Equipment and method of high-efficiency high-speed environmentally-friendly energy-saving sludge treatment system

A sludge treatment, environmental protection and energy-saving technology, applied in the direction of temperature control sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of human health hazards, waste of resources, secondary pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

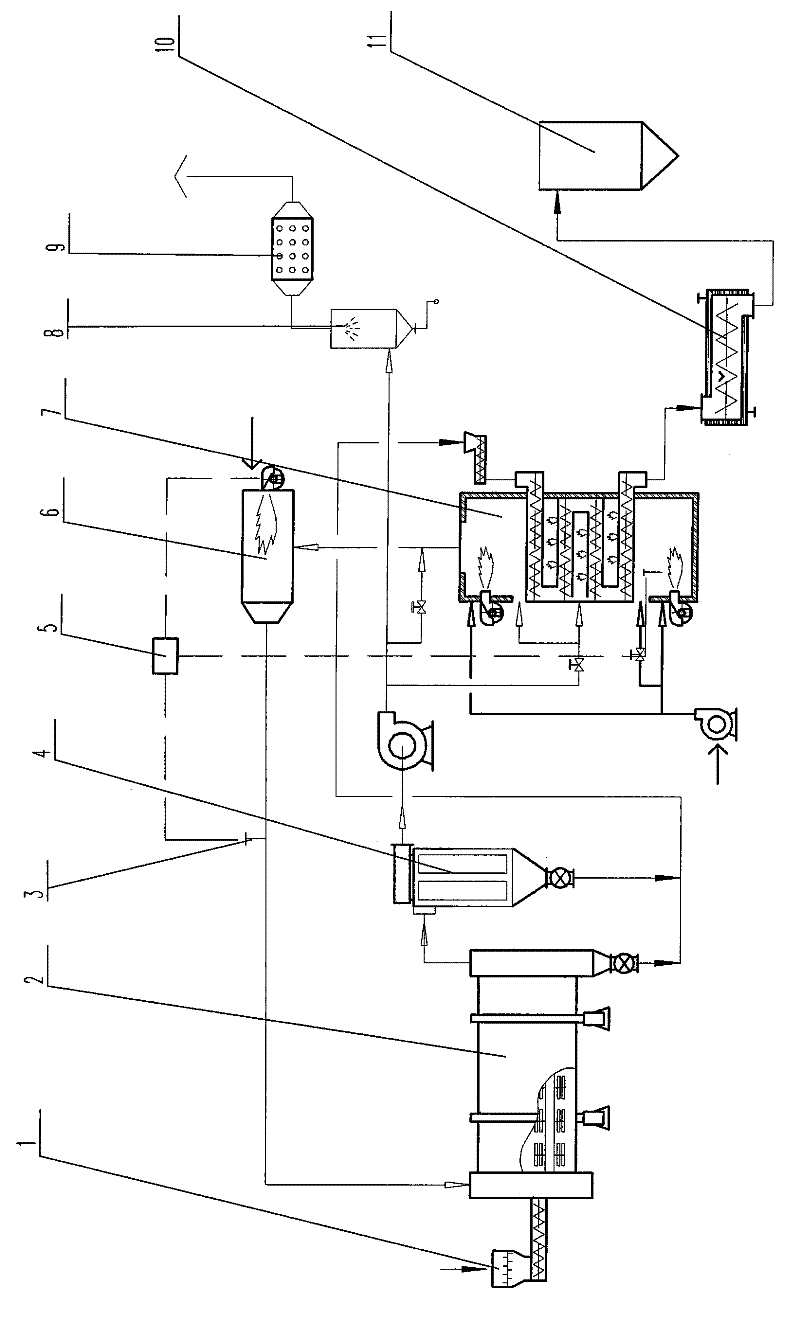

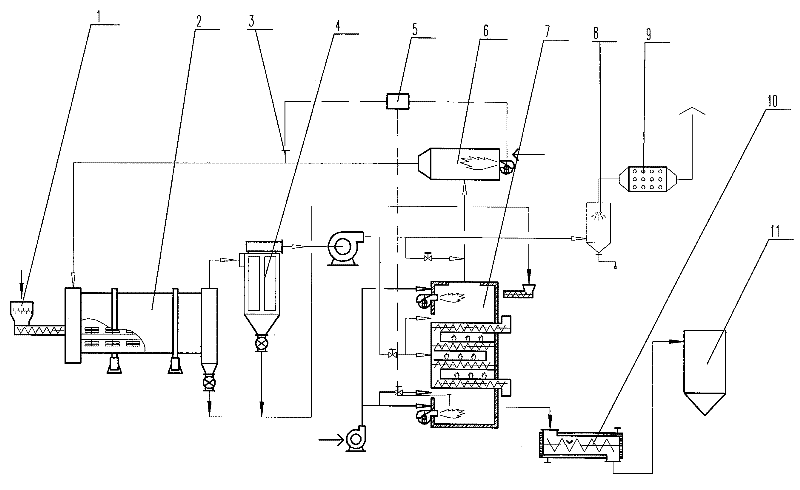

[0013] Such as figure 1 As shown, the sludge treatment system is mainly composed of a feeding device 1, a sludge dryer 2, a temperature sensor 3, a dust collector 4, a temperature controller 5, a spare furnace 6, a sludge carbonization furnace 7, and a wet dust collector 8. Photochemical deodorizer 9, cooling humidifier 10, storage bin 11, II temperature sensor 12, blower 13 and induced draft fan 14, etc., which communicate with each other through air ducts. Firstly, the standby furnace 6 is ignited and the temperature controller 5 controls the temperature of the hot air sent into the sludge dryer 2 by the air pipe through the I temperature sensor 3. When the temperature of the hot air sent into the sludge dryer 2 reaches the set drying temperature of 800°C, the wet sludge is fed The device 1 is put into the sludge dryer 2, and after the wet sludge is dried, it is sent to the activated sludge carbonization furnace 7, and then, the carbonized sludge particles enter the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com