Process and apparatus for wastewater by batched membrane-bioreactor

A sewage treatment device and bioreactor technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., to achieve land saving, easy automatic control and operation and maintenance , The effect of shortening the operating cycle of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

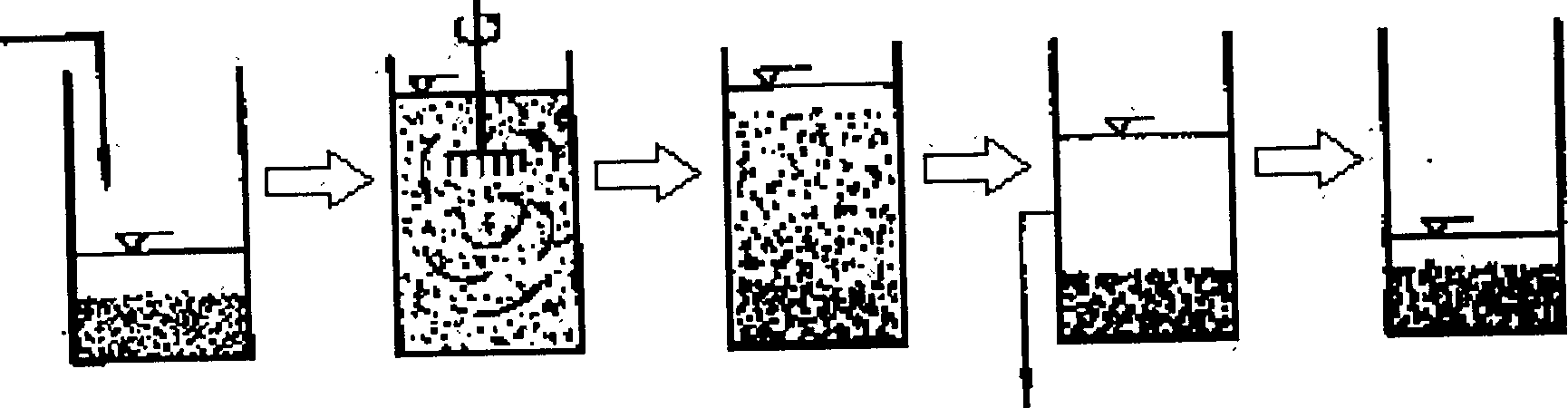

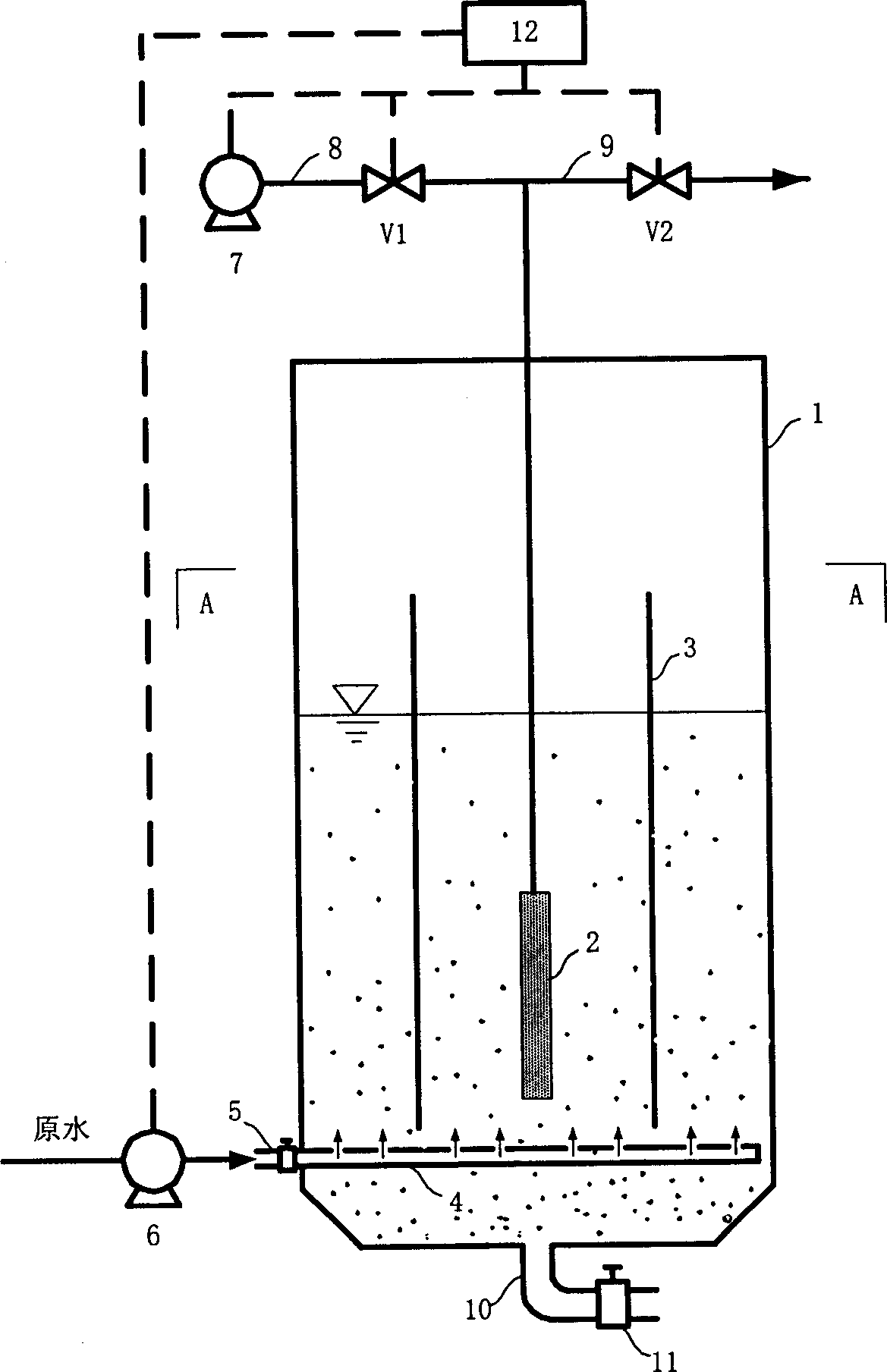

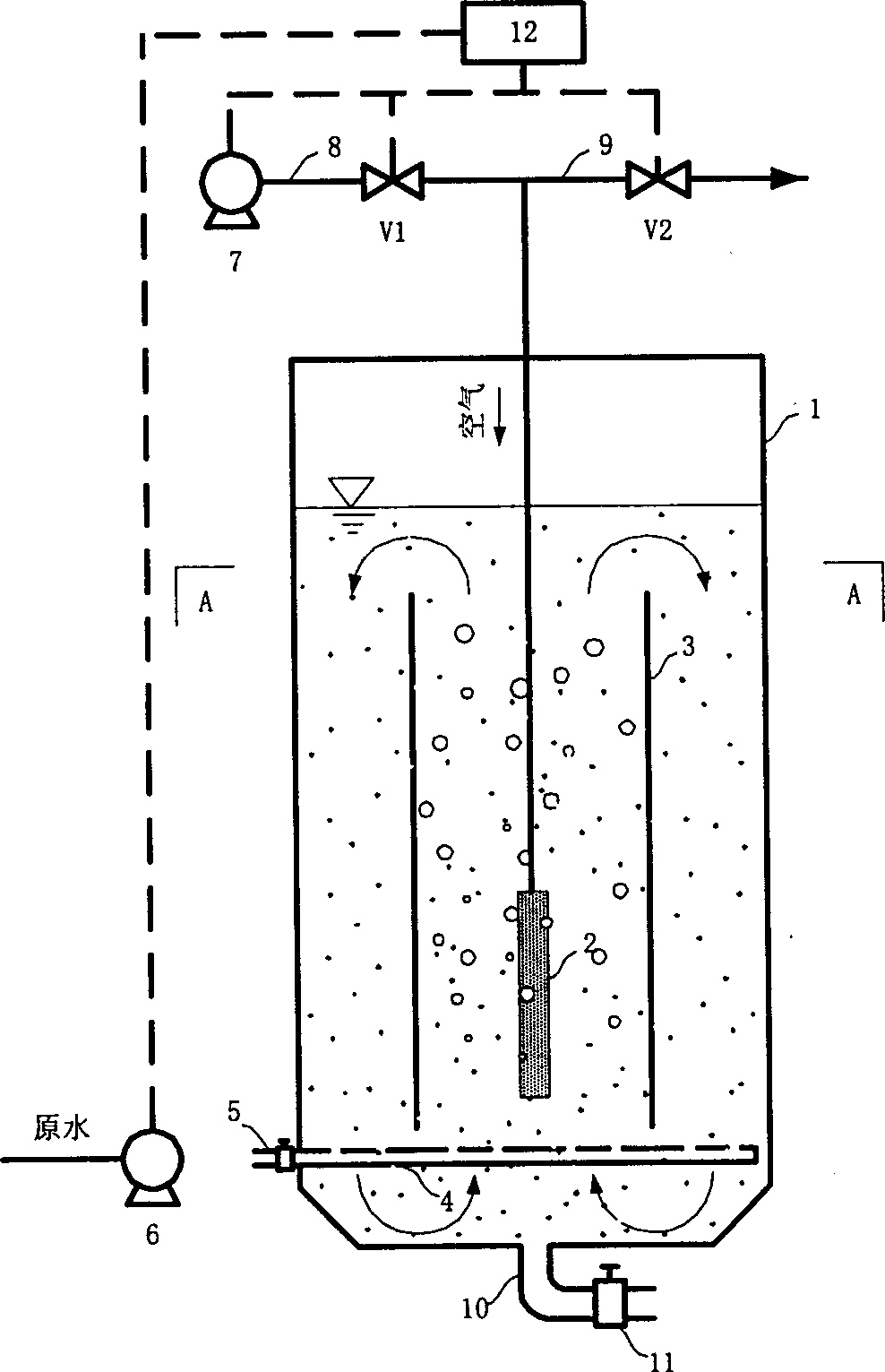

[0052] Such as figure 2 As shown, within 1.5 hours of the inflow process, the raw water is pressurized by the water inlet pump, sprayed into the reaction tank through the water distribution pipe, and the activated sludge deposited at the bottom of the reaction tank is boiled and fully contacted with the raw water. At this time, the activated sludge is mixed The liquid is in an anaerobic state, and the organic pollutants in the raw water provide carbon sources for the denitrifying bacteria, and the denitrifying bacteria further reduce the nitrite nitrogen and nitrate nitrogen formed in the previous operation cycle to gaseous nitrogen (N 2 ), to achieve the removal of total nitrogen (TN). The phosphorus-removing bacteria decompose the polyphosphate in the body to produce ATP, and use ATP to take the organic matter in the wastewater into the cell, store it in the cell in the form of poly-β-hydroxybutyric acid and other organic particles, and decompose polyphosphate at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com