Patents

Literature

127results about How to "Achieve reorganization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

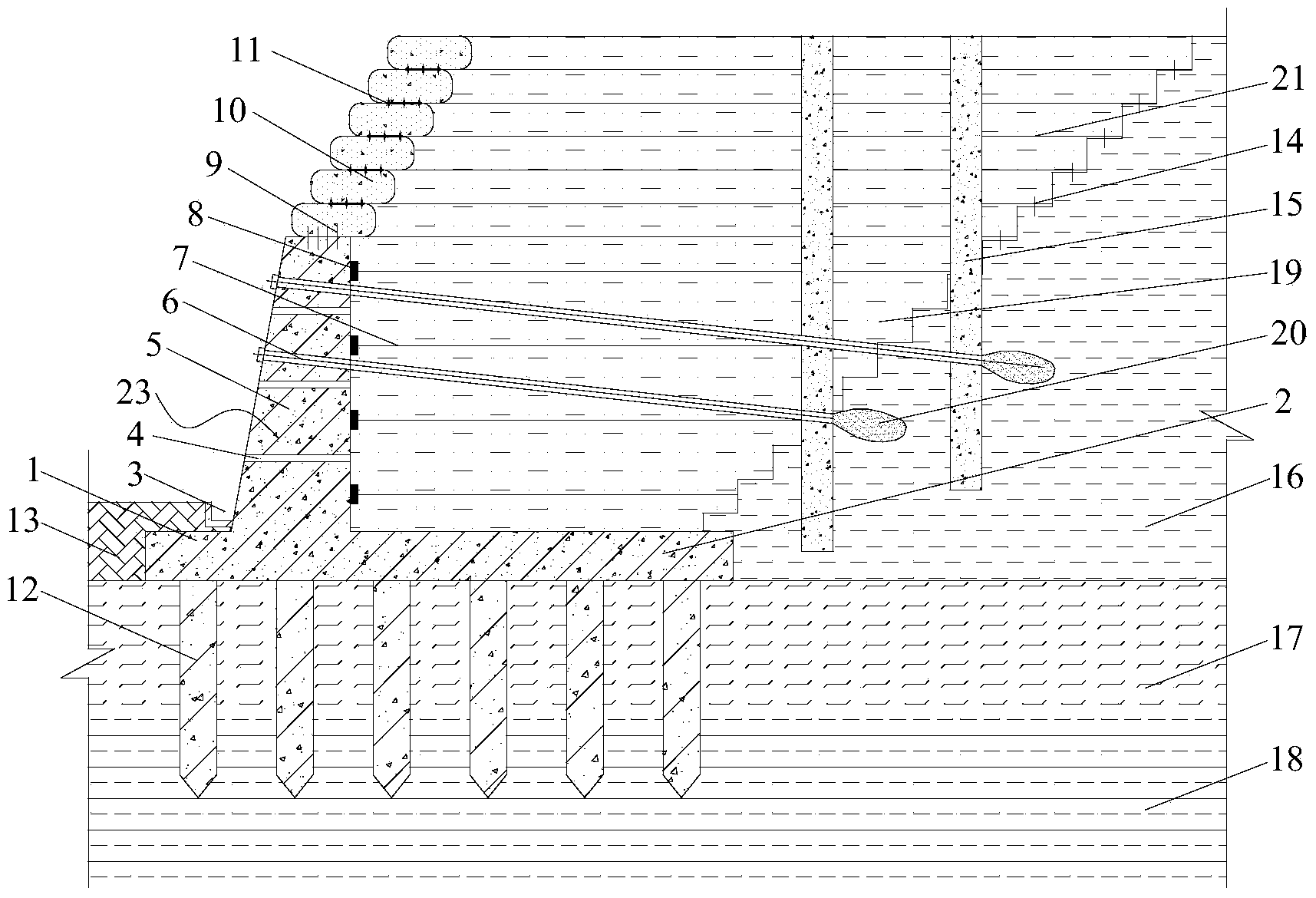

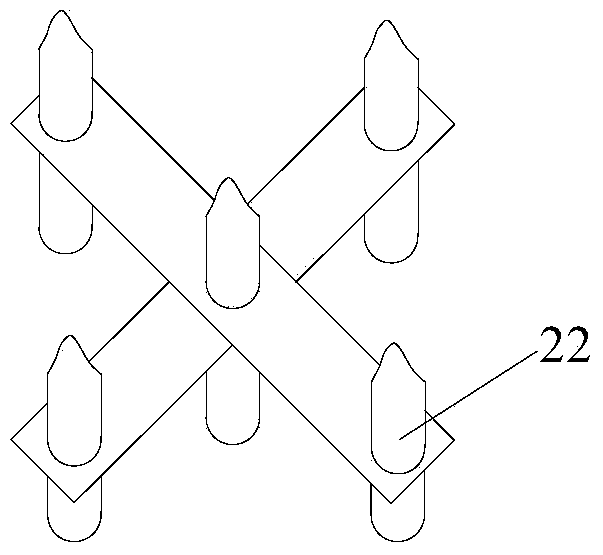

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167AHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsEngineering

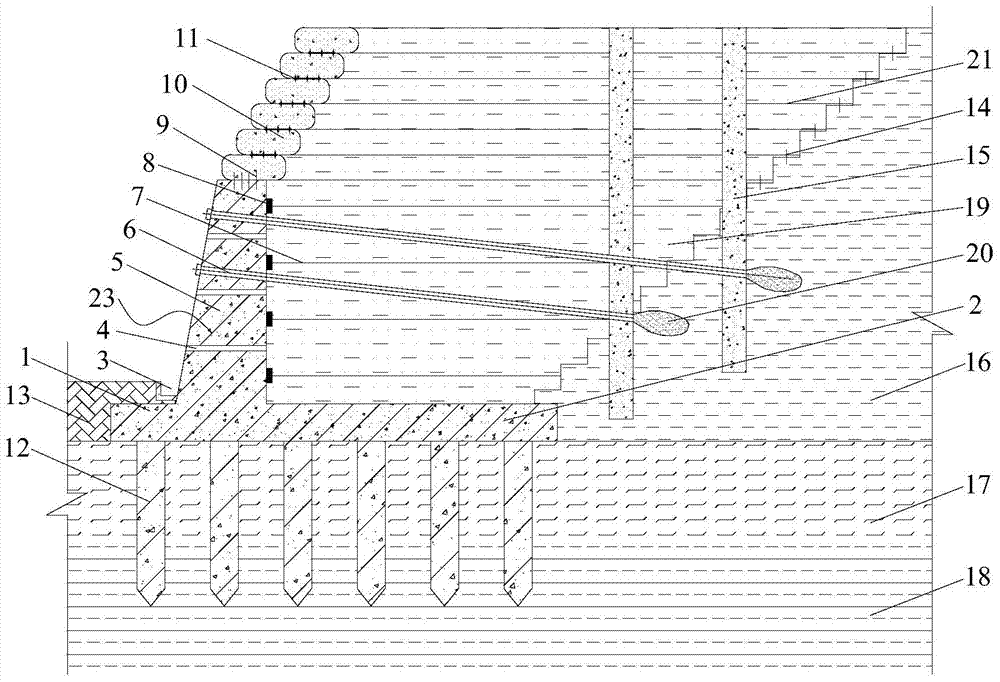

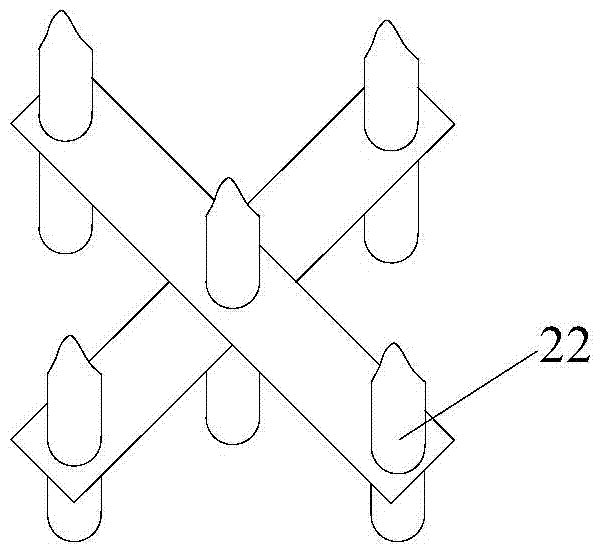

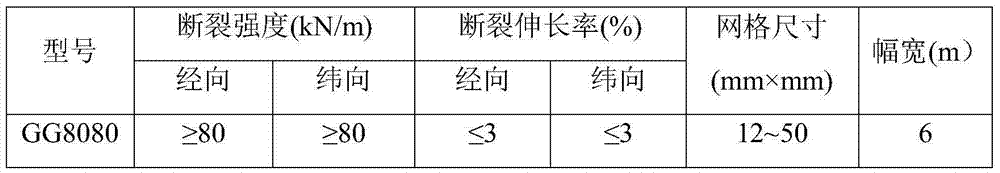

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

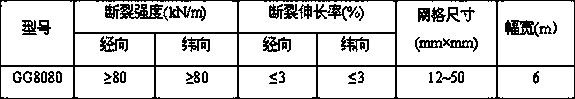

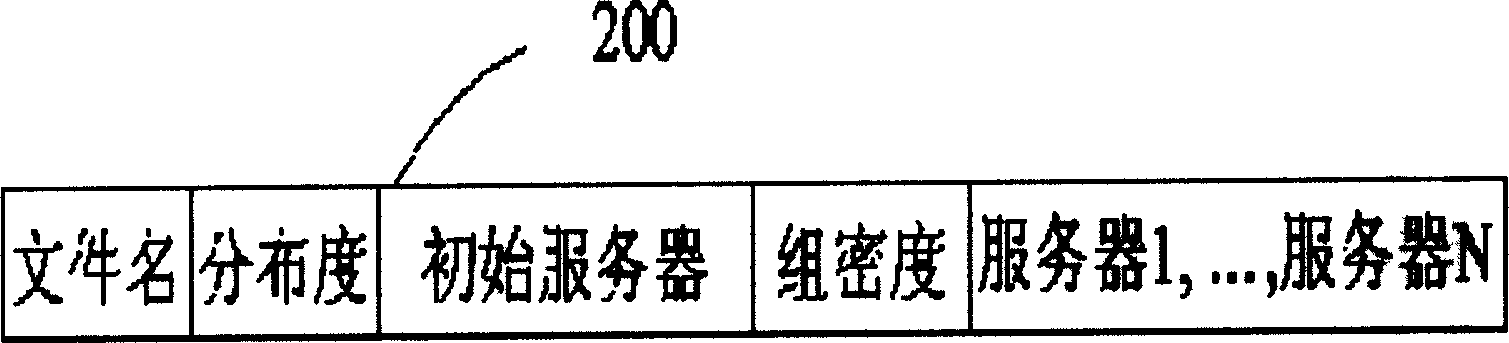

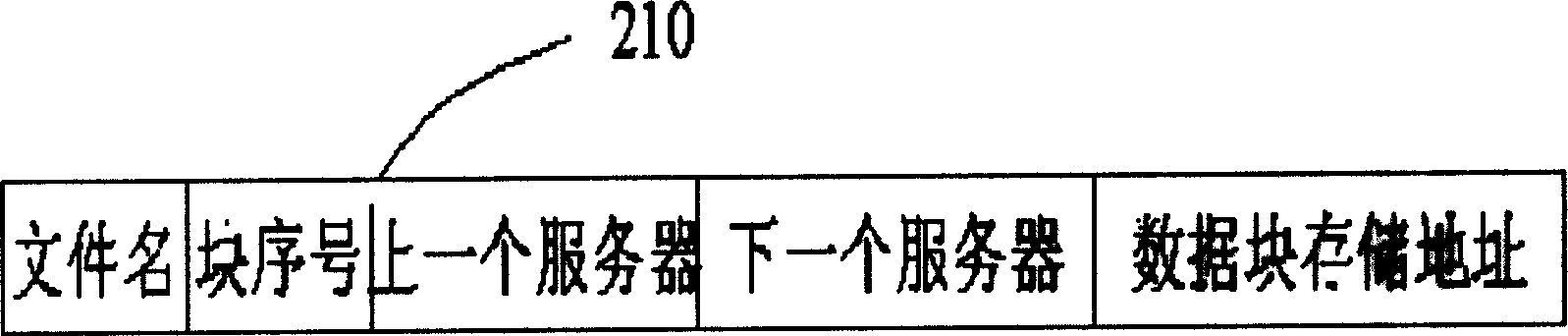

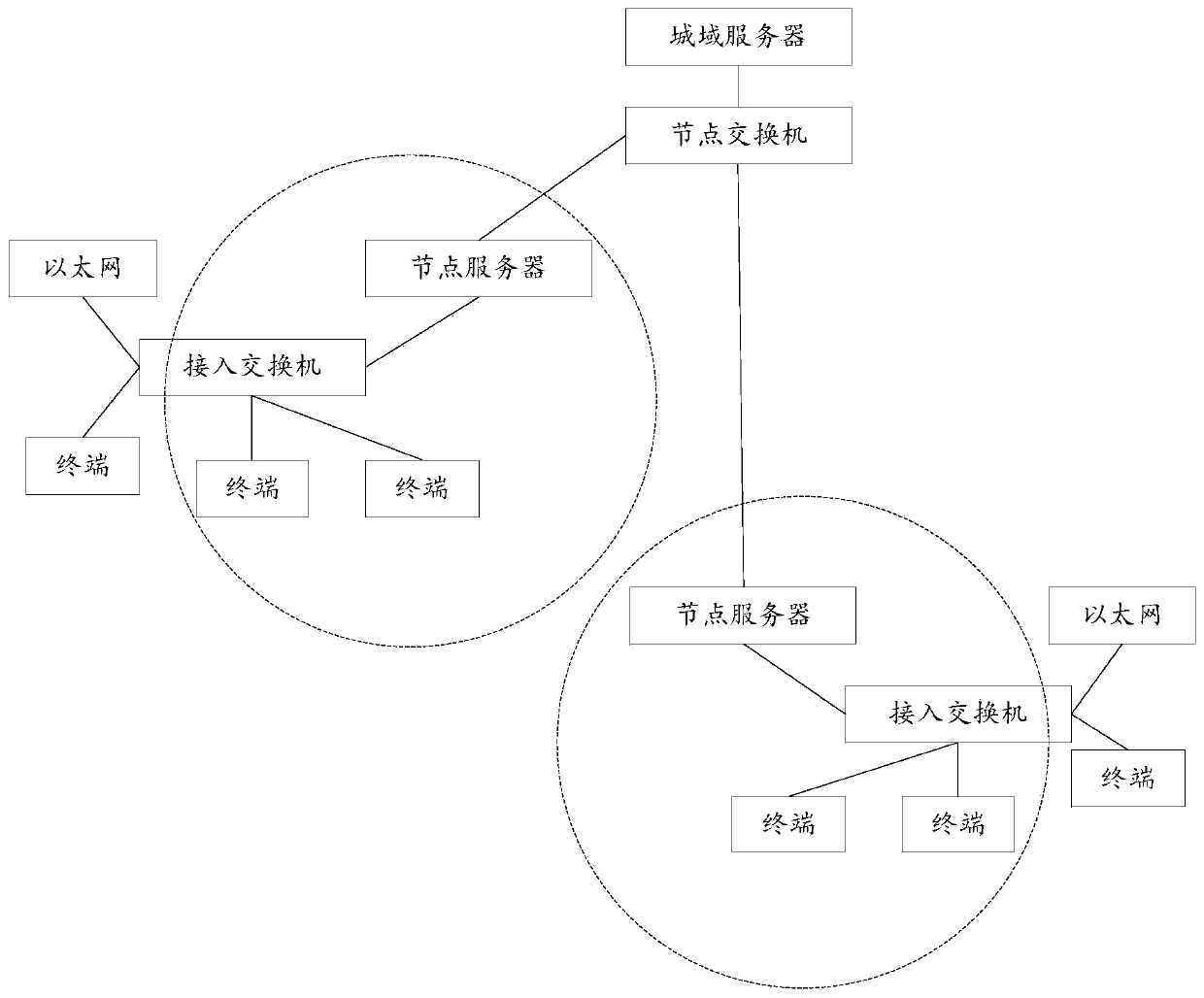

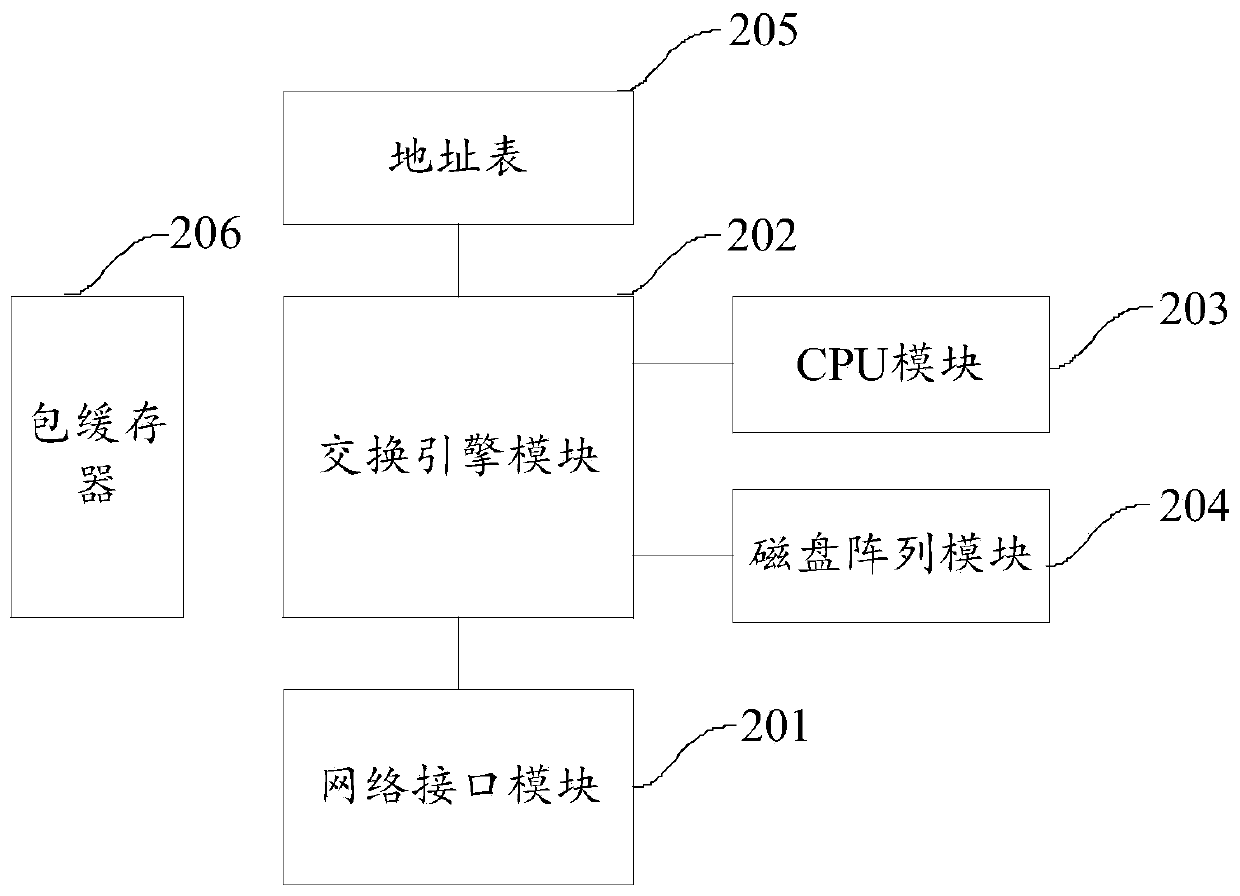

Distributive video interactive system and its data recording and accessing method

InactiveCN1472963AImprove securityAchieve reorganizationError detection/correctionTwo-way working systemsData fileData recording

The present invention discloses a distribution type of audience-choose-broadcasting video system and its data storing and accessing method. Said storing method includes the following steps: dividing a data file into data blocks in a predetermined manner; forming a data checking block for calculating the data blocks having predetermined number; storing the said data blocks and the data checking block into a plurality of predetermined buffer-server in turn in a predetermined manner; and creating corresponding index information for storing data blocks in each said buffer-server. The technical solution of the invention can improve storing efficiency and save a lot of storing space; and increase the safety of data because adopting the distribution type of memory and the data are distributed among a plurality of buffer-server.

Owner:ZTE CORP

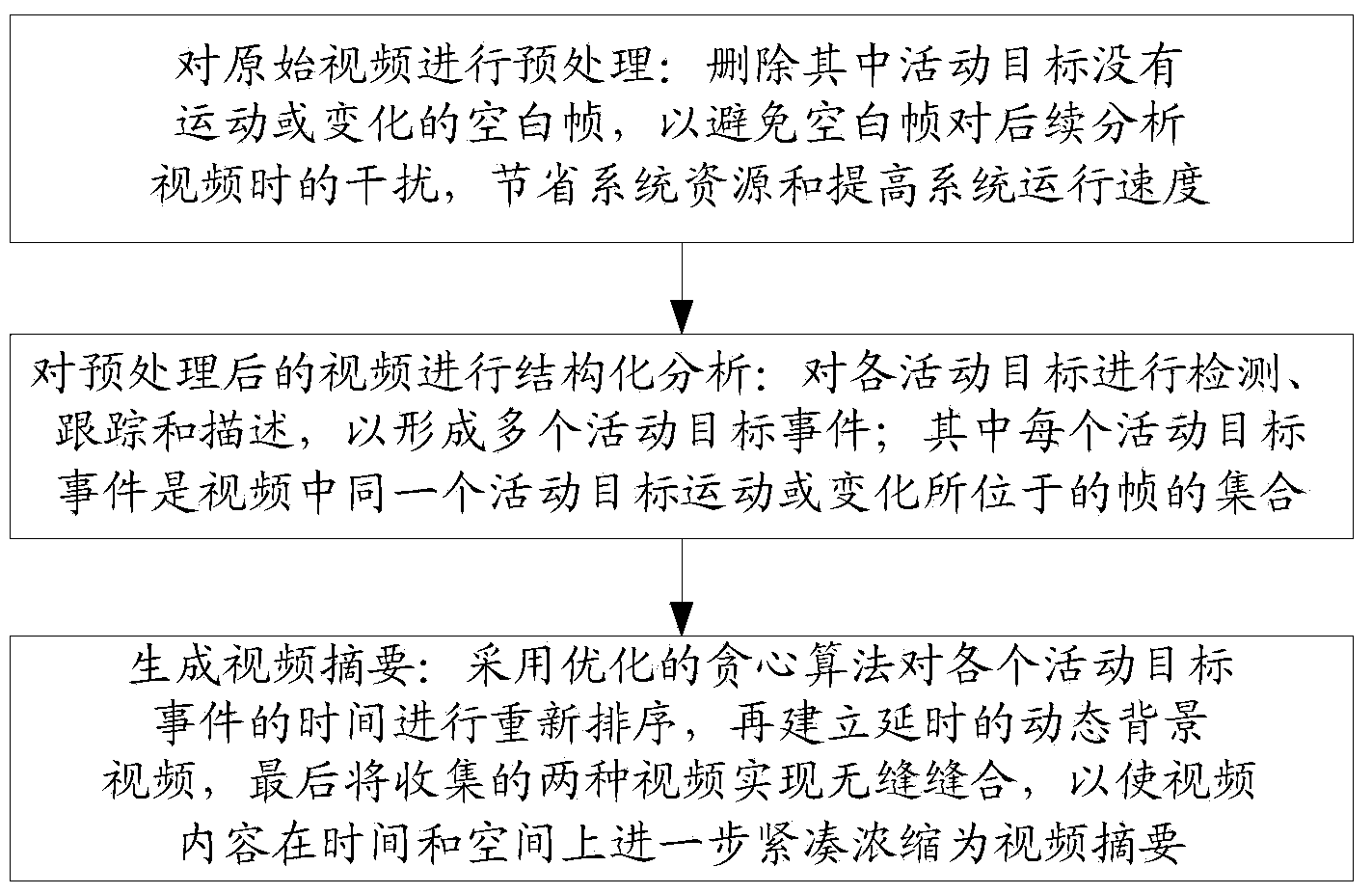

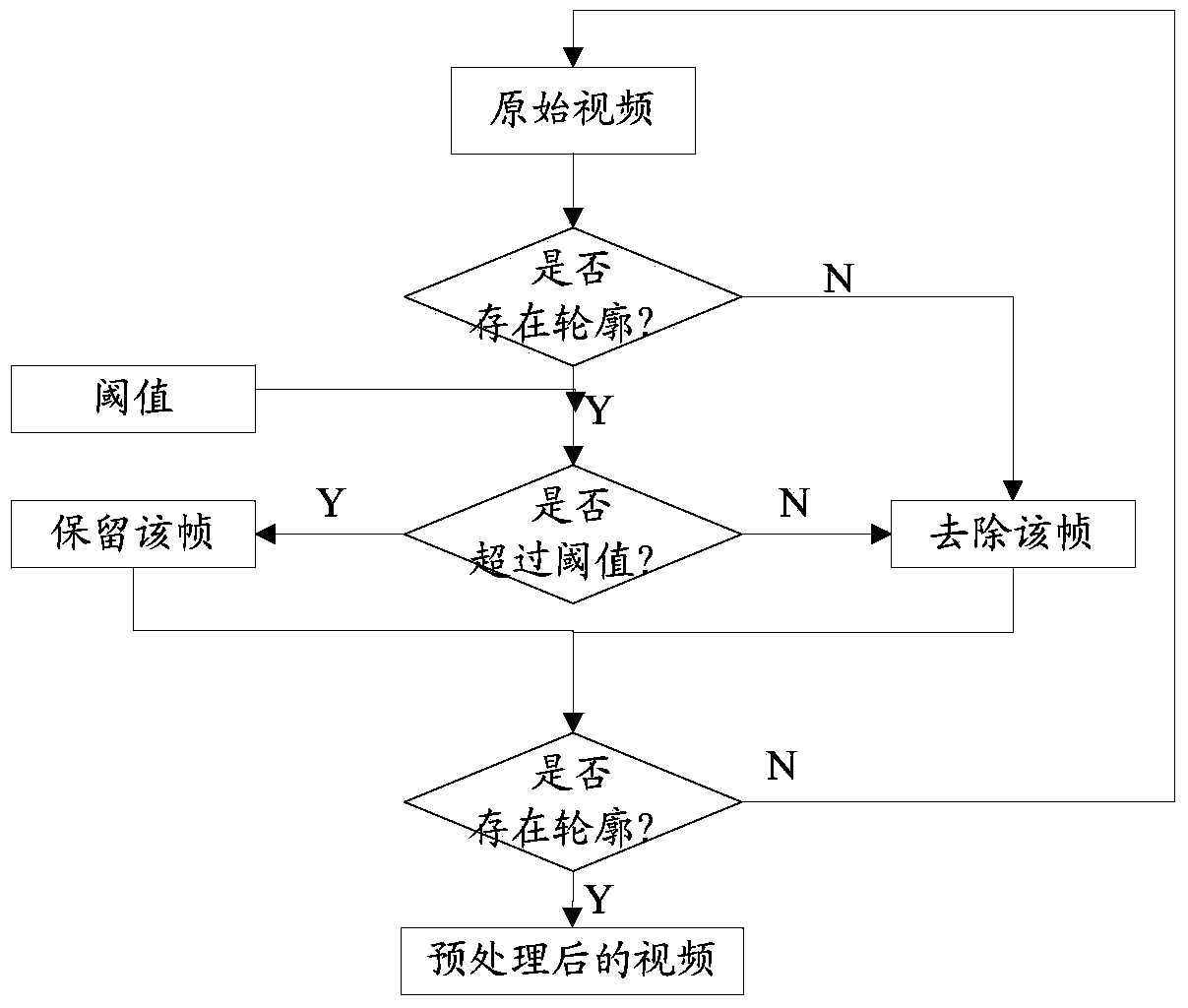

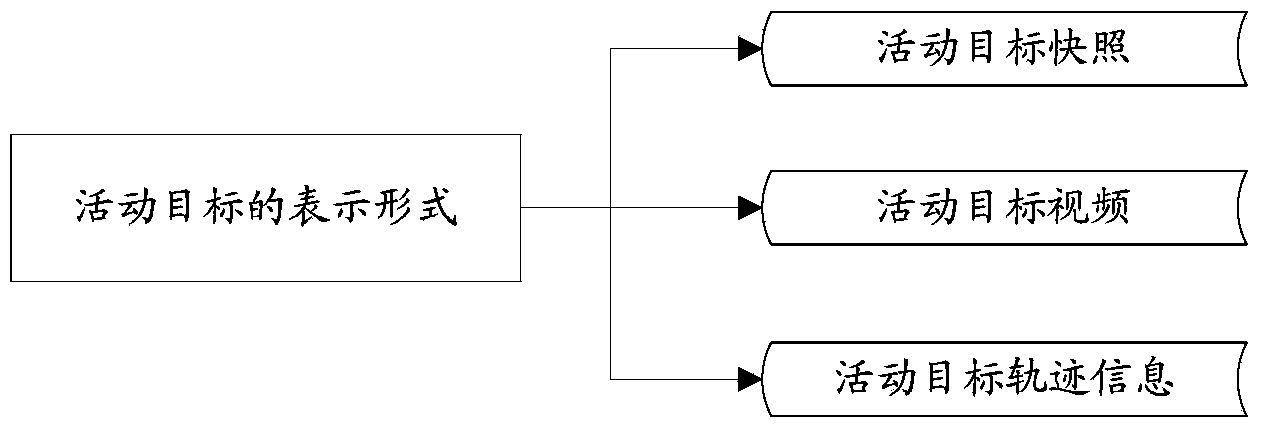

Video abstraction generation method based on space-time recombination of active events

ActiveCN103778237AAvoid interferenceSave resourcesSpecial data processing applicationsTime correlationStructured analysis

The invention provides a video abstraction generation method based on space-time recombination of active events. According to the method, an original video is pre-treated, blank frames are removed, and the video after pretreatment is subjected to structured analysis as follows: moving targets in the original video are taken as an object, videos of all key moving target events are extracted, time correlation between the moving target events is weakened, and time sequence recombination is performed on the moving target events based on the principle that activity ranges are not conflicted; meanwhile, background images are extracted reasonably based on the reference of the visual perception of a user, and a delayed dynamic background video is generated; and finally, the moving target events and the delayed dynamic background video are sutured seamlessly, a video abstraction with short time, concise content and comprehensive information is formed, and a plurality of moving targets can occur simultaneously in the finally generated video abstraction. The video abstraction generation method can generate the video abstraction used for video browsing or searching efficiently and rapidly, and the video abstraction can express semantic information of the video more reasonably and better meets the visual perception of the user.

Owner:BEIJING UNIV OF POSTS & TELECOMM

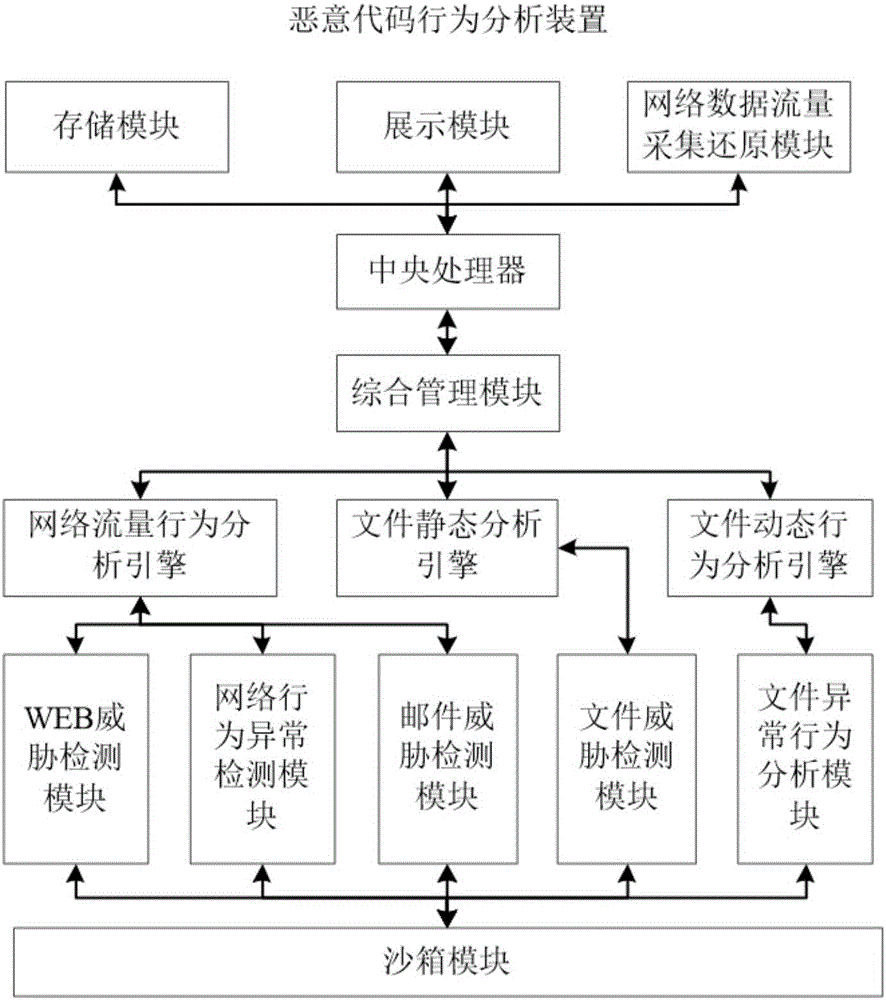

Malicious code behavior analyzer

InactiveCN106341282AAchieve reorganizationAchieve restorationData switching networksWeb threatBehavioral analytics

The invention provides a malicious code behavior analyzer which comprises a storage module, a display module, a network data flow collecting and reducing module, a central processor, an integrated management module, a network flow behavior analysis engine, a file static analysis engine, a file dynamic behavior analysis engine, a WEB threat detection module, a network behavior abnormity detection module, a threat detection module, a file threat detection module, a file abnormal behavior module and a sandbox module. According to the analyzer, the network data flow can be recombined and reduced, abnormal network behaviors are detected, suspected files can be reduced, extracted and analyzed, and placed in a sandbox template to monitor and analyze file behaviors dynamically, results of static analysis and dynamic analysis are combined to provide the degree of information safety risk of the suspected files, and the technical problem that high-level malicious code attacks which is increasingly serious cannot be handled is solved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

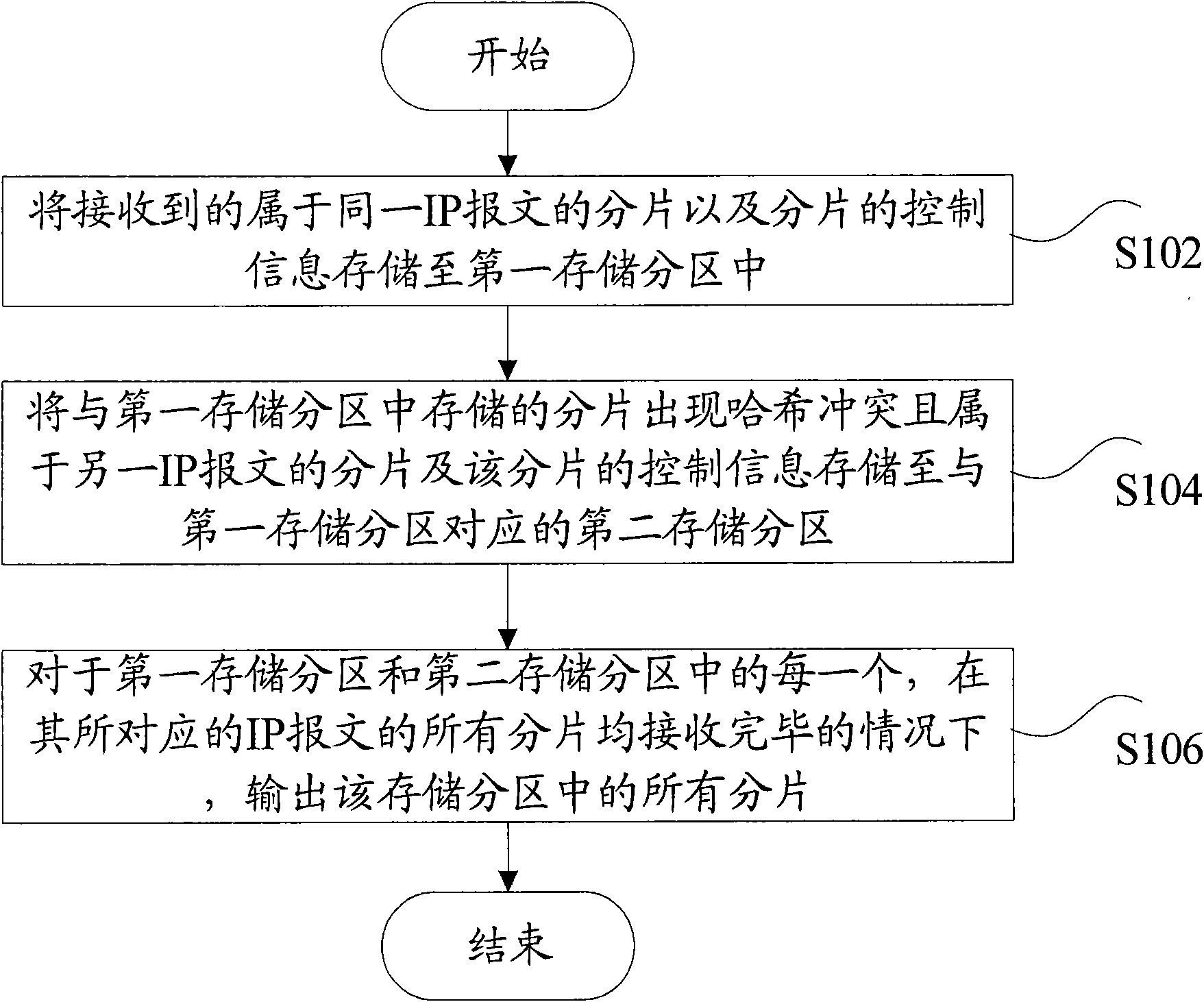

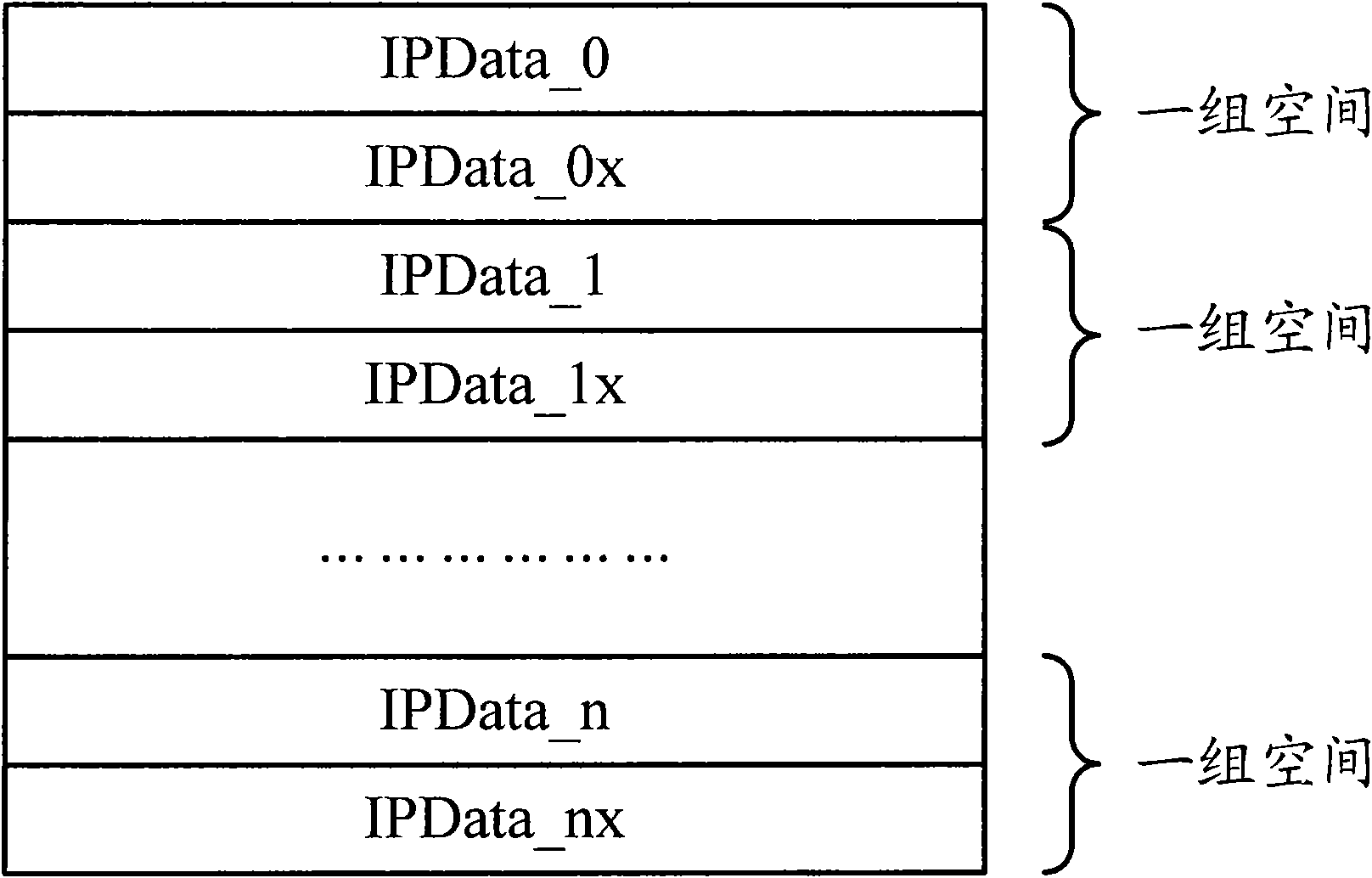

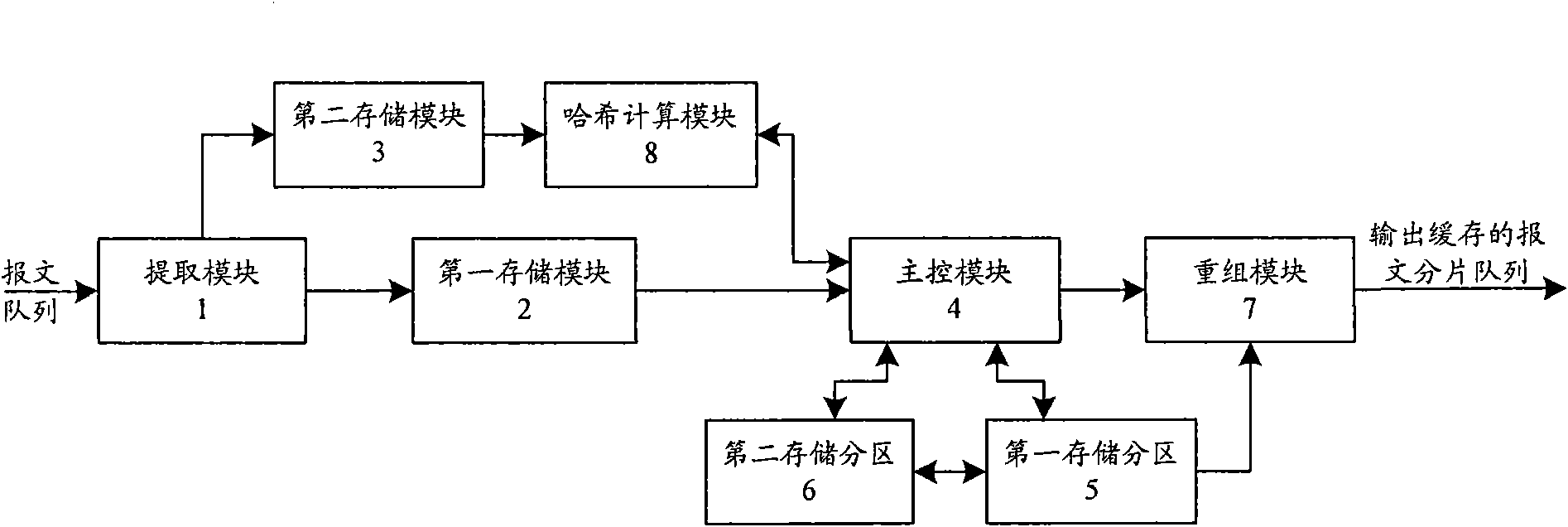

Fragments-reassembling method of IP messages and device thereof

ActiveCN101674234AReorganization is achieved quicklyAchieve reorganizationData switching networksComputer hardwareInformation storage

The invention provides a fragments-reassembling method of IP messages and a device thereof, wherein the method comprises the steps: memorizing received fragments affiliated to the same IP message andcontrol information of the fragments into a first memory subarea; memorizing the fragments which are memorized in the first memory subarea, have the hash collision and is affiliated to another IP message and the control information of the fragments into a second memory subarea corresponding to the first memory subarea; and for each one of the first memory subarea and the second memory subarea, under the condition that the all fragments according to the IP messages are completely received, outputting all the fragments in the memory subarea. The invention can immediately and fast realize the reassembly of the fragment messages, effectively answers to the attack of the fragments, avoids the hash collision, and avoids increasing the process load to CPU.

Owner:DAWNING INFORMATION IND BEIJING +1

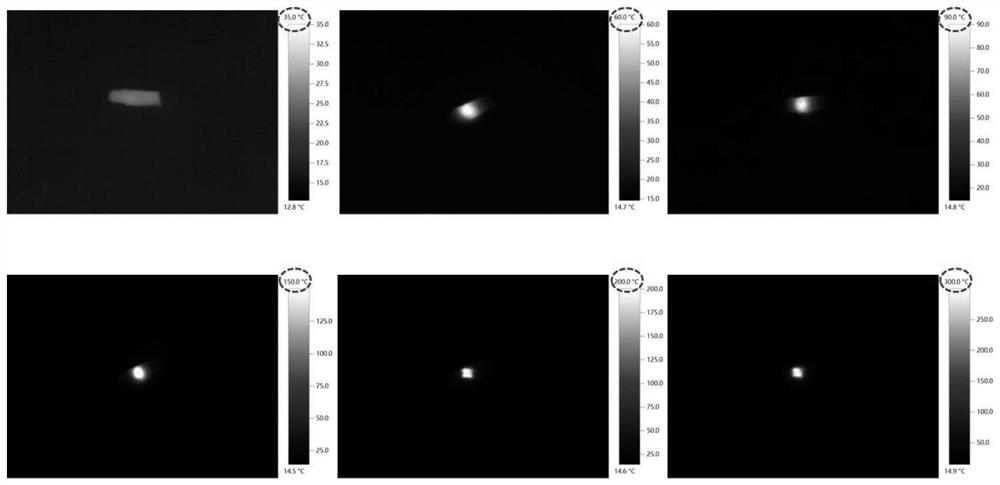

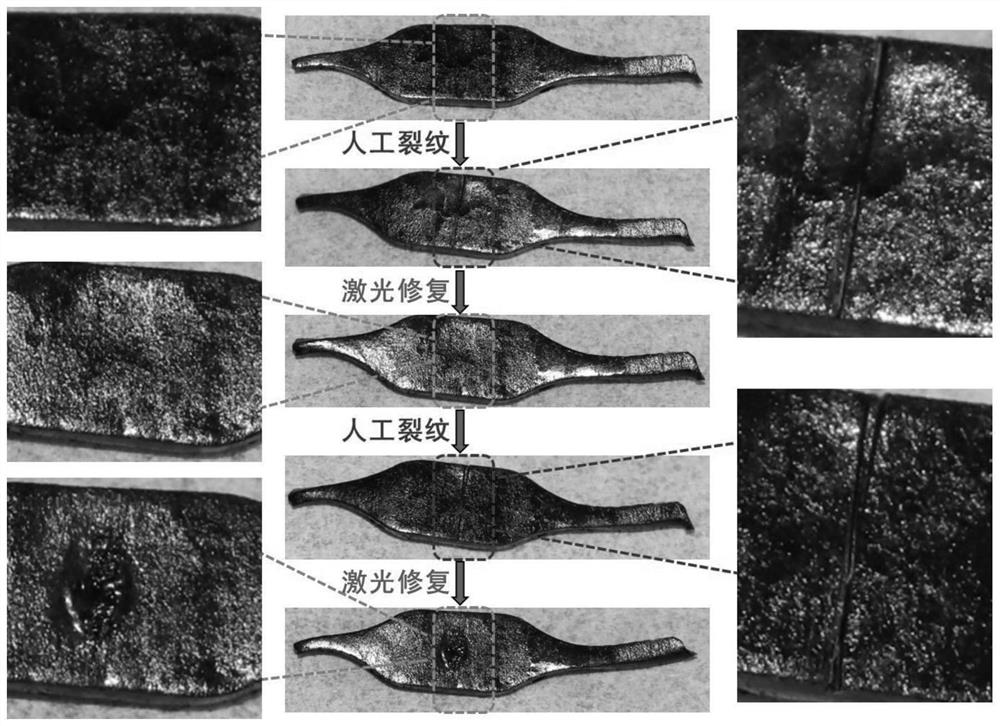

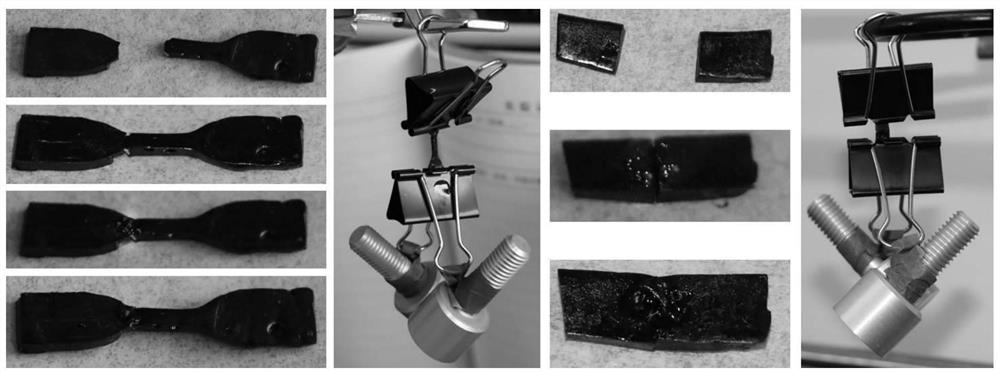

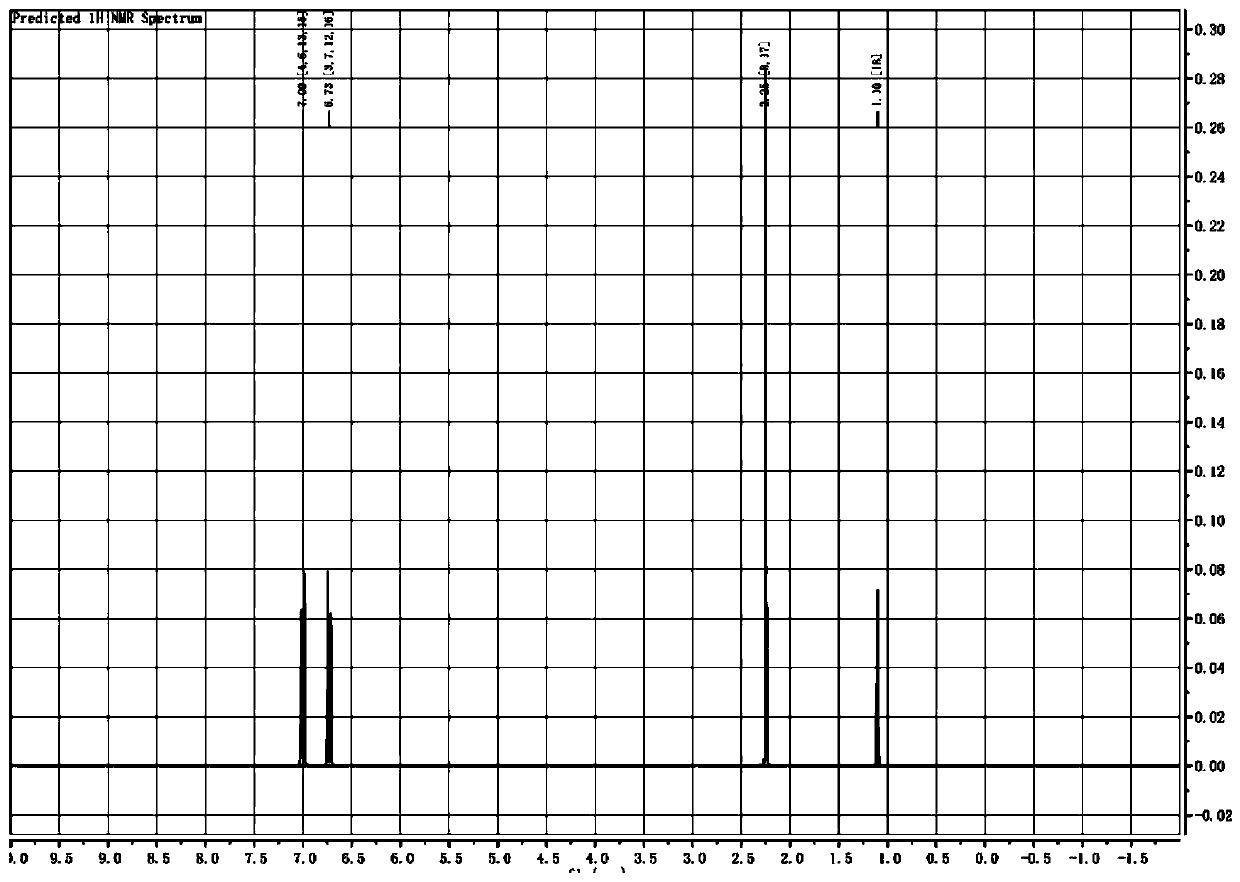

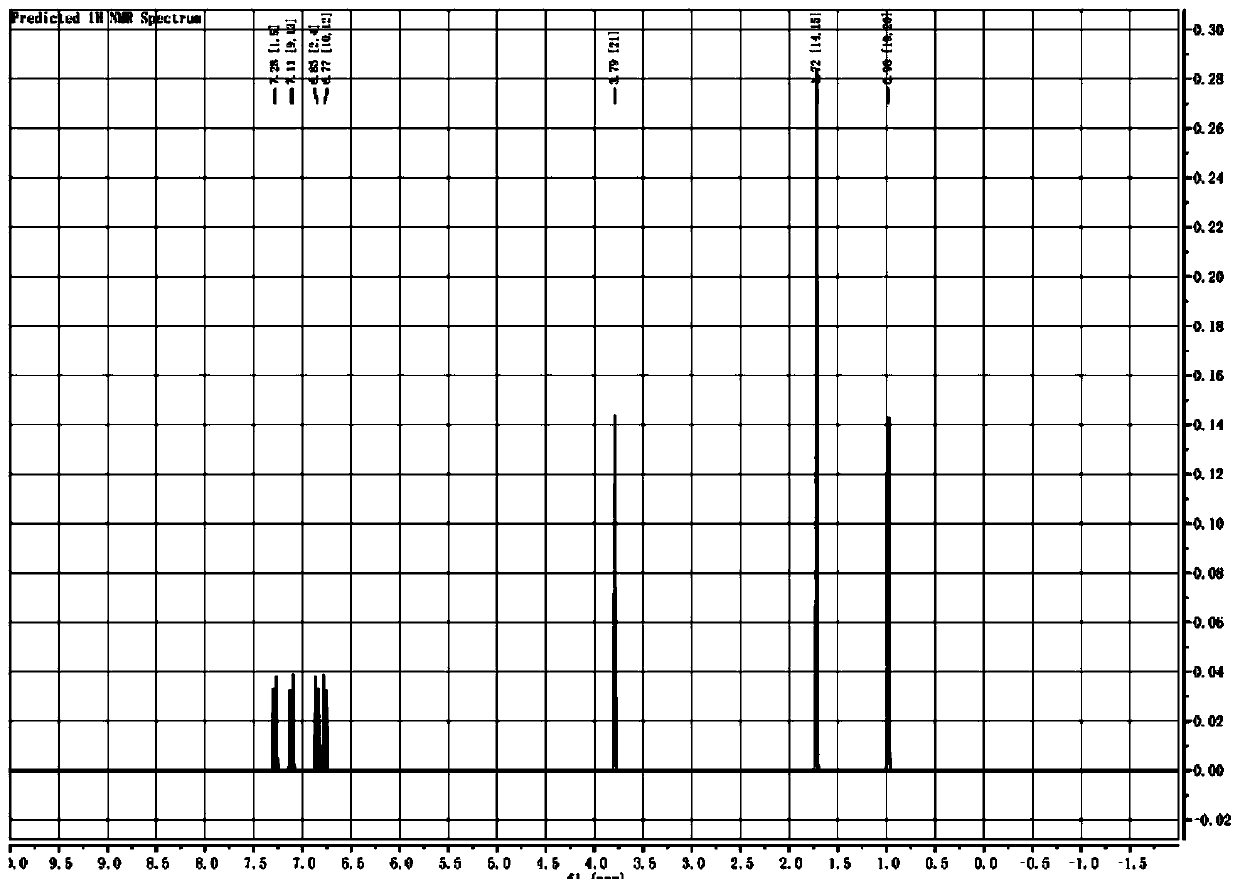

Method for preparing visible light self-repairing waterborne polyurethane coating material with double selenium bonds on main chain

ActiveCN106497385AAchieve self-healingAchieve brokenPolyurea/polyurethane coatingsPhotochemistryDiselenide

The invention discloses a method for preparing a visible light self-repairing waterborne polyurethane coating material with double selenium bonds on a main chain. The method comprises the following steps: firstly, preparing an isocyanate end capped polyurethane prepolymer with double selenium bonds on a main chain from raw materials of diisocyanate, dihydroxyethyl diselenide, macromolecule dihydric alcohol and dimethylolpropionic acid; secondly, adding triethylamine for neutralization, further adding a proper amount of deionized water for rapid emulsification, slowly adding a diamine chain extender which is diluted with water, and performing emulsification chain expansion under a condition that the rotation speed is greater than 1200r / min, thereby obtaining the visible light self-repairing waterborne polyurethane coating material with the double selenium bonds on the main chain. On the basis of the visible light reversibility characteristic of double-selenium dynamic covalent bonds, the waterborne polyurethane coating material with the double selenium bonds on the main chain is capable of achieving self-repairing of cracks and broken parts under radiation of gentle visible illumination, so that the service life of the material can be greatly prolonged, the potential safety hazard in use can be reduced, and a relatively long service life can be achieved for the waterborne polyurethane coating material. The waterborne polyurethane coating material with double selenium bonds on the main chain is applicable to coating of leather, textiles, paper, furniture, wall surfaces and the like, and has wide application prospects.

Owner:SICHUAN UNIV

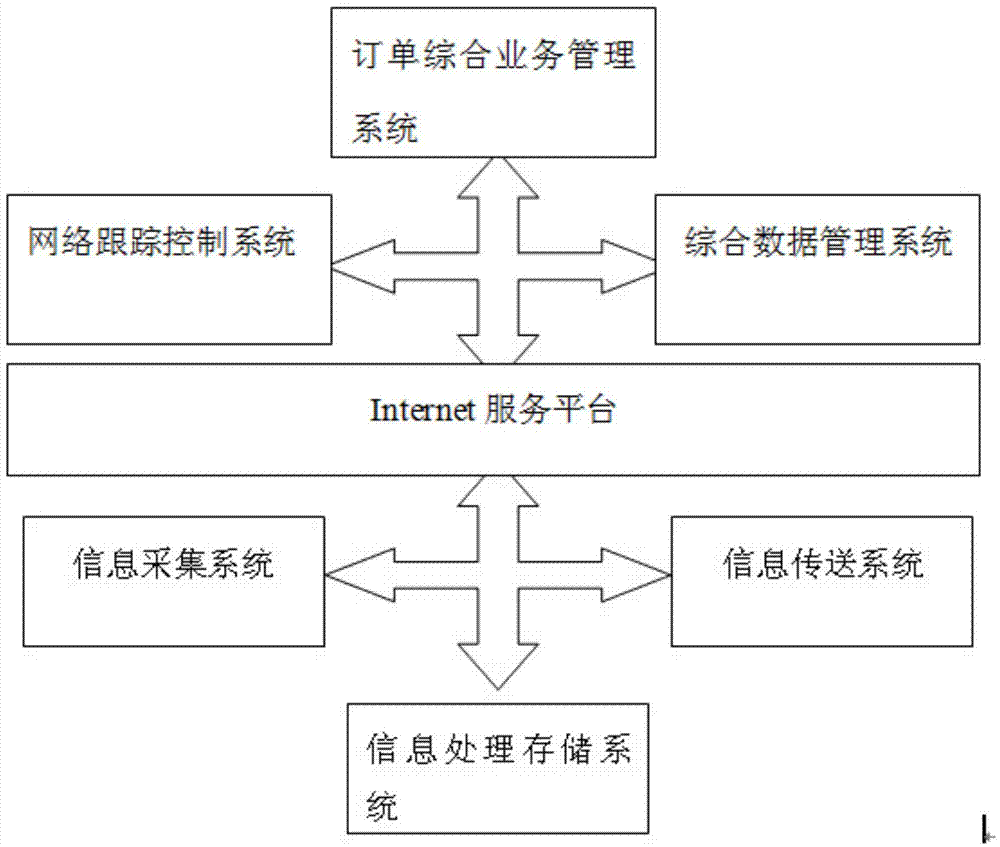

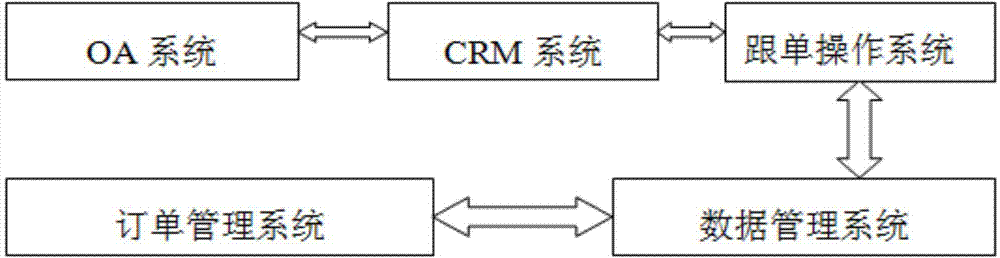

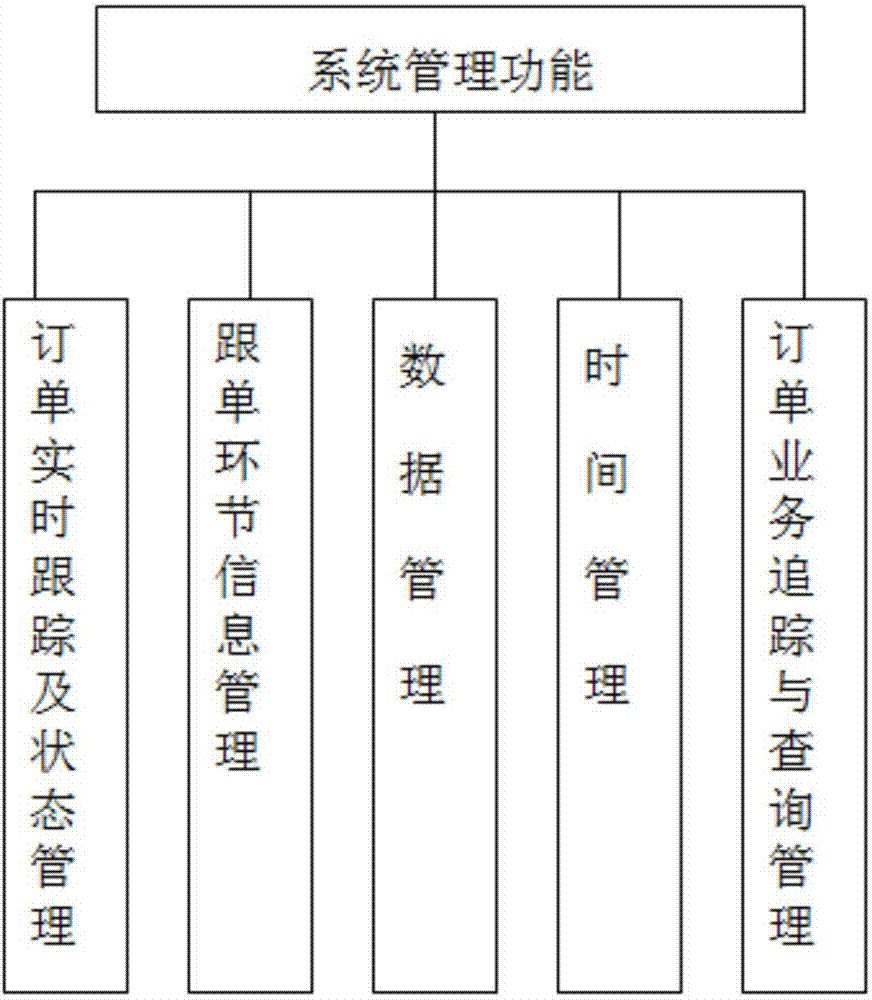

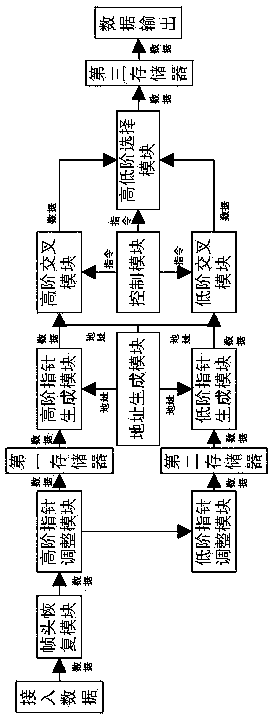

Network based multi-mode intelligent order following management method and intelligent management system

The invention discloses a network based multi-mode intelligent order following management method and an intelligent management system. The method comprises the steps as follows: defined order information is read by a data collection terminal and associated with specific data, so that node information of basic data is acquired; a customized information entry interface is set, according to different order data requirements, basic information formats are designed respectively, and information formats are customized; definition of a database and an interface for maintaining database capacity are set, a current state is prompted automatically during data dispatch or selection, and specific capacity information of storage space is dynamically updated during order following; and according to data classes and state analysis, comparison of condition of data provided by the user and the current actual basic data condition is automatically prompted, and document details for data call are automatically generated. Therefore, intelligentization and punctuality of order following management are realized, and predictability is improved; and further, flexibility of order following management service of an enterprise is enhanced, the order following time is shortened, and the flexibility is improved.

Owner:杨斯智 +6

All media on-line editing tool

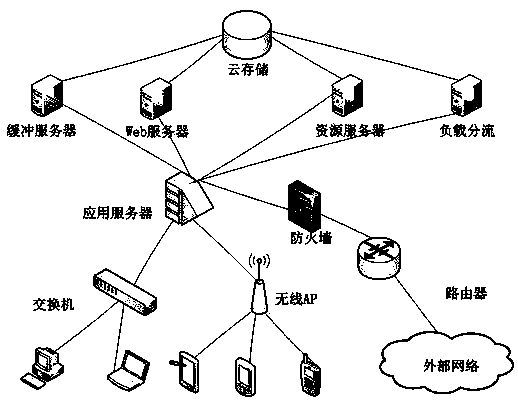

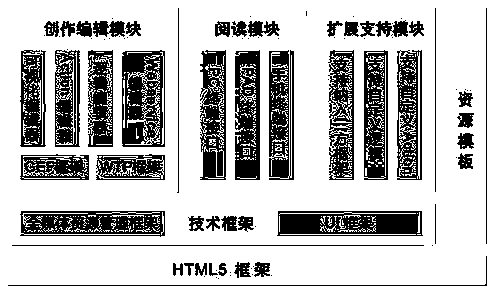

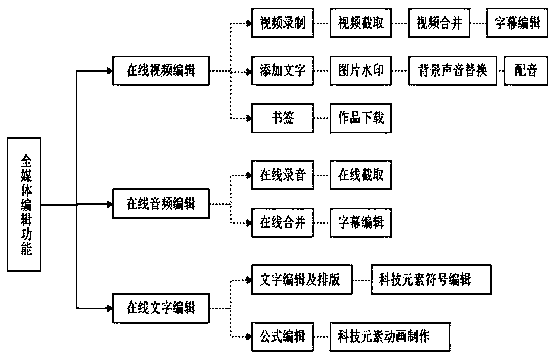

InactiveCN105376502AFully functionalUtilize and restructure wellTelevision system detailsColor television detailsApplication serverSelf adaptive

The invention relates to an all media on-line editing tool. The all media on-line editing tool comprises an application server, a cloud server and a cross-platform and cross-terminal application template. The application server is based on a JQuery framework of HTML5 technology, and is used for processing on-line editing of digital publications and automatically generating templates; the cloud server is used for storing the templates which are created in the application server and are capable of being called directly, and resource for editing, and can browse and display after calling of web; and the cross-platform and cross-terminal application template can be represented adaptively in different platforms and terminals of different models. Therefore, the all media on-line editing tool has the following advantages: (1) complete functions, concretely, utilization and reorganization of resource can be realized better through the tool, and the resource can be used more sufficiently through an on-line reading and editing function; (2) high safety, concretely, the tool can realize reliable communication of data; (3) the system has expandability, users can perform selection and creation according to own needs, and secondary utilization of the resource is realized.

Owner:HUAZHONG NORMAL UNIV

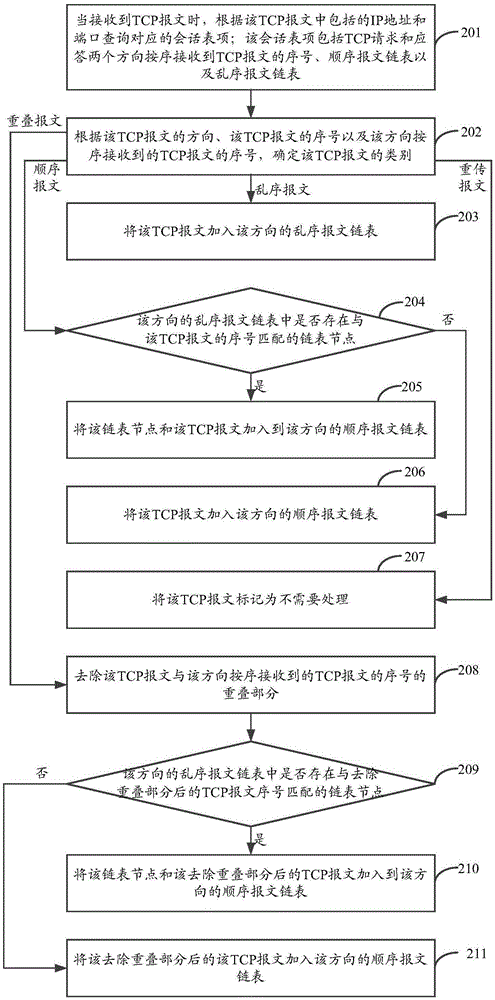

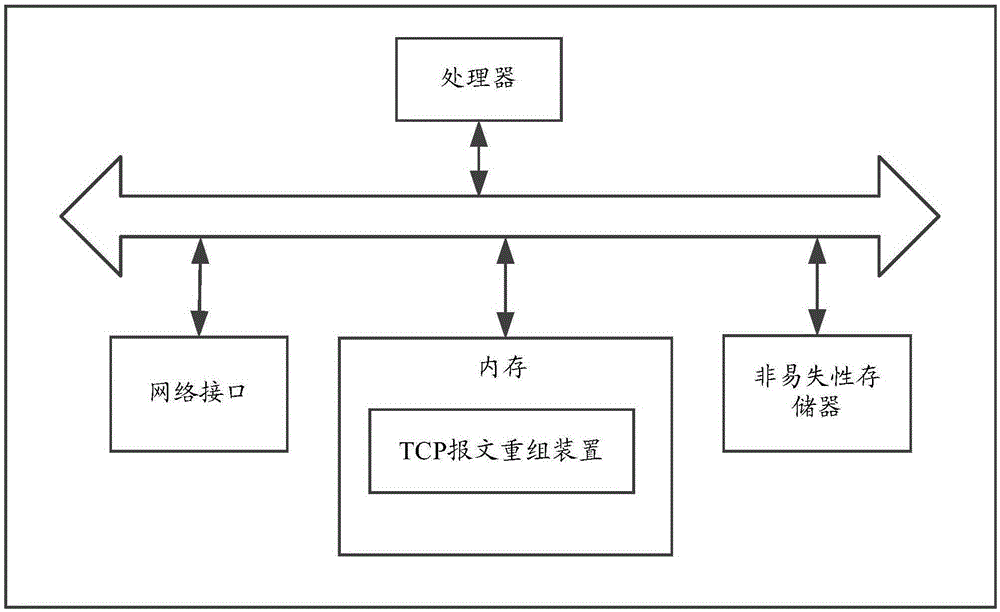

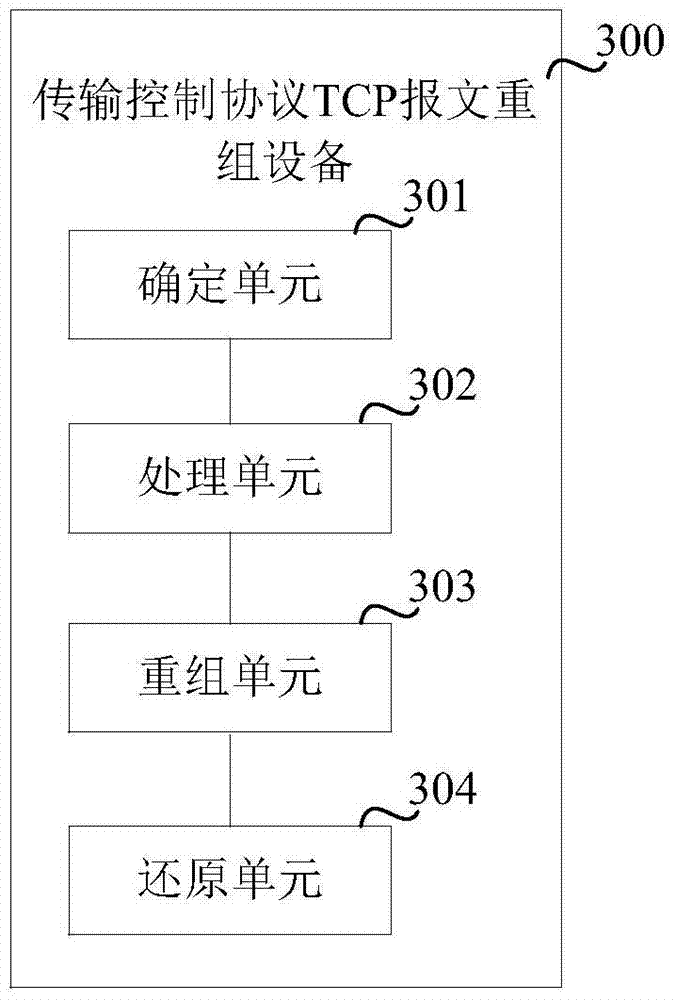

TCP message reassembling method and TCP message reassembling device

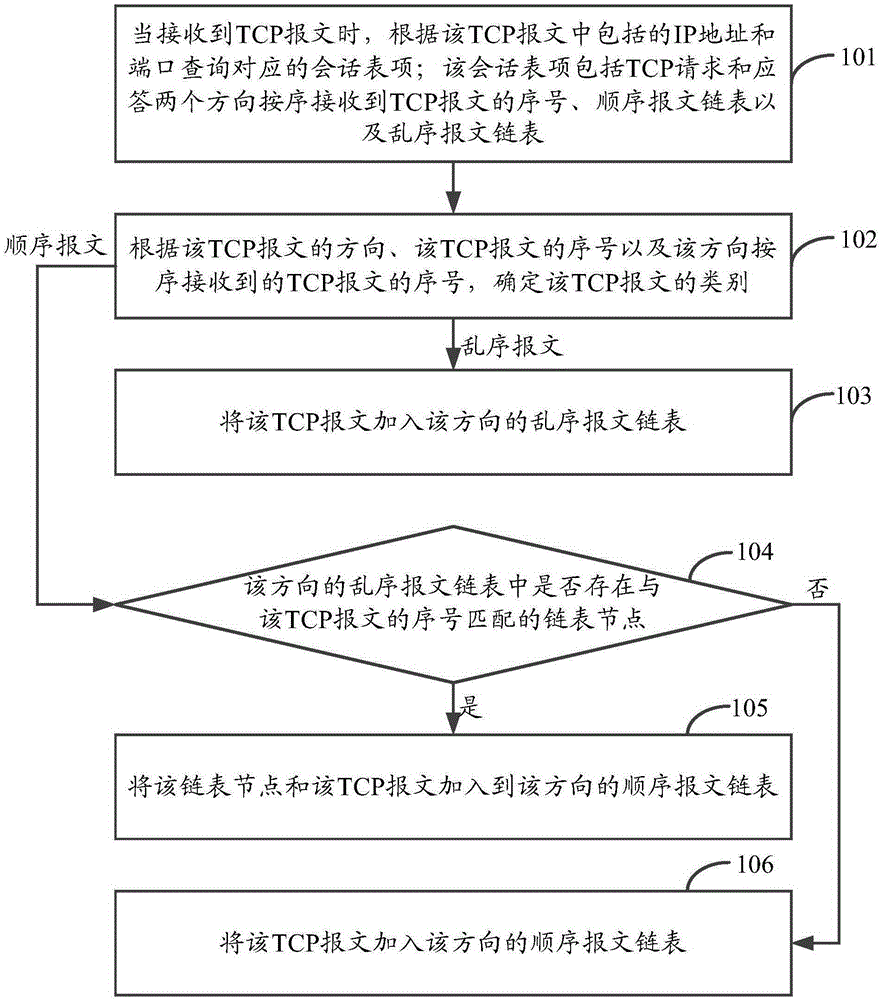

The invention provides a TCP message reassembling method and a TCP message reassembling device, wherein the method comprises the following steps of: when a TCP message is received, inquiring a corresponding conversation table item according to an IP address and a port contained in the TCP message; according to a direction of the TCP message, a serial number of the TCP message and a serial number of the TCP message orderly received in the direction, determining type of the TCP message; if the TCP message is a disordered message, adding the TCP message in a disordered message link list of the direction; if the TCP message is an ordered message, judging whether a link list node matched with the TCP message exists in the disordered message link list of the direction; if so, adding the link list node and the TCP message into an ordered message link list of the direction; and otherwise, adding the TCP message into the ordered message link list of the direction. By application of the embodiment of the invention, reassembling of TCP streams can be realized.

Owner:HANGZHOU DPTECH TECH

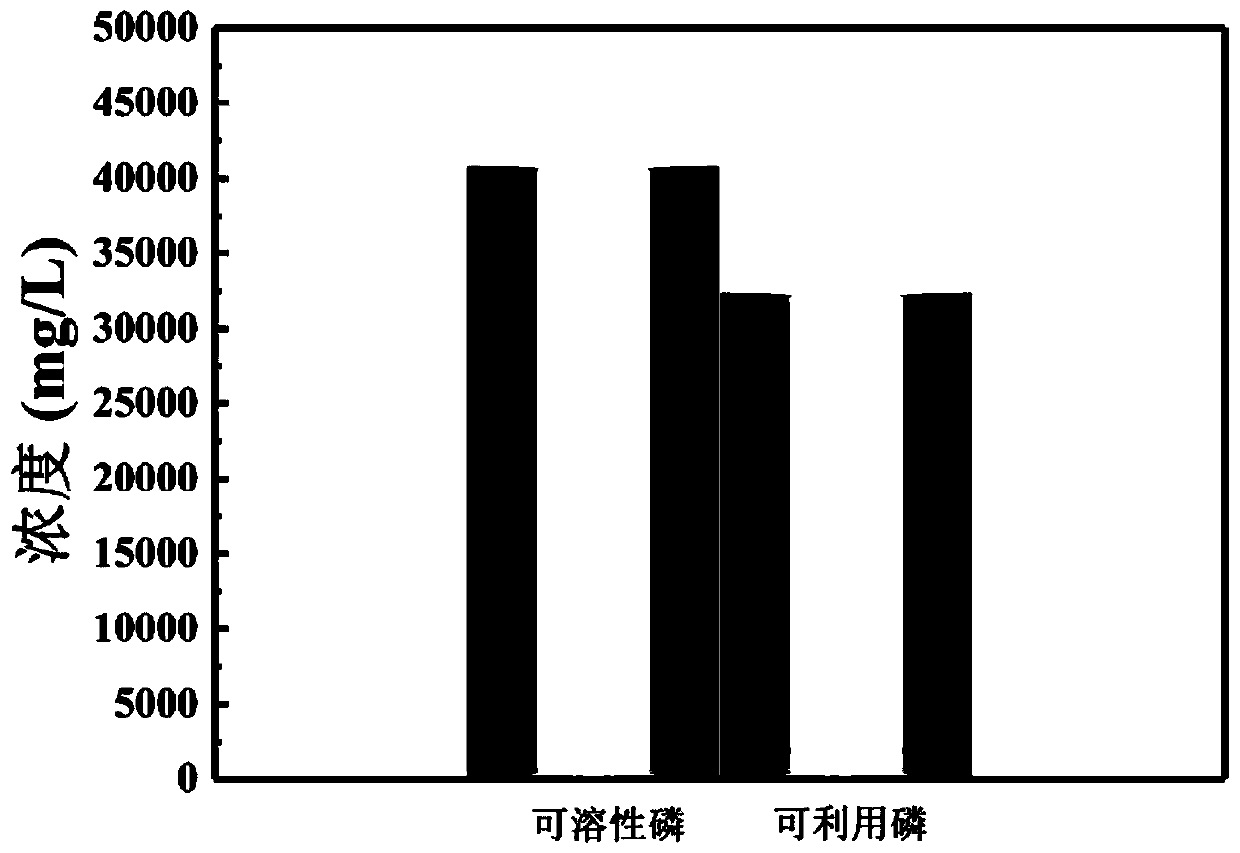

Sludge recycling treatment method

ActiveCN110540479AAvoid depositionAchieve recyclingBio-organic fraction processingCarbon preparation/purificationLiquid productSludge

The invention discloses a sludge recycling treatment method, relates to a solid waste recycling method, and aims to solve the problems that heavy metal ions are difficult to recover and phosphorus resources are wasted in a traditional sludge treatment method. The sludge recycling treatment method comprises the steps of firstly, preparing a reaction precursor mixture; secondly, carrying out hydrothermal humification reaction to obtain a reaction product; and thirdly, centrifuging the reaction product to obtain a liquid product I and a solid product I, specifically, the liquid product I is a liquid compound fertilizer; carrying out strong acid digestion on the solid product I, and then centrifuging the digested solid product I to obtain a solid product II and a liquid product II; washing thesolid product II to be neutral by using deionized water, and then carrying out vacuum drying on the neutral solid product II to obtain hydrothermal biochar; and adding a reducing agent into the liquid product II, and centrifuging the liquid product II to obtain a solid substance which is the heavy metal. The liquid compound fertilizer and the hydrothermal biochar prepared by the sludge recyclingtreatment method are applied to rapidly replenishing the effective phosphorus content of soil and promoting plant growth.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Reduction antibacterial material and preparation method thereof

ActiveCN108623224AImprove efficiencyReduce use costWater/sewage treatment by substance additionCeramicwareSilicon oxideAntibacterial agent

The invention discloses a reduction antibacterial material and a preparation method thereof. The reduction antibacterial material is prepared from 25 to 90 weight parts of base material, 15 to 55 weight parts of reducing agent, 5 to 35 weight parts of antibacterial agent and 10 to 30 weight parts of bonding agent, wherein the base material is prepared from medical stone, clay, tourmaline, ferric oxide, silicon oxide, calcium oxide and kieselguhr; the reducing agent is prepared from metallic magnesium powder, magnesia powder, zirconium oxide, titanium oxide, iron powder and nano zinc; the antibacterial agent is prepared from nano zinc, titanium oxide, cerium oxide, nano silver and copper; the bonding agent is prepared from water and one or several of hydroxypropyl cellulose, attapulgite andkaolin.

Owner:杭州三滴水科技有限公司

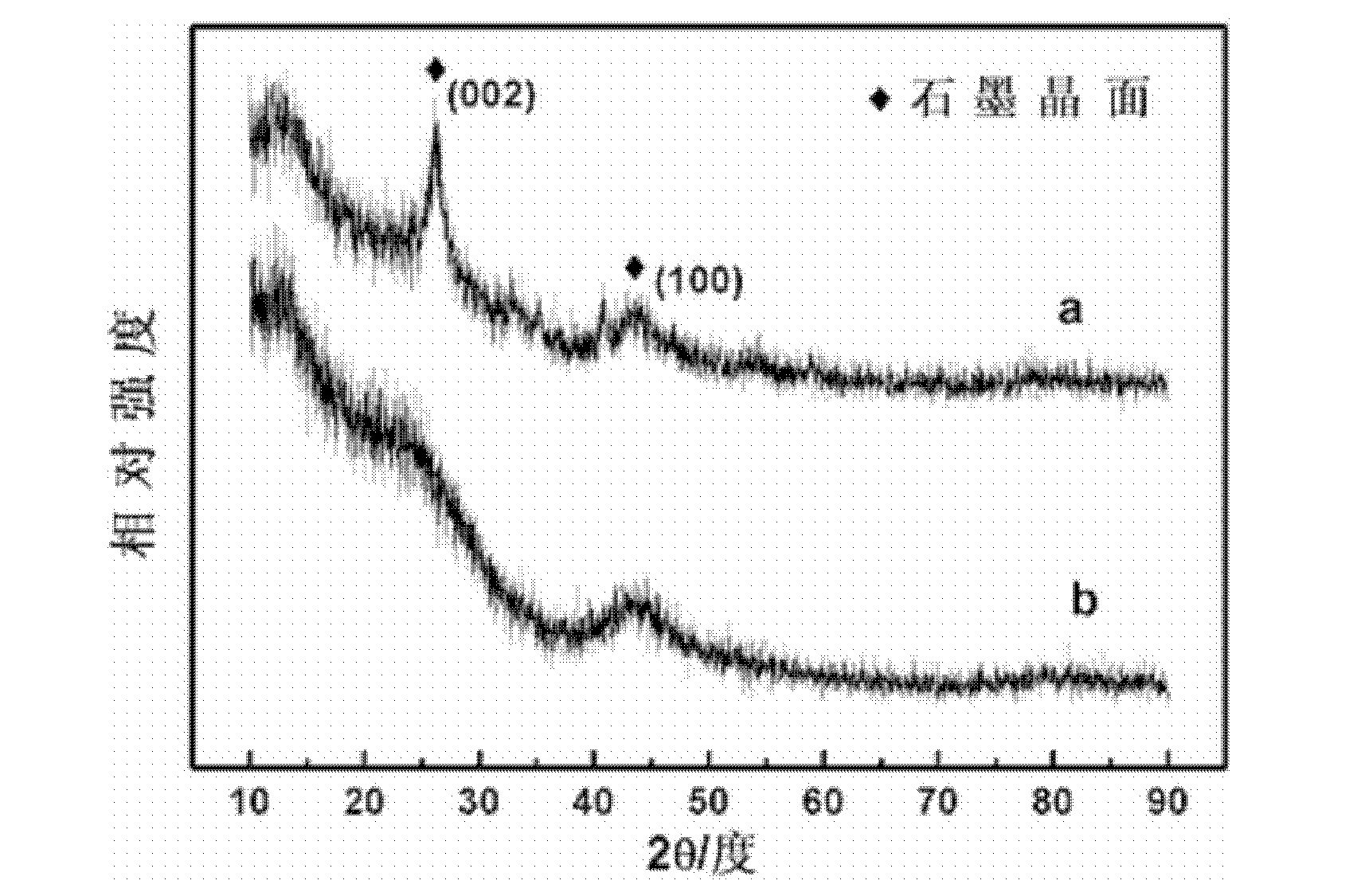

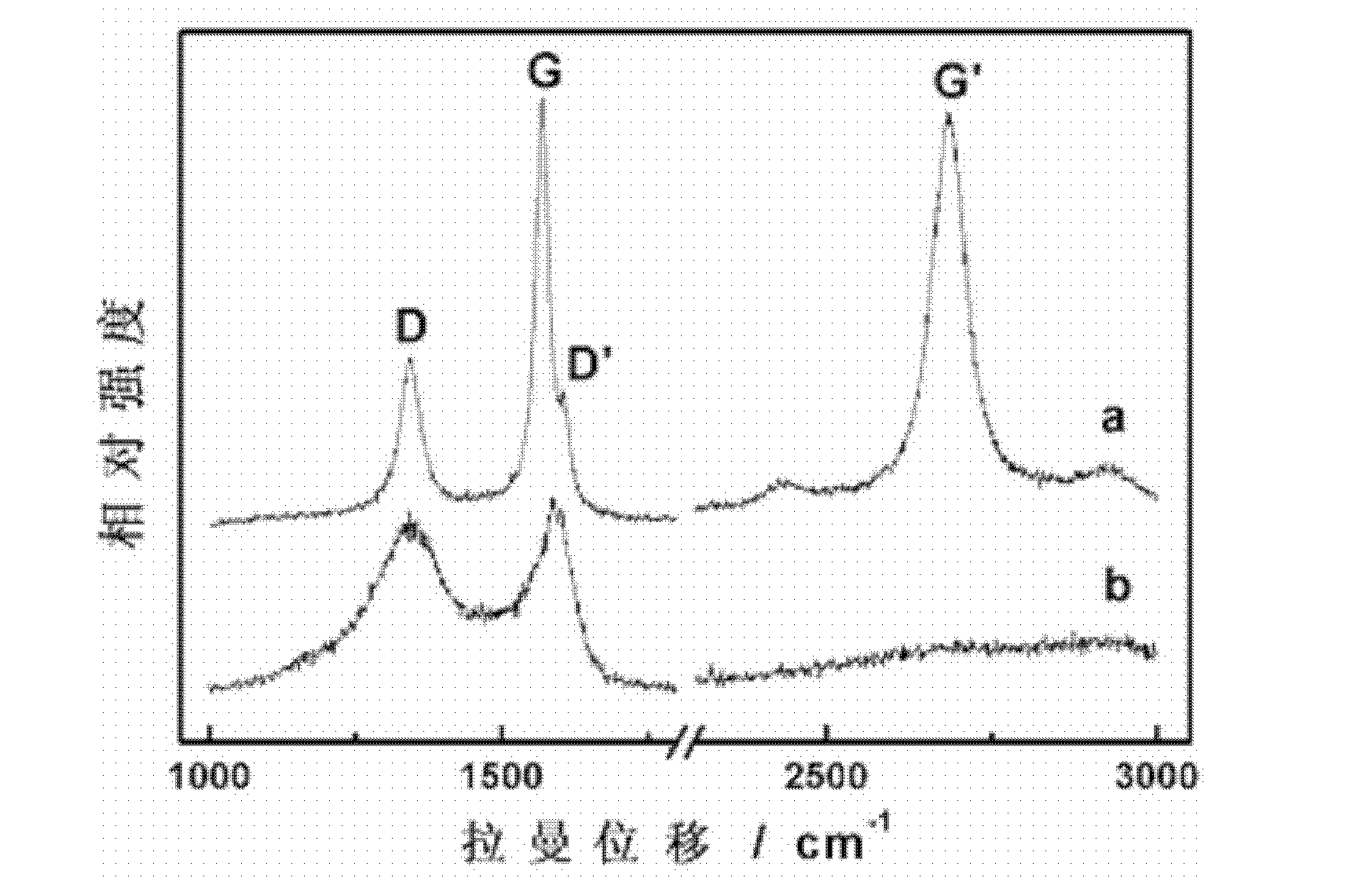

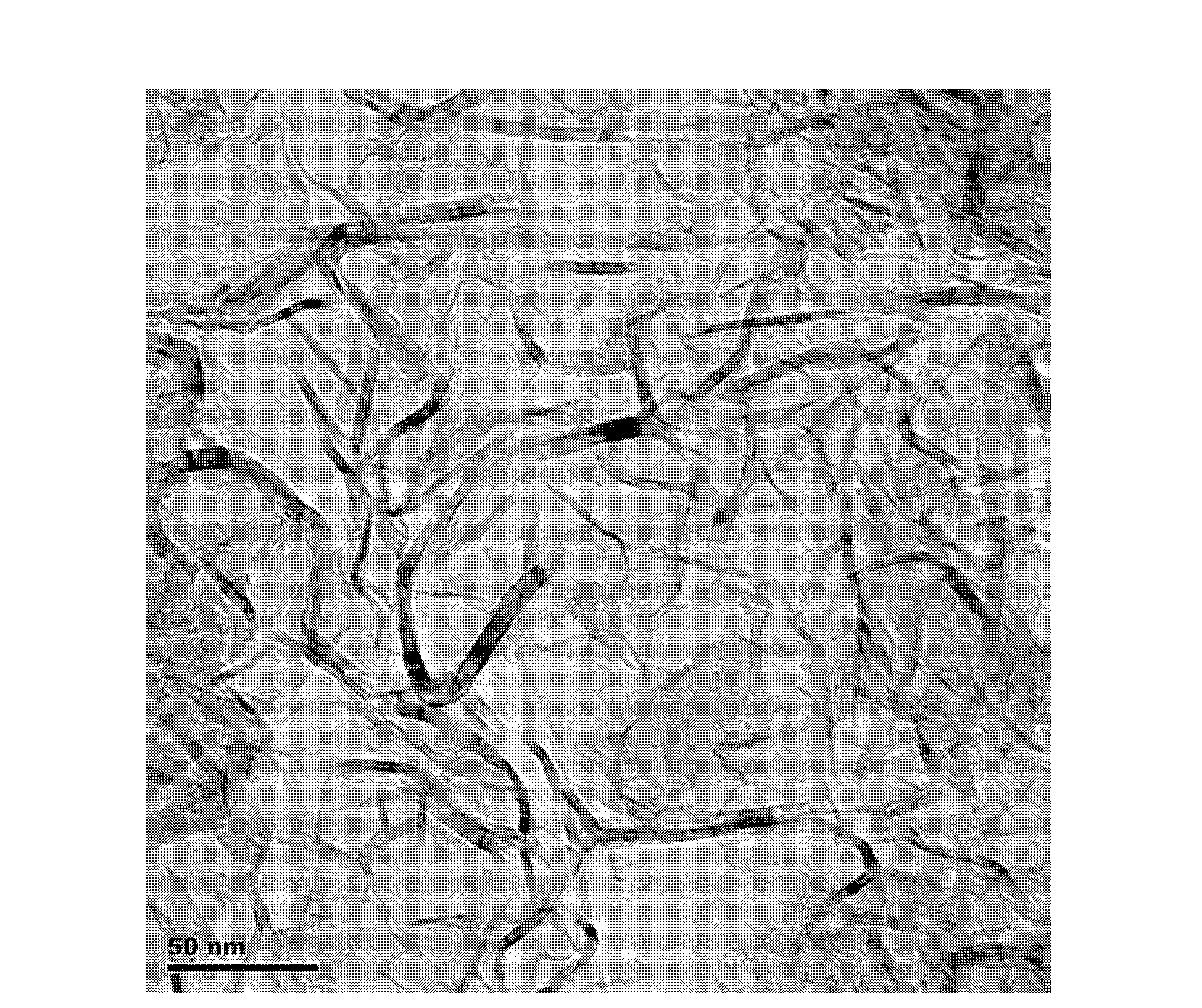

Method for preparing multilayer graphene-carbon material

InactiveCN102515150AAchieve reorganizationSimple manufacturing processGrapheneCarbon layerArgon atmosphere

The invention relates to a method for preparing a multilayer graphene-carbon material. The method provided by the invention is characterized in that a home-made amorphous carbon material is transformed into the multilayer graphene-carbon material at a low temperature under normal pressure; and concretely, the method provided by the invention comprises the following steps that metal elements are doped into the home-made amorphous carbon material; and the home-made amorphous carbon material is transformed into the multilayer graphene-carbon material at a temperature of 500 to 1000 DEG C in the presence of an elemental metal sodium as a catalyst and a medium in the nitrogen or argon atmosphere. The method provided by the invention realizes that amorphous turbostratic carbon is transformed into multilayer graphene at a low temperature under normal pressure, inhibits the increasing of the number of piled carbon layers in carbon atom rearrangement, and prevents that a large amount of the multilayer graphene obtained in structure rearrangement is transformed into graphite crystals. The multilayer graphene-carbon material obtained by the method has wide application prospects in the fields of sensors, capacitors, catalysis and energy storage.

Owner:TONGJI UNIV

Integrated on-line trading and extension service system for cultural and creative products

InactiveCN104268778ABuild brand influenceExpand sales channelsBuying/selling/leasing transactionsMarketingPaymentLogistics management

The invention provides an integrated on-line trading and extension service system for cultural and creative products. The system consists of an enterprise portal subsystem, a mobile business subsystem, a network integrated marketing subsystem, an on-line trading subsystem, an on-line interaction show subsystem, a supply chain coordination management subsystem, a data analysis subsystem and an application integration subsystem, wherein the enterprise portal subsystem consists of an enterprise introducing module, a product show module and an enterprise dynamic module; the mobile business subsystem consists of a mobile portal module, a mobile order module and a mobile service management module; the network integrated marketing subsystem consists of a website promotion module and a website marketing module; the on-line trading subsystem consists of a price management module, an order management module, an on-line payment module and an enterprise authentication module; the supply chain coordination management subsystem consists of a client management module, a plan management module, a sales management module, a purchasing management module, a physical distribution management module and a supplier management module; the data analysis subsystem consists of a user behavior data analysis module and a data mining module. The system disclosed by the invention has the advantages of enhancing brand influence, widening product sales channels and improving market occupancy.

Owner:CHONGQING ACADEMY OF SCI & TECH

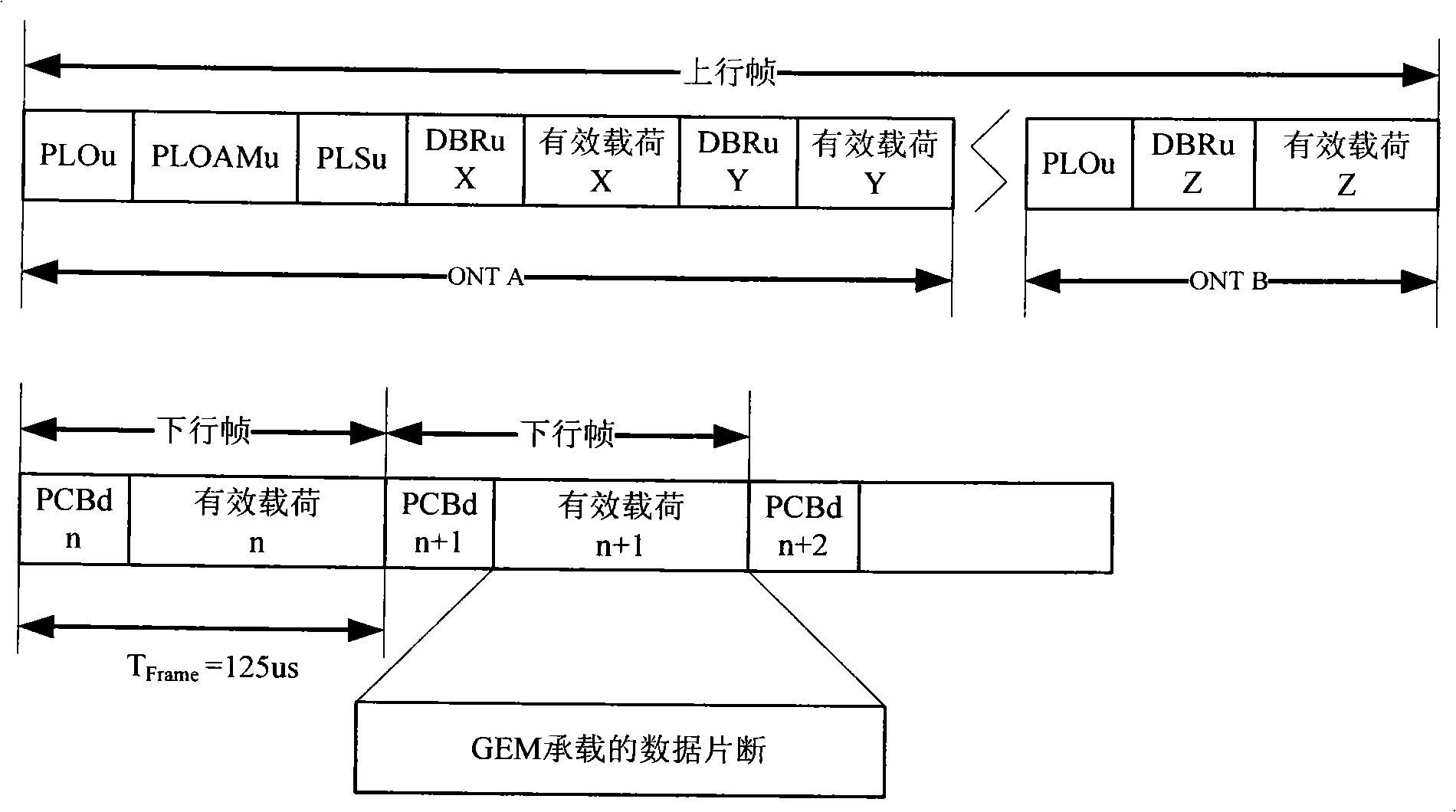

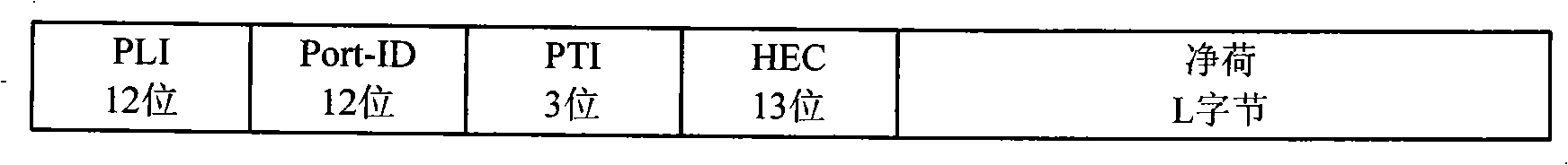

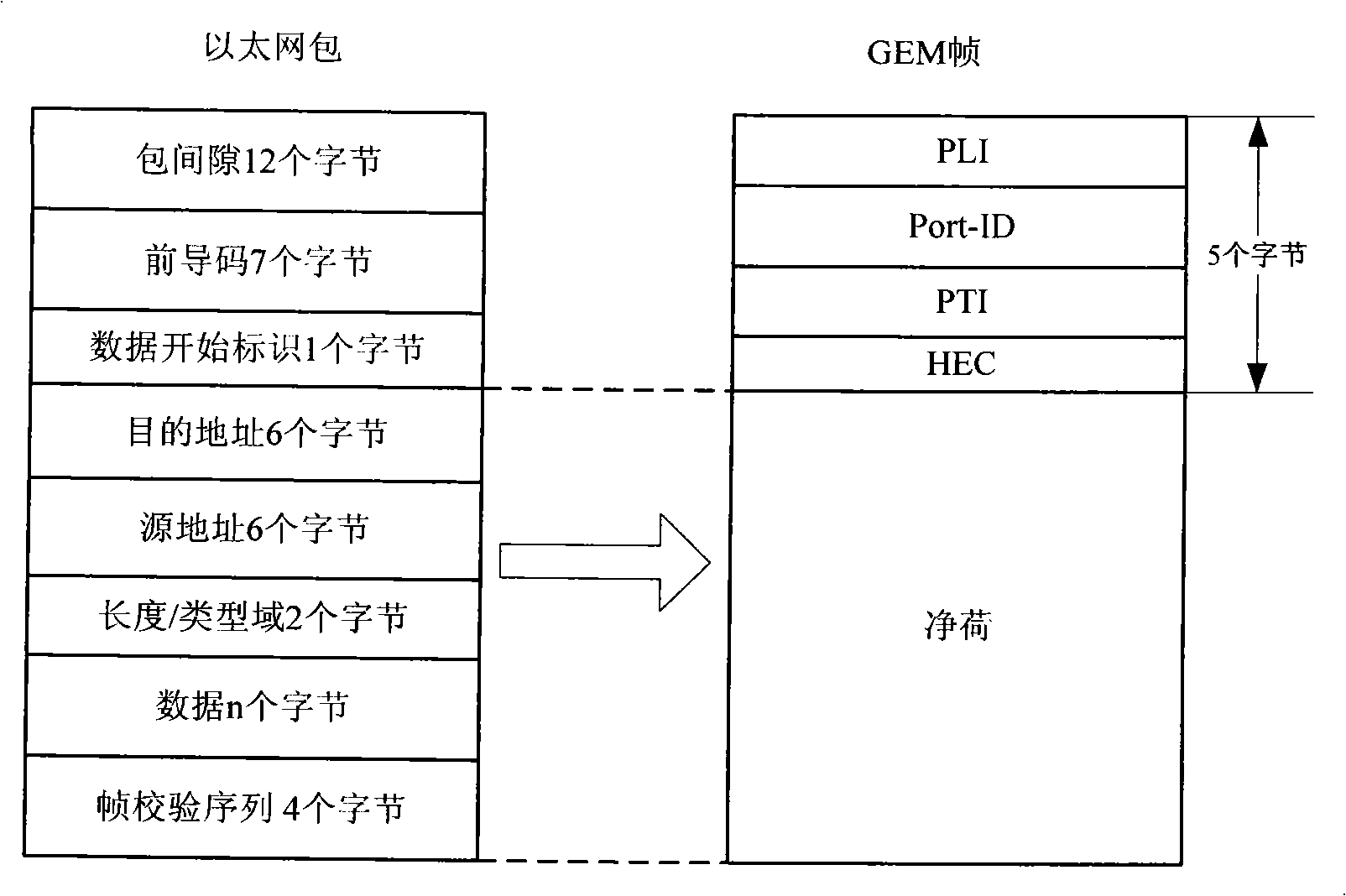

System and method for realizing encapsulation mode frame recombination of gigabit passive optical network

ActiveCN101552931AAchieve reorganizationVersatilityMultiplex system selection arrangementsTransmissionExternal storageGigabit

The invention discloses a system for realizing GEM frame recombination, comprising a GEM frame head processing module and a payload recombination processing module. The invention also discloses a method for realizing the GEM frame recombination, comprising the following steps: 1) after receiving GEM frames, the GEM frame head processing module reads GEM frame heads to obtain interface identifiers of the GEM frame heads; 2) the payload recombination processing module applies a storage space for the GEM frames of a same interface identifier in an external memory, and writes a first GEM frame payload to a pointed address space of the external memory, as for sequent GEM frame payloads of the interface identifiers, if the tail part of the previous GEM frame is judged with slack bytes written in, the slack bytes of the tail part of the previous GEM frame are covered by the sequent GEM frame payload, and then the sequent GEM frame payloads are sequentially written into a sequent address space of the external memory. The invention can realize the GEM frame recombination on the basis of Port ID with least resources and support the interleave transmission of different Port ID data.

Owner:SANECHIPS TECH CO LTD

Preparation method of organic titanium precursor polymer TPP-II and application of organic titanium precursor polymer TPP-II in special coating

InactiveCN108503841AHigh surface activityImprove surface activityAnti-corrosive paintsEpoxy resin coatingsEpoxyNano al2o3

The invention discloses a preparation method of an organic titanium precursor polymer TPP-II and application of the organic titanium precursor polymer TPP-II in a special coating, and belongs to the technical field of preparation and application of new materials. Under the catalysis of gamma-phase nano-alumina, a mixture of hydrogenated titanium powder, epoxy resin, a nano-dispersant, a titanate coupling agent, a silane coupling agent and a solvent is placed in a ball-milling reaction tank for a ball milling reaction under ultrasonic conditions; under the coupling action of mechanical force and ultrasonic wave, not only is the micron-sized titanium hydride refined to the nanometer scale, but also the break-chain graft polymerization of a high-molecular polymer is induced; and the organic titanium precursor polymer TPP-II with a hydroxyl group structure is obtained by ring opening of epoxy groups. The organic titanium precursor polymer TPP-II can be used to prepare high-temperature environmentally acid-resistant corrosion protective coatings, such as primers and topcoats of a flue gas desulfurization system and heat exchanger equipment.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

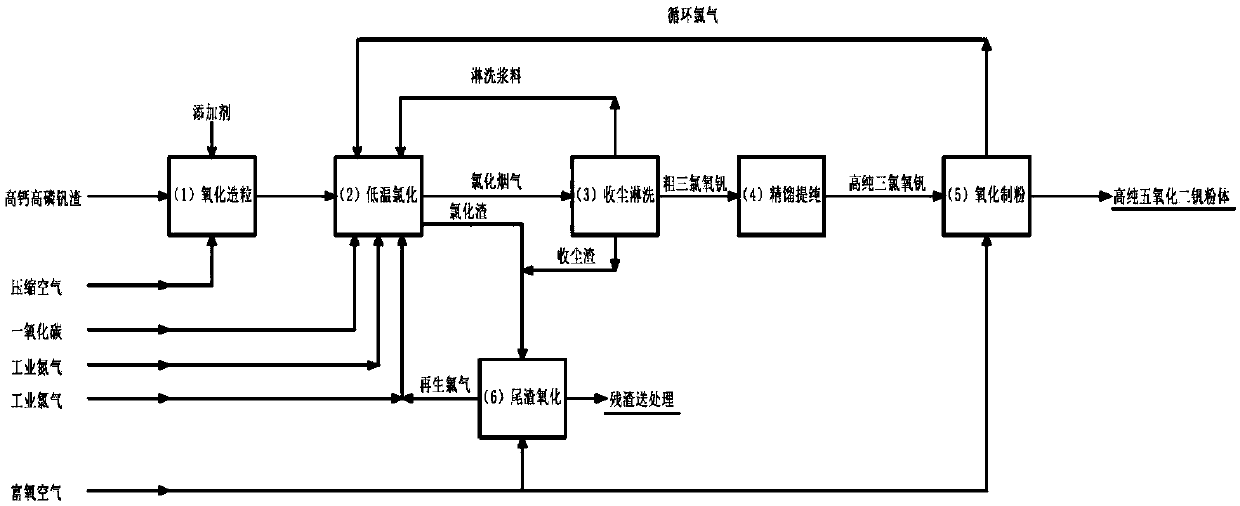

Method for preparing high-purity vanadium pentoxide by low-temperature chlorination of high-calcium and high-phosphorus vanadium slag

The invention discloses a method for preparing high-purity vanadium pentoxide by low-temperature chlorination of high-calcium and high-phosphorus vanadium slag. The method includes the six processes of (1) an oxidation granulation process, (2) a low-temperature chlorination process, (3) a dust collection and elution process, (4) a rectification and purification process, (5) an oxidation powderingprocess, and (6) a tailings oxidation process. In this method, an additive is added in the oxidation granulation process, so that calcium in the vanadium slag is converted into a silicate phase or analuminosilicate phase, and the loss of flow caused by a large amount of calcium chlorination is avoided. In the low-temperature chlorination process, carbon monoxide is used as a carbon source to decrease the chlorination temperature and prevent the loss of flow caused by the melting of calcium and magnesium chlorides. In the oxidation powdering process and the tailings oxidation process, the recycling of chlorine gas is realized by blowing oxygen-enriched air. The method for preparing high-purity vanadium pentoxide by low-temperature chlorination of high-calcium and high-phosphorus vanadium slag is suitable for the high-calcium and high-phosphorus vanadium slag and has the advantages of being good in selectivity, low in reaction temperature, having no loss of flow, being environment-friendly, and high in added value of products.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

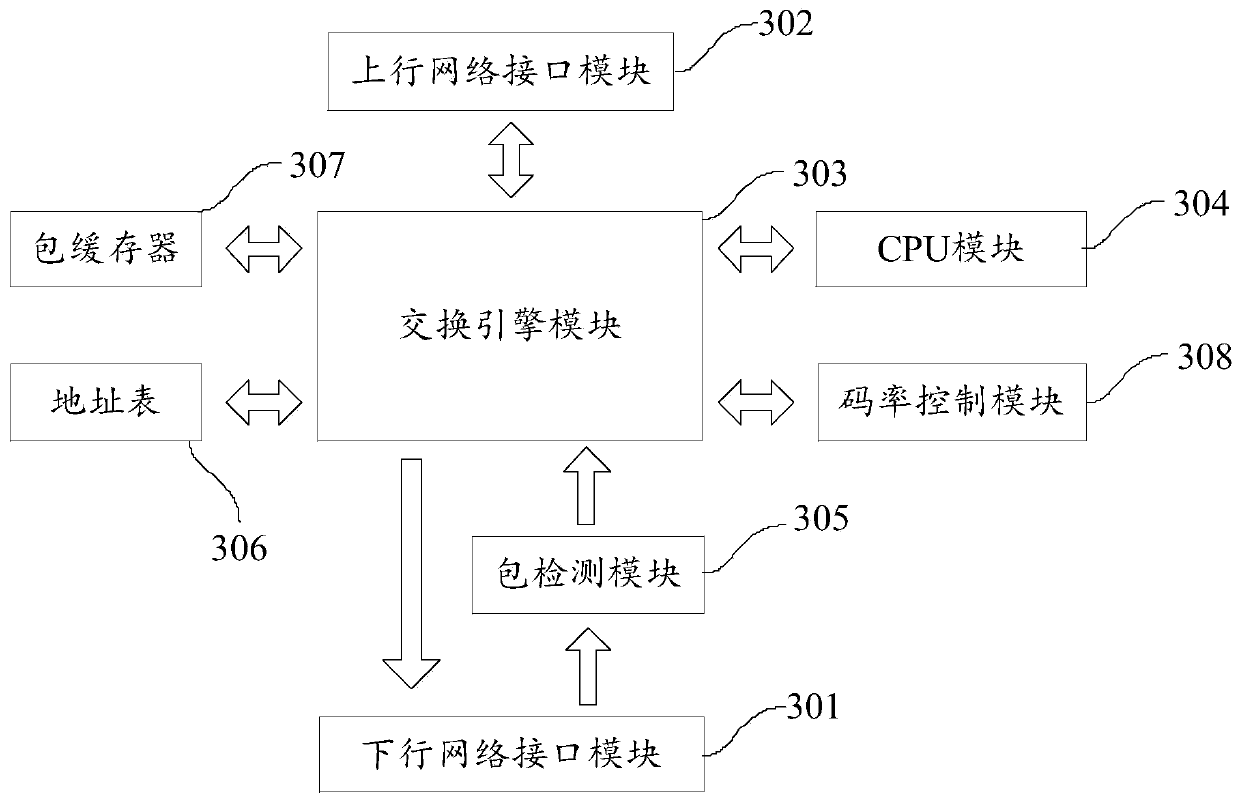

Message out-of-order processing method and device

ActiveCN109889779AAchieve reorganizationAvoid discardingTelevision conference systemsClosed circuit television systemsThe InternetComputer terminal

The embodiment of the invention provides a message out-of-order processing method and device. The method and device are applied to an articulated naturality web, and the articulated naturality web comprises an articulated naturality web cat terminal and an Internet terminal connected with the articulated naturality web cat terminal; Storing the first message into the first corresponding position by the articulated naturality web modem terminal; the arrival of a target second message can be waited; or after the second message is stored in the second corresponding position, the arrival of the target first message can be waited so as to realize data recombination, and when the data forwarded by the articulated naturality web modem terminal is out of order in a small range, the embodiment of the invention can avoid the discarding of the fragmented message, thereby achieving the purpose of reducing the packet loss rate.

Owner:VISIONVERA INFORMATION TECH CO LTD

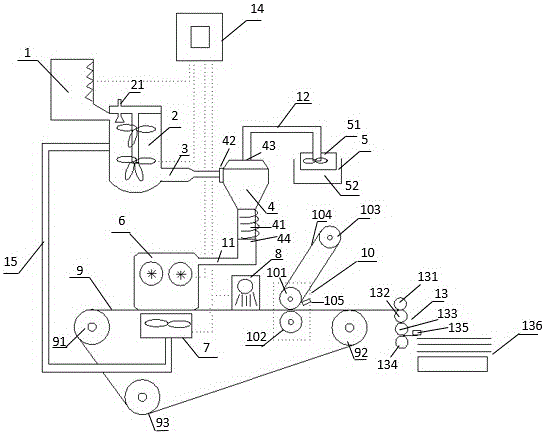

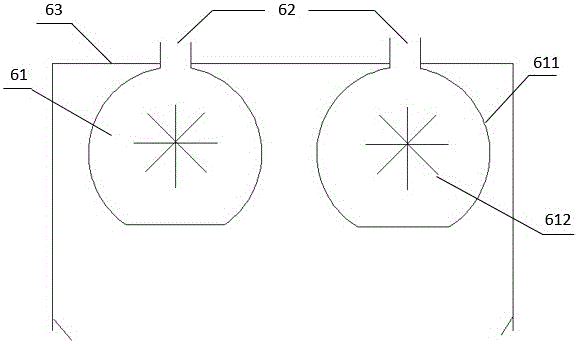

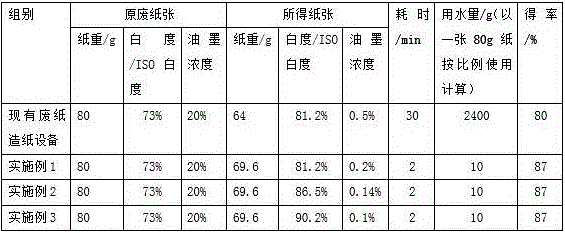

Water-saving, high-efficiency and environment-friendly paper machine for office and home use

InactiveCN106337308AAchieve reorganizationEliminate traces of usePaper recyclingCalendersHome useDeinking

A water-saving, high-efficiency and environment-friendly paper machine for an office and home use comprises a paper shredding unit, a repulping unit, an accelerating unit, a deinking unit, a dispersing unit, a fiber distributing unit, a fiber sticking unit, a conveying unit, a paper forming unit, a cutting unit and a pigment collecting unit. The water-saving, high-efficiency and environment-friendly paper machine adopts the coordination of laser clearance and physical fluid motion, reduces the chemical reagent used in the deinking process, and decreases the water consumption accordingly, thereby achieving the purpose of dry fiber processing. Compared with traditional handmade paper making and an existing small-sized paper machine for an office, the whole set of equipment has high production efficiency and a good paper deinking effect.

Owner:李璇

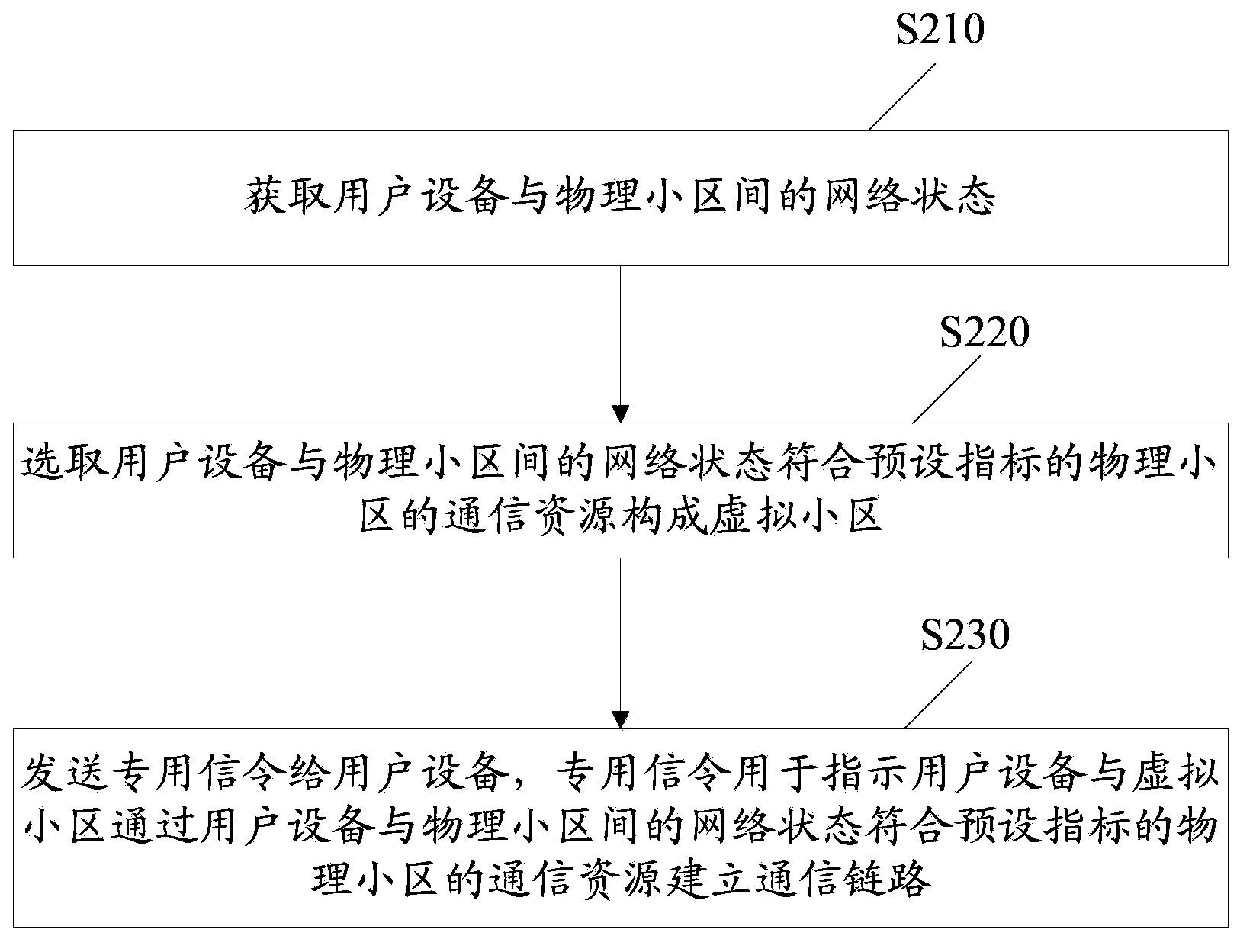

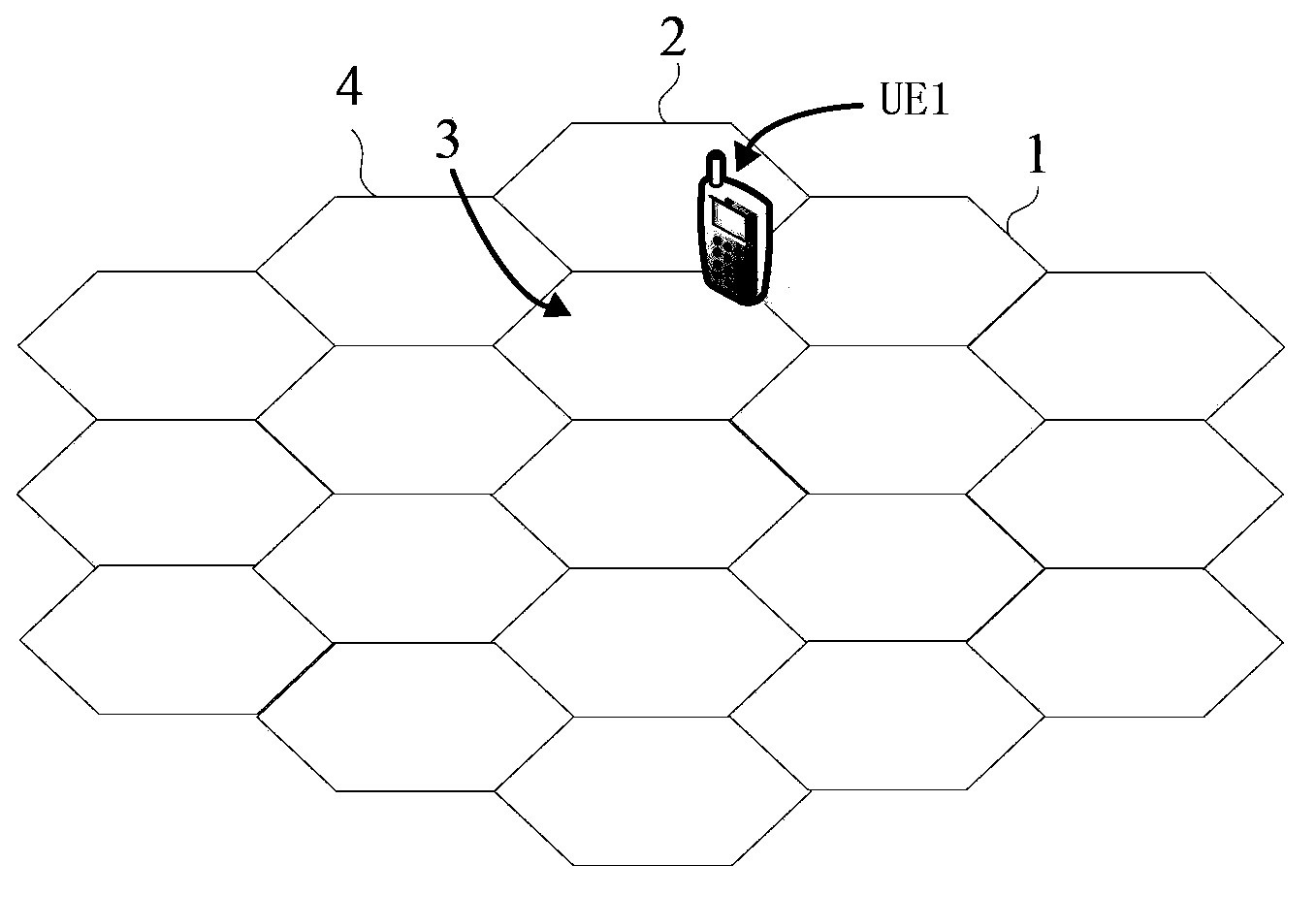

Wireless communication method, device and system

InactiveCN103841588AAchieve reuseAchieve reorganizationWireless communicationTelecommunications linkUser device

The embodiment of the invention discloses a wireless communication method, device and system. According to the embodiment, by acquiring network states between a user device and a physical cell, communication resources of the physical cell are selected to form a virtual cell, wherein the network states between the user device and the physical cell meet preset indicators; a special signaling is sent to the user device; the user device and the virtual cell are instructed to establish a communication link through the communication resources, which are comprised by the virtual cell, of the physical cell; available communication resources matching communication requirements of the user device are recombined, which is no longer confined to the traditional physical cell demarcation based on a provision; a honeycomb-shaped cell demarcation communication mode is shown, so that the physical cell serving the user device can come from different launching points or different processing points, and is no longer subject to geographical constraints; free dynamic changes of the communication resources of the service cell are realized; and multiple-dimension combination is realized.

Owner:HUAWEI TECH CO LTD

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167BHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsRebar

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

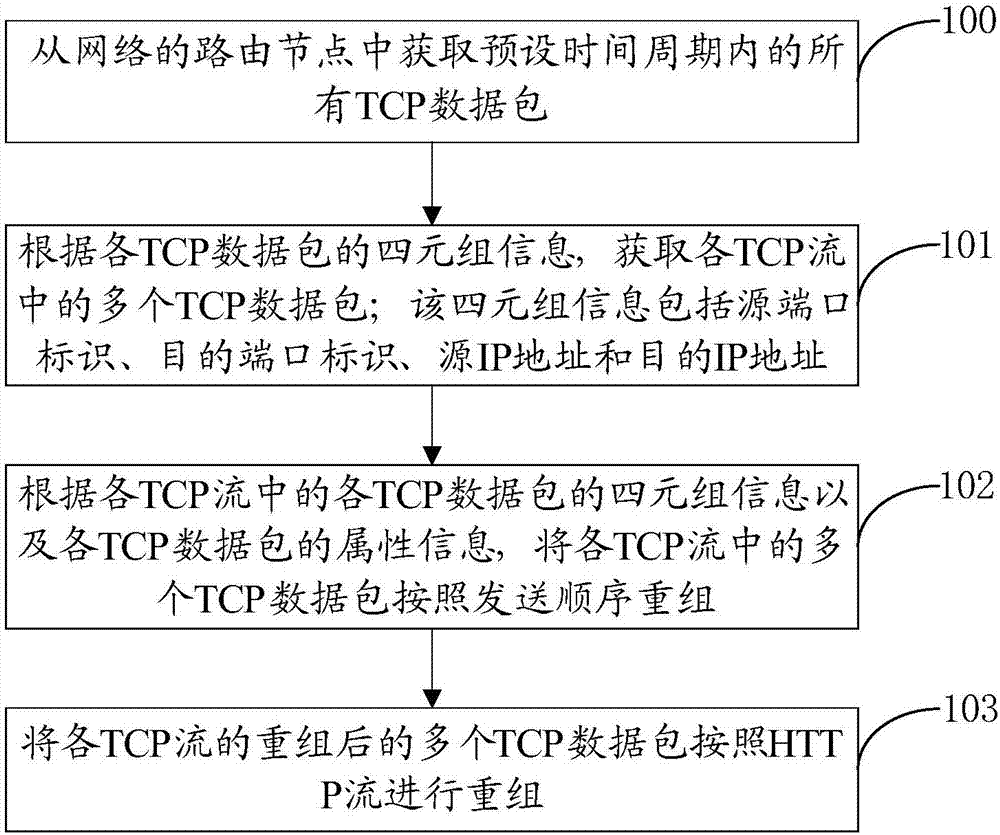

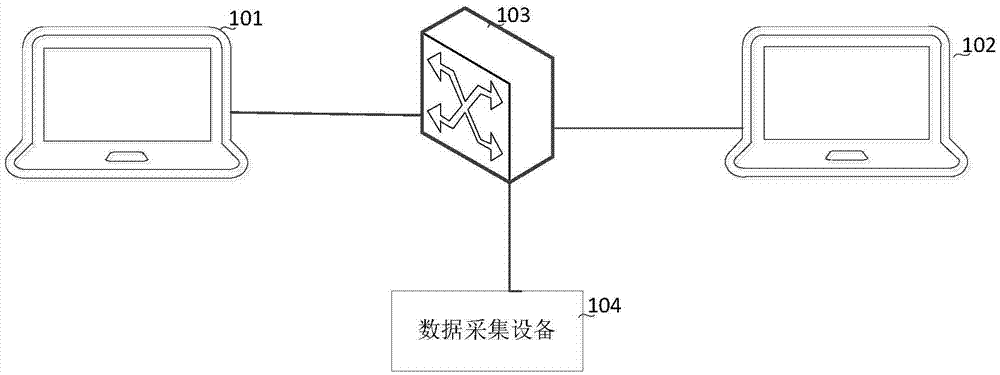

Data packet recombination method and apparatus, computer device and readable medium

ActiveCN108011850ARestore accuratelyAchieve reorganizationData switching networksNetwork packetIp address

The invention provides a data packet recombination method and apparatus, a computer device and a readable medium. The method comprises the following steps: obtaining all TCP data packets in a preset time period from a routing node of the network; and obtaining multiple TCP data packets in TCP streams according to quadruple information of the TCP data packets, wherein the quadruple information comprises a source port identifier, a destination port identifier, a source IP address and a destination IP address; recombining the multiple TCP data packets in the TCP streams according to the quadrupleinformation of the TCP data packets in the TCP streams and the attribute information of the TCP data packets; and recombining the multiple recombined TCP data packets in the TCP streams according toHTTP streams. The technical scheme of the invention can recombine the data packets in the TCP streams in any forms, so that the use mode is very flexible, and the scheme can be applied to a very largenumber of scenes, so that the practicality is very high.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

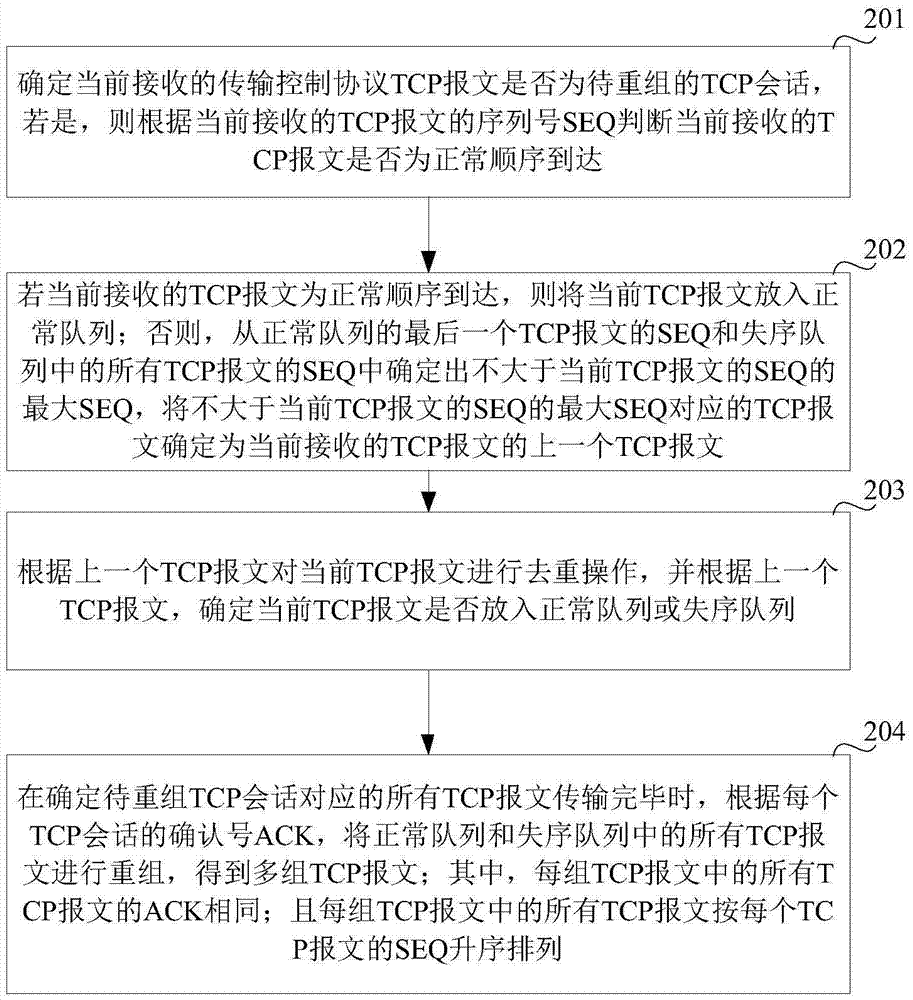

Message regrouping method and equipment

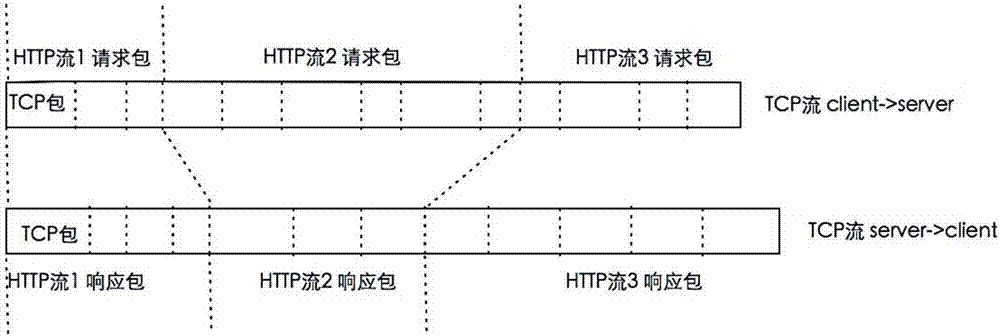

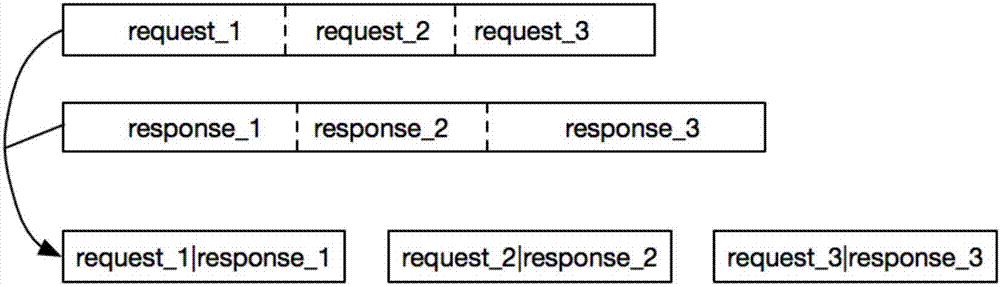

InactiveCN106911644AAvoid overlapping problemsAchieve reorganizationData switching networksOperating systemTransfer control protocol

The embodiment of the invention relates to the technical field of communications, and especially relates to a message regrouping method and equipment used for realizing message regrouping through a simple method. The method of the embodiment of the invention comprises the following steps: receiving TCP (Transfer Control Protocol) messages corresponding to a TCP session to be regrouped, when determining that the transmission of all TCP messages corresponding to the TCP session to be regrouped is finished, regrouping all TCP messages in a normal queue and a disordered queue according to an acknowledgement ACK of each TCP session, and obtaining multiple groups of TCP messages, wherein the ACKs of all TCP messages in each group of TCP messages are the same, and all TCP messages in each group of TCP messages are arranged according to the ascending order of an SEQ (Sequence) of each TCP message. Thus, message regrouping can be realized only through the ACKs and the SEQs of the TCP messages, and the method is simple and efficient.

Owner:中国移动通信集团广西有限公司

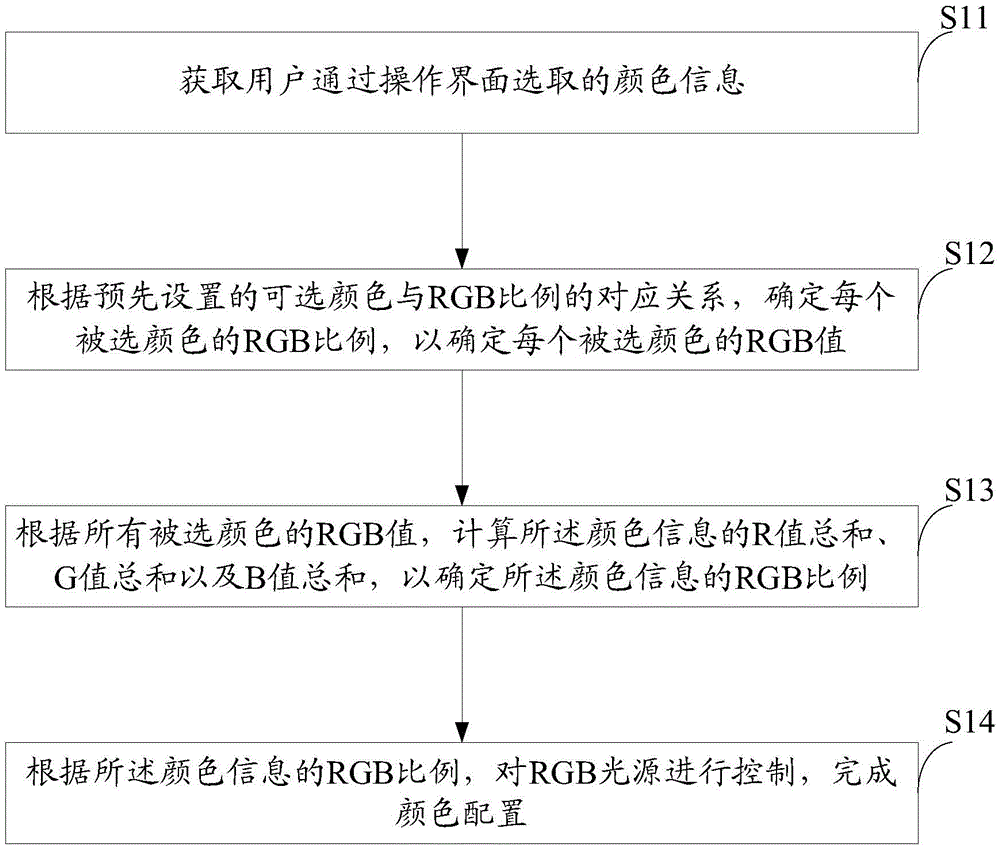

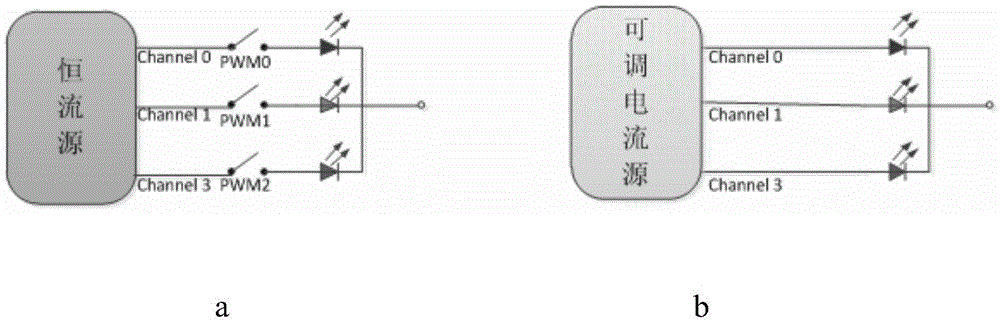

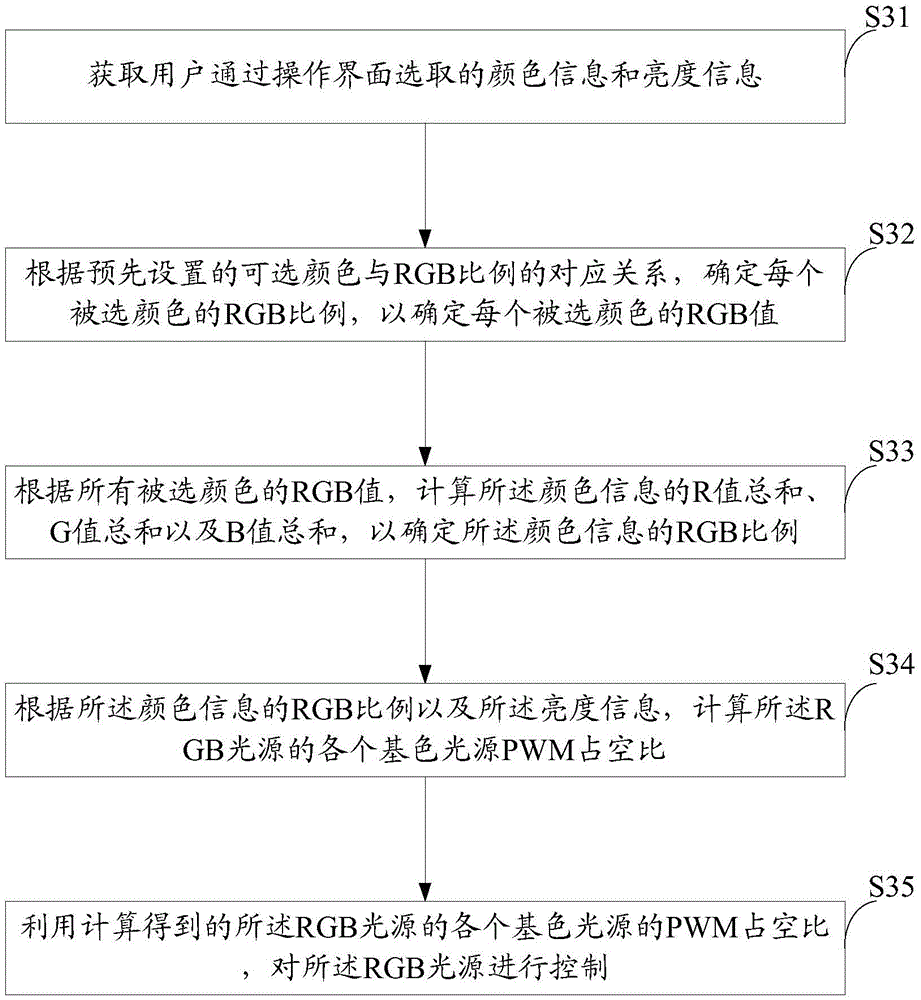

Color configuration method and apparatus for atmosphere lamp

ActiveCN105611694AMeet the requirements of color experienceAchieve reorganizationElectrical apparatusElectric light circuit arrangementComputer visionAtmosphere

The invention discloses a color configuration method and apparatus for an atmosphere lamp. The color configuration method comprises the steps of after obtaining color information selected by a user through an operation interface, determining RGB proportion of each selected color based on a preset corresponding relationship between available colors and the RGB proportion so as to obtain the R value, the G value and the B value of each selected color; moreover, obtaining the R value sum, the G value sum and the B value sum of the color information, and finally determining the RGB proportion of the color information; and furthermore, controlling an RGB light source according to the RGB proportion of the color information for realizing color configuration. Namely, color splitting and recombination can be realized; different colors are split into minimum units; and different colors are represented by the RGB proportions, and are recombined to realize the configuration for different colors, so that the requirements on color experience of different users are satisfied.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

Photo-electromagnetic response epoxy glass polymer

The invention discloses a photo-electromagnetic response epoxy glass polymer which is prepared from the following components in parts by weight: 50-100 parts of epoxy resin, 20-60 parts of an epoxy curing agent, 0-30 parts of an epoxy diluent, 5-100 parts of inorganic filler and 0-5 parts of a catalyst. The photo-electromagnetic response epoxy glass polymer can drive reversible exchange reaction of dynamic ester bonds or disulfide bonds, exchange of polymer chain segments and recombination of a cross-linked network under specific laser, voltage / current or alternating magnetic fields, so that repair and welding of the epoxy glass polymer under various external stimulations of photo-electromagnetism are realized.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

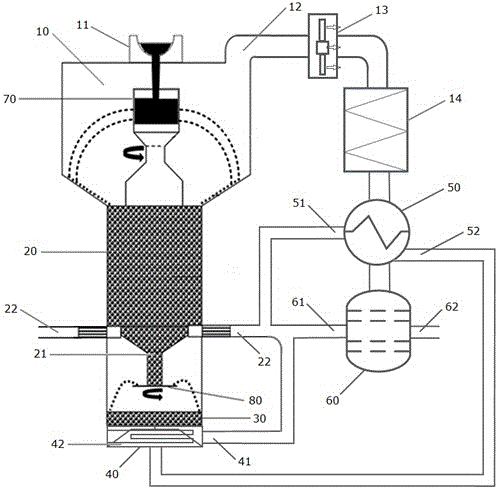

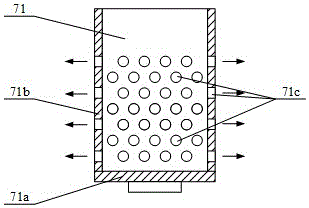

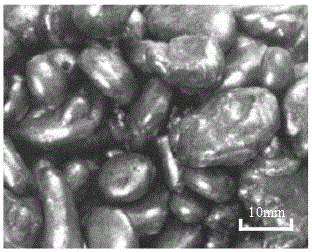

Nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device and method

ActiveCN106041108AGuaranteed fine granulation effectReduce manufacturing costHydrogenEnergy inputSteam reformingRecovery method

The invention provides a nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device and method. According to the nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device, the structure is simple; production, implementation, using and operation are all easy and convenient; the nickel-iron alloy dry granulation and methane steam reforming waste heat recovery method is combined; the nickel-iron alloy refining granulation effect is better ensured by adopting the dry granulation method; meanwhile, nickel-iron alloy waste heat can further be converted into resources required by methane steam reforming reaction in a multistage recovery mode that a physical method is combined with a chemical method; increasing of the nickel-iron alloy waste heat resource recovery utilization rate can be facilitated, so that the problems that the stainless steel smelting process requirements are difficult to meet by molten nickel-iron alloy granulation processing, and the waste heat resource recovery utilization rate of molten nickel-iron alloy granulation processing is low in the prior art are effectively solved; and the nickel-iron alloy dry granulation and methane steam reforming waste heat recovery device and method have very good industrial application value and can be applied and popularized in domestic metallurgical enterprises.

Owner:CHONGQING UNIV

Recovery treatment method of phosphine-containing industrial by-products

PendingCN111187297AAchieve reorganizationRealize comprehensive utilizationGroup 5/15 element organic compoundsDiethyl phosphatePhosphorous acid

The invention discloses a recovery treatment method of a phosphine-containing industrial by-product, and belongs to the technical field of chemistry. The method comprises the following steps: puttinga byproduct generated in a production process of diethyl methyl phosphite into a reaction container, adding at least one of a phenolic compound, a binary or higher arylamine compound or a compound containing an ethylene oxide functional group, and carrying out a heating reaction under an air-isolated condition to obtain the phosphorus-based flame retardant. The preparation method is high in yield,and the obtained phosphorus-based flame retardant is good in flame retardant efficiency.

Owner:洪湖源泰科技有限公司

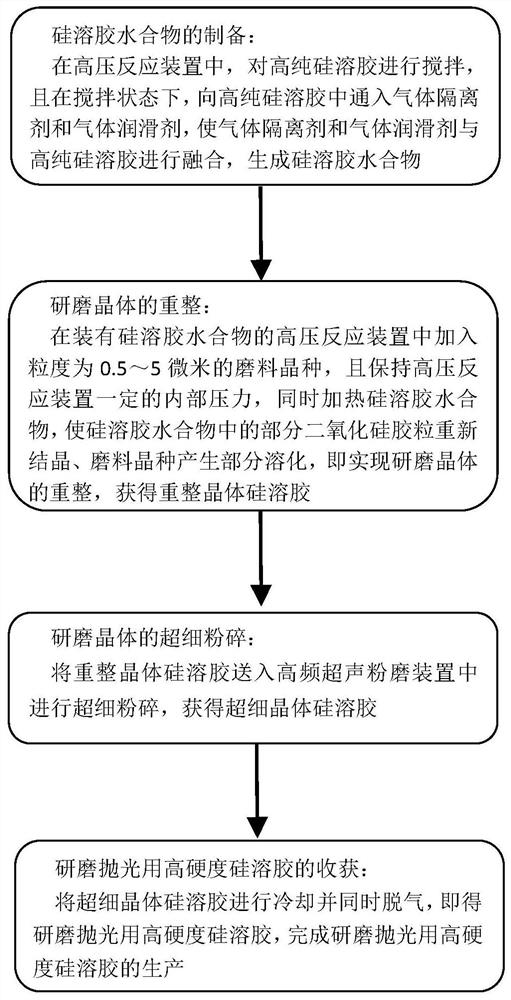

Production method of high-hardness silica sol used for grinding and polishing

InactiveCN111909619AAchieve reorganizationSuit one's needsOther chemical processesPolishing compositions with abrasivesSocial benefitsEconomic benefits

The invention relates to a production method of high-hardness silica sol used for grinding and polishing. The production method comprises the following steps: preparing a silica sol hydrate, reforminggrinding crystals, carrying out superfine grinding on the grinding crystals, and harvesting the high-hardness silica sol used for grinding and polishing. According to the method, a gas separant and agas lubricant are introduced into high-purity silica sol to generate a silica sol hydrate, then abrasive seed crystals with particle sizes of 0.5-5 microns are added, a part of silicon dioxide colloidal particles in the silica sol hydrate are crystallized and recrystallized at a certain pressure and a certain temperature, and the abrasive seed crystals are partially dissolved, so reforming of thethe grinding crystals is realized; and then, superfine grinding and cooling degassing are conducted, and finally, the high-hardness silica sol for grinding and polishing is obtained. The method is unique and stable in process and high in operability; the produced high-hardness silica sol can meet various requirements; no pollution is caused to the environment in the production process, and energyconservation and environmental protection are achieved; and good economic benefits can be obtained for enterprises while positive social benefits are provided.

Owner:马惠琪

Method and system for realizing high-order and low-order hybrid crossing of SDH based on FPGA

InactiveCN107800503APrecise positioningAlign inputTime-division multiplexCrossbar switchData selection

The invention discloses a method and system for realizing SDH high-low order mixed crossover based on FPGA. The access data first finds the frame header of SDH through the frame header recovery module and restores the frame structure; the data finds the high and low order pointers of SDH through the high and low order pointer adjustment module and restores the high and low order time slots; the data is copied twice respectively Processing is carried out through high and low order processing branches; the control module generates cross instructions, controls the high and low order cross modules to perform cross exchange of corresponding data, controls the high and low order selection modules to select and switch data, and realizes the convergence and reorganization of high and low order data. The present invention realizes simultaneous access and processing of high and low order mixed data and arbitrary cross exchange, and the final output data is arbitrary high and low order mixed data, which solves the problem that high and low order data in traditional cross can only be processed separately, making access, Interleaving is more flexible, and the implementation cost is saved by combining the high and low order processing methods compared with separate processing methods.

Owner:TOEC TECH

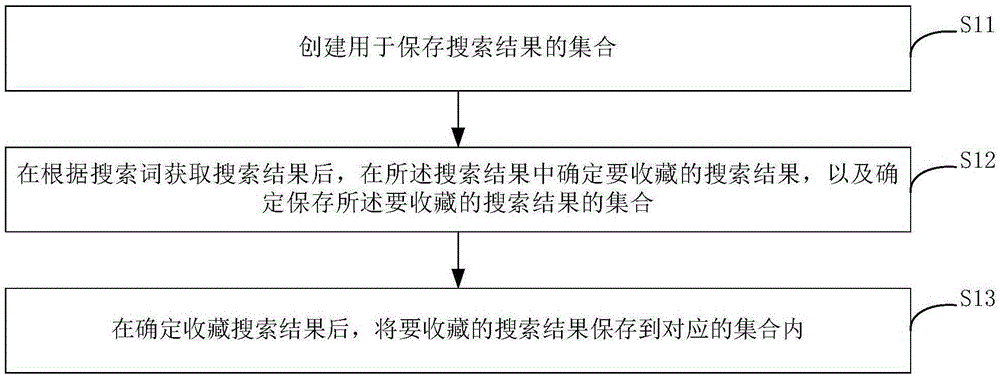

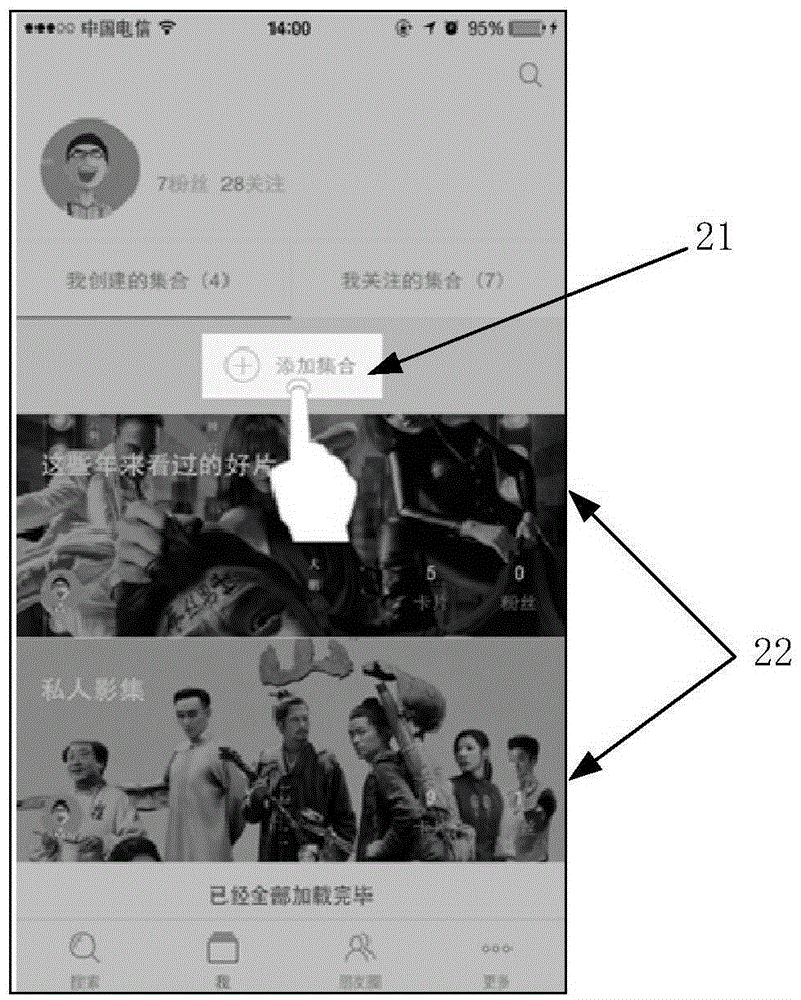

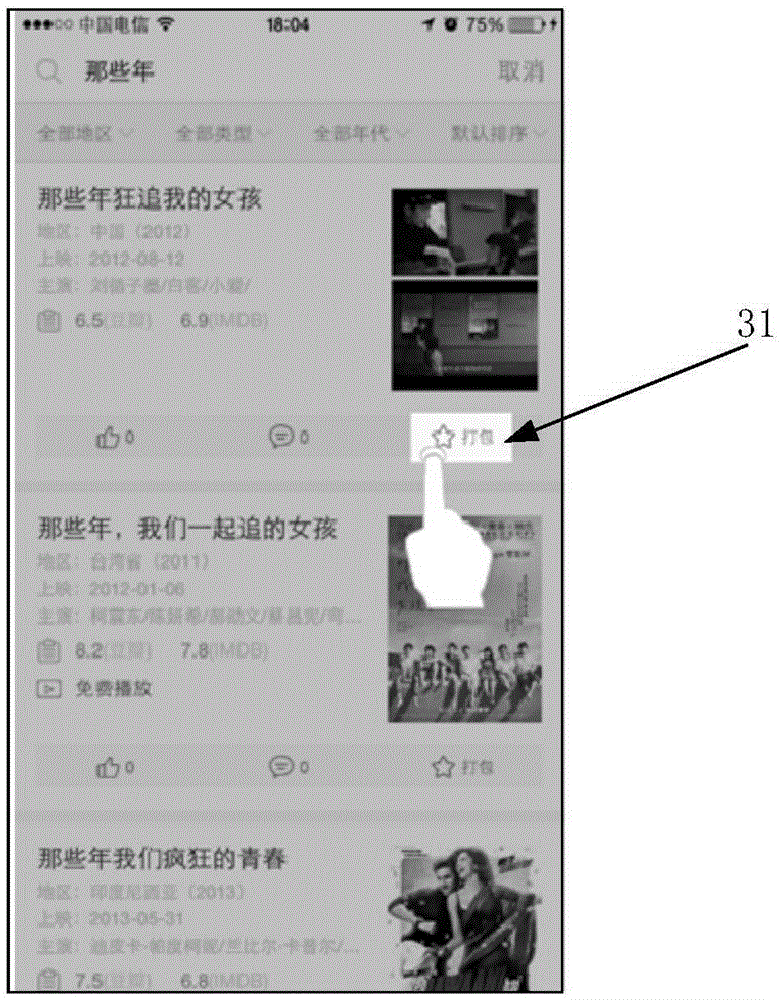

Searching result processing method and searching result processing system

InactiveCN105260382AAchieve reorganizationIncrease valueSpecial data processing applicationsWeb data retrieval using information identifiersSearch wordsData mining

The invention provides a searching result processing method and a searching result processing system. The searching result processing method comprises the following steps of creating a set used for storing searching results; after the searching results are obtained according to searching words, determining the searching results to be collected in the searching results, and determining and storing the set of the searching results to be collected; and after the collected searching results are determined, storing the searching results to be collected into the corresponding sets. The method has the advantage that the searching results can generate a great value.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

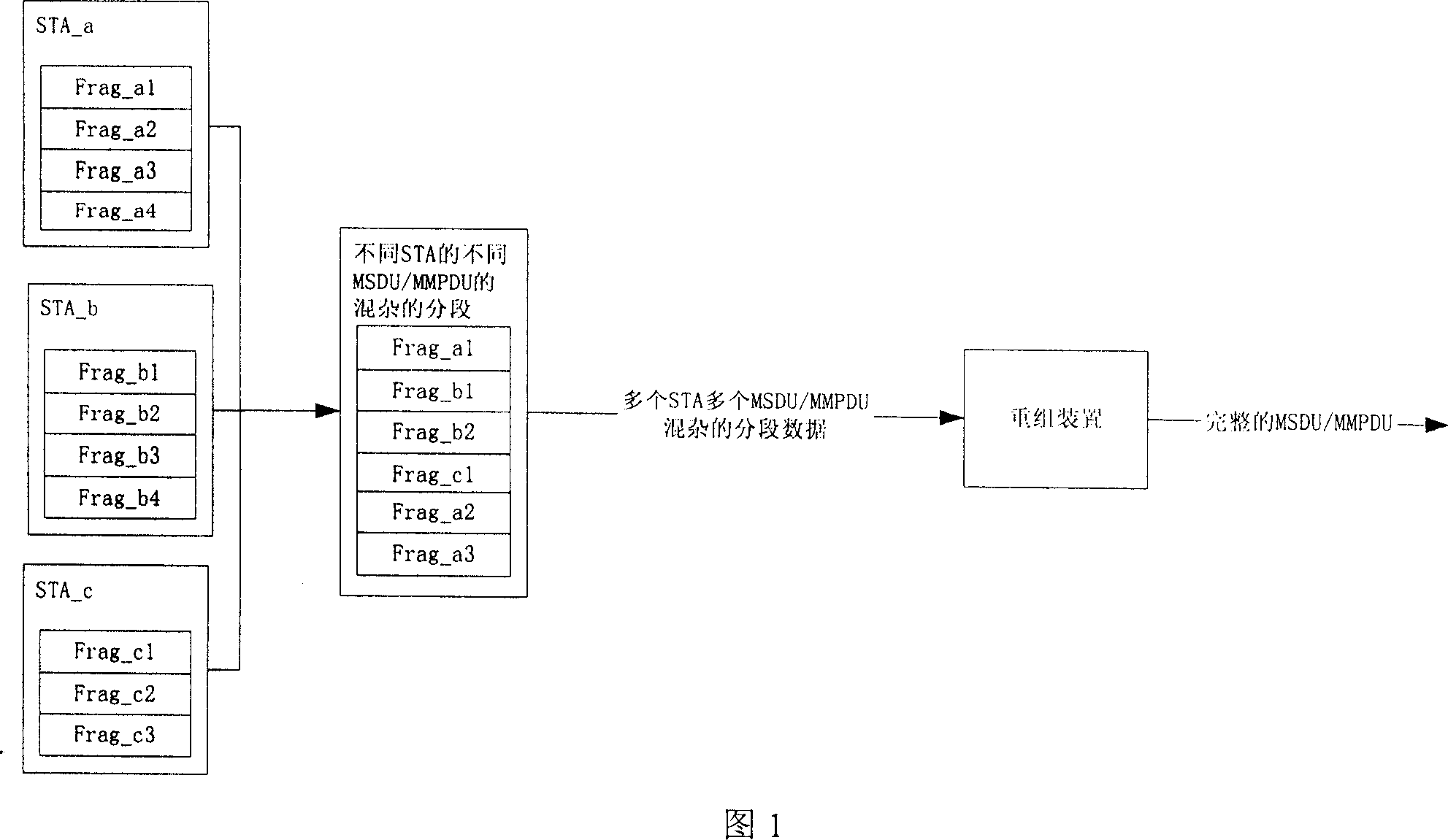

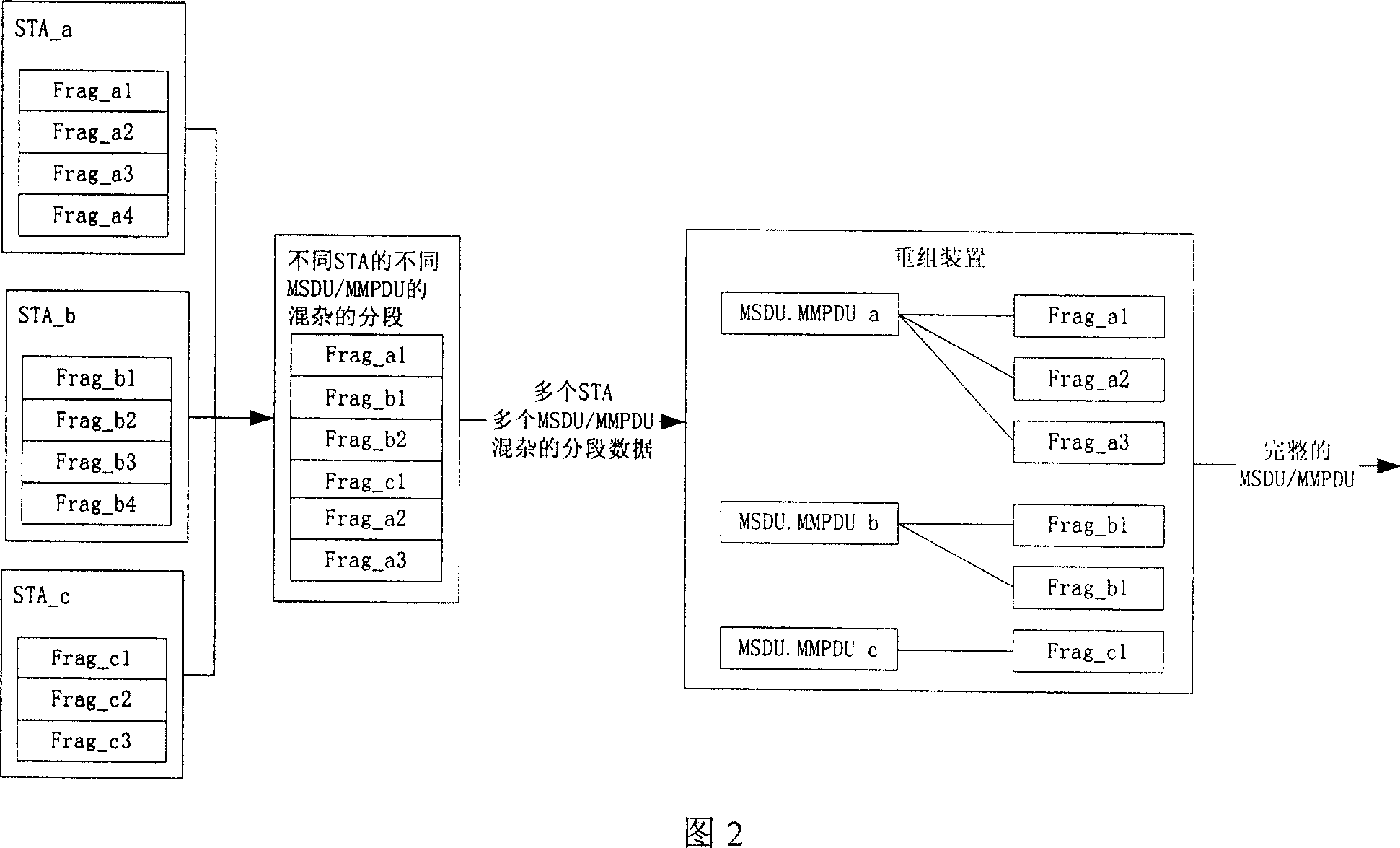

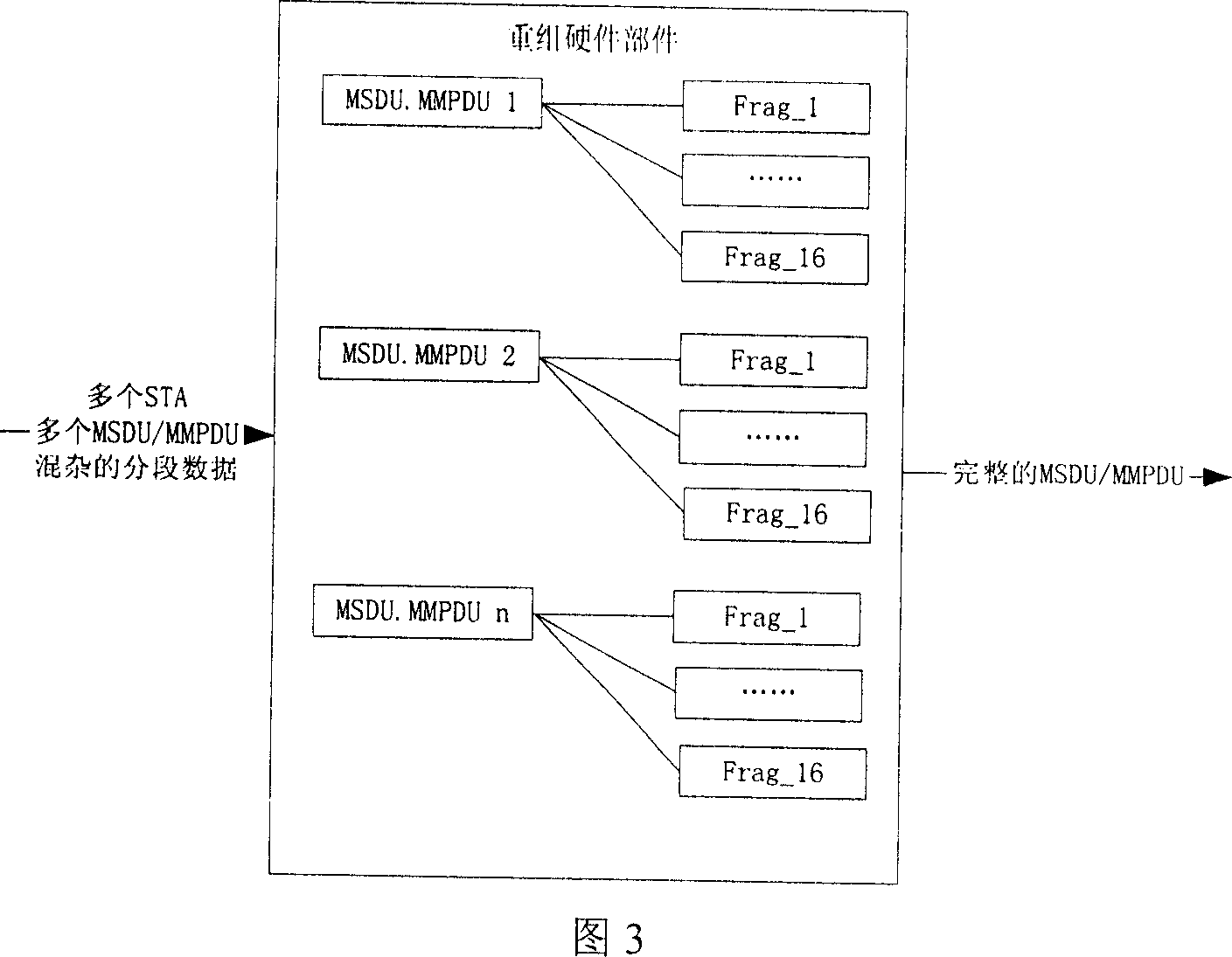

Method and device for solving recombination problem in WLAN

InactiveCN1929437ASmall footprintLow costData switching by path configurationIndex registerData management

This invention provides one method and device to realize WLAN MSDU / MMDU, which sends other MSDU / MMPDU sections through other STA competition due to send process is intercepted and receives different mixture sections with multiple terminals, wherein, the receive part processes the mixture section to output integral MSDU / MMPDU. The reset function device, which comprises one receive buffer RxBuff, one RxBuff occupation status register, one RxBuff slice data management register and one RxBuff slice index register.

Owner:BEIJING CEC HUADA ELECTRONIC DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com