Patents

Literature

179results about How to "Smooth engagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transmission

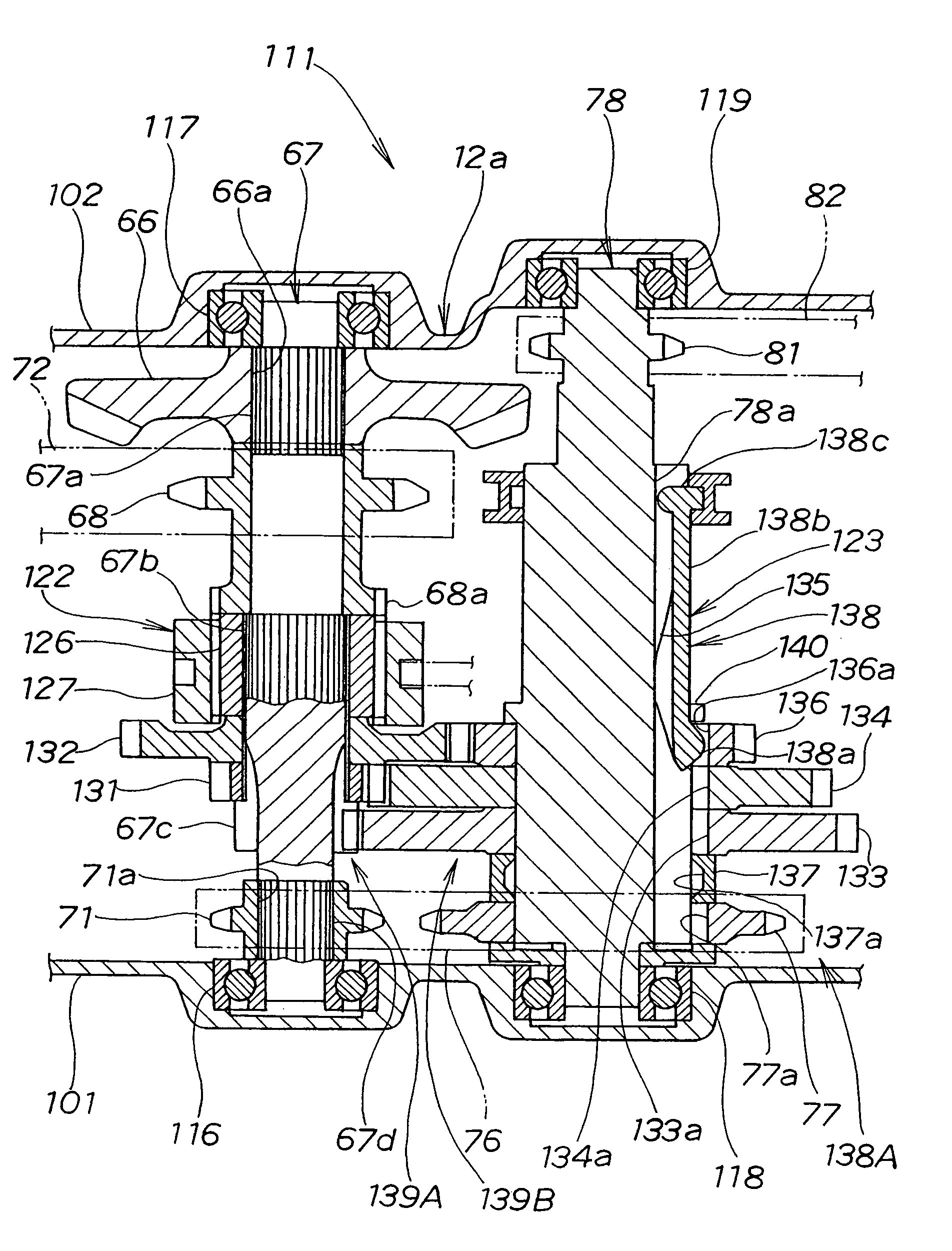

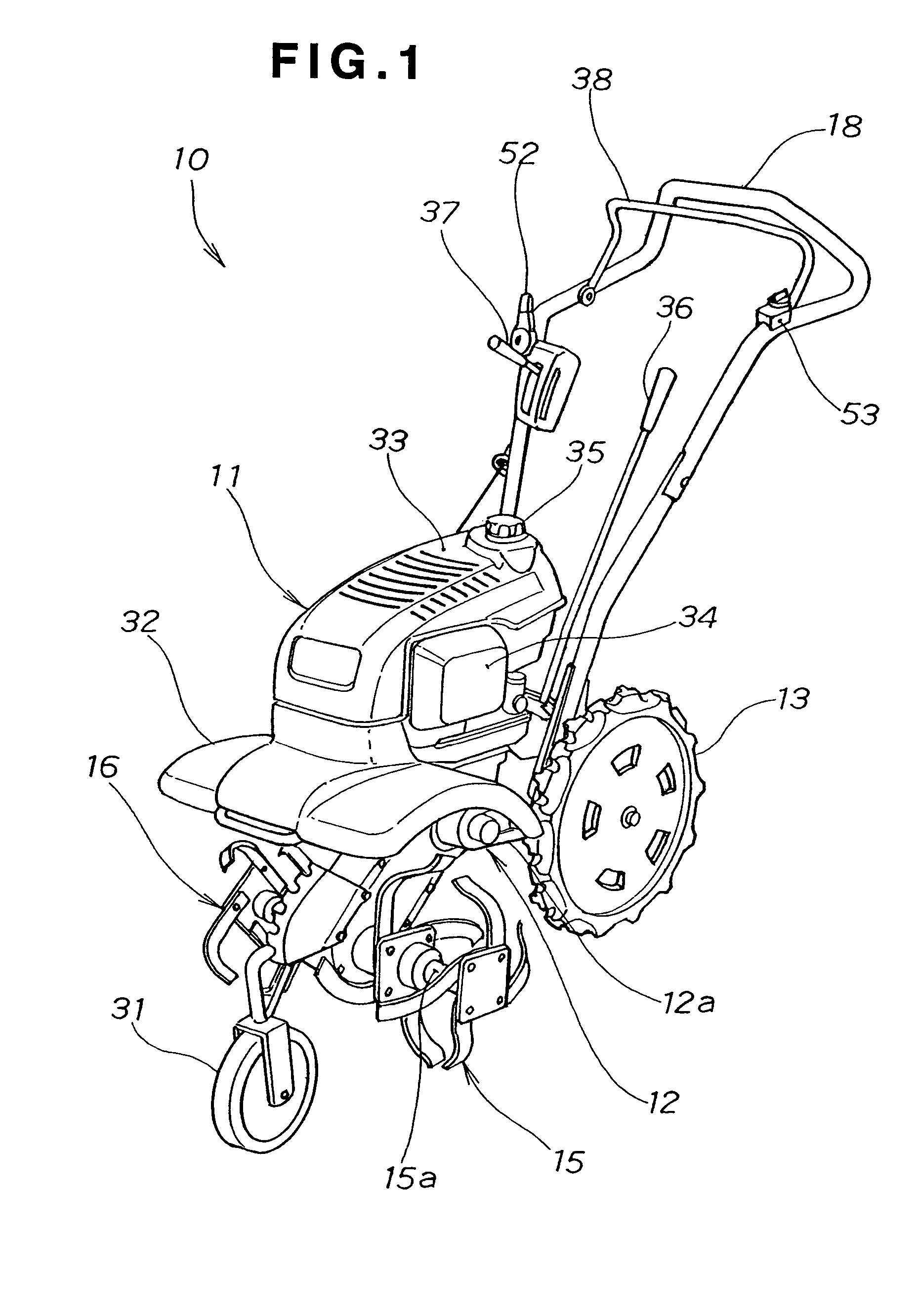

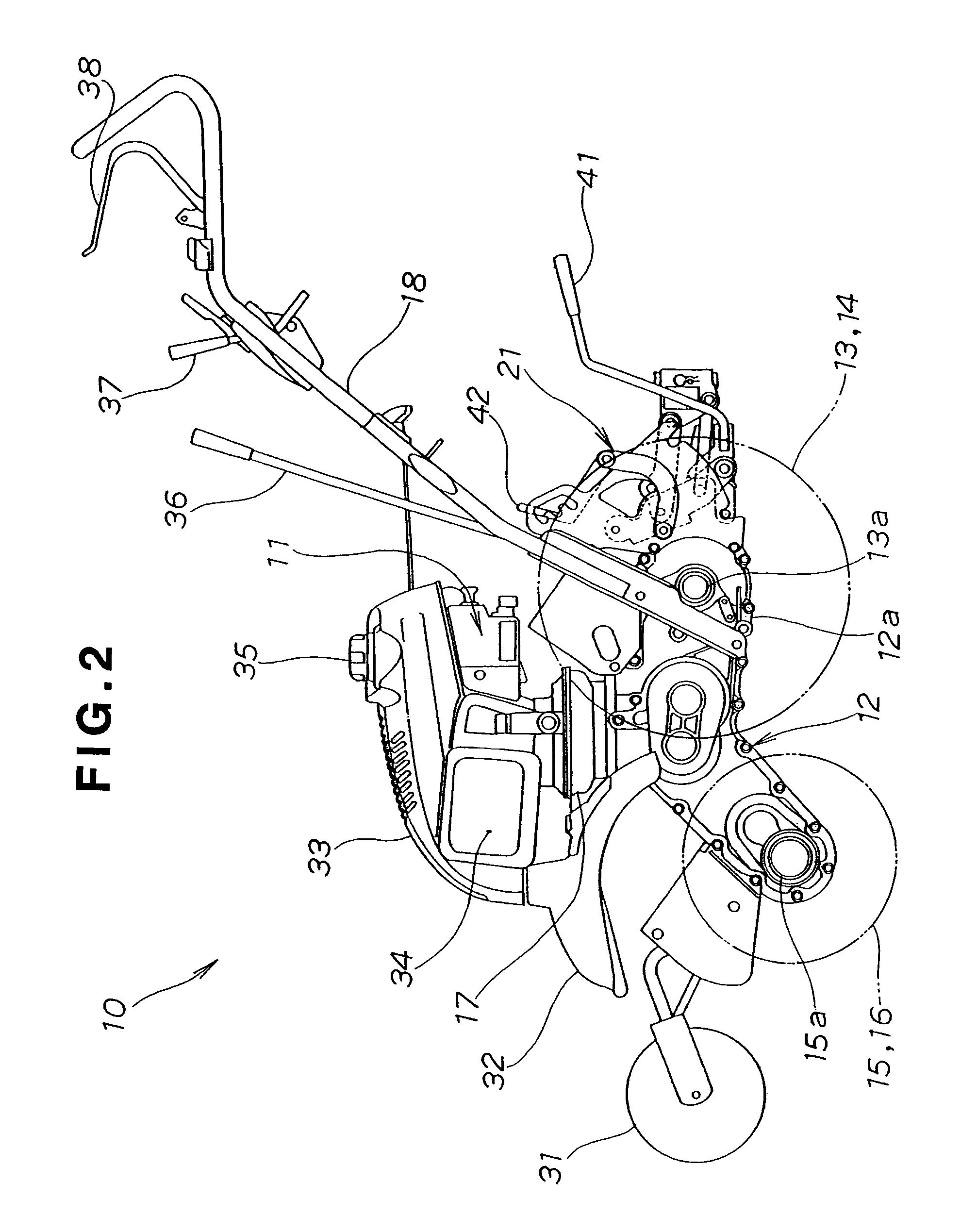

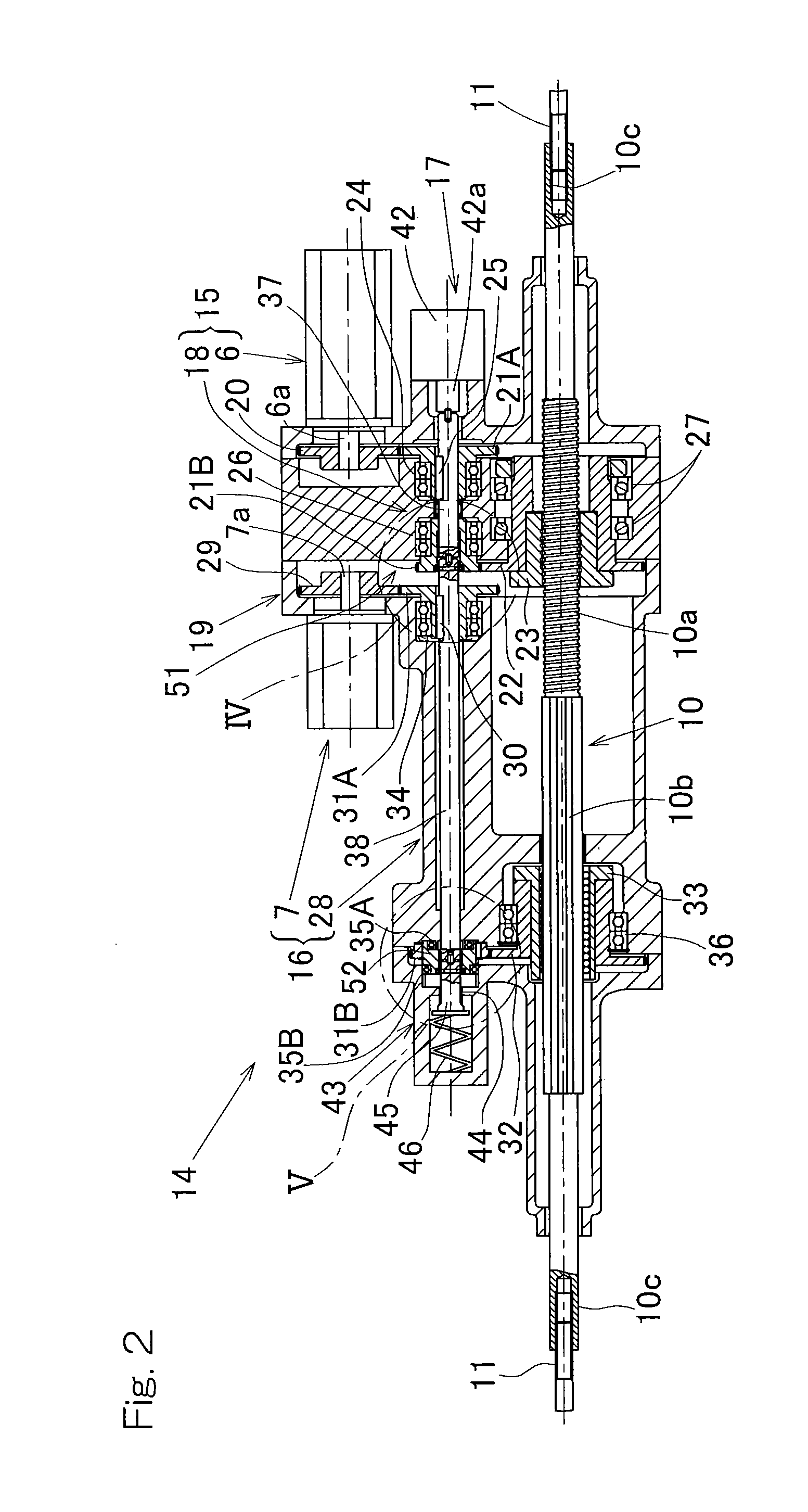

InactiveUS7028570B2Easy to participateSmooth connectionTilling equipmentsToothed gearingsDrive wheelTransmitted power

A transmission for a working machine including a drive transmission mechanism and a working transmission mechanism operated by swinging a shift lever is provided. The drive transmission mechanism has a key-sliding transmission mechanism axially mounted on a drive shaft. The key-sliding transmission mechanism causes a selected one of a plurality of gears rotatably mounted on the drive shaft and the drive shaft to rotate together to transmit power to drive wheels.

Owner:HONDA MOTOR CO LTD

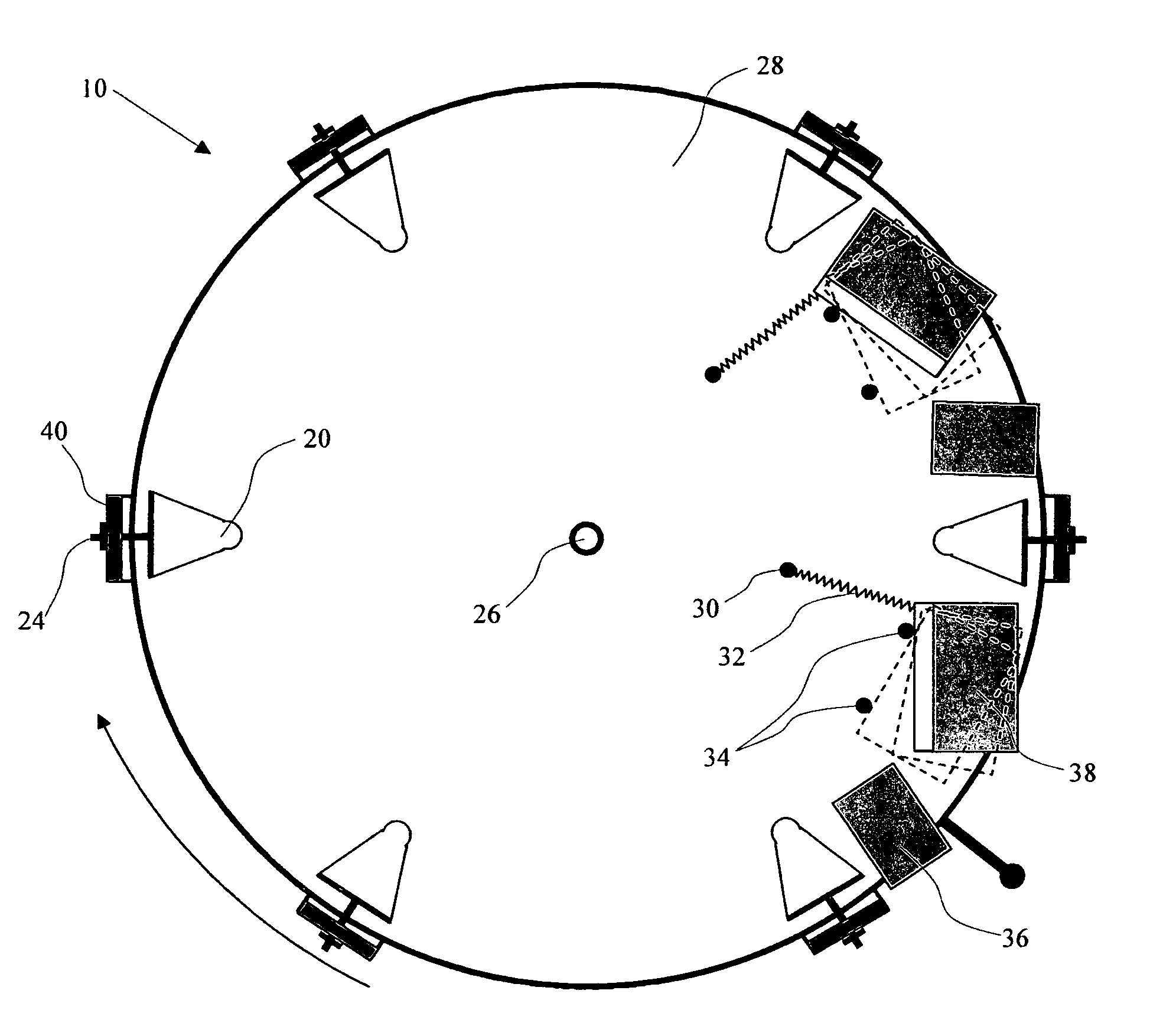

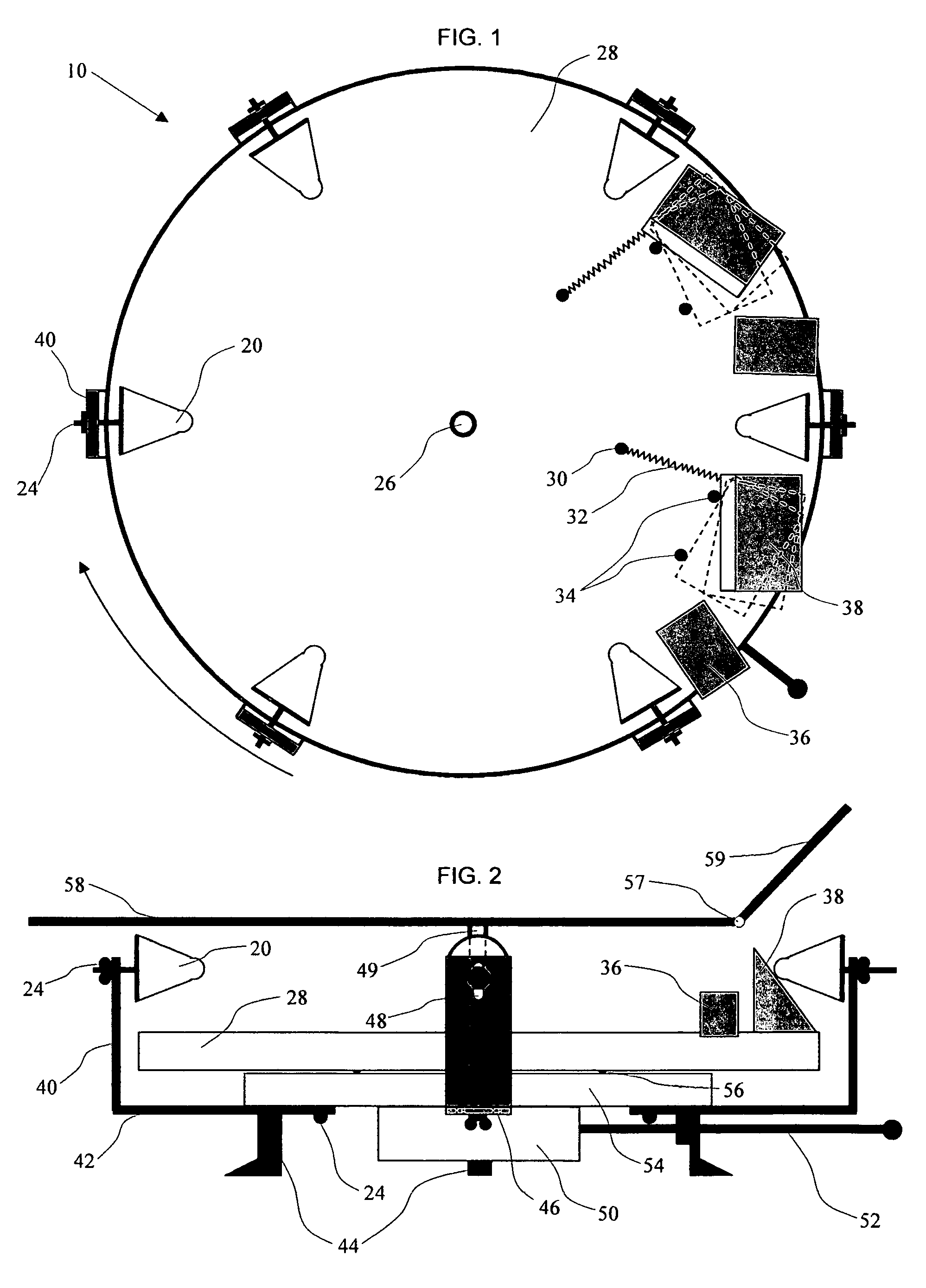

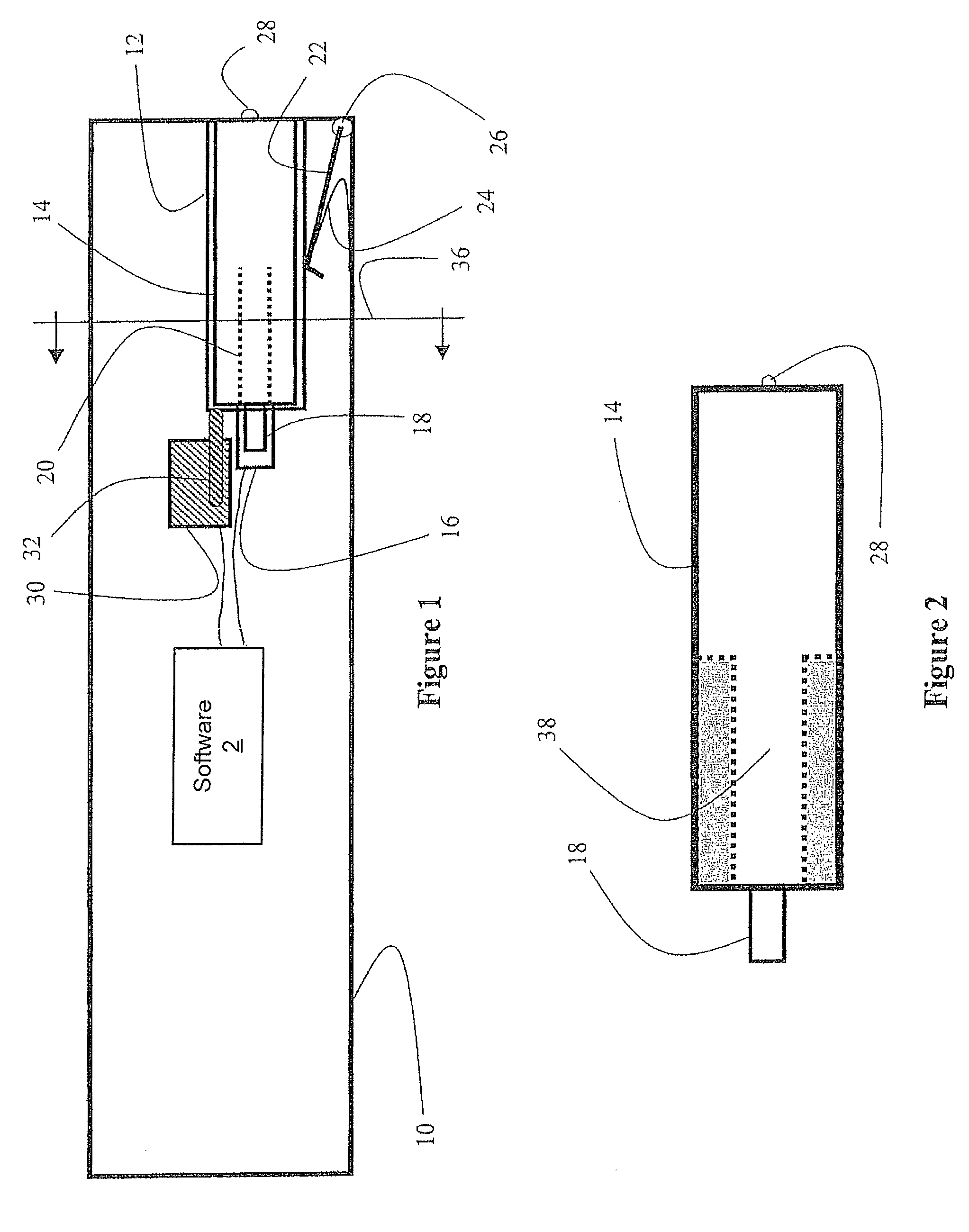

Automatic card shuffler and dealer

An automatic system for shuffling and distributing cards includes two embodiments. One embodiment includes fixed and rotating plates on which a deck of cards is supported. The device according to this embodiment, can be placed on the table. Shuffling is achieved by a plurality of card magazines and delivery trays located on the rotating plate. The fixed plate includes fixed card ejection devices which operate during and in response to rotation of the rotating plate, which eject cards at a plurality of locations about the system. The device is electrically powered and includes means to automatically stop its rotation after the last card in the deck has been distributed. In another embodiment, a hand-hold device is designed so the user can hold it in one hand and by pressing on switch the topmost card is automatically ejected to the location aimed by the user.

Owner:MOTI SHAI

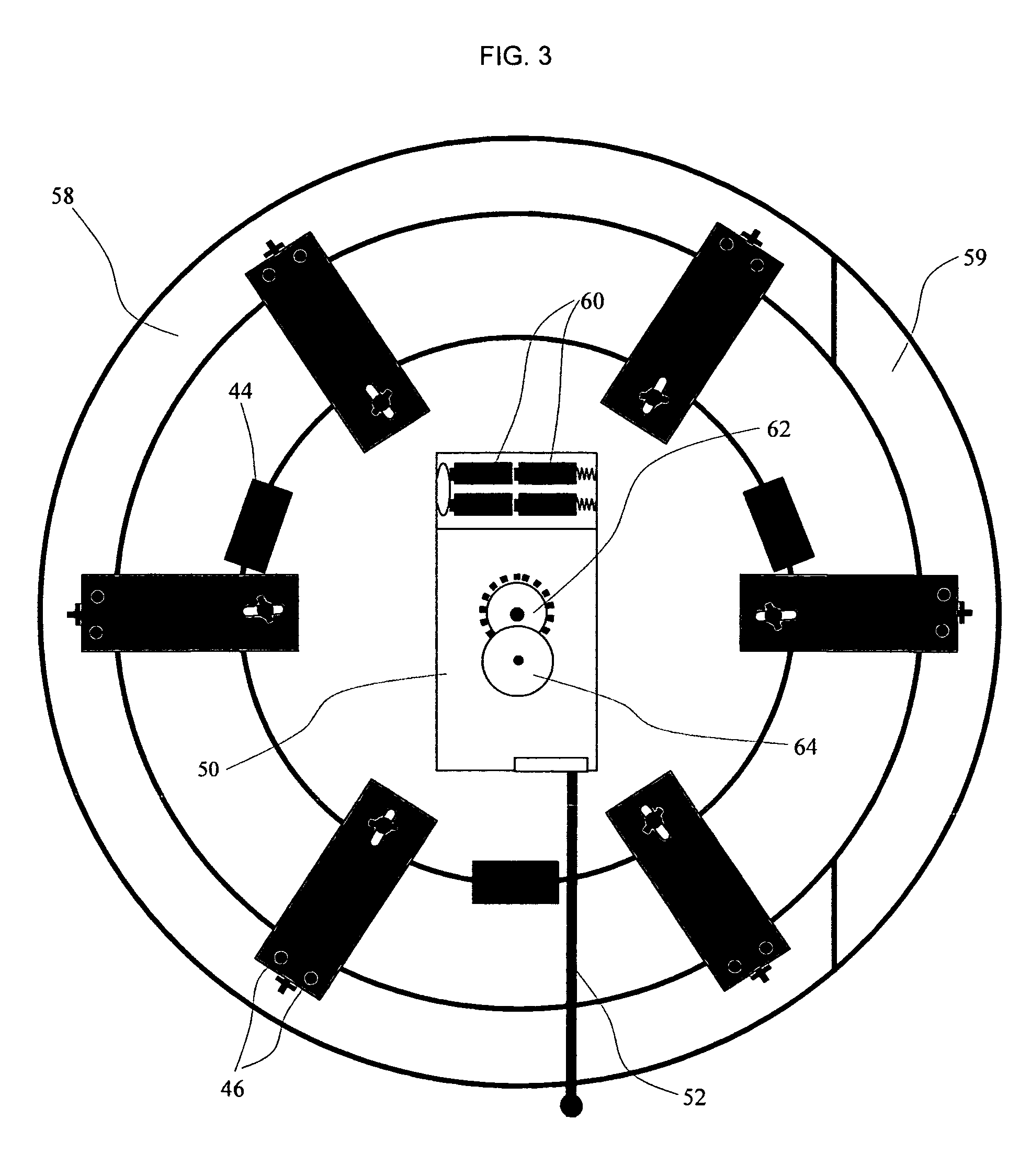

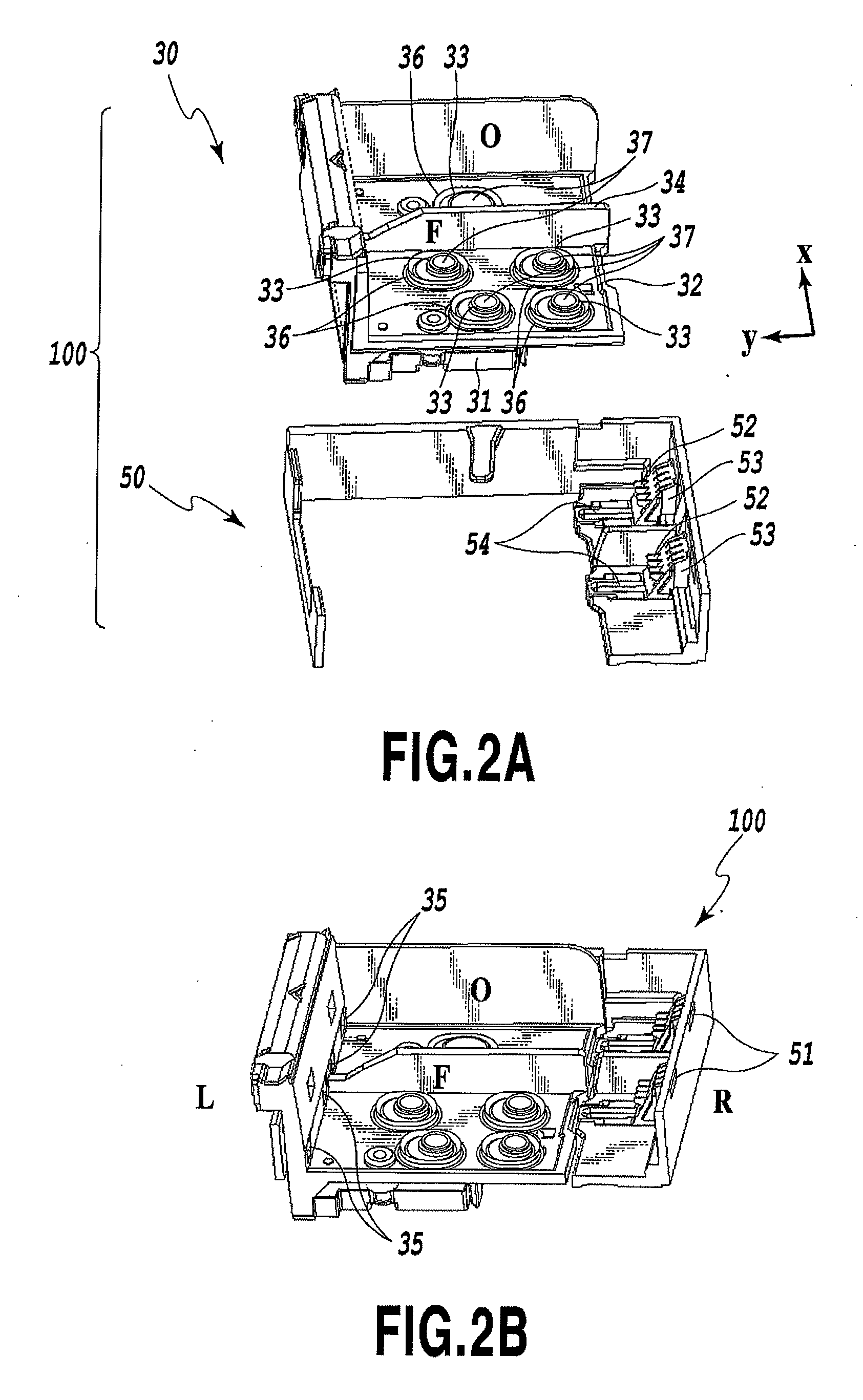

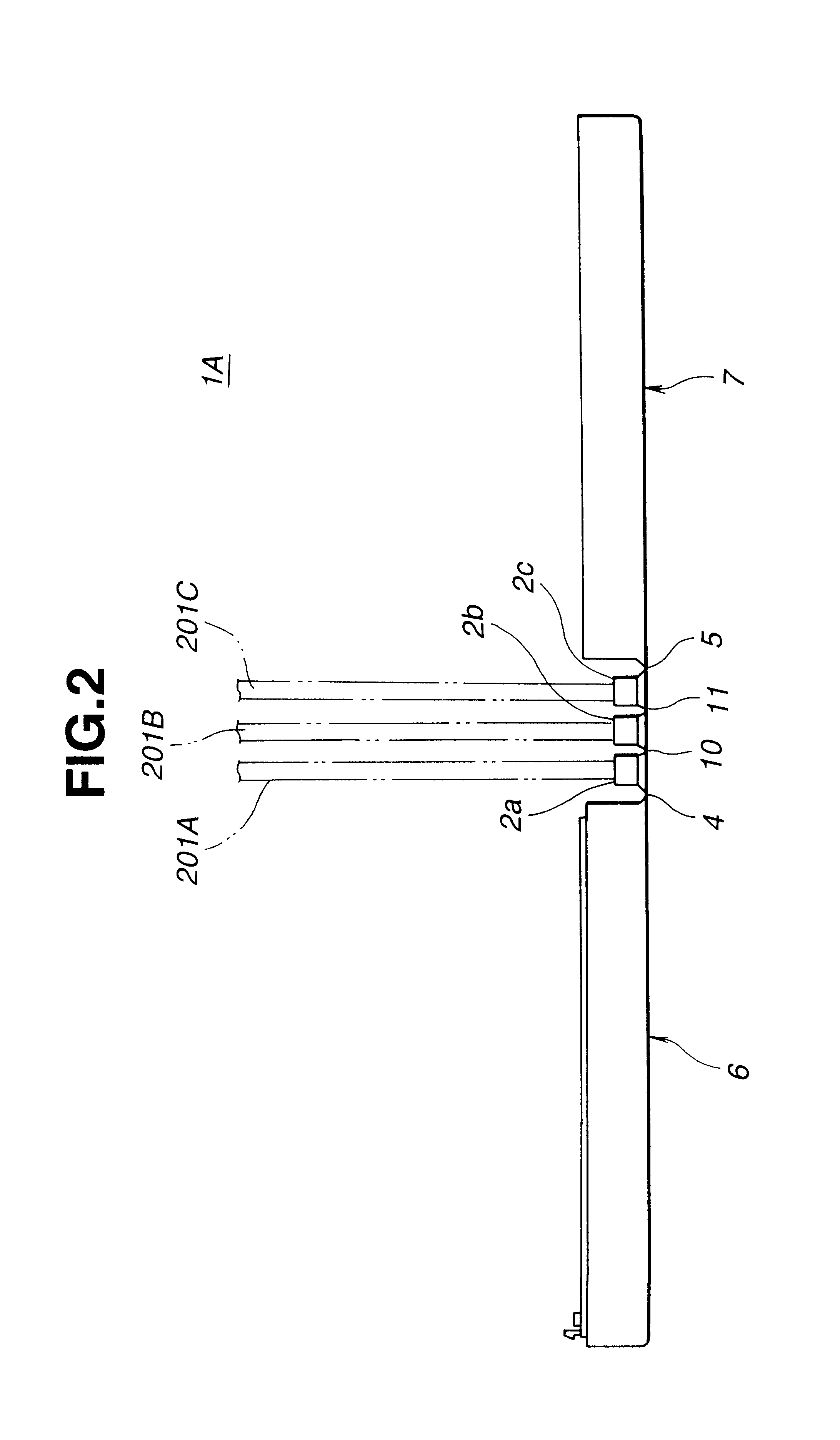

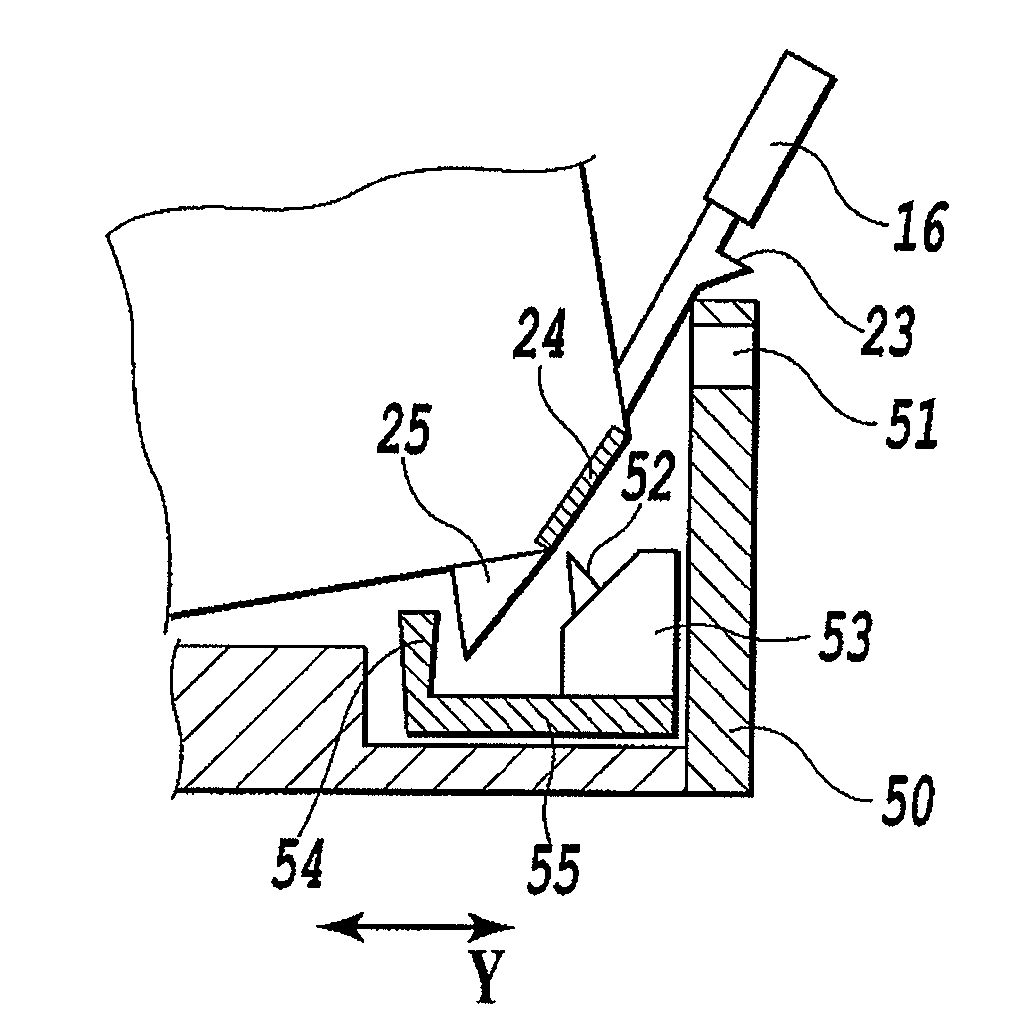

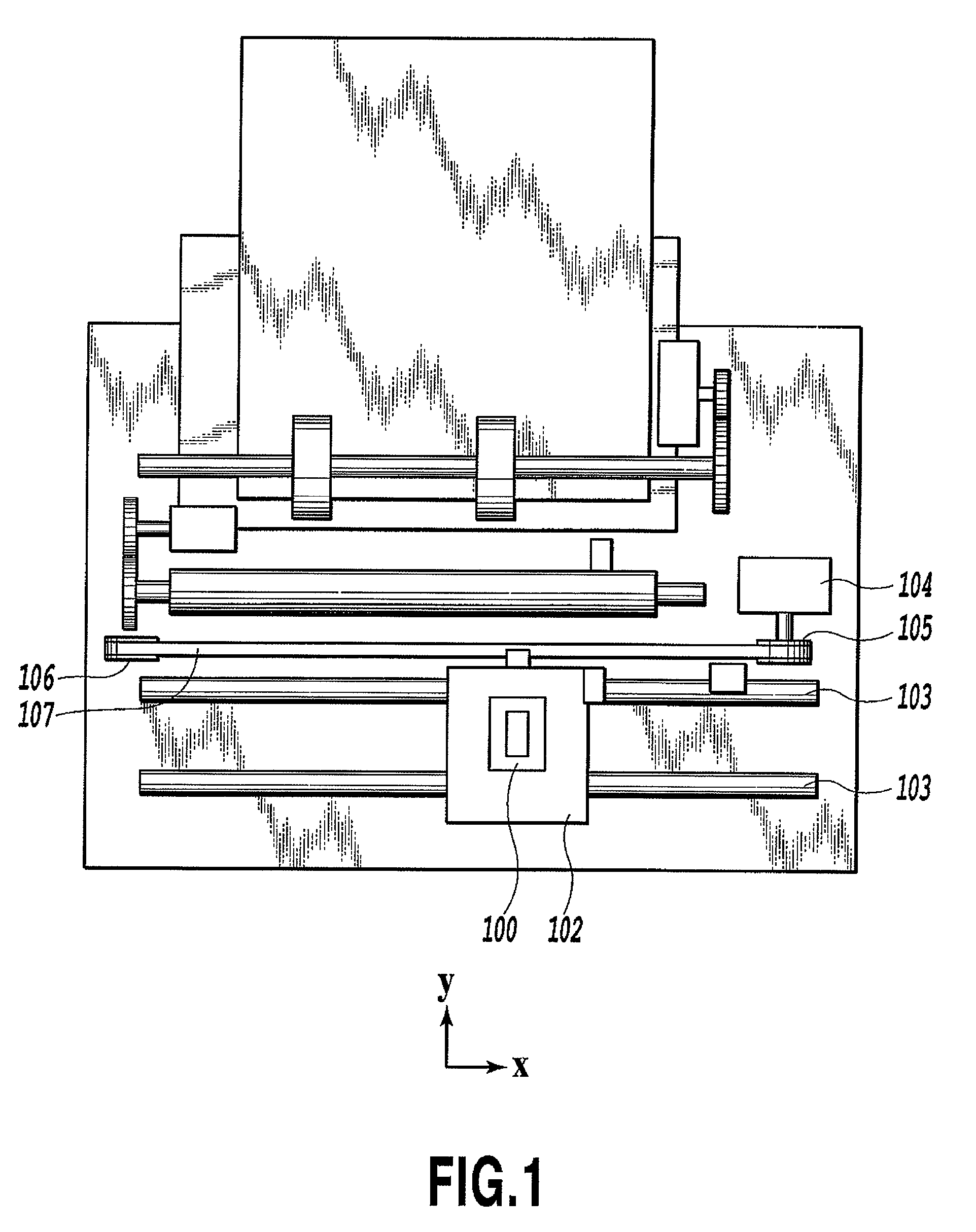

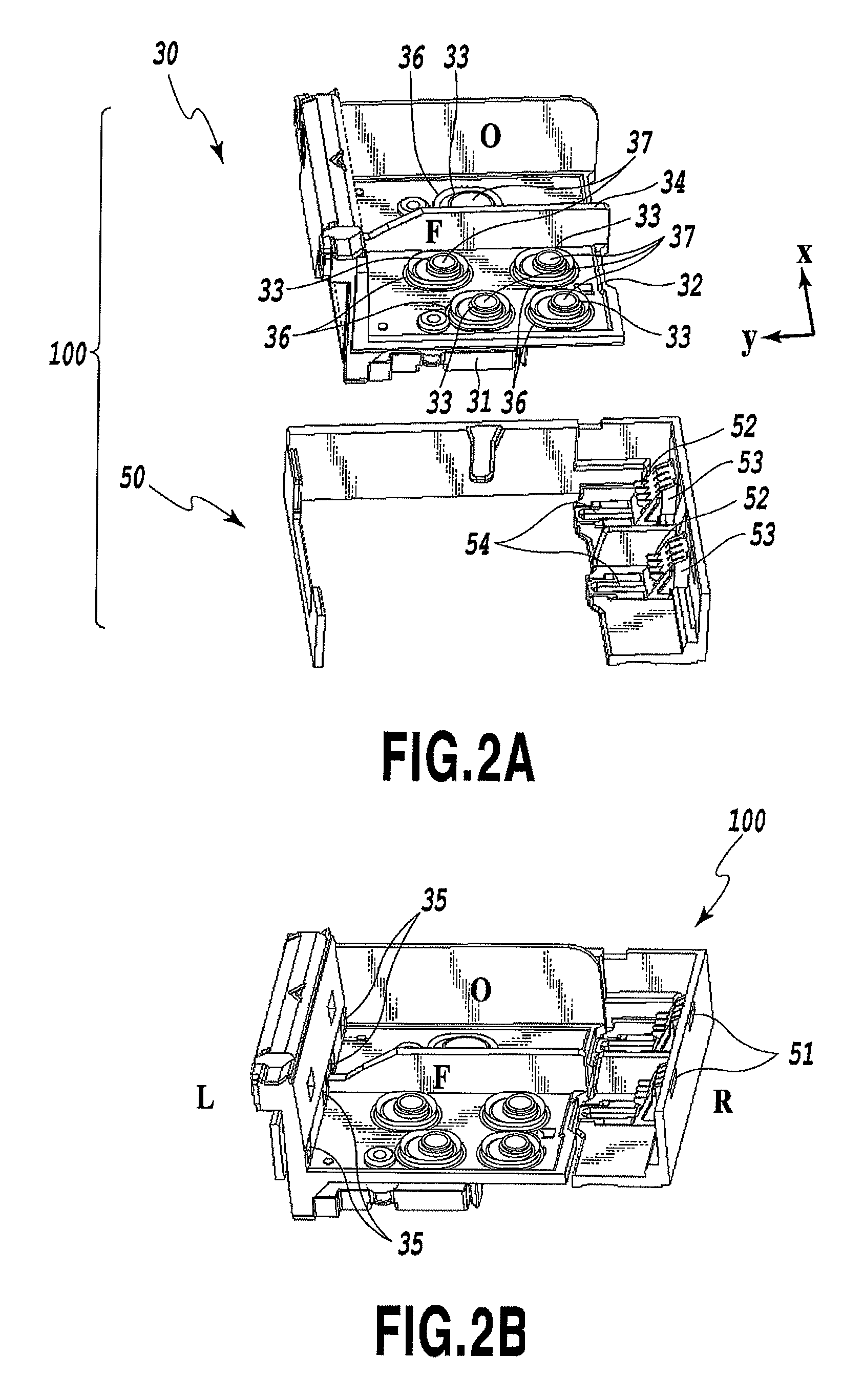

Ink tank

An ink tank provided with a supply port for supplying the ink contained therein and an electric contact for information transmission is smoothly and securely attached to an attachment section of a printing apparatus while achieving secure connection of an electric contact section at the same time. The ink tank is configured to be attachable to the attachment section by positioning a first engagement section at a first fitting section on the attachment section, and then by rotating the ink tank around the positioned first engagement section to lock a second engagement section to a second fitting section on the attachment section. The supply port and a positioning section for the contact are disposed on the bottom face of the ink tank so as to be on the respective two sides of the center line in the width direction of the ink tank therebetween.

Owner:CANON KK

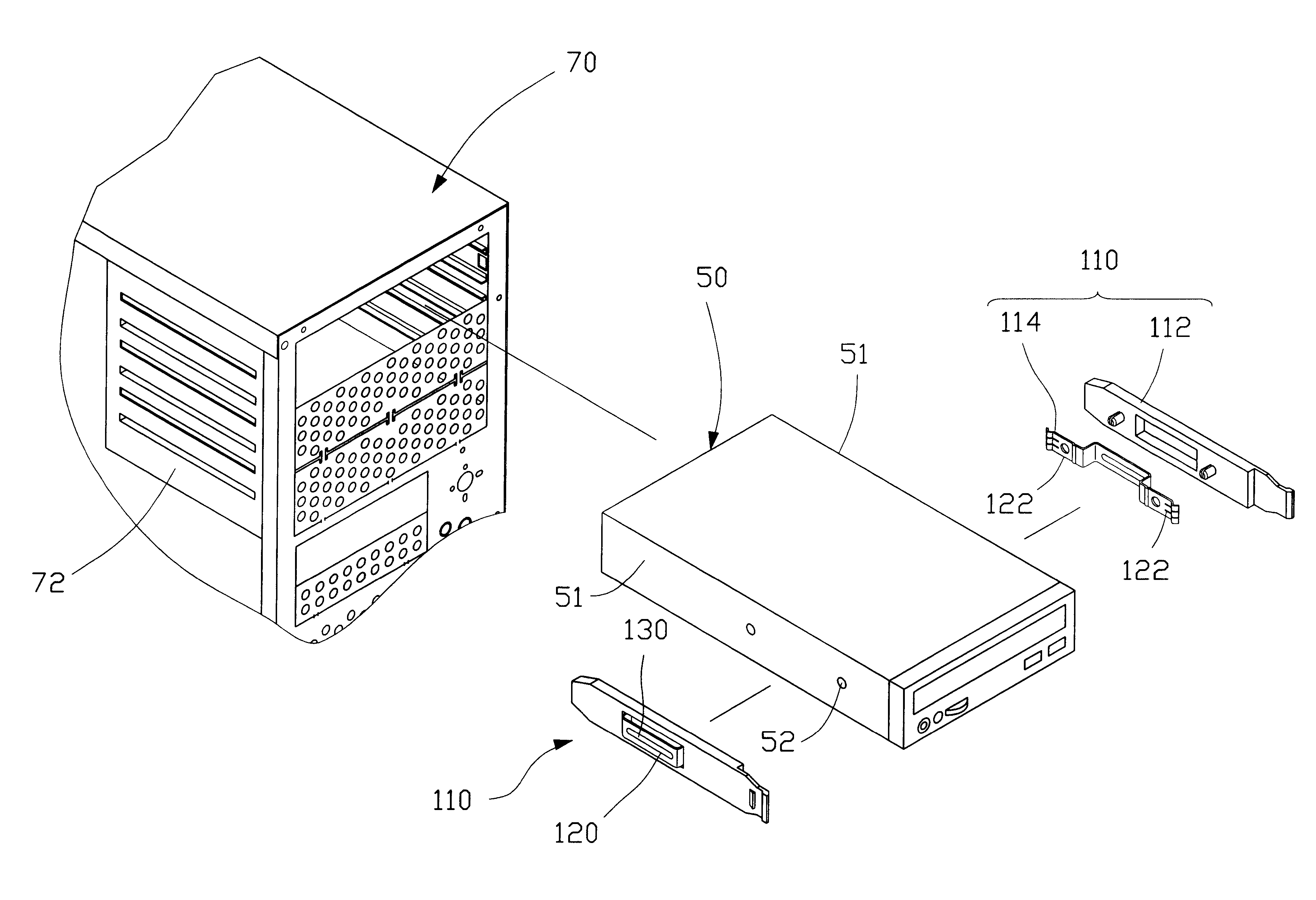

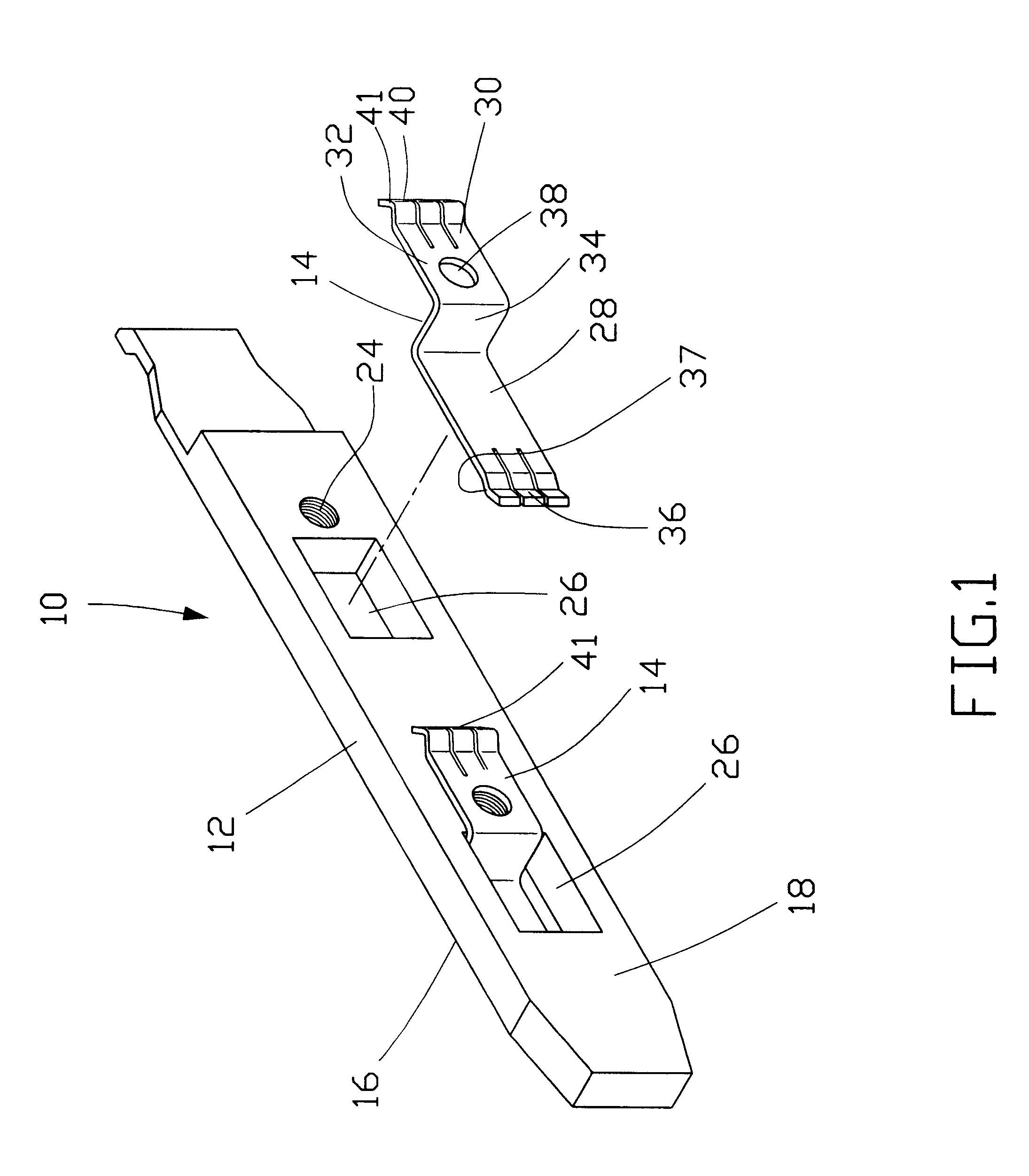

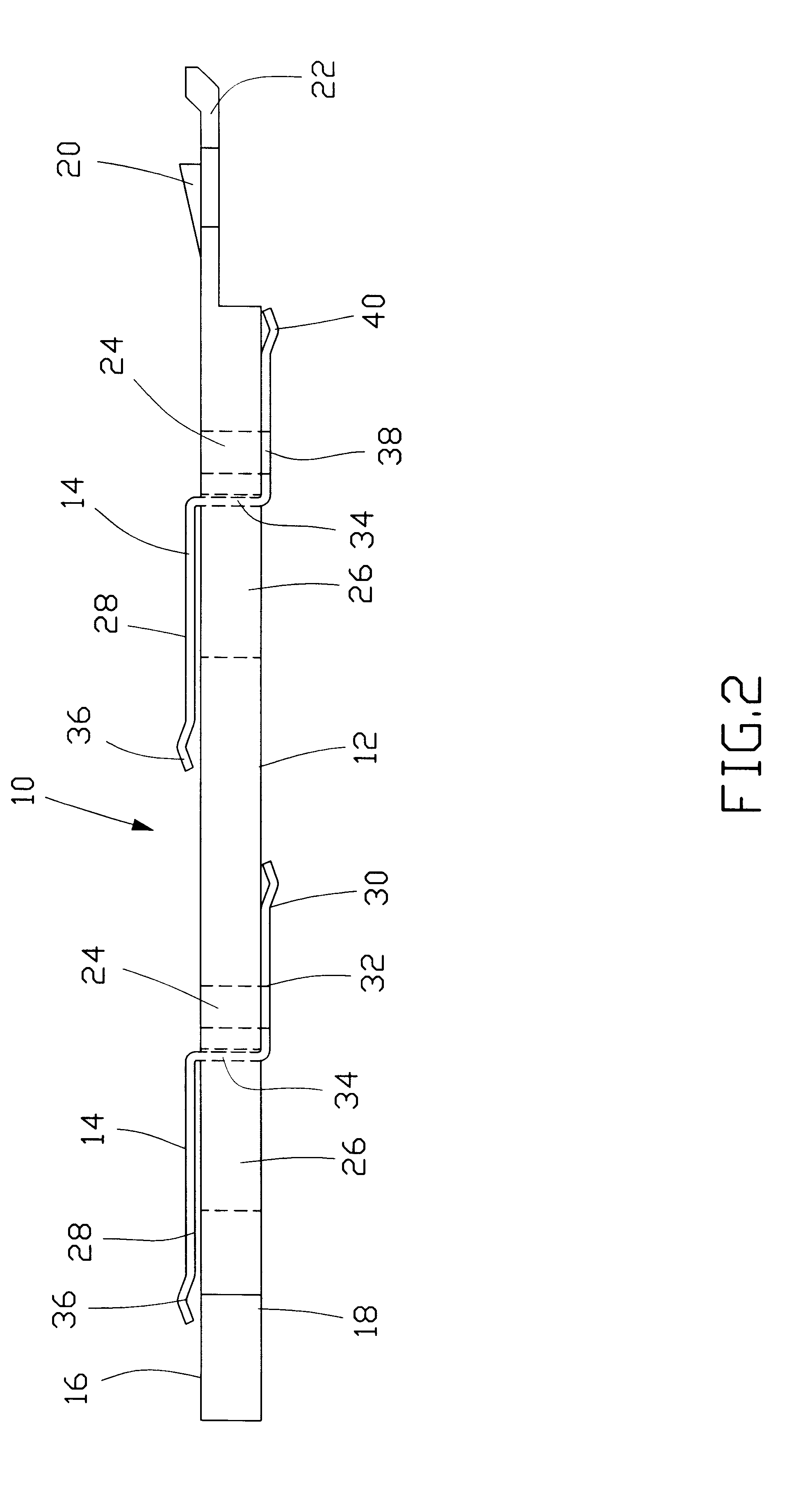

Mounting device for mounting a data storage device

A mounting device for mounting a data storage device to a receiving bracket of a computer enclosure includes a board body and at least one grounding clip. Two of the mounting devices are attached to opposite sides of the data storage device and engage with the receiving bracket. Each grounding clip includes a securing section, a first section and a second section. A bolt extends through a hole defined in the securing section of the grounding clip and a through hole defined in the board body for engaging with a screw hole defined in the data storage device thereby fixing the grounding clip and the board body to the data storage device. The fist and second sections of each grounding clip form a plurality of fingers for respectively contacting the data storage device and the computer enclosure thereby forming a grounding path therebetween while fixing the data storage device to the computer enclosure.

Owner:HON HAI PRECISION IND CO LTD

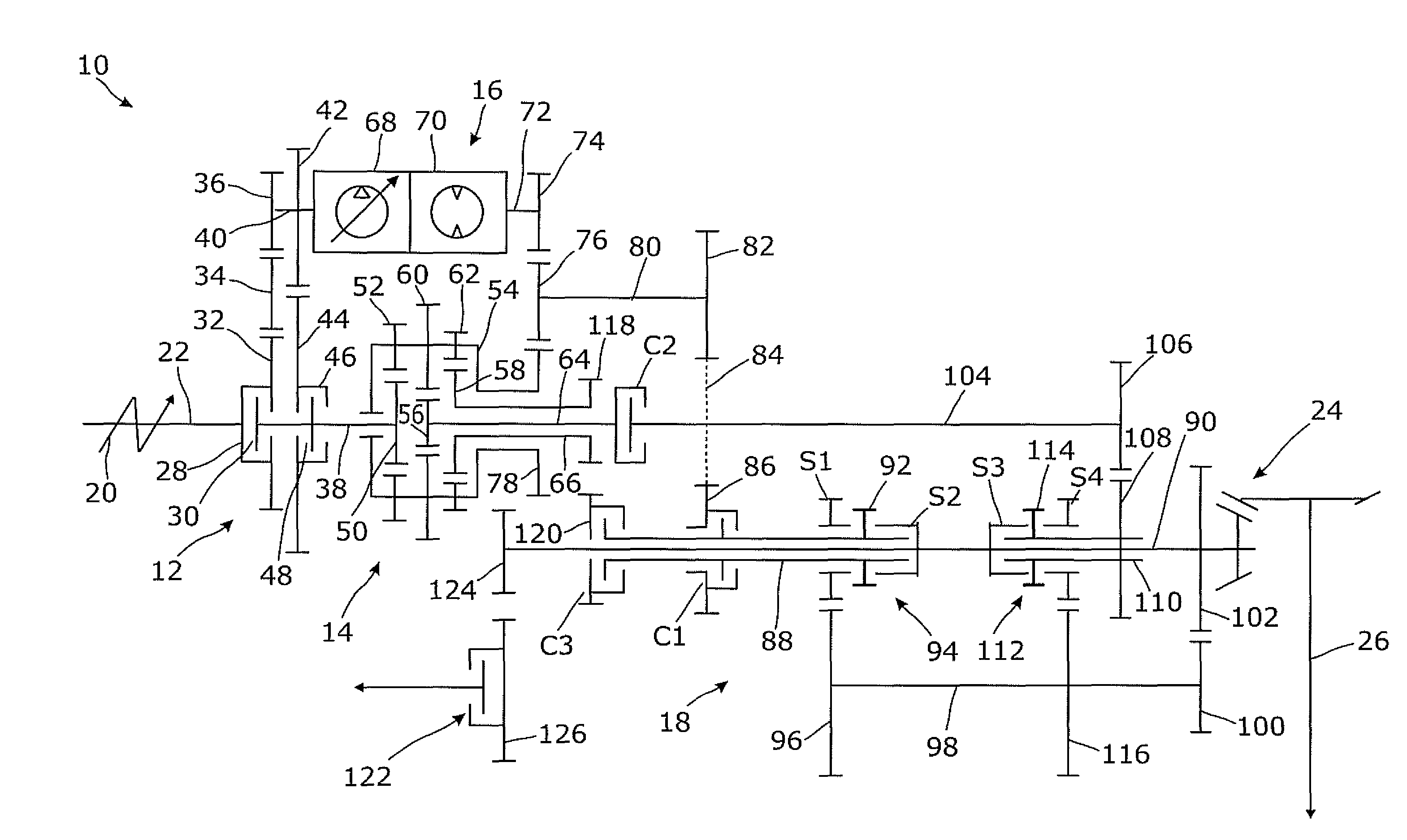

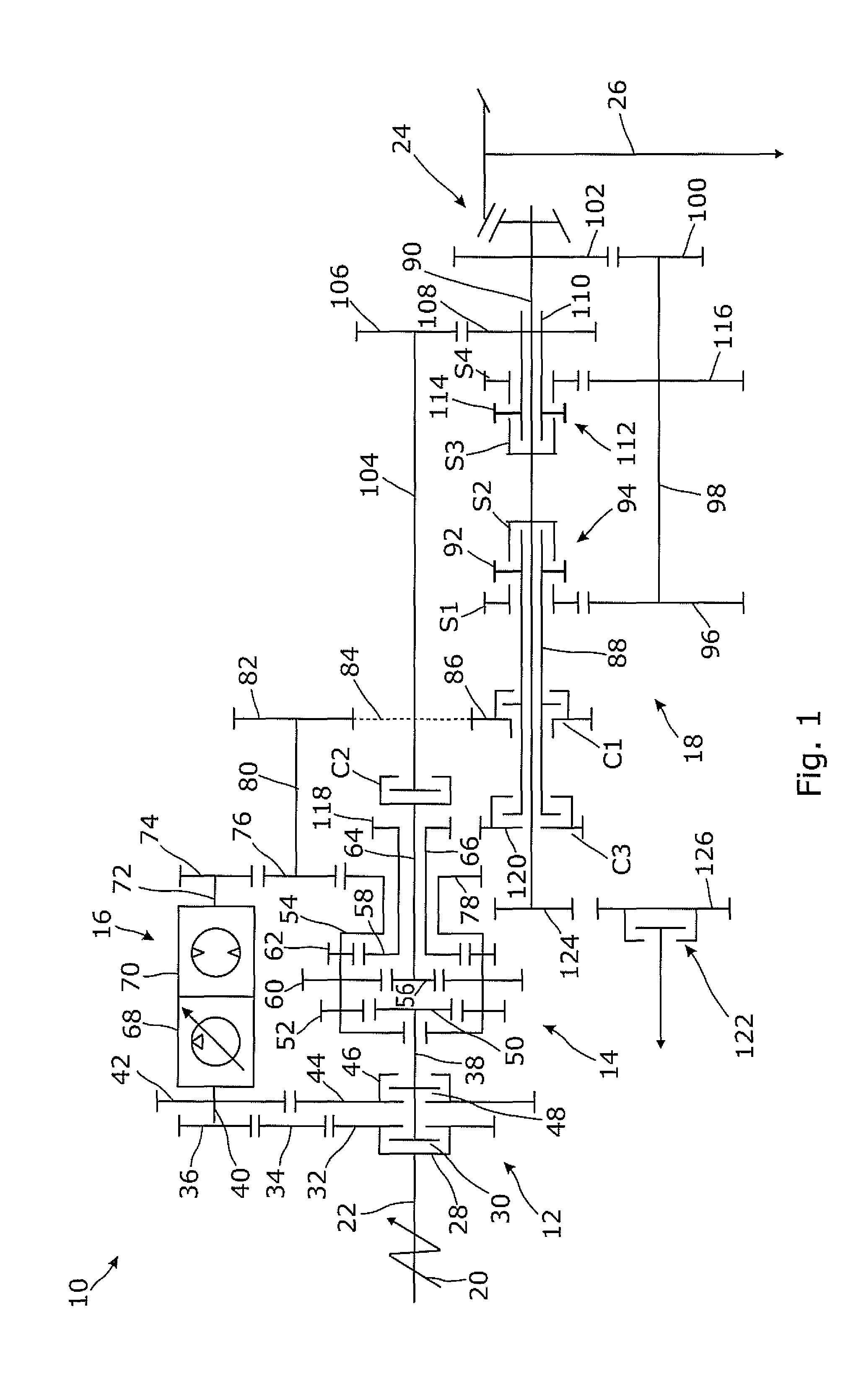

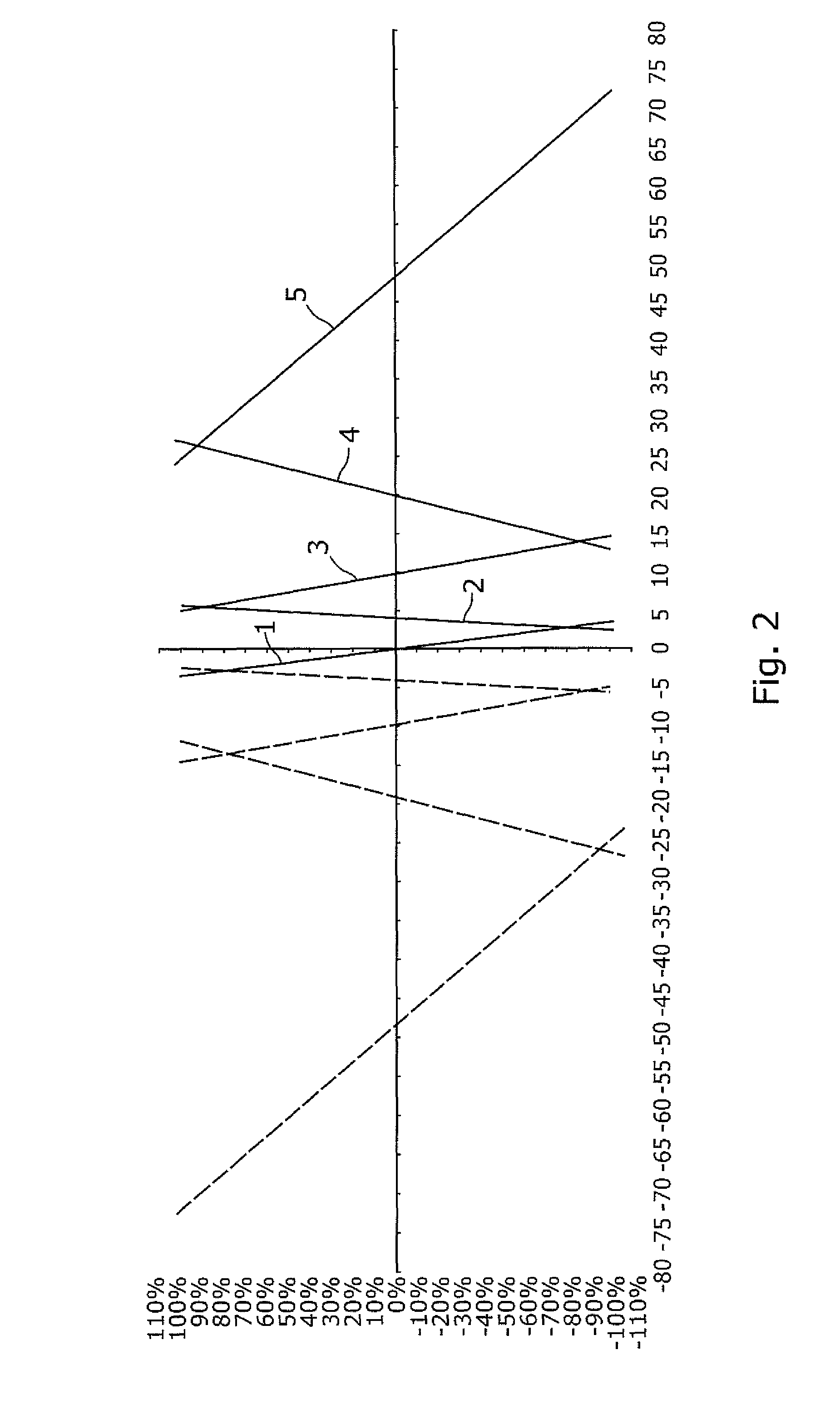

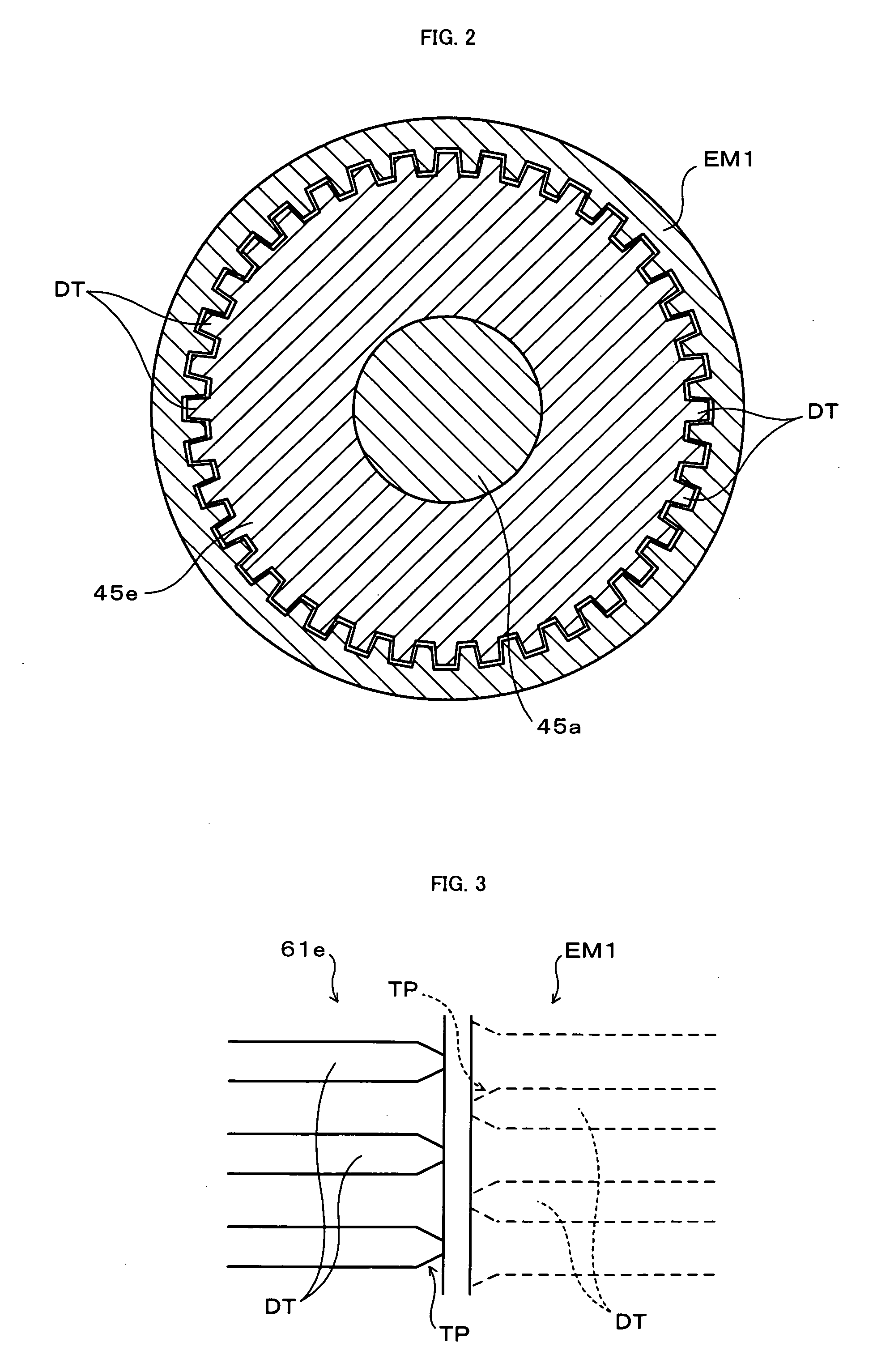

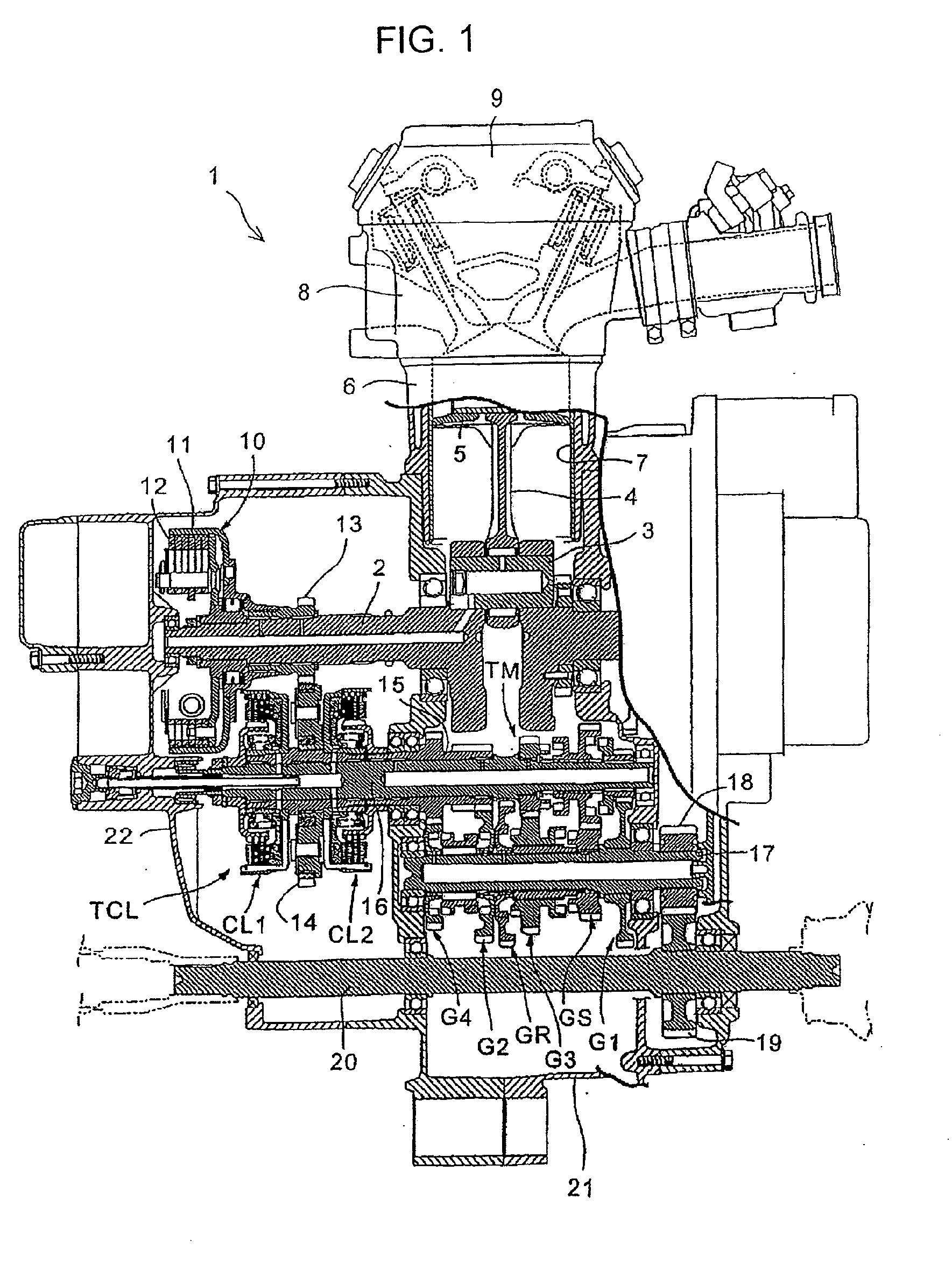

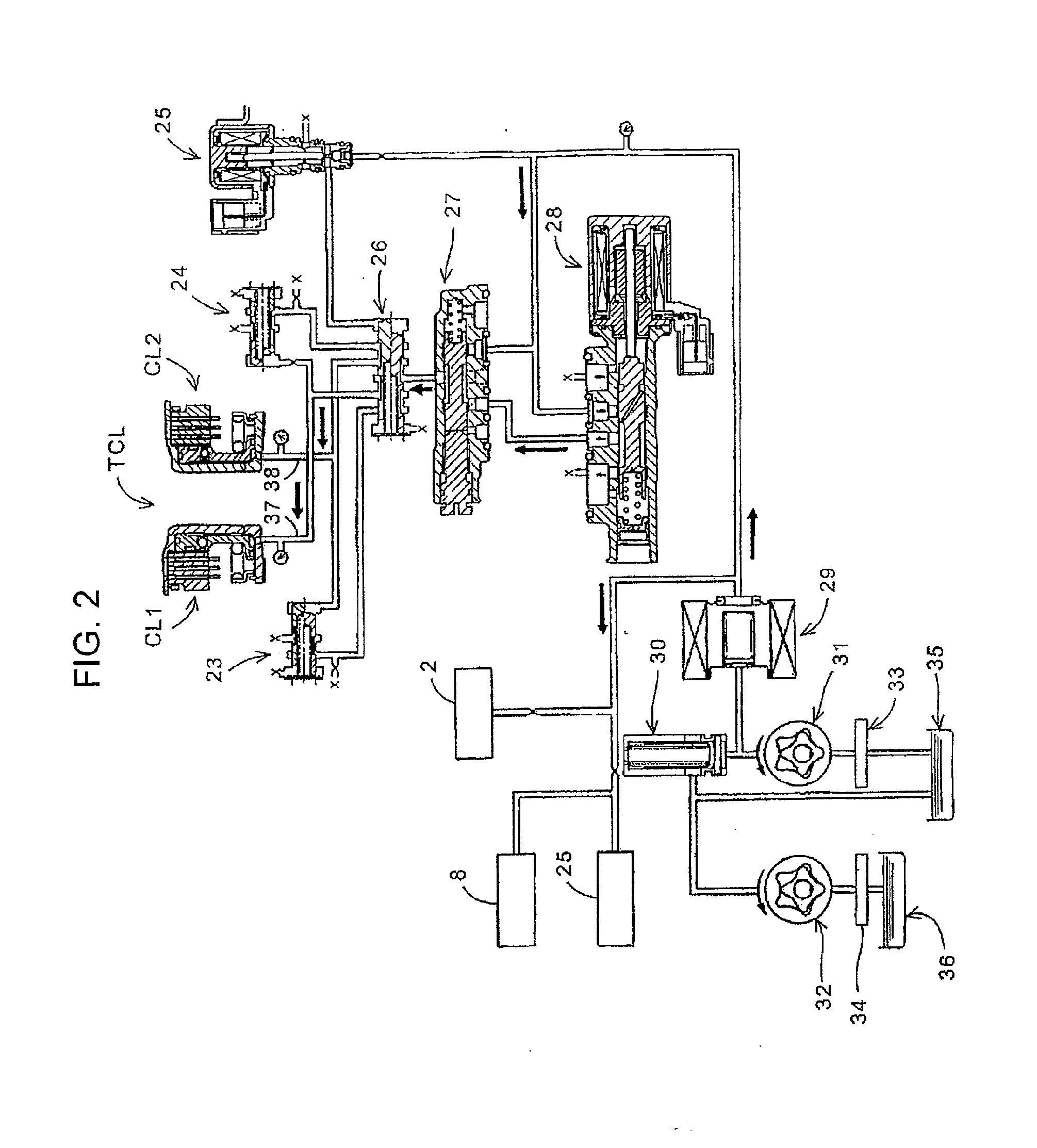

Power split transmission

ActiveUS20150072823A1Maximize efficiencyComplexity costToothed gearingsGearing controlClutchPower transmission

Owner:VOLTRA OY AB

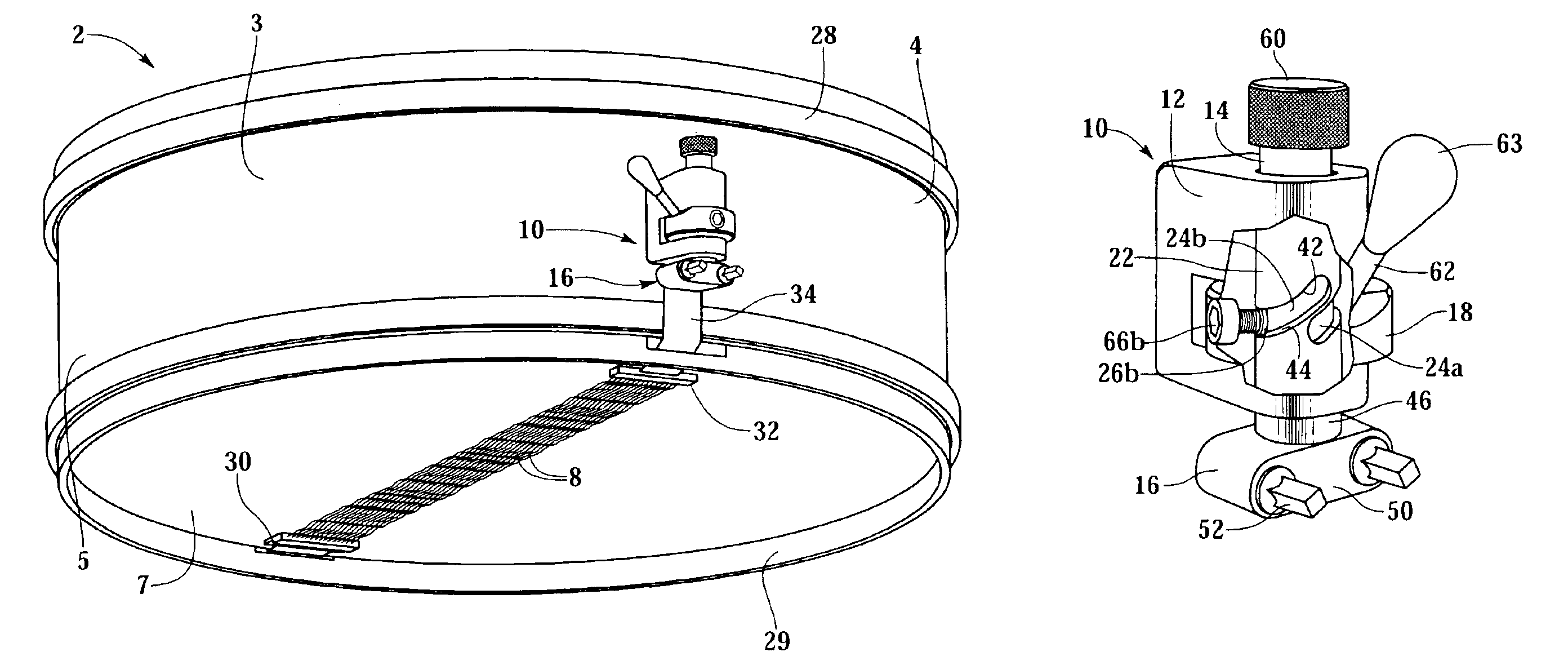

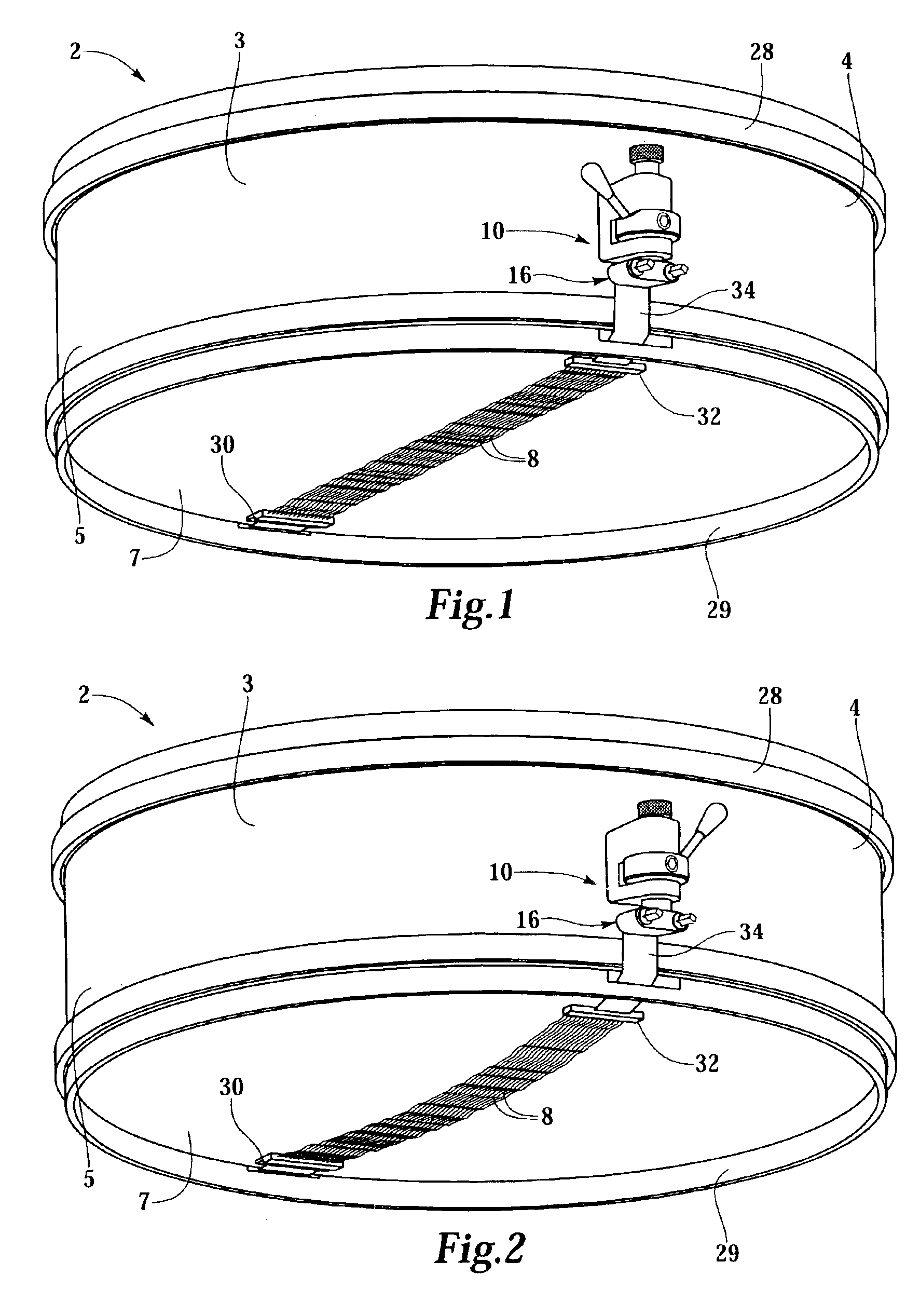

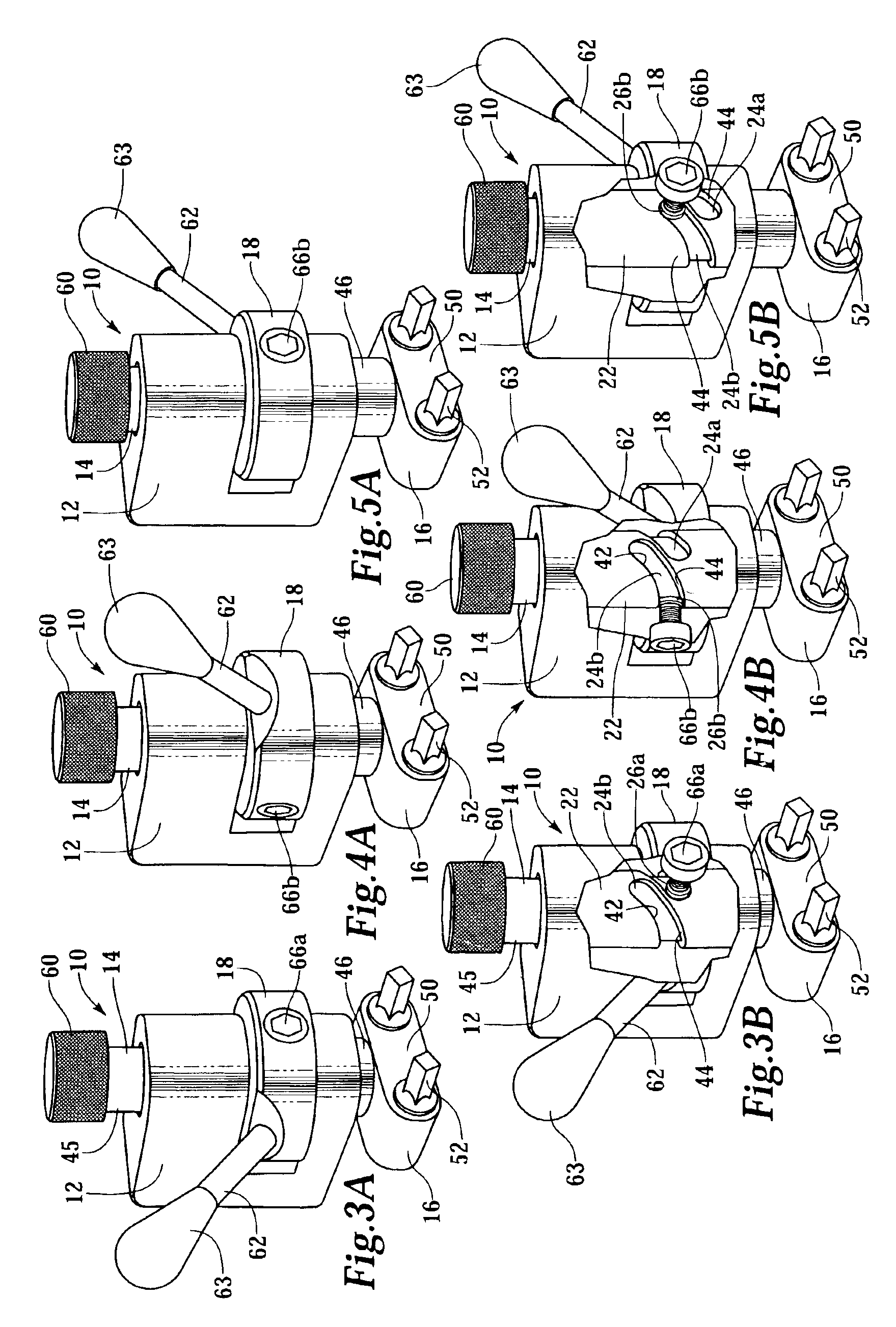

Strainer for a drum

A snare drum strainer mountable to the shell of a drum comprises a piston and an actuator. The piston has an axis and a surface curved about an axis generally parallel to the piston axis, and the piston is operatively connected to snares. The actuator and the curved surface rotate one with respect to the other about an axis generally parallel to the piston axis to reciprocate the piston and to tension and untension the snares. In another embodiment, the piston includes a generally cylindrical surface with a generally helical groove, the piston is operatively connected to snares, and the actuator includes a follower insertable into the generally helical groove. The follower and the generally cylindrical surface rotate one with respect to the other to reciprocate the piston and tension and untension the snares.

Owner:TRICK PERCUSSION PRODS

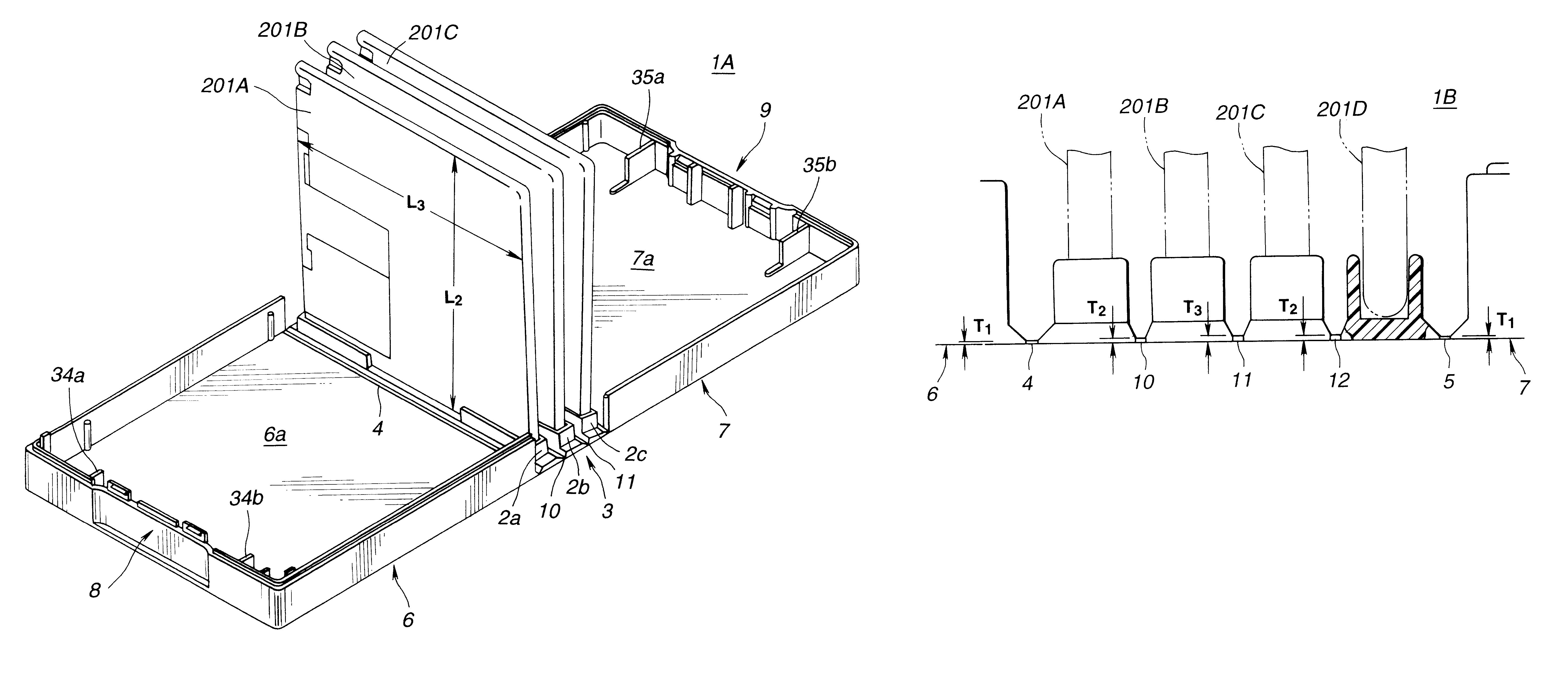

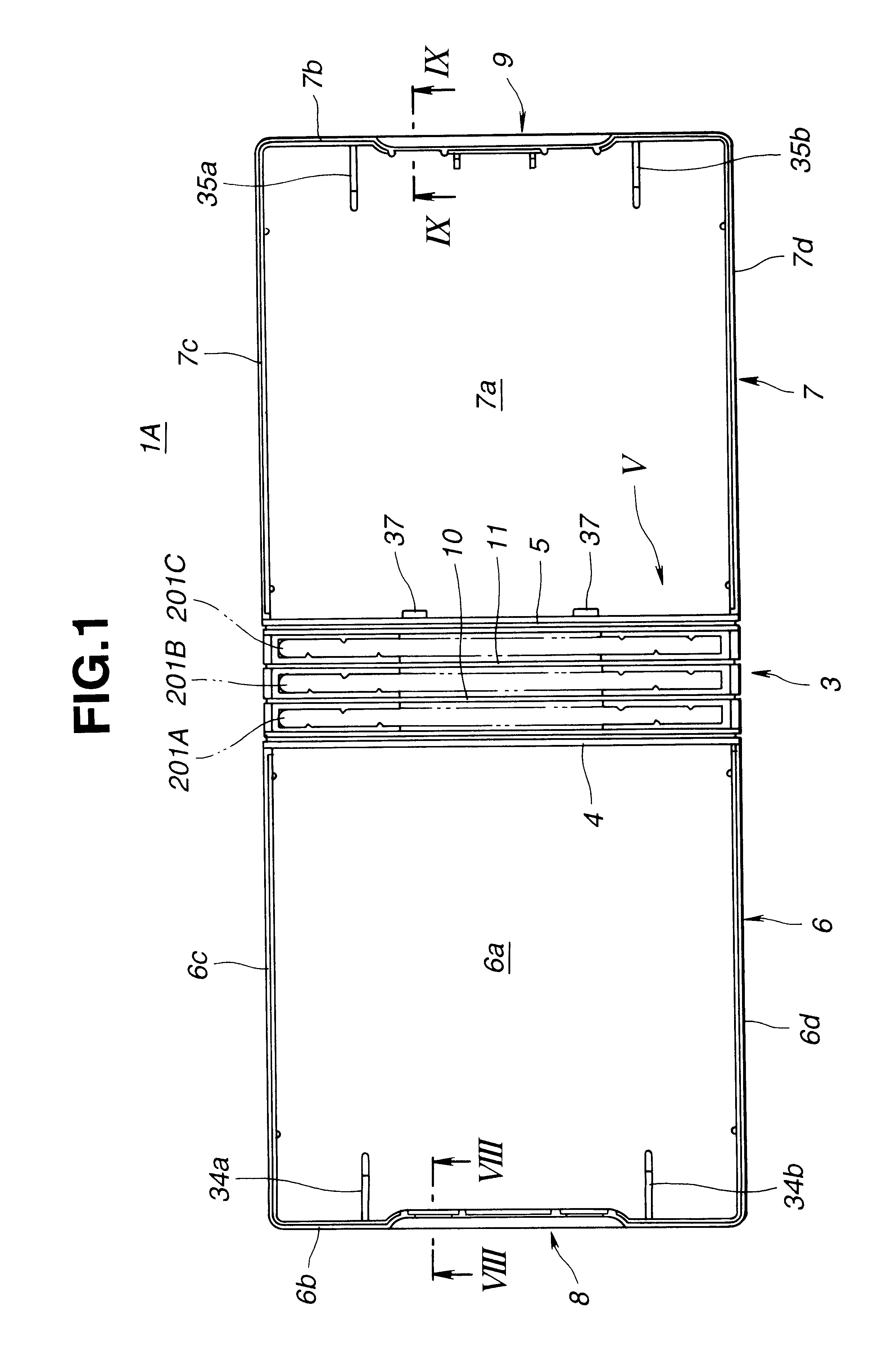

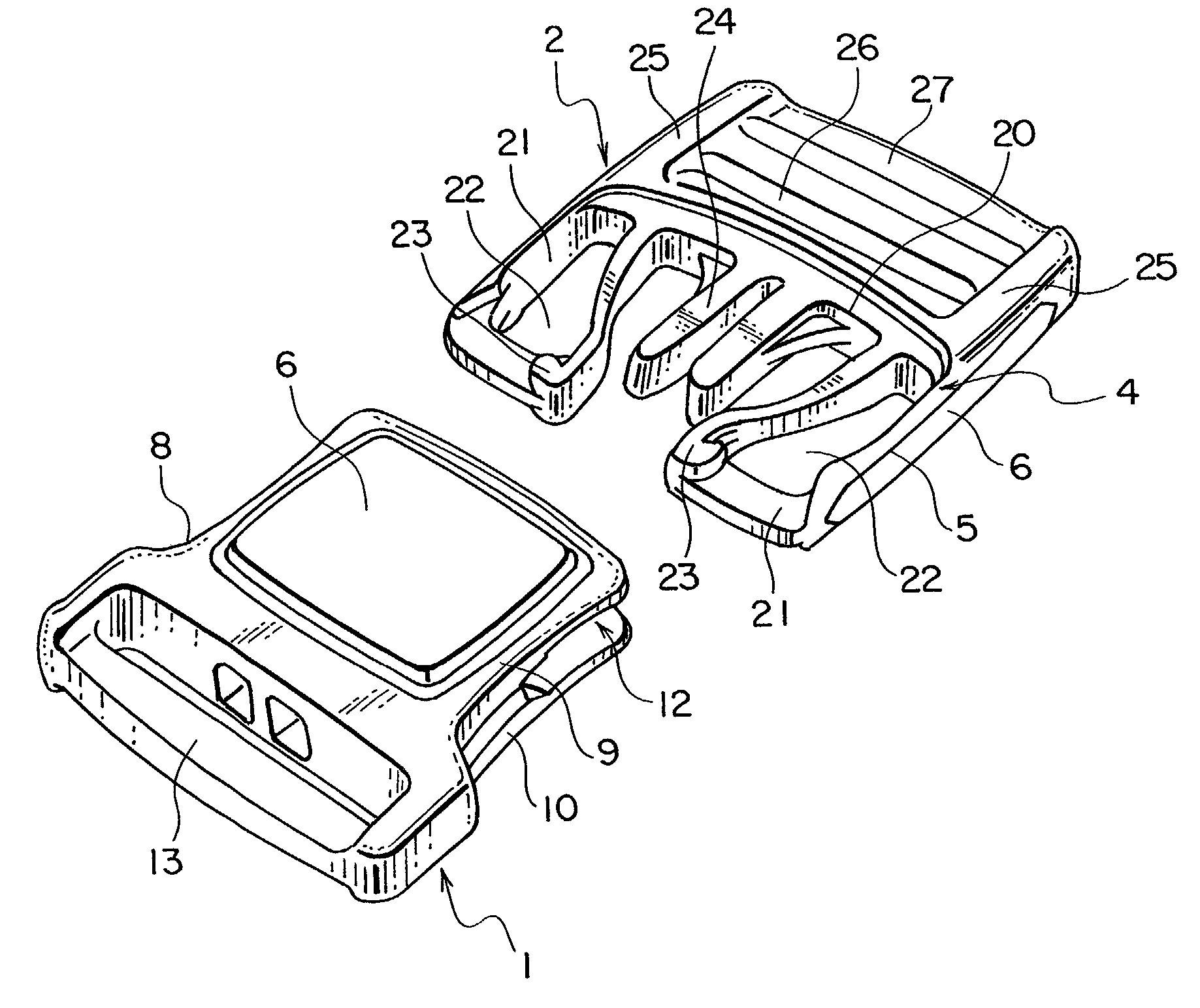

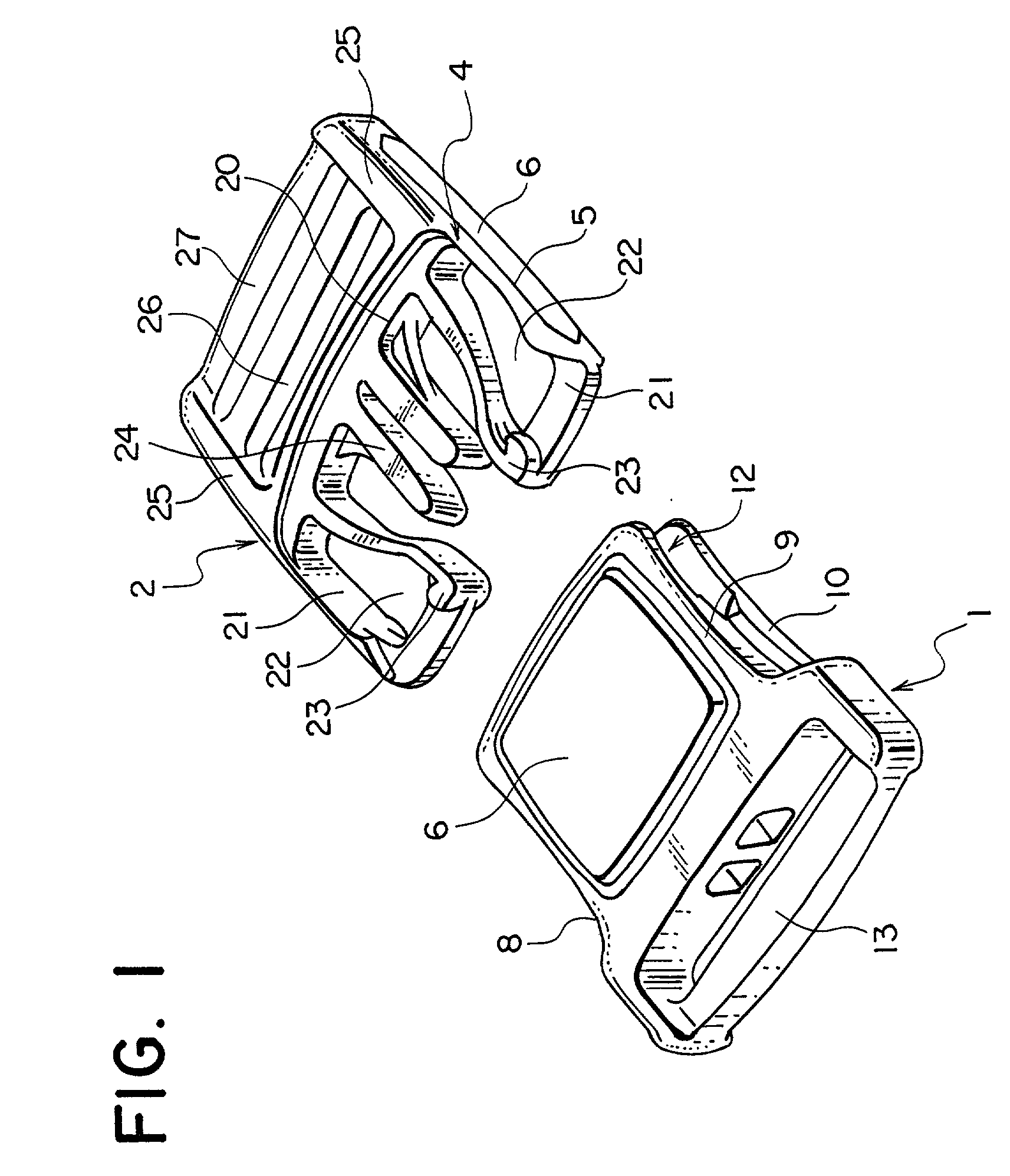

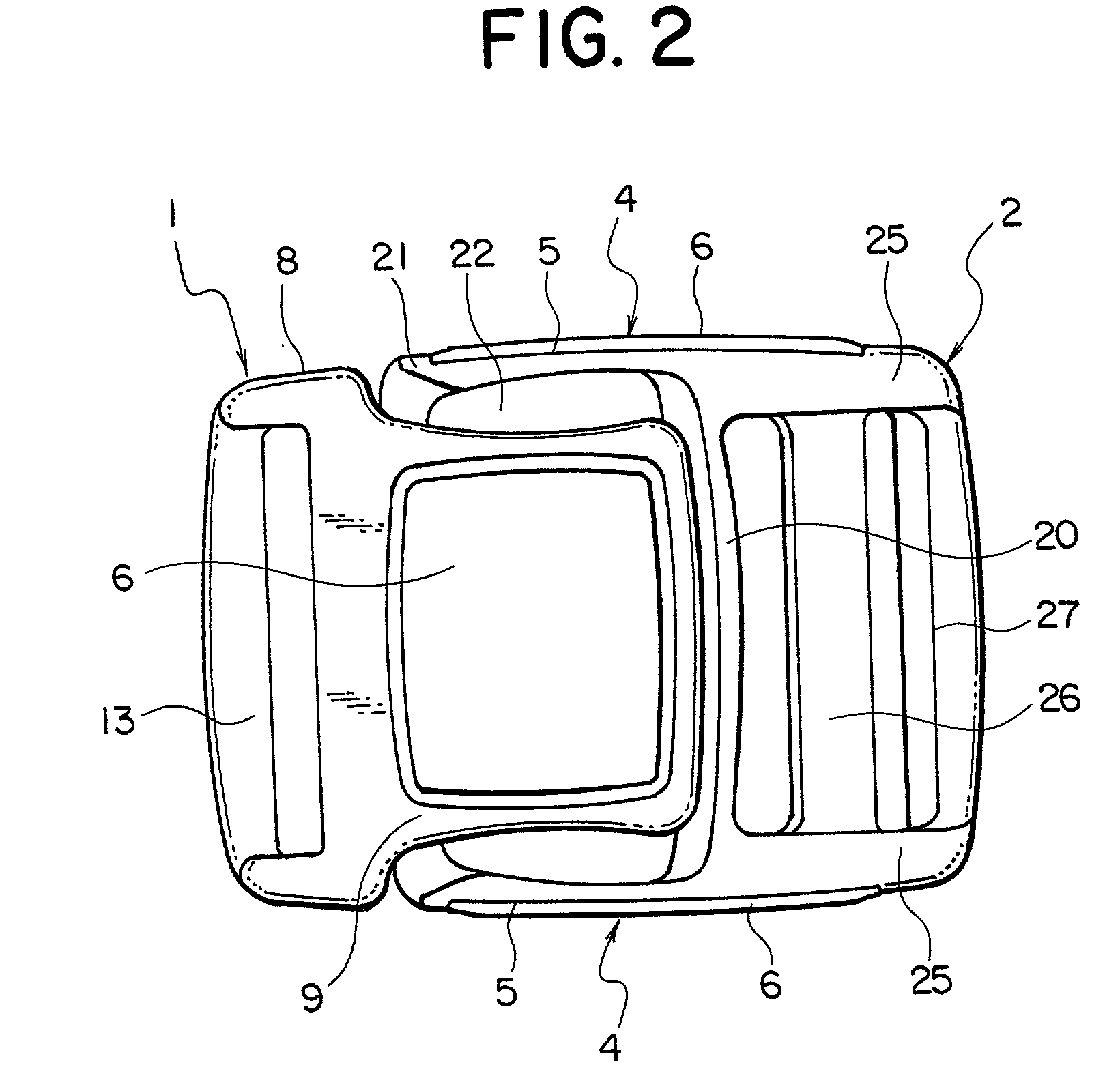

Cartridge holder

InactiveUS6199689B1Easy to handleReduce thicknessApparatus modification to store record carriersRecord information storageEngineeringMechanical engineering

A cartridge holder is shown which comprises a back portion which has at an inner surface a plurality of cartridge gripping parts by which one sides of cartridges are gripped, a pair of lid portions which are pivotally connected to opposed sides of the back portion through respective major hinge portions; catching and caught portions which are provided at free ends of the lid portions and lock the lid portions when the lid portions are pivoted toward their closed position; and a plurality of extra hinge portions which are defined by the back portion. By roundly flexing the back portion at the major hinge portions, the cartridge gripping parts, that is, the cartridges gripped by these cartridge gripping parts are opened like a fan. Thus, upper ends of the cartridges are separated thereby facilitating handling of the upper ends of the cartridges by the fingers of a user. In order to prevent a swell-out phenomenon of the back portion which would occur when the back portion is roundly flexed, there is provided a swell-out phenomenon suppressing means. In order to prevent removal of the cartridges from the cartridge gripping parts which would occur when vibration and shock are applied thereto under conveying of the holder, there is provided a cartridge retaining rib.

Owner:SONY CORP

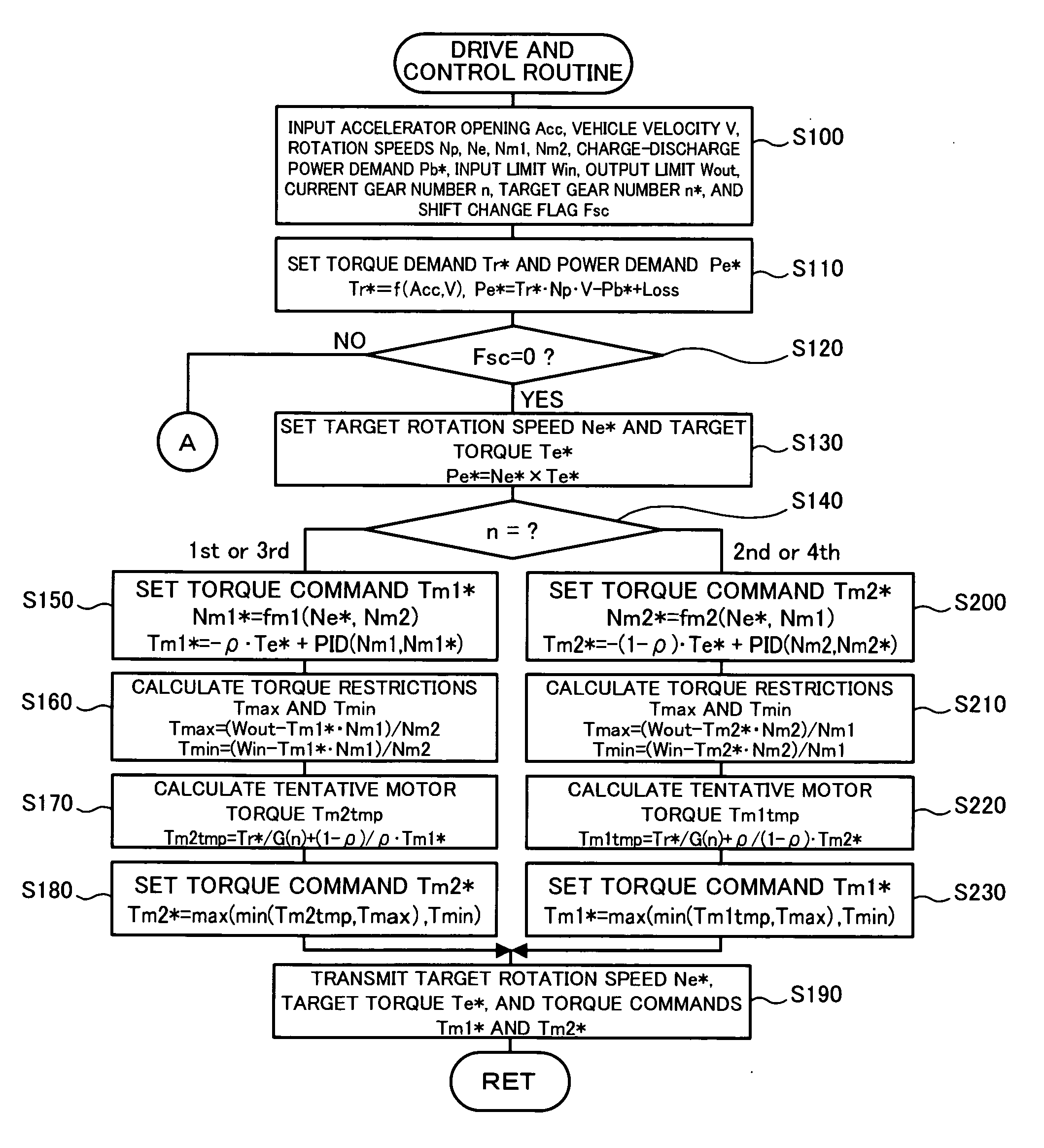

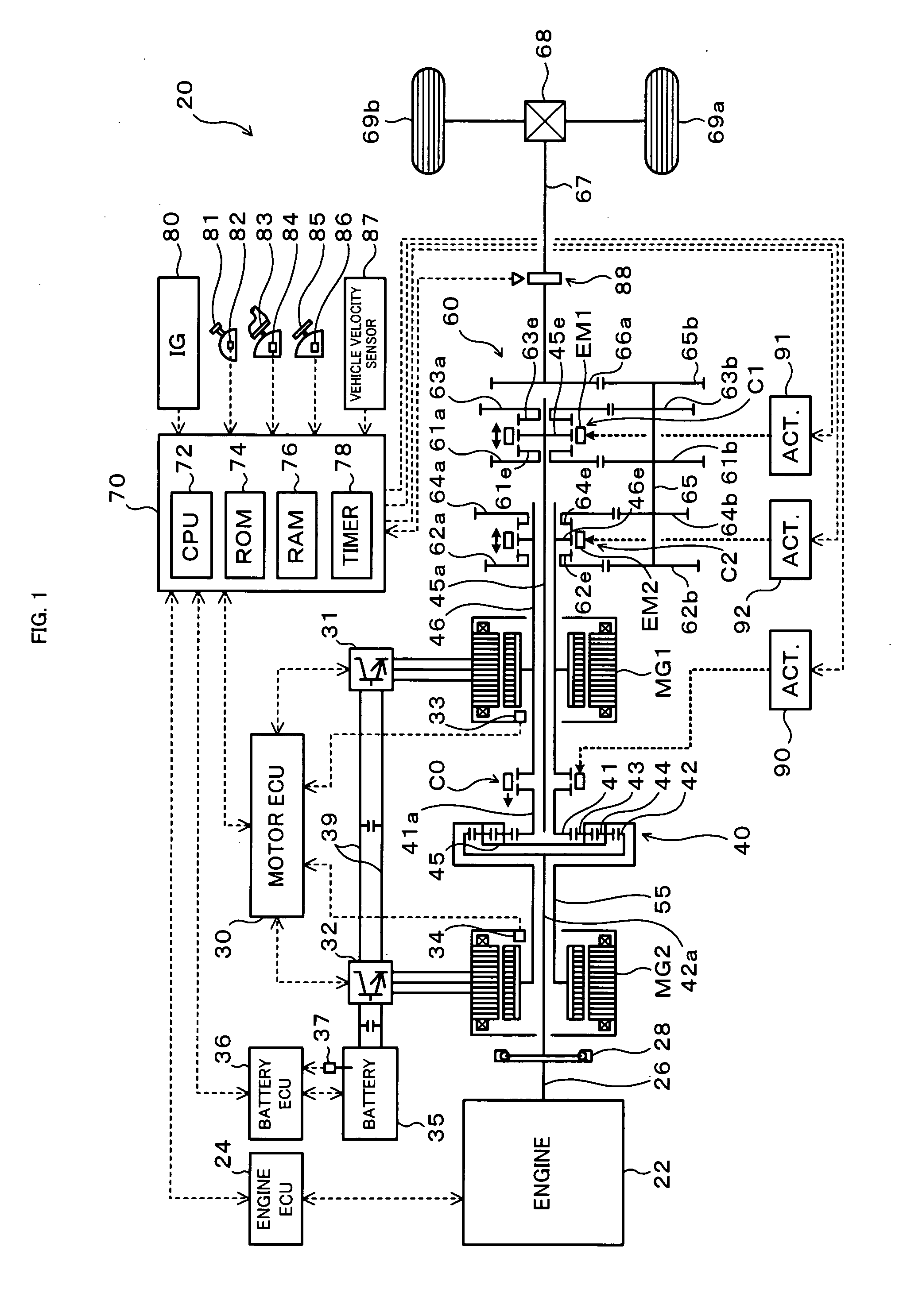

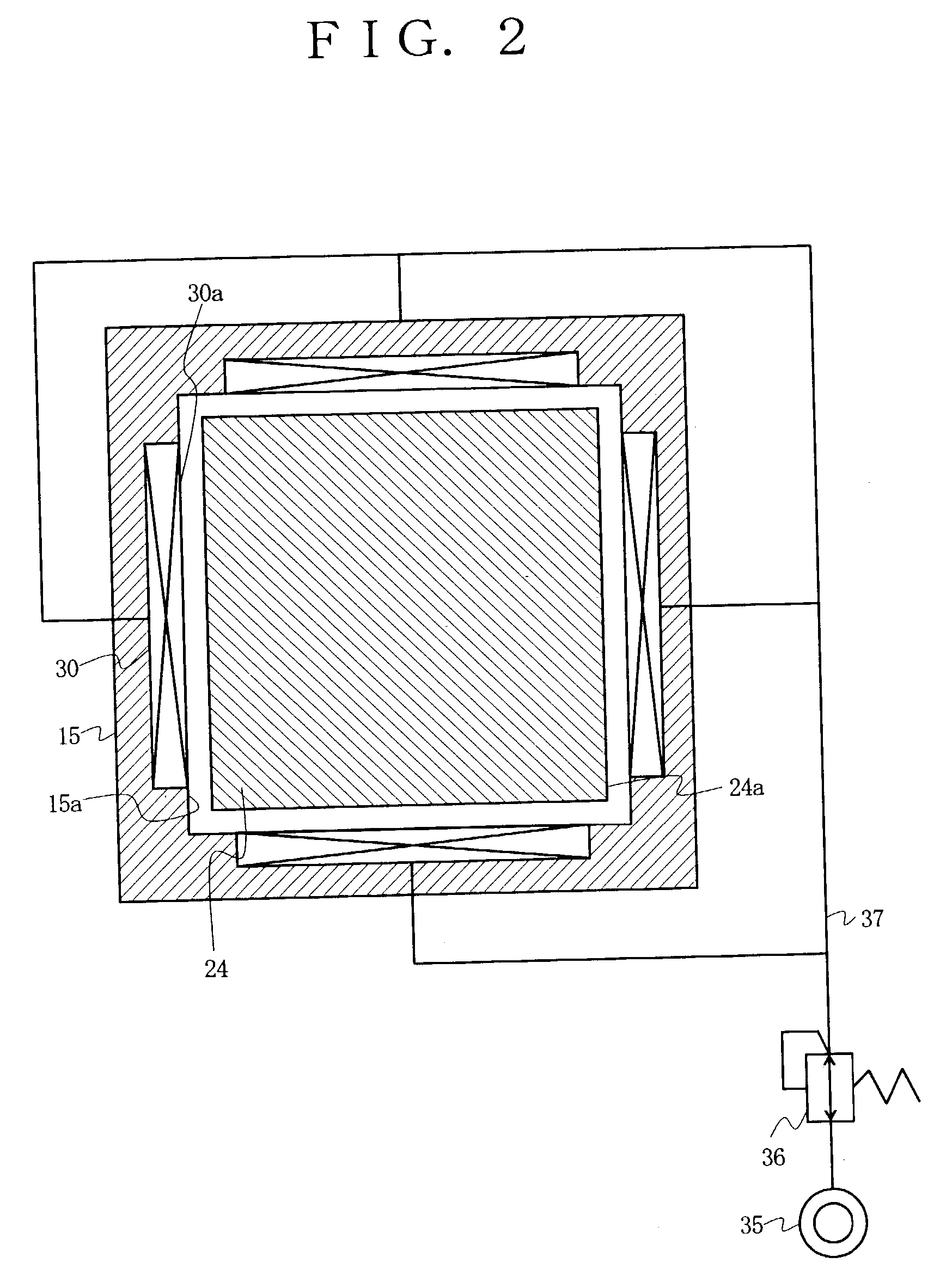

Connecting device, transmission, power output apparatus including the transmission, and method of controlling connecting device

InactiveUS20080300744A1Firmly connectedSmooth engagementHybrid vehiclesDigital data processing detailsActuatorControl theory

A motor MG1 is controlled so that the rotation speed deviation of the rotation speed of a first motor shaft 46 from the rotation speed of a second gear 62a matches a predetermined target rotation speed deviation and an actuator 92 is controlled so that a movable engaging member EM2 moves toward an engaging portion 62e for a predetermined time after the rotation speed has matched the target rotation speed deviation, if, for example, the movable engaging member EM2 is to be engaged with both of an engaging portion 46e and the engaging portion 62e of the second gear 62a to connect the first motor shaft 46 and the second gear 62a when the movable engaging member EM2 is engaged only with the engaging portion 46e of the first motor shaft 46.

Owner:TOYOTA JIDOSHA KK

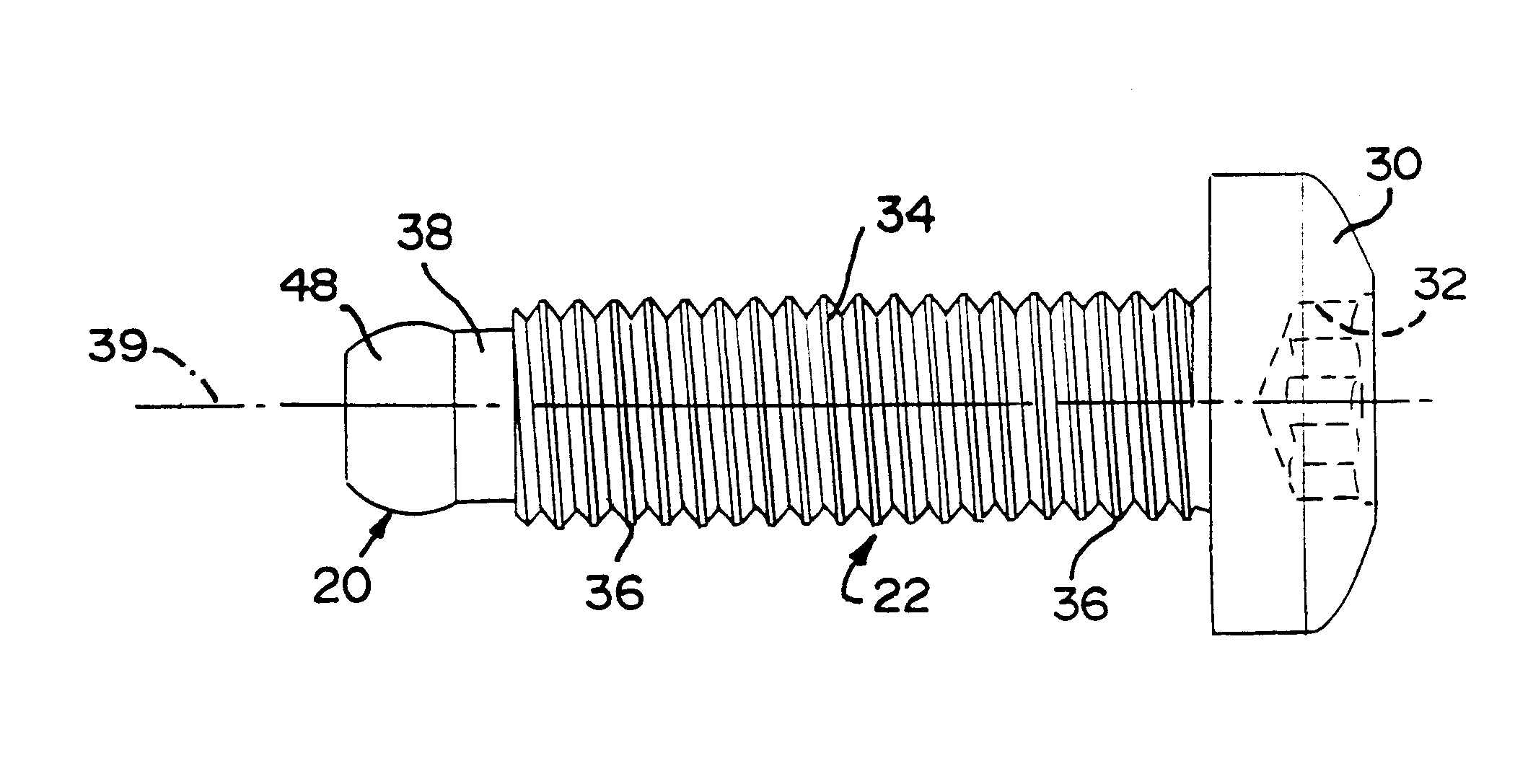

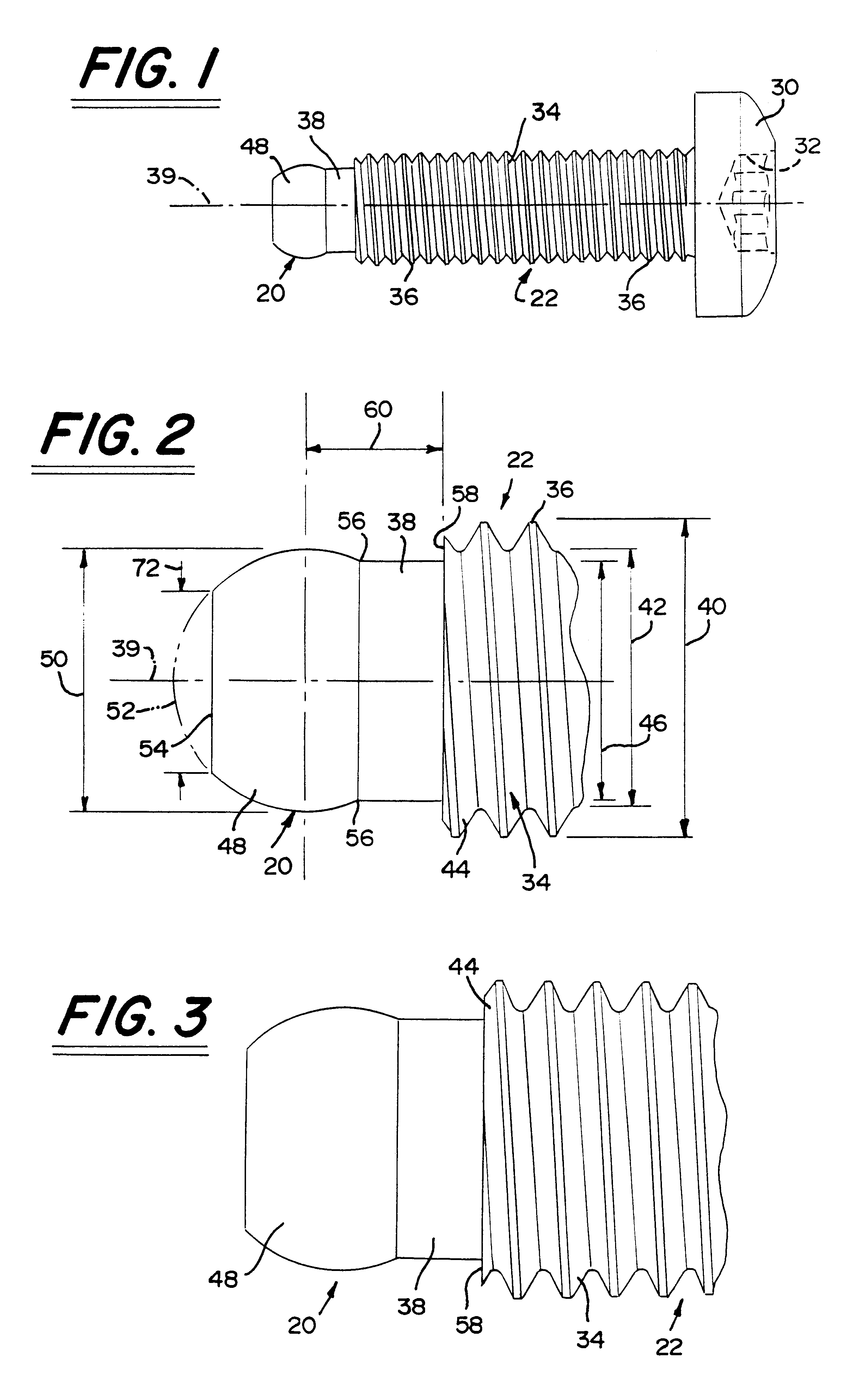

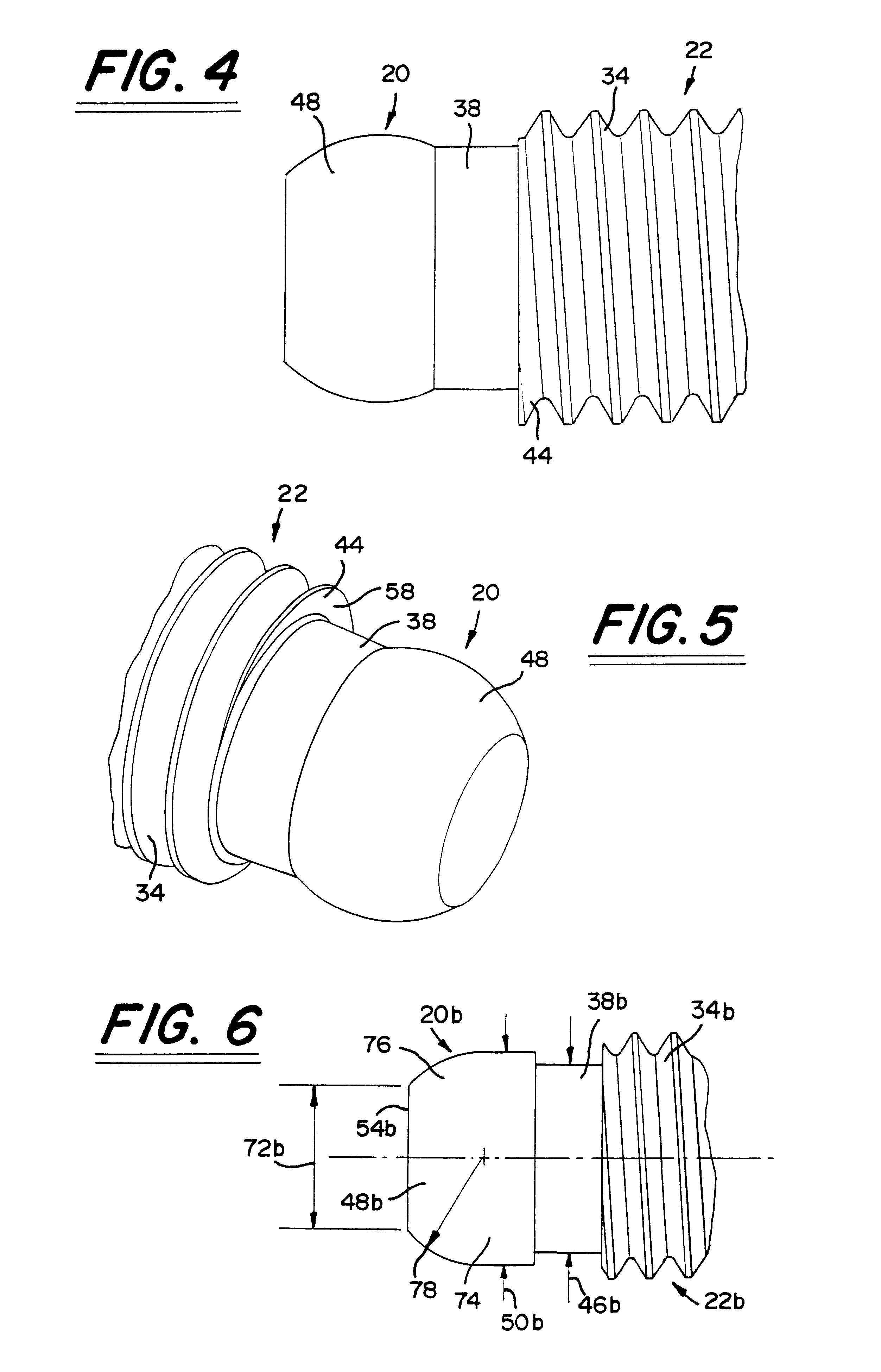

Fastener with anti-cross-threading point and method of assembly

InactiveUS6328515B1Rapid engagementReduce the time required for installationRivetsSheet joiningMultiple formsMaximum diameter

A novel fastener member and a novel method of assembly are provided for engagement of the fastener member with a female member having an internally threaded bore. The fastener member includes a threaded shank portion and a novel point at a work entering end thereof. The point includes a radiused portion which is engaged within the female member threaded bore to start engagement of the fastener member therewith. In certain embodiments, the point further includes an unthreaded portion, which has a diameter that is slightly less than a minor diameter of the shank portion, connecting the radiused portion and the threaded portion. The radiused portion has a maximum diameter which is slightly less than a minor diameter of the threaded bore. The radiused portion may take many forms and, for example, may be spherical; partially spherical; or formed from a predetermined number of radiused portions integrally formed with each other. To engage the fastener member and the female member, the radiused portion is disposed within the threaded bore and thereafter, rotational movement and an end load are applied to one or the other of the fastener member or the female member. The radiused portion is completely inserted into the bore prior to engagement of the shank portion with the threads in the bore, and will promote lateral as well as pivotal moment as required to align the respective members to attain proper thread engagement.

Owner:TEXTRON IPMP +1

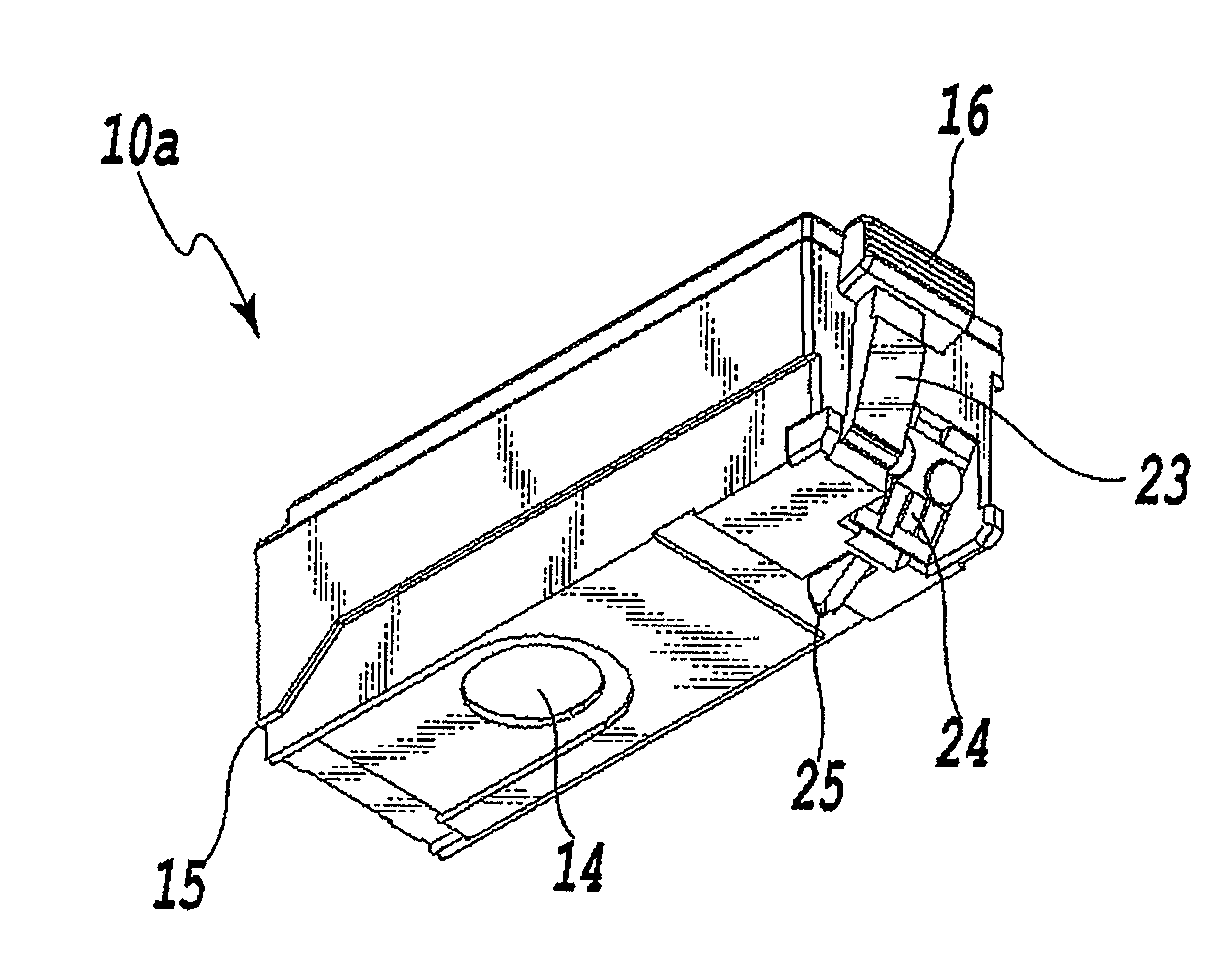

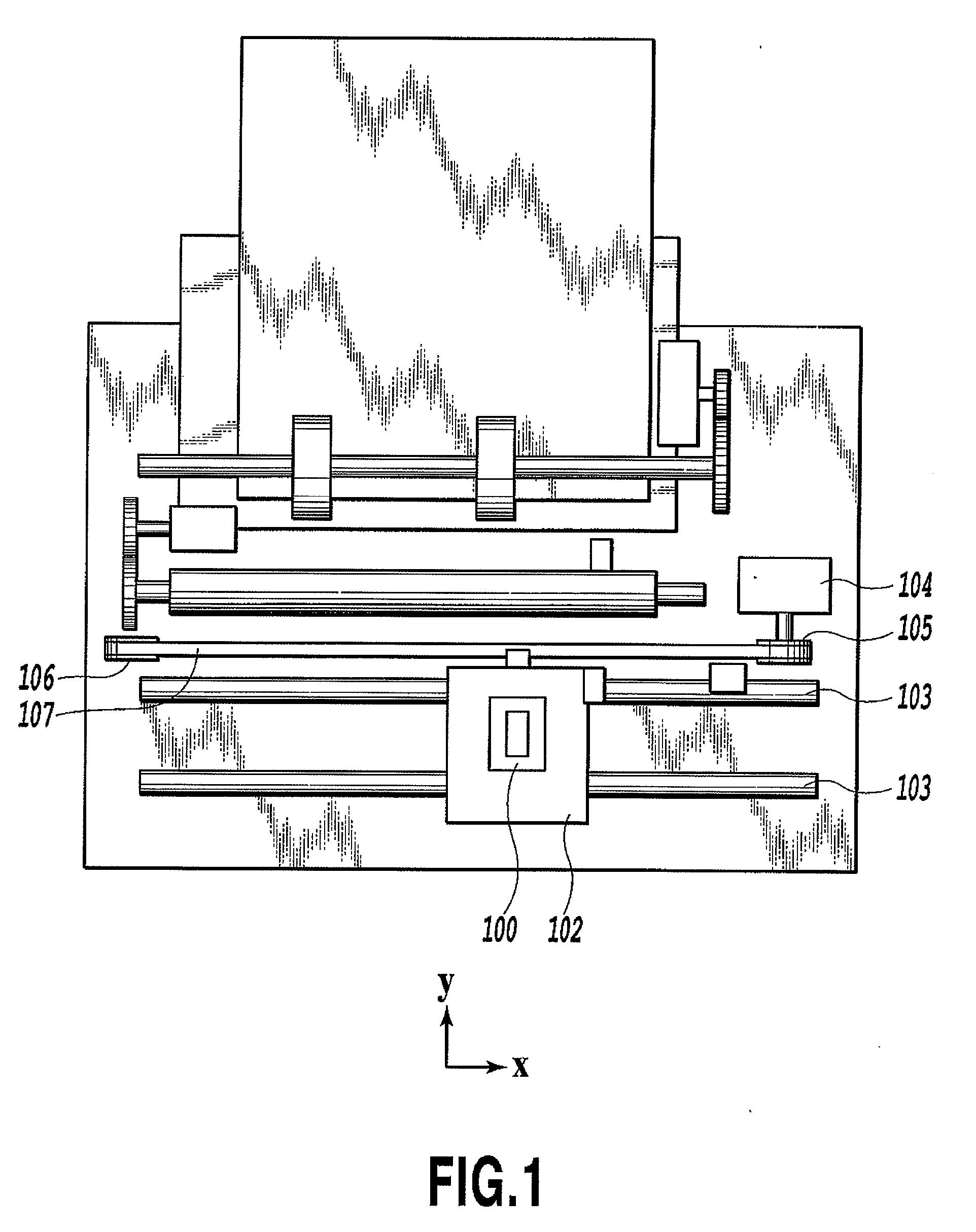

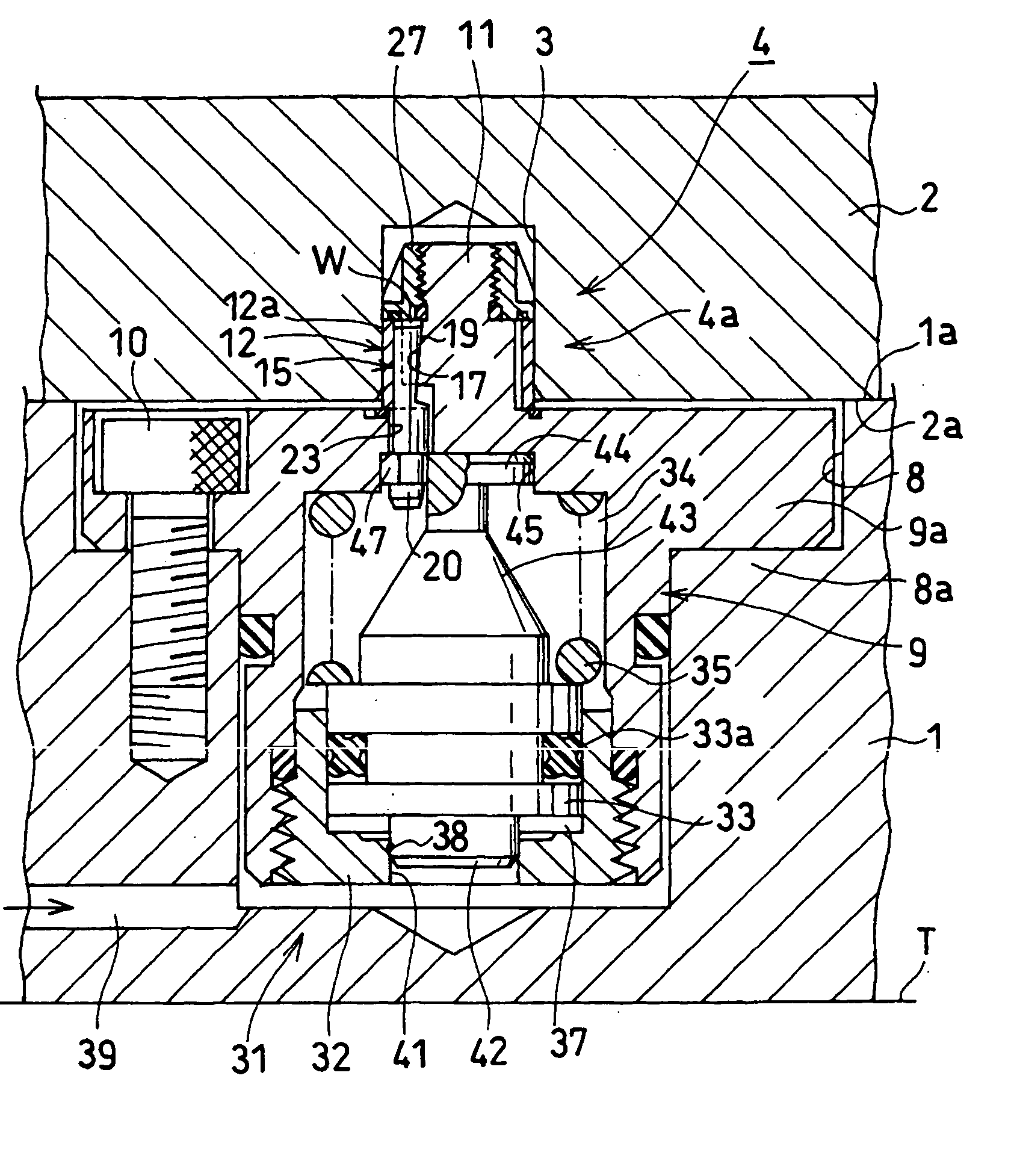

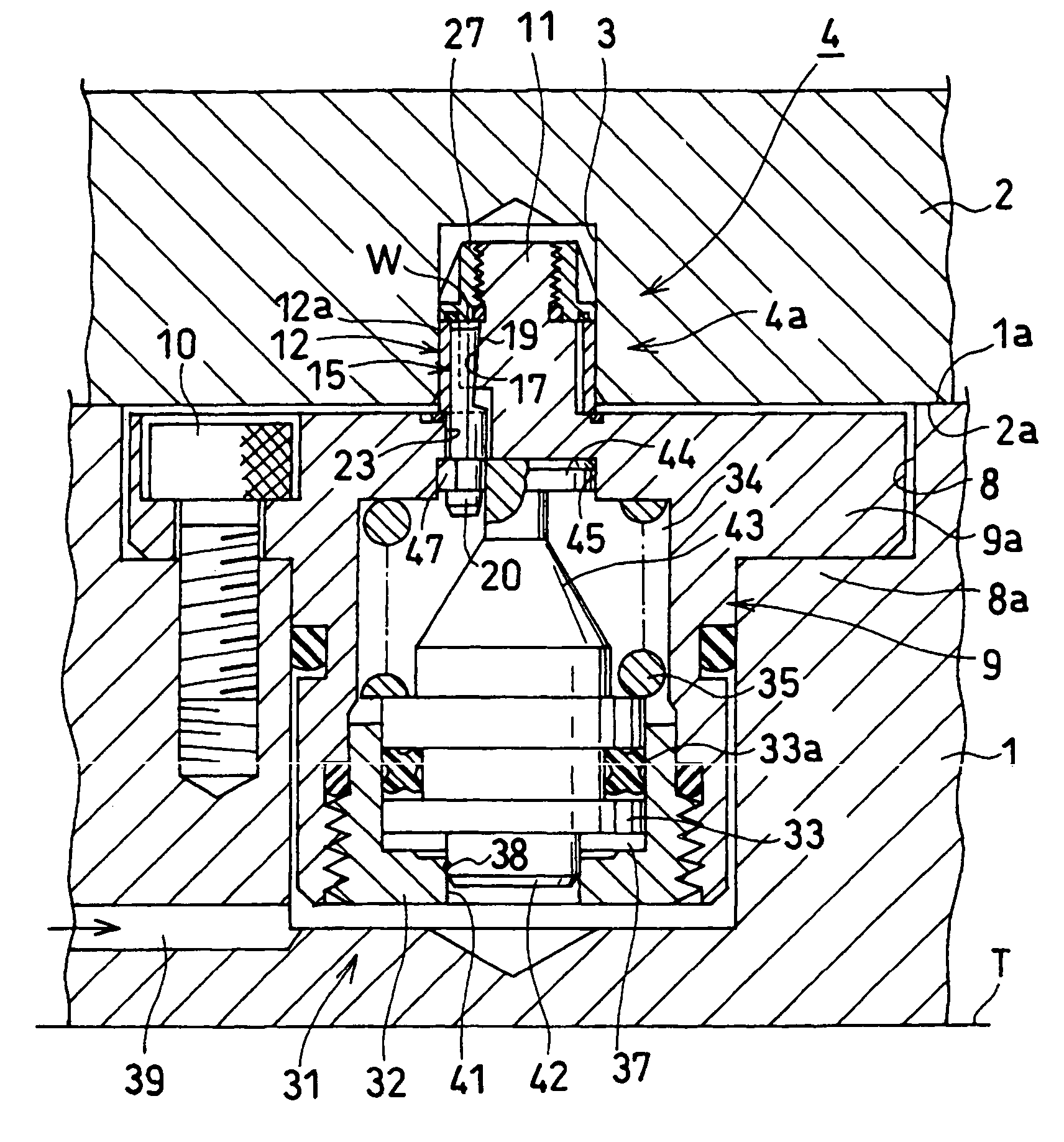

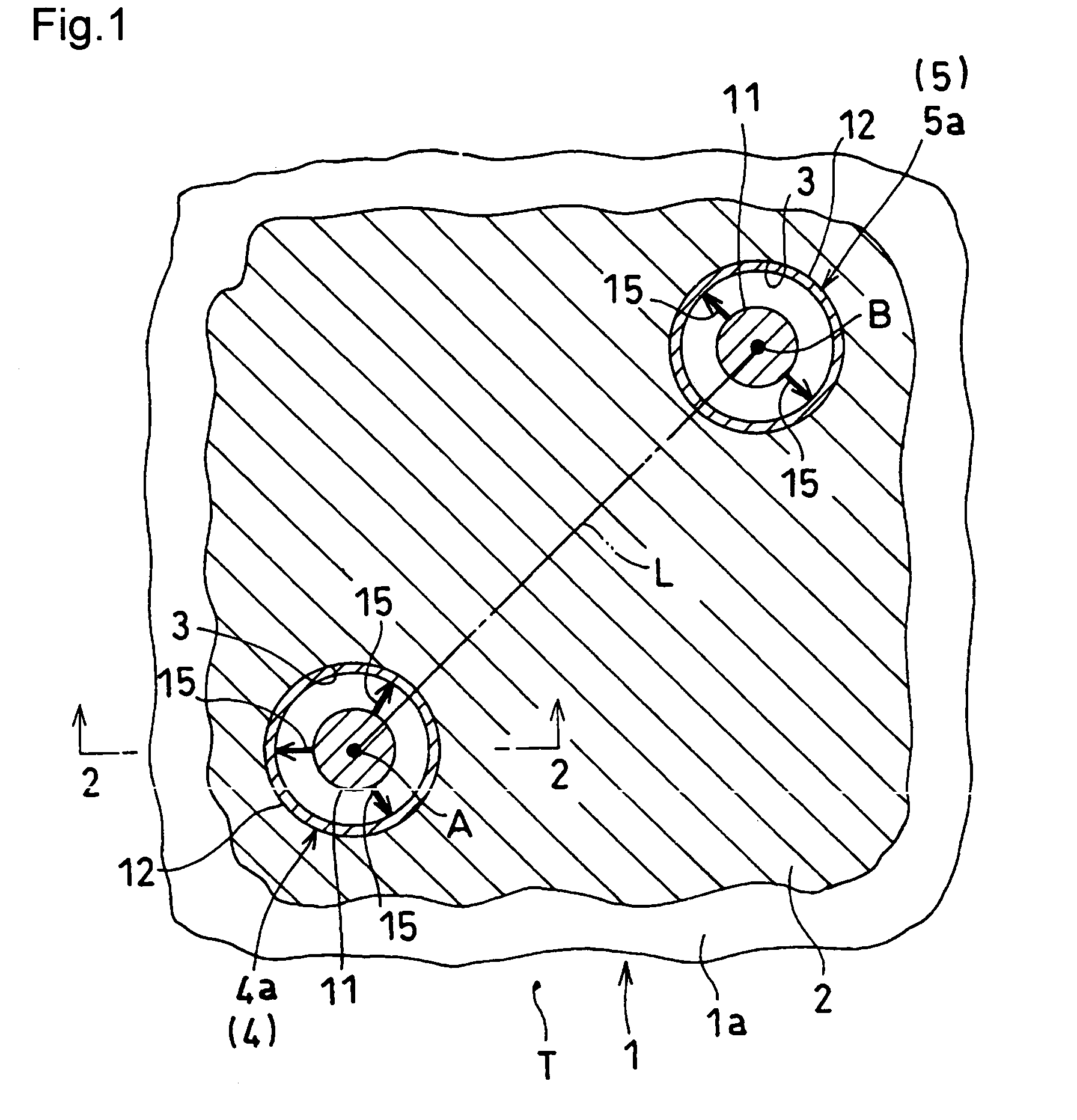

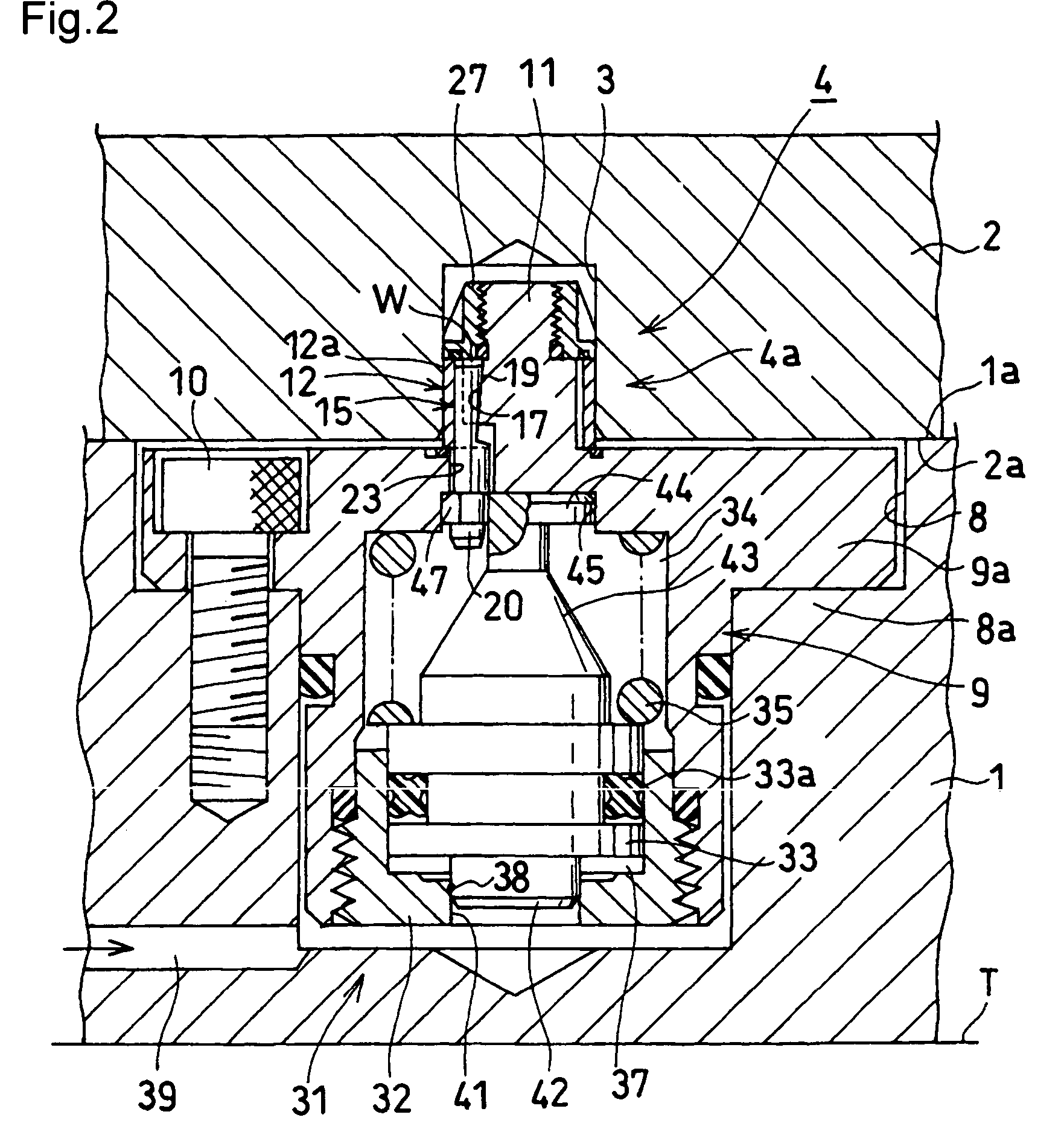

Positioning device

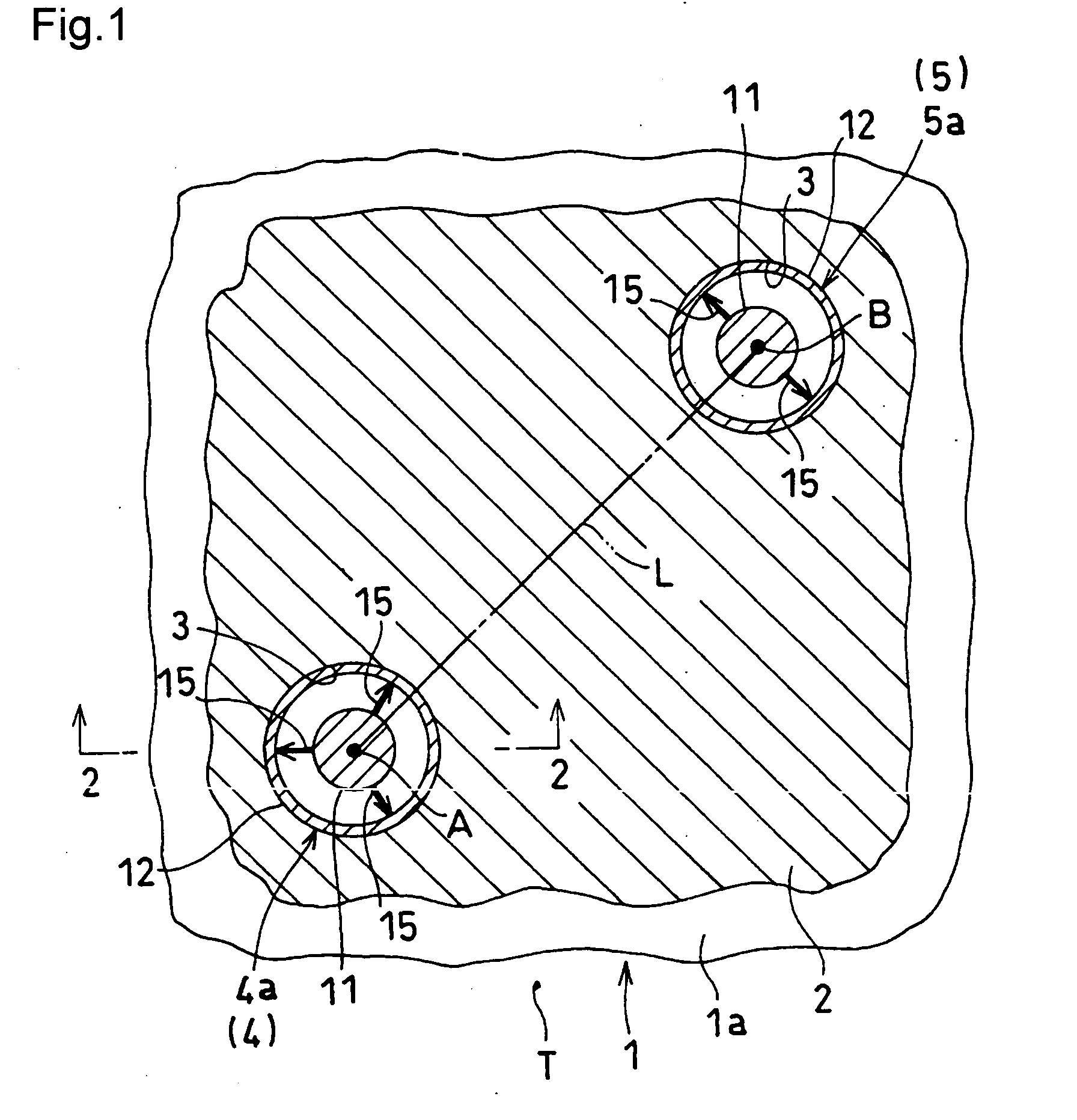

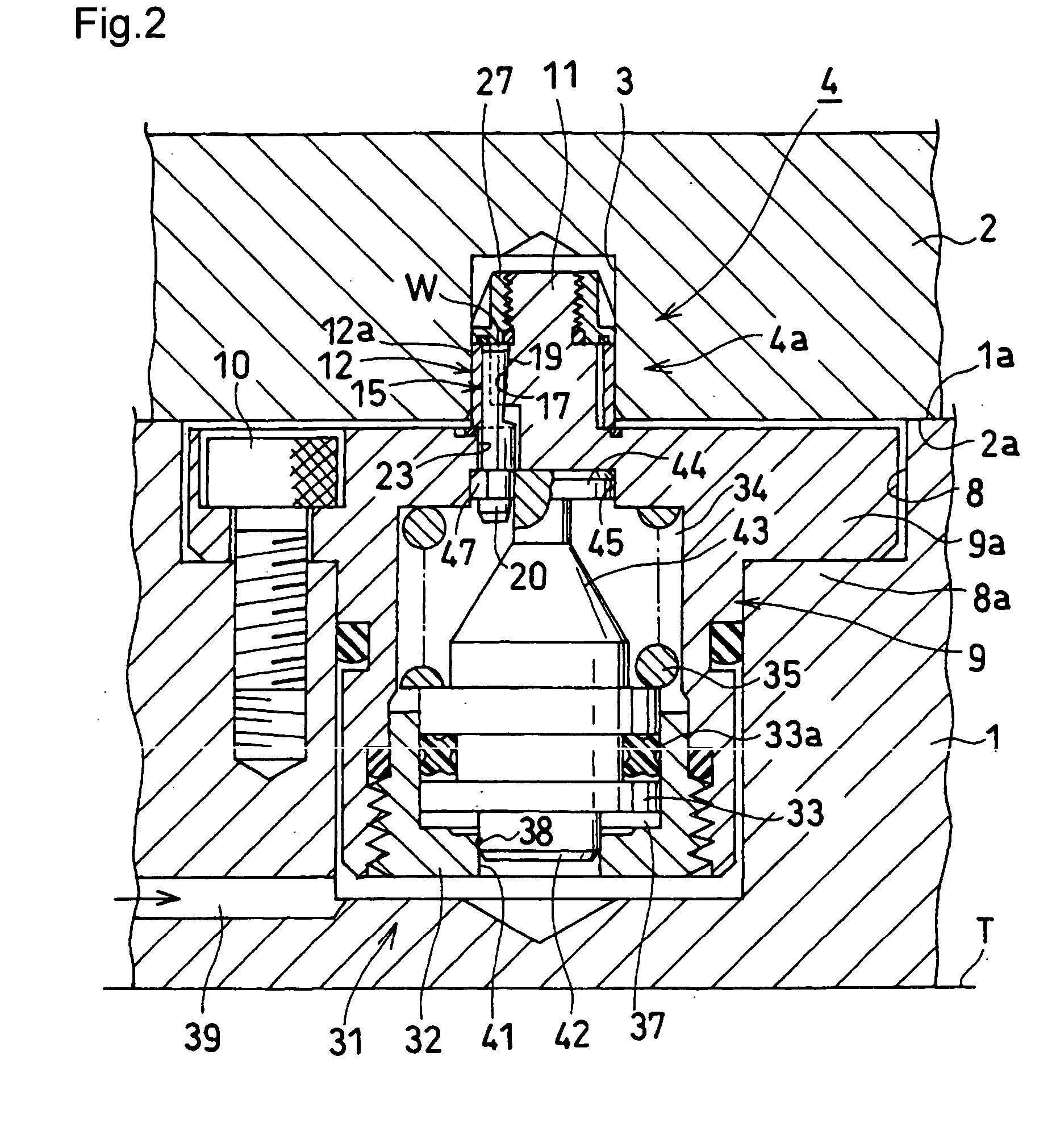

InactiveUS20060033255A1Reliable and highly accurate positioningHigh precisionLarge fixed membersMetal working apparatusEngineering

A supporting face (1a) is provided on a base plate (1), a face (2a) to be supported is provided on a work pallet (2), and an engagement hole (3) is opened in the face (2a) to be supported. A core column (11) is projected upward from a housing (9) fixed to the base plate (1). An elastic sleeve (12) that fits in the engagement hole (3) is supported in a space at the outer periphery of the core column (11), on the upper face of the housing (9). Wedge spaces (W) narrowing downward are circumferentially arranged at substantially equal intervals between the core column (11) and the elastic sleeve (12). Wedge members (15) are vertically movably inserted in each of the wedge spaces (W). Input portions (20) of the wedge members (15) are connected to an output portion (44) of an upper rod (43) of a piston (33).

Owner:KOSMEK LTD (JP)

Buckle

InactiveUS20020040515A1Soft touchLow costSnap fastenersClothes buttonsThermoplastic elastomerEngineering

A buckle is composed of a buckle body and an insertion body. The buckle includes an engagement and disengagement system in which the insertion body is inserted into the buckle body. An elastic member provided with elasticity, which is made of, for example, natural rubber, synthetic rubber or thermoplastic elastomer, is integrally molded on a pressing surface formed on an operating portion for performing an engagement and disengagement operation of the buckle by bicolor molding means or insert molding means. The pressing surface of the operating portion may be disposed on the buckle body or may be disposed on the insertion body. In either case, it is possible to produce a buckle having a good touch. Consequently, since the operating portion is flexible and soft to the touch, a smooth engagement and disengagement operation of the buckle can be realized.

Owner:YKK CORP

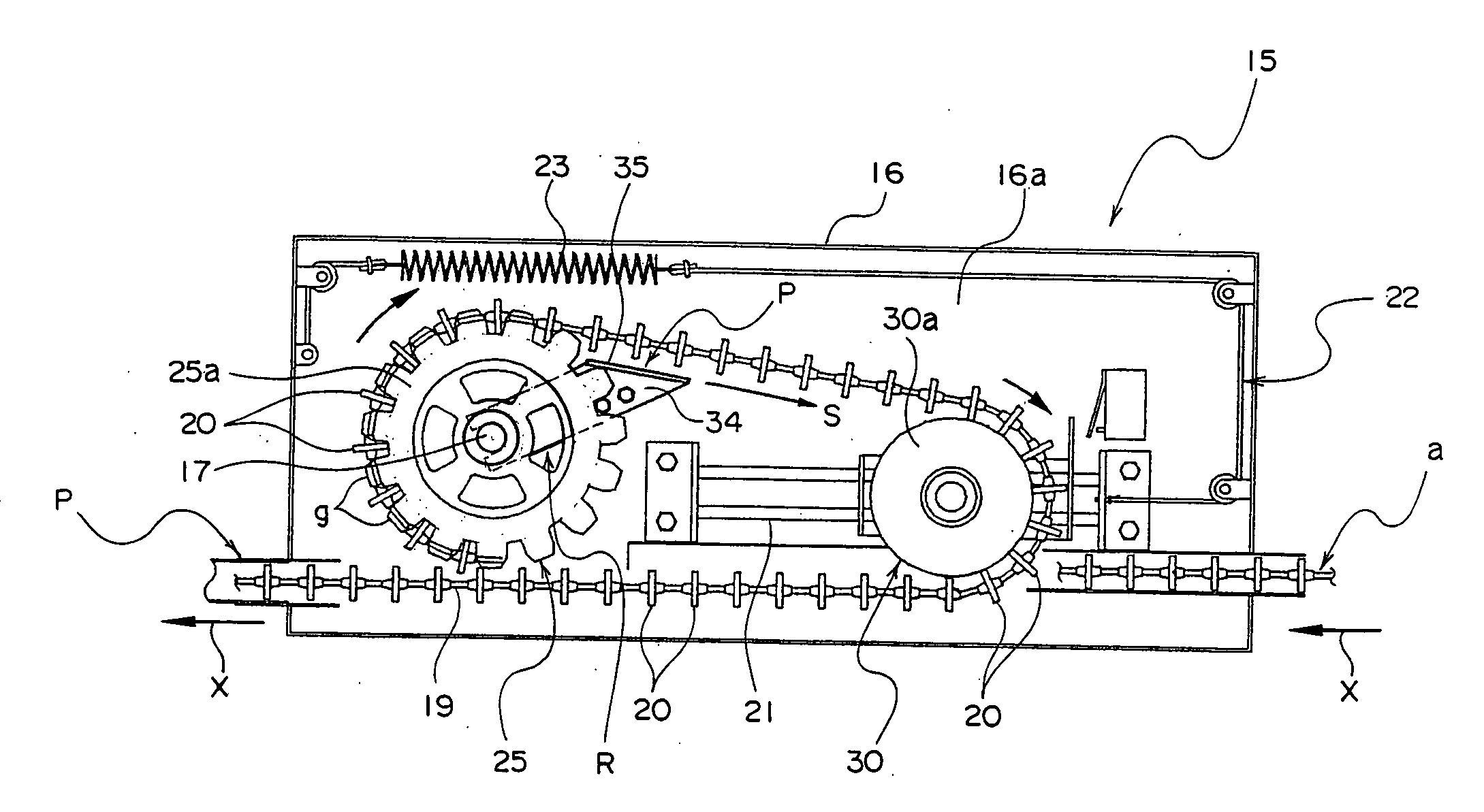

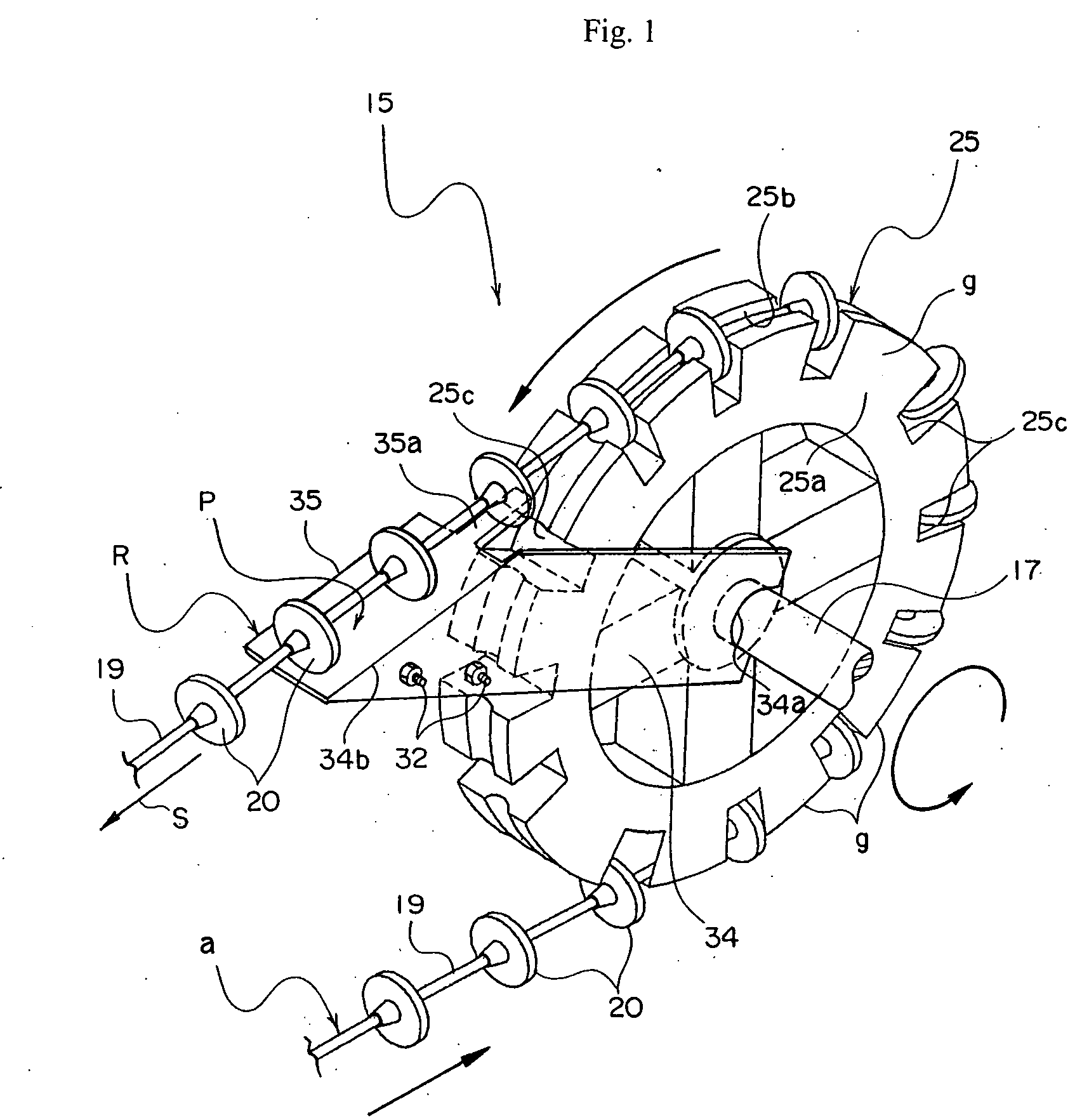

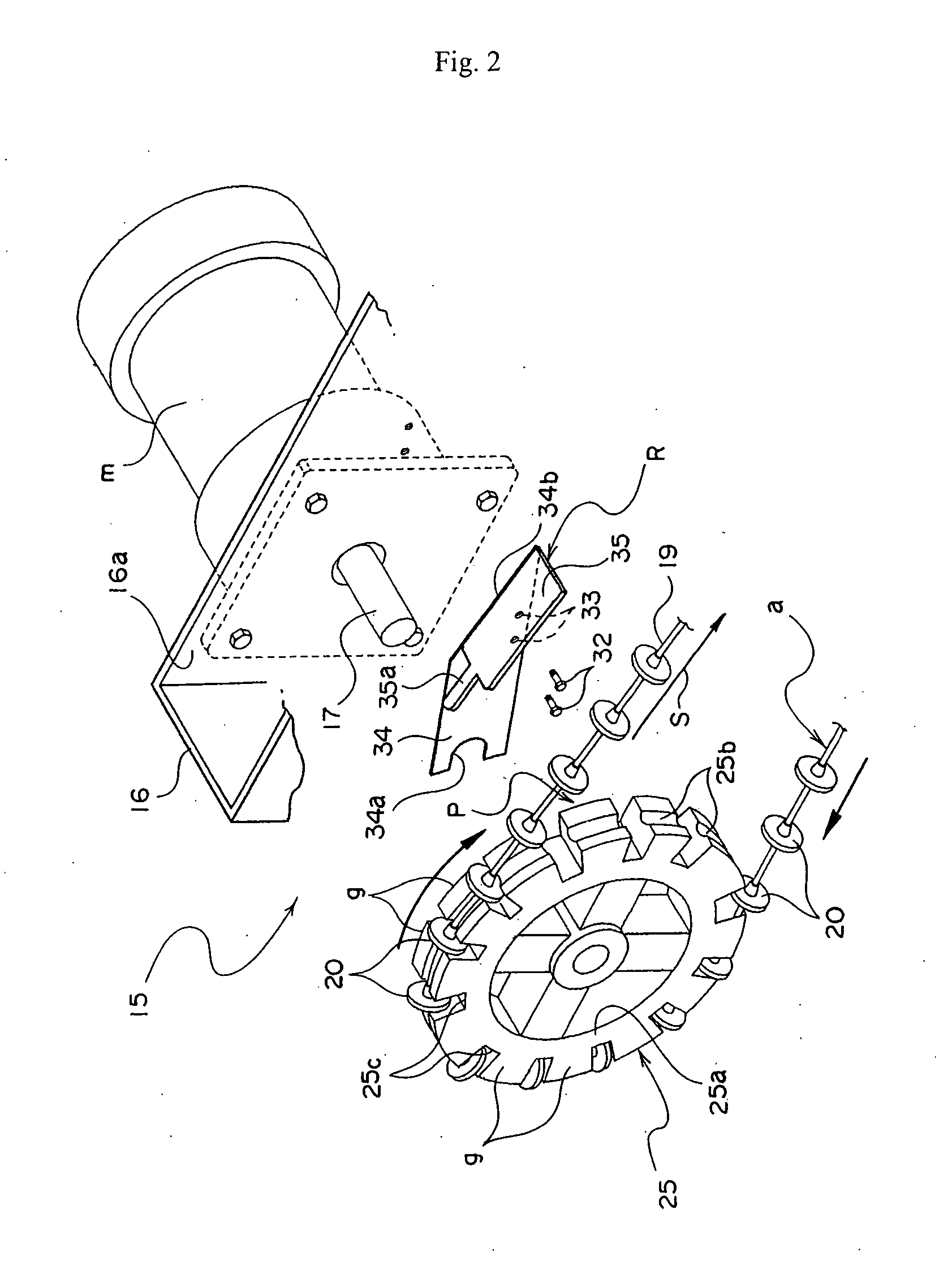

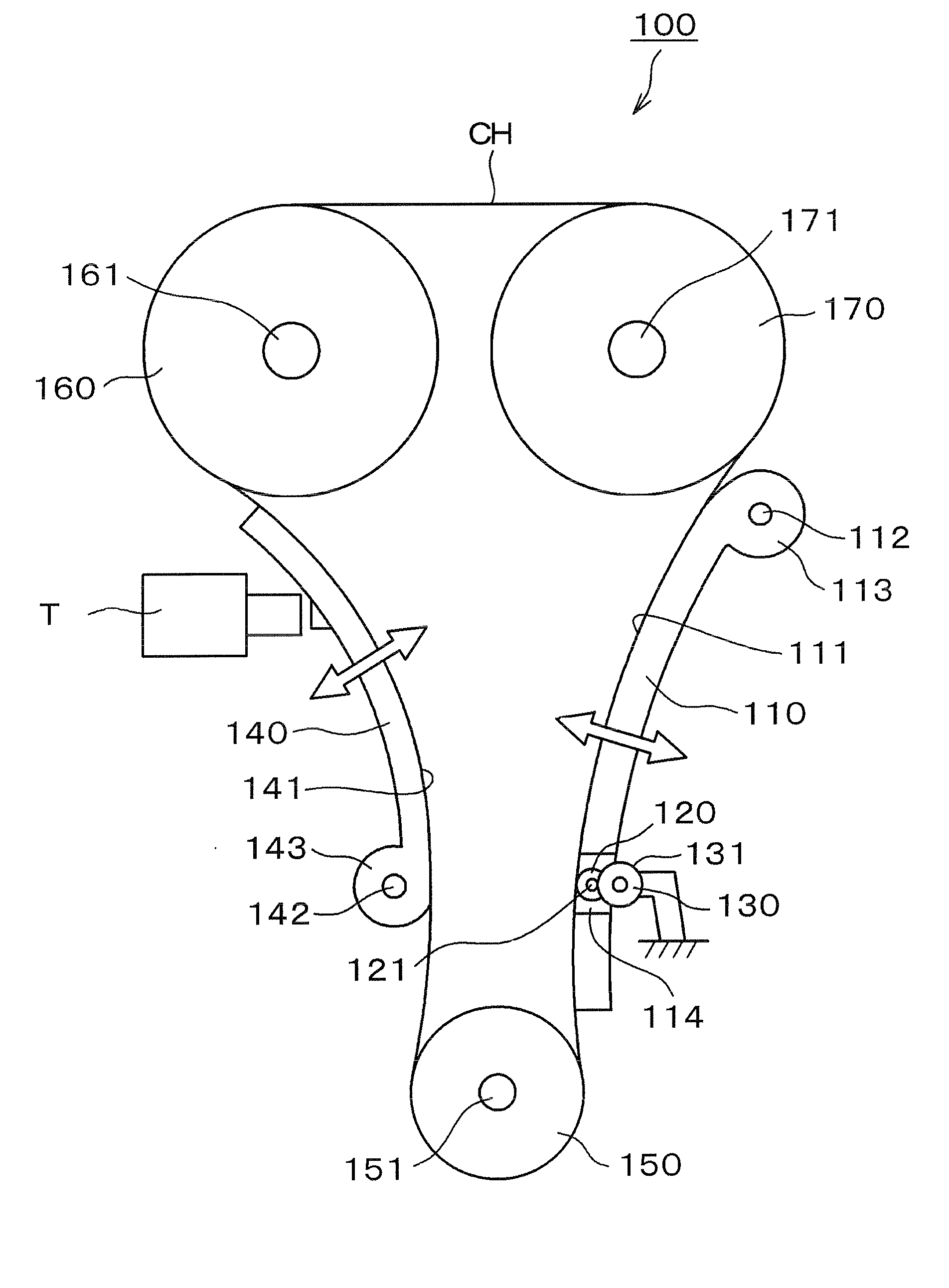

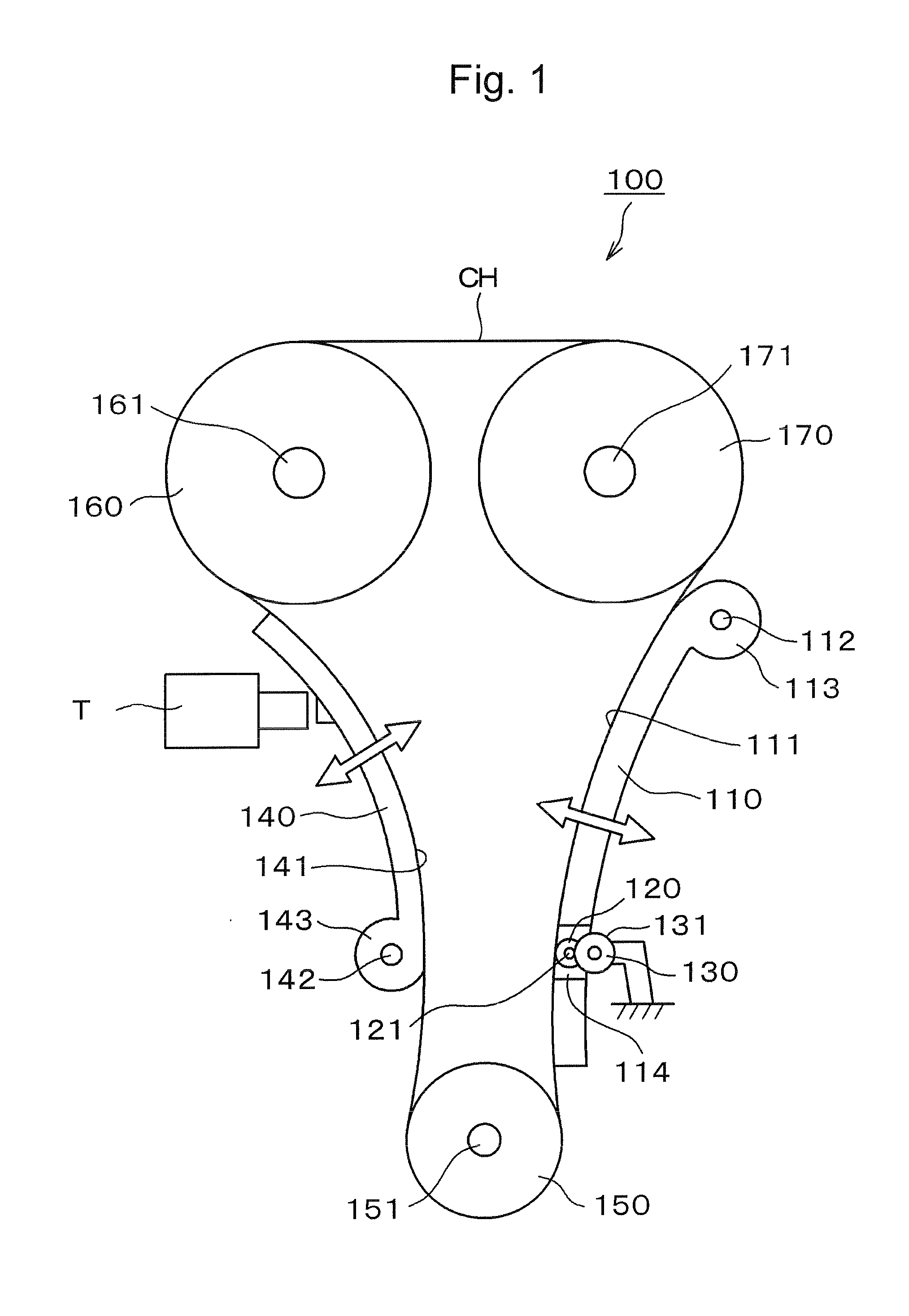

Feed conveying apparatus

InactiveUS20090008223A1Efficient and stable transportationAvoid it happening againConveyorsAnimal feeding devicesDrive wheelEngineering

There is provided a feed conveying apparatus in which the occurrence of a trouble due to a looseness of a disk cable is certainly prevented and feed is efficiently and stably conveyed into a feed conveying path by the disk cable without being left in the path.A cable driving unit has a looseness eliminating member for guiding the feeding direction of the disk cable and eliminating the looseness at a feeding start position where the disk cable is fed out from a tooth portion of the outer circumference of the driving wheel toward the downstream side in the tangential direction. The feed conveying path formed by a pipe or the like is equipped with a cable pressing metal fitting for guiding the disk cable along a bottom surface portion in the feed conveying path while suppressing the floating of the disk cable running in the feed conveying path from an upper position.

Owner:FUJII SHOKAI

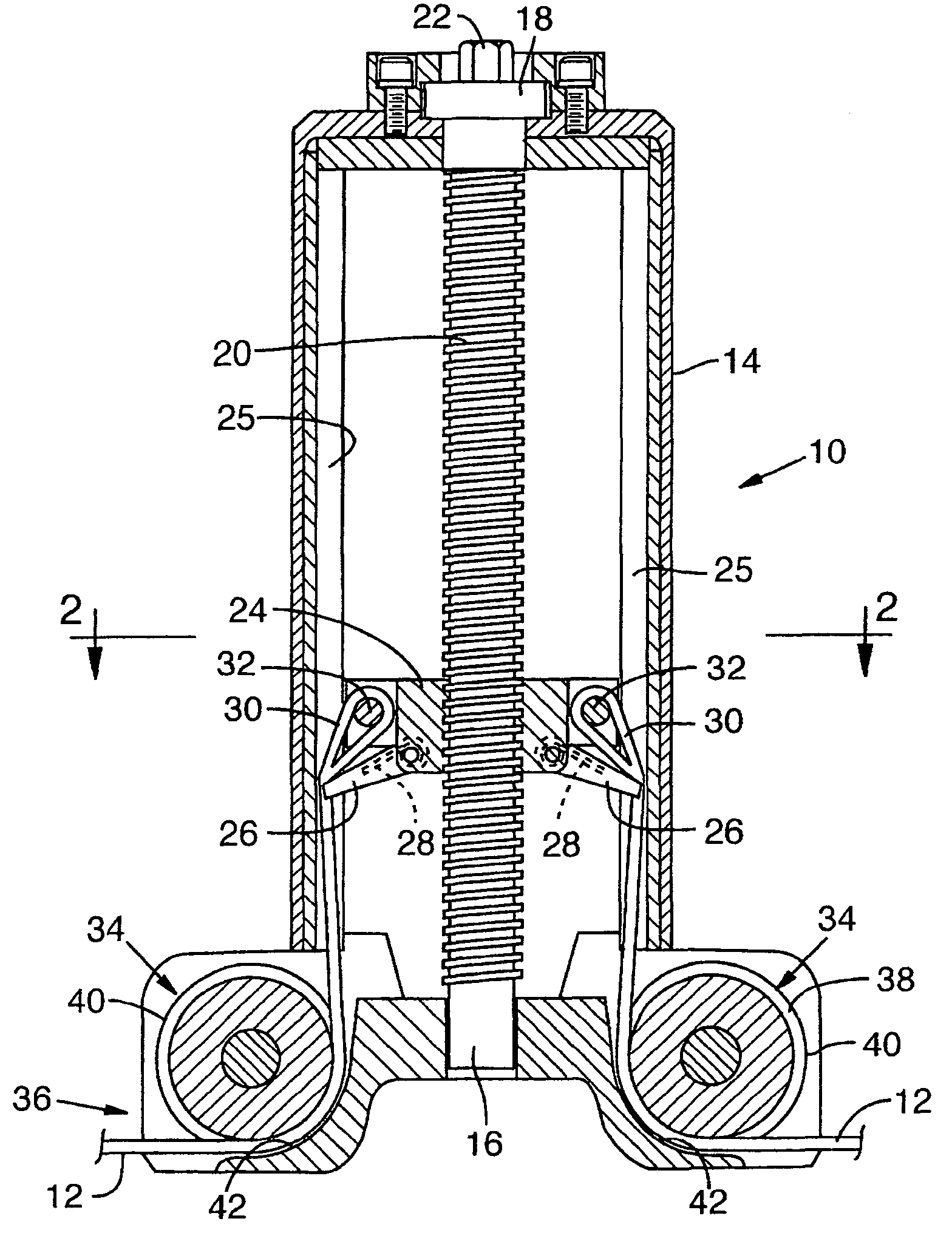

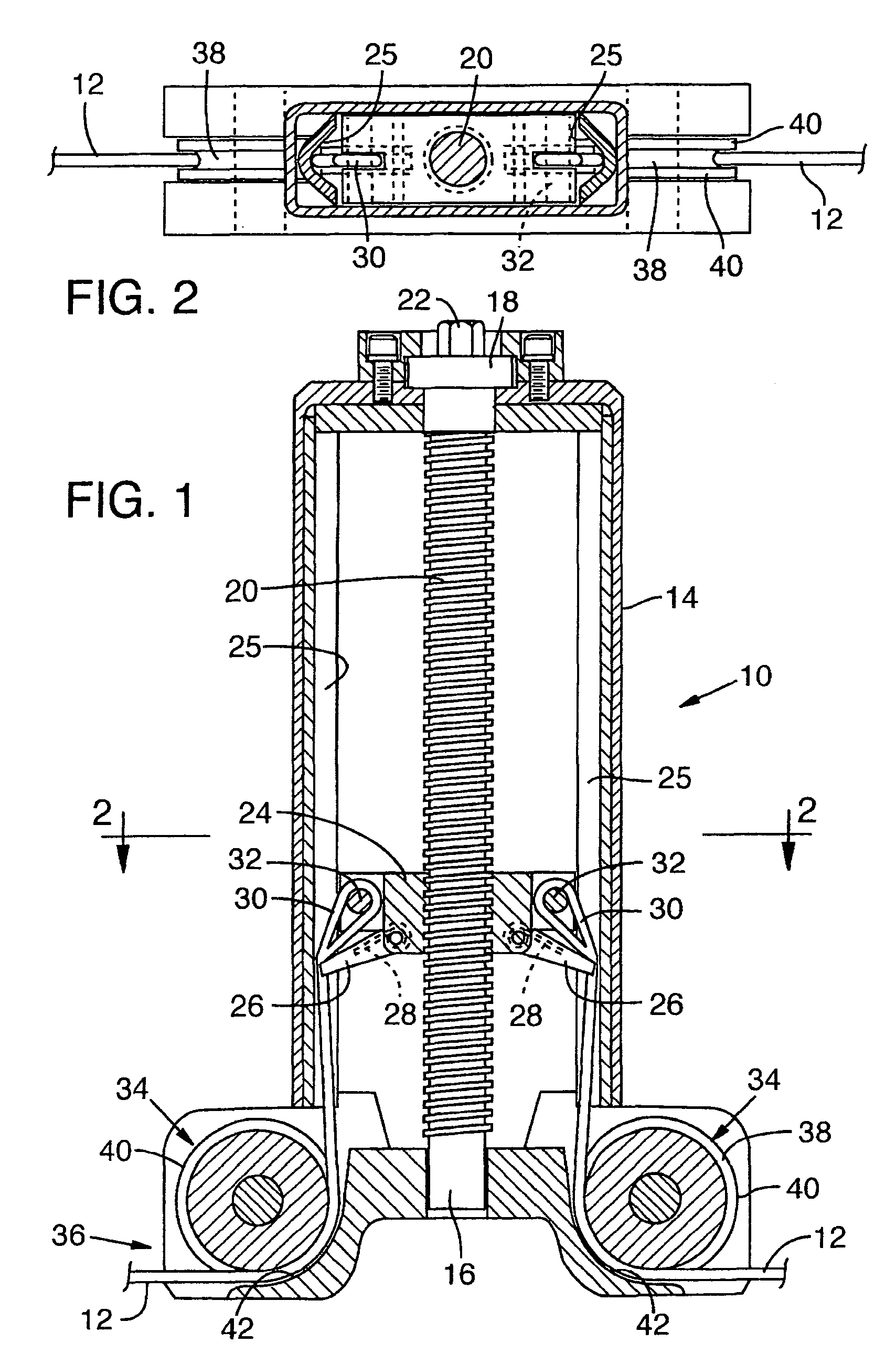

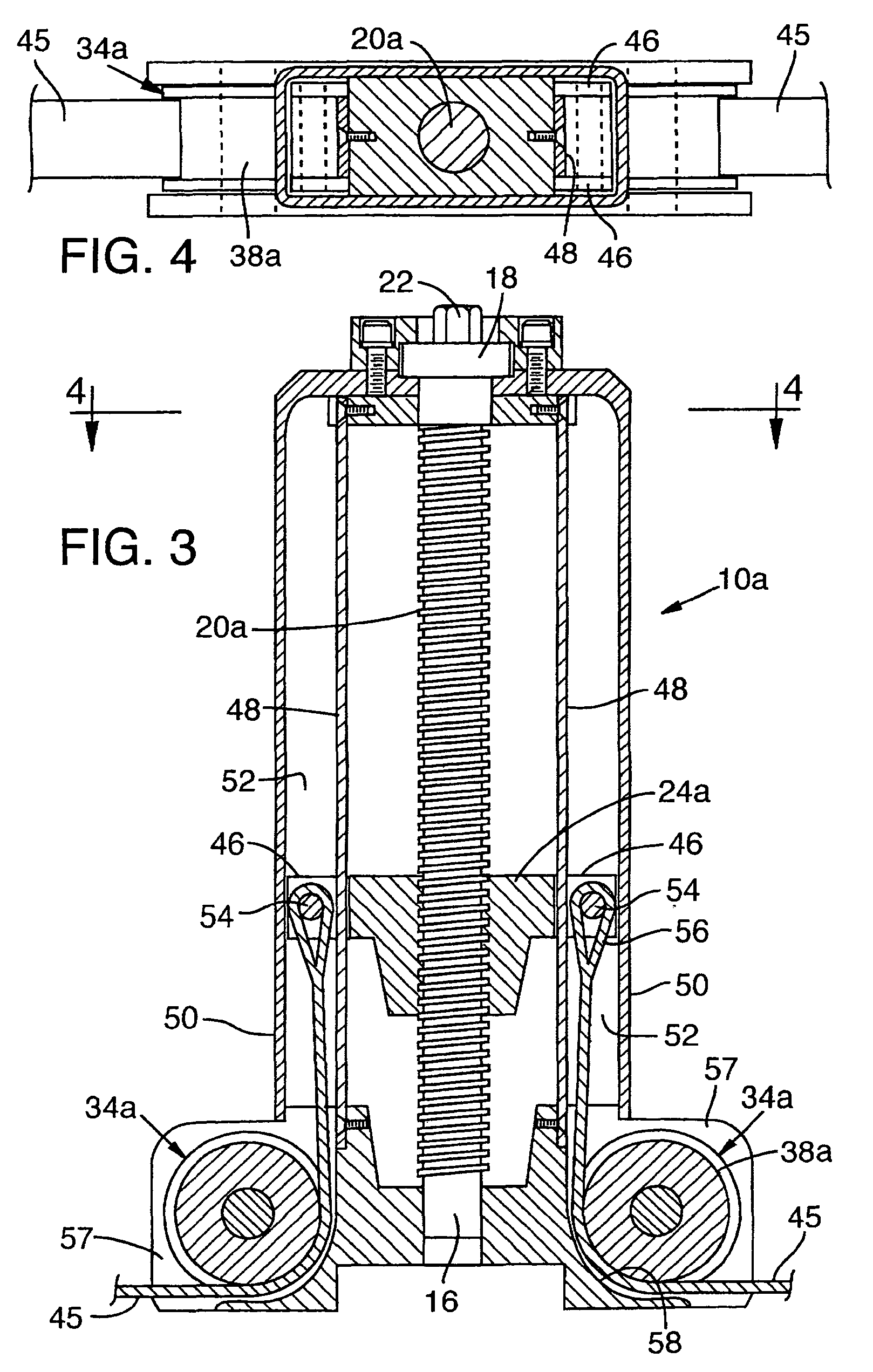

Screw driven hoist

InactiveUS7175162B1High mechanical advantageLoad accuratelyPortable liftingLifting devicesEngineeringTension member

A hoist provides high mechanical advantage and accurate positioning, driven by hand or with a powered rotary implement such as a drill. The hoist includes flexible tension members, such as chains, cables or straps, for applying force and tension to a load. A load nut is connected to the tension members for high mechanical advantage from rotational drive input to a load screw threadedly connected to the load nut. Alongside the tension members are guides forming channel-like spaces within which the flexible tension members travel. The guides, or portions of the guides, pass through the load nut in most forms of the invention.

Owner:RATCLIFF BRUCE E

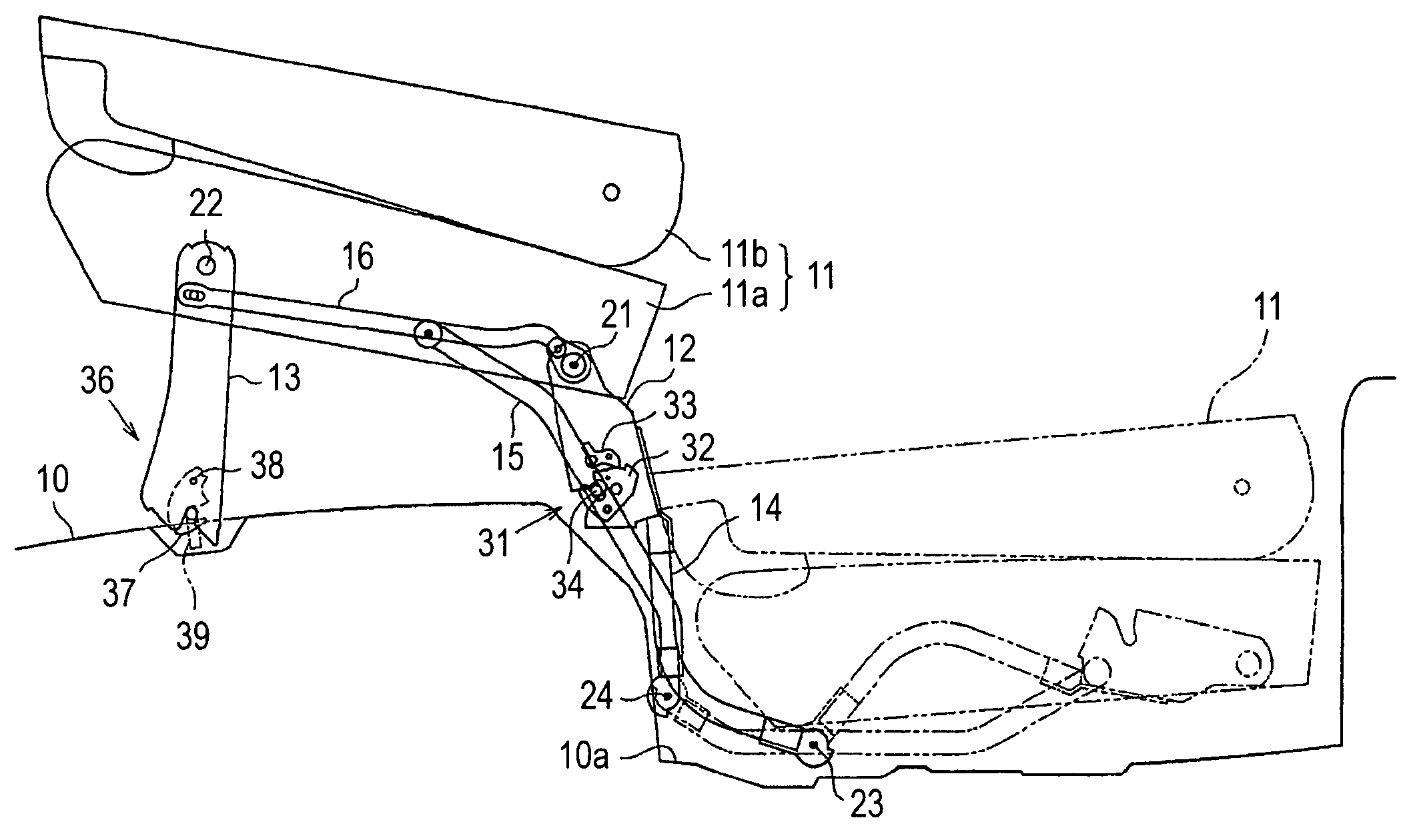

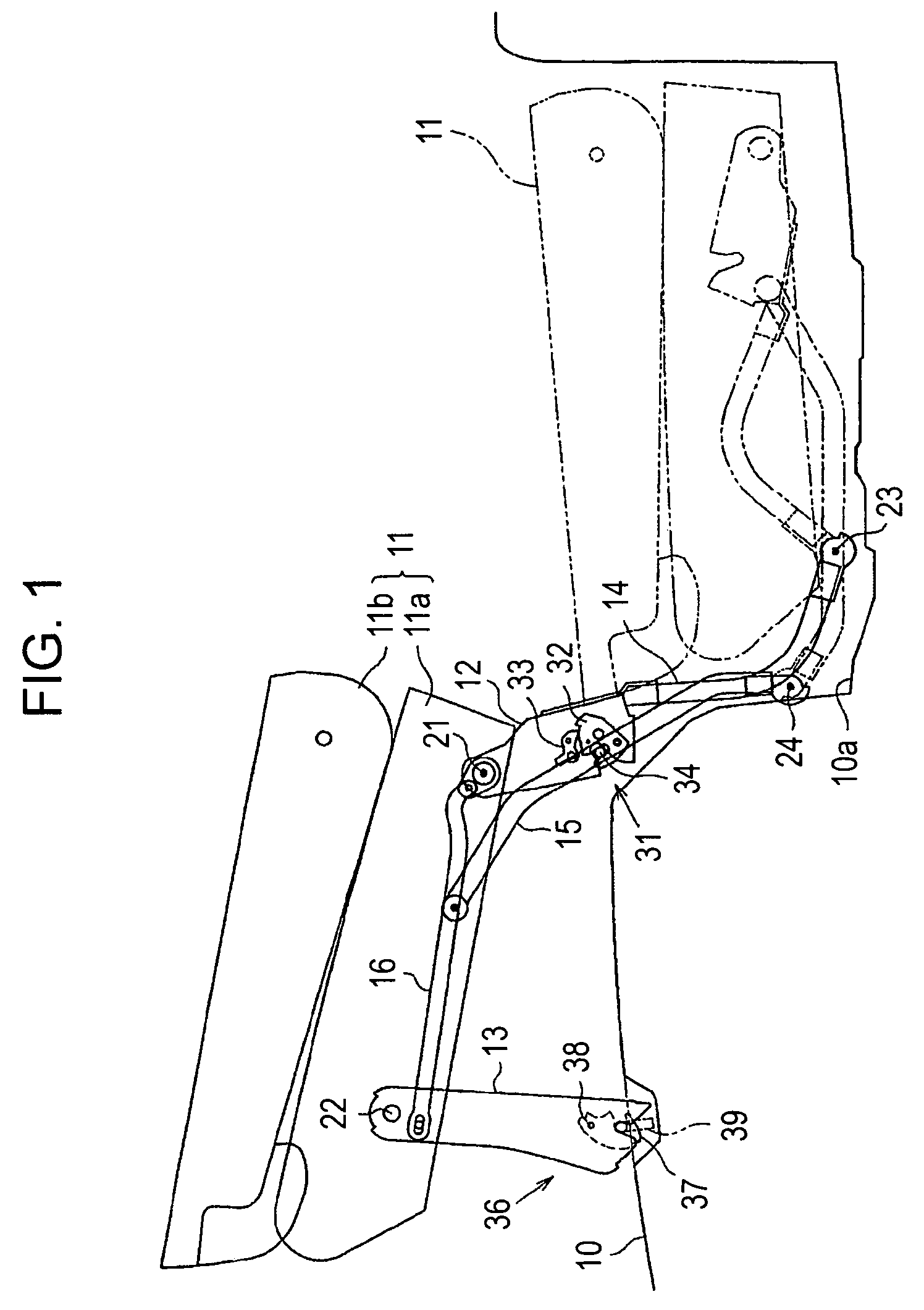

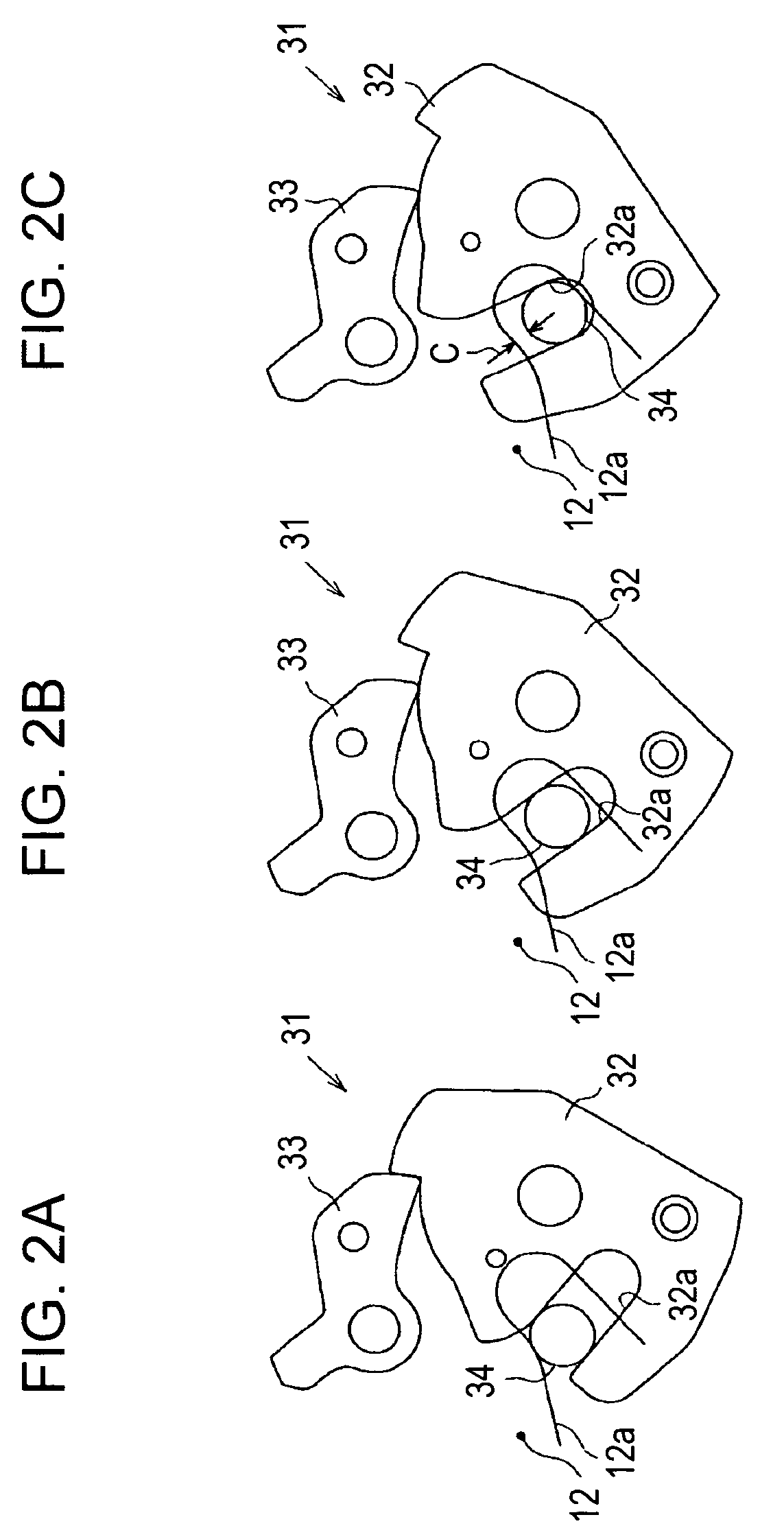

Retractable seat device

ActiveUS7213861B2Suppression of abnormal noiseAnnoyanceWall stoolsPassenger spaceLocking mechanismEngineering

Owner:AISIN SEIKI KK

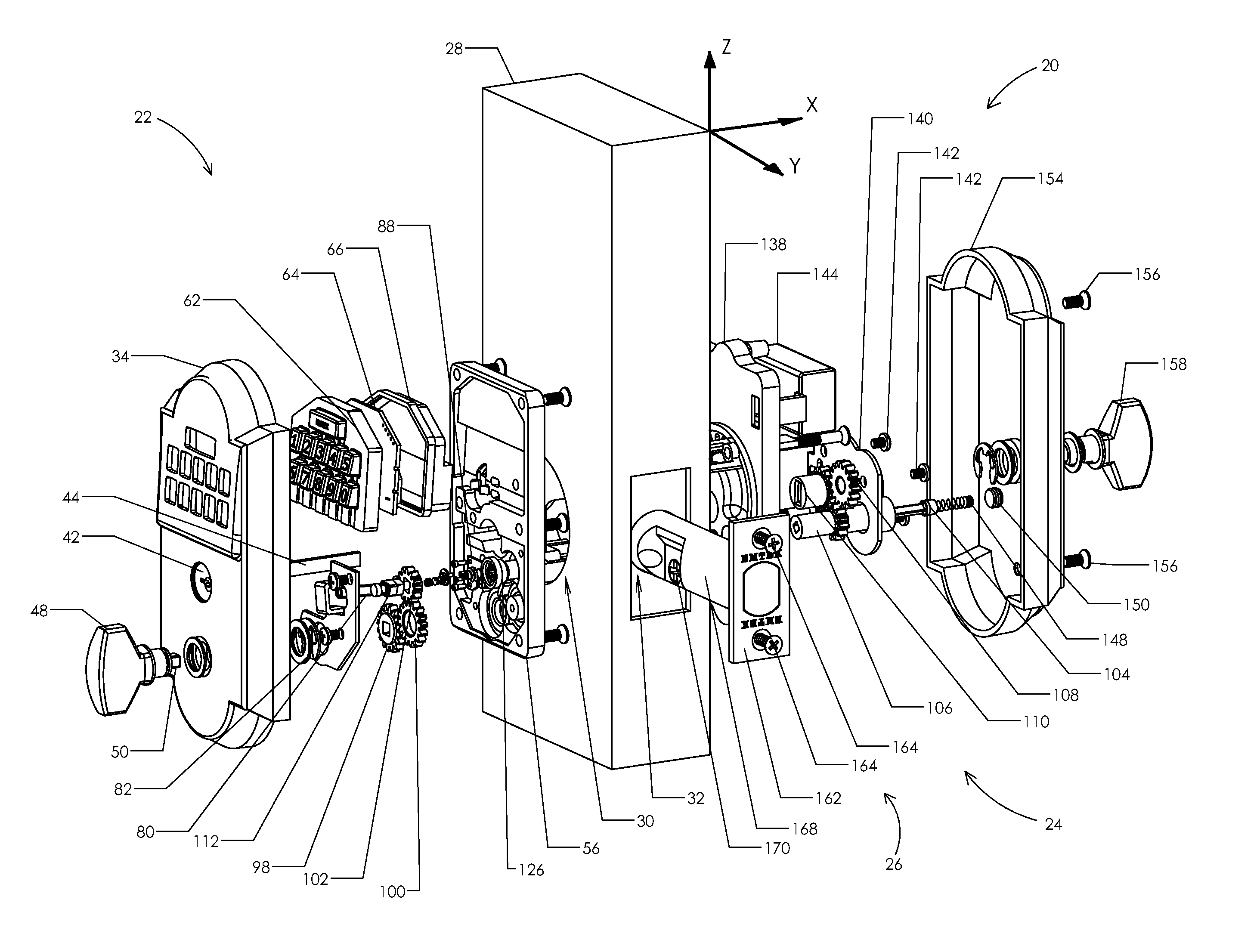

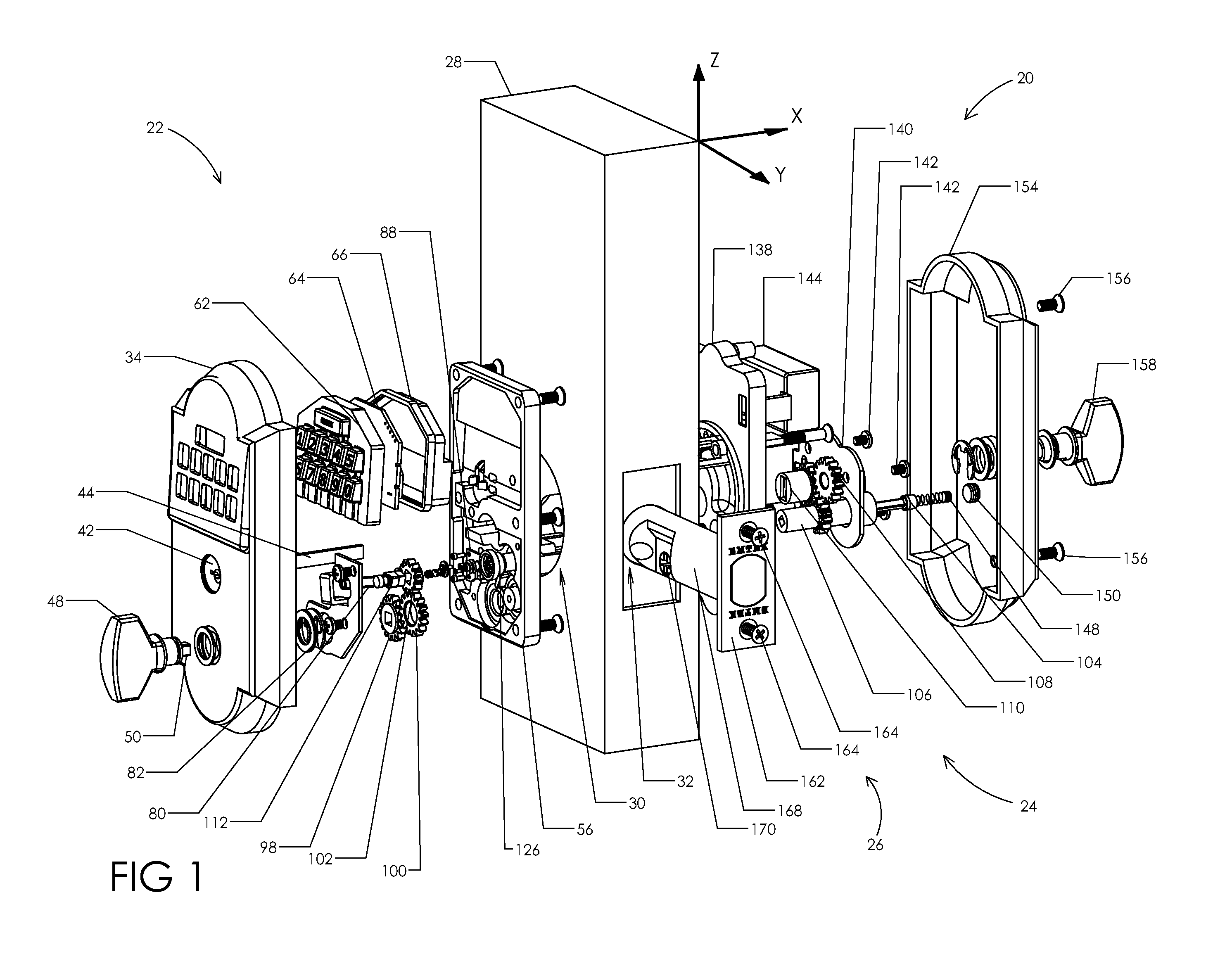

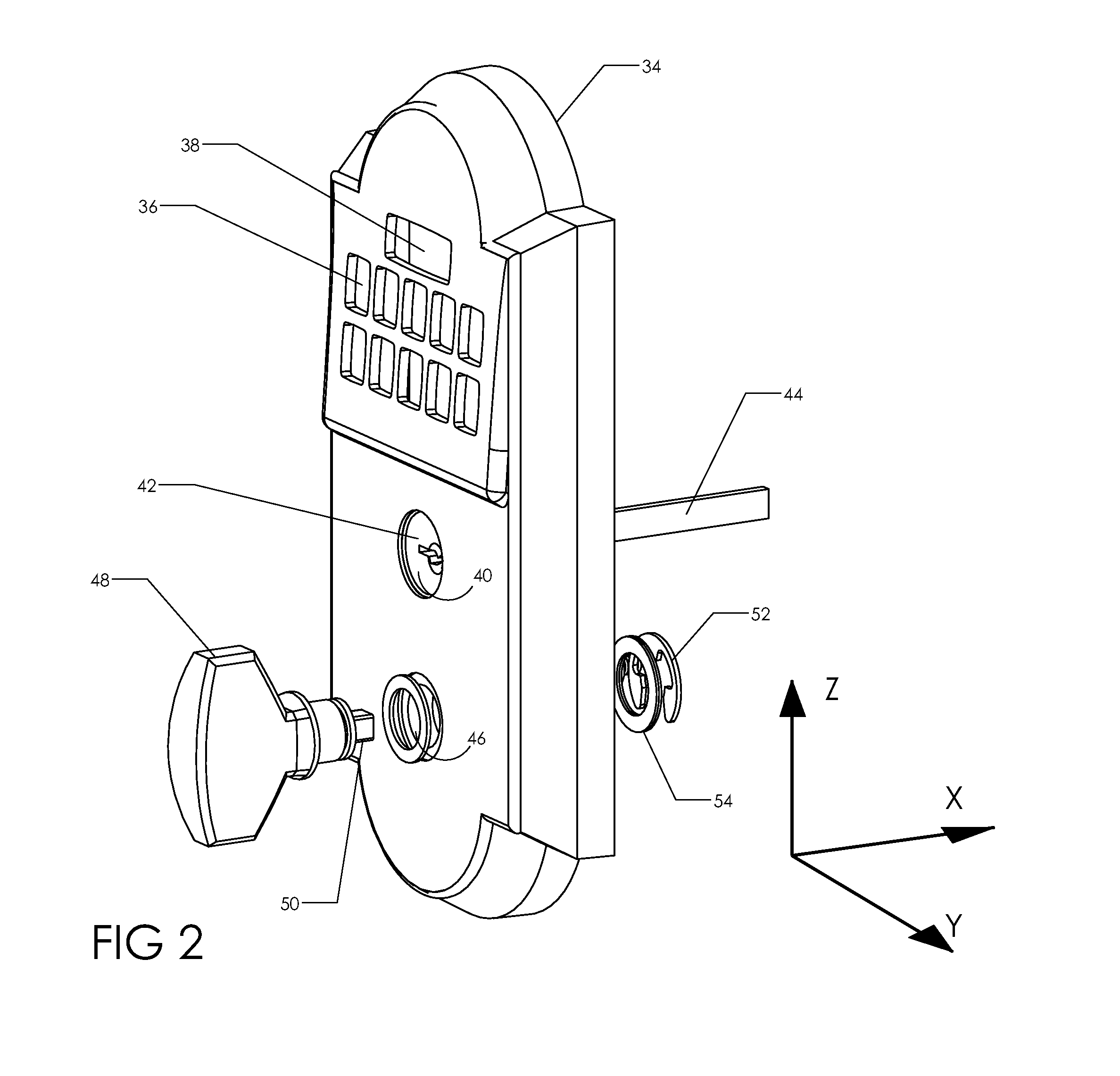

Keypad lockset

ActiveUS20120055213A1Low profileAbility to useNon-mechanical controlsConstruction fastening devicesElectrical FailureEngineering

A keypad lockset adapted for deadbolt as well as lever locks, and having as a first embodiment an exterior gear train, an interior gear train, and an electronically controlled clutch for coupling the gear trains when engaged and for uncoupling the gear trains when the clutch is disengaged, so that when the clutch is engaged rotation of an external thumb turn will permit the door latch to be withdrawn and thus to permit opening of the door, and a mechanical override mechanism that can be operated in case of electrical failure, and in which clutch mechanism and the override mechanism both operate through the single, standard 2 and ⅛ inch door preparation hole, or alternatively as a second embodiment, a keypad lockset in which two four-bar mechanical linkages are used in place of gears as means to actuate the clutch, and alternatively to provide for a pass-through override function.

Owner:ASSA ABLOY RESIDENTIAL GRP INC

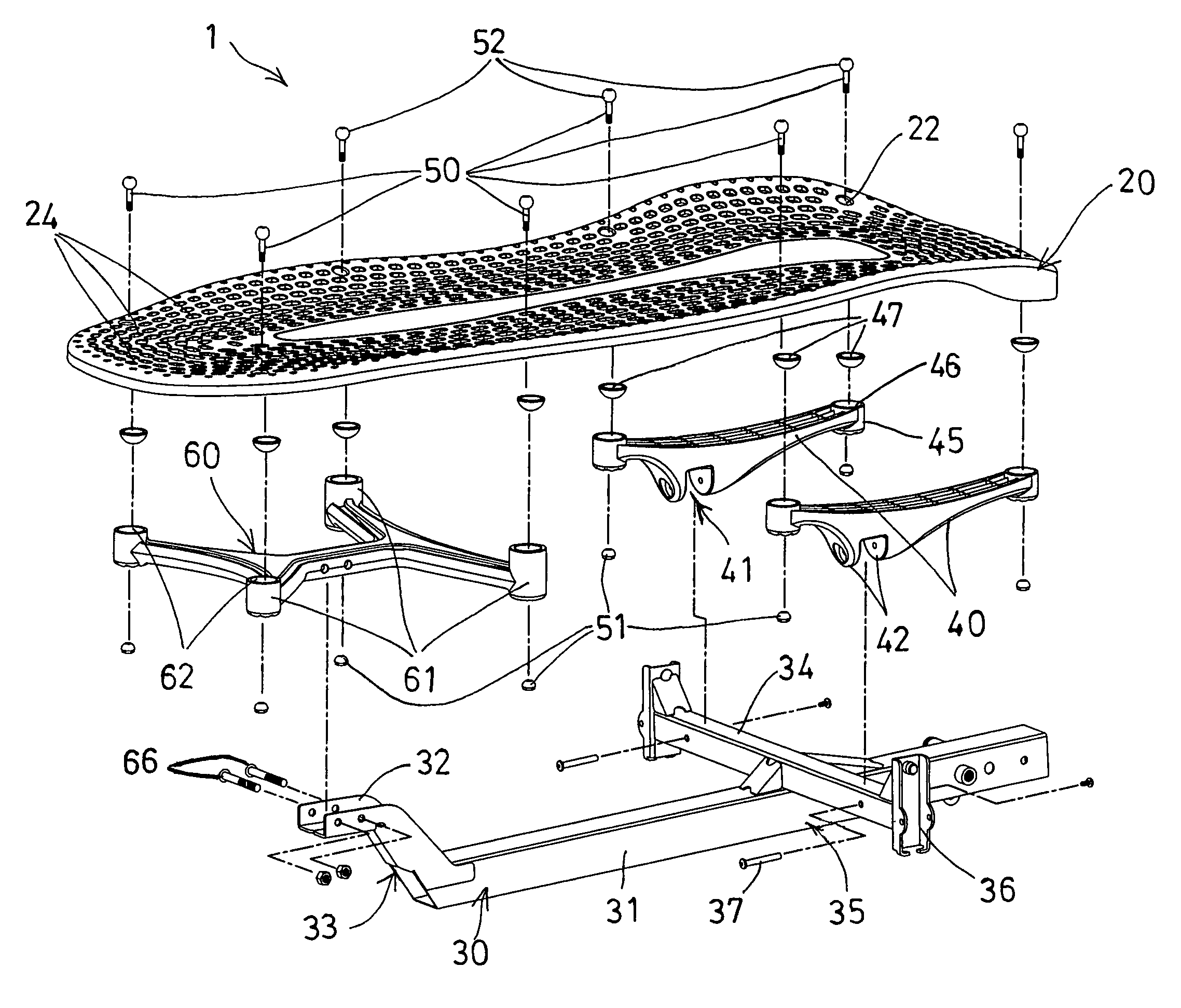

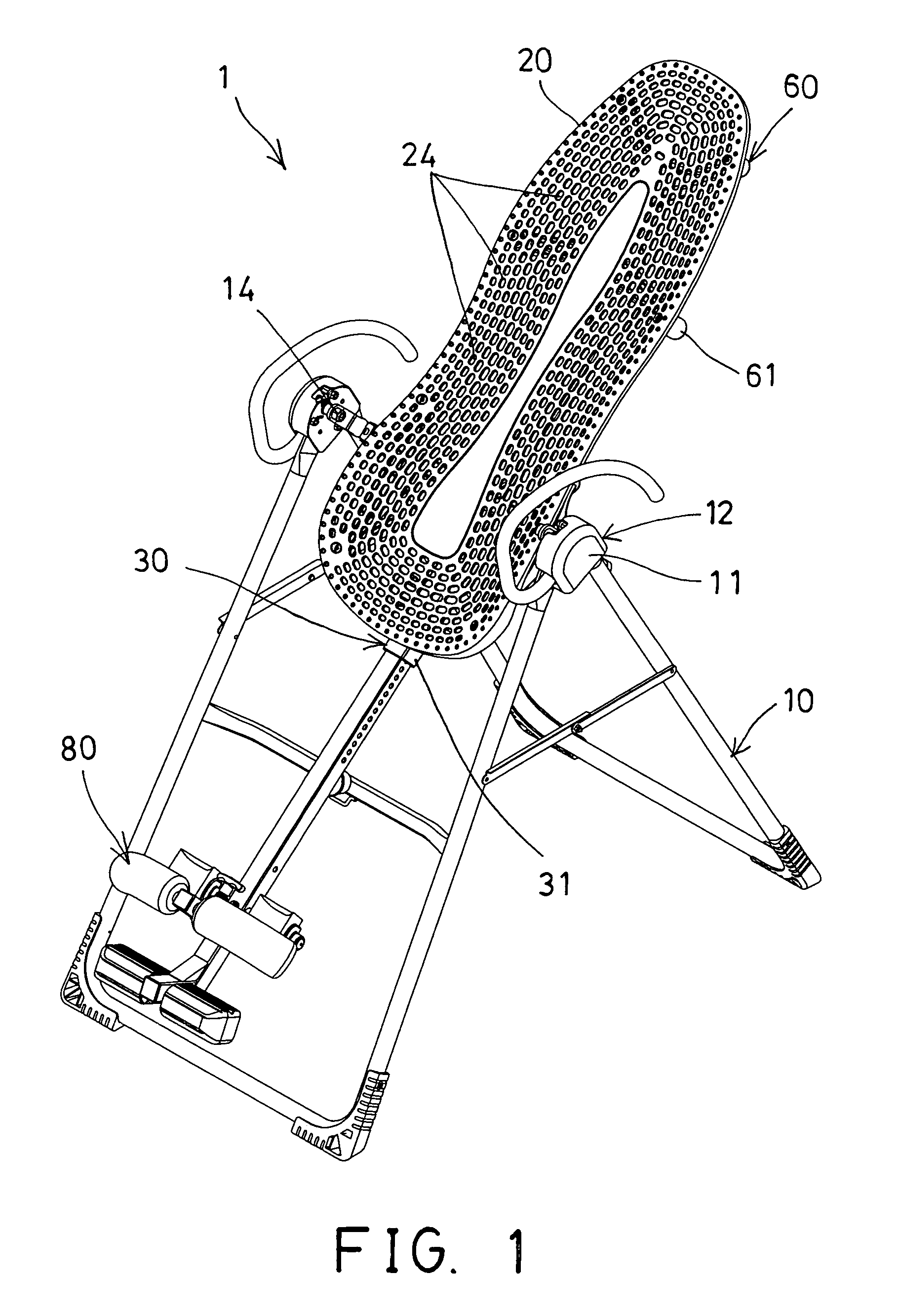

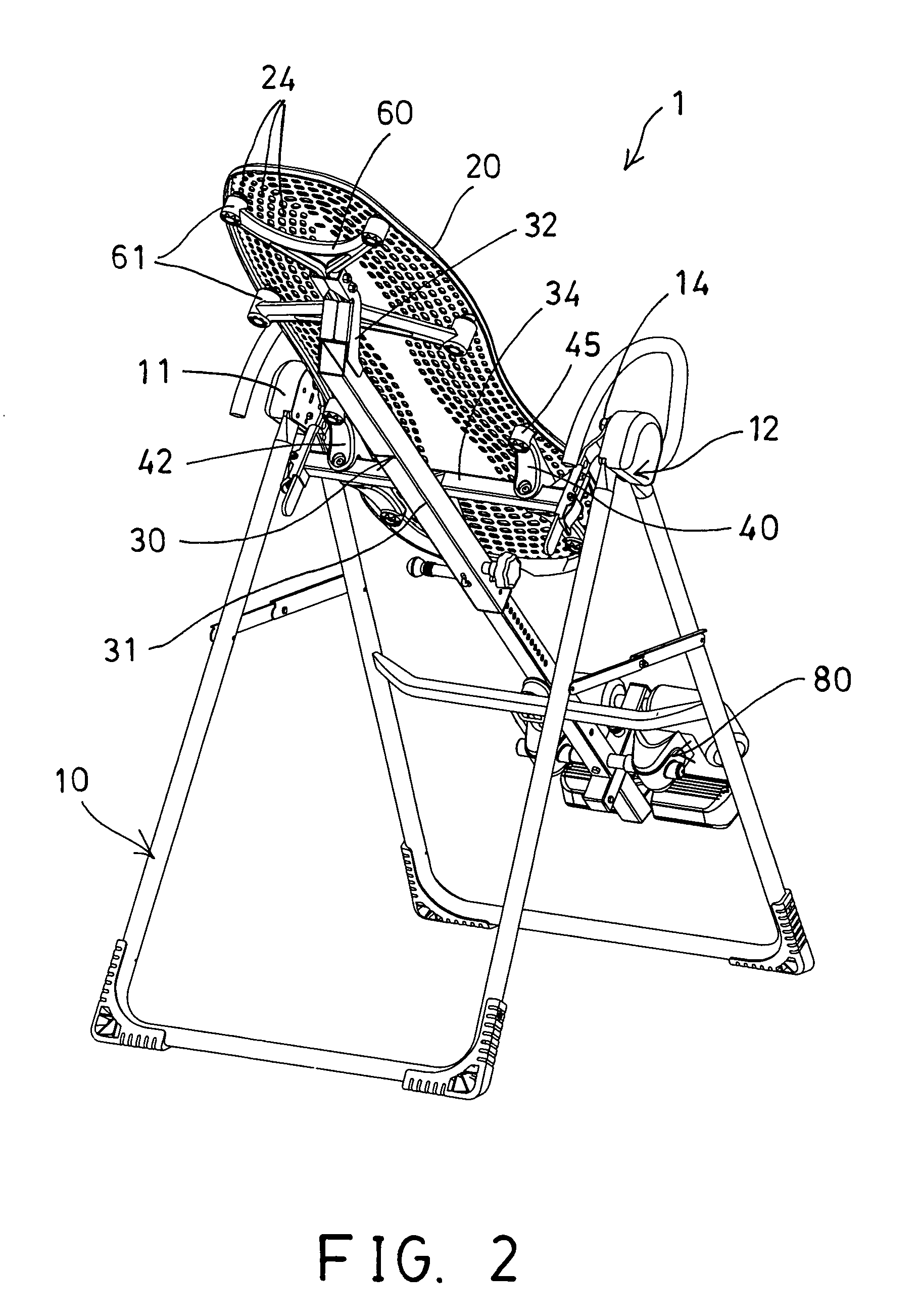

Table for tilting inversion exerciser

ActiveUS7625326B2Comfortable supportSmoothly engagedChiropractic devicesStiltsPlastic materialsEngineering

Owner:TEETER ROGER C +1

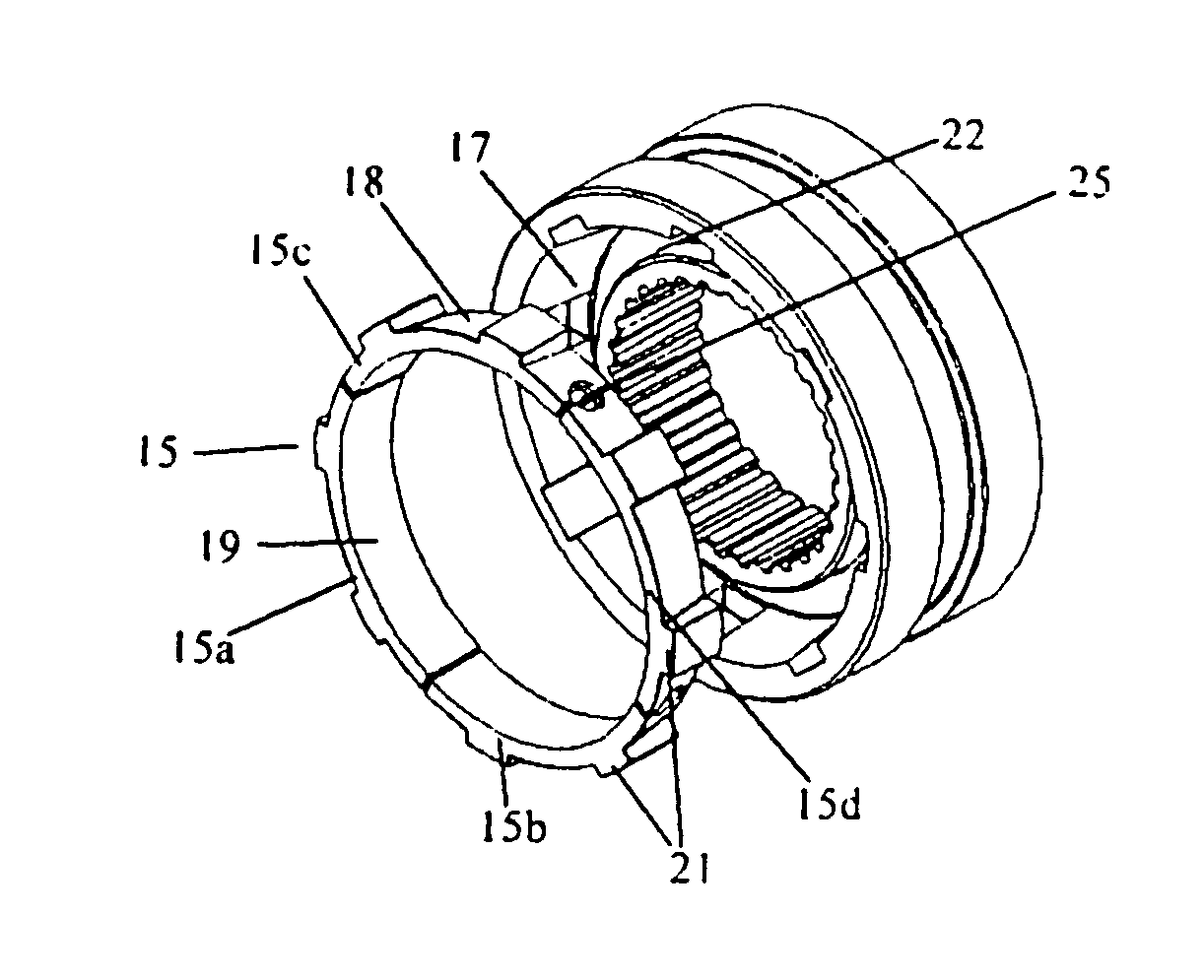

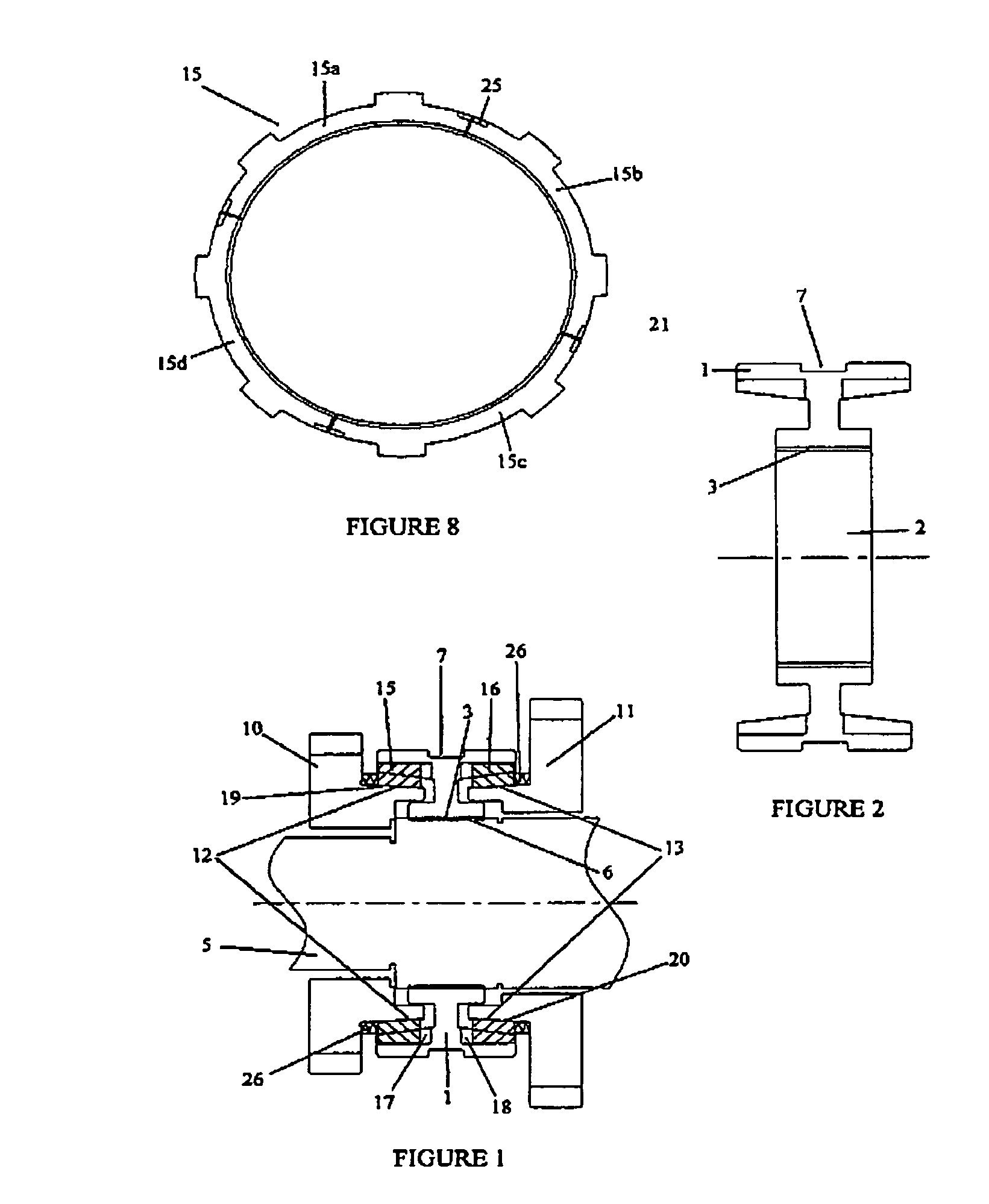

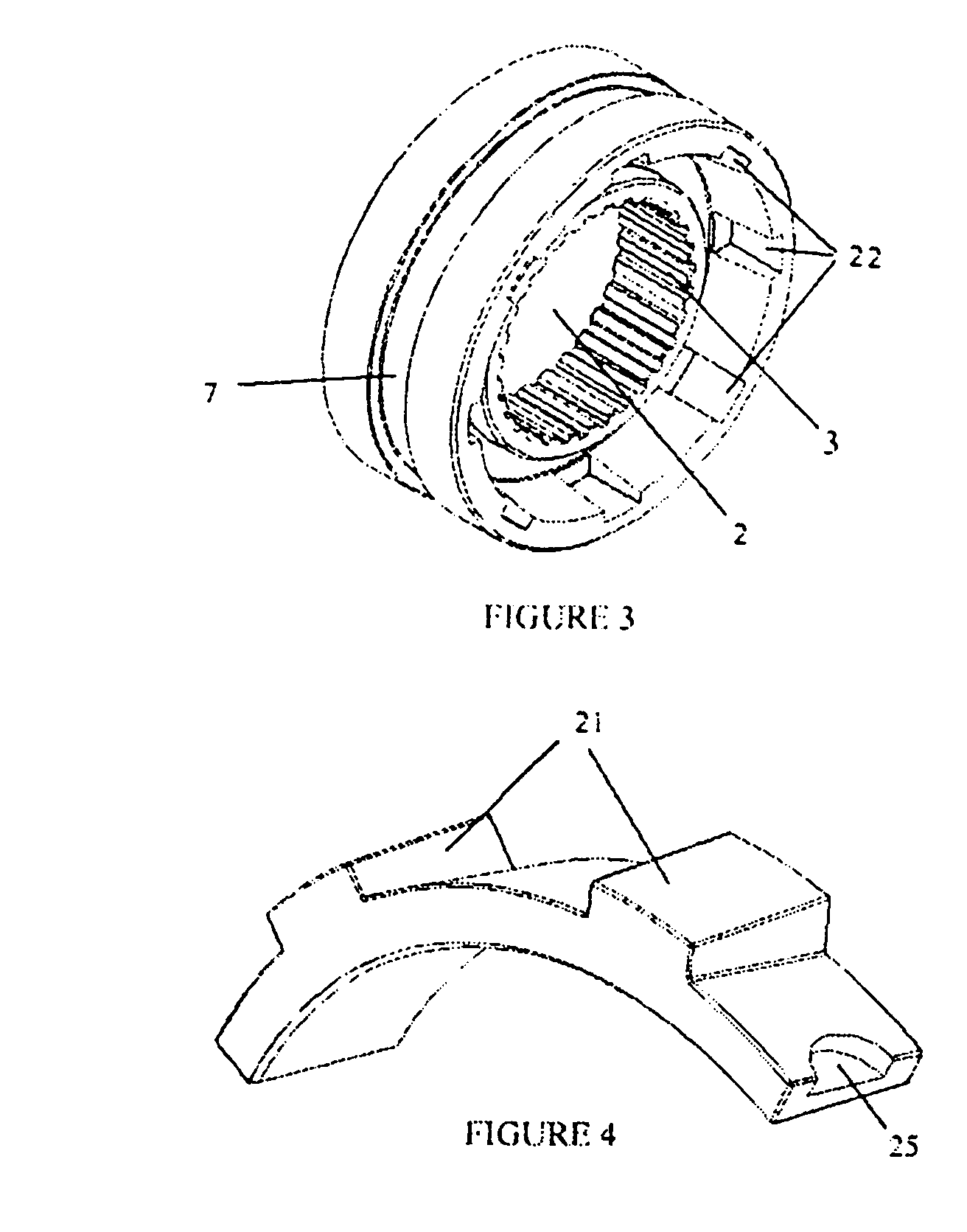

Segmented synchronizer clutch

ActiveUS7121393B1Easy to assembleReliable couplingFriction clutchesInterengaging clutchesEngineeringFriction force

A synchronizer clutch assembly includes a clutch hub which is axially movably mounted on a shaft, a gear which is axially spaced from the hub and which is journally mounted on the shaft and rotatable independent thereof, one of the hub or the gear having a conical friction surface formed thereon, and a synchronizer ring positioned between the hub and the gear. The synchronizer ring is coupled to the hub or the gear for rotation therewith and has a complementary conical friction surface formed thereon which is engageable with the conical friction surface on the hub or the gear. The synchronizer ring is composed of a plurality of separate arcuate segments arranged in a ring, which are movable between a first expanded configuration and a second, contracted configuration.

Owner:SULZER FRICTION SYST US

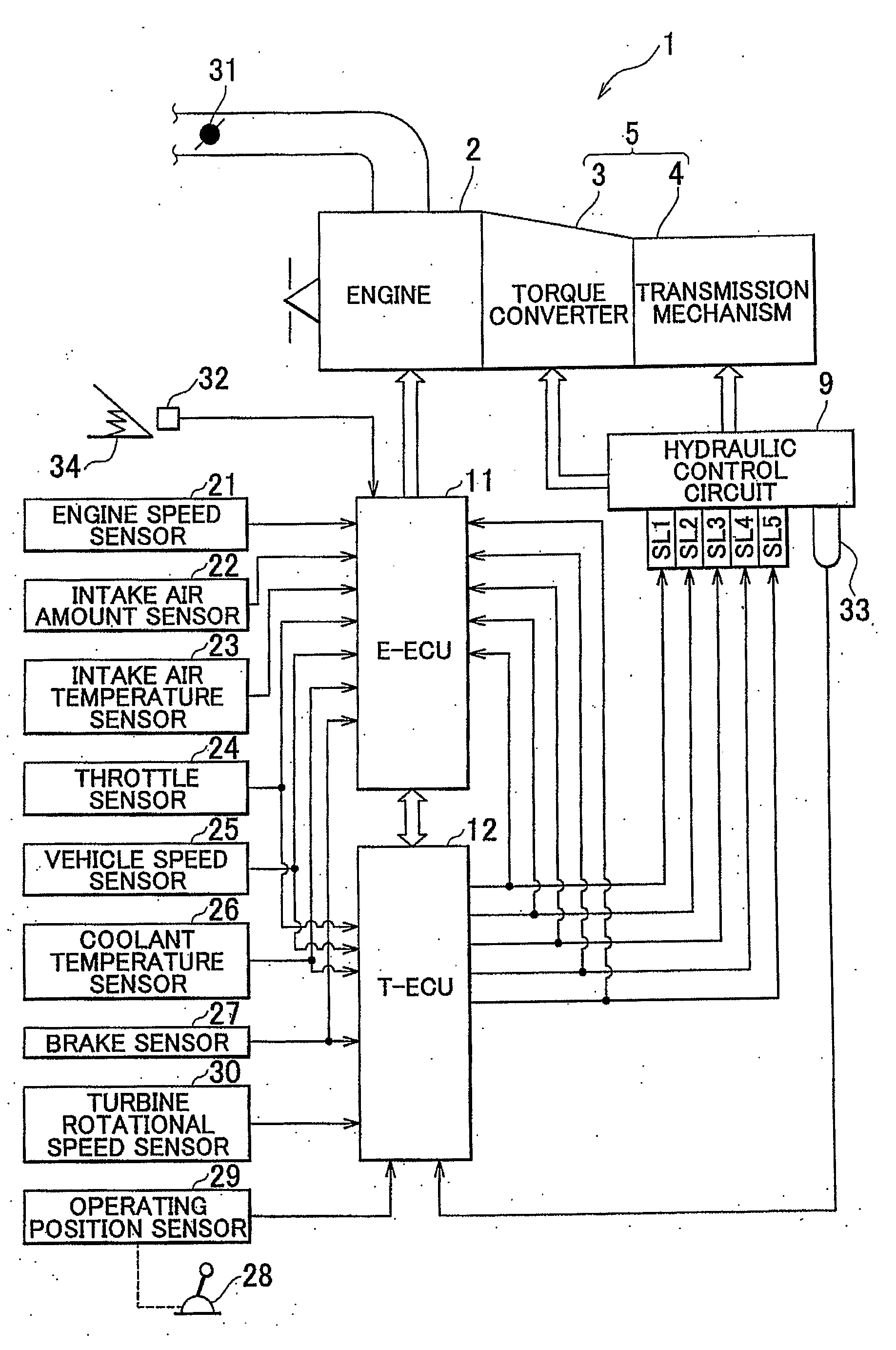

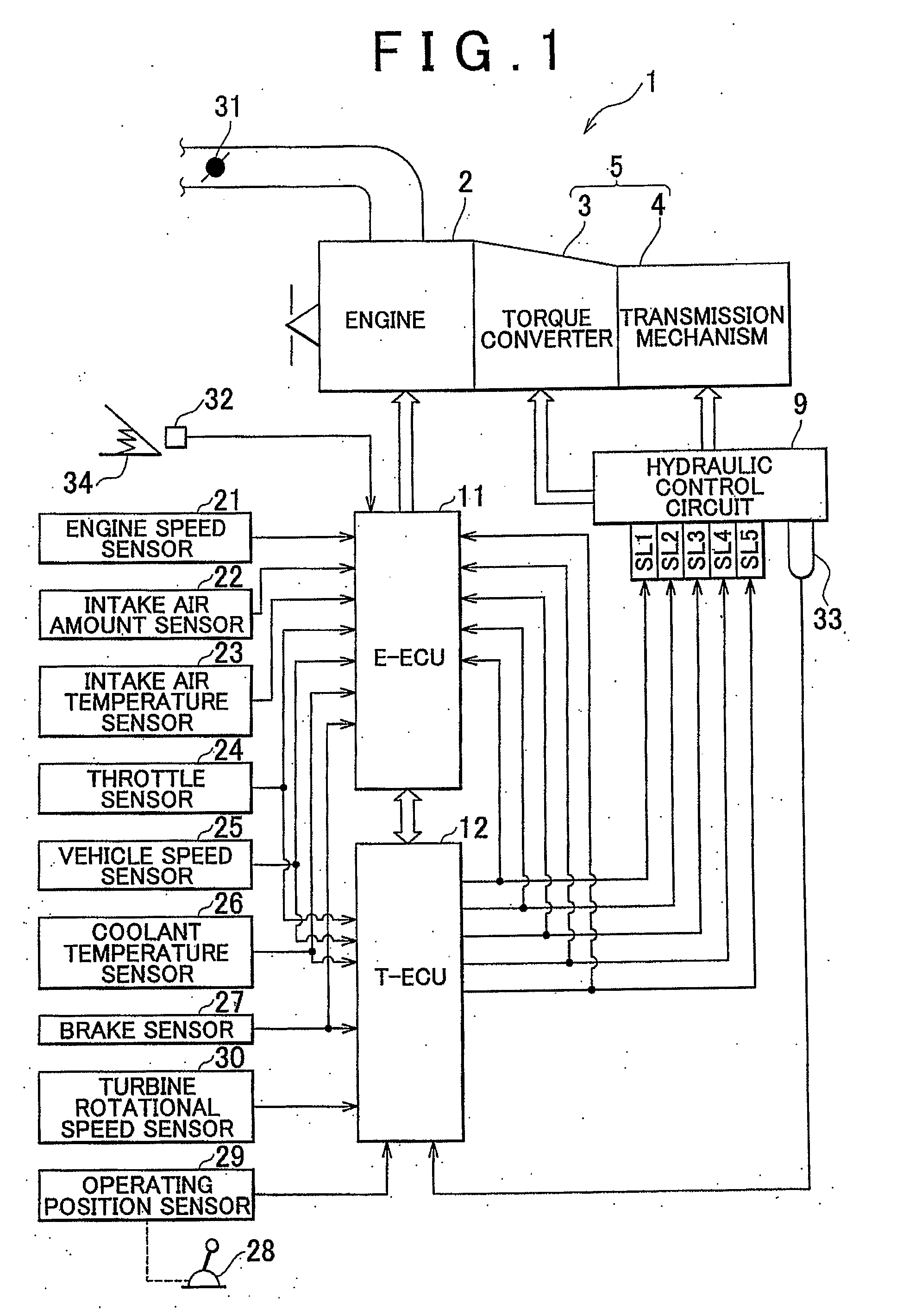

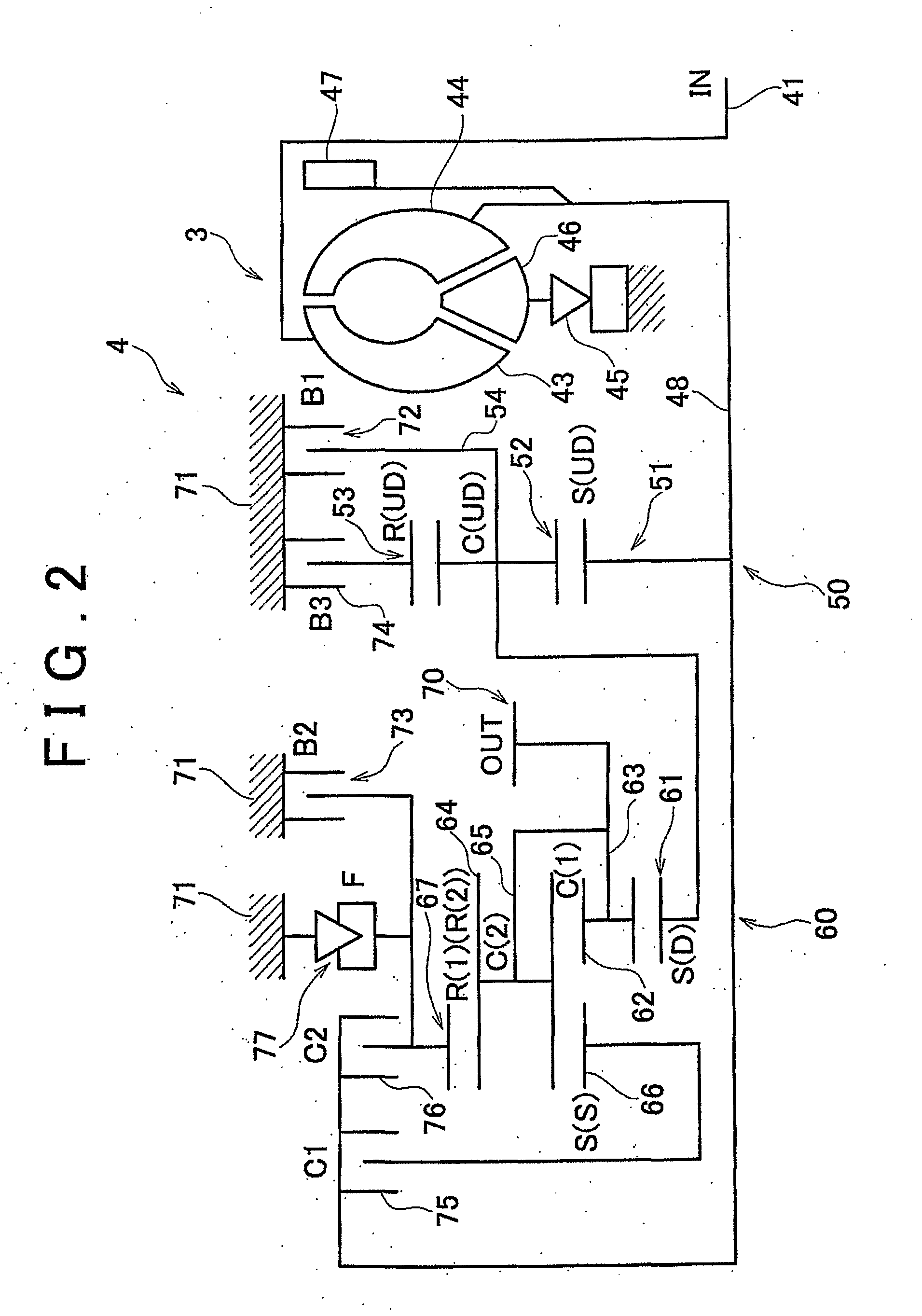

Control device for an automatic transmission

InactiveUS20100121542A1Improve drivabilitySmooth engagementDigital data processing detailsGearing controlAutomatic transmissionOil temperature

A transmission ECU 12 determines whether or not the conditions for executing a neutral control operation are satisfied (step S11), and measures hydraulic oil temperature if it determines that the execution conditions are satisfied (step S12). Then, the transmission ECU 12 sets a target speed ratio for a torque converter 3 corresponding to the measured hydraulic oil temperature (step S13), and performs a neutral control operation to bring the speed ratio of the torque converter 3 equal to the target speed ratio (step S14).

Owner:TOYOTA JIDOSHA KK

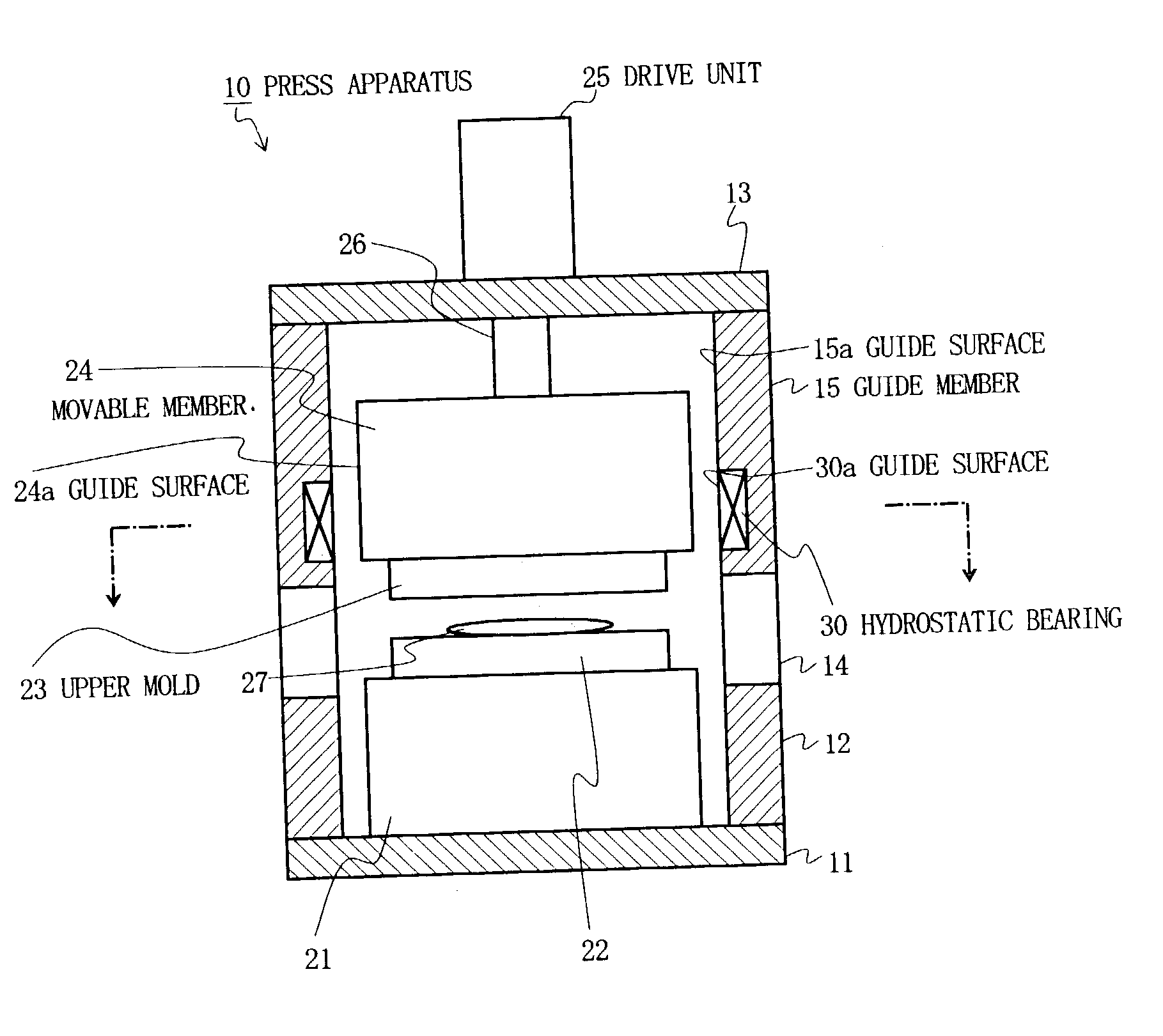

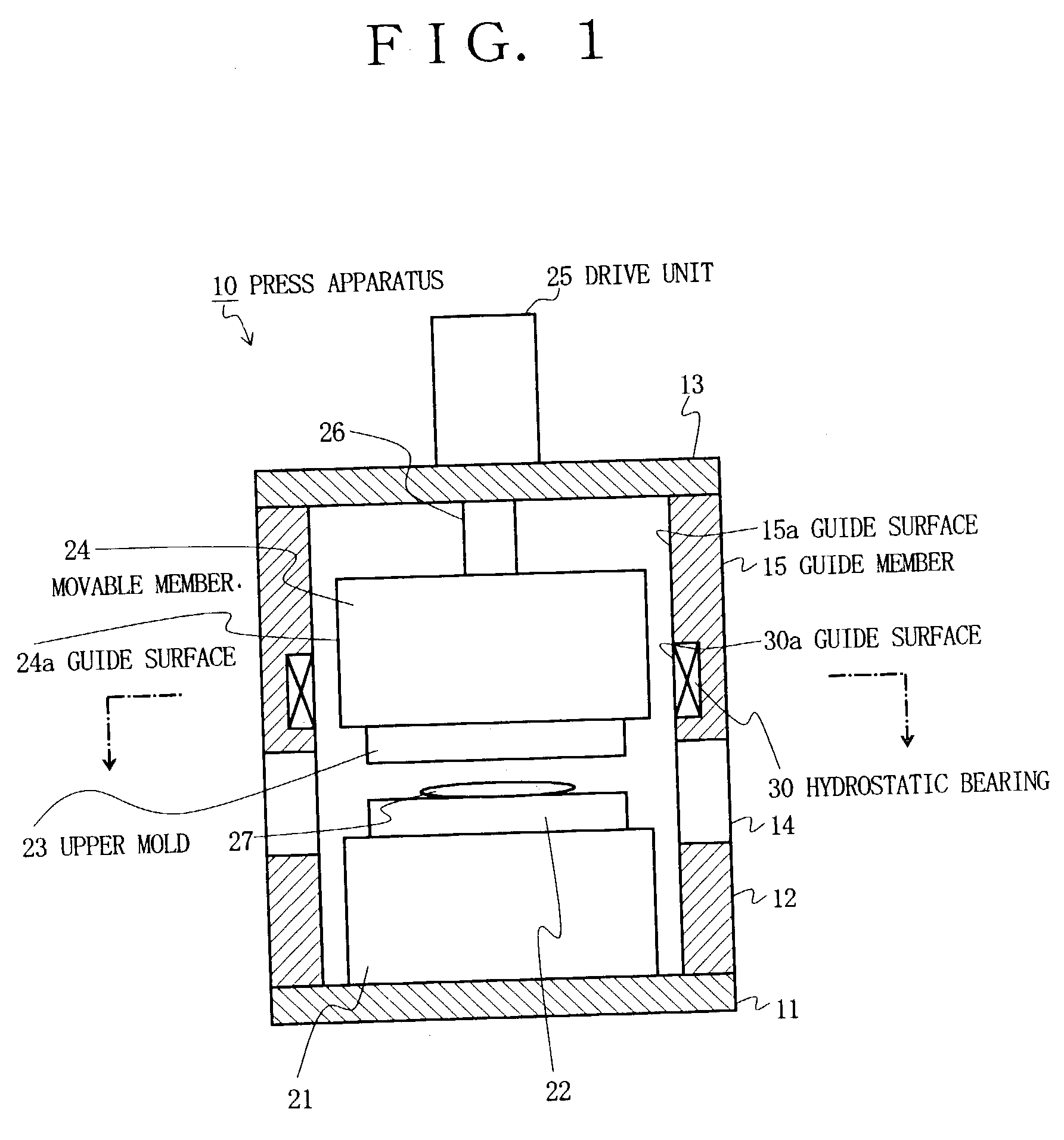

Press apparatus

InactiveUS20030234471A1Smooth engagementAvoid breakingConfectioneryGlass pressing apparatusMechanical engineeringEngineering

Owner:SUMITOMO HEAVY IND LTD

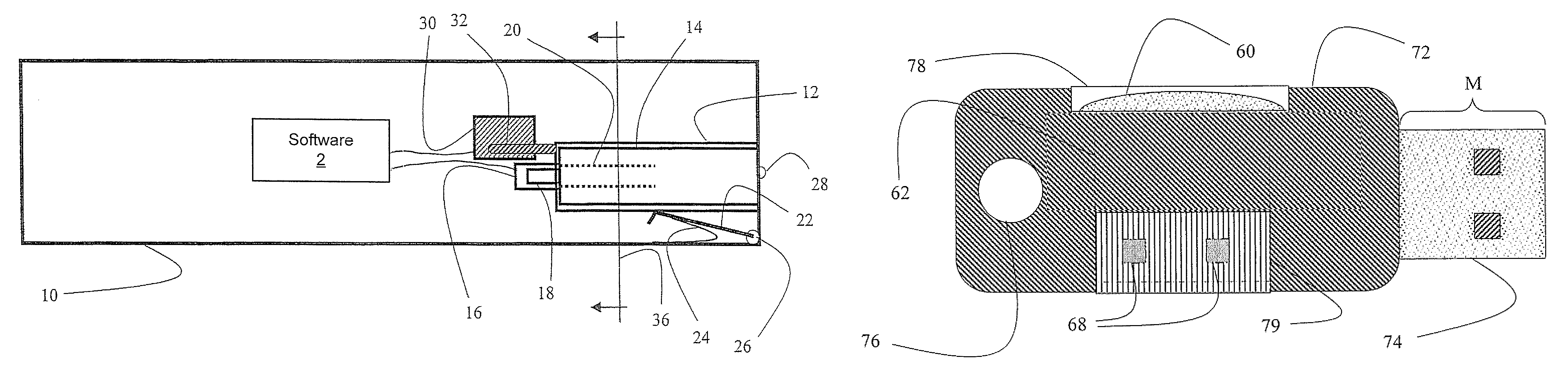

Internal UFD

InactiveUS7866996B2Safely and conveniently carried and usedEliminates untimely ejectionEngagement/disengagement of coupling partsDigital data processing detailsEngineeringElectronic assemblies

The present invention discloses a system including: (a) a host device including: (i) a cavity; and (ii) a socket, recessed in the cavity; and (b) a UFD configured to be reversibly operationally connected to the host device via the socket, wherein the UFD is configured to physically reside substantially in the cavity when the UFD is operationally connected to the socket. Also disclosed is a UFD system including: (a) a first part having components of a UFD, wherein the components include a primary connector and an electronics assembly; and (b) a second art having a UFD holder and a secondary connector, wherein the UFD holder is configured to reversibly accommodate the first part, wherein a dimension of the first part parallel to an insertion direction of the primary connector is shorter than a dimension of the second part parallel to an insertion direction of the secondary connector. In another embodiment, a UFD may be inserted into a UFD slot in an edge of a host panel.

Owner:WESTERN DIGITAL ISRAEL LTD

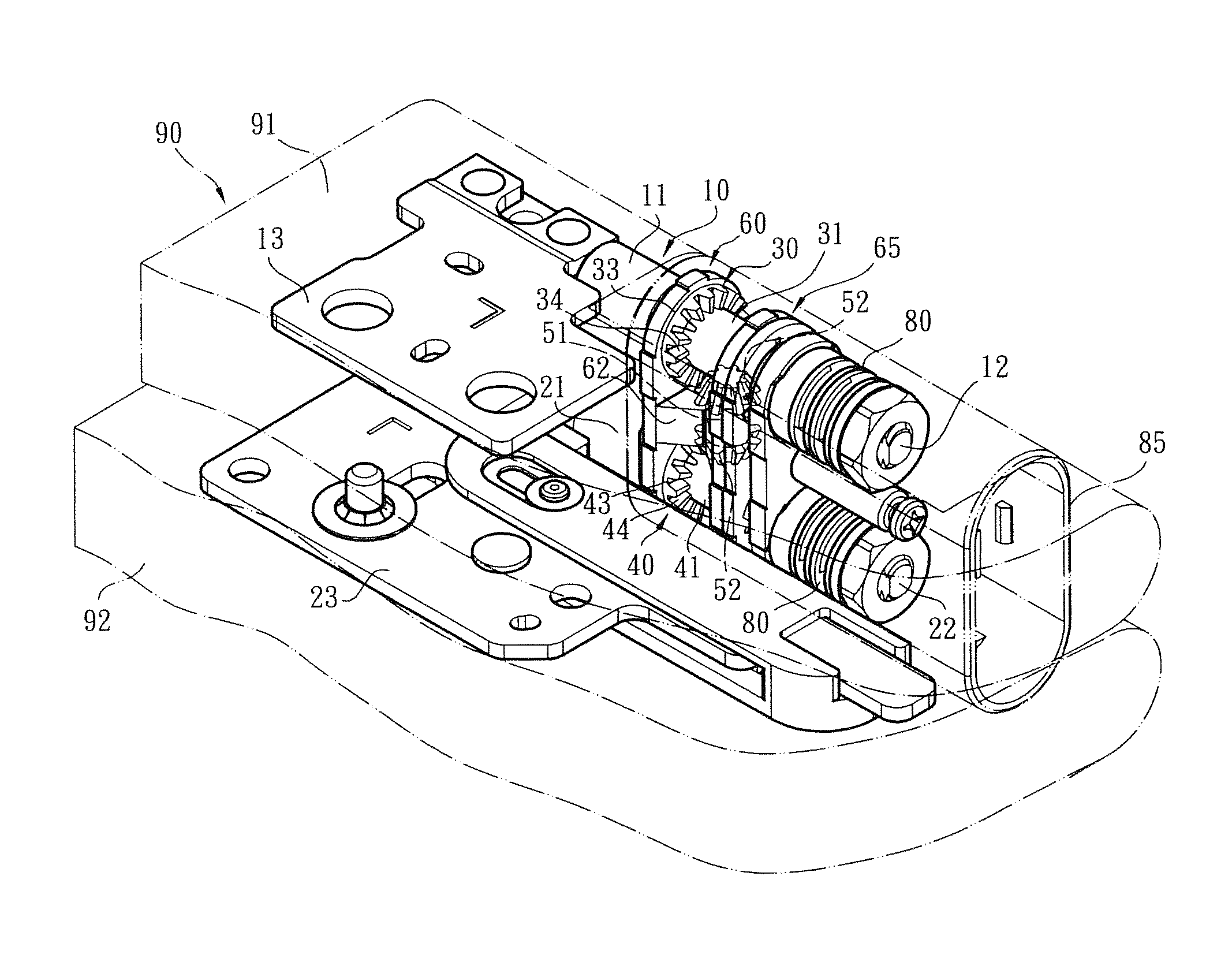

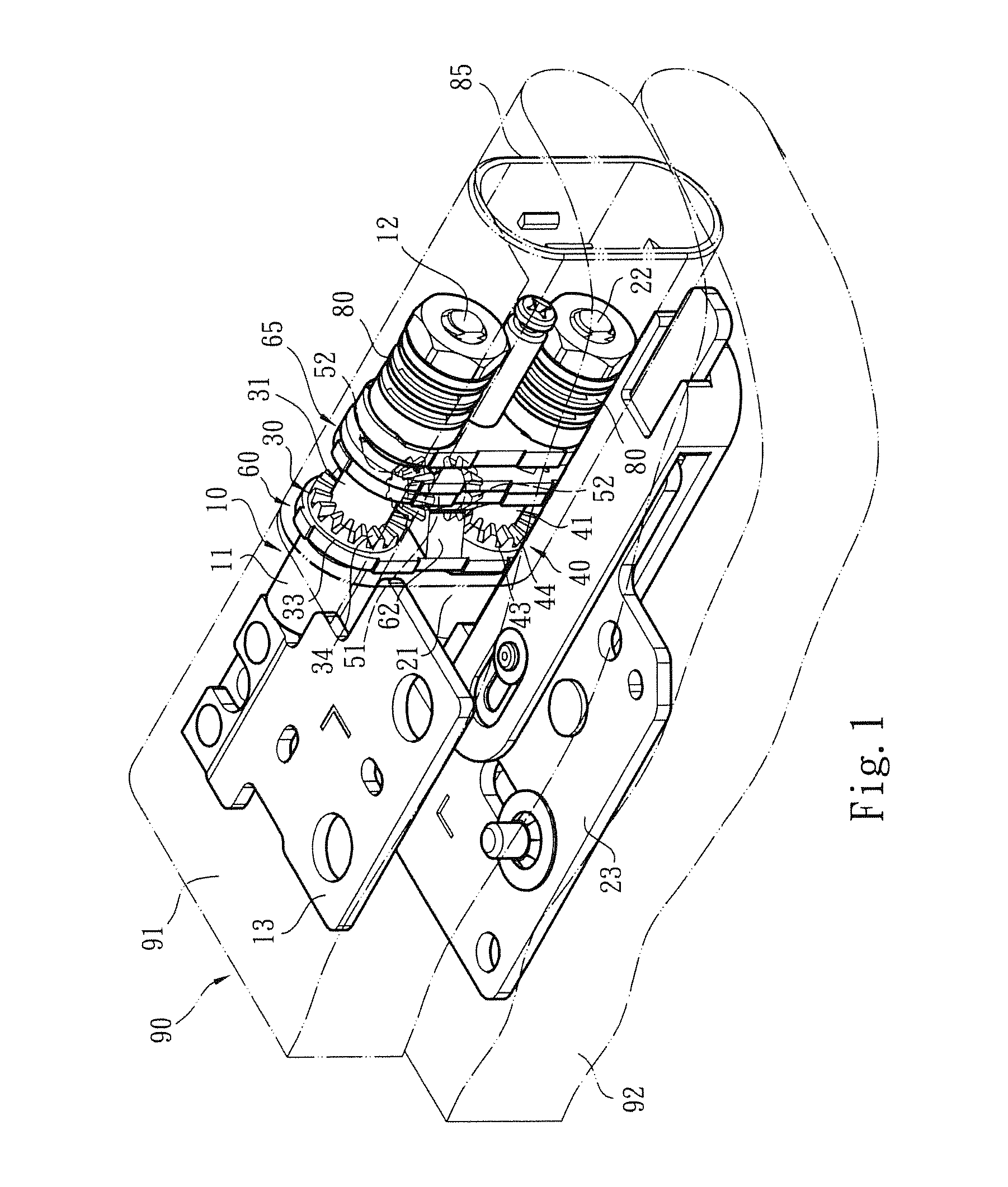

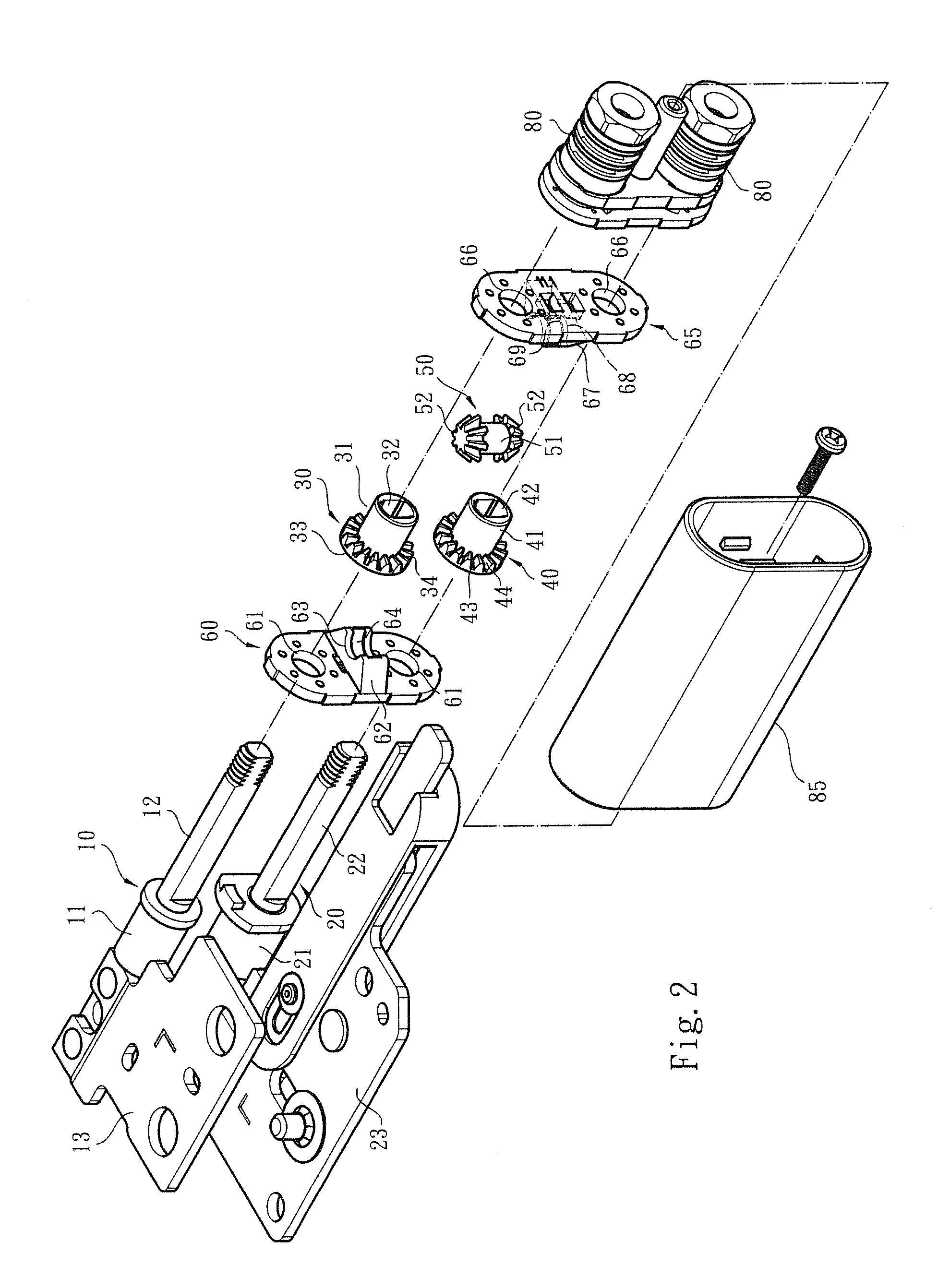

Pivot mechanism of synchronous hinge device

ActiveUS9524000B2Reduce distanceMiniaturized and lightweight structureDigital data processing detailsCasings/cabinets/drawers detailsTransmitted powerGear wheel

Owner:FIRST DOME

Timing chain drive unit

In an engine timing chain drive, a pivoted chain guide is provided on the tension side of the chain, and a synchronizing sprocket is incorporated into the chain guide and driven by the chain. The synchronizing sprocket rotates a cam which effects reciprocating movement of the guide to compensate for cyclic variations in tension resulting from operation of intake and exhaust valves.

Owner:TSUBAKIMOTO CHAIN CO

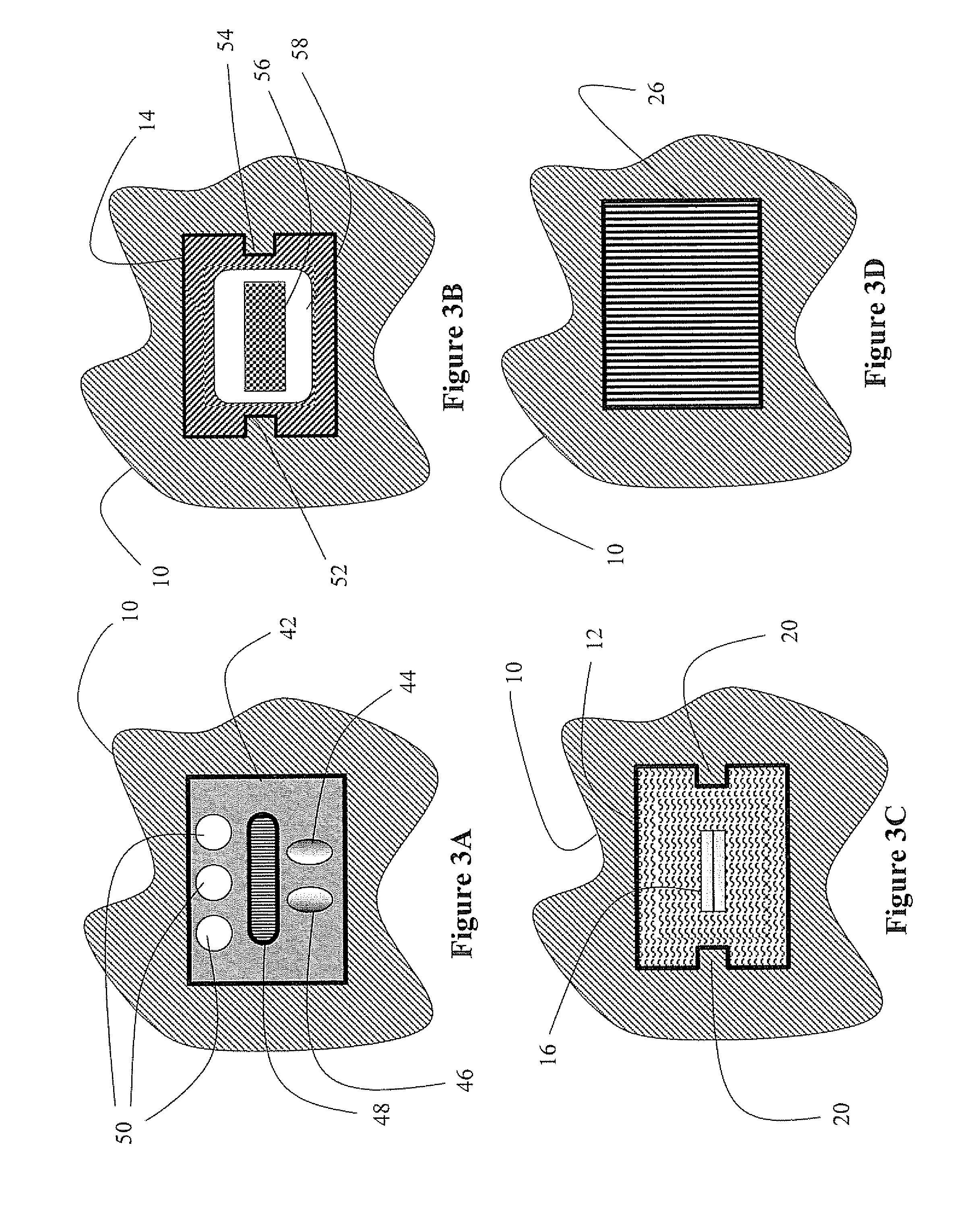

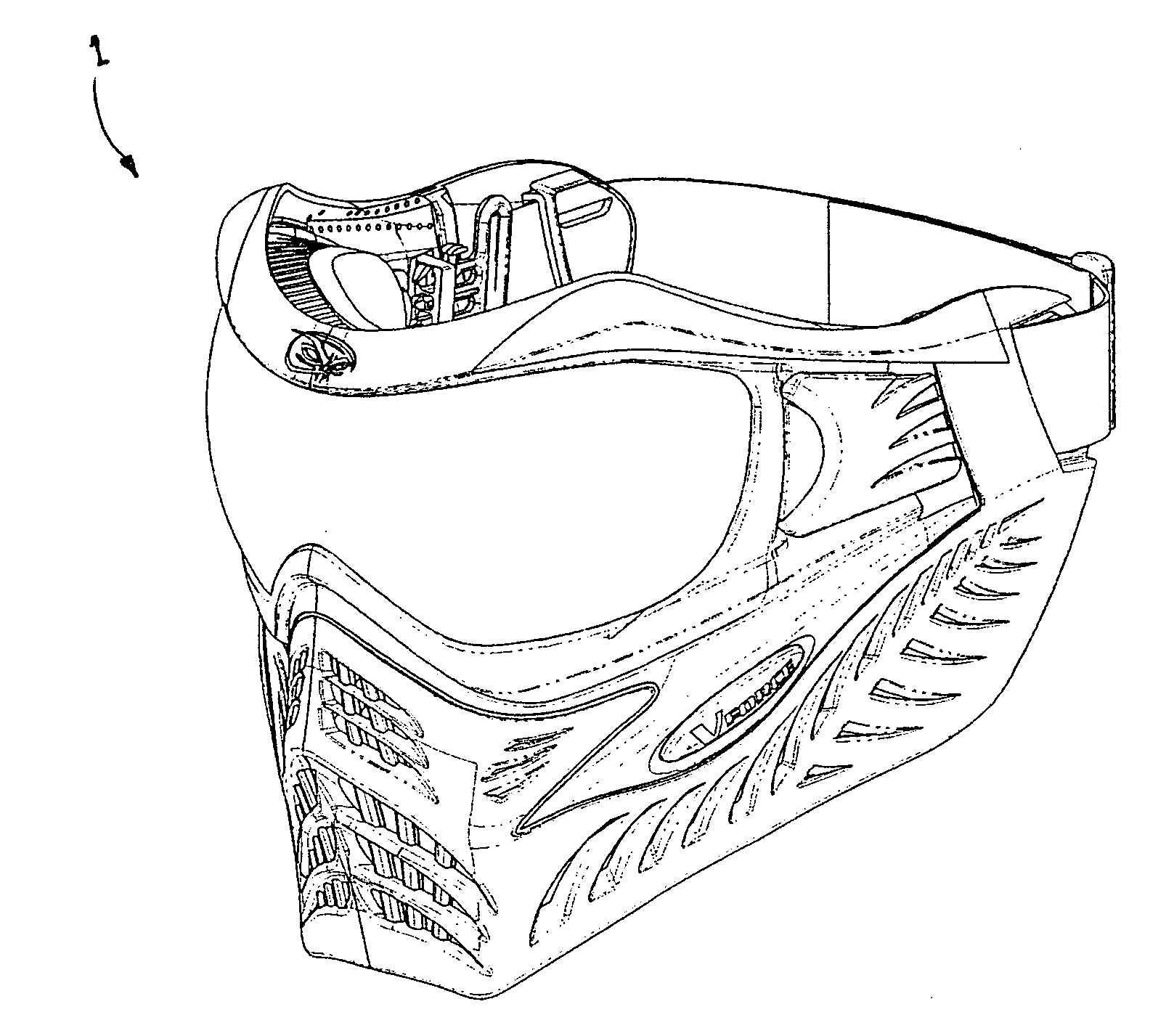

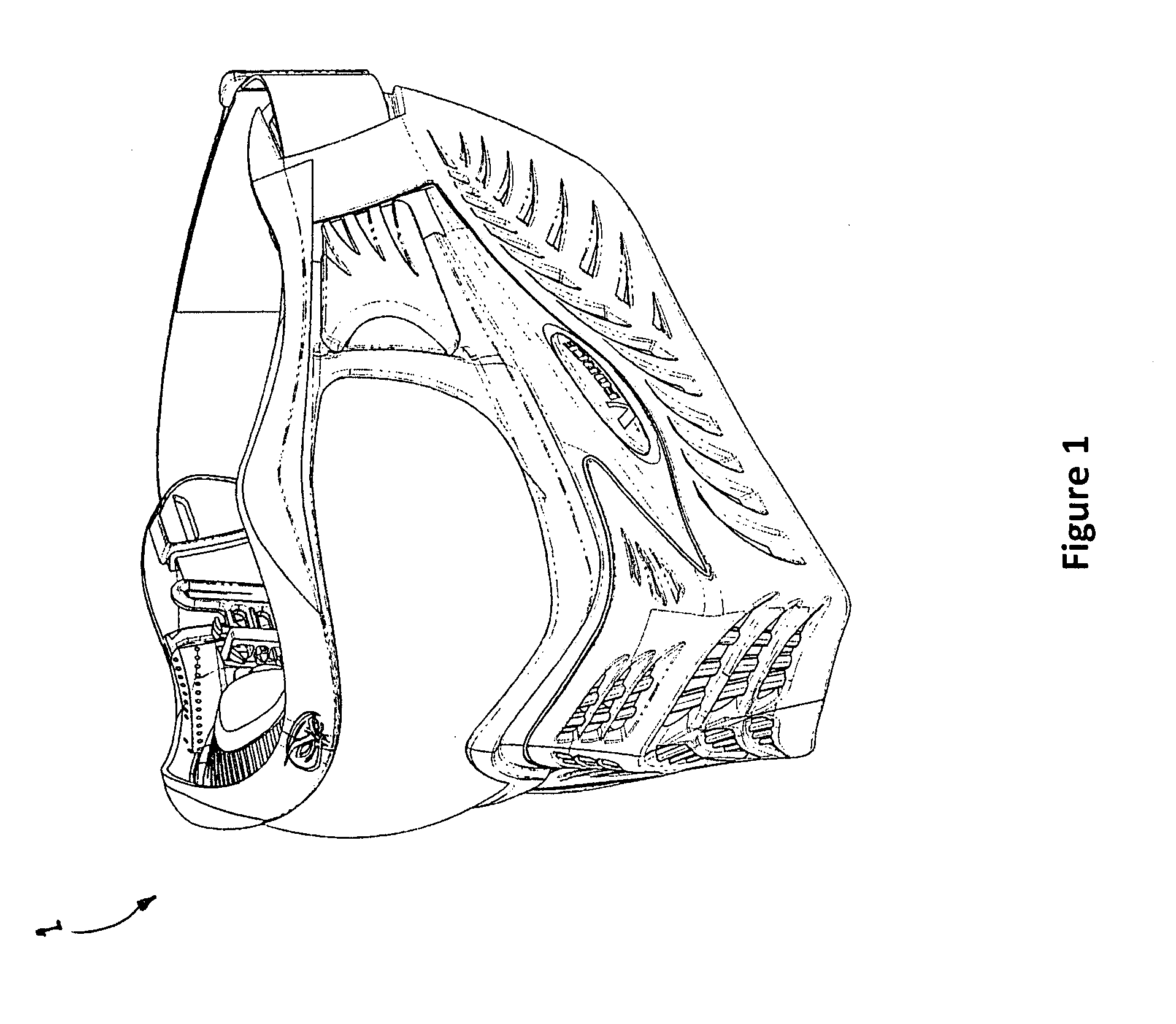

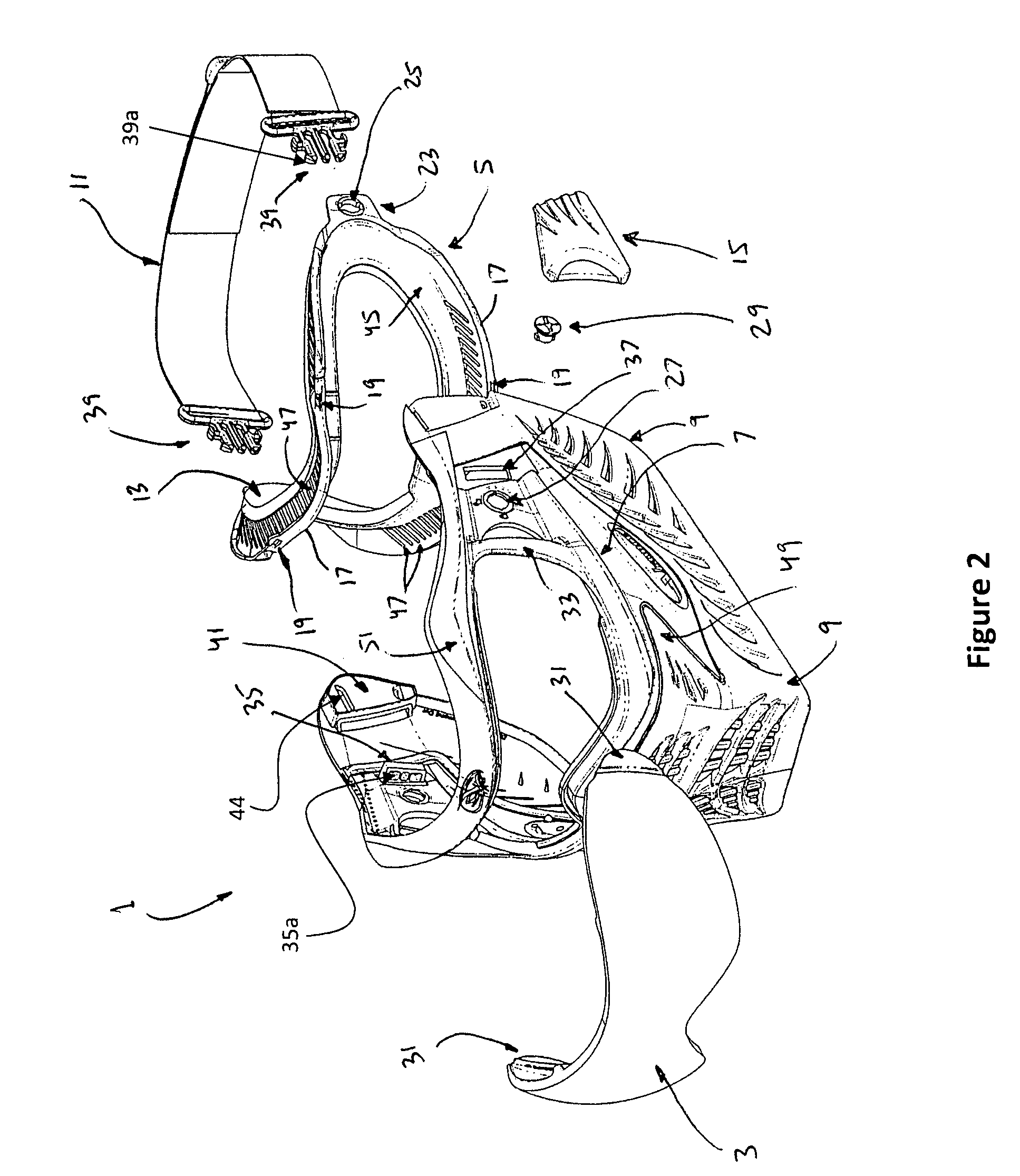

Protective face mask

ActiveUS20080086795A1Secure supportSmooth engagementChemical protectionHeat protectionEngineeringLens plate

The present invention relates to a protective mask adapted to be worn by a person engaging in the game of paintball. The mask has a main body to cover the front, sides, mouth and ears of a user's face. It also has a removable flexible transparent lens that locks into a rigid support frame formed in the mask. The mask also has a strap to securely support the mask on a wearer's head, and a removable face engaging element provided to accommodate a face of the wearer. This face engagement element evenly engages around the wearer's face in a cushioned manner because its face engagement portion is made of foam that engages the user's face along the entire perimeter of the face engagement element. The face engagement element is securely locked onto the mask by locking clips that fit into openings on both sides of the face engagement element.

Owner:KORE OUTDOOR LTD +1

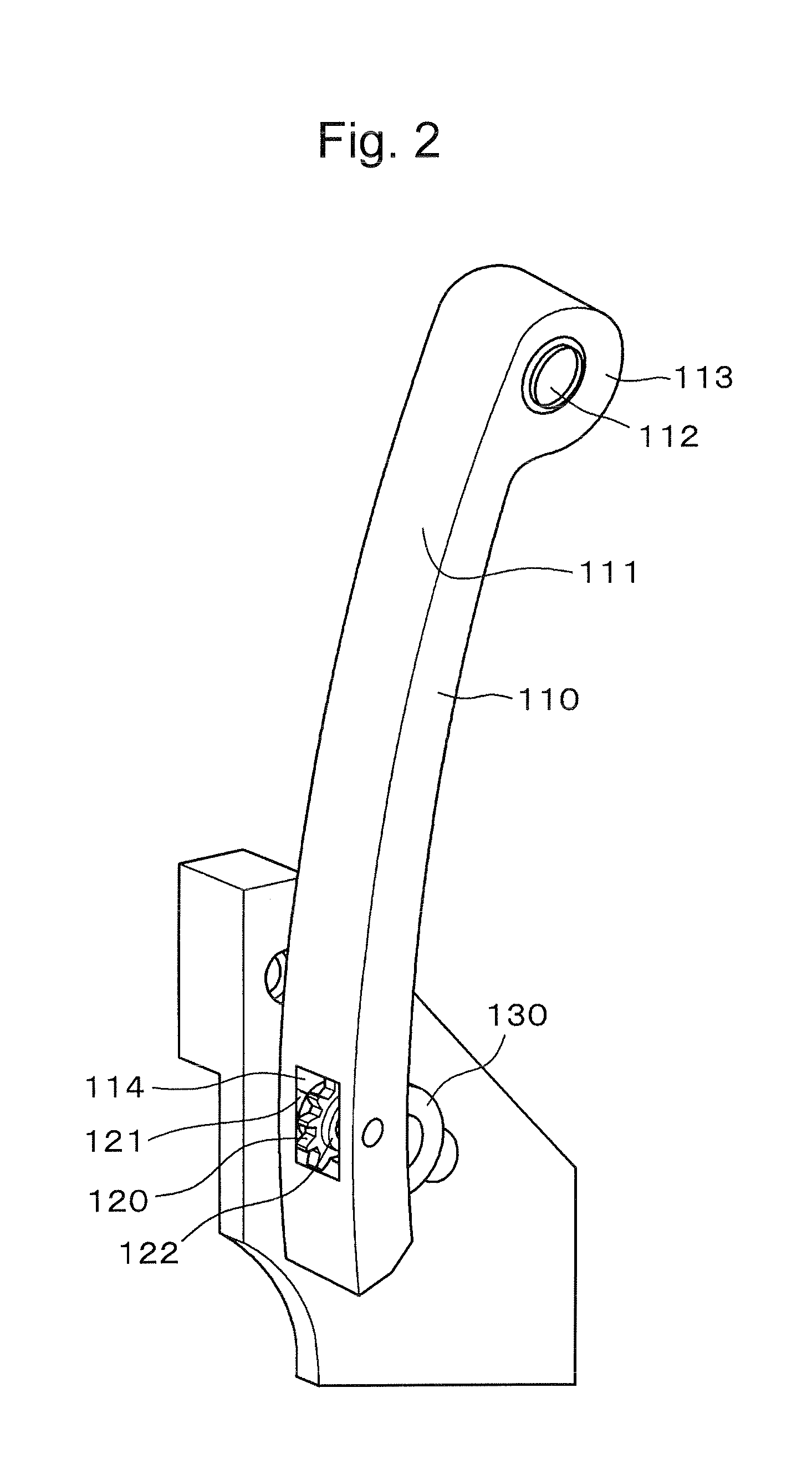

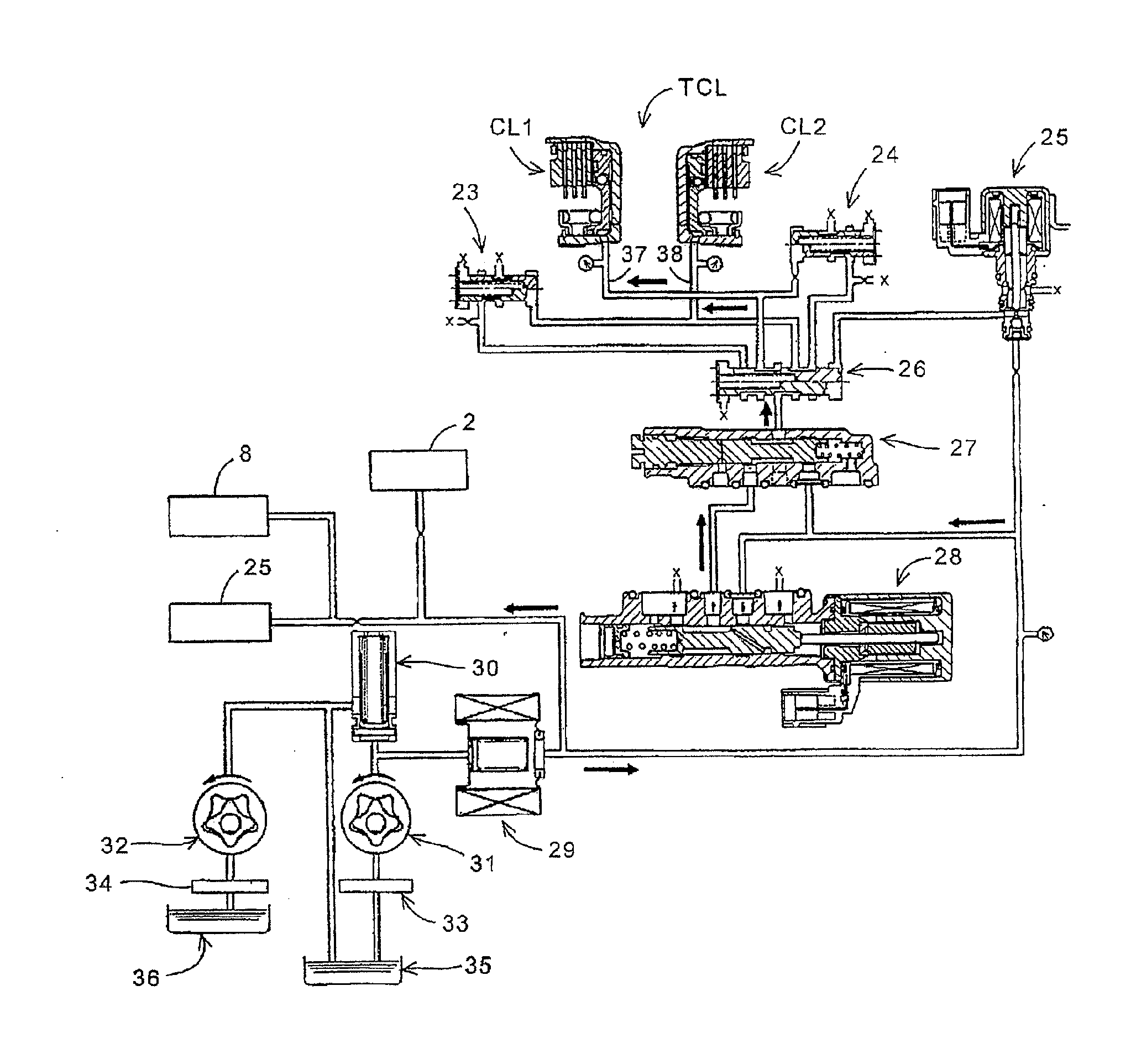

Shift controller

ActiveUS20100081547A1Smooth engagementShorten the timeGearing controlEngine controllersSolenoid valveControl theory

A shift controller with a first clutch CL1 that connects / disconnects the torque to a first main shaft and a second clutch CL2 connects / disconnects the torque to a second main shaft. A transmission is configured so that dog clutches DC1, DC2 for first speed and for second speed are engaged in a predetermined turned position P1-2 of a shift drum. A linear solenoid valve that supplies clutch oil pressure, a shift solenoid that switches a destination of the supply oil pressure between both clutches and a controller that controls the supply oil pressure and the turning of the shift drum are provided. The controller supplies predetermined oil pressure P1 to the CL2 in neutral, switches the destination of supply oil pressure to the CL1 when the shift drum is turned to P1-2 according to a shift instruction to engage gears and supplies maximum oil pressure P3 to the CL1 in predetermined time ta.

Owner:HONDA MOTOR CO LTD

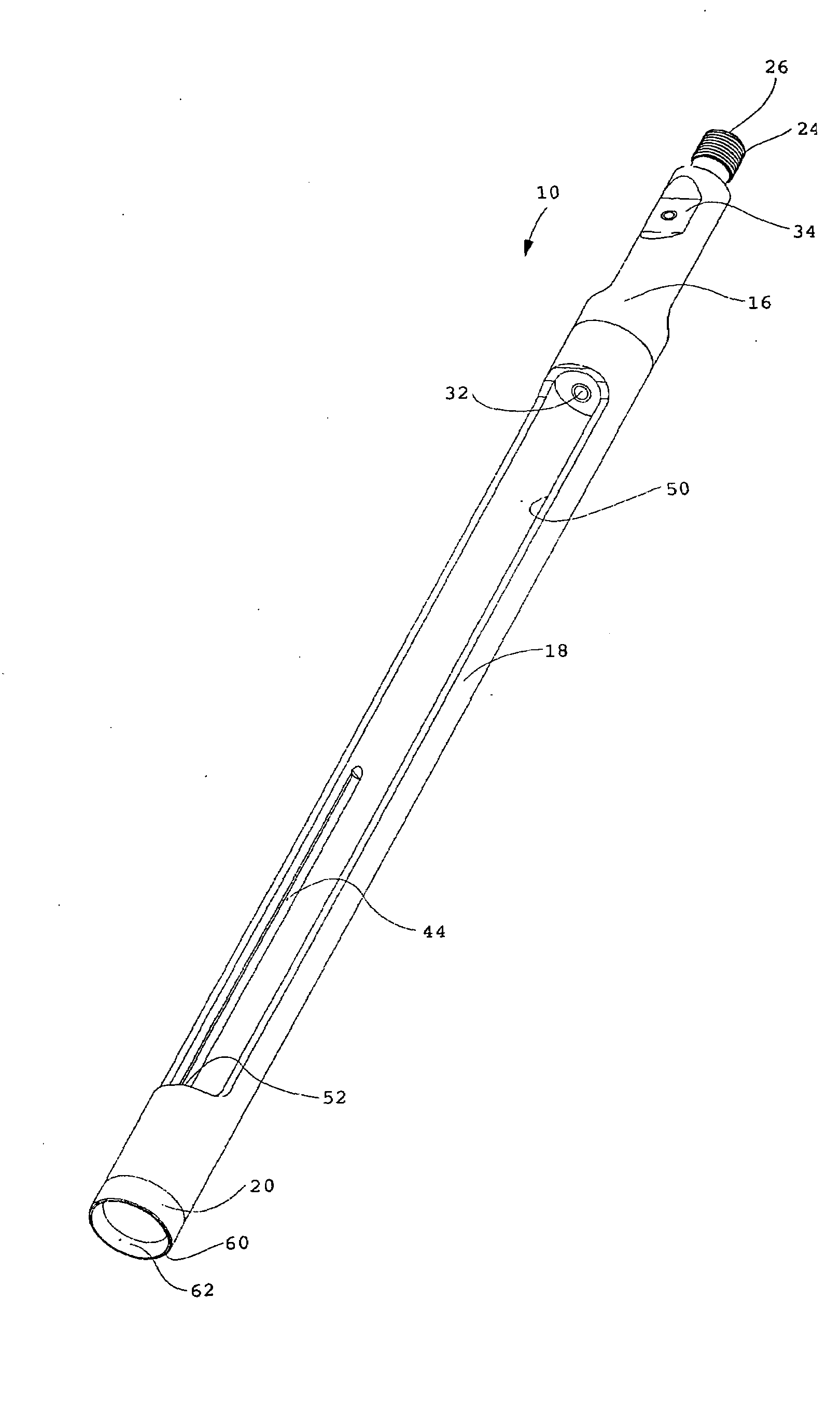

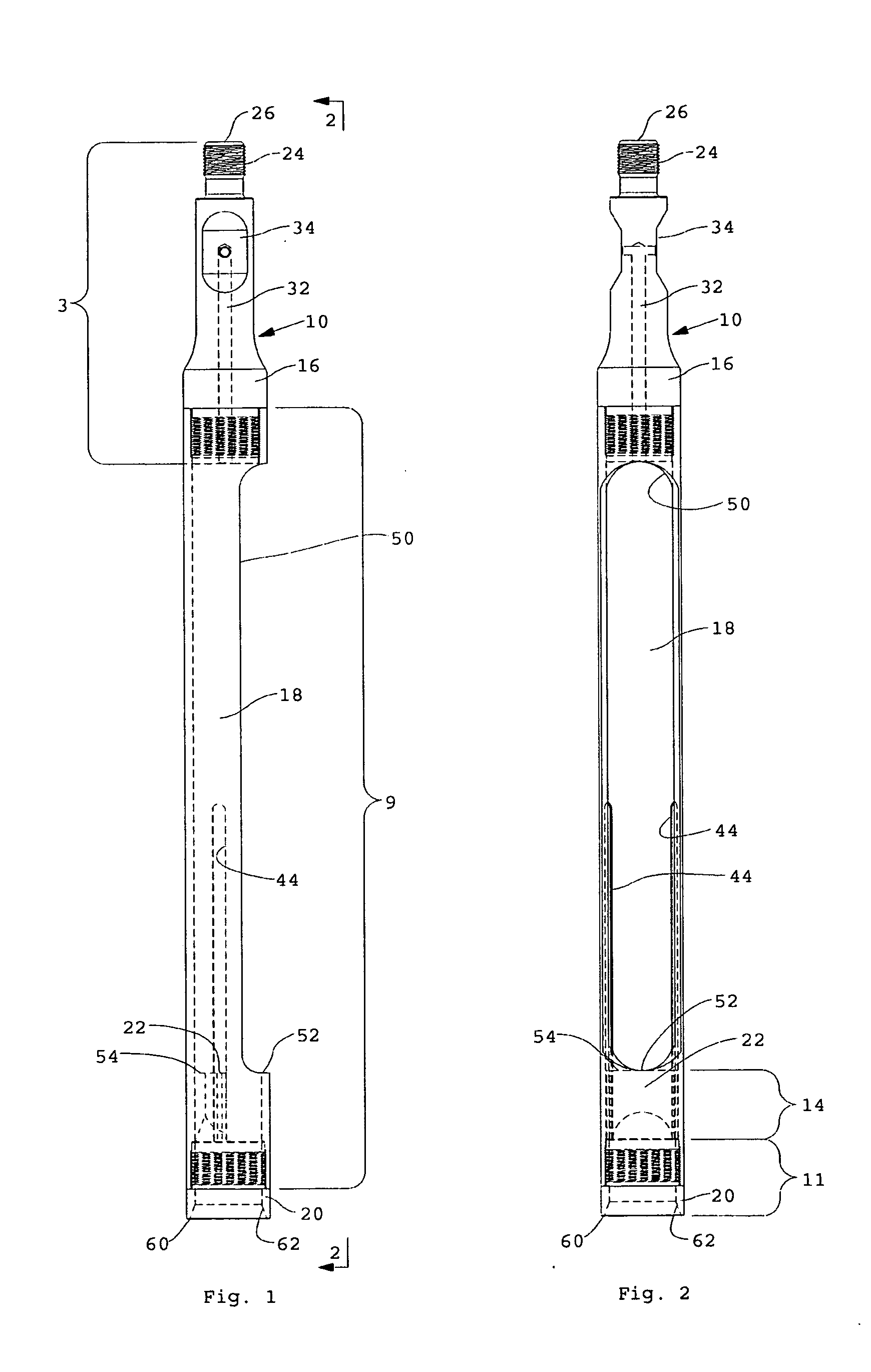

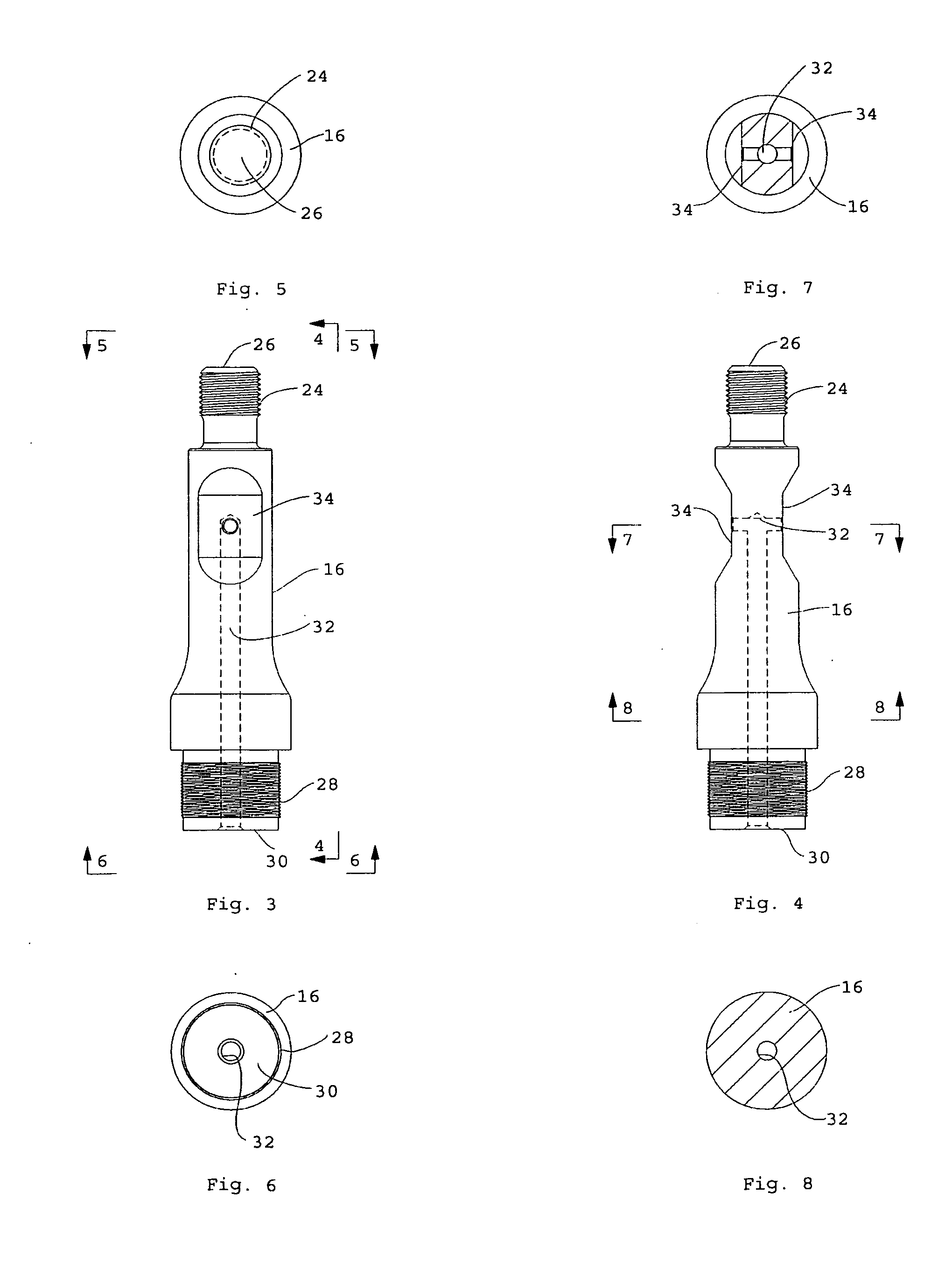

Sucker rod fishing tool

InactiveUS20090146442A1Smooth engagementResist rotational slippageBorehole/well accessoriesMilling cutterEngineering

A fishing tool for fishing sucker rods from a subterranean well. The tool is a top piece, a barrel piece and bottom piece that all thread together. One or more extender sections are added by unthreading the top piece from the barrel piece and threading the extender sections therebetween to effectively lengthen the barrel piece and increase its functionality. The bottom piece retains a curved cast metal slip movable within grooves milled internally into the body. A lower end of a side opening provided in the barrel piece is level with an upper shoulder of the slip when the slip is at its lowest position. Optionally, the bottom piece can be replaced with a bell, lip guide, mill shoe, or other types of tools and the top piece can be replaced by a prior art fishing tool or other tools.

Owner:KELSO WELL SERVICING TOOLS

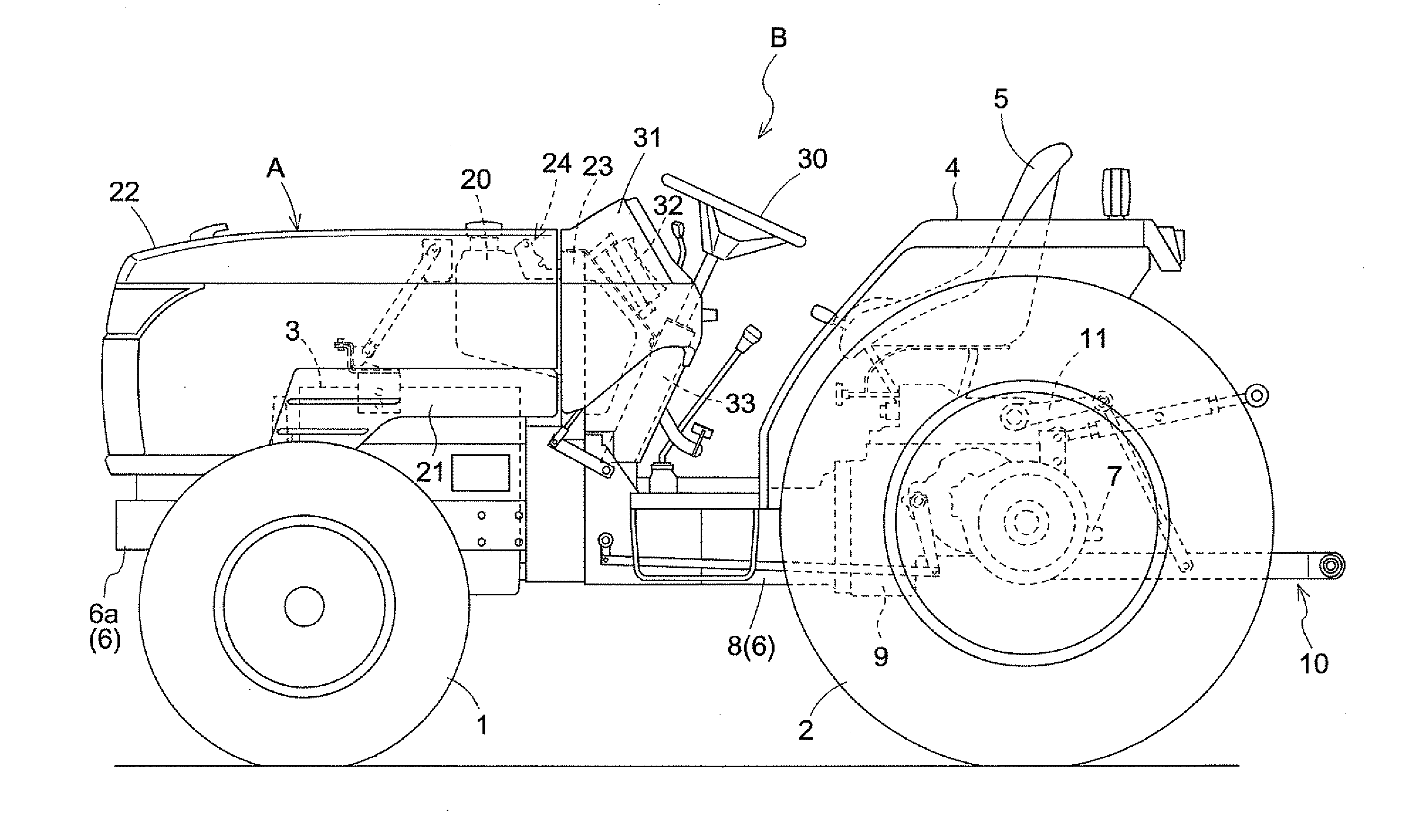

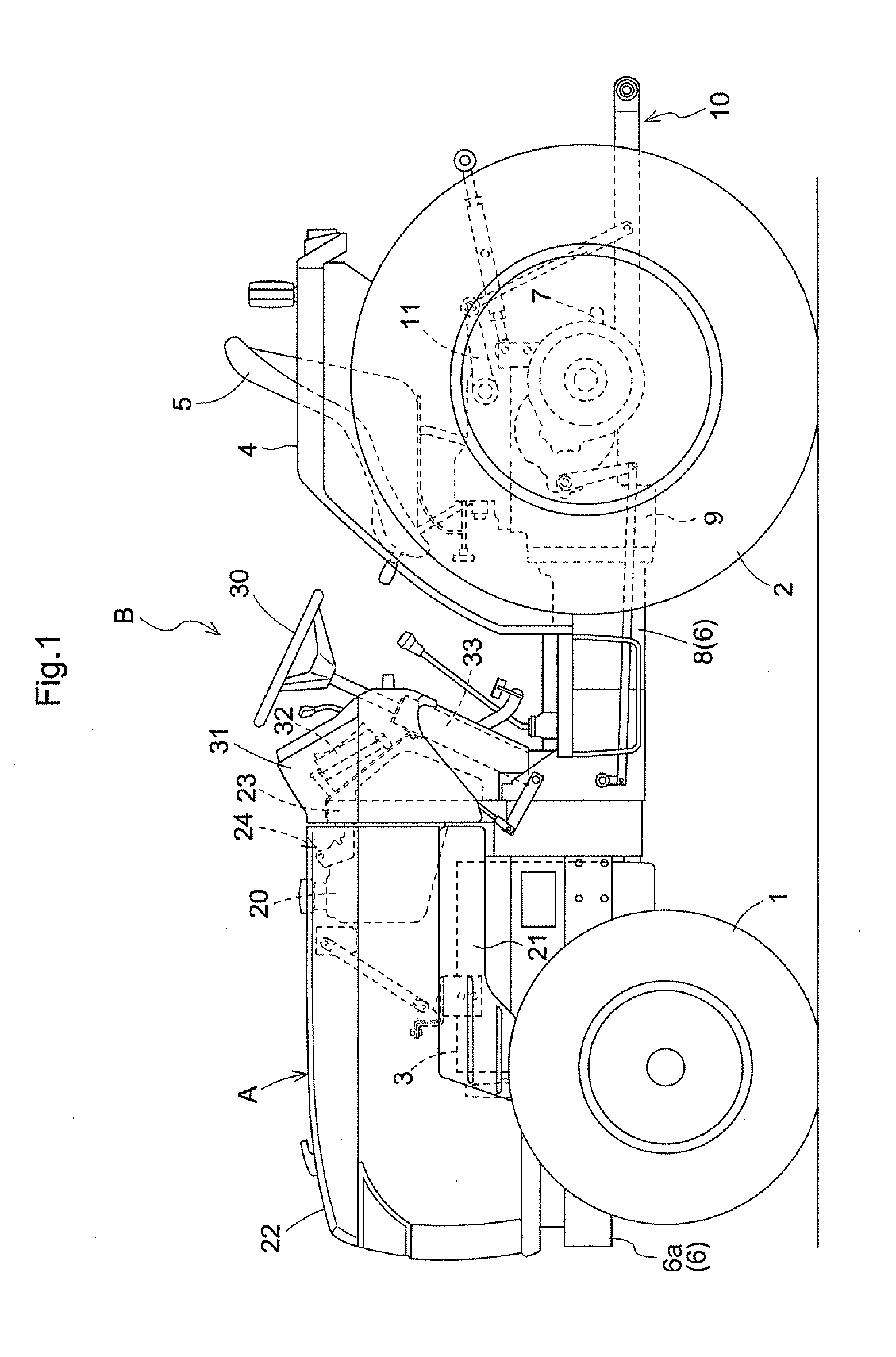

Tractor

ActiveUS20090236876A1Smooth engagementEasy to operateVehicle seatsSuperstructure subunitsSteering columnBraced frame

Provided are a vehicle body frame, a support frame that is erected on the vehicle body frame and that supports a hood, a steering wheel, a steering column that is erected on the vehicle body frame and that supports the steering wheel, an instrument panel, an operation panel that is provided below the steering wheel and that has a display window at a position facing the instrument panel, and a connecting member connected at one end to the support frame and connected at the other end to the steering column; wherein the instrument panel is mounted on the connecting member.

Owner:KUBOTA LTD

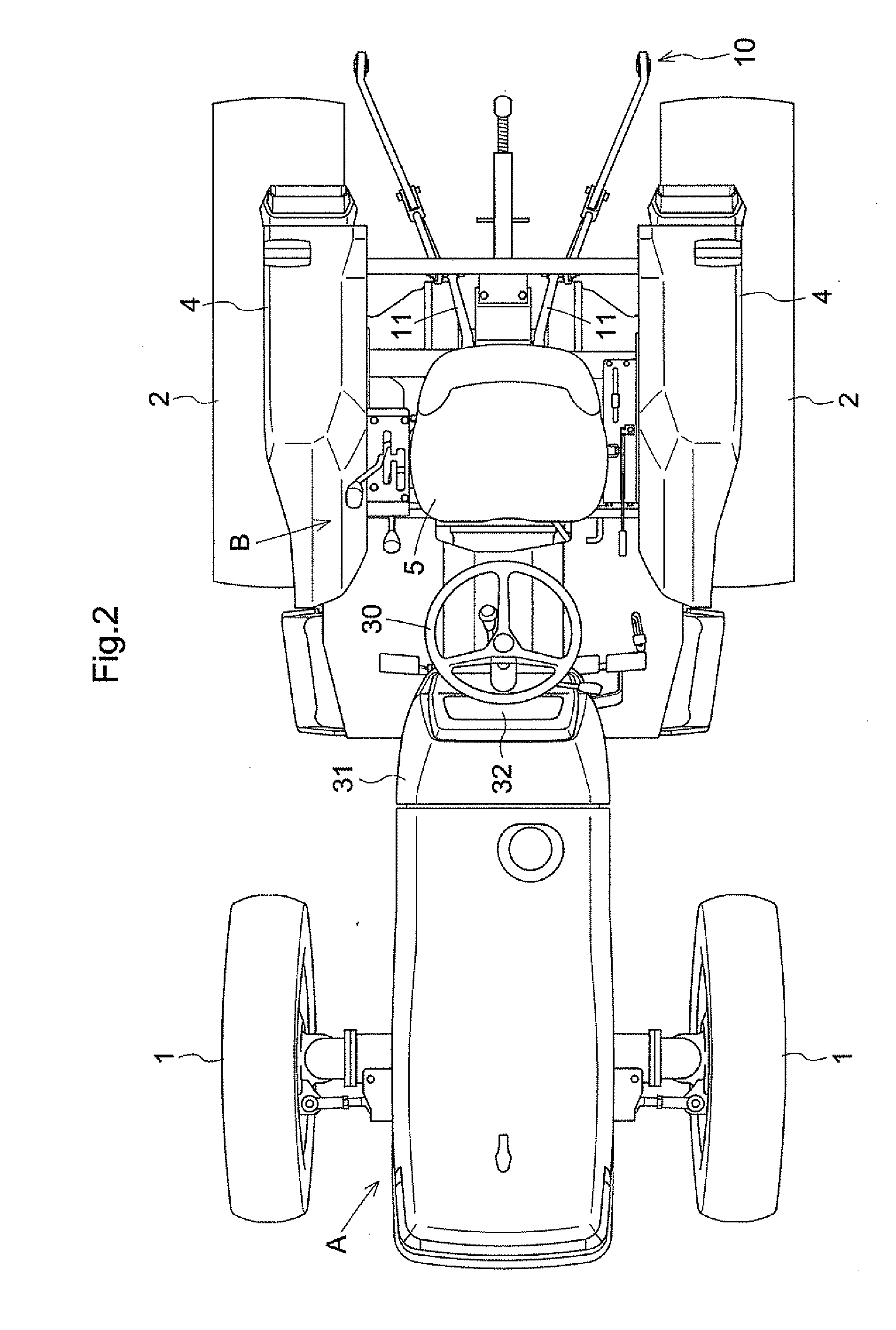

Steer-by-wire steering device

InactiveUS20130075185A1Increased power capacityIncreased torque capacitySteering linkagesMechanical steeringSteering wheelSteering angle

A steer-by-wire steering device includes a steering wheel connected with a steering shaft, a steering angle sensor, a steering reactive force motor, and a steering control unit for controlling a steering shaft drive motor and the steering reactive force motor. Provided is a power transmitting mechanism for transmitting the power from the steering shaft drive motor to the steering shaft. A changeover unit for selectively connecting and disconnecting the power is disposed on the way thereof. The changeover unit includes a clutch mechanism comprised of an input member and an output member juxtaposed in an axial direction for movement in the axial direction and, also, rotatable relative to each other, a clutch groove provided in one of those members, and a clutch rolling element provided in the other of those members and biased in a radial direction by the clutch groove so that it can be selectively engaged and disengaged.

Owner:NTN CORP

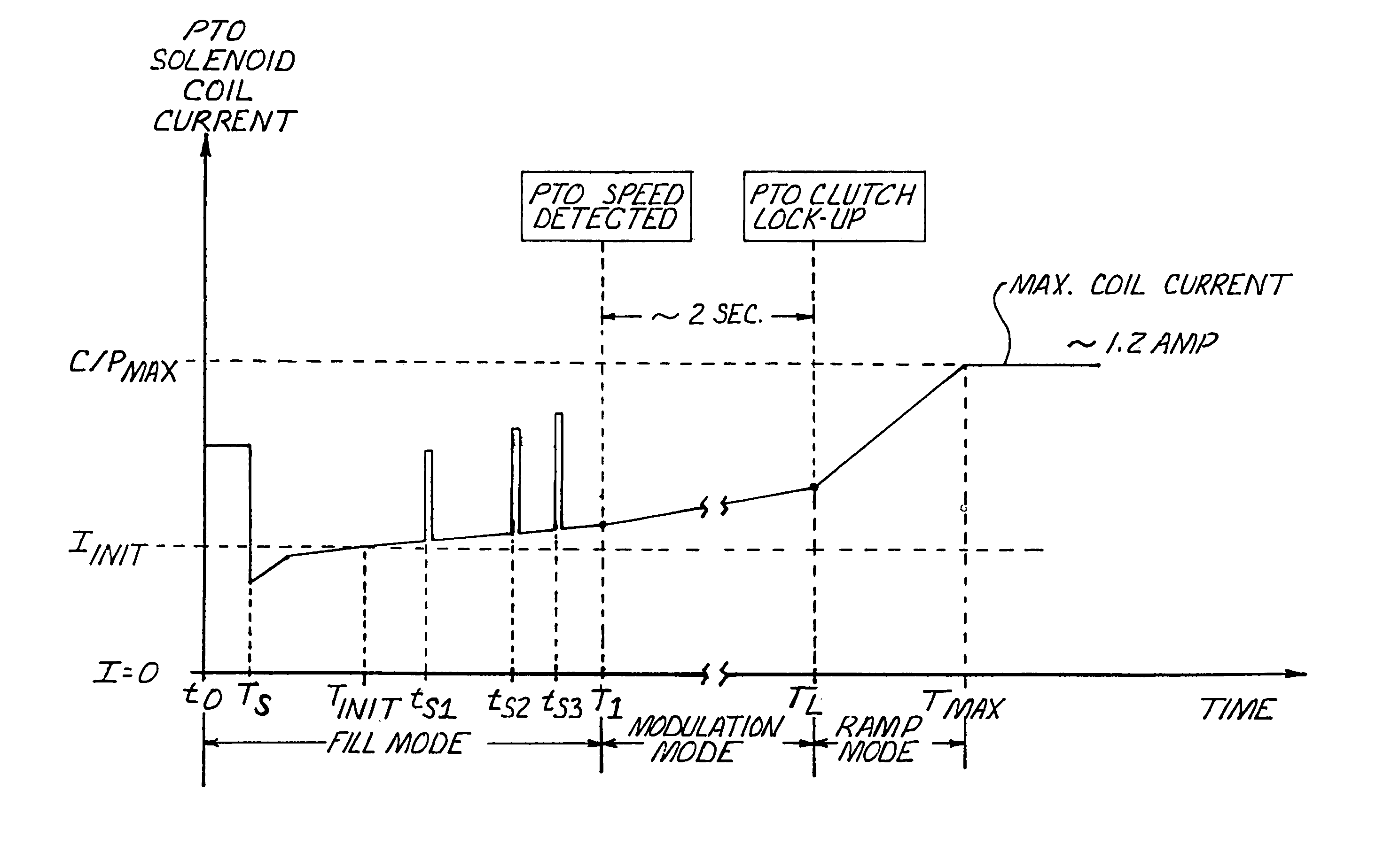

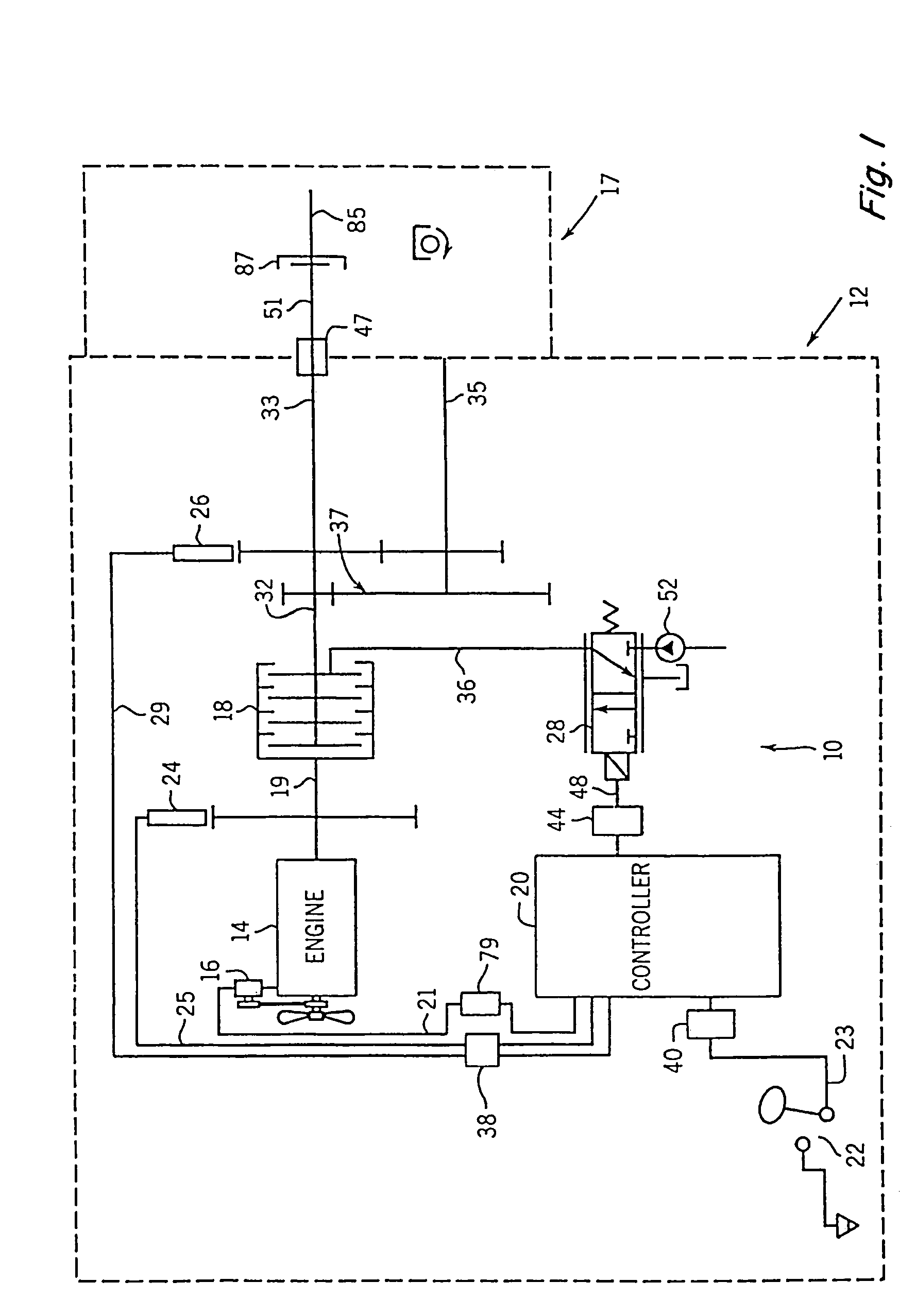

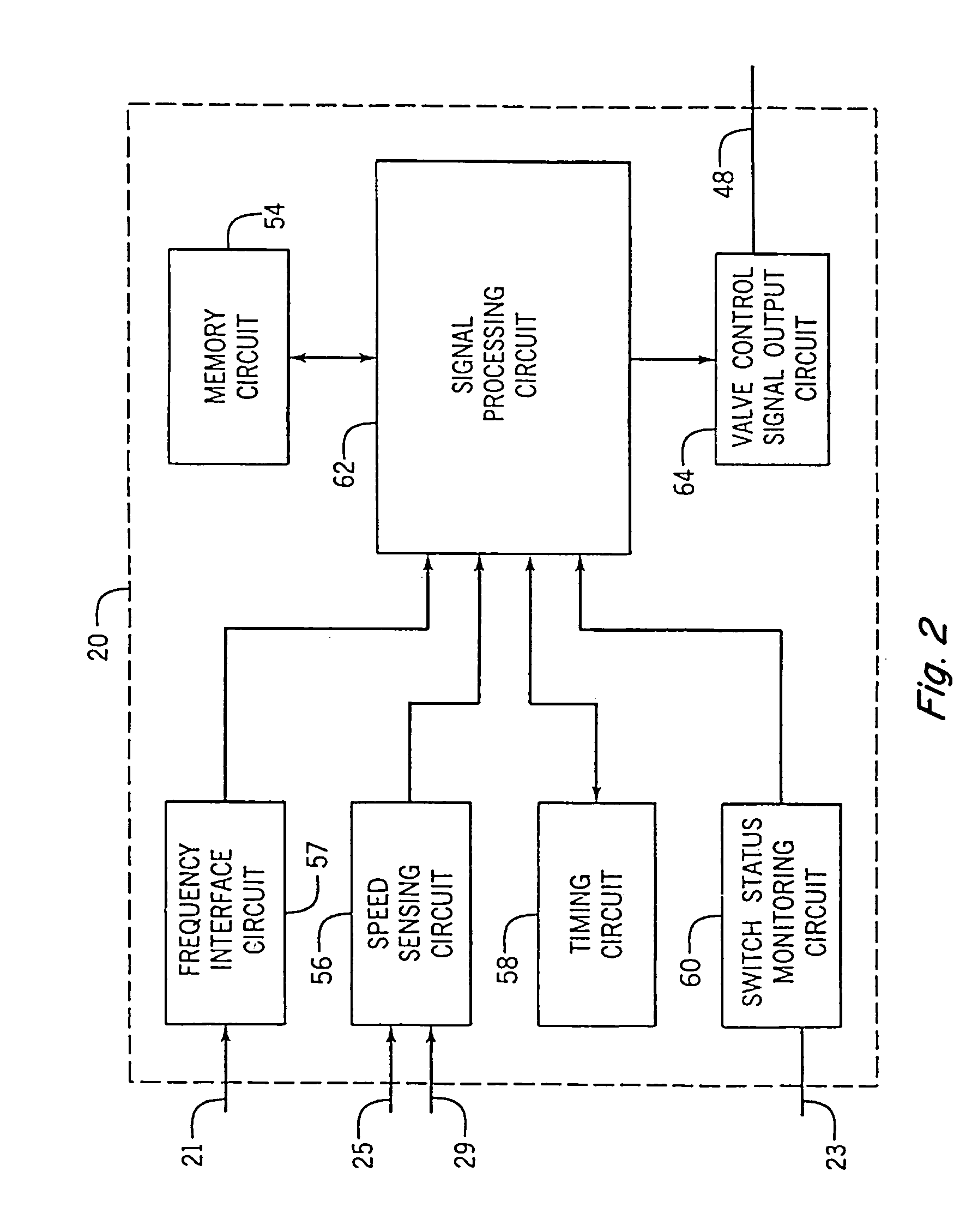

Power take-off control system

ActiveUS7234367B2Precious timeLong modulationDigital data processing detailsGearingControl systemControl signal

A control system and method for detecting variable load types and controlling the operation of a PTO clutch to effect engagement of the clutch with variable loads, and especially to more optimally effect the engagement of a clutch with a heavy load is disclosed. The control system includes a controller that receives input and output clutch shaft speed signals and generates control signals to control the pressure applied by the clutch. When heavier loads are applied to the PTO shaft, during the time when control signals are being generated before detection of initial movement of the output shaft, the controller generates one or more shock signals of short duration to cause momentary applications of significantly greater pressure to the clutch in order to break loose the applied load. Based upon the time of detection of initial movement by the output shaft, load categorization can be made, and control signals that are thereafter generated before lockup may be dependent, in part, upon the determined load categorization.

Owner:BLUE LEAF I P INC

Ink tank

An ink tank provided with a supply port for supplying the ink contained therein and an electric contact for information transmission is smoothly and securely attached to an attachment section of a printing apparatus while achieving secure connection of an electric contact section at the same time. The ink tank is configured to be attachable to the attachment section by positioning a first engagement section at a first fitting section on the attachment section, and then by rotating the ink tank around the positioned first engagement section to lock a second engagement section to a second fitting section on the attachment section. The supply port and a positioning section for the contact are disposed on the bottom face of the ink tank so as to be on the respective two sides of the center line in the width direction of the ink tank therebetween.

Owner:CANON KK

Positioning device

InactiveUS7168695B2High precisionSmooth engagementLarge fixed membersPositioning apparatusEngineering

A supporting face (1a) is provided on a base plate (1), a face (2a) to be supported is provided on a work pallet (2), and an engagement hole (3) is opened in the face (2a) to be supported. A core column (11) is projected upward from a housing (9) fixed to the base plate (1). An elastic sleeve (12) that fits in the engagement hole (3) is supported in a space at the outer periphery of the core column (11), on the upper face of the housing (9). Wedge spaces (W) narrowing downward are circumferentially arranged at an substantially equal intervals between the core column (11) and the elastic sleeve (12). Wedge members (15) are vertically movably inserted in each of the wedge spaces (W). Input portions (20) of the wedge members (15) are connected to an output portion (44) of an upper rod (43) of a piston (33).

Owner:KOSMEK LTD (JP)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com