Zero discharge method of stainless steel cold rolling acidic waste water concentrated liquid

A technology for acid waste water and waste water concentration, which is applied in the field of water treatment, can solve the problems of zero discharge technology report of reverse osmosis concentrate of acid waste water from stainless steel cold rolling, etc., and achieve good social and environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

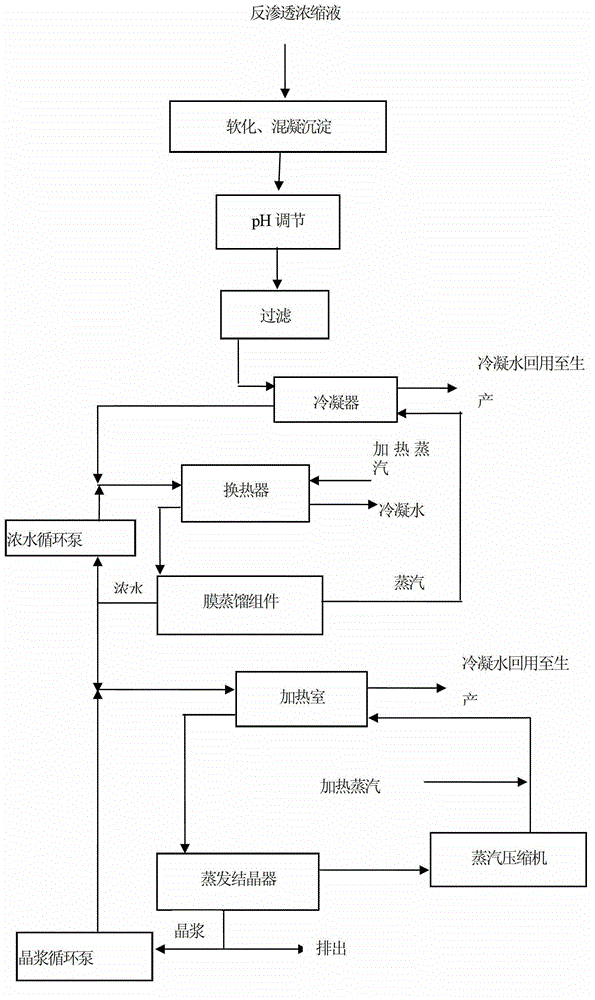

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the examples, and those skilled in the art should understand that the examples are only for illustration and do not constitute any limitation to the present invention.

[0040] (1) softening, coagulation and precipitation

[0041] The concentrated solution from the reverse osmosis system first enters the softening system, and sodium carbonate solution is added to the softening pool to control the pH at 9.5-10, and at the same time, coagulant (dosing amount 5-30ppm) and coagulant aid ( 0~3ppm), after coagulation and reaction, it enters the sedimentation tank for mud-water separation.

[0042] (2) pH adjustment

[0043] The pH of the effluent from the sedimentation tank is adjusted to 6-7 with hydrochloric acid.

[0044] (3) filter

[0045] After pH adjustment, it enters the filter for filtration. The filter material can be quartz sand, anthracite, or quartz sand for the lower part and anthracite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com