Patents

Literature

99results about How to "Reduce earth pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167AHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsEngineering

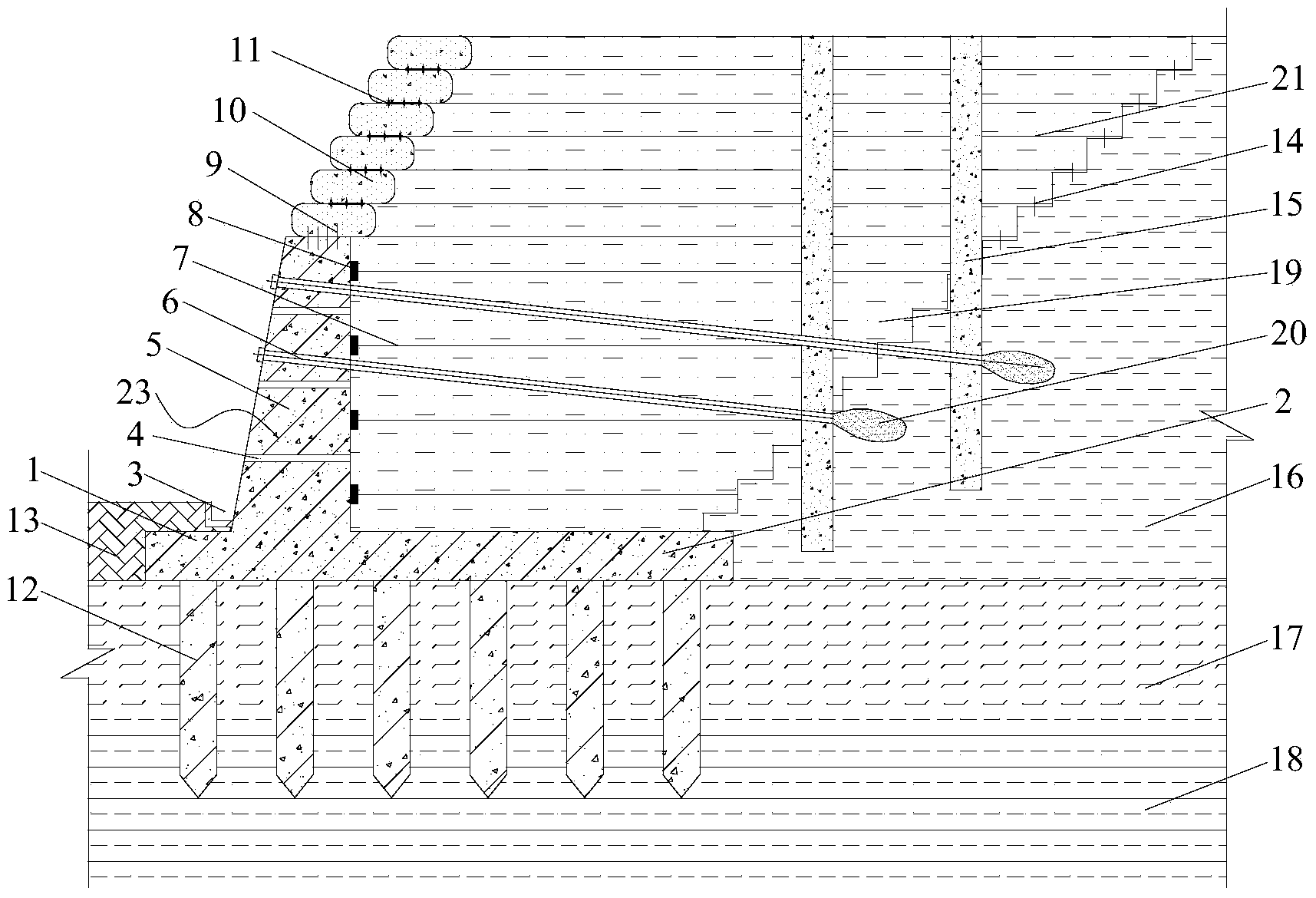

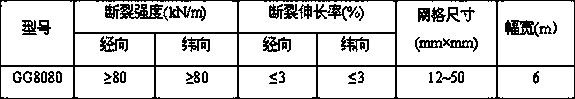

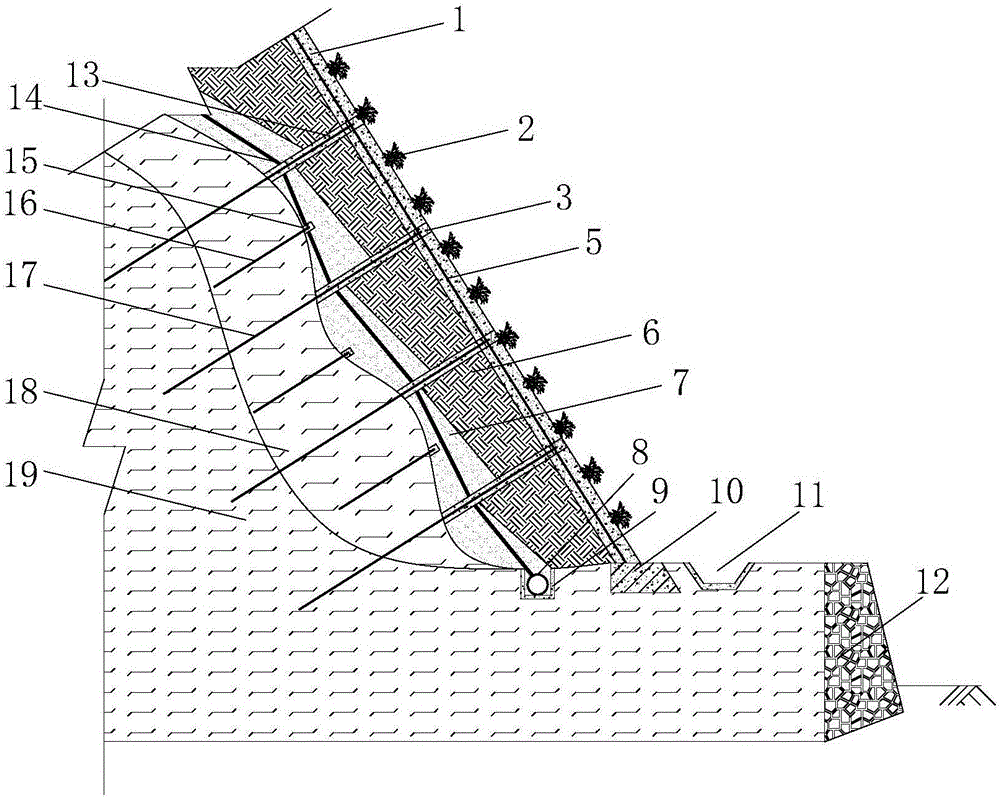

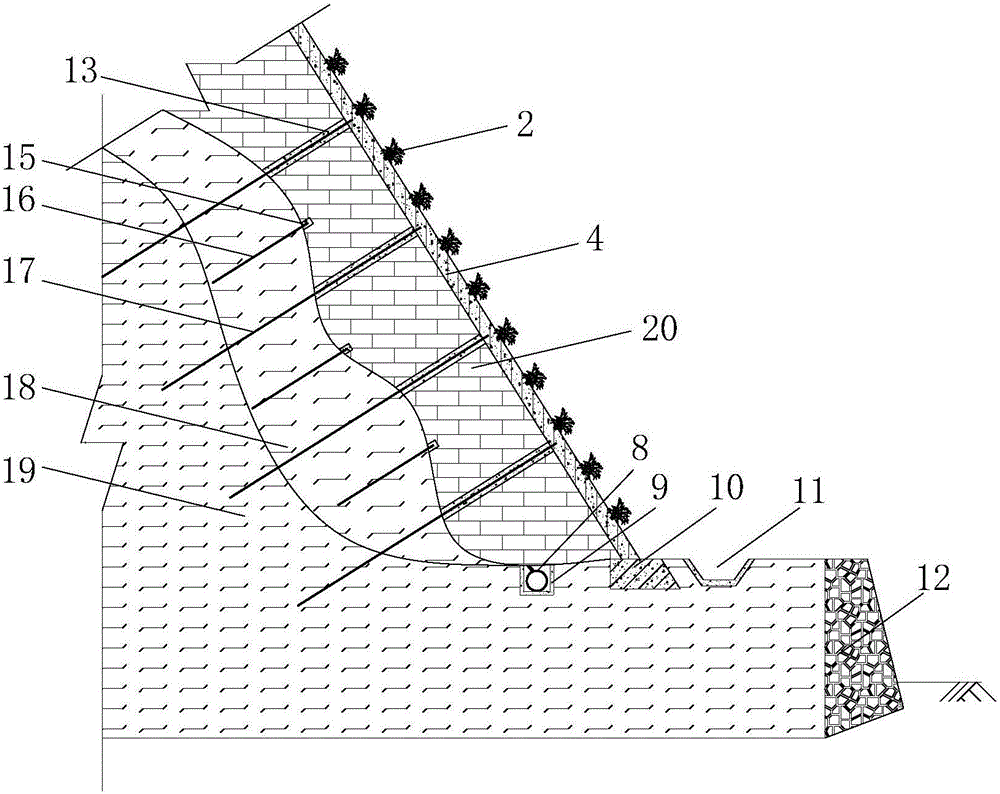

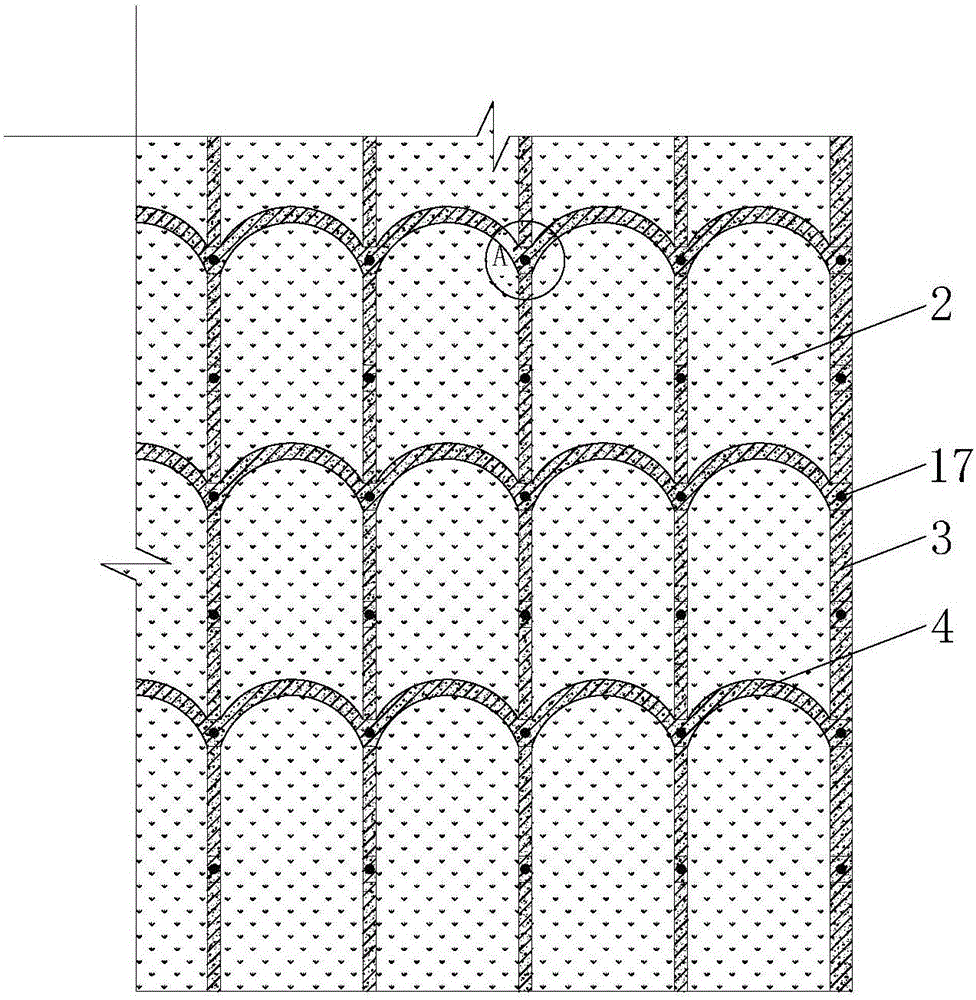

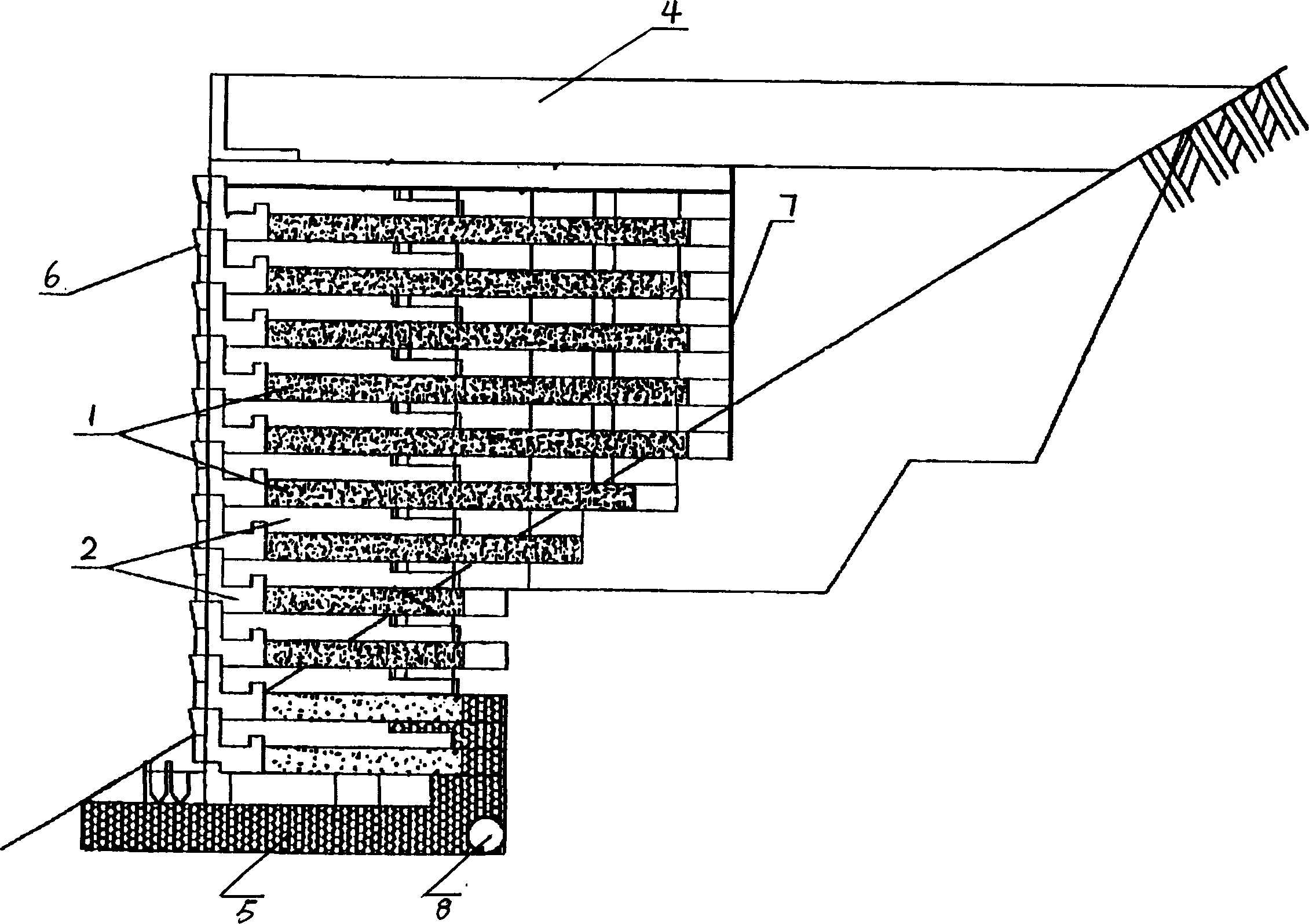

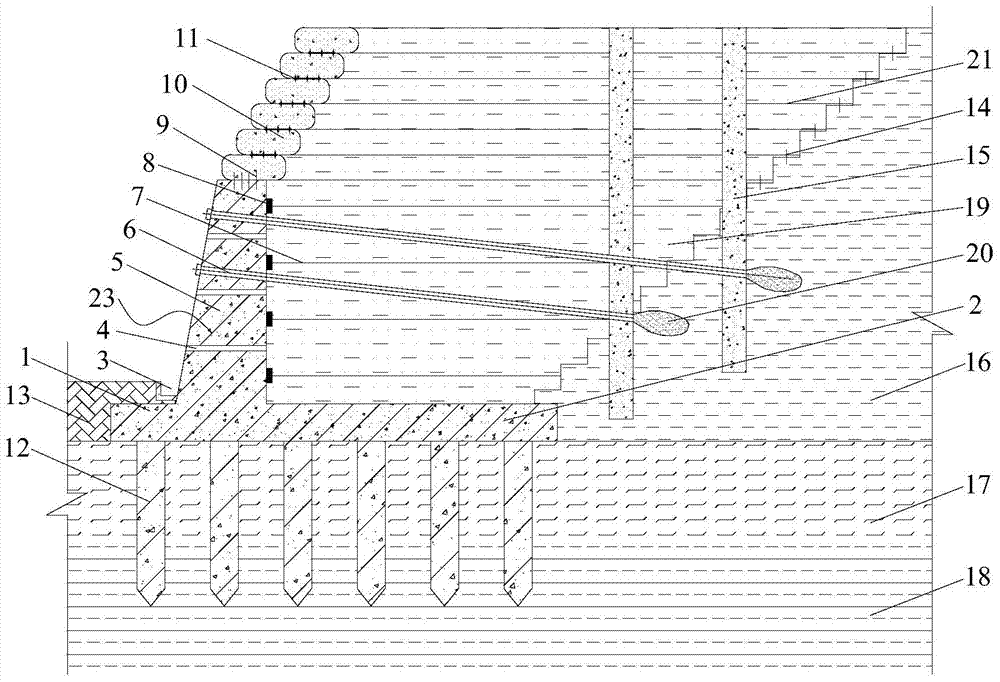

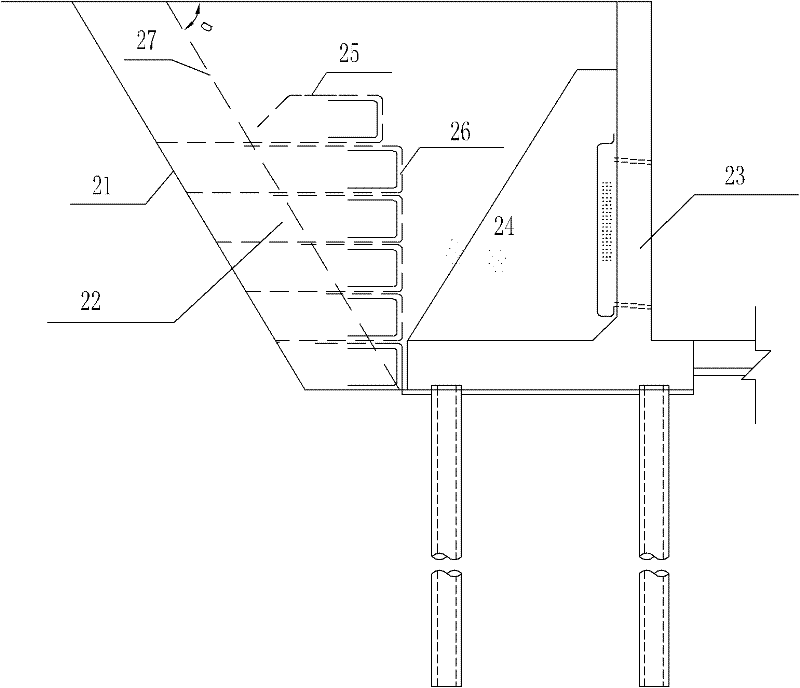

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

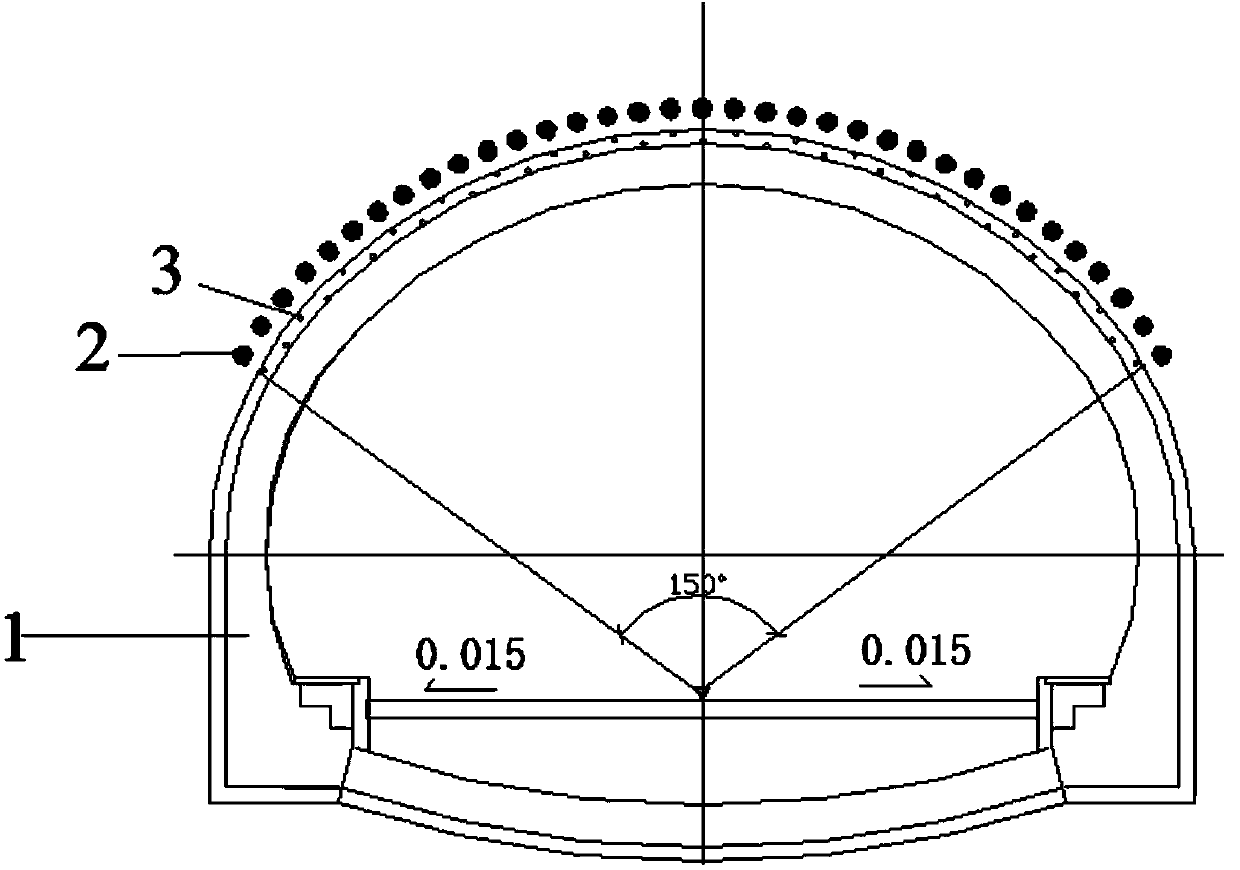

Supporting method for soft broken nonuniform stratum tunnel construction

InactiveCN103993892AImprove self-stabilityReduce construction difficultyUnderground chambersMine roof capsEngineeringSelf-stabilization

The invention discloses a supporting method for soft broken nonuniform stratum tunnel construction. The supporting method includes the steps that firstly, an arch support is erected in a bottom layer tunnel through steel pipes, and the portion, on the top of the arch support, of the bottom layer tunnel is drilled; secondly, a small pipe roof is constructed on the drilled portion of the arch crown of the arch support; thirdly, during construction of the small pipe roof for supporting, advanced reinforcement treatment is conducted on a top arch of the tunnel through advanced small pipes in a floor staggered mode; fourthly, the tunnel is excavated; fifthly, after the tunnel is excavated, preliminary supporting construction is conducted in time each cycle; sixthly, after excavation and supporting of a tunnel trunk of the tunnel, an inverted arch is constructed and sealed into a loop; and then secondary lining following operation is conducted. The method has the advantages that deformation of tunnel surrounding rocks can be effectively reduced, self-stabilization and seepage prevention capacity of the tunnel is permanently improved, a multifunctional surrounding rock reinforcement region is formed, and safety of tunnel constructors and equipment is guaranteed.

Owner:SHANDONG UNIV

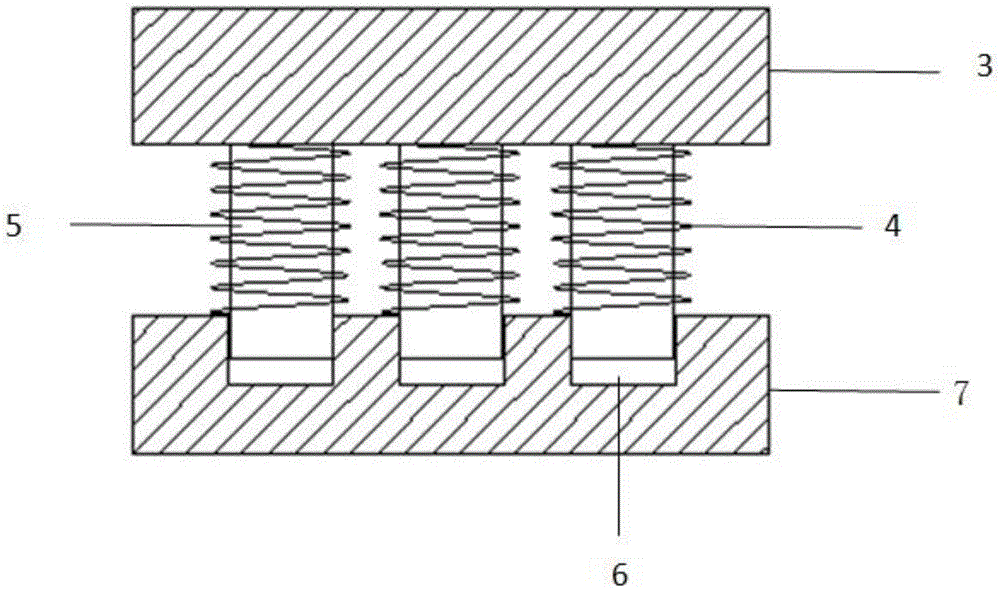

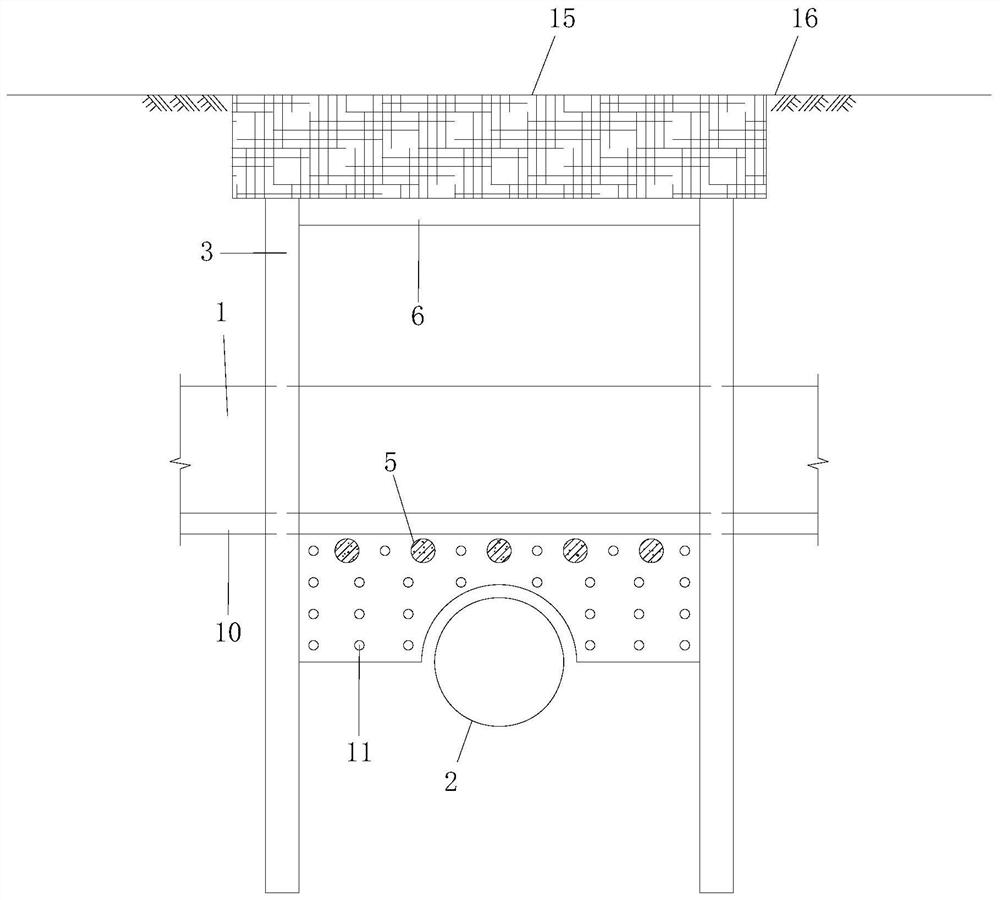

Load-shedding type rigid culvert structure

InactiveCN103952986AReduce the maximum bending momentRelieve pressureGround-workLoad SheddingStress distribution

The invention relates to the technical field of geotechnical engineering and road engineering, and particularly discloses a load-shedding type rigid culvert structure, which comprises a foundation, culvert side walls, a culvert top plate, load-shedding blocks and load-shedding holes, wherein the load-shedding blocks are positioned just above the culvert side walls, and form an integral structure together with the culvert side walls, the load-shedding holes are positioned between the two load-shedding blocks just above a culvert, and the interior of each load-shedding hole is filled with light-weight flexible material. The culvert structure has the advantages that after the structure is adopted, the construction and operation are easy and convenient, and the implementation is easy; the pressure of soil at the top of the culvert is obviously reduced, and the problem of cracking of the culvert is effectively solved; one part of load at the top of the culvert is transferred into the surrounding soil through the soil arch effect at the top of the culvert, the other part of load is transferred to the foundation through the culvert side walls, and then the vertical compressive capability of the culvert side walls is fully realized; the maximum bending moment of the culvert side walls is effectively reduced, and the stress distribution of the culvert is more reasonable; the stress asymmetry of the culvert is effectively reduced, and the separation and cracking of the connecting part of the top of the culvert and the side wall are avoided; the load-shedding effect is obviously improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

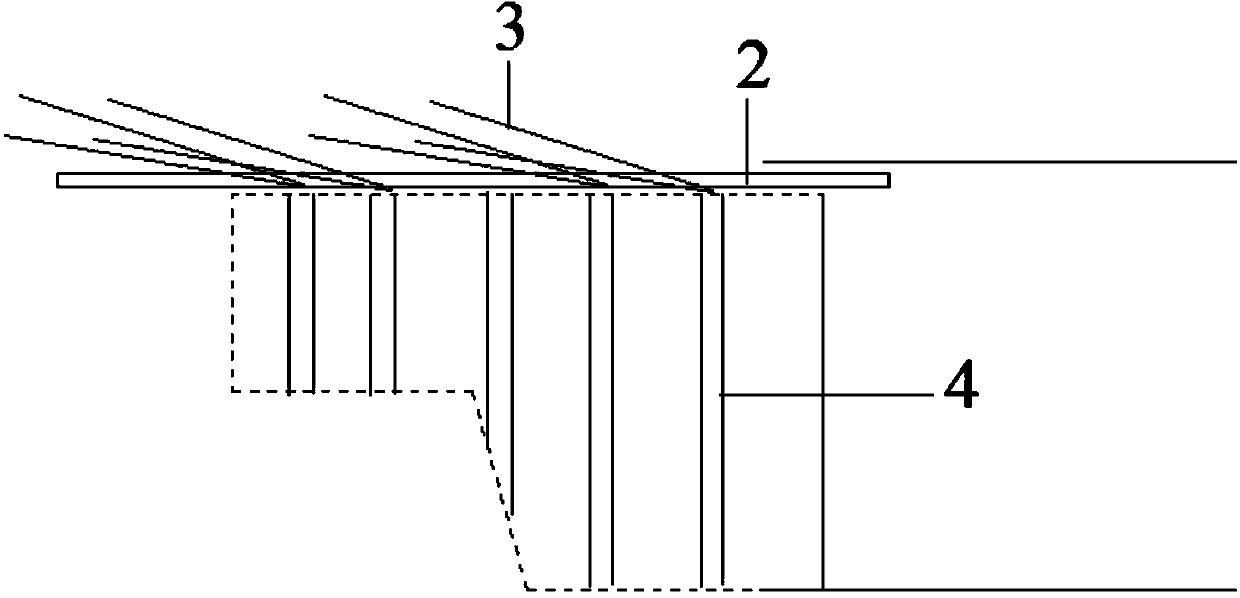

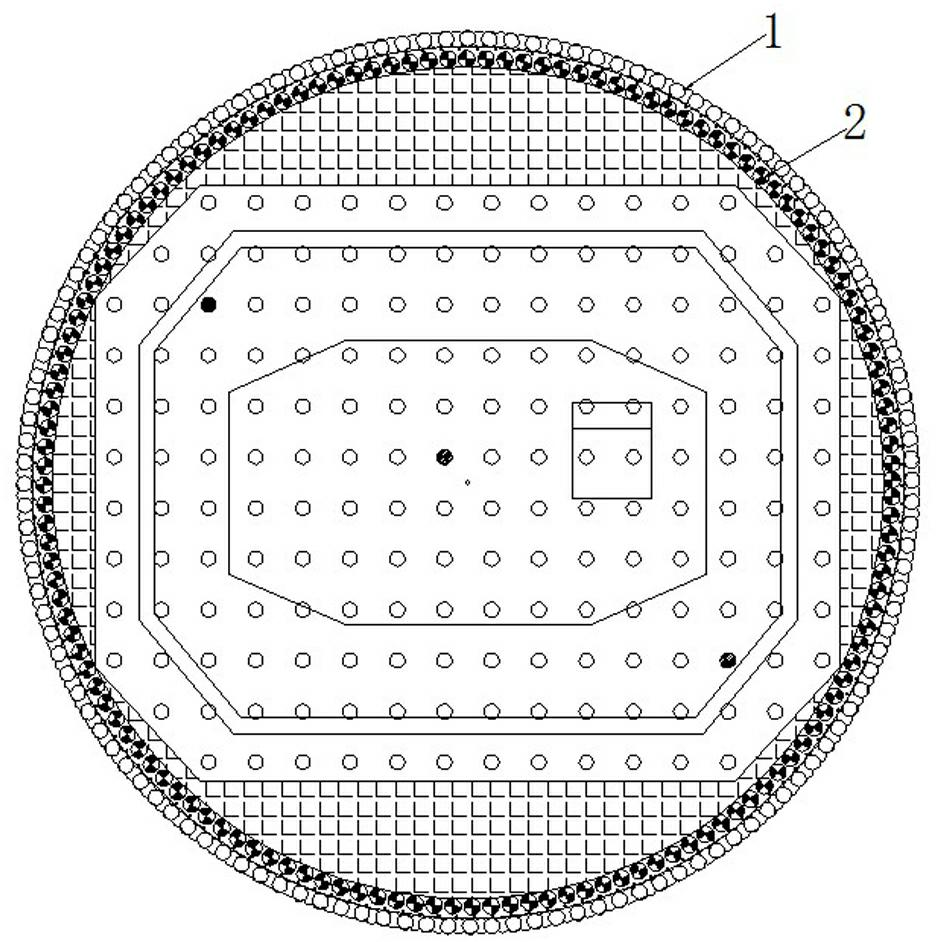

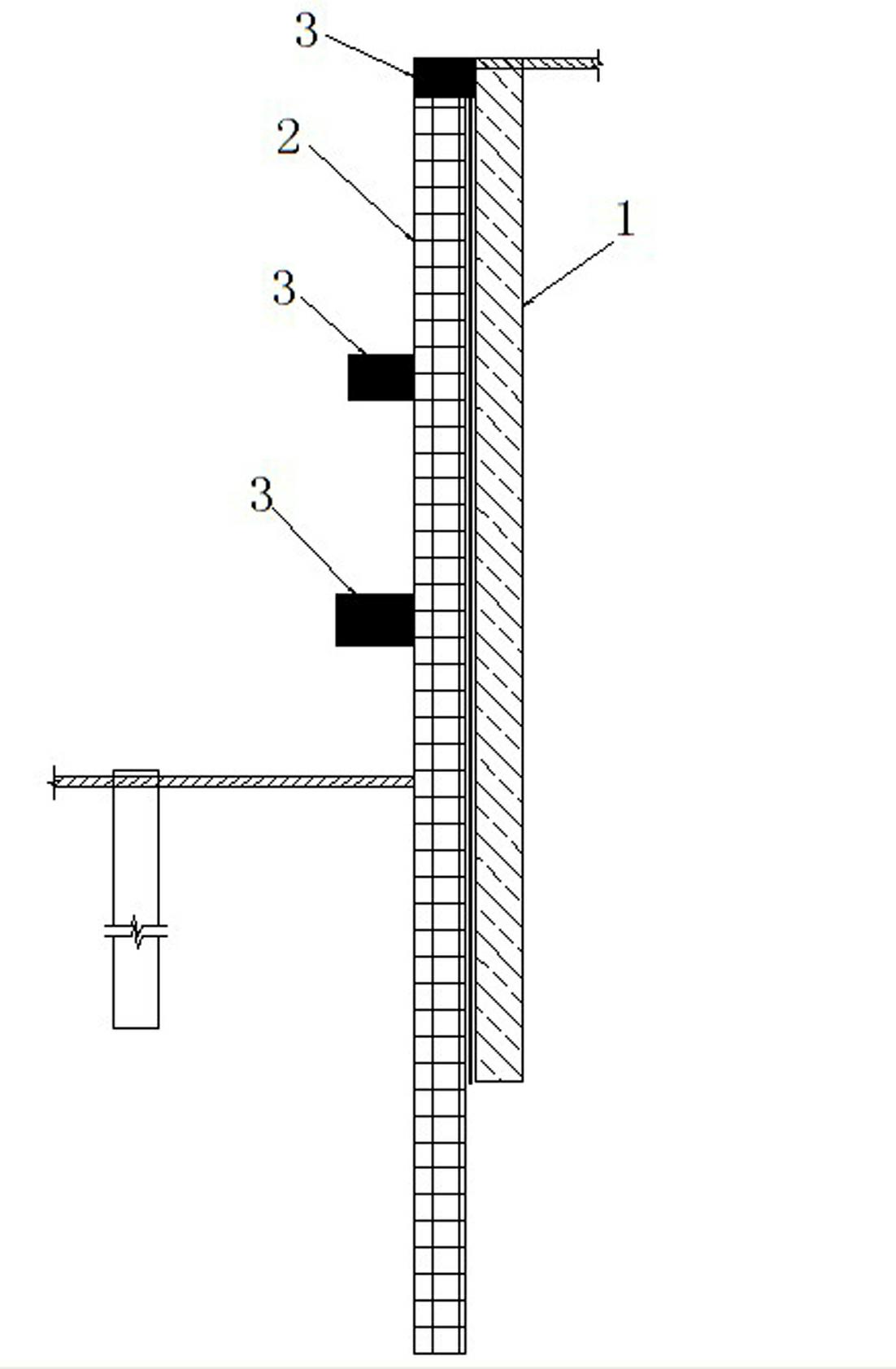

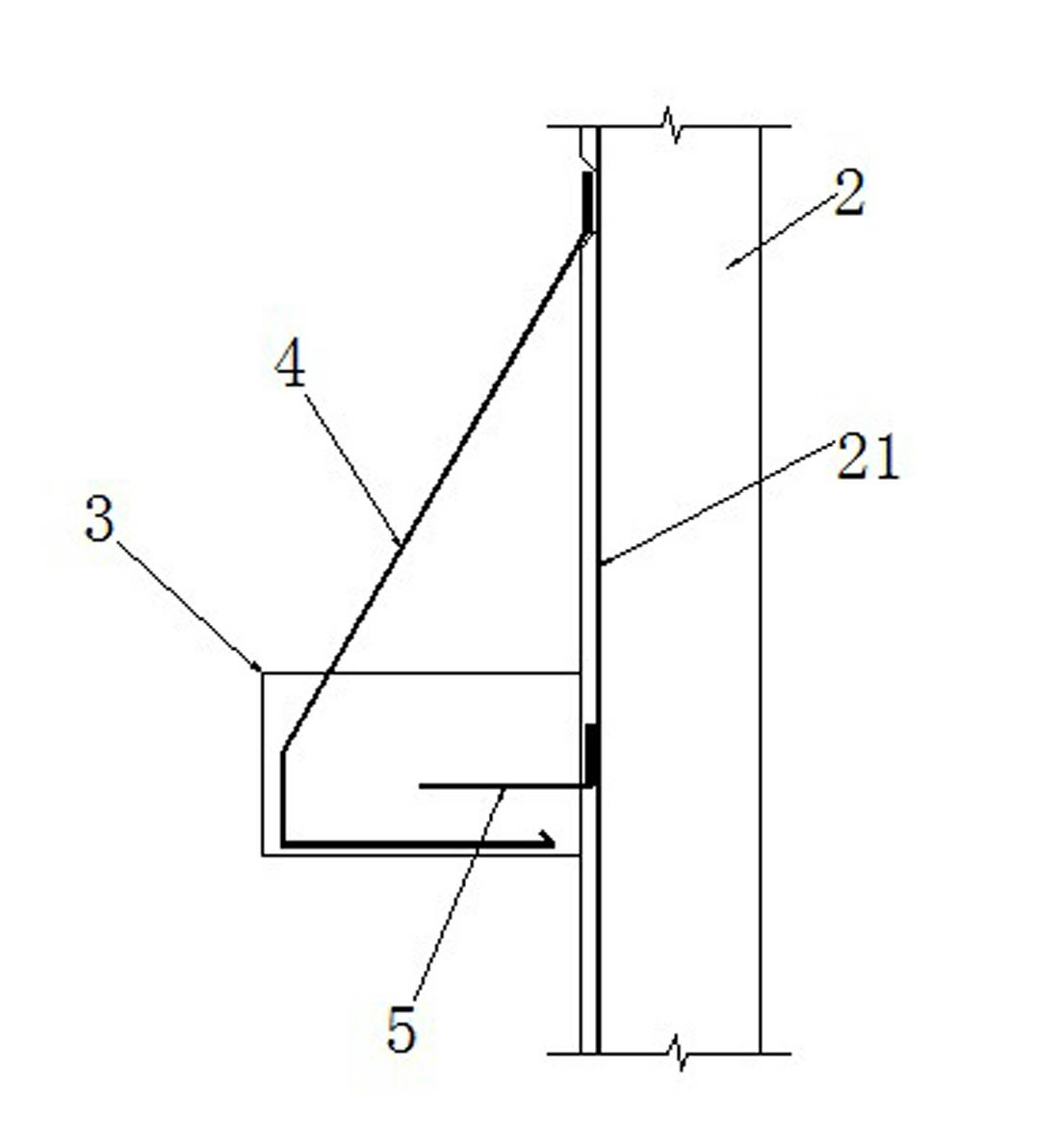

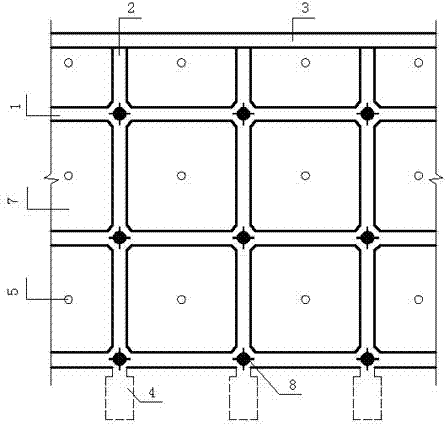

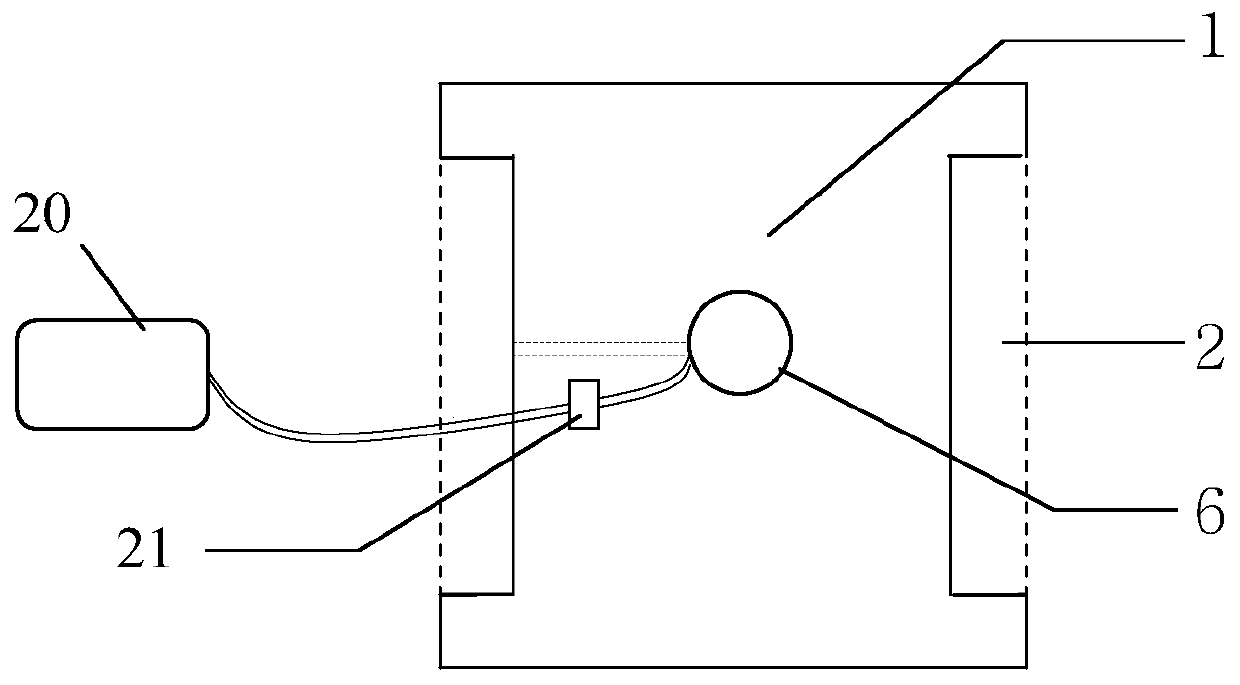

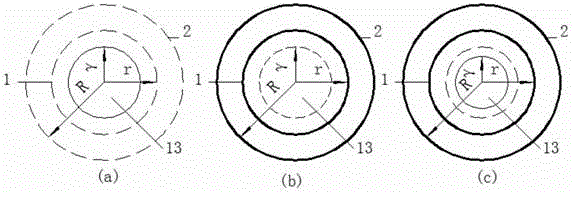

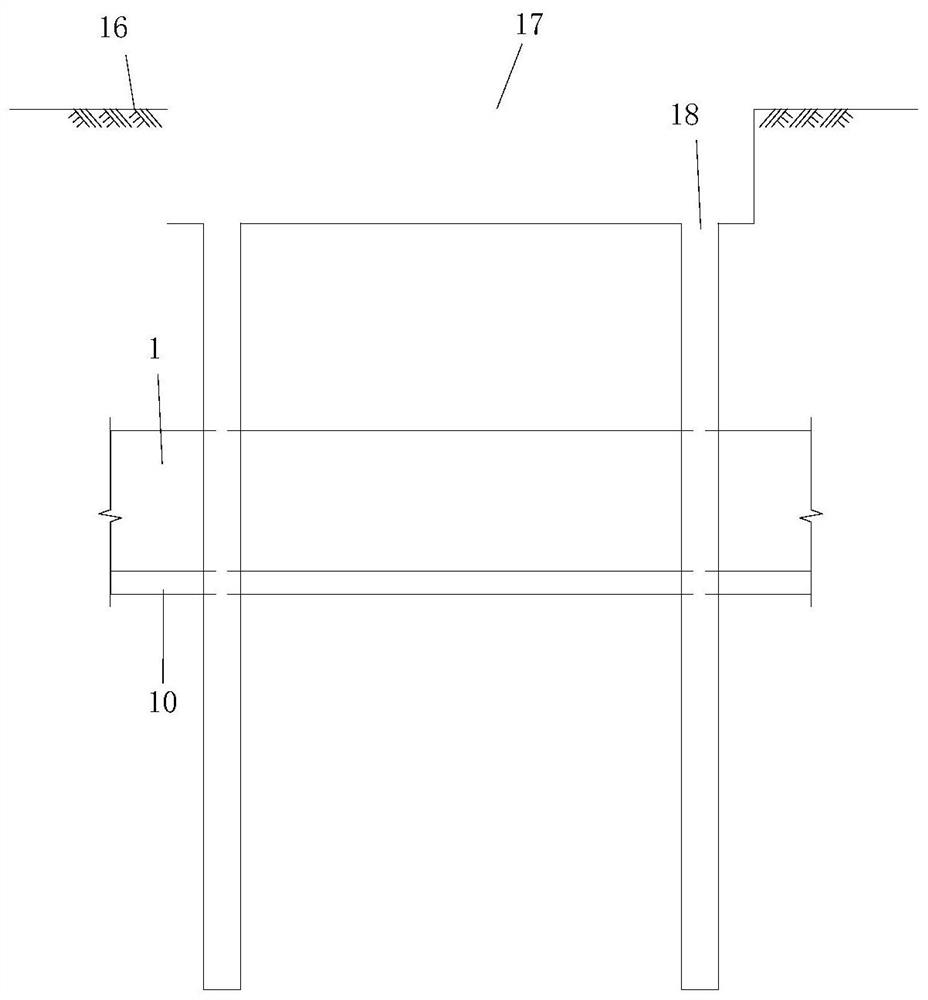

Supportless construction structure and supportless construction method for round deep base pit

InactiveCN102635120AConservation cost reductionFast constructionExcavationsBulkheads/pilesInternal pressurePurlin

The invention discloses a supportless construction structure and a supportless construction method for a round deep base pit. The supportless construction method comprises the steps as follows: carrying out three-shaft stirring pile construction, cast-in-situ bored pile construction, earth mass grouting reinforcement, earth excavation, first enclosing purlin construction, subsequent earth excavation, next enclosing purlin construction, subsequent earth excavation and cushion layer and bottom plate construction so as to obtain a deep base pit bracing structure mainly comprising a circle of three-shaft stirring pile, a circle of cast-in-situ bored pile and a plurality of enclosing purlins. The bracing structure has no supporting structure; the arch effect of the earth mass is utilized; the earth pressure on the bracing structure is reduced; the external load is converted into the internal pressure on the enclosing purlins by the arch effect of the enclosing purlins at the same time; the characteristic of good pressure resistance of concrete is brought into full play; and as no supports are provided, the processes of dismounting and replacing the supports are removed, so that the maintenance expense of the base pit is reduced and the construction speed is quick.

Owner:张全胜

Environmental-friendly grass concrete highway slope protection structure and construction method thereof

ActiveCN106013191AImprove stabilityGood economic and technical benefitsExcavationsBulkheads/pilesSoil nailingDitch

The invention relates to an environmental-friendly grass concrete highway slope protection structure which mainly comprises grass concrete, prefabricated framed girders, anchor rods, soil nails, a mortar flag stone wall, a hillslope drainage system and a gravity retaining wall. The soil nails are arranged in an unstable rock mass of an original highway slope. Concrete piers are arranged at anchor heads. The mortar flag stone wall is additionally arranged on an original hillslope. The interior of the mortar flag stone wall is sequentially filled with a gravel bed, a clay bed and the grass concrete from bottom to top. The prefabricated framed girders are mounted at the top of the mortar flag stone wall. The anchor rods are arranged at the intersections of the prefabricated framed girders. Concrete inclusions are arranged at the peripheries of the anchor rods. The hillslope drainage system is arranged in the gravel bed. A drainage channel is arranged at a slope bottom. The gravity retaining wall is arranged on the outer side of a highway subgrade side ditch at a slope foot. The environmental-friendly grass concrete highway slope protection structure is high in integrality and stability, and combines safety embankment with environment protection really, and the traffic environment is effectively improved. The invention further provides a construction method of the environmental-friendly grass concrete highway slope protection structure.

Owner:ANHUI ROAD & BRIDGE GRP

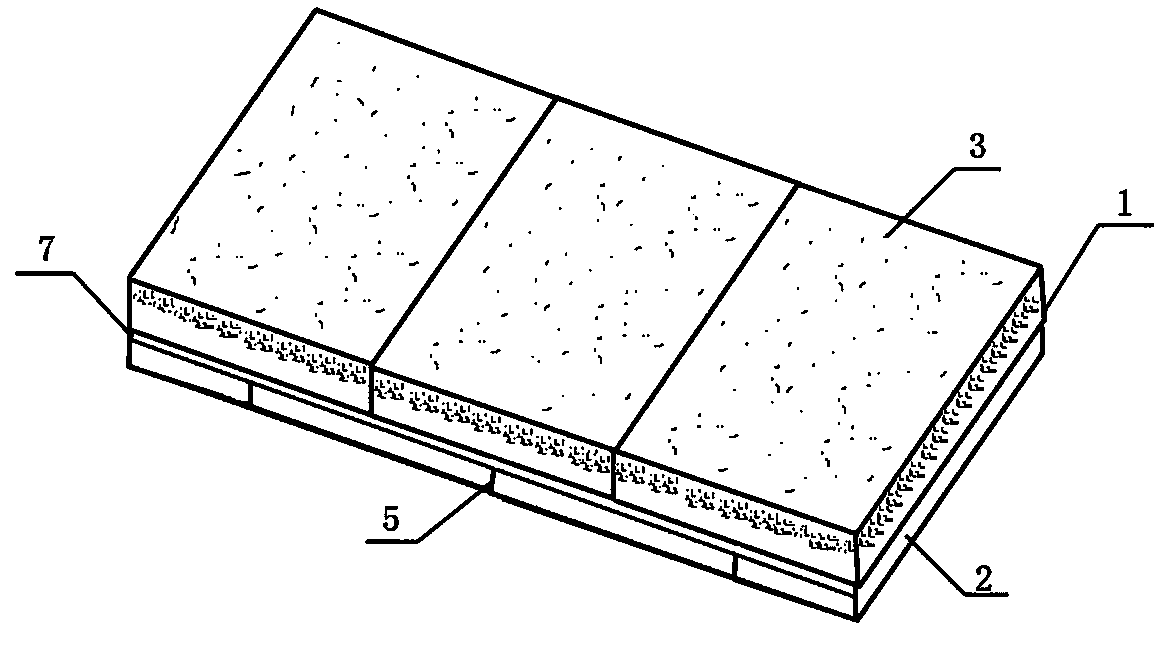

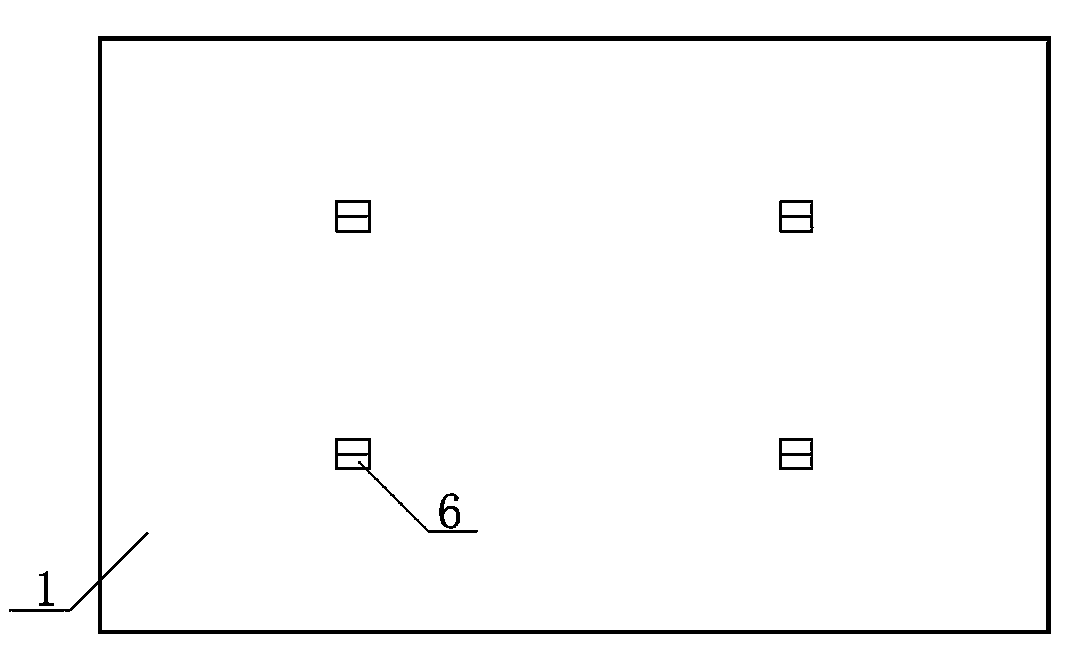

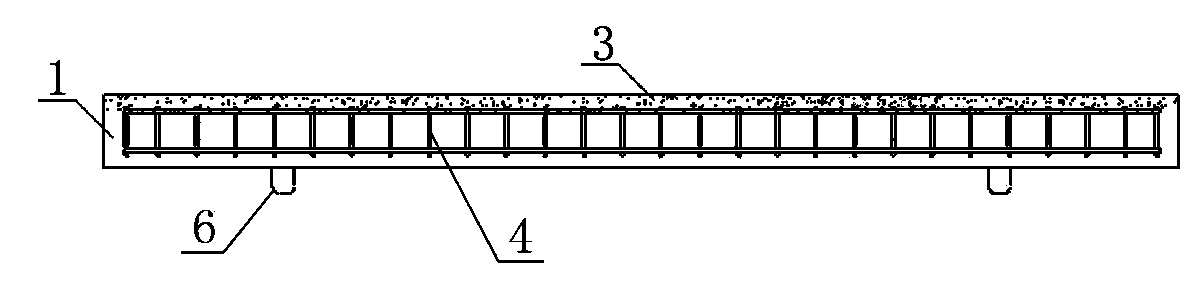

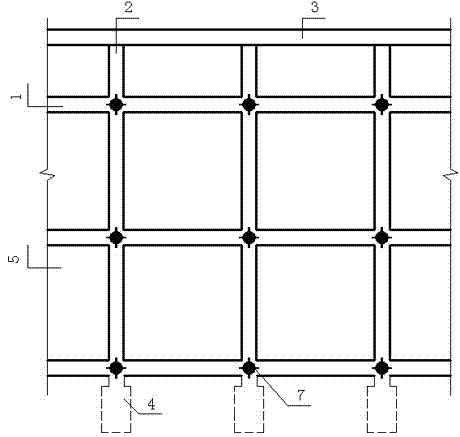

Novel fabricated vehicle bearing pavement and construction method thereof

InactiveCN103866670AImprove structural strengthEasy to transportSingle unit pavingsTemporary pavingsFiberWear resistant

The invention discloses a novel fabricated vehicle bearing pavement and a construction method thereof. The novel fabricated vehicle bearing pavement is formed by superposing, assembling and laying fabricated reinforced concrete plate members in double layers, wherein double-layer bidirectional steel reinforcement frameworks are uniformly distributed inside upper pavement slabs and lower pavement slabs; lifting rings are embedded on lower parts of the frameworks in advance; rubber films are laid between the upper pavement slabs and the lower pavement slabs; a wear-resistant steel fiber concrete layer is arranged on the upper parts of the upper pavement slabs. The construction method comprises the following steps: 1. fabricating reinforced concrete pavement members; 2. lifting and transporting the prefabricated pavement members; 3. flattening the roadbed, laying the lower pavement slabs, rubber films and upper pavement slabs sequentially, laying the pavement slabs in a manner of staggering from each other according to seams, namely the seams between the slabs are not communicated with one another. The construction quality is easily guaranteed, the prefabricated pavement member is light in structure, high in strength, and convenient to transport and construct, can be repeatedly used and is particularly suitable for laying temporary vehicle bearing roads on the construction site, the rubber films can achieve a buffer effect, the friction force between the pavement slabs can be increased, and the pavement slabs are prevented from slipping.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

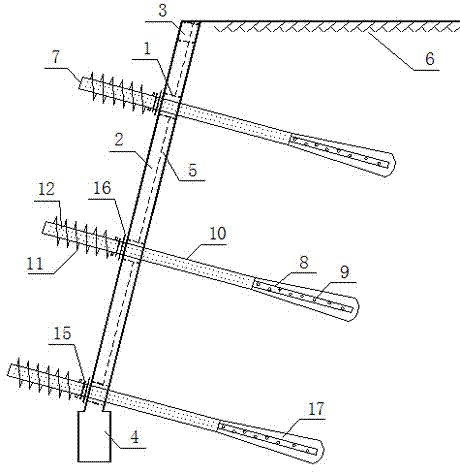

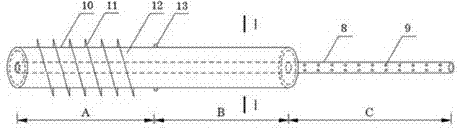

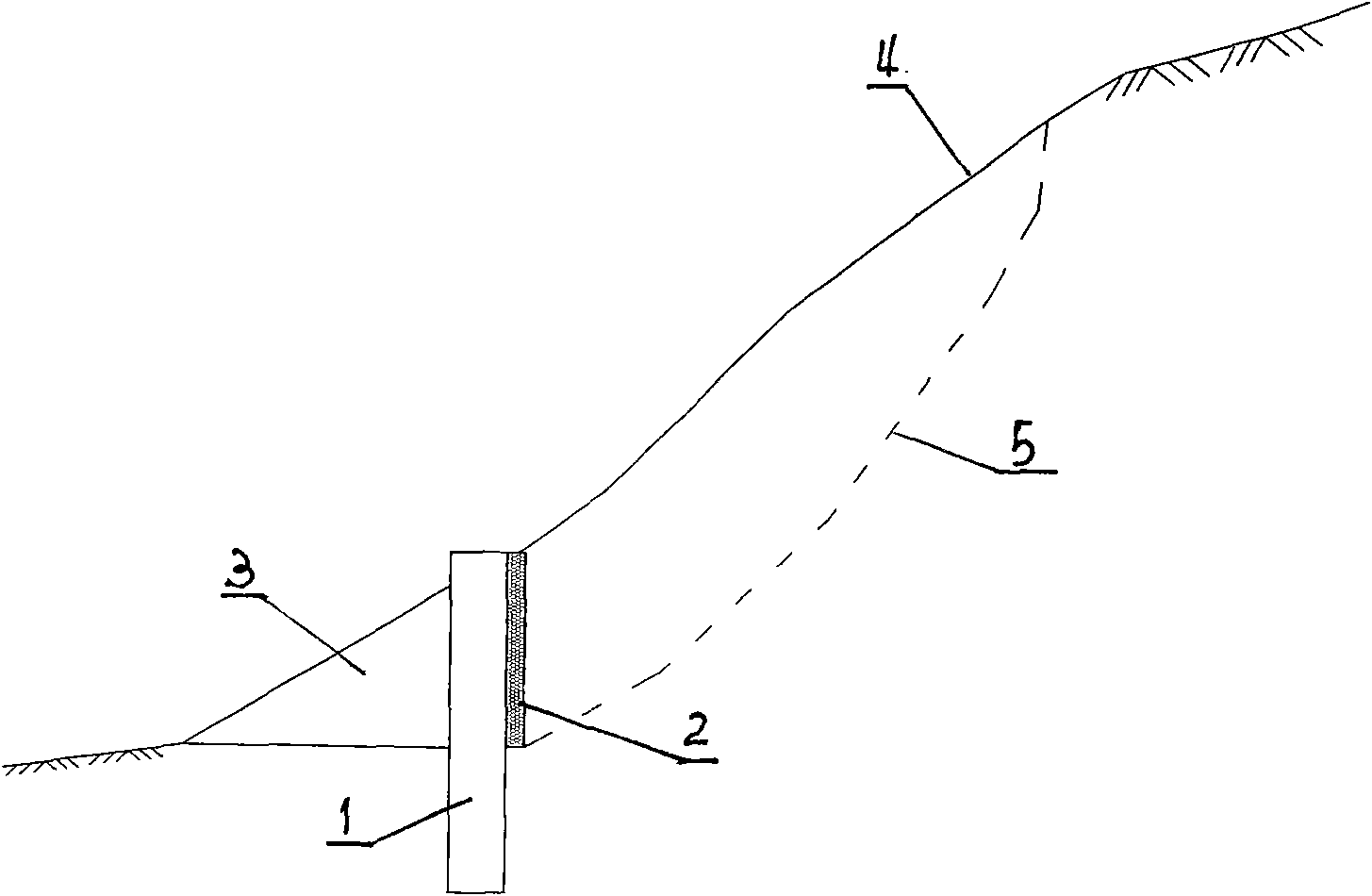

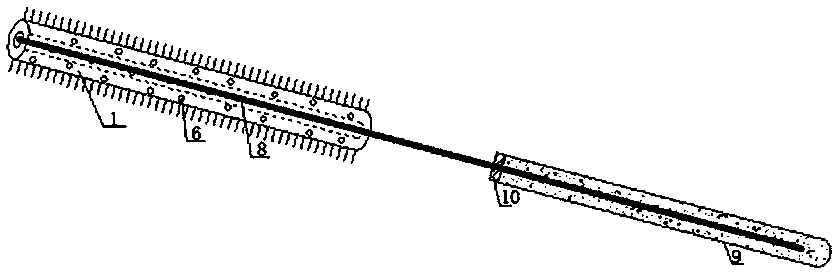

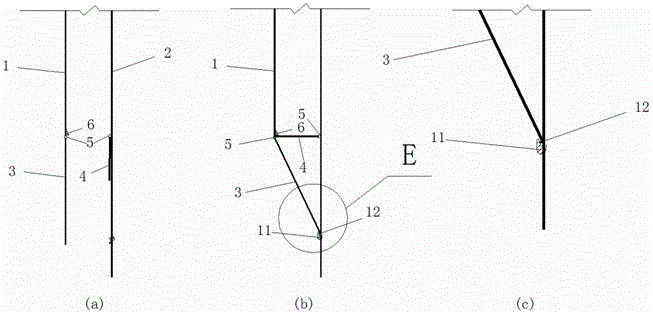

Frame-heat anchor pipe structure for preventing and treating cold-region slope collapse due to freeze thawing and construction method

InactiveCN103485355AImprove stabilityReduce thicknessExcavationsSoil preservationFreeze thawingThermodynamics

The invention discloses a frame-heat anchor pipe structure for preventing and treating cold-region slope collapse due to freeze thawing and a construction method. The structure is composed of a cross beam (1), an upright (2), a protective cover (5) and a heat anchor pipe (7), wherein the heat anchor pipe (7) is composed of a condensation section (A), an evaporation section (B) and an anchoring section (C). When the frame-heat anchor pipe structure for preventing and treating cold-region slope collapse due to freeze thawing is used, the evaporation section of the heat anchor pipe absorbs the heat of a freeze thawing layer in the slope under the action of temperature difference and transfers the heat to the condensation section, and then the heat is dispersed to atmosphere so that the temperature of the soil body of the slope is reduced; as a result, soil pressure transferred to the frame by freeze thawing collapse is reduced; the heat anchor pipe is anchored in well frozen stable stratum by the anchoring section. The frame is connected with the heat anchor pipe to form a space structure, and the frame and the heat anchor pipe work synergetically to improve the overall stability of the frozen soil slope, and therefore, the frame-heat anchor pipe structure is applicable to prevention and treatment of freeze thawing collapse of slopes in a cold region; moreover, the frame-heat anchor pipe structure is convenient to construct, short in construction period, and low in construction cost.

Owner:甘肃中盛矿业有限责任公司

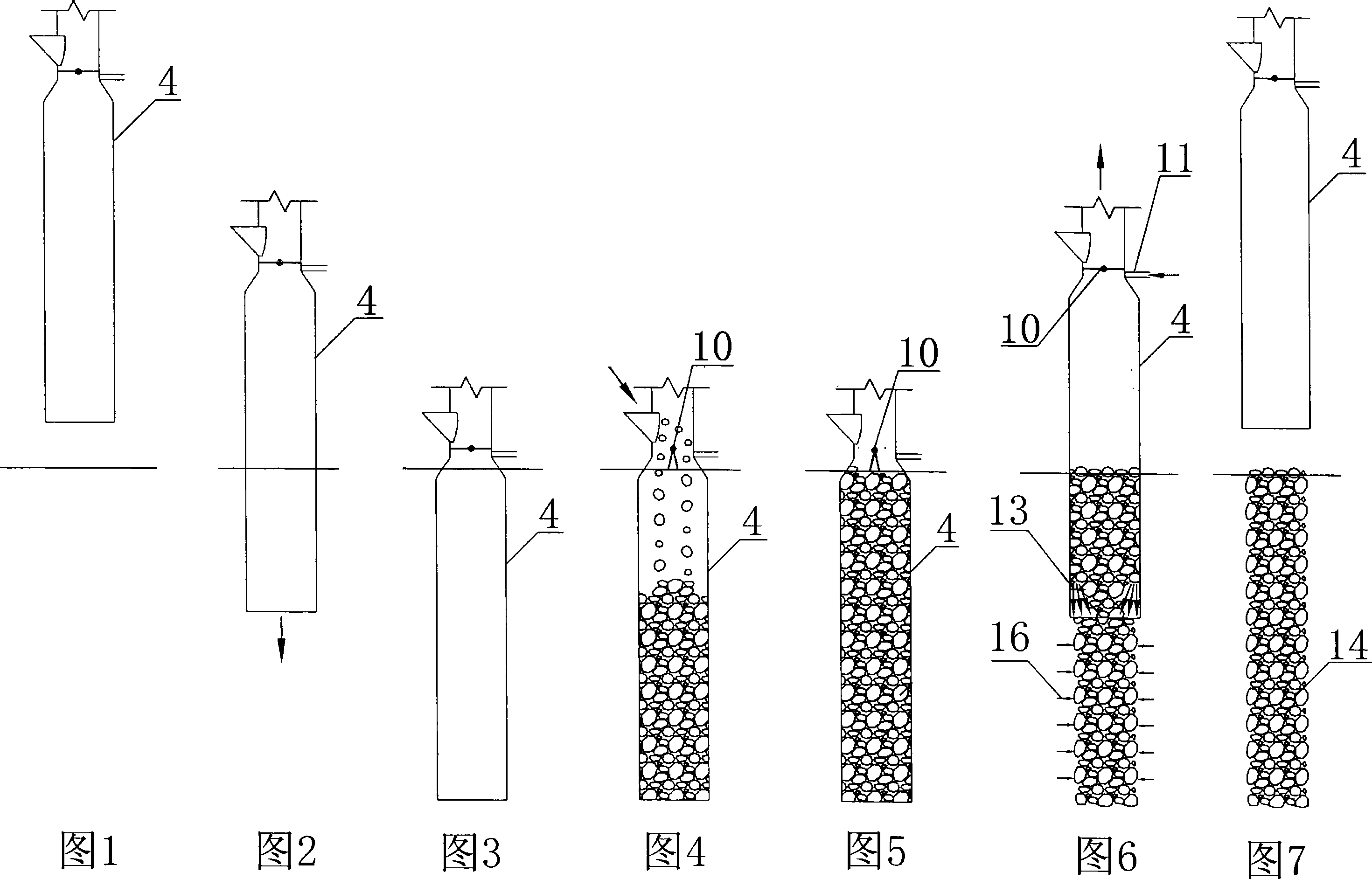

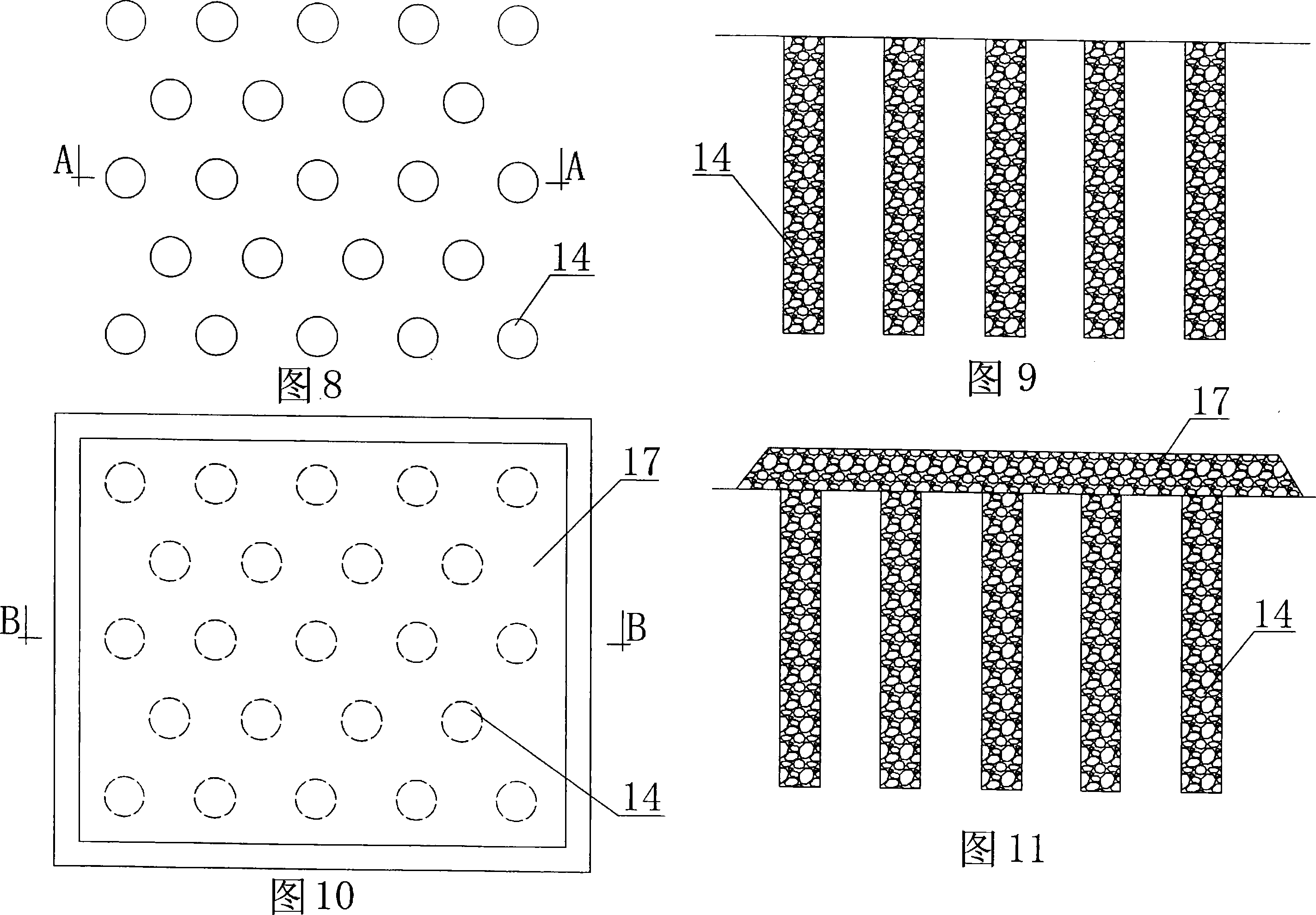

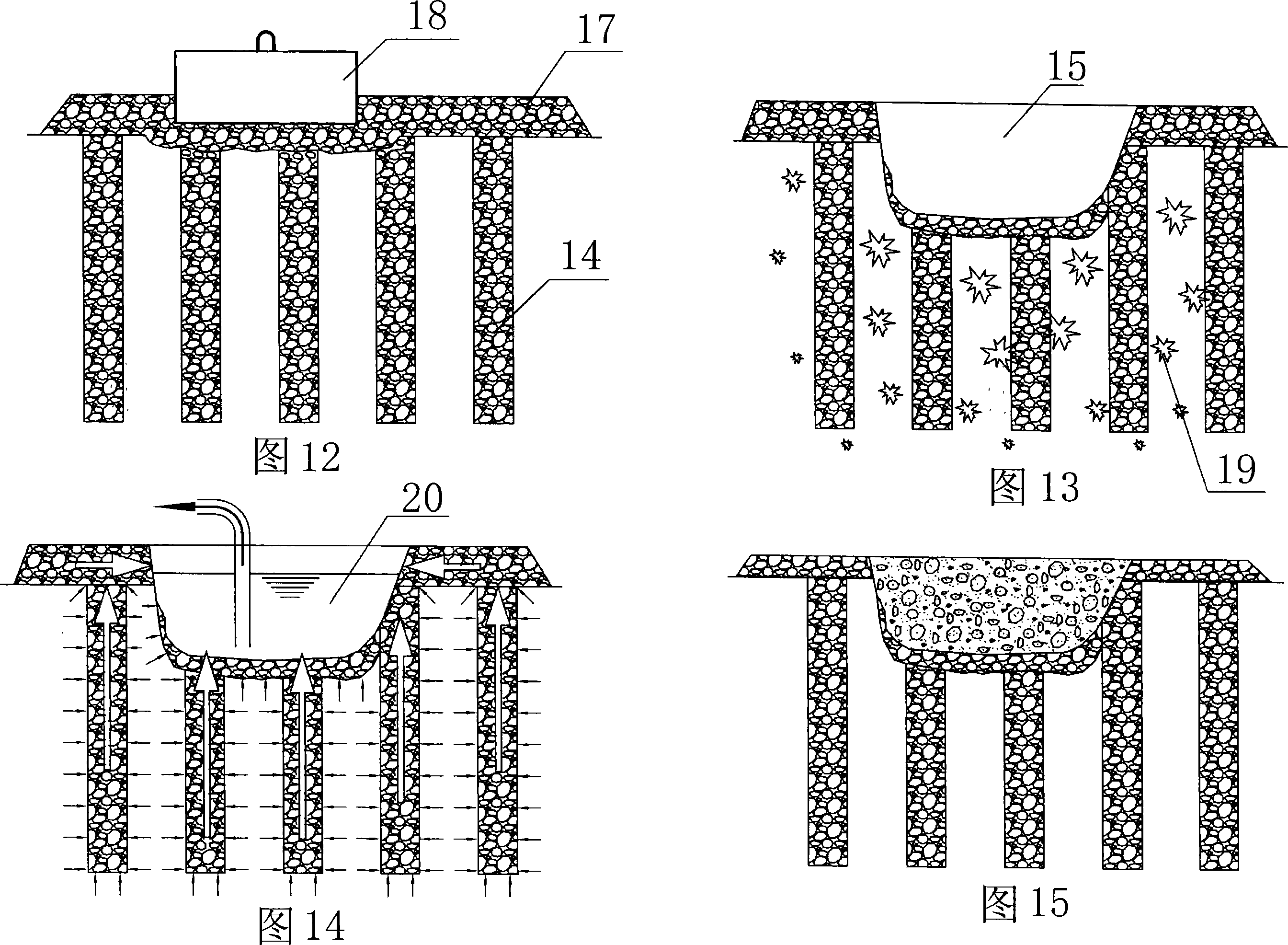

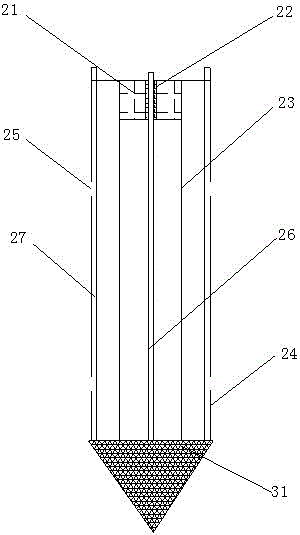

Salinized-soil-strong tamping and water-discharging pile foundation processing method

ActiveCN101024950AHigh densitySolve the emission problemBulkheads/pilesSoil preservationSurface layerWater discharge

The invention is a saline soil region strongly ramming and drainage pile foundation processing method, called PDP strongly ramming method for short, comprising the steps of: firstly making pile machine in position, then starting the pile machine to make pile pipe vertically sink from the set position to the designed depth, casting gravels, screes, rough sand and other rough particular pile materials into the sunk pipe; after completing casting materials and drawing the pipe to form drainage pile; constructing other drainage piles; laying a layer of rough particular materials in the covering position of each drainage pile on the surface of the processed region to form a drainage surface layer; making click strong ramming on the drainage surface layer to form rammed pits; when the ground water in the foundation seeps into each drainage piles and converges through the drainage surface layer into the rammed pits, pumping out the ground water from the rammed pits to the outside of the construction site; and finally backfilling the rammed pits and leveling. And it can save foundation processing expenses, improve construction quality and raise working efficiency.

Owner:JIAN YAN FOUND ENG

High cutting slope advanced supporting construction method

InactiveCN101624829ASimple structural designSimple designExcavationsBulkheads/pilesPolystyreneUltimate tensile strength

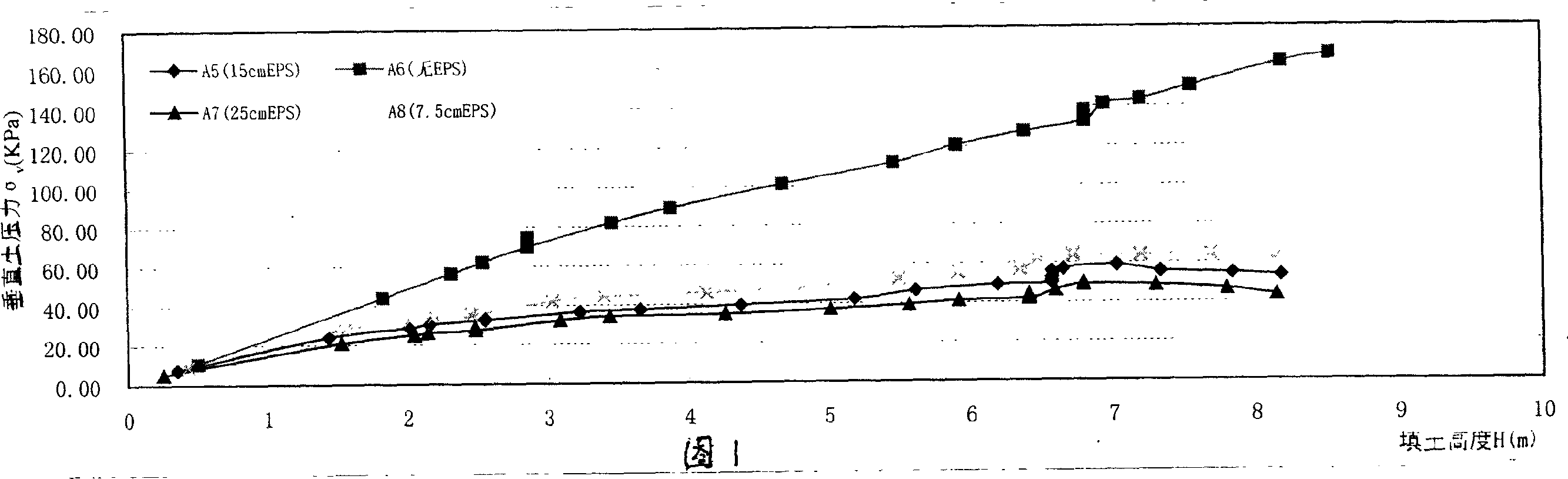

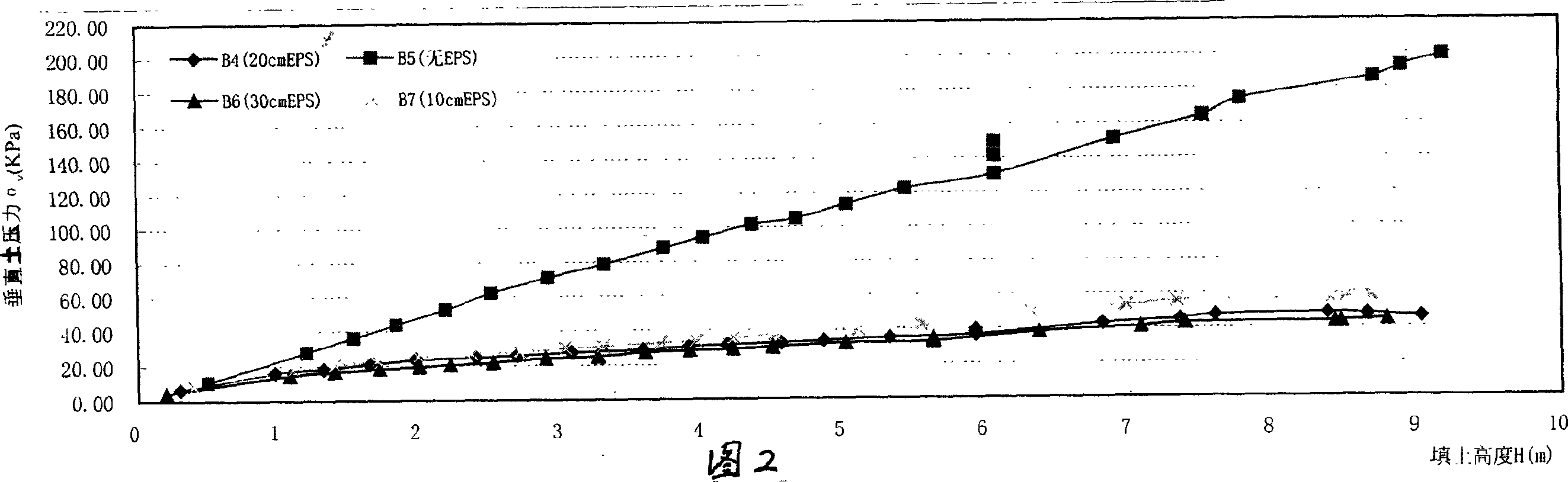

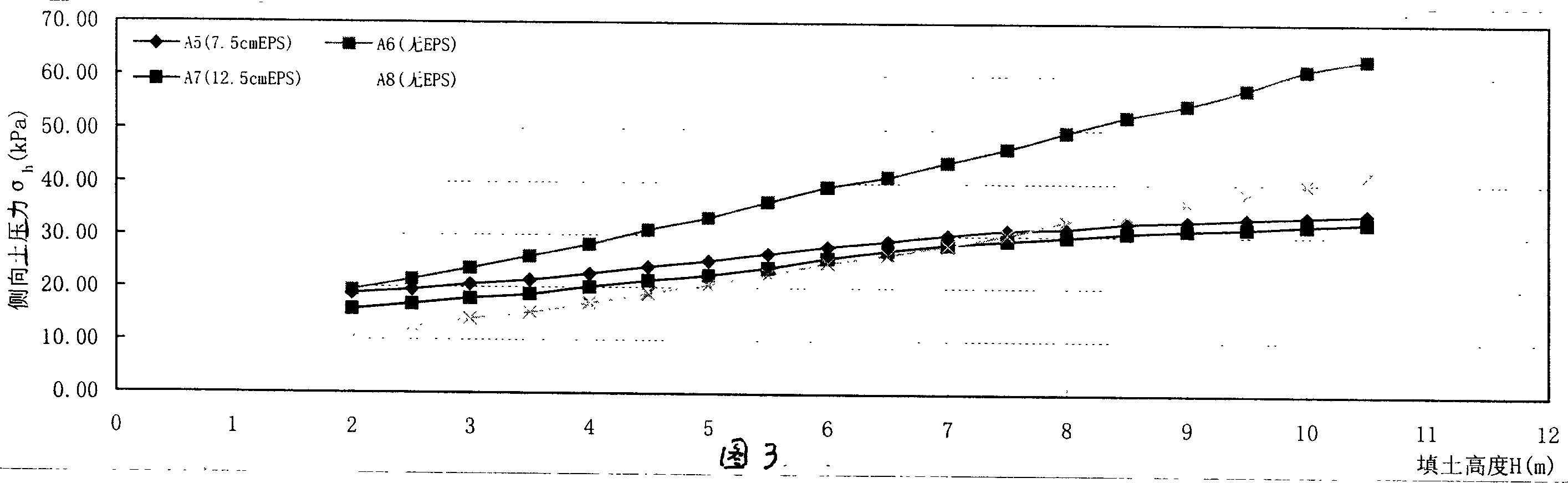

The invention relates to a high cutting slope advanced supporting construction method which is characterized in that: before digging a high cutting slope, an advanced supporting pile is dug and constructed firstly, polystyrene foam carpet material with a certain thickness is arranged above the digging surface of the backing side of the advanced supporting pile, and then a pile body concrete is poured, so as to form a novel structure of the advanced supporting pile with the polystyrene foam material, after the advanced supporting structure has 70 percent of intensity, the high cutting slope is dug; by adopting the self deformation of the polystyrene foam material (EPS), the soil pressure on the advanced supporting pile is reduced and the section size and reinforcing bars of the advanced supporting pile are optimized, thereby greatly reducing the construction investment of the high cutting slope advanced supporting structure and ensuring the whole stability and construction safety of the high cutting slope.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

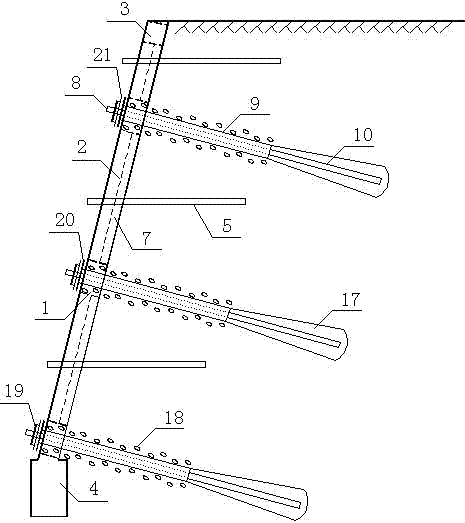

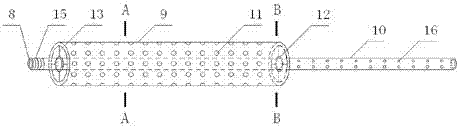

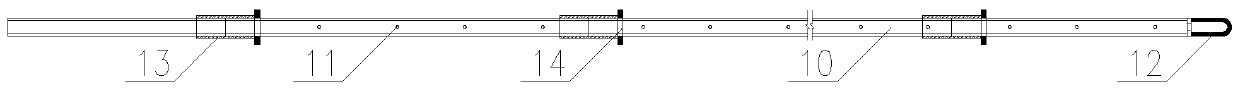

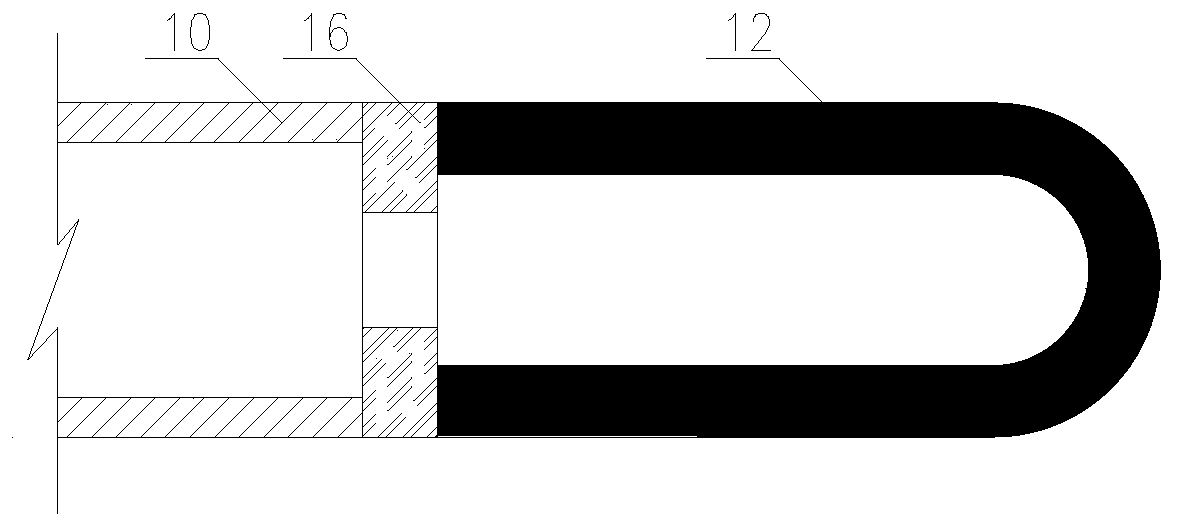

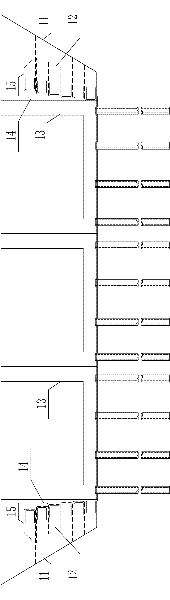

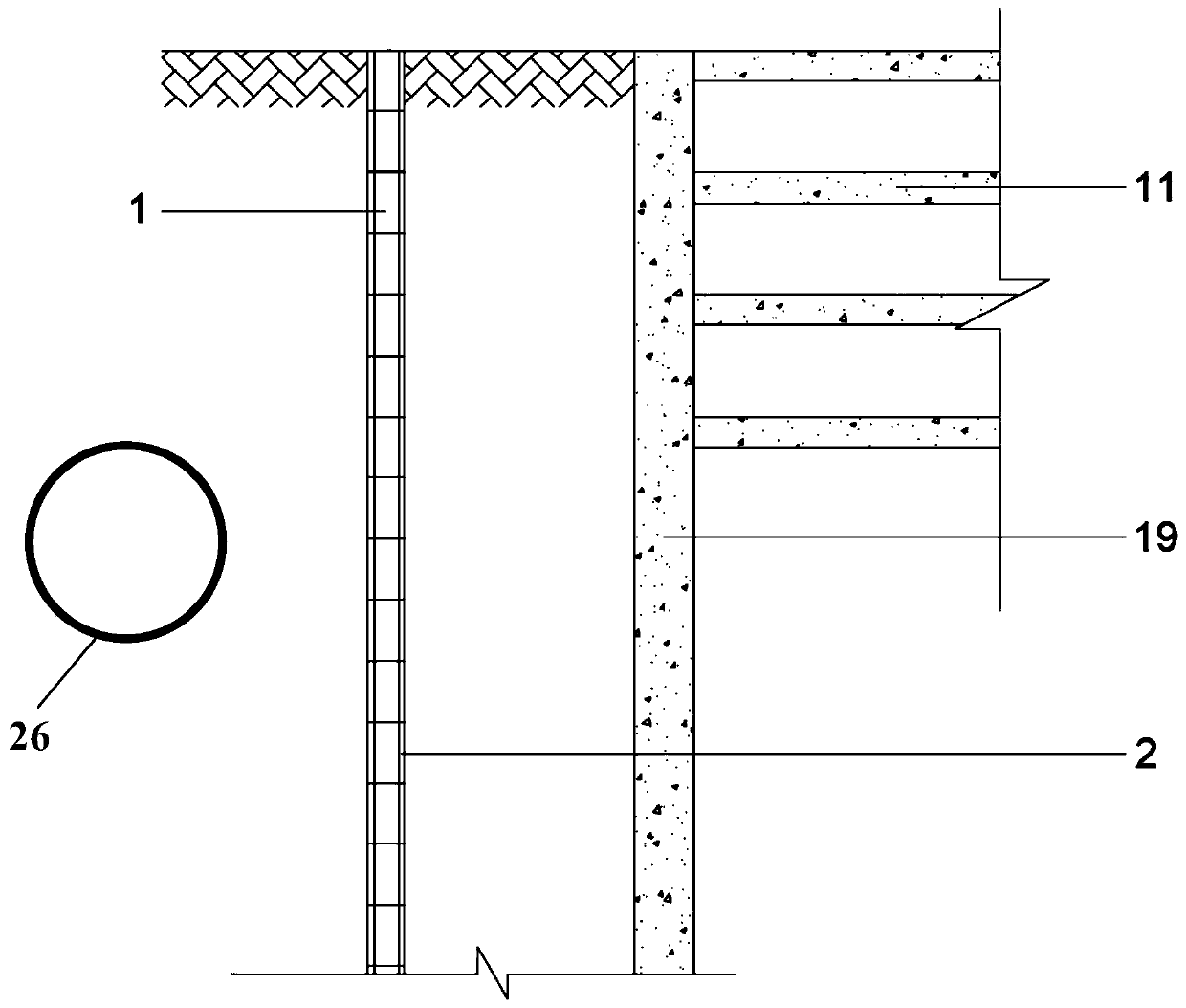

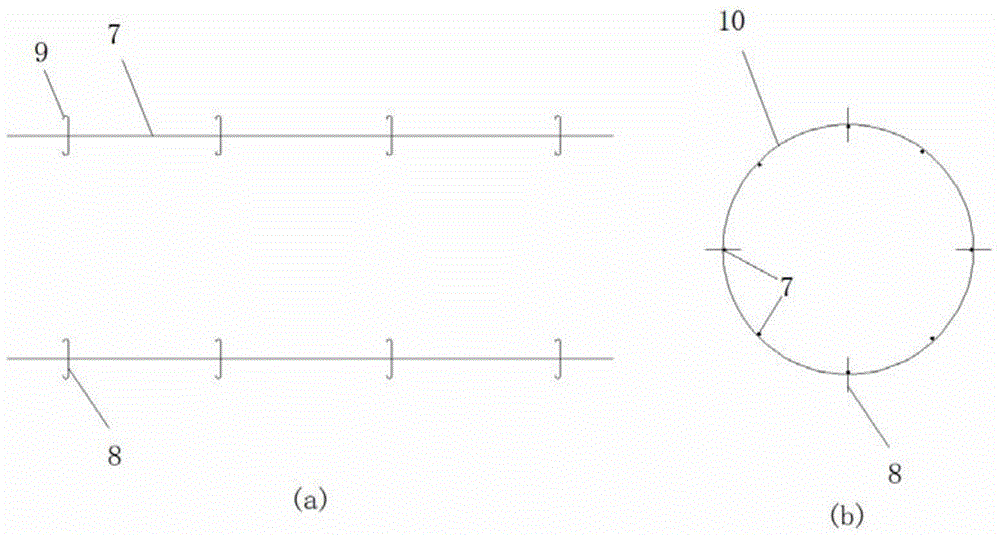

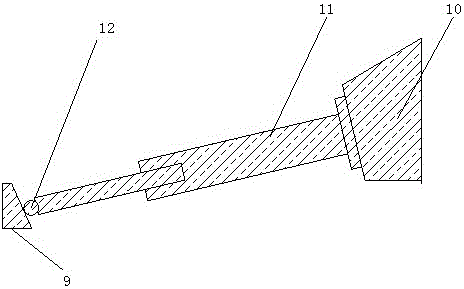

Frame-aeration cooling anchor pipe structure for keeping frozen soil slope stable and construction method

The invention discloses a frame-aeration cooling anchor pipe structure for keeping a frozen soil slope stable and a construction method. The frame-aeration cooling anchor pipe structure is composed of a cross beam (1), an upright (2), a protective cover (7), an aeration anchor pipe (8) and gravels (18). The aeration anchor pipe (8) is composed of an aeration pipe (9) for aeration, and an anchor pipe (10) which is arranged in the aeration pipe (9) and used for pressure grouting and anchoring. In the use of the frame-aeration cooling anchor pipe structure for keeping the frozen soil slope stable, convective heat exchange is aroused between air in the aeration pipe and air in the gravel layer under the action of temperature difference, so that heat in the slope body is exchanged into atmosphere; in addition, cold air enters a freeze thawing layer through the aeration pipe under the action of wind to reduce the temperature of the slope body; as a result, soil pressure transferred to the frame by freeze thawing collapse is reduced; the frame is anchored in the well-frozen stable stratum by the anchor pipe. The frame is connected with the aeration anchor pipe to form a space structure, and the frame and the aeration anchor pipe work integrally to improve the overall stability of the slope, and therefore, the frame-aeration cooling anchor pipe structure is applicable to prevention and treatment of slope instability in a freeze soil area; moreover, the construction process is simple, and the construction cost is low.

Owner:DALIAN KENVIS IND TECH CO LTD

Light filled structure and its construction process

The light fill body structure includes soil layers and foamed plastic block layers superposed alternately. In all the foamed plastic block layers, there are drilled soil column holes. There are also concrete layer over the top foamed plastic block layer, bottom crushed stone layer below the lowest foamed plastic block layer, and retaining wall to the sides of the fill body structure. The present invention is easy to construct, and has density lower than common soil, adjustable strength, light pressure to soil, and less deposit and side flow. The present invention makes it possible to refill soil vertically.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

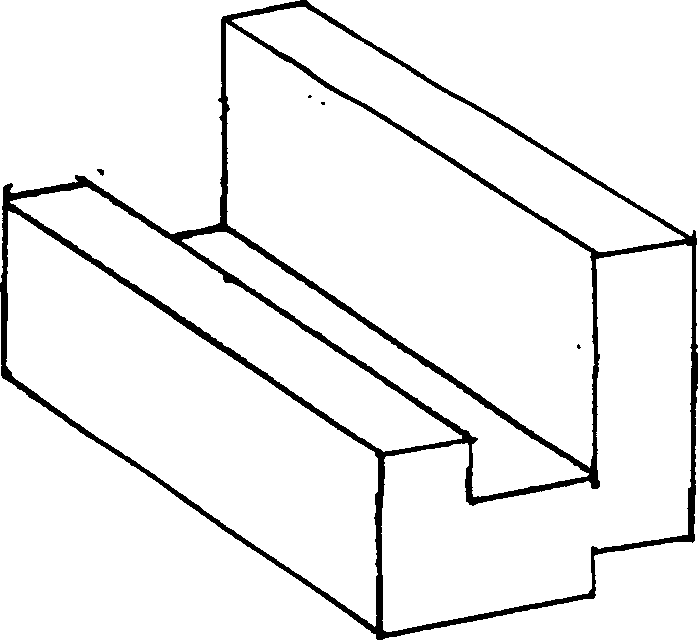

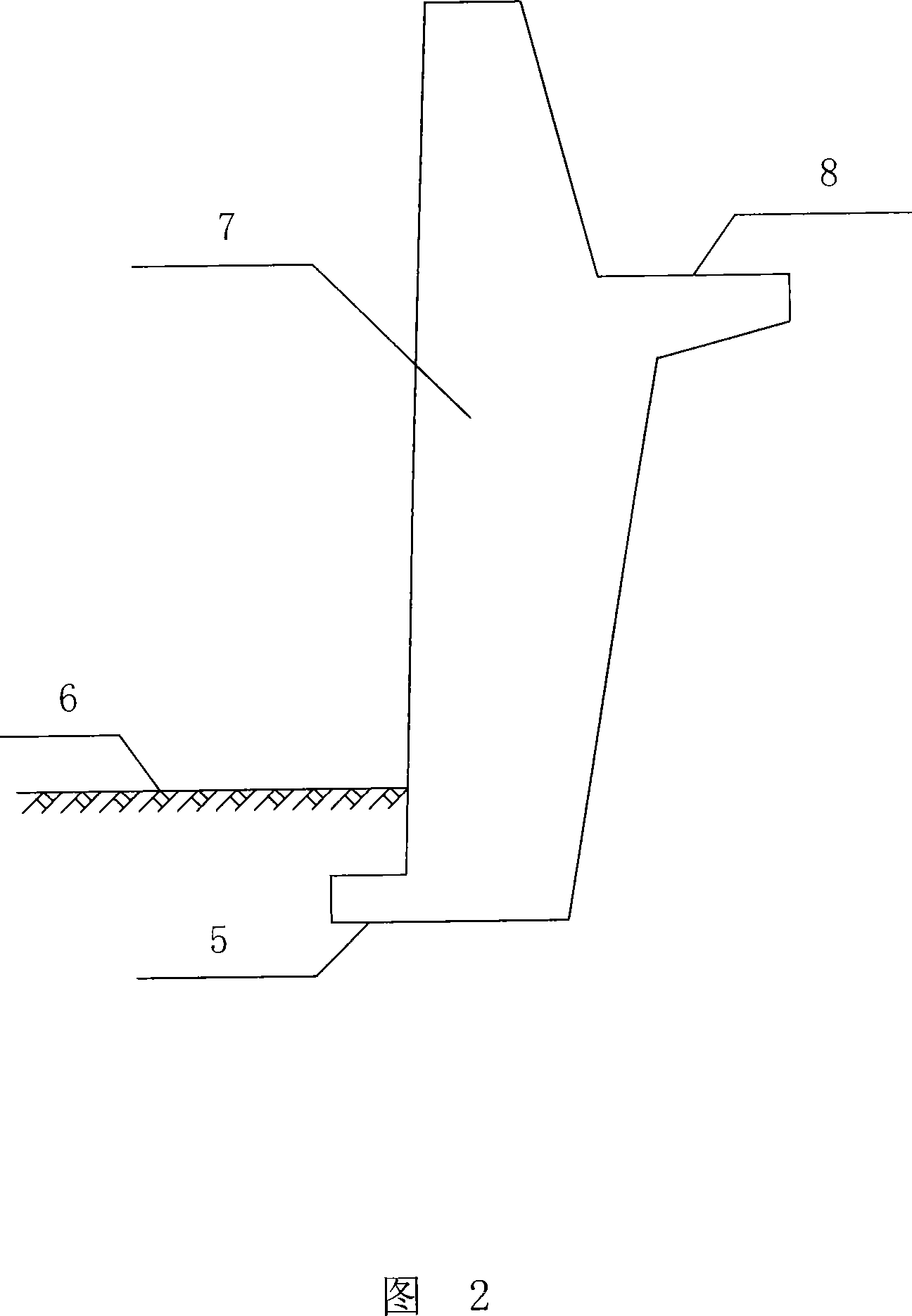

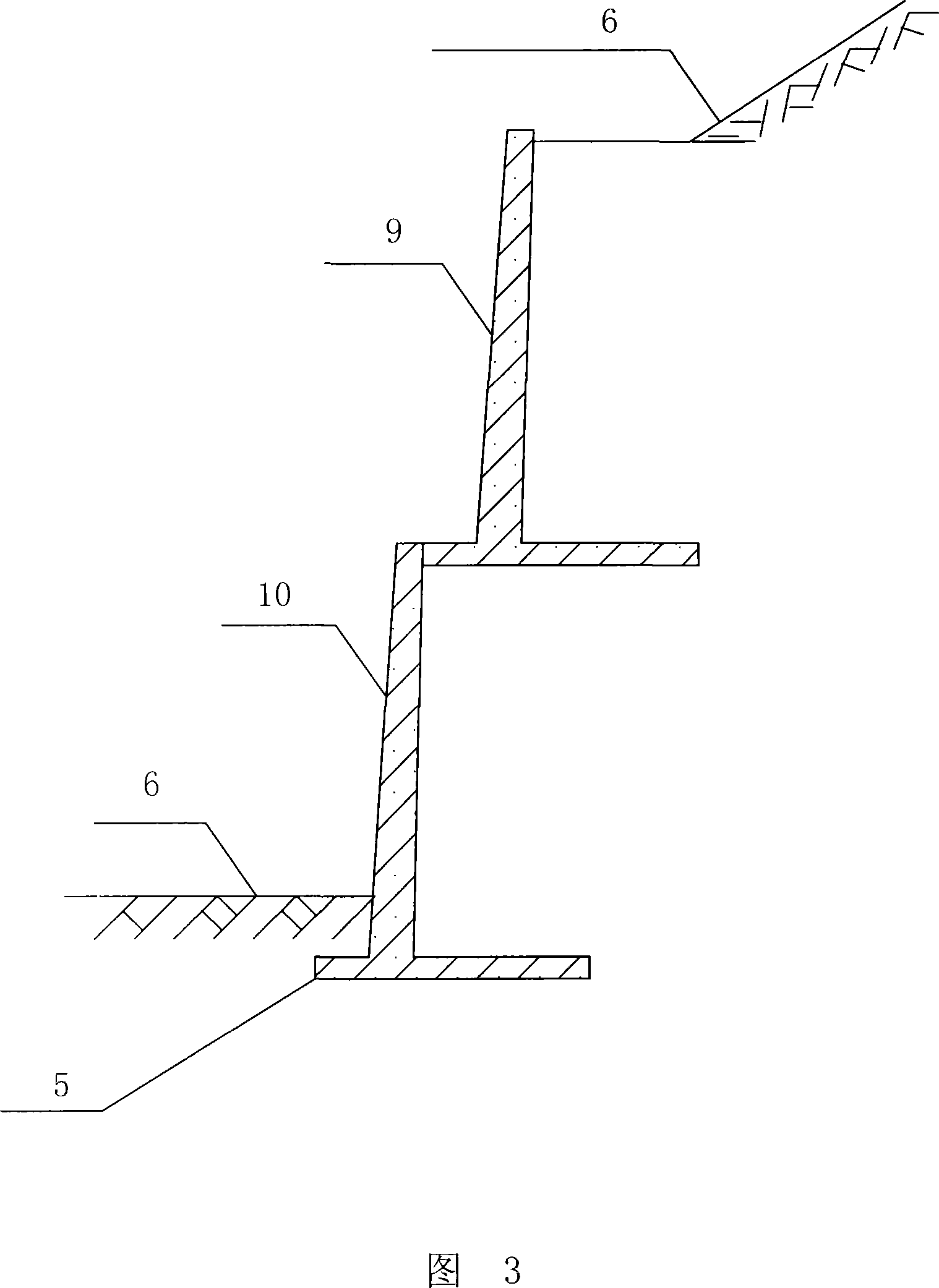

Two-stage stack-type cantilevered L-shaped blank wall and construction method thereof

InactiveCN101240548AReduce earth pressureAvoid large foundation bearing capacity requirementsArtificial islandsExcavationsSingle levelEngineering

The invention discloses a two-level battlements type cantilevered L-shaped barricade and a construction method thereof. The composite barricade is composed of an upper layer single level cantilevered L-shaped barricade and a lower layer single level cantilevered L-shaped barricade both of which are blocked up down. An unloading platform is formed by using the bottom plate of the upper level single level cantilevered L-shaped barricade. The invention also discloses an administration method for the two-level battlements type cantilevered L-shaped barricade. According to the invention, single level cantilevered L-shaped barricade has a single structure, a small weight, little land occupied, and low requirement for foundation stress, and is adaptive to alternation distortion and ecological protection. Both the anti-overturn ability and skid resistance character of the single level cantilevered L-shaped barricade are utilized. Barricade height is increased in precondition the self weight of the barricade after soil is filled is utilized.

Owner:CHONGQING JIAOTONG UNIVERSITY

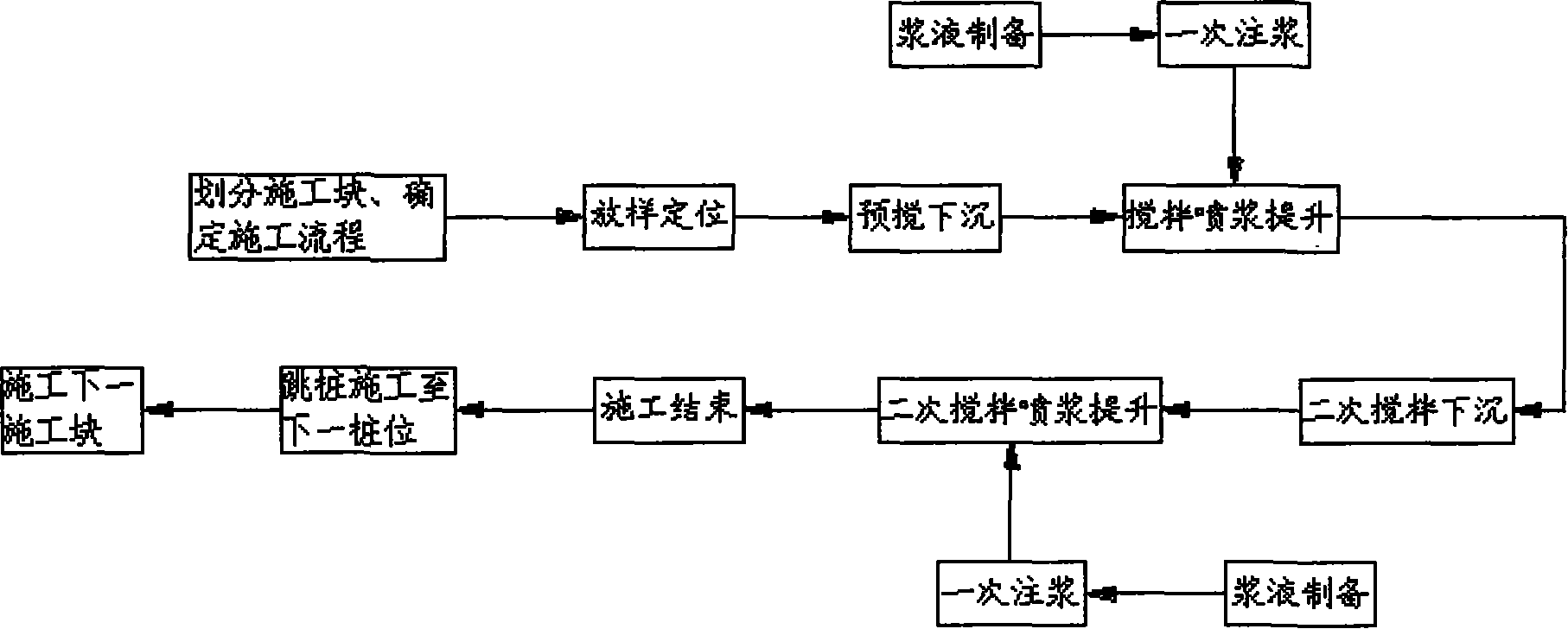

Construction method for reinforcing subway station side soil body

InactiveCN101250885AReduce earth pressureControl deformationArtificial islandsProtective foundationMetro stationEngineering

The invention discloses a construction method for reinforcing soil body on one side of a metro station, which comprises the following steps: V1ing, the soil body on one side of the metro station is divided into construction blocks, and the construction blocks are sectionally divided on the longitudinal length of the reinforced soil body. V2ing, the construction blocks are orderly done with a stirring pile reinforcement construction, and a jumping bin construction mode is used when each construction block is constructed. V3ing, when each construction block is constructed, a row of piles which are close to one side of the metro station is firstly constructed and are used as isolation piles, after the row of piles are formed, the outer side of the metro station is constructed, and a jump beating mode is used when the row of piles are constructed. Through optimizing a reinforcing process of a stirring pile soil body, the construction method of the invention uses the mode of partition construction and jumping pin construction, the effect to the metro station when the soil body on one side of the metro station which is reinforced is capable of being effectively solved, and the deformation of the metro station is reduced.

Owner:SHANGHAI CONSTR NO 1 GRP

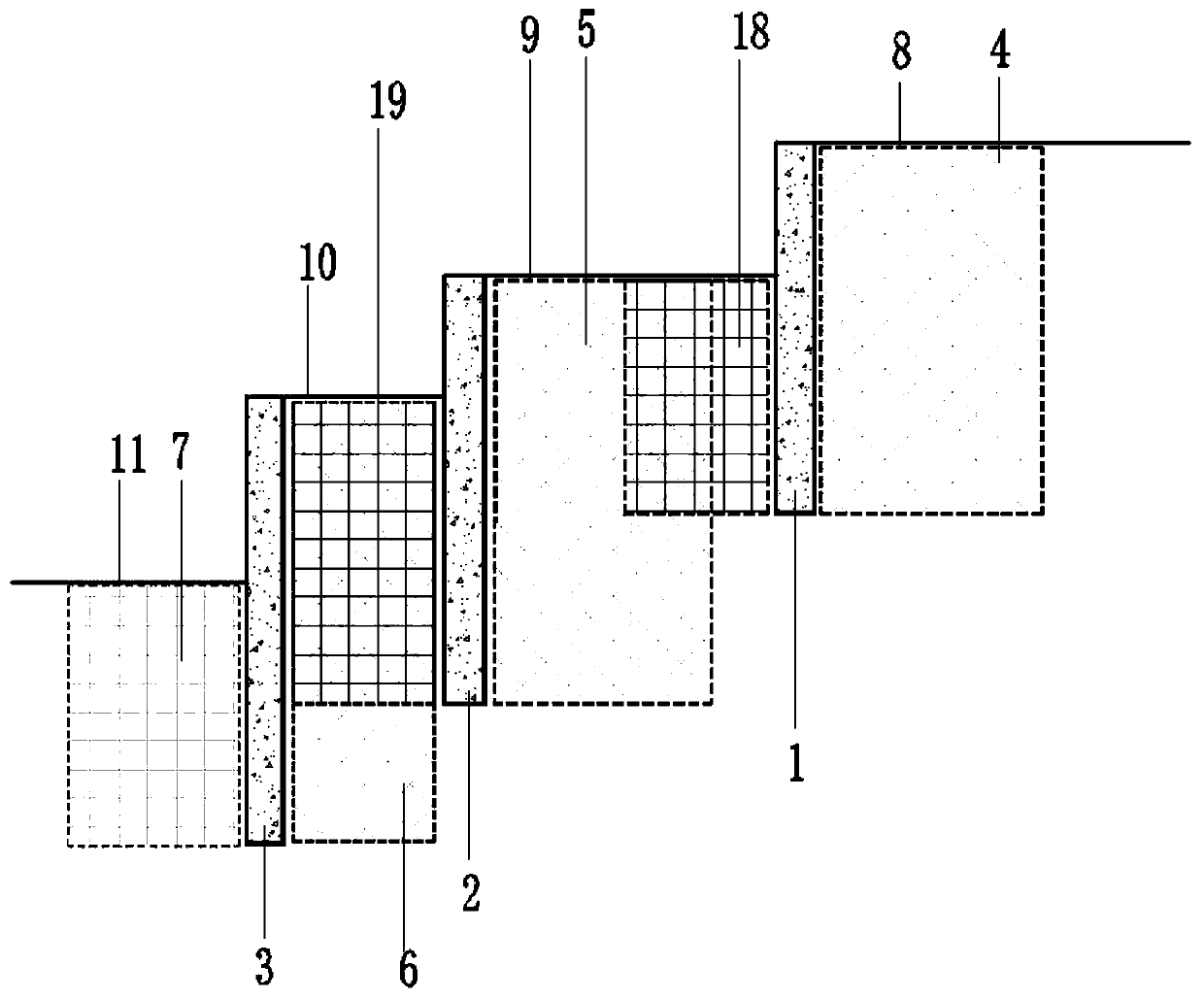

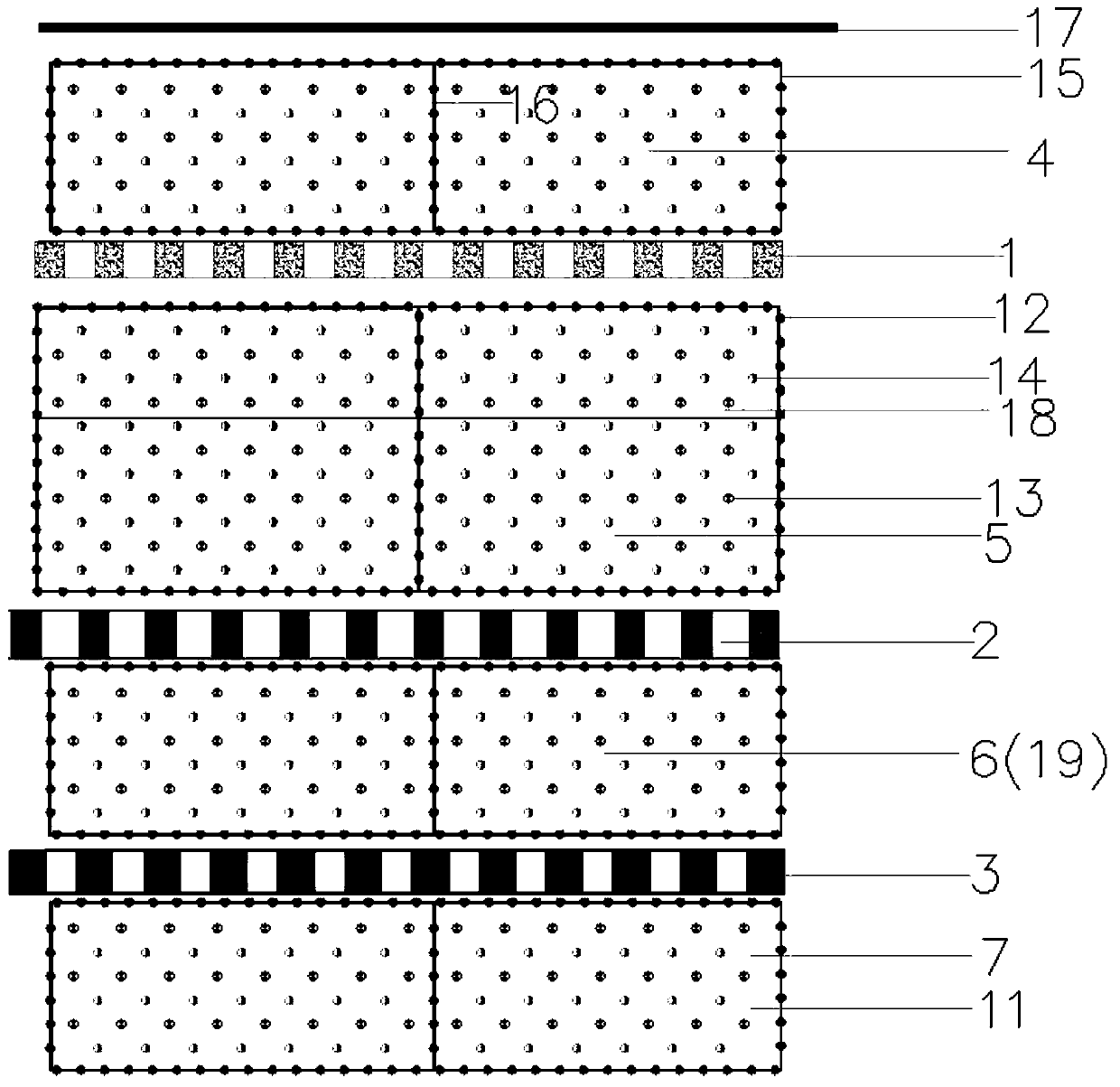

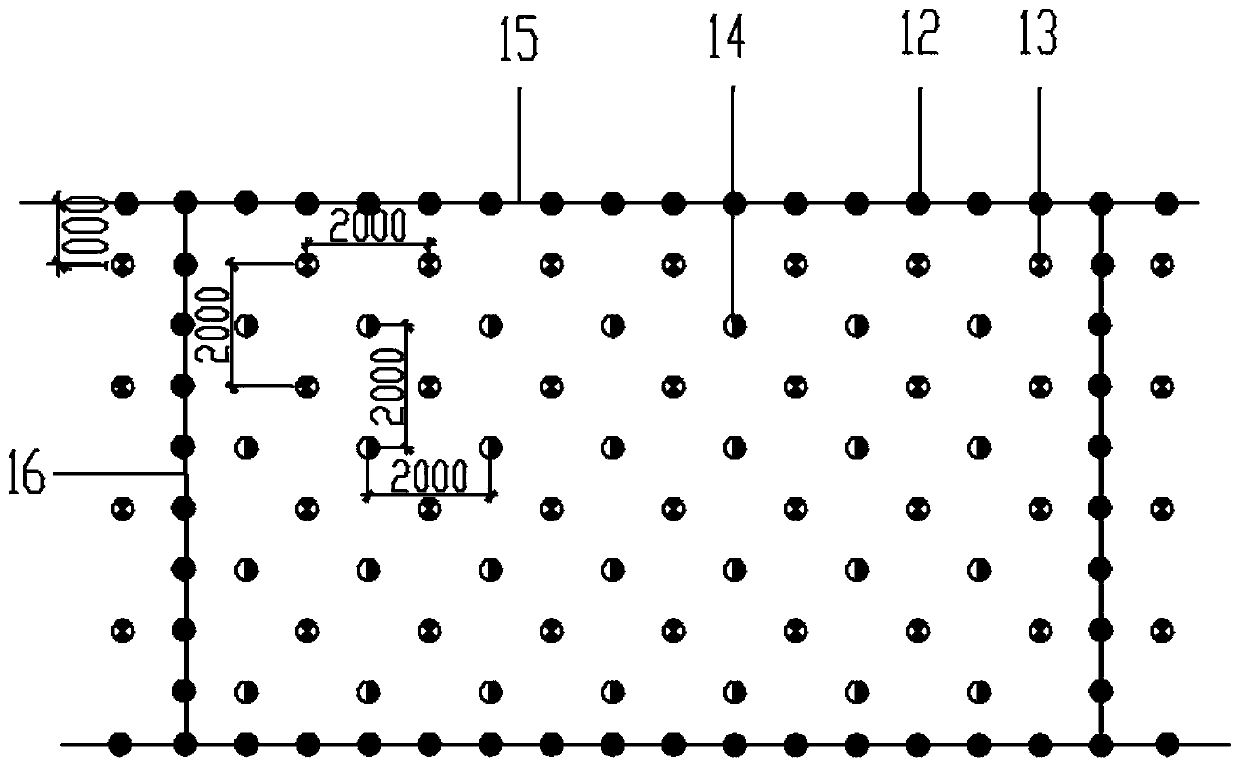

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167BHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsRebar

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

Layered inner lifting unloading type ground pulling anchor rod and construction method

ActiveCN108842792AImprove soil propertiesExpand the range of supportExcavationsBulkheads/pilesEngineeringRock bolt

The invention discloses a layered inner lifting unloading type ground anchor rod structure and a construction method thereof, and belongs to the field of supporting and retaining engineering. The layered inner lifting unloading type ground anchor rod support structure comprises lifting unloading steel pipes, anchor rods and an outer tension anchor structure. The lifting unloading steel pipes are composed of first type sleeves, second type sleeves and circular ring steel sheets. The anchor rods are composed of free sections, anchoring sections and stop grouting plugs. The outer tension anchor structure is composed of steel strands, a fixed pulley, a concrete pit, an anchorage pier and twine tighteners. The end, with the circular ring steel sheets, of the lifting unloading steel pipes are arranged on the free sections of the anchor rods in a sleeving mode, and are placed in a stable soil layer. The other ends of the lifting unloading steel pipes are connected with the outer tension anchor structure through the steel strands, and are fixed to the outer surface of a side slope (or a foundation pit). The layered inner lifting unloading type ground anchor rod structure has a simple structure and high bearing capacity, can fully utilize the stable soil layer and the free sections of the anchor rods, and solves the problems that a support structure is difficult to construct and the support structure is prone to crossing a building restriction line due to the face that an current high slope or certain special foundation pits cannot be subjected to piling or pore-forming.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

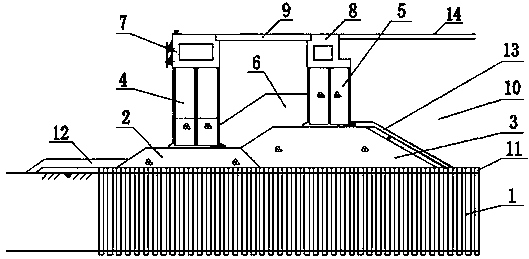

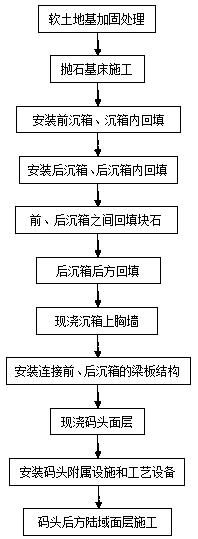

Dock wall type wharf structure with deepwater soft soil foundation and construction method thereof

PendingCN107700423AImprove bearing capacitySkip the trestleBreakwatersQuaysEngineeringStructural engineering

The invention discloses a dock wall type wharf structure with a deepwater soft soil foundation and a construction method thereof. The dock wall type wharf structure comprises a reinforced soft soil foundation, a riprap front foundation bed, a riprap rear foundation bed, a front caisson, a rear caisson, a riprap slope dyke, a front breast wall, a rear breast wall, a beam plate structure and behind-wall backfill. The riprap front foundation bed is arranged at the end, close to deep water, of the reinforced soft soil foundation, the front caisson is arranged on the top of the riprap front foundation bed, and the front breast wall is arranged on the top of the front caisson; the riprap rear foundation bed is arranged behind the riprap front foundation bed, the rear caisson is arranged on the top of the riprap rear foundation bed, the rear breast wall is arranged on the top of the rear caisson, and the behind-wall backfill is arranged behind the rear caisson; and the riprap slope dyke is arranged between the front caisson and the rear caisson, and the beam plate structure is arranged between the front breast wall and the rear breast wall. A dock wall type wharf can be directly built onthe deepwater soft soil foundation, the functions of the wharf and a circle levee are achieved, a trestle can be omitted, the land region using area can be increased substantially, and high value is achieved.

Owner:CCCC THIRD HARBOR CONSULTANTS

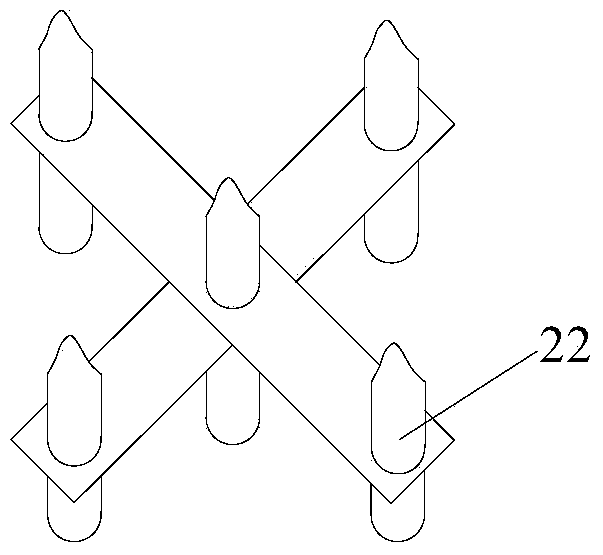

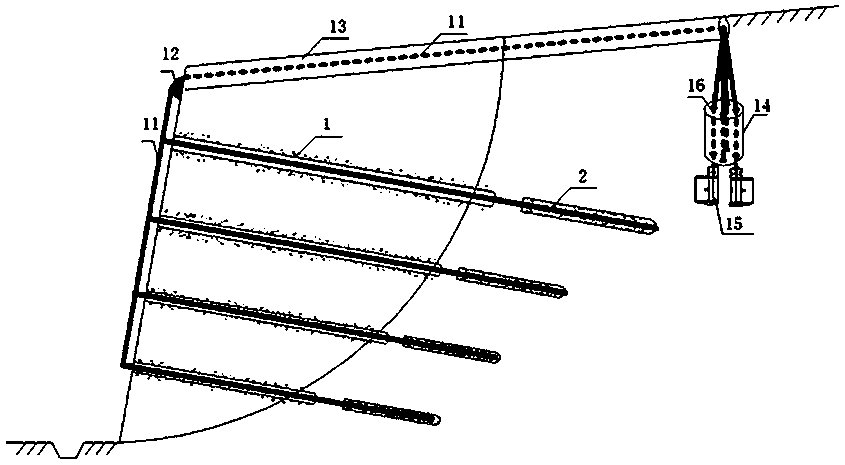

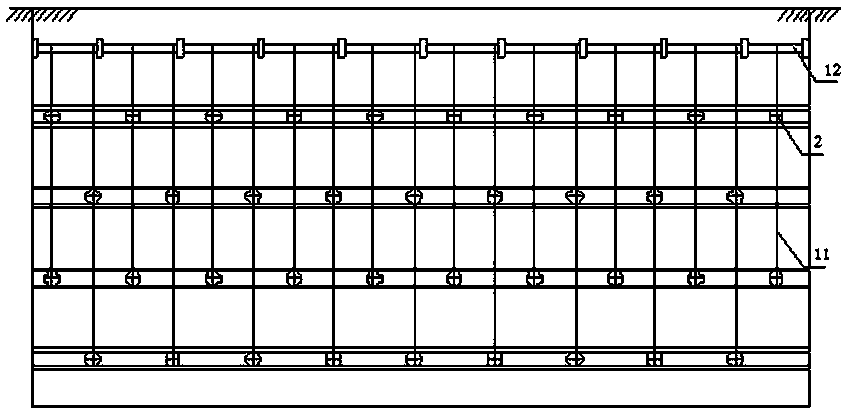

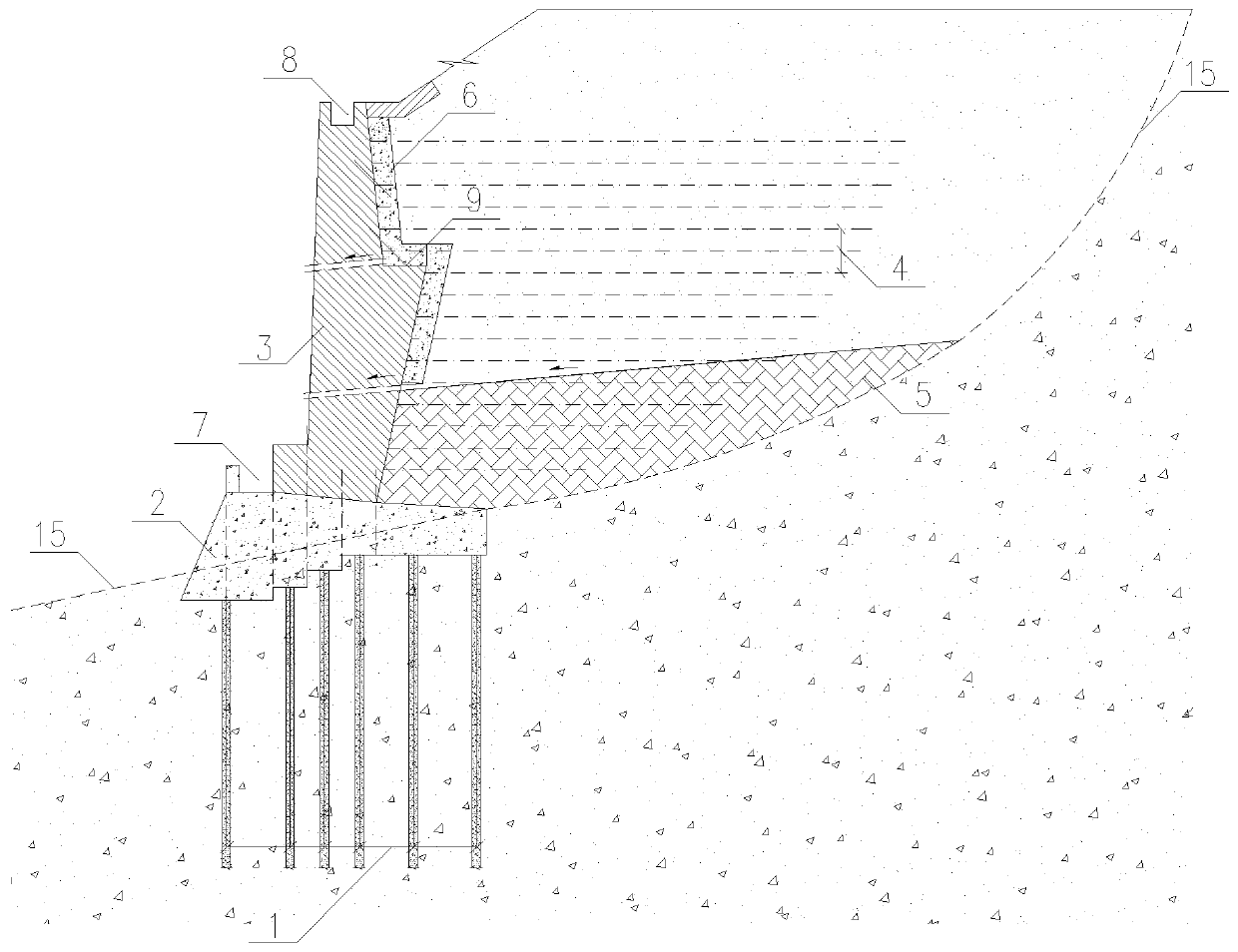

Steel anchor pipe reinforced weathered rock stratum reinforced balance weight type retaining wall structure and construction method

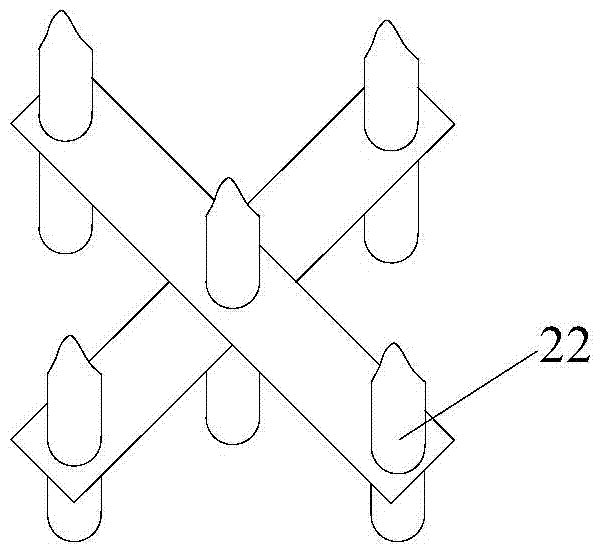

ActiveCN109736346AImprove stabilityReduce earth pressureArtificial islandsUnderwater structuresEconomic benefitsGeogrid

The invention discloses a steel anchor pipe reinforced weathered rock stratum reinforced balance weight type retaining wall structure and a construction method, the weathered rock stratum is reinforced by the steel anchor pipes through grouting inside and outside the pipes, the bearing capacity of a treated rock mass foundation is greatly improved, and the foundation bearing requirement of an upper embankment retaining structure is completely met. Meanwhile, the stability of the treated weathered rock stratum is improved, the steel anchor pipe can also serve as a side slope anti-sliding structure, and the effect of preventing sliding and reducing disasters on an original weathered rock stratum side slope is achieved. According to the reinforced soil (balanced weight type) retaining wall, breakthrough of the wall thickness size of a traditional retaining wall is achieved, and meanwhile laying of the geogrid has great significance for the stability of the retaining wall. The constructionmethod is mature in technology and reasonable in procedure, has the advantage of rapid construction and has outstanding economic benefits. The method has a wide prospect in application of road embankment filling and retaining structures on weathered rock stratum geology.

Owner:CHINA FIRST HIGHWAY ENG +1

Method for reducing side load influence

ActiveCN102535476AEliminate the effects ofReduce earth pressureArtificial islandsEmbankmentsEngineeringBuilding construction

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

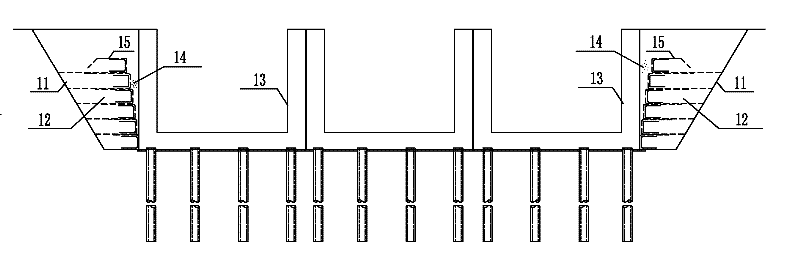

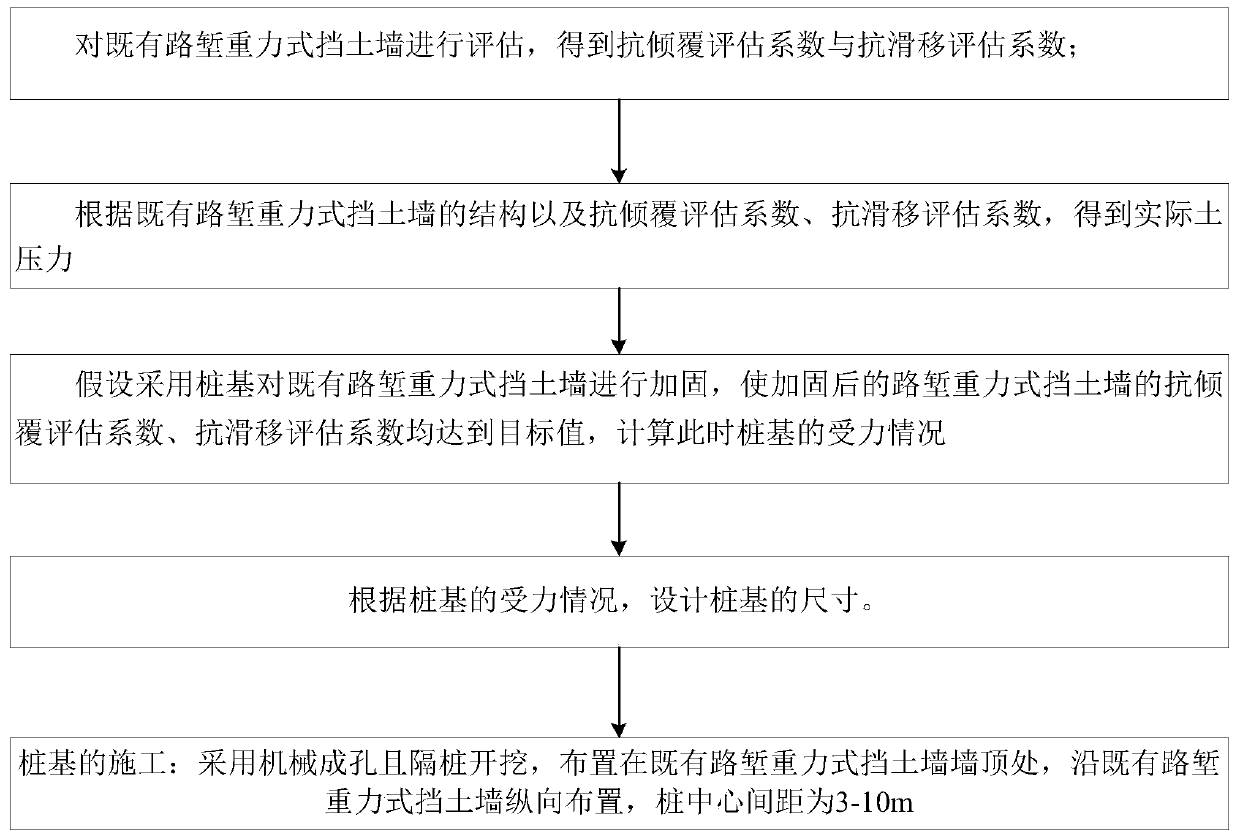

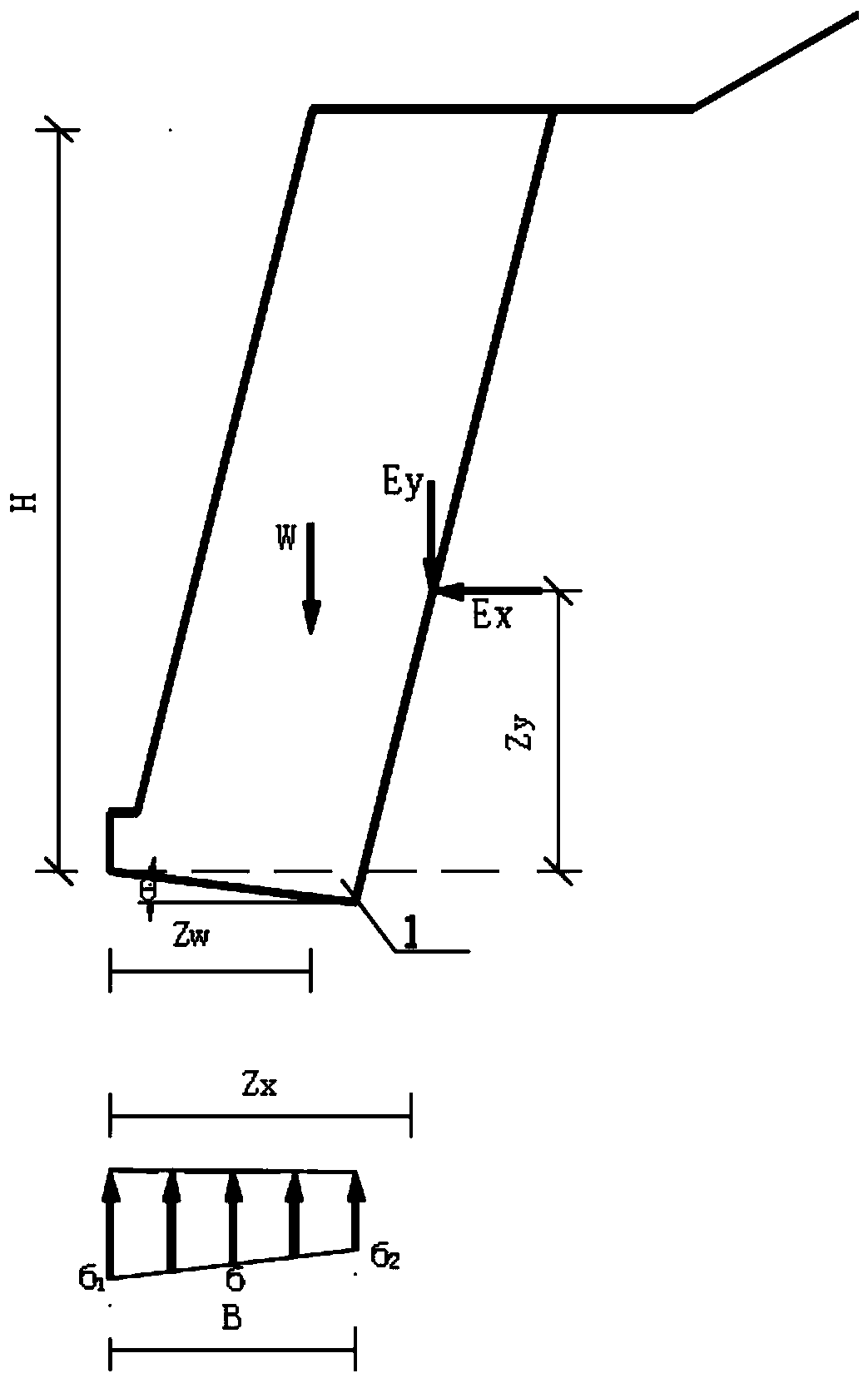

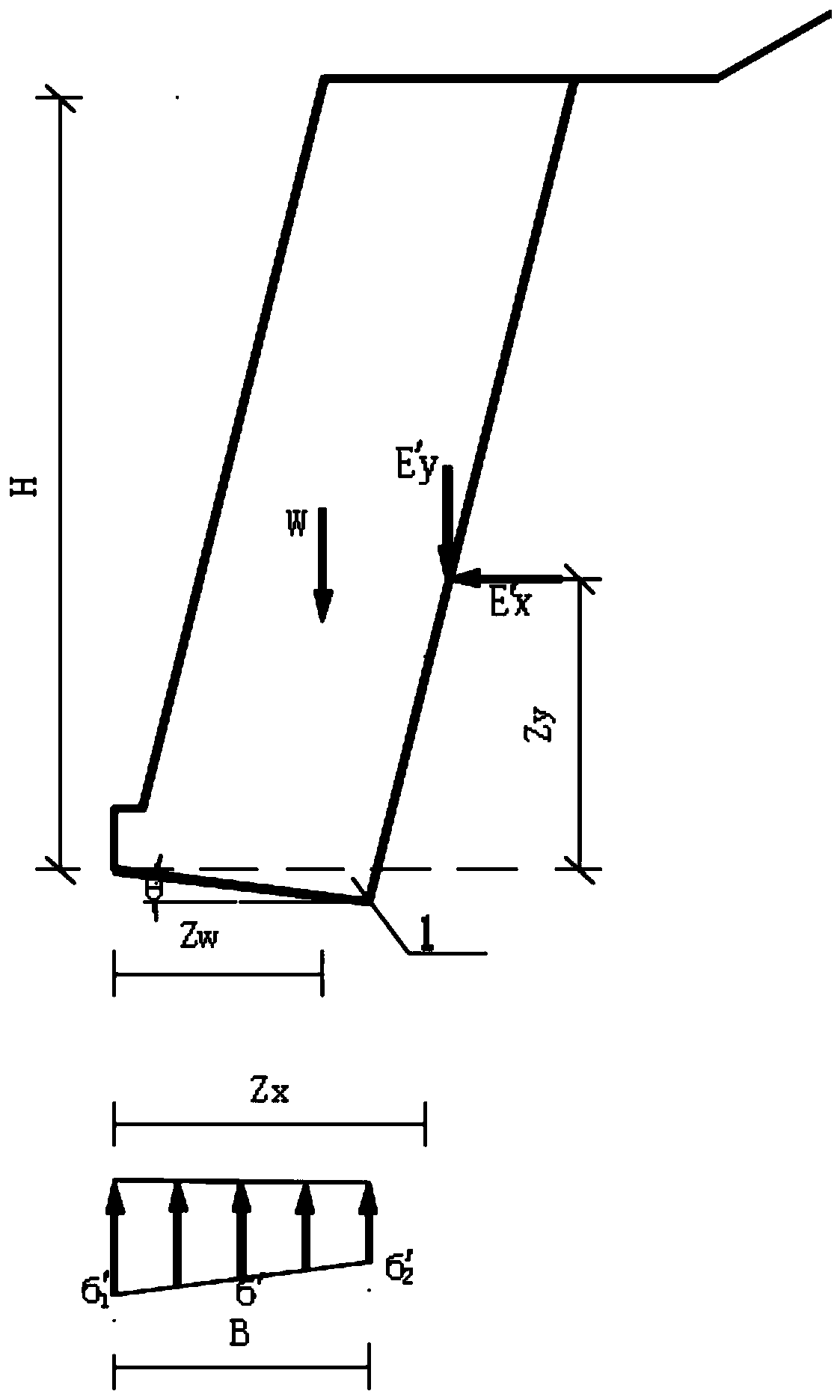

Method for restraining deformation of existing cutting gravity type retaining wall

ActiveCN111259478AReduce earth pressureReduce loadGeometric CADArtificial islandsArchitectural engineeringRetaining wall

The invention discloses a method for restraining deformation of an existing cutting gravity type retaining wall. The partial bearing capacity still reserved by the existing cutting gravity type retaining wall is fully considered; a row of drilling piles are arranged behind the wall; the soil pressure of the existing cutting gravity type retaining wall is reduced; the anti-sliding and anti-overturning safety of the structure is improved; the sizes of the pile foundations are designed according to the stress of the existing cutting gravity type retaining wall and the stress of the newly-built pile foundations; compared with the prior art, the brand-new calculation design method considering the bearing effect of the existing cutting gravity type retaining wall is provided, dismantling and rebuilding of the existing retaining wall are avoided, the load shared by pile foundations is reduced, the sizes of the pile foundations are optimized, and therefore on the premise that safety is guaranteed, engineering investment is reduced, and economical efficiency is improved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

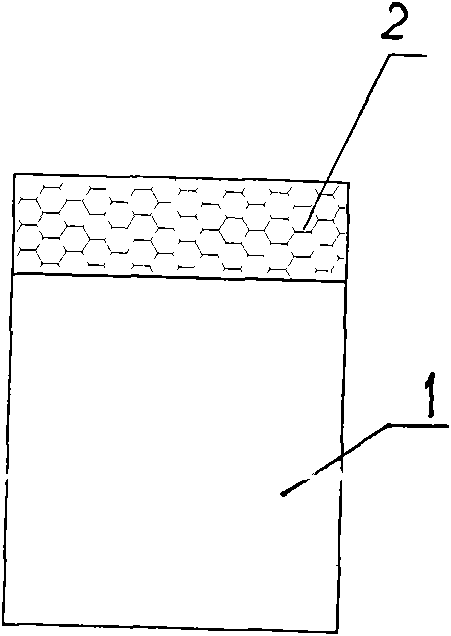

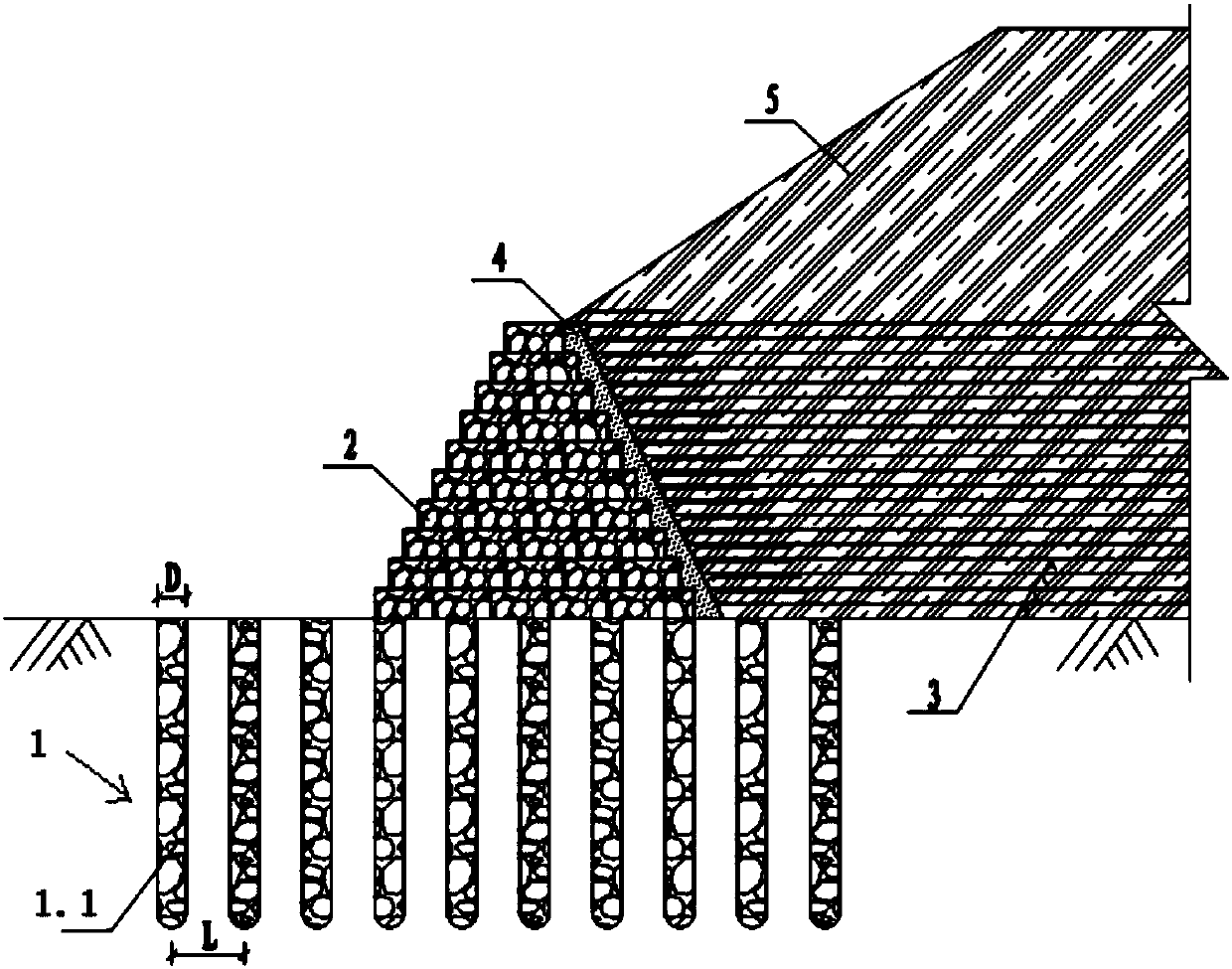

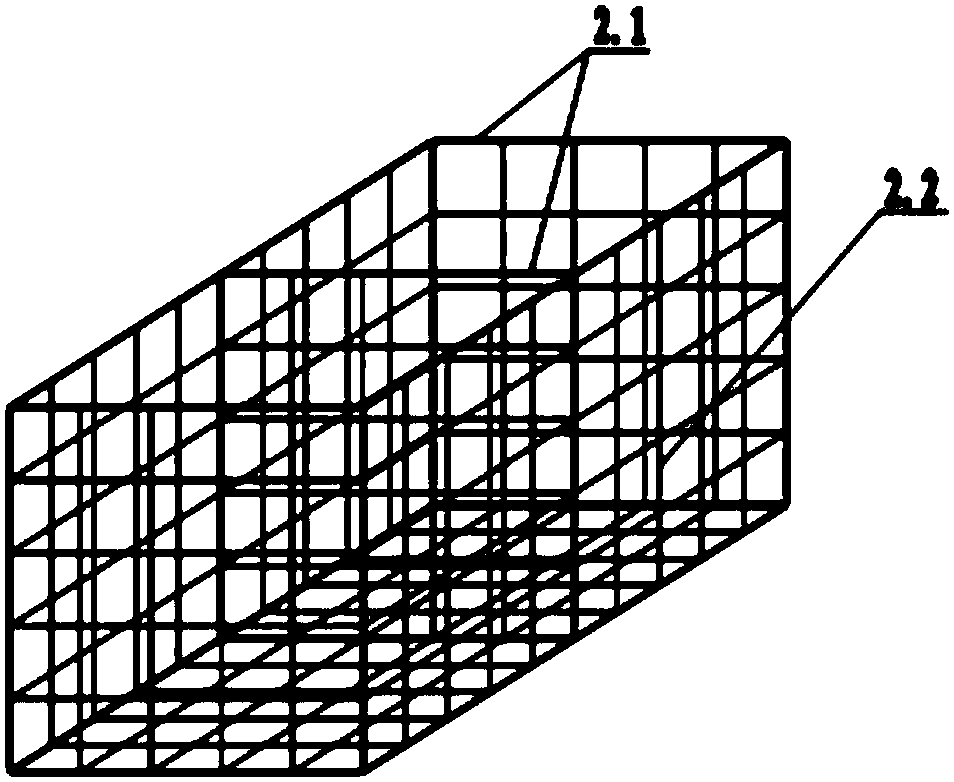

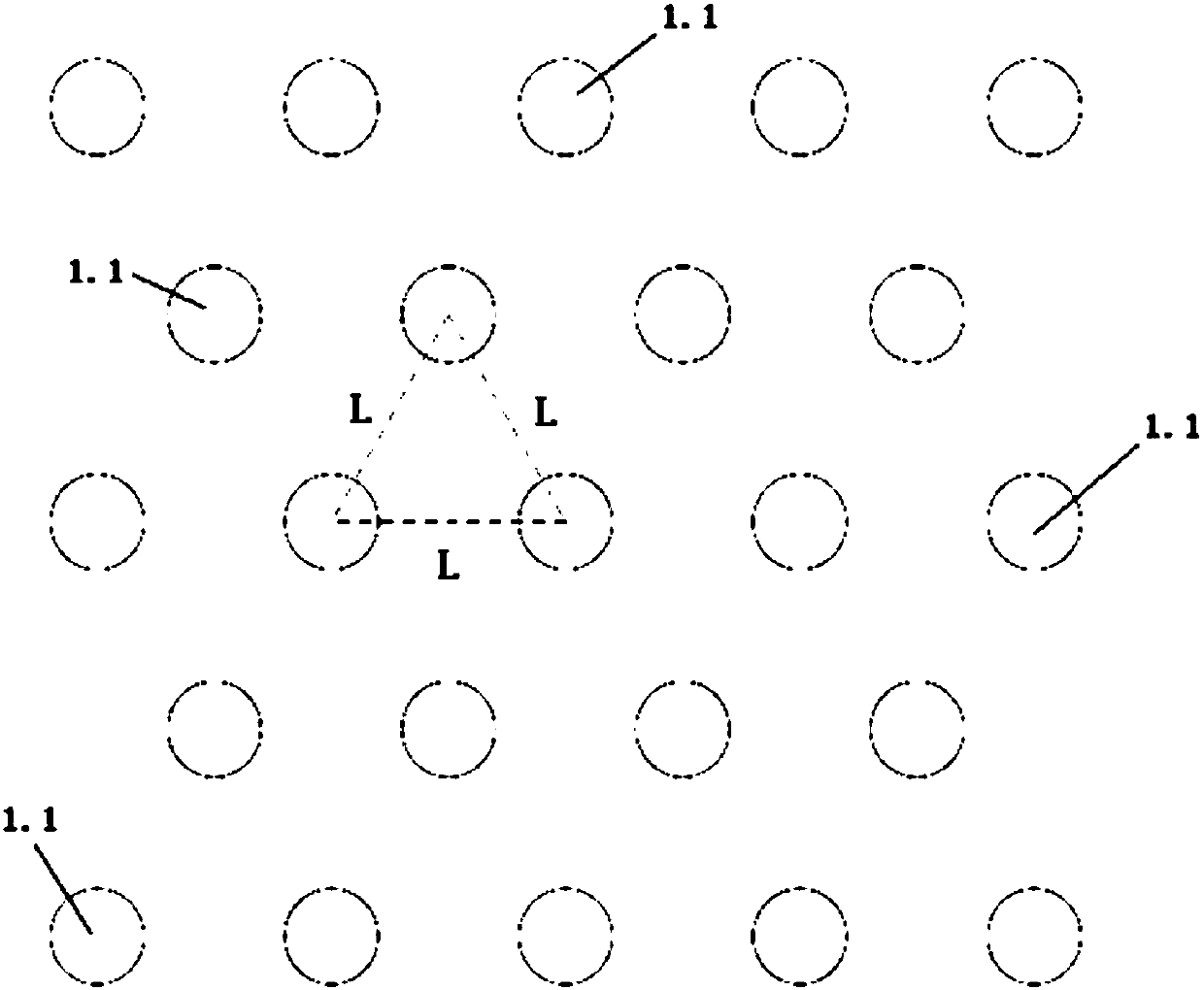

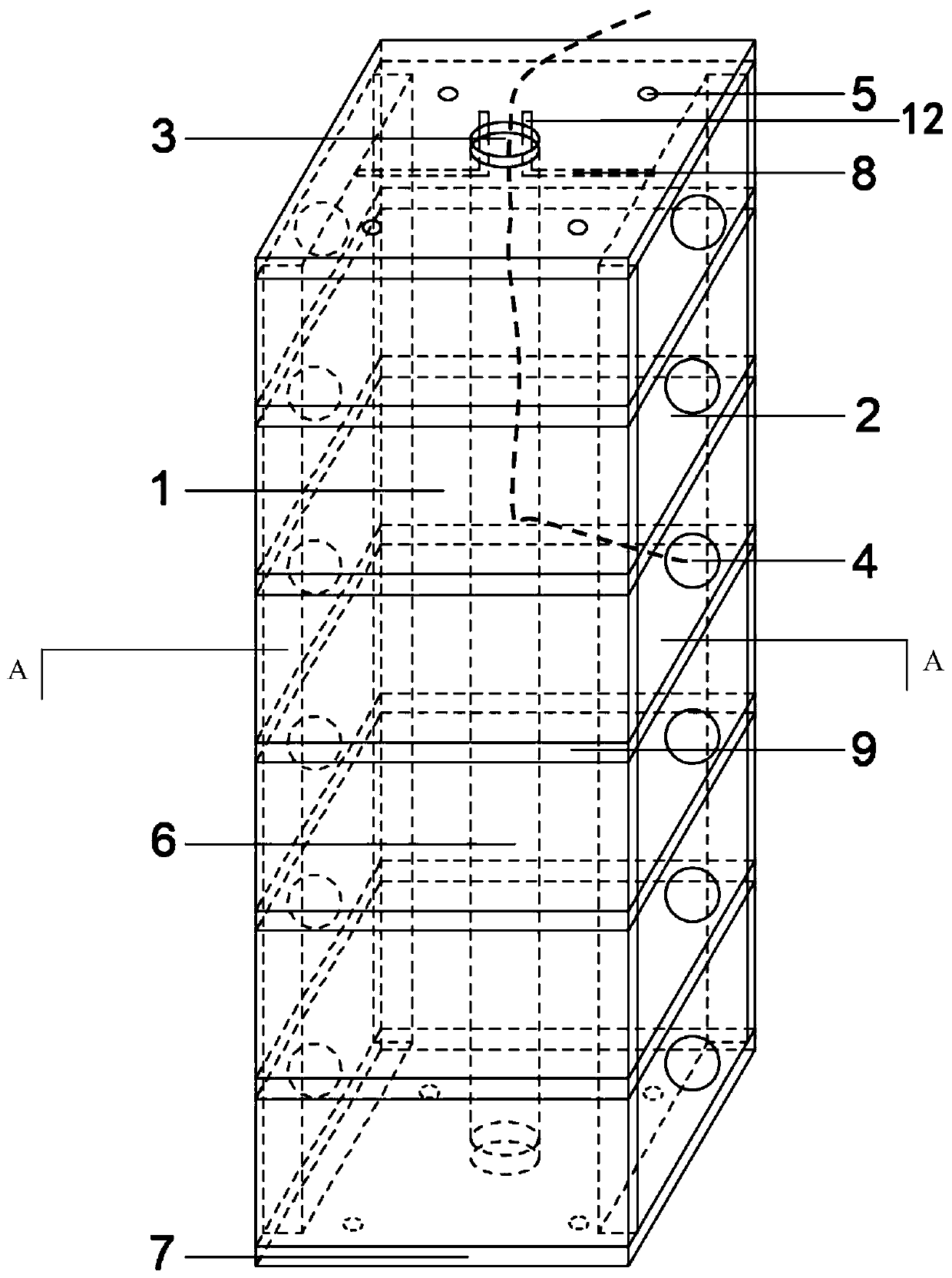

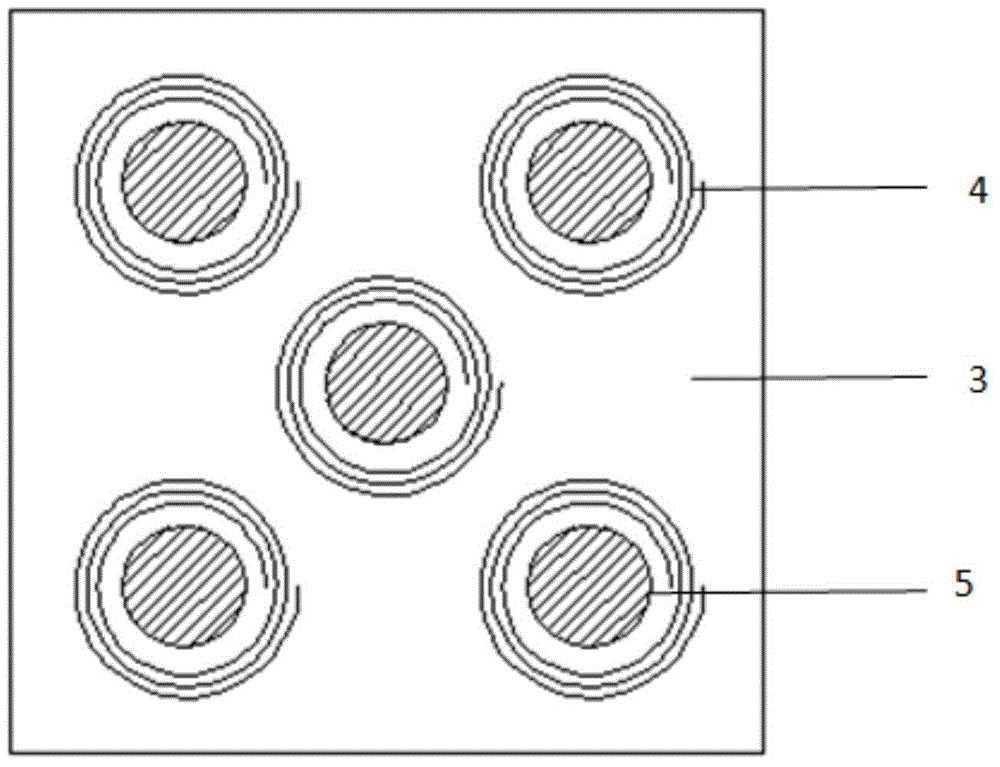

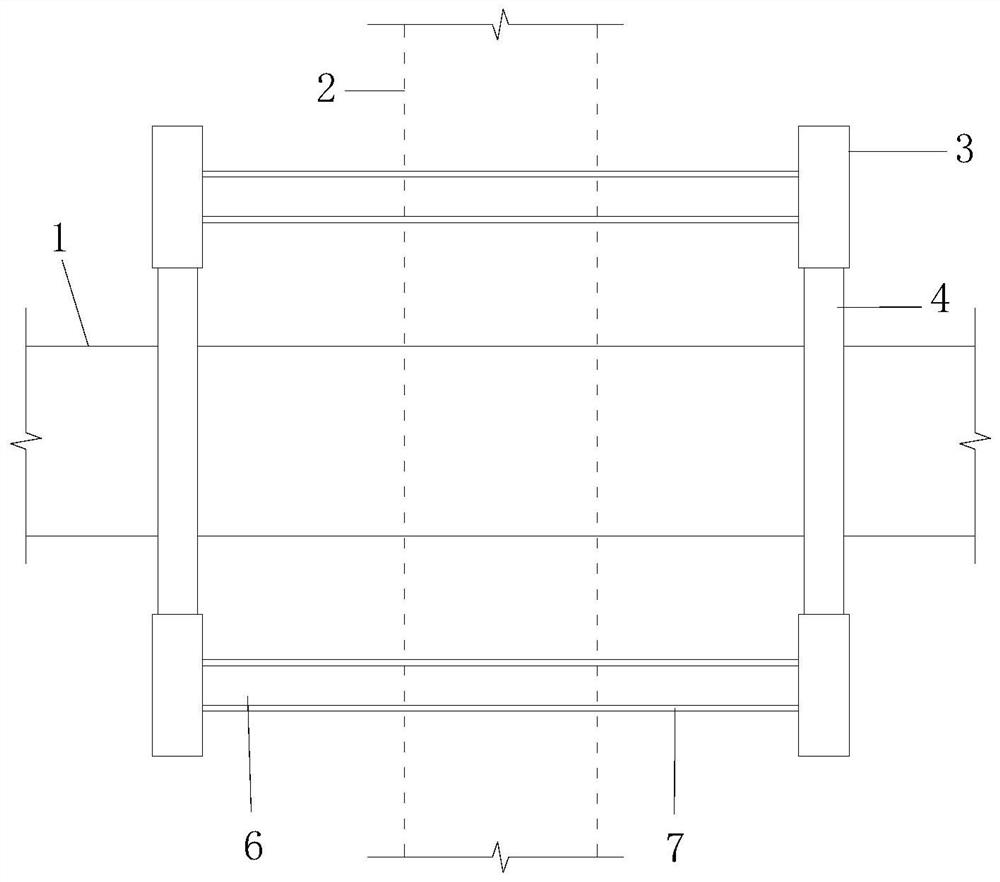

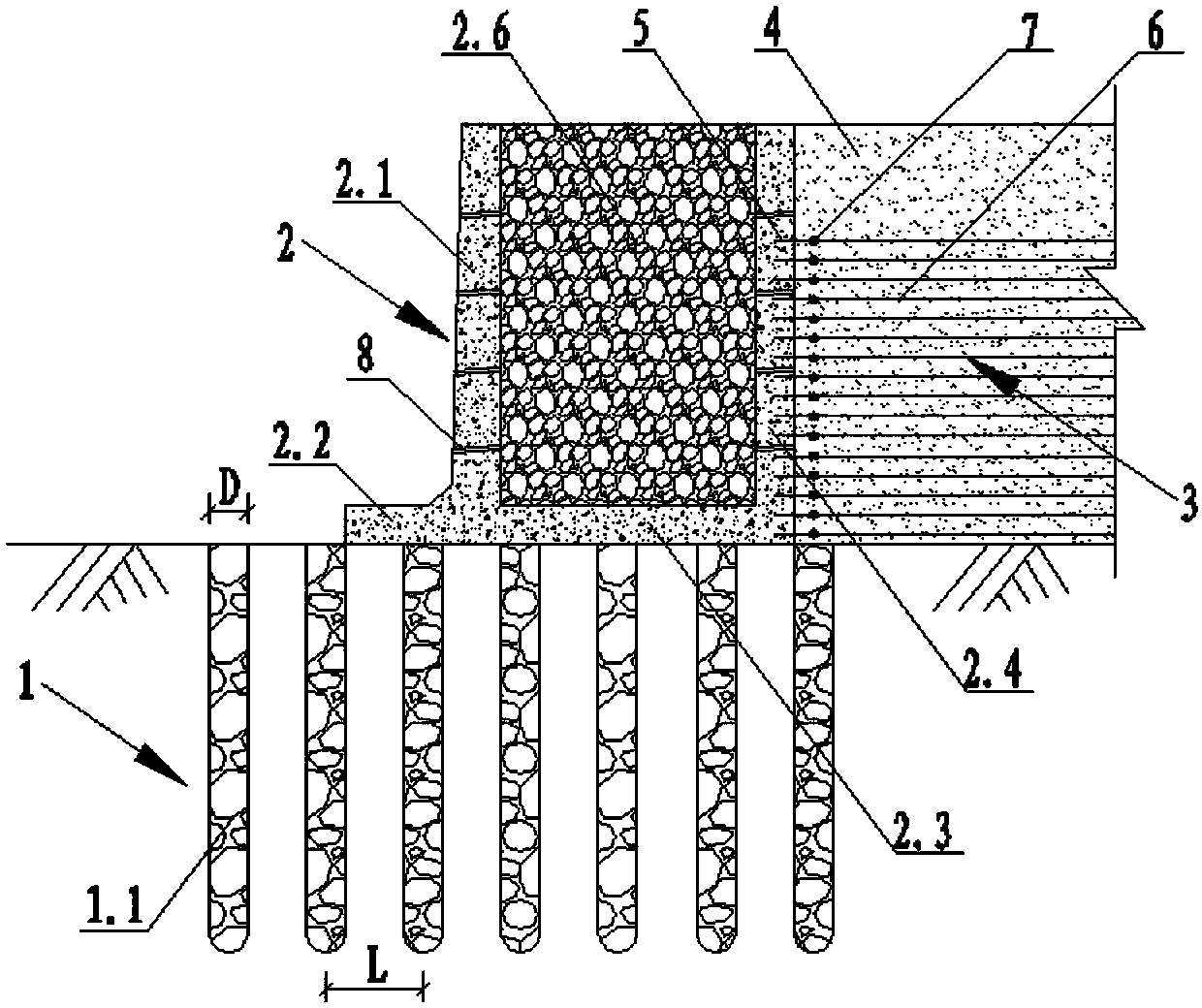

Retaining wall structure with composite foundation and reinforced gabions and construction method

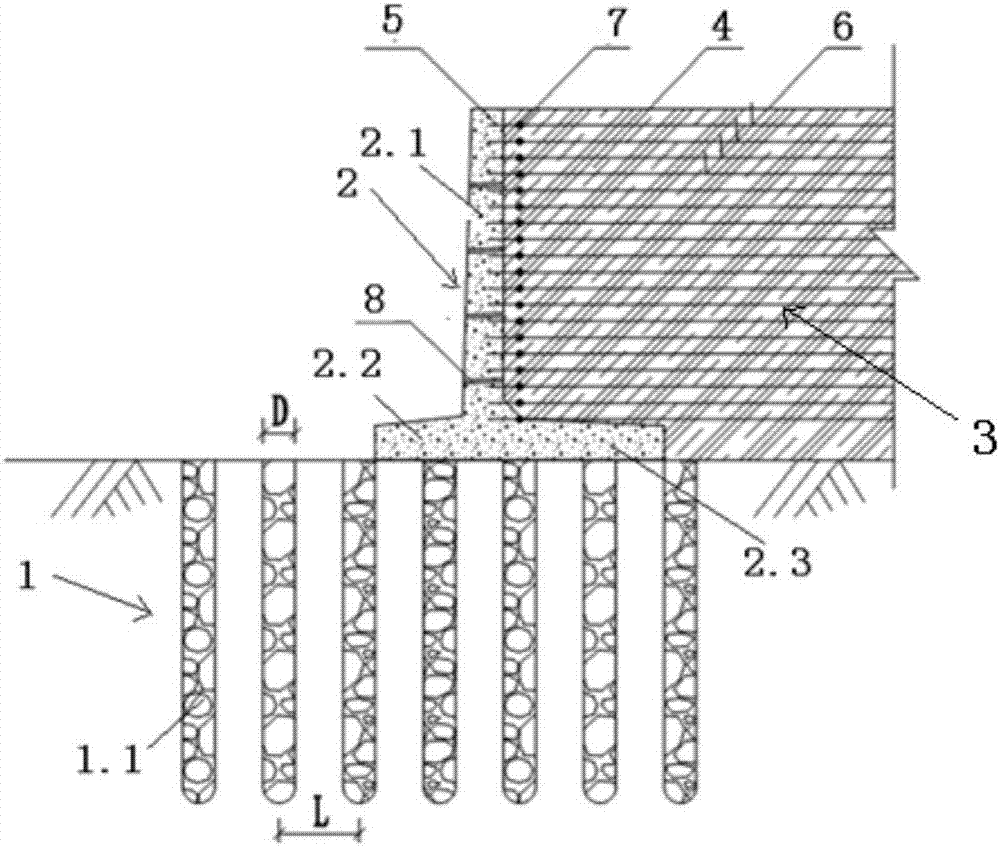

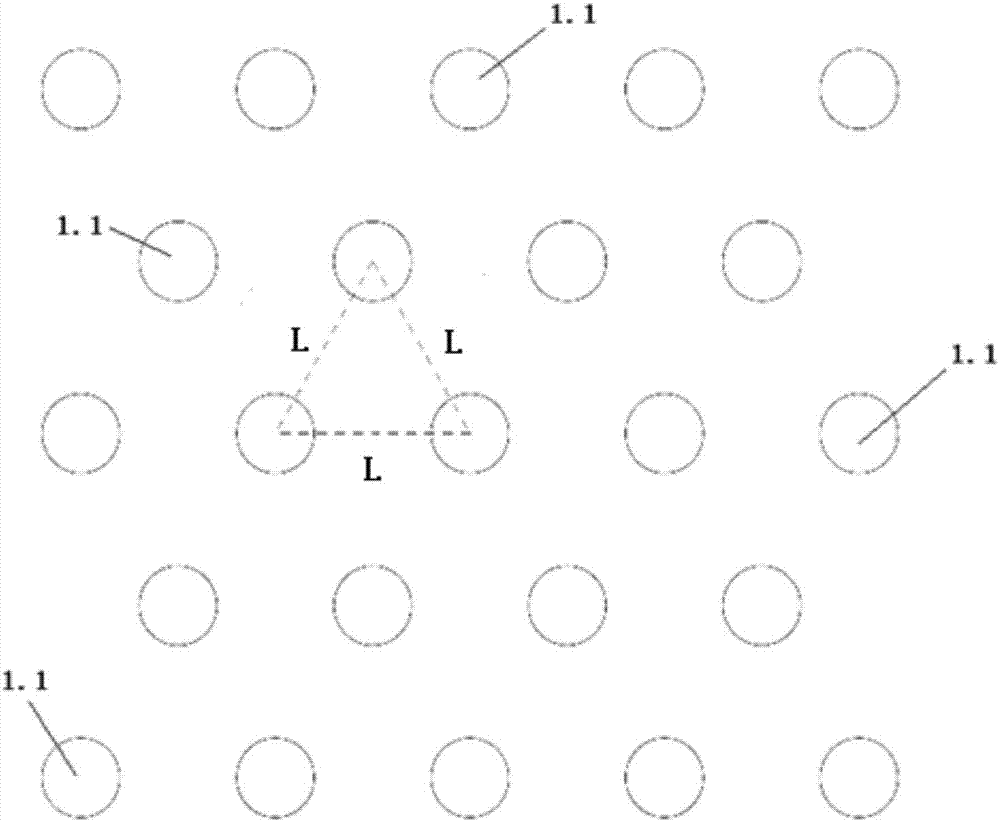

The invention discloses a retaining wall structure with a composite foundation and reinforced gabions and a construction method. The retaining wall structure is composed of the composite foundation (1), the multiple reinforced gabions (2), a geogrid (3), inverted filter layers (4) and filling bodies (5). The composite foundation (1) is located underground and composed of a plurality of vibration blunt gravel piles (1.1), the multiple reinforced gabions (2) are stacked on the upper portion of the composite foundation (1), the filling bodies (5) are arranged on the inner sides of the reinforcedgabions (2), and the geogrid (3) is arranged on the lower portions of the filling bodies (5). The inverted filter layers (4) are arranged between the reinforced gabions (2) and the filling bodies (5).According to the retaining wall structure and the construction method, the defects that in the prior art, the bearing capacity of a foundation is low, and a retaining wall and filling bodies behind the wall greatly deform accordingly and are even instable to be damaged are overcome, and the retaining wall structure and the construction method have the advantages that construction is easy and convenient, the construction speed is high, and the wall body manufacturing cost is low.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Prefabricated high-pressure airbag isolation pile structure with grouting function and construction method

PendingCN110144901AMake up for displacement deformationControlled Diffusion RangeExcavationsBulkheads/pilesEngineeringHigh pressure

The invention relates to a prefabricated high-pressure airbag isolation pile structure with a grouting function and a construction method. The structure comprises a prefabricated high-pressure airbagpile body, an automatic adjusting system and a grouting system. The structure has the following beneficial effects: the prefabricated high-pressure airbag isolation pile is adopted to replace a traditional isolation pile; a high-pressure airbag is distributed in soil near the bottom of a foundation pit by a certain depth range, high-pressure gas is injected in the high-pressure airbag to form expansion pressure to change a peripheral stress field to cut off a stress transfer path, so that the horizontal traction effect of the rigid isolation pile is eliminated, and the displacement deformationgenerated by self deformation of the traditional isolation pile is made up; and the inflation expansion of the prefabricated high-pressure airbag is used for assisting the prefabricated pile to resist the deformation of the soil to realize real-time adjustment of the displacement of deep soil, so that the effect is better compared with the traditional isolation pile, the displacement deformationof the traditional isolation pile due to insufficient rigidity is made up, and the displacement of the deep soil on the outer side of an active area is reduced.

Owner:NINGBO UNIV

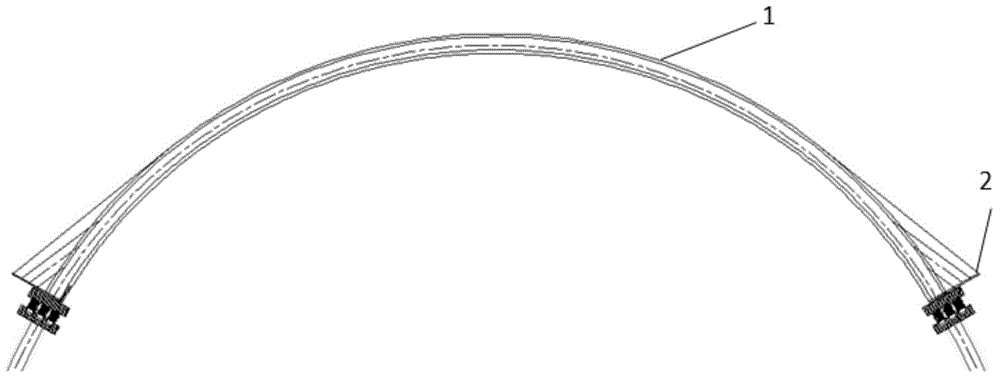

Device for improving bearing performance of steel arch of dilative soil large-section tunnel

InactiveCN104948207ASimplify the construction processQuality assuranceUnderground chambersTunnel liningSheet steelHigh intensity

The invention discloses a device for improving the bearing performance of a steel arch of a dilative soil large-section tunnel. The device comprises an arched support. High-strength round spiral steel bars and rigid supporting bases are arranged at large arch feet at the bottom of the arched support, each large arch foot comprises an upper-layer steel plate and a lower-layer steel plate connected with the upper-layer steel plate through five high-strength round spiral steel bars in a plum pile mode, and the rigid supporting bases penetrate through the high-strength spiral steel bars; five supporting base insertion grooves are formed in each lower-layer steel plate, and the supporting base insertion grooves are used for fixing the supporting bases so as to guarantee the overall stability of the steel arch. The device can relieve the settlement deformation of surrounding rock at the initial stage of excavation of the dilative soil tunnel, improve the self-stabilization capacity of the tunnel effectively and lastingly, form a multifunctional surrounding rock reinforcement area and guarantee the safety of tunnel constructors and protect equipment.

Owner:SHANDONG UNIV

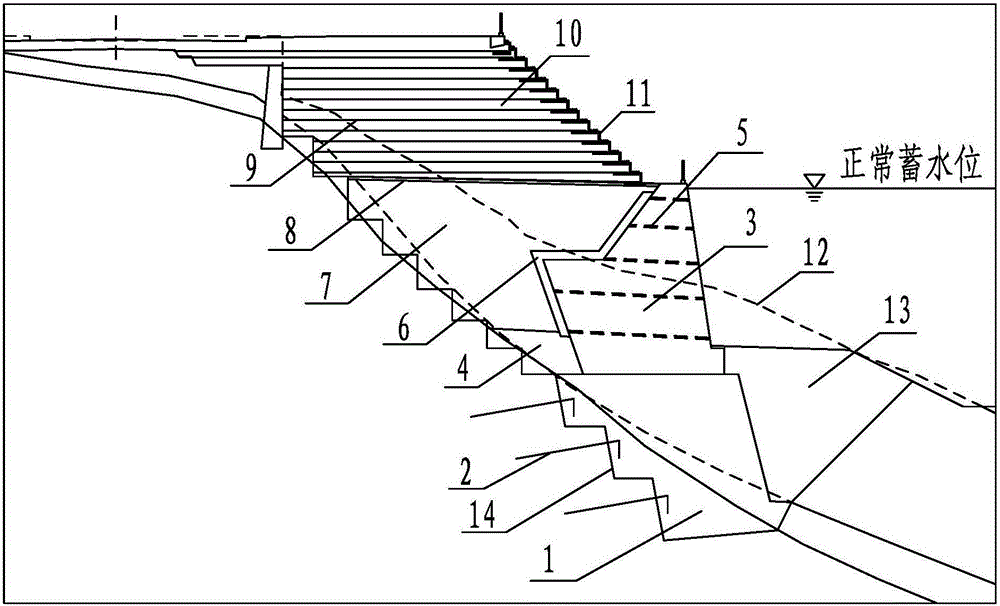

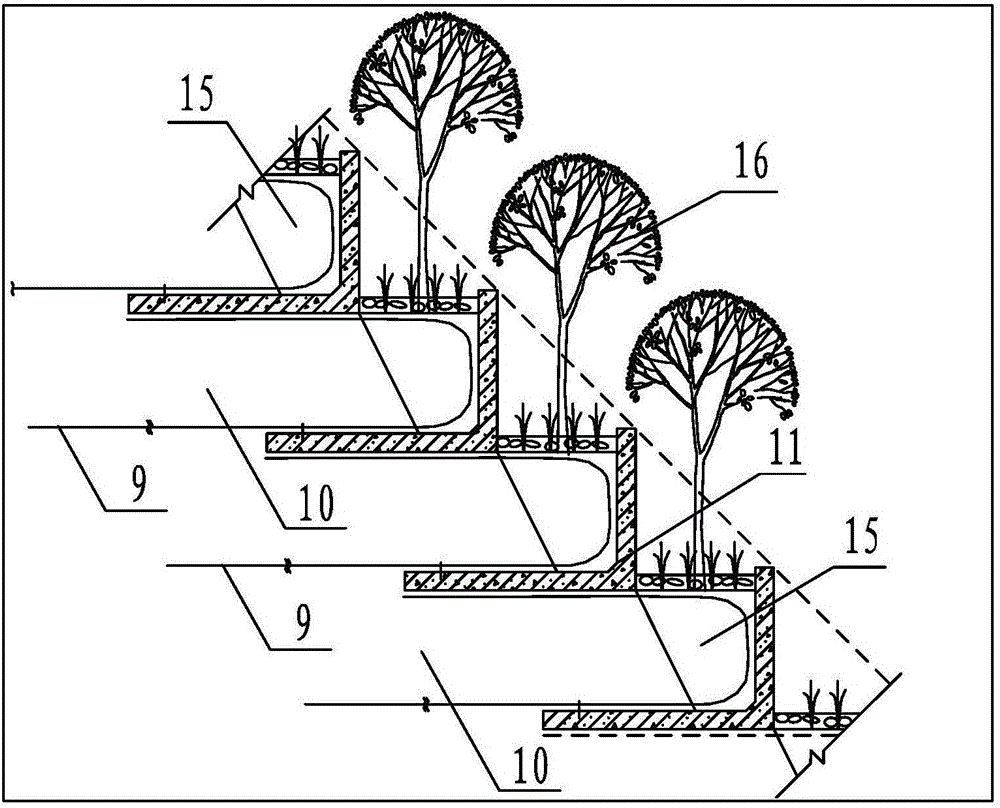

Ecological slope protection composite retaining wall structure and construction method

The invention discloses an ecological slope protection composite retaining wall structure which comprises an ecological abrupt slope and a basic retaining wall constructed along a bank slope of a reservoir. The ecological abrupt slope is located above the normal pool level. The basic retaining wall is located below the normal pool level. The basic retaining wall comprises a retaining wall step-type foundation and a retaining wall body. The retaining wall body is located above the retaining wall step-type foundation. The retaining wall step-type foundation is arranged on intermediary weathered rock below a basic slot excavation line. The ecological slope protection composite retaining wall structure is applicable to geological conditions with the large water level amplitude and abrupt slope, occupies the small flood control capacity of a reservoir, and can also be soaked into water for a long time. The invention further relates to a construction method of the ecological slope protection composite retaining wall structure.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Construction method of hard soil field PCC pile

ActiveCN104929108AReduce side frictionAvoid disturbanceBulkheads/pilesExtrusionBuilding construction

The invention discloses a construction method of a hard soil field PCC pile. A valve pile shoe is arranged in a pile mold inner pipe; the length of a pile mold outer pipe is increased; and after a pile machine is in place, soil having the same section with a pile mold is taken in the center of a pile position. The outer pipe is longer than the closed valve pile shoe; a pile tip formed by the valve pile shoe is inwards inclined; in the vibration mold sinking process, the pile mold mainly generates inward horizontal component force on pile core soil, so that the pile core soil is inwards deformed to fill a reserved cavity, and the disturbance on pile side soil is little; meanwhile, the extrusion stress of the pile core soil on the inner pipe is reduced, and the mold sinking difficulty is reduced in the pile mold driving process; and in the pile mold hoisting process, the side friction resistance of the pile core soil on the inner pipe is reduced, that is, the ascending force of the pile core soil is reduced. The construction method is simple in structure, easy to realize, convenient for operation and low in cost, can effectively reduce the mold dipping difficulty on the hard soil layer and the ascending force of the pile core soil, and is an efficient and practical method in the PCC pile construction.

Owner:江苏斯维尔工程技术有限公司

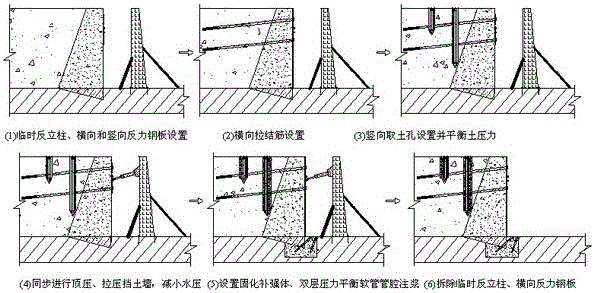

Construction method for repairing lateral displacement of retaining wall

ActiveCN105672350AReduce disturbanceReduce earth pressureArtificial islandsUnderwater structuresPull forcePressure balance

The invention relates to a construction method for repairing lateral displacement of a retaining wall. The method is characterized by comprising steps as follows: vertical borrow holes are vertically drilled in a soil body on the outer side of the wall back of the retaining wall, and dual-layer pressure balance hoses are inserted; transverse reaction steel plates and vertical reaction steel plates are arranged on the wall surface of the retaining wall, and transverse tie bar penetration holes and retaining wall ejection limiting grooves are formed in the transverse reaction steel plates and the vertical reaction steel plates respectively; a temporary reaction column is arranged on the outer side of the retaining wall, ejection devices are arranged between the reaction column and the reaction steel plates, and obliquely downward ejection force is applied to the retaining wall; transverse tie bars are arranged between the retaining wall and the soil body on the outer side of the wall back; obliquely downward ejection force and transverse pull force are applied to the retaining wall while vertical borrowing is performed; finally, oblique grouting holes are formed in the bottom of a foundation of the retaining wall, and solidified reinforcing bodies are formed through grouting. With the adoption of the method, the lateral displacement of the retaining wall can be repaired quickly, the integrity of the repaired retaining wall and the soil body on the outer side of the wall back can be enhanced, and the carrying capacity of the foundation of the retaining wall can also be improved.

Owner:洪都建设集团有限公司

Multi-pile stepped retaining structure combined with manual filling soil grouting-reinforcement technology and construction method of multi-pile stepped retaining structure

InactiveCN109881683AReasonable forceStrong deformation control abilityExcavationsStructure of the EarthDeformation control

The invention provides a multi-pile stepped retaining structure combined with a manual filling soil grouting-reinforcement technology and a construction method of the multi-pile stepped retaining structure. The multi-pile stepped retaining structure comprises multiple levels of slopes with different heights, each level of slope is retained through a plurality of cantilever piles distributed linearly, and loose filling soil between multiple rows of support piles on all the levels of slopes are reinforced in a grouting mode. According to the multi-pile stepped retaining structure, the mechanicalproperties of filling soil bodies in front of and behind the support piles are improved through grouting reinforcement, and thus internal force values of the support piles are lowered substantially;and by arranging a multi-step platform, the soil pressure value of each step of slope is effectively decreased, and the vital effect on control over displacement of a support structure and deformationof an adjacent existing building is achieved. The retaining structure is reasonable in structural force and high in deformation control capability, and is constructed through a reverse construction method, disturbance on soil bodies around the adjacent existing building is little, and the safety risk of overlarge slope deformation to the ambient environment can be effectively prevented.

Owner:CCTEG CHONGQING ENG CO LTD

Load shedding measure of foam sheet applied to upper burying type constructional work (such as culvert)

InactiveCN1563589AReduce earth pressureEasy to implement on siteGround-workLoad SheddingCut and fill

This is a measure for reduce load on the EPS plates in covertly-up structure members (for example the culvert). 1) To define the strength intensity and thickness of EPS plate on the top of culvert according to the 1 / 2-1 / 3 pressure data of filled soil cylinder to define the thickness of it according the 2%-6% height of the culvert above the ground, for the pile based culvert according the practice condition. To define the strength intensity for use to side may be in accorded with the 1 / 2-1 / 3 value for use to the top. 2) To reduce load measures of the plane structure members use to the hole's side, adopt the calculate formula of horizontal pressure of soil cylinder, and for the members use to hole's top don't adopt the formula of pressure of soil cylinder.

Owner:四川川东高速公路有限责任公司

Penetrating protective structure realizing near-distance downward penetration of jacking pipe through pipe rack and construction method

ActiveCN111851597AImprove anti-settling performanceStable structureProtective foundationDirectional drillingReinforced concreteArchitectural engineering

The invention relates to the field of jacking pipe construction, in particular to a penetrating protective structure realizing near-distance downward penetration of a jacking pipe through a pipe rackand a construction method. The structure aims to solve the problems that according to relevant technologies, construction is inconvenient, protective effects are limited and structural stability is limited. The method comprises the steps of conducting stress pile hole digging operation; conducting earth cutting construction of a force transmission wall and a horizontal connecting beam; forming anintegral reinforced concrete structure composed of a stress pipe, the force transmission wall and the horizontal connecting beam; digging a working pit at the rear side of the force transmission wall;conducting construction of a supporting beam; conducting non-penetrating construction on a grouting hole; and conducting layered backfill of backfilled earth. The structure is convenient for construction, stable and good in protective effect.

Owner:ANHUI HIGHWAY ENG CORP

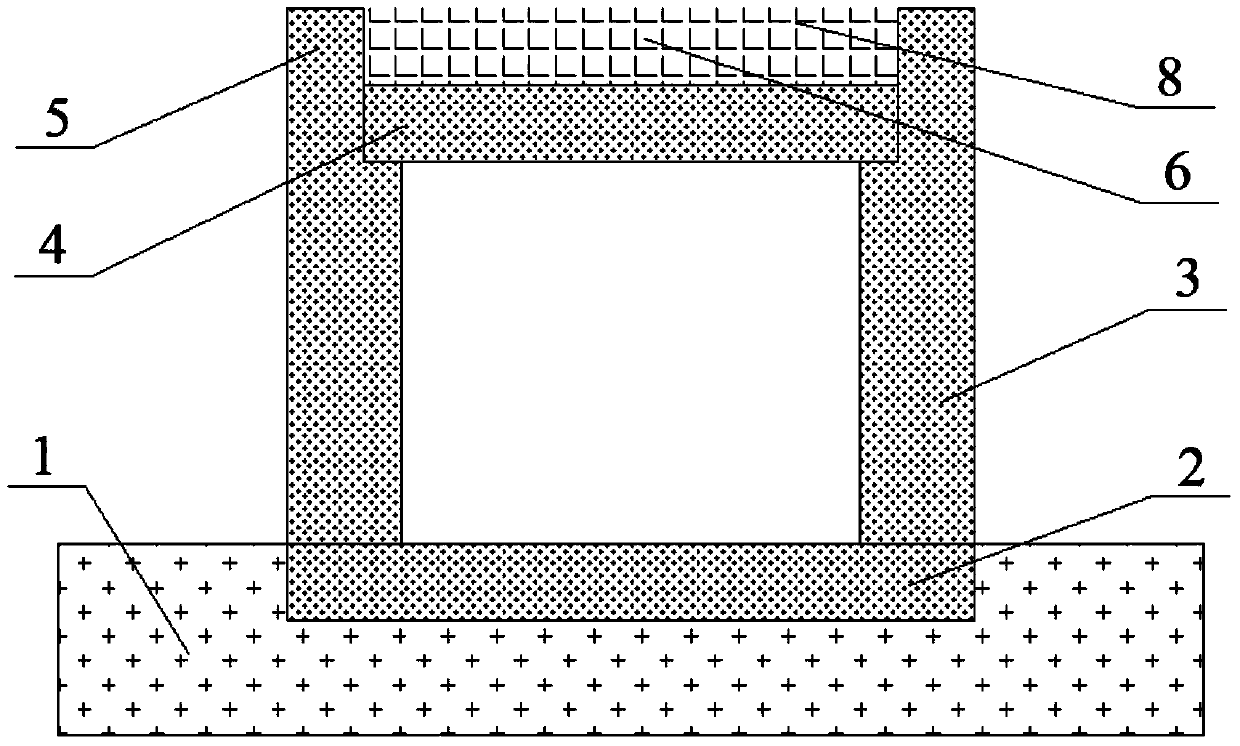

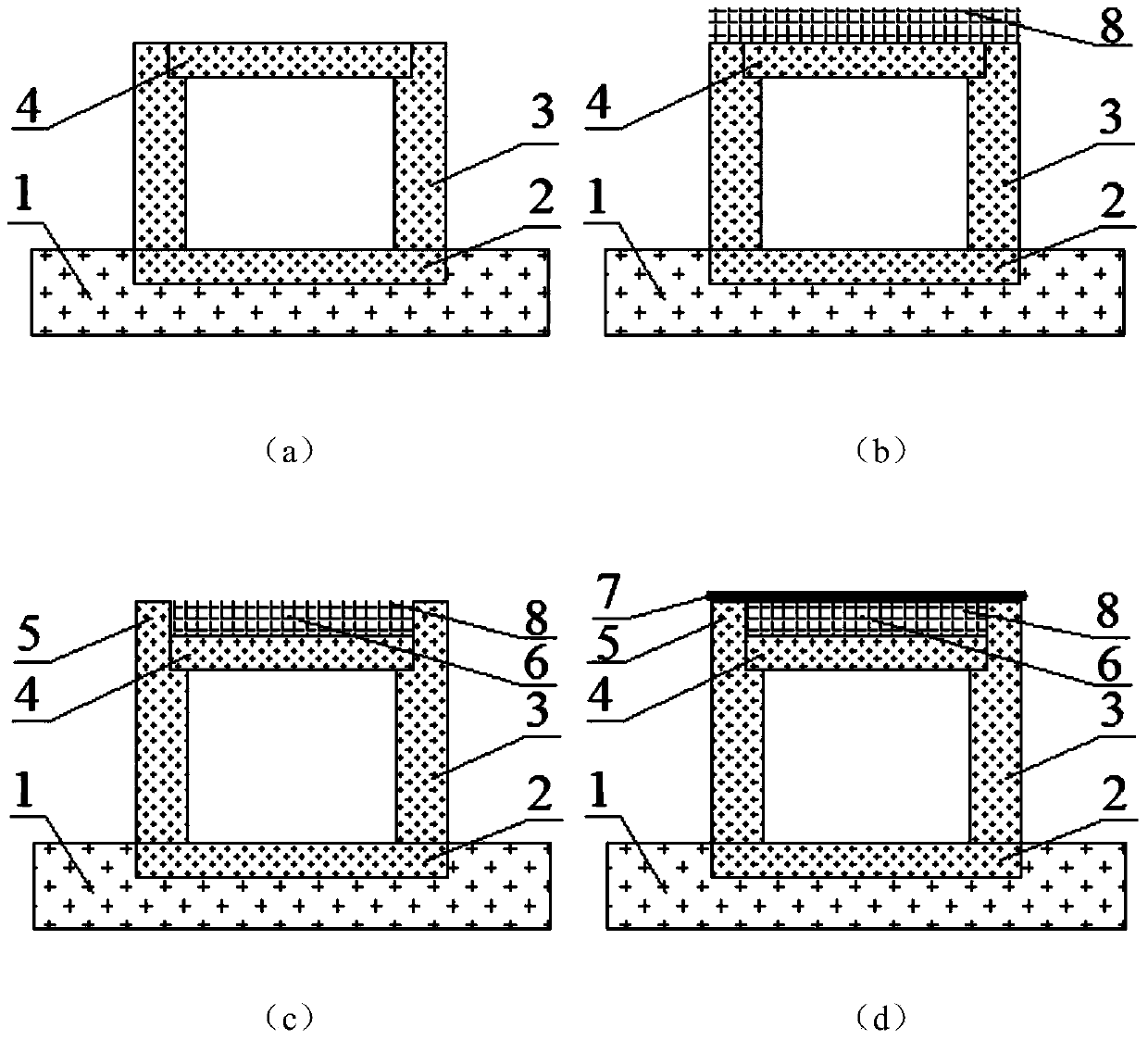

Composite foundation reinforced arch box retaining wall structure and construction method

PendingCN109653242ALow costSimple construction processArtificial islandsUnderwater structuresReinforced concreteCrushed stone

The invention relates to the technical field of retaining wall projects, in particular to a composite foundation reinforced arch box retaining wall structure and a construction method. The composite foundation reinforced arch box retaining wall structure comprises a composite foundation, an arch box retaining wall, a geogrid and a filling body, wherein the composite foundation is positioned belowthe ground and comprises a plurality of vibration crushed stone piles, the arch box retaining wall is positioned on the composite foundation, the filling body is arranged on the right side of a rear arch wall of the arch box retaining wall, and the geogrid is horizontally arranged in the filling body. A spongy soil foundation and a deep overburden foundation are reinforced by a vibro-replacement method, a wall body is provided with an arch box reinforced concrete structure, the geogrid is added into the filling body on the rear side of the retaining wall and connected with the rear arch wall,integrity and deformation resistance of the retaining wall and reinforcement can be improved, and the applicable wall height of the arch box retaining wall can be increased, so that project requirements are met.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

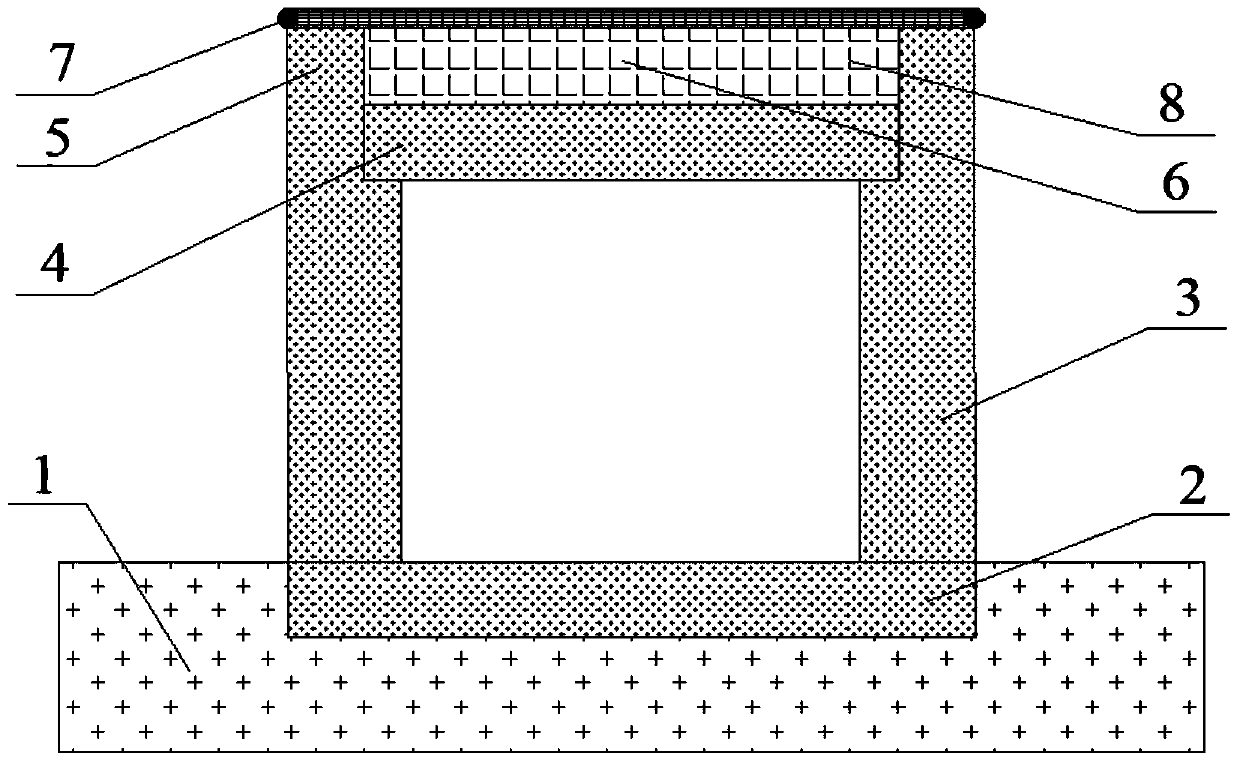

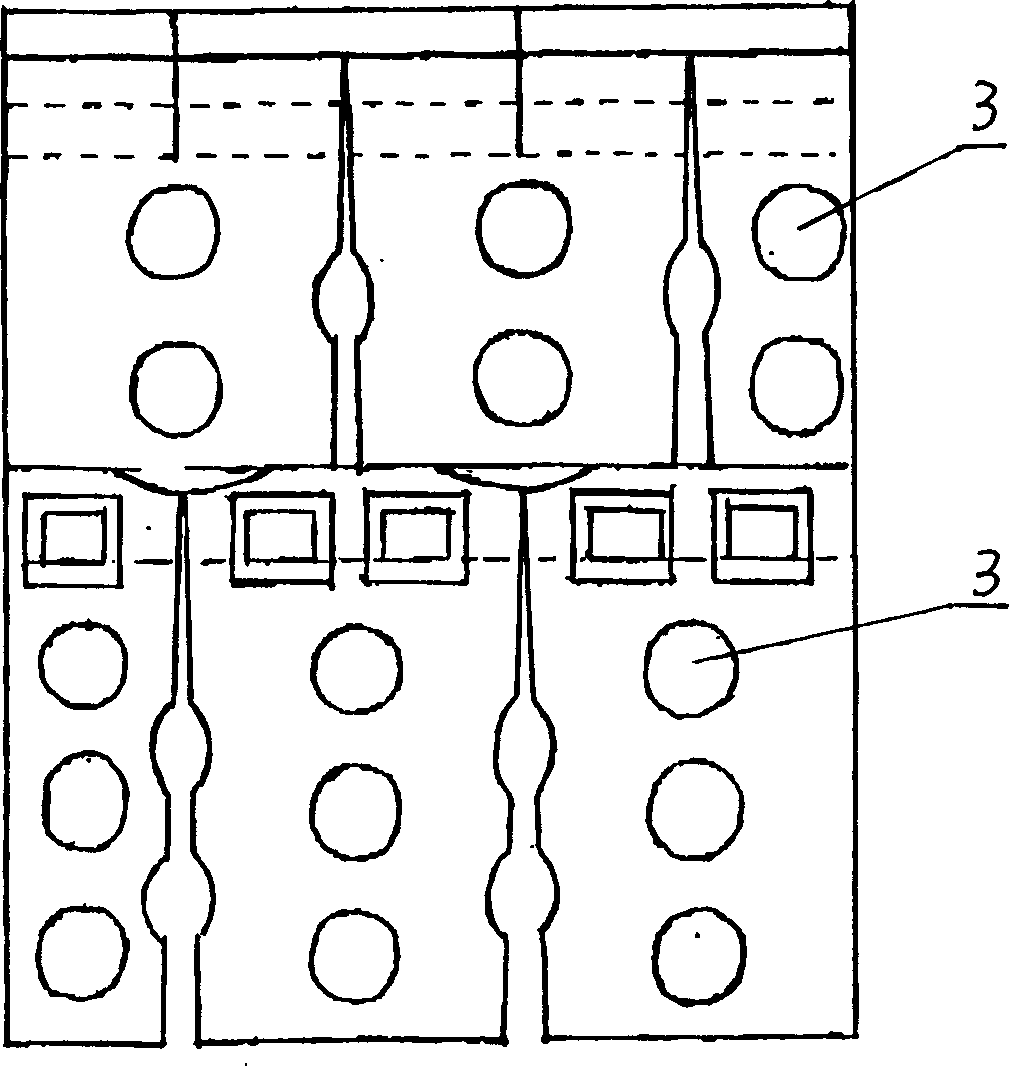

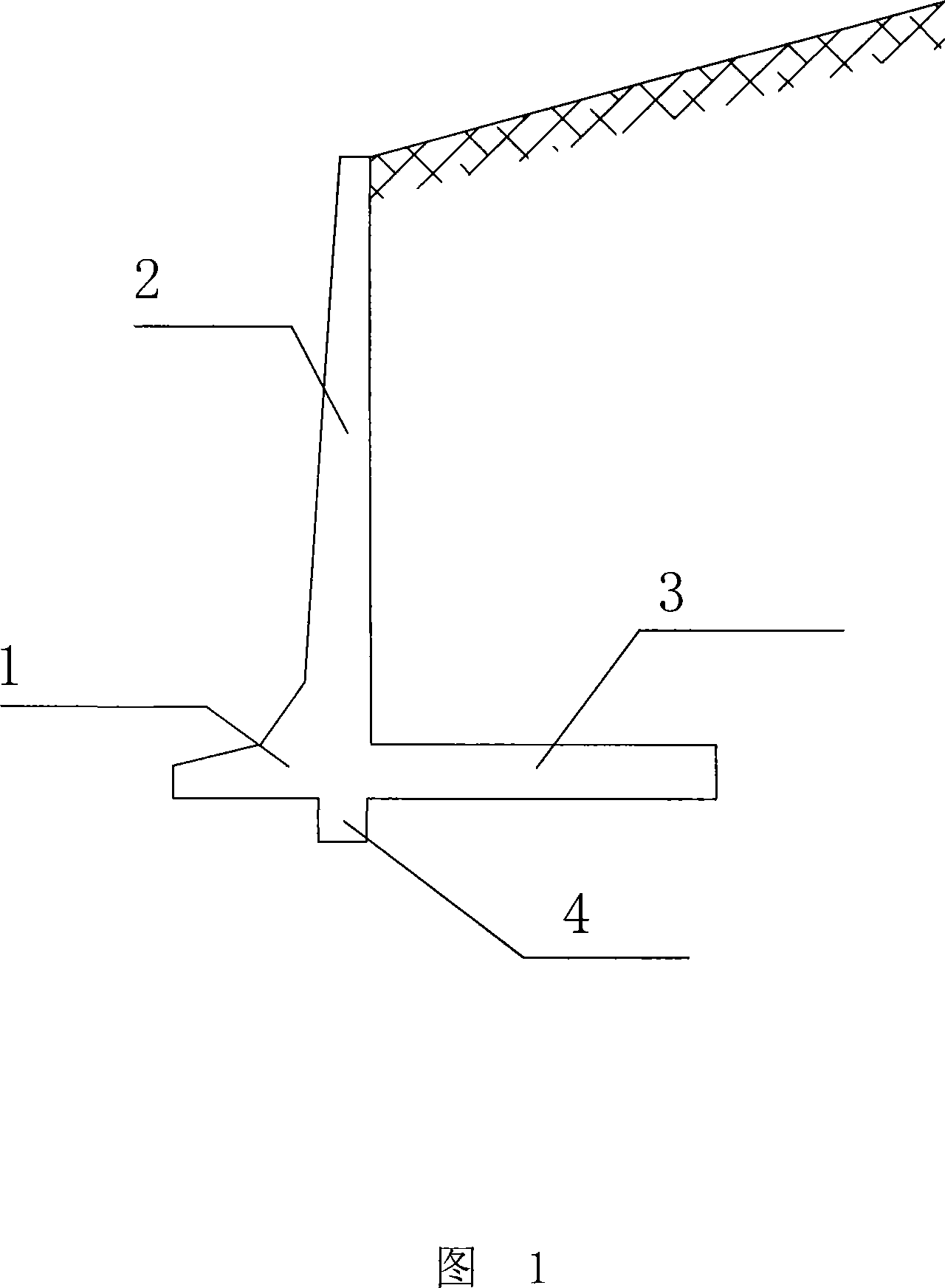

Composite foundation reinforced cantilever retaining wall structure and construction method thereof

PendingCN107514008ALow costReduce earth pressureArtificial islandsUnderwater structuresCrushed stoneEngineering

The invention discloses a composite foundation reinforced cantilever retaining wall structure and a construction method of the composite foundation reinforced cantilever retaining wall structure. The composite foundation reinforced cantilever retaining wall structure comprises a composite foundation (1), a cantilever retaining wall (2), a geogrid (3) and a filling body (4). The composite foundation (1) is located underground and composed of multiple vibro-replacement crushed stone piles (1.1). The cantilever retaining wall (2) is located above the composite foundation (1). The inner side of the cantilever retaining wall (2) is provided with the filling body (4). The geogrid (3) is transversely arranged on the lower portion of the filling body (4). The composite foundation reinforced cantilever retaining wall structure overcomes the defects that in the prior art, a traditional cantilever retaining wall structure cannot meet the stability requirements of the cantilever retaining wall structure and the filling body behind the wall and has the advantages that the construction technology is simple, convenient and rapid.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com