Patents

Literature

231results about How to "Easy to implement on site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tunnel deformation online monitoring system based on image analysis and application of system

InactiveCN102620673AEasy to implement on siteEasy to retrospective analysisImage enhancementImage analysisAdaptive filterImaging analysis

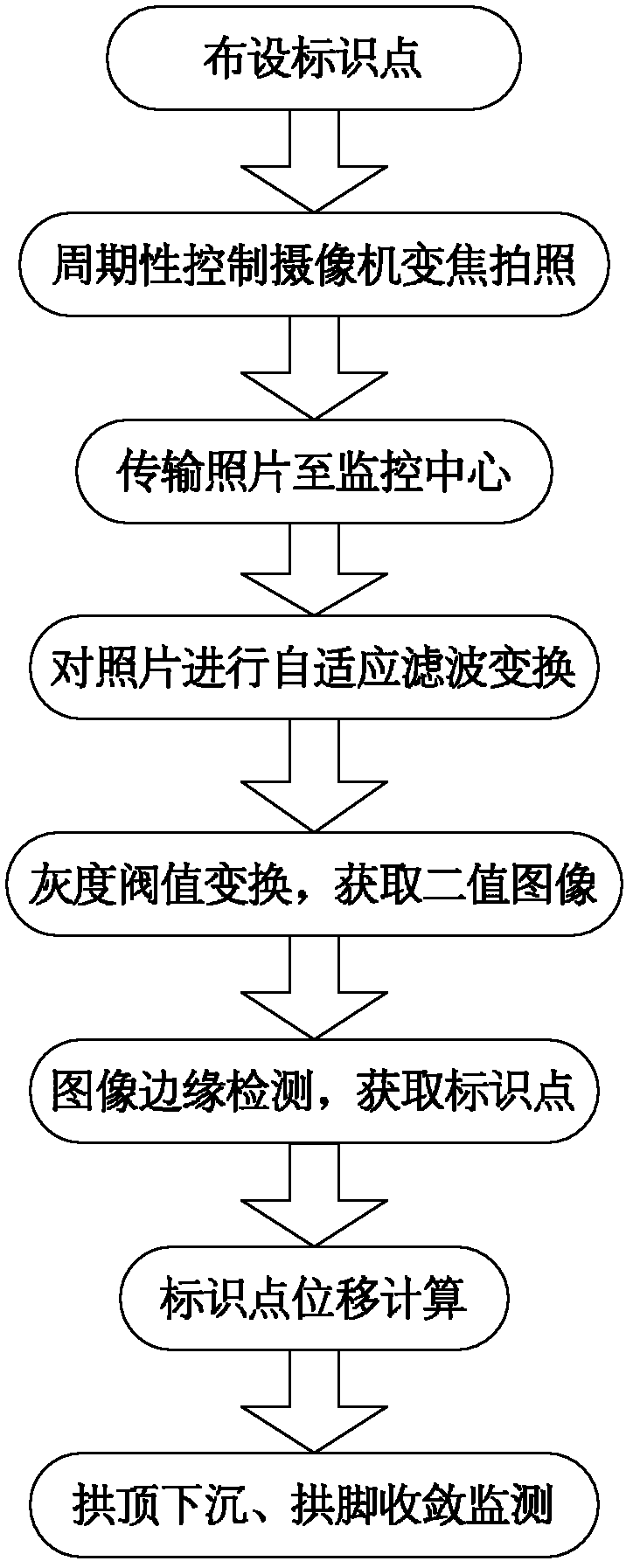

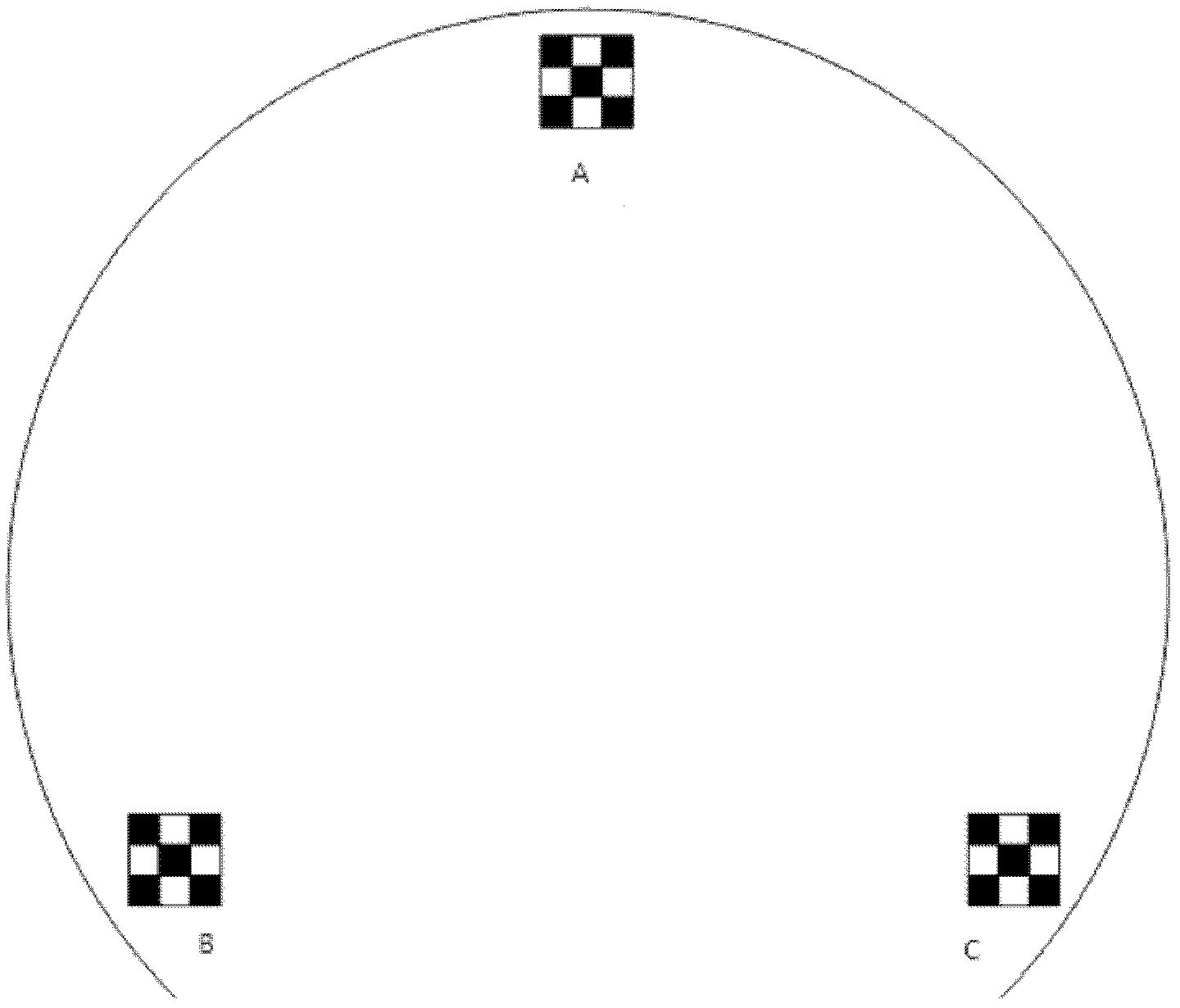

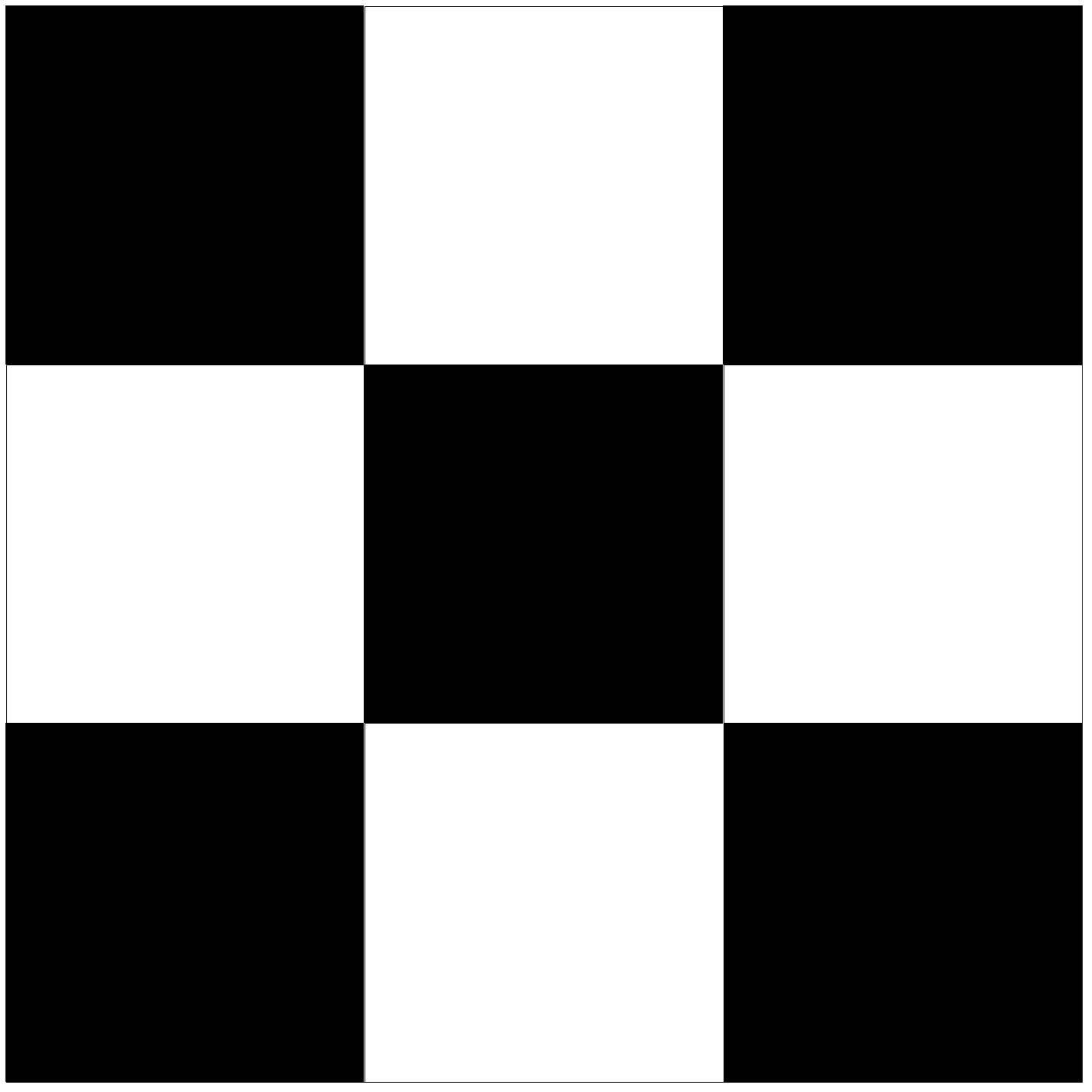

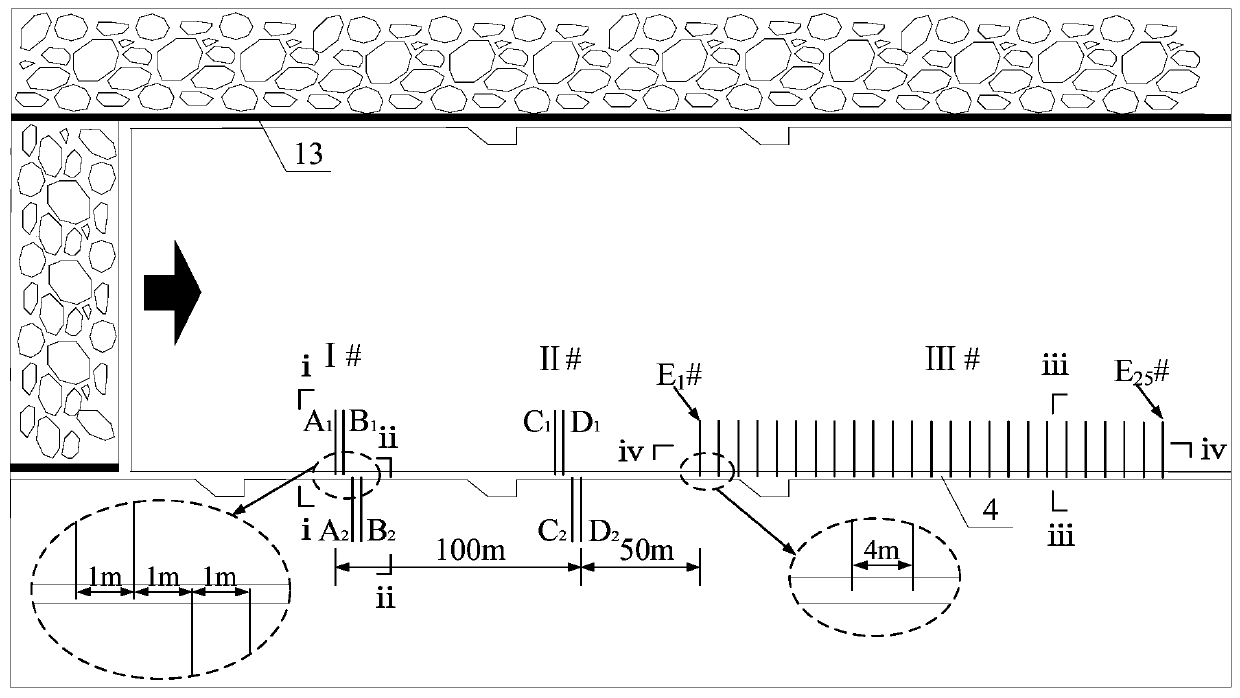

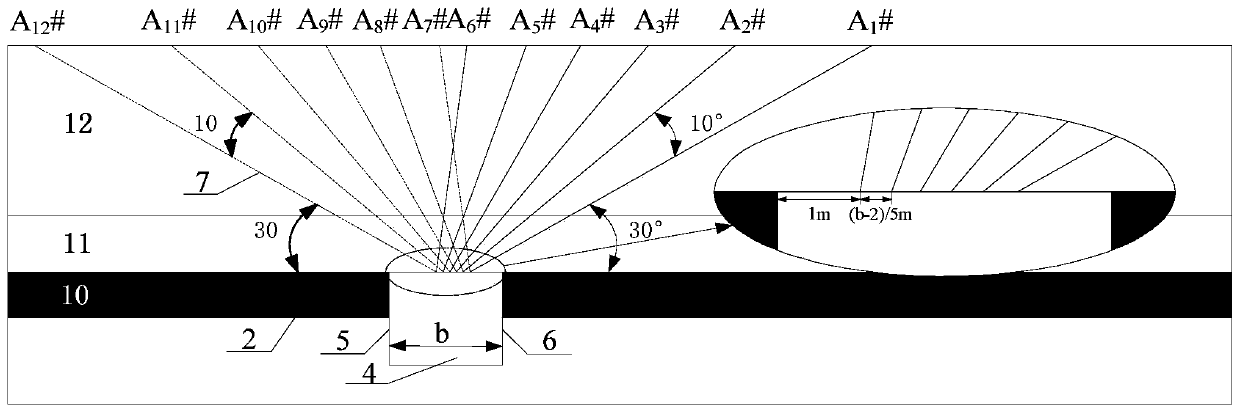

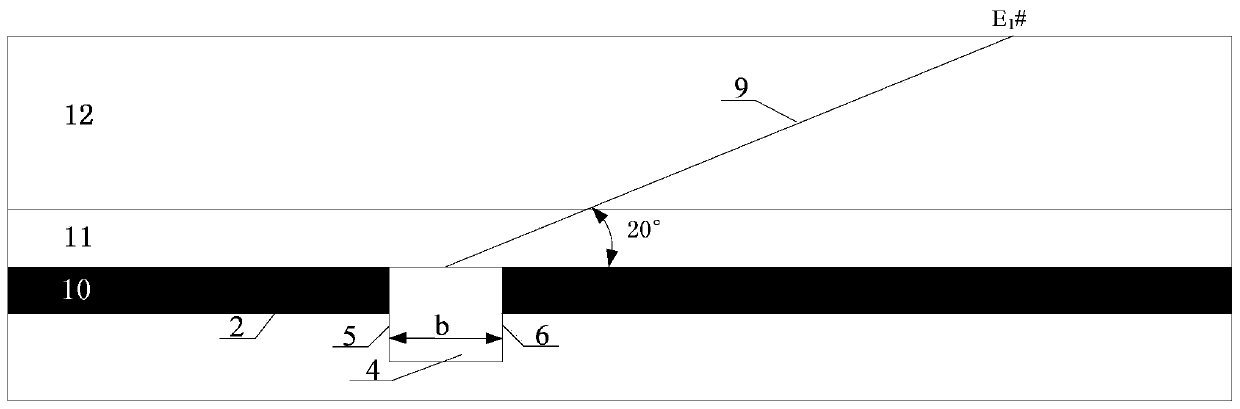

The invention relates to a tunnel deformation online monitoring system based on image analysis and application of the system. The system comprises an identification point, a network camera, a central control computer and a transmission network. The application of the system comprises the following steps of: 1) arranging the identification point; 2) periodically controlling the network camera to carry out zooming photography by the central control computer; 3) transmitting photos to the central control computer by the network camera; 4) performing adaptive filter transformation on the photos by the central control computer; 5) performing gray threshold value transformation by the central control computer; 6) performing image edge detection by the central control computer to acquire the identification point; 7) calculating arch crown sinking displacement and arch springing convergence displacement of the identification point; and 8) judging whether the arch crown sinking displacement and the arch springing convergence displacement are smaller than set threshold values, if so, returning to the step 2), otherwise, giving an alarm. Compared with the prior art, the invention has the advantages that the system is easy to implement and can realize online monitoring and automatic alarm.

Owner:TONGJI UNIV

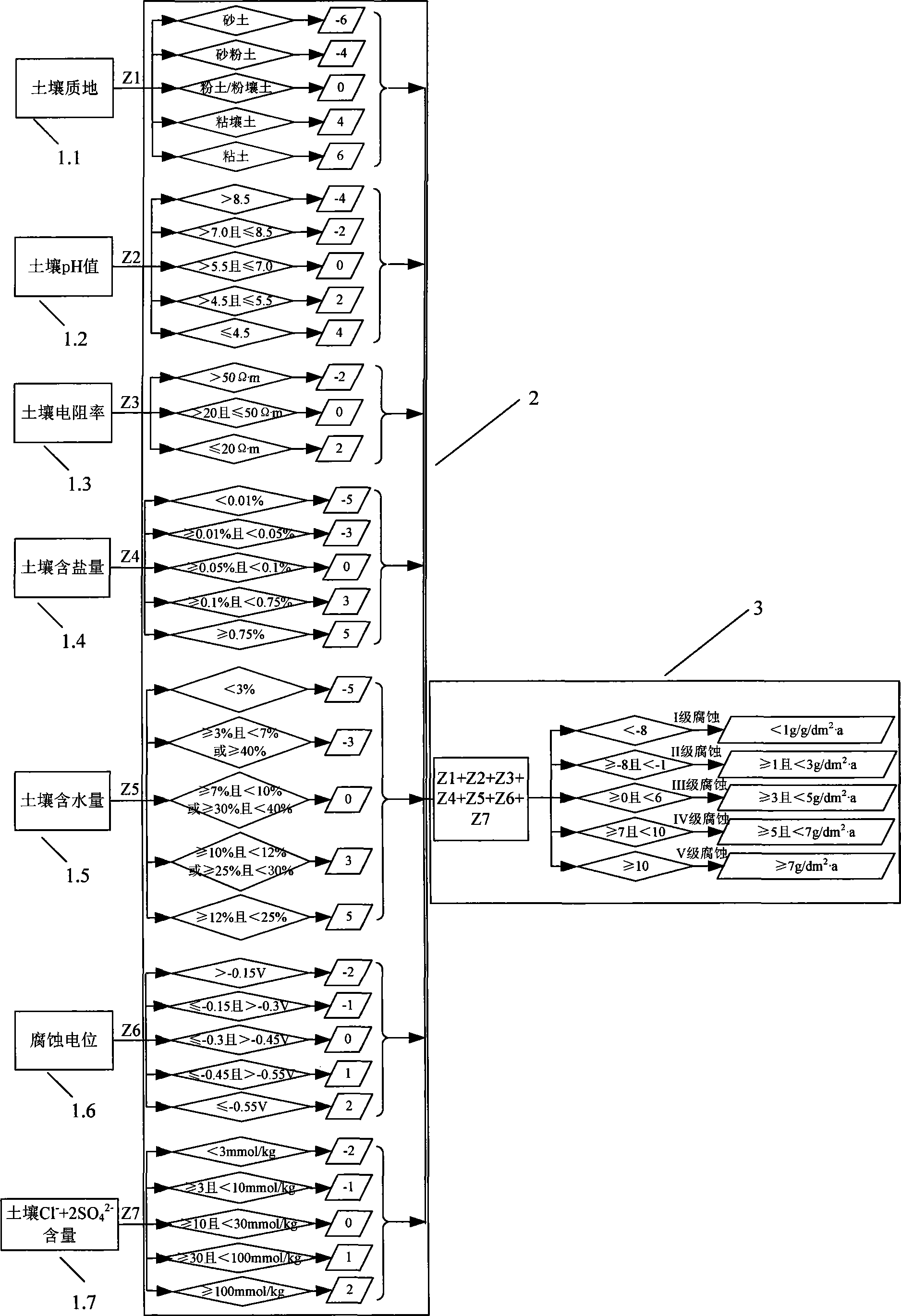

Soil corrosivity evaluation method for substation grounding network in Guangdong area

InactiveCN101504404AMeet practical application requirementsPredicted Corrosion LevelResistance/reactance/impedenceCurrent/voltage measurementGrounding gridSoil science

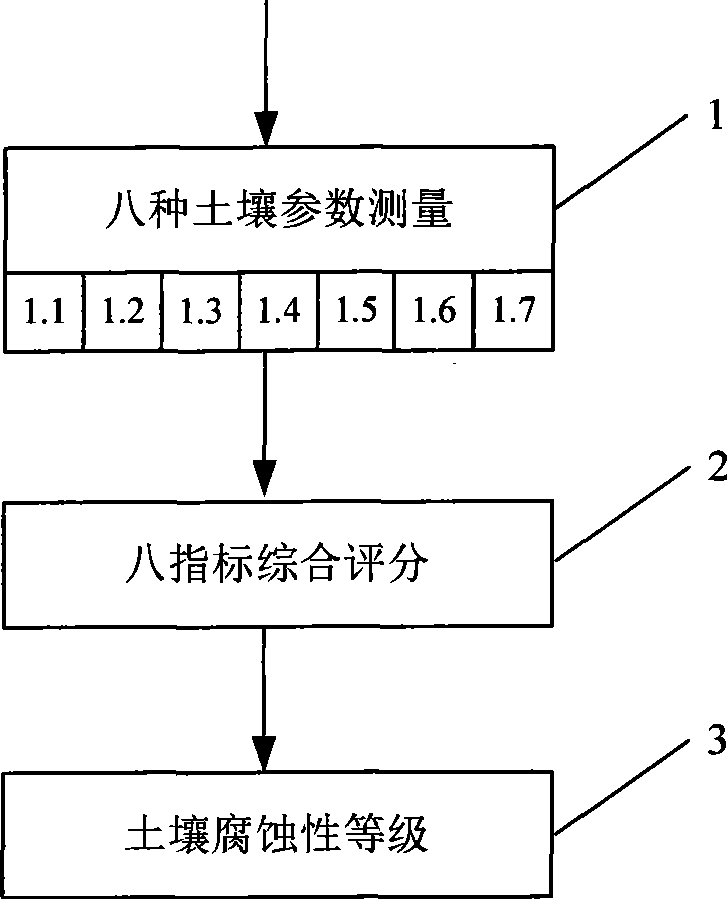

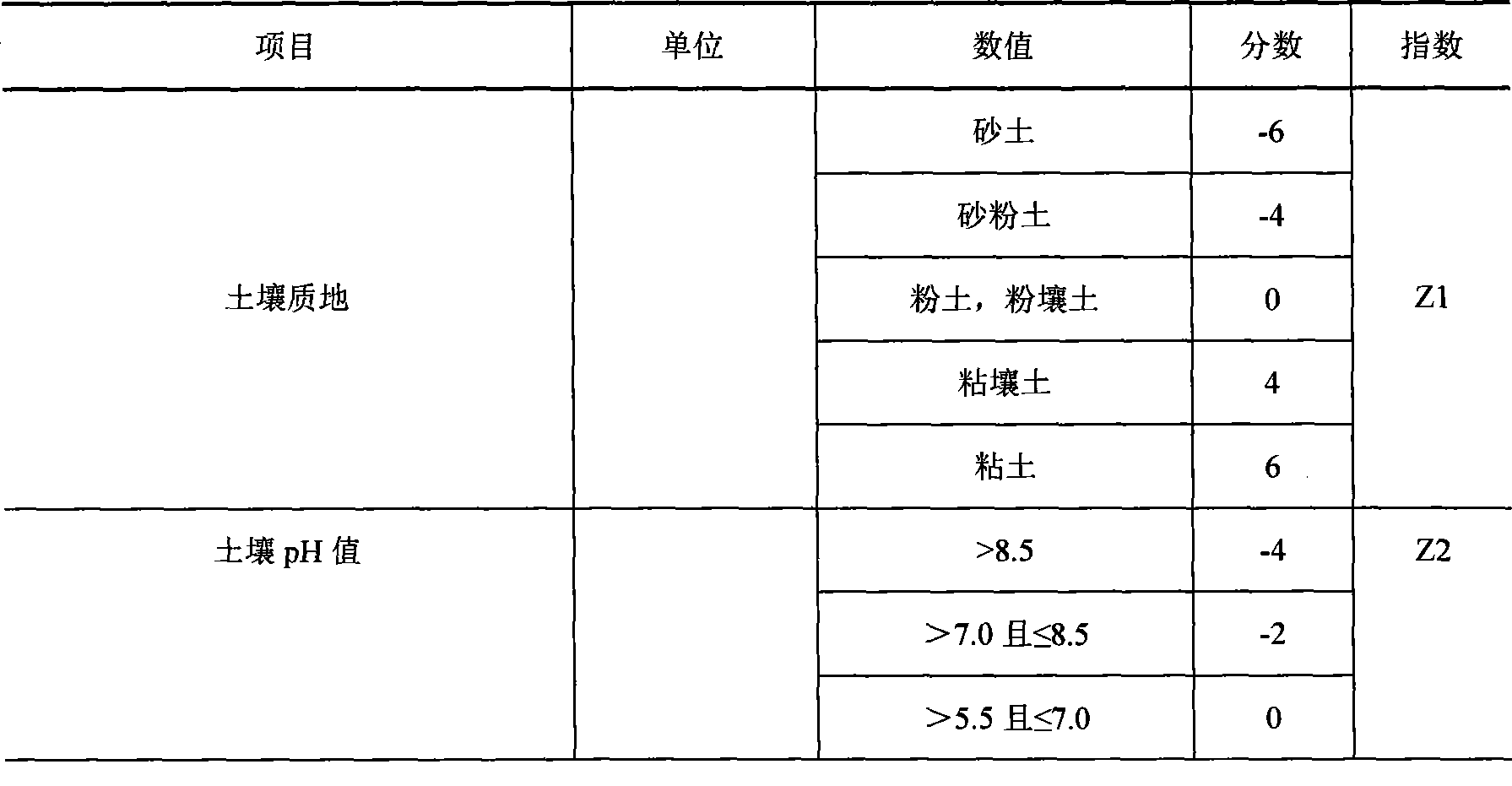

The invention discloses a method for evaluating soil corrosivity of a grounding grid of a substation in Guangdong region, and relates to a method for evaluating the soil corrosivity. The method comprises the following steps: (1) picking up the soil on the buried depth position of the grounding grid to measure eight soil parameters(1) by conventional methods; (2) utilizing an eight index comprehensive grading method to determine a comprehensive grade(2); and (3) determining the grade of the soil corrosivity according to an eight index comprehensive grading result(3). The eight soil parameters include soil texture(1.1), soil pH value(1.2), soil electric resistivity(1.3), soil salt content(1.4), soil water content(1.5), corrosion potential(1.6), and soil C1+2SO4 content (1.7). The method is not only used for evaluating the soil corrosivity environment caused by the grounding grid steel of the substation operated in Guangdong region and predicting the soil corrosivity environment caused by the grounding grid steel of a newly built substation, but also applied to evaluating the corrosive protection of the buried steel in other industries in Guangdong region.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

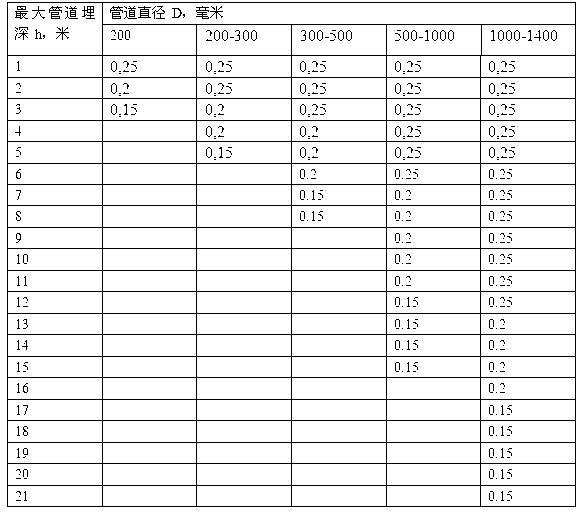

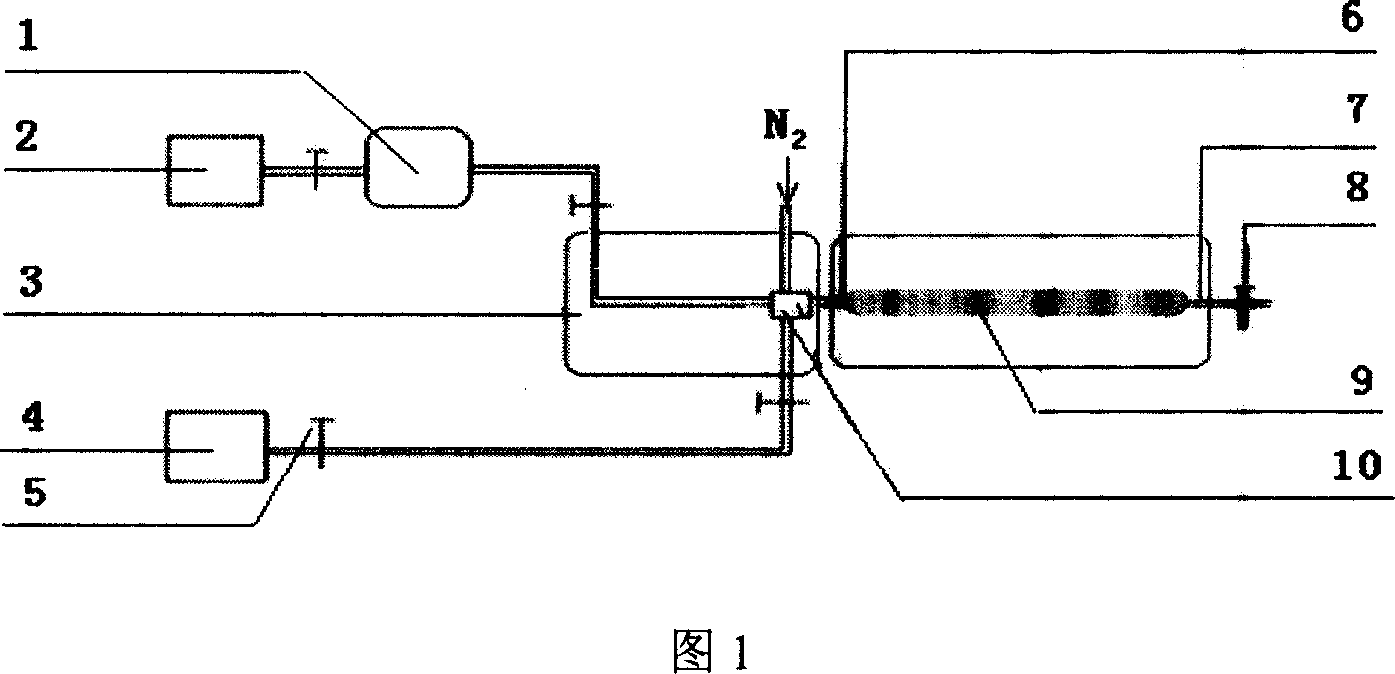

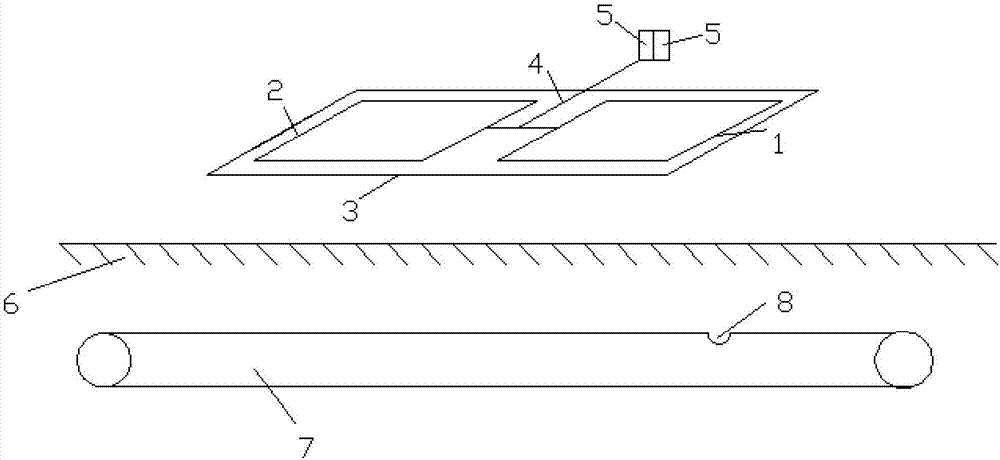

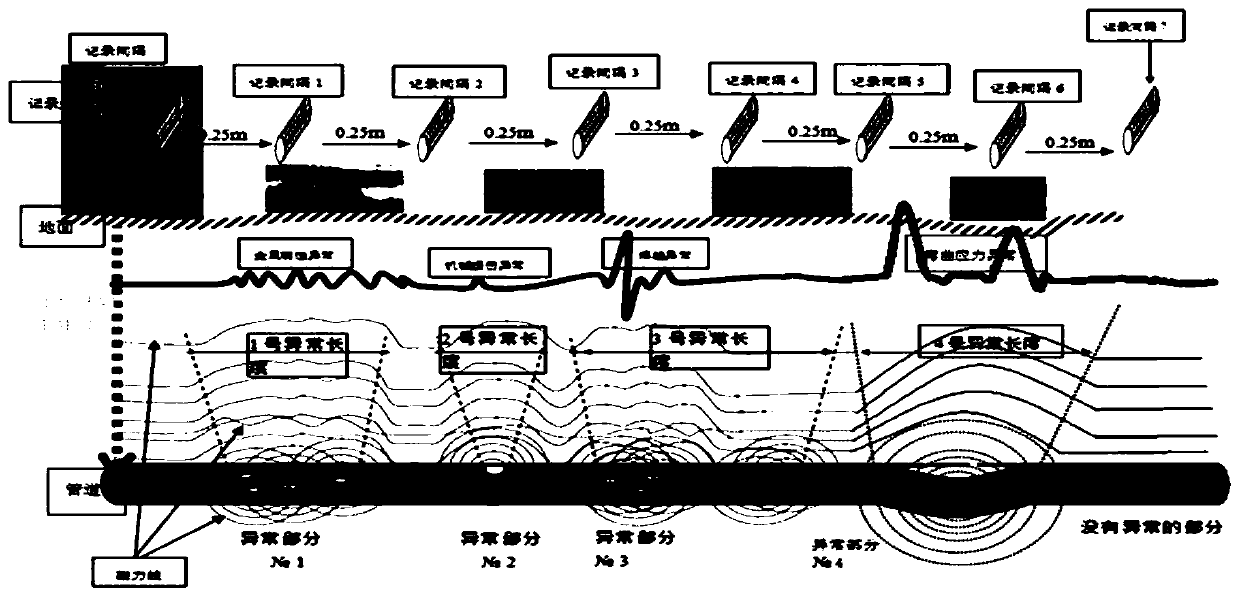

Non-contact pipeline magnetic detection method

ActiveCN103075641AUniform magnetizationEasy to detectPipeline systemsMaterial magnetic variablesPetroleumGeophysics

The invention discloses a non-contact pipeline magnetic detection method which relates to a damage detection technology of petroleum and natural gas buried metal pipelines. The non-contact pipeline magnetic detection method comprises the following steps that (1) initial analysis is conducted and the construction period is determined; (2) the ground is cleared and a route is marked; (3) a pipeline is detected; (4) detection data is analyzed and processed; and (5) a data result is processed. According to the non-contact pipeline magnetic detection method, the defects of an existing contact method for detecting the local defects of the pipeline, such as a complicated process in which blind excavation is carried out, the pipeline is cleared and demagnetized, and finally the pipeline is uniformly magnetized, are overcome; and the pipeline is uniformly magnetized by the earth magnetic field, on-line detection can be carried out on the surface of a work piece without clearing the surface of the detected work piece or pre-treating the surface of the detected work piece in other ways, so that the detection process is greatly simplified, the speed is high, the efficiency is high, and the detection depth is greatly increased.

Owner:SICHUAN HUIZHENG PIPELINE TECH

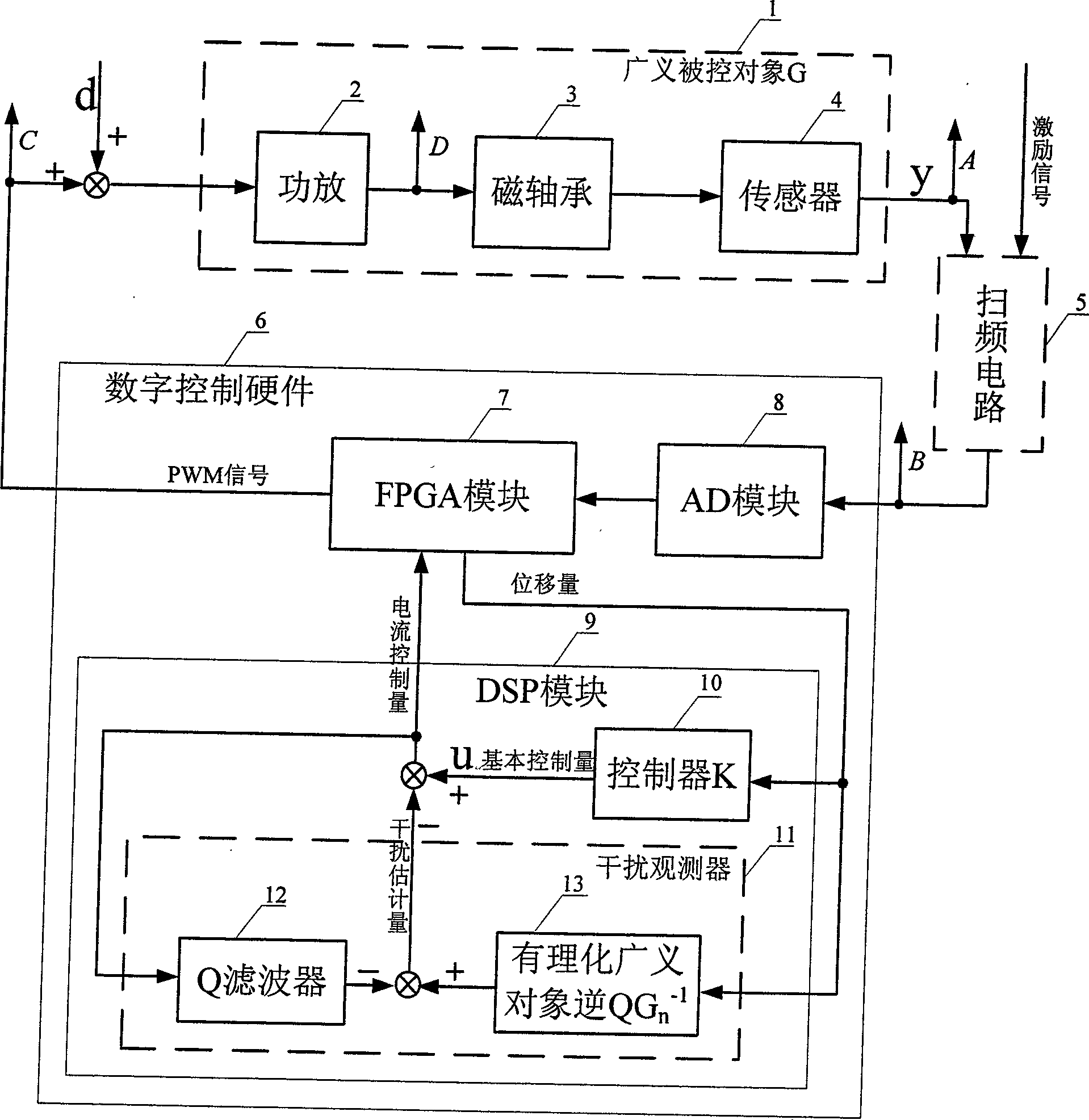

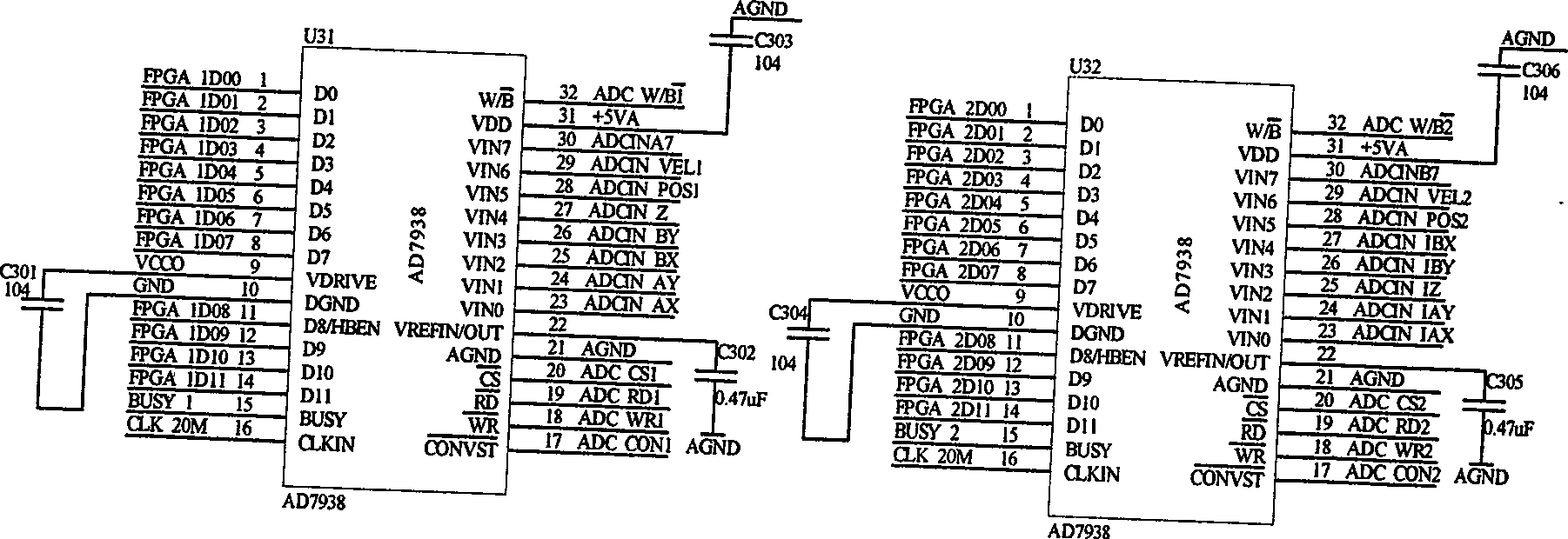

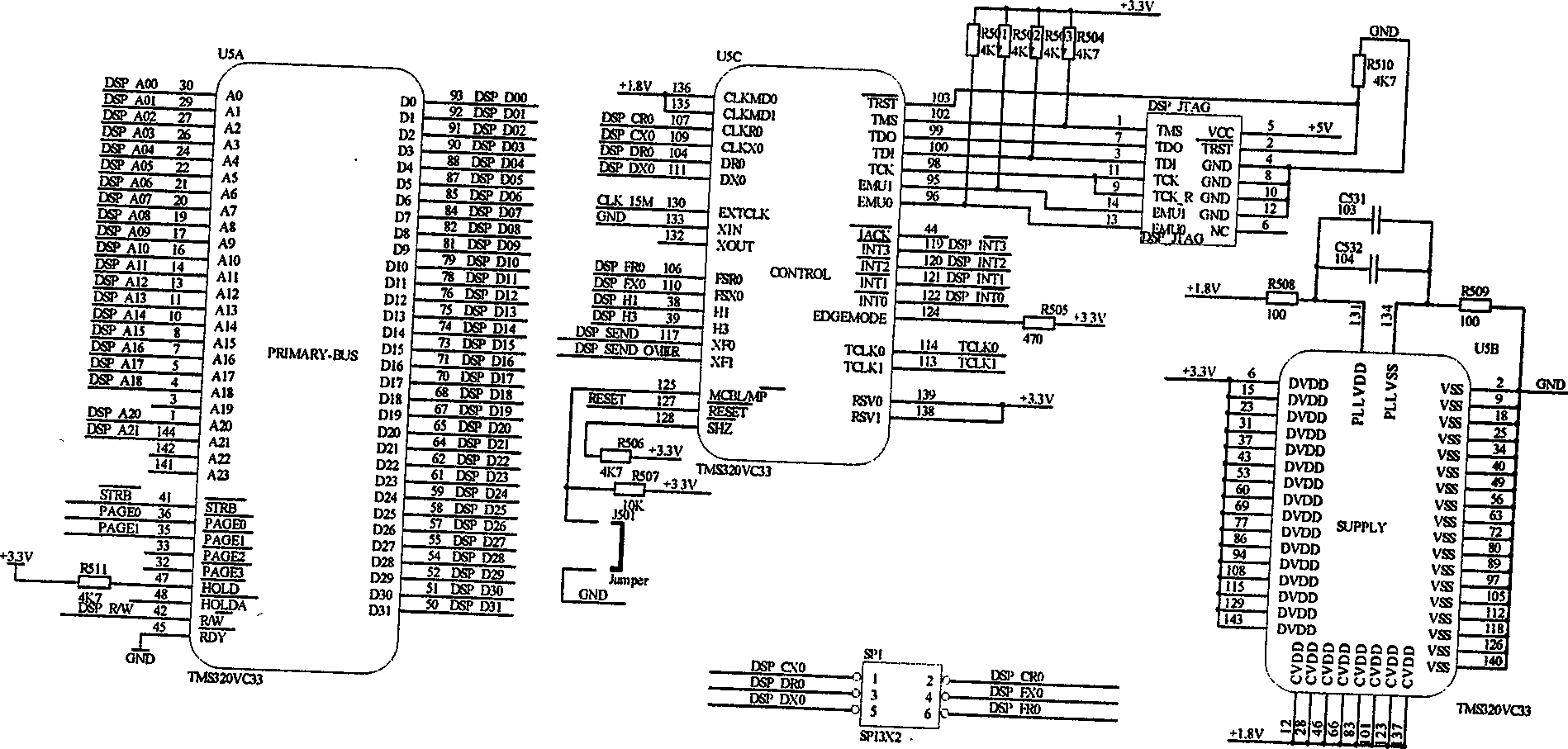

High-precision magnetic bearing axial control method based on interference observer

InactiveCN101488031AHigh precisionAchieve observationControl using feedbackBearingsMagnetic bearingControl system

The invention provides a method for controlling axial direction of a high-precision magnetic bearing based on an interference observer. The method consists of a controller and the interference observer, wherein the interference observer comprises a Q filter and a rationalization generalized object inverse QGn part; the controller in a control system calculates according to displacement deviation to obtain basic control quantity so as to form a position closed loop control system; an interference value obtained by observation of the interference observer is negatively fed back into the basic control quantity to compensate exterior interference; and the formed current control quantity drives power amplification to realize high precision suspension of the magnetic bearing. The method leads differences caused by both exterior interference and objective parameter variation to be equivalent to a control input end, and introduces equivalent compensation into the control quantity to realize interference inhabitation. The method can carry out online observation and effective inhabitation against exterior interference which is not modeled or known, thereby improving control precision of suspension, and contributing to stability of the system.

Owner:BEIHANG UNIV

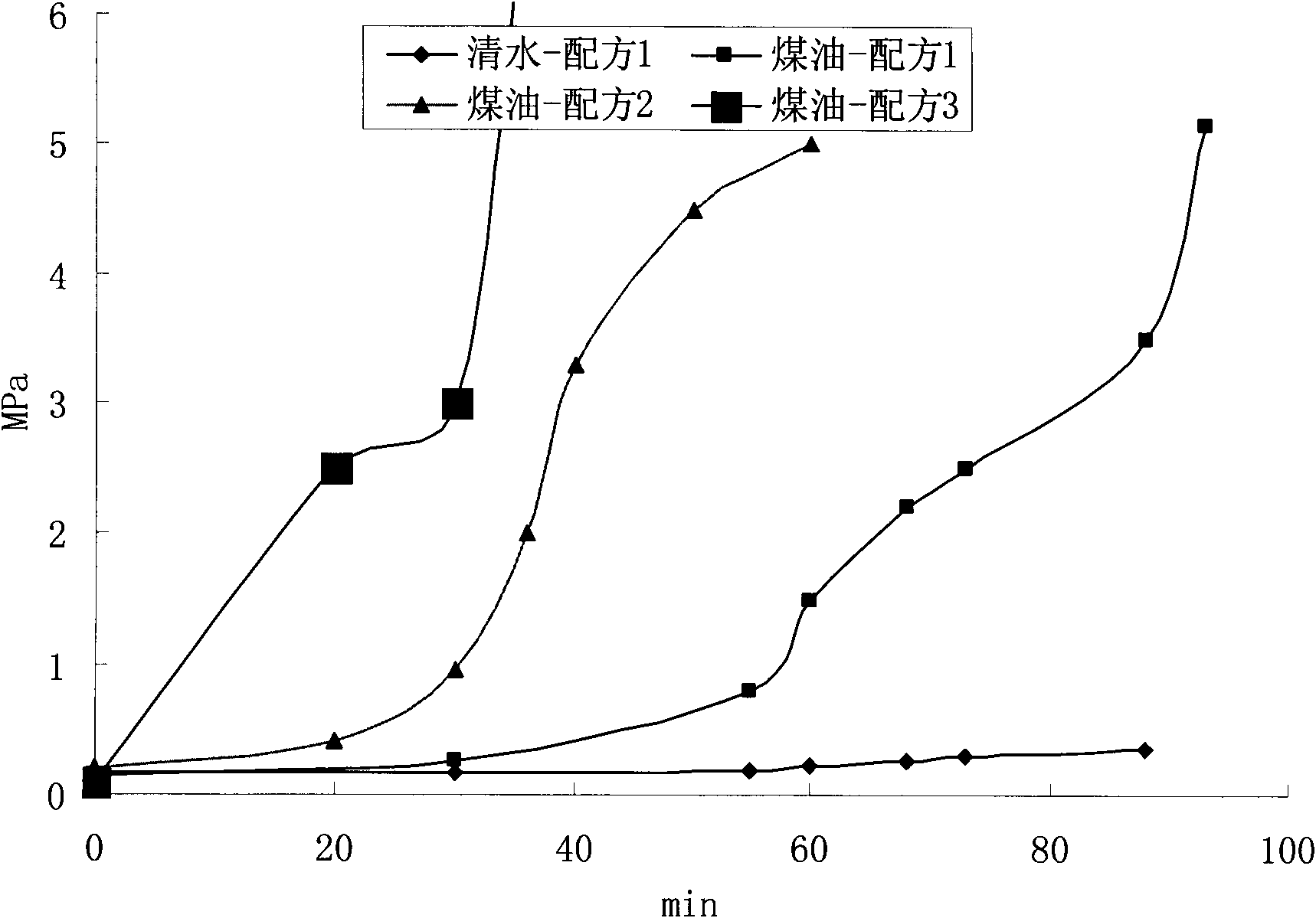

Highly effective pour depressant for thermodynamic oil extraction process

ActiveCN101210173AImprove applicabilityStrong pouring capacityDrilling compositionWater basedDepressant

A high-efficiency pour point depressant for thermal recovery process comprises (1) biphenyl, polycyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbon derivatives free of chlorine and sulfur elements; (2) liquid petroleum products containing arene larger than 5%, petroleum resin in liquid state at normal temperature or natural hydrocarbon aggregates in particle state at normal temperature; (3) surfactant; (4) fusel oil; (5) alcohol ethers having a closed cup flash point larger than 20 DEG C; and (6) oil-soluble or water-soluble polymers respectively having a nonpolar section eutectic with paraffin molecule and a polar section for twisting crystal form of wax crystal on a main chain and / or a branch chain. The high-efficiency pour point depressant of the invention performs all functions of both water-base pour point depressant and oil-base pour point depressant, and can efficiently assist the prior various thermal recovery processes in exploring high pour-point oil and heavy oil reservoirs, with the advantages of greatly reduced exploitation cost, prolonged production cycle of the oil well, increased output of the oil well, increased ultimate recovery of the oil reservoir,as well as significant economic benefit.

Owner:盘锦河升大地石油科技有限公司

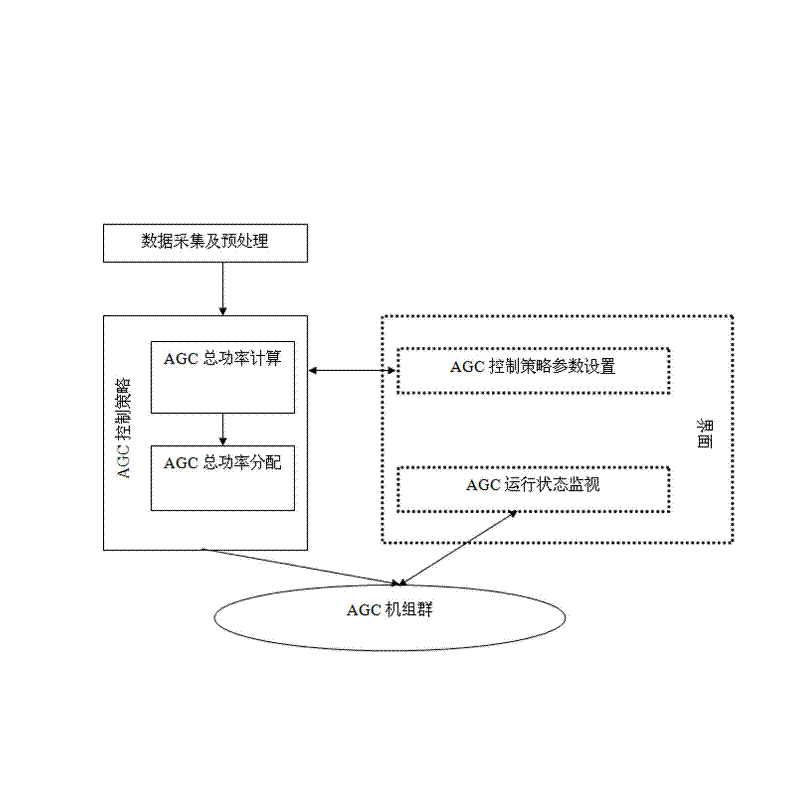

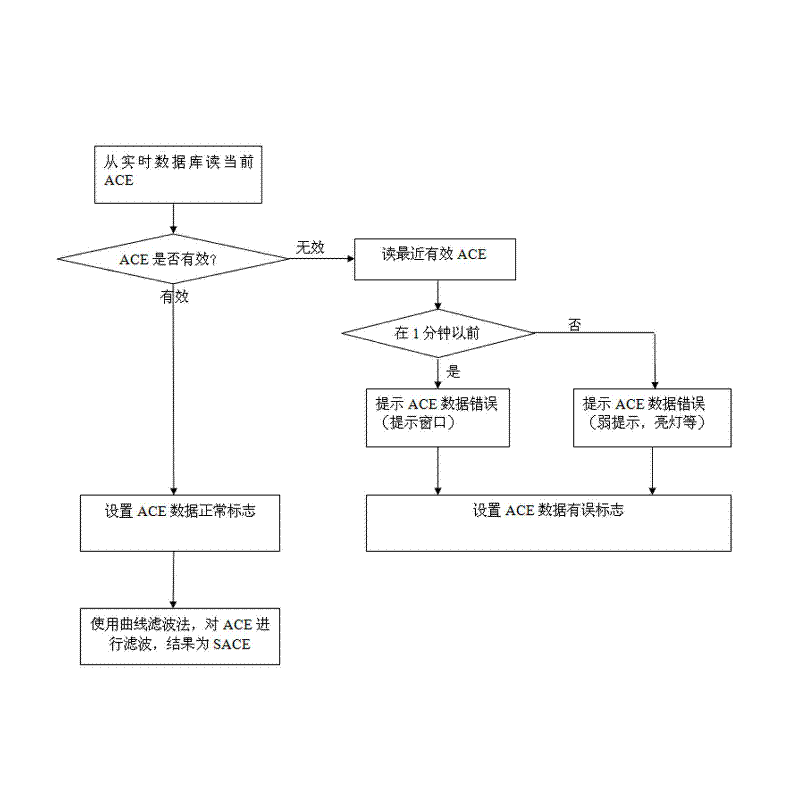

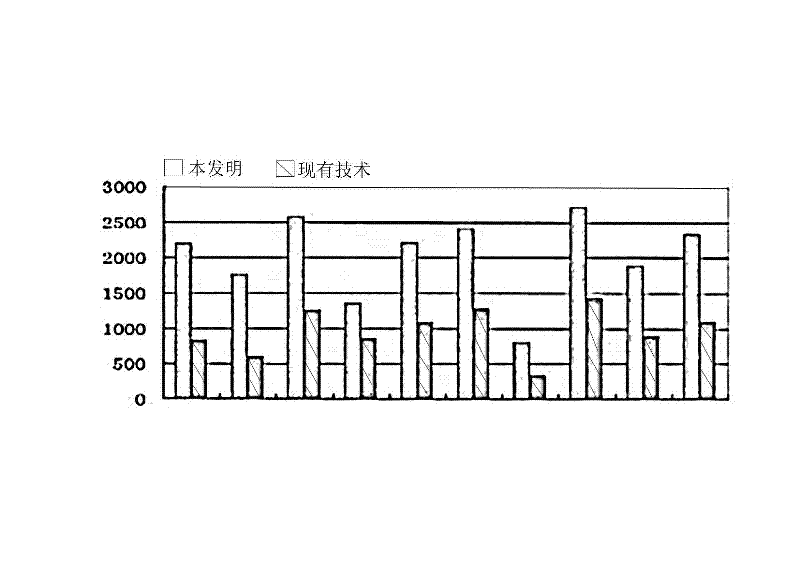

Control method of AGC facing control performance standard (CPS) and control system thereof

InactiveCN102497147AReduce the number of adjustmentsReduce wearElectric generator controlAutomatic Generation ControlControl oriented

The invention relates to a control method of AGC facing a control performance standard (CPS) and a control system thereof. Through setting structures of a data acquisition and pretreatment portion, an AGC total power calculating portion, an AGC total power distribution portion, a parameter set interface, an AGC state monitoring portion and the like, based on a frequency difference expectation, AGC regulating variable can be determined and an integral control link is canceled so that AGC set adjustment times can be effectively reduced. Set wear can be greatly reduced and energy consumption can be effective reduced too. The method and the system are beneficial to realize energy saving and emission reduction for power grid.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST

High temperature stratum self-generating foam composition and application thereof in viscous oil exploitation

InactiveCN1927993AImprove the spread factorEnhanced heavy oil recoveryDrilling compositionChemistryChemical substance

The present invention is foam-generating composition for high temperature stratum and its application in exploiting thick oil, and belongs to the field of surfactant technology. Chemicals capable of producing N2, CO2 and other gas are adopted to produce gases through the reaction of A+B+C-->N2+NH3+CO2+C, where A is reductant, B oxidant and C foaming agent. The reaction is controlled by temperature, and the foam-generating composition contains also surfactant with high heat resistance, high salt tolerance, high oil / water interface activity and high foam stability. After the chemicals are injected into the stratum at normal temperature, steam is injected to initiate reaction producing stable foam in the stratum, and the foam can plug to avoid steam fleeing, raise high temperature steam sweep efficiency, raise blotter efficiency, promote crude oil to disperse and raise the thick oil exploiting rate greatly.

Owner:SHANDONG UNIV

Field welding repair method particularly suitable for bead weld layer defects on low alloy and carbon steel

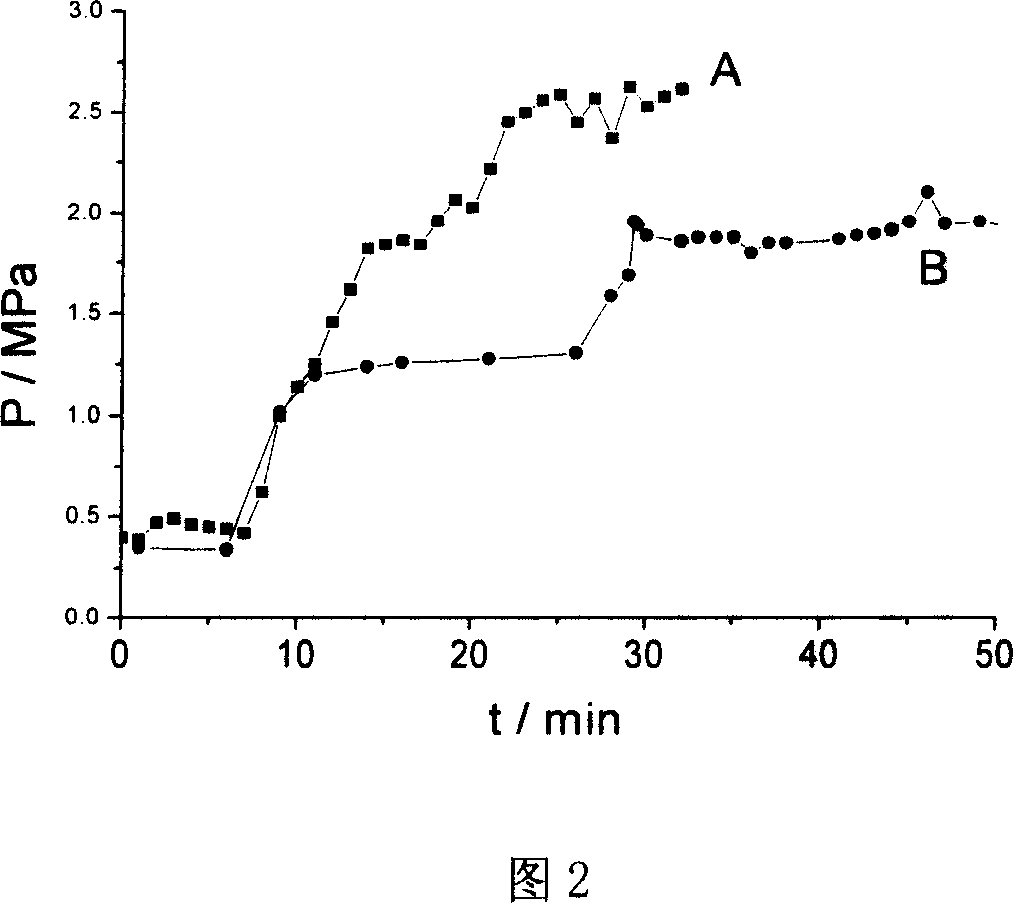

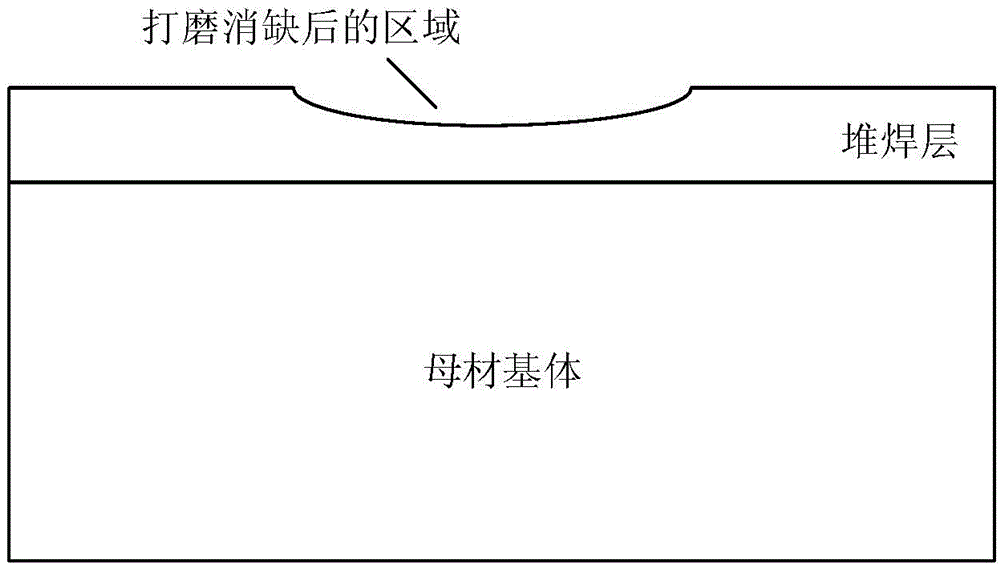

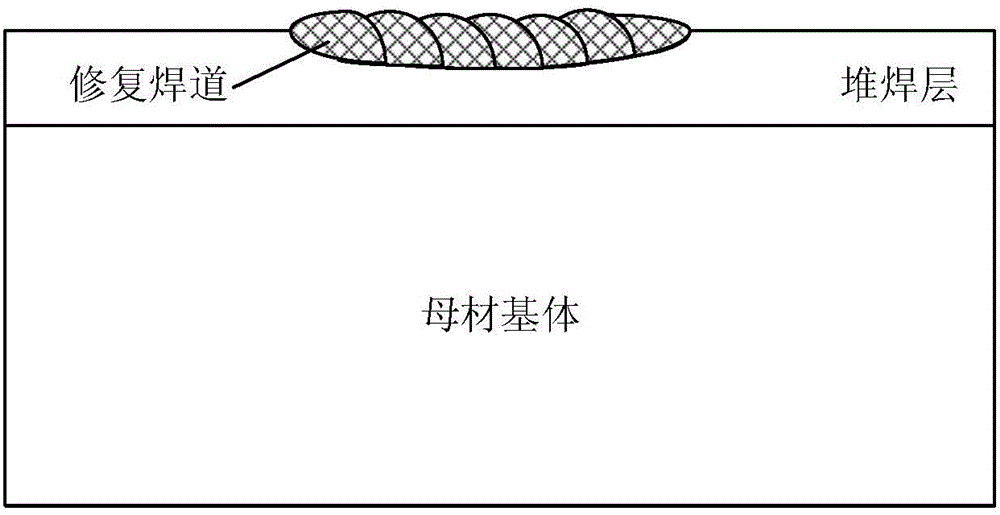

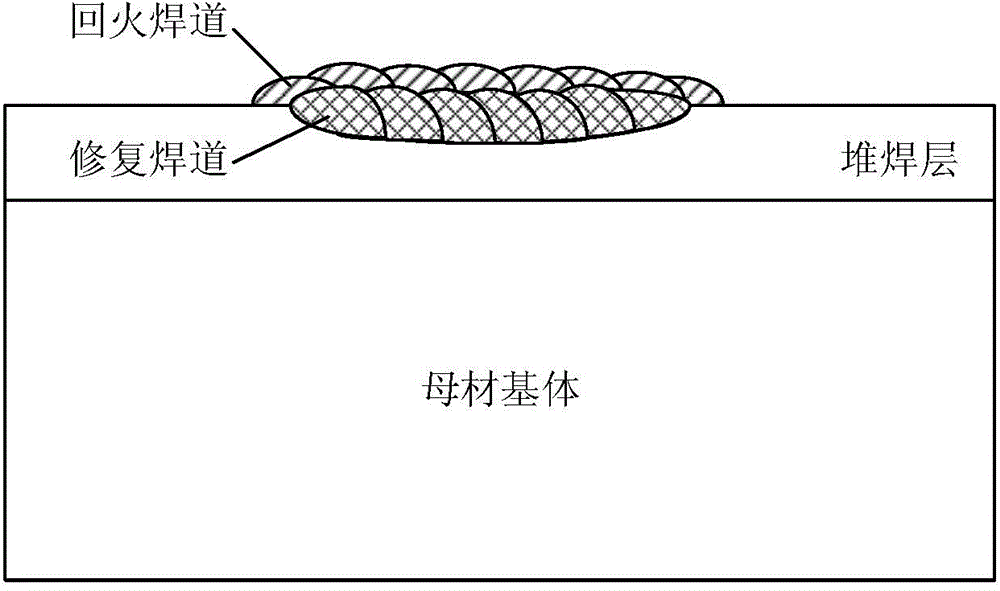

InactiveCN104084749AReduce adverse effectsImprove organizationArc welding apparatusTemperingHardness

The invention relates to a field welding repair method particularly suitable for bead weld layer defects on low alloy and carbon steel. The field welding repair method includes the steps that firstly, the defects are eliminated in a polished mode; secondly, welding materials having the same quality with bead weld layer materials are used for conducting welding repair on the defects, and a repair bead is obtained; thirdly, after the welding repair in the second step is completed, welding of a tempering bead is immediately conducted, and welding materials having the same or similar material mark with the bead weld layer materials are selected in welding of the tempering bead; fourthly, after welding of the tempering bead is completed and the temperature is reduced to the room temperature, excess weld metal of the tempering bead and excess weld metal of the repair bead are removed in a polished mode. According to the field welding repair method, the rigidity of the area, close to a fusion line area, of a base material of a base layer can be reduced while heat treatment is not conducted, the good tissue of the base material is ensured, and field construction is well facilitated.

Owner:SUZHOU NUCLEAR POWER RES INST +2

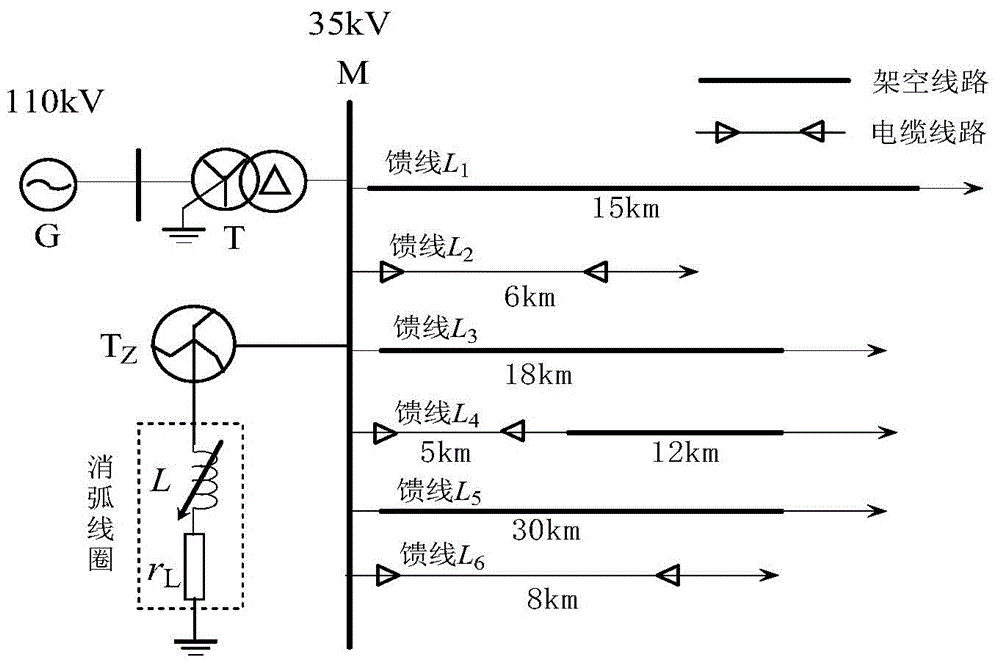

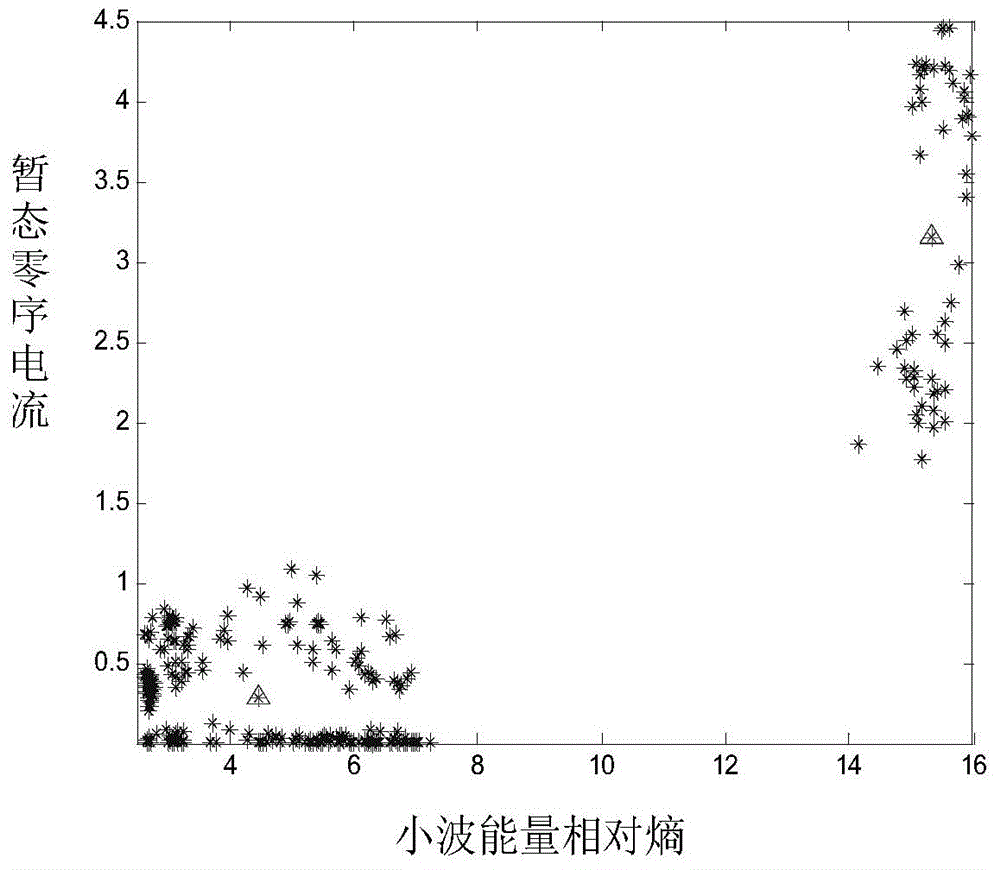

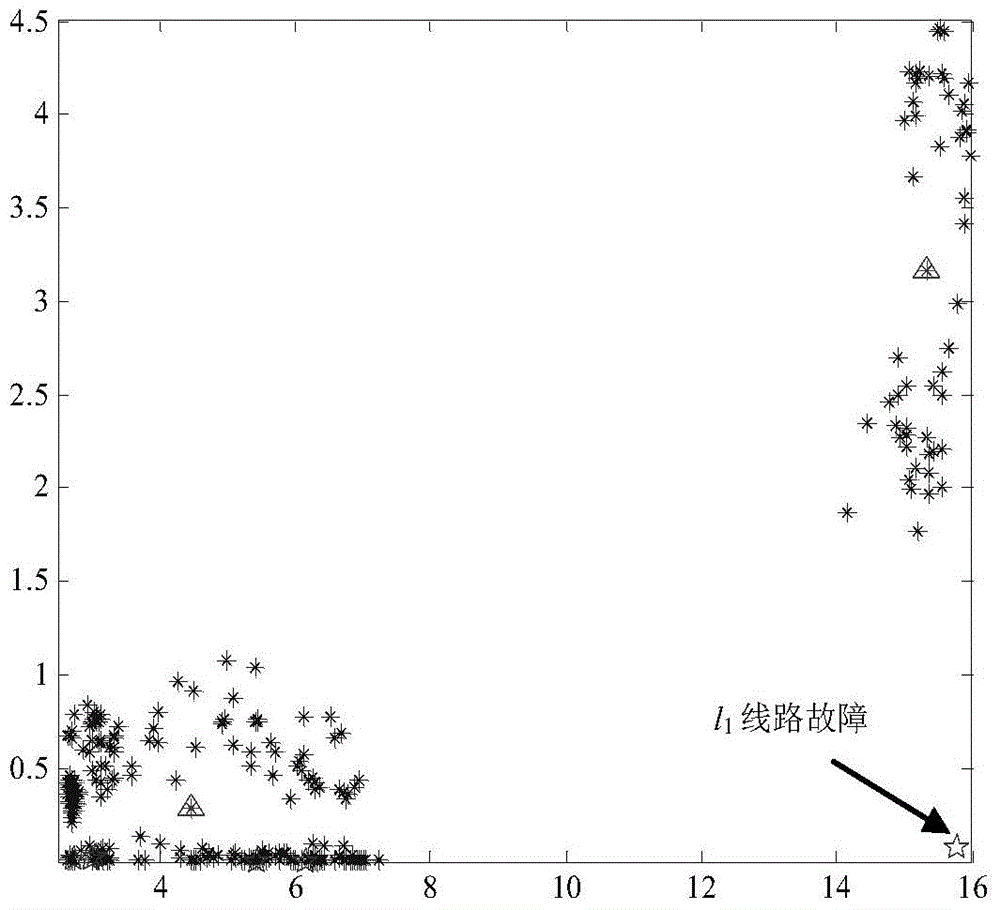

Fault line selecting method based on k-means cluster analysis for power distribution network

ActiveCN104898021AEasy to implement on siteImprove fault toleranceFault locationTransient stateWavelet decomposition

The invention relates to a fault line selecting method based on k-means cluster analysis for a power distribution network. The method includes setting fault position on lines along a resonant grounding system, selecting zero sequence current 5ms after fault with fault current curve clusters obtained by electromagnetism transient simulation as sample data, carrying out six-layer wavelet decomposition with db wavelets, calculating the total energy of transient zero sequence current under full spectrum band, calculating comprehensive wavelet energy relative entropy, measuring symptom fault characteristics with two dimensions of the total energy of transient zero sequence current and the comprehensive wavelet energy relative entropy, mapping the symptom fault characteristics onto a two dimensional plane, and calculating the cluster centers of the said data on the two dimensional plane by employing k-means cluster analysis algorithm. In a cluster space, the fault lines form a cluster center, and the non-fault lines form a cluster center. After fault line selection element starts, fault current data in 5ms time window serves as a test sample, and whether the line fails or not is determined according to the Euler's distance between the test data and two kinds of cluster centers.

Owner:KUNMING UNIV OF SCI & TECH

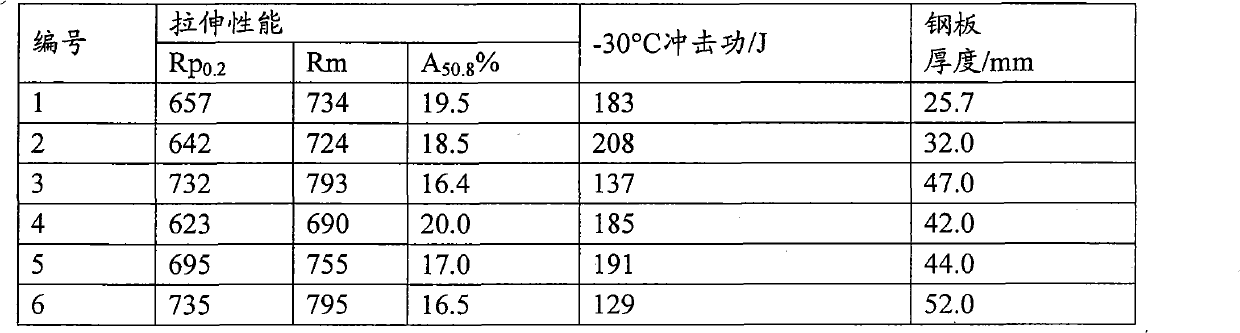

High-strength pipe steel and method for manufacturing same

ActiveCN102021499AImprove toughnessImprove corrosion resistanceManufacturing convertersElectric furnacePetroleumQuenching

The invention relates to a method for manufacturing pipe steel. The pipe steel comprises the following components in percentage by weight: 0.02-0.12 percent of C, 0.10-0.35 percent of Si, 1.40-2.00 percent of Mn, no more than 0.015 percent of P, no more than 0. 005 percent of S, 0.021-0.05 percent of Ti, 0.05-0.40 percent of Cr, 0.05-0.30 percent of Mo, 0.10-0.30 percent of Cu, 0.10-0.24 percent of Ni, no more than 0. 008 percent of N, 0.02-0.07 percent of Nb, 0.01-0.08 percent of V and the balance of Fe and inevitable impurities. The method comprises the steps of smelting, external refining, casting, slab reheating, controlled rolling, controlled cooling, quenching and tempering in a converter or an electric furnace. The reheating temperature of the slab is 1100-1250 DEG C. The controlled rolling comprises a recrystallization zone rolling step and a non-recrystallization zone rolling step. The quenching and tempering comprises a quenching step and a tempering step. The pipe steel has the characteristics of high strength, excellent low temperature impact toughness and excellent weldability, and can be used for constructing long-distance petroleum and natural gas transmission pipelines, slurry transmission pipeline, city pipeline networks and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

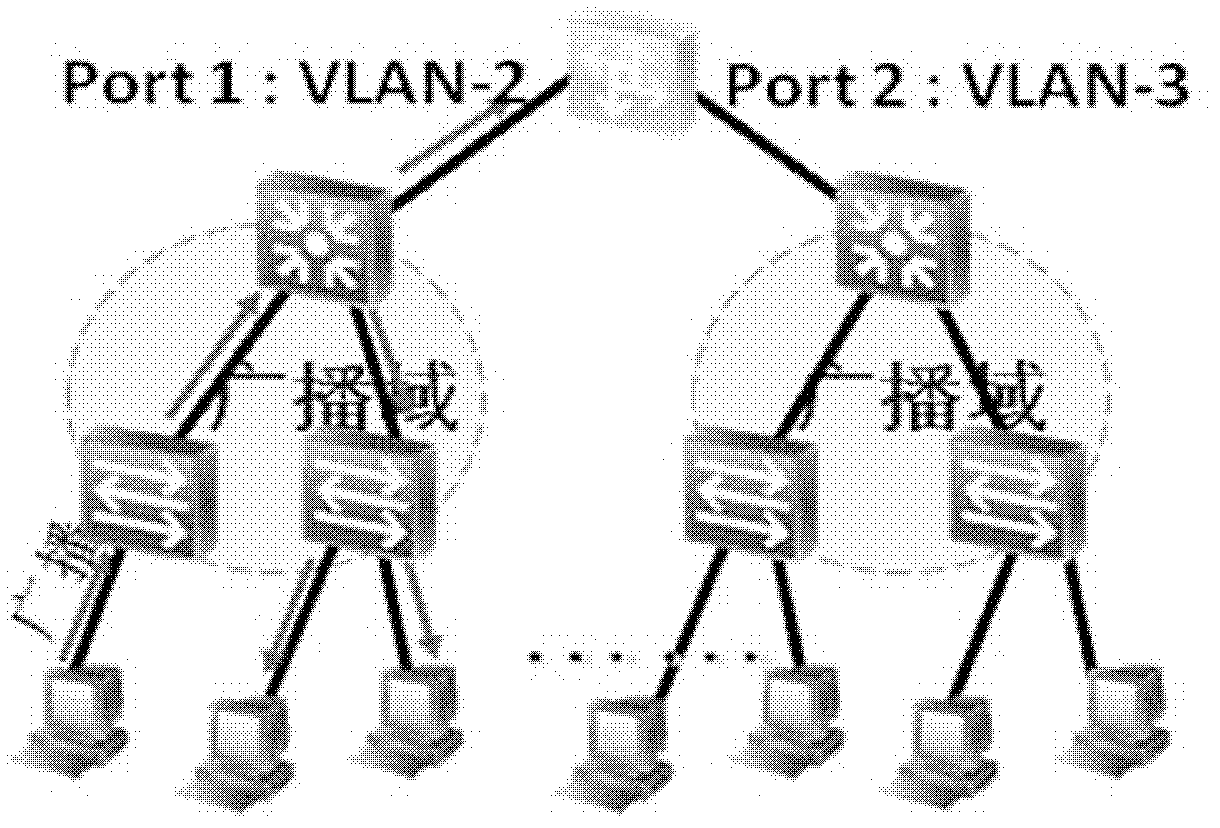

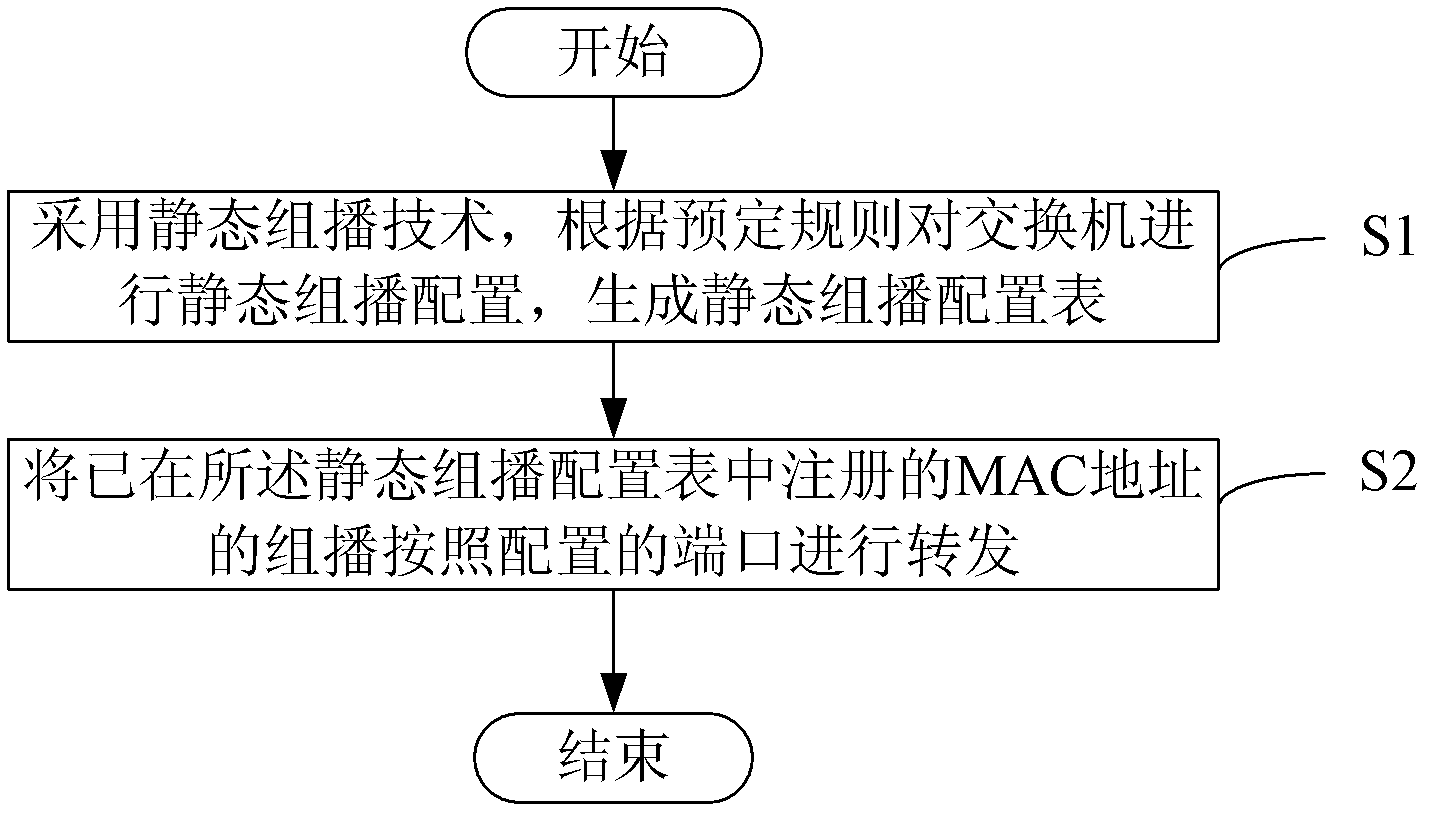

Multicast management method and device for intelligent substation process level

ActiveCN102664456AGuaranteed reliabilityEasy to maintain on siteSpecial service provision for substationPower network operation systems integrationSmart substationMulticast address

The invention provides a multicast management method and a device for an intelligent substation process level. The multicast management method includes the steps of according to a scheduled rule, performing static multicast configuration by utilizing a static multicast technology to generate a static multicast configuration table; and forwarding multicast of a media access control (MAC) address registered in the static multicast configuration table according to a configuration port. According to the multicast management method and the device for the intelligent substation process level, the multicast technology is adopted, the static multicast configuration table is generated in advance, the forwarding of the registered multicast at a designated port is achieved according to the static multicast configuration table, which multicast addresses are received by each intelligent electronic device (IED), namely, which merging unit (MU) are associated with the IED is quite intuitive, when the designated port receives other multicast massages, problems can be determined to exist in network settings or other network aspects, and therefore on-site maintenance of engineering debugging staff is greatly facilitated.

Owner:ZHUHAI POWER SUPPLY BUREAU GUANGDONG POWER GIRD CO

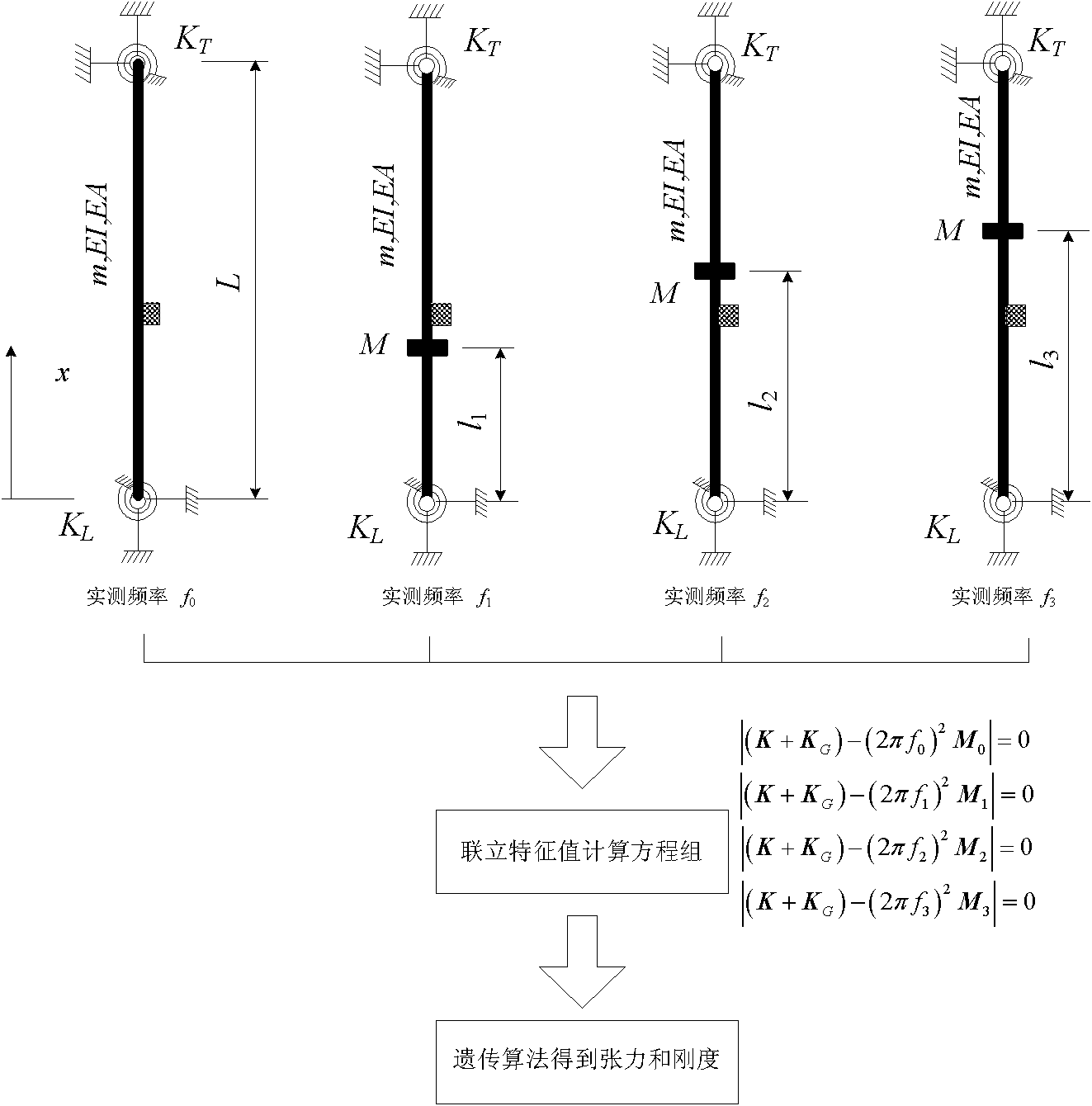

Method for testing tension and rigidity of short derrick boom of arch bridge

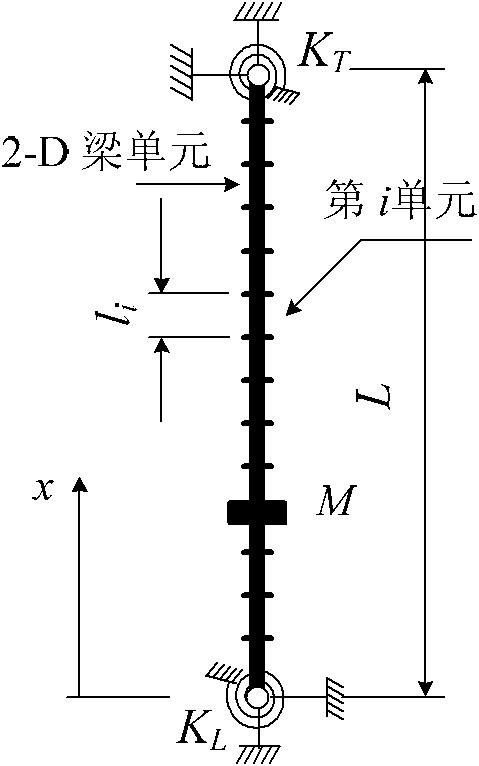

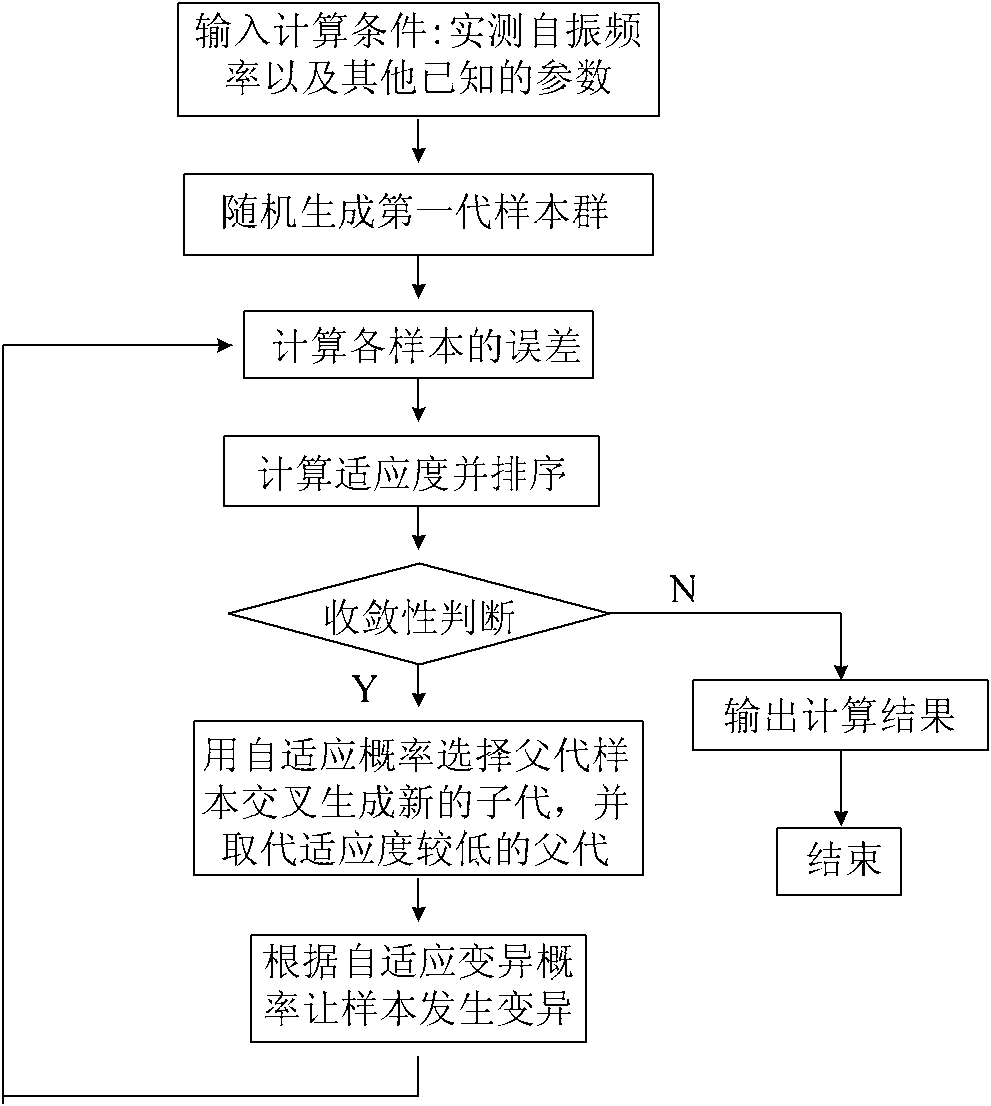

InactiveCN102128694AEasy to implement on siteThe test results are simple and clearForce measurement by measuring frquency variationsElasticity measurementGenetic algorithmSimultaneous equations

The invention provides a method for testing tension and rigidity of a short derrick boom of an arch bridge. An aim of calculating the tension of the derrick boom according to a fundamental frequency can be fulfilled by increasing a derrick boom parameter identification condition by a method of arranging a mass block on the derrick boom. According to the characteristic that the fundamental frequency of the short derrick boom is sensitive due to the mass change of the derrick boom, four groups of equations on the relation between the fundamental frequency of the short derrick boom and the additional mass can be obtained according to a test result, and the tension, the bending stiffness and a boundary restraining condition of the derrick boom can be obtained by calculating a characteristic value by using a genetic algorithm in combination with the equation groups. The method for testing the tension and the rigidity of the short derrick boom of the arch bridge is easy to implement on the site; and the test method is simple and the test result is accurate.

Owner:ZHEJIANG UNIV

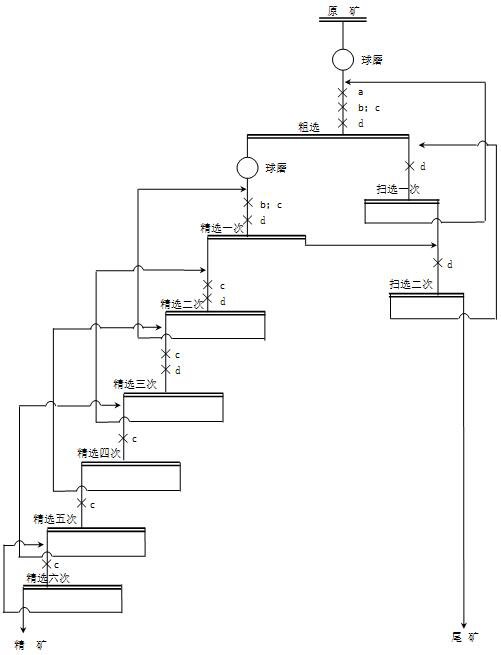

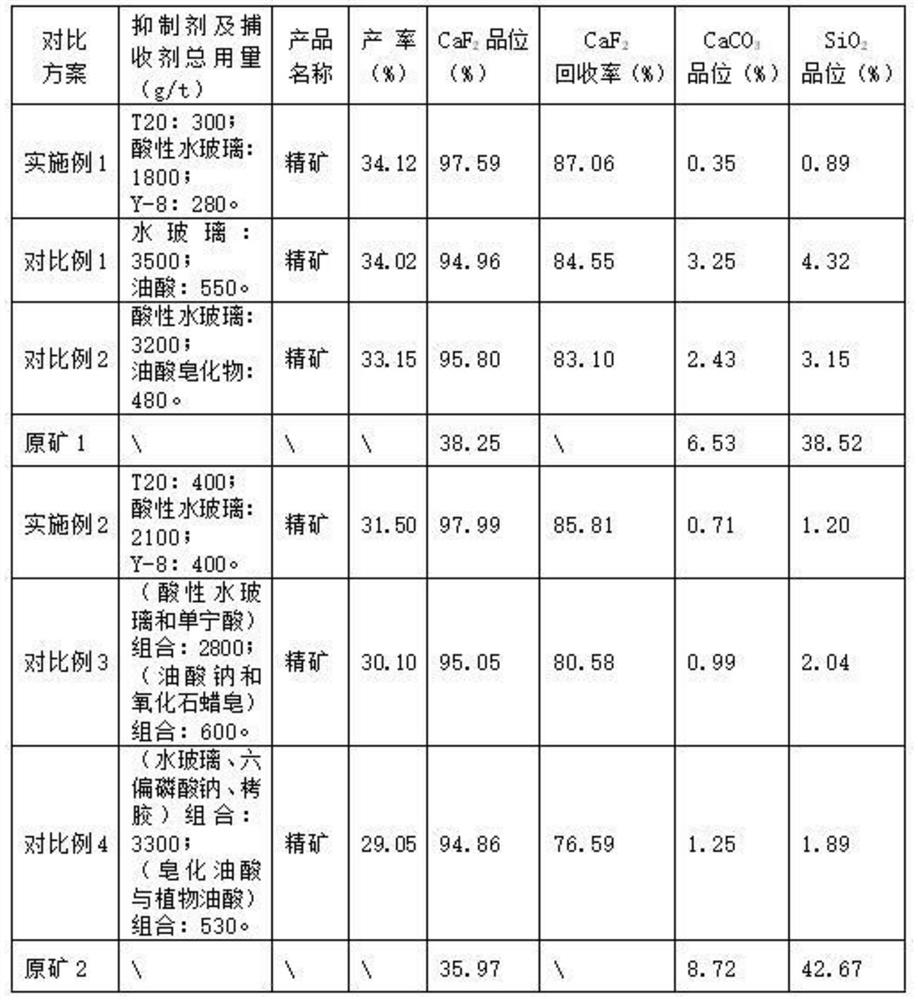

Beneficiation method for silicate and carbonate type fluorite ores

ActiveCN111632747AIncrease the grade of concentrateLow impurity contentFlotationWet separationSoluble glassPhenyl Ethers

The invention discloses a beneficiation method for silicate and carbonate type fluorite ores, and belongs to the technical field of non-metal ore beneficiation. The problems of low recovery rate and high impurity content of concentrate products in the conventional beneficiation method are solved. The method comprises the following steps of ore grinding; roughing, that is, a gangue inhibitor is a combination of T20 and acidic soluble glass, the collecting agent is Y-8, the gangue inhibitor T20 comprises polyaspartic acid, aluminum sulfate and hydroxyethylidene-1,1-diphosphonic acid in a mass ratio of 3-6: 4: 0.5-1, and the collecting agent Y-8 comprises sodium oleate, 4-epoxytetradecanoic acid and octylphenylpolyethylene glycol in the mass ratio is 6-7: 2-3: 1; scavenging operation, that is, a collecting agent Y-8 is added; regrinding rough concentrate; concentration, that is, an inhibitor T20 and acidic soluble glass are adopted, and Y-8 is adopted as the collecting agent. Under the condition of low temperature, the impurity content in the concentrate product can be effectively reduced, and the fluorite concentrate grade is improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

On-site detection method for hard basic top fracture parameters of stope face

The invention discloses an on-site detection method for hard basic top fracture parameters of a stope face, which comprises the following steps: respectively arranging a basic top lateral fracture andbasic top strike fracture monitoring station at two different positions of a roadway with a cutting hole, respectively arranging drill holes at the monitoring stations, and combining a deep hole rockstratum displacement meter and a drill hole camera peeping instrument at the basic top lateral fracture monitoring station to detect the basic top lateral fracture condition of the working face; monitoring the basic top strike fracture condition by using a rock stratum displacement meter at the basic top strike fracture monitoring station; and the on-site detection method for hard basic top fracture parameters of a stope face can directly obtain field data, more truly and effectively analyze basic top fracture parameters and provide data reference for determining the position of the gob-sideroadway.

Owner:SHANDONG UNIV OF SCI & TECH

Method for enhancing oil well cement slurry

ActiveCN102031097AWide variety of sourcesImprove plugging of micro-cracksDrilling compositionWell cementingCement slurry

The invention relates to a method for enhancing oil well cement slurry for petroleum and natural gas well cementation. The method is mainly characterized in that: an oil absorbing expansion component such as oil absorbing component or the like in an amount which is 0.1 to 3 percent of the total mass of the solid phase and with the particle diameter of 40 to 320 meshes is added into the oil well cement slurry, and the oil absorbing expansion component and the oil well cement slurry are fully stirred; and by using the characteristic that the volume of the oil absorbing expansion component is expanded in oil or after oil absorption, the capability of the oil well cement slurry on plugging micro cracks and micro annular clearances so as to reduce annular cross flow is improved. The method is simple, does not need additional equipment, is favorable for field construction, has wide main material sources and low cost, and can effectively solve the problems of micro cracks in cement stones and / or micro annular clearances on two well cementation interfaces and cross flow of gas, oil and water among underground layers or flow on the ground due to poor initial well cementation quality, influence of subsequent operation on the well cementation quality and change of temperature and pressure in a shaft.

Owner:中国石油集团西部钻探工程有限公司克拉玛依钻井工艺研究院

Well cementing cement slurry and preparation method thereof

InactiveCN107628781AImprove the micro interfaceImprove deformation abilityDrilling compositionCement slurryFlexural strength

The invention discloses a well cementing cement slurry and a preparation method thereof, wherein the well cementing cement slurry comprises the following components in parts by weight: 100 parts of cement, 1-4 parts of an elastic toughness material, 1-4 parts of an expanding agent, 5-10 parts of a latex, 10-100 parts of a density regulator, 1-2 parts of an early strength agent, 2-8 parts of a filtration-reducing agent, 1-2 parts of a drag reducer, 1-10 parts of a retarder, and 20-80 parts of water. The prepared well cementing cement slurry not only has low elastic modulus, but also has high impact resistance and flexural strength as well as compressive strength.

Owner:四川弘晟石油工程技术服务有限公司

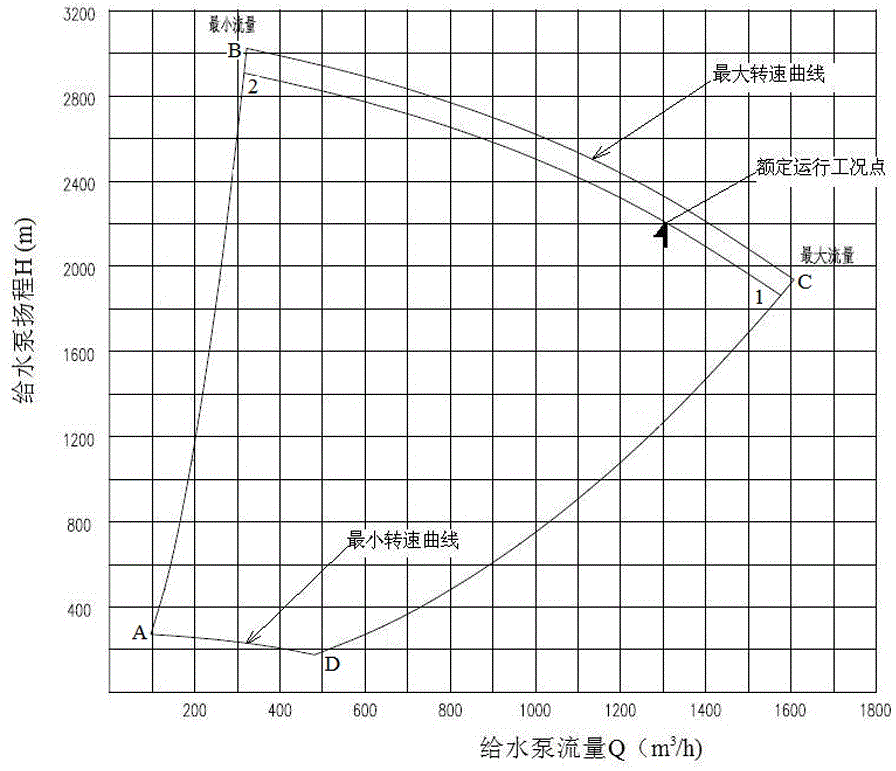

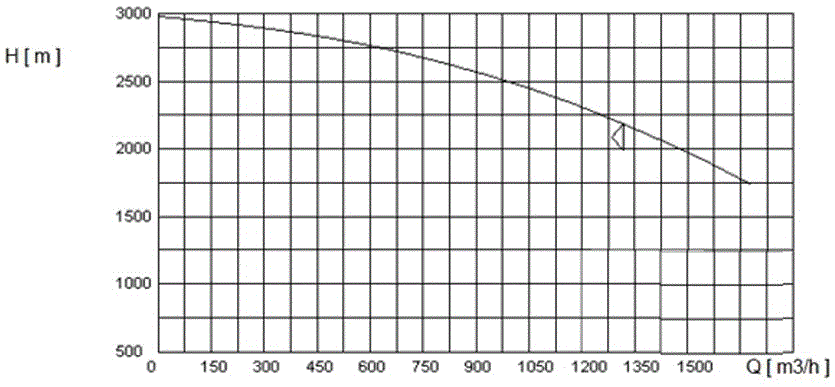

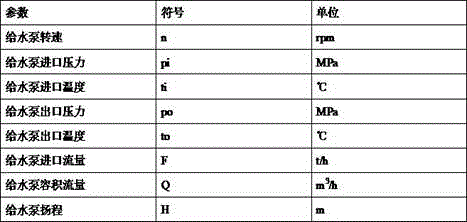

Online monitoring method for operation state of large-sized variable-speed water-feeding pump

ActiveCN106050637AMeet the needs of condition-based maintenanceEasy accessPump testingPump controlDaily operationEngineering

The invention relates to an online monitoring method for the operation state of a large-sized variable-speed water-feeding pump. The method comprises the steps of recording the operation parameter of the water-feeding pump in a monitored state, according to a designed flow-head curve of the water-feeding pump, determining the numerical function of the boundaries of the normal operation area of the water-feeding pump, collecting the operation data of the water-feeding pump in a normal new running state, fitting out the flow-head performance curve of the water-feeding pump at a certain specific rotation speed after amendment, judging whether the water-feeding pump operates in the normal operation area or not according to the operation parameter of the water-feeding pump in the monitored state, if not, giving out an abnormal operation state alarm prompt, carrying out amendment till the certain specific rotation speed of the water-feeding pump is matched with the normal state curve according to the operation parameter of the water-feeding pump in the monitored state, and giving out an alarm prompt for the abnormal operation state of the water-feeding pump if the deviation between the rotation speed and the normal state curve exceeds a certain degree. By means of the method, the daily operation state of the water-feeding pump can be monitored, and judging criteria for the situation that the operation state of the water-feeding pump deviates from the normal operation area are provided

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +2

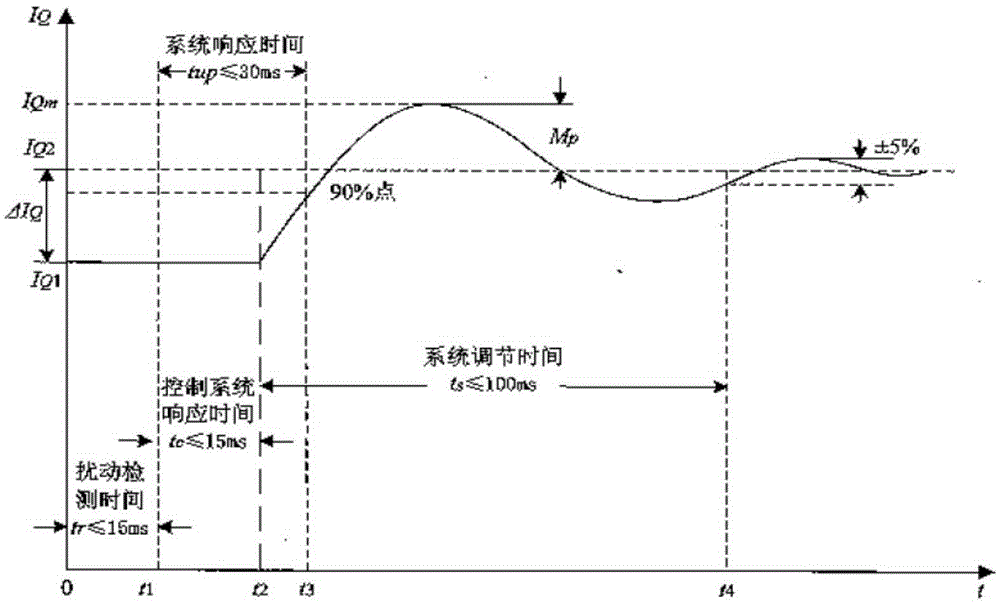

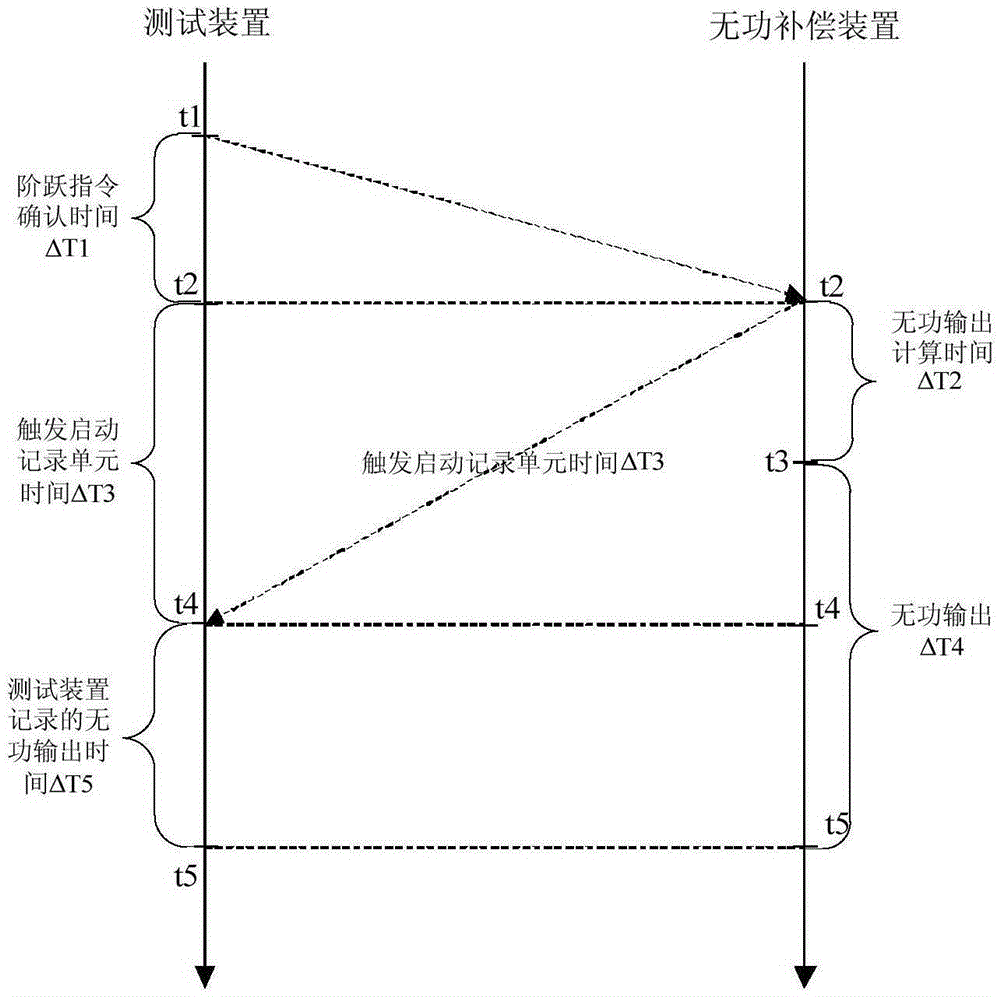

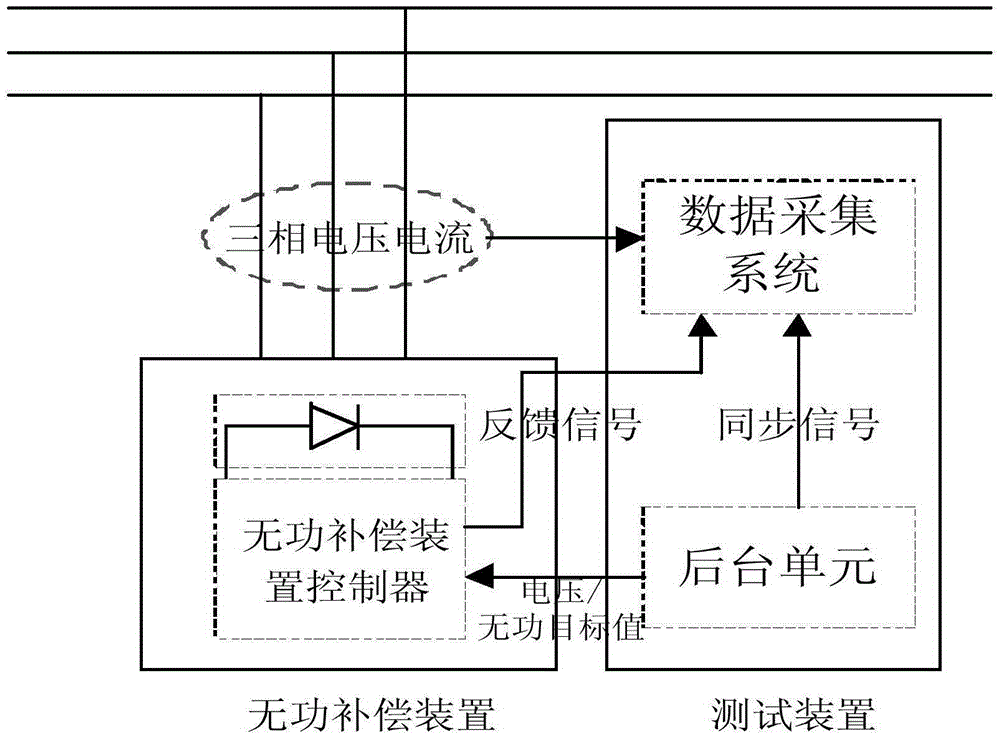

Wind farm reactive power compensation device dynamic response time detection method

ActiveCN105388372ATrue reflection of dynamic response timeEasy to operateElectrical testingPower compensationData acquisition

The present invention provides a wind farm reactive power compensation device dynamic response time detection method. The method comprises a step of analyzing a reactive power compensation device dynamic response time requirement, a step of determining the time of sending a synchronization signal to a data acquisition system by a testing device background unit, the time of sending a voltage / reactive power target value to a reactive power compensation device and the time of outputting a feedback signal to the data acquisition system by the reactive power compensation device, a step of obtaining a reactive power compensation device dynamic response time, and a step of sending the synchronization signal and the feedback signal to the data acquisition system, calling the data acquisition system to obtain a reactive power compensation device accurate dynamic response time and verifying whether the accurate dynamic response time meets a standard requirement or not. The method is simple to operate and easy to realize, and the method can be automatically completed by a testing system without human intervention, in the condition of satisfying a wind farm safety requirement, the accurate measurement of the reactive power compensation device dynamic response time is realized.

Owner:CHINA ELECTRIC POWER RES INST +3

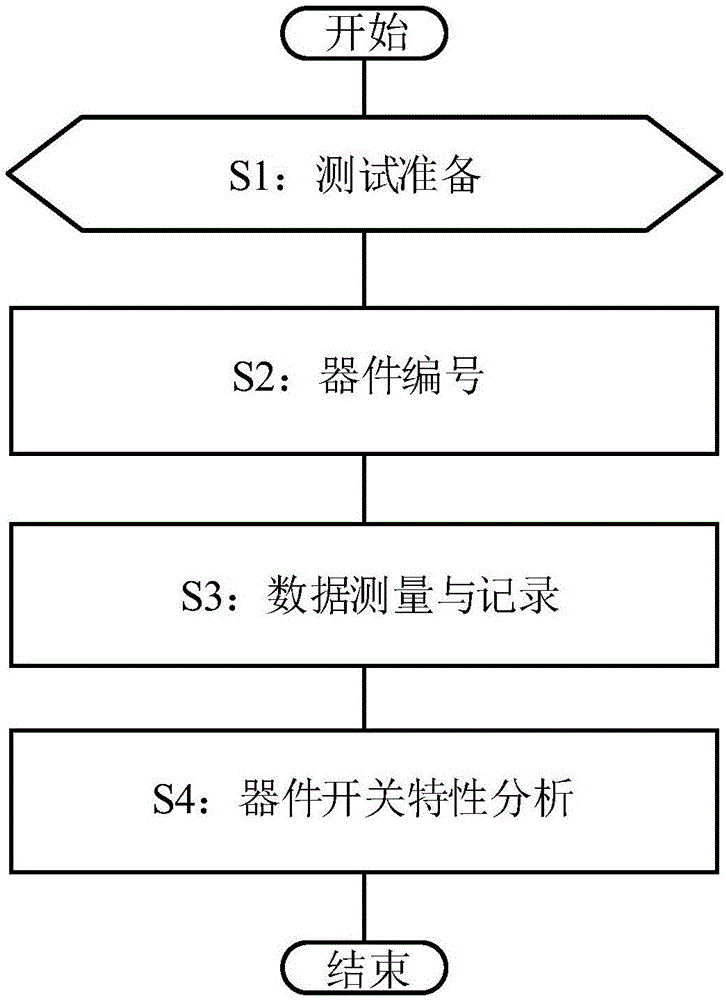

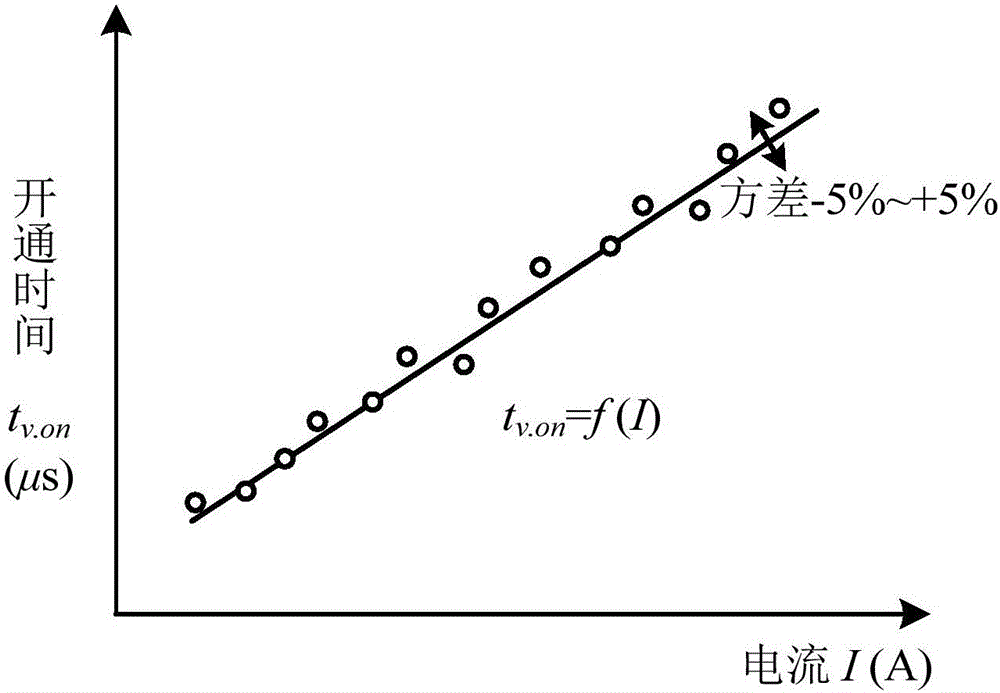

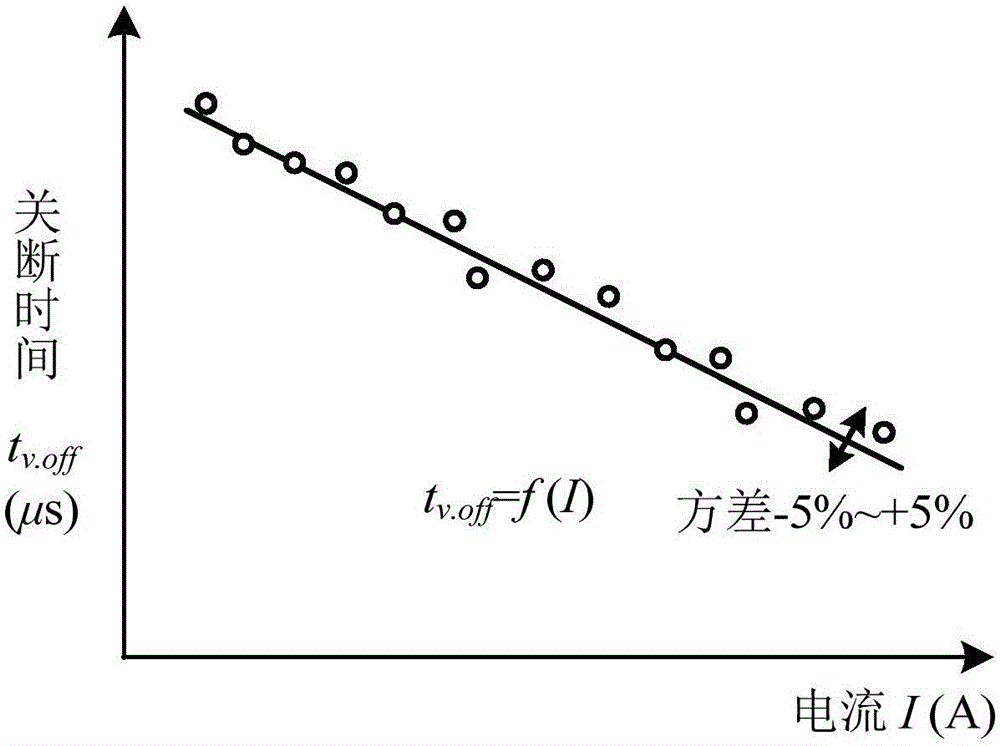

Switching characteristic-based converter IGBT module fault pre-diagnosis method

ActiveCN106291305ASimple structureEasy to implement on siteIndividual semiconductor device testingElectrical and Electronics engineeringDiagnostic accuracy

The invention relates to a switching characteristic-based converter IGBT module fault pre-diagnosis method. The method includes the following steps that: a converter is operated, the turn-on characteristic curve and turn-off characteristic curve of each IGBT tube in an IGBT module to be pre-diagnosed, as well as IGBT module meter case temperature are obtained; the turn-on characteristic curve and turn-off characteristic curve of each IGBT tube in a health IGBT module of which the model is the same as the model of the IGBT module to be pre-diagnosed under the same meter case temperature are obtained; and the turn-on characteristic curves and the turn-off characteristic curves of corresponding IGBT tubes in the IGBT module to be pre-diagnosed are compared with the turn-on characteristic curves and the turn-off characteristic curves of corresponding IGBT tubes in the health IGBT module, so that whether the characteristic curves of the IGBT tubes are abnormal can be judged, if the characteristic curves of at least one IGBT tube are abnormal, the IGBT module to be pre-diagnosed malfunctions. Compared with the prior art, the method has the advantages of simplicity, convenience, high diagnostic accuracy and high applicability.

Owner:阆芯上海电子科技有限公司

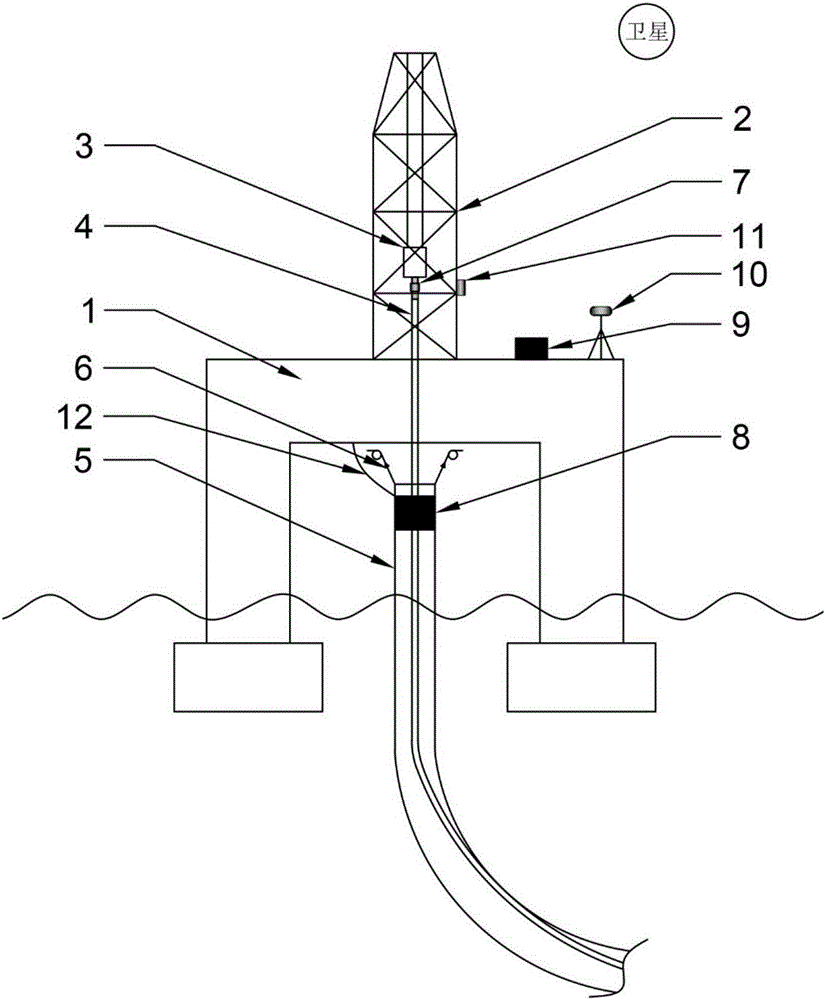

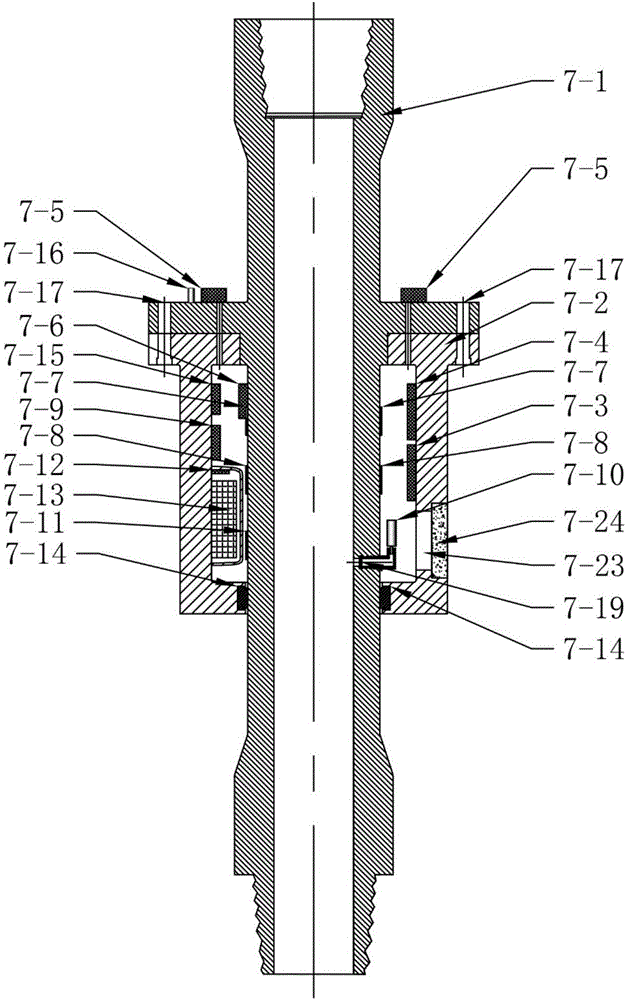

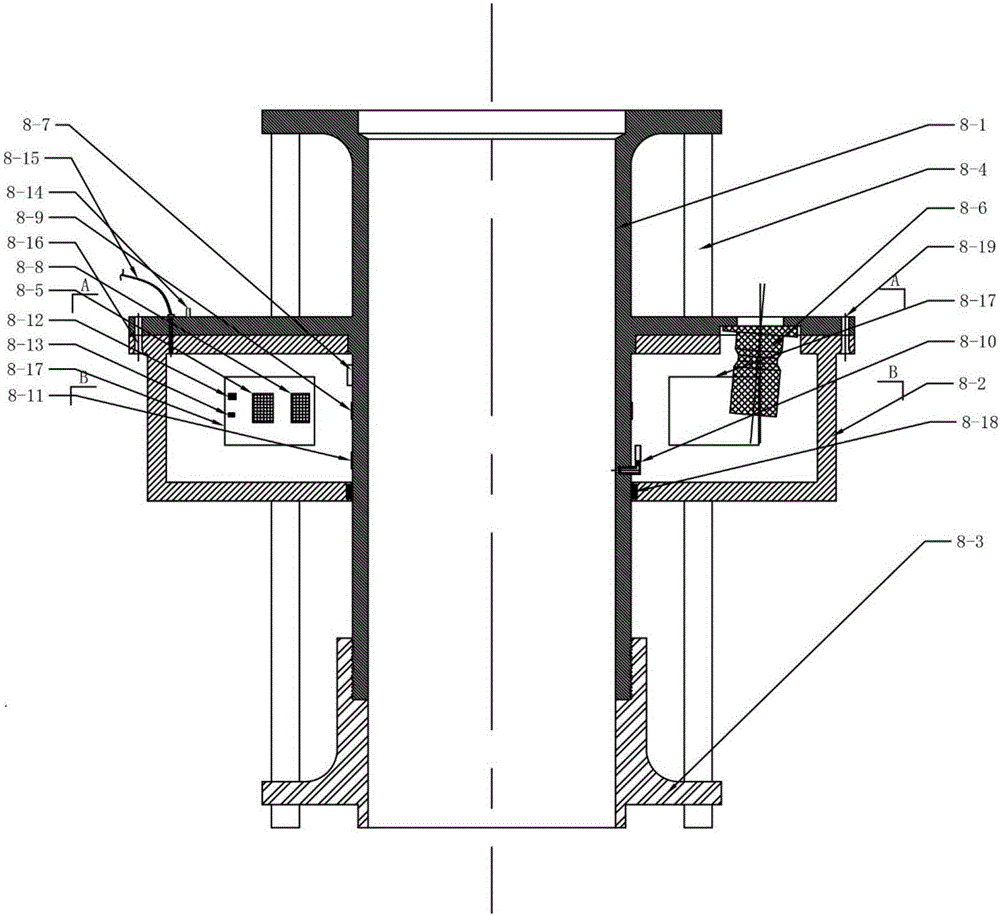

Deepwater drilling pipe monitoring-while-drilling device and method

The invention provides a deepwater drilling pipe monitoring-while-drilling device and method. The device comprises a Wi-Fi router, a satellite navigation mobile station, a deepwater drill string engineering parameter measurement-while-drilling nipple, a drilling riser kinetic parameter measurement nipple and a deepwater drilling pipe monitoring-while-drilling and optimized analysis workstation; the Wi-Fi router is used for providing a wireless local area network to the deepwater drilling pipe monitoring-while-drilling device, the satellite navigation mobile station is arranged on a drilling platform, the deepwater drill string engineering parameter measurement-while-drilling nipple is arranged at the upper end of a drill string and used for measuring the tension-compression stress, torque, bending moment, displacement, rotating speed, three-dimension acceleration, drilling fluid pressure and temperature of the upper portion of a drilling riser, and the deepwater drilling pipe monitoring-while-drilling and optimized analysis workstation is arranged on the drilling platform and used for drilling pipe dynamic response real-time analysis, operation parameter analysis and pipe fatigue analysis. According to the deepwater drilling pipe monitoring-while-drilling device and method, the deepwater drilling pipe state can be monitored comprehensively.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

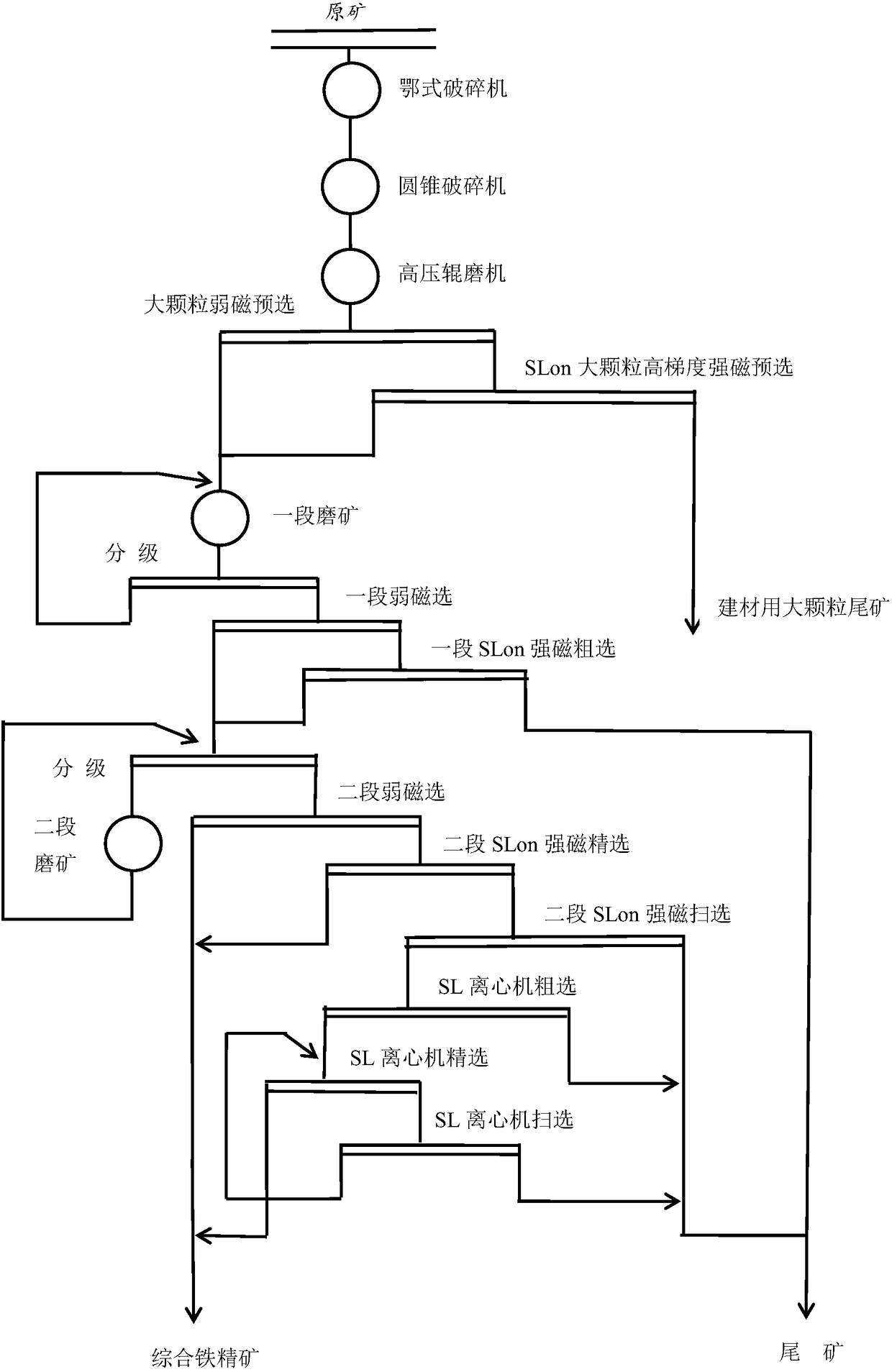

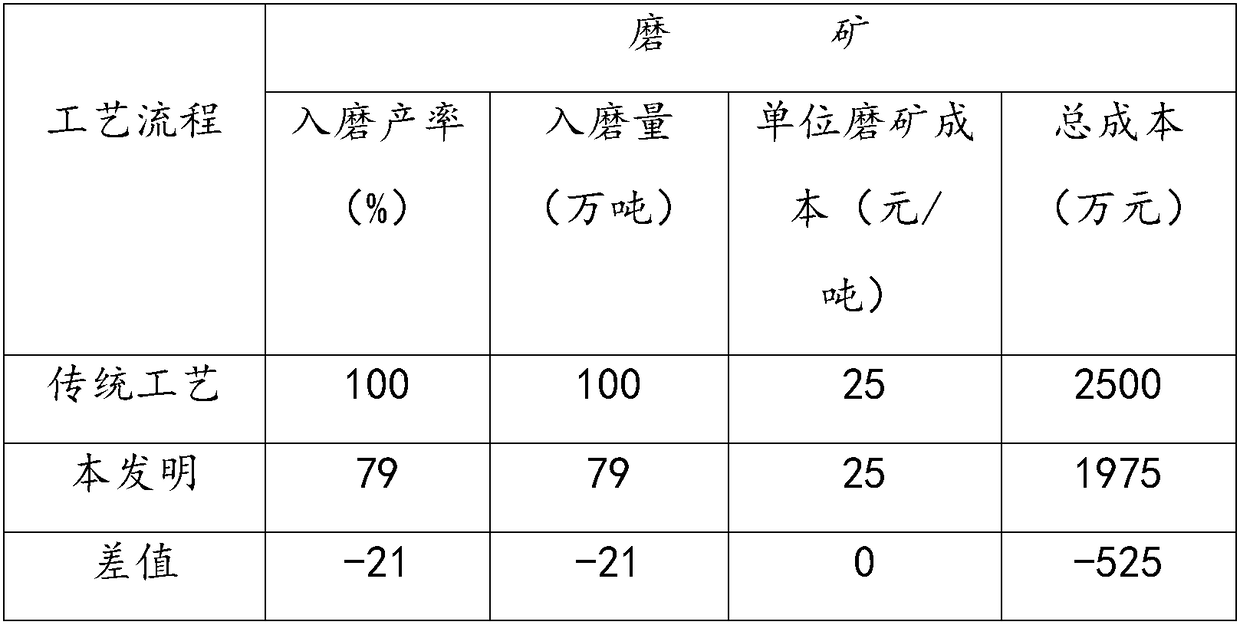

Efficient environment-friendly type beneficiation method for low-grade magnetic mirror iron ores

The invention discloses an efficient environment-friendly type beneficiation method for low-grade magnetic mirror iron ores. The efficient environment-friendly type beneficiation method is characterized in that iron ore concentrate which meets smelting requirements is obtained by adopting processes such as raw material three-stage crushing, large particle medium-magnetism and SLon strong-magnetismpre-selection, one-stage ore grinding and grading, one-stage weak magnetic-selecting and one-stage SLon strong magnetic-selecting, pre-grading and two-stage ore grinding and grading, two-stage weak magnetic-selecting and two-stage SLon strong magnetic-selecting and SL centrifugal machine selecting operation for the magnetic mirror iron ores. The efficient environment-friendly type beneficiation method can throw 21% of coarse-particle barren rocks through high-pressure roller-grinding, large-particle medium-magnetism pre-selecting and SLon strong-magnetism pre-selecting, and meets the beneficiation principle of preferably crushing instead of grinding and throwing as early as possible. A selecting process of roughing, cleaning and scavenging of a centrifugal machine is adopted, so that re-selecting operation completely replaces reverse flotation operation, and therefore, the efficient environment-friendly type beneficiation method is a pollution-free beneficiation method, is high in degree of automation, is great in processing amount, is liable to realize field operation and implementation, and greatly reduces manual operation.

Owner:WUHAN UNIV OF TECH

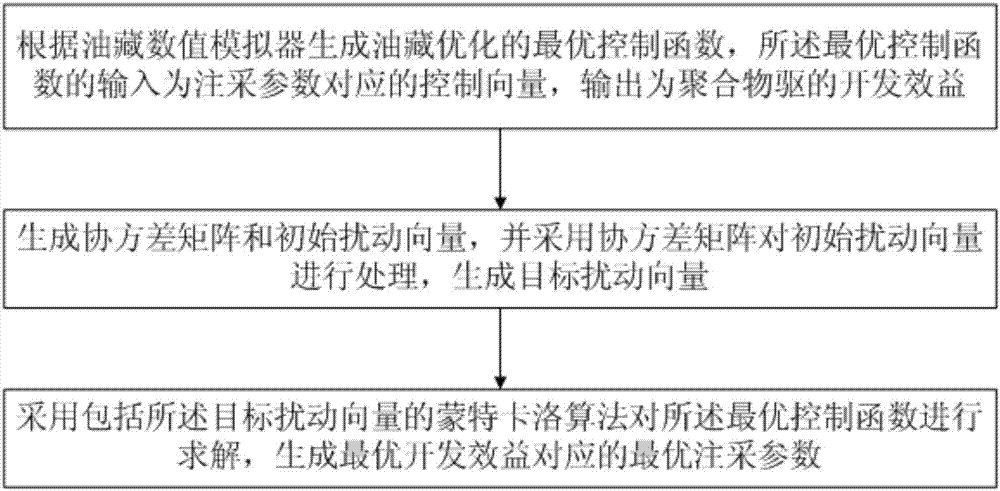

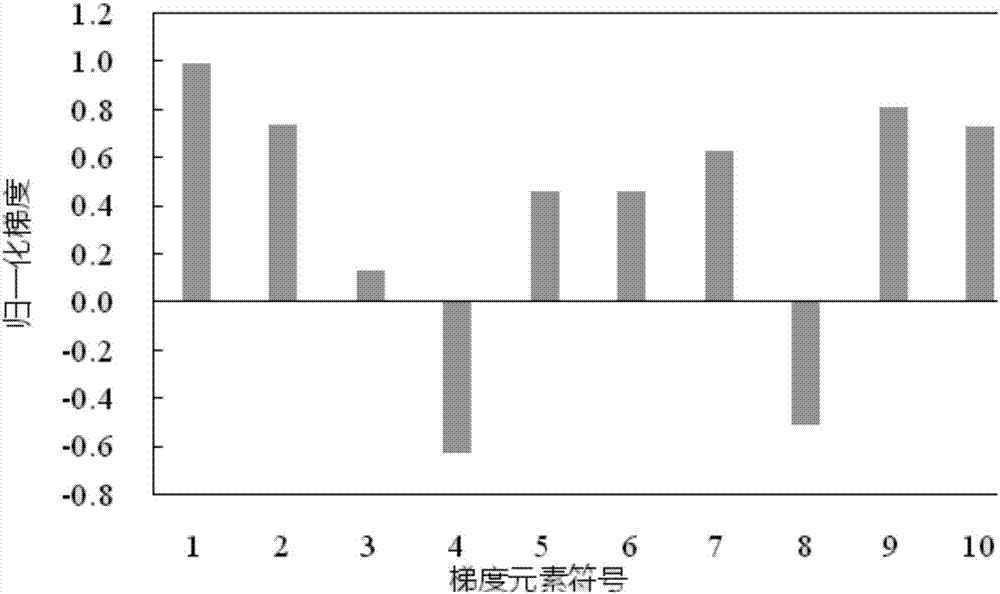

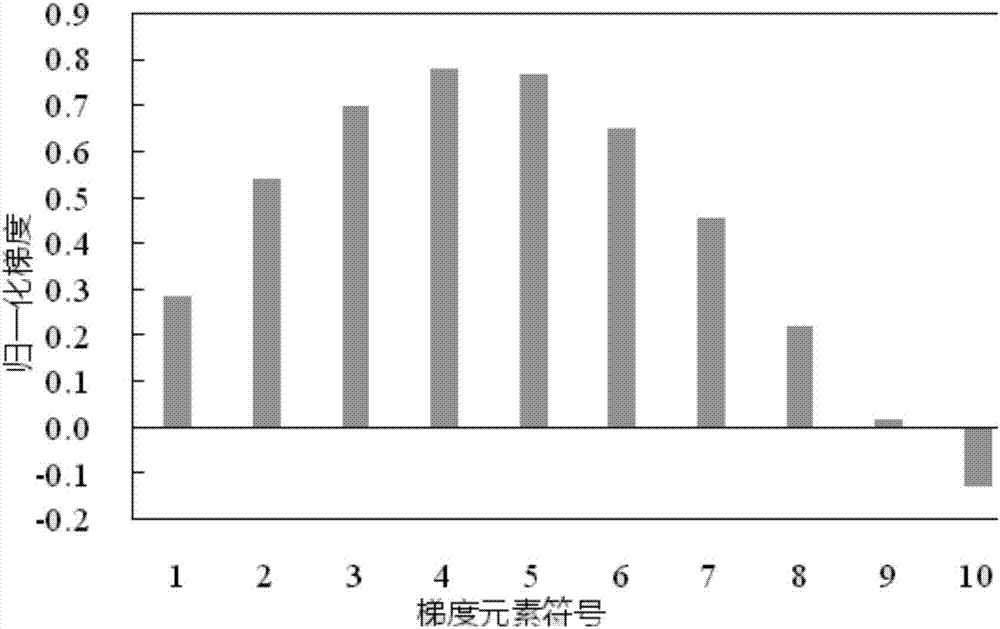

Polymer flooding production optimization method and system based on Monte Carlo algorithm

ActiveCN107218019AThe calculation process is simpleEasy to implementClimate change adaptationFluid removalPolymer floodingField development

The invention relates to a polymer flooding production optimization method and system based on a Monte Carlo algorithm. The method comprises the steps that an optimum control function for oil reservoir optimization is generated by a simulator according to an oil reservoir value; a covariance matrix is generated by a solving model, an initial disturbance vector is generated nearby an optimum control variable by utilizing the Monte Carlo approach algorithm, the initial disturbance vector is processed by adopting the covariance matrix to generate a target disturbance vector; the Monte Carlo algorithm including the target disturbance vector is adopted to solve the optimum control function, and an optimum injection-production parameter corresponding to optimum exploitation benefit is generated. The calculation process of the method is simple and easy to achieve, the optimization efficiency is high, the convergence rate is high, the system is easily combined with any oil reservoir value simulator to calculate polymer flooding production, injection-production well production parameters and injection polymer concentration can be simultaneously optimized, an oil reservoir development effect can be remarkably improved, and a basis can be provided for scientific, reasonable and efficient oil field development. The method can be widely applied to the field of oil-gas field development.

Owner:CHINA NAT OFFSHORE OIL CORP +1

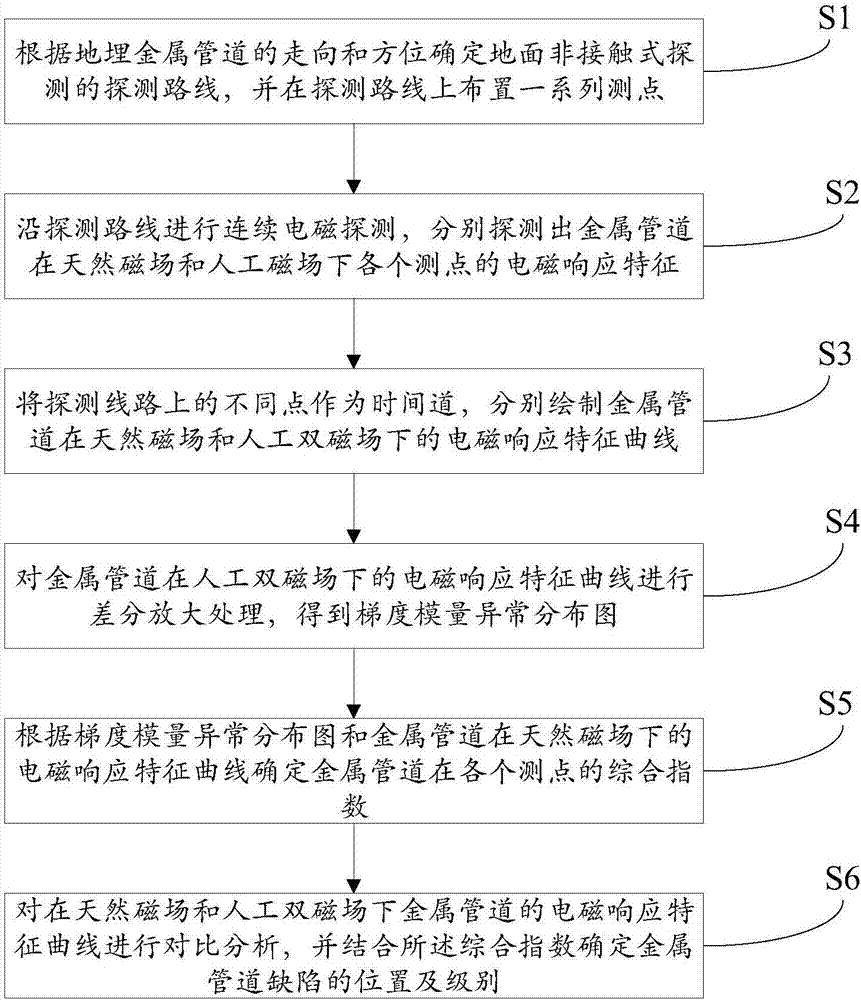

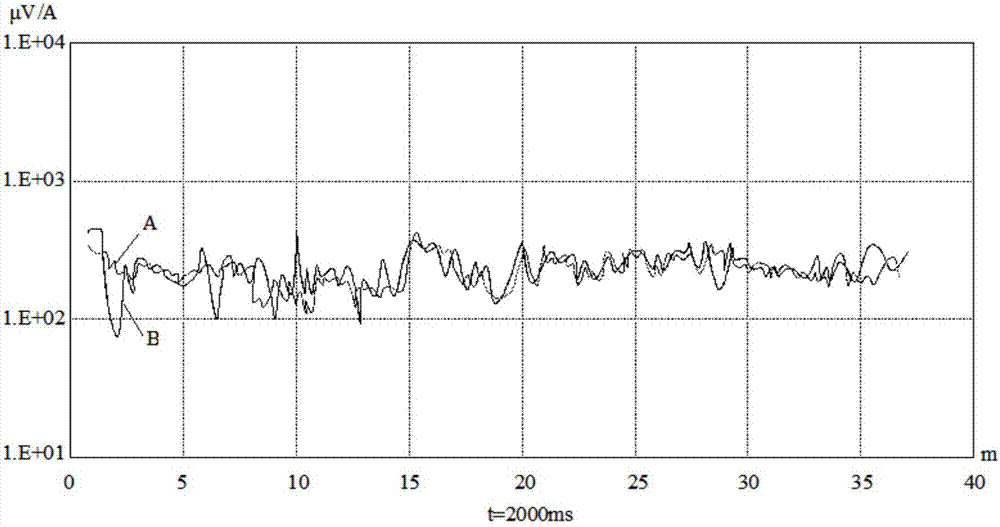

Method for comprehensively detecting defects of metal pipe in non-contact dual-source magnetic field

InactiveCN106970143AReduce missed detection rateReduce the missed detection rate and greatly reduce the detection costElectric/magnetic detectionAcoustic wave reradiationElectromagnetic responseContact mode

The invention relates to a method for comprehensively detecting defects of a metal pipe in a non-contact dual-source magnetic field. The method comprises the following steps: S1, determining a detection route for non-contact detection on the ground, and laying a series of detection points; S2, at each detection point, detecting electromagnetic response characteristics of the metal pipe in a natural magnetic field and an artificial magnetic field respectively; S3, drawing electromagnetic response characteristic curves of the metal pipe in the natural magnetic field and the artificial magnetic field respectively; S4, performing differential amplification on the electromagnetic response characteristic curve in the artificial dual magnetic field to obtain a gradient modulus abnormality distribution map; S5, according to the gradient modulus abnormality distribution map and the electromagnetic response characteristic curve in the natural magnetic field, determining a comprehensive index; S6, performing contrastive analysis on the electromagnetic response characteristic curves of the metal pipe in the natural magnetic field and the artificial dual magnetic field, and with the combination of the comprehensive index, determining positions and levels of the defects of the metal pipe. By the method, various drawbacks in the conventional method for detecting local defects of the metal pipe in a contact mode are overcome.

Owner:武汉地大华睿地学技术有限公司

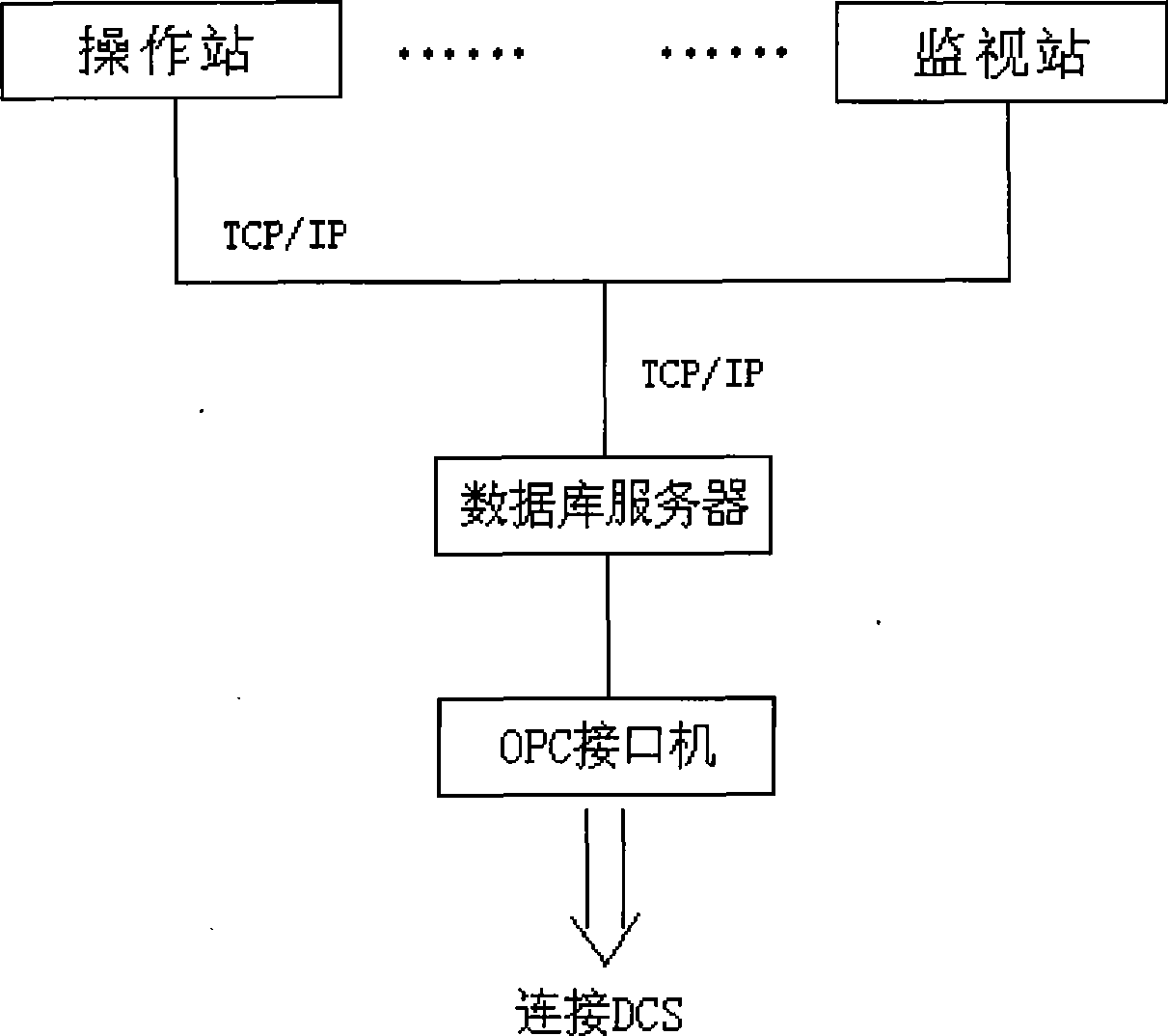

Multifunctional operation monitoring method for polythene production process

InactiveCN101430555AEasy to implement on siteSpare parts are easyTechnology managementTotal factory controlUpgradeMode selection

The invention discloses a multifunction operation monitoring method for the production process of petrothene, which is realized by replying on three layers of architectures connected by Internet; the method has the advantages of simple network deployment, convenient upgrade, interconnection, update, and maintenance in implementation and application. Plant mode selection is common and standard. The method solves the problem that the current process units of petrothene are short of an omnibearing operation monitoring method and overcomes the defect that a DCS system can not directly realize various advanced monitoring techniques; and the architectures and the plant mode selection can be conveniently popularized and applied to other types of industry devices.

Owner:ZHEJIANG UNIV

Ferromagnetic pipeline stress detection and monitoring method

PendingCN109799279AFind exactlyEasy to detectApparatus for force/torque/work measurementMaterial magnetic variablesElectrical resistance and conductanceStress concentration

The invention relates to a ferromagnetic pipeline stress detection and monitoring method. The method includes the steps of firstly, collecting pipeline basic information, and primarily judging parts where stress concentration possibly occurs; secondly, determining a pipeline route and buried depth, to be more specific, visually measuring the pipeline route, cleaning sundries, using a pipe locatorto detect the route, setting positioning piles, and measuring pipeline buried depth at the same time; thirdly, using a noncontact scanning magnetometer to collect magnetic signals along the calibratedroute; fourthly, analyzing and processing data, to be more specific, determining the axial position and circumferential position of the stress concentration parts of the pipeline; fifthly, detectingand monitoring pipeline stress, to be more specific, circumferentially adhering resistance strain gauges to the surfaces of the stress concentration points of the pipeline, and determining the stressvalue of the stress concentration points according to stress-strain relation; using the general packet radio service technology to transmit data to achieve remote data transmission and control. By themethod, the defects that existing ferromagnetic pipeline stress detection cannot accurately position the pipeline stress concentration points and determine the stress value of the stress concentration points are overcome, and omission factor is lowered greatly.

Owner:CHENGDU QIBO NEW ENERGY RES INST +1

Emulsion self-dispersion relative-permeability regulator and preparation method

ActiveCN109401746AImprove permeabilityEnhanced ultimate recoveryDrilling compositionCarvacryl acetateSolvent

The invention relates to an emulsion self-dispersion relative-permeability regulator. The emulsion self-dispersion relative-permeability regulator comprises an oil-soluble dispersant and a water-soluble dispersant, wherein the volume ratio of the oil-soluble dispersant to the water-soluble dispersant is (1: 9) to (9: 1); based on 100 parts (by weight) of the oil-soluble dispersant, the oil-solubledispersant is prepared from the following ingredients: 20-35 parts of octadecyl acrylate, 1-5 parts of acrylic acid, 10-18 parts of vinyl acetate, 5-12 parts of styrene, 10-20 parts of dibutyl maleicanhydride and the balance of solvent oil; based on 100 parts (by weight) of the water-soluble dispersant, the water-soluble dispersant is prepared from the following ingredients: 15-30 parts of water-soluble anionic surfactant, 10-25 parts of water-soluble nonionic surfactant, 5-12 parts of anhydrous ethanol and the balance of deionized water. The invention further relates to a preparation methodof the emulsion self-dispersion relative-permeability regulator.

Owner:CHINA PETROLEUM & CHEM CORP +1

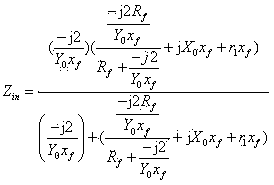

Pi-type equivalent circuit based direct current earth electrode line fault location method

ActiveCN103743996ASimple calculationEasy to implement on siteFault locationLocation technologyEngineering

The invention relates to a pi-type equivalent circuit based direct current earth electrode line fault location method which belongs to the field of power system fault location technology. According to the method, when an earth fault happens to a high-voltage direct current earth electrode line, a circuit from a fault point to a measuring end is equivalent to a pi-type equivalent circuit; input impedance is calculated by single-ended voltage and current magnitudes; a fault location function is determined according to the fact that the input impedance is equivalent to equivalent impedance of the circuit from the fault point to the measuring end; and the fault location function is solved to calculate the fault distance. Based on the pi-type equivalent model, an equivalent way is conducted on the circuit model. Calculation is simplified. Based on onsite recording data, the method provided by the invention is easy to implement on scene. Single-ended measurable voltage and current magnitudes are only needed. Data of opposite ends is not required.

Owner:KUNMING UNIV OF SCI & TECH +1

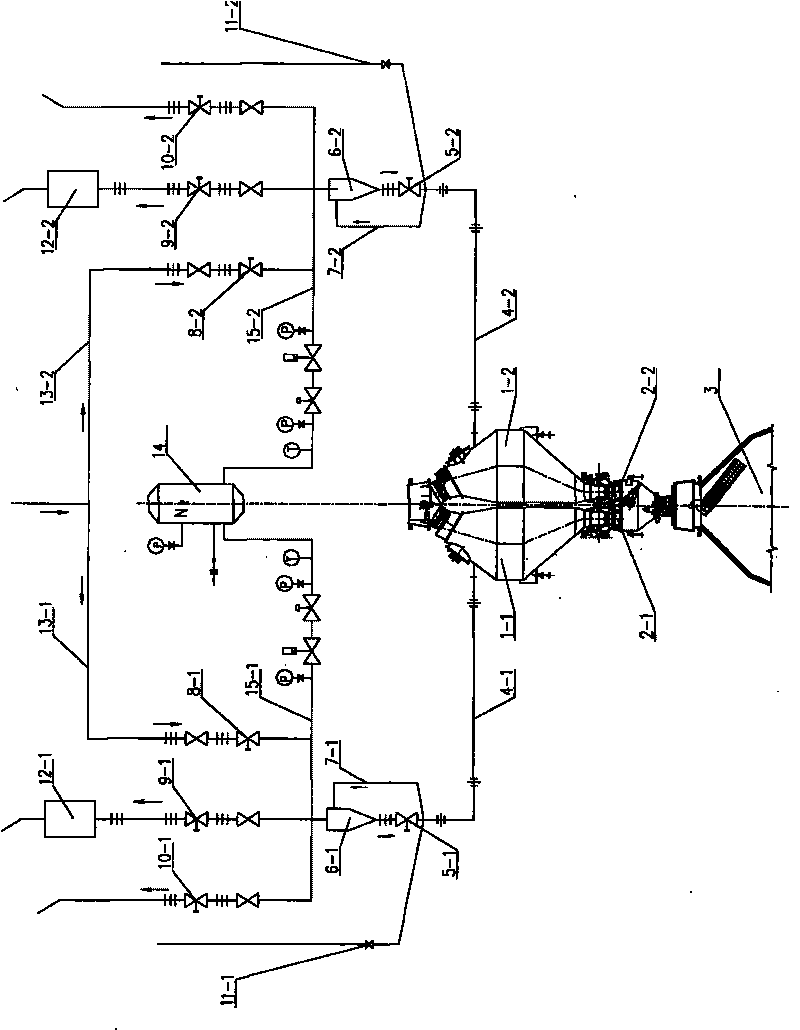

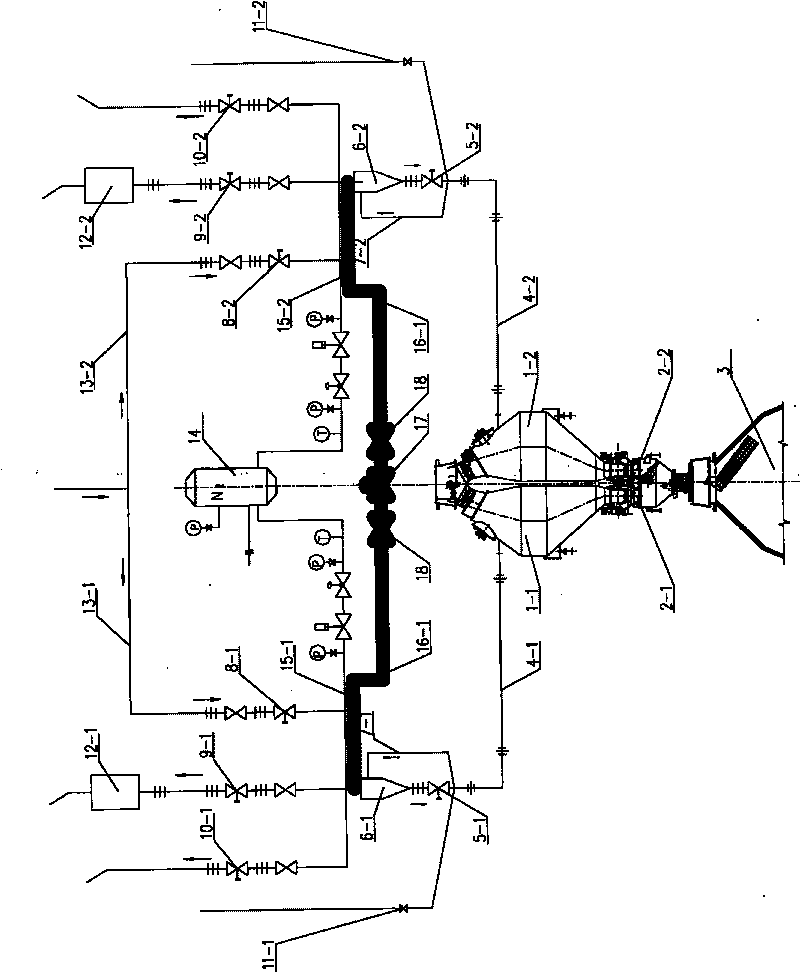

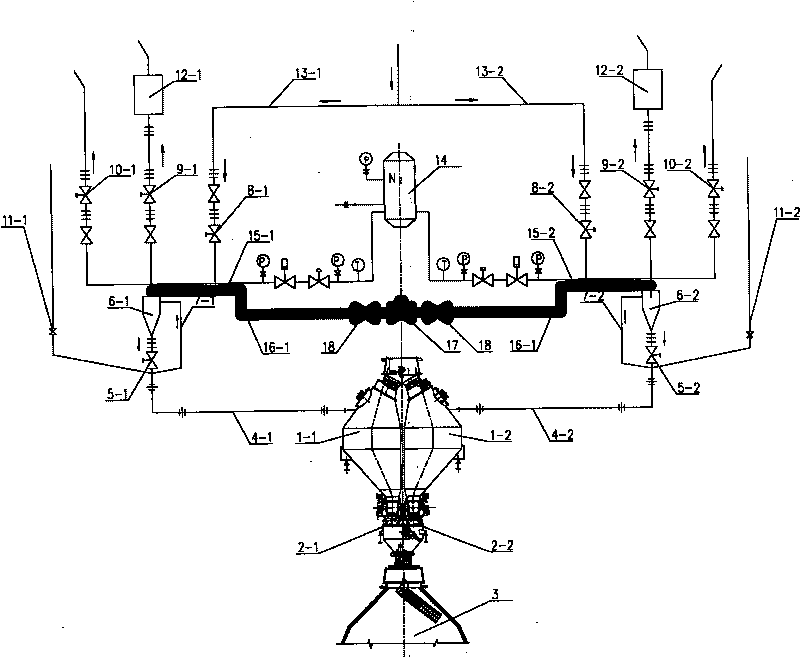

Blast-furnace pressure-discharging gas recovering device and method

ActiveCN101724722AEmission reductionSimple processBlast furnace componentsBlast furnace detailsMetallurgical industryIndustrial technology

The invention discloses blast-furnace pressure-discharging gas recovering device and method of a blast-furnace top pressure equalizing-discharging system, belonging to the technical field of metallurgical industry. The device is suitable for the blast-furnace top pressure equalizing-discharging system which adopts a parallel-tank or three-tank bell-less top charging device and comprises a material tank, a pressure equalizing-discharging system and a secondary pressure-equalizing system, wherein the material tank is connected with a blast furnace through a seal valve, and meanwhile, the material tank is connected with the pressure equalizing-charging system; and the secondary pressure-equalizing system is connected with a pipeline of the pressure equalizing-discharging system. The device is characterized in that: on the pressure equalizing-discharging system of the parallel-tank or three-tank bell-less top charging device, a pressure equalizing-discharging subsystem of each material tank is connected with a pressure-discharging gas recovering system. The invention has simple process, reliable operation and convenient field construction, can reduce the blast-furnace gas consumption and the dust-containing gas emission, and is practical technology with energy saving and environmental protection.

Owner:CISDI ENG CO LTD

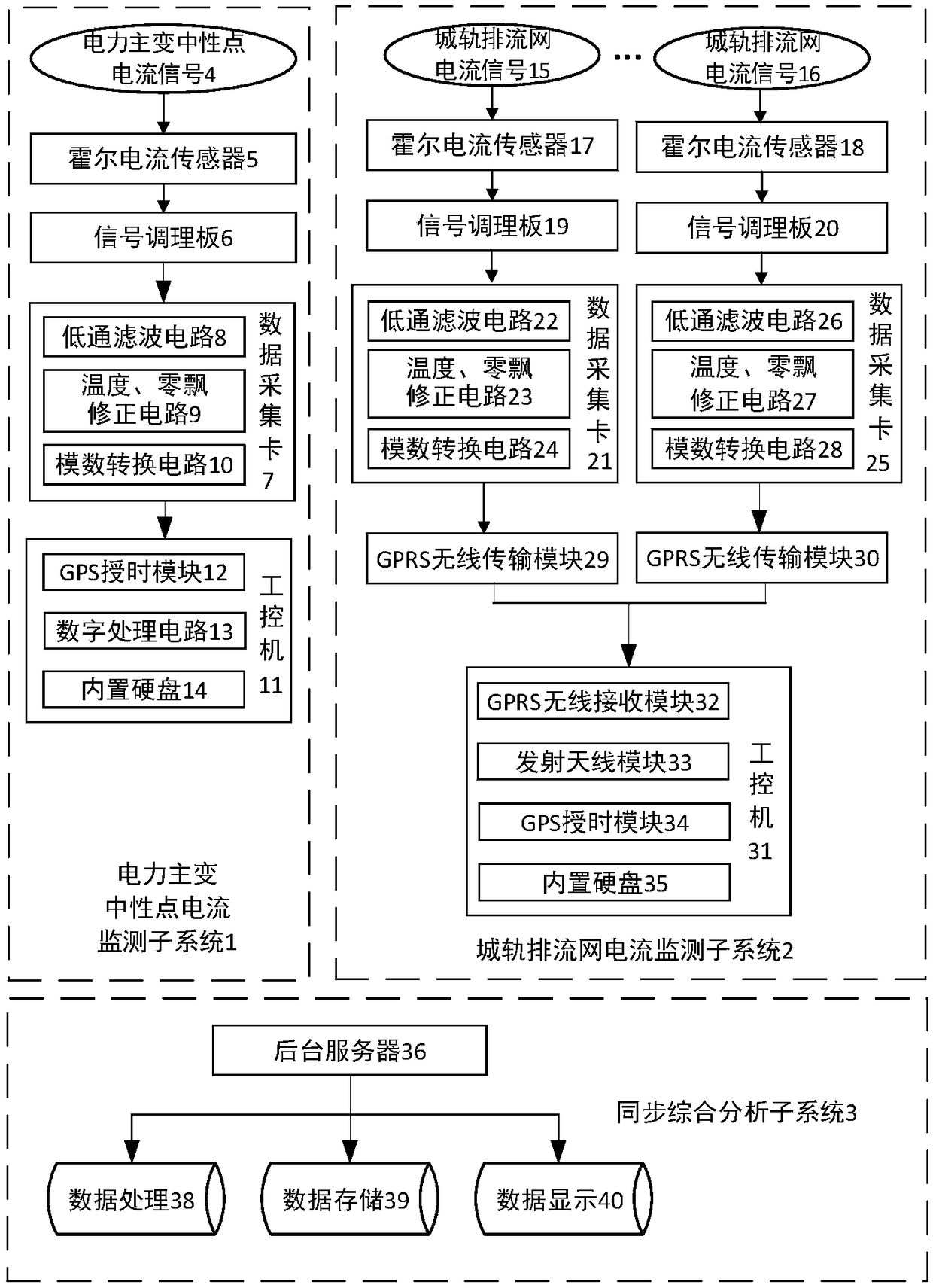

Urban rail traction power supply system and urban power main transformer direct current bias synchronous monitoring system

ActiveCN109387680ATime synchronizationDoes not affect normal operationCurrent/voltage measurementVoltage/current isolationTransformerCurrent sensor

The invention discloses an urban rail traction power supply system and urban power main transformer direct current bias synchronous monitoring system, which is used for monitoring the problem of urbanpower main transformer direct current bias caused by urban rail stray currents. The synchronous monitoring system is composed of three subsystems: an urban rail drainage network current monitoring subsystem, a power main transformer neutral point current monitoring subsystem, and a comprehensive analysis subsystem. The hardware of the urban rail drainage network current monitoring subsystem consists of a Hall sensor, a signal conditioning board, a data acquisition card, a GPRS wireless transmission module and an industrial control computer. The hardware of the power main transformer neutral point current monitoring subsystem consists of a Hall current sensor, a signal conditioning board, a data acquisition card and an industrial control computer.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

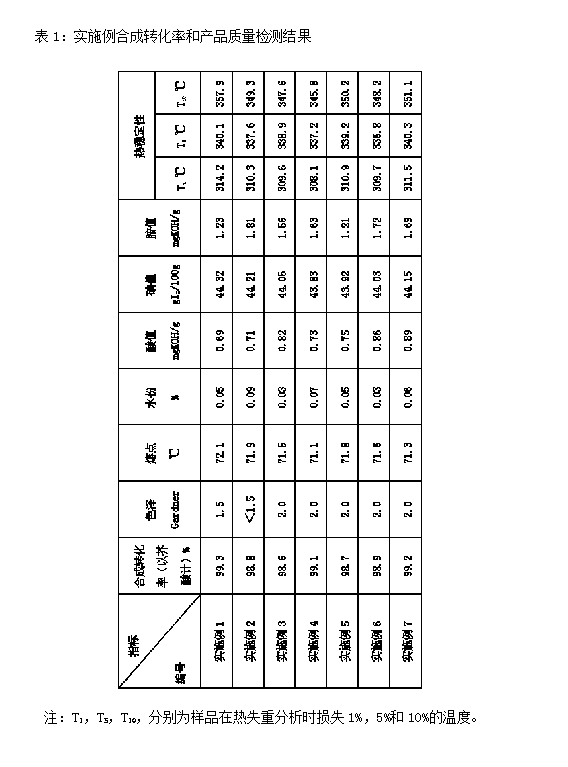

Synthetic method of octadecyl erucyl amide

ActiveCN104230741AOmit removalNo pollution in the processOrganic compound preparationCarboxylic acid amides preparationPhosphomolybdic acidStrong acids

The invention discloses a synthetic method of octadecyl erucyl amide. The synthetic method is characterized in that octadecyl amine and erucic acid are selected as raw materials according to comprehensive factors such as source and price of raw materials, the yield of the octadecyl erucyl amide, the difficulty level in controlling byproducts and environmental influence of synthetic reaction, the raw materials directly react in the presence of a catalyst, and the octadecyl erucyl amide is synthesized by a one-step process. The catalyst consists of solid strong acid, 12-30% of metatitanic acid and 50-88% of silica gel for chromatography. The solid is one of 0-12% of phosphomolybdic acid or 0-20% of silicotungstic acid or 0-15% of phosphotungstic acid. The catalyst is prepared by processes of loading and activating. The synthetic method has the advantages that site operation performance is simple and easy, processes of refining and purifying octadecyl erucyl amide are omitted, the production process is free of a solvent and environmental pollution, the octadecyl erucyl amide yield is high, the synthetic method is environment-friendly, the production cost is low, and the large-scale high-grade production can be realized.

Owner:江西威科油脂化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com