Composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane, a combined technology, applied in chemical instruments and methods, membranes, membrane technology and other directions, can solve the problems of poor acid resistance and poor alkali resistance of nanofiltration membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

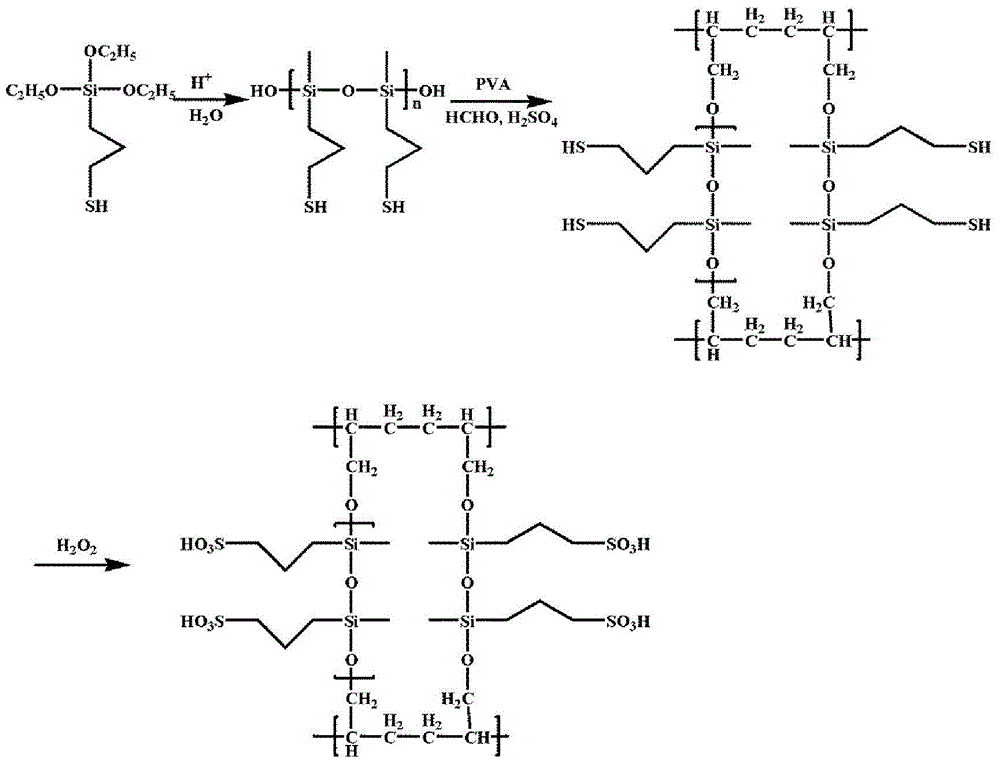

[0034] The present invention also provides a kind of preparation method of composite nanofiltration membrane, and this method comprises the following steps:

[0035] (1) dissolving a polymer containing a hydroxyl group and a silane coupling agent containing a mercapto group in a solvent to prepare a coating solution;

[0036] (2) coating the coating solution on the support layer to form an initial film;

[0037] (3) immerse the supporting layer formed with the initial film in step (2) into a solution containing a crosslinking agent and a crosslinking catalyst to carry out a crosslinking reaction to obtain a crosslinked network structure comprising the supporting layer and the surface of the supporting layer Initial composite nanofiltration membrane;

[0038] (4) Post-treating the initial composite nanofiltration membrane with an aqueous solution containing an oxidant to obtain a modified composite nanofiltration membrane.

[0039] According to the present invention, the pres...

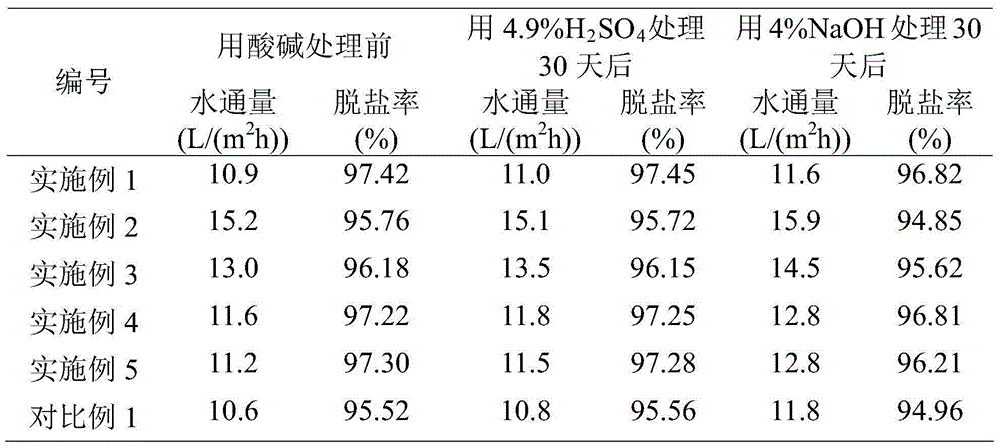

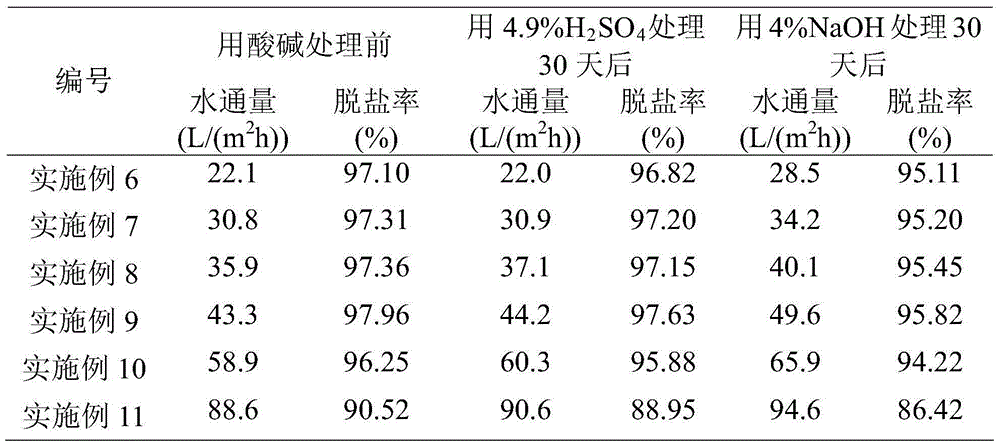

Embodiment 1

[0069] This embodiment is used to illustrate the composite nanofiltration membrane provided by the present invention and its preparation method.

[0070] Dissolve 1.0g of polyvinyl alcohol (PVA) and 1.0g of γ-mercaptopropyltriethoxysilane (KH580) in 100g of deionized water, then add 1mol / L dilute hydrochloric acid dropwise under stirring to adjust the pH of the solution to 1. At room temperature, after stirring for 24 hours, filter to obtain a clear coating solution;

[0071] After coating the dilute coating solution evenly on the polysulfone bottom membrane, put it into an oven at 60°C and heat it for 30 minutes to ensure that the solvent is completely evaporated; then soak the obtained initial composite nanofiltration membrane in a solution containing 100g In a solution of sulfuric acid, 10g formaldehyde and 15g sodium sulfate, at 50°C, after heating for 30min, take out the initial composite nanofiltration membrane, wash it with water and soak it in deionized water for late...

Embodiment 2

[0078] This embodiment is used to illustrate the composite nanofiltration membrane provided by the present invention and its preparation method.

[0079] Dissolve 1.0 g of PVA and 0.75 g of γ-mercaptopropyltrimethoxysilane in 100 g of deionized water, and then add 1 mol / L dilute hydrochloric acid dropwise under stirring to adjust the pH value of the solution to 4. At room temperature, after stirring for 24 hours, filter to obtain a clear coating solution;

[0080] After coating the dilute coating solution evenly on the polysulfone bottom membrane, put it into an oven at 60°C and heat it for 30 minutes to ensure that the solvent is completely evaporated; then soak the obtained initial composite nanofiltration membrane in a solution containing 100g In a solution of sulfuric acid, 15g formaldehyde and 20g sodium sulfate, at 50°C, after heating for 30min, the initial composite nanofiltration membrane was taken out, washed with water and soaked in deionized water for later use;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com