Reverse osmosis water purification and dispensing machine structure and energy saving method therefor

A drinking machine and reverse osmosis technology, applied in reverse osmosis, chemical instruments and methods, semi-permeable membrane separation, etc., can solve problems such as increased power consumption, increased salinity of purified water, increased water pressure, etc., to achieve The effect of reducing power consumption, improving recovery rate, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

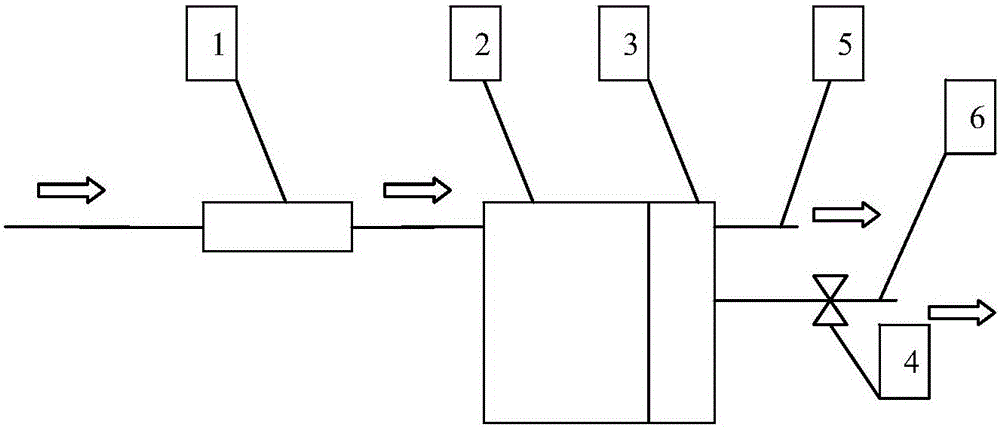

[0032] Please combine figure 1 As shown, a reverse osmosis drinking machine structure of the present invention includes a self-priming booster pump 1, a pre-filtration system 2 and a reverse osmosis membrane 3, wherein the inlet of the self-priming booster pump 1 is connected to an external water source, and the self-priming The outlet of the booster pump 1 is connected to the inlet of the pre-filtration system 2, and the outlet of the pre-filtration system 2 is connected to the inlet of the reverse osmosis membrane 3; one end of the outlet of the reverse osmosis membrane 3 also includes a clean water outlet 5 and a concentrated water outlet 6. The water is connected to the user through the clean water outlet 5 for use.

[0033] In the structure of the reverse osmosis water purifier mentioned above, a wastewater ratio electromagnetic valve 4 is installed at one end of the concentrated water outlet 6 , and the outlet of the wastewater ratio solenoid valve 4 is connected to the ...

Embodiment 2

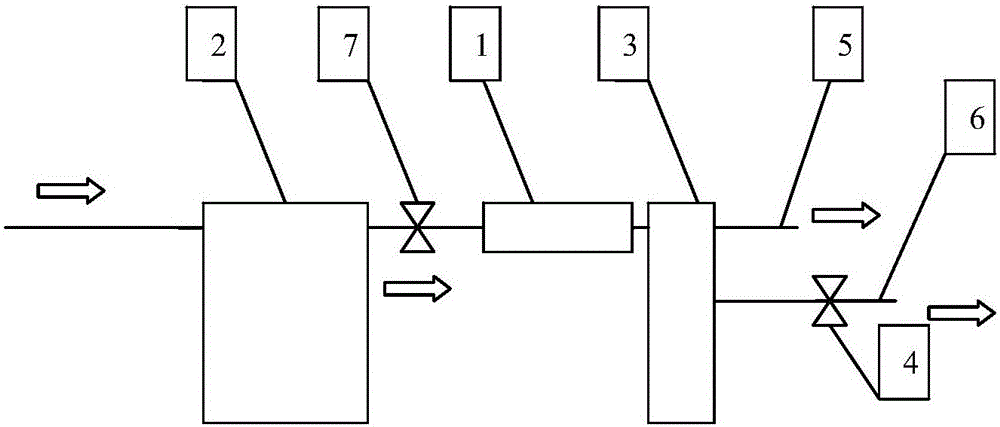

[0050] See figure 2 As shown, in this embodiment, the specific structure of the reverse osmosis drinking machine includes: a common booster pump 1, a pre-filtration system 2, a reverse osmosis membrane 3, a waste water ratio solenoid valve 4, a clean water outlet 5, a concentrated water outlet Water port 6 and pressure reducing valve 7. The tap water is connected to the inlet of the pre-filtration system 2, the outlet of the pre-filtration system 2 is connected to the inlet of the pressure reducing valve 7, the outlet of the pressure reducing valve 7 is connected to the inlet of the self-priming booster pump 1, the outlet of the self-priming booster pump 1 is connected to the inlet of the reverse osmosis membrane 3, net The water is connected to the user through the clean water outlet 5, the concentrated water end is connected to the inlet of the wastewater ratio solenoid valve 4, and the outlet of the wastewater ratio solenoid valve 4 is connected to the concentrated water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com