Patents

Literature

294 results about "Reverse osmosis plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

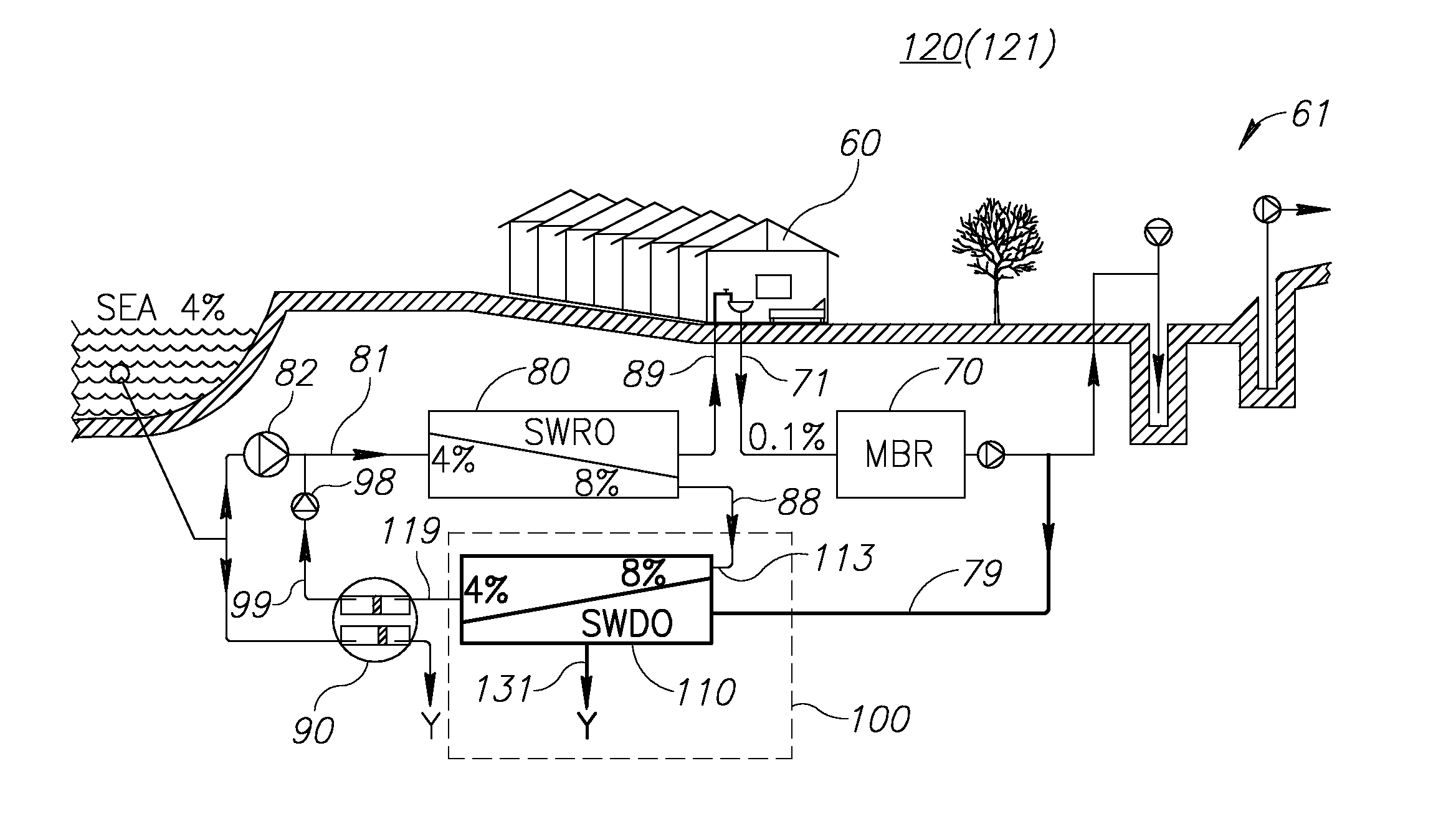

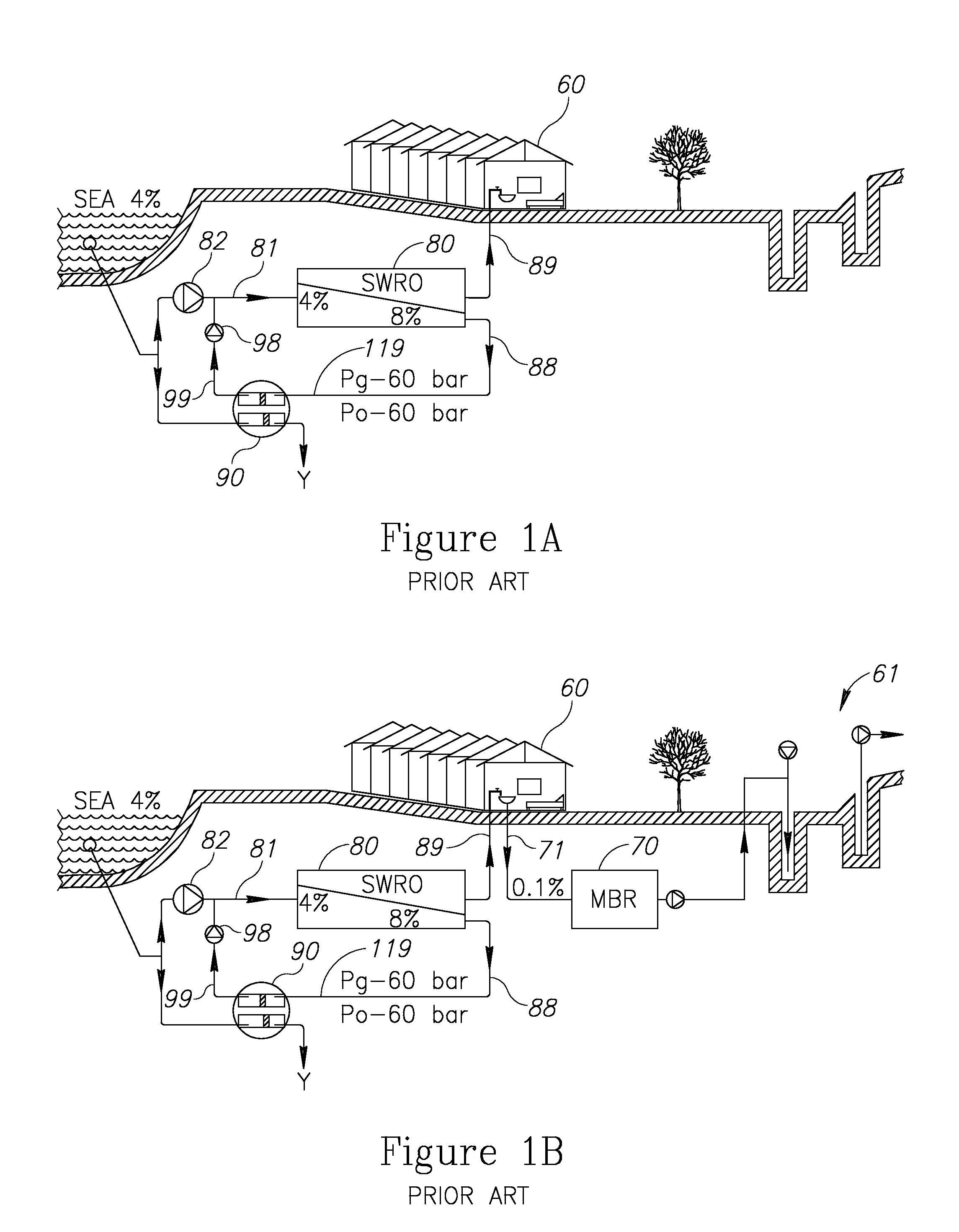

A reverse osmosis plant is a manufacturing plant where the process of reverse osmosis takes place. An average modern reverse osmosis plant needs six kilowatt-hours of electricity to desalinate one cubic metre of water. The process also results in an amount of salty briny waste. The challenge for these plants is to find ways to reduce energy consumption, use sustainable energy sources, improve the process of desalination and to innovate in the area of waste management to deal with the waste. Self-contained water treatment plants using reverse osmosis, called reverse osmosis water purification units, are normally used in a military context.

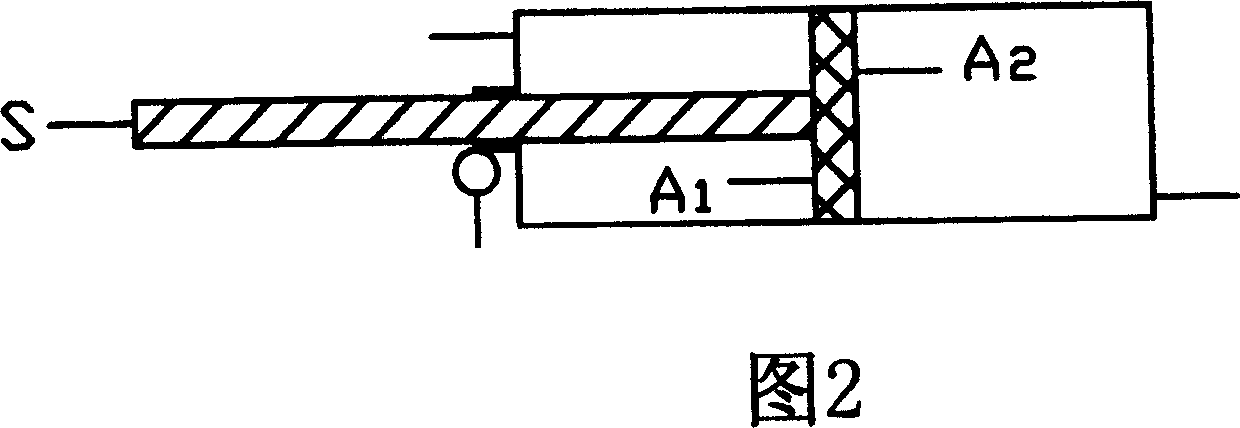

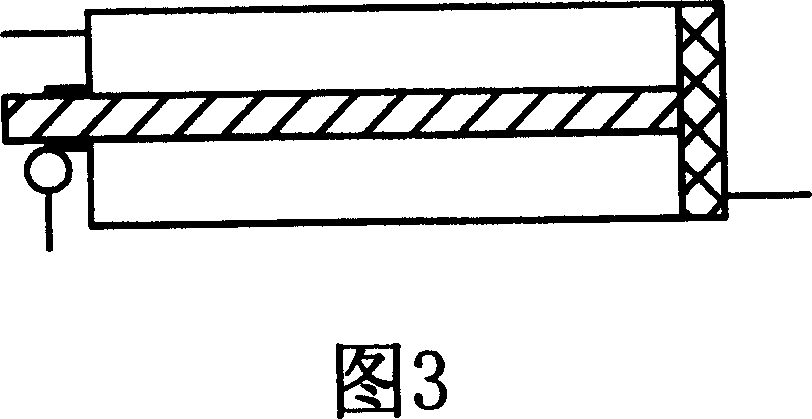

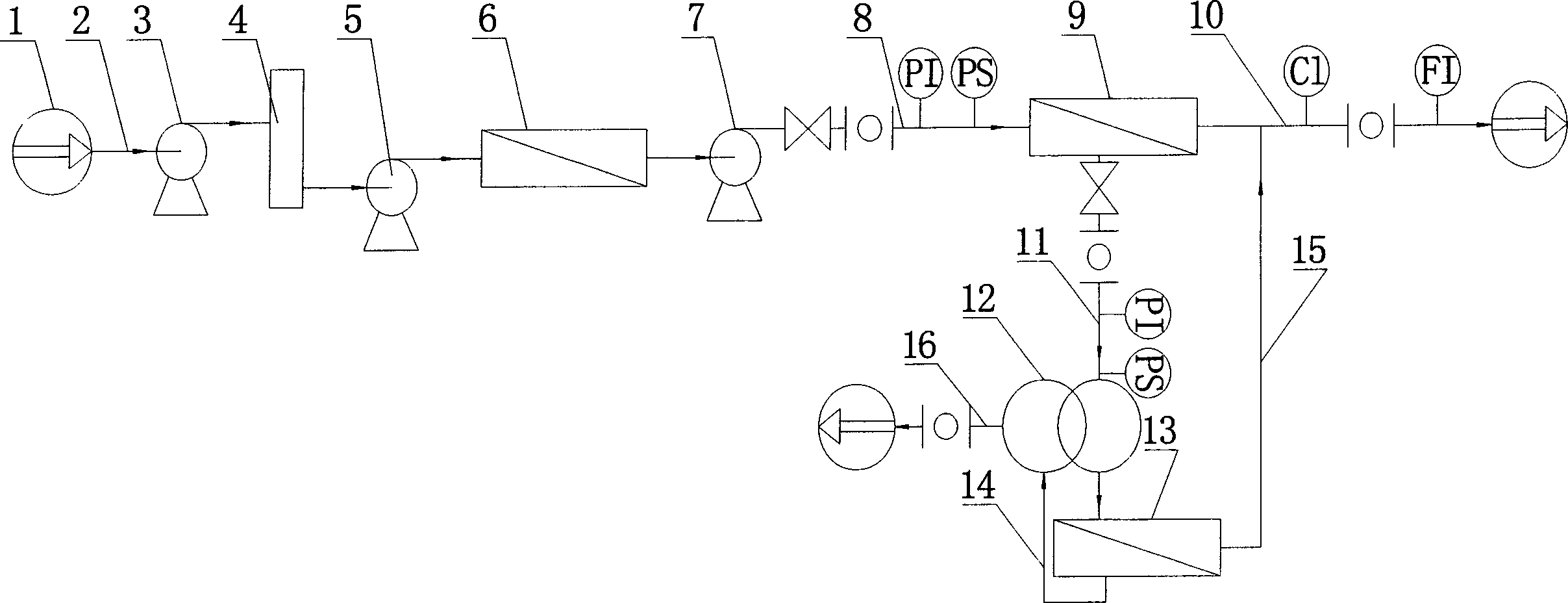

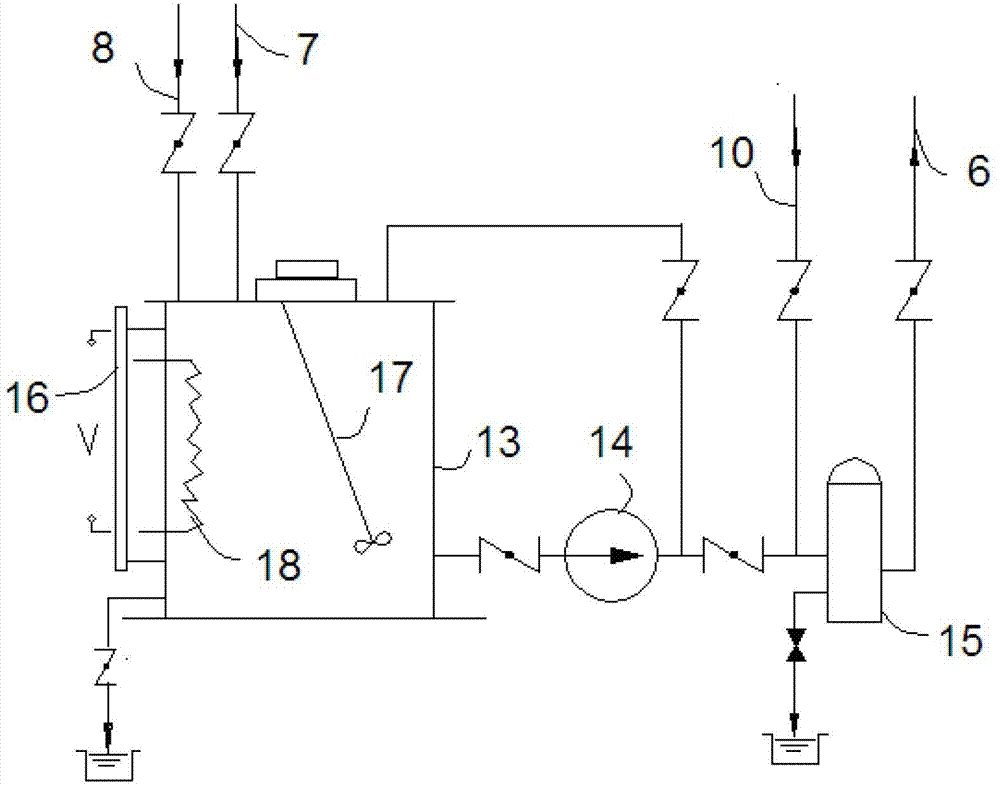

Strong brine energy recovery device based on reverse osmosis desalination technology

InactiveCN100341609CGuaranteed uptimeReduce consumptionGeneral water supply conservationReverse osmosisHydraulic cylinderSaline water

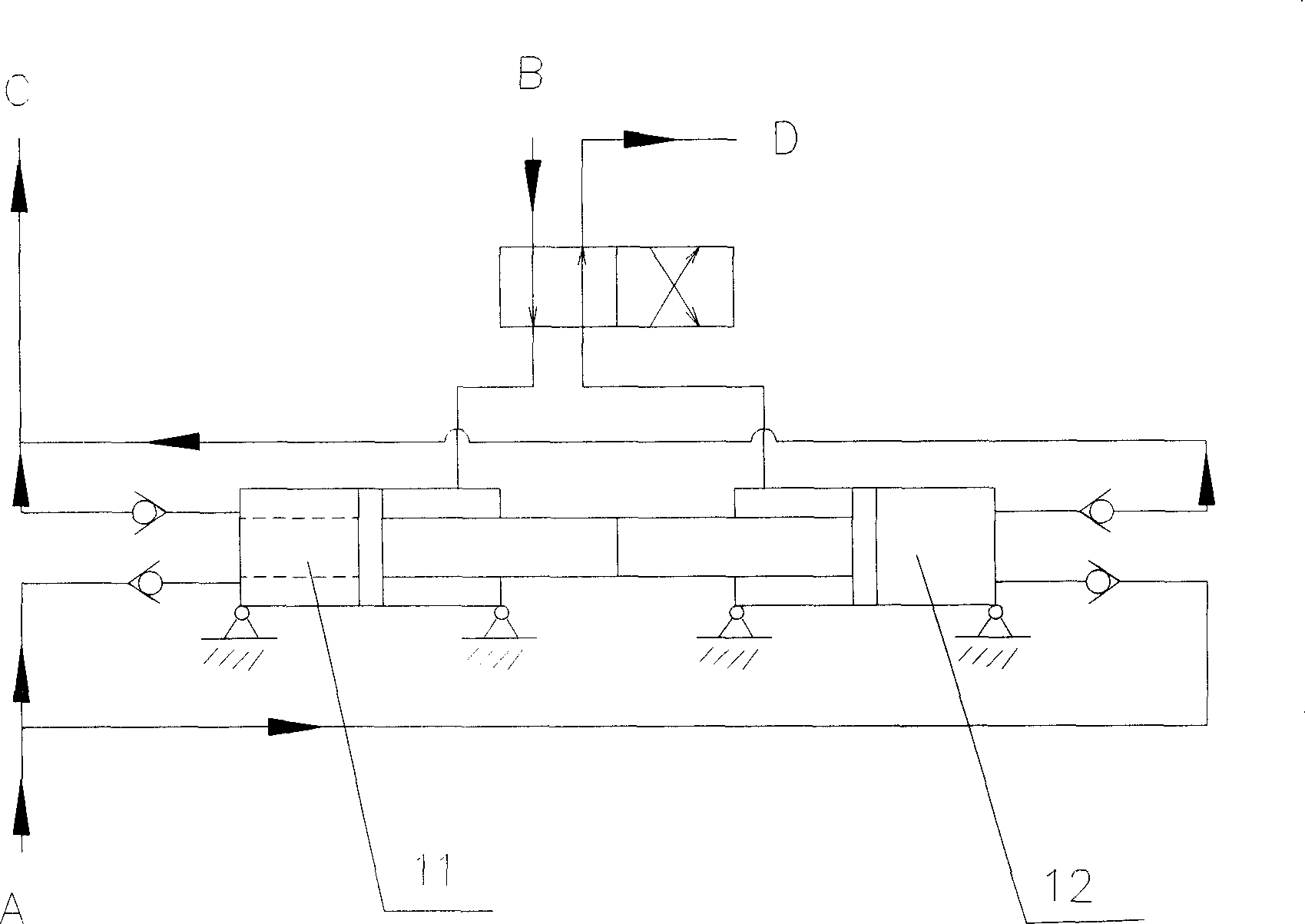

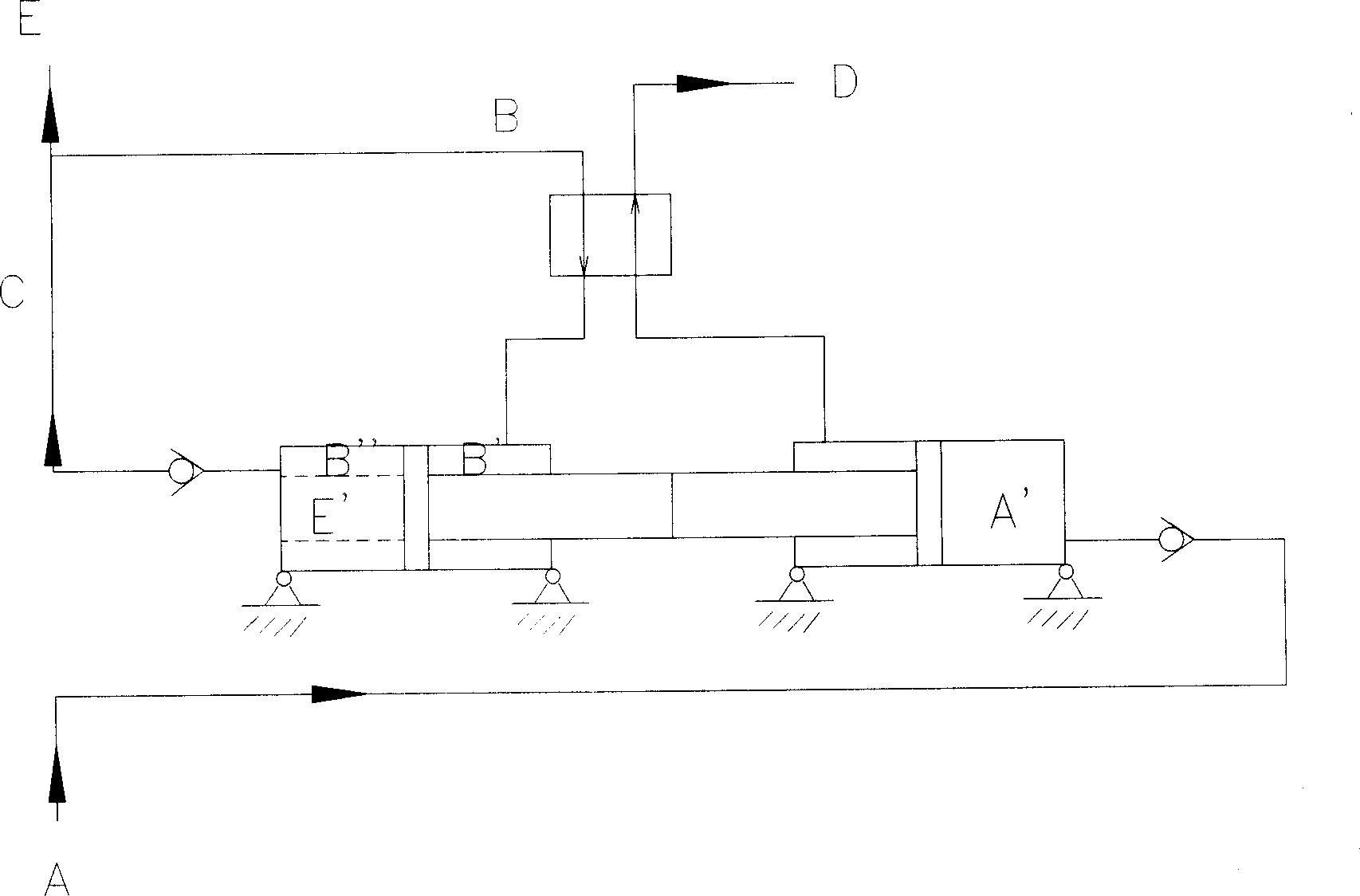

This invention discloses energy-recovery device for strong brine based on desalination technique by reverse osmosis, which comprises hydraulic cylinder with guide bar connected to piston; water inlet three-way solenoid valve with one end connected to end of guide bar, and other two ends connected separately to water outlets of low and high pressure water-feed pumps; drainage three-way solenoid valve with one end connected to the hydraulic cylinder end far away guide bar, and other two ends connected to strong brine discharge pipes of reverse osmosis membrane; sensor, to obtain the position signal of piston; controller, to control the synchronized open and shut of two aforementioned three-way solenoid valves. It has high efficiency, runs stably, switches quickly and fit to spread in industry.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

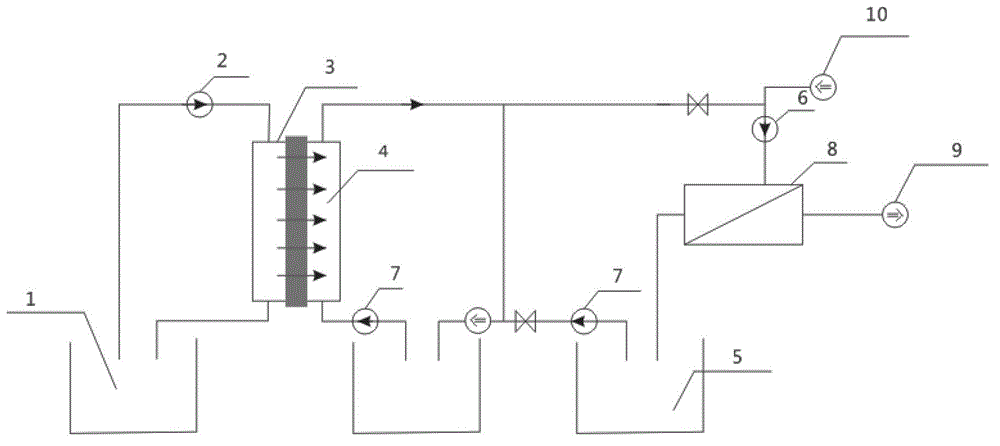

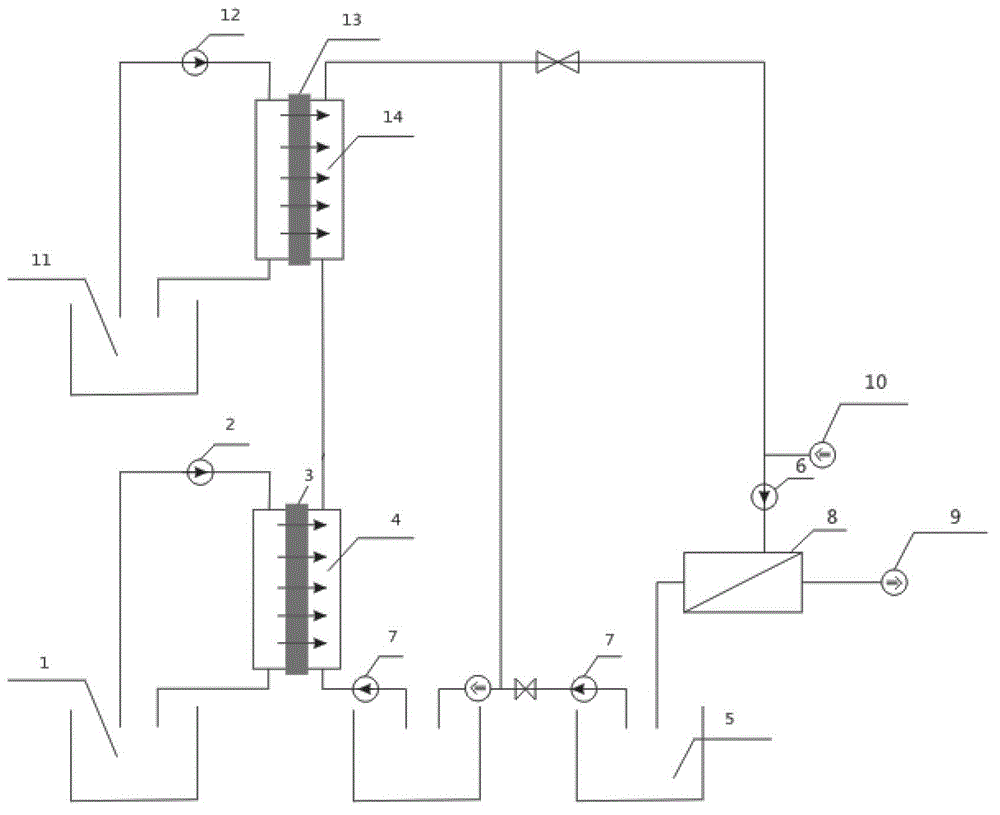

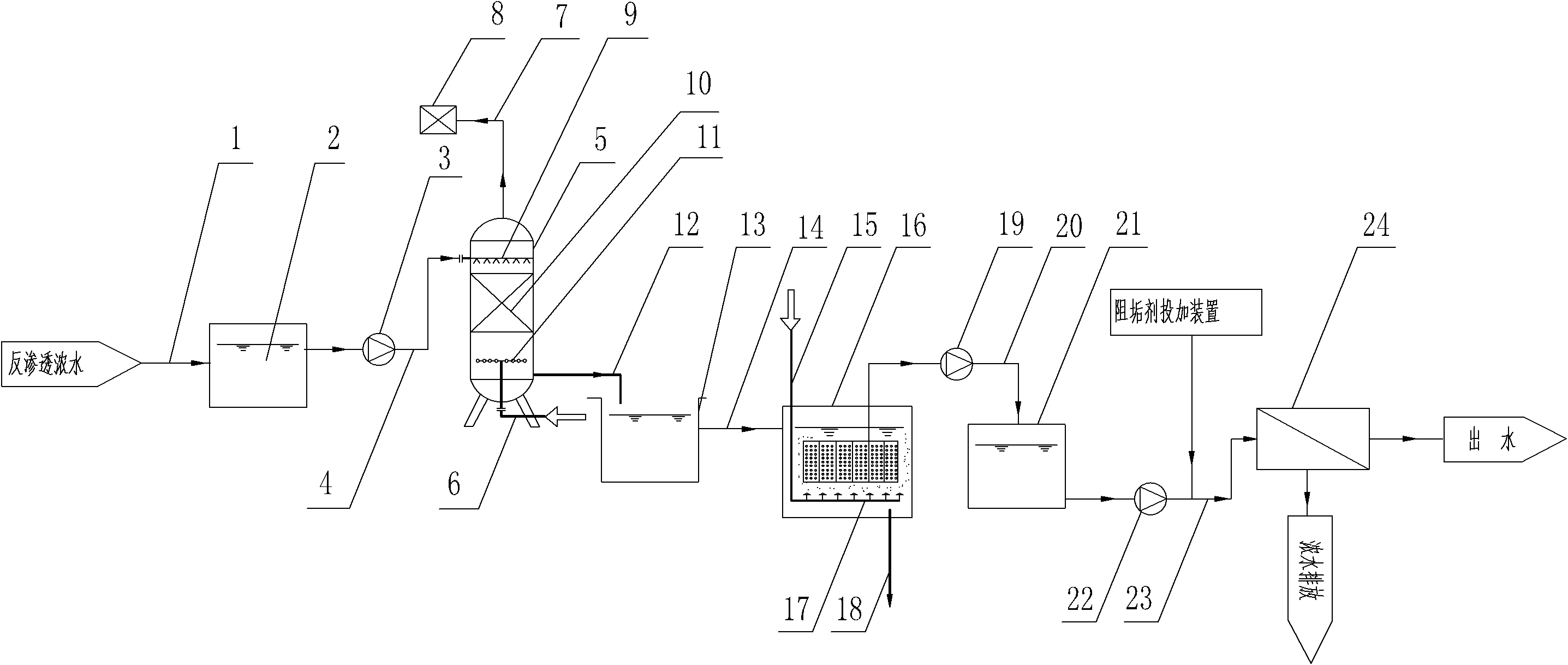

Method and apparatus for treatment of concentrated reverse osmosis drainage through coupled forward osmosis and reverse osmosis

InactiveCN102745776AImprove utilizationNo pollution in the processSemi-permeable membranesGeneral water supply conservationHigh pressureReverse osmosis plant

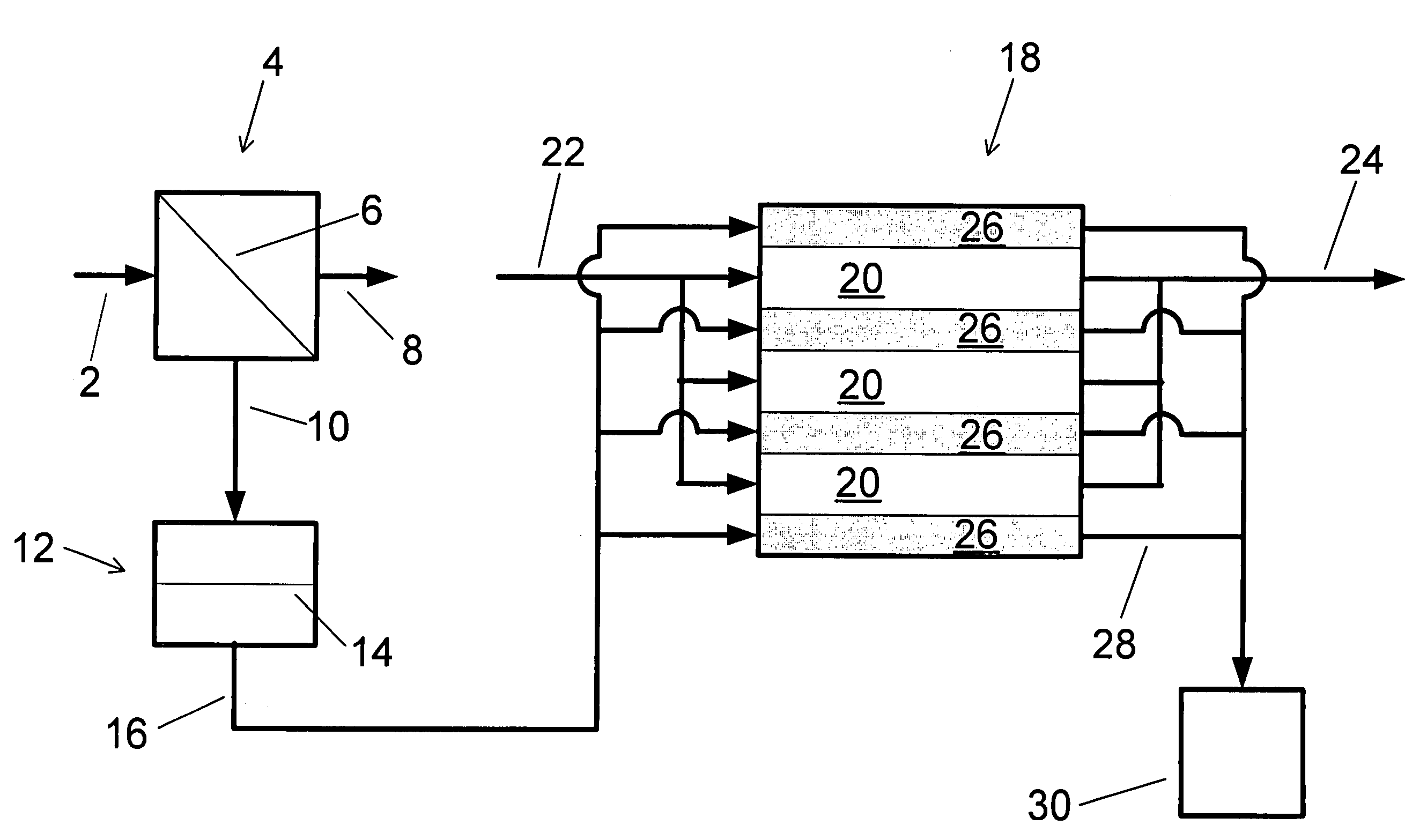

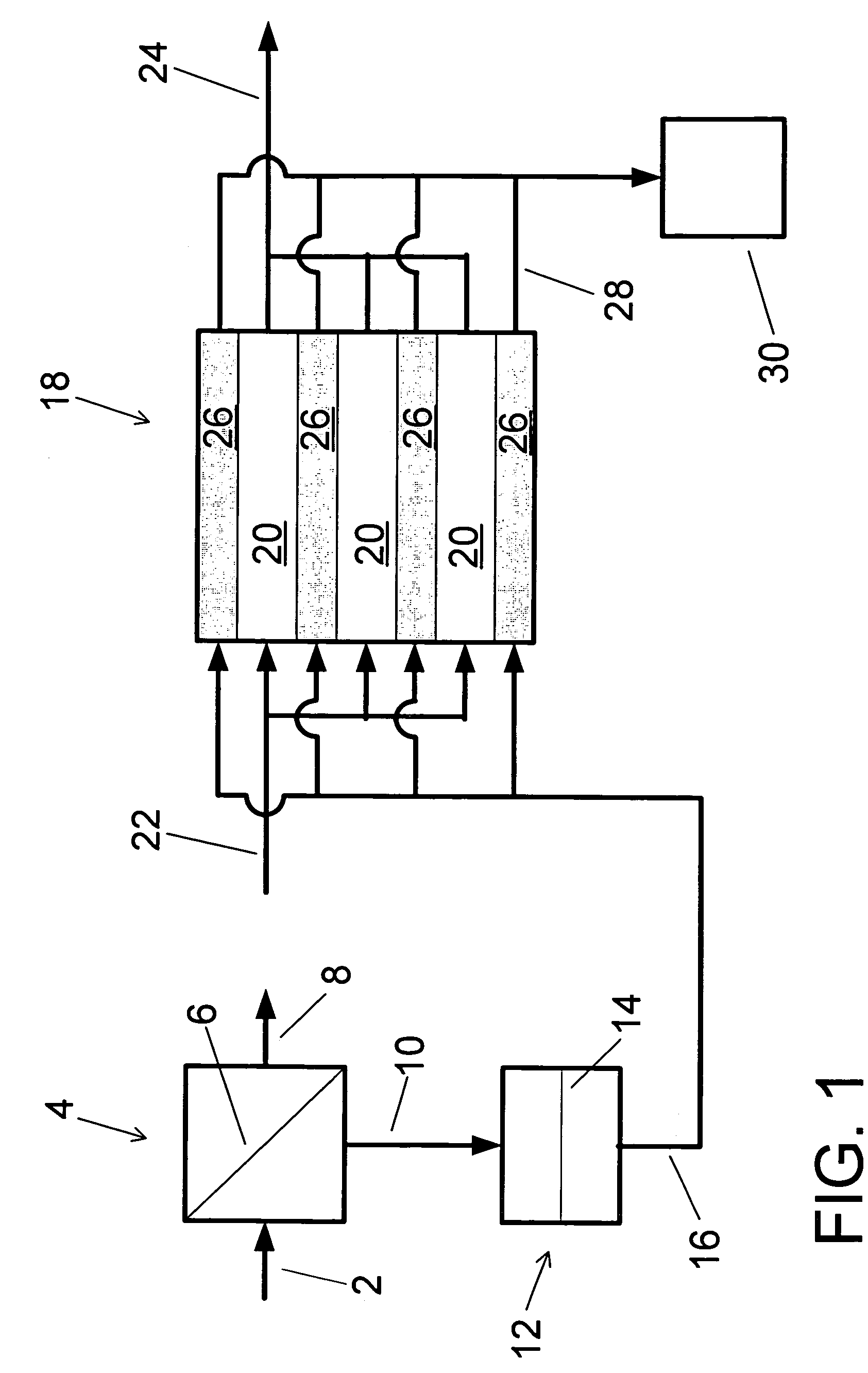

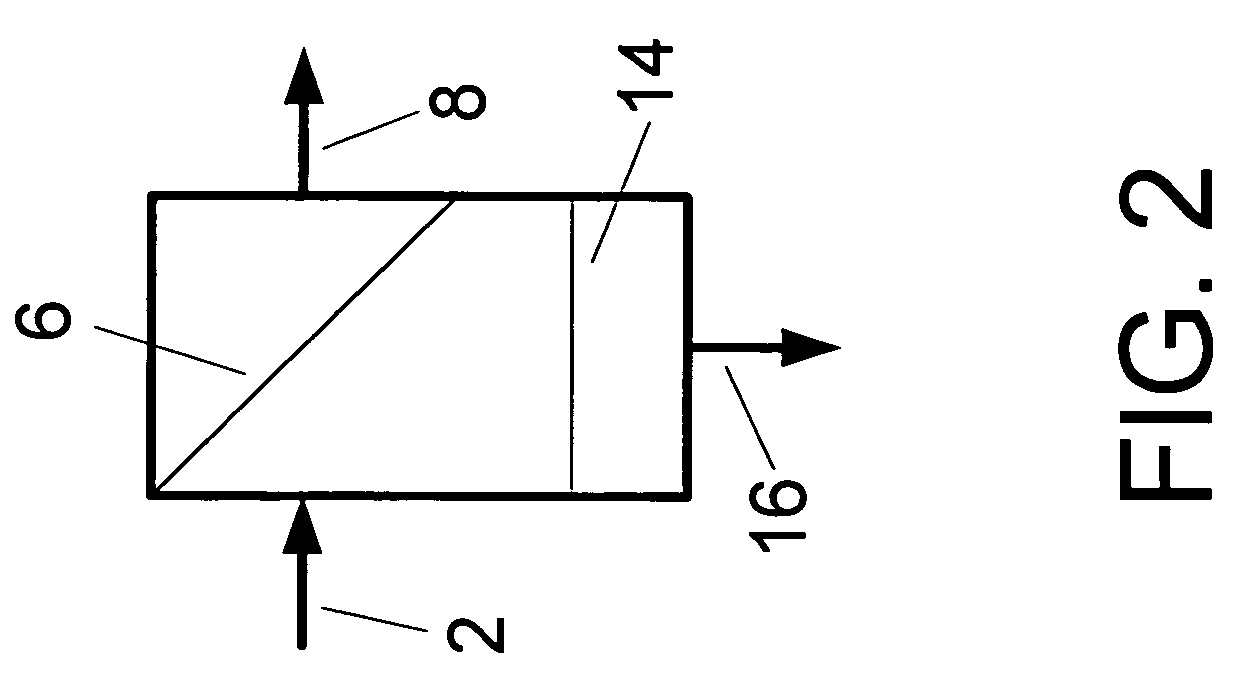

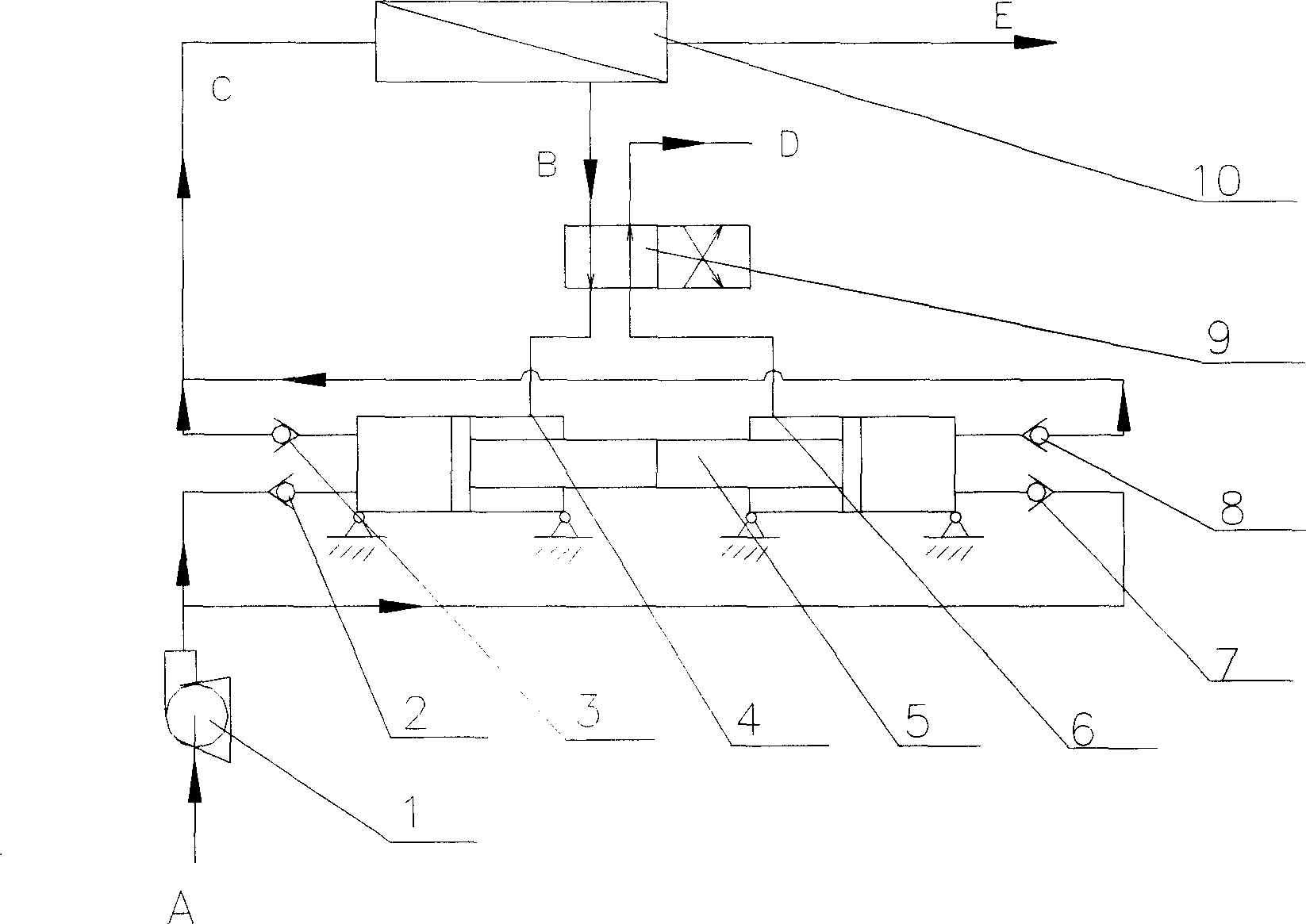

The invention discloses a method and an apparatus for treatment of a concentrated reverse osmosis drainage through coupled forward osmosis and reverse osmosis. The method comprises the following steps that: a raw forward osmosis solution directly enters into a forward osmosis assembly, a concentrated reverse osmosis drainage is used as a driving solution for forward osmosis, water of the raw forward osmosis solution permeates a membrane, the concentrated reverse osmosis drain is diluted and then mixed with raw reverse osmosis water, then flows through a high-pressure pump and enters into a reverse osmosis assembly as inflowing reverse osmosis water, water penetrating to one side of the driving solution from the raw forward osmosis solution is recycled through reverse osmosis, and the concentrated reverse osmosis drainage is circulated as the driving solution for forward osmosis. The apparatus comprises a first feed pump, a second feed pump, the forward osmosis assembly, the high-pressure pump and the reverse osmosis assembly. According to the invention, the utilization rate of the concentrated reverse osmosis drain can be increased; pollution of the concentrated reverse osmosis drainage to the environment can be reduced; the method and the apparatus can also be used for liquid concentration and desalination, producing significant economic values; and the apparatus provided by the invention has the advantages of a small occupied land area, a compact structure, simple operation, low running cost and low energy consumption.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

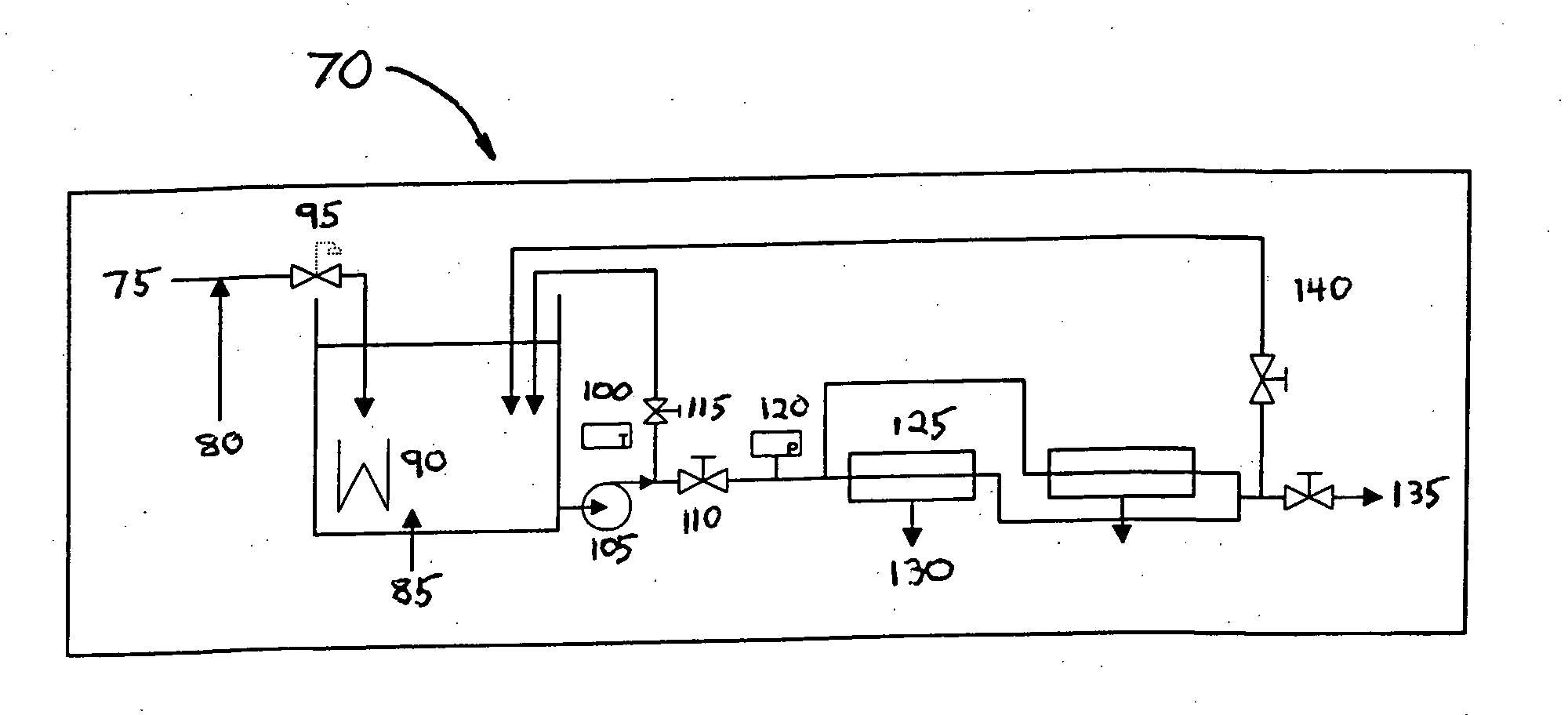

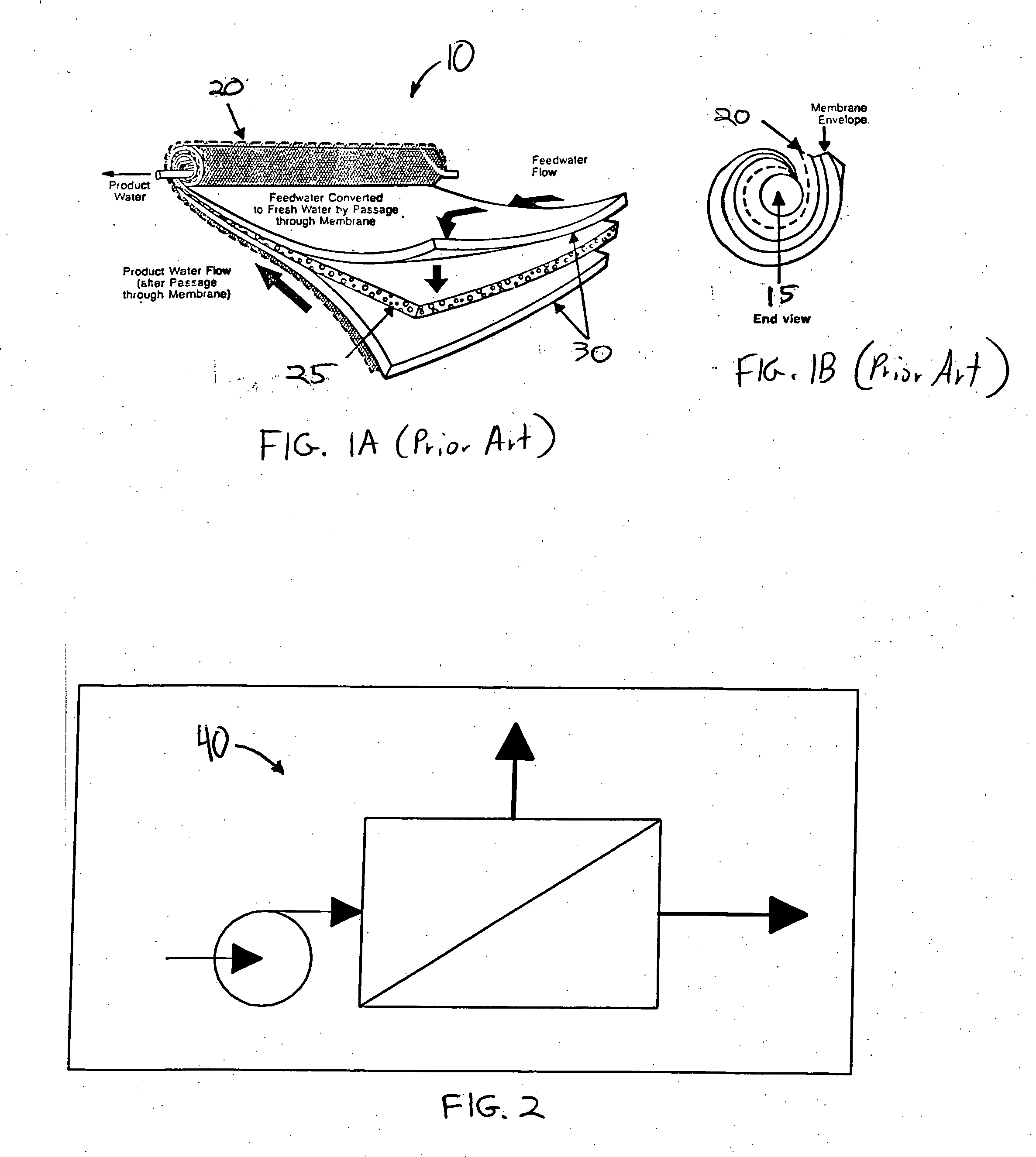

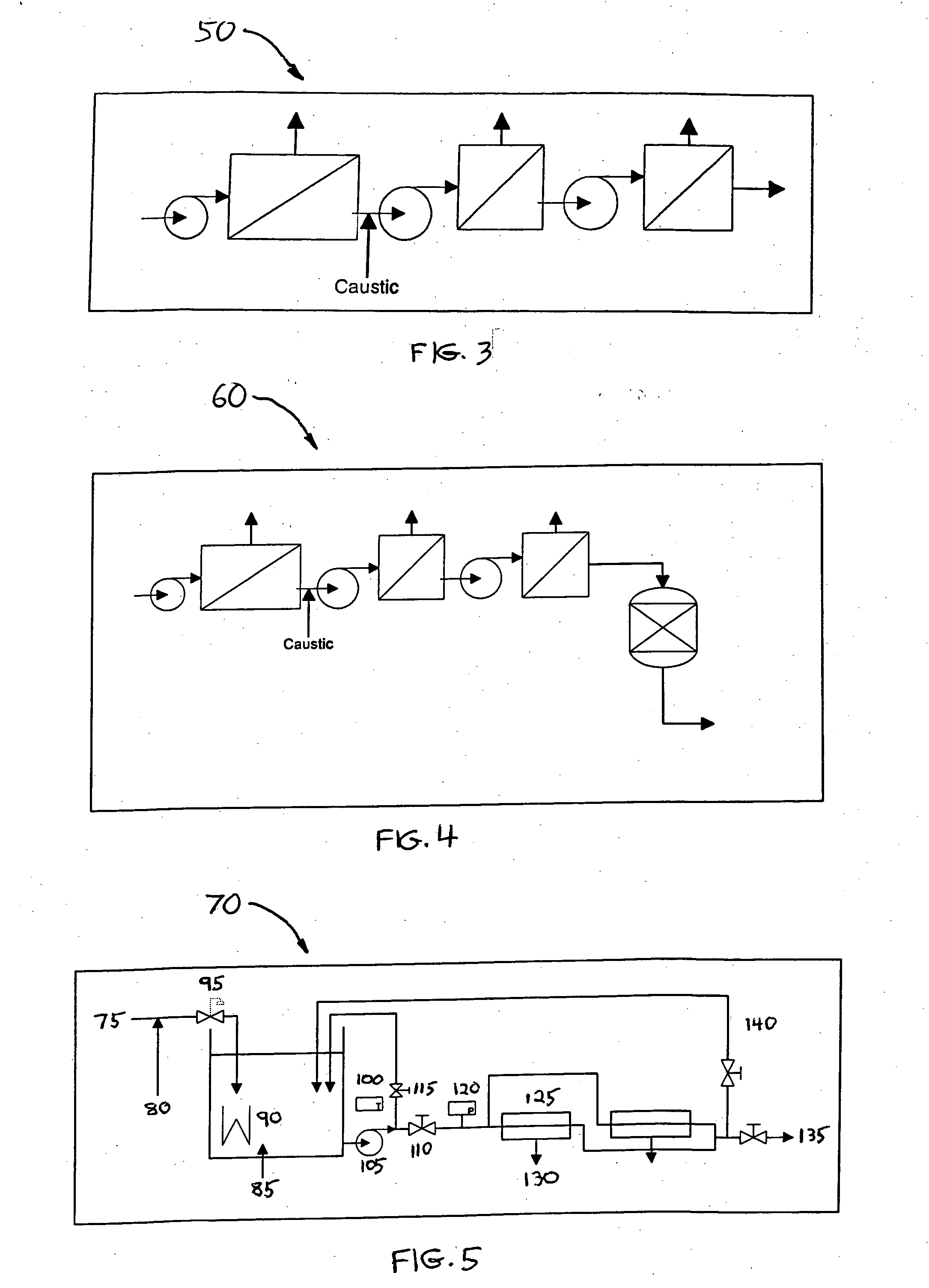

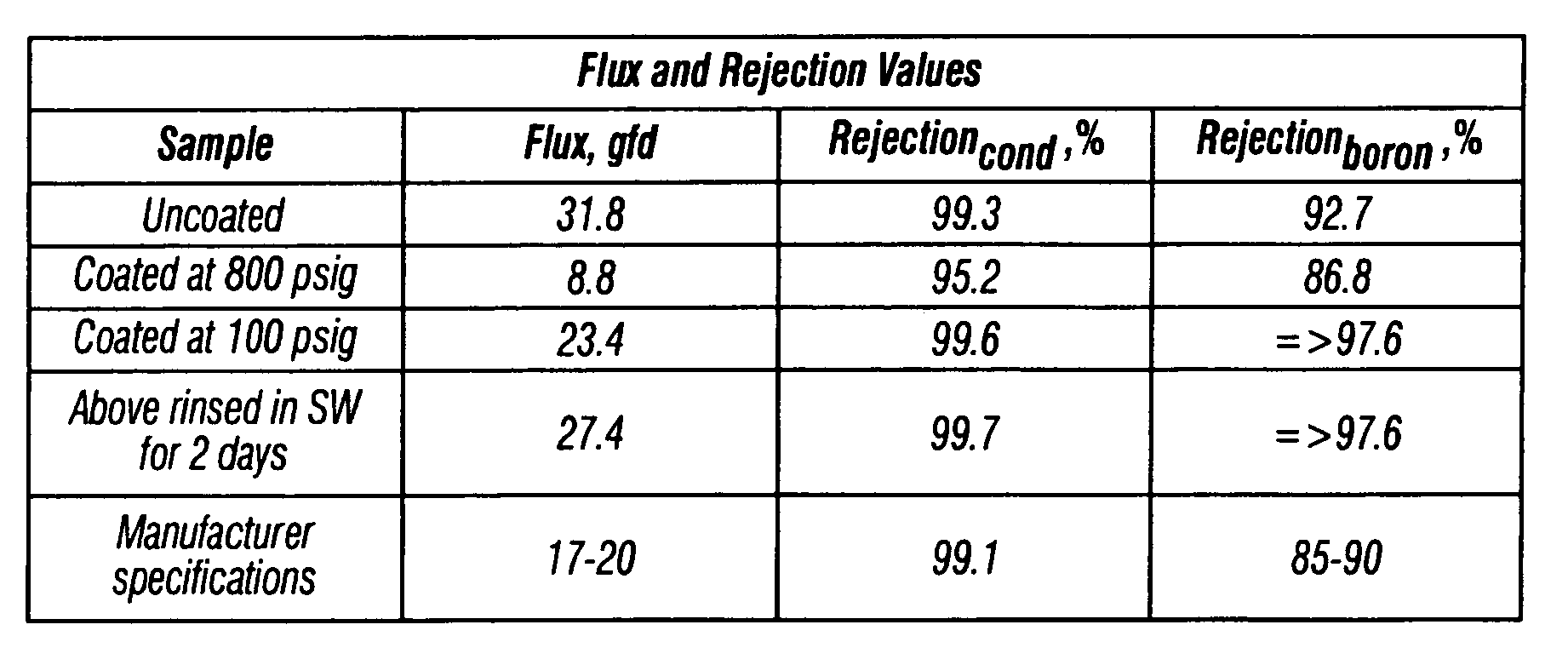

Method of treating reverse osmosis membranes for boron rejection enhancement

InactiveUS20060065598A1Reducing boron concentrationReduce concentrationLiquid separation auxillary apparatusMembranesBrackish waterReverse osmosis plant

The present invention provides a method of treating a reverse osmosis membrane for boron rejection enhancement, comprising contacting the reverse osmosis membrane with a chemical coating such as PHMB, wherein the reverse osmosis membrane is part of a single-pass reverse osmosis system is configured to reduce the boron concentration of normal seawater or brackish water to less than a predetermined amount.

Owner:KURITA WATER INDUSTRIES LTD

Method of treating reverse osmosis membranes for boron rejection enhancement

InactiveUS7491334B2Reduce concentrationImprove abilitiesMembranesWater/sewage treatment bu osmosis/dialysisBrackish waterReverse osmosis plant

The present invention provides a method of treating a reverse osmosis membrane for boron rejection enhancement, comprising contacting the reverse osmosis membrane with a chemical coating such as PHMB, wherein the reverse osmosis membrane is part of a single-pass reverse osmosis system is configured to reduce the boron concentration of normal seawater or brackish water to less than a predetermined amount.

Owner:KURITA WATER INDUSTRIES LTD

Reciprocal enhancement of reverse osmosis and forward osmosis

ActiveUS20120285886A1Water treatment parameter controlGeneral water supply conservationSaline waterConcentration polarization

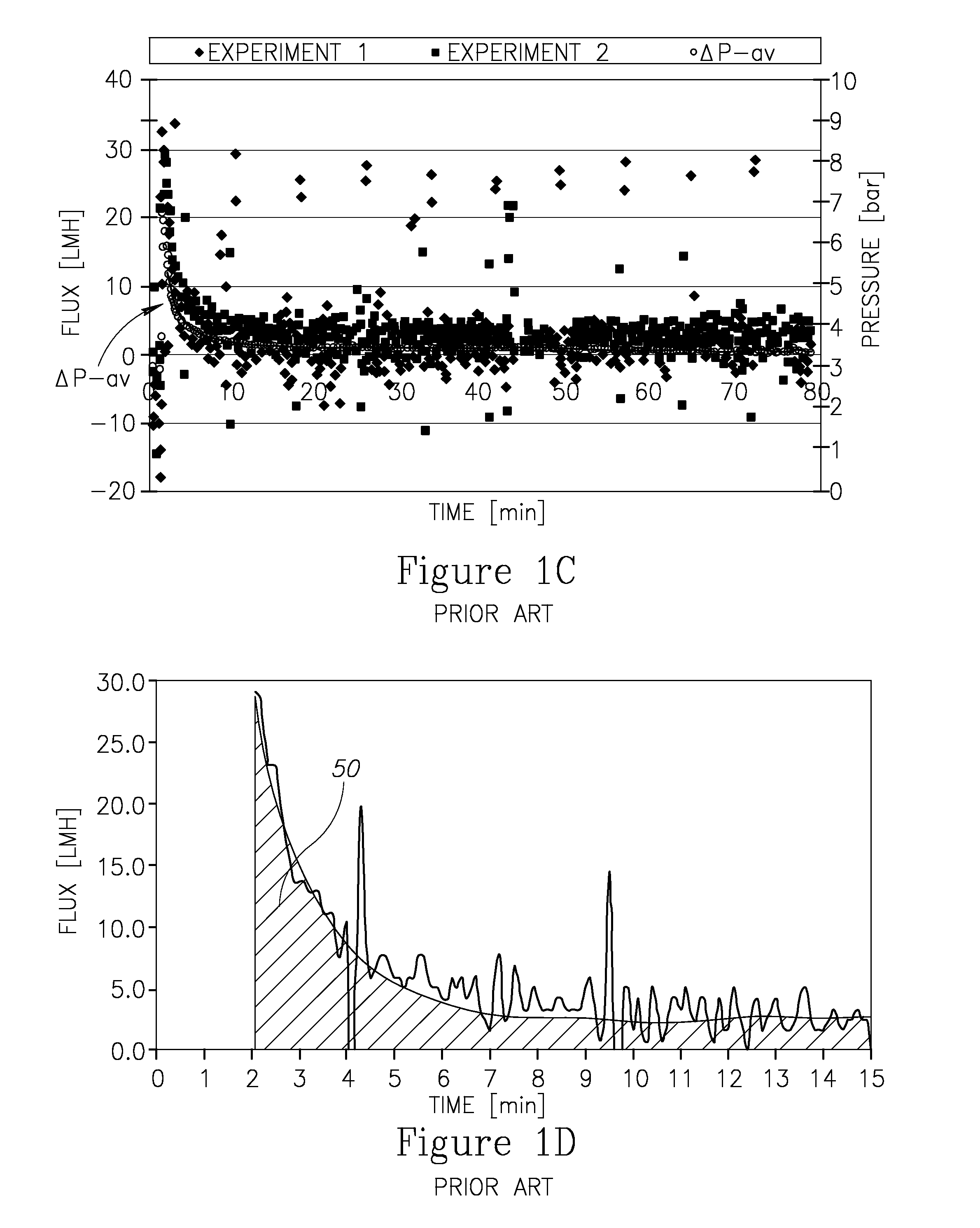

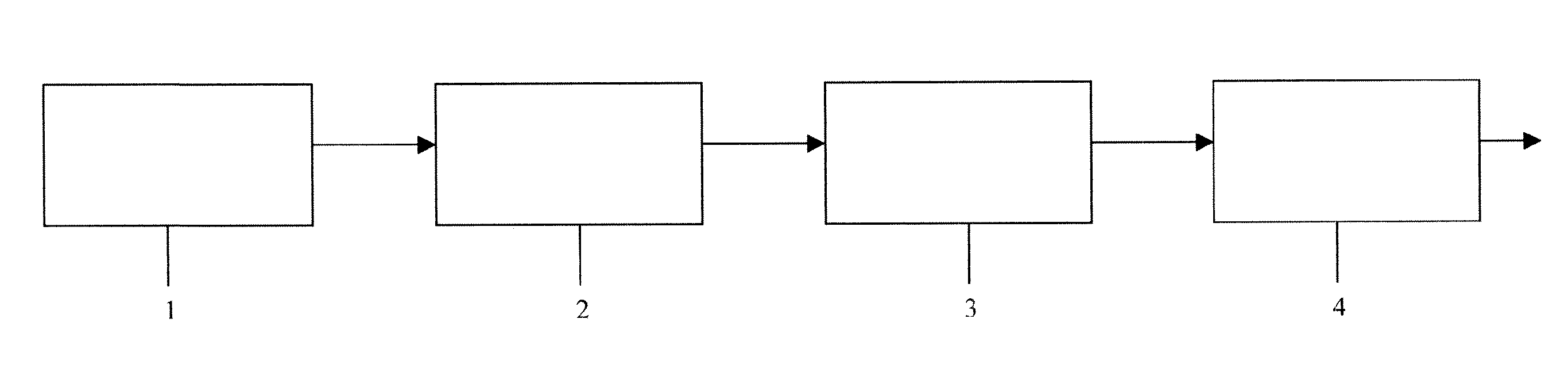

Periodically operating a forward osmosis (FO) semi-permeable membrane element in reverse osmosis (RO), to yield product extraction on a feed side of the membrane, to flush out a concentration polarization (salt concentration of the feed side and dilution of draw solution on the draw side) across the membrane. Utilizing treated waste water to generate the flushing solution of low osmotic pressure, and gauge pressurizing the flushing solution to the gauge pressure of the draw solution to keep a constant gauge pressure of the solutions. FO process is interrupted every 5-20 minutes for a 10-60 seconds long flushing RO process, thereby increasing the FO throughput five fold and recovering power from the increased throughput, i.e. from the osmotic pressure of the brine.

Owner:I D E PROJECTS LTD

Packed bed bioreactor for biofouling control of reverse osmosis and nanofiltration membranes

ActiveUS20120193287A1Simpler design of equipmentEasy to operateMembranesWater treatment parameter controlVoid ratioSurface water

An installation and a method for removing dissolved biodegradable compounds as a biological treatment step up-stream of an equipment to be protected from biofouling being part of a ground water, surface water or tertiary wastewater treatment line, wherein said upstream biological treatment step is carried out in at least one packed bed bioreactor comprising a vessel or a tank filled with packing elements, characterized in that: iv) said packing elements of said packed bed show a void fraction of at least 70% and the flow velocity of water through said packed bed bioreactor is at least 20 m / h, so that said packed bed does not have a removal efficiency of suspended solids in water, if any, of more than 30%; v) said packing elements of said packed bed show a specific surface area of at least 750 m2 / m3; vi) said process does not require the use of any biocide or biostatic compound.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

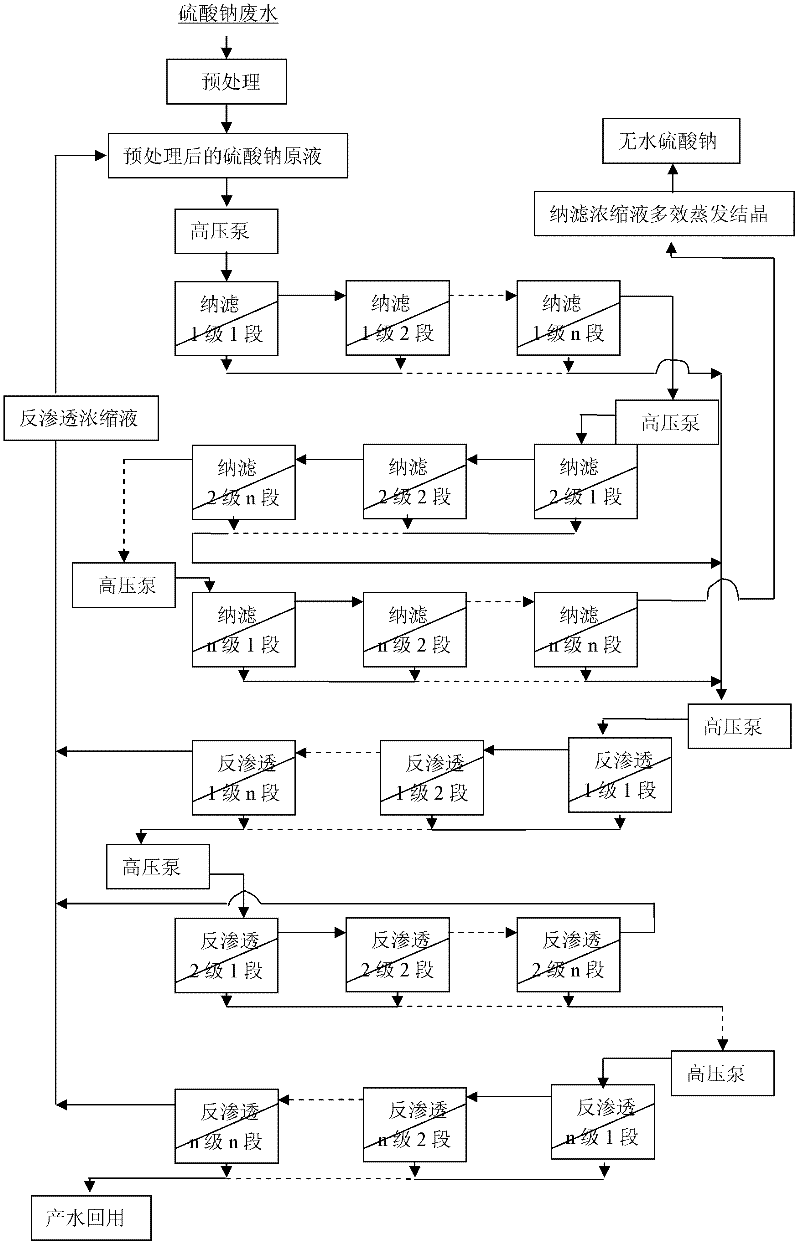

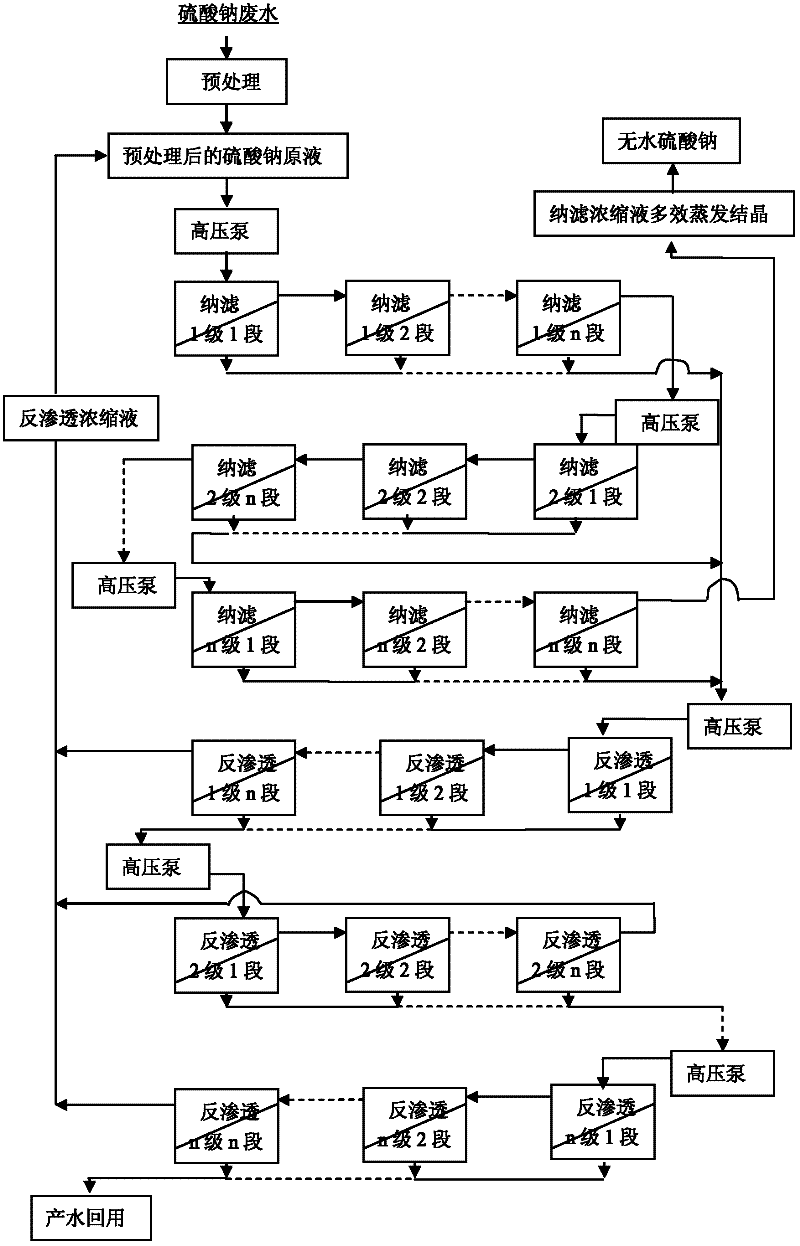

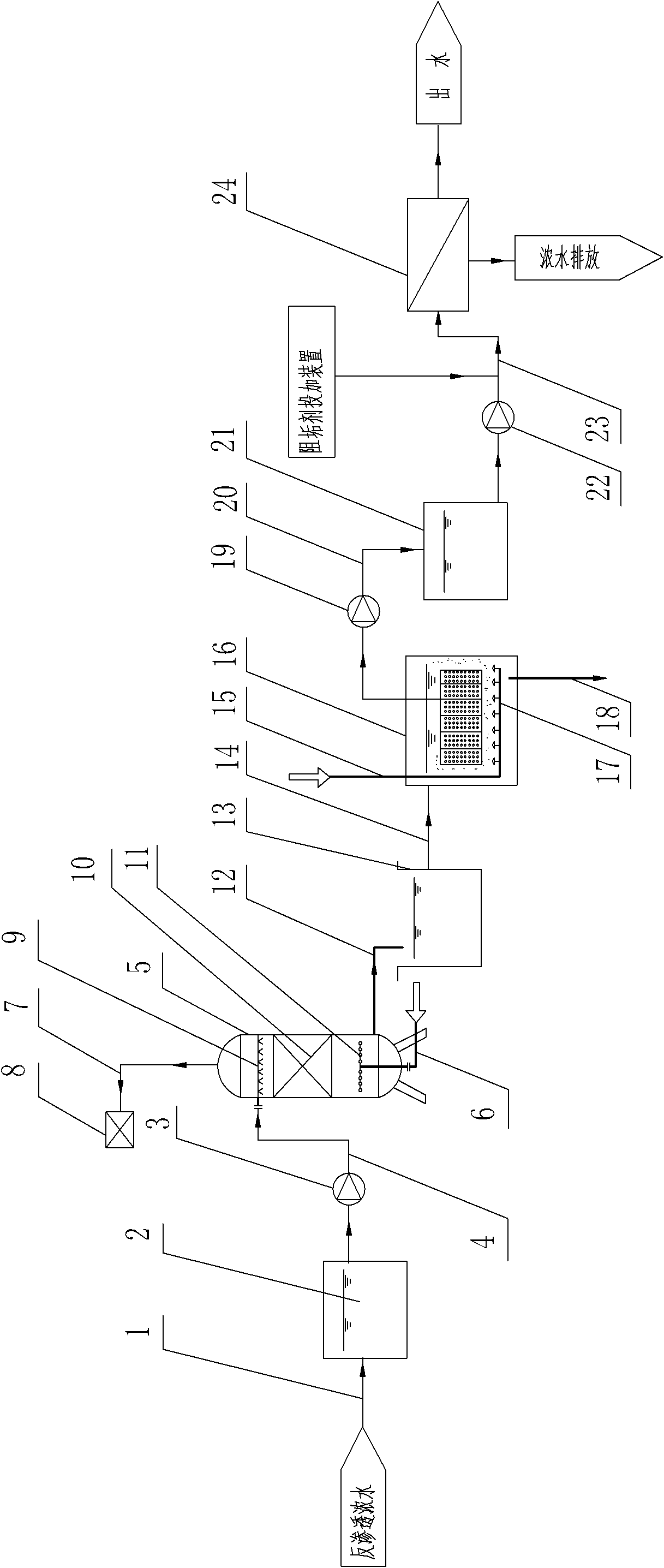

Process for treating sodium sulfate wastewater by using nanofiltration-reverse osmosis combined membrane

InactiveCN102491452AAchieving zero emissionsSmall footprintAlkali metal sulfite/sulfate purificationWater/sewage treatment bu osmosis/dialysisEvaporationReverse osmosis plant

The present invention relates to a process for treating sodium sulfate wastewater by using a nanofiltration-reverse osmosis combined membrane. According to the process, the pretreated sodium sulfate wastewater is conveyed to a nanofiltration membrane stack through a high pressure pump, and the nanofiltered concentrated solution is subjected to multiple effect evaporation crystallization to obtain an anhydrous sodium sulfate product and condensed water, wherein the condensed water is recycled; the nanofiltered producing water is conveyed to a reverse osmosis membrane stack through the high pressure pump, the resulting concentrated solution returns to the pretreated sodium sulfate stock solution to carry out the secondary nanofiltration, and the reverse osmosis producing water is recycled, wherein the concentrated solution is subjected to the reverse osmosis membrane stack. Compared to other pollution control technologies, the process of the present invention has the following advantages that: the equipment is compact, and the land occupation is small; no morphological and chemical influence is generated to the treated object; the process is a continuous process, and the automatic and uninterrupted operating can be achieved; the process has characteristics of low energy consumption, no phase change, no temperature change, easy control and simple operation; the process can be directly circulated on the site; the sodium sulfate is subjected to concentration, evaporation crystallization, and recovery utilization in the absence of chemical and physical changes, such that the zero discharge of the sodium sulfate wastewater is achieved; the reverse osmosis producing water is adopted as the process pure water to use so as to save a large amount of the process water.

Owner:JILIN JIEN NICKEL IND +1

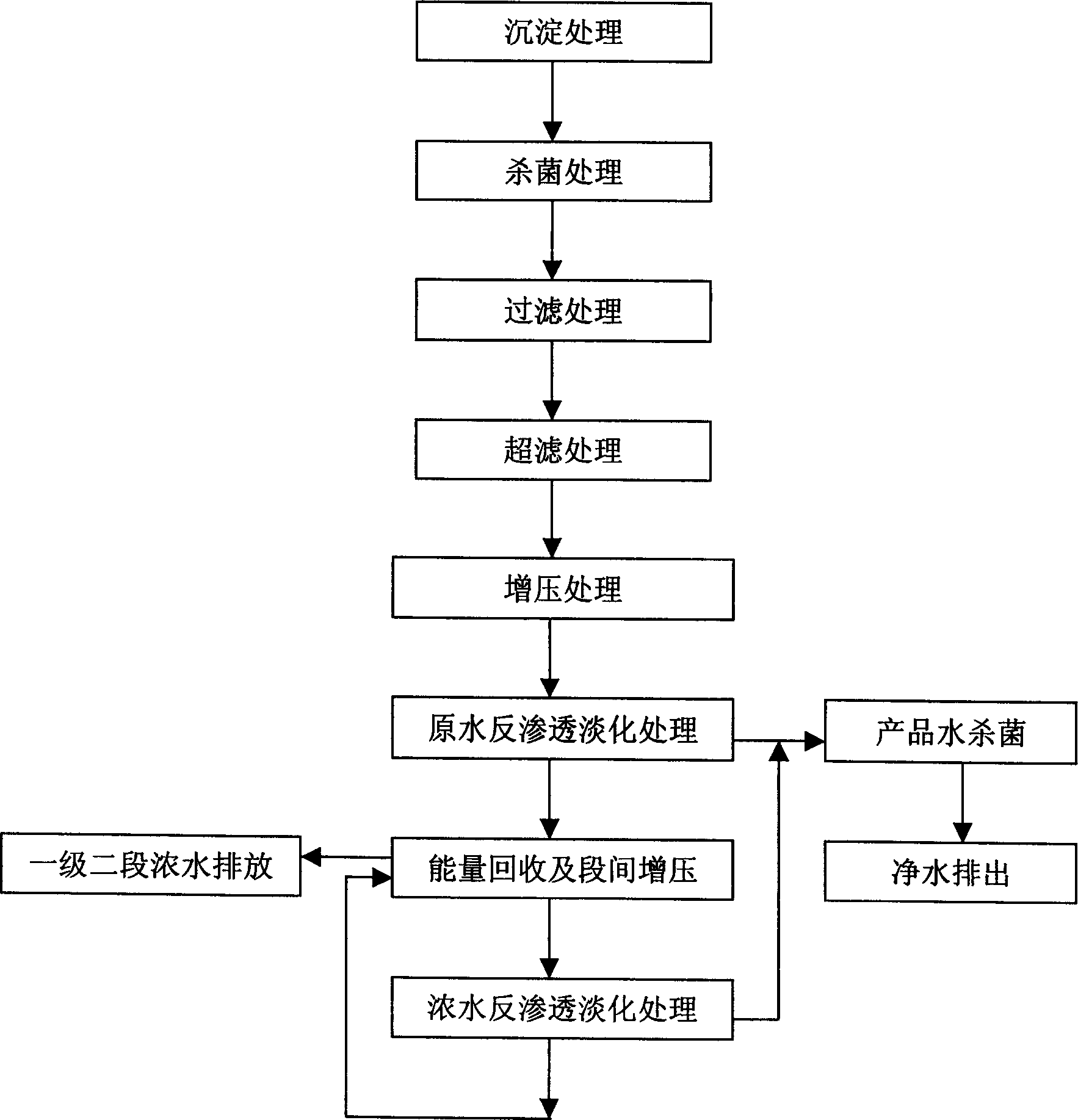

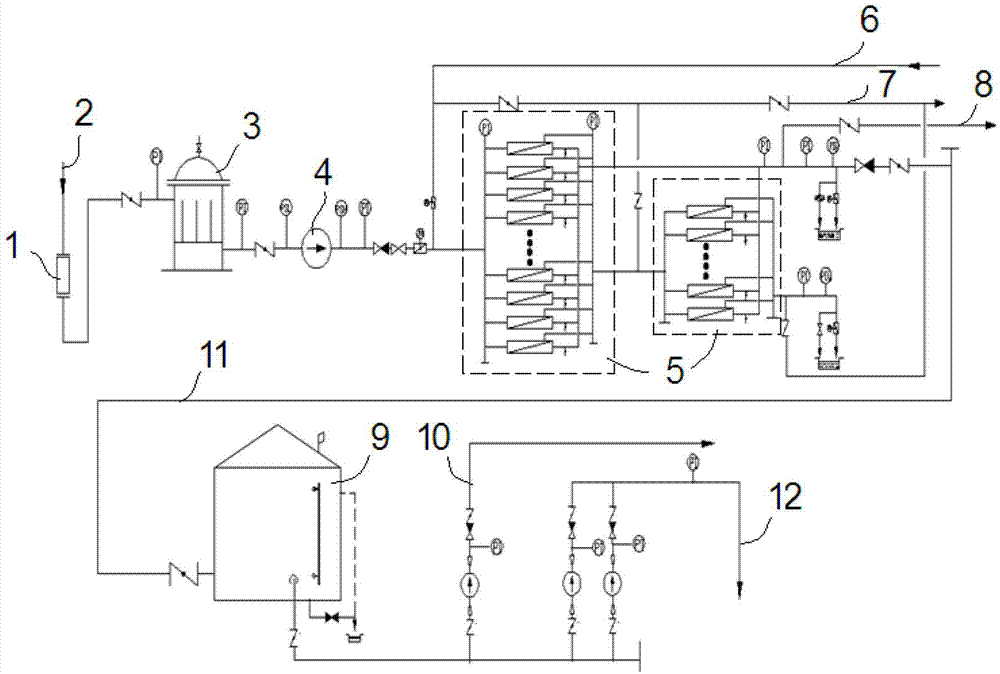

Desalination process for high recovery ratio seawater (brackish water)

InactiveCN1552643AExtended service lifeSimple processGeneral water supply conservationMultistage water/sewage treatmentWater desalinationBrackish water

A process for desalinating seawater with high recovery rate of fresh water (more than 60%) includes such steps as depositing, disinfecting, filtering, ultrafiltering, pressurizing, taking reverse osmosis of raw water, energy recovering, intersegment pressurizing, taking reverse osmosis of fresh water, discharging concentrated water, disinfecting and discharging fresh water.

Owner:天津市海跃水处理高科技有限公司

Water purification system and method using reverse osmosis reject stream in an electrodeionization unit

InactiveUS7470366B2Energy efficiencySimple designFluid pressure measurement by electric/magnetic elementsIsotope separationReverse osmosis plantTreatment unit

Water purification systems include a reverse osmosis unit, a treatment unit, and an electrodeionization unit. A reverse osmosis reject stream from the reverse osmosis unit is treated in the treatment unit and provided to concentrating compartments of the electrodeionization unit.

Owner:ECOLOCHEM

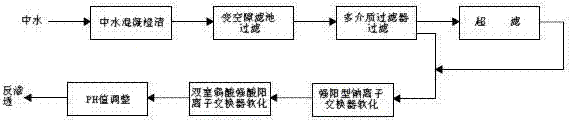

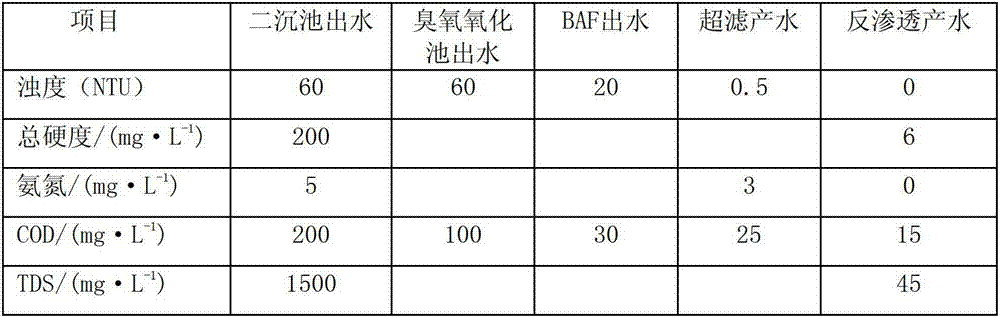

A reverse osmosis pretreatment method when reclaimed water is reused in power plants

ActiveCN102285736AImprove stabilityExtend your lifeMultistage water/sewage treatmentChemical oxygen demandPretreatment method

The invention discloses a reverse osmosis pre-treatment method for recycling reclaimed water in an electric power plant. The reverse osmosis pre-treatment method comprises the following steps: 1) coagulating and clarifying the reclaimed water; 2) filtering in a filtering tank with variable pore aperture; 3) filtering with a multi-medium filter; 4) softening with a strong-cationic sodium ion exchanger; 5) softening with a double-chamber weak-acid and strong-acid cationic exchanger; and 6) adjusting the pH value. The reverse osmosis pre-treatment method has the advantages that: the reclaimed water is pre-treated before reverse osmosis, thereby greatly reducing the reverse osmosis scale formation and contamination blockage risks caused by hardness, COD (chemical oxygen demand), SiO2 and the like in the reclaimed water, prolonging the service life of a reverse osmosis membrane element, and improving the reverse osmosis operation stability of the electric power plant.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +1

Washing method for preventing reverse osmosis membrane or nano-filtration membrane from being polluted

ActiveCN103301753ALarge water supplyReduce operating pressureSemi-permeable membranesGeneral water supply conservationSocial benefitsWater desalination

The invention belongs to the technical field of seawater desalting and water treatment and relates to a washing method for preventing a reverse osmosis membrane or a nano-filtration membrane from being polluted. The washing method comprises the following steps of: firstly carrying out gas-water two-phase flow washing or simultaneous chemical washing; then extracting reverse osmosis concentrated water to wash the surface of the reverse osmosis membrane; discharging the reverse osmosis concentrated water through a concentrated water discharging valve; then, conveying pretreated water to a reverse osmosis module and displacing and discharging washing concentrated water on a reverse osmosis concentrated water side until the conductivity is recovered to 98% of the conductivity of the pretreated water; finally, closing a washing water discharging valve and opening the concentrated water discharging valve to recover normal operation of the reverse osmosis module; and sequentially washing other sets of reverse osmosis modules. The washing method disclosed by the invention is reliable in process, simple and convenient to operate, lower in energy consumption, good in economic benefits and social benefits, and environment-friendly.

Owner:OCEAN UNIV OF CHINA

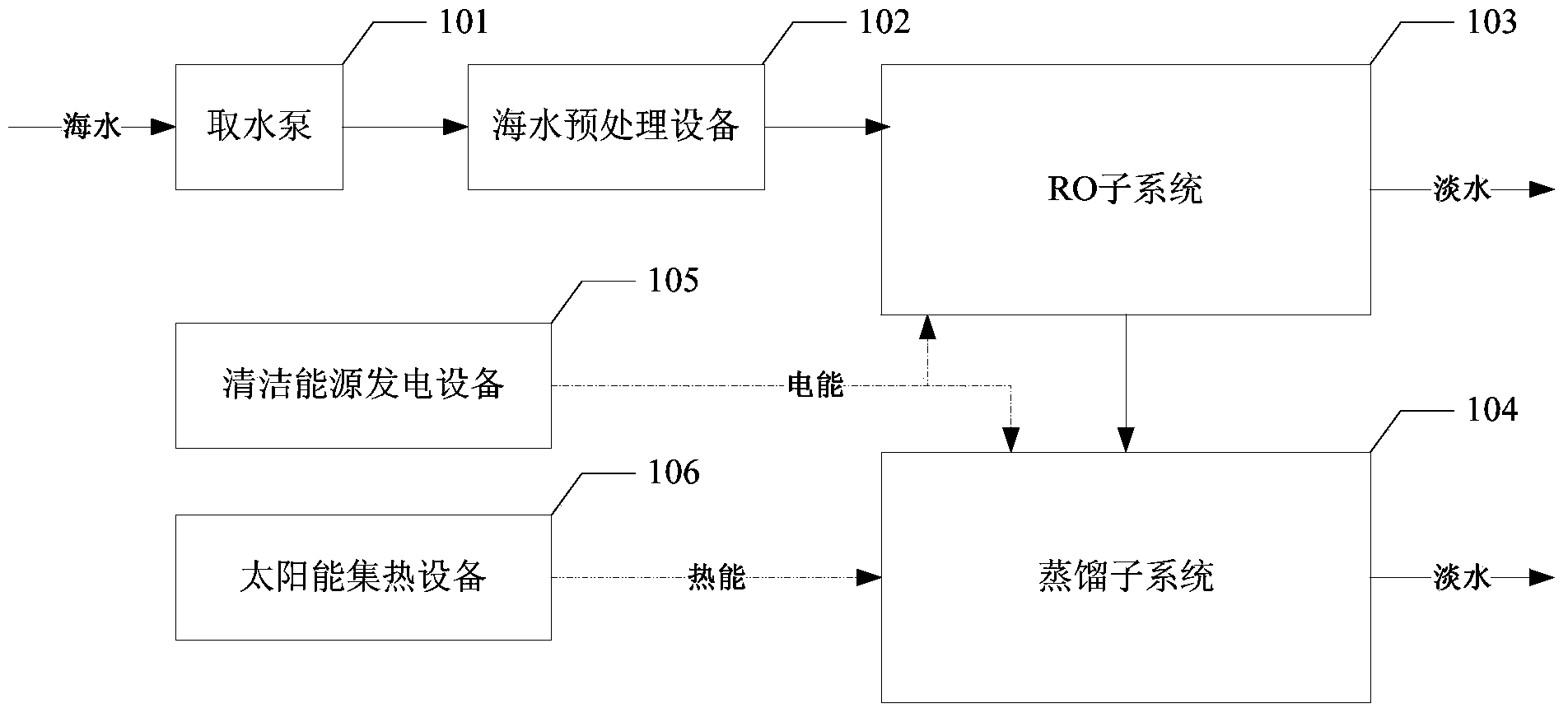

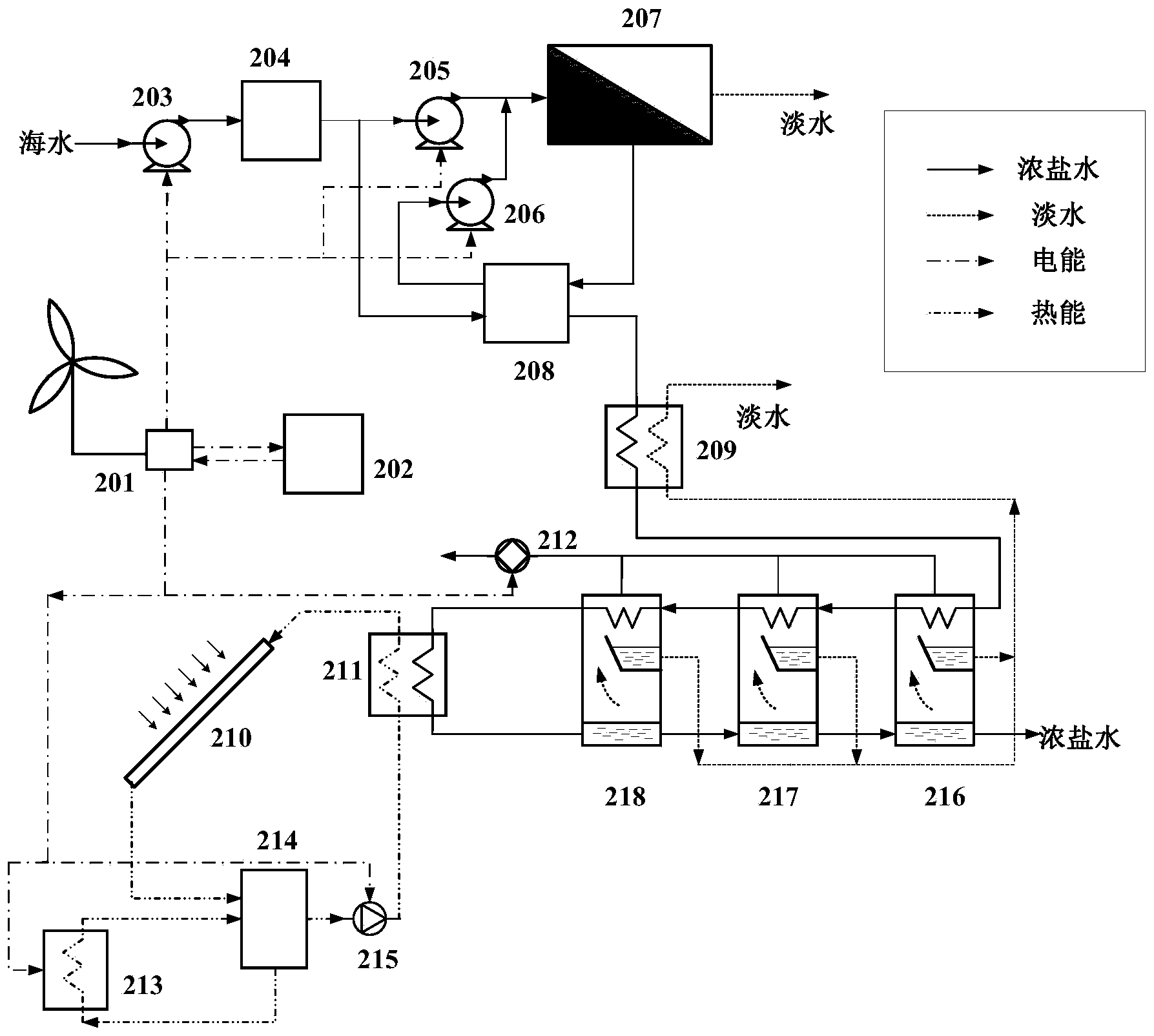

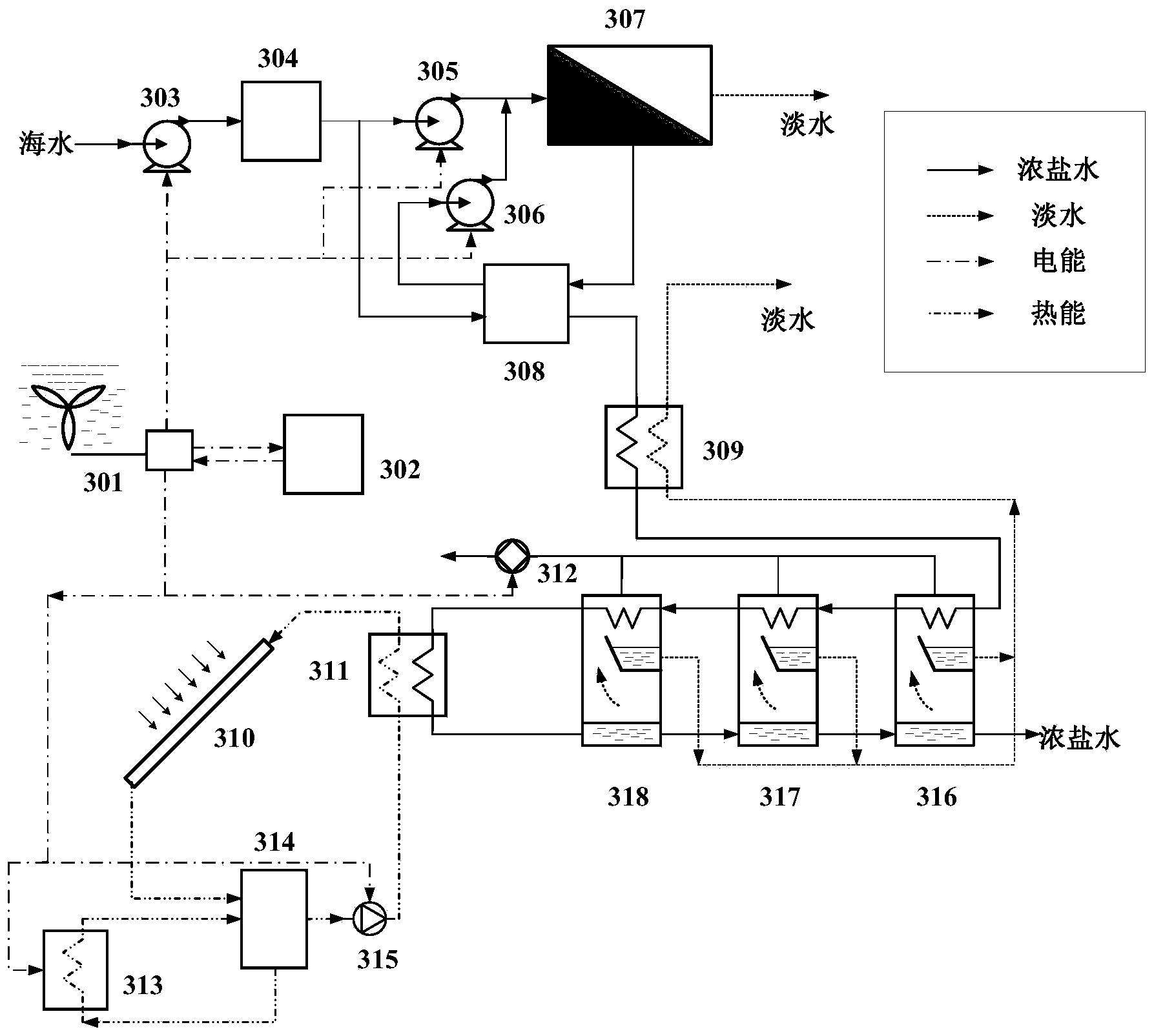

Hybrid MSF (multistage flash)/RO (reverse osmosis) sea water desalination system

InactiveCN103663835AImprove desalination efficiencyReduce manufacturing costGeneral water supply conservationSeawater treatmentThermal energyWater desalination

The invention provides a hybrid MSF (multistage flash) / RO (reverse osmosis) sea water desalination system and is applied to the technical field of sea water desalination. The system comprises a water pump, sea water pre-treatment equipment, an RO subsystem, a distillation subsystem, clean energy generating equipment and solar heat collection equipment, wherein the water pump is used for obtaining sea water; the sea water pre-treatment equipment is used for pre-treating the sea water; the RO subsystem is used for desalinating the pre-treated sea water to obtain fresh water through an RO technology and providing strong brine produced in the desalination process for the distillation subsystem; the distillation subsystem is used for desalinating the strong brine produced by the RO subsystem to obtain fresh water through a distillation technology; the clean energy generating equipment is used for generating electricity with clean energy and providing electric energy for the RO subsystem and the distillation subsystem; and the solar heat collection equipment is used for generating heat through solar energy and providing heat energy for the distillation subsystem. According to the system, the strong brine produced by the RO subsystem is used as feed water of the distillation subsystem, characteristics of the RO technology and the distillation technology are effectively utilized, and the system has the advantages of high sea water desalination efficiency, low production cost, proneness to popularization and use and the like.

Owner:CHINA POWER ENG CONSULTING GRP

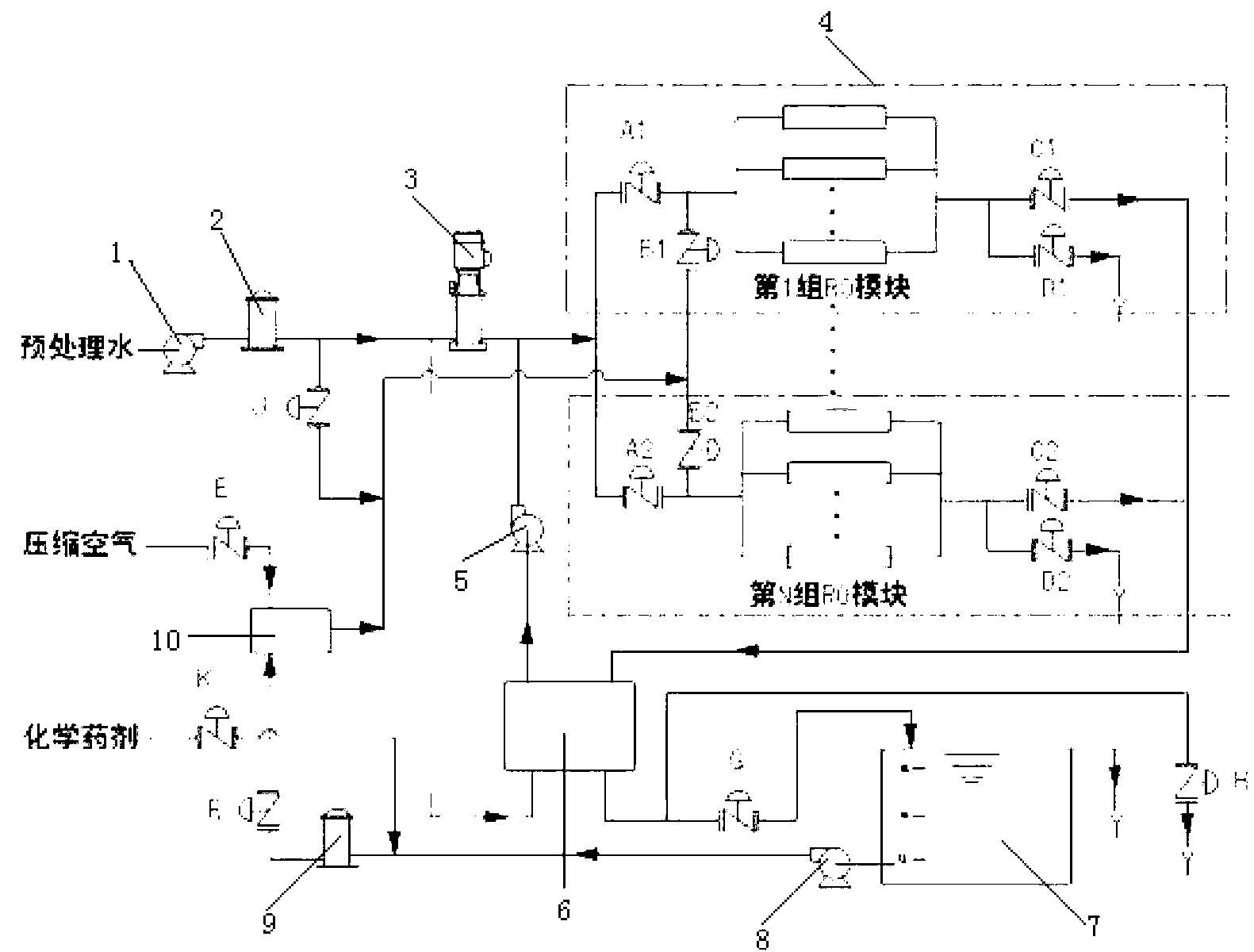

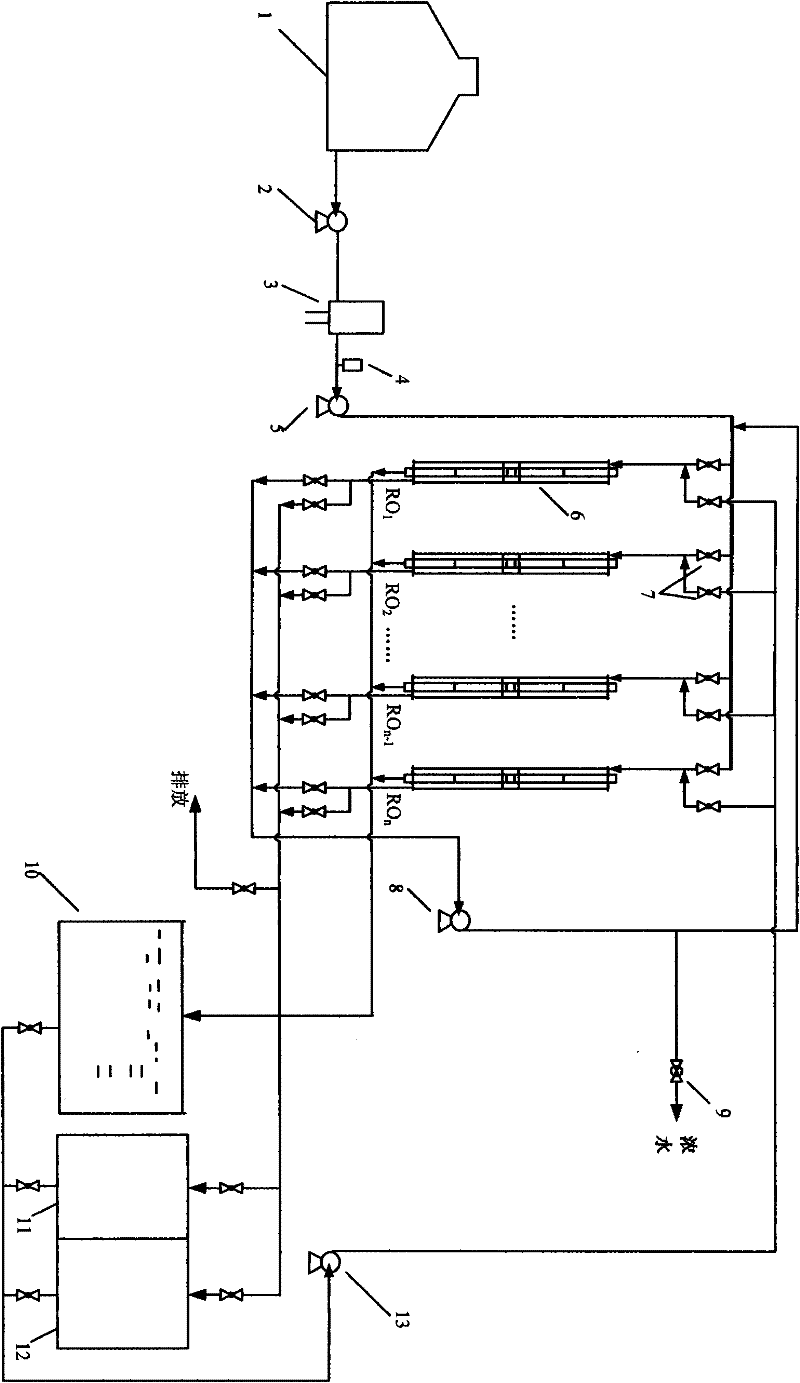

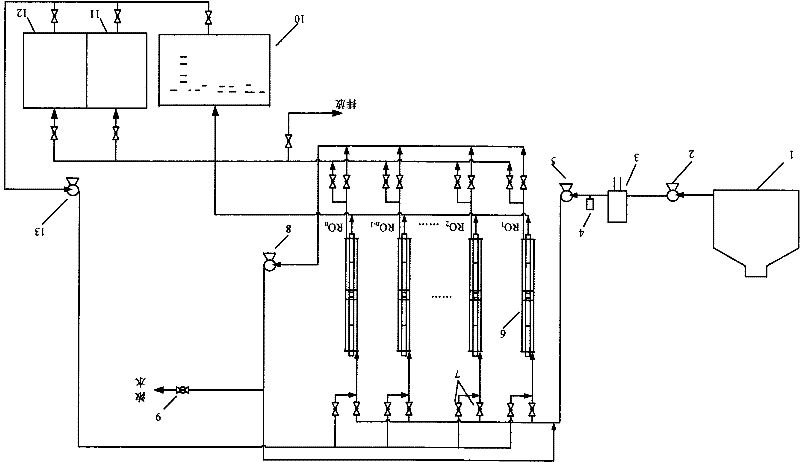

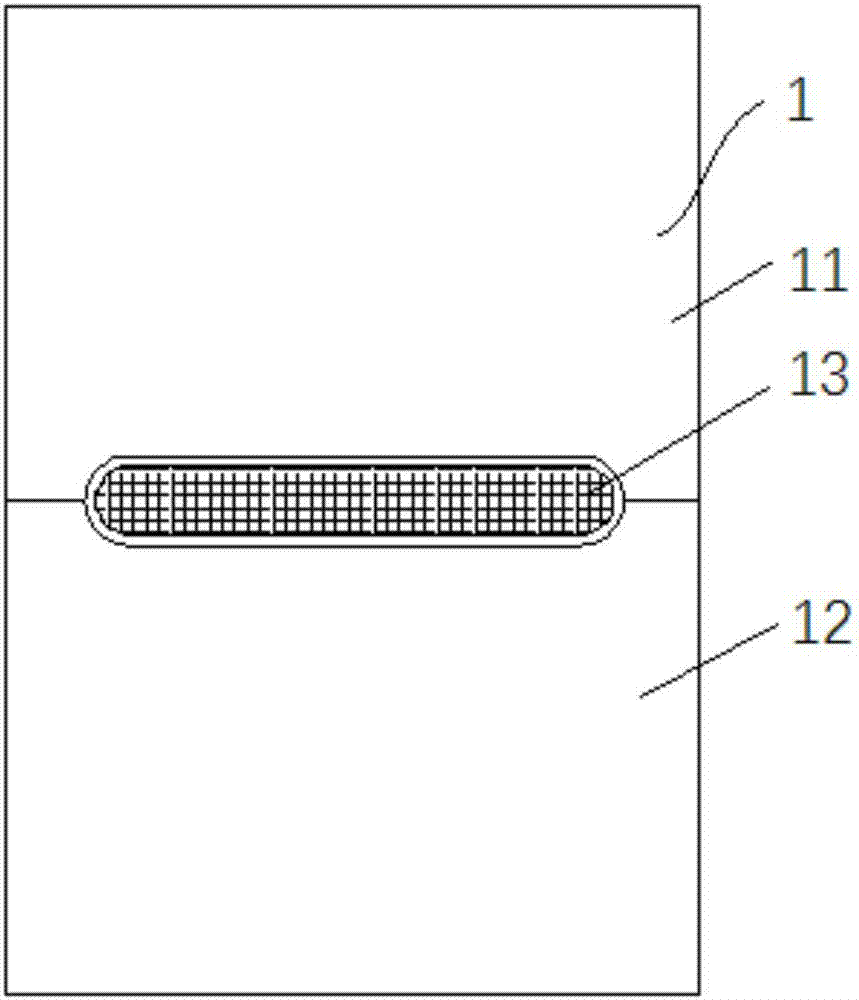

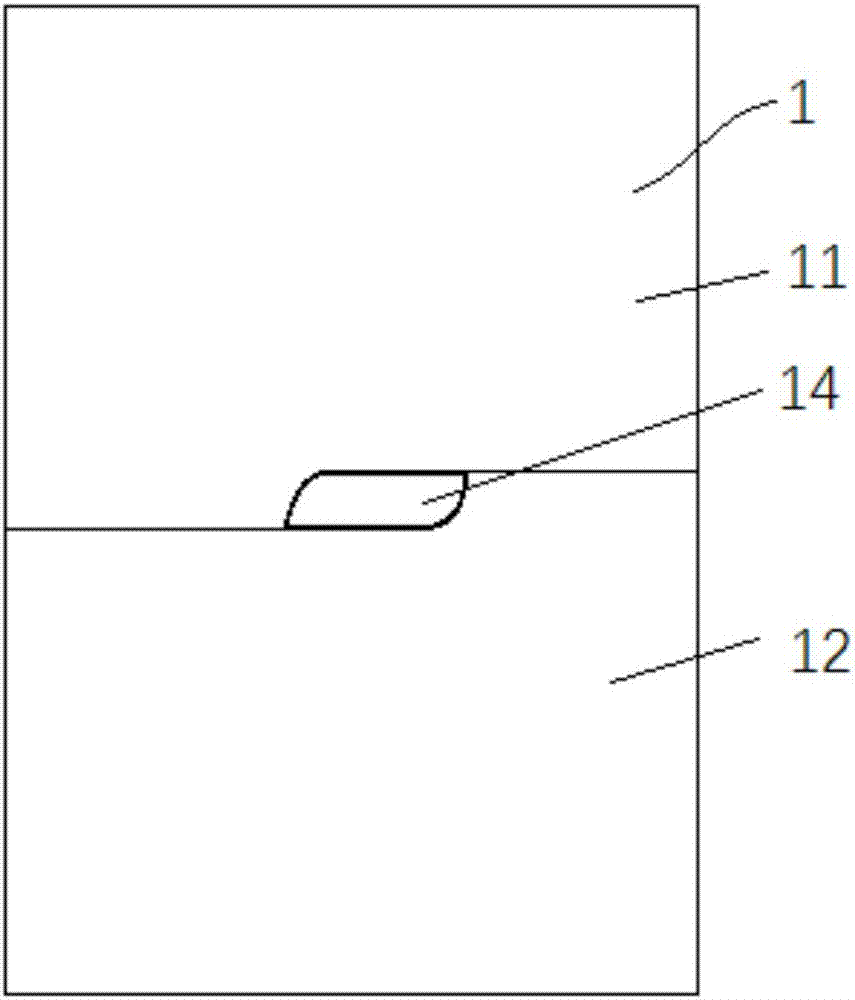

Anti-pollution reverse osmosis device and use method thereof

InactiveCN102452704AIncrease flow rateHigh recovery rateGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisSaline waterWater flow

The invention relates to an anti-pollution reverse osmosis device and a use method thereof. The anti-pollution reverse osmosis device is added with desalinated water circulating pumps in a connection way that a plurality of groups of pumps are in parallel based on the combination and permutation of reverse osmosis membranes, wherein part of desalinated water returns in the front of the entrance to raise the recovery rate and increase the membrane surface flow velocity. The device sequentially cleans the reverse osmosis membranes in groups by reverse osmosis membranes or cleaning fluid. When the reverse osmosis membranes are working, the reverse osmosis high-pressure pump works at a lower frequency intermittently. The water inflow pressure is also lowered, which is helpful for a pollutant layer adsorbed on the membrane surface to be desorbed from the membrane surface and taken away by the water flow. A reducing agent and antisludging agent feeding hole is arranged behind a security filter core, wherein non-oxidizing bactericides are fed through the medicine feeding hole regularly, and varieties of the non-oxidizing bactericides are changed frequently to prevent microorganisms from producing drug resistance. In comparison with the common reverse osmosis devices, the device disclosed by the invention has a higher membrane surface flow speed and an on-line automatic cleaning function. The device also employs the non-oxidizing bactericides to sterilize regularly such that the device has a better anti-pollution performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

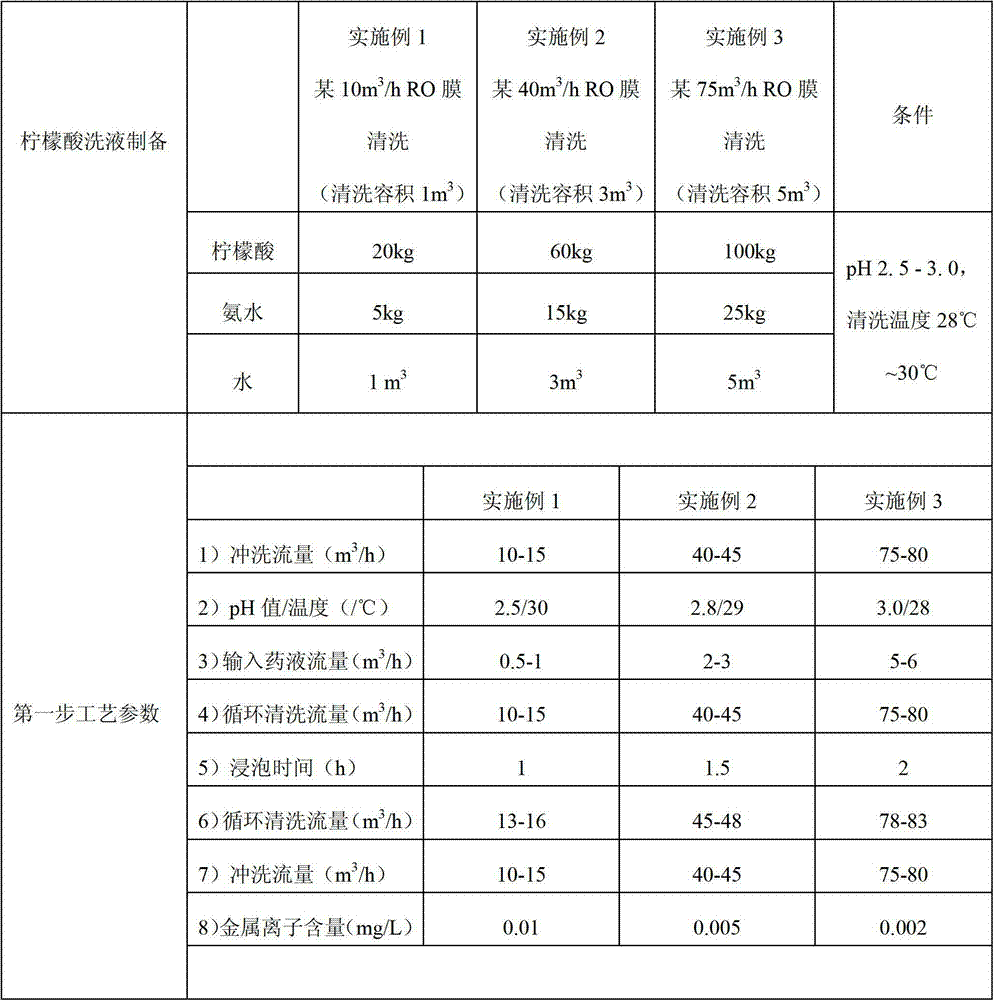

Reverse osmosis membrane chemical cleaning method

InactiveCN102814123AIncrease profitExtended service lifeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisInorganic saltsPhysical chemistry

The invention discloses a reverse osmosis membrane chemical cleaning method which performs chemical cleaning on a polluted reverse osmosis membrane by a combination of acid cleaning and chlorine cleaning. The method comprises the following steps: carrying out acid cleaning on the reverse osmosis membrane by using citric acid to remove inorganic salt scales and metallic ions on the membrane surface; and carrying out chlorine cleaning technique to perform deeper cleaning on the reverse osmosis membrane, wherein the chlorine cleaning not only can remove biological sewage, but also can have favorable sterilizing effect. The chlorine cleaning process is implemented by carrying out chemical cleaning on the membrane by using an oxydol solution under the condition of certain residual chlorine concentration. Repeated field reverse osmosis polluted membrane cleaning by combining acid cleaning and chlorine cleaning proves that the technique can be popularized and implemented and has especially obvious effect on the reverse osmosis system with reduced membrane flux due to biological sewage.

Owner:西安兴仪启动发电试运有限公司

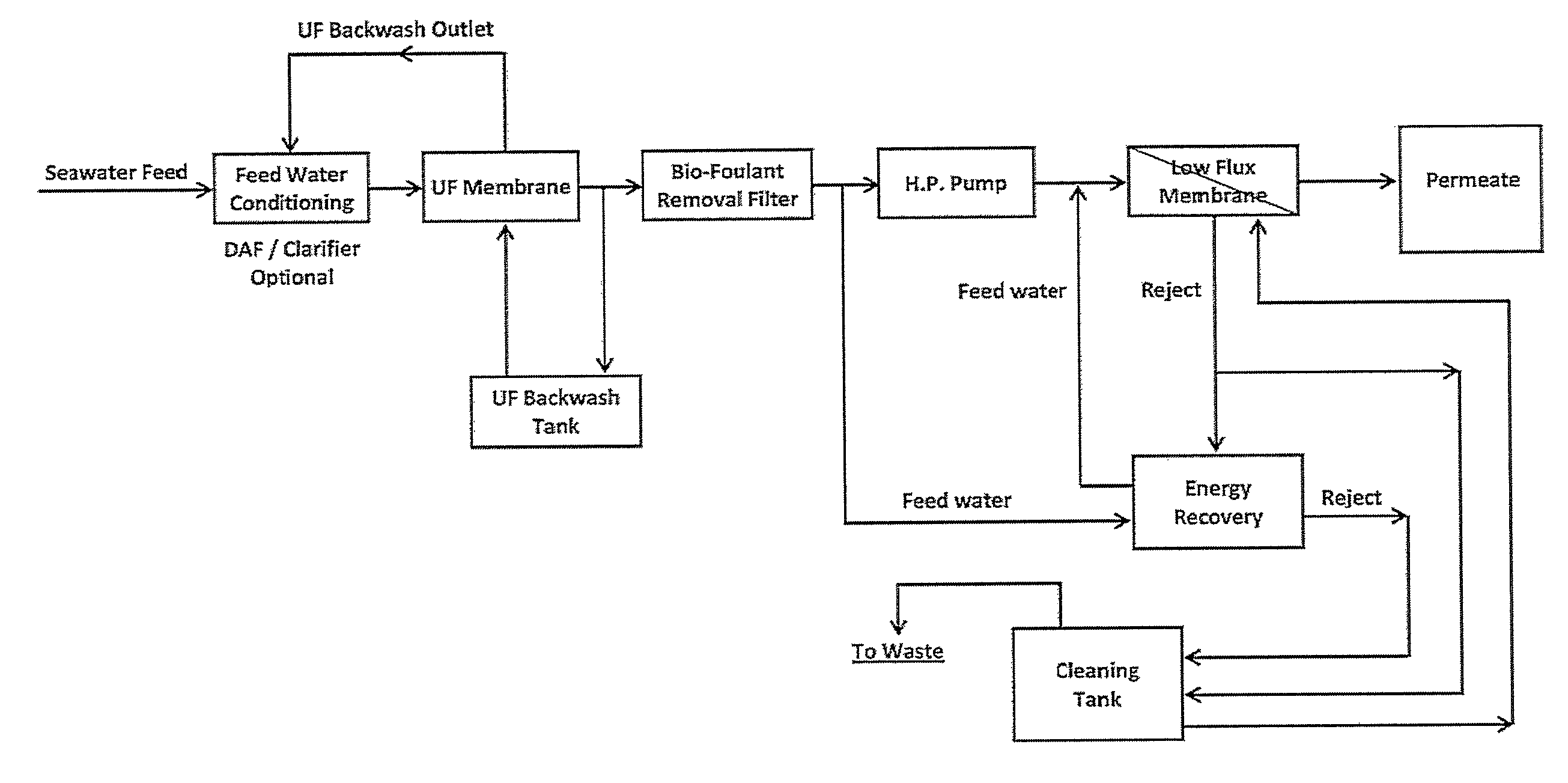

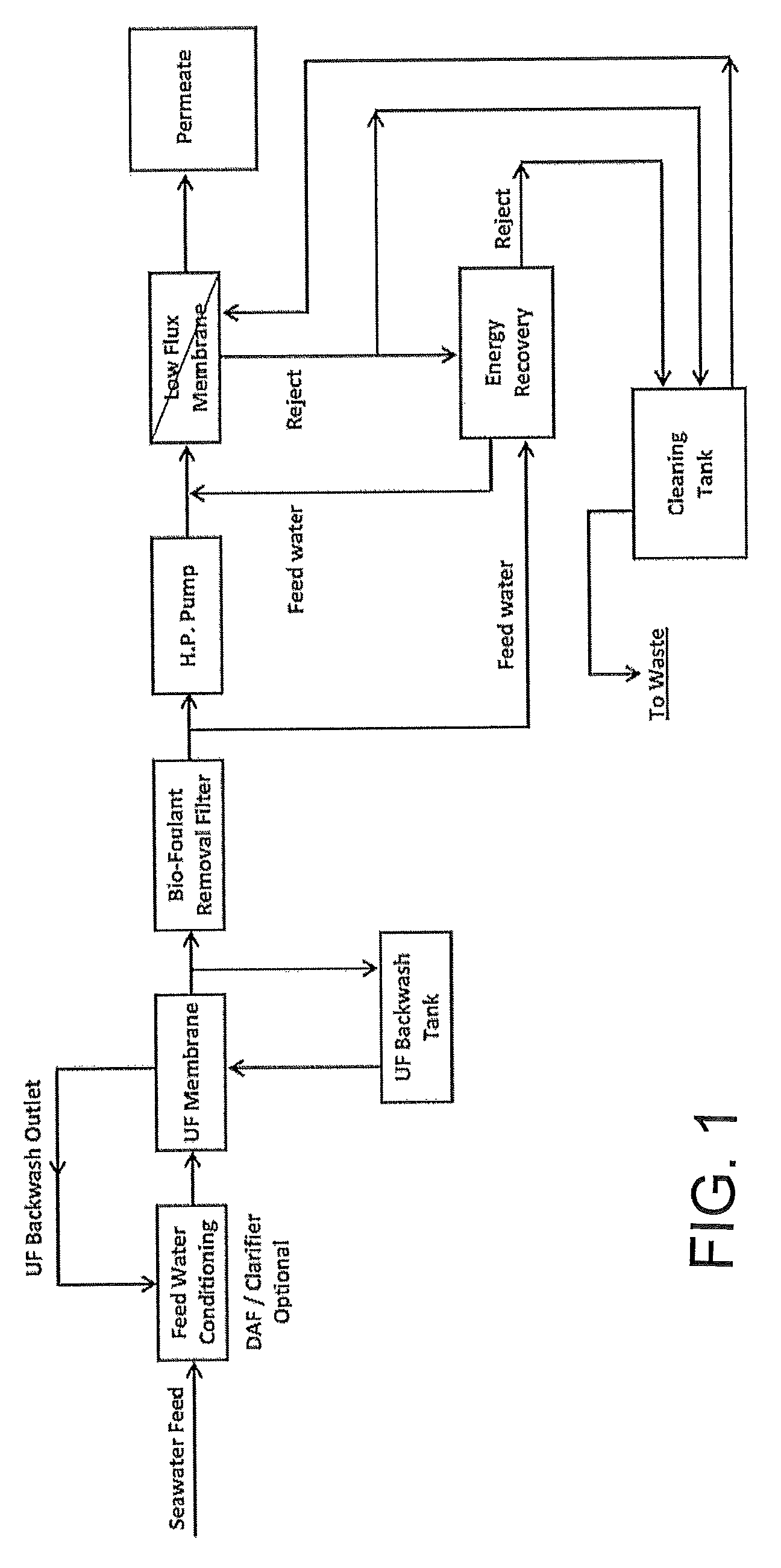

Low energy reverse osmosis process

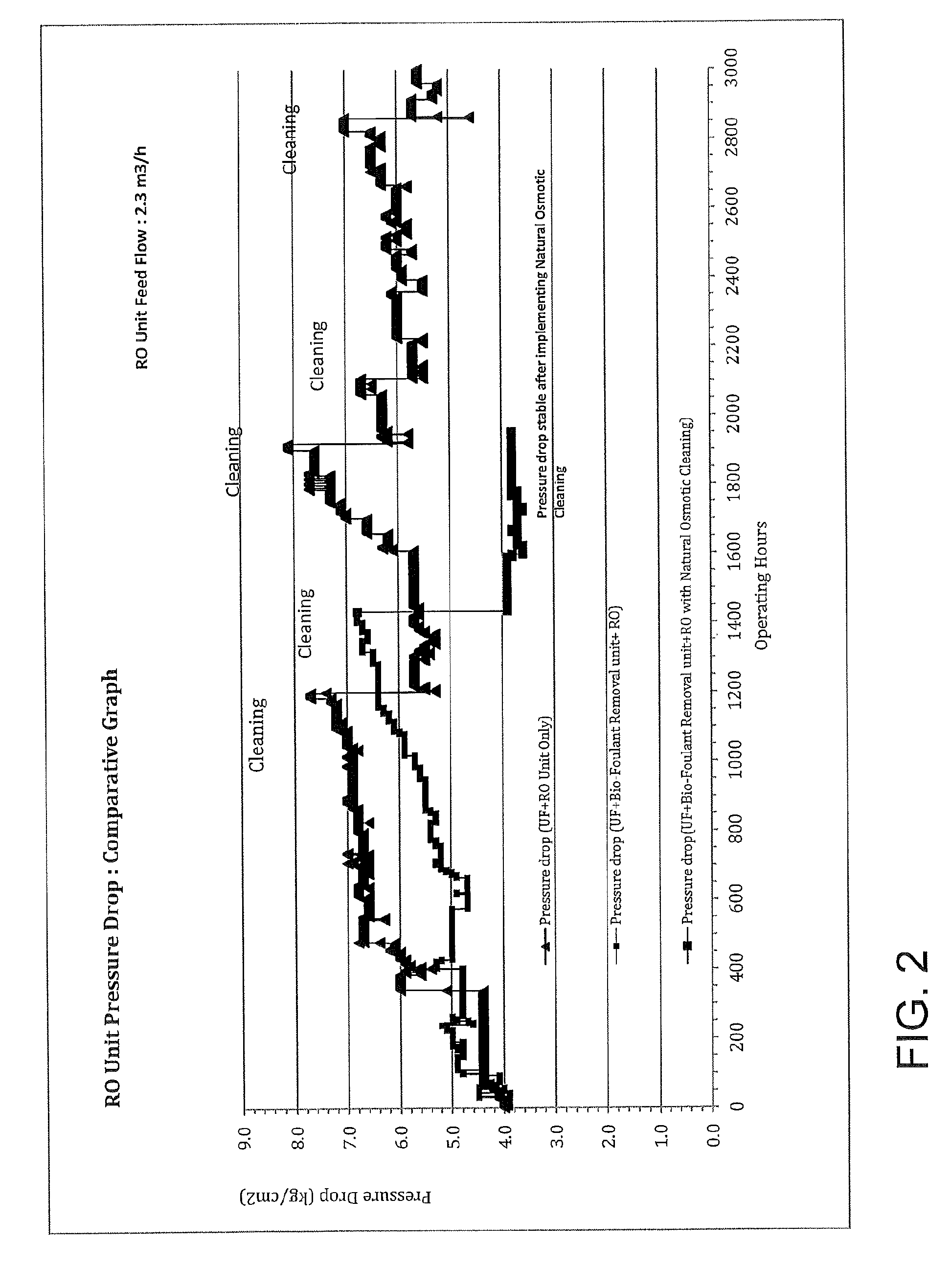

ActiveUS8980100B2Prevent buildupReduce energy consumptionUltrafiltrationSolid sorbent liquid separationBrackish waterUltrafiltration

We provide a system and method for reverse osmosis treatment of water, including seawater and brackish water. Methods and systems of embodiments of the invention may include, for example, ultrafiltration followed by biofoulant removal, both of which precede reverse osmosis. In preferred embodiments the system is run at a low flux. For example, a flux of 6-8 GFD may be used with seawater. Additional embodiments may provide the above process in conjunction with a reverse-osmosis membrane cleaning system. The membrane cleaning system is a “clean in place” system that includes use of the natural pressure differential in the reverse osmosis system to remove biofoulants and their precursors.

Owner:AQUATECH INT LLC

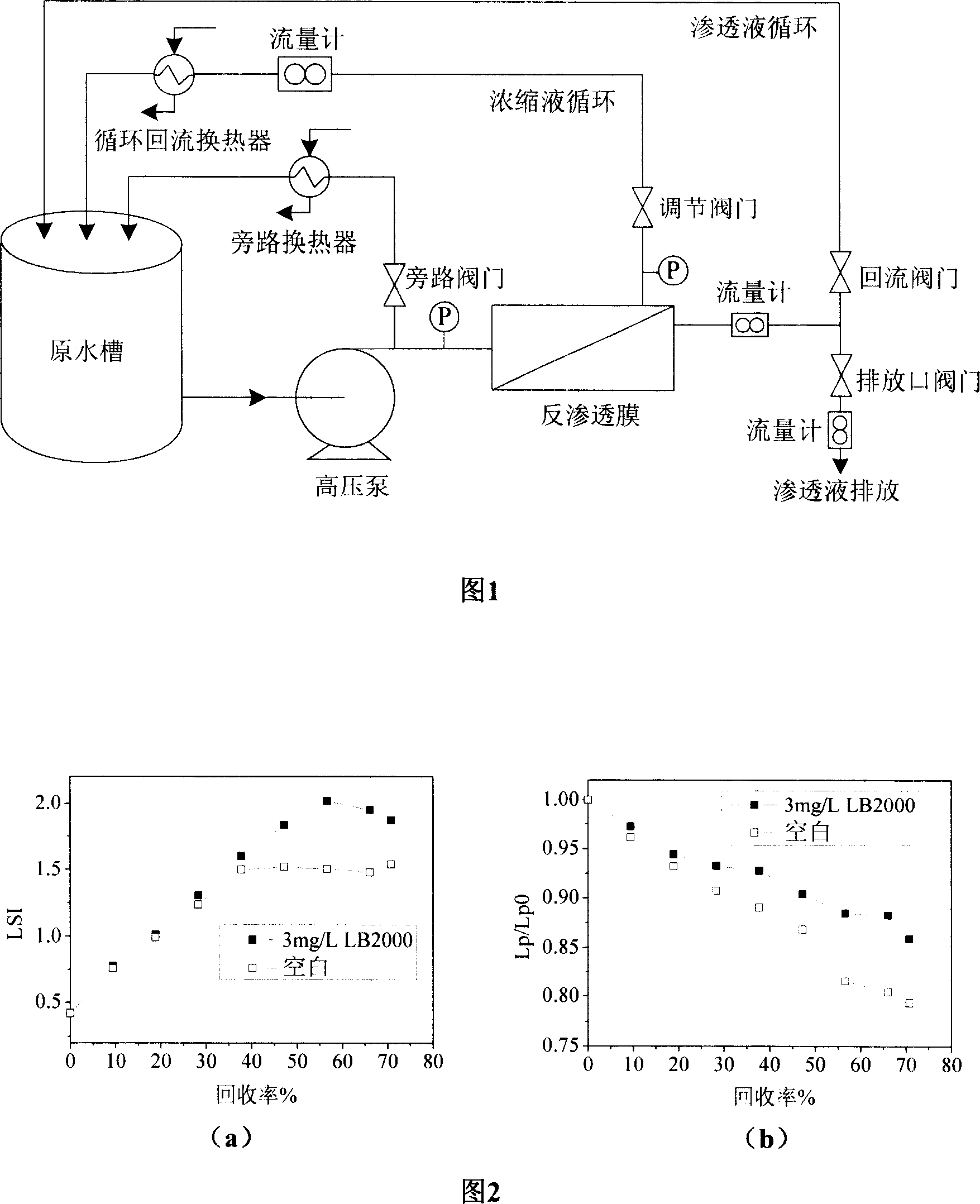

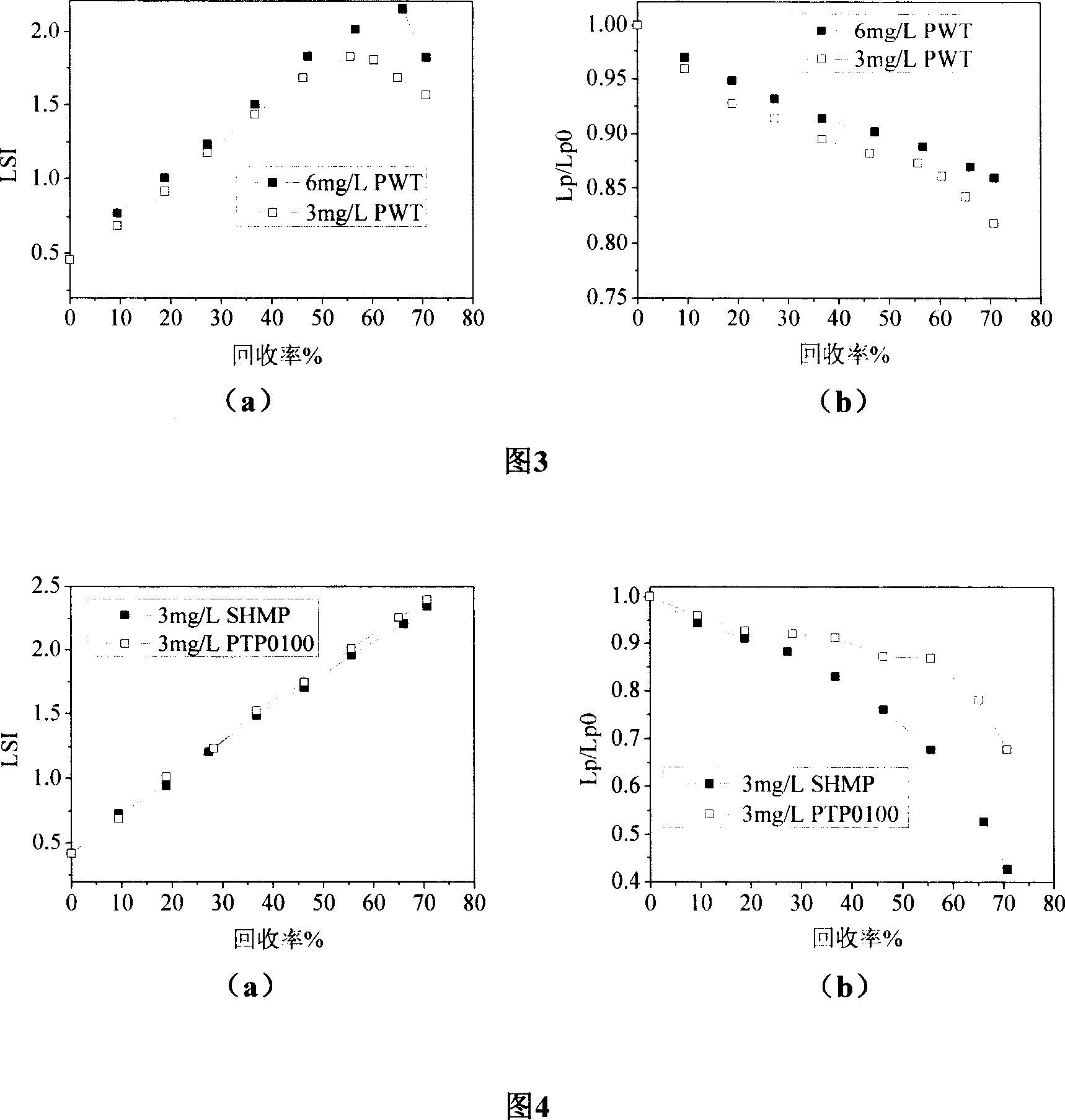

Dynamic investigating method for performance of reverse osmosis antisludging agent

InactiveCN101000336AUltimate anti-scaling abilityShorten the timeSurface/boundary effectPermeability/surface area analysisTurbidityReverse osmosis plant

A method for dynamically investigating property of antisludging agent used at reverse osmosis includes increasing concentration of solution in reverse osmosis original water tank continuously; recording water inlet operation pressure, pressure-drop of solution at flowing through membrane and solution temperature; monitoring solution ion concentration, solution pH value, turbidity and osmotic fluid water-output in flowing passage of time; enabling to use obtained data to quickly test out antisludging effect of said antisludging agent.

Owner:浙江凯锐环保股份有限公司

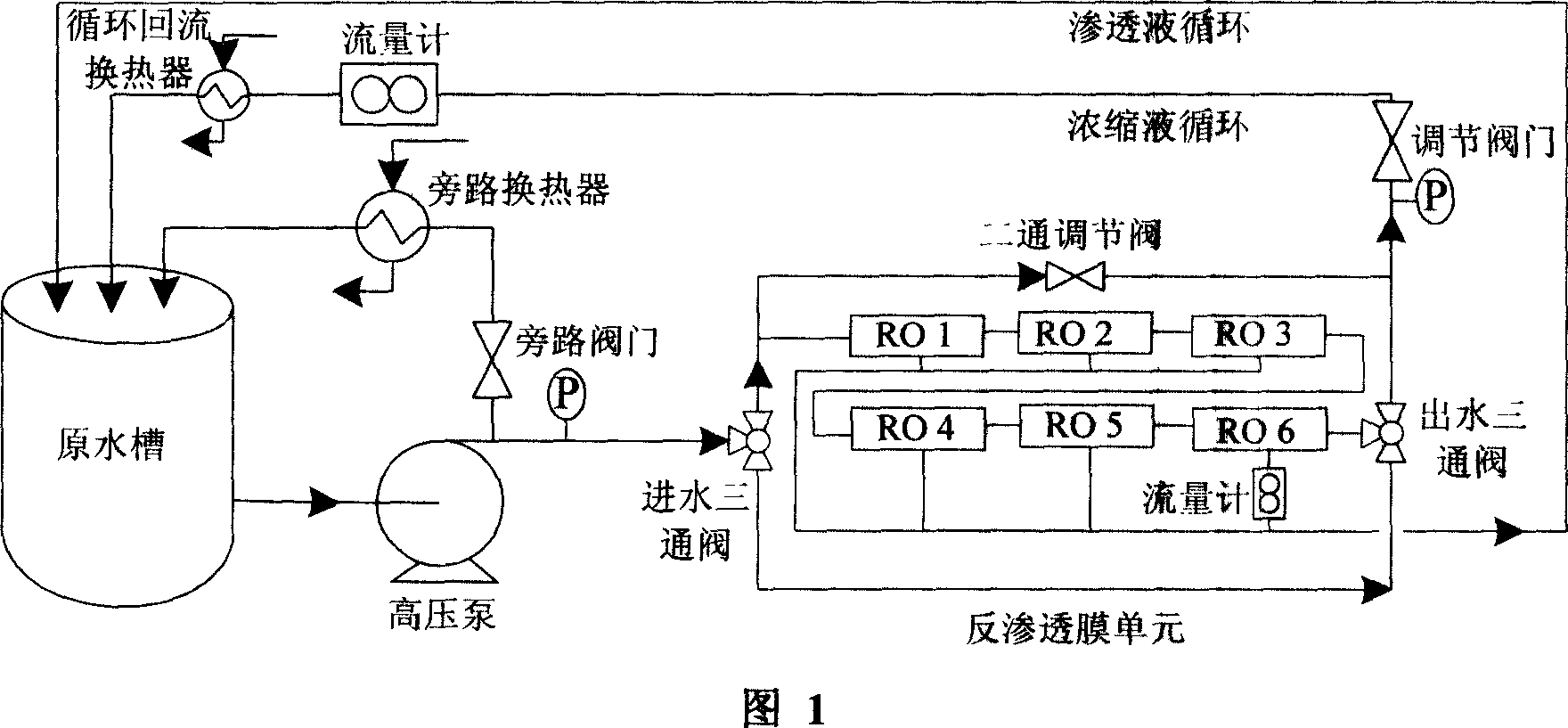

Energy-saving reverse osmosis treatment system

InactiveCN1721047ALess investmentSave energyWater/sewage treatment bu osmosis/dialysisReverse osmosisDecreased energyEnergy recovery

The invention discloses energy-saving reverse osmosis treatment system. It uses high pressure operation condition of itself, recoveries and uses the residual pressure energy to achieve purpose. According to fluid pressure principle, connect two hydraulic equipments to form energy recovery device; uses reverse osmosis dense water pressure as drive force to complete conveying process and recovery. The advantage of this invention is that decreases energy consumption, convenient to operate and simple, and fits to all kinds situations for reverse osmosis system.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Reverse osmosis membrane scale inhibitor and applications thereof

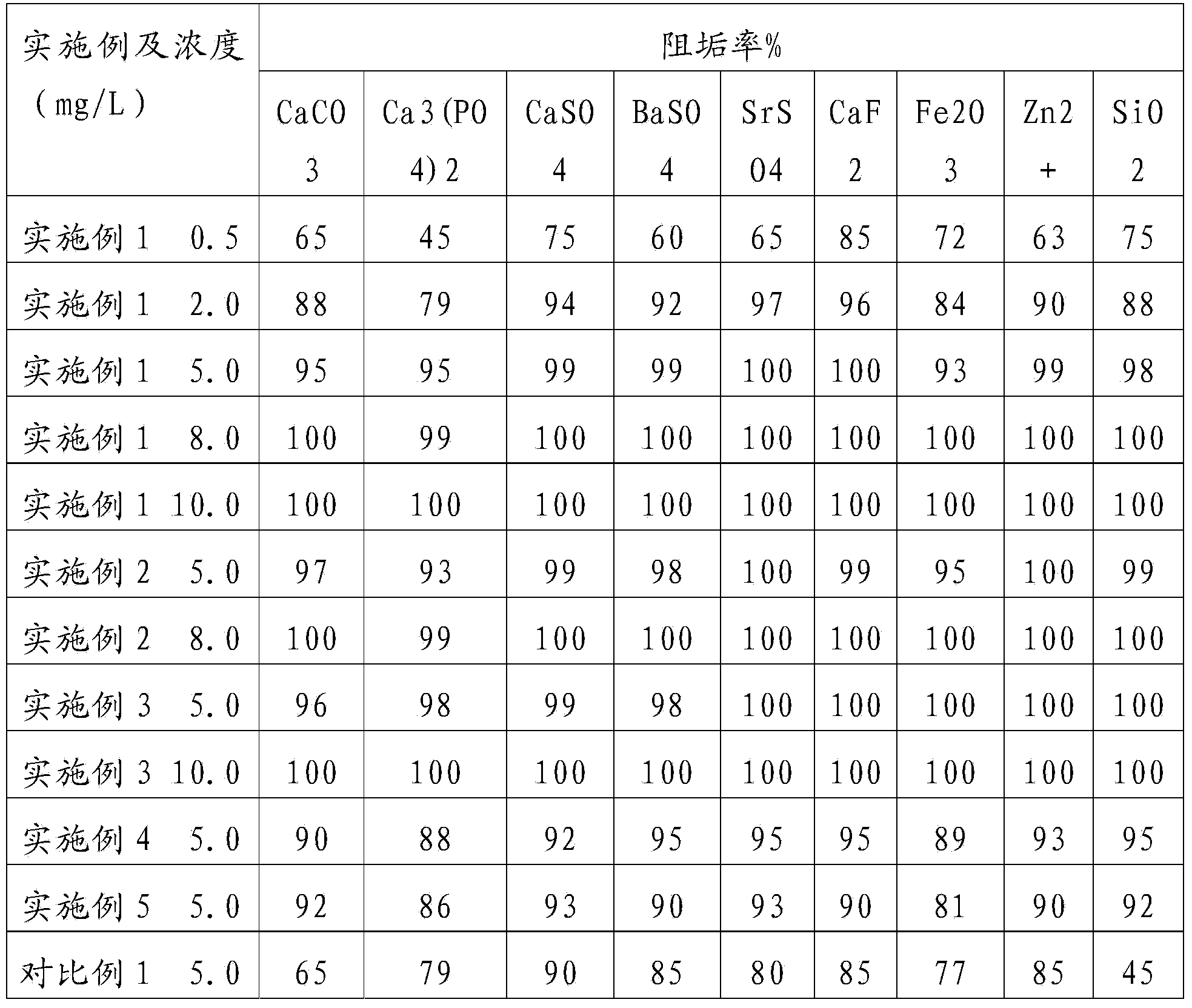

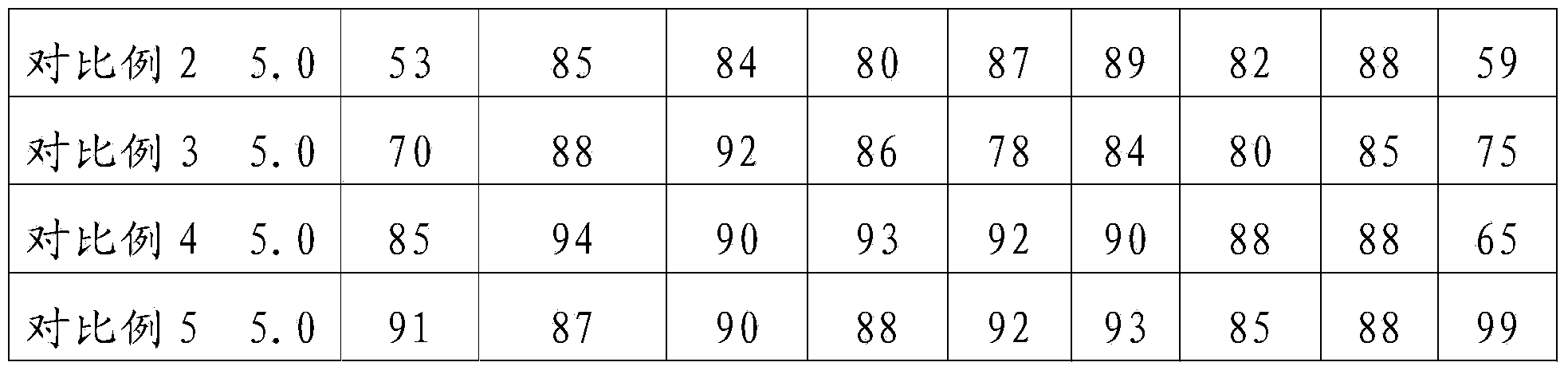

ActiveCN103394289AExtend the life cycleGuaranteed uptimeSemi-permeable membranesSilicic acidCarboxylic acid

The present invention relates to a reverse osmosis membrane scale inhibitor and applications thereof. The scale inhibitor contains an organic phosphonate, an organic carboxylic acid polymer, an organic amine and a surfactant, wherein a weight ratio of the components is 1:0.2-2.0:0.02-0.10:0.02-0.15. With application of the scale inhibitor of the present invention in a reverse osmosis system water treatment, the problem of membrane pollution caused by deposition of CaCO3, Ca3(PO4)2, CaSO4, BaSO4, SrSO4, CaF2, iron oxide and zinc salts on a reverse osmosis membrane can be solved, a reverse osmosis system work efficiency can be increased, a service life of reverse osmosis membrane agents and reverse osmosis equipment can be prolonged, and an operation cost of reverse osmosis can be reduced.

Owner:深圳市爱康泉水处理服务有限公司

Environmentally friendly phosphorus-free scale inhibitor for seawater desalination reverse osmosis membranes, and preparation method thereof

ActiveCN107362691ACaused by pollutionAvoid foulingSemi-permeable membranesGeneral water supply conservationReverse osmosis plantPollution

The invention belongs to the field of water treatment, and particularly relates to an environmentally friendly phosphorus-free scale inhibitor for seawater desalination reverse osmosis membranes, and a preparation method thereof, wherein the environmentally friendly phosphorus-free scale inhibitor comprises, by weight, 20-30% of a maleic acid-acrylic acid copolymer, 40-60% of polyepoxysuccinic acid, 10-30% of an acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 1-5% of citric acid, 0.5-1% of a surfactant, and the balance of deionized water. According to the present invention, the environmentally friendly phosphorus-free scale inhibitor is especially suitable for the seawater desalination reverse osmosis system, can effectively solve the membrane pollution problem caused by the deposition of CaCO3, CaSO4, BaSO4, SrSO4, iron oxide and silicon scale on the reverse osmosis membrane, can prevent the membrane scale from fouling, can prevent the reverse osmosis membrane from pollution and clogging, can improve the working efficiency of the reverse osmosis system, can prolong the service life of the reverse osmosis membrane, does not contain phosphorus, can discharge the pollution-free concentrated water, and is the environmentally friendly water treatment agent.

Owner:INLEN CHEM TECH

Method of solvent recovery from a dilute solution

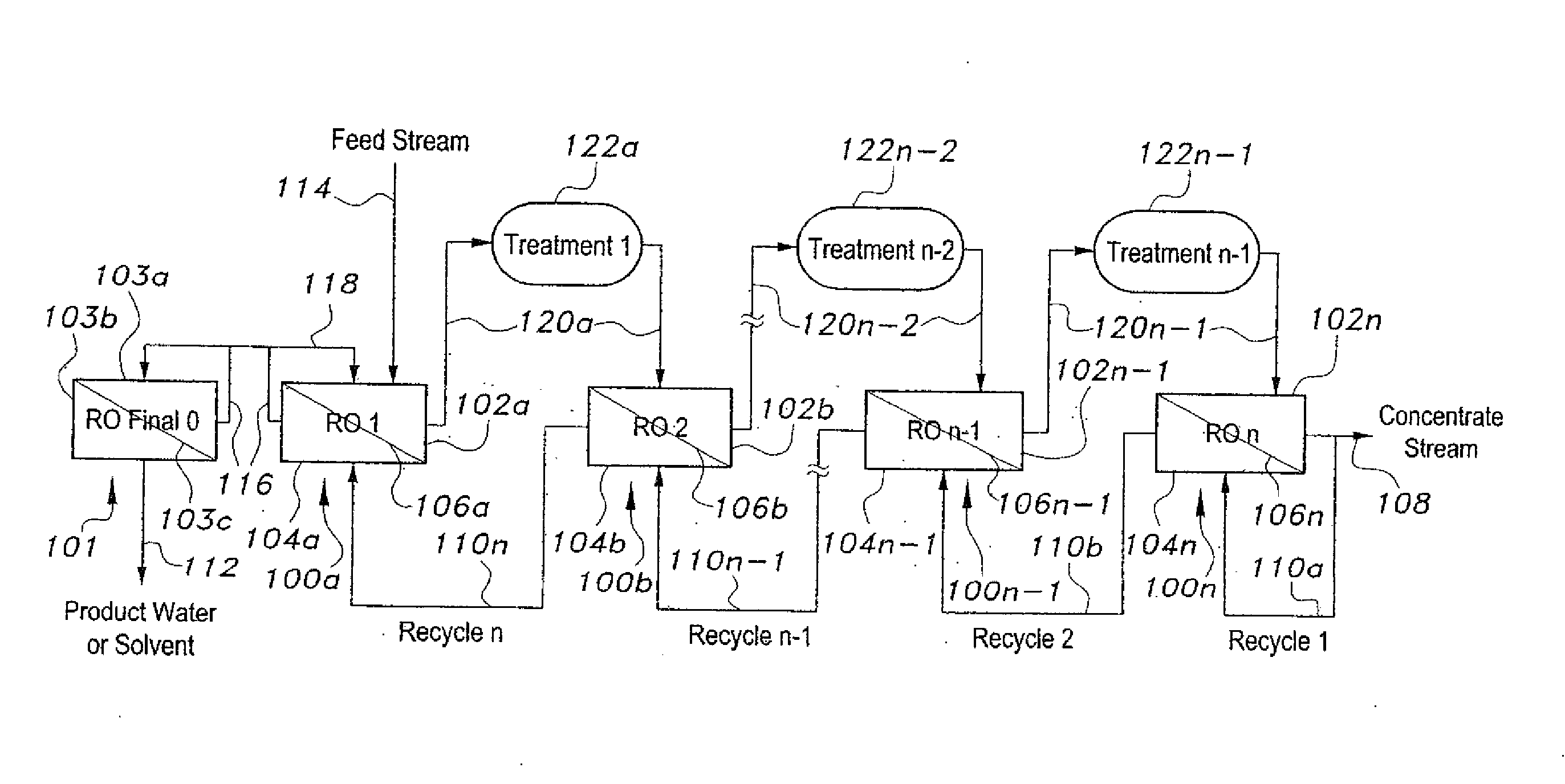

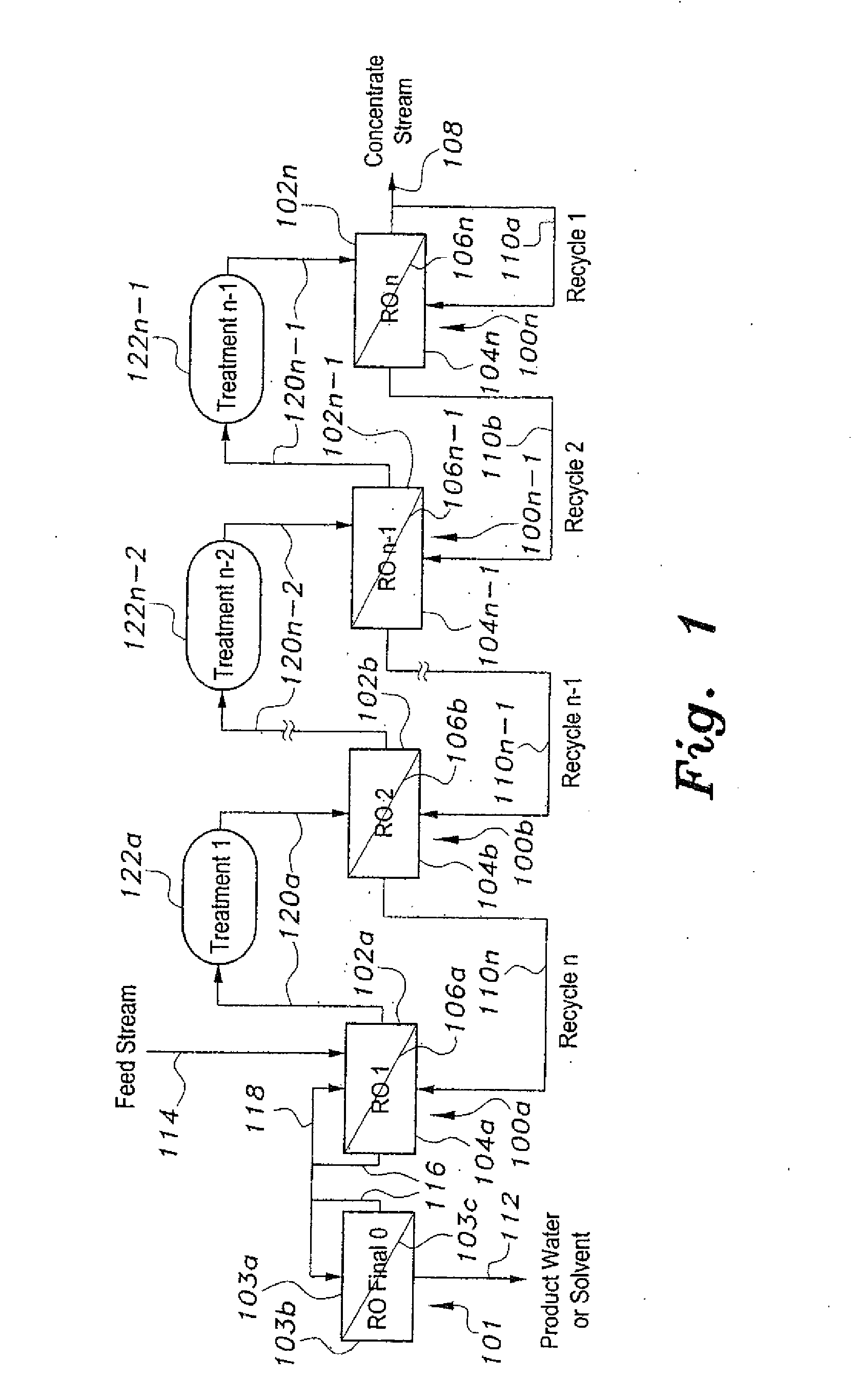

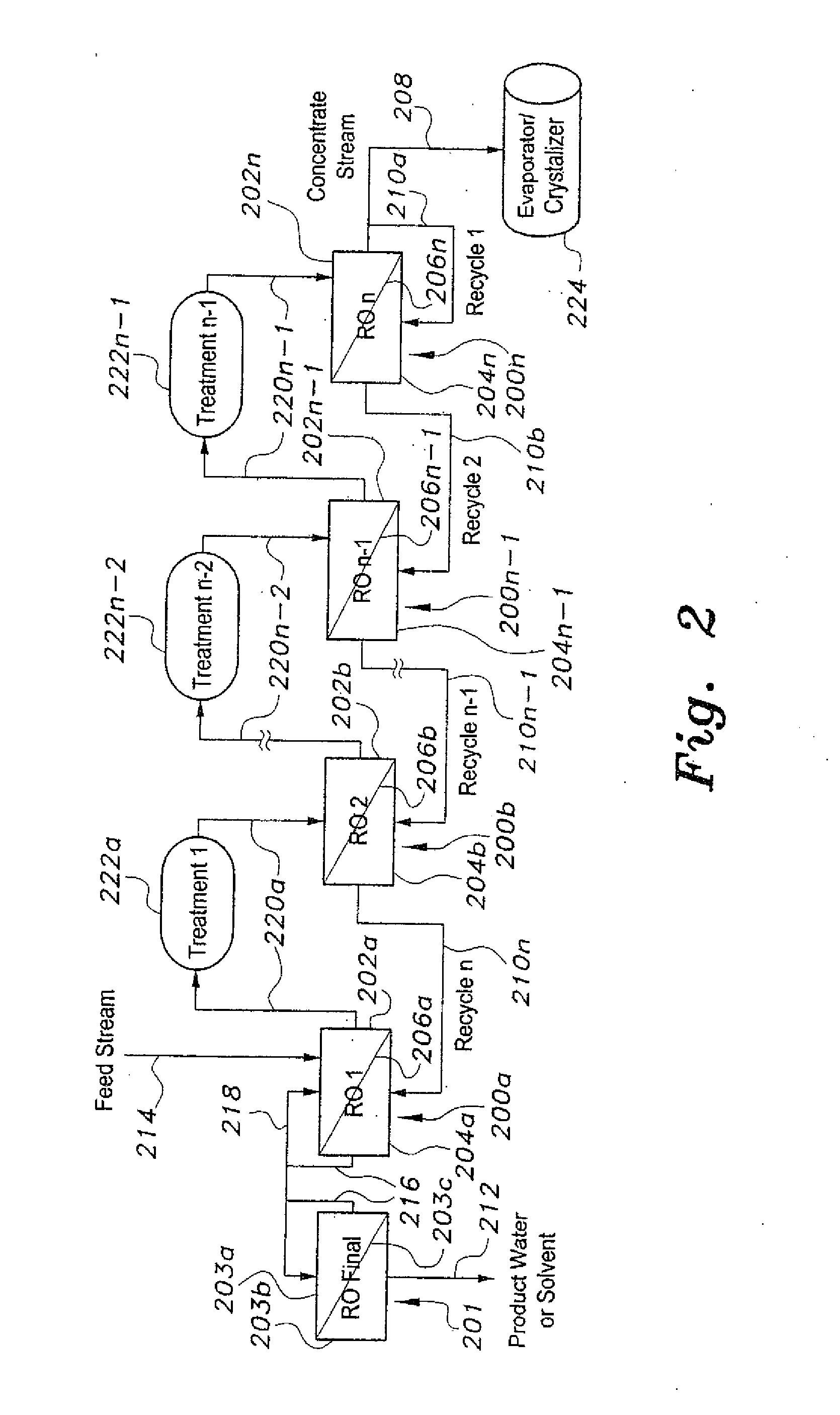

ActiveUS20160339390A1Reduce gradientHigh rejectionReverse osmosisWater/sewage treatment by flocculation/precipitationEvaporationSolvent

The method of solvent recovery includes using a plurality of solvent recovery units to recover solvent from a dilute solution. The solvent recovery units can include a plurality of reverse osmosis or forward osmosis membrane systems arranged in series. For reverse osmosis, at least some of the concentrate in a last reverse osmosis unit of the series is recycled back to the permeate of that unit to provide a mixed permeate. The mixed permeate is then passed successively to the permeate side of each preceding reverse osmosis unit in the series. For forward osmosis, a draw solution is passed sequentially from the permeate side of each unit to the permeate side of the preceding unit. The draw solution may be prepared by concentrating part of the concentrate stream by evaporation and recycling it back as a draw solution.

Owner:AL BAKRI SAMI ABDULRAHMAN

Comprehensive utilization technology of viscose fiber acid wastewater

ActiveCN106145496AAchieve reuseNo emissionsWater treatment parameter controlSpecific water treatment objectivesFiberReverse osmosis plant

Comprehensive utilization technology of viscose fiber acid wastewater includes the steps: firstly, filtering the viscose fiber acid wastewater by a filter, removing suspended matters in the wastewater and treating filtered solution in a next step; secondly, leading the filtered solution into a reverse osmosis system to obtain membrane concentrated solution and membrane permeate liquid, directly reusing the membrane permeate liquid as process water and treating the membrane concentrated solution in a step C; finally, leading the membrane concentrated solution obtained by reverse osmosis treatment into a multi-effect evaporator for concentration, feeding the membrane concentrated solution into a crystallizing tank for crystallization to obtain sodium sulfate crystals. Crystallized mother liquid is sulfuric acid, contains sodium sulfate and zinc sulfate and can be directly reused in a coagulating bath. By membrane combination technology, the sulfuric acid, the zinc sulfate, the sodium sulfate and the water are recycled, the problems of zinc discharge and solid waste are solved, and resources are comprehensively utilized.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

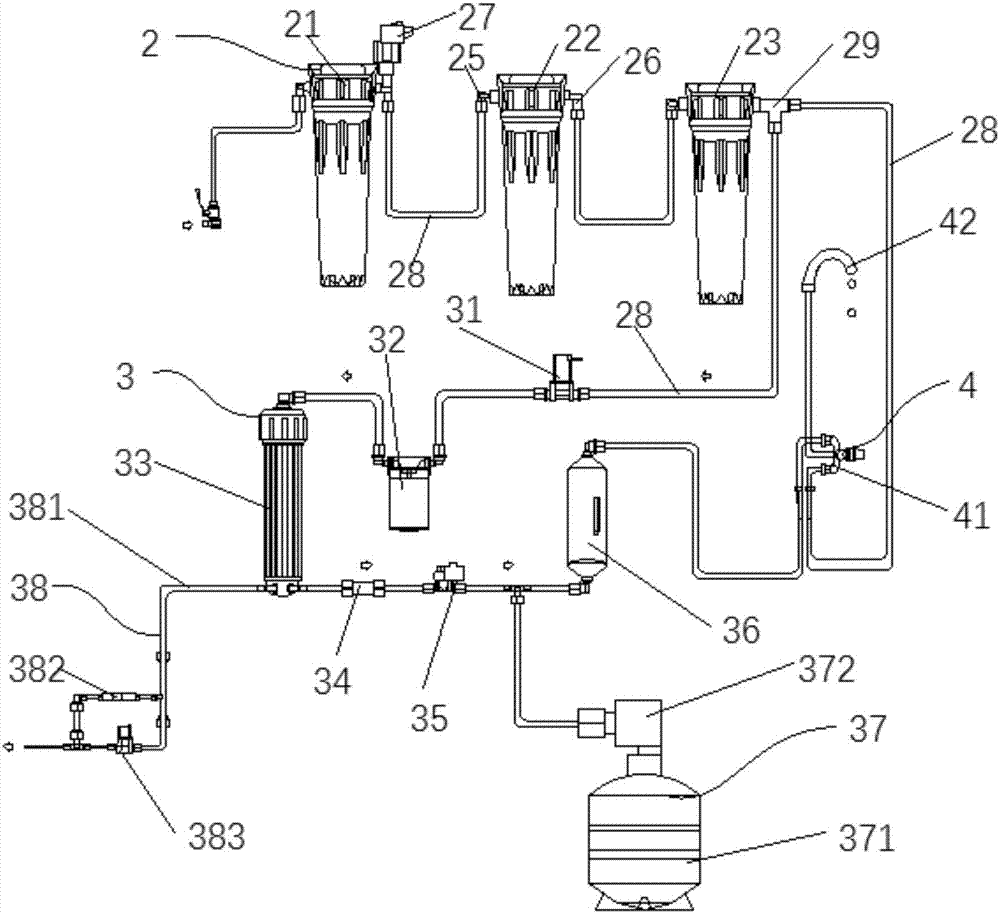

TDS value-adjustable direct drinking water purifier

InactiveCN107324525AEnhance physical fitnessSimple structureWater treatment parameter controlTreatment involving filtrationThree stageUltrafiltration

The invention provides a TDS value-adjustable direct drinking water purifier. The water purifier comprises a hollow shell, an ultrafiltration system, a reverse osmosis system and a mixing system, and the ultrafiltration system and the reverse osmosis system are arranged in the shell and the mixing system is arranged outside the shell. The ultrafiltration system is used for purifying raw water to obtain mineral water. The reverse osmosis system is used for further purifying mineral water produced by the ultrafiltration system to obtain purified water. The mixing system is used for mixing and adjusting mineral water produced by the ultrafiltration system and purified water produced by the reverse osmosis system so that direct drinking water is produced. The ultrafiltration system comprises three stages of filter cores orderly connected in series through pipes. The reverse osmosis system comprises a reverse osmosis film and is connected to the ultrafiltration system through a pipe. The mixing system is connected to the ultrafiltration system and the reverse osmosis system through pipes. The water purifier can conveniently and effectively regulate the mineral content in the direct drinking water and make the direct drinking water satisfy the demand for drinking of different populations in different regions and is safe and healthy.

Owner:江苏全给净化科技有限公司

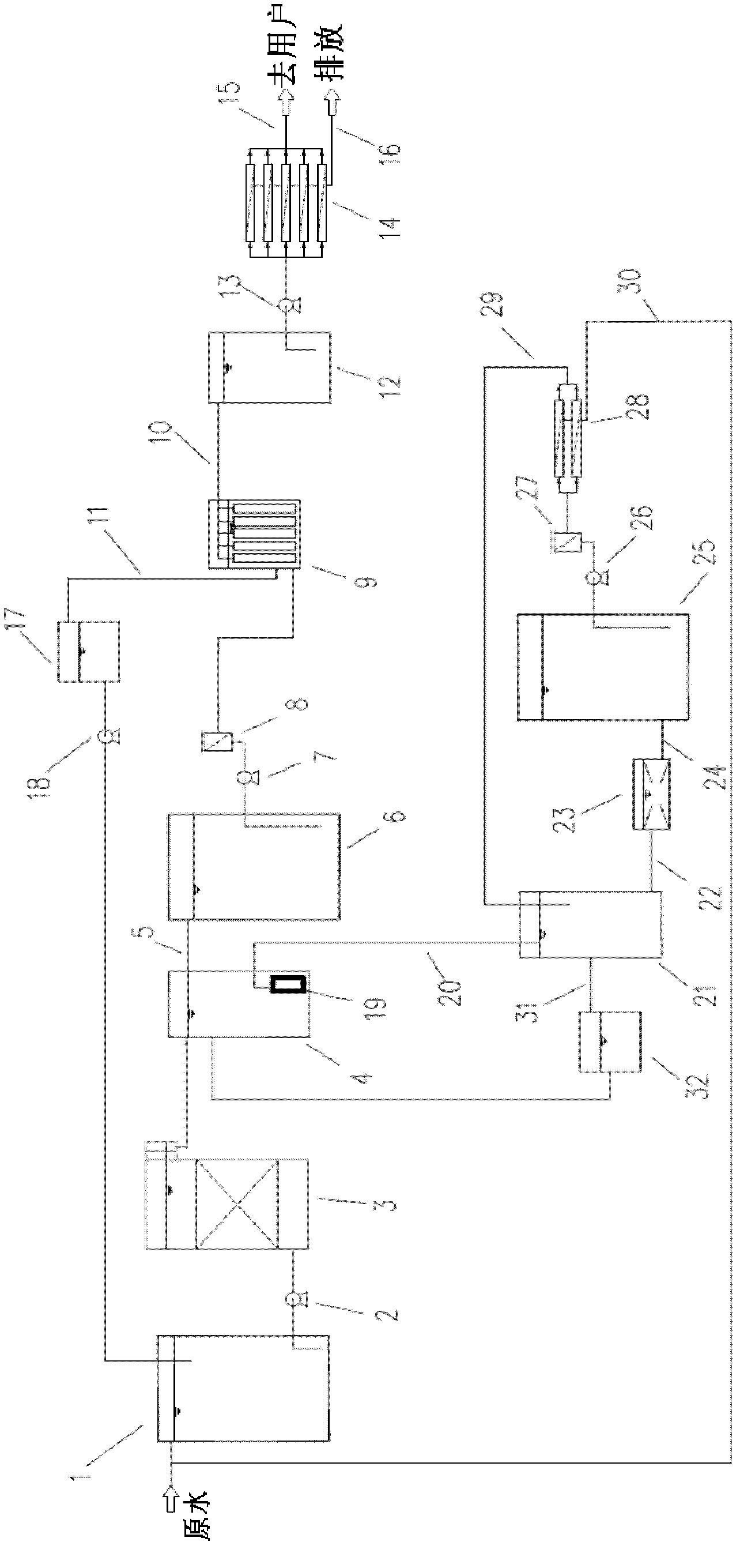

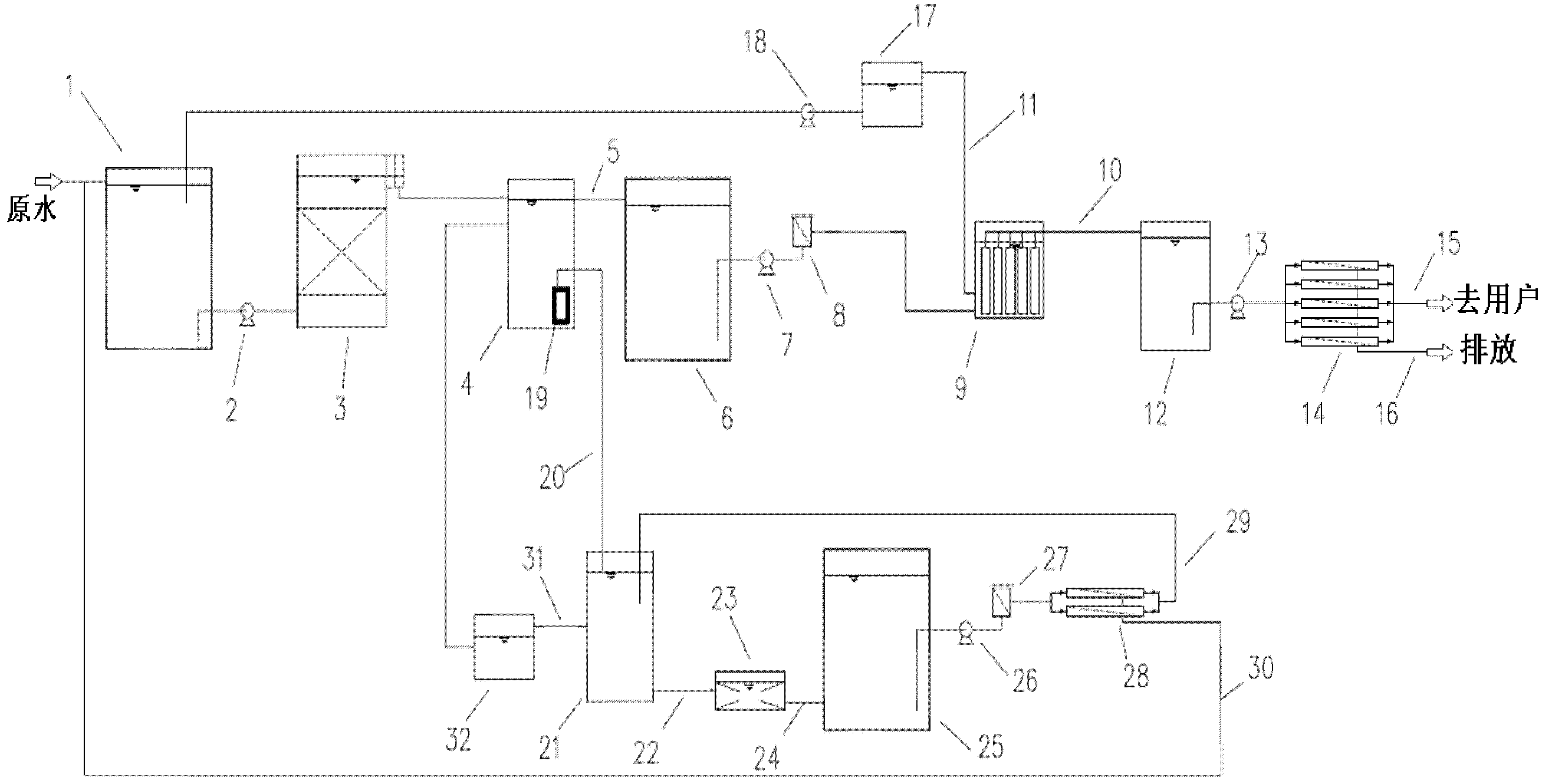

Wastewater treatment method and wastewater treatment system

ActiveCN102583889AReduce pollutionReduce contentWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisElectrolysisUltrafiltration

The invention discloses a wastewater treatment method and a wastewater treatment system. The wastewater treatment method disclosed by the invention comprises the following steps: biological treatment, magnetic ion exchange resin adsorption, ultrafiltration treatment, reverse osmosis treatment, regeneration, regenerated resin return, electrolytic oxidation and nano-filter membrane treatment. According to the wastewater treatment method disclosed by the invention, since the magnetic ion exchange resin is utilized to adsorb the organic substances in the ultrafiltration influent water, the organic content in the ultrafiltration and reverse osmosis is greatly lowered, and the concentrated water of reverse osmosis can be directly discharged after reaching the discharge standard; and meanwhile, the organic pollution of the reverse osmosis membrane at the concentrated water side is reduced, so that the continuous operation period of the reverse osmosis becomes longer. In addition, since the magnetic ion exchange resin can be regenerated on line and recycled, the cost is lowered, and other concentrated water in the system can be totally treated without secondary pollution.

Owner:美景(北京)环保科技有限公司

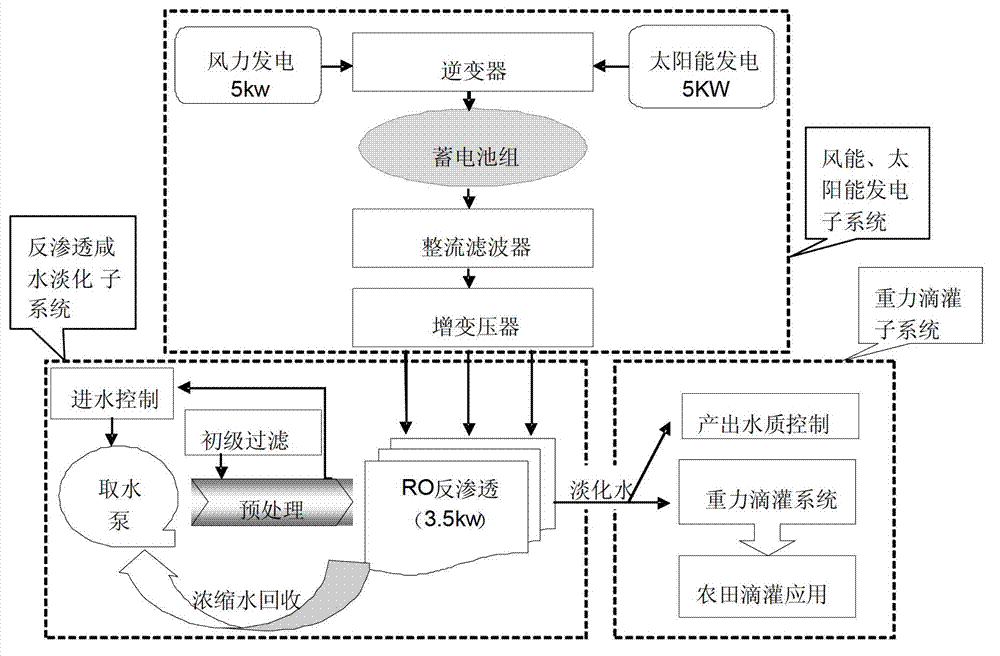

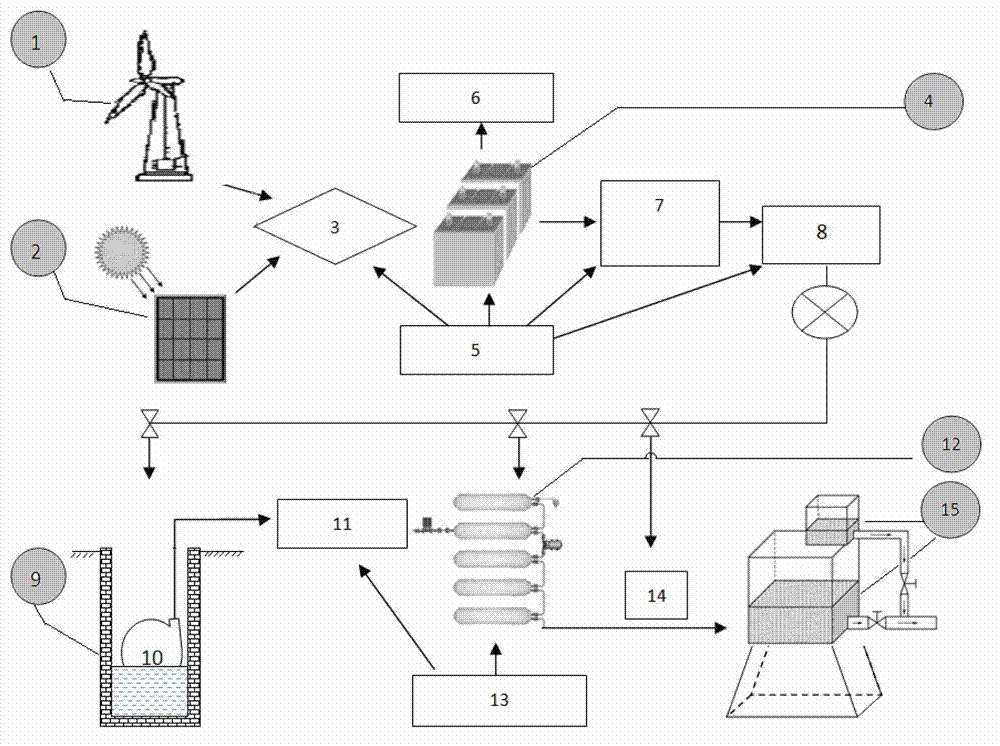

Farmland drip irrigation system for driving saline groundwater reverse osmosis treatment by miniature wind energy and solar energy

ActiveCN102812884AIncrease output powerImprove work efficiencyBatteries circuit arrangementsGeneral water supply conservationSaline waterElectricity

The invention discloses a farmland drip irrigation system for driving saline groundwater reverse osmosis treatment by miniature wind energy and solar energy. The farmland drip irrigation system comprises three parts, namely a wind energy and solar energy generating device, a saline groundwater reverse osmosis treatment system, and a farmland gravity drip irrigation device. According to the invention, wind electricity and solar power generation are utilized to drive reverse osmosis to carry out saline water desalination. The system is simple and reliable in structure, and can be directly accessed into electric supply or generate electricity by diesel oil; no extra equipment is needed, and the system has good expansibility.

Owner:BEIJING NORMAL UNIVERSITY

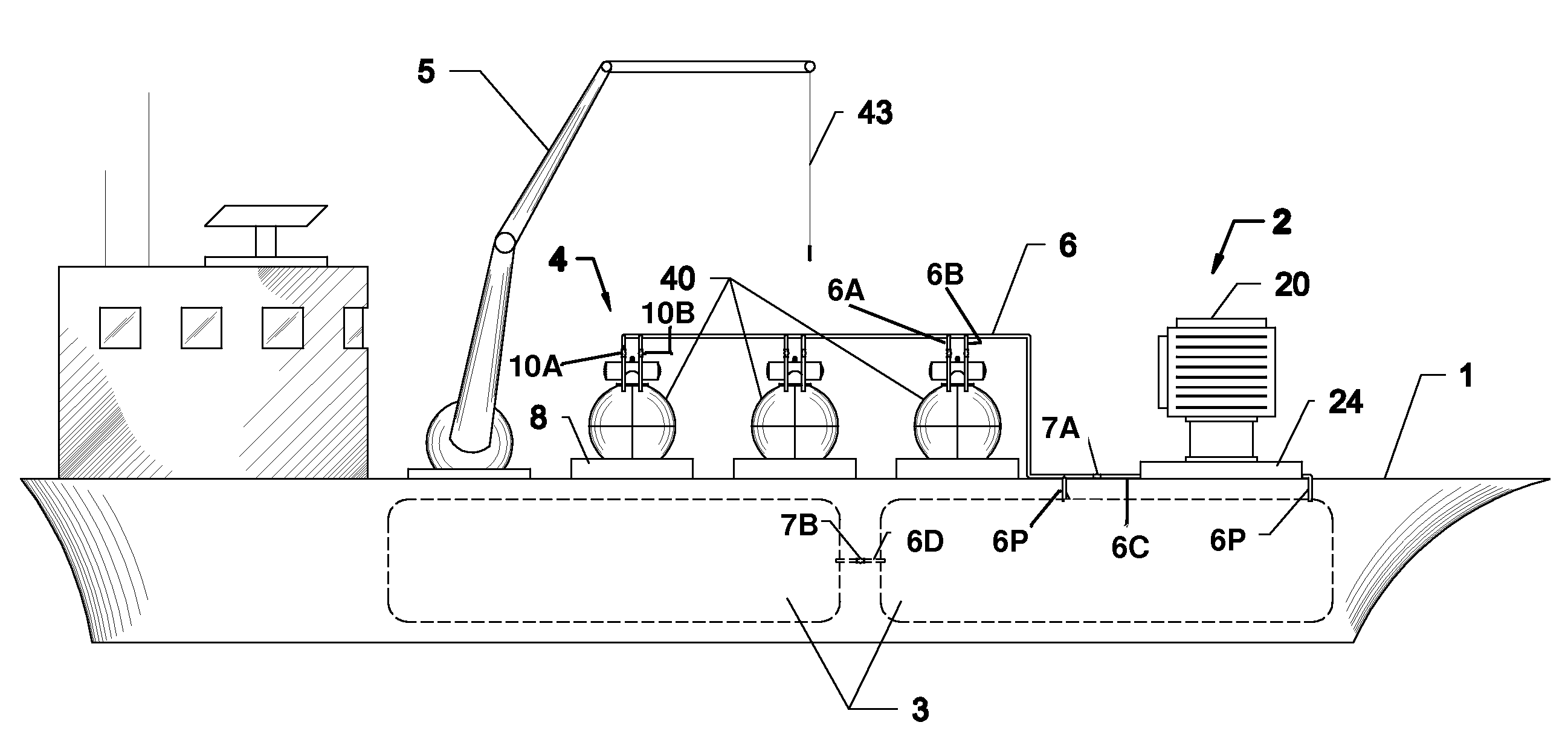

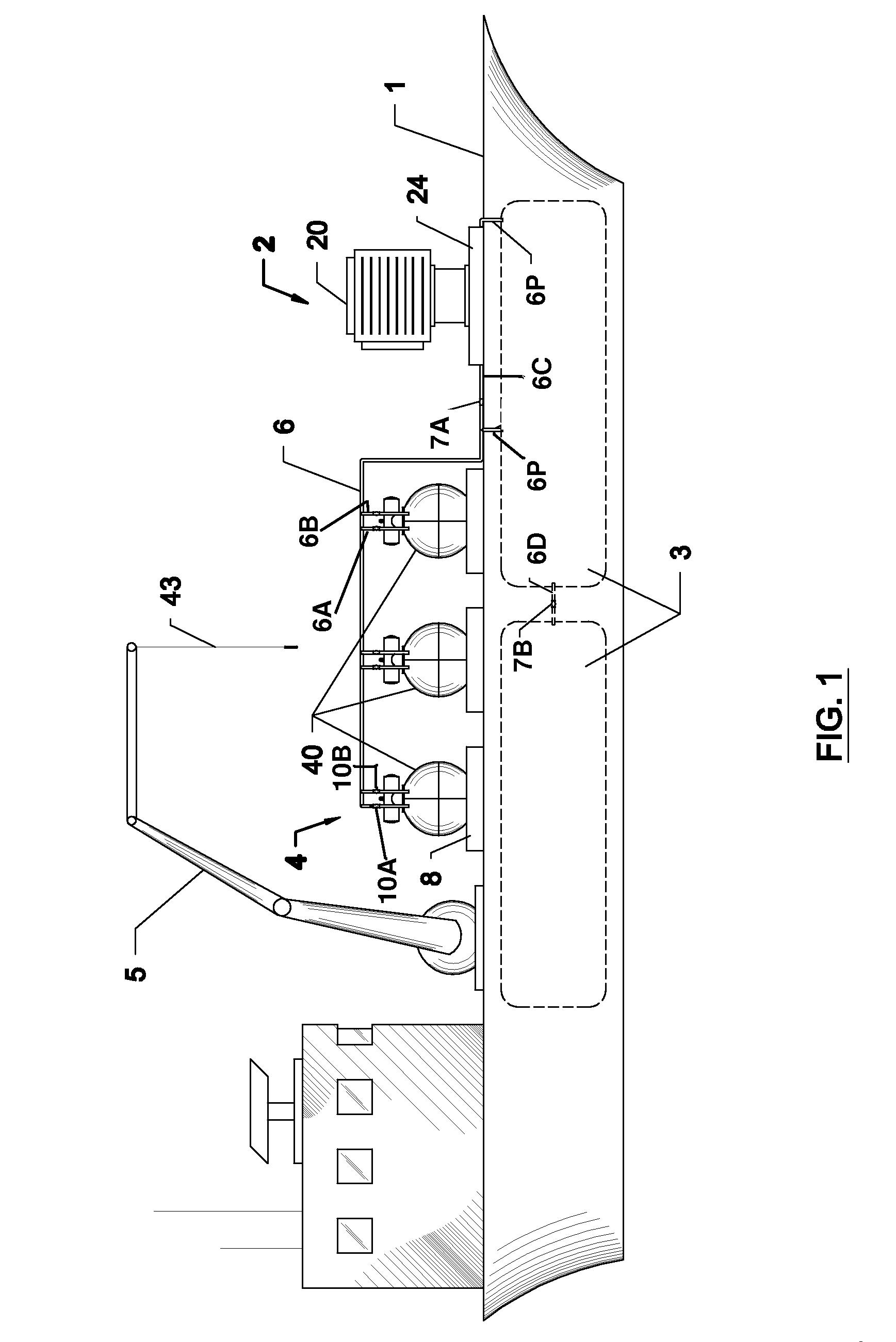

Method, apparatus, and processes for producing potable water utilizing reverse osmosis at ocean depth in combination with shipboard moisture dehumidification

InactiveUS7901580B2Great advantageReduce the possibilityAuxillariesGeneral water supply conservationSaline waterWater source

Devices and methods for producing purified water. The device includes a reverse osmosis subsystem, a dehumidification subsystem and a purified water storage tank fluidly coupled to the subsystems such that purified water produced by each can be locally stored. A vehicular platform, such as a ship, can be used to locate the device adjacent a supply of saline water and humid air. A saline water inlet, membrane and purified water outlet cooperate in the reverse osmosis subsystem to allow preferential passage of water relative to salt in a saline water supply, while the dehumidification subsystem includes a heat exchanger that extracts moisture from the ambient humid air. Purified water produced by each of the subsystems can be used as a potable water source. When used in conjunction with a ship, part or all of the reverse osmosis subsystem can be submersed to a depth sufficient to generate a hydrostatic pressure that is in turn sufficient to passively operate the reverse osmosis membrane such that additional pressurizing equipment, such as a pump, is not needed. Furthermore, the temperature of the water purified by the reverse osmosis subsystem may be low enough to be used as a condensing agent for the ambient humid air passing through the dehumidification subsystem.

Owner:SALYER IVAL O

Reverse osmosis concentrated water treatment process and treatment system in cold rolling steel plant

InactiveCN102276121AGuaranteed uptimeGet rid of the dilemma of low recovery rateMultistage water/sewage treatmentReverse osmosis plantHigh pressure

The invention belongs to the technical field of wastewater treatment in the metallurgical industry, and in particular relates to a reverse osmosis concentrated water treatment process and a treatment system of a cold rolling steel plant. The reverse osmosis concentrated water treatment process in cold rolling steel mills is characterized in that it includes the following steps: 1) the reverse osmosis concentrated water first enters the adjustment tank, and the reverse osmosis concentrated water after the adjustment treatment in the adjustment tank enters the ozone contact reactor; 2) passes through the ozone The effluent treated by the contact reactor enters the attenuation tank, and the wastewater treated by the attenuation tank enters the MBR membrane bioreaction tank. The effluent after liquid separation is pumped into the intermediate water production pool by the suction pump to obtain the intermediate water production; 3) The intermediate product water is pumped into the reverse osmosis unit through the high pressure pump for the second reverse osmosis desalination treatment; the effluent treated by the reverse osmosis unit It is used as reuse water; the concentrated water produced by the reverse osmosis unit is directly discharged. The process has the characteristics of high waste water recovery rate.

Owner:WISDRI ENG & RES INC LTD

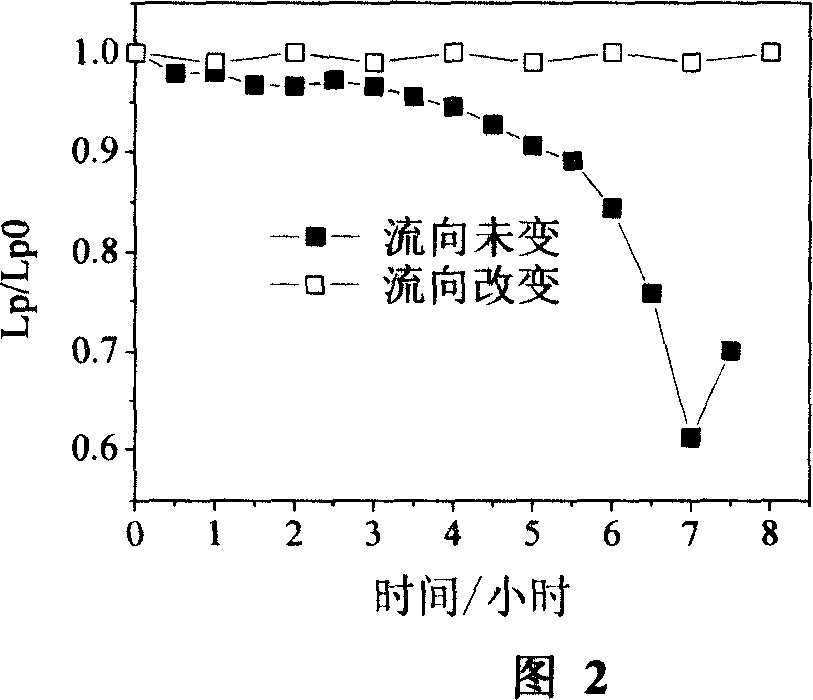

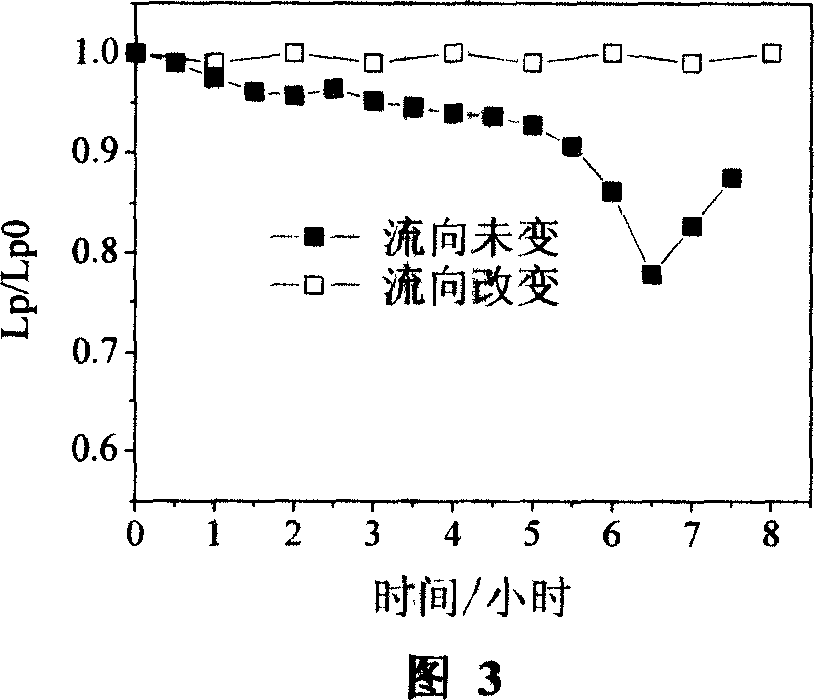

Changing flow direction method for blocking reverse osmosis membrane fouling under the scale inhibitor existing

InactiveCN101053776APrevent scalingExtend your lifeSemi-permeable membranesHigh concentrationMembrane fouling

The invention relates to a switching flow method for preventing the reverse osmosis membrane from fouling via a scale inhibitor, which connects in series plurality of branch putaminas to form a reverse osmosis membrane unit, the penetrating fluid tube of each branch putamina is connected and together flows into the penetrating fluid conduit, and in the process of operation of reverse osmosis system and in the interval smaller than membrane fouling induction period, the flow direction of water in the membrane unit is alternately changed to break the high concentration boundary layer built at the surface of the membrane to extend fouling induction period to prevent the reverse osmosis membrane from fouling. The permeability coefficient of the reverse osmosis membrane can be obtained, and then the retarding degree for the membrane fouling can be obtained by monitoring the penetrating fluid flow of the last breach putamina, based on the operation pressure and the osmotic pressure of the solution. The invention can prevent the membrane from fouling effectively, reduce the washing frequency for the commercial reverse osmosis system, prolong the using life of the membrane, and provide a simple method to reduce the run cost.

Owner:浙江凯锐环保股份有限公司

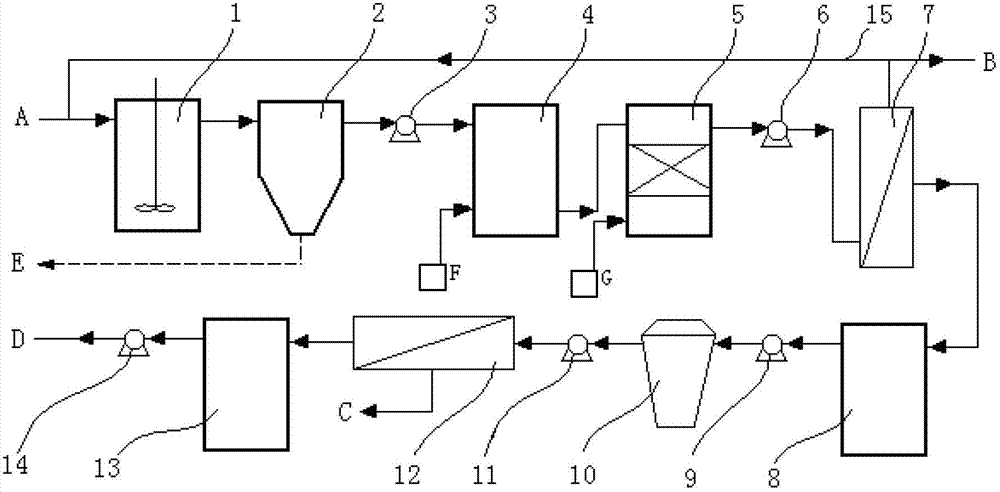

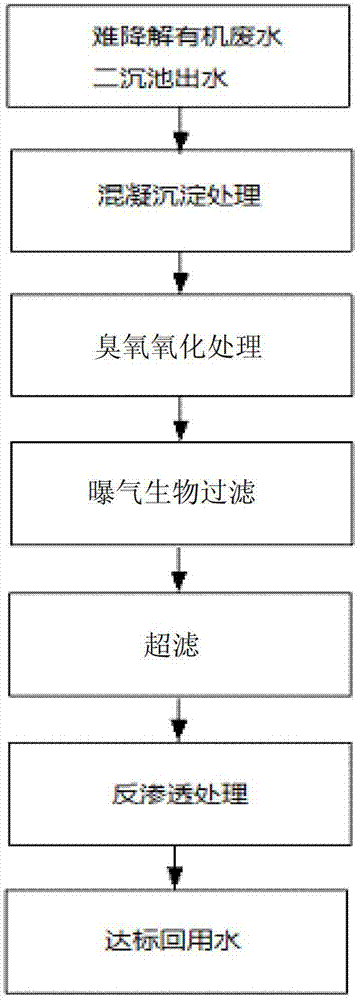

Treating system and treating method for hardly degradable organic waste water

InactiveCN102815836AExtend your lifeImprove effluent qualityMultistage water/sewage treatmentWater qualityWater requirement

The invention discloses a treating system and a treating method for hardly degradable organic waste water, belonging to the field of sewage treatment. The system comprises a coagulating sedimentation treatment zone, an ozone reaction zone, a biological aerated filter treatment zone, an ultrafiltration treatment zone and a reverse osmosis treatment zone, wherein the coagulating sedimentation treatment zone is successively connected with the biological aerated filter treatment zone, the ultrafiltration treatment zone and the reverse osmosis treatment zone, an ultrafiltration concentrated water outlet of the ultrafiltration treatment zone is in return connection with the coagulating sedimentation treatment zone through an ultrafiltration concentrated water return line, and a water outlet of the reverse osmosis treatment zone is connected with a reuse device. According to the invention, the system utilizes the ozone reaction zone and the biological aerated filter treatment zone for pretreatment after coagulating sedimentation, then ultrafiltration is carried out in the ultrafiltration treatment zone to remove suspended solids, colloids and a part of organic matters in water after pretreatment, the effluent of ultrafiltration enters into the reverse osmosis treatment zone for reverse osmosis treatment so as to further remove macro-molecular organic matters in water and hardness and salinity of water and improve water quality of the effluent, and the treated hardly degradable organic waste water reaches water requirements on recirculated cooling water or boiler feed water.

Owner:BEIJING SOUND ENVIRONMENTAL ENG

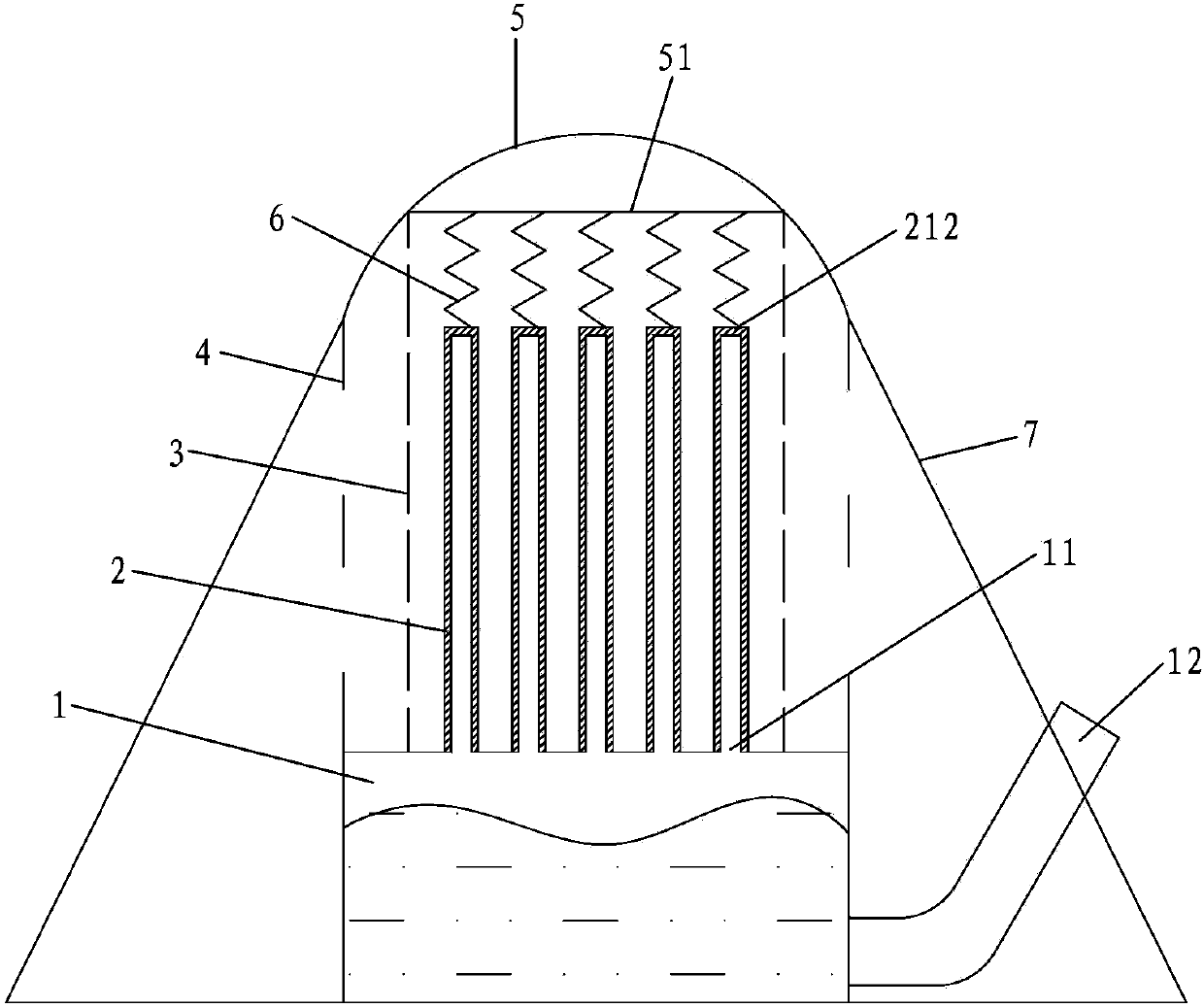

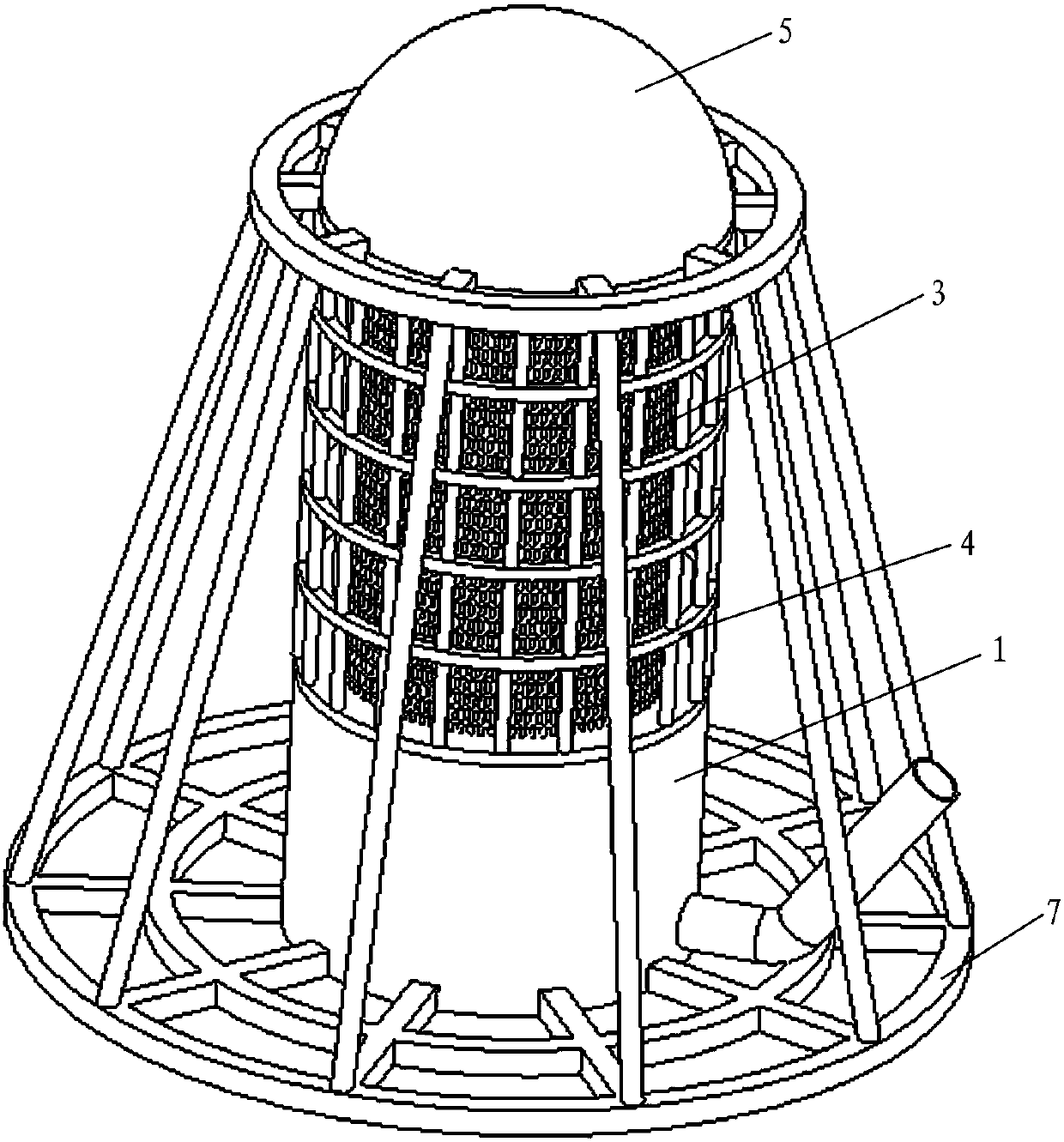

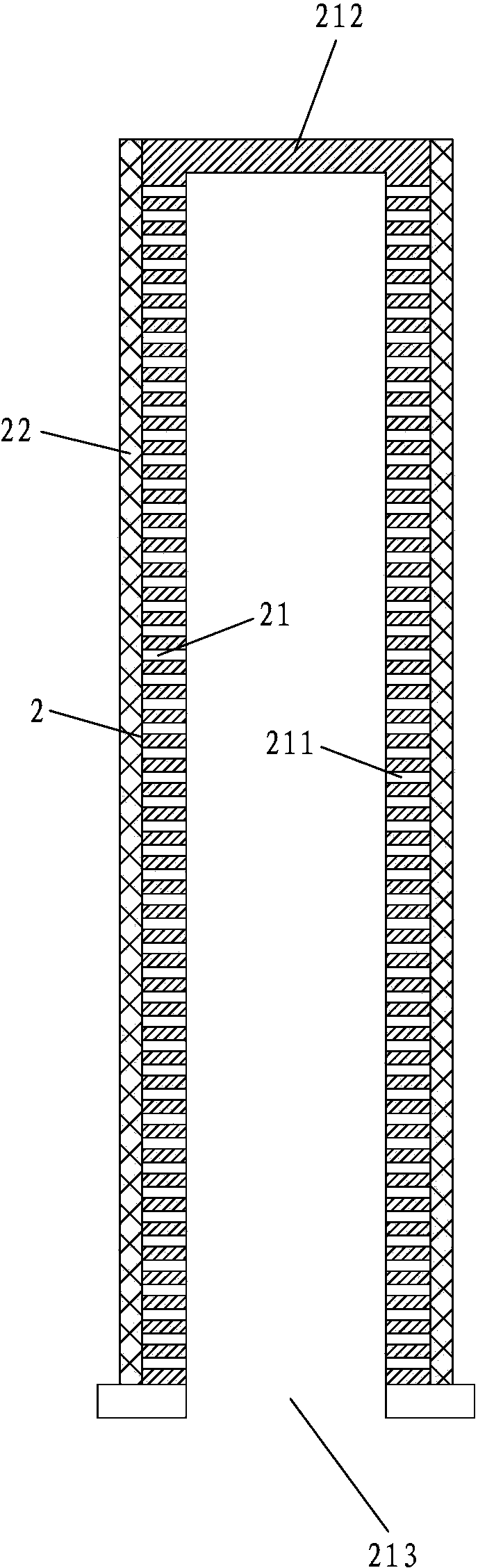

Reverse osmosis seawater desalination machine put in deep sea

InactiveCN103771606AReduce energy consumptionIncrease valueGeneral water supply conservationSeawater treatmentFresh water organismMembrane surface

The invention discloses a reverse osmosis seawater desalination machine put in deep sea, which comprises a freshwater collection tank, multiple reverse osmosis membrane pipes, a filter screen, a protection cage, a compression-resistant cover, multiple springs and an anti-toppling mechanism, wherein the reverse osmosis membrane pipes are mounted at the top of the freshwater collection tank, the filter screen surrounds the reverse osmosis membrane pipes, and the filter screen is externally covered with the protection cage and the compression-resistant cover. Since the deep seawater is filtered by the filter screen and then reaches the membrane surfaces of the reverse osmosis membrane pipes, the water molecules in seawater penetrate through the reverse osmosis membrane under the effect of the potential energy of seawater and reach the outer wall surface of a hollow circular pipe; the freshwater enters an inner cavity of the hollow circular pipe through micropores on the wall surface of the hollow circular pipe and flows into the freshwater collection tank under the gravity effect; finally, the freshwater is pumped onto the land through a freshwater outlet pipeline while a certain water level in the freshwater collection tank is maintained. The machine disclosed by the invention has the advantages of low energy consumption, high freshwater value, simple and compact equipment structure, good overall performance, environmental friendliness and the like, is suitable for the complicated-environment deep sea, and can be widely applied to the field of seawater desalination.

Owner:JIMEI UNIV

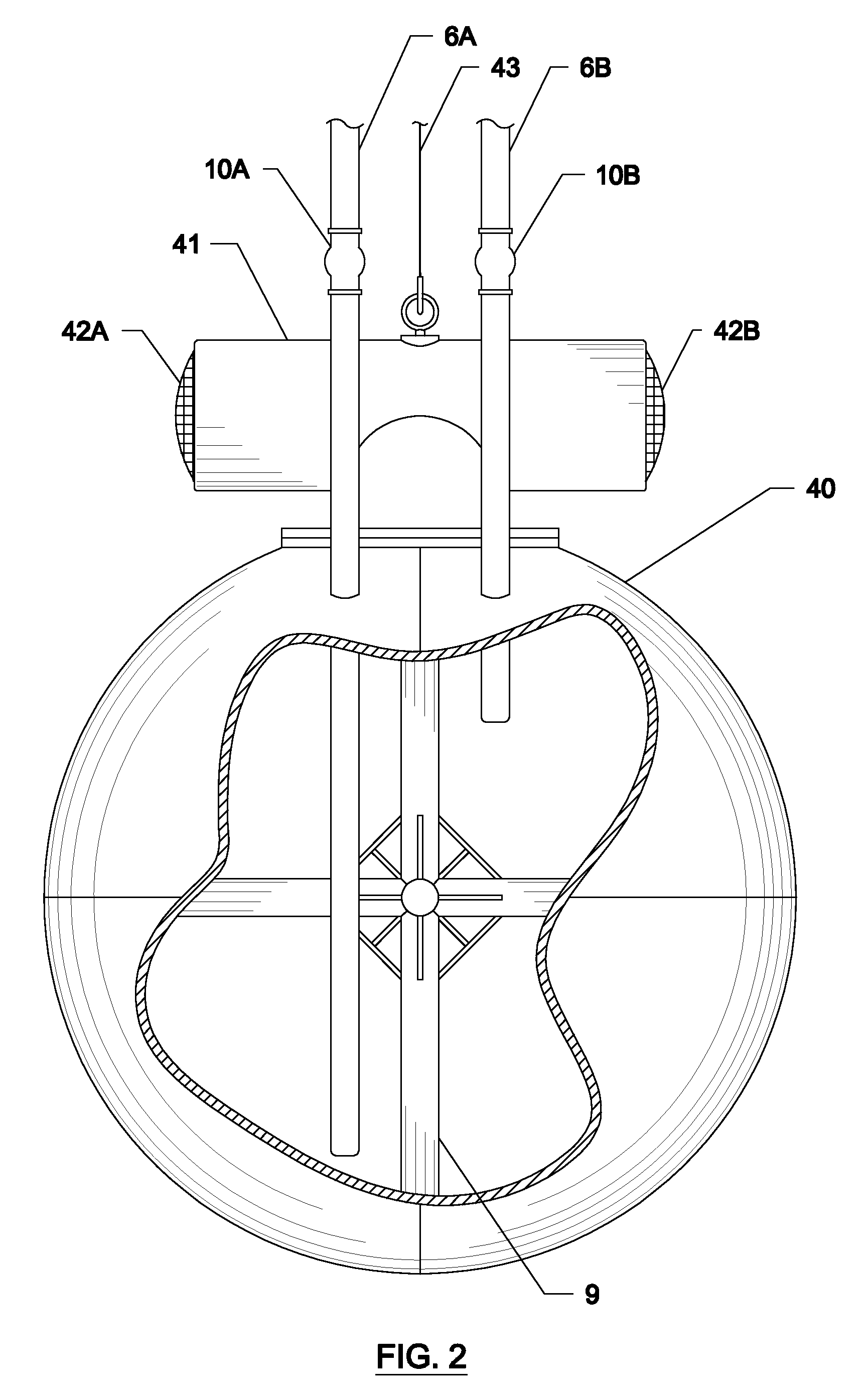

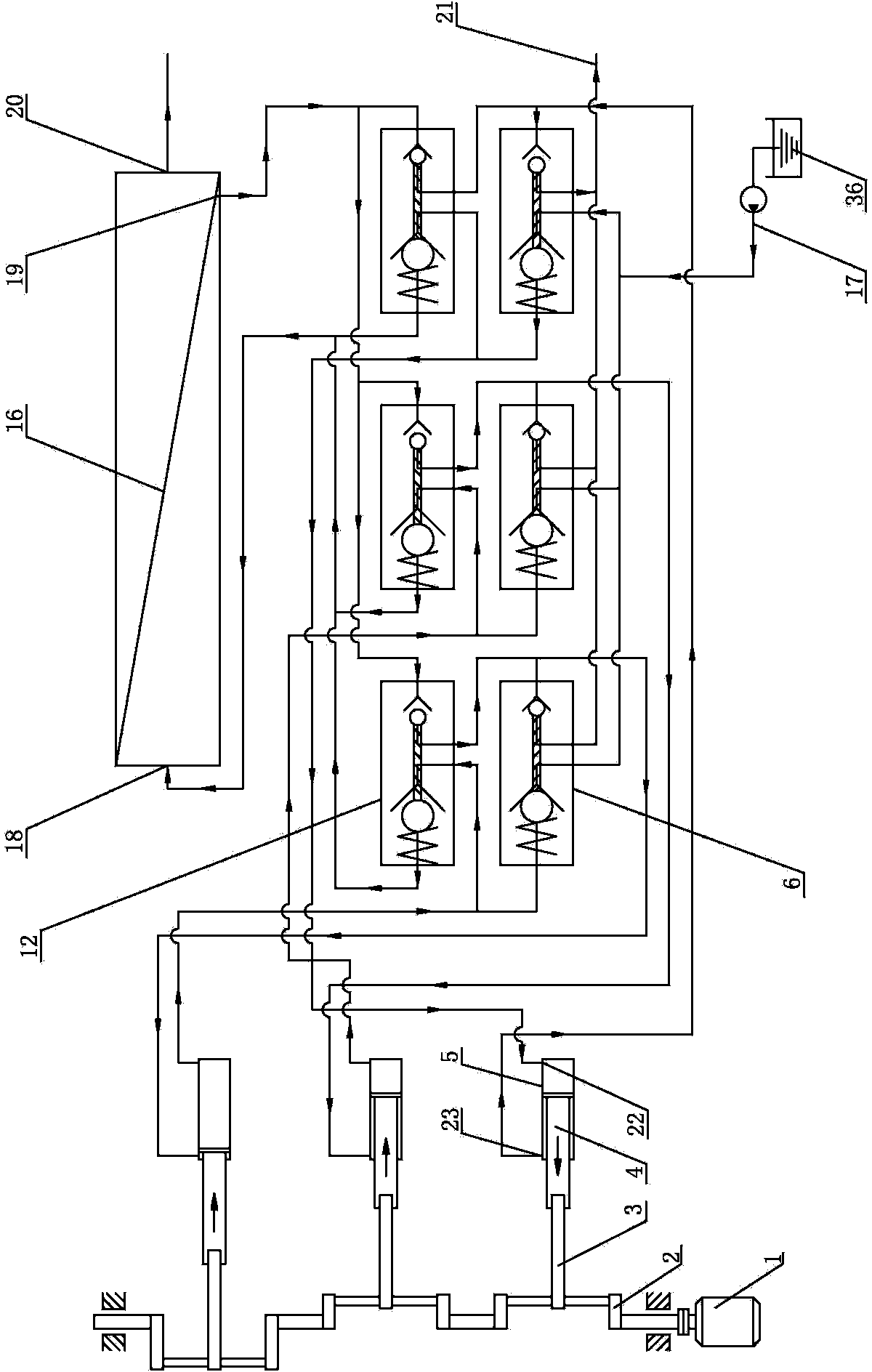

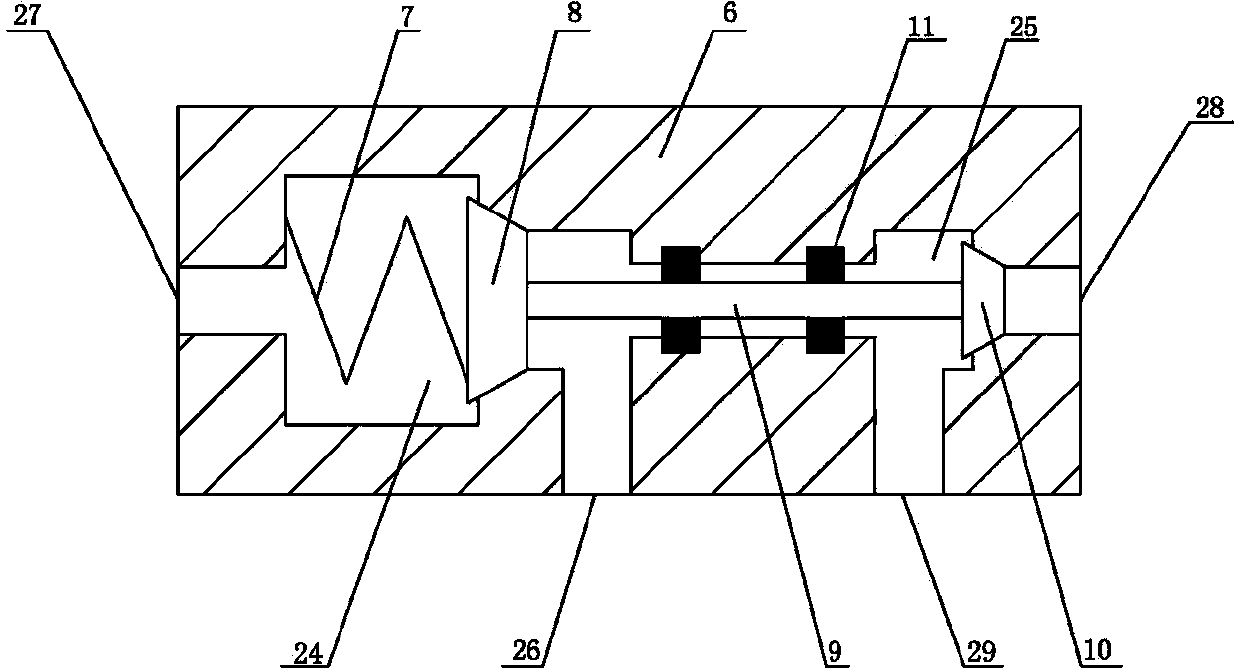

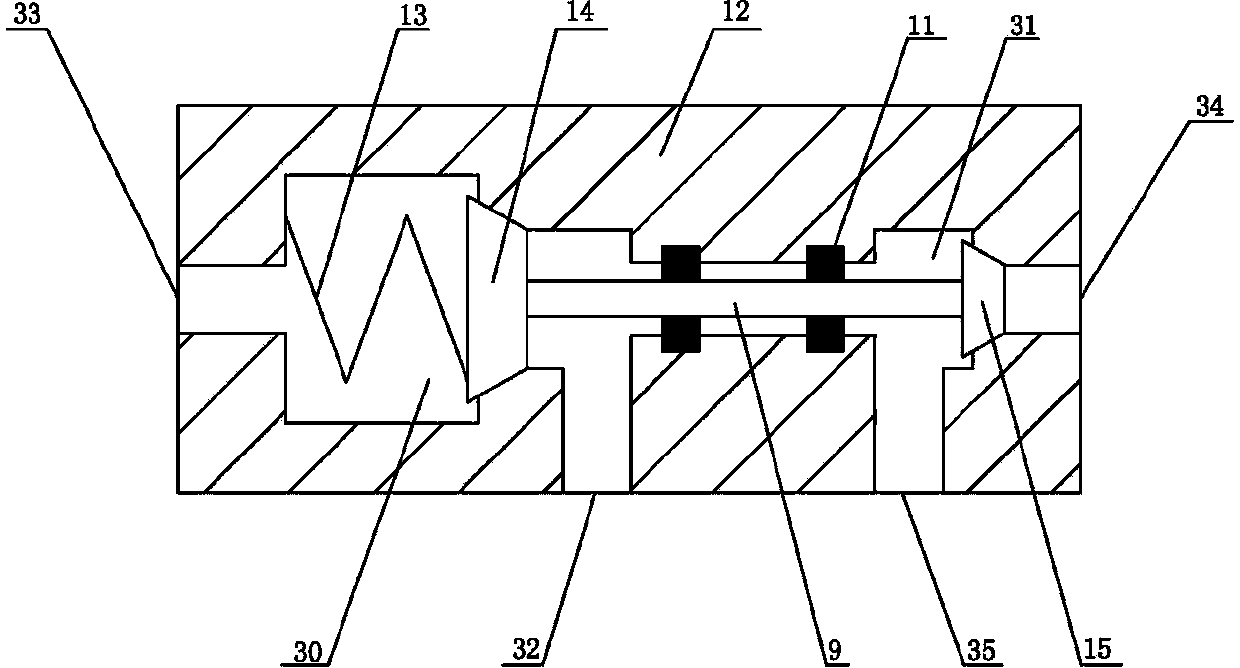

Three-cylinder reverse osmosis seawater desalting and concentrated seawater energy recycling system

InactiveCN102974220BDesign scienceEasy to useGeneral water supply conservationReverse osmosisHigh pressureReverse osmosis plant

The invention discloses a three-cylinder reverse osmosis seawater desalting and concentrated seawater energy recycling system, and relates to seawater desalting. The three-cylinder reverse osmosis seawater desalting and concentrated seawater energy recycling system comprises a power device, energy recycling devices, a reverse osmosis membrane and a water inlet pipe, wherein the power device and the water inlet pipe are both connected with the energy recycling devices; and the reverse osmosis membrane is connected with the energy recycling devices in two directions. The three-cylinder reverse osmosis seawater desalting and concentrated seawater energy recycling system is characterized by comprising three sets of mutually linked energy recycling devices, wherein each energy recycling device consists of a piston, a water pressure cylinder, a water feeding and draining valve and an energy recycling valve; the pistons are arranged on the water pressure cylinders and are connected with the power device; the water pressure cylinders are provided with raw material seawater inlets and concentrated seawater inlets; the water feeding and draining valves are connected with the raw material seawater inlets and the concentrated seawater inlets; the reverse osmosis membrane is connected with the energy recycling valves; the water inlet pipe are connected with the water feeding and draining valves; and the water feeding and draining valve are connected with waste concentrated seawater discharging ports. By the three-cylinder reverse osmosis seawater desalting and concentrated seawater energy recycling system, pressure energy of high-pressure concentrated seawater discharged by the reverse osmosis membrane is fully used, and the energy consumption is effectively reduced.

Owner:云南玮昊能源发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com