Washing method for preventing reverse osmosis membrane or nano-filtration membrane from being polluted

A reverse osmosis membrane, reverse osmosis technology, applied in osmosis/dialysis water/sewage treatment, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem that microbubbles cannot achieve sufficient turbulence of gas-liquid two-phase flow and scrub membranes face, inability to provide sufficient shear force, and difficulty in restoring flux, etc., to avoid environmental pollution of concentrated water, reduce scale, and avoid mass use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

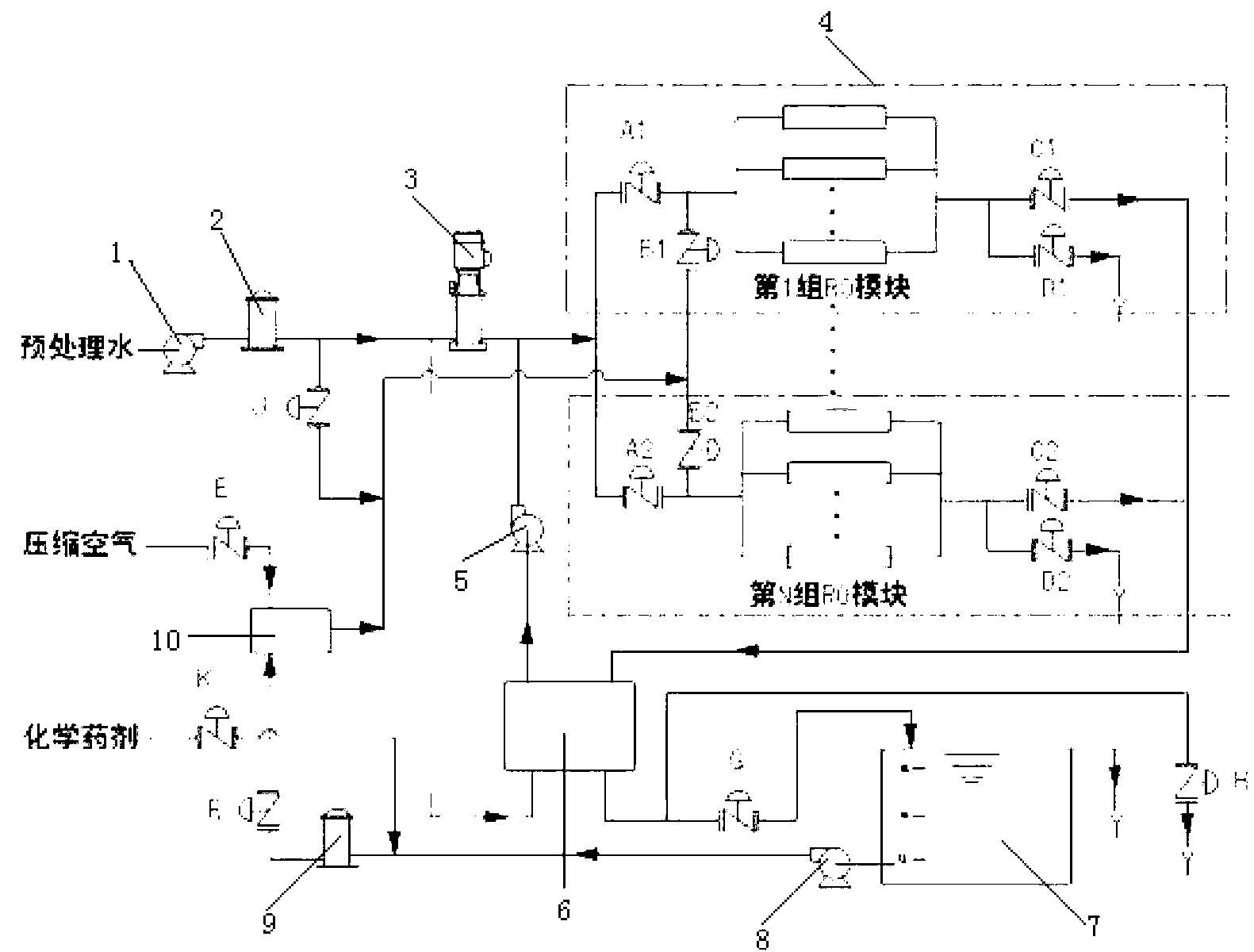

[0016] The reverse osmosis device involved in this embodiment adopts a one-stage reverse osmosis process and uses an energy recovery device. The reverse osmosis device is composed of a set of reverse osmosis modules. The set of modules has two reverse osmosis pressure vessels. The main structure of the reverse osmosis device includes Low pressure pump 1, security filter 2, high pressure pump 3, reverse osmosis module 4, booster pump 5, energy recovery device 6, reverse osmosis flushing water tank 7, flushing water pump 8, security filter 9, static mixer 10, inlet water Valves A1, A2, flushing water inlet valves B1, B2, concentrated water discharge valves C1, C2, flushing water discharge valves D1, D2, compressed air intake valve E, flushing water valve F, concentrated water flow regulating valve G, concentrated water Water flow regulating valve H, replacement valve J and dosing valve K; when the reverse osmosis module is working, it is divided into operating state and cleaning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com