2), hydraulic pump station (3 ) and the supporting wall-mounted air conditioner (4), installed in the closed control room (5) in the simple machine room on the ground, its compression storage box (12) and scissor type hydraulic lifting parts (13), or left or right It is installed in the pit (16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com