Treating system and treating method for hardly degradable organic waste water

A technology for organic wastewater treatment and organic wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high operating costs and failure to reach circulating cooling water or boiler feed water Standard water use, inability to remove the hardness and salt content of refractory organic wastewater, to achieve the effects of prolonging life, excellent effluent quality, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

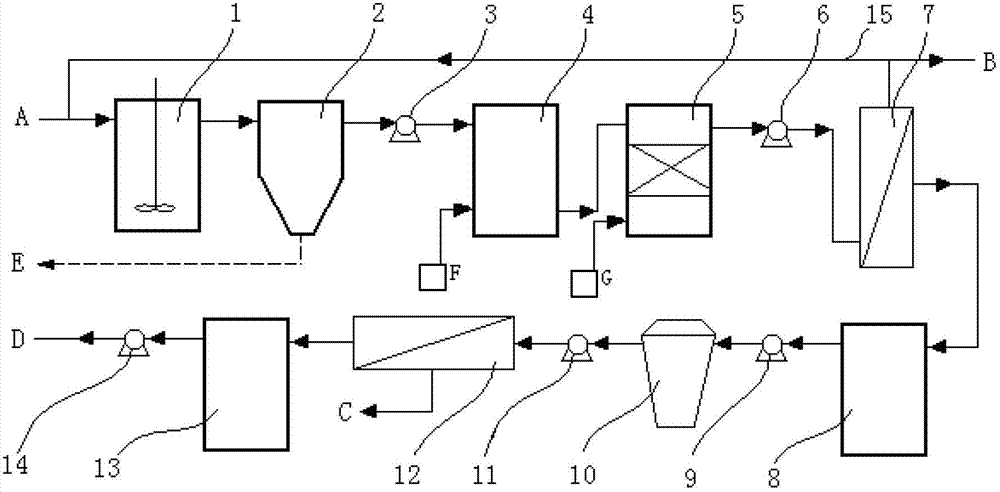

[0027] This embodiment provides a kind of refractory organic wastewater treatment system, such as figure 1 As shown, the treatment system includes: coagulation sedimentation treatment area, ozone reaction area, biological aerated filter treatment area, ultrafiltration treatment area and reverse osmosis treatment area;

[0028] Among them, the coagulation and sedimentation treatment area is connected with the biological aerated filter treatment area, the ultrafiltration treatment area, and the reverse osmosis treatment area in sequence, and the ultrafiltration concentrated water outlet of the ultrafiltration treatment area is connected back to the coagulation and sedimentation treatment area through the return pipeline. area, the water outlet of the reverse osmosis treatment area is used to connect with the recycling device.

[0029] The coagulation-sedimentation treatment area in the above-mentioned treatment system is formed by sequentially connecting the coagulation reaction...

Embodiment 2

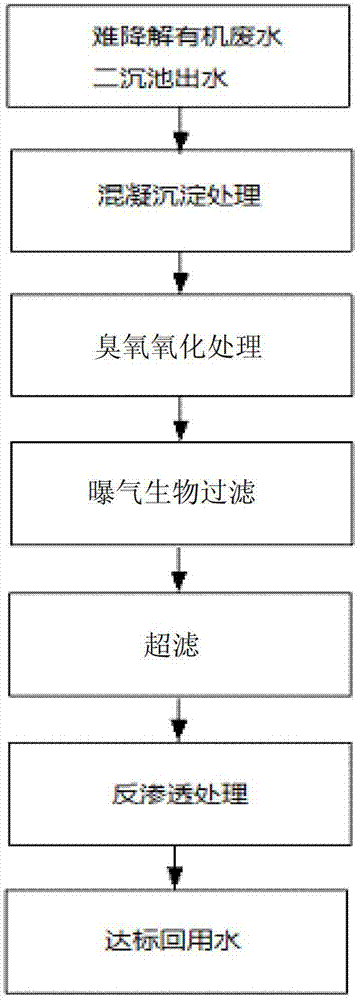

[0039] The embodiment of the present invention provides a method for advanced treatment of refractory organic wastewater, using the refractory organic wastewater treatment system given in the first embodiment above, such as figure 2 As shown, the method includes the following steps:

[0040] The effluent of the treated refractory organic wastewater after being settled in the secondary settling tank enters the coagulation-sedimentation treatment area of the system for coagulation-sedimentation treatment;

[0041] The effluent after coagulation and sedimentation treatment in the coagulation and sedimentation treatment area enters the ozone reaction area, and undergoes ozone oxidation treatment to remove part of the organic matter and improve the biodegradability of the wastewater;

[0042] The effluent after ozone oxidation treatment in the ozone reaction area enters the biological aerated filter treatment area, and the remaining organic matter in the water is removed by aera...

Embodiment 3

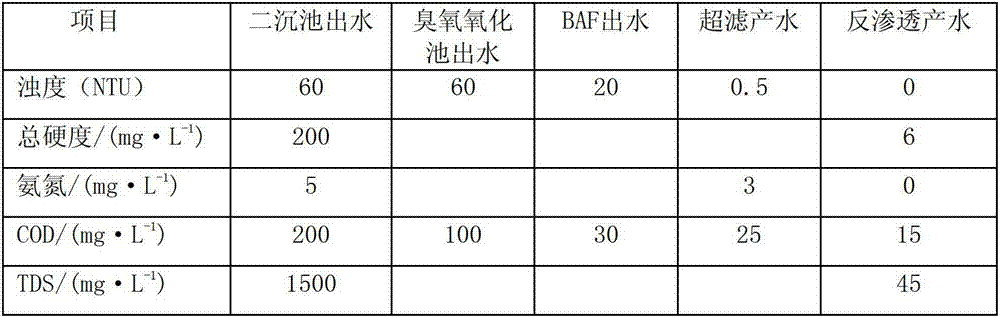

[0055] This embodiment provides a method for advanced treatment of refractory organic wastewater. The treatment system described in Example 1 is used to treat the refractory organic wastewater after being treated in a secondary sedimentation tank. The specific process is as follows:

[0056] The 280m3 / h effluent of the refractory organic wastewater secondary sedimentation tank enters the coagulation reaction tank and then enters the coagulation sedimentation tank after adding the flocculant PAC. Gas biofilter, the effluent of aerated biological filter enters the intermediate pool, the effluent of the intermediate pool is lifted by the ultrafiltration feed water pump as a lifting pump, and then enters the ultrafiltration equipment, the ultrafiltration effluent enters the ultrafiltration water production pool, and the ultrafiltration production crystal lift pump lifts After entering the reverse osmosis equipment, 210m3 / h reverse osmosis produced water is reused, and 70m3 / h revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com