Clarification tank with submersible reflux pump composite micro-vortex reaction process

A submersible backflow and micro eddy current technology, applied in the field of water treatment, can solve the problems of ineffective utilization of chemical consumption, small collision probability of suspended particles, increase in chemical consumption, etc., and achieve good effluent quality, fast floc formation, and reduced installed capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

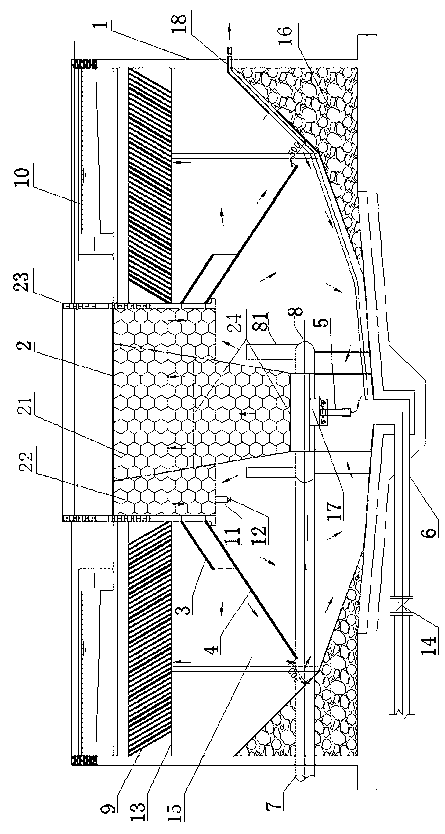

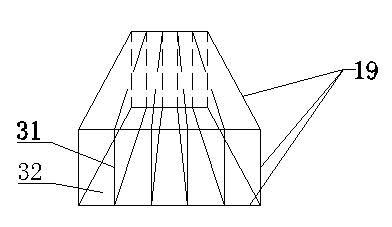

[0029] Such as figure 1 As shown, the clarification tank using the submersible reflux pump compound micro-vortex reaction process includes the structure of the tank body 1, and the central cylinder 2 is arranged in the middle of the tank body 1. The central cylinder 2 should be located at the geometric center when looking down on the tank body 1, and the deviation is not greater than 0.1 m, made of steel plate. The central cylinder 2 is divided into a first reaction zone 21 and a second reaction zone 22. The first reaction zone 21 is in the shape of a conical cylinder, and the periphery of the first reaction zone 21 is welded with a second reaction zone 22. The second reaction zone 22 is cylindrical, and its bottom is Made of annular steel, the inner ring of the second reaction zone 22 is welded to the first reaction zone, the outer ring is sealed with a concrete peripheral cylinder 23, and both the first reaction zone 21 and the second reaction zone 22 are filled with micro-v...

Embodiment 2

[0039] As a preferred solution of the present invention, other technical features are the same as in Embodiment 1, the difference is that the bottom of the pool is also laid with a small mud discharge pipe 18 that discharges mud upwards along the gentle slope to the outside of the pool, and the small mud discharge pipe 18 is added to play a role. The role of auxiliary mud discharge ensures that the part where the submersible return pump is located will not be silted up by sediment and affect its heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com