Patents

Literature

247results about How to "Reduce air pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

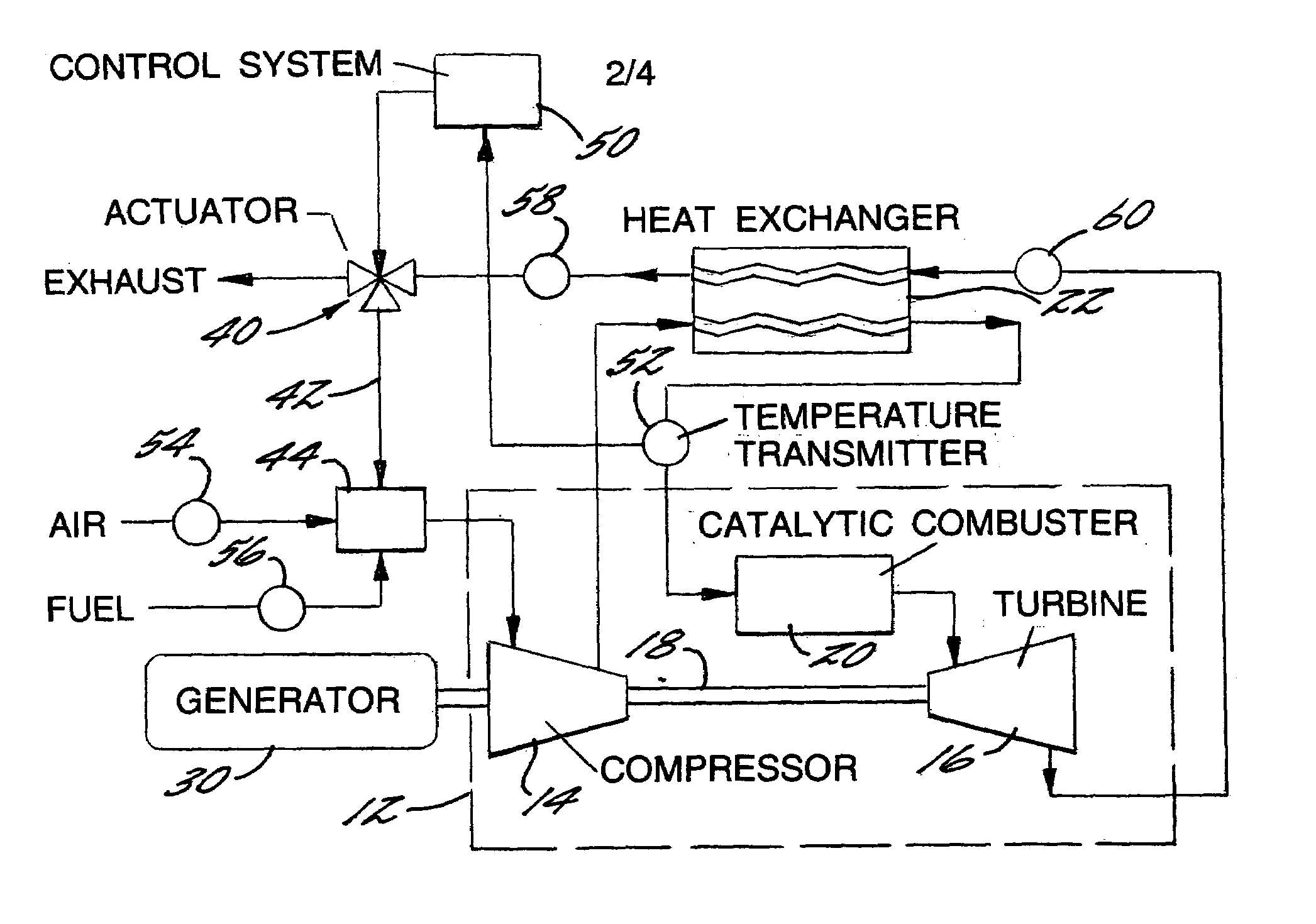

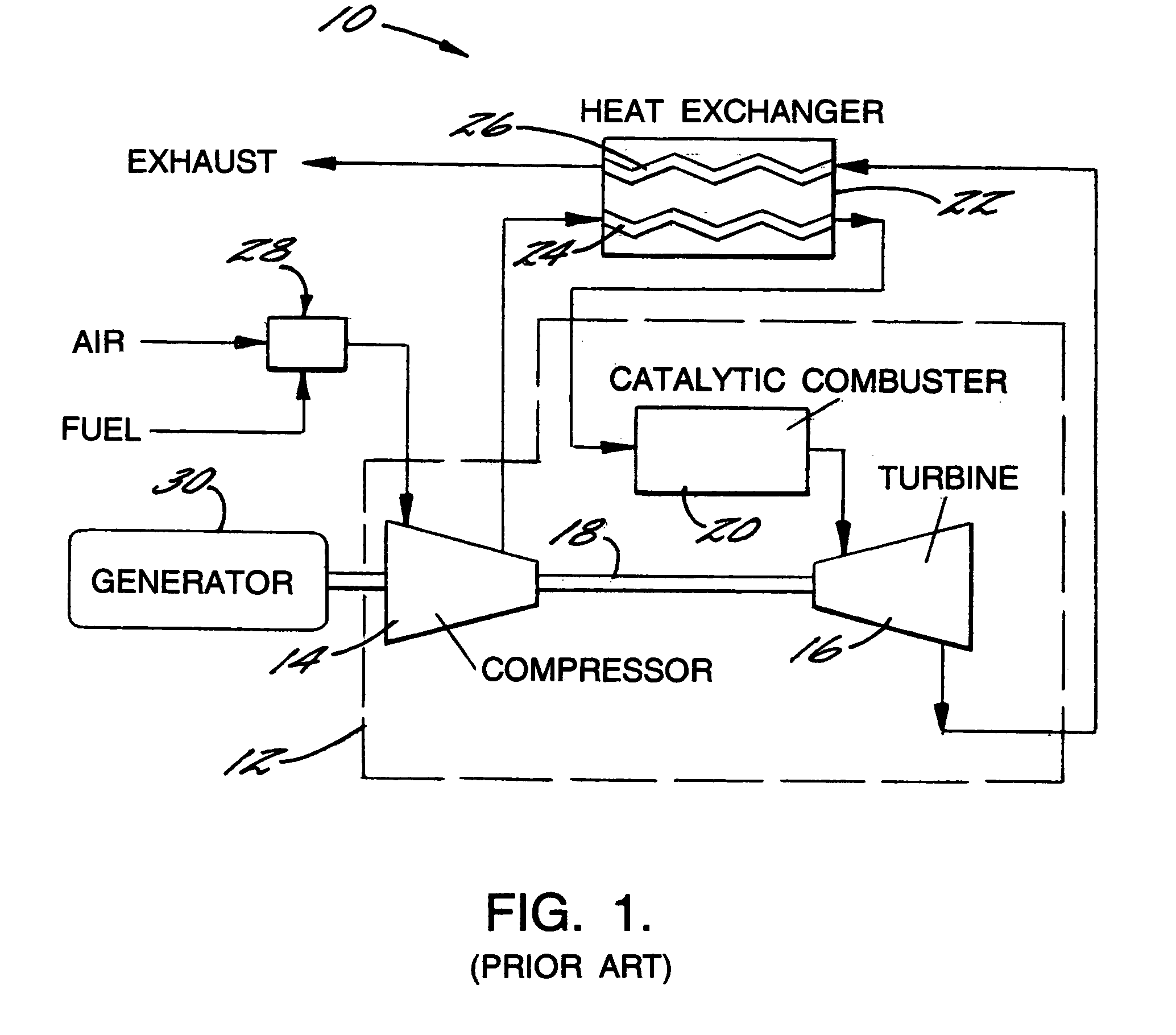

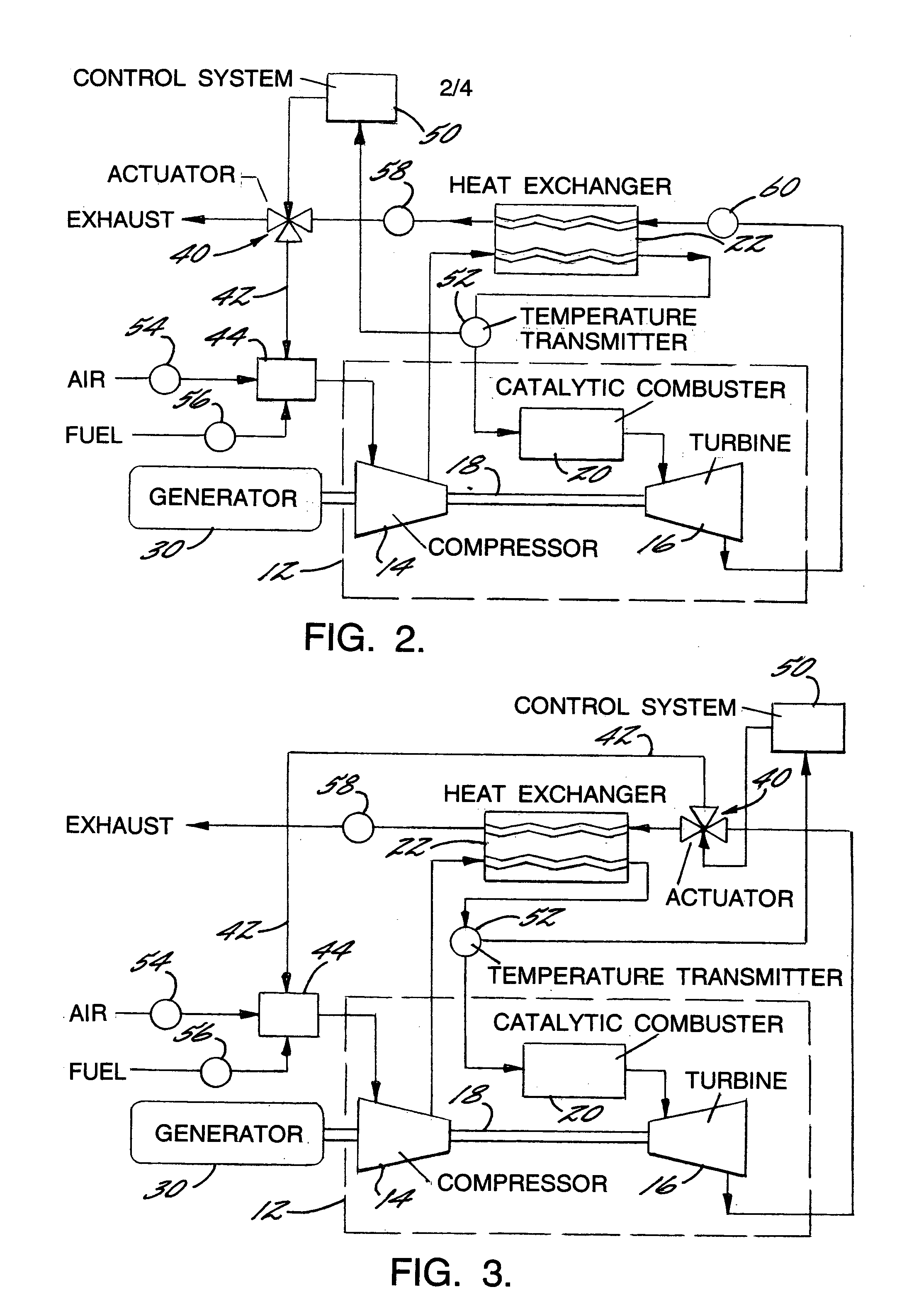

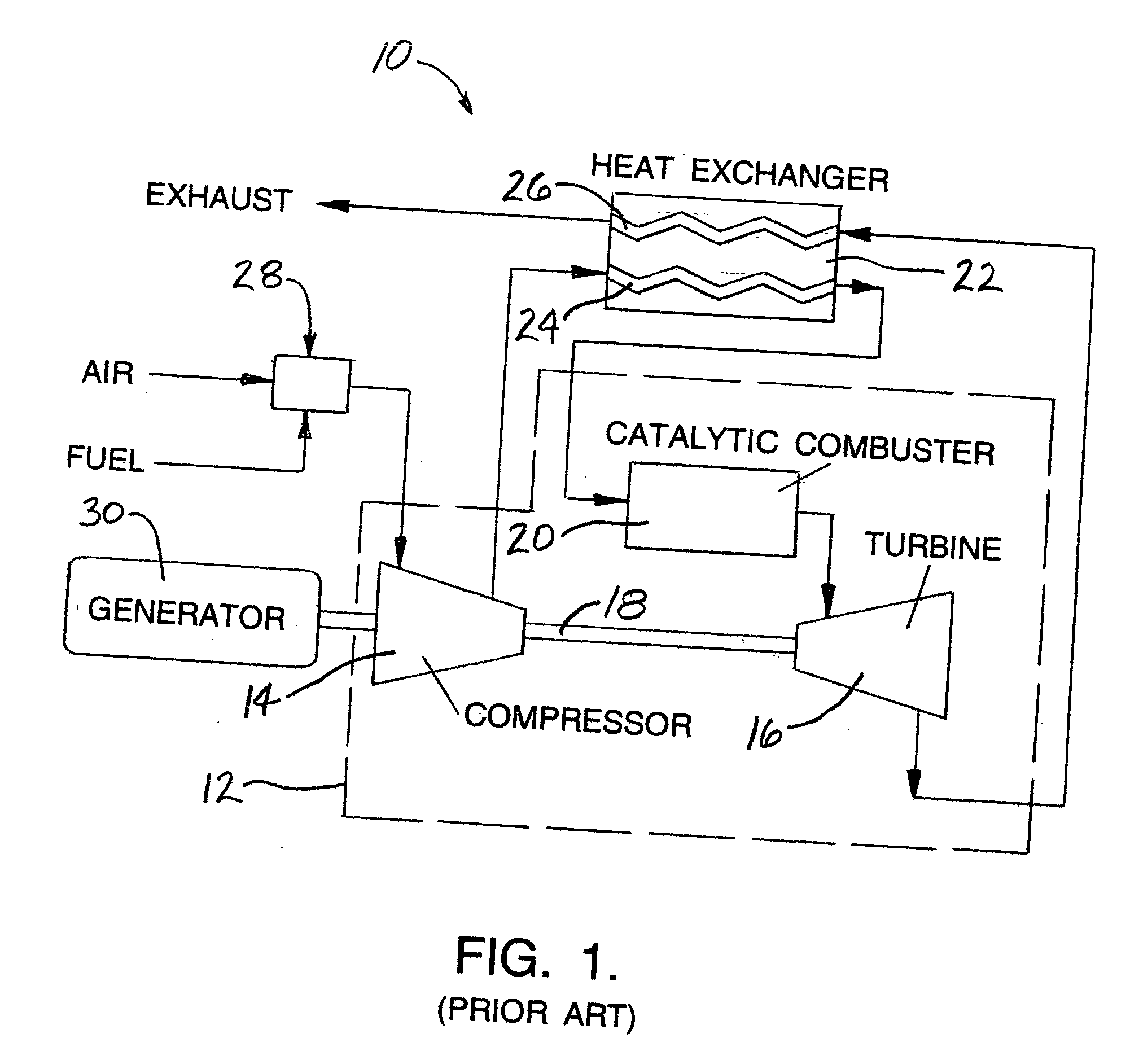

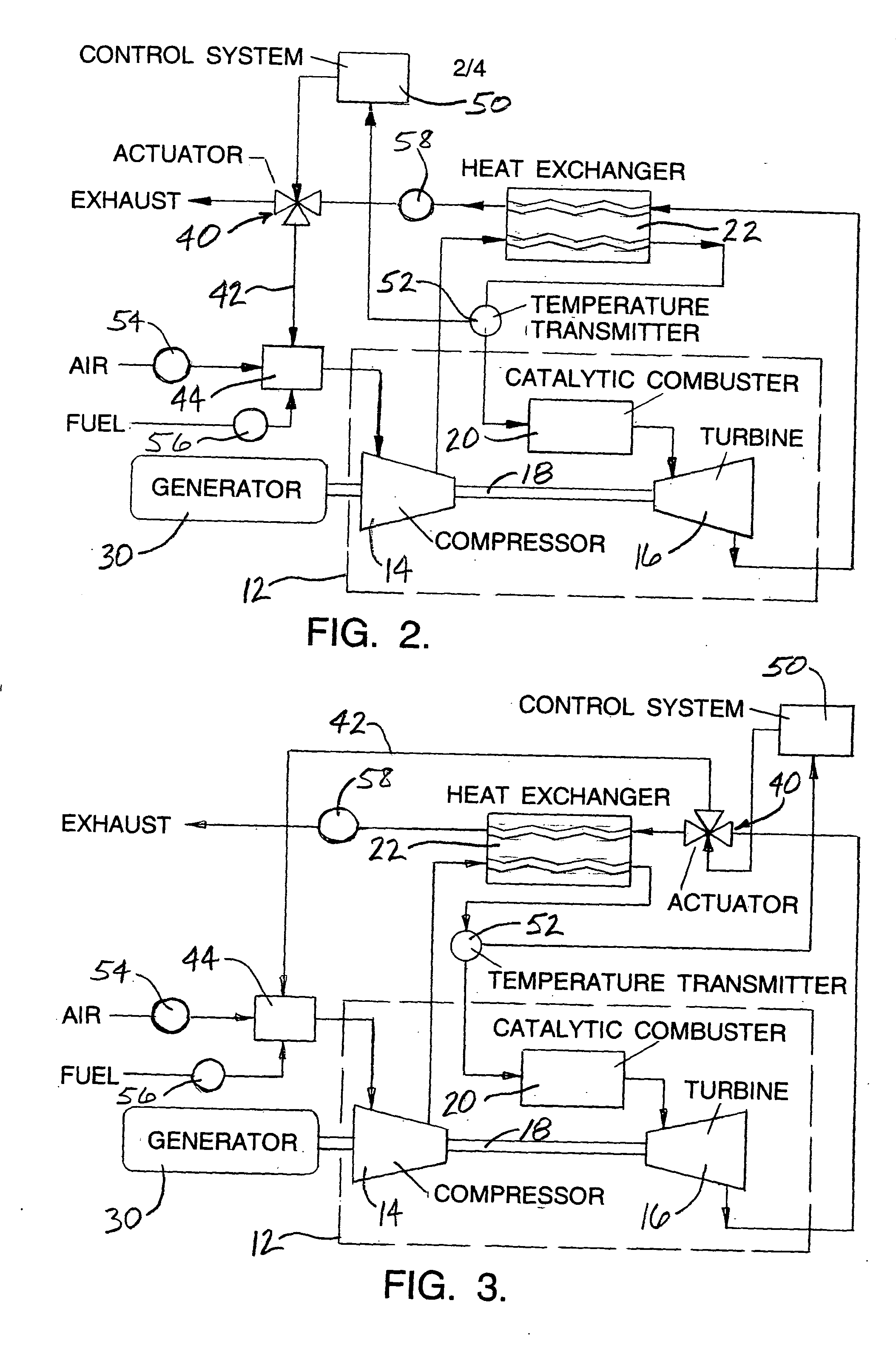

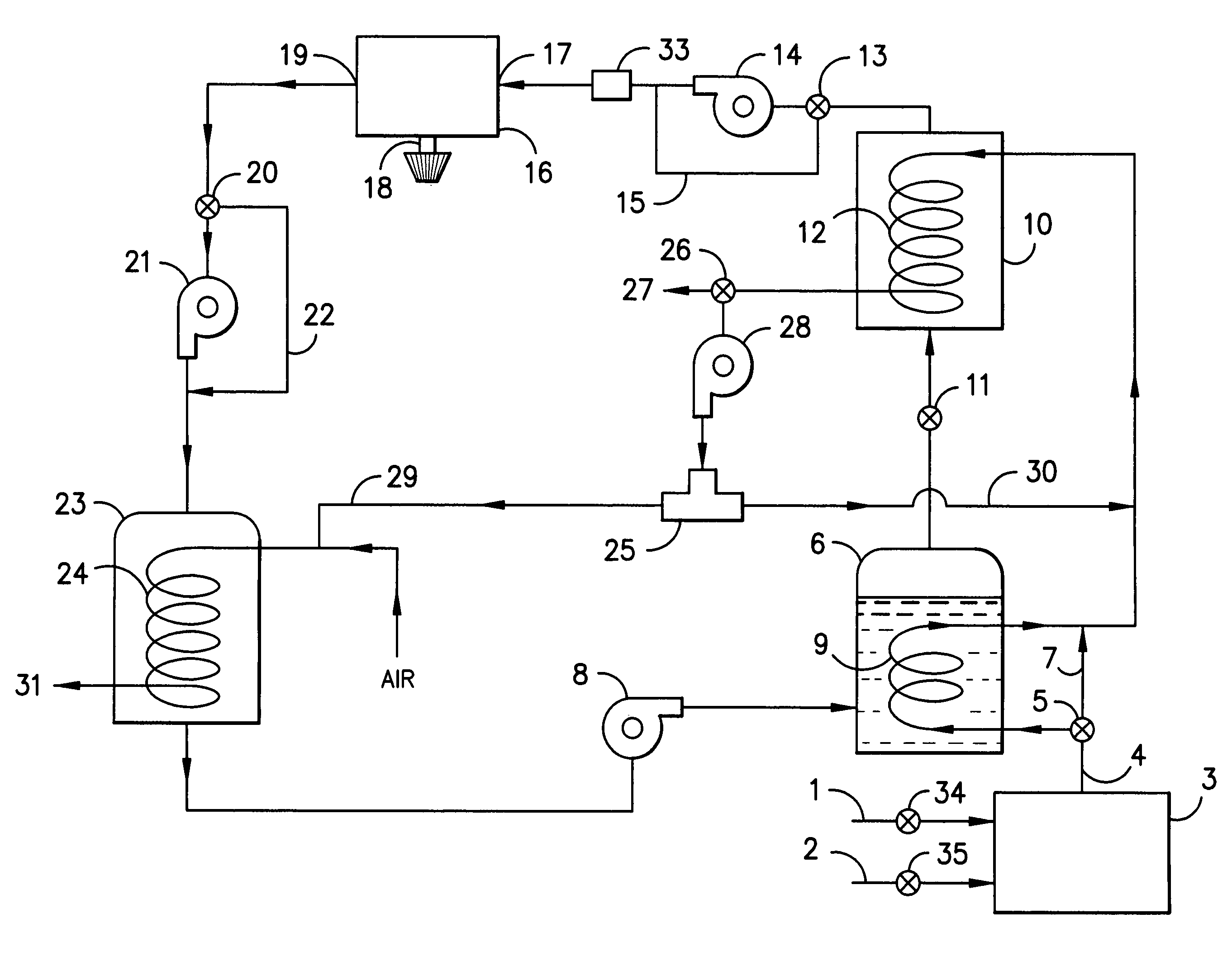

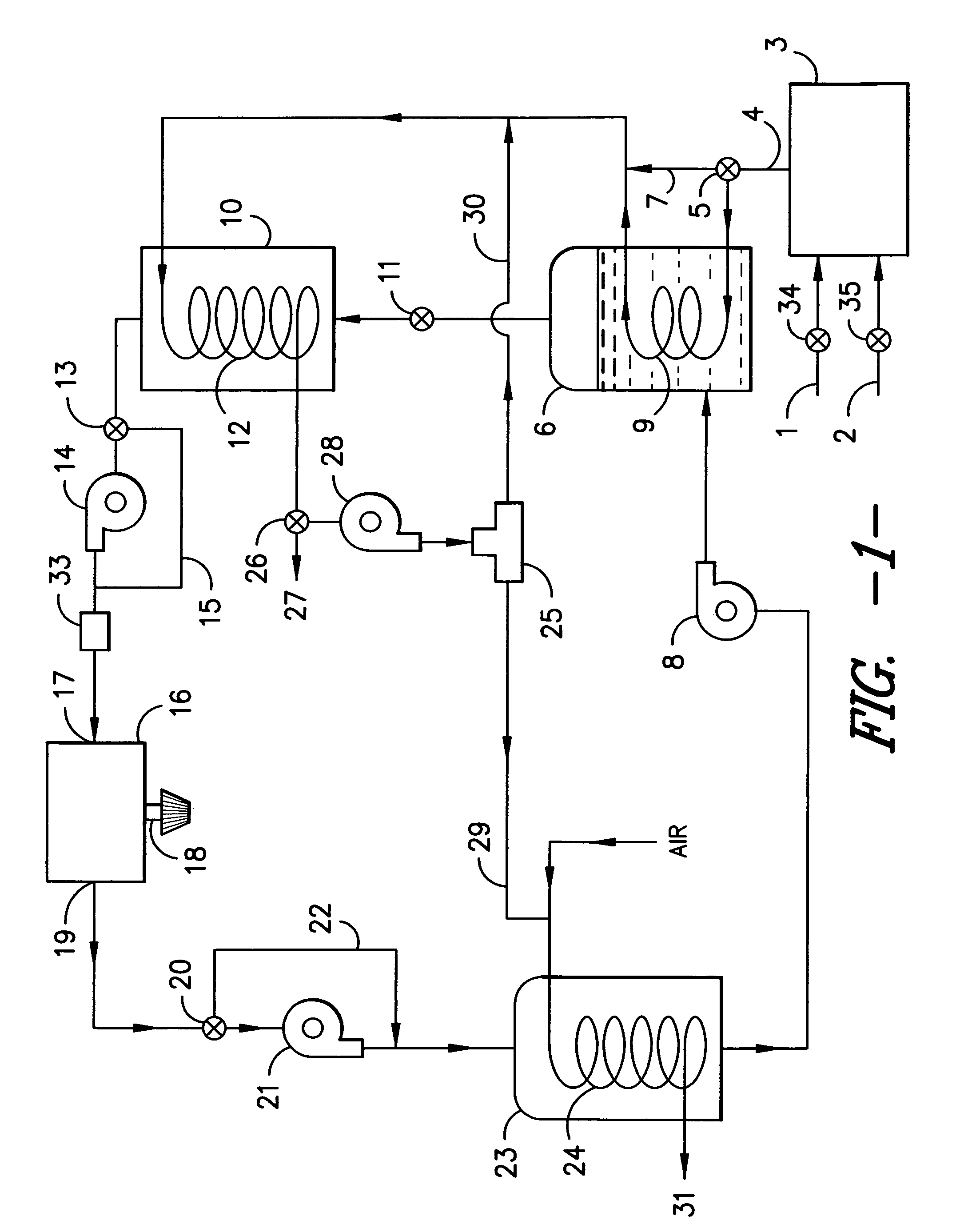

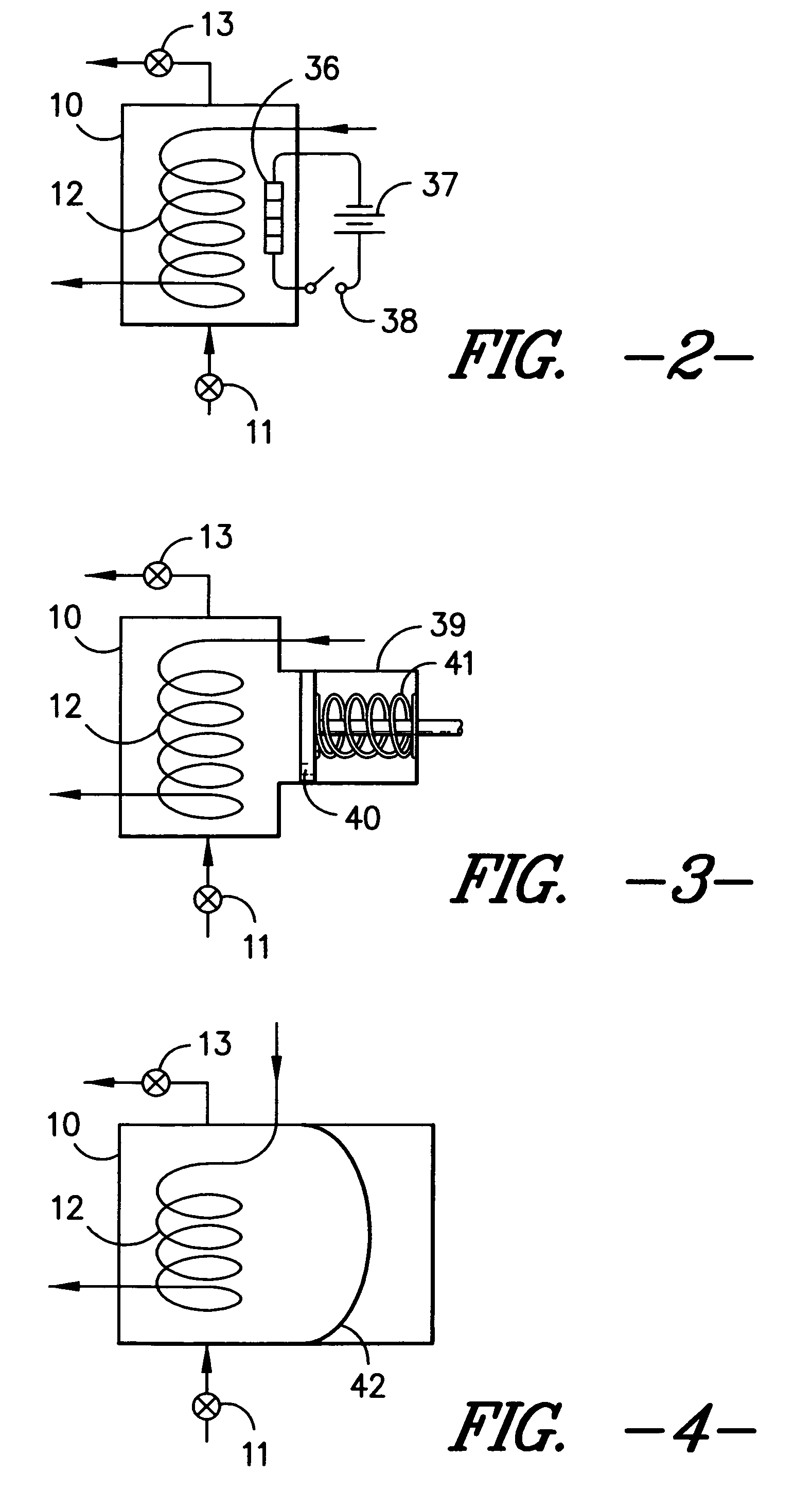

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

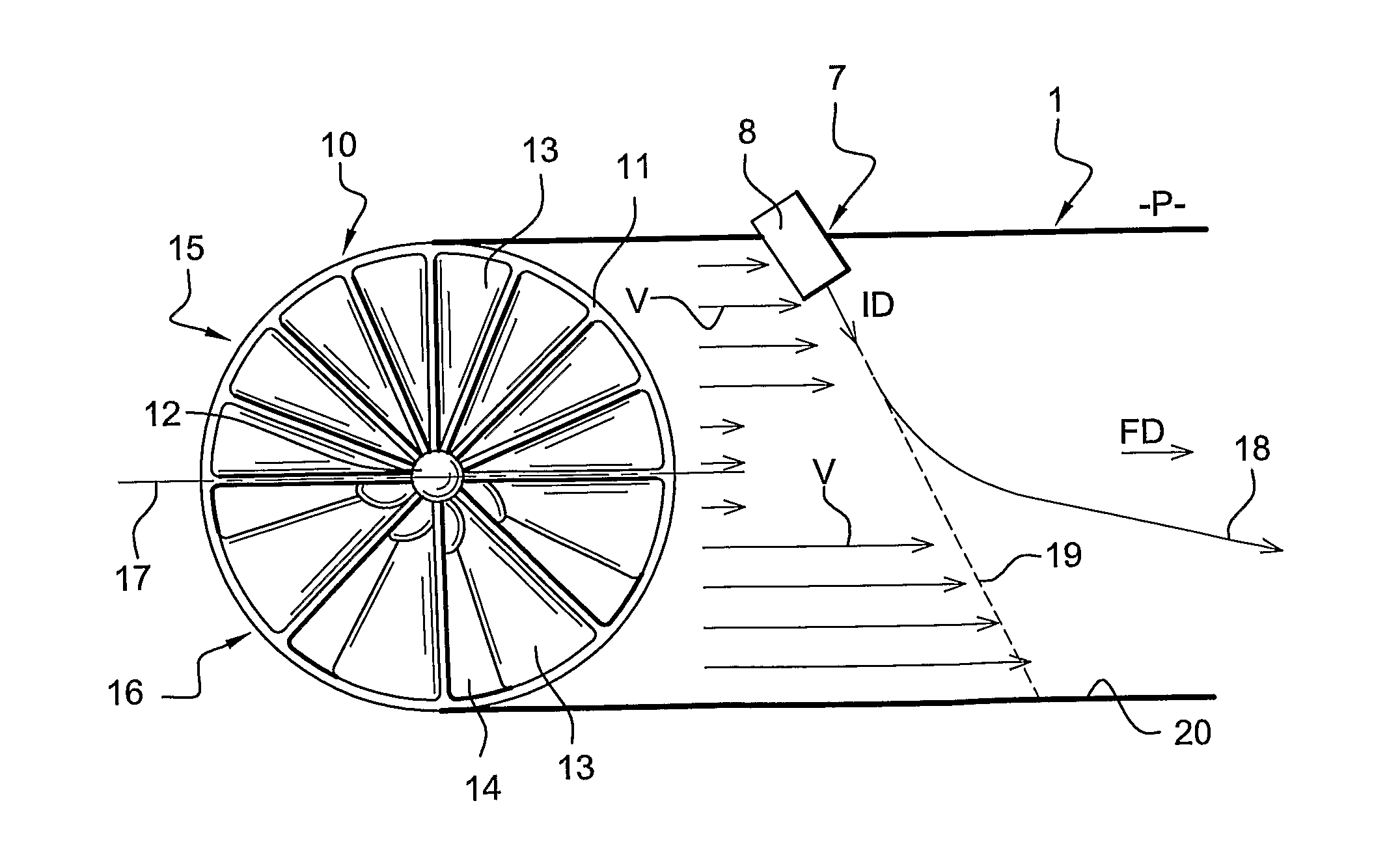

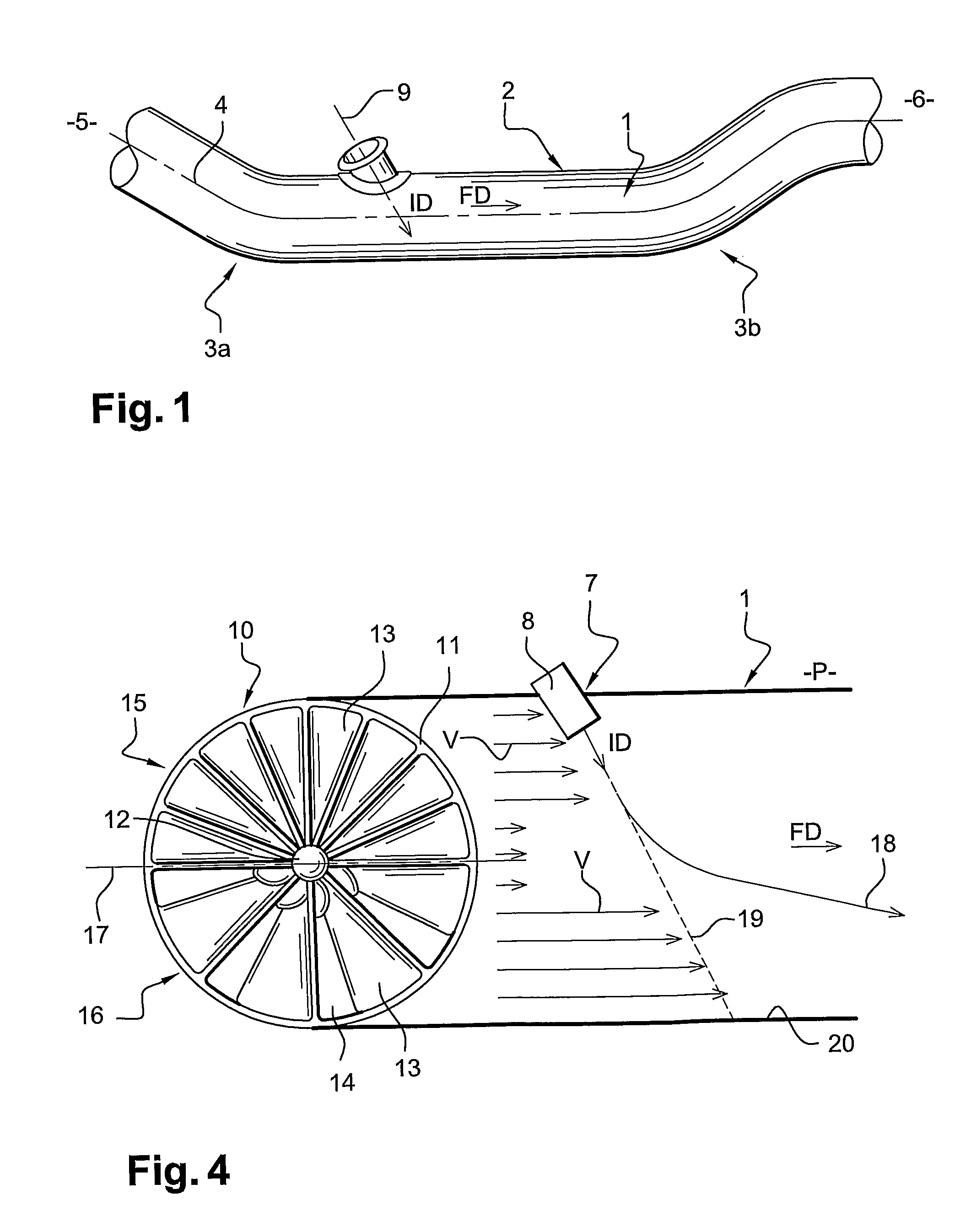

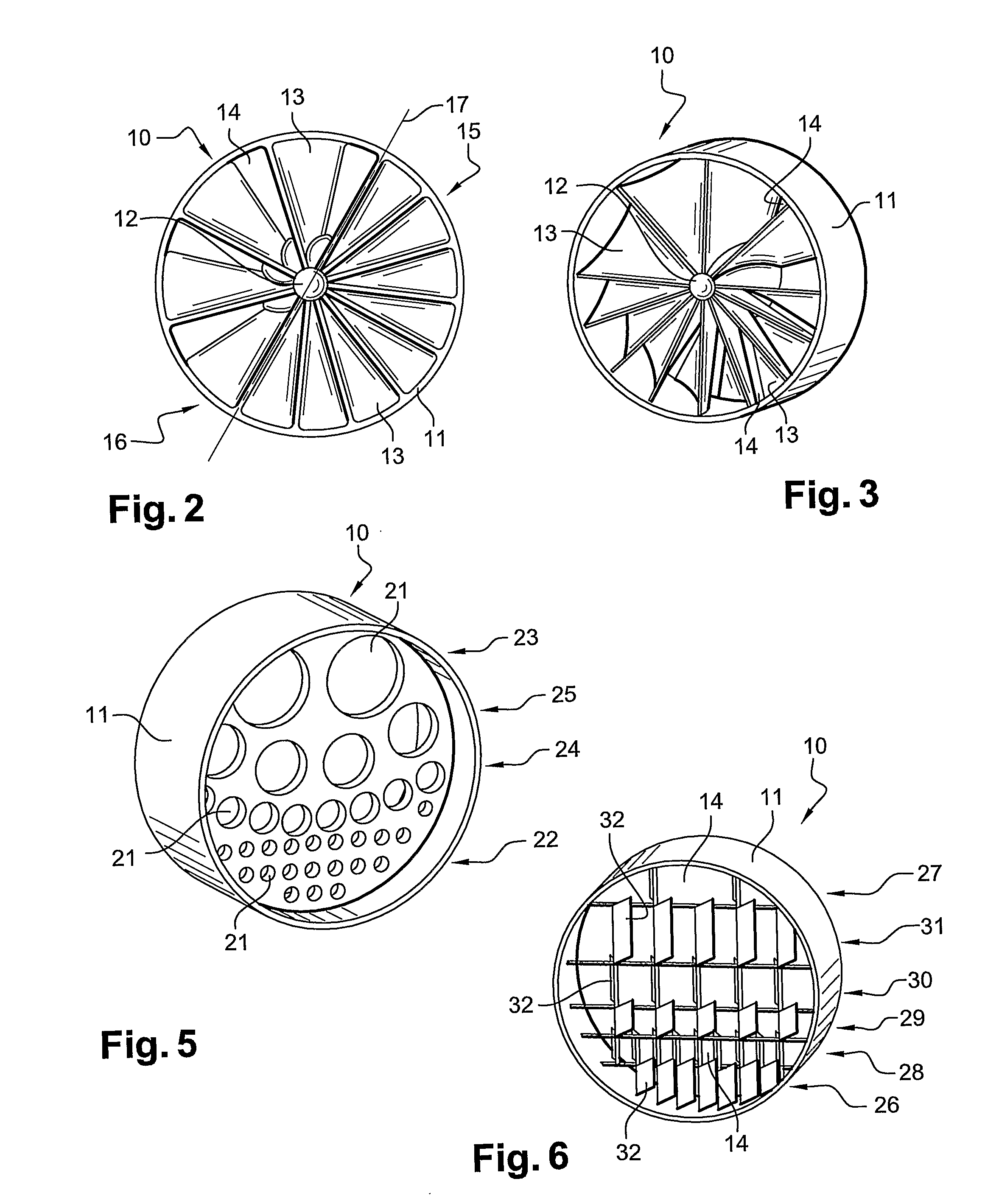

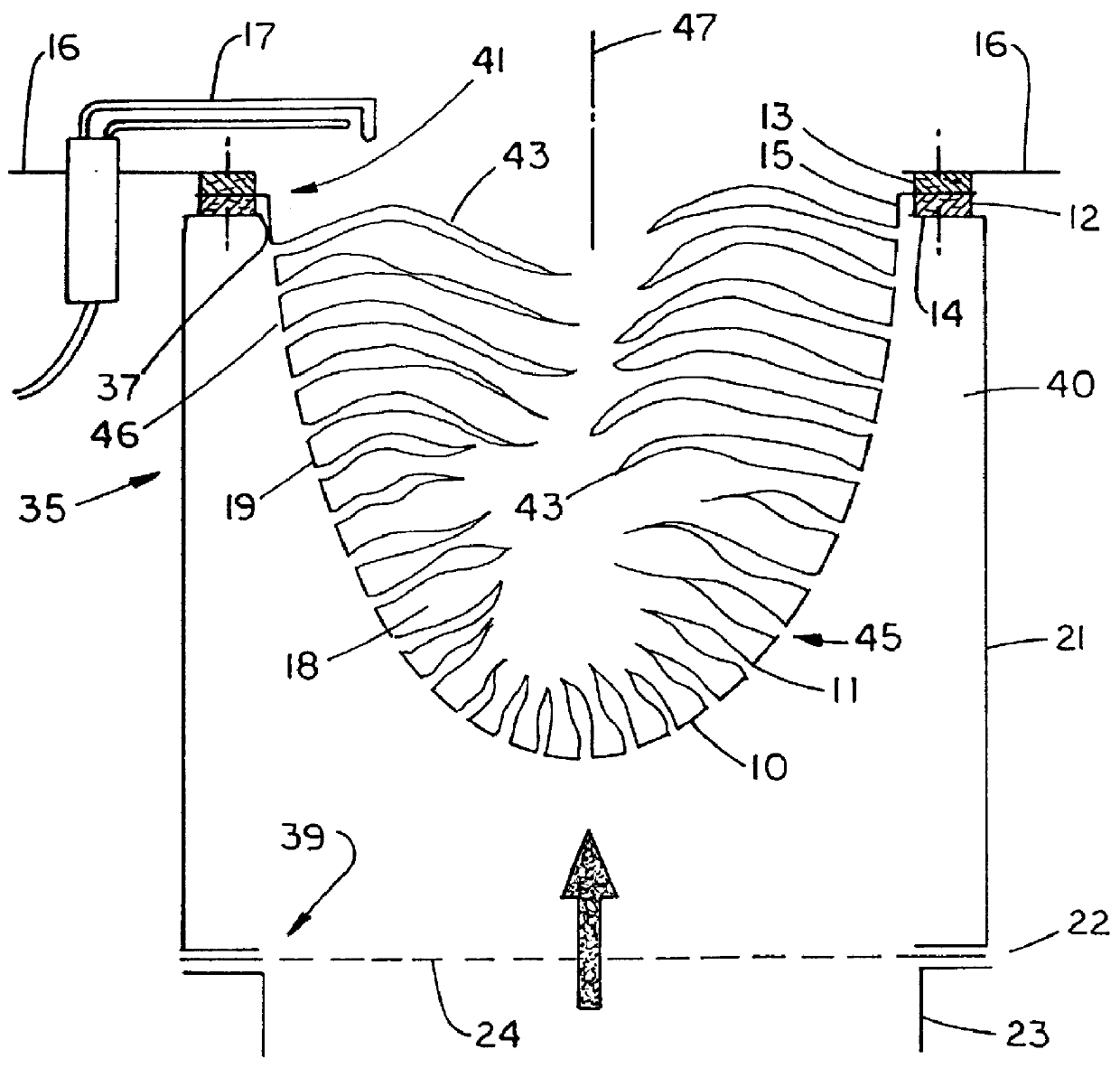

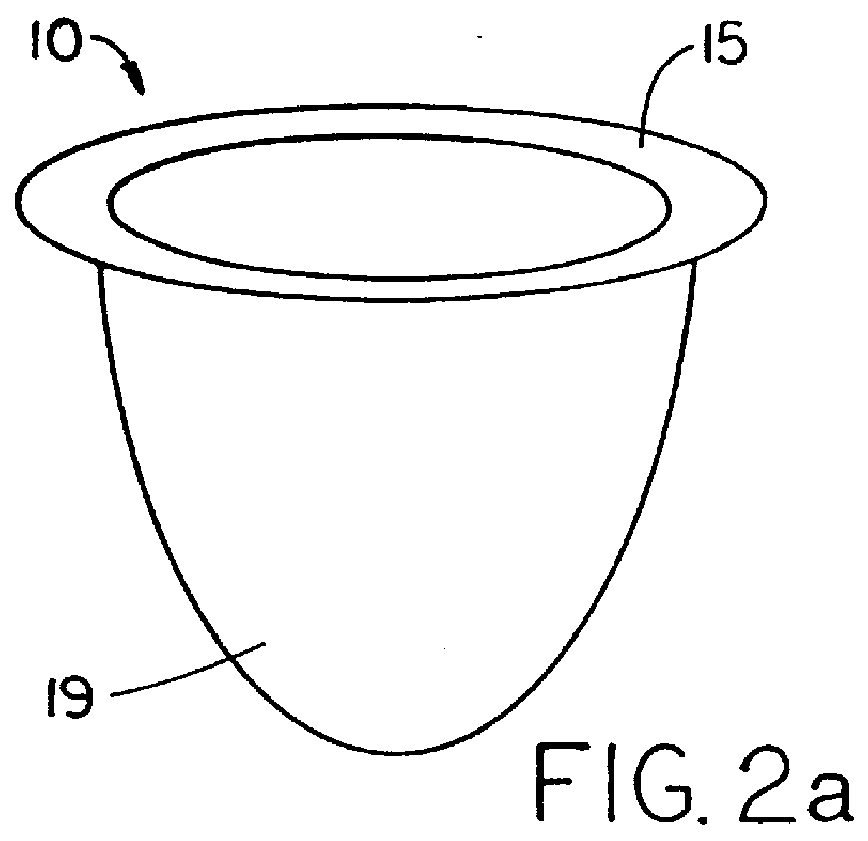

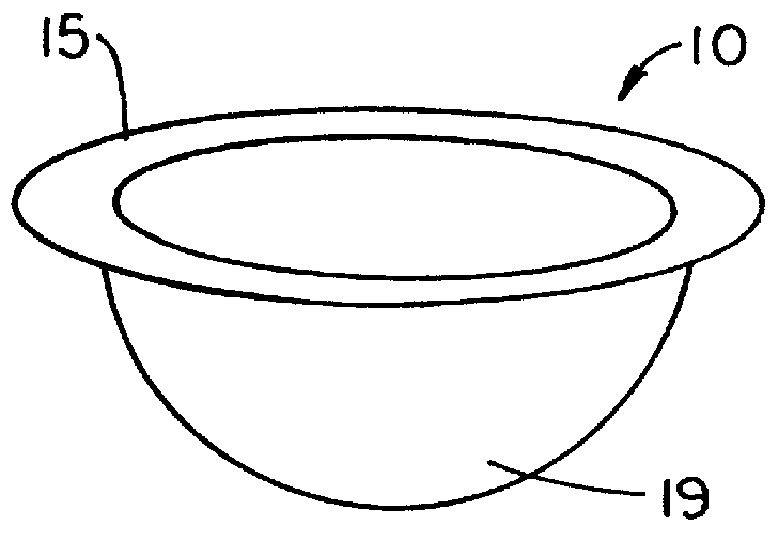

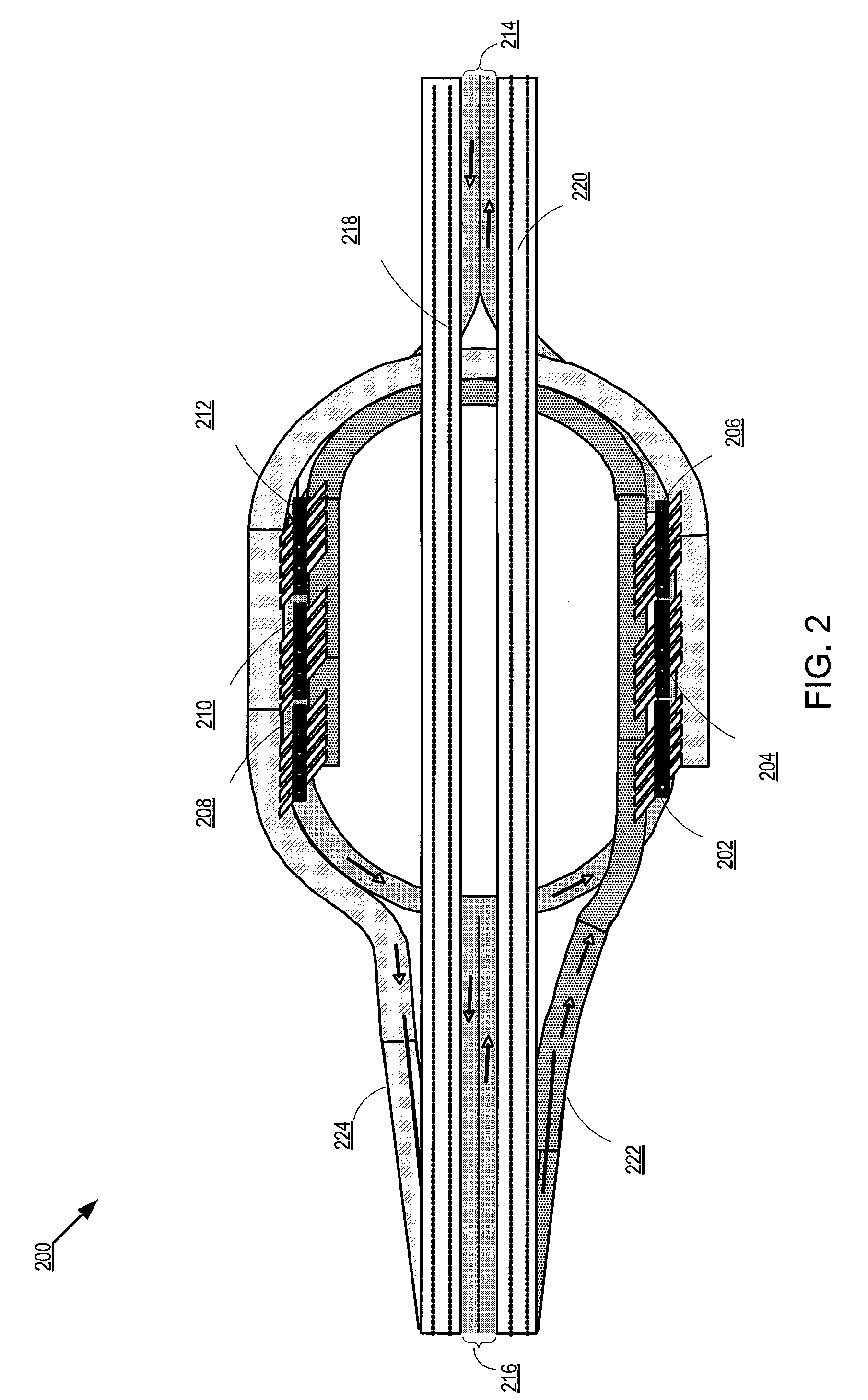

Mixing device in an exhaust gas pipe

ActiveUS20110162353A1Flow fastBetter mixing of fluidGas treatmentInternal combustion piston enginesExhaust fumesEngineering

In an exhaust gas pipe, a first fluid flows in a flow direction in the pipe, and a second fluid is injected inside the pipe by a nozzle, from an injection inlet arranged in the pipe wall, according to an injection direction. A mixing device fastened inside the pipe upstream from the injection inlet creates turbulence that helps the mixing of the fluids. The mixing device has a first portion located on the injection inlet side of the pipe and a second portion located opposite the injection inlet side of the pipe, the portions being designed so that the fluid velocity is higher downstream from the mixing device second portion than downstream from the mixing device first portion. An aqueous solution of urea can be injected inside an exhaust pipe of a diesel engine.

Owner:VOLVO LASTVAGNAR AB

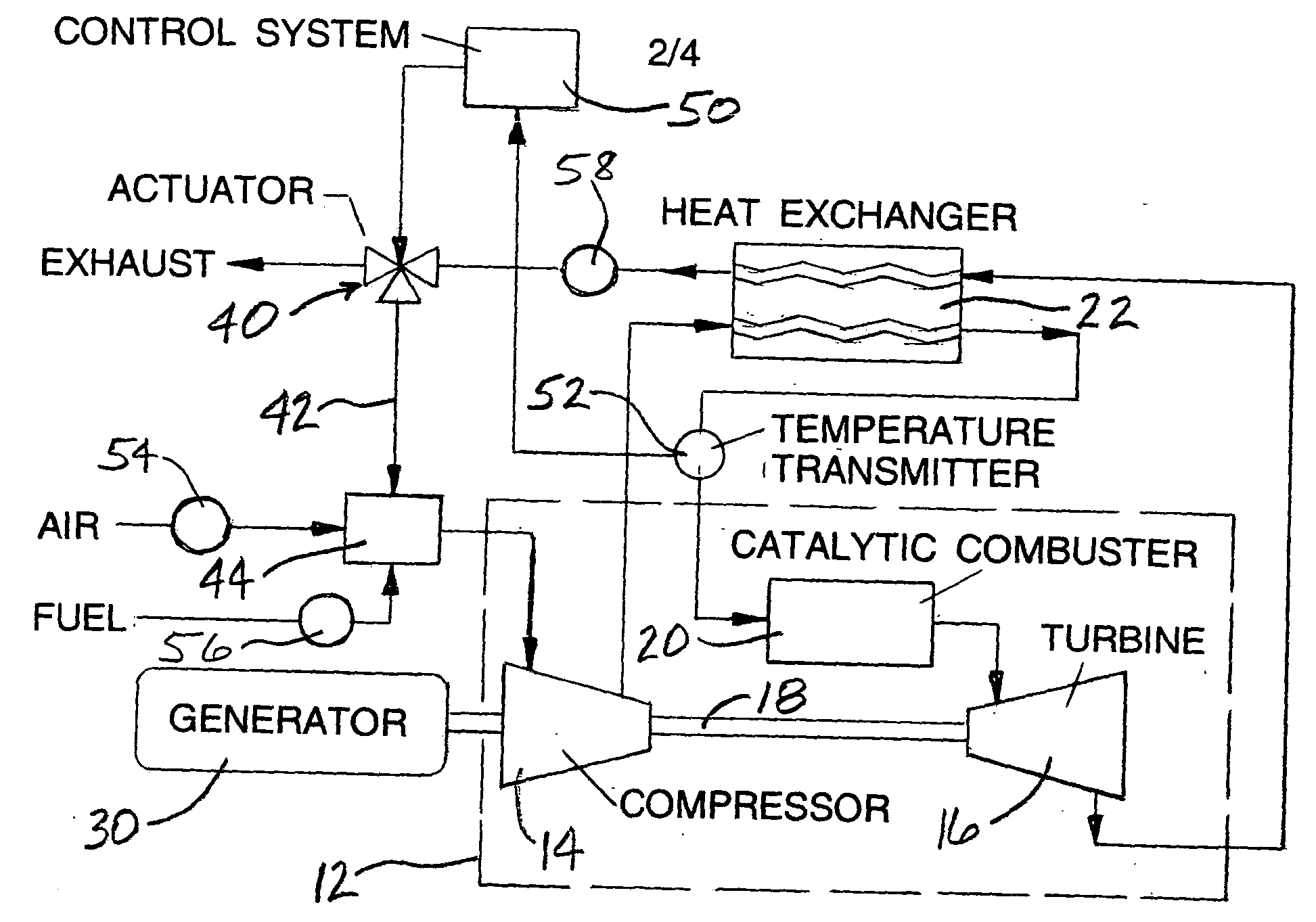

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS20050022499A1Increase flow rateReduce the temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

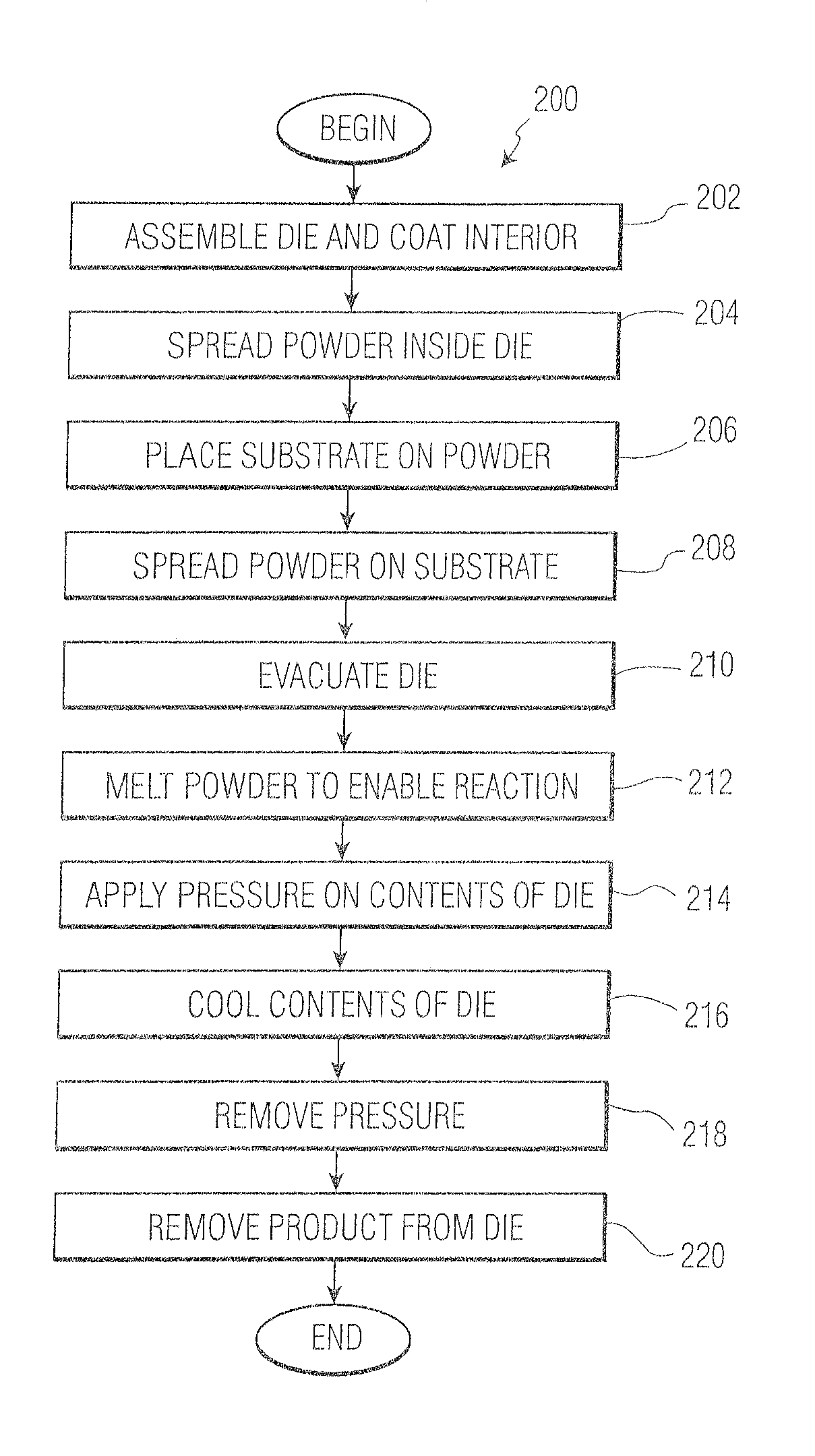

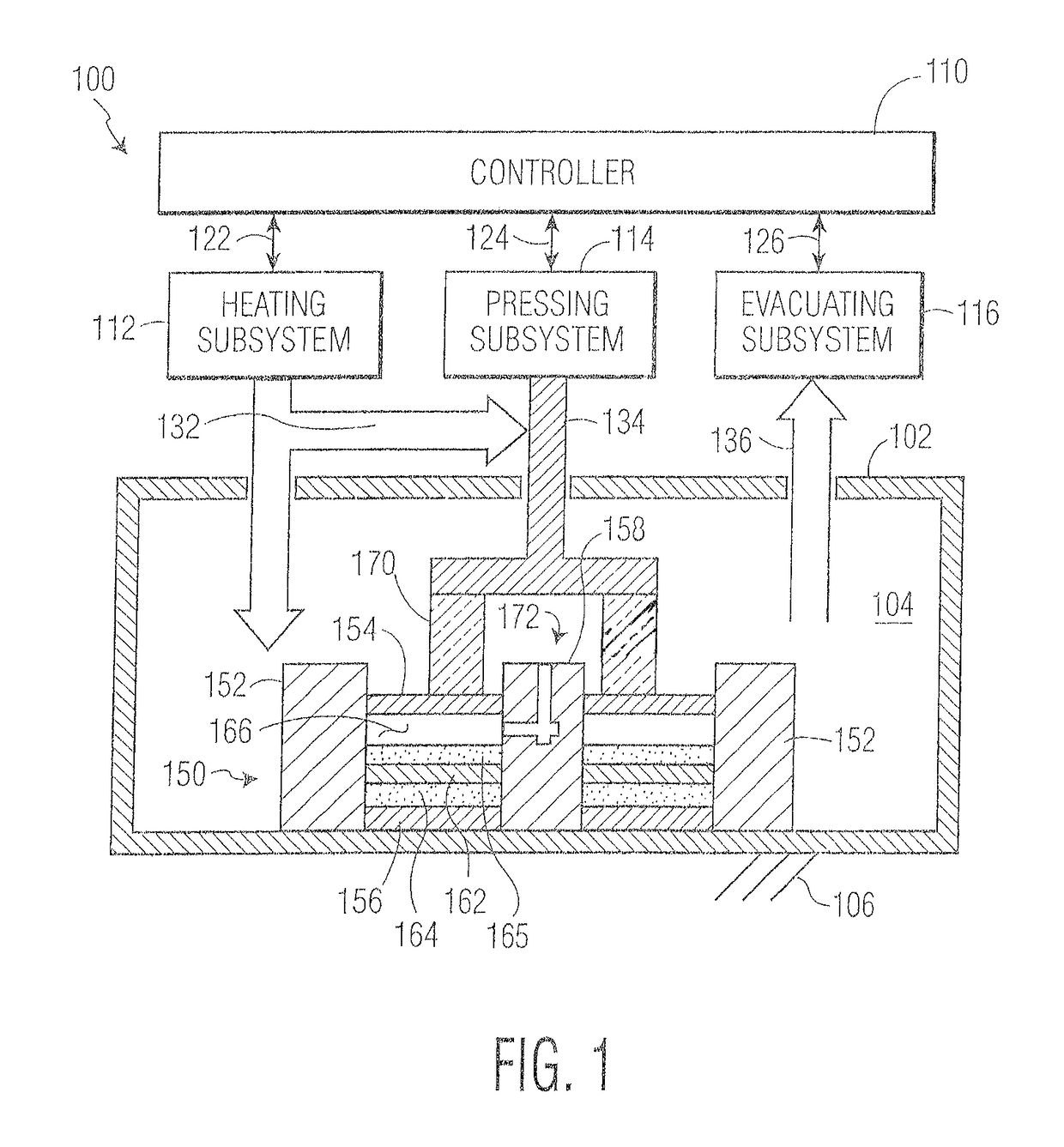

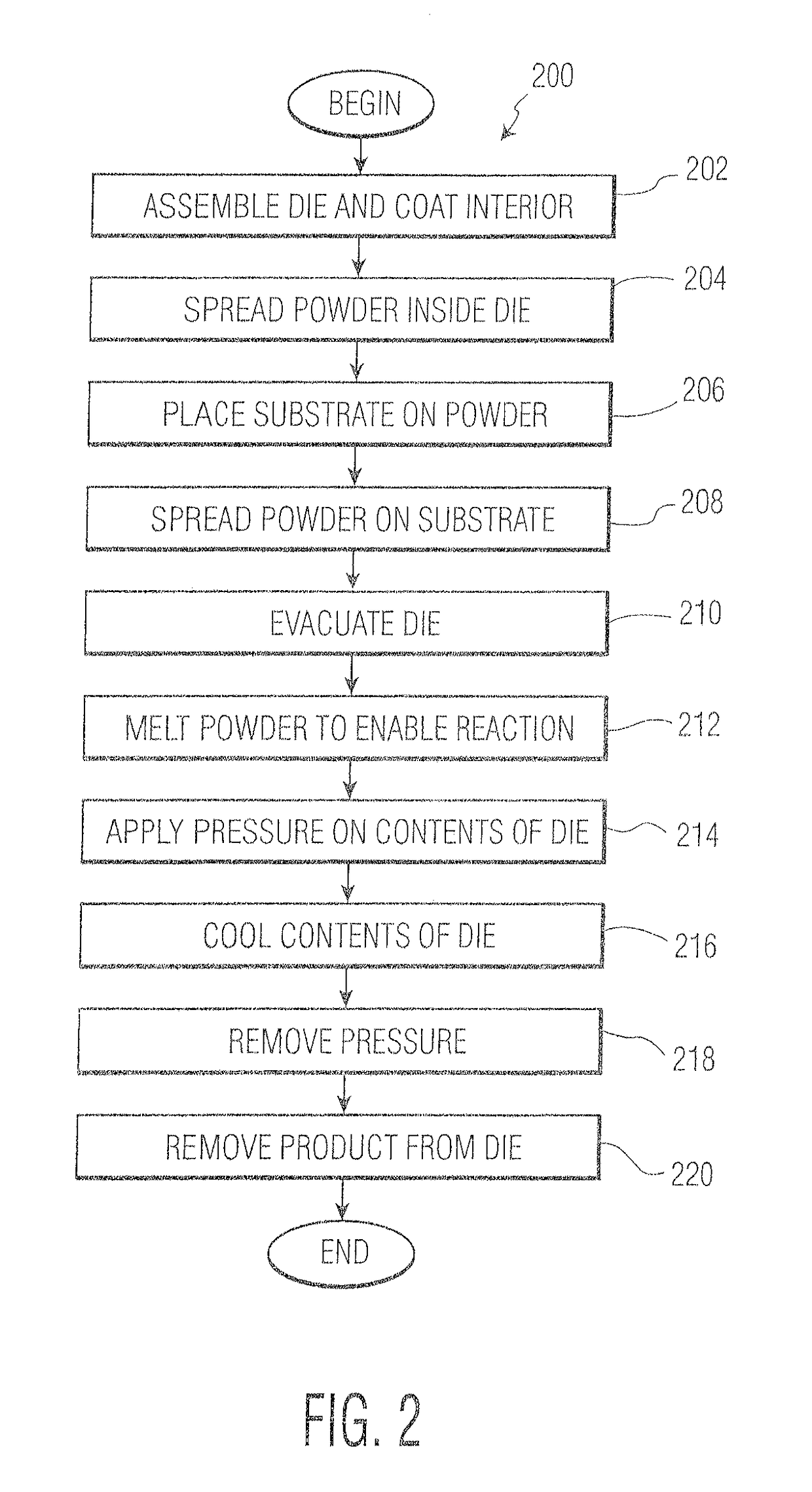

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

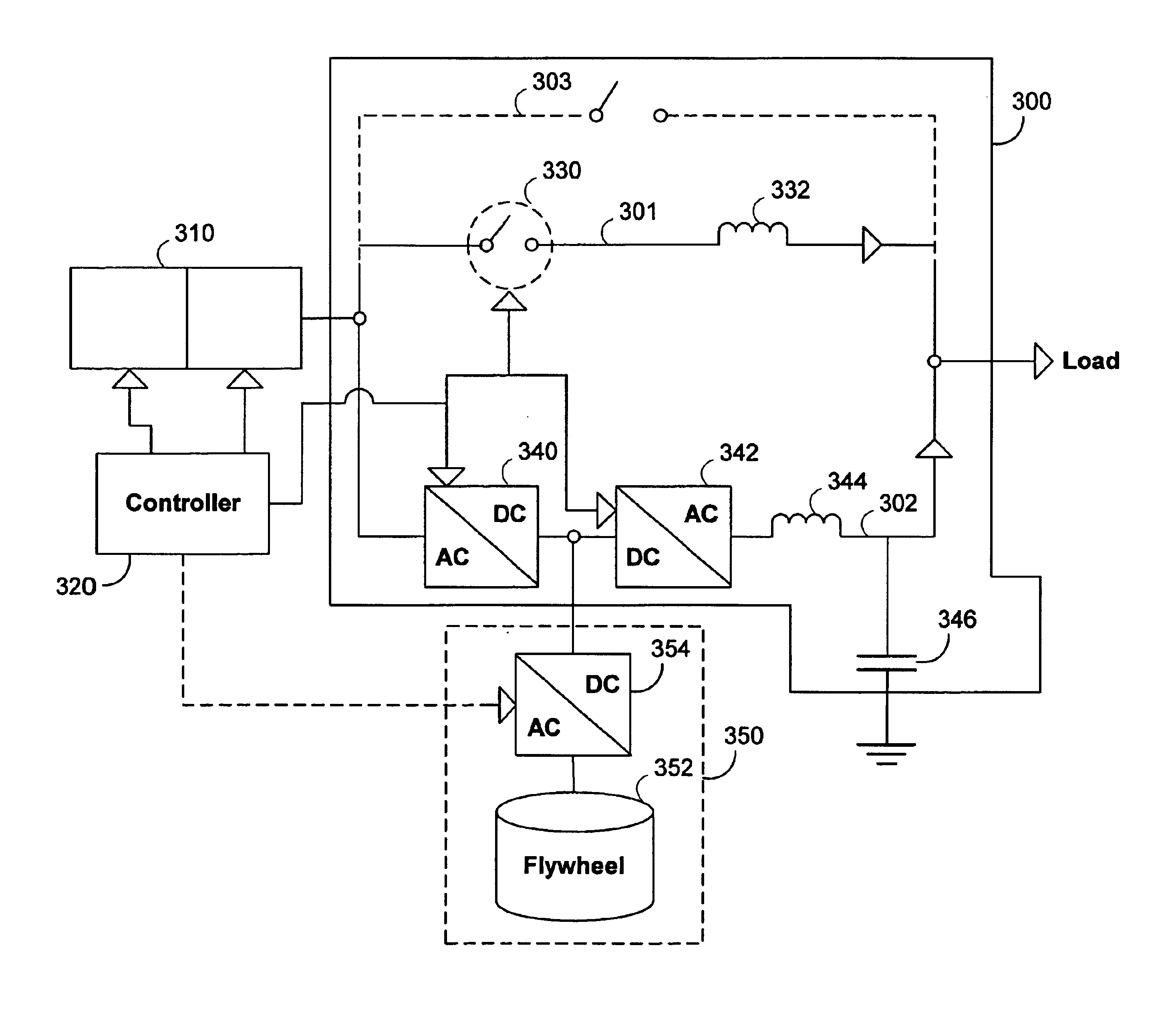

Multiple path variable speed constant frequency device having automatic power path selection capability

InactiveUS6844706B2Maximize engine efficiencySave fuelBatteries circuit arrangementsEmergency protective circuit arrangementsConstant frequencyInductor

The present invention relates to variable speed constant frequency (VSCF) devices and methods for maximizing engine generator efficiency. In one embodiment, a VSCF device may include at least two paths for conducting power to the load. One path, a line inductor path, may advantageously incur minimal power loss when the engine generator is supplying rated power to a load. A second path, a VSCF path, may be used to ensure that the frequency of the power is maintained at a substantially constant frequency under various load conditions. Another embodiment of the invention describes a process for determining optimal engine generator speed for a particular load. Because engine speed can be varied using any VSCF device, this process determines a speed that minimizes fuel consumption, emissions, and noise pollution for a given load.

Owner:PILLER USA INC

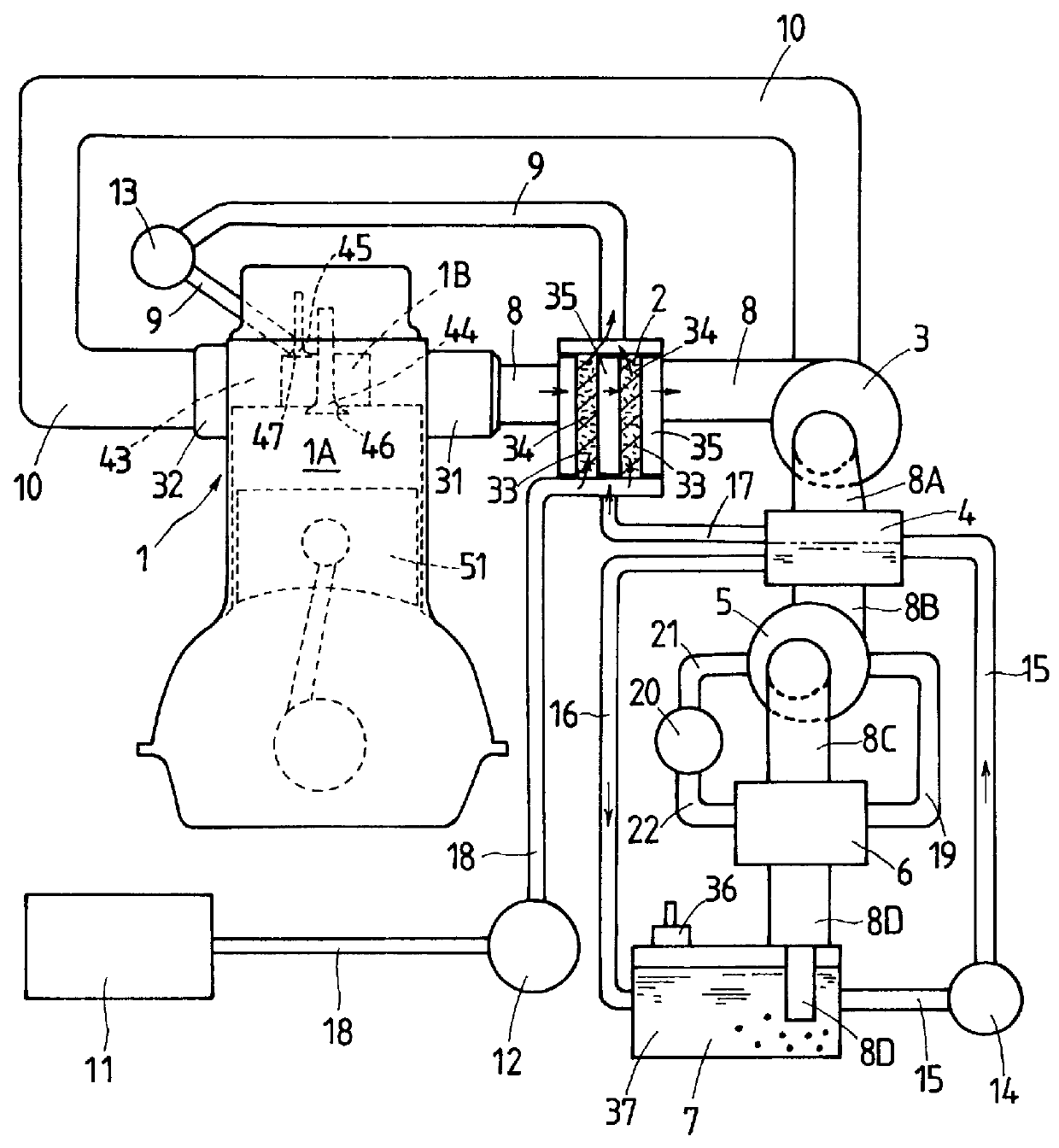

Gas engine with a gas fuel reforming device

InactiveUS6079373AReduce air pollutionMinimize formationInternal combustion piston enginesExhaust apparatusThermal energyCO2 content

The gas engine with a gas fuel reforming device thermally decomposes CH4, a major component of natural gas, into a reformed fuel of CO and H2 to increase the heat produced and thereby reduce the CO2 content in the exhaust gas and prevent the formation of NOx. The gas engine mixes CH4 with CO2 and sends the gas mixture to the catalyst reactor installed in the exhaust passage where the gas mixture is thermally decomposed into a reformed fuel by using the thermal energy of the exhaust gas. CO2 is extracted from the exhaust gas by the CO2 supply device which in turn sends the CO2 to the catalyst reactor. The CO2 supply device comprises a CO2 dissolving device that accommodates a solution to dissolve CO2 of low-temperature exhaust gas and a CO2 delivery device installed in the exhaust passage through which high-temperature exhaust gas flows and adapted to release CO2 from the solution supplied from the CO2 dissolving device. The CO2 supply device can be formed of a CO2 separation membrane that separates CO2 from the exhaust gas.

Owner:ISUZU MOTORS LTD

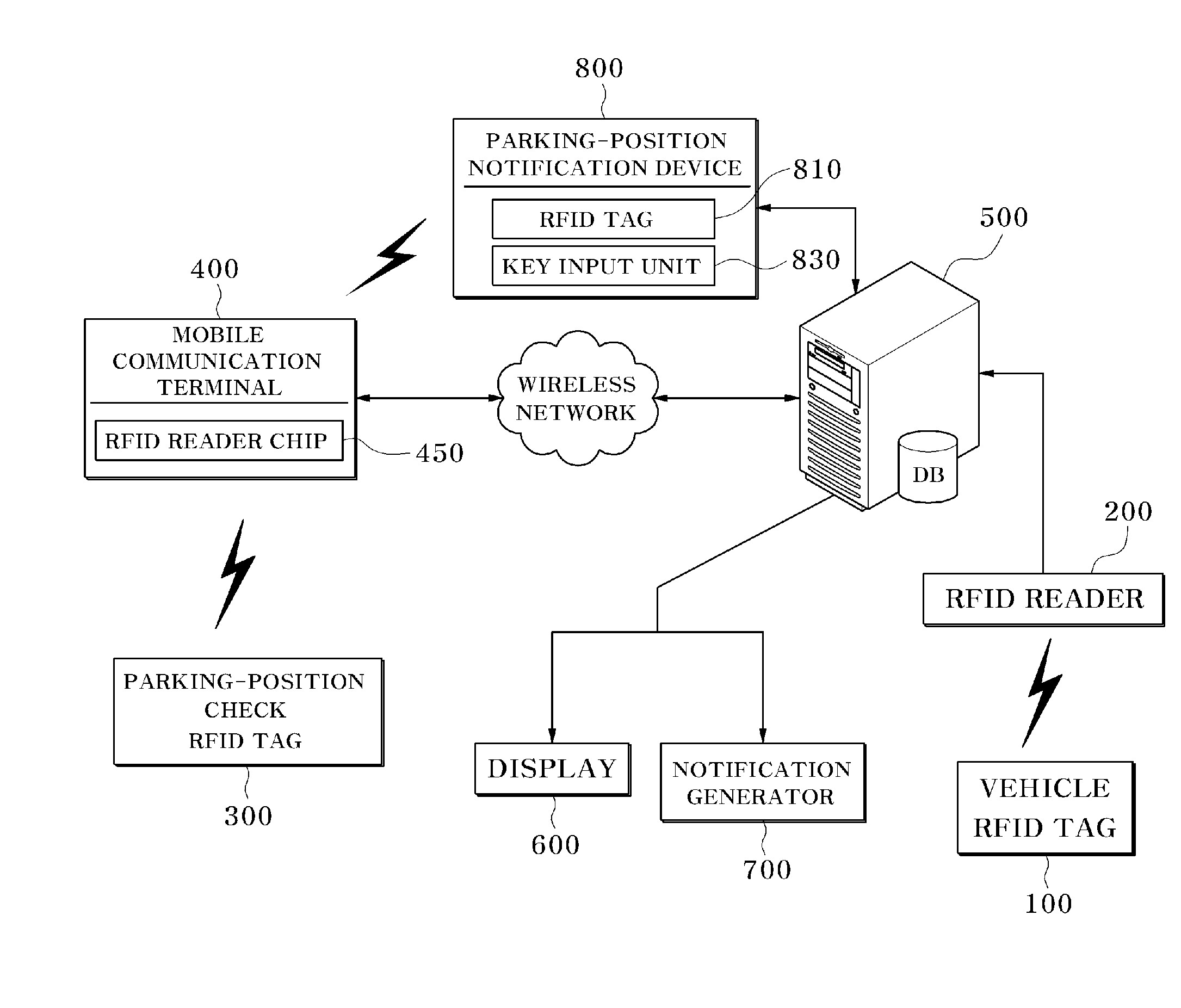

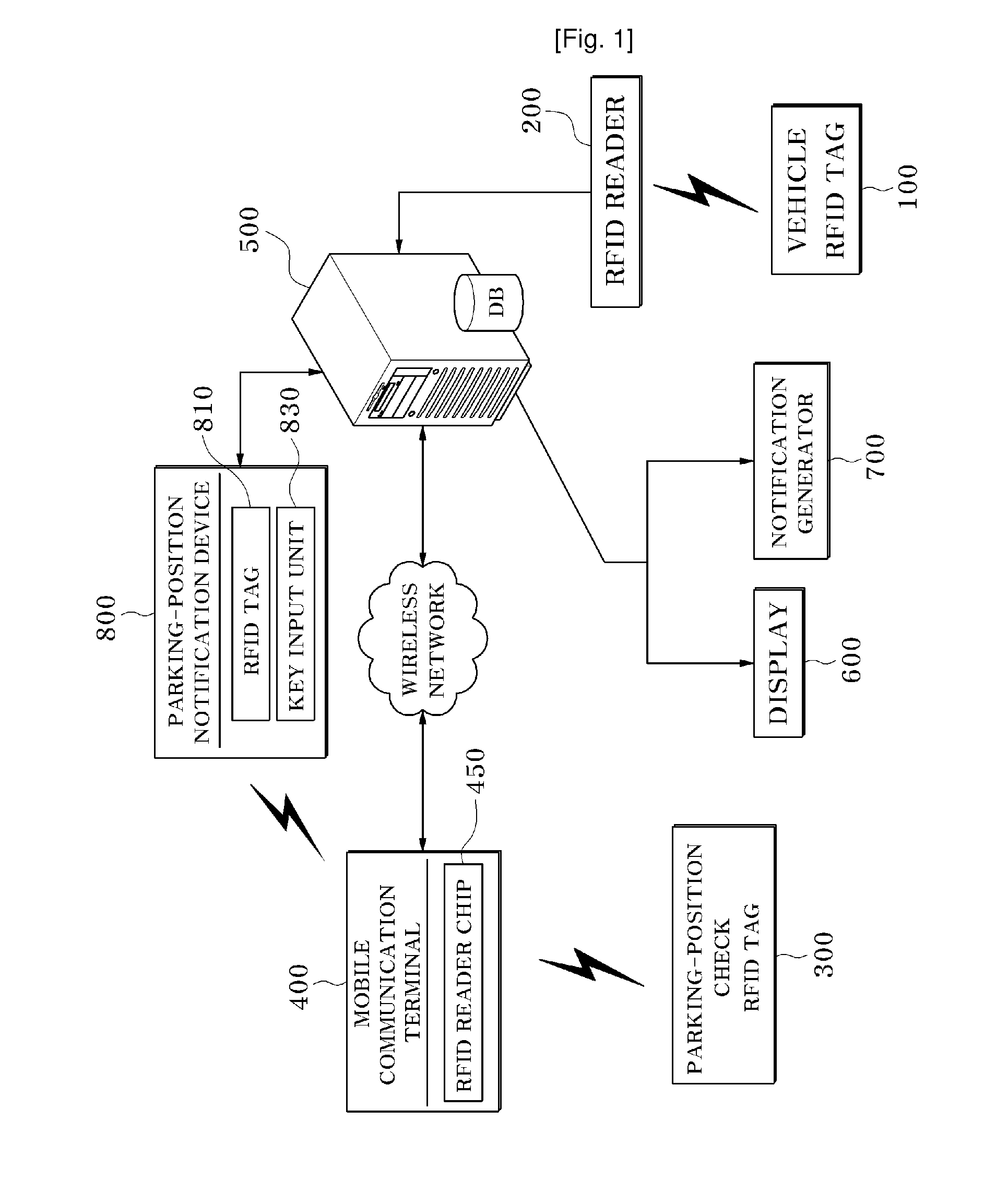

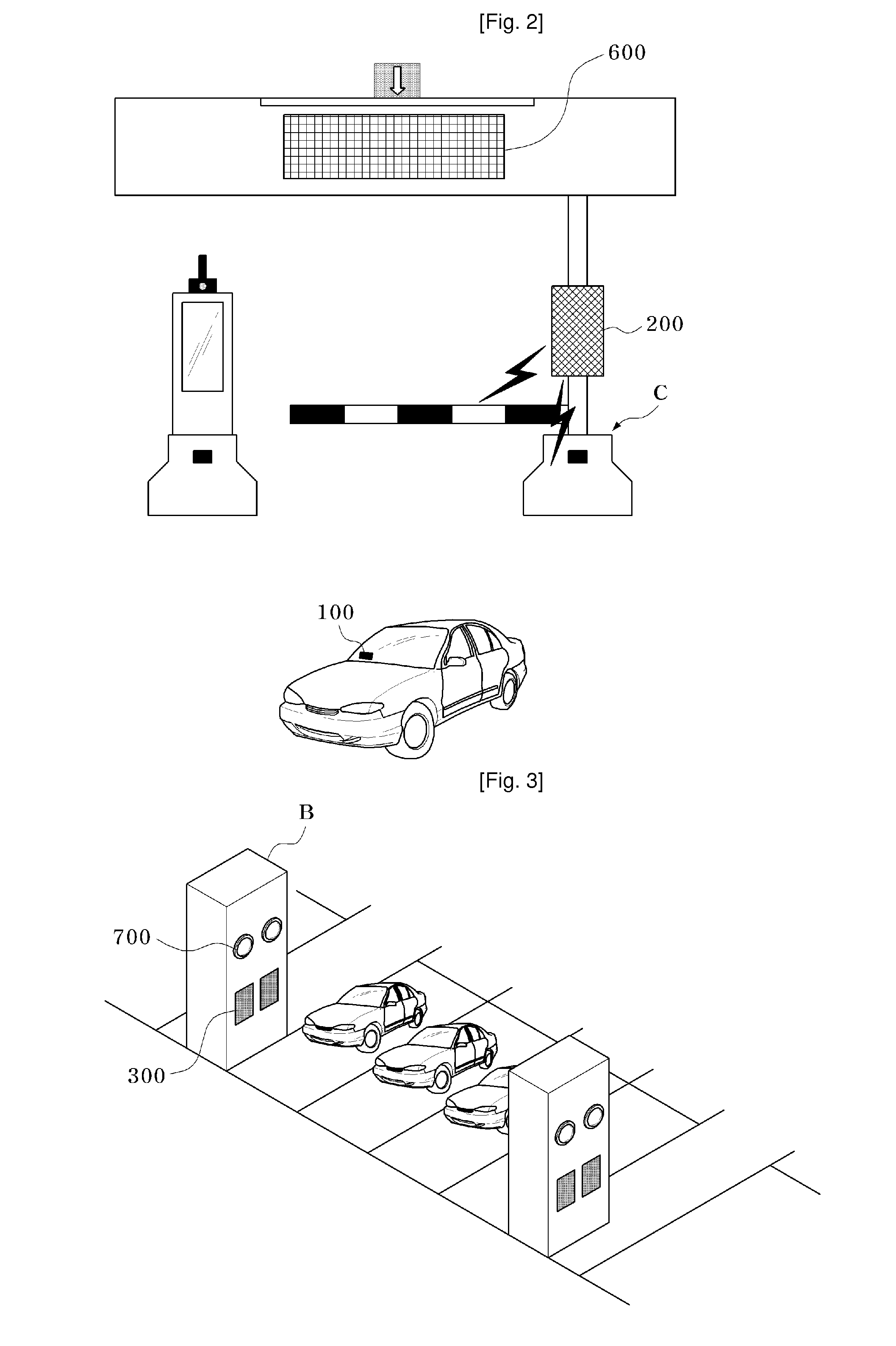

Parking Place Confirmation System and Method Thereof

ActiveUS20100085214A1Easy to knowShorten the timeDetection of traffic movementIndication of parksing free spacesParking areaParking space

Disclosed is a system and method for checking a parking position that enables a parking lot user to conveniently check a position of a vehicle that he / she has parked using his / her mobile communication terminal. When a customer with a mobile communication terminal having a built-in Radio Frequency IDentification (RFID) reader chip moves his / her vehicle close to an RFID tag for checking a parking position installed at a parking stall, the position information regarding the parking stall stored in the RFID tag is transmitted to a parking management server, and the parking management server transmits it again to the mobile communication terminal in text or graphic format.

Owner:SAMSUNG SDS CO LTD

Organic biomass fractionation process

InactiveUS20030041982A1Economical and efficientLow costPretreatment with acid reacting compoundsWaste based fuelFractionationNitration

A method for fractionating fibrous biomass comprising cellulose, hemicellulose and lignin components to separate said lignin, cellulose and hemicellulose from one another comprises: (a) shredding said fibrous biomass; (b) concurrently with or subsequent to said shredding, contacting said biomass with an aqueous solution of a nitrate ion source at a concentration of about 0.1-0.3% at a temperature in the range of about 60° to about 80° C. to initiate nitration of the lignin component of said biomass; (c) submerging said partially nitrated biomass in an aqueous solution of a nitrate ion source in the presence of an aluminum compound at a temperature within the range of about 75-100° C. for a time sufficient to complete the nitration of said lignin component; (d) contacting the nitrated biomass produced in step (c) with an alkaline extraction liquor comprising NH4OH at an initial concentration sufficient to solubilize said nitrated lignin component and said hemicellulose component from said cellulose component of said biomass; e) recovering said cellulose from said extraction liquor containing said solubilized nitrated lignin and hemicellulose components, wherein said cellulose comprises at least about 88% alpha cellulose; (f) treating said extraction liquor with an acid to precipitate lignin contained therein, and (g) separating said lignin from soluble hemicellulose in said extraction liquor. The recovered cellulose component comprises at least 88% alpha cellulose and is useful as a starting material for the production of ethanol.

Owner:PRIOR ERIC S

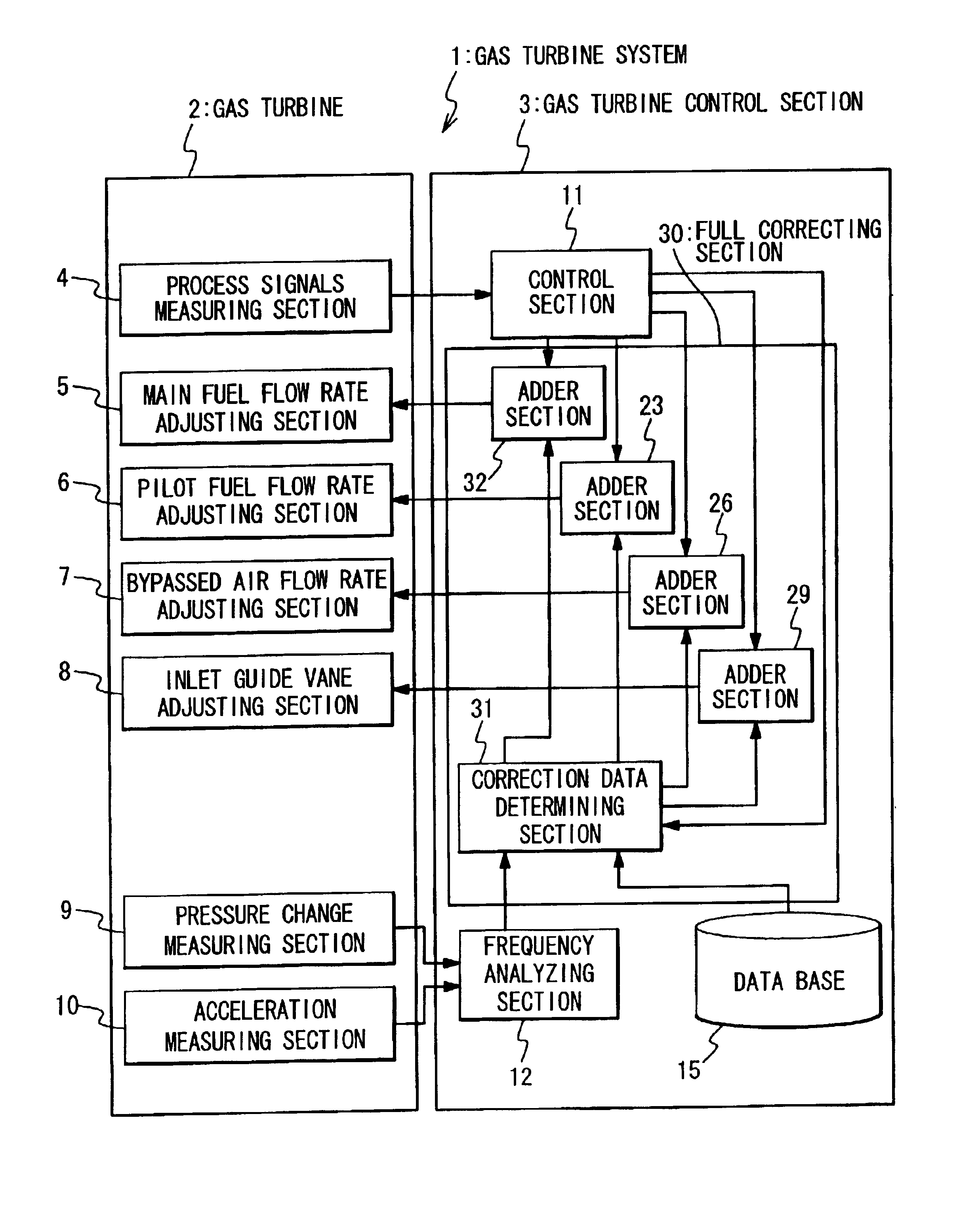

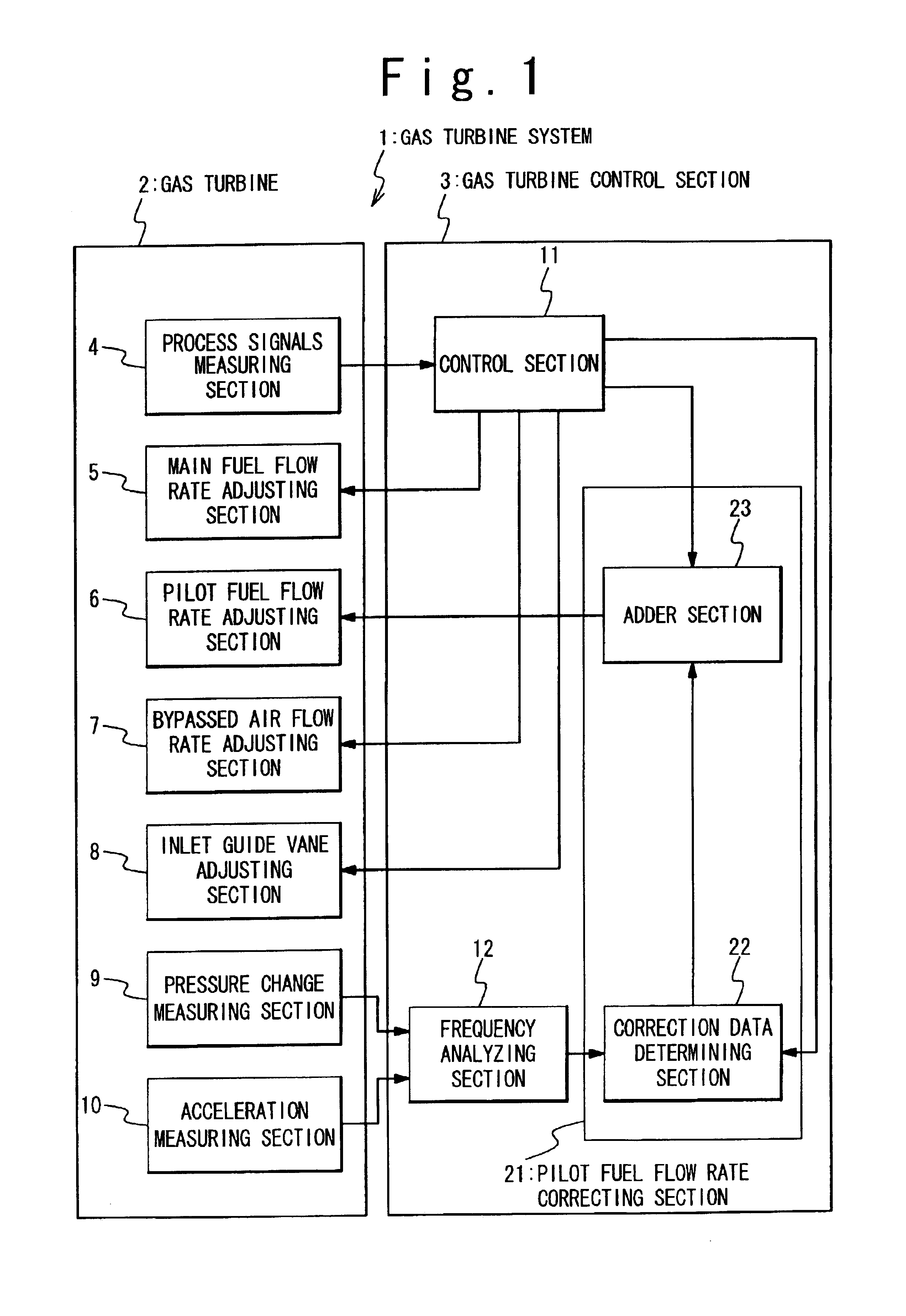

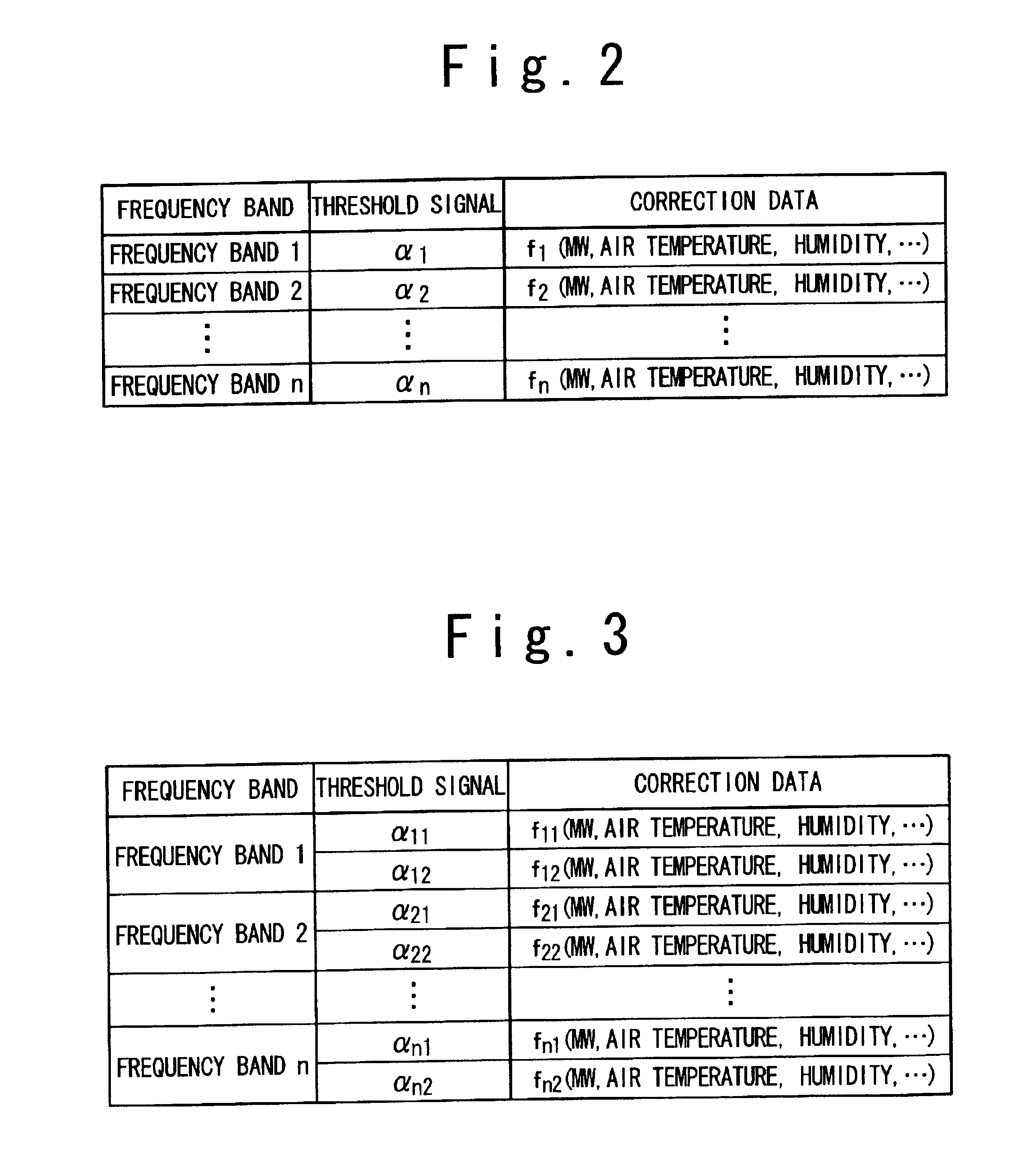

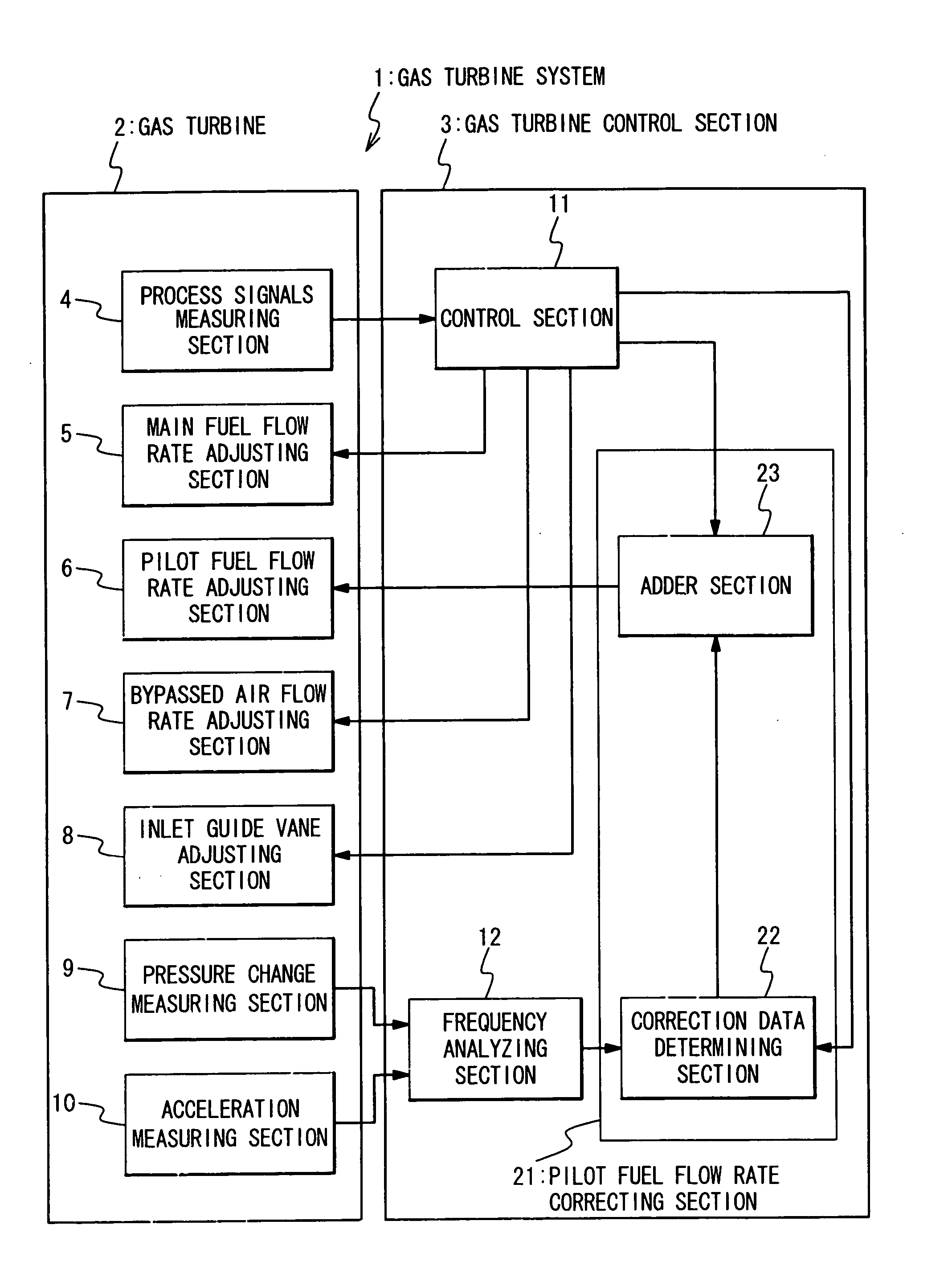

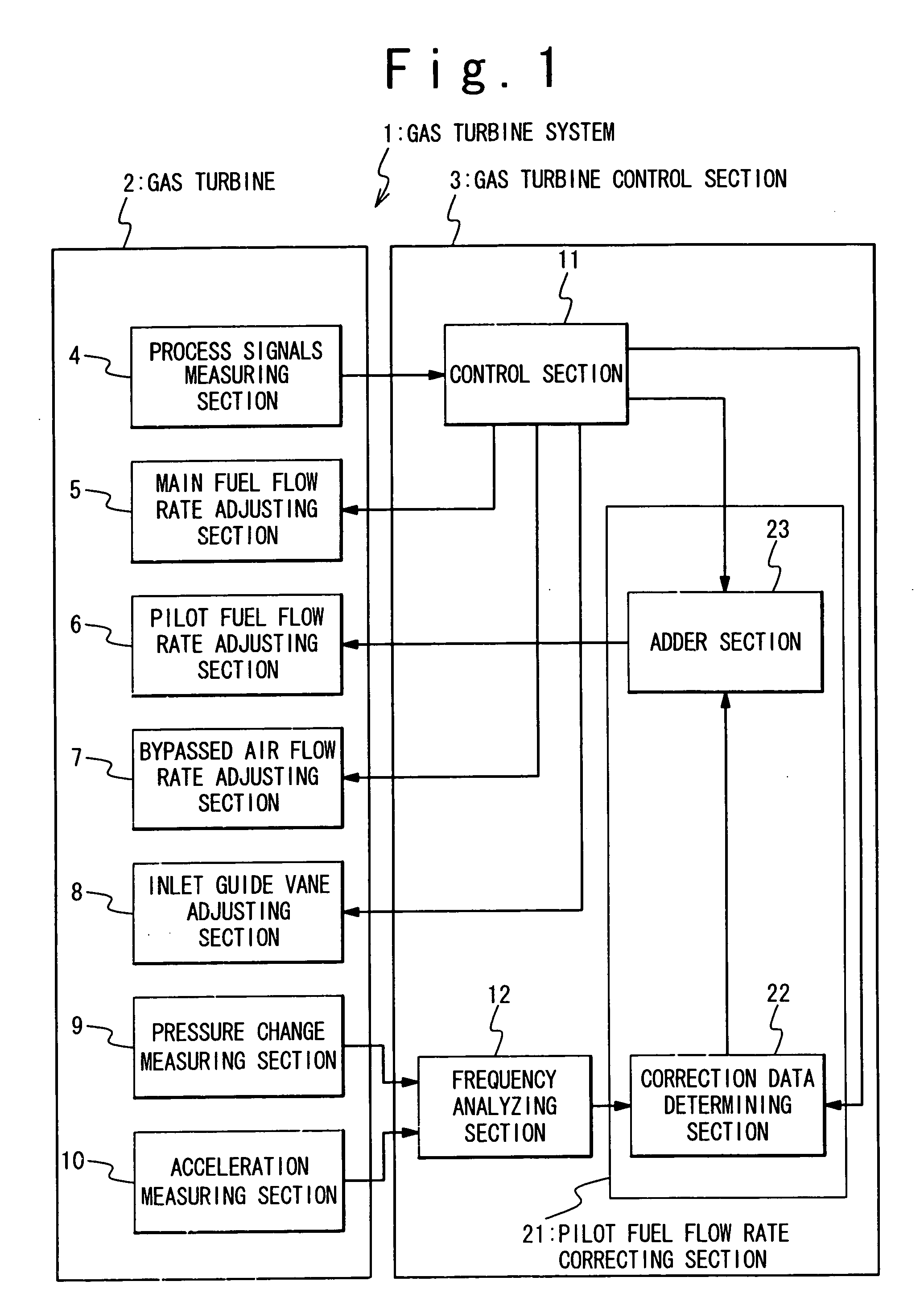

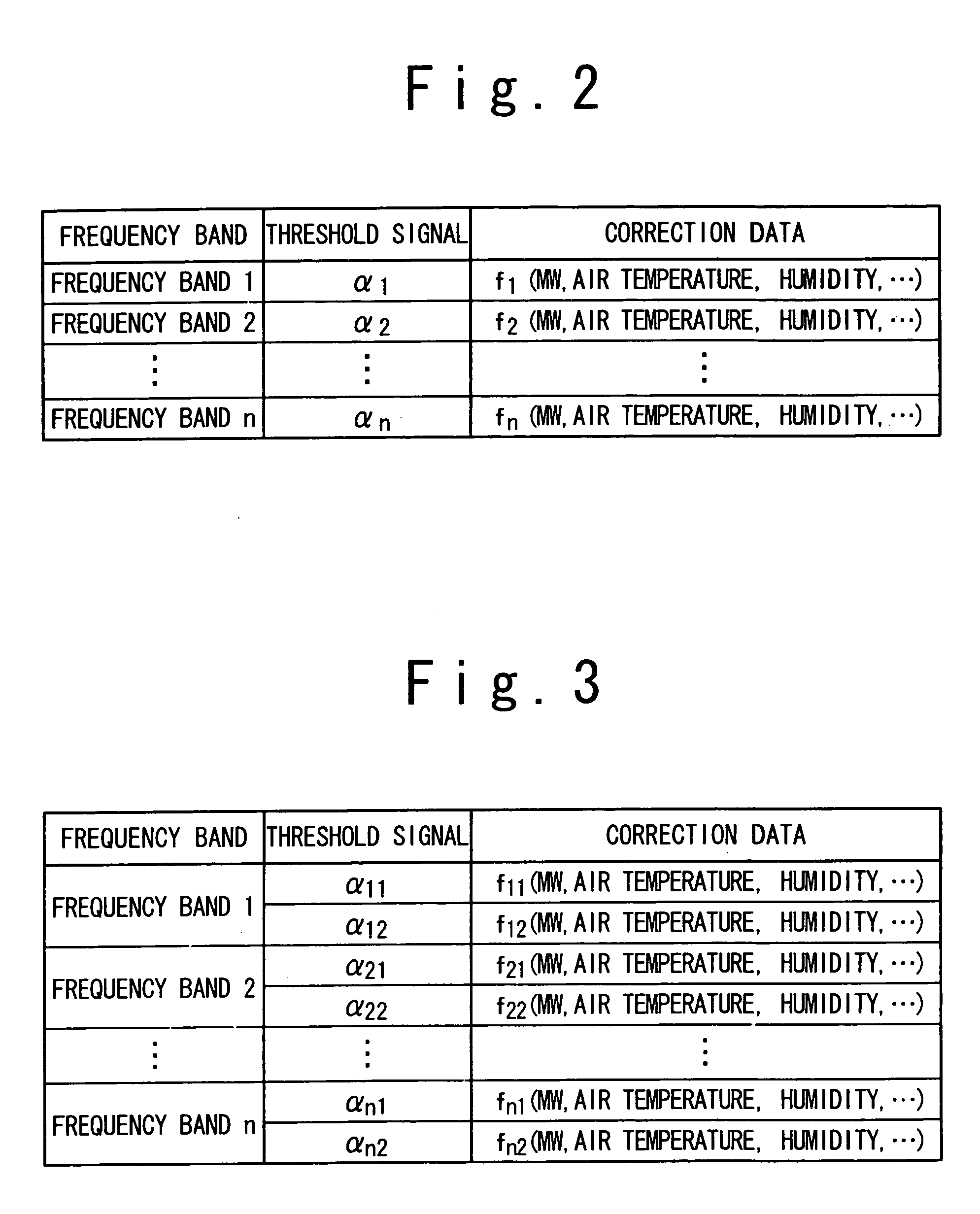

Gas turbine control apparatus and gas turbine system using the same

InactiveUS6955039B2Promote combustionOscillation suppressionContinuous combustion chamberEngine fuctionsCombustorGas turbines

In a gas turbine control apparatus, a frequency analyzing section frequency-analyzes at least one of pressure oscillation in combustors of a gas turbine and acceleration oscillation of each of the combustors and outputs a first frequency analysis result as the result of frequency analysis for a plurality of predetermined frequency bands. A control unit controls at least one of a first fuel flow rate of fuel and a first air flow rate of air based on the first frequency analysis result for the plurality of frequency bands. The fuel and the air are supplied to the gas turbine.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

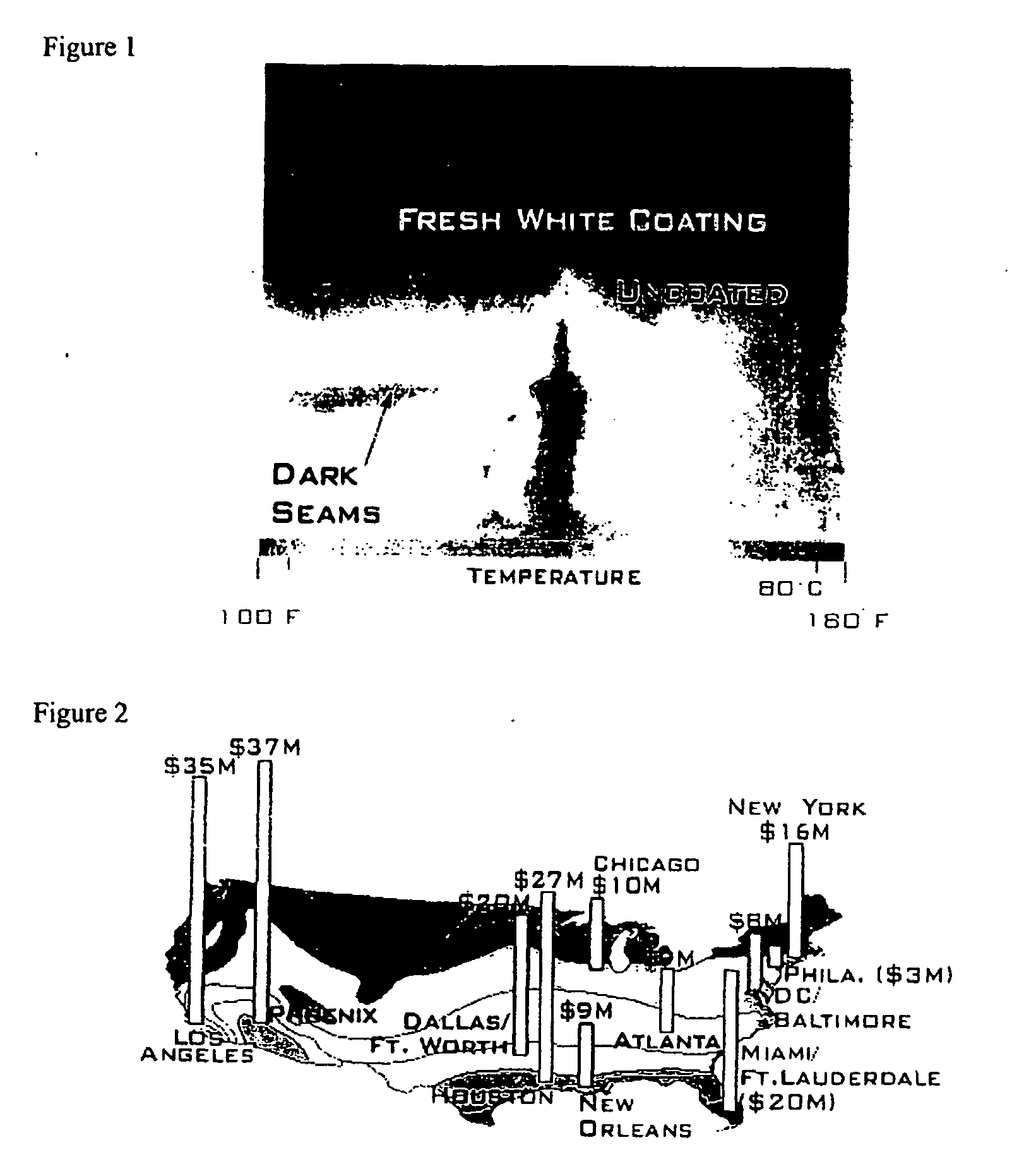

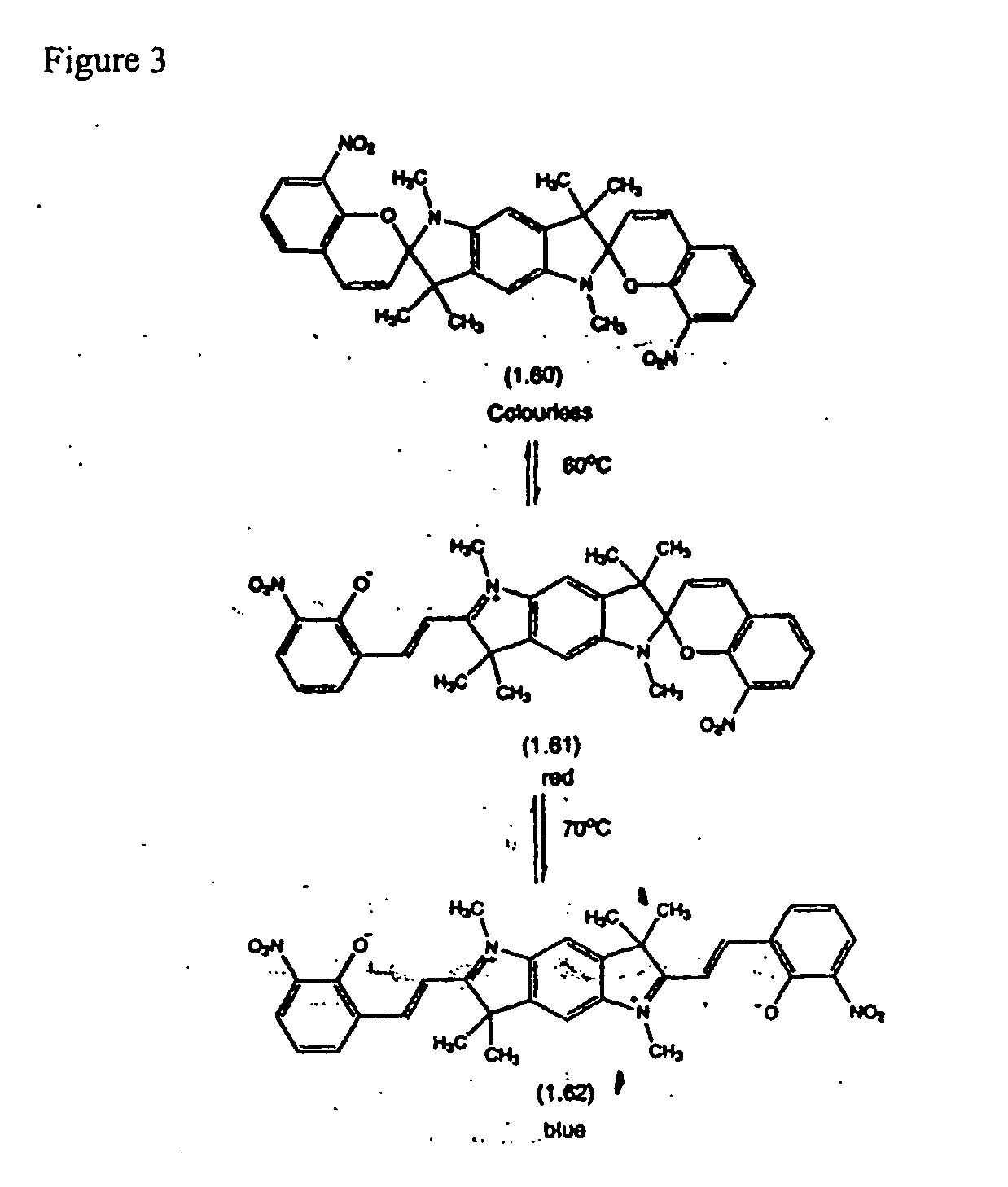

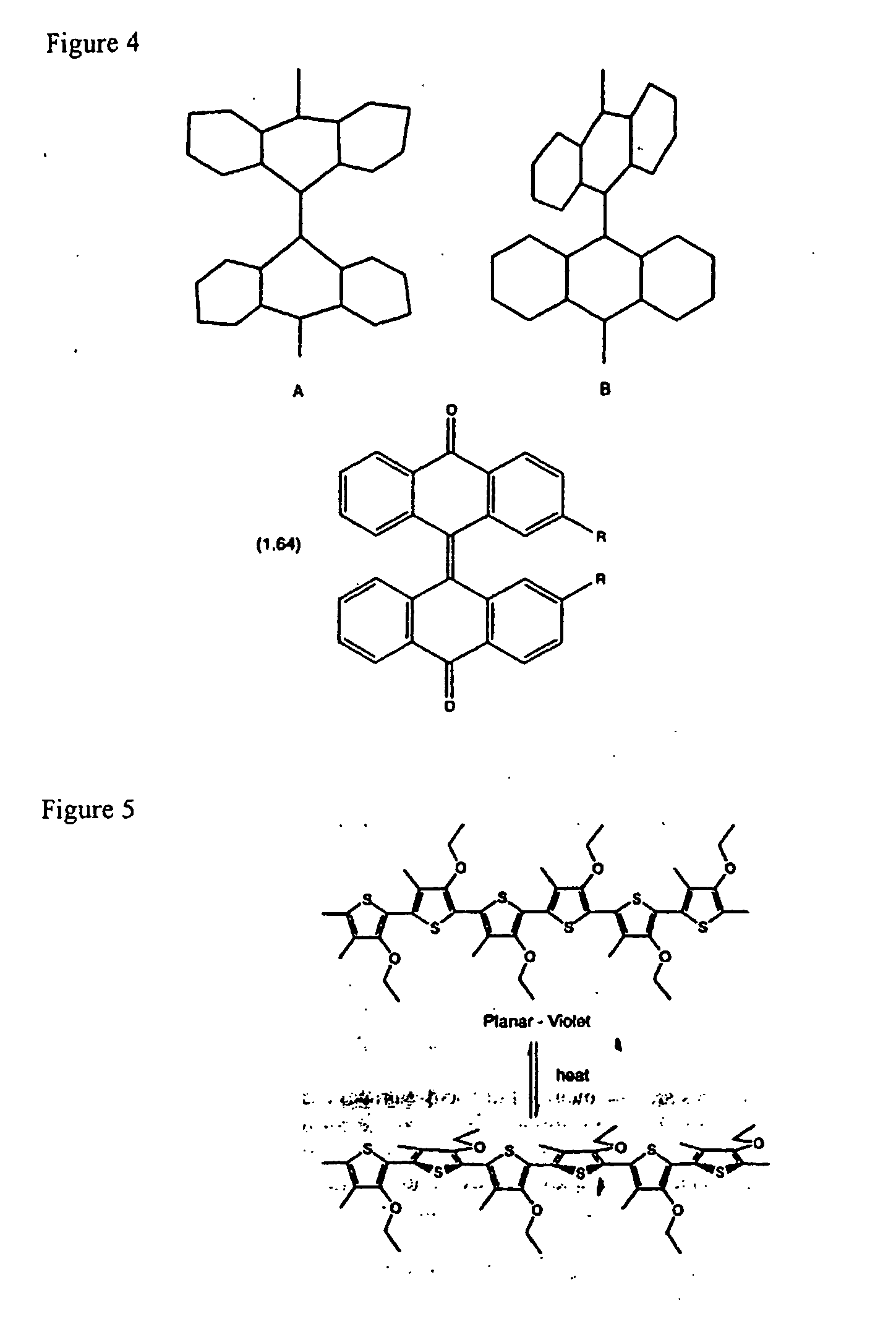

System and method for energy-conserving roofing

InactiveUS20050064175A1Reduce air pollutionLess cooling/heatingRoof covering using slabs/sheetsLayered productsAbsorbed energyEngineering

An energy-conserving building covering material includes a building panel, such as a roofing panel or a siding panel, coated with a thermomorphic material that can change its energy reflectance. The thermomorphic coating material can be combined with a carrier material, or it can be encapsulated with a solvent and optionally a color former in a microcapsule suspended in the carrier material. Alternatively, the building panel can include an electrophoretic material sandwiched between two transparent panels acting as electrodes. The building panel, when covered with said coating material and carrier material combination, can reflect radiant energy during warmer temperatures and can absorb radiant energy during cooler temperatures and re-radiate said absorbed energy into an interior of a building.

Owner:AZARI SHAUN +1

Fiber-cast packaging with inner bag and method for the production thereof

InactiveUS20080210584A1Reduce air pollutionImprove water resistancePackage recyclingFlexible coversFiberMolded pulp

A package for free-flowing media comprising a molded pulp vessel partly or completely surrounding two or more film pouches or a film pouch having a plurality of chambers. An environmentally friendly package whose constituents can be reused without any great complexity.

Owner:HENKEL KGAA

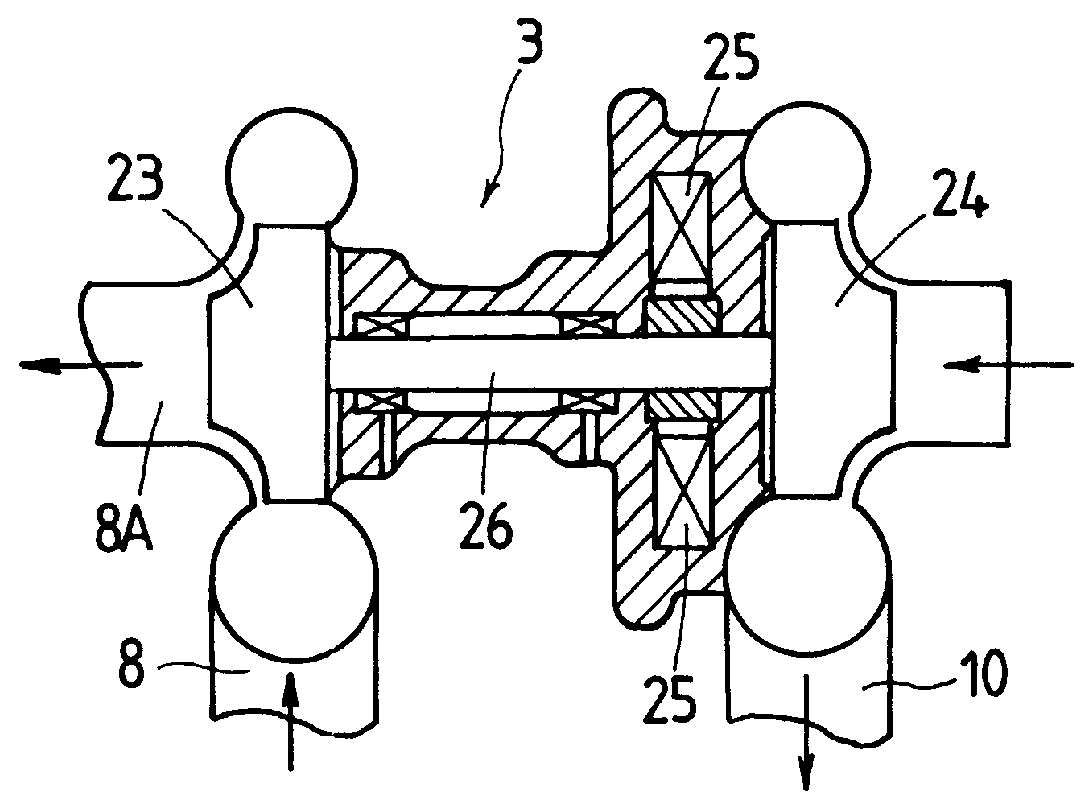

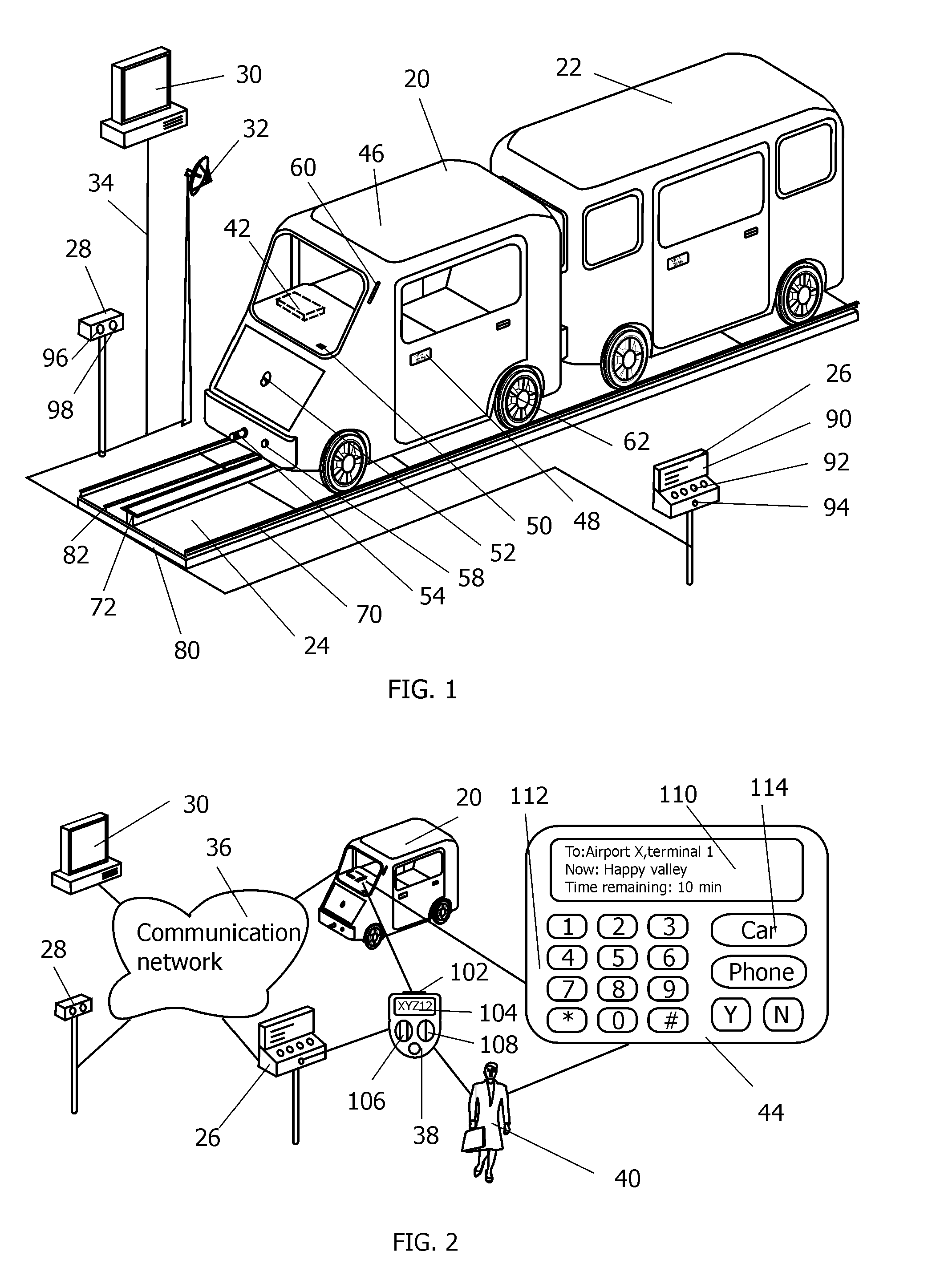

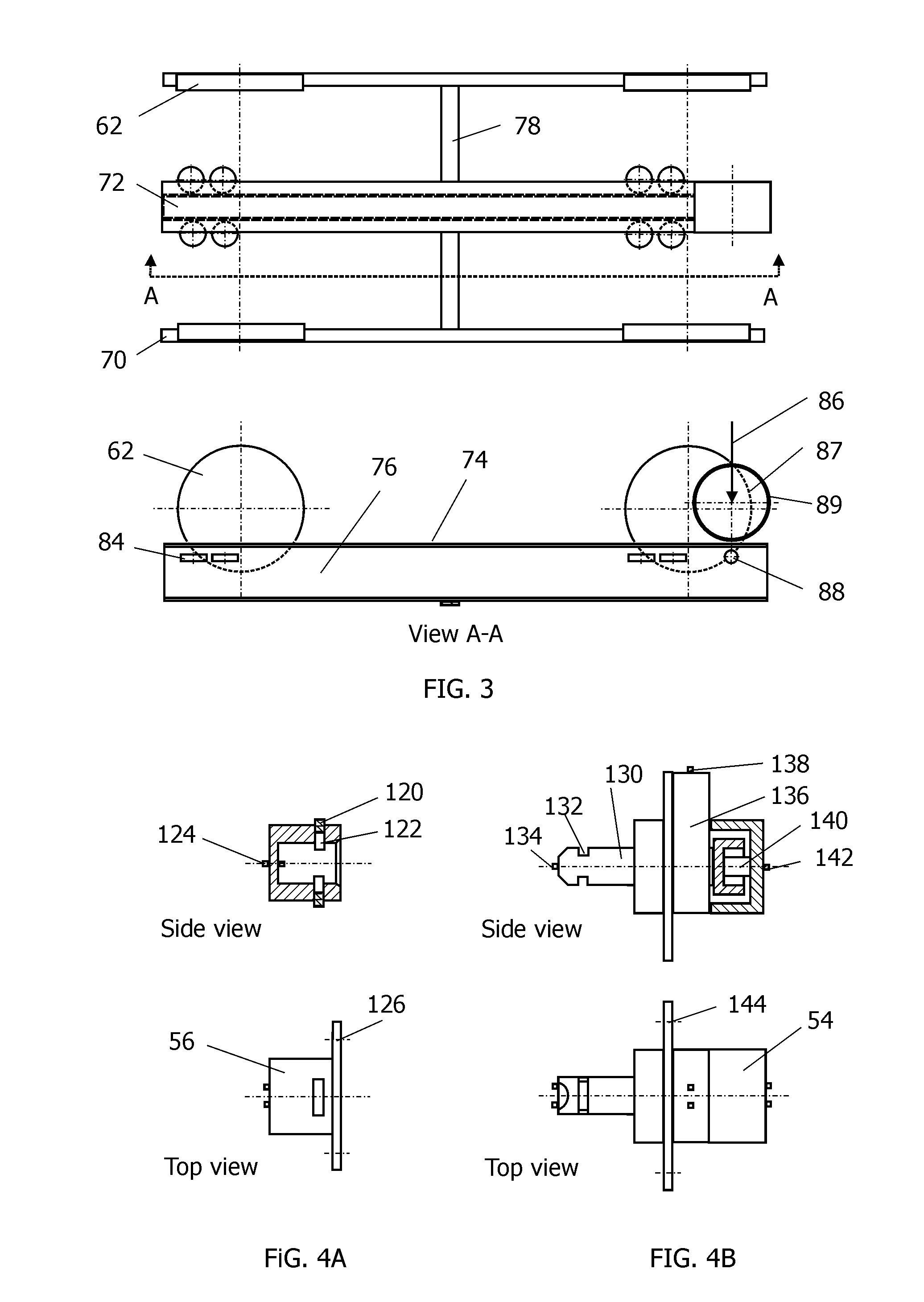

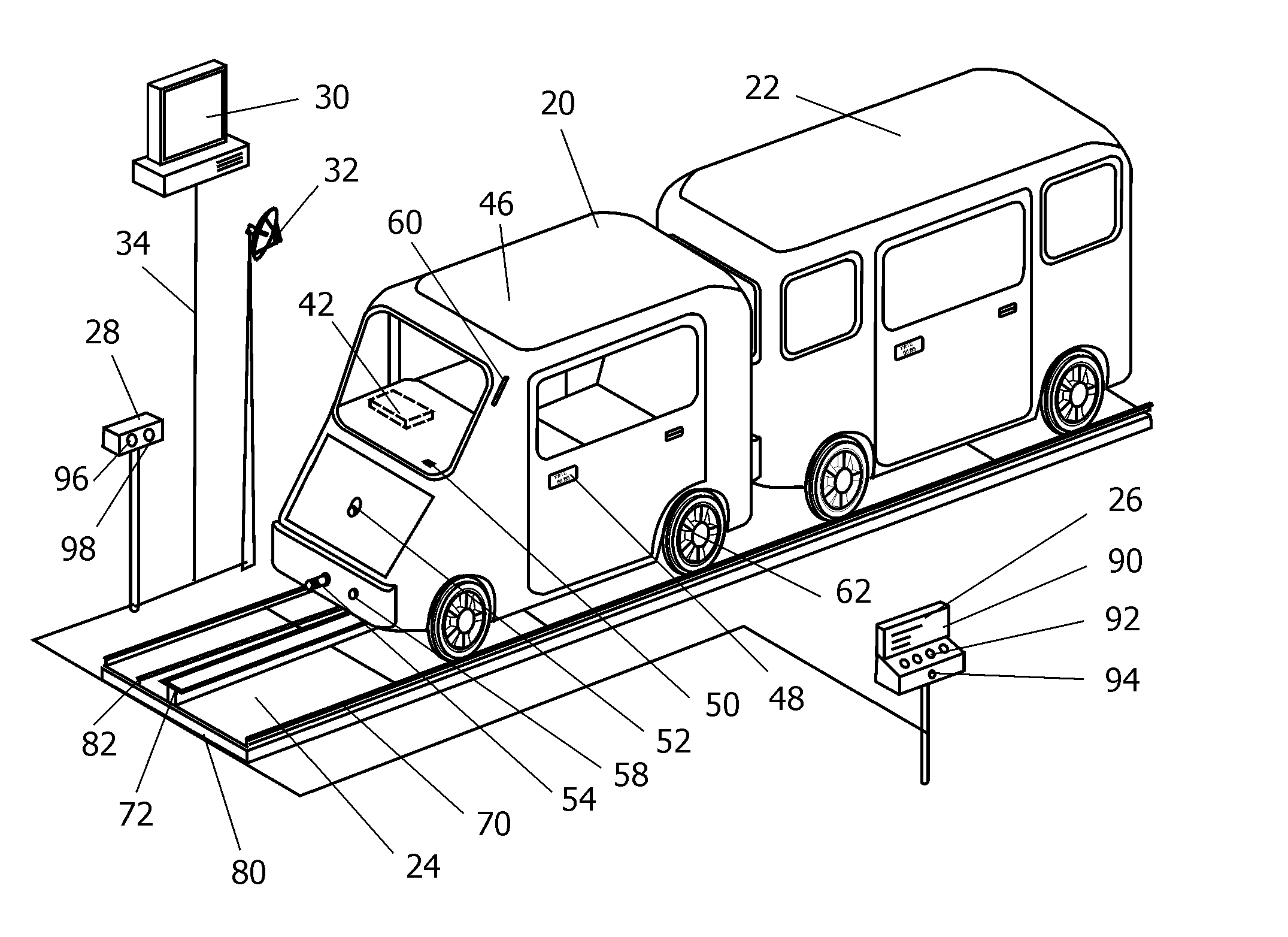

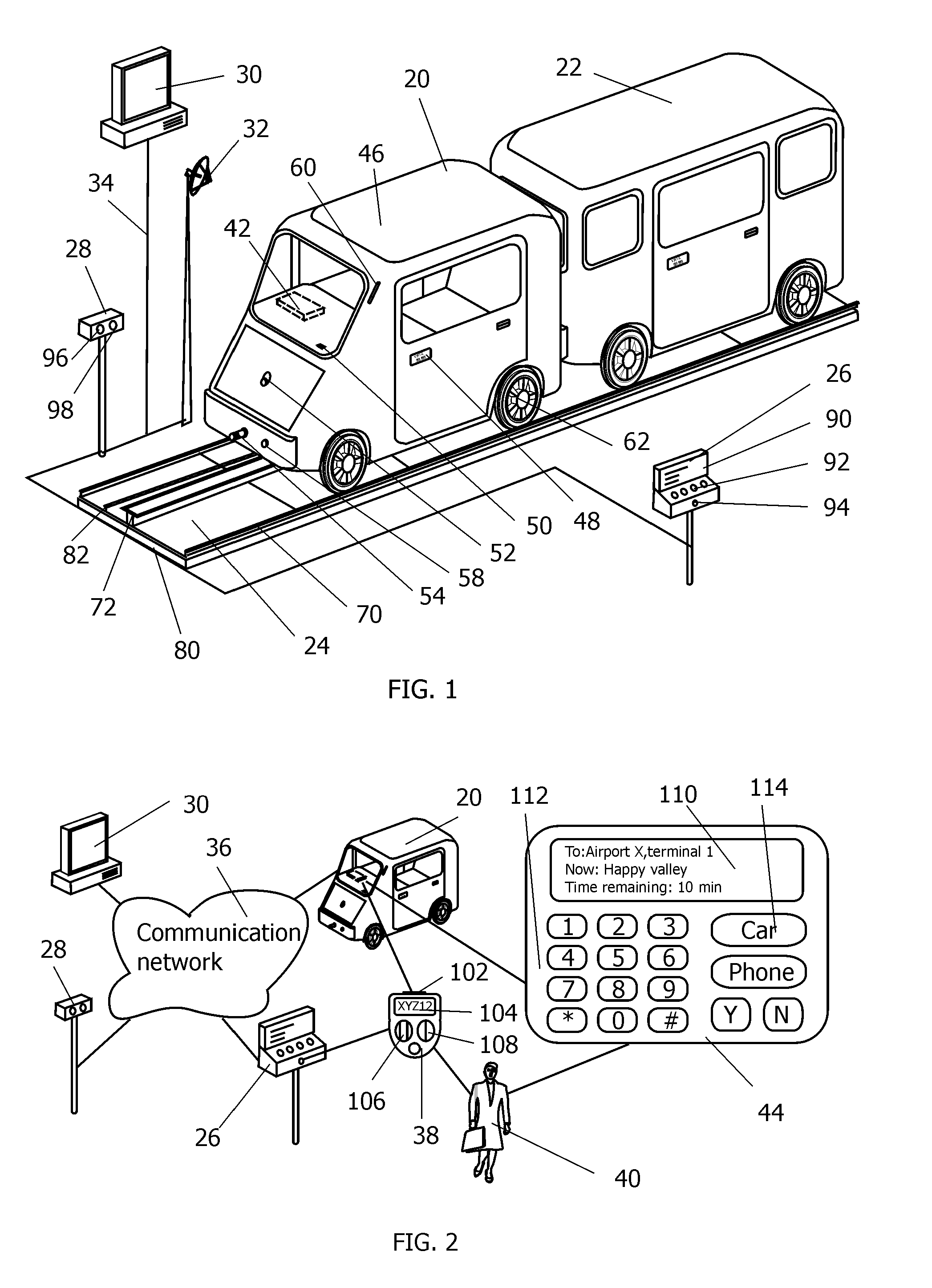

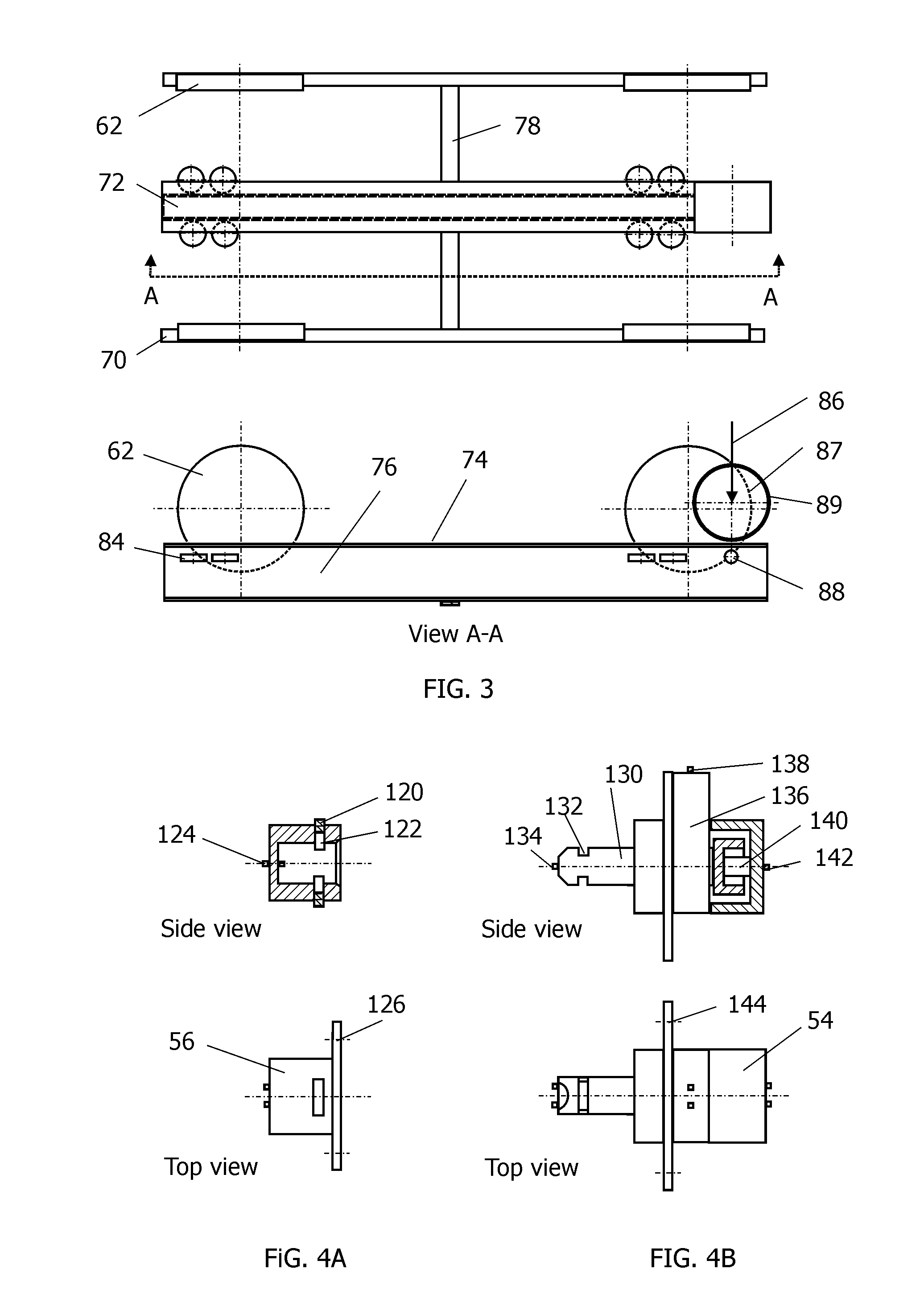

Personal transportation system

InactiveUS7302319B2Increase speedIncrease volumeRefuge islandsAutomatic systemsThree levelControl system

An autonomous personal transportation system for moving passengers and light freights is constructed with a track network and small vehicles on the track network. There are a number of stations and stops for loading and unloading on side tracks off the mainline of the track network. The vehicle width is limited to a dimension for one seat. The vehicles can be coupled statically or dynamically to form a train. The track has side rails for the rigid wheels of the vehicle and a central rail for centering the vehicle on the guideway and providing additional acceleration and braking capability. The control system for the movement of vehicles is divided into three levels: the central control system, the wayside control system and the vehicle control system.

Owner:WU HENGNING

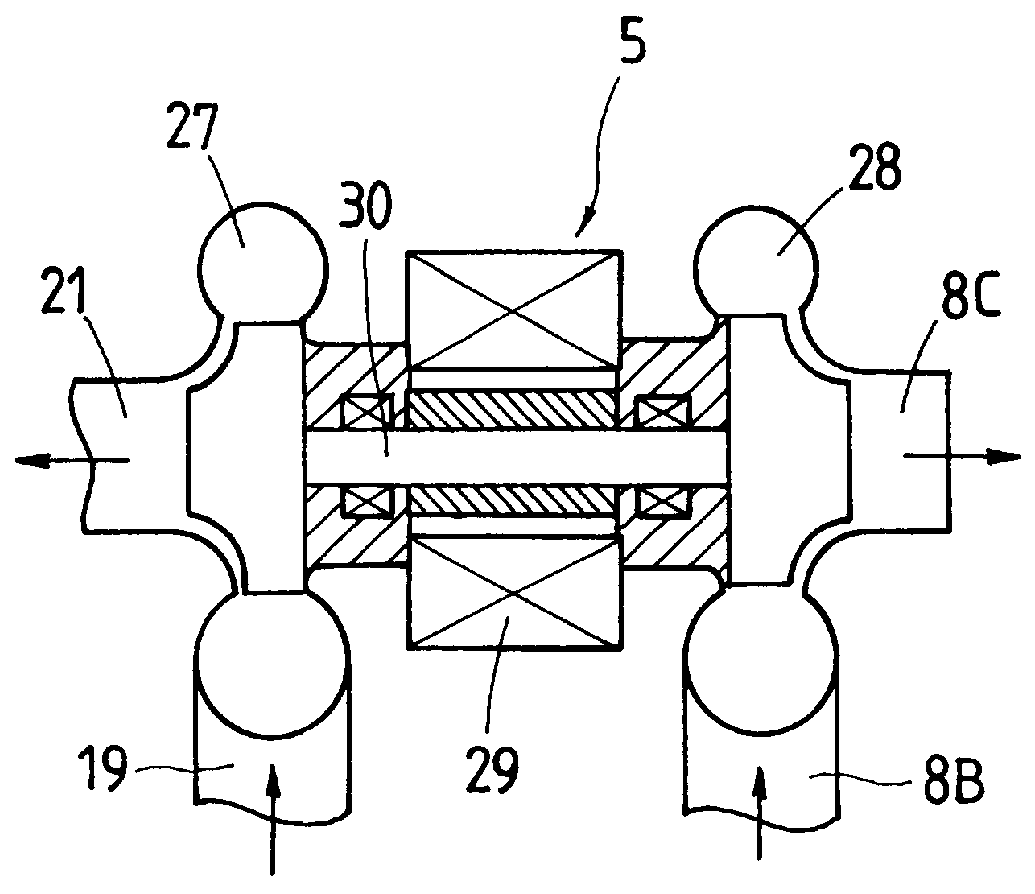

Personal Transportation System

InactiveUS20050038575A1Increase speedTransportation is highRefuge islandsAutomatic systemsThree levelControl system

An autonomous personal transportation system for moving passengers and light freights is constructed with a track network and small vehicles on the track network. There are a number of stations and stops for loading and unloading on side tracks off the mainline of the track network. The vehicle width is limited to a dimension for one seat. The vehicles can be coupled statically or dynamically to form a train. The track has side rails for the rigid wheels of the vehicle and a central rail for centering the vehicle on the guideway and providing additional acceleration and braking capability. The control system for the movement of vehicles is divided into three levels: the central control system, the wayside control system and the vehicle control system.

Owner:WU HENGNING

Gas burner with pollution-reducing features

InactiveUS6129545AReduce air pollutionEasy to adaptDomestic stoves or rangesStoves/ranges topsCombustion chamberExhaust gas emissions

A gas burner has a perforated, hollow body around and defining a combustion chamber. Gaseous fuel is fed to one side of the body, combustion occurs on the other side and the perforations provide a spatial connection between the fuel feed side and the combustion side. The new burner reduces exhaust gas emissions and offers a wide range of performance in the amount of heat energy provided, in the permissible range of gas pressure and in the range of fuels and fuel / air mixtures that can be used with it.

Owner:CERAMAT +1

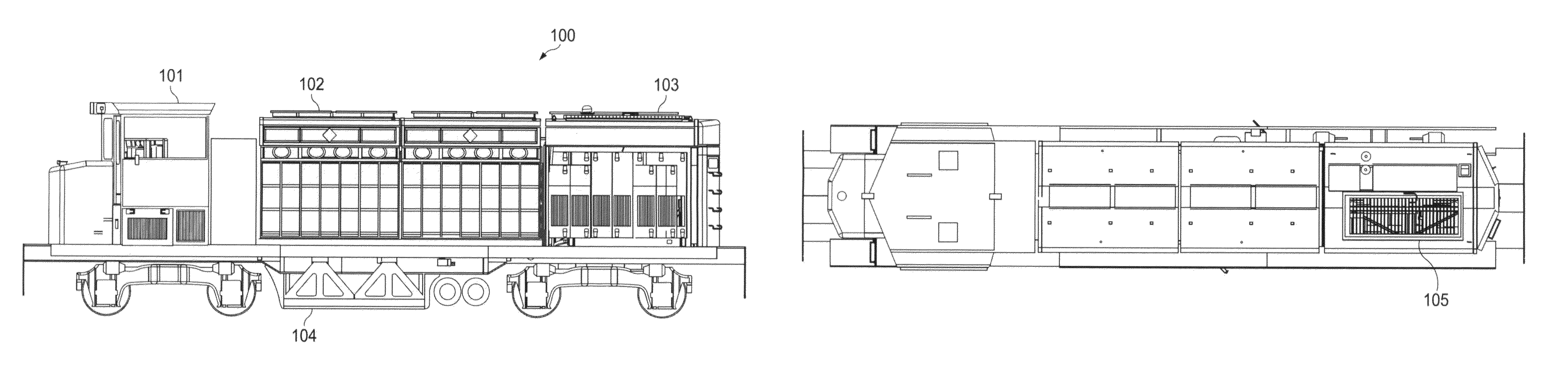

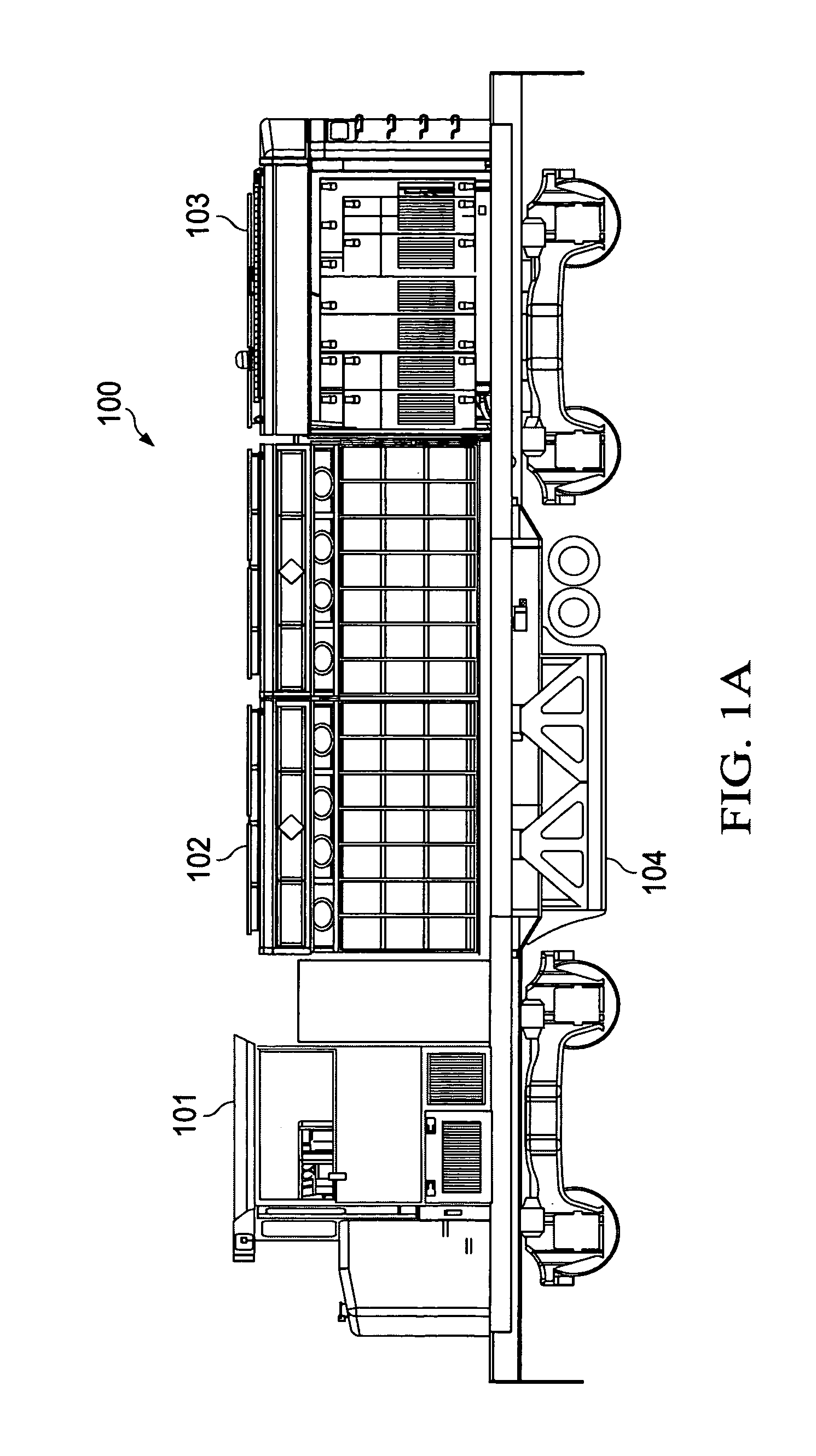

Power management systems for hydrogen hybrid locomotives and hydrogen hybrid locomotives using the same

ActiveUS7971538B1Reduce air pollutionReduce dependenceSteam locomotivesFuel cell auxillariesElectrical batteryHydrogen fuel cell

A hydrogen hybrid locomotive including traction motors for moving the locomotive along a set of tracks, a set of batteries for providing electrical power to the traction motors, a hydrogen fuel cell power plant for charging the set of batteries, an air system having a variable speed compressor for providing air flow to the power plant, and a DC to DC converter for managing power distribution from the hydrogen fuel cell power plant to the batteries. A controller determines an amount of current required from the power plant to produce a selected amount of power, determines a stoic operating setpoint for the power plant based on the current required, sets the speed of a compressor within the air system to provide a selected amount of air flow to the power plant for the determined stoic operating setpoint, determines from a resulting actual air flow to the power module available power, and sets an operating setpoint of the DC to DC converter from the determined an available power.

Owner:BNSF RAILWAY

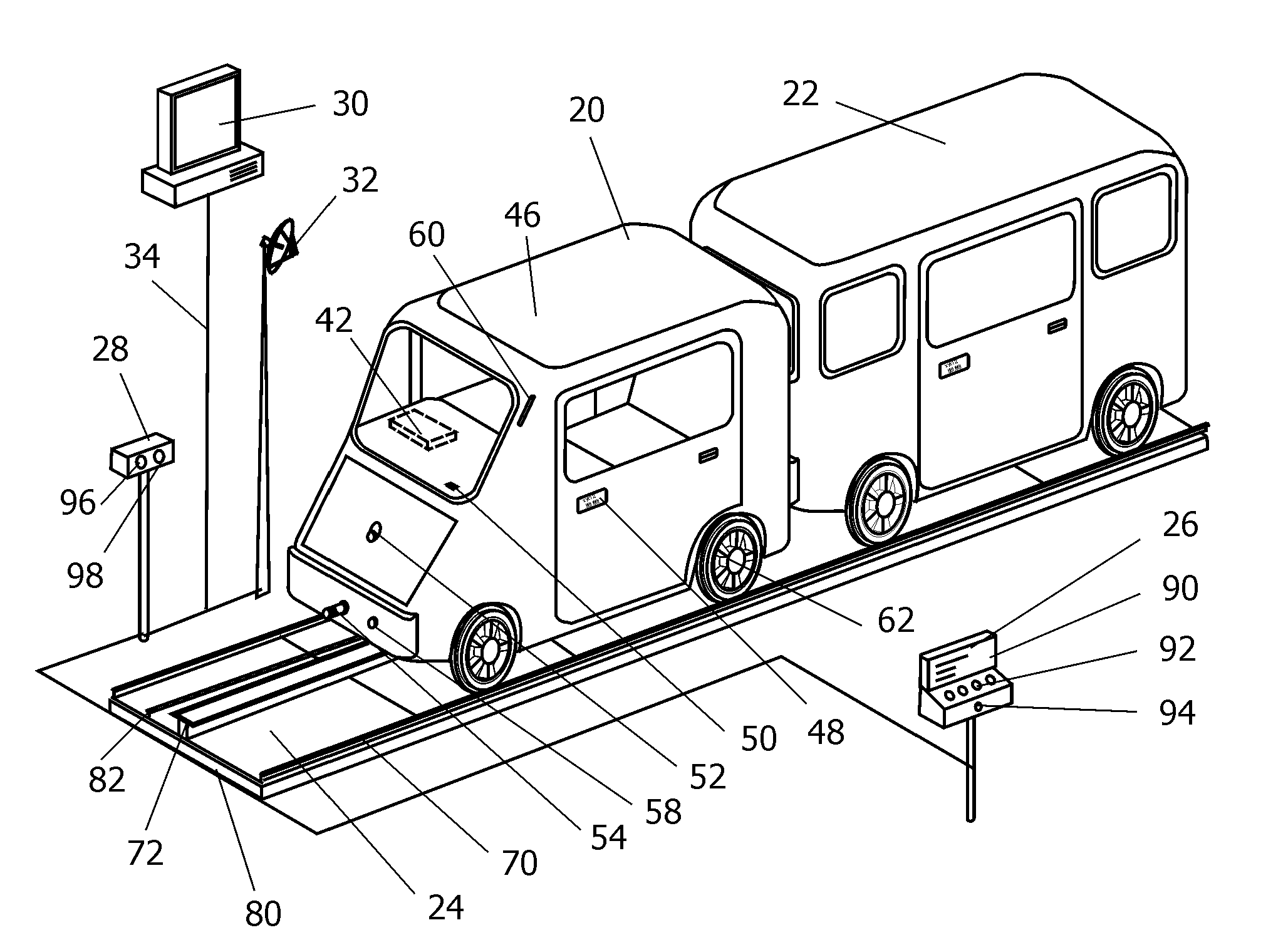

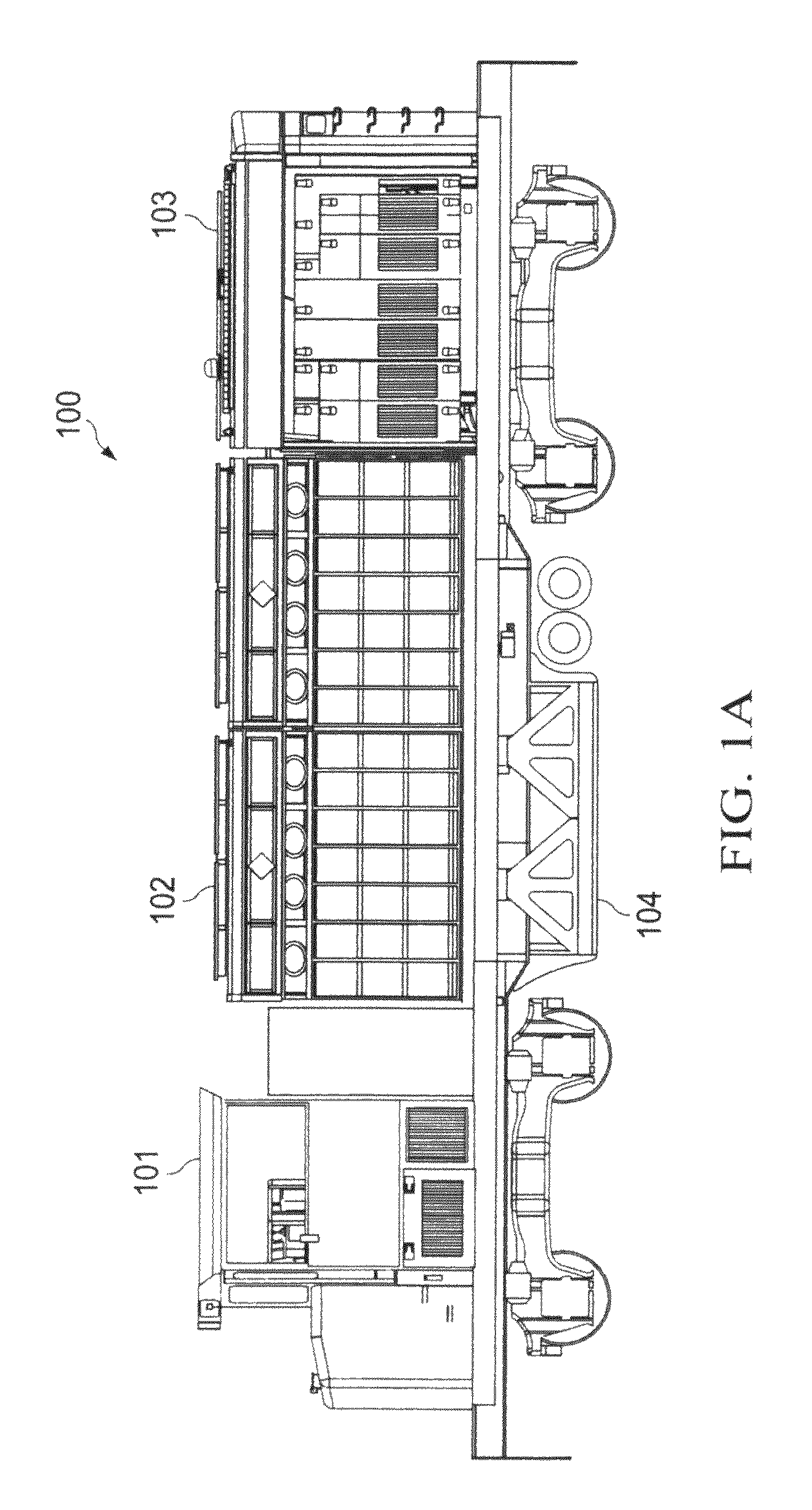

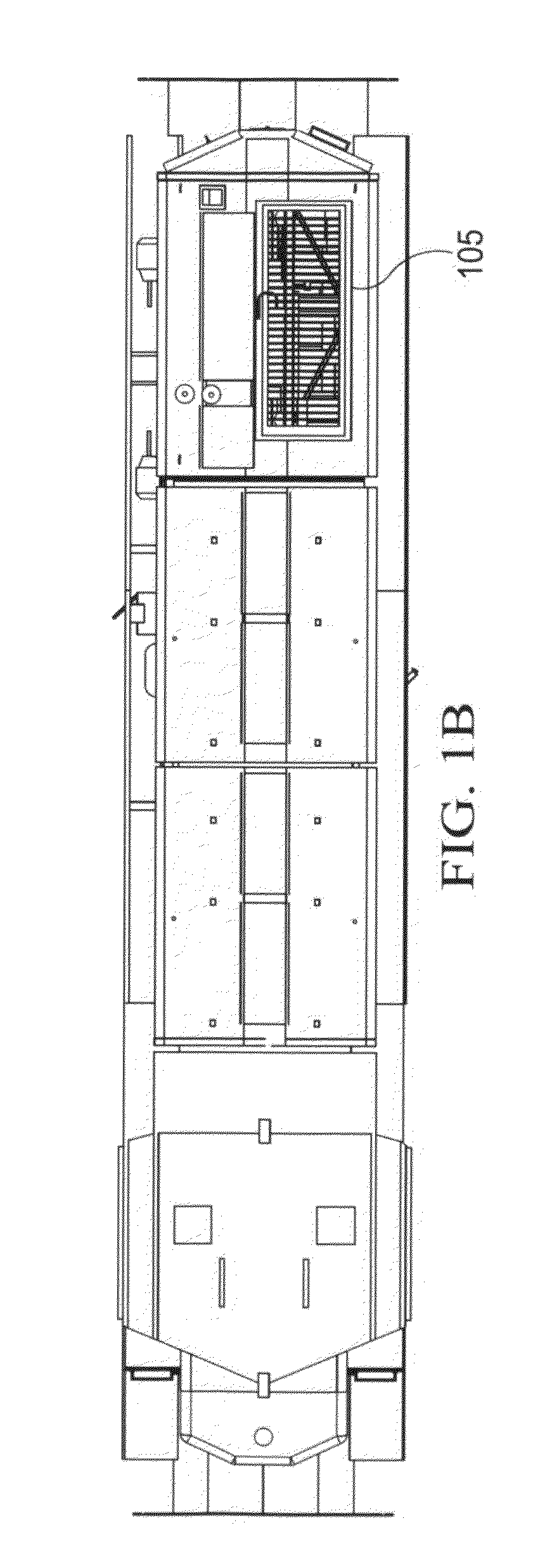

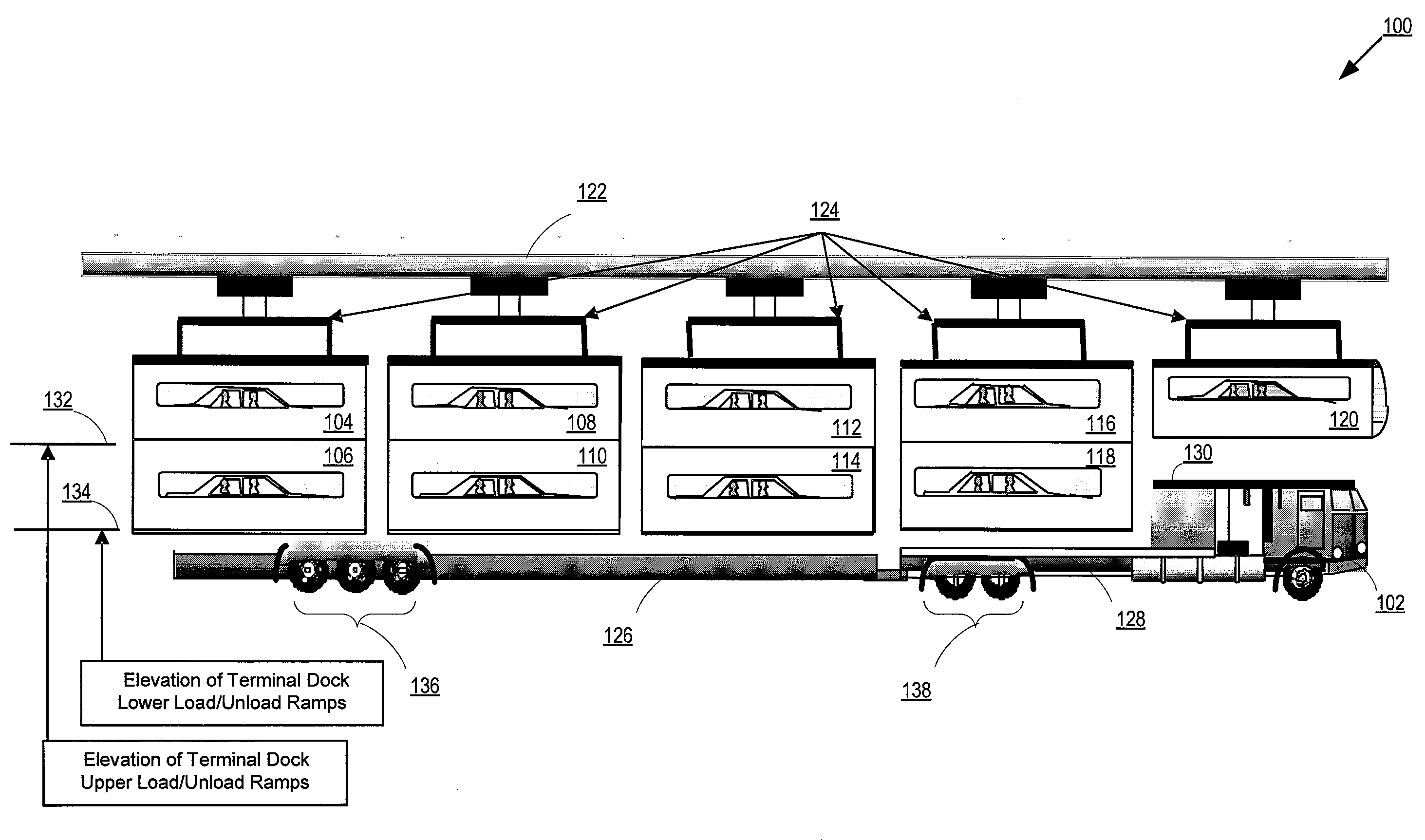

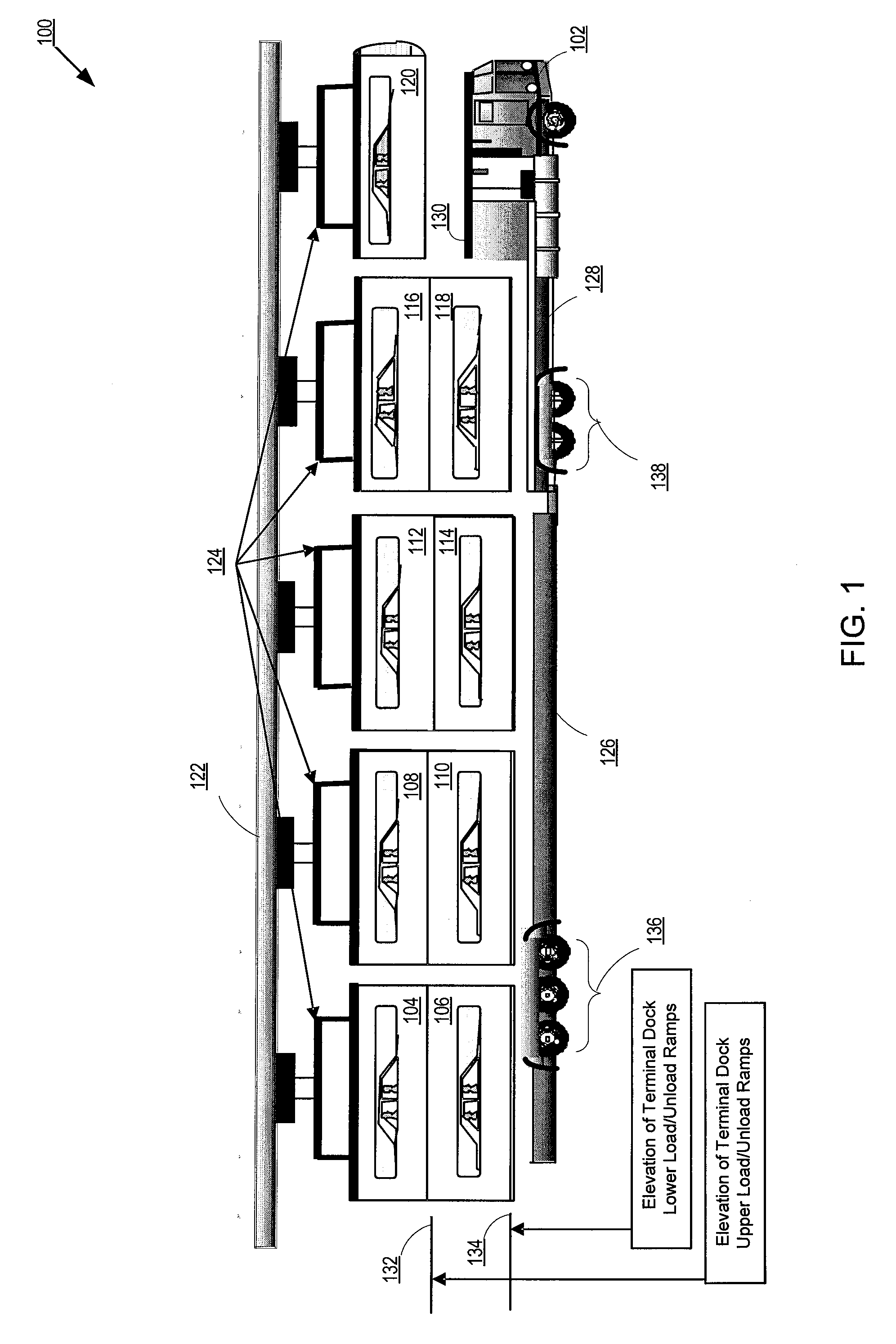

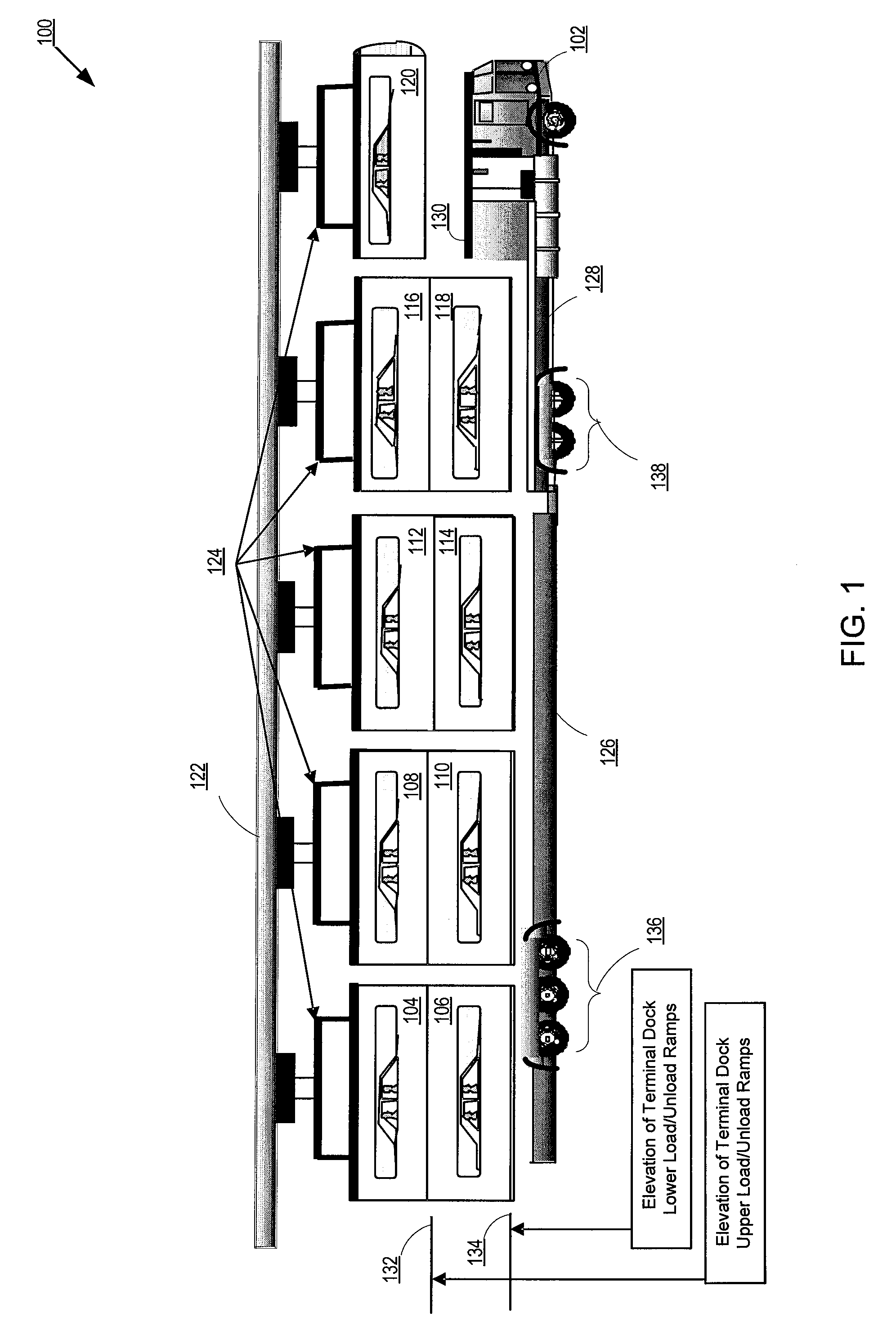

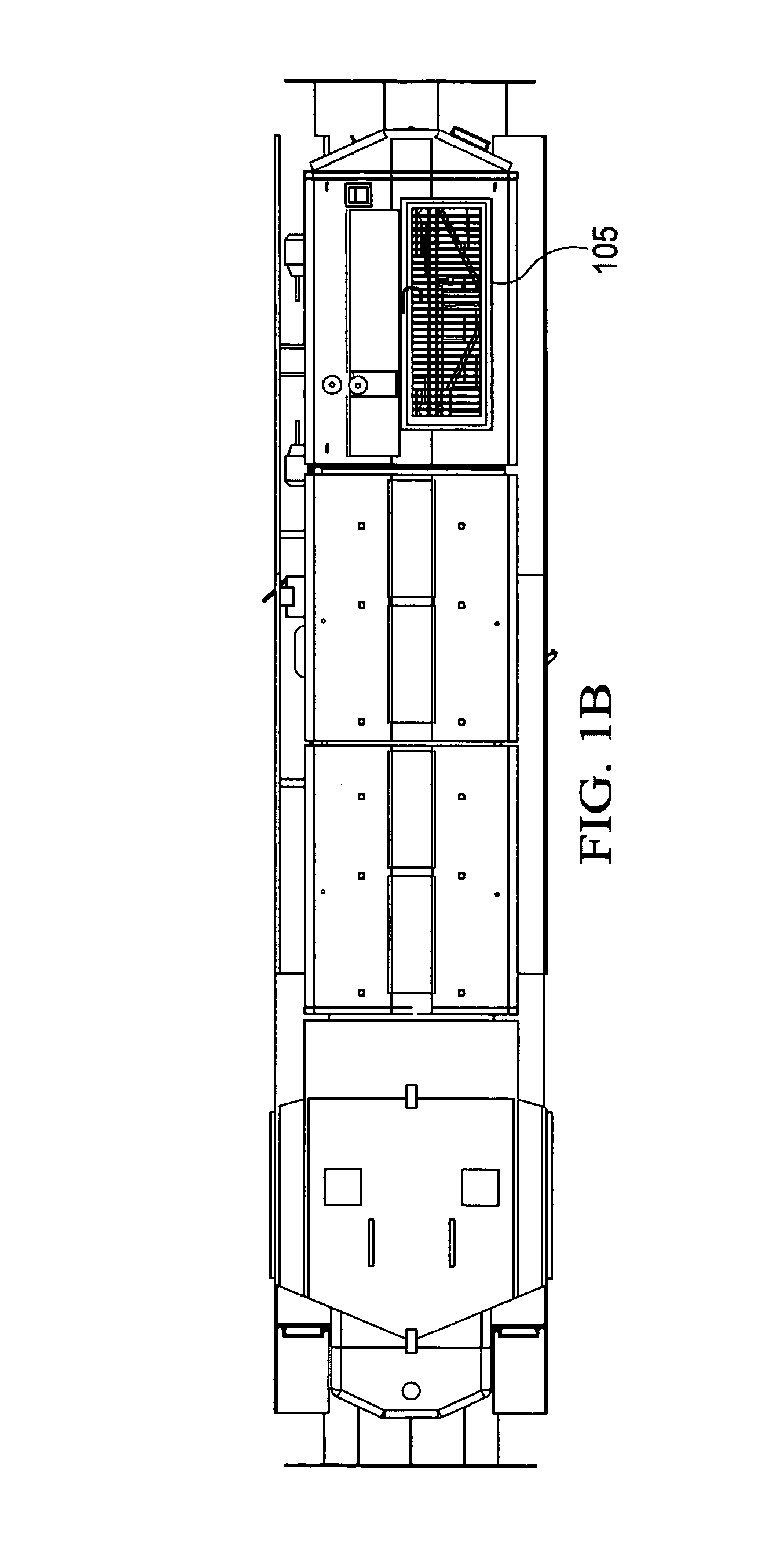

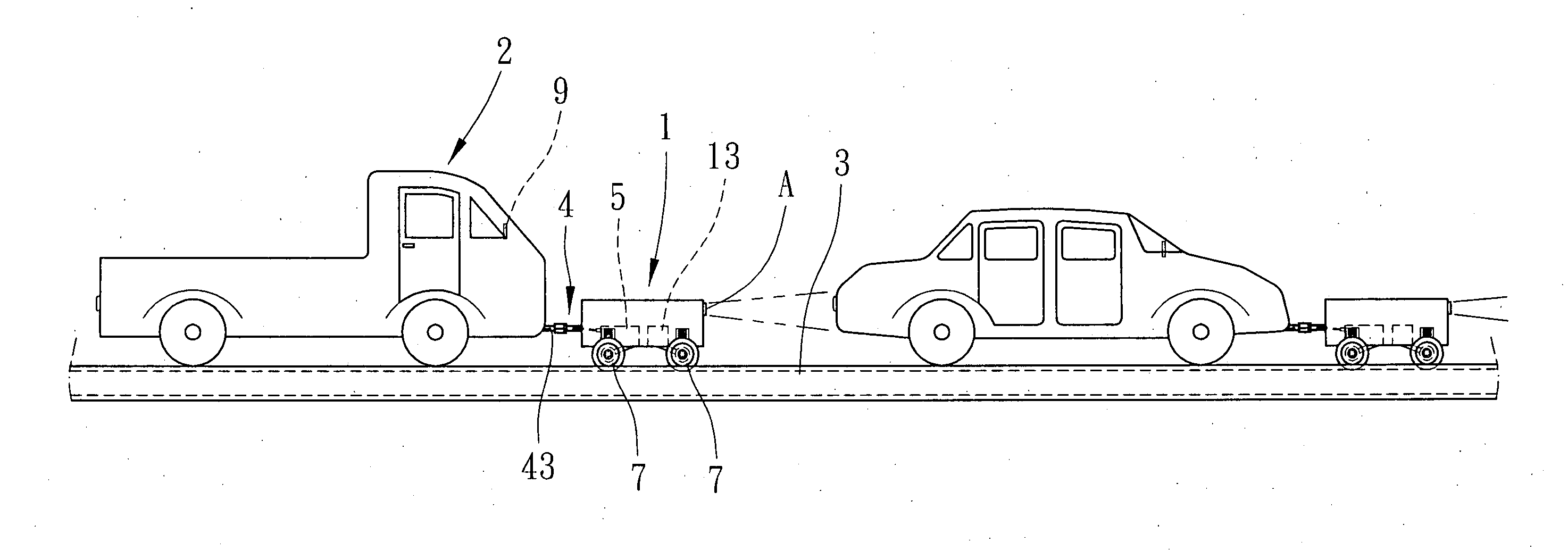

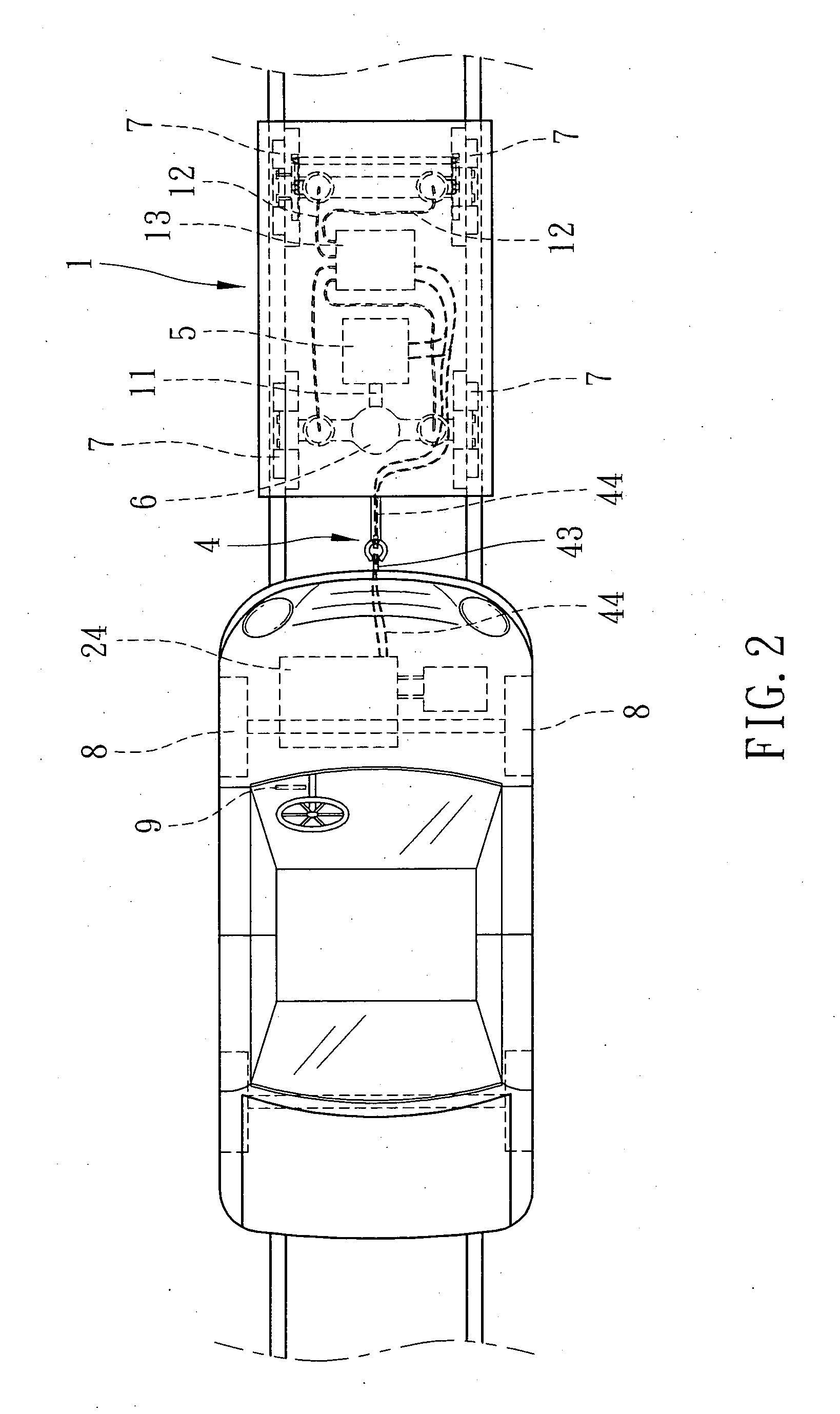

Multiple driver occupied passenger vehicles transporter system

InactiveUS20100104392A1Increase flow rateTransportation safetyAnalogue computers for vehiclesAnalogue computers for trafficTraffic capacityDriver/operator

The multiple driver occupied passenger vehicles transporter system (Autobus) provides a way to efficiently, economically and safely increase the highway vehicle flow rate of cars per lane per hour. Autobus employs a vehicle transporter, terminal, sensors and systems that provide a way to quickly load and unload driver occupied passenger vehicles on and off of the vehicle transporter. Autobus provides a way to safely transport multiple driver occupied passenger vehicles, including cars, sport utility vehicles (SUVs) and light trucks.

Owner:CLEAN TRANSPORT

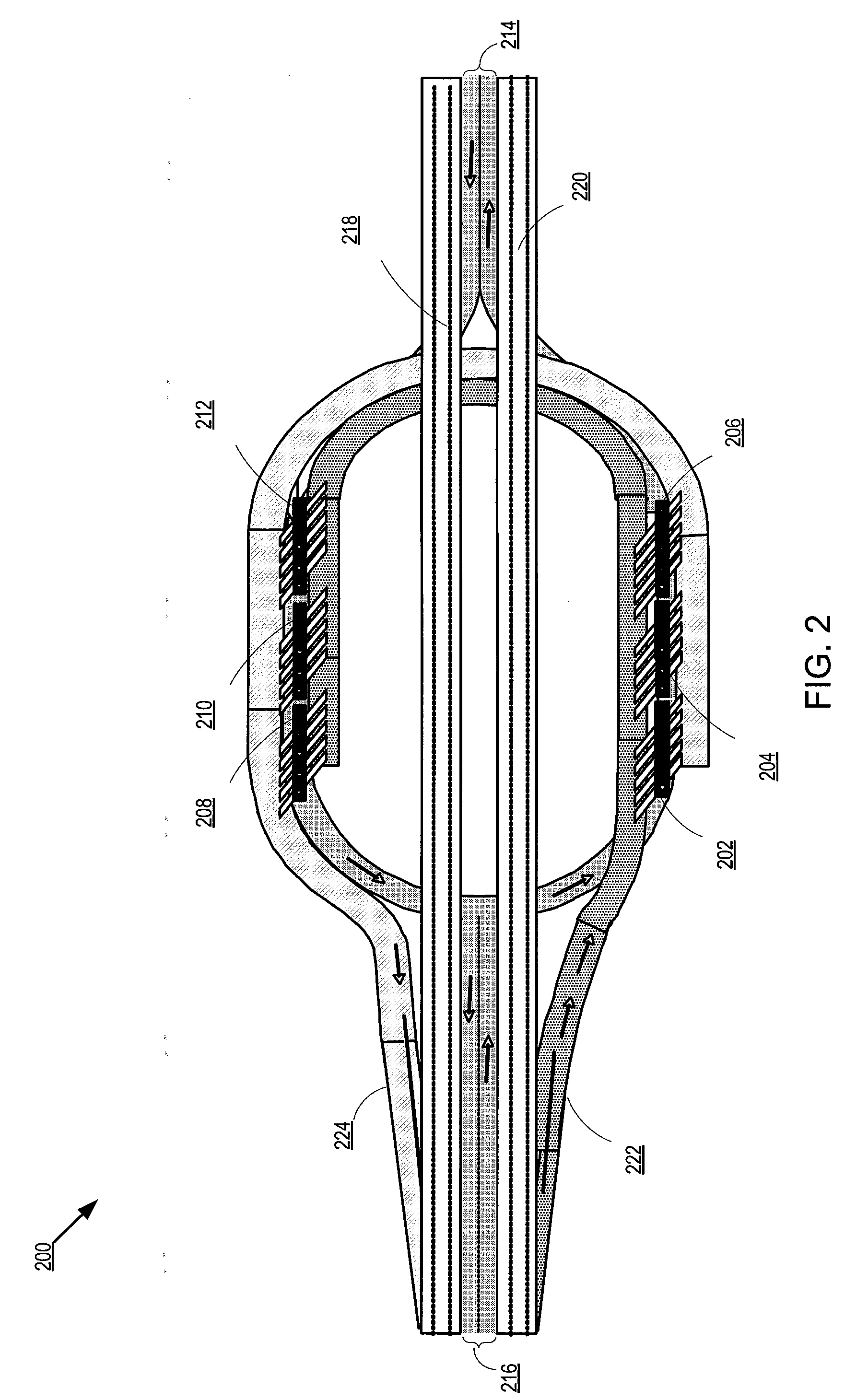

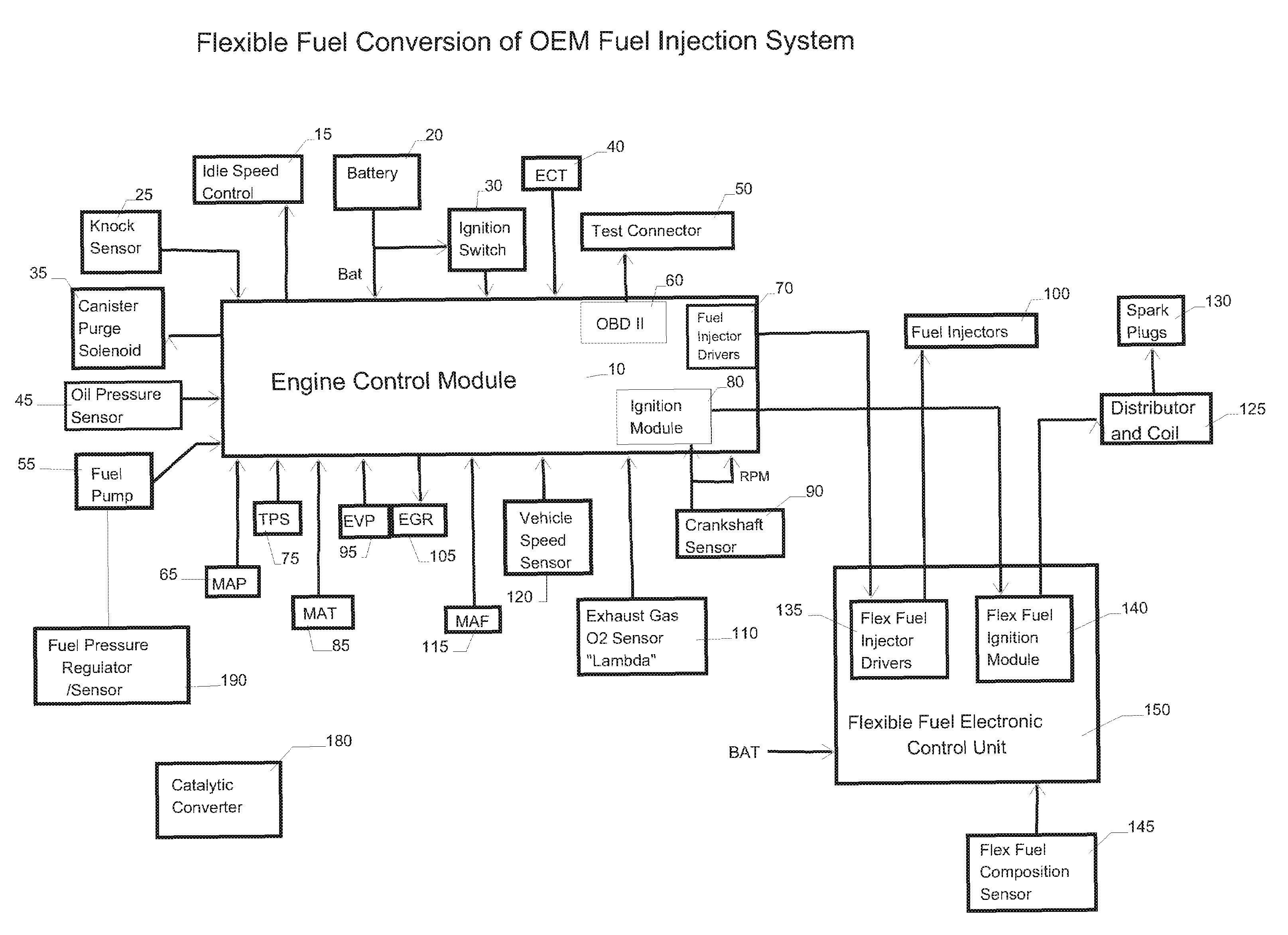

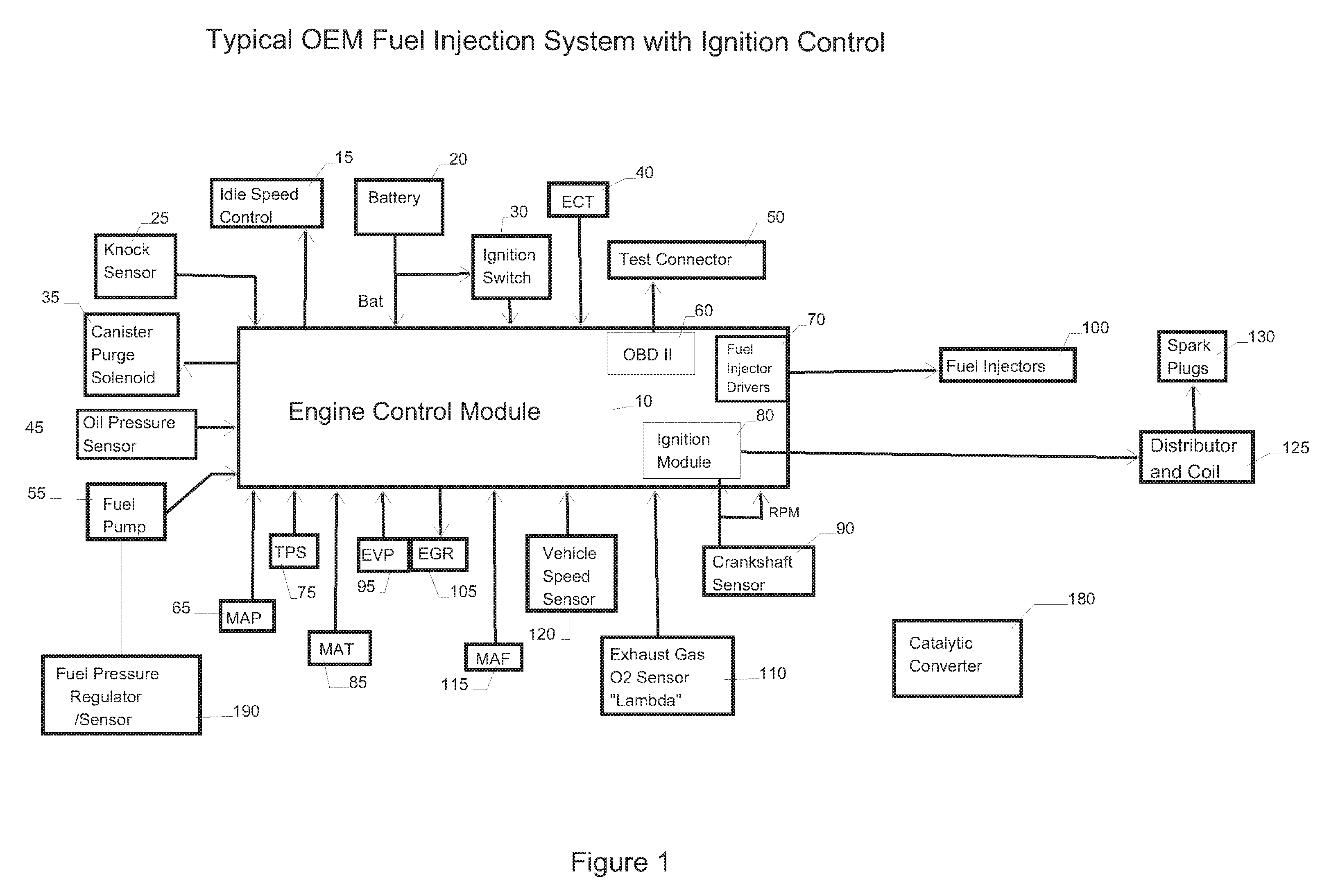

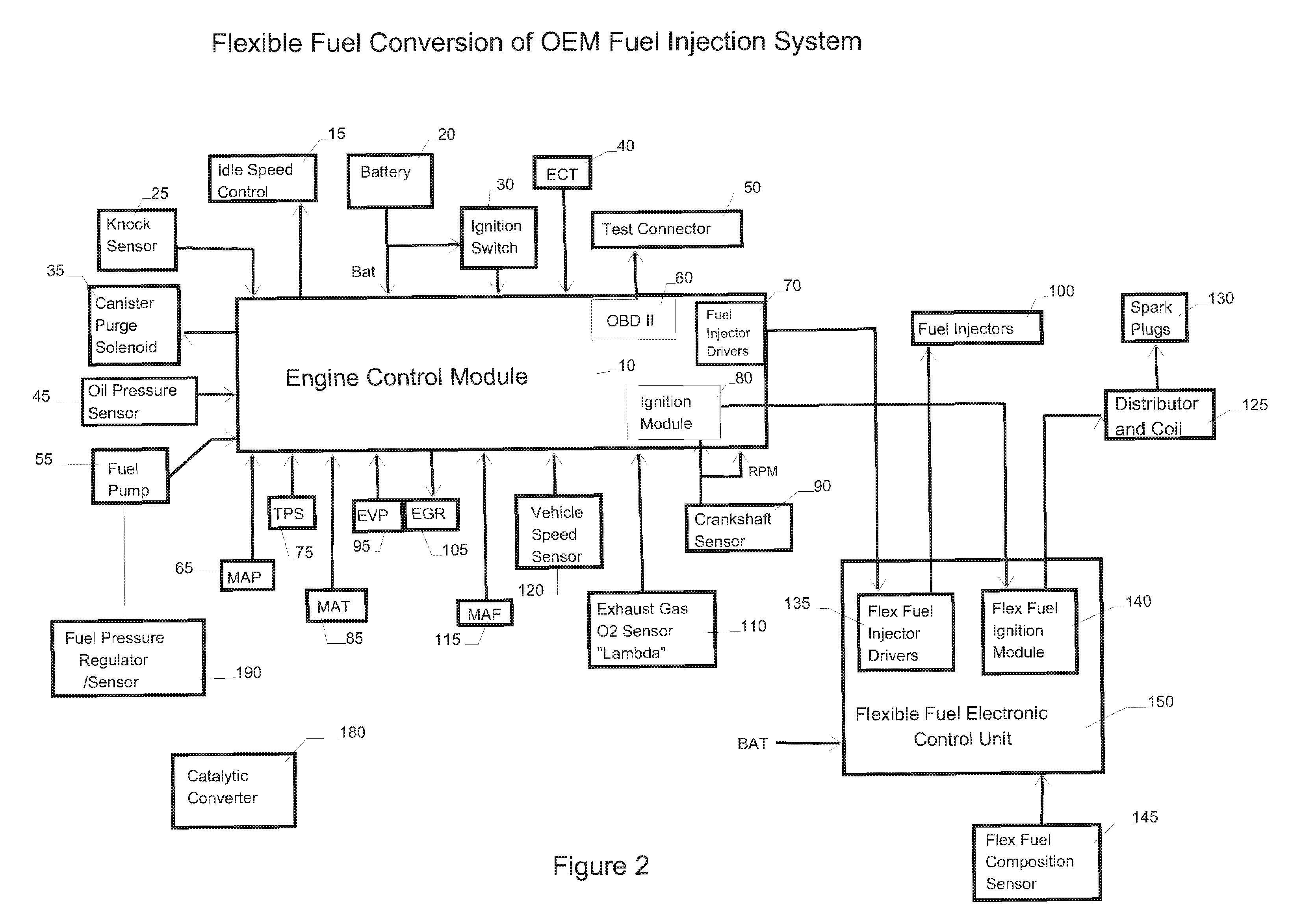

Addition of flexible fuel engine control system

InactiveUS7305939B2Reduce dependenceInexpensively convertElectrical controlInternal combustion piston enginesDriver circuitAlternative fuels

The apparatus and method convert the fuel system of an internal combustion engine in a pre-existing (used) vehicle to operate on a mixture of fuels (like ethanol and gasoline) from a single fuel tank. The apparatus includes a fuel composition sensor installed in the fuel line and an electronic control unit with at least one fuel injector driver circuit for controlling an output signal to at least one fuel injector for controlling the air to fuel ratio of the engine. The electronic control unit controls both ignition timing and the air to fuel ratio of the engine based upon the percentage or ratio of the alternative fuel to gasoline from the fuel composition sensor. The electronic control unit receives both timing signals and fuel injector control signals from the engine's original Engine Control Module and the original emission control devices are not modified or replaced.

Owner:ROCHESTER PROD

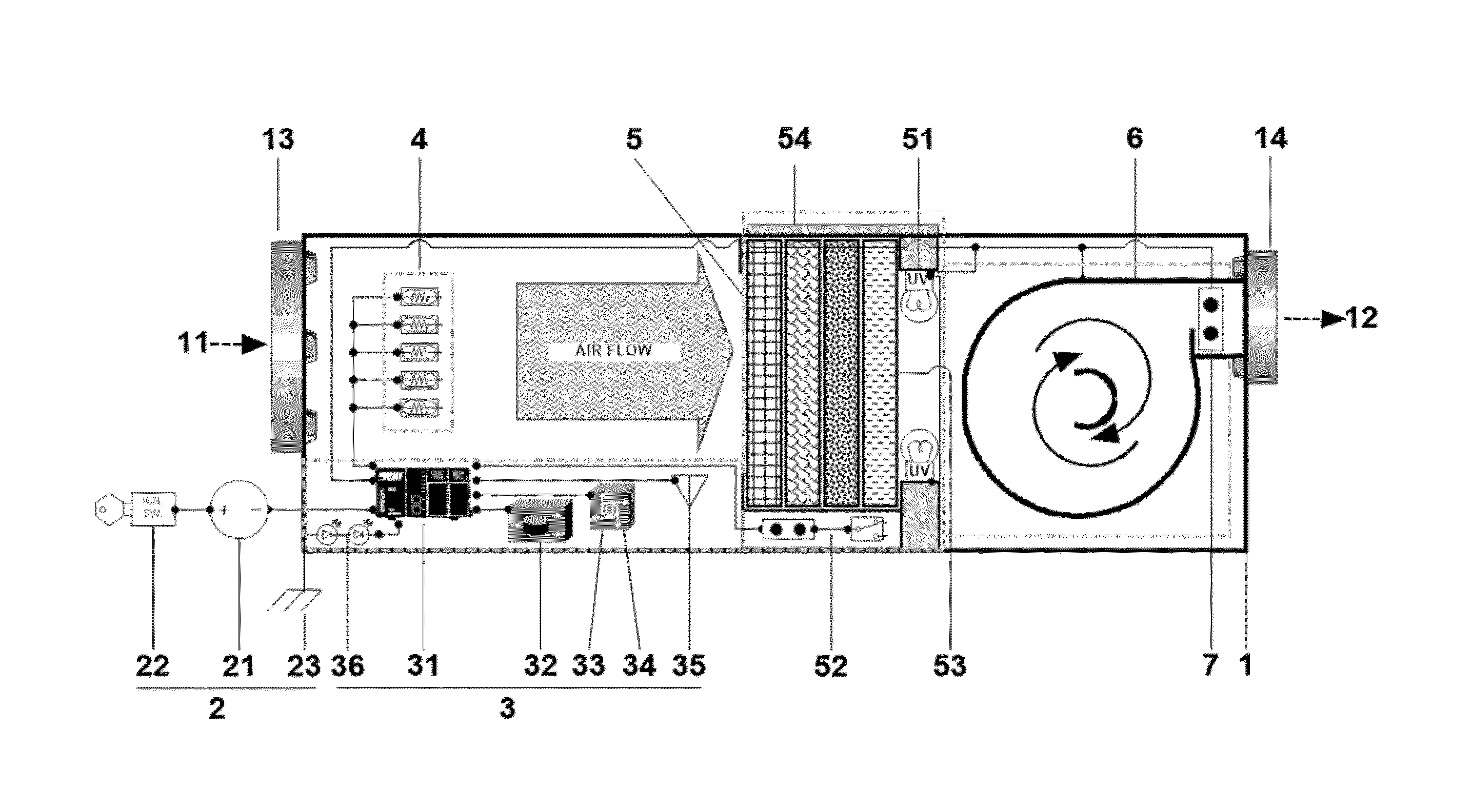

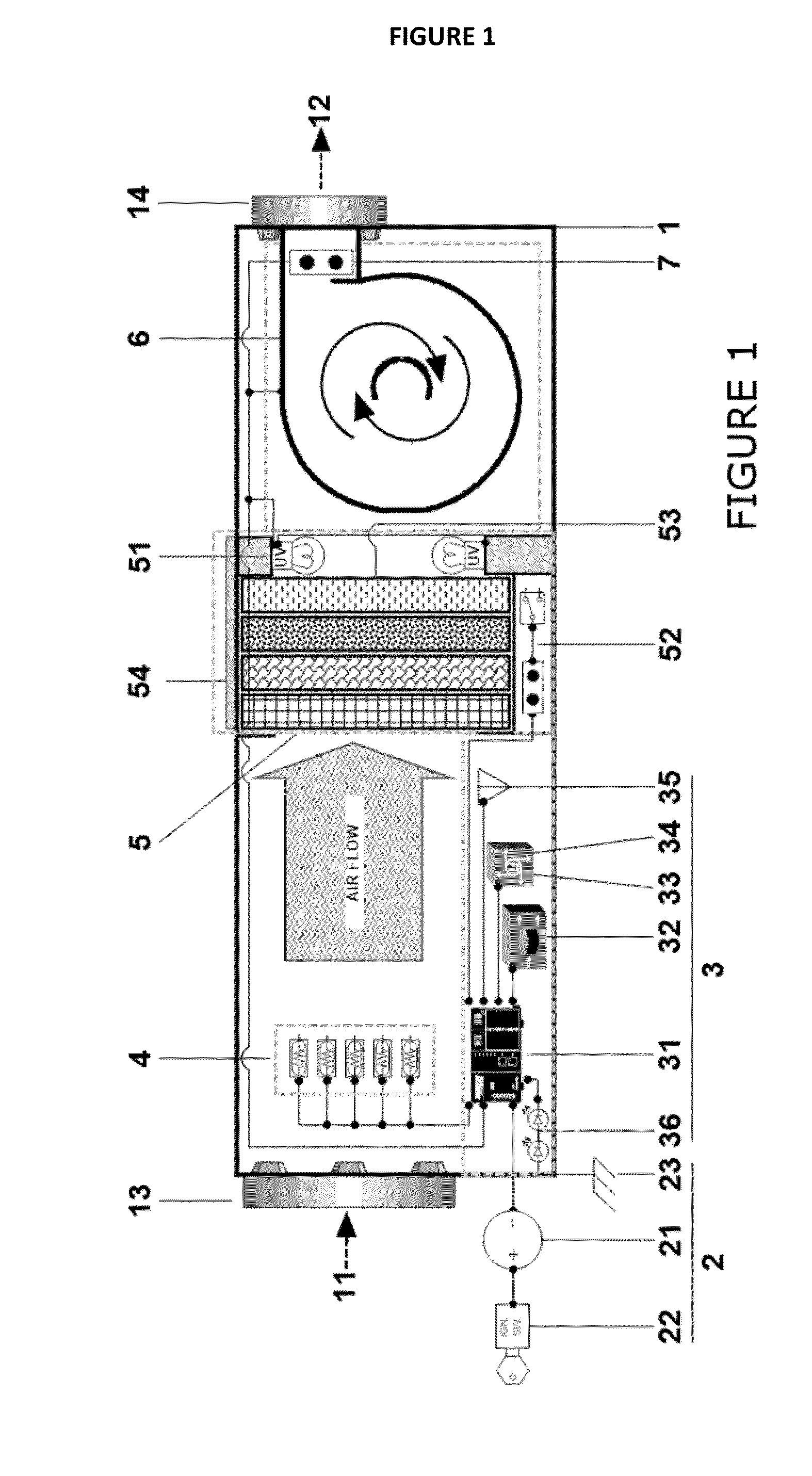

Filter

ActiveUS20160097311A1Lower Level RequirementsCost of energyCombination devicesMethane captureJet aeroplaneKerosene

Filter for application in motor vehicles in general, urban or rural use, terrestrial, aquatic or aerial use, such as car, motorcycle, truck, bus, train, boat, ship, vessel, airplane, jet ski, snowmobile, tractor, any vehicle or machine powered by a combustion engine, electric, hybrid, hydrogen, gasoline, methanol, ethanol, butanol, diesel, kerosene, or any other technology or fuel, which can also be applied to any equipment using a combustion engine, like generators or turbines for stationary power generation, large water pump and agricultural equipment use, and aircraft powered by turbo-jets, turbo-fans, turbo propellers, piston engines or others, and may also provide versions for residential, commercial, industrial and hospital use, among others, with the addition of a power supply (transformer) on the power input and a possible adjustment in a cabinet with appropriate design for each use.

Owner:COELHO FERREIRA CARLOS EDUARDO

Multiple driver occupied passenger vehicles transporter system

InactiveUS8195382B2Increase flow rateTransportation safetyAnalogue computers for vehiclesAnalogue computers for trafficEngineeringTruck

The multiple driver occupied passenger vehicles transporter system (Autobus) provides a way to efficiently, economically and safely increase the highway vehicle flow rate of cars per lane per hour. Autobus employs a vehicle transporter, terminal, sensors and systems that provide a way to quickly load and unload driver occupied passenger vehicles on and off of the vehicle transporter. Autobus provides a way to safely transport multiple driver occupied passenger vehicles, including cars, sport utility vehicles (SUVs) and light trucks.

Owner:CLEAN TRANSPORT

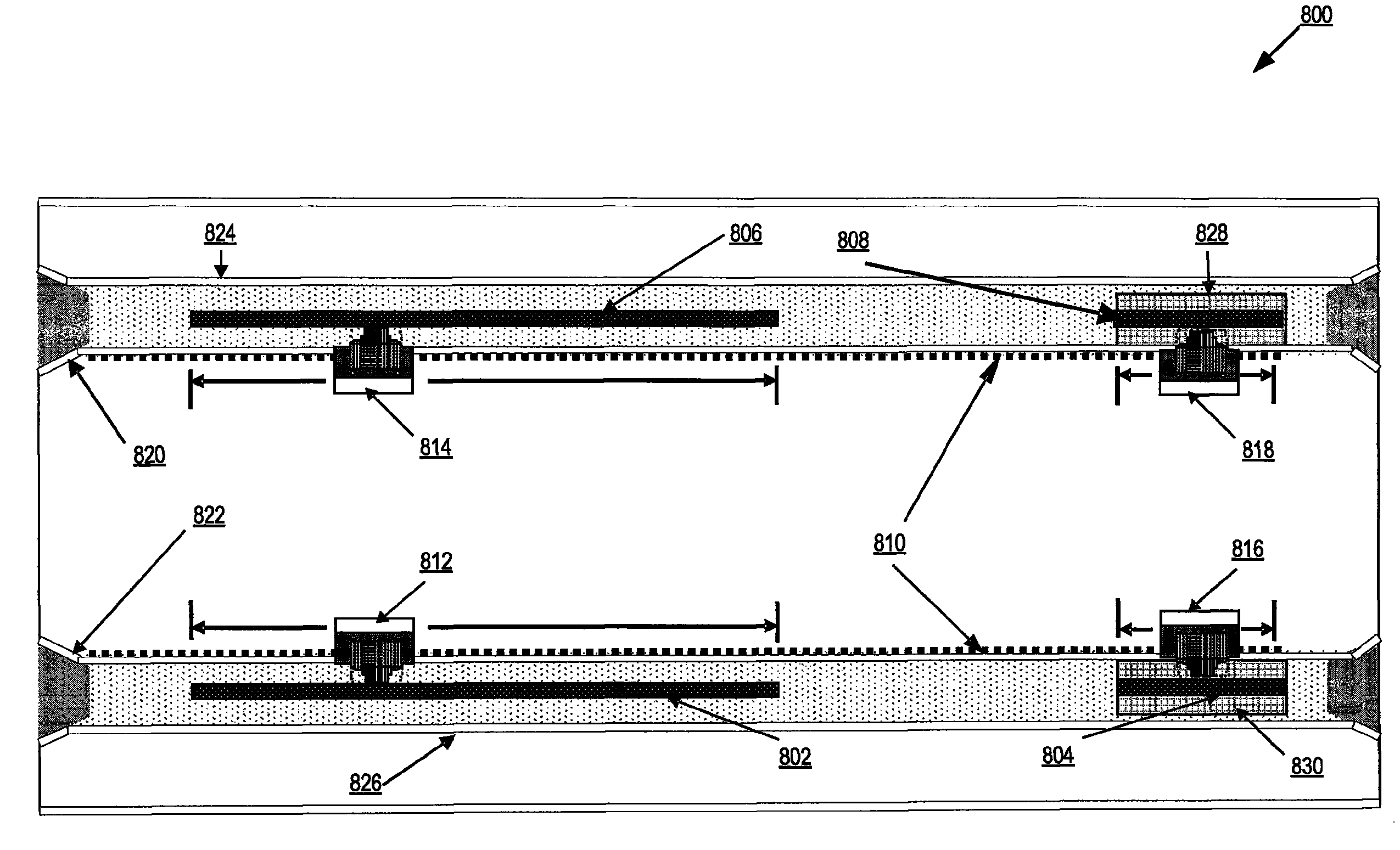

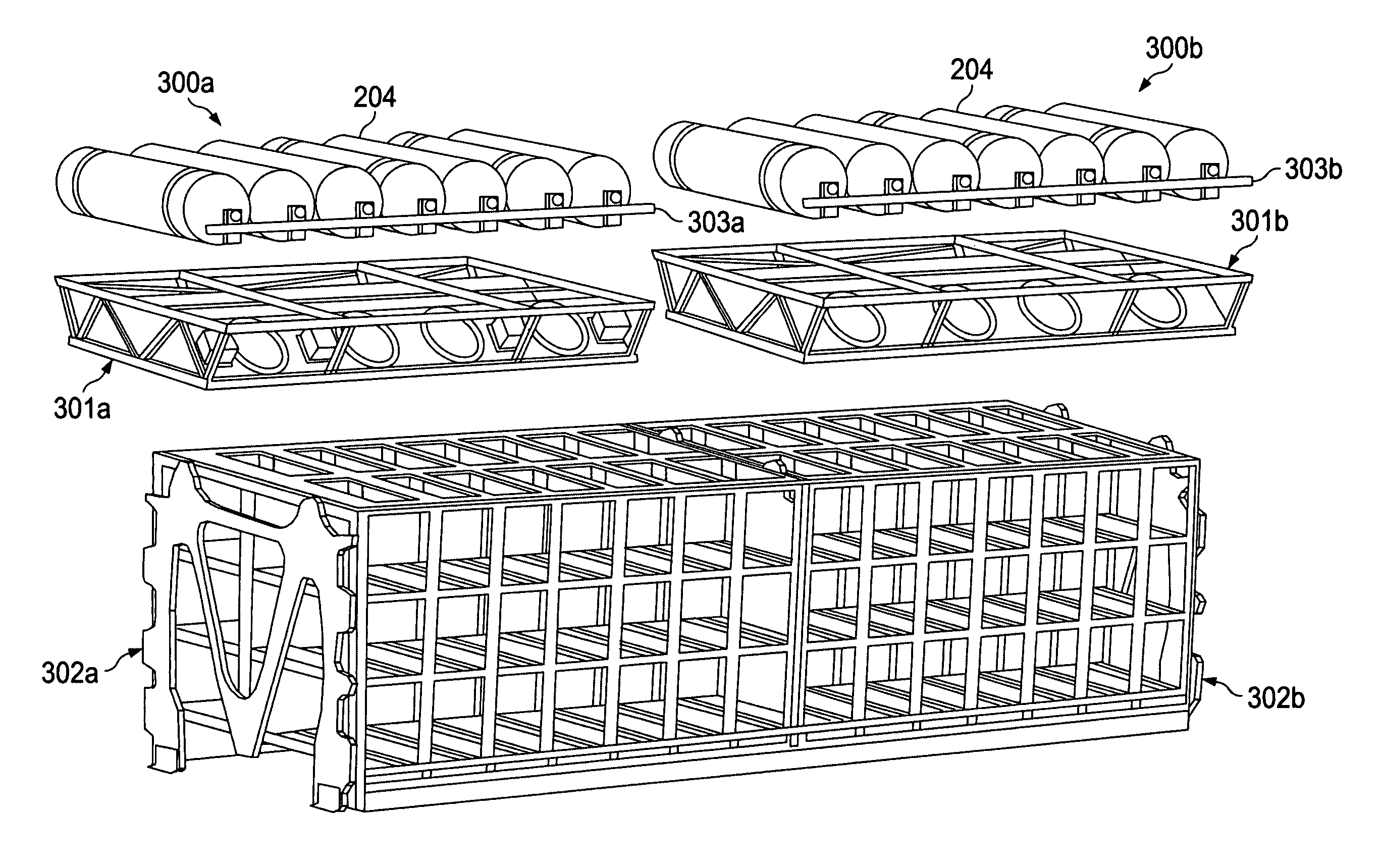

Isolation and support structures for hydrogen hybrid locomotives and hydrogen hybrid locomotives using the same

ActiveUS7966945B1Reduce air pollutionReduce amountElectric locomotivesPlural diverse prime-mover propulsion mountingElectrical batteryHydrogen tank

A hydrogen hybrid locomotive driven by a set of electric traction motors powered by at least one hydrogen fuel cell power module and plurality of batteries includes a chassis, an isolation structure disposed on the chassis for isolating the at least one hydrogen fuel cell power module from shock and vibration and a battery rack disposed on the chassis for supporting the plurality of batteries. A hydrogen containment module is disposed above the battery rack and includes a support rack supporting a plurality of hydrogen tanks and a manifold coupled to each of the plurality of hydrogen tanks for allowing charging and discharging of the hydrogen tanks.

Owner:BNSF RAILWAY

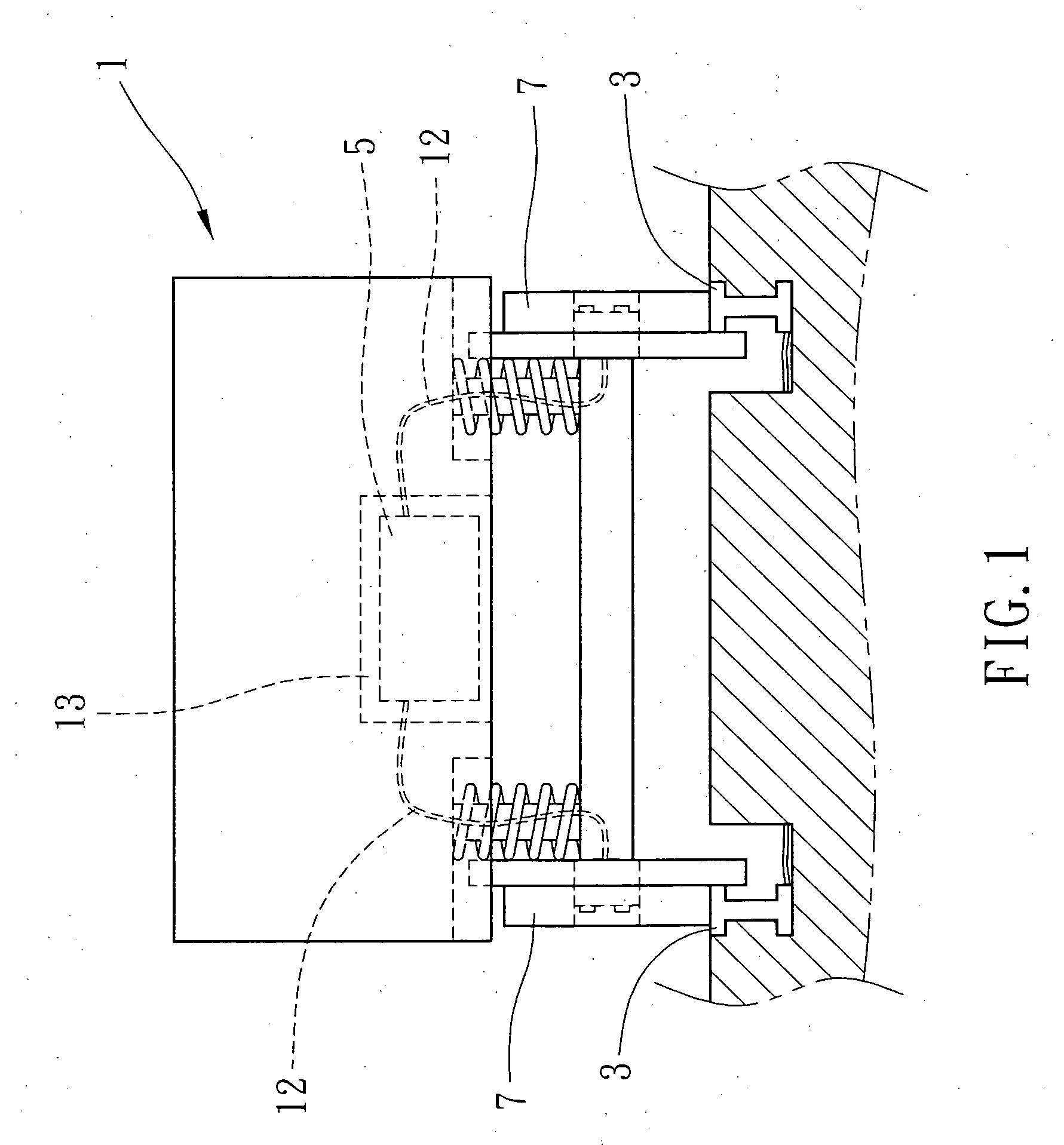

Highway vehicle towing system

InactiveUS20110079167A1Reduce air pollutionTowing hybridAnalogue computers for vehiclesTicket-issuing apparatusElectricityDrive shaft

A highway vehicle towing system includes a light railroad track embedded in a highway and capable of transmitting electricity from a power supply plant, and a towing tractor movable along the light railroad track to tow a car. The owing tractor has multiple pairs of metal wheels movably supported on the light railroad track, a motor, electrical wires connecting the metal wheels to the motor for transmitting electricity from the light railroad track to the motor, a transmission shaft coupled to and rotatable by the motor, and a differential mechanism coupled between the transmission shaft and the metal wheels for enabling the metal wheels to be rotated along the light railroad track by the motor.

Owner:YAO YI SHAN

Gas turbine control apparatus and gas turbine system using the same

InactiveUS20050262849A1Promote combustionOscillation suppressionContinuous combustion chamberEngine fuctionsCombustorGas turbines

In a gas turbine control apparatus, a frequency analyzing section frequency-analyzes at least one of pressure oscillation in combustors of a gas turbine and acceleration oscillation of each of the combustors and outputs a first frequency analysis result as the result of frequency analysis for a plurality of predetermined frequency bands. A control unit controls at least one of a first fuel flow rate of fuel and a first air flow rate of air based on the first frequency analysis result for the plurality of frequency bands. The fuel and the air are supplied to the gas turbine.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

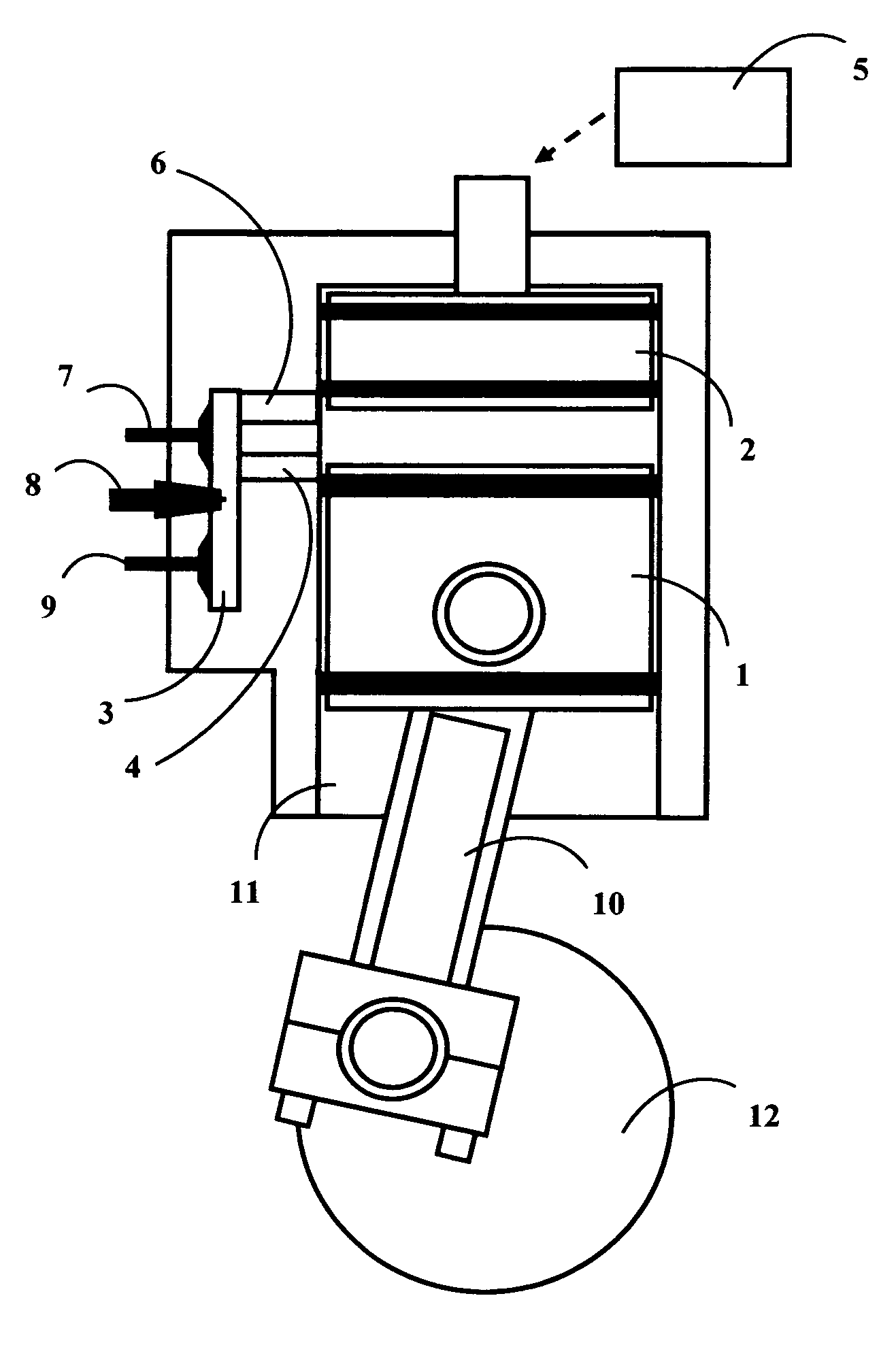

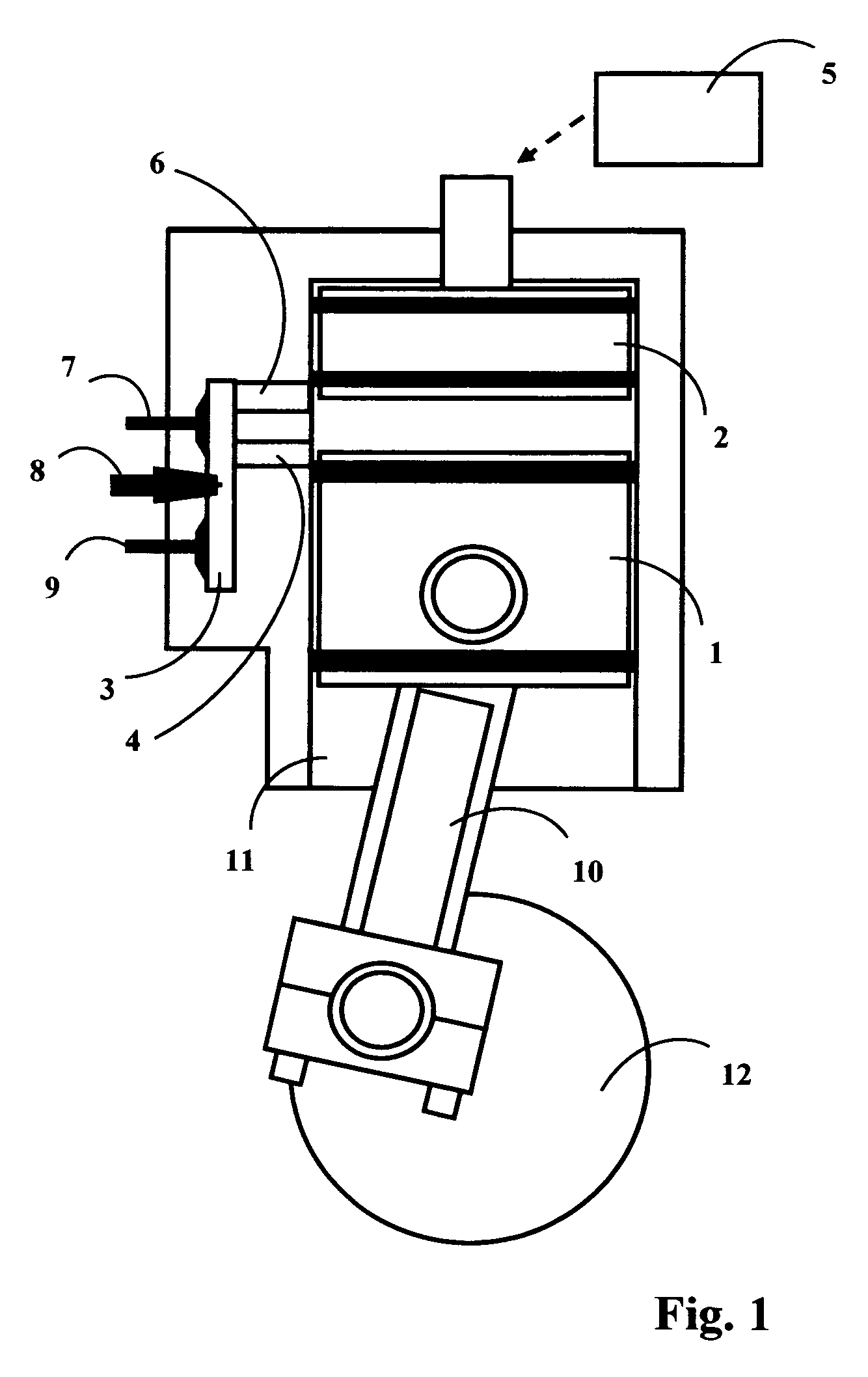

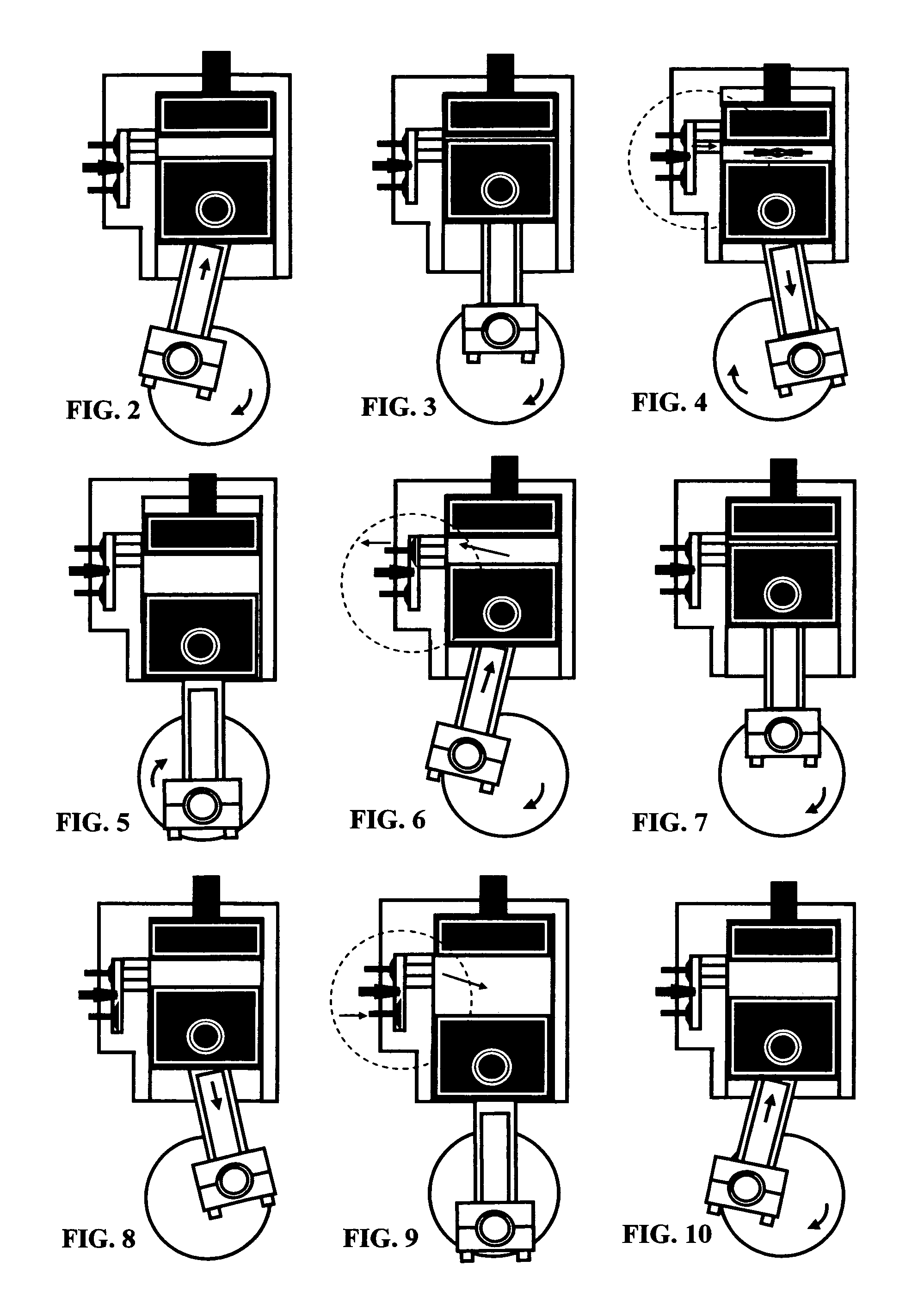

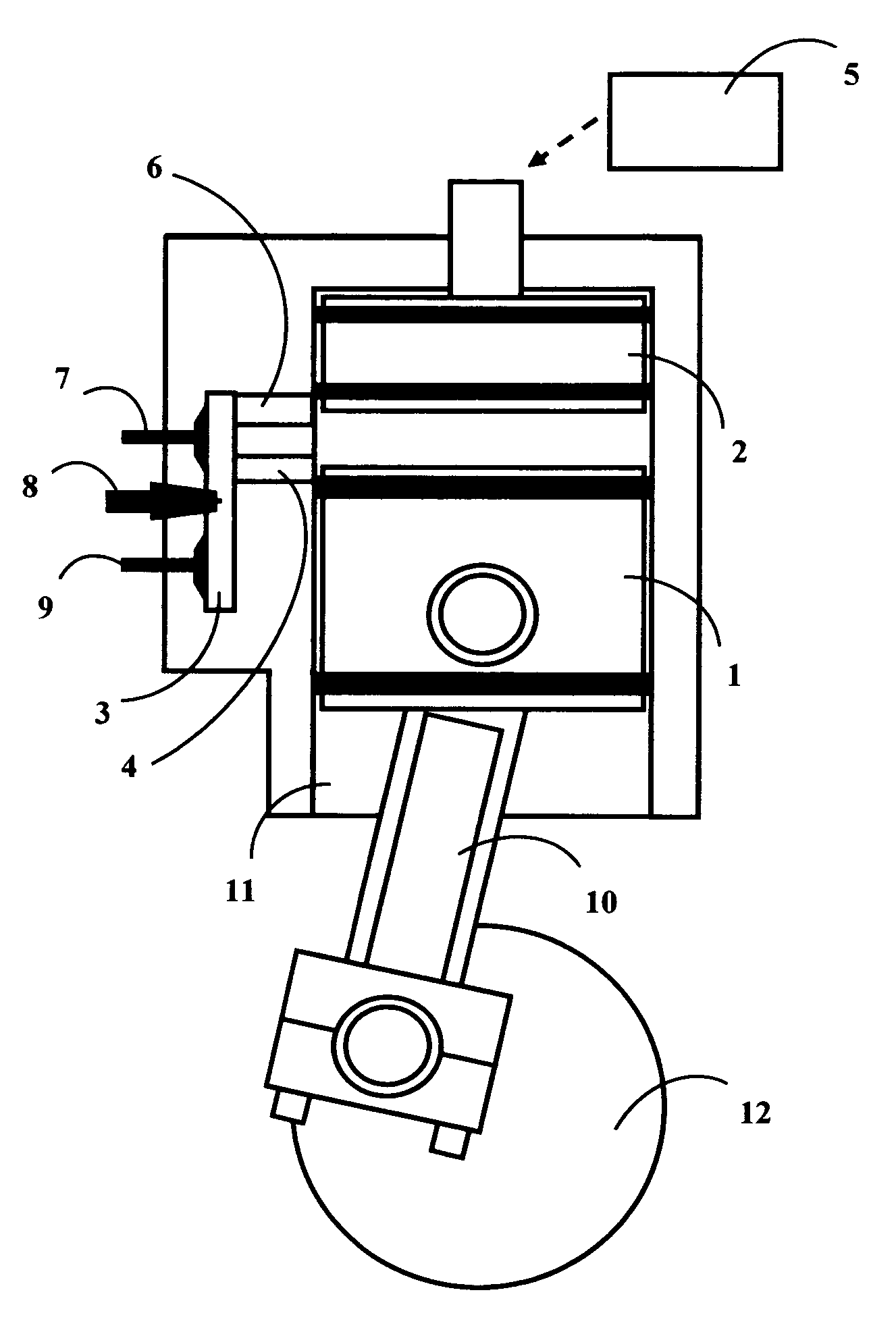

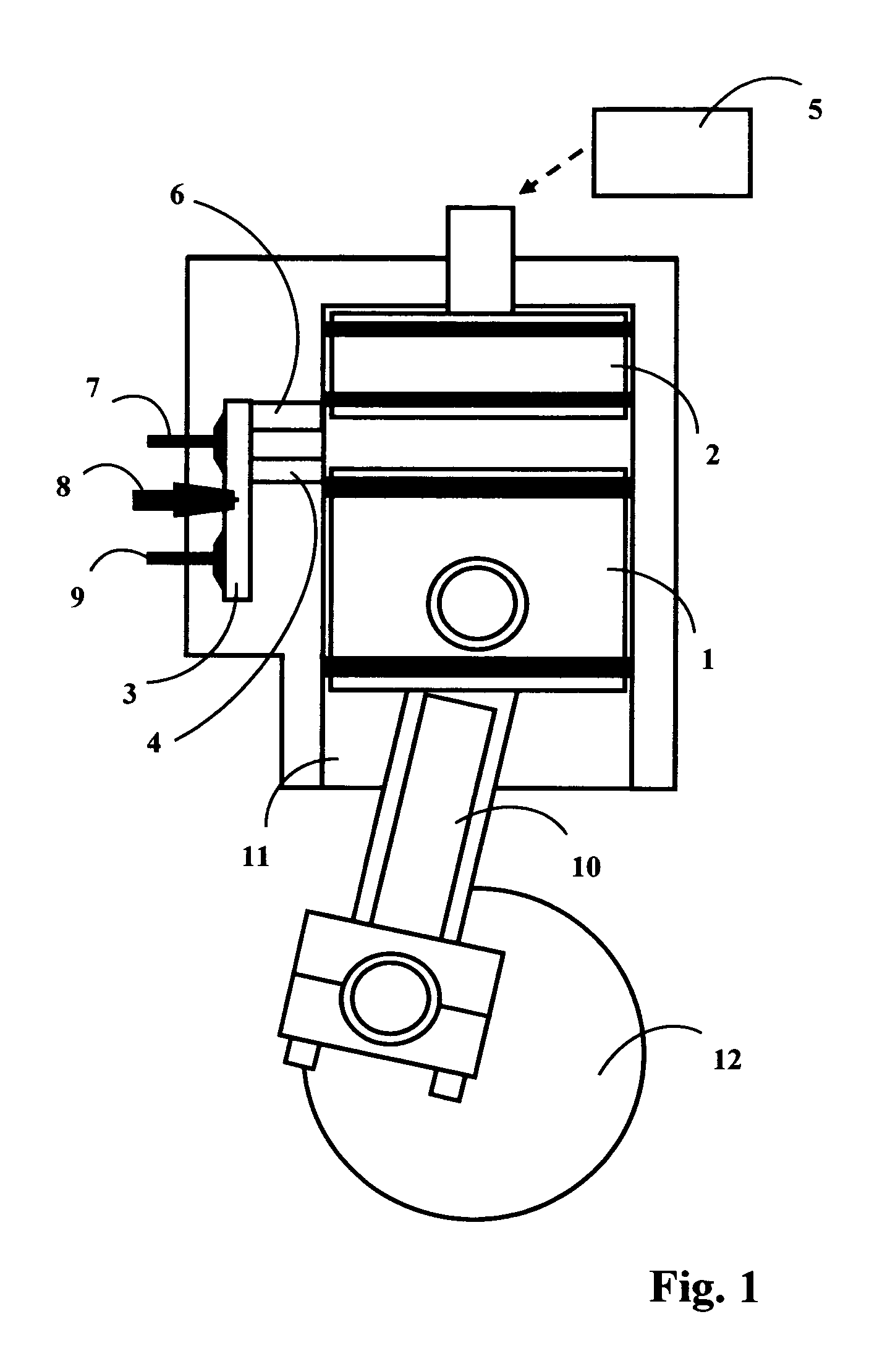

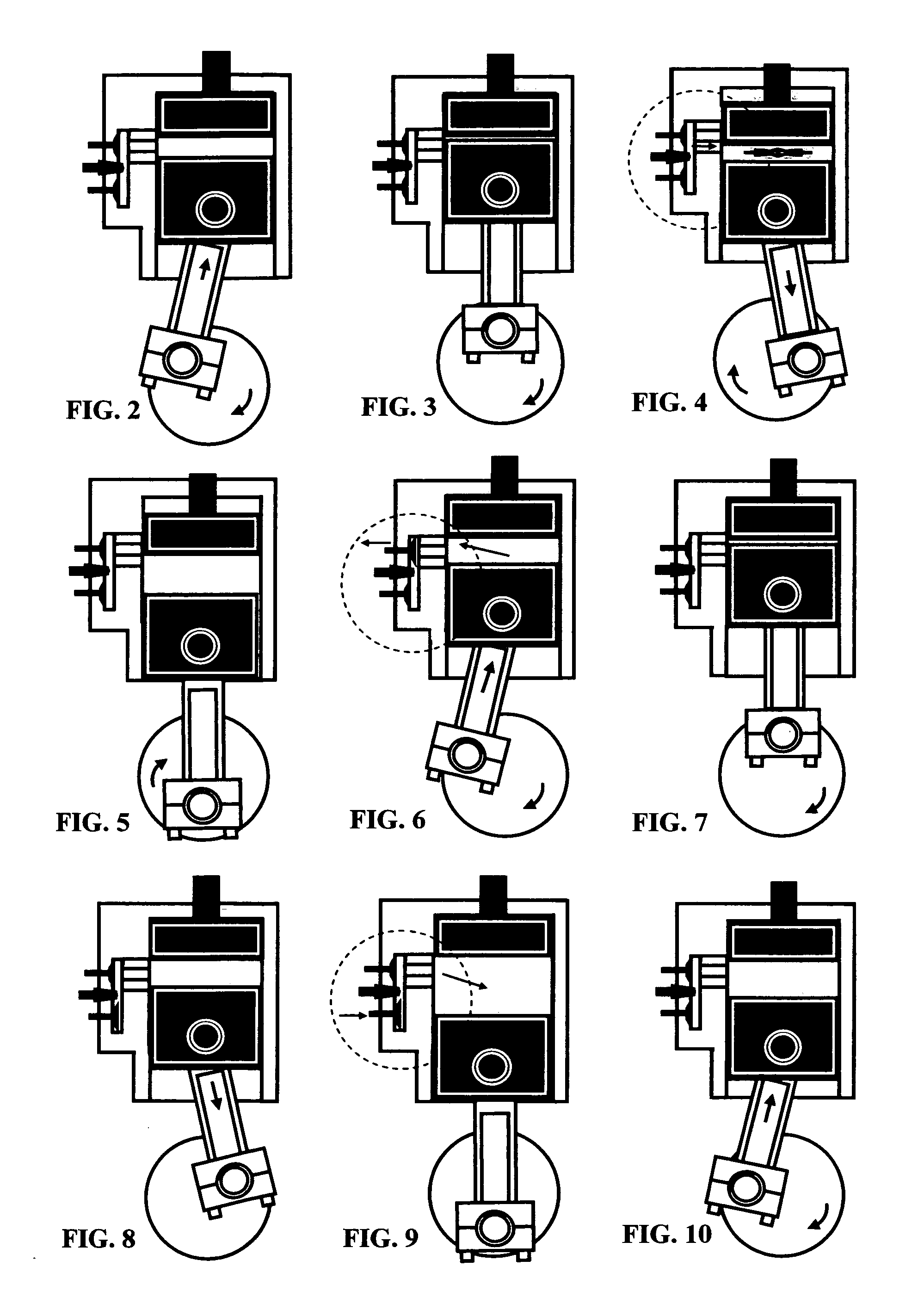

Internal combustion engine with sidewall combustion chamber and method

InactiveUS7387093B2Improve effectiveness and efficiencyLess complexInternal combustion piston enginesReciprocating piston enginesCombustion chamberTop dead center

An internal-combustion, reciprocating-piston engine operating on the Otto cycle and associated method are provided where a sidewall combustion chamber is employed that is capable of receiving highly-compressed air or a mixture of any gas and fuel from a cylinder while a main piston is positioned at or near top-dead-center in the cylinder, and where the sidewall combustion chamber is also capable of temporarily storing a highly-compressed air or a mixture of any gas and fuel before sending and re-injecting an ignited or burning mixture of highly-compressed air or a mixture of any gas and fuel into the same cylinder between the main piston and the displacer-piston when the main piston is located in the cylinder at an optimum position for receiving and transferring energy or forces.

Owner:HACSI JAMES SCOTT

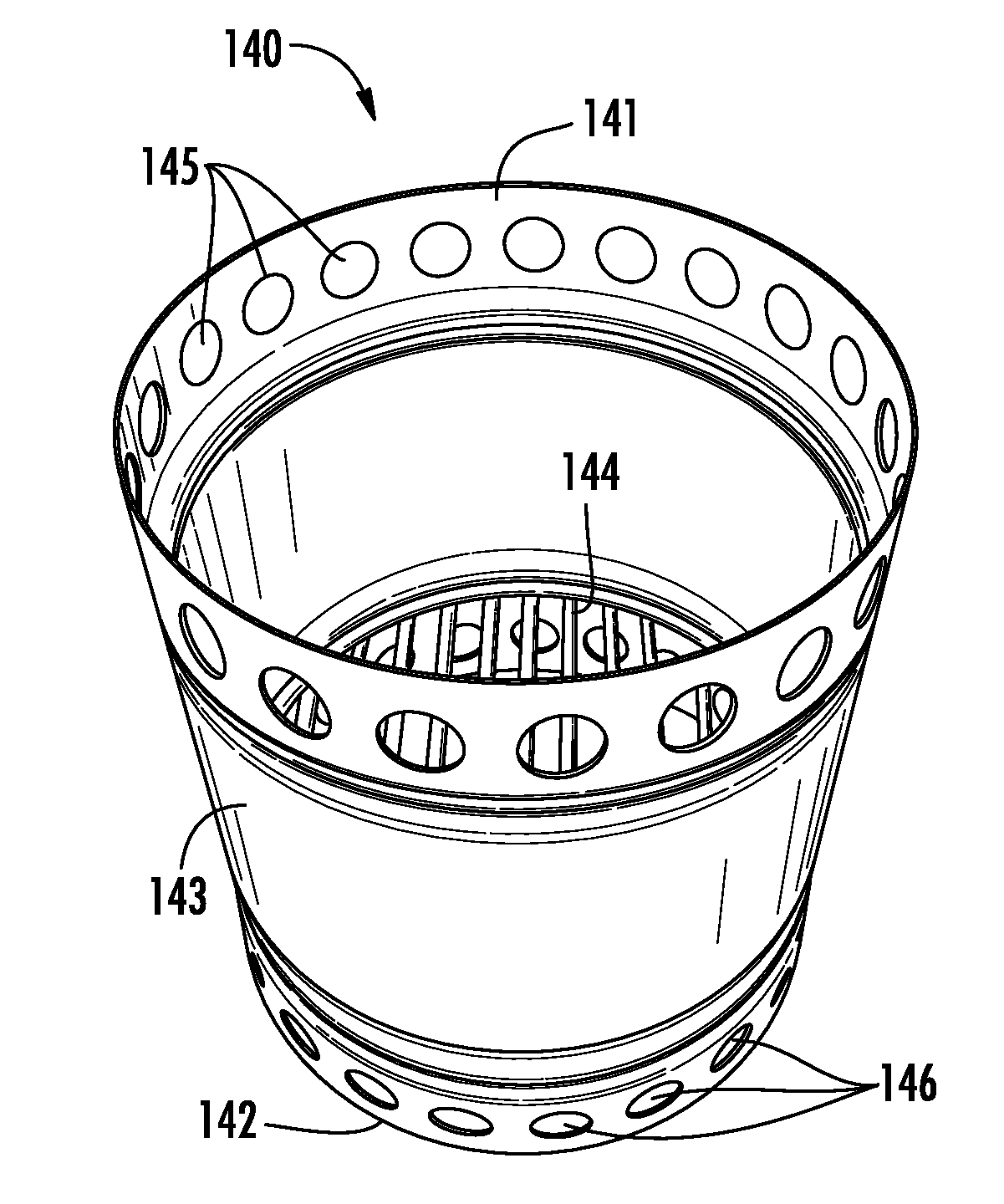

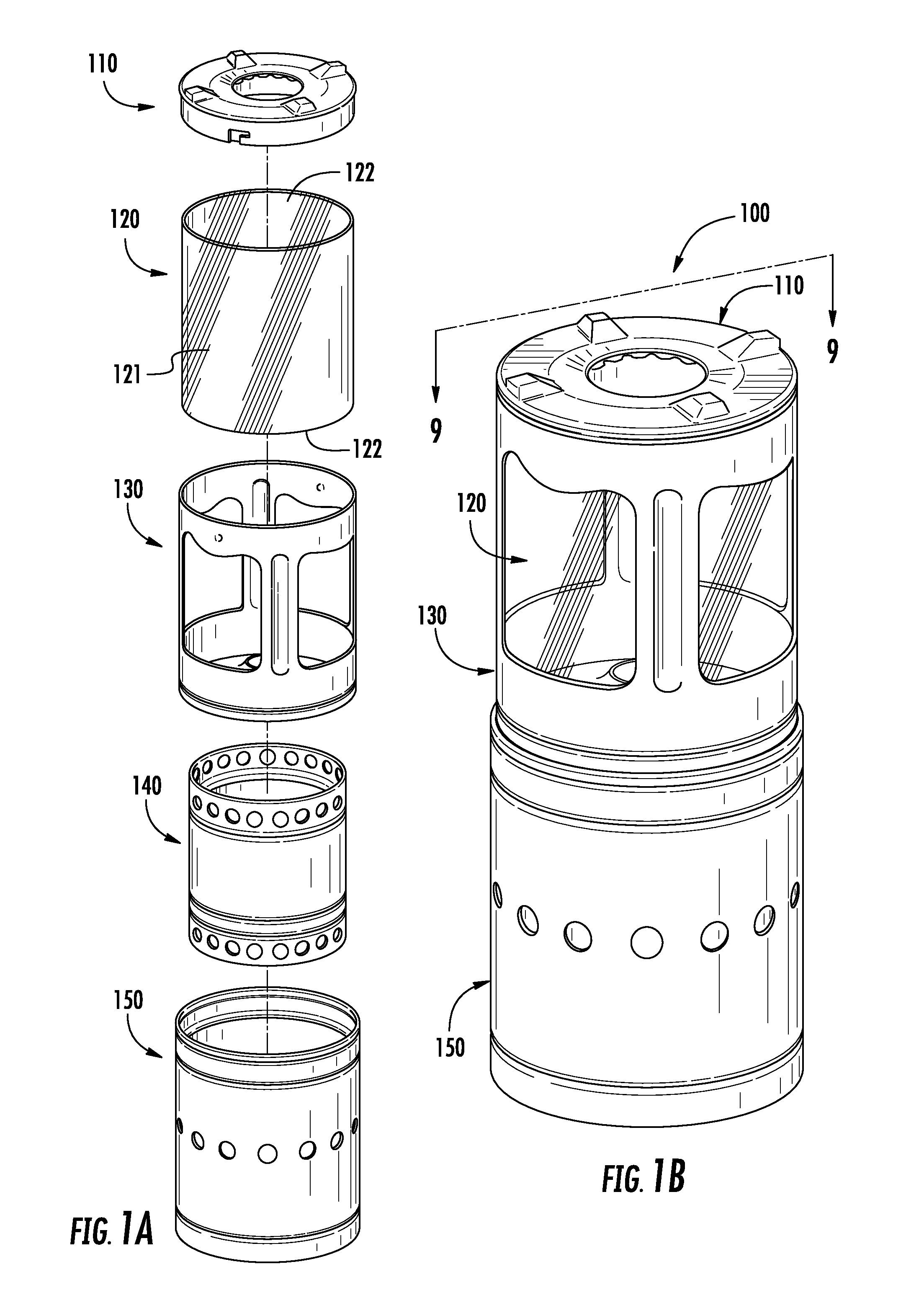

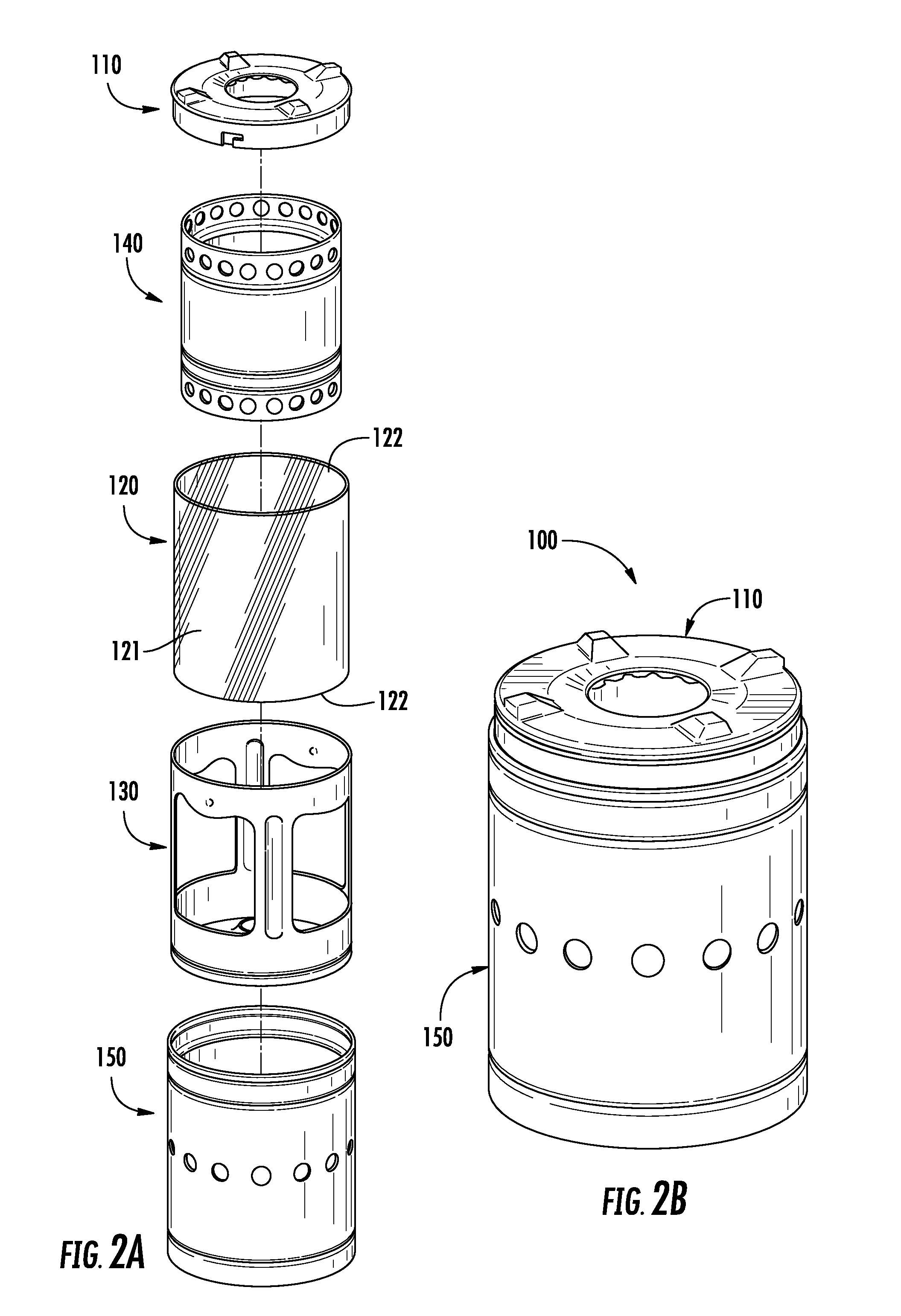

Portable collapsible biomass stove and lantern

InactiveUS20160245529A1Reduce air pollutionMechanical apparatusDomestic stoves or rangesCombustionEngineering

A portable and collapsible stove and lantern allowing clean combustion of biomass fuels found in the natural environment comprises a top member, a transparent member, a support member having an orifice and a plurality of windows, a chamber having a plurality of top and bottom openings and a mesh to support biomass fuels, and a main body having an insulation member, a reflecting member and a plurality of middle openings. When used, the transparent member is disposed within the support member that is disposed on top of the chamber which is then disposed within the main body, and the top member is disposed on top of the support member. Air drawn into the main body by the plurality of middle openings is further drawn into the chamber by the pluralities of top and bottom openings, mixed with fuels for combustion, producing flame into the support member through the orifice.

Owner:APROVECHO RES CENT

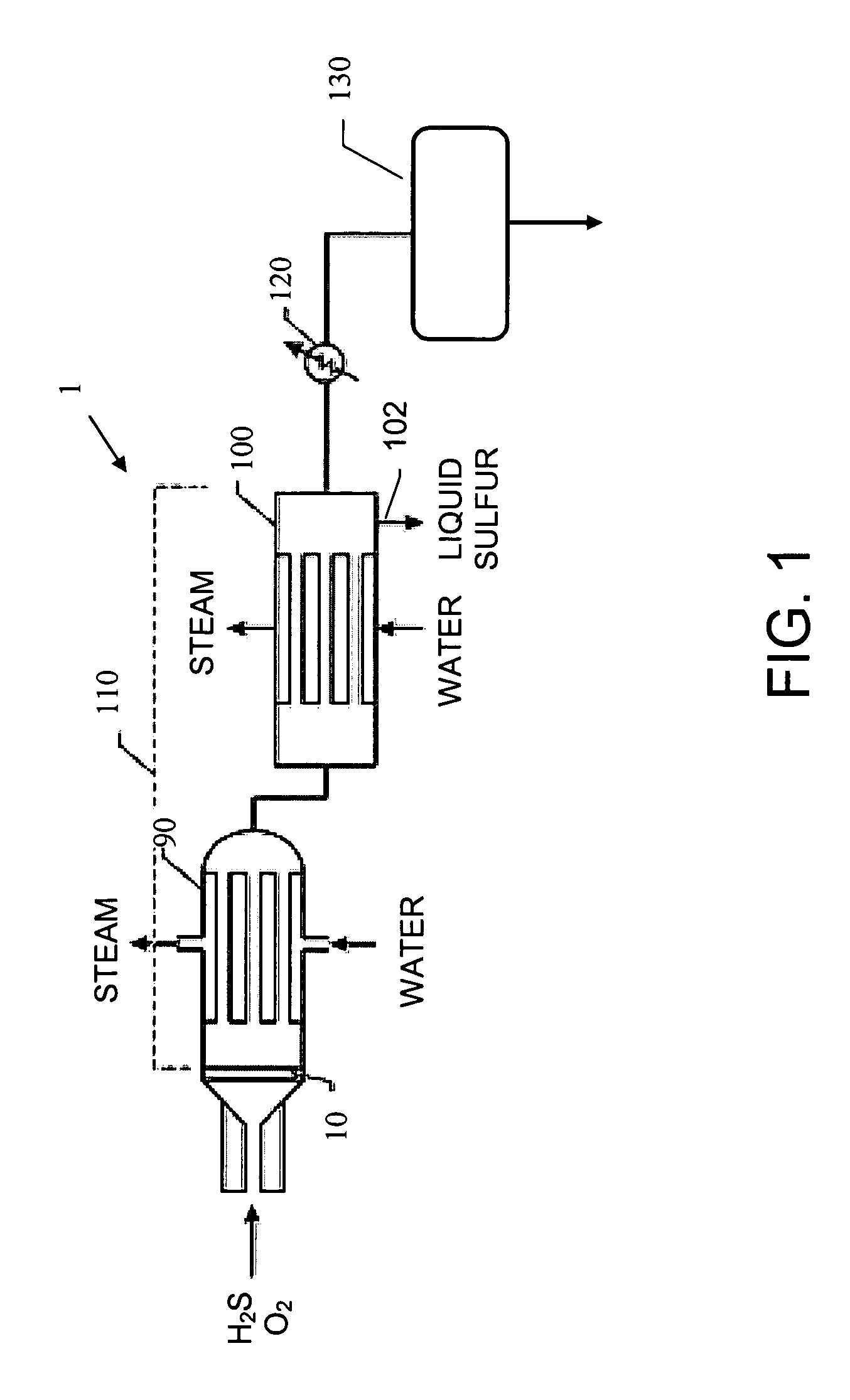

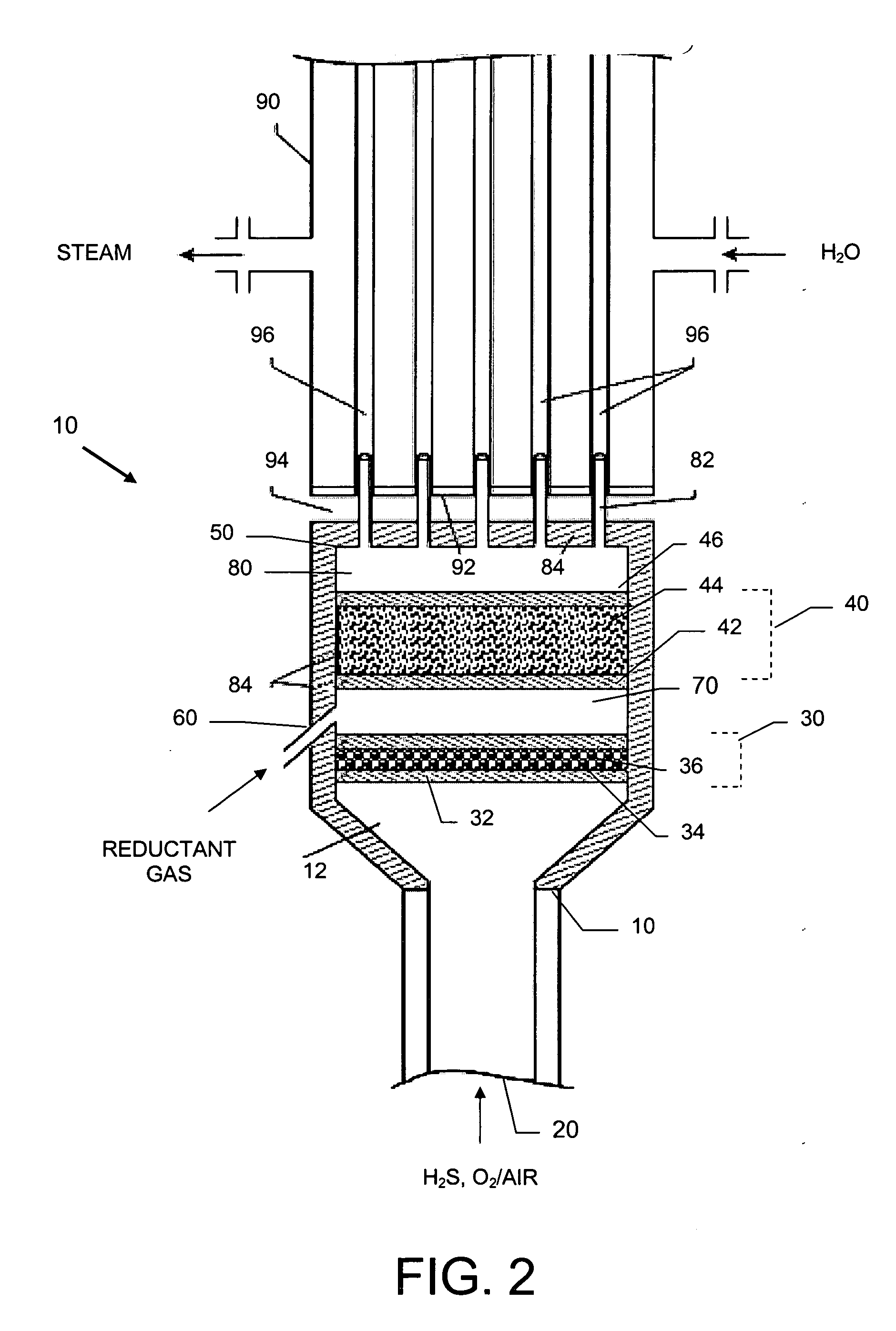

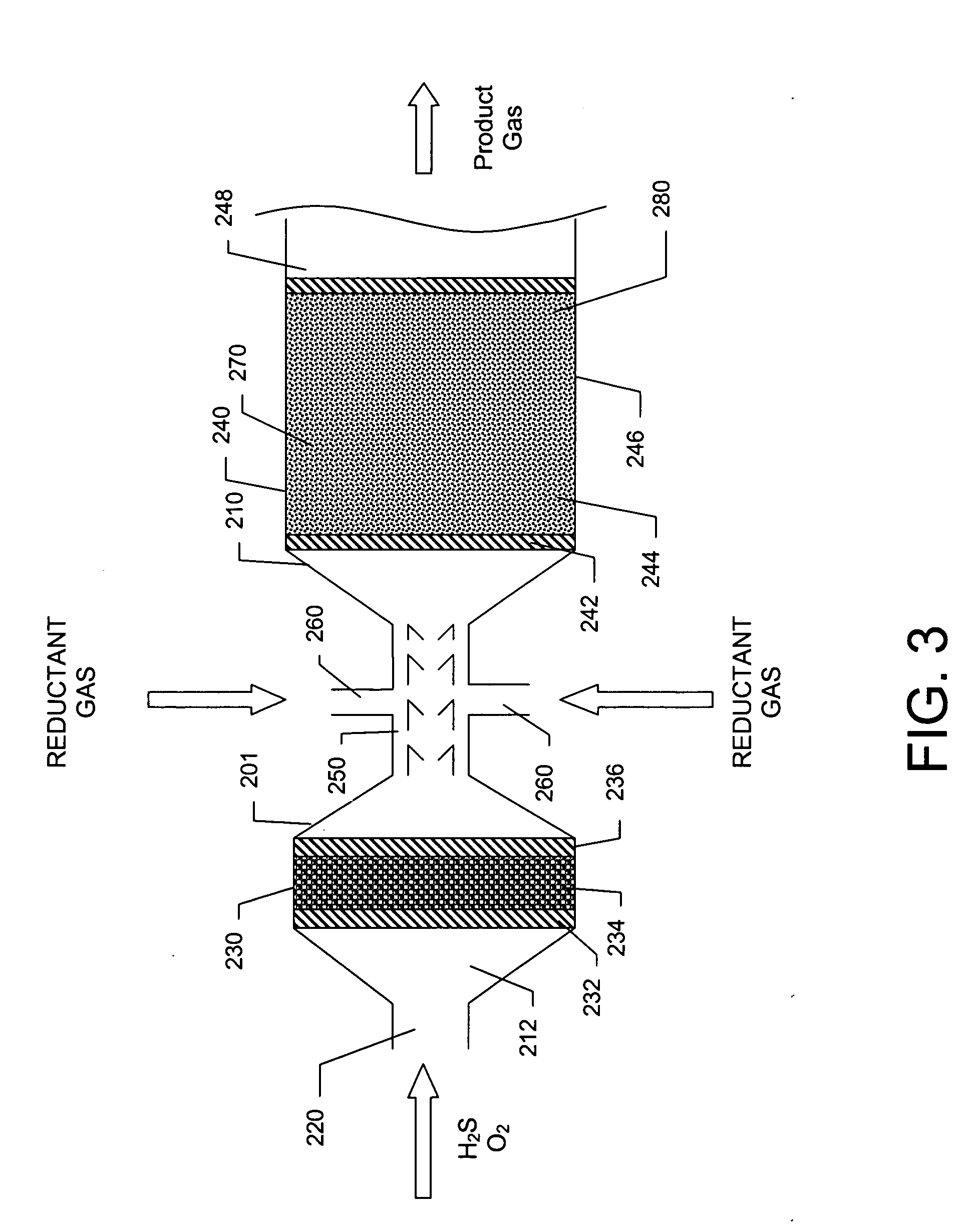

Two-stage catalytic process for recovering sulfur from an H2S-containing gas stream

InactiveUS20050180914A1Easy to operateImprove stabilityCombination devicesPhysical/chemical process catalystsPartial oxidationSulfur

Apparatus and process for recovering elemental sulfur from a H2S-containing waste gas stream are disclosed. The apparatus preferably comprises a first reaction zone for carrying out the catalytic partial oxidation of H2S, a second reaction zone for the catalytic partial reduction of any incidental SO2 produced in the first reaction zone, and a cooling zone including a sulfur condenser. According to a preferred embodiment of the process, a mixture of H2S and O2 contacts a catalyst in the first reaction zone very briefly (i.e, less than about 200 milliseconds) producing primarily S0 and H2O. Some SO2 is also present in the first stage product gas mixture. A reductant gas (e.g. CO, or CH4 or natural gas) is fed together with the first stage product gas mixture to a second catalytic reaction zone where the partial reduction of the SO2 component to elemental sulfur and CO2 is carried out.

Owner:CONOCOPHILLIPS CO

External combustion engine

InactiveUS7260934B1Reduce volatilityReduce flammabilitySteam engine plantsElectricityExternal combustion engine

An organic Rankine engine used to power a vehicle is provided with a quick-start system of pumps, electric heaters or pistons to generate a pressure differential across the motor, prior to the engine reaching operating conditions.

Owner:ROBERTS JOHN HAMLIN

Internal combustion engine with sidewall combustion chamber and method

InactiveUS20070089694A1Efficient and effectiveImprove effectiveness and efficiencyInternal combustion piston enginesEngine controllersTop dead centerCombustion chamber

An internal-combustion, reciprocating-piston engine operating on the Otto cycle and associated method are provided where a sidewall combustion chamber is employed that is capable of receiving highly-compressed air or a mixture of any gas and fuel from a cylinder while a main piston is positioned at or near top-dead-center in the cylinder, and where the sidewall combustion chamber is also capable of temporarily storing a highly-compressed air or a mixture of any gas and fuel before sending and re-injecting an ignited or burning mixture of highly-compressed air or a mixture of any gas and fuel into the same cylinder between the main piston and the displacer-piston when the main piston is located in the cylinder at an optimum position for receiving and transferring energy or forces.

Owner:HACSI JAMES SCOTT

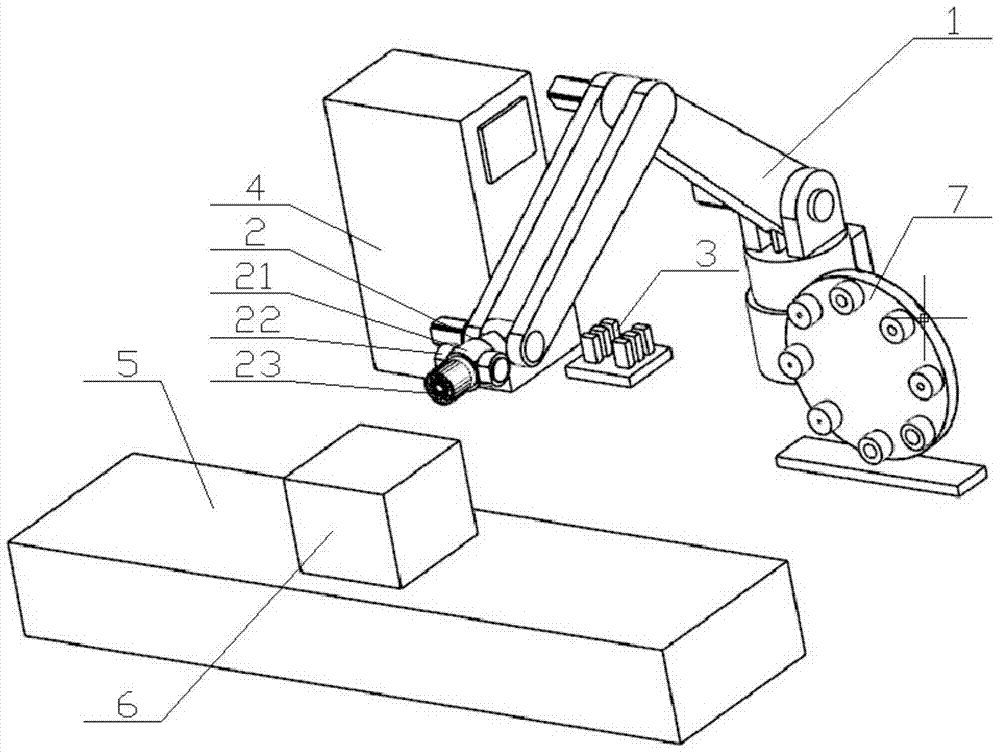

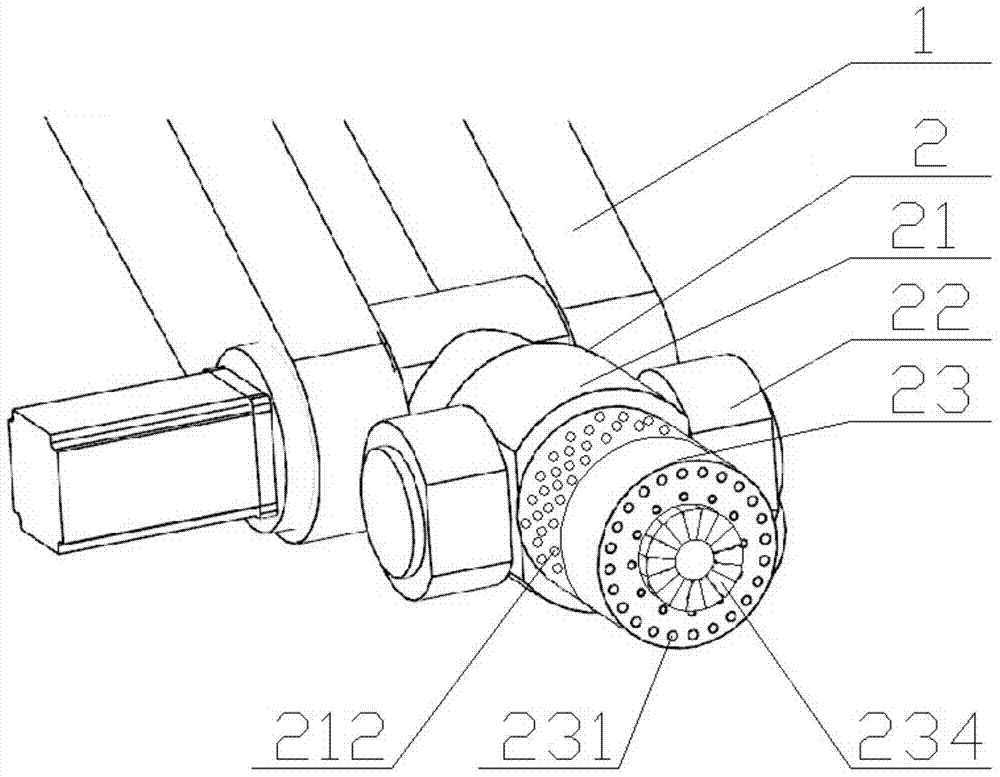

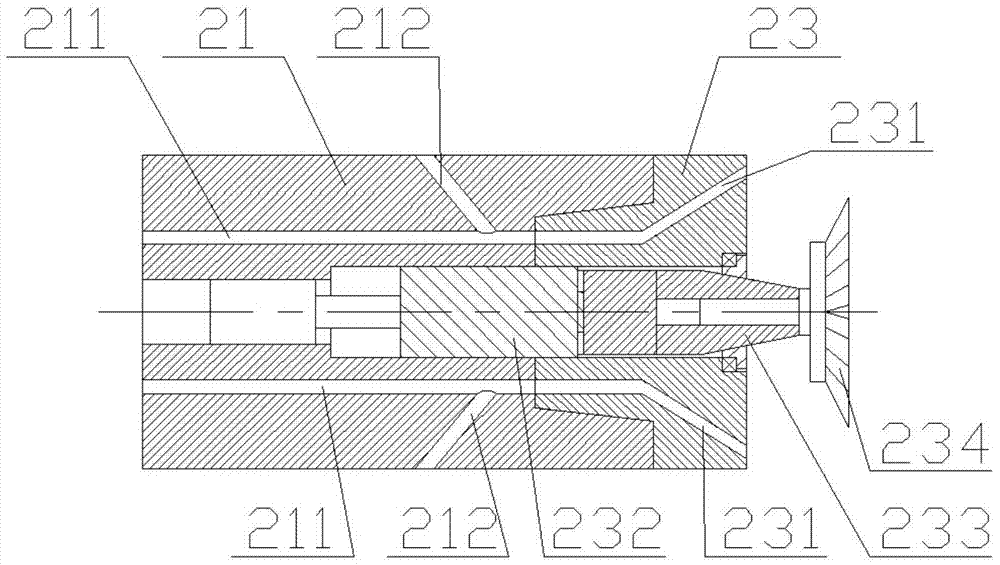

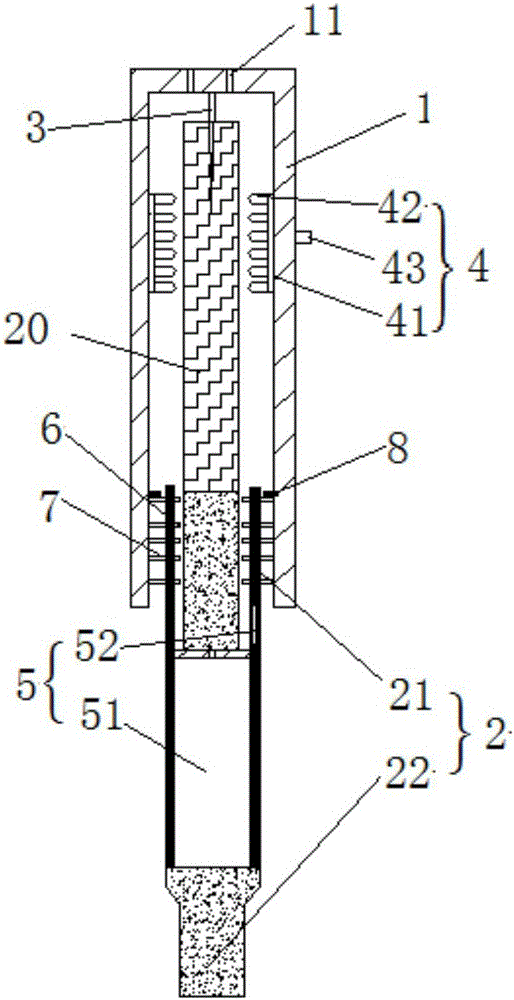

Intelligent automatic grinding and polishing unit based on digital bus and usage method thereof

ActiveCN104842238AImprove grinding and polishing efficiencyReduce air pollutionGrinding machinesGrinding/polishing safety devicesProduct gasDistance sensors

The invention discloses an intelligent automatic grinding and polishing unit based on a digital bus and a usage method thereof. The intelligent automatic grinding and polishing unit comprises a grinding and polishing device (2), a control valve bank (3) and the like. A body (21) of the grinding and polishing device is at least provided with two inner channels (211) and outer channels (212) which are identical to the inner channels in number and are communicated with the inner channels respectively. The body is further provided with a pattern recognition sensor, a position sensor and a range sensor. A working device (23) is internally provided with spraying orifices (231) communicated with the inner channels. The intelligent automatic grinding and polishing unit further comprises a grinding head drive mechanism (232) and a grinding head (234). The control valve bank comprises a positive-pressure gas control solenoid valve, a negative-pressure gas control solenoid valve and a brightener control solenoid valve which are connected with the inner channels and the outer channels. The intelligent automatic grinding and polishing unit can decrease the air pollution degree of a working site, lower the probability of secondary pollution and achieve intelligent grinding and polishing, thereby being suitable for grinding and polishing procedures in digital bus factories.

Owner:XUZHOU DKEC ELECTRICAL TECH

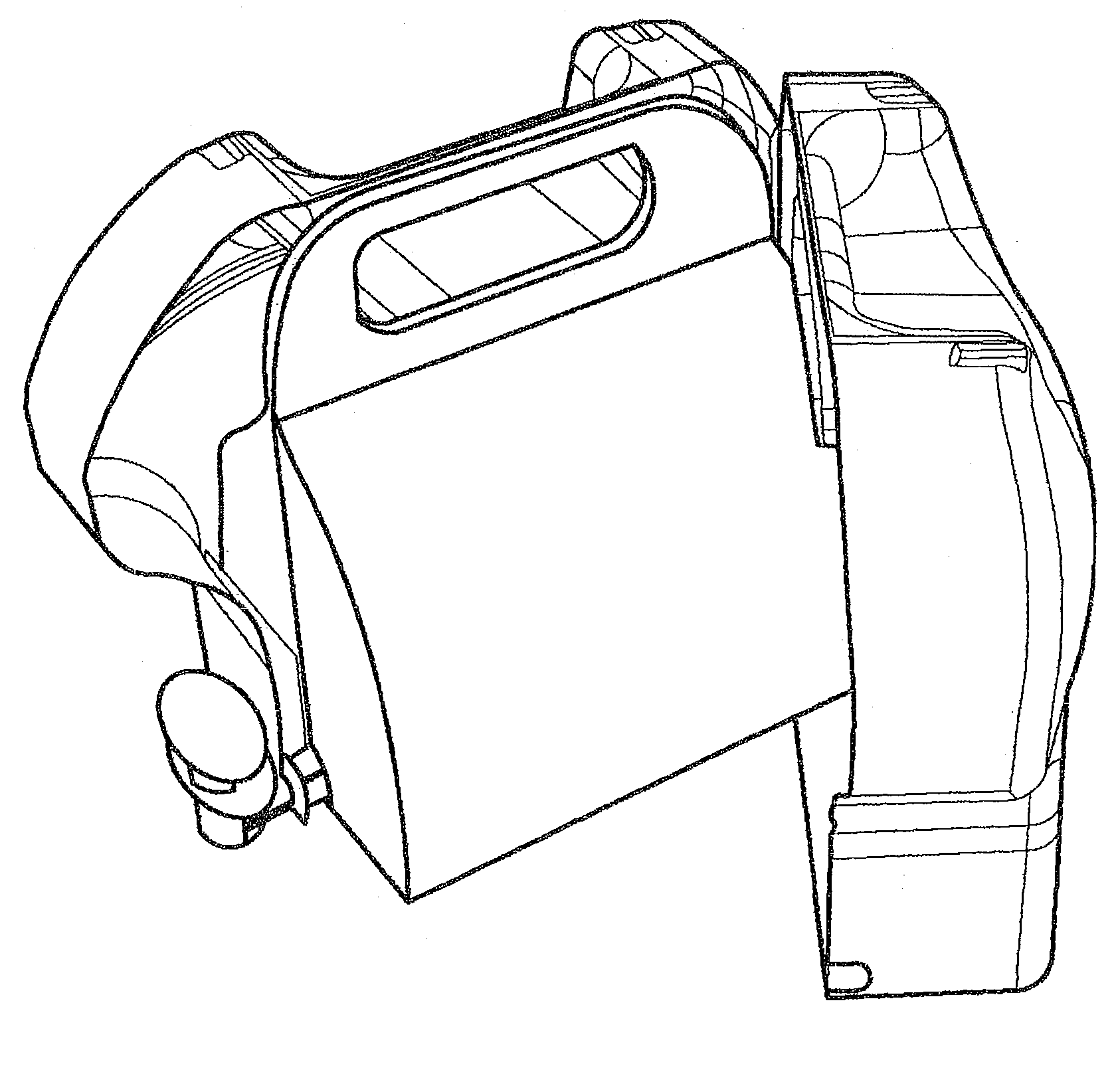

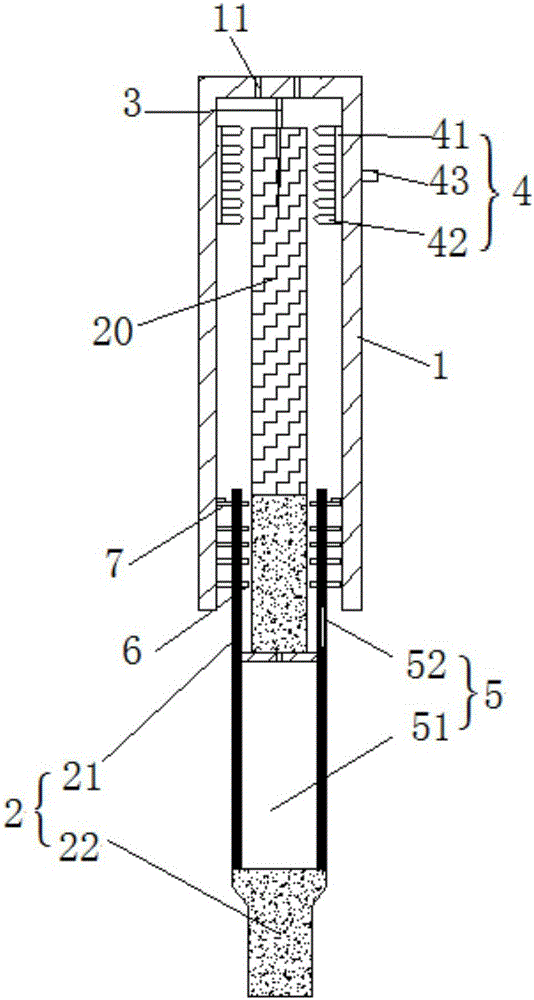

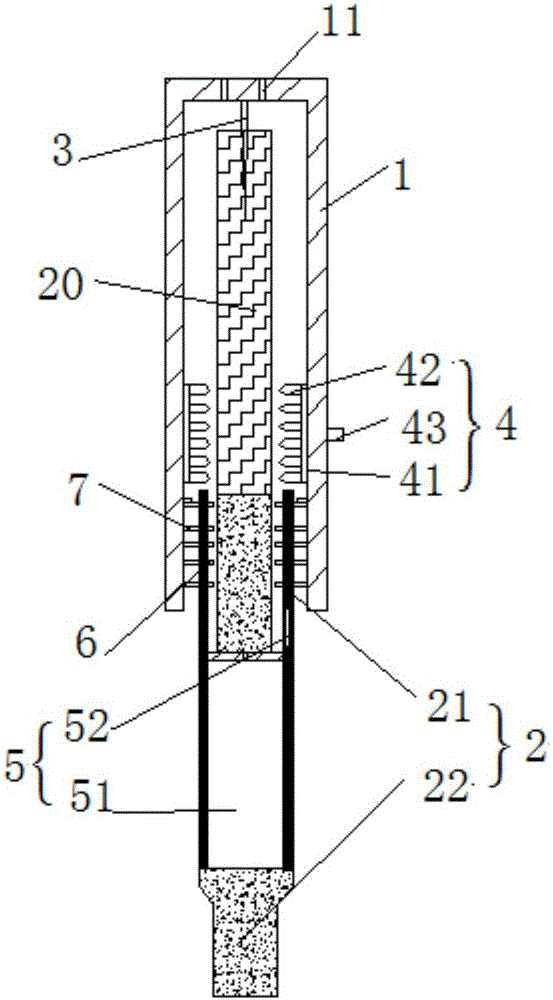

Unfired cigarette heating device

The invention discloses an unfired cigarette heating device which comprises a hollow heating casing with one end opening and further comprises a circuit control carrier. A vent hole is molded in the heating casing; a piercing internal-heating structure and an annular external-heating structure are arranged in an inner cavity of the heating casing, the piercing internal-heating structure is arranged at the bottom of the heating casing, and the annular external-heating structure is arranged on the annular cavity wall of the heating casing. A cigarette clamp part is arranged at one end of the circuit control carrier, a smoking part which is in gas-flow circulation with the cigarette clamp art is arranged at the other end of the circuit control carrier, the cigarette clamp part is inserted in the inner cavity of the heating casing and is in sealed connection with the same; an airflow actuator used for starting the piercing internal-heating structure and the annular external-heating structure to heat cigarettes is also arranged in the circuit control carrier. During smoking by the smoking part of the circuit control carrier, the piercing internal-heating structure and the annular external-heating structure are started to simultaneously heat the cigarettes. The cigarettes are heated from all sides by means of combination of the piercing internal-heating structure and the annular external-heating structure; meanwhile, air pollution caused by leaked smoke can be reduced in use of the unfired cigarette heating device; and by the unfired cigarette heating device, the whole cigarettes can be heated uniformly with low requirement for heating temperature.

Owner:CHINA TOBACCO GUANGXI IND

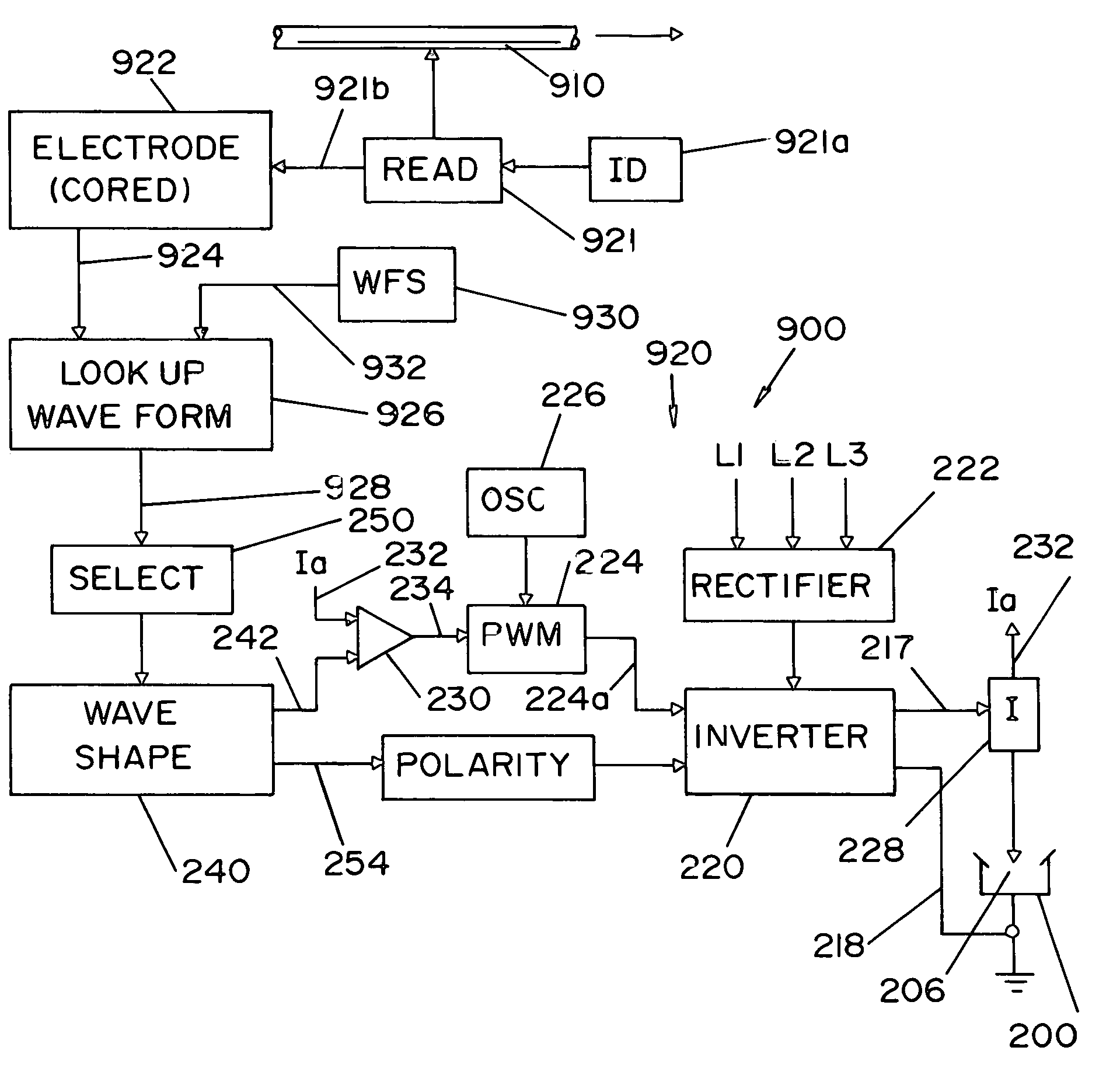

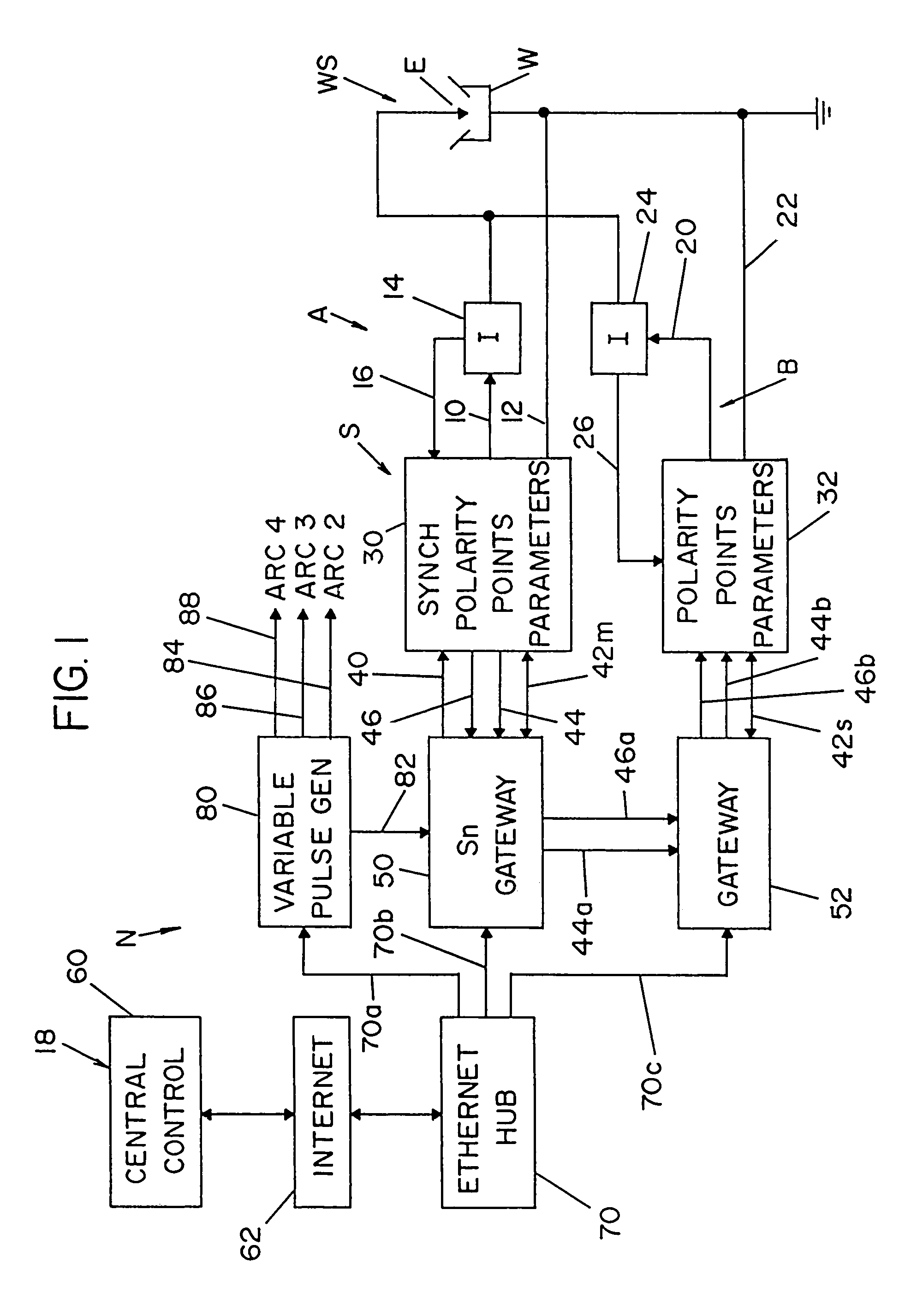

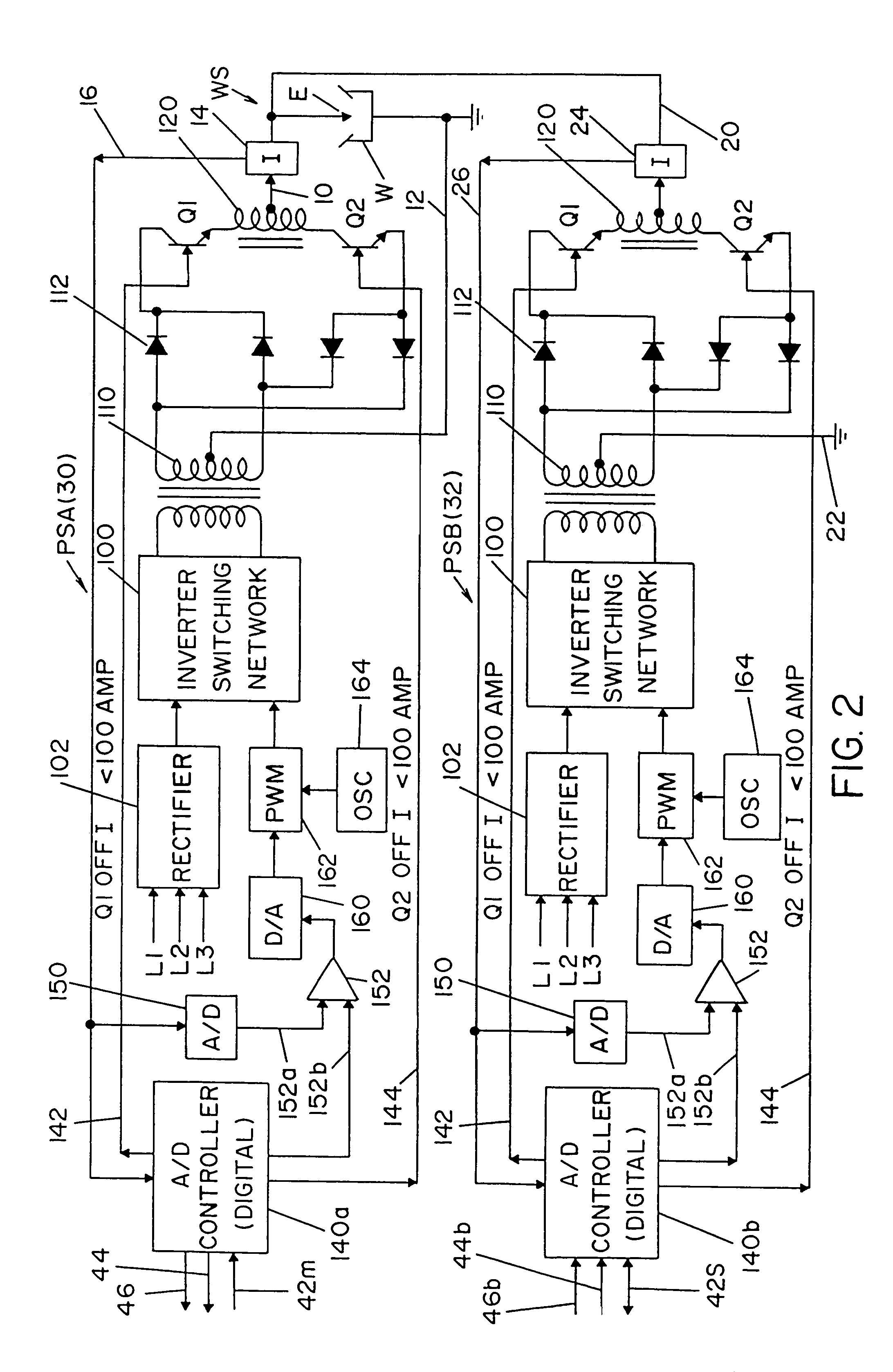

Electric ARC welder system with waveform profile control for cored electrodes

ActiveUS7166817B2Benefit in qualityIncrease productivityArc welding apparatusWaveform shapingEngineering

An electric arc welder for creating a welding process in the form of a succession of AC waveforms between a particular type of cored electrode, with a sheath and core, and a workpiece by a power source comprising an high frequency switching device for creating the individual waveforms in said succession of waveforms, each waveform having a profile is formed by the magnitude of each of a large number of short current pulses generated at a frequency of at least 18 kHz where said profile is determined by the input signal to a wave shaper controlling said short current pulses; a circuit to create a profile signal indicative of said particular type of electrode; and a select circuit to select said input signal based upon said profile signal whereby said wave shaper causes said power source to crate a specific waveform profile for said particular type of cored electrode.

Owner:LINCOLN GLOBAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com