Polyurethane three-proofing coating

A technology of polyurethane conformal paint and polyurethane modification, which is applied in the direction of polyurea/polyurethane coatings and coatings, and can solve problems such as harmfulness to the human body and application restrictions of polyurethane conformal paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

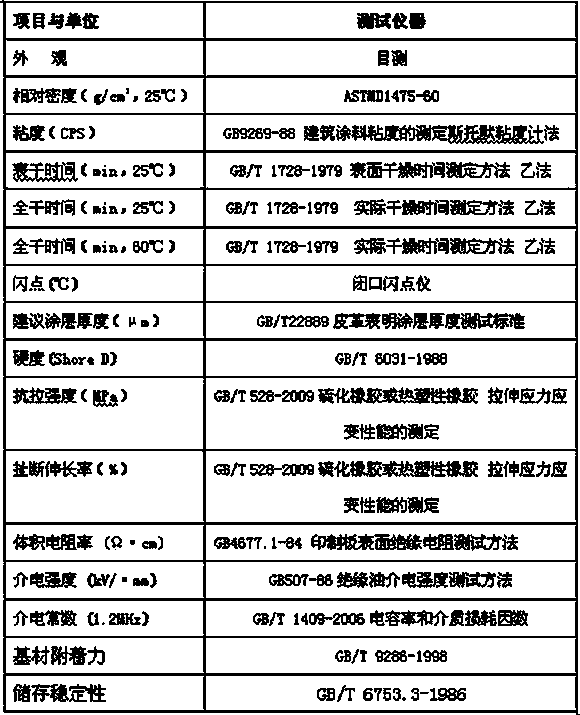

[0043] The preparation method of polyurethane three-proof paint is characterized in that it consists of the following steps:

[0044] Add the alkyd resin and polyisocyanate into the three-necked bottle according to the metering, mix evenly and heat up to 88-90°C, and react for 1.5h; after 1.5h, add the metered small molecule polyol into the three-necked bottle, and adjust the temperature to 68-90°C 70°C, react for 5h; add measured solvent after 5h, react at 60-62°C for 3h; after the reaction, cool and discharge to obtain polyurethane modified alkyd resin;

[0045] First add a drier to the polyurethane modified alkyd resin, stir, then add an anti-skinning agent and fluorescent powder, and stir to obtain a polyurethane conformal coating.

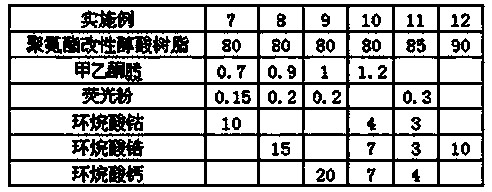

[0046]

[0047] The following is a detailed description of the synthesis and application of polyurethane conformal coatings.

[0048] Phosphor: Ciba OB phosphor

[0049] Cobalt naphthenate: Shanghai Huanqi Chemical Co., Ltd., cobalt naphthe...

Embodiment 13-18

[0072] The preparation method is the same as before.

[0073]

[0074]

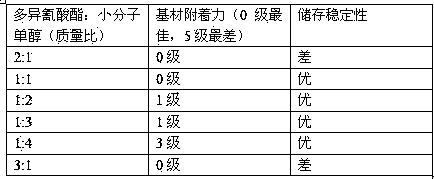

[0075] For the polyurethane conformal paint prepared above, by testing the substrate adhesion and storage stability, it can be seen that the best adhesion and storage stability are obtained with a mass ratio of 1:1-1:3. is 1:1.

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com