Recovery treatment method of phosphine-containing industrial by-products

A technology for recycling and processing by-products, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of difficult storage and purchase, and achieve good flame retardancy, Realize the effect of reorganization and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment discloses a method for recovery and treatment of phosphine-containing industrial by-products, which comprises the following steps:

[0036] Take 200g of solid by-products produced in the production process of diethyl methylphosphite and put them in the reaction kettle, then add 10g of p-cresol, heat to 135-140°C under air-isolated conditions, and stir and react at this temperature for 2h; Gray-black solid, cooled to room temperature, added the gray-black solid to 400mL water several times, controlled the addition rate so that the reaction would not be too violent, stirred for 30 minutes after the addition, cooled to below 20°C, filtered to obtain brown-black Solid and the first filtrate; the phosphorus content in the first filtrate is measured to be 420ppm; wherein, the brown-black solid is a phosphorus-based flame retardant; the yield is 87%;

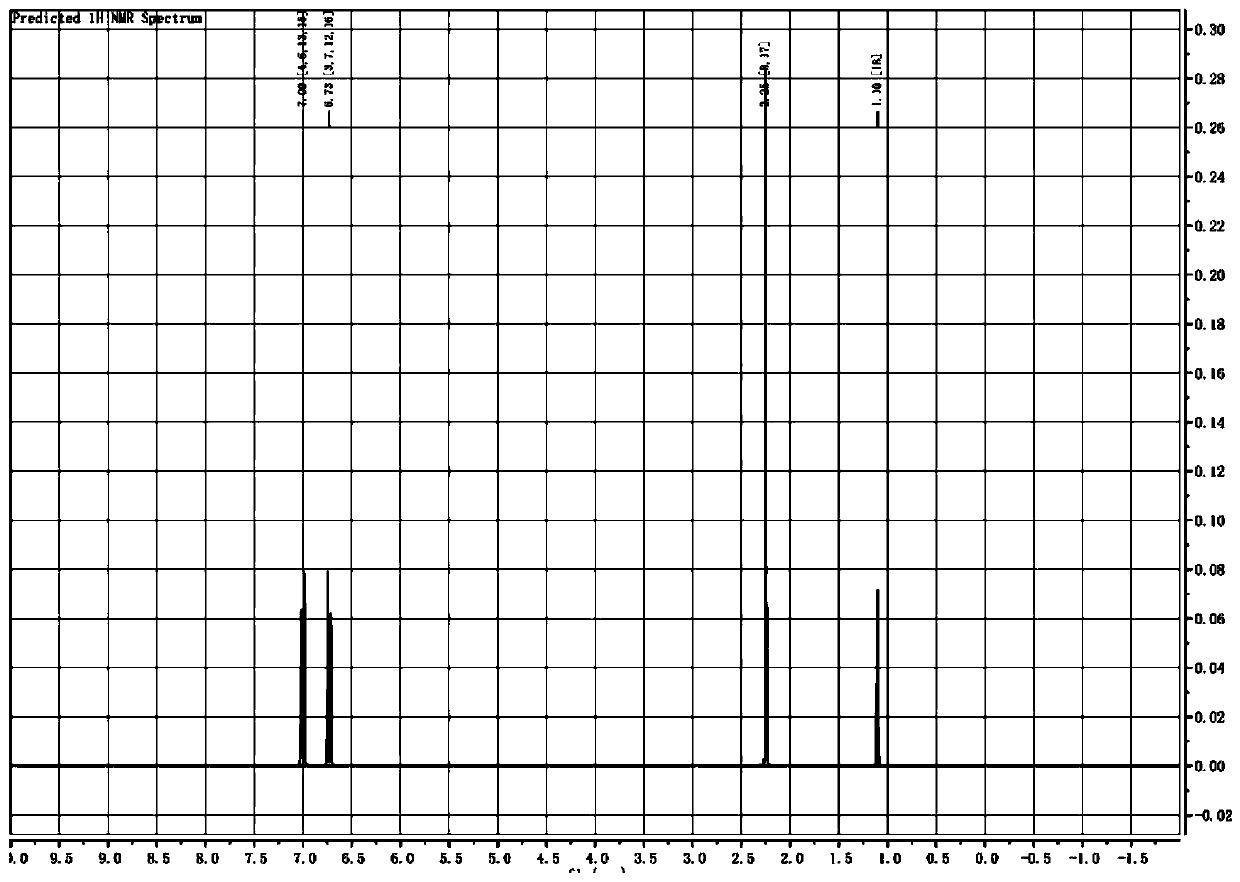

[0037] And the chemical reaction equation of phosphorus flame retardant is as follows:

[0038]

[0039] W...

Embodiment 2

[0041] This embodiment discloses a method for recovery and treatment of phosphine-containing industrial by-products, which comprises the following steps:

[0042] Take 1000g of solid by-products produced in the production process of diethyl methyl phosphite and put them in the reactor, then add 50g of bisphenol A, heat to 135-145°C under air-isolated conditions, and stir and react at this temperature for 2.5h; Gray-black solid, cooled to room temperature, added the gray-black solid to 2000mL water several times, controlled the addition rate so that the reaction would not be too violent, stirred for 30 minutes after the addition, cooled to below 25°C, filtered to obtain a gray solid And the first filtrate; the phosphorus content in the first filtrate is measured to be 390ppm; wherein, the gray solid is a phosphorus-based flame retardant; the yield is 90%;

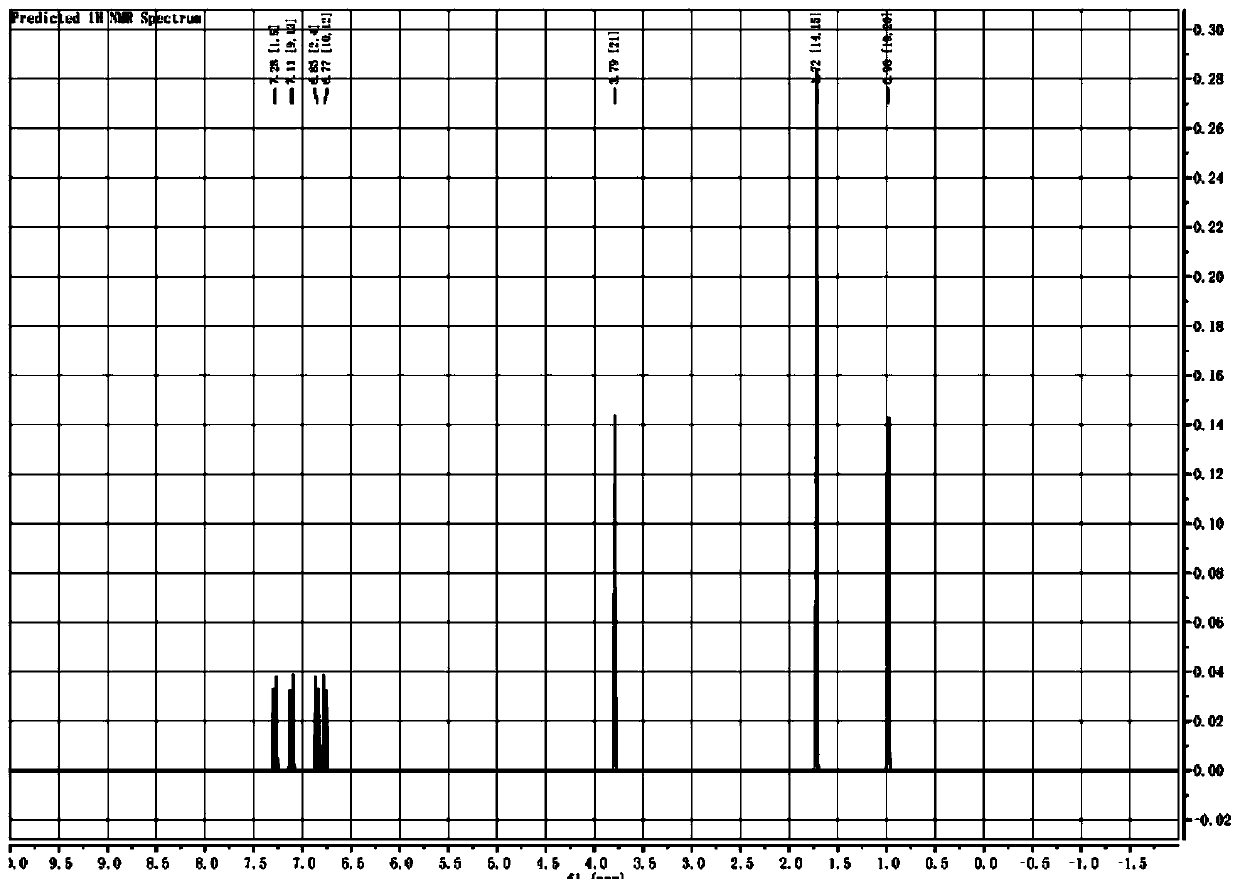

[0043] And the chemical reaction equation of phosphorus flame retardant is as follows:

[0044] n is 0.85;

[0045] Wher...

Embodiment 3

[0047] This embodiment discloses a method for recovery and treatment of phosphine-containing industrial by-products, which comprises the following steps:

[0048] Take 1000g of the solid by-product produced in the production process of diethyl methyl phosphite and put it in the reaction kettle, then add 60g of bisphenol A, heat to 140-150°C under air-isolated conditions, and stir and react at this temperature for 2.5h; Gray-black solid, cooled to room temperature, added the gray-black solid to 2000mL water several times, controlled the addition rate so that the reaction would not be too violent, stirred for 30 minutes after the addition, cooled to below 25°C, filtered to obtain a gray solid And the first filtrate; the phosphorus content in the first filtrate is measured to be 410ppm; wherein, the gray solid is a phosphorus-based flame retardant; the yield is 85%;

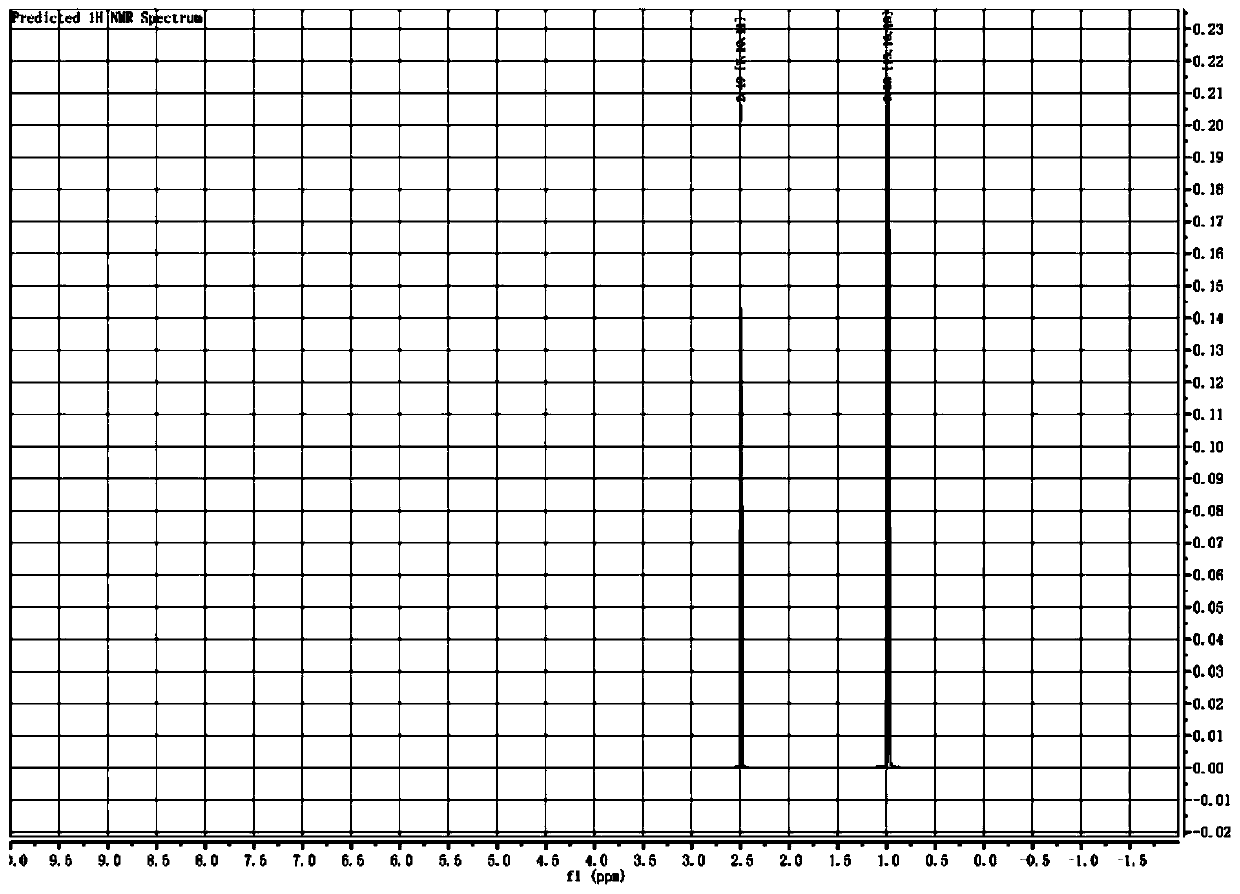

[0049] And the chemical reaction equation of the phosphorus-based flame retardant is as in the above-mentioned em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com