Patents

Literature

559results about "Screening gaskets/seals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

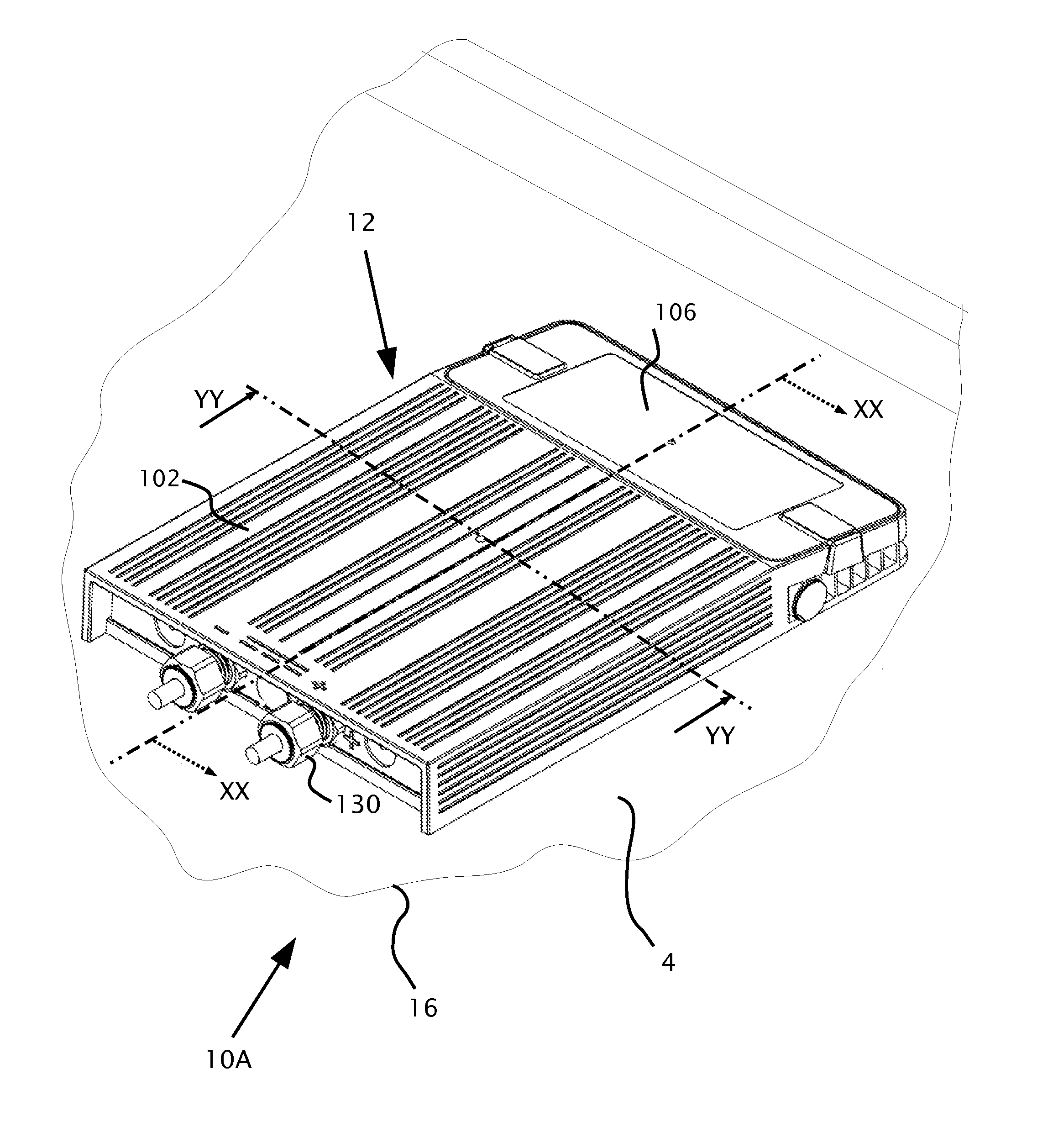

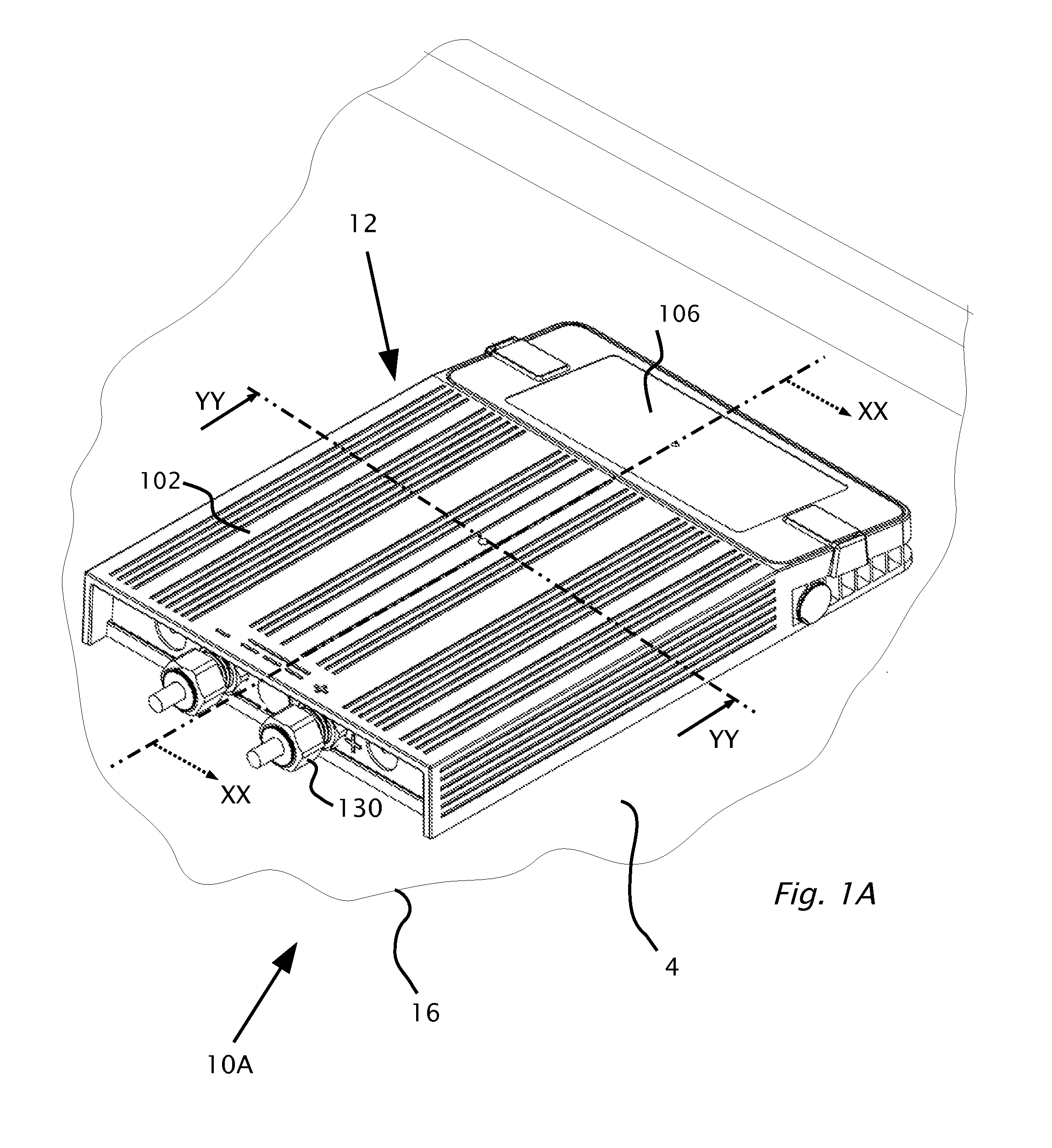

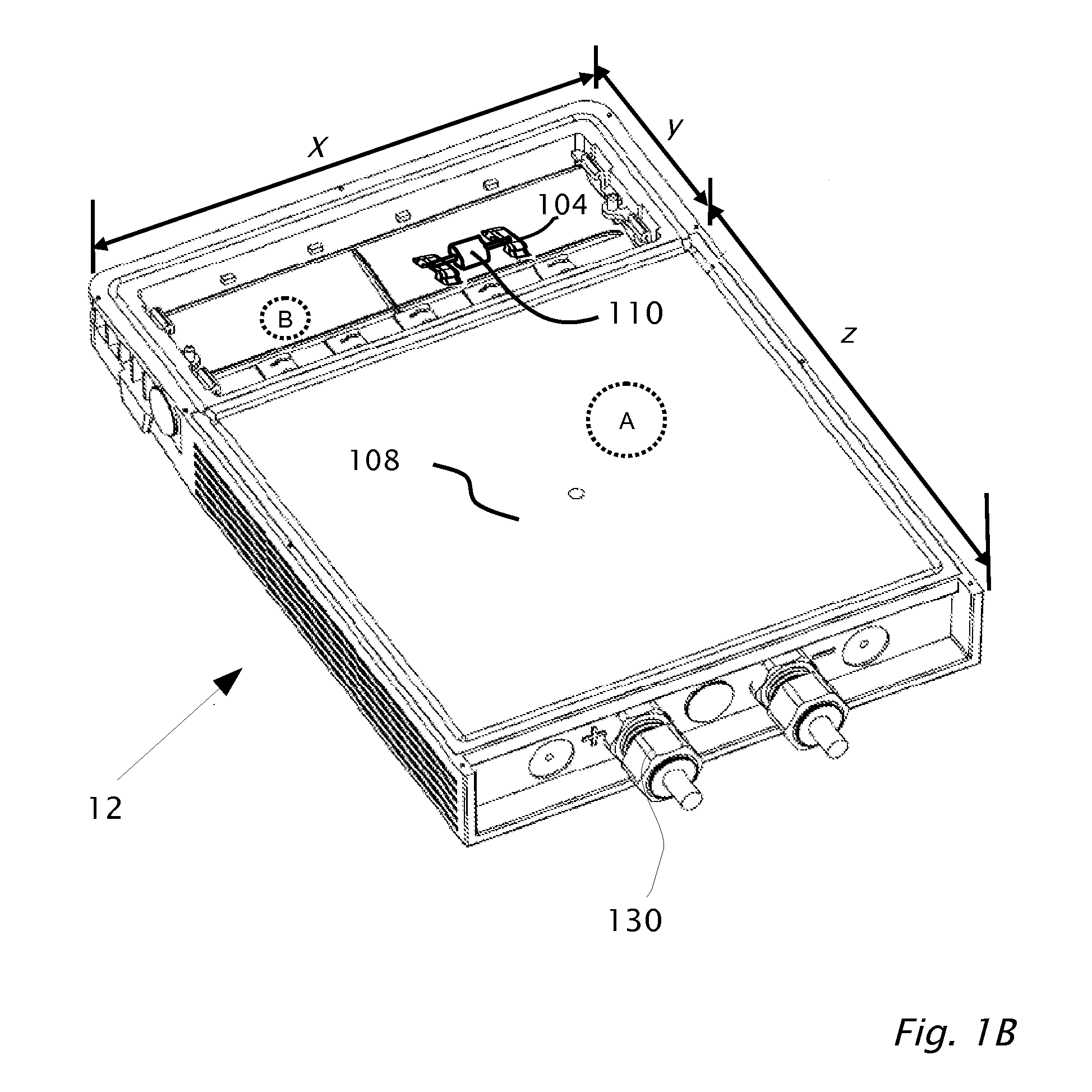

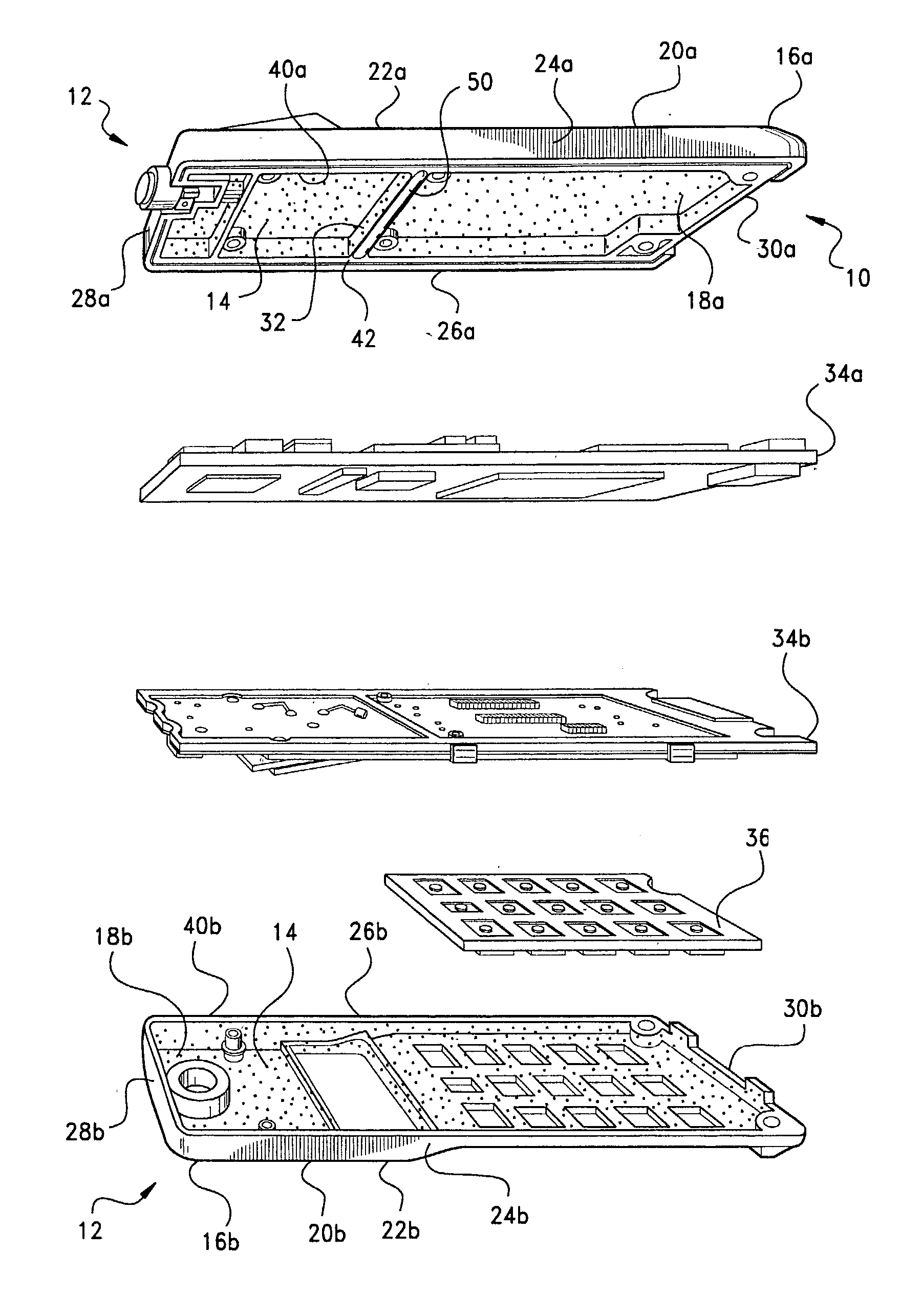

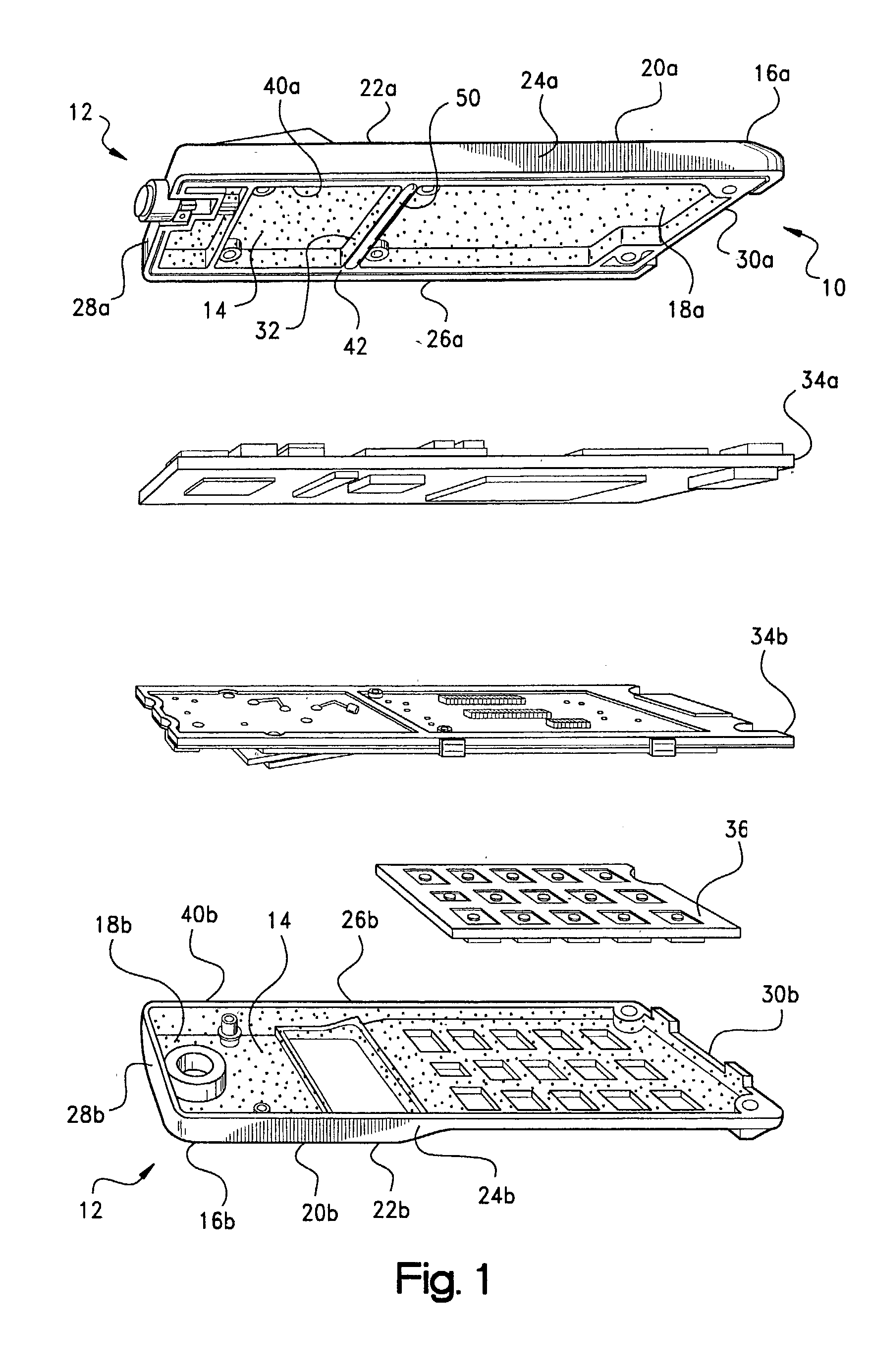

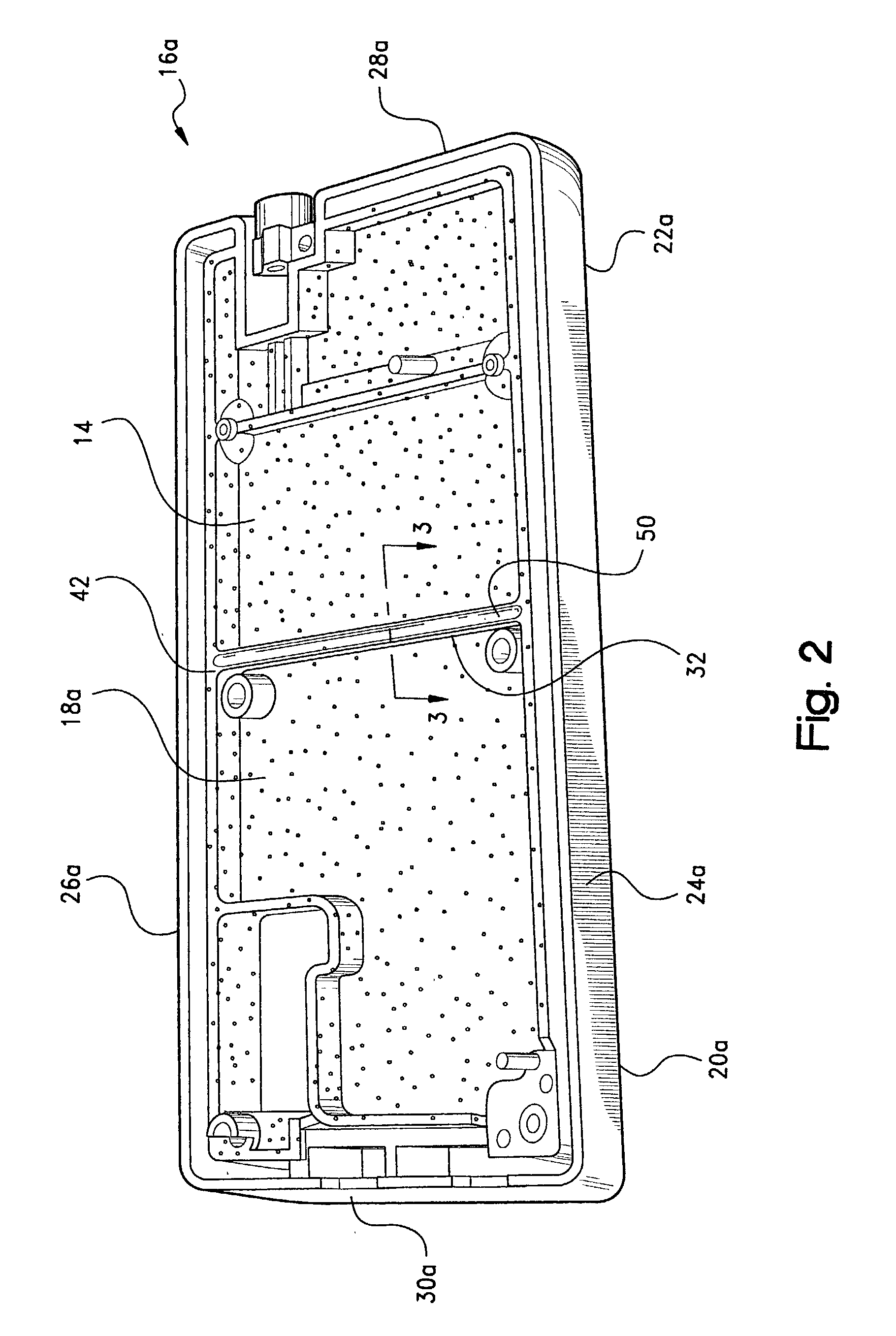

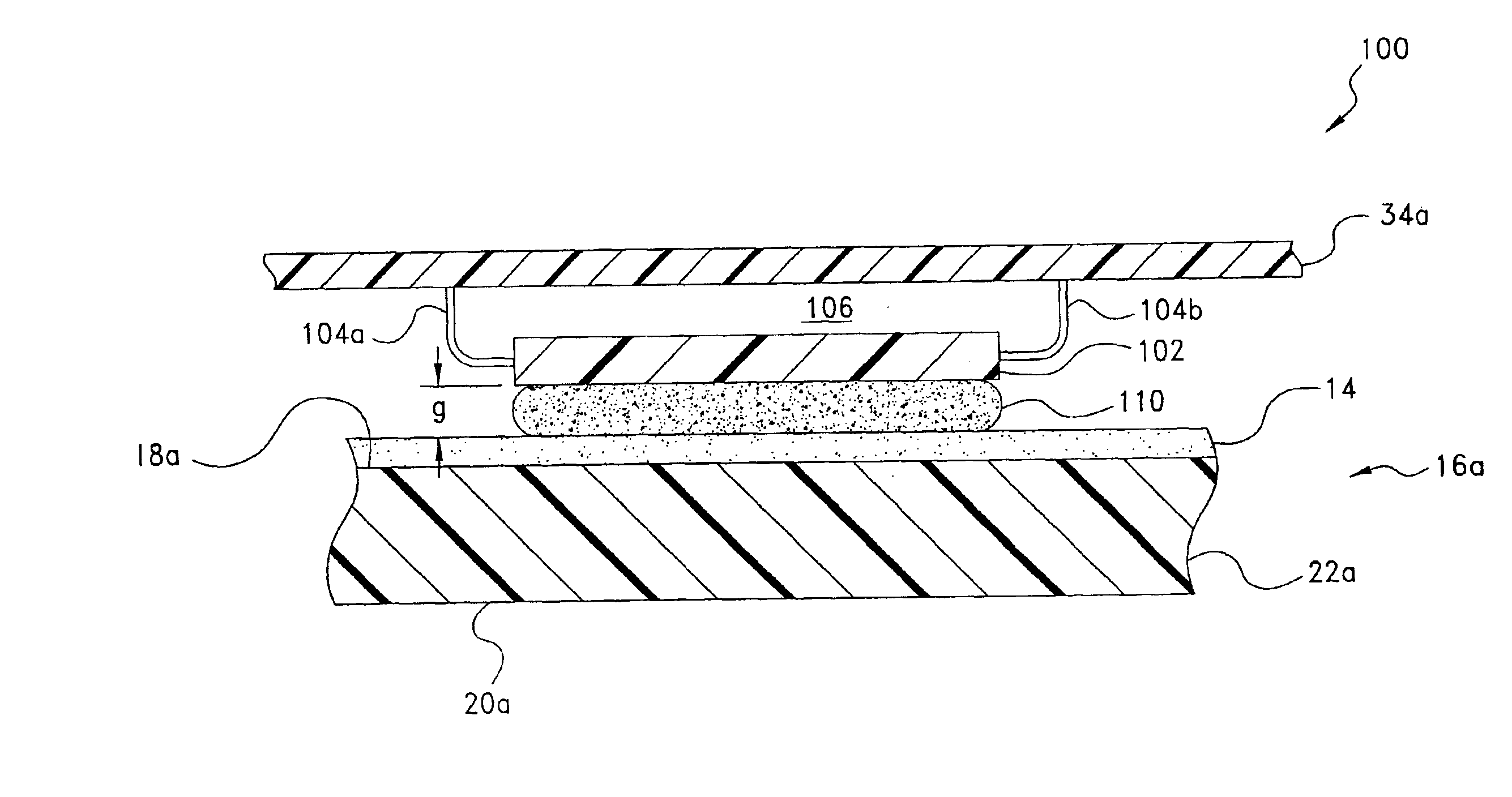

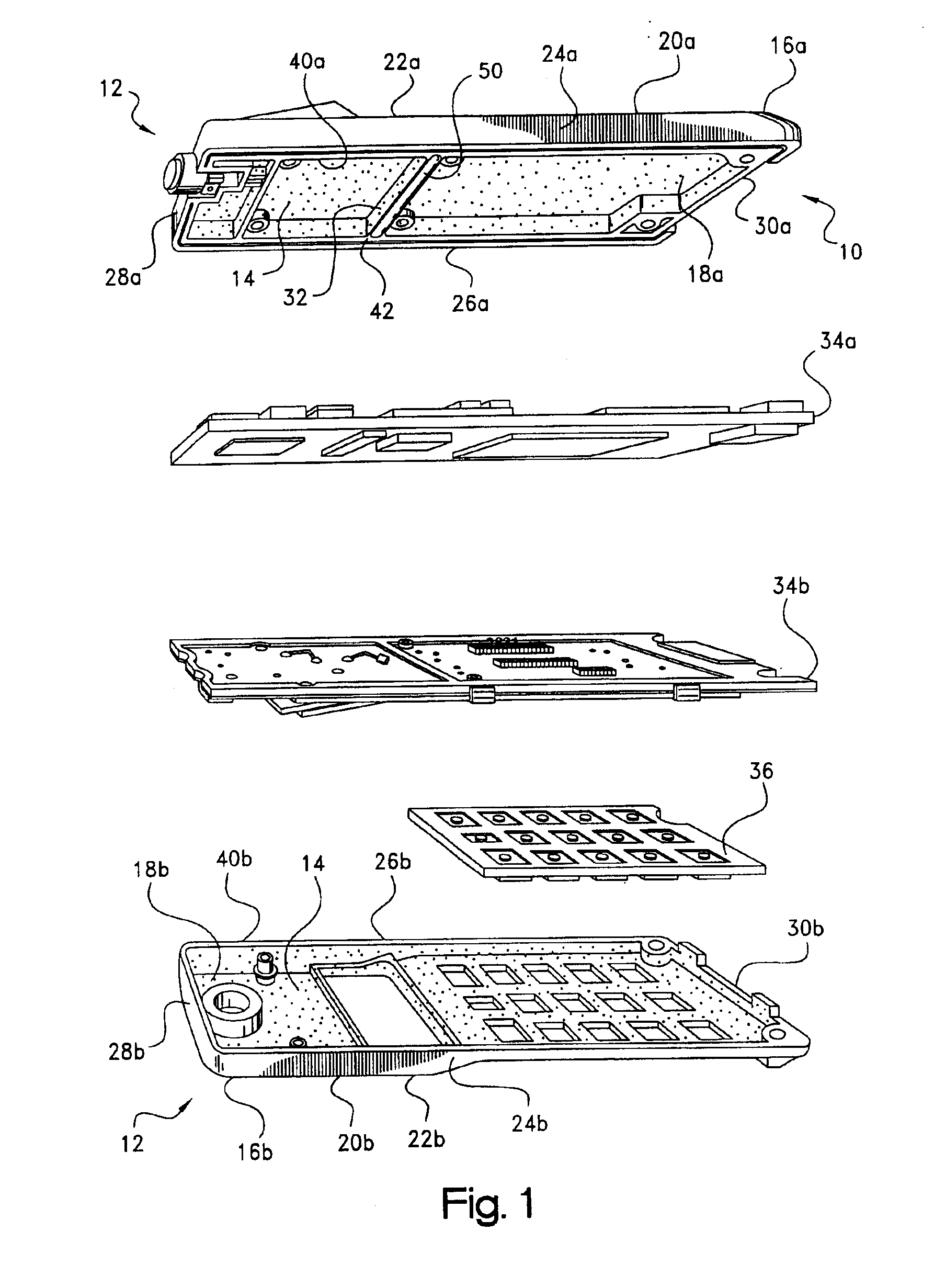

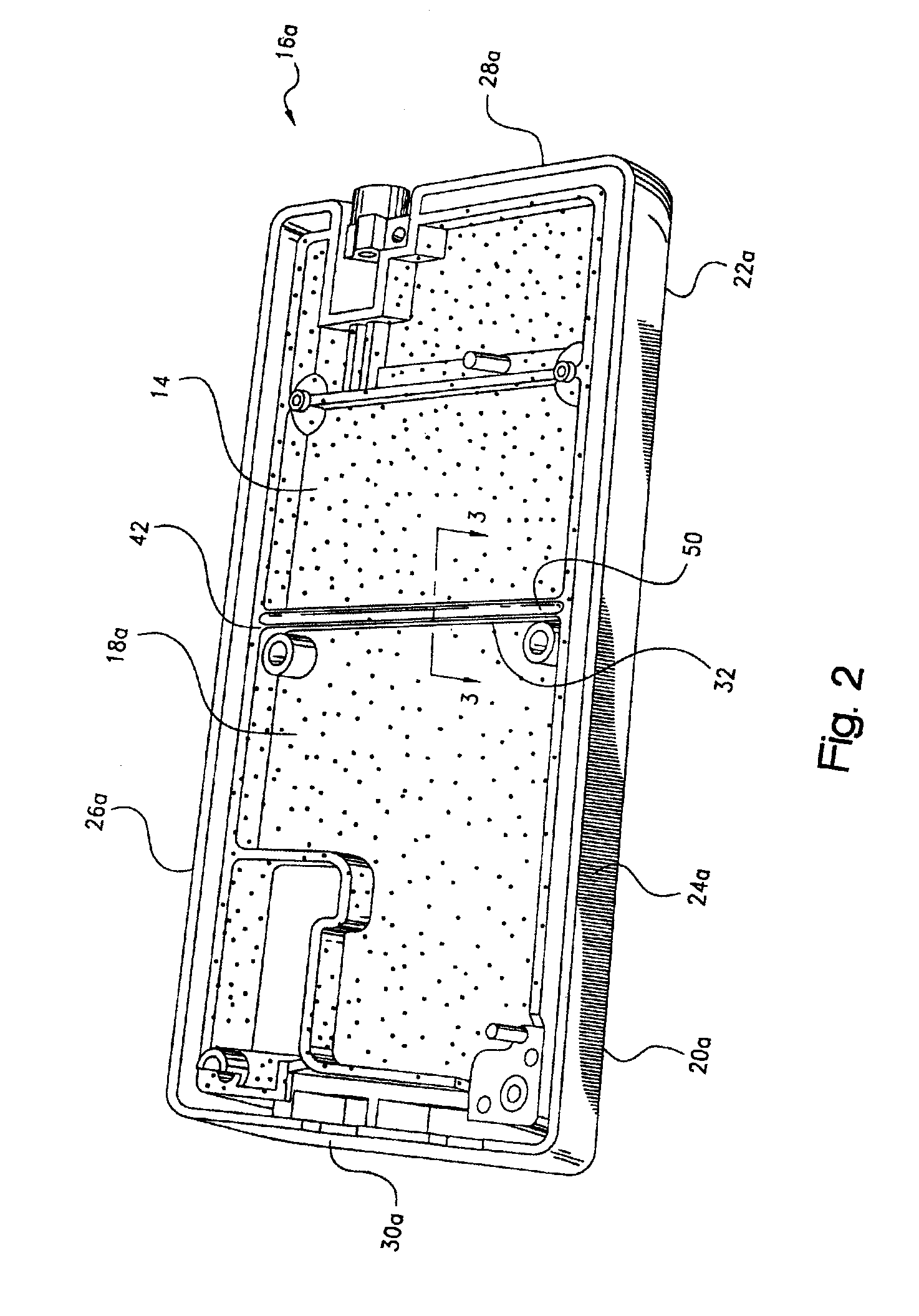

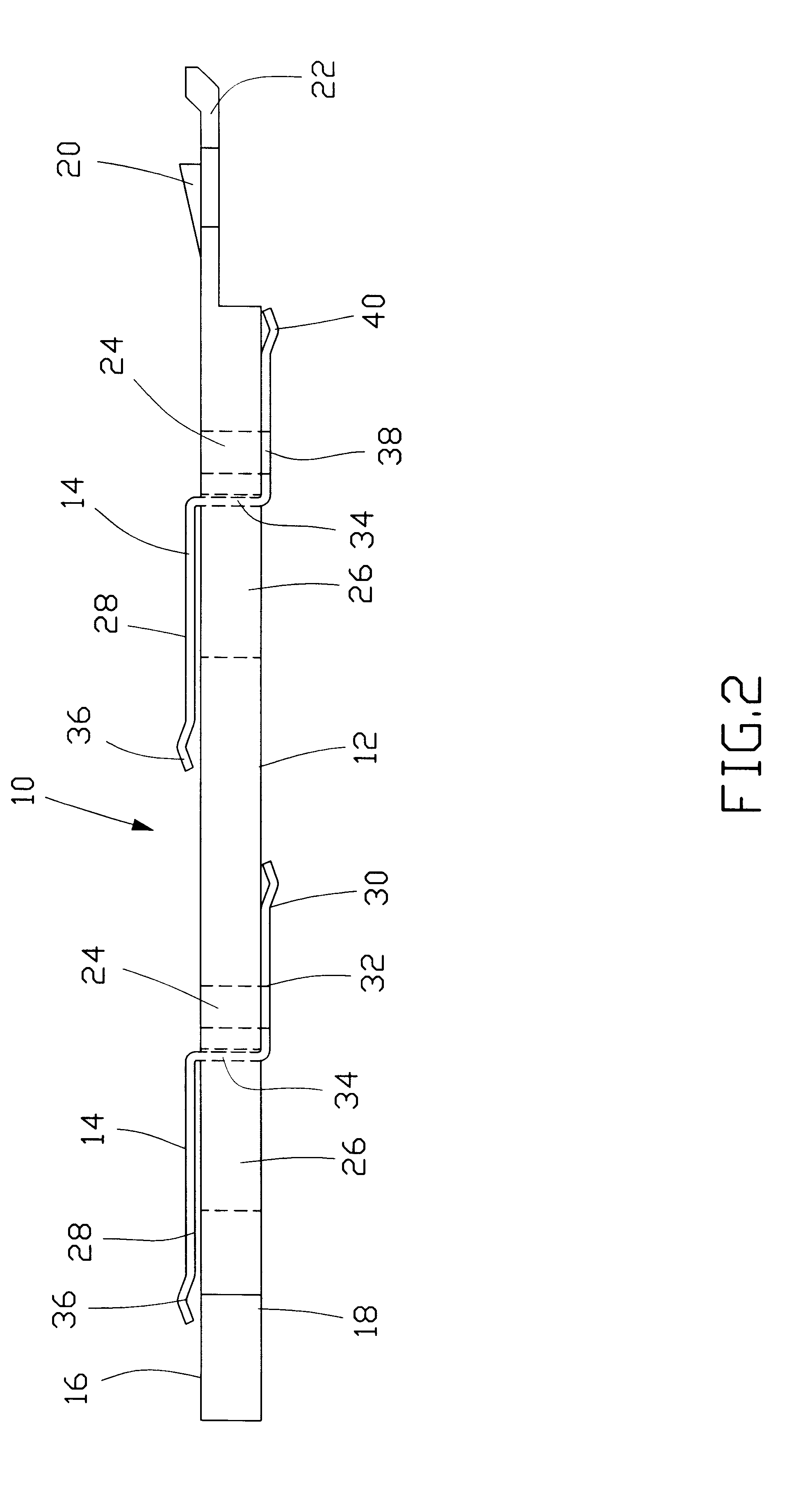

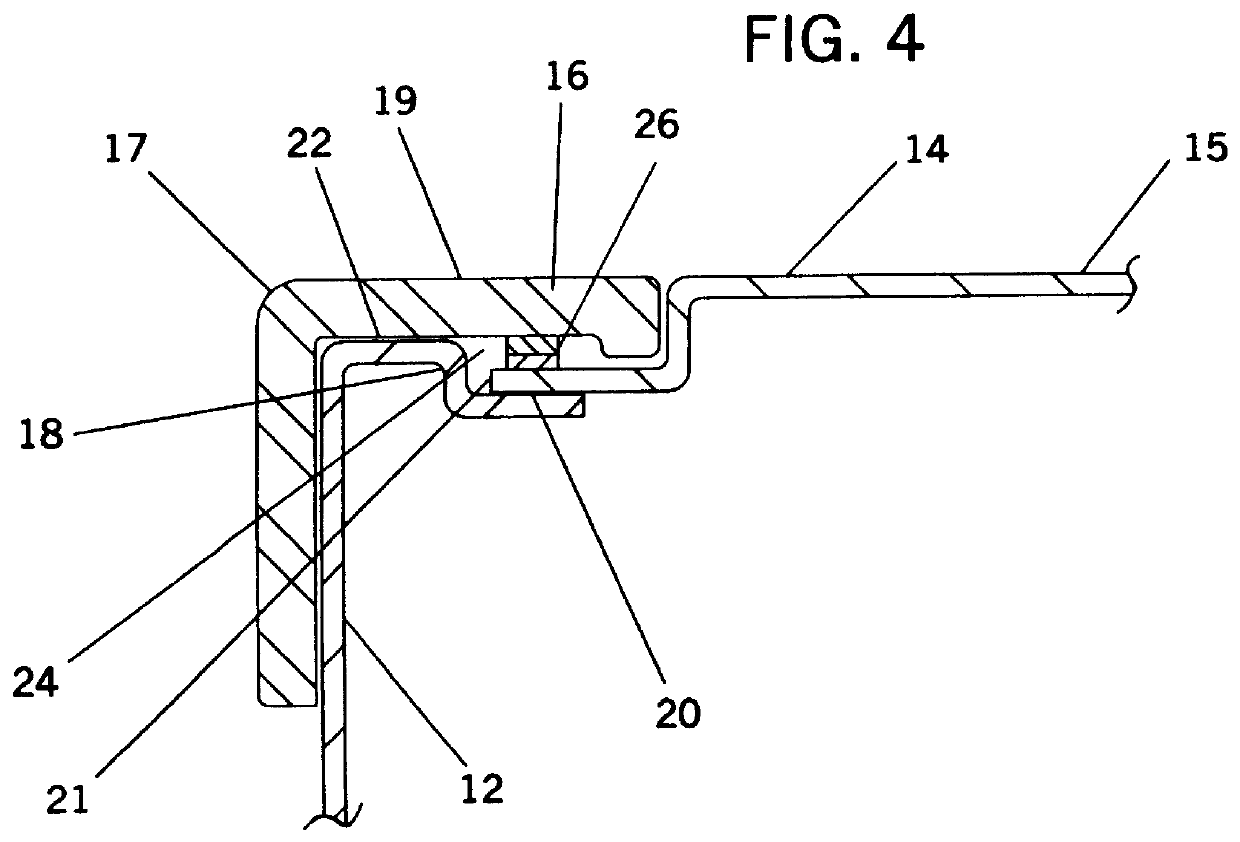

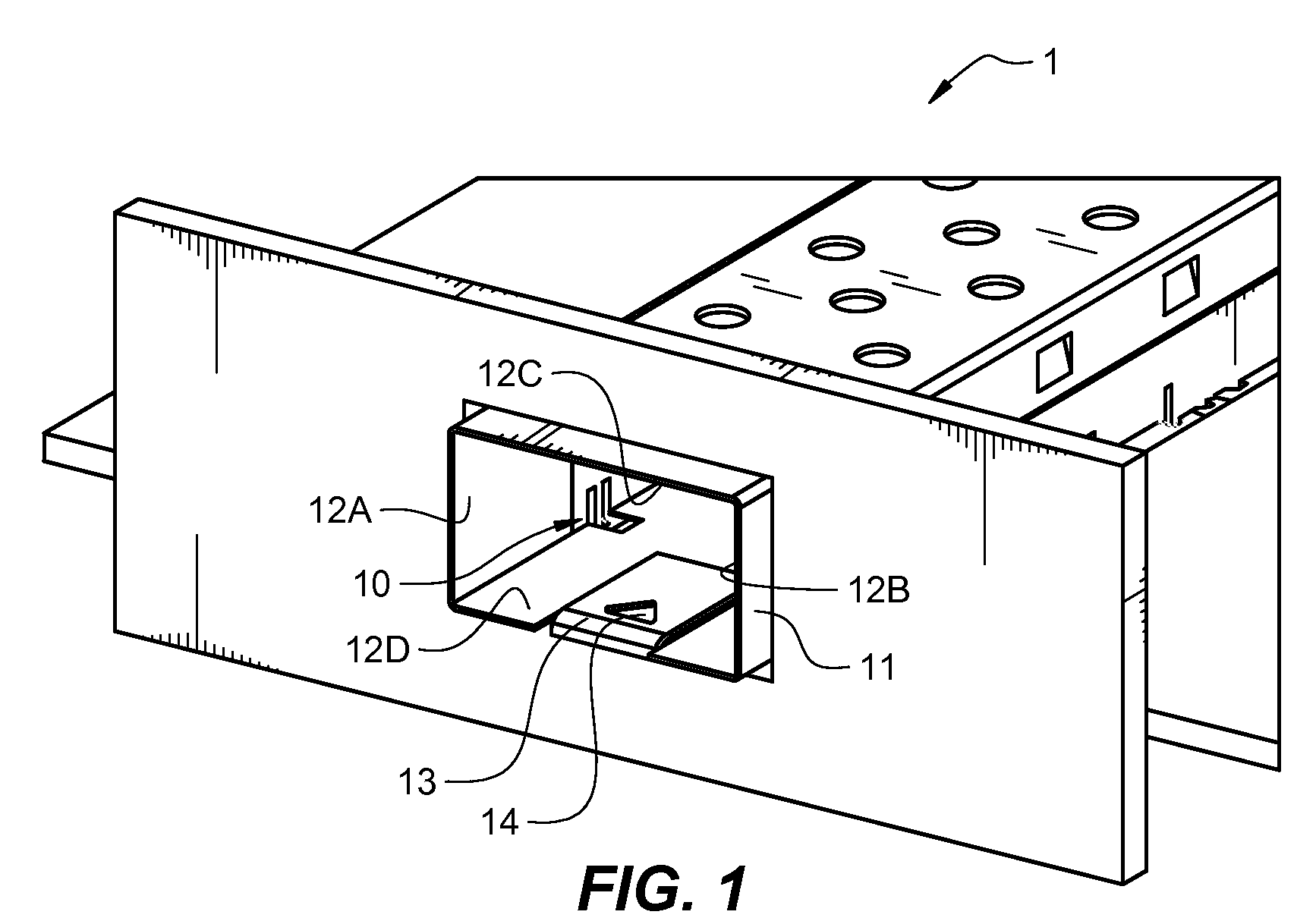

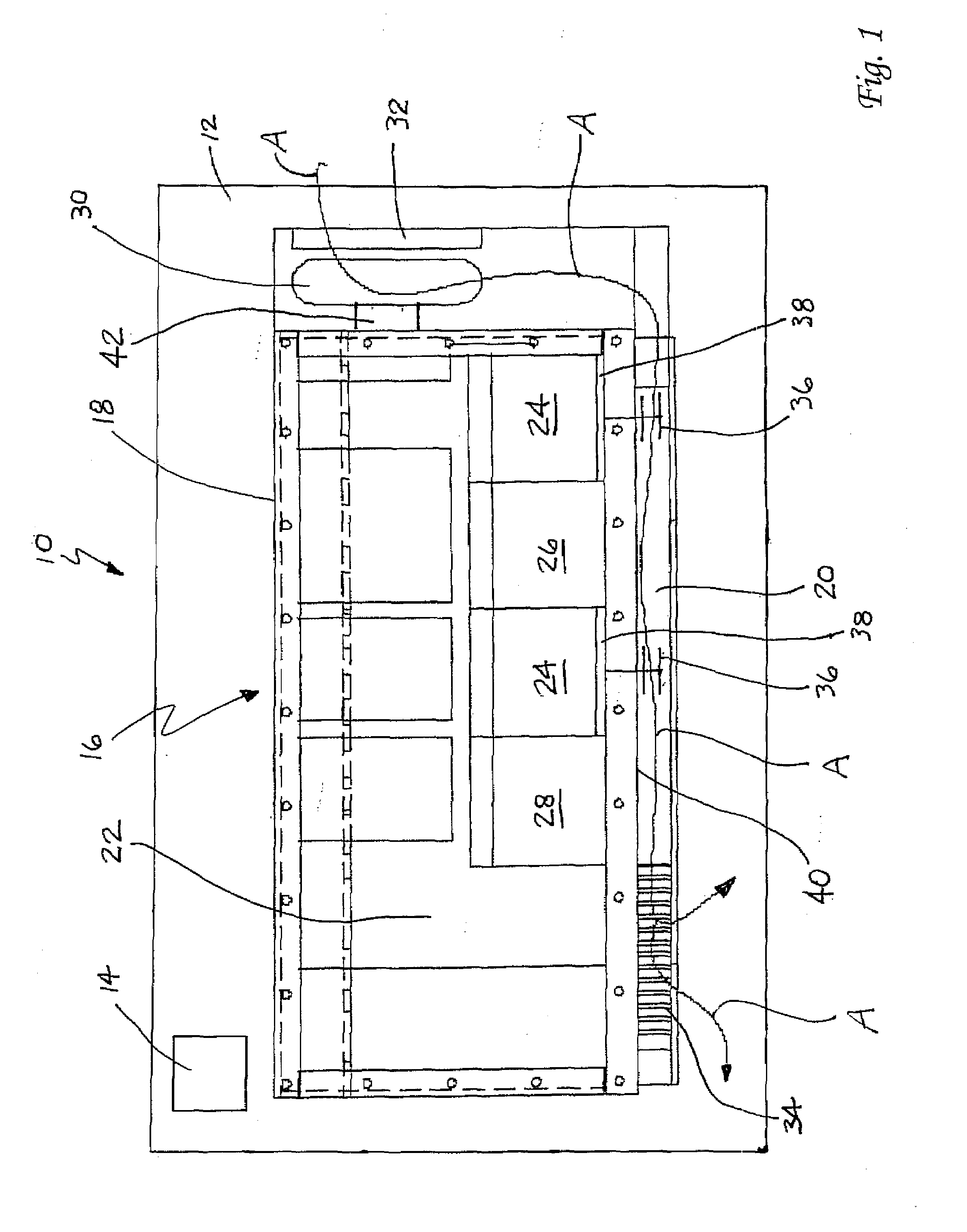

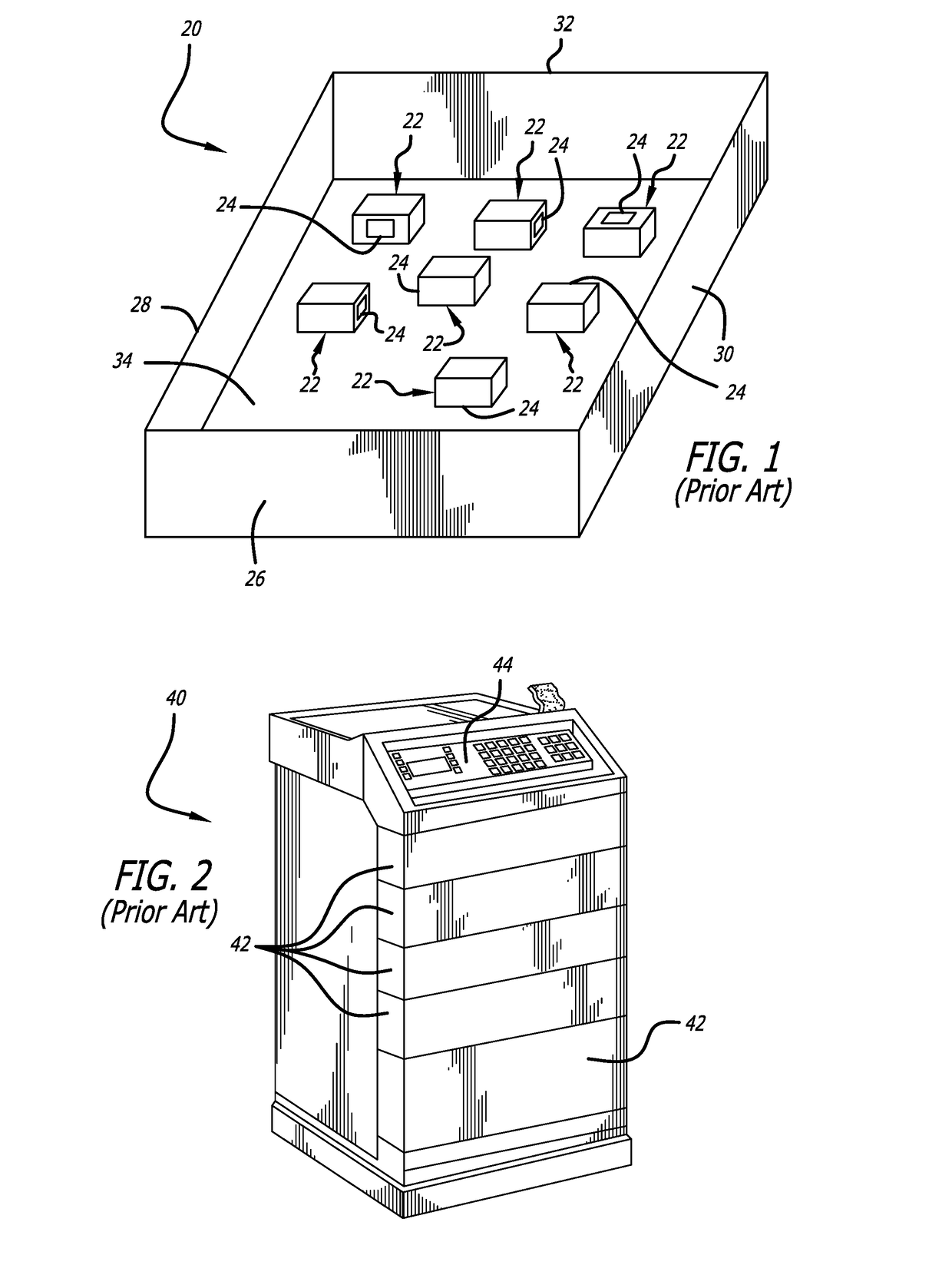

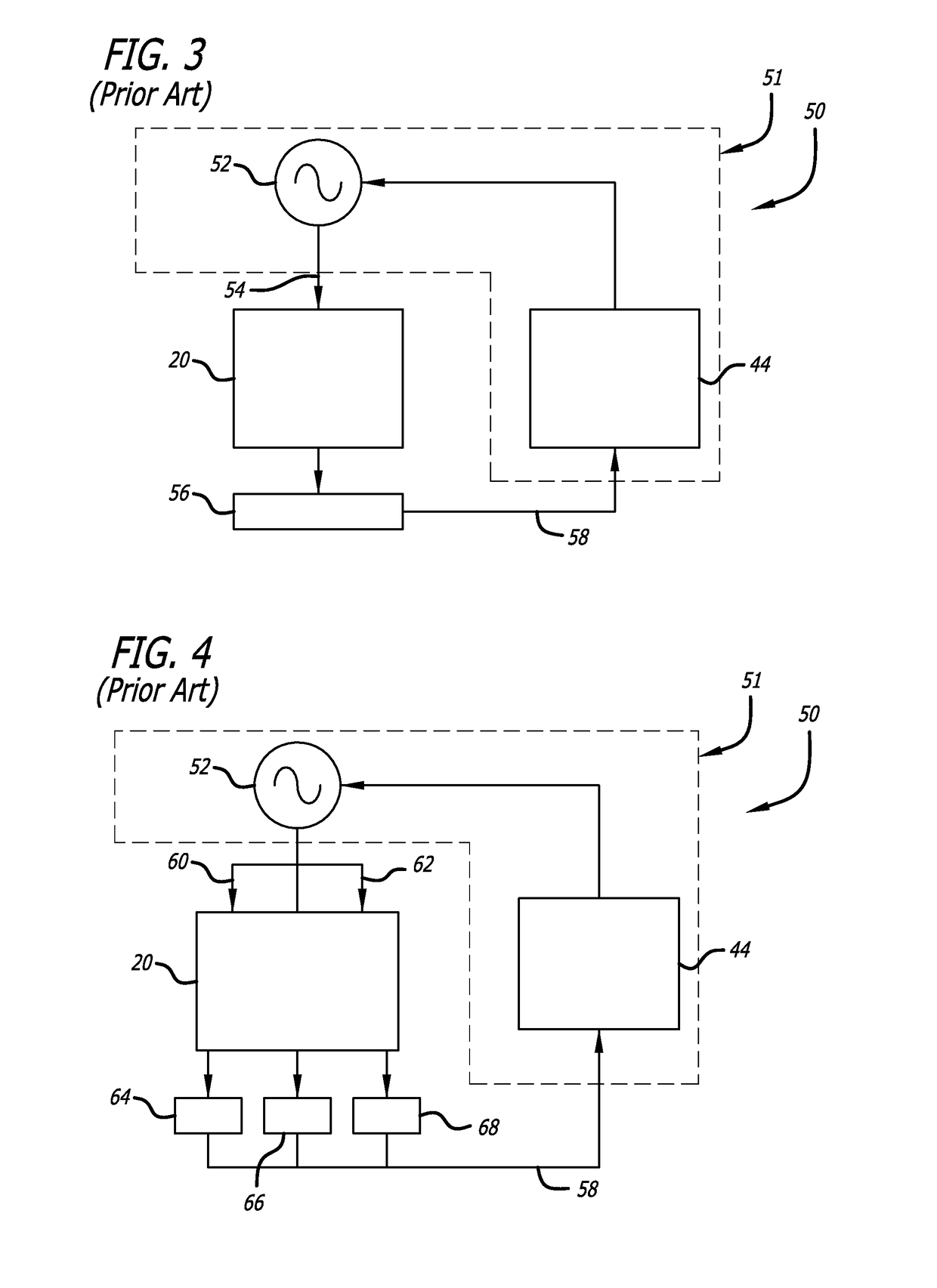

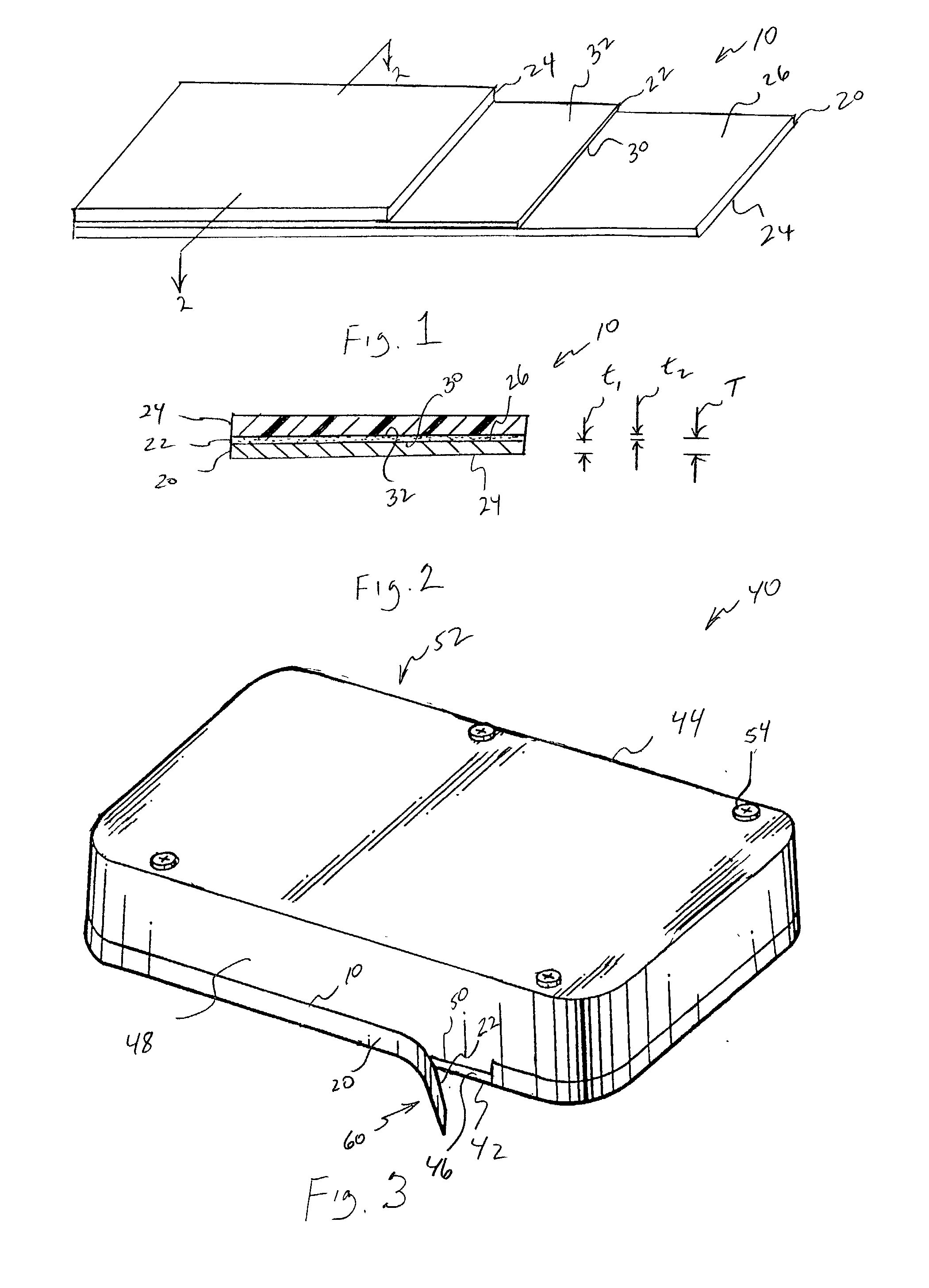

Electrically isolated heat dissipating junction box

ActiveUS20100294528A1Heat dissipationPrevent mutual separationMachine supportsScreening gaskets/sealsElectricityElectrical connection

A junction box used for making electrical connections to a photovoltaic panel. The junction box has two chambers including a first chamber and a second chamber and a wall common to and separating both chambers. The wall may be adapted to have an electrical connection therethrough. The two lids are adapted to seal respectively the two chambers. The two lids are on opposite sides of the junction box relative to the photovoltaic panel. The two lids may be attachable using different sealing processes to a different level of hermeticity. The first chamber may be adapted to receive a circuit board. The junction box may include supports for mounting a printed circuit board in the first chamber. The second chamber is configured for electrical connection to the photovoltaic panel. A metal heat sink may be bonded inside the first chamber. The first chamber is adapted to receive a circuit board for electrical power conversion, and the metal heat sink is adapted to dissipate heat generated by the circuit board.

Owner:SOLAREDGE TECH LTD

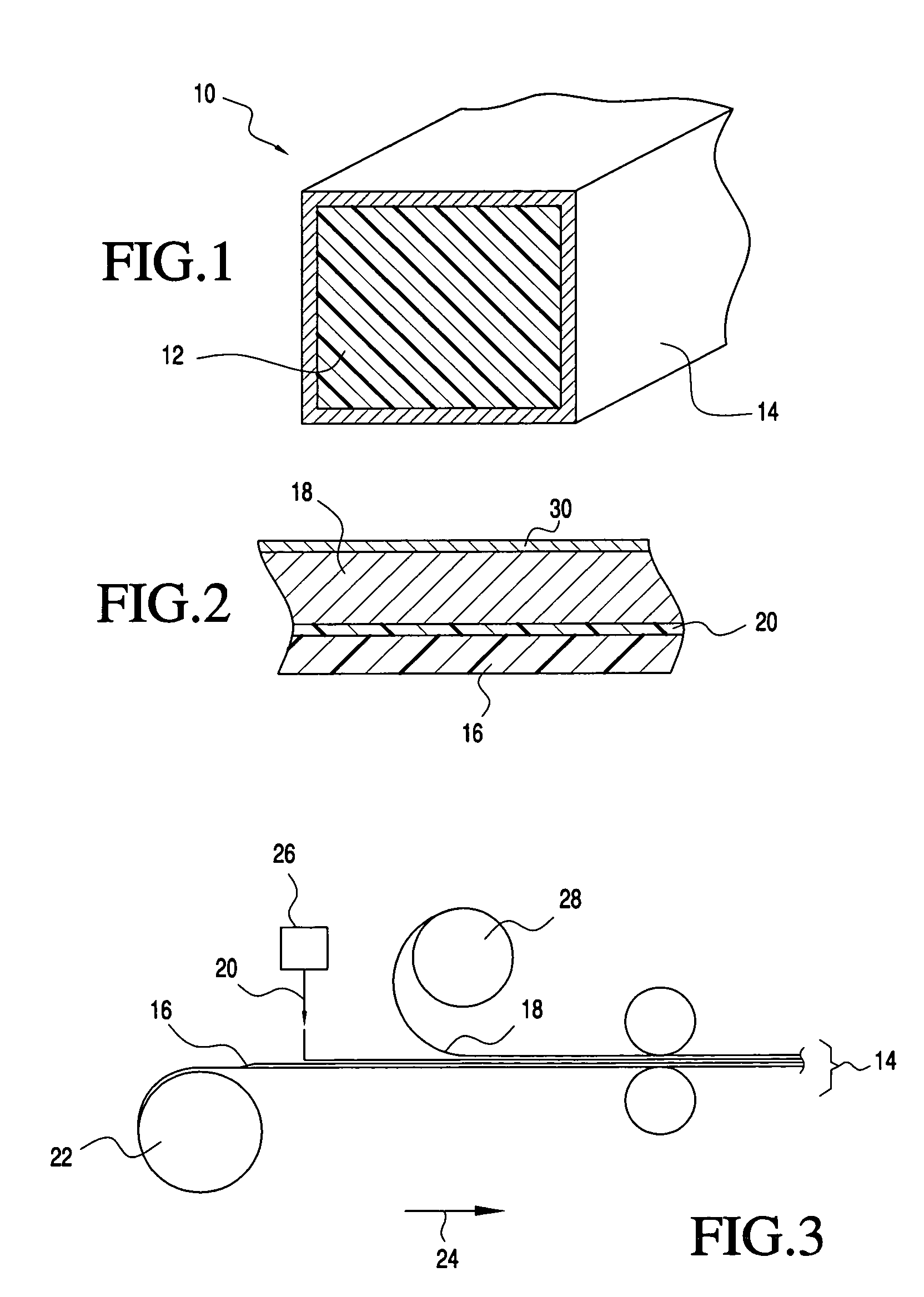

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

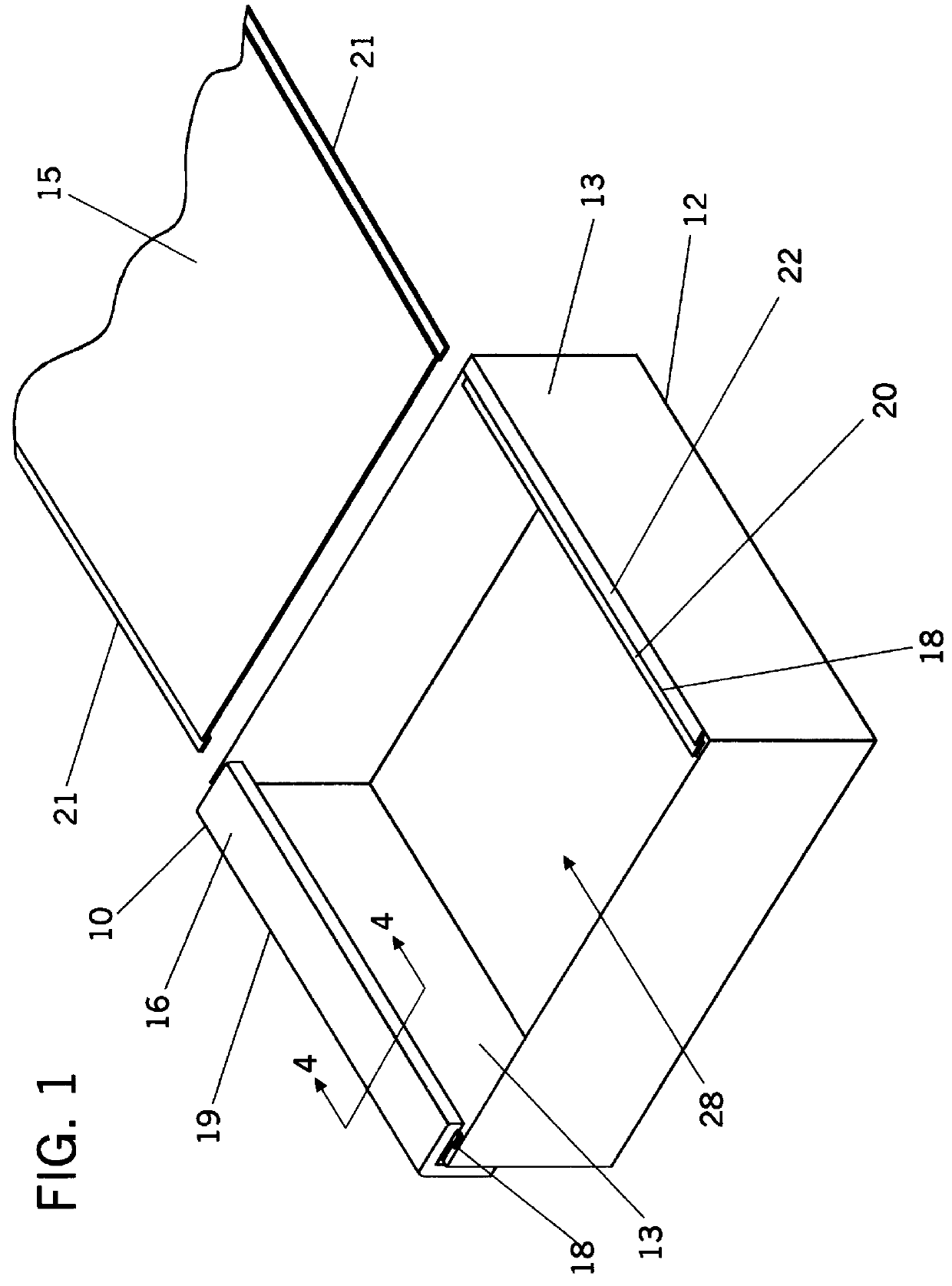

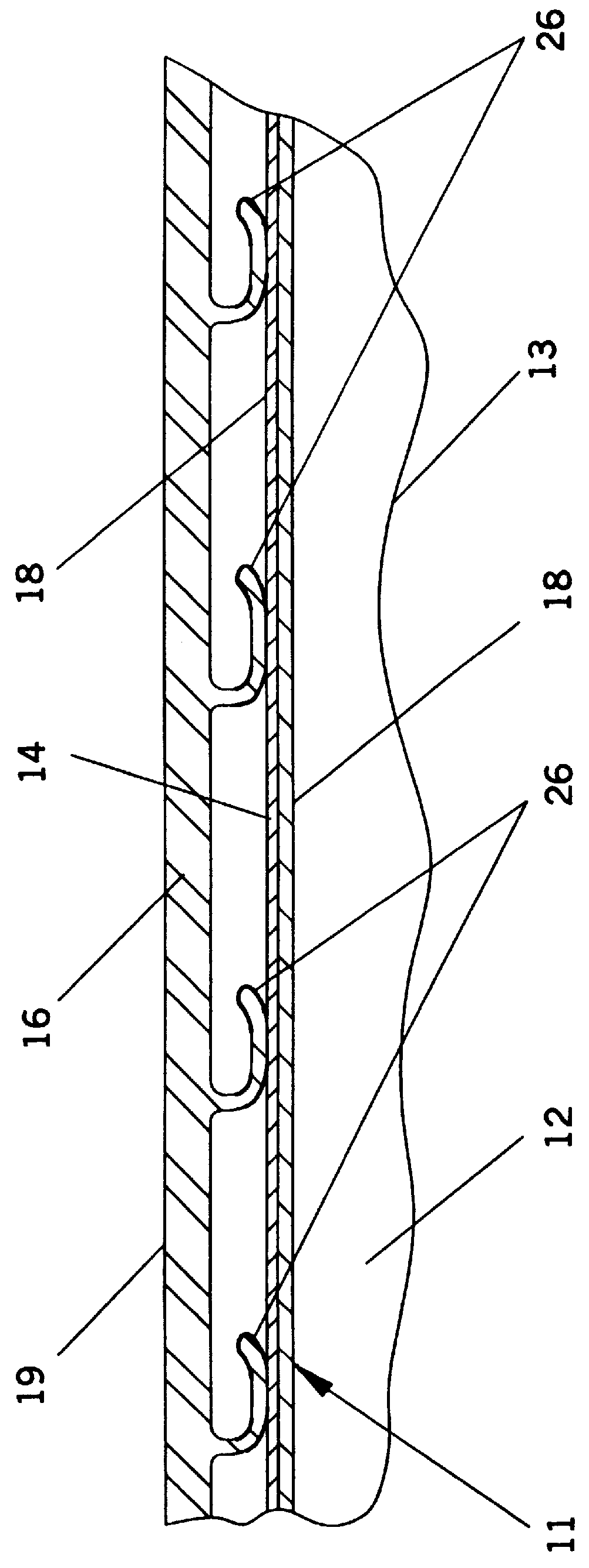

Low closure force EMI shielding spacer gasket

InactiveUS6121545AEnhance the imageEnsure electrical continuityEngine sealsScreening gaskets/sealsEdge surfaceBending moment

An EMI shielding spacer gasket assembly for interposition under a predetermined compressive load within an electronics enclosure between a first surface and an oppositely-disposed second surface of the enclosure. The assembly includes a frame member and an electrically conductive, elastomeric member extending along at least a portion of the perimeter of the frame member as retained on a corresponding peripheral edge surface thereof. The elastomeric member has an outboard side which is compressible axially under the compressive load for providing an electrically conductive pathway between the surfaces of the enclosure. In an uncompressed orientation, the outboard side of the elastomeric member exhibits elongate upper and lower bearing portions which are disposed at a spaced-apart radial distance from the frame member to define a corresponding bending moment arm. Each of the bearing portions is angularly deflectable relative to the moment arm to effect the compression of the elastomeric member under a relatively low compressive load.

Owner:PARKER INTANGIBLES LLC

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS20030066672A1Eliminate needHeat dissipationMolten spray coatingScreening gaskets/sealsMolten stateThermal spraying

Heat dissipation and electromagnetic interference (EMI) shielding for an electronic device having an enclosure. An interior surface of the enclosure is covered with a conformal metallic layer which, as disposed in thermal adjacency with one or more heat-generating electronic components or other sources contained within the enclosure, may provide both thermal dissipation and EMI shielding for the device. The layer may be sprayed onto the interior surface in a molten state and solidified to form a self-adherent coating.

Owner:PARKER INTANGIBLES LLC

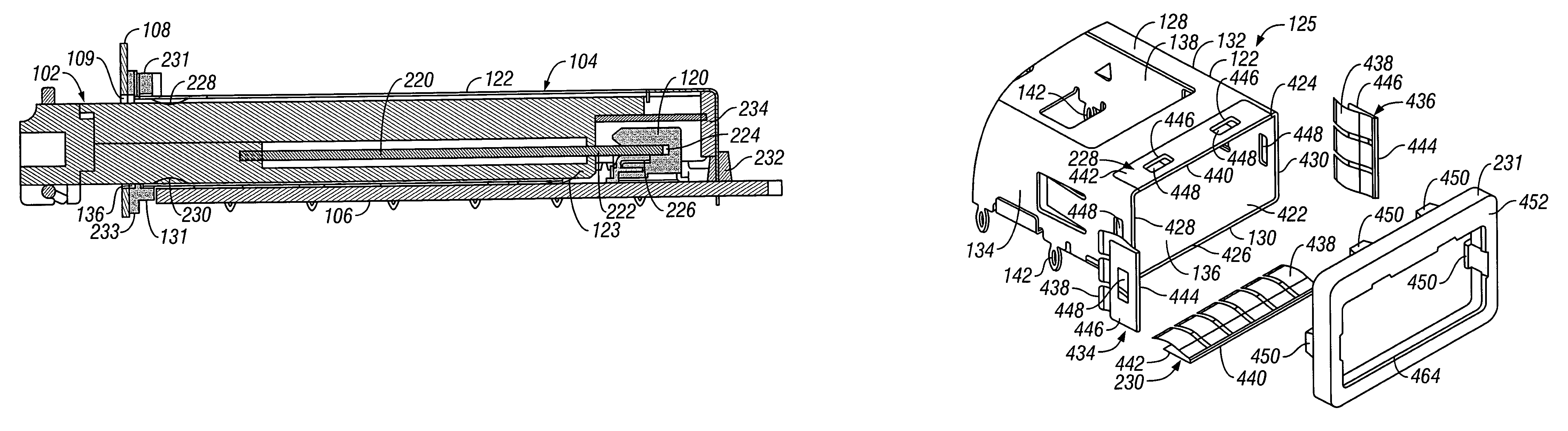

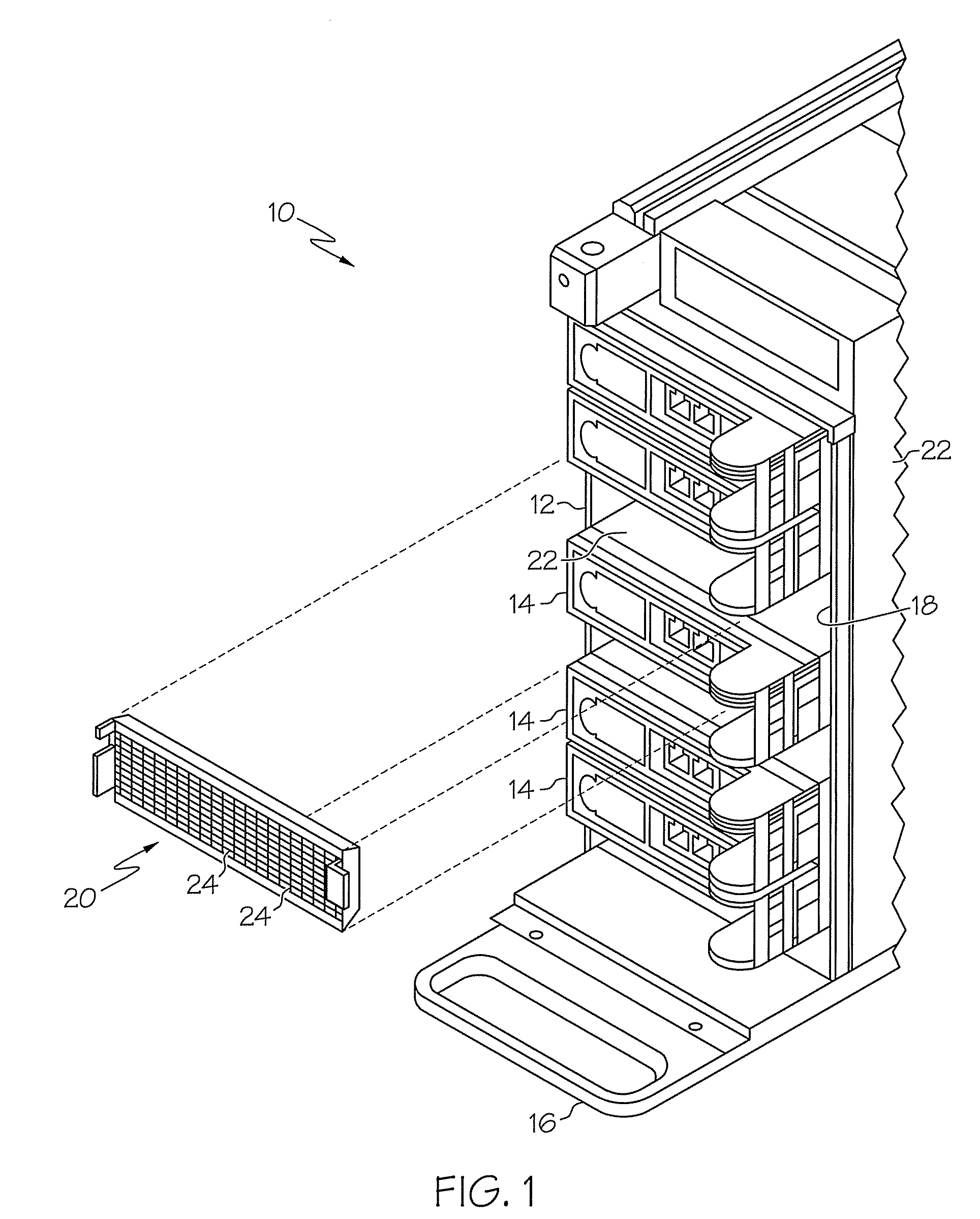

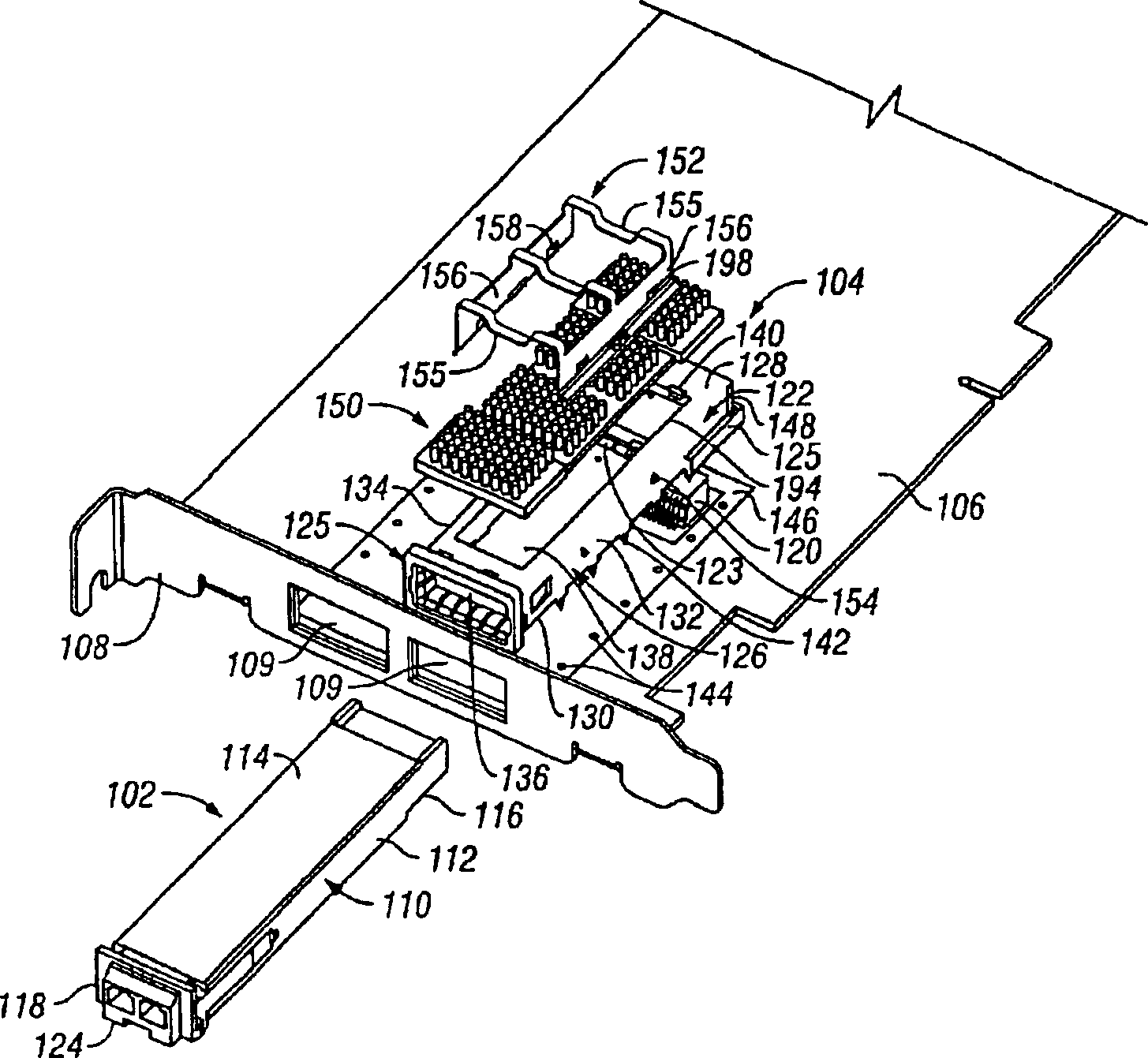

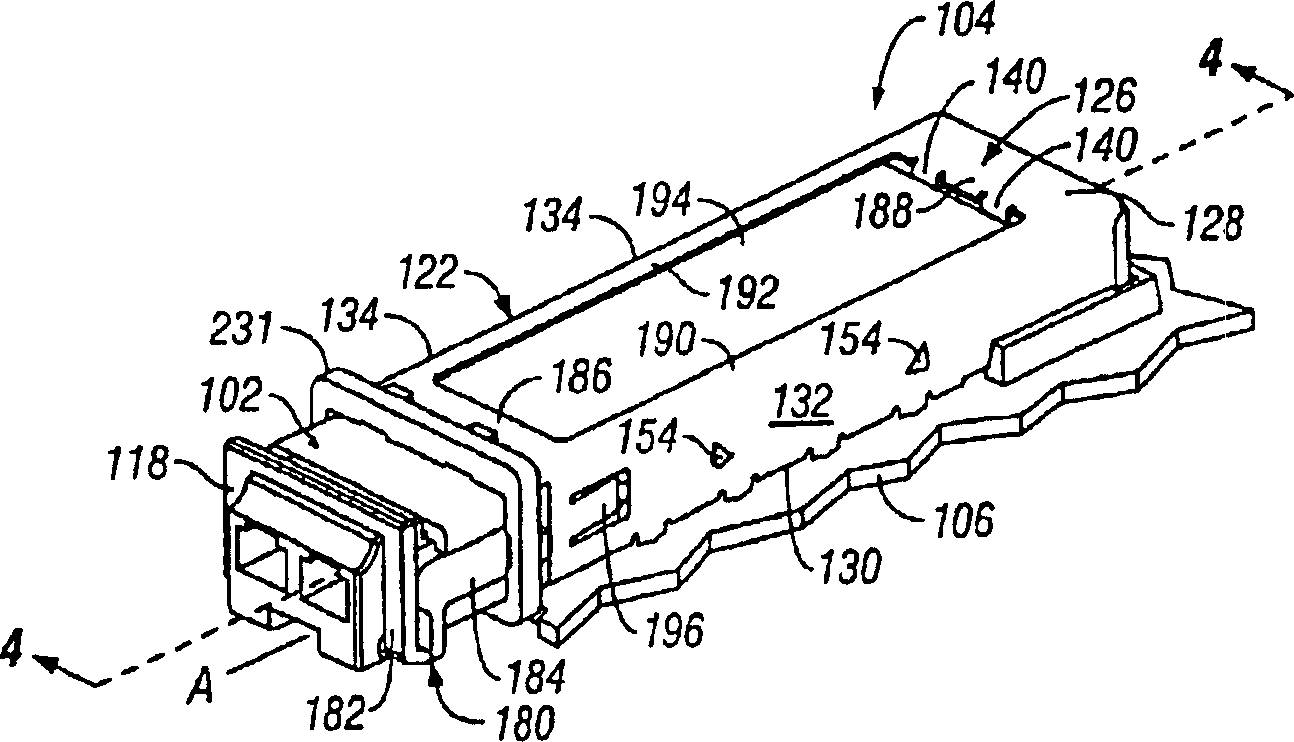

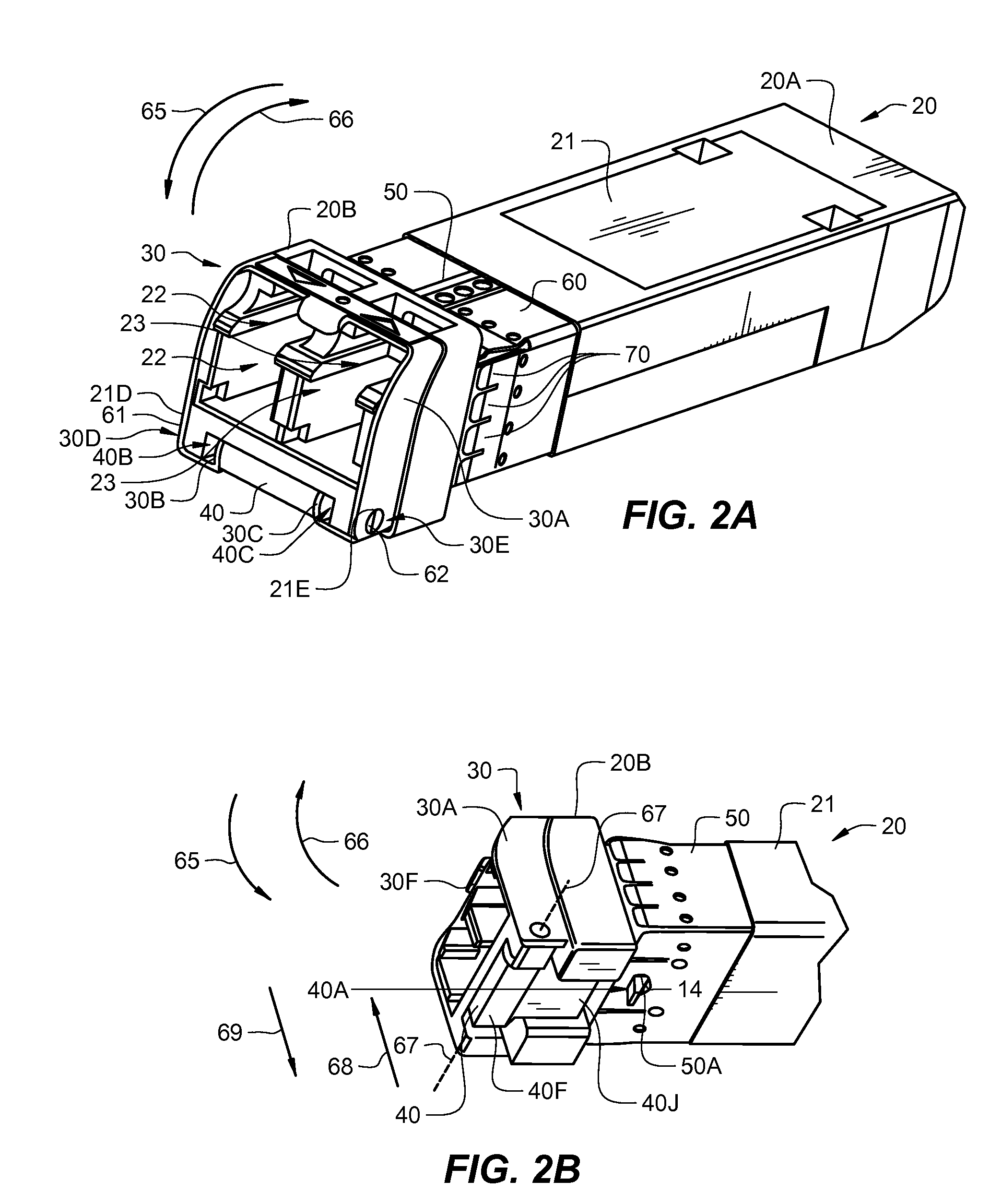

Receptacle assembly having shielded interface with pluggable electronic module

ActiveUS7001217B2Simple designIncrease data rateEngagement/disengagement of coupling partsScreening gaskets/sealsEngineeringActuator

A receptacle assembly includes a guide frame having a front end with an opening to an interior cavity of the guide frame. The front end is configured to receive a module assembly; and an EMI gasket is secured to an edge of the opening. The EMI gasket includes at least one conductive strap extending along a length of the edge, and the conductive strap covers a substantial majority of the edge to form a shielded EMI interface along the edge. A continuous conductive collar is provided on peripheral edges surrounding the opening. The collar is configured to form an uninterrupted and continuous EMI shielding interface with a gasket secured to a bezel. A bail ion the module may be used to cause actuators on the module to move and to press guide frame latches to a release position.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

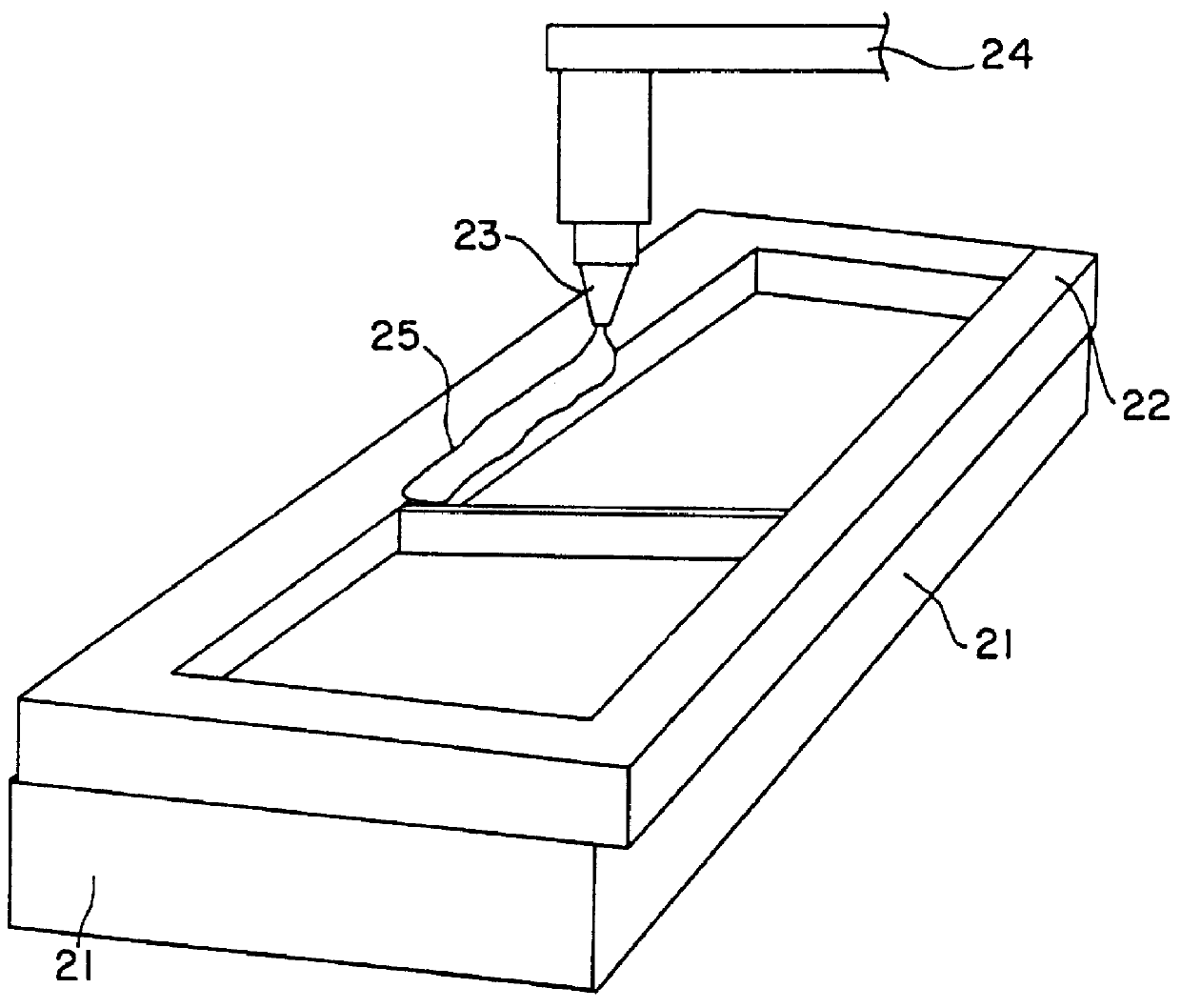

Form-in-place EMI gaskets

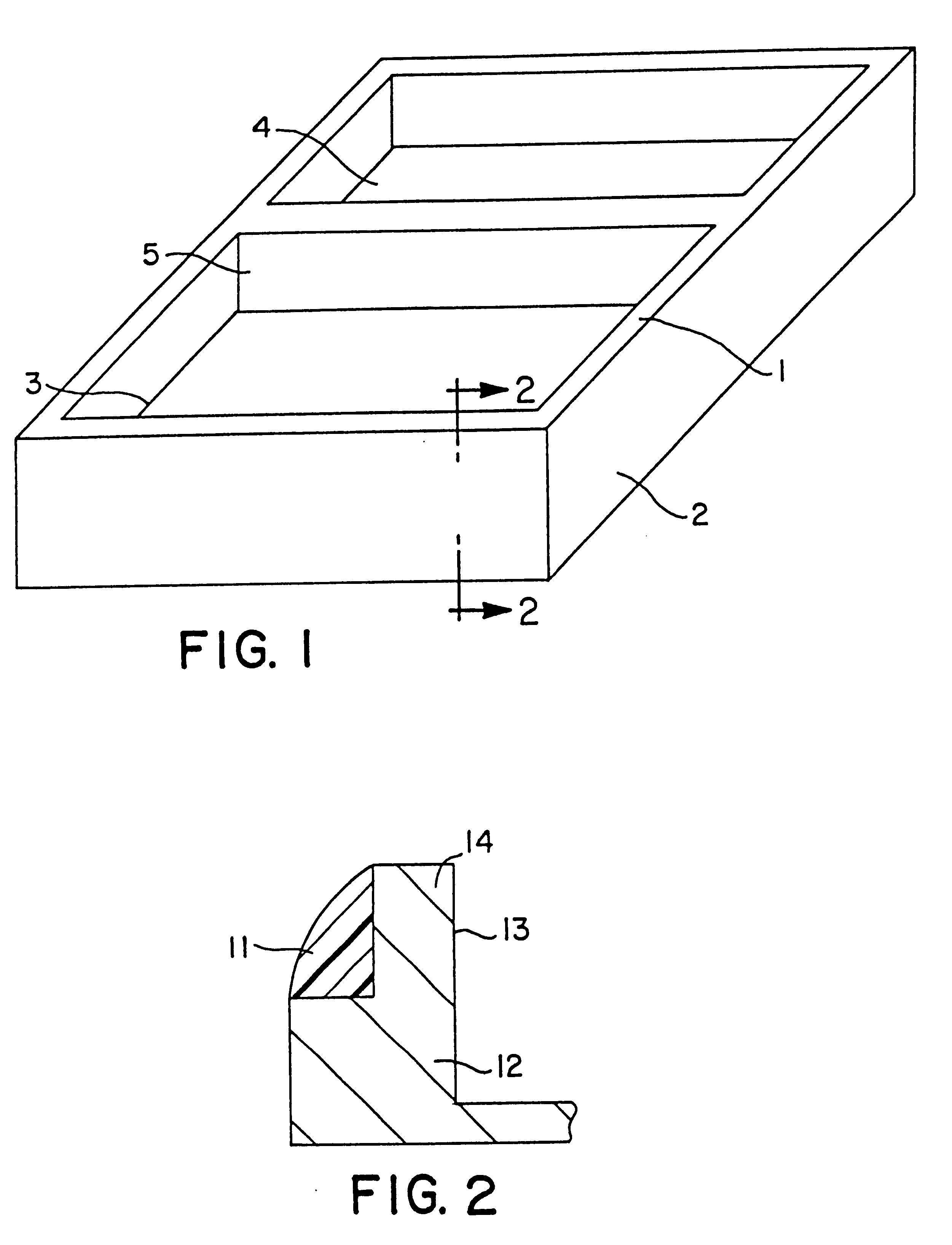

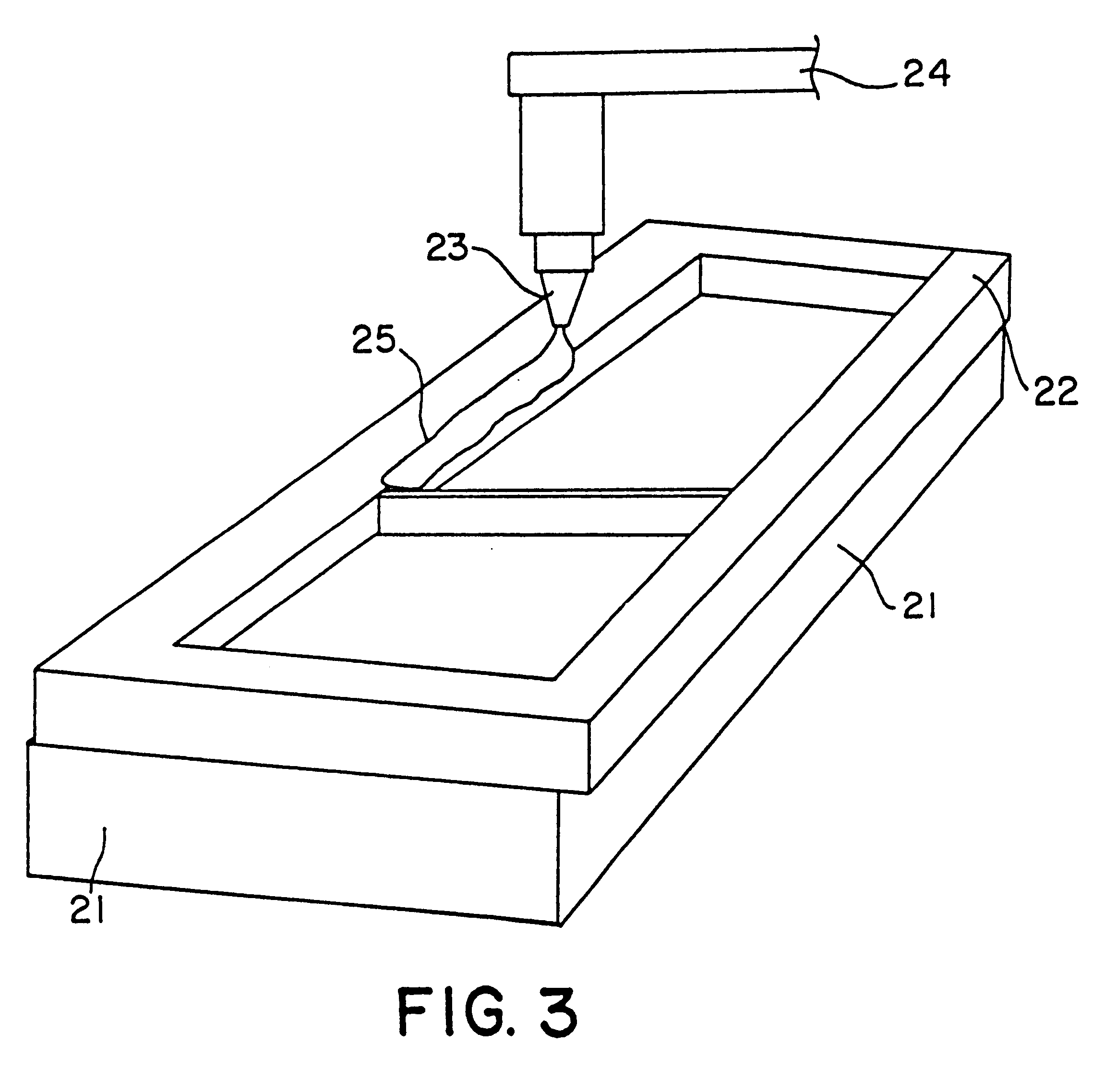

InactiveUS6096413AReduce wasteMinimal investmentEngine sealsElectrically conductive connectionsElastomerEngineering

A form in place conductive gasket is disclosed. The gasket, foamed, gelled or unfoamed is made of one or more elastomer resins, such as silicone urethane and / or thermoplastic block copolymers and is either filled with a conductive filler and lined onto a desired substrate or lined onto the substrate unfilled and then coated with a conductive outerlayer, such as a silver filled elastomer or a conductive flocked layer. A process and system for making the gaskets are also disclosed.

Owner:PARKER INTANGIBLES LLC

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS6965071B2Eliminate needReduce device temperatureMolten spray coatingScreening gaskets/sealsElectromagnetic interferenceEngineering

Owner:PARKER INTANGIBLES LLC

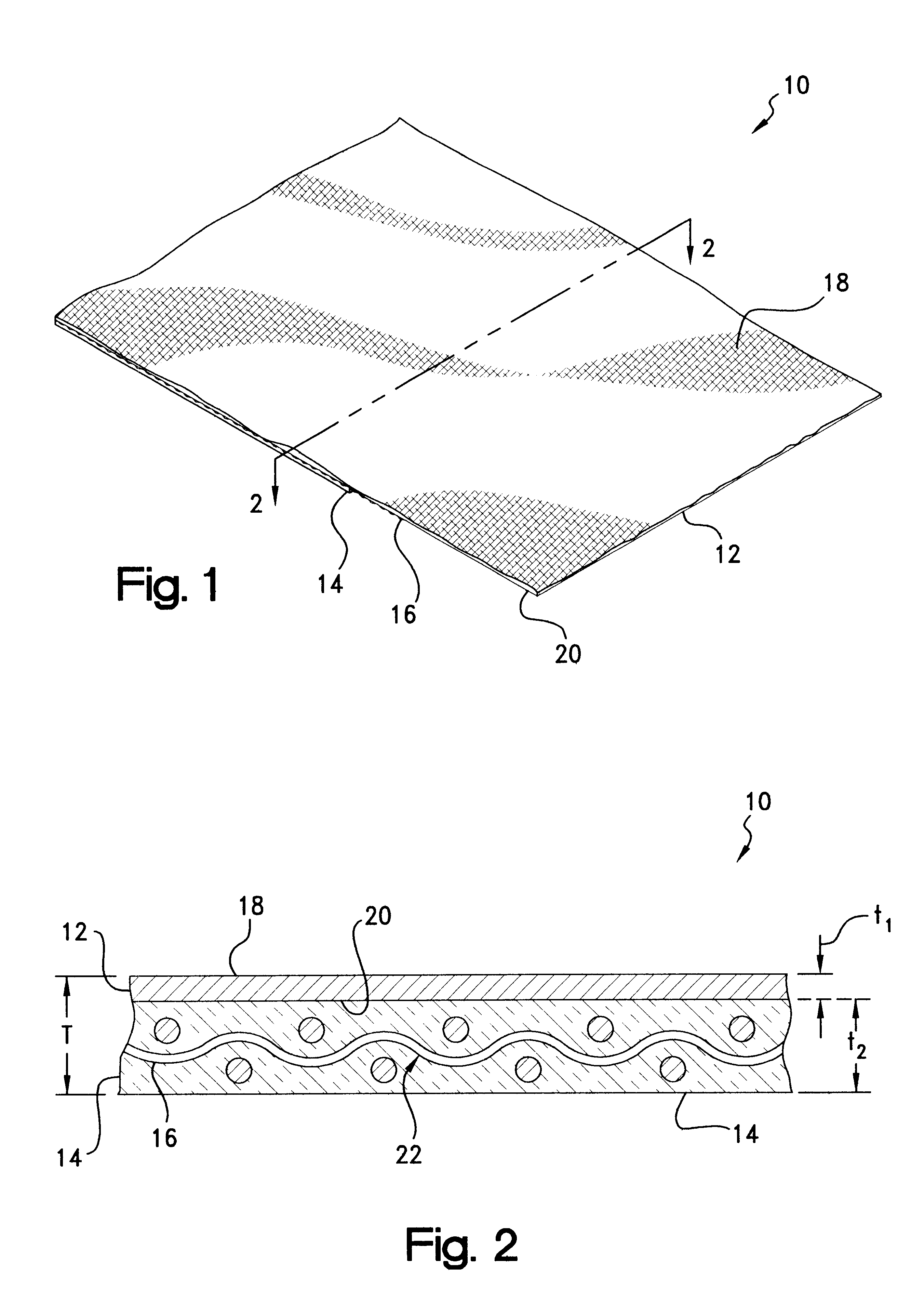

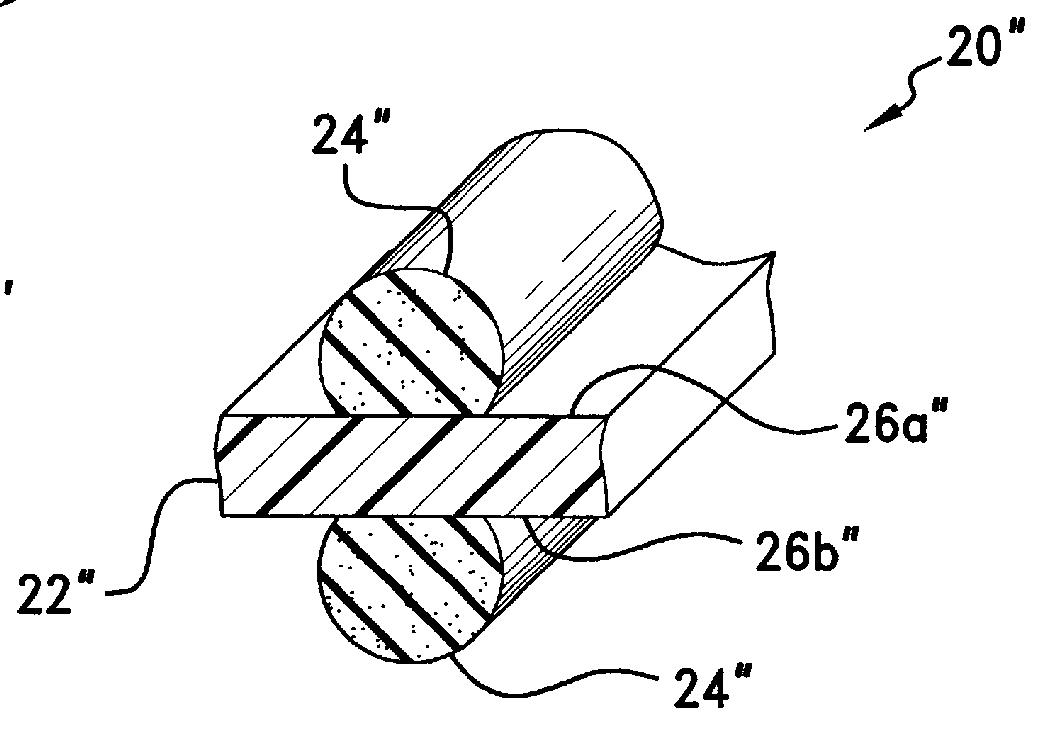

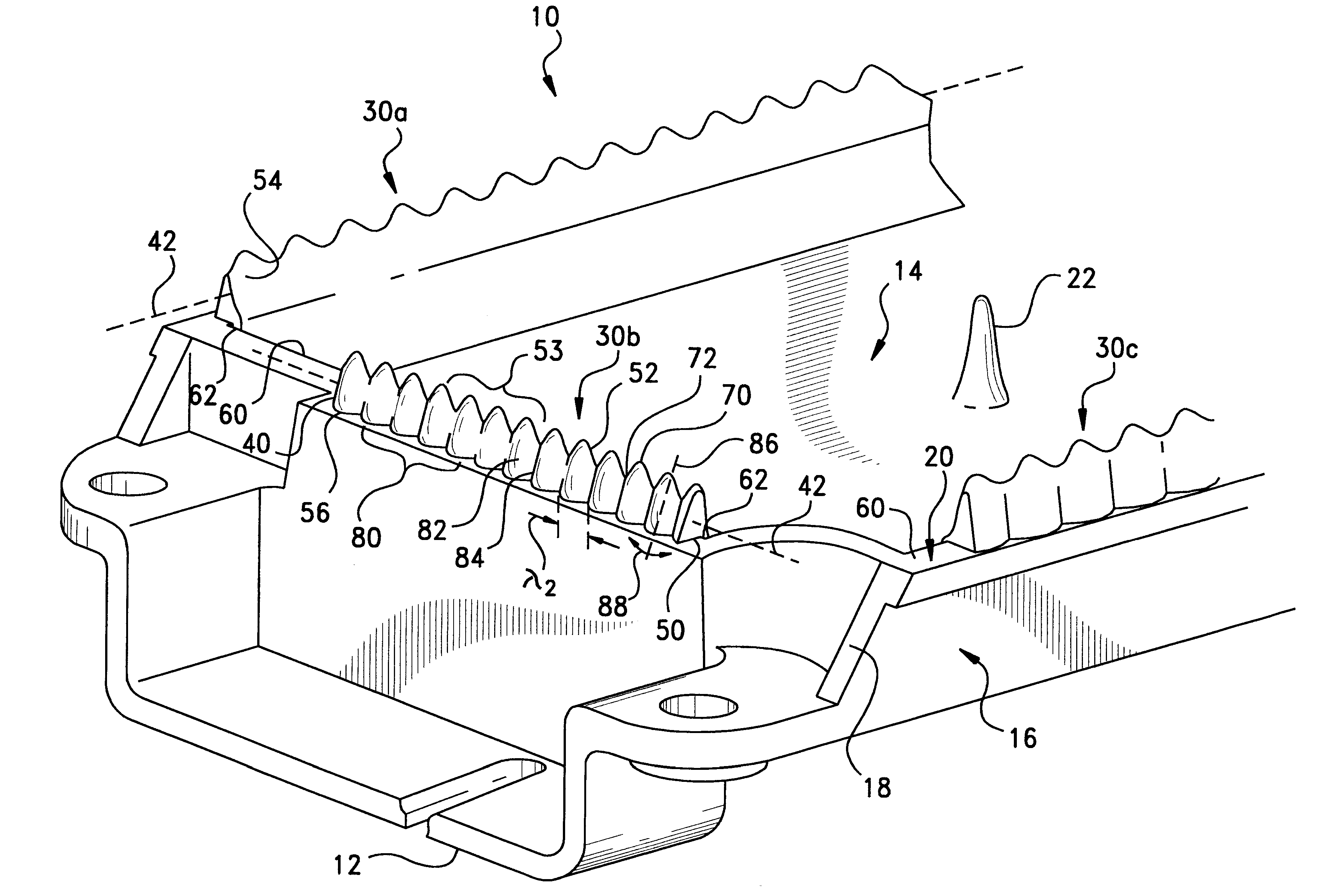

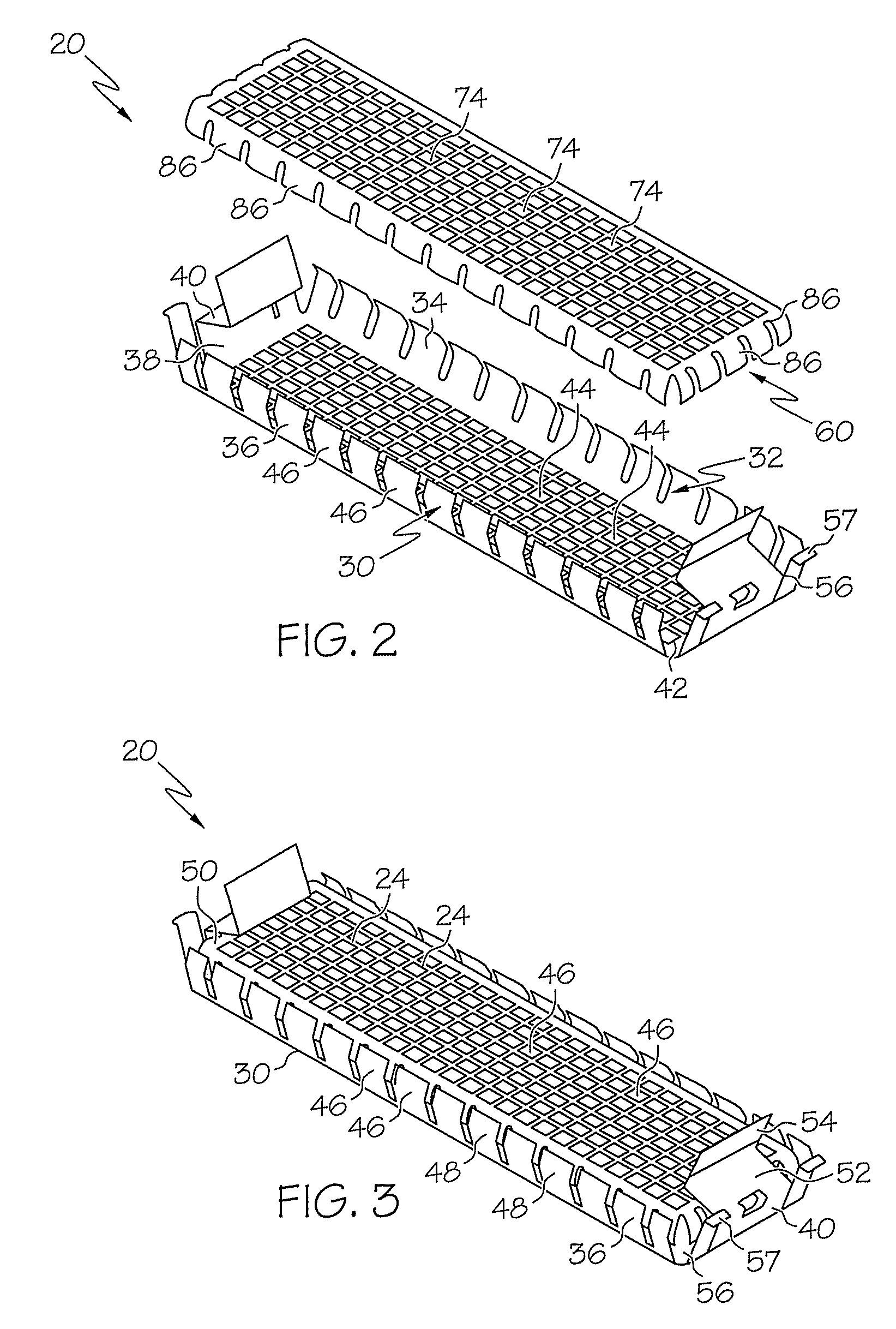

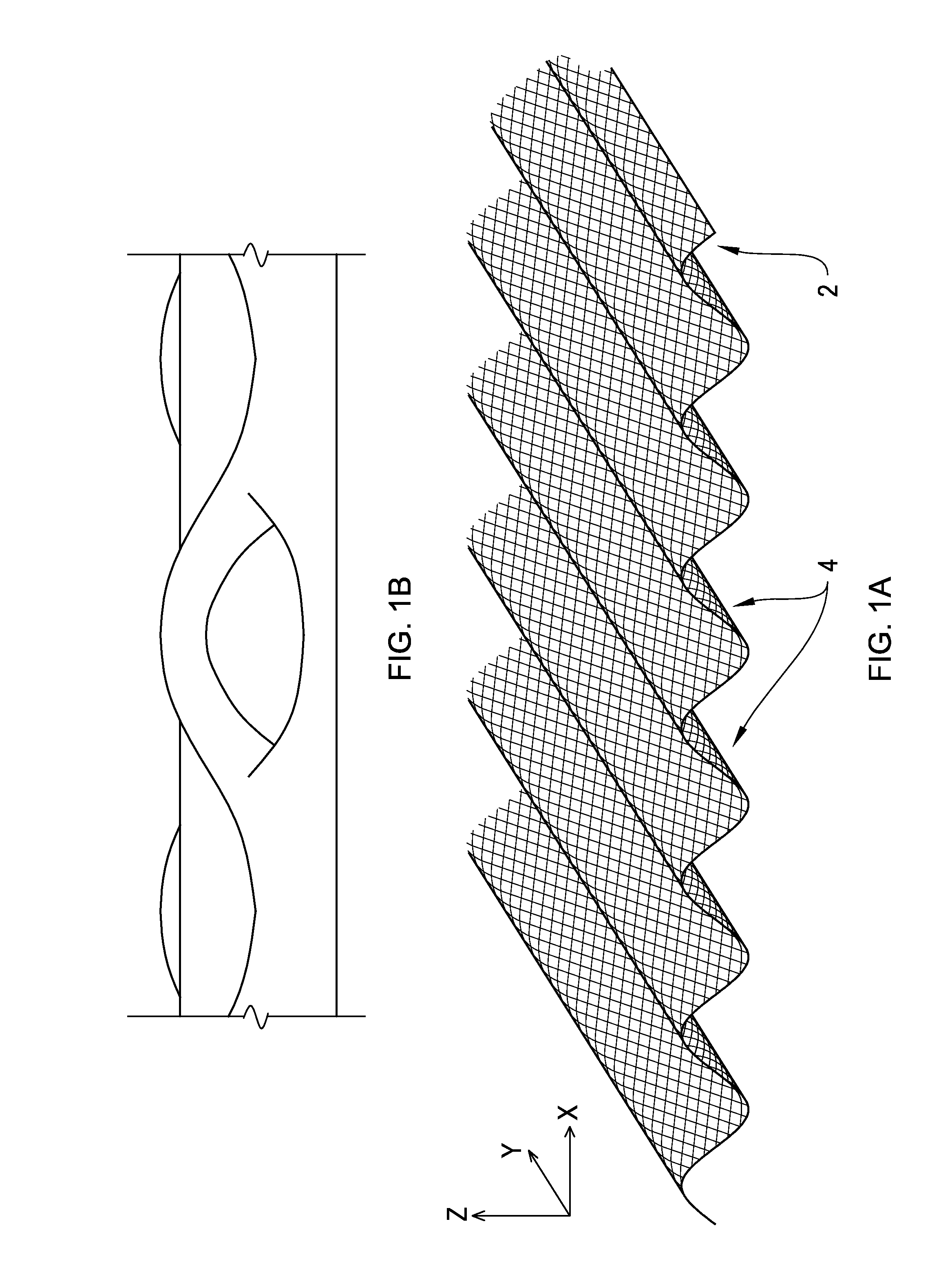

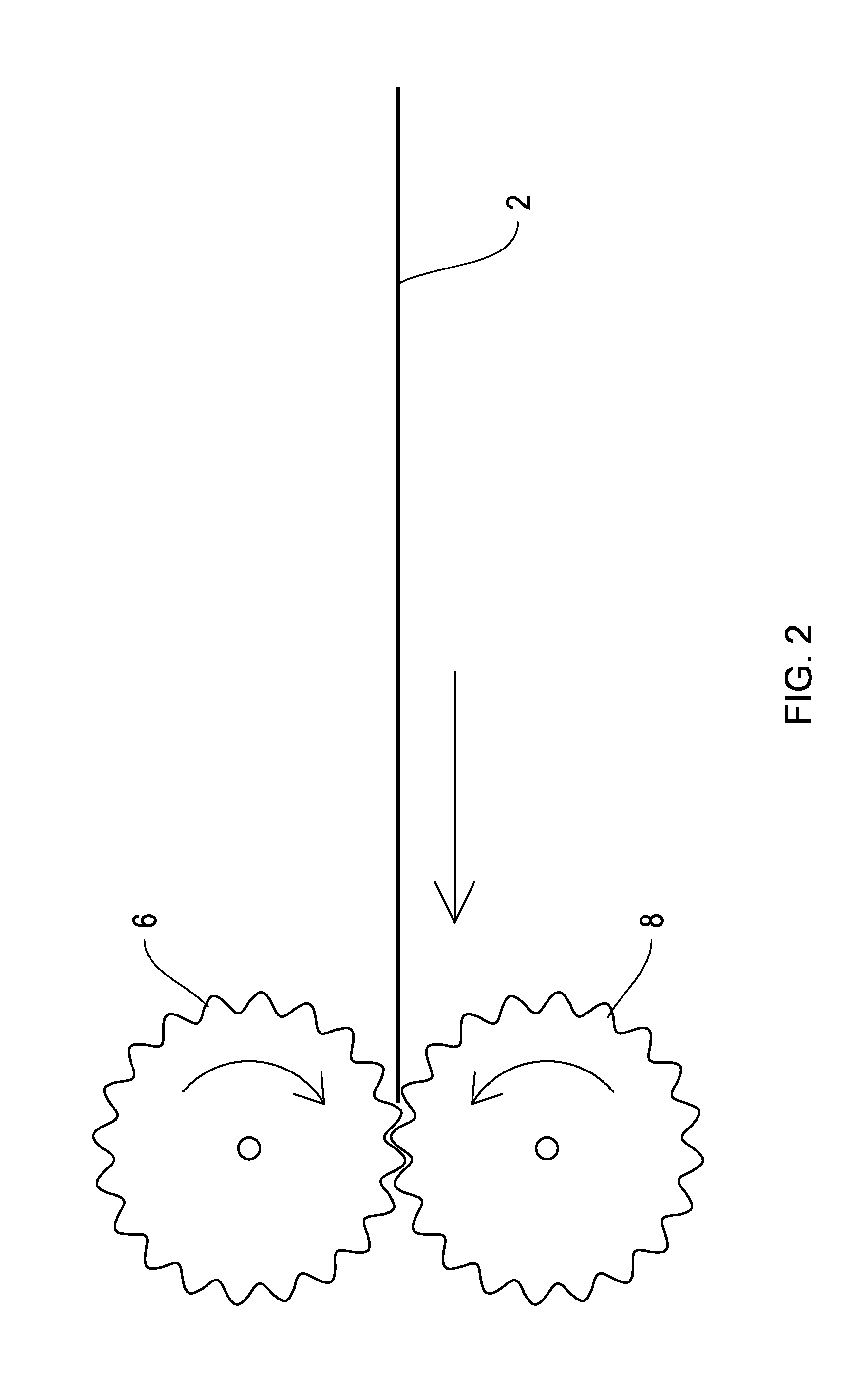

Compound waveform gasket for low closure force EMI shielding applications

InactiveUS6348654B1Reduce loadAssured electrical and physical continuityEngine sealsScreening gaskets/sealsWave shapeEngineering

A resilient EMI shielding and / or environmental sealing gasket for interposition between a first interface surface and an oppositely-disposed second interface surface. The gasket is formed of an elongate body of indefinite length which extends along a longitudinal axis. The body includes base and apex surfaces, and opposing first and second lateral surfaces which extend intermediate the base and apex surfaces. The base surface itself extends along the length the body as configured for proximally supporting the gasket on the first interface surface. The apex surface, in turn, extends radially from the longitudinal axis for distal contact with the second interface surface, and further extends along the longitudinal axis as defining a first waveform profile characterized as having a first periodic series of alternating first high and low amplitude intervals. The second lateral surface also extends along the longitudinal axis as defining a second waveform profile which is disposed generally transverse to the first waveform profile and which is similarly characterized as having a second periodic series of alternating second high and low amplitude intervals. The gasket so formed is deformable under a predetermined compressive force between the first and second interface surfaces into a stressed orientation characterized in that the body is deflected intermediate the base and apex surfaces.

Owner:PARKER INTANGIBLES LLC

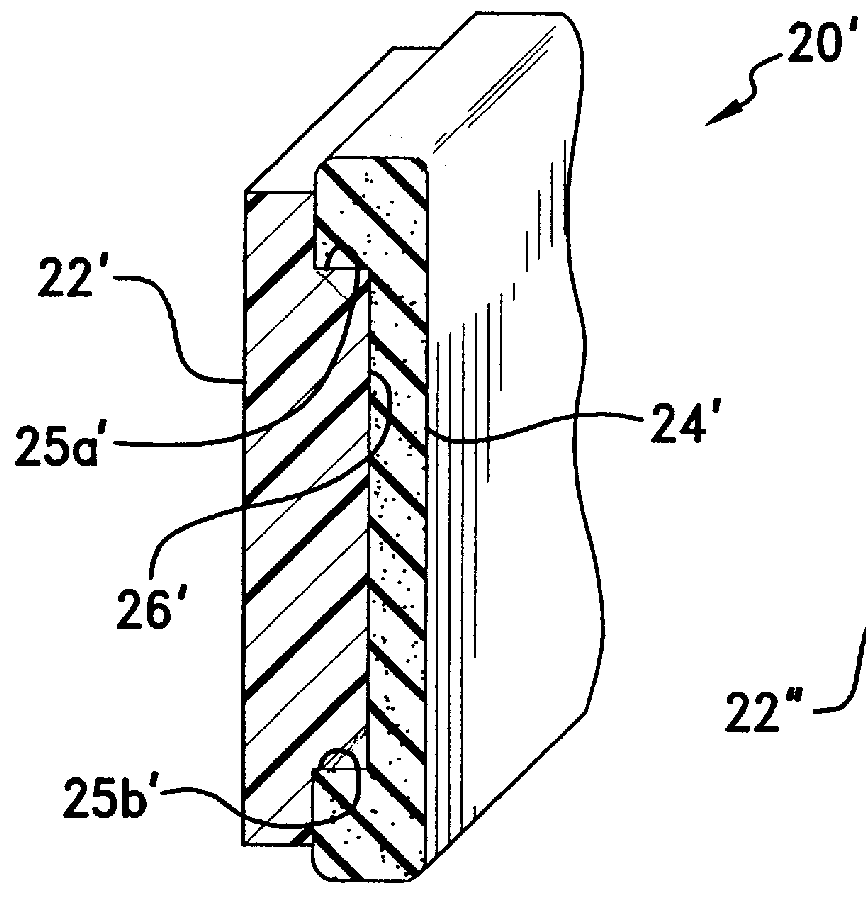

Electrically conductive gasket

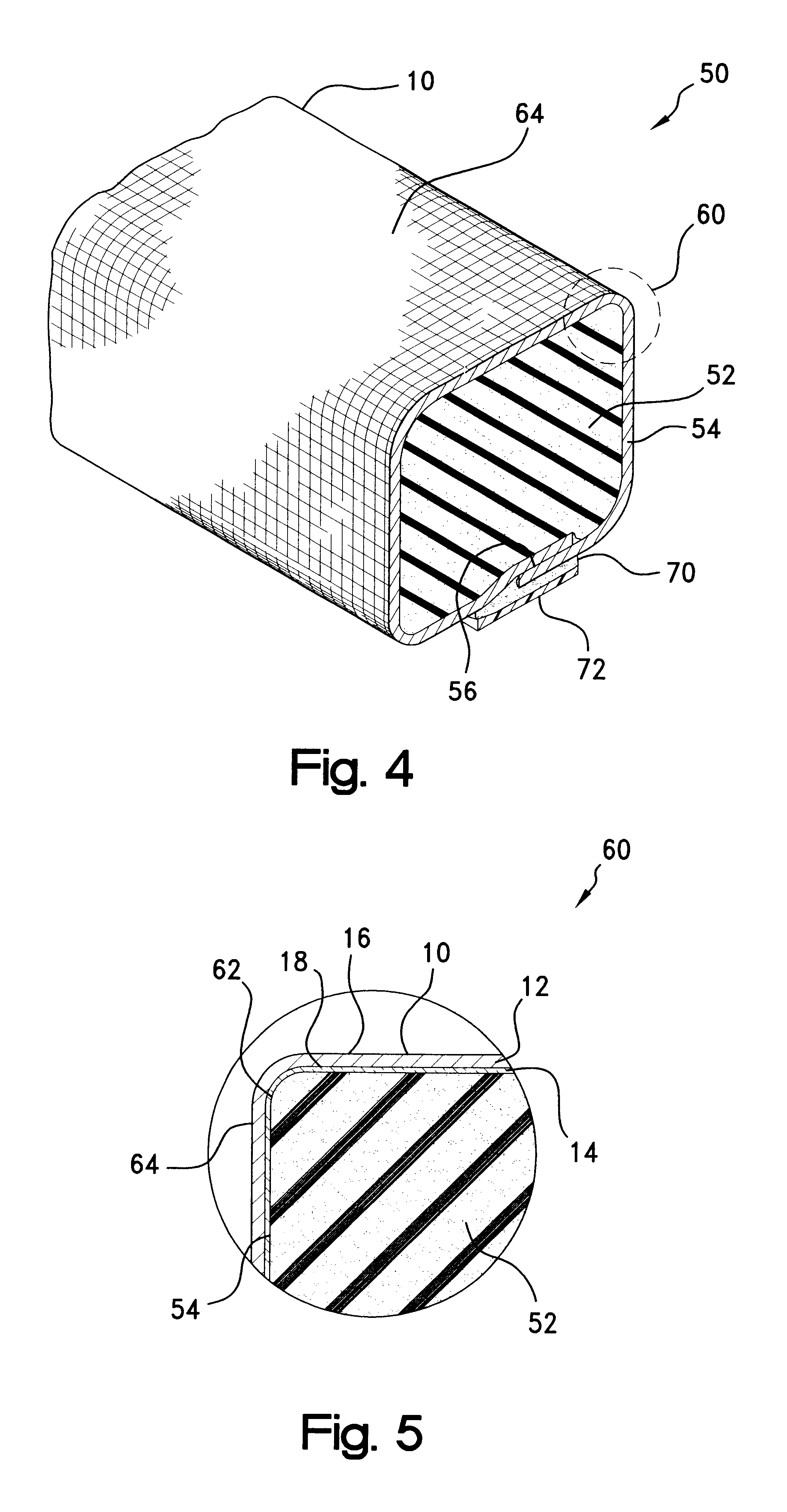

An electrically conductive gasket and methods of manufacturing electrically conductive gaskets. In one embodiment, the gasket includes a core that supports an electrically conductive cover thereon. The electrically conductive cover may be attached to the core or portions of the core by one or more adhesives used to also affix the gasket to an electrically conductive object. In other embodiments, a mechanical fastener may be affixed to the core by the one or more adhesives employed to affix the electrically conductive cover to the core.

Owner:JEMIC SHIELDING TECH

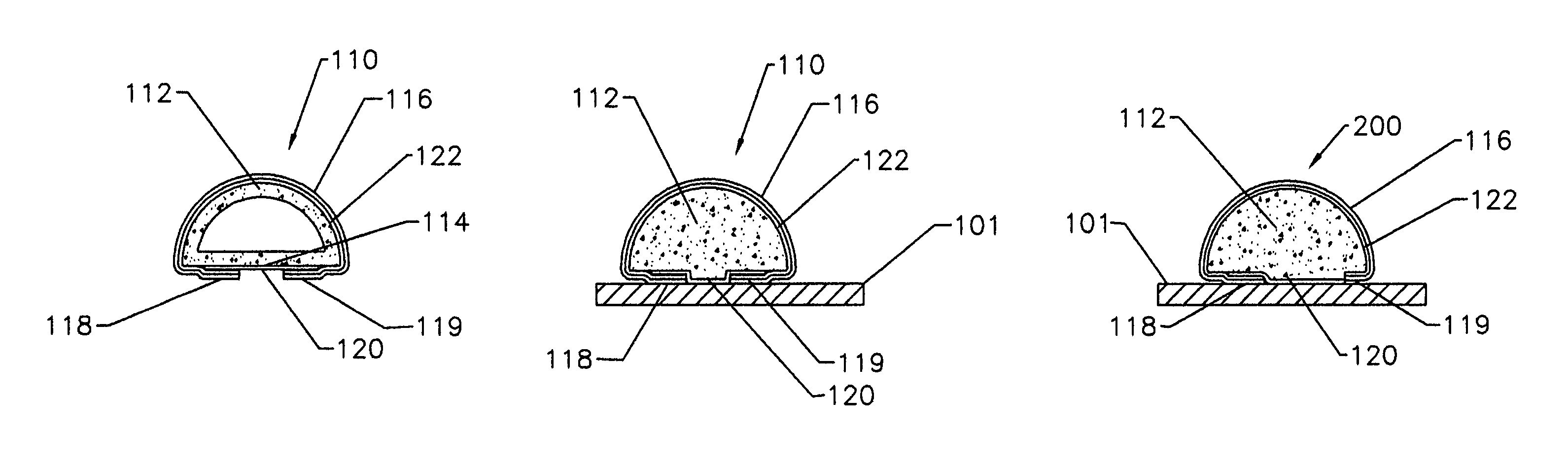

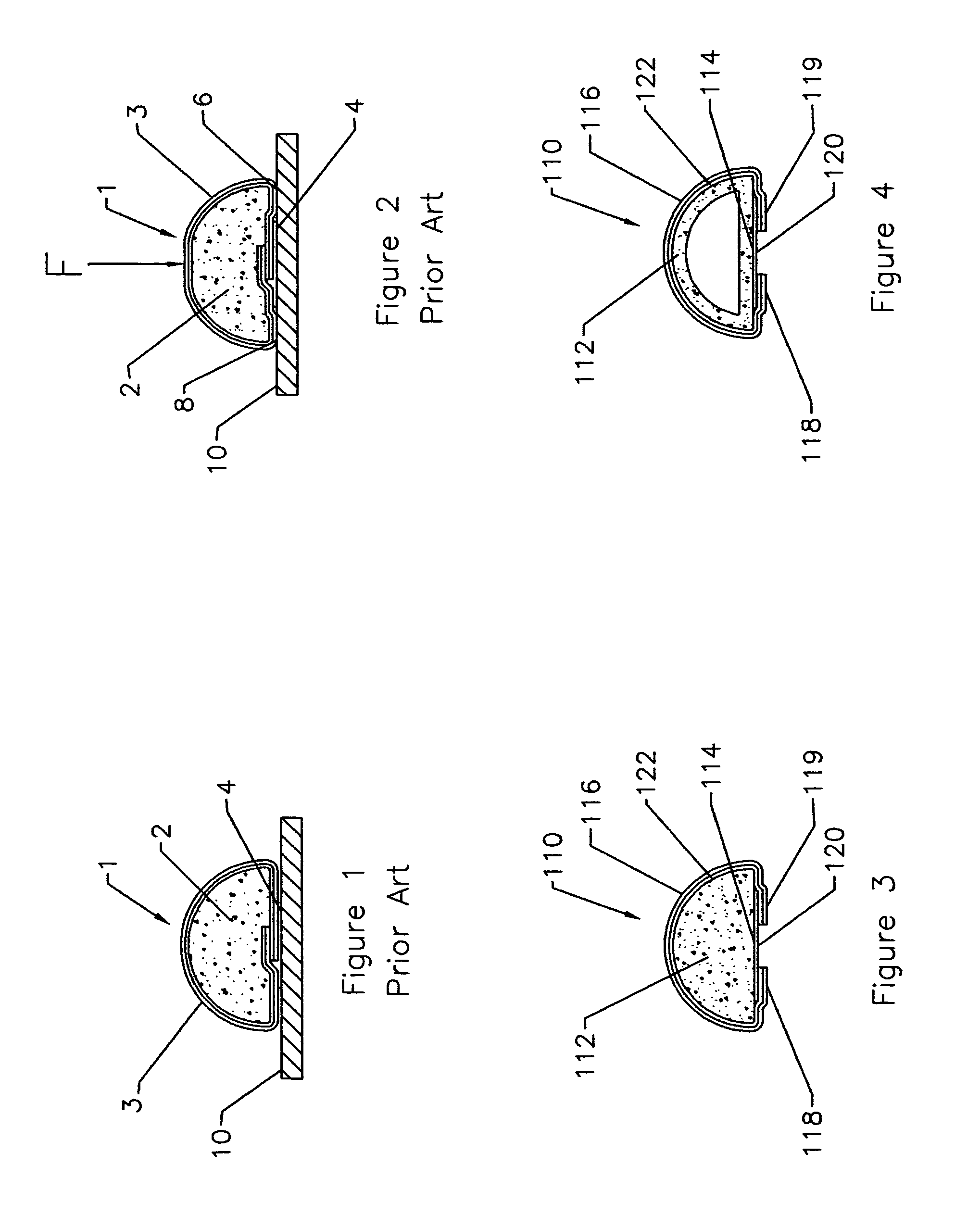

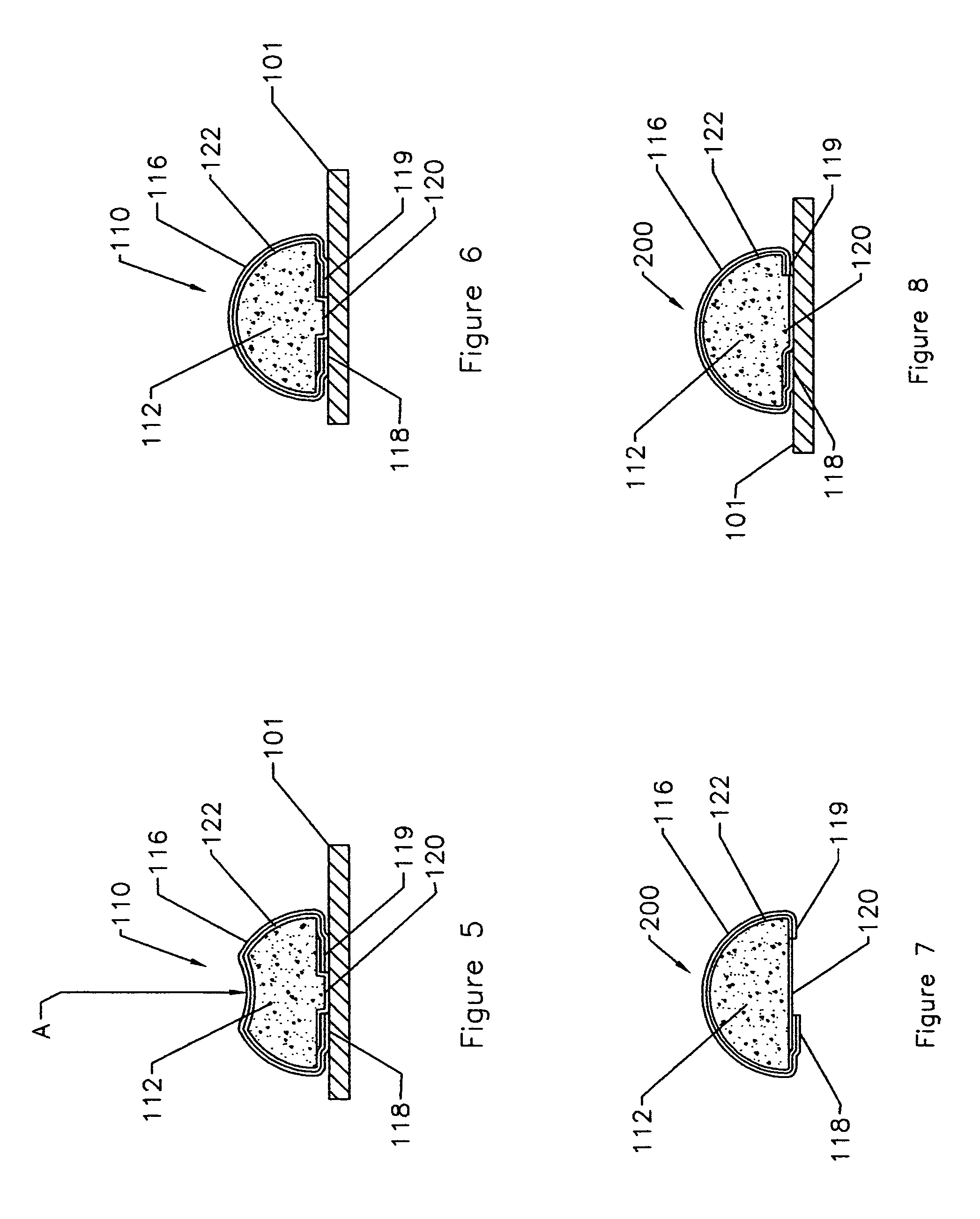

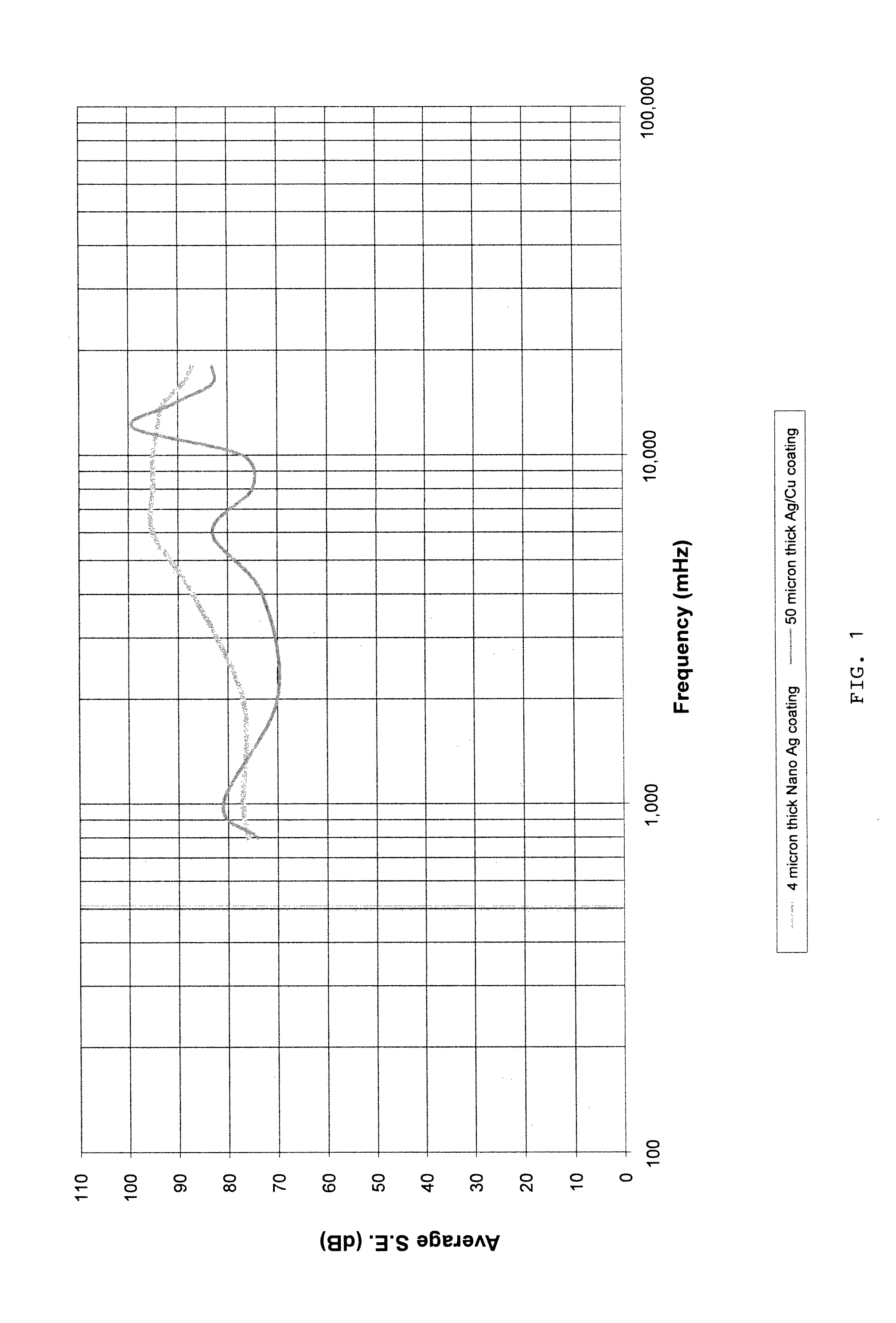

NANO coating for EMI gaskets

EMI shielding gaskets prepared by coating a resilient nonconductive core gasket with a coating or ink containing conductive nanoparticles. The coating layer can be applied at a thickness of 10 microns or less to achieve shielding levels comparable to conventional coatings which are typically an order of magnitude thicker.

Owner:PARKER HANNIFIN CORP

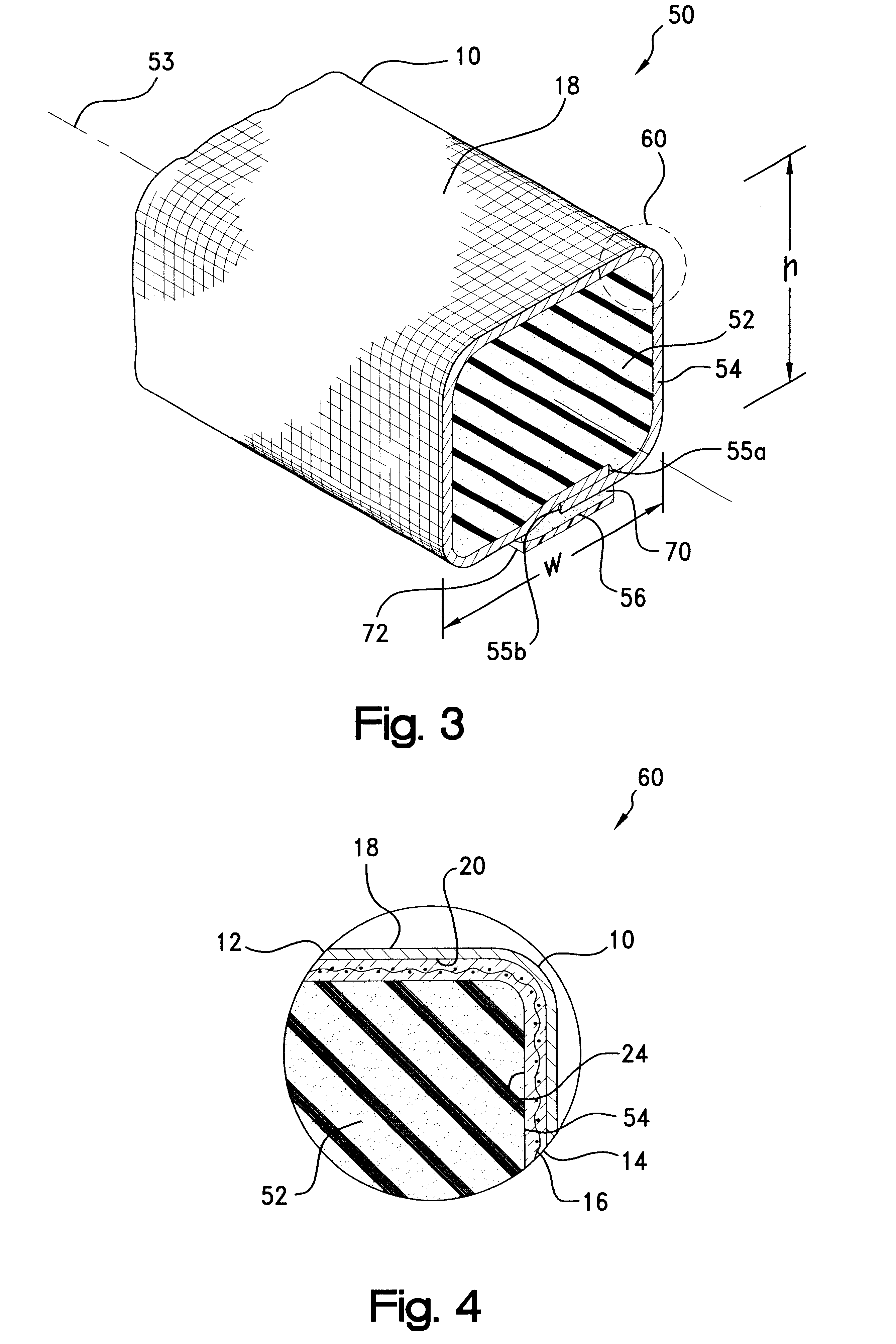

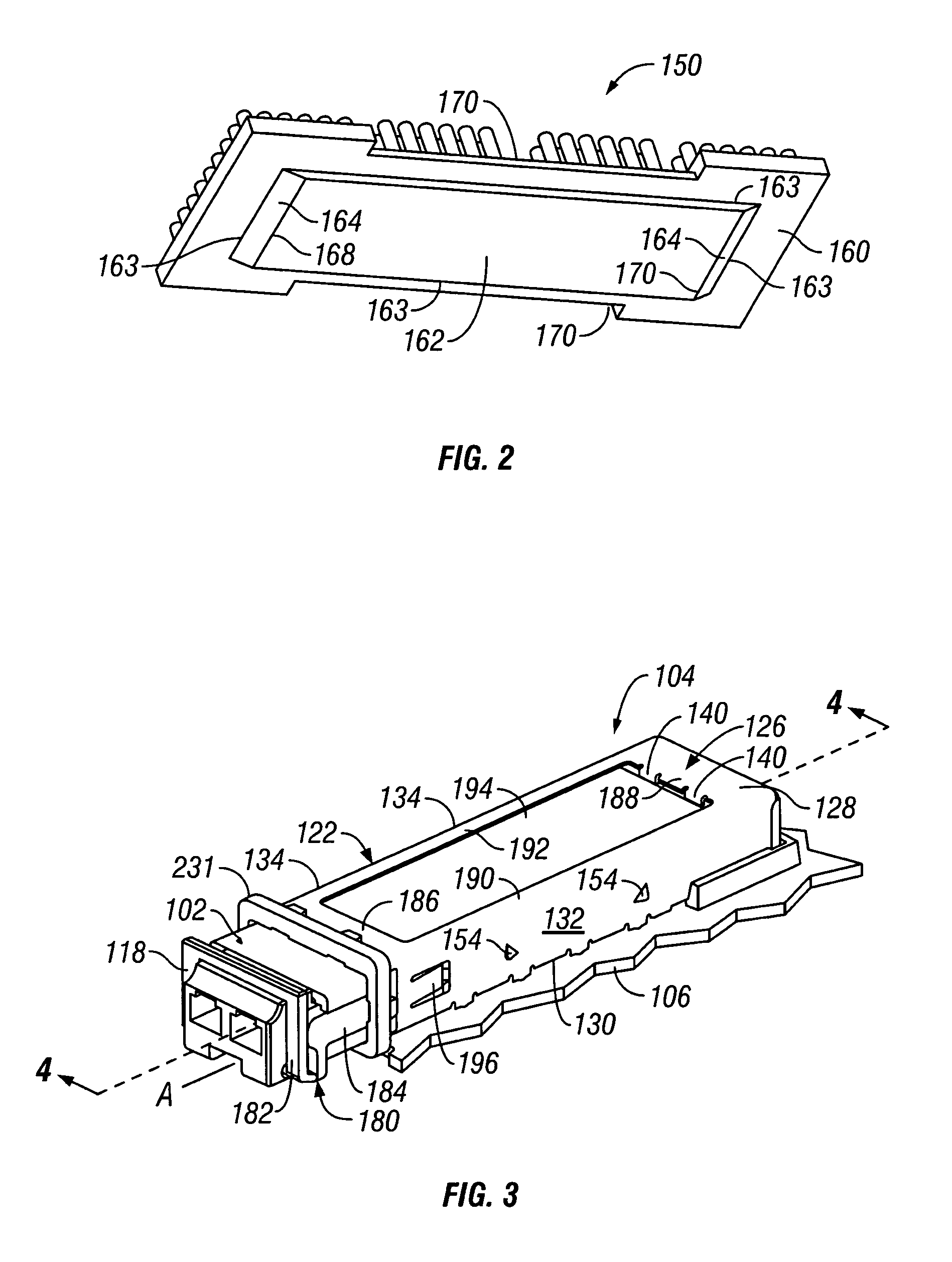

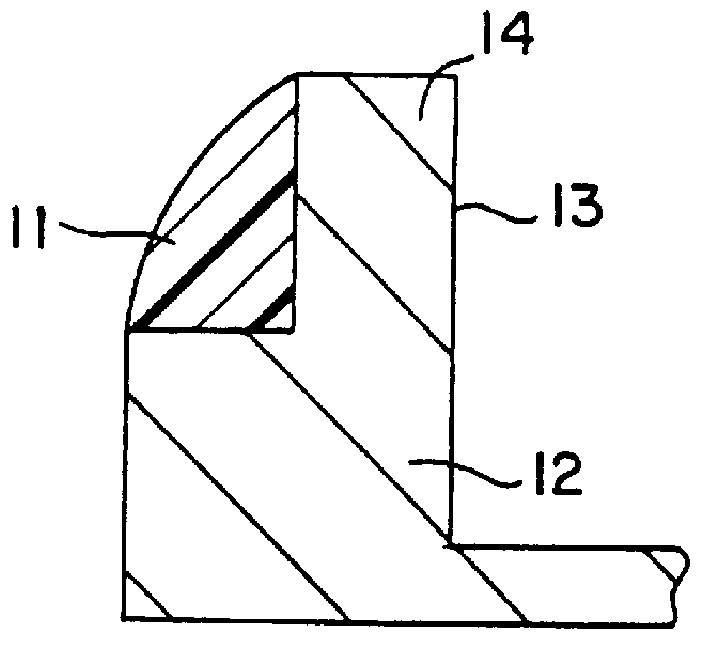

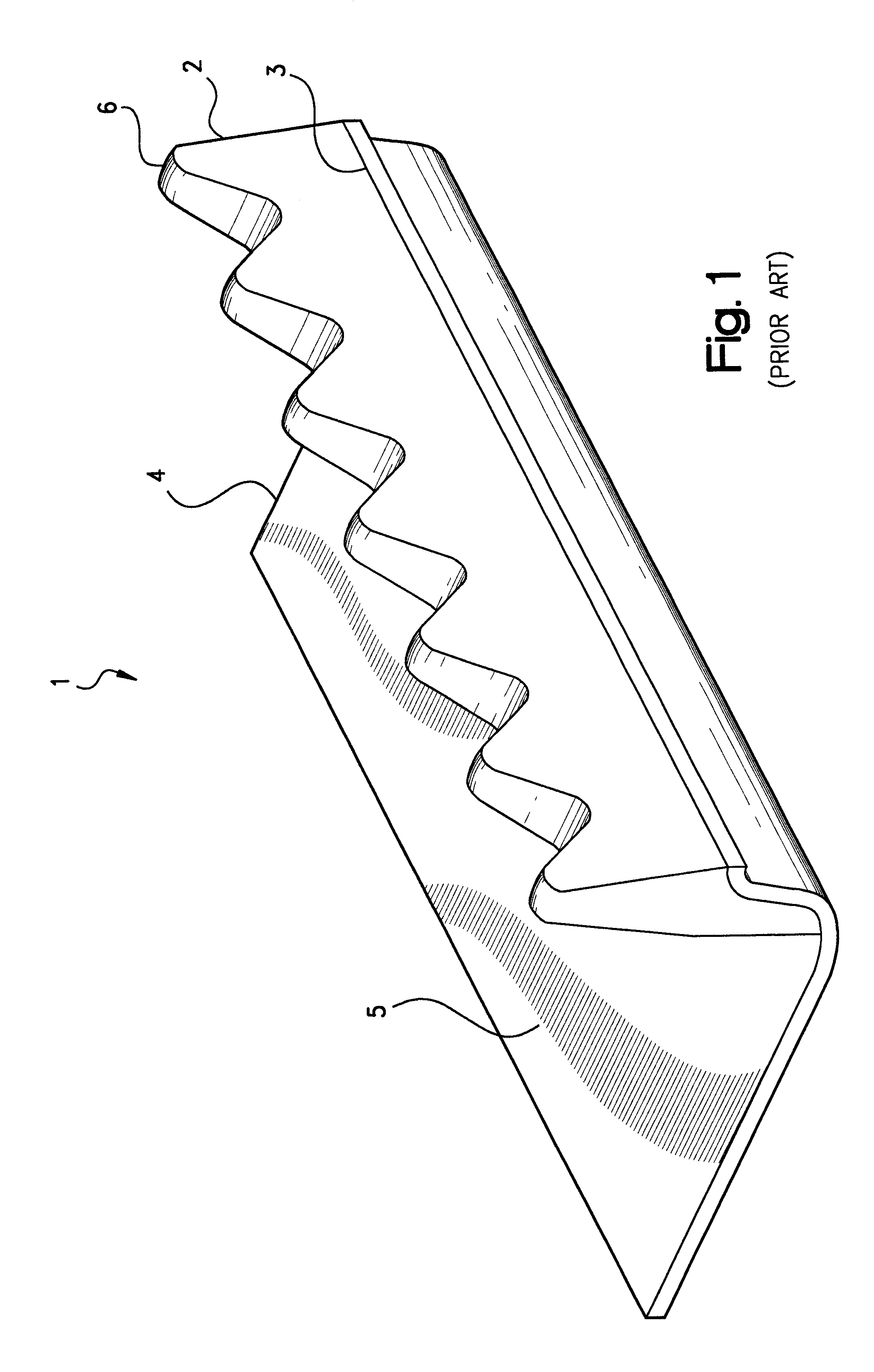

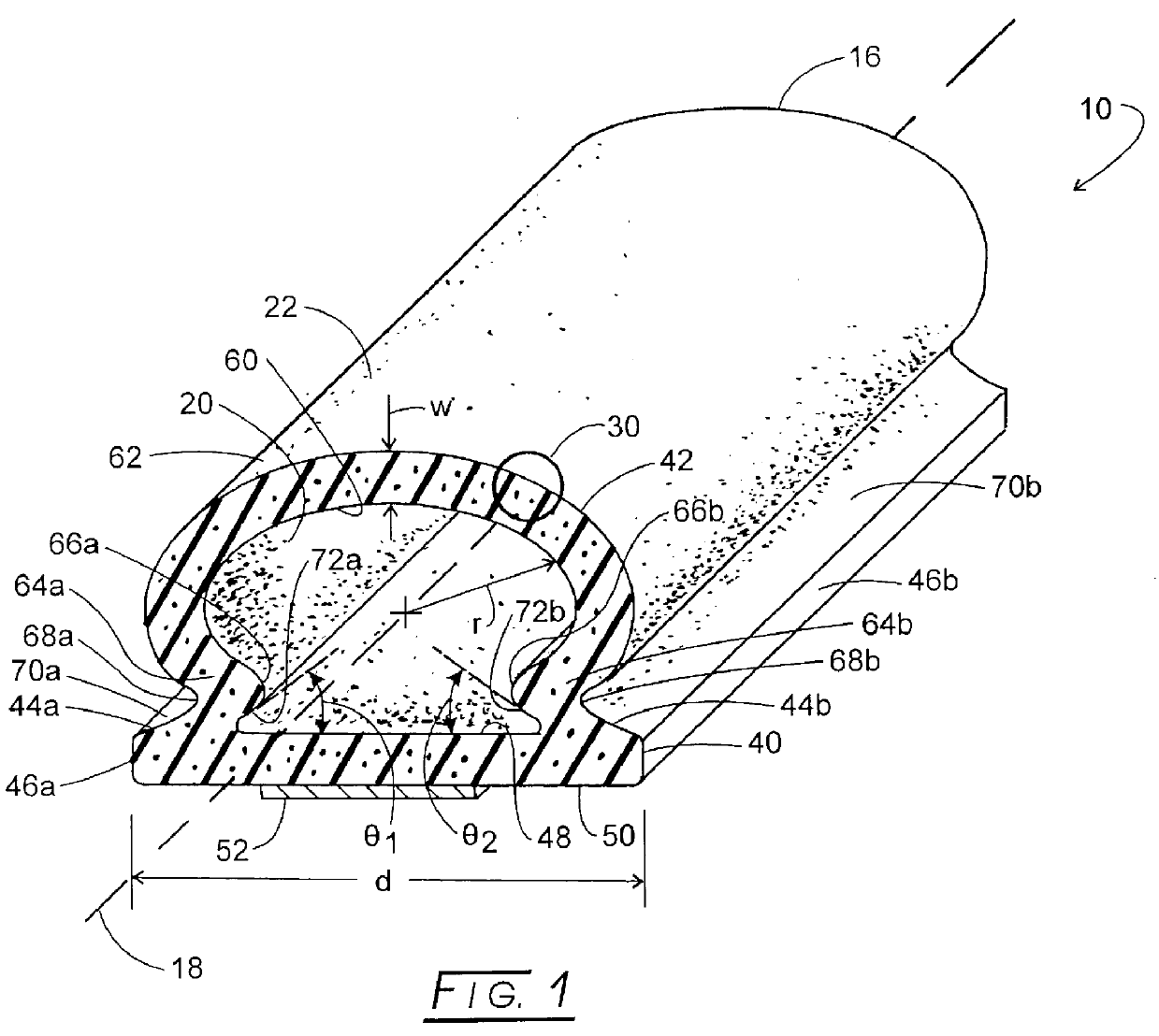

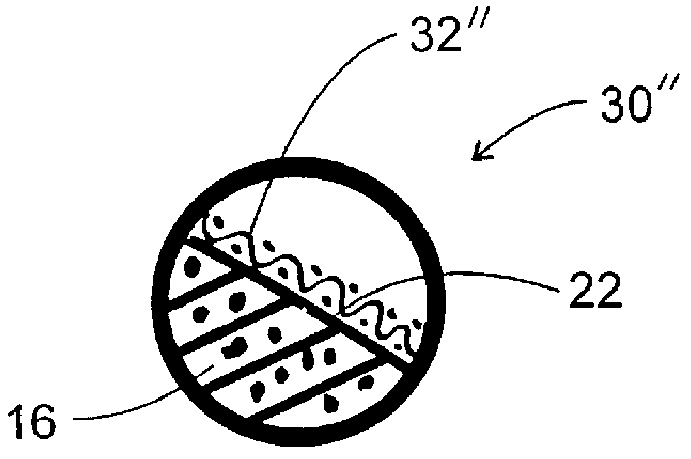

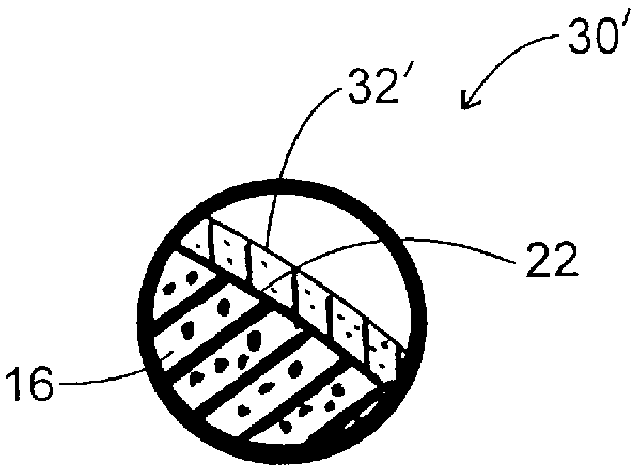

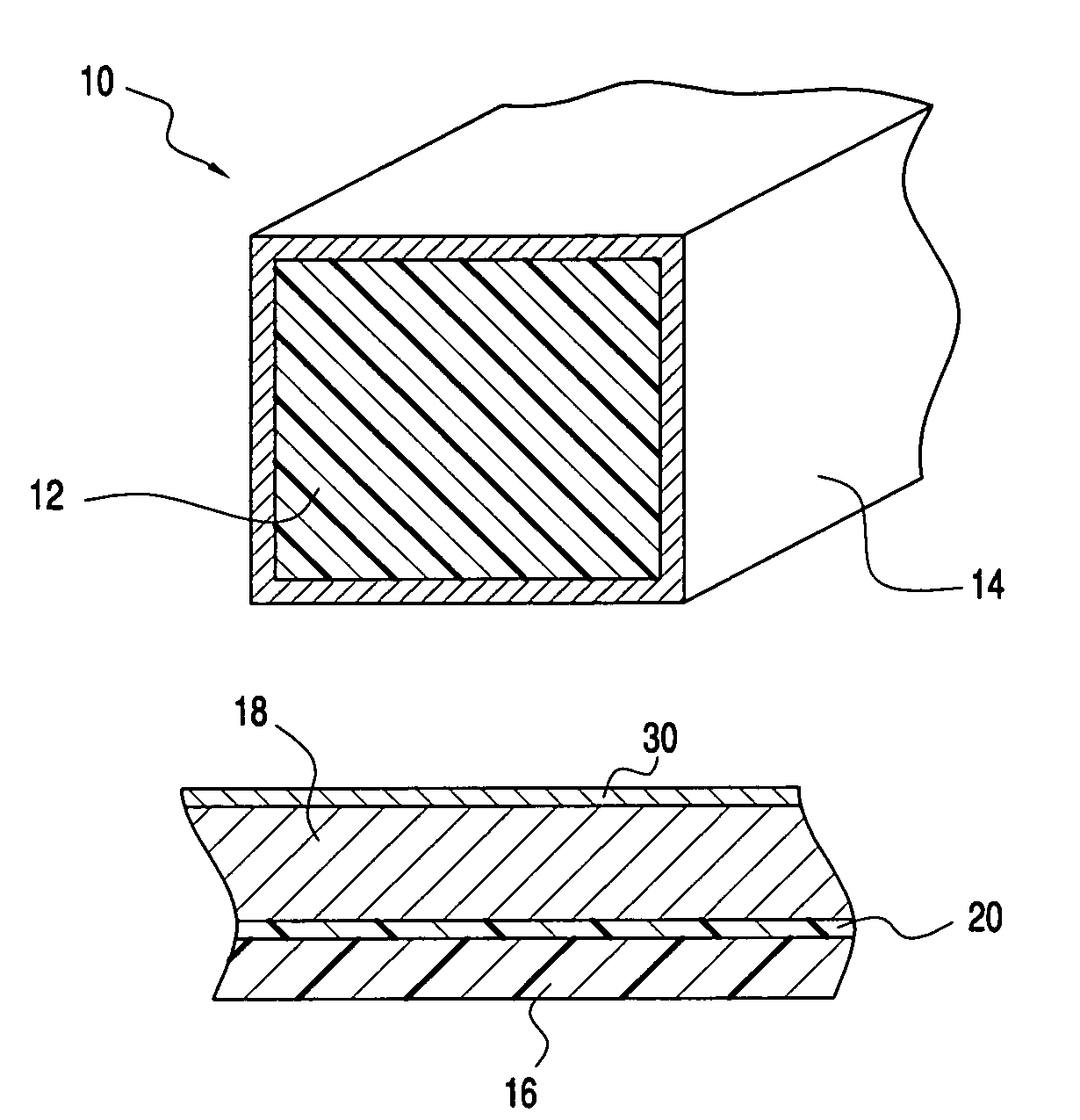

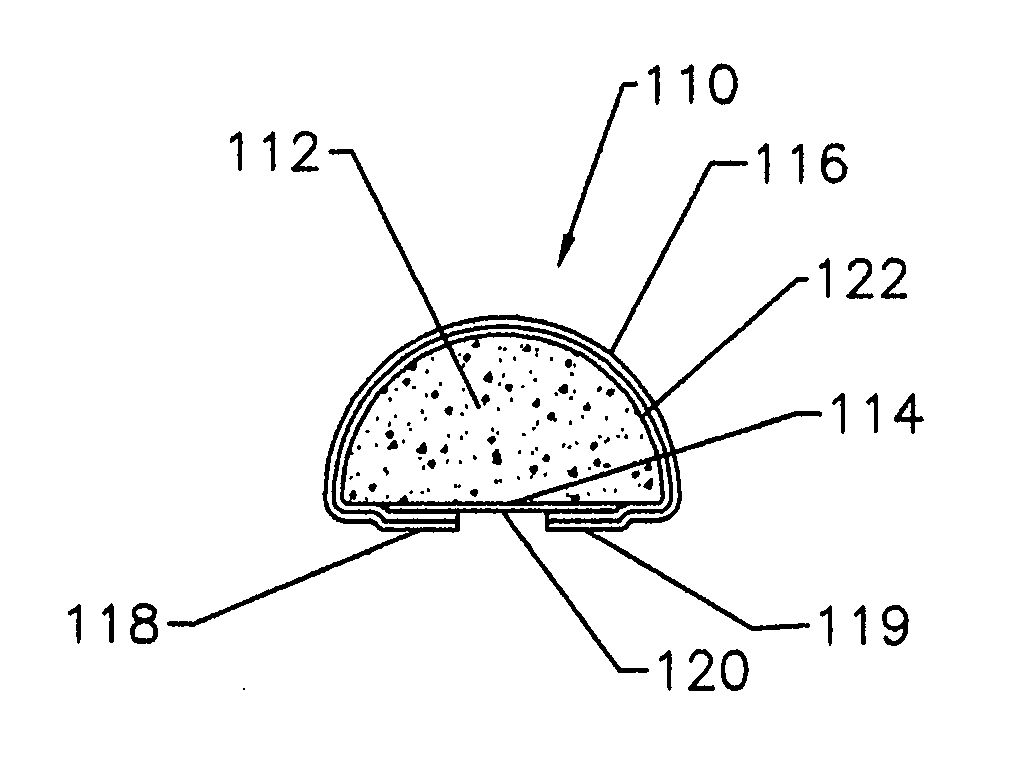

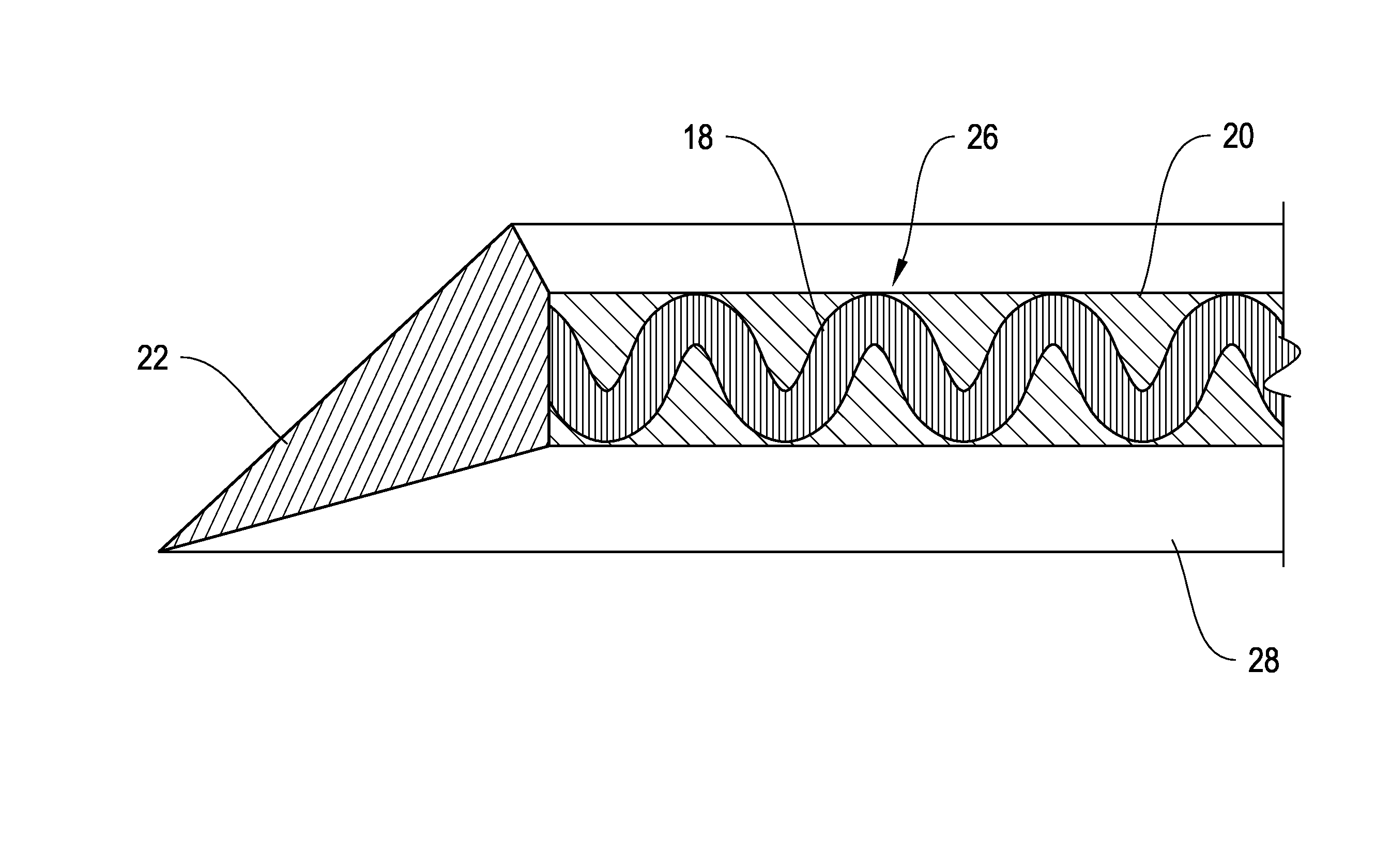

Tubular extrusion gasket profile exhibiting a controlled deflection response for improved environmental sealing and EMI shielding

InactiveUS6075205AEnvironmental sealing effectivenessMinimizes bending momentScreening gaskets/sealsSealingAcute angleCircular segment

An EMI shielding and environmental sealing gasket for interposition between a first substrate and an oppositely-disposed second substrate. The gasket is formed of a resilient, tubular body having a generally continuous interior and exterior surface defining a wall thickness of the gasket therebetween, and including base, arcuate, and lateral members. The base member extends intermediate a first and a second edge and has an inner and outer for contact with the second substrate. The arcuate member, which has an inner surface spaced apart radially from the inner surface of the base member and an outer surface for contact with the first substrate, extends intermediate a first proximal end disposed radially inwardly of the first edge of the base member, and a second proximal end disposed radially inwardly of the second edge of the base member. A first lateral member extends from the first edge of the base member to the first proximal end of the arcuate member, with a second lateral member extending from the second edge of the base member to the second proximal end of the arcuate member. Each of the lateral members has an outer surface and an inner surface which defines a acute angle with the inner surface of the base member. The gasket so constructed is deflectable under a predetermined compressive force between the first and second substrates into a collasped orientation characterized in that substantially continuous contact is maintained between the outer surface of the base member and the second substrate.

Owner:PARKER INTANGIBLES LLC

EMI foil laminate gasket

A conductive electromagnetic interference (EMI) shielding gasket having a compressible non-conductive core enwrapped with a conductive sheath. The sheath is a laminate formed by laminating a conductive metal foil at least 0.2 mils thick to a flexible non-conductive substrate, preferably a non porous polyester film.

Owner:SCHLEGEL SYST

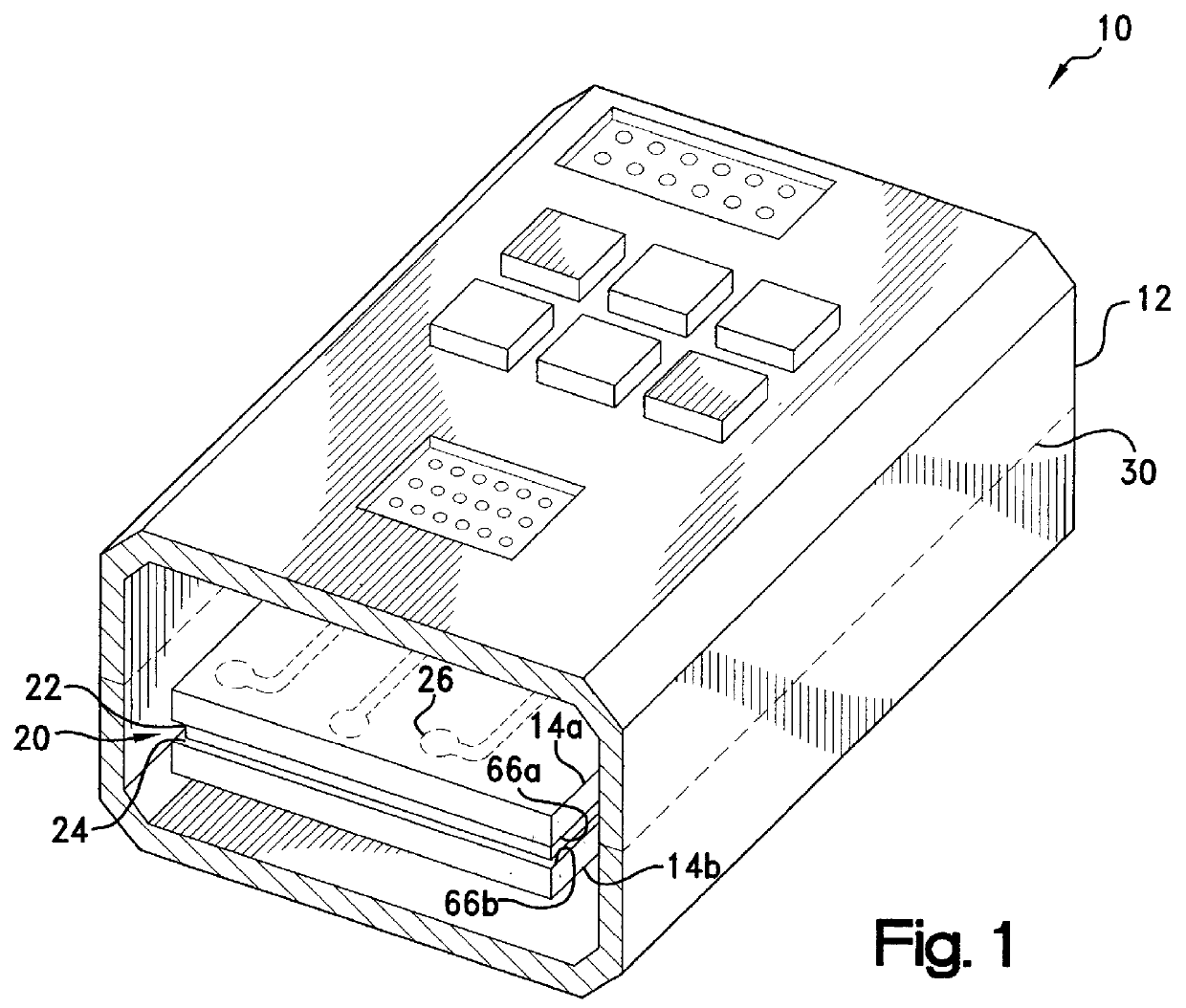

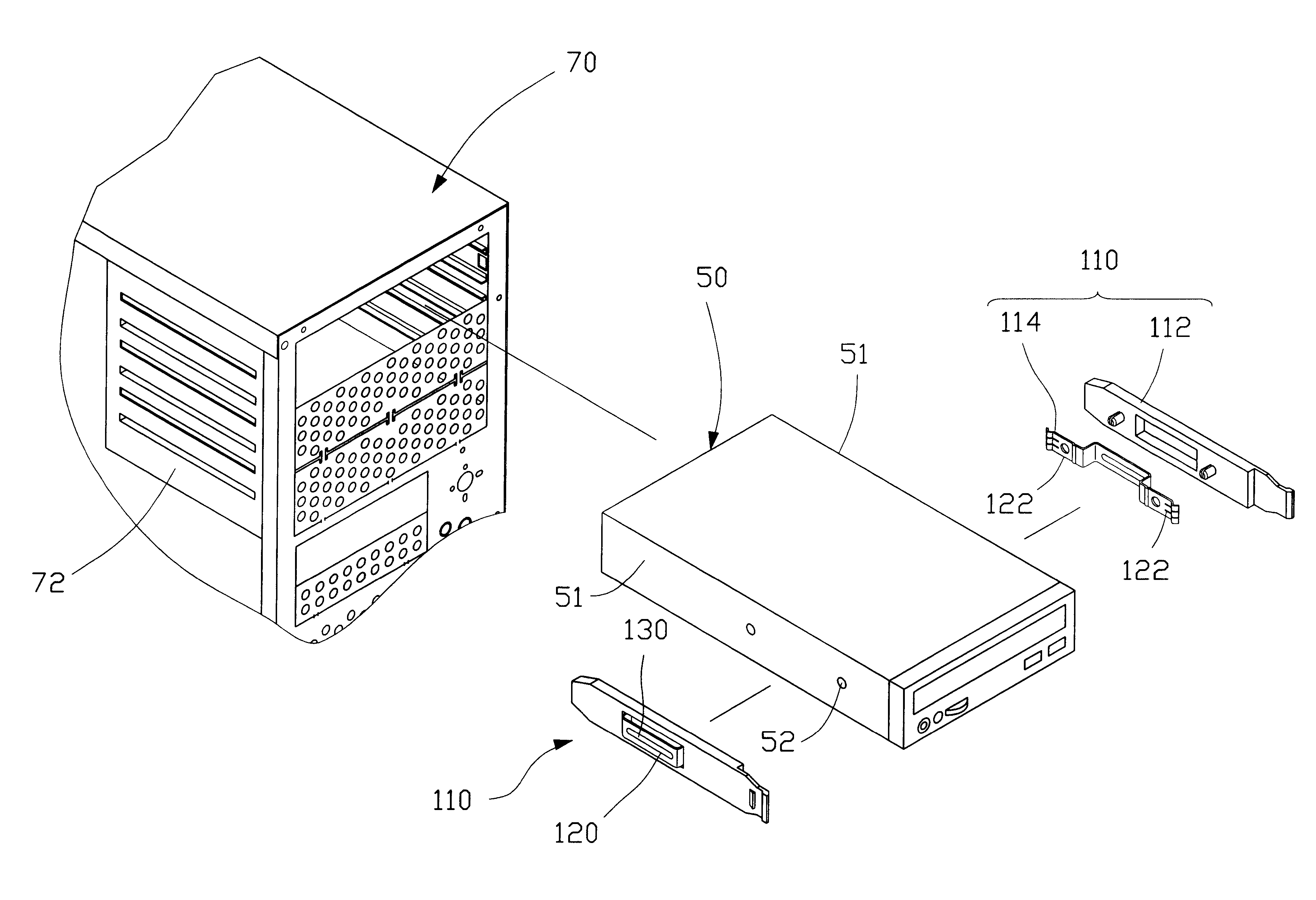

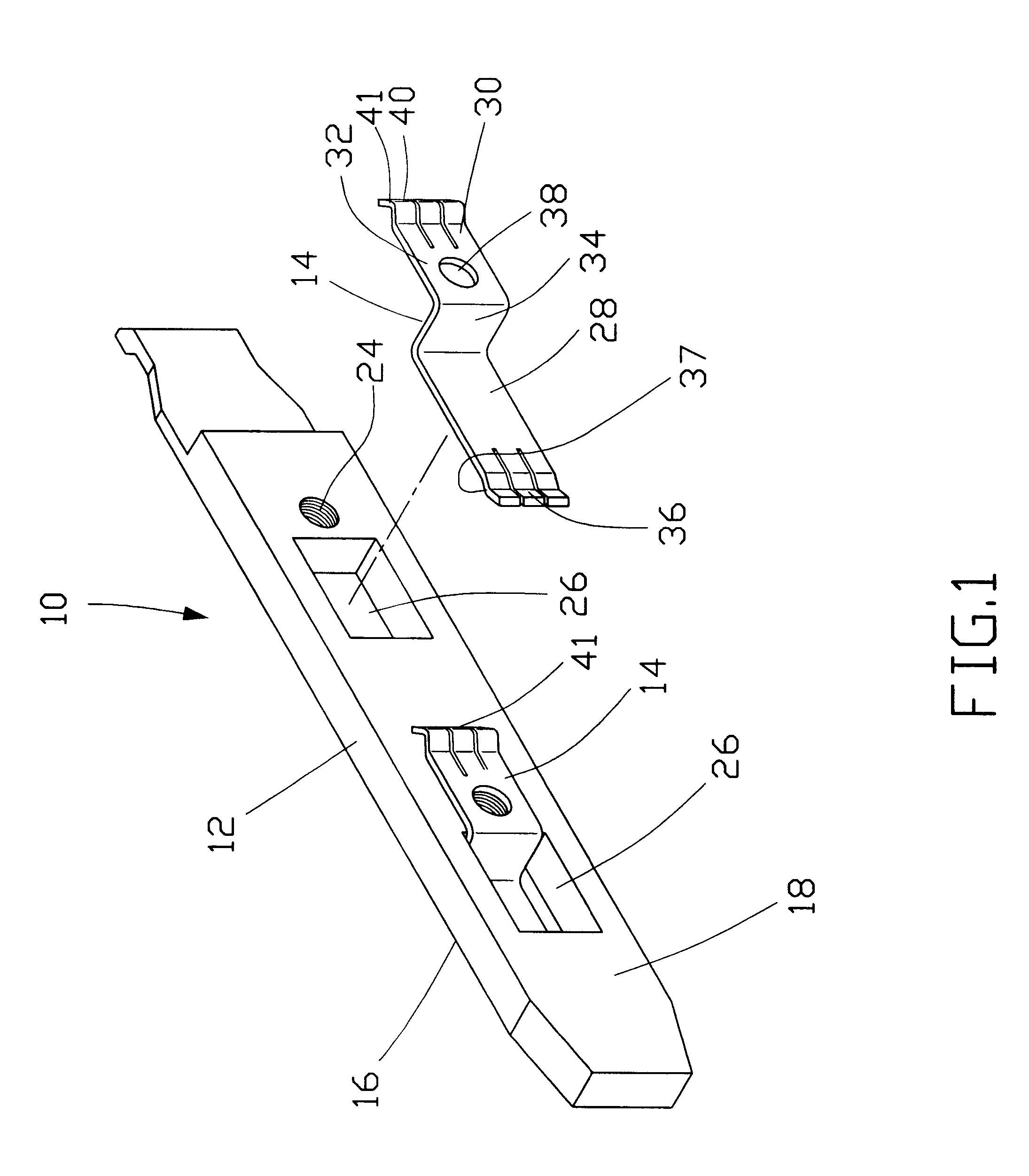

Mounting device for mounting a data storage device

A mounting device for mounting a data storage device to a receiving bracket of a computer enclosure includes a board body and at least one grounding clip. Two of the mounting devices are attached to opposite sides of the data storage device and engage with the receiving bracket. Each grounding clip includes a securing section, a first section and a second section. A bolt extends through a hole defined in the securing section of the grounding clip and a through hole defined in the board body for engaging with a screw hole defined in the data storage device thereby fixing the grounding clip and the board body to the data storage device. The fist and second sections of each grounding clip form a plurality of fingers for respectively contacting the data storage device and the computer enclosure thereby forming a grounding path therebetween while fixing the data storage device to the computer enclosure.

Owner:HON HAI PRECISION IND CO LTD

Electromagnetic wave shielding gasket having elasticity and adhesiveness

InactiveUS20090291608A1Impart conductivitySimply fabricatedScreening gaskets/sealsConductive materialEngineeringPolymer

Disclosed is a gasket having electric and adhesive properties as well as electromagnetic wave shielding functions and a method for manufacturing the same. The gasket includes an adhesive polymer sheet having electrical conductivity and being disposed in the longitudinal and transverse directions of an electroconductive substrate, so that the gasket has impact and vibration absorbing properties in addition to an adhesive property.

Owner:3M INNOVATIVE PROPERTIES CO

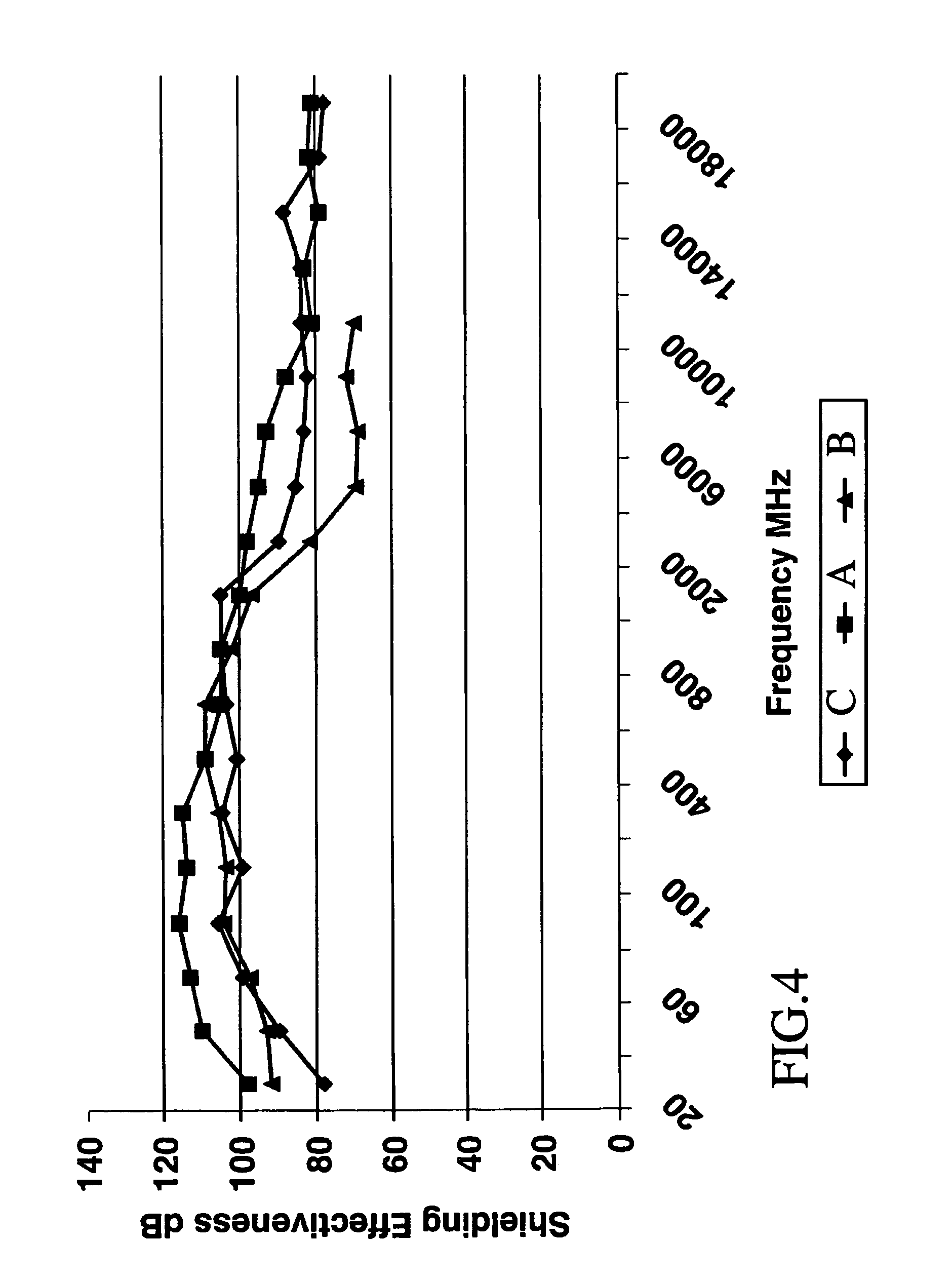

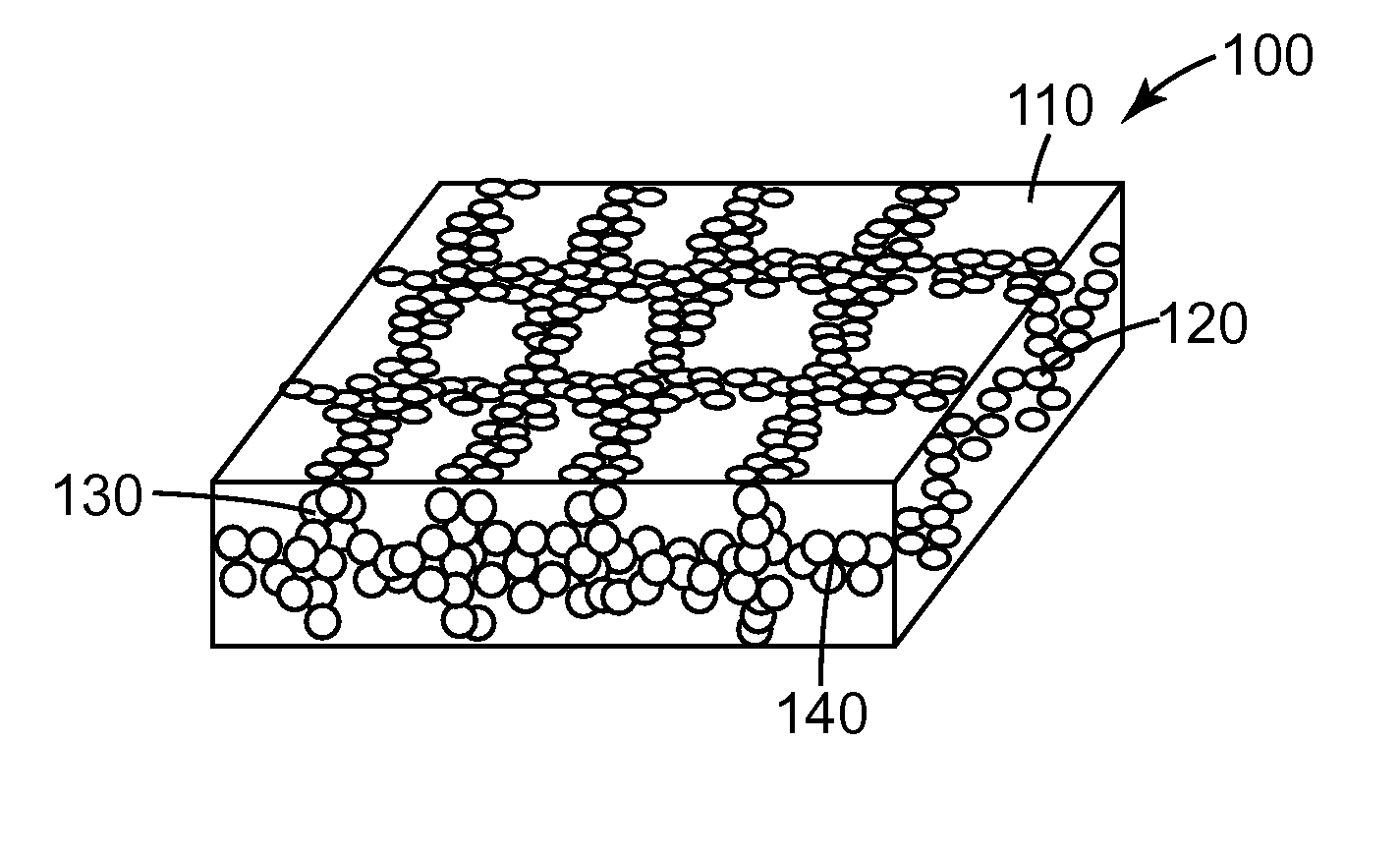

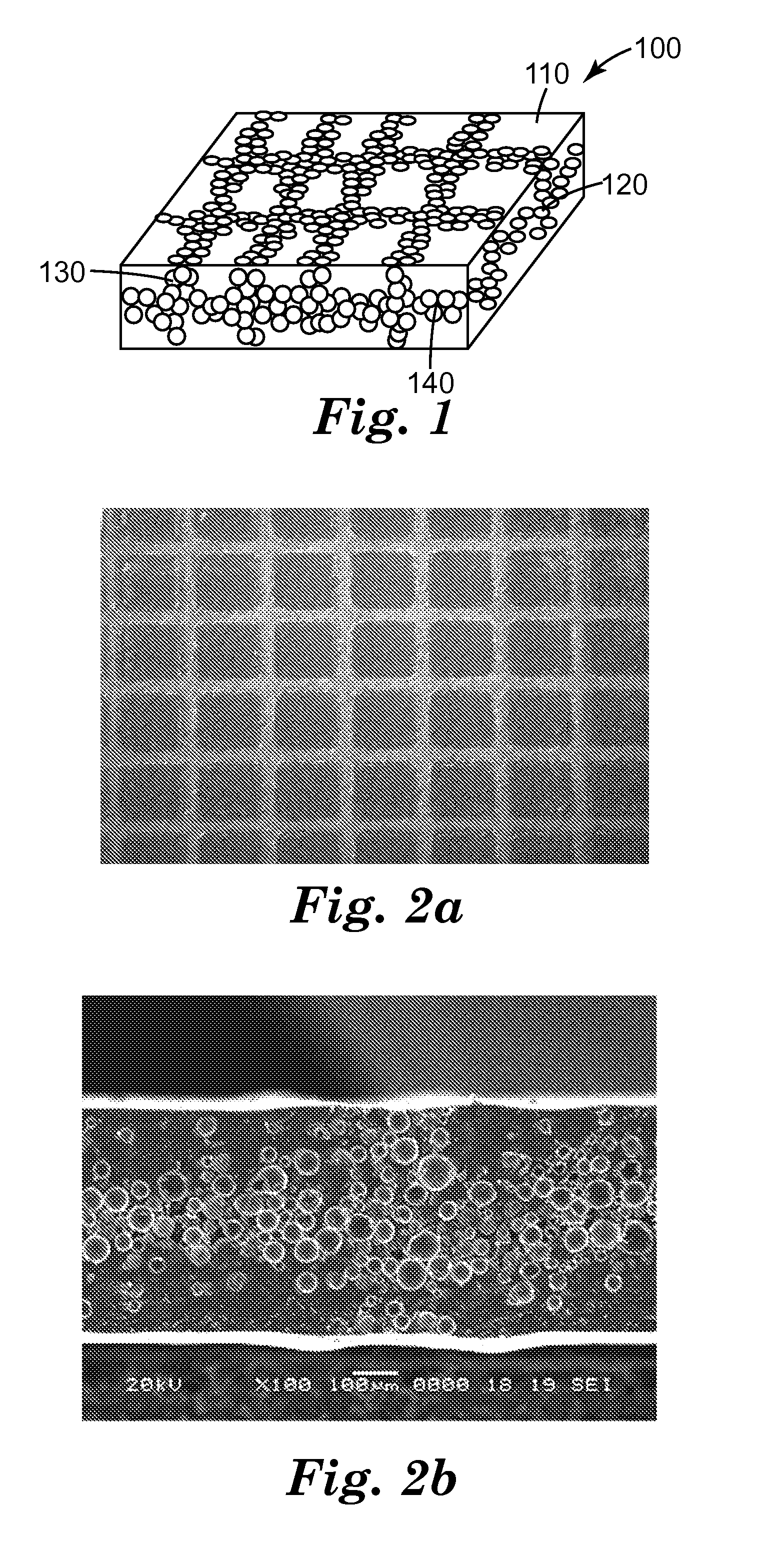

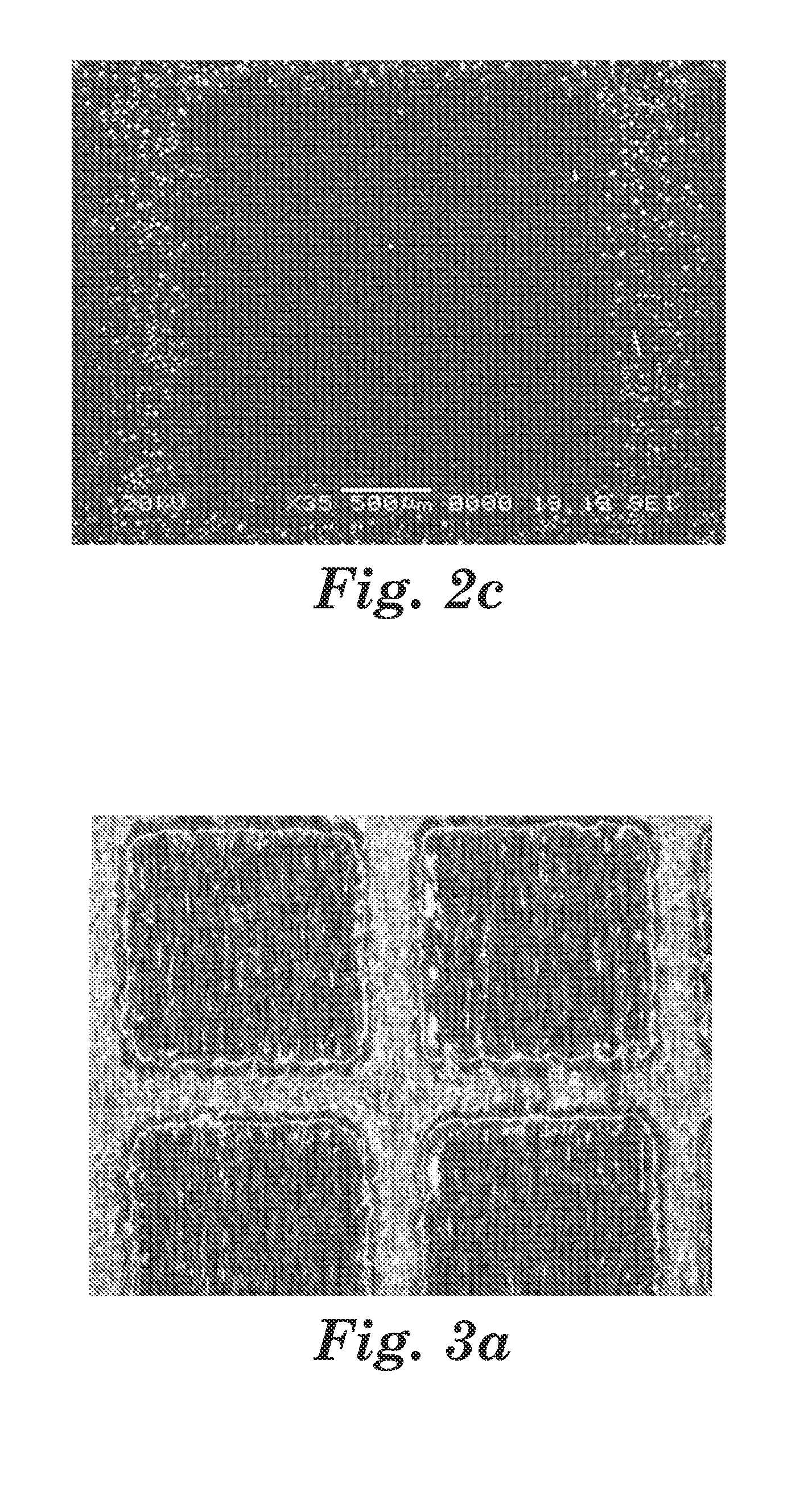

Composite polymeric material for EMI shielding

ActiveUS20070056769A1Improve conductivityScreening gaskets/sealsLayered productsPolymer scienceConductive polymer

An EMI shielding material is provided for making EMI shielding gaskets, coating and other articles. The EMI shielding material includes a non-conductive polymer, an inherently conductive polymer and a conductive metal powder. These components are intimately combined to prepare EMI shielding materials having superior electrical and mechanical performance when used in applications such as housings for electronic components.

Owner:PARKER INTANGIBLES LLC

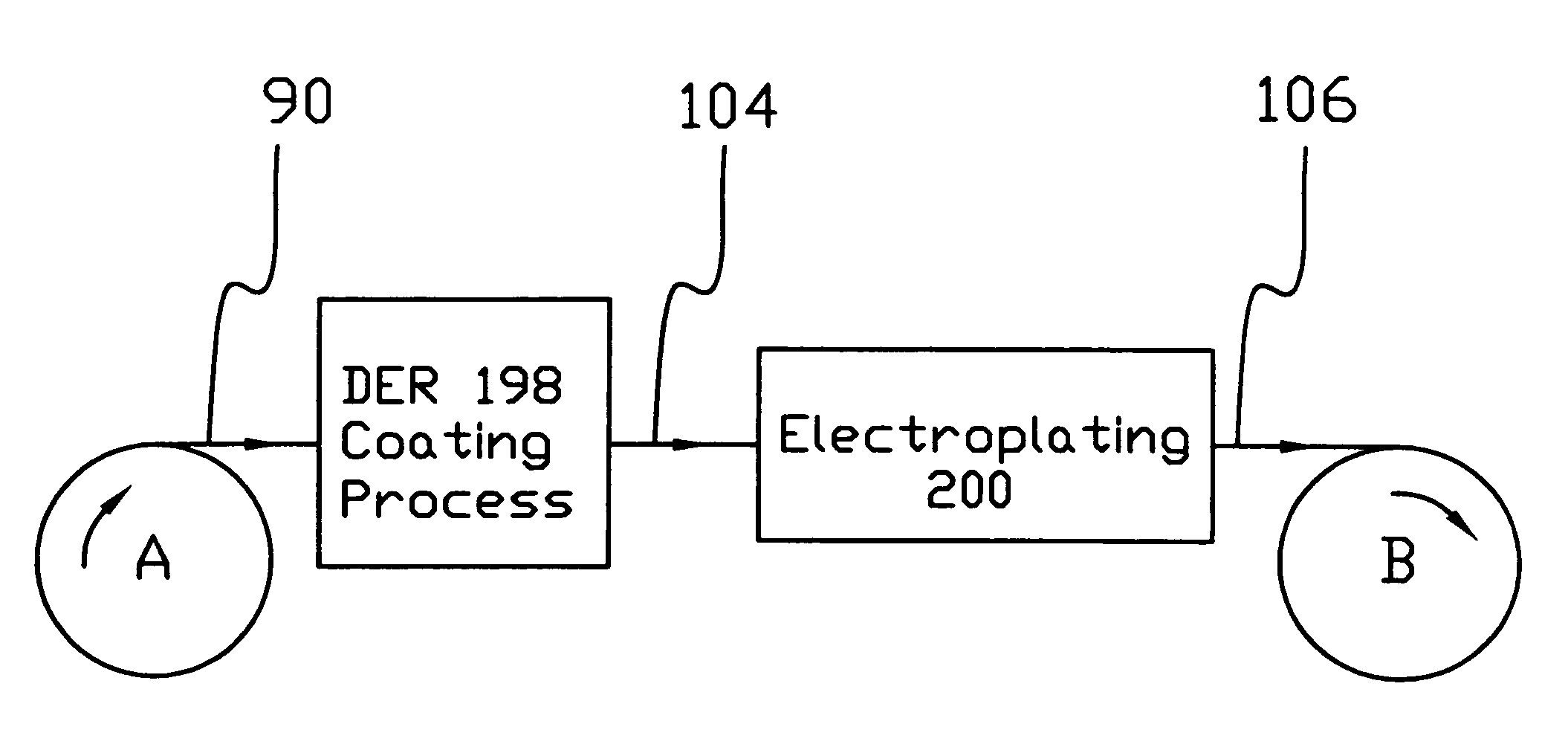

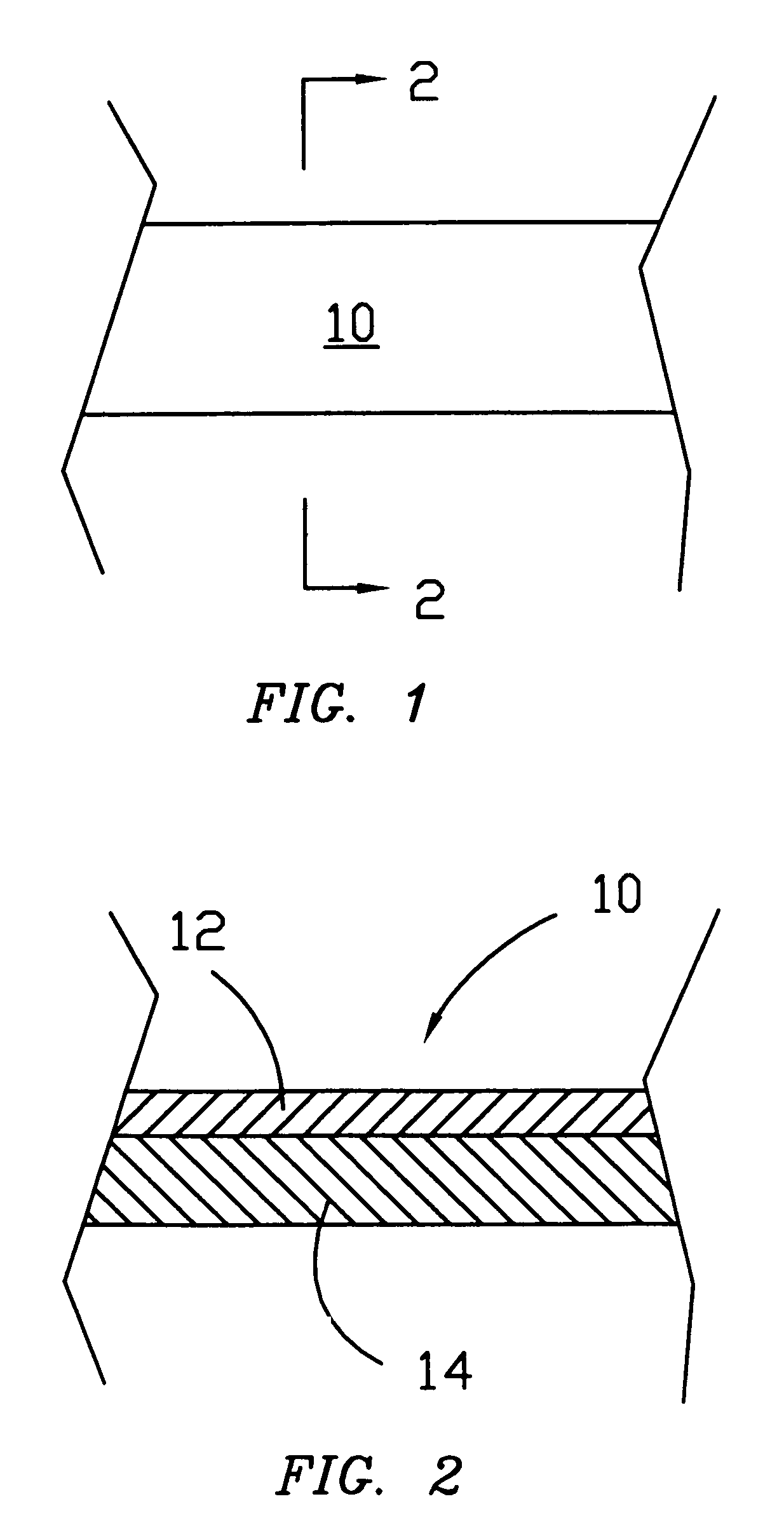

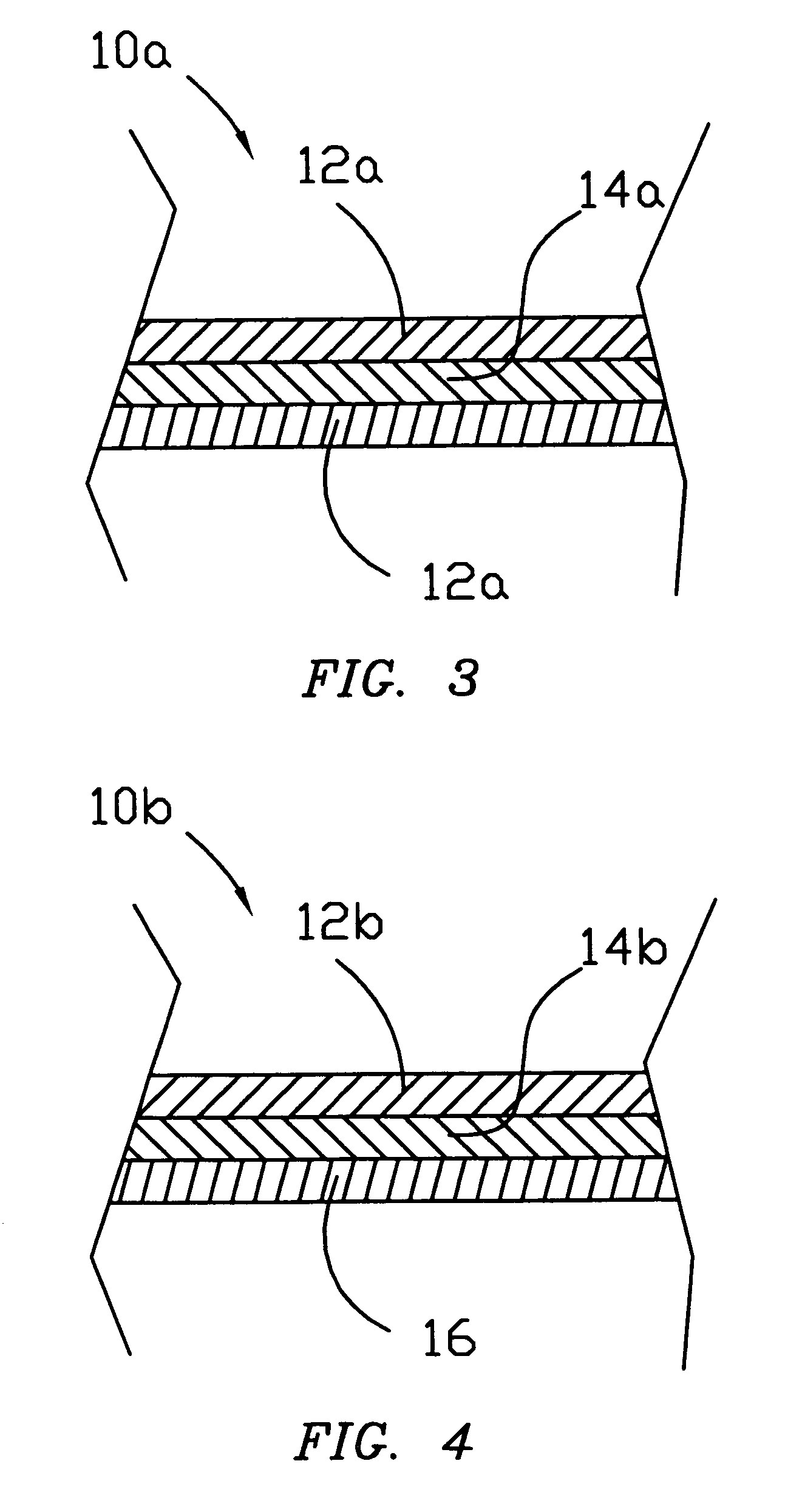

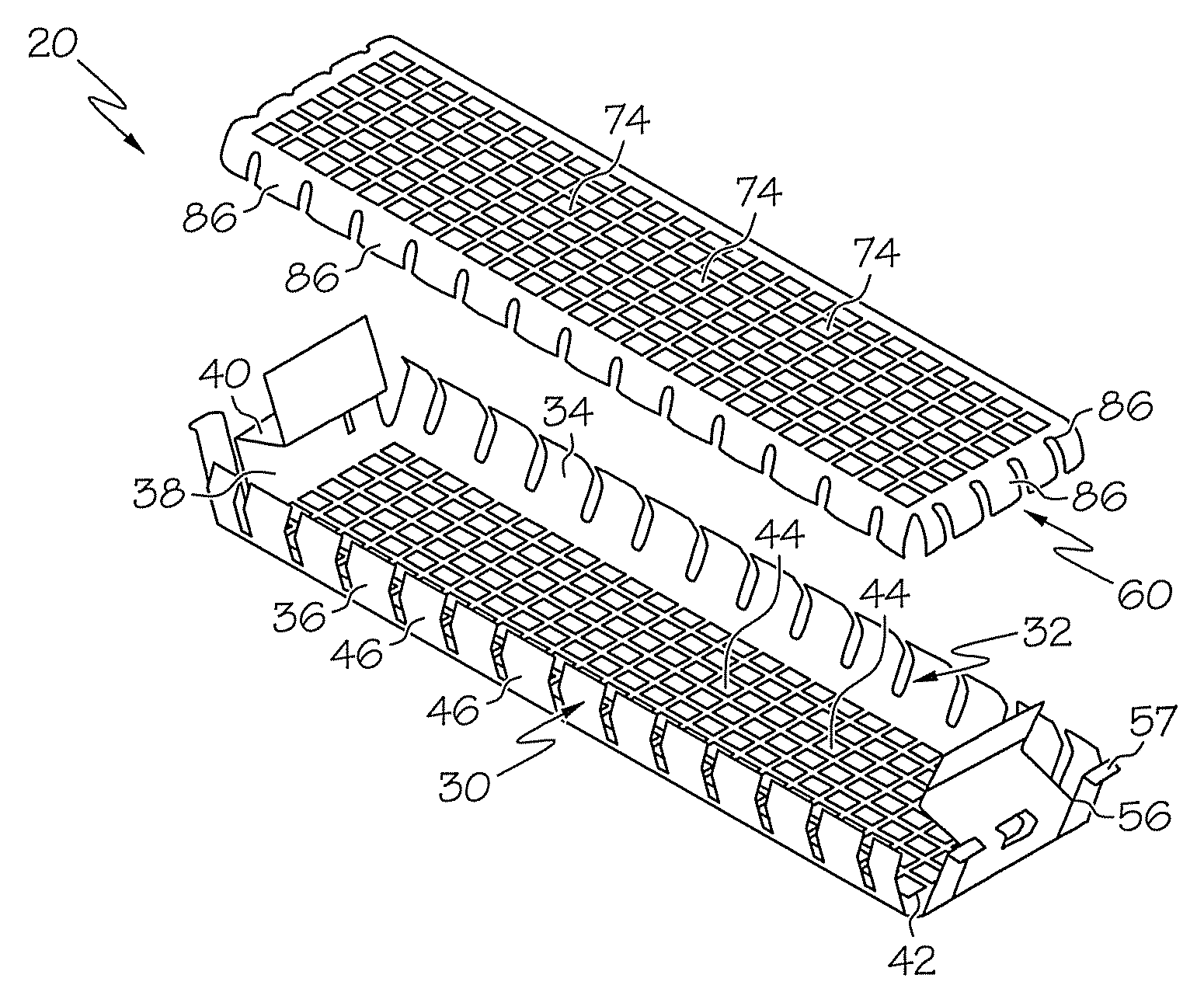

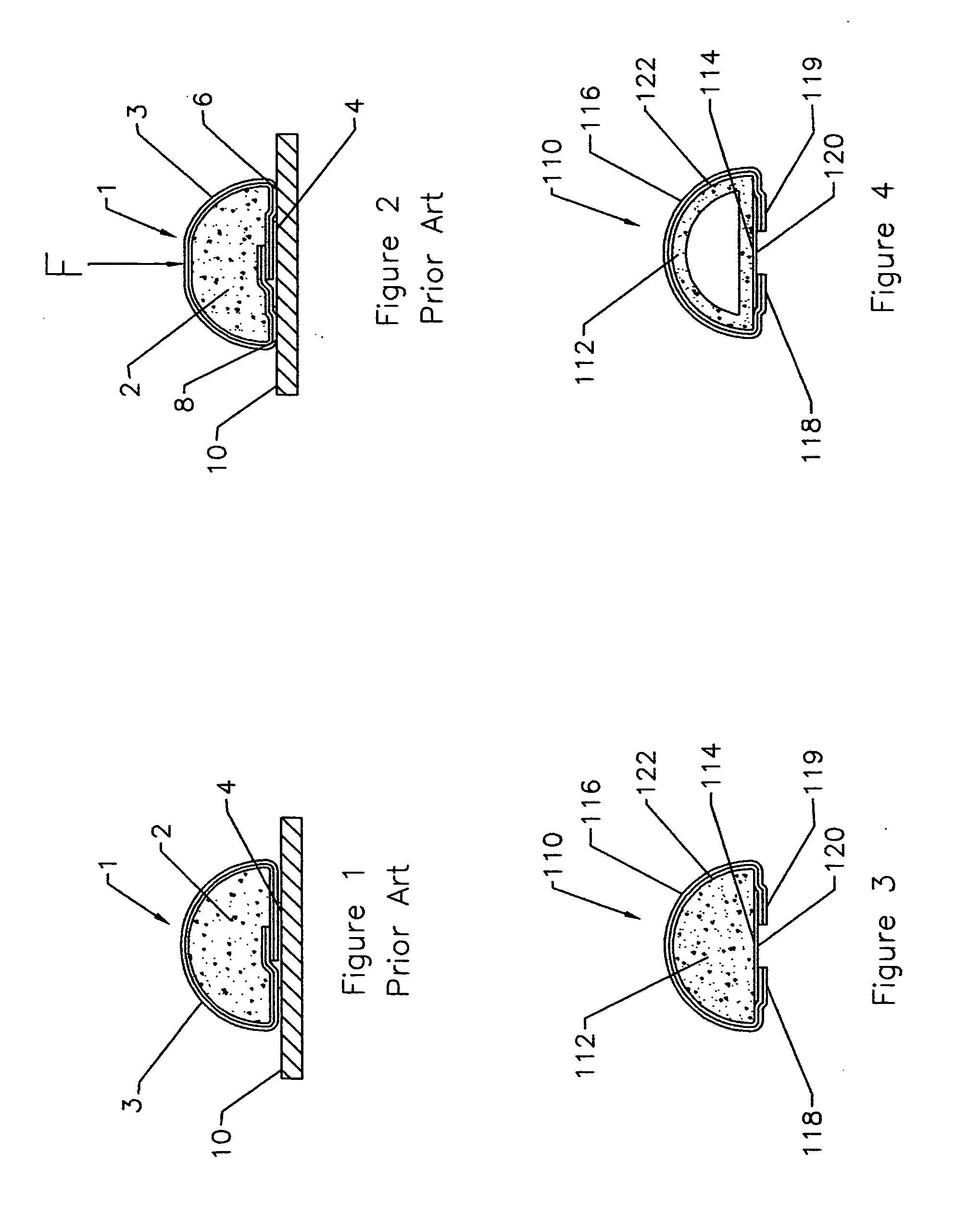

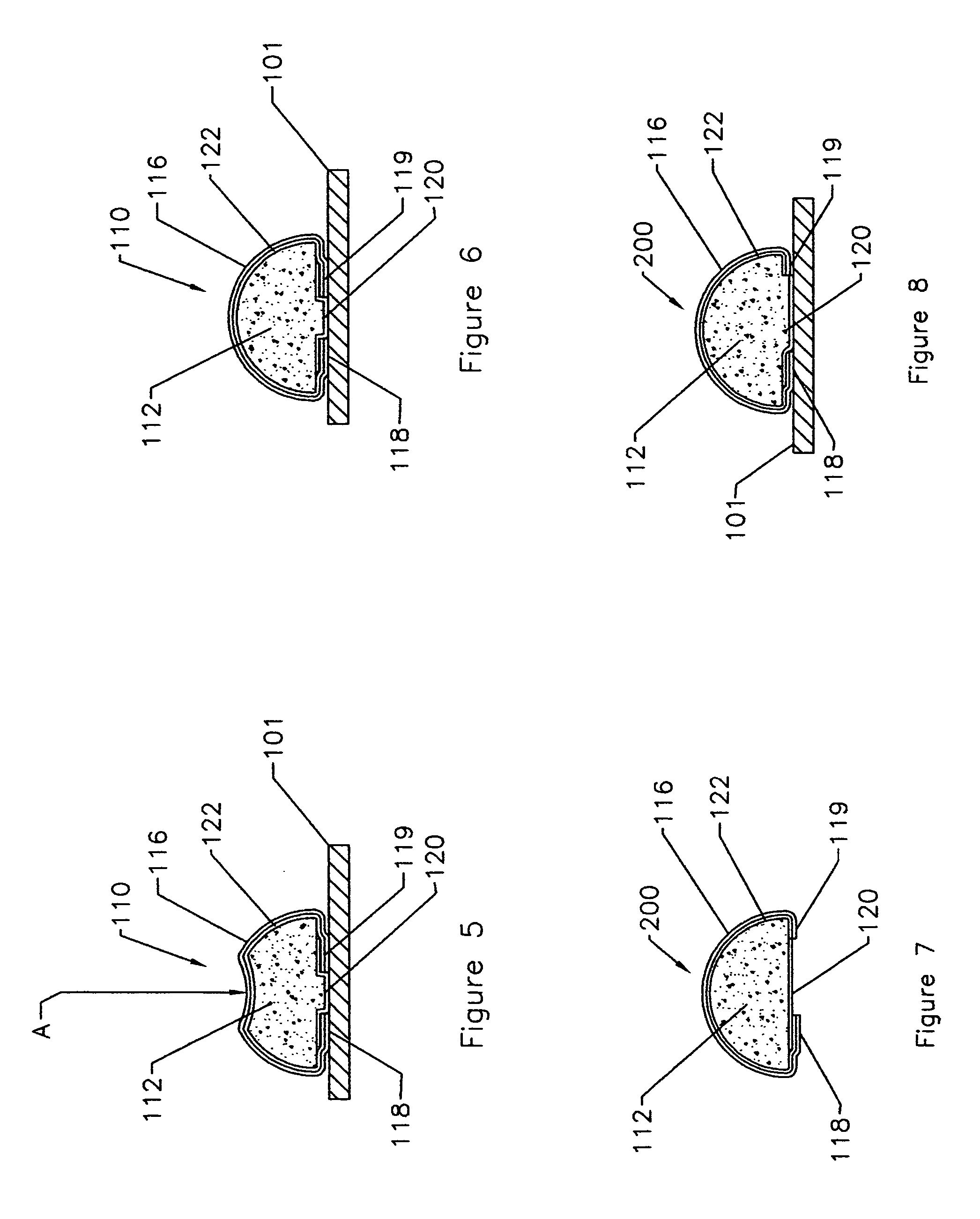

Electromagnetic interference shields and methods of manufacture

InactiveUS7120005B1Improve shielding effectDesign flexibility is limitedScreening gaskets/sealsRelaysElectromagnetic interferenceEngineering

The invention teaches improved materials and processes for production of structures to shield against ingress or egress of electromagnetic radiation. The structures and processes taught are based on the recognition and use of directly electroplateable resins. The directly electroplateable resins are combined with electrodeposited metal-based coatings to result in uniquely suitable structures to achieve radiation shielding. Fabrication and compositional flexibility of directly electroplateable resins and low cost material possibilities contribute to the unique suitability of directly electroplateable resins in the production of improved electromagnetic radiation shields.

Owner:LUCH DANIEL

EMC gasket filler and method

InactiveUS7491900B1Screening gaskets/sealsSubstation/switching arrangement boards/panels/desksEngineeringElectrical and Electronics engineering

An electromagnetic gasket includes a first conductive shell having a pair of first side walls and a pair of first end walls extending from a first bottom wall defining a first opening, the pair of first side walls each having at least one first outward bias positioned thereon, the pair of first end walls each having a first tab extending therefrom, and the first bottom wall having an array of first openings and a pair of apertures; and a second conductive shell having a pair of second side walls and a pair of second end walls extending from a second bottom wall defining a second opening, the pair of second side walls and pair of second end walls each having at least one second outward bias positioned thereon, and the second bottom wall having an array of second openings. The First outward bias is configured to electrically connect to an inner surface defining an empty slot of an electrical enclosure. The second outward bias electrically connects the second conductive shell to first conductive shell when the second conductive shell is disposed within the first opening defined by the first conductive shell.

Owner:IBM CORP

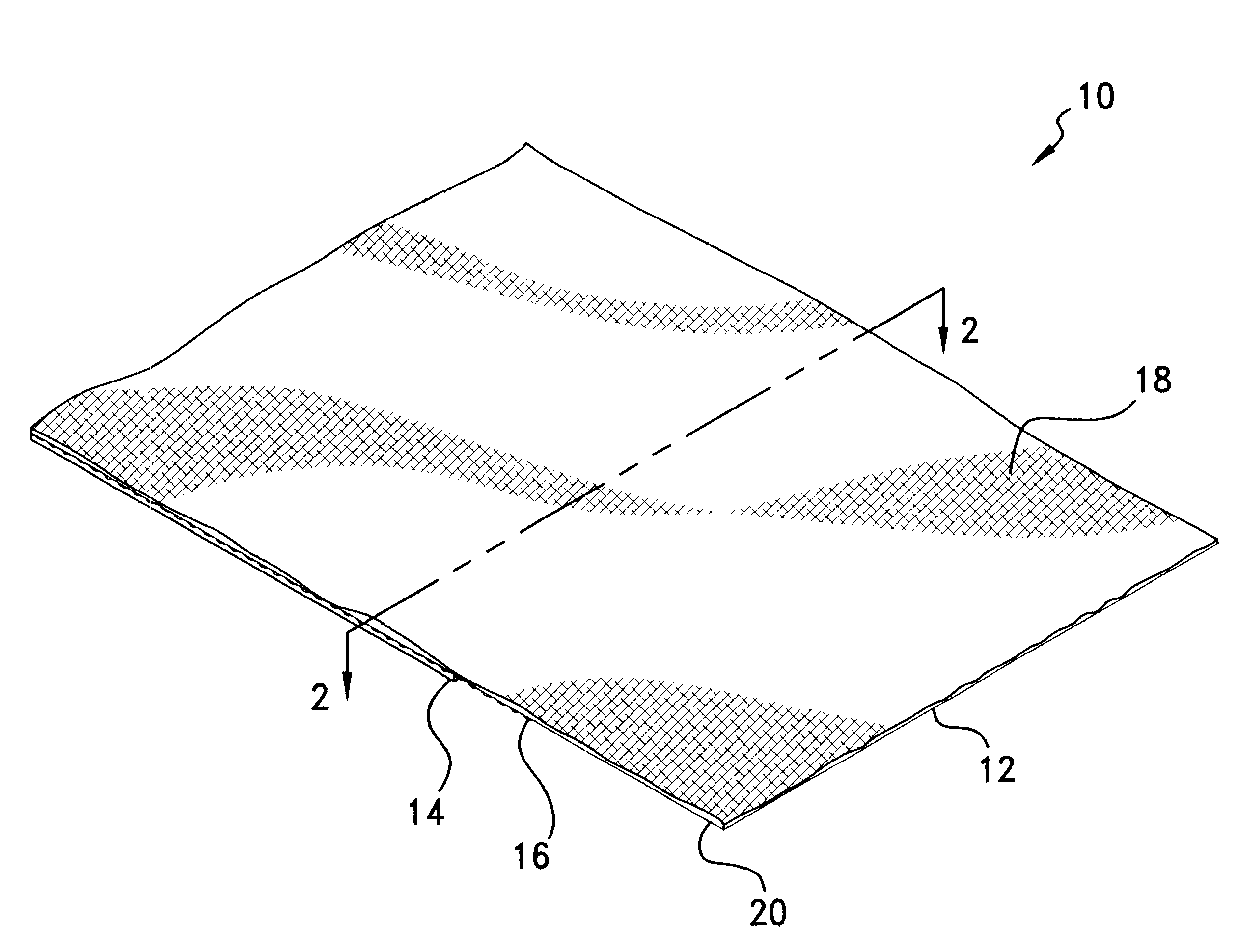

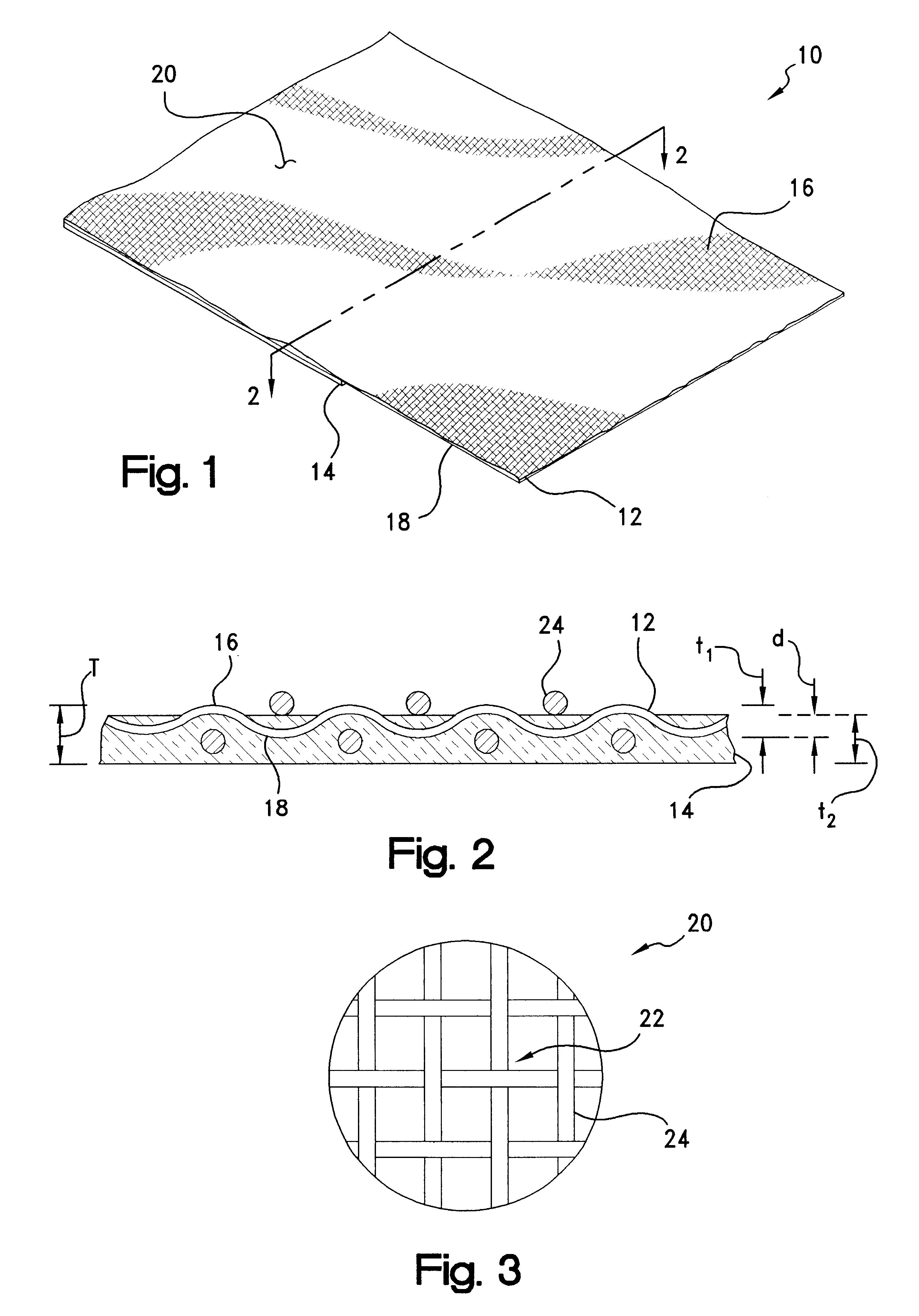

Flame retardant EMI shielding materials and method of manufacture

InactiveUS6248393B1Maintains drapabilityEasy constructionScreening gaskets/sealsPretreated surfacesEngineeringViscosity

An flame retardant, electrically-conductive EMI shielding material and method, the material being particularly adapted for use in fabric-over-foam EMI shielding gasket constructions. In construction, a generally planar, porous fabric member is provided as having at least an electrically-conductive first side and a second side defining a thickness dimension therebetween. A curable layer of a fluent, flame retardant composition is applied under a predetermined hydrodynamic pressure and viscosity to at least a portion of the second side of the fabric member. The hydrodynamic pressure and viscosity of the composition are controlled to delimit the penetration of the layer into the fabric member to a depth which is less than the thickness dimension of said fabric member. The layer then is cured to form a flame retardant surface coating on the second side of the fabric member such that the first side of said fabric member remains electrically-conductive.

Owner:PARKER INTANGIBLES LLC

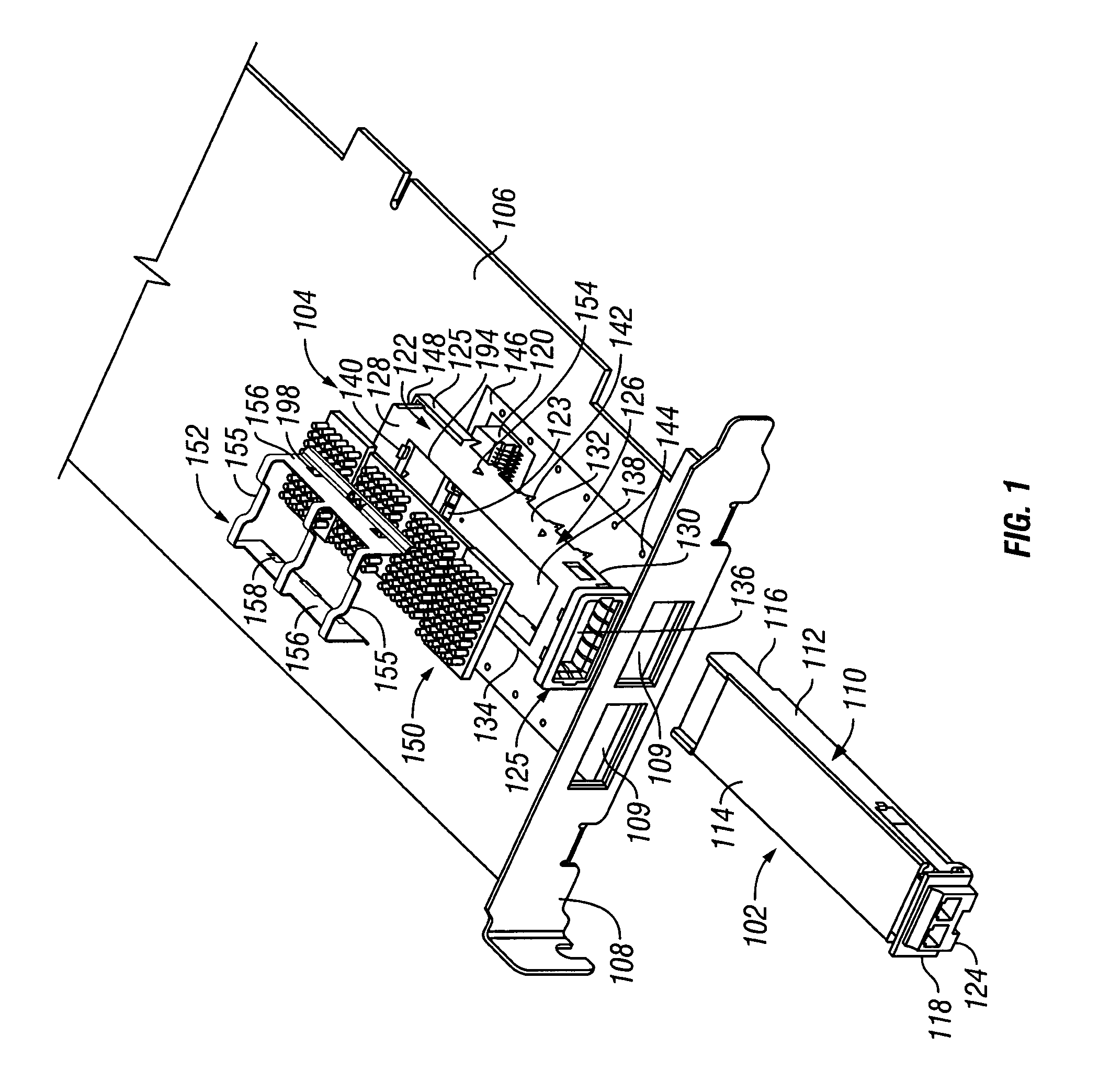

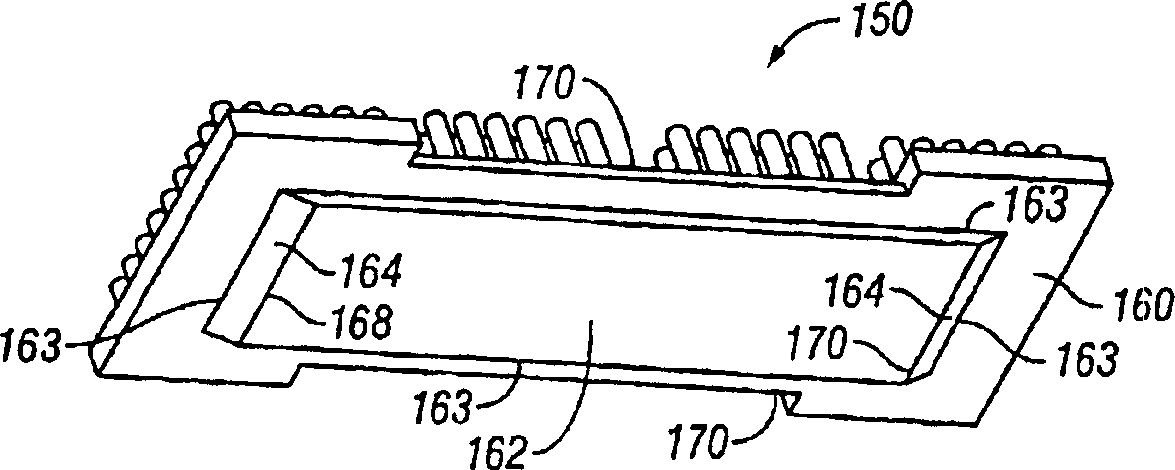

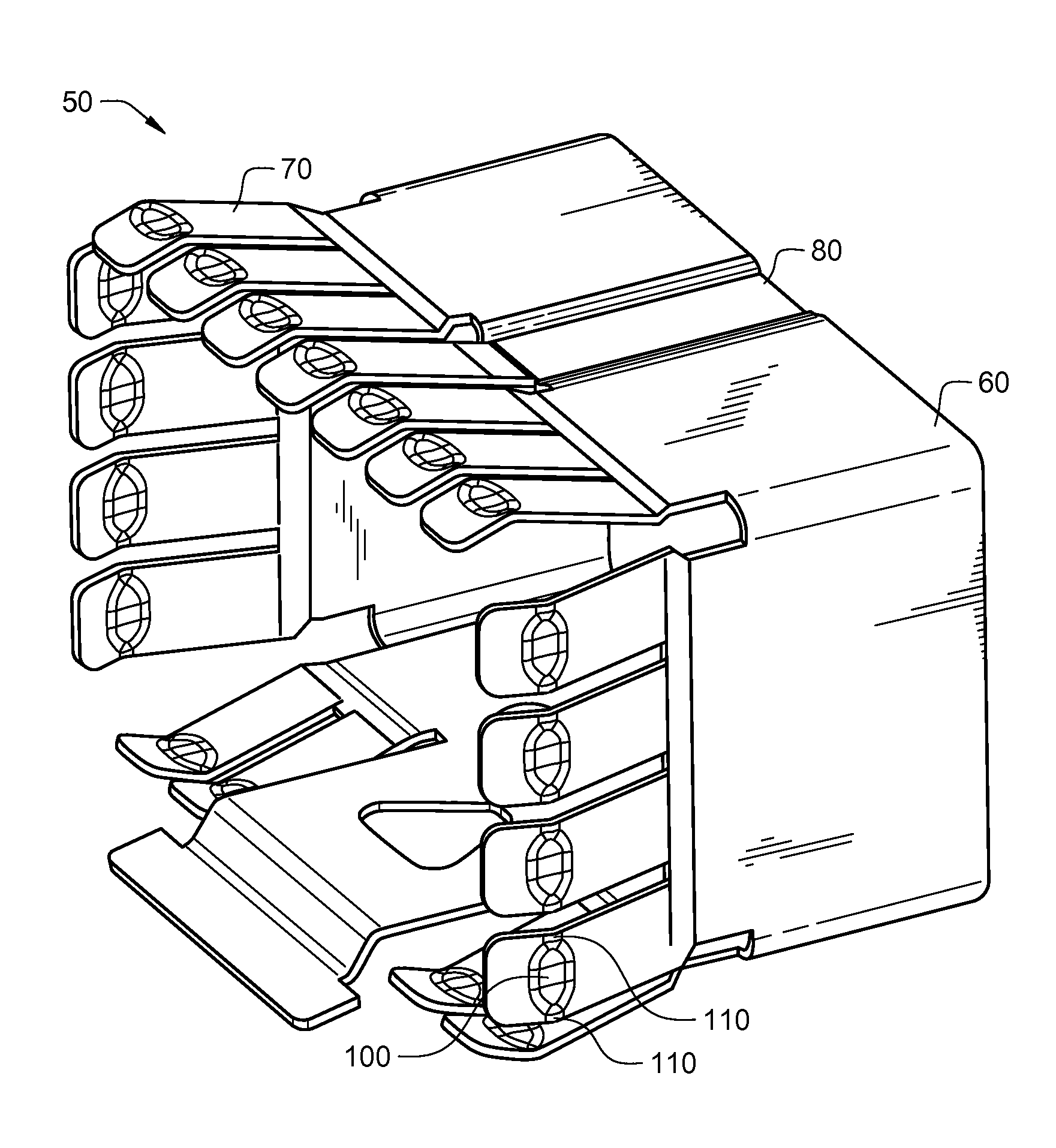

Pluggable electronic module and receptacle with heat sink

InactiveCN1647599AEngagement/disengagement of coupling partsScreening gaskets/sealsLeading edgeComputer module

A receptacle assembly includes a guide frame having a front end with an opening to an interior cavity of the guide frame. The opening is configured to receive a module assembly. The guide frame has a bottom with a bottom opening to the interior cavity, and the bottom is configured to be joined to a circuit board. An EMI gasket is provided along at least a portion of a perimeter of the bottom opening to be held between the guide frame and a circuit board. The EMI gasket forms a shielded interface along the portion of the perimeter of the bottom opening. Conductive straps are provided along the leading edge of the opening and have widths sufficient to cover a substantial majority of the leading edge to form a shielded interface along the leading edge. An EMI gasket including a skirt extending partially along a portion of the perimeter of the bottom opening is also provided.

Owner:TE CONNECTIVITY CORP

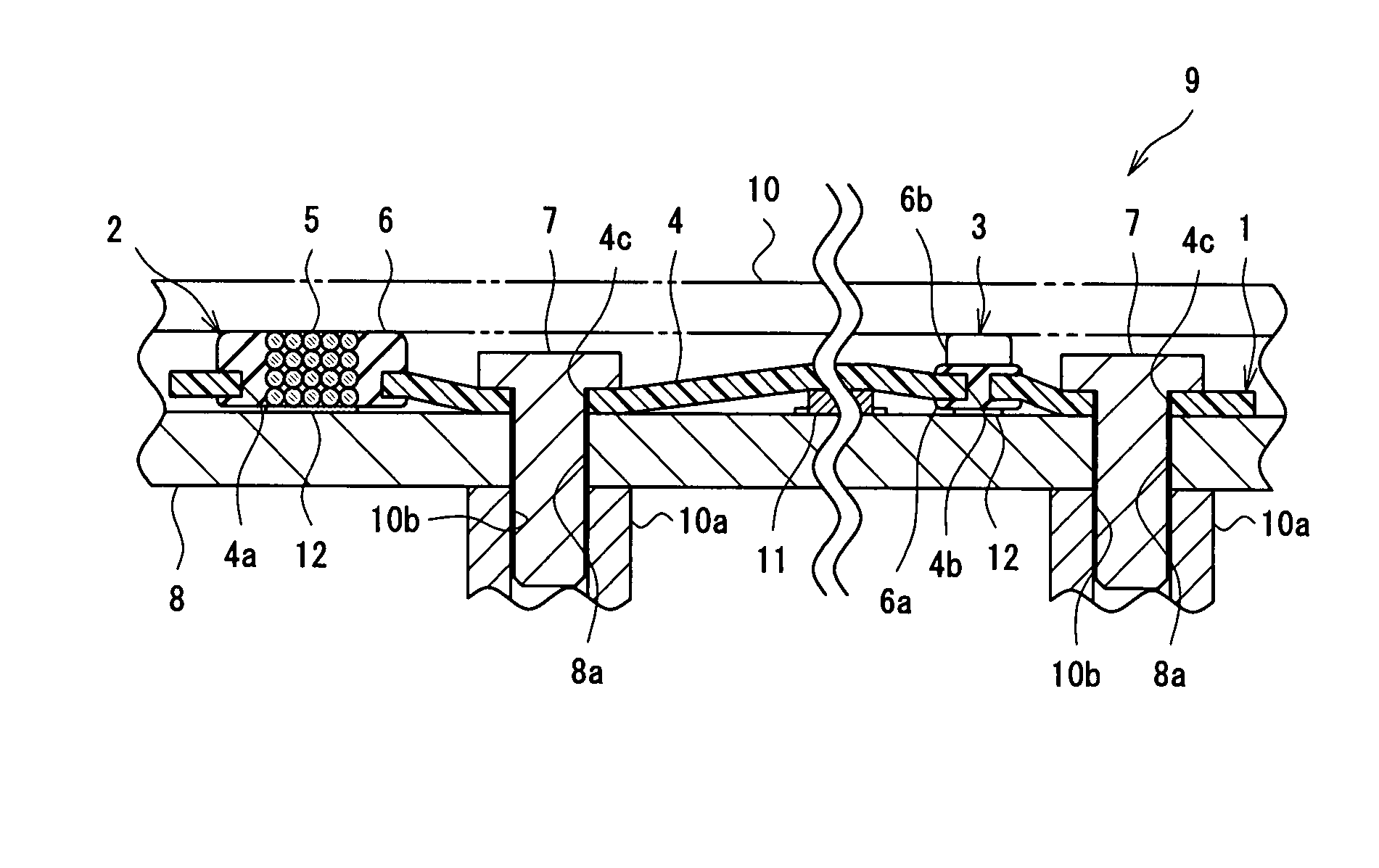

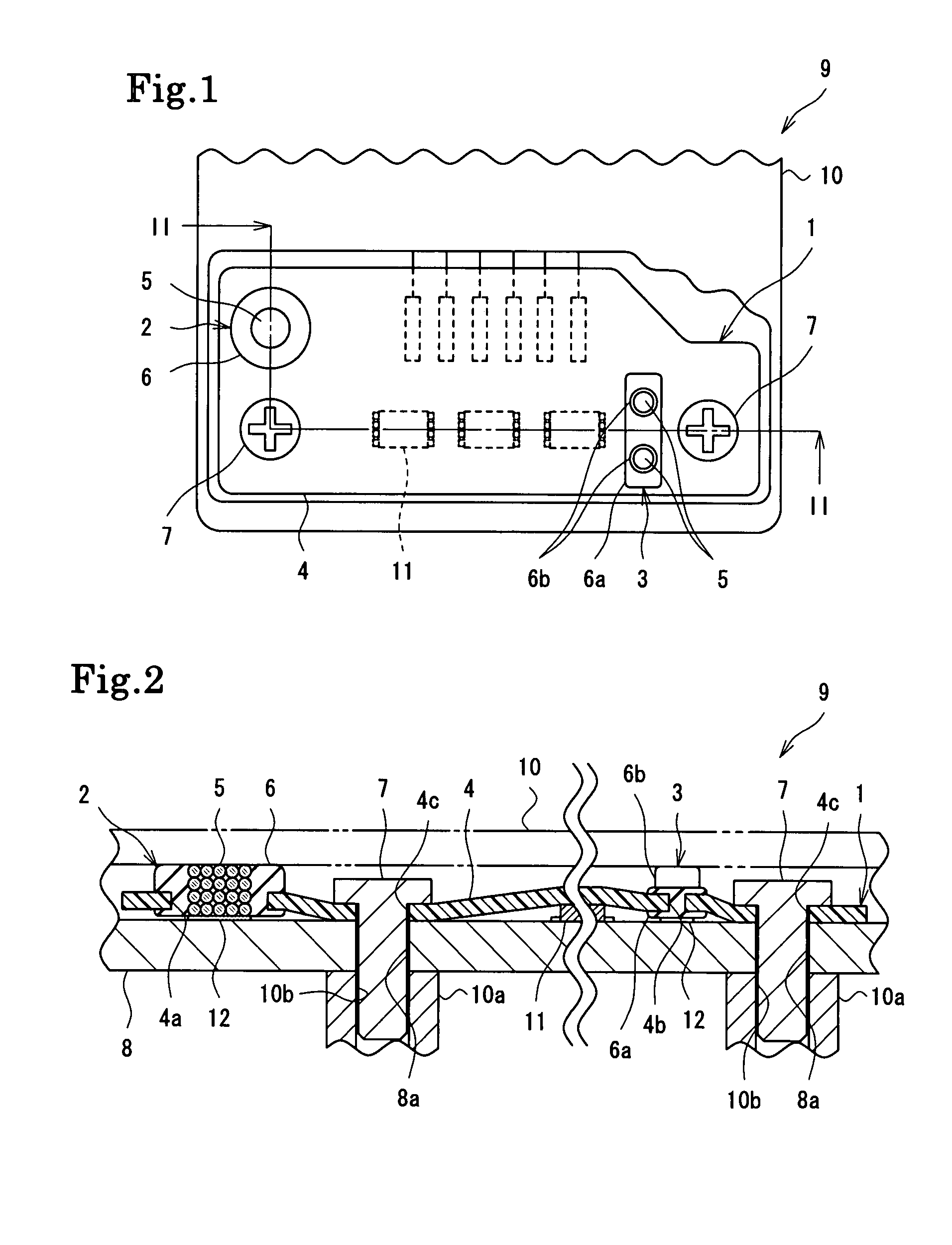

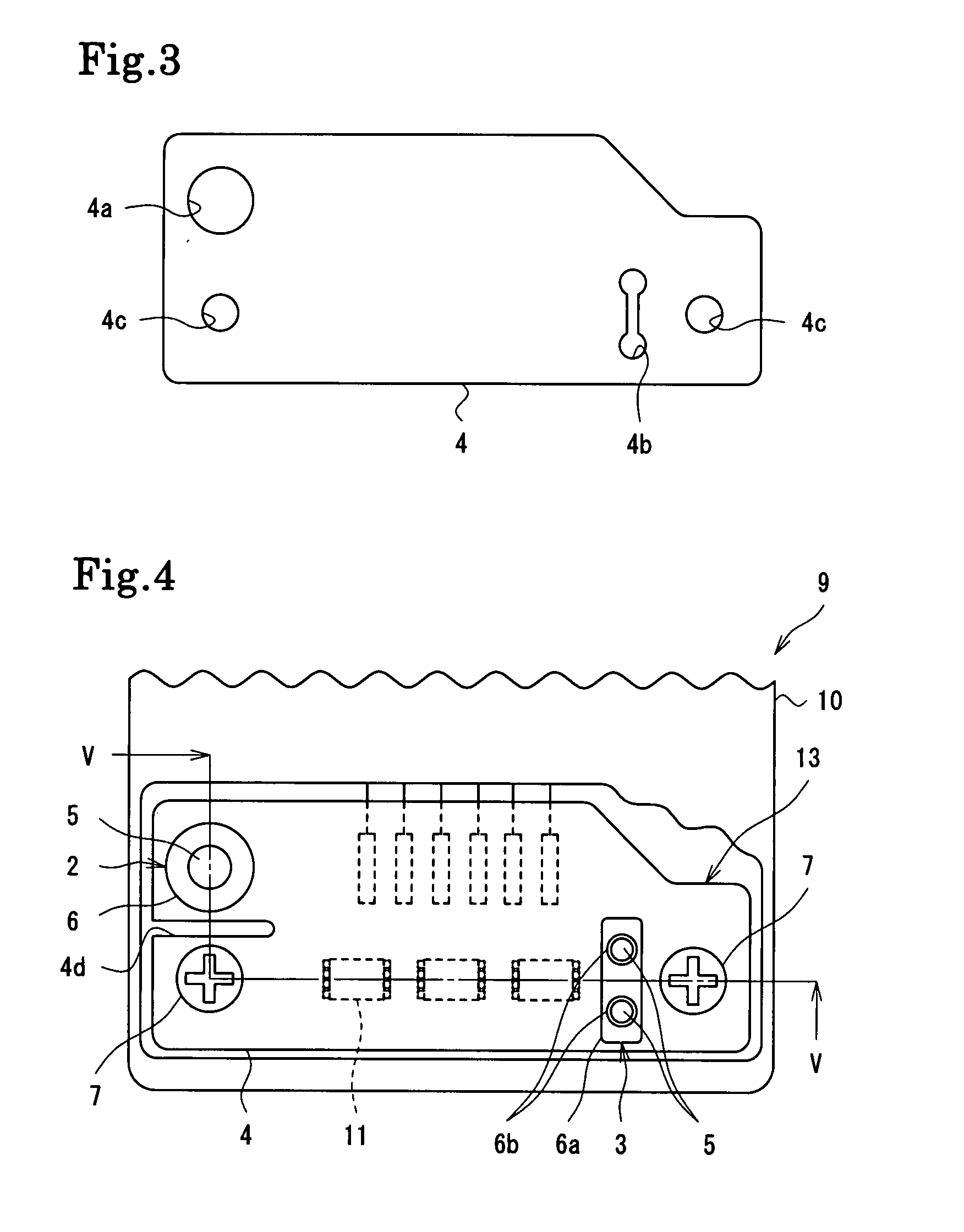

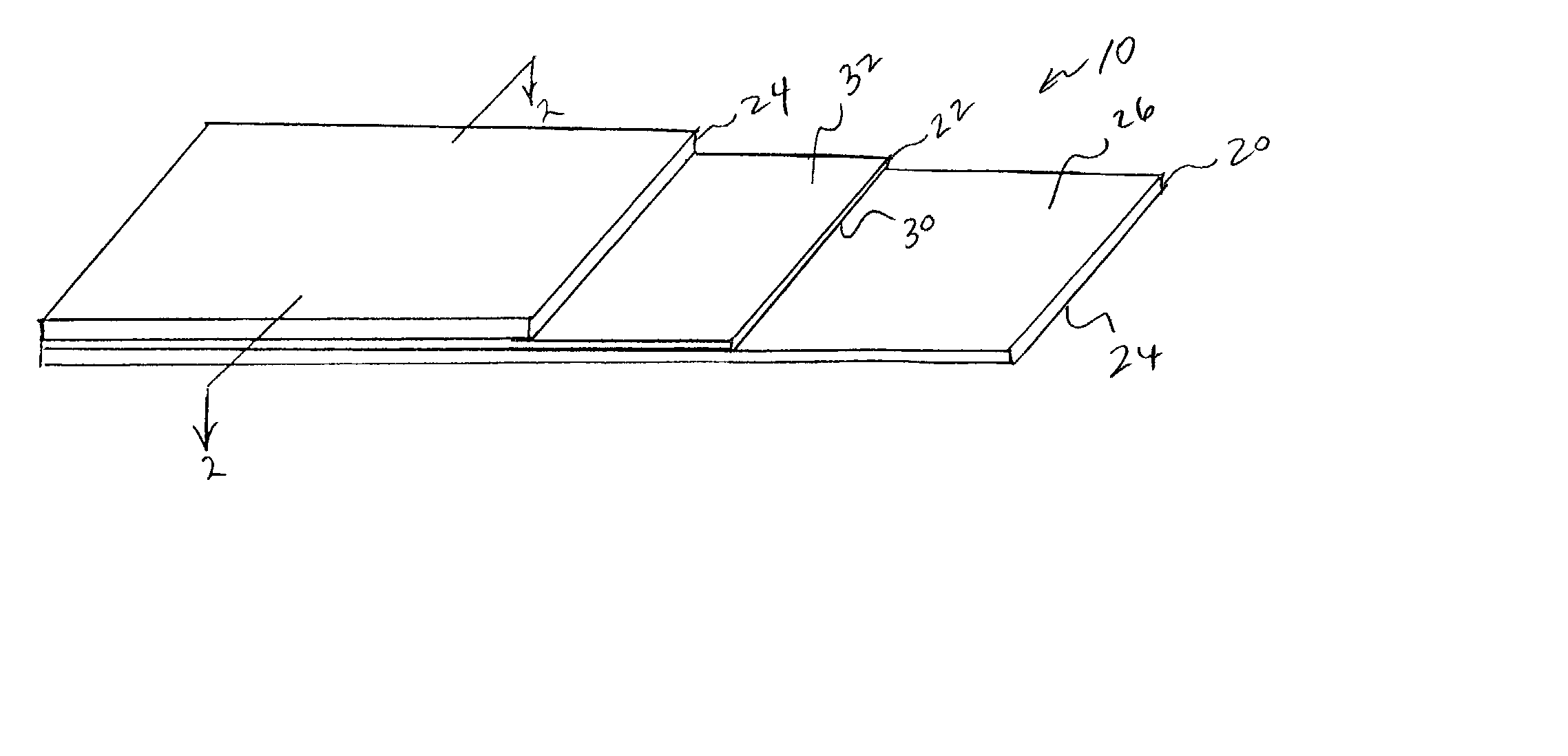

Connector sheet and portable electronic apparatus

InactiveUS20070195512A1Simplify the installation processSmall sizeScreening gaskets/sealsPrinted circuit groundingMetalStatic electricity

Provided is a connector sheet exhibiting requisite conduction property for removal of electromagnetic wave noise and static electricity, allowing ground connection between a metal portion of a casing and a circuit board through a simple mounting operation, and capable of meeting requirement for a reduction in electronic apparatus size, and a portable electronic apparatus equipped with the same. The connector sheet is conductively connected to a metal casing and a ground-connecting portion of a circuit board through a conducting portion of a connector portion in which conductive particles are serially oriented. Further, the connector portion and a resin sheet are integrated with each other.

Owner:POLYMATECH CO LTD

Form-in-place EMI gaskets

InactiveUS6331349B1Prevent and reduce potentialMinimal investmentScreening gaskets/sealsConductive materialElastomerEngineering

A form in place conductive gasket is disclosed. The gasket, foamed, gelled or unfoamed is made of one or more elastomer resins, such as silicone urethane and / or thermoplastic block copolymers and is either filled with a conductive filler and lined onto a desired substrate or lined onto the substrate unfilled and then coated with a conductive outerlayer, such as a silver filled elastomer or a conductive flocked layer. A process and system for making the gaskets are also disclosed.

Owner:PARKER INTANGIBLES LLC

Electronic chassis electro-magnetic interference seal and sealing device

InactiveUS6140577AMinimize Electro-Magnetic Interference (EMI) leakageEliminate needElectrically conductive connectionsScreening gaskets/sealsElectromagnetic interferenceComputerized system

An improved apparatus for reducing and minimizing Electro-Magnetic Interference (EMI) leakage from electrical devices or assemblies contained in a cabinet or other similar enclosure such as a computer system unit. Spring fingers or arms contained in the enclosure force two adjacent faces of the enclosure components together to create an EMI minimizing seal.

Owner:GATEWAY

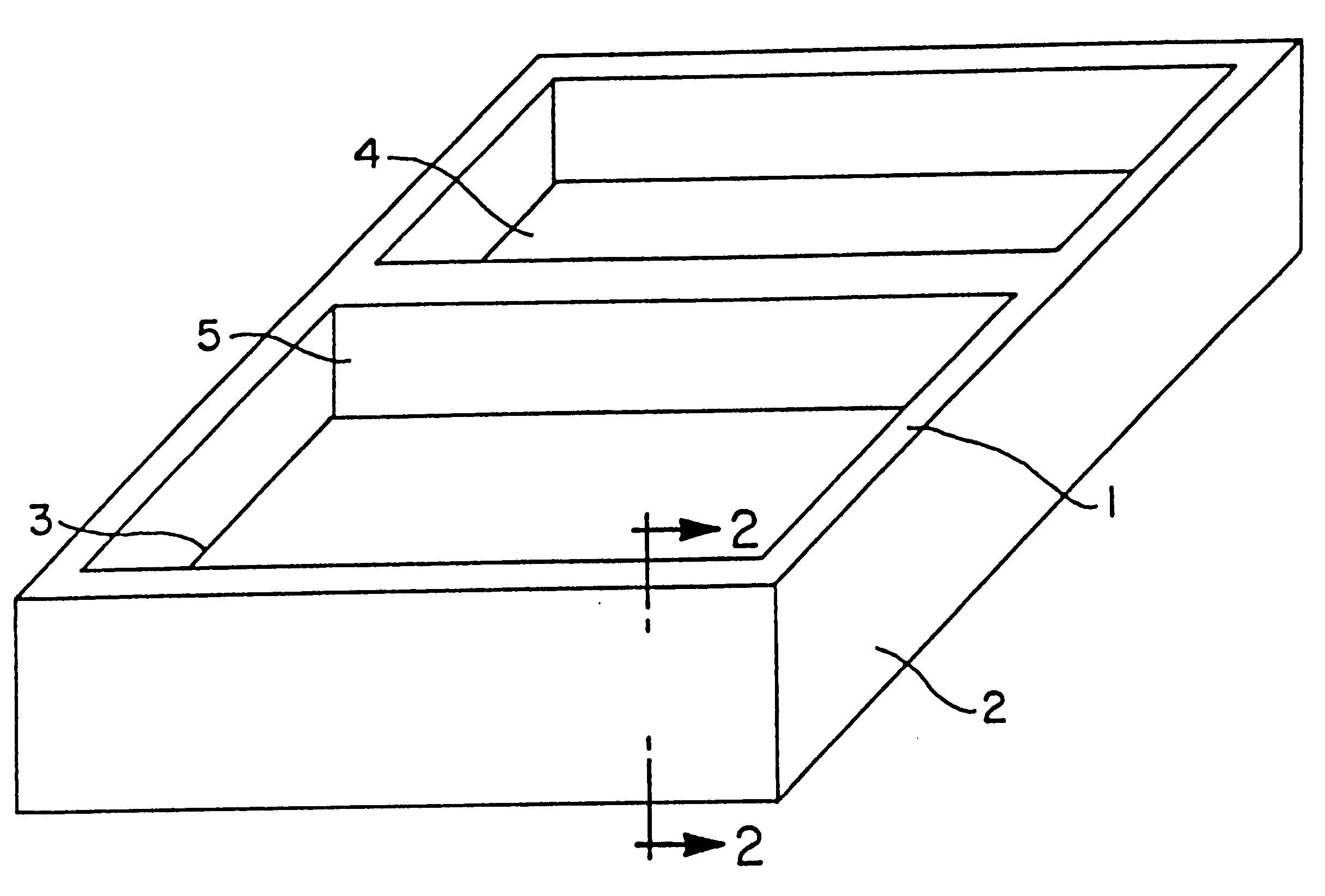

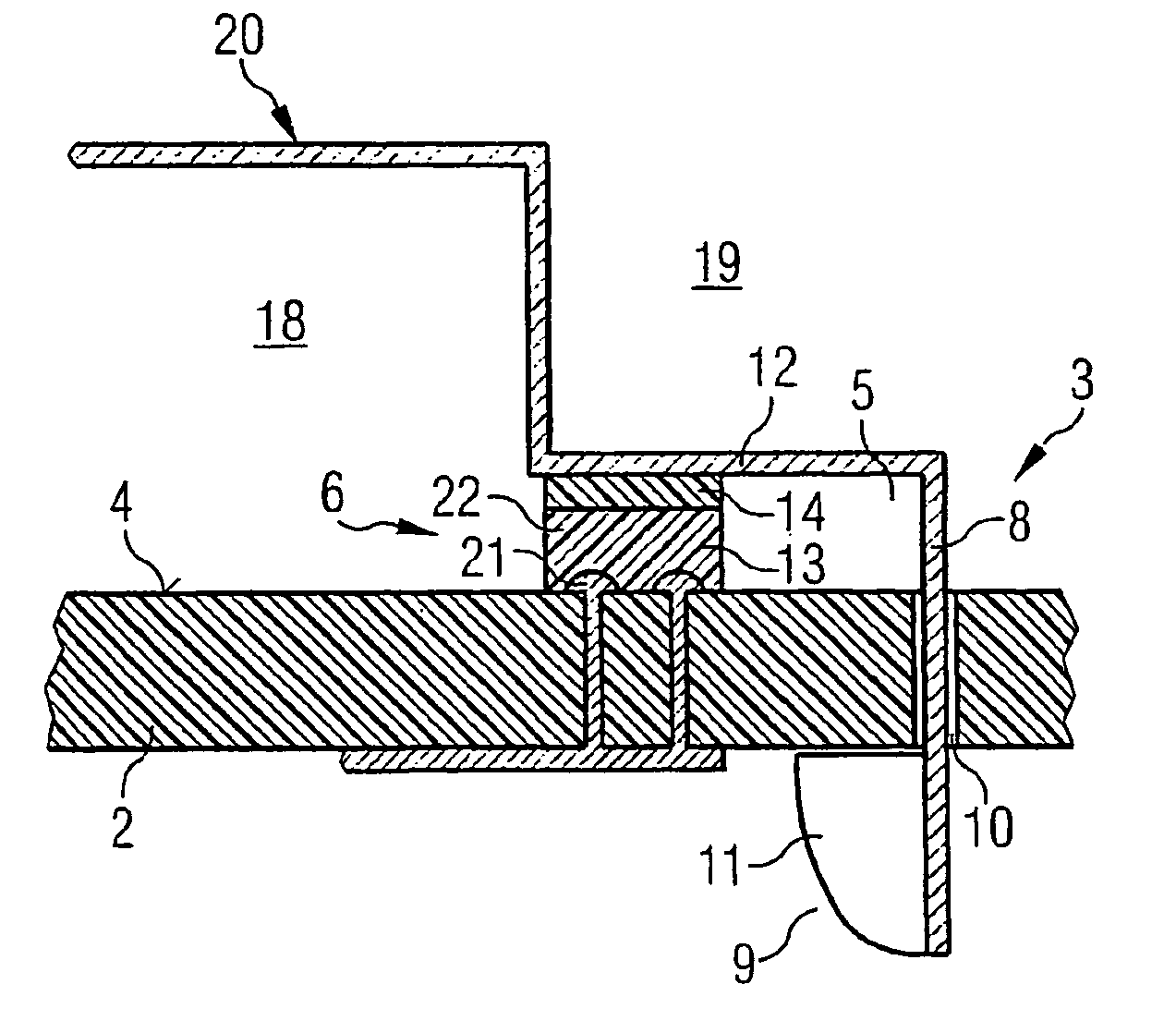

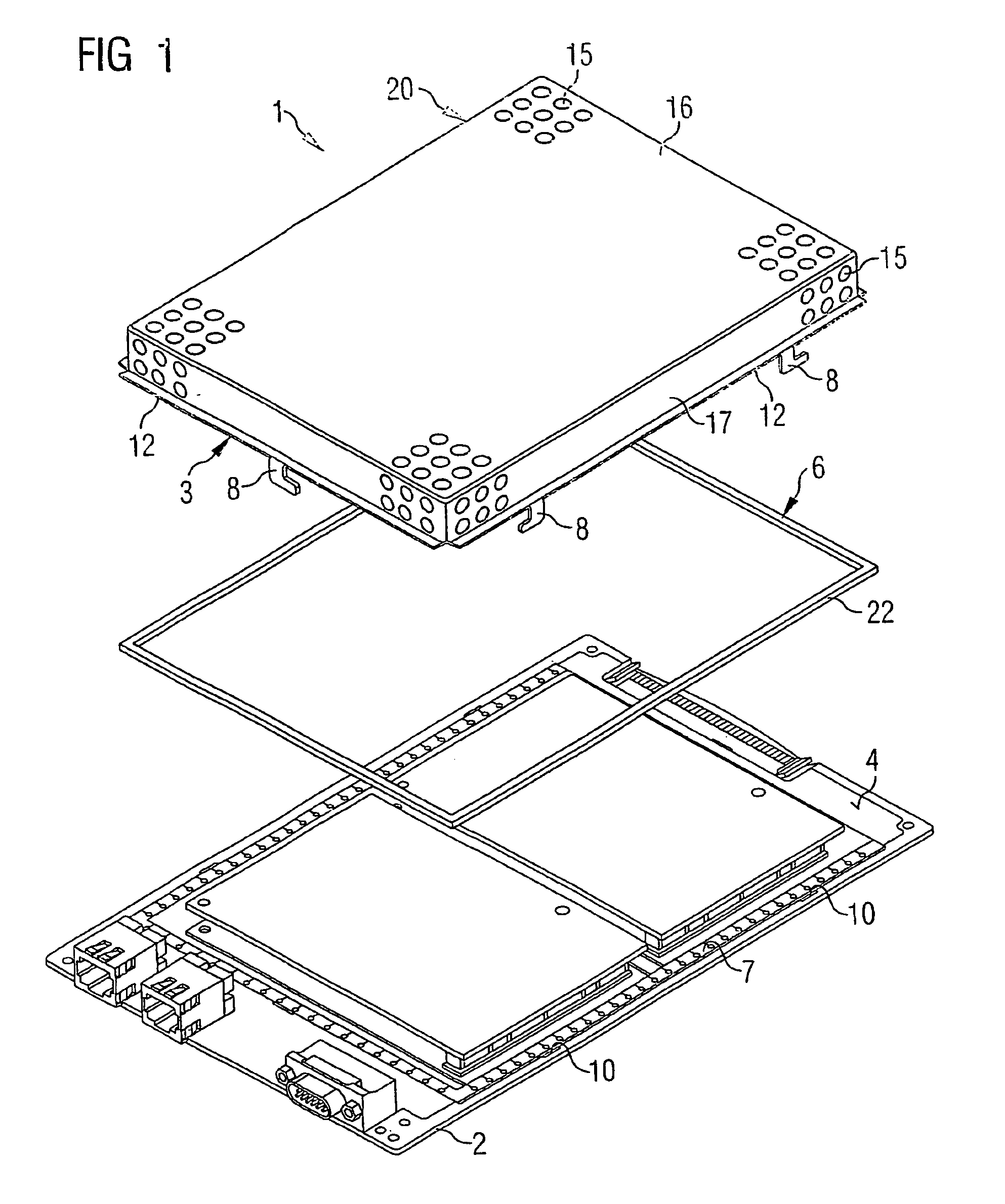

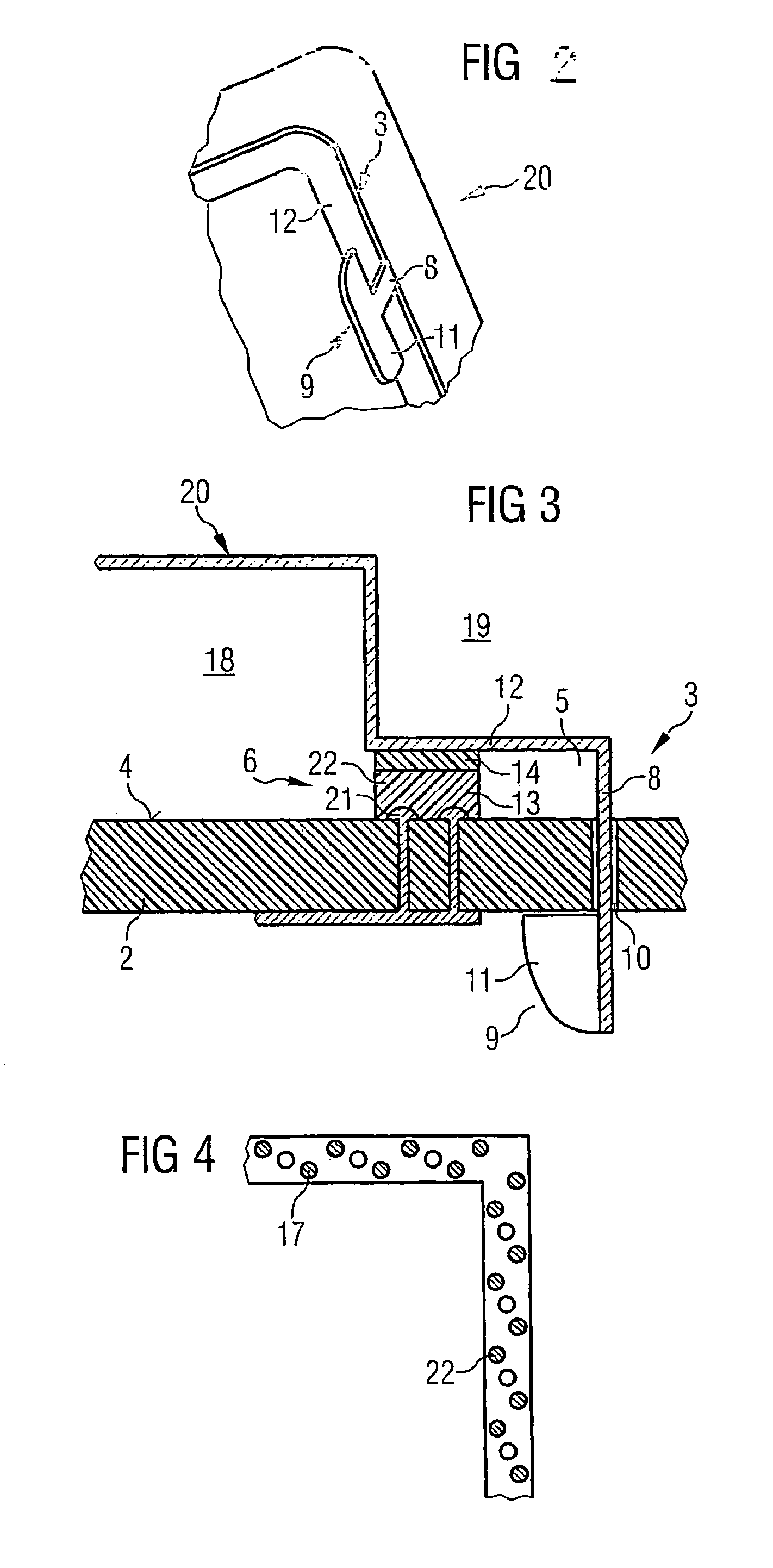

Screening device for electronic subassemblies on a printed circuit board

InactiveUS6979773B2Improve screening efficiencyLess effortLocalised screeningScreening gaskets/sealsElectricityEngineering

The invention relates to a screening device comprising: a screening cover, which covers an electronic circuit located on a printed circuit board and comprises an edge that is separated from the component side of the printed circuit board by a gap and a contact device, which is located in the gap and produces an electric connection between the screening cover and a conductive contour element on the printed circuit board. According to the invention, lugs are formed on the edge of the screening cover, said lugs fixing the screening cover on the printed circuit board and maintaining an elastic pretension on the contact device. The contact device is configured as an elastic sealing body that extends continuously through the gap and absorbs electromagnetic waves.

Owner:UNIFY GMBH & CO KG

Soft surface mount technology compatible EMI gasket

InactiveUS7129421B2Pipe supportsElectrically conductive connectionsElectromagnetic interferenceConductive materials

An Electromagnetic Interference (EMI) gasket formed of a hollow, conductive material which is mechanically fastened to a metal support layer. The assembly can be installed using standard high speed SMT pick and place equipment.

Owner:WL GORE & ASSOC INC

Electromagnetic interference (EMI) collar and method for use with a pluggable optical transceiver module

InactiveUS7597590B2Improves EMI shielding effectivenessImprove shielding effectContact member manufacturingScreening gaskets/sealsTransceiverElectromagnetic interference

An EMI collar is provided that is configured to be secured about a housing of a pluggable optical transceiver module. The configuration of the EMI collar and the method by which the collar is attached to the housing of the transceiver module ensures that the collar will not be damaged when the transceiver module housing is inserted into a cage. Ensuring that the collar will not be damaged during insertion ensures that electrically conductive contact points on the collar will not be eliminated by insertion of the housing into a cage. In addition, dimples, or indentations, formed on the spring fingers of the EMI collar result in additional electrically conductive contact points on the fingers that result in a reduction in the size of the maximum EMI aperture dimension of the collar. Reducing the maximum EMI aperture dimension of the collar greatly improves the ability of the collar to attenuate EMI signals, even EMI signals having high frequencies.

Owner:BROADCOM INT PTE LTD

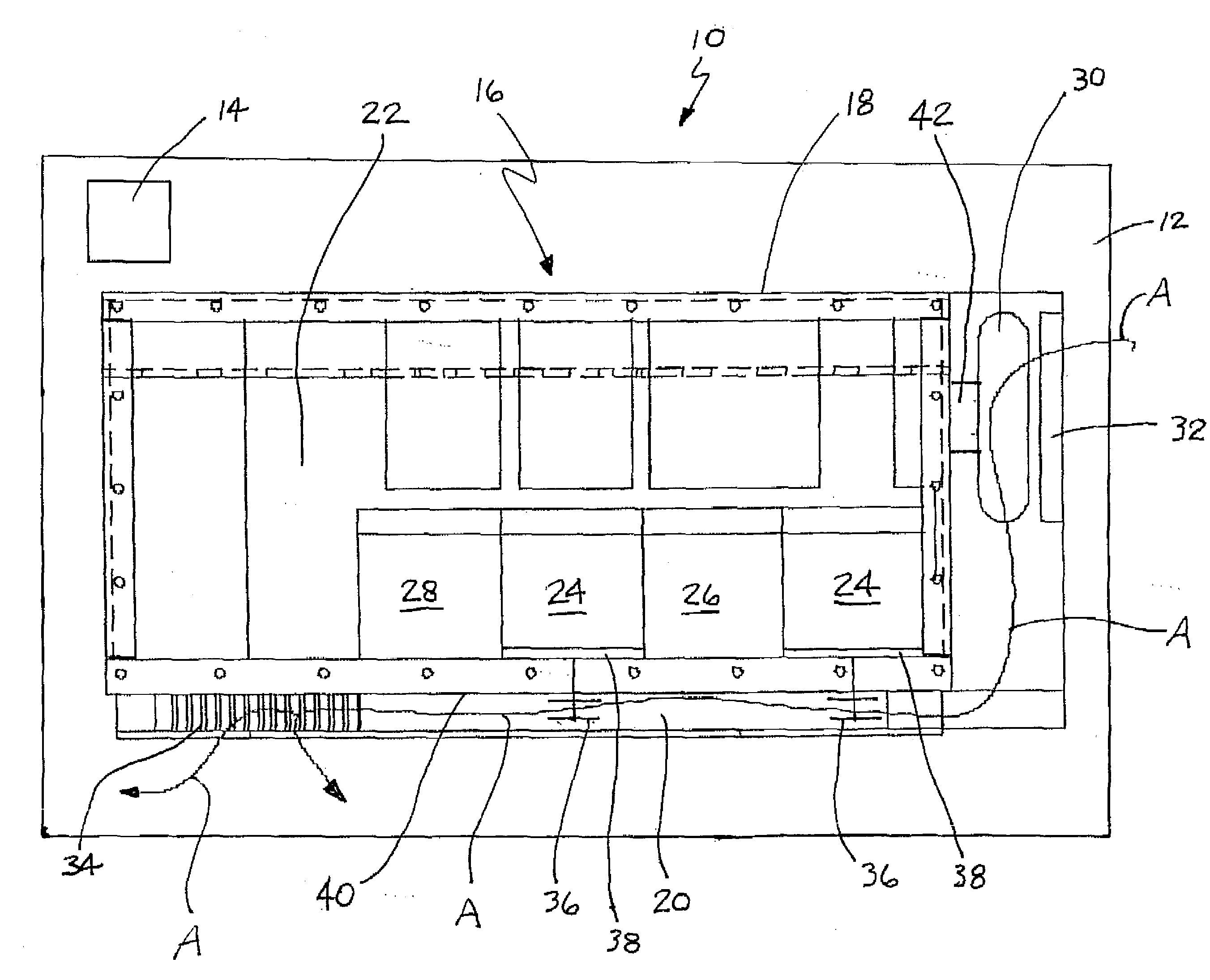

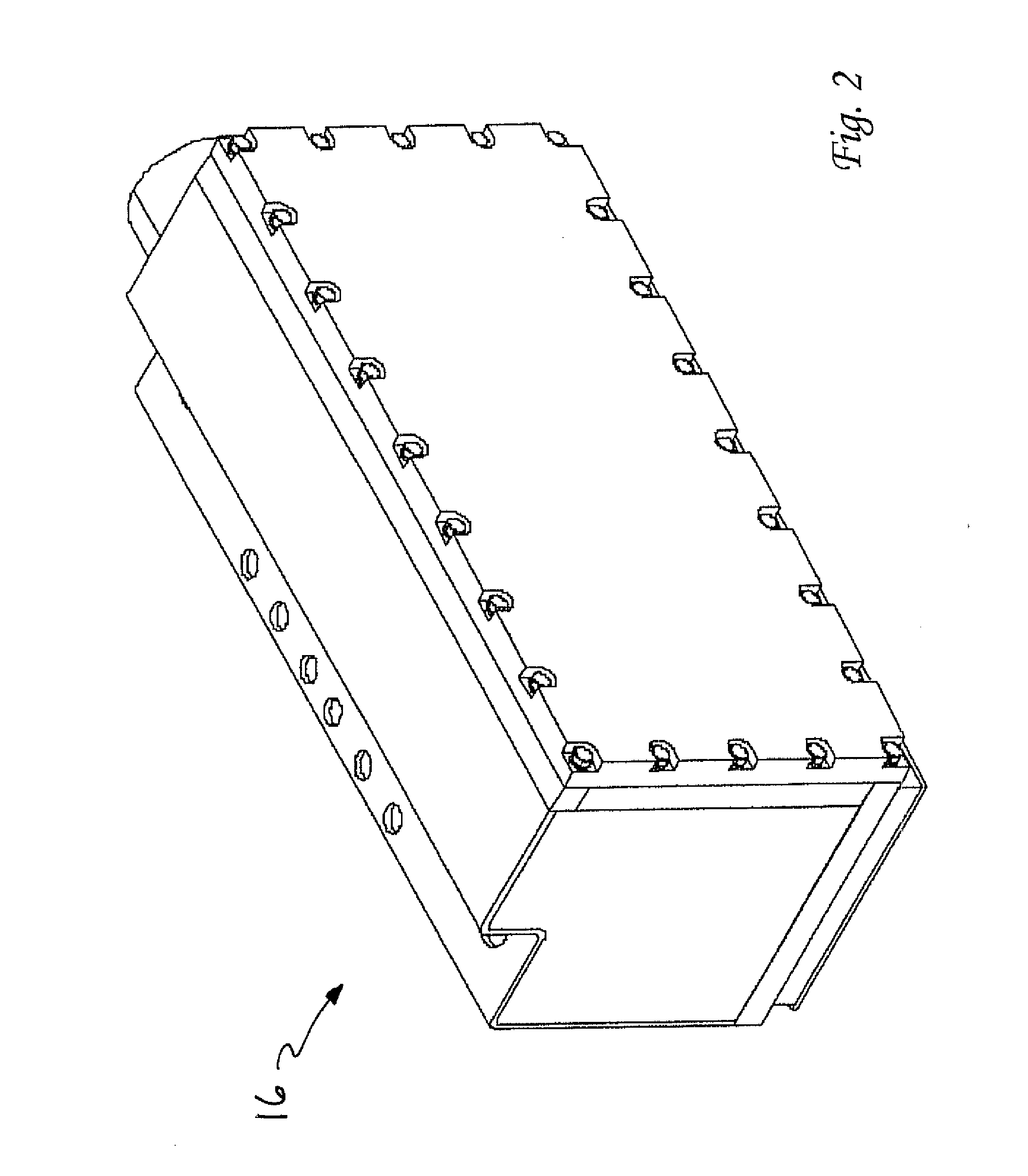

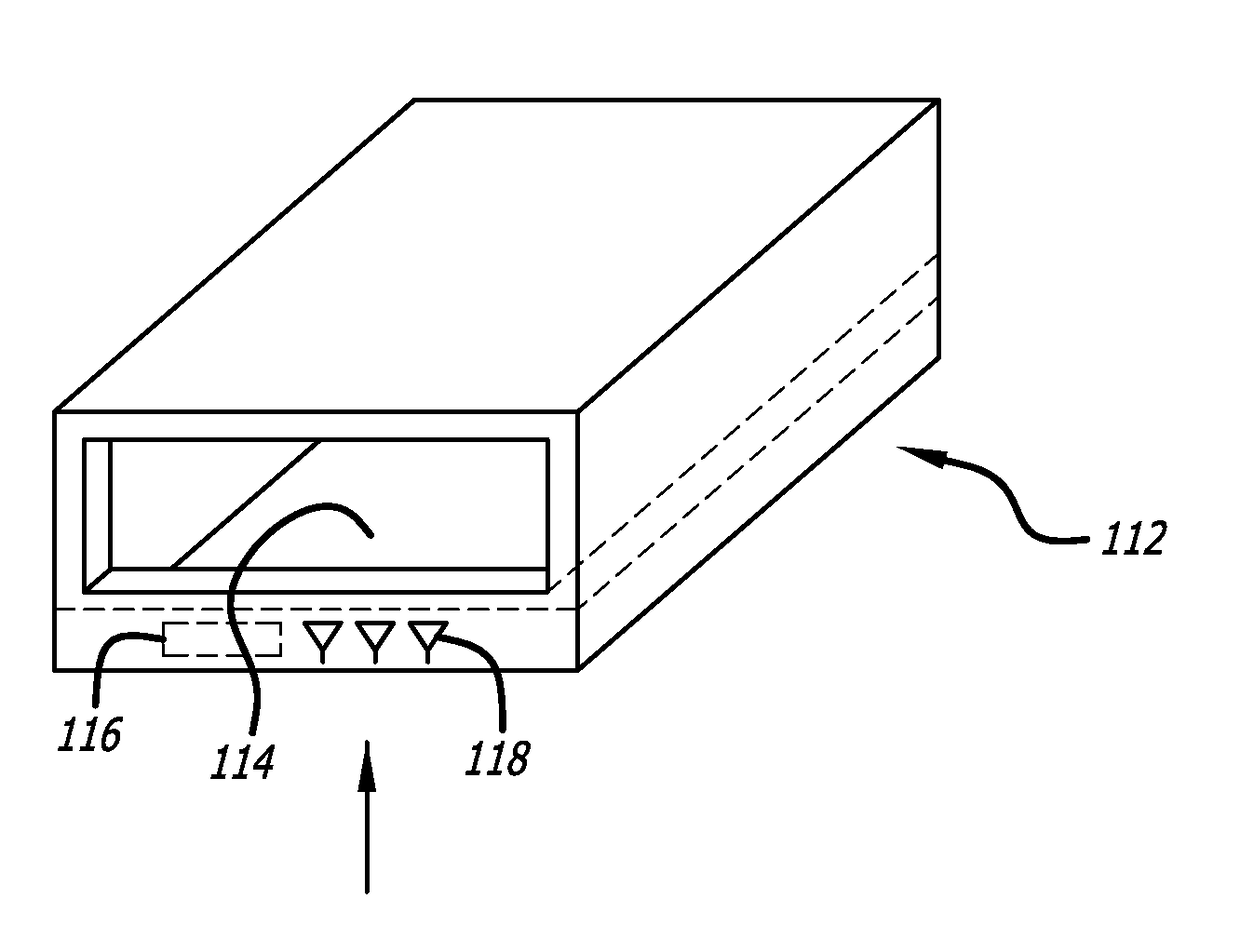

Forced air cooled electrical box for mining equipment

InactiveUS20070285889A1Screening gaskets/sealsCooling/ventilation/heating modificationsForced-airEngineering

Owner:ALLIANCE COAL LLC

Shielded enclosure having tortuous path seal

ActiveUS20170196128A1Reduce Medication ErrorsLow costShielding materialsSurgical furnitureEngineeringMechanical engineering

A modular system of plastic walls having embedded and coextensive electrically conductive components configured to electrically connect with each other when the walls are mated. The walls have joining edges that form joint seams with other walls when joined together to create an enclosure. When enough walls are used to surround a storage space, a Faraday cage is created. The walls additionally have portions of tortuous paths at each joining edge that mate with a complementary portion of a tortuous path of another wall when the walls are joined together. A torturous path seal is thereby created at each joint seam. The plastic walls can be configured in a multiplicity of combinations to create various enclosures necessary for RFID-enabled storage and tracking of medical articles. Containers, enclosures, cabinets, and drawers of differing heights and sizes can be made and they may be stacked or otherwise assembled.

Owner:MEPS REAL TIME

Electrically conductive gasket

An electrically conductive gasket and methods of manufacturing electrically conductive gaskets. In one embodiment, the gasket includes a core that supports an electrically conductive cover thereon. The electrically conductive cover may be attached to the core or portions of the core by one or more adhesives used to also affix the gasket to an electrically conductive object. In other embodiments, a mechanical fastener may be affixed to the core by the one or more adhesives employed to affix the electrically conductive cover to the core.

Owner:JEMIC SHIELDING TECH

Clean release tape for EMI shielding

InactiveUS20030091777A1Adhesive residueScreening gaskets/sealsLayered productsSilicone tapeMechanical engineering

An EMI shielding tape adherable to a surface of a structure. The tape includes a backing layer, and an adhesive layer carried on at least one side of the backing layer. The adhesive layer has an inner face bonded the backing layer, and an opposite outer face which is bondable under pressure to the structure surface to adhere the tape thereto. The adhesive layer is formulated as an admixture of a pressure sensitive adhesive (PSA) composition and one or more electrically-conductive particulate fillers. When adhered to the structure surface, the tape is substantially cleanly releasable therefrom.

Owner:PARKER HANNIFIN CORP

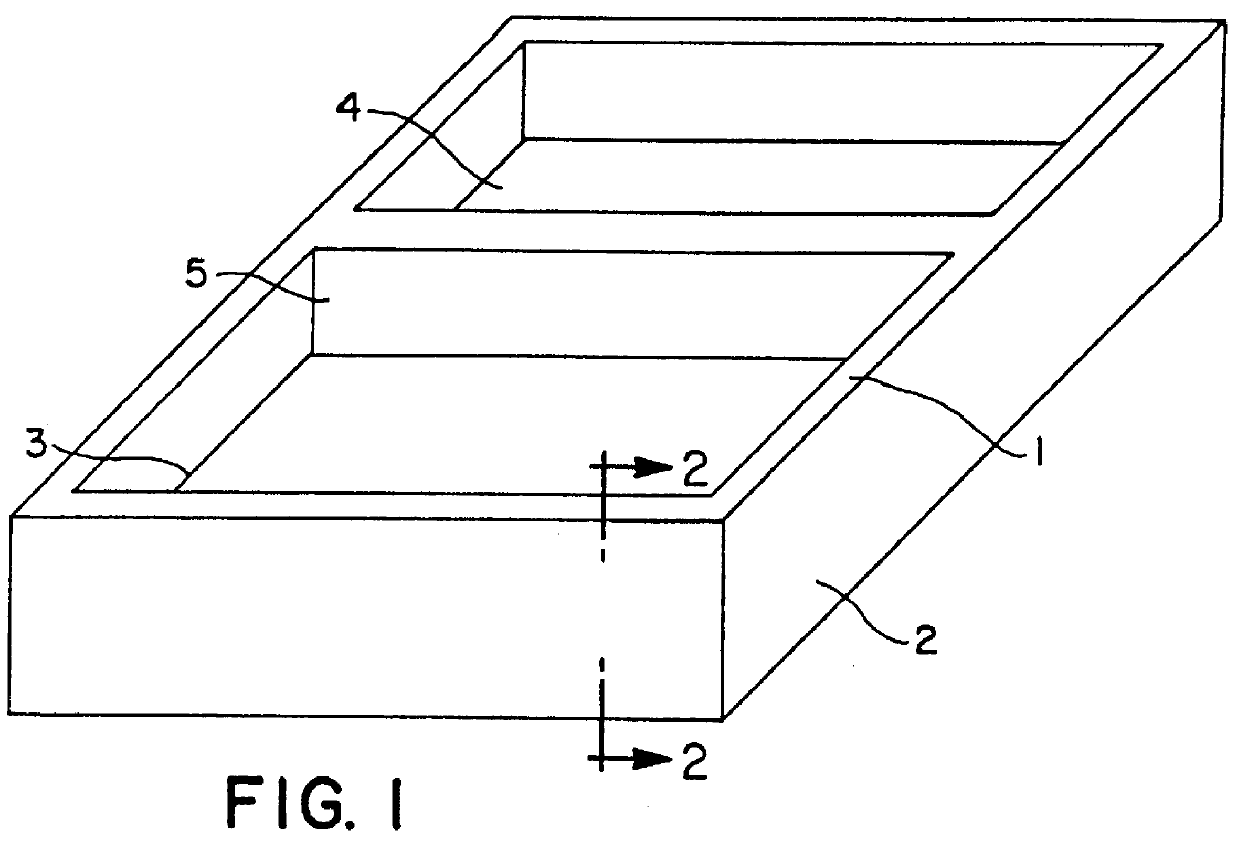

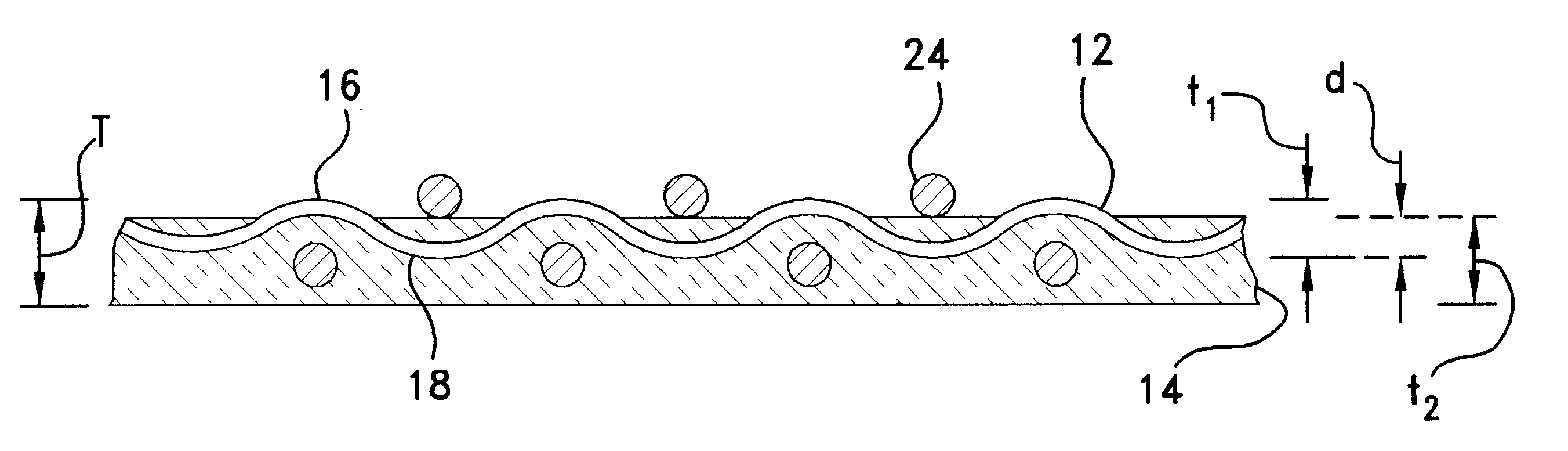

Encapsulated expanded crimped metal mesh for sealing and EMI shielding applications

ActiveUS8766108B2Avoid distortionPrevent elongationShielding materialsLine/current collector detailsGlass fiberElastomer

A composite gasket for sealing and EMI shielding is provided. The gasket has a resilient conductive mesh sheet embedded with an elastomer gel layer. The conductive mesh is corrugated to provide a series of repeating waveforms, providing the gasket with a lower deflection force, better corrosion resistance, and a higher EMI shielding capability. A second elastomer can be used around the edge portions of the gasket for improved abrasion resistance and increased tensile strength. A fiberglass sheet can be incorporated in the mesh for added reinforcement and support. The gaskets of the invention can be used on external aircraft components, such as external aircraft antenna mounts.

Owner:PARKER INTANGIBLES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com