Energy-saving DC frequency conversion water pump and its control method

A DC frequency conversion, water pump technology, applied in pump control, non-variable capacity pump, single motor speed/torque control, etc., can solve the problems of shortening the service life of the water pump, the water pump not working normally, and inconvenient assembly and maintenance. The overall structure design is compact, the structure design is ingenious, and the effect of easy assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

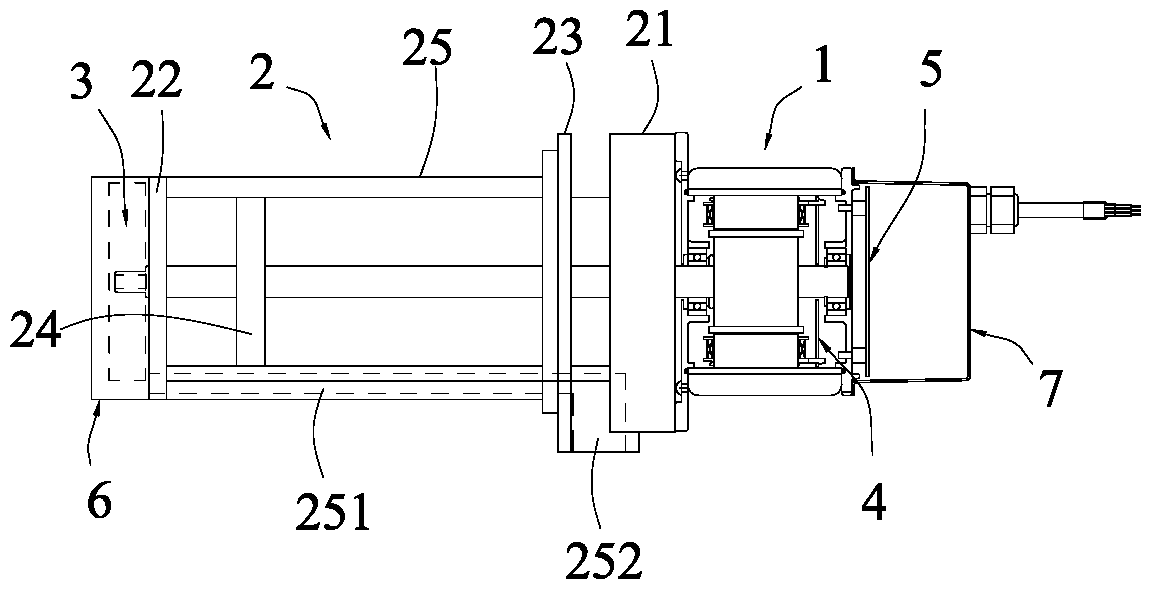

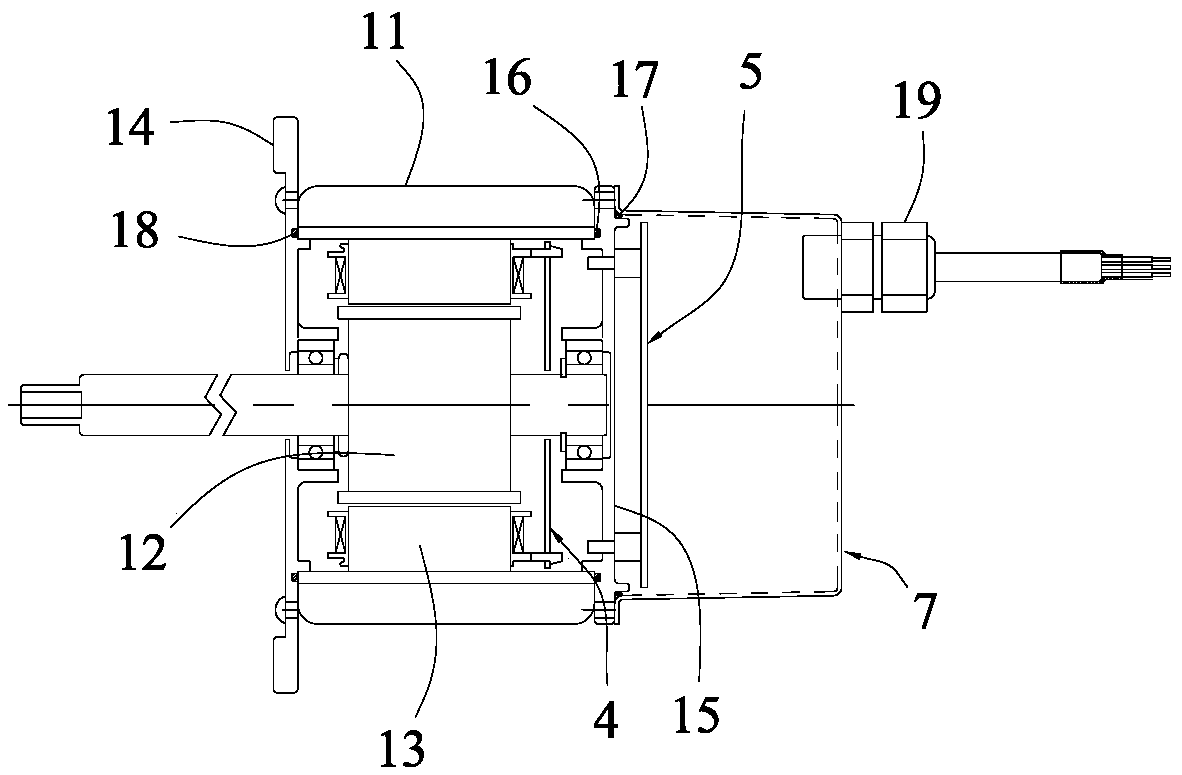

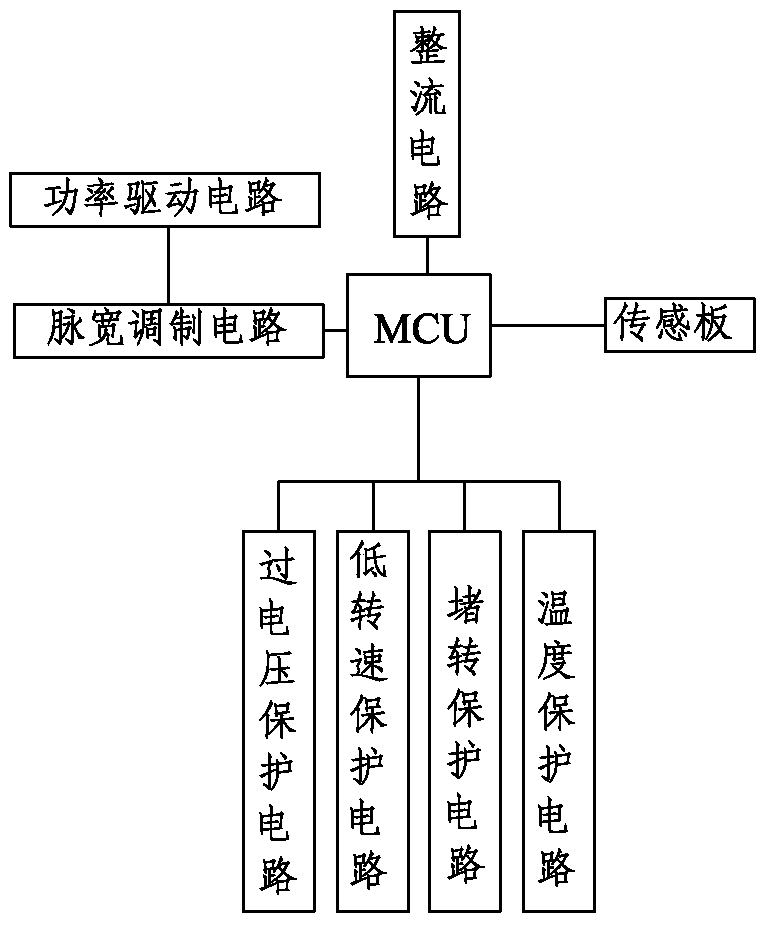

[0018] see figure 1 and figure 2 , an energy-saving DC variable frequency water pump provided in this embodiment, which includes a DC brushless motor 1, a bracket 2, an impeller 3, a sensor assembly 4, a drive circuit board 5, a front cover 6 and an electrical box 7, and the DC brushless The front end of the motor 1 group is fixed on the bracket 2, and the drive shaft of the DC brushless motor 1 group passes through the bracket 2 and extends out to form a mounting part, the impeller 3 is arranged on the mounting part, and the front end cover 6 is set on the bracket 2 and can cover the impeller 3, the sensor assembly 4 is set in the 1st brushless DC motor group, and the driving circuit board 5 is set in the 1st brushless DC motor set The tail end face is connected with the sensor assembly 4 and the DC brushless motor group 1 respectively. The electrical box 7 is arranged on the DC brushless motor group 1 and can cover the drive circuit board 5 . The sensing component 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com