Power split transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0021]The present invention is susceptible of embodiments of many different forms. While the drawings illustrate, and the specification describes, certain preferred embodiments of the invention, it is to be understood that such disclosure is by way of example only. There is no intent to limit the principles of the present invention to the particular disclosed embodiments.

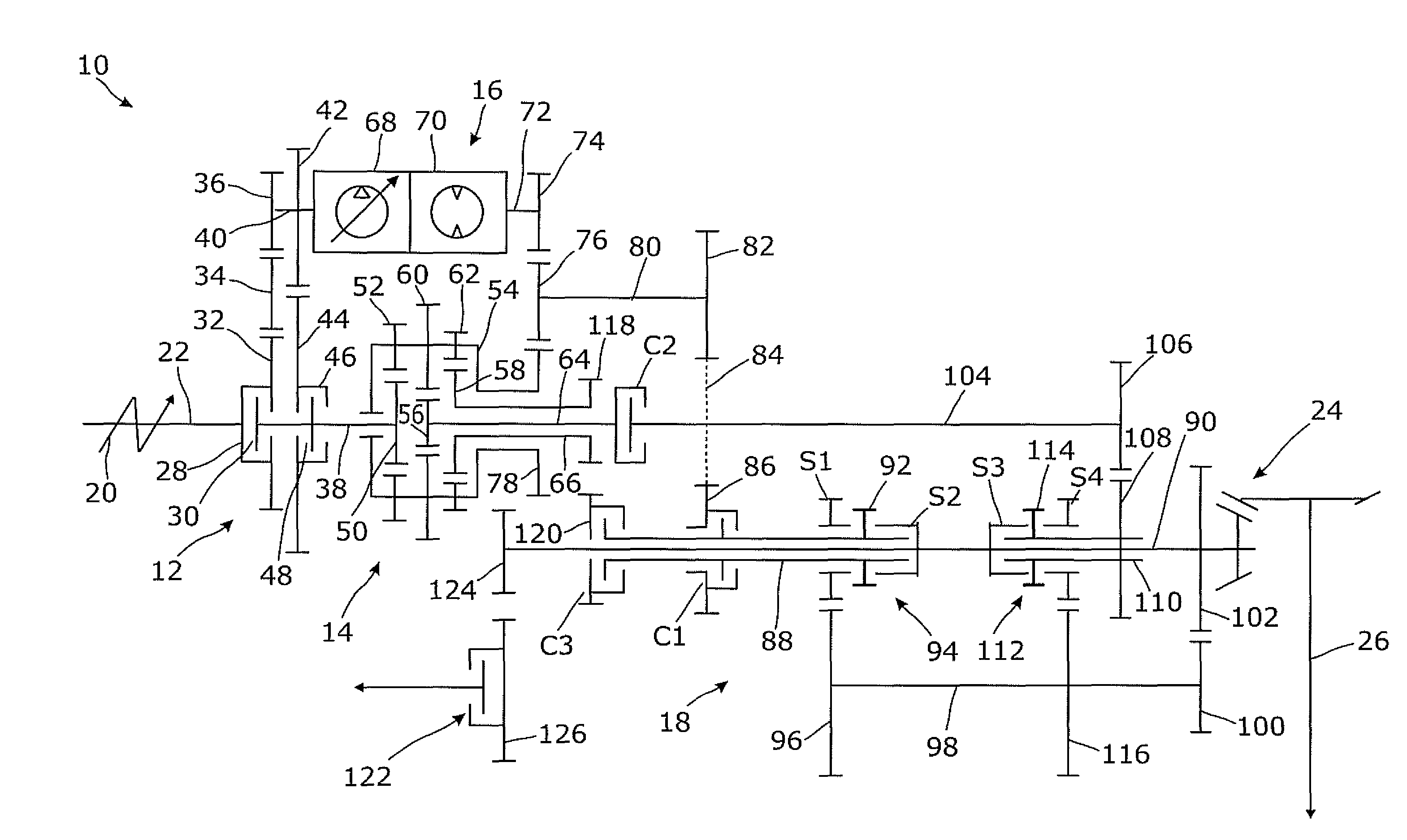

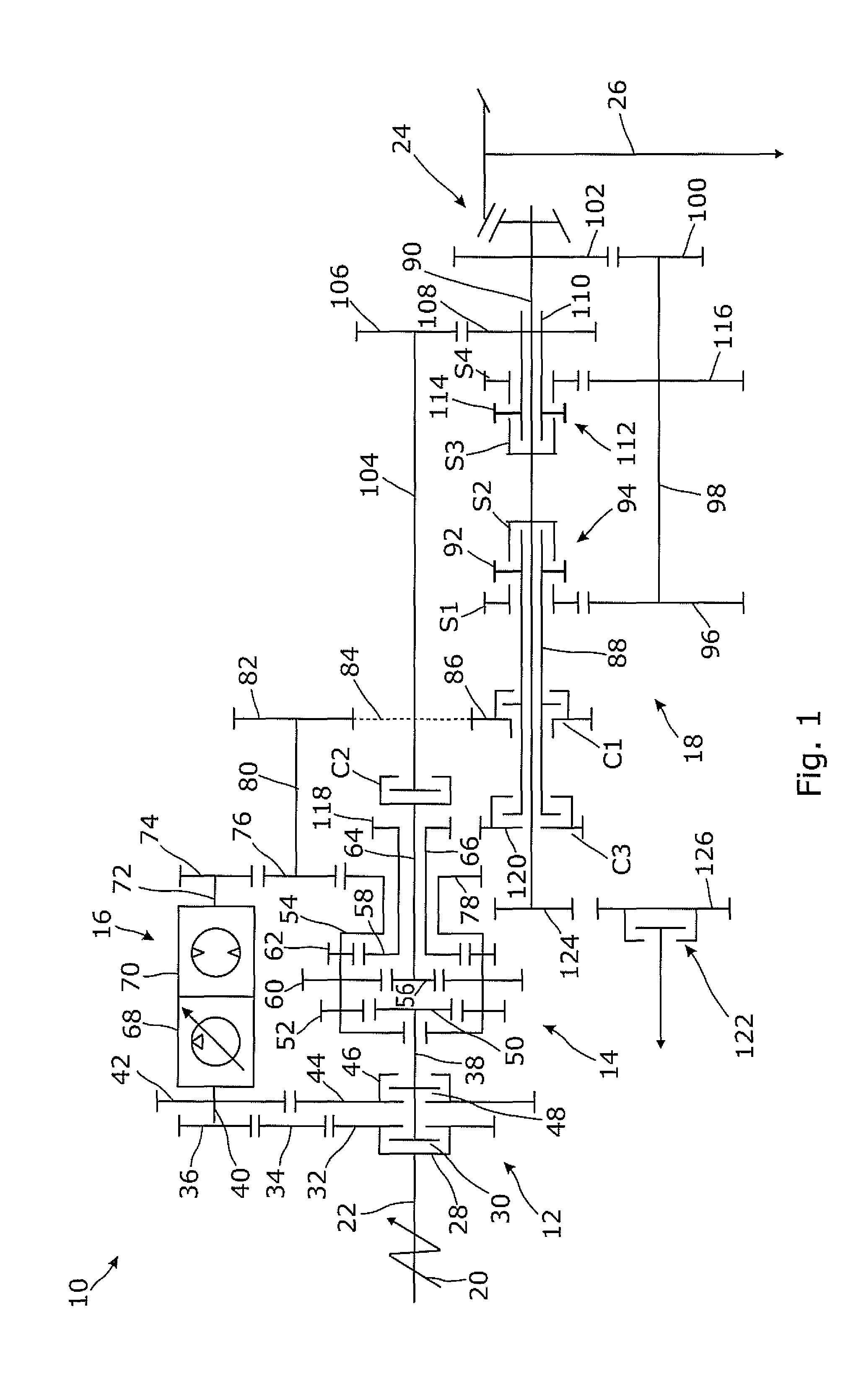

[0022]With reference to FIG. 1, an agricultural tractor transmission 10 is shown diagrammatically. The transmission 10 includes a forward-reverse transmission module 12, and epicyclic module 14, a hydrostatic drive branch 16 and a direct shift transmission (DSG) module 18. The inter-relationship between these components will be described in the following passages. At its input end, transmission 10 is coupled to an internal combustion engine 20 which generates torque via a driveshaft 22 which is transferred via transmission 10 to a differential gearing 24. The invention is not limited to vehicles with internal combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com