Substrate processing device and substrate processing method

A technology for a substrate processing device and a substrate processing method, which is applied in the directions of transportation and packaging, ion implantation and plating, lighting and heating equipment, etc., can solve the problems of uneven brightness, mixed crystal planes, and insufficient for high-precision large-scale PDP, etc. Achieve the effect of reducing film peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

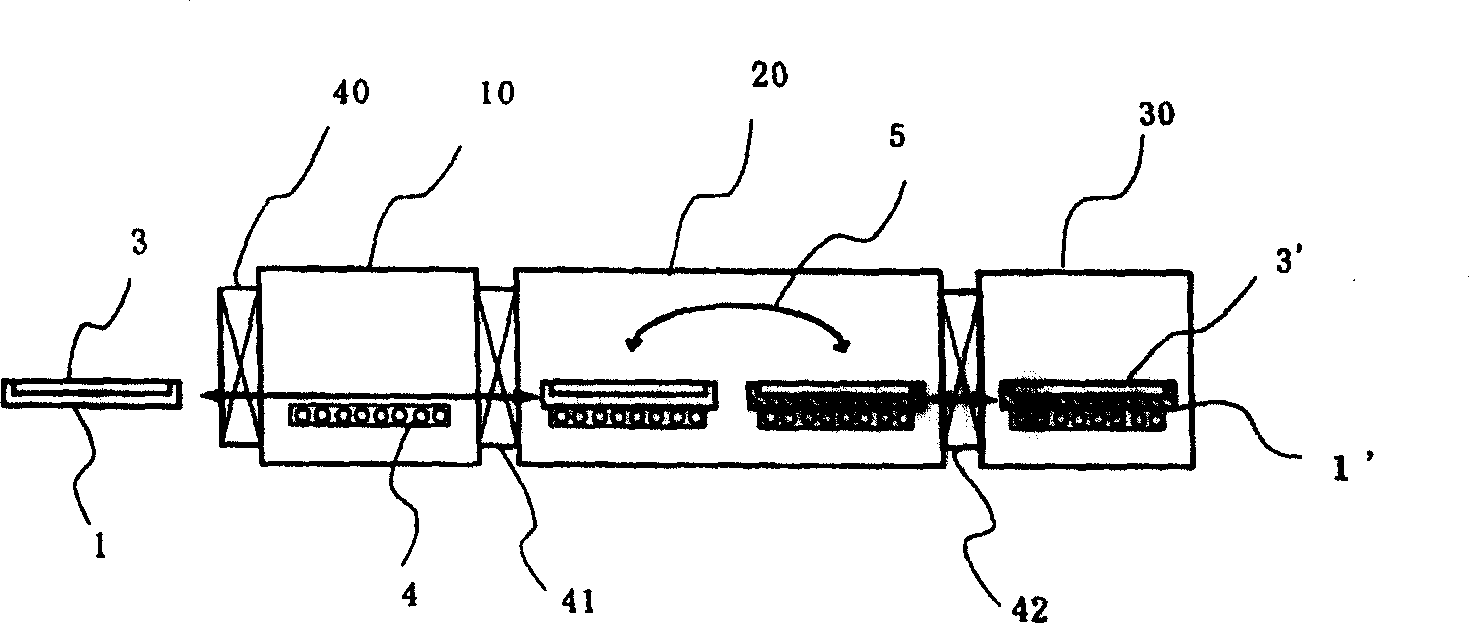

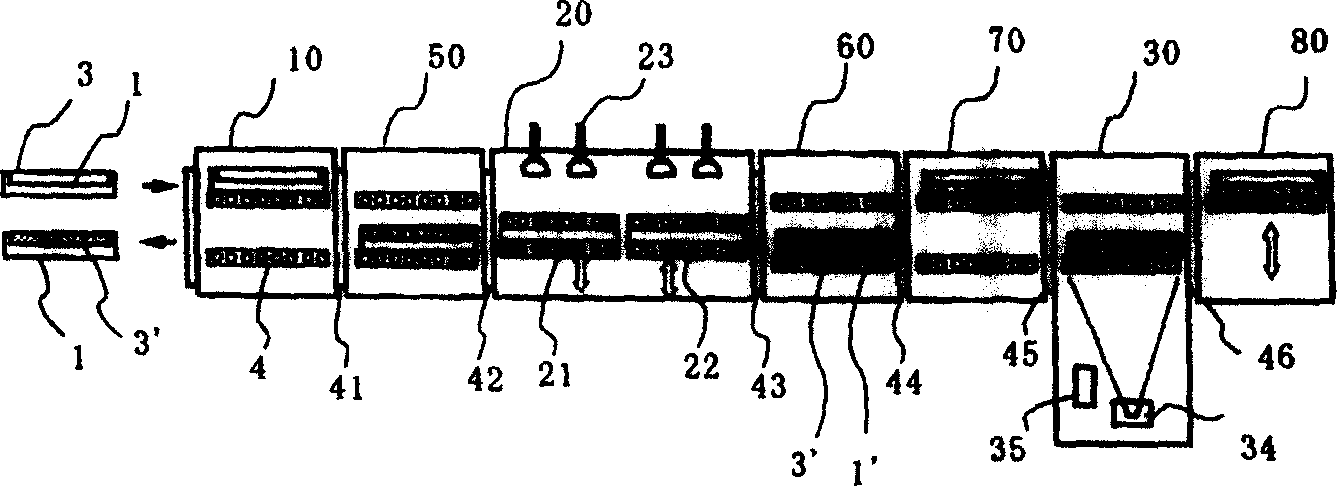

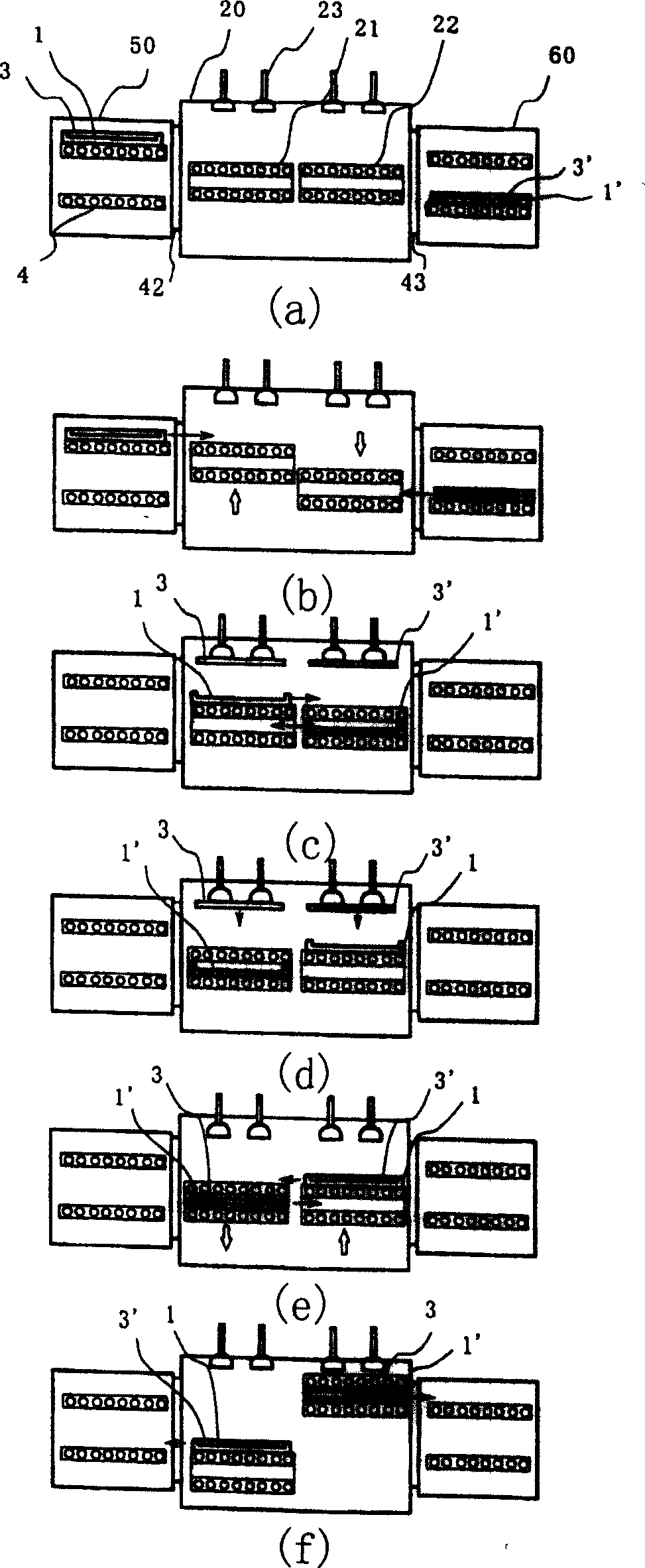

[0047] figure 1 A schematic diagram showing the basic structure of the substrate processing apparatus of the present invention.

[0048] Such as figure 1 As shown, the substrate processing apparatus has a structure in which the load-lock vacuum chamber 10, the substrate transfer chamber 20, and the processing chamber 30 are connected by gate valves 41 and 42, so that the first carrier 1 can be moved between the load-lock vacuum chamber 10 and the processing chamber 30. The substrate is transferred between the substrate transfer chambers 20 , and the second carrier 1 ′ can be moved between the substrate transfer chamber 20 and the processing chamber 30 to transfer the substrate. Here, the substrate transfer chamber 20 is maintained at a temperature such as N 2 Gas or other dry gas environment or vacuum state, and a substrate transfer mechanism 5 is installed.

[0049] In the atmosphere, the substrate 3 is loaded on the first carrier 1, carried into the load-lock vacuum cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com