A reverse osmosis pretreatment method when reclaimed water is reused in power plants

A technology of reverse osmosis and pretreatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of reverse osmosis output decline, high investment cost, organic matter and microorganism removal effect Poor problems, to improve stability and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

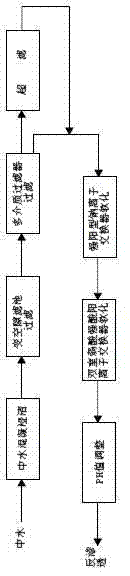

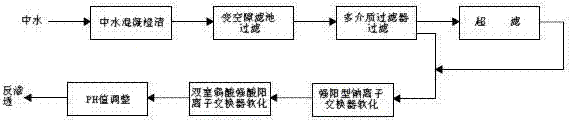

[0015] like figure 1 A reverse osmosis pretreatment method when the shown a kind of reclaimed water is reused in the power plant is characterized in that, comprises the following steps:

[0016] 1) Coagulation and clarification of reclaimed water; input the reclaimed water to be treated into the mechanical agitation acceleration clarification tank, and add quicklime, polyferric sulfate and polyacrylamide into the clarification tank for coagulation and clarification treatment, wherein the dosage of quicklime is to make the water hydrogen The oxygen radical reaches 0.1-0.3mmol / L, the dosage of polyferric sulfate is 10-40mg / L, and the dosage of polyacrylamide is 0.3-2.0mg / L; When the alkalinity value is large and exceeds 3mmol / L, add sodium carbonate to the system to make the difference between the hardness value and the alkalinity value less than 1mmol / L;

[0017] 2) Filtration by variable pore filter; the water treated by the clarifier is input into the variable pore filter fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com