Method for comprehensively detecting defects of metal pipe in non-contact dual-source magnetic field

A metal pipeline, non-contact technology, applied in the direction of electric/magnetic exploration, measuring devices, material magnetic variables, etc., to achieve the effects of increased sensitivity, easy on-site implementation, and low operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

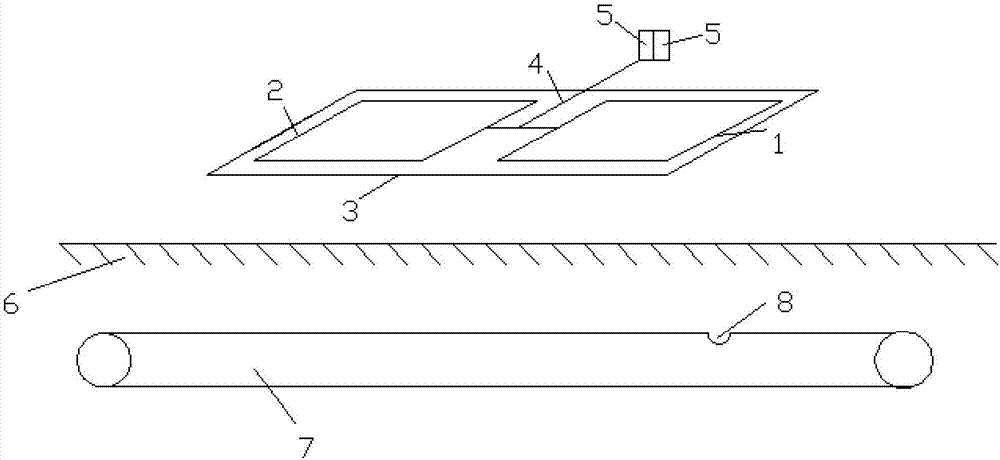

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

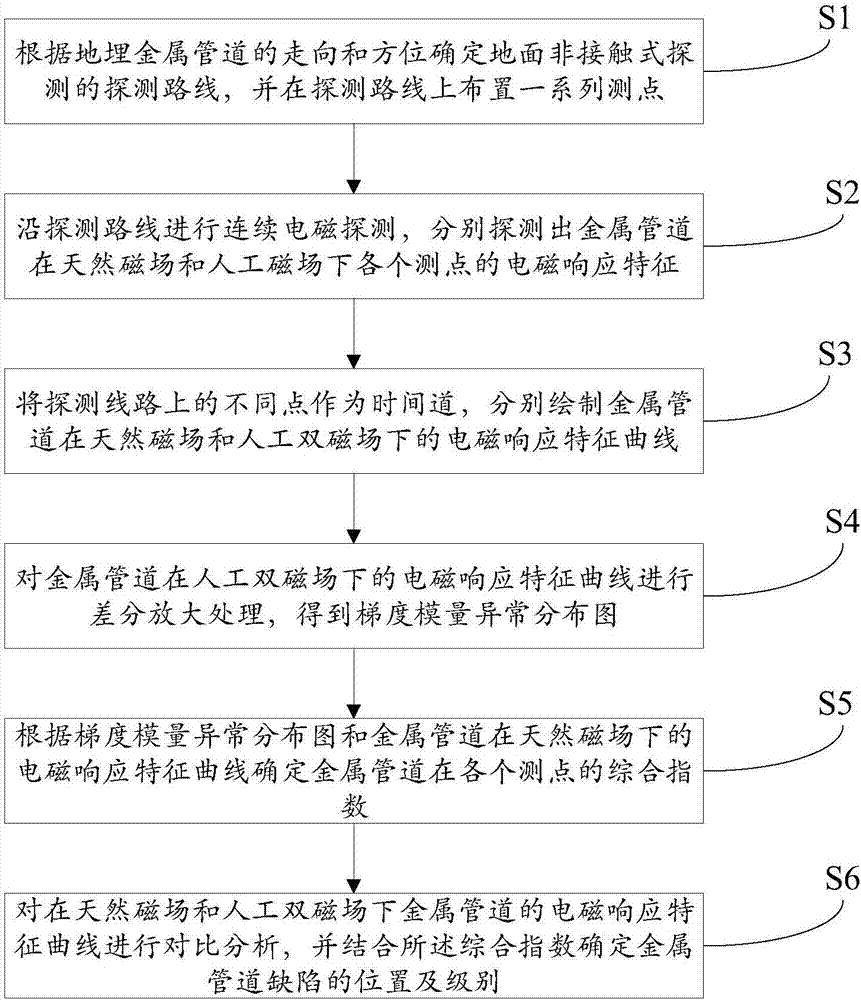

[0028] Such as figure 1 As shown, a non-contact dual-source magnetic field comprehensive detection method for metal pipeline defects, including the following steps,

[0029] S1, determine the detection route of ground non-contact detection according to the direction and orientation of the buried metal pipeline, and arrange a series of measuring points on the detection route;

[0030] S2, carry out continuous electromagnetic detection along the detection route, respectively detect the electromagnetic response characteristics of each measuring point of the metal pipeline under the natural magnetic field and artificial magnetic field;

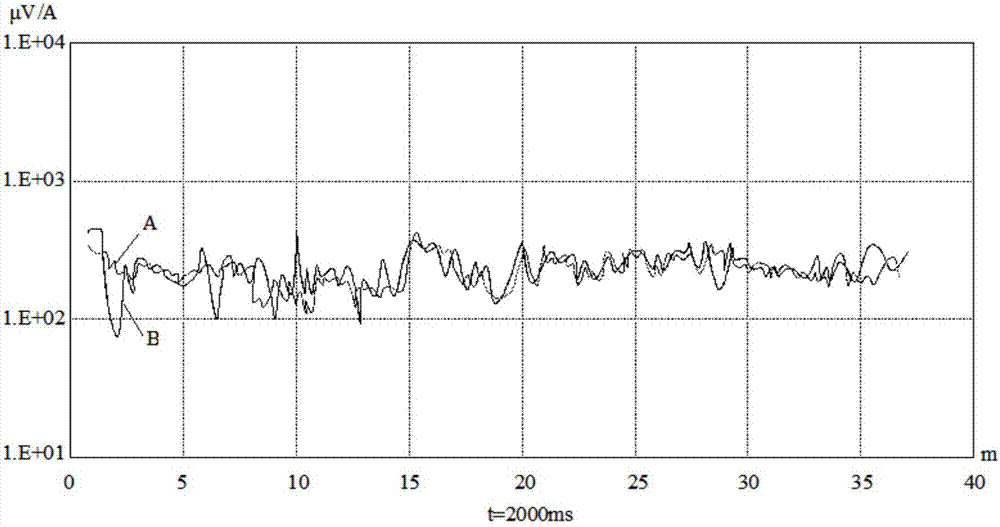

[0031] S3, taking different measuring points on the detection route as the time tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com