Patents

Literature

439 results about "Conformal coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conformal coating material is a thin polymeric film which conforms to the contours of a printed circuit board to protect the board's components. Typically applied at 25-250 μm(micrometers) thickness, it is applied to electronic circuitry to protect against moisture, dust, chemicals, and temperature extremes.

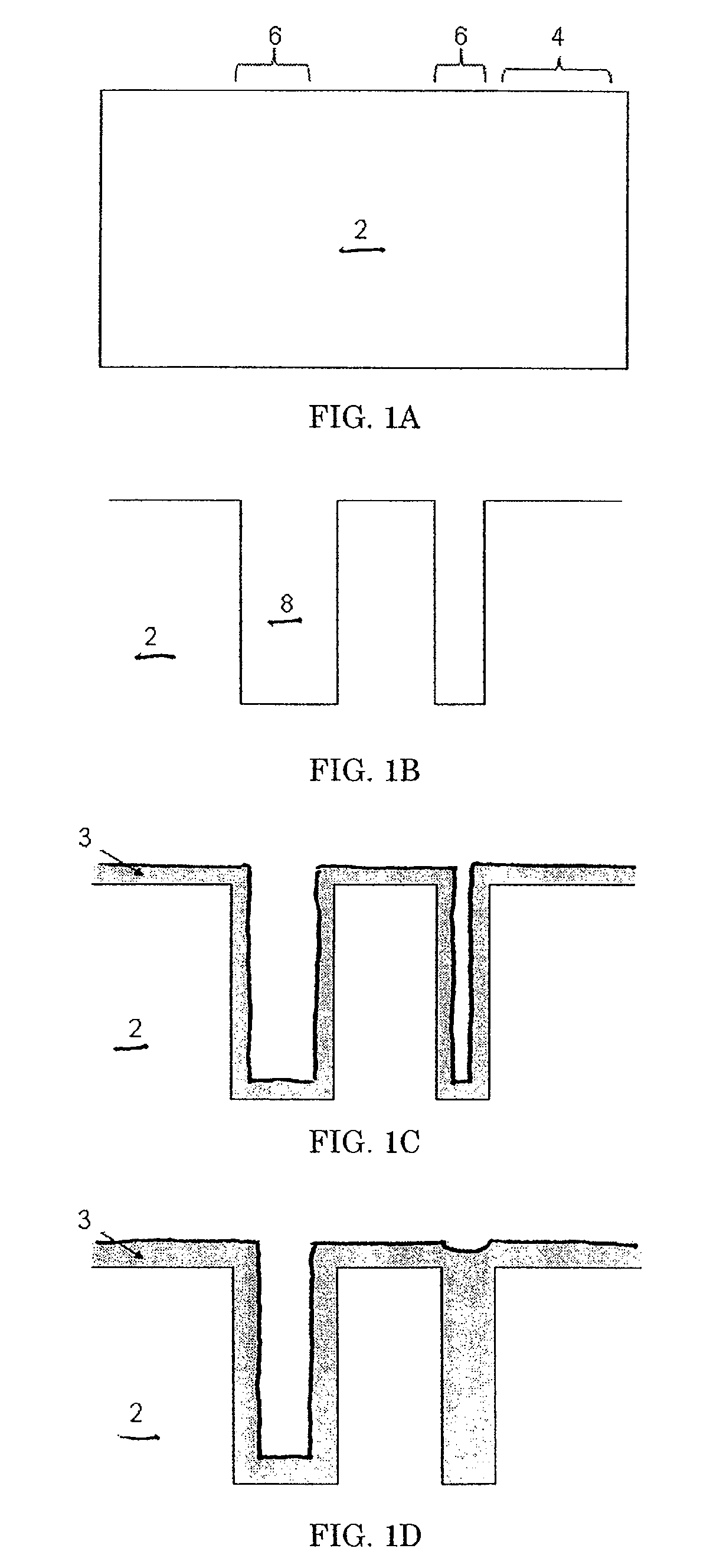

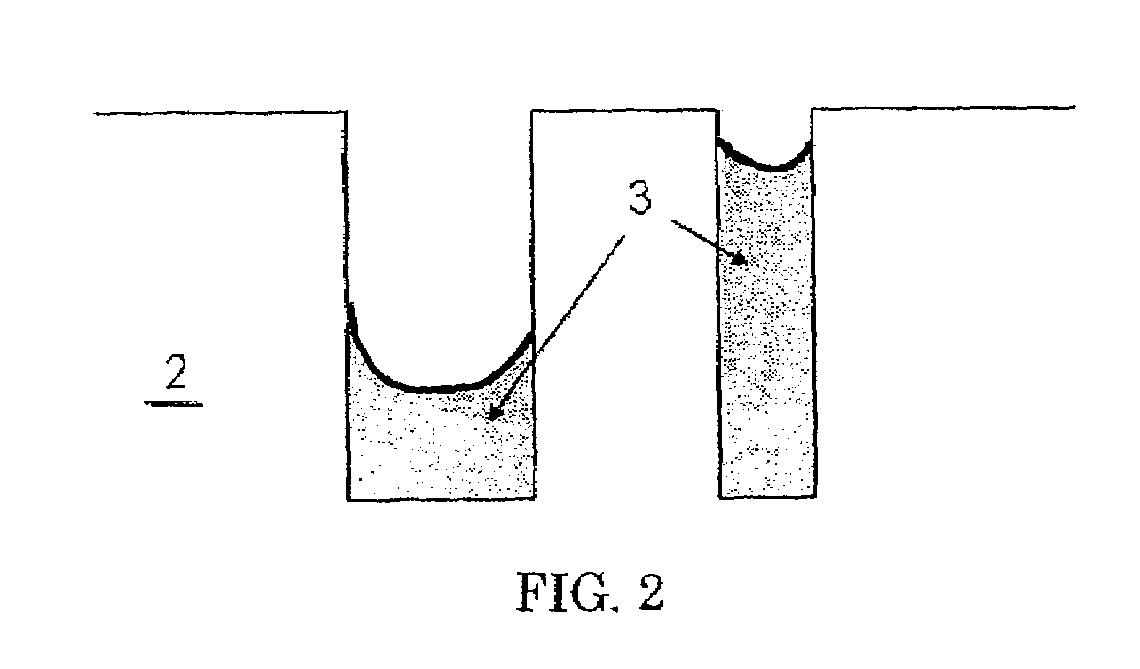

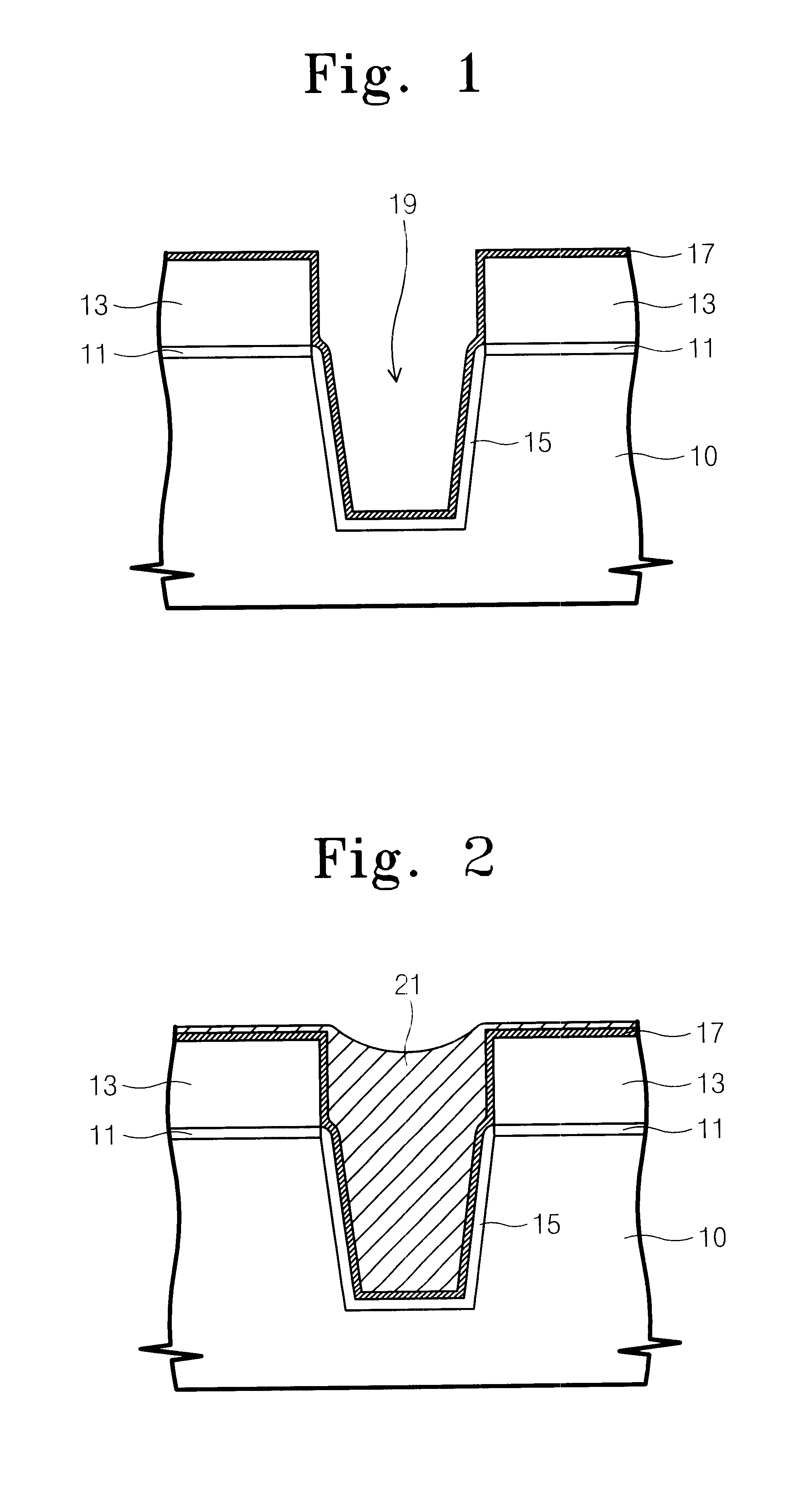

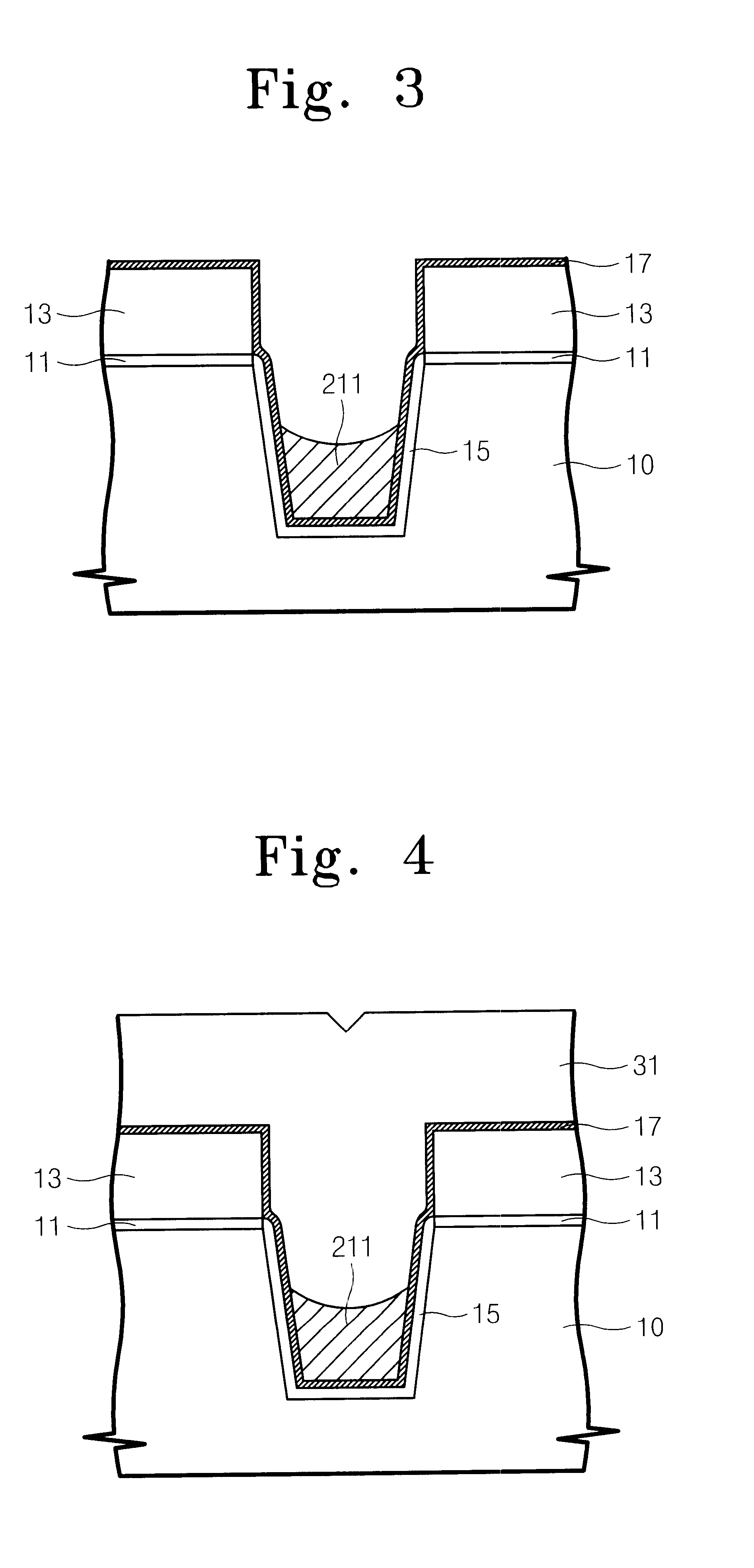

Device isolation technology on semiconductor substrate

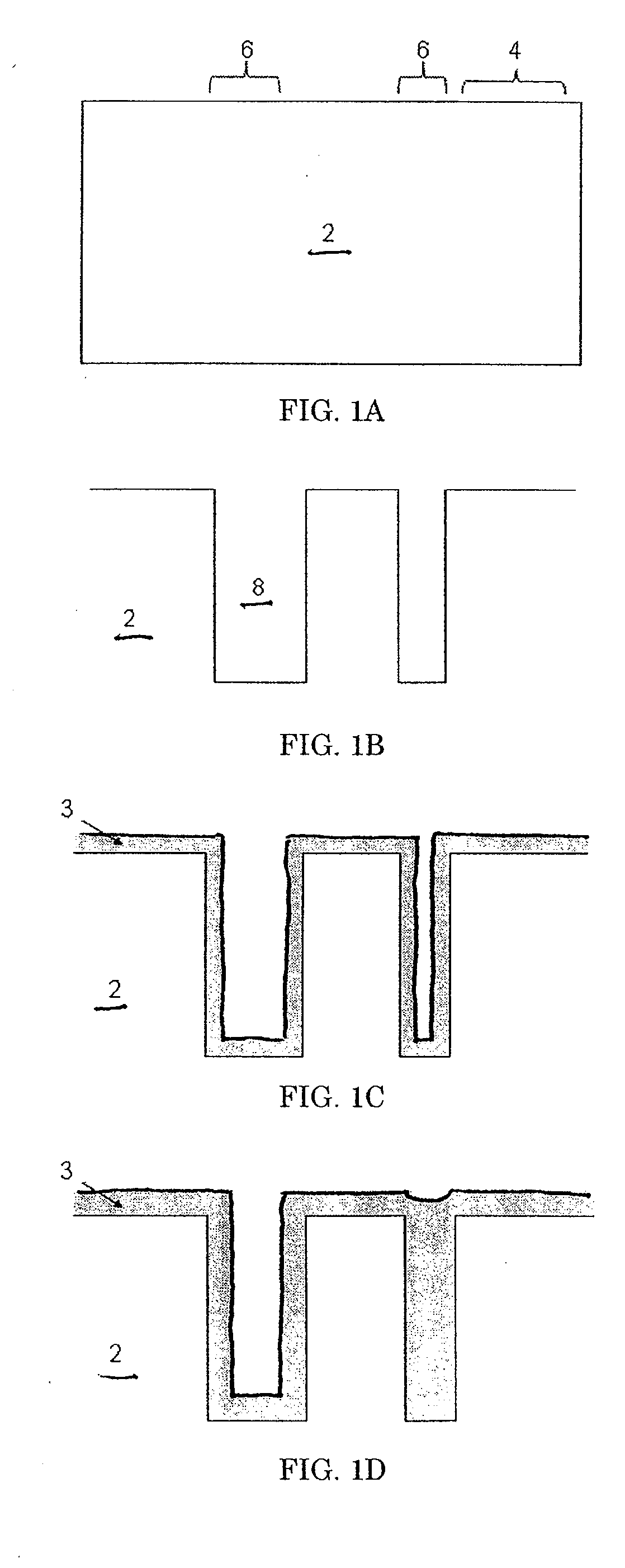

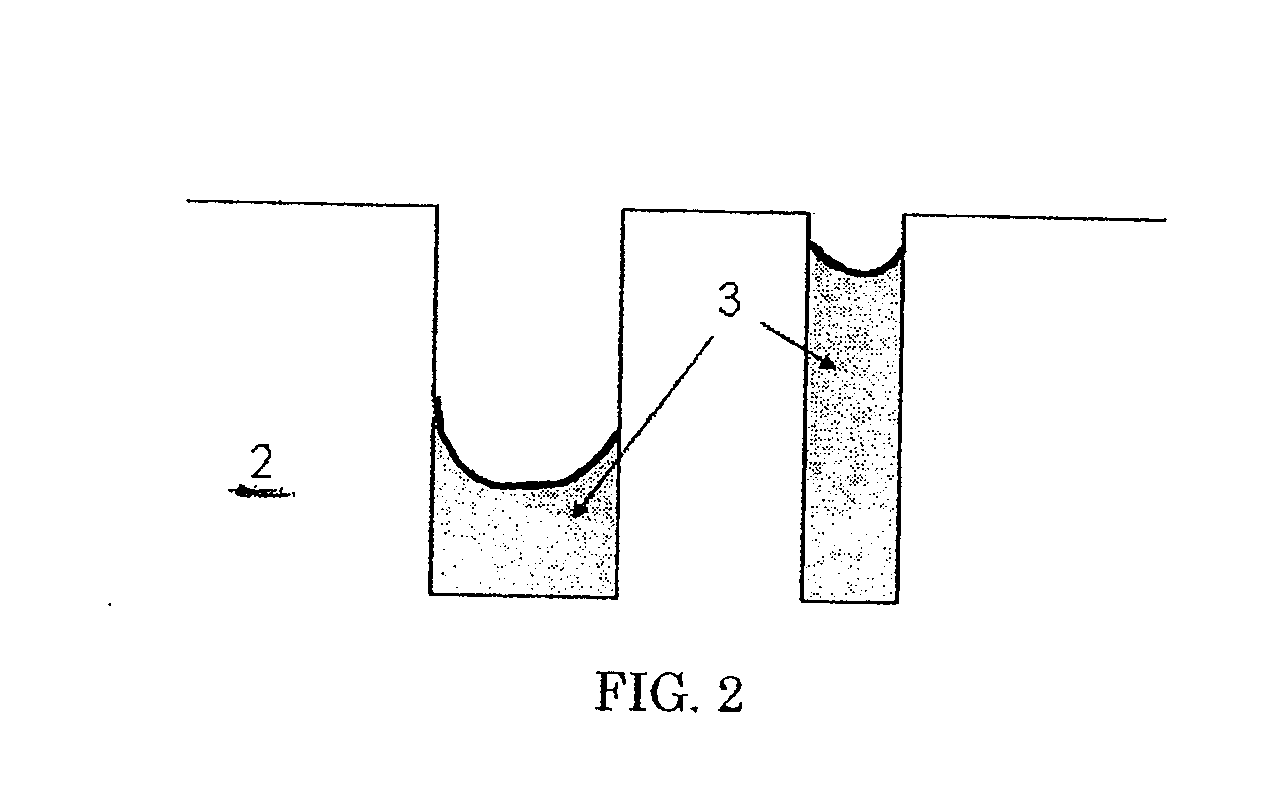

A method of forming device isolation regions on a trench-formed silicon substrate and removing residual carbon therefrom includes providing a flowable, insulative material constituted by silicon, carbon, nitrogen, hydrogen, oxygen or any combination of two or more thereof; forming a thin insulative layer, by using the flowable, insulative material, in a trench located on a semiconductor substrate wherein the flowable, insulative material forms a conformal coating in a silicon and nitrogen rich condition whereas in a carbon rich condition, the flowable, insulative material vertically grows from the bottom of the trenches; and removing the residual carbon deposits from the flowable, insulative material by multi-step curing, such as O2 thermal annealing, ozone UV curing followed by N2 thermal annealing.

Owner:ASM JAPAN

Device isolation technology on semiconductor substrate

A method of forming device isolation regions on a trench-formed silicon substrate and removing residual carbon therefrom includes providing a flowable, insulative material constituted by silicon, carbon, nitrogen, hydrogen, oxygen or any combination of two or more thereof; forming a thin insulative layer, by using the flowable, insulative material, in a trench located on a semiconductor substrate wherein the flowable, insulative material forms a conformal coating in a silicon and nitrogen rich condition whereas in a carbon rich condition, the flowable, insulative material vertically grows from the bottom of the trenches; and removing the residual carbon deposits from the flowable, insulative material by multi-step curing, such as O2 thermal annealing, ozone UV curing followed by N2 thermal annealing.

Owner:ASM JAPAN

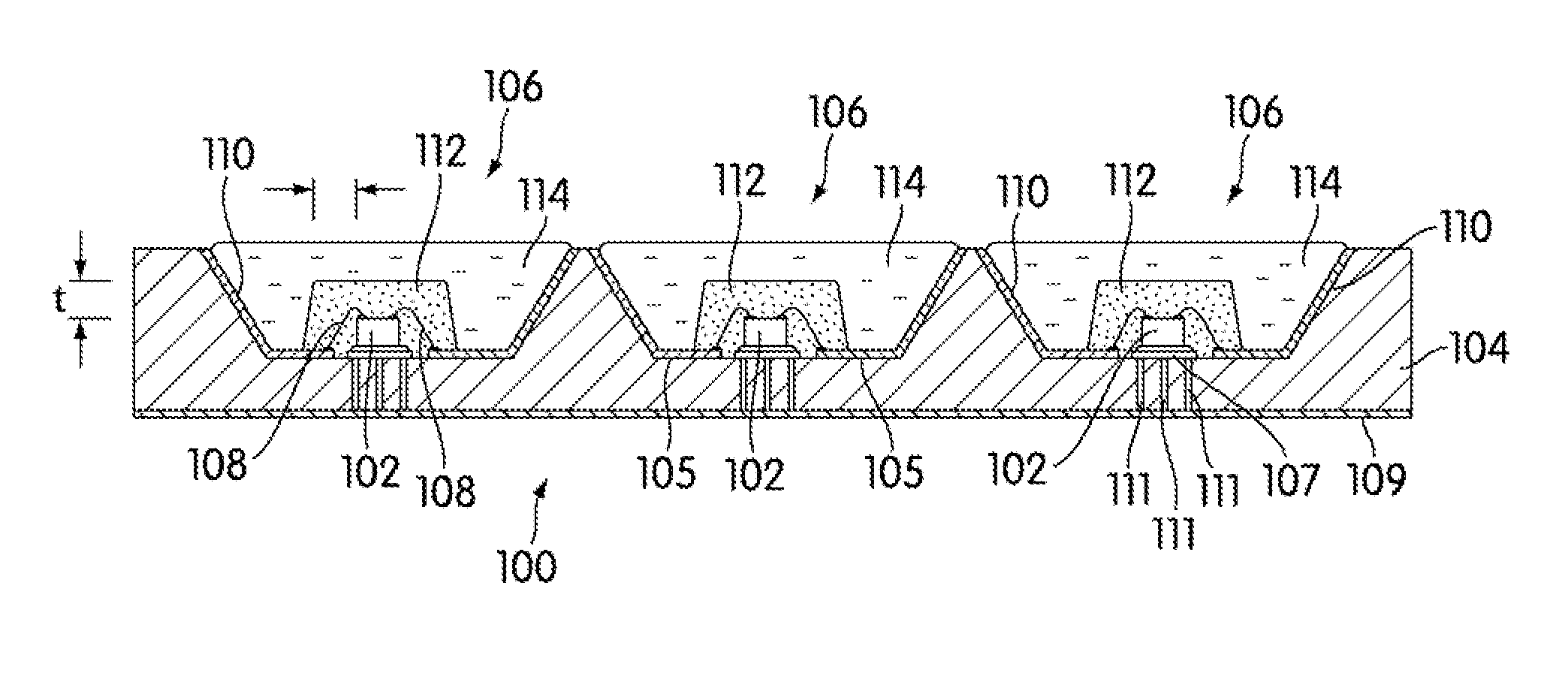

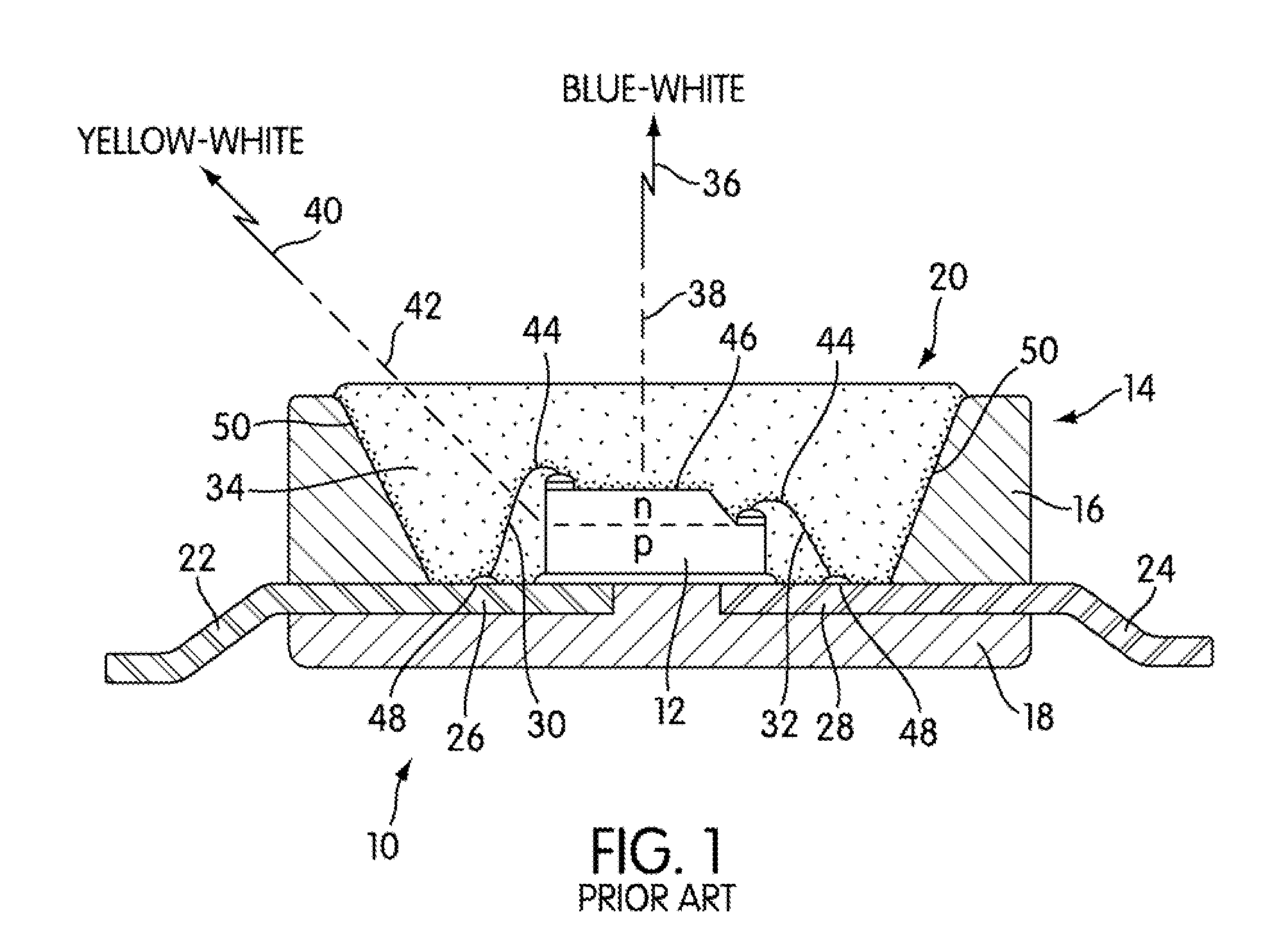

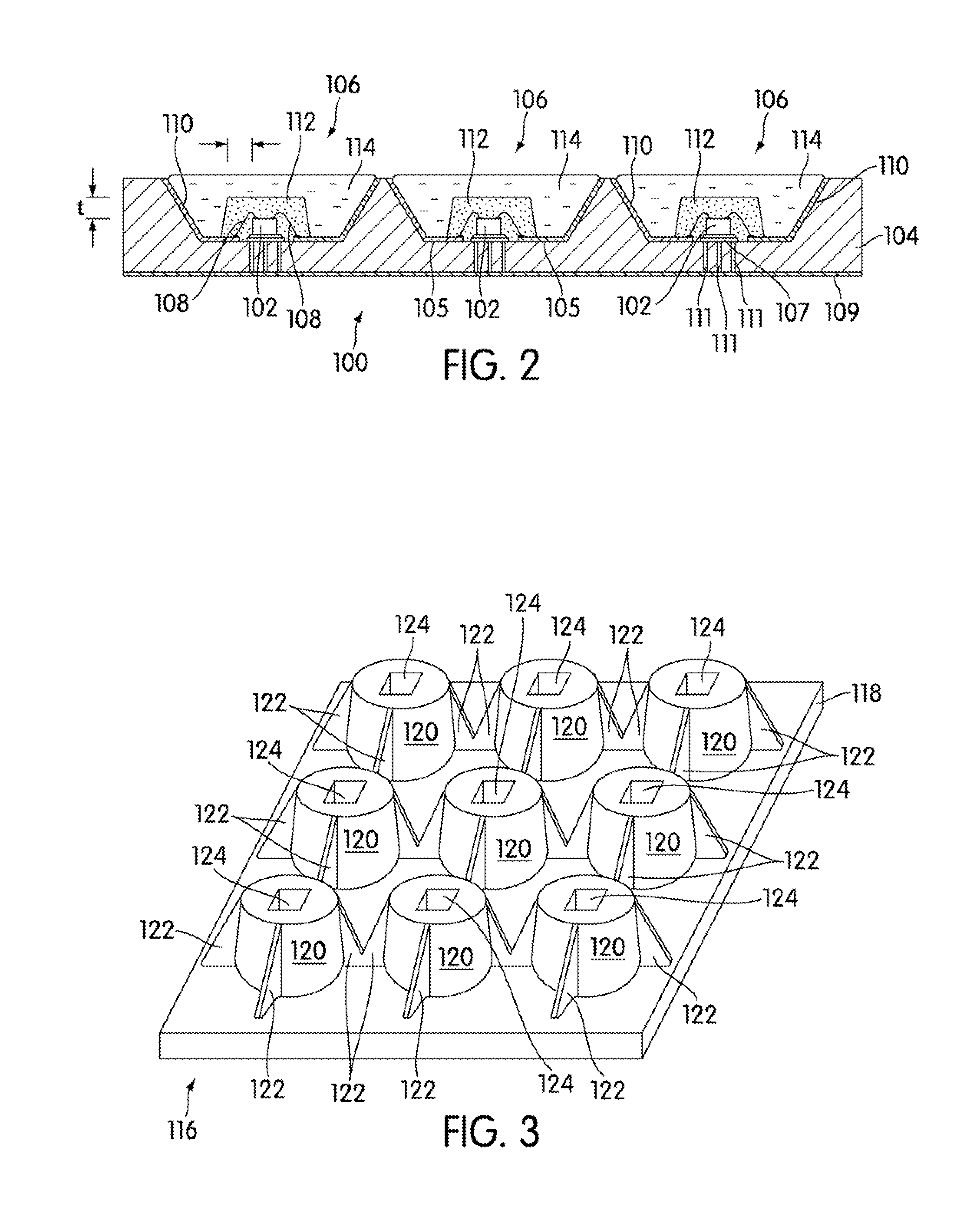

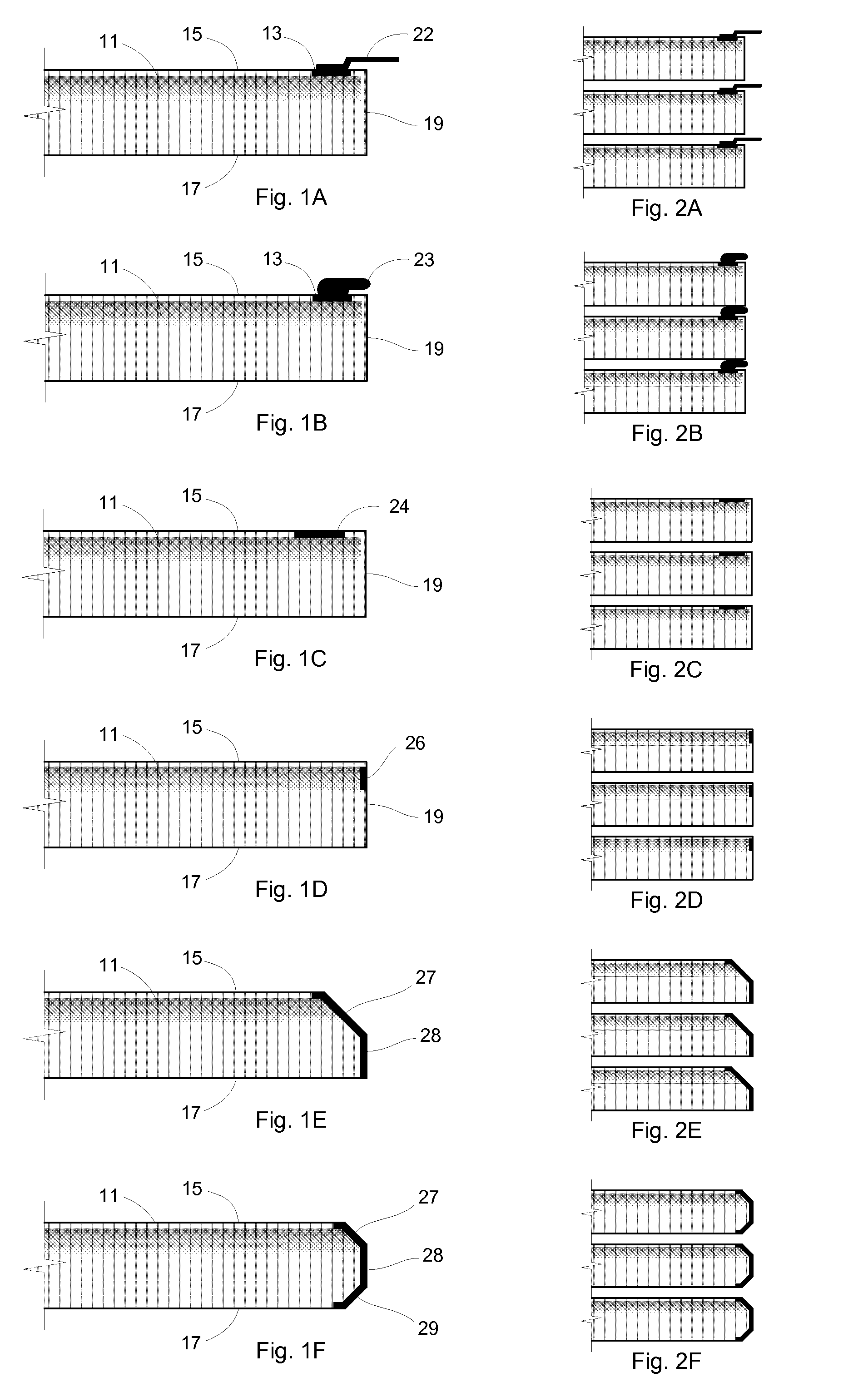

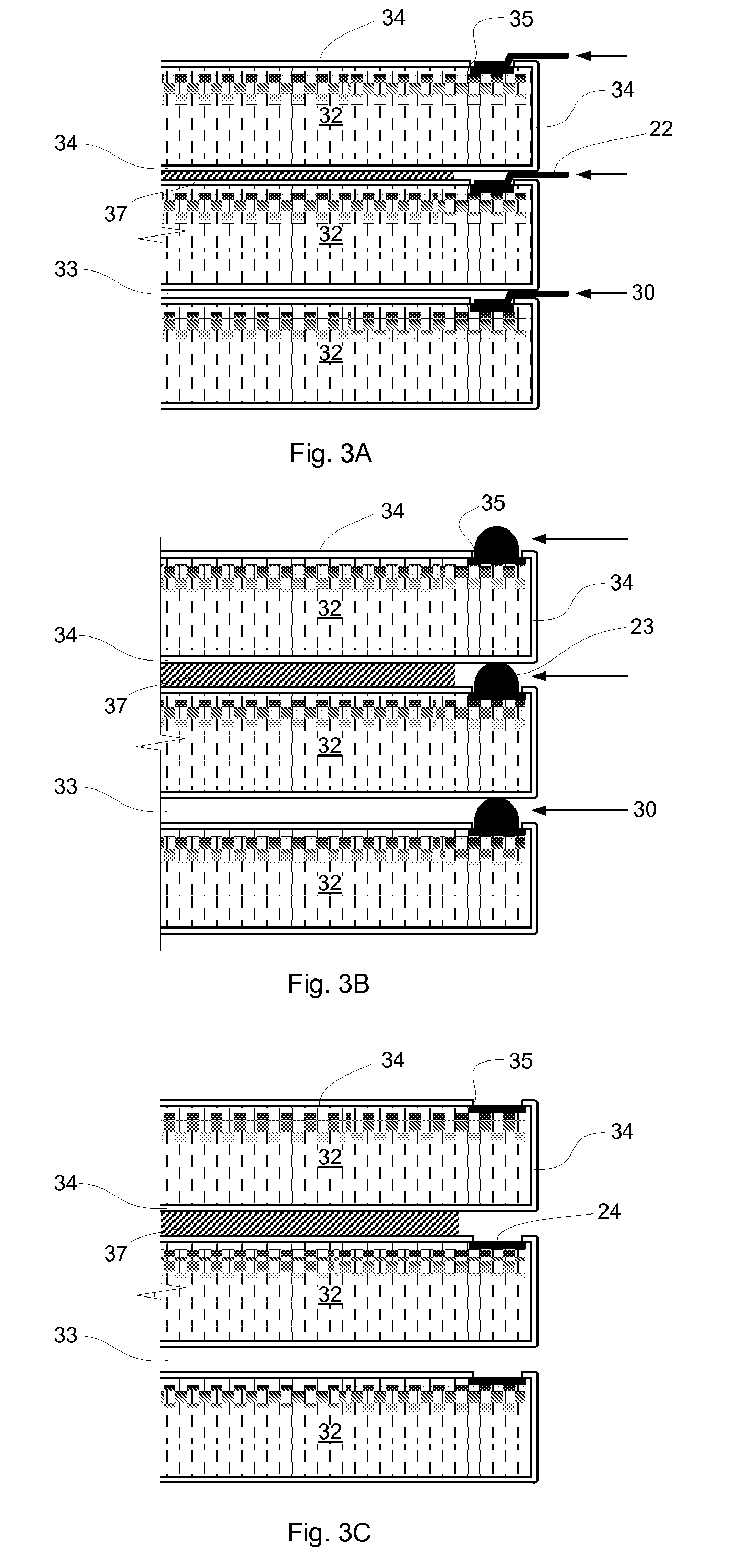

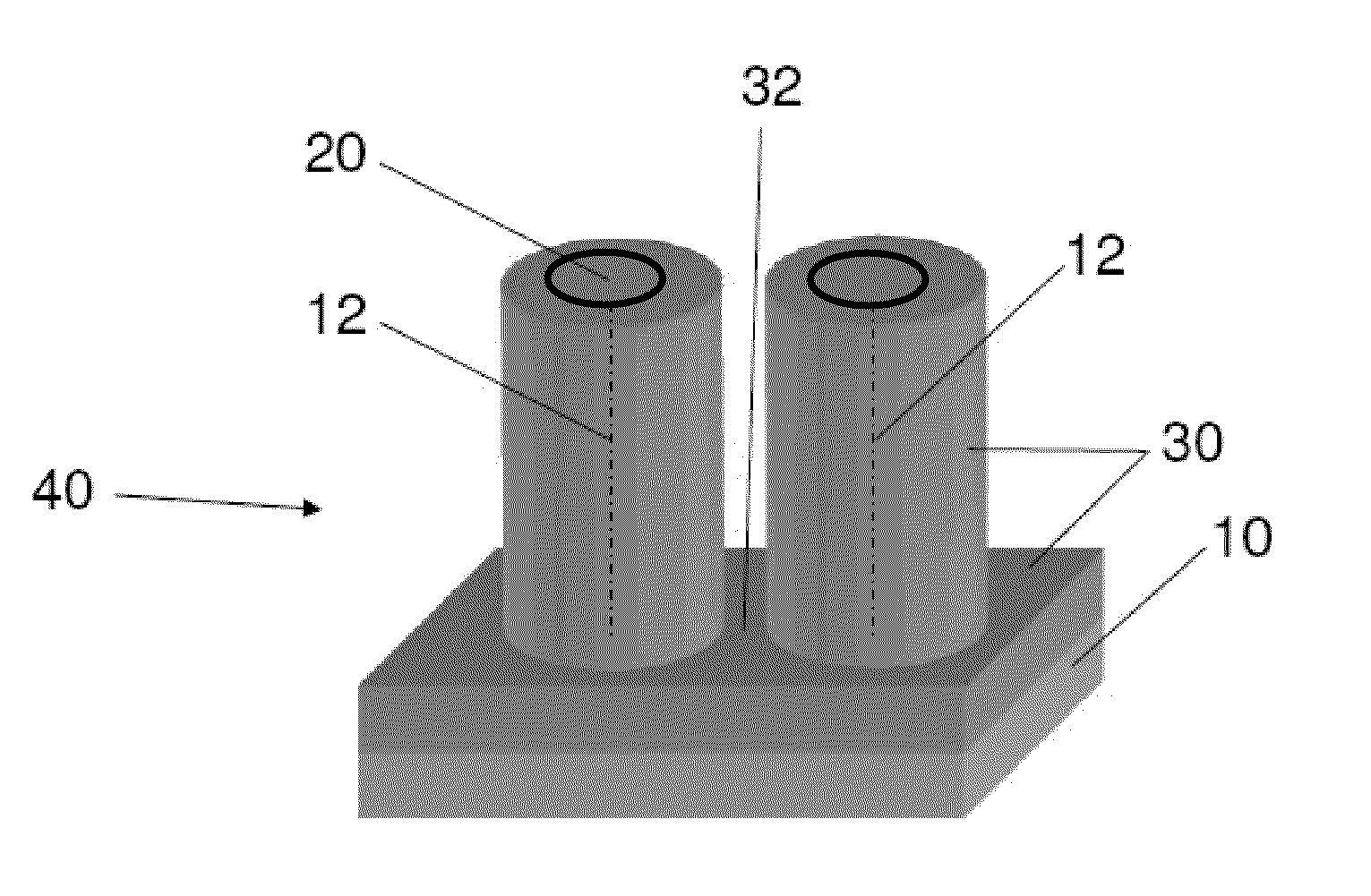

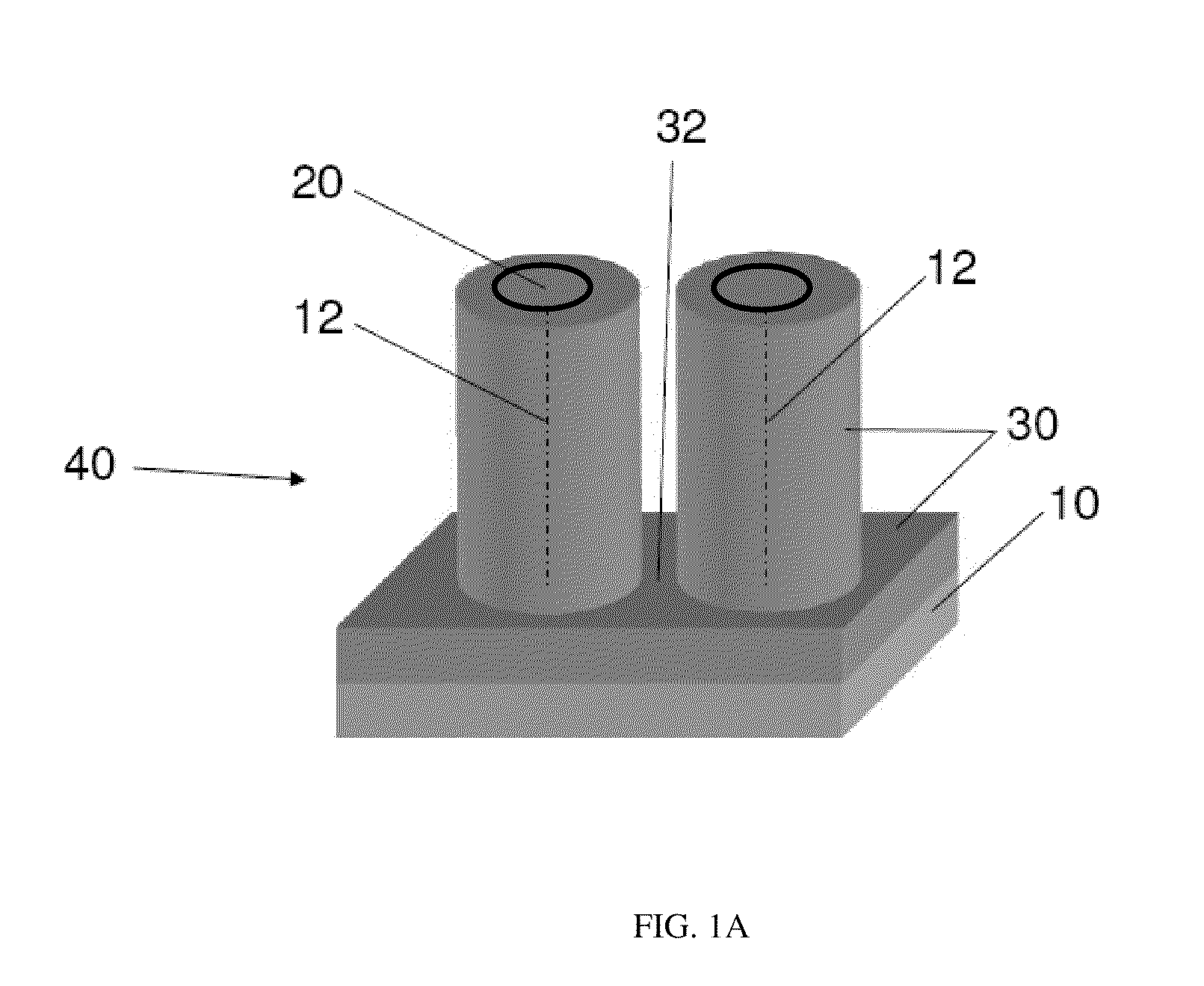

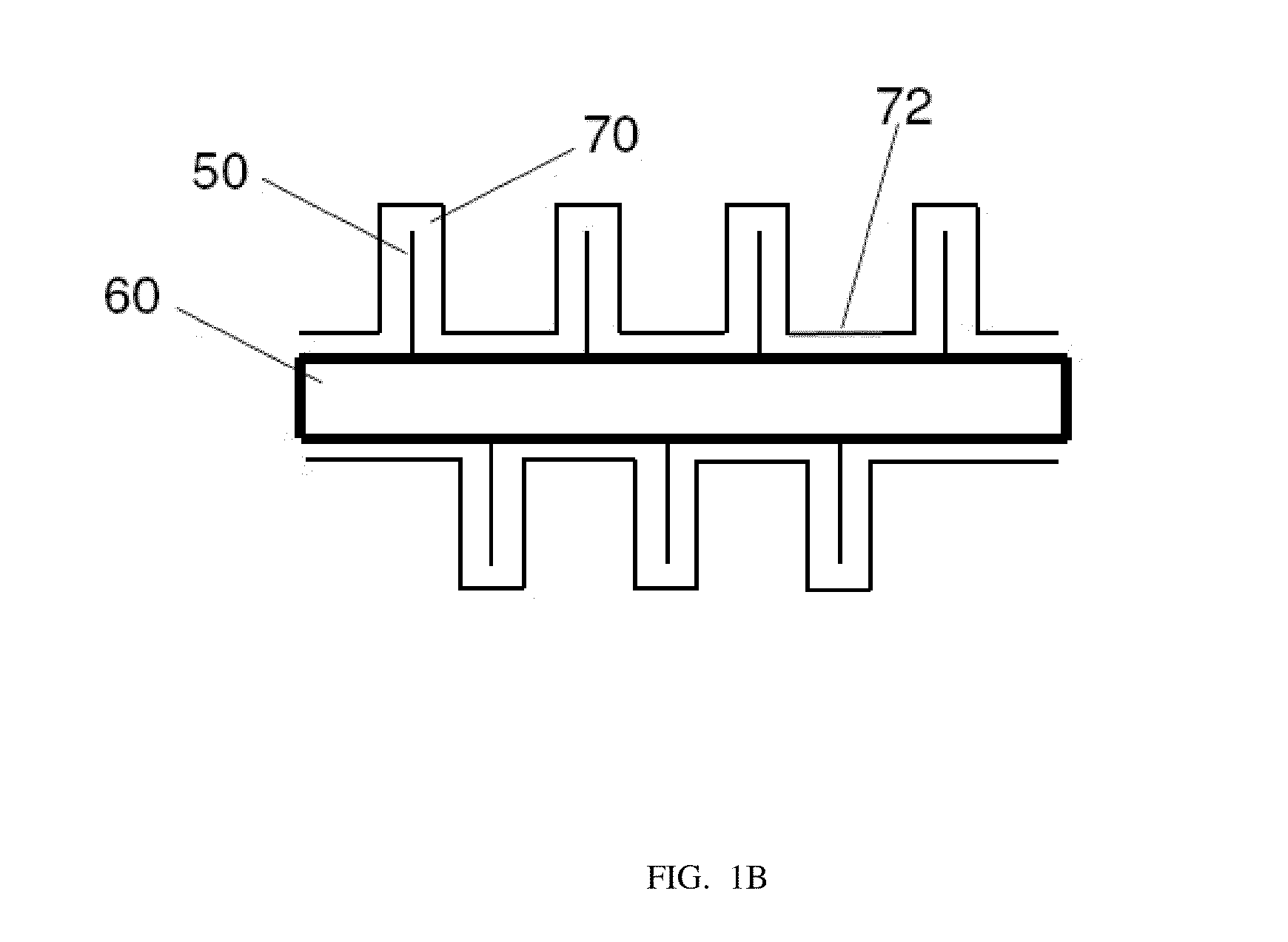

Light emitting devices with phosphor wavelength conversion and methods of manufacture thereof

InactiveUS20100181582A1Reduces the formation of air bubblesEasy to fillSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorPlanar substrate

A light emitting device comprises: a package (low temperature co-fired ceramic) having a plurality of recesses (cups) in which each recess houses at least one LED chip and at least one phosphor material applied as coating to the light emitting light surface of the LED chips, wherein the phosphor material coating is conformal in form. In another arrangement a light emitting device comprises: a planar substrate (metal core printed circuit board); a plurality of light emitting diode chips mounted on, and electrically connected to, the substrate; a conformal coating of at least one phosphor material on each light emitting diode chip; and a lens formed over each light emitting diode chip.

Owner:INTEMATIX

Nanocoated primary particles and method for their manufacture

InactiveUS6913827B2Granule coatingSemiconductor/solid-state device detailsConformal coatingElectronic packaging

Particles have an ultrathin, conformal coating are made using atomic layer deposition methods. The base particles include ceramic and metallic materials. The coatings can also be ceramic or metal materials that can be deposited in a binary reaction sequence. The coated particles are useful as fillers for electronic packaging applications, for making ceramic or cermet parts, as supported catalysts, as well as other applications.

Owner:UNIV OF COLORADO THE REGENTS OF

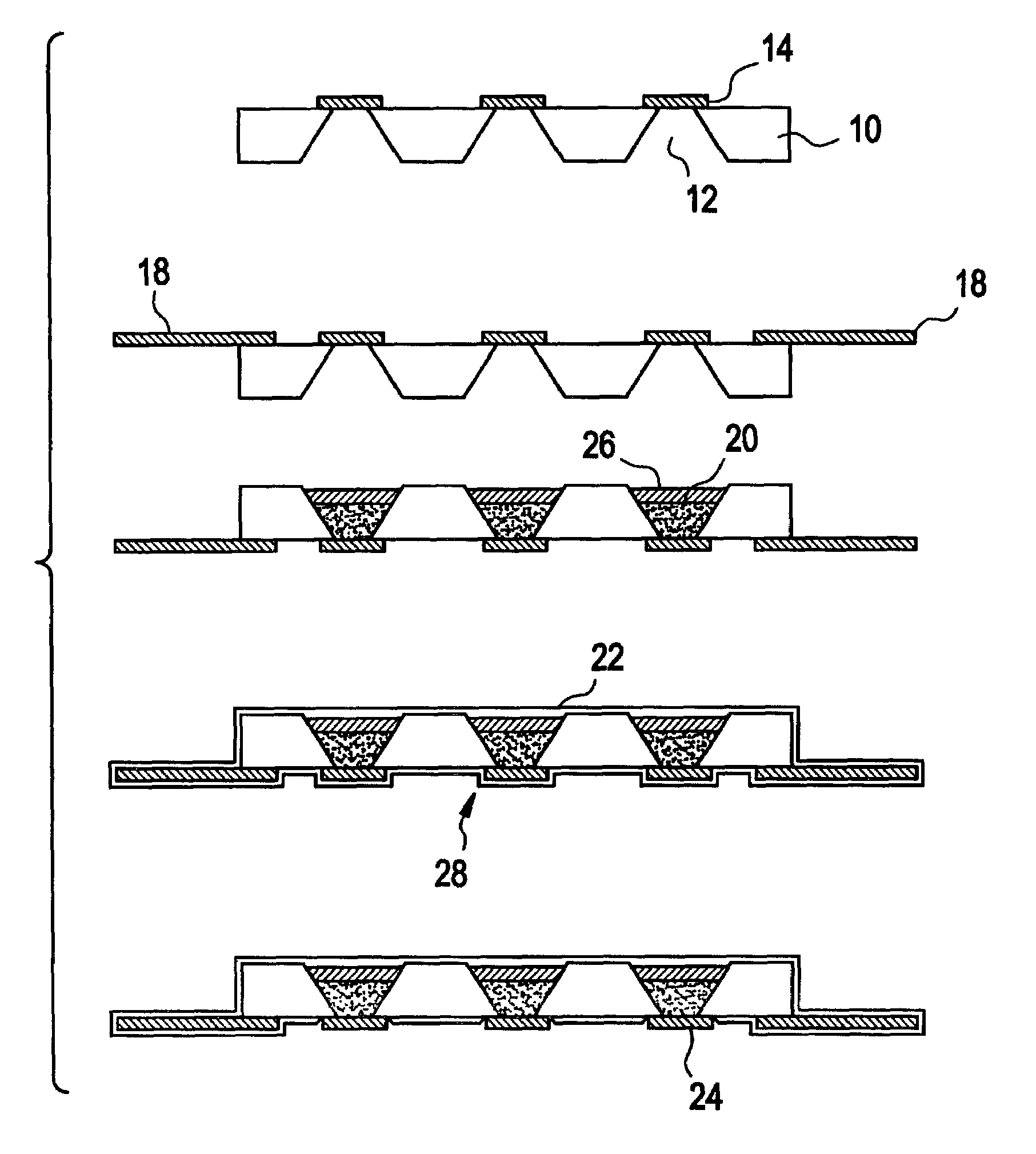

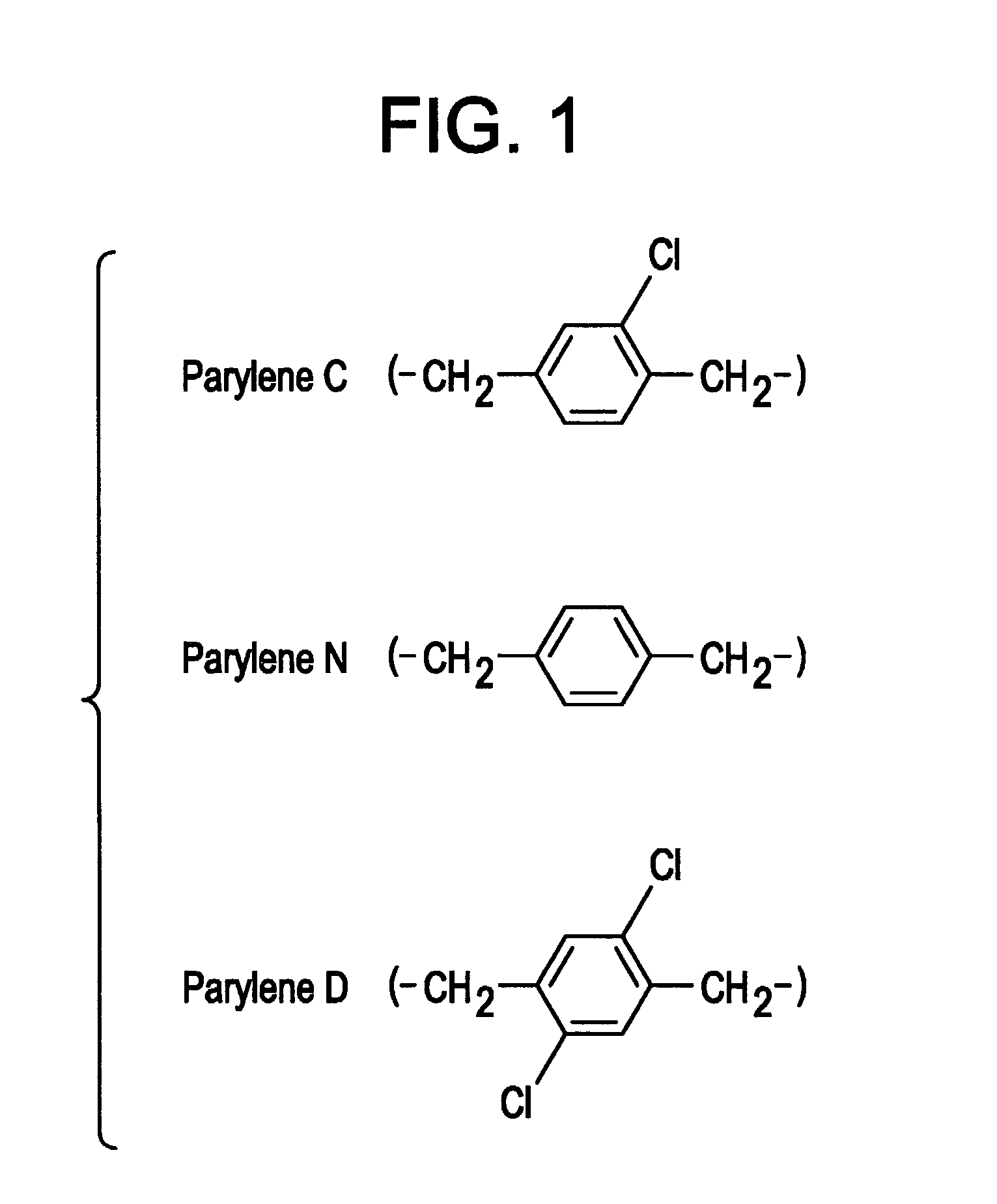

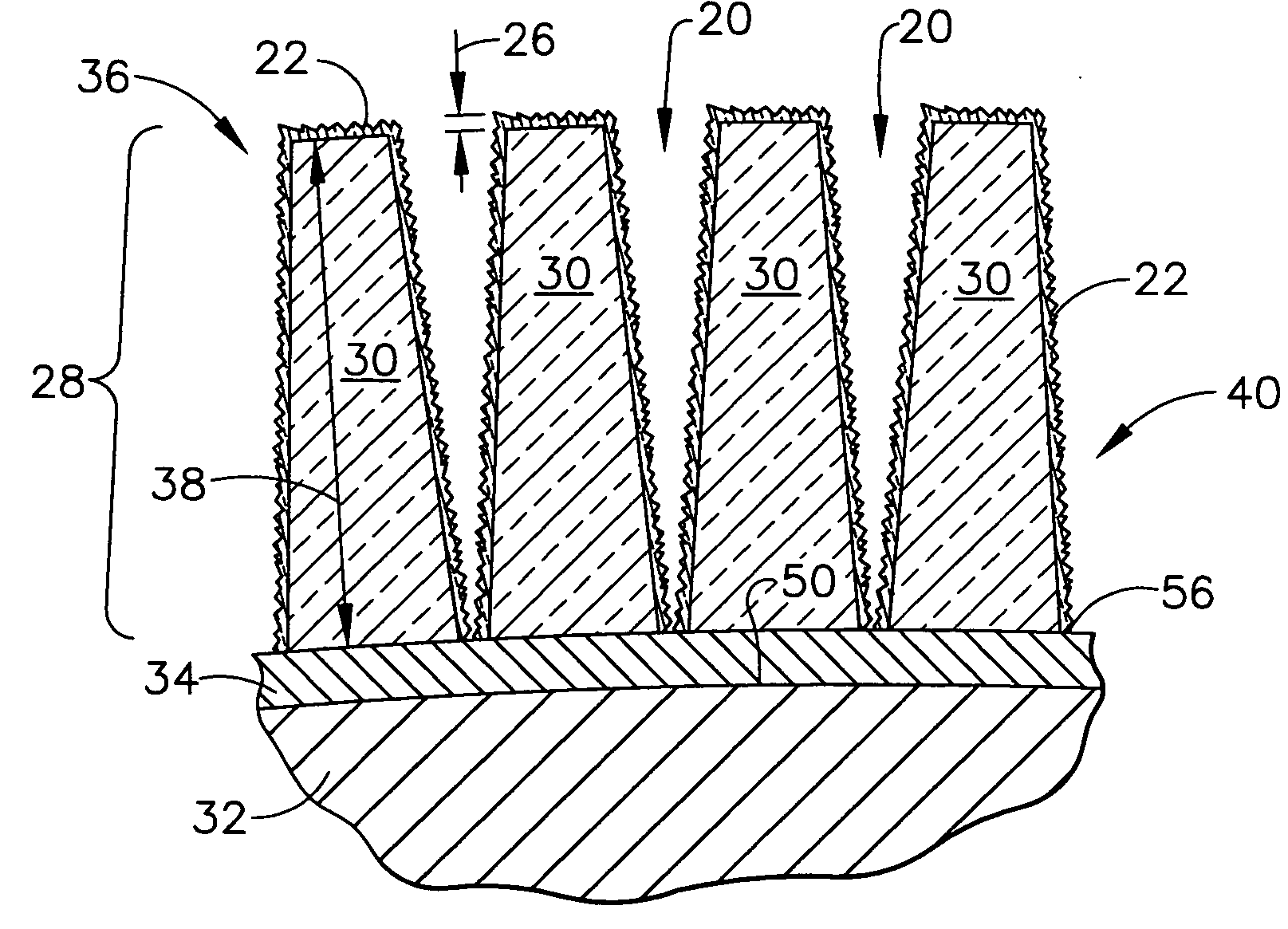

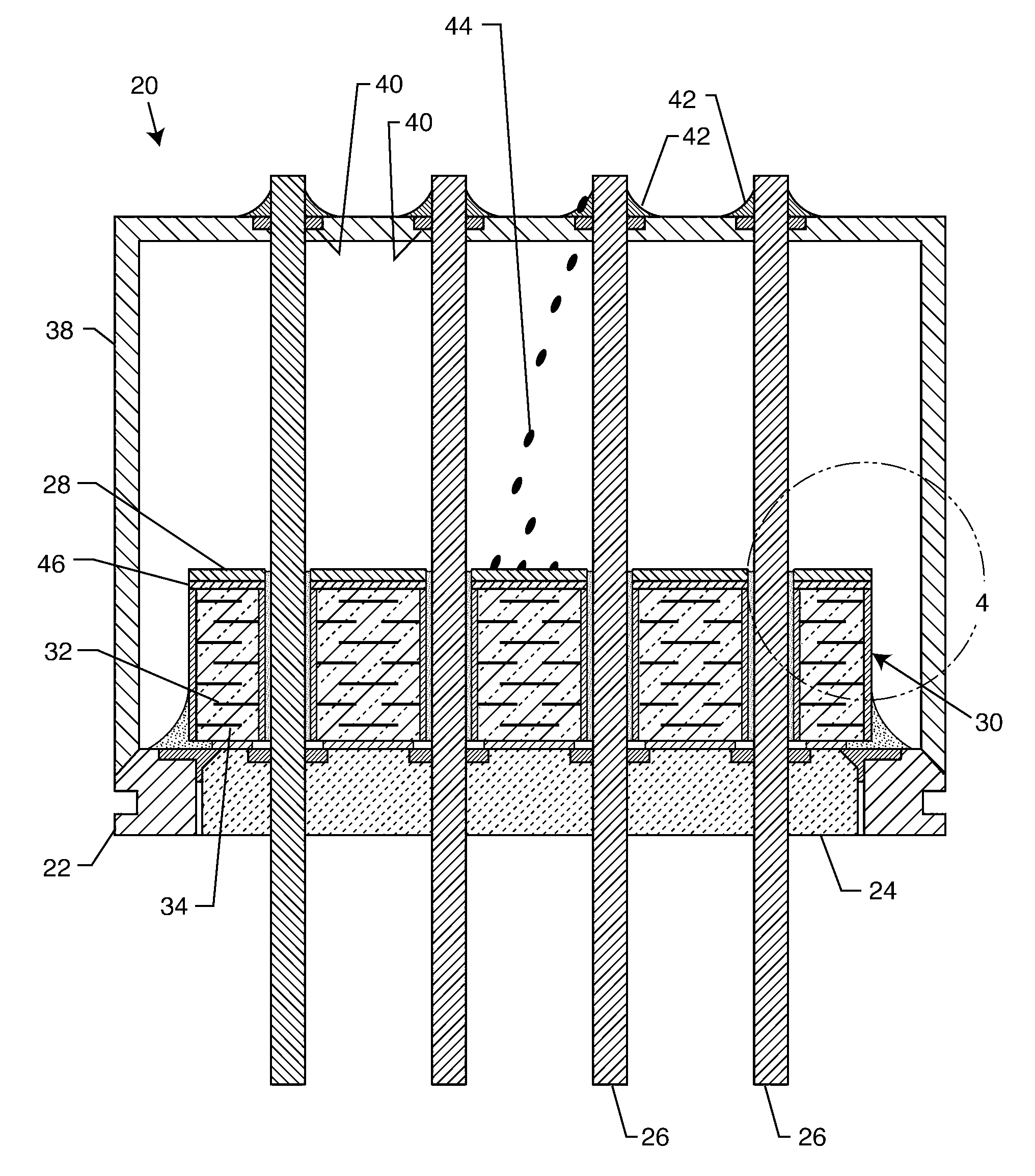

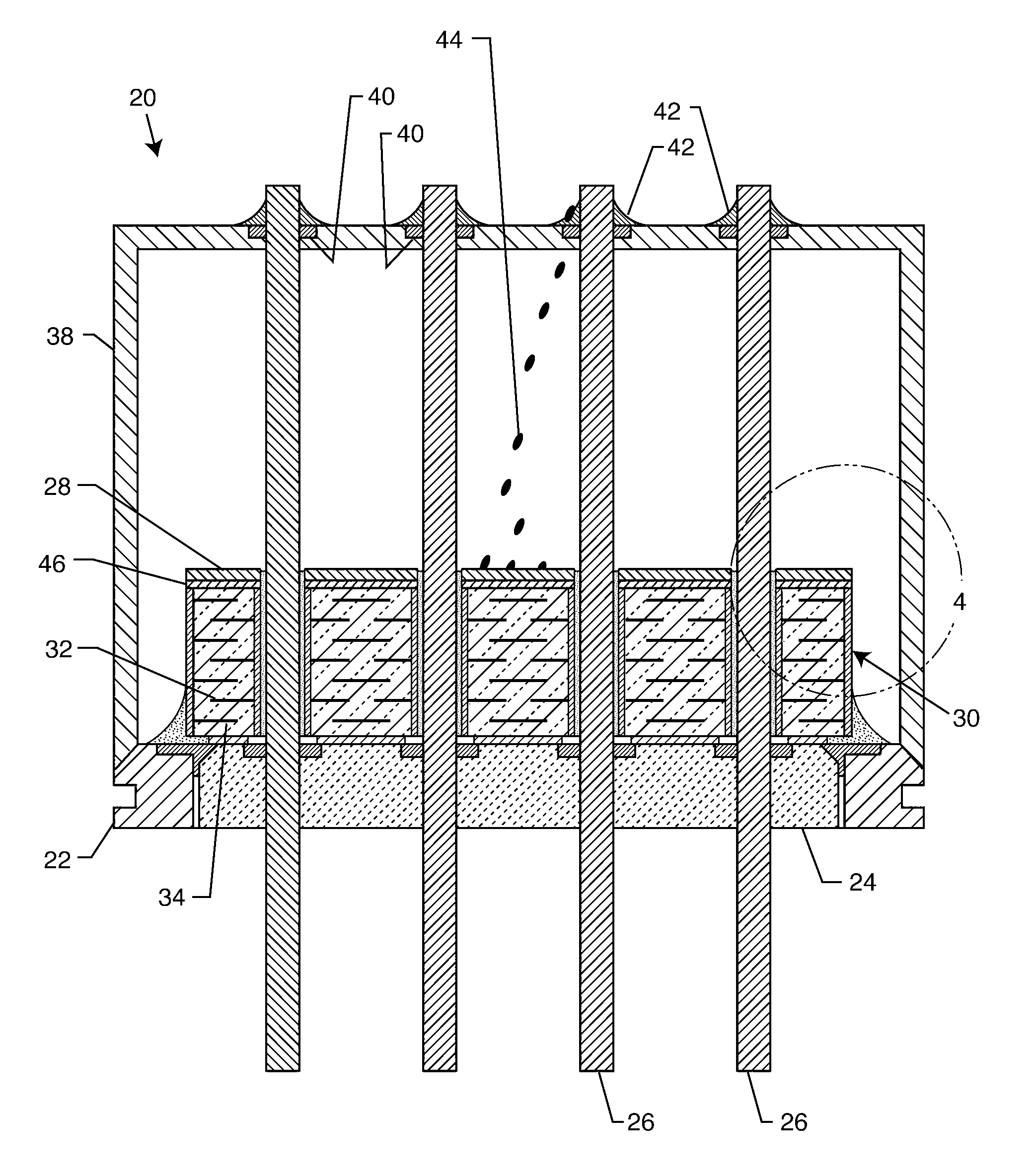

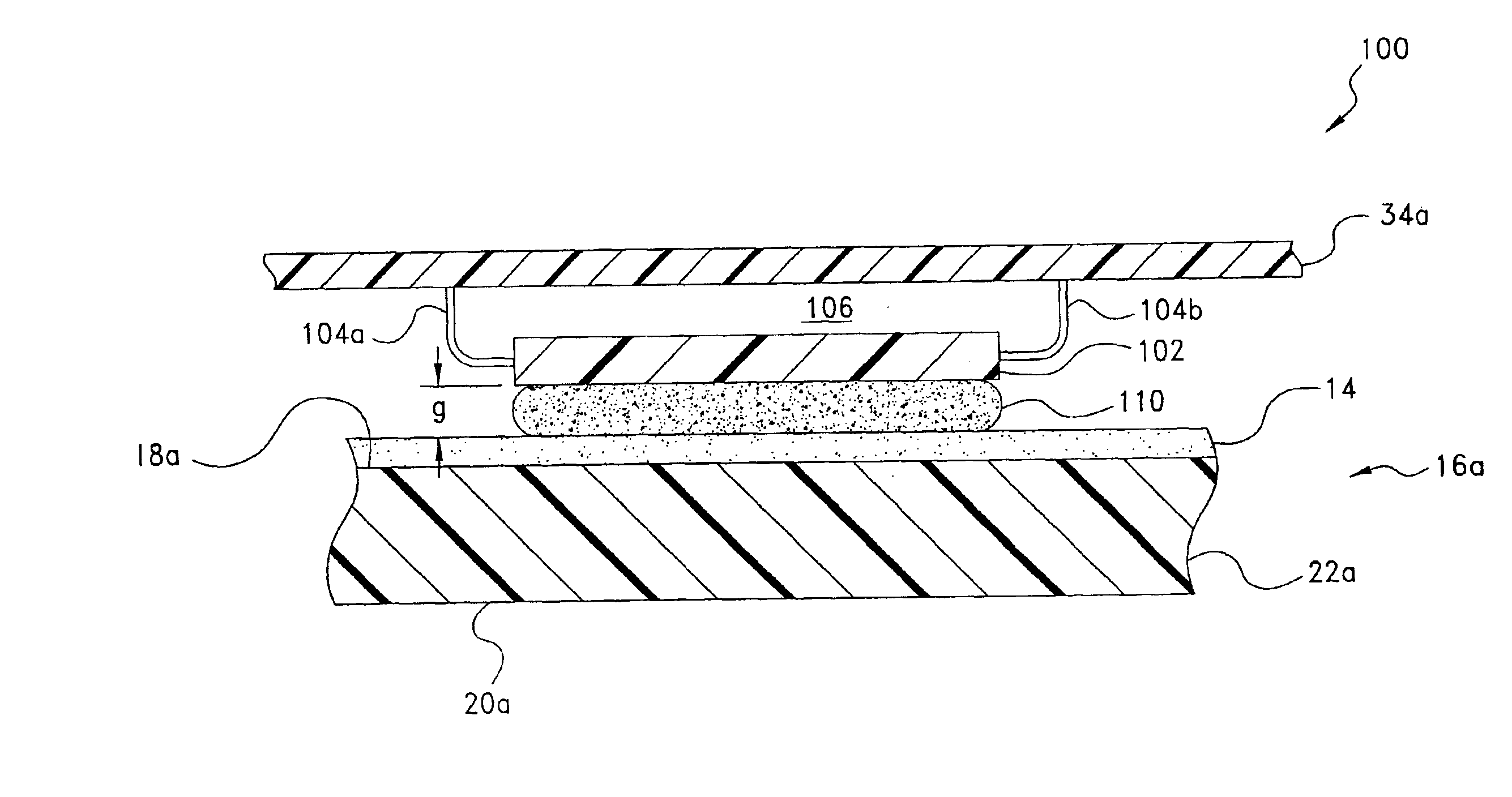

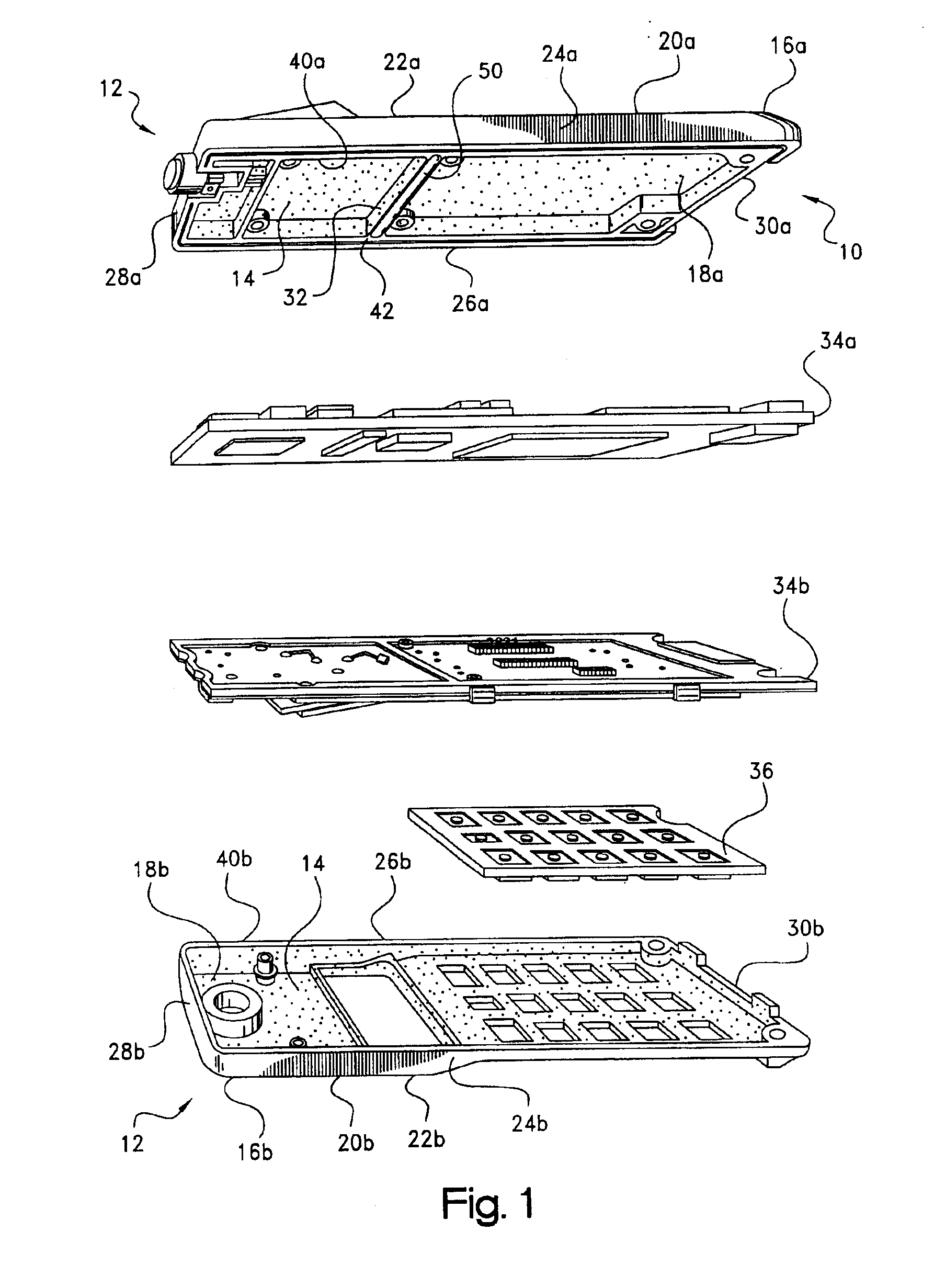

Methods for conformal coating and sealing microchip reservoir devices

InactiveUS6973718B2Reduce adverse reactionsPrinted circuit assemblingLiquid surface applicatorsParyleneGas phase

Methods are provided for conformally coating microchip devices and for sealing reservoirs containing molecules or devices in a microchip device. One method comprises (i) providing a substrate having a plurality of reservoirs having reservoir openings in need of sealing; (ii) loading reservoir contents comprising molecules, a secondary device, or both, into the reservoirs; and (iii) applying a conformal coating barrier layer, such as a vapor depositable polymeric material, e.g., parylene, onto the reservoir contents over at least the reservoir openings to seal the reservoir openings. Another method comprises vapor depositing a conformal coating material onto a microchip device having at least two reservoirs and reservoir caps positioned over molecules or devices stored in the reservoirs, and providing that the conformal coating does not coat or is removed from the reservoir caps.

Owner:MICROCHIPS INC

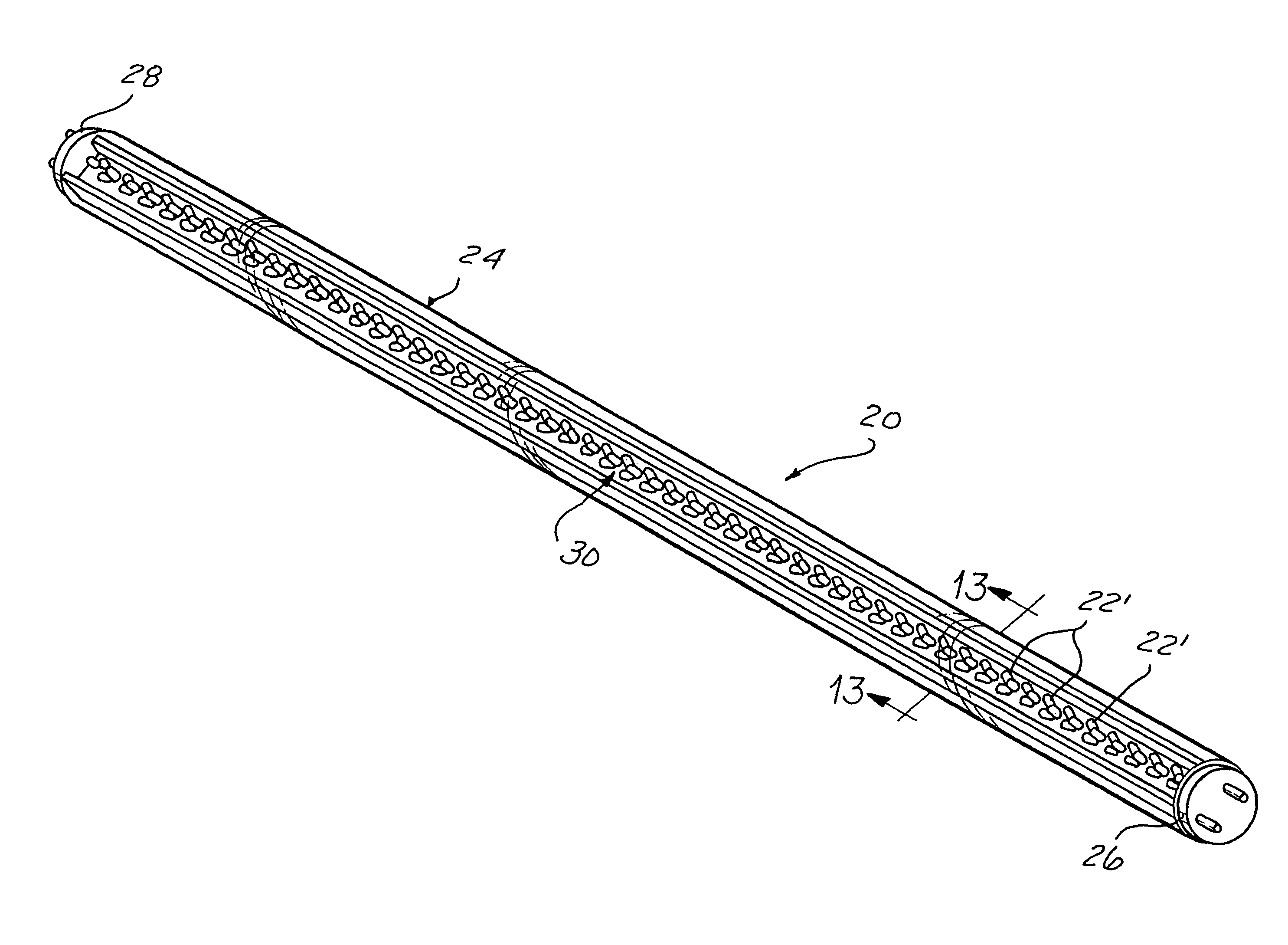

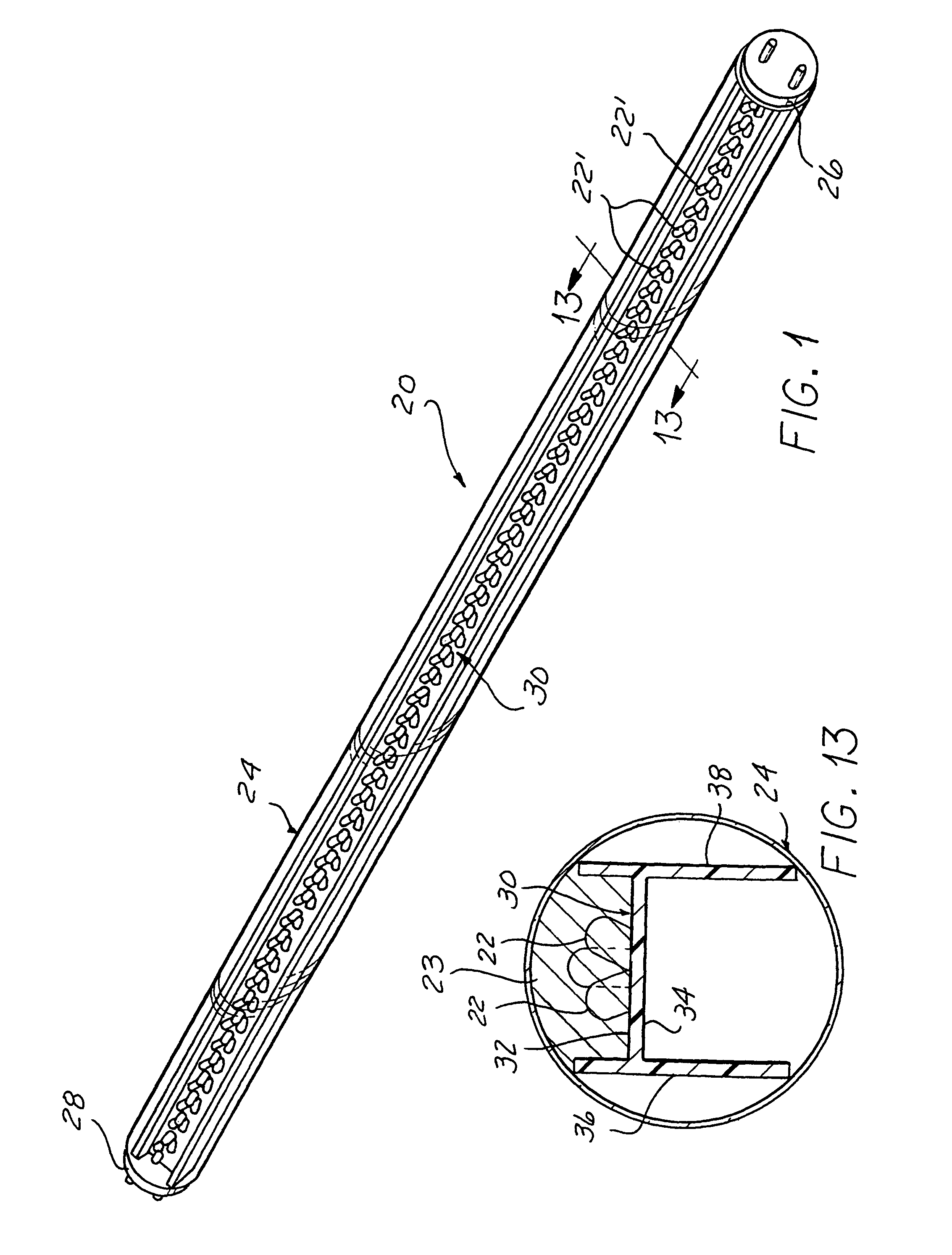

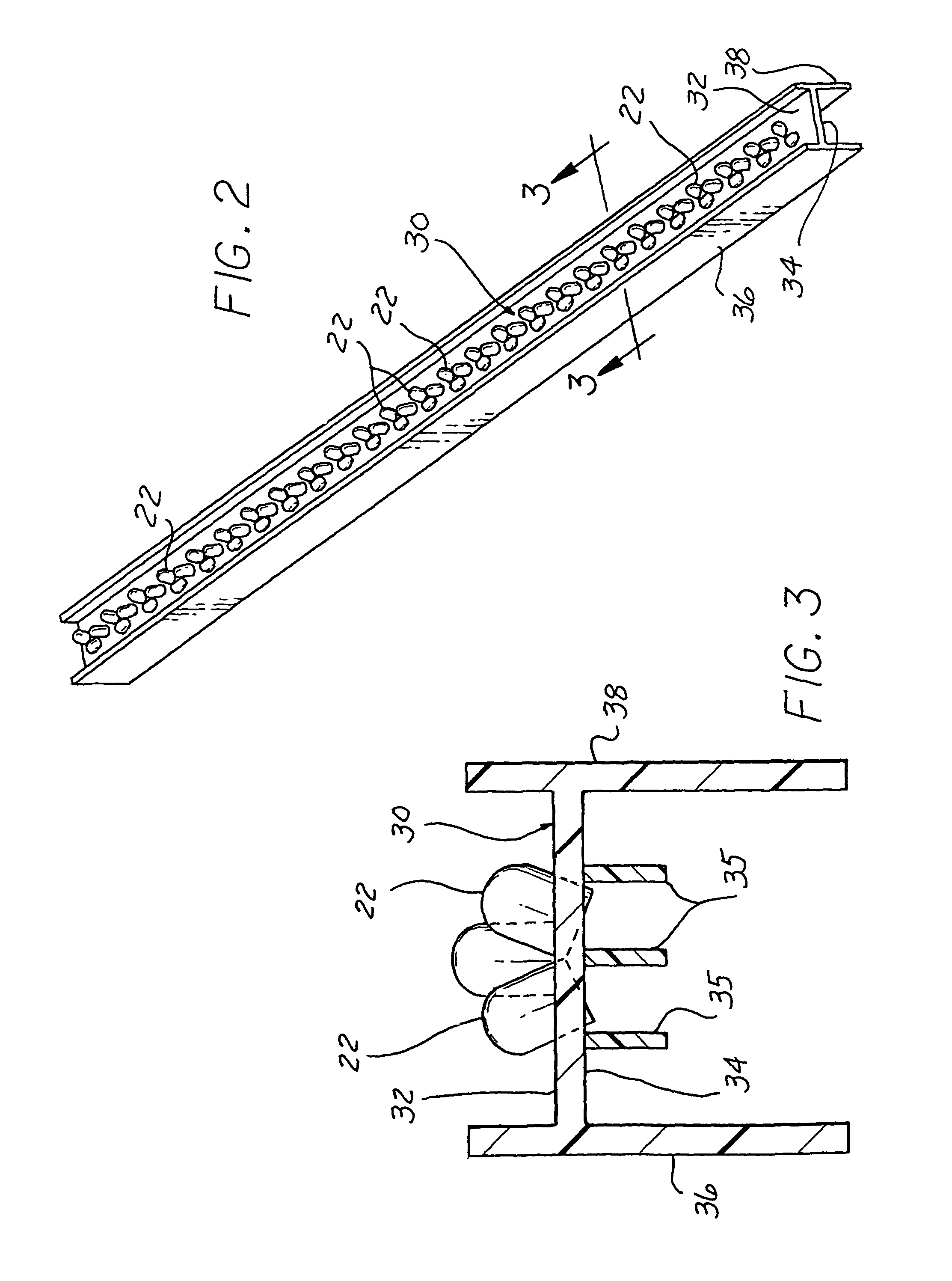

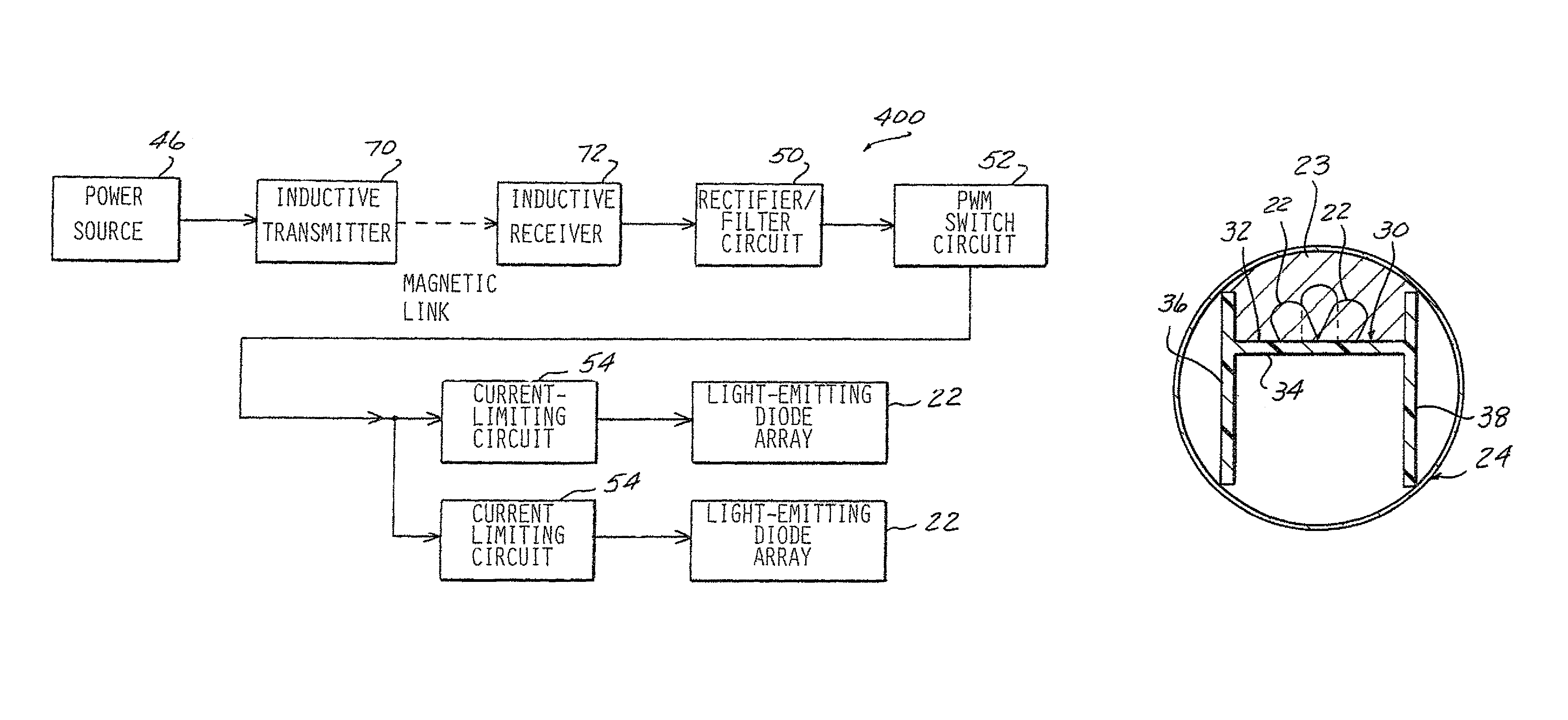

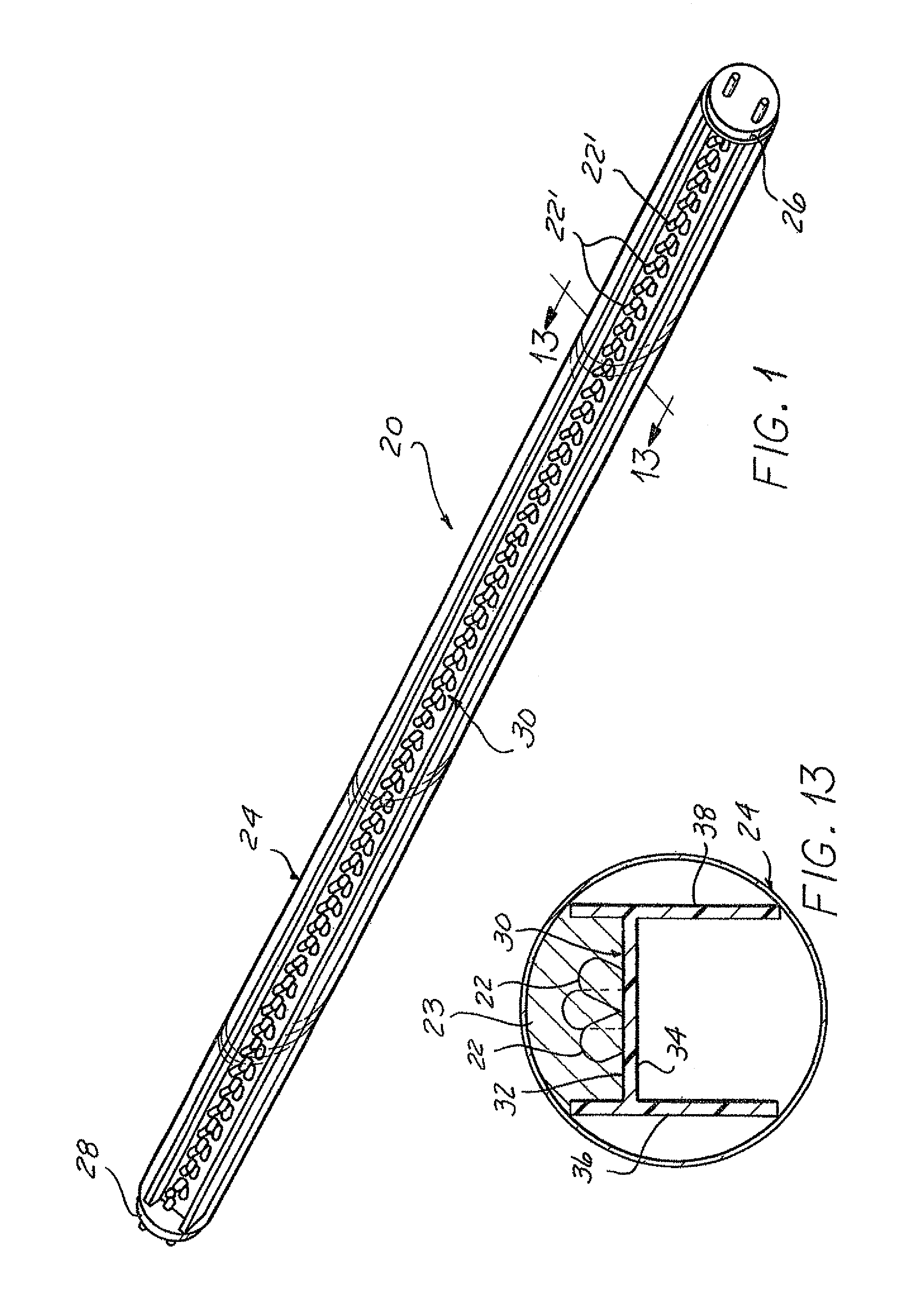

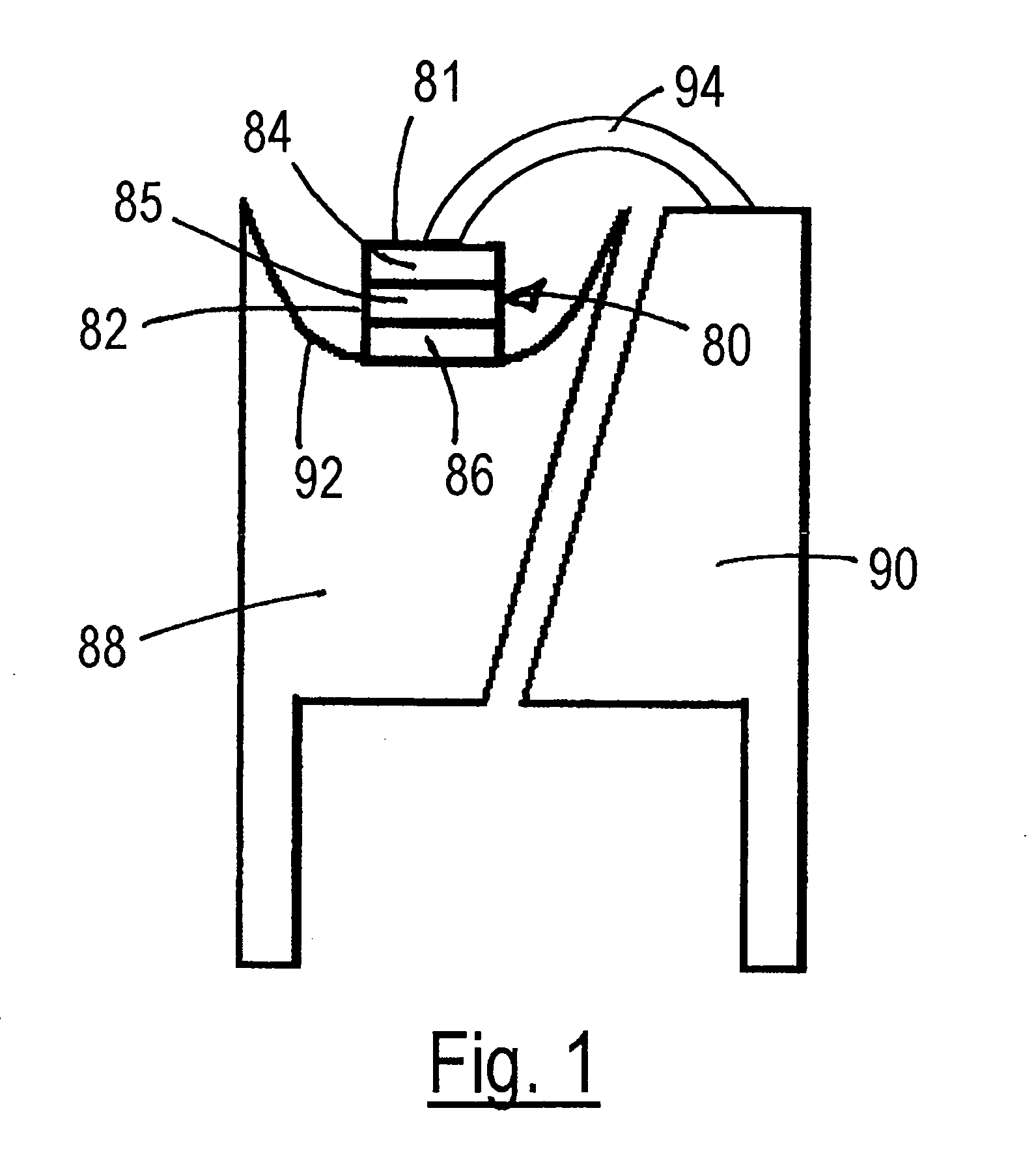

Light sources incorporating light emitting diodes

InactiveUS8093823B1Good colorQuality improvementPlanar light sourcesPoint-like light sourceConformal coatingLight-emitting diode

A light source including at least one light emitting diode and, optionally, a housing portion surrounding the light emitting diode. The at least one light emitting diode can be an organic light-emitting diode sheet. The at least one light emitting diode is preferably enclosed in a housing portion comprising a hollow bulb-shaped portion formed of glass, plastic, etc. The housing portion can be filled partially or completely by a potting material. Alternatively, the housing portion can be formed of a potting material or a conformal coating material. At least one connector is coupled to the end of the housing portion. A power supply circuit supplies electrical current to the at least one light emitting diode through the connector.

Owner:ILUMISYS

Conformal coatings comprising carbon nanotubes

InactiveUS7118693B2Material nanotechnologyMagnetic/electric field screeningModified carbonElectromagnetic interference

Owner:EIKOS

Capacitive liquid level indicator

A capacitive liquid level indicator having a capacitive sensor array superposed on each side of a dielectric substrate, wherein the sensor signal detection electronics are located immediately adjacent each capacitive sensor. These provisions result in high sensitivity of detection of submergence in the liquid, as well as essentially eliminating parasitic electric fields. The preferred capacitive sensors are interdigitated capacitors, and the preferred sensor signal detection circuit is an RC bridge and a comparator, wherein the comparator senses a voltage difference in the RC bridge between a sensor resistor and sensor capacitor of a first leg thereof and a reference resistor and reference capacitor of a second leg thereof. It is preferred for the capacitive liquid level indicator to be coated with a low dielectric conformal coating to thereby insulate the electronic components (inclusive of the capacitive sensors) thereof with respect to the liquid into which it is submerged. The sensitivity of the capacitive liquid level sensor according to the present invention is extremely high; as a result, a reference capacitive sensor is obviated, and there are no false indications of liquid due to any film of the liquid clinging to an exposed portion of the capacitive liquid level sensor.

Owner:GDM

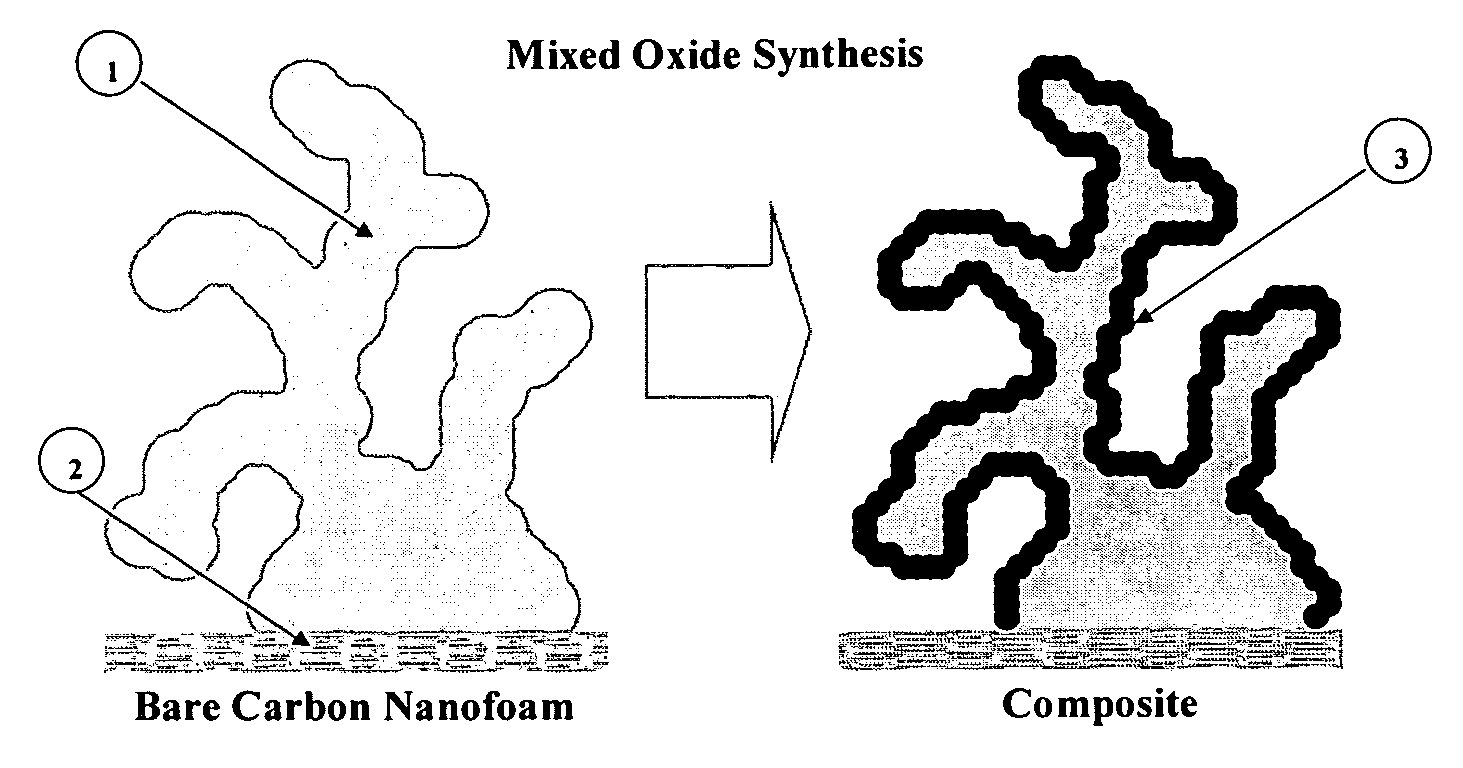

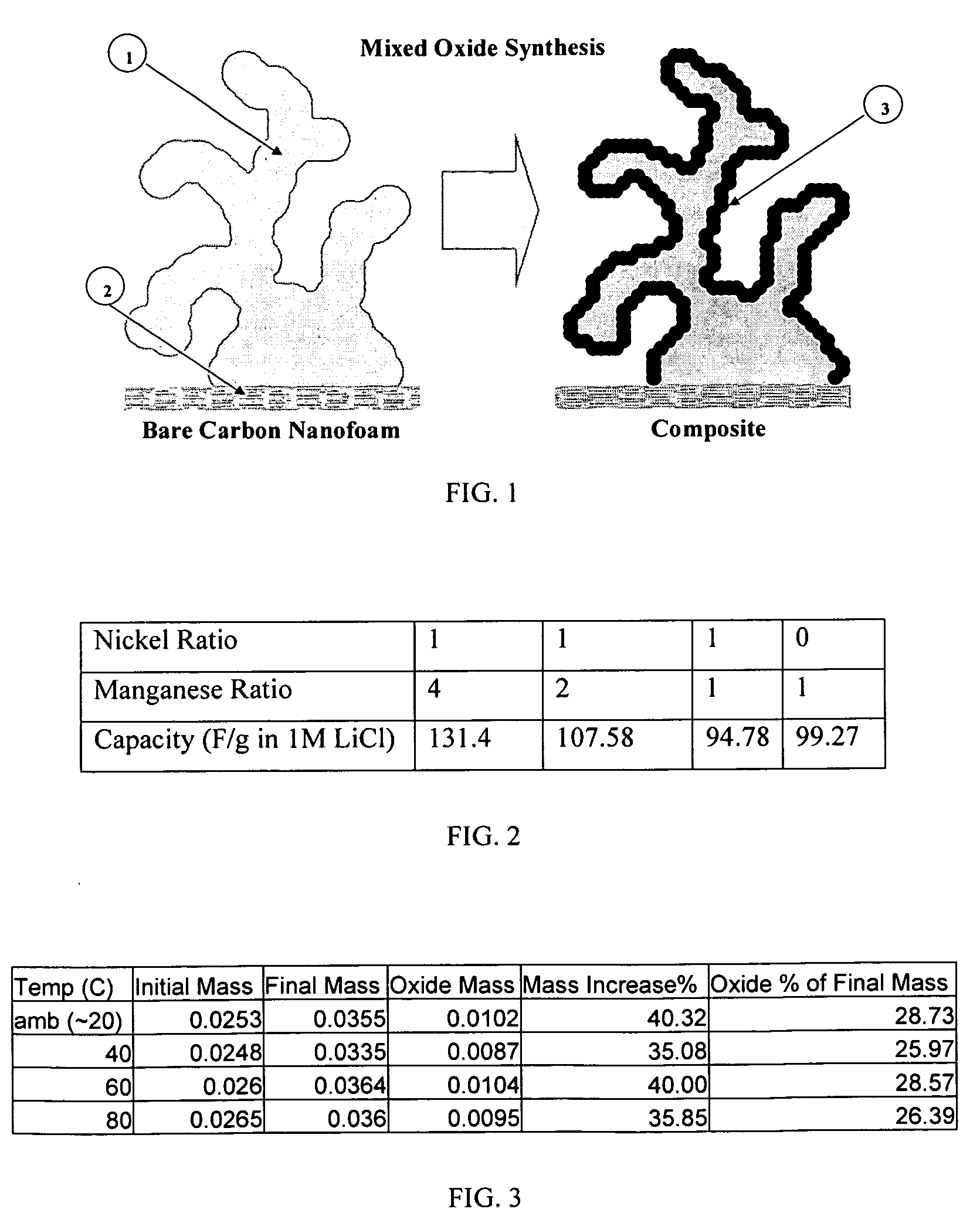

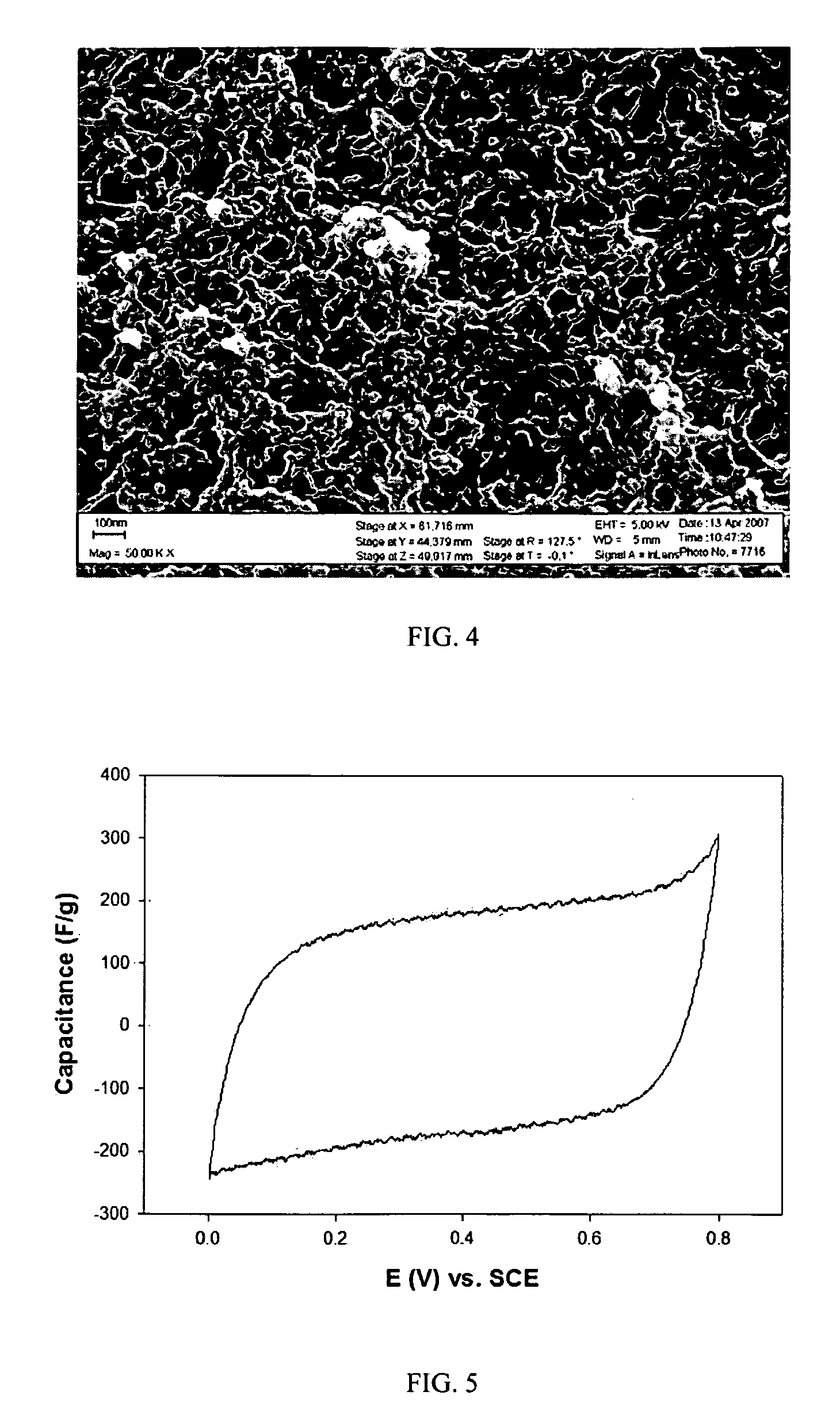

Composite electrode comprising a carbon structure coated with a thin film of mixed metal oxides for electrochemical energy storage

InactiveUS20090185327A1Increase capacityProlong lifeLiquid electrolytic capacitorsFinal product manufactureComposite electrodeMixed oxide

A composite electrode is created by forming a thin conformal coating of mixed metal oxides on a highly porous carbon structure. The highly porous carbon structure performs a role in the synthesis of the mixed oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of mixed metal oxides. The metal oxide mixture shall include two or more metal oxides. The composite electrode, a process for producing said composite electrode, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said composite electrode are disclosed.

Owner:SEYMOUR FRASER WADE

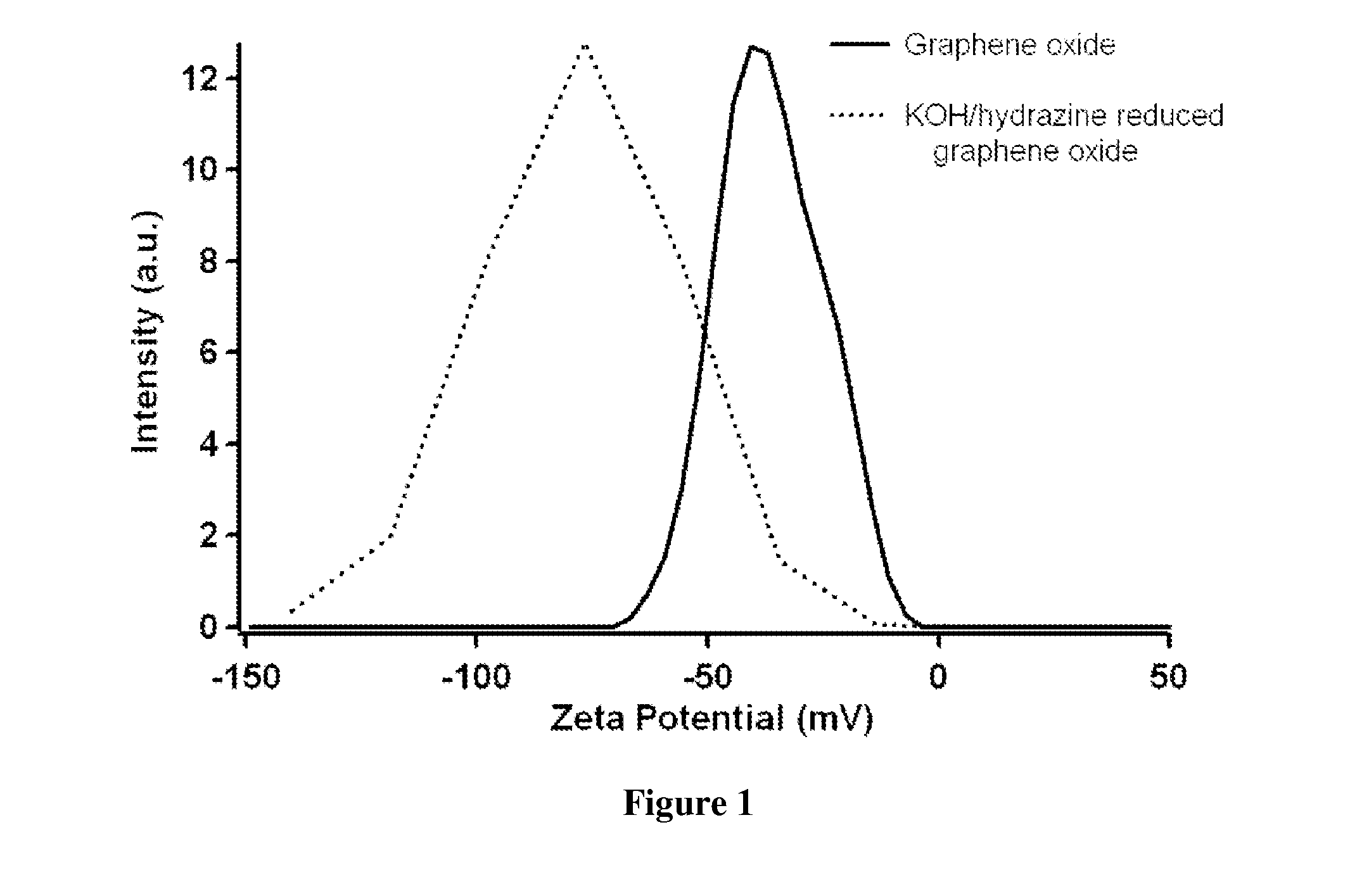

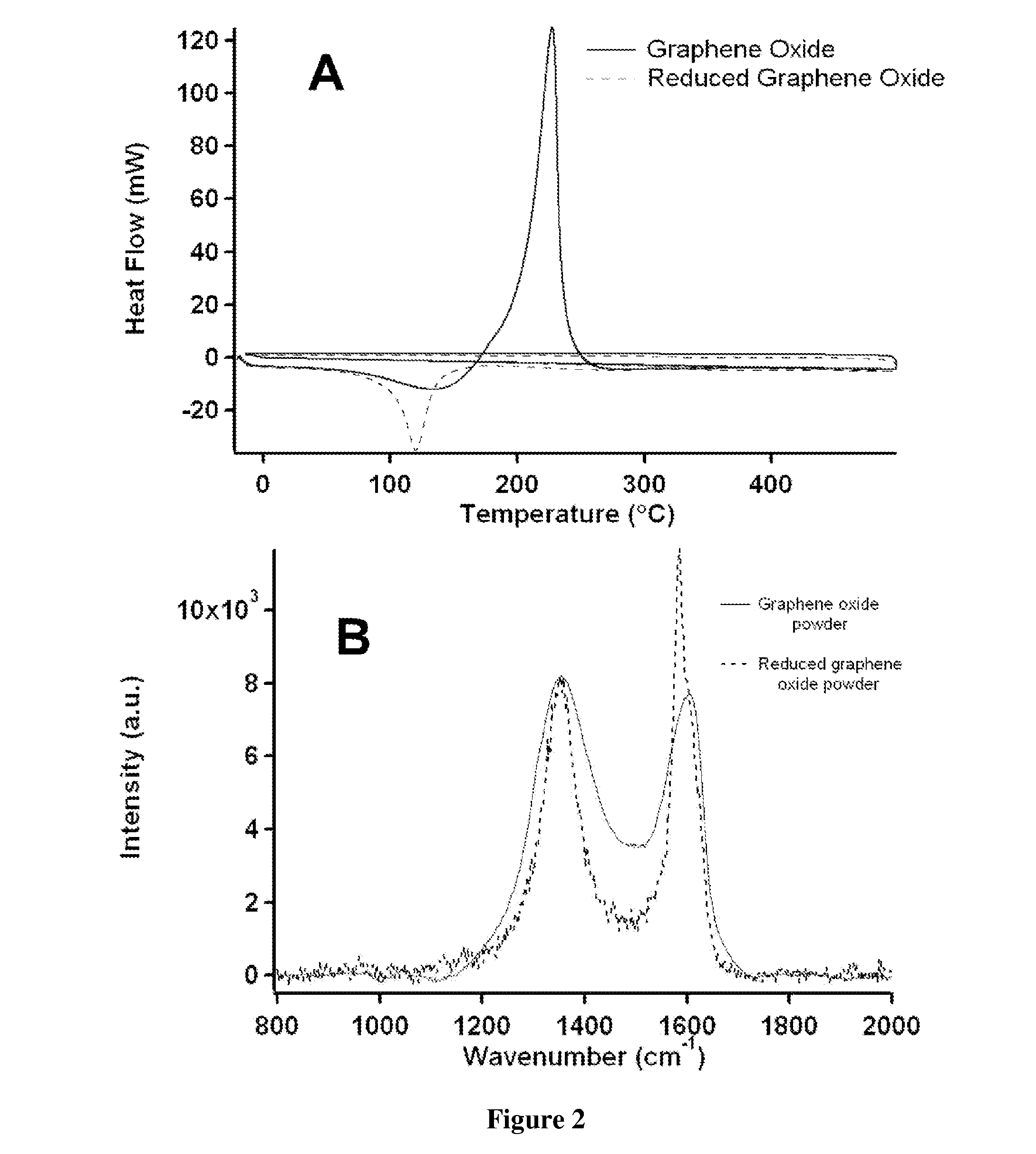

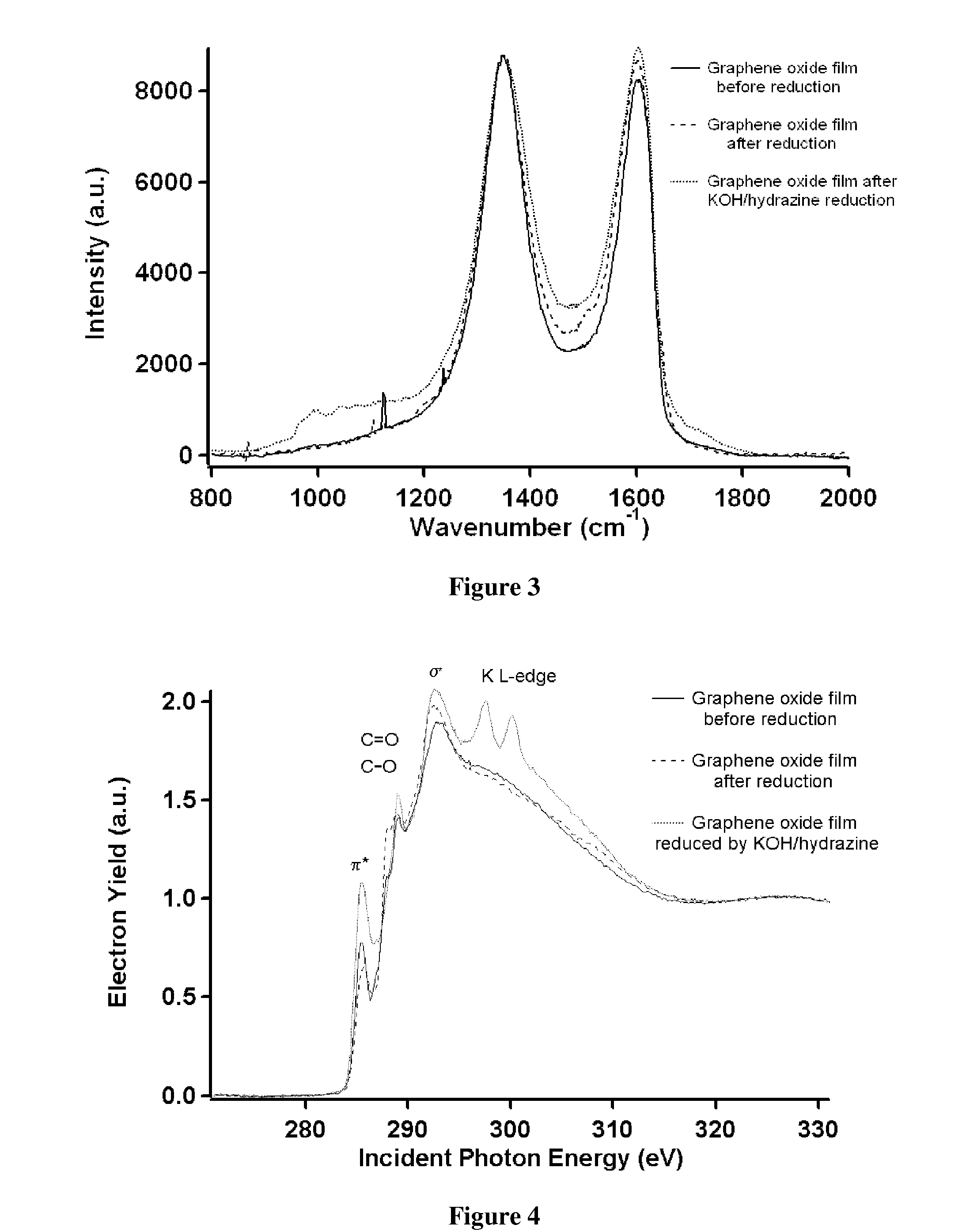

Graphene Films and Methods of Making Thereof

ActiveUS20130156678A1Material nanotechnologyElectrolysis componentsPlanar substrateConformal coating

Provided are methods for forming graphene or functionalized graphene thin films. Also provided are graphene and functionalized graphene thin films formed by the methods. For example, electrophoretic deposition methods and stamping methods are used. Defect-free thin films can be formed. Patterned films can be formed. The methods can provide conformal coatings on non-planar substrates.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

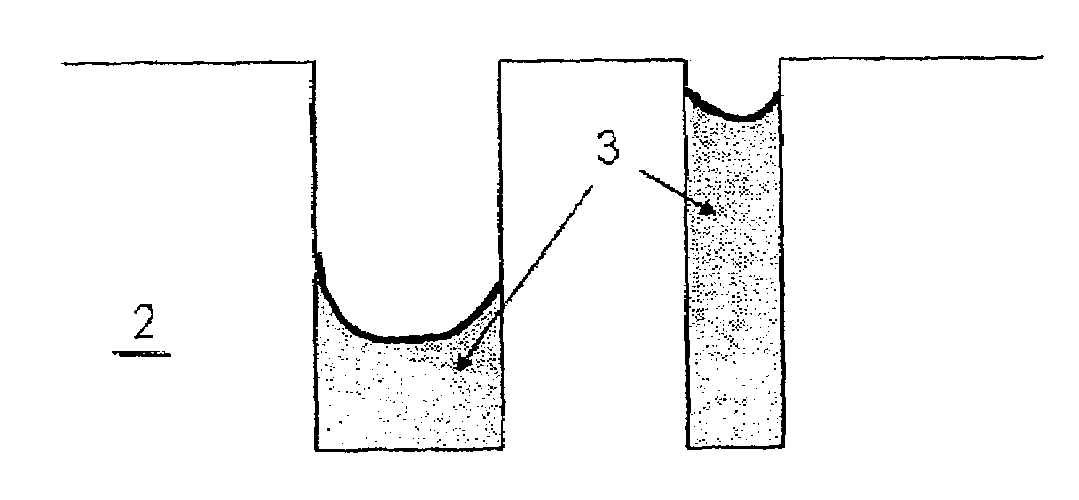

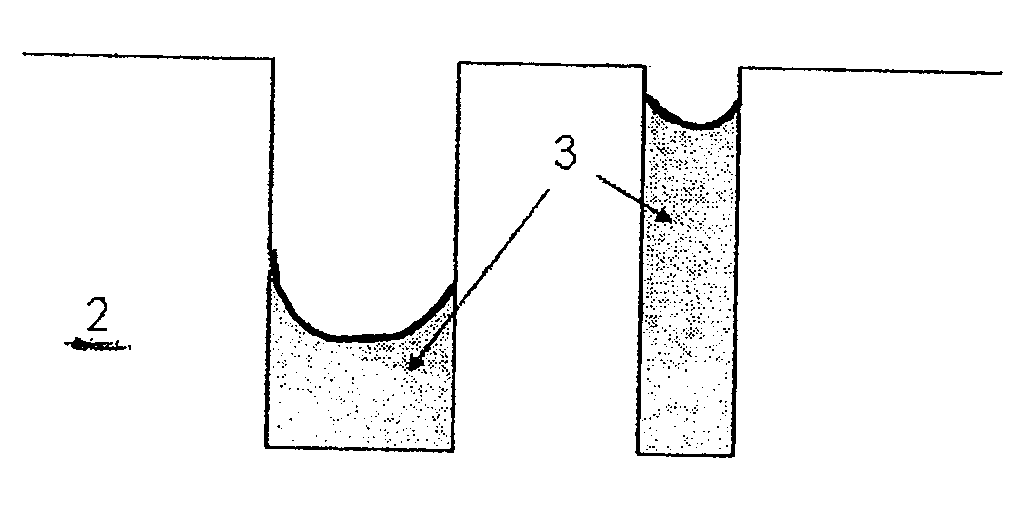

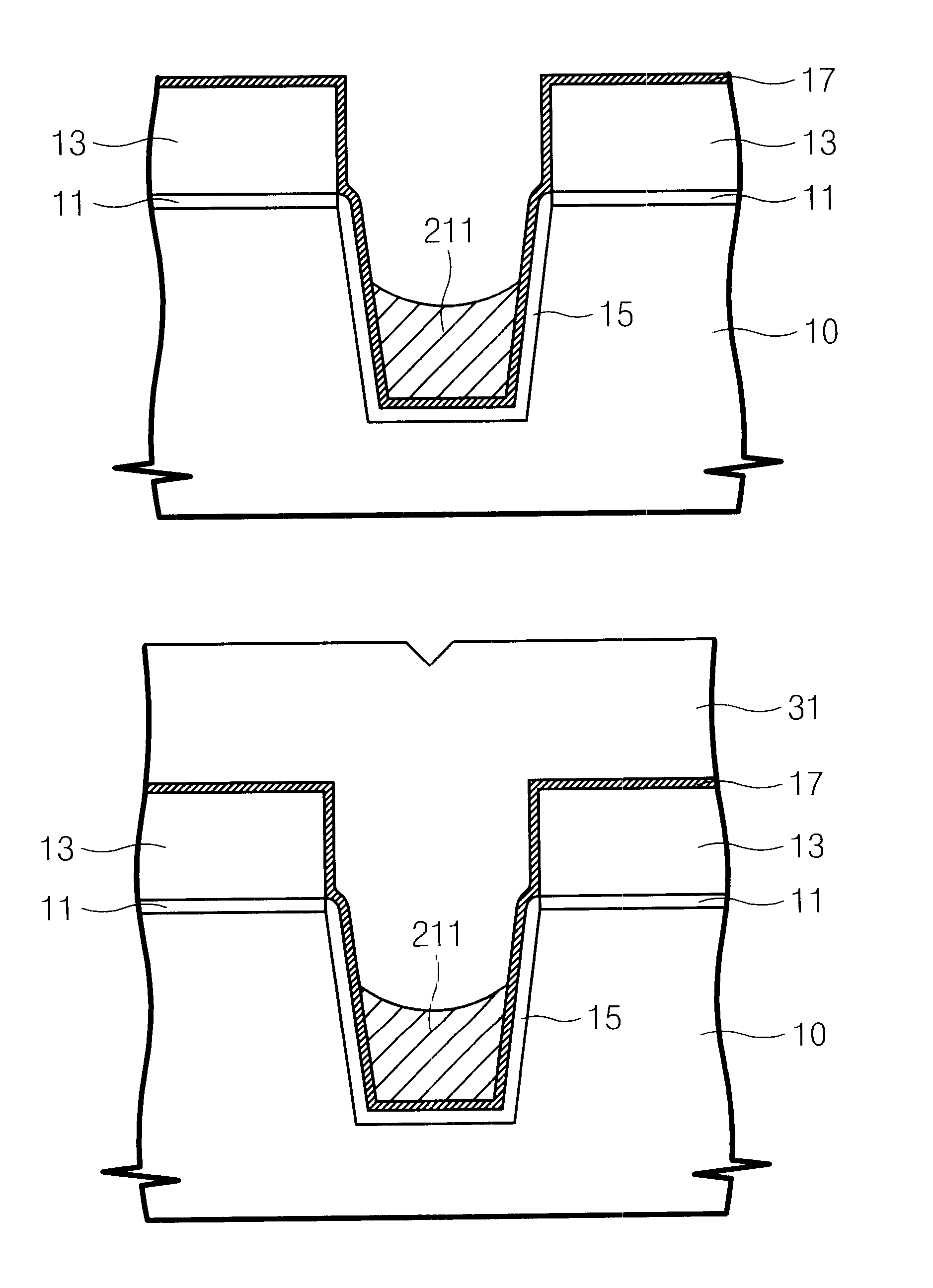

Method of forming an insulating layer in a trench isolation type semiconductor device

InactiveUS6566229B2Good shape retentionEasy annealingSemiconductor/solid-state device manufacturingDevice materialPolysilazane

A method of forming a trench-type device isolation layer in which a trench is filled through two steps, wherein a polysilazane solution is coated on a semiconductor substrate, in which a trench for device isolation layer is formed, in a spin on glass (SOG) manner to form an SOG layer filling a predetermined portion of the trench. In order to maintain a conformal coating thickness without overfilling the trench, the polysilazane solution preferably has a solid-state perhydro polysilazane ([SiH2NH]n) of between about 5 to about 15 percent by weight. Following formation of the SOG layer, a subsequent annealing process is carried out. The SOG layer is etched to make a top surface of the remaining SOG layer recessed down to a degree of about 1000 Å from an inlet of the trench, and a remaining space of the trench is filled with an ozone TEOS USG layer or an HDP CVD layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS20030066672A1Eliminate needHeat dissipationMolten spray coatingScreening gaskets/sealsMolten stateThermal spraying

Heat dissipation and electromagnetic interference (EMI) shielding for an electronic device having an enclosure. An interior surface of the enclosure is covered with a conformal metallic layer which, as disposed in thermal adjacency with one or more heat-generating electronic components or other sources contained within the enclosure, may provide both thermal dissipation and EMI shielding for the device. The layer may be sprayed onto the interior surface in a molten state and solidified to form a self-adherent coating.

Owner:PARKER INTANGIBLES LLC

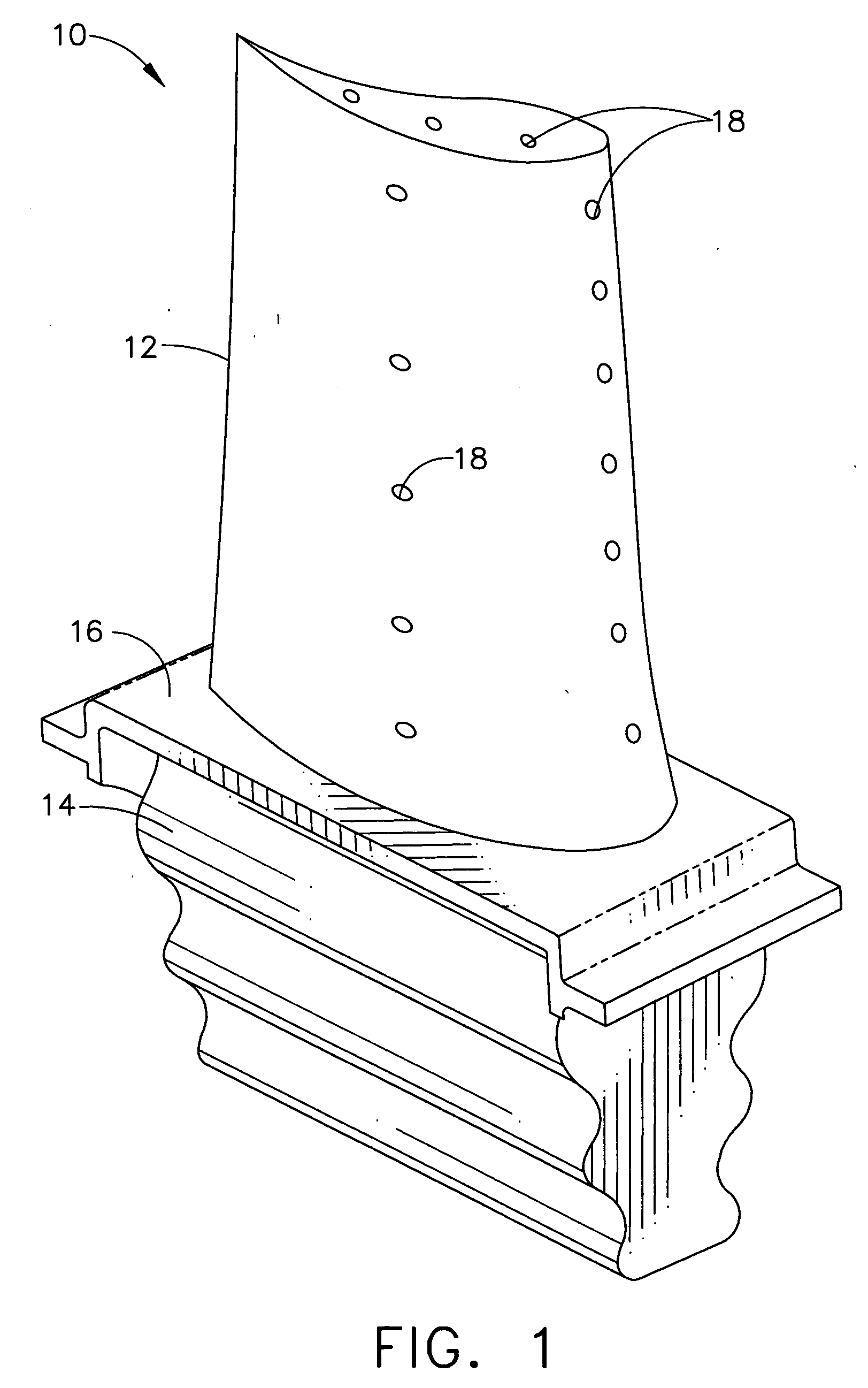

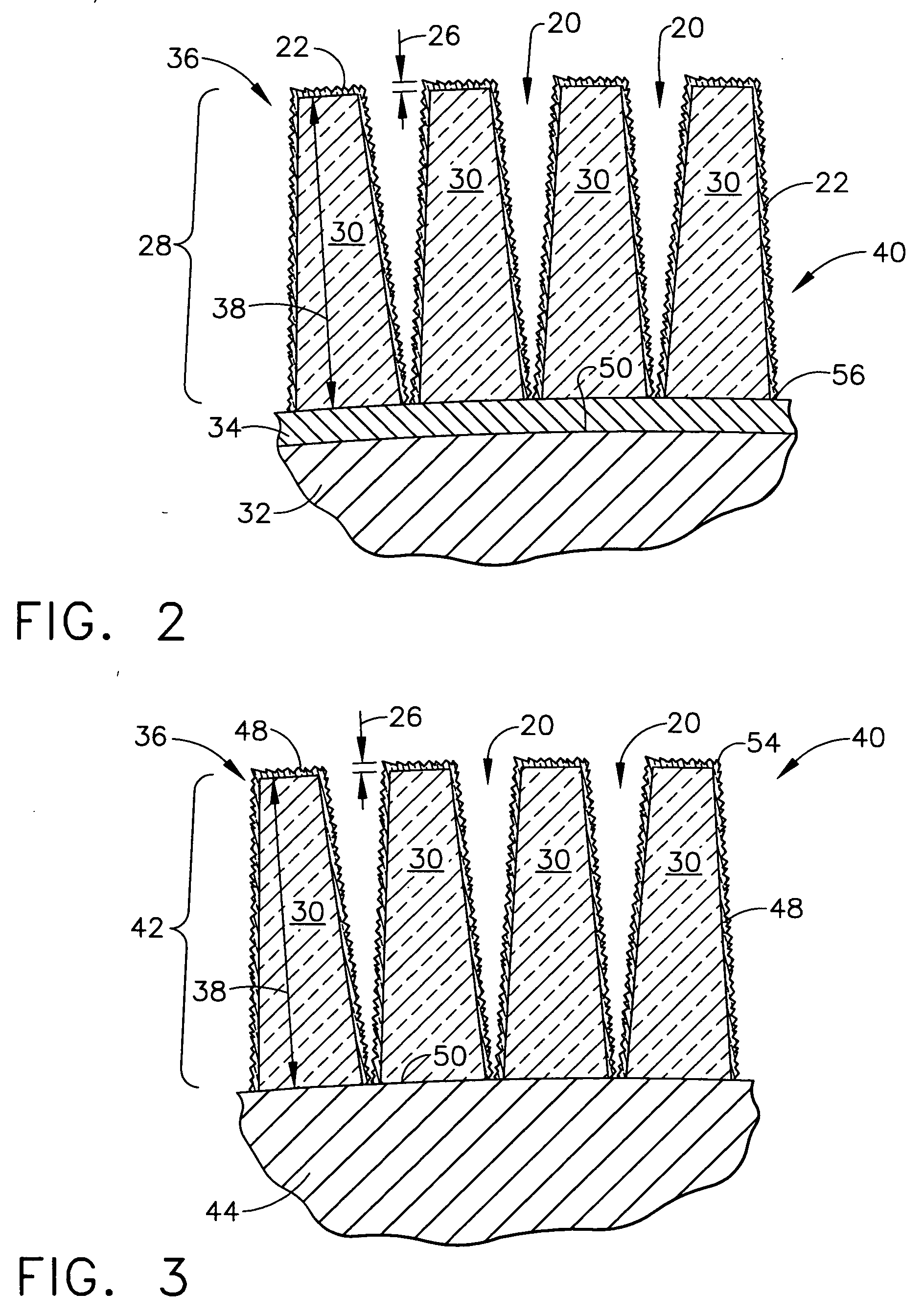

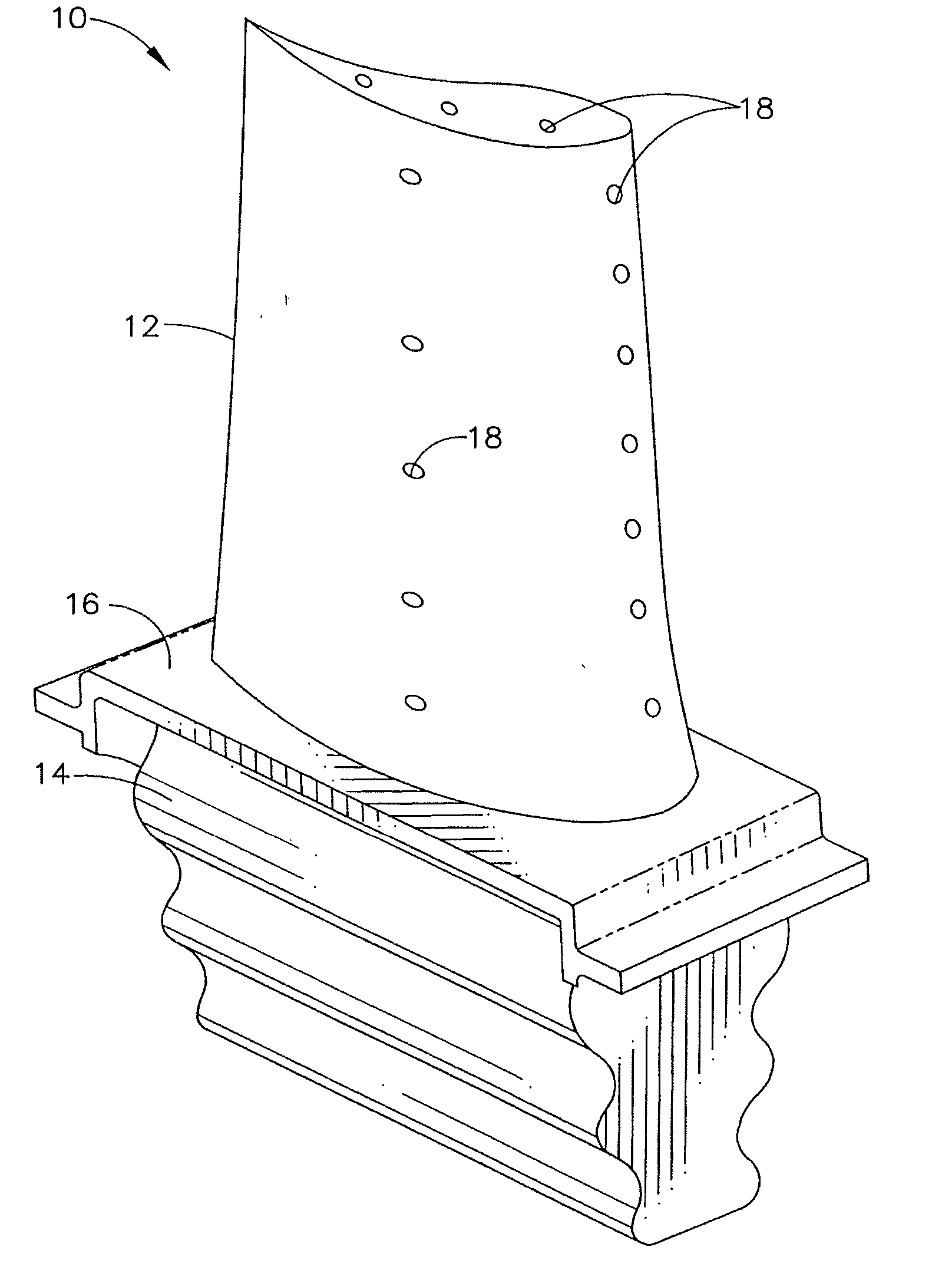

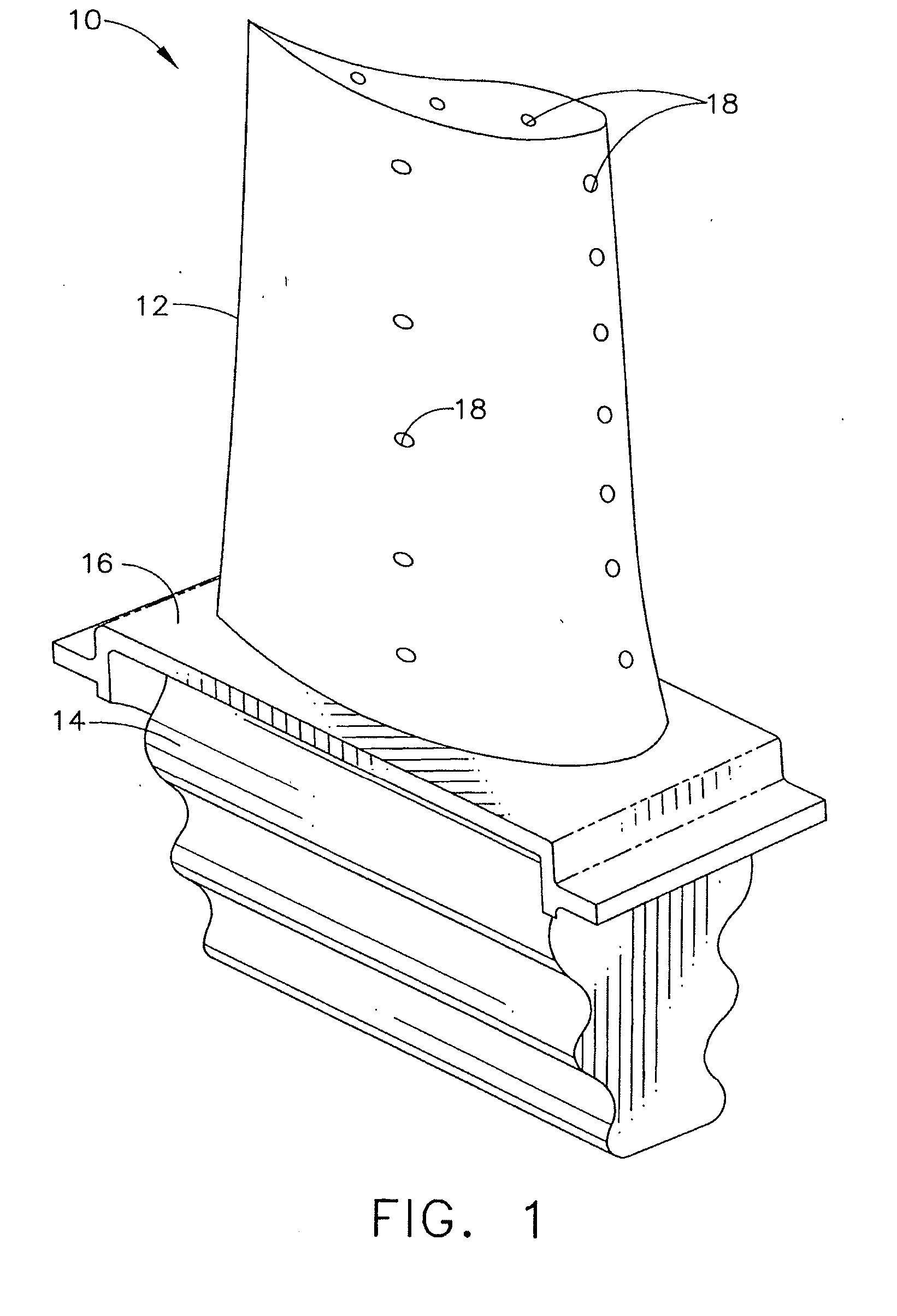

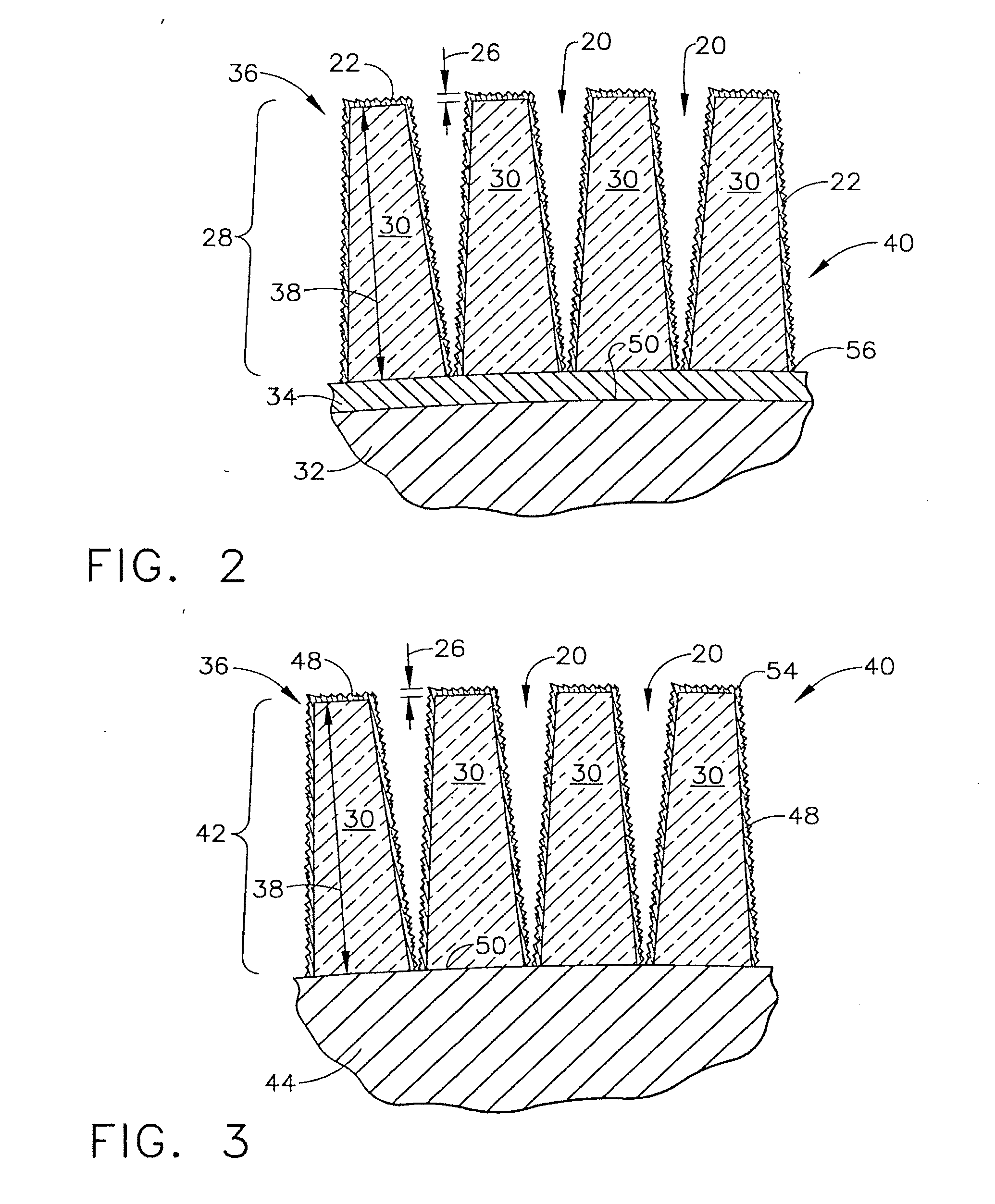

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

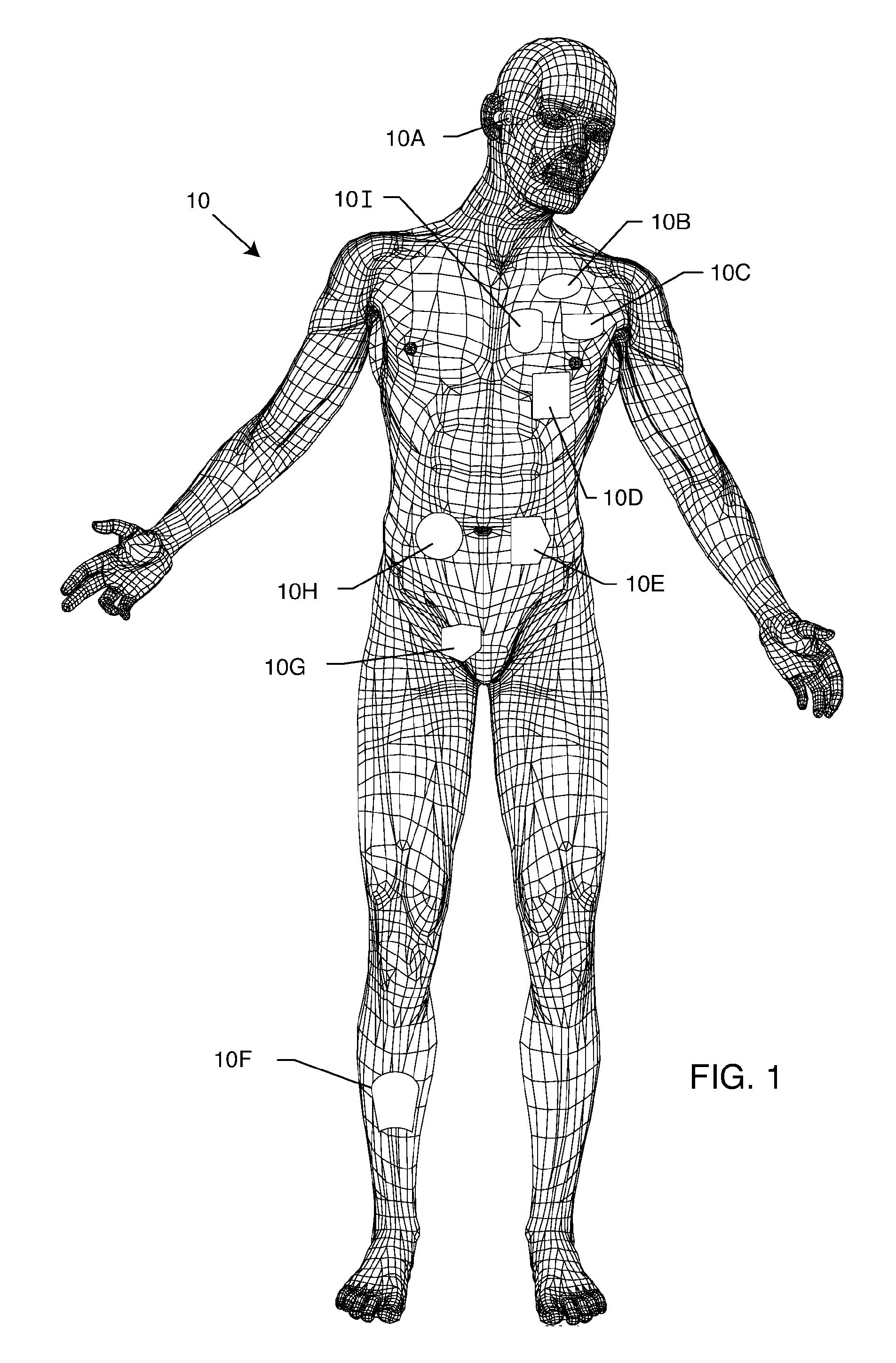

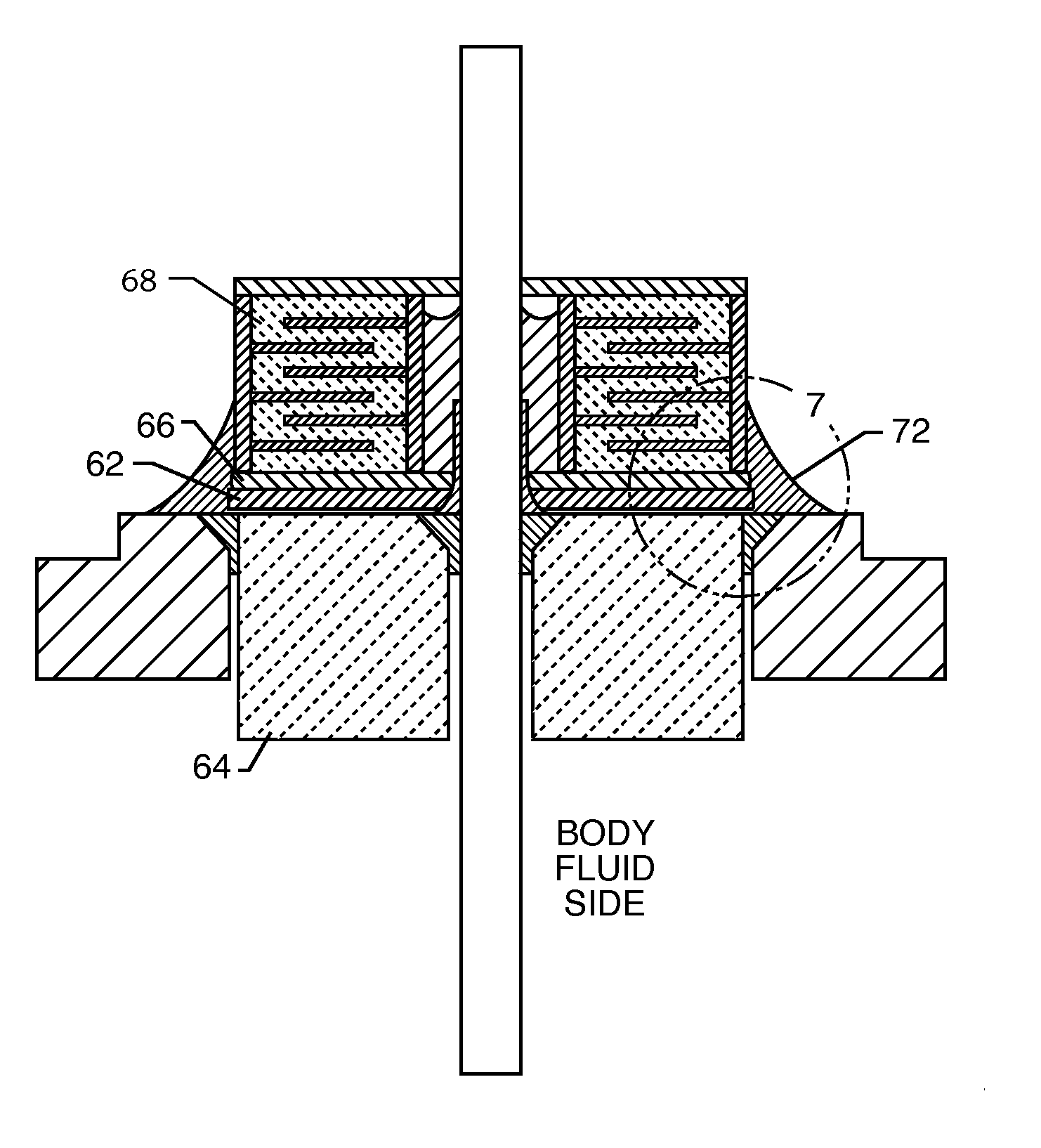

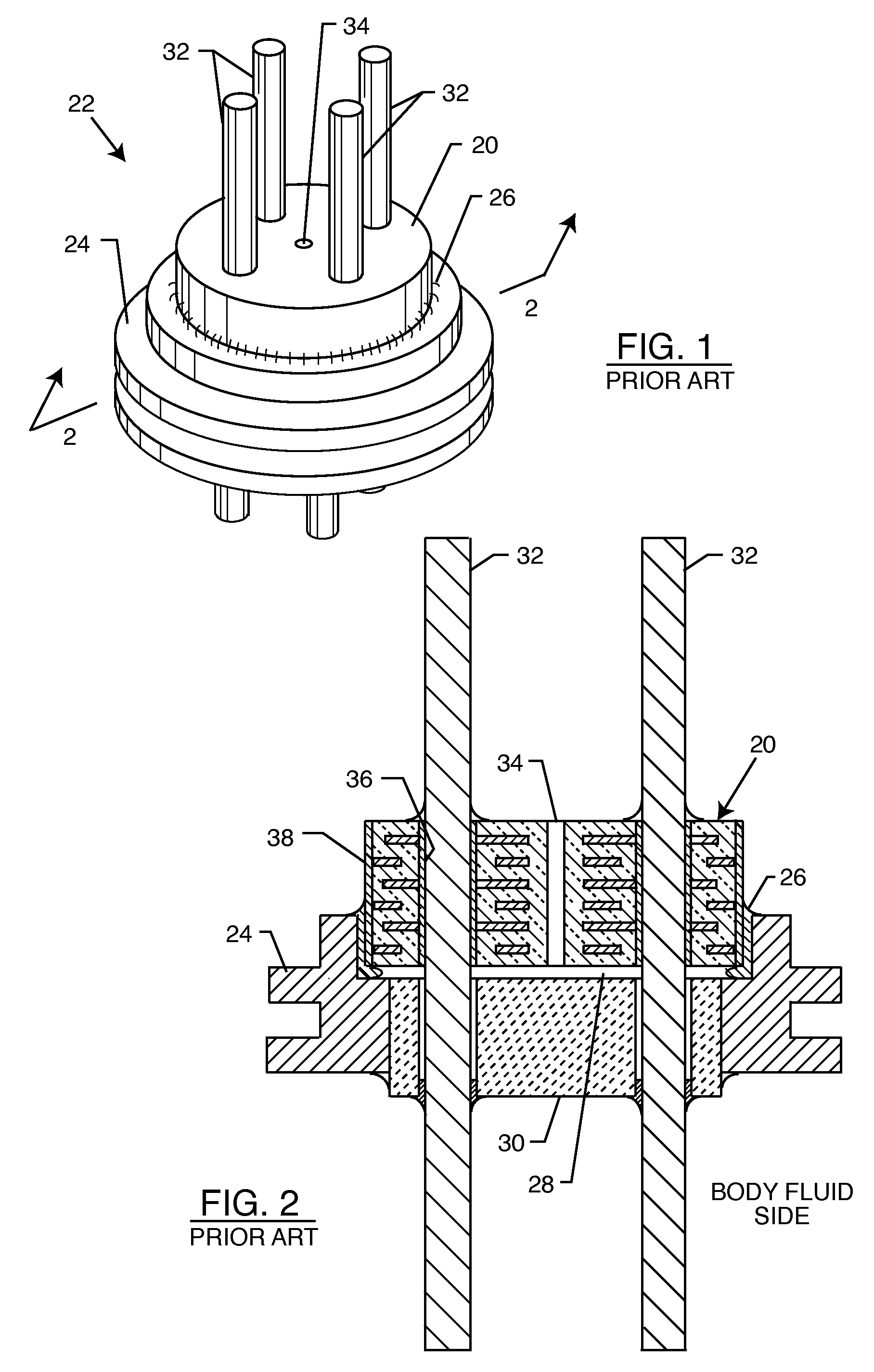

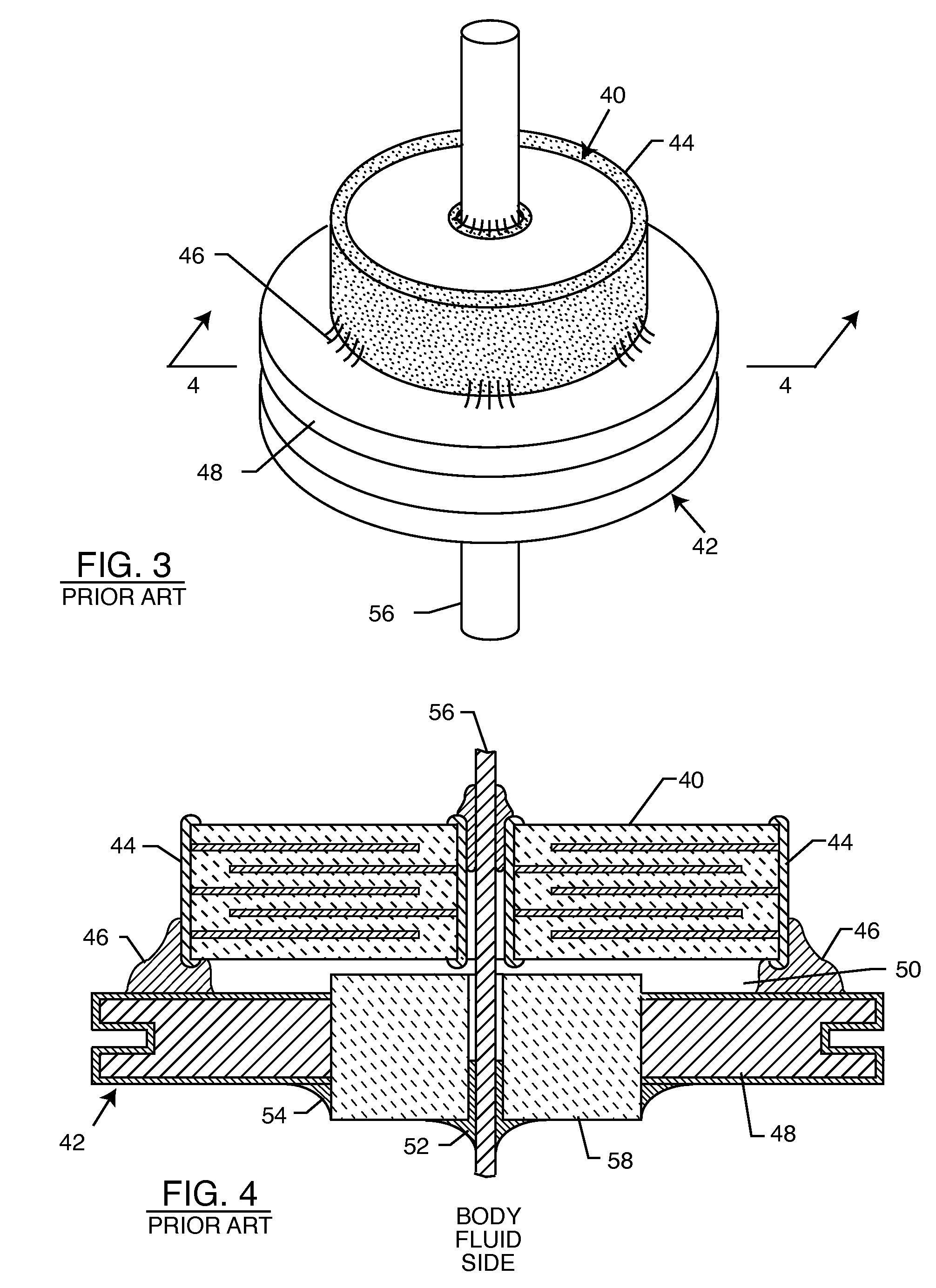

Device to protect an active implantable medical device feedthrough capacitor from stray laser weld strikes, and related manufacturing process

An insulative shield is co-bonded to the top of a ceramic capacitor in a feedthrough terminal assembly on an active implantable medical device. The insulative shield is a thin substrate that provides protection against damage and degradation of the feedthrough capacitor and / or its conformal coating from heat, splatter or debris resulting from the electromechanical connection of components during construction of the assembly. Laser welding, thermal or ultrasonic bonding, soldering, brazing or related lead attachment techniques can create such heat, splatter or debris. In a preferred embodiment, the insulative shield is co-bonded using the capacitor's own conformal coating.

Owner:WILSON GREATBATCH LTD

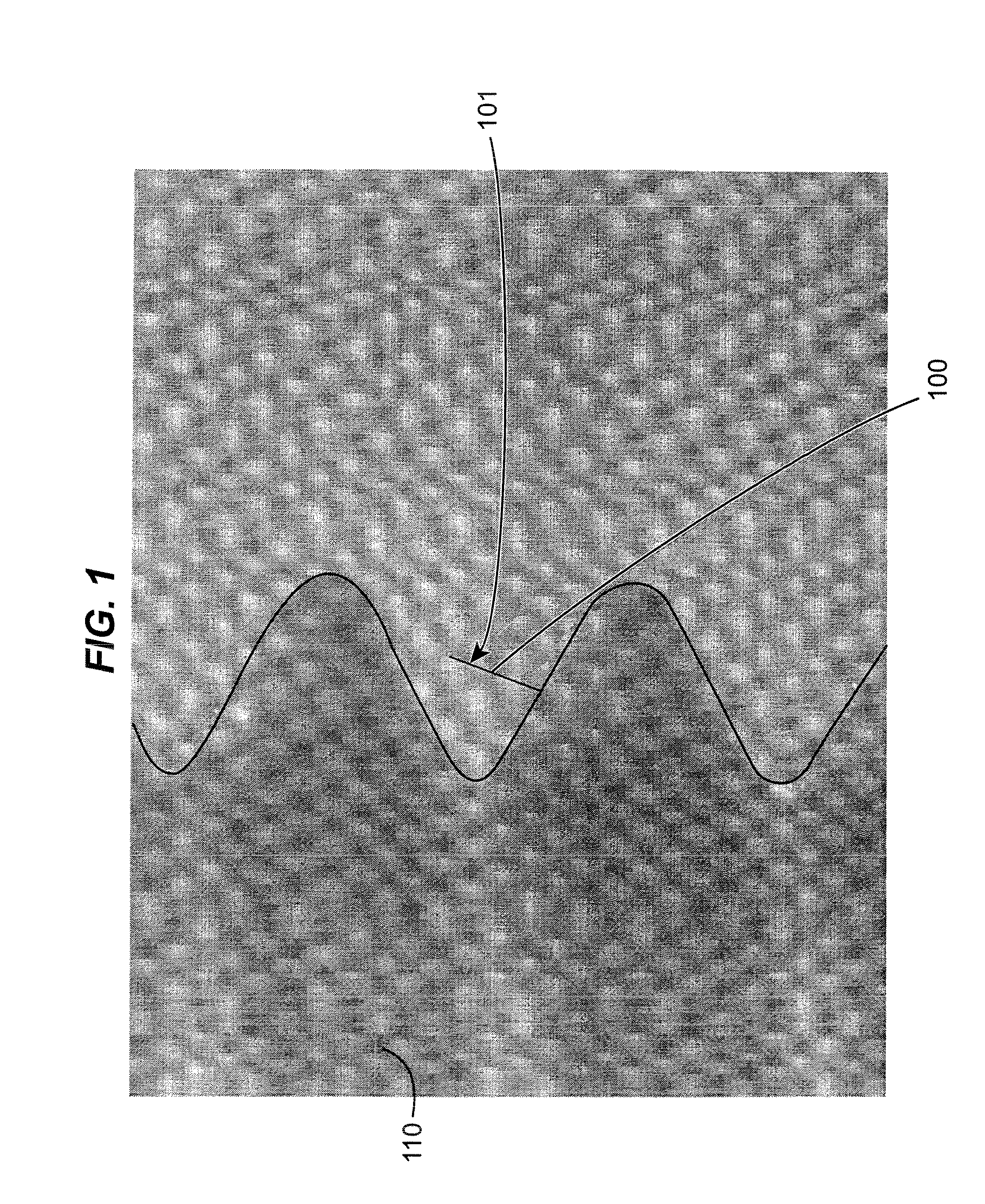

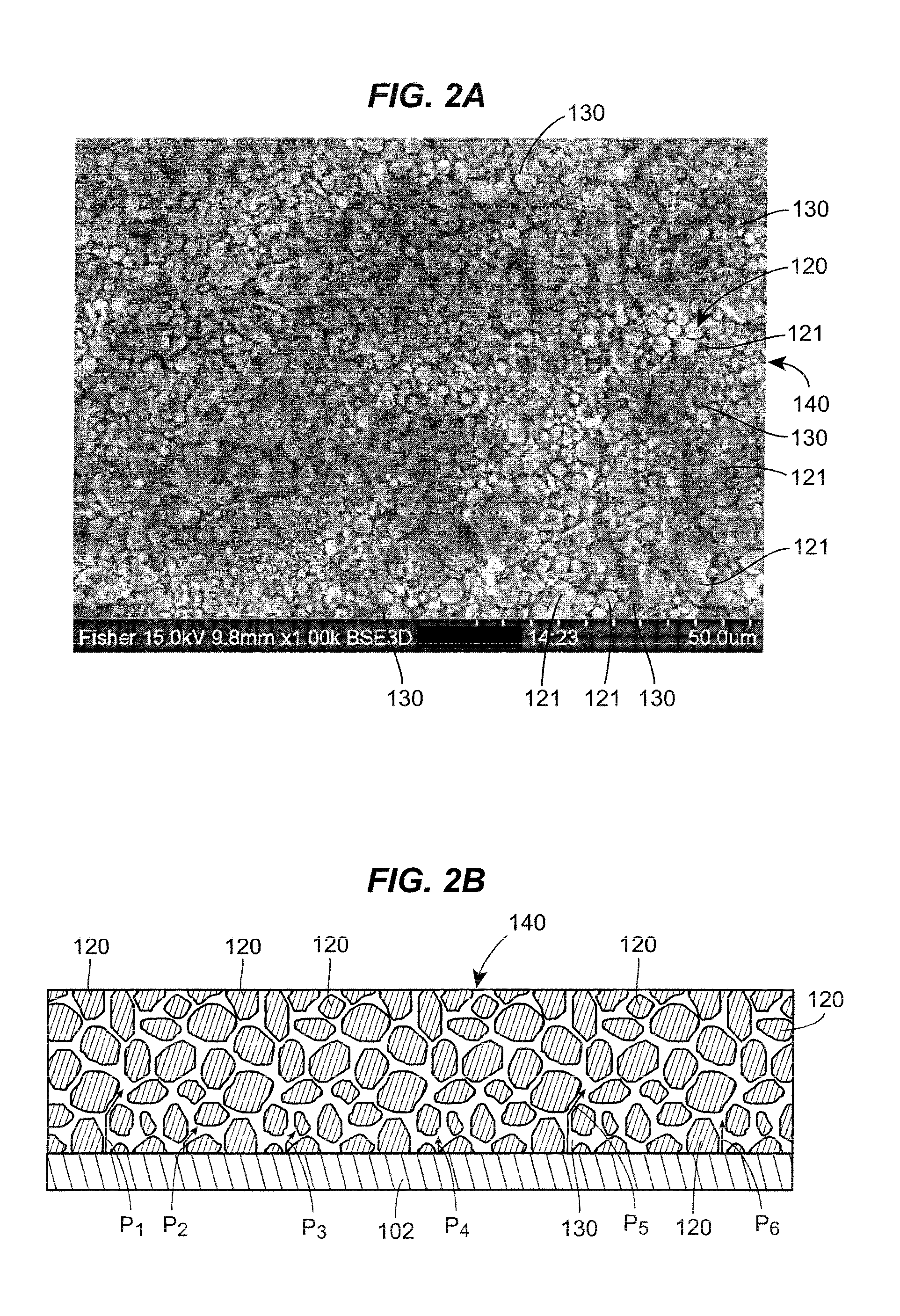

Conformal Coating

InactiveUS20080216704A1Growth inhibitionImprove crystal structureLiquid surface applicatorsOther chemical processesParticulatesConformal coating

A conformal coating comprises a binding layer and a particulate which provides shielding against conductive crystalline structure growth. The particulate comprises materials that provide a tortuous path to substantially inhibit the growth of conductive crystalline structure on electrically conductive surfaces.

Owner:FISHER CONTROLS INT LLC

Device to protect an active implantable medical device feedthrough capacitor from stray laser weld strikes, and related manufacturing process

InactiveUS20060028784A1Protect the surfaceAnti-noise capacitorsElectrotherapyManufacturing technologyCeramic capacitor

An insulative shield is co-bonded to the top of a ceramic capacitor in a feedthrough terminal assembly on an active implantable medical device. The insulative shield is a thin substrate that provides protection against damage and degradation of the feedthrough capacitor and / or its conformal coating from heat, splatter or debris resulting from the electromechanical connection of components during construction of the assembly. Laser welding, thermal or ultrasonic bonding, soldering, brazing or related lead attachment techniques can create such heat, splatter or debris. In a preferred embodiment, the insulative shield is co-bonded using the capacitor's own conformal coating.

Owner:WILSON GREATBATCH LTD

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS6965071B2Eliminate needReduce device temperatureMolten spray coatingScreening gaskets/sealsElectromagnetic interferenceEngineering

Owner:PARKER INTANGIBLES LLC

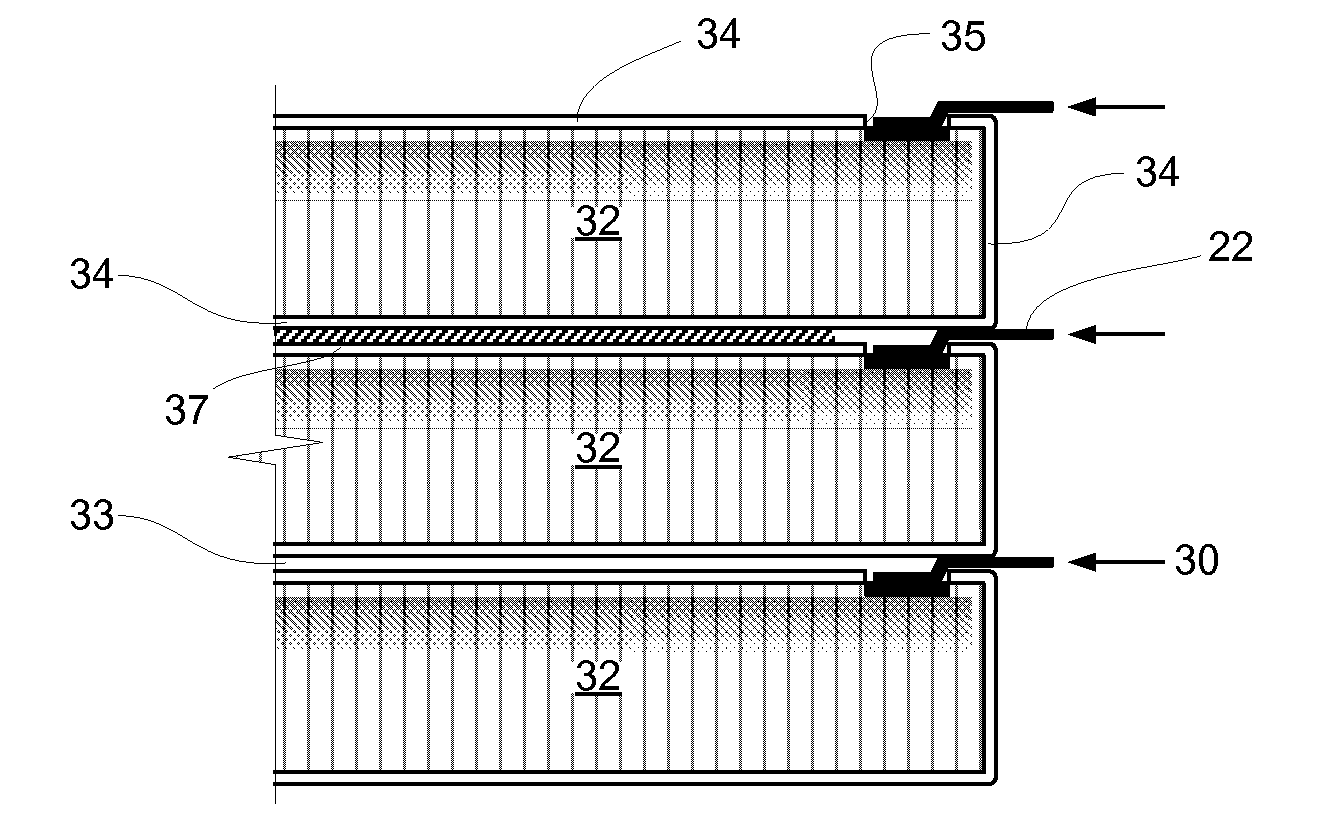

Electrically Interconnected Stacked Die Assemblies

ActiveUS20110037159A1Semiconductor/solid-state device detailsSolid-state devicesConductive polymerConformal coating

In die stack assembly configurations successive die in the stack are offset at a die edge at which die pads are situated, and the die are interconnected by electrically conductive traces. In some embodiments the electrically conductive traces are formed of an electrically conductive polymer. An electrically insulative conformal coating is provided having openings at die pads that are electrically connected.

Owner:INVENSAS CORP

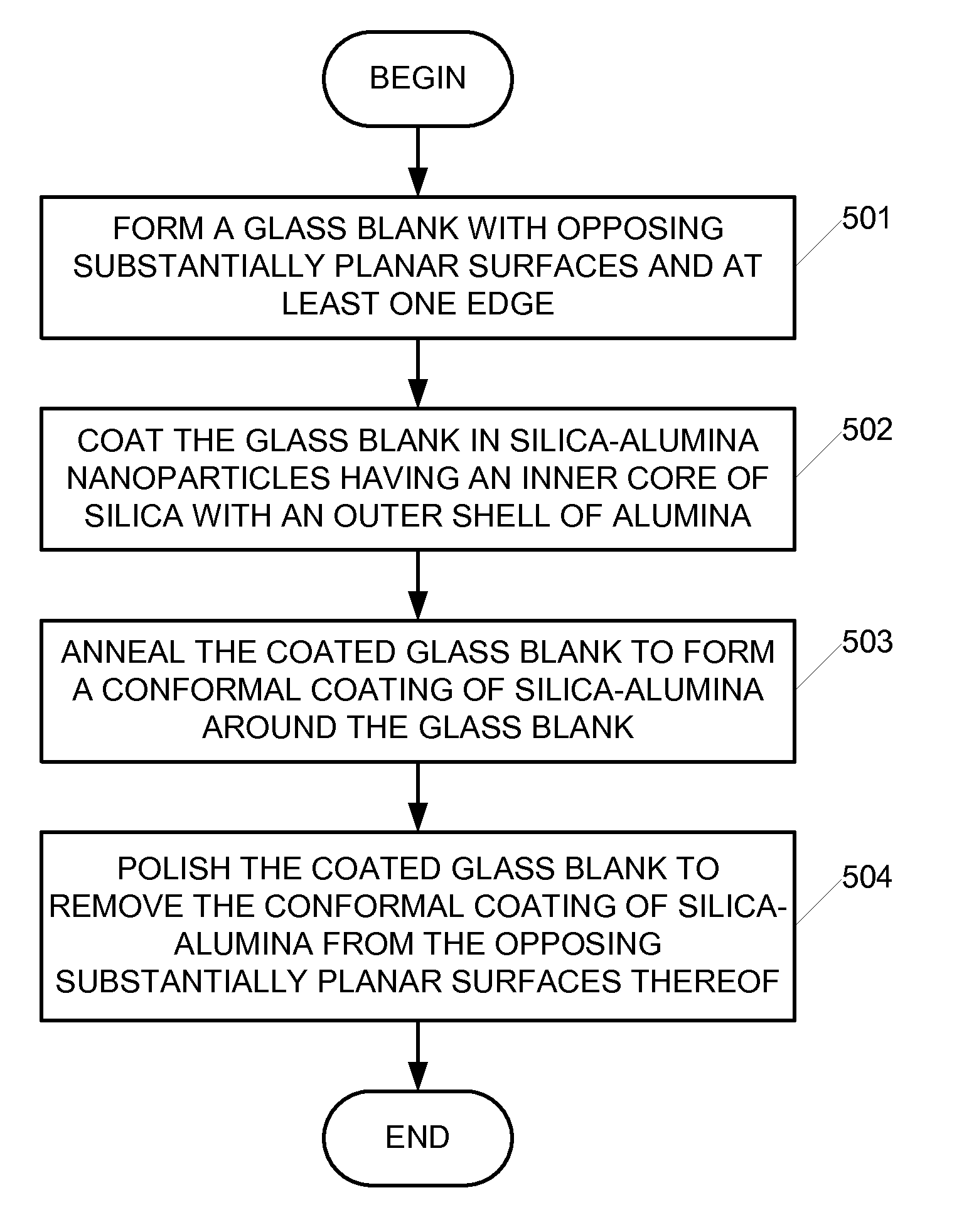

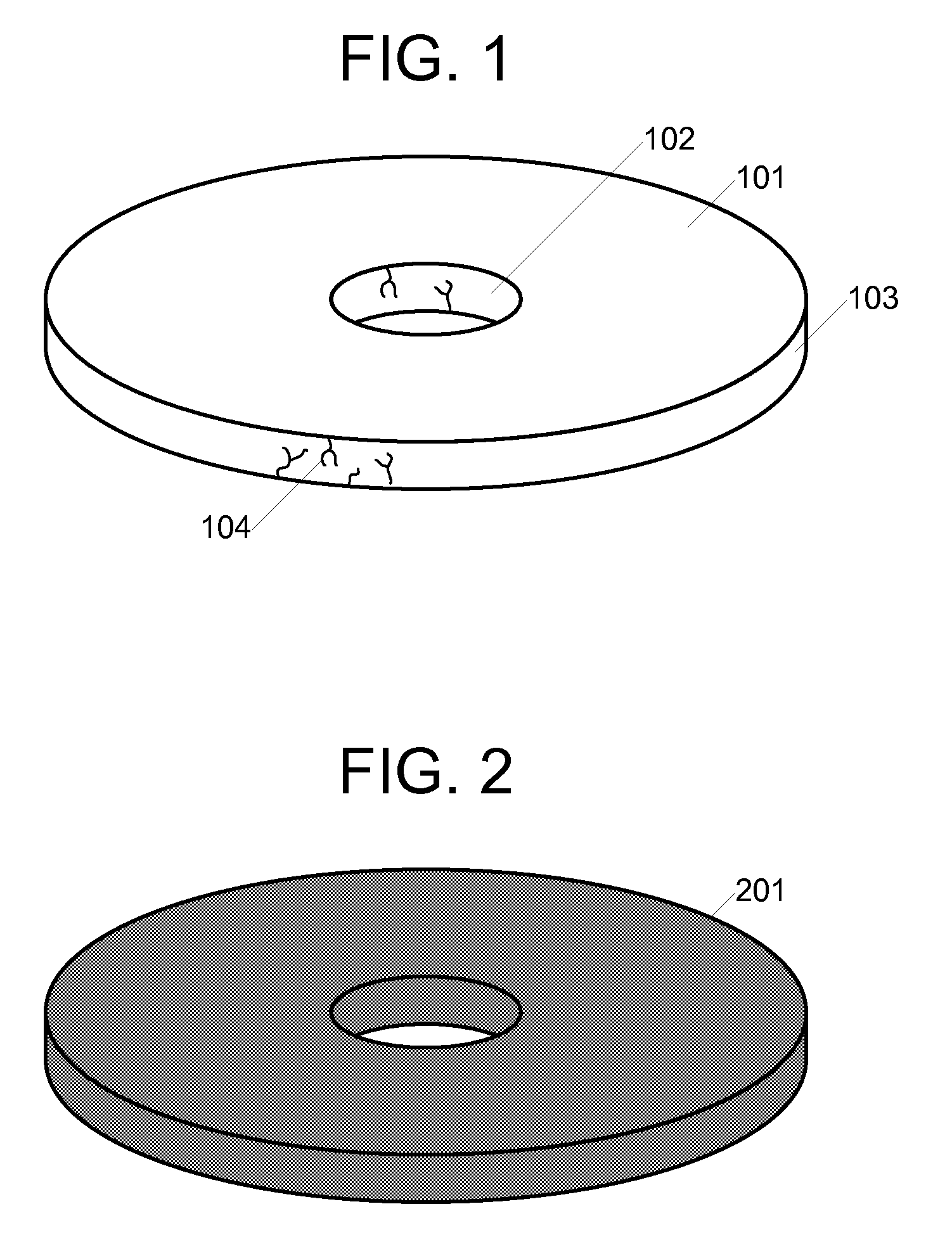

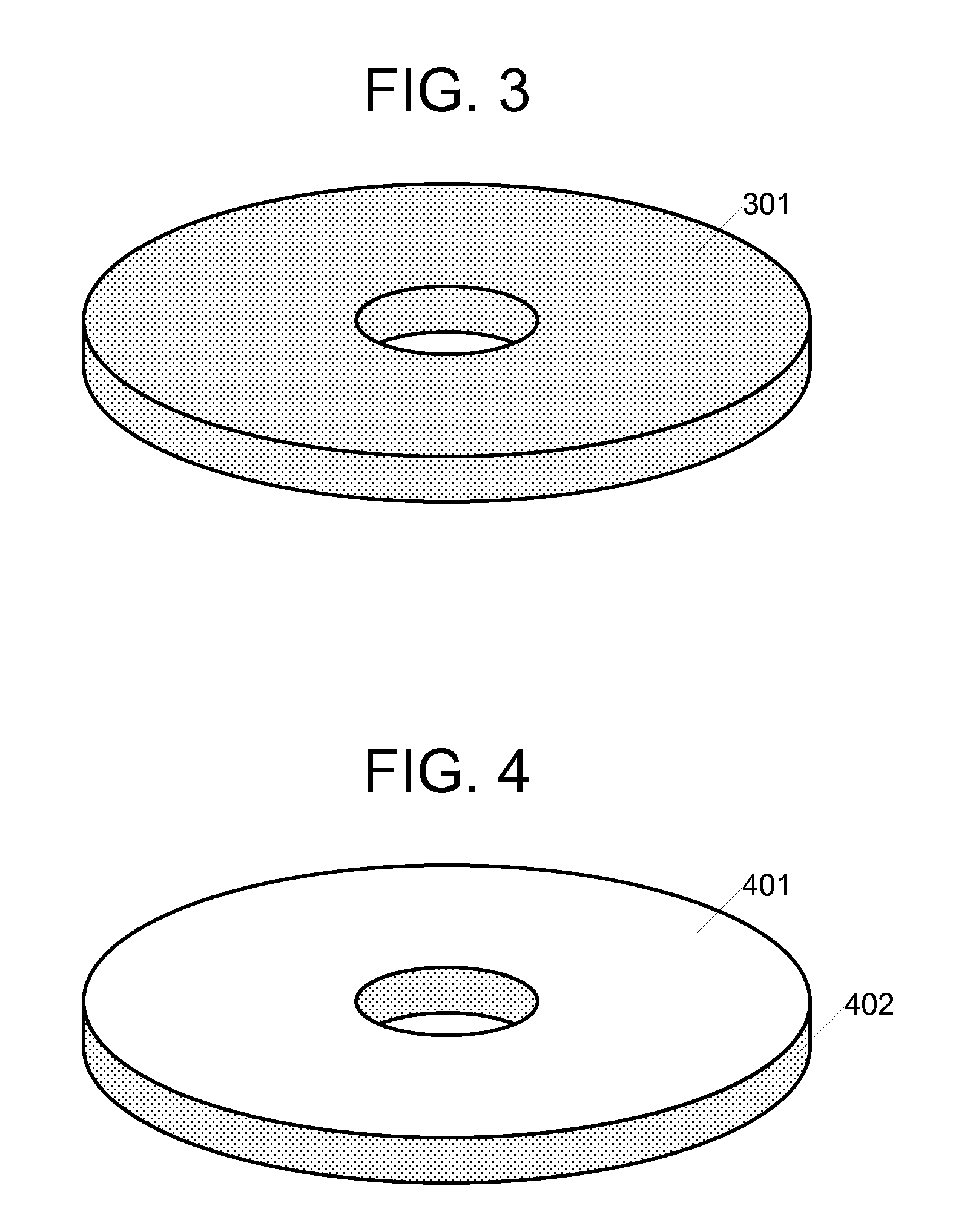

Glass substrates and methods of annealing the same

ActiveUS8206789B2Improve fracture resistanceDisc-shaped record carriersMagnetic materials for record carriersNanoparticleConformal coating

A method for forming a glass substrate comprises the steps of forming a glass blank with opposing substantially planar surfaces and at least one edge, coating the glass blank in silica-alumina nanoparticles, the silica-alumina nanoparticles comprising an inner core of silica with an outer shell of alumina, annealing the coated glass blank to form a conformal coating of silica-alumina around the glass blank, and polishing the coated glass blank to remove the conformal coating of silica-alumina from the opposing substantially planar surfaces thereof.

Owner:WESTERN DIGITAL TECH INC

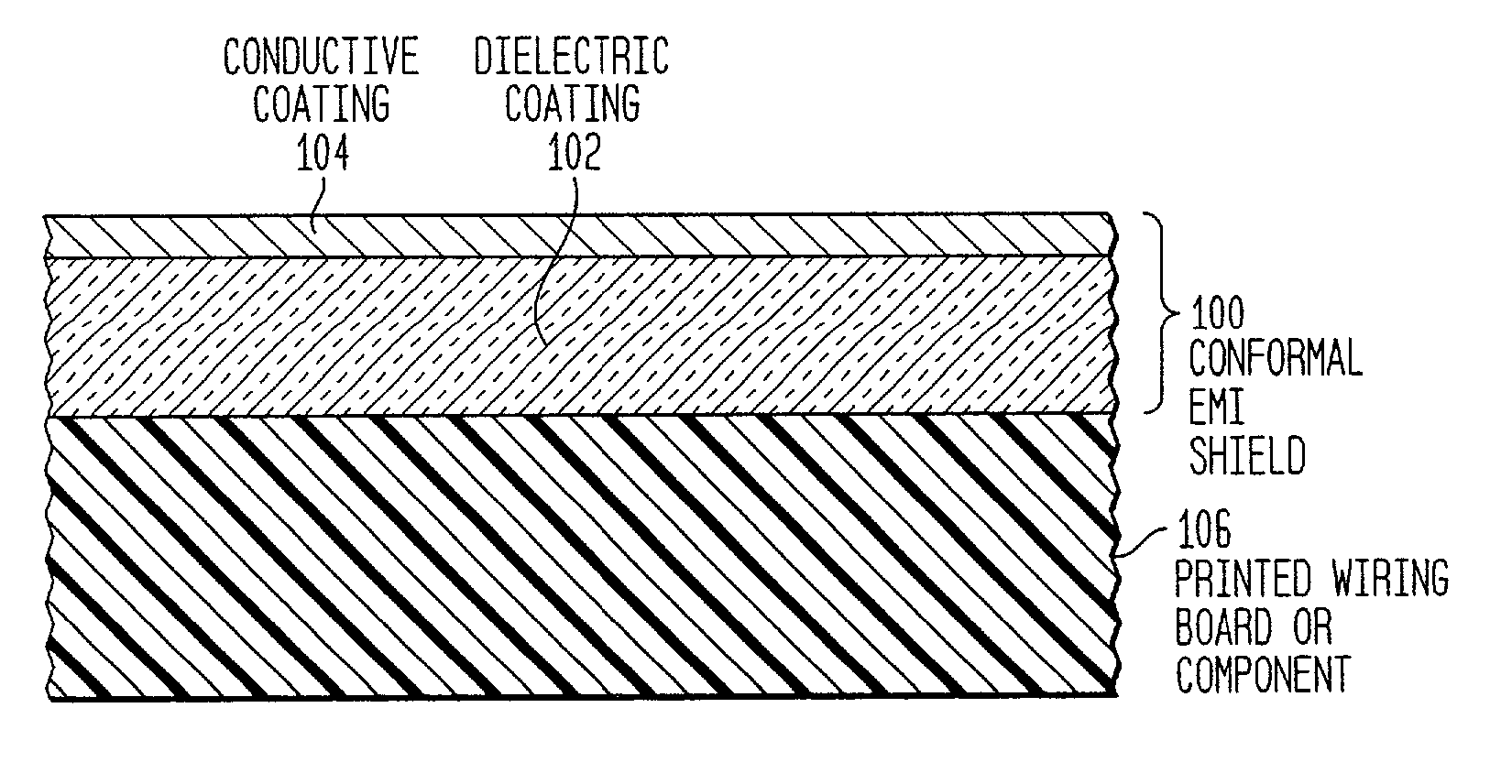

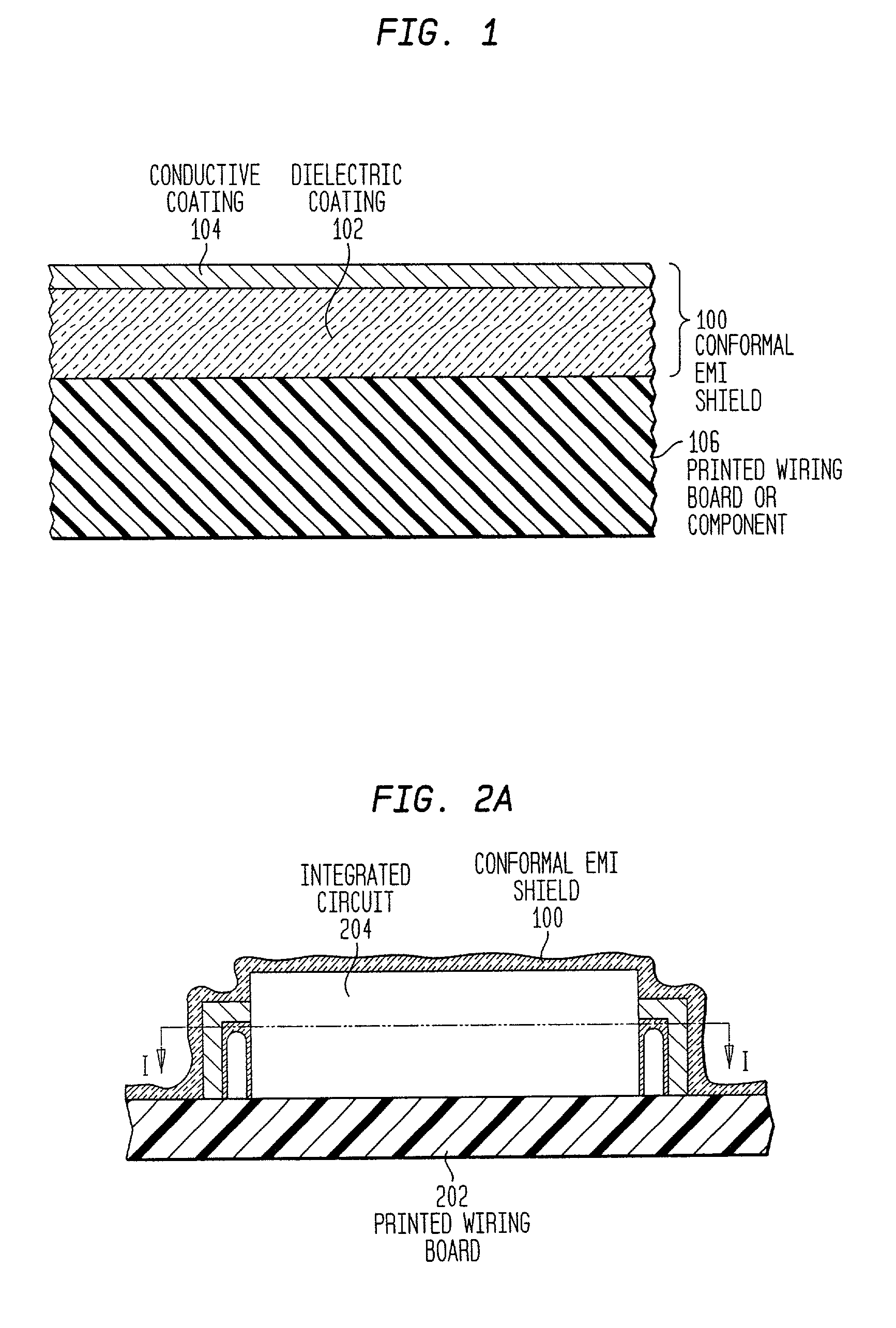

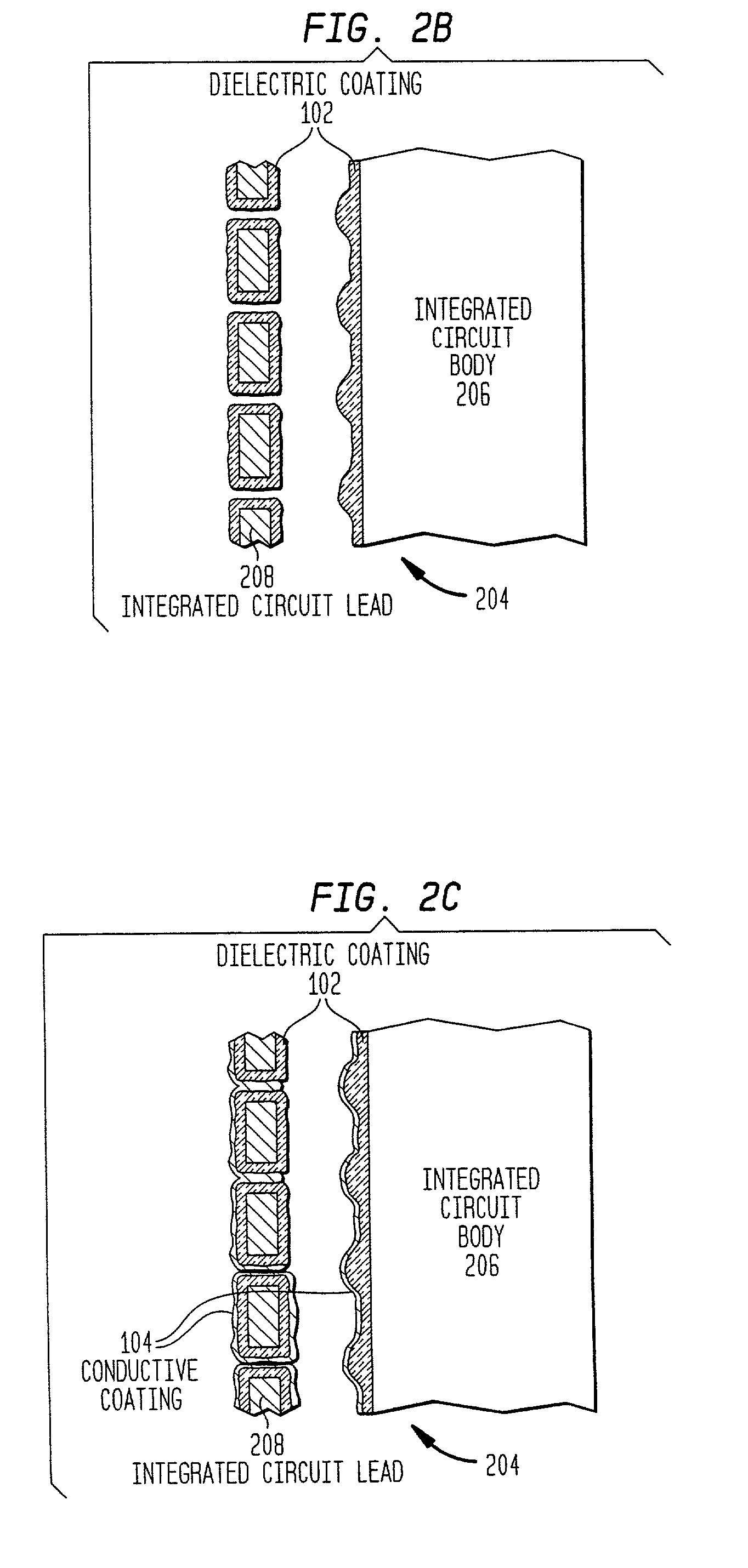

Board-level EMI shield that adheres to and conforms with printed circuit board component and board surfaces

InactiveUS20020129951A1Optimize allocationLift restrictionsElectrically conductive connectionsMagnetic/electric field screeningFilling materialsConductive coating

An electrically continuous, grounded conformal EMI protective shield and methods for applying same directly to the surfaces of a printed circuit board. The EMI shield adheres and conforms to the surface of the components and printed wiring board. The shield takes the shape of the covered surfaces while adding little to the dimensions of the surfaces. The EMI shield includes low viscosity, high adherence conductive and dielectric coatings each of which can be applied in one or more layers using conventional spray techniques. The conductive coating prevents substantially all electromagnetic emissions generated by the shielded components from emanating beyond the conformal coating. The dielectric coating is initially applied to selected locations of the printed circuit board so as to be interposed between the conductive coating and the printed circuit board, preventing the conductive coating from electrically contacting selected components and printed wiring board regions. A high viscosity, non-electrically-conductive filler material is applied to printed circuit board regions that have surfaces that are cavitatious and / or which have a highly variable slope. The filler material can be used in conjunction with conformal EMI shield board level coating. The high viscosity, electrically non-conductive filler material substantially covers each cavity such that the covered cavity is inaccessible and that the covered region of the printed circuit board has a contiguous, contoured surface. A pre-manufactured non-electrically-conductive component cover can be mounted over a corresponding component and secured to the printed wiring board. The component cover and printed wiring board surround the component, forming a sealed enclosure. The component cover has a thin cross-section and an interior surface that follows closely the surface of the component. This minimizes the volume enclosed by the component cover. In addition, the exterior surface of the component cover has a low profile, and prevents the conformal EMI shield from physically contacting the covered component. Instead, the exterior surface of the component cover is coated with the EMI shield. This enables the covered component to be removed from the printed circuit board for repair, replacement or salvage without having to risk damage to the printed wiring board or component that may occur with the removal of a conformal EMI shield applied directly to the component.

Owner:HEWLETT PACKARD DEV CO LP

Light sources incorporating light emitting diodes

InactiveUS8482212B1Good colorQuality improvementPlanar light sourcesPoint-like light sourceConformal coatingOLED

A light source including at least one light emitting diode and, optionally, a housing portion surrounding the light emitting diode. The at least one light emitting diode can be an organic light-emitting diode sheet. The at least one light emitting diode is preferably enclosed in a housing portion comprising a hollow bulb-shaped portion formed of glass, plastic, etc. The housing portion can be filled partially or completely by a potting material. Alternatively, the housing portion can be formed of a potting material or a conformal coating material. At least one connector is coupled to the end of the housing portion. A power supply circuit supplies electrical current to the at least one light emitting diode through the connector.

Owner:ILUMISYS

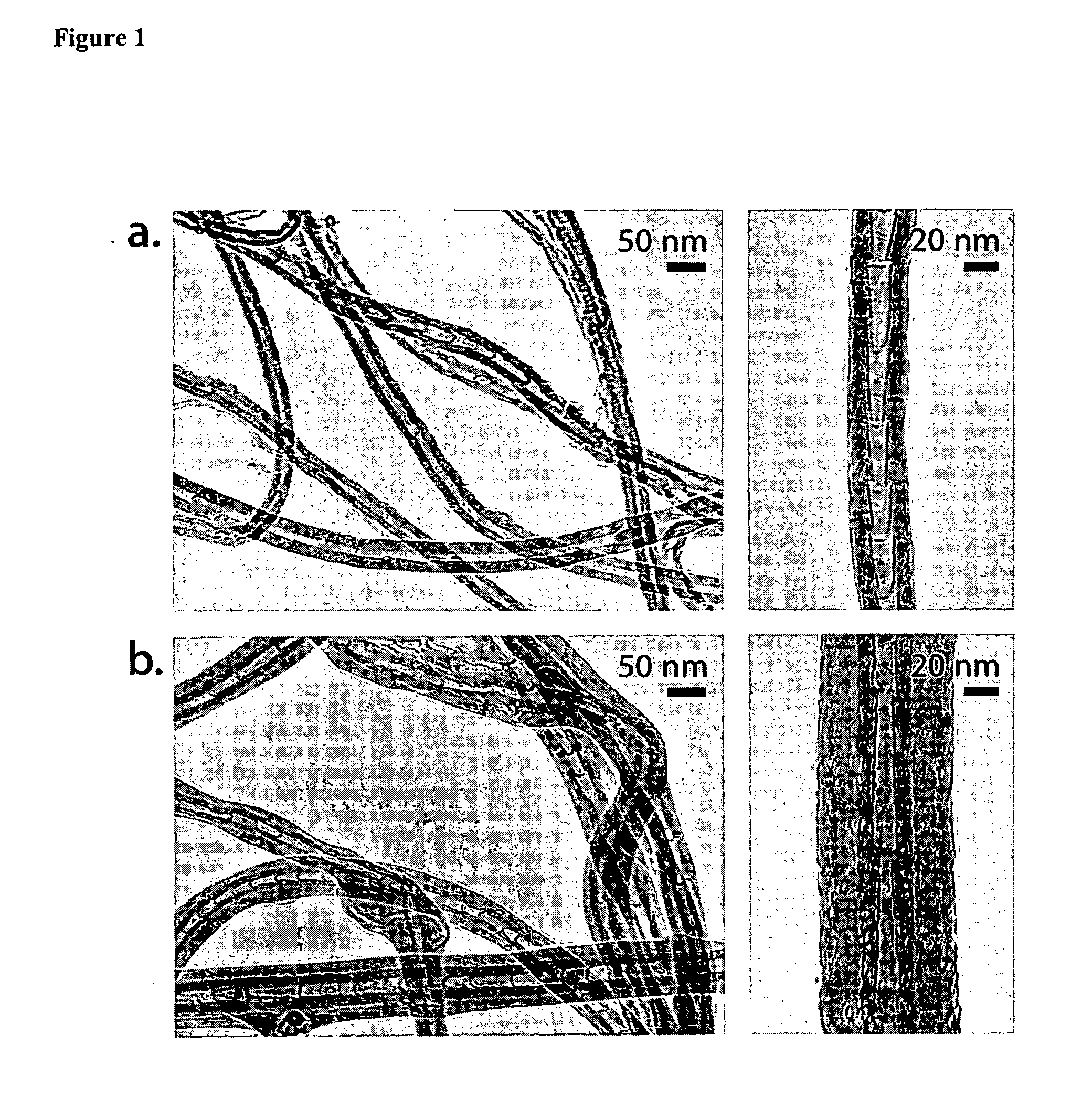

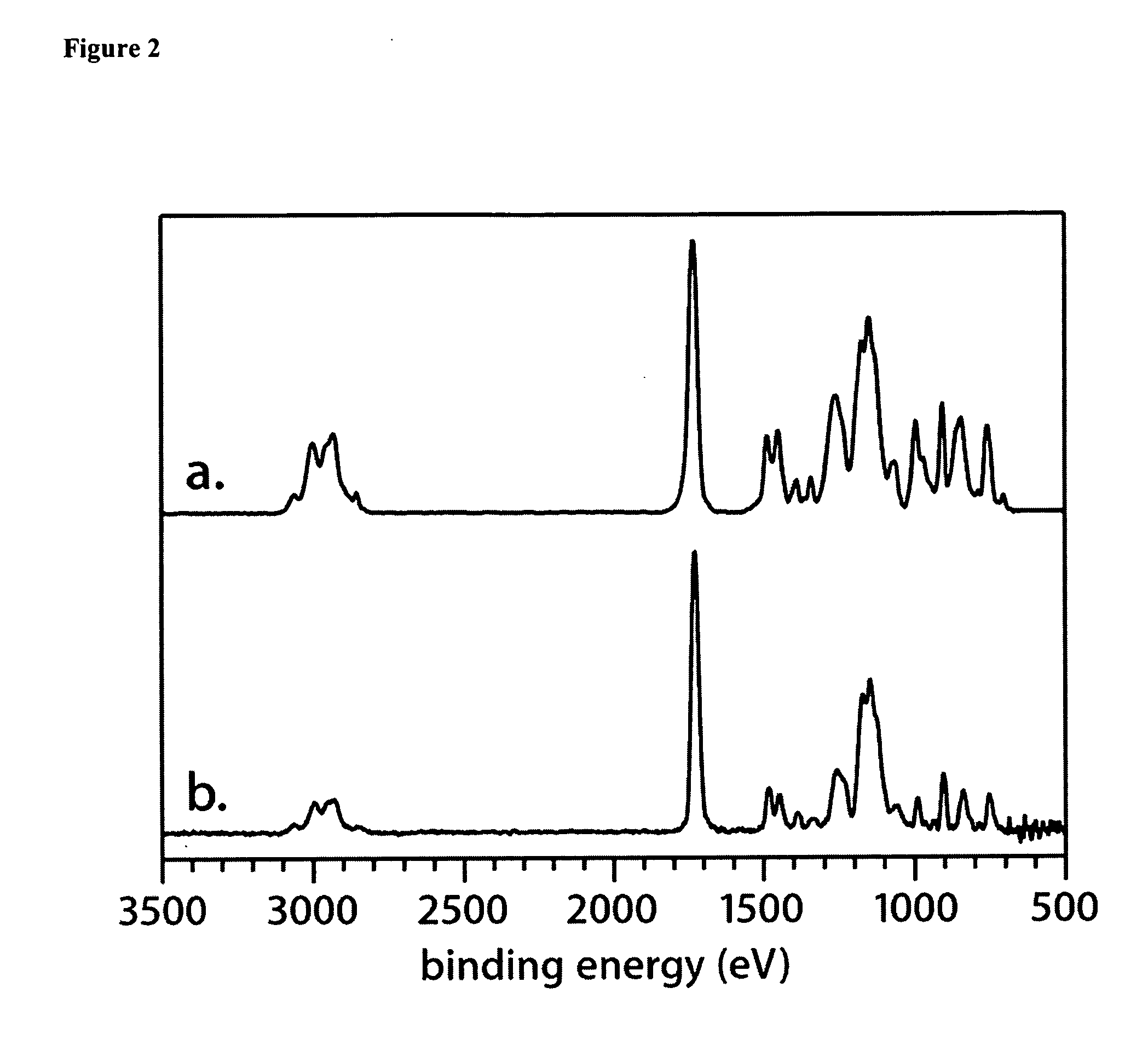

Multifunctional composites based on coated nanostructures

InactiveUS20100255303A1Individual molecule manipulationNanoinformaticsConformal coatingNanostructure

Processing of nanostructures, composite materials comprising nanostructures, and related systems and methods are described. In some embodiments, conformal coatings are applied to nanostructures.

Owner:MASSACHUSETTS INST OF TECH

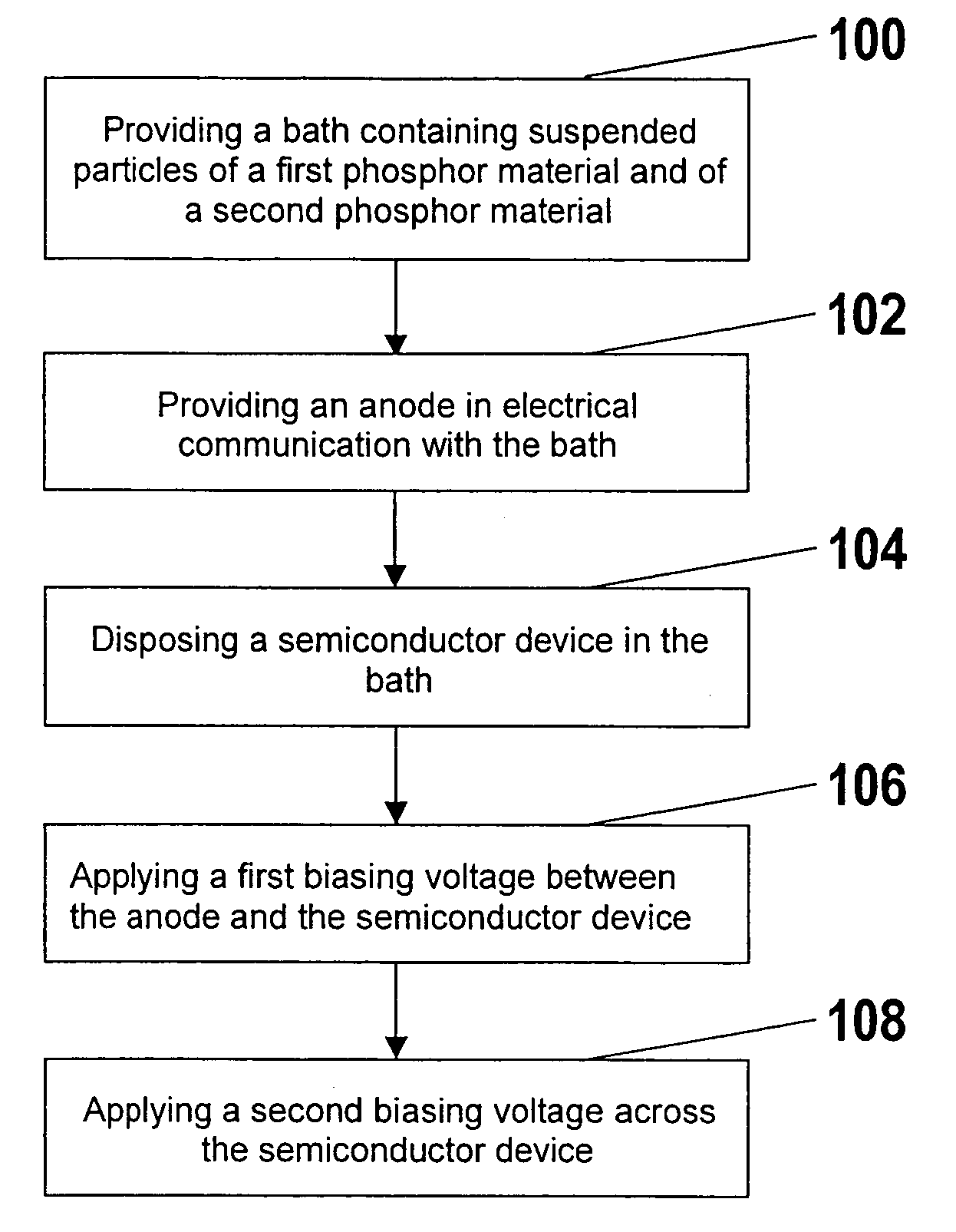

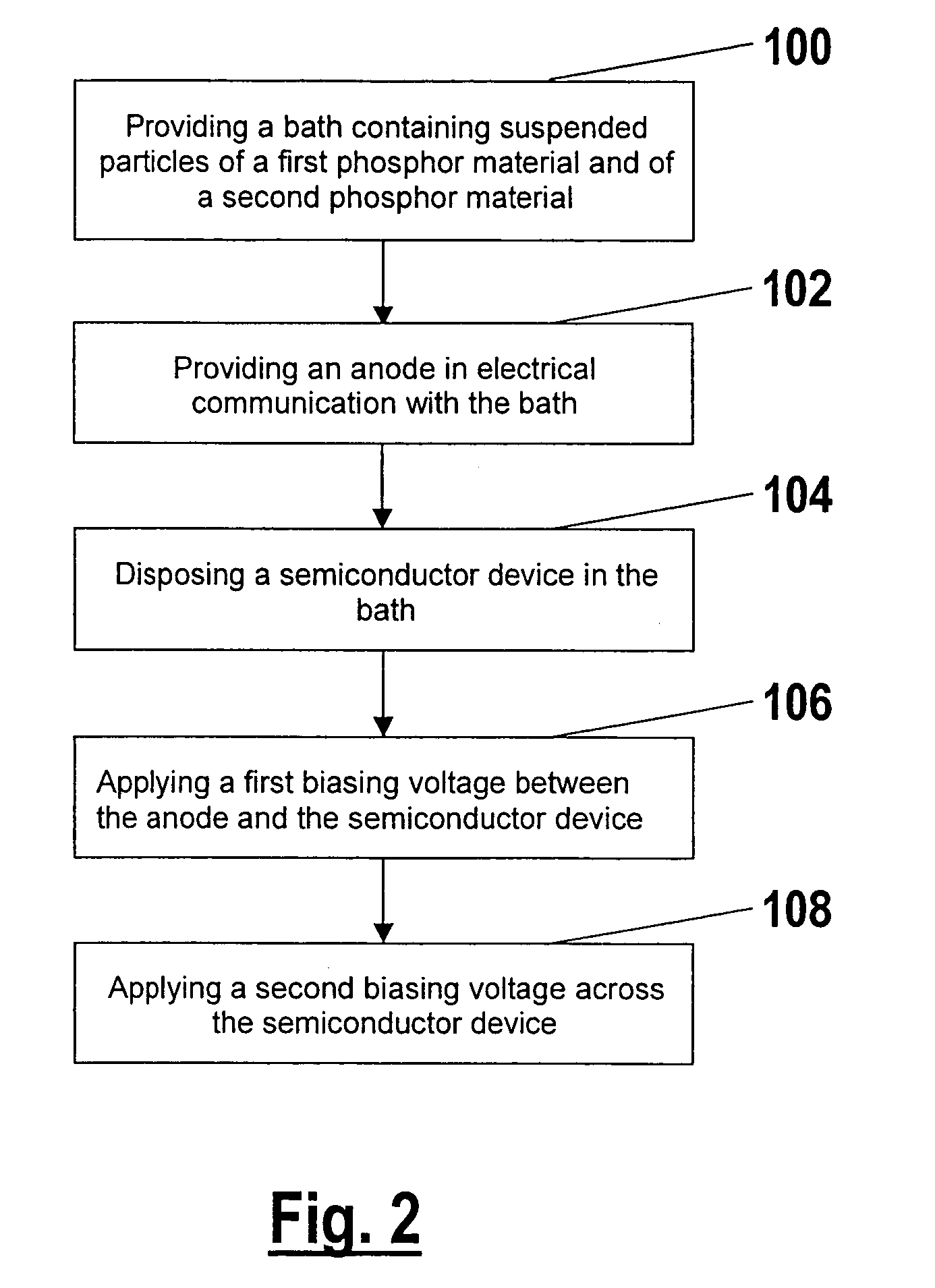

Phosphor deposition methods

ActiveUS6924233B1High resistivitySolid-state devicesSemiconductor/solid-state device manufacturingSuspended particlesSemiconductor structure

Methods of coating a semiconductor device with phosphor particles are disclosed. In the methods, a bath is provided which contains suspended particles of a first phosphor material and suspended particles of a second phosphor material. The particles of the first phosphor material have a mean particle size in the range from about 1 micron to about 6 microns, and the particles of the second phosphor material have a mean particle size in the range from about 12 microns to about 25 microns, wherein the particle size distribution of the phosphor material in the bath is bimodal. The semiconductor device is disposed in the bath containing the suspended particles, and a first biasing voltage is applied between an anode in electrical contact with the bath and the p side to hold the anode at a positive voltage with respect to the p side. A second biasing voltage is applied between the p side and the n side. In particular embodiments, the method results in a substantially conformal coating of the phosphor particles being deposited on at least one surface of the semiconductor structure.

Owner:BENCH WALK LIGHTING LLC

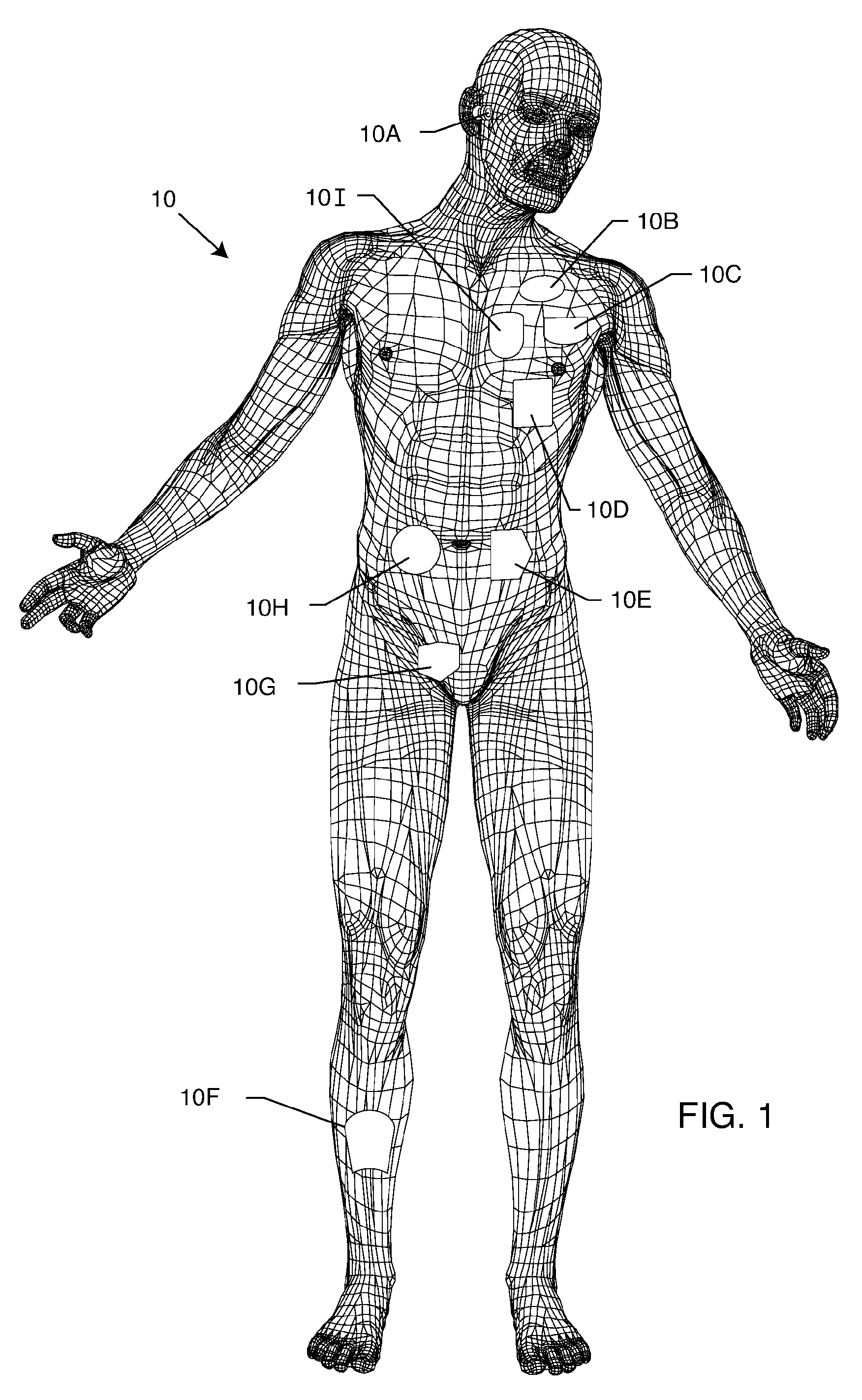

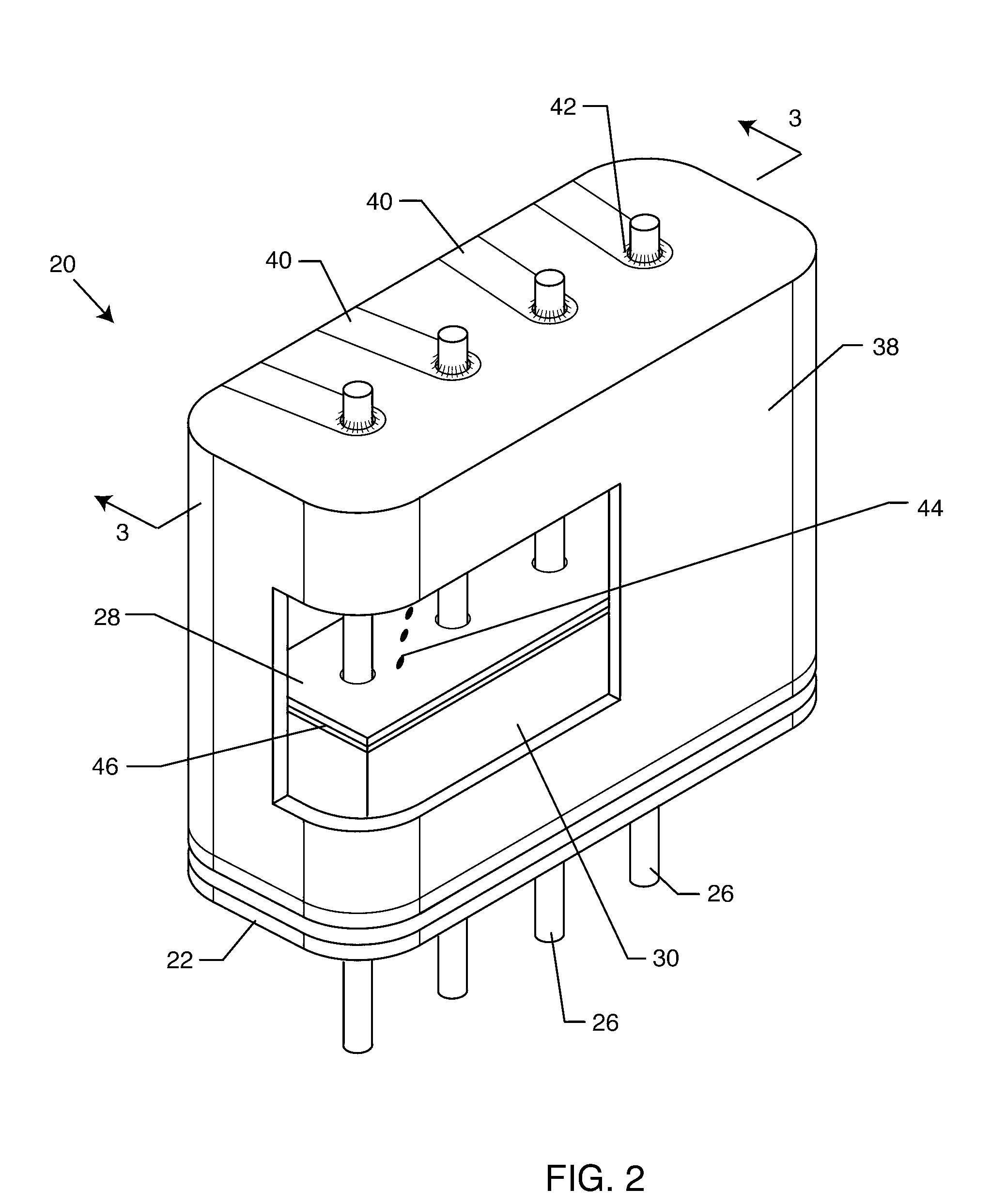

Feedthrough filter terminal assemblies with breathable components to facilitate leak testing

ActiveUS7797048B2Avoid flowPrevent arcing or high-voltage flashoverAnti-noise capacitorsElectrotherapyGround planeConformal coating

A feedthrough terminal assembly for an active implantable medical device (AIMD) includes a conductive terminal pin or lead wire which extends through a conductive ground plane of the AIMD in non-conductive relation. A feedthrough capacitor associated with the terminal pin or lead wire has first and second sets of electrode plates coupled, respectively, to the conductive pin or lead wire and to the ground plane. A breathable electromechanical connection material conductively couples the capacitor's electrode plates to respective components of the AIMD, which allows helium gas to pass freely therethrough during a standard pressurized or vacuum pull helium leak detection test. A breathable washer may be disposed between an alumina insulator and a surface of the capacitor. An additional further breathable coating or conformal coating may be placed over a surface of the feedthrough capacitor disposed toward the interior of the AIMD.

Owner:WILSON GREATBATCH LTD

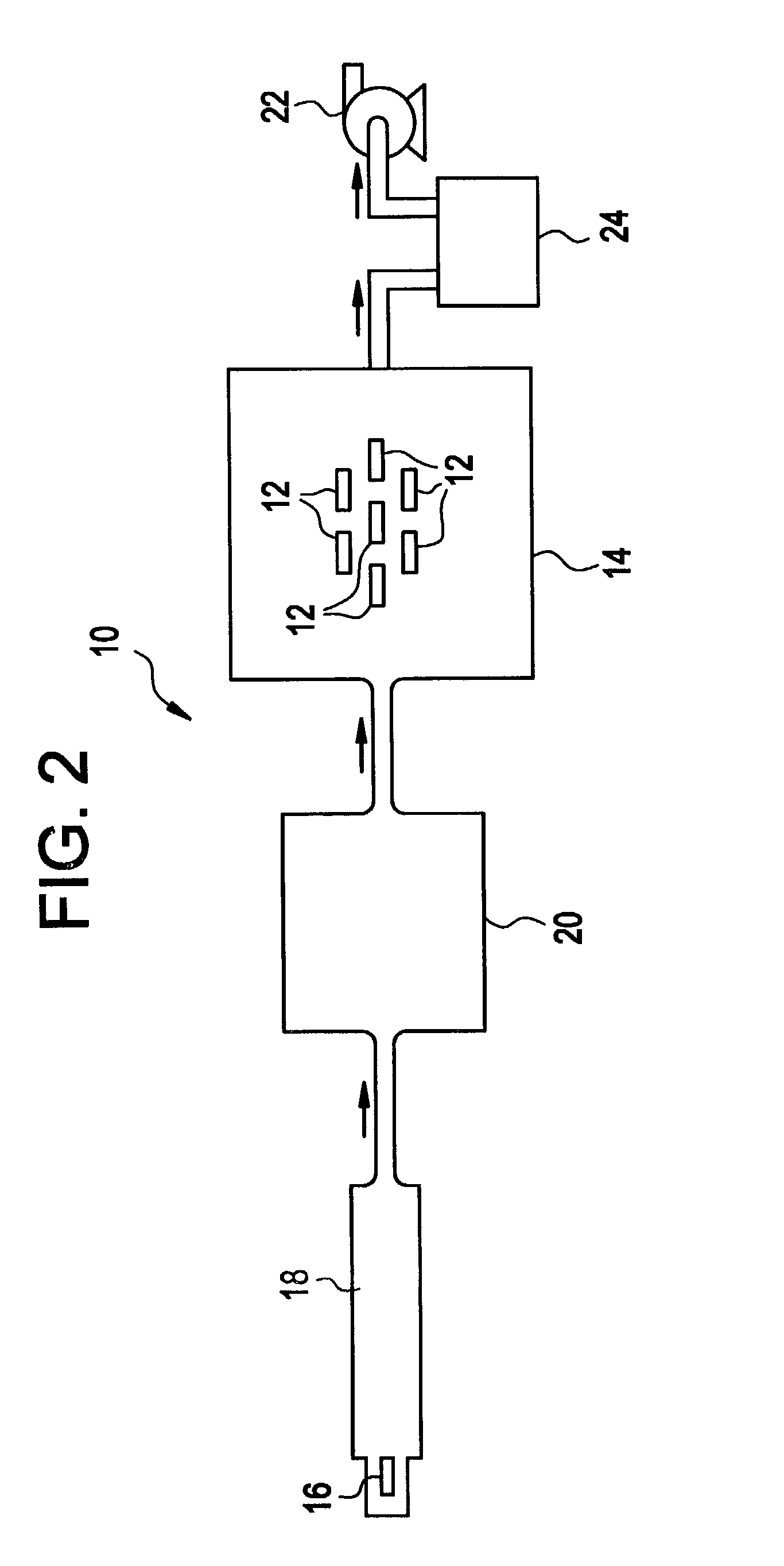

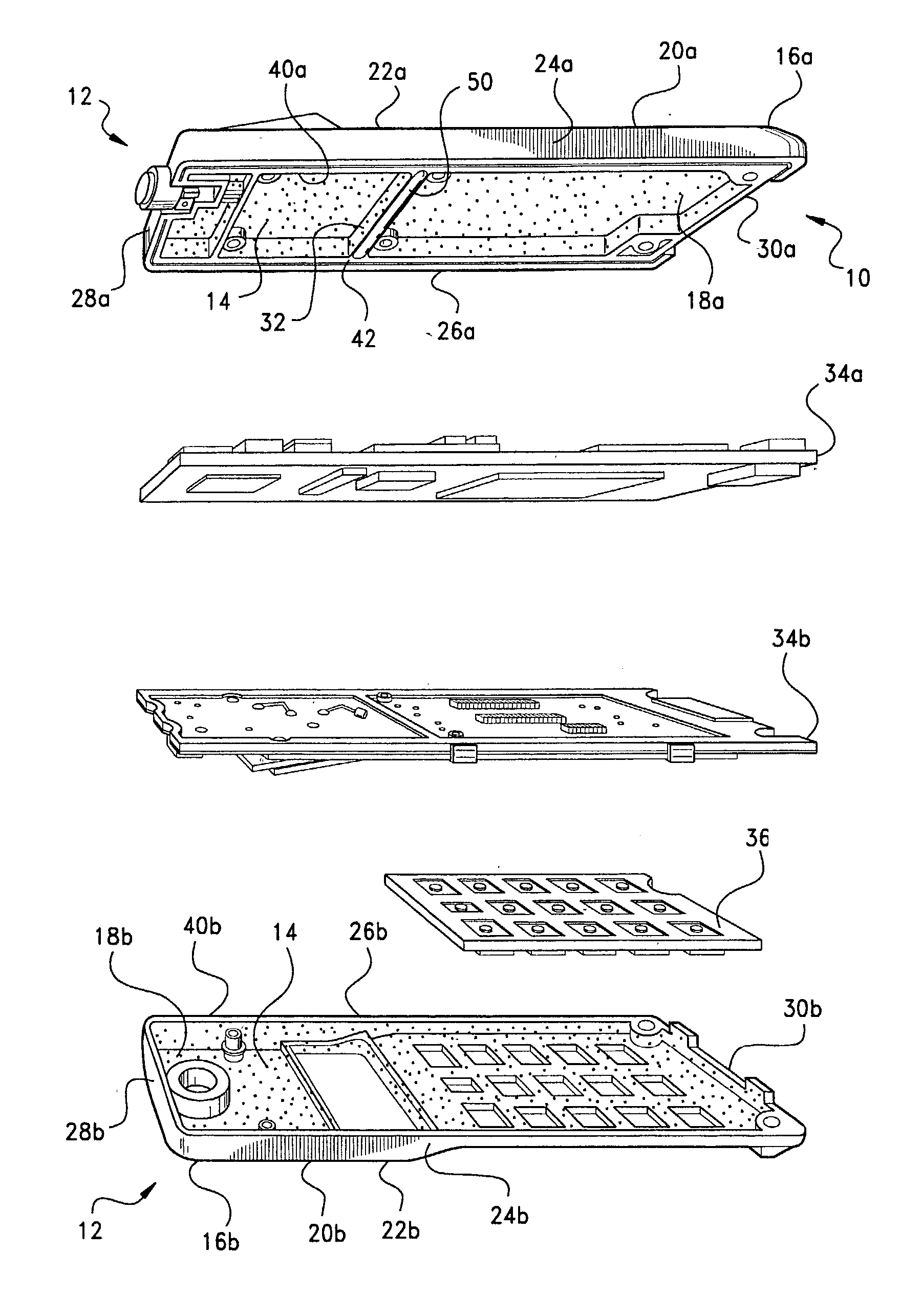

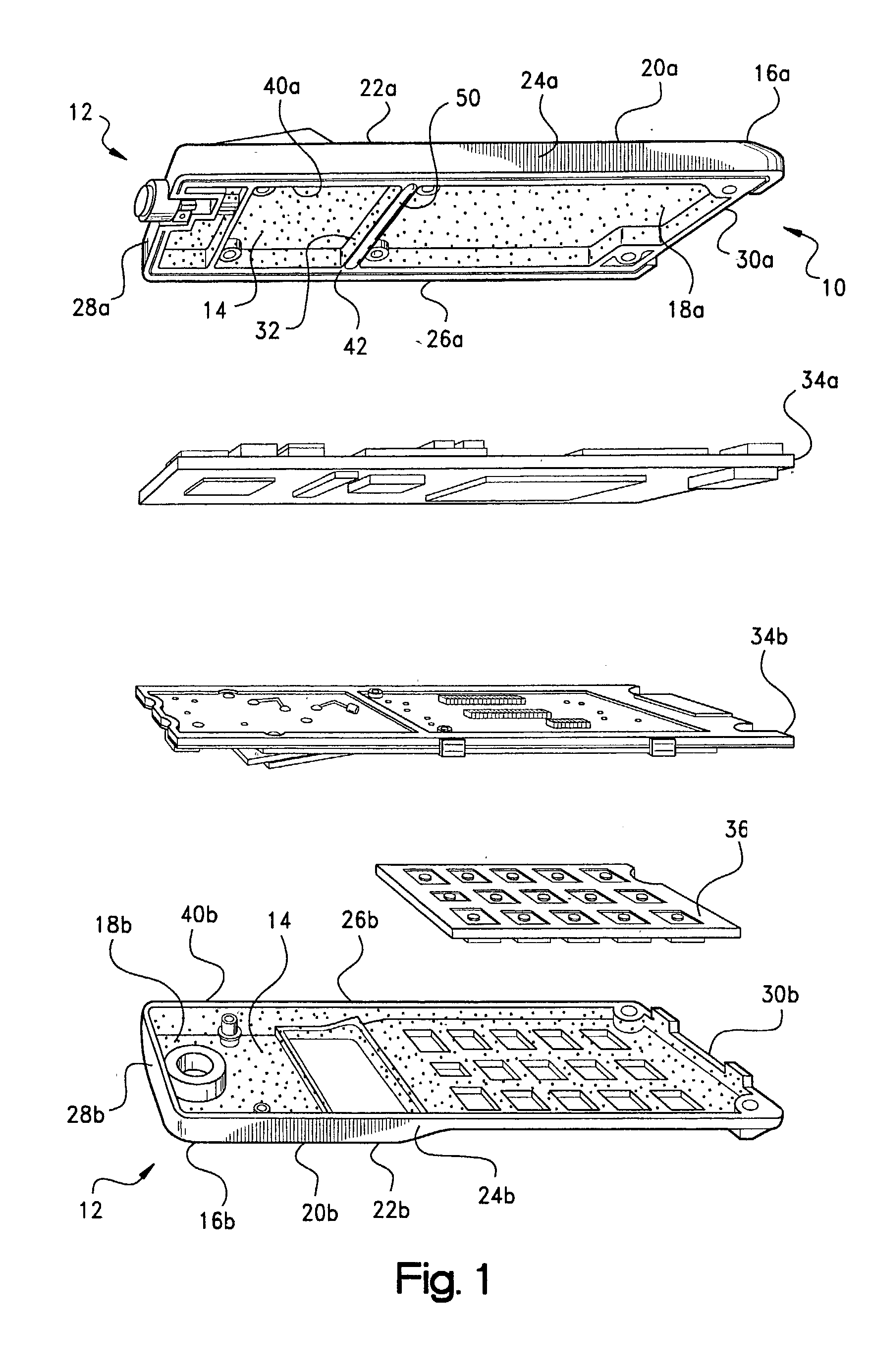

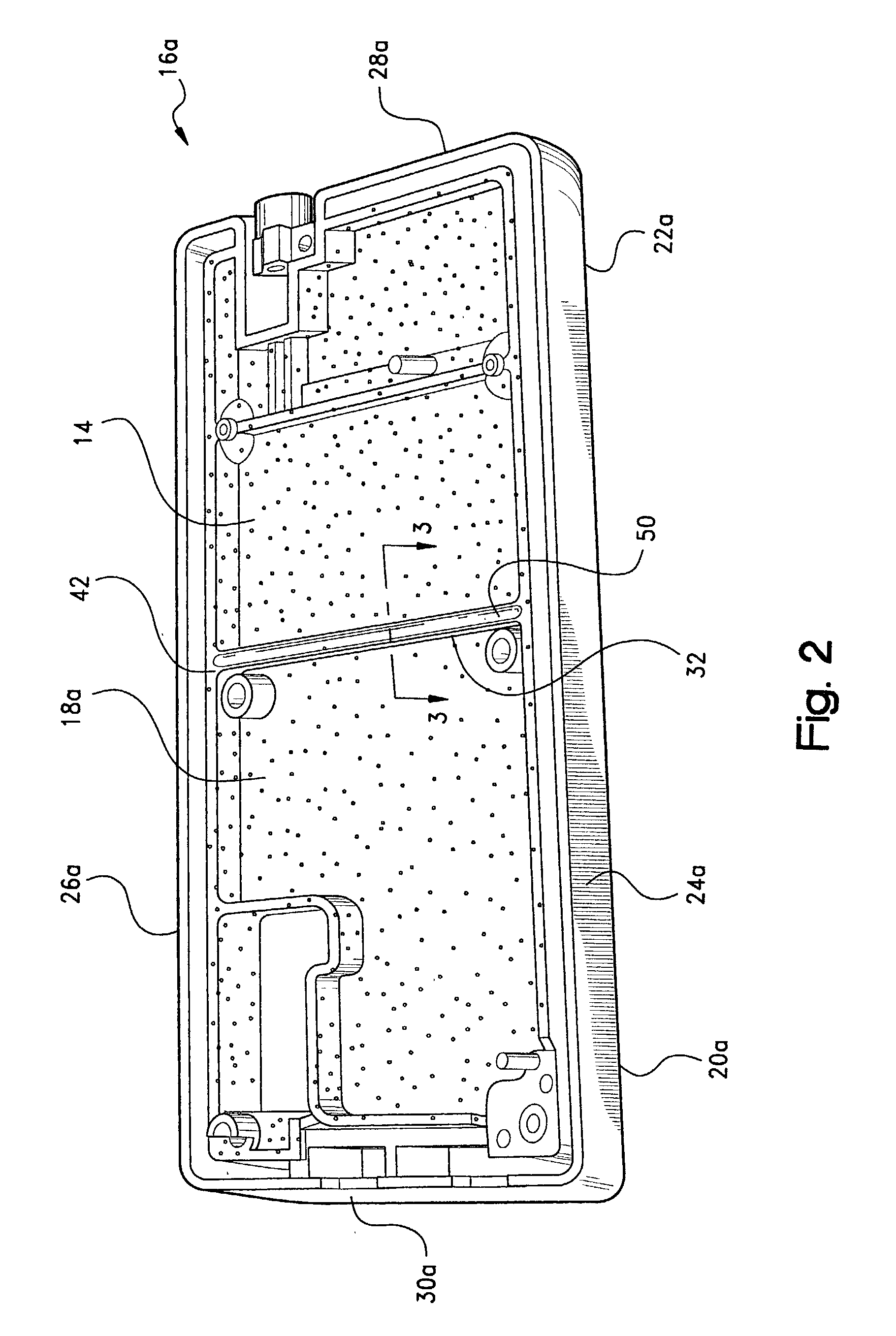

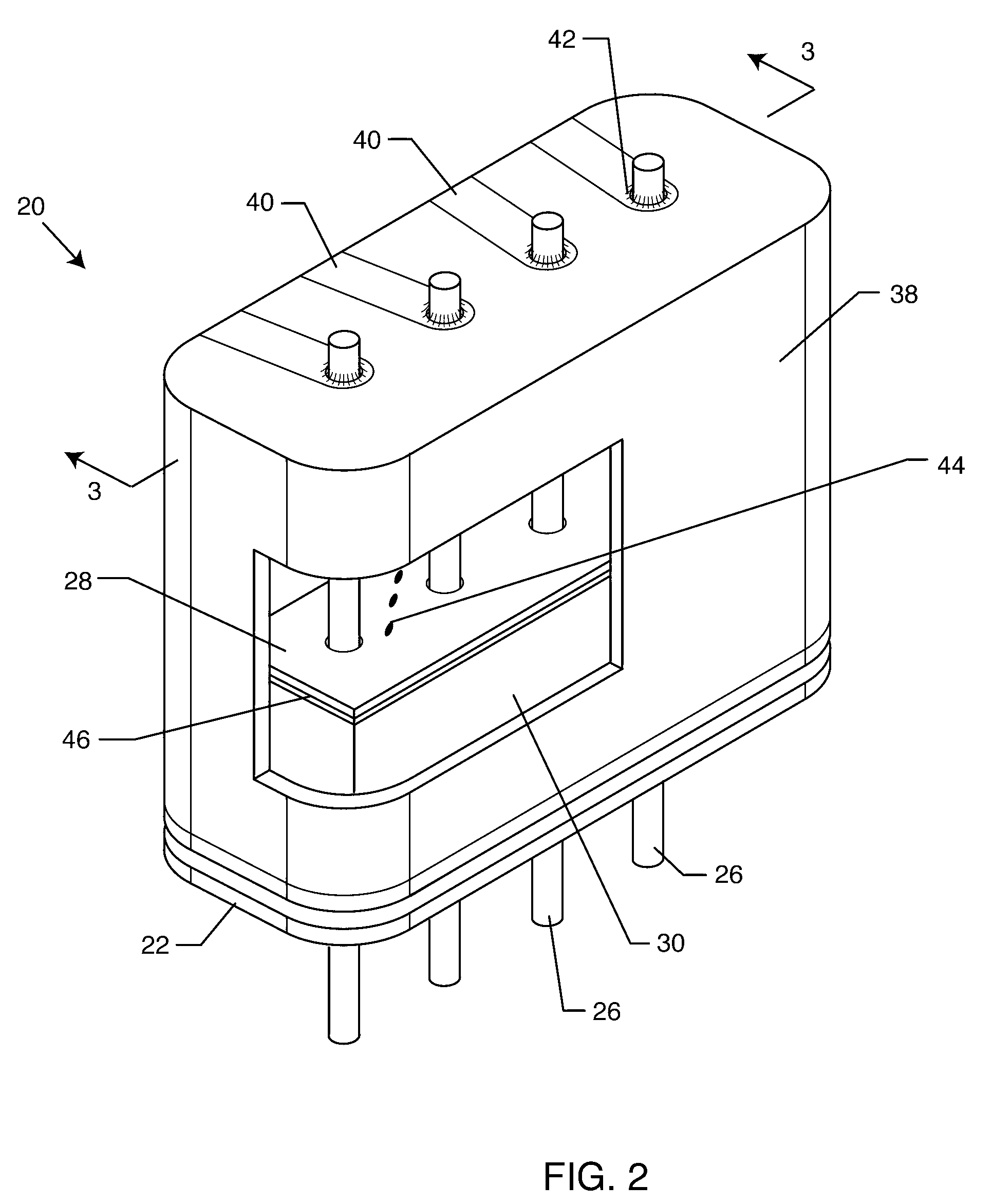

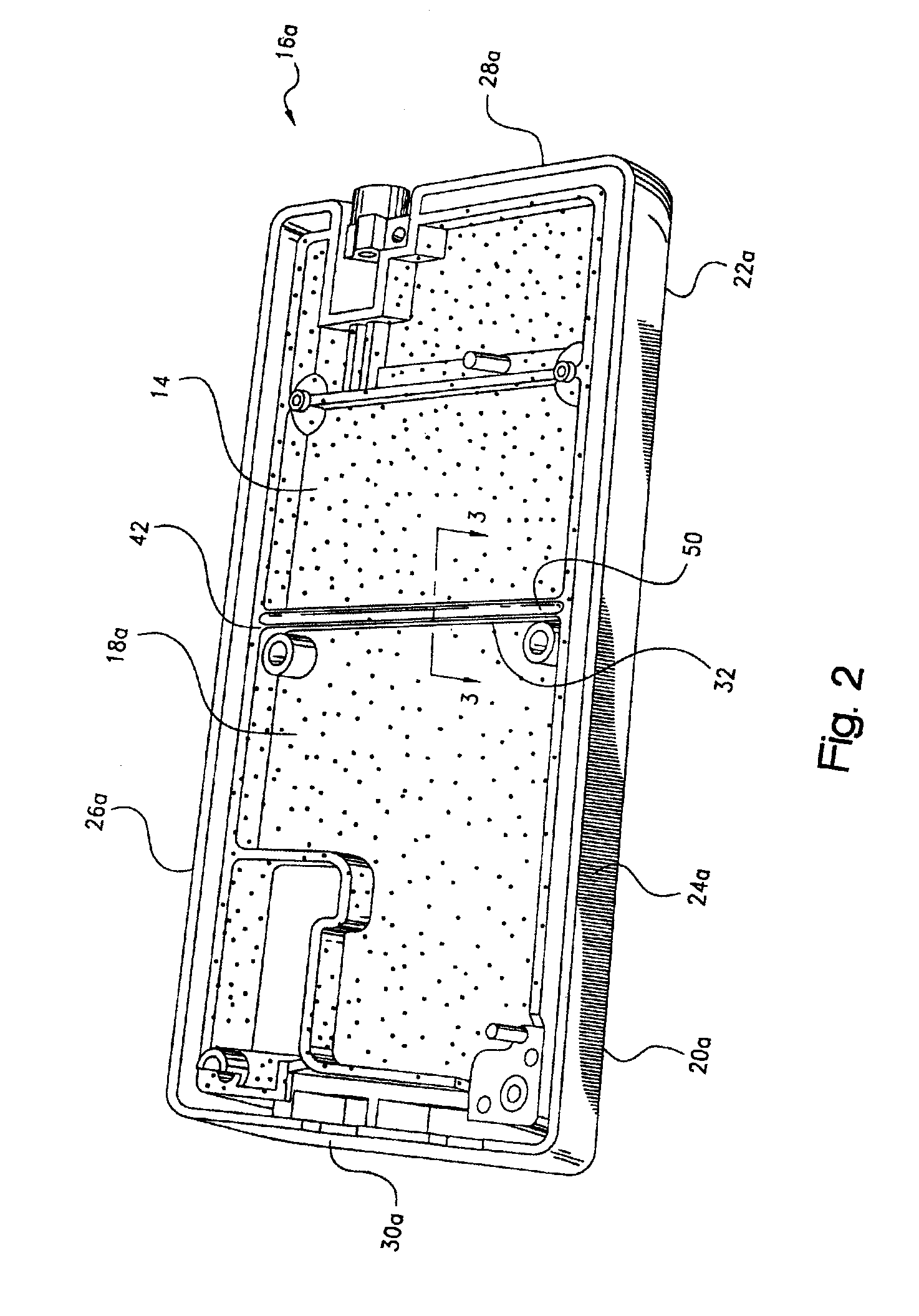

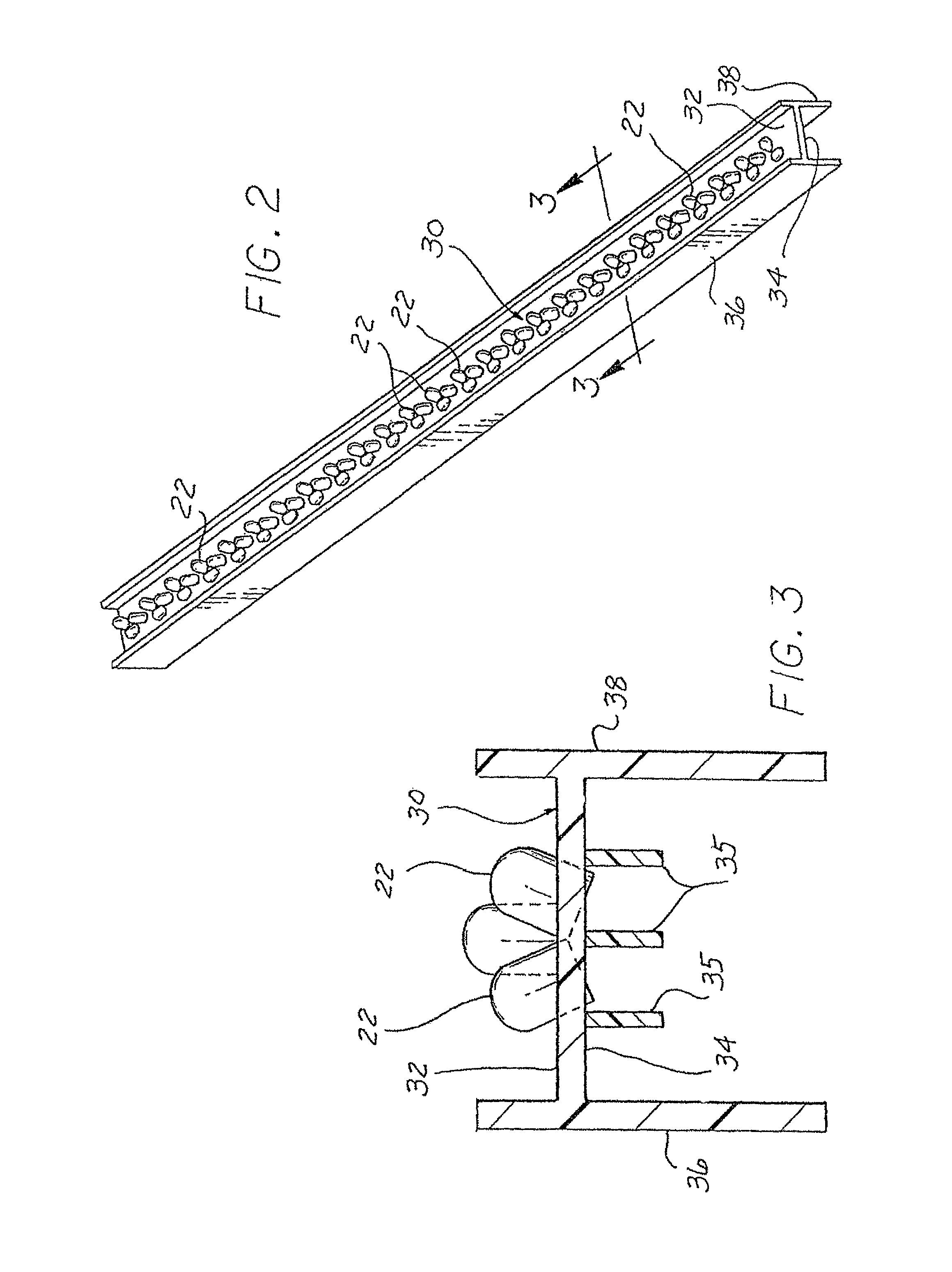

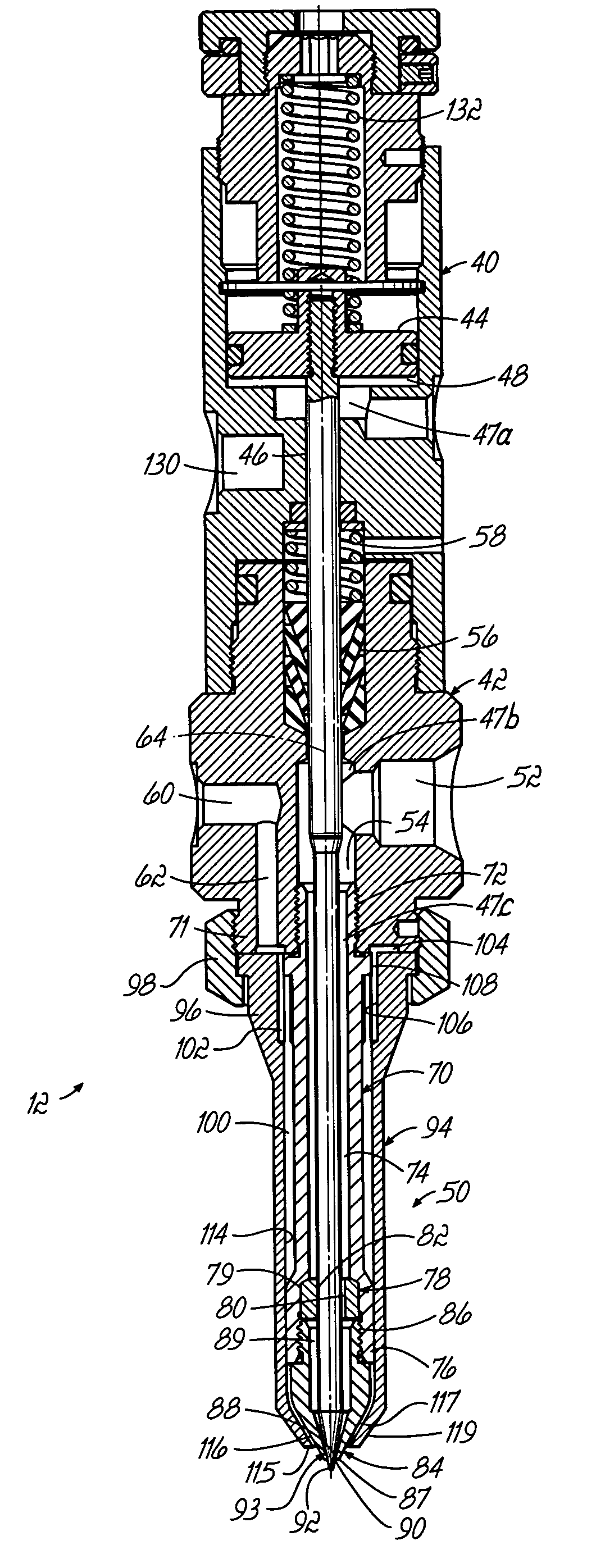

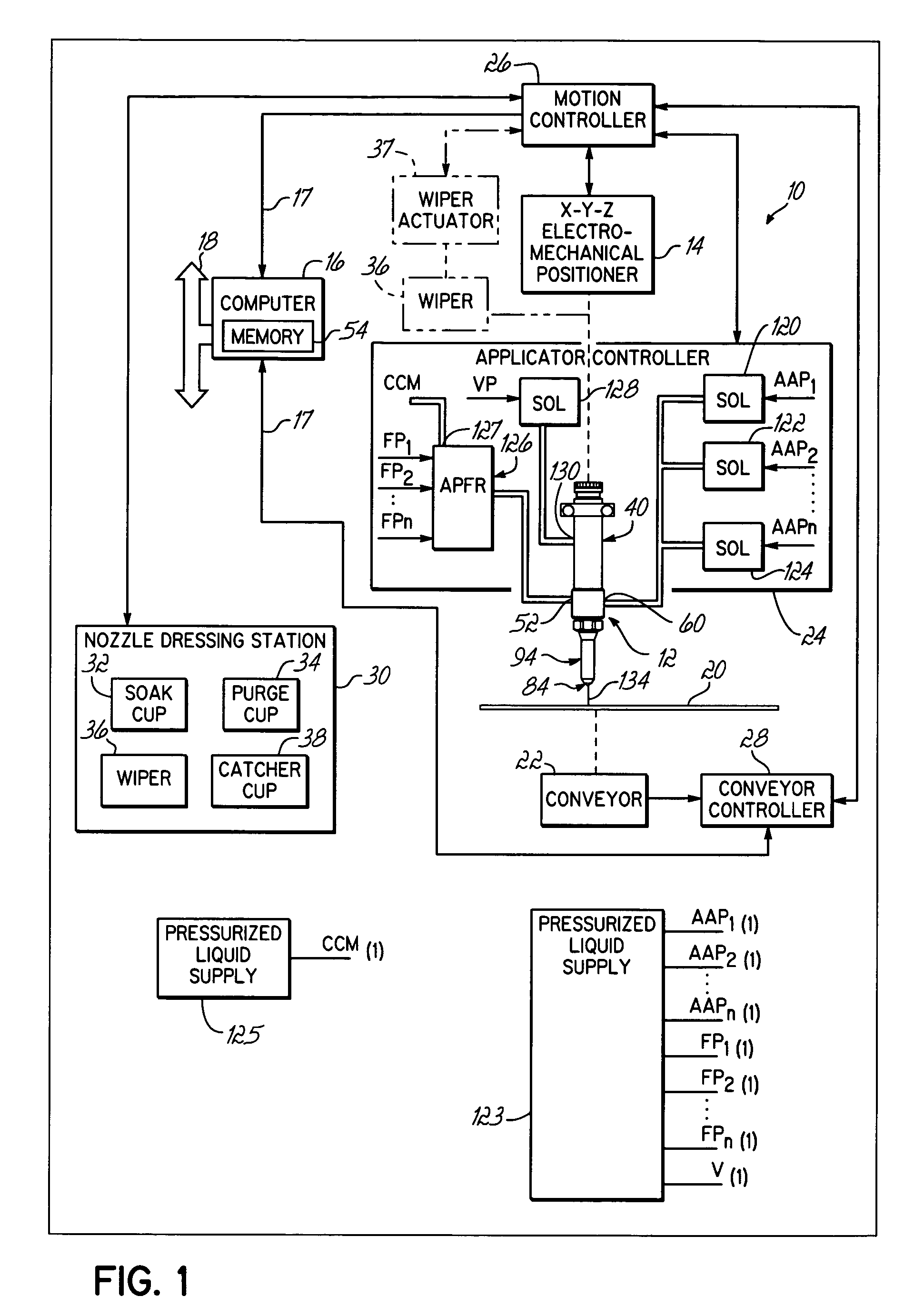

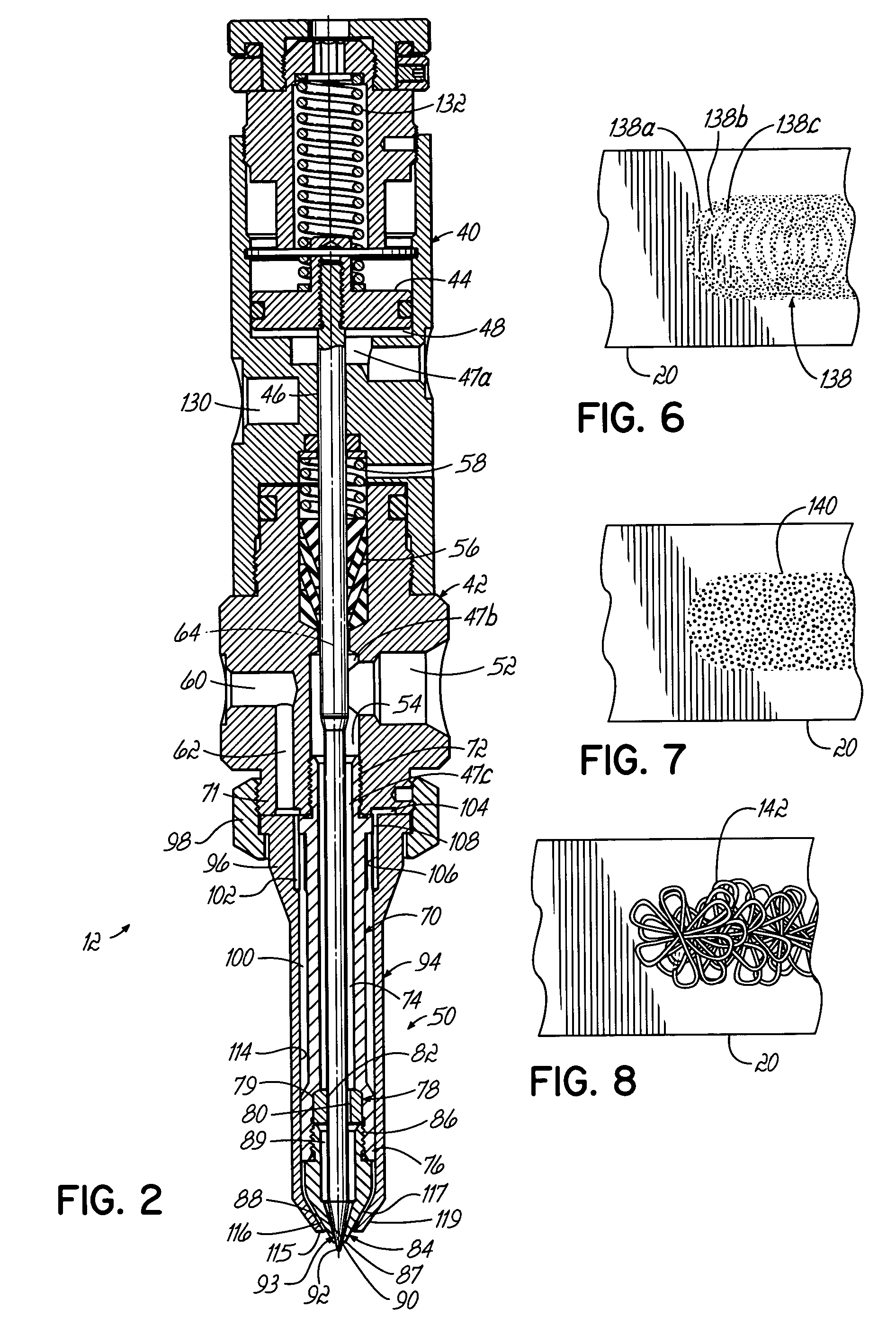

Conformal coating applicator and method

ActiveUS7028867B2Easy to handleSimplify disassemblyMovable spraying apparatusLiquid flow controllersConformal coatingNeedle guide

An applicator for dispensing a conformal coating material onto a substrate. The applicator has a body with a nozzle having a dispensing orifice at a distal end of the body, and assist air is supplied to a location adjacent the dispensing orifice. A seat is disposed in the nozzle around the dispensing orifice, and an end of a needle is movable into contact with and through the seat to terminate a flow of the coating material through the dispensing orifice and eliminate any coating material flow path downstream of the seat. A needle guide is used to laterally support the needle above the nozzle. The distal end of a nozzle is the distal end of the applicator and is exposed for cleaning.

Owner:NORDSON CORP +1

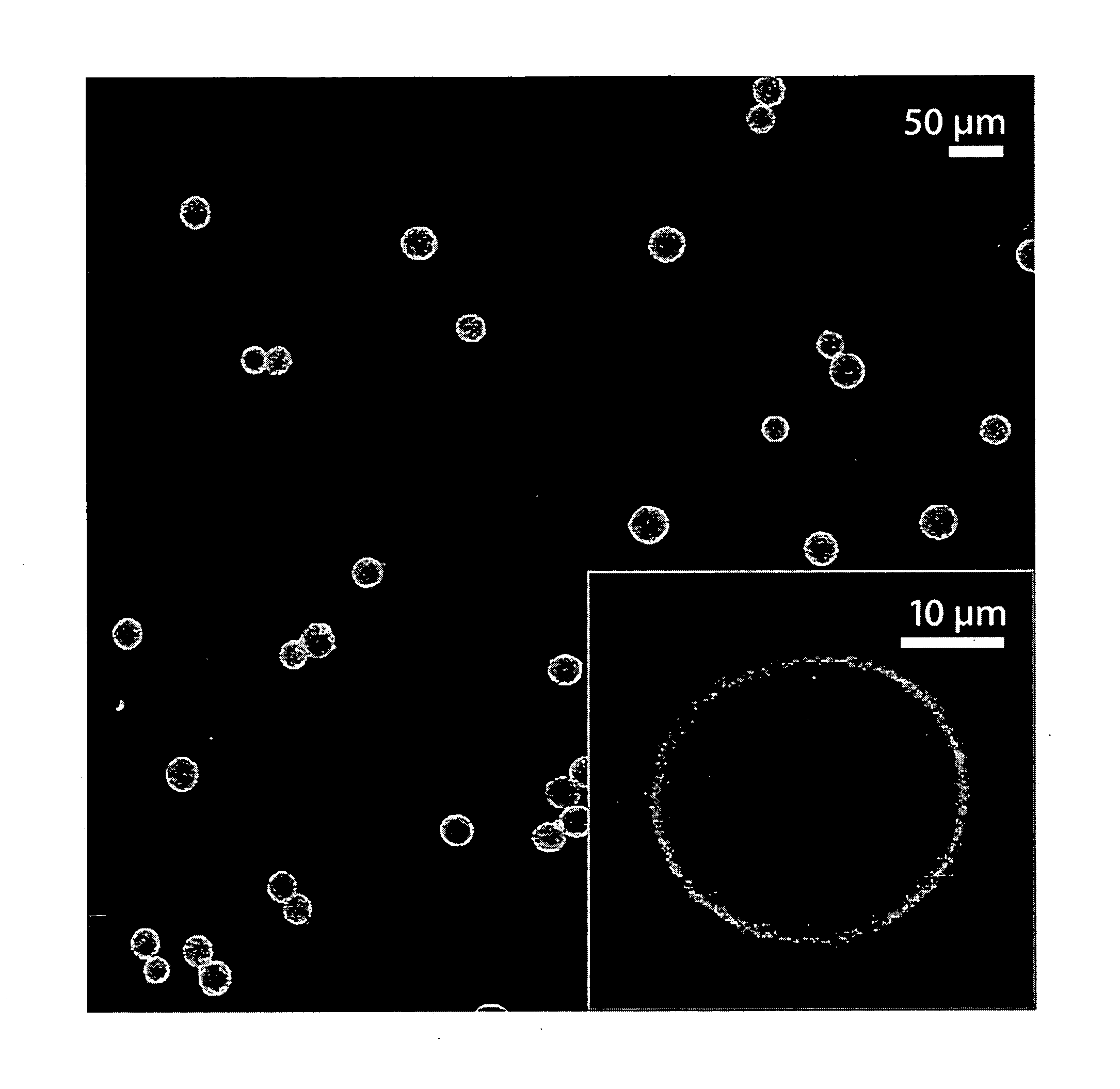

Initiated chemical vapor deposition of vinyl polymers for the encapsulation of particles

ActiveUS20070104860A1Quality improvementClear processPretreated surfacesChemical vapor deposition coatingGas phaseConformal coating

One aspect of the present invention relates to an all-dry encapsulation method that enables well-defined polymers to be applied around particles of sizes down to the nanoscale. In certain embodiments, the methods are modified forms of initiated chemical vapor deposition (iCVD) using a thermally-initiated radical polymerization to create conformal coatings around individual particles while avoiding agglomeration. The present invention also enables the coating of particle surfaces with a range of functional groups via direct incorporation of the functionality into the monomers used or indirectly through a subsequent modification of the surface of a coated particle. In certain embodiments, the method produces high quality functional polymer coatings.

Owner:MASSACHUSETTS INST OF TECH

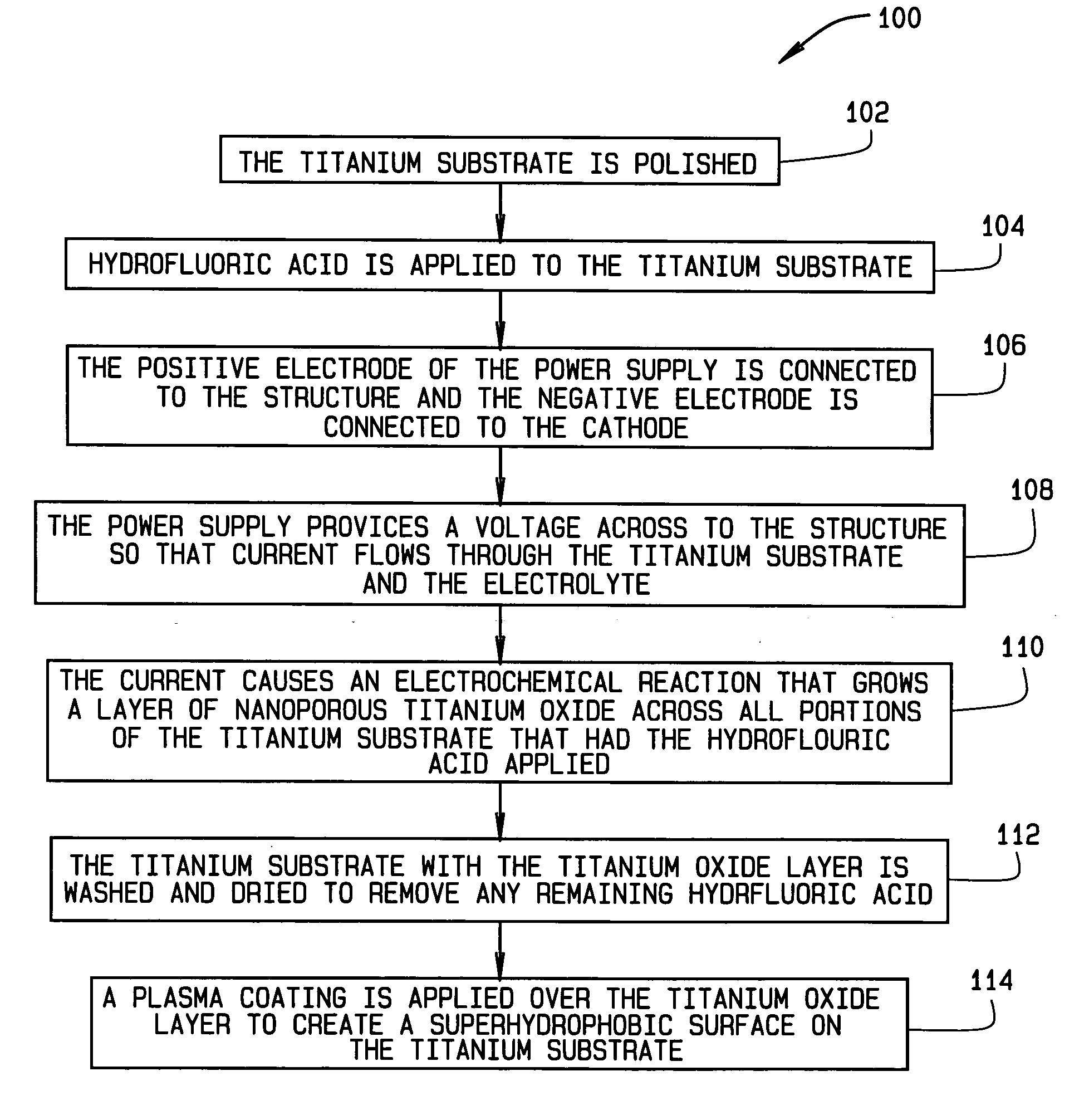

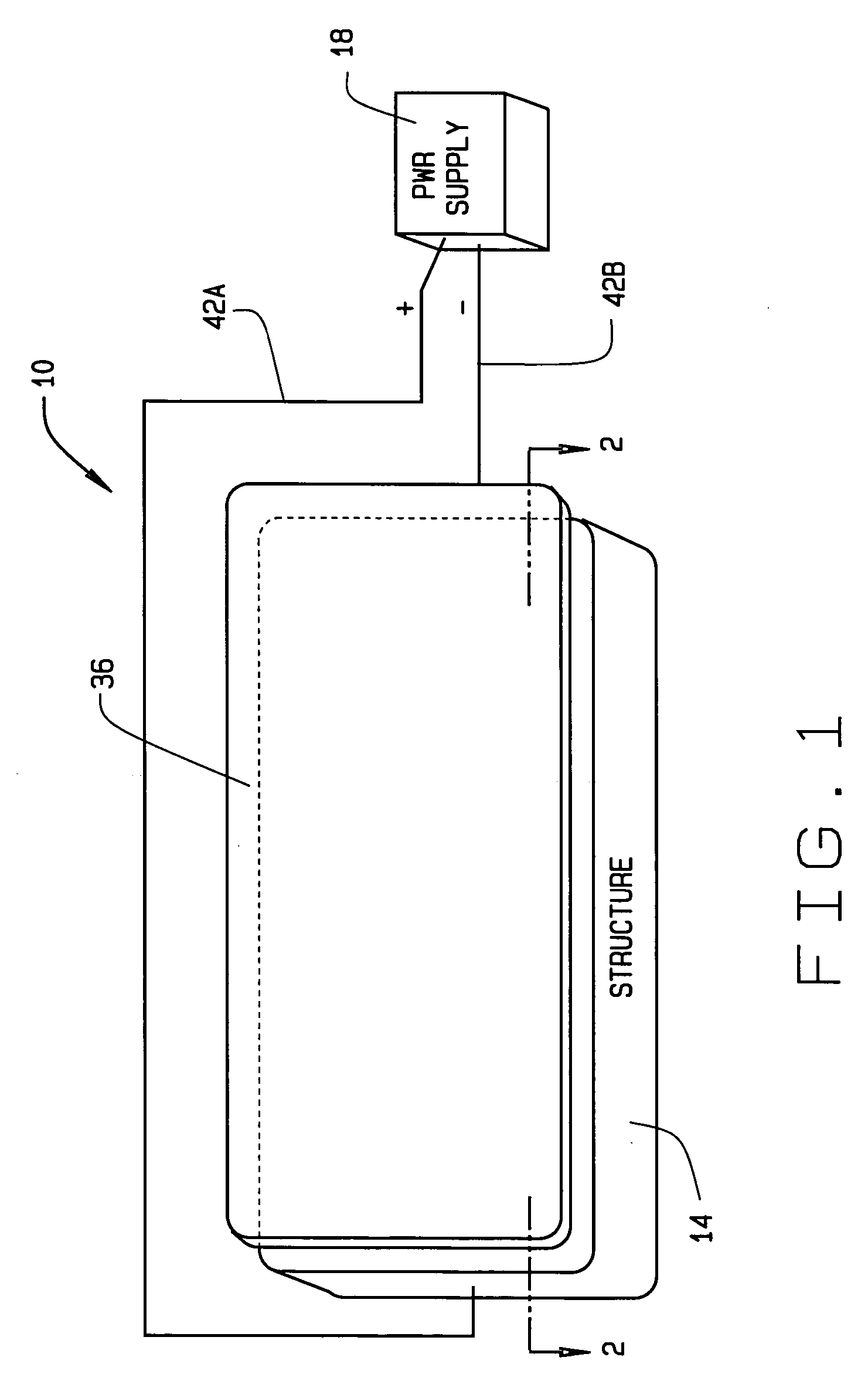

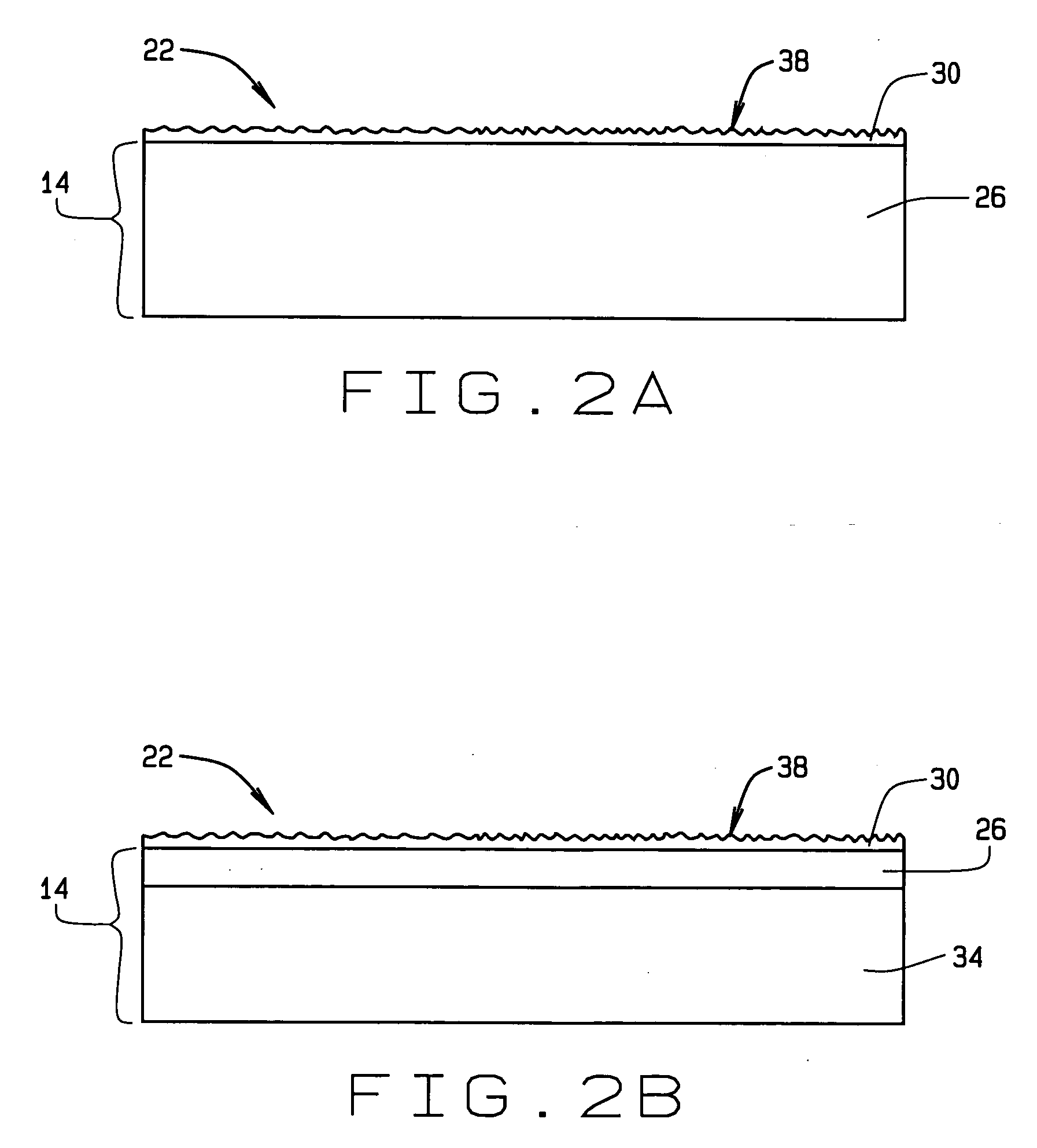

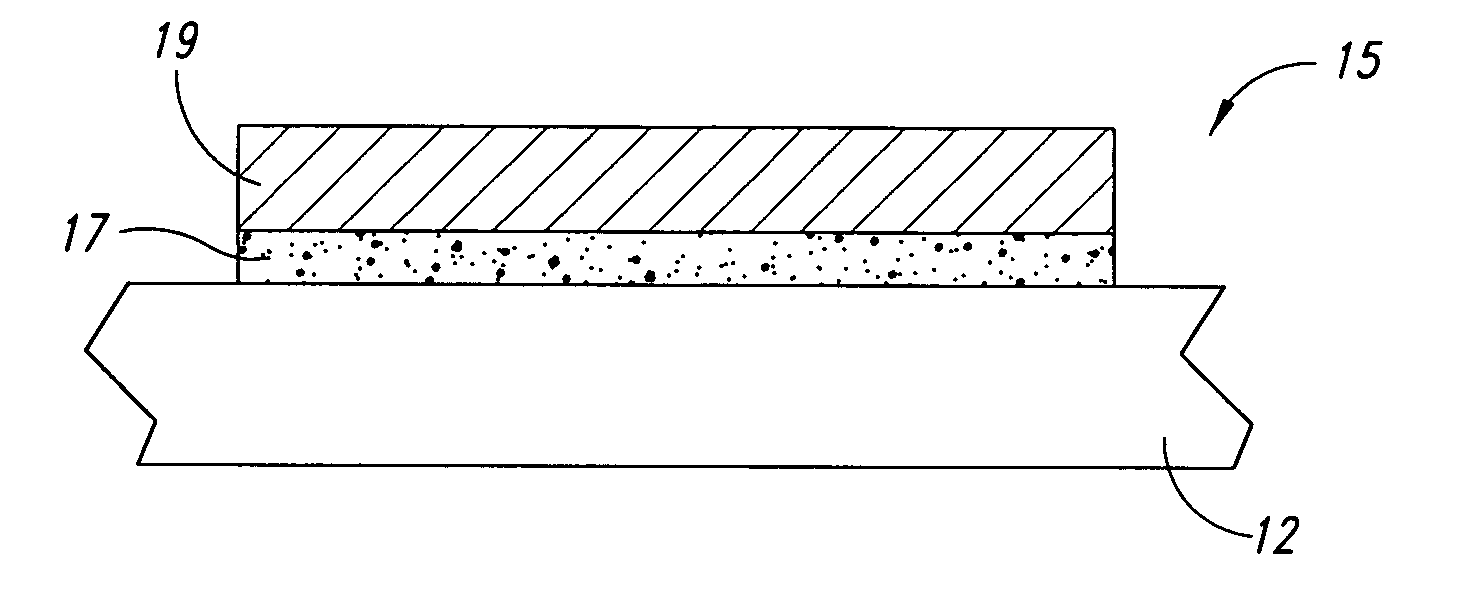

Self-cleaning superhydrophobic surface

ActiveUS20060147634A1Material nanotechnologyNanoinformaticsPhotocatalytic reactionUltraviolet lights

A method for providing a superhydrophobic surface on a structure, for example aircraft wings, propellers and / or rotors, is set forth. The method includes applying a coating of hydrofluoric acid over a titanium substrate. A voltage is then applied across the titanium substrate so that current flows through the titanium substrate. The current flowing through the titanium substrate causes the hydrofluoric acid to react with the titanium substrate to anodize the titanium substrate. The anodization causes a nanoporous titanium oxide layer to grow across the titanium substrate. The titanium oxide layer includes a plurality of nano-tube structures that, once the remaining hydrofluoric acid is washed away, provide a microscopically rough surface on the titanium substrate. A conformal coating of a hydrophobic compound is then desposited on the microscopically rough surface to create a superhydrophobic surface. Thus, a substantially self-cleaning superhydrophobic surface is created on the titanium substrate, whereby, when exposed to ultraviolet light, the titanium oxide layer has a photocatalytic reaction with oxygen to oxidize any organic contaminants that may gather on the superhydrophobic surface.

Owner:THE BOEING CO

Coated particles and sunscreen and cosmetic products containing same

InactiveUS20070280895A1Increasing bed volumeEqually distributedCosmetic preparationsToilet preparationsMetallic materialsConformal coating

Particles have an ultrathin, conformal coating are made using atomic layer deposition methods. The base particles include ceramic and metallic materials. The coatings can also be ceramic or metal materials that can be deposited in a binary reaction sequence. The coated particles are useful as fillers for electronic packaging applications, for making ceramic or cermet parts, as supported catalysts, as well as other applications.

Owner:WEIMER ALAN W +1

Printable electric circuits, electronic components and method of forming the same

InactiveUS7902639B2Easy to controlMaterial nanotechnologyNanoinformaticsLiquid-crystal displayNanoparticle

Improved methods and articles providing conformal coatings for a variety of devices including electronic, semiconductor, and liquid crystal display devices. Peptide formulations which bind to nanoparticles and substrates, including substrates with trenches and vias, to provide conformal coverage as a seed layer. The seed layer can be further enhanced with use of metallic films deposited on the seed layer. Seed layers can be characterized by AFM measurements and improved seed layers provide for better enhancement layers including lower resistivity in the enhancement layer. Peptides can be identified by phage display.

Owner:SILURIA TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com