Patents

Literature

134results about How to "Improve grinding and polishing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

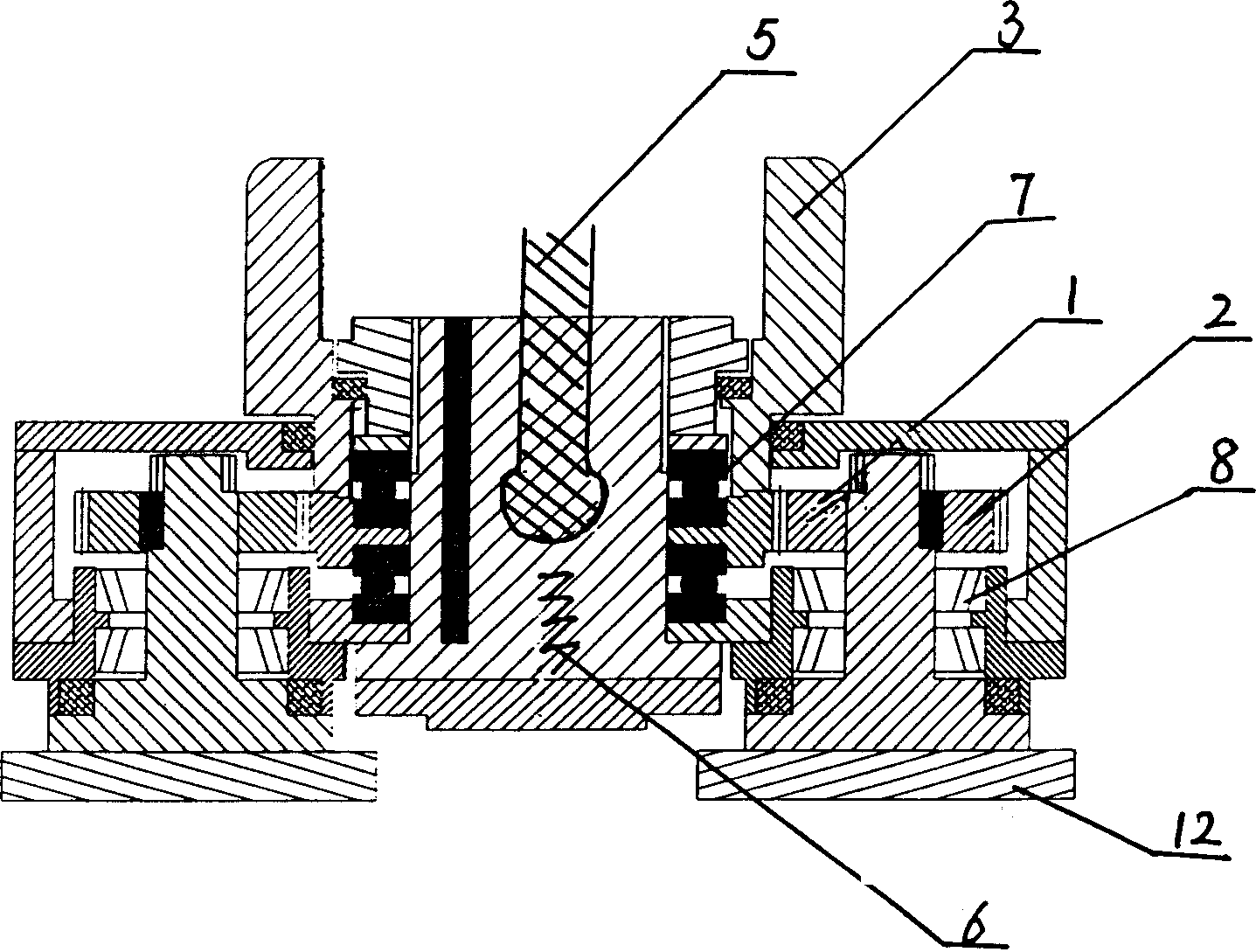

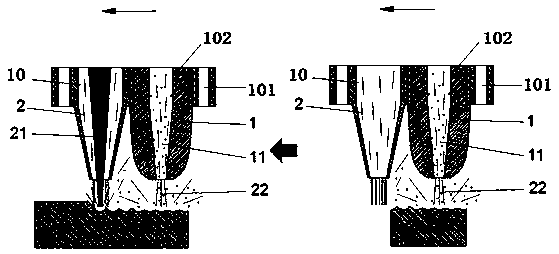

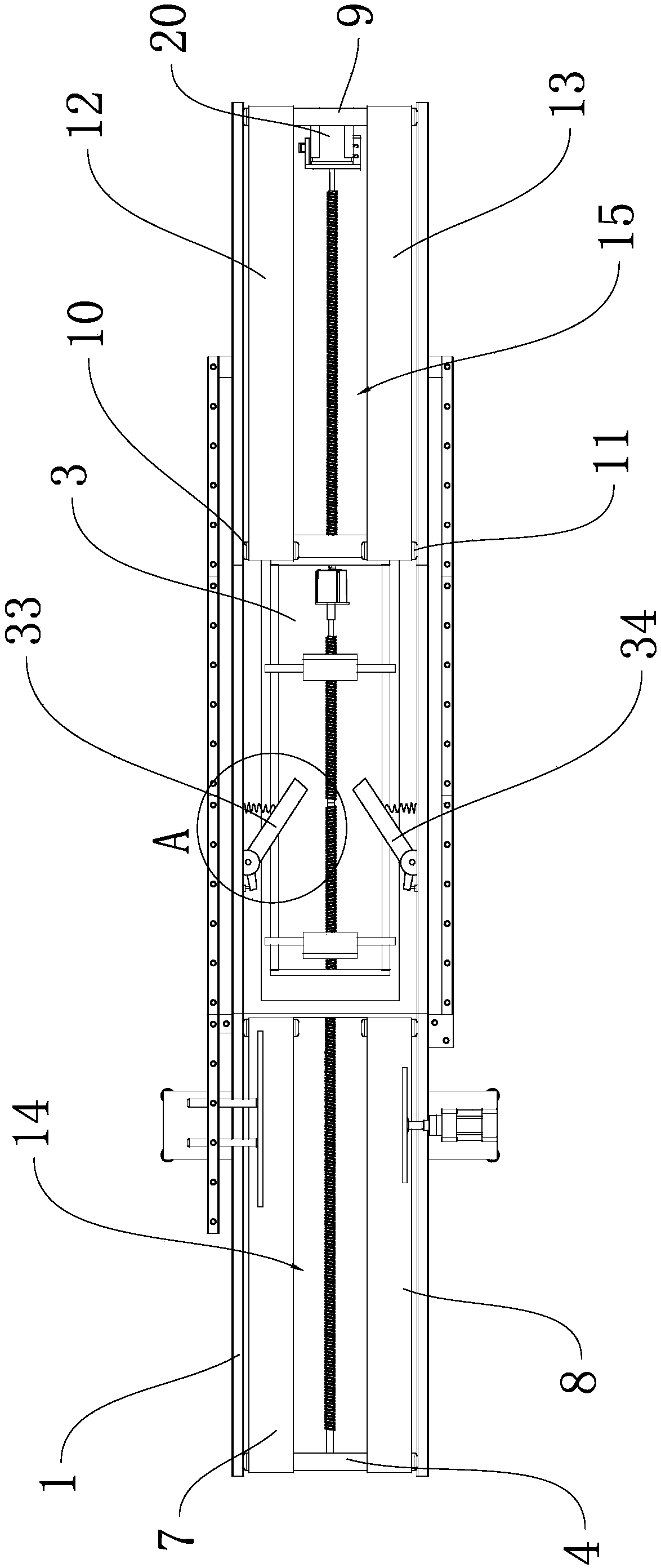

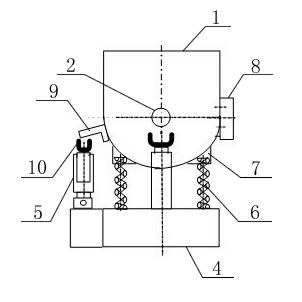

Two-sided synchronous high-efficiency milling and casting machine tool for impeller vane

InactiveCN101244531APrevent processing deformationImprove grinding and polishing efficiencyGrinding machinesImpellerEngineering

The invention relates to a grinding and polishing machine tool of synchronous double-faced blade with a high efficiency, belonging to the mechanical manufacturing field. A moving mechanism in Y direction and two moving mechanism in X direction are fixed on the bed, two moving mechanism in X direction are coaxial and are distributed in symmetrically horizontally vertical to the moving mechanism in Y direction; two grinding and polishing tool system of sand belt variable gear trains are respectively connected with two moving mechanism in Z direction; the two moving mechanism in Z direction are respectively connected with two upright columns; the two upright columns are respectively connected with the two moving mechanism in X direction; a reversing jig is arranged on the rotary worktable, and the reversing jig can achieve the clamping of the blade and the rotation of the blade around the central shaft B of the reversing jig; the rotary worktable is connected with the moving mechanism in Y direction, and the rotary worktable provides the rotation around the central shaft C. The grinding and polishing machine tool of synchronous double-faced blade with a high efficiency has the advantages that the faces of the blade at double sides has synchronous grinding and polishing, not only the efficiency of grinding and polishing is improved obviously, but also because force is exposed on double sides of the blade during grinding and polishing process, the process deformation of the blade is effectively avoided.

Owner:JILIN UNIV

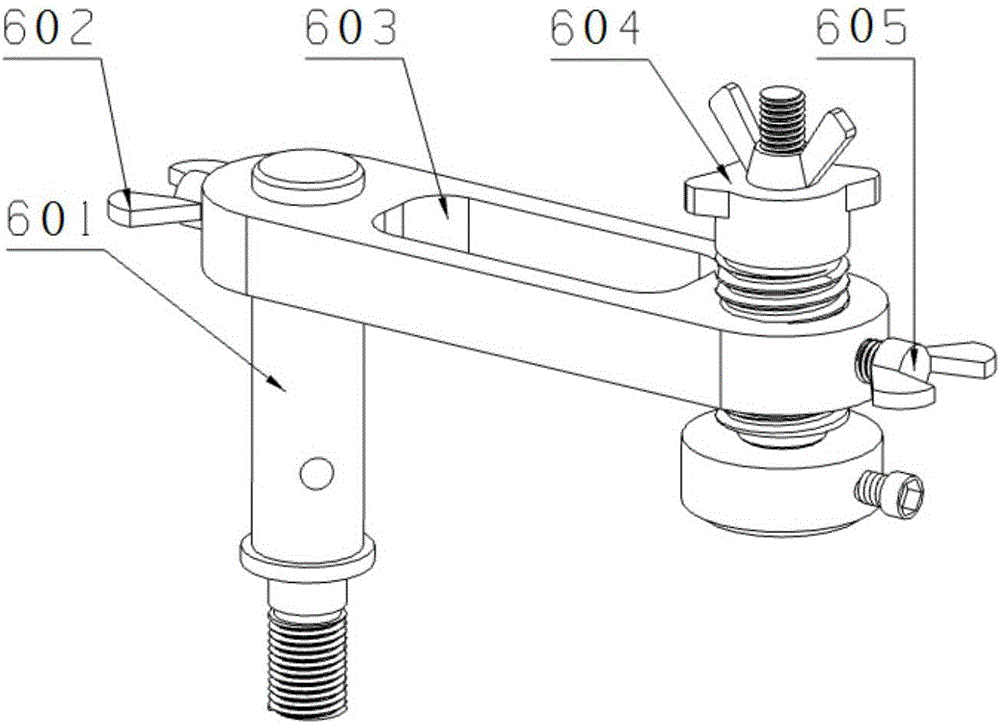

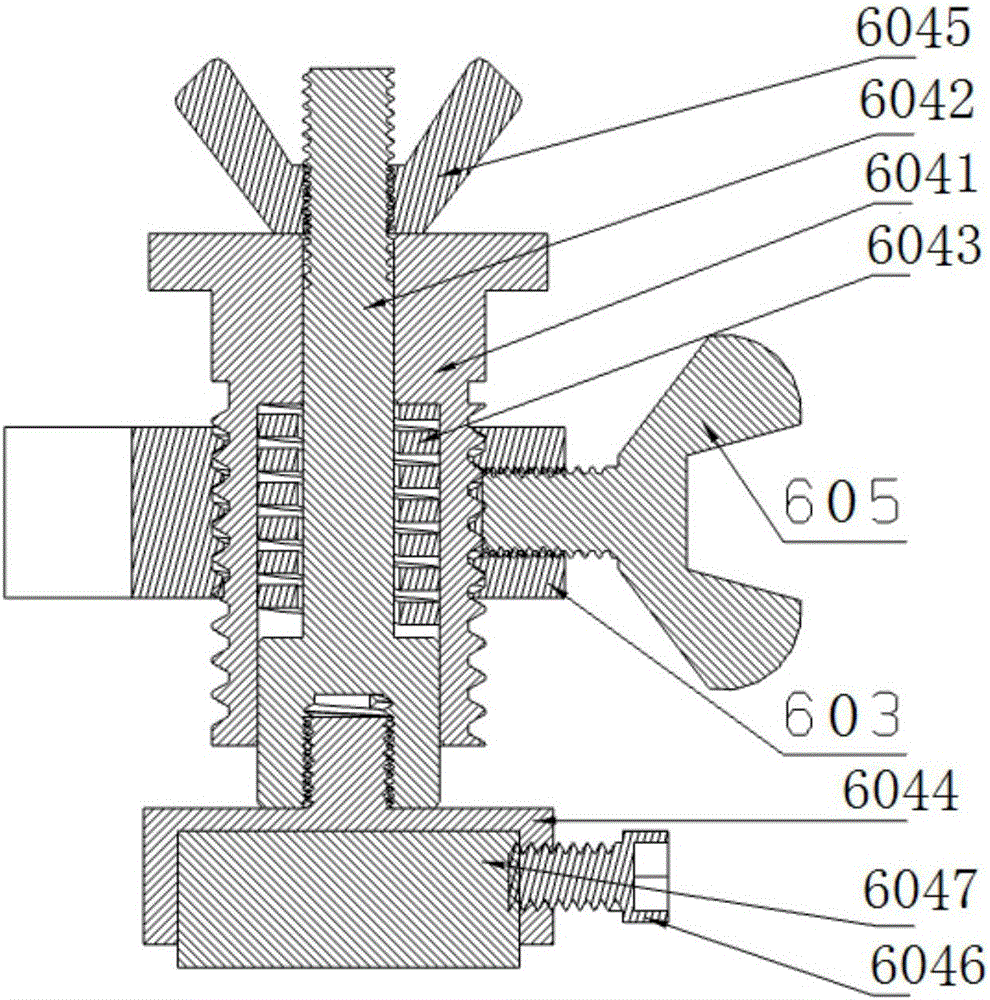

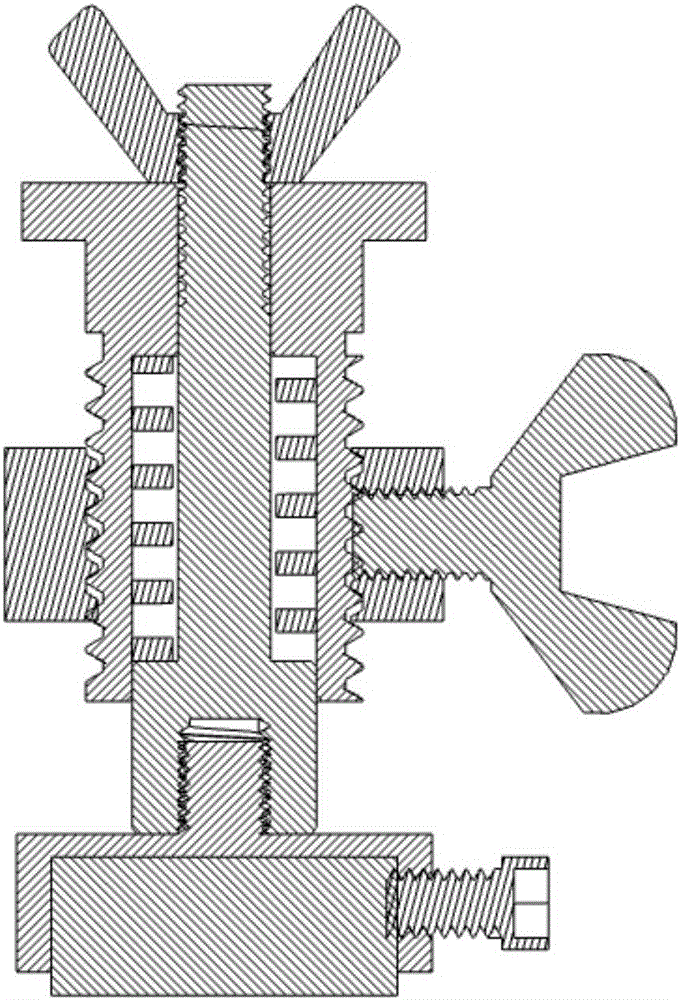

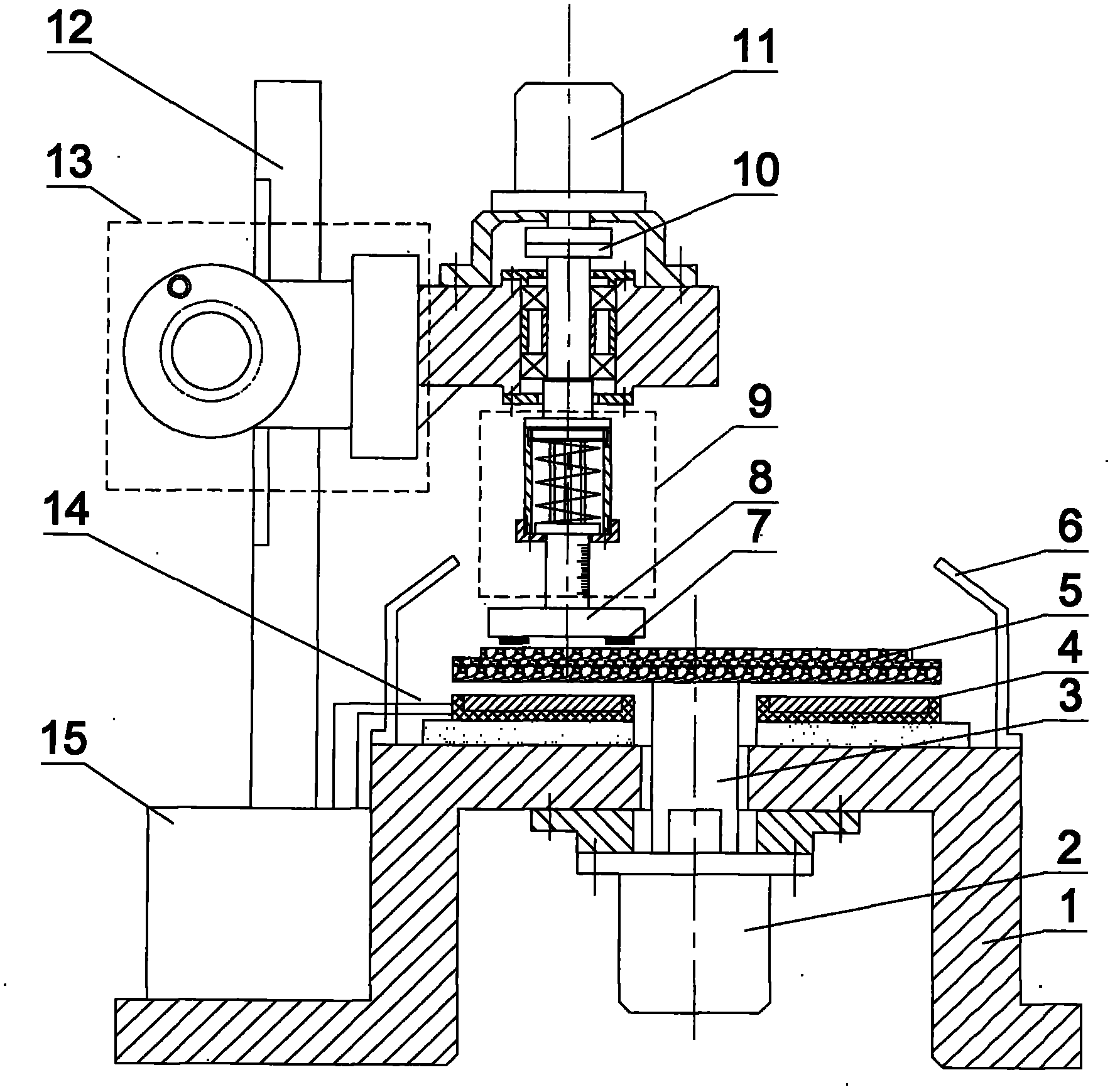

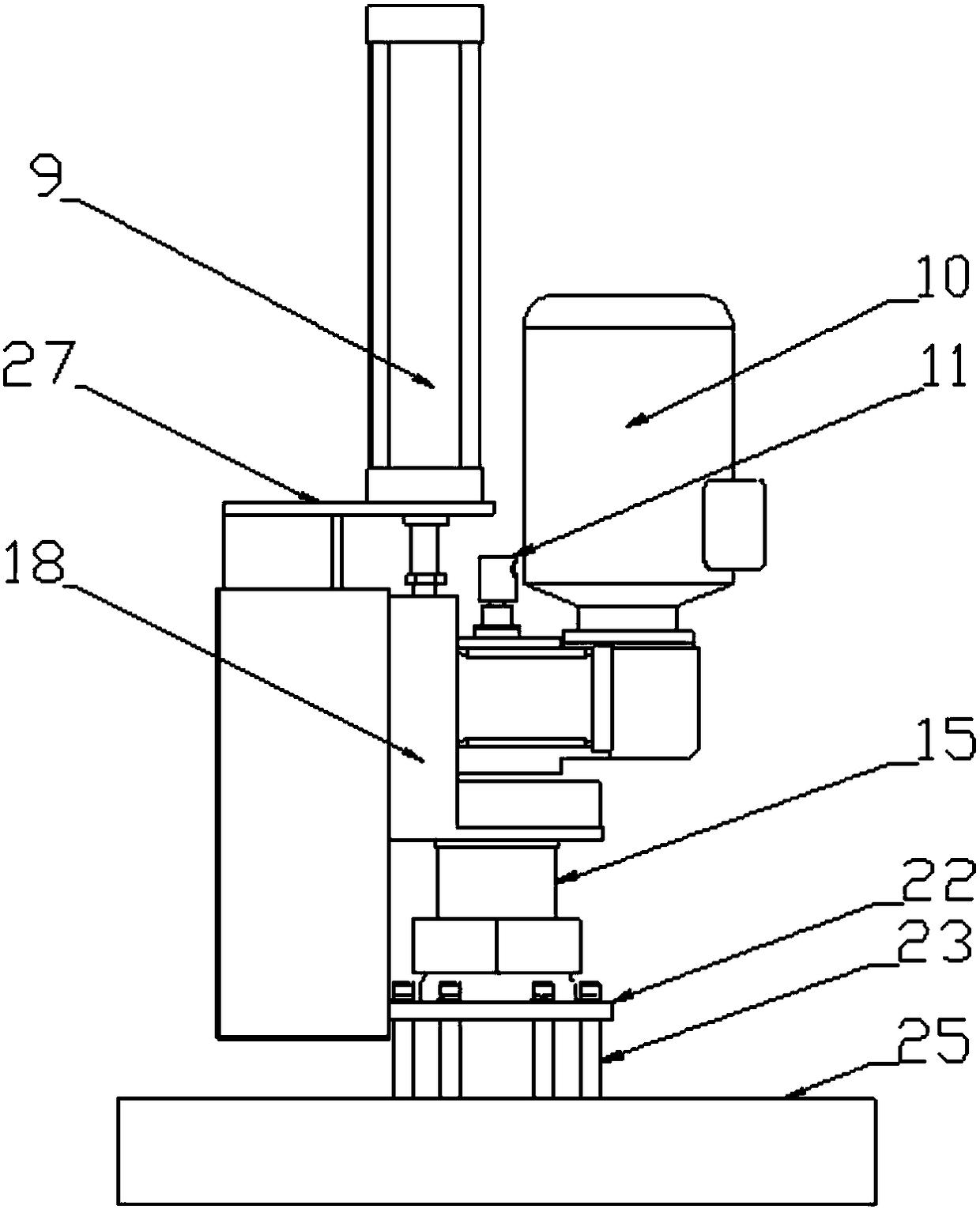

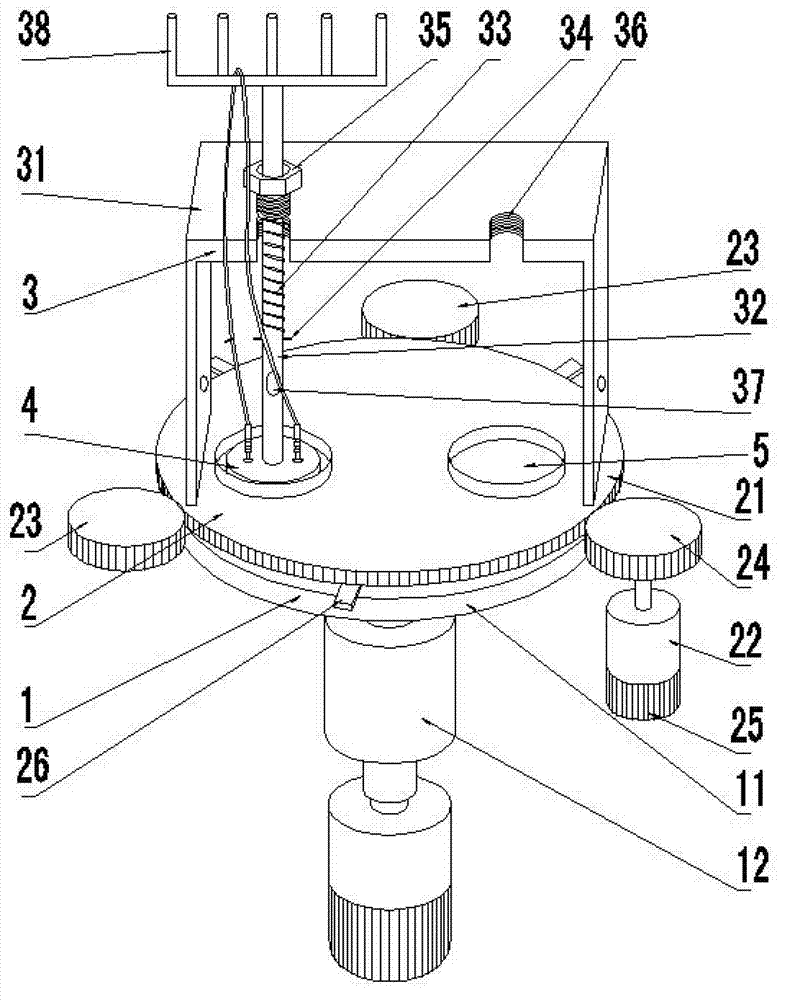

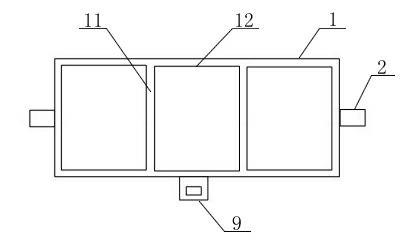

Metallographic phase grinding sample pressure adjusting device and metallographic phase grinding and polishing device and method

ActiveCN105904336AAchieve polishAdjustable speedLapping machinesWork carriersPulp and paper industryFastener

The invention relates to the technical field of metallographic phase grinding, in particular to a metallographic phase grinding sample pressure adjusting device and a metallographic phase grinding and polishing device and method. The metallographic phase grinding sample pressure adjusting device comprises a fixed rod, a rotary connection rod and a sample clamping mechanism which are all sequentially connected; the sample clamping mechanism comprises an adjusting sleeve, a pin shaft arranged in the adjusting sleeve, a fastener installed at the upper end of the pin shaft, a spring arranged on the pin shaft in a sleeving manner and pressed in the adjusting sleeve through the pin shaft, and a sample clamping sleeve detachably installed at the lower end of the pin shaft and used for clamping a metallographic phase sample. The metallographic phase grinding and polishing device comprises the metallographic phase grinding sample pressure adjusting device, a cushion plate, a grinding and polishing disk and a motor. During grinding and polishing, firstly, pressure is preset, and then by adjusting the fastener of the pin shaft to be connected with the adjusting sleeve, the pressure is loaded onto the metallographic phase sample. According to the metallographic phase grinding sample pressure adjusting device and the metallographic phase grinding and polishing device and method, one or more metallographic phase samples can be pre-ground and polished on the same equipment, and pressure acting on the samples is adjustable and can be automatically released.

Owner:NORTHEASTERN UNIV

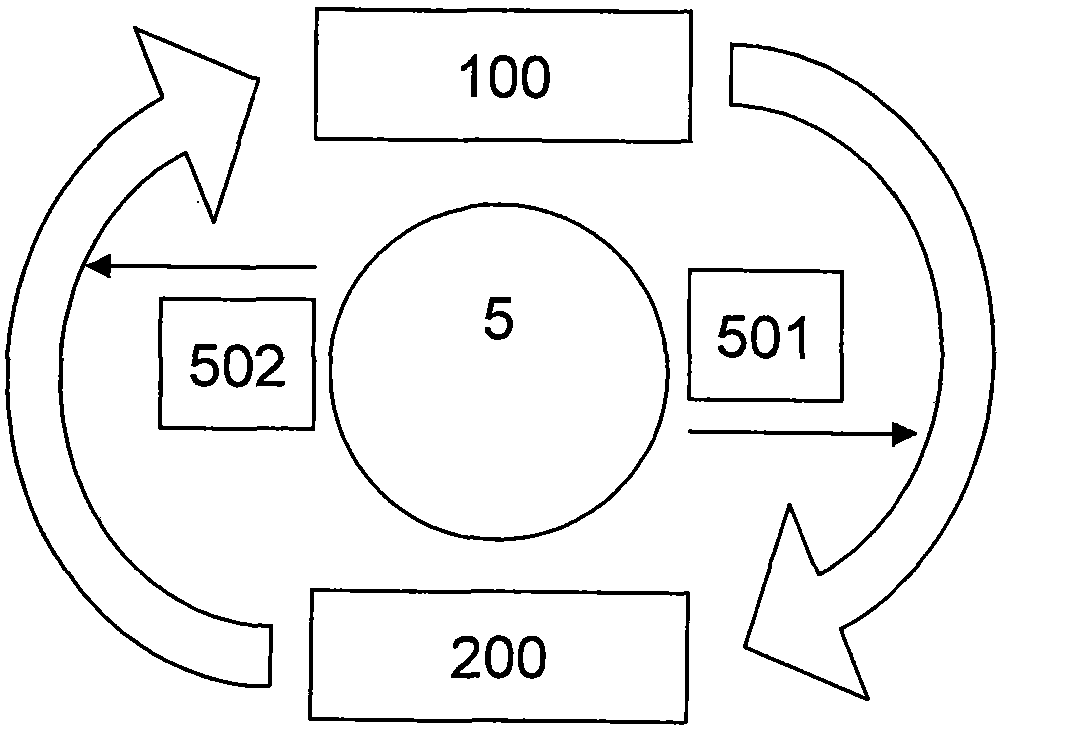

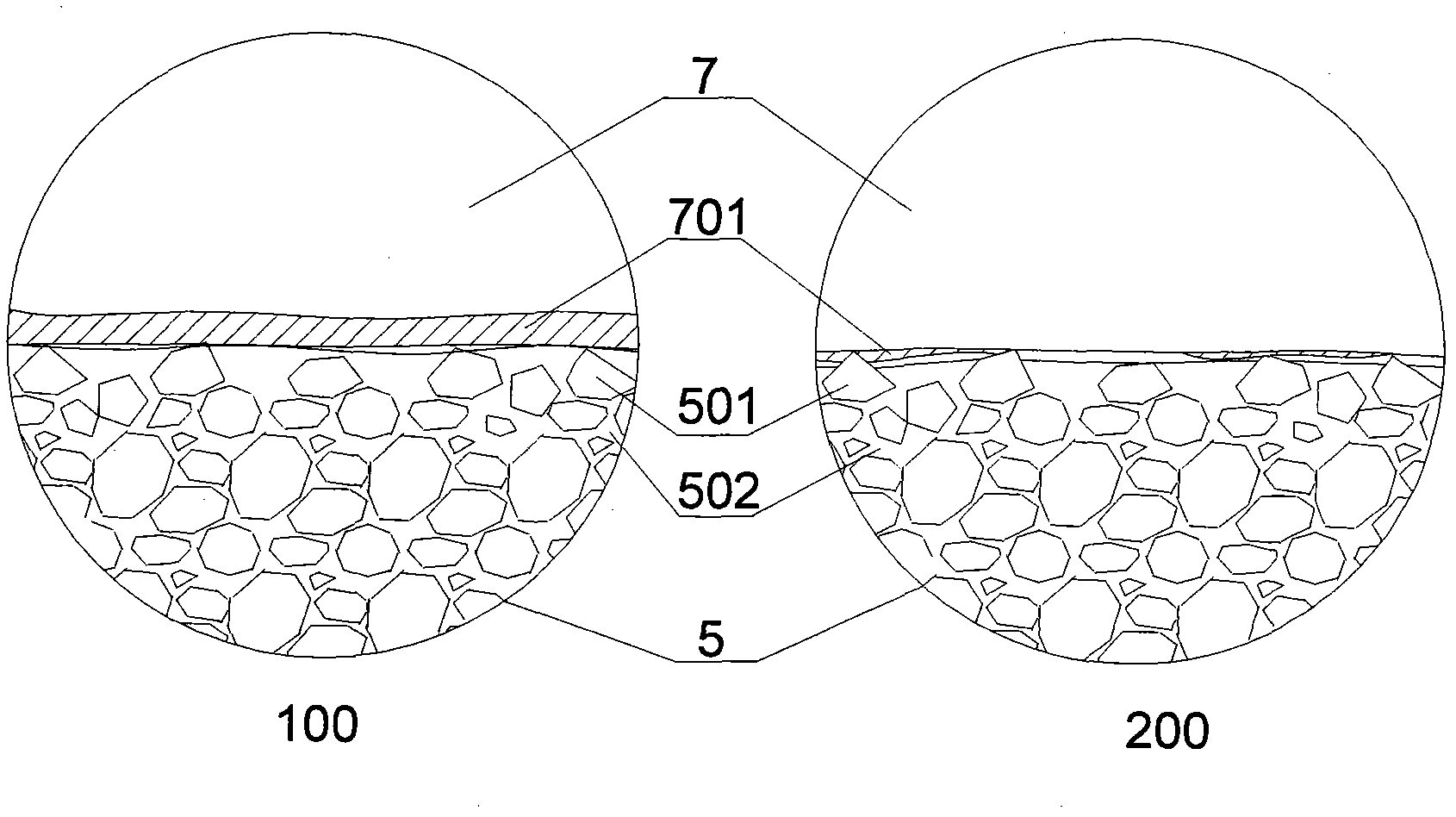

Diamond surface chemical mechanical combined machining method and device thereof

InactiveCN101972979AImprove the efficiency of graphitizationGuaranteed grinding qualityLapping machinesGraphiteAdamite

The invention relates to a diamond surface chemical mechanical combined grinding and polishing method. Composite material is adopted as a tool millstone used for grinding and polishing, the tool millstone is heated to appropriate temperature, and then high speed rotational motion is carried out; certain pressure is utilized to press a diamond film / block to be processed onto the surface of the millstone, so that high speed friction is produced between the diamond film / block and the surface of the millstone, and high efficiency grinding and polishing on the surface of the diamond is realized under the chemical-mechanical combined circulation action of friction region. The method adopts a chemical-mechanical combined way, and the grinding process includes a catalytic surface graphitizing process and a mechanical graphite scraping process. In the combined circulation process of chemical action and mechanical action, diamond surface material is efficiently removed. The related device integrates heating and loading functions, a combined millstone is used as a tool millstone, and the beneficial effects include that processing efficiency is high, mechanical acting force is small and processing quality is good. The invention also relates to a diamond surface chemical mechanical combined grinding and polishing device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

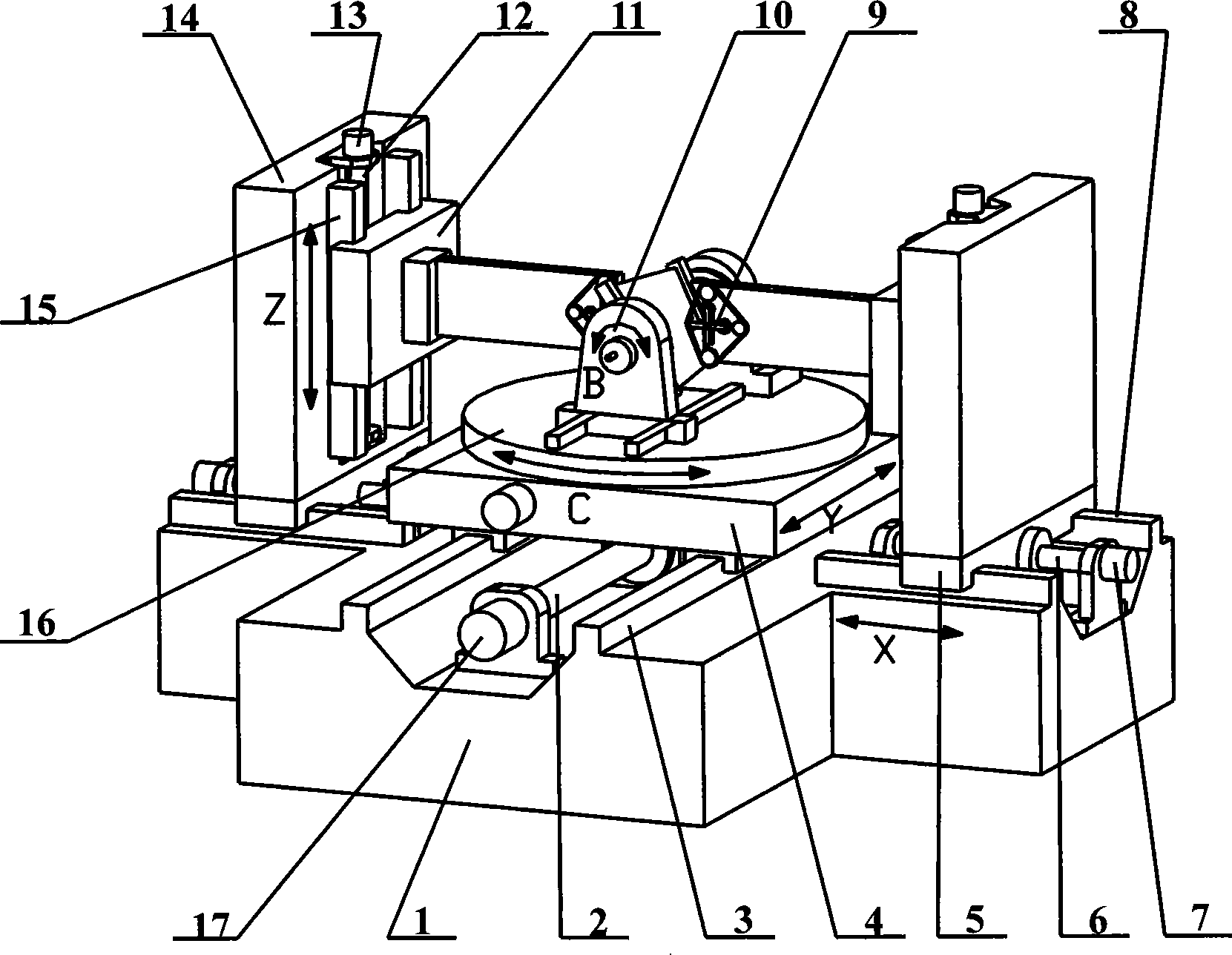

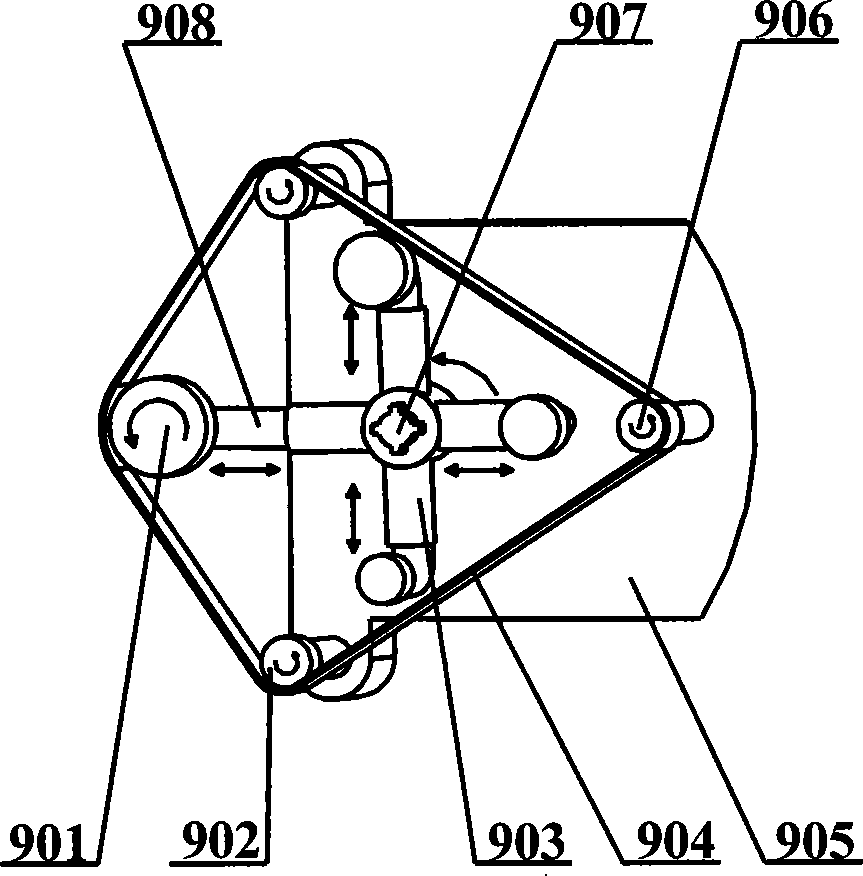

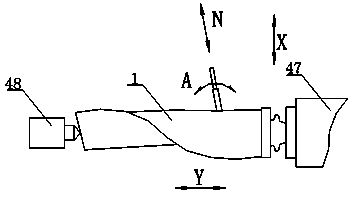

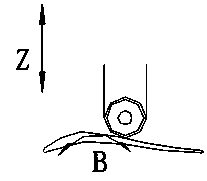

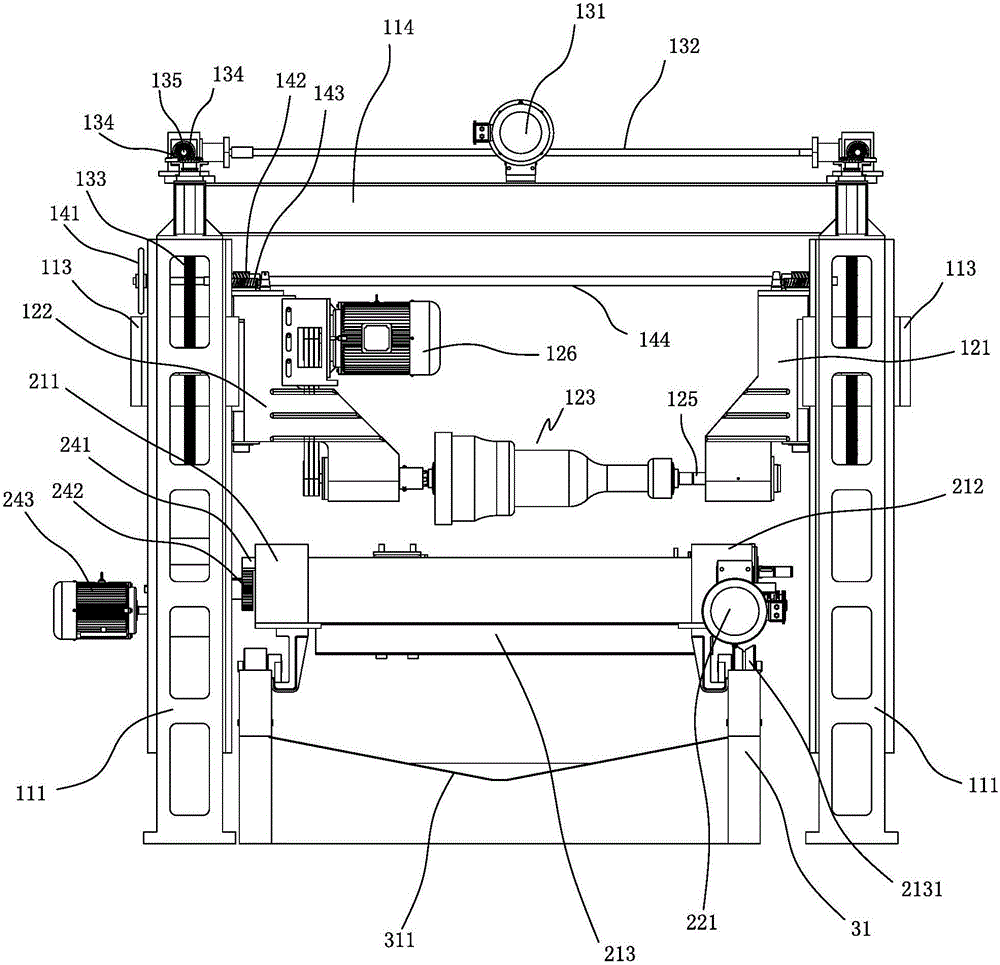

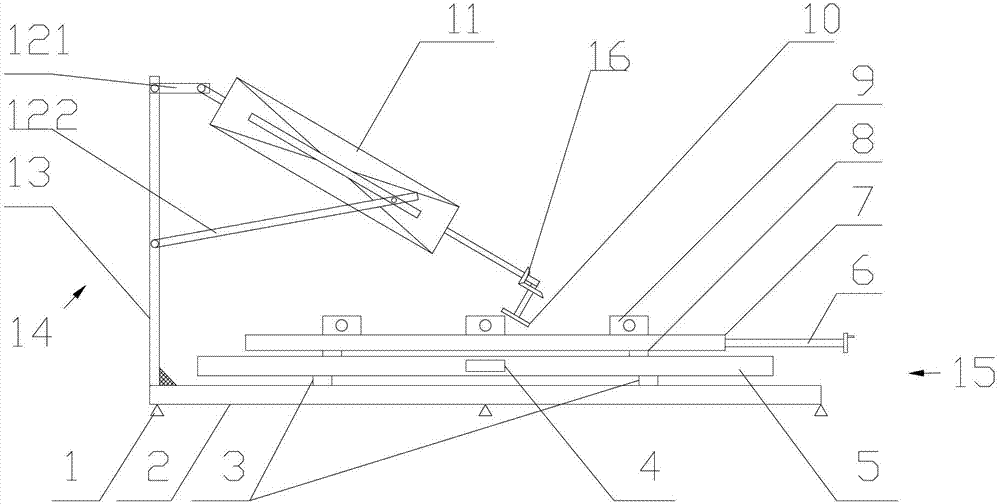

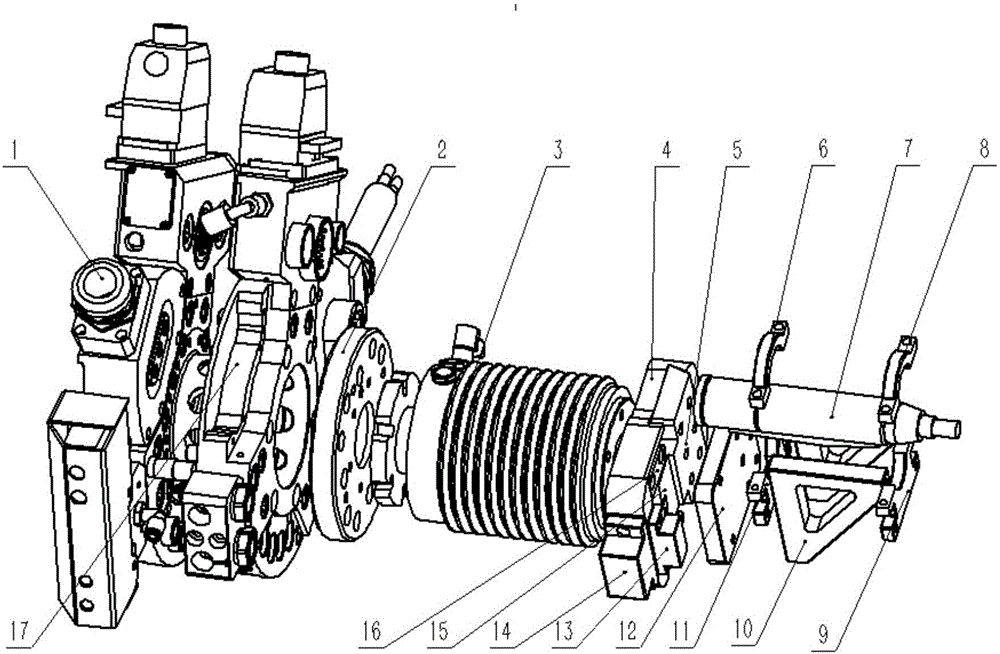

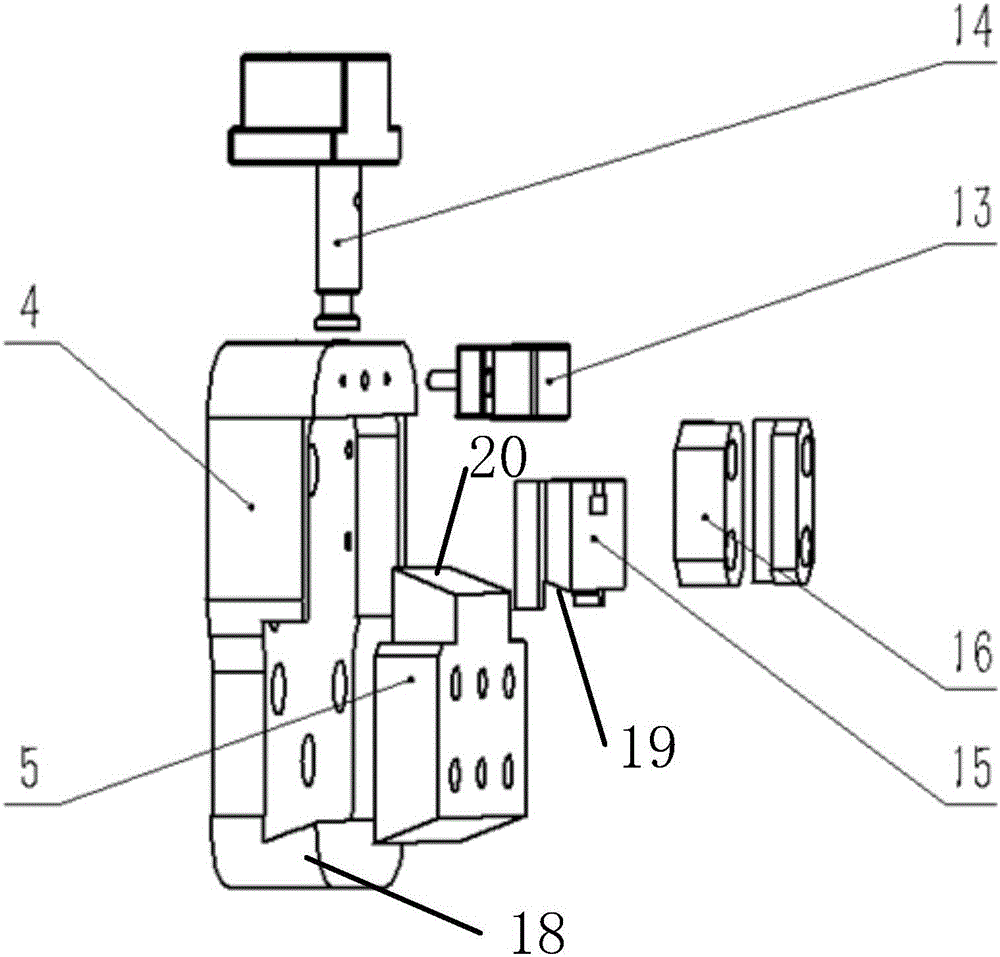

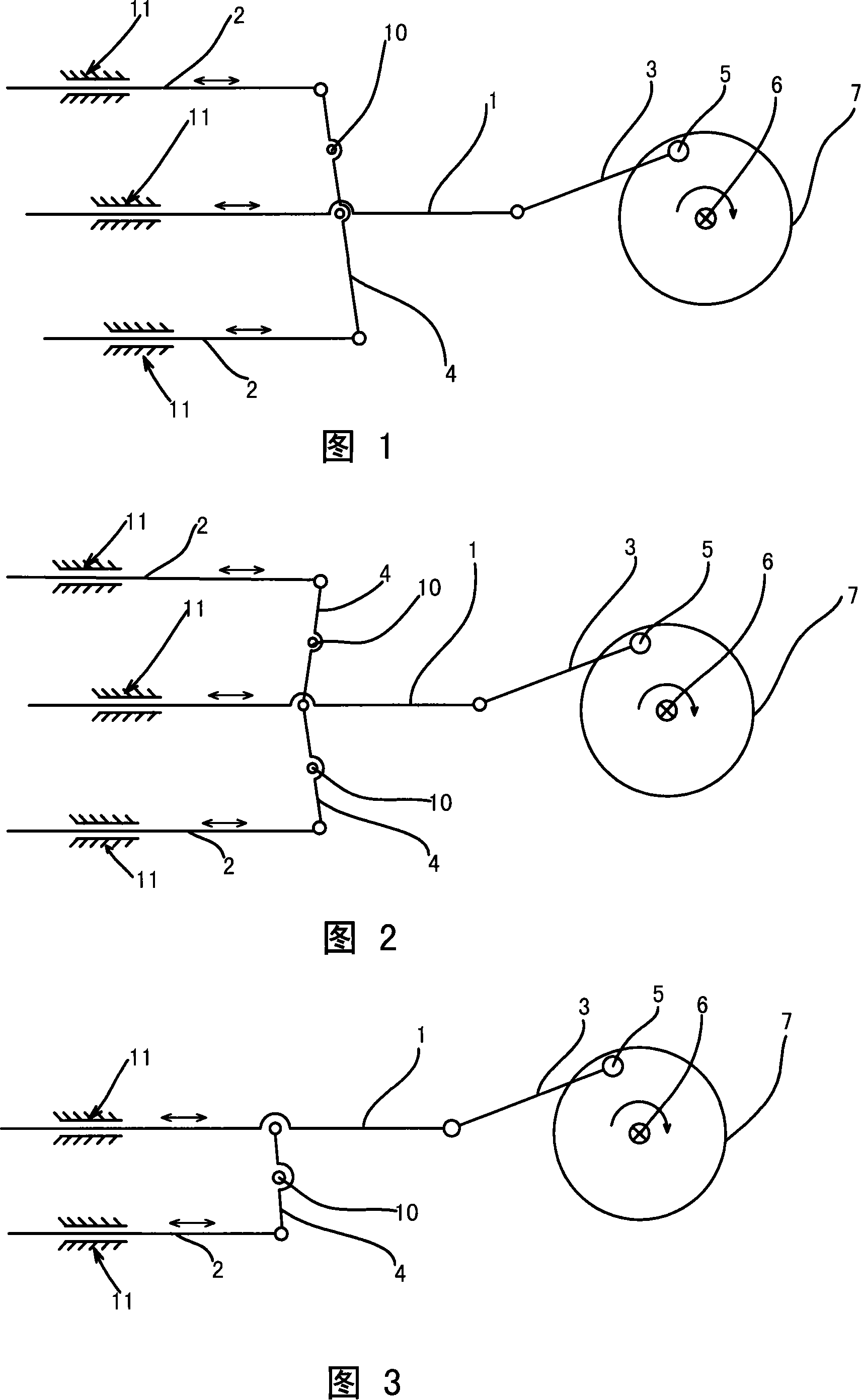

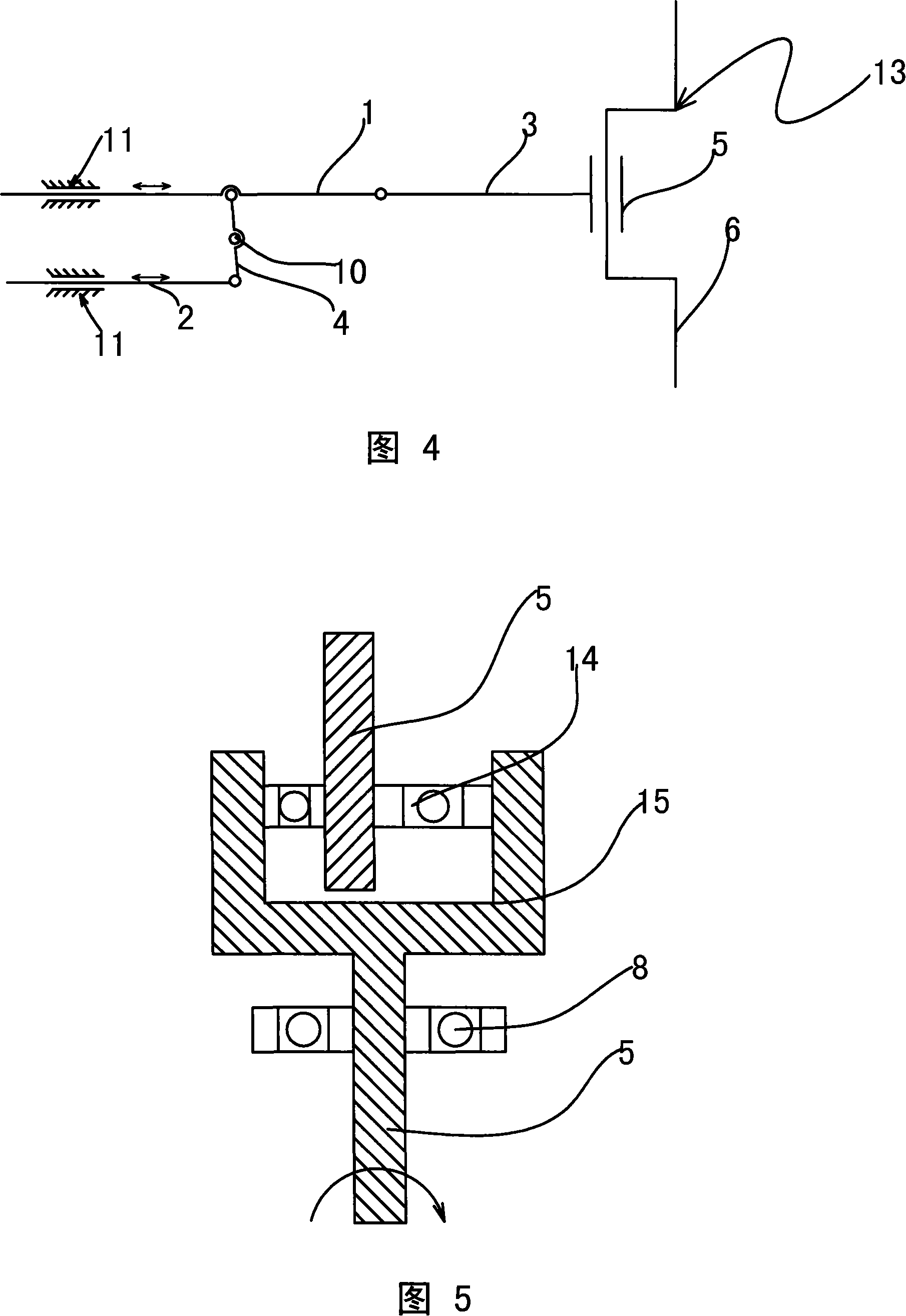

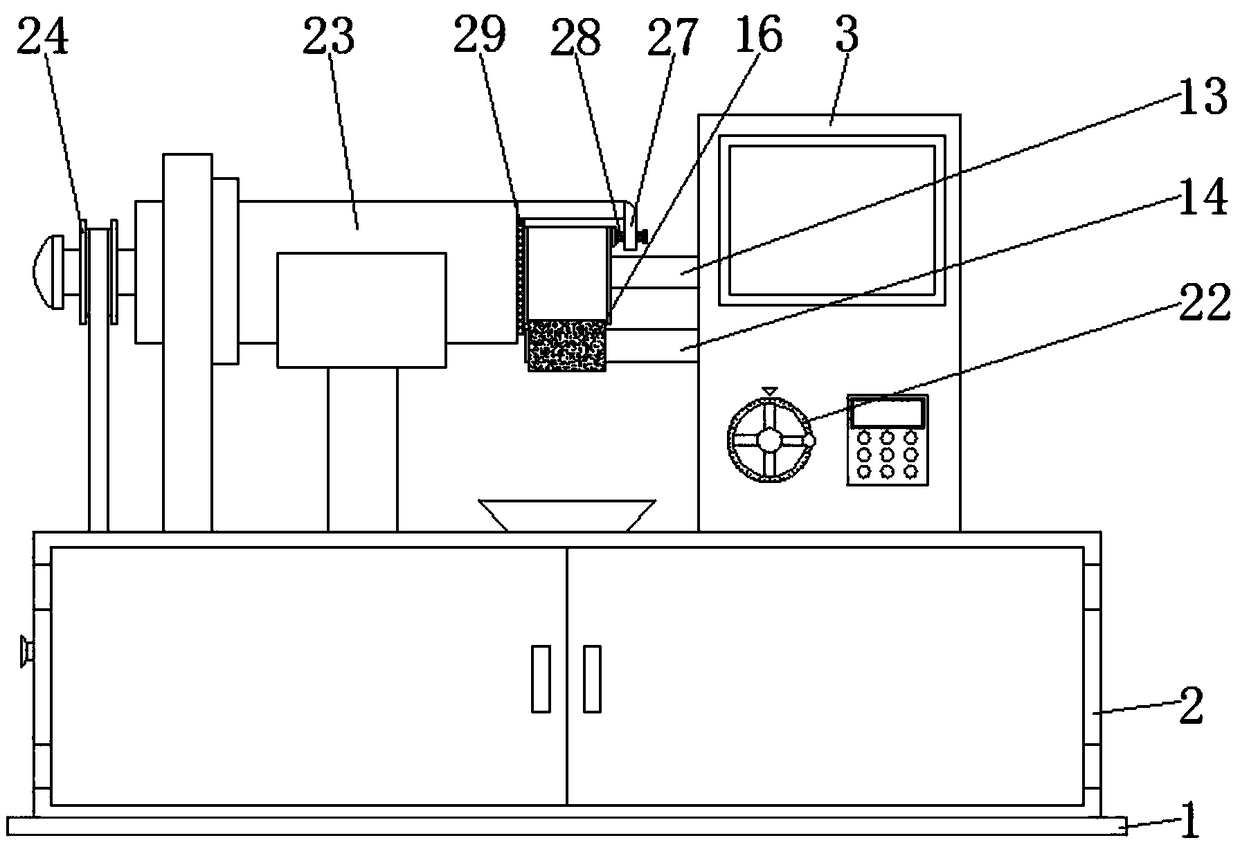

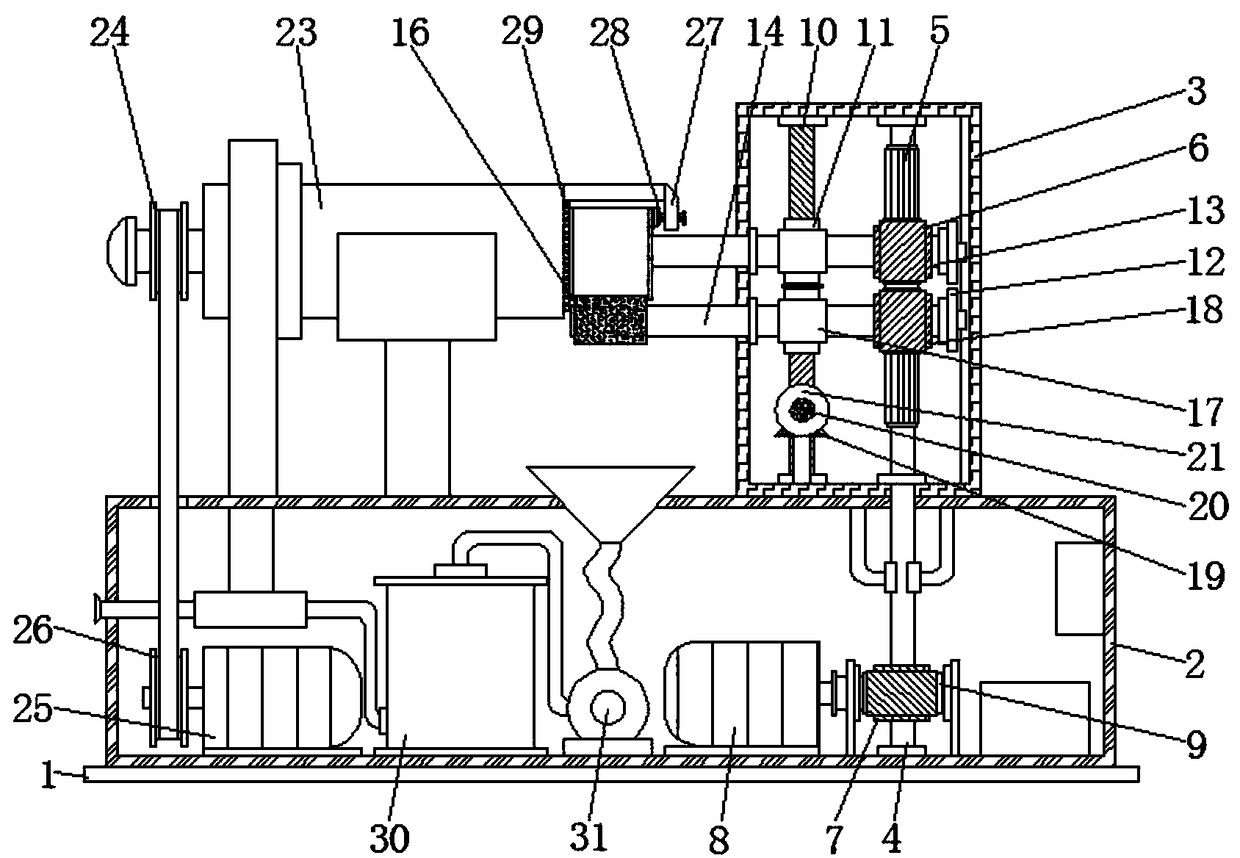

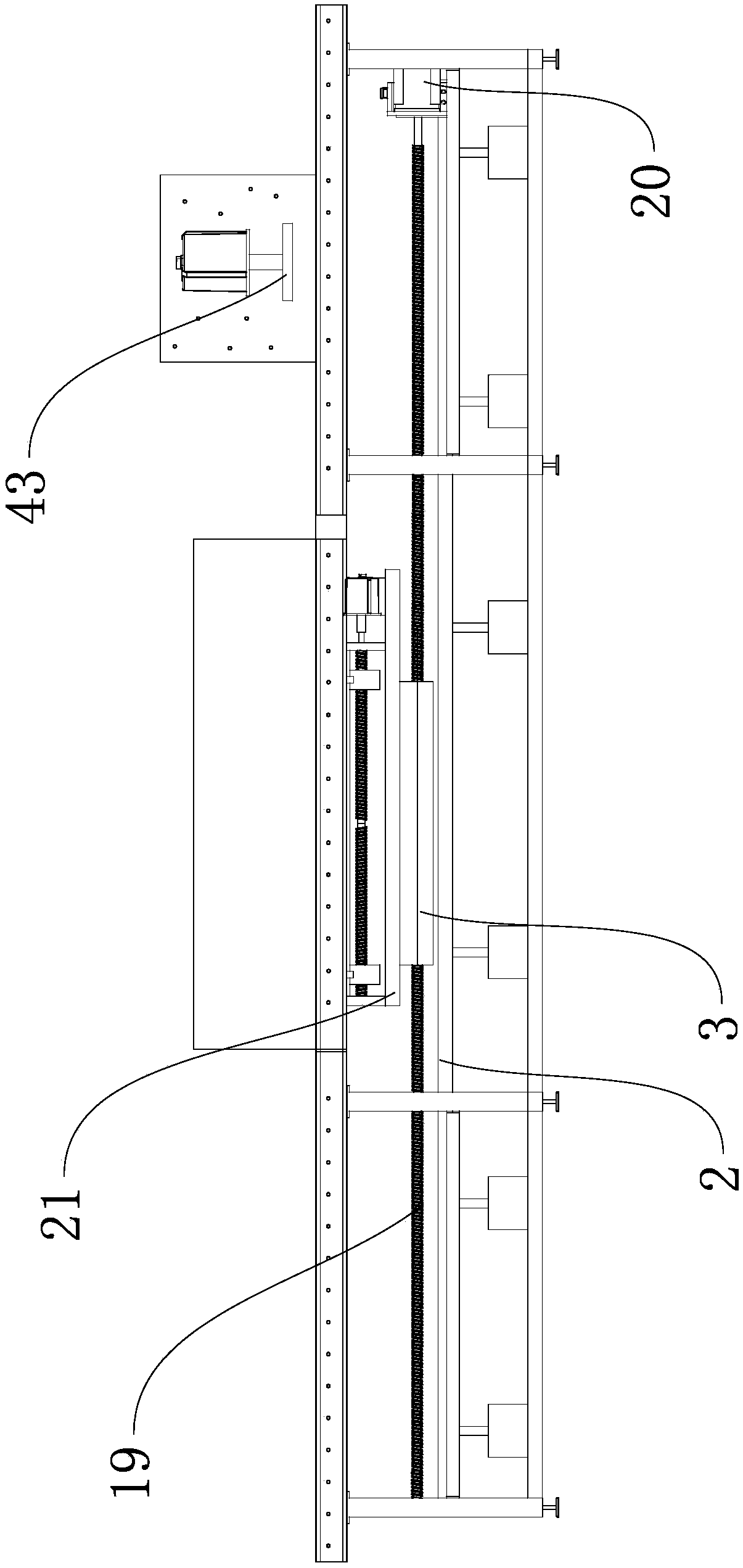

Seven-axis linkage numerical control abrasive belt grinding and polishing machine tool

ActiveCN103612185AStable contact pressureEliminate distractionsGrinding drivesBelt grinding machinesNumerical controlEngineering

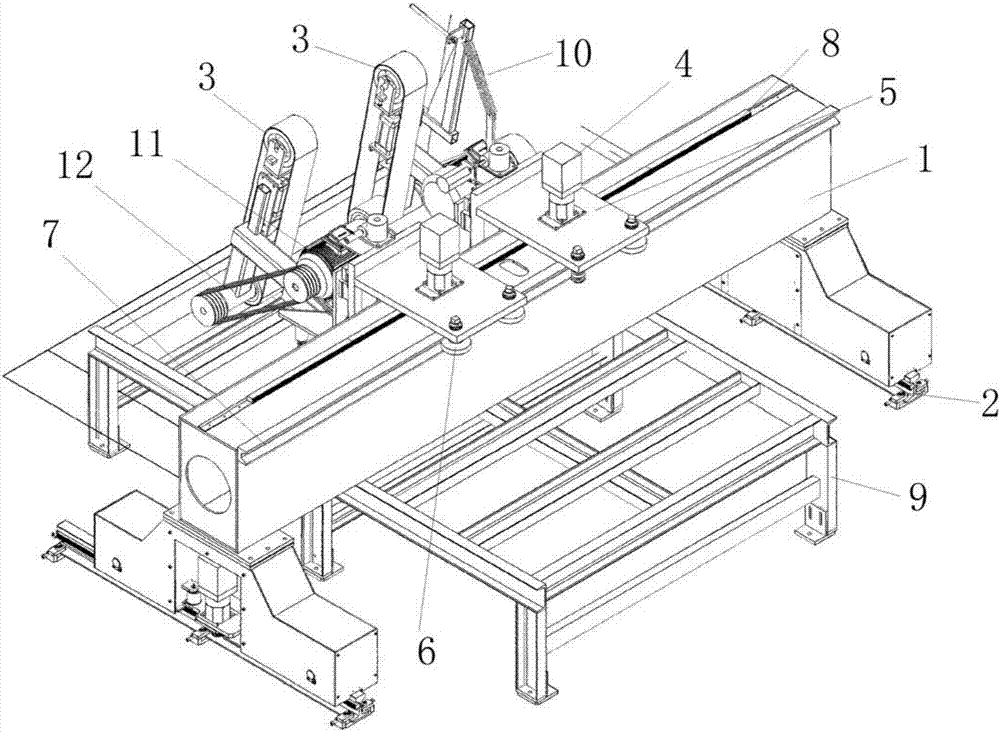

The invention discloses a seven-axis linkage numerical control abrasive belt grinding and polishing machine tool. The seven-axis linkage numerical control abrasive belt grinding and polishing machine tool mainly solves the problems that according to a vertical six-axis linkage abrasive belt grinding and polishing method in the prior art, asymmetrical margins on a curved face can not be stably removed and excessive cutting or insufficient cutting is easy to occur. The seven-axis linkage numerical control abrasive belt grinding and polishing machine tool comprises a rotation clamp, a top tip, a horizontal machine tool body, a pillar, a Y-direction motion device, a Z-direction motion device, an X-direction motion device, a B-direction rotation drive device and a grinding and polishing device, wherein the rotation clamp and the top tip are used for fixing a blade part. The Y-direction motion device drives the pillar to move linearly in the Y direction, the Z-direction motion device drives the pillar to move linearly in the Z direction and the X-direction motion device is used for fixing the top tip and driving the top tip to move linearly in the X direction. The B-direction rotation drive device is used for fixing the rotation clamp and driving the rotation clamp to achieve 360-degree rotation motion. The grinding and polishing device is installed on the horizontal machine tool body and on the position corresponding to the pillar. By means of the technical scheme, the objects of convenient construction, the high performance cost ratio and high precision are achieved and high utility value and popularization value are achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

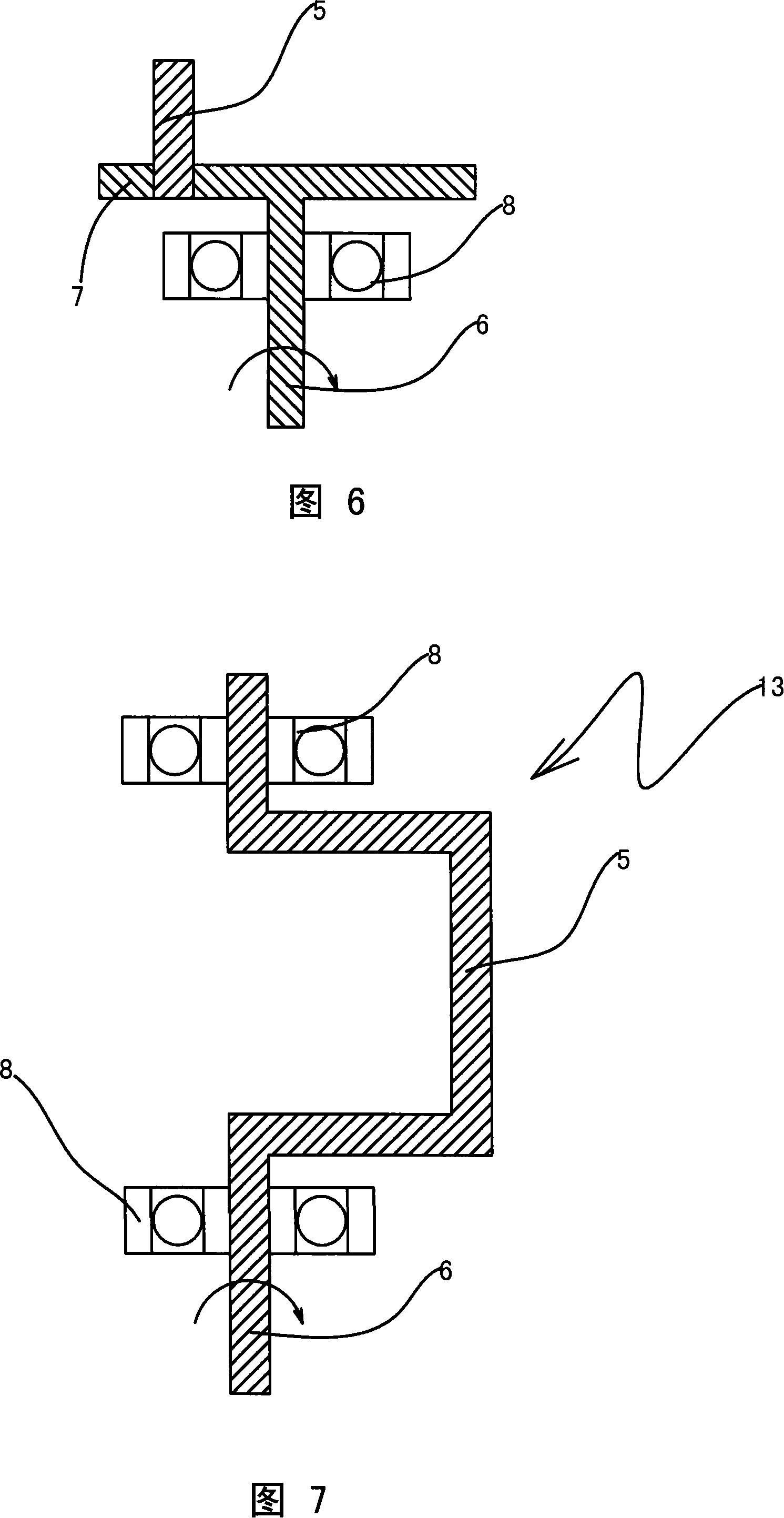

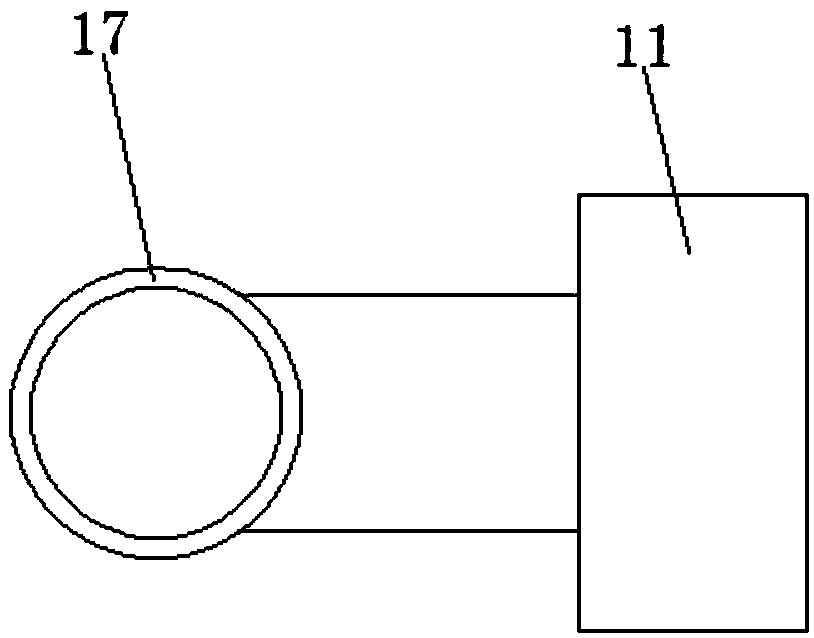

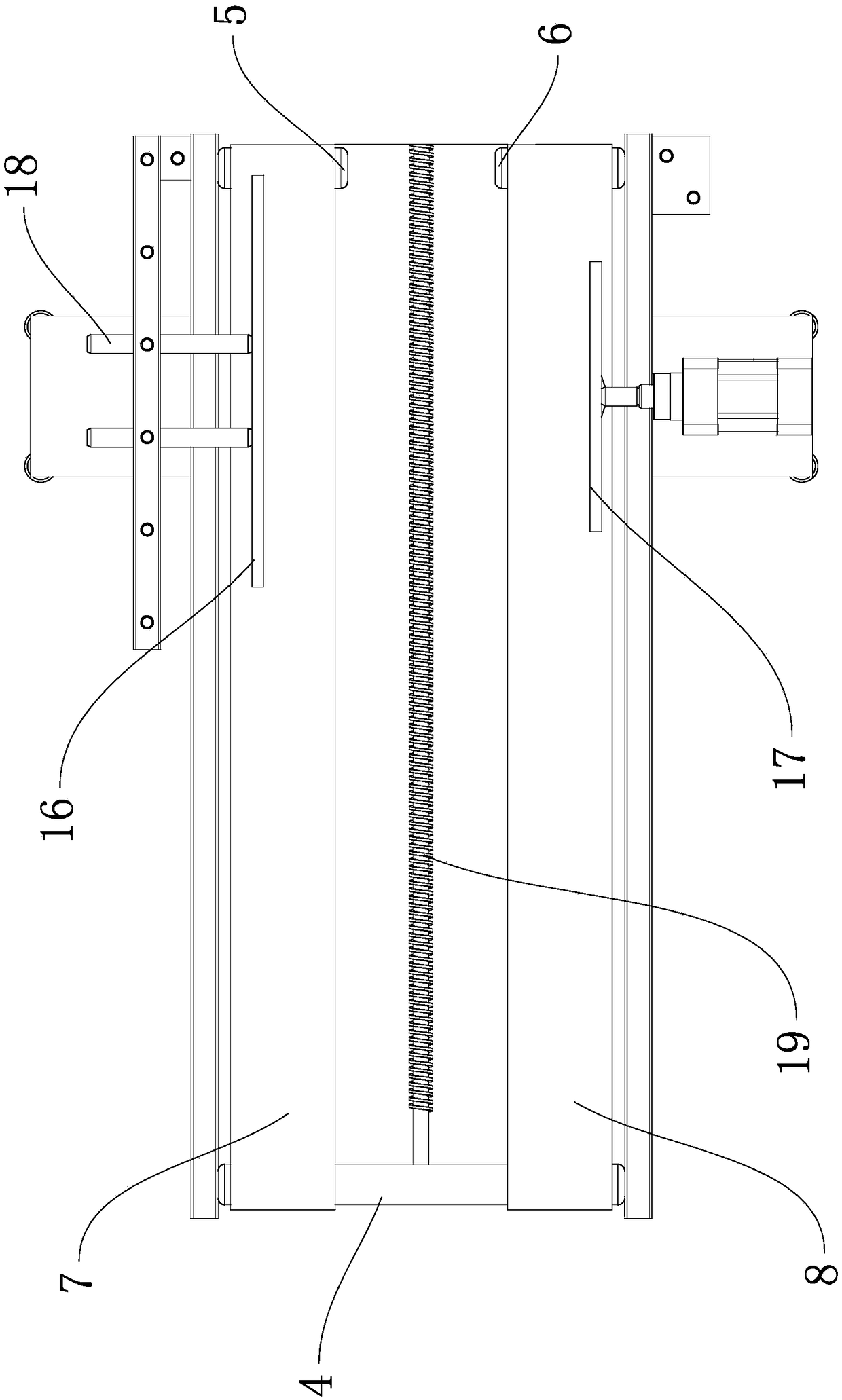

Grinding and polishing device and grinding and polishing machine

InactiveCN105081913AImprove grinding and polishing efficiencyIncrease productivityGrinding carriagesGrinding drivesDrive shaftEngineering

The invention discloses a grinding and polishing device and a grinding and polishing machine. The grinding and polishing device and the grinding and polishing machine are used for grinding and polishing the peripheral face of a cylindrical workpiece rotating around the axis of the workpiece. The grinding and polishing device comprises a knife rest, a driving shaft, a driven shaft, a main motor and a grinding tool. The driving shaft and the driven shaft are coaxially and oppositely arranged on the knife rest, and the main motor drives the driving shaft to rotate. The grinding tool comprises a knife shaft installed between the driving shaft and the driven shaft and a cylindrical grinding wheel fixedly arranged on the knife shaft. The outline of the peripheral face of the cylindrical grinding wheel is meshed with the outline of the peripheral face of the cylindrical workpiece. When the grinding and polishing device works, the knife shaft and the cylindrical workpiece are arranged in parallel, and the grinding wheel can be attached to the peripheral face of the cylindrical workpiece in a seamless manner to carry out grinding and polishing.

Owner:QUANZHOU JIANENG MACHINERY MFG

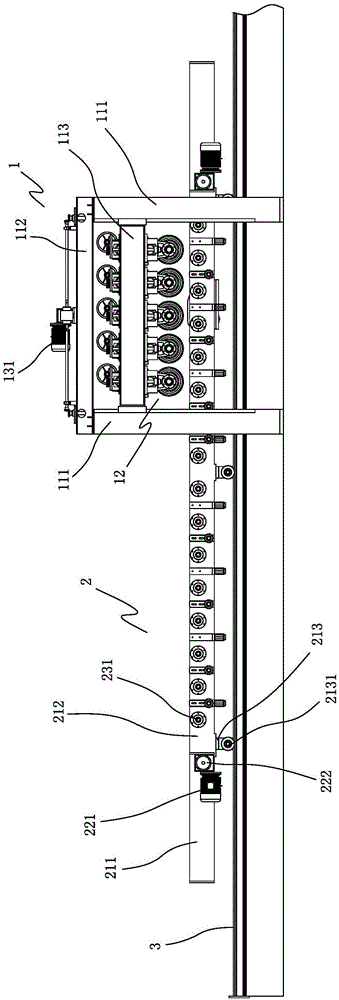

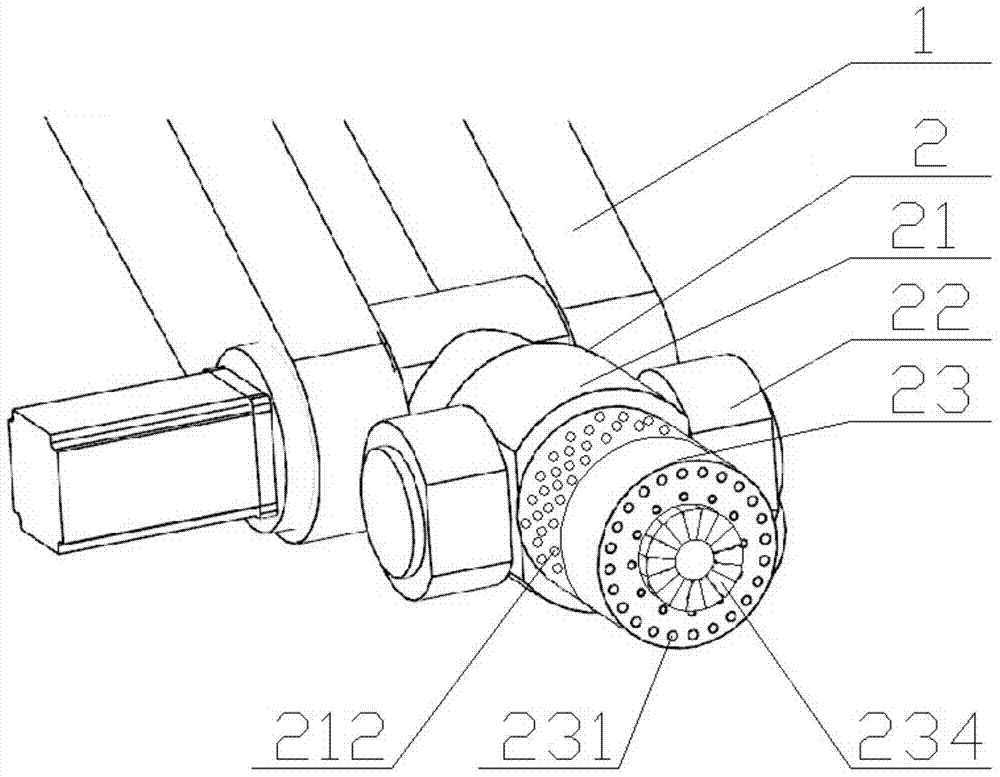

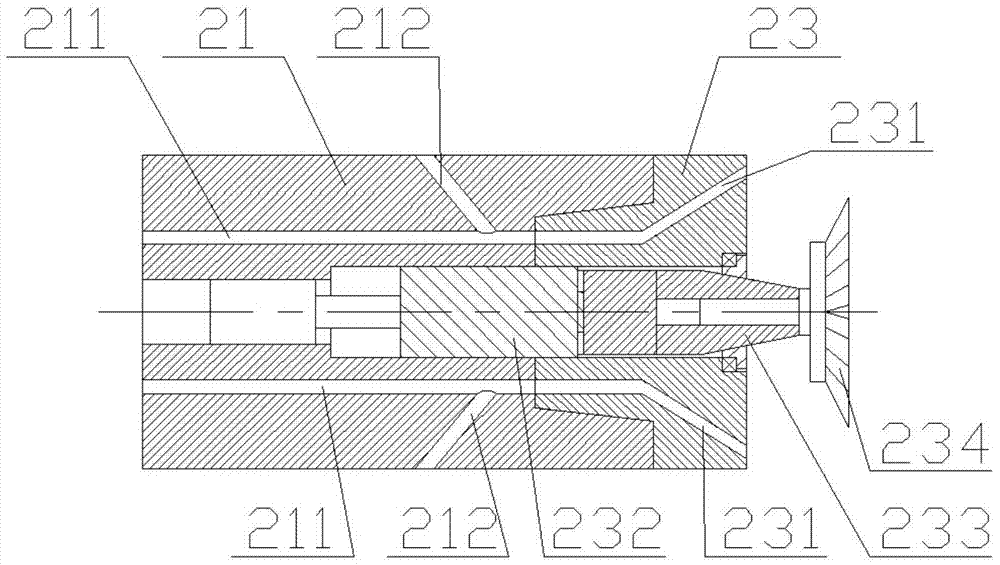

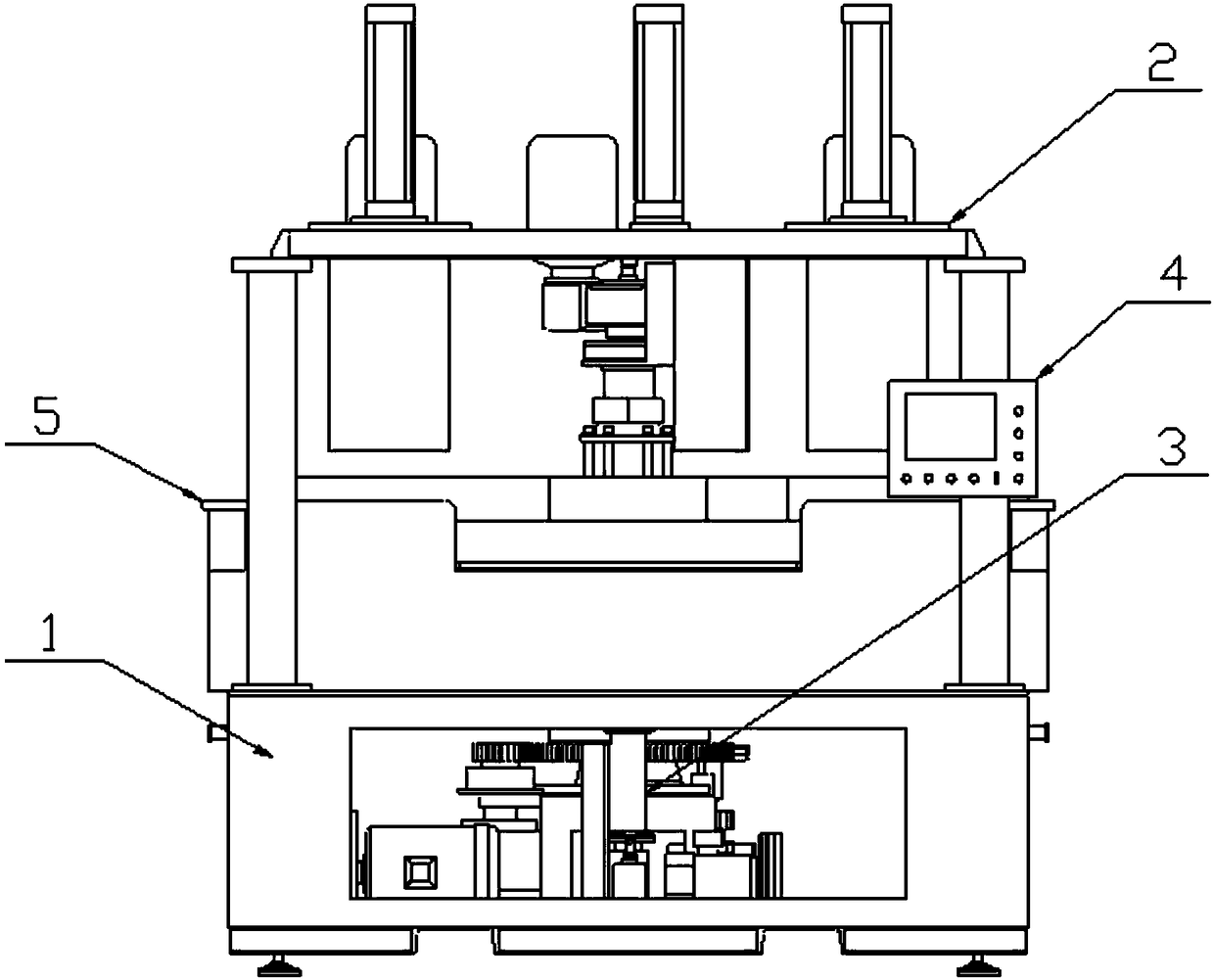

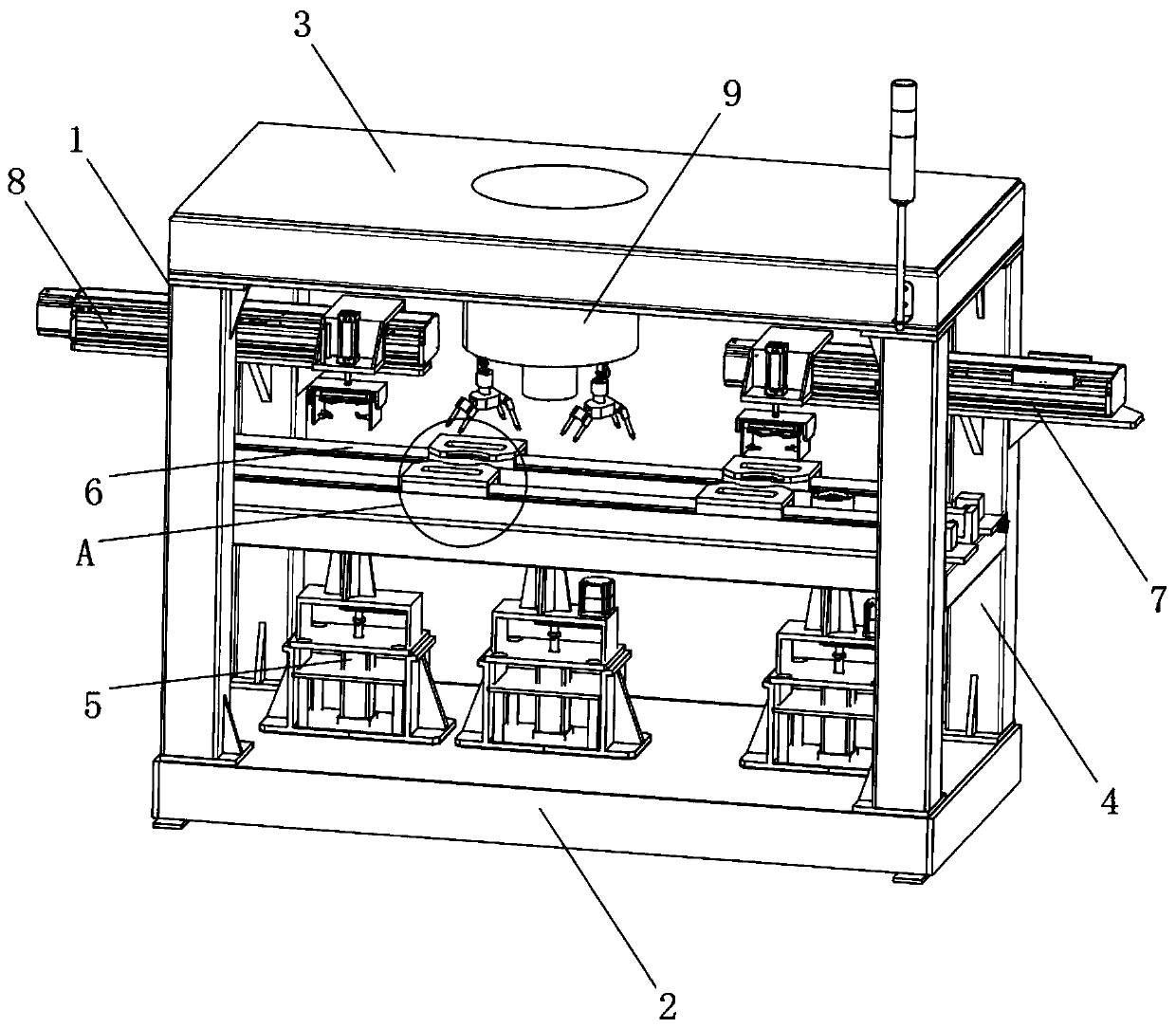

Intelligent automatic grinding and polishing unit based on digital bus and usage method thereof

ActiveCN104842238AImprove grinding and polishing efficiencyReduce air pollutionGrinding machinesGrinding/polishing safety devicesProduct gasDistance sensors

The invention discloses an intelligent automatic grinding and polishing unit based on a digital bus and a usage method thereof. The intelligent automatic grinding and polishing unit comprises a grinding and polishing device (2), a control valve bank (3) and the like. A body (21) of the grinding and polishing device is at least provided with two inner channels (211) and outer channels (212) which are identical to the inner channels in number and are communicated with the inner channels respectively. The body is further provided with a pattern recognition sensor, a position sensor and a range sensor. A working device (23) is internally provided with spraying orifices (231) communicated with the inner channels. The intelligent automatic grinding and polishing unit further comprises a grinding head drive mechanism (232) and a grinding head (234). The control valve bank comprises a positive-pressure gas control solenoid valve, a negative-pressure gas control solenoid valve and a brightener control solenoid valve which are connected with the inner channels and the outer channels. The intelligent automatic grinding and polishing unit can decrease the air pollution degree of a working site, lower the probability of secondary pollution and achieve intelligent grinding and polishing, thereby being suitable for grinding and polishing procedures in digital bus factories.

Owner:XUZHOU DKEC ELECTRICAL TECH

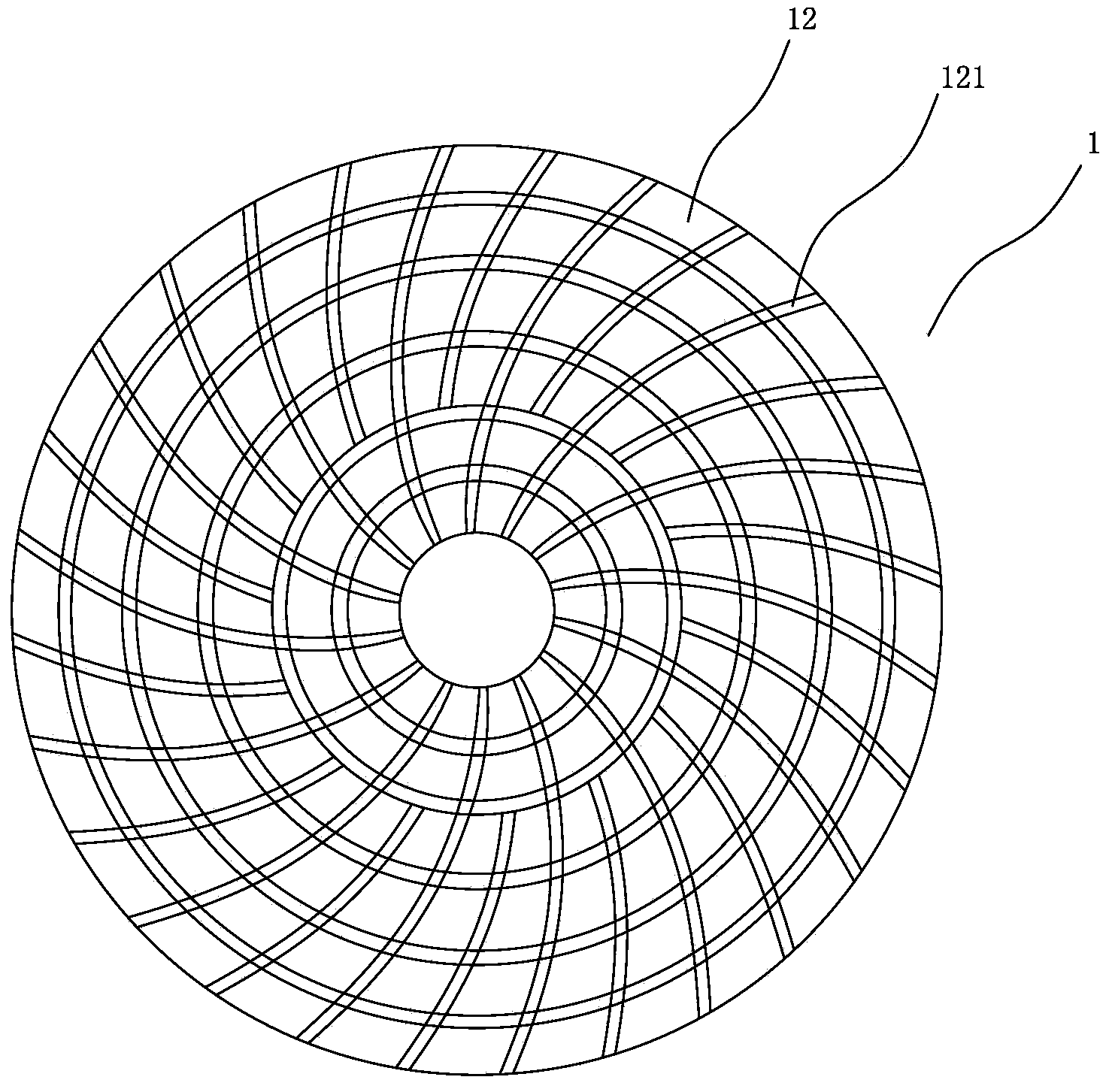

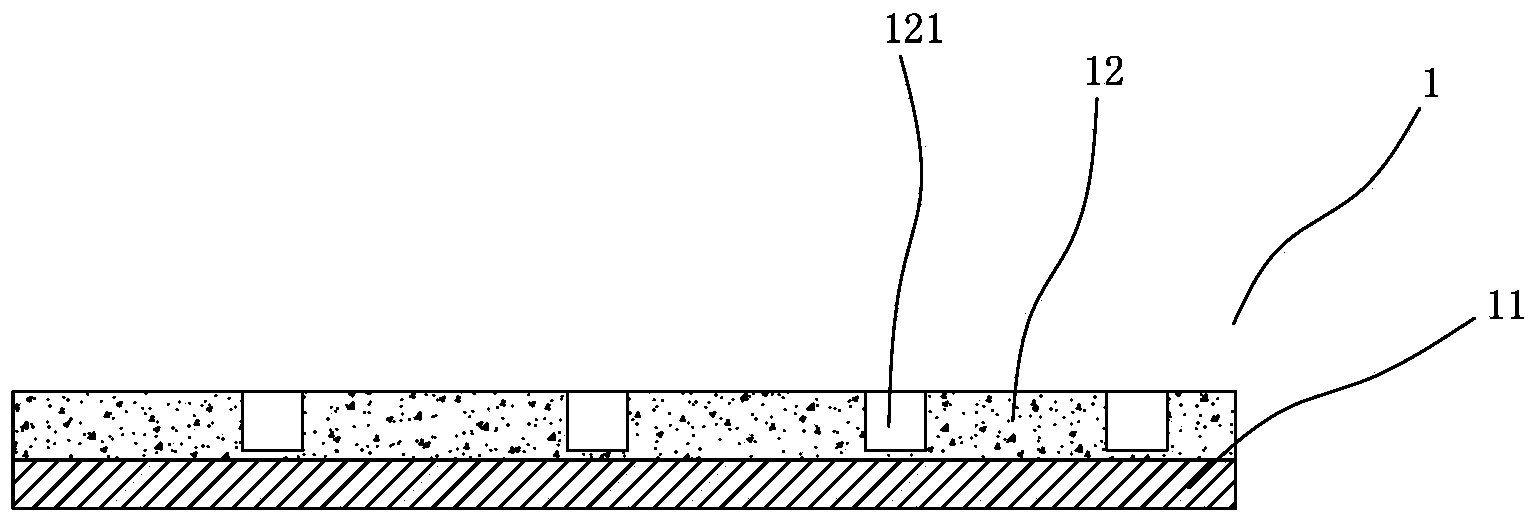

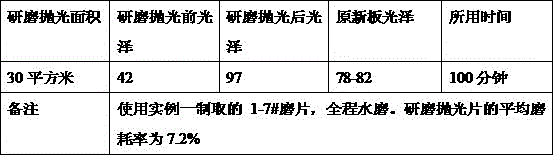

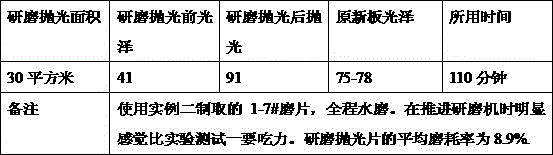

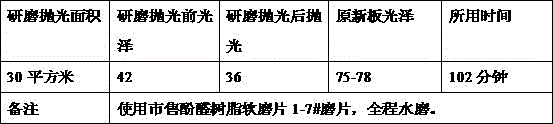

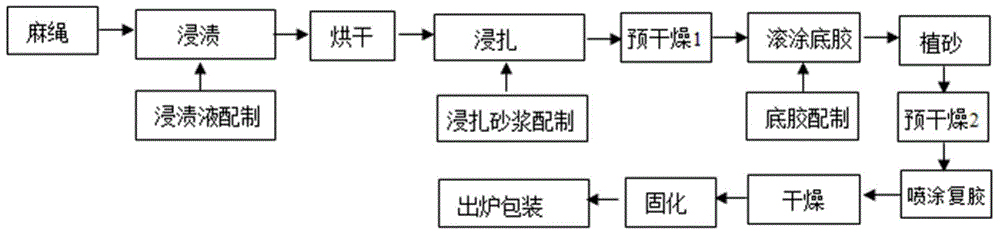

Flexible diamond abrasive disc and manufacturing and polishing technology thereof

InactiveCN103707207AHigh speedImprove grinding and polishing efficiencyOther chemical processesFlexible-parts wheelsFiberCarbide

The invention relates to a flexible diamond abrasive disc and a manufacturing and polishing technology of the flexible diamond abrasive disc. The flexible diamond abrasive disc comprises a flexible substrate and a polishing working layer adhering to the substrate and is characterized in that the working layer is composed of, by weight, 35-38 parts of phenolic resin powder, 8-12 parts of melamine powder, 13-15 parts of copper powder, 8-10 parts of diamond, 9-12 parts of oxide abrasive material, 4-5 parts of carbide abrasive material, 2-3 pars of release agent and 4-5 parts of plant fibers. The granular diameters of the oxide abrasive materials and the carbide abrasive materials are smaller than the granular diameter of the diamond. The flexible diamond abrasive disc can effectively improve the polishing speed and simplify the polishing technology.

Owner:QUANZHOU SHUANGYANG DIAMOND TOOL

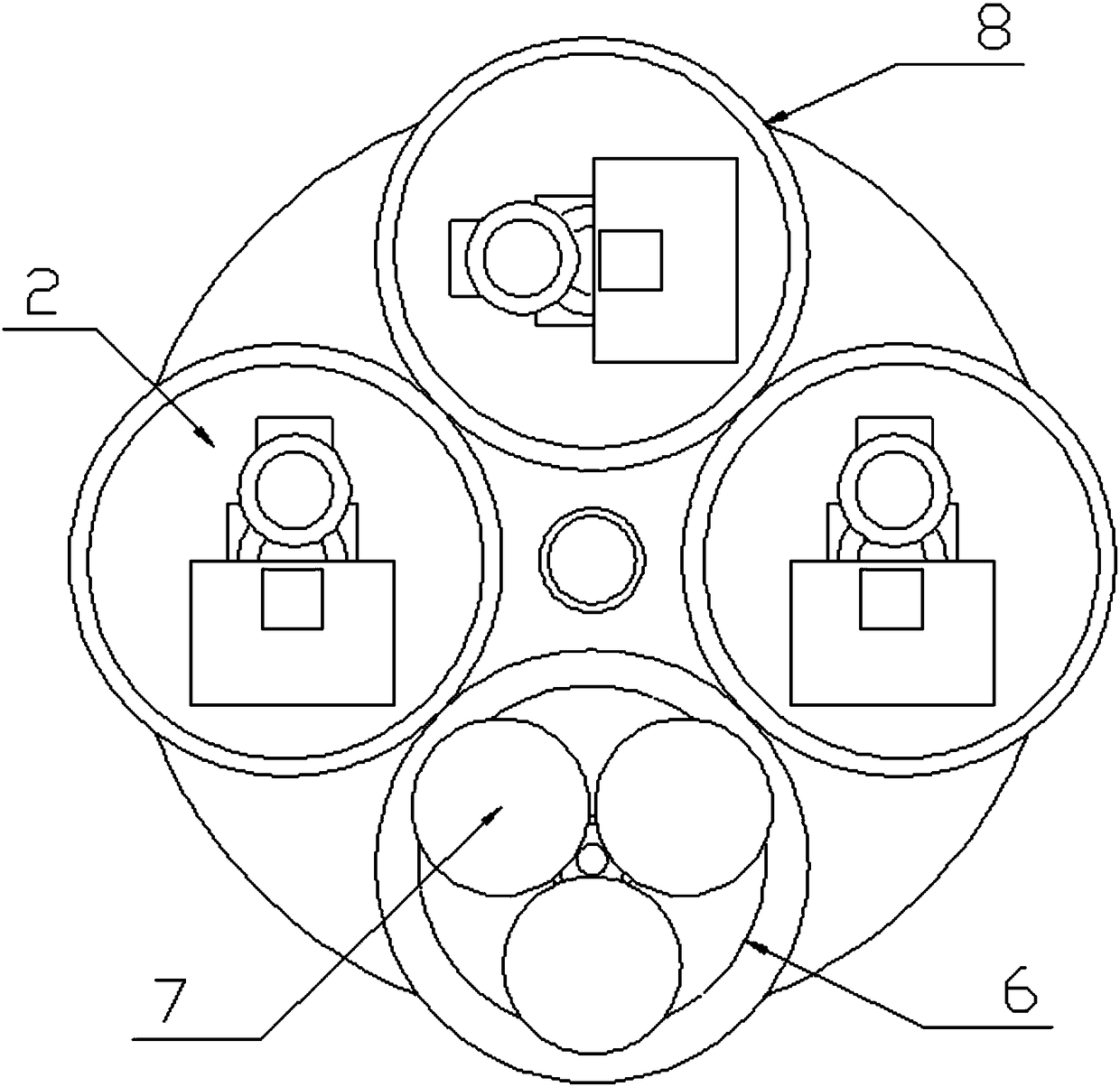

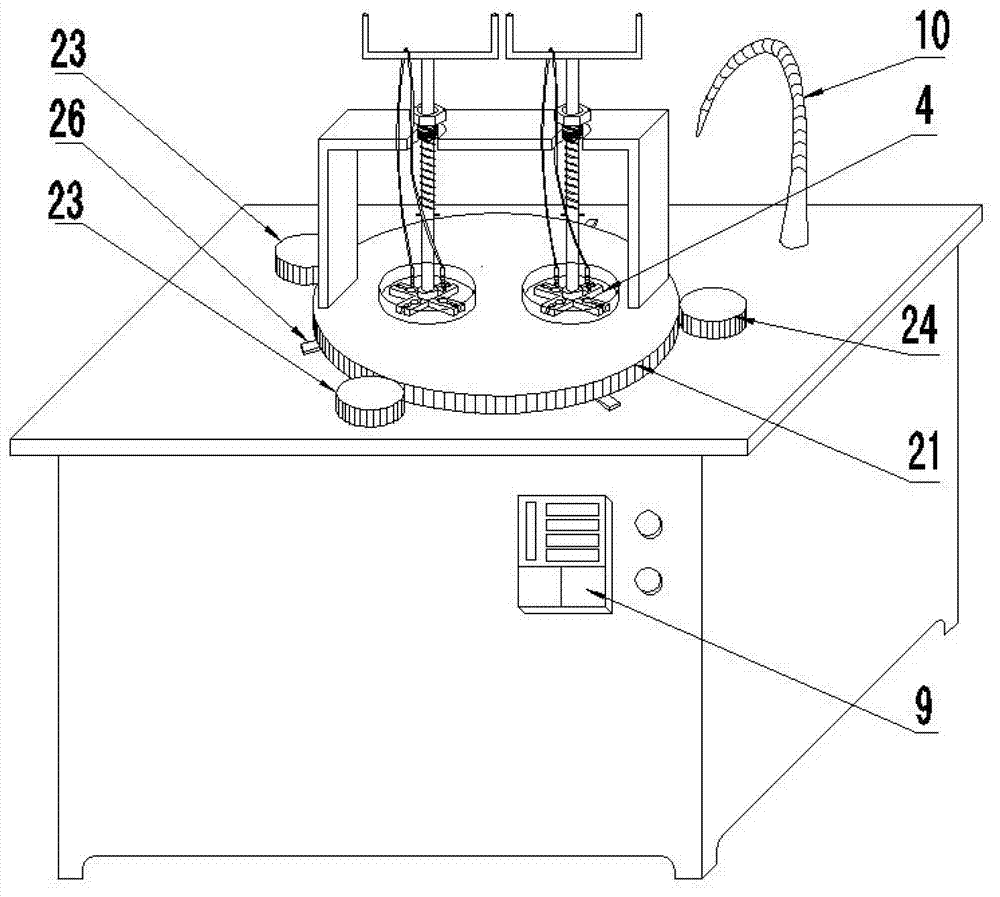

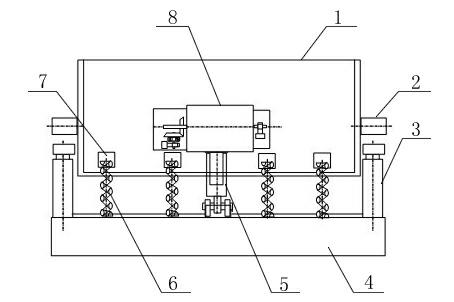

Continuous multi-station curved surface polishing machine

PendingCN108214265ARealize multi-station polishingRealize continuous operationPolishing machinesGrinding feedersReducerEngineering

The invention provides a continuous multi-station curved surface polishing machine. The continuous multi-station curved surface polishing machine comprises a machine frame, an upper disc unit, a transmission main body, an electric control operation box and a vacuum adsorption device; the upper disc unit comprises an upper disc rotating device and an upper disc lifting device, and the upper disc rotating device comprises an upper disc speed reducing motor, a rotary joint, a main shaft, a round nut, a bearing cover, a bearing block, a bearing, a shaft sleeve, a lifting movable plate, a water retaining cover, an end cover, a universal device, a connecting seat, a supporting screw rod, an upper polishing disc, an upper disc retainer ring and a brush clamping piece; and the transmission main body comprises a station unit, a large liquid baffle cover, a station disc, a tray shaft, a bearing, a tray bearing seat and a large gear, a gear seat, a transmission gear, a revolution speed reducer gear, a station transmission gear, a station speed reducer gear, a four-channel rotary joint, a gear claw type clutch device, a station speed reducing motor set and a revolution speed reducing motor set. According to the continuous multi-station curved surface polishing machine, multi-station polishing can be achieved, continuous operation can be achieved, and the grinding and polishing efficiency is greatly improved; and meanwhile, the automatic batch production is facilitated.

Owner:HUNAN YUJING MACHINE

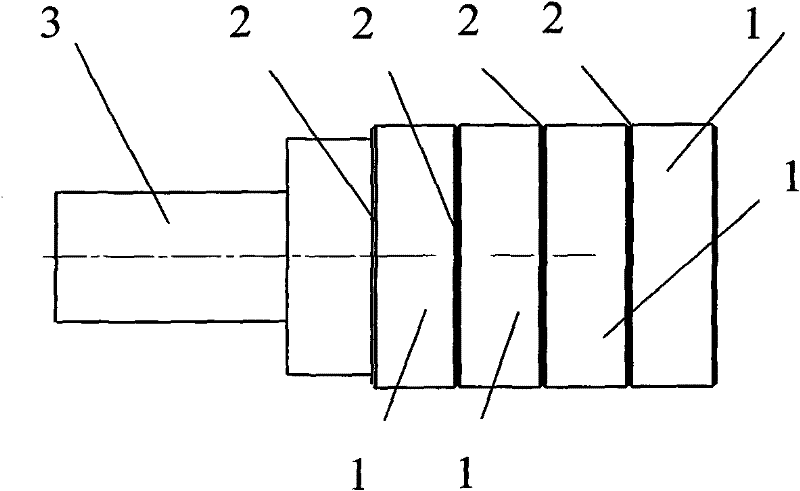

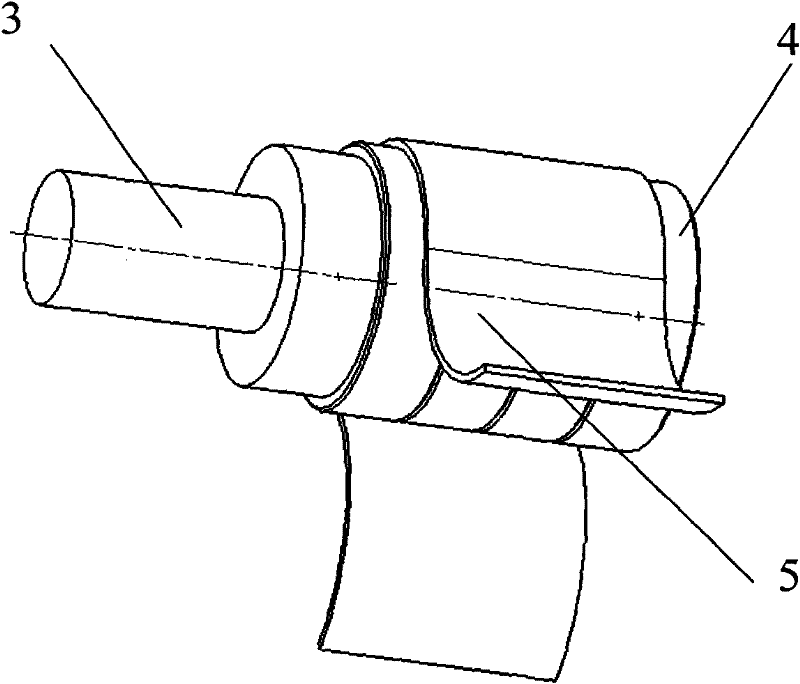

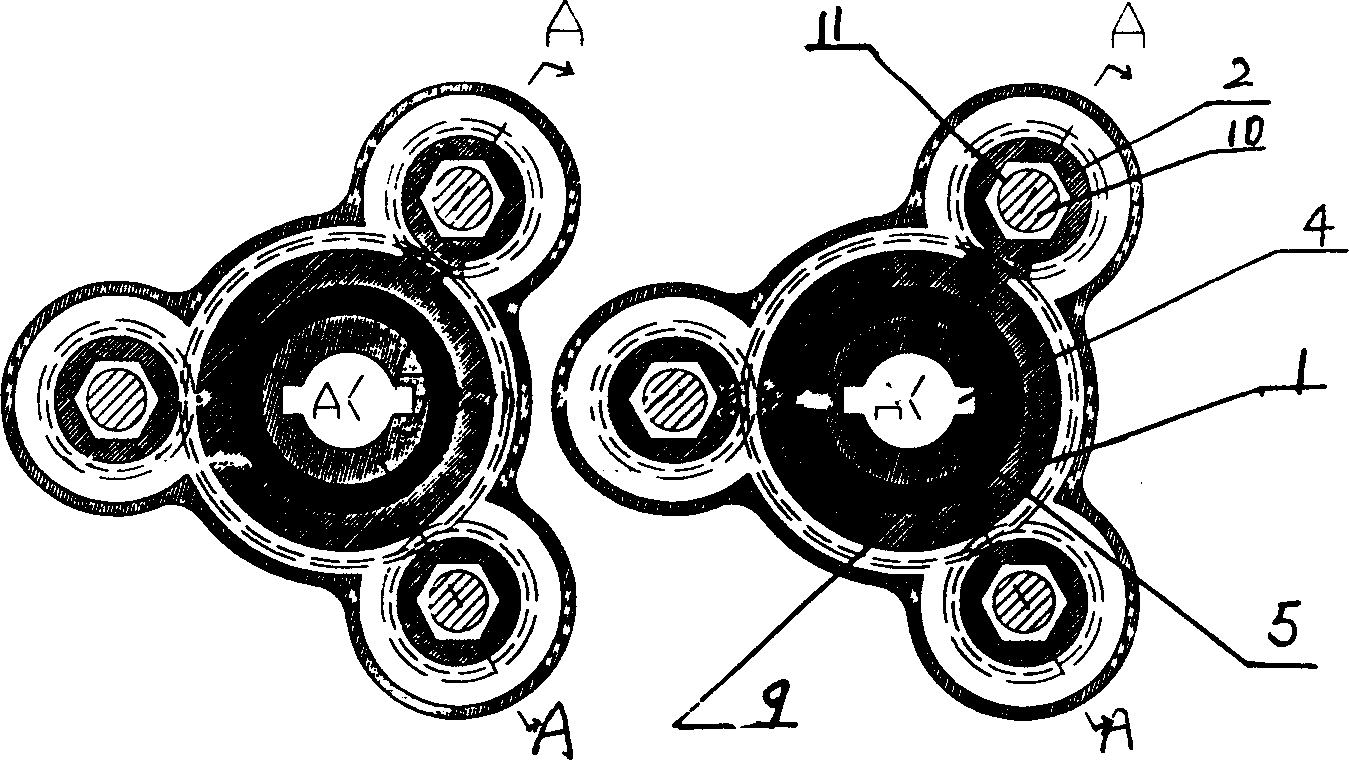

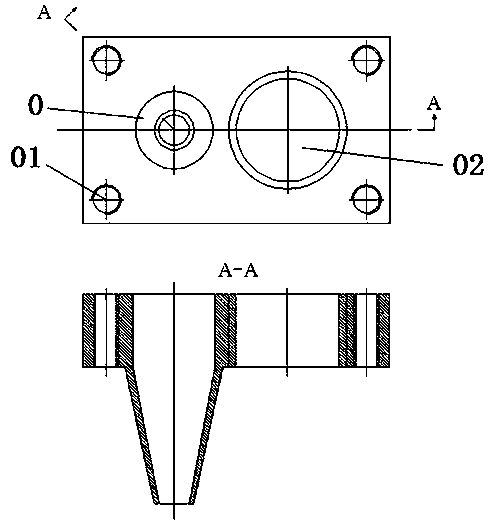

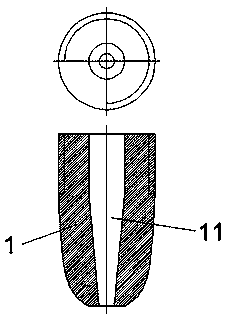

Laser gyro lens excircle grinding and polishing method

ActiveCN102049728AImprove grinding and polishing efficiencyImprove grinding and polishing qualityLapping machinesAdhesiveEngineering

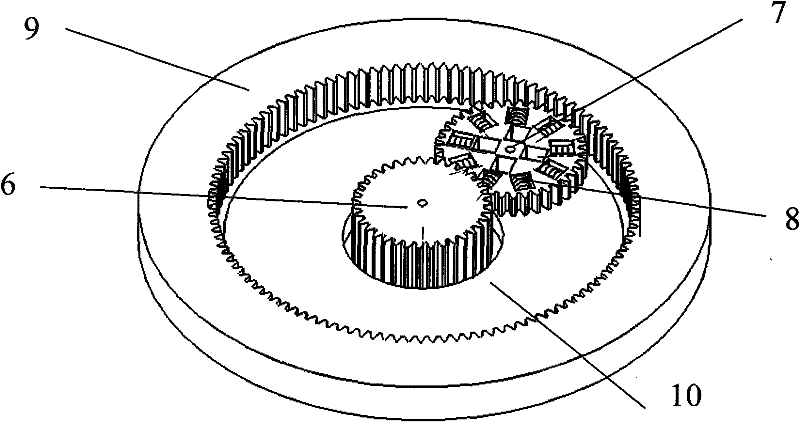

The invention relates to a laser gyro lens excircle grinding and polishing method which comprises the following steps of: bonding a lens and a bonded joint into a pillar with the bonded joint (see the figure 1) by using a bonding adhesive, and fixing the bonded joint by using a three-jaw clamp of a grinding machine to ensure that the runout of the excircle of the lens pillar is less than 0.3 mm; disconnecting the adhesive to remove the bonded joint after the excircle of the lens pillar is ground to grinding size, and chamfering the sharp edges of both end faces of the lens pillar; placing a wandering star wheel carrier on a double-face grinding machine or polishing machine, and placing the lens pillar in the wandering star wheel carrier; starting the machine, introducing a liquid (a grinding powder liquid or a polishing powder liquid), and driving the wandering star wheel carrier to rotate through the rotation of an inner gear ring and an outer gear ring; and suspending an upper disc of the equipment to ensure that the lens pillar rotates around central axis per se on a lower disk to achieve the effect of grinding and polishing the excircle. The laser gyro lens excircle grinding and polishing method provided by the invention is convenient to operate and has the advantages of high grinding and polishing efficiency, good machining consistency and high quality.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

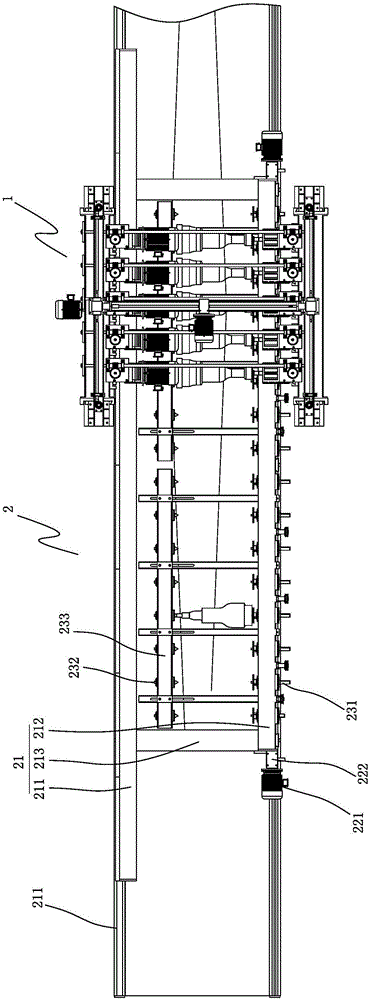

Numerical control gantry type environment-friendly plane grinding and polishing machine

ActiveCN107350936ARealize surface grinding workNo secondary pollutionGrinding carriagesBelt grinding machinesNumerical controlFrequency conversion

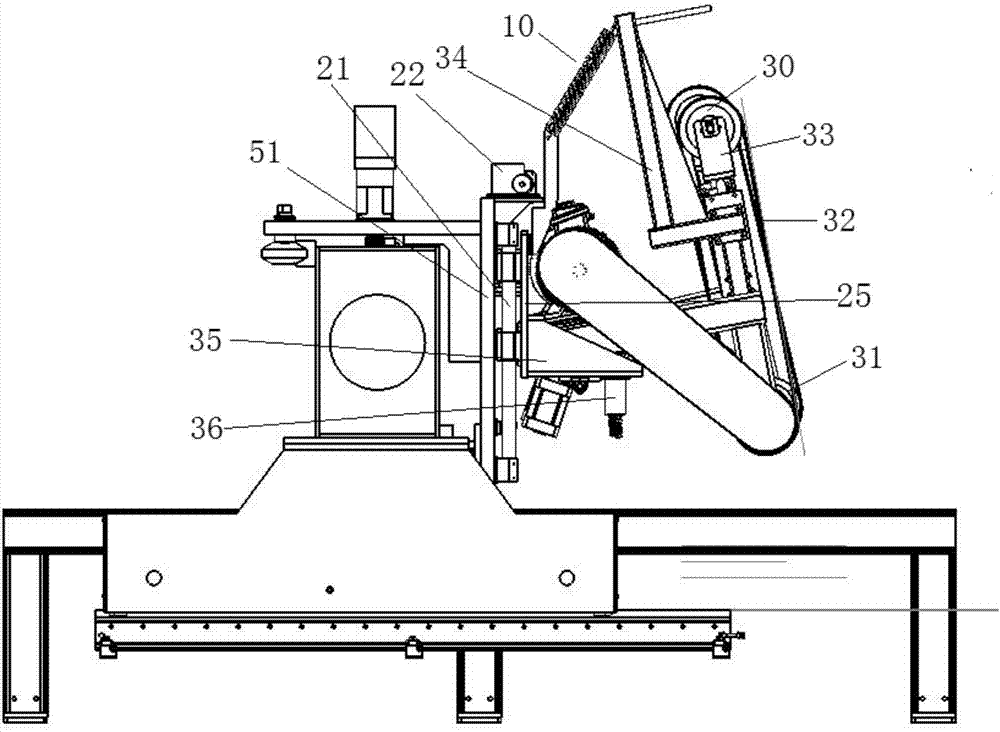

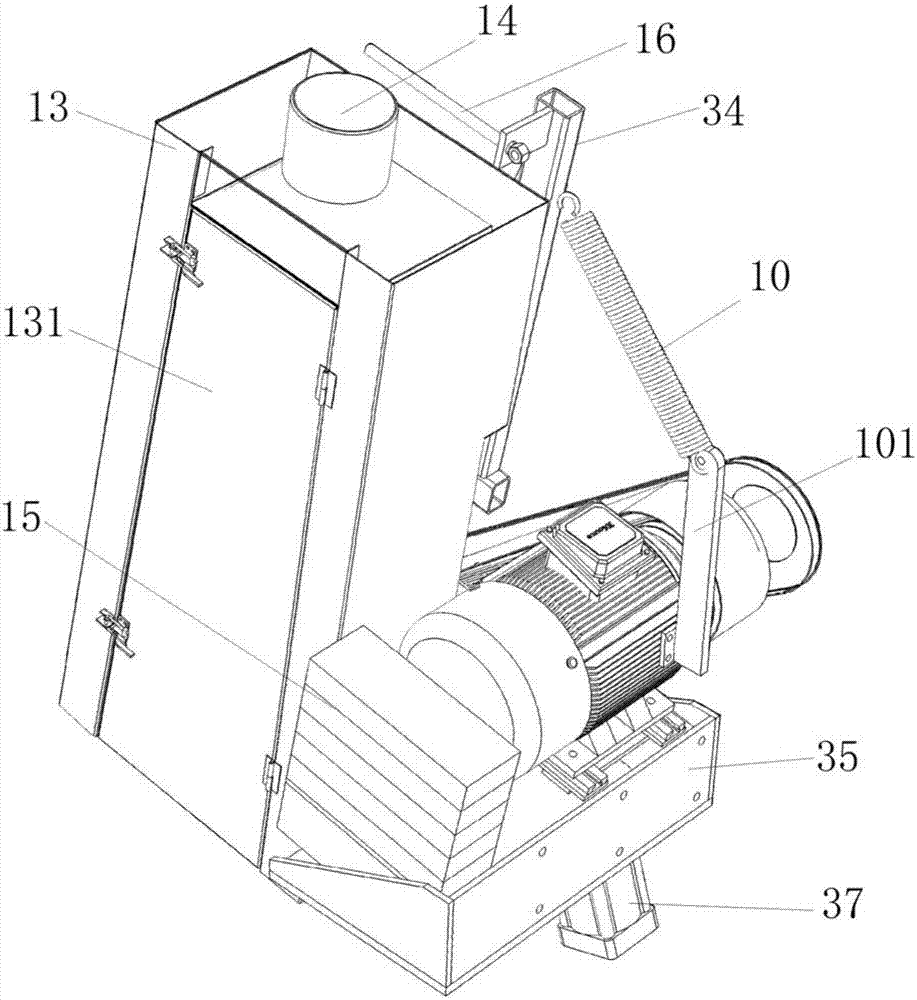

The invention discloses a numerical control gantry type environment-friendly plane grinding and polishing machine. The numerical control gantry type environment-friendly plane grinding and polishing machine comprises a gantry rack, tracks used for walking of the gantry rack, and abrasive belt grinding devices arranged on the gantry rack and driven to vertically ascend and descend and horizontally move. Each abrasive belt grinding device comprises an angle adjusting arm, an abrasive belt assembly fixed to the angle adjusting arm, and a frequency conversion reversing grinding motor capable of driving the abrasive belt assembly to rotate in the forward direction and the reverse direction, wherein elastic supporting devices are arranged on the two sides of the angle adjusting arm, and the bottom of the angle adjusting arm is connected with a cardan joint arm. The angle adjusting arms can be driven to rotate around the cardan joint arms. Each abrasive belt assembly is externally provided with a sealing dustproof cover, wherein a vacuum dust discharging port is formed in the top of the sealing dustproof cover so that dust sucked in from a bottom dust inlet can be discharged from the vacuum dust discharging port. The numerical control gantry type environment-friendly plane grinding and polishing machine can achieve dustless work, is high in grinding efficiency and capable of adapting to grinding and polishing work of plane panels different in material.

Owner:天津圣弘业环保科技有限公司

Automatic grinding and polishing device for end surfaces of optical fibers and cables

ActiveCN102922383AAutomatic grinding and polishingHardwiredGrinding work supportsPlane surface grinding machinesDrive wheelEngineering

The invention discloses an automatic grinding and polishing device for end surfaces of optical fibers and cables. The automatic grinding and polishing device comprises a machine case, a grinding and polishing assembly and an electric control unit. The grinding and polishing assembly comprises a plane grinding and polishing mechanism, an emulational hand assembly, a grinding and polishing clamp and an elastic boosting device, wherein the emulational hand assembly comprises a working disc, a driving wheel, a transmission motor, a driven wheel and a working disc rotating booster; the driven wheel and the driving wheel are in external meshing with the working disc; the elastic boosting device comprises a grinding and polishing clamp connection rod and a working disc gantry base; the grinding and polishing clamp connection rod is connected with the working disc gantry base; the working disc gantry base is arranged on the working disc, the grinding and polishing clamp connection rod is connected with the grinding and polishing clamp, and the grinding and polishing clamp is assembled in a working hole; and the working disc rotating booster is respectively connected with the working disc and the plane grinding and polishing disc. The automatic grinding and polishing device for end surfaces of the optical fibers and cables can perform automatic grinding and polishing, can stimulate human hands to exert force on the grinding and polishing clamp of the optical fibers and cables, and is high in grinding and polishing efficiency, stable in grinding and polishing quality and safe and reliable to operate.

Owner:NANJING CHUNHUI SCI & TECH IND

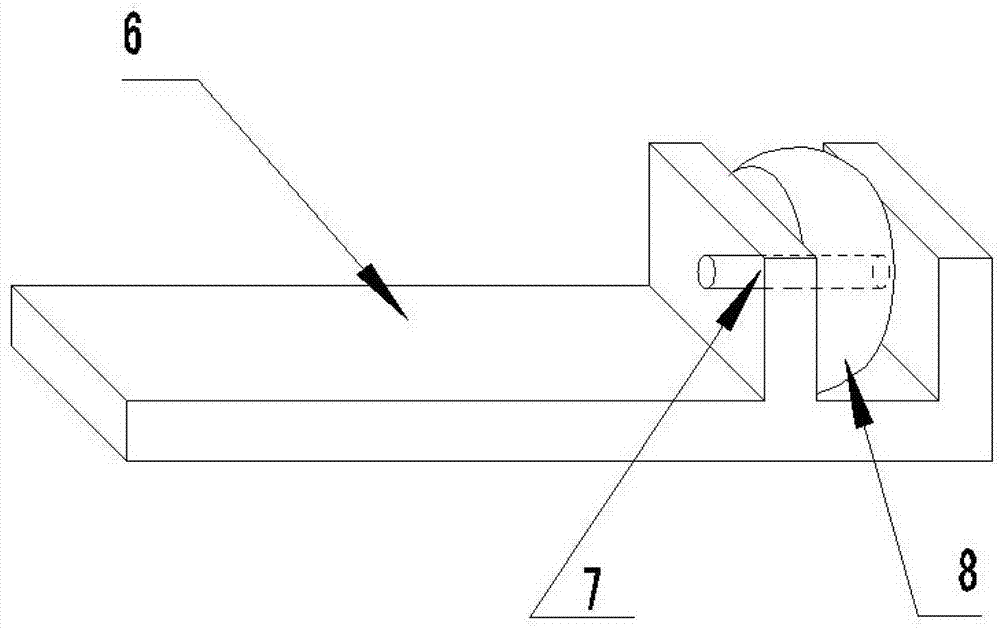

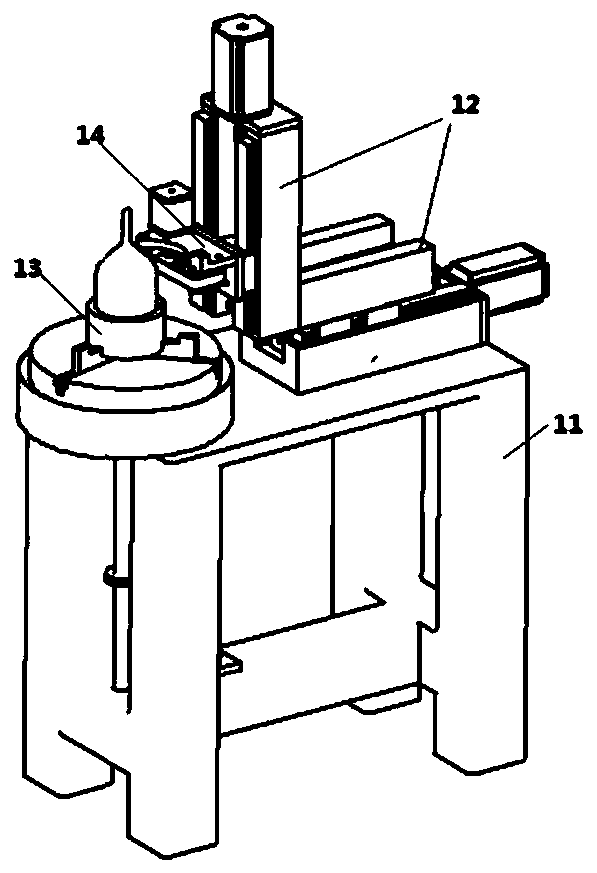

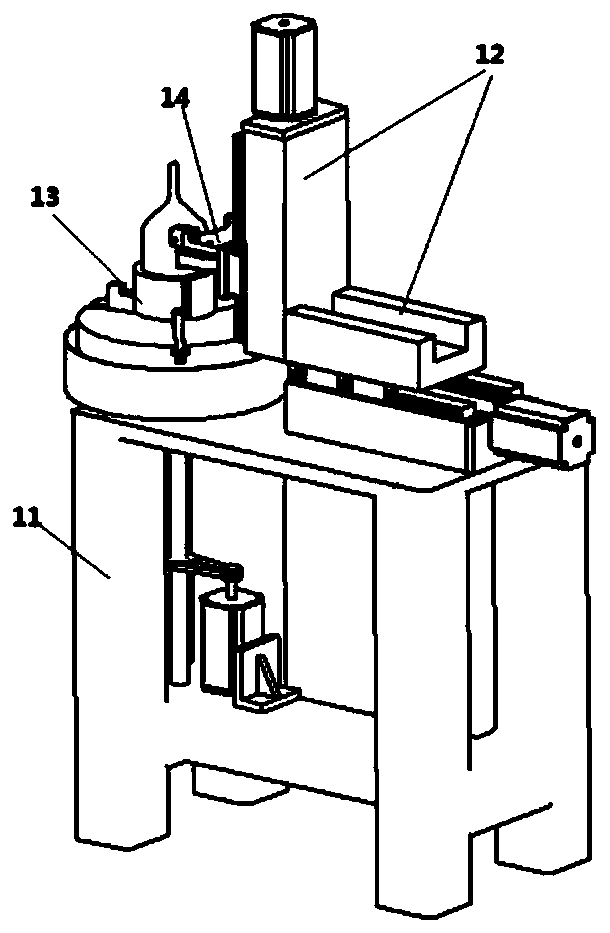

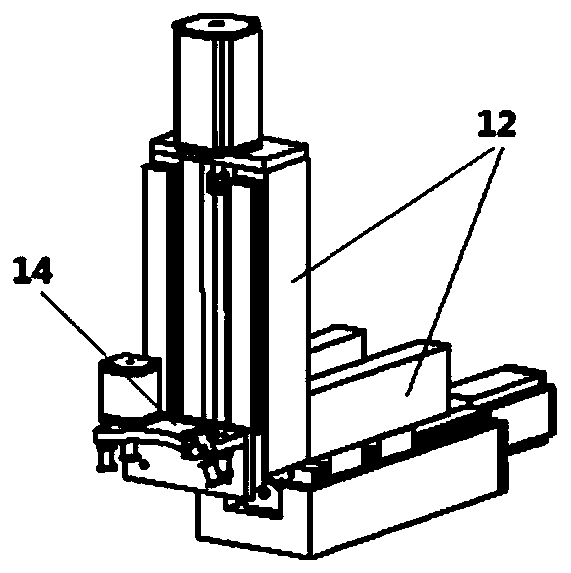

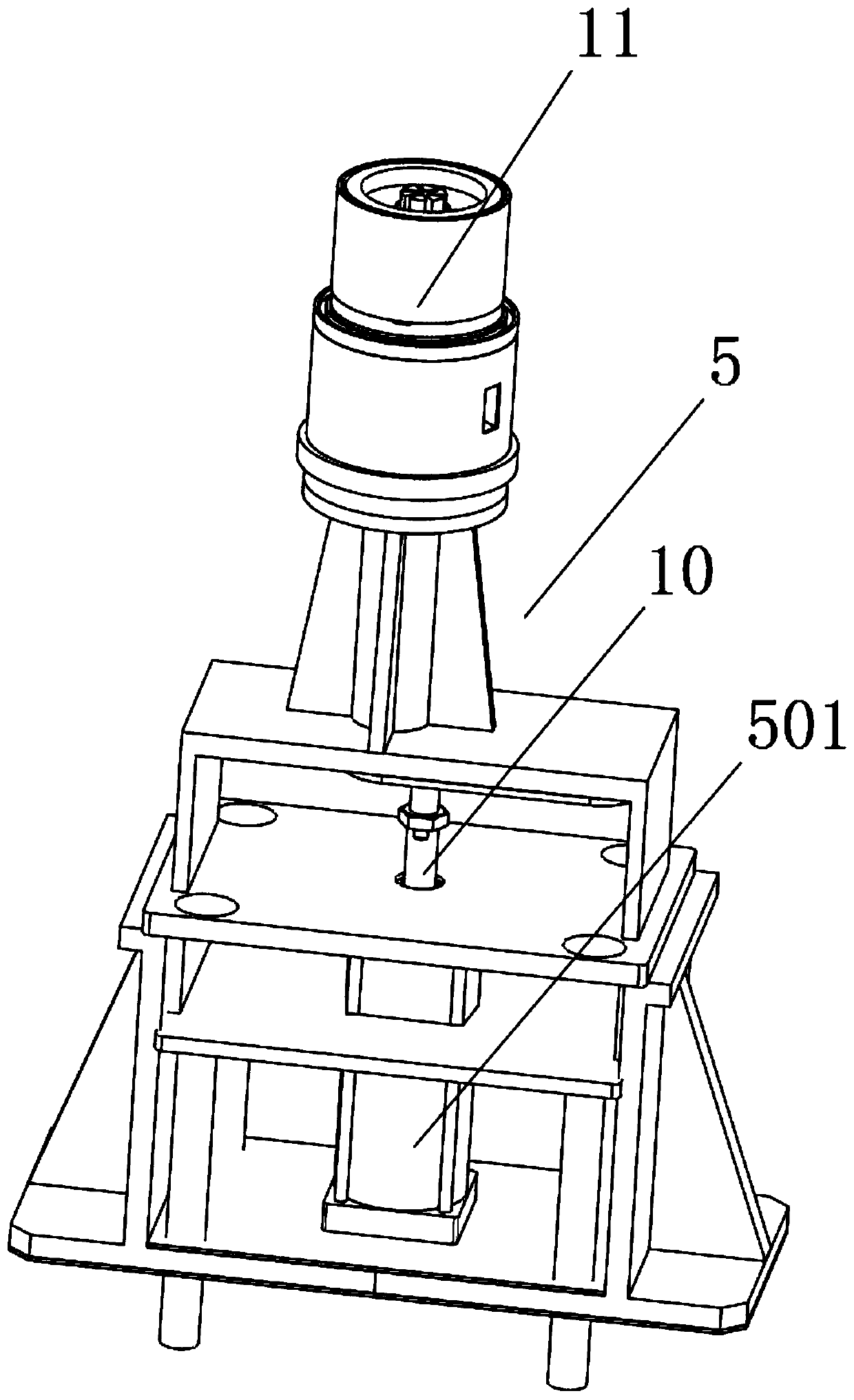

Metallographic specimen grinding and polishing equipment and application method thereof

ActiveCN103398891AImprove grinding and polishing efficiencySimple structurePreparing sample for investigationMechanical engineering

The invention relates to metallographic specimen grinding and polishing equipment and an application method thereof. The metallographic specimen grinding and polishing equipment comprises a fixed bottom plate, a position adjusting mechanism, a motor for polishing, a polishing grinding head and a supporting frame, wherein the position adjusting mechanism is used for fixing a metallographic specimen and is connected with the fixed bottom plate in a sliding manner; the supporting frame is mounted on the fixed plate and is used for supporting the motor; the length of the upper end face of the fixed bottom plate is in the longitudinal direction and the width of the upper end face of the fixed bottom plate is in the transverse direction; the position adjusting mechanism comprises a lower slide rail which is fixed on the fixed bottom plate and extends along the transverse direction, a transverse bottom plate which is connected with the lower slide rail in the sliding manner, an upper slide rail which is fixed on the transverse bottom plate and extends along the longitudinal direction, and a longitudinal bottom plate which is connected with the upper slide rail in the sliding manner. According to the metallographic specimen grinding and polishing equipment and the application method thereof provided by the invention, when the large metallographic specimen is polished, the large metallographic specimen is fixed between two clamping seats and the position of the polishing grinding head is adjusted so that polishing can be carried out; the metallographic specimen grinding and polishing equipment is simple in structure and convenient to clamp; the efficiency of grinding and polishing the large metallographic specimen is greatly improved.

Owner:SUZHOU NUCLEAR POWER RES INST +2

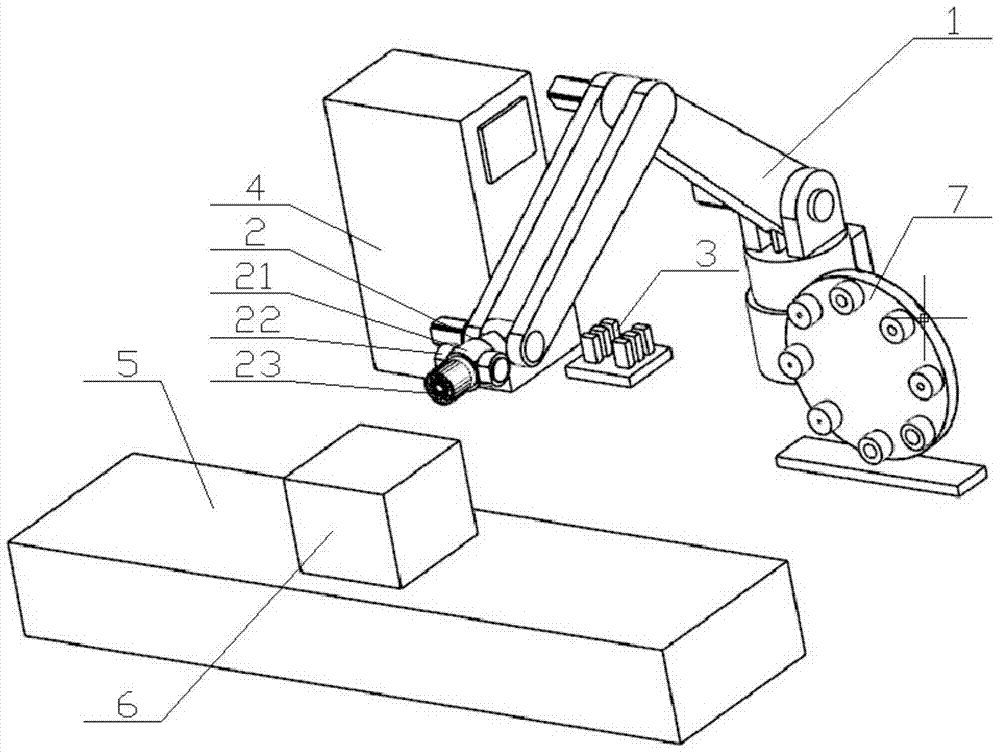

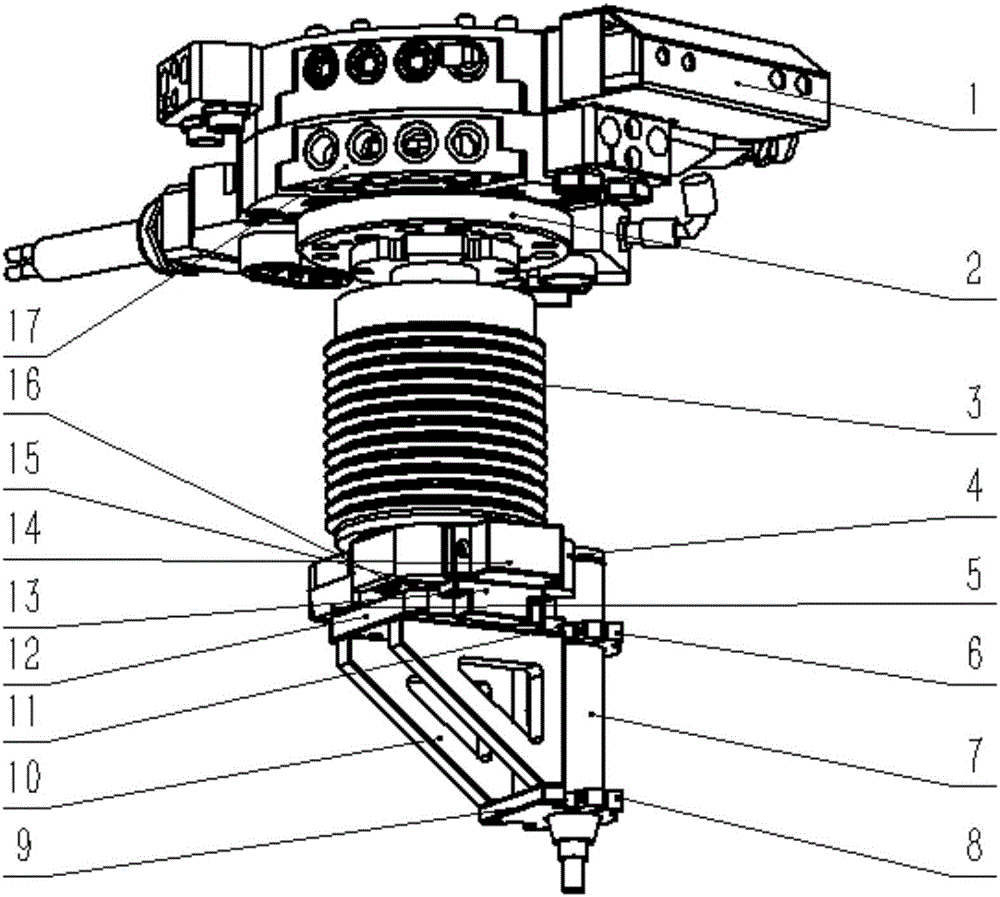

Polishing device for robot-terminal flexible motorized spindle

ActiveCN105856047ASolve processabilitySolve the problem of matching workpiece tolerancesPolishing machinesGrinding work supportsElectricityLocking mechanism

The invention provides a polishing device for a robot-terminal flexible motorized spindle, comprising a quick-change male disc, a quick-change female disc, a terminal flange, a flexible flange, an auto-locking mechanism, a motorized spindle clamping device and a motorized spindle that are connected in succession; the quick-change male disc and the quick-change female disc are detachably connected; the motorized spindle clamping device is detachably connected with the auto-locking mechanism. By introducing the flexible flange, it is possible to control and adjust in real time, nominal force for the motorized spindle during polishing; automatic polishing by robot replacing labor is achieved, and the problem that a severe field environment for polishing causes health damage to workers is solved; the polishing device has constant polishing force, the matching problem between a robot fixed processing path and a workpiece tolerance is solved, stable polishing process parameters are maintained, high bearing capacity and stability of a robot are made full use, polishing efficiency is improved greatly, consumables cost is reduced, the service life of tooling is prolonged, and homogenous high-level polishing quality is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Grinding polishing machine

InactiveCN101143425AShorten the timeImprove grinding and polishing efficiencyGrinding drivesGrinding machinesMulti axisSupport point

A lapping and polishing machine consists of a shell, an eccentric rotating structure, a reciprocating straight-line motion mechanism and a clamp, wherein a rotating shaft is provided on the first end of the eccentric structure of the eccentric rotating structure and the rotating shaft supports the shell by an axle bearing; an eccentric shaft is provided on the second end of the eccentric structure, and axes of the eccentric shaft and the rotating shaft are parallel to each other and the spacing between each other is fixed. The reciprocating straight-line motion mechanism consists of a plurality of axes, a connecting rod and at lease a swinging rod, wherein one end of the connecting rod hinges with the eccentric shaft, and the other end of the connecting rod hinges with a principal axis. When the principal axis glides the axle bearing along axial direction, the swinging rod is horizontally fixed relatively opposite to the principal axis, and a supporting point is fixed to swing the axle bearing. The principle axis and an auxiliary axis are respectively hanged on different positions along the longitudinal direction of the swinging rod. Due to the multi-axis design of the invention, the lapping and polishing efficiency is greatly improved and the lapping and polishing time of work-pieces is shortened, besides, a plurality of working processes relating to lapping and polishing can be conducted at the same time and the lapping and polishing is simpler. The invention has the advantages of compact structure and easy-to-use.

Owner:HYPIC SUZHOU

Diamond lapping paste and preparation method thereof

InactiveCN107400499AImprove grinding and polishing efficiencyOther chemical processesPolishing compositions with abrasivesGraphiteStearic acid

The invention relates to diamond lapping paste and a preparation method thereof. The diamond lapping paste is composed of artificial diamond micro powder, vaseline, diesel, oleic acid, graphite, stearic acid and polytetrafluoroethylene. The diamond lapping paste disclosed by the invention has excellent lapping and polishing properties, is fine and smooth in paste body and has an excellent effect of polishing sapphire lens materials.

Owner:YUNNAN MINZU UNIV

Preparation method of polyurethane matrix stone grinding and polishing disc

ActiveCN106272125AGood self-sharpeningImprove grinding effectAbrasion apparatusGrinding devicesSilicon oxideZinc

The invention discloses a preparation method of a polyurethane matrix stone grinding and polishing disc, and relates to a synthesis technology adopting a prepared polyurethane matrix and mixed artificial diamond micro powder, silicon carbide, silicon oxide, aluminium oxide and zinc oxide super fine powder as abrasive components. The novel stone grinding and polishing material can better meet the requirement on high luster during the decorative stone processing process or the later renovation process, the efficiency is higher, and the material has better environmental protection property.

Owner:王建秋

Internal combustion machine bearing bush machining device and machining method thereof

ActiveCN108356648AEasy dischargeImprove grinding and polishing effectRevolution surface grinding machinesGrinding work supportsCombustionEngineering

The invention discloses an internal combustion machine bearing bush machining device, and relates to the technical field of internal combustion machine bearing bush production equipment. The device comprises a bottom plate, the top of the bottom plate is fixedly connected with a box body, one side of the top of the box body is fixedly connected with a transmission box, the bottom of the inner wallof the box body is rotatably connected with a rotating shaft through a bearing pedestal, the top end of the rotating shaft sequentially penetrates the box body and the transmission box and extends into the transmission box, and the rotating shaft extends into the outer surface inside the transmission box and is rotatably connected with the top of the inner wall of the transmission box through a bearing. According to the internal combustion machine bearing bush machining device and the machining method thereof, the grinding and polishing effect is greatly improved, the grinding and polishing efficiency is well improved, a person does not need to waste a large amount of time for grinding and polishing a bearing bush, work burdens of the person are well reduced, work efficiency of the personis improved, the inner surface and the outer surface of the bearing bush can be rapidly and efficiently ground and polished at the same time, and grinding machining of the bearing bush by the personis greatly facilitated.

Owner:湖北安达精密工业有限公司

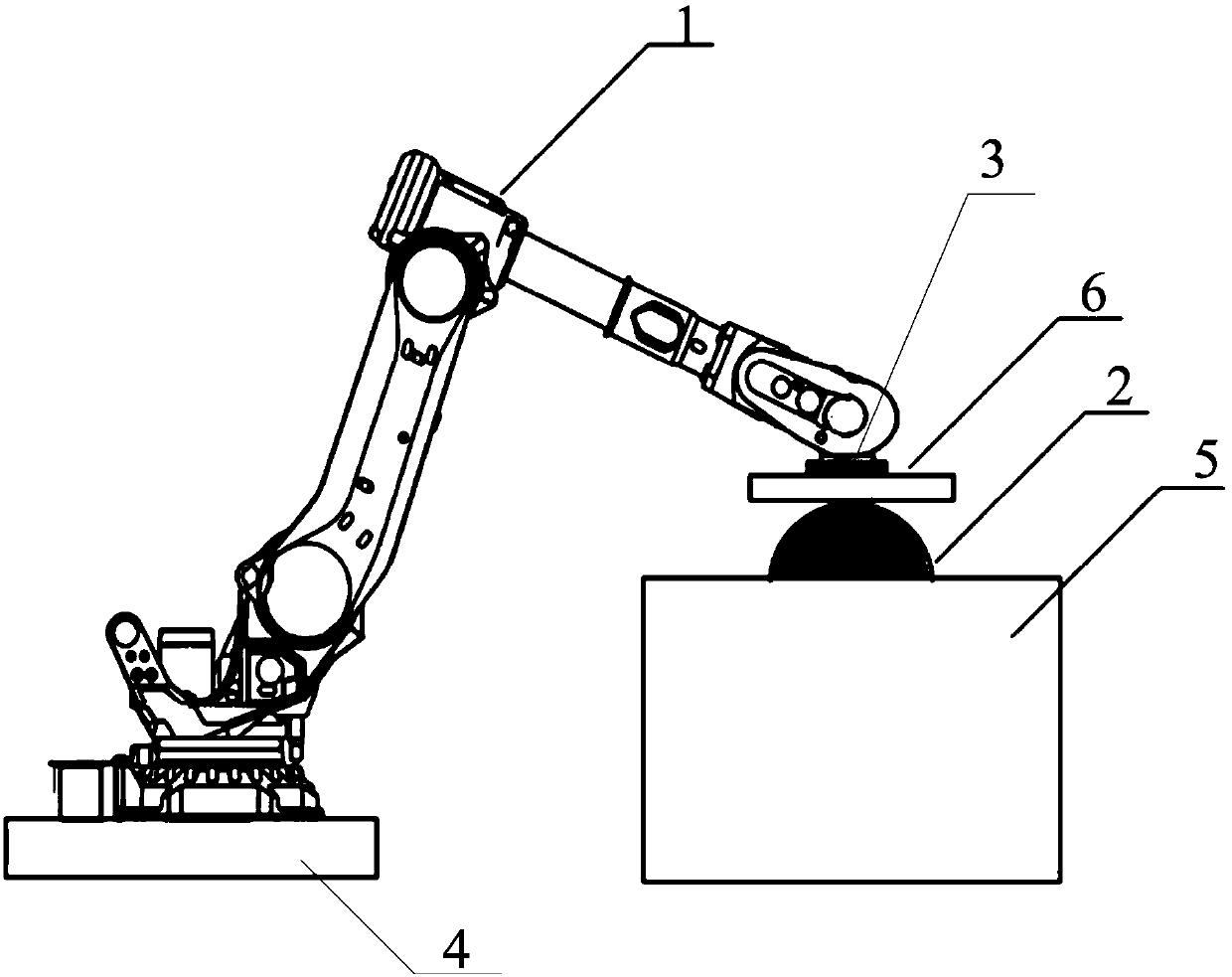

Magneto-rheological polishing machining system

PendingCN109759905ALighten the loadFlexible operationGrinding carriagesPolishing machinesEngineeringMulti degree of freedom

The invention provides a magneto-rheological polishing machining system. The system comprises a mechanical arm, a workpiece fixing device installed at one end of the mechanical arm and a workbench provided with a magneto-rheological polishing wheel and a magneto-rheological circulation system, wherein the magneto-rheological circulation system provides a magneto-rheological fluid for the magneto-rheological polishing wheel, the workbench is installed on a base, and the magneto-rheological polishing wheel extends out of the workbench. According to the system, the workpiece fixing device is driven by the mechanical arm to realize position changes relative to the magneto-rheological polishing wheel, based on the advantages of the space multi-degree-of-freedom, speed and acceleration of the mechanical arm, the magneto-rheological polishing wheel is arranged on the workbench, so that bearing of the mechanical arm can be reduced, the mechanical arm can operate more flexibly during machining,in addition, a magneto-rheological polishing wheel with a larger diameter and a larger weight can be used for machining, so that the machining is efficient and rapid, and the overall efficiency of polishing is further improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

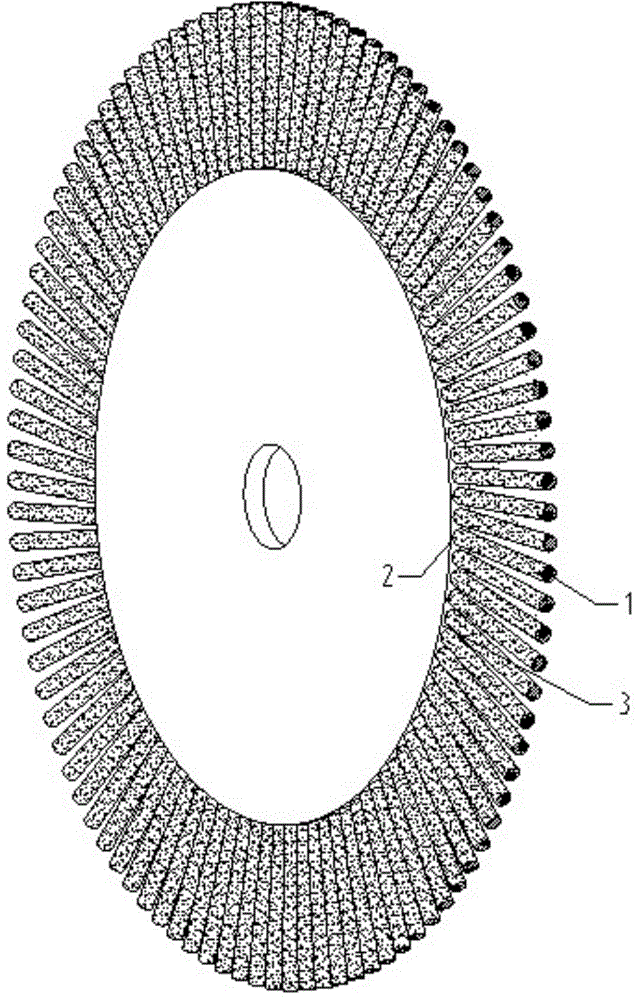

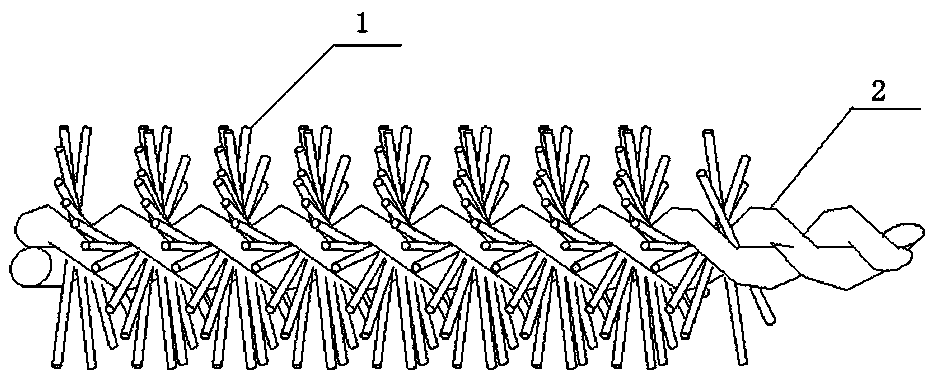

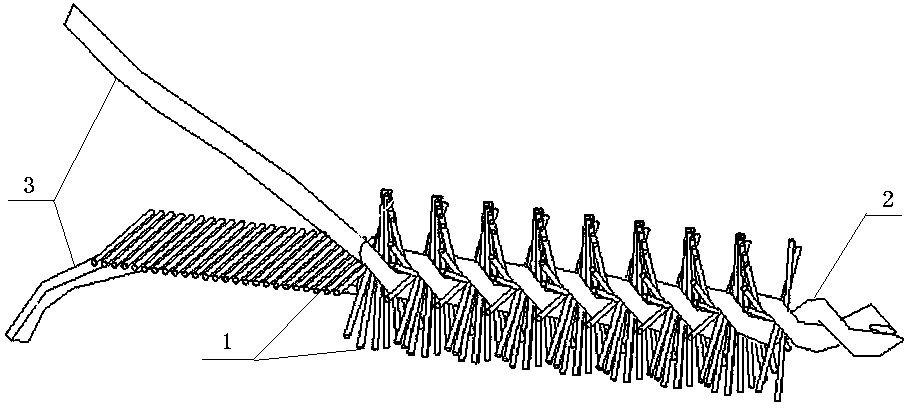

Polishing wheel based on fiber adhesive rope coated abrasive tool

InactiveCN103552002AReduce manufacturing costReduced grinding and polishing process costsFlexible-parts wheelsGrinding devicesFiberEngineering

The invention discloses a polishing wheel produced with a fiber adhesive rope coated abrasive tool, which comprises a skeleton core and fiber adhesive rope sections, and the fiber adhesive rope sections are evenly and radially stuck on the circumferential surface of the skeleton core by binder, shaped and solidified. The polishing wheel can greatly reduce the manufacturing cost of polishing abrasive disk disks, so the cost of the grinding and polishing process is reduced as well; moreover, the grooves between the abrasive rope sections play the role of dissipating heat and removing chips; the circumferential edge of an abrasive disk can be inserted into the groove of a workpiece to be ground for grinding and polishing; and the polishing wheel has the characteristics of high grinding and polishing efficiency and long service life.

Owner:谢泽

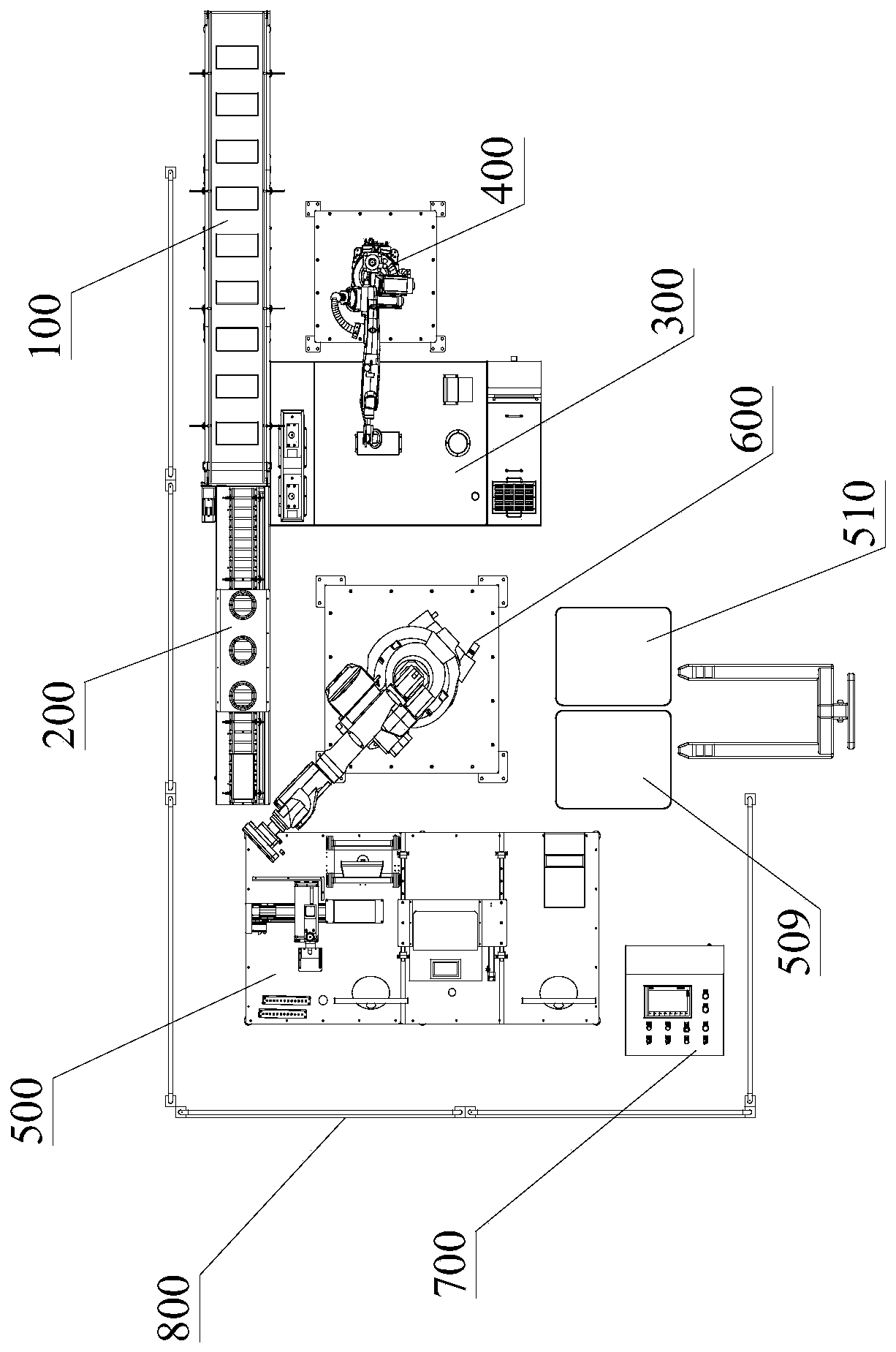

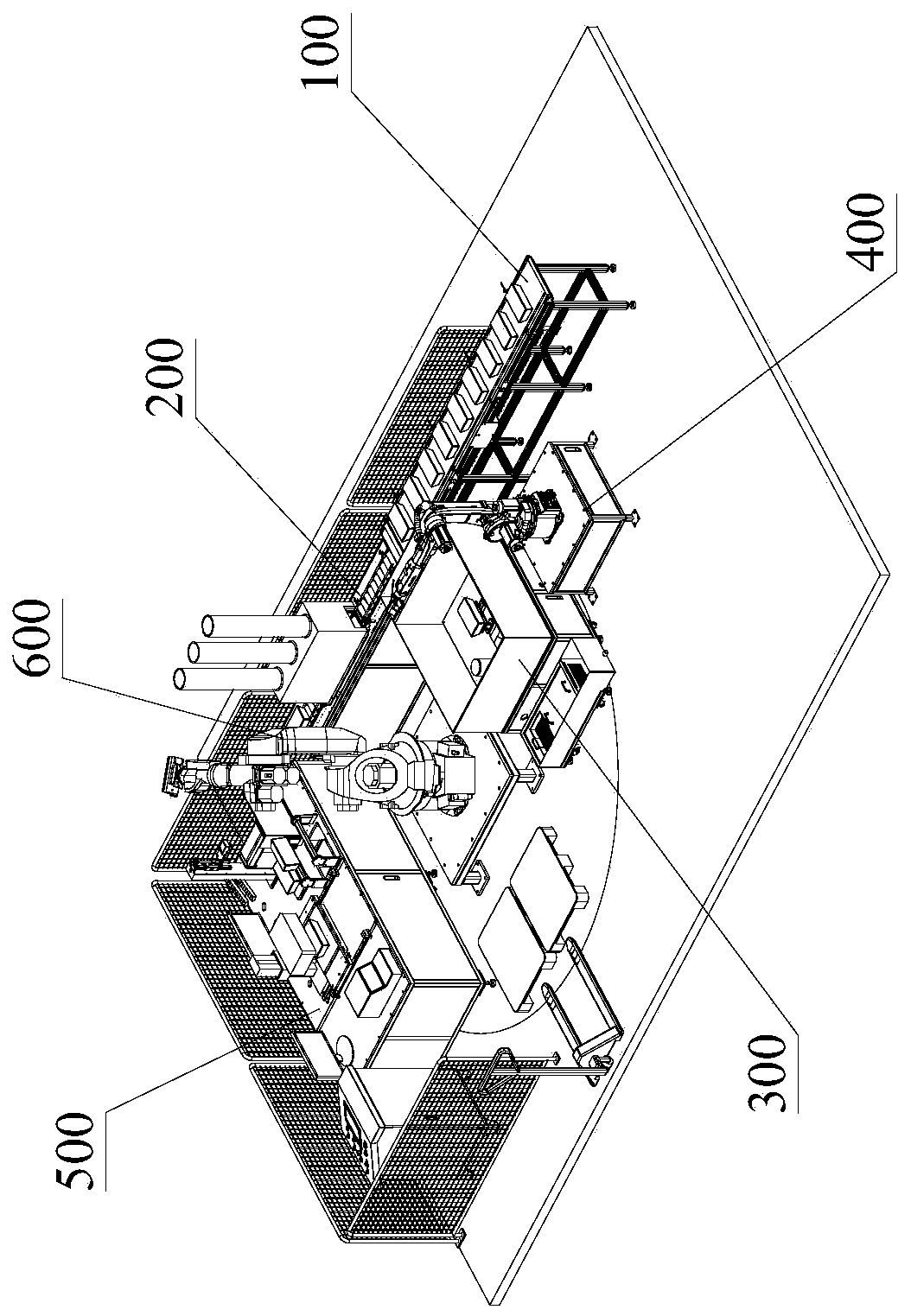

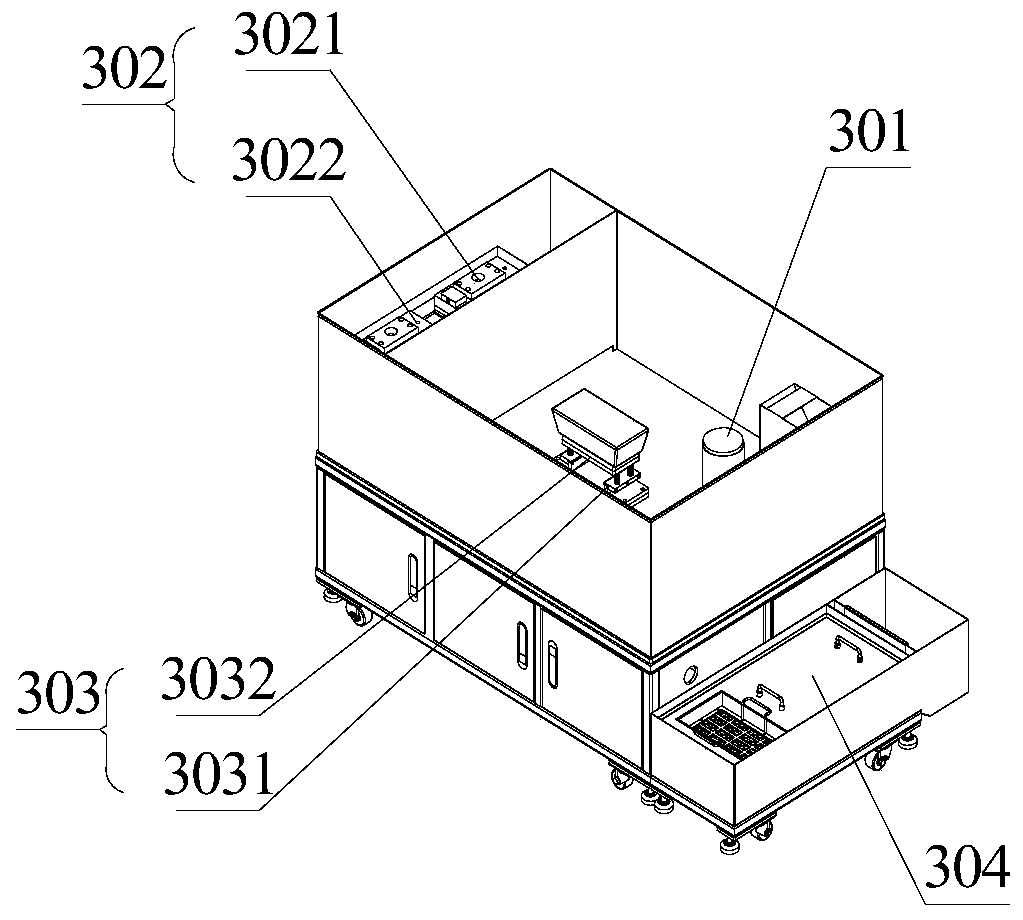

Automatic silver ingot polishing system

PendingCN110948365ARealize automatic grinding and polishingImprove grinding and polishing efficiencyPolishing machinesMaterial analysis by optical meansAssembly lineIngot

The invention discloses an automatic silver ingot polishing system. A polishing robot is arranged at the perpendicular corner of a grinding module and a conveying device. The polishing robot is used for grabbing a grinding disk in the grinding module and conducting grinding a silver ingot in the grinding module. A CCD visual detection device is used for detecting the silver ingot and completing marking operation. Through the automatic silver ingot polishing system, mechanized assembly line operation replaces traditional manual operation, automatic grinding and polishing on the silver ingot isrealized, the grinding and polishing efficiency of the silver ingot is improved, misoperation caused by manual polishing is reduced, and the polishing stability of the silver ingot is improved; the labor cost is reduced, the production cost is lowered, the stability of the polishing process is improved, and the qualified rate of grinding and polishing is increased; and moreover, workers do not need to get close to the silver ingot to carry out grinding, the operation environment of the processing worker is improved, and the situation that operators inhale dust and have physical discomfort is avoided.

Owner:SHENZHEN JINDINGFENG PRECIOUS METALS EQUIP SCI & TECH CO LTD

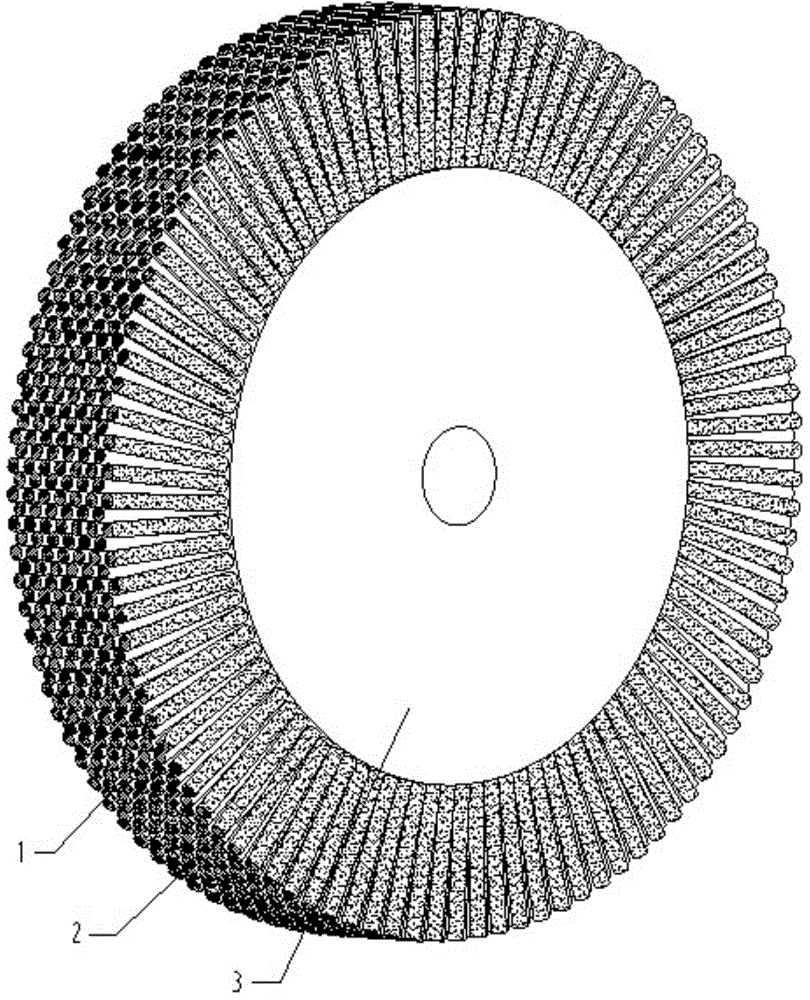

Buffing wheel based on fiber ropes containing chopped fibers and production method of buffing wheel

InactiveCN103659628AGood for polishingImprove grinding and polishing efficiencyFlexible-parts wheelsGrinding devicesAdhesive glueAutomotive engineering

The invention discloses a buffing wheel based on fiber ropes containing chopped fibers. The fiber ropes are wound, shaped and cured to form the buffing wheel after being subjected to glue and / or base glue treatment, wherein the fiber ropes contain the chopped fibers penetrating the fiber ropes. Through surface grooves formed by stereo structures of the fiber ropes, grinding, scrap returning and cooling of the buffing wheel are facilitated, and conditions are provided for development of new self-sharpening crazing; through the round structures of the fiber ropes, certain gaps are formed among the fiber ropes during shaping so as to form flat structures facilitating grinding, scrap returning and cooling; the chopped fibers penetrating the fiber ropes completely puncture all independent fiber ropes so as to improve structural strength and interlayer stripping of the whole buffing wheel, and further, safety is improved and losses caused by breakage of interlayer stripping are reduced.

Owner:谢泽

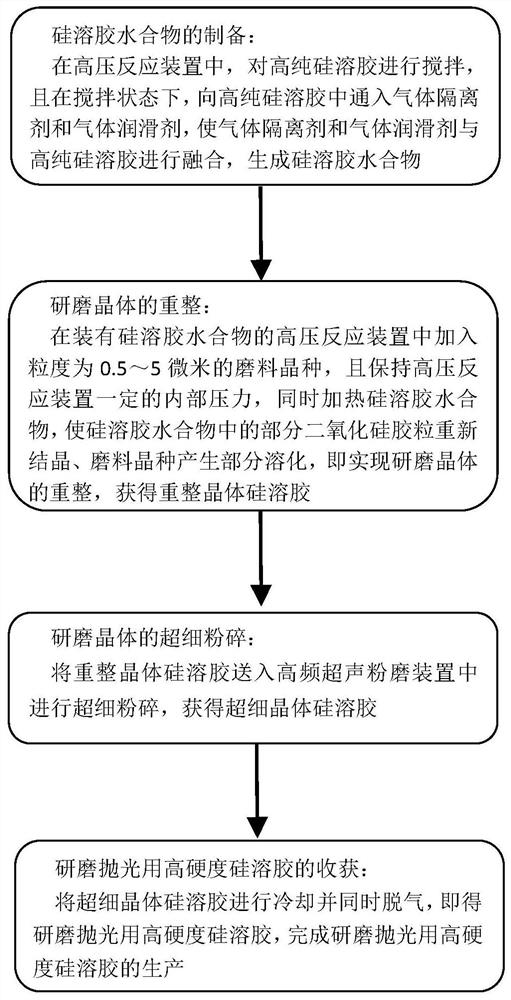

Production method of high-hardness silica sol used for grinding and polishing

InactiveCN111909619AAchieve reorganizationSuit one's needsOther chemical processesPolishing compositions with abrasivesSocial benefitsEconomic benefits

The invention relates to a production method of high-hardness silica sol used for grinding and polishing. The production method comprises the following steps: preparing a silica sol hydrate, reforminggrinding crystals, carrying out superfine grinding on the grinding crystals, and harvesting the high-hardness silica sol used for grinding and polishing. According to the method, a gas separant and agas lubricant are introduced into high-purity silica sol to generate a silica sol hydrate, then abrasive seed crystals with particle sizes of 0.5-5 microns are added, a part of silicon dioxide colloidal particles in the silica sol hydrate are crystallized and recrystallized at a certain pressure and a certain temperature, and the abrasive seed crystals are partially dissolved, so reforming of thethe grinding crystals is realized; and then, superfine grinding and cooling degassing are conducted, and finally, the high-hardness silica sol for grinding and polishing is obtained. The method is unique and stable in process and high in operability; the produced high-hardness silica sol can meet various requirements; no pollution is caused to the environment in the production process, and energyconservation and environmental protection are achieved; and good economic benefits can be obtained for enterprises while positive social benefits are provided.

Owner:马惠琪

Multi-axis laser-abrasive water jet precision polishing synchronous machining method

ActiveCN109048054AInhibited DiffusionImprove grinding and polishing efficiencyLaser beam welding apparatusLaser processingMachined surface

The invention provides a multi-axis laser-abrasive water jet precision polishing synchronous machining method. The multi-axis laser-abrasive water jet precision polishing synchronous machining methodcomprises the following steps that first, a laser-air curtain machining head and an abrasive water jet spraying head are mounted on a special clamp; then, the clamp provided with the laser-air curtainmachining head and the abrasive water jet spraying head is mounted on the Z axis of a multi-axis machine tool; then, in the machining process, machining compensation is set according to the distancebetween the laser spot center and the water jet dispersion area center; and finally, according to parameters required by machining, laser-abrasive jet polishing synchronous machining is implemented. The process is simple, real-time accurate polishing of a machining area during machining is guaranteed, and the machining efficiency is improved while the grinding and polishing uniformity is guaranteed. In the aspect of application expansion, machining surface modification can be synchronously achieved by changing the temperature difference between a jet or air flow and the laser machining area, or precision polishing of the complex curved surface is conducted only through the water jet.

Owner:GUANGDONG UNIV OF TECH

Tellurium-zinc-cadmium crystal surface polishing device

ActiveCN110788710AFully automatedImprove grinding and polishing efficiencyGrinding drivesBelt grinding machinesEngineeringBoule

The invention provides a tellurium-zinc-cadmium crystal surface polishing device used for solving the problem that the manual grinding efficiency is low in the soft and brittle tellurium-zinc-cadmiumcrystal ingot surface polishing process. The tellurium-zinc-cadmium crystal surface polishing device comprises a rack, a vertical and horizontal transmission mechanism, a crystal clamping and rotatingmechanism and an abrasive belt rotating machining mechanism, the vertical and horizontal transmission mechanism and the crystal clamping and rotating mechanism are fixed to the rack, and the abrasivebelt rotating machining mechanism is fixed to the vertical and horizontal transmission mechanism through a support frame; the crystal clamping and rotating mechanism is used for clamping a to-be-machined crystal and driving the to-be-machined crystal to rotate according to the set speed under the control of a first motor; the vertical and horizontal transmission mechanism is used for controllingthe abrasive belt rotating machining mechanism to move in the horizontal direction and in the vertical direction; and the abrasive belt rotating machining mechanism is used for being close to the to-be-machined crystal under the control of the vertical and horizontal transmission mechanism and rotating under the control of a second motor to polish the surface of the to-be-machined crystal.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Metal surface grinding and polishing agent and preparation method thereof

InactiveCN108192506AIncrease flow rateConsistent surface temperaturePolishing compositions with abrasivesFoaming agentAnticoagulant

The invention relates to the technical field of metal surface treatment, in particular to a metal surface grinding and polishing agent and a preparation method thereof. The metal surface grinding andpolishing agent is prepared from the following ingredients in parts by weight: 16 to 33 parts of grinding agents, 1 to 2 parts of anti-foaming agents, 0.5 to 2 parts of sodium carbonate, 0.5 to 2 parts of surfactants, 0.5 to 2 parts of fatty alcohol ammonium sulfate, 0.5 to 1.5 parts of surface dimming agents, 0.5 to 1.5 parts of corrosion inhibitors, 0.2 to 0.5 part of suspending agents, 0.2 to 0.6 part of anticoagulants and 60 to 70 parts of water. By using the metal surface grinding and polishing agent provided by the invention, during the grinding and polishing on the metal surface, the multi-time coarse grinding and medium grinding links in the middle can be reduced; the production efficiency is improved.

Owner:东莞华拓研磨材料有限公司

Automatic grinding device for permanent magnet ferrite square block and grinding method thereof

ActiveCN110962005AMobile fasteningThe clamping movement is fastened firmlyEdge grinding machinesGrinding drivesElectric machineryHydraulic pump

The invention discloses an automatic grinding device for a permanent magnet ferrite square block and a grinding method of the automatic grinding device. The automatic grinding device comprises a loading frame, a carrying and support table, a first mounting table, a second mounting table and a vertical loading cylinder. The carrying and support table is horizontally arranged in the middle of the loading frame. A bottom support plate is arranged at the bottom of the carrying and support table. A top mounting plate is arranged on the top of the carrying and support table. Two side support rods are vertically arranged at the two ends between the top mounting plate and the bottom support plate. The first mounting table is arranged above one end of the carrying and support table. The automatic grinding device has the beneficial effects that a fourth hydraulic pump drives a grinding column to vertically adjust the height through a fourth hydraulic shaft, in cooperation with a sixth motor, a rotating disc drives a grinding and loading seat to rotate to adjust the position, it is guaranteed that the grinding position of the permanent magnetic ferrite square block by the device is more precise and suitable, the precision of grinding the permanent magnetic ferrite square block by the device is greatly improved, and it is guaranteed that the area of the device for grinding and covering thepermanent magnet ferrite square block is more comprehensive. The device has the beneficial effects of high automation degree and very time-saving and labor-saving use.

Owner:安徽中马磁能科技股份有限公司

Polishing and grinding machine for wood-plastic composite floor

ActiveCN108555742AEasy to fixImprove grinding and polishing efficiencyPolishing machinesBonded abrasive wheelsMechanical engineeringWood-plastic composite

The invention provides a polishing and grinding machine for a wood-plastic composite floor, belongs to the field of mechanical technology and solves the technical problem of low grinding and polishingefficiency of conventional floor processing equipment. The polishing and grinding machine comprises a rack, wherein an input mechanism for inputting a wood-plastic composite floor for processing andan output mechanism for outputting the wood-plastic composite floor are arranged on the rack; a limiting mechanism for limiting the wood-plastic composite floor on the input mechanism is arranged on the rack; a lifting board is arranged between the input mechanism and the output mechanism and fixedly arranged on the rack through a lifting positioning mechanism; a moving station is arranged on thelifting board in a sliding manner and connected to a driving mechanism which drives the moving station to move back and forth; and a fixing and supporting mechanism for fixing and supporting the wood-plastic composite floor is arranged on the moving station. The polishing and grinding machine has the advantage of high grinding and polishing efficiency.

Owner:ZHEJIANG JUNTONG PLASTICS TECH

Three-dimensional full-vibration type grinding and polishing machine

The invention relates to grinding and polishing equipment, in particular relates to a three-dimensional full-vibration type grinding and polishing machine which is formed by matching a base, an automatic discharging device arranged on the base, a trough and a three-dimensional vibration motor arranged on the trough. Two ends of a shell of the trough are provided with discharging shaft heads; the middle on one side of the shell of the trough is provided with a side discharging trough; lift cylinders arranged on the base are matched with the discharging shaft heads arranged at two ends of the trough; an overturn cylinder is matched with the side discharging trough arranged on the side surface of the trough; when the three-dimensional full-vibration type grinding and polishing machine acts, firstly, the lift cylinders arranged at two ends of the base simultaneously act to push up the trough, and then, the overturn cylinder acts to drive the trough to rotate around the discharging shaft heads so that an article is discharged; and the shell of the trough is provided with the vibration motor, two ends of the vibration motor are respectively provided with an eccentric block with an eccentric sleeve, and the eccentric blocks at two ends respectively vibrate in the vertical, front-and-back, horizontal and vertical direction, and thus the trough vibrates in three directions, namely the vertical, the front-and-back and the horizontal directions to realize the three-dimensional vibration of the vibration motor.

Owner:HUZHOU VOCATIONAL TECH COLLEGE

High-gloss precise cylindrical terminal manufacturing method

InactiveCN105922120AImprove application efficiencyHigh dimensional accuracy requirementsEdge grinding machinesPolishing machinesEngineeringCylindrical grinding

The invention discloses a high-gloss precise cylindrical terminal manufacturing method. The method includes the following steps that firstly, machining is conducted through a lathe, wherein a blank is conveyed into a lathe feeding tank for turning to obtain a turned blank material, the lathe comprises a rotation driving assembly driving a turning cutter to rotate and a feeding driving assembly driving turning feeding of the blank, and the feeding driving assembly comprises a motor which is a variable-frequency motor; secondly, hydraulic horizontal milling is conducted, wherein the turned blank material machined in the first step is conveyed into a hydraulic horizontal milling machine to obtain a milled blank material; thirdly, polishing is conducted, wherein the milled blank material manufactured in the second step is conveyed into a polishing barrel, regrinding round particles, cylindrical grinding particles and polishing auxiliary materials are added according to a proportion, then a barrel cover is locked, the polishing barrel is placed on a polishing machine rotary frame for polishing, and a polished material is obtained; fourthly, packaging is conducted, wherein the polished material is packaged after being electroplated.

Owner:WANANDA PRECISE COMPONENT PART SHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com