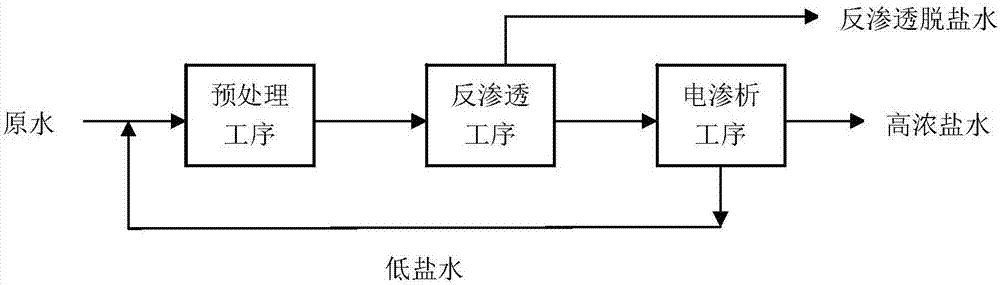

High-hardness salt-containing water concentration method based on monovalent cationic selective electrodialysis

An electrodialysis and cation technology, applied in separation methods, osmosis/dialysis water/sewage treatment, general water supply saving, etc., can solve the problems of complex equipment and low recovery rate, achieve high efficiency, good adaptability, and avoid scaling effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

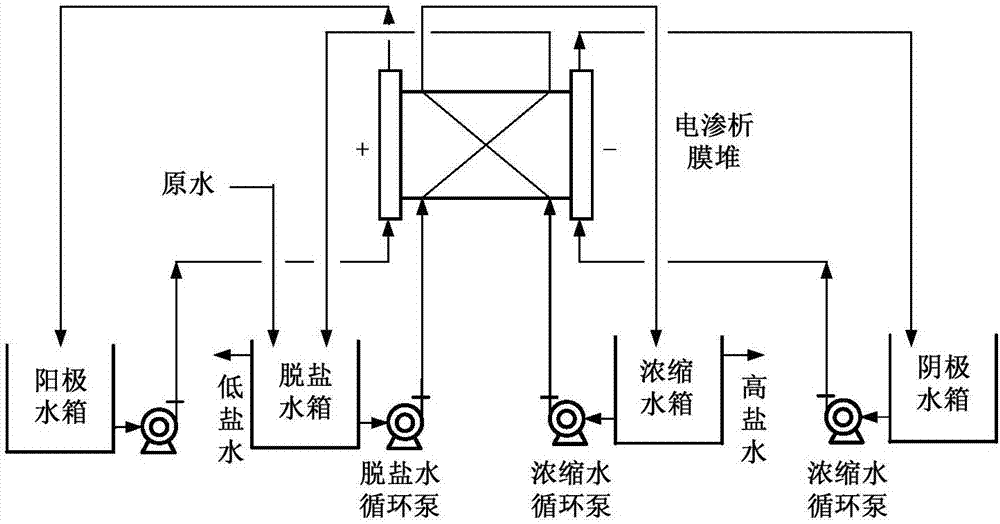

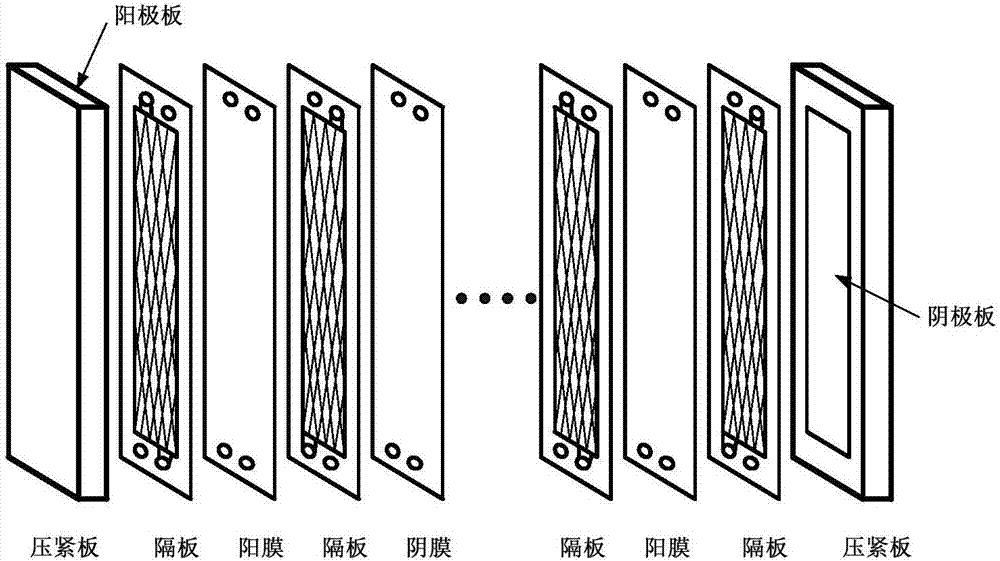

Method used

Image

Examples

Embodiment 1

[0038] The raw water in this part is the mixed water of wastewater from a chemical enterprise and the return water from each unit, and the water quality is shown in the table

[0039] Element concentration Na 2 SO 4 / mg·L -1

7 000 Ca 2+ / mg·L -1

20 Cl - / mg·L -1

36 COD / mg·L -1

3 000 SS / mg·L -1

50 pH 8.2

[0040] The first step, raw water pretreatment process

[0041] The above raw water 98.7m 3 / h, the SS value is removed by the mechanical clarifier, the anaerobic / aerobic (A / O) biological reaction tank, and the biological aerated filter (BAF) are used to remove COD in the water, and after ultrafiltration, the water produced is 88m 3 / h, TDS 7050mg / L, SS 0mg / L, COD 100mg / L, SDI value: 3. Among them, the ultrafiltration adopts PVDF hollow fiber membrane, adopts the form of cross-flow filtration, the recovery rate is 90%, and the operating pressure is 0.1MPa.

[0042] The second step, reverse osmos...

Embodiment 2

[0055] The raw water in this part is wastewater from an enterprise, with a water volume of 360m 3 / h, pH=7 water quality as shown in the table.

[0056] water quality index Valuemg / L K 50 Na +

1700 Mg 2+

100 NO 3 -

260 Cl -

1100 SO 4 2-

3800 total hardness 3000 TDS 8300 COD Cr

120

[0057] The first step, raw water pretreatment process

[0058] 360m from the raw water adjustment pool 3 / h flow rate and each part of return water enters the regulating pool, with a total water volume of 400m 3 / h into the ozone + BAF process, this process mainly removes COD in the water, the design removal rate is 40%, the COD of the produced water is 70mg / L, and the other indicators are basically unchanged; then add Na 2 CO 3 , coagulant FeCl 3 (mg / L) and coagulant PAM (mg / L) enter the high-density clarification tank to mainly remove hardness in raw water, the design removal rate is 95%, and part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com