Cloth defect detecting method based on machine vision

A defect detection and machine vision technology, which is applied in the direction of optical test defects/defects, instruments, computer parts, etc., can solve the problems of large amount of calculation and slow detection speed, so as to save labor costs, reduce the number of filters, The effect of reducing the missed detection rate and false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

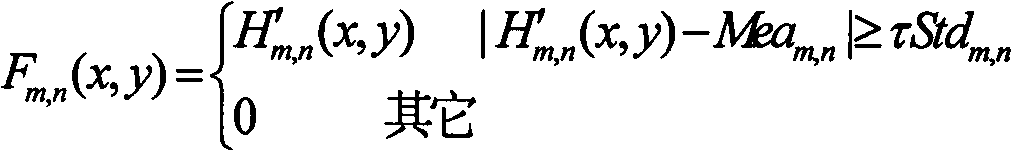

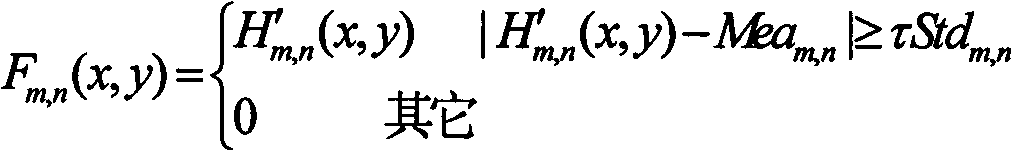

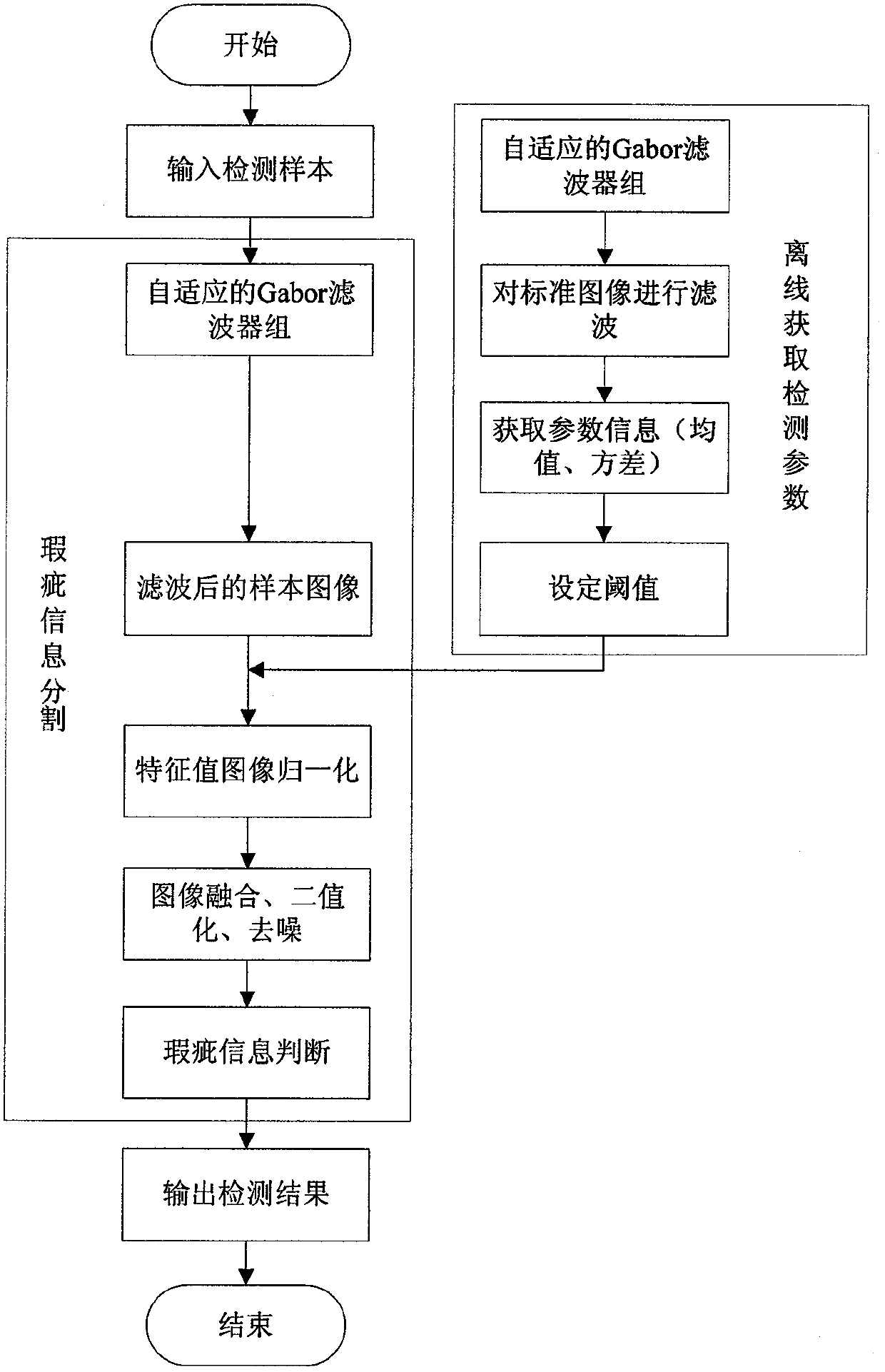

[0025] The general flow chart of the cloth defect detection technology method based on machine vision of the present invention is as follows figure 1 As shown, firstly, the power spectrum analysis is performed on the normal cloth texture image, and the acquired texture feature information is used to set the adaptive Gabor filter bank (see figure 2 ), by filtering the cloth sample image, extracting features and judging the defect information to detect cloth defects.

[0026] see image 3 , Common cloth defects are broken weaves, flour grains, dense roads, oil stains, rough knots, colored threads, skipped yarns, holes, skipped flowers, slubs, double warp, double weft defects, etc. Use the following Figure 4 The entire detection process of the broken weave image is further described in detail.

[0027] 1. Power Spectrum Analysis of Cloth Texture Image

[0028] The image power spectrum is expressed as the distribution of image energy in frequency, and the image energy is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com