Patents

Literature

934results about How to "Pollution suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

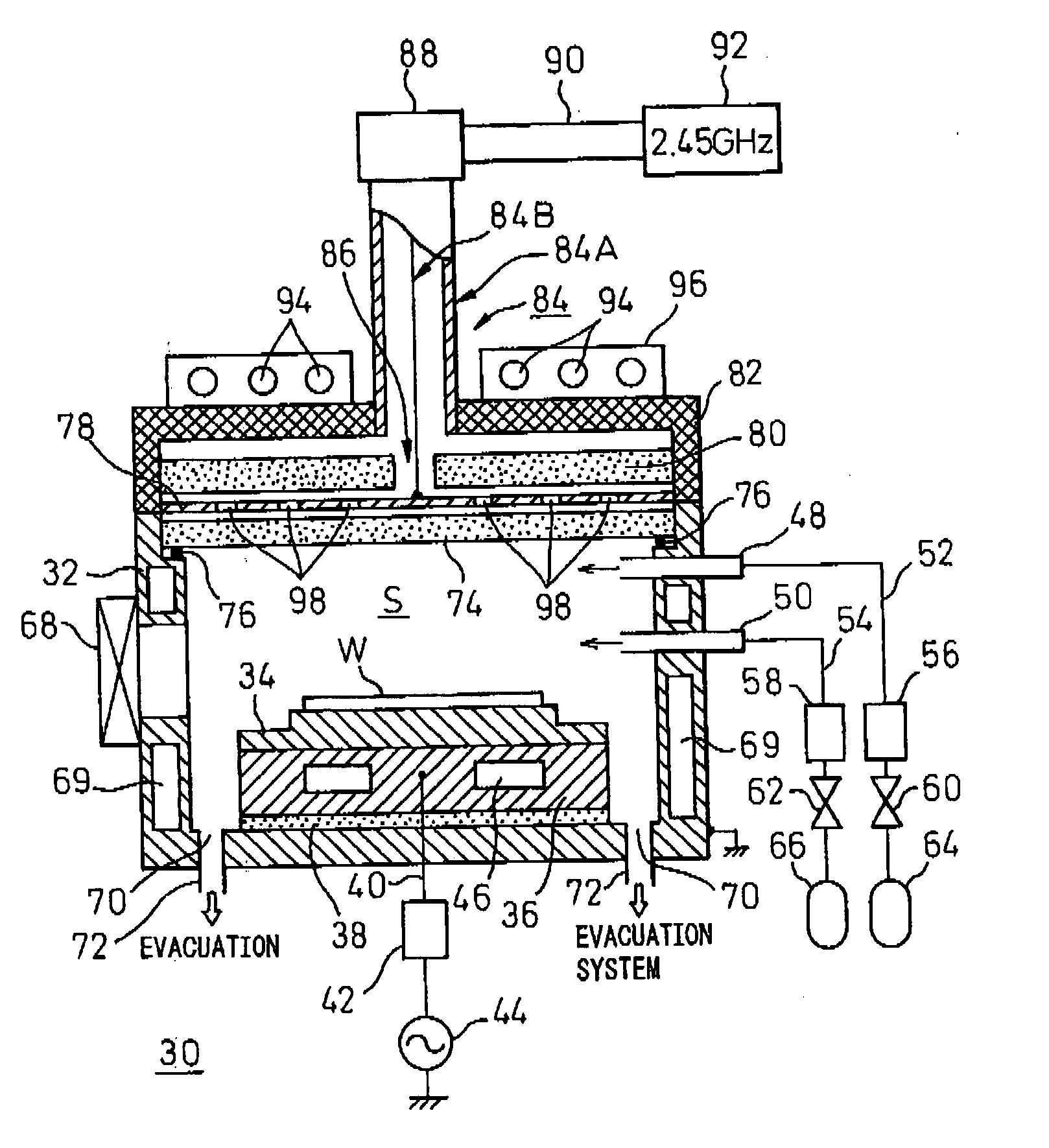

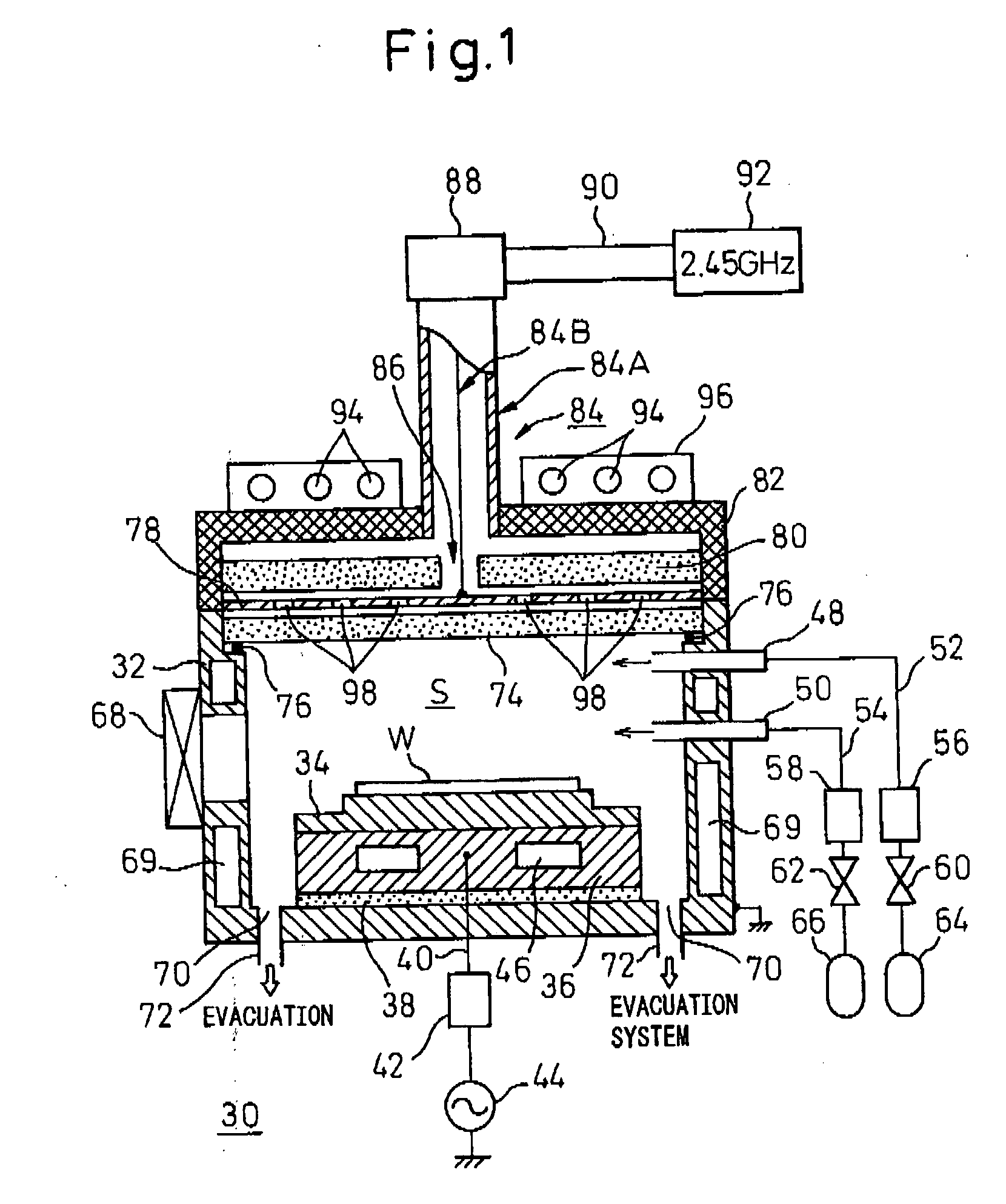

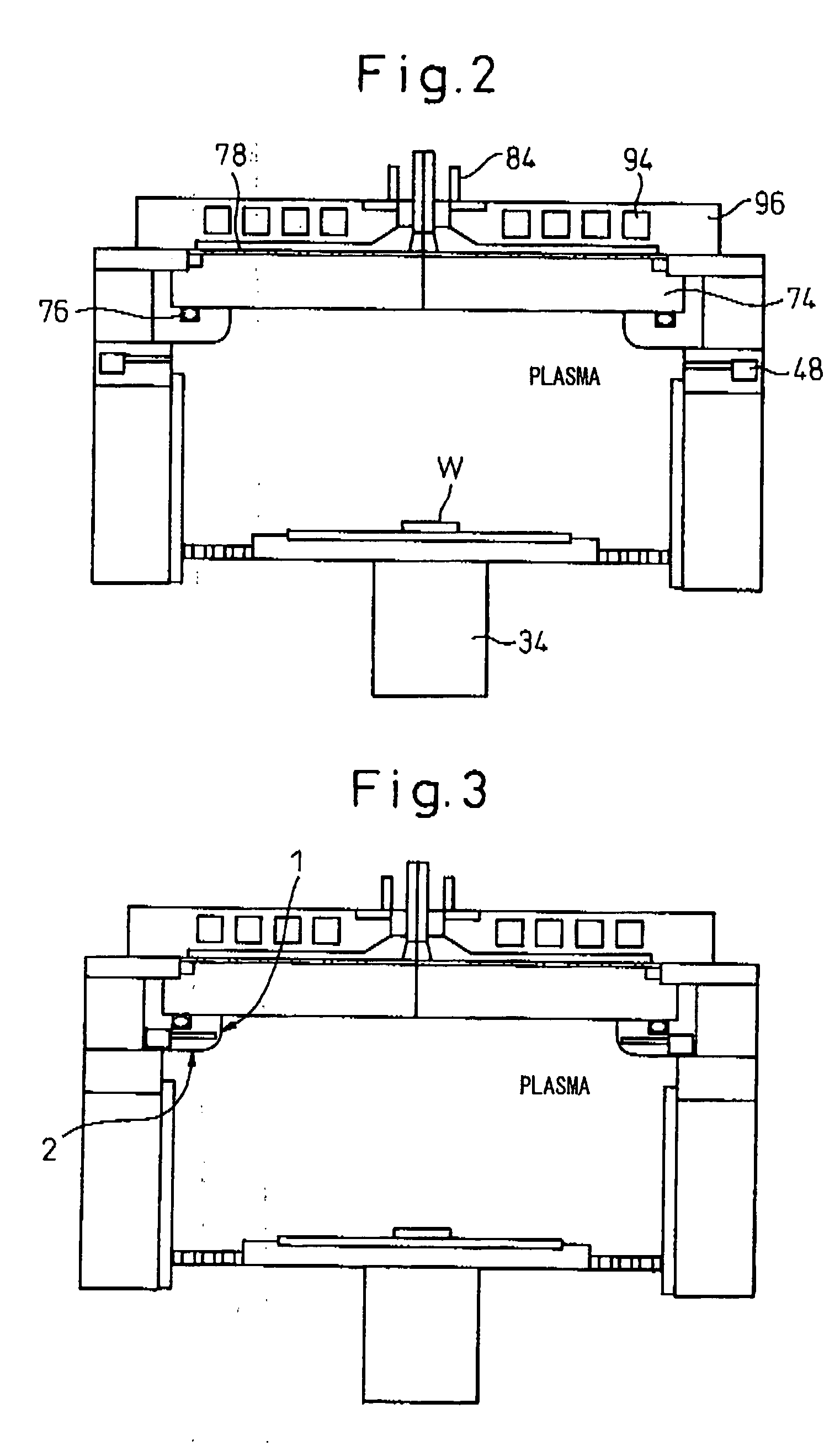

Plasma processing apparatus and plasma processing method

InactiveUS20060108331A1Reduce defectsPollution suppressionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingPre treatment

A plasma processing apparatus comprising at least a plasma processing chamber for plasma-processing an object; object-holding means for disposing the object in the plasma processing chamber; and plasma-generating means for generating a plasma in the plasma processing chamber. The inner wall of the plasma processing chamber is at least partially covered with an oxide film based on a pre-treating plasma. A plasma processing apparatus and a plasma processing method effectively prevent the spluttering and the etching of the inner wall of the plasma processing chamber while suppressing contamination to the object.

Owner:TOKYO ELECTRON LTD

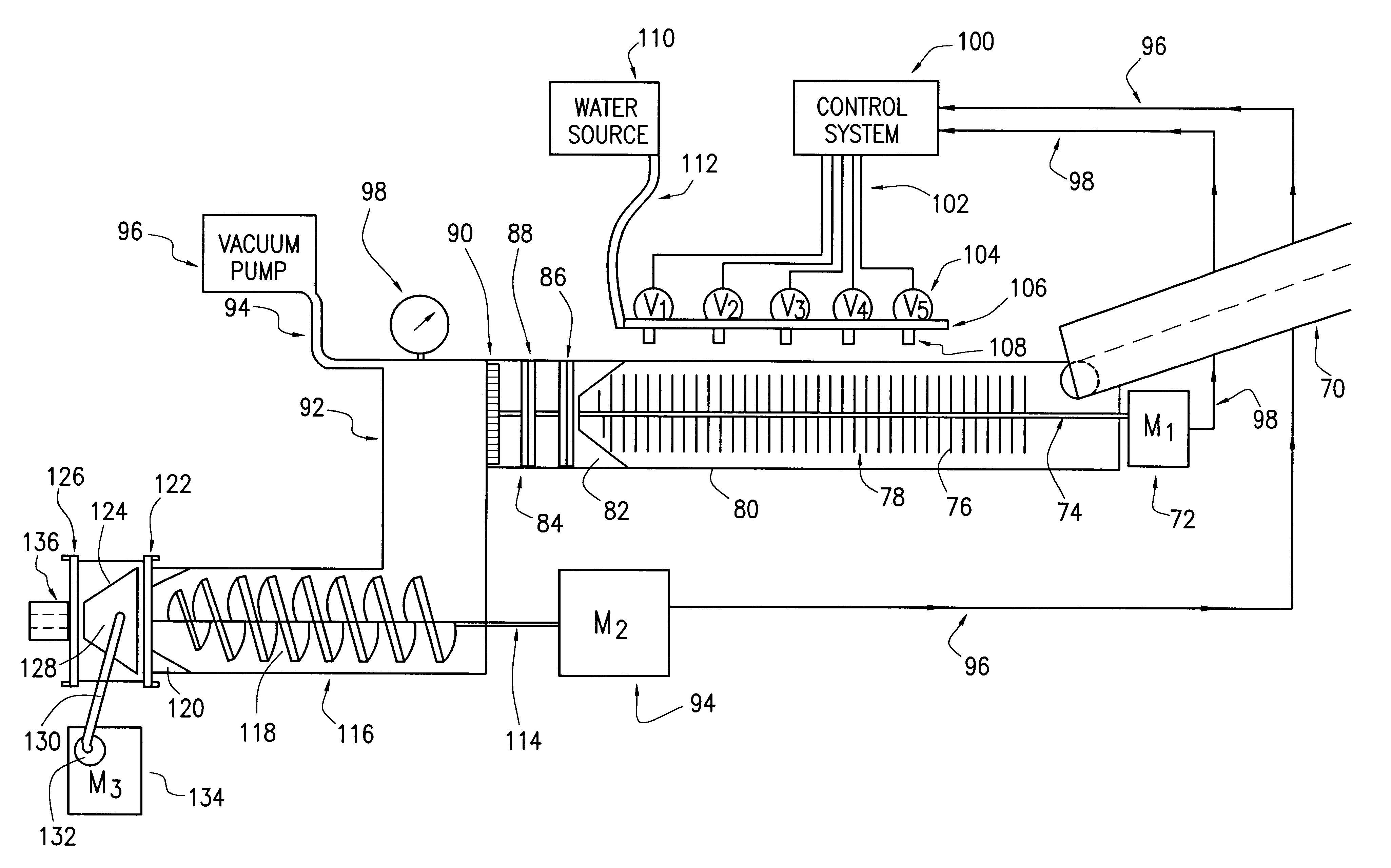

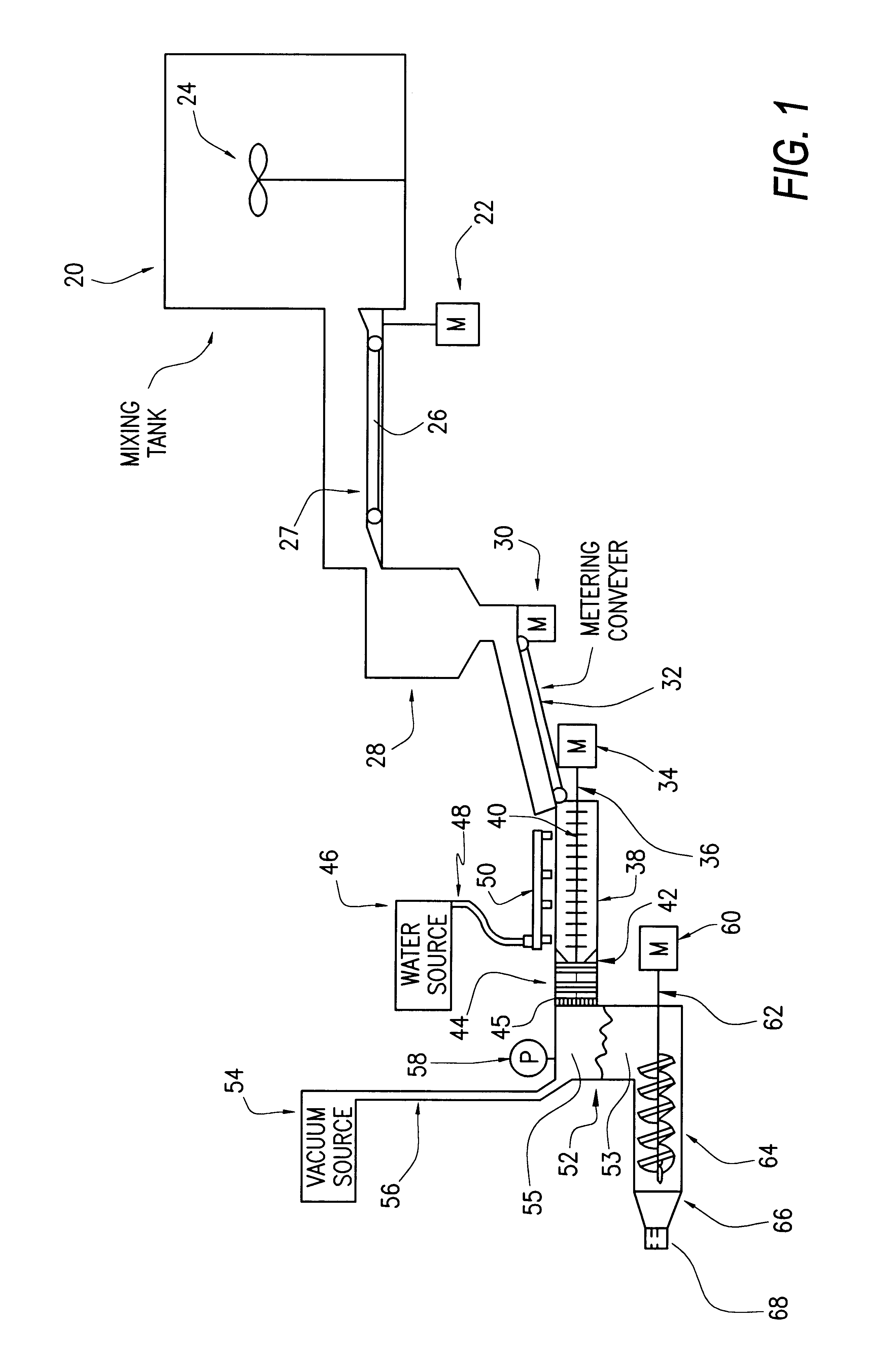

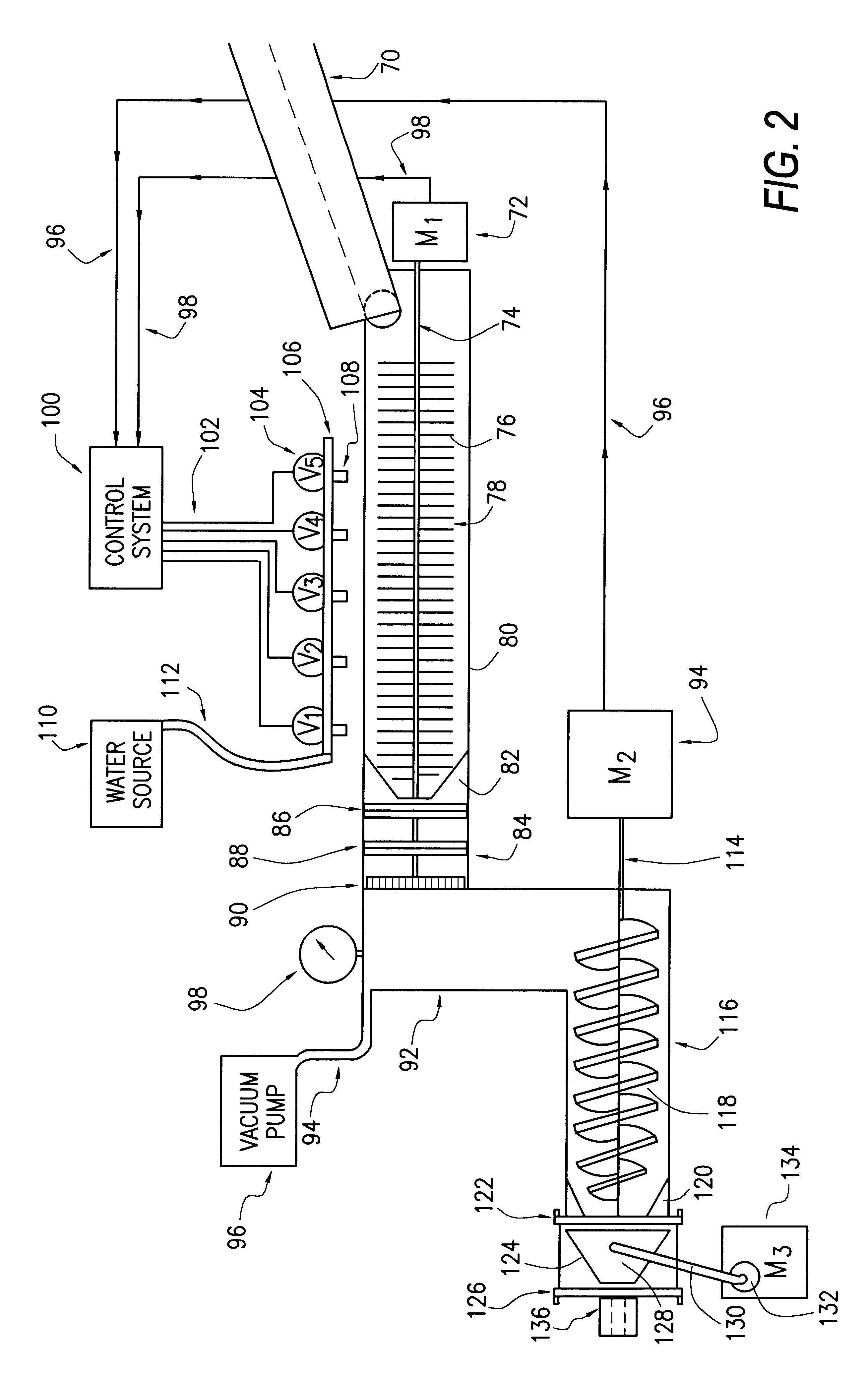

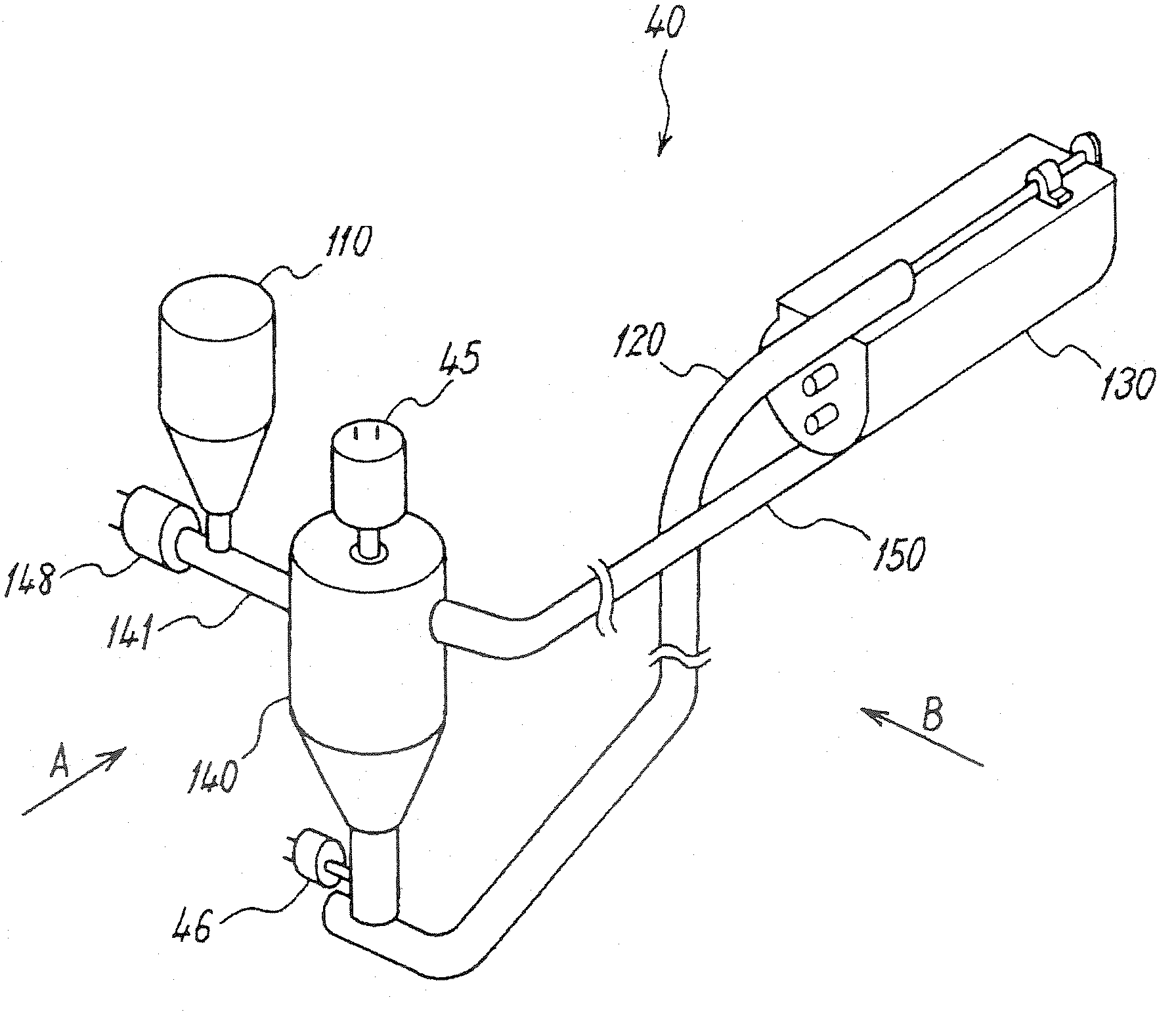

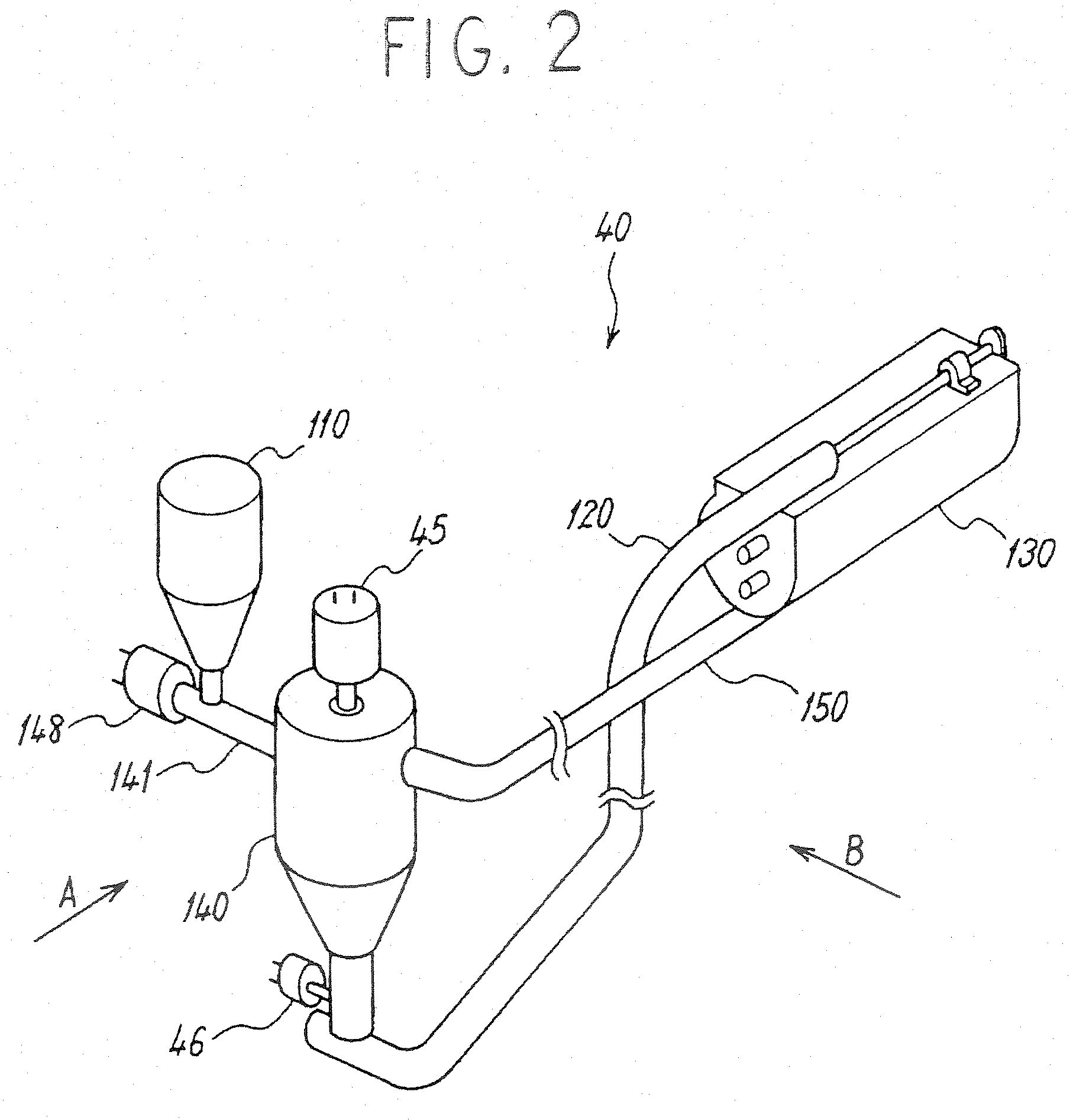

Vacuum extrusion system for production of cement-based articles

InactiveUS6309570B1Reduce frictionReduce the amount requiredFrozen sweetsConfectioneryMaterials scienceExcess water

A system for making extruded cement-based articles. The process can include forming a cement-based feed mixture including water, aggregate and binder and directing the feed mixture to a vacuum zone, wherein sufficient vacuum is maintained in the vacuum zone to remove entrained air and, preferably, excess water, from the feed mixture. The feed mixture is held in the vacuum zone at a negative pressure for a time sufficient to form a vacuum-treated or densified mixture. The vacuum-treated or densified mixture is passed through an extruder at an elevated pressure to provide an extruded cement-based article.

Owner:BLEECKER LEE M

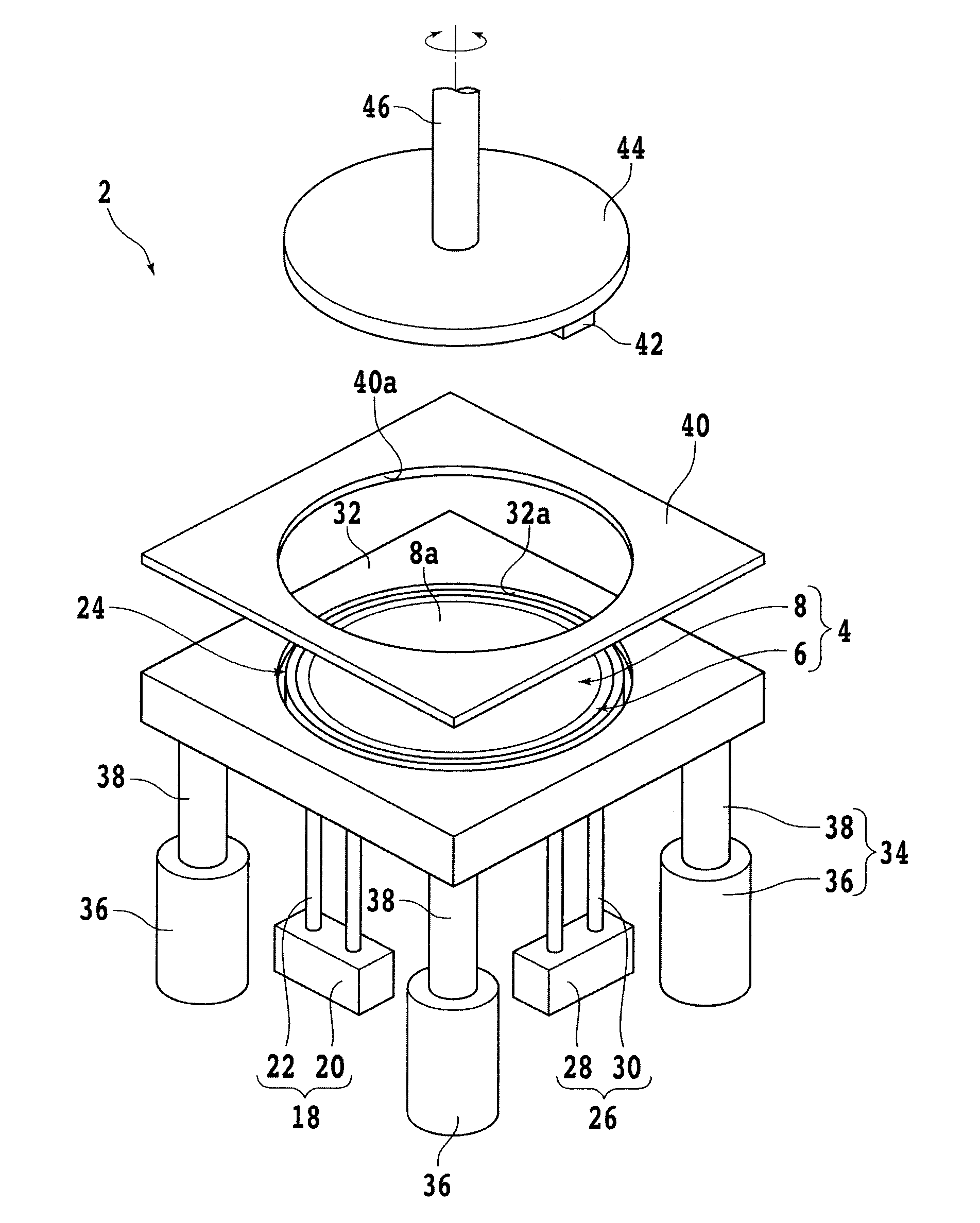

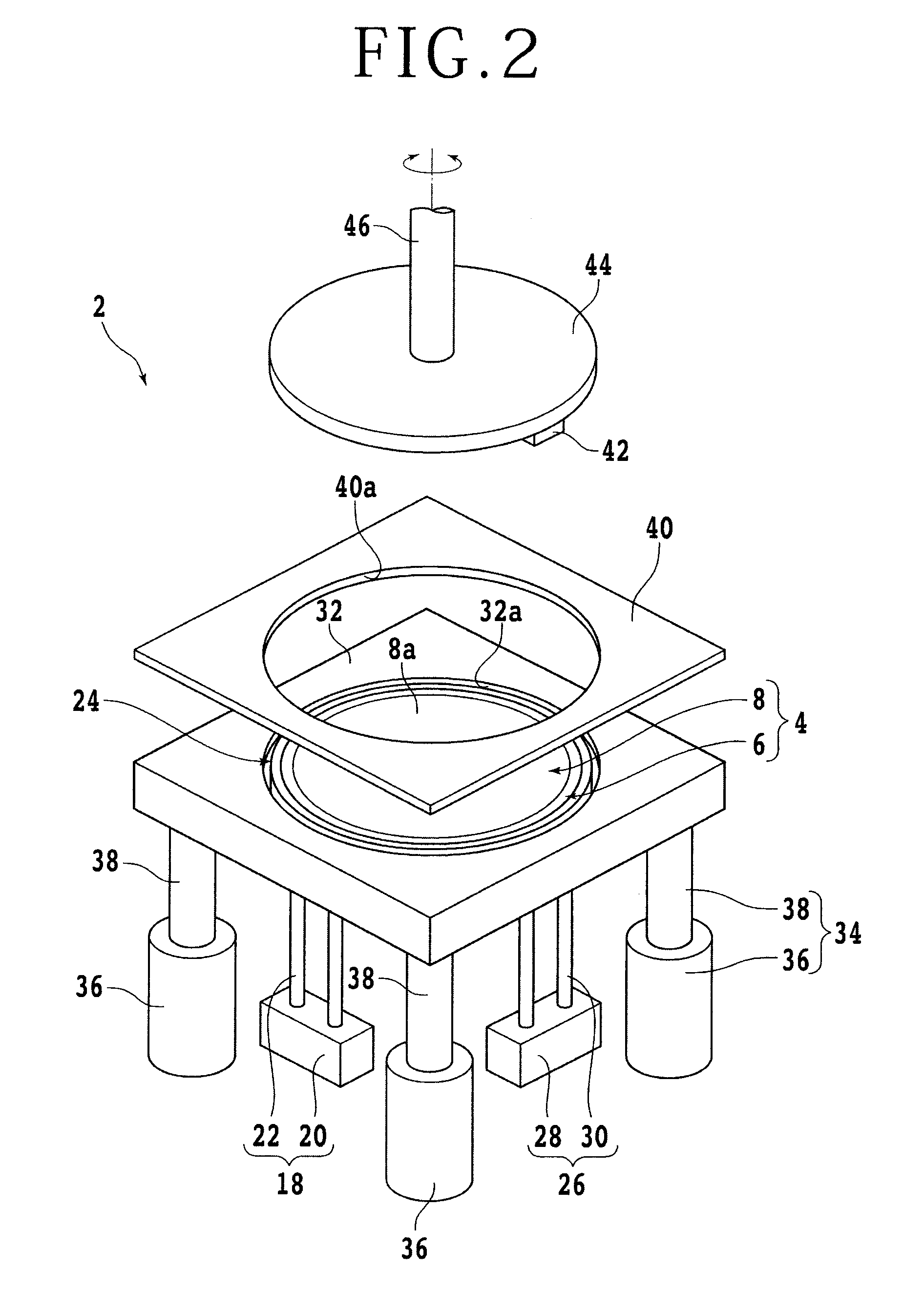

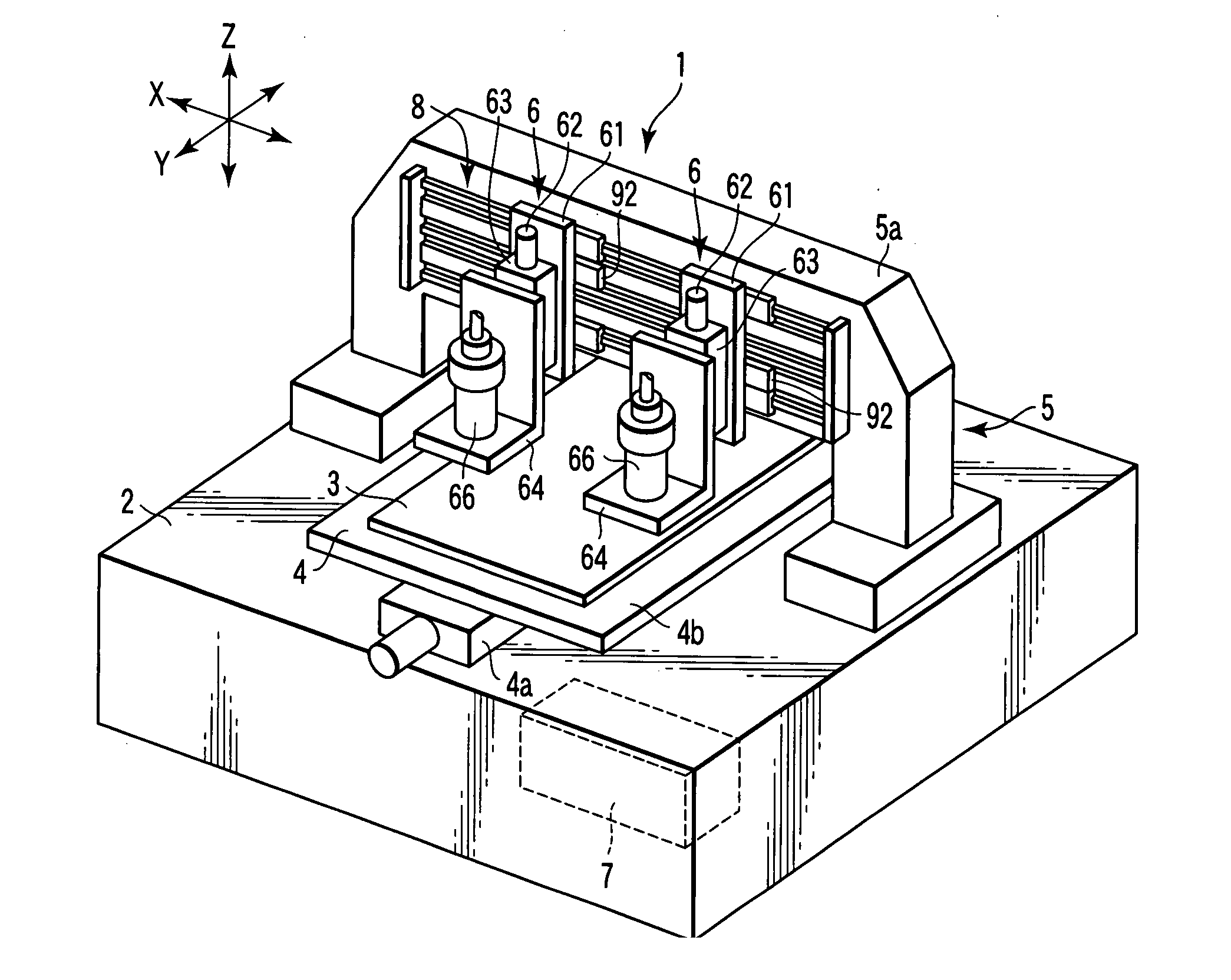

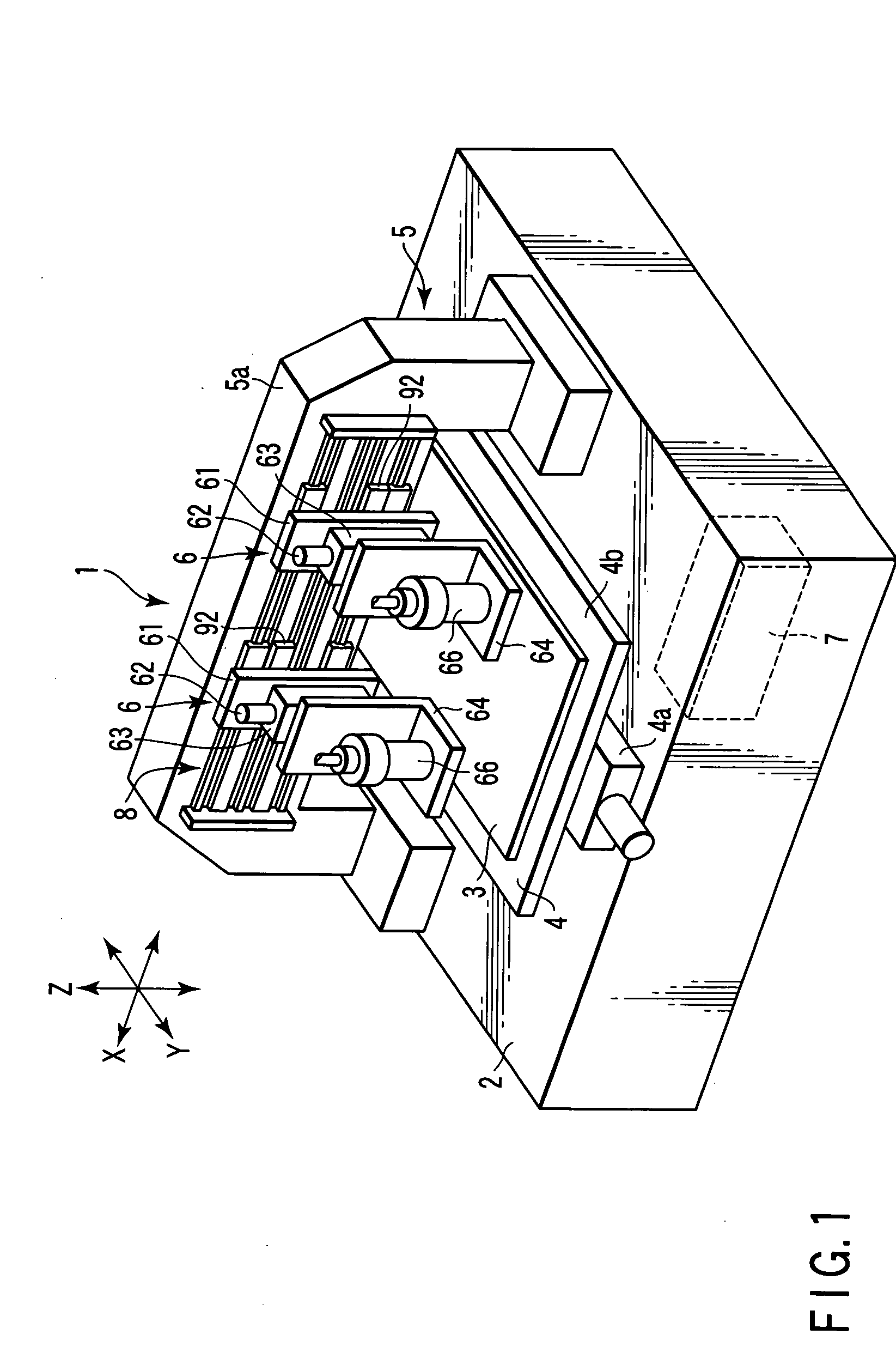

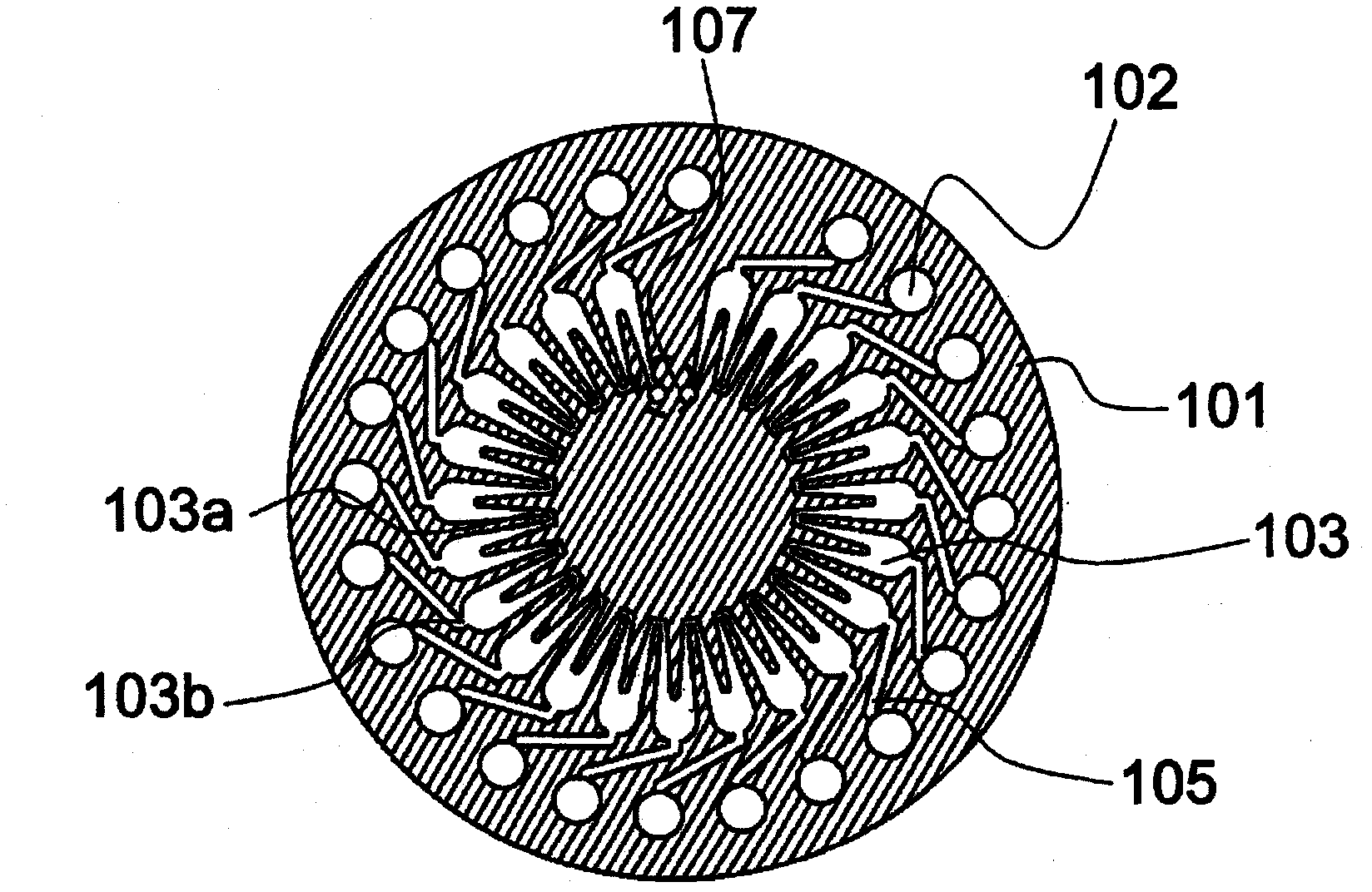

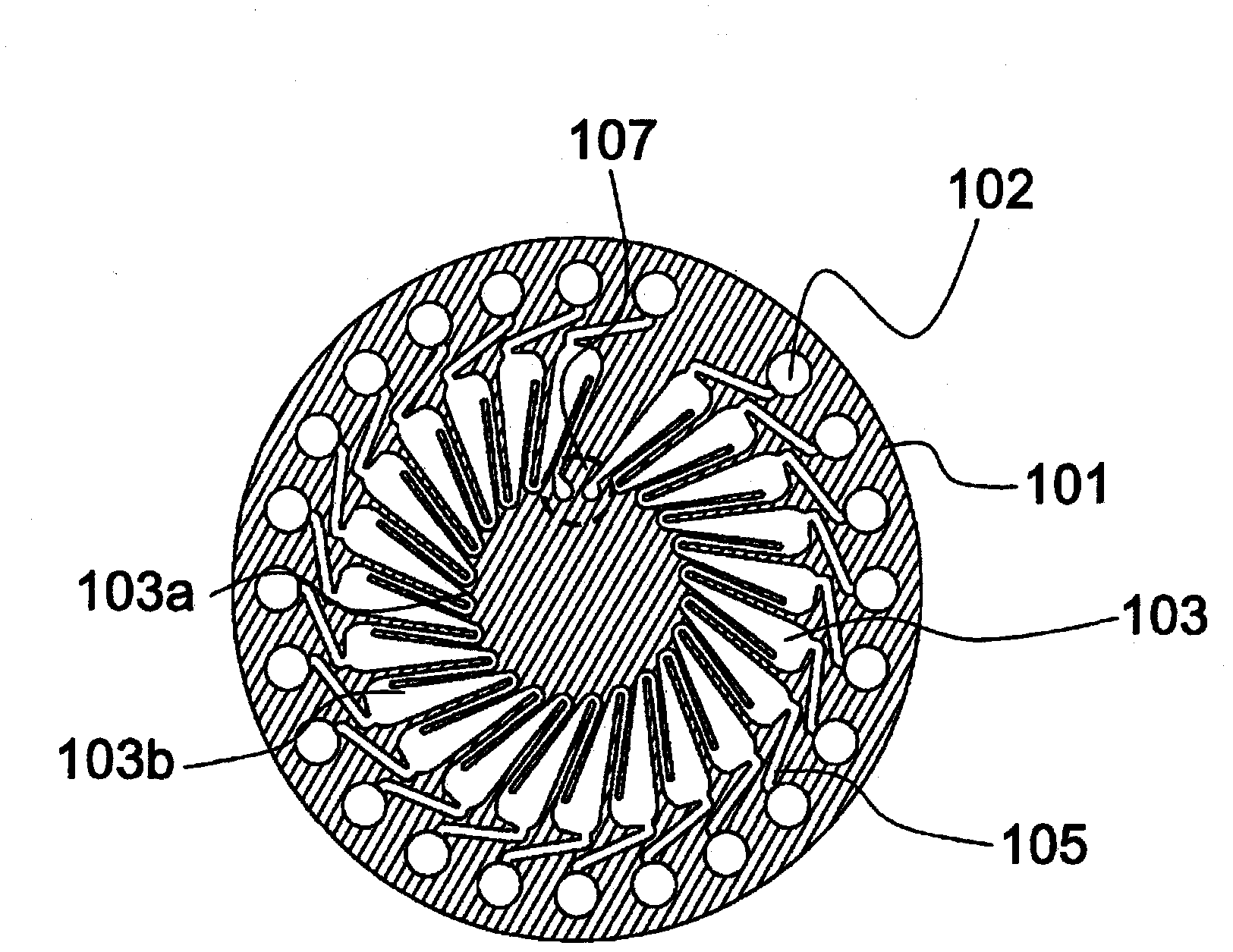

Chip spacing maintaining apparatus

ActiveUS20160007479A1Increase spacingPollution suppressionPrinted circuit assemblingSolid-state devicesSpray nozzleFar infrared

A chip spacing maintaining apparatus for maintaining the spacing between any adjacent ones of a plurality of chips obtained by dividing a workpiece attached to an expand sheet, the expand sheet being supported at its peripheral portion to an annular frame is provided. The chip spacing maintaining apparatus includes a far-infrared radiation applying unit for applying far-infrared radiation toward the expand sheet expanded in a target area between the outer circumference of the workpiece and the inner circumference of the annular frame, thereby shrinking the expand sheet in the target area, and an air layer forming unit provided adjacent to the far-infrared radiation applying unit, the air layer forming unit having a nozzle hole for discharging a gas toward the workpiece in applying the far-infrared radiation from the far-infrared radiation applying unit toward the expand sheet, thereby forming an air layer above the workpiece.

Owner:DISCO CORP

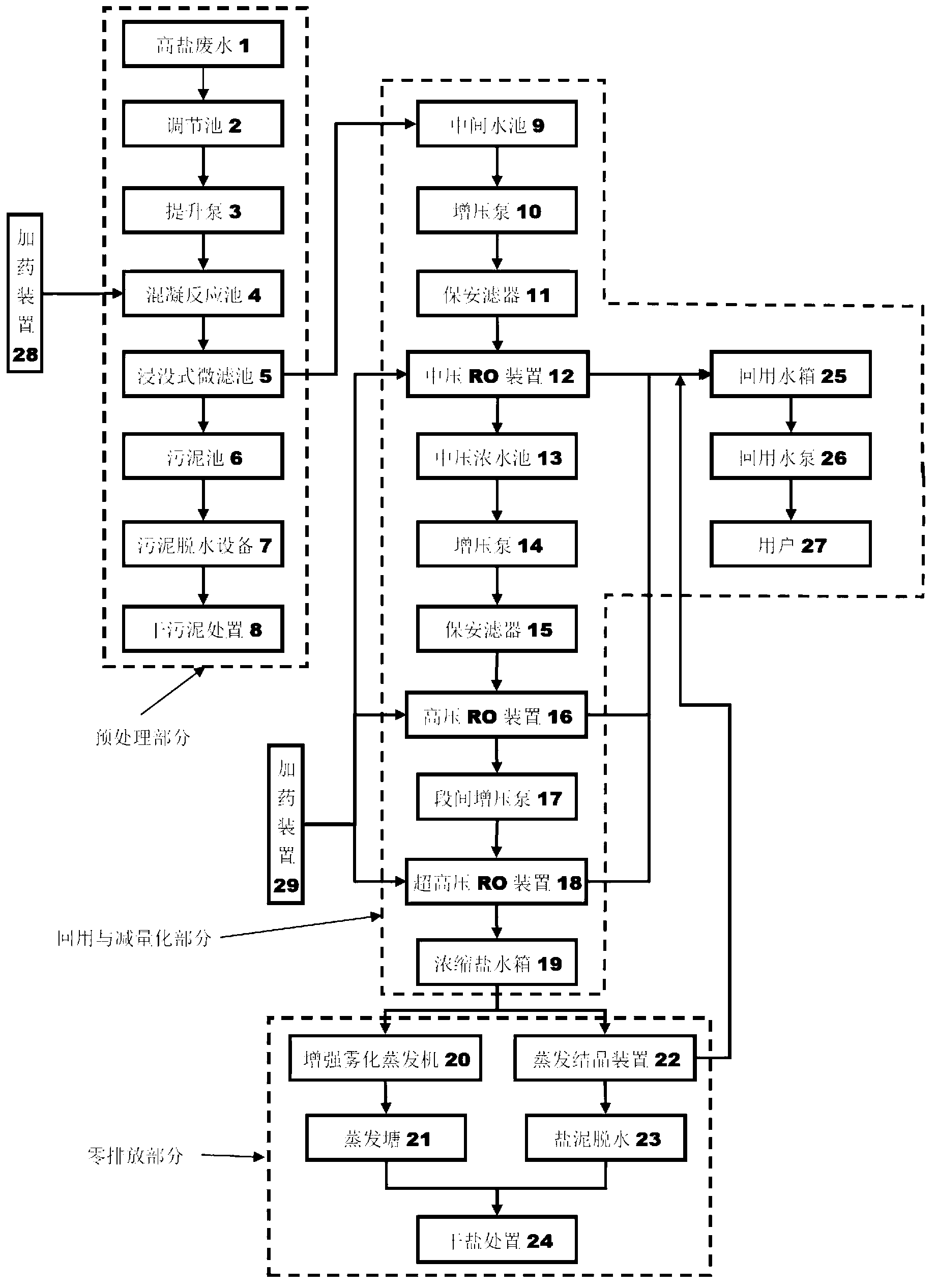

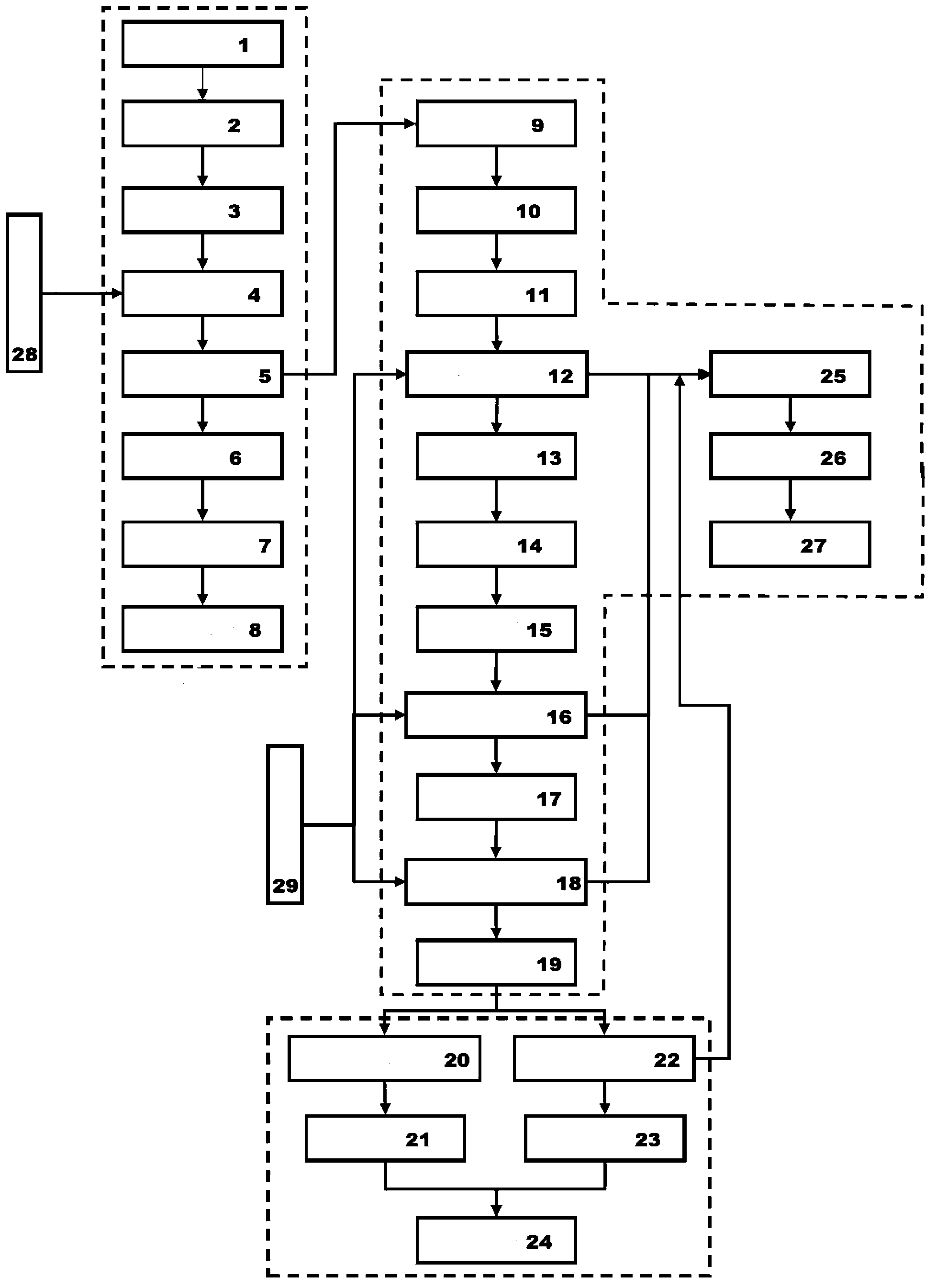

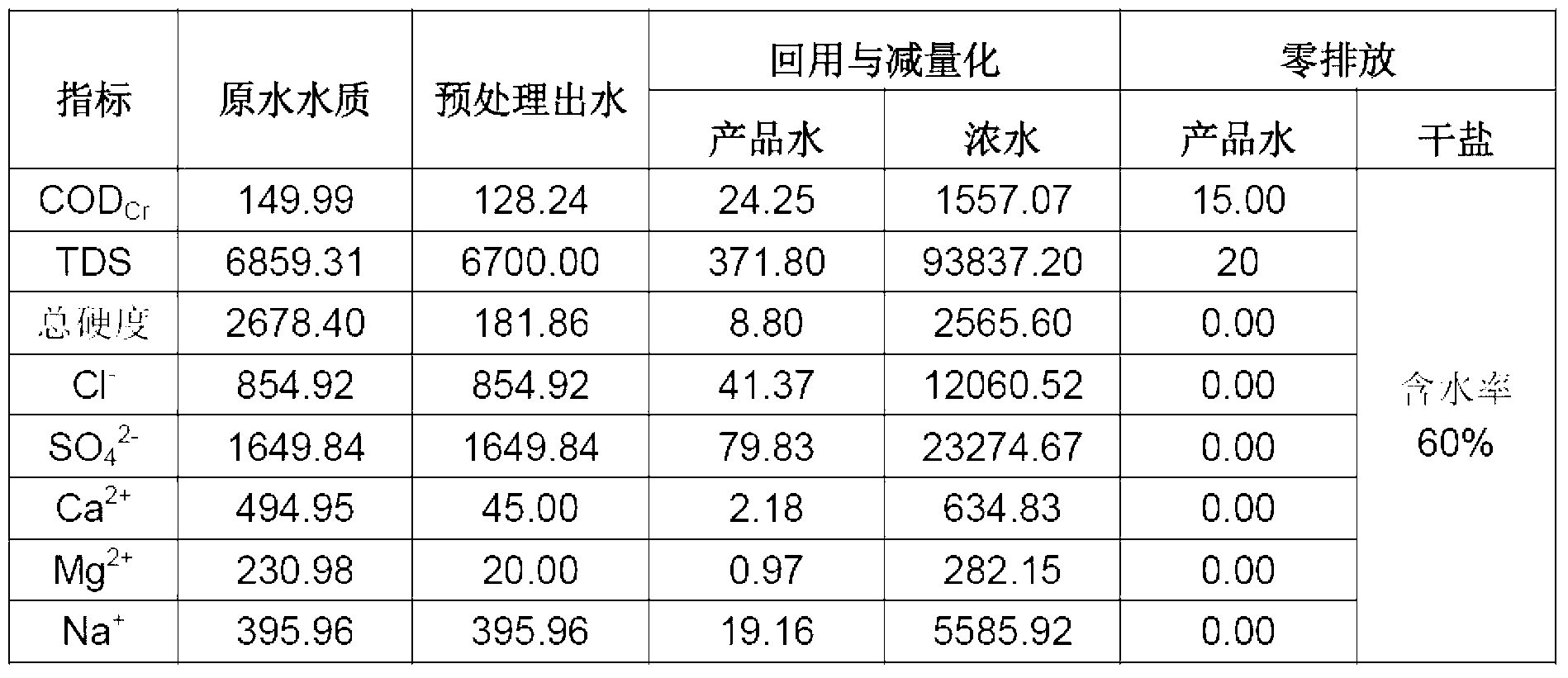

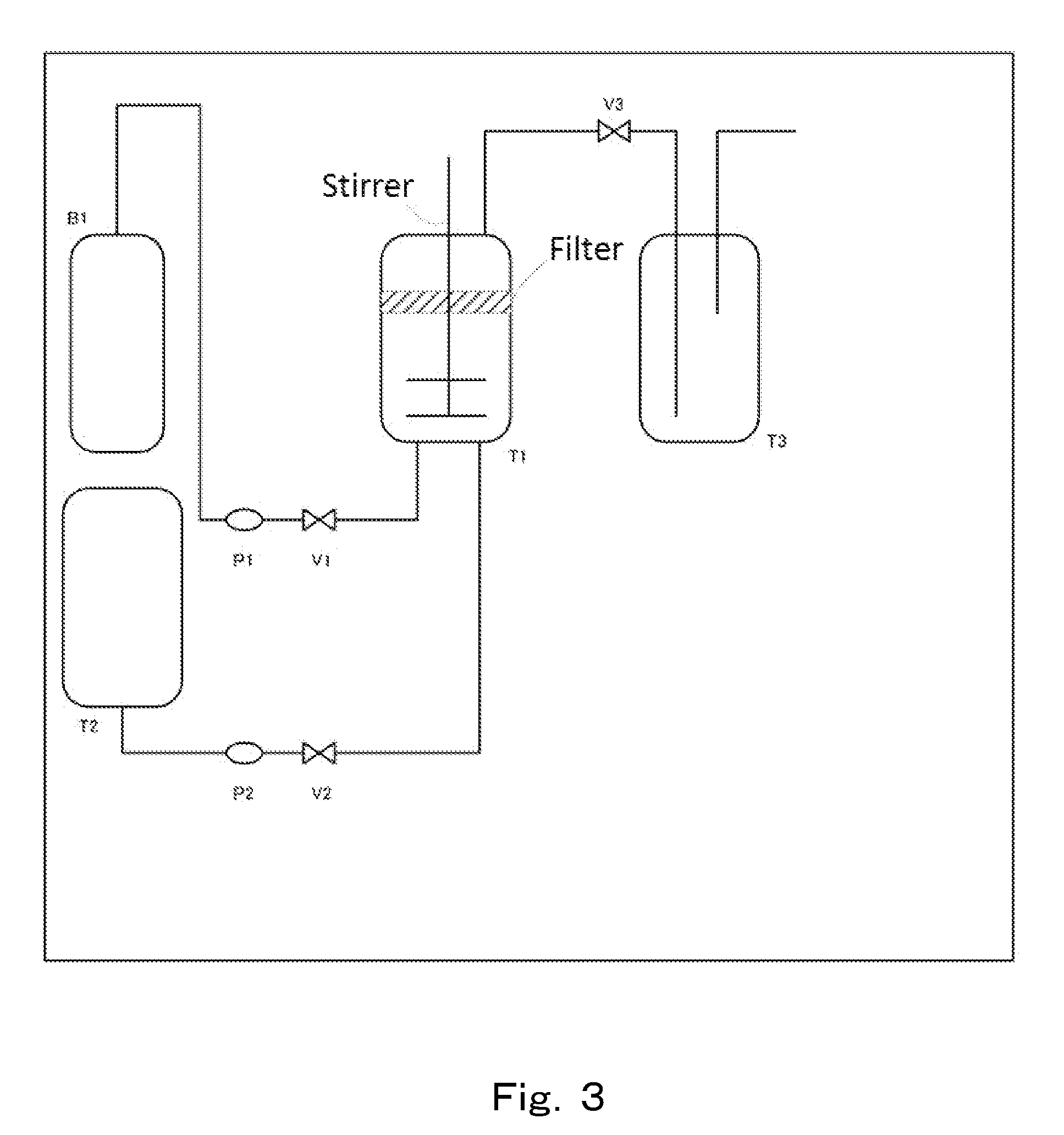

High-salt complex wastewater reuse and zero discharge integrated equipment and technology

ActiveCN103319042AReliable operationInhibits silicon scaling and organic foulingGeneral water supply conservationMultistage water/sewage treatmentSaline waterThree level

The invention relates to high-salt complex wastewater reuse and zero discharge integrated equipment and a technology. The equipment provided by the invention comprises a pretreatment system, a reuse and reduction system and a zero discharge system. The technology comprises the following steps: carrying out homogenization and averaged quantity on high-salt complex wastewater, successively adding sodium hydroxide, sodium carbonate, PAC and PAM to carry out coagulation treatment, letting a mixed liquor which has undergone coagulation treatment enter a filter tank for sedimentation and filtration by the use of an immersed microfiltration membrane, letting a supernatant enter a reverse osmosis treatment process, letting pure water obtained by reverse osmosis treatment enter a reuse water tank for utilization, further condensing condensed brine, and crystallizing the condensed brine or putting the condensed brine into an evaporation pond for atomization and evaporation processing, wherein the reverse osmosis treatment adopts three-level RO: a medium-pressure membrane element is firstly used for desalination and condensation; a high-pressure membrane element is then used for further desalination and condensation; and a ultrahigh-pressure membrane element is finally used for further desalination and condensation. According to the invention, 95% of reverse osmosis concentrated water or analogous high-salt complex wastewater can be recovered for reutilization, only 5% of high strong brine is left to undergo evaporative crystallization or enter the natural evaporation pond. Water resources are fully recycled, and reuse and zero discharge costs of high-salt complex wastewater are reduced.

Owner:BGT GRP CO LTD

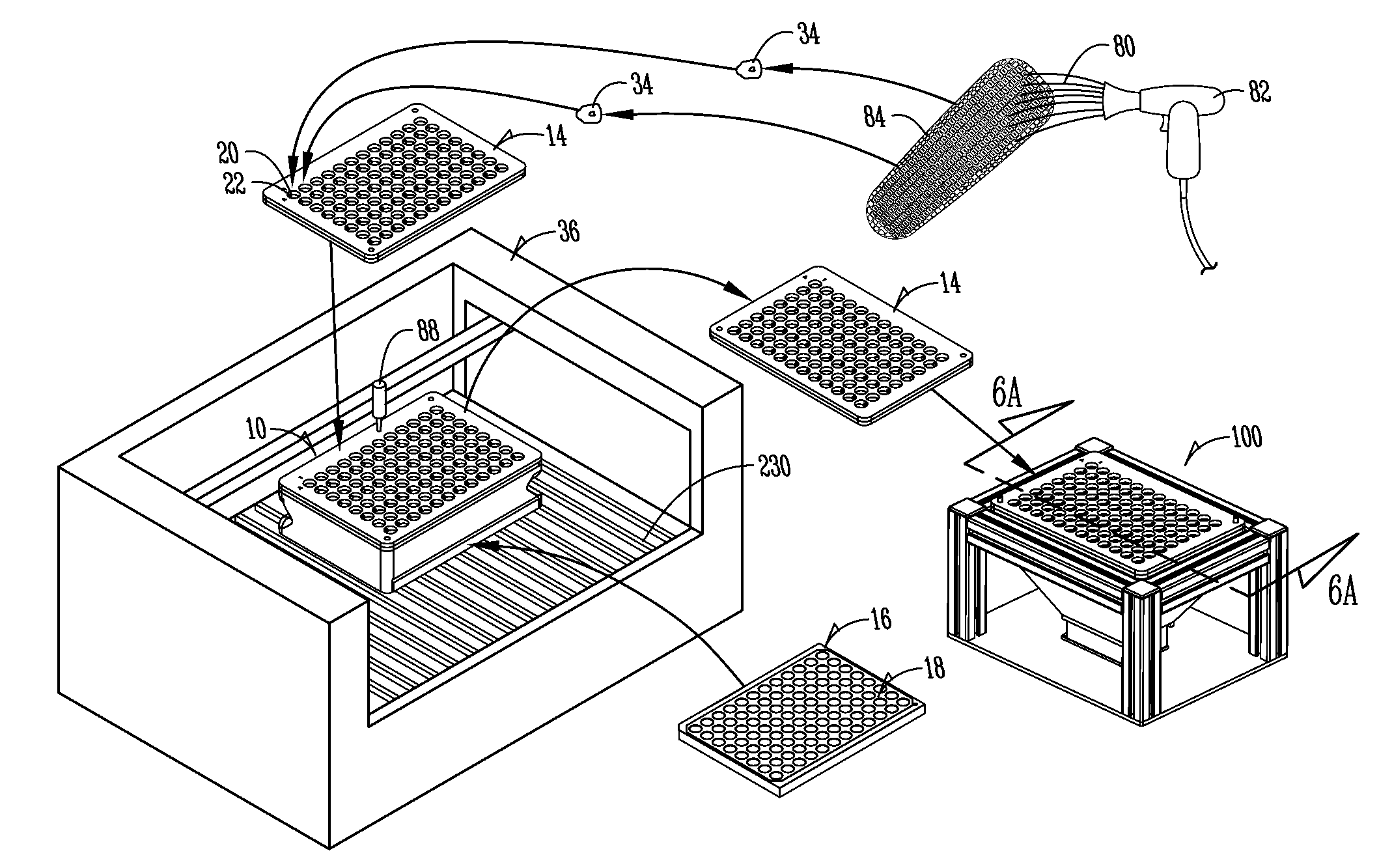

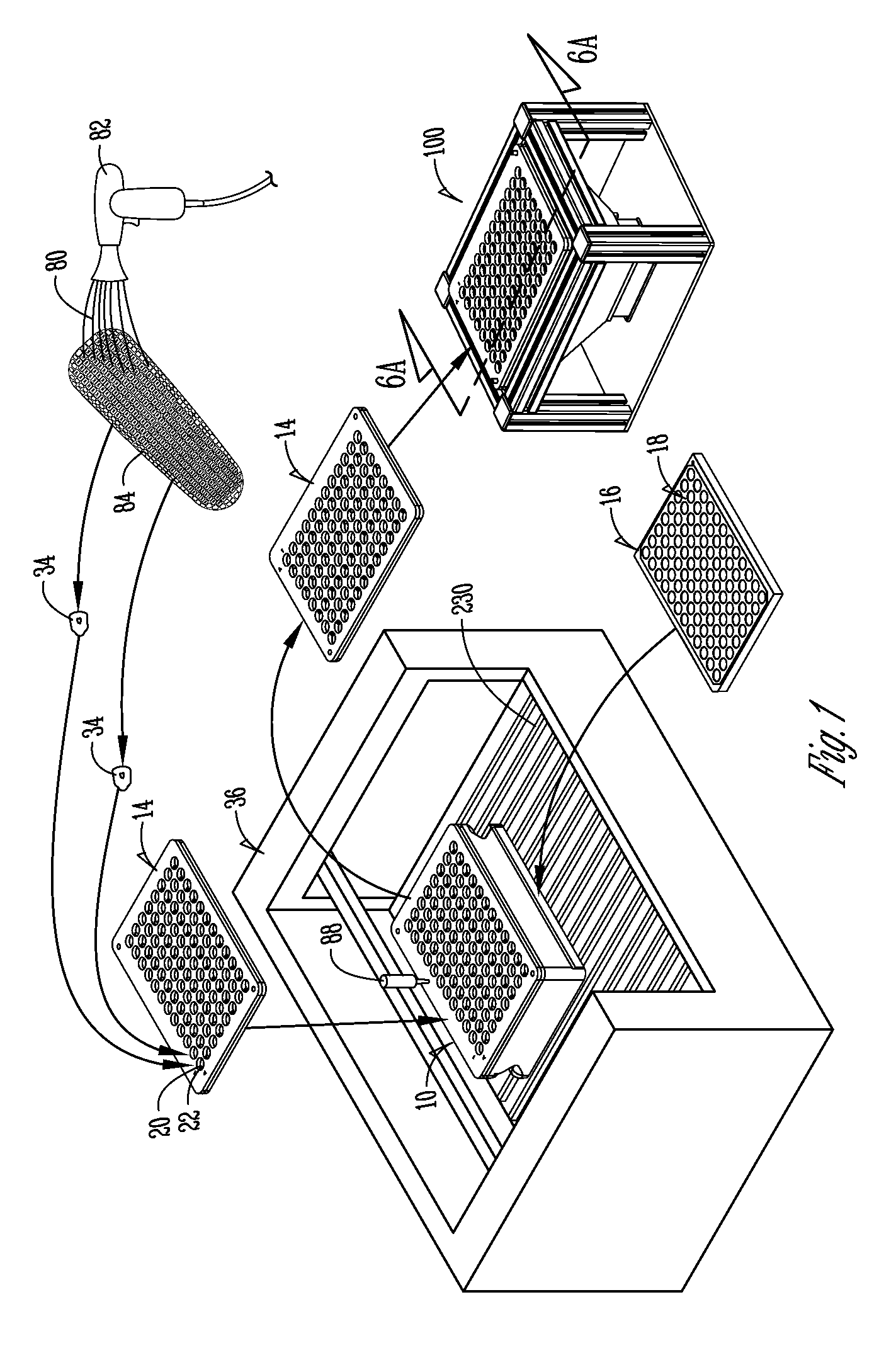

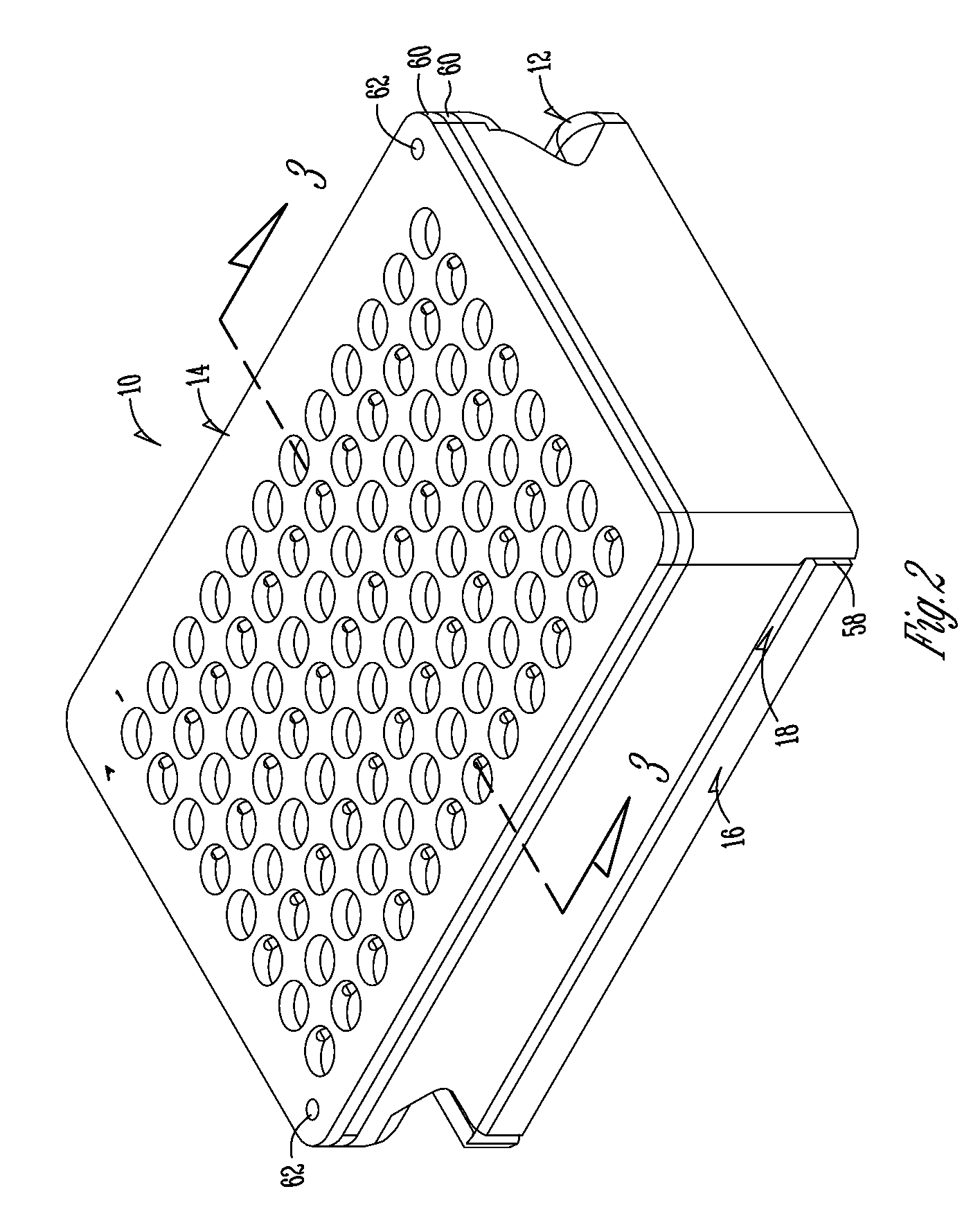

Apparatus, method and system for creating, handling, collecting and indexing seed and seed portions from plant seed

ActiveUS20090155878A1Pollution suppressionPreserve viabilityBioreactor/fermenter combinationsBiological substance pretreatmentsPlanting seedEngineering

An apparatuses, methods and systems for creating, handling and collecting seed portions are highly beneficial. The apparatus includes a carrier having one or more carrying positions adapted to carry a seed. The carrying positions having a seed orienter adapted to orient the seed relative to the carrying position in the carrier for creating seed portions therefrom. The method includes taking a carrier having one or more carrying positions, orienting a seed relative to the carrying position in the carrier, ablating the seed with a seed ablation device, and communicating seed portions through a manifold into a compartment layer. The system includes a seed manifold adapted to dock thereon a seed carrier having pre-positioned and pre-oriented seed therein. Seed and seed portions removed from the seed in the carrier are communicated into a collector and compartment layer respectively using the seed manifold.

Owner:PIONEER HI BRED INT INC

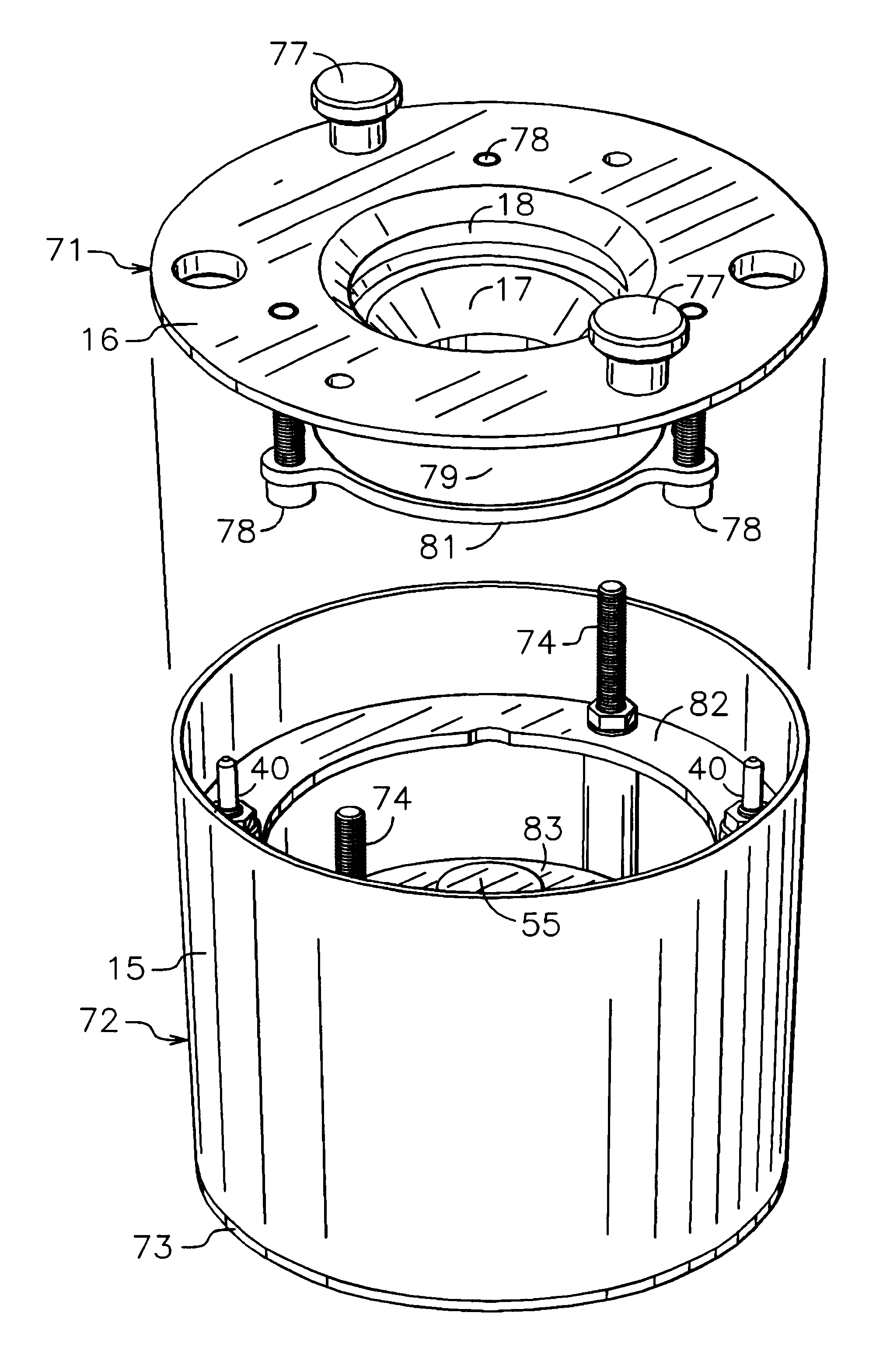

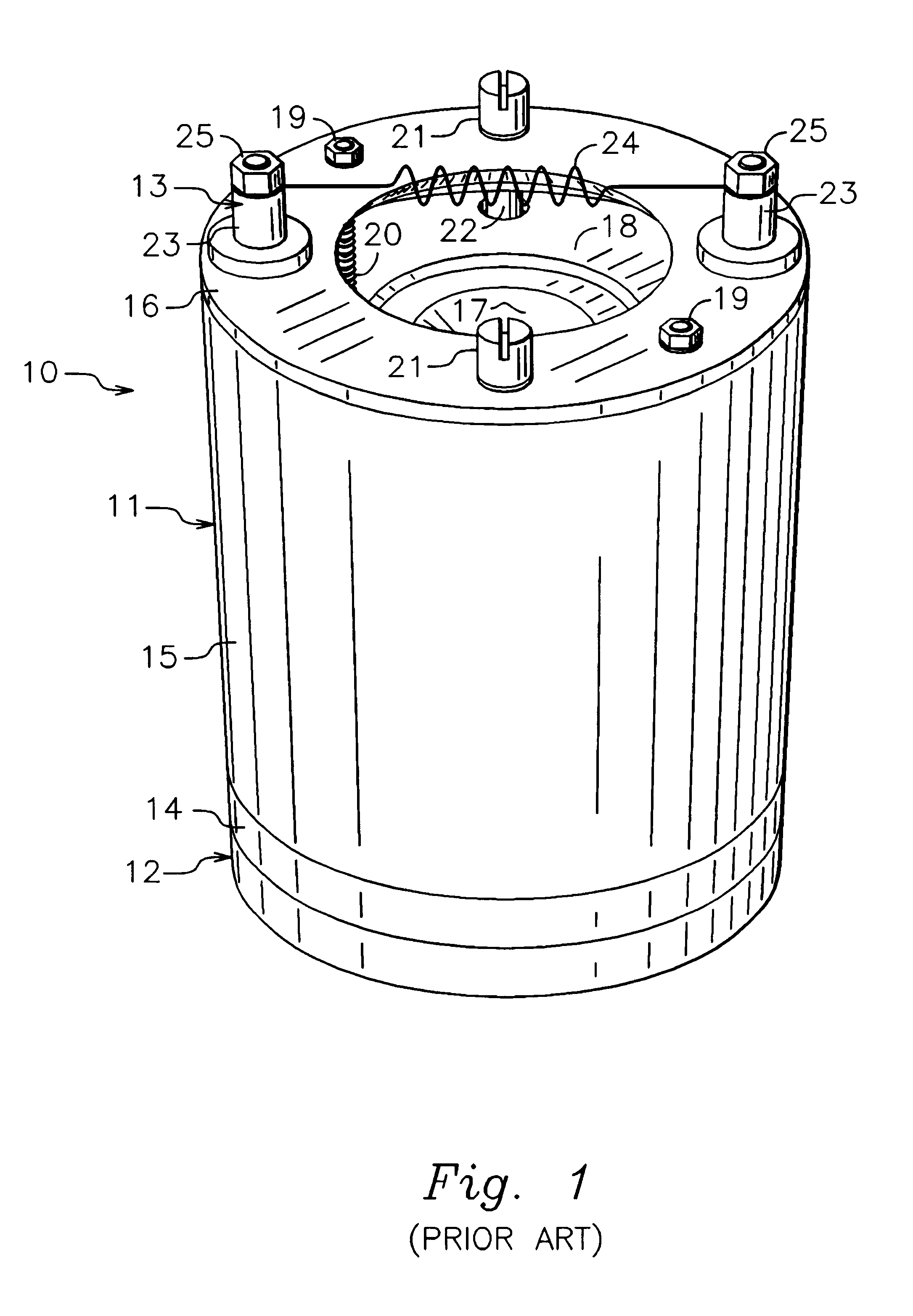

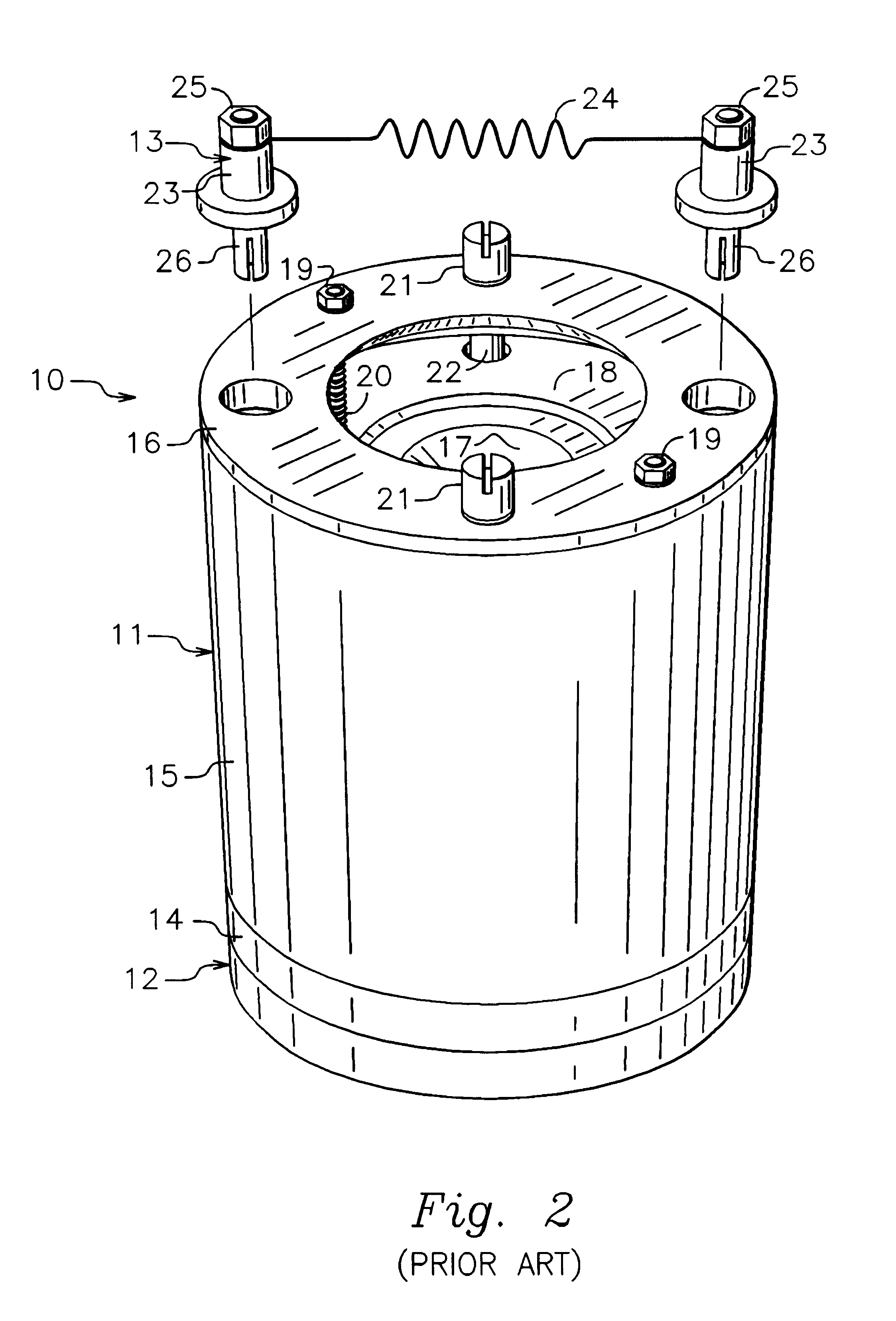

Modular gridless ion source

InactiveUS6608431B1Minimize workReduce lossesElectric arc lampsMachines/enginesModularityReduced size

In accordance with one embodiment of the present invention, the ion-beam apparatus takes the form of an end-Hall ion source in which the detachable anode module incorporates the outer pole piece and includes an enclosure around the anode that both minimizes the loss of working gas and confines sputter contamination to the interior of this enclosure. This detachable anode module is substantially smaller than the entire end-Hall ion source, weighs substantially less, and can be duplicated for significantly less cost than the duplication of the entire ion source. In general, the components of the magnetic circuit determine the overall size, weight, and much of the cost of a gridless ion source. The reduced size, weight, and cost of the detachable anode module compared to the entire ion source is due to most of the magnetic circuit being excluded from the detachable module.

Owner:KAUFMAN & ROBINSON

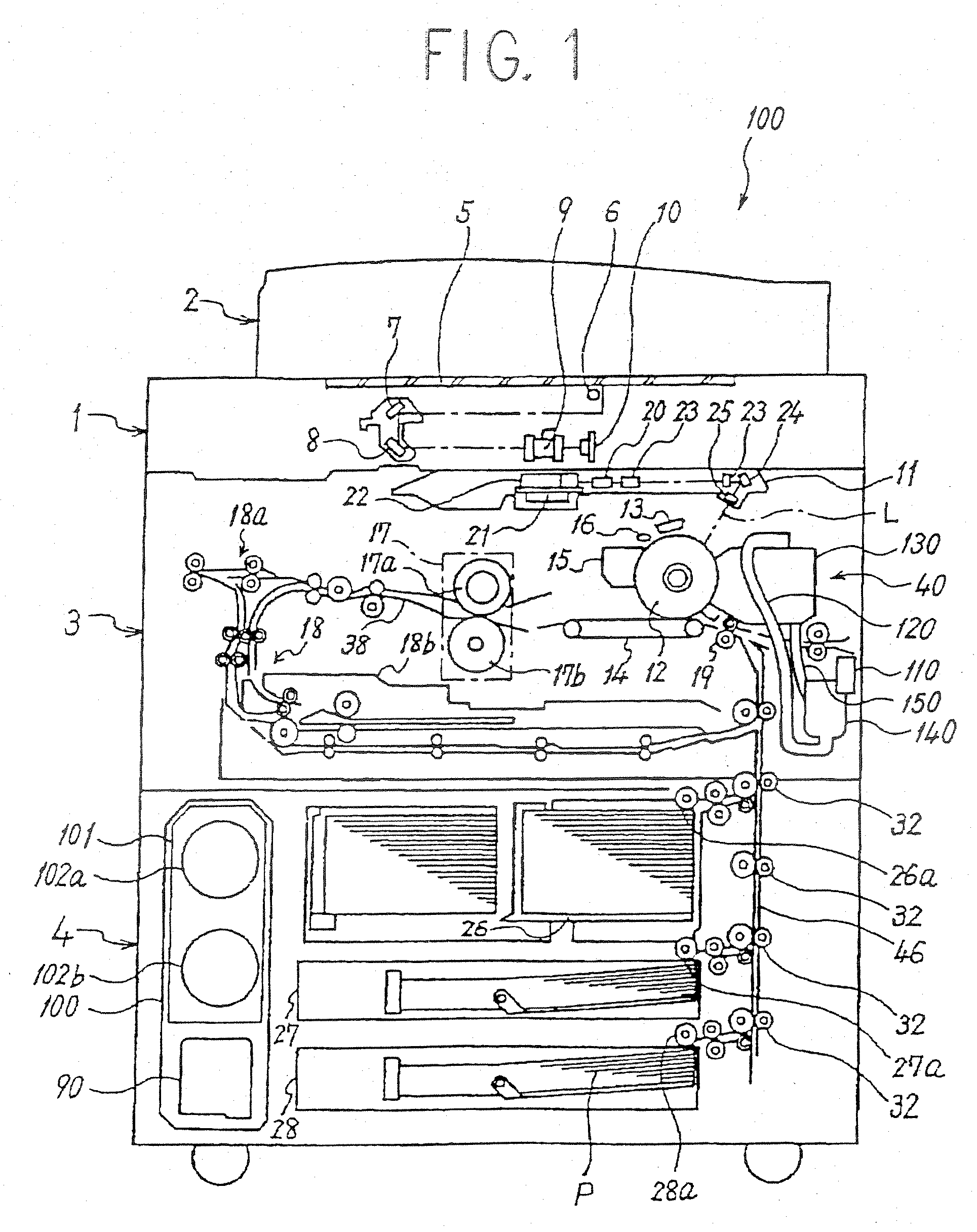

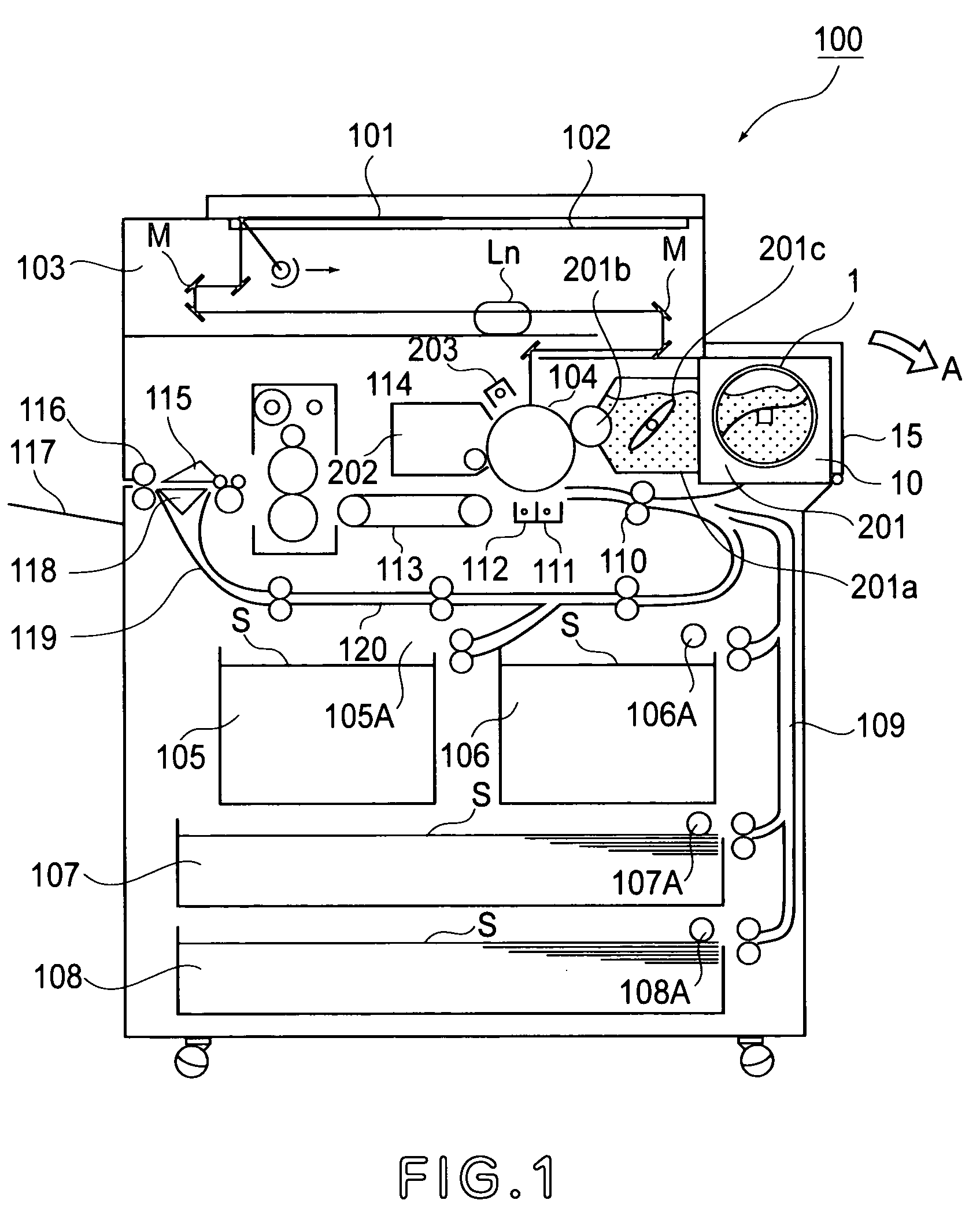

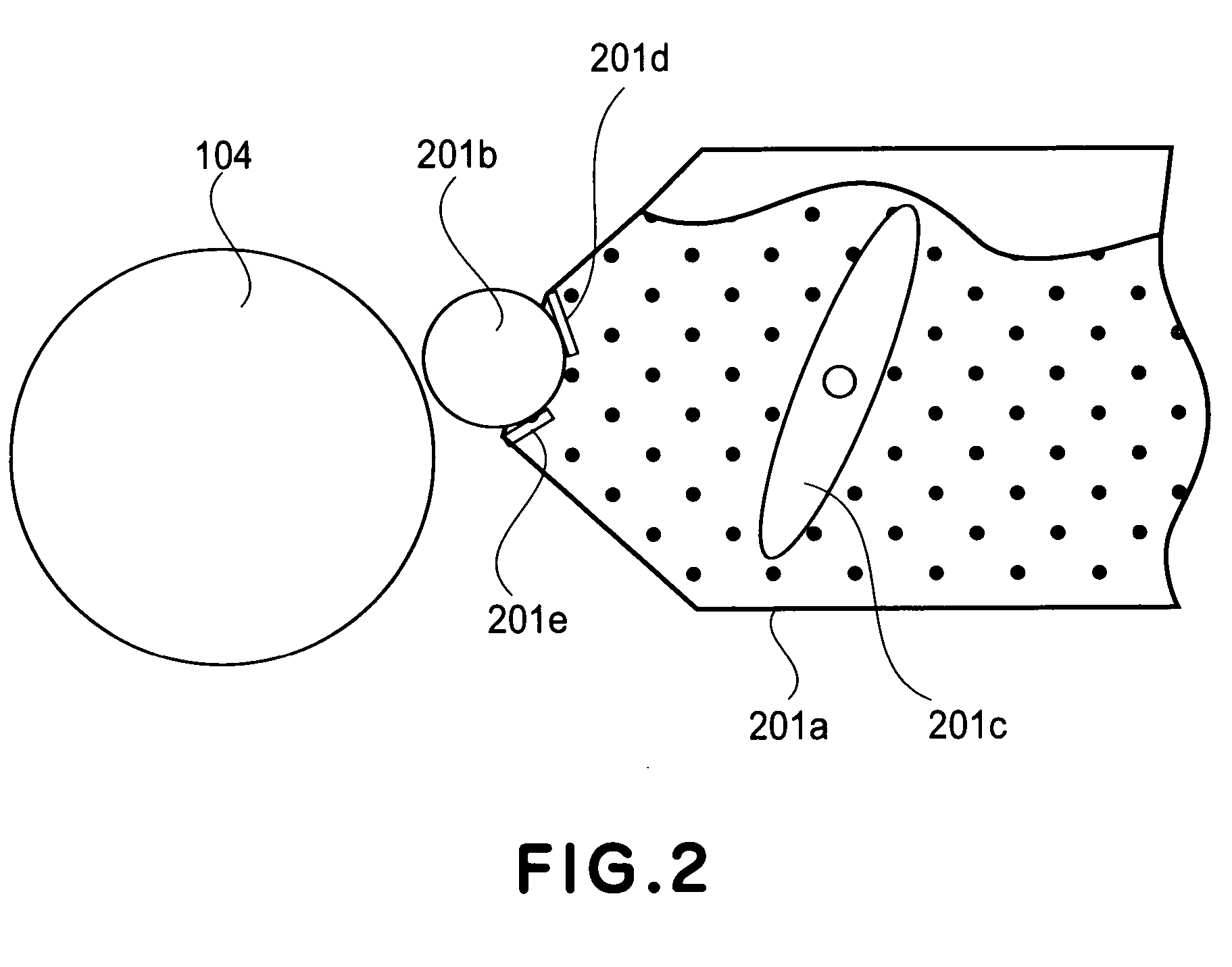

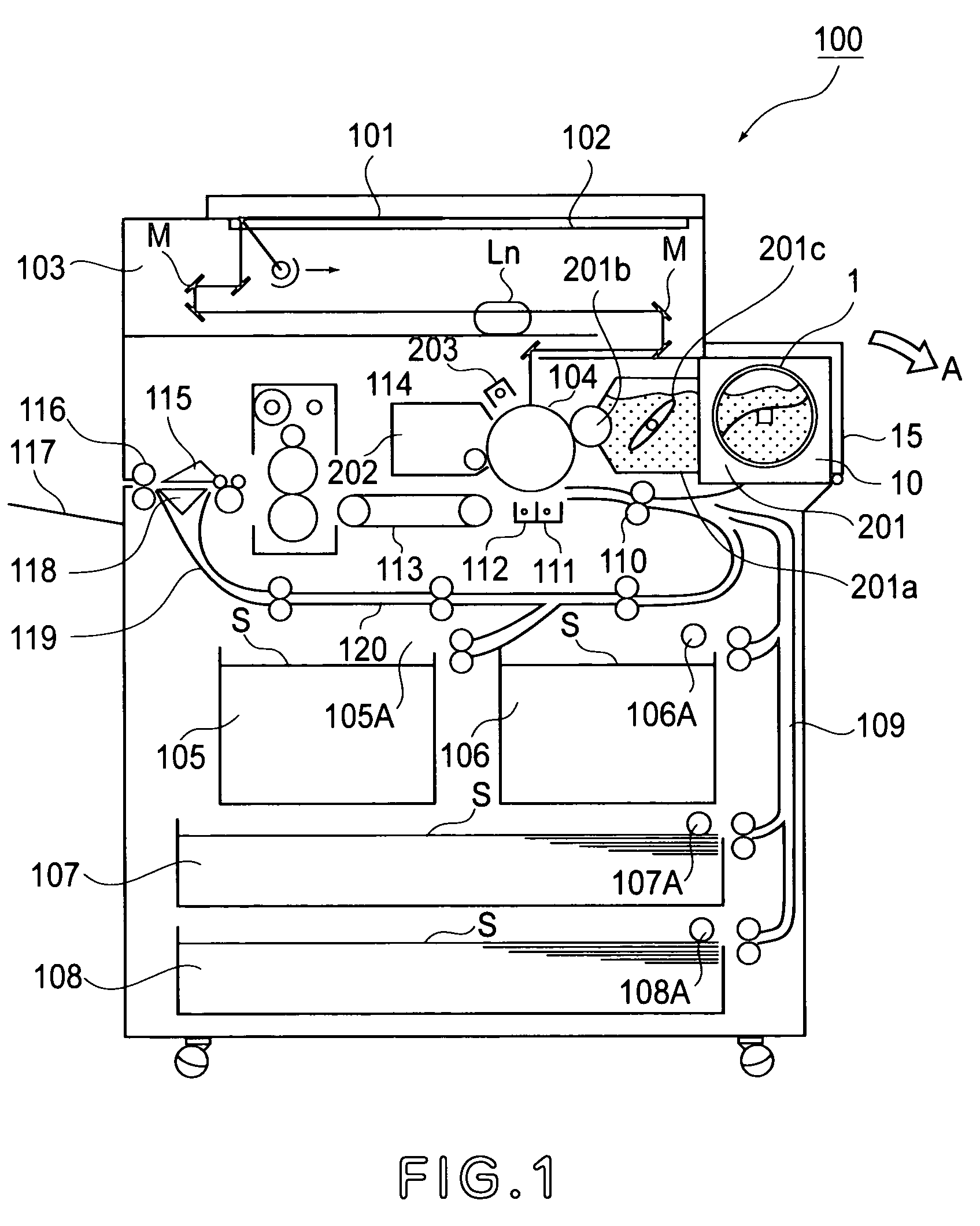

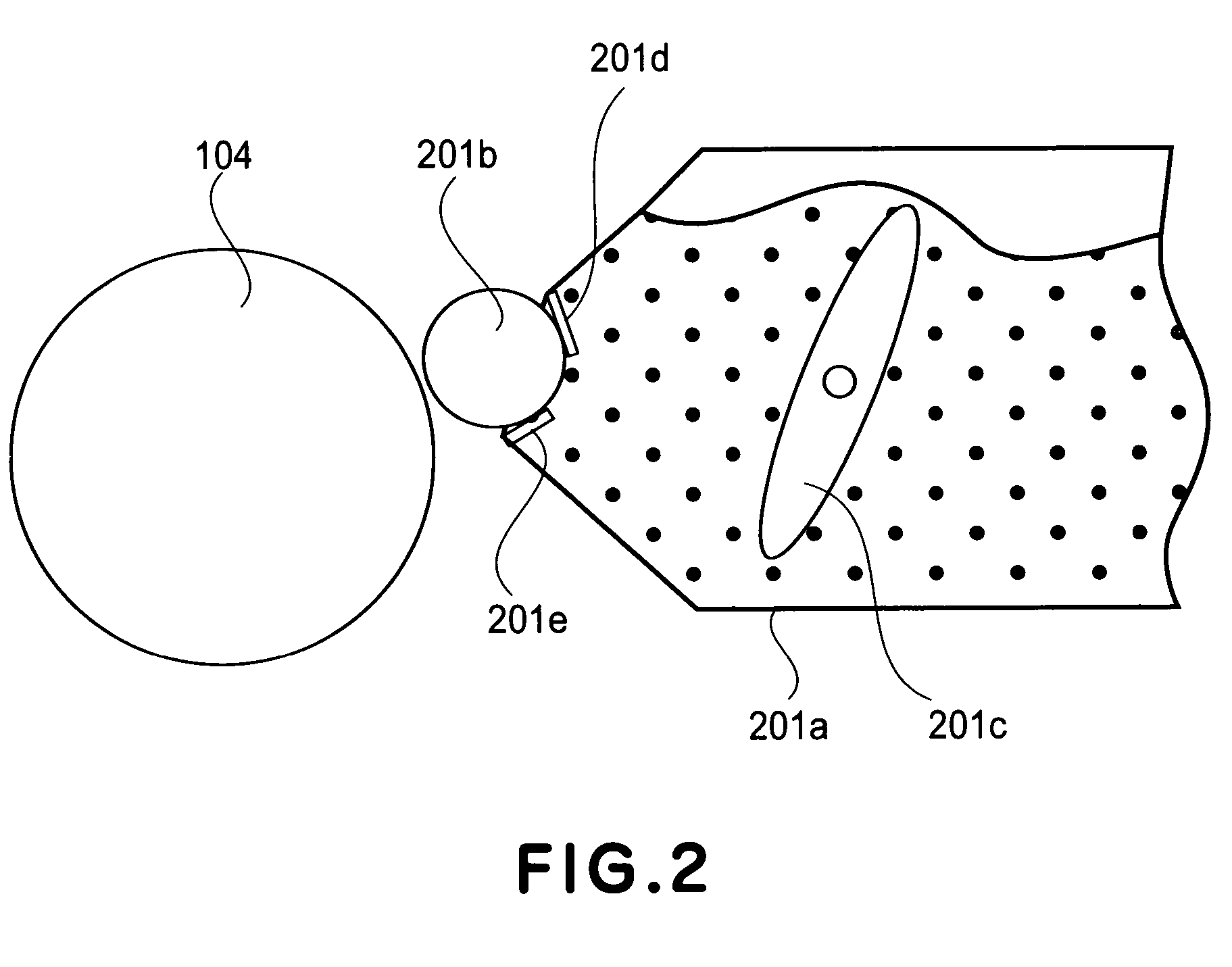

Developing apparatus and image forming apparatus using same

ActiveUS20070166079A1Pollution suppressionSuppressing toner scatteringElectrographic process apparatusImage formationMagnetic flux

A developing apparatus using a two-component developer constituted by a magnetic carrier and a toner, and an image forming apparatus comprising the developing apparatus. A developing unit and a stirring unit are provided, and in order to suppress toner scattering that may occur after a development operation has been halted for a long time, and thereby suppress contamination of the apparatus interior, the developer in a developing machine is transferred to a stirrer serving as a developer storage unit on the exterior of the developing machine when the development operation ends. Further, to extend the life of the developer, a range in which an angle of a restricting member upstream side central angle α, which is a central angle of the surface of a developing roller serving as a developer carrier on the upstream side of a restricting member opposing position opposing a doctor blade serving as a developer amount restricting member in a surface motion direction of the developing roller, is not less than 0[°] and not more than 60[°] is set as a low magnetic flux density area γ in which the maximum value of a normal direction magnetic flux density on the surface of the developing roller is not more than 30 [mT].

Owner:RICOH KK

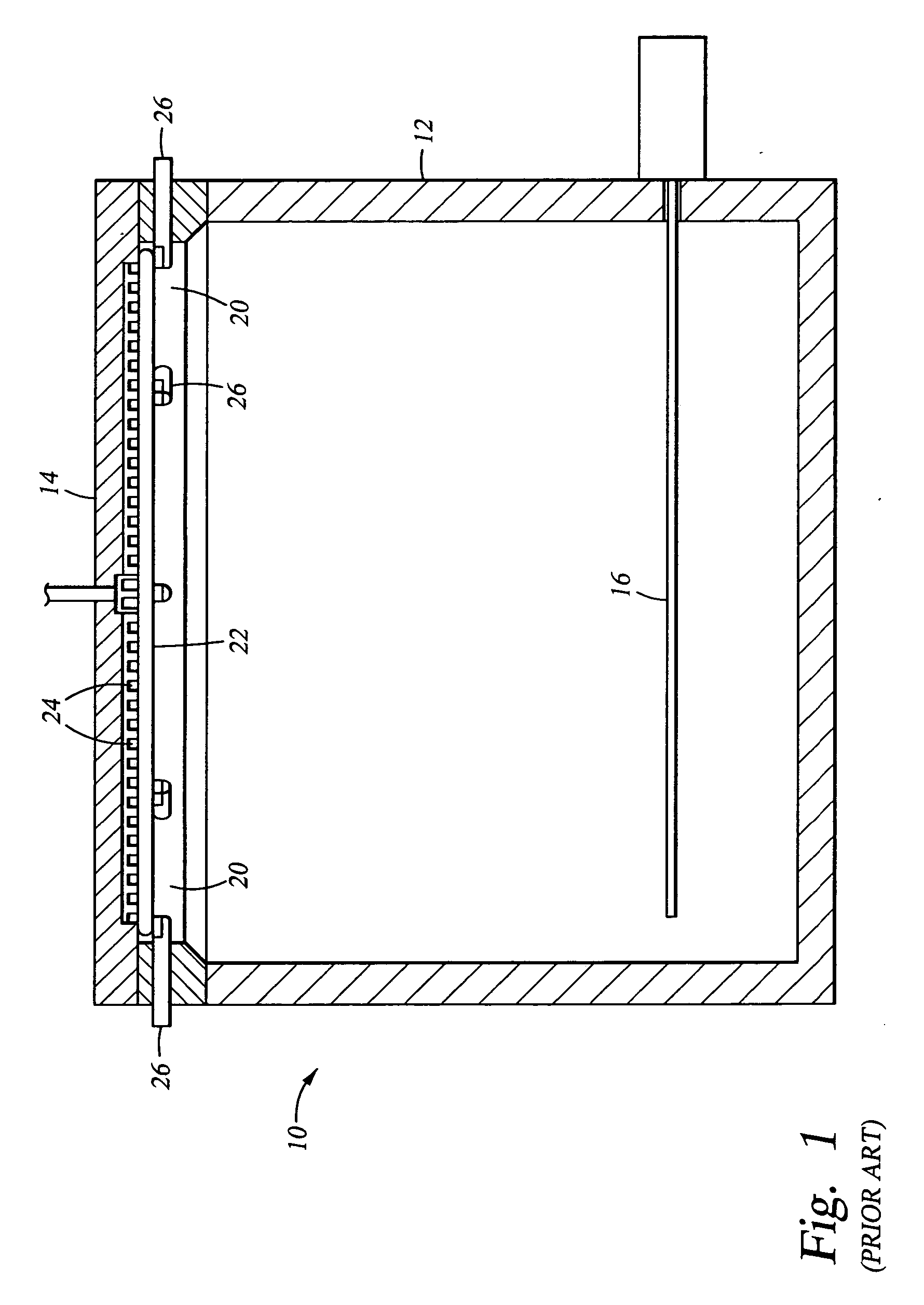

Sealing composition for liquid crystal displays and process for production of liquid crystal display panels

InactiveCN1682149APollution suppressionImprove featuresOther chemical processesNon-linear opticsEpoxyMethacrylate

The sealing composition for liquid crystal displays according to the invention is characterized by consisting of a one-pack type photo- and thermo-setting resin composition comprising (1) a solid epoxy resin having a softening point of 40 DEG C or above as determined by ring and ball method, (2) an acrylate ester monomer and / or a methacrylate ester monomer or an oligomer thereof, (3) a thermoplastic polymer obtained by copolymerizing an acrylate ester monomer and / or a methacrylate ester monomer with a monomer copolymerizable therewith and having a softening point of 50 to 120 DEG C as determined by ring and ball method, (4) a photoradical polymerization initiator, and (5) a latent epoxy curing agent. The photo- and thermo-setting sealing composition for liquid crystal displays is applicable to the dispenser method, can give a cured product having excellent characteristics through photosetting in the first step, and permits the formation of stable cell gaps. Further, the sealing composition is inhibited from polluting liquid crystal in thermosetting in the second step and attains excellent setting properties in the shaded areas and high adhesion reliability.

Owner:MITSUI CHEM INC

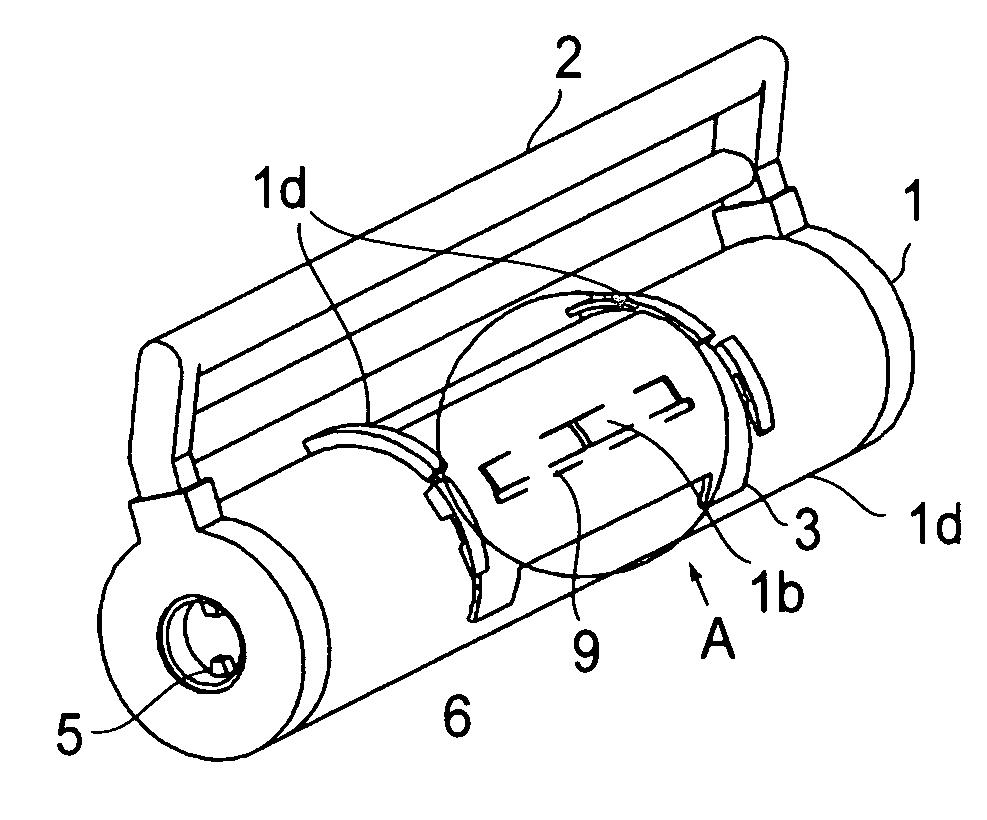

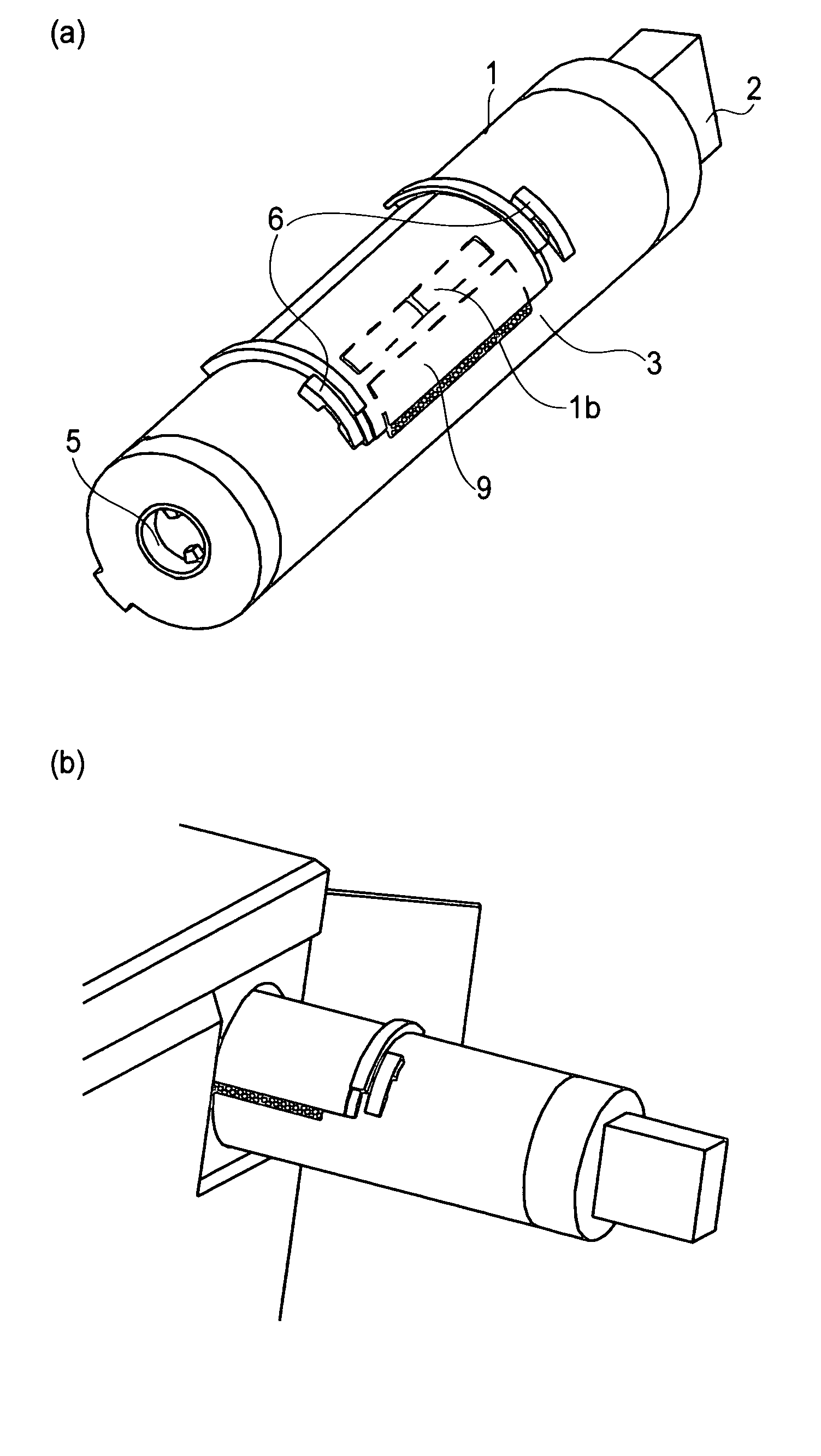

Developer supply container

InactiveUS20060104671A1Pollution suppressionElectrographic process apparatusEngineeringMechanical engineering

A developer supply container is detachably mountable to a developer receiving apparatus having a receiving opening for receiving a developer and a shutter for opening and closing the receiving opening, the developer supply container includes an engaging portion which is engageable with the shutter and movable to open and close the shutter by movement of the developer supply container; and a cleaning member for cleaning the shutter when the developer supply container is moved relative to the shutter between a removal position permitting removal of the developer supply container from the developer receiving apparatus and a supply position at which the developer is supplied from the developer supply container to the developer receiving apparatus.

Owner:CANON KK

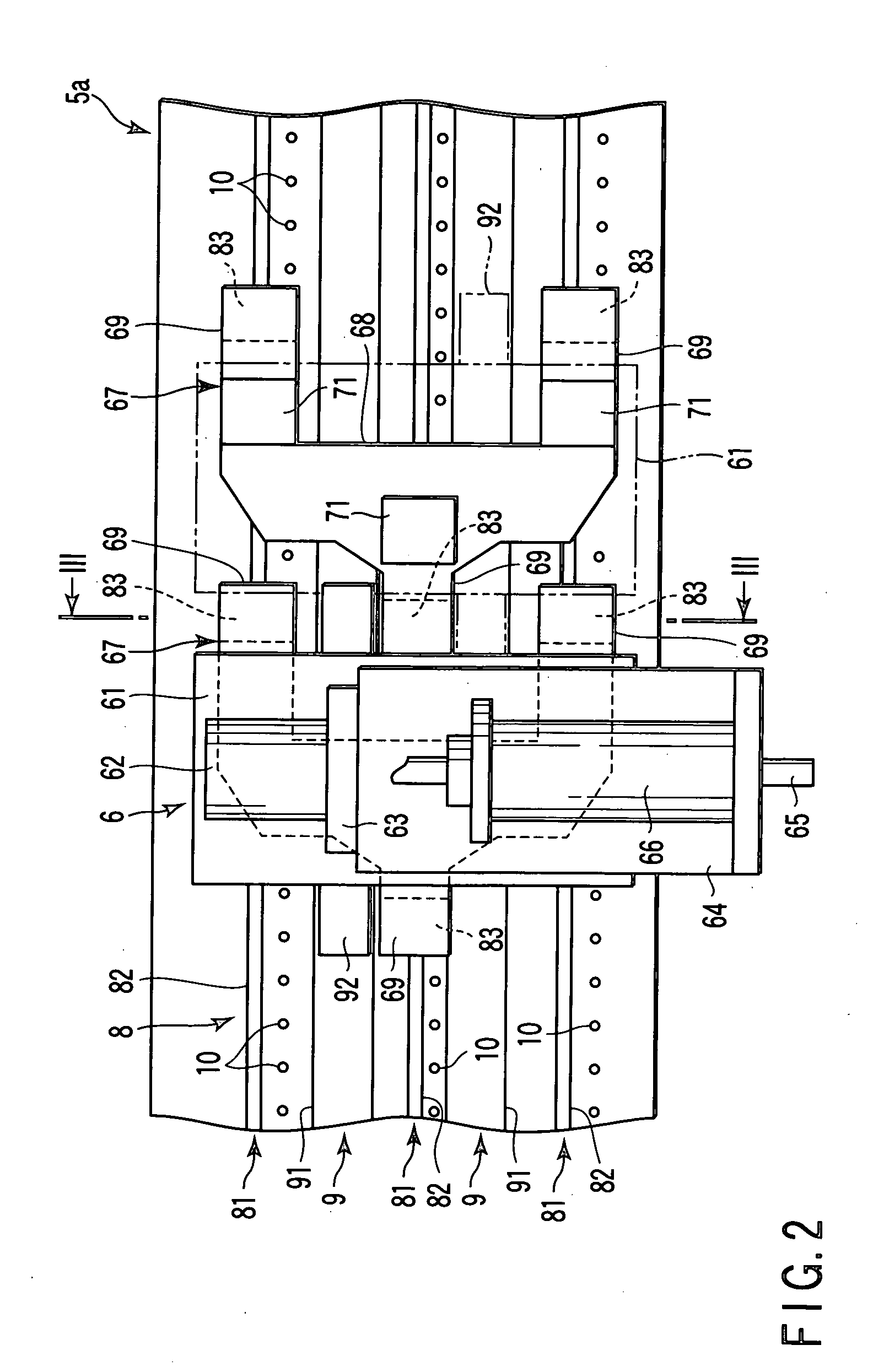

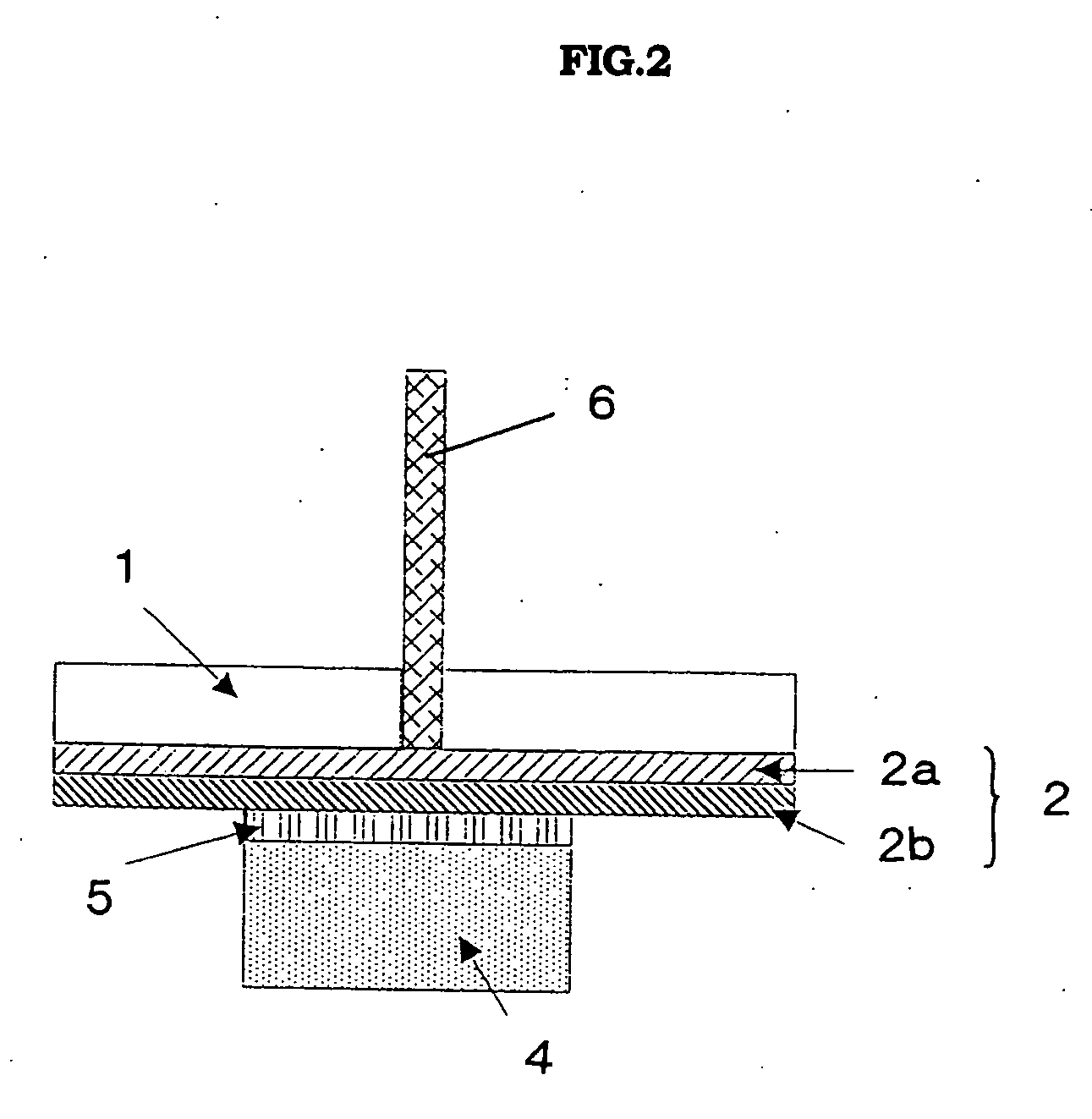

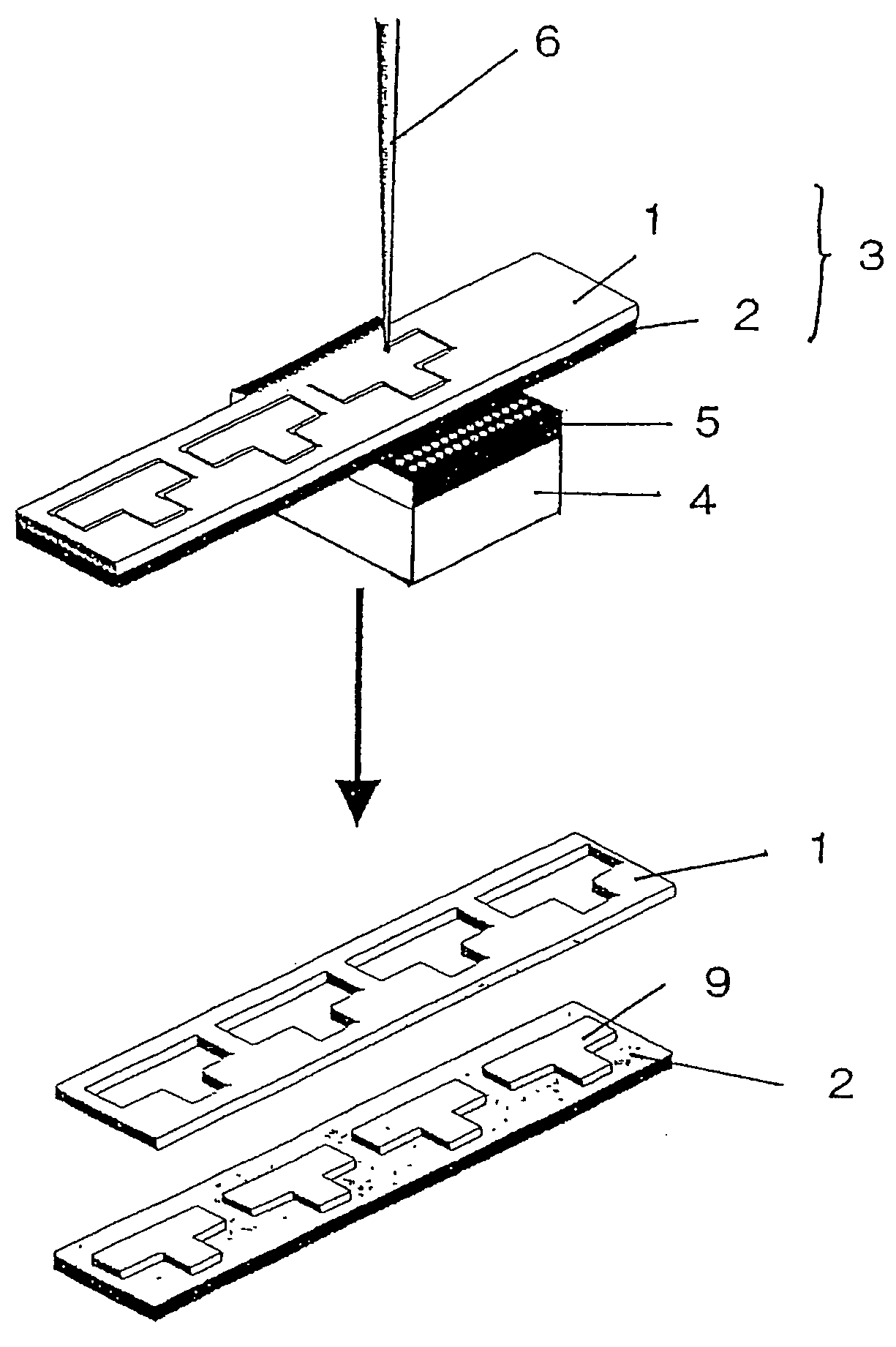

Apparatus for applying paste and method of applying paste

InactiveUS20050056215A1Pollution suppressionGood paste applicationLiquid surface applicatorsAnimal housingEngineeringHead parts

Owner:SHIBAURA MECHATRONICS CORP

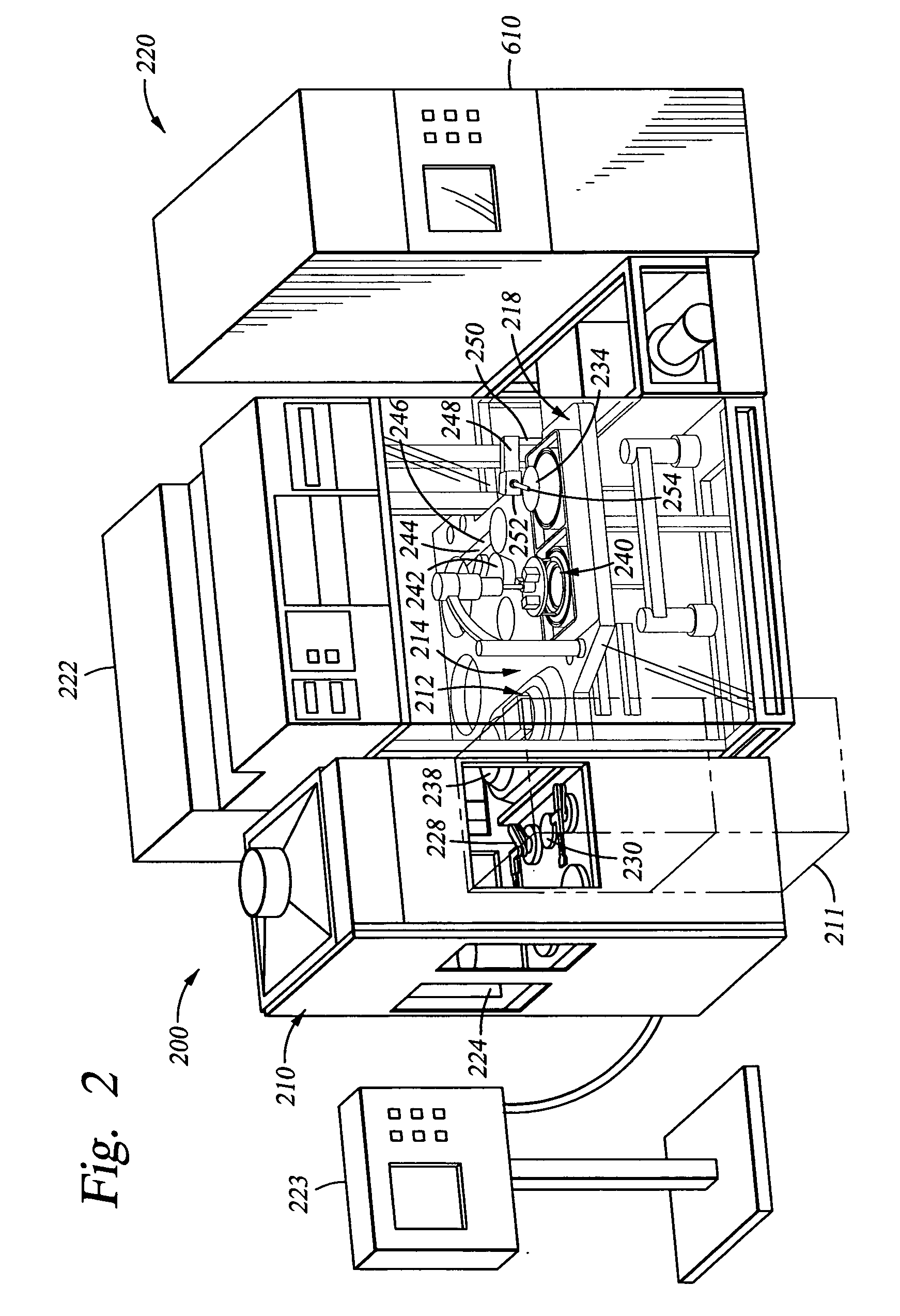

Electro-chemical deposition system

InactiveUS20060246690A1Enhance resultRapid treatmentAnodisationVacuum evaporation coatingElectricityEngineering

The present invention provides an electro-chemical deposition system that is designed with a flexible architecture that is expandable to accommodate future designs and gap fill requirements and provides satisfactory throughput to meet the demands of other processing systems. The electro-chemical deposition system generally comprises a mainframe having a mainframe wafer transfer robot, a loading station disposed in connection with the mainframe, one or more processing cells disposed in connection with the mainframe, and an electrolyte supply fluidly connected to the one or more electrical processing cells. Preferably, the electro-chemical deposition system includes a spin-rinse-dry (SRD) station disposed between the loading station and the mainframe, a rapid thermal anneal chamber attached to the loading station, and a system controller for controlling the electro-chemical deposition process and the components of the electro-chemical deposition system.

Owner:APPLIED MATERIALS INC

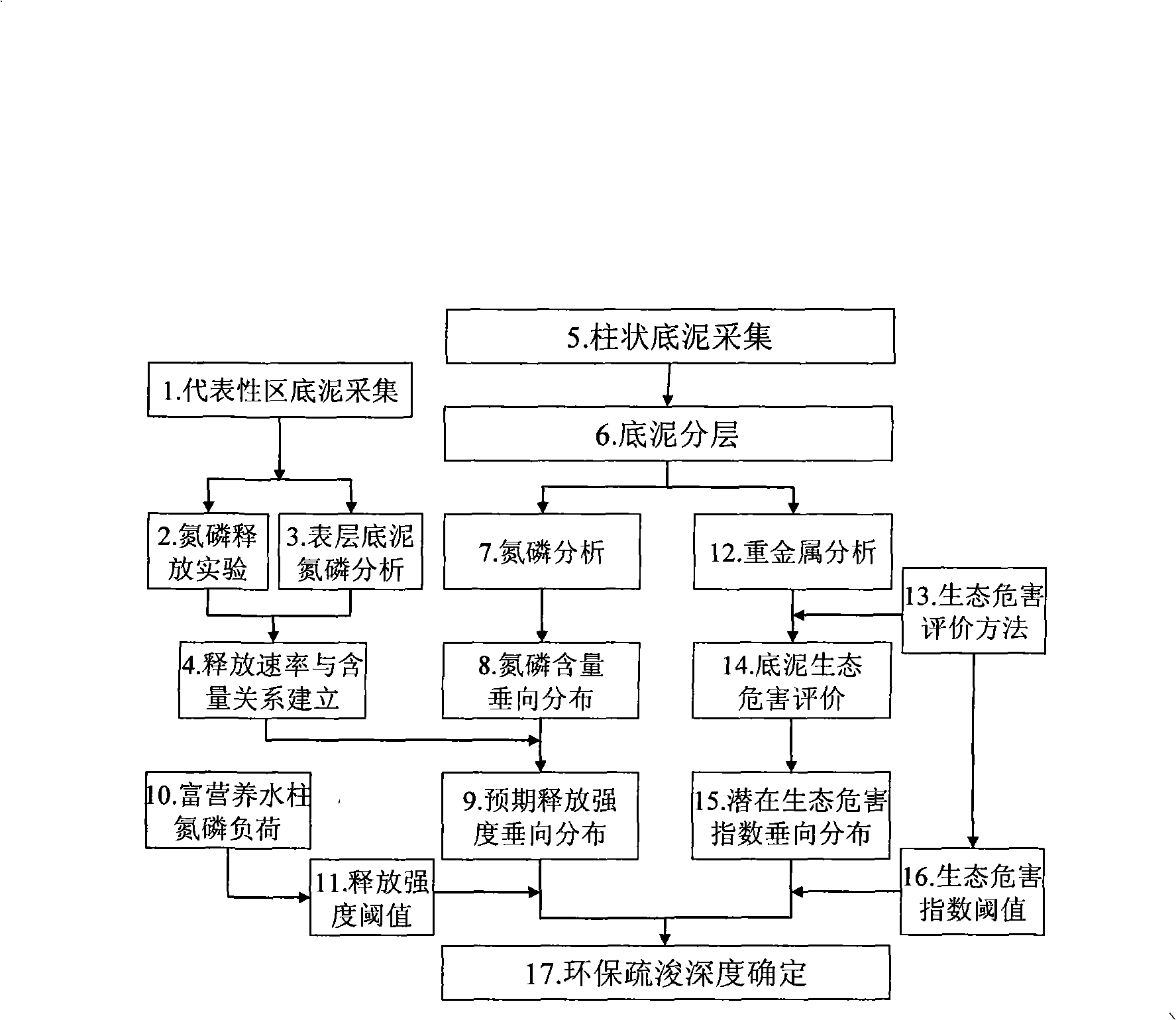

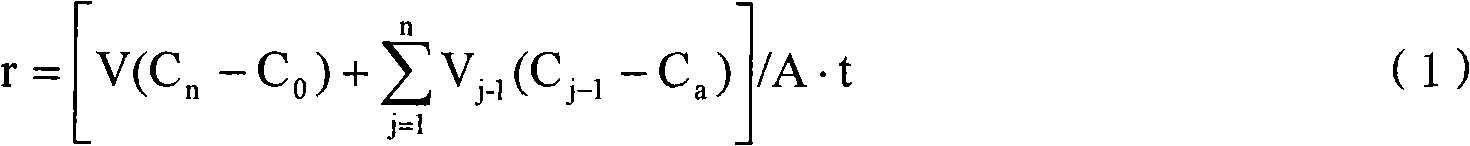

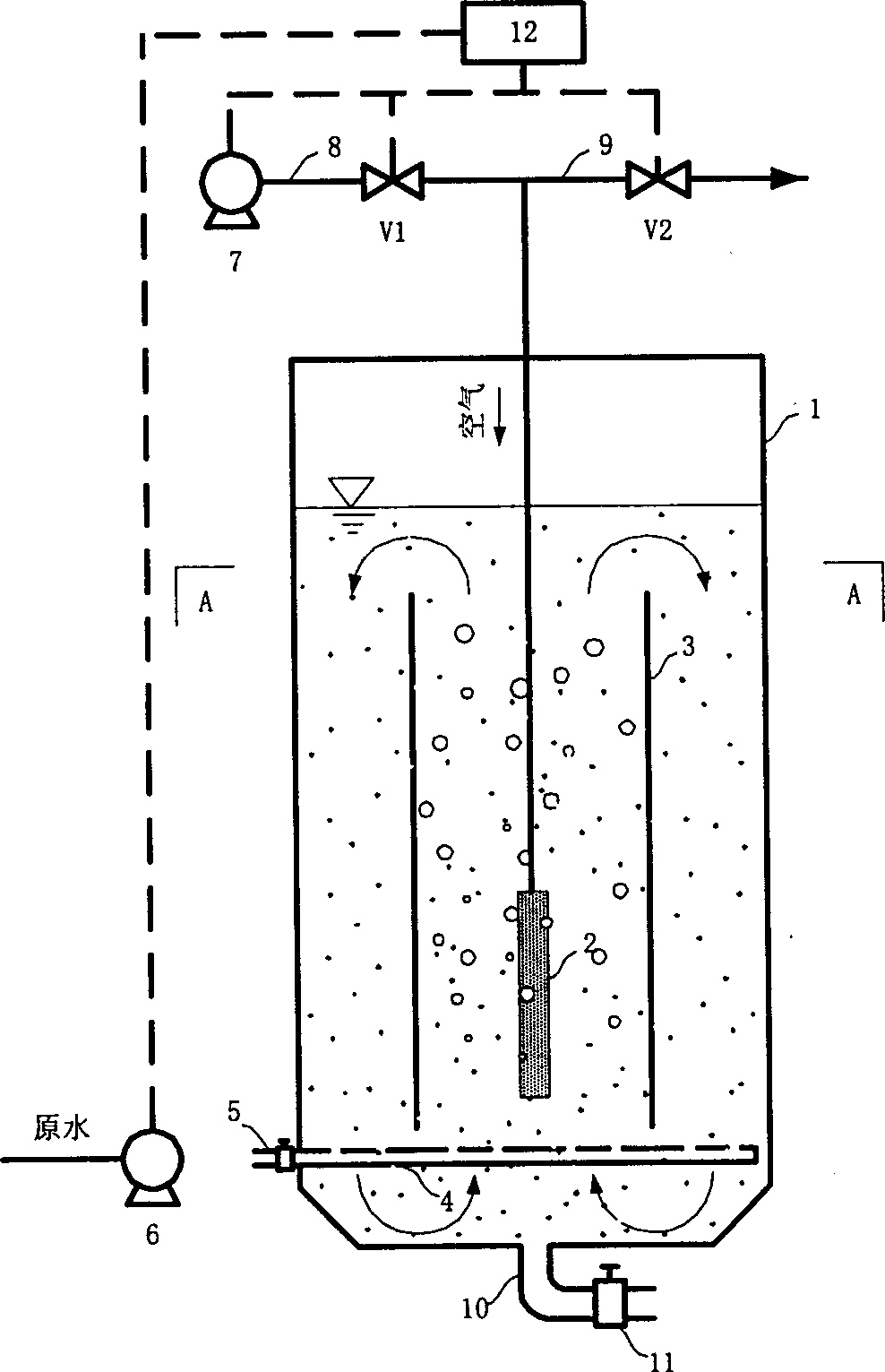

Polluted water body deposit environment-friendly dredging depth determination method

InactiveCN101266235APollution suppressionReduce ecological riskMaterial analysisSurface layerRed mud

The invention provides a determining method for polluted water bed mud environmental protection dredging depth, comprising analyzing and evaluating the releasing risk and ecological hazard risk of the pollutant at different layer side of the mud based on the vertical distribution of the pollutant in the bed mud by researching the relation of the releasing of bed mud pollutant nitrogen, phosphor or the like and the corresponding pollutant content and the ecological hazard evaluation corresponding with the content of the bed mud pollutant containing heavy metal; and determining the bed mud dredging depth based on the divided corresponding risk grade. After dredging, the anticipated release rate of the key pollutant such as nitrogen, phosphor at the new surface layer of bed mud-hydrosphere achieves or exceeds a release intensity threshold and the latent ecological hazard index of the heavy metal at the new surface layer of bed mud achieves or exceeds a hazard threshold, therefore the basis of the dredging depth is determined.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

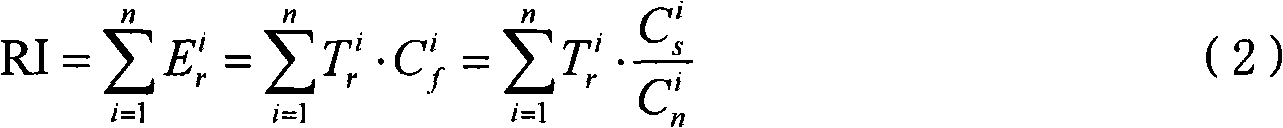

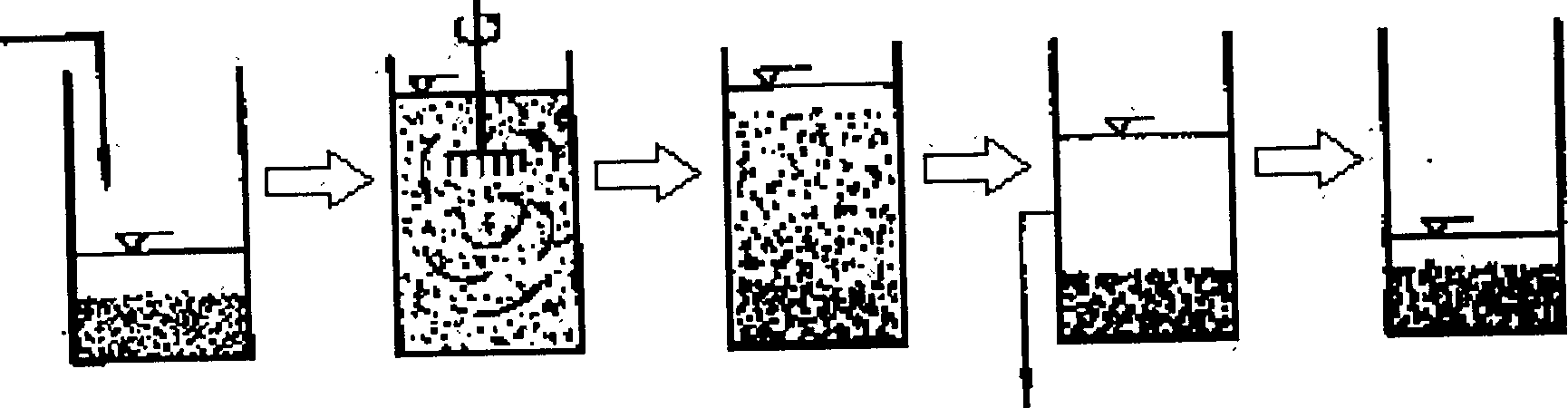

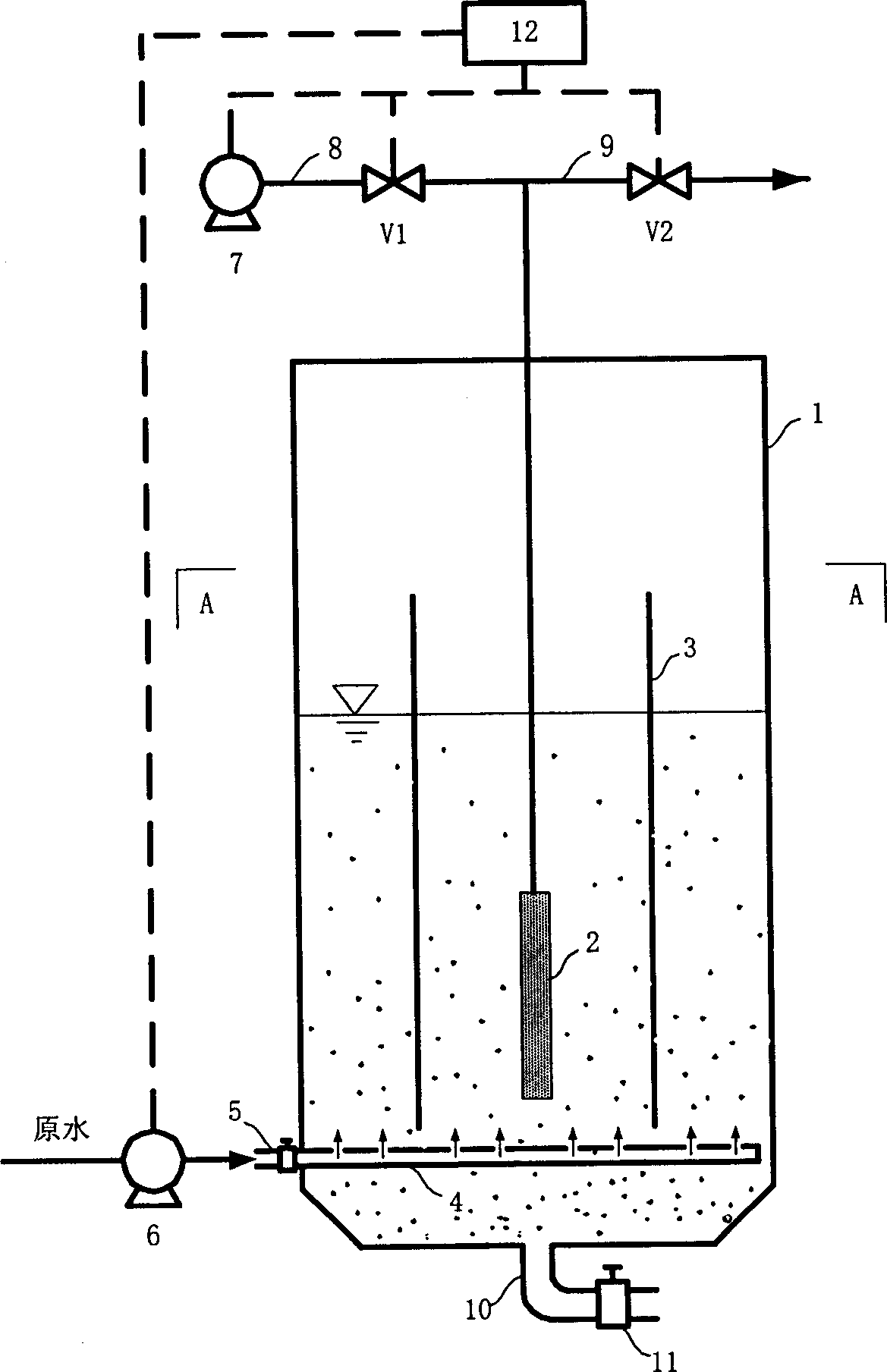

Process and apparatus for wastewater by batched membrane-bioreactor

InactiveCN1424265AGood water qualitySimple device structureWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesAutomatic controlPollutant

A process for treating sewage by integrating sequential active sludge method with membrane-bioreactor features that the membrane assembly is put in bioreacting pool, its outlet is respectively connected to air inlet pipe and water outlet pipe via two control valves, the whole system sequentially passes through flow-in, reaction, discharge and idle steps, that is, anaerobic, aerobic and anoxic states, and said membrane assembly plays the roles of aerating unit in reaction step or separator in discharge step. Its advantages are simple structure and high effect.

Owner:TSINGHUA UNIV

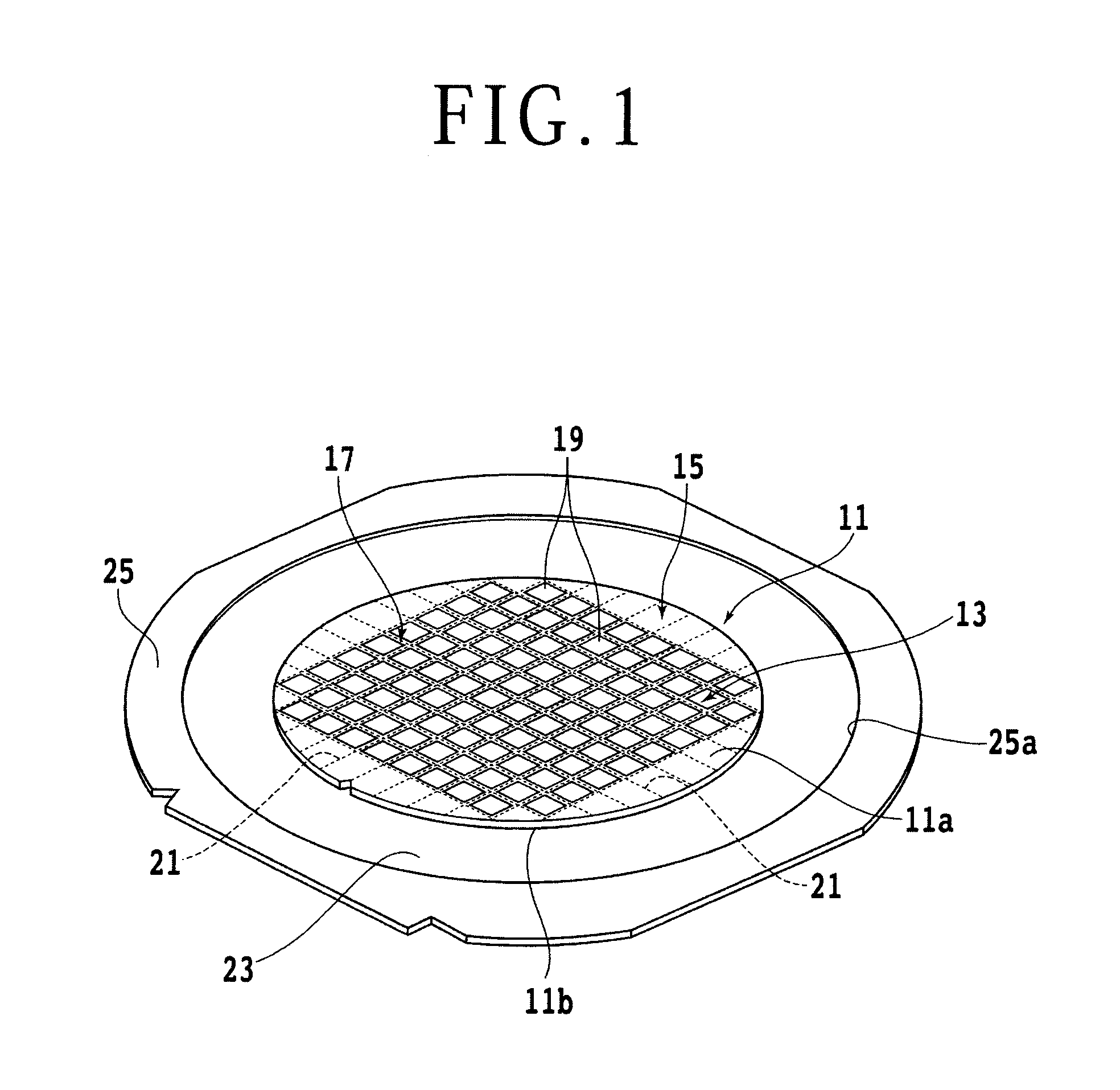

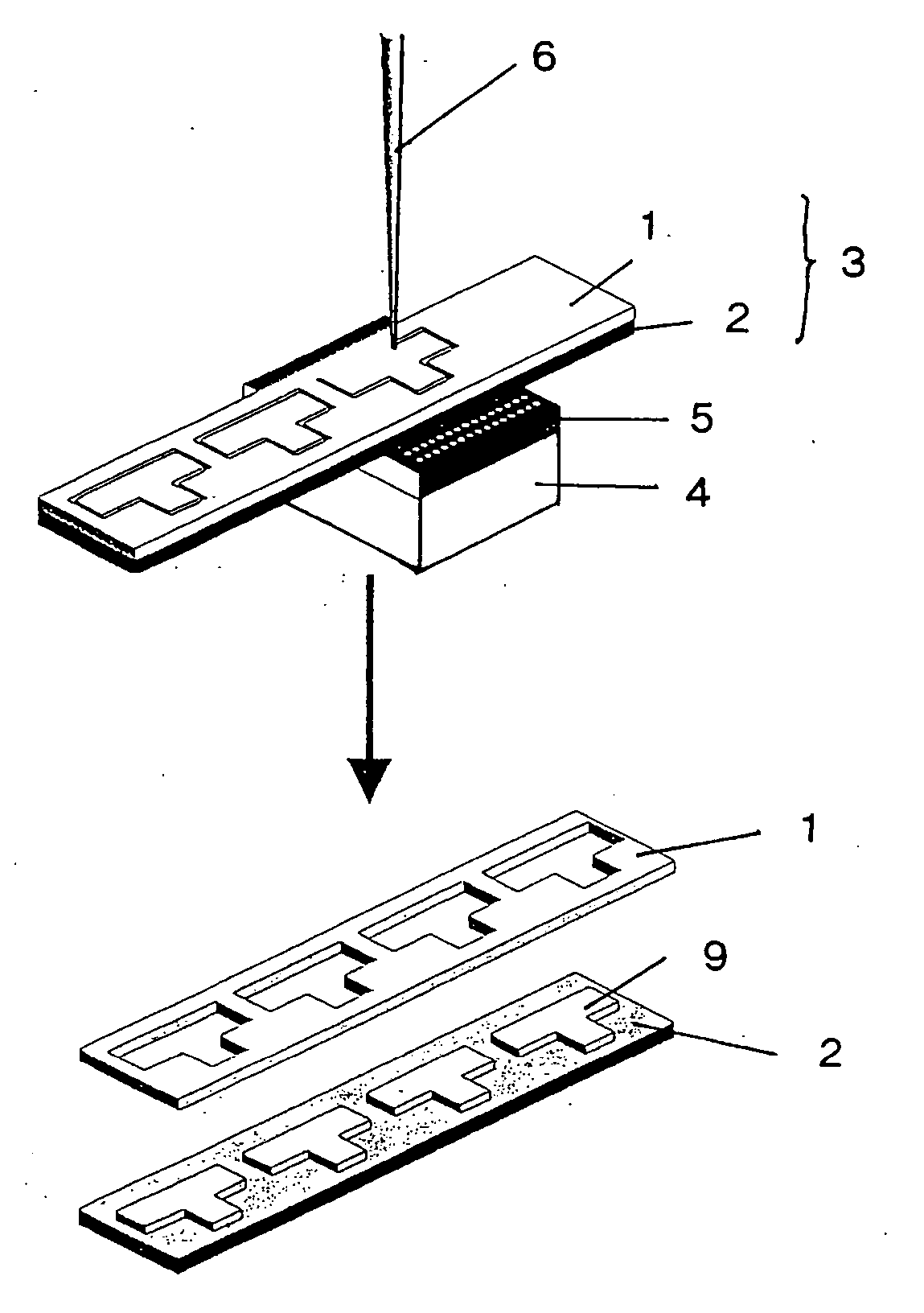

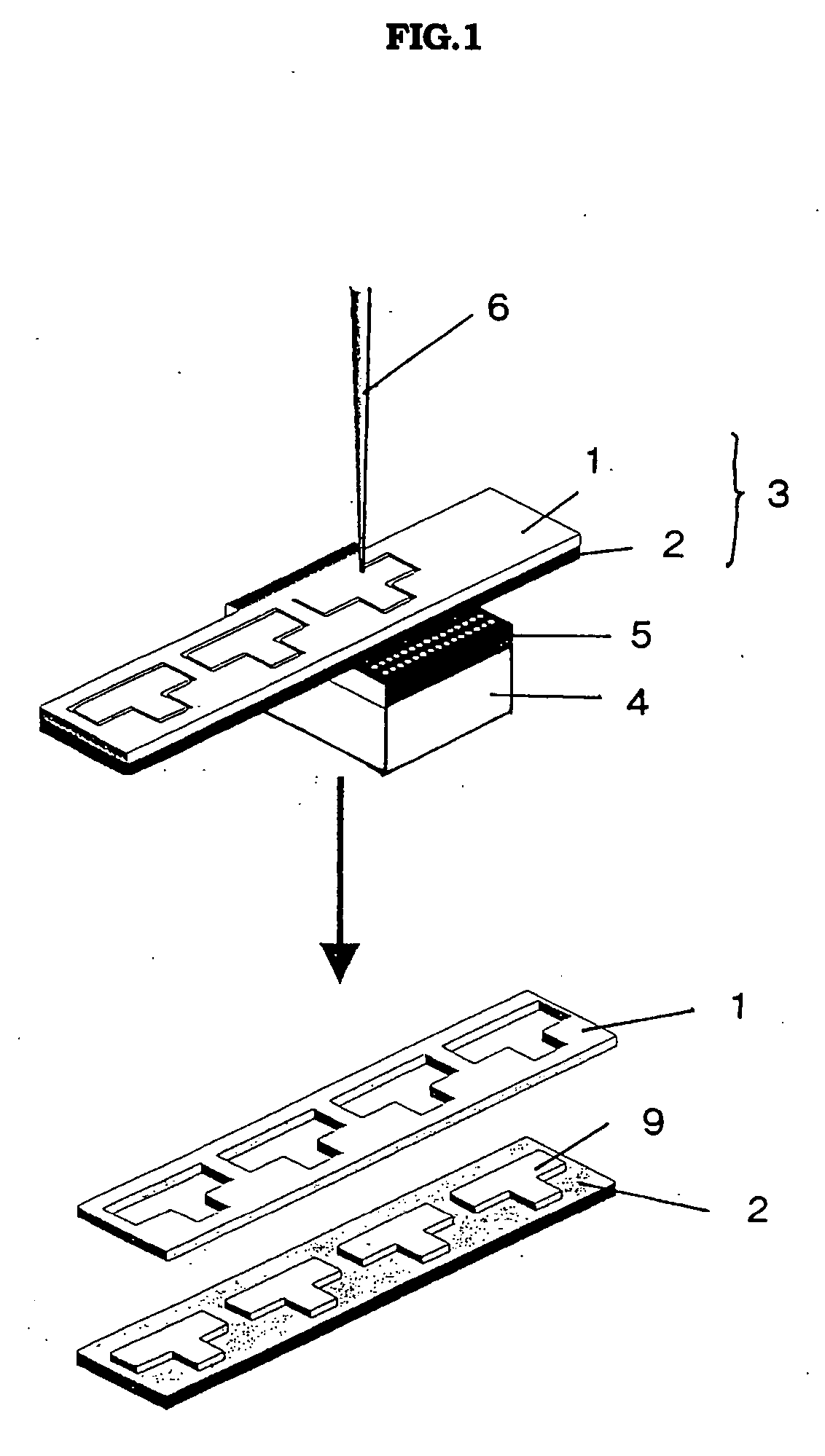

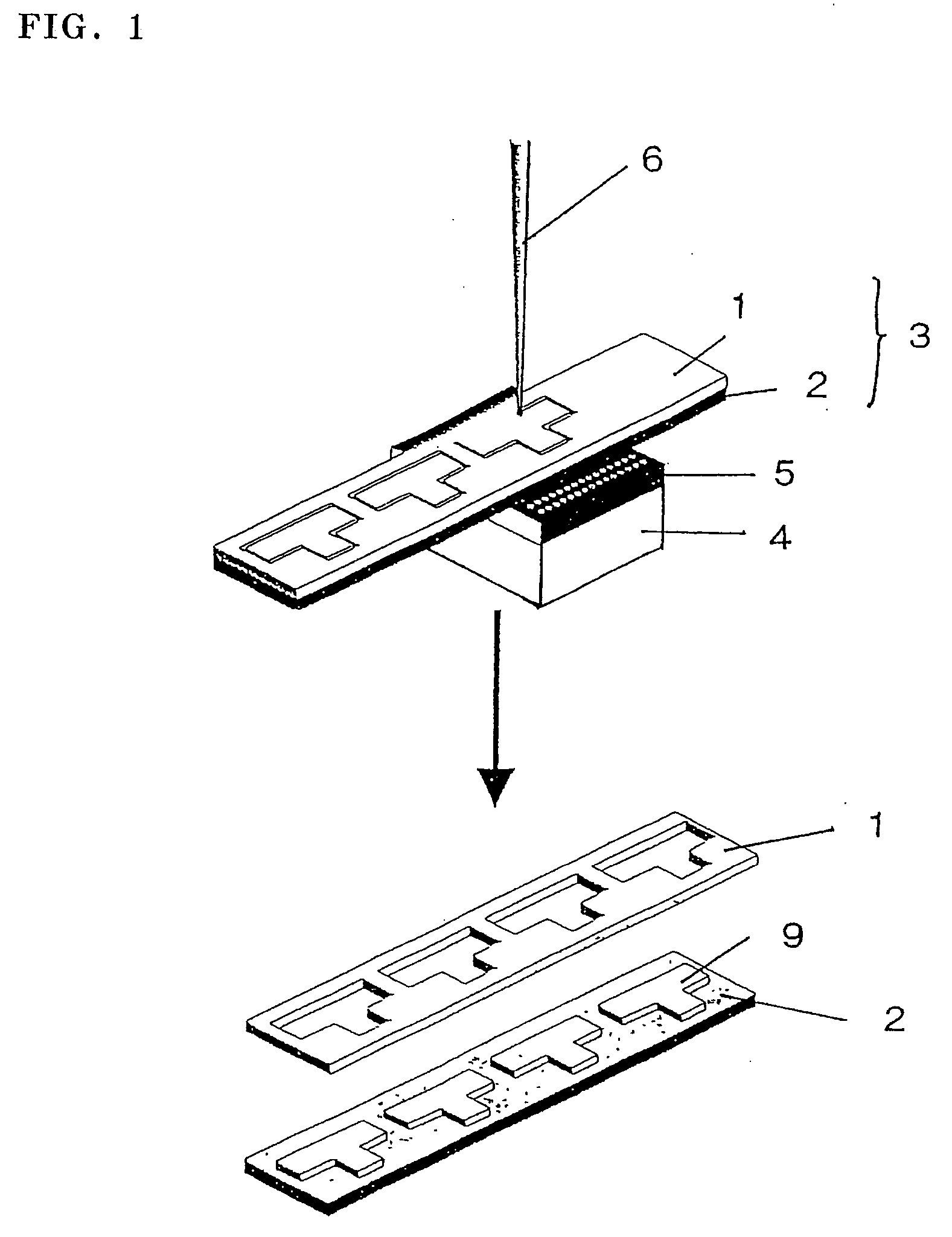

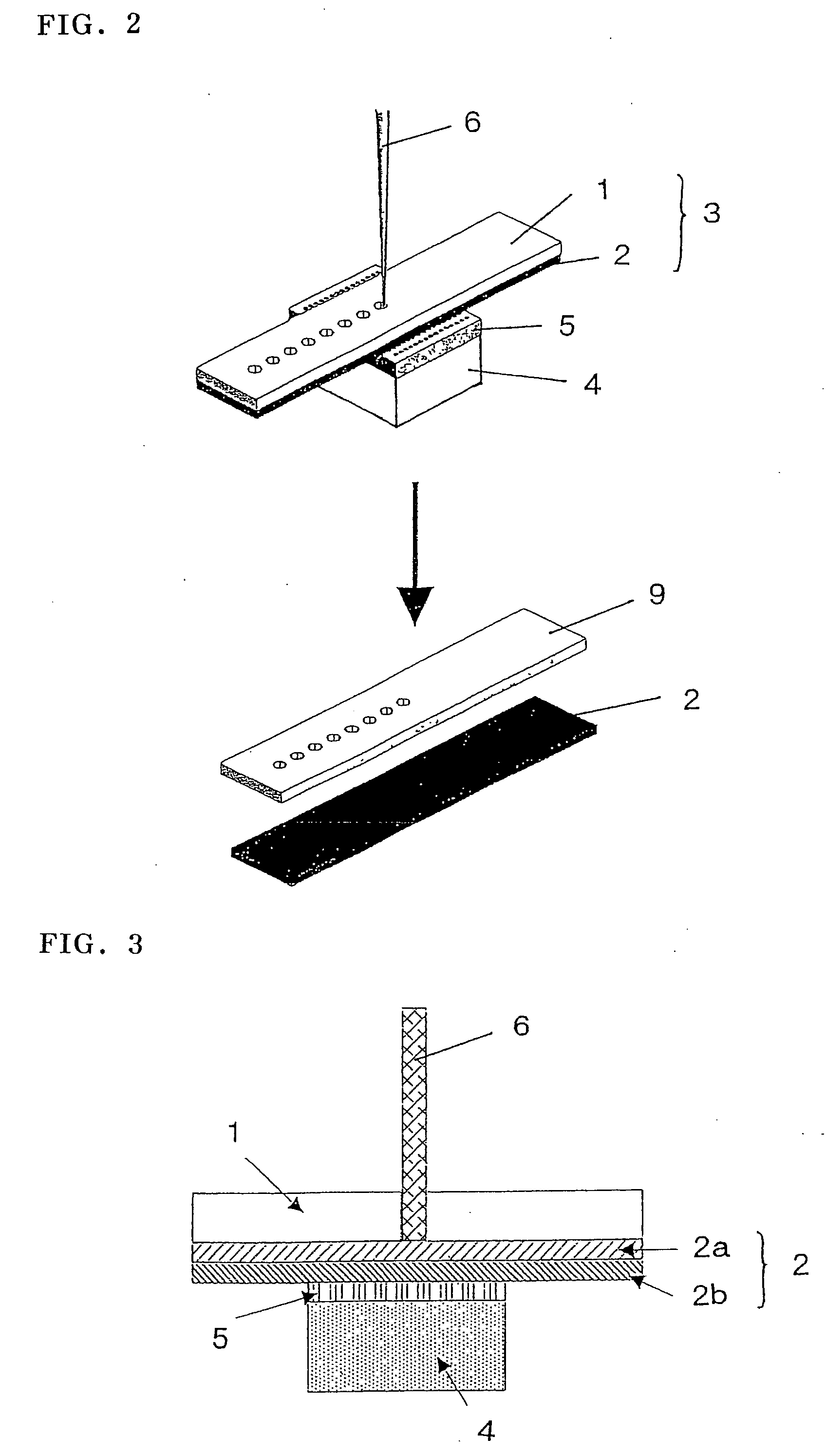

Method of producing laser-processed product and adhesive sheet, for laser processing used therefor

InactiveUS20060246279A1Easy and efficient processingPollution suppressionSemiconductor/solid-state device manufacturingPrinted circuit manufactureLaser processingDecomposition

A manufacturing method of laser processed parts is characterized in that at least a pressure-sensitive adhesive layer is provided on a base material as a pressure-sensitive adhesive sheet (2) for laser processing, using a material having specified physical properties, and this method comprises a step of adhering the pressure-sensitive adhesive sheet (2) for laser processing to the laser beam exit side of the work (1) by way of the pressure-sensitive adhesive layer, a step of processing the work by irradiating the work with a laser beam (6) of within 2 times of the irradiation intensity for forming a through-hole in the work (1), at higher than the irradiation intensity of threshold for inducing ablation of the work (1), and a step of peeling the pressure-sensitive adhesive sheet (2) for laser processing from the work (1) after the machining. Therefore, contamination of the work surface by decomposition products can be effectively suppressed, and laser processed parts can be manufactured easily and at high production efficiency.

Owner:NITTO DENKO CORP

Manufacturing method of laser processed parts and adhesive sheet for laser processing

InactiveUS20060157191A1Pollution suppressionPromote recoveryLamination ancillary operationsPaper/cardboard articlesLaser processingOptoelectronics

Providing a method of manufacturing a laser processed part capable of processing at high speed and high precision when processing a workpiece by optical absorption ablation of laser beam, effectively suppressing contamination of a workpiece surface by decomposition products, and recovering the workpiece easily after processing. Another object is to present an adhesive sheet for laser processing preferably used in the method of manufacturing a laser processed part.

Owner:NITTO DENKO CORP

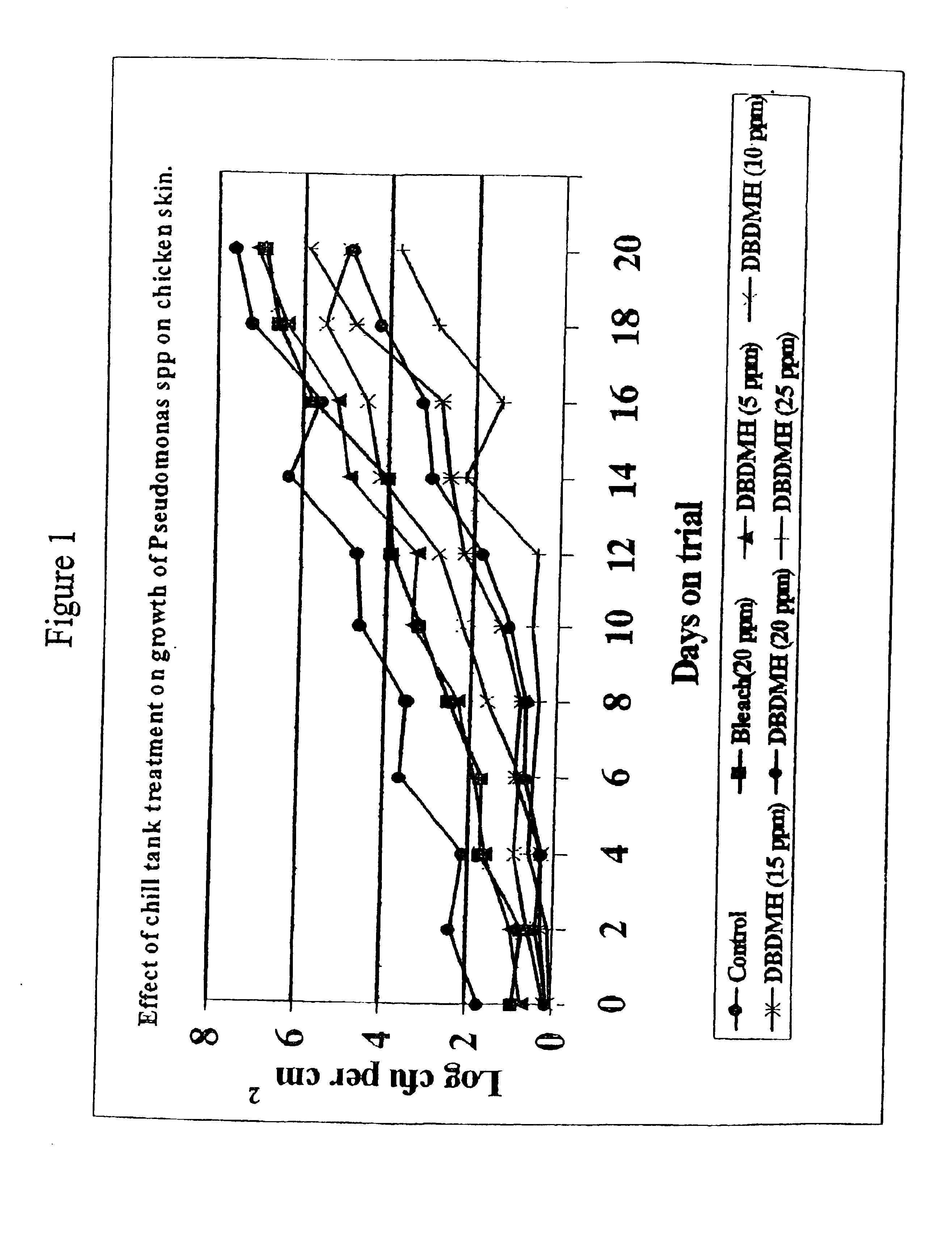

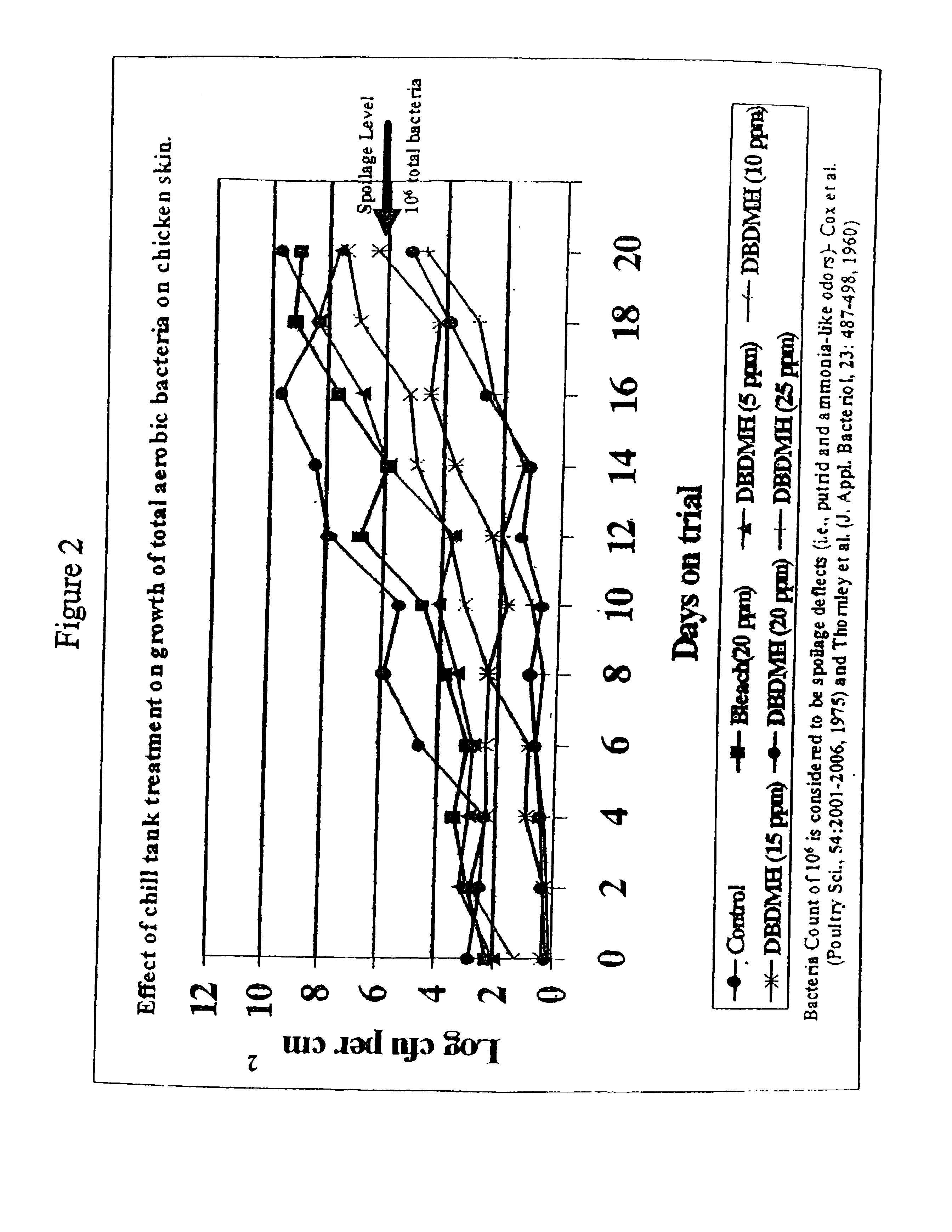

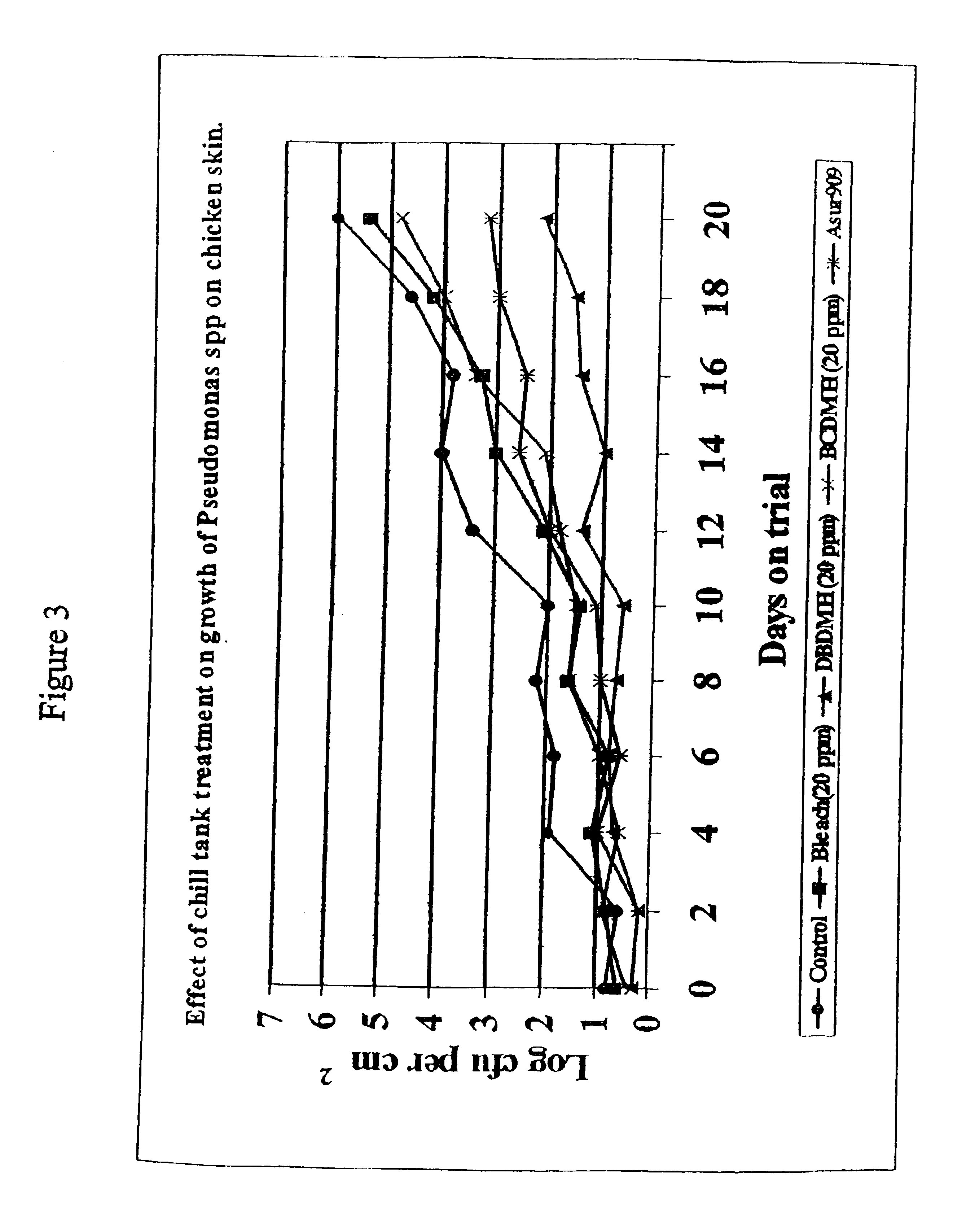

Microbiological control in poultry processing

InactiveUS6986910B2Produced economicallyLow costBiocideDough treatmentBiotechnologyEffective microorganism

Owner:ALBEMARLE CORP

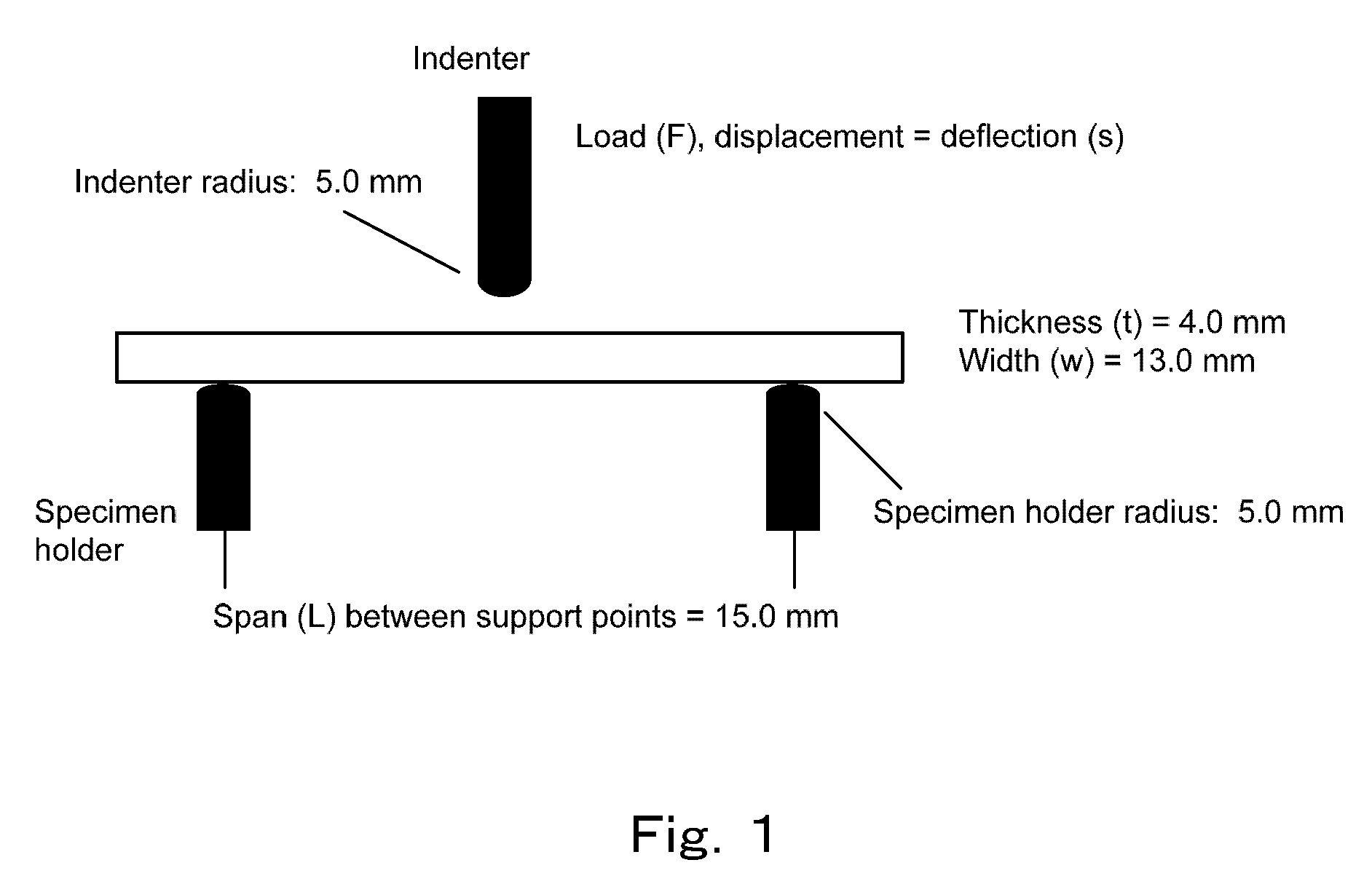

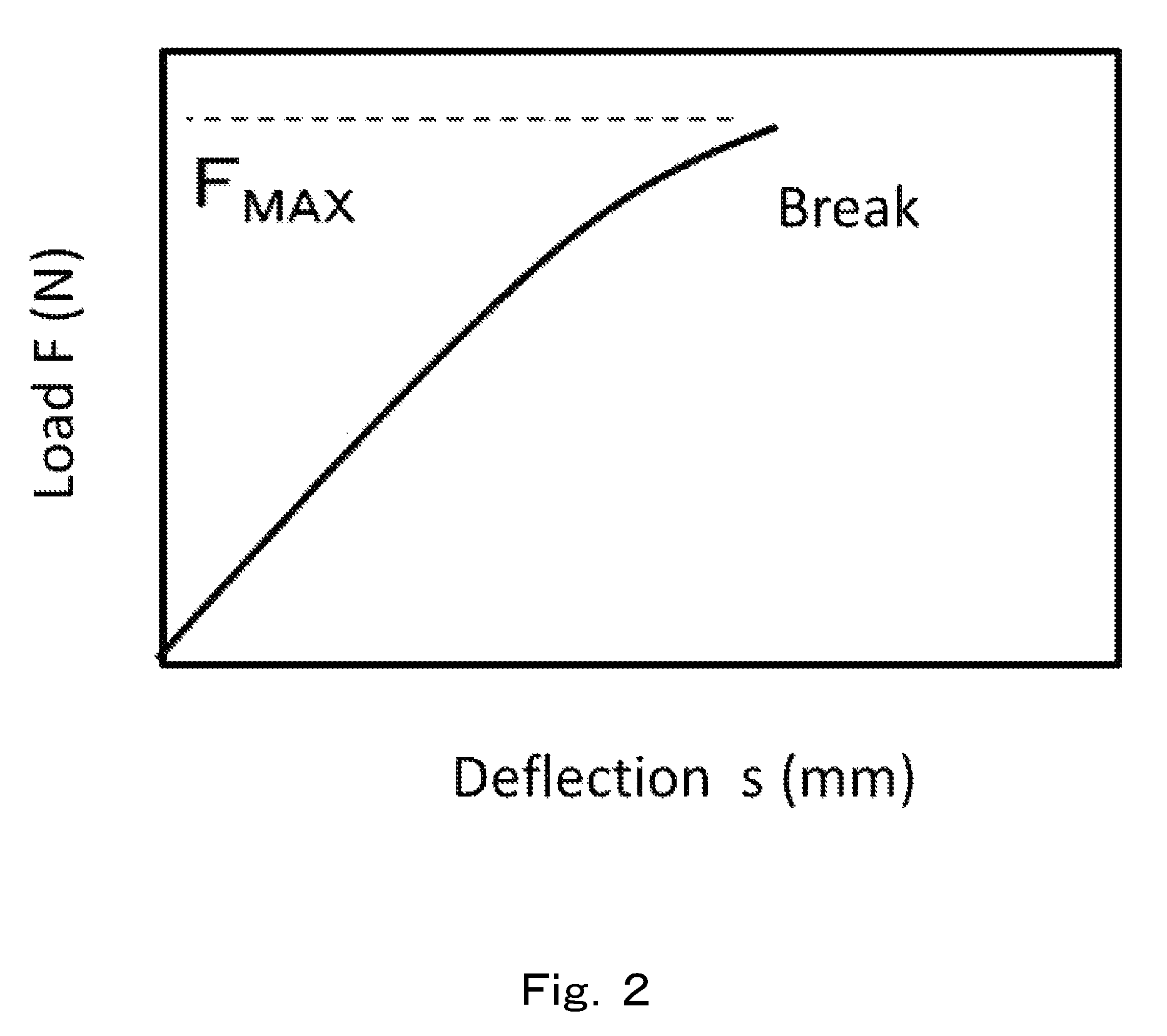

Toner

A toner has toner particles containing a binder resin that comprises a block polymer as a main component, obtained by chemically bonding a crystalline polyester resin with an amorphous polyurethane resin, wherein the binder resin has a specific content of a crystalline polyester resin component, and has a concentration of ester bonds derived from the crystalline polyester resin component of not more than 5.2 mmol / g, and The maximum value EMAX of the flexural elasticity modulus E in a three-point bending test on the toner and the strain energy u for the toner satisfy specific values.

Owner:CANON KK

Developer supply container having a shutter cleaning feature

InactiveUS7450890B2Pollution suppressionElectrographic process apparatusMechanical engineeringEngineering

A developer supply container is detachably mountable to a developer receiving apparatus having a receiving opening for receiving a developer and a shutter for opening and closing the receiving opening. The developer supply container including an engaging portion provided on a periphery of the developer supply container, and is engageable with the shutter to open and close the shutter with a rotational movement of either the developer supply container mounted in the developer receiving apparatus or a rotatable container body; and a cleaning member, provided on a periphery of the developer supply container for cleaning the shutter with the rotational movement of the developer supply container.

Owner:CANON KK

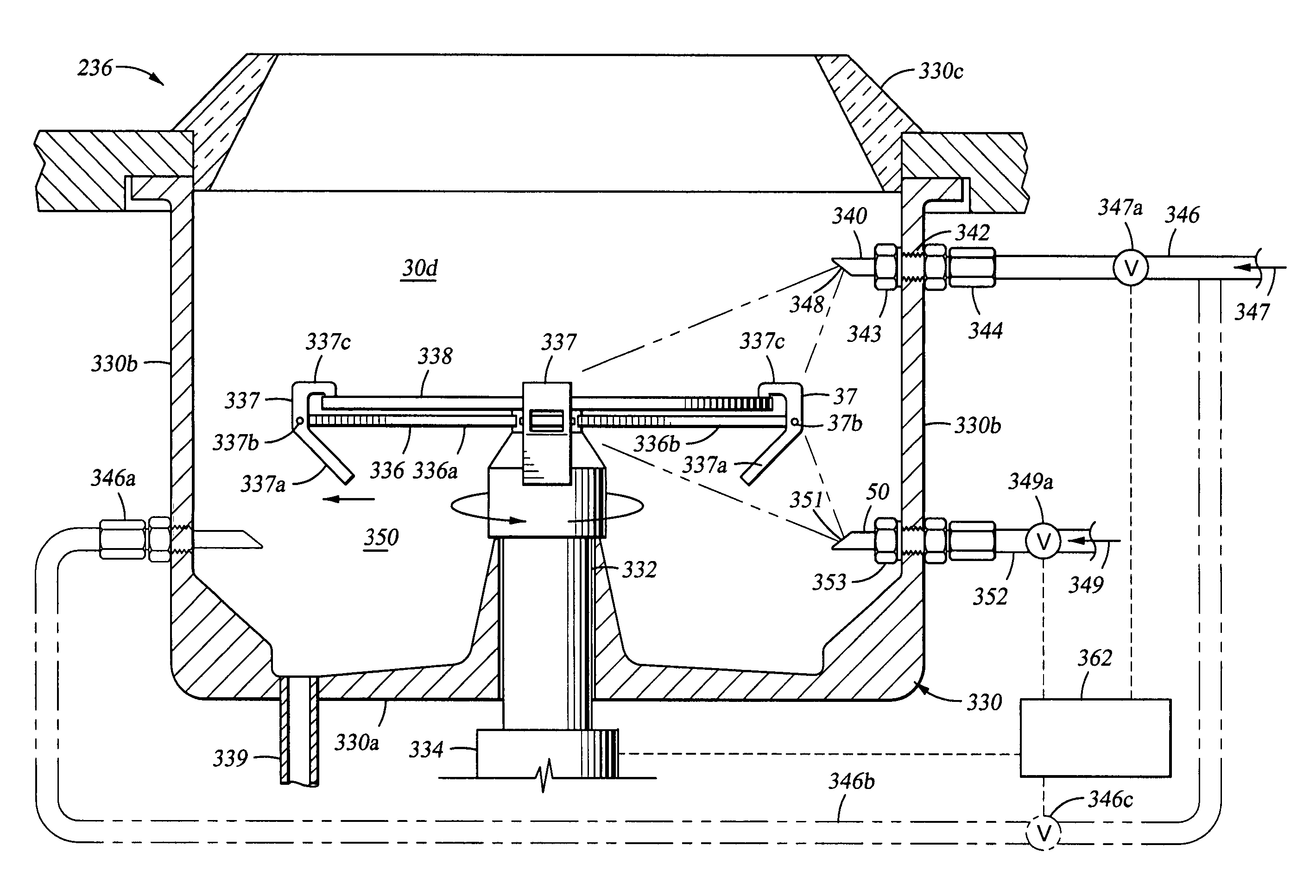

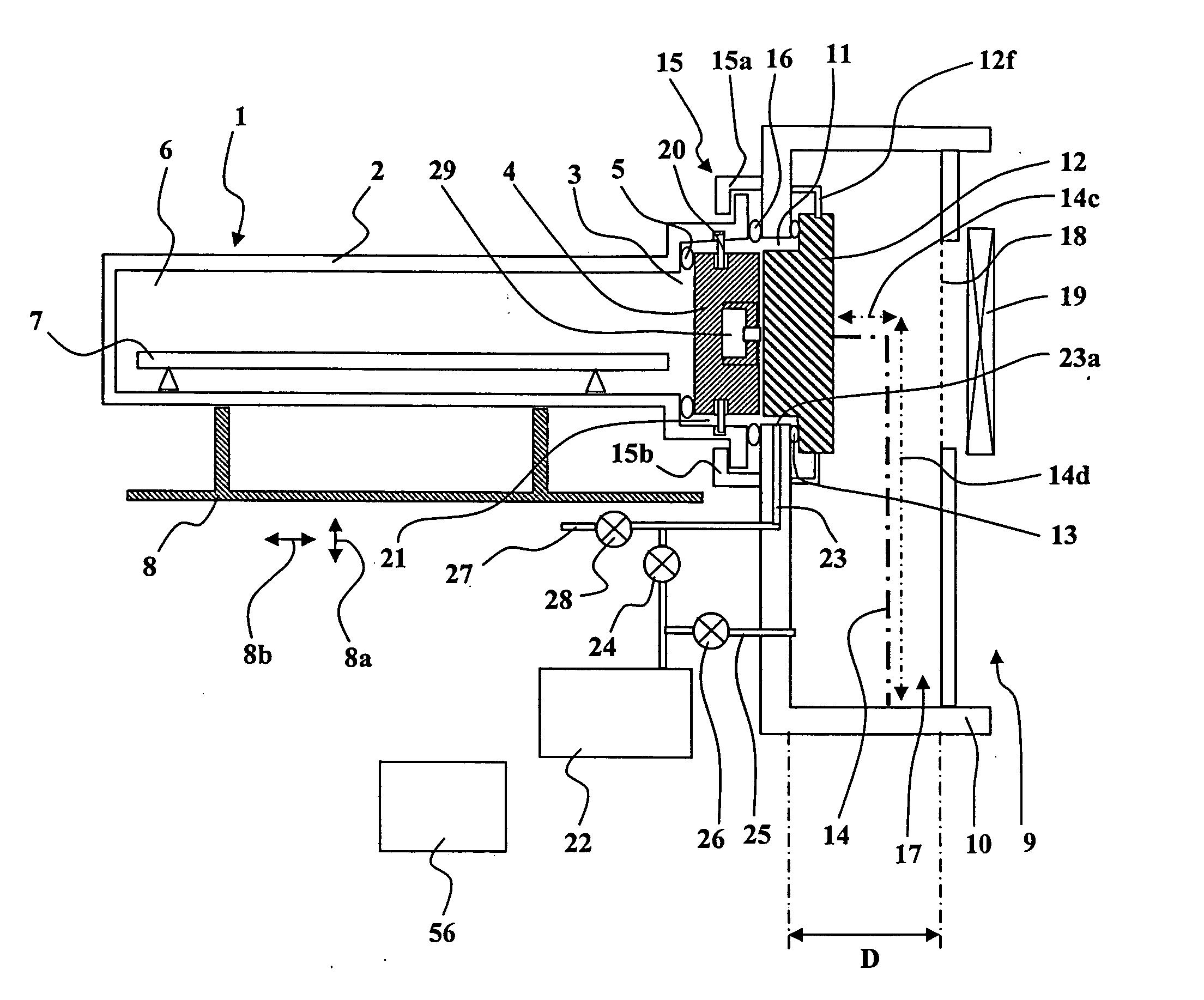

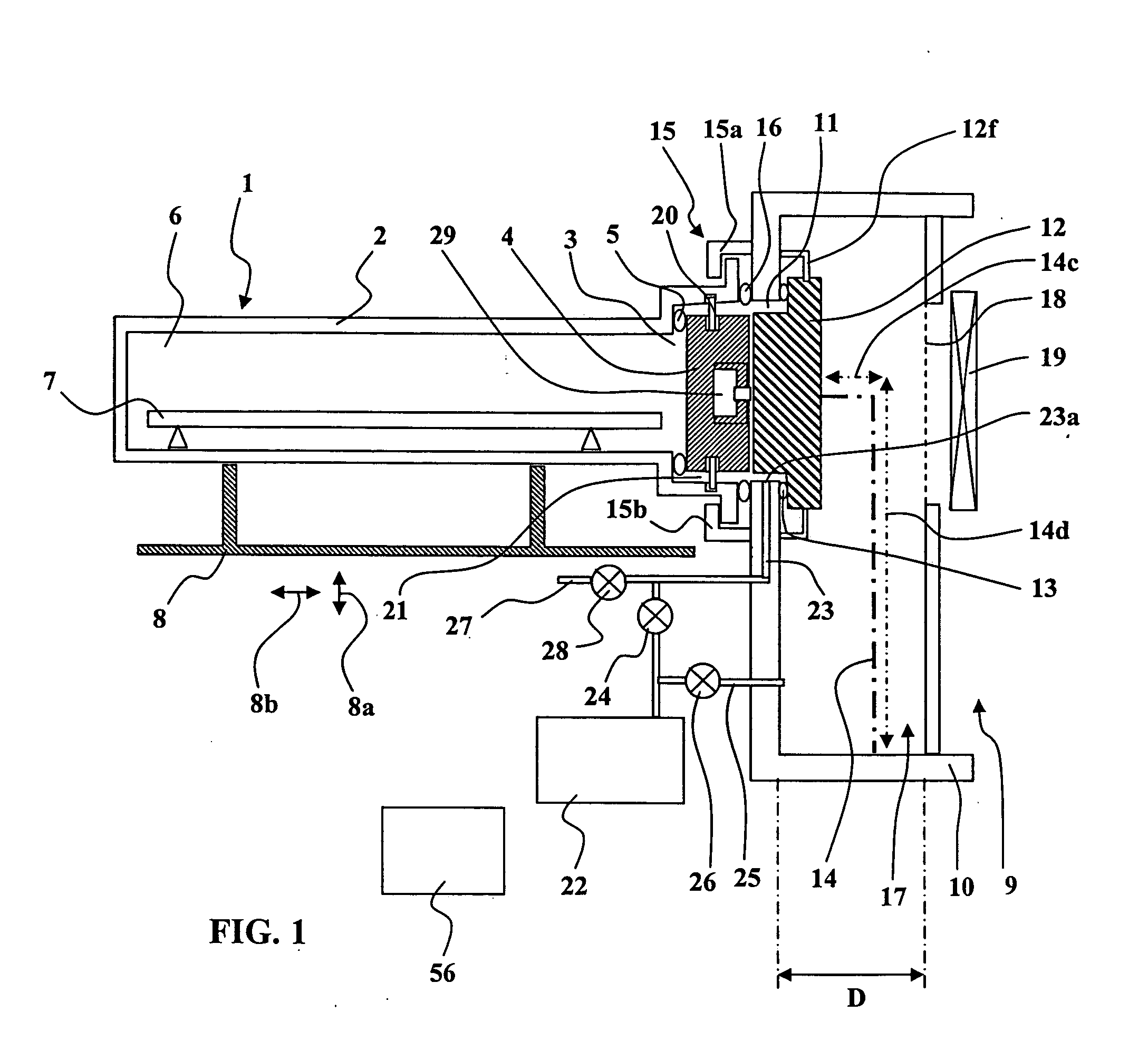

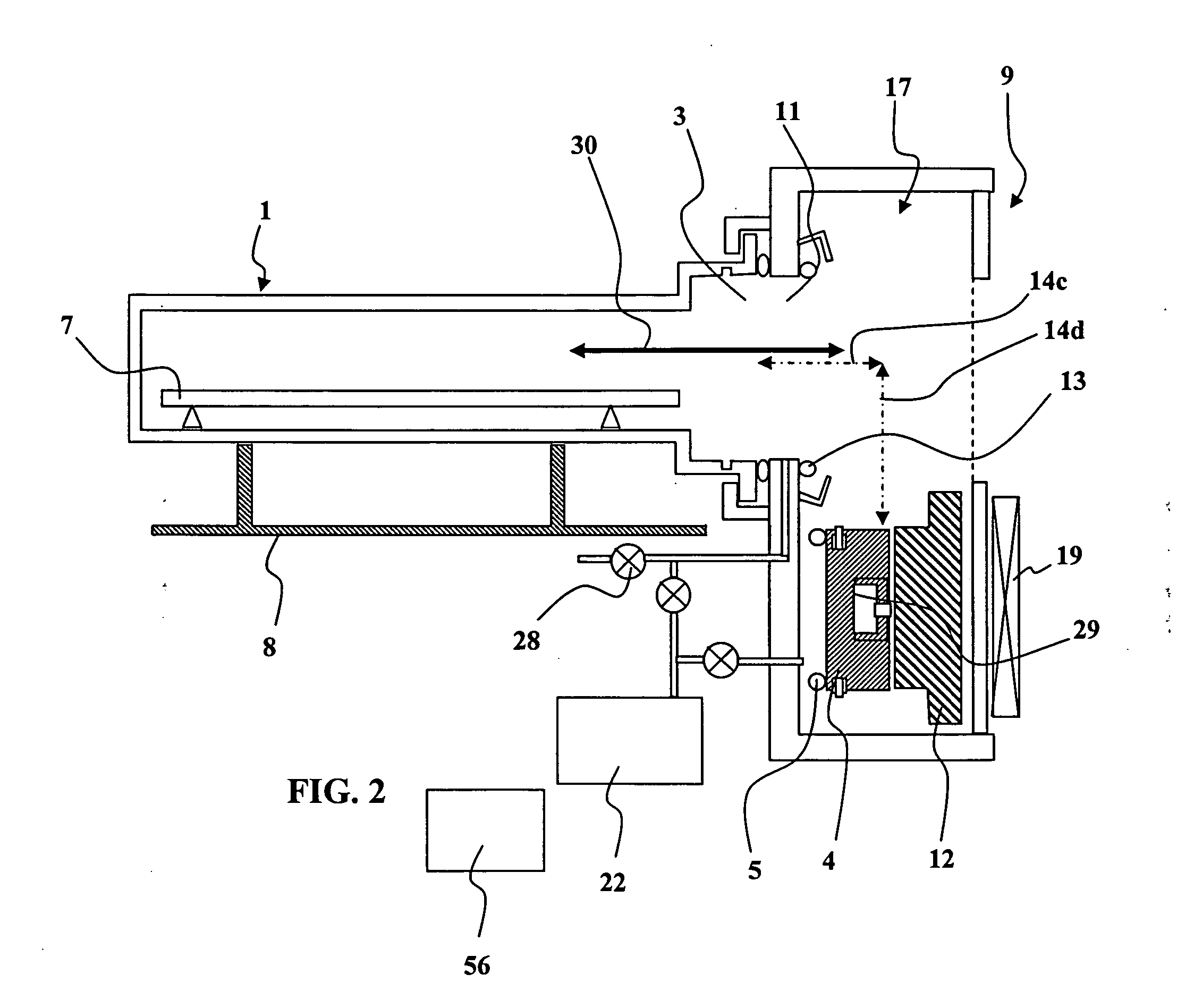

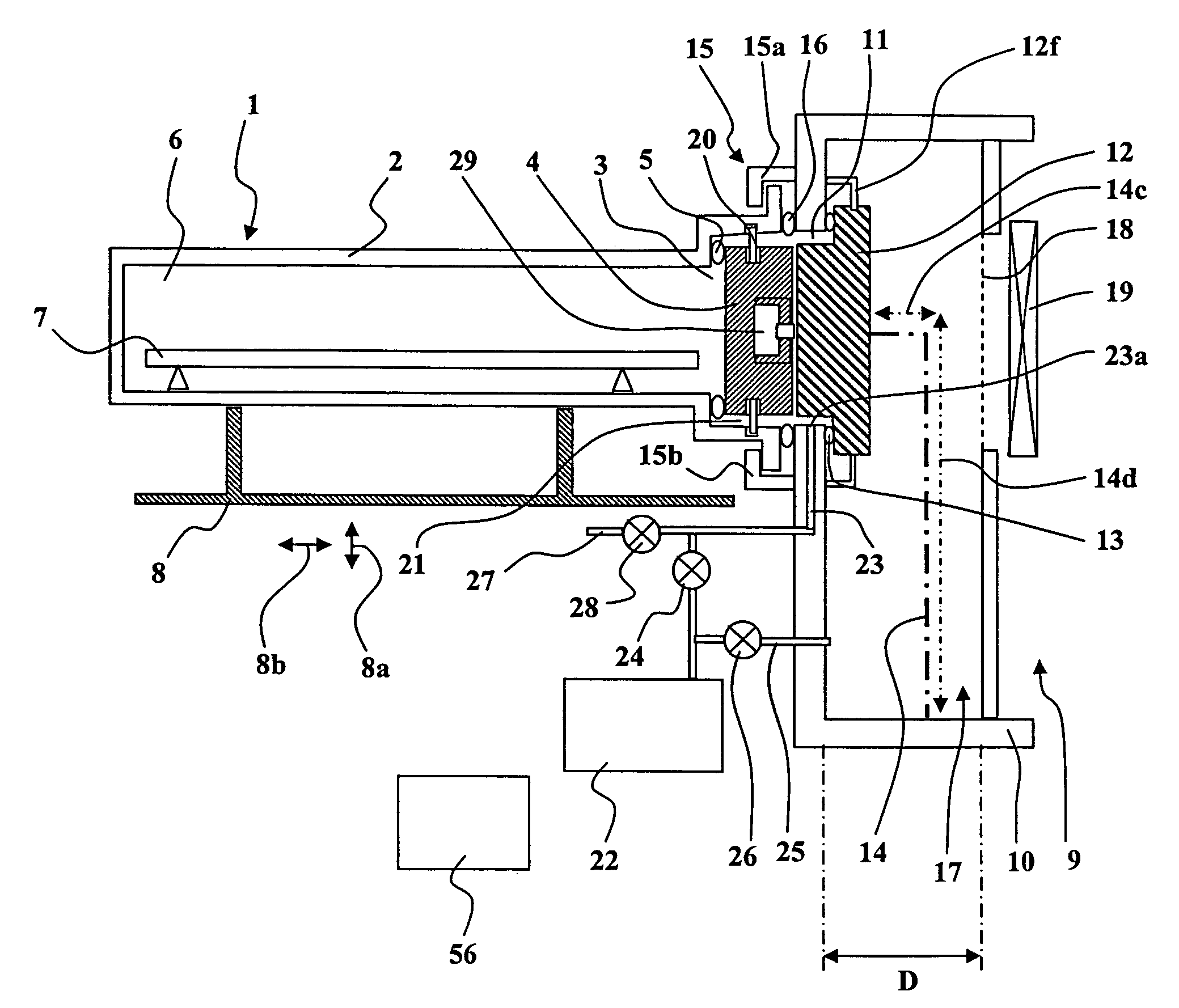

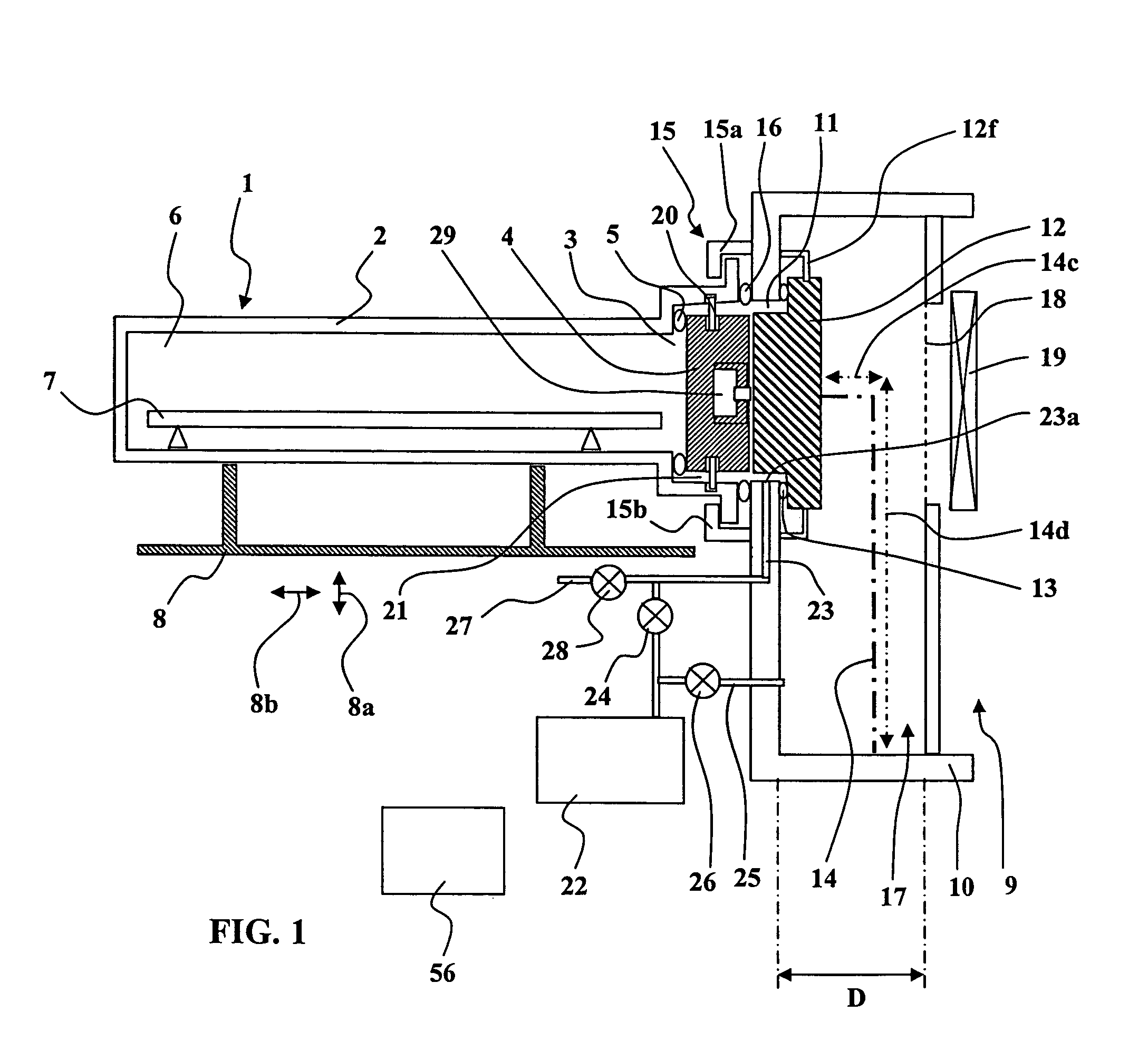

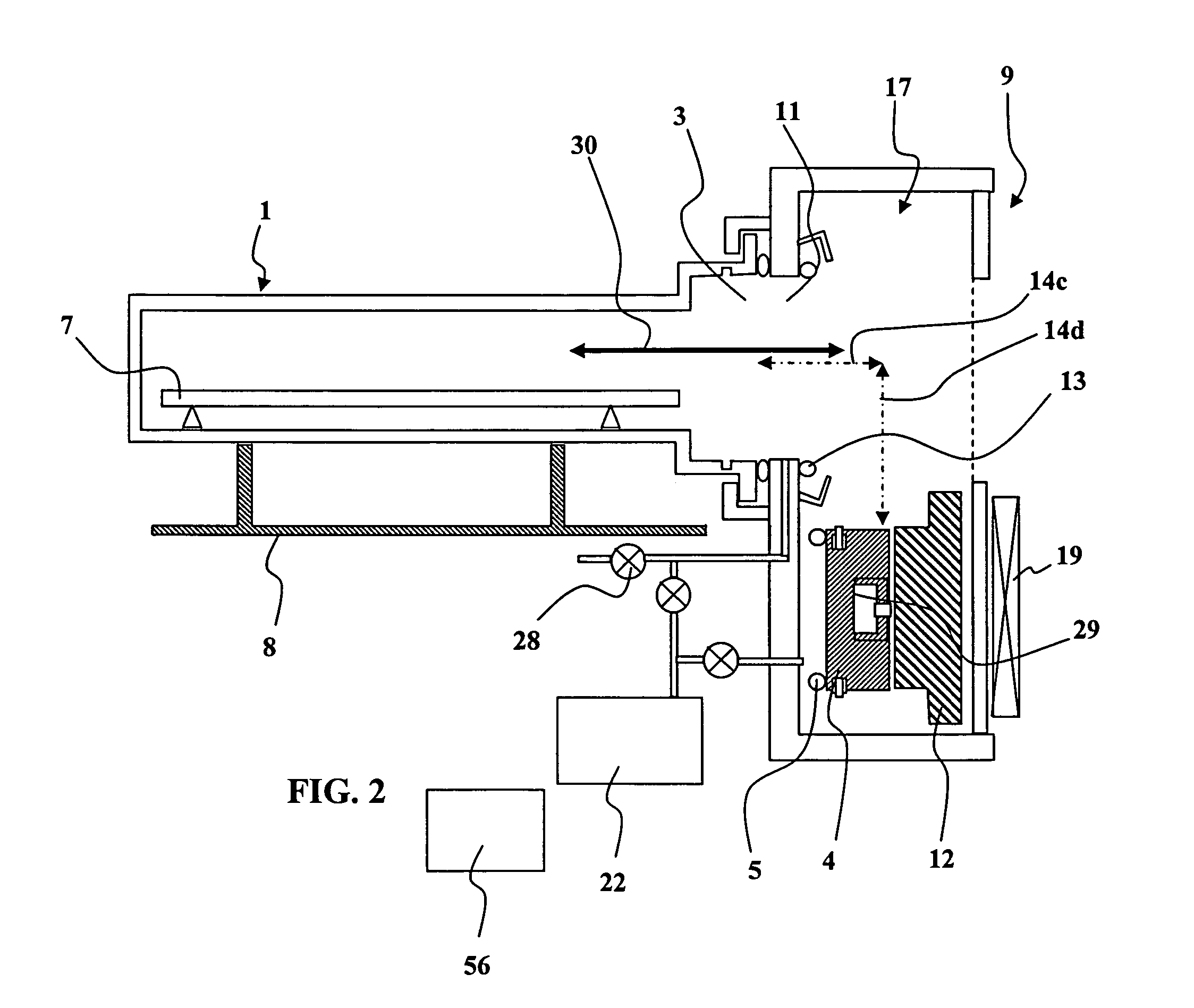

Vacuum interface between a mini-environment pod and a piece of equipment

ActiveUS20060102237A1Reduce riskImprove productivityPipe supportsServomotor componentsProcess equipmentEngineering

In apparatus of the invention, a transport pod (1) can be coupled to an article-passing opening (11) of process equipment (9) in leaktight manner with sealing being provided by an interposed interface peripheral gasket (16). The pod door (4) can be secured selectively to the interface door (12) so that they can be moved together as a unit along an axial stroke followed by a transverse stroke under drive from door actuator means (14). The transport pod (1) is held by retaining means (15). The peripheral volume (21) around the two doors can be pumped out by means of a pump (22) and a duct (23). The pod door (4) can be locked on the transport door (1) by locking means (20) that guarantee good sealing while the transport pod (1) is separate from the process equipment (9). This ensures good sealing of the transport pod (1), and enables the doors (4, 12) to be opened under a vacuum without polluting the inside atmosphere.

Owner:ALCATEL LUCENT SAS

Biaxially-oriented polyester film for fabrication and method of producing the same

InactiveUS6905774B2Improve hygieneEnhancing carnauba wax dispersion propertySynthetic resin layered productsSpecial tyresPolyesterHeat resistance

Biaxially-drawn polyester film for fabrication which is characterized in that it is a film comprising polyester in which ethylene terephthalate units and / or ethylene naphthalate units are the chief structural component, and the melting point of said film is 180-270° C., the angle of contact to water is 70°-120°, and the planar orientation coefficient is 0.08-0.15. This film shows outstanding release properties following repeated use, use after fabrication and use in an aqueous environment and, furthermore, it exhibits stable properties with little variation and, in particular, following lamination to metal sheet such as steel or aluminium, when used as the inner face of a fabricated metal can, it is outstanding in its non-stick properties to the contents, and provides a combination of heat resistance and processability.

Owner:TORAY IND INC

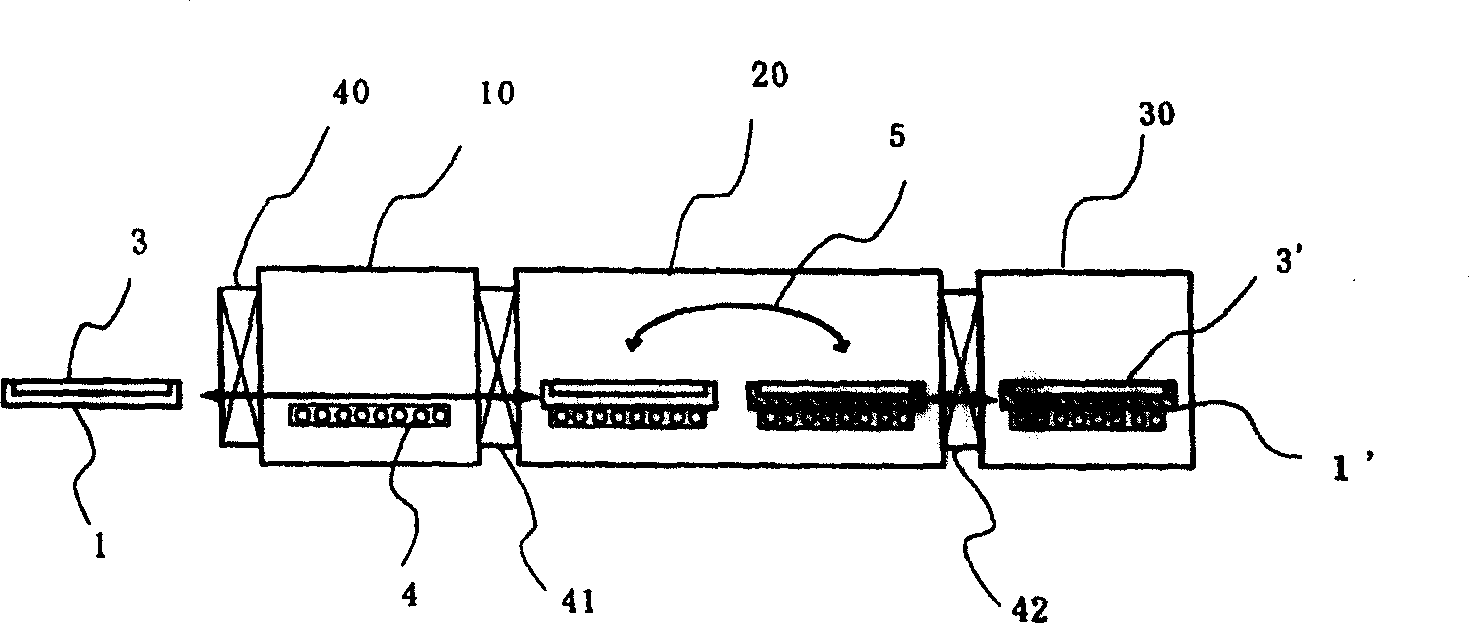

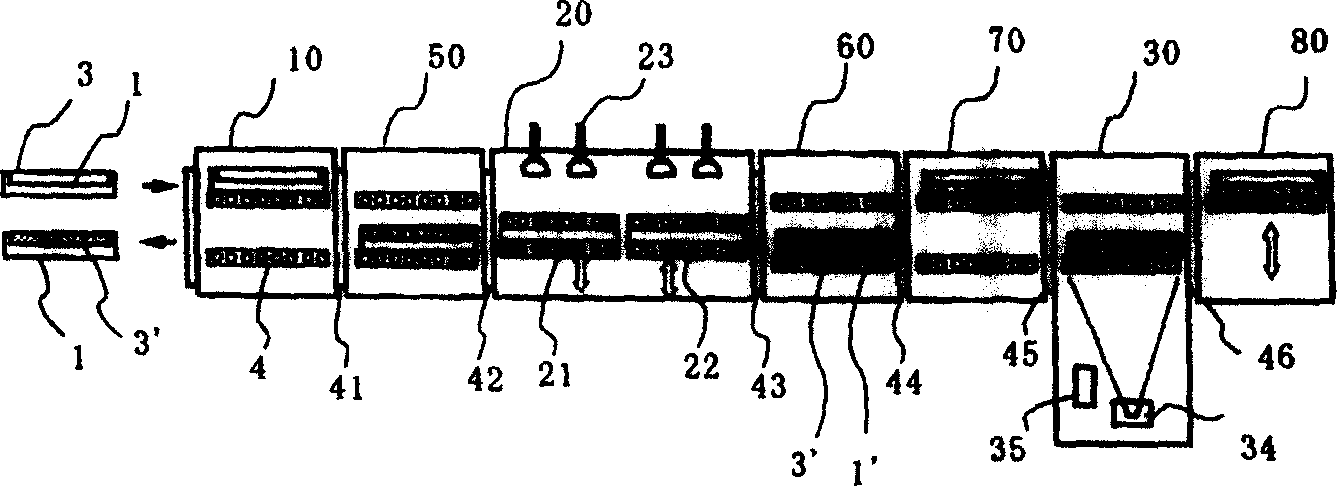

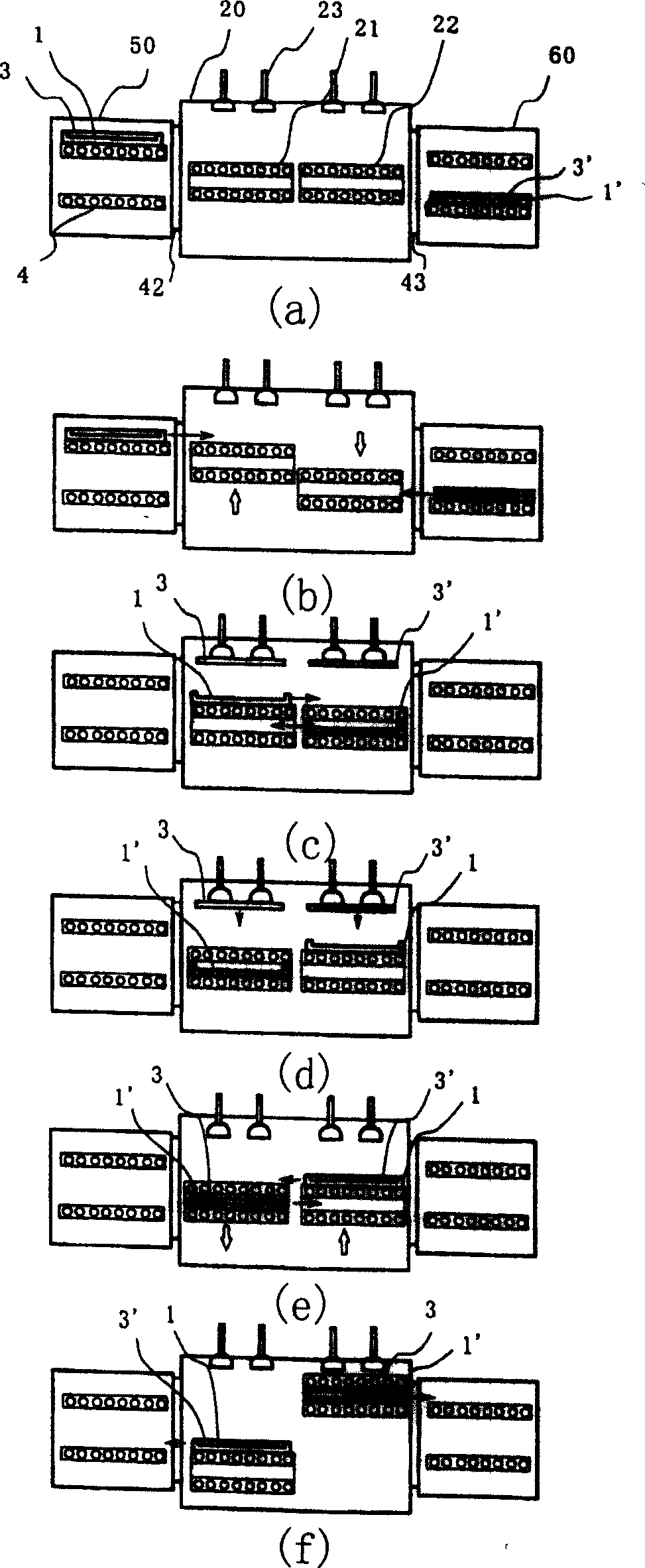

Substrate processing device and substrate processing method

ActiveCN1650416AReduced film peelingContinuous processingVacuum evaporation coatingSemiconductor/solid-state device manufacturingTransfer mechanismEngineering

A substrate processing device and a substrate processing method for general purpose capable of suppressing the contamination of atmosphere in a processing chamber through carriers, continuously performing a stable conveyance and a high quality substrate processing, and coping with further upsizing substrates and various substrate dimensions, the device comprising a load lock chamber allowing the carriers having the substrate mounted thereon to be carried therein, a substrate transfer chamber having a transfer mechanism for transferring the substrate between the carriers, and a substrate processing chamber for applying a specified processing to the substrate, characterized in that the first carrier moves between the load lock chamber and the substrate transfer chamber and the second carrier moves between the substrate transfer chamber and the substrate processing chamber, and the substrate is transferred between the first carrier and the second carrier by the transfer mechanism.

Owner:ANELVA CORP

Method for preparing microbial symbiotic fermented bread kvass beverage

Owner:HARBIN DE MUOLI MINERAL WATER

Vacuum interface between a mini-environment pod and a piece of equipment

ActiveUS7568875B2Reduce riskImprove productivitySemiconductor/solid-state device manufacturingArticle unpackingProcess equipmentEngineering

In apparatus of the invention, a transport pod (1) can be coupled to an article-passing opening (11) of process equipment (9) in leaktight manner with sealing being provided by an interposed interface peripheral gasket (16). The pod door (4) can be secured selectively to the interface door (12) so that they can be moved together as a unit along an axial stroke followed by a transverse stroke under drive from door actuator means (14). The transport pod (1) is held by retaining means (15). The peripheral volume (21) around the two doors can be pumped out by means of a pump (22) and a duct (23). The pod door (4) can be locked on the transport door (1) by locking means (20) that guarantee good sealing while the transport pod (1) is separate from the process equipment (9). This ensures good sealing of the transport pod (1), and enables the doors (4, 12) to be opened under a vacuum without polluting the inside atmosphere.

Owner:ALCATEL LUCENT SAS

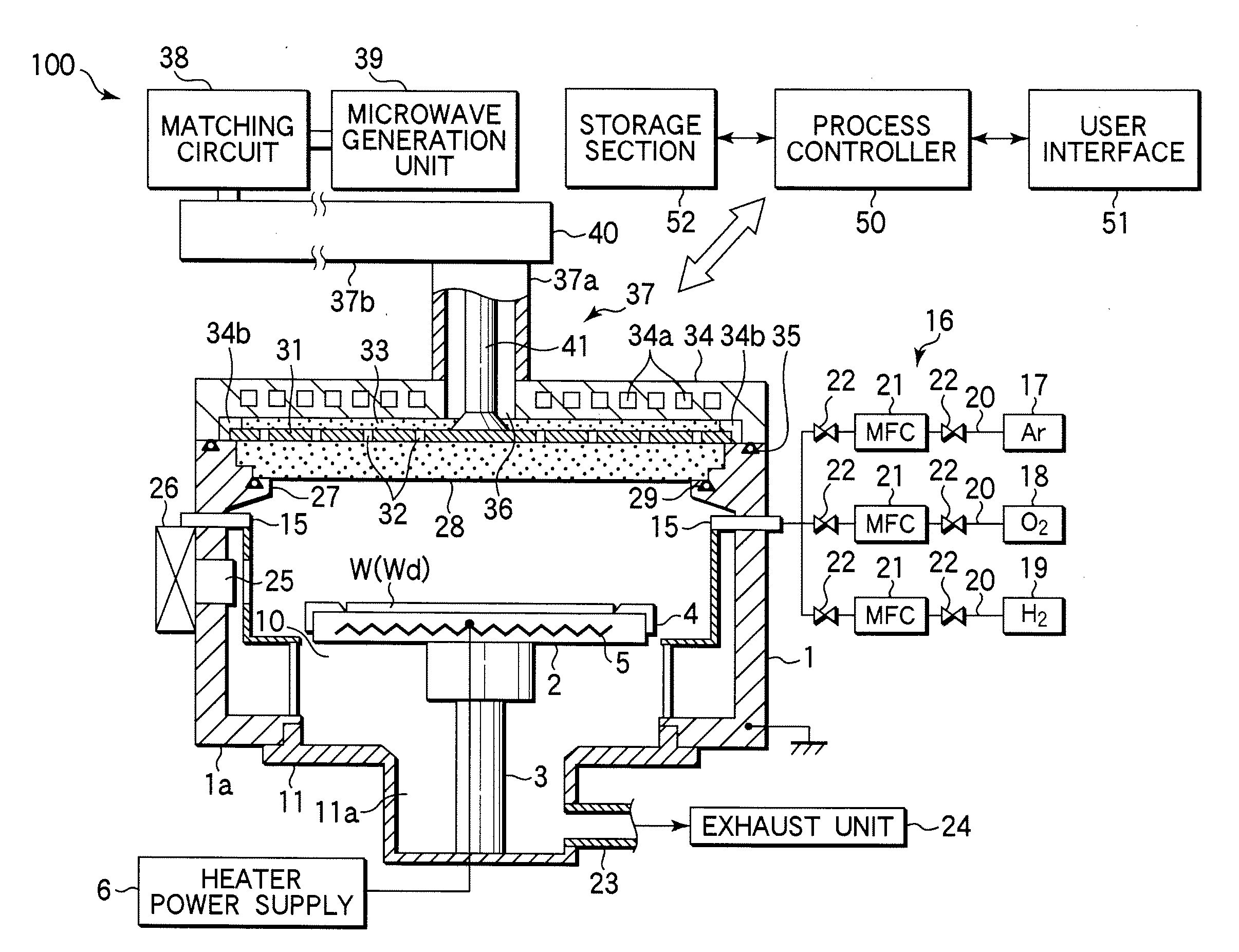

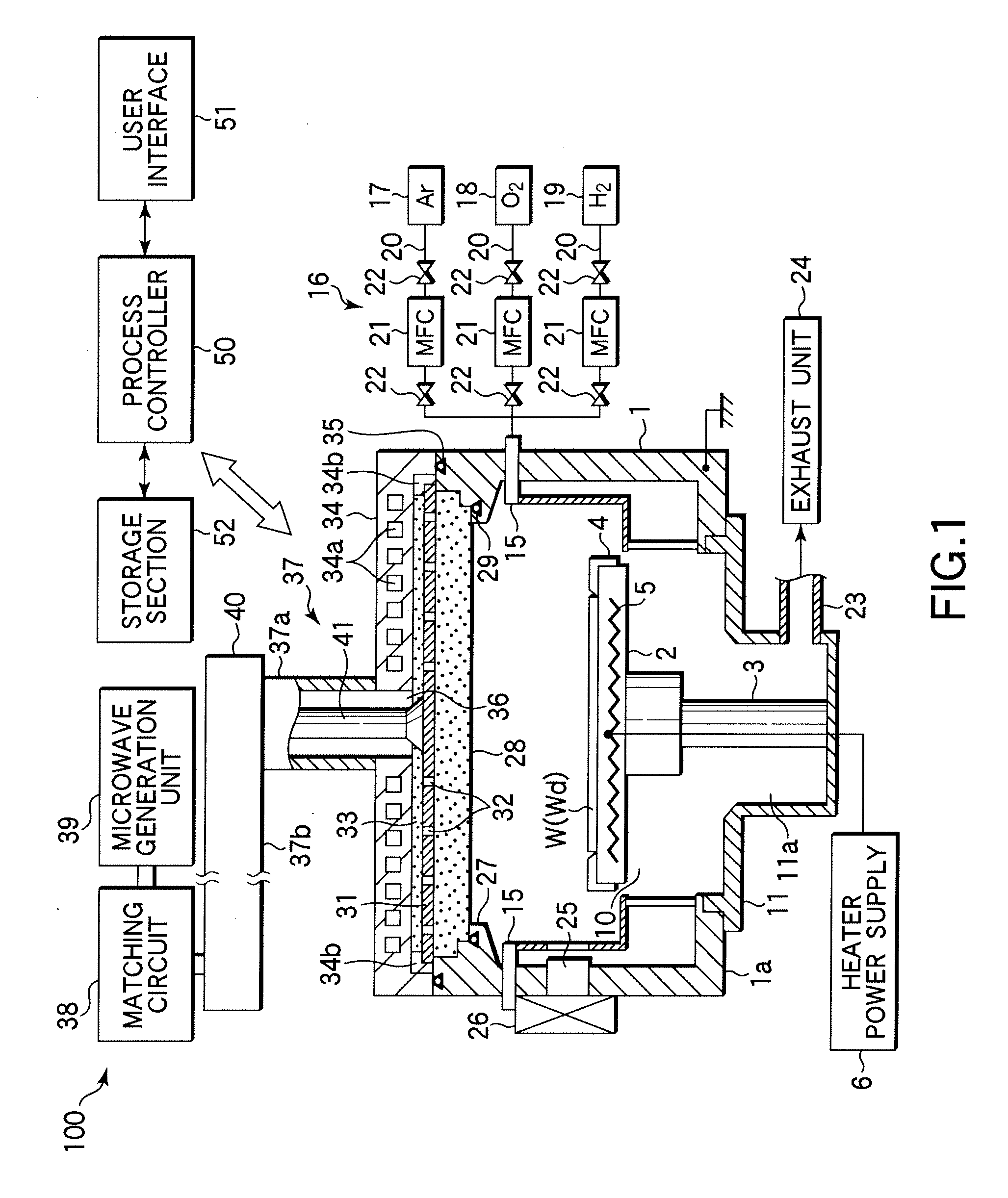

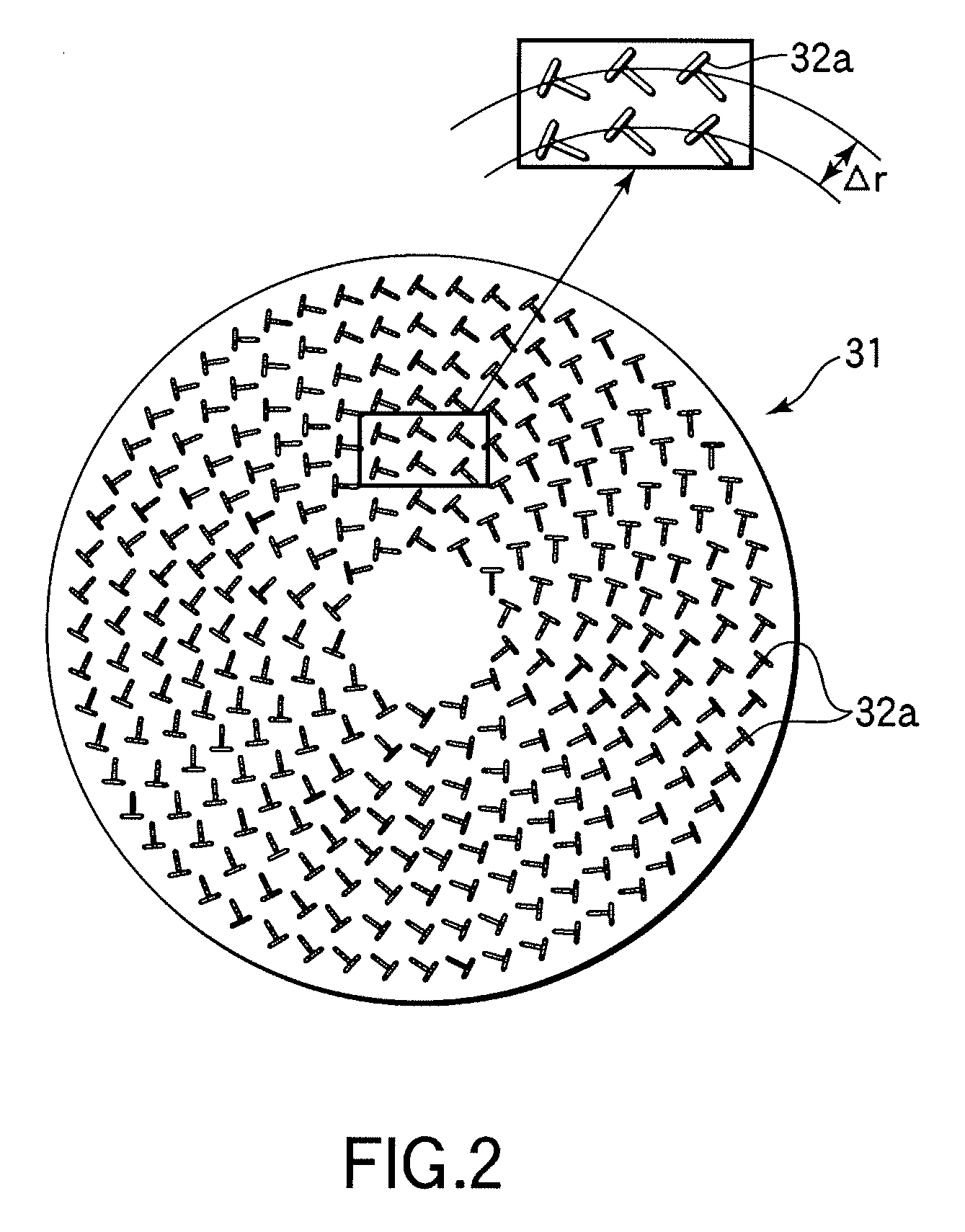

Semiconductor Device Manufacturing Method and Plasma Oxidation Treatment Method

InactiveUS20080032511A1Pollution suppressionSpeed up the processElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorEngineering

A selective oxidation process is performed on a gate electrode in a plasma processing apparatus 100. A wafer W with the gate electrode formed thereon is placed on a susceptor 2 within a chamber 1. Ar gas, H2 gas, and O2 gas are supplied from an Ar gas supply source 17, an H2 gas supply source 18, and an O2 gas supply source 19 in a gas supply system 16 through a gas feed member 15 into the chamber 1. At this time, a flow rate ratio H2 / O2 of H2 gas relative to O2 gas is set to be 1.5 or more and 20 or less, preferably to be 4 or more, and more preferably to be 8 or more. Further, the pressure inside the chamber is set to be 3 to 700 Pa, such as 6.7 Pa (50 mTorr).

Owner:TOKYO ELECTRON LTD

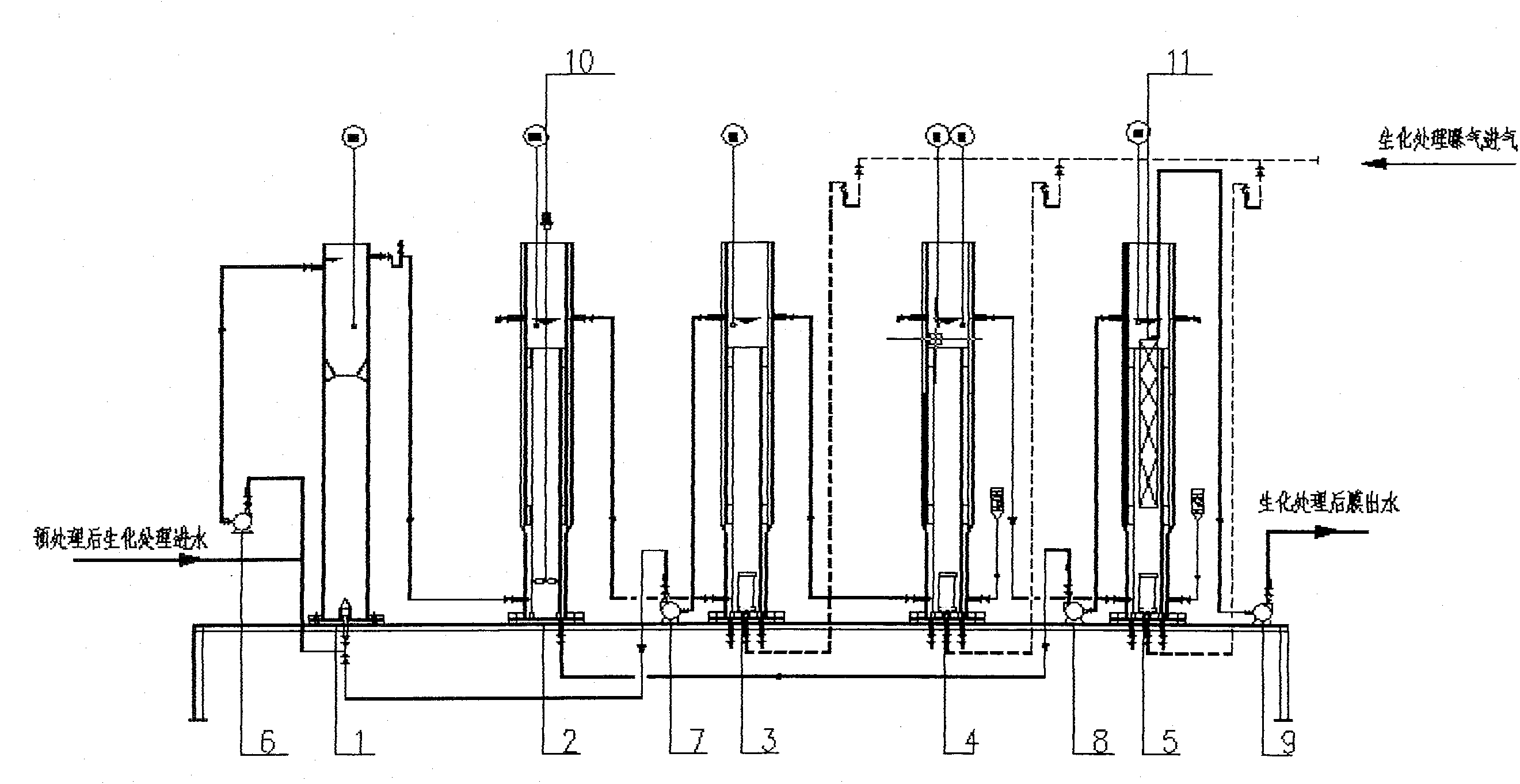

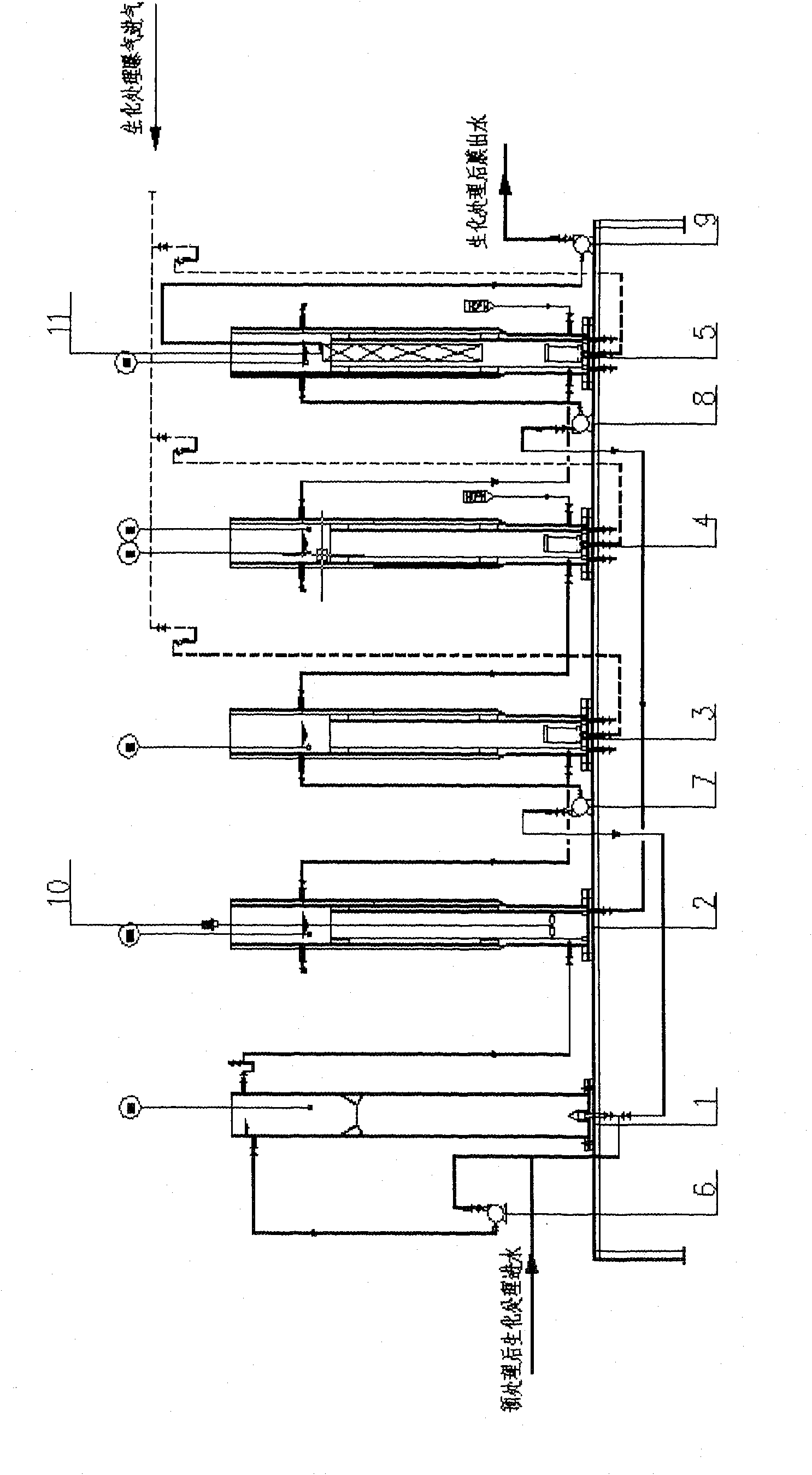

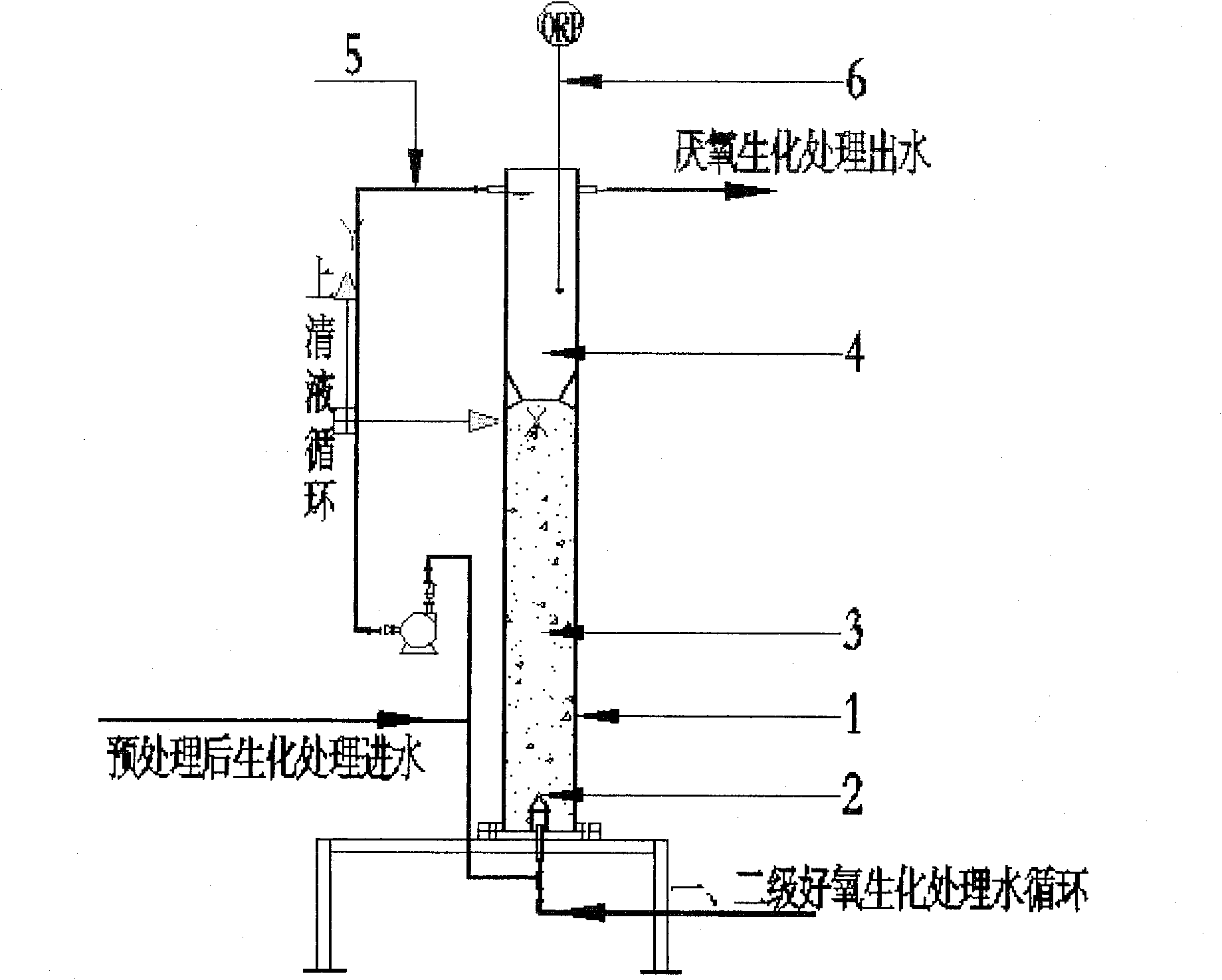

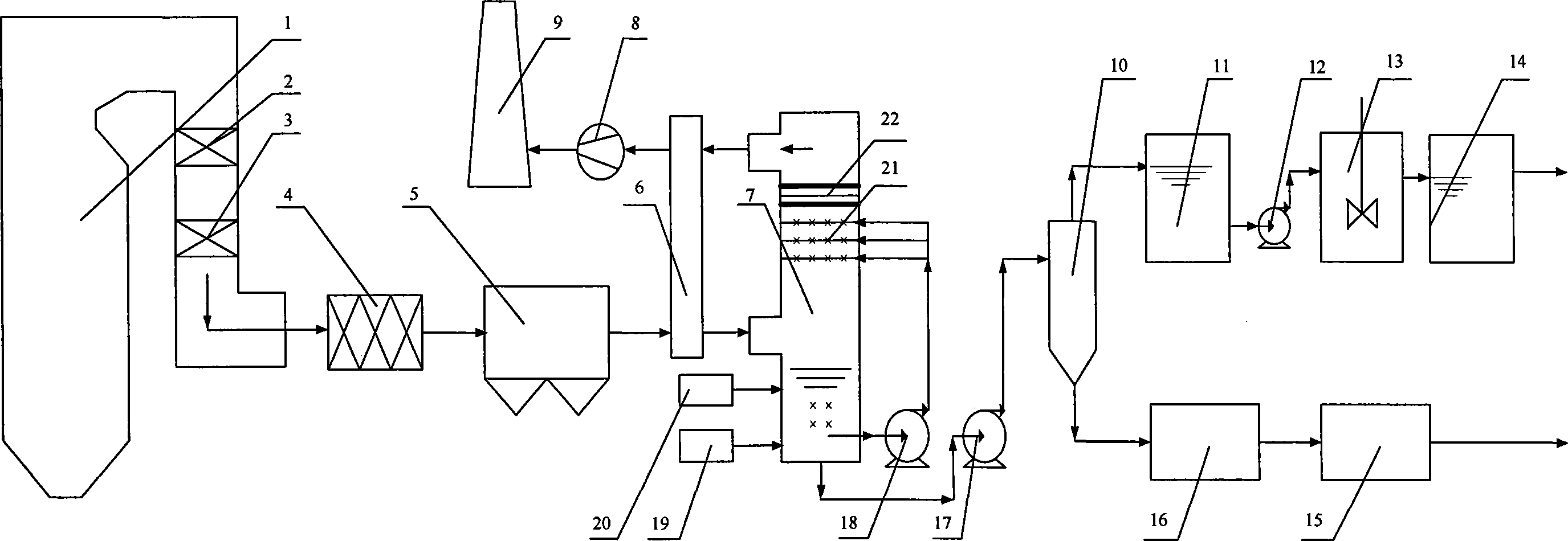

Coal gasification waste water biochemical treatment equipment and method

ActiveCN101811797AIncrease concentrationPollution suppressionTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisCoal gasification wastewaterBiochemical engineering

The invention provides coal gasification waste water biochemical treatment equipment and a method. The equipment comprises an anaerobic biochemical treatment unit, an anoxic biochemical treatment unit, a one-grade or multiple-grade aerobic biochemical treatment unit and a membrane biological response unit which are communicated in sequence. In addition, the aerobic biochemical treatment unit is also communicated with the anoxic biochemical treatment unit, and the membrane biological response unit is communicated with the anoxic biochemical treatment unit; each biochemical treatment unit has the characteristics of biochemistry and slurry and water separation integration. The coal gasification waste water biochemical treatment equipment and the method have high COD load and high ammonia nitrogen load and can realize high COD removal rate and high ammonia nitrogen removal rate.

Owner:ENN ENVIROTECH CO LTD

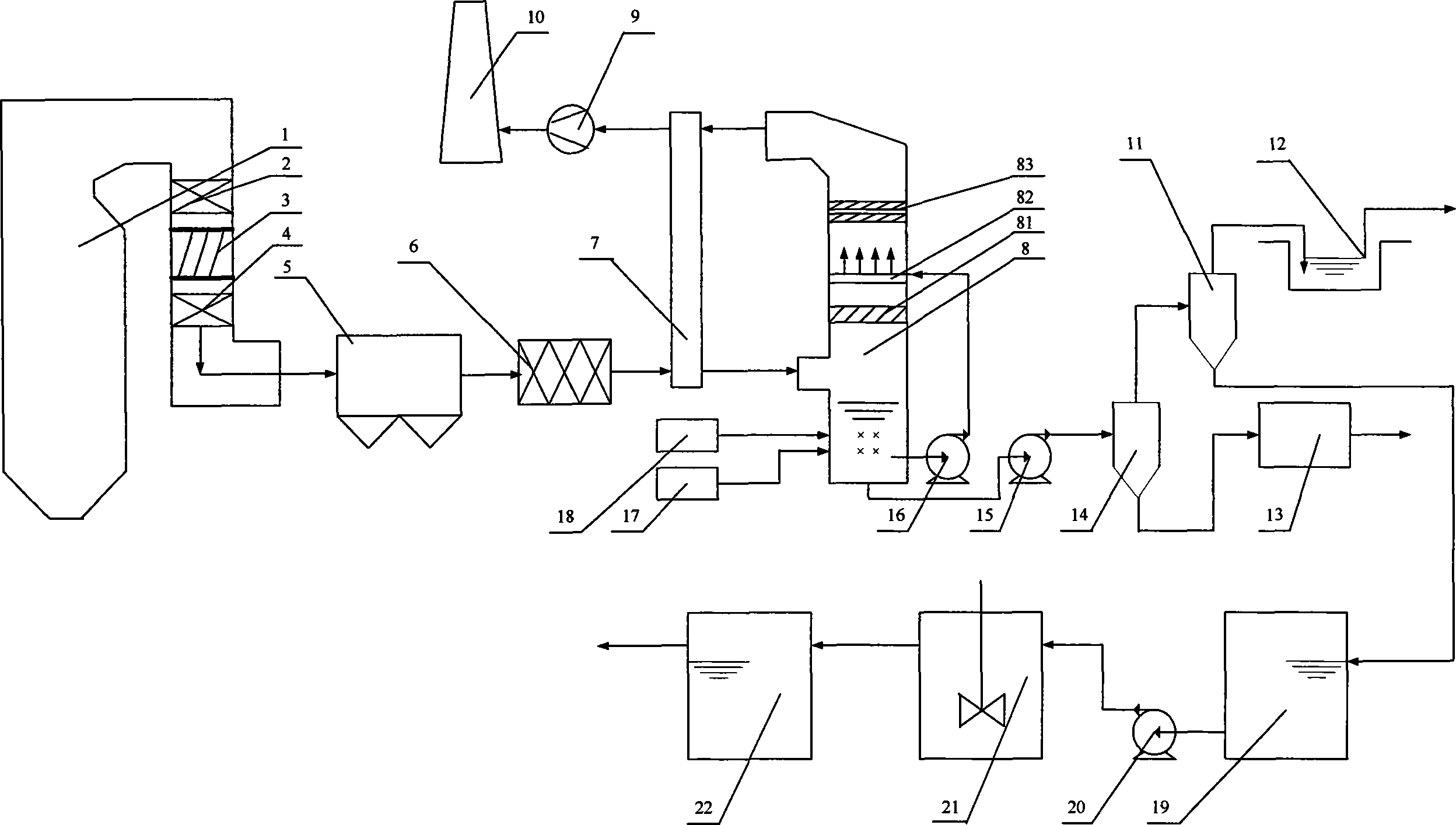

Wet flue gas desulfurizing and hydrargyrum-removing technology based on two-stage oxidation reaction and system thereof

A wet flue gas desulfurization and demercuration process and a system thereof based on two-stage oxidizing reaction. The process does two-stage oxidizing treatment to the simple substance HgO in flue gas utilizing to ultraviolet radiation and oxidant of halogen series, transmutes the gas phase divalent ion Hg2+ therein to liquid phase divalent ion Hg2+ using the modified limestone-gesso wet desulfurization process, and then transmutes the liquid phase divalent ion Hg2+ to the stable mercuric sulfide-HgS deposition via stabilizer of liquid phase divalent ion Hg2+. The system comprises desulfurization and demercuration equipments such as an ultraviolet irradiator, an electrical precipitator, an oxidant spraying unit and a reaction absorber etc, gesso treatment equipments of desulfurization byproduct, and a treating equipment for mercuric sulfide-HgS deposition. The process and the system thereof can raise the oxidation rate of simple substance Hg in the flue gas effectively, and at the same time effectively overcome the reduction release of divalent ion Hg2+ to avoid secondary pollution and be capable of raise desulfurization and demercuration efficiency of limestone-gesso wet desulfurization system.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

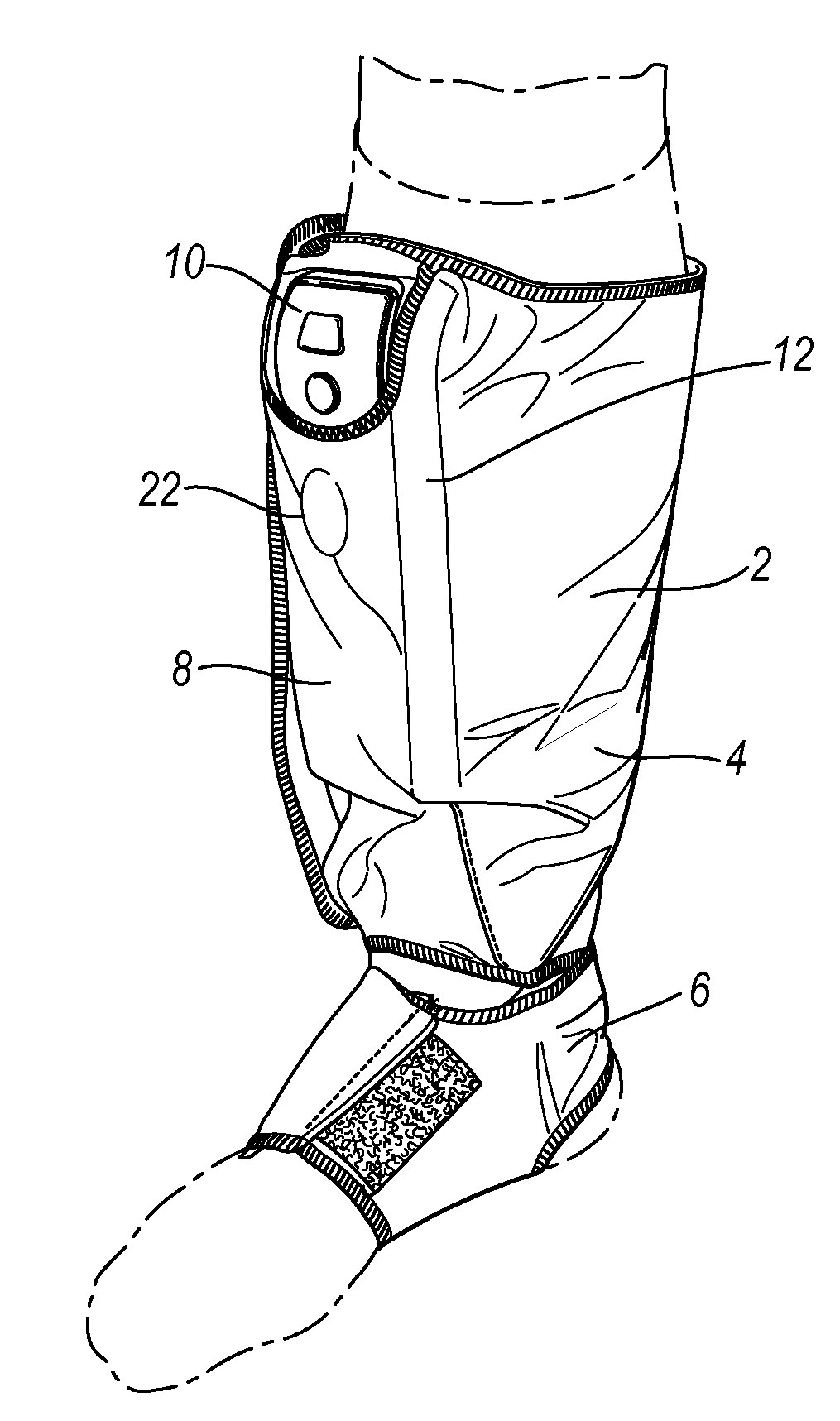

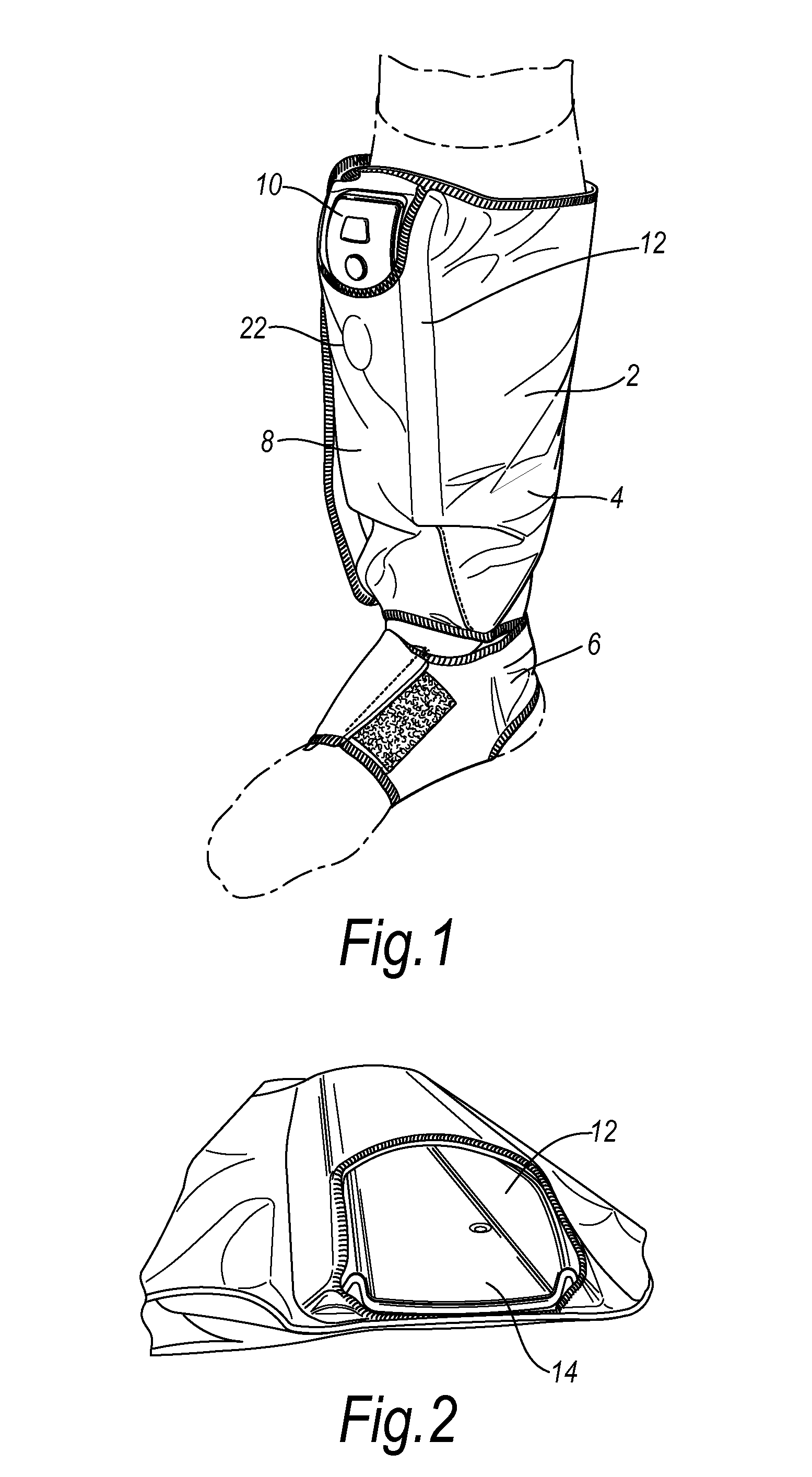

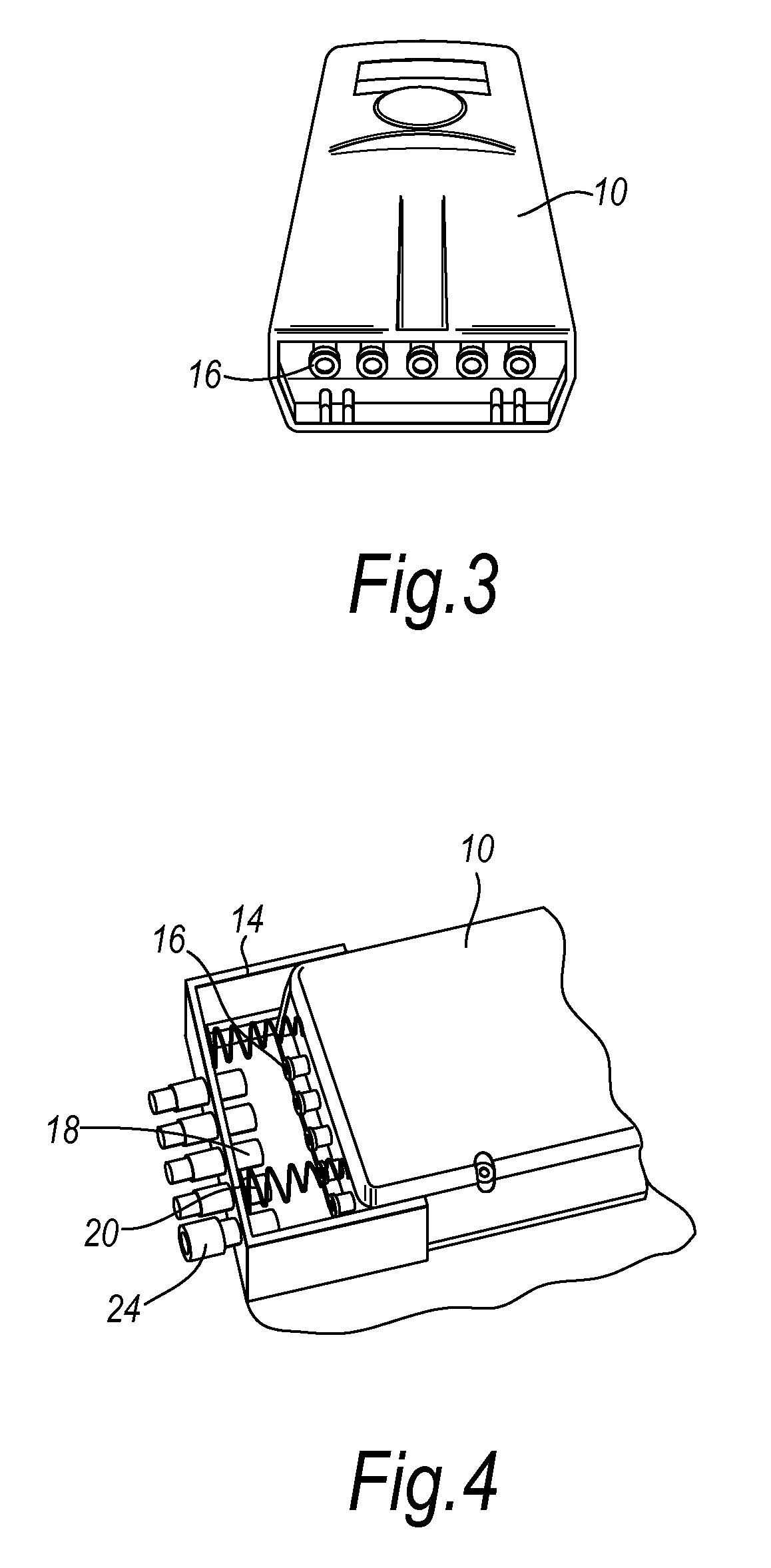

Proximity detection apparatus

ActiveUS20070249976A1Reduce in quantityPatient compliance is goodPneumatic massageVibration massageEngineeringMedical device

A control unit for a medical device wherein the control unit comprises a pump, a conduit and control means for controlling the flow of fluid from the pump through the conduit; and wherein the conduit is a rigid internal passage located in the control unit.

Owner:SWELLING SOLUTIONS

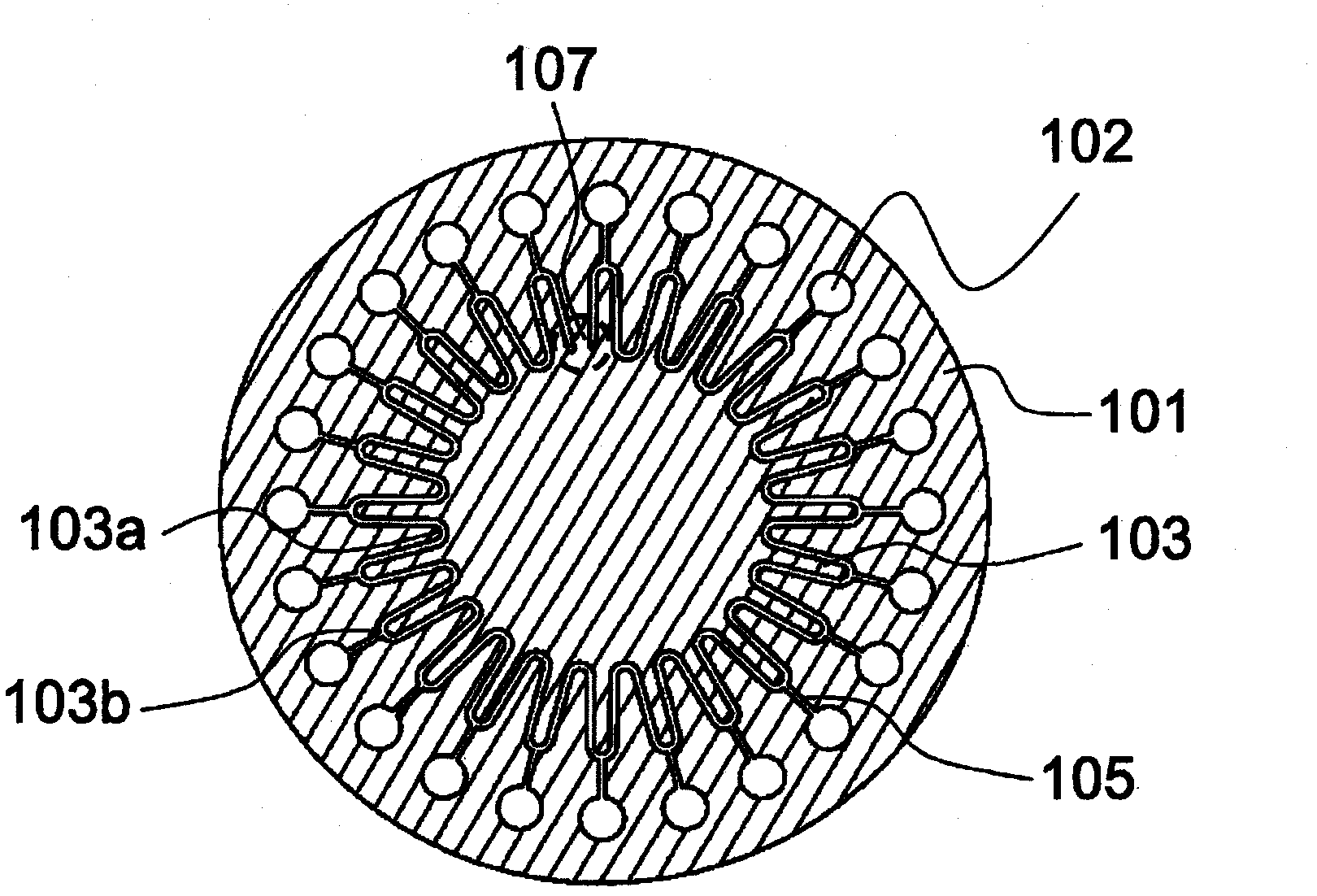

Sample analysis chip, sample analyzer using sample analysis chip, sample analysis method, and method of producing sample analysis chip

ActiveCN102369443AVersatileReduce uneven distributionBioreactor/fermenter combinationsBiological substance pretreatmentsMain channelAnalysis method

Provided is a low cost sample analysis chip wherein liquid is fed to wells formed on the chip so as to carry out reaction by simple liquid feed method while preventing variation in the quantity of liquid among respective wells. A sample analysis chip has a plurality of wells (102) and channels leading to respective wells, wherein the channels includes a main channel (103) which feeds liquid to each well, and the sample analysis chip is characterized in that the main channel is provided closer to the rotation center side than the well, and is formed to have one peak between adjoining wells in the direction of rotation center.

Owner:TOPPAN HLDG INC

Wet-type ammonia flue gas spiritualization technics of associated desulfuration demercuration

The invention relates to a wet ammonia flue gas purification process for the combined sulfur and mercury removing and the system thereof. The process adopts chlorine gas as oxidizing agent to completely oxidize elemental mercury in the flue gas, and gas phase divalent mercuric ion after being oxidized is converted into liquid phase divalent mercuric ion through the improved wet ammonia desulphurization process, and further the liquid phase divalent mercuric ion is converted into stable mercuric sulfide sendimentation through liquid phase divalent mercuric ion stabilizing agent. The system comprises a flue gas oxidizing demercuration preprocessing system composed of an oxidizing agent injection device and an electrostatic precipitator, a wet ammonia flue gas sulfur and mercury removing system composed of a reaction absorbing tower, a sulfur removing accessory substance processing system composed of a cyclone cleaner, a dewaterer, and a dryer, and a mercuric sulfide HgS sendimentation processing system composed of a wastewater buffer pool, a liquid phase mercuric ion reaction chamber, and a settling pond. The process and the system can effectively improve the oxidation rate of the elemental mercury in the flue gas, overcome the defaults that the divalent mercuric ion is easy to be reduced and released and the secondary pollution problem is caused by excess oxidizing agent, and greatly improve the efficiency of sulfur removing and mercury removing.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

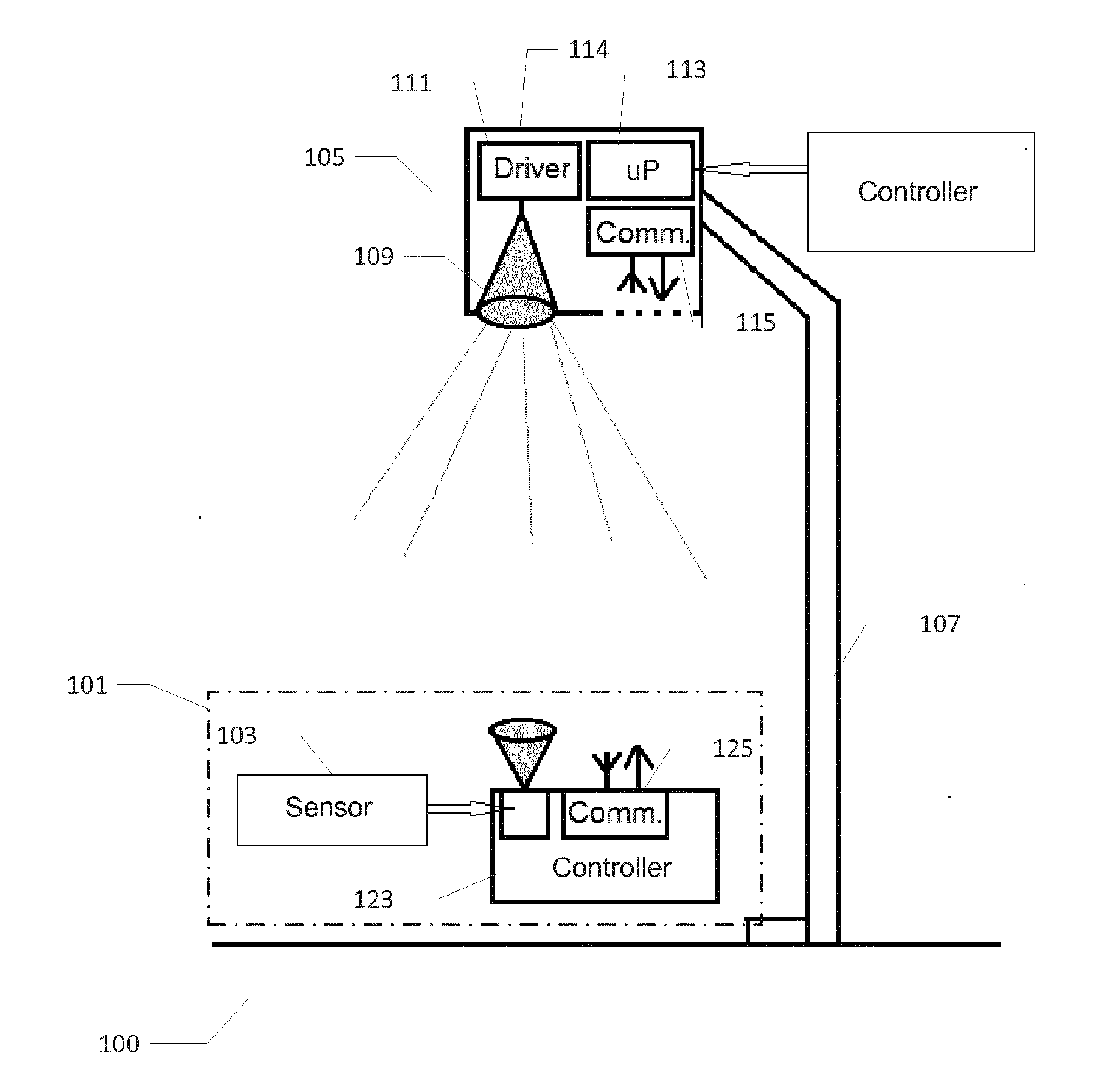

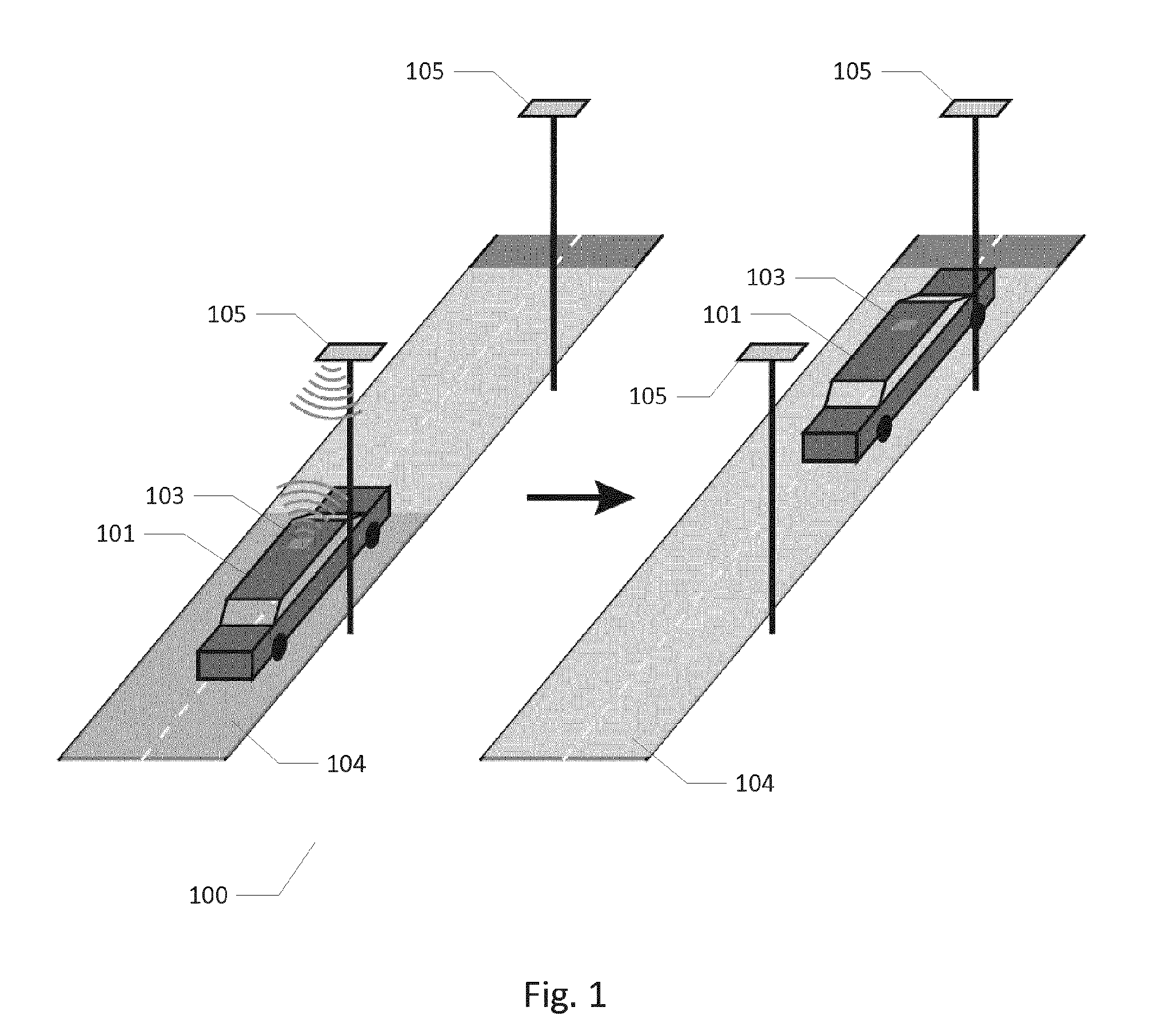

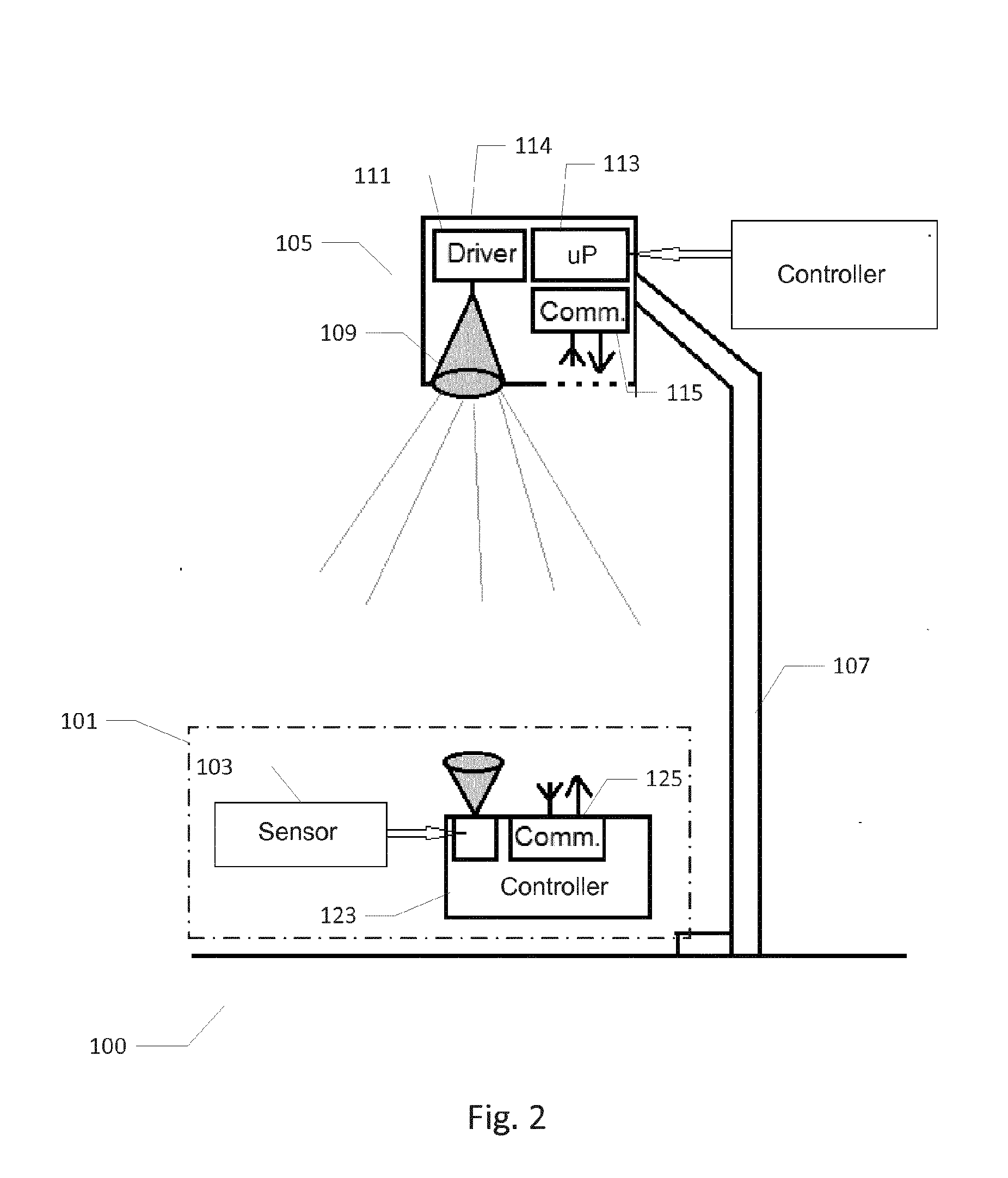

Lighting system with illuminance control

InactiveUS20150173156A1Reducing predetermined light illuminanceSave energyElectrical apparatusElectroluminescent light sourcesLight equipmentIlluminance

The present invention relates to an illumination control system comprising a plurality of outdoor luminaries and a motorized service vehicle. Each luminaire comprises a controllable light source producing a light illuminance. The motorized service vehicle comprises a light sensor configured to detect the light illuminance generated by the controllable light source at the motorized service vehicle. The motorized service vehicle computes light illuminance data based on the detected light illuminance and transmits these to the outdoor luminaire through a wireless communication link or stores the light illuminance data on a data recording device of the motorized service vehicle. The outdoor luminaire receives may use the light illuminance data to set or adjust a light illuminance of the controllable light source.

Owner:HESA LIGHT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com