Method for optimizing chemical intermittent production operation and optimized production operation system

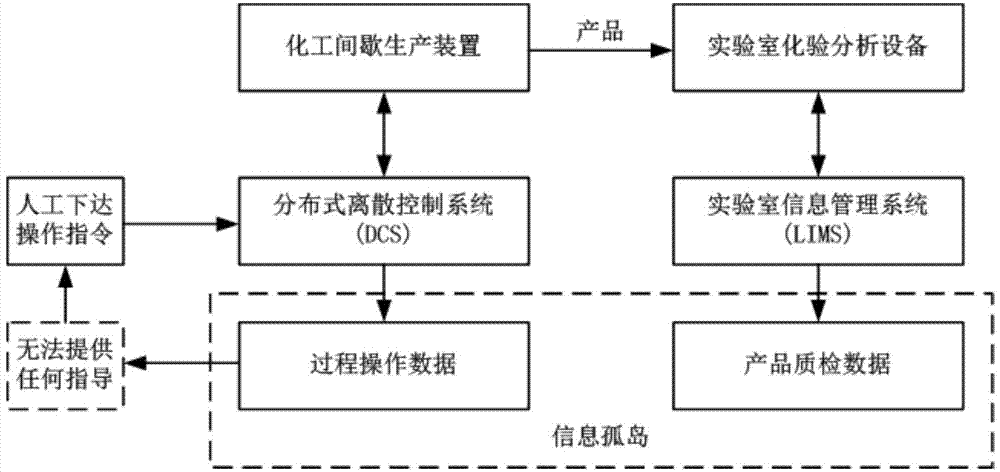

A chemical production and operating system technology, applied in the general control system, control/adjustment system, comprehensive factory control, etc., can solve the problem that product quality inspection data cannot be effectively combined to improve product quality in a timely manner, so as to reduce human intervention and avoid product failure. Quality issues, the effect of ensuring the level of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

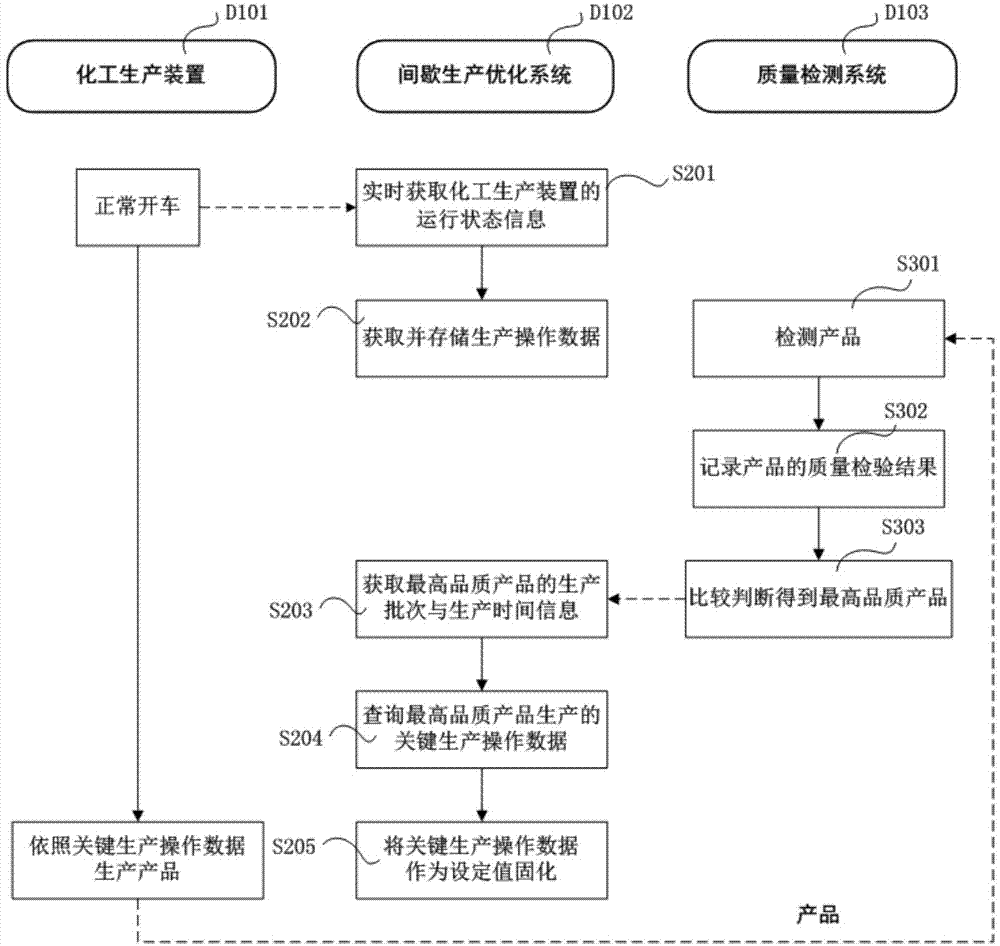

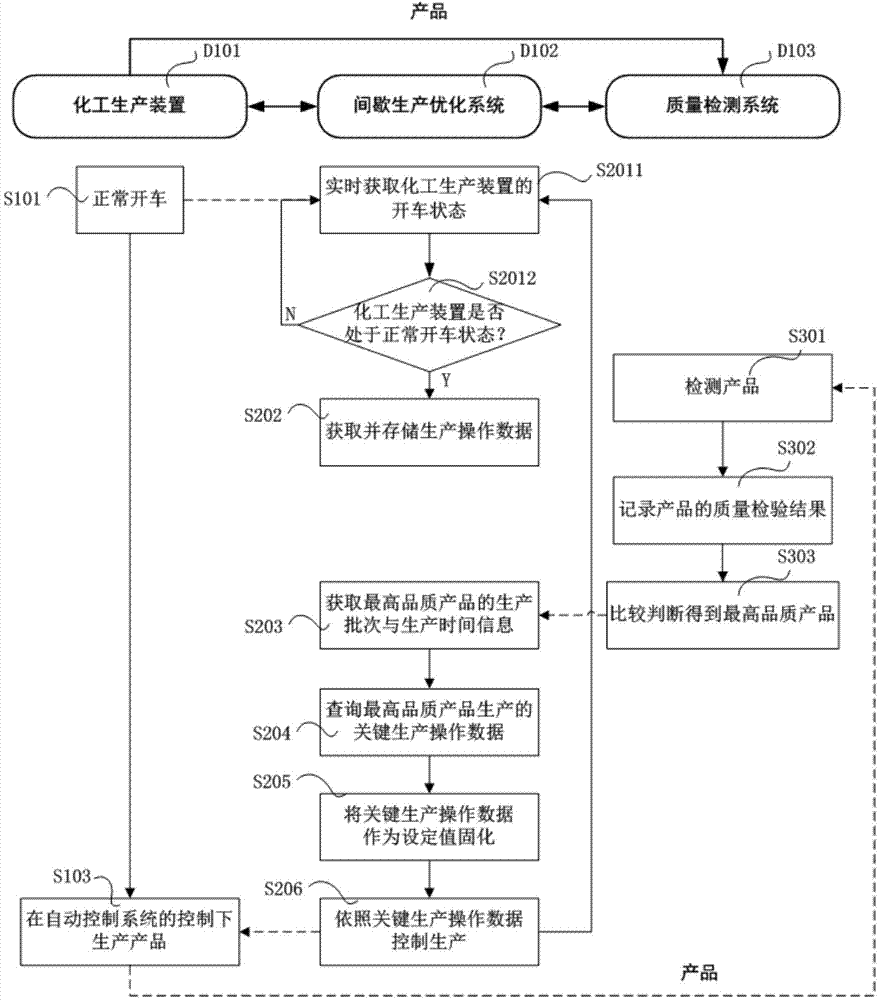

[0028] In order to achieve the technical purpose of the present invention, as a first aspect of the present invention, a method for optimizing chemical batch production operations is provided, see Figure 2 to Figure 5 shown. The method includes the following steps:

[0029] Step S201, the operation state detection step, obtains the operation state information of the chemical production device in real time;

[0030] Step S202, step S301 and step S302, the production and testing data acquisition step, acquiring and storing the production operation data of the chemical production device when producing the product; testing the produced product, and recording the quality inspection result of the product;

[0031] Step S303, the comparison and judgment step, according to the quality inspection results of the products,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com