Reverse osmosis membrane chemical cleaning method

A technology of chemical cleaning and reverse osmosis membrane, which is applied in the field of reverse osmosis system, can solve problems such as difficult cleaning measures, achieve the effects of restoring membrane flux and desalination rate, high cleaning efficiency, and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

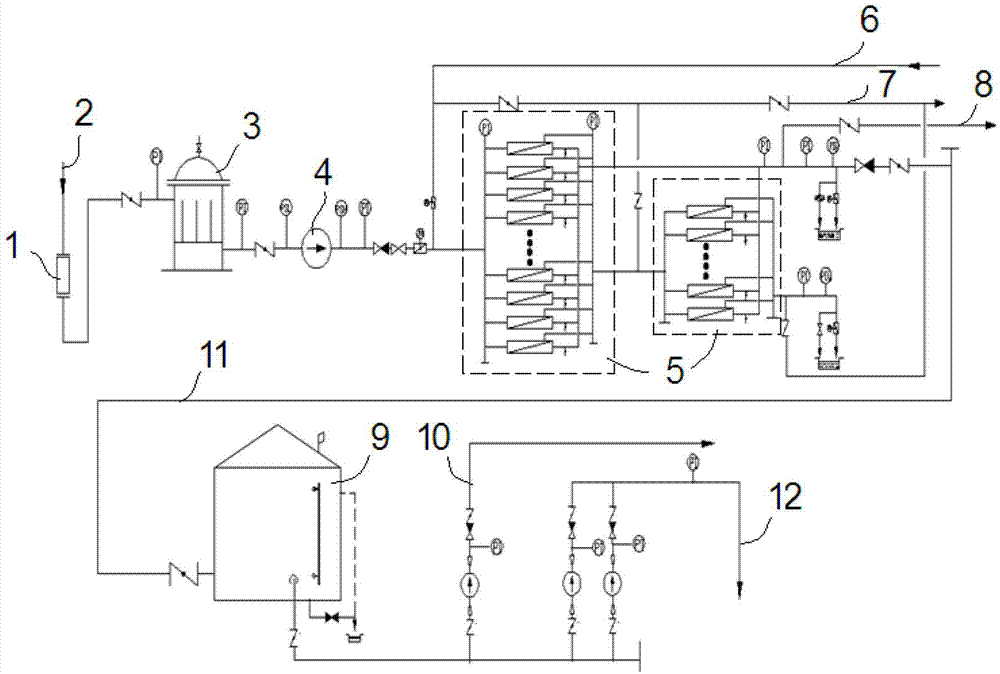

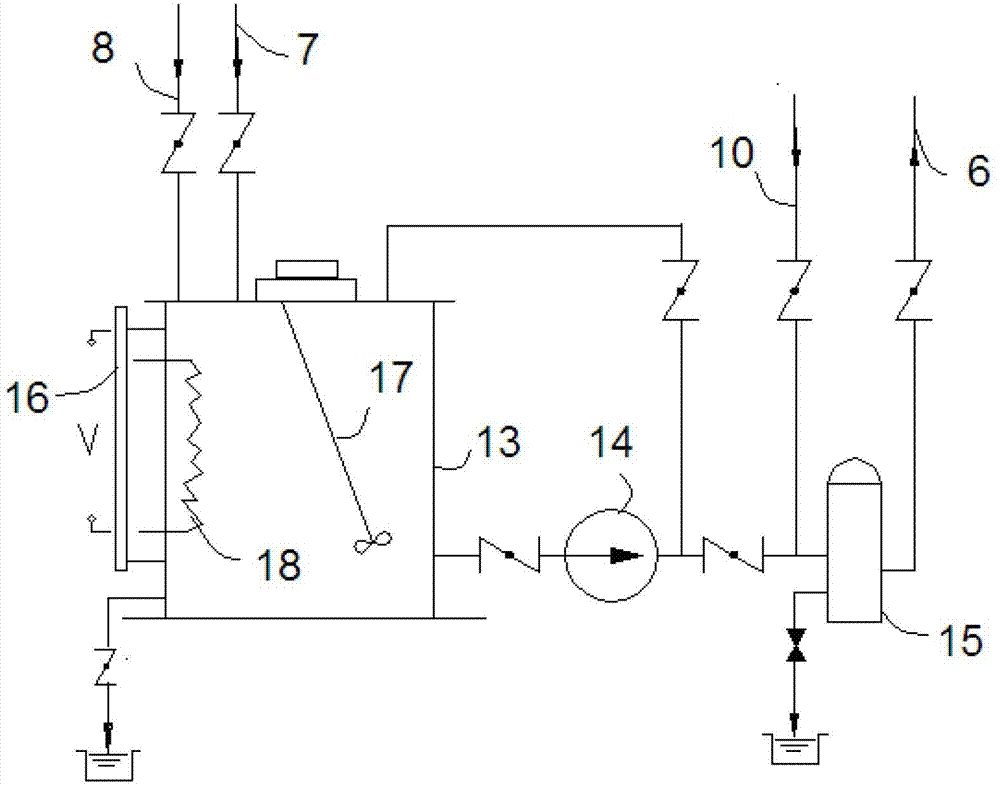

Method used

Image

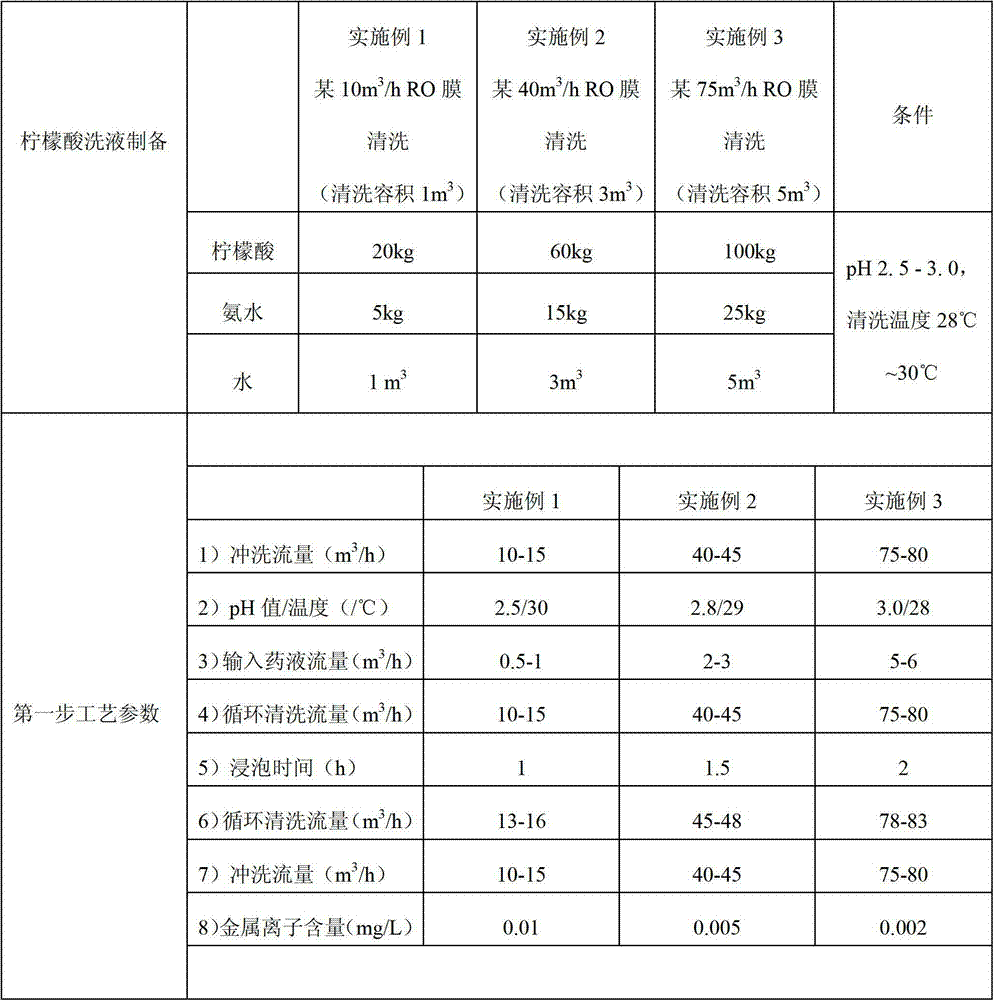

Examples

specific Embodiment

[0072]

[0073]

[0074] The invention provides a novel chemical cleaning method for reverse osmosis membranes, which adopts the method of combining pickling and chlorine washing to chemically clean the polluted reverse osmosis membranes. First, use citric acid to pickle the reverse osmosis membrane to remove inorganic salt scale and metal ions on the surface of the membrane, and then use chlorine washing technology to clean the reverse osmosis membrane at a deeper level. Chlorine washing can not only remove biological fouling well, but also It also has a good bactericidal effect. Chlorine washing is to use hydrogen peroxide solution to chemically clean the membrane under the condition of a certain residual chlorine concentration. The practice of cleaning reverse osmosis polluted membranes through the combination of multiple on-site pickling and chlorine washing has proved that this technology can be fully promoted and implemented, and It is especially effective for reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com