Sample analysis chip, sample analyzer using sample analysis chip, sample analysis method, and method of producing sample analysis chip

A technology for analyzing chips and manufacturing methods, applied in chemical instruments and methods, biochemical equipment and methods, analytical materials, etc., can solve the problems of damaged metal substrate flatness, insufficient thermal responsiveness, erroneous test results, etc., Achieving the effect of reducing deviation, small and inexpensive reaction chip, and reducing non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0180] Example 1 shows an example of using the sample analysis chip of the present invention as a SNPs analysis chip.

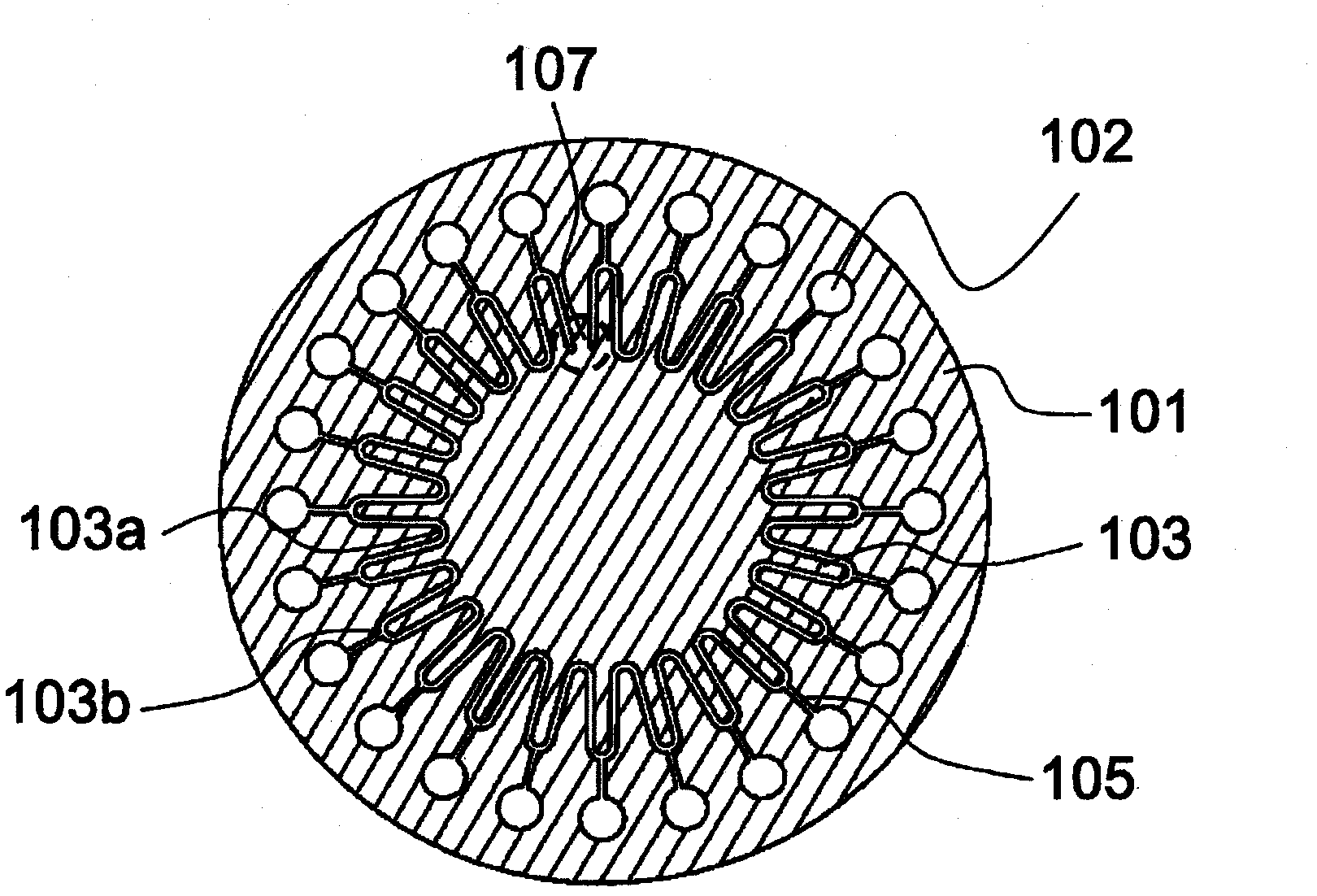

[0181] Polypropylene resin is used as the base material of the SNPs chip, and it is formed by injection molding figure 2 The chip shown has a disk-shaped shape and has a corrugated main channel 103 on a concentric circle, a side channel 105 with a connection port at the main channel valley 103b, and a chip with a sample injection hole 102 at the end of the side channel. The substrate (polypropylene substrate) was formed with 23 sample injection holes and side passages, respectively. In addition, the area of the main flow path is periodically changed, and the volume of the main flow path between adjacent main flow path mountain portions 103a is set to be 12 μL.

[0182] As the second base material to be bonded to the above-mentioned polypropylene base material, an aluminum flake base material coated with a polypropylene resin as a resin coating layer was u...

Embodiment 2

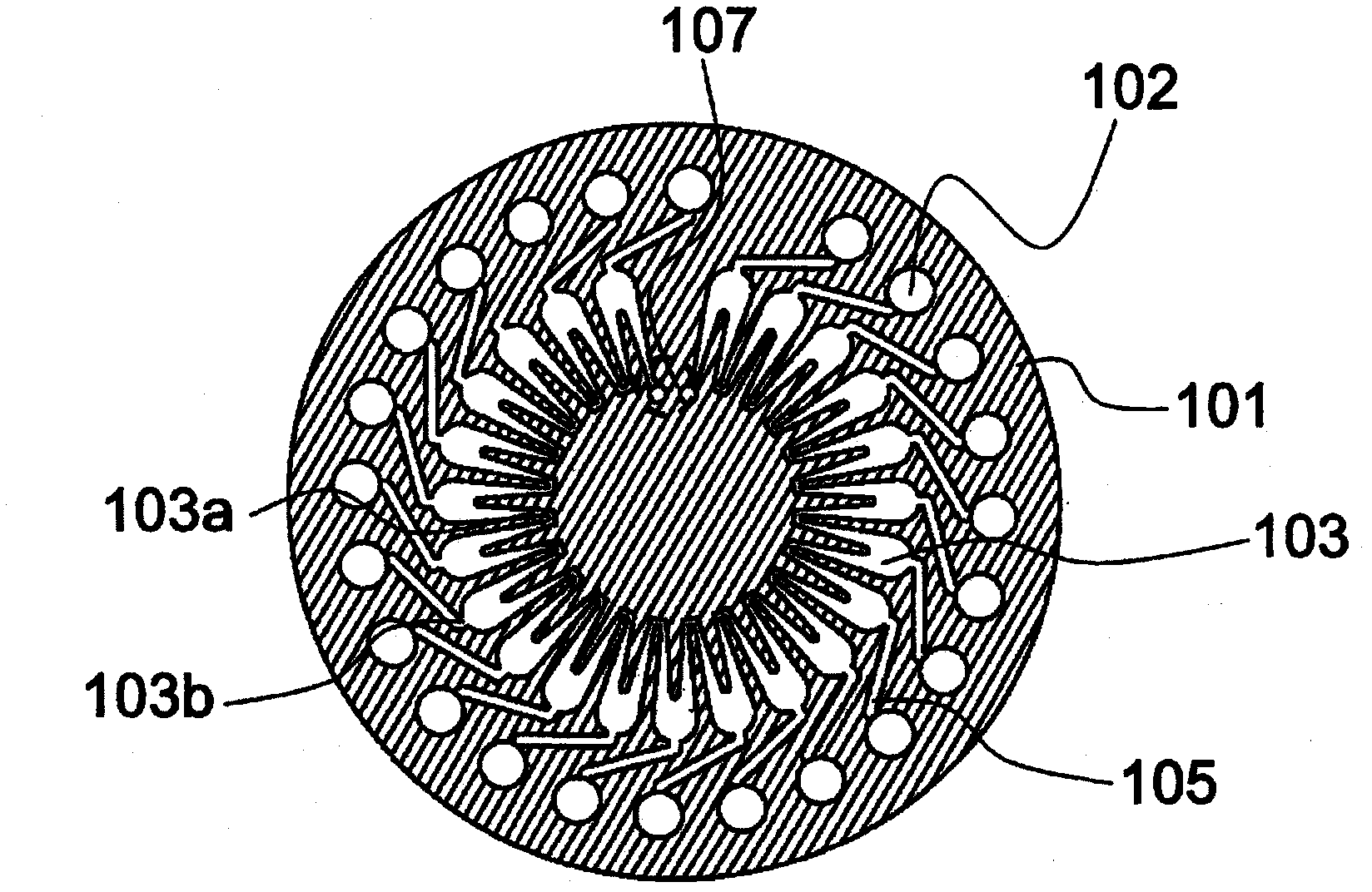

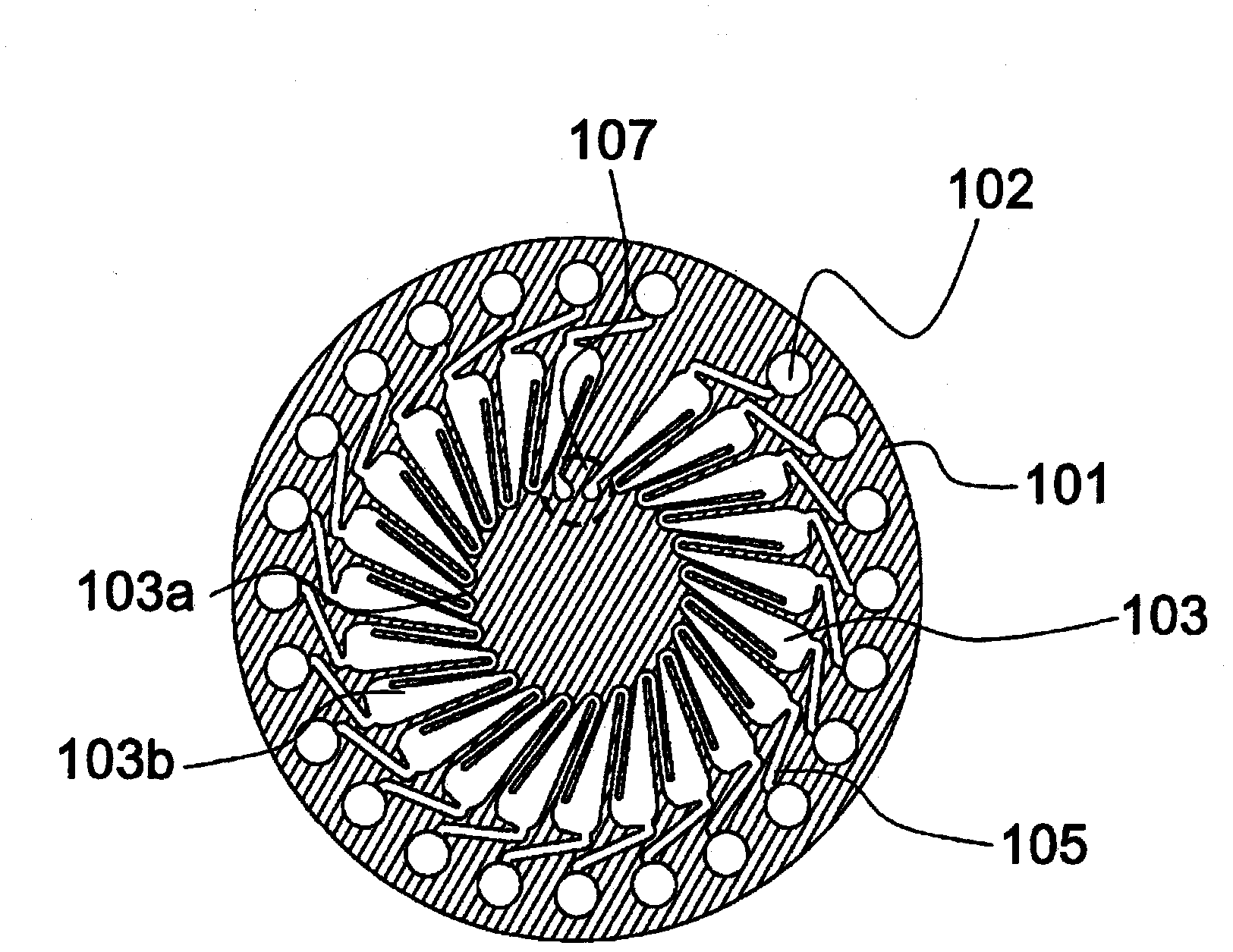

[0202] As Example 2, a sample analysis chip having another channel shape of the present invention was studied.

[0203] In this example, a image 3 A sample analysis chip of the shape shown. In Example 1, in order to prevent the mixing of substances that inhibit the reaction, the chip was produced by injection molding a polypropylene resin with high chemical resistance. However, in order to study the shape of the flow path, this arrive The end mill machine cuts the acrylic resin to form the shape of the flow path.

[0204] Used in Example 1 with figure 2 The shape of the sample analysis chip (chip 1) and having the above image 3 In the shape of the sample analysis chip (chip 2), pure water colored with bromophenol blue was sent to the main flow, and the chip was rotated around the center of the center-shaped chip at a rotational speed of 5000 rpm in the same manner as in Example 1. , measure the deviation after implementing 10 times. In addition, assuming that the li...

Embodiment 3

[0207] In Example 3, polypropylene resin was used as the first substrate 401 of the sample analysis chip of the present invention, and the following chip was formed by injection molding: having Figure 7 The shown disc-shaped shape has a concentric wavy main channel 103, a side channel 105 with a connection port in the main channel valley 103, and a sample injection hole 102 at the end of the side channel, and also includes branches from the side channel. The injection hole branch flow path 105a, the waste liquid chamber branch flow path 104a, and the waste liquid chamber 105b. The substrate (polypropylene substrate) was formed with 23 sample injection holes and side passages, respectively. The area of the main channel changes periodically, and the volume of the valley 103b between the mountain and the mountain in the main channel is 15 μL. In addition, the volume of the branch flow channel of the sample injection hole is 2 μL, the volume of the sample well is 11 μL, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com