Production method of high-hardness silica sol used for grinding and polishing

A production method and technology of silica sol, applied in polishing compositions containing abrasives, chemical instruments and methods, other chemical processes, etc., can solve the problems of poor grinding and polishing effect, inability to effectively improve grinding and polishing efficiency, low hardness and the like, Achieve the effect of improving efficiency and meeting the requirements of special ultra-fine grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

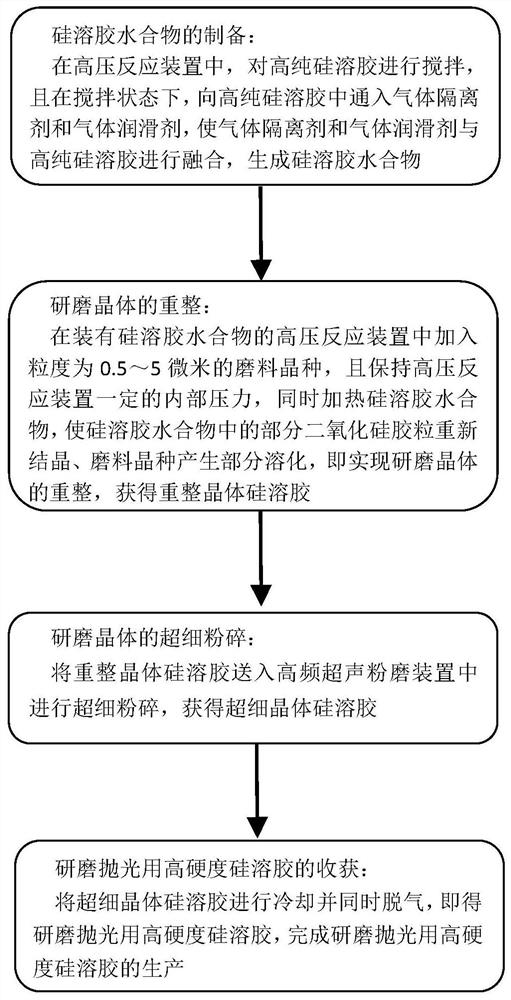

[0055] Such as figure 1 A production method of high hardness silica sol for grinding and polishing provided by the embodiment of the present invention is shown in a schematic block diagram:

[0056] A method for producing high-hardness silica sol for grinding and polishing, comprising:

[0057] The preparation step of silica sol hydrate, the reforming step of ground crystal, the ultrafine pulverization step of ground crystal, and the harvesting step of high hardness silica sol for grinding and polishing, wherein:

[0058] The preparation steps of silica sol hydrate include:

[0059] In the high-pressure reaction device, the high-purity silica sol is stirred, and in the stirring state, the gas separation agent and the gas lubricant are passed into the high-purity silica sol, so that the gas separation agent and the gas lubricant are separated from the high-purity silica sol. Fusion to generate silica sol hydrate;

[0060] The reformation steps for ground crystals include:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com