SMT central intelligent optimal management and monitoring system

An intelligent optimization and monitoring system technology, applied in the direction of comprehensive factory control, data processing application, comprehensive factory control, etc., can solve the problems of scrapped PCB boards, high operation and maintenance requirements, and expensive placement machines, so as to improve product quality. , Improve the level of automation and overall efficiency, and improve the effect of equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

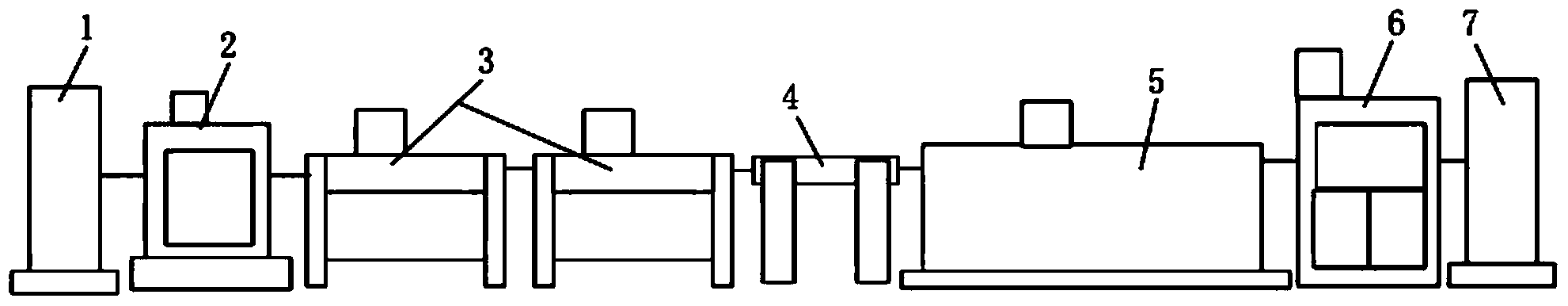

[0040] Such as figure 1 As shown, the main equipment of the SMT production line is shown, including a feeder 1, a screen printing machine 2, a placement machine 3, a conveyor belt 4, reflow soldering 5, a detector 6, and a feeder 7, wherein the feeder 1 And blanking device 7 is used for loading and unloading of PCB board; Described screen printing machine 2 is used for coating solder on PCB board; Described placement machine 3 is the key equipment of SMT production line, is used for mounting element device; the conveyor belt 4 is used to transfer the PCB board from one device to another device; the reflow soldering 5 is used to melt the solder paste into a tin point, so that the component pin and the PCB pad are connected; the detector 6 It is used to check whether the components have defects such as lack of soldering and missing soldering.

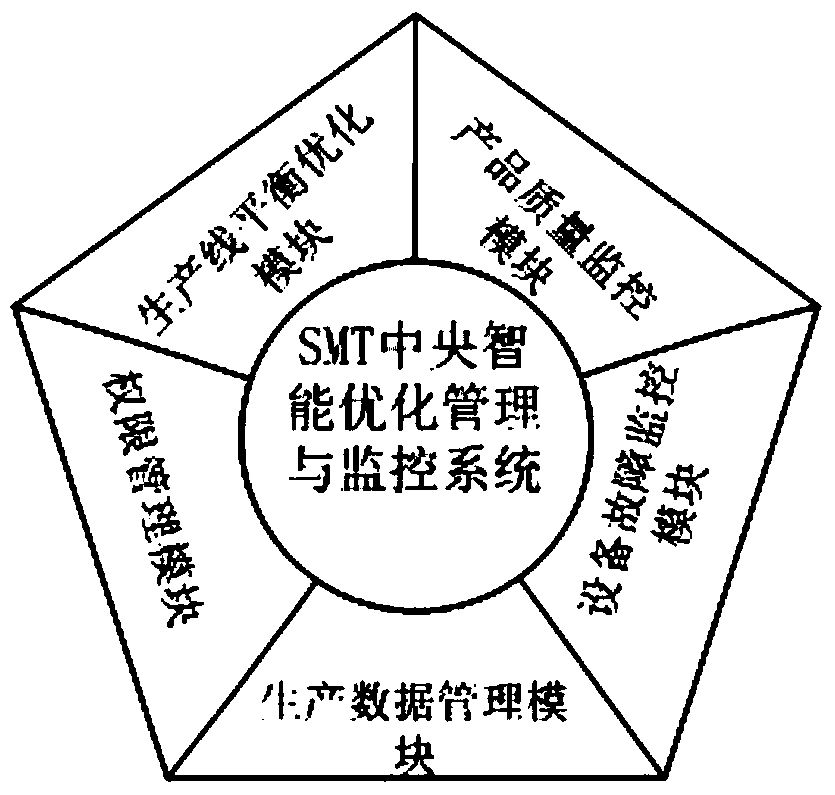

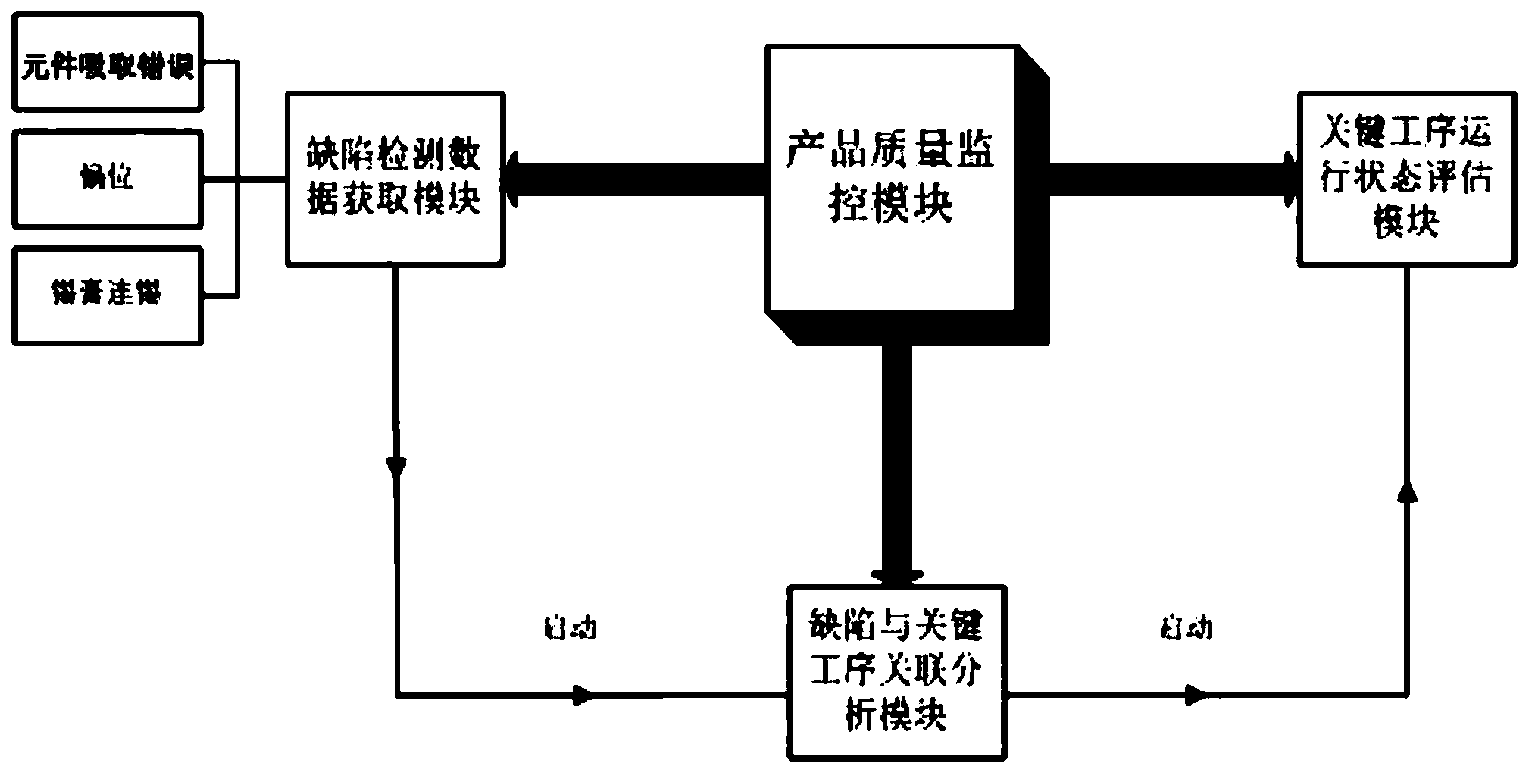

[0041] Such as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com