Patents

Literature

132 results about "Production optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production optimization is the practice of making changes or adjustments to a product to make it more desirable. A product has a number of attributes.

Systems and Methods for Optimization of Real Time Production Operations

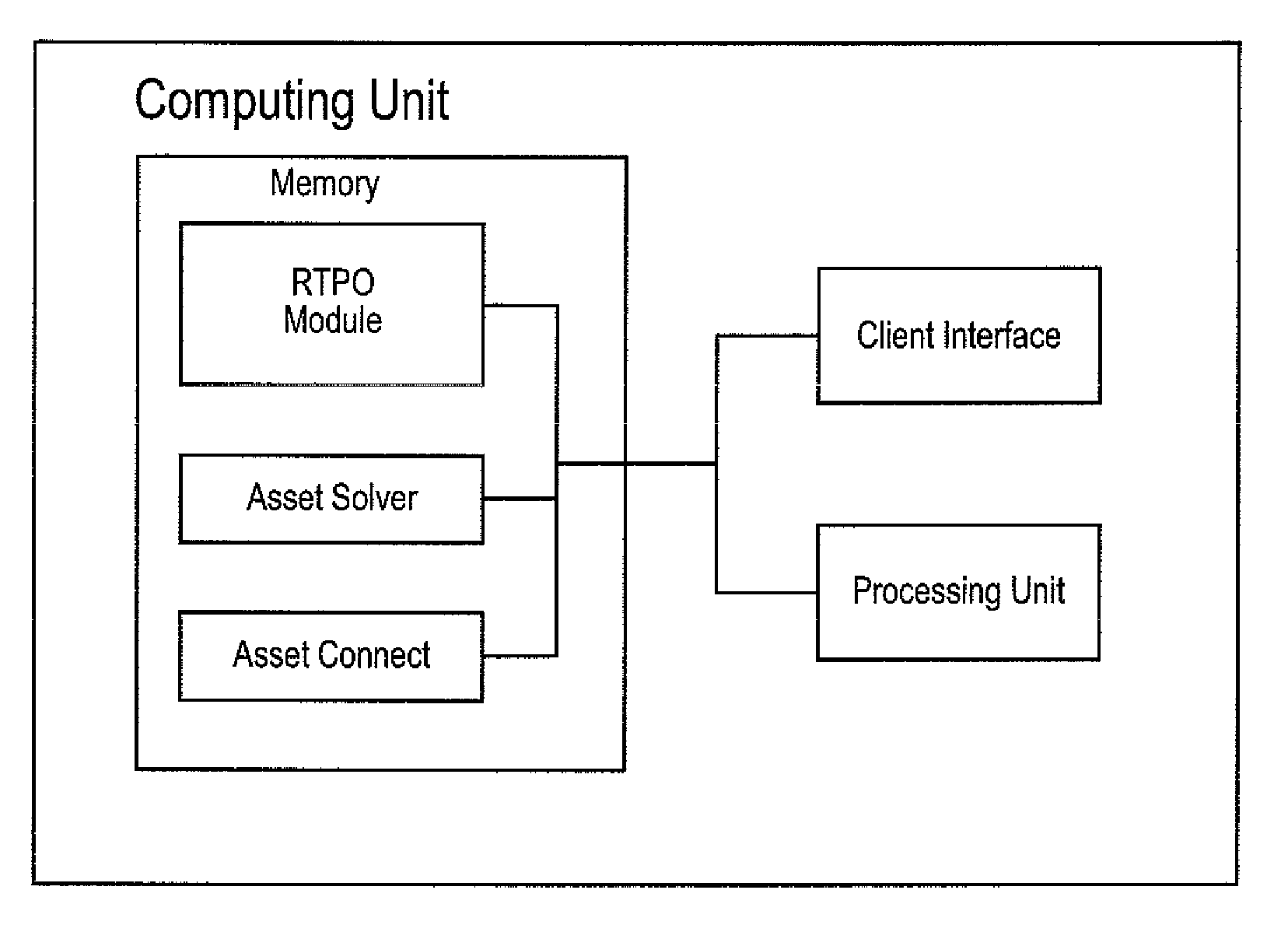

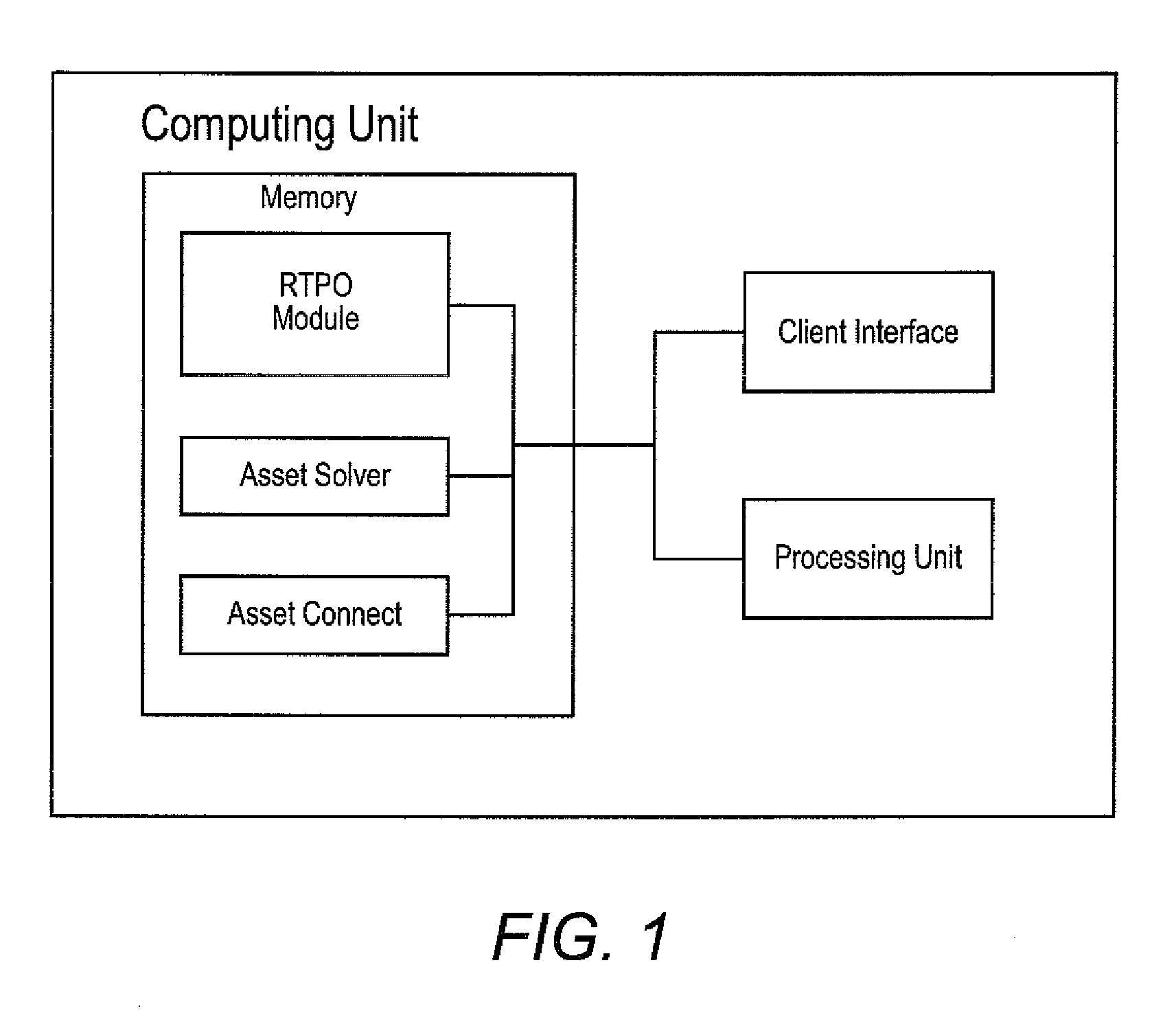

Systems and methods for optimization of real time production operations. In one embodiment, a moving time horizon based parametric model provides fast predictions for production optimization in a short-term framework. In another embodiment, multiple technologies are selected in connection with asset performance workflows that are uniquely implemented in a multi-phase approach.

Owner:LANDMARK GRAPHICS

Statistical determination of historical oilfield data

InactiveUS20090194274A1Optimizing and increasing productionElectric/magnetic detection for well-loggingSurveyProduction optimizationOil processing

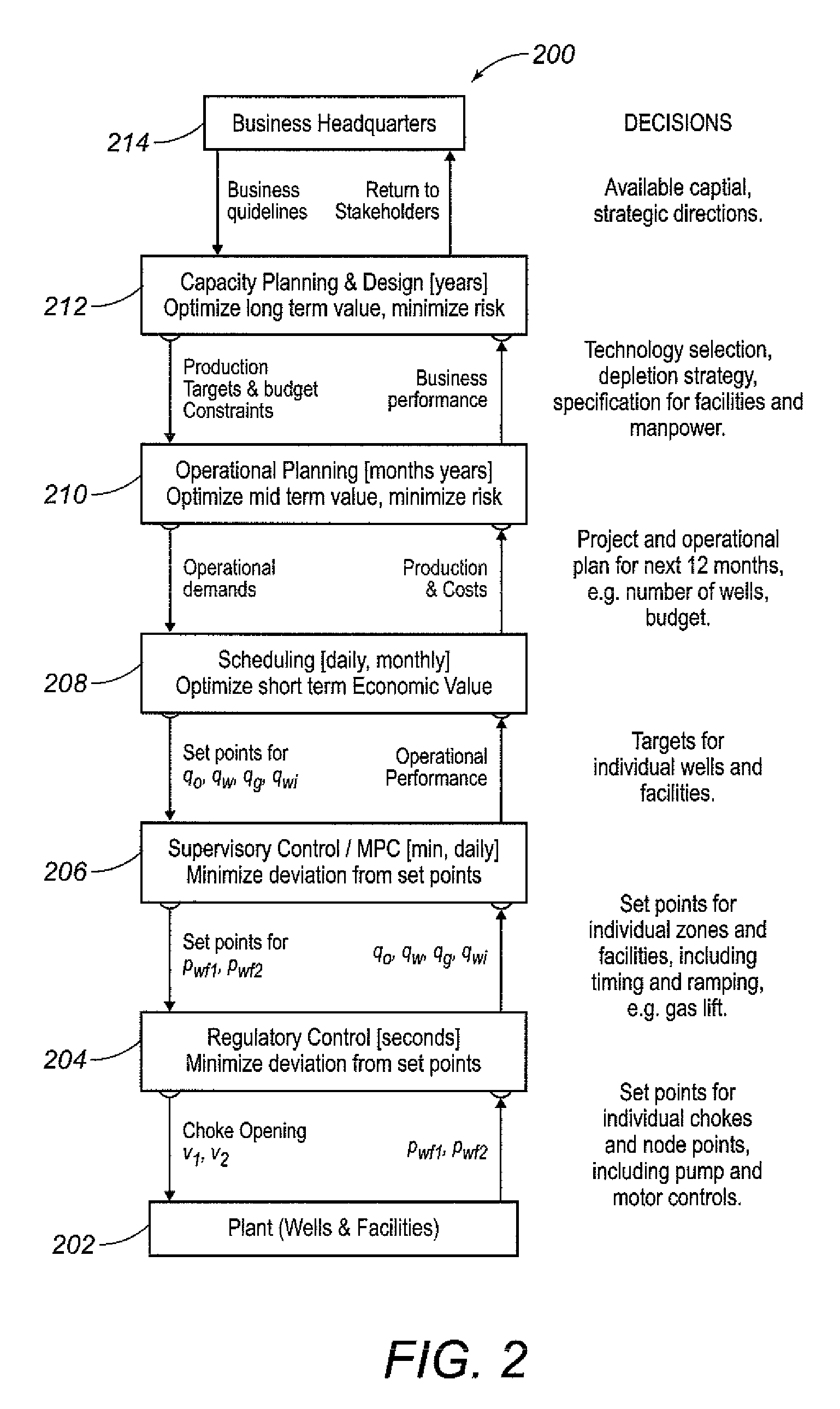

A method, system, and computer program product for performing oilfield surveillance operations. The oilfield has a subterranean formation with geological structures and reservoirs therein. The oilfield is divided into a plurality of patterns, with each pattern comprising a plurality of wells. Historical production / injection data is obtained for the plurality of wells. Two independent statistical treatments are performed to achieve a common objective of production optimization. In the first process, wells and / or patterns are characterized based on Heterogeneity Index results and personalities with the ultimate goal of field production optimization. In the second process, the history of the flood is divided into even time increments. At least two domains for each of the plurality of wells are determined. Each of the at least two domains are centered around each of the plurality wells. A first domain of the at least two domains has a first orientation. A second domain of the at least two domains has a second orientation. An Oil Processing Ratio is determined for each of the at least two domains, then an Oil Processing Ratio Strength Indicator is calculated. At least one Meta Pattern within the field is then identified. An oilfield operation can then be guided based either on the well and / or pattern personality or the at least one Meta Pattern.

Owner:SCHLUMBERGER TECH CORP

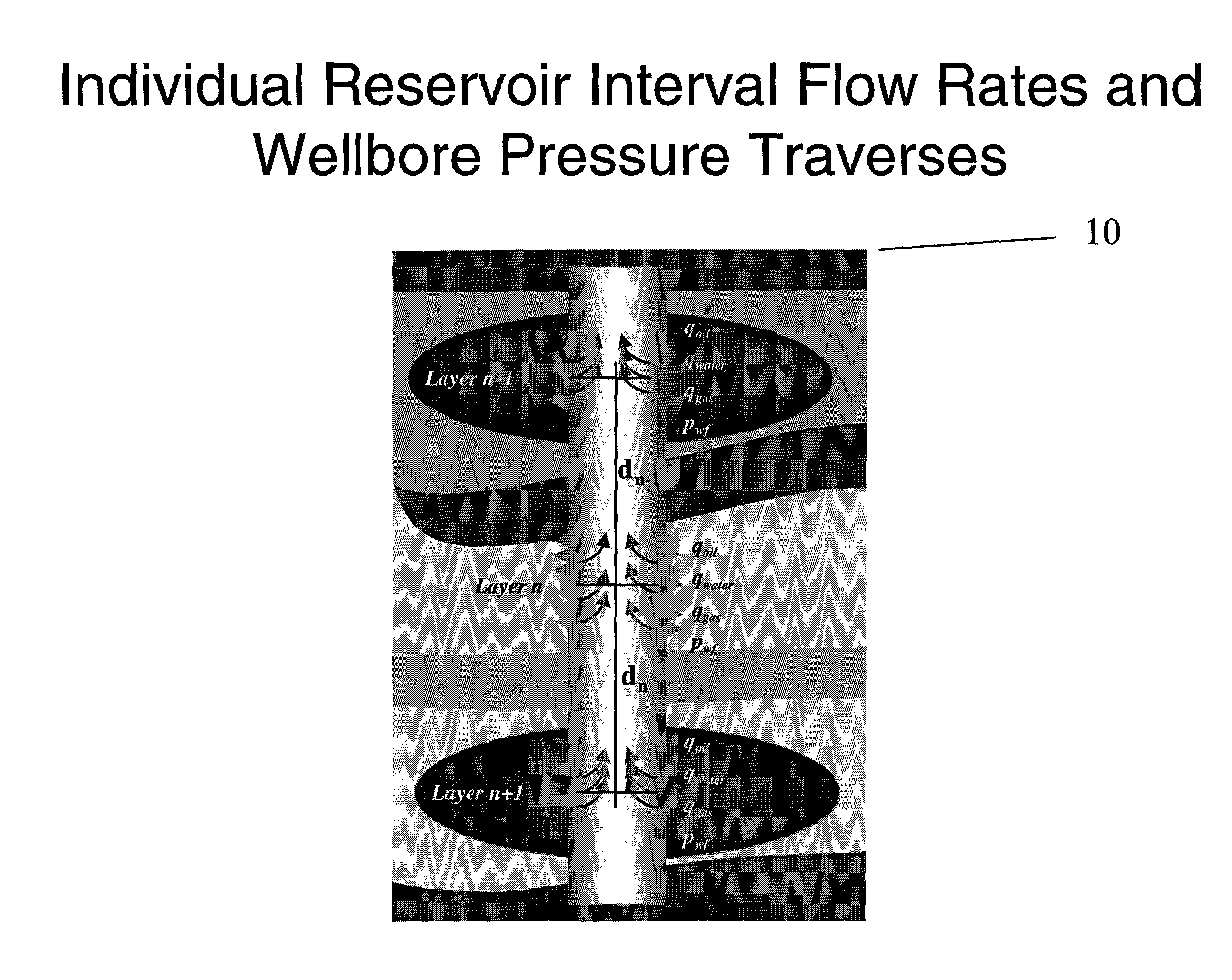

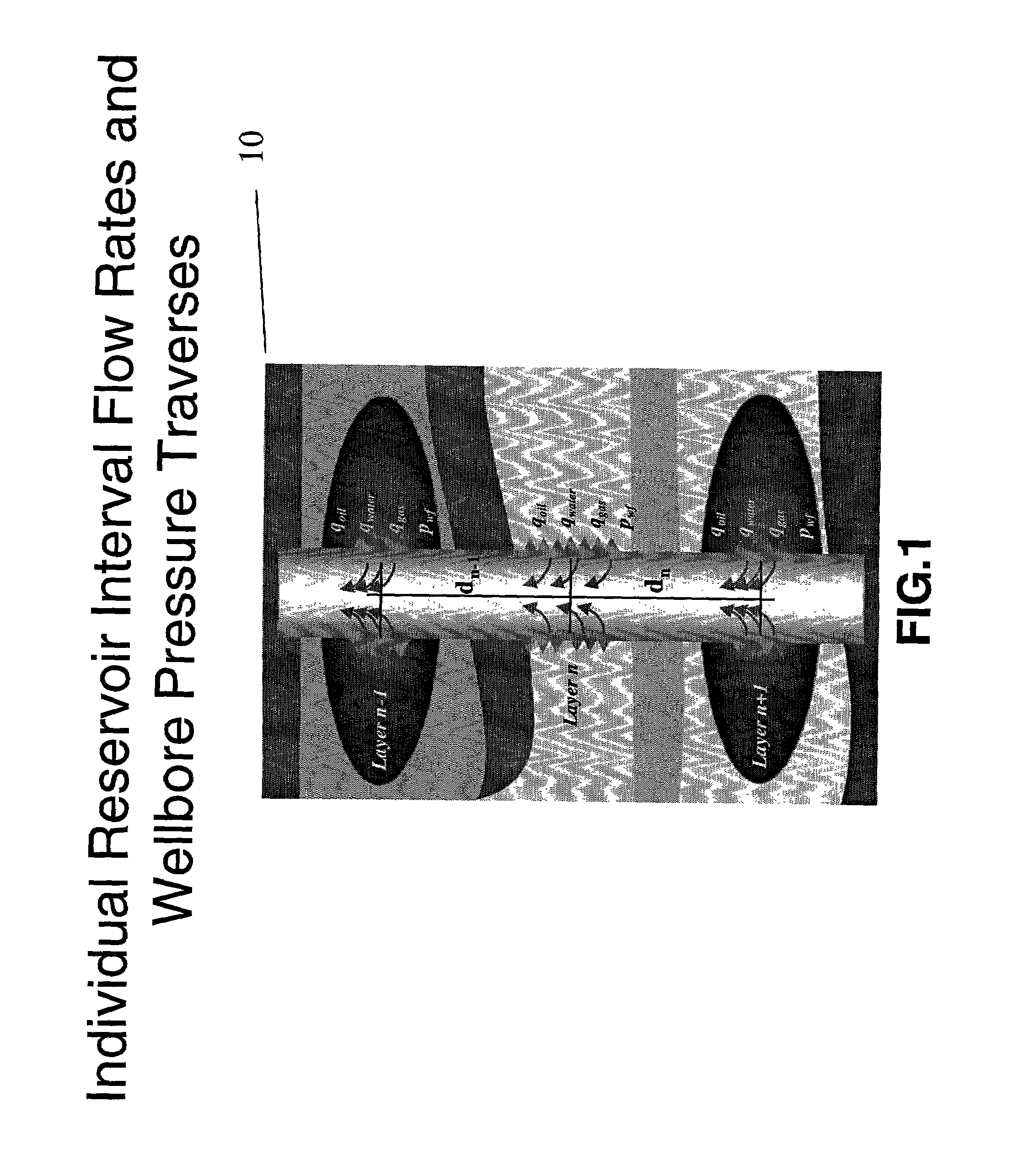

Production optimization methodology for multilayer commingled reservoirs using commingled reservoir production performance data and production logging information

InactiveUS7062420B2Improve productivityEasy to manageElectric/magnetic detection for well-loggingSurveyProduction rateProduction optimization

An overall petroleum reservoir production optimization methodology permits the identification and remediation of unstimulated, under-stimulated, or simply poorly performing reservoir completed intervals in a multilayer commingled reservoir that can be recompleted using any of various recompletion methods (including but not limited to hydraulic fracturing, acidization, re-perforation, or drilling of one or more lateral drain holes) to improve the productivity of the well. This provides an excellent reservoir management tool and includes the overall analysis and remediation methodology that has been developed for commingled reservoirs. The specialized recompletion techniques can be used to improve the productivity of previously completed individual reservoir intervals in a commingled reservoir.

Owner:SCHLUMBERGER TECH CORP

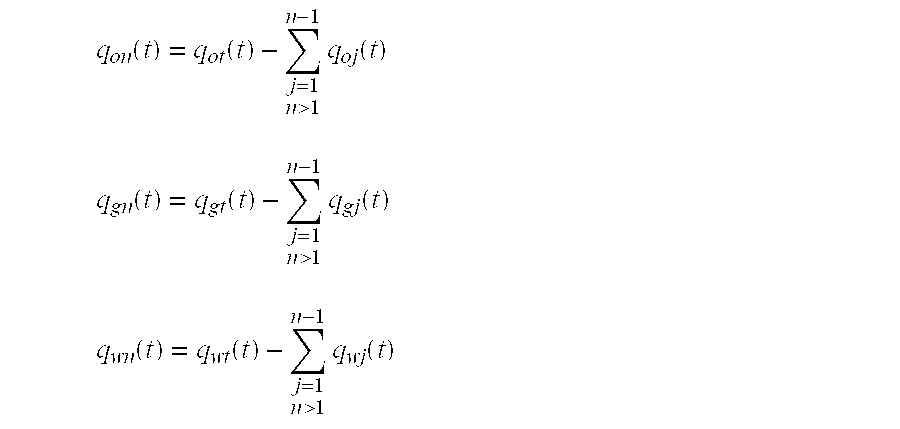

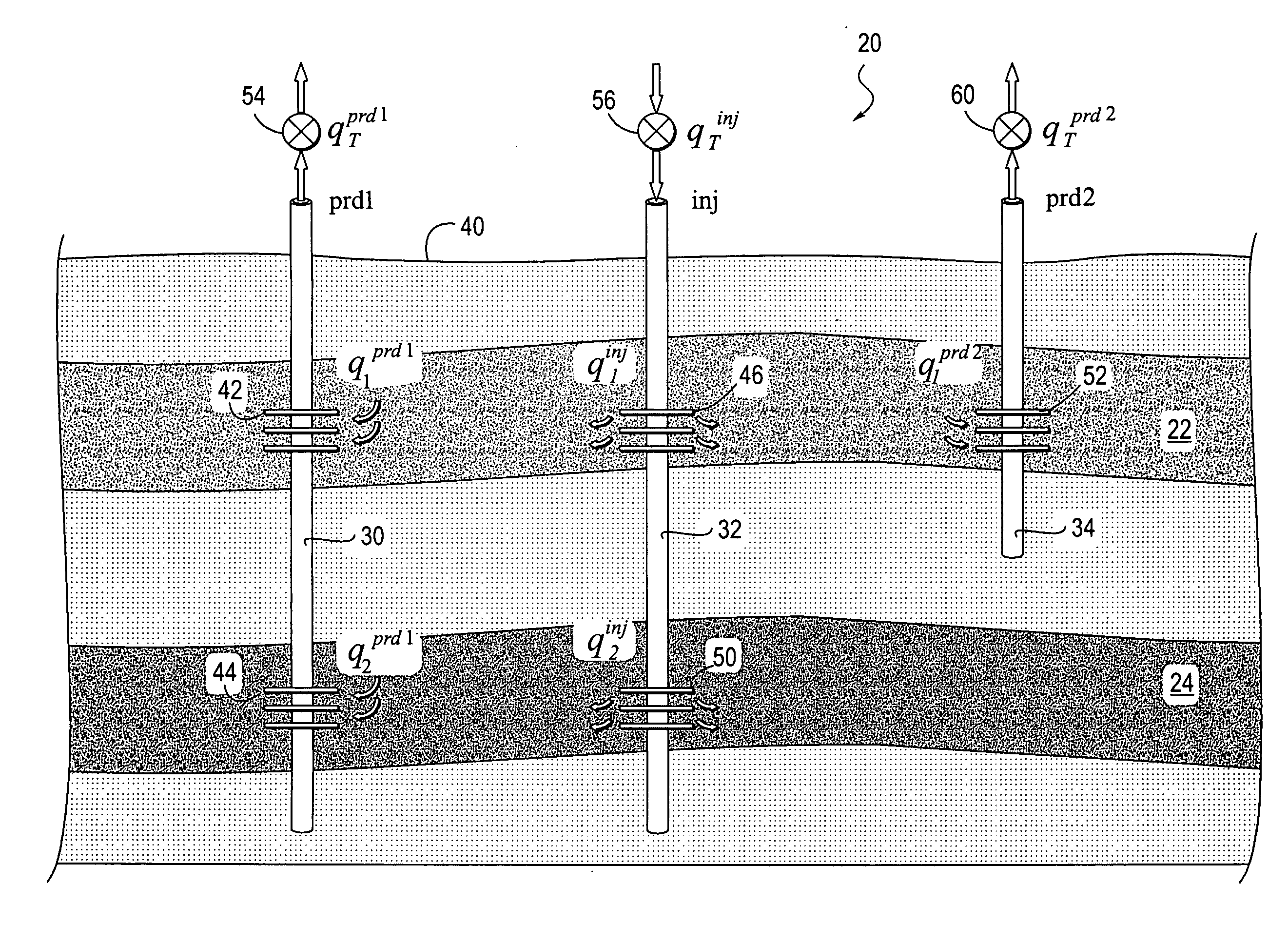

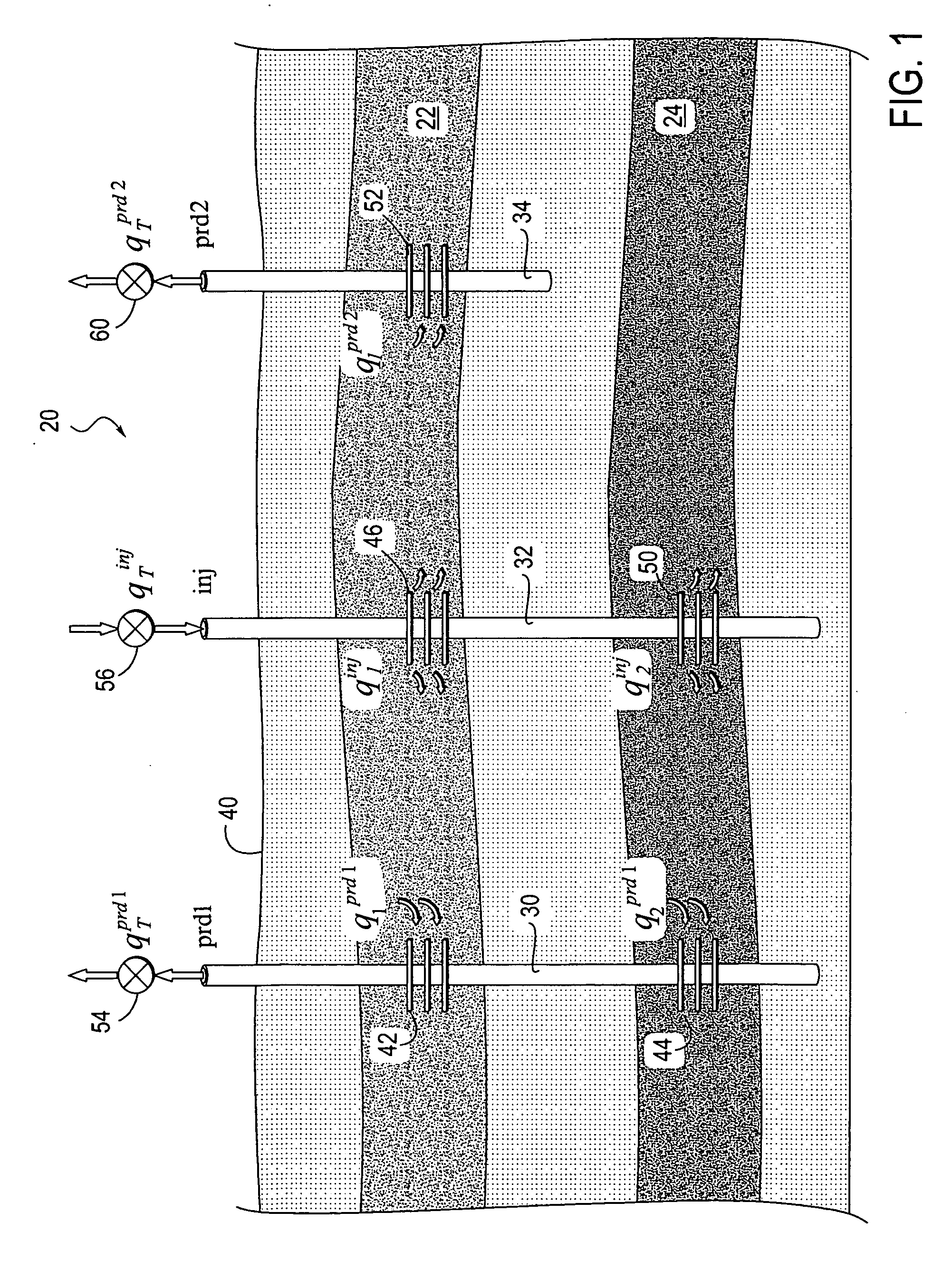

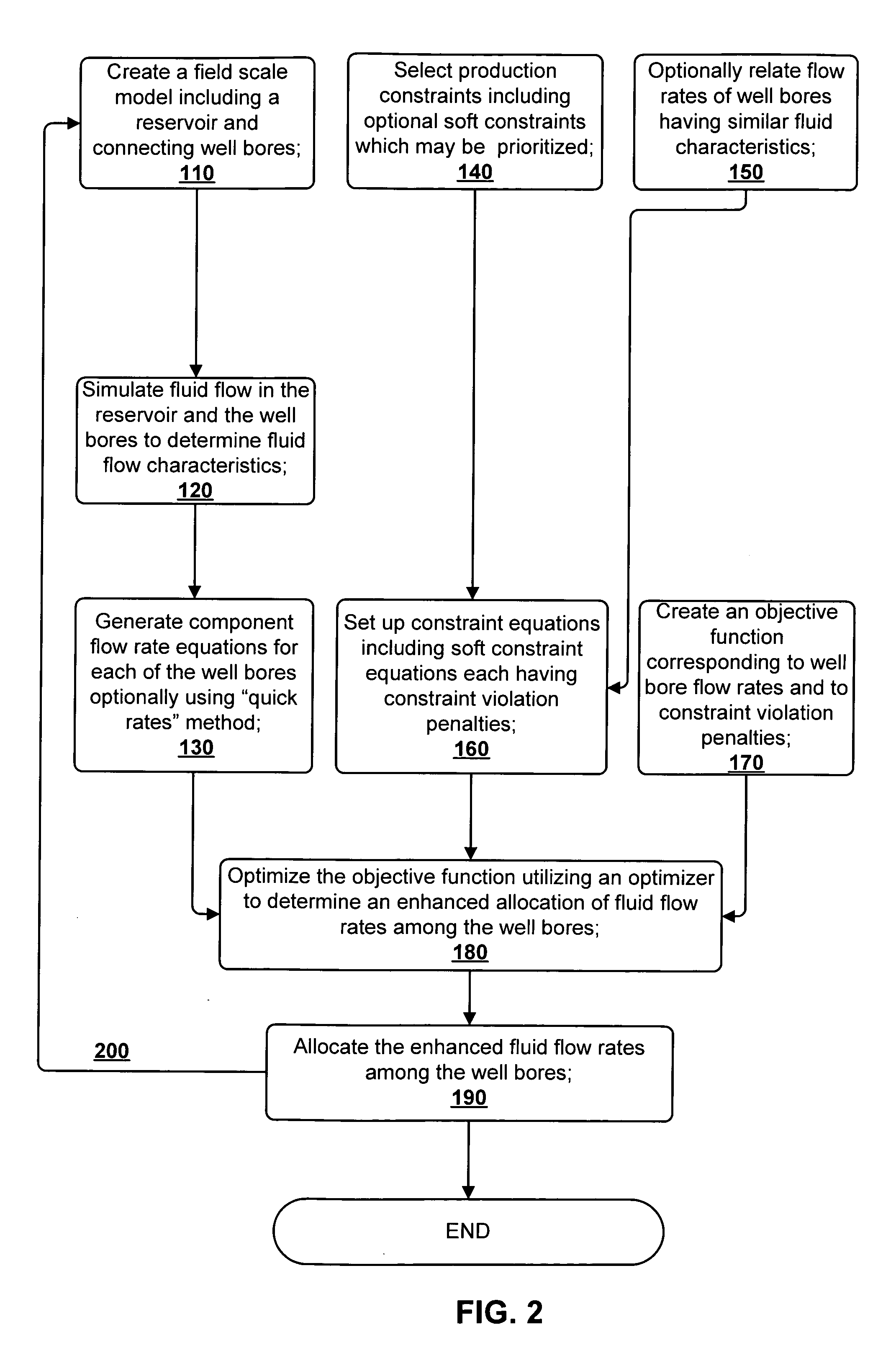

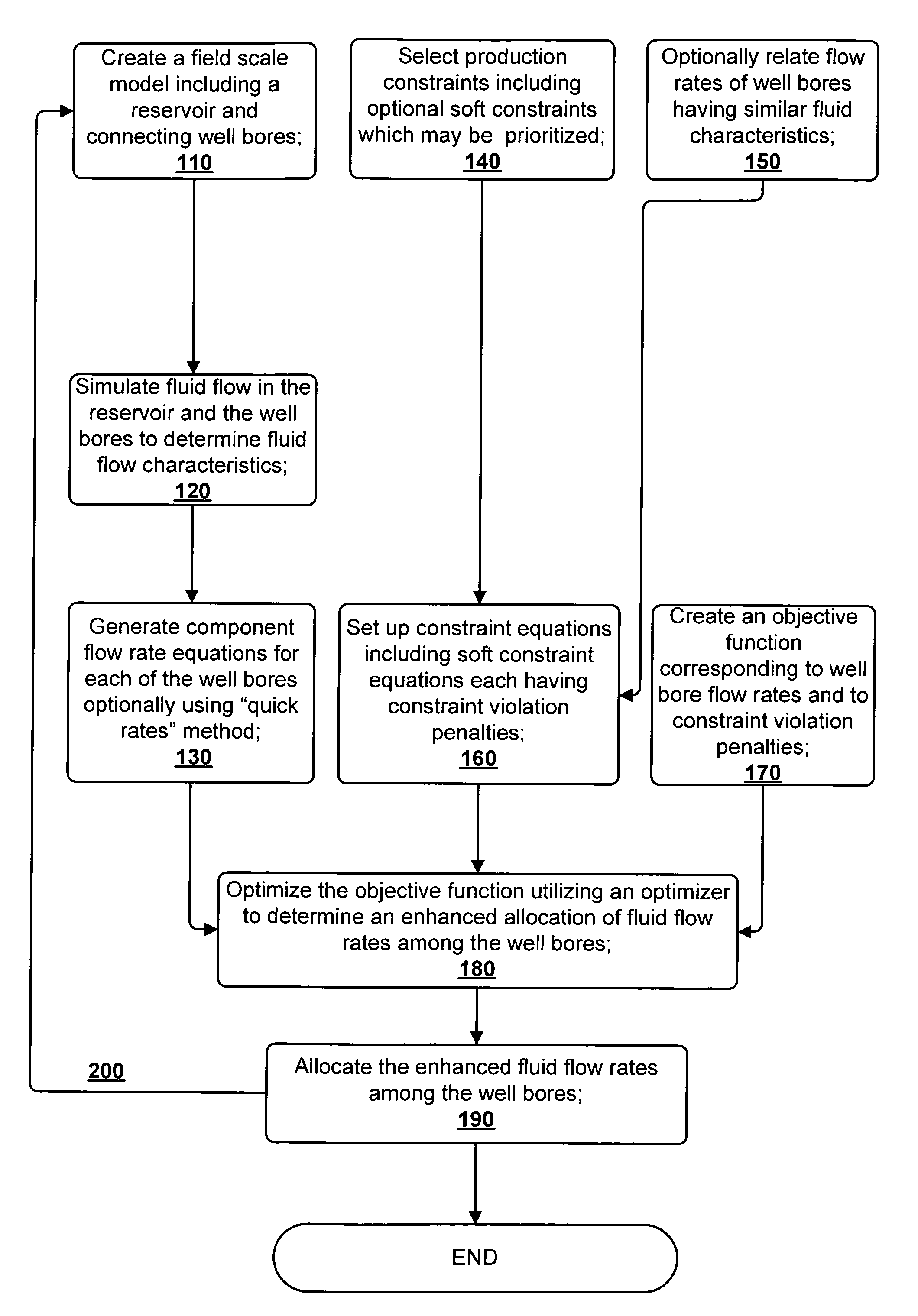

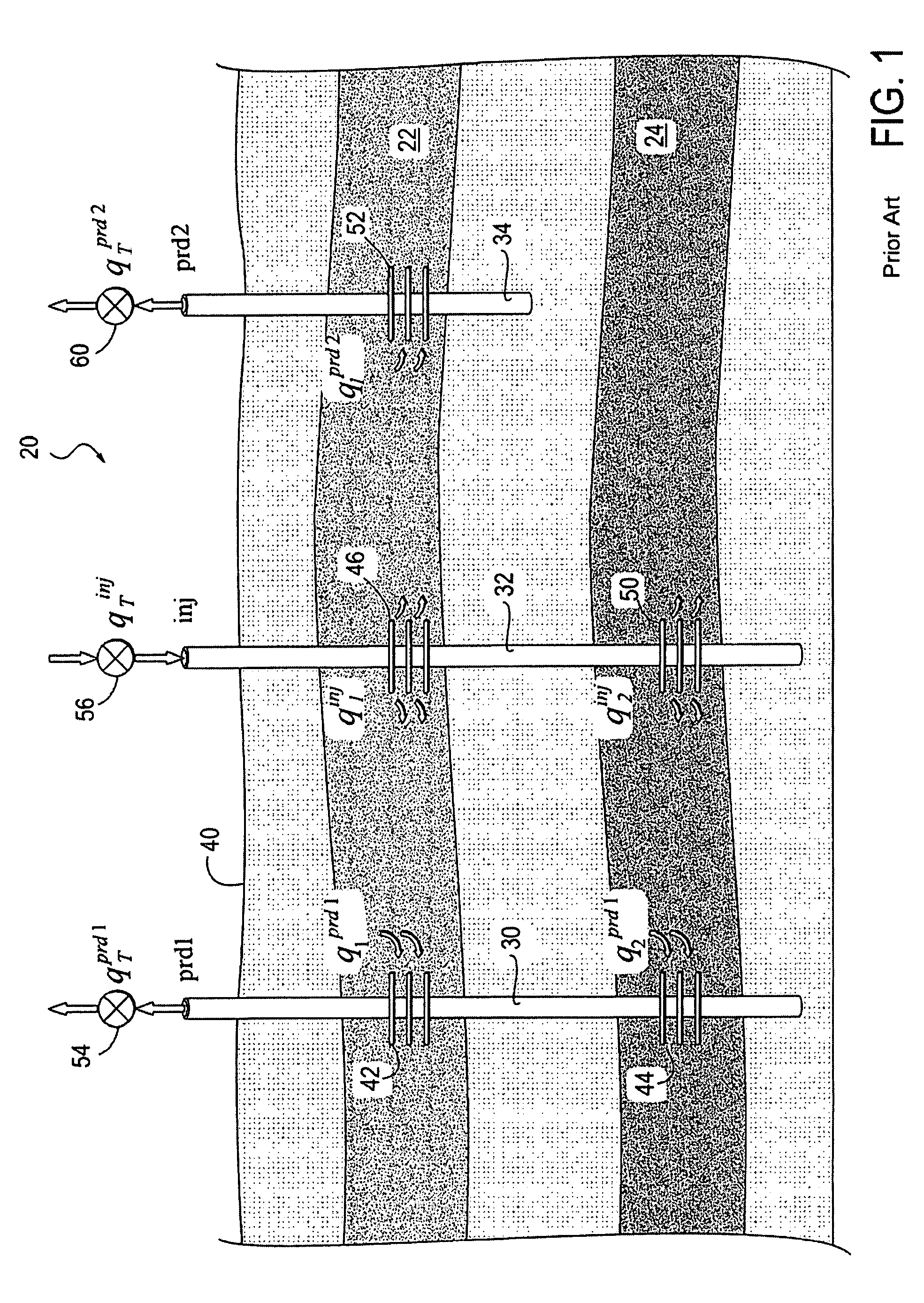

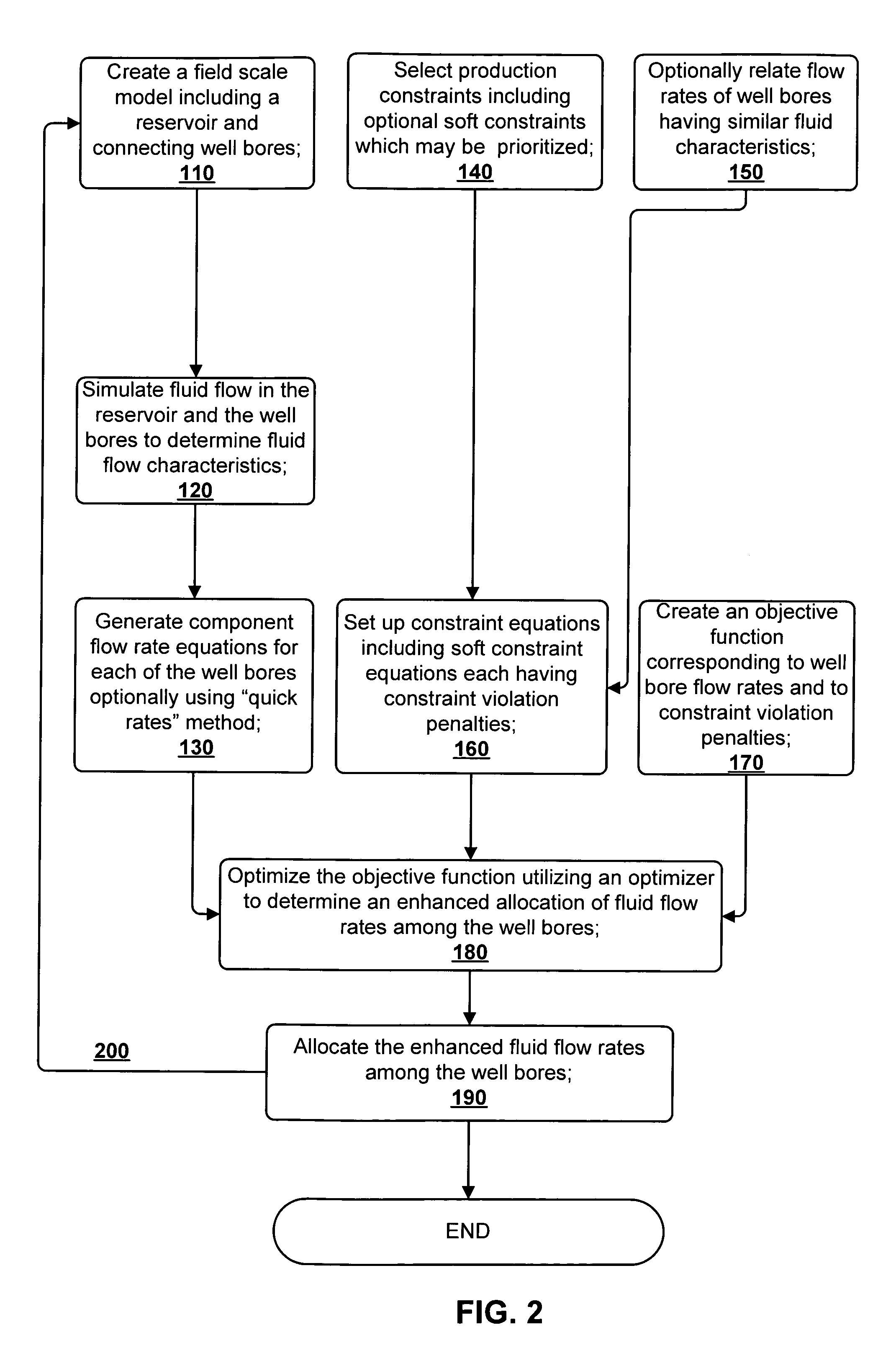

Method for field scale production optimization by enhancing the allocation of well flow rates

A method for enhancing the allocation of fluid flow rates among a plurality of well bores in fluid communication with at least one subterranean reservoir is disclosed. An objective function and system equations are generated which utilize constraint violation penalties associated with soft constraints. The soft constraints are constraints which may be violated if necessary to arrive at a feasible solution to optimizing the objective function and the system equations. The fluid flow rates are then allocated among the well bores as determined by the optimizing of the objective function and system equations. Fluid flow rates among well bores, particularly those exhibiting similar fluid characteristics, may be related to one another. Initial flow rates of components (oil, gas, and water) and pressures in the well bores may be determined by an initial simulation run. Then additional component flow rates may be estimated by scaling the original component flow rates based upon changing pressure draw downs in the well bores.

Owner:CHEVROU USA INC

Method for field scale production optimization by enhancing the allocation of well flow rates

ActiveUS7627461B2Control flowFluid removalAnalogue computers for fluid flowProduction optimizationObject function

A method for enhancing the allocation of fluid flow rates among a plurality of well bores in fluid communication with at least one subterranean reservoir is disclosed. An objective function and system equations are generated which utilize constraint violation penalties associated with soft constraints. The soft constraints are constraints which may be violated if necessary to arrive at a feasible solution to optimizing the objective function and the system equations. The fluid flow rates are then allocated among the well bores as determined by the optimizing of the objective function and system equations. Fluid flow rates among well bores, particularly those exhibiting similar fluid characteristics, may be related to one another. Initial flow rates of components (oil, gas, and water) and pressures in the well bores may be determined by an initial simulation run. Then additional component flow rates may be estimated by scaling the original component flow rates based upon changing pressure draw downs in the well bores.

Owner:CHEVROU USA INC

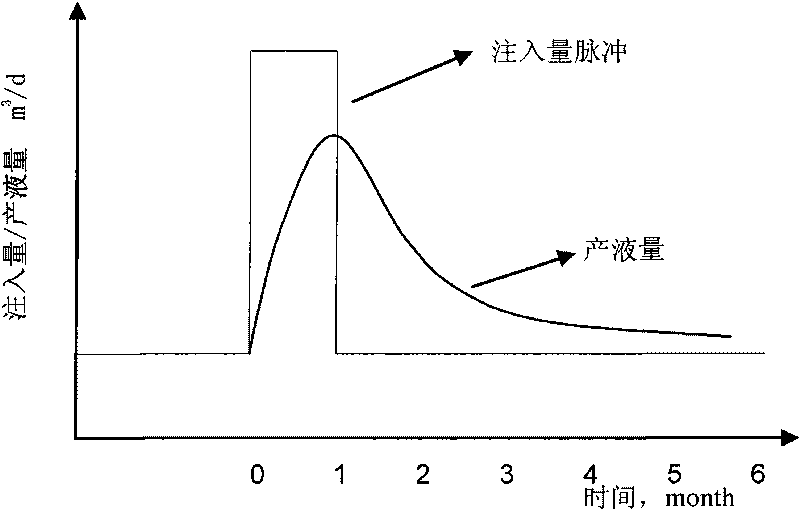

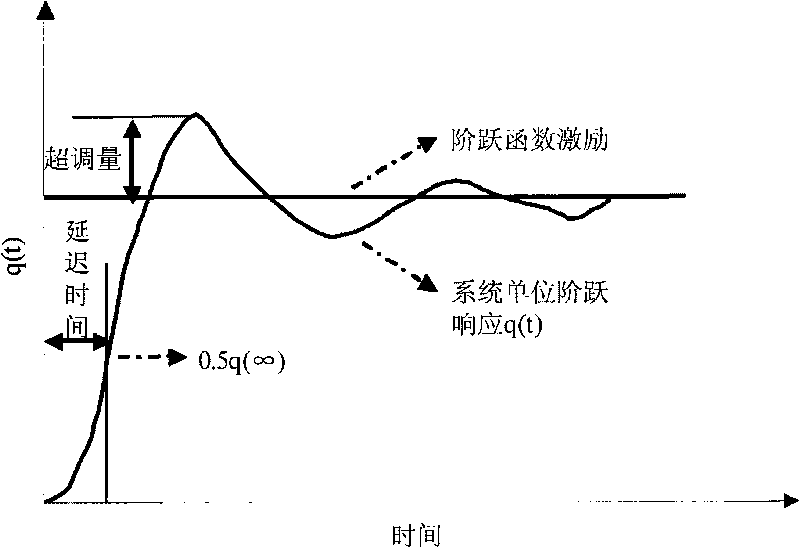

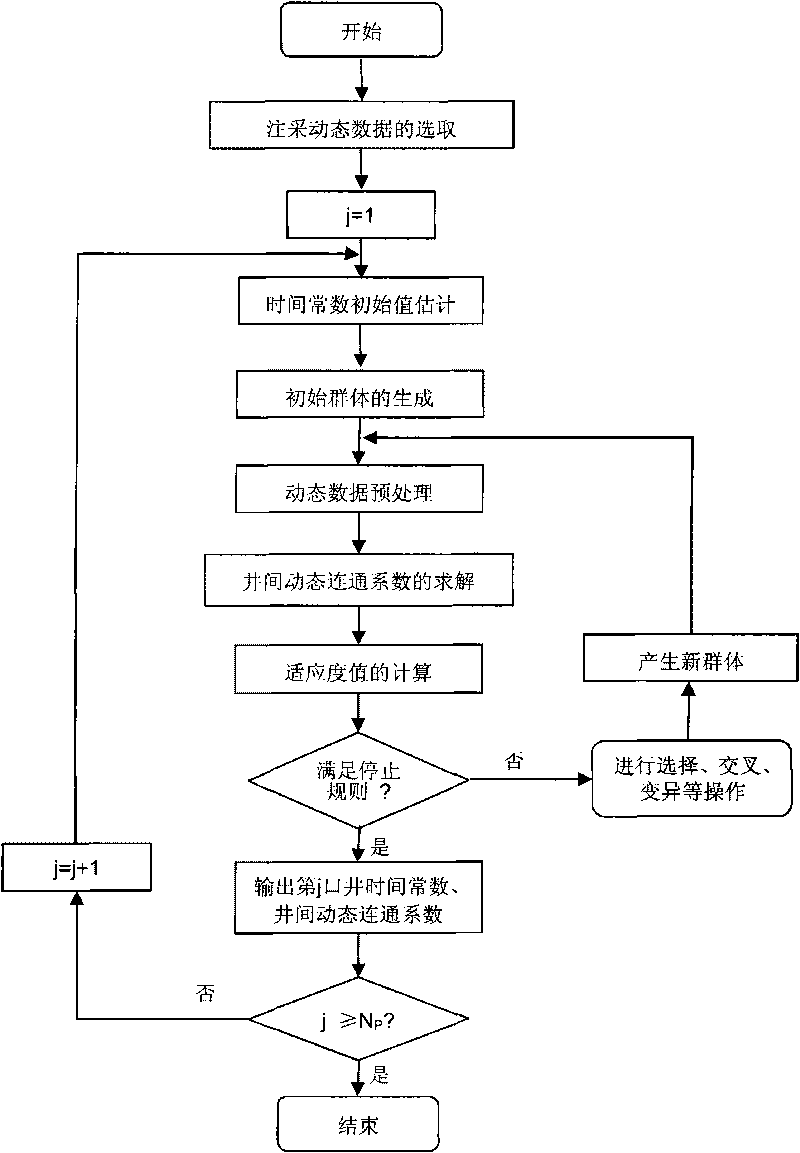

Oil deposit inter-well dynamic connectivity inverting method

InactiveCN101725346AEasy accessDoes not affect normal productionGenetic modelsBorehole/well accessoriesUltrasound attenuationProduction optimization

The invention discloses an oil deposit inter-well dynamic connectivity inverting method. The oil deposit inter-well dynamic connectivity is obtained by adopting oil deposit injection and withdrawal dynamic data inverting based on signal processing technology. Firstly a multiple regression model of oil deposit inter-well dynamic connectivity is established, a first order linear system convolver is built according to the transmission characteristic of injectivity signal in oil deposit, the convolver is applied to pre-treatment on the injectivity signal, genetic algorithm is induced into optimization solution of inverting model, systematic training is carried out on parameters to be optimized, and inverting is carried out to obtain connectivity factor representing oil deposit inter-well dynamic connectivity and time constant representing time delay and attenuation properties of the injectivity signal. The invention has strong practicability and high universality, is mainly used for evaluating oil deposit inter-well dynamic connectivity and further guides oil-field development scheme formation and production optimization.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

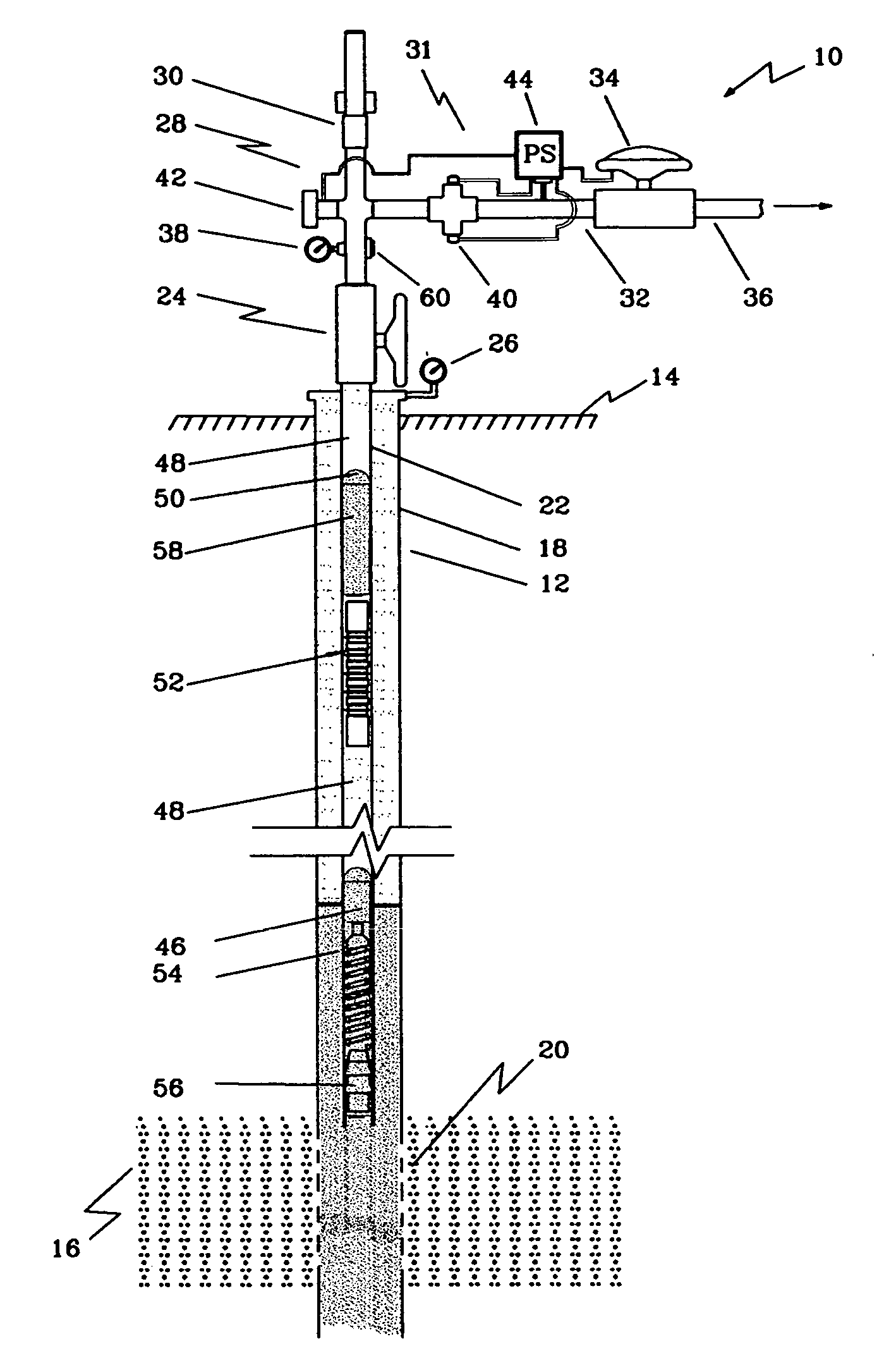

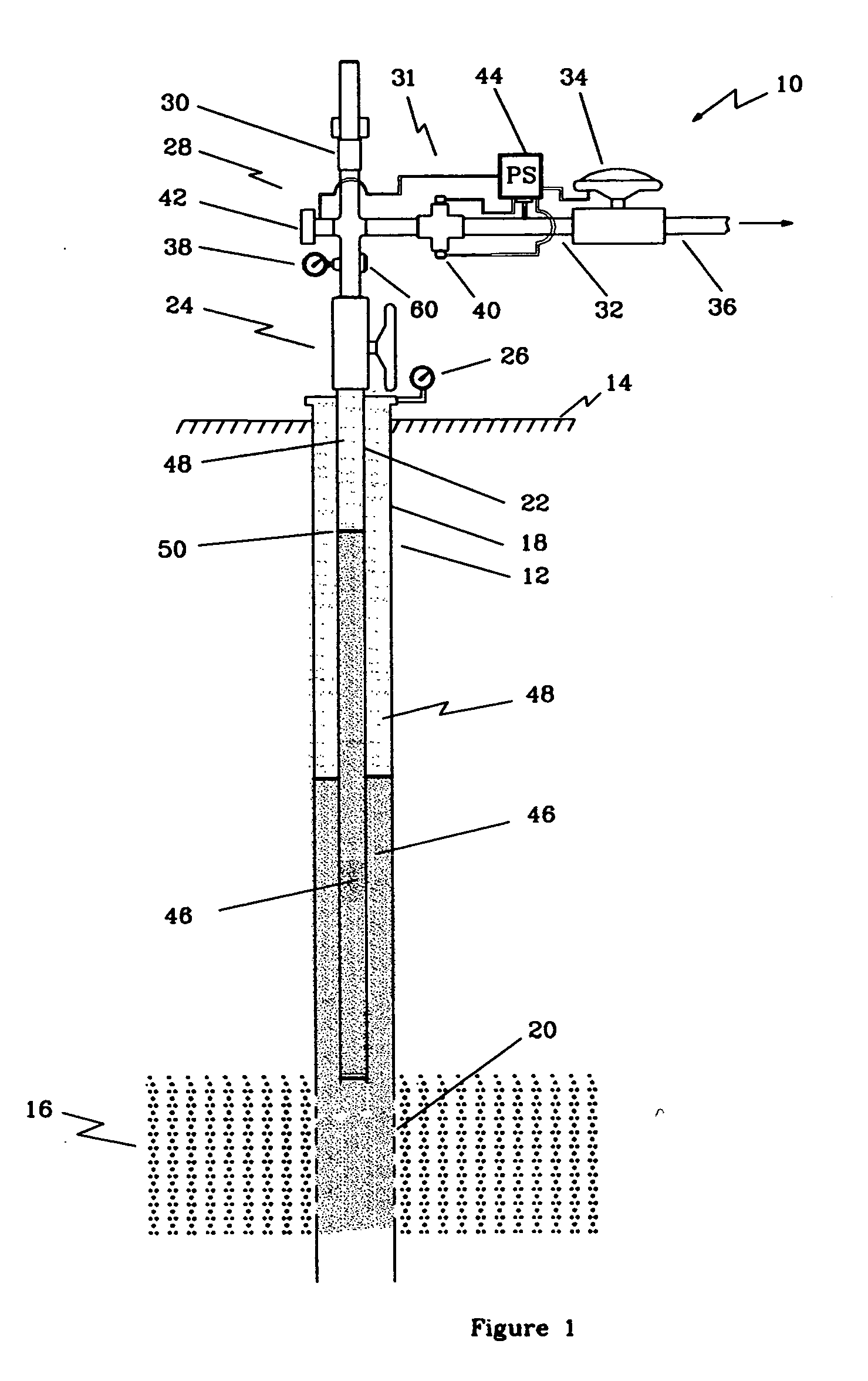

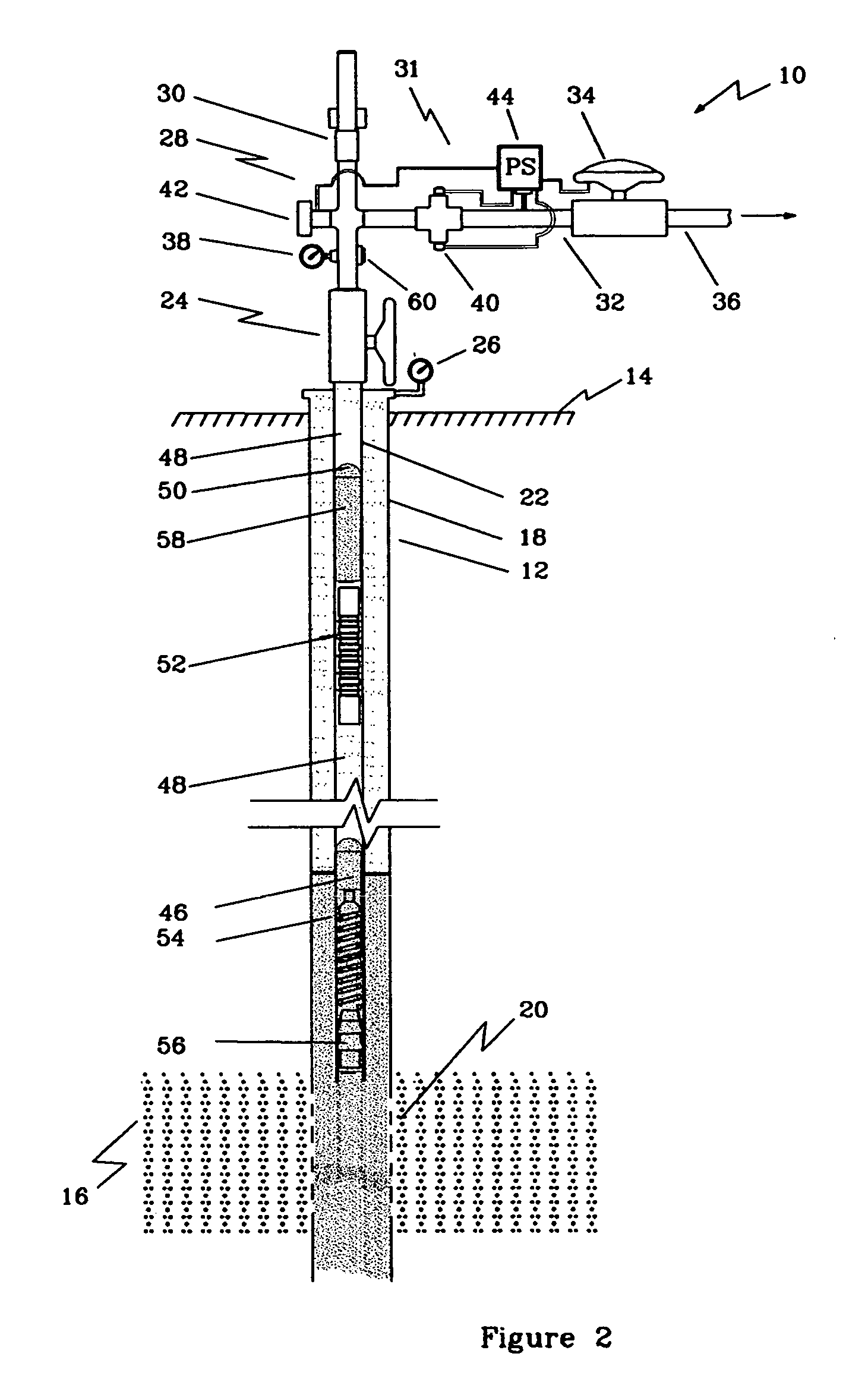

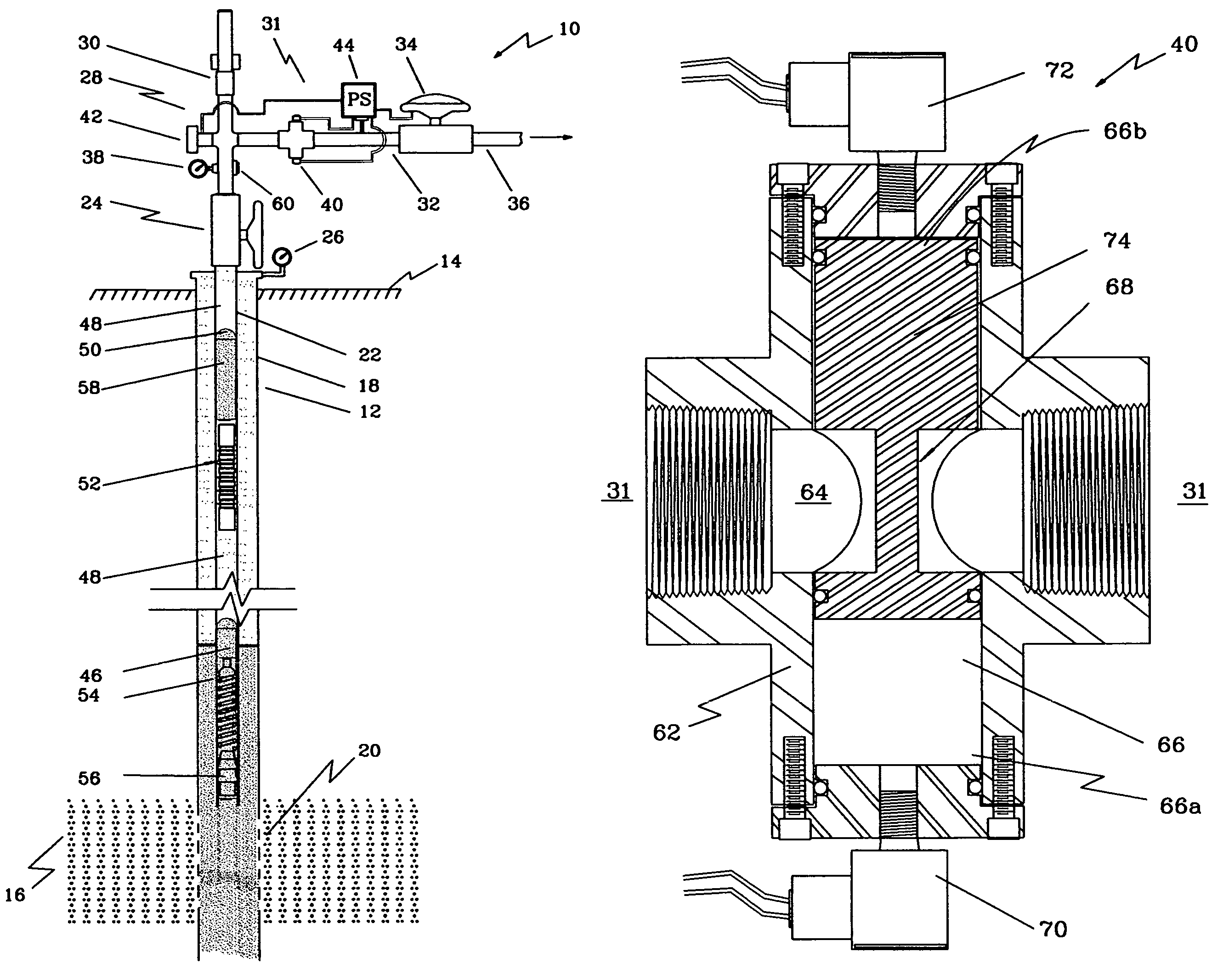

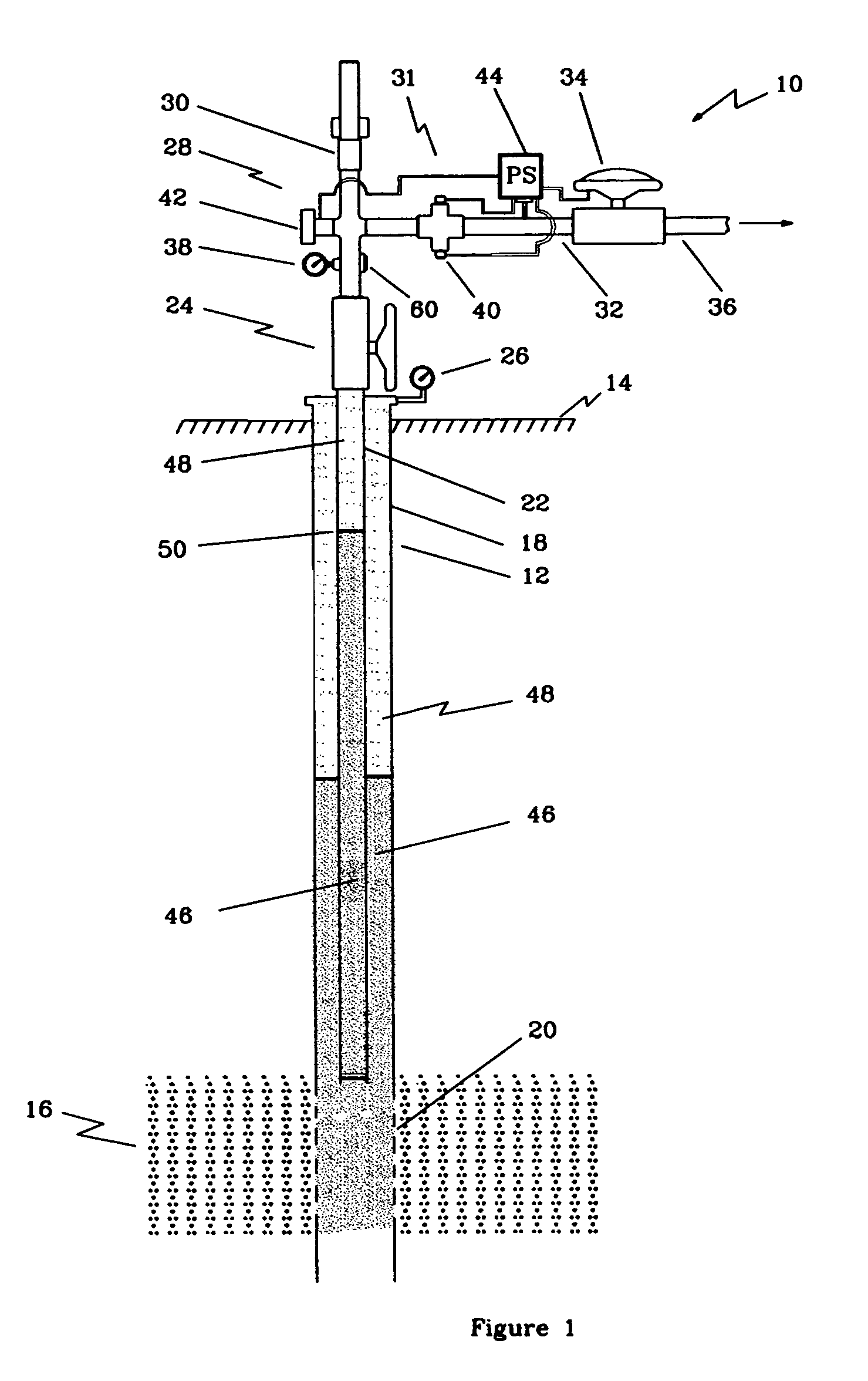

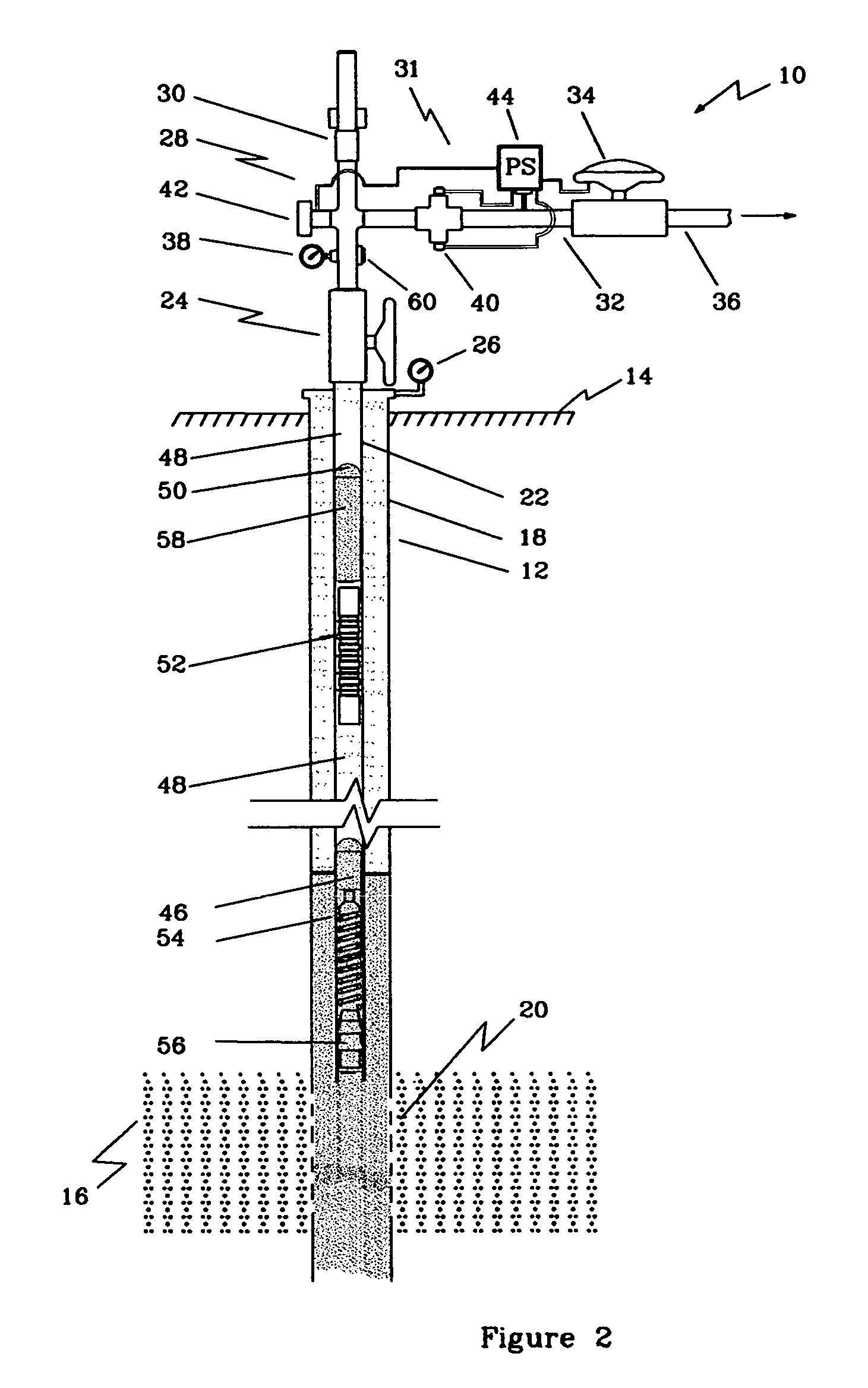

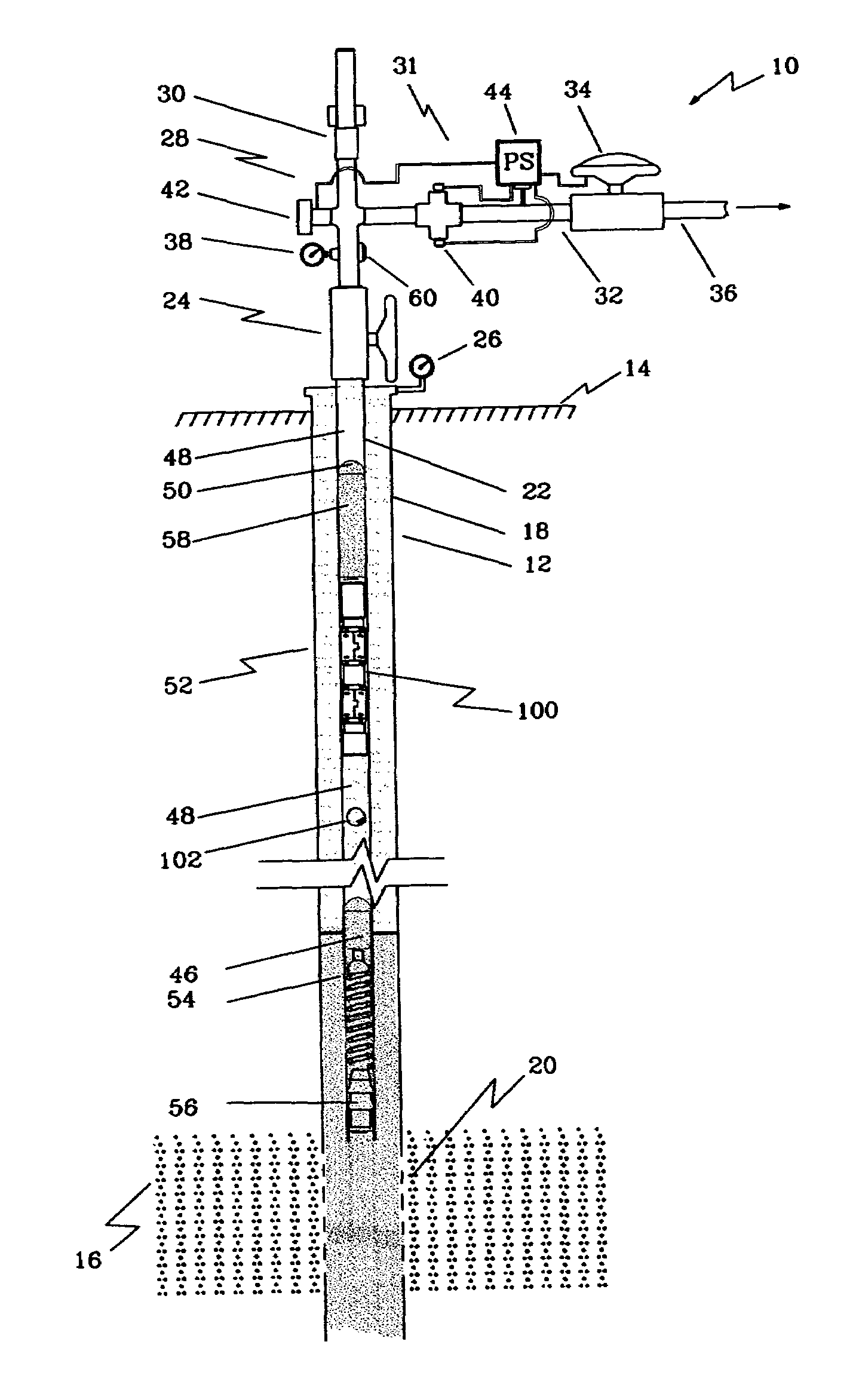

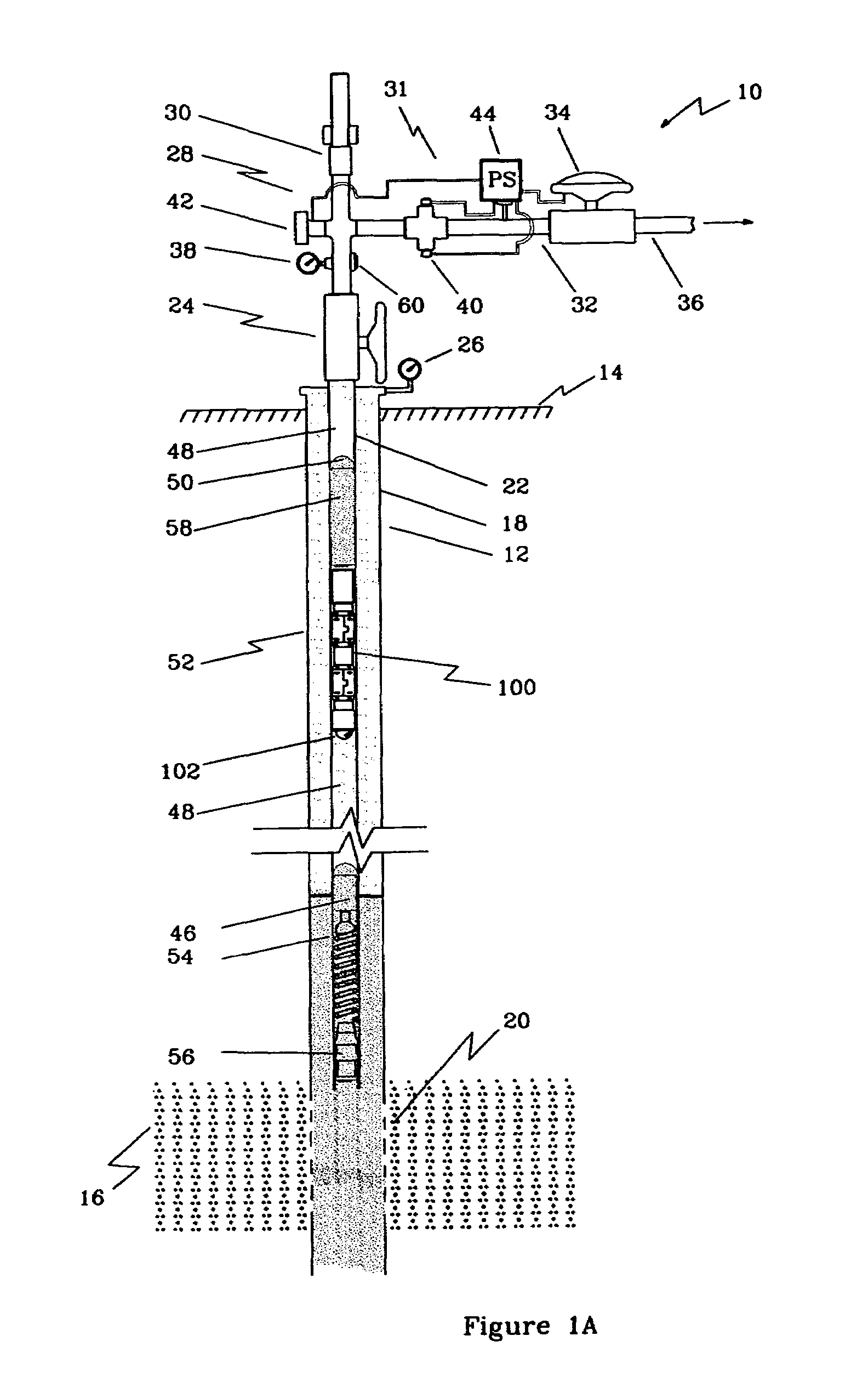

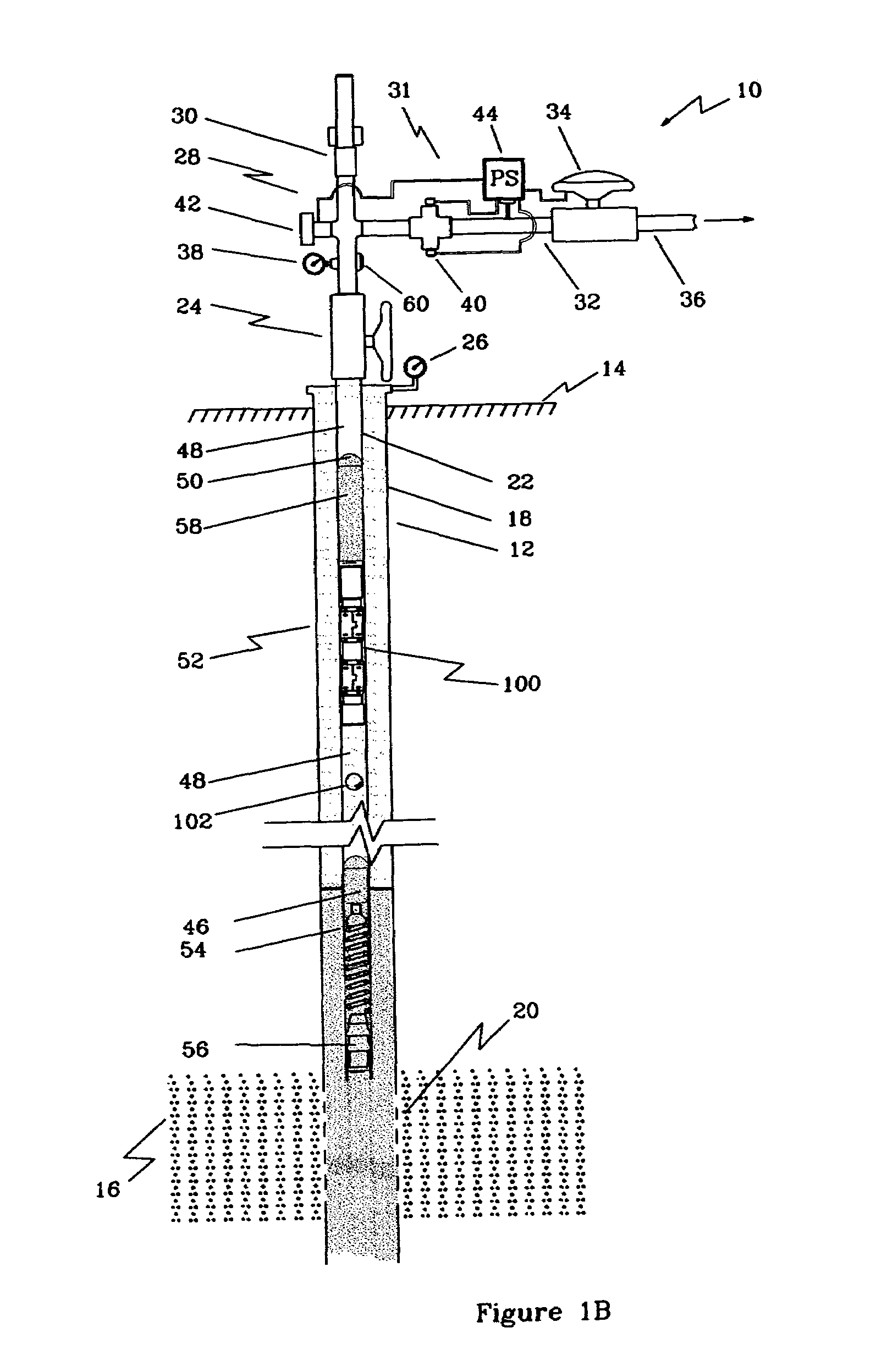

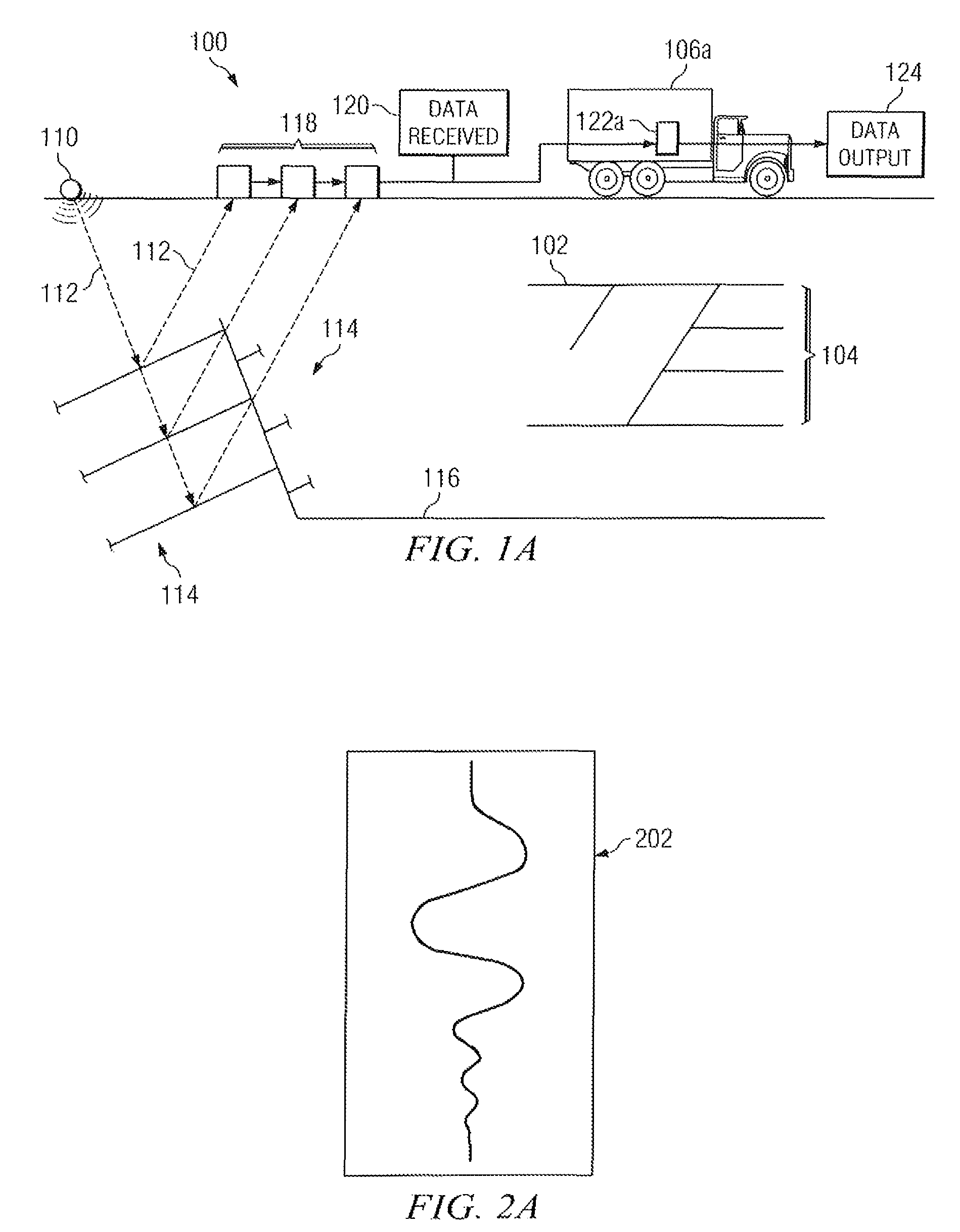

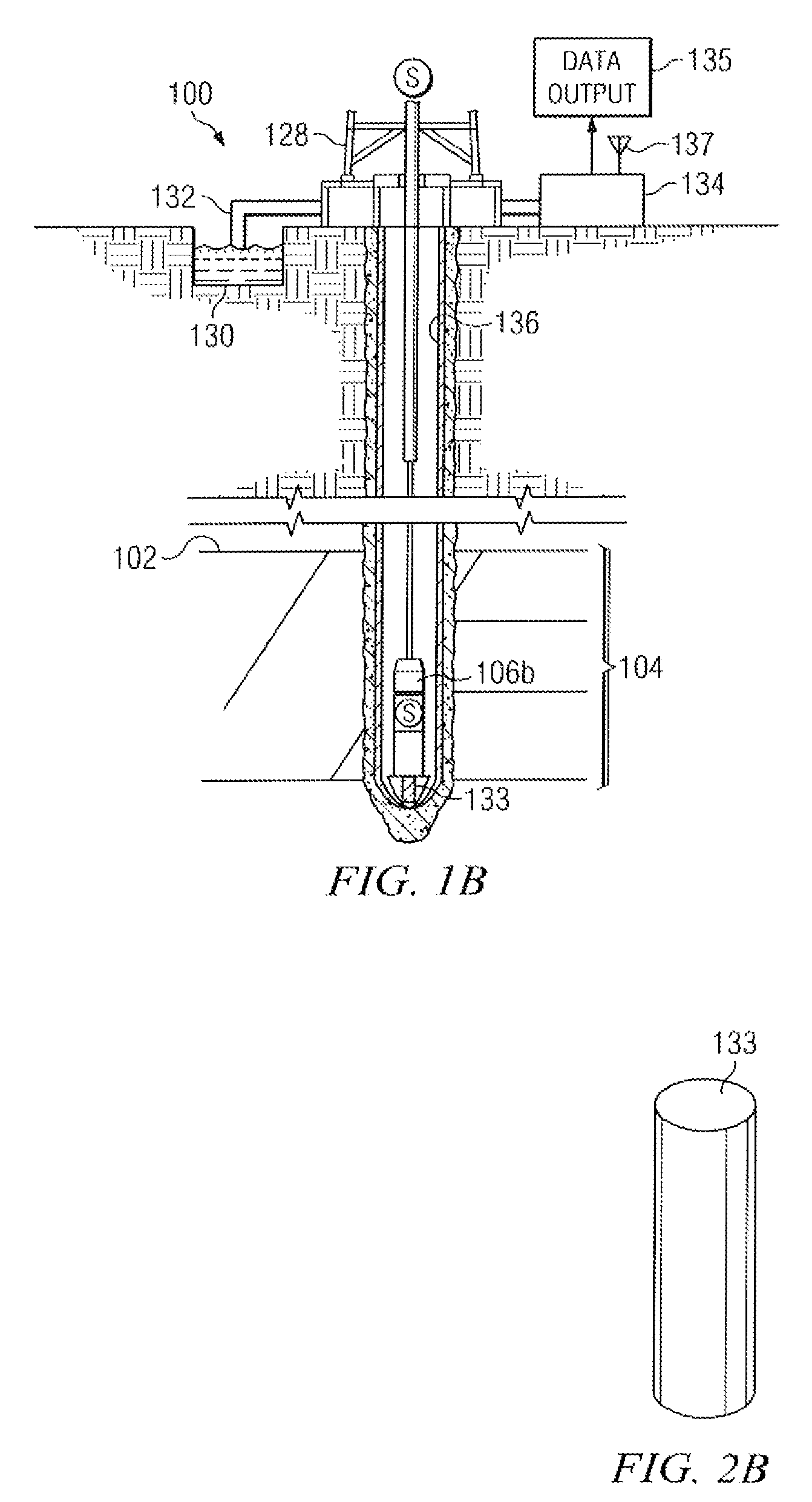

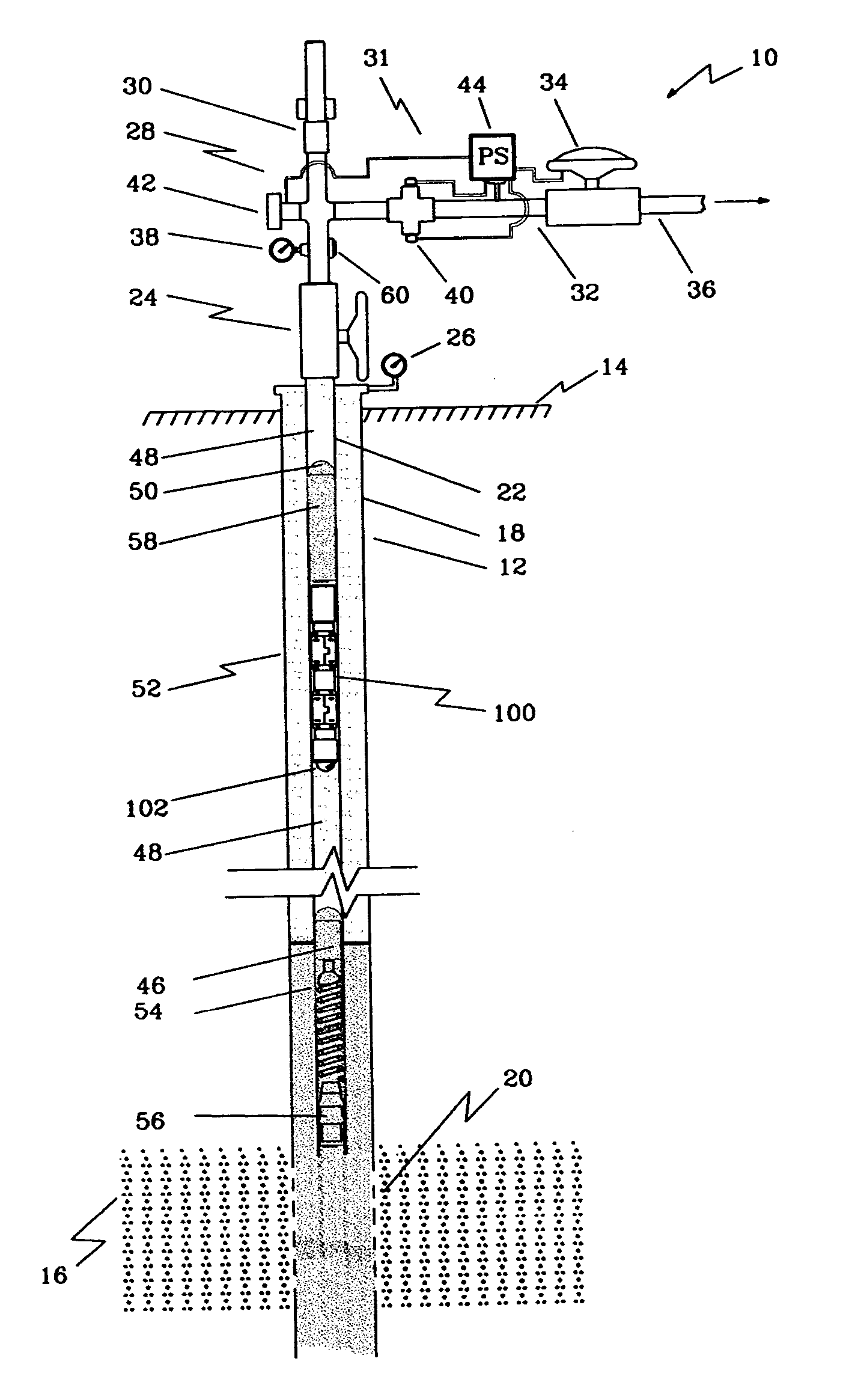

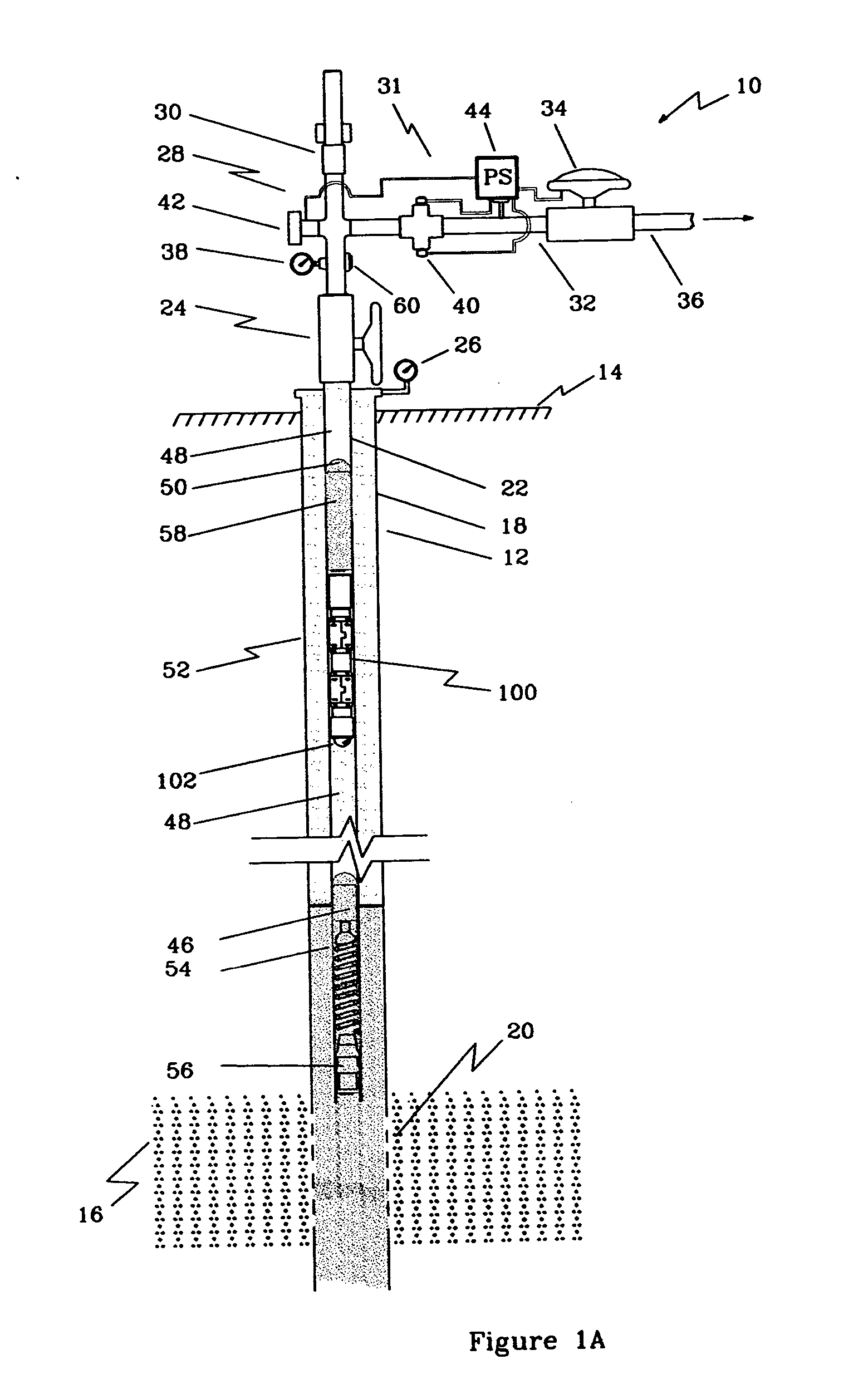

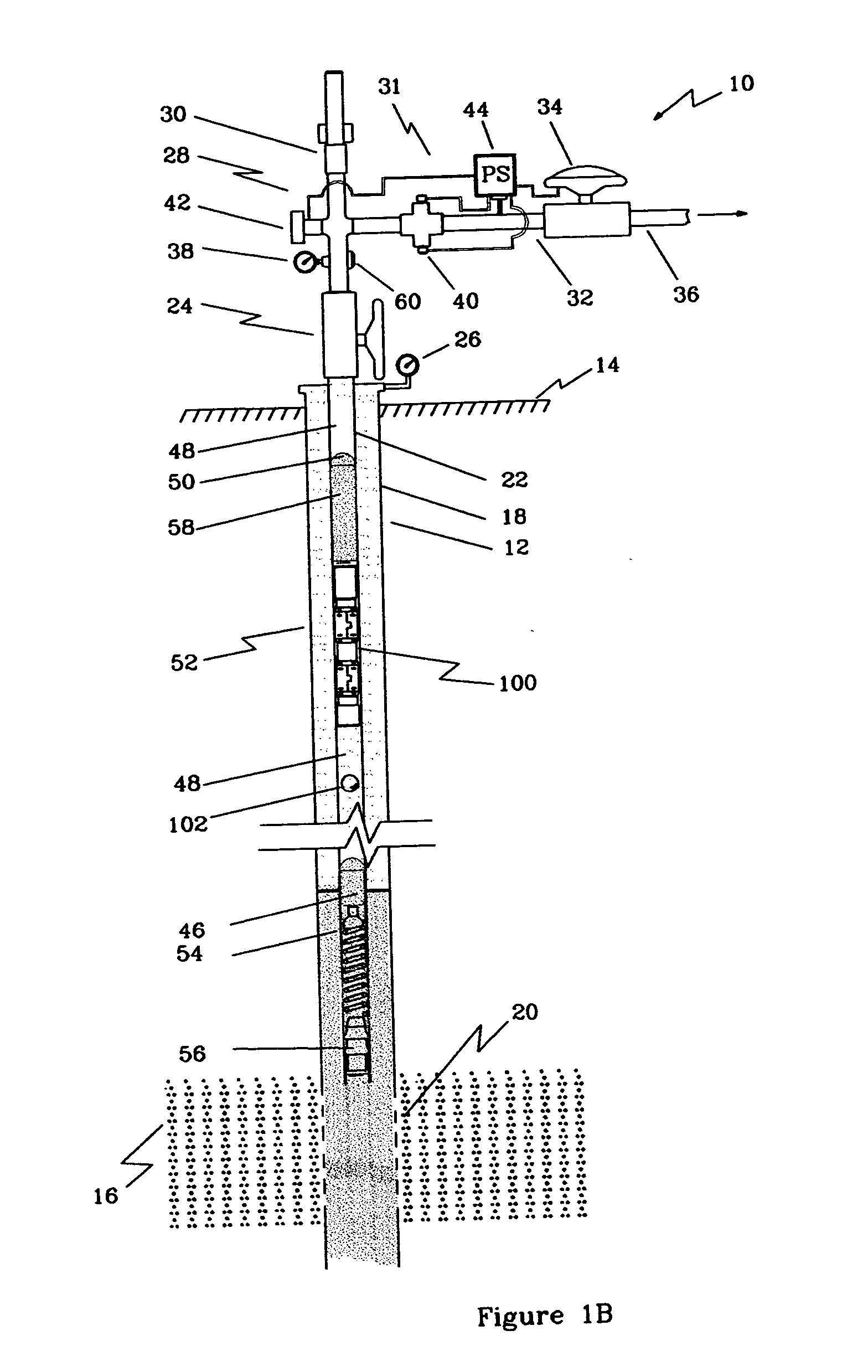

Well production optimizing system

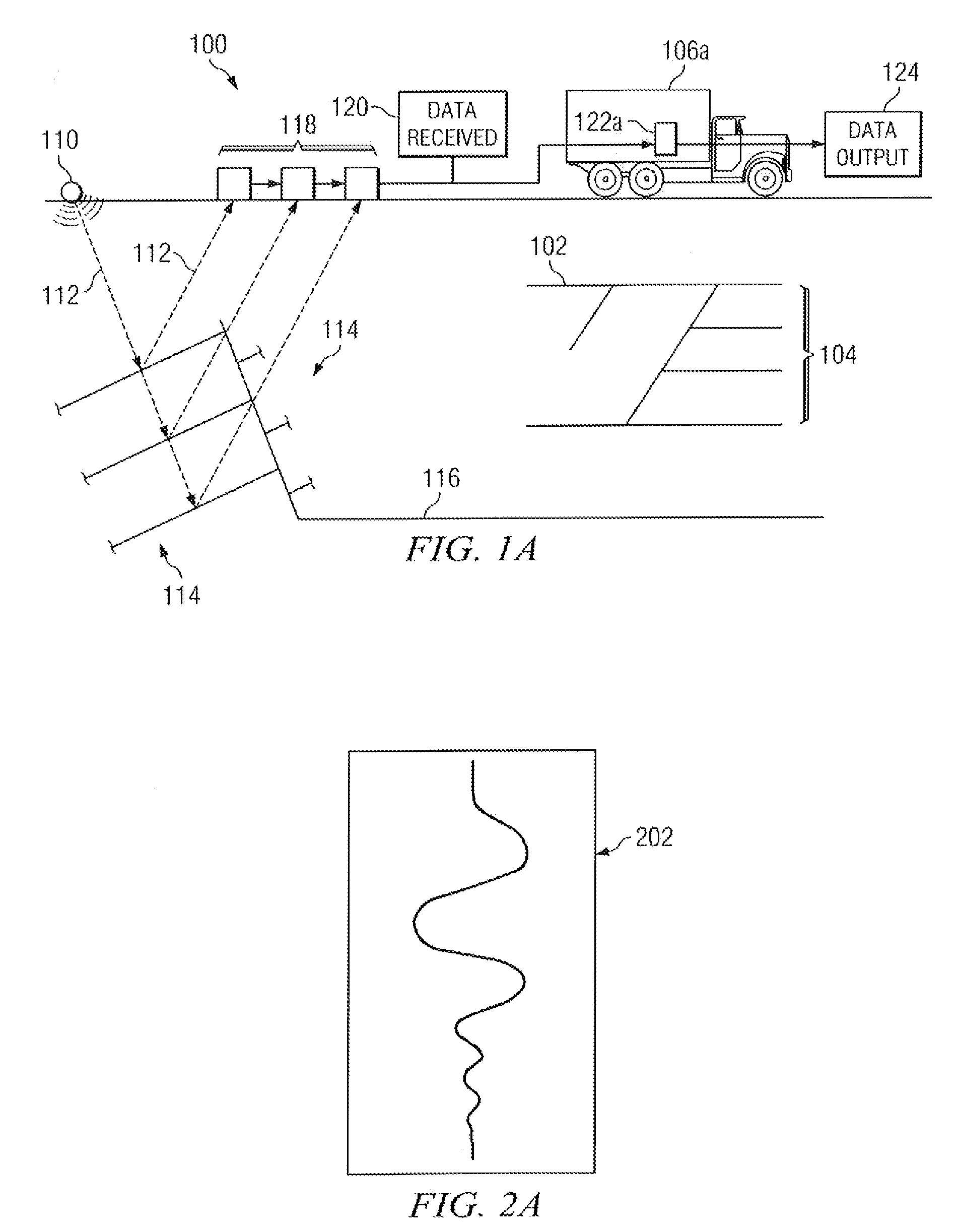

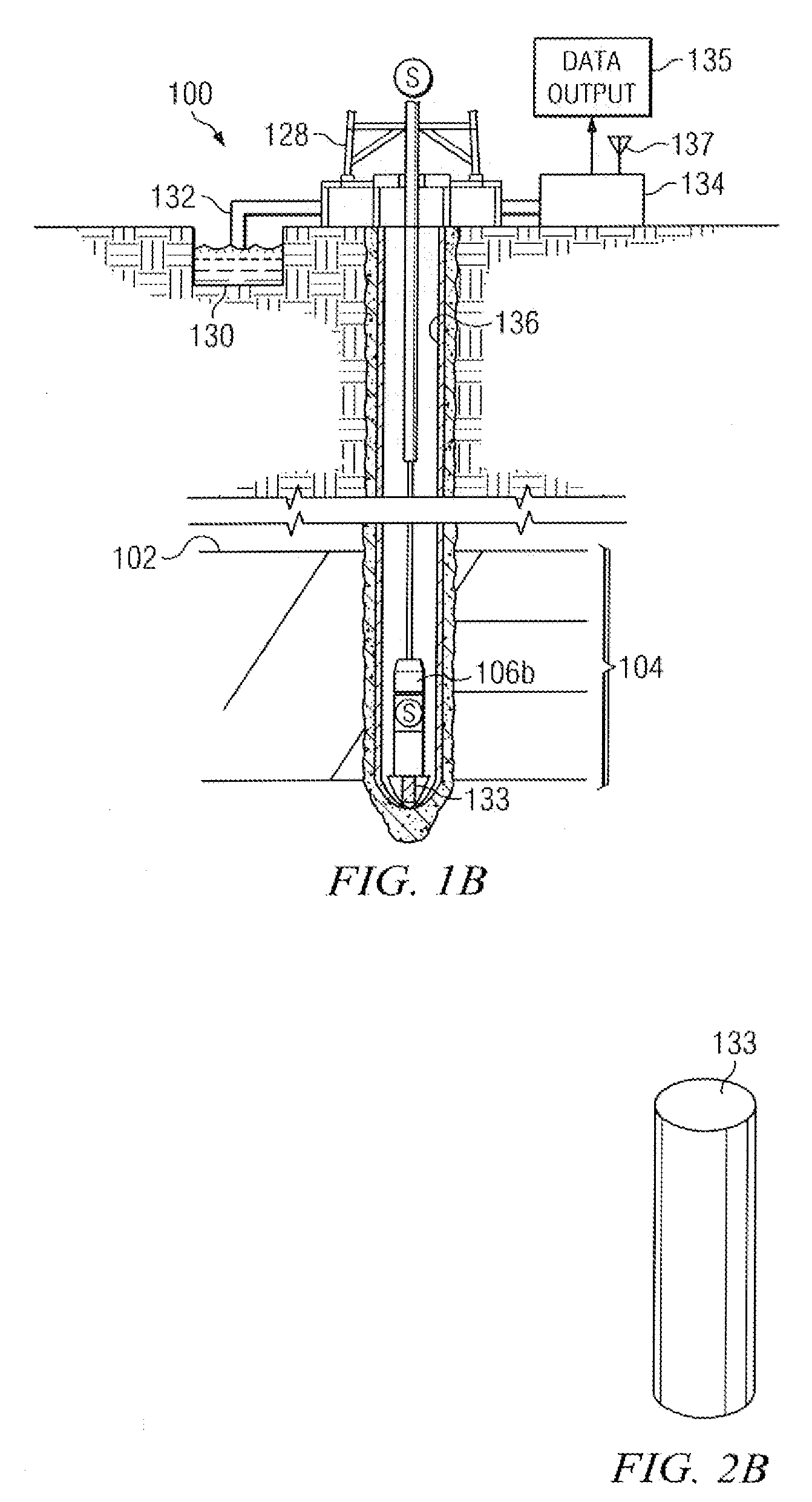

A method and system for controlling a producing cycle in a well, during the production cycle, for optimizing production from the well including disrupting fluid in a wellbore with a pulse generator to create a pressure pulse transmitted through the fluid in the wellbore, detecting the pressure pulse created and the pressure pulse reflected from objects located within the wellbore, wherein the objects may include a liquid / gas interface and a producing apparatus such as a plunger, converting the detection of the pressure pulse and the reflected pressure pulses to a signal, computing the signals to determine the well status and controlling production of the fluid from the wellbore based on the well status.

Owner:CASEY DANNY M

Well production optimizing system

Owner:CASEY DANNY M

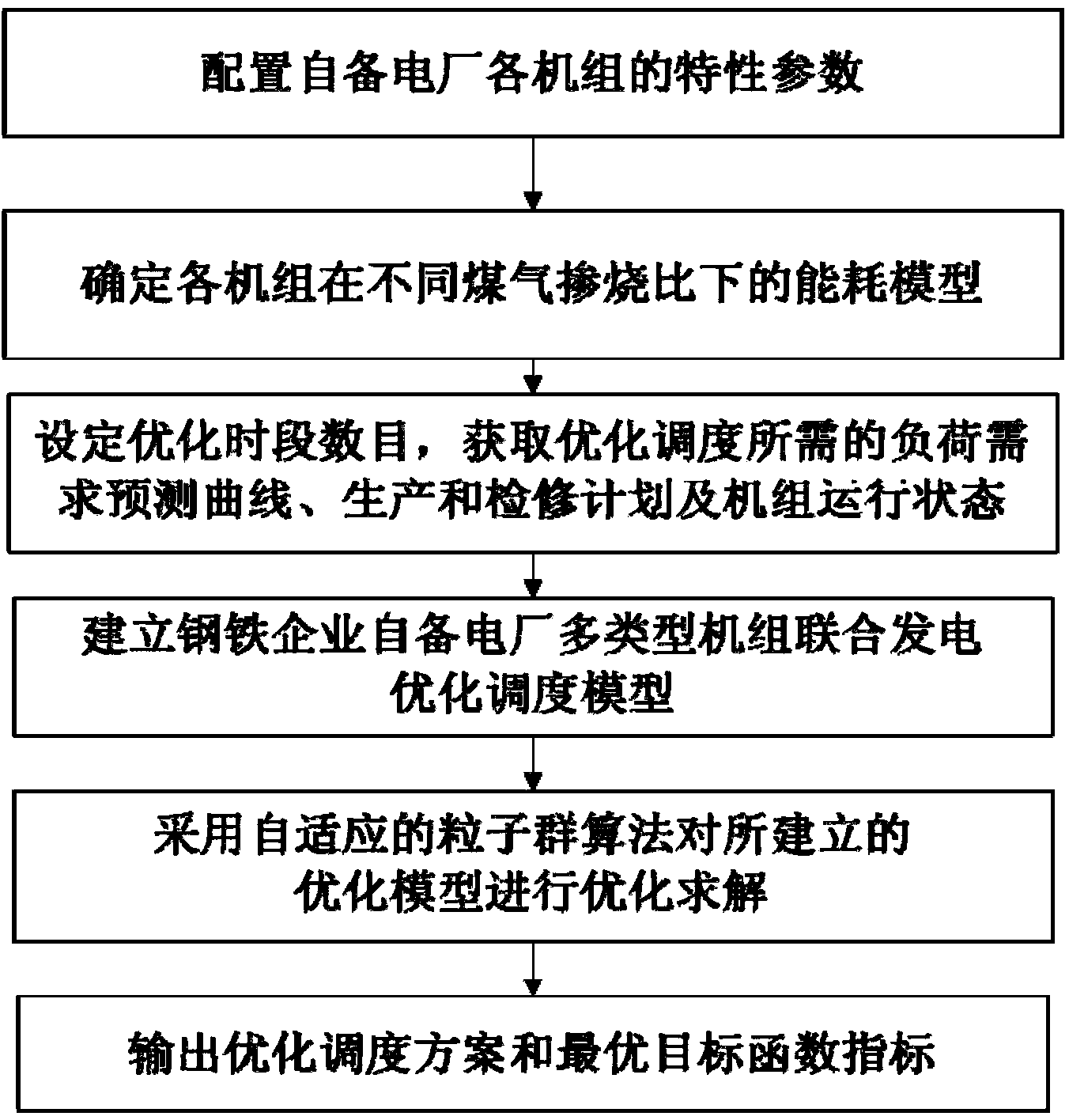

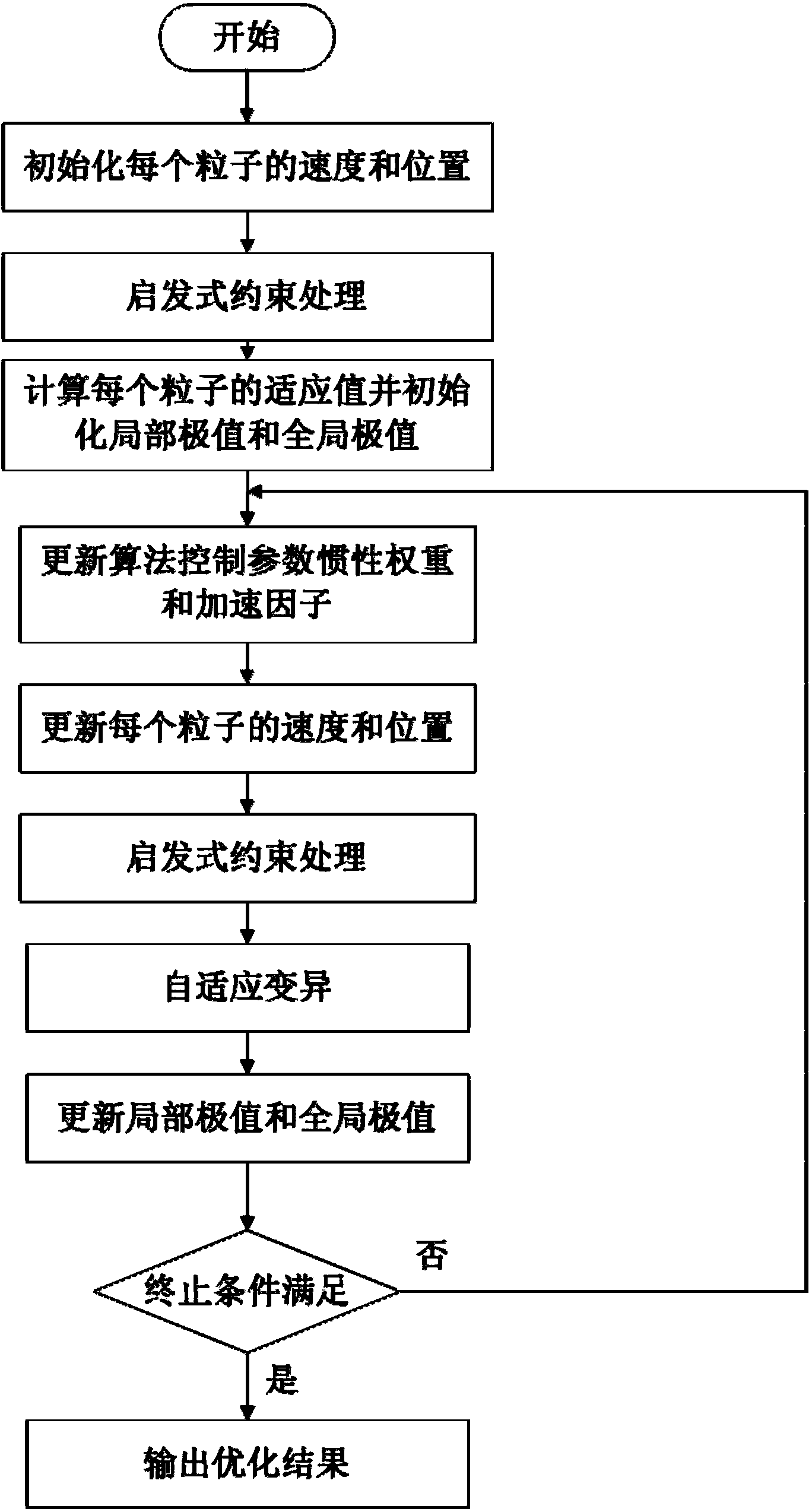

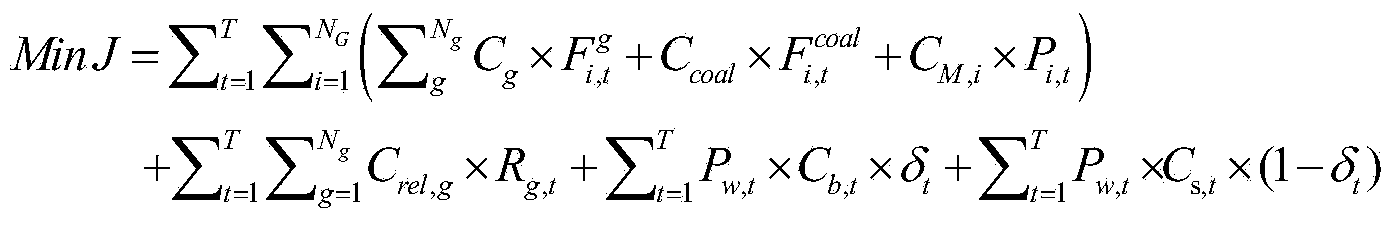

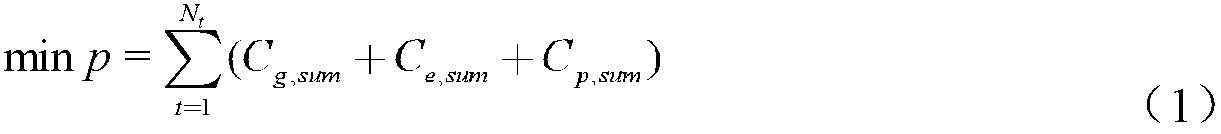

Joint optimized scheduling method for multiple types of generating sets of self-supply power plant of iron and steel enterprise

InactiveCN104392334AImprove accuracyImprove representationEnergy industryResourcesProduction optimizationElectricity price

The invention discloses a joint optimized scheduling method for multiple types of generating sets of a self-supply power plant of an iron and steel enterprise, and belongs to the technical field of energy optimized scheduling of the iron and steel enterprise. Influence of fuel types and gas mixed burning amount on energy consumption of the sets is taken into consideration in construction of a set energy consumption characteristic model, fitting is performed under different gas mixed burning, and the accuracy and representativeness of the model are improved; and influence of the fuel cost, time-of-use power price and surplus gas dynamic change on the generating cost is considered comprehensively in construction of an optimized scheduling model, meanwhile, various constraint conditions including power balance constraint, generating set self-running constraint, purchased power quantity constraint, gas supply constraint, variable load rate limit and the like are considered, and the performability of a generation schedule is guaranteed. Optimization solution is performed on the models by adopting the adaptive particle swarm optimization algorithm, the problems of high dimensionality, nonconvexity, nonlinearity and multiple constraints of the power generation scheduling of the self-supply power plant can be well solved, power production optimization and purchasing rationalization are realized, surplus gas is sufficiently used, and the power supply cost is reduced to the greatest extent.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

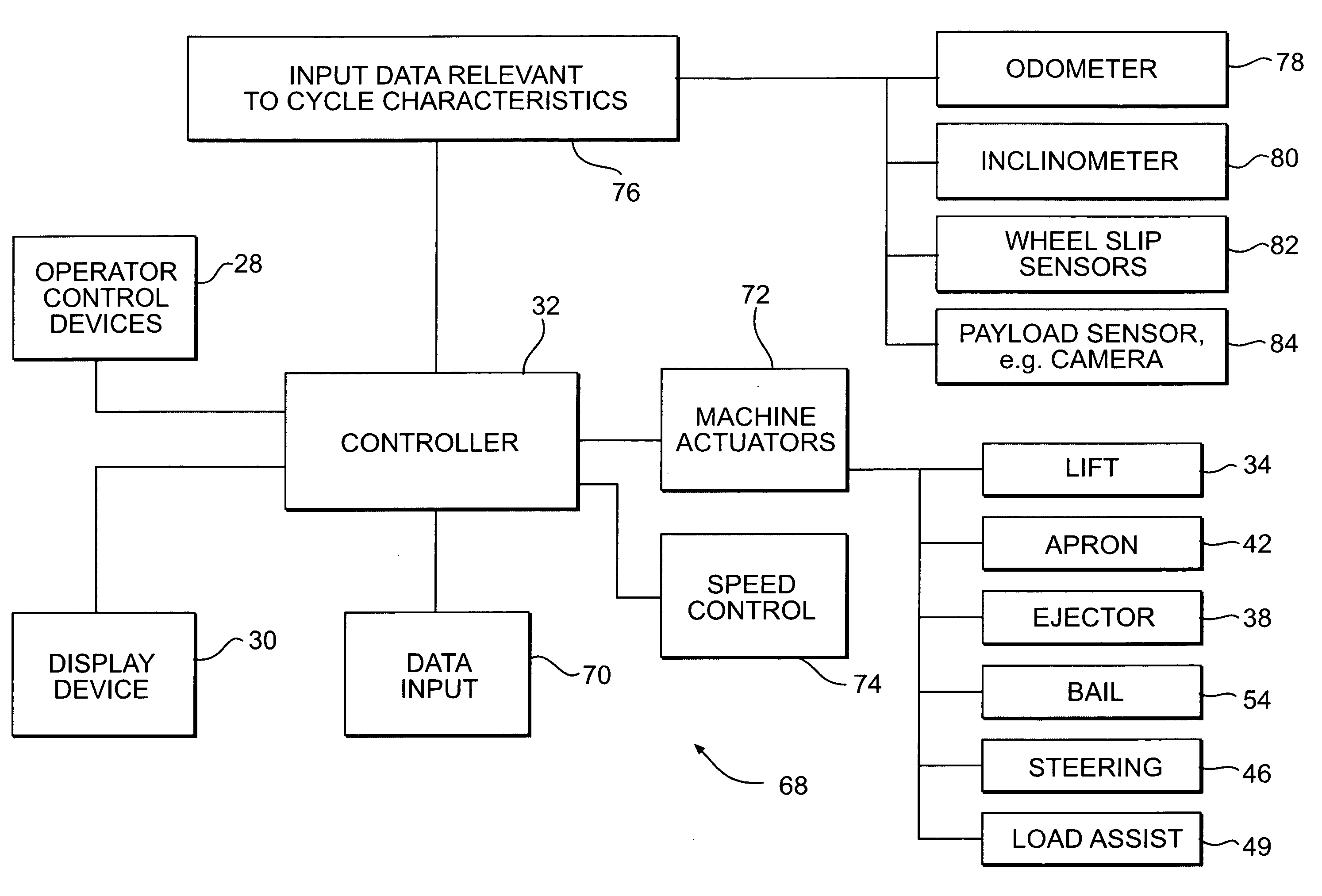

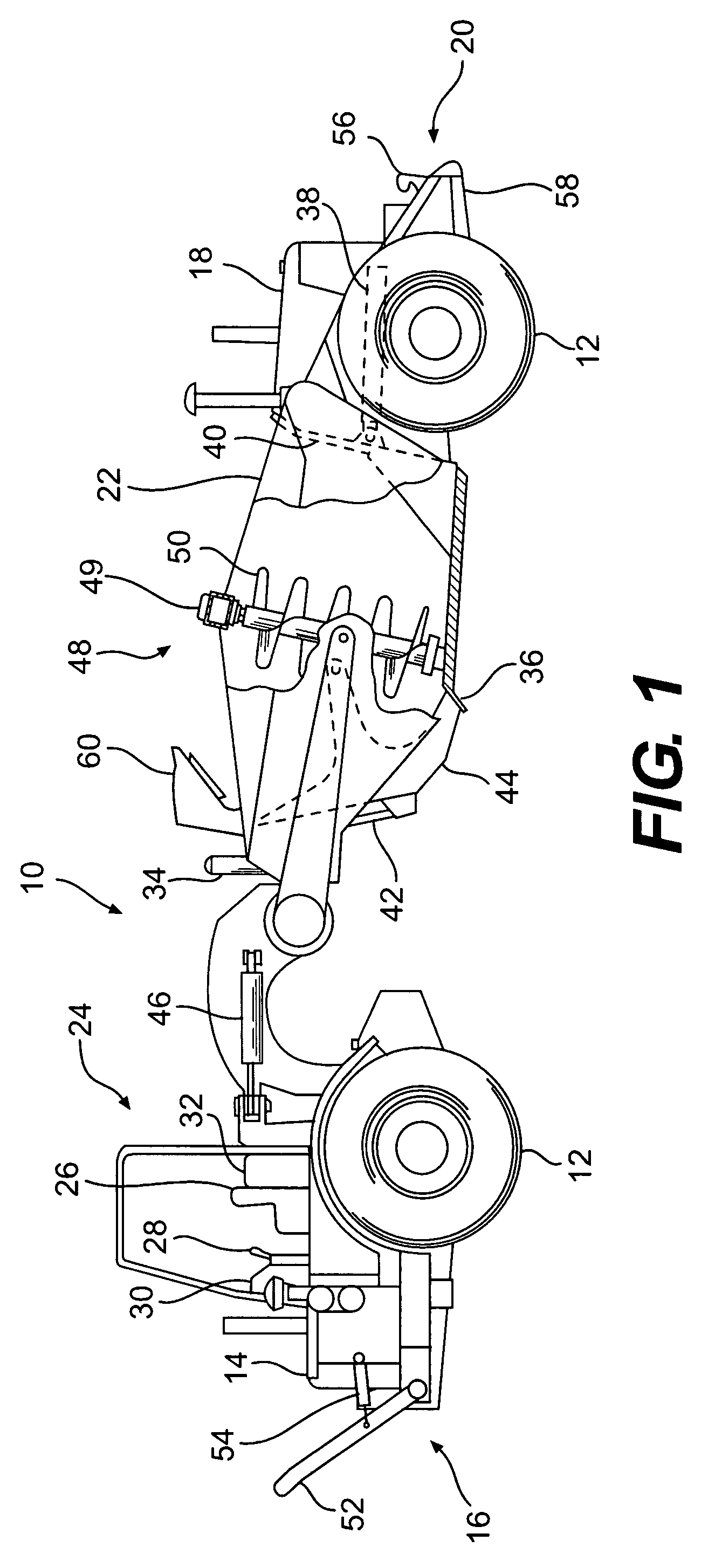

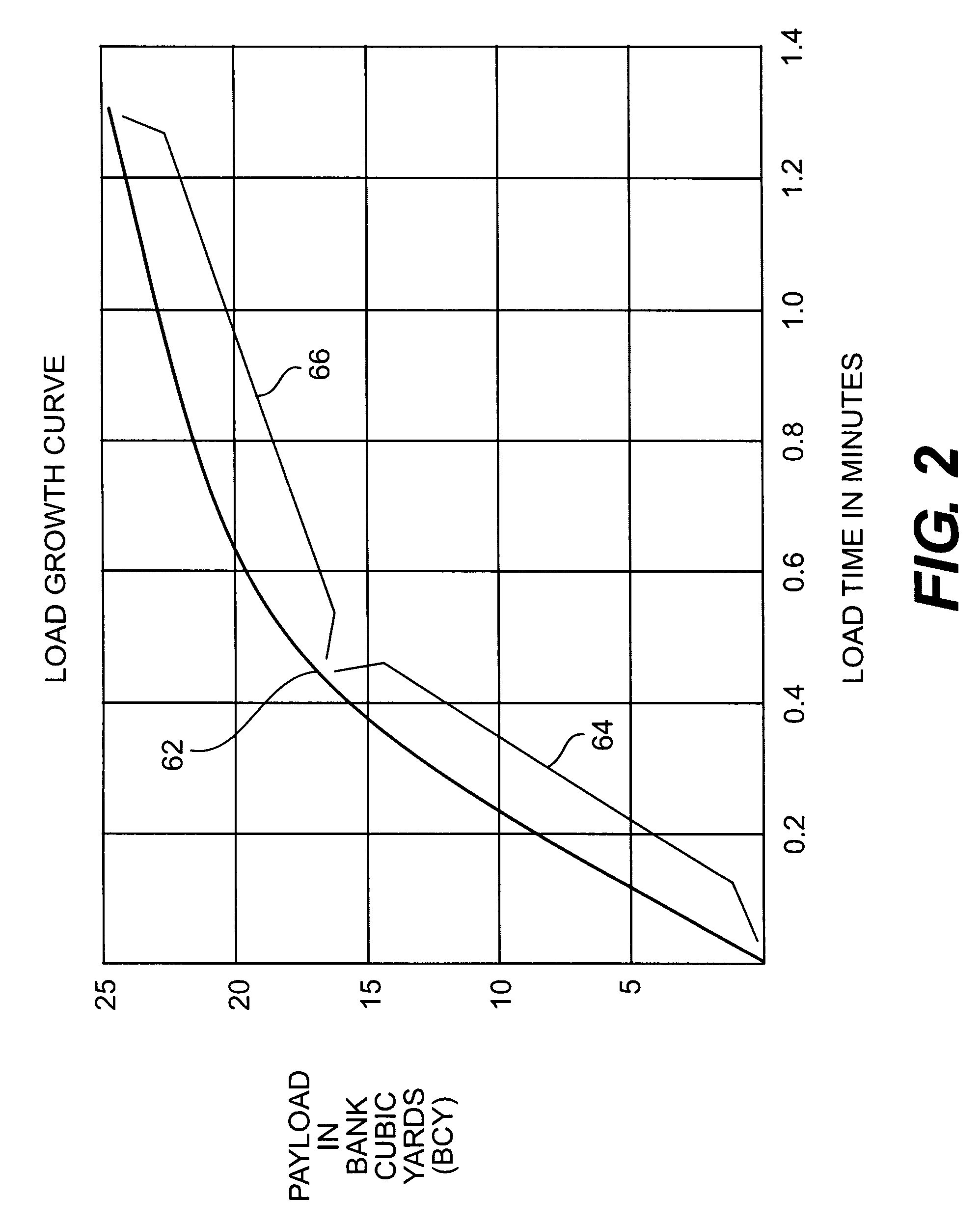

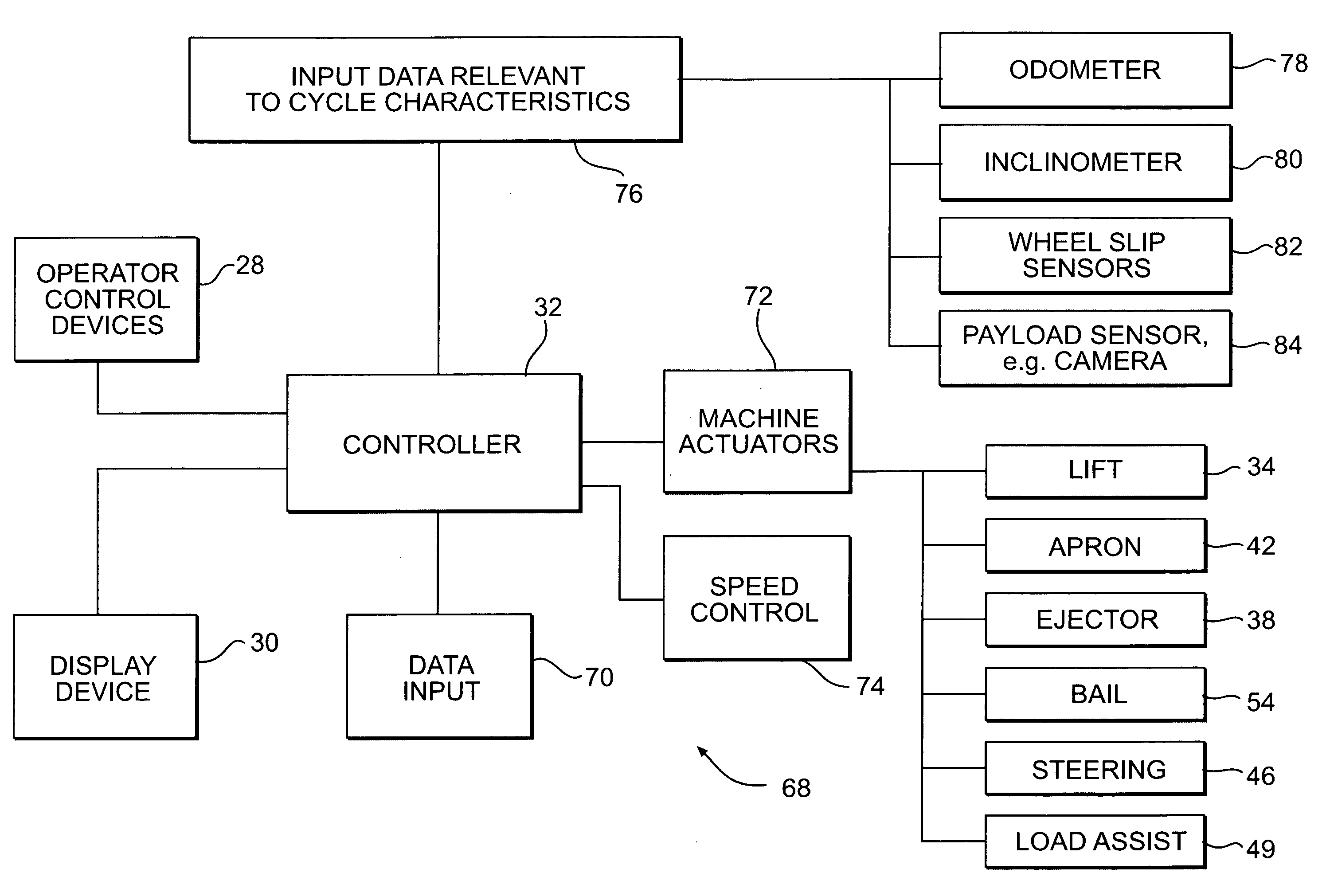

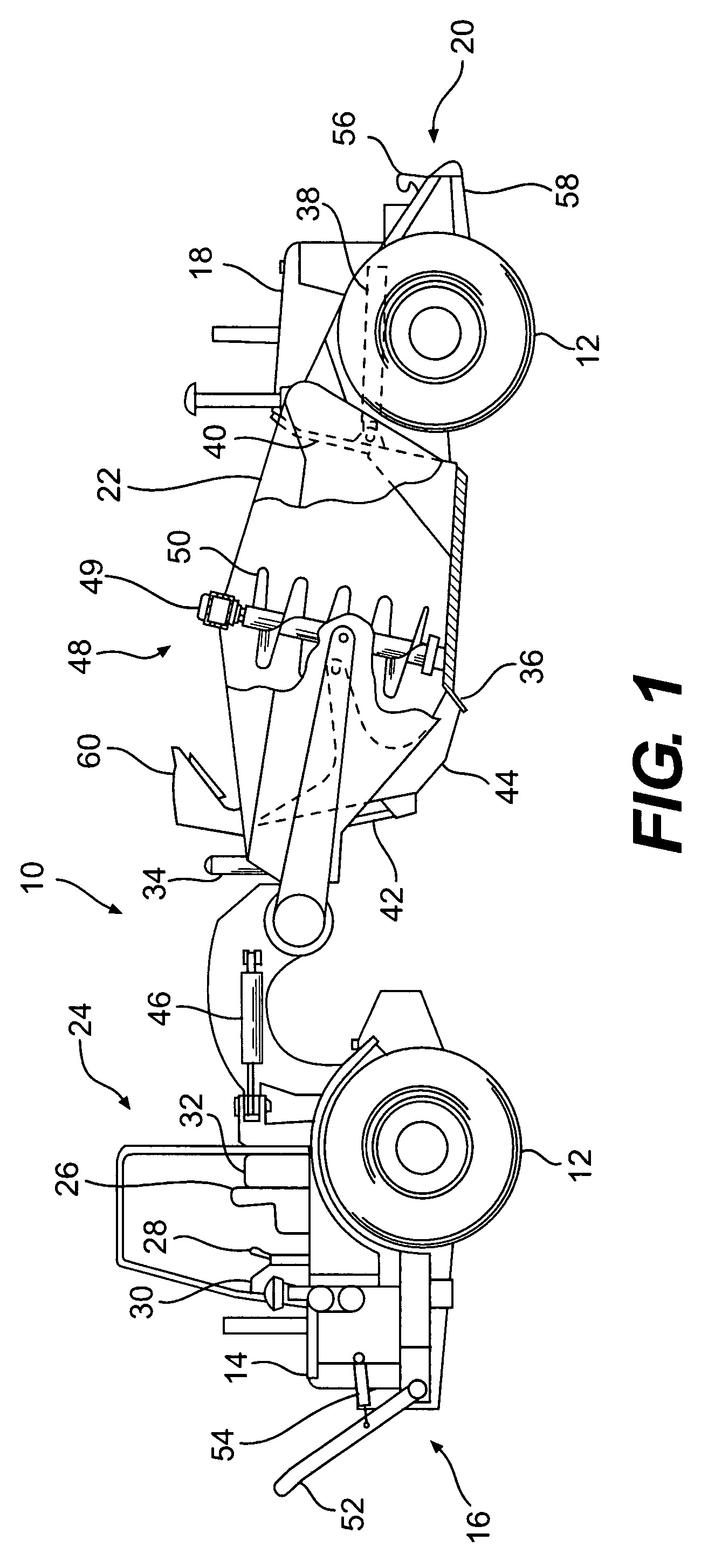

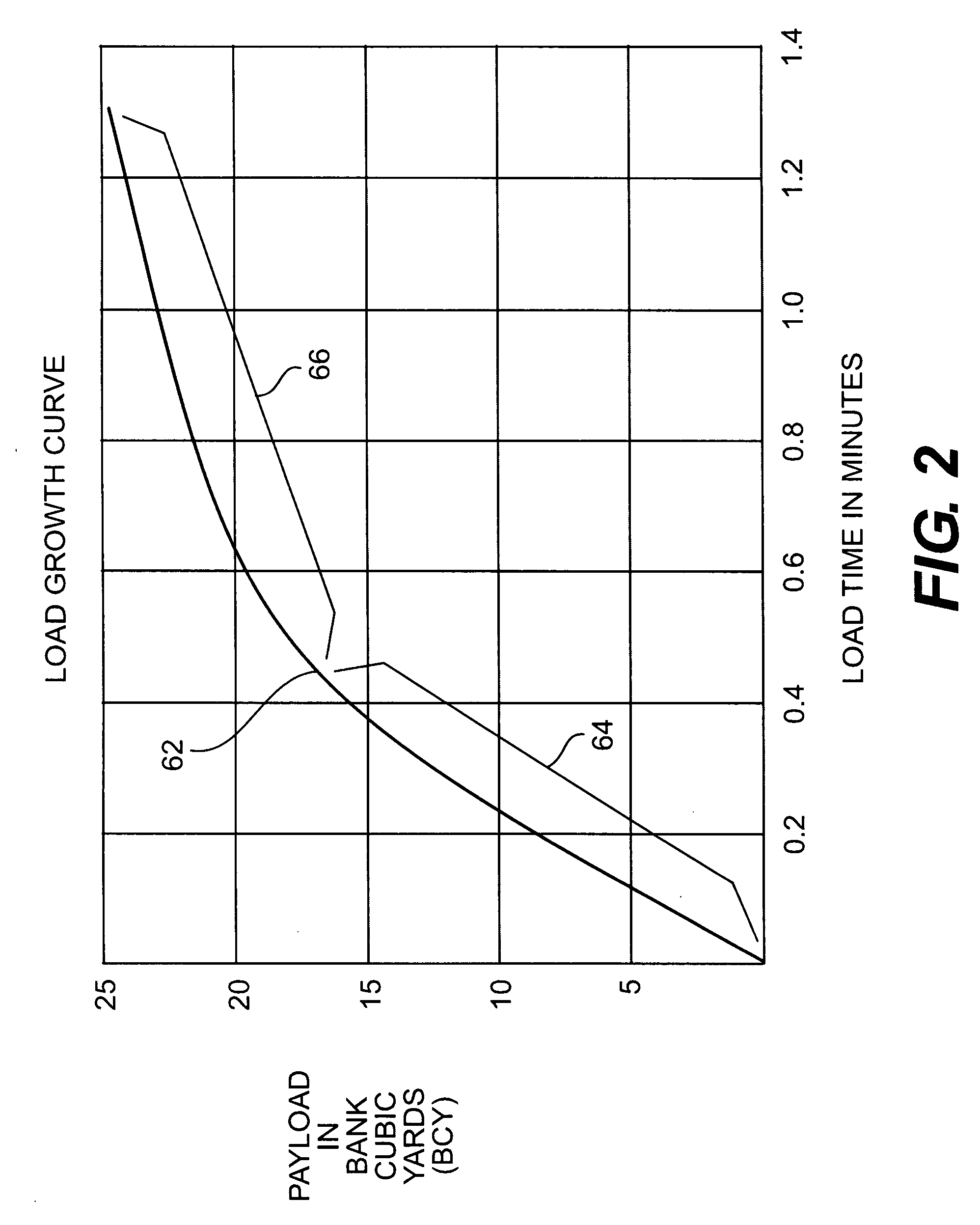

Wheel tractor scraper production optimization

ActiveUS8229631B2Improve productivityAnalogue computers for trafficComputer controlWheel tractor-scraperProduction rate

A method for enhancing productivity for an excavating machine is disclosed. The method includes determining at least one cycle characteristic for an operating cycle of the excavating machine. The method also includes measuring payload accumulated by the machine during a loading phase of an operating cycle of the excavating machine. The method further includes controlling payload accumulated by the machine based on at least one of the at least one determined cycle characteristics.

Owner:CATERPILLAR INC

Well production optimizing system

InactiveUS7243730B2Eliminating fluid flow through the passageFluid removalSealing/packingProduction optimizationEngineering

Owner:CASEY DAN

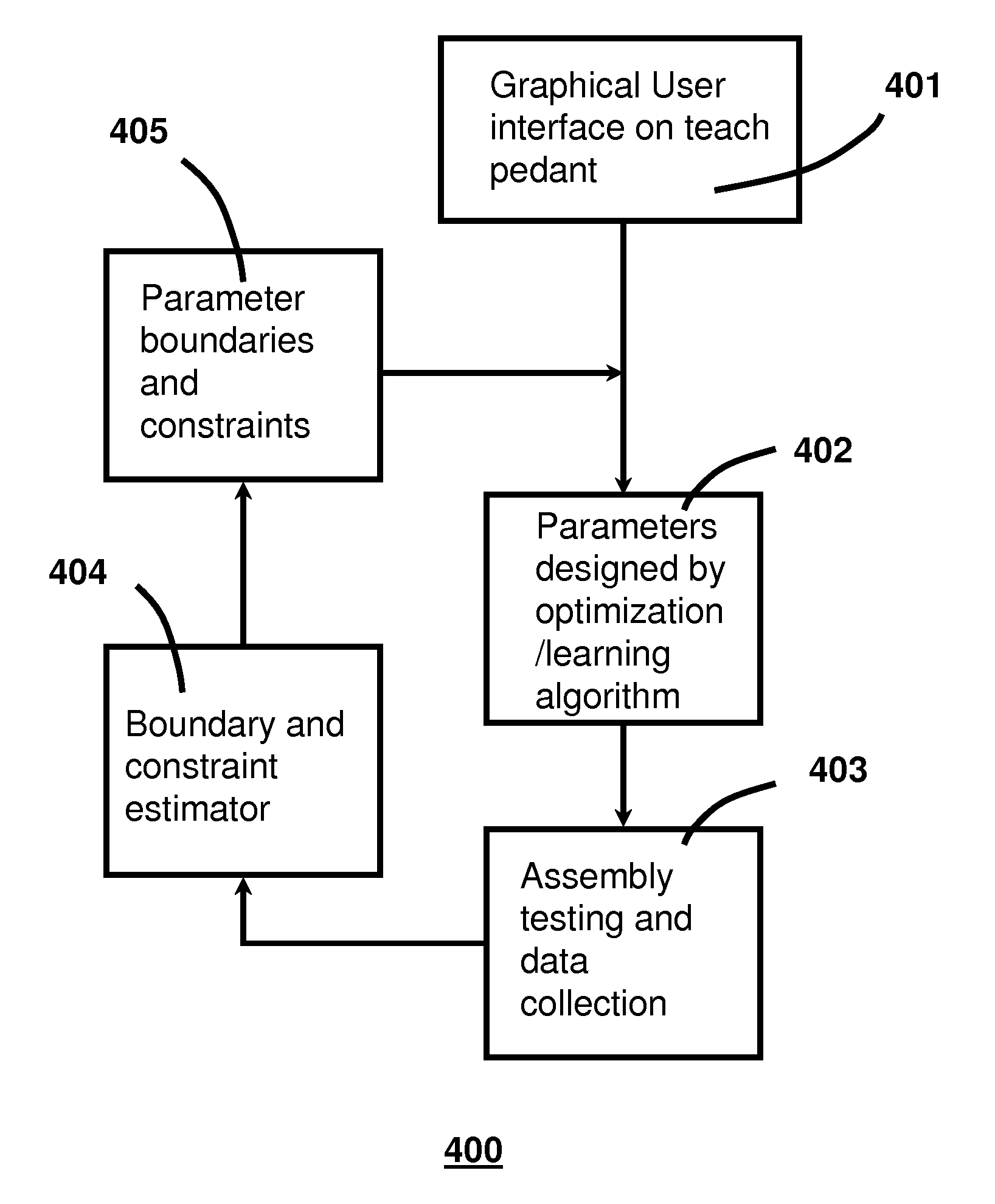

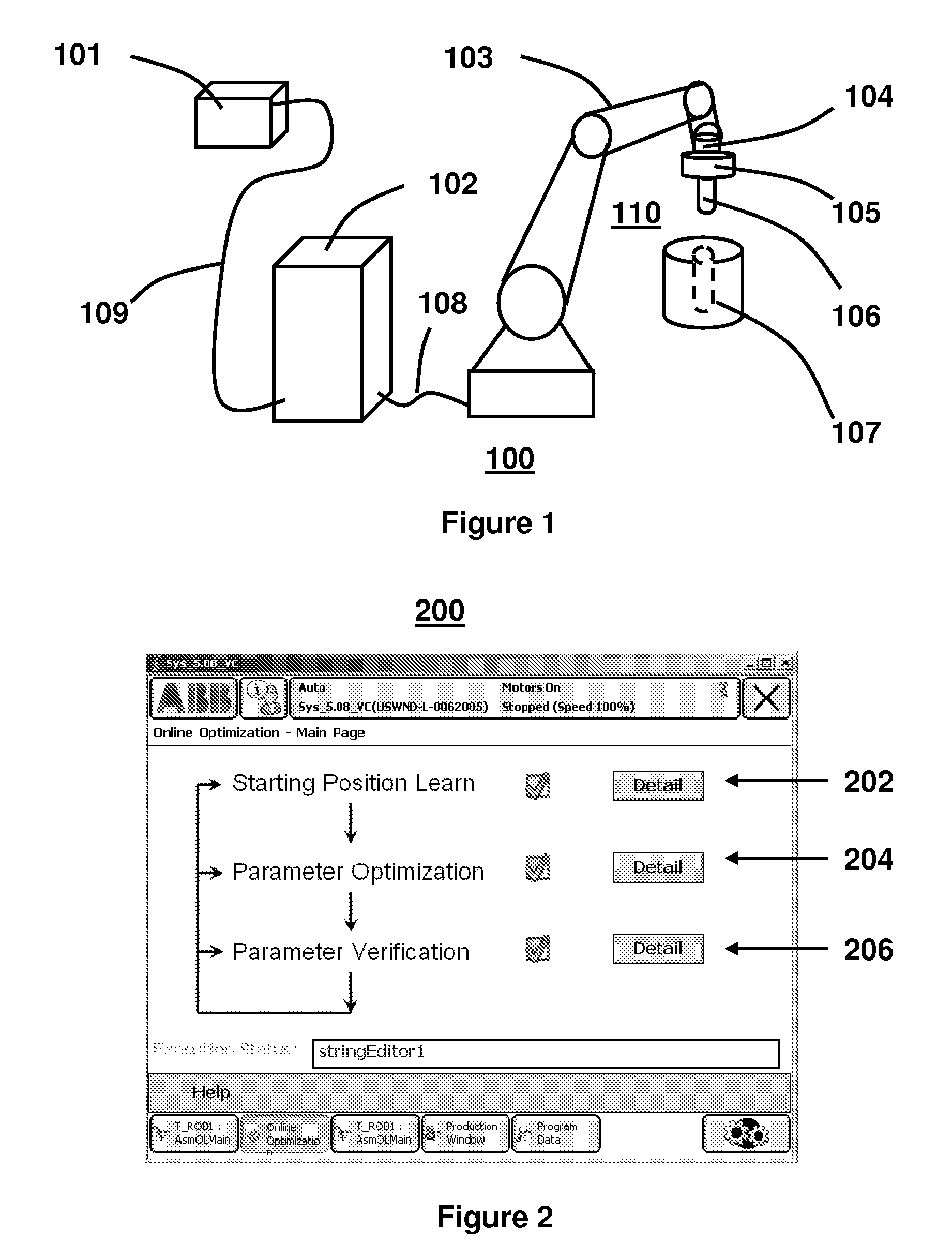

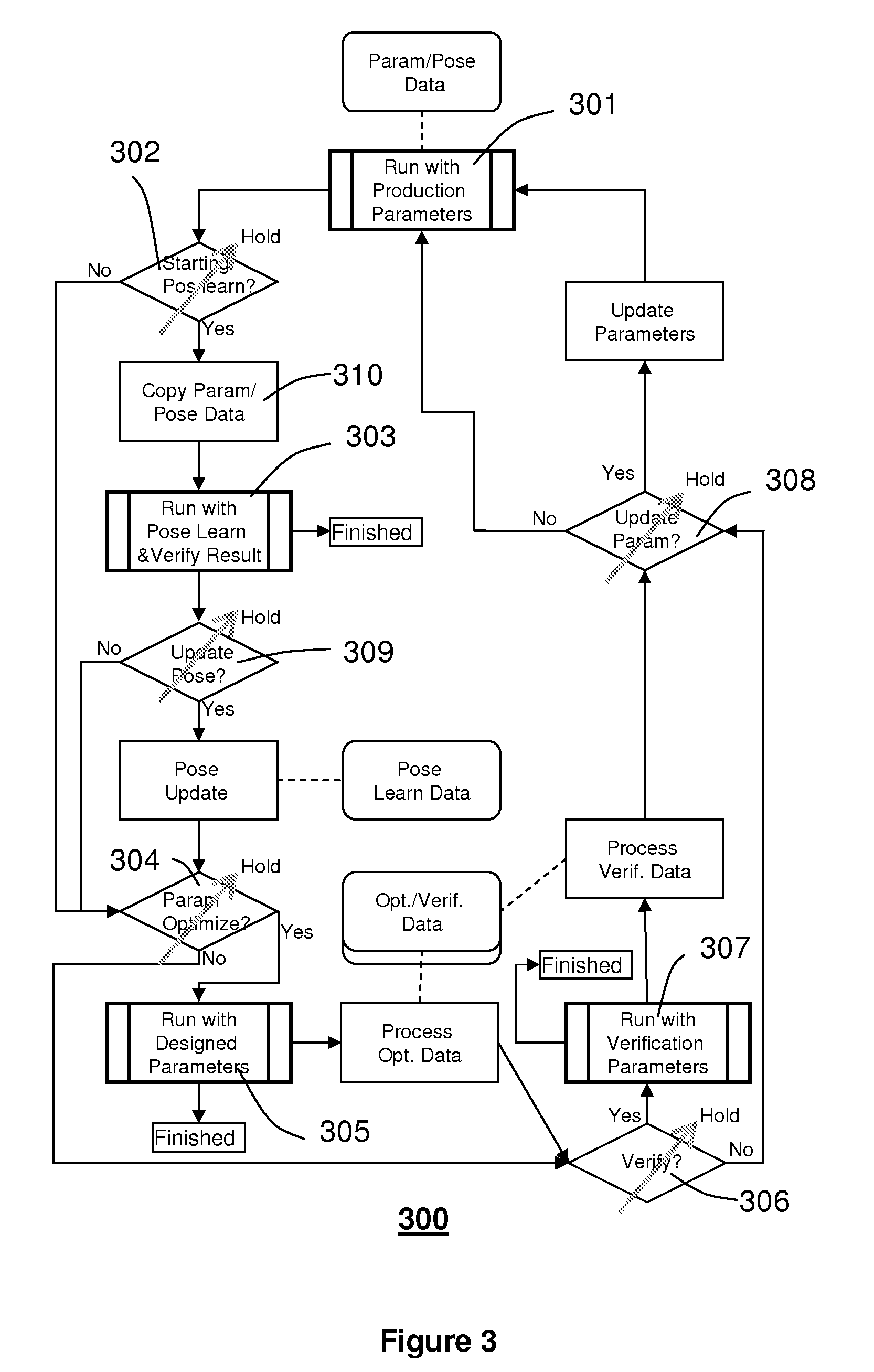

Method And System For In-Production Optimization of The Parameters Of A Robot Used for Assembly

ActiveUS20100145509A1Programme controlProgramme-controlled manipulatorProduction optimizationSimulation

A robot is used to repeatedly assemble part during a continuous production run of parts to be assembled. There are parameters of the robot associated with the assembly. These parameters are used to assemble the parts. Simultaneously with that repeated assembly the robot parameters are optimized. The parts to be assembled have a starting position for the assembly and the simultaneous optimization of the robot assembly parameters also includes the learning of the starting position. The robot assembly parameters can be optimized in a predefined manner. The optimized parameters can then be verified and the optimized and verified robot assembly parameters may then be used in place of the parameters of the robot associated with the parts assembly along with the learned starting position.

Owner:ABB RES LTD

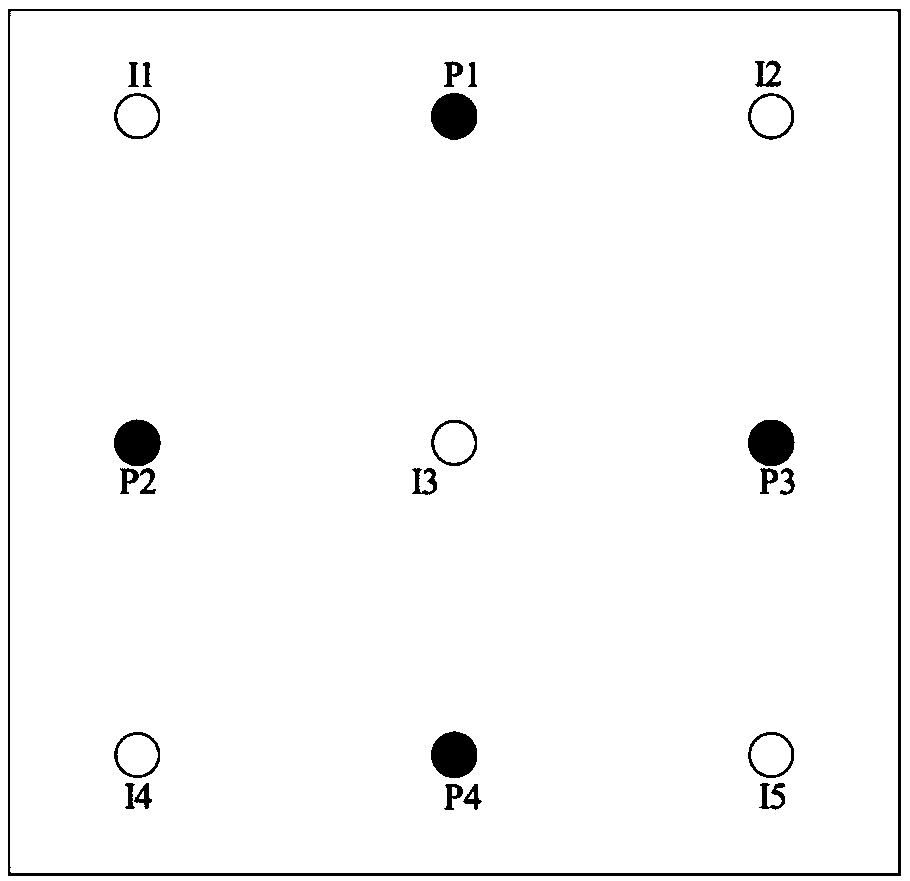

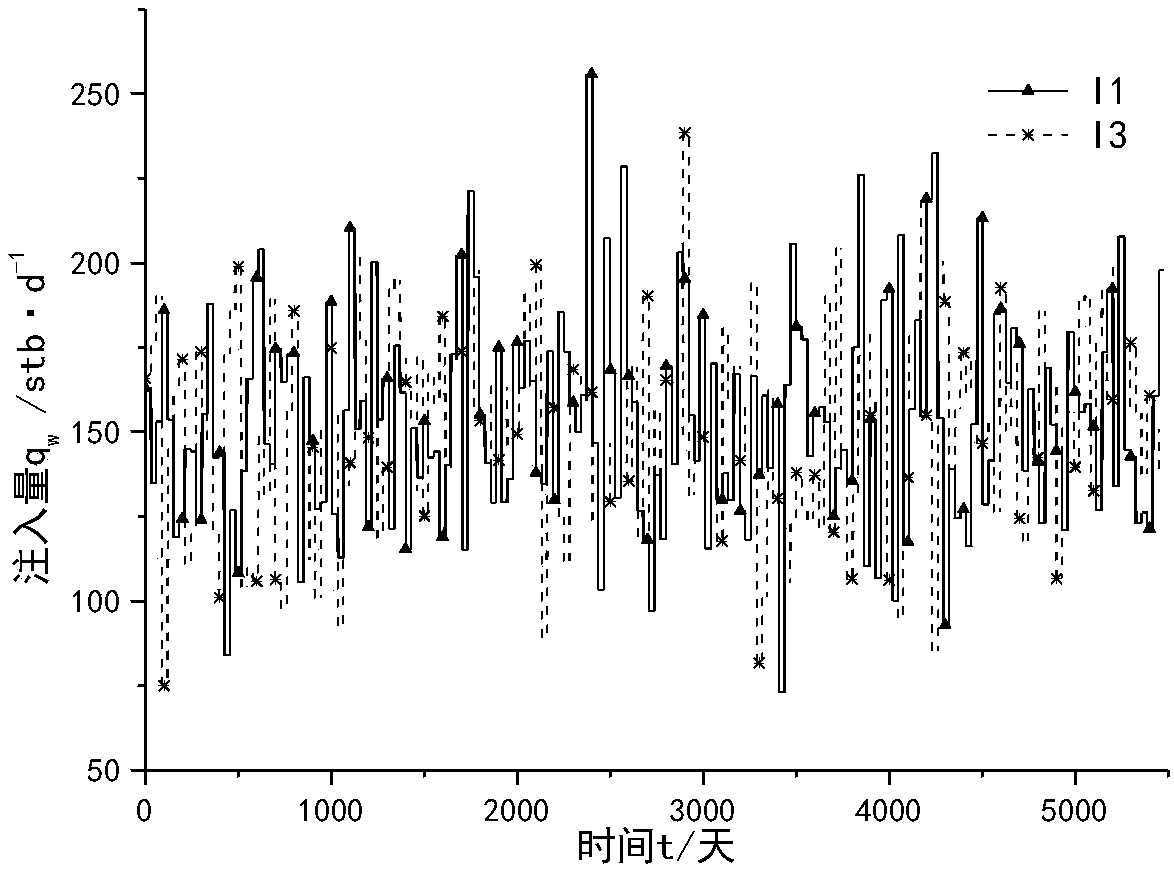

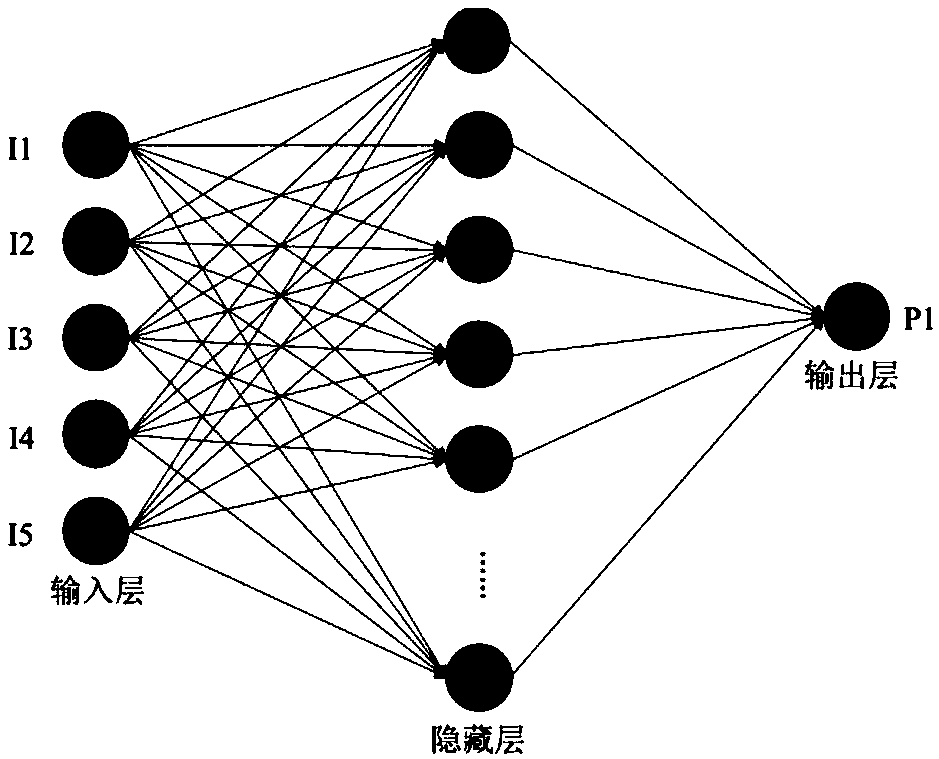

An oil reservoir inter-well connectivity determination method based on data driving

ActiveCN109447532ASimple methodComputationally efficientDigital data information retrievalNeural architecturesProduction optimizationUltrasound attenuation

The invention discloses an oil reservoir inter-well connectivity determination method based on data driving, and the method comprises the steps of firstly collecting related parameters of an oil fieldblock, obtaining a filtering coefficient of each injection signal, carrying out the preprocessing of injection and production data, and correcting the time lag and attenuation of the injection and production data; performing normalization processing on the injection-production data to form a standard sample set of neural network learning and training; building a neural network, using a conjugategradient algorithm as a learning algorithm, and achieving the rapid optimization solution of neural network model parameters; and performing parameter sensitivity analysis based on the trained neuralnetwork model to obtain a connection coefficient for representing the inter-well connectivity of the oil reservoir. The method is simple and convenient, is high in calculation efficiency, is used forevaluating the dynamic connectivity between oil reservoir wells, has a better yield prediction effect while having the same inter-well connectivity coefficient calculation precision of a traditional inter-well connectivity judgment method, and can further guide formulation of optimization measures such as profile control and water plugging and intelligent oil field layered injection and productionhistory fitting and production optimization.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

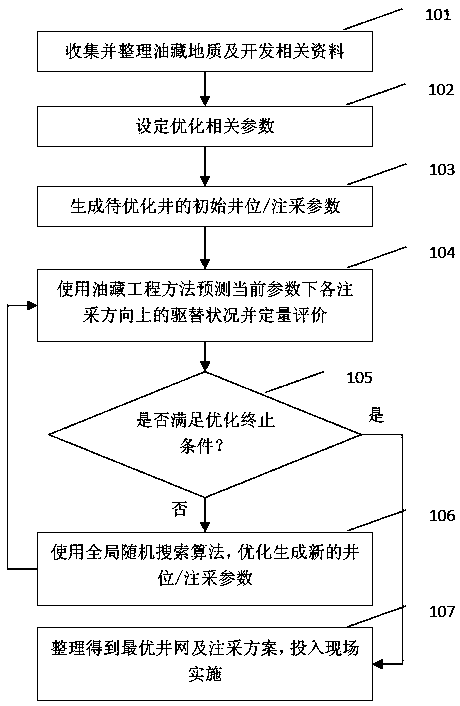

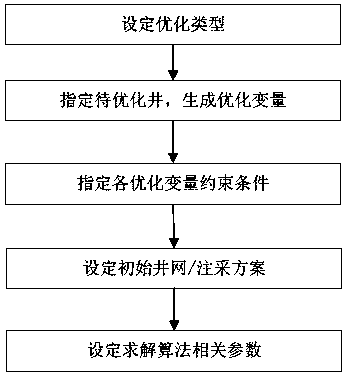

Oil deposit well pattern and injection-production scheme optimum design method based on balanced water drive idea

ActiveCN107829718AAvoid iterative calculationsReduce work intensityFluid removalProduction optimizationProcess engineering

The invention provides an oil deposit well pattern and injection-production scheme optimum design method based on a balanced water drive idea. The method comprises the steps of 1, collecting and arranging block geological and development related data; 2, setting optimizing related parameters, and completing the well pattern and injection-production optimization preparation work; 3, adopting an oildeposit engineering method, predicting the displacement condition on each direction under current well location and injection-production parameters and performing quantitative evaluation; 4, adoptinga global random search algorithm, optimizing and generating novel well location / injection-production parameters, and predicting and evaluating the displacement condition in each injection-productiondirection under novel well location injection-production parameters; 5, arranging the optimization result, forming a well pattern injection-production design scheme, and performing on-site implementation. According to the method, the water drive development index calculation method built on the basis of the oil deposit engineering idea is combined with the optimization theory, the global random search algorithm is adopted for automatic solving, the calculation efficiency is ensured while the well pattern and injection-production scheme matched with the actual oil deposit is obtained, and the oil deposit recovery efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

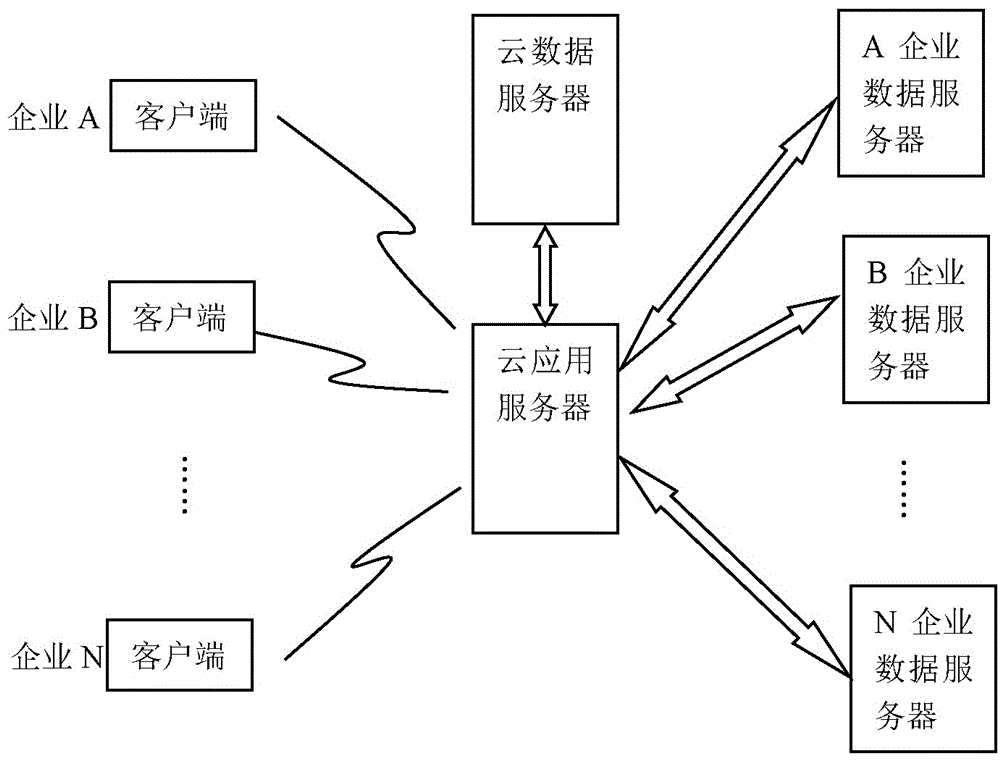

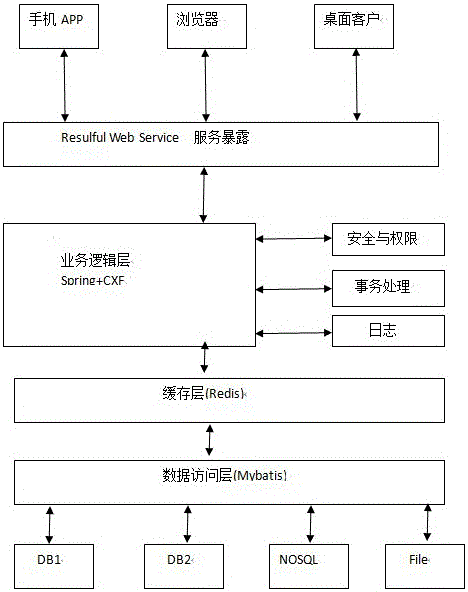

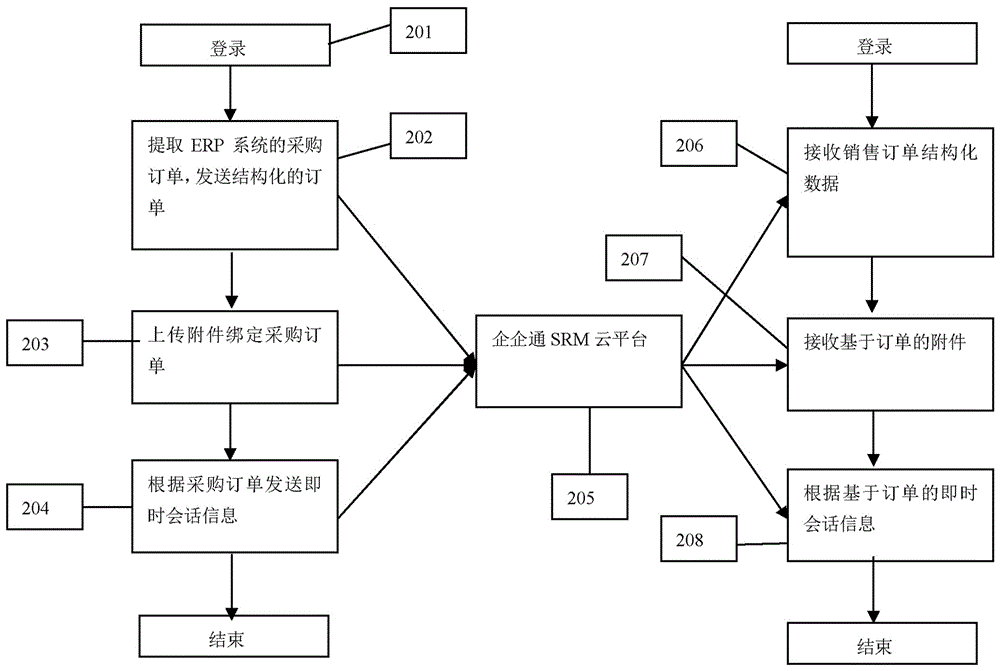

Business connection system between enterprises based on cloud platform

InactiveCN105913179AExcellent adhesionChange the way you workResourcesRelation graphProduction optimization

The invention discloses a business connection system between enterprises based on a cloud platform, comprising a cloud database server for storing all enterprise account basic data, an enterprise database server for storing business data of all enterprises, a cloud application server for visiting the cloud database server, the enterprises database server, providing corresponding business ports to the enterprises and performing processing on the businesses of all enterprises, and a client terminal for visiting the cloud data server and the corresponding enterprise database server to execute the business through the cloud application server according to the authorization conditions of all enterprises. The business connection system between enterprises based on cloud platform combines the business information of the upstream enterprises and the downstream enterprises with the production information and arranges the information into a net mode enterprise relation graph, which benefits the production optimization and cooperation optimization between the enterprises.

Owner:SHENZHEN ELS TECH CO LTD

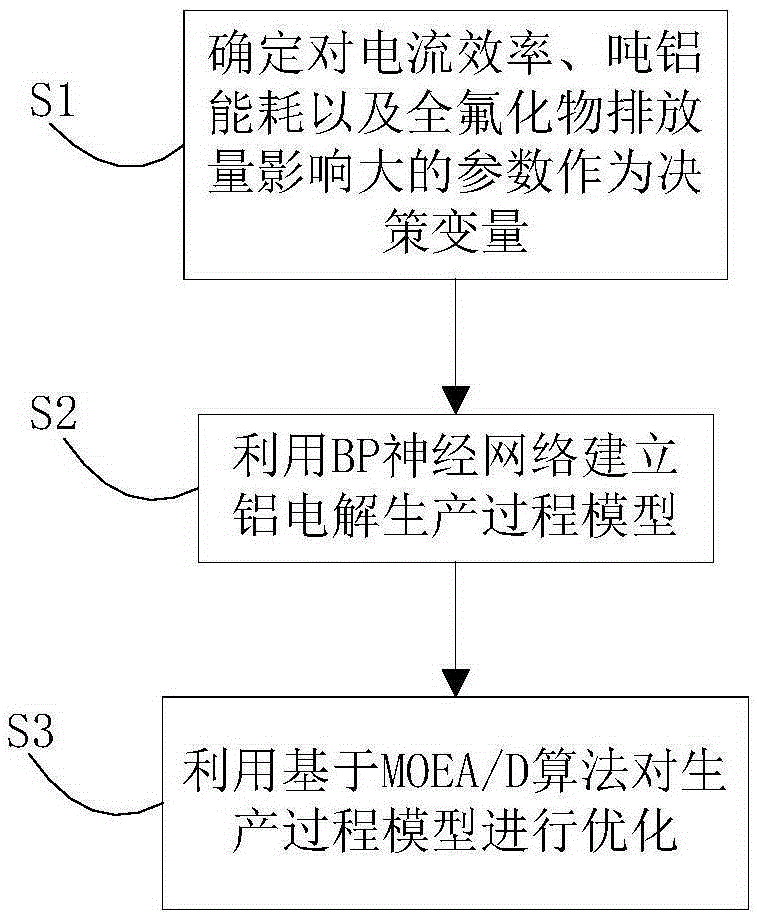

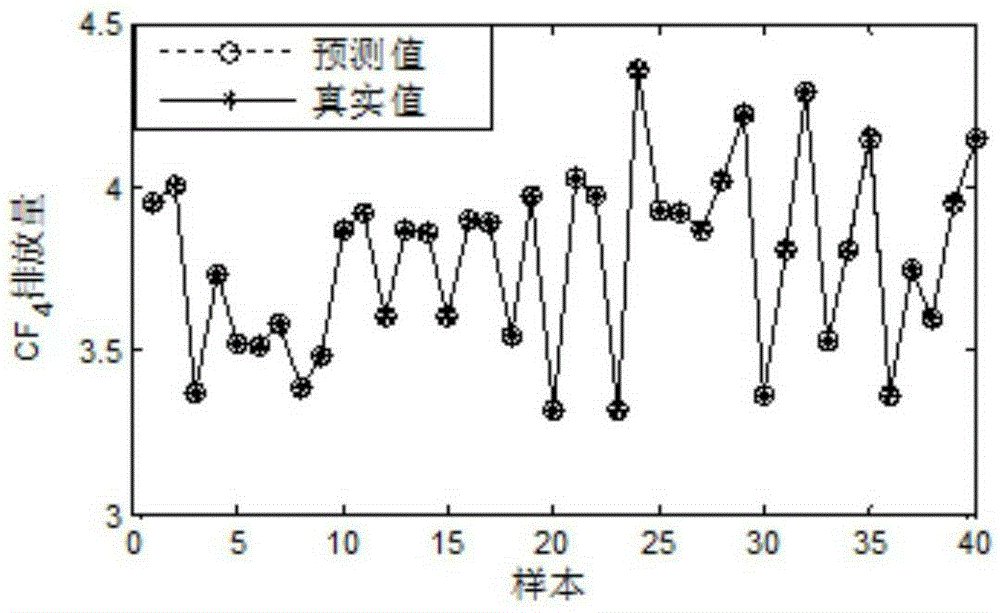

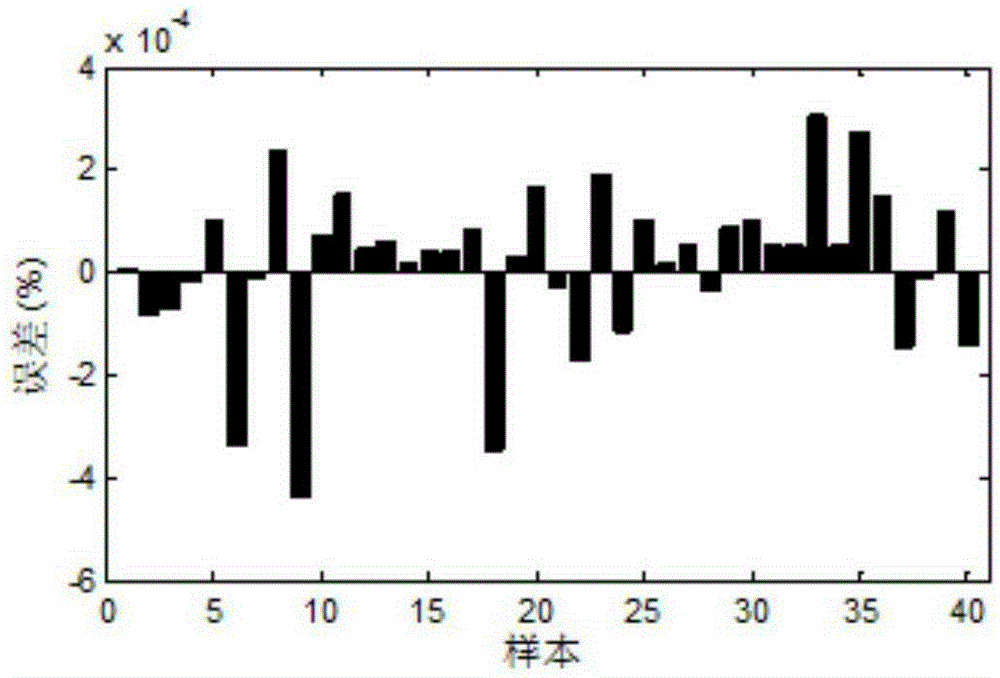

MOEA/D algorithm based aluminum electrolysis production optimization method

InactiveCN105302973AEmission reductionImprove current efficiencySpecial data processing applicationsProduction optimizationD algorithm

The invention provides an MOEA / D algorithm based aluminum electrolysis production optimization method. The method comprises: at first, modeling an aluminum electrolysis production process by utilizing a BP neural network; and then, optimizing a production process model by utilizing an MOEA / D algorithm to obtain a group of optimal solutions of decision variables as well as current efficiency, ton aluminum energy consumption and perfluoro-compound discharge amount corresponding to the optimal solutions, wherein the MOEA / D algorithm decomposes multi-target optimization into a plurality of single-target optimization sub-problems, and a core idea of the MOEA / D algorithm is that information of other sub-problems adjacent to one sub-problem is obtained and then cooperative optimization is performed, so that the optimization speed of multi-target optimization is greatly increased. The method determines an optimal value of process parameters in the aluminum electrolysis production process, effectively improves the current efficiency, reduces the greenhouse gas discharge amount, and truly achieves the purposes of energy conservation and discharge reduction.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

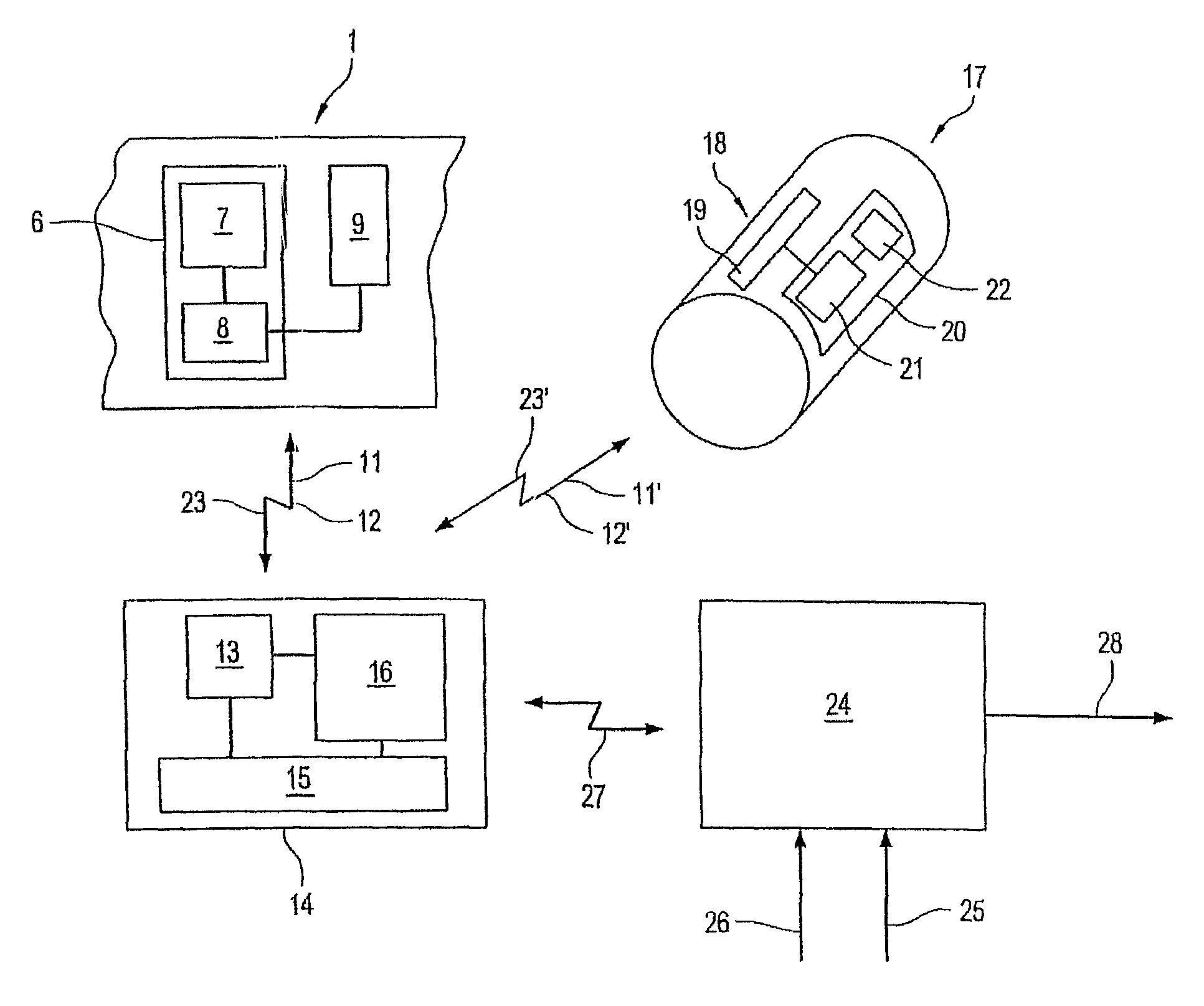

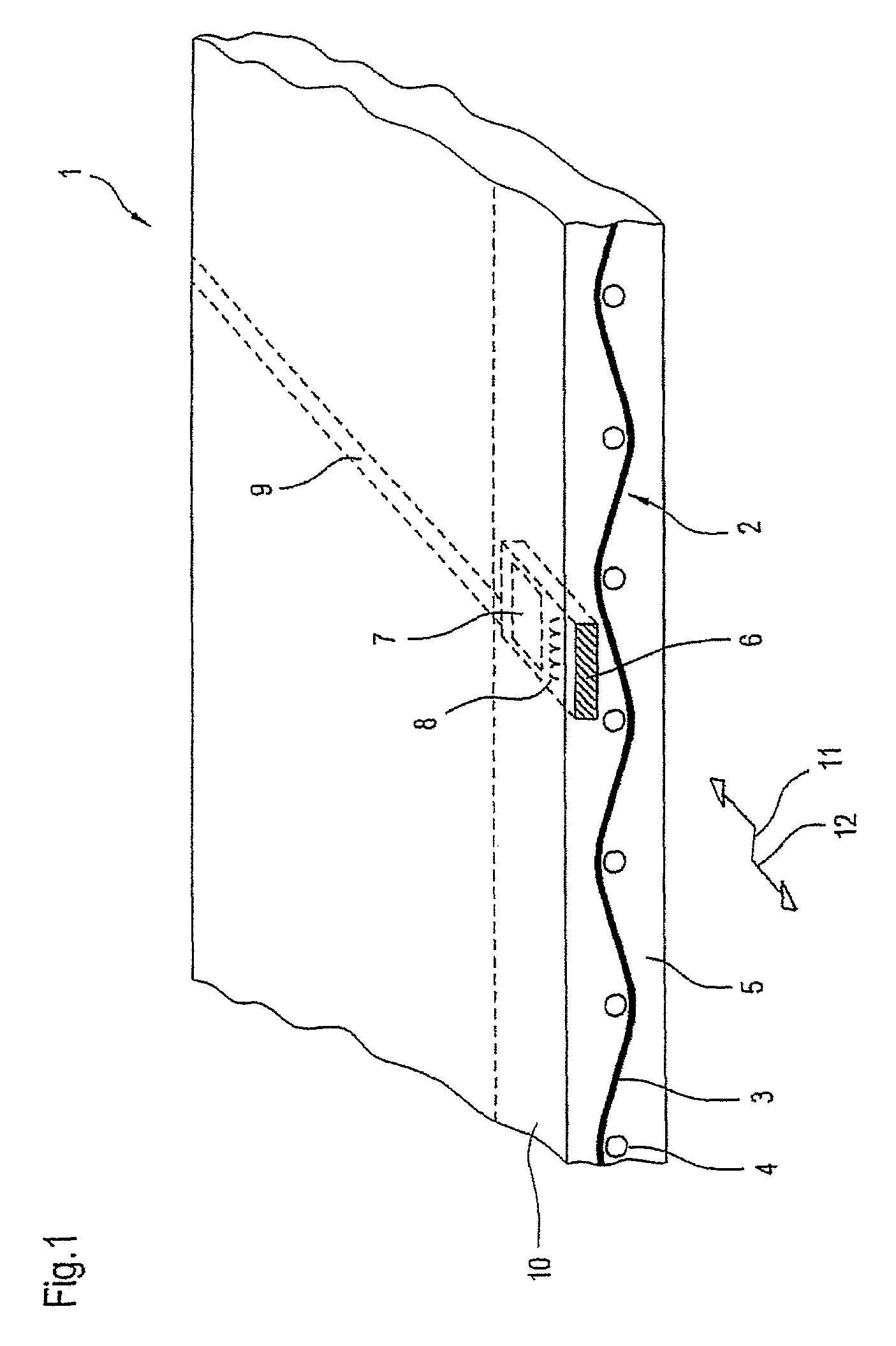

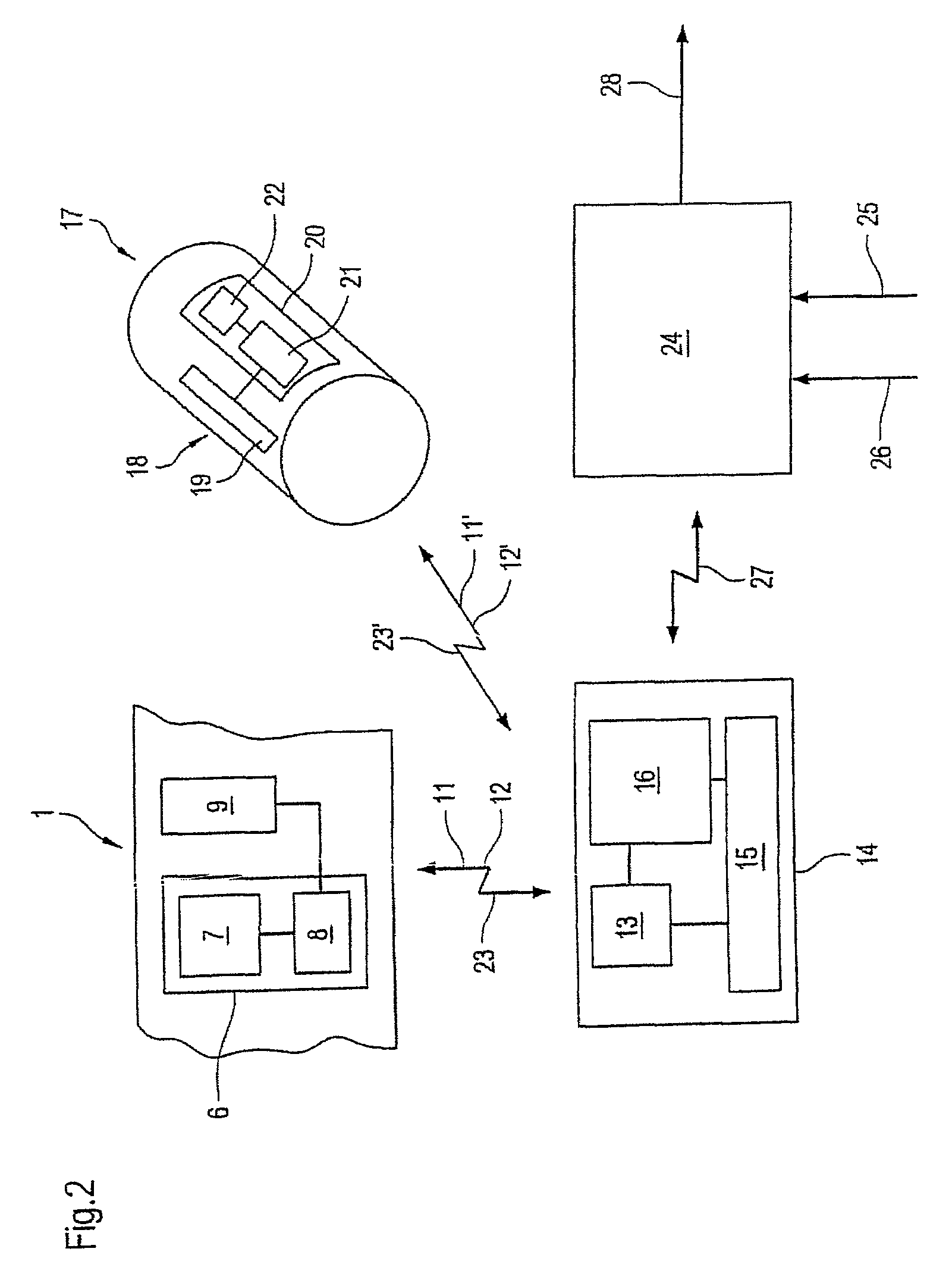

Production optimization using data received from a removable component

InactiveUS7873433B2Increase production capacityReduce the amount requiredNon-fibrous pulp additionNatural cellulose pulp/paperProduction optimizationLoop control

This invention relates to a system and a method for optimization of the process performance of a web-processing machine, in particular a machine for the production or further processing of paper, paperboard or tissue, including the following steps: storage of specific data of a component on a data storage unit fitted to the component; and / or measurement of relevant properties of the component by way of a sensor unit fitted to the component; sending of the specific data and / or the measured relevant properties to an open-loop control unit and / or a closed-loop control unit; and optimization of the process performance by way of the open-loop control unit and / or the closed-loop control unit using specific data and / or the measured properties of the component.

Owner:VOITH PATENT GMBH

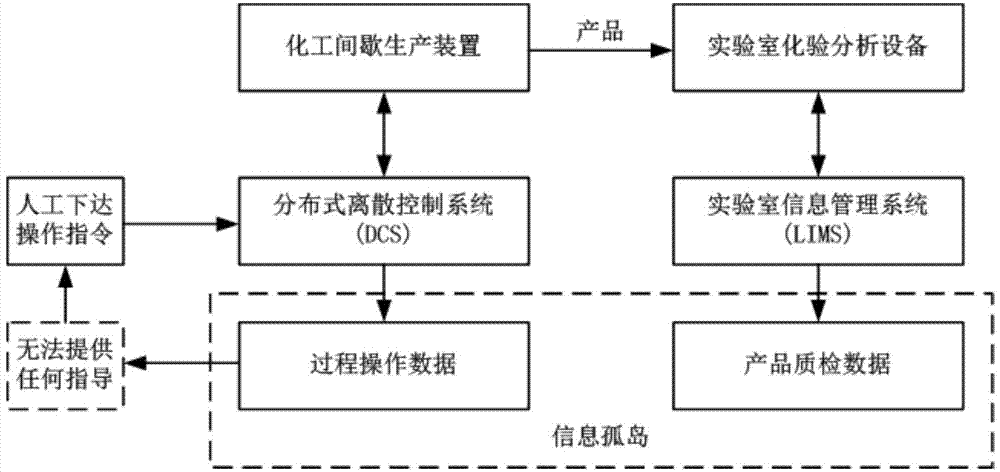

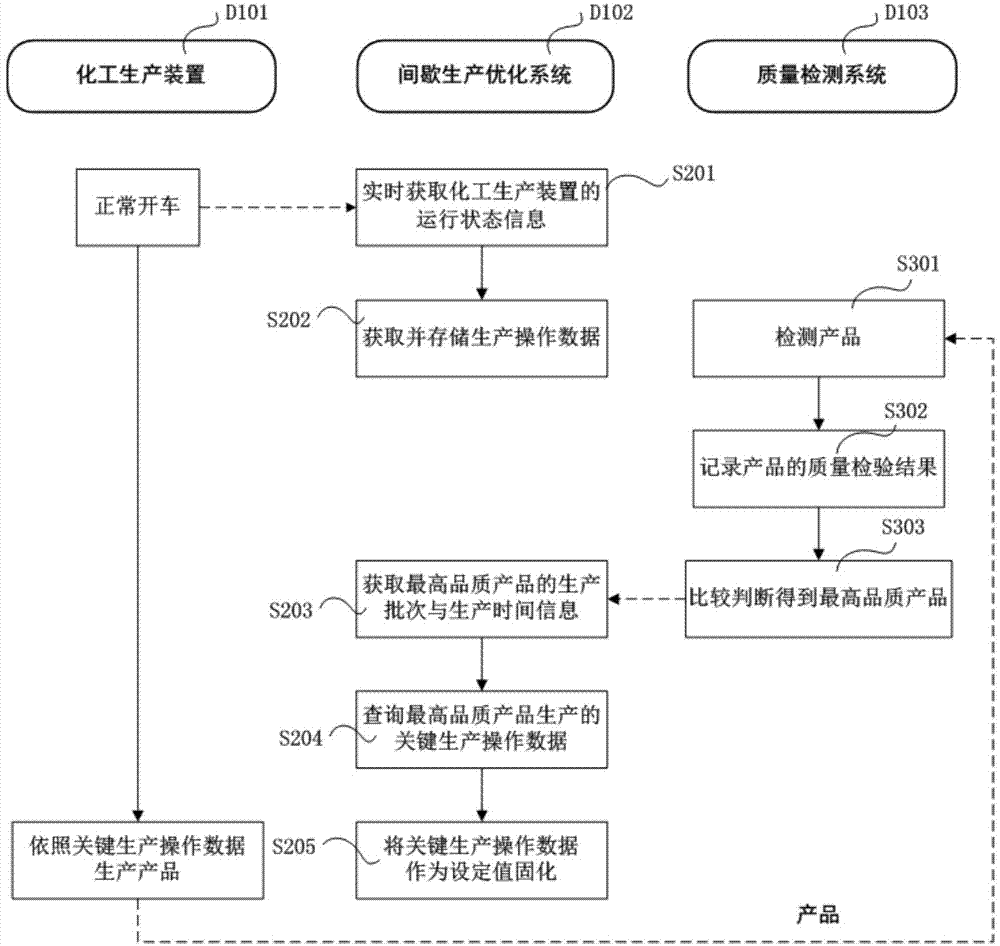

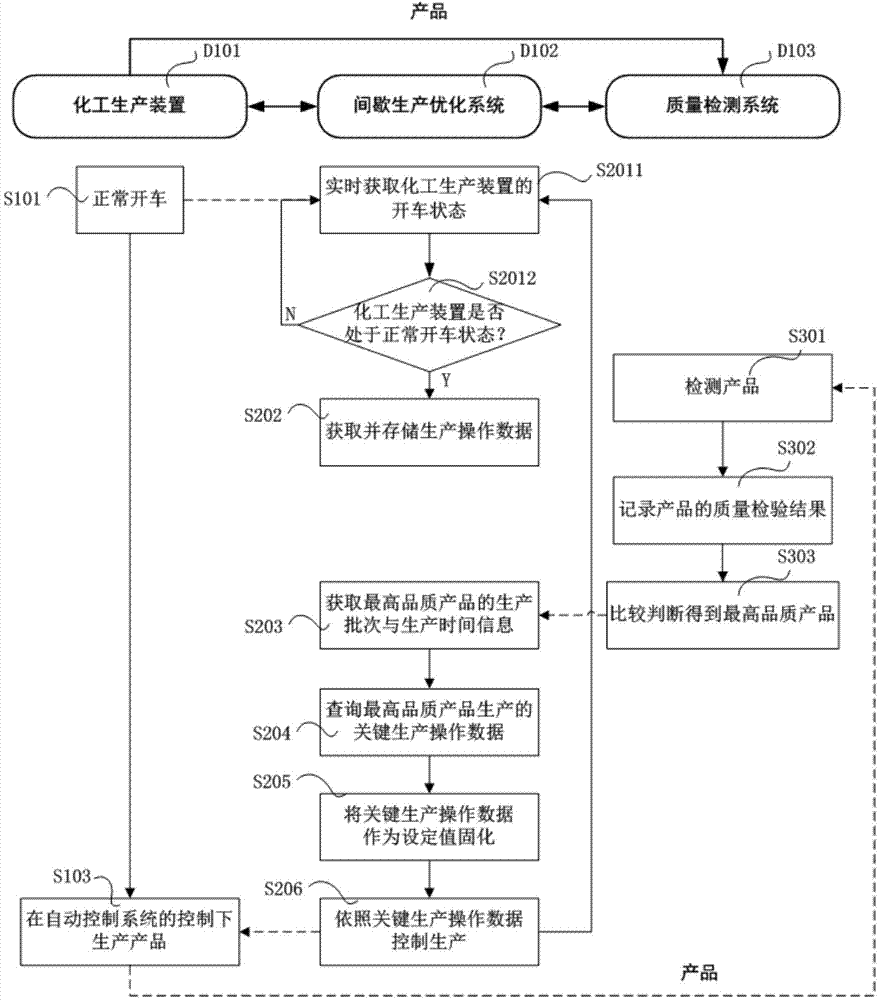

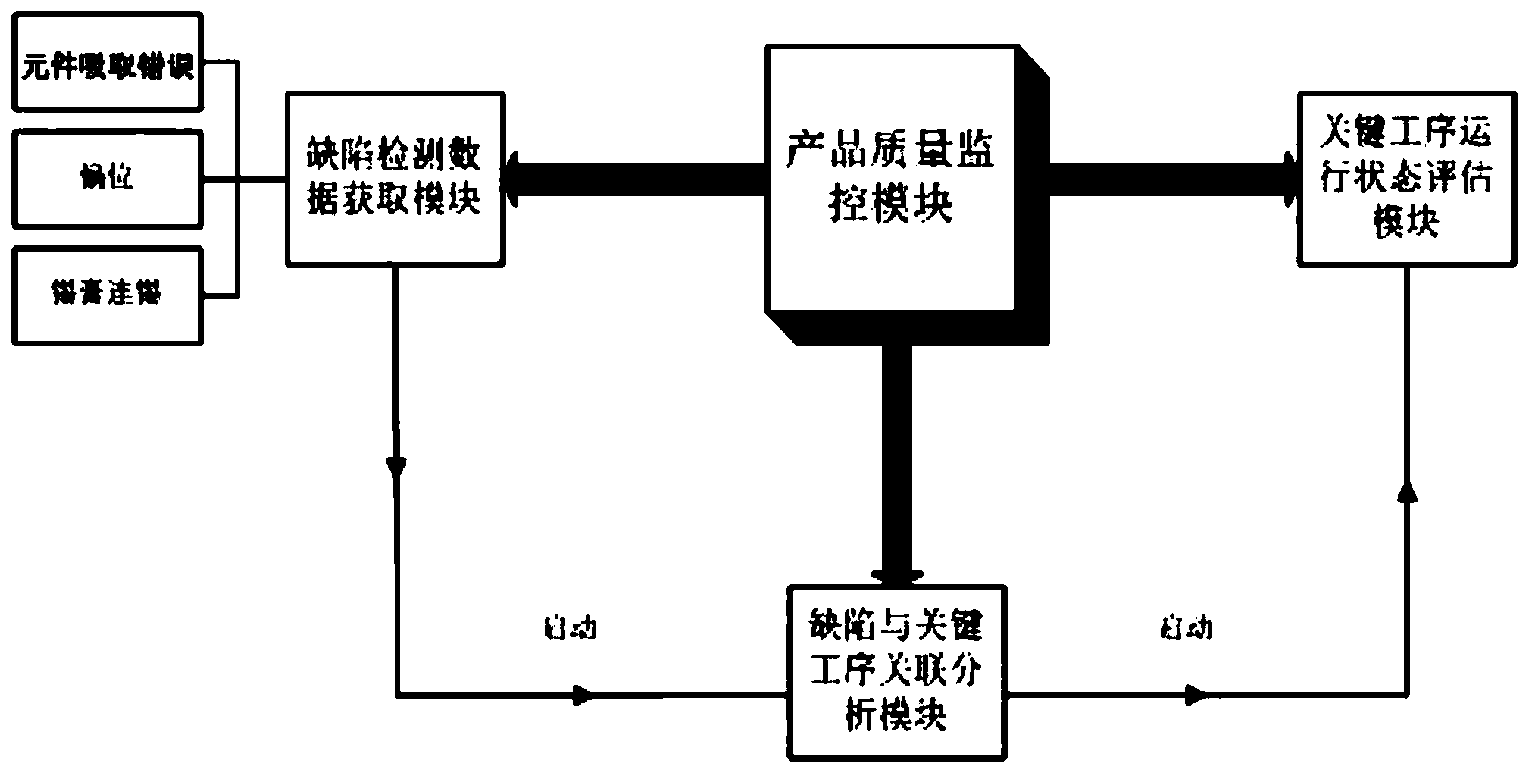

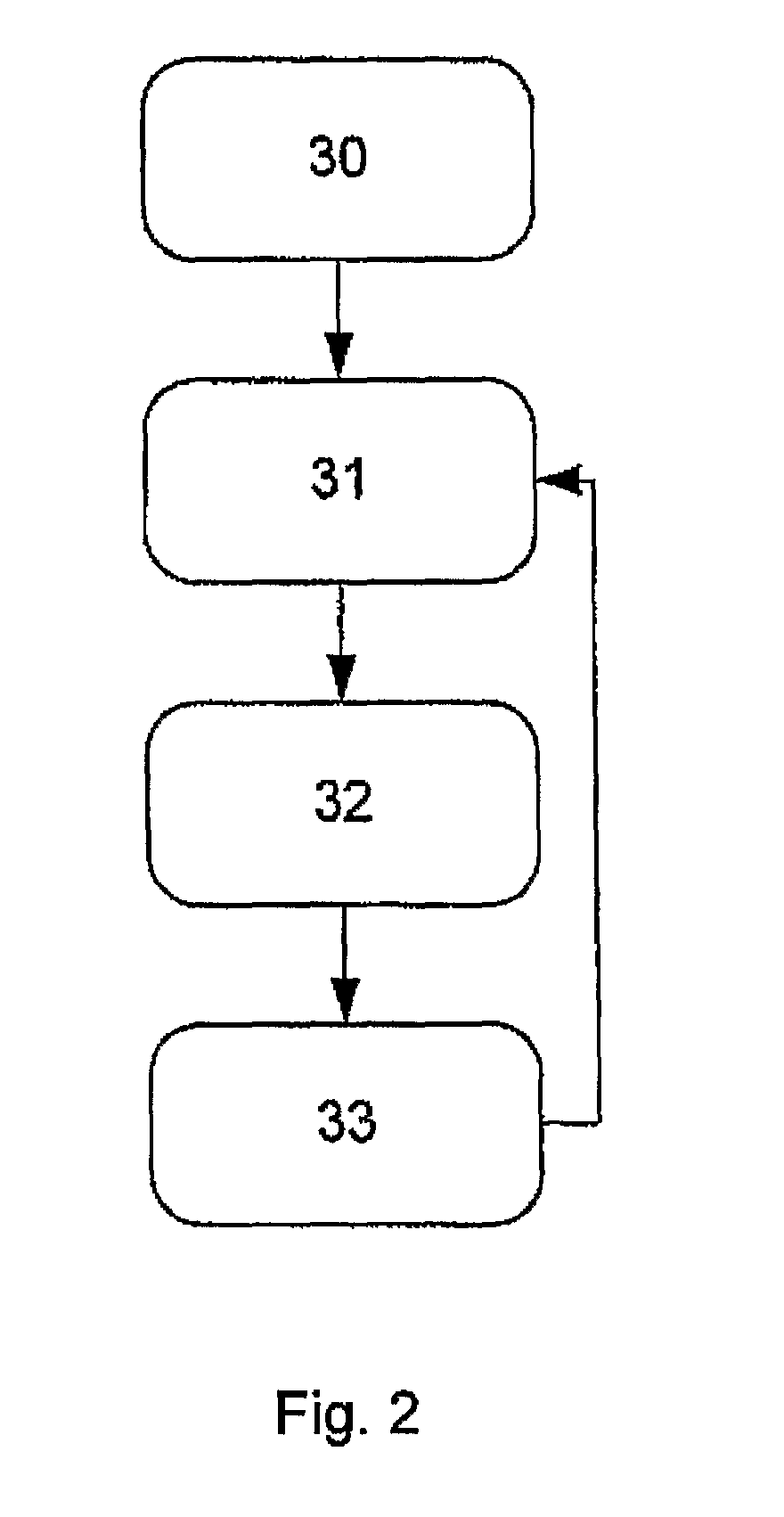

Method for optimizing chemical intermittent production operation and optimized production operation system

ActiveCN104516339AQuality improvementReduce human interventionTotal factory controlProgramme total factory controlProduction optimizationOperational system

The invention relates to the field of chemical engineering and provides a method for optimizing chemical intermittent production operation. The method comprises the steps of running state detection, production and detection data acquisition, comparison and judgment, operation parameter acquisition, operation parameter curing and the like. The invention further provides a chemical intermittent production operation system, a chemical production device, an intermittent production optimization system and a quality detection system. The intermittent production optimization system comprises a running state detection module, a data acquisition and storage module, a data query module, a data curing module and the like. The invention further provides an intermittent batch production control method for production control by taking a batch as a unit. After the original information islands, i.e., 'process operation data' and 'product quality inspection data', are organically combined based on a real-time database technology, the chemical intermittent production operation method is optimized, automatic reaction initiation is realized based on an optimum operation parameter, the product quality is guaranteed, and the production efficiency is improved.

Owner:BLUESTAR BEIJING TECH CENT

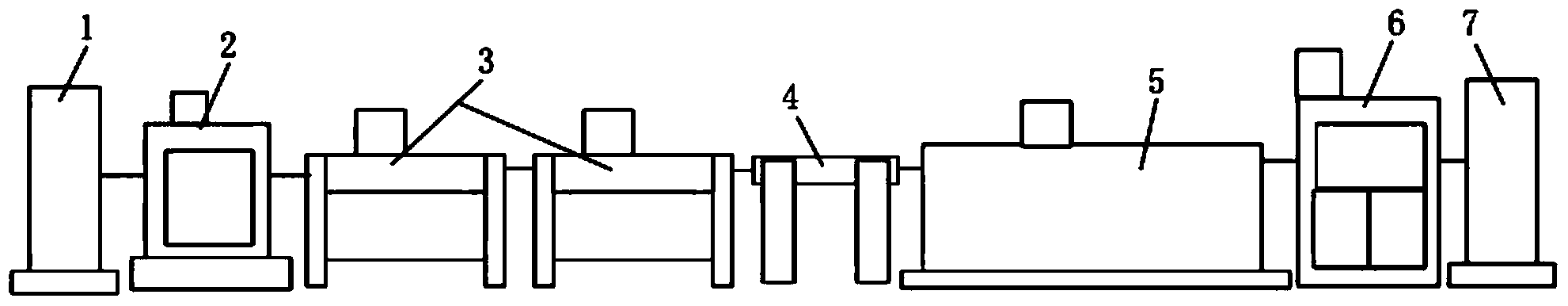

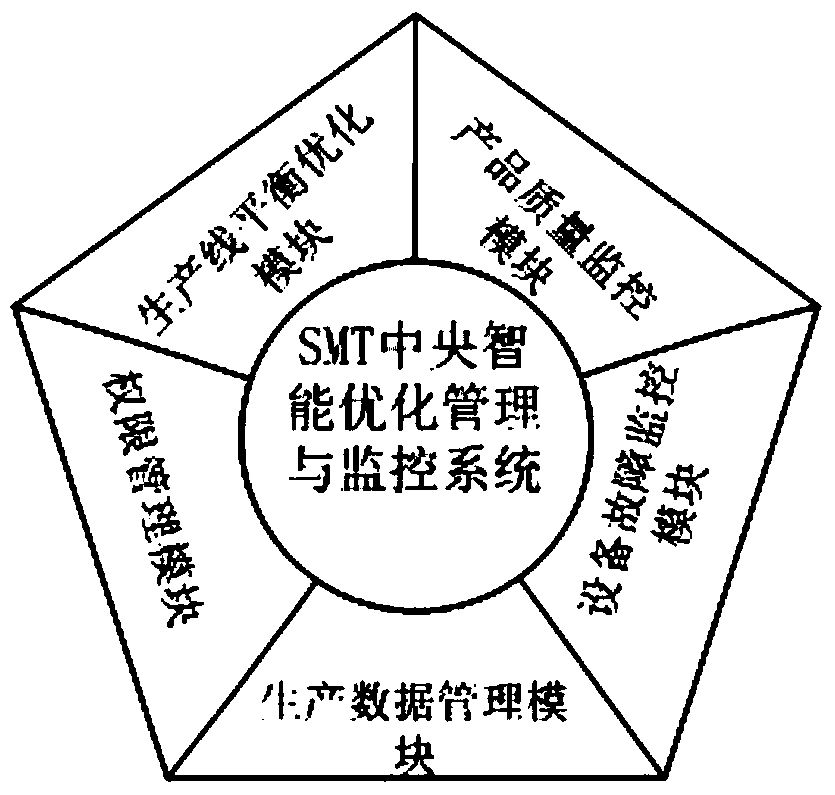

SMT central intelligent optimal management and monitoring system

InactiveCN103679359AIncrease the level of automationImprove efficiencyResourcesTotal factory controlProduction optimizationManufacturing cost reduction

The invention discloses an SMT central intelligent optimal management and monitoring system which comprises a production line balancing optimization module, a product quality monitoring module, a device fault monitoring module, an authority management module and a production data management module. The SMT central intelligent optimal management and monitoring system carries out production optimization, monitoring and management on an SMT production line through the production line balancing optimization module, the product quality monitoring module, the device fault monitoring module, the authority management module and the production data management module, and has the advantages of improving production efficiency and product quality, reducing manufacturing cost, comprehensively improving the automation level of the SMT production line and the like.

Owner:SOUTH CHINA UNIV OF TECH

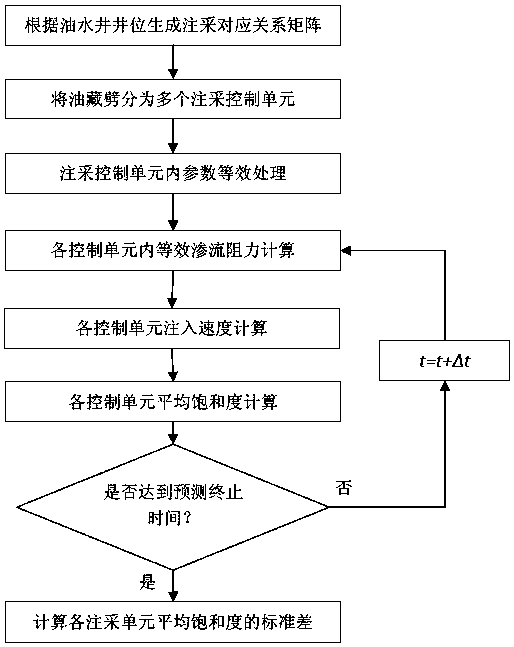

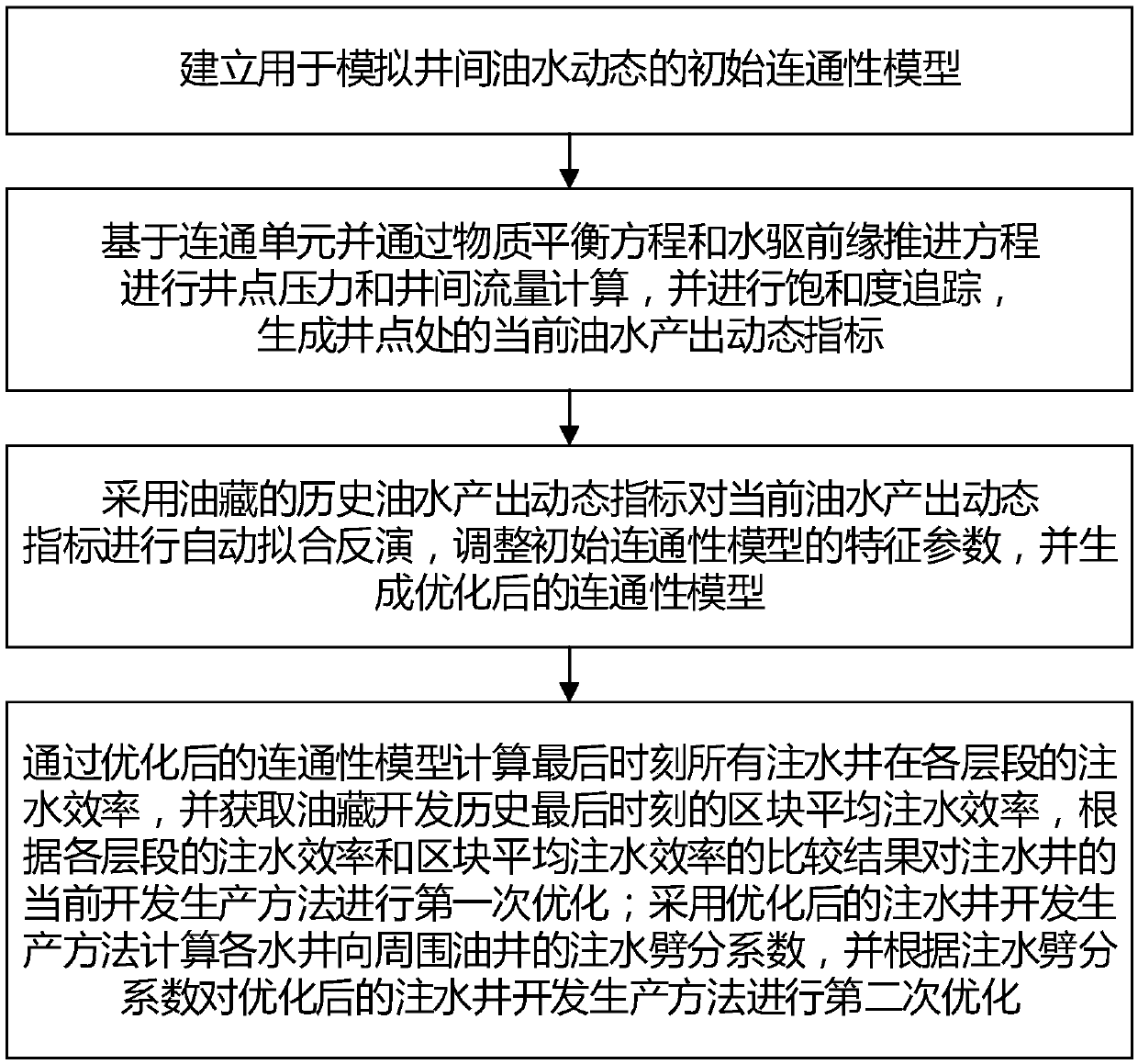

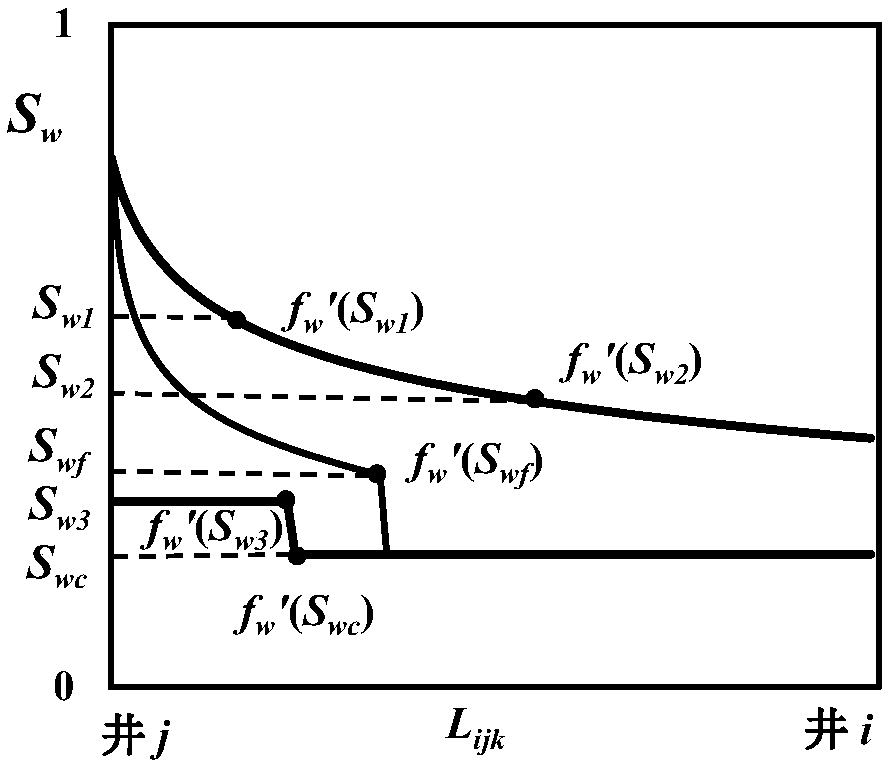

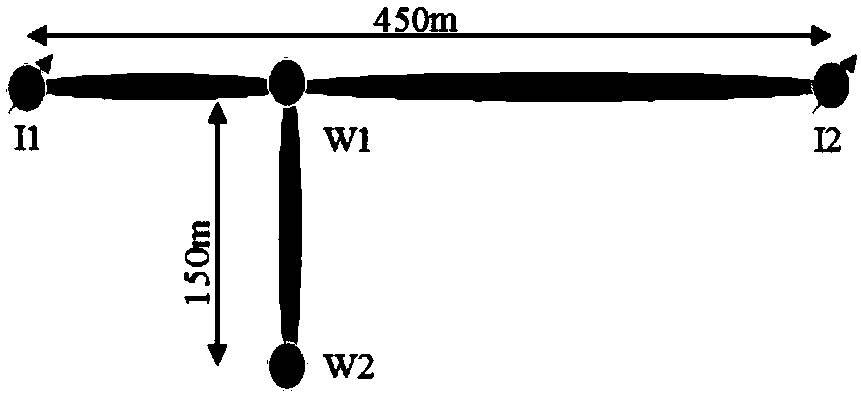

Oil deposit development production optimization method and system based on connectivity method

ActiveCN108868712AQuick calculationReduce inefficient water channeling flowFluid removalDesign optimisation/simulationProduction optimizationCommunication unit

The invention relates to a production method of an oil deposit, in particular to an oil deposit development production optimization method and system based on a connectivity method. The method comprises the steps that saturation calculation is conducted by taking inter-shaft communication units as objects to establish a precise front edge tracking method to obtain oil-water dual-phase production dynamics of each layer at shafts; information of inter-shaft conductivity, flow splitting, water injection efficiency and the like is obtained by inverting connectivity model parameters though automatically fitting oil deposit historical dynamics, and the information is taken as the basis to perform layered dynamic production allocation and injection allocation automatic optimizing design on the oil deposit through iterative computation to reduce low-efficiency water drive direction flow and improve injection-exploitation conflict. Application examples show that the method can perform rapid computation, accurate saturation tracking and production dynamics computation, an obtained layered water injection scheme can well achieve a water reducing and oil increasing effect, 50,000 cubic metersof predicted oil increasing after actual optimization of the oil deposit is conducted is achieved, and a novel idea for performing real-time optimization on an oil field injection-exploitation schemeis provided.

Owner:YANGTZE UNIVERSITY

Ammonia converter production optimization method based on data excavation technology

InactiveCN101187803ASmooth and optimized production operationsMeet needsAdaptive controlProduction optimizationReal-time data

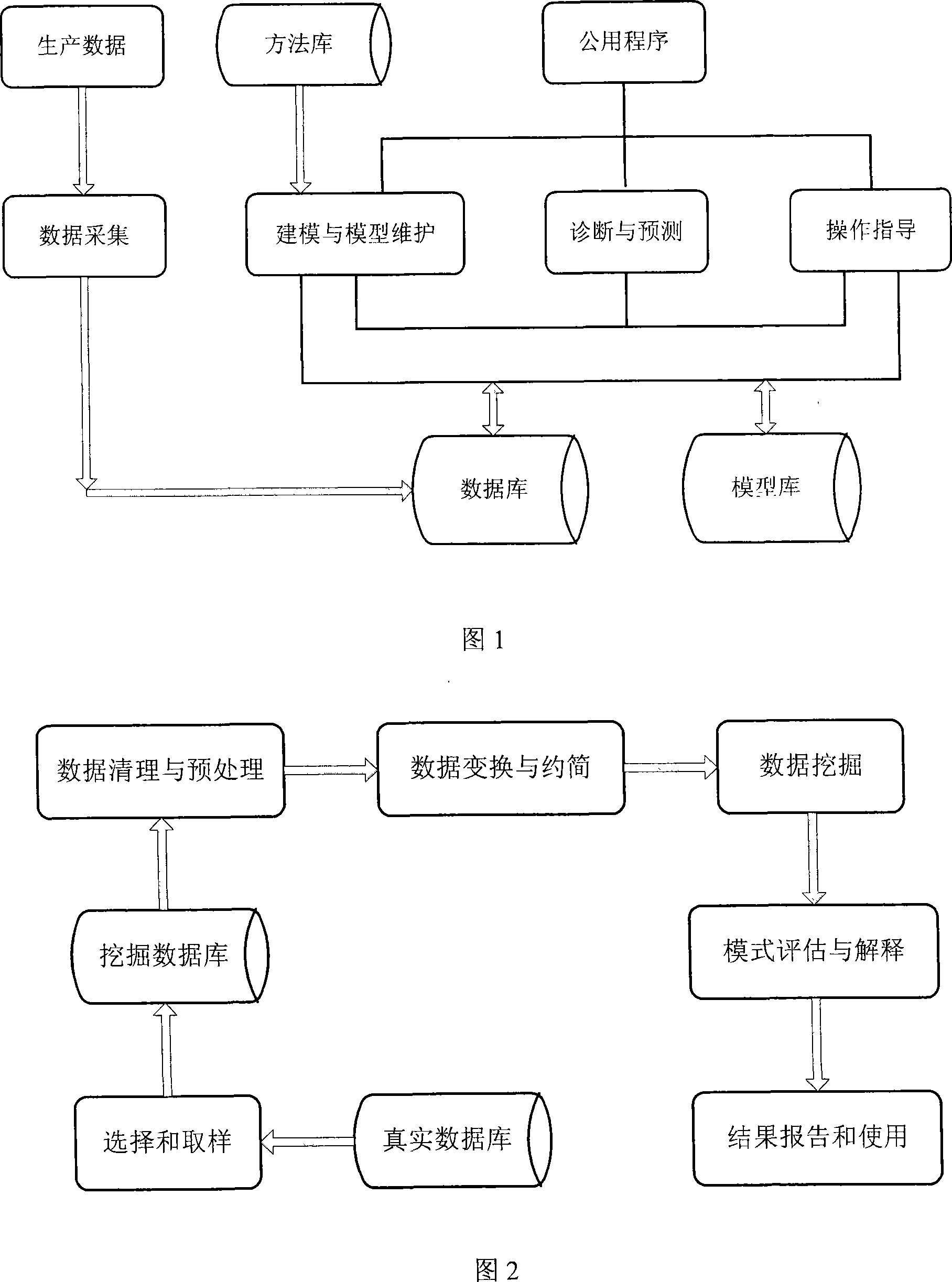

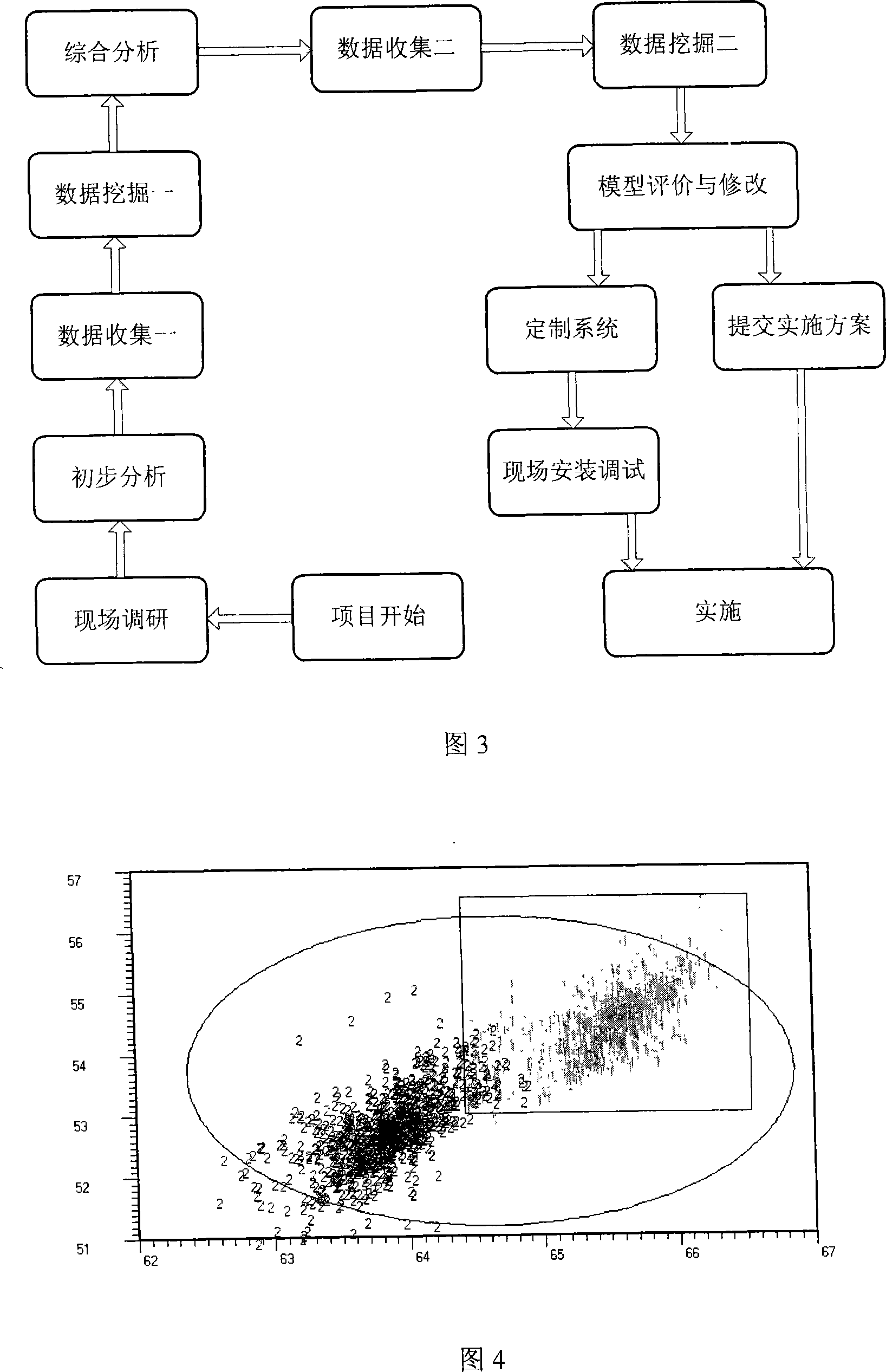

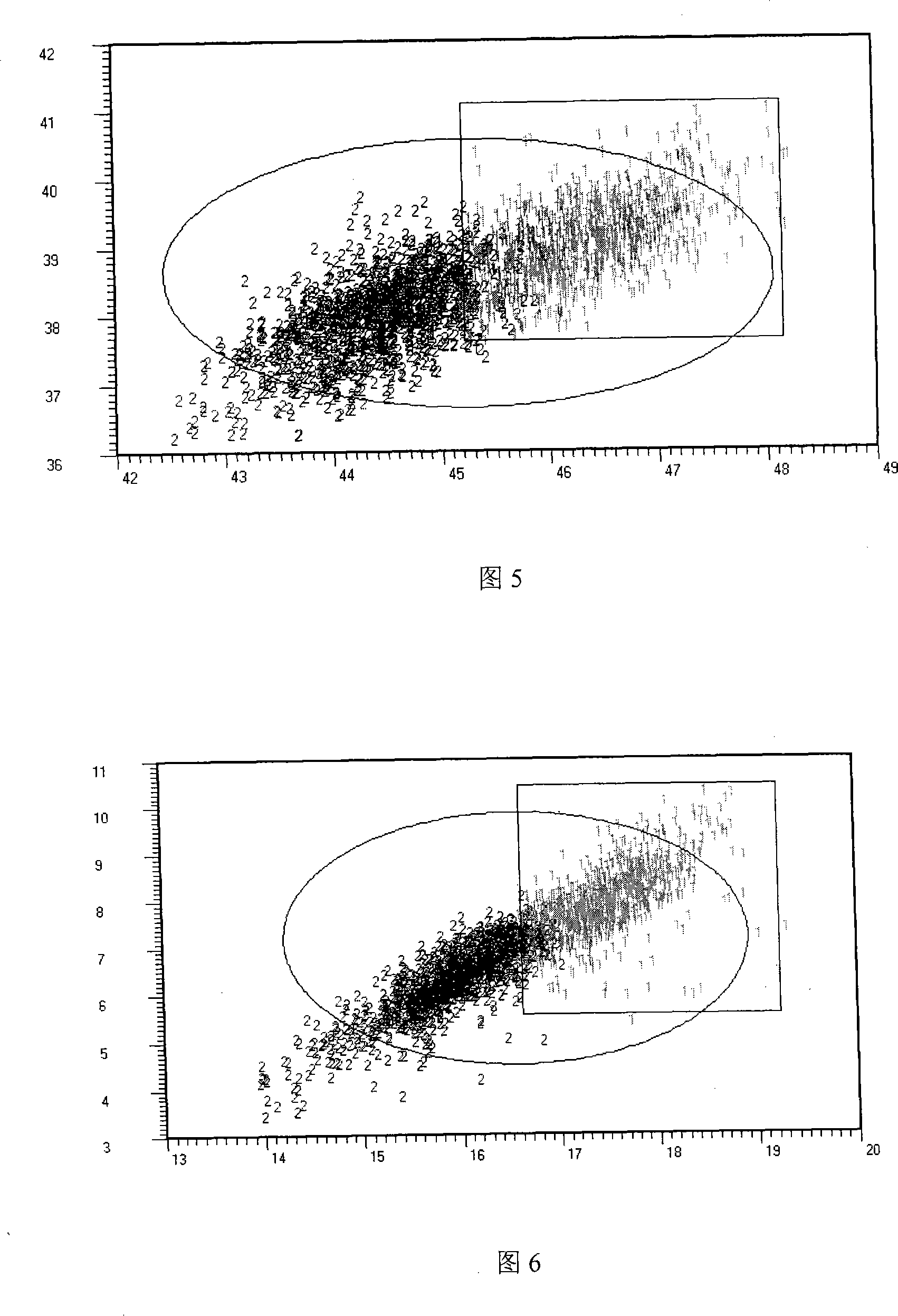

A production method optimization method of an ammonia synthesizer which is based on the data mining technology belongs to a research frontier of the cross discipline field of chemical engineering, system engineering, and data mining and the like. The invention combines production characteristics of ammonia synthesizers, in accordance to parameter data and analytical measurement data of history production technology of the ammonia synthesizers which are gathered by the distributed control system, namely DCS, production and optimization target of the ammonia synthesizers and mathematical models between the relative technological parameters are established by utilizing the data mining technology. And real time data which are produced by the ammonia synthesizers are input in the mathematical models which are established, and production status of the ammonia synthesizers are assured by the models, and models establishing and maintenance, working order diagnosing, target predicting, and optimum operation guide of ammonia synthesizers are achieved. And the ammonia synthesizers are operated under optimum state, and production capability and control level of the device are improved. The method has the advantages of safety and reliability, small risk, low cost, and easy pauperization.

Owner:宁波思华数据技术有限公司 +1

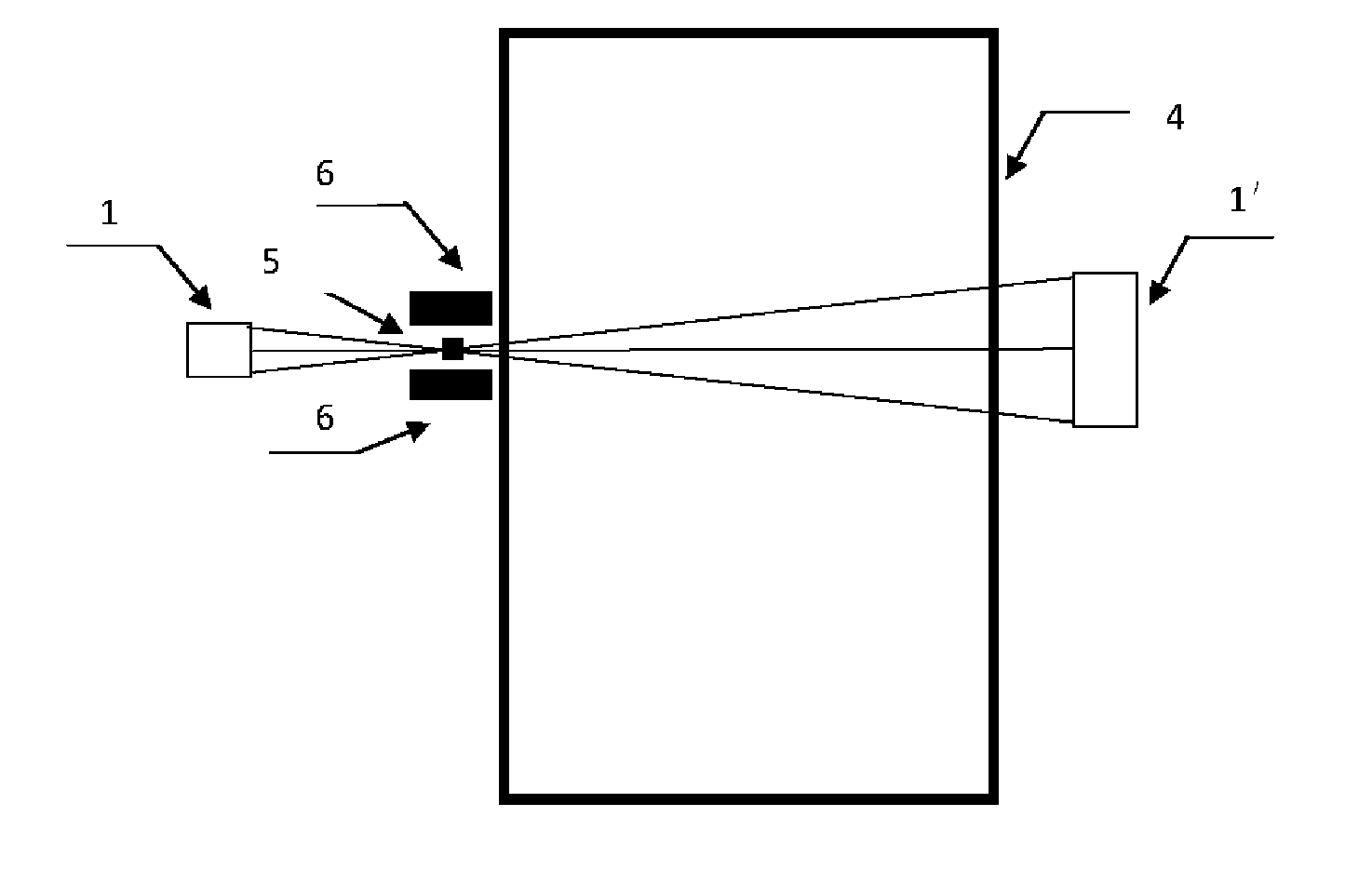

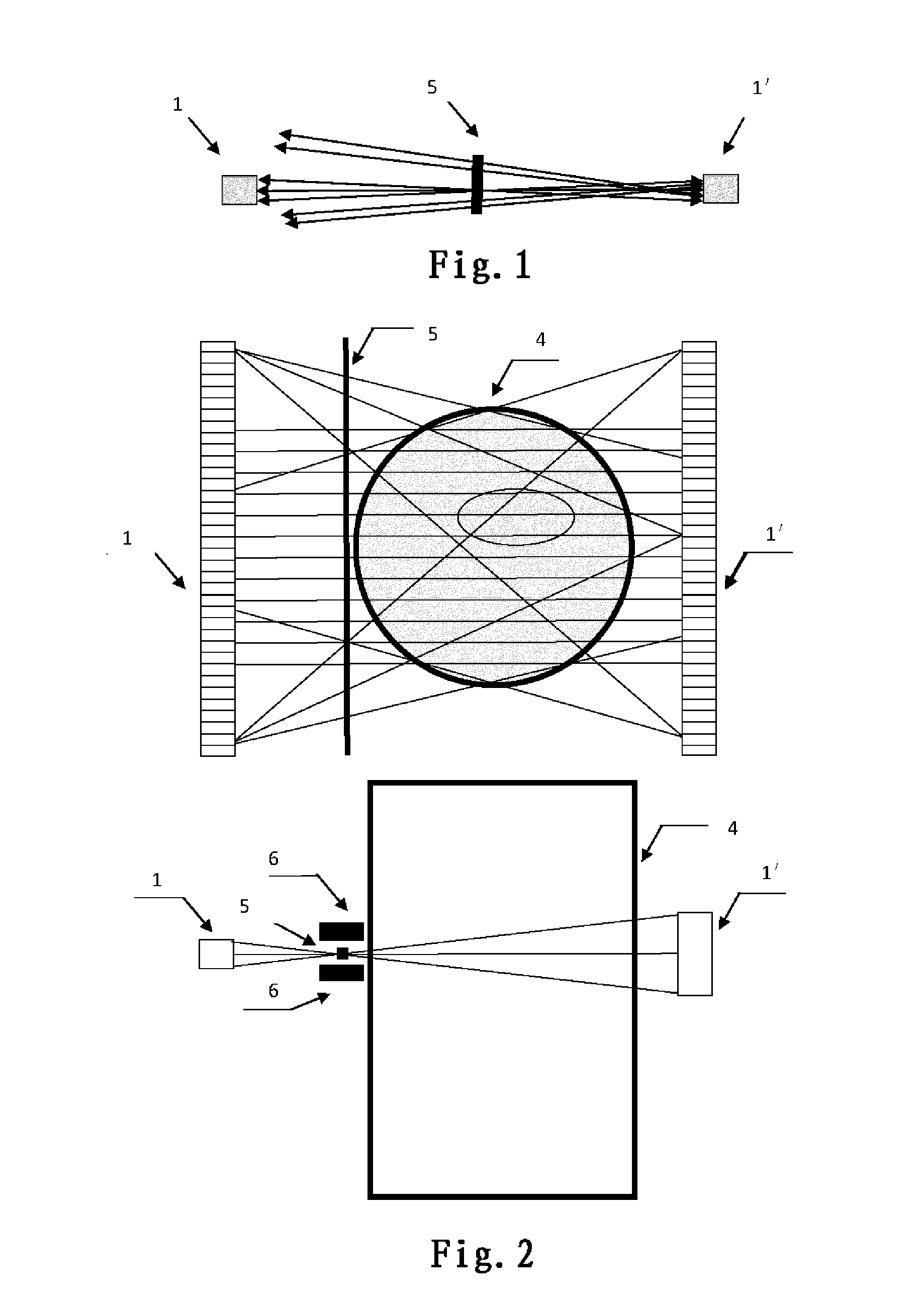

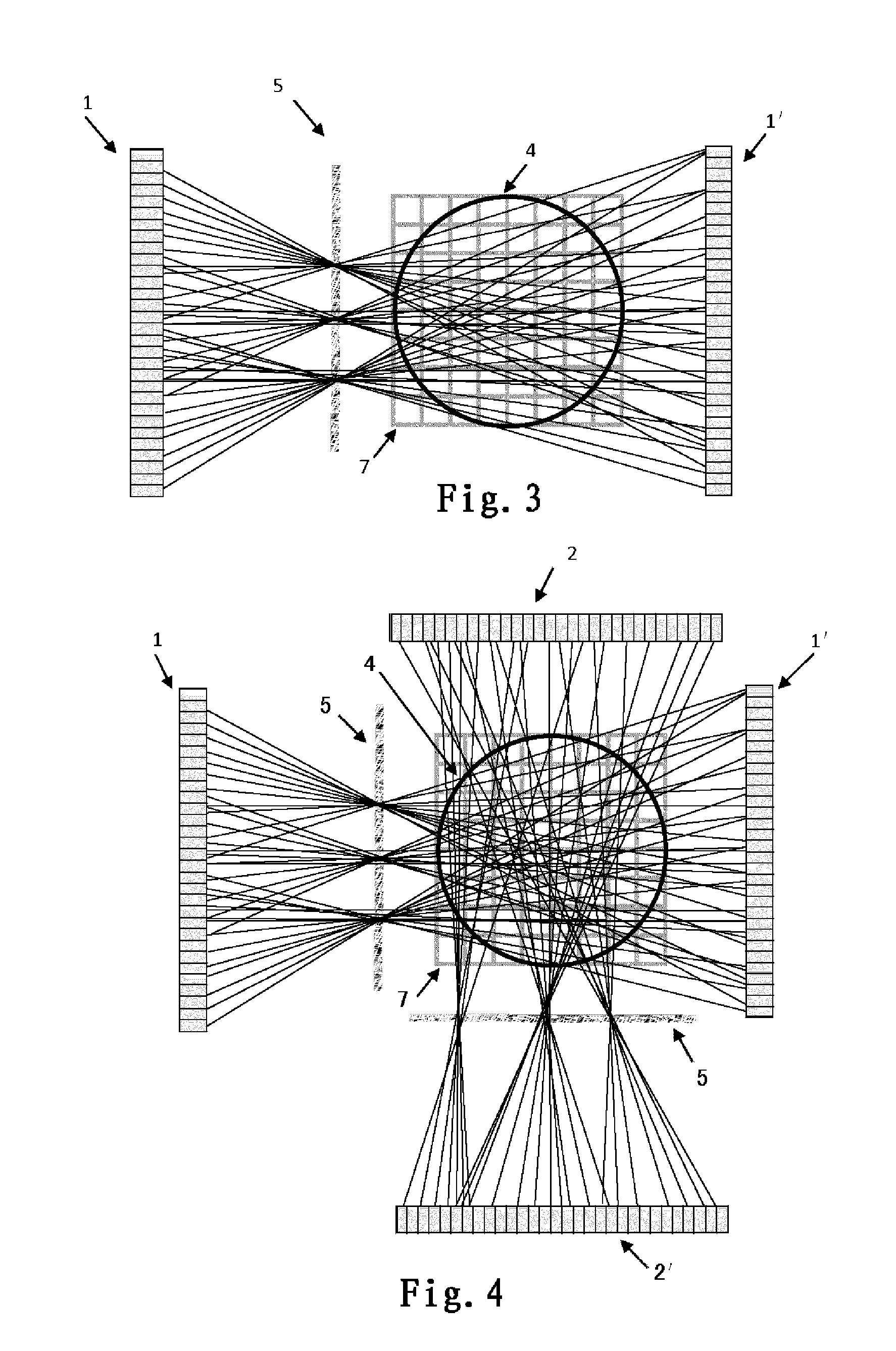

Positron tomography imaging apparatus and method for multiphase flow

ActiveUS20130313437A1High measurement accuracyReduced measurement accuracyMaterial analysis using wave/particle radiationSolid-state devicesProduction optimizationDetector array

The present invention relates to a positron tomography imaging apparatus for a multiphase flow in an oil pipeline, which apparatus utilizes positron and electron annihilation generating a pair of coincidence gamma-rays of 511 keV energy as tomography imaging means and provides an on-line tomography imaging function for metering a multiphase flow in an oil pipeline of an oil field. The apparatus comprises a plurality of sets of parallel high-precision gamma-ray detector arrays with a particular space structure arrangement, a positron radioactive source and a shield, and can acquire a phase fraction of such multiphase flow mixture as oil, gas and water under a condition of a single radioactive source by combining an image processing function. The design of a plurality of sets of high-precision detector arrays also greatly improves accuracy of a multiphase flow metering and its applicability in multiphase flows of different flow patterns. The video information of fluid generated by it will significantly enrich oil, gas metering information for petroleum industry and provide basic data for a more effective reservoir management and production optimization.

Owner:LANZHOU HAIMO TECH CO LTD +1

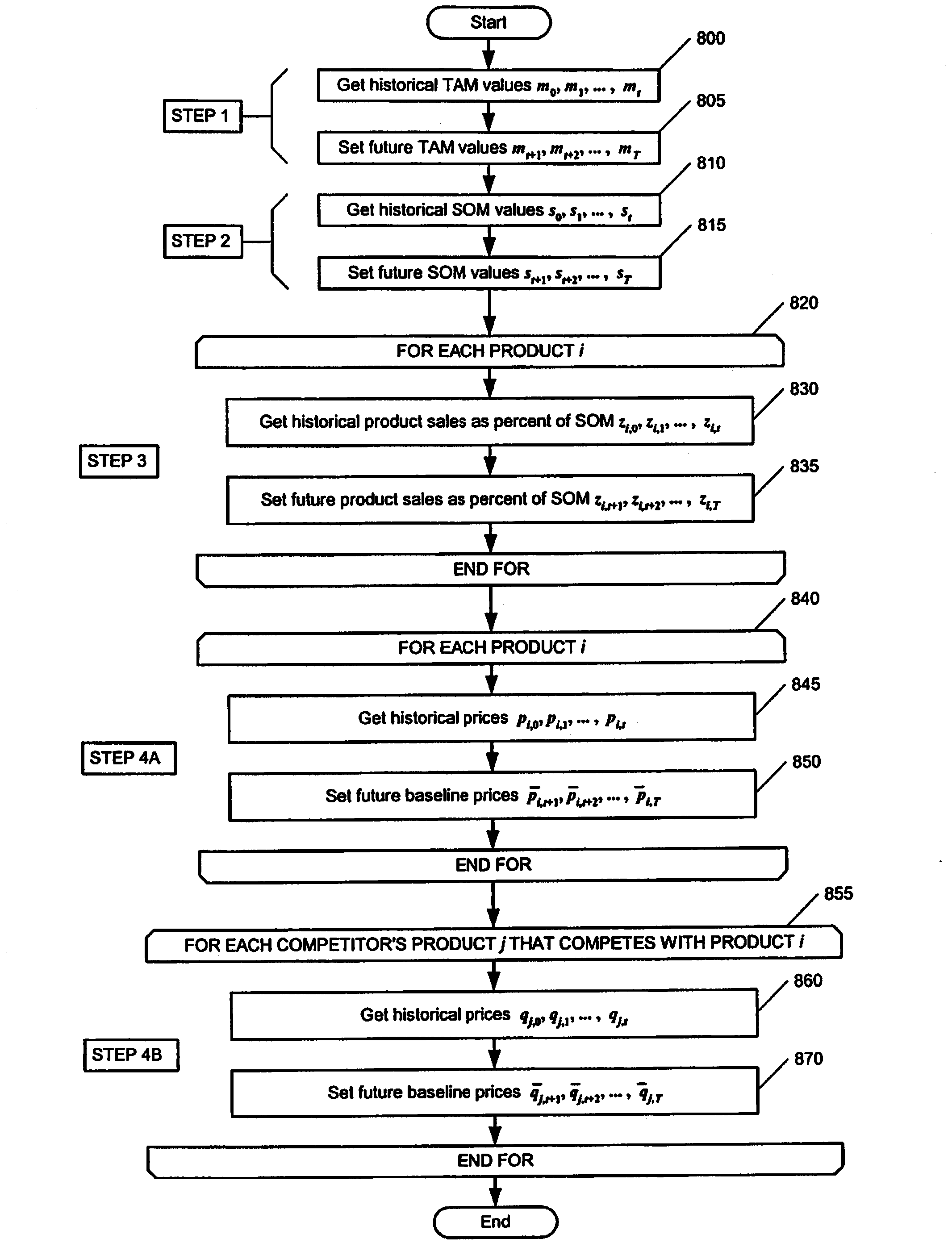

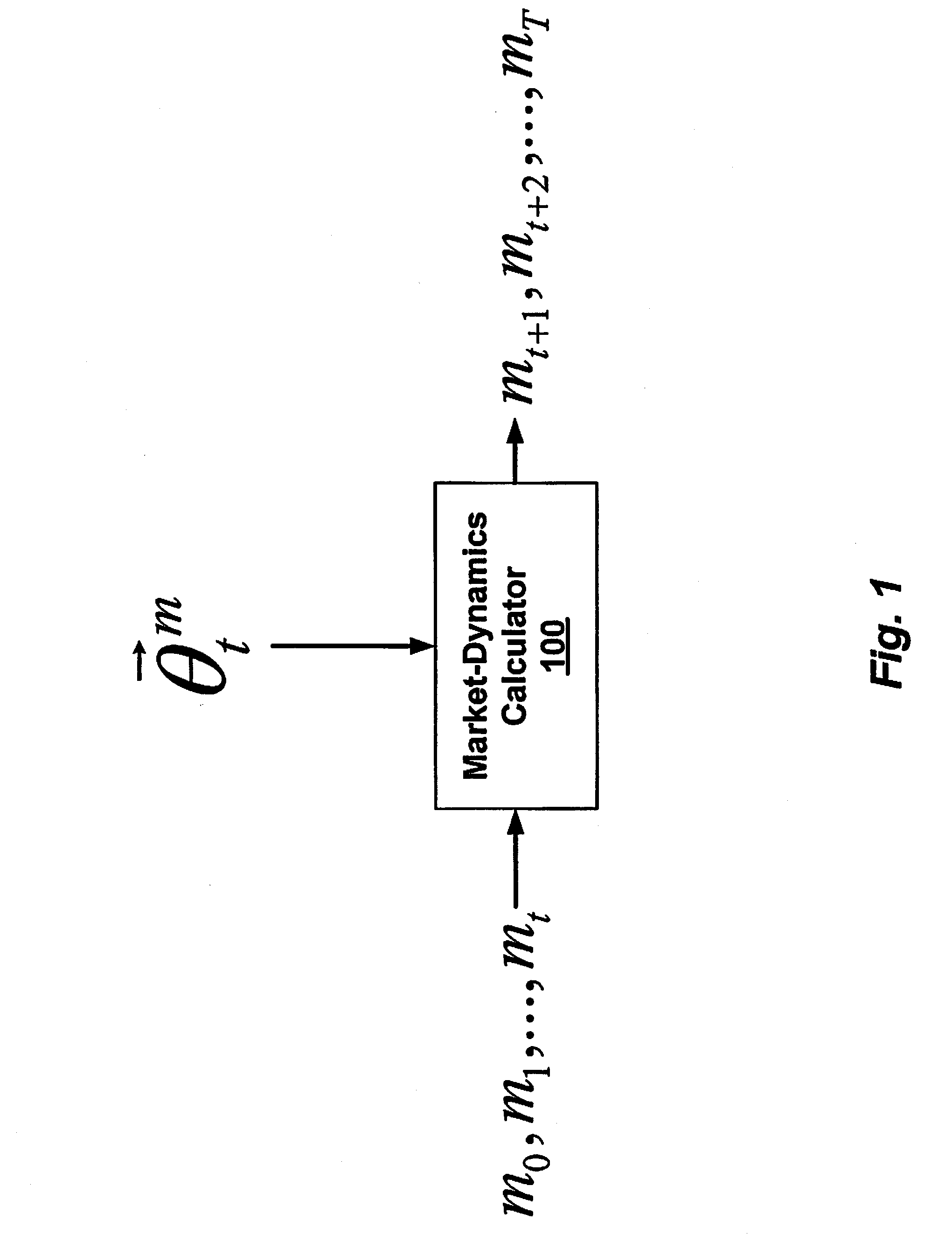

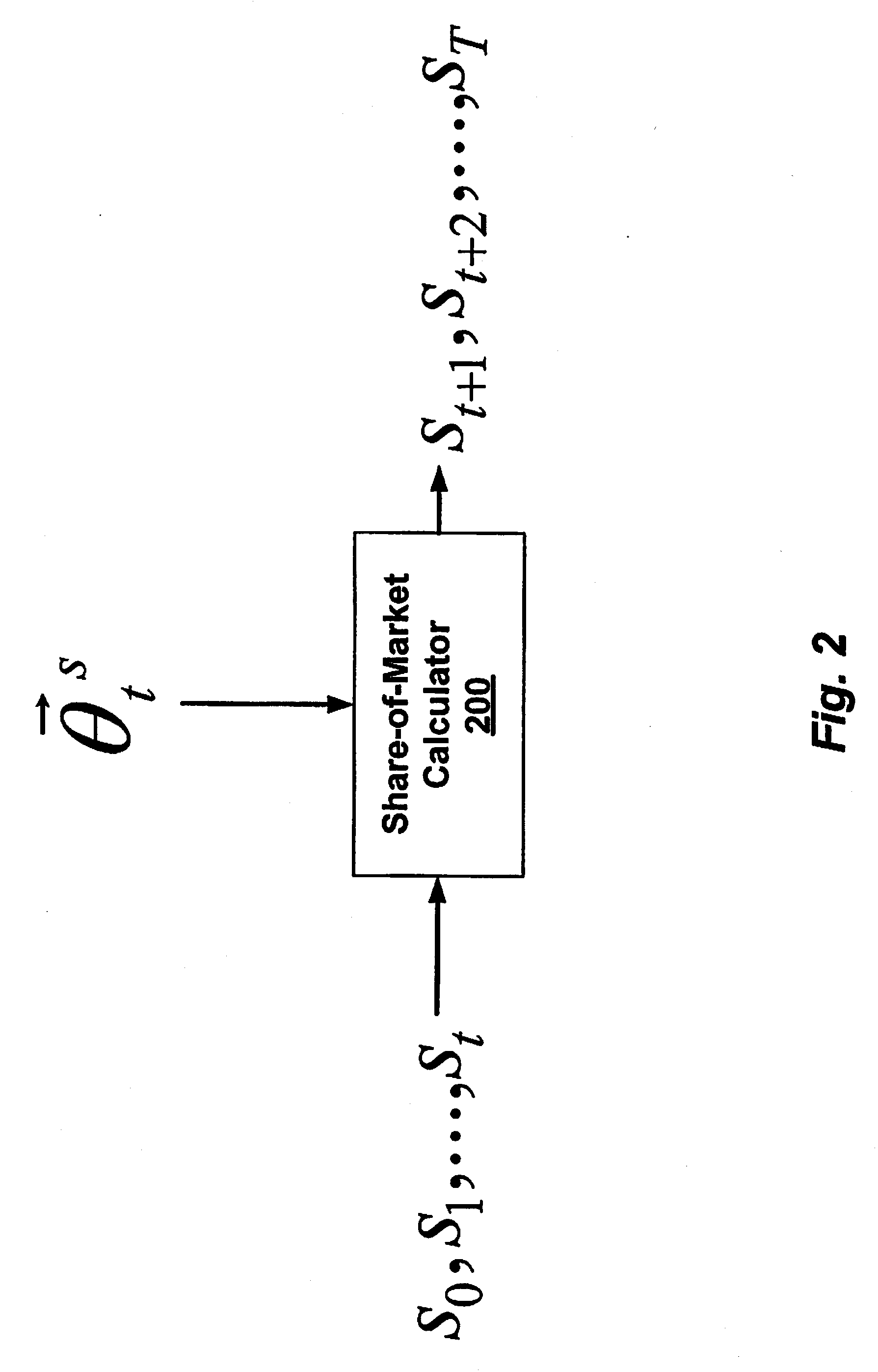

Method and system for producing optimized prices for products for sale

InactiveUS20090210355A1Electric/magnetic computingMarketingProduction optimizationEnvironmental geology

Owner:MICROSOFT TECH LICENSING LLC

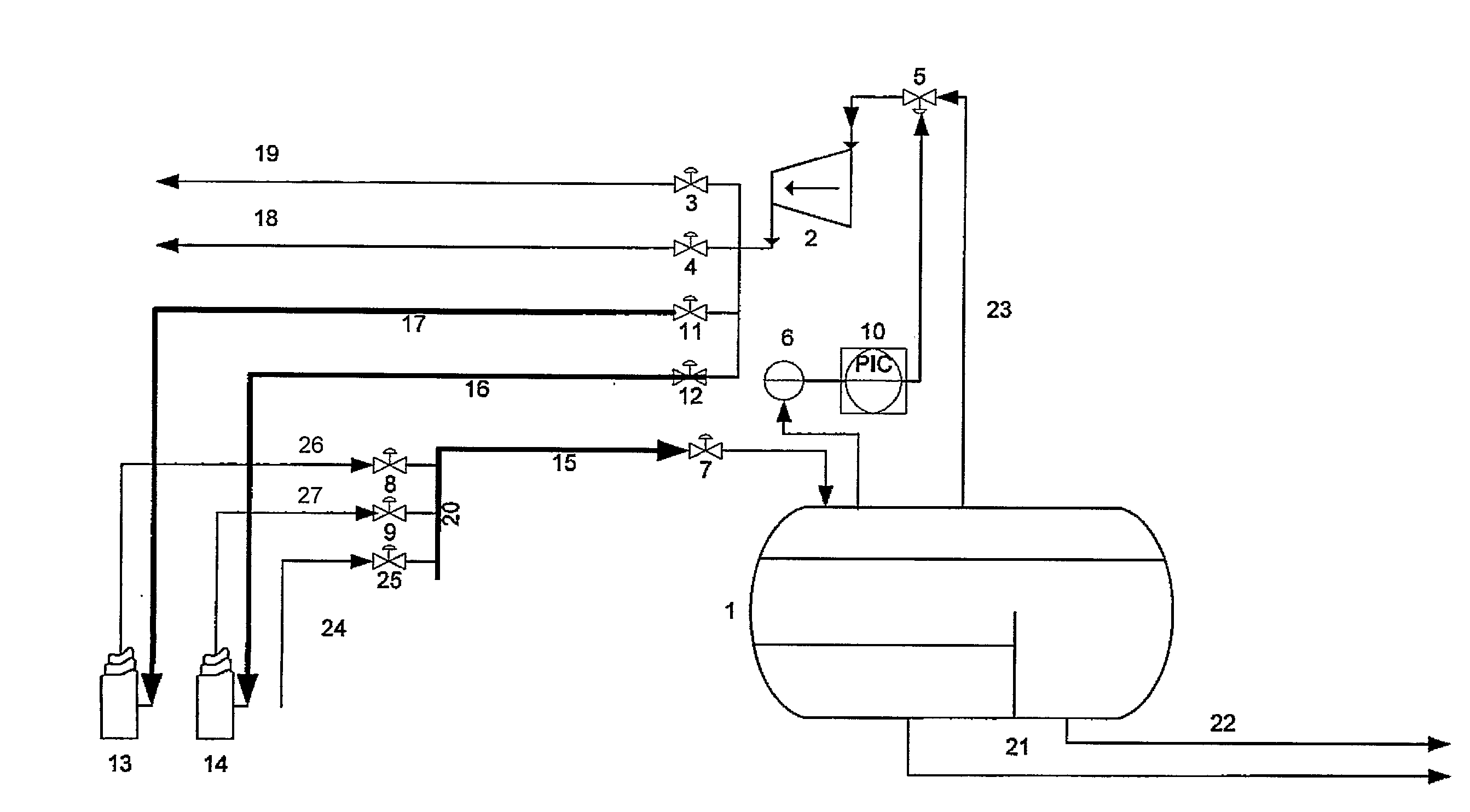

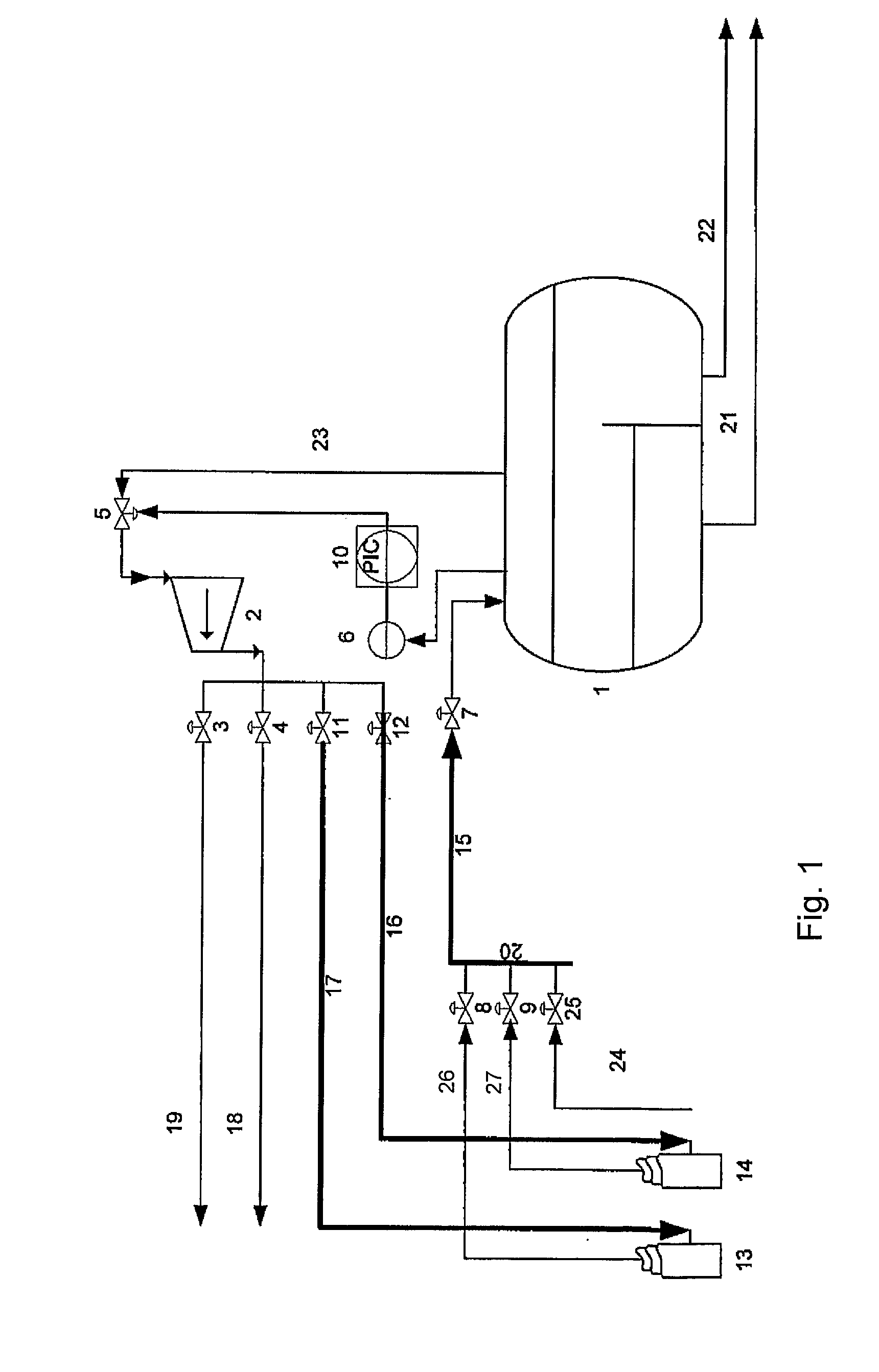

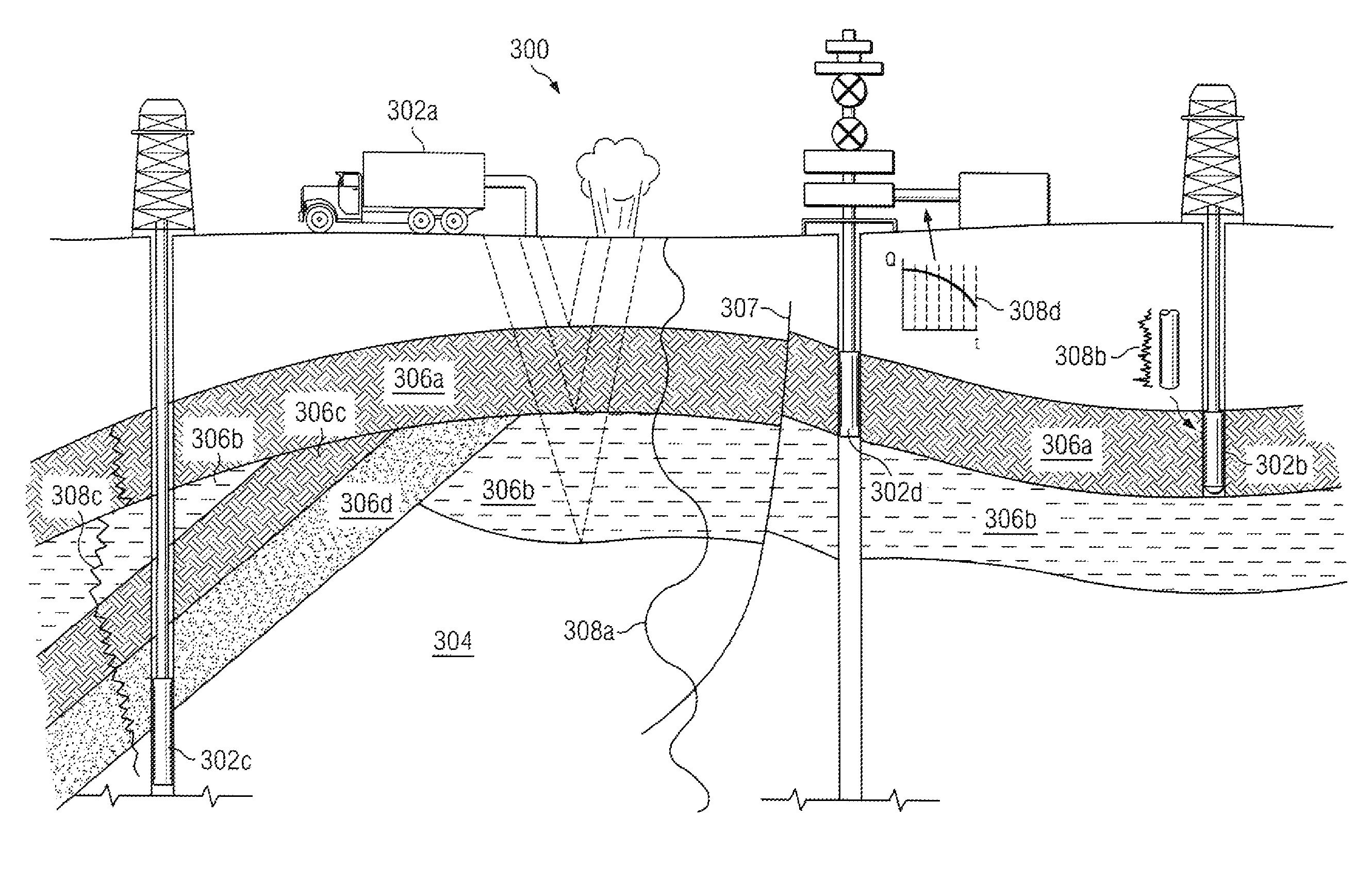

Method for production optimization in an oil and/or gas production system

InactiveUS20100036537A1Increase ratingsIncrease profitabilityControlling ratio of multiple fluid flowsFlow control using electric meansProduction optimizationLine tubing

A method for production optimization in an oil and / or a gas production system. The system including at least two flow sources leading to at least one common downstream flow line, and at least one manipulated variable of the production system. The method includes use of a computational model of the production system including an interdependence between flow rates of the flow sources and a flow rate of the downstream flow line, and values of the manipulated variable; a feasible set defined by at least one constraint of the manipulated variable, and an objective function, to be optimized within said feasible set, defined by using the computational model. The method includes splitting by calculation the feasible set into at least two subsets, calculating, for each of the subsets, a best bound of the objective function by using the computational model, and manipulating the manipulated variable by using the best bound to optimize the oil and / or gas production.

Owner:ABB AS

Statistical determination of historical oilfield data

InactiveUS7894991B2Electric/magnetic detection for well-loggingSurveyProduction optimizationOil processing

A method, system, and computer program product for performing oilfield surveillance operations. The oilfield has a subterranean formation with geological structures and reservoirs therein. The oilfield is divided into a plurality of patterns, with each pattern comprising a plurality of wells. Historical production / injection data is obtained for the plurality of wells. Two independent statistical treatments are performed to achieve a common objective of production optimization. In the first process, wells and / or patterns are characterized based on Heterogeneity Index results and personalities with the ultimate goal of field production optimization. In the second process, the history of the flood is divided into even time increments. At least two domains for each of the plurality of wells are determined. Each of the at least two domains are centered around each of the plurality wells. A first domain of the at least two domains has a first orientation. A second domain of the at least two domains has a second orientation. An Oil Processing Ratio is determined for each of the at least two domains, then an Oil Processing Ratio Strength Indicator is calculated. At least one Meta Pattern within the field is then identified. An oilfield operation can then be guided based either on the well and / or pattern personality or the at least one Meta Pattern.

Owner:SCHLUMBERGER TECH CORP

Wheel tractor scraper production optimization

ActiveUS20090043460A1Improve productivityAnalogue computers for trafficComputer controlWheel tractor-scraperProduction optimization

A method for enhancing productivity for an excavating machine is disclosed. The method includes determining at least one cycle characteristic for an operating cycle of the excavating machine. The method also includes measuring payload accumulated by the machine during a loading phase of an operating cycle of the excavating machine. The method further includes controlling payload accumulated by the machine based on at least one of the at least one determined cycle characteristics.

Owner:CATERPILLAR INC

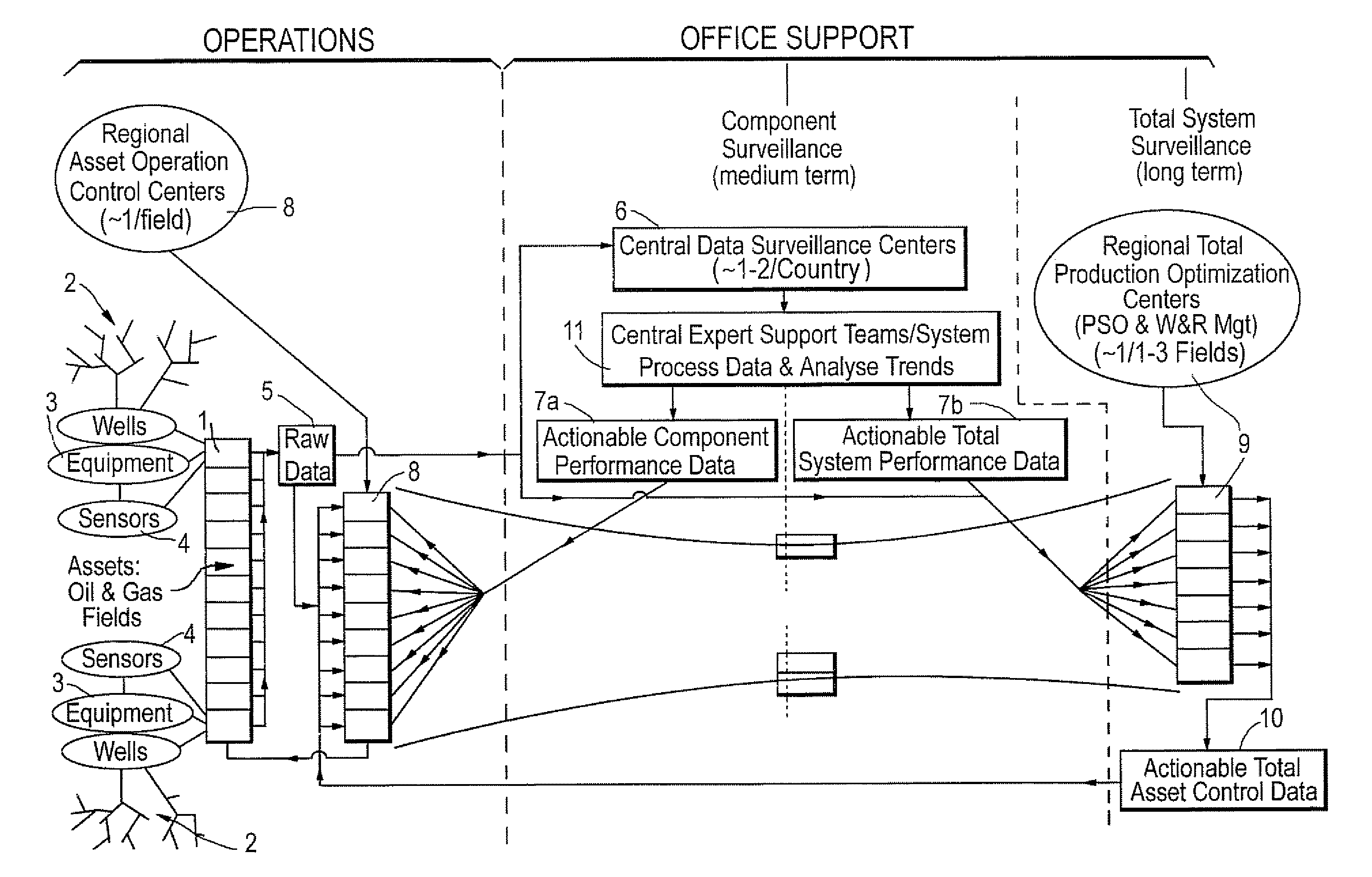

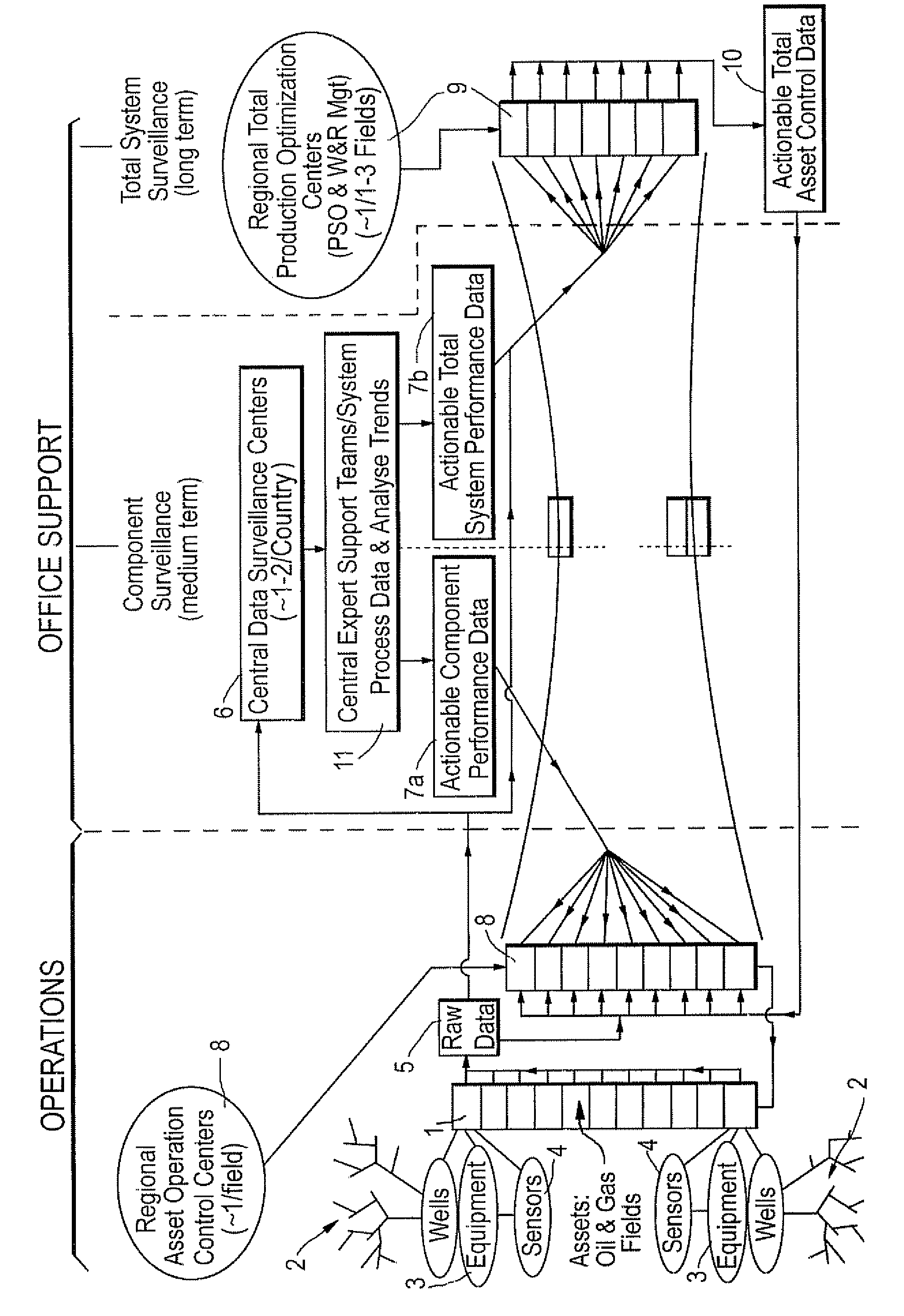

Method for controlling and/or optimizing production of oil and/or gas wells and facilities

A method for controlling and optimizing production operations oil and / or gas production wells and facilities, which are equipped with sensors that generate raw reservoir, production and / or production equipment performance data comprises:collecting raw data in at least a central data center;processing, trends in the collected raw data to produce component data and system performance data;transferring the component data to a regional asset operation control center;transferring the system performance data to a regional total production optimization center, in which the system performance data and trends in the data are interpreted, analysed and converted into actionable total asset control data that are subsequently transferred to at least one regional control center; andoptimizing or controlling production of the operations by action taken in the regional asset operation control center on the basis of the component data and the actionable total asset control data.

Owner:SHELL USA INC

Well production optimizing system

InactiveUS20060144597A1Eliminating fluid flow through the passageFluid removalSealing/packingProduction optimizationControl system

A well optimizing system and method for lifting fluid that accumulates and retards production in a well. The system includes a plunger having a piston and a detachable plugh. The piston has a sealing section and a retrieval end and defines a passage through the length thereof. One or more pads are radially extendable from the sealing section. The detachable plug is positional in the retrieval end in a position to substantially block the flow of fluid through the passage from below the plunger. The system may further include a production control system.

Owner:CASEY DAN

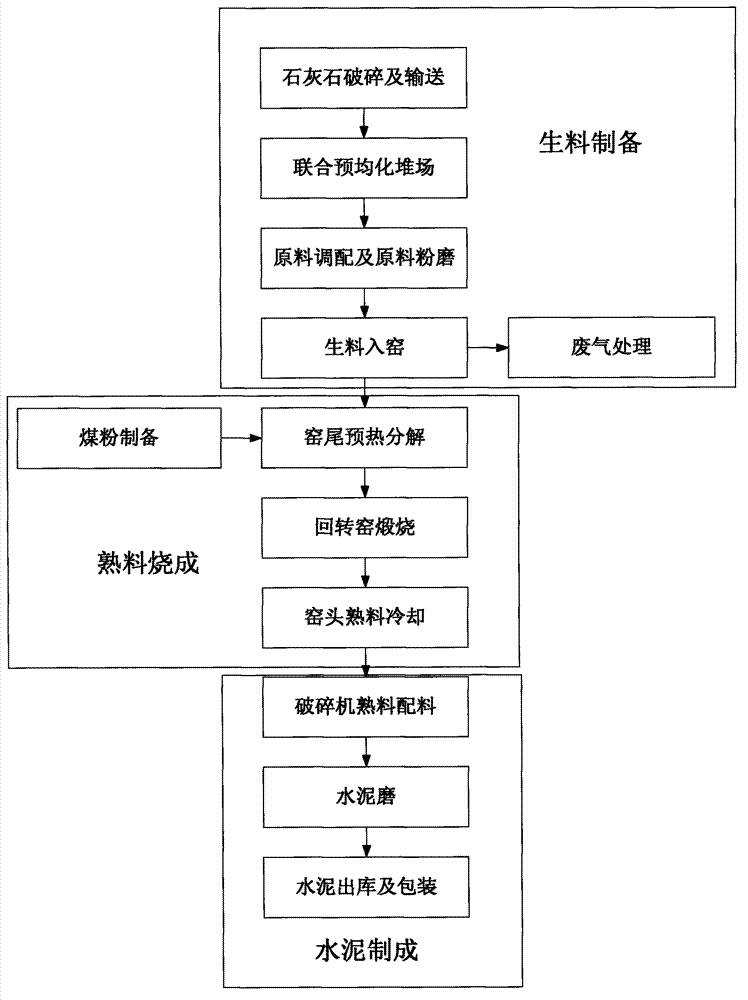

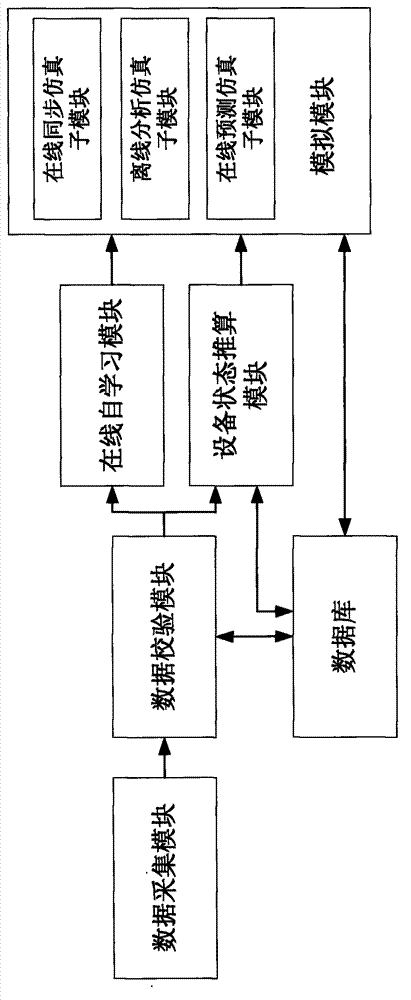

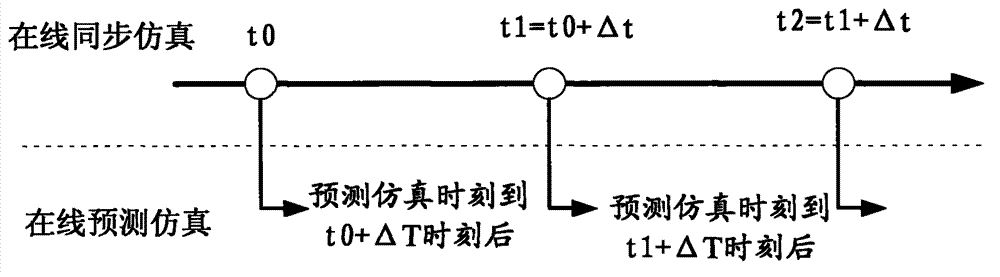

Cement on-line simulation system and implementation method thereof

ActiveCN103034130AImprove the level of safe operationImprove analytical performanceSimulator controlProduction optimizationMathematical model

The invention discloses a cement on-line simulation system and an implementation method thereof. The cement on-line simulation system comprises a data acquisition module, a data check module, a database, an equipment status calculation module, an on-line self-learning module and a simulation module. The data acquisition module collects the current operating parameters of each production equipment during cement production in real time, the data check module checks the current operating parameters according to the range of operating parameters set in the database, the equipment status calculation module determines the current operating status of each equipment, the on-line self-learning module corrects the coefficients of each mathematical model of cement production, and the simulation module performs synchronous simulation calculation of cement production. The system can perform simulation calculation, analysis and early warning of the current status in real time to provide on-line and intelligent additional information for safe and economical operation of cement plants. The data can be applied to production optimization and management optimization to provide a basis for timely and scientific decision on management and production in cement plants.

Owner:武安市新峰水泥有限责任公司

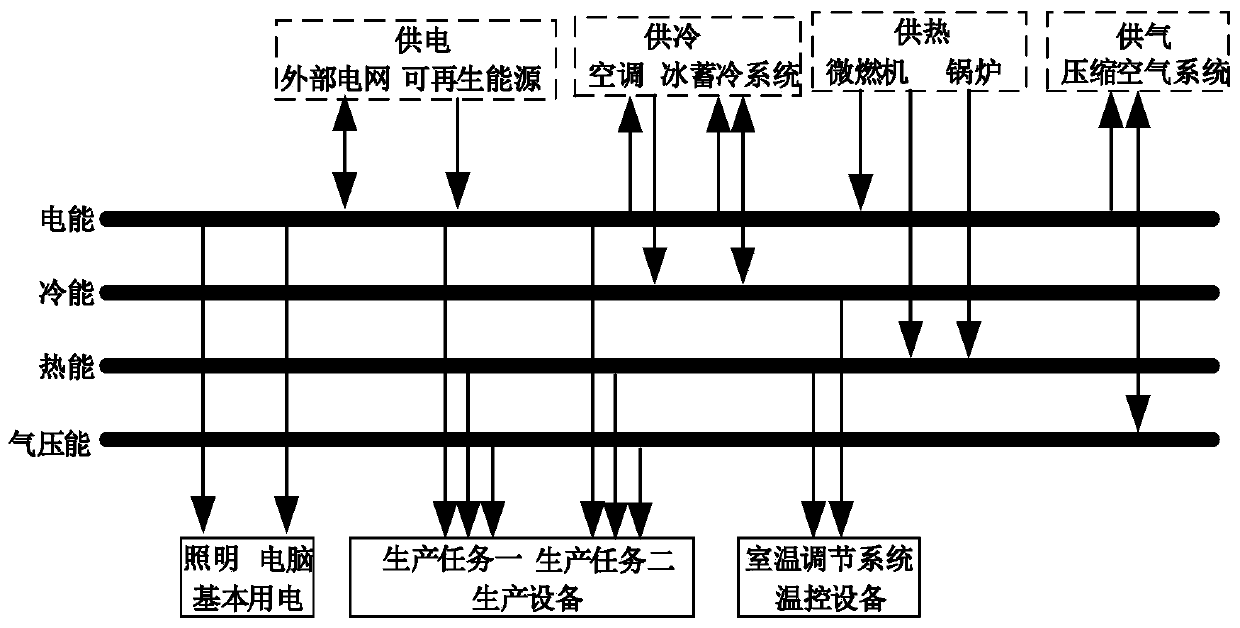

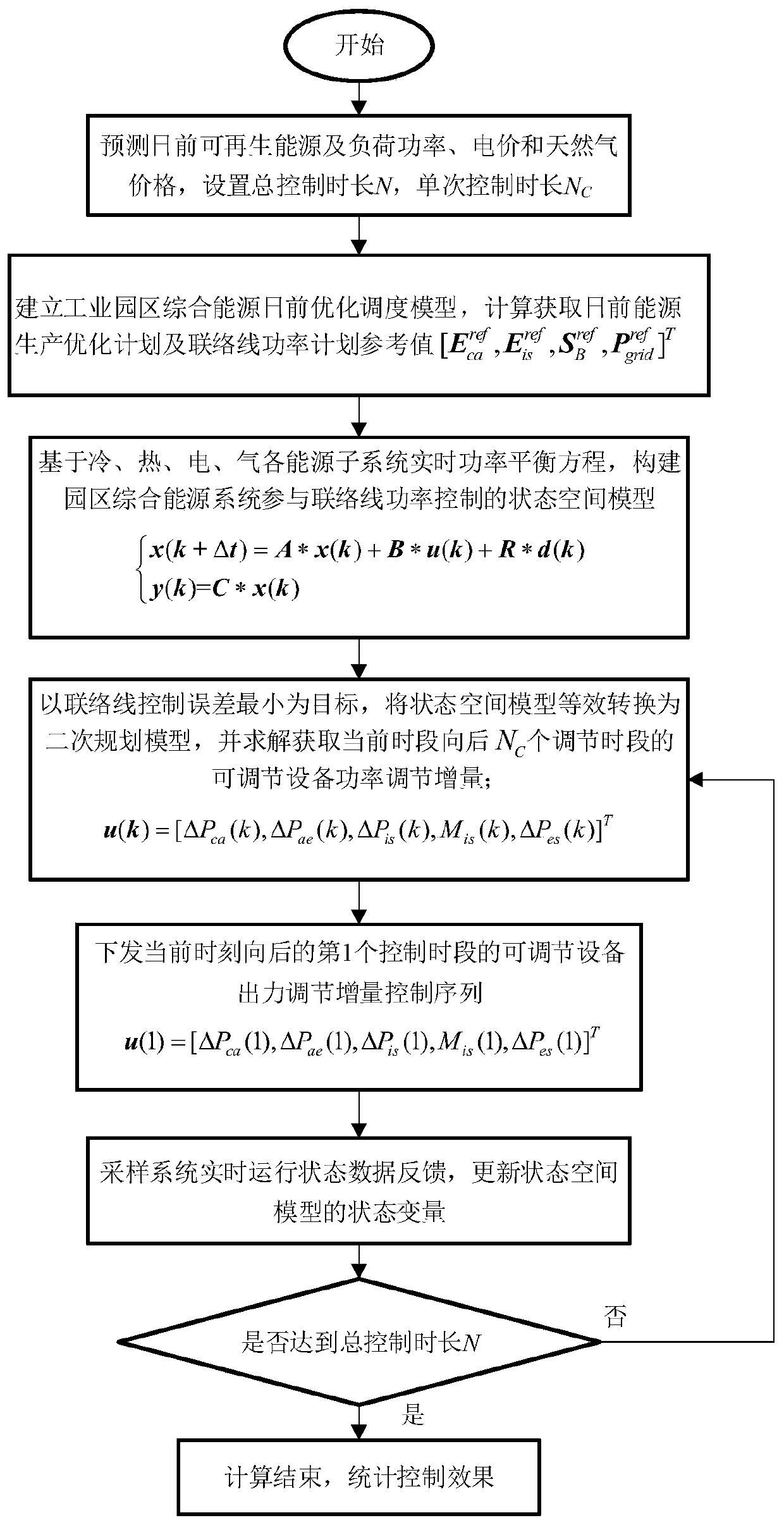

Comprehensive energy system tie line power control method

ActiveCN110400059AAvoid powerImprove robustnessEnergy industrySingle network parallel feeding arrangementsProduction optimizationIntegrated energy system

The invention provides a comprehensive energy system tie line power control method, which comprises the following steps of: (1) establishing a comprehensive energy optimization scheduling model for dynamically coupling energy supply and production, and calculating to obtain a day-ahead energy production optimization plan and a tie line power plan reference value; (2) based on the real-time power balance equation of each energy subsystem in the comprehensive energy system, constructing a state space model of the comprehensive energy system participating in tie line power control; (3) equivalently converting the state space model of the tie line power control into a quadratic programming model, solving the model by adopting a sequential quadratic programming algorithm, and obtaining adjustable equipment power adjustment quantities of the current time period to the last T control time periods; and (4) issuing the power regulation quantity of the current time period to the first time period after the current time period, and sampling the real-time state of the comprehensive energy system for feedback correction. According to the invention, the tie line power of the integrated energy system is accurately controlled in a complex time-varying environment, and the tie line power of the integrated energy system is ensured to meet the examination of superior power grid departments.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com