Patents

Literature

250 results about "Reverse osmosis desalination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reverse Osmosis (RO) desalination uses the principle of osmosis to remove salt and other impurities, by transferring water through a series of semi-permeable membranes. Thermal desalination uses heat, often waste heat from power plantsor refineries, to evaporate and condense water to purify it.

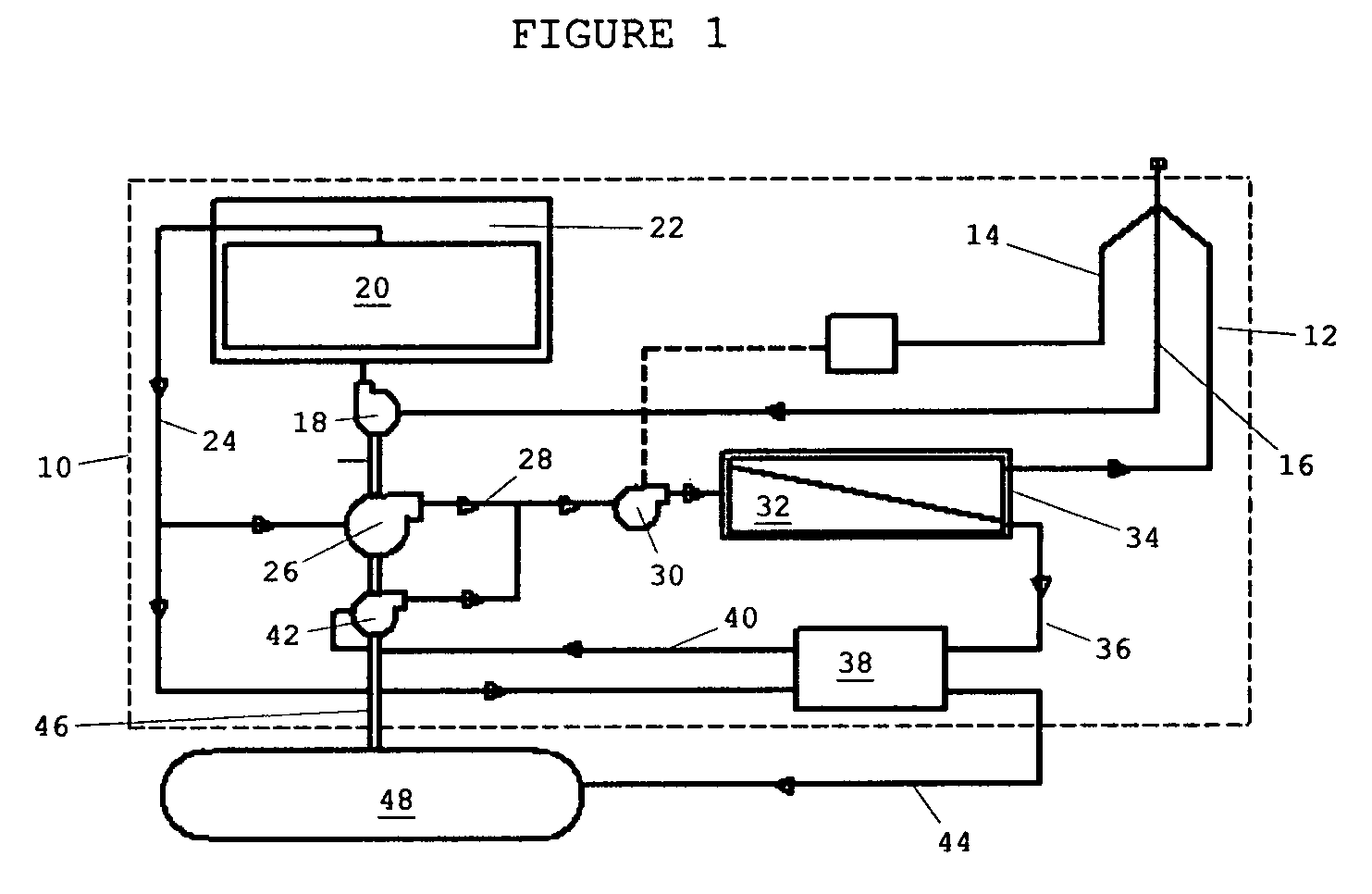

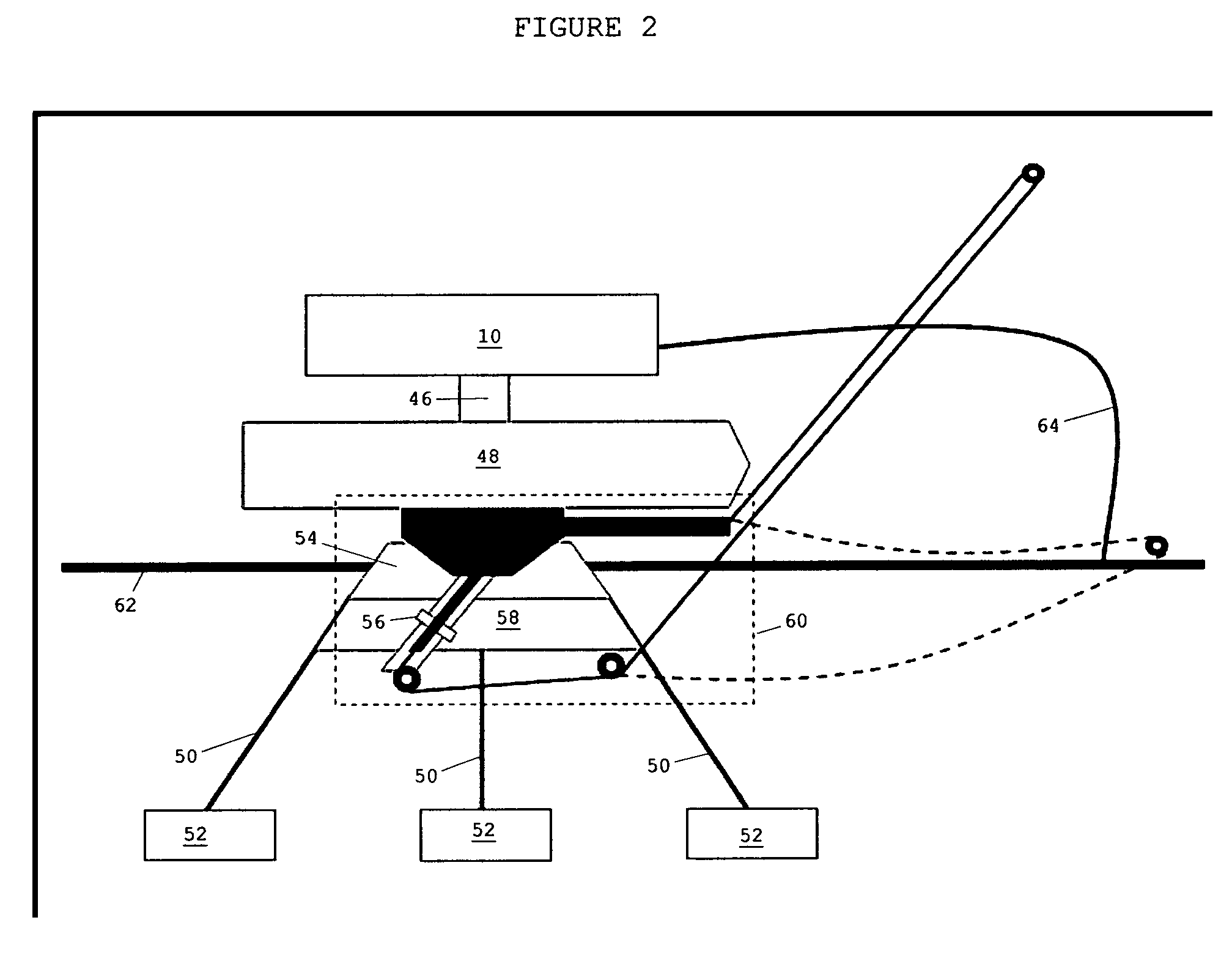

Wave energy conversion device for desalination, ETC

InactiveUS7023104B2Improve efficiencyEasy to operateWind motor controlGeneral water supply conservationWater qualityEngineering

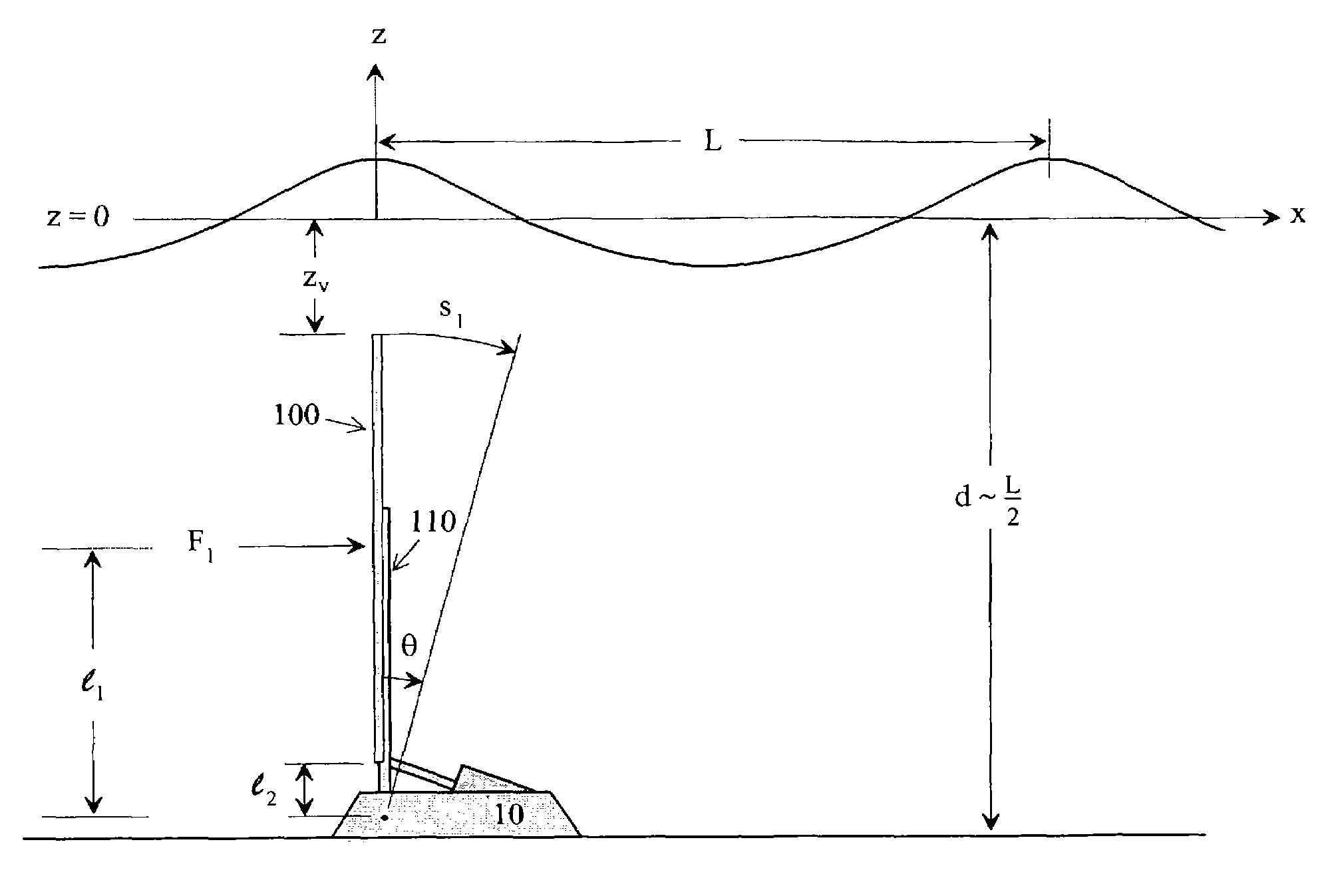

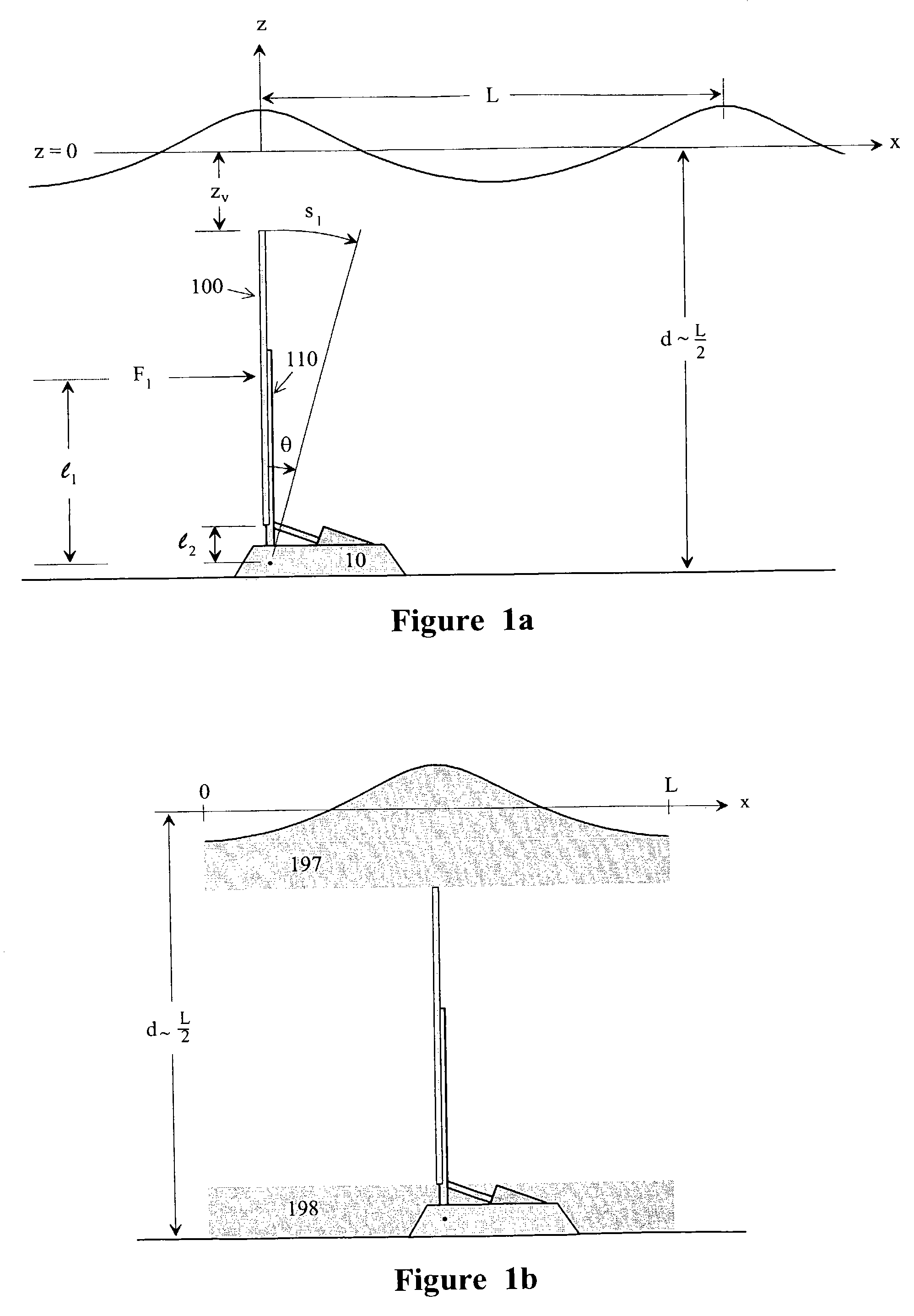

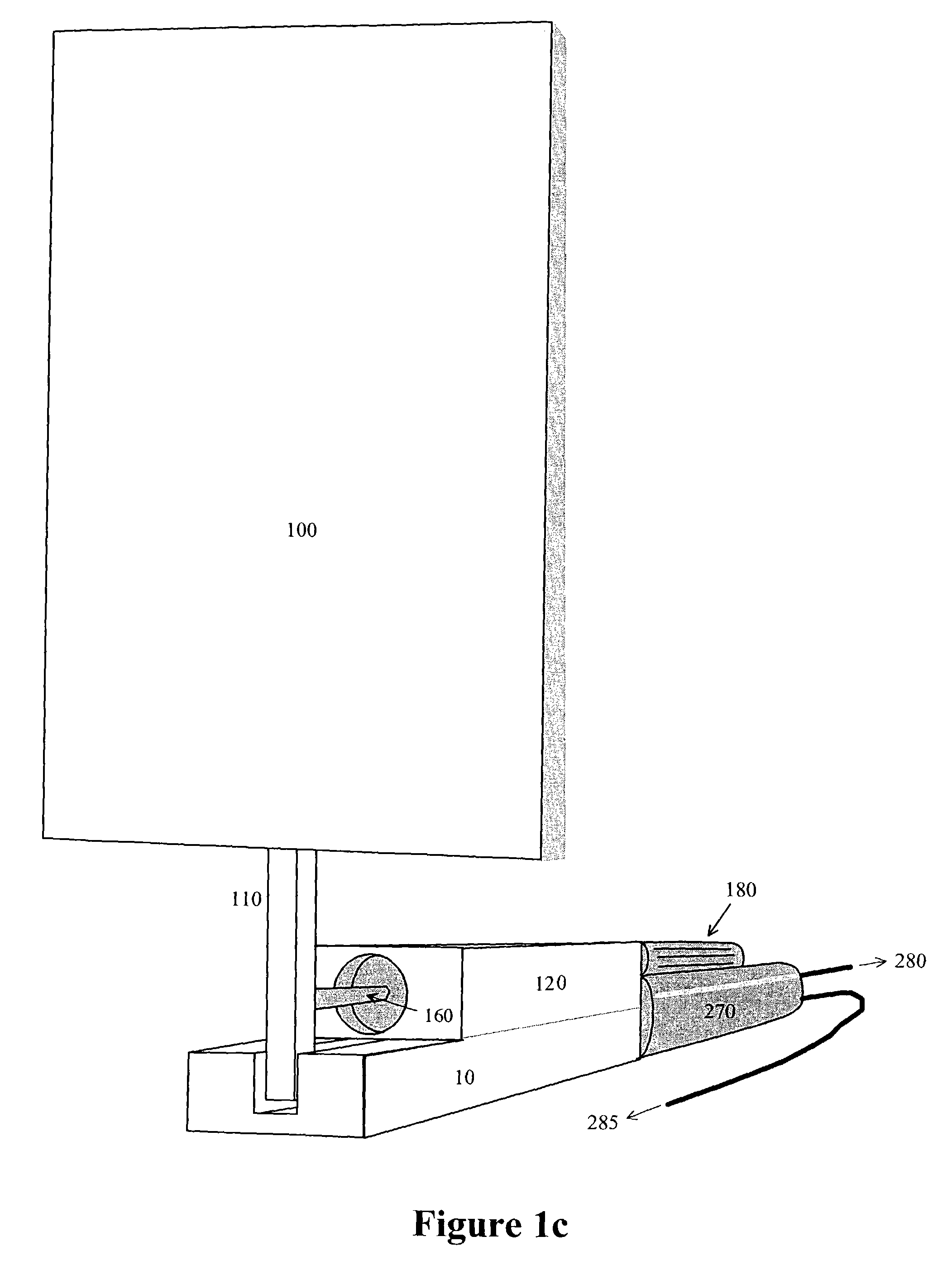

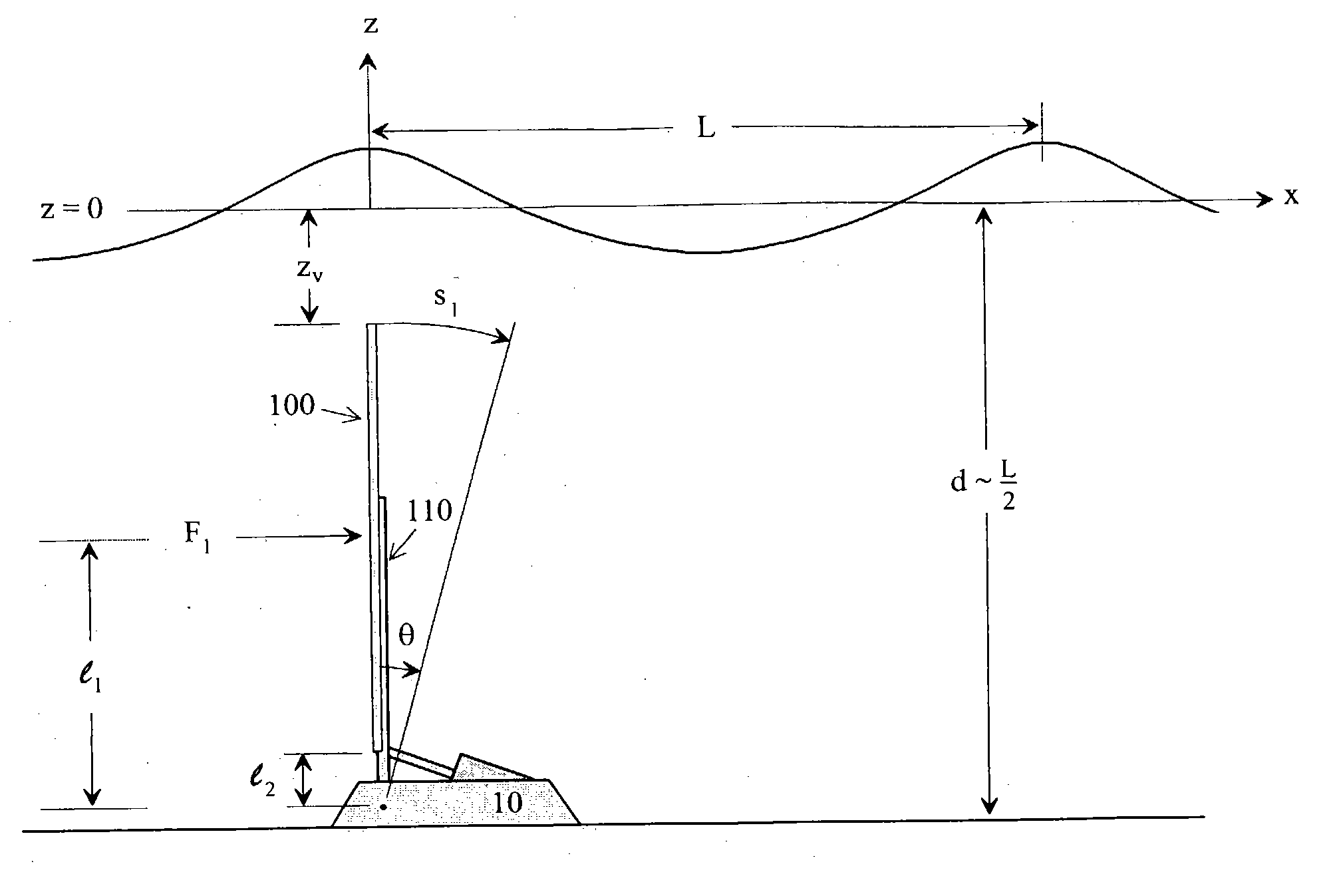

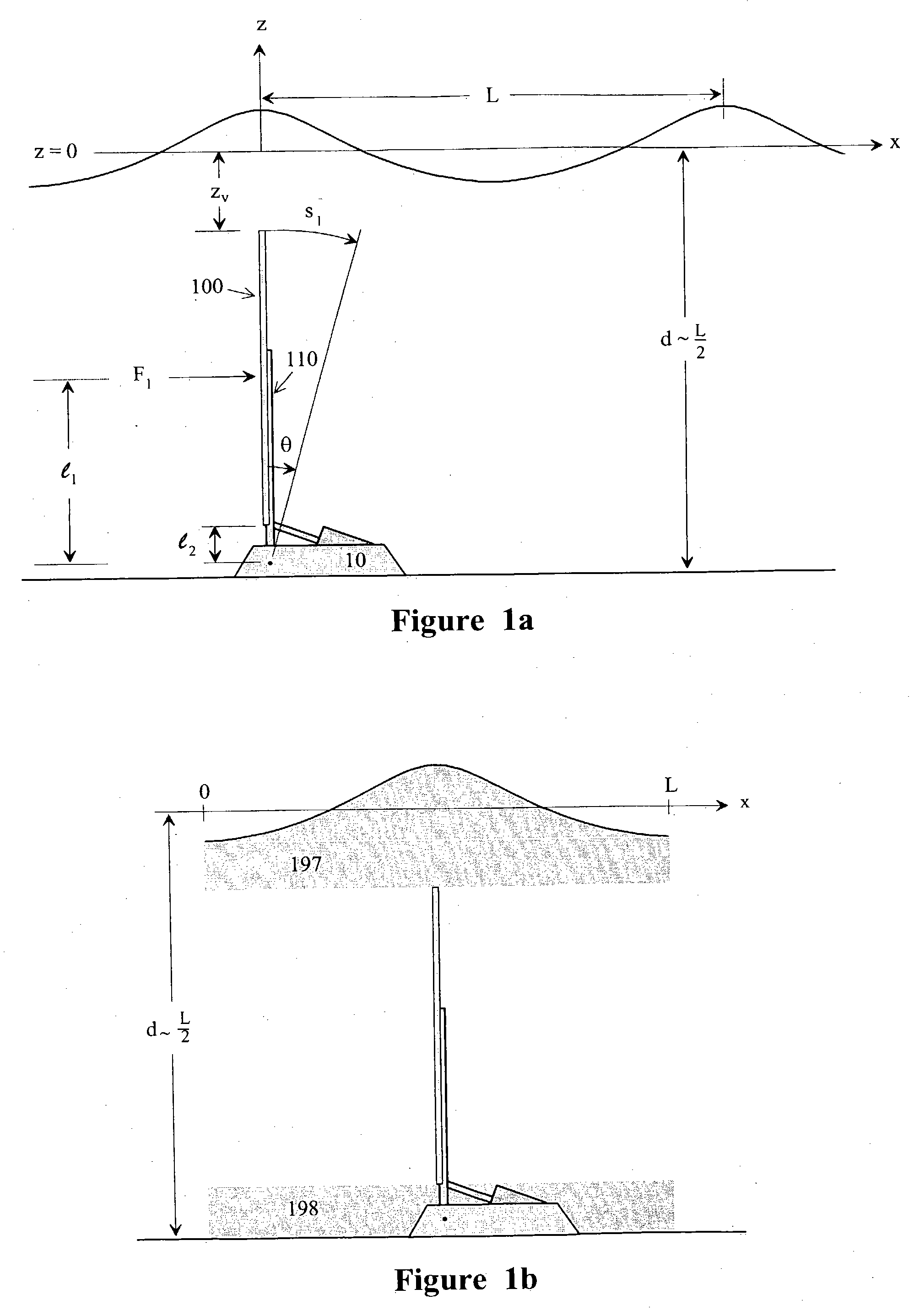

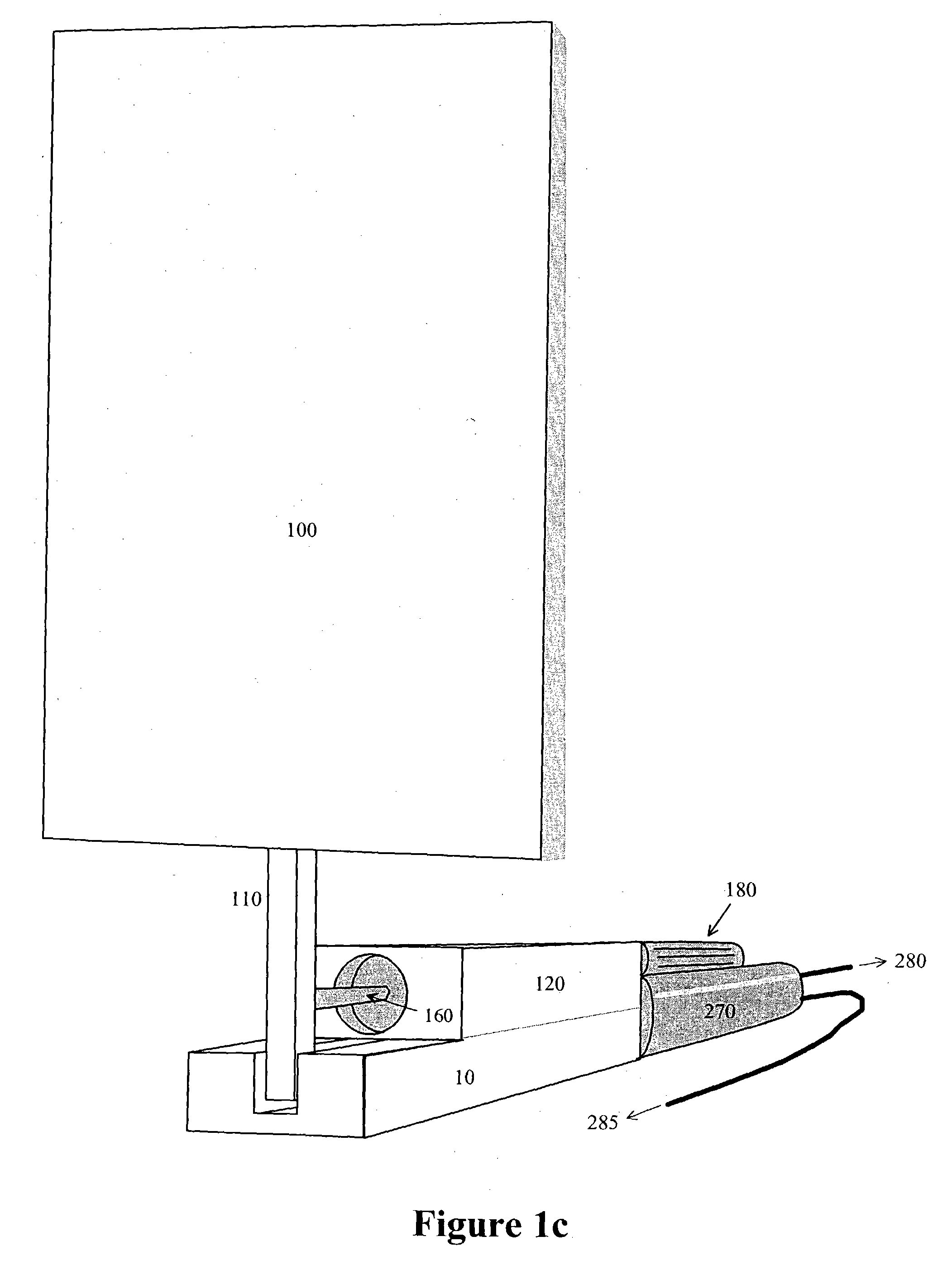

An impulse-type “wave motor” employs a seabed-mounted or supported structure mounting a wave energy absorbing panel on a hinged lever arm for reciprocation motion to obtain optimal absorption of wave energy from wave motion in the sea. For deepwater wavelengths of L, the panel is optimally positioned in a region within L / 2 depth from the sea surface. The panel motion is coupled by a connecting rod to a fluid pump which generates a high-pressure fluid output that may be used to drive a reverse osmosis desalination unit or to produce other useful work. Seawater or brackish water may be desalinated through reverse osmosis membranes to produce water quality for consumption, agricultural, or other uses. The submerged operating environment of the device in a region of one-half the design wavelength provides the maximum available energy flux and forced oscillations. The pump may be of the positive-displacement piston type, plunger type, or multi-staging driver type, or a variable volume pump.

Owner:KOBASHIKAWA ALVIN +1

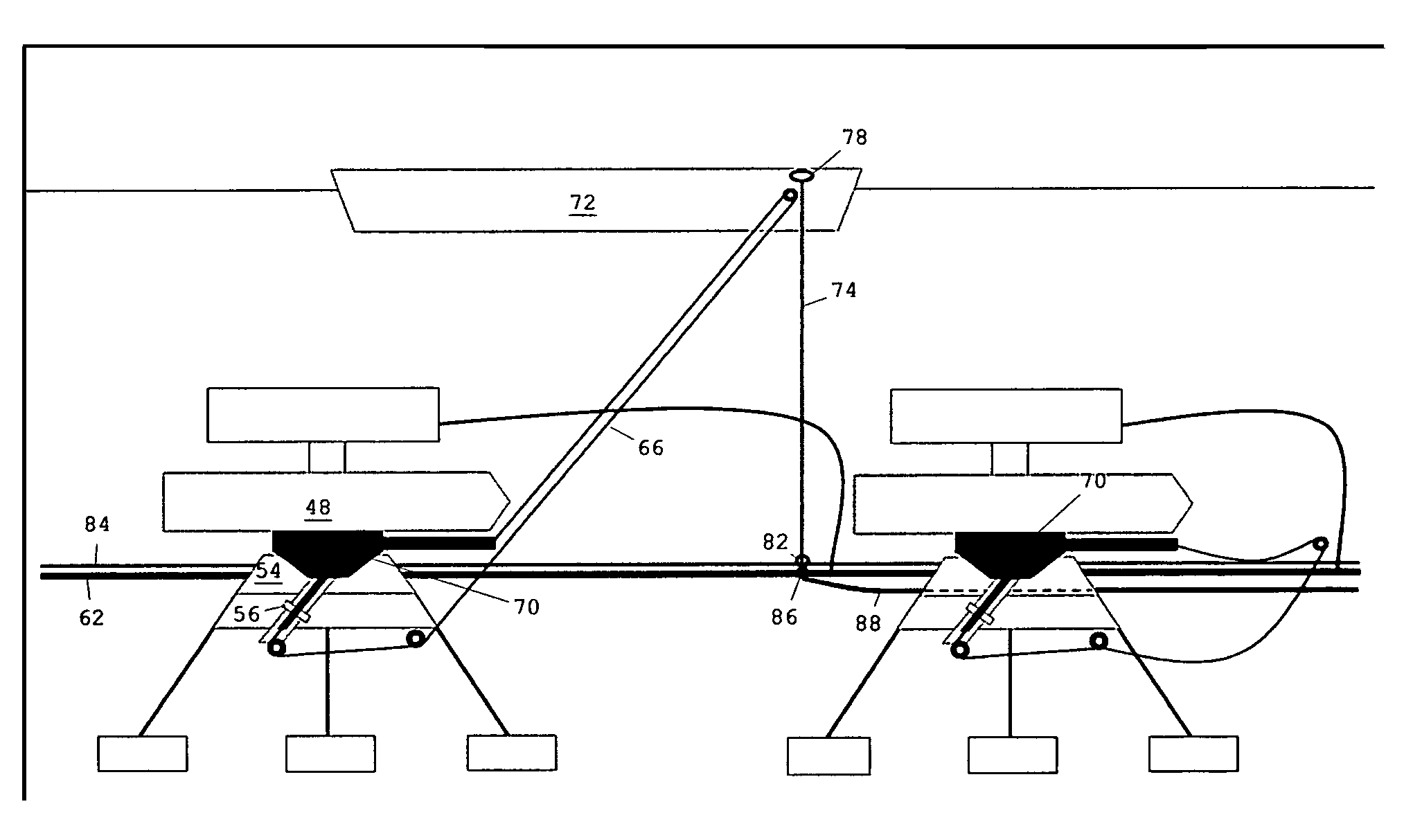

Wave energy conversion device for desalination, ETC

InactiveUS20040007881A1Minimize exposureLow profileWind motor controlGeneral water supply conservationWater qualityWave motor

An impulse-type "wave motor" employs a seabed-mounted or supported structure mounting a wave energy absorbing panel on a hinged lever arm for reciprocation motion to obtain optimal absorption of wave energy from wave motion in the sea. For deepwater wavelengths of L, the panel is optimally positioned in a region within L / 2 depth from the sea surface. The panel motion is coupled by a connecting rod to a fluid pump which generates a high-pressure fluid output that may be used to drive a reverse osmosis desalination unit or to produce other useful work. Seawater or brackish water may be desalinated through reverse osmosis membranes to produce water quality for consumption, agricultural, or other uses. The submerged operating environment of the device in a region of one-half the design wavelength provides the maximum available energy flux and forced oscillations. The pump may be of the positive-displacement piston type, plunger type, or multi-staging driver type, or a variable volume pump.

Owner:KOBASHIKAWA ALVIN +1

Strong brine energy recovery device based on reverse osmosis desalination technology

InactiveCN100341609CGuaranteed uptimeReduce consumptionGeneral water supply conservationReverse osmosisHydraulic cylinderSaline water

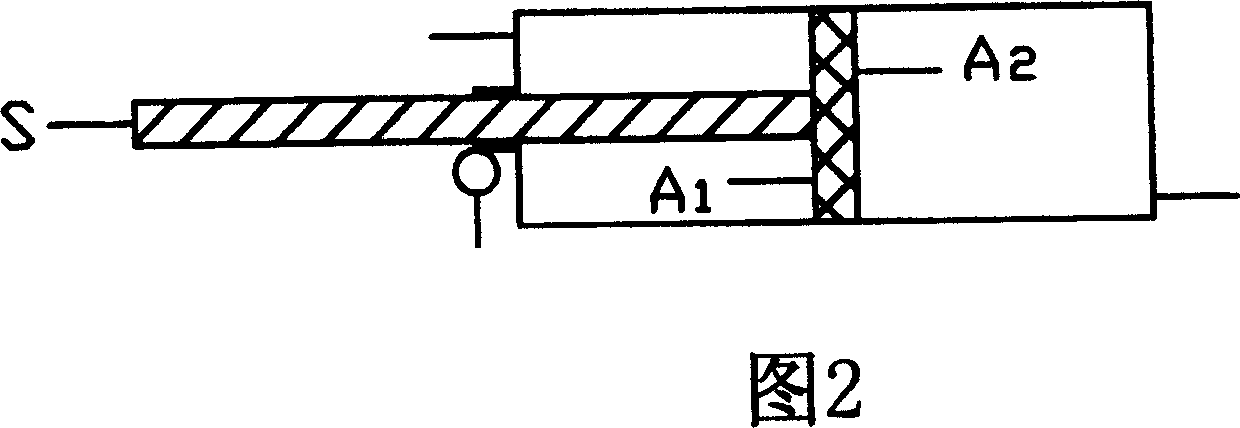

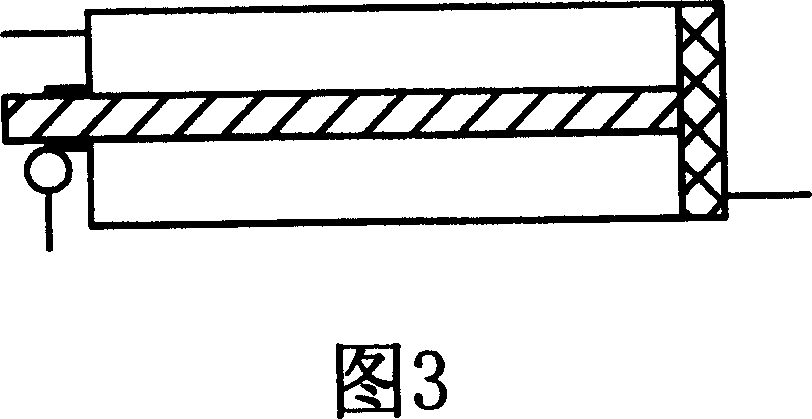

This invention discloses energy-recovery device for strong brine based on desalination technique by reverse osmosis, which comprises hydraulic cylinder with guide bar connected to piston; water inlet three-way solenoid valve with one end connected to end of guide bar, and other two ends connected separately to water outlets of low and high pressure water-feed pumps; drainage three-way solenoid valve with one end connected to the hydraulic cylinder end far away guide bar, and other two ends connected to strong brine discharge pipes of reverse osmosis membrane; sensor, to obtain the position signal of piston; controller, to control the synchronized open and shut of two aforementioned three-way solenoid valves. It has high efficiency, runs stably, switches quickly and fit to spread in industry.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

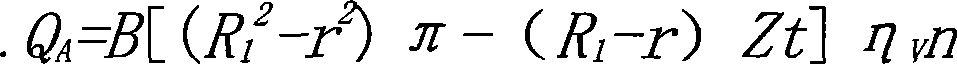

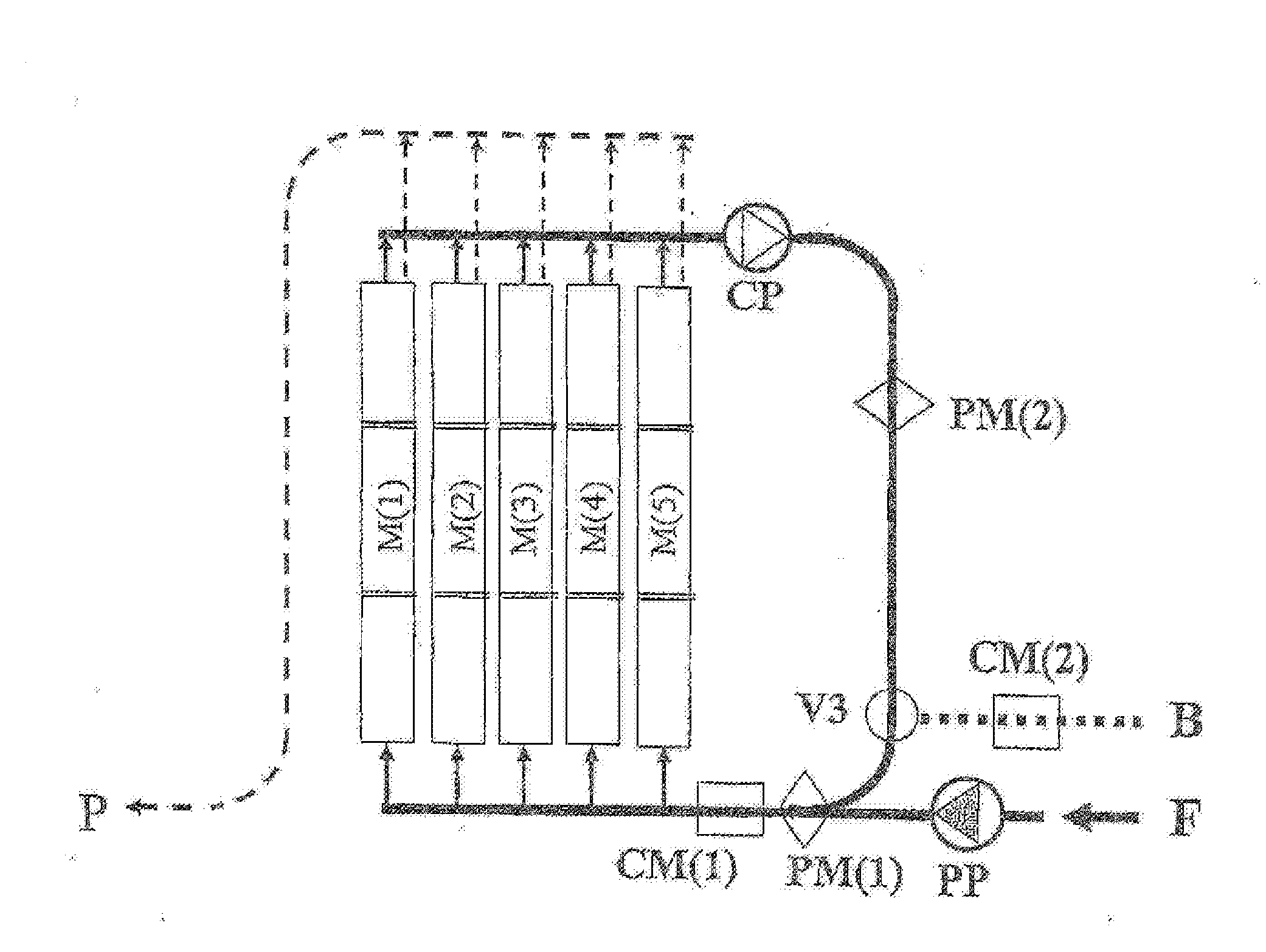

Continuous Closed-Circuit Desalination Apparatus Without Containers

ActiveUS20080023410A1Simple inexpensive designFewer power componentsGeneral water supply conservationSeawater treatmentSaline waterControl system

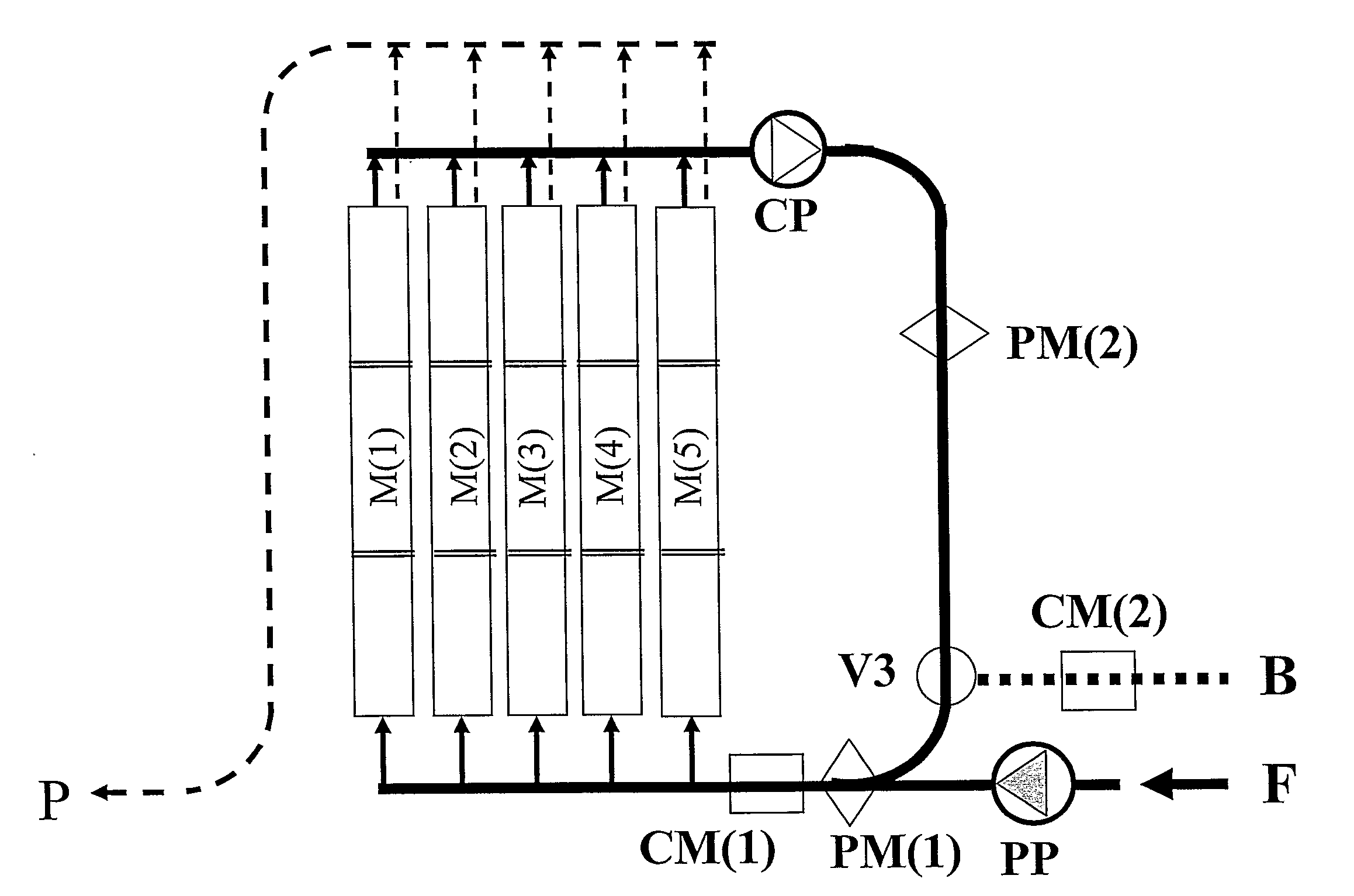

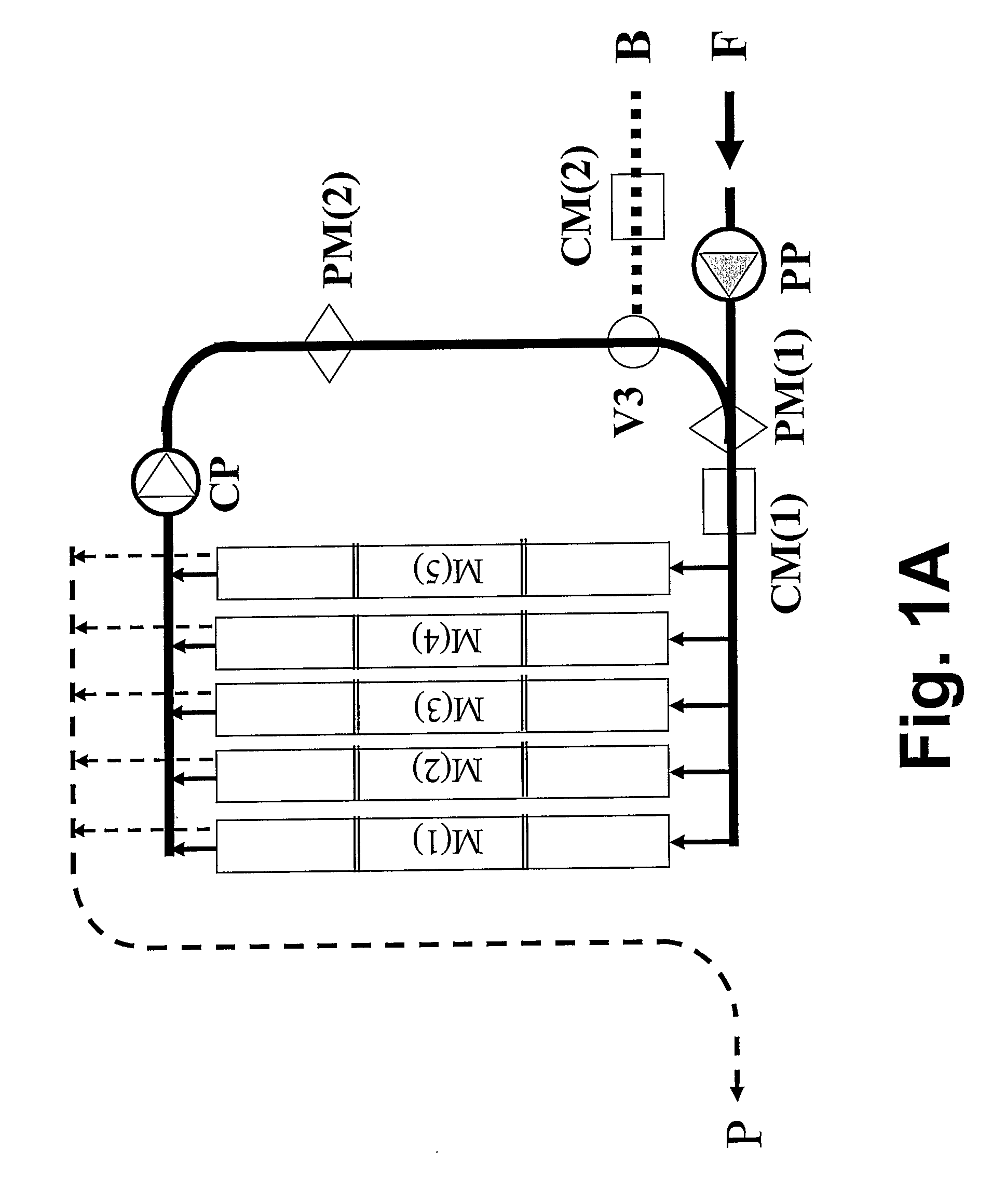

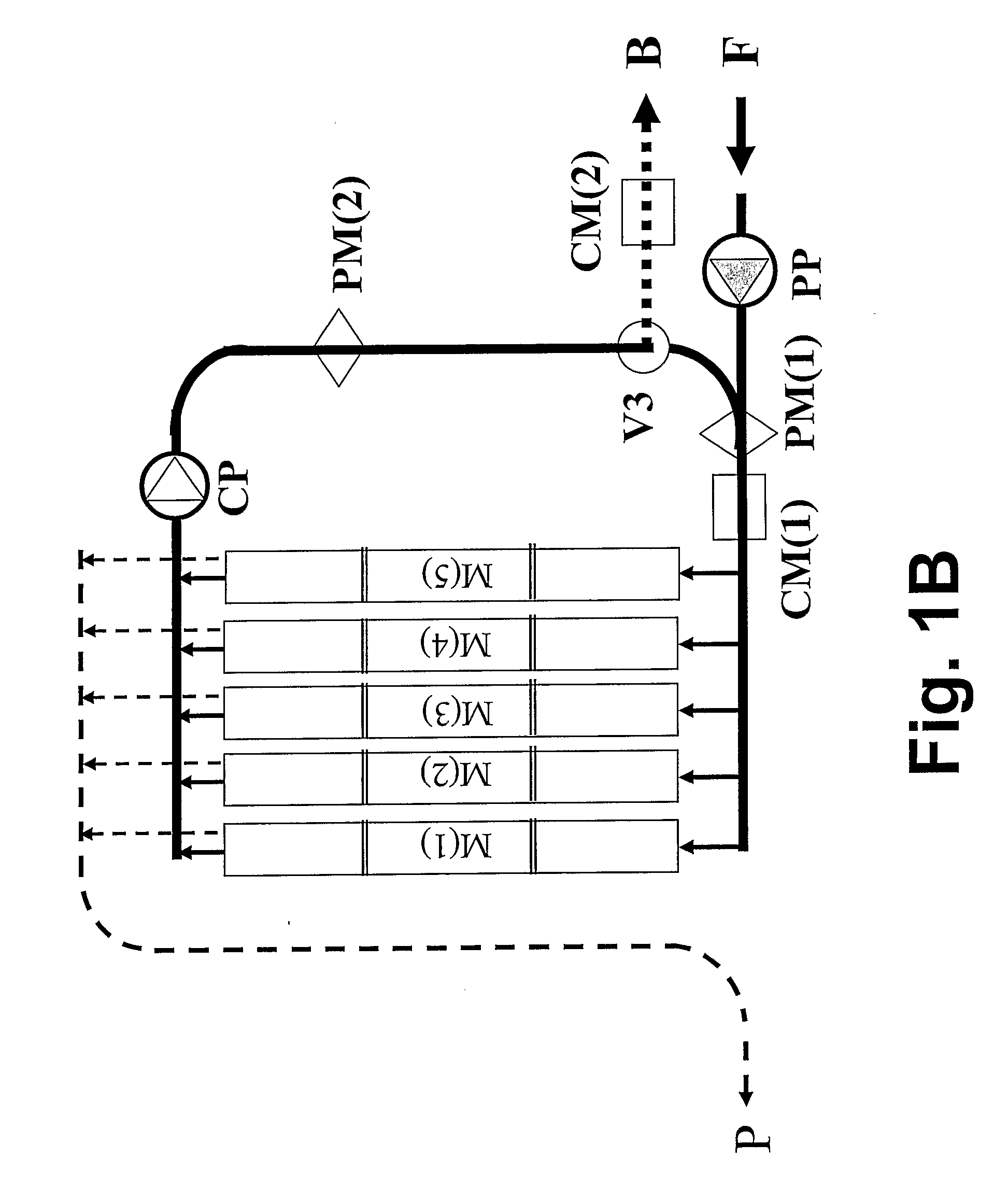

An apparatus for continuous closed-circuit consecutive sequential desalination of a salt water solution by reverse osmosis that comprises a closed circuit system comprising one or more desalination modules having their respective inlets and outlets connected in parallel by conducing lines, each of desalination modules comprising of one or more membrane elements, a pressurizing device for creating counter pressure to enable reverse osmosis desalination and replacement of released permeate by fresh, a circulation system for recycling the desalinated solution through the desalination modules, a conducting line systems for permeate collection from the desalination modules, a conducting line system for removing brine effluent a valve system to enable periodic discharge of brine from the closed circuit without stopping desalination, and monitoring and control systems to enable continuous closed circuit desalination of desired recovery proceed in consecutive sequential steps under variable or constant pressure conditions.

Owner:DESALITECH

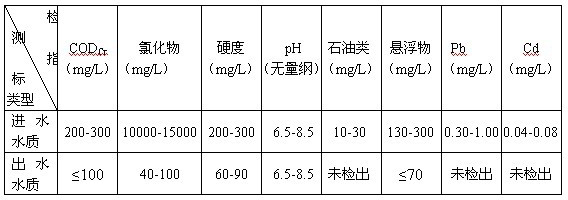

Electroplating wastewater treatment reclaiming technique

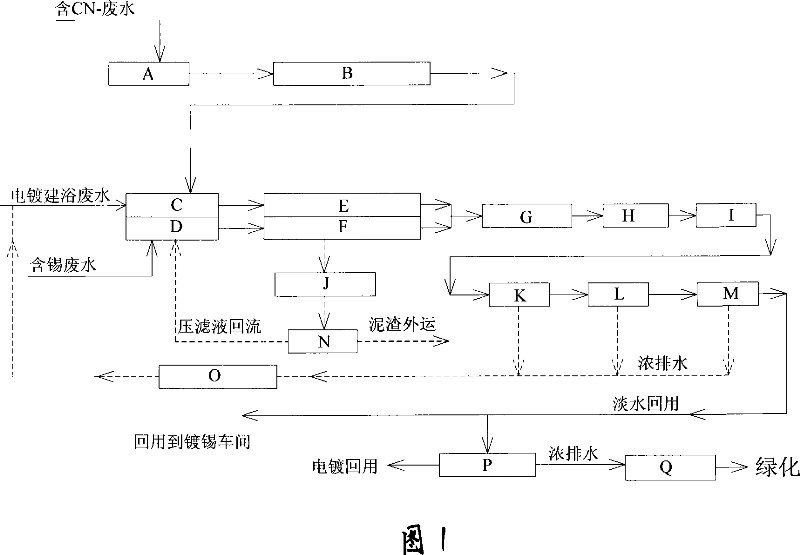

ActiveCN101041534AReduce contentHigh desalination rateTreatment using aerobic processesGeneral water supply conservationFiltrationUltrafiltration

The invention discloses a reclaimed craft to dispose electroplating waste water, which comprises the following steps: adopting oxidation-reduction and chemical precipitation disposing method and film technology (fold filtration, hyperfiltration, Na filtration and reverse osmosis desalination) deep purifying method; avoiding accumulation of salt effectively; reverse osmosis sloughing monovalent salt at last grade; trapping bivalent salt in innocent treatment system; proceeding depositing treatment continually; removing accumulating BOD and COD in water body through biochemical treatment effectively; realizing zero discharge of waste water.

Owner:JINAN JINGHENG ELECTRONICS

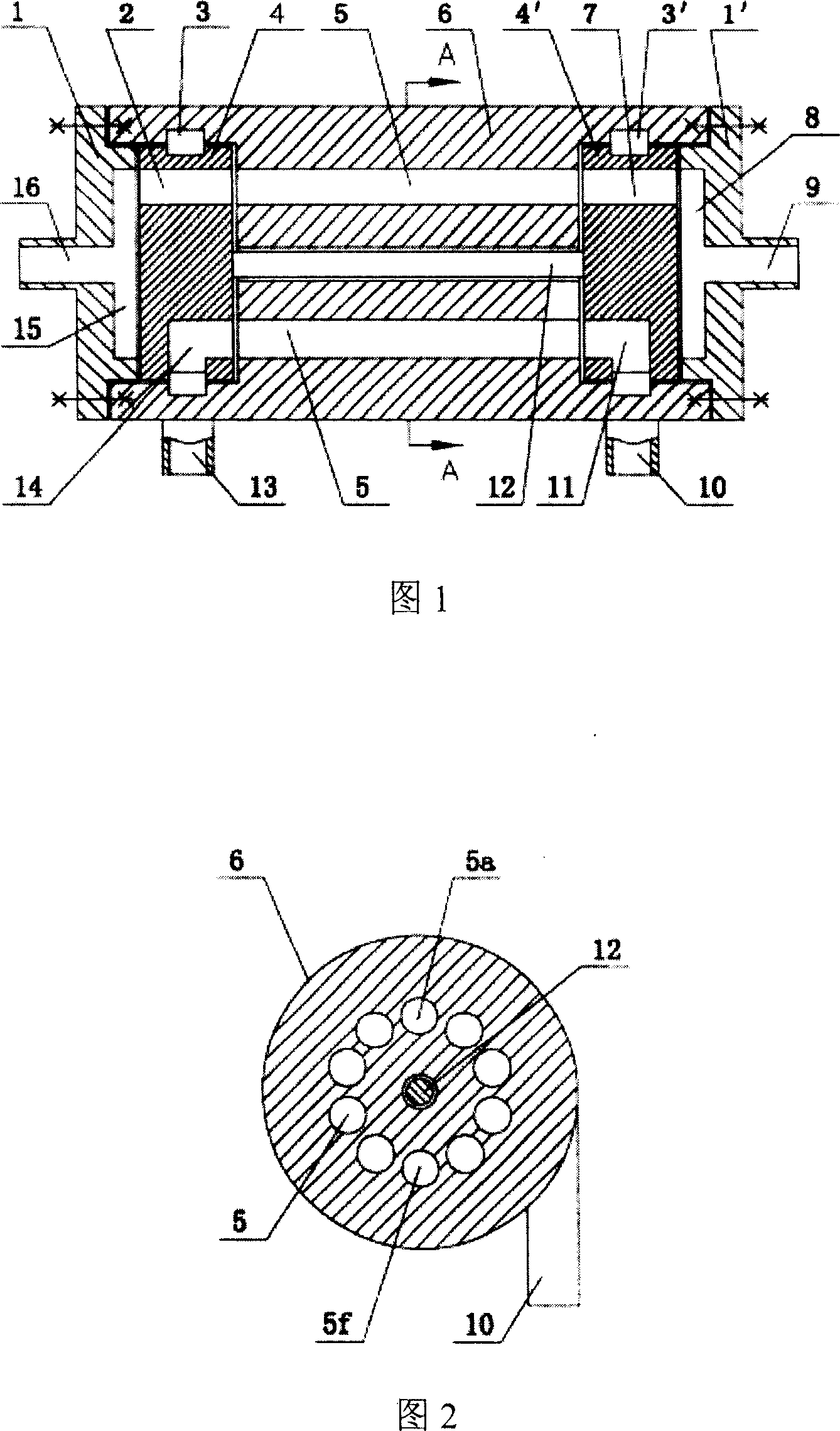

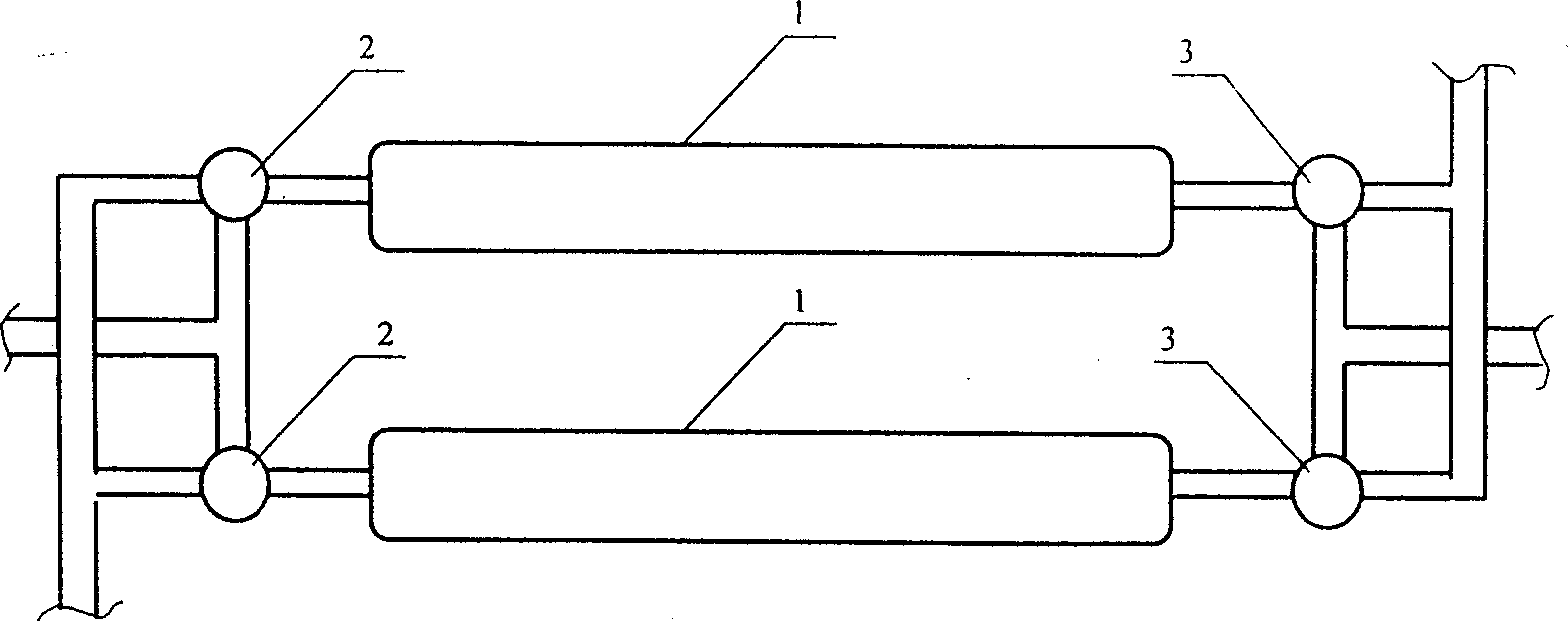

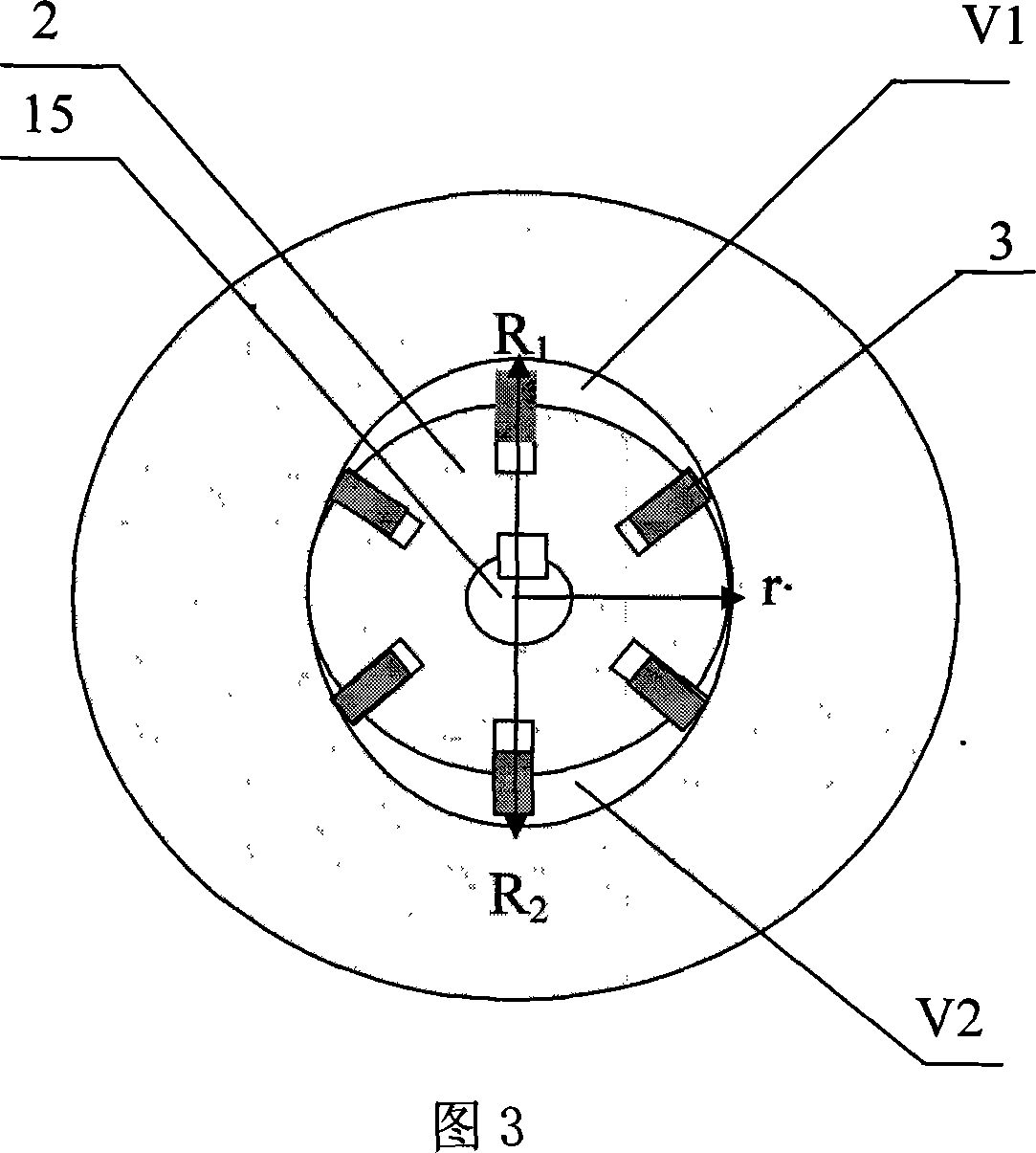

Double-dial coupled type pressure exchanger for sea water or brine reverse osmosis desalination system

InactiveCN1994905AReduce rotation speedIncrease the processing load of a single machineGeneral water supply conservationSeawater treatmentSaline waterCoupling

The invention discloses a double-rotary disc coupling typed pressure exchanger of seawater or bitter saline water reverse osmosis desalination system, which comprises the following parts: cylinder, left rotary disc, right rotary disc, left end lid, right end lid and middle axle. The invention increases single set disposing load of pressure exchanger, which reduces rotary speed to flow working liquid continuity and stability.

Owner:TIANJIN UNIV

Coking wastewater deep treatment and reuse process and equipment thereof

InactiveCN101746923AGuaranteed uptimeImprove biodegradabilityGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisProcess equipmentSludge

The invention discloses a coking wastewater deep treatment and reuse process and equipment thereof, belonging to the technical field of environmental protection, and the main steps are as follows: dosing a coagulant in biochemical treatment water, then leading the biochemical treatment water to enter into a sedimentation tank, discharging sludge from a sludge hopper, leading treated water to enter into a three-dimensional electrode reactor, leading the outlet water after electro-oxidation treatment to enter into a biological filter tank, and leading the water after the treatment of the biological filter tank to enter into a follow-up ultrafiltration treatment; the ultrafiltration outlet water has two selections, one is to reuse the outlet water as the process water directly, the other one is to continuously pass through a reverse osmosis membrane system for treatment; and the coagulation and sedimentation tank, the process equipment of the three-dimensional electrode reactor, the biological filter tank, the ultrafiltration system and the reverse osmosis desalination system are adopted during the treatment process, thereby achieving the purposes of removing residual refractory organic matters, suspended impurities and salt in the waste water, reusing the outlet water, simultaneously leading the content of the organic matters in the reverse osmosis concentrated water not to exceed the national environmental protection standard, also reusing the concentrated water in occasions with less stringent requirements on the water quality and achieving the purpose of zero emission of the wastewater.

Owner:赵立功

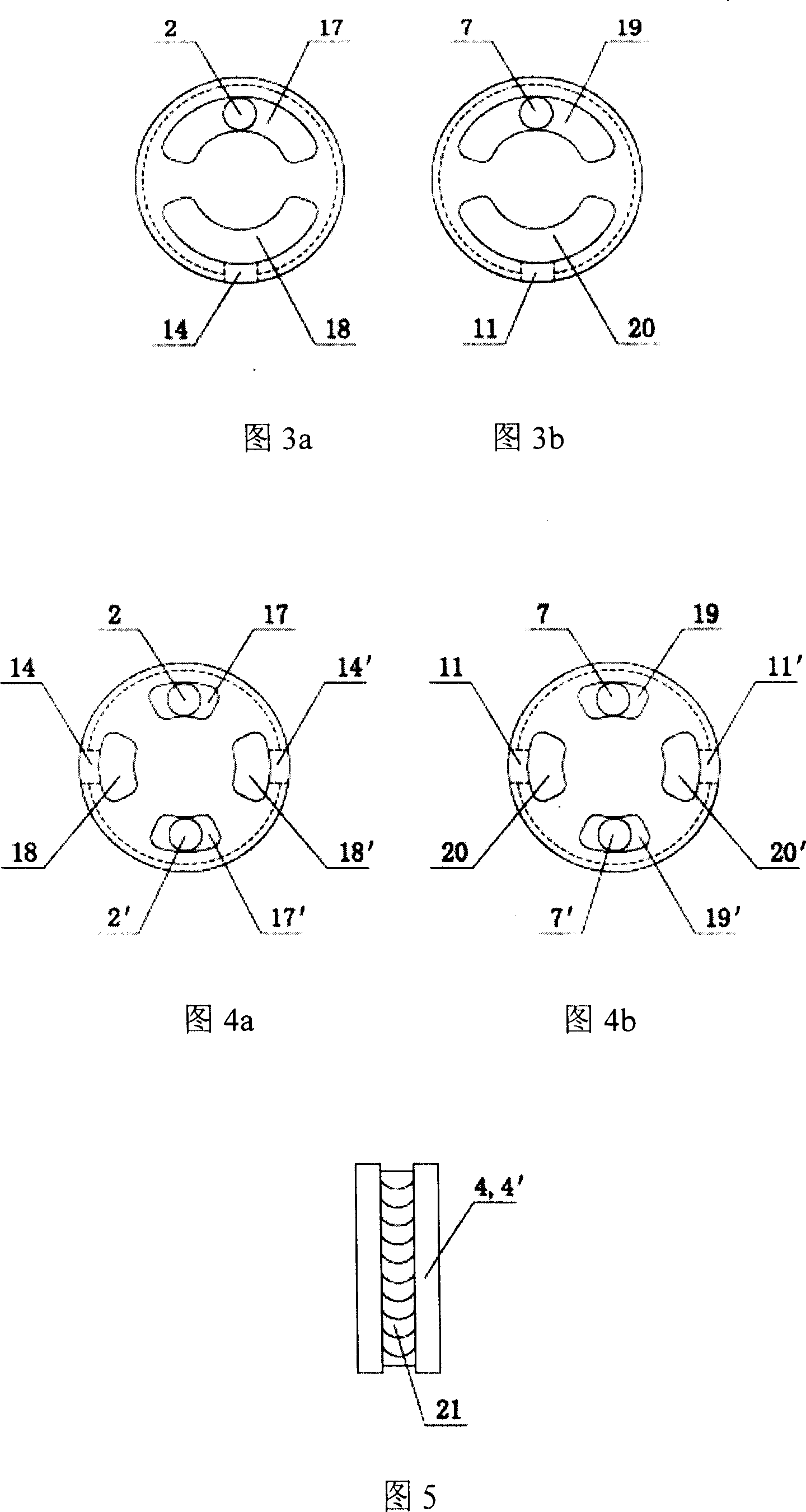

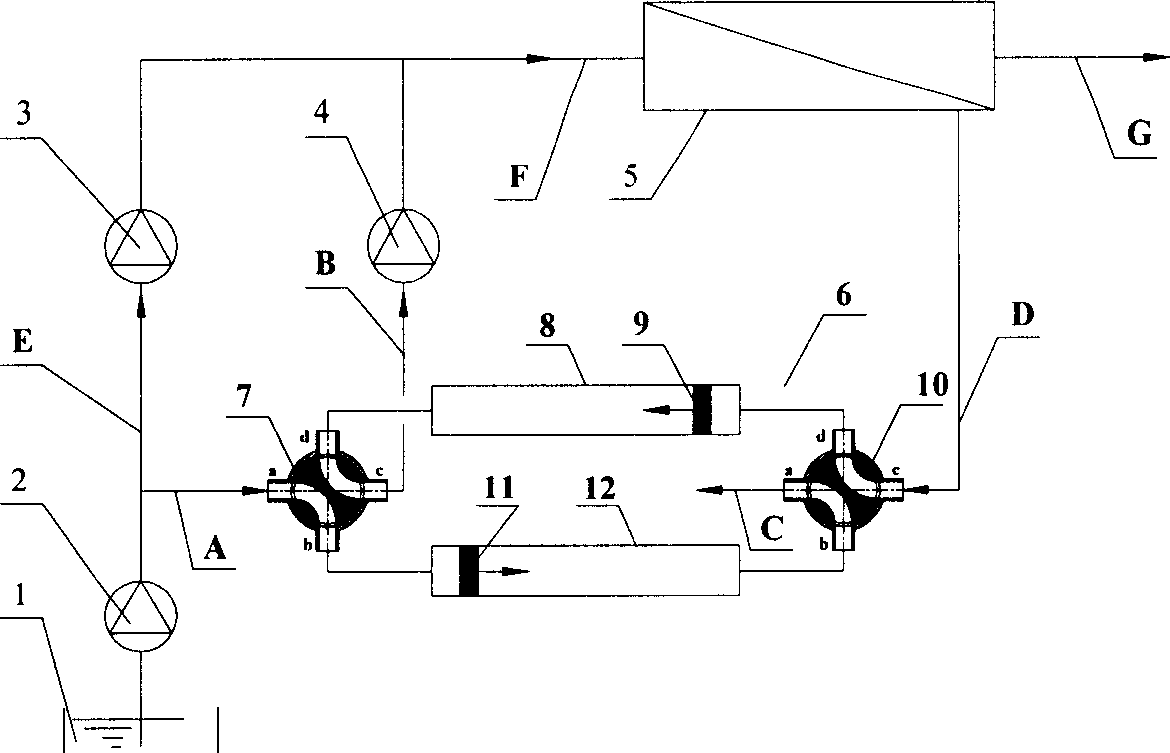

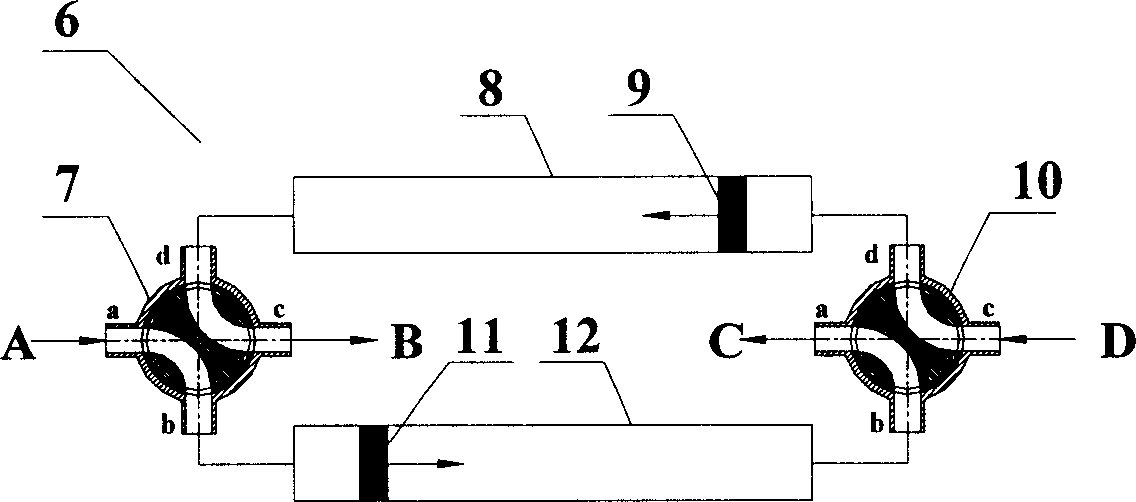

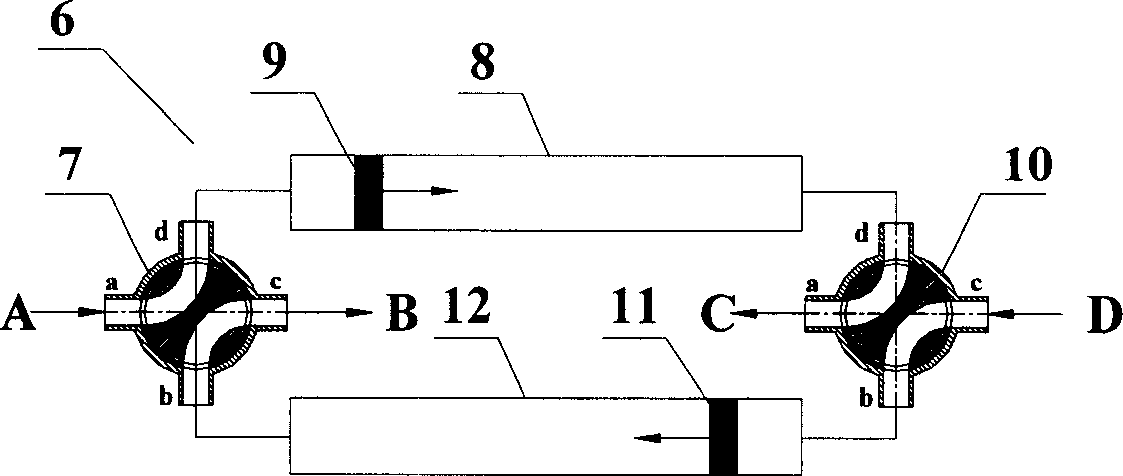

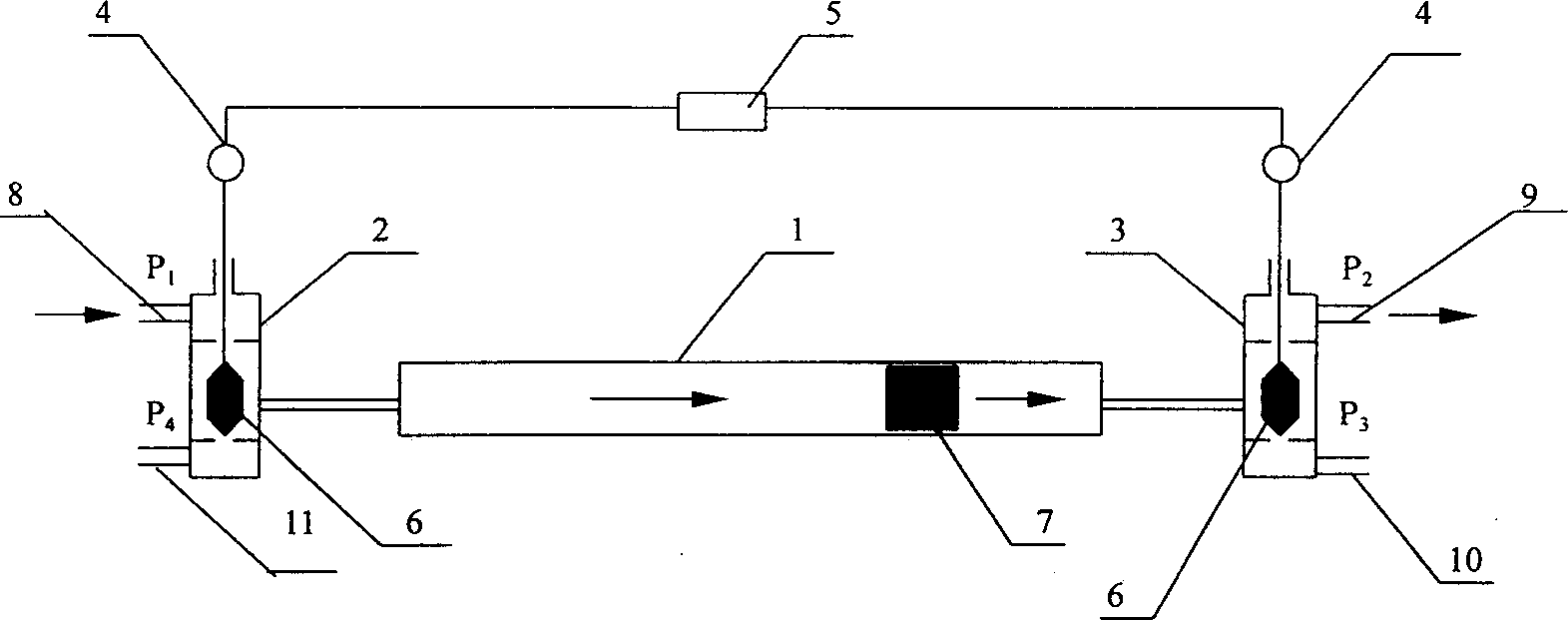

Energy-saving reverse osmosis desalting process and device for seawater/brackish water

InactiveCN1733615AFlexible realization of reverse osmosis desalination processReduce operating energy consumptionGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisSaline waterBrackish water

The invention discloses an energy-saving reverse-osmosis desalination technique for seawater / salt water. Wherein, using lifting water pump to force some seawater / salt water into water cylinder by transfer valve to push piston and extrude strong brine on another side and discharge from another valve, and other seawater / salt water into reverse-osmosis membrane from high-pressure pump to discharge strong brine into another water cylinder and push piton to extrude seawater / salt water on another side into reverse-osmosis membrane from transfer valve and booster pump; adjusting and switching the operation of valves to realize desalination process. The said equipment also comprises energy-recovery device with transfer valves on two ends that composes of valve body, lining and valve core with two flow paths; there are four connection ports distributed evenly on the valve body and core. This method is flexible and reliable.

Owner:TIANJIN UNIV

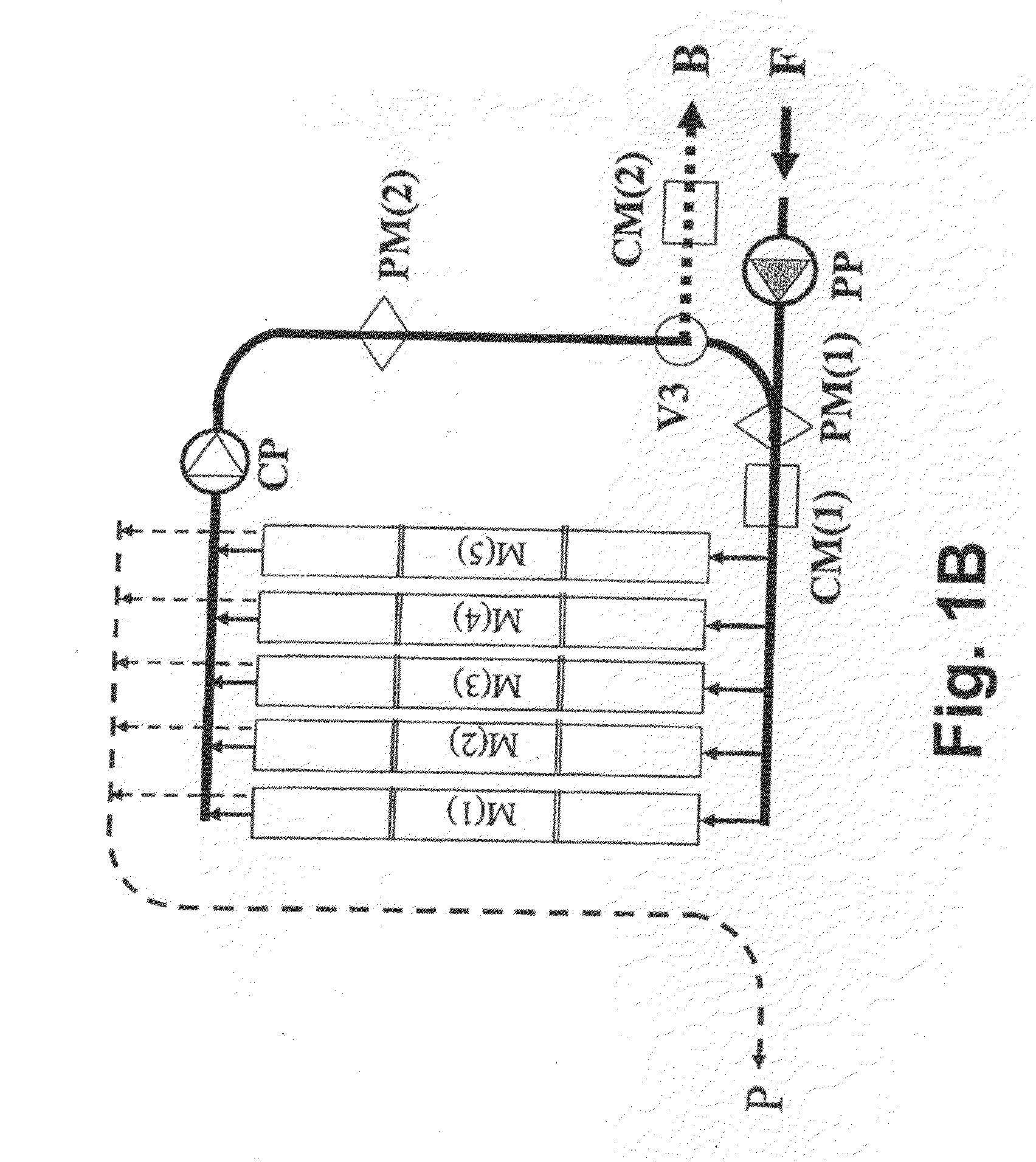

Submersible reverse osmosis desalination apparatus and method

Owner:TON THAT HUY

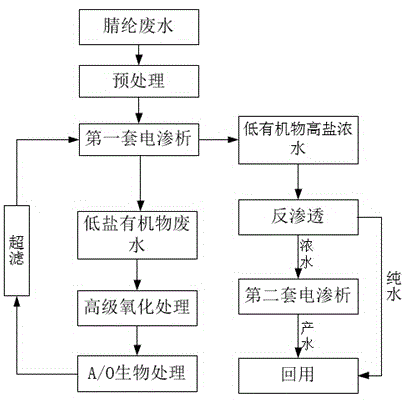

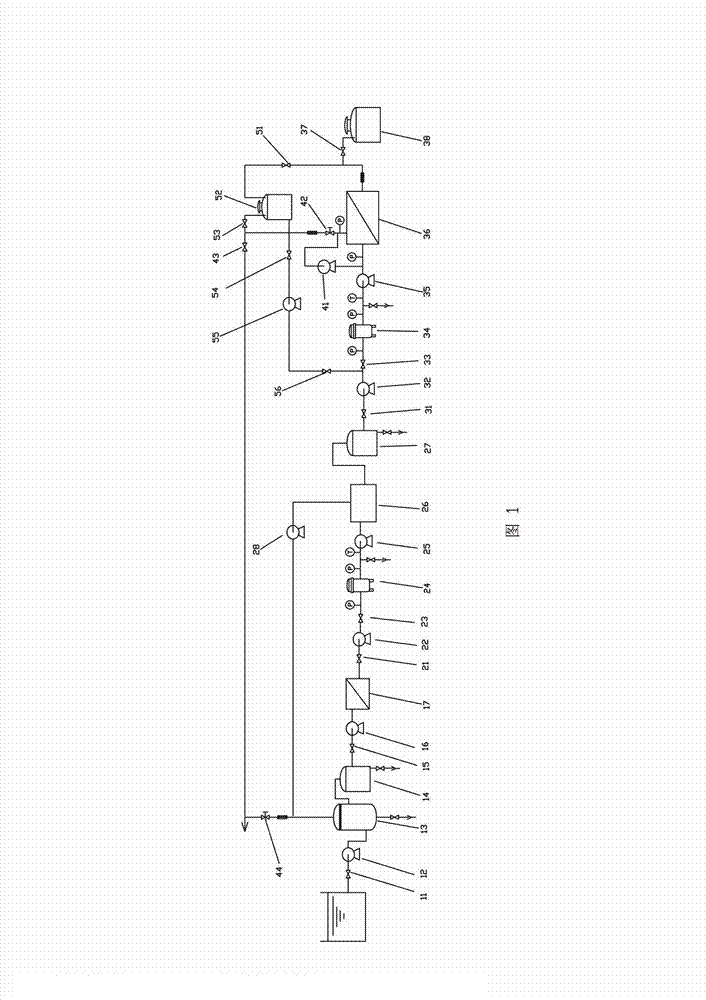

Treatment process for acrylic fiber waste water

ActiveCN104150722AEfficient degradationImprove processing efficiencyGeneral water supply conservationMultistage water/sewage treatmentSeparation technologyEnvironmental engineering

The invention discloses a treatment process for acrylic fiber waste water. The acrylic fiber waste water is pretreated and then is subjected to first-set electrodialysis separation to obtain organic waste water with low salt content and high-salinity concentrated water containing organic matters with low concentration; the organic waste water with the low salt content is subjected to advanced oxidation treatment to improve the biodegradability, and then is subjected to A / O biological treatment to reach the standard; the high-salinity concentrated water containing the organic matters with the low concentration is subjected to reverse osmosis desalination to obtain purified water and reverse osmosis concentrated water; the purified water is used for production; the reverse osmosis concentrated water is subjected to second-set electrodialysis concentration to produce water. According to the process method provided by the invention, on the basis of an advanced oxidation technology and a biological treatment technology, the degradation of refractory organics and macromolecule organic matters which are difficult to naturally settle is realized relatively fully and effectively by comprehensively utilizing a membrane separation technology; the degraded waste water is recycled; the obtained purified water can be used for production, so the resourceful treatment is really realized.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

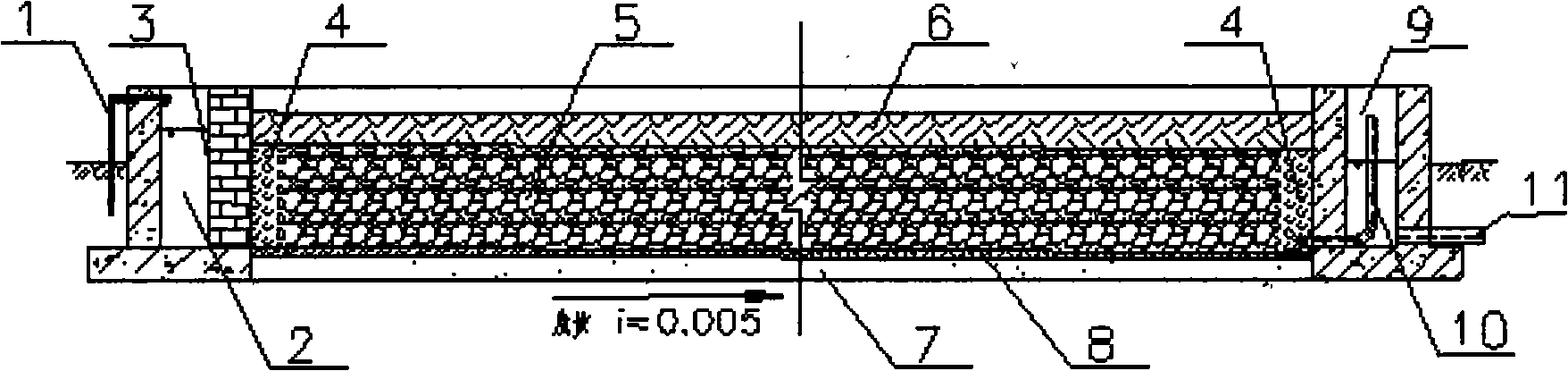

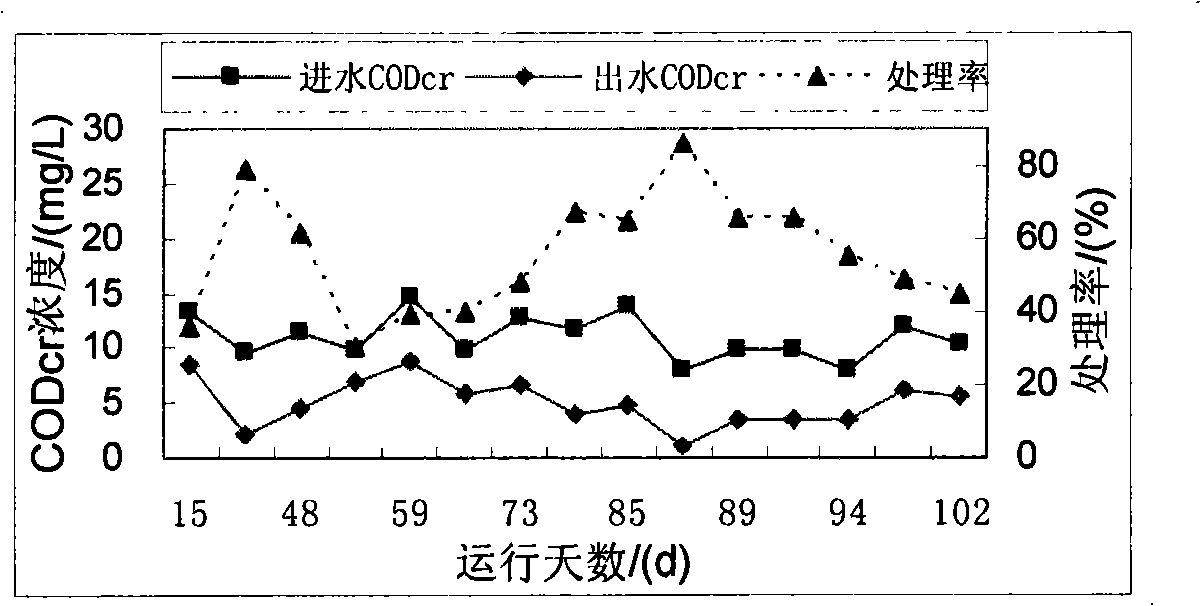

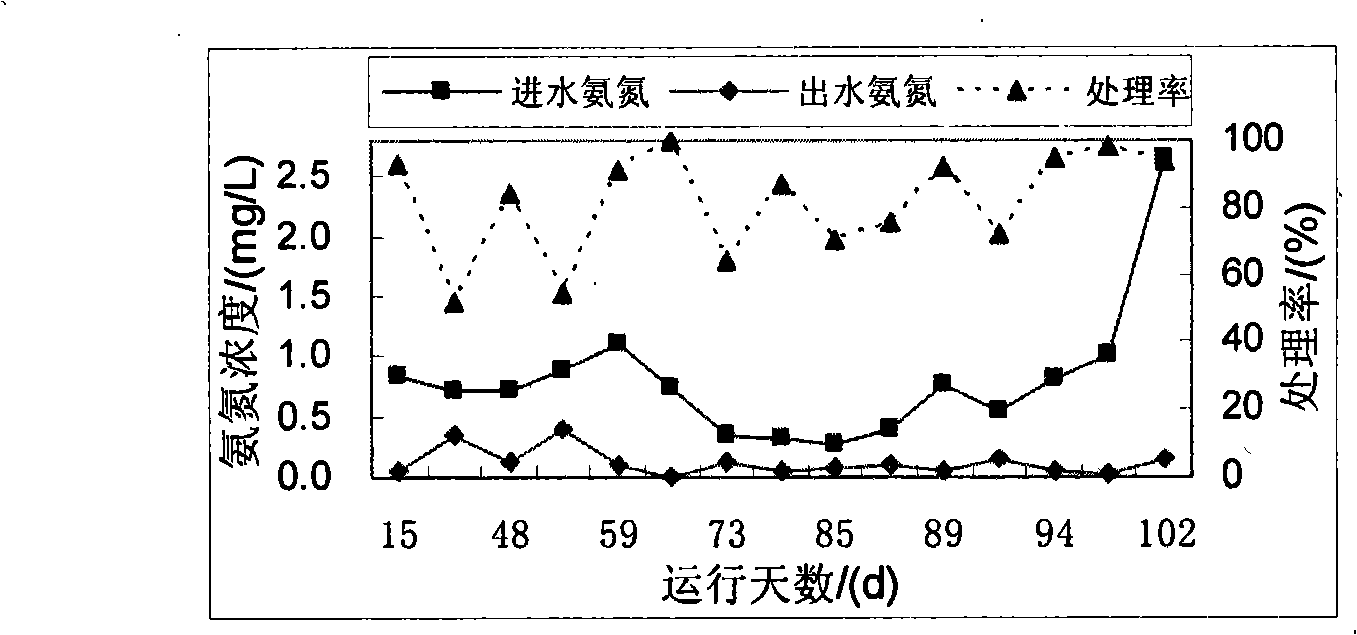

Artificial wet land and uses thereof

ActiveCN101293708ALow construction costReduce processing costsWaste water treatment from metallurgical processSustainable biological treatmentConstructed wetlandWater use

The invention provides a constructed wetland and the application thereof; wherein, the constructed wetland takes gravels and manganese sands as combined packing and can be used for treating wastewater in industries, such as iron and steel industry, etc., the wetland can reduce the nutrient content of organics, nitrogen, phosphorus, etc. in water, and meanwhile can remove metal ions, such as Fe, Mn, Cd, Pb, etc., more particularly, can reduce higher content of ions of Fe and Mn in iron and steel industry wastewater so that the index achieves the water quality standard of reclaimed water used as cooling water and the water intake quality requirement of reverse osmosis desalination process in Code for Engineering Design of Wastewater Reclamation and Reuse. The wetland has less engineering investment, simple management, low operation and maintenance cost, stable processing effect, so as to have better environmental, economic and social benefits. The wetland has better wastewater processing effect, stronger treatment capacity and stronger shock resistance loading capability, so the wetland can greatly solve the problem of excessively high concentration of Fe and Mn ions in wastewater reuse of the iron and steel industry, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

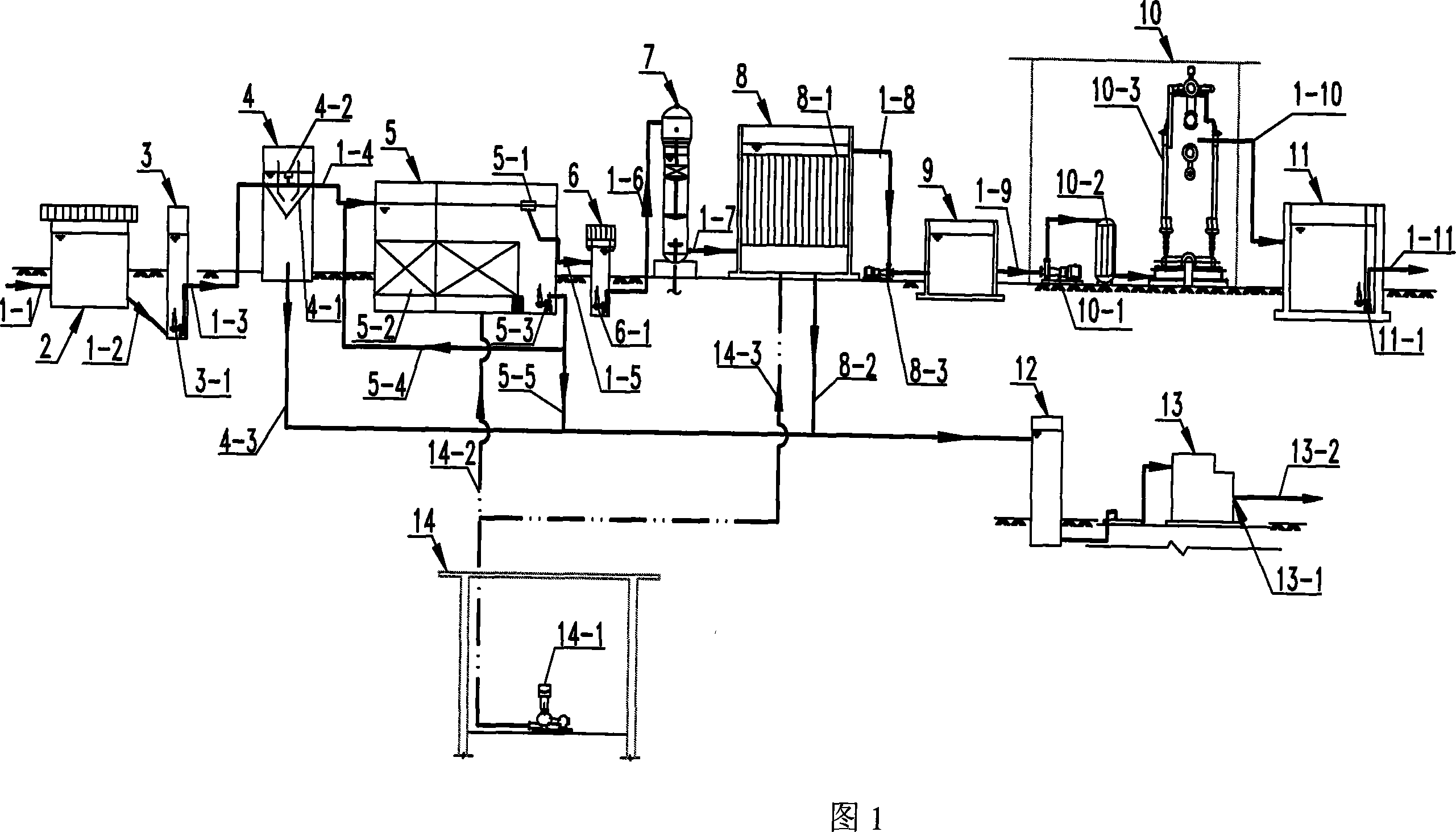

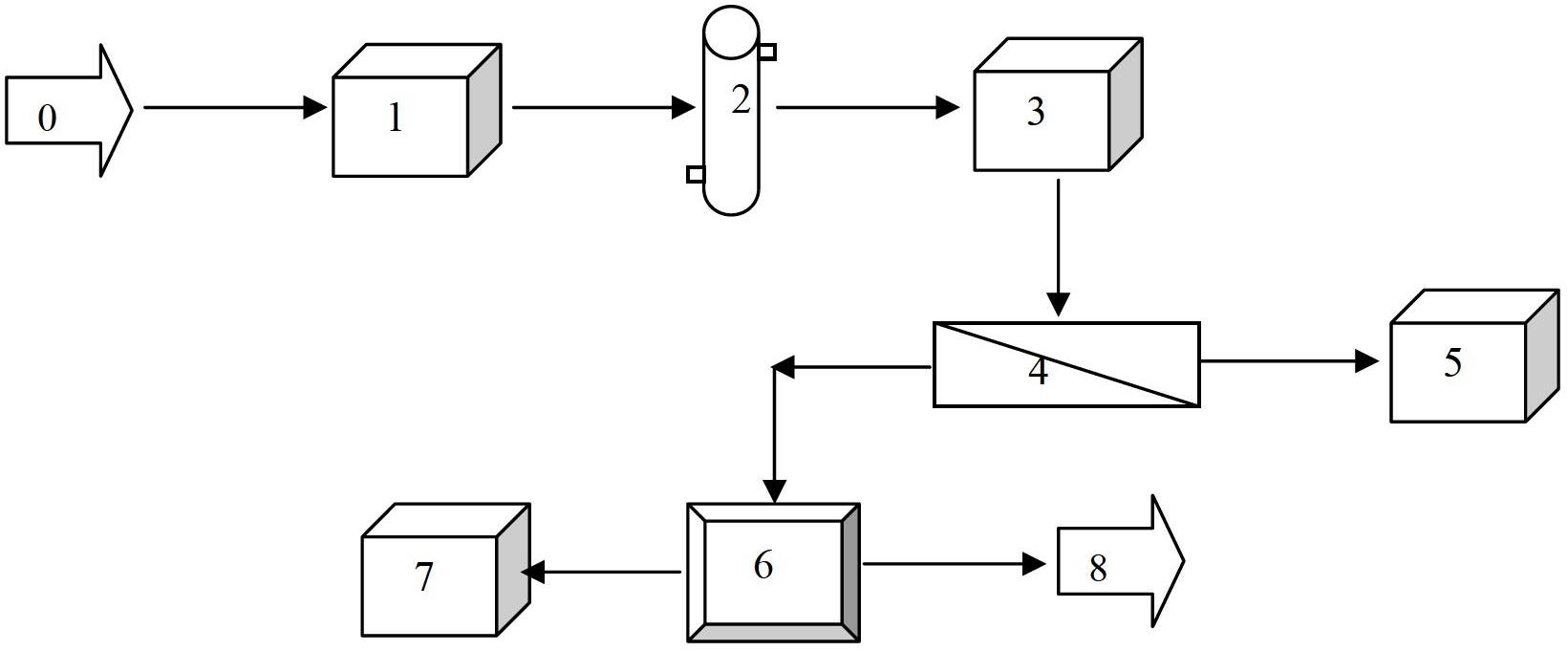

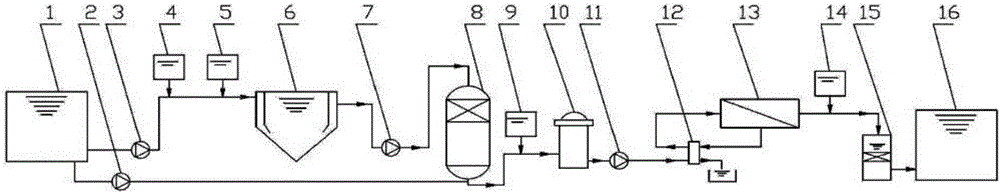

Technique and equipment for recycling leachate of garbage

InactiveCN101219842AEfficient decompositionFlexible configurationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWater qualityMicrofiltration

The invention discloses a process for reusing waste leachate and a device thereof. Which comprises a homogenization process stage, an anaerobic process stage, an aerobic process stage 1, an advance oxidization stage, an aerobic process stage 2 and a reverse osmosis desalination stage.The device comprises the following equipments connected in series by pipes in turn: a water regulating tank, a collecting well, an up-flow anaerobic sludge bed reactor, a reaction tank for continuous and interval aerating, an ozonation system, a membrane biological reactor, a middle tank in which a water pump is arranged, a reverse osmosis system in which a pump, a precise filter and reverse osmosis component are arranged as well as a clean water tank.The beneficial effects of the invention lie in that: a plurality of organic matters which are difficult to degrade can be effectively resolved; a whole set of processes such as the anaerobic process, the aerobic process, the advance oxidization process and the microfiltration are used as pretreatments of the reverse osmosis(RO) system and the water quality index fully meets the water quality requirements of the reverse osmosis system. The last desalination is carried out by using reverse osmosis system to ensure the water quality index reused by the leachate.

Owner:张大群

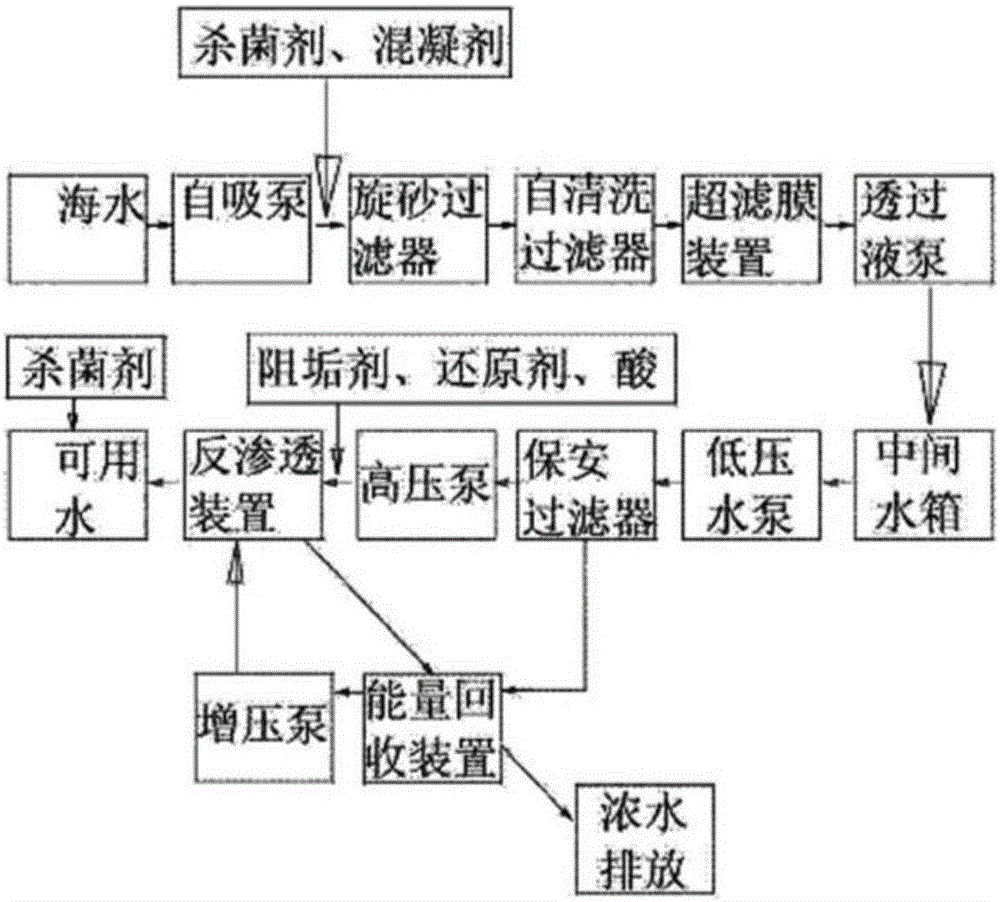

Desalination process for high recovery ratio seawater (brackish water)

InactiveCN1552643AExtended service lifeSimple processGeneral water supply conservationMultistage water/sewage treatmentWater desalinationBrackish water

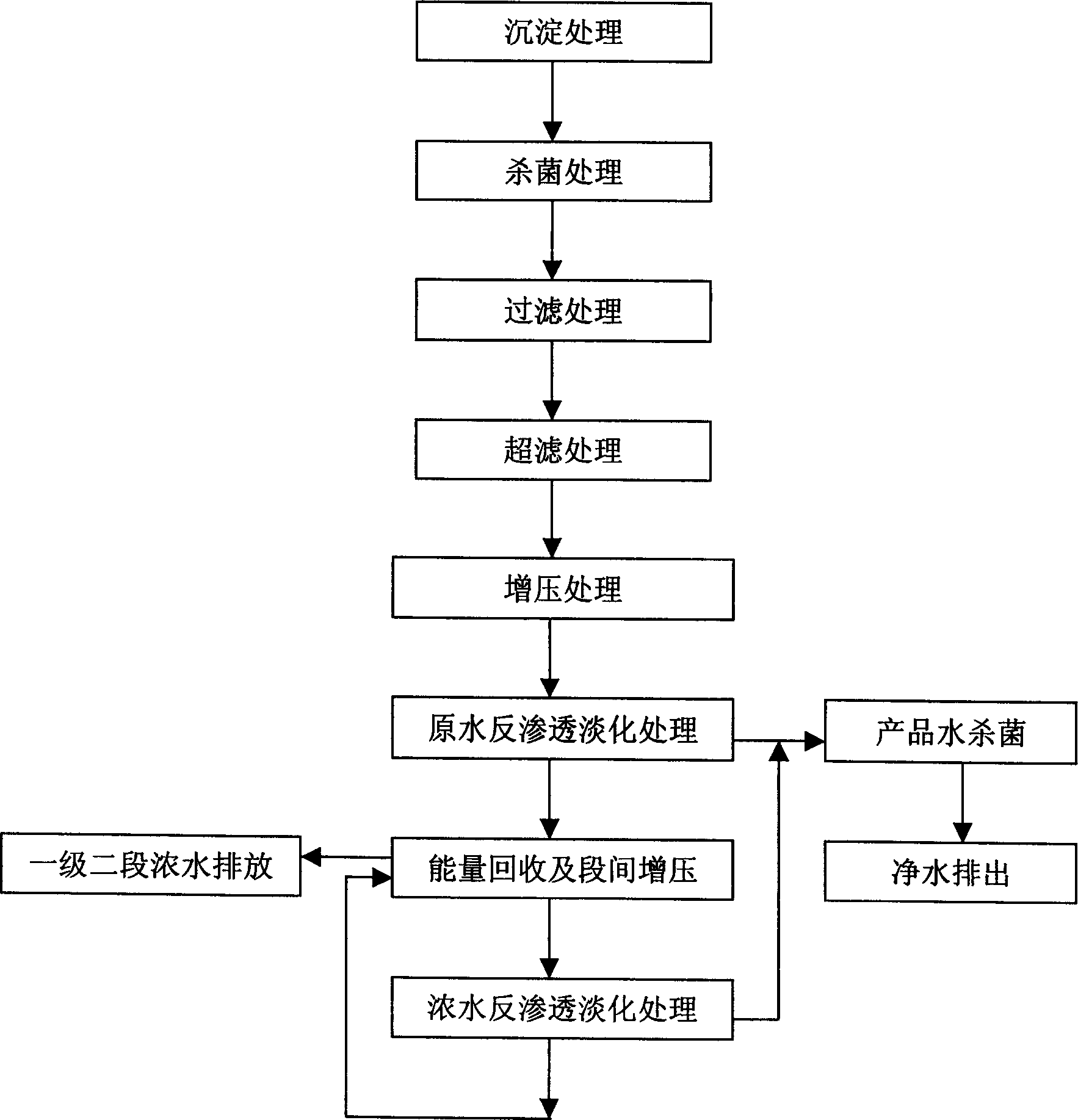

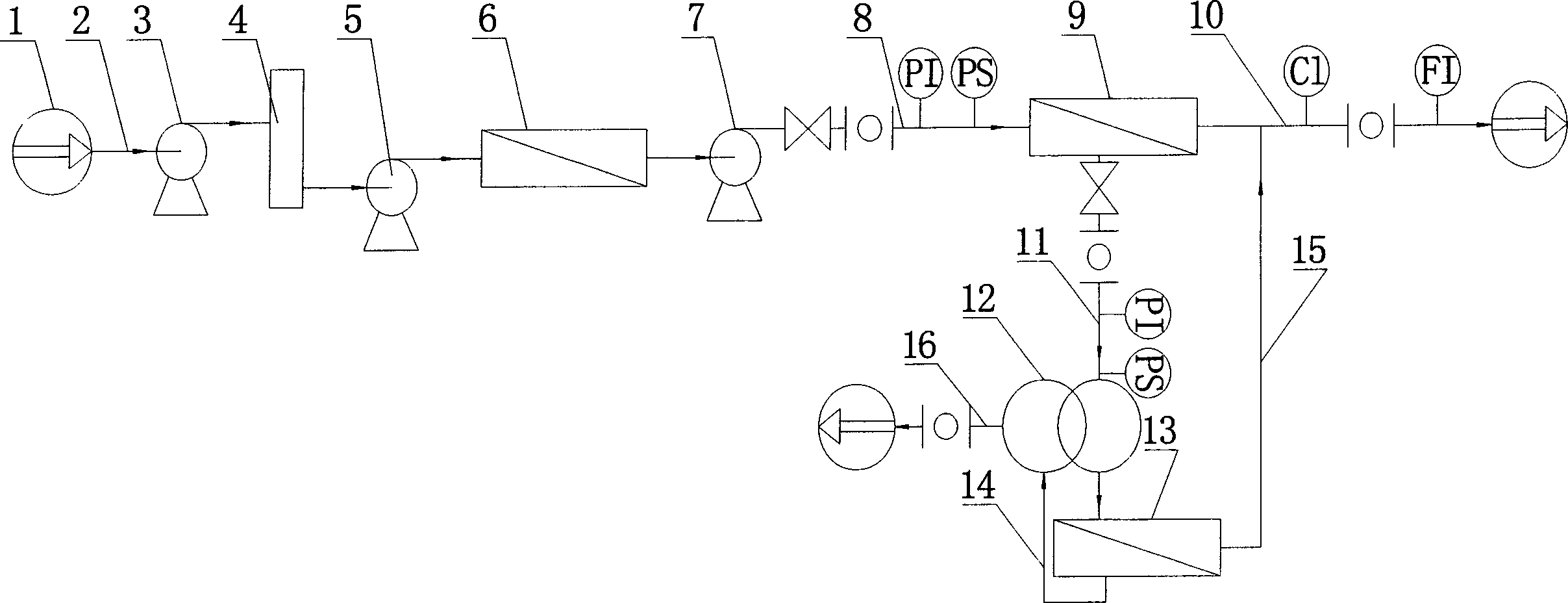

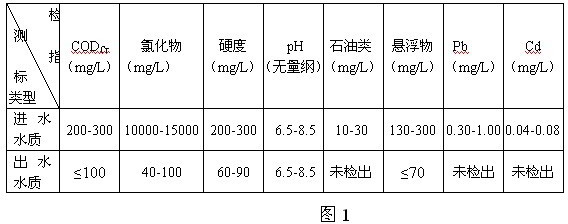

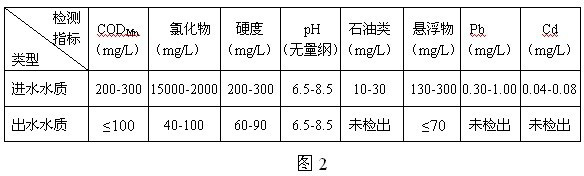

A process for desalinating seawater with high recovery rate of fresh water (more than 60%) includes such steps as depositing, disinfecting, filtering, ultrafiltering, pressurizing, taking reverse osmosis of raw water, energy recovering, intersegment pressurizing, taking reverse osmosis of fresh water, discharging concentrated water, disinfecting and discharging fresh water.

Owner:天津市海跃水处理高科技有限公司

Treating method for desalting high-salt-content waste water in oil and gas field

InactiveCN102603092AMeet emission requirementsEfficient removalGeneral water supply conservationMultistage water/sewage treatmentSolubilityFiltration membrane

The invention relates to a treating method for desalting high-salt-content waste water in an oil and gas field during exploration and transmission of oil and natural gas. The method comprises the following steps of: a, adding a hard water softener and a flocculant to waste water, wherein based on each stere of waste water, the addition amounts of the components are as follows: 0.5-0.9kg of hydroxide, 0.5-0.9kg of carbonate and 1.5-3.0kg of the flocculant; b, filtering the waste water by utilizing an ultra-filtration membrane, and filtering by sequentially utilizing a quartz sand filter and a fine filter; and c, carrying out a reverse osmosis desalination treatment on filtered water. According to the treating method for desalting the high-salt-content waste water in the oil and gas field, disclosed by the invention, through various forms and multi-level treatments, organic matters and soluble salt-type matters in water bodies of the oil and gas filed are effectively removed, and thus the chloride concentration of the high-salt-content waste water of the oil and gas field is less than 250mg / L, and other indexes of the high-salt-content waste water can meet first-level standard requirements of the Sewage Comprehensive Drainage Standard (GB8978-1996).

Owner:SICHUAN RENZHI PETROCHEMICAL TECHNOLOGY CO LTD

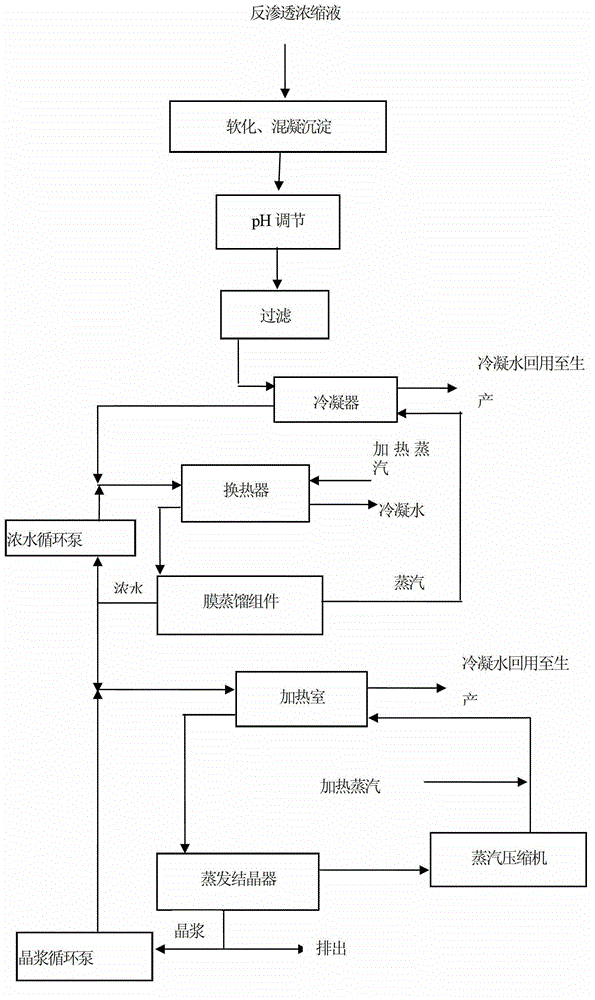

Zero discharge method of stainless steel cold rolling acidic waste water concentrated liquid

InactiveCN104058536AAchieving zero emissionsImprove economyGeneral water supply conservationWaste water treatment from metallurgical processInorganic saltsSocial benefits

The invention provides a zero discharge method of stainless steel cold rolling acidic waste water concentrated liquid, which orderly comprises the following steps: (1) softening, and coagulating sedimentation; (2) pH adjustment; (3) filtration; (4) membrane distillation, that is, heating the waste water concentrated liquid treated in step (3) to 55-75 DEG C, allowing the waste water concentrated liquid to enter a membrane distillation assembly, wherein the obtained condensed water can be recycled for production; (5) evaporative crystallization, that is, allowing the concentrated liquid discharged after membrane distillation treatment in step (4) to enter an evaporating crystallizer for evaporative crystallization to obtain crystal slurry, heating the crystal slurry in a heating chamber to 95-100 DEG C, allowing the heated crystal slurry to enter a crystallization chamber, boiling the crystal slurry to allow the solution to reach a saturation state, and discharging the generated crystals. The zero discharge method of the invention carries out membrane distillation and evaporative crystallization treatment of concentrated liquid generated by reverse osmosis desalination treatment of stainless steel cold rolling waste water, recycles obtained pure water for production, converts inorganic salt in the concentrated liquid into solids, realizes zero discharge of waste water, and has good social benefit and environment benefit.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Asymmetric nanotube containing membranes

ActiveUS20110186506A1Increase the diameterImprove skinMaterial nanotechnologySemi-permeable membranesCrystallographyUltrafiltration

This invention relates to heterogenous pore polymer nanotube membranes useful in filtration, such as reverse osmosis desalination, nanofiltration, ultrafiltration and gas separation.

Owner:NAGARE MEMBRANES

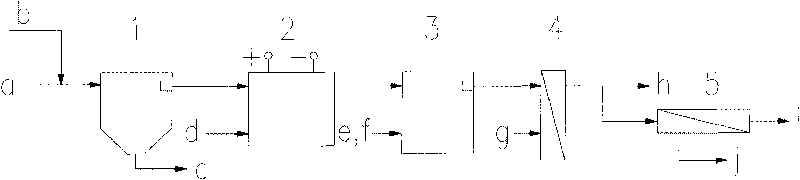

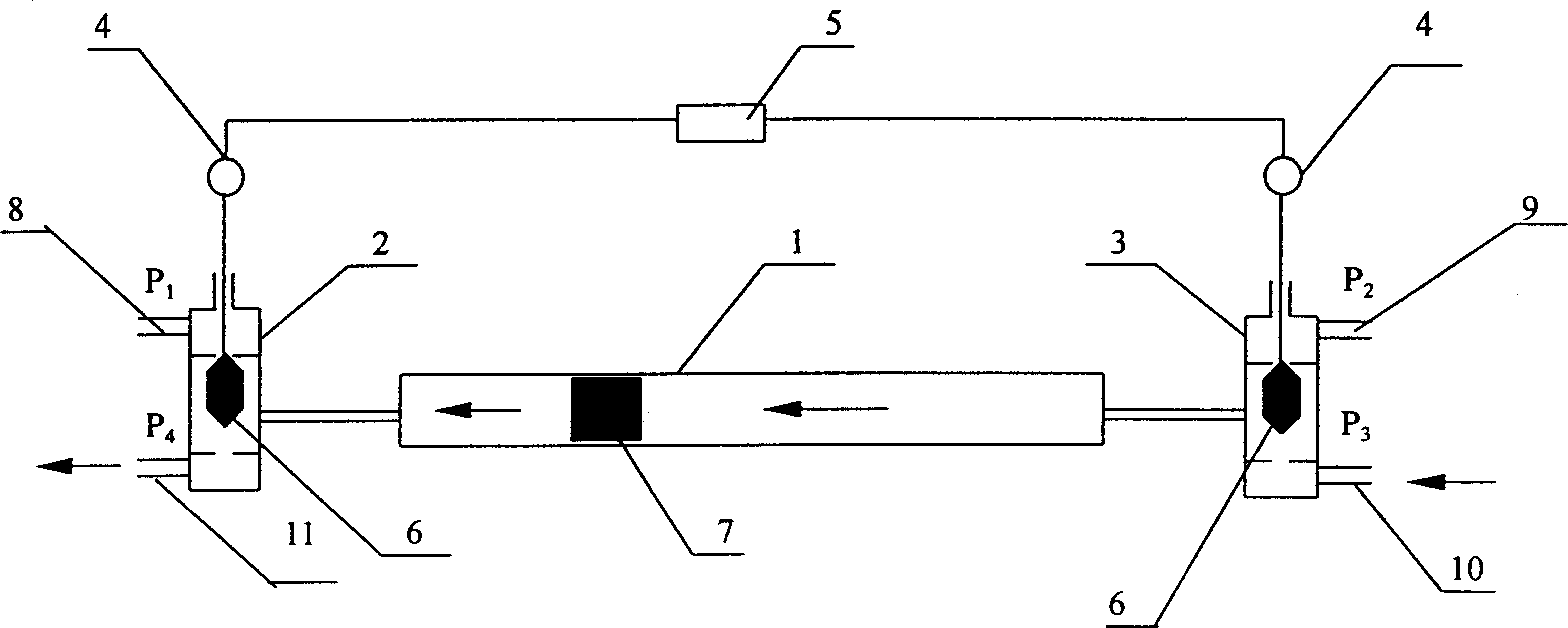

Valve controlled residual pressure recovering equipment for impervious desalination system

InactiveCN1343528ASimple structureImprove use reliabilityGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisHydraulic cylinderEnergy recovery

A valve-controlled residual pressure recovering equipment for impervious seawater desalinating system is composed of hydraulic cylinder, free piston in the cylinder, and high-and low-pressure three-way electromagnetic valves at both ends of the said cylinder. The position and operating time of the cores of the said electromagnetic valves are controlled by computer program. The inlet of high-pressure concentrated saline and the outlet of pressurized seawater are opened or closed simultaneously. The inlet of raw seawater and the outlet of concentrated saline are opened or closed at same time. Its advantages are simple structure, high reliability,and high efficiency of recovering residual pressure (up to 70-90%).

Owner:TIANJIN UNIV

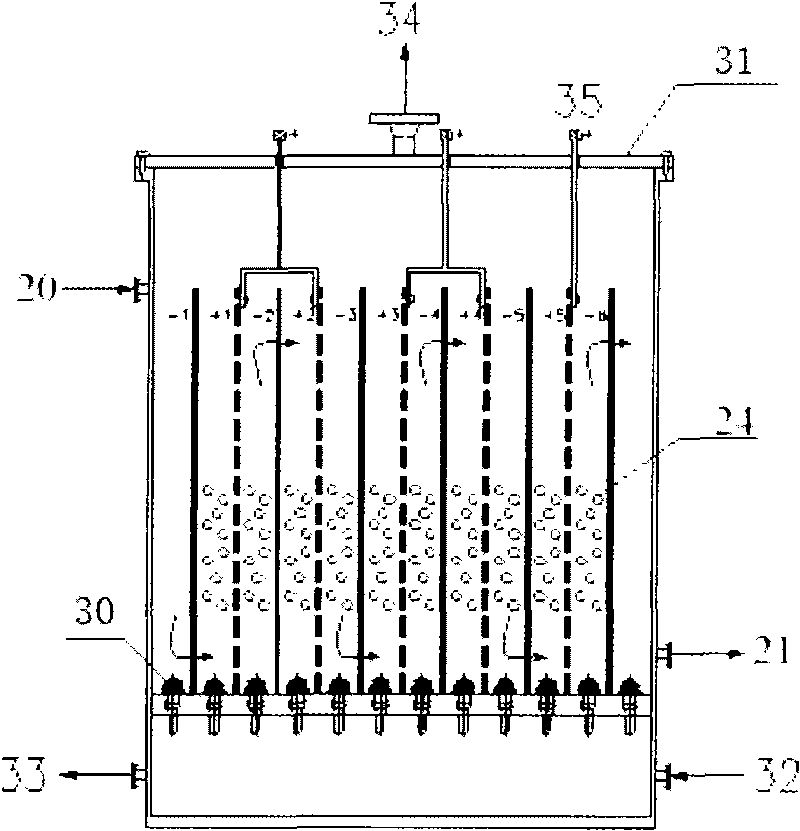

Seawater desalination device and method

InactiveCN102786174ASolve the technical problems of seawater desalinationEliminate pollutionGeneral water supply conservationSeawater treatmentCapacitanceElectrolysis

The invention relates to a seawater desalination device and a method, and relates to the seawater device and its method by combining an electrolytic technology, a capacitance adsorption deionization technology and a low pressure reverse osmosis technology. The device comprises an electrolytic purifying system, a capacitance adsorption deionization system and a low pressure reverse osmosis system; the electrolytic purifying system comprises a stop valve, a water supply pump, an electrolytic machine, a deposition pot and a microfiltration apparatus; the capacitance adsorption deionization system comprises the stop valve, an elevator pump, a cartridge filter, the water supply pump, a capacitance adsorption deionization apparatus, a primary fresh water storage tank and a concentrated water booster pump; the low pressure reverse osmosis system comprises the stop valve, the water supply pump, the cartridge filter, a high pressure pump, a low pressure reverse osmosis membrane component and a fresh water storage tank. The method comprises the following steps: electrolyzing, performing capacitance adsorption deionization and primarily desalinating, finally performing low pressure reverse osmosis desalination. The method has the advantages of short process flow, small investment and less environmental pollution, the reverse osmosis system material has the advantages of low requirement and low cost, and solves the problem of nationalization, and the seawater desalination device has the advantages of high efficiency, low energy consumption, low production cost, high integrated level of the device, small volume, easy operation and the like.

Owner:BOYING XIAMEN SCI & TECH

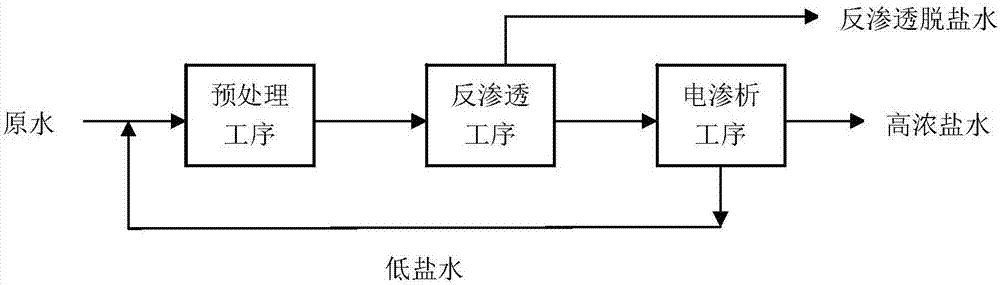

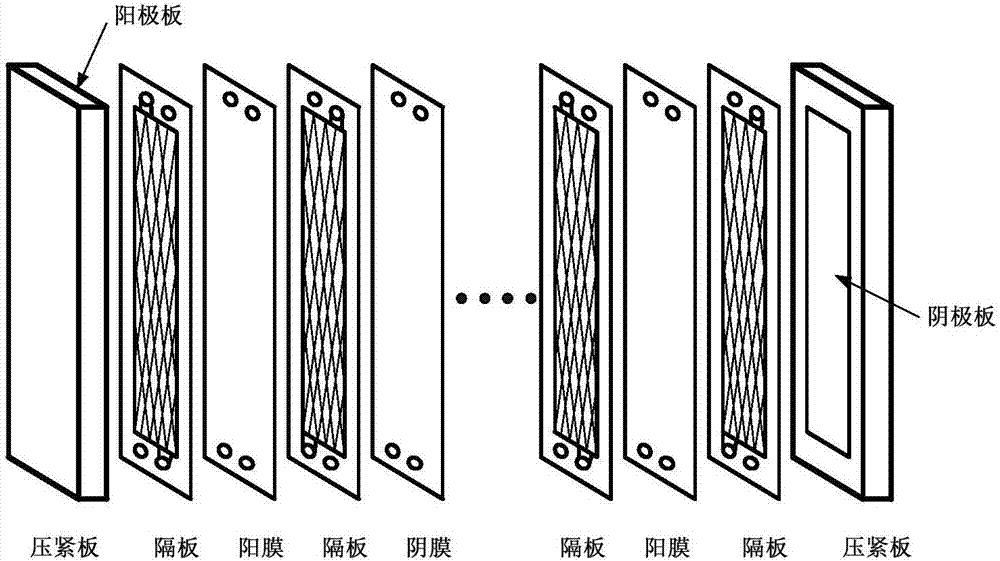

High-hardness salt-containing water concentration method based on monovalent cationic selective electrodialysis

ActiveCN107055713AHigh desalination rateAchieve separationGeneral water supply conservationDispersed particle separationPermeationPrecipitation

The invention discloses a high-hardness salt-containing water concentration method based on monovalent cationic selective electrodialysis. The method comprises the following steps: 1, performing chemical precipitation hardness removal and pretreatment on raw water; 2, performing reverse osmosis desalination treatment; and 3, regulating the pH value of reverse osmosis concentrated saltwater with hydrochloric acid or sulfuric acid to be 4-6 so as to serve as raw electrodialysis water, and enabling the water to respectively enter a desalting chamber and a concentration chamber formed by an anode membrane and a cathode membrane at an interval in an electrodialysis membrane stack, thereby obtaining high-salt electrodialysis water and low-salt electrodialysis water. According to the method disclosed by the invention, extra equipment and devices are not needed, and two ions forming a scale forming matter are separated under the condition that the recovery rate is not changed, so that a scaling phenomenon caused by simultaneous interception or simultaneous permeation is avoided.

Owner:HEBEI UNIV OF TECH

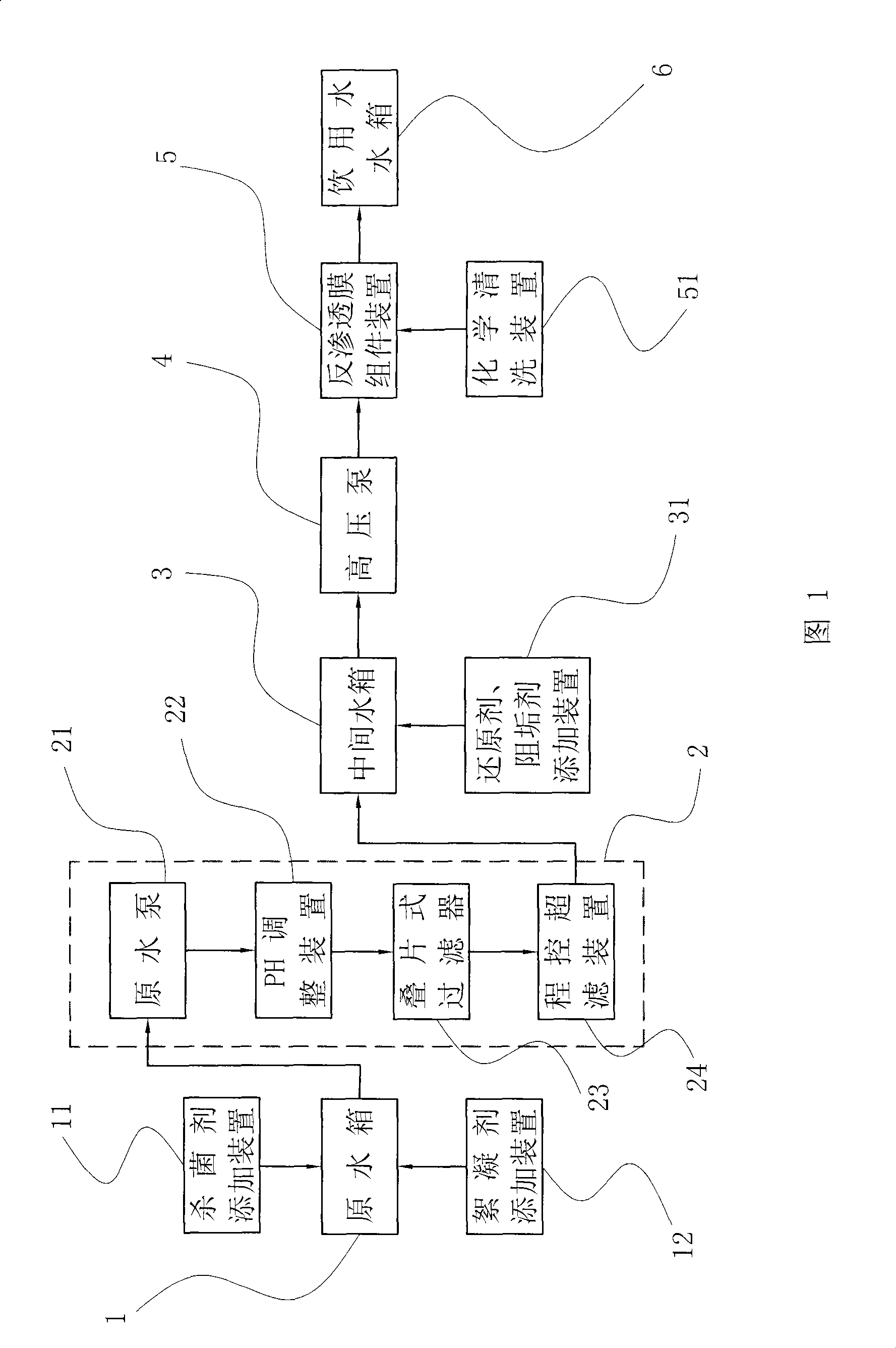

Brackish water desalination device

InactiveCN101381126AMeet water requirementsIncrease permeation flux per unit areaGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisUltrafiltrationFiltration

The invention discloses bitter saline water desalination equipment, which comprises a raw water tank, and a high pressure pump, a reverse osmosis membrane component and a drinking water tank which are sequentially connected. The bitter saline water desalination equipment further comprises a physical-chemical program controlled composite coupling preprocessor consisting of a raw water pump, a laminated filter and a program controlled ultrafiltration device which are sequentially connected. The bitter saline water desalination equipment has the advantages that the process of physical-chemical program controlled composite coupling preprocessing filtration is adopted so that the raw water with different types and different qualities can be pretreated to meet the inlet water requirement for the reverse osmosis membrane component, thus the inlet water quality for the reverse osmosis desalination is improved, the rubber body pollution and the microorganism pollution to membrane elements in the reverse osmosis membrane component are prevented, the unit area permeation flux of the reverse osmosis membrane component is improved, and the protection of the reverse osmosis membrane elements is increased; at the same time, the chemical cleaning frequency of the reverse osmosis membrane elements is reduced, the service life of the membrane elements is prolonged, the operating cost is reduced, and the production efficiency is improved.

Owner:陆惠民

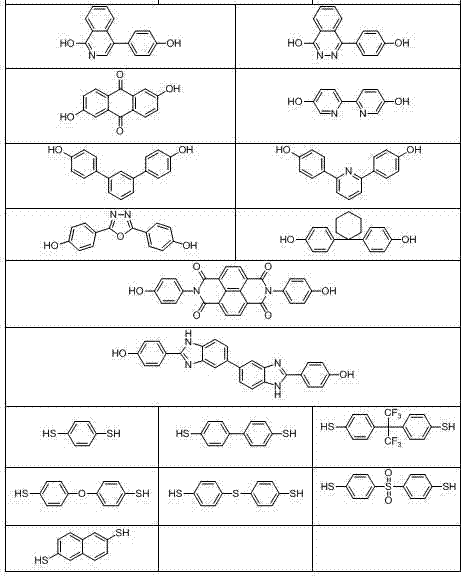

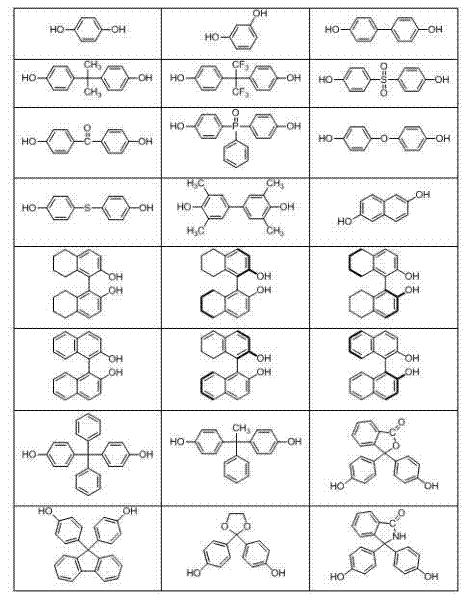

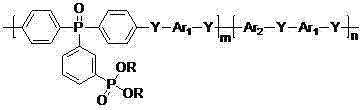

Novel polymer containing phosphonate group and preparation method and application of novel polymer

ActiveCN102643421ASemi-permeable membranesGroup 5/15 element organic compoundsPolymer scienceChlorobenzene

The invention discloses a polymer containing phosphonate group. The polymer is prepared by mixing a monomer containing phosphonate group and a diphenol (dithio) monomer (or to different kinds of diphenol (dithio) monomers with dihalide monomer according to a certain proportion; heating to a certain temperature in high-boiling-point aprotic solvent with existence of medium strong base and methylbenzene, subjecting the mixture to backflowing and water diversion for some time before evaporating the methylbenzene, increasing reaction temperature, reacting for some time continuously, pouring reaction liquid into deionized water after reaction, and obtaining solid; then washing the solid three times by deionized water and obtaining a polymer I or II by drying in vacuum, wherein the monomer containing phophonate group is di (4-fluorine phenyl) (3'-diethyoxyl phosphonic acyl phenyl) phosphonic oxide or di (4-chlorphenyl) (3'-diethyoxyl phosphonic acyl phenyl) phosphonic oxide. The polymer containing phophonate group expresses excellent reverse osmosis desalination and proton conduction performances.

Owner:TIANJIN NORMAL UNIVERSITY

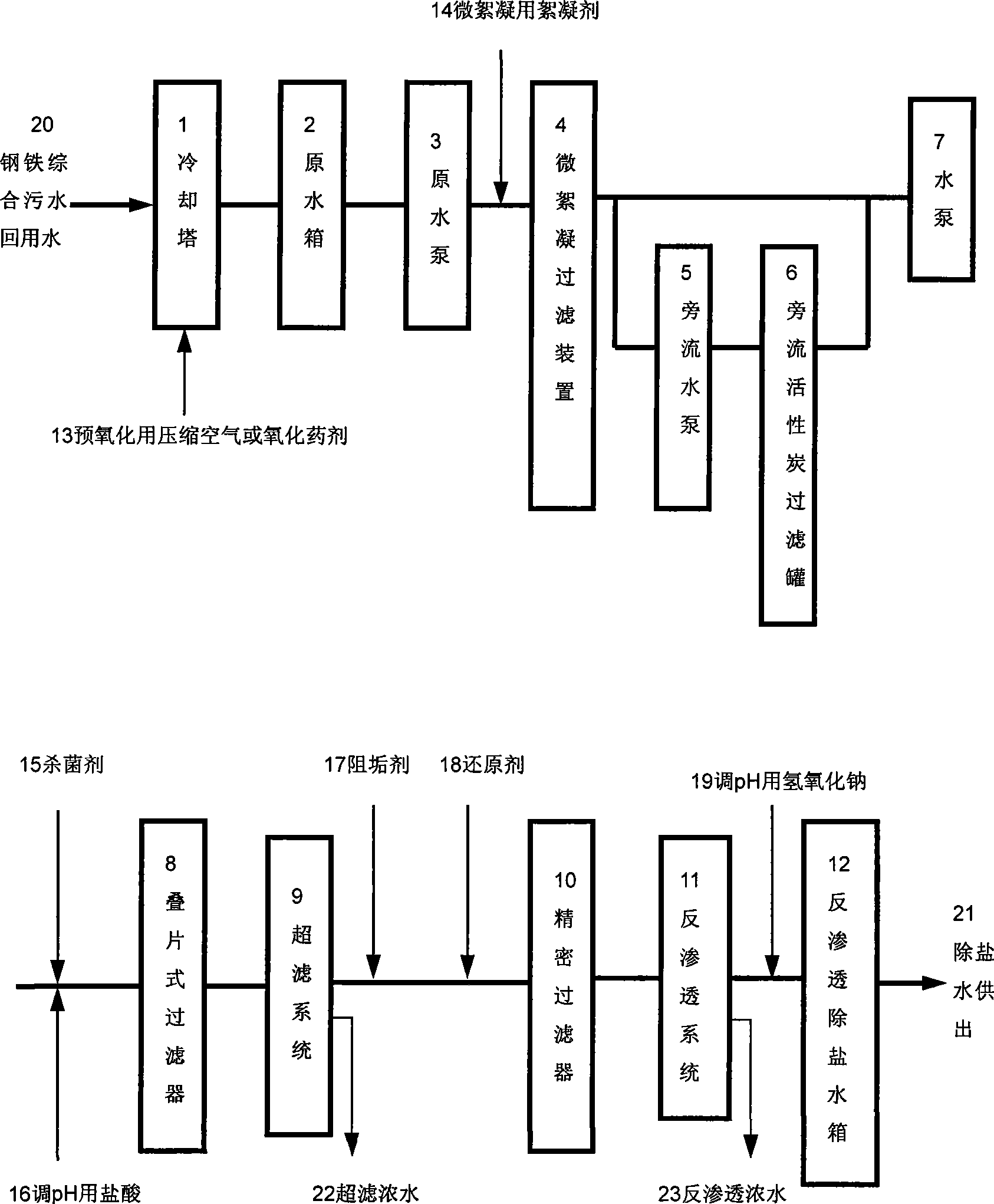

Steel composite wastewater recycle-water double-membrane demineralization system and technique

ActiveCN101462801ARealize resourcesAchieving "Zero Emissions"General water supply conservationWaste water treatment from metallurgical processCooling towerUltrafiltration

The invention provides a system and a process for desalting recycle-water of iron and steel combined sewage by a bi-membrane method, which belong to the technical field of treatment and recycling of sewage. The system comprises a cooling tower, a raw water tank, a micro-flocculation filter device, a flow by-pass activated carbon filter kettle, a laminated filter, an ultrafiltration system, an ultrafilter, a reverse osmosis system, and a reverse osmosis desalination water tank. The system and the process are used for solving the problem of desalination of the recycle-water of sewage by the bi-membrane method for steel enterprises. In the system and the process, the pretreated water is treated through the ultrafiltration device by bi-membrane desalination to meet the requirement that SDI is less than or equal to 3, and the water is subjected to desalinating treatment through the reverse osmosis device. The system and the process treat the recycle-water of the iron and steel combined sewage by a mode combining preoxidation, micro-flocculation filtration, flow by-pass activated carbon filtration and self-cleaning filtration, thereby greatly improving the operating stability and the service life of the bi-membrane desalination system, effectively realizing sewage reclamation and 'zero drainage' of the sewage, and having important practical value on the desalination of the recycle-water of the iron and steel combined sewage.

Owner:SHOUGANG CORPORATION +2

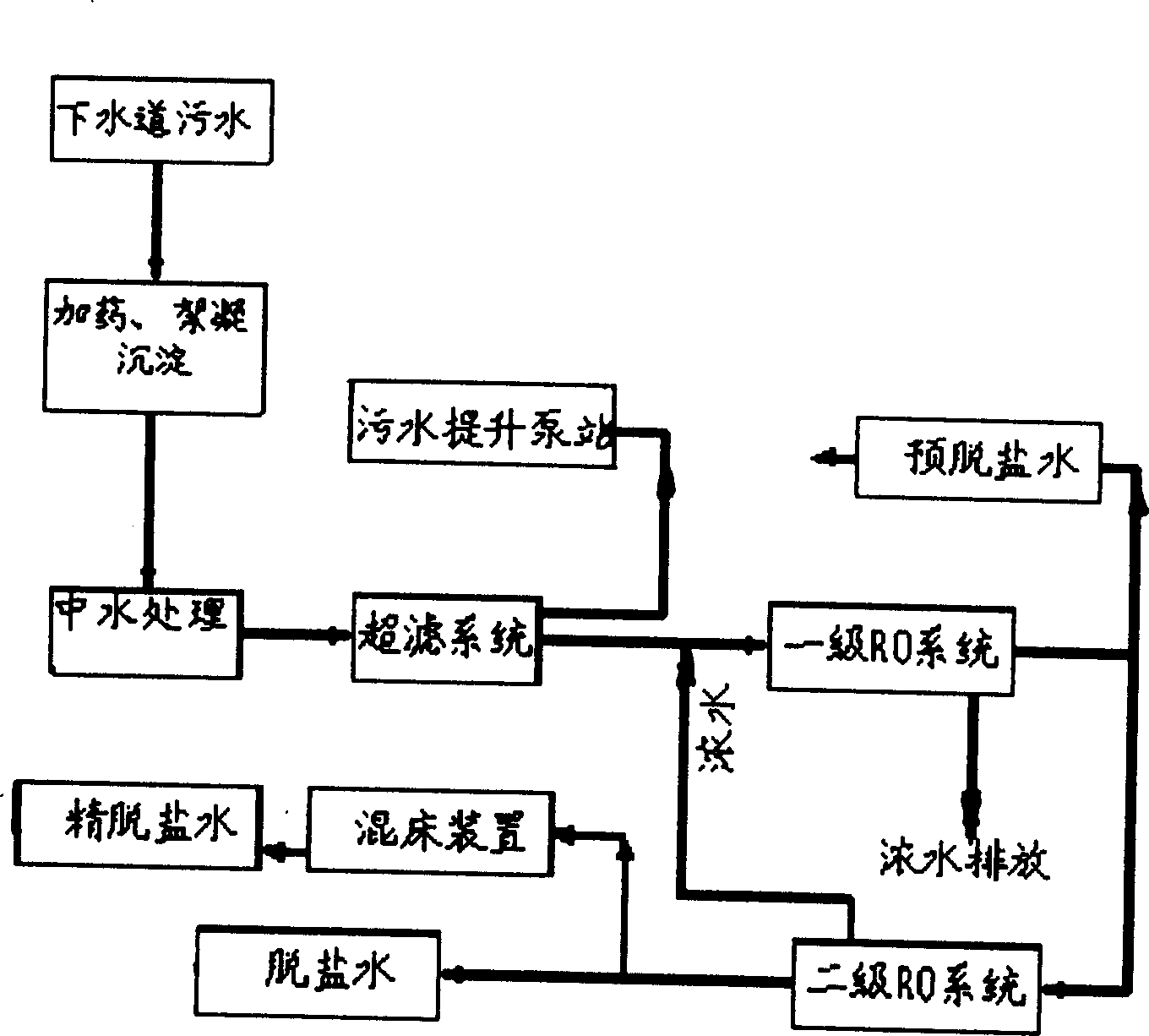

Method of preparing pure water using metallurgic sewage

InactiveCN1699223AAchieve sustainable developmentRealize the recycling of sewageGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWater useFlocculation

The invention relates to a method of preparing pure water using metallurgic sewage which comprises the following steps, (1) reclaiming sewage water, preparing recycled water, wherein the water outlet suspended matter <100mg / l, (2) treating the recycled water, subjecting the recycled water to fine grid filtration, sterilizing, micro-flocculation, entrapping hairs, making the COD <30mg / l, (3) ultra-filtration treatment, passing the recycled water through external pressured immersion type ultra-filtration apparatus for treatment, meeting the requirement of SDI<2, (4) reverse osmosis desalination treatment, loading the ultrafiltrated water into reverse osmosis apparatus for desalinization treatment.

Owner:HEBEI IRON AND STEEL

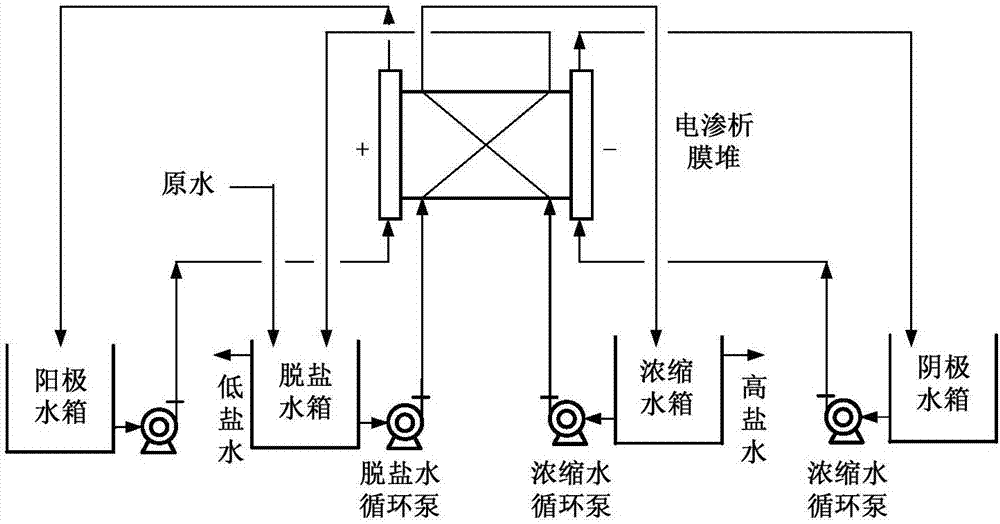

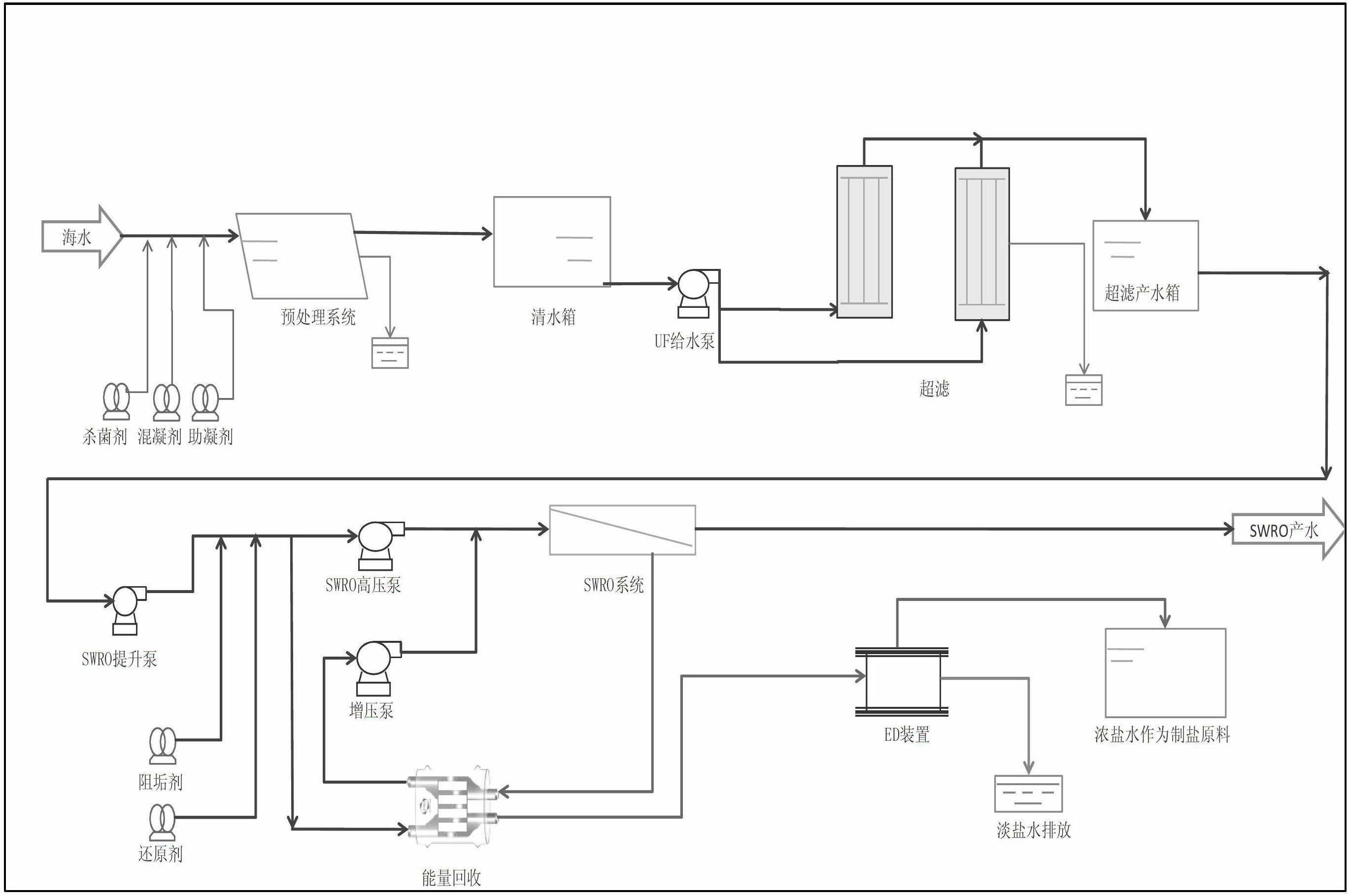

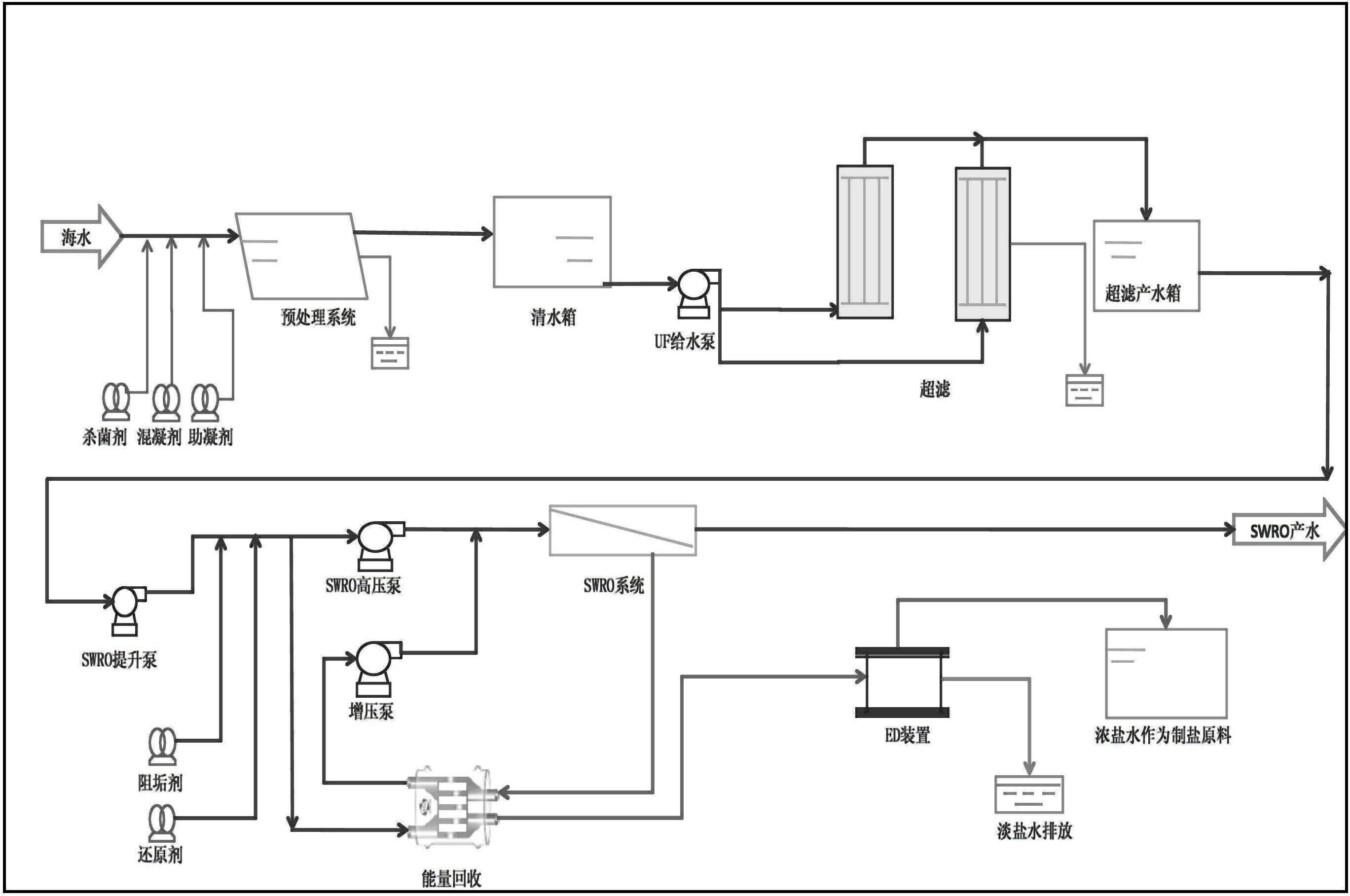

Novel membrane-process sea water desalination and fresh water and salt preparation system and technique

InactiveCN102659272AReduce salt contentGeneral water supply conservationSeawater treatmentWater desalinationEcological environment

The invention relates to a novel membrane-process sea water desalination and fresh water and salt preparation system and technique. The novel membrane-process sea water desalination and fresh water and salt preparation system comprises a raw water tank, an ultrafiltration device, an ultrafiltration water tank, a sea water reverse-osmosis desalination device, a water production tank, an electroosmosis salt and water separation device and a concentrated salt water tank, wherein the raw water tank, the ultrafiltration device, the ultrafiltration water tank, the sea water reverse-osmosis desalination device and the water production tank are connected sequentially through pipelines or pipelines and pumps. The sea water reverse-osmosis desalination device, the electroosmosis salt and water separation device and the concentrated salt water tank are sequentially connected through pipelines. By the aid of the technique, high-quality refined salt or salt chemical raw materials and high-quality fresh water can be produced, and meanwhile, adverse effects on the ecological environment of the sea area from discharge of SWRO (sea water reverse osmosis) concentrated salt water are avoided, costs for salt manufacturing by sea water and sea water desalination can be greatly reduced, and particularly, the novel membrane-process sea water desalination and fresh water and salt preparation system has high use value for water-deficient regions in northern of China.

Owner:BEIJING SCINOR WATER TECH CO LTD

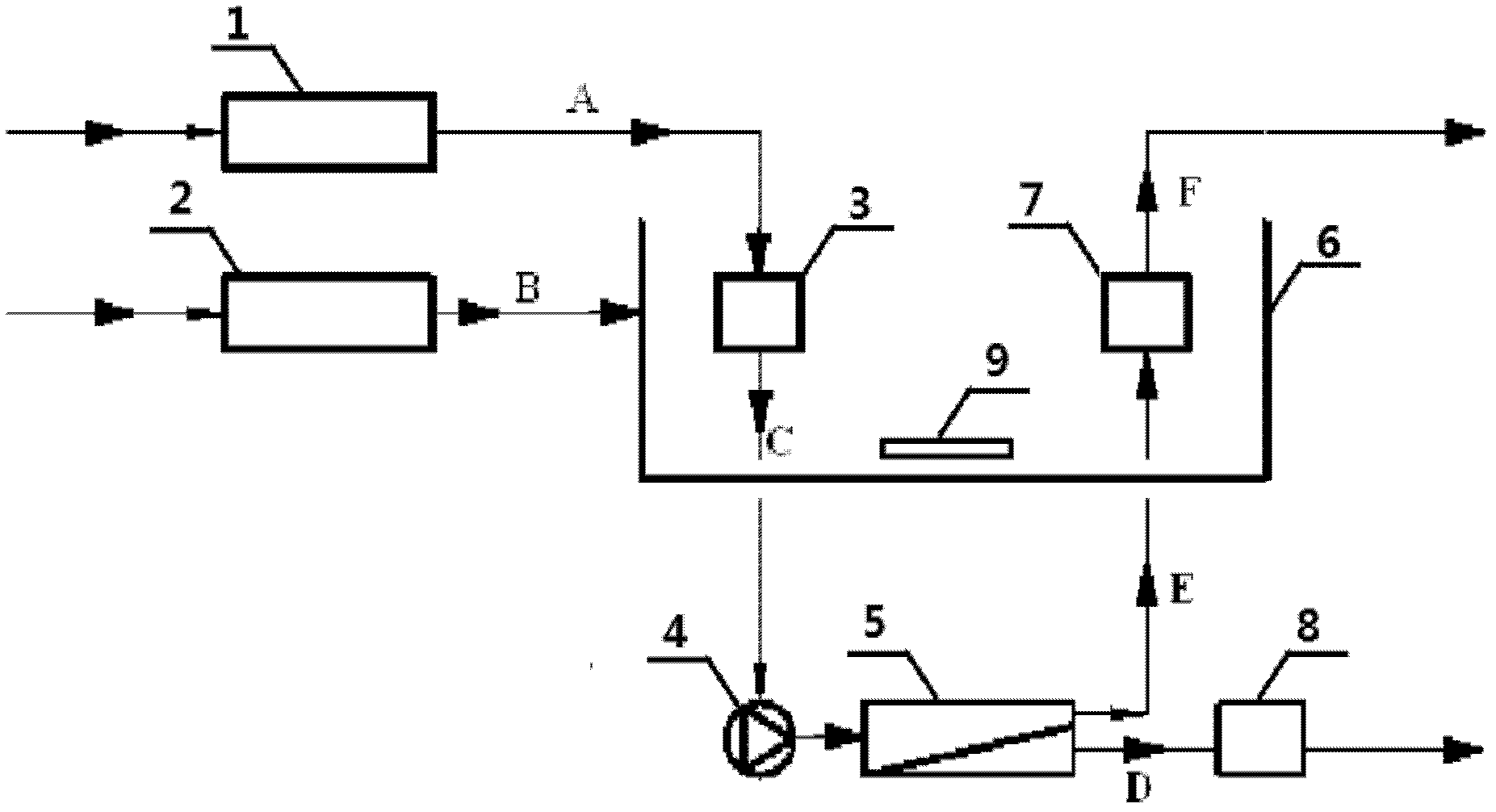

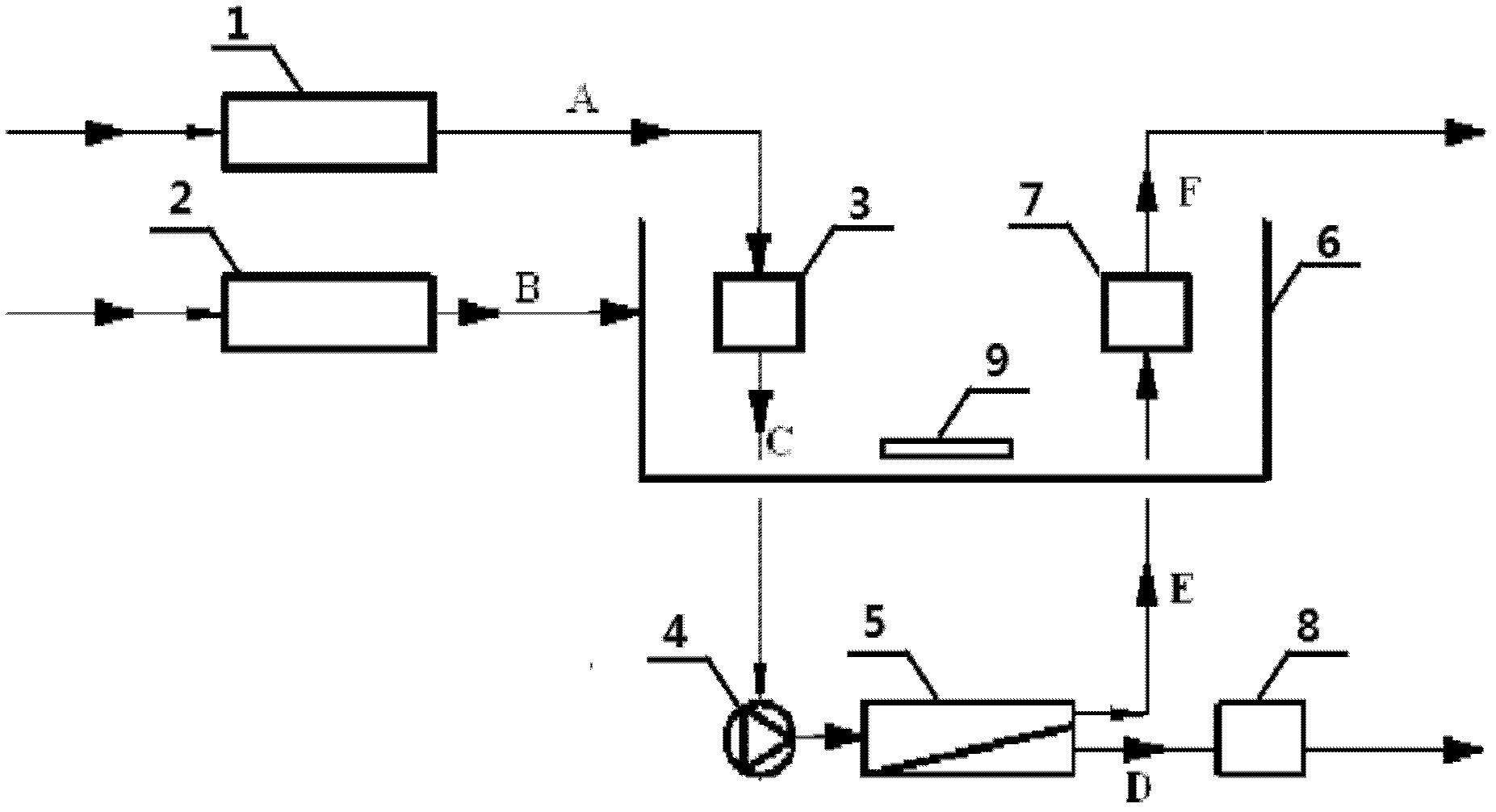

A forward osmosis membrane bioreactor/reverse osmosis combined fresh water increment method

InactiveCN102276113AImprove throughputExtended service lifeGeneral water supply conservationSeawater treatmentWater desalinationFresh water organism

The invention discloses a forward osmosis membrane bioreactor / reverse osmosis combined fresh water increasing method, which comprises the following steps: setting the first-stage and second-stage forward osmosis membrane components in the forward osmosis membrane bioreactor, after pretreatment The sewage water flow B is input into the forward osmosis membrane bioreactor, the pretreated seawater flow A is input into the first-stage forward osmosis membrane module, and the output water flow C is boosted by the booster pump and then input into the reverse osmosis membrane module for liquid Membrane separation, the output product water flow D becomes finished fresh water after being sterilized by the sterilizer, and the remaining concentrated brine flow E is input to the second-stage forward osmosis membrane module for infiltration, and the output water flow F is discharged to the sea, and is set in the forward osmosis membrane biological The aerator at the bottom of the reactor is used for aeration. The method of the invention improves the water recovery rate of the reverse osmosis desalination system and reduces system energy consumption; reduces the sea discharge concentration of seawater desalination concentrated brine; improves the flux of the forward osmosis membrane, prolongs the service life of the membrane, and improves the system water recovery rate.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

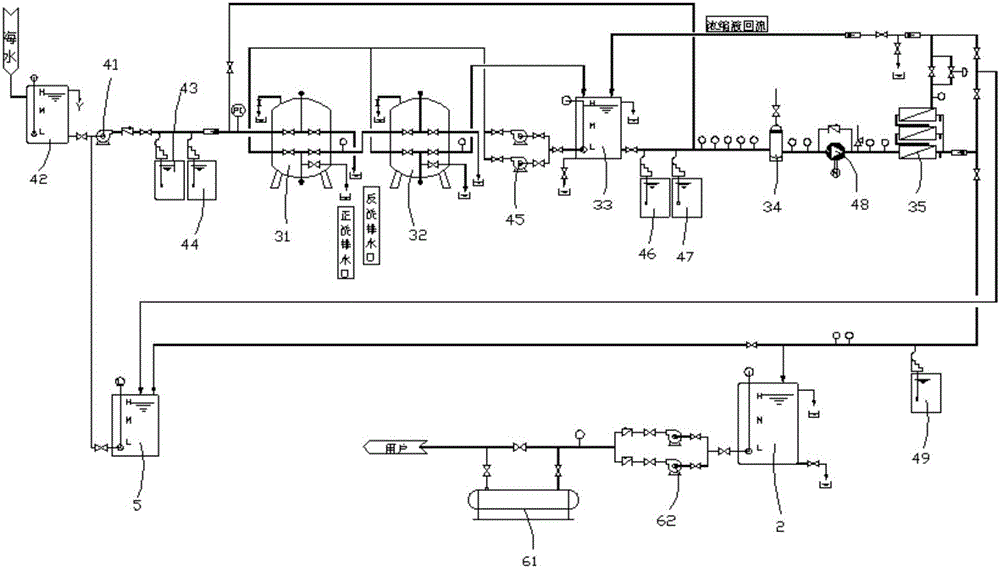

Reverse osmosis container-type sea water desalination plant and water producing process thereof

ActiveCN105152399AProtect the environmentOvercome costsGeneral water supply conservationSeawater treatmentWater desalinationAutomatic control

The invention discloses a reverse osmosis container-type sea water desalination plant and a water producing process thereof. The reverse osmosis container-type sea water desalination plant comprises a container, a pre-treatment system, a sea water desalination system, an automatic control system, a reagent feeding system, a sea water inlet and a produced-water outlet, wherein the container is located outside; the pre-treatment system, the sea water desalination system, the automatic control system and the reagent feeding system are arranged in the container in sequence in a matching manner, and the sea water inlet and the produced-water outlet are formed in the same side of the container. The process flow sequences are shown as follows: taking source sea water, initially filtering by a sand filter, precisely filtering by a security filter, performing reverse osmosis desalination, supplying water by a water producing pump and feeding reagents by a supporting reagent feeding system; a reverse osmosis system also comprises an energy recovery plant and a chemical cleaning / fresh water replacement device, wherein the energy recovery plant is used for recovering energy, and the chemical cleaning / fresh water replacement device is used for performing cleaning or replacement. The reverse osmosis container-type sea water desalination plant and the water producing process thereof disclosed by the invention have the advantages that the energy conversion efficiency is high; the structure is compact; the occupied area is small, and while a high-pressure strong brine emission risk is lowered, the system investment and operating cost can be reduced.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

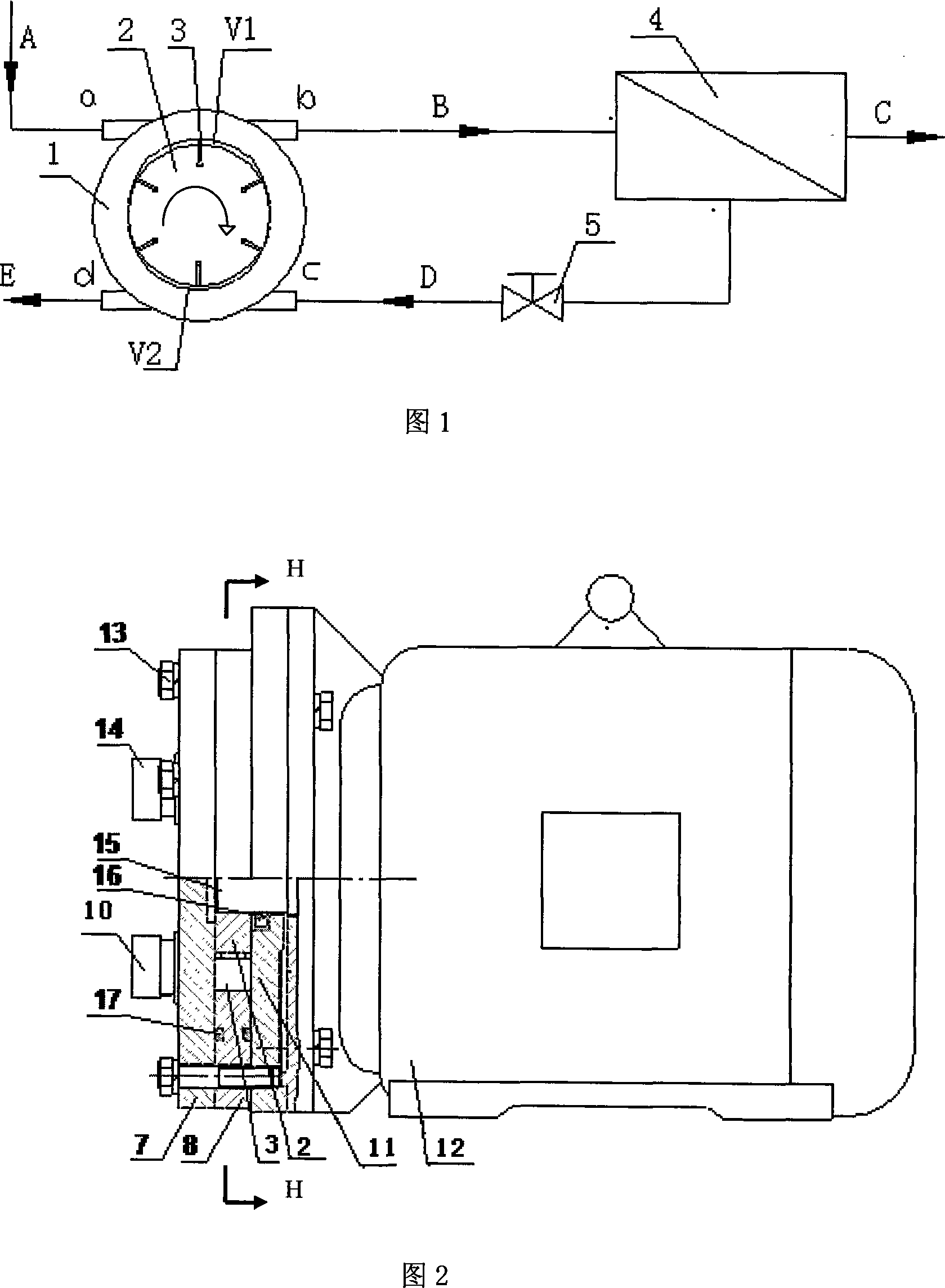

Method and device of desalination process by reverse osmosis for water

InactiveCN101092257AReduce loadSimple structureGeneral water supply conservationSeawater treatmentBrackish waterPump chamber

This invention discloses apparatus and method for reverse osmosis desalination treatment of water with high efficiency in recovering energy. The method comprises: sending pre-treated seawater / brackish water flow A into the pressure chamber of the pump chamber of an energy recovery pump cylinder, rotating rotor and blades by motor, raising the pressure of outflow seawater / brackish water flow B, sending into a reverse osmosis module, performing liquid membrane separation to produce water flow C, sending the residual high-pressure concentrated salt water flow D into a recovery chamber of the same pump chamber of the energy recovery pump cylinder for energy recovery, rotating motor by blades for doing work, and discharging low-pressure concentrated salt water flow E after doing work. This invention has such advantages as high water treatment ability, easy operation, simple apparatus structure, stable operation and low cost.

Owner:XI AN JIAOTONG UNIV

Continuous closed-circuit desalination apparatus without containers

ActiveUS20100270237A1Simple inexpensive designReduce in quantityLiquid separation auxillary apparatusMembranesSaline waterControl system

An apparatus for continuous closed-circuit consecutive sequential desalination of a salt water solution by reverse osmosis that comprises a closed circuit system comprising one or more desalination modules having their respective inlets and outlets connected in parallel by conducing lines, each of desalination modules comprising of one or more membrane elements, a pressurizing device for creating counter pressure to enable reverse osmosis desalination and replacement of released permeate by fresh, a circulation system for recycling the desalinated solution through the desalination modules, a conducting line systems for permeate collection from the desalination modules, a conducting line system for removing brine effluent a valve system to enable periodic discharge of brine from the closed circuit without stopping desalination, and monitoring and control systems to enable continuous closed circuit desalination of desired recovery proceed in consecutive sequential steps under variable or constant pressure conditions.

Owner:DESALITECH

High-salt iron phosphate liquid waste zero-emission treatment device and method

ActiveCN104609631ALow costTo achieve the purpose of emissionGeneral water supply conservationMultistage water/sewage treatmentLiquid wasteEvaporation

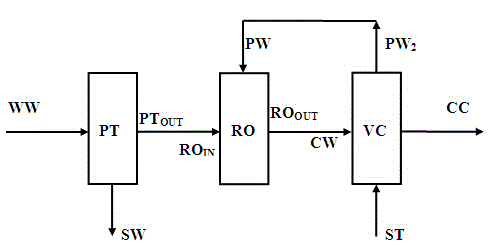

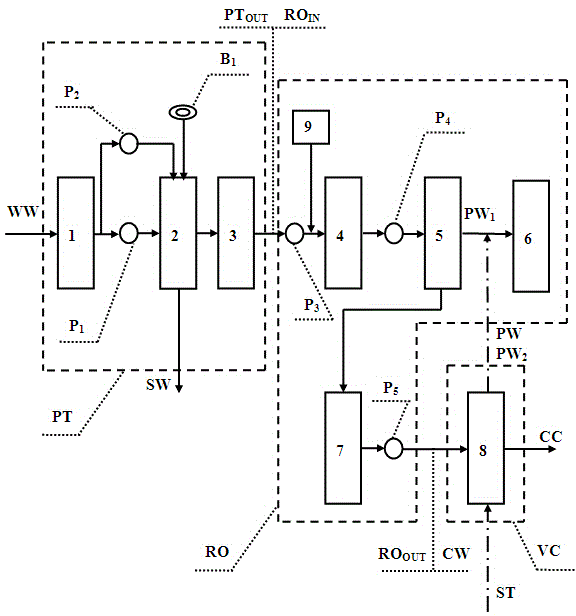

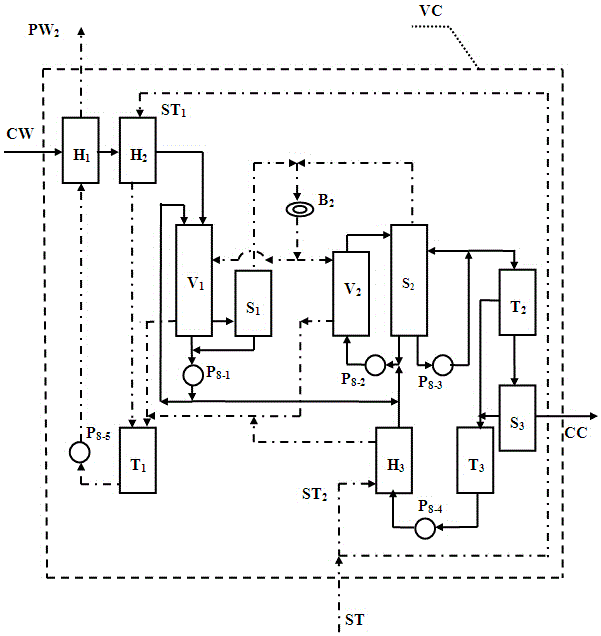

The invention discloses a high-salt iron phosphate liquid waste zero-emission treatment device. The device structurally comprises a pre-treatment (PT) system, a reverse osmosis (RO) treatment system and an evaporative crystallization (VC) treatment system. The high-salt iron phosphate liquid waste zero-emission treatment device has the advantages as follows: the device is designed for high salt of the high-salt iron phosphate liquid waste, the high-salt iron phosphate liquid waste is subjected to pre-treatment to remove part of suspended solids and is subjected to reverse osmosis desalination, concentration reduction and reverse osmosis producing water recycling, reverse osmosis concentrated water is subjected to evaporative crystallization treatment finally, condensate water produced through evaporative crystallization is recycled, waste salt is conveyed outwards, and the purpose of zero liquid emission is achieved. The high-salt iron phosphate liquid waste zero-emission treatment device has the specific advantages as follows: pre-treatment, reverse osmosis and evaporative crystallization are organically combined; 2, the reverse osmosis is adopted for concentration reduction, so that the cost of follow-up evaporative crystallization is reduced; 3, an evaporative crystallization technology combining falling film evaporation and MVR (mechanical vapor recompression) is adopted, energy is saved, the efficiency is high, and the operation cost is reduced; 4, the purposes of water recycling and zero liquid emission are achieved.

Owner:深圳市华虹清源环保科技有限公司

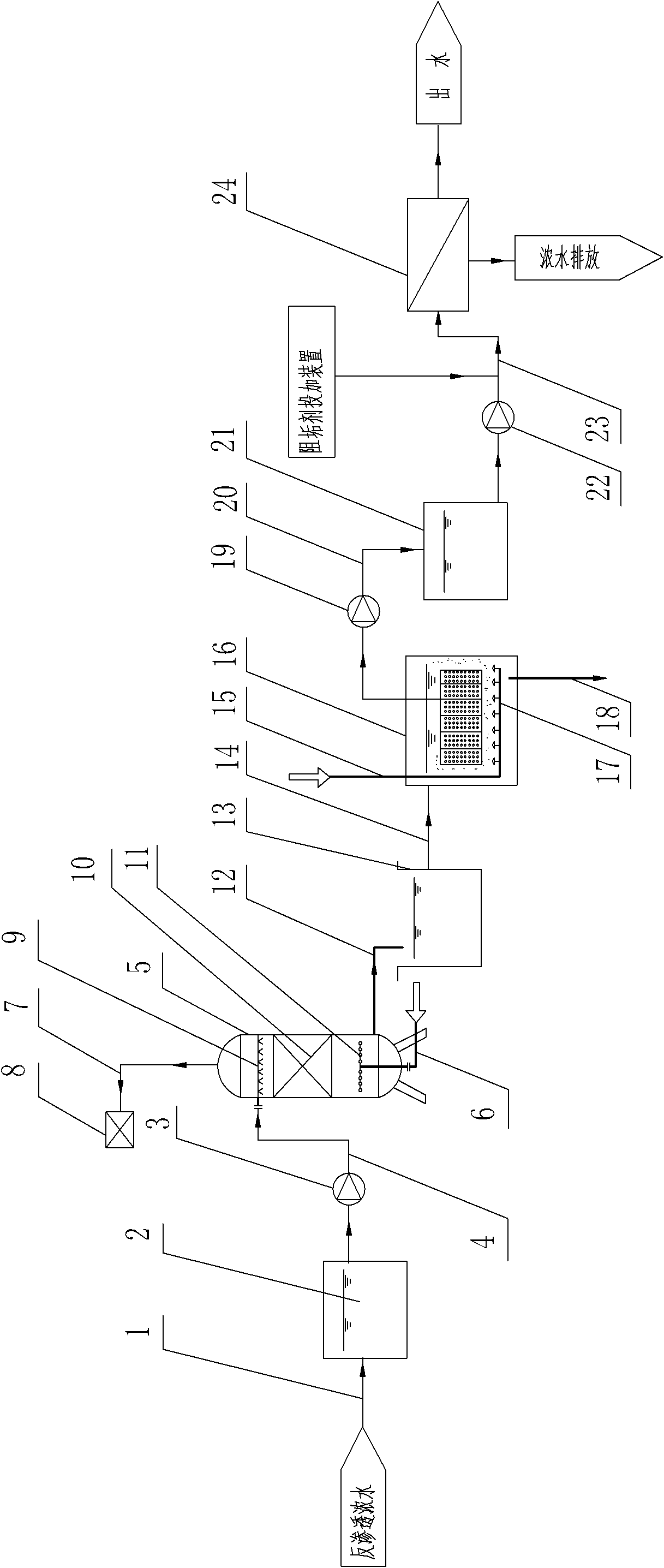

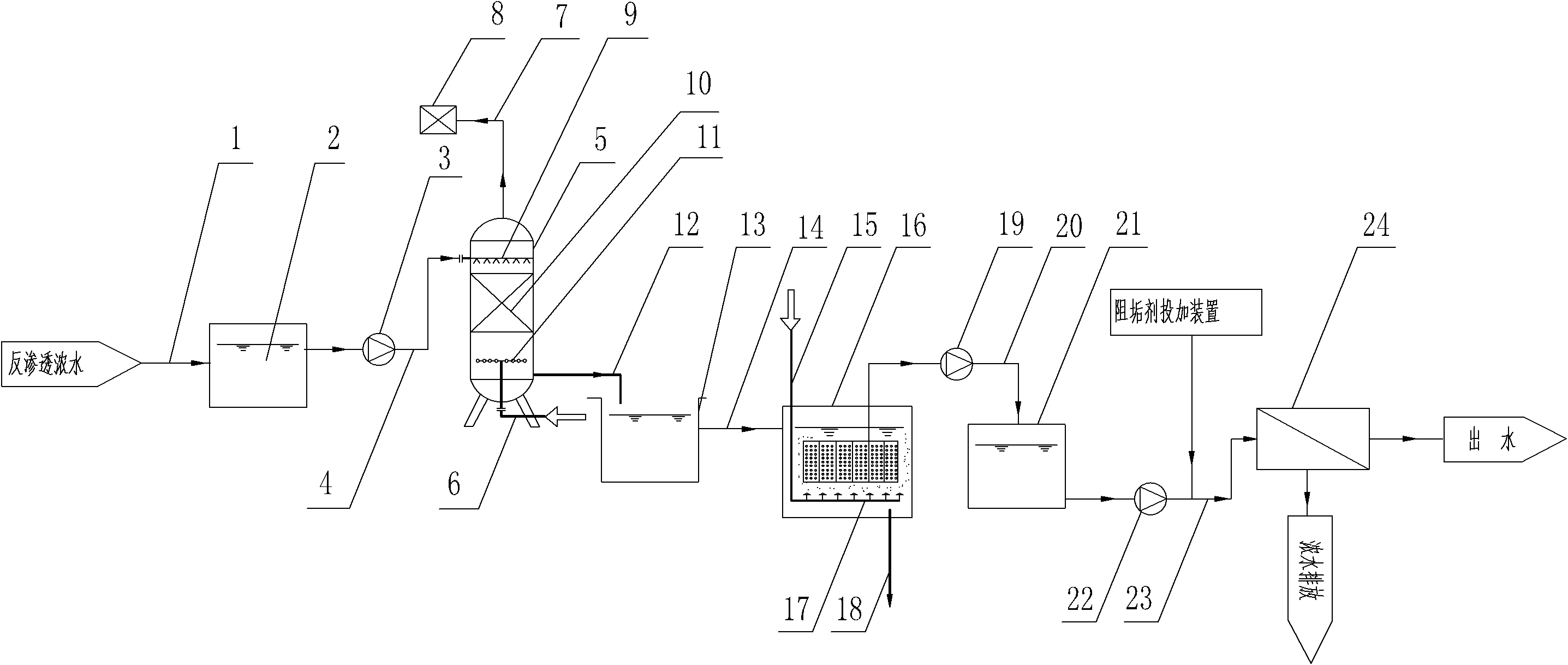

Reverse osmosis concentrated water treatment process and treatment system in cold rolling steel plant

InactiveCN102276121AGuaranteed uptimeGet rid of the dilemma of low recovery rateMultistage water/sewage treatmentReverse osmosis plantHigh pressure

The invention belongs to the technical field of wastewater treatment in the metallurgical industry, and in particular relates to a reverse osmosis concentrated water treatment process and a treatment system of a cold rolling steel plant. The reverse osmosis concentrated water treatment process in cold rolling steel mills is characterized in that it includes the following steps: 1) the reverse osmosis concentrated water first enters the adjustment tank, and the reverse osmosis concentrated water after the adjustment treatment in the adjustment tank enters the ozone contact reactor; 2) passes through the ozone The effluent treated by the contact reactor enters the attenuation tank, and the wastewater treated by the attenuation tank enters the MBR membrane bioreaction tank. The effluent after liquid separation is pumped into the intermediate water production pool by the suction pump to obtain the intermediate water production; 3) The intermediate product water is pumped into the reverse osmosis unit through the high pressure pump for the second reverse osmosis desalination treatment; the effluent treated by the reverse osmosis unit It is used as reuse water; the concentrated water produced by the reverse osmosis unit is directly discharged. The process has the characteristics of high waste water recovery rate.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com