Frame-heat anchor pipe structure for preventing and treating cold-region slope collapse due to freeze thawing and construction method

A technology for hot anchor pipes and slopes, which is applied in the direction of infrastructure engineering, excavation, soil protection, etc., can solve the problems of increased project cost, long construction period, unfavorable stability of high and steep slopes, etc., to prolong the working life and improve The overall stability and the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

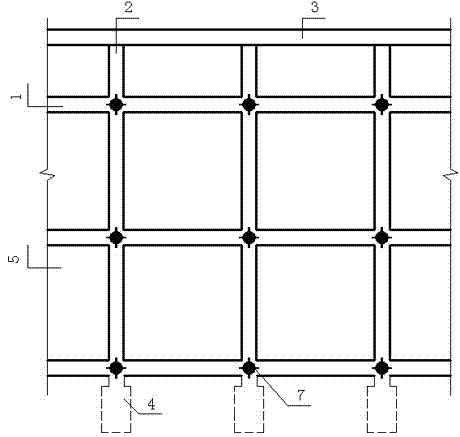

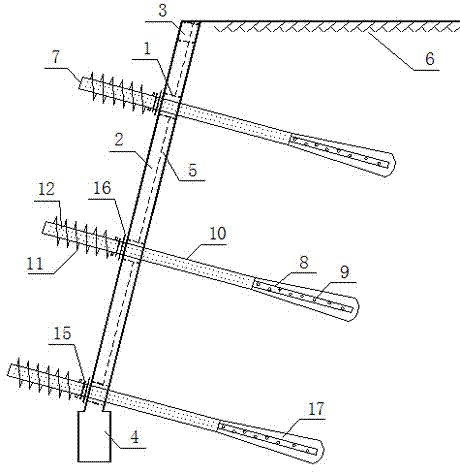

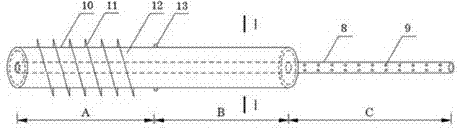

[0018] like figure 1 , 2 , 3, 4, and 5 show that the present invention is a frame thermal anchor pipe structure and a construction method for preventing and controlling cold region slope freeze-thaw slump, and a frame heat anchor pipe structure for preventing and controlling cold region slope freeze-thaw slump, and its structure consists of The beam 1, the column 2, the protective surface 5 and the heat anchor pipe 7 are composed of the condensation section A, the evaporation section B and the anchor section C; the metal inner pipe 8 is nested in the metal outer pipe 10, and the metal The two ends of the outer tube 10 are closed with entities to form a hollow closed cylinder, and liquid ammonia or other heat transfer working medium 12 is filled in the closed cylinder to form the condensation section A and the evaporation section B; There is a grout hole 9, and the cement anchoring agent 17 is injected into the pipe under pressure to make it seep out from the grout hole 9 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com