Patents

Literature

1589results about How to "Avoid product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

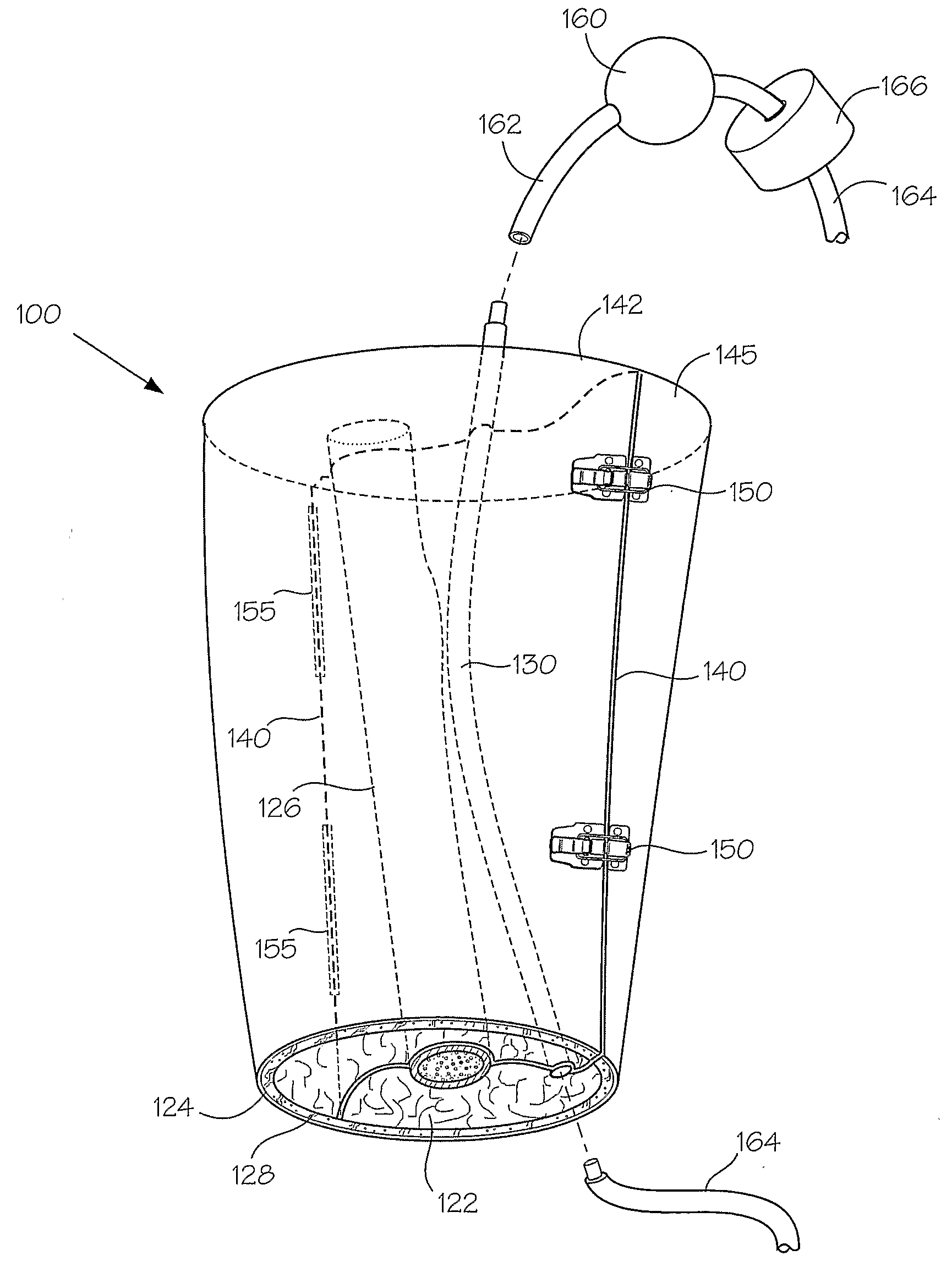

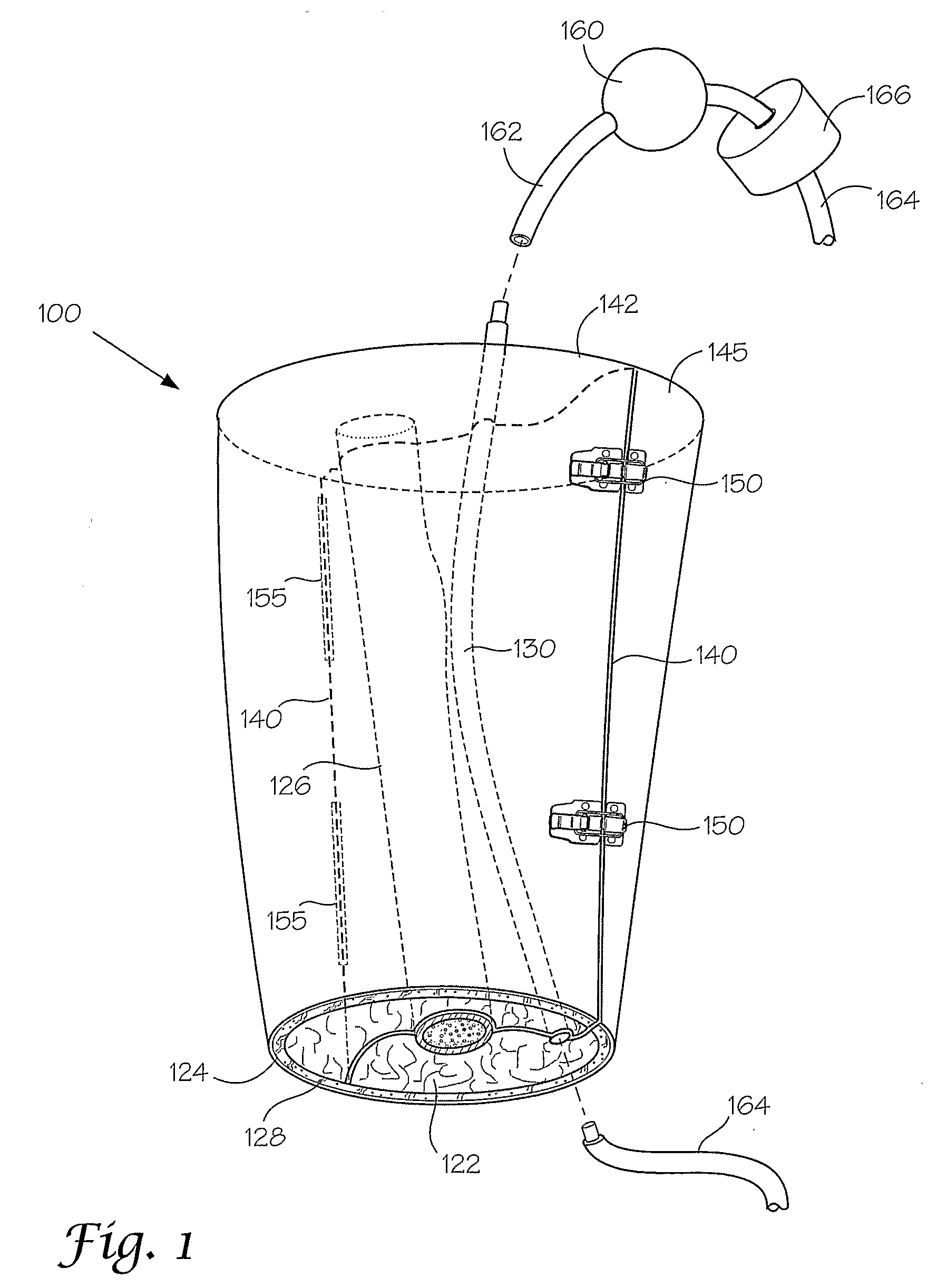

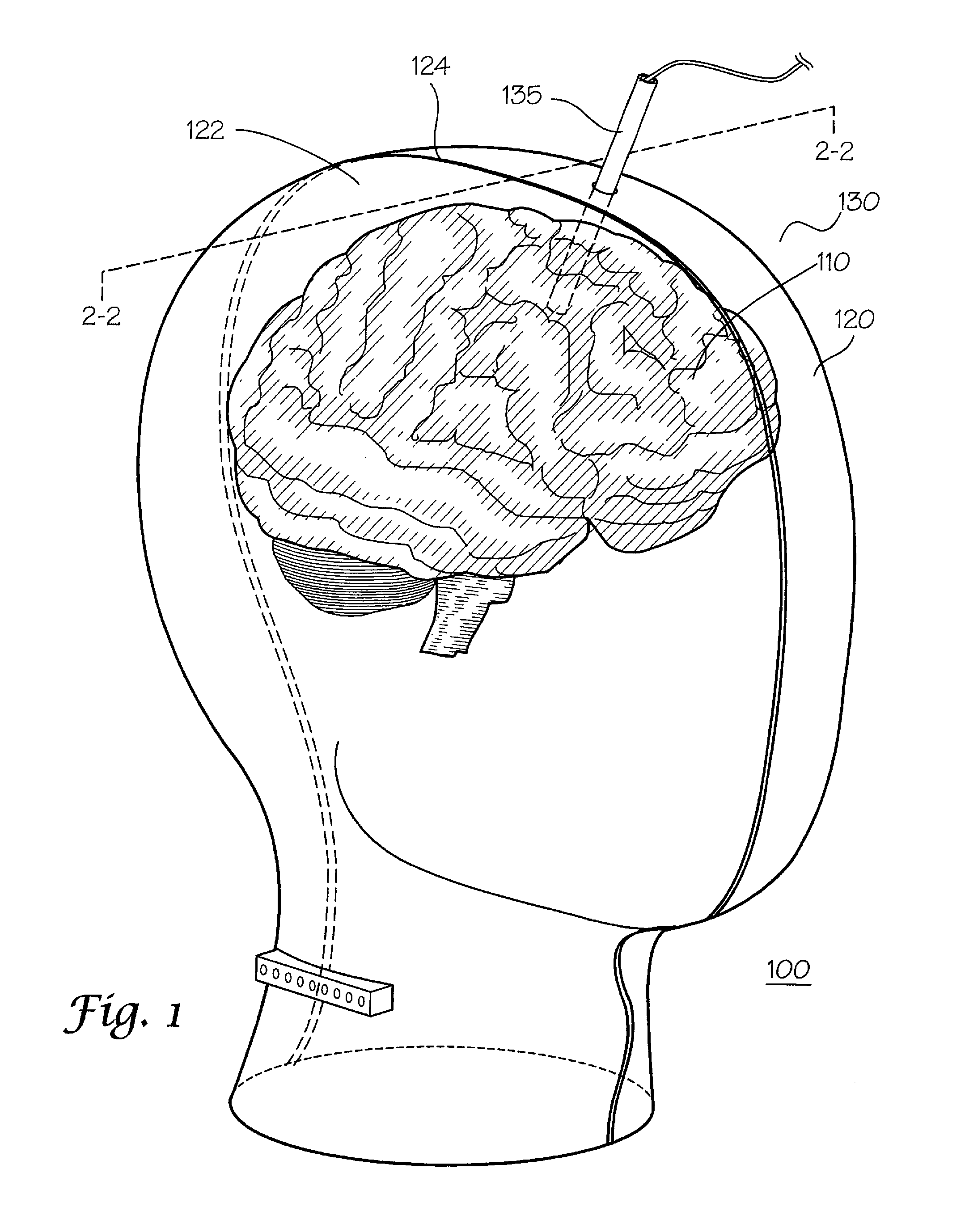

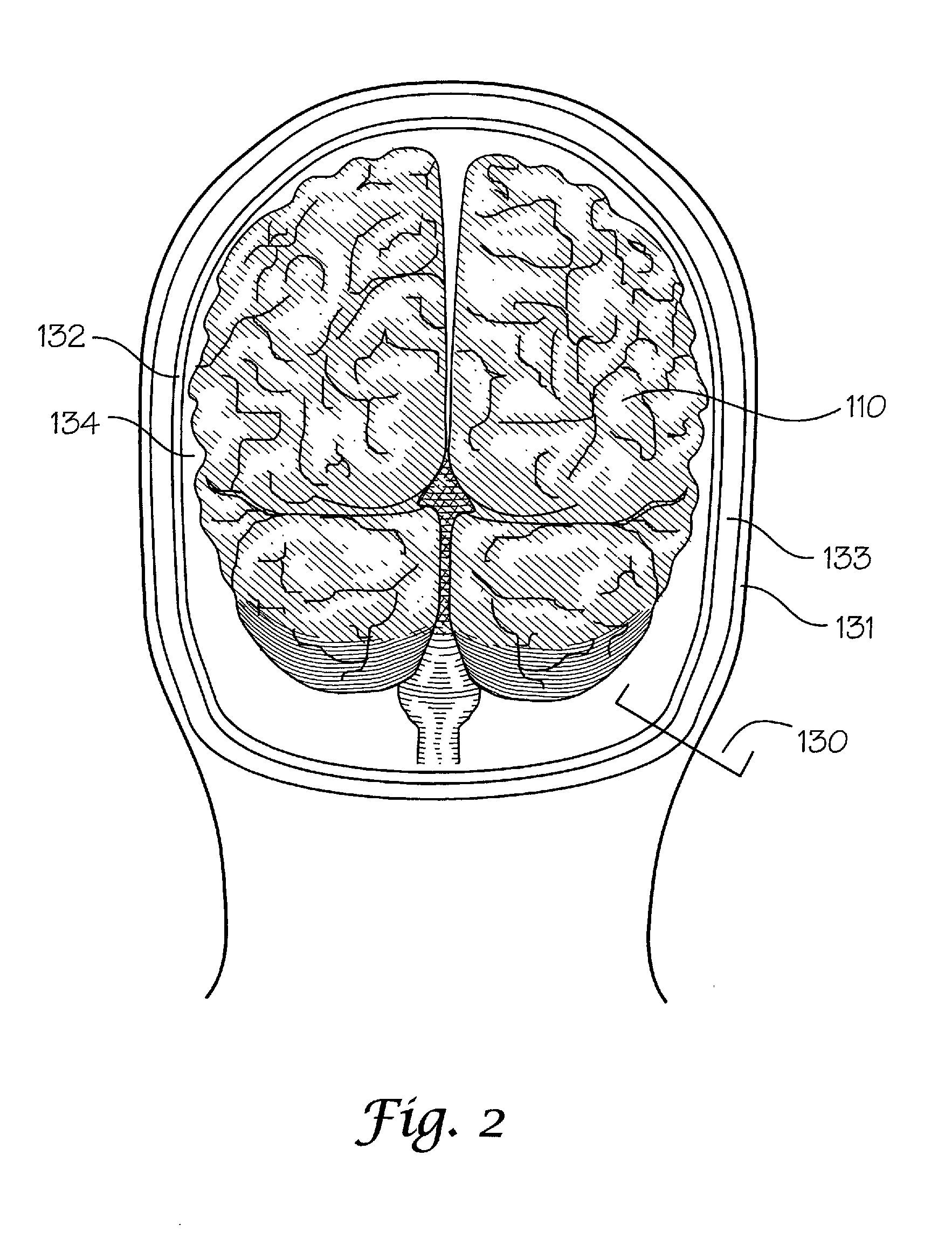

Models and methods of using same for testing medical devices

ActiveUS7993140B2Avoid product qualityLengthened product timelinesAdditive manufacturing apparatusEducational modelsTarget tissueMedical device

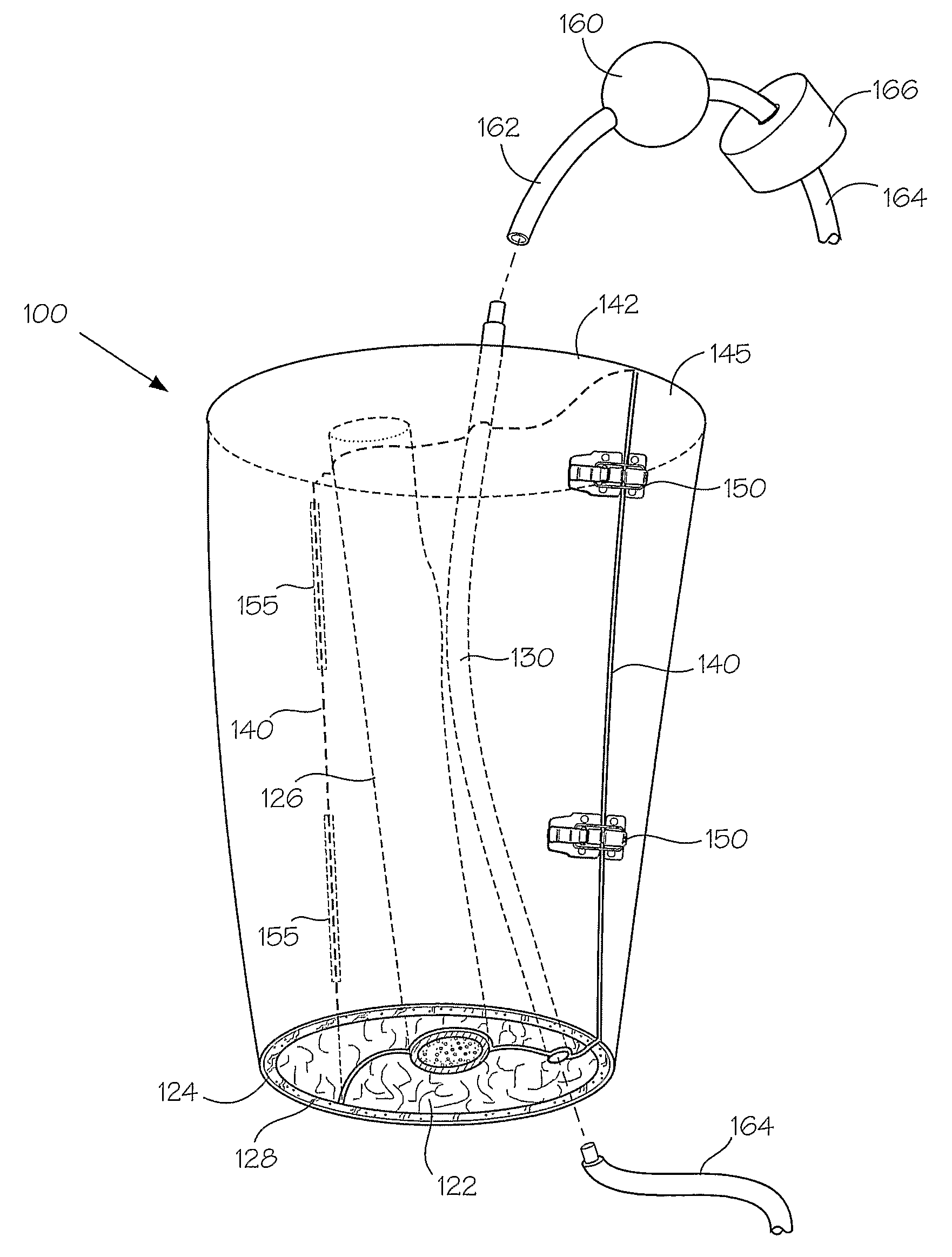

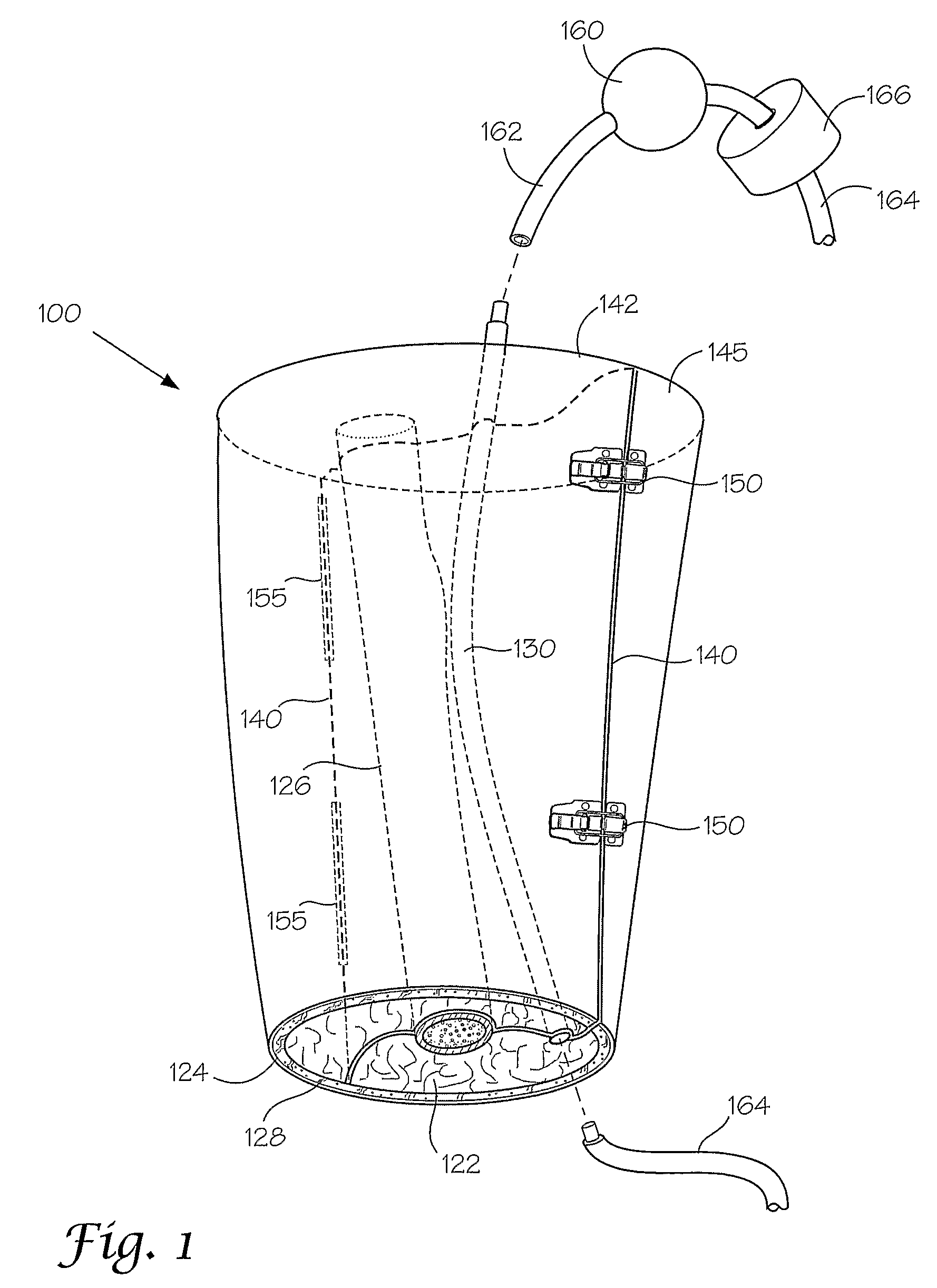

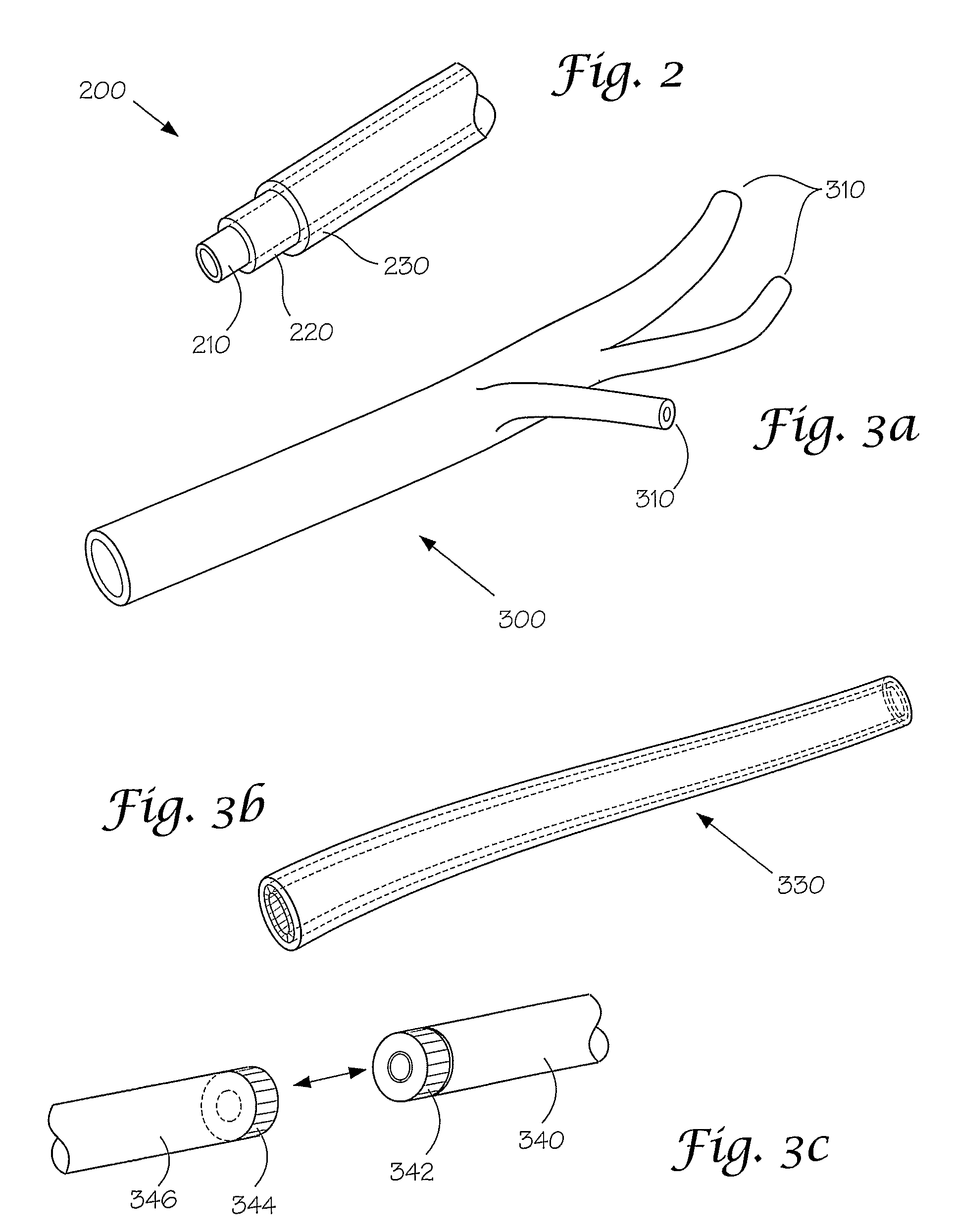

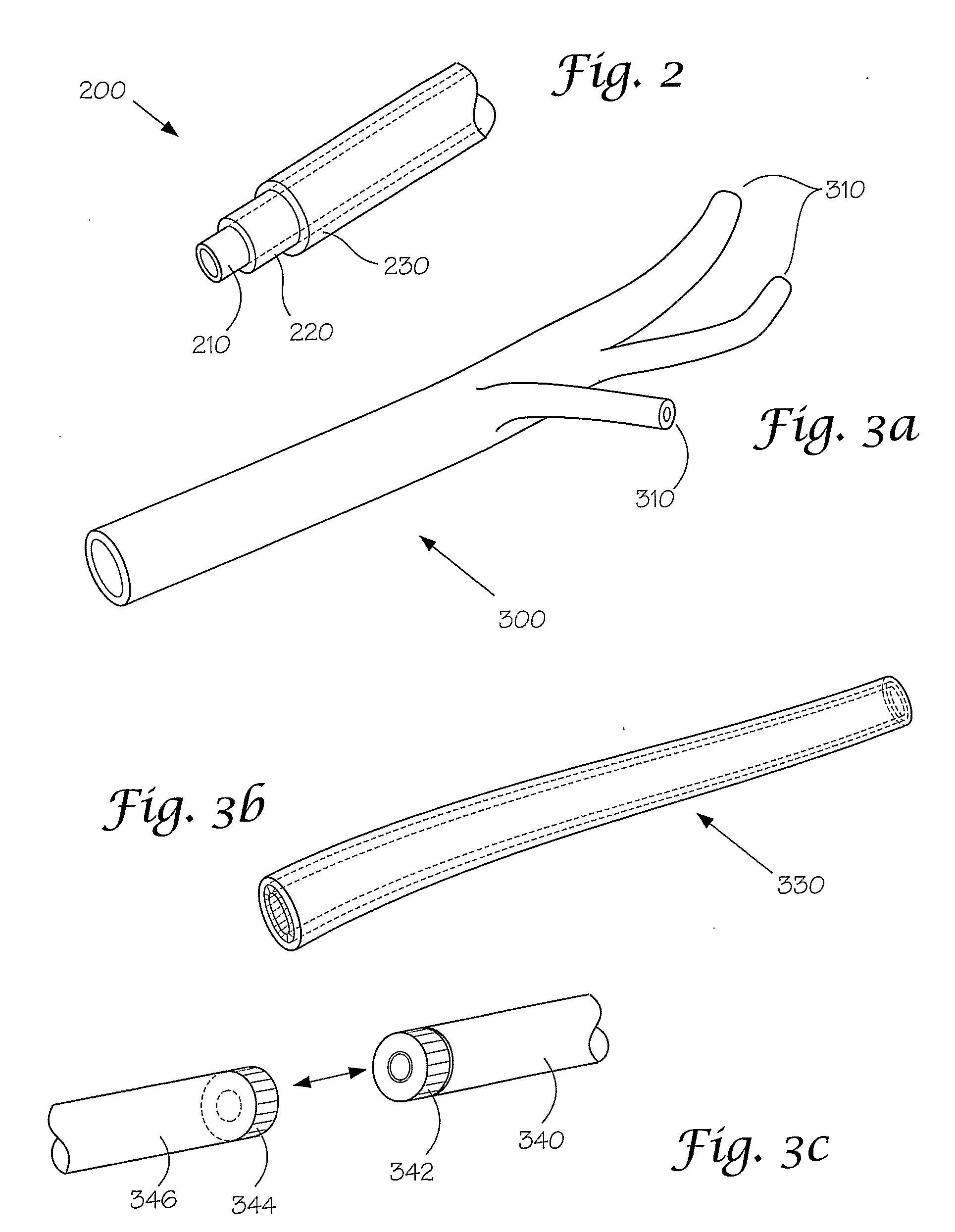

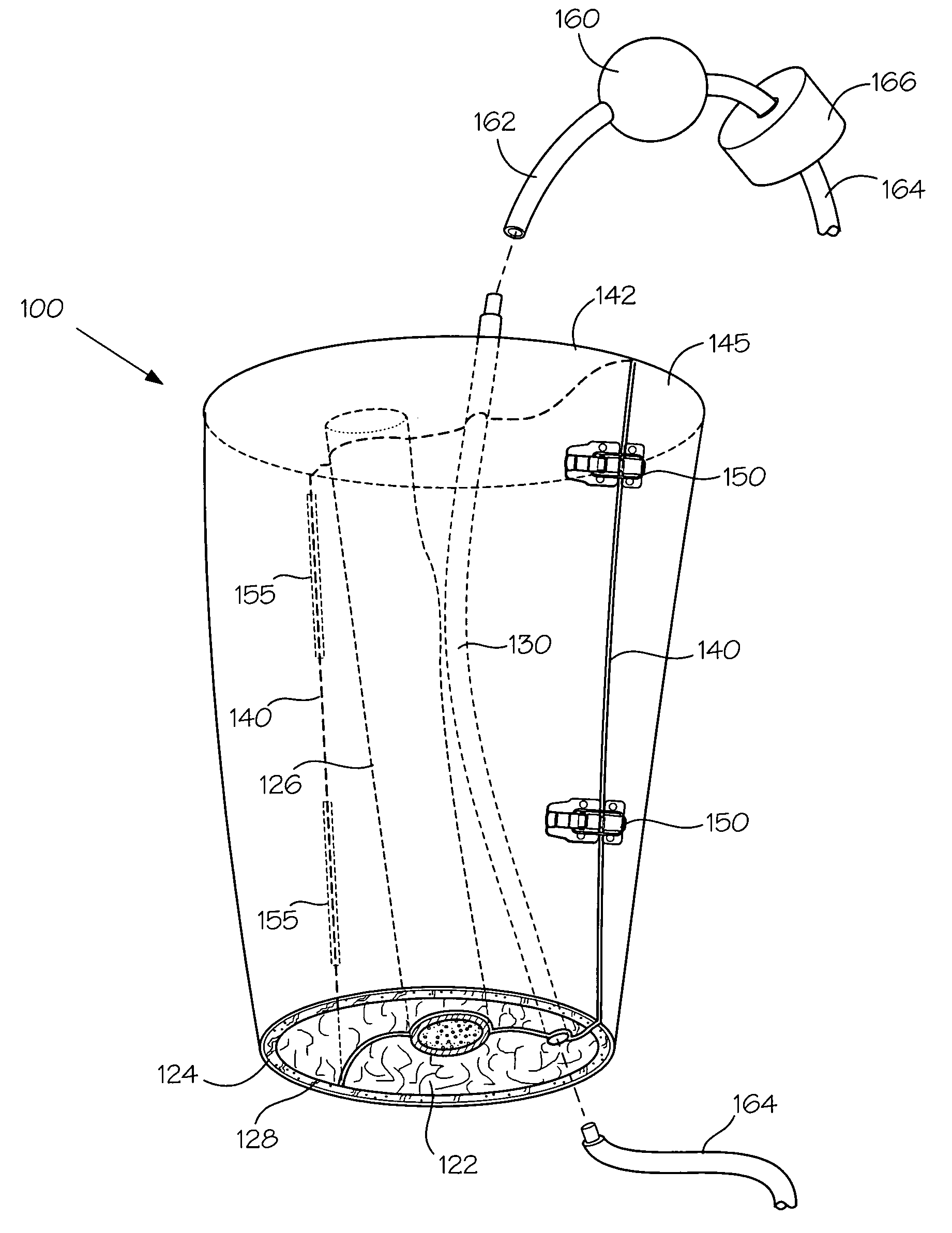

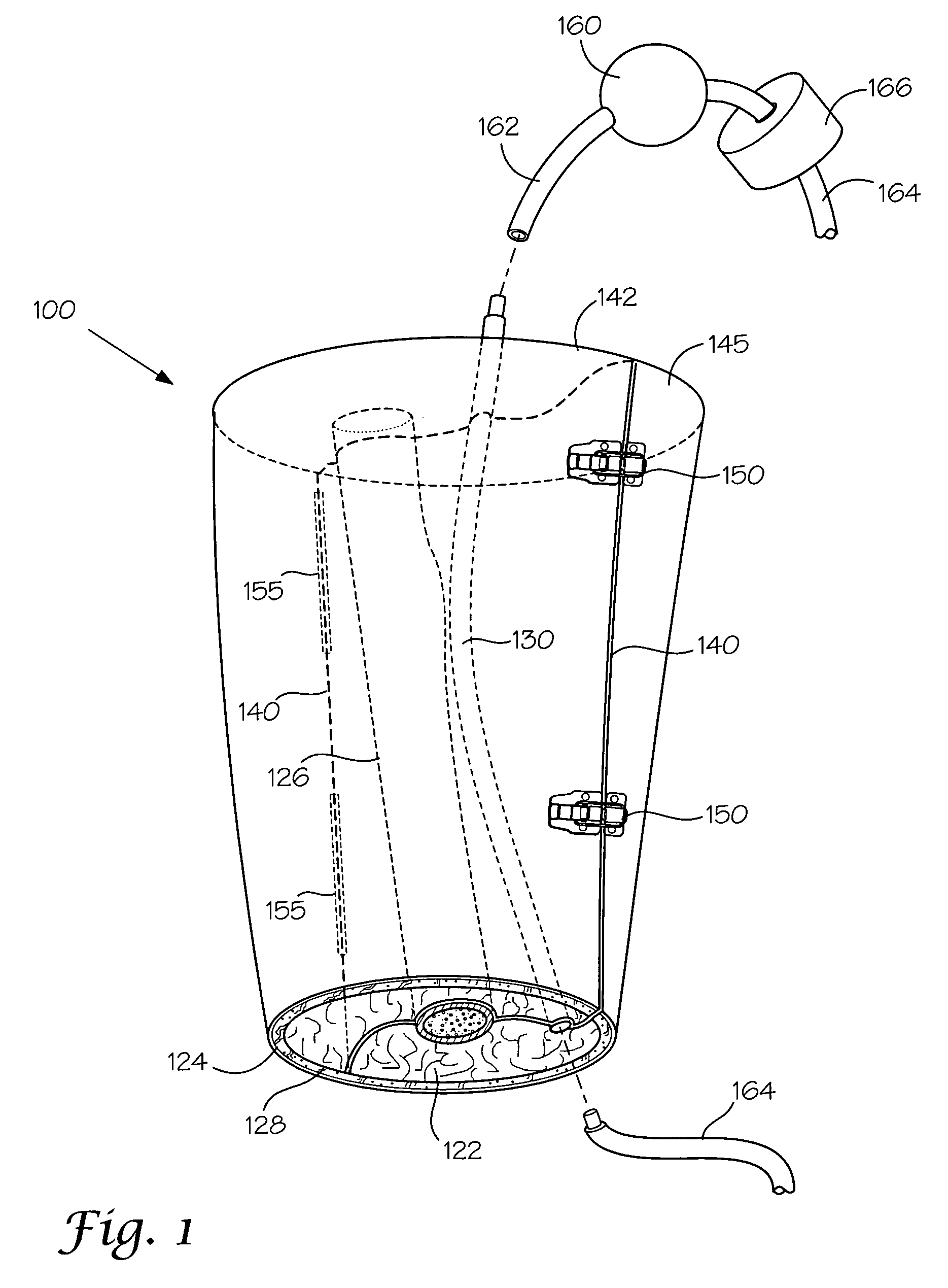

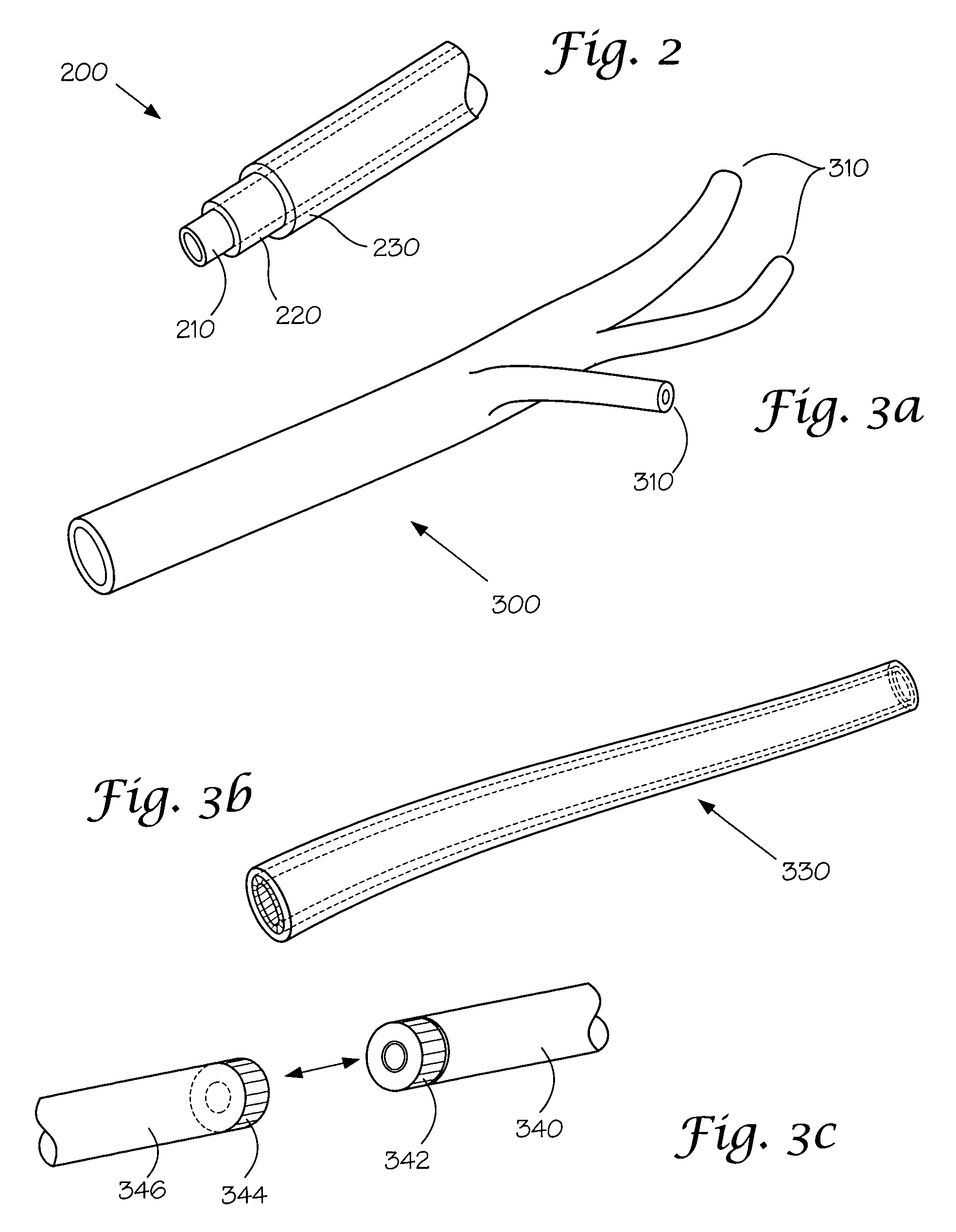

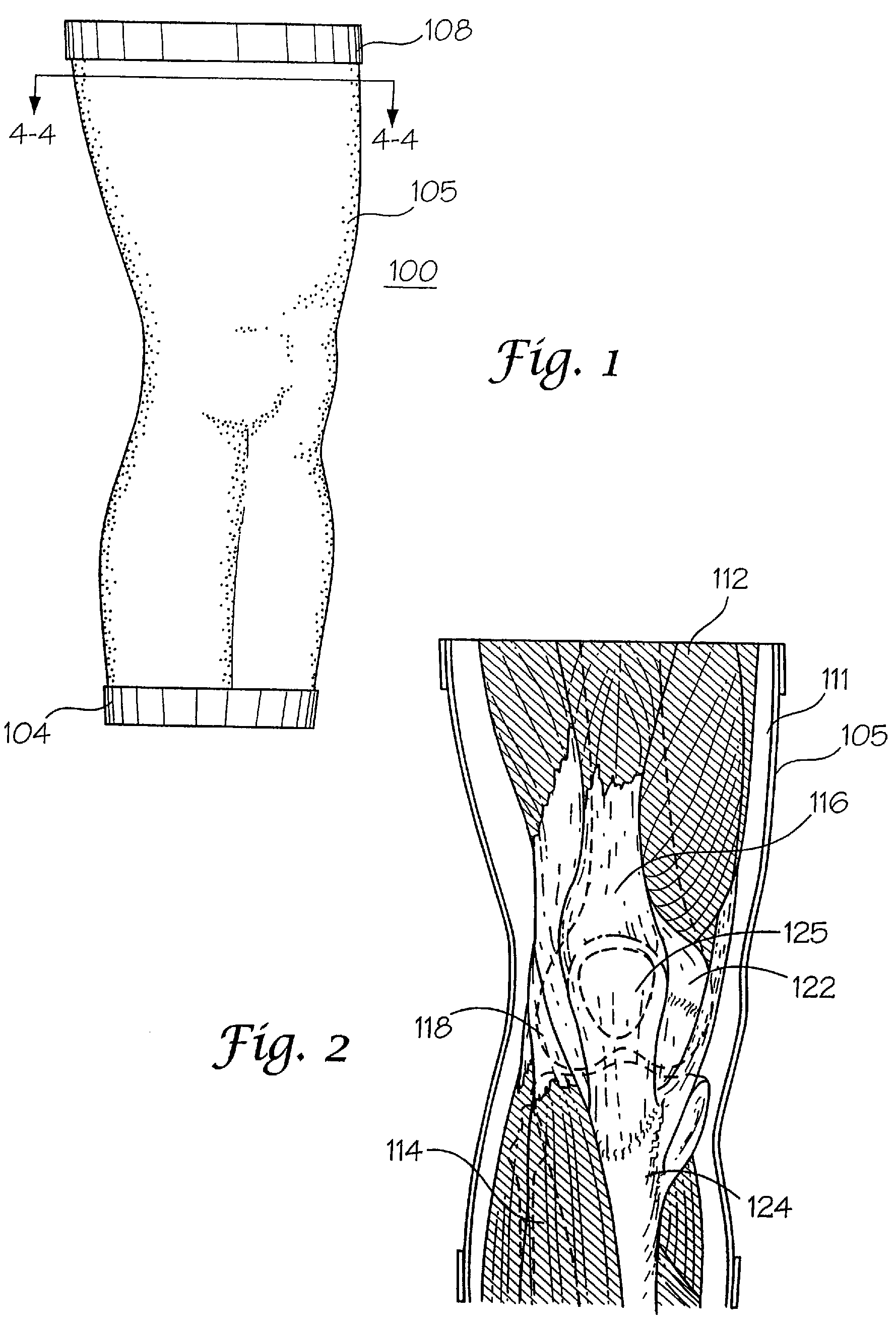

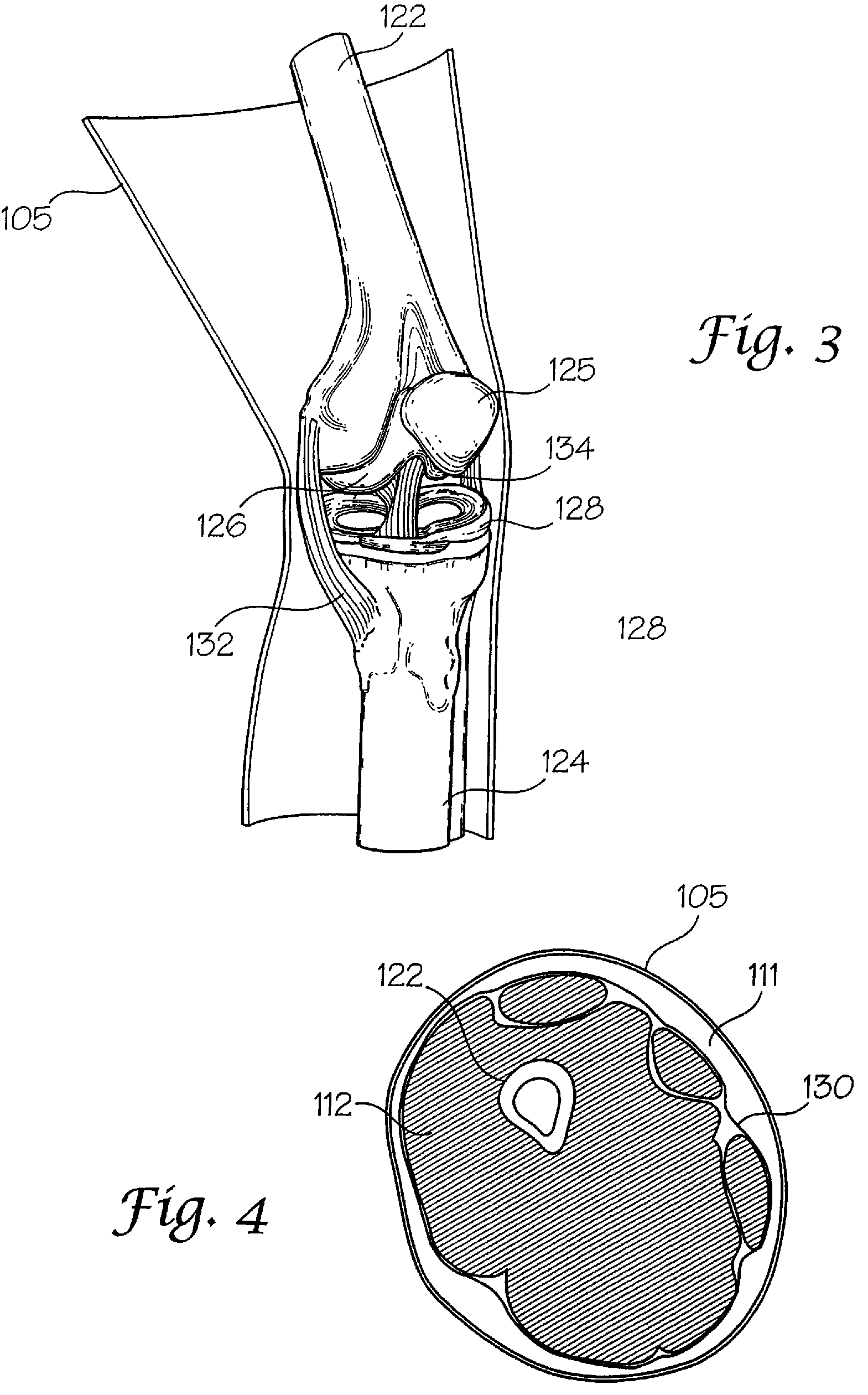

Disclosed herein are synthetic anatomical models that are designed to enable simulated use testing by medical device compam'es, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

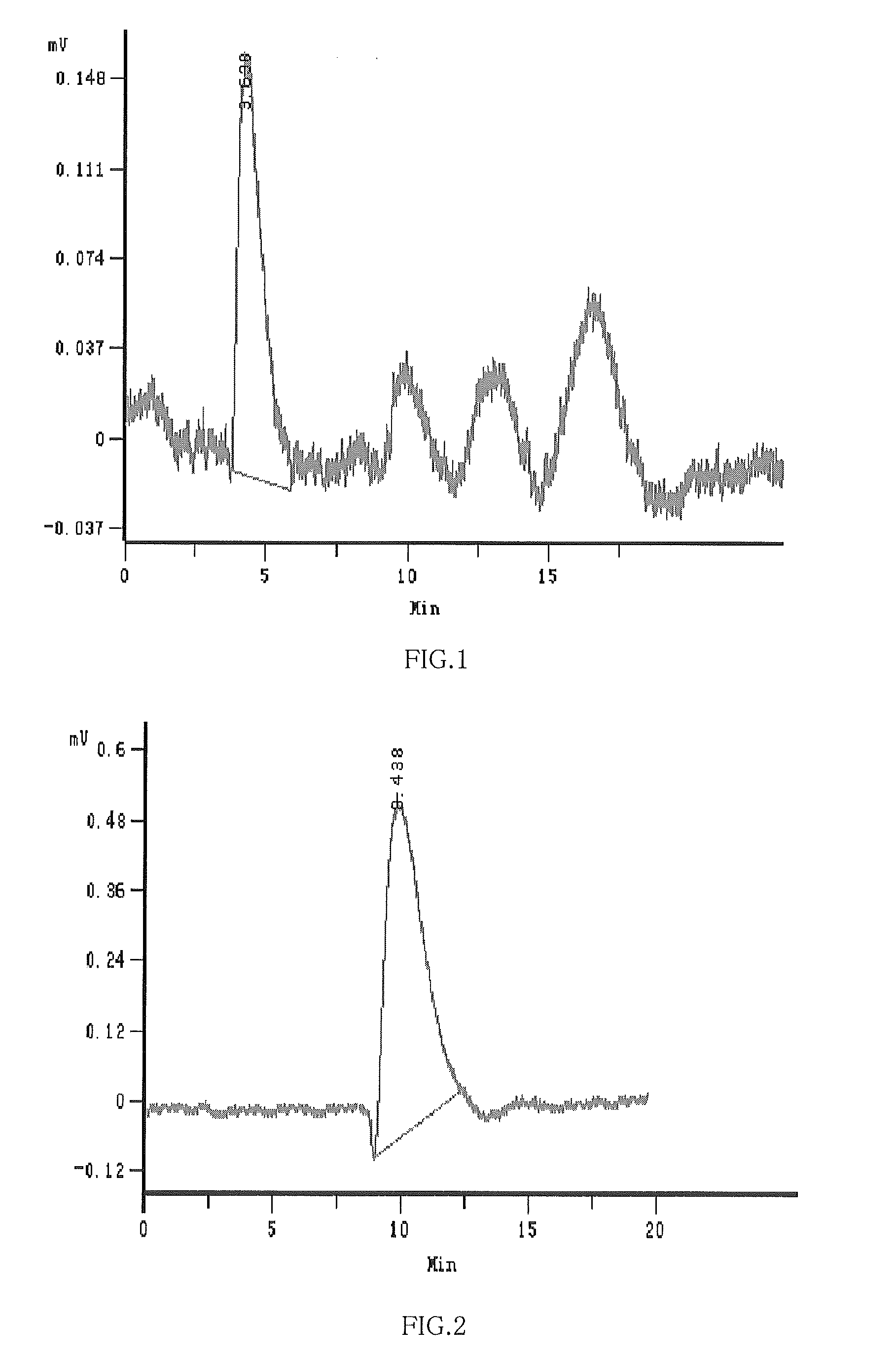

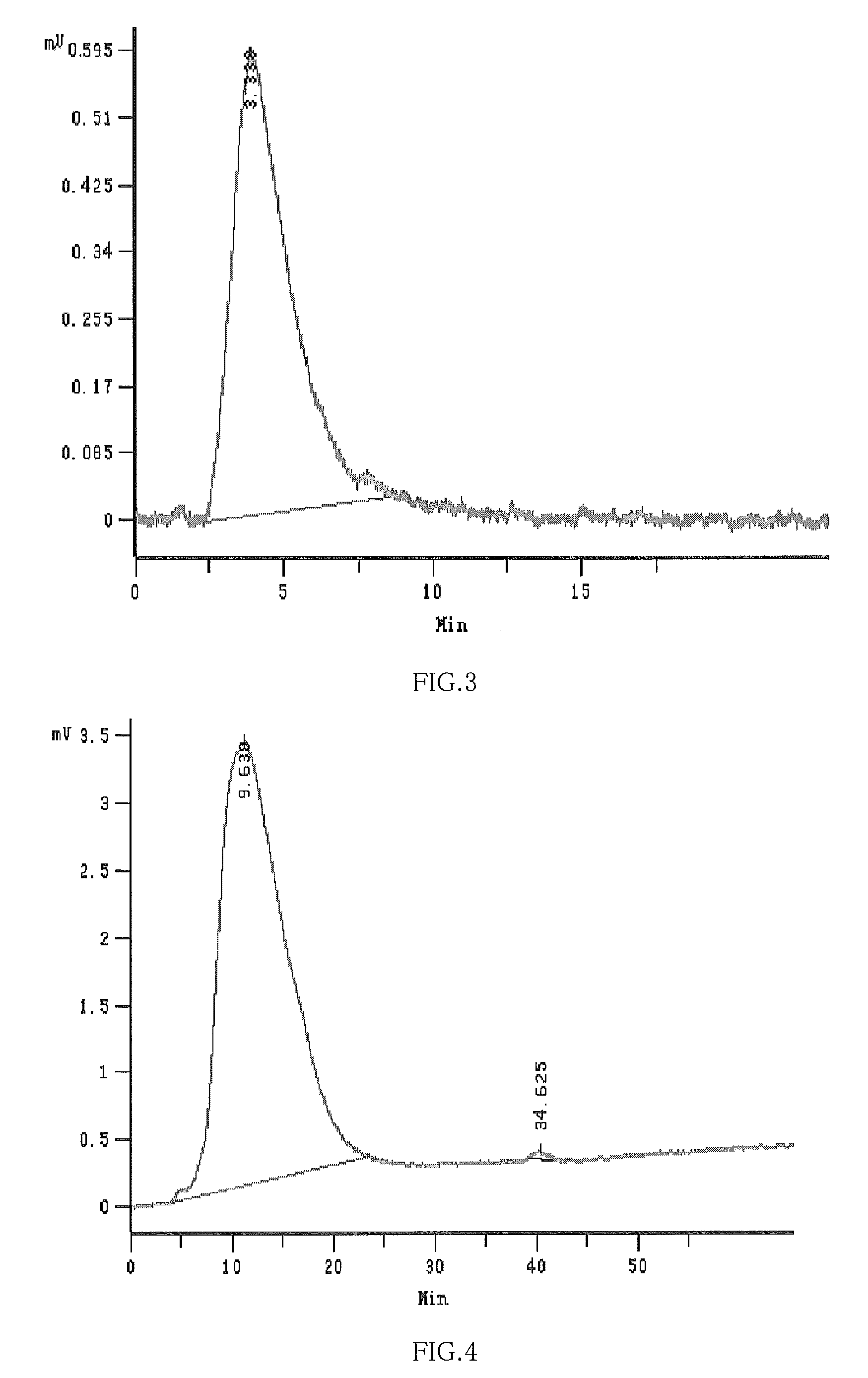

Hydroxypropyl-Sulfobutyl-Beta-Cyclodextrin, the Preparation Method, the Analytical Method, and the Pharmacutical Application Thereof

ActiveUS20090012042A1Little hemolysisLow toxicityBiocideOrganic active ingredientsHaemolysisCyclodextrin

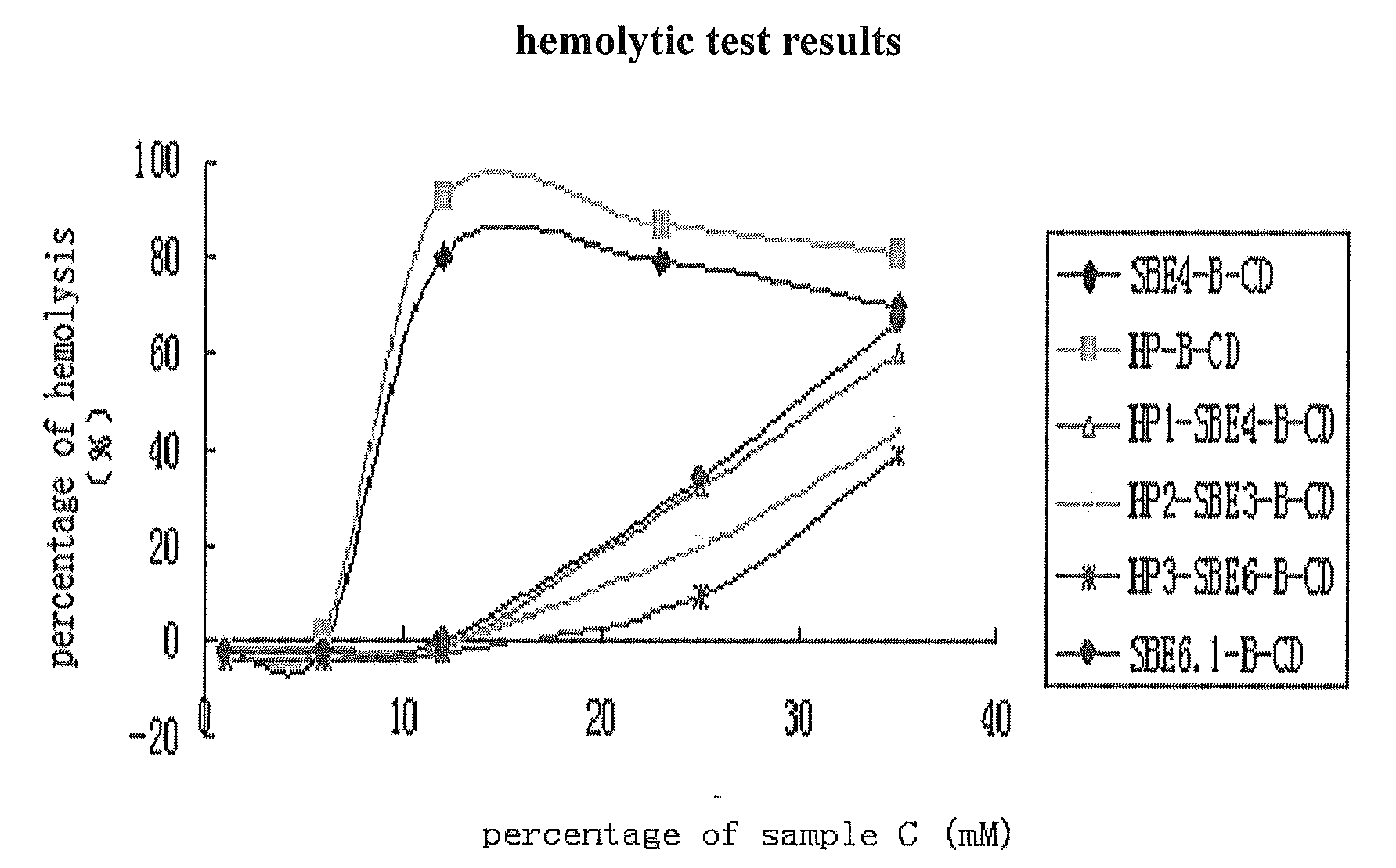

Hydroxypropyl-sulfobutyl-&bgr;-cyclodextrin, the preparation method, analytical method, and the pharmaceutical application thereof. The hydroxypropyl-sulfobutyl-&bgr;-cyclodextrin is a derivate of cyclodextrin which is substituted by hydroxypropyl group and sulfobutyl group: n-(2,3,6-O-2-hydroxypropyl)-m-(2,3,6-O-sulfobutyl)-&bgr;-cyclodextrin. The number of substituent groups per mole cyclodextrin is n hydroxypropyl groups and m sulfobutyl groups. “n” represents the average substituent degree of hydroxypropyl groups; “m” represents the average substituent degree of sulfobutyl groups; “n+m=z” is the gross average substituent degree, in which n is a random integer chosen from 1, 2, 3, 4, 5, 6, 7, 8, 9; m is a random integer chosen from 1, 2, 3, 4, 5, 6, 7, 8, 9; and the gross average substituent degree z is a random integer chosen from 2, 3, 4, 5, 6, 7, 8, 9, 10. The present invention shows low haemolysis and low toxicity.

Owner:SUN XIAODONG

Method of making tissue simulating analog materials and models made from same

ActiveUS7272766B2Avoid product qualityLengthened product timelinesAdditive manufacturing apparatusElectronic circuit testingAnatomical structuresHuman body

Owner:SAKEZLES CHRISTOPHER

Models And Methods Of Using Same For Testing Medical Devices

ActiveUS20080187895A1Avoid product qualityIncreased development costAdditive manufacturing apparatusEducational modelsHuman bodyAnatomical structures

Disclosed herein are synthetic anatomical models that are designed to enable simulated use testing by medical device compam'es, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

Models and methods of using same for testing medical devices

ActiveUS7427199B2Avoid product qualityLengthened product timelinesAdditive manufacturing apparatusDiagnostic recording/measuringAnatomical structuresMedical device

Disclosed herein are synthetic anatomical models that are designed to enable simulated use testing by medical device companies, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

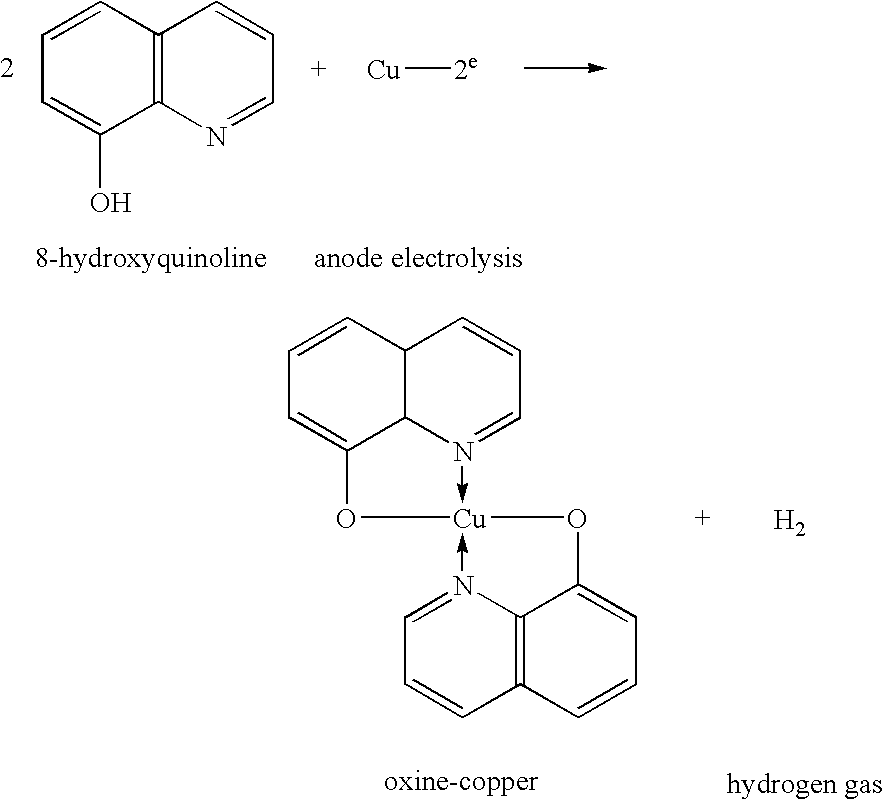

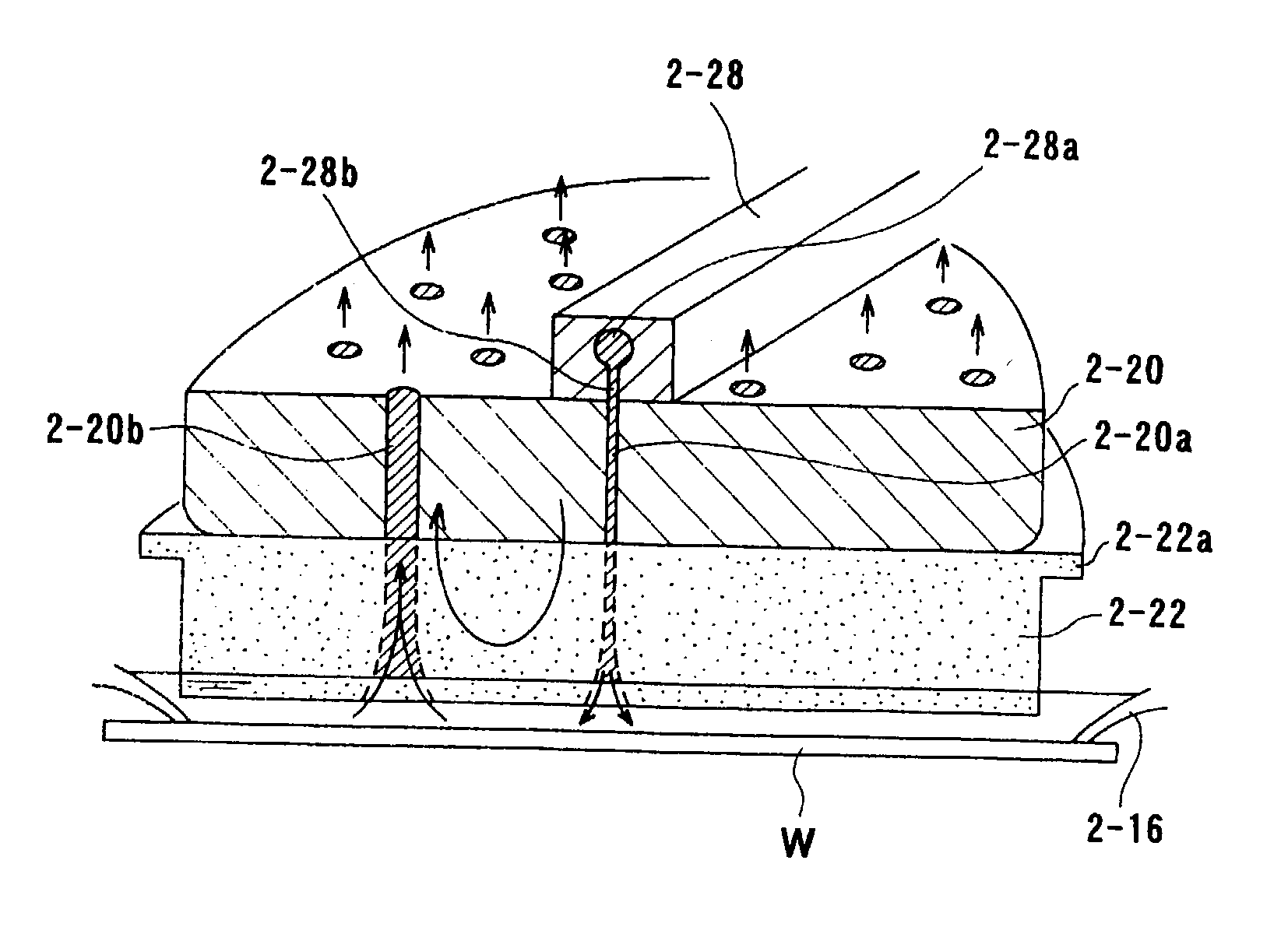

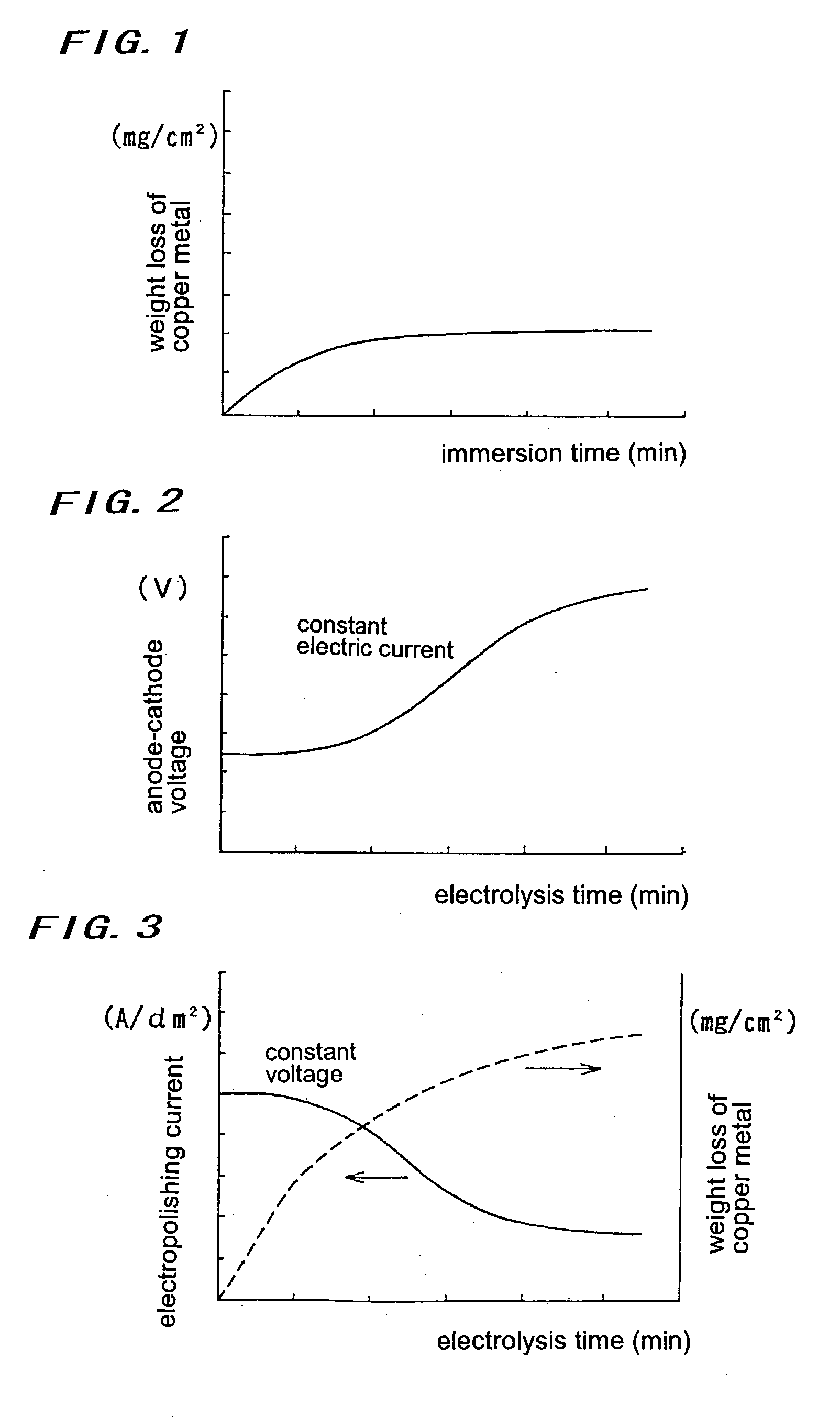

Polishing liquid, polishing method and polishing apparatus

InactiveUS20040154931A1Low costAvoid product qualityMachining working mediaElectrolysis componentsOrganic acidPhysical chemistry

The present invention relates to a polishing liquid for polishing the surface of a substrate having a copper film and fine recesses filled with the copper, comprising, at least one water-soluble inorganic acid or its salt, or water-soluble organic acid or its salt, and at least one hydroxyquinoline.

Owner:EBARA CORP

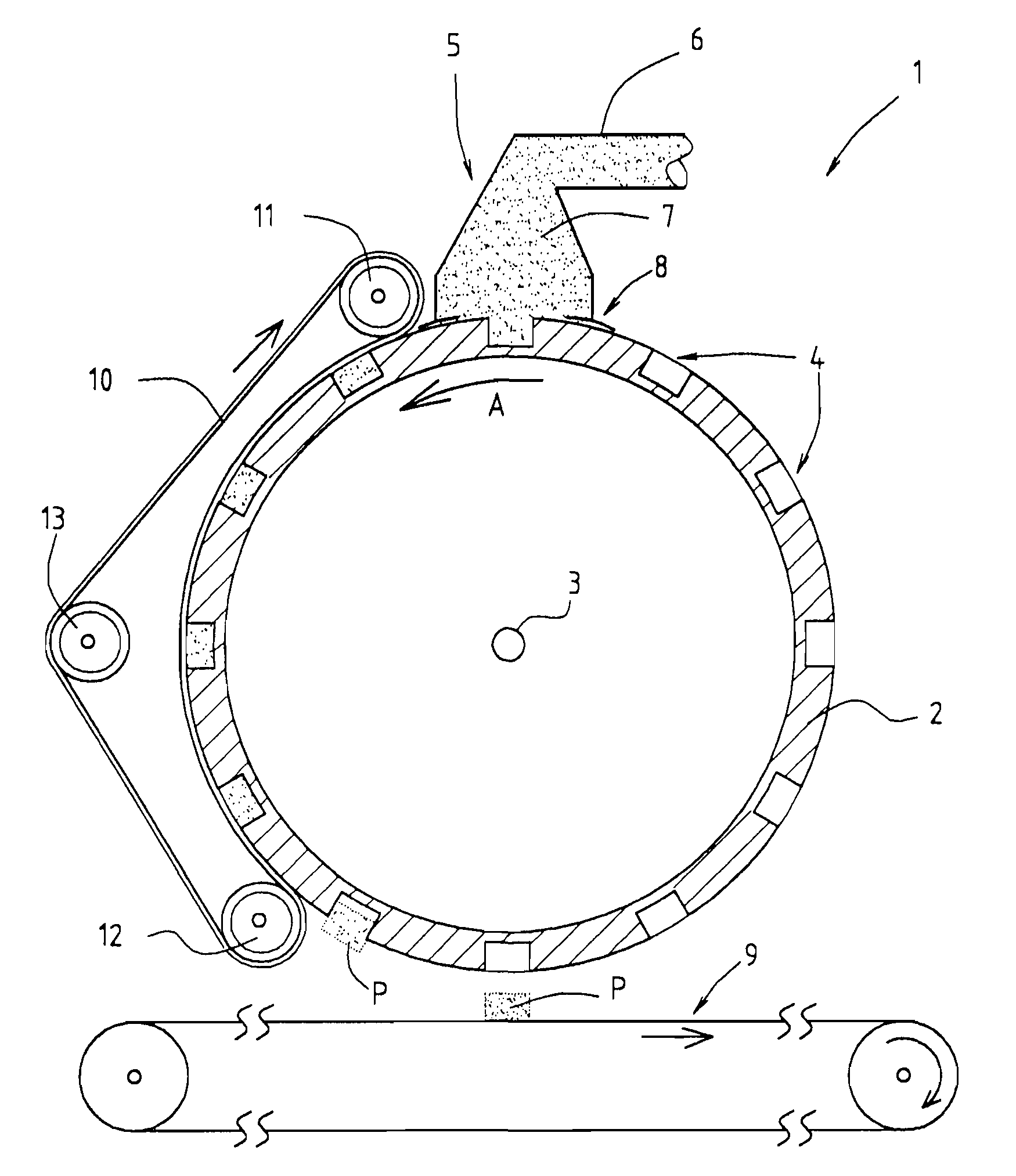

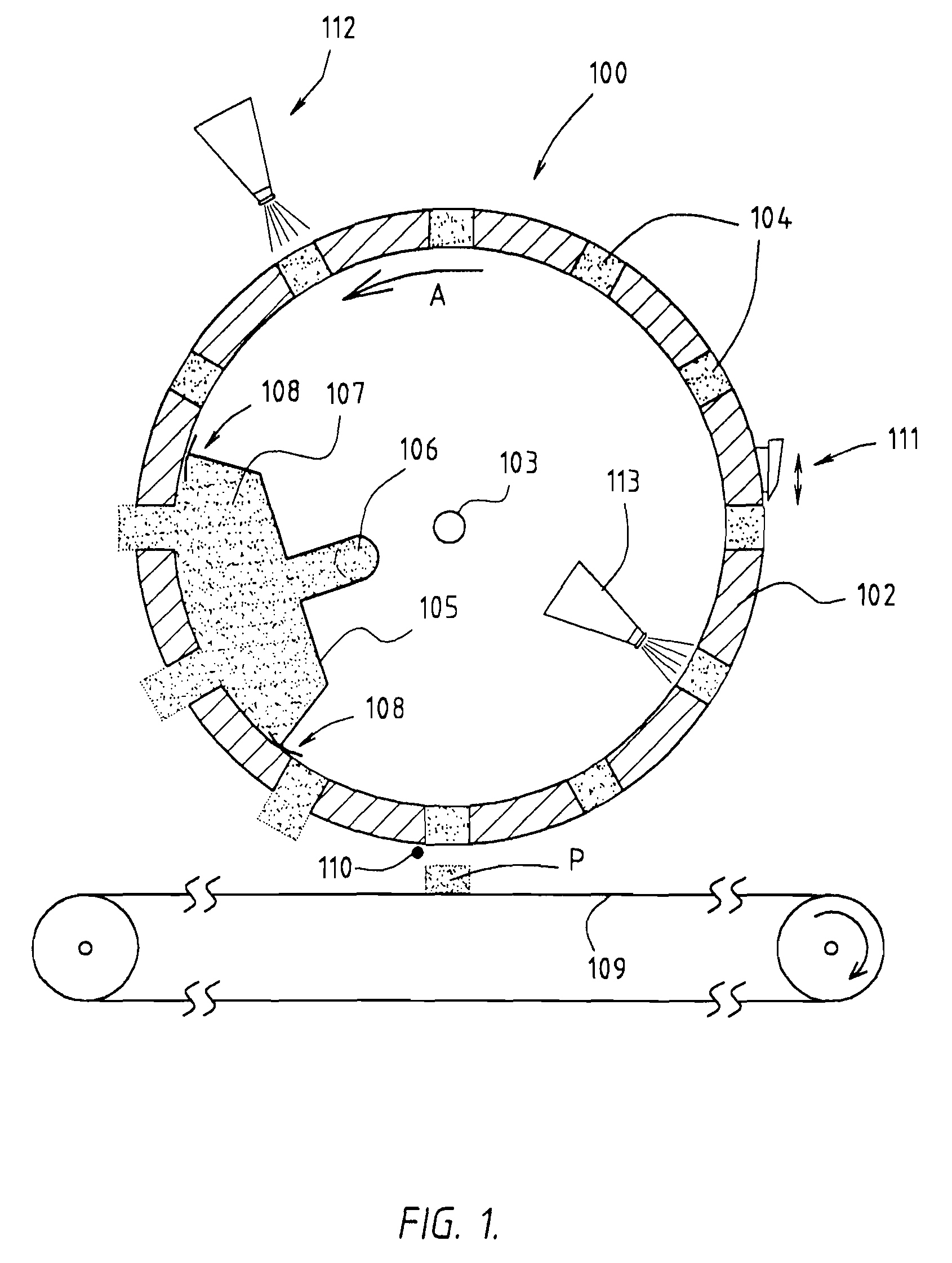

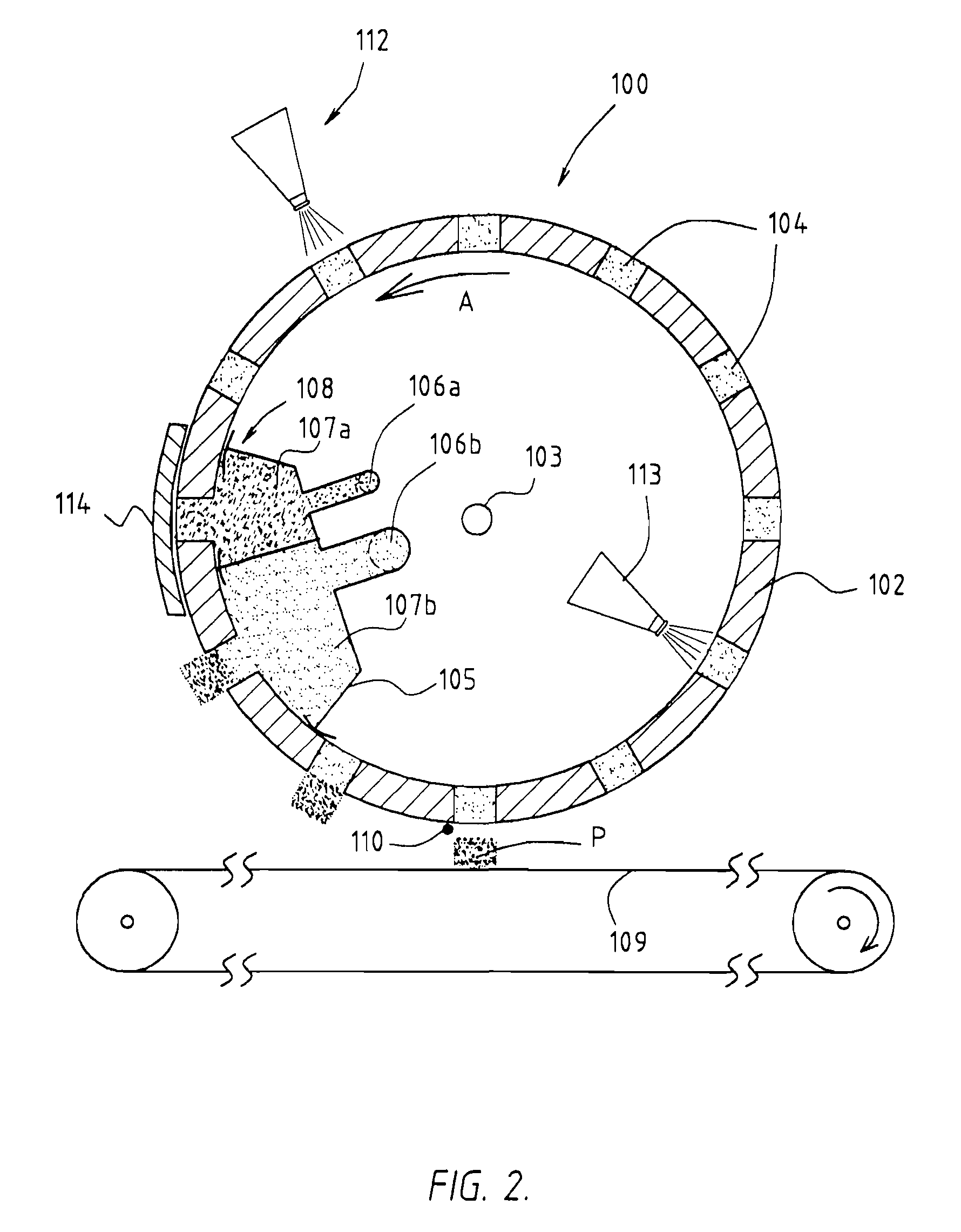

Moulding

InactiveUS20070224306A1High priceLarge capacityConfectioneryCeramic shaping apparatusPartial fillingMaterials science

Owner:STORK PMT

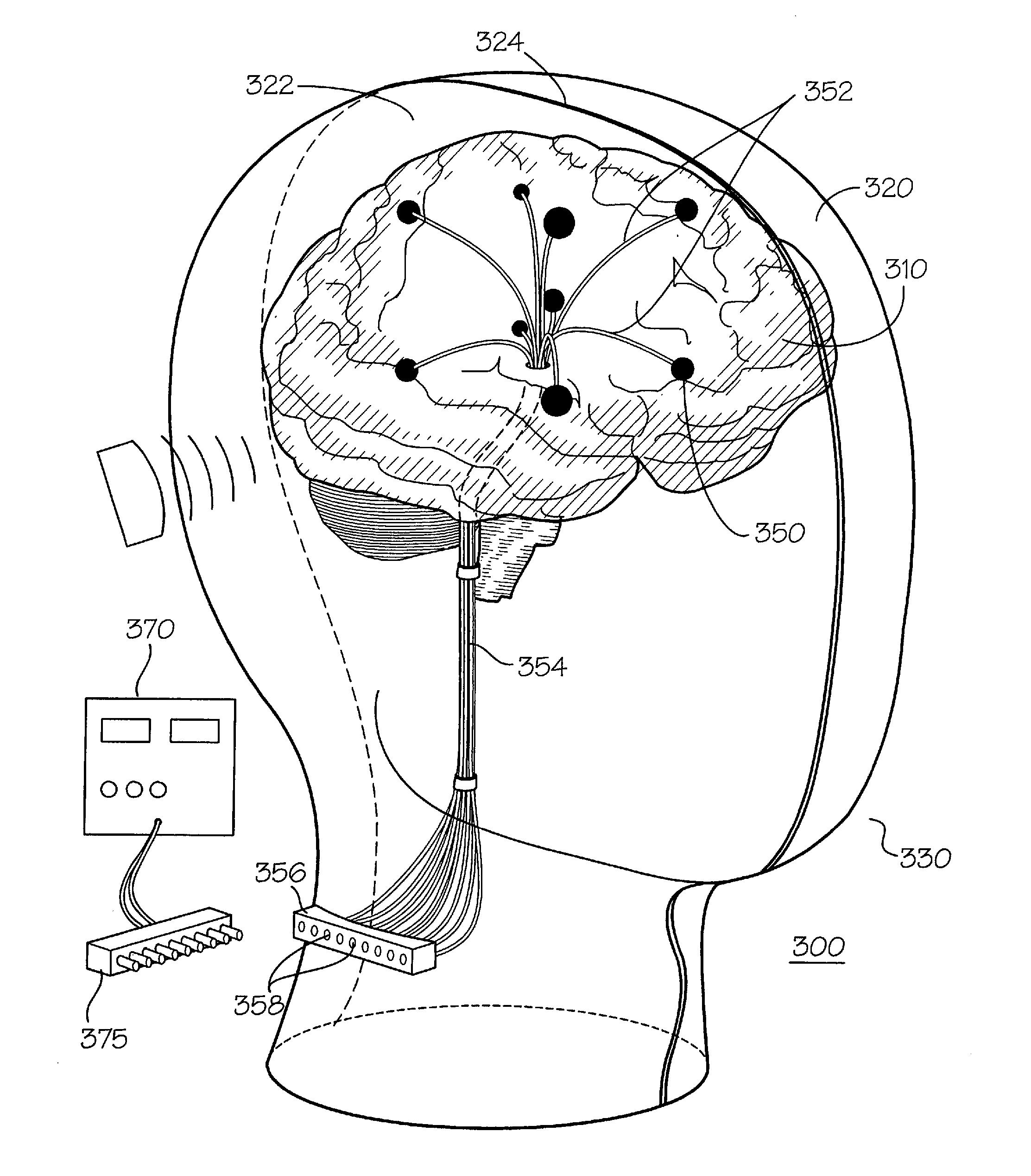

Dielectric properties models and methods of using same

ActiveUS8137110B2Avoid product qualityLengthened product timelinesAdditive manufacturing apparatusDiagnostic recording/measuringAnatomical structuresElectricity

Disclosed herein are dielectric properties models that are designed to enable simulated use testing by medical device companies, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of correlation to dielectric properties of human or nonhuman animal tissues that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

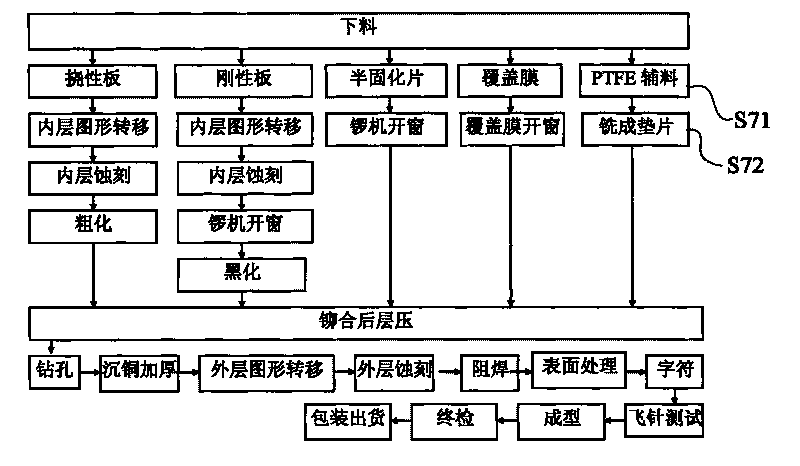

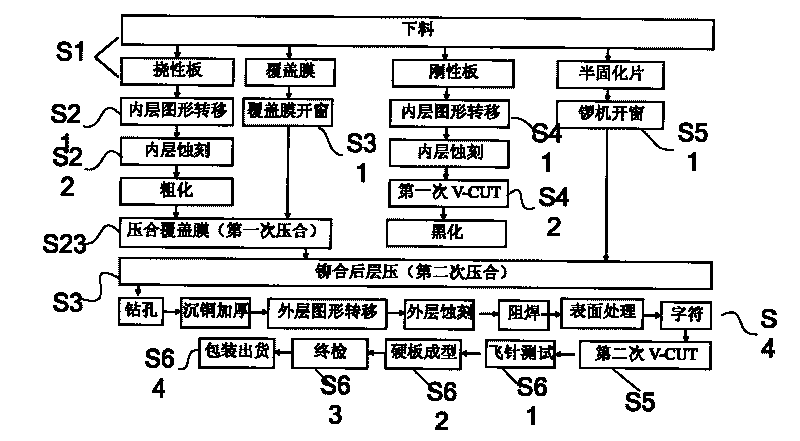

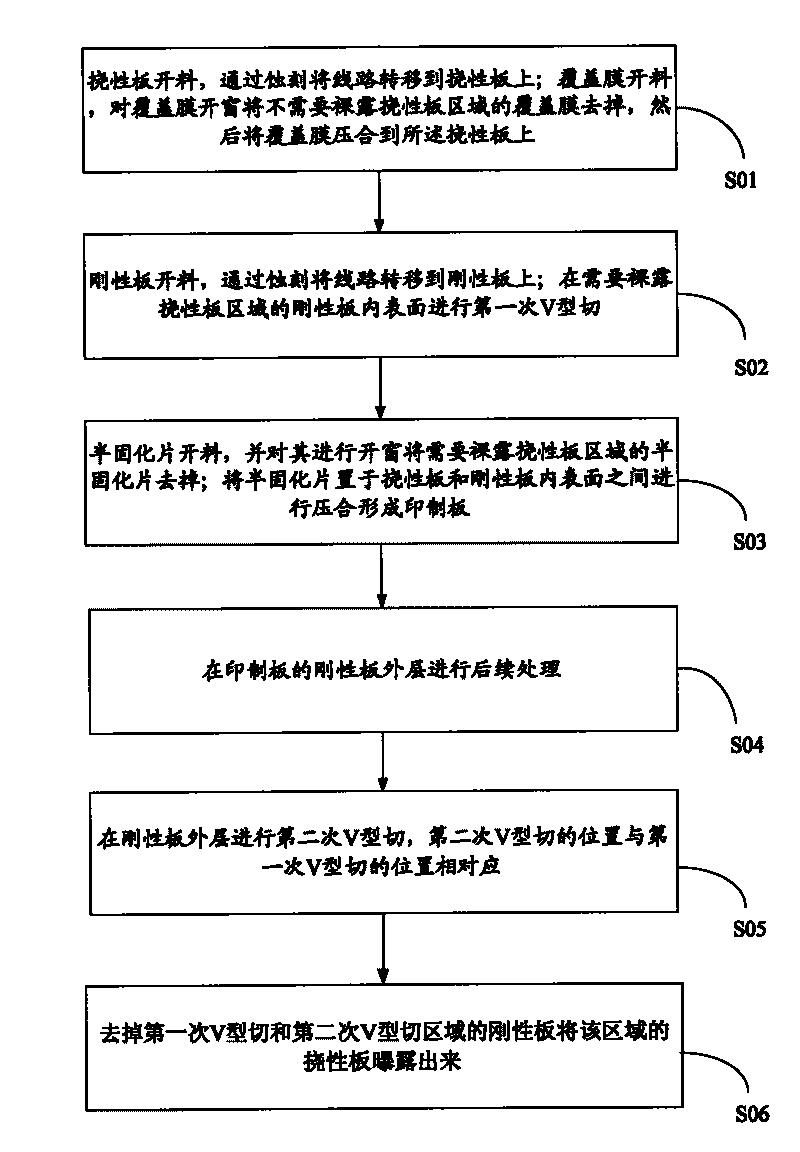

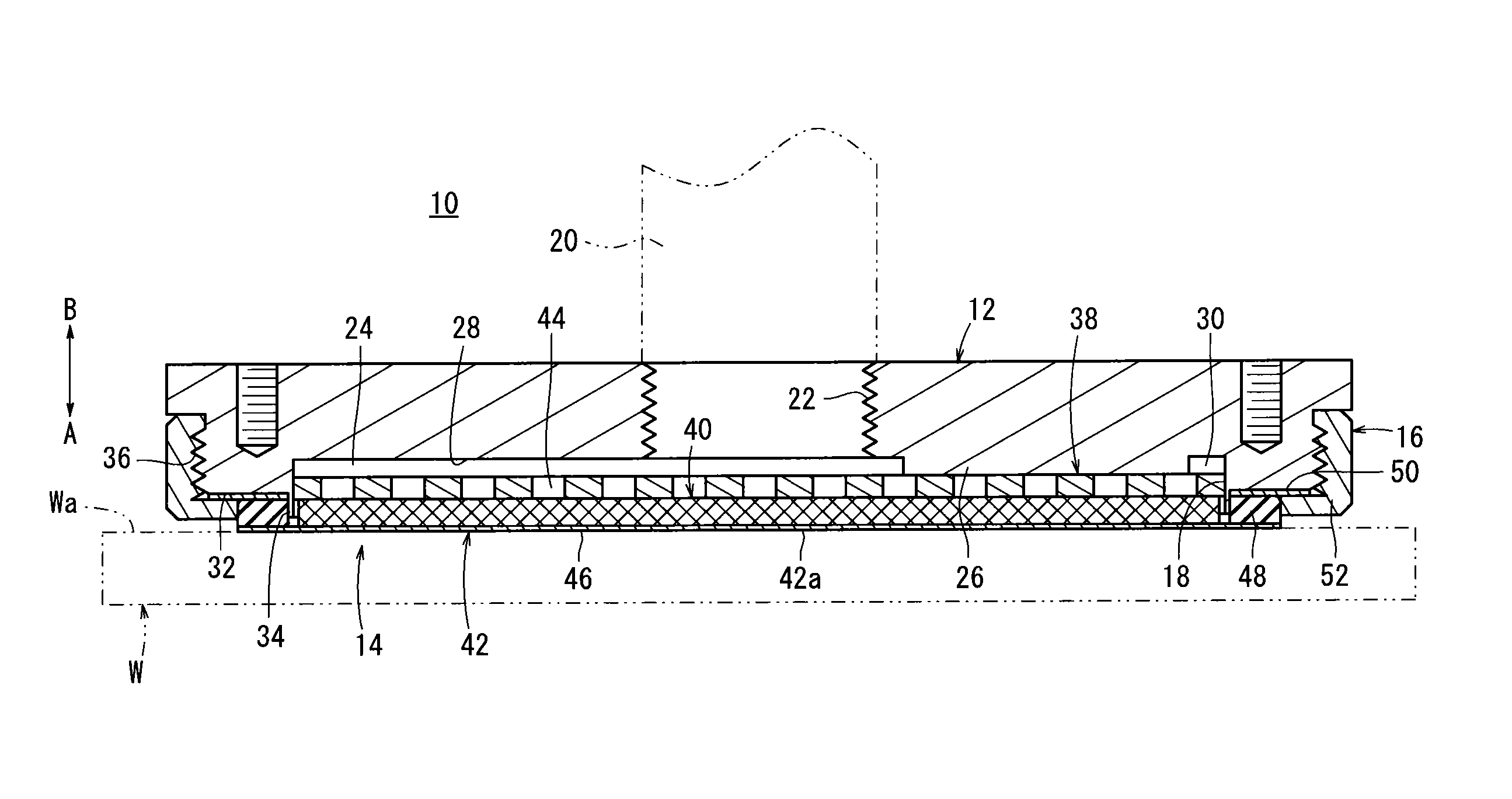

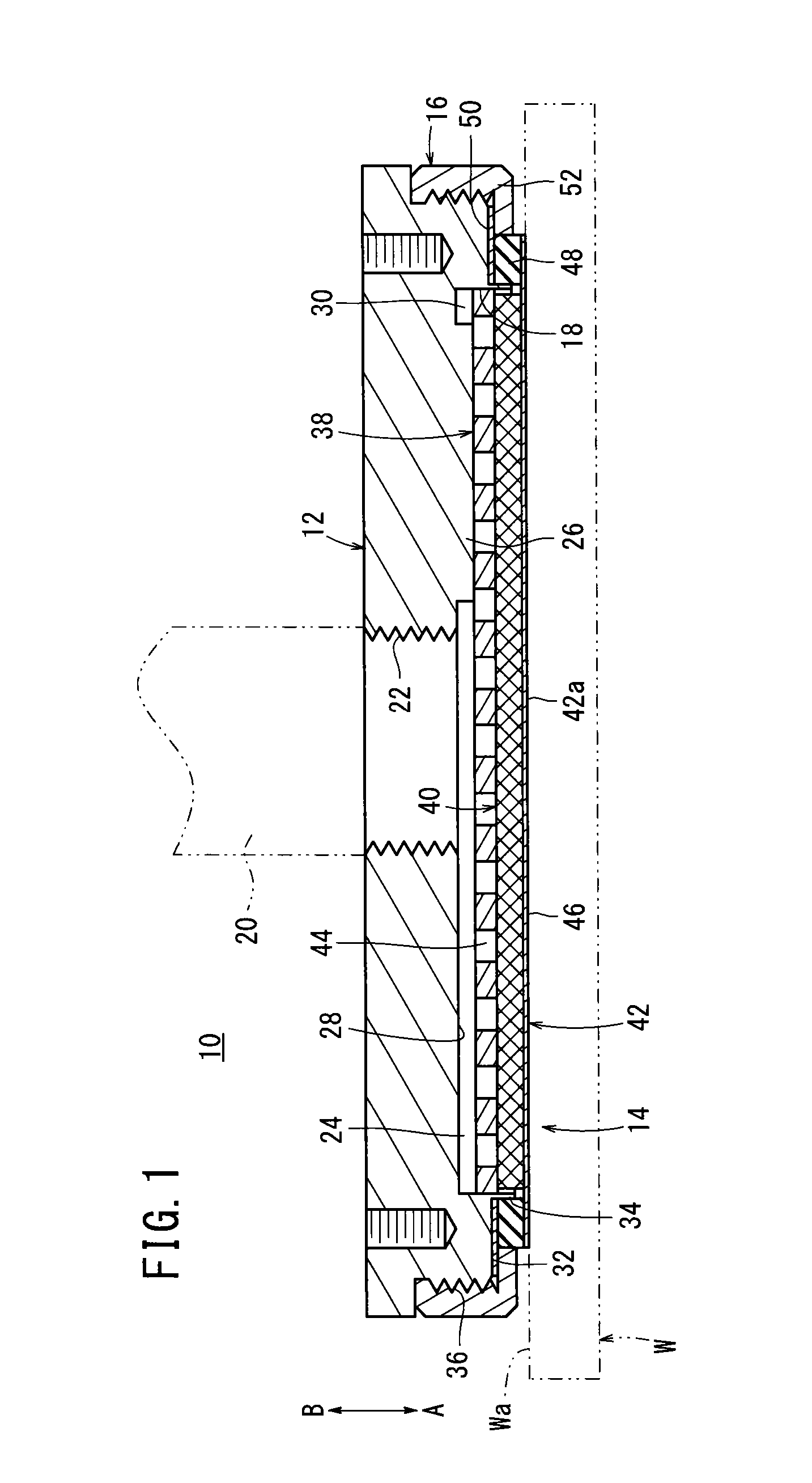

Method for producing printed board combining rigidness and flexibleness

ActiveCN101695217AAvoid product qualityImprove product qualityPrinted circuit assemblingEngineeringProduction quality

The invention provides a method for producing a printed board combining rigidness and flexibleness, comprising the following steps: cutting a flexible board and transferring an inner-layer circuit pattern onto the flexible board; cutting a covering film, implement windowing on the covering film, and pressing the covering film onto the flexible board; cutting a rigid board and transferring the inner-layer circuit pattern onto the rigid board; implementing a primary V type cutting at an outline position needing to baring the flexible board area; cutting a prepreg, implementing windowing on the prepreg and removing the prepreg needing to baring the flexible board area; placing the prepreg between the inner surfaces of the flexible board and the rigid board for implementing pressing so as to form a printed board; implementing subsequent processing at the outer layer of the rigid board of the printed board; implementing a secondary V type cutting at the outer layer of the rigid board, and leading the position of the secondary V type cutting to correspond to the position of the primary V type cutting; removing the rigid board of the primary V type cutting and the secondary V type cutting area; and exposing the flexible board of the area. The method improves the production quality of the printed board combining rigidness and flexibleness.

Owner:SHENZHEN KING BROTHER ELECTRONICS TECH

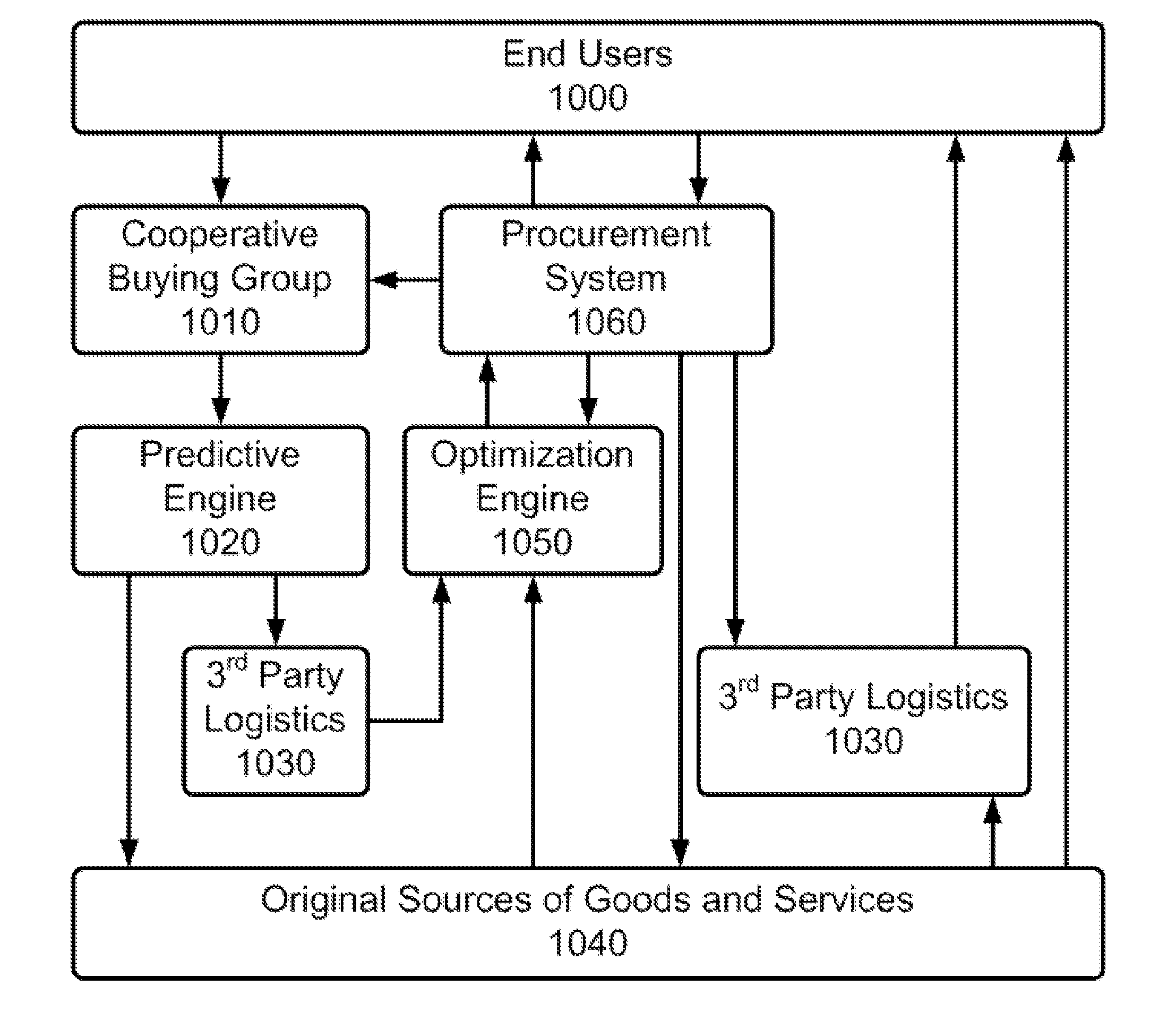

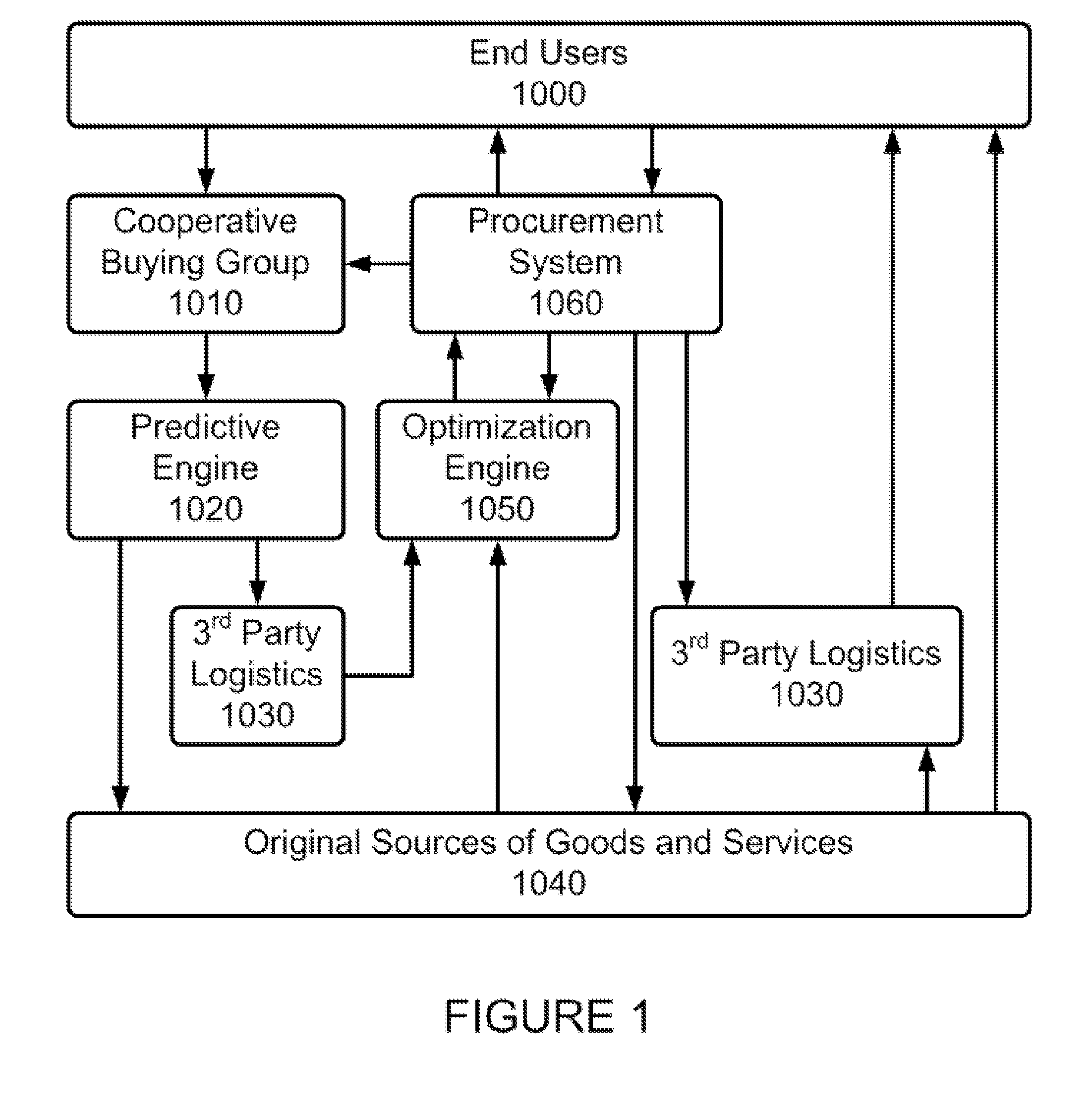

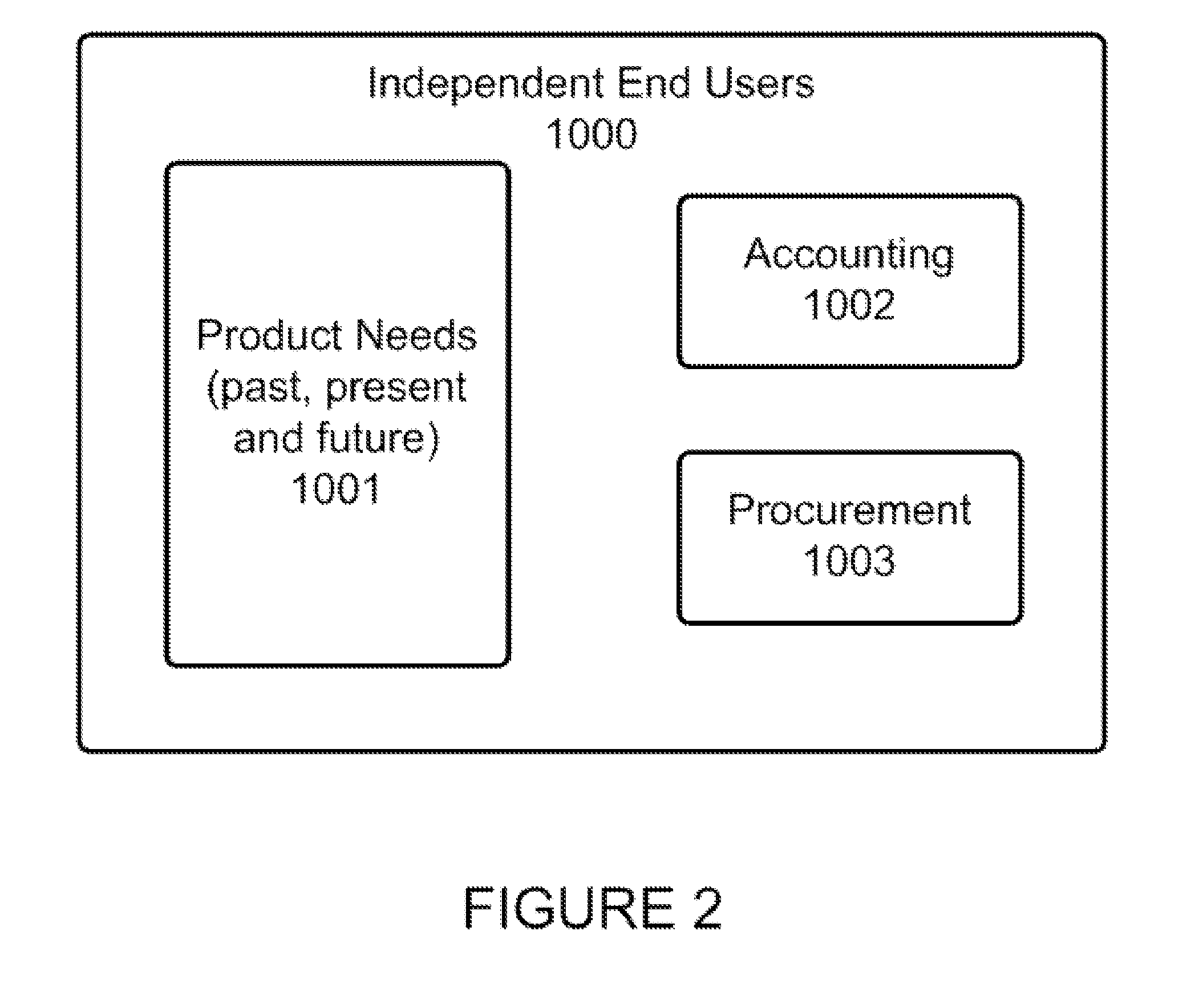

Method and Apparatus for Consumer Procurement Aggregation

InactiveUS20140136282A1Reduce chain lengthShorten the timeBuying/selling/leasing transactionsResourcesProduct orderService provision

A method, system and computer program for accumulating information relating to product demand and consumption for each of a plurality of end users by a buying group representing a single purchase in bulk to disintermediate the supply chain, accumulating the received product demand into a predictive demand schedule by an expert service provider, and transmitting the accumulated predictive product demand schedule to a manufacturer / original source of the product by the expert service provider. Product availability information based upon the accumulated predictive product demand is received from the manufacturer / original source of the product, and is provided to the plurality of end users. One or more product orders are received, the product is ordered from the manufacturer / original source of the product, all aspects of the supply chain being managed by the expert service provider, and the product is shipped to one or more of the plurality of end users.

Owner:FEDELE JOSEPH

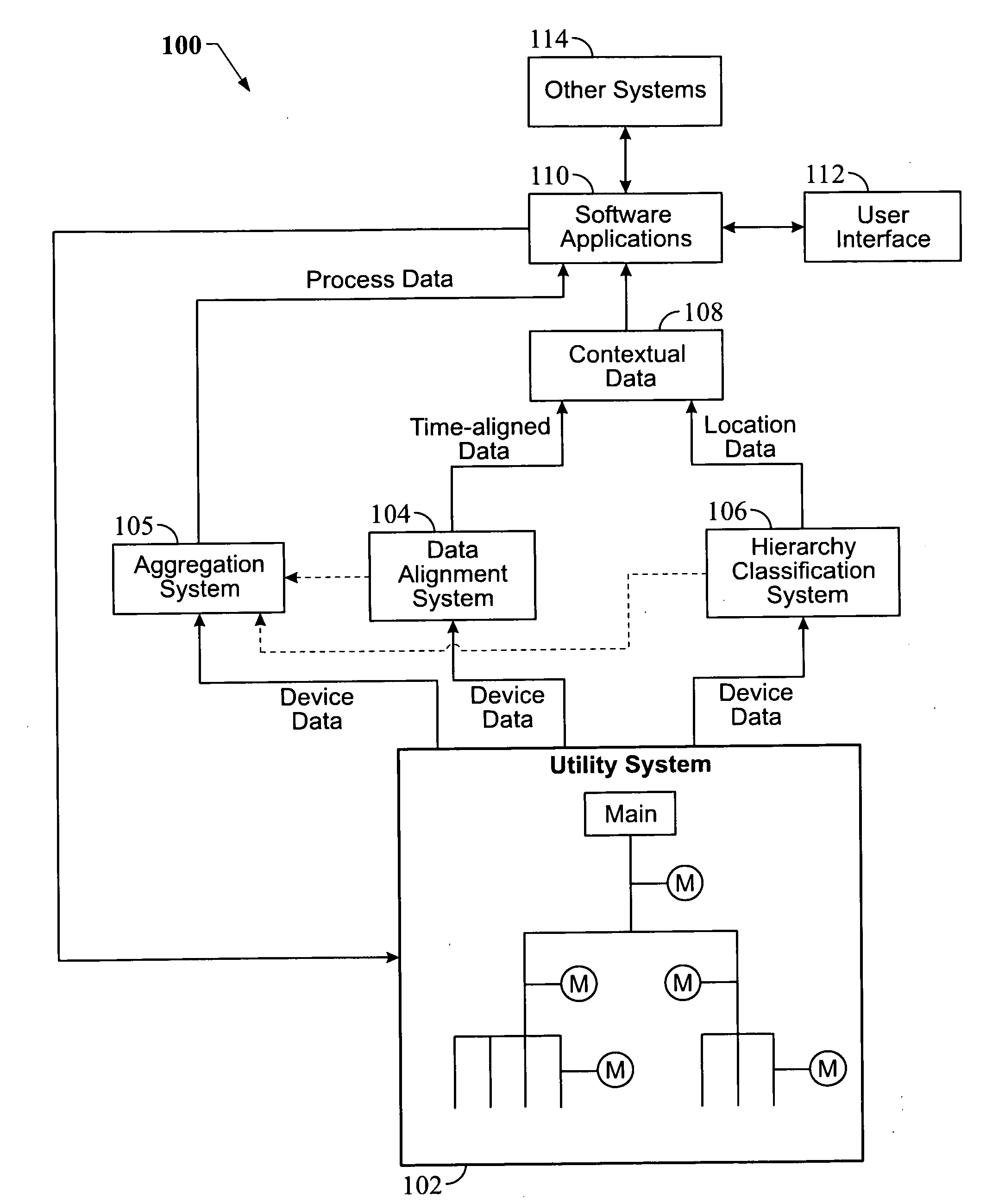

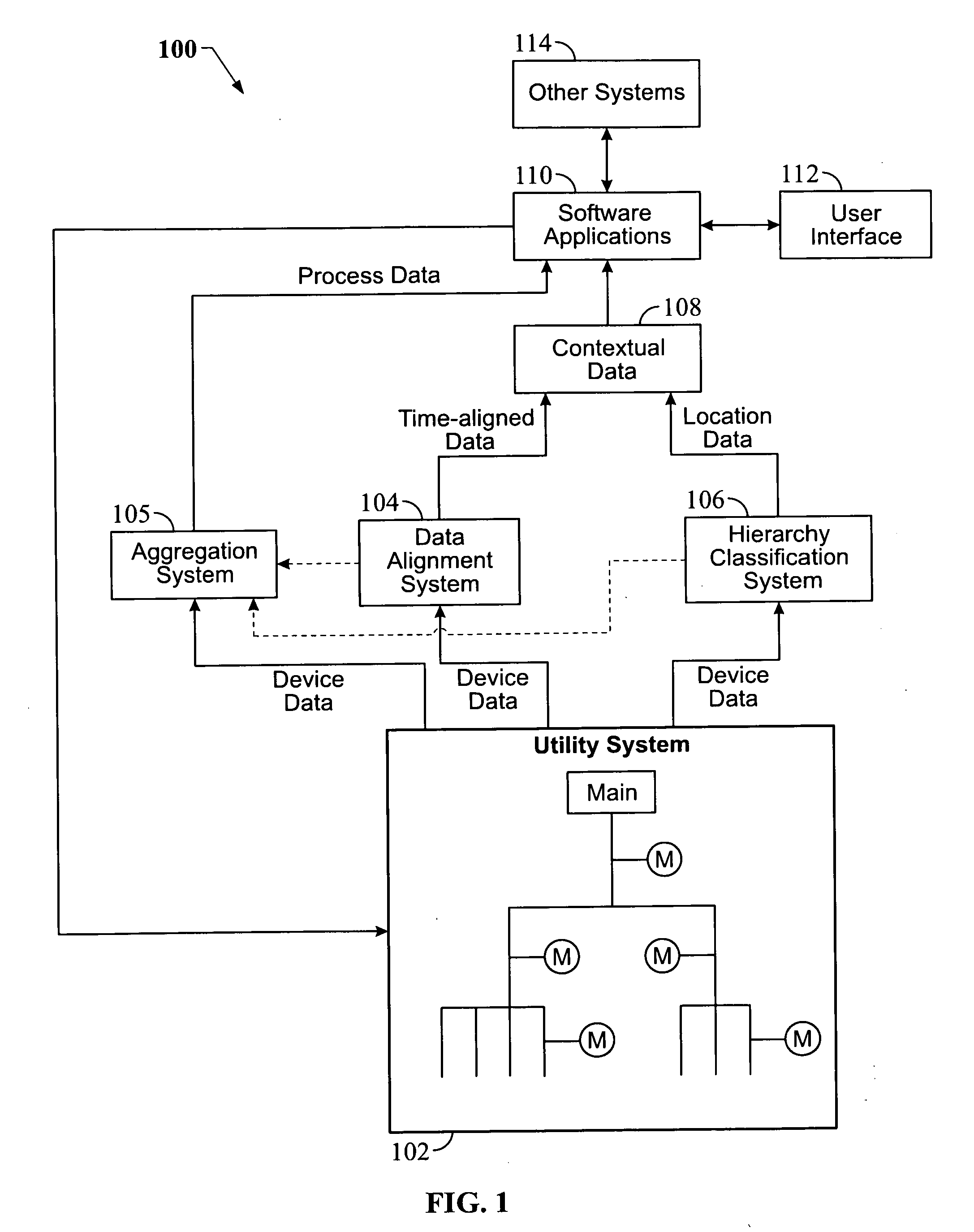

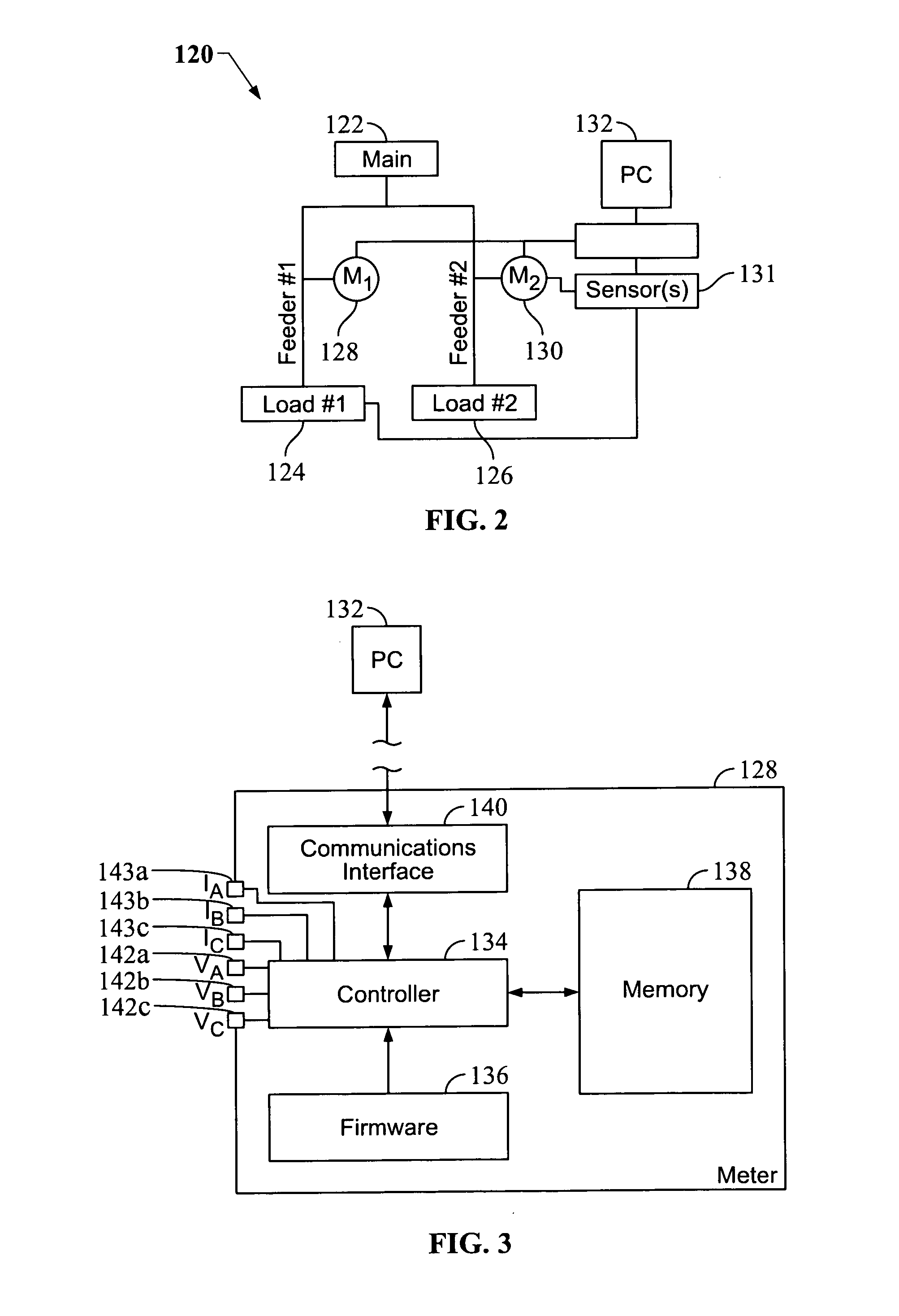

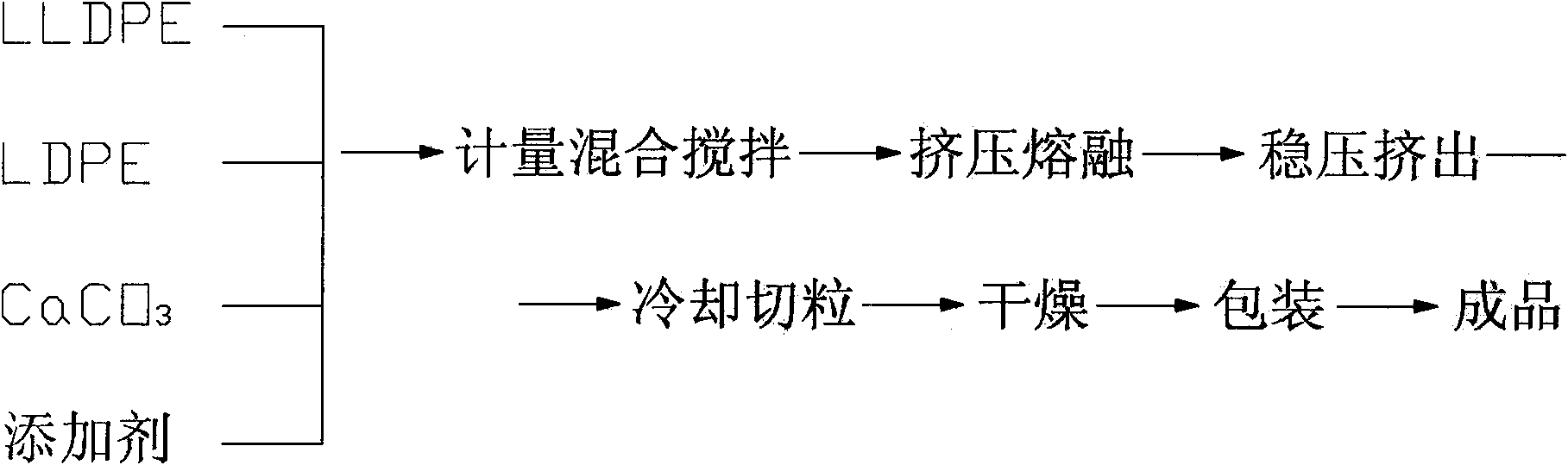

Method for process monitoring in a utility system

ActiveUS20090204368A1Simpler assessmentLow efficiencyAmplifier modifications to reduce noise influenceTariff metering apparatusCorrelation coefficientMonitoring system

A process monitoring method that aggregates monitoring devices and optionally sensors into one or more groups that are each related to a process of a utility system. The monitoring devices are organized into a monitoring system hierarchy manually or automatically. A process algorithm determines from the hierarchy which monitoring devices are connected to a load. Monitored data from load-connected monitoring device pairs are correlated to produce a correlation coefficient that is compared against a correlation threshold selected between 0 and 1. When the correlation coefficient exceeds the threshold, the device pair is grouped into a process group. Other device pairs exceeding the threshold are likewise grouped into the process group. Multiple processes may be determined with the process algorithm. Sensors may also be grouped manually with the process group containing monitoring devices, which may include virtual monitoring devices. Alarms associated with monitoring devices and sensors are aggregated into one process alarm.

Owner:SQUARE D CO

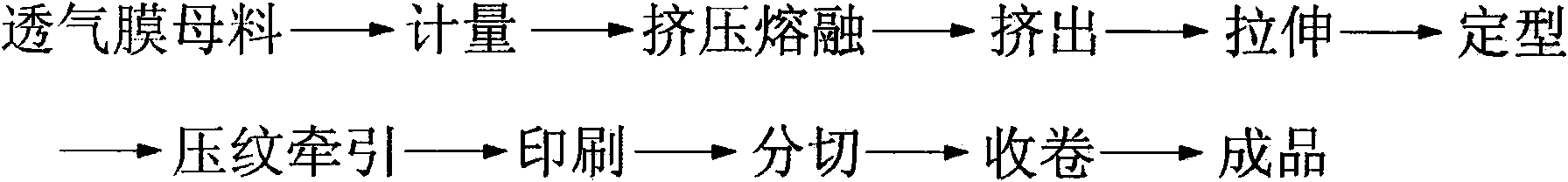

Ultrathin high porosity film and preparation method thereof

The invention discloses an ultrathin high porosity film and a preparation method thereof. The film comprises the following components by weight percent: 40-50% of : PE(LLDPE / LDPE), 45-55% of calcium carbonate and 3-5% of modified additives (plastic additive and film forming additive). The preparation method of the invention comprises the following steps: (1) breathable film master batch process flow and (2) breathable film process flow. The product of the invention can replace imported products, thus reducing the production cost of the breathable film, improving the current dilemma of foreignmonopoly, filling the domestic blank to develop and produce the breathable film material with independent intellectual property rights and having practical and great economic benefit and social benefit.

Owner:ZHEJIANG YUEHAN TECH BREATHABLE MATERIAL

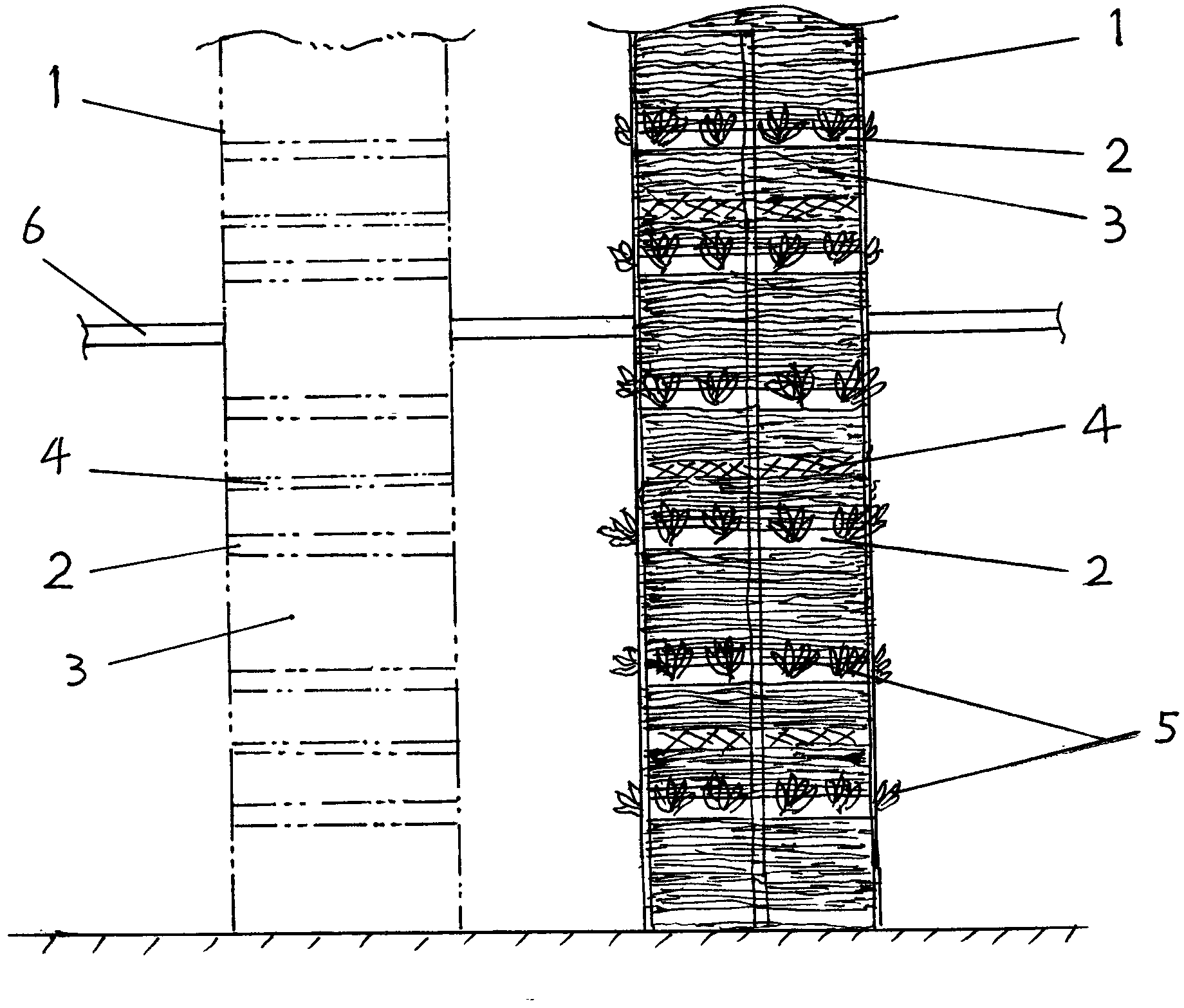

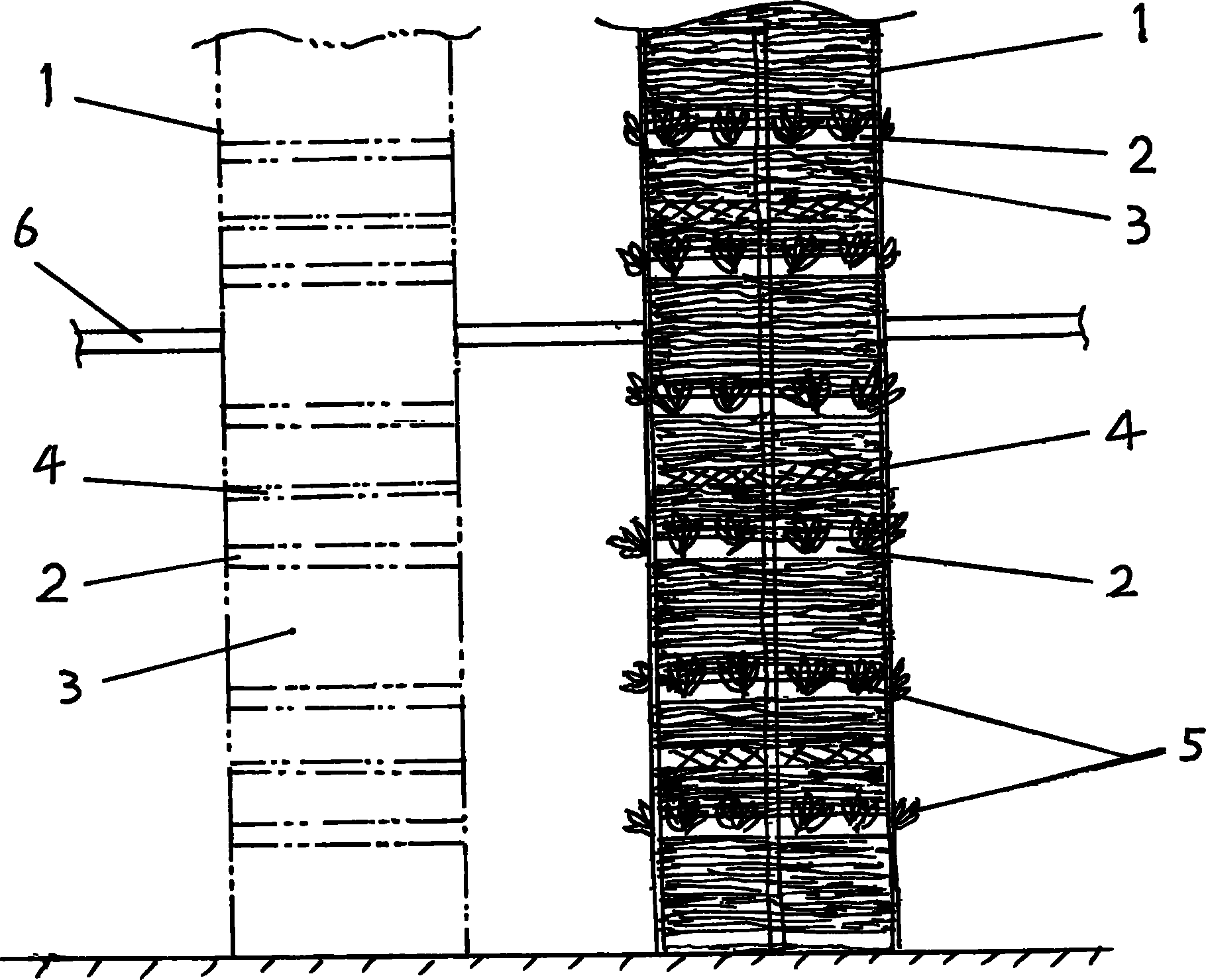

Novel column-shaped three-dimensional cultivation method and device for medical dendrobium

InactiveCN102172205APromote healthy growthEasy to obtainAgriculture gas emission reductionCultivating equipmentsVolumetric Mass DensityHabit

The invention provides a novel column-shaped three-dimensional cultivation method and device for medical dendrobium. The method is characterized by comprising the following steps of making a cultivation device serving as an auxiliary article in a hollow column-shaped body structure; filling a cultivation medium in the interior cavity of the hollow column-shaped body, wherein the hollow column-shaped body is at least 0.5 m in height and at least 8 cm in diameter, the external surface of the hollow column-shaped body is uniformly provided with seedling planting areas, and a cultivation medium composition mainly comprises the following raw materials in parts by volume: 5-15 parts of barks, 10-30 parts of saw dust and 3-10 parts of vermiculite; selecting healthily-growing seedlings to be hardened and then washing the hardened seedlings during cultivating and transplanting the dendrobium seedlings; and after sterilizing by using 800-1000 times of liquid carbendazim, transplanting the seedlings in different plant bunches according to the seedling planting areas, wherein row spaces of the transplanted plants are 4-6 cm*10-15 cm. Compared with the prior art, the cultivation method provided by the invention is very suitable for growth habits of the wild medical dendrobium; and the medical dendrobium cultivated by using the invention has the advantages of easiness for material obtaining, low cost, long service life, good water retention and fertilizer securing effects, high planting density, land utilization rate capable of being increased by 6-7 times, high and stable yield, good product quality and convenience for management.

Owner:杨旺利

Composite microbial feed additive for beasts and birds and production method

ActiveCN101461453AGuaranteed shelf lifeLow costAnimal feeding stuffPediococcus acidilacticiLivestock

The invention relates to a composite microorganism livestock and poultry feed additive and manufacturing method thereof, belonging to the feed technology field. The invention discloses a composite microorganism livestock and poultry feed additive, which is characterized in comprising composite bacterium powder in 1.0-15% of total mass protion; wherein, the composite bacterium powder is compatible of any two or more of the lactobacillus, yeast, pediococcus acidilactici and fecal streptococcus. the strains in the microorganism feed additive of the invention can symbiose to each other, which is favorable to performance their biological activities, and can keep enough shelf life and live bacteria quantity. The invention also achieves the advantages of controlled production process, lower cost and stable product quality.

Owner:BIOGROWING CO LTD

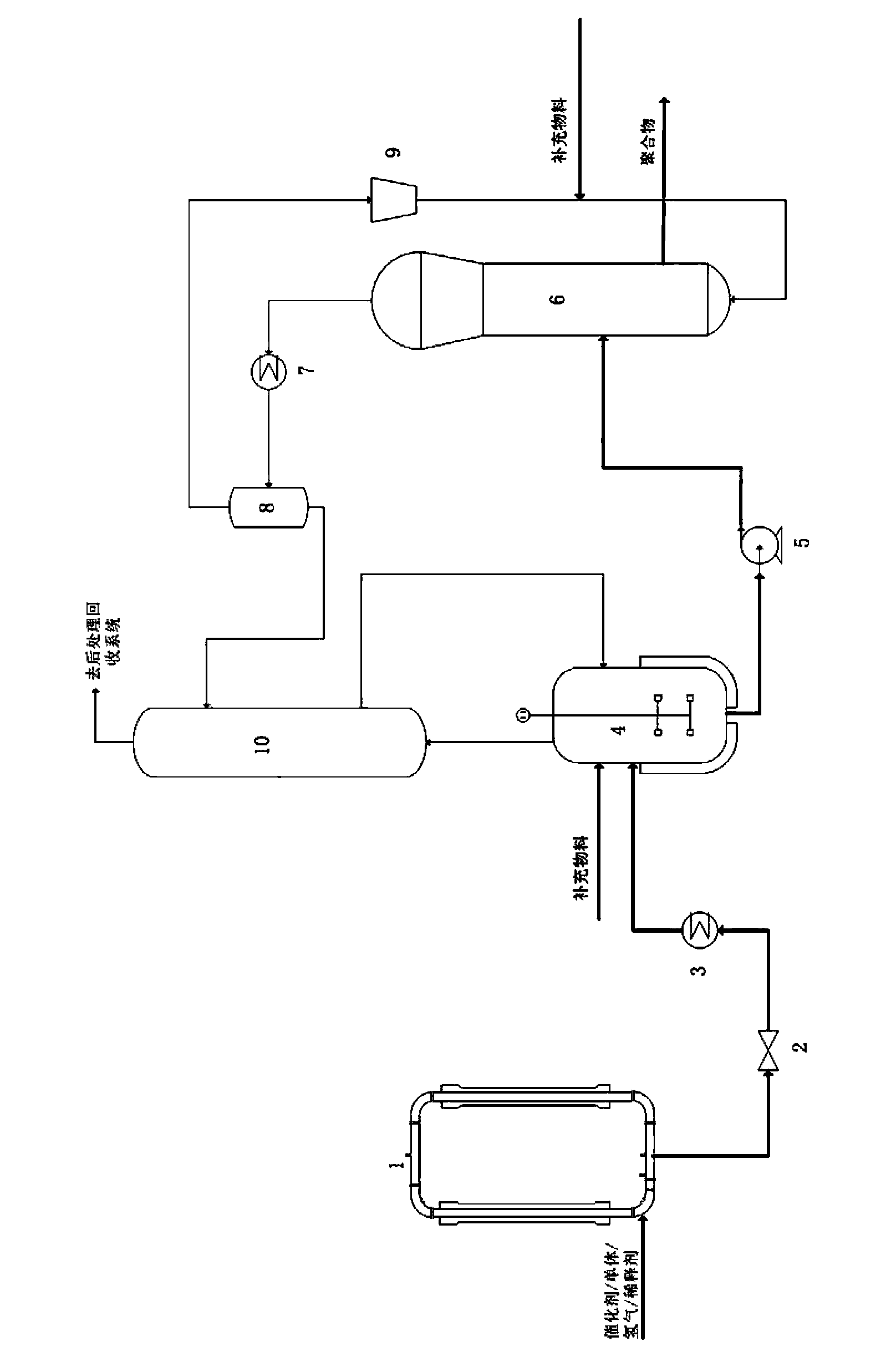

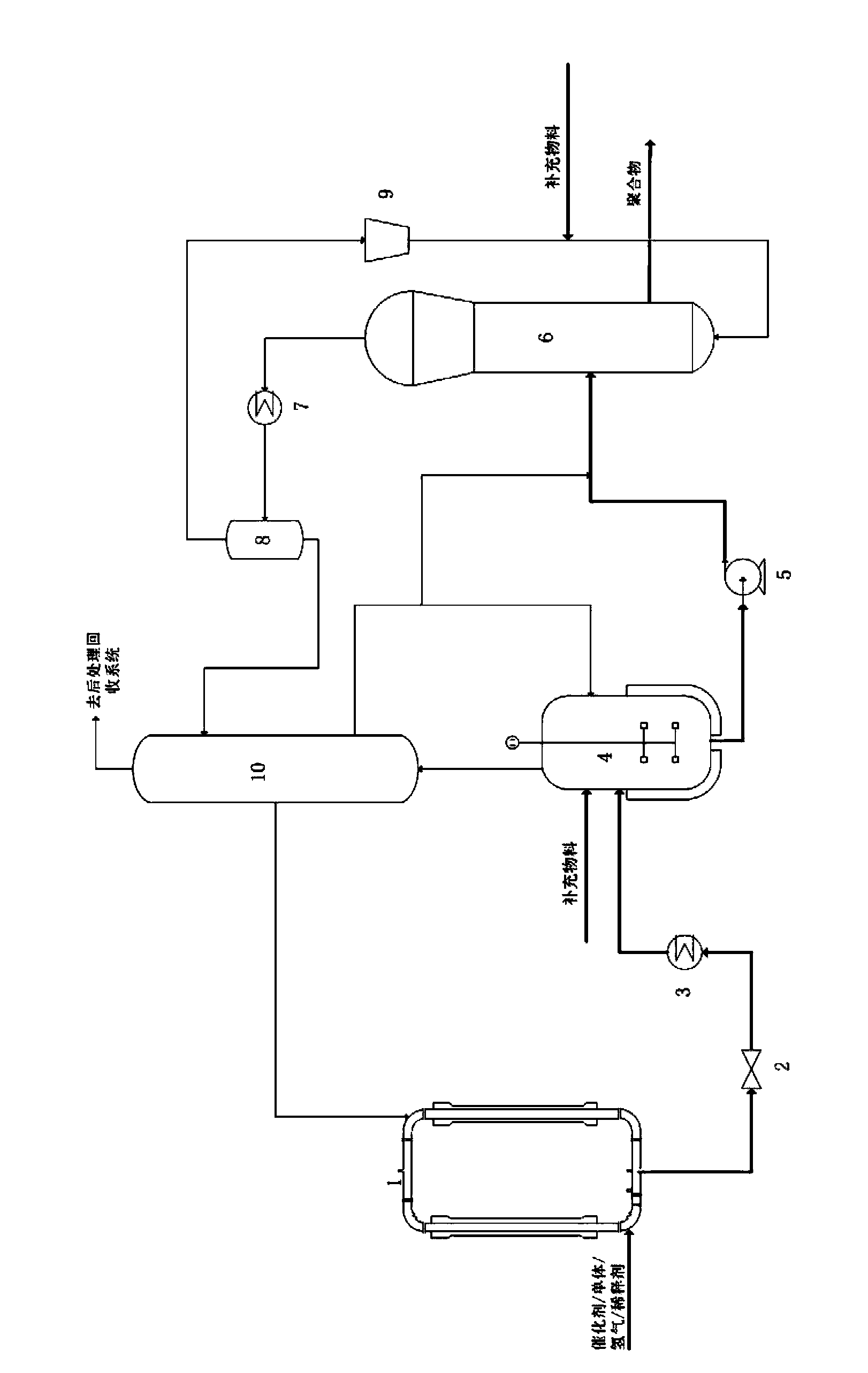

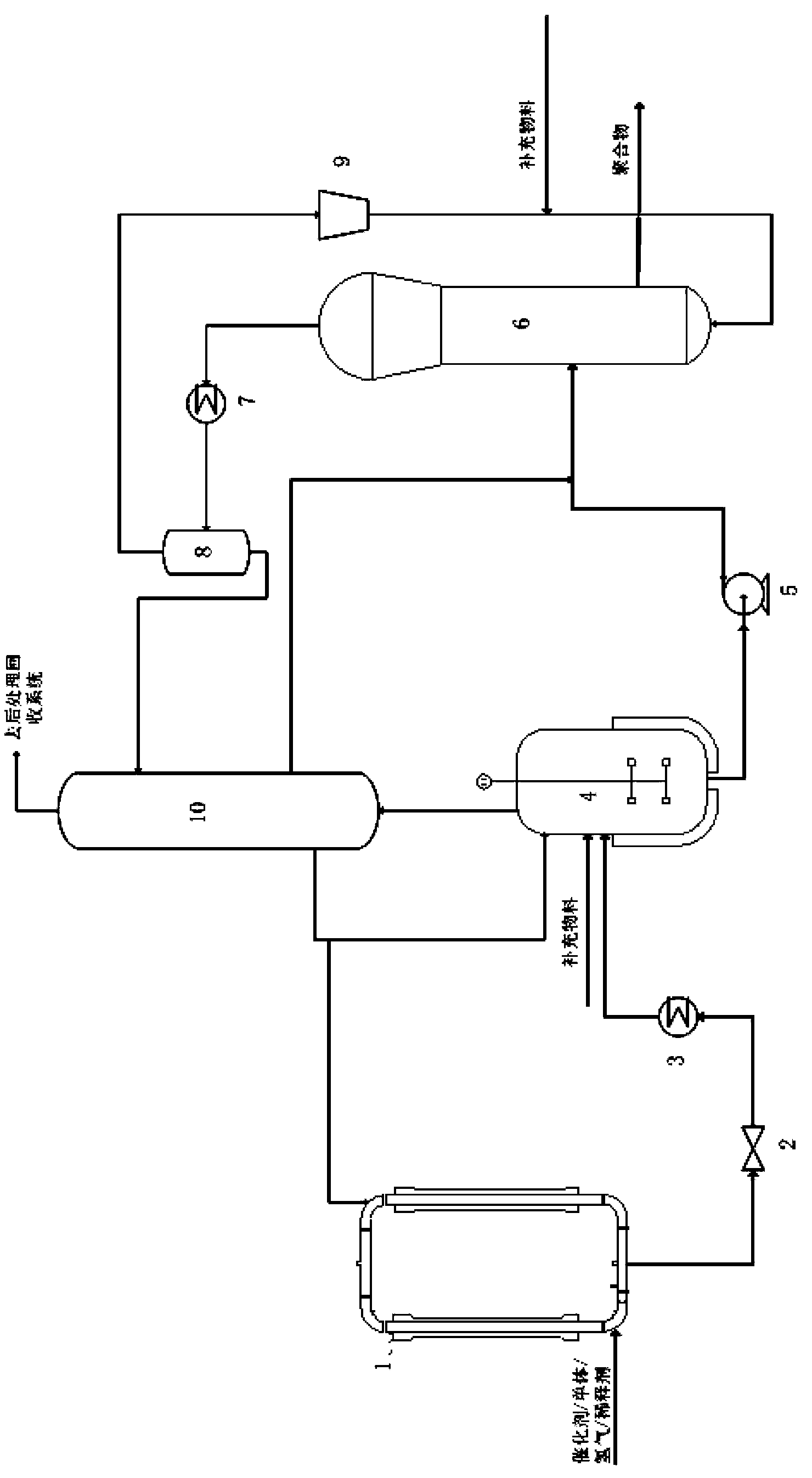

Alkene polymerization system and method

The invention provides an alkene polymerization system and method. The system comprises more than three reactors connected in series. The first reactor is one or more than two annular pipe reactors; the second reactor is one or more than two stirring kettle reactors; and the third reactor is one or more than two gas-phase fluidized-bed reactors. A catalyst and a reaction material enter a first reactor and is subjected to a polymerization reaction; the reaction product with the catalyst enters the second reactor, the material is supplemented into the second reactor, and a reaction is carried out; the product from the outlet of the second reactor enters the third reactor, the material is supplemented into the third reactor, and a reaction is carried out; and a final product is obtained in the third reactor. The system and method provided by the invention is used for producing ultra-wide-molecular-weight-distribution polyolefin with excellent mechanism performances and processing performances.

Owner:CHINA PETROLEUM & CHEM CORP +2

Novel dental zirconium oxide prosthesis and its preparing process

InactiveCN1943538AColoring natureFix color problemsImpression capsDentistry preparationsColor transparencyProsthesis

The invention relates to a dental prosthesis of zirconia material with tetragonal nanometer-sized ZrO2-CaO powder and much added amount of alumina. Said invention also relates to tooth body and false tooth prepared by said above tetragonal nanometer-sized ZrO2-CaO powder and zirconia material for prosthesis, so that making color transparency L*=64-81,colority a*=-1.04- 5.63 and b*=6.95-21.88,thus natural color.

Owner:温宁

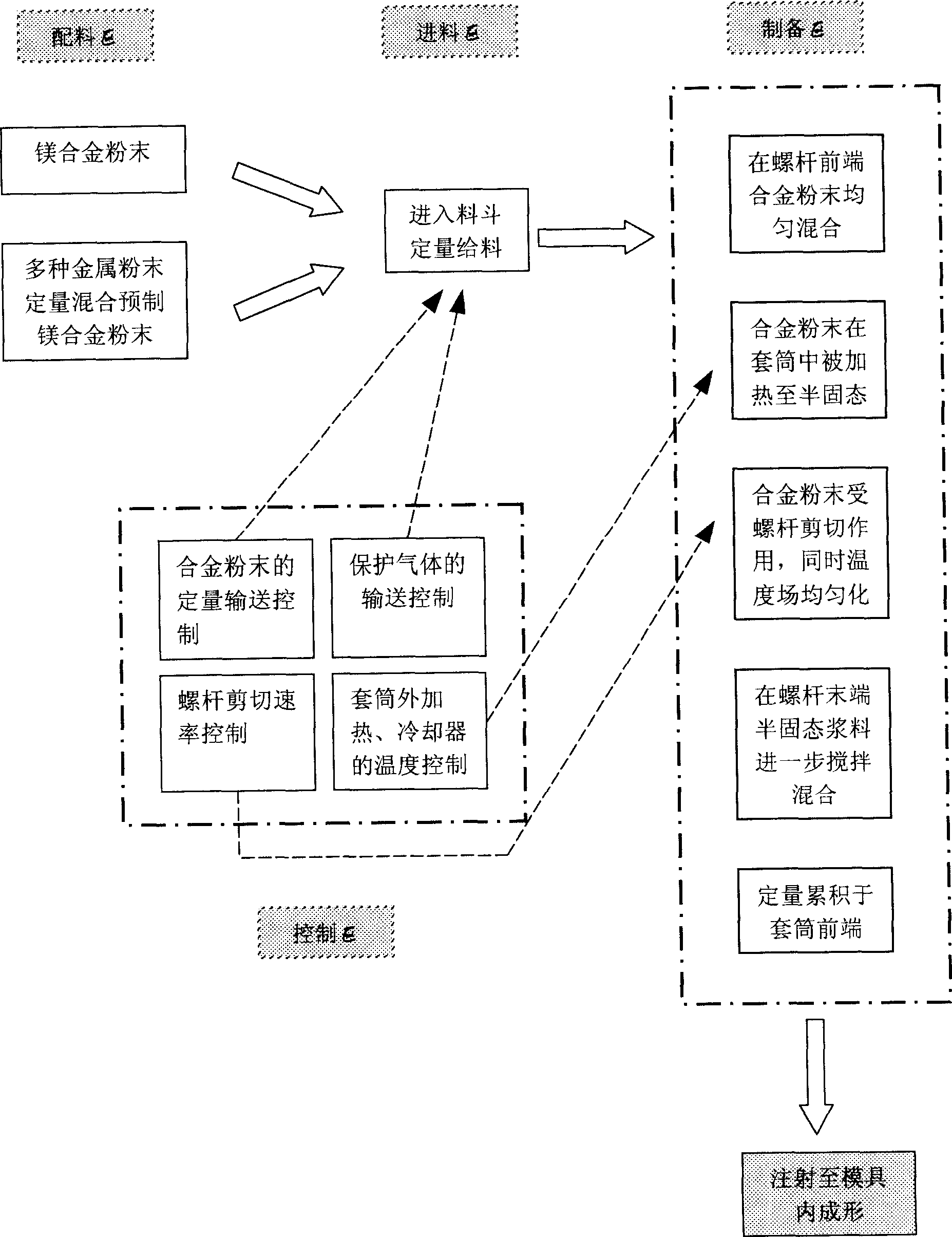

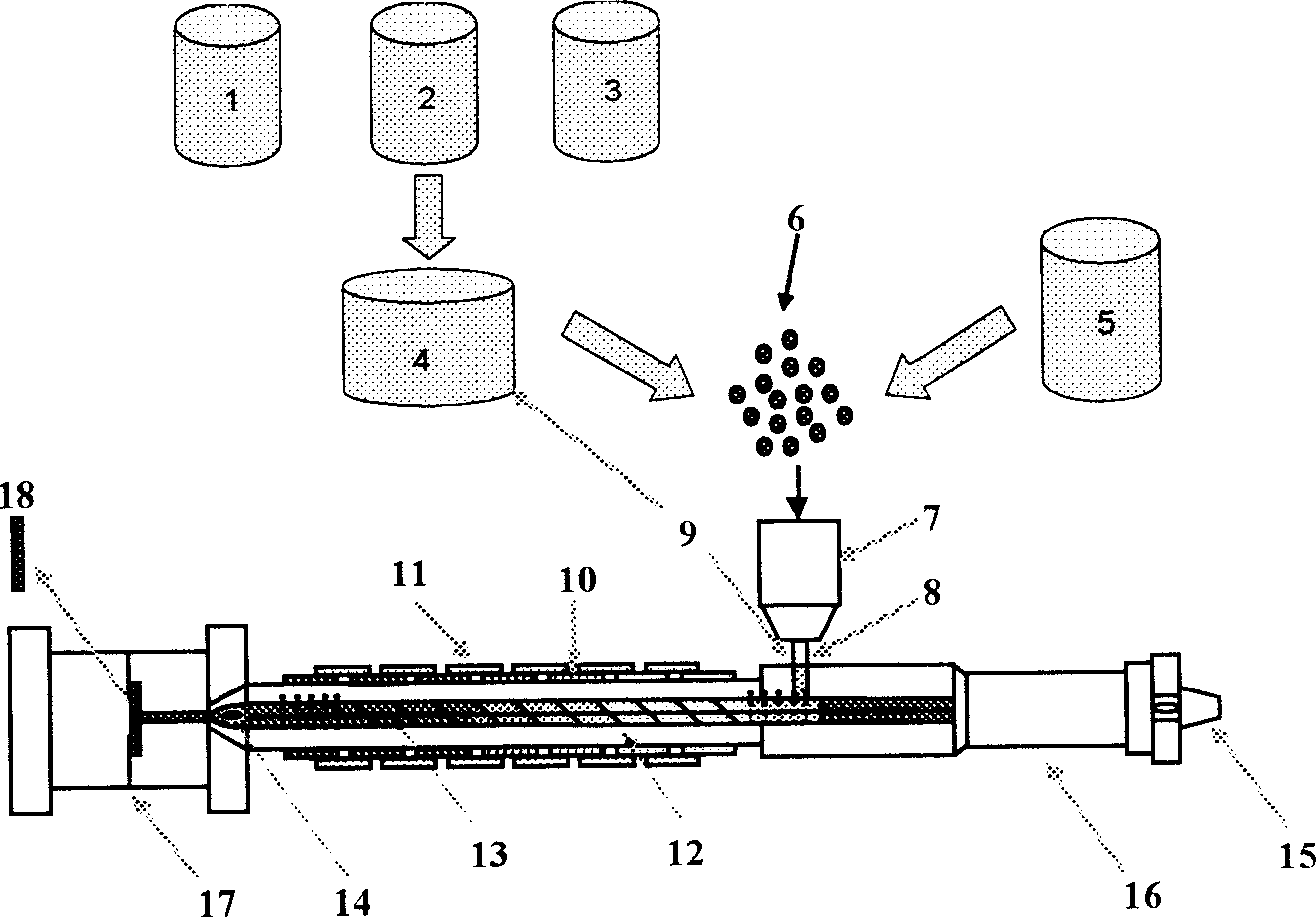

Semi-solid injection moulding method and device for magnesium alloy

A semi-solid injection moulding method for Mg alloy includes such steps as mixing metallic powder, gas protecting, quantitative supply, solid-liquid mixing, and semi-solid injection moulding. Its apparatus is composed of a metallic powder mixer consisting of stirring container and storage container, and an injection unit consisting of the metallic sleeve pipe unit comprising sleeve pipe and internal spiral delivering rod, and the cooler and heater for controlling the temp at different positions of sleeve pipe.

Owner:长春利镁科技发展有限公司

Chewing soft capsule shell, chewing soft capsule drug and prepration method thereof

ActiveCN101628117ALow mechanical strengthReduce toughnessCapsule deliveryMacromolecular non-active ingredientsCarrageenanPolyvinyl alcohol

The invention relates to a chewing soft capsule shell, a chewing soft capsule drug and a prepration method thereof. The soft capsule shell consists of the following raw materials: 25-35 wt% of gelatin, 15-25 wt% of glycerol, 35-50 wt% of purified water, 0.1-1 wt% of sodium alginate, 0.1-1 wt% of carrageenan, 0.1-1 wt% of pectin, 1.5-2.5 wt% of sorbitol and 2-5 wt% of polyvinyl alcohol 400. The chewing soft capsule shell further comprises the following components: 0.1-0.3 wt% of sweetener, 0.2-0.4 wt% of acidifier, 0.001-0.01 wt% of spice, 0.001-0.01 wt% of preservative and 0.001-0.01 wt% of pigment. The soft capsule shell prepared by the raw materials has the advantages of small mechanical strength and toughness, and the invention further provides the method for preparing the chewing soft capsule drug.

Owner:BEIJING HANGYANG CAPSULE TECH

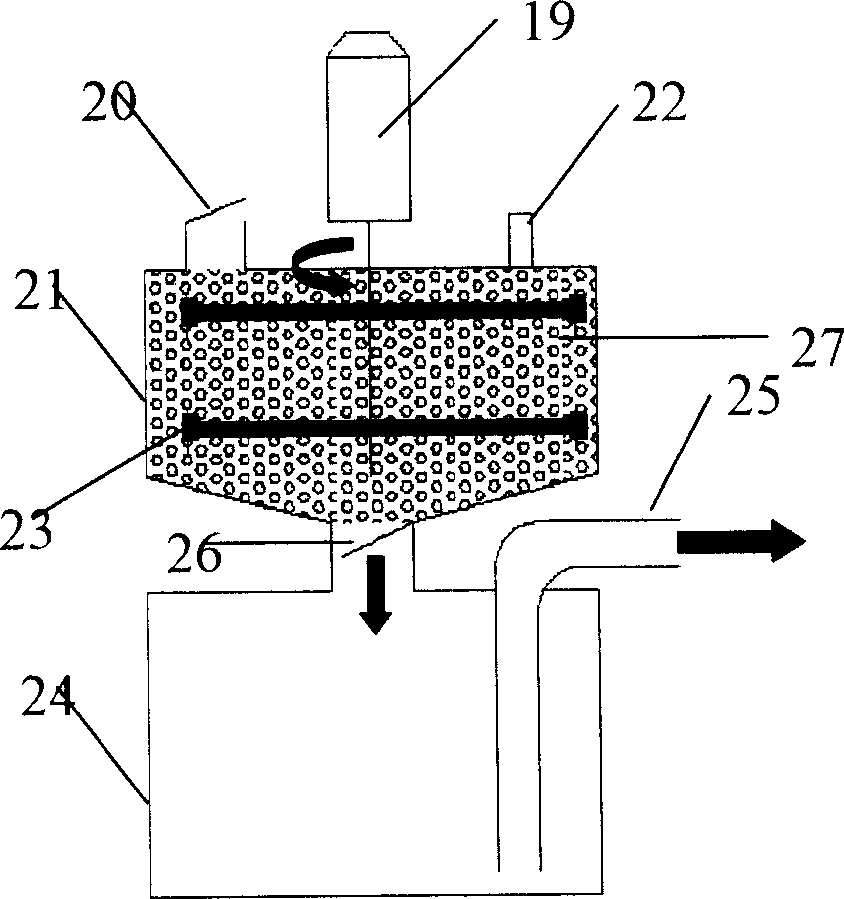

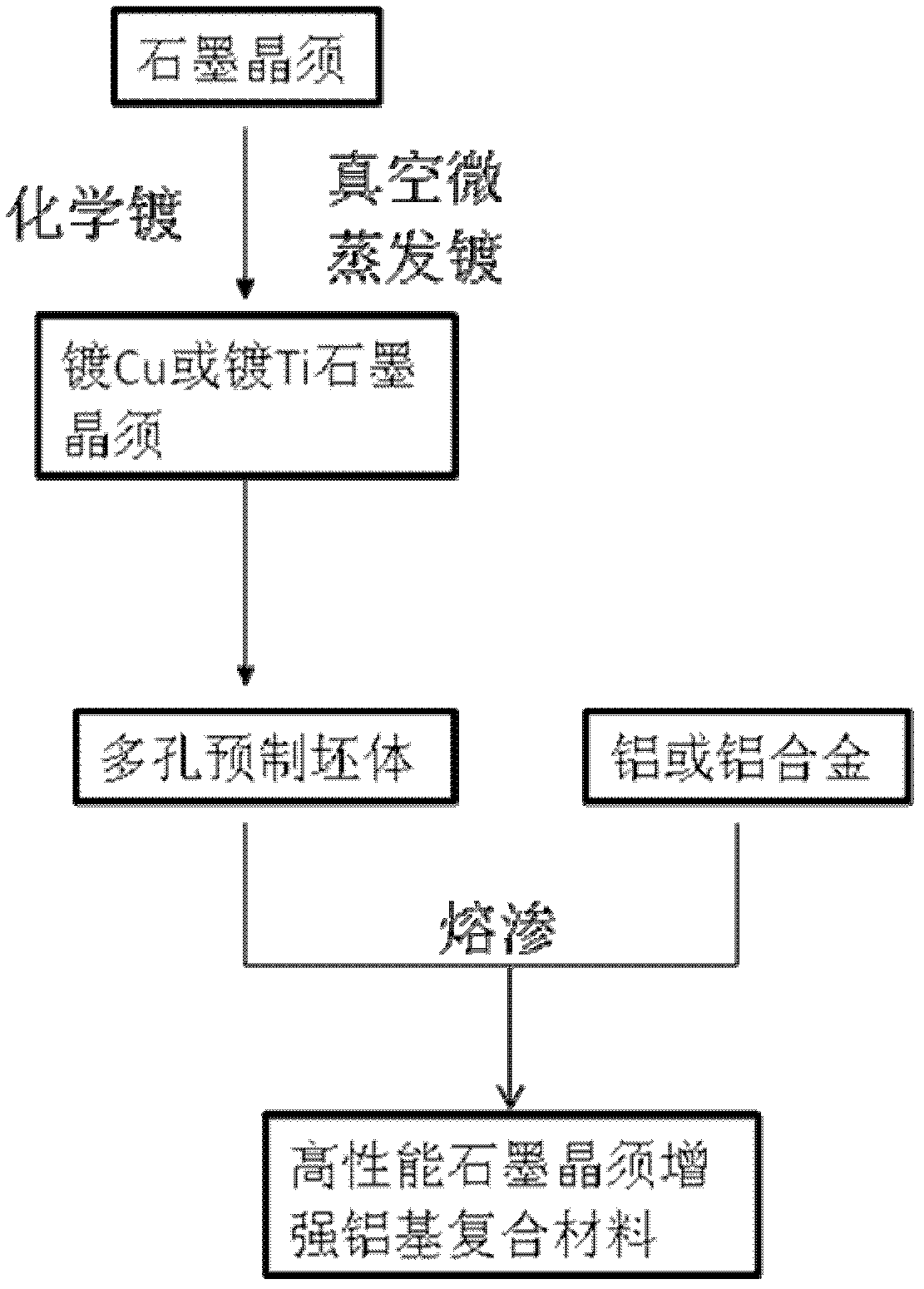

Method for preparing graphite whisker reinforced aluminum matrix composite material

InactiveCN102586703AHigh thermal conductivitySmall coefficient of thermal expansionThermal dilatationChemical plating

The invention discloses a method for preparing a graphite whisker reinforced aluminum matrix composite material. The composite material consists of plated high-reinforced-phase heat conducting graphite whiskers and matrix aluminum or aluminum alloy, wherein the volume fraction of the matrix aluminum or the aluminum alloy is 40%-65%, and the volume fraction of the plated graphite whiskers is 35%-60%. The production process comprises the steps of 1 adopting a chemical plating or vacuum salt bath plating method to plate copper or titanium on the surfaces of the graphite whiskers so as to form a plating layer with thickness of 0.1-1.5mum; 2 adding an appropriate amount of binder on the graphite whiskers with modified surfaces to perform die forming, and then adopting thermal degreasing to remove the binder and manufacture a porous prefabricated blank; and 3 stacking up the prefabricated blank and the aluminum or the aluminum alloy to perform vacuum pressure infiltration processing so as to finally obtain a graphite whisker-aluminum composite material part. The composite material prepared by means of the method has the advantages of being high in heat conductivity, low in thermal expansion coefficient, light in weight, high in densification, easy to process and the like.

Owner:UNIV OF SCI & TECH BEIJING

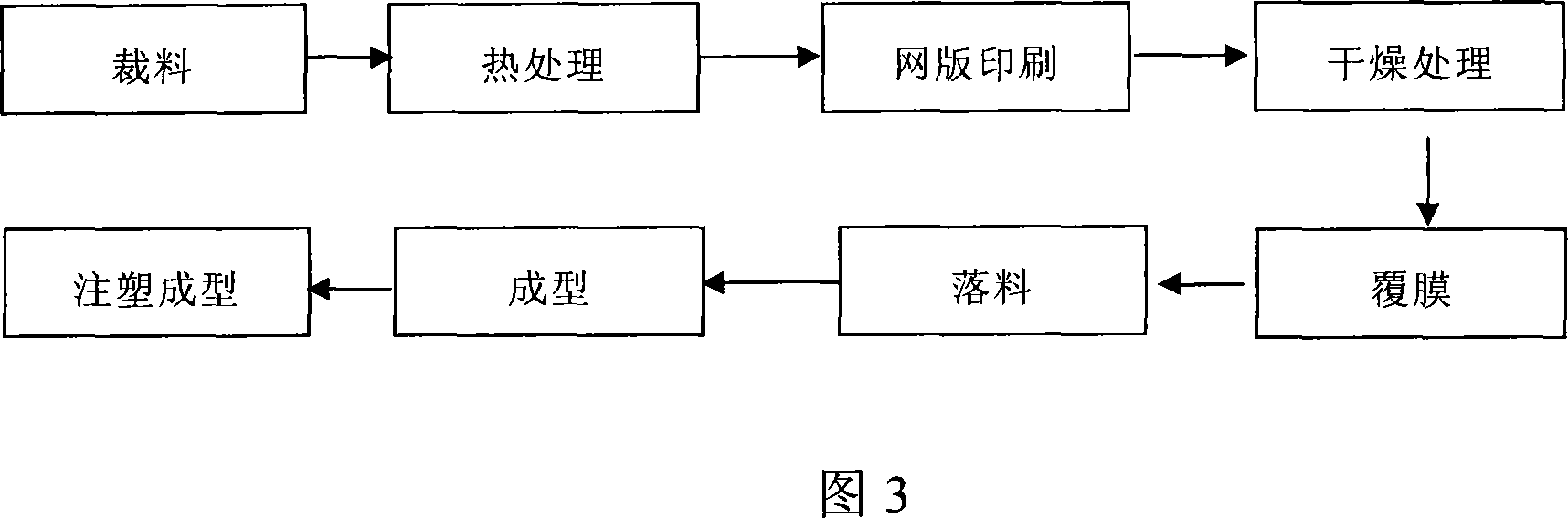

Surface decoration and process for making the same

InactiveCN101200156ABulb uniformAvoid cumbersome stepsSynthetic resin layered productsSpecial ornamental structuresScreen printingGraphics

The invention relates to a surface decoration piece (IMD) and the production process of the surface decoration piece, which is in particular widely used in the information technology products, household appliances, electronic products, personal computers, car accessories and so on and belongs to the technical field of injection molding decoration. The invention is characterized in that the screen-printing of ink patterns is adopted on the reverse side of a transparent sheet. The ink pattern is disposed between the injection molding layer sheet and the formed transparent sheet, which is integrated through the drying, cutting, molding and the injection molding. With the invention, the production time can be shortened and the costs can be reduced with the improvement of product quality and the enhancement of the scratch resistance of the products. With strong solvent resistance, excellent three-dimensional sense, the patterns are clear with excellent anti-light and moisture proof performance. The graphic, logo and color can be changed at any time without the need to replace the die. The convex bubbles of the function keys are uniform with good feel, in which the life expectancy can be up to one million times. The printing precision of the products with three-dimensional shapes is accurate and the error is small.

Owner:无锡市红光标牌有限公司

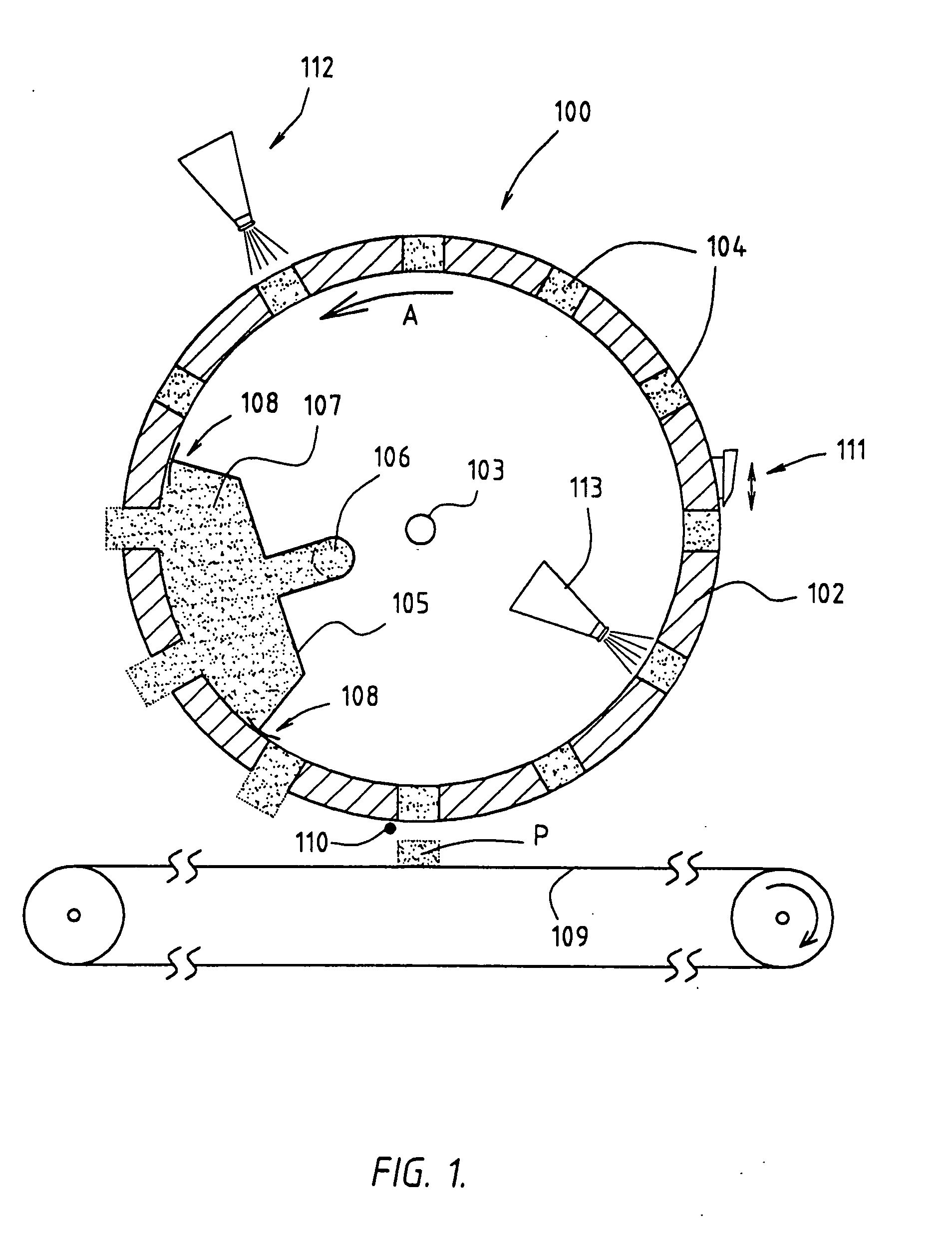

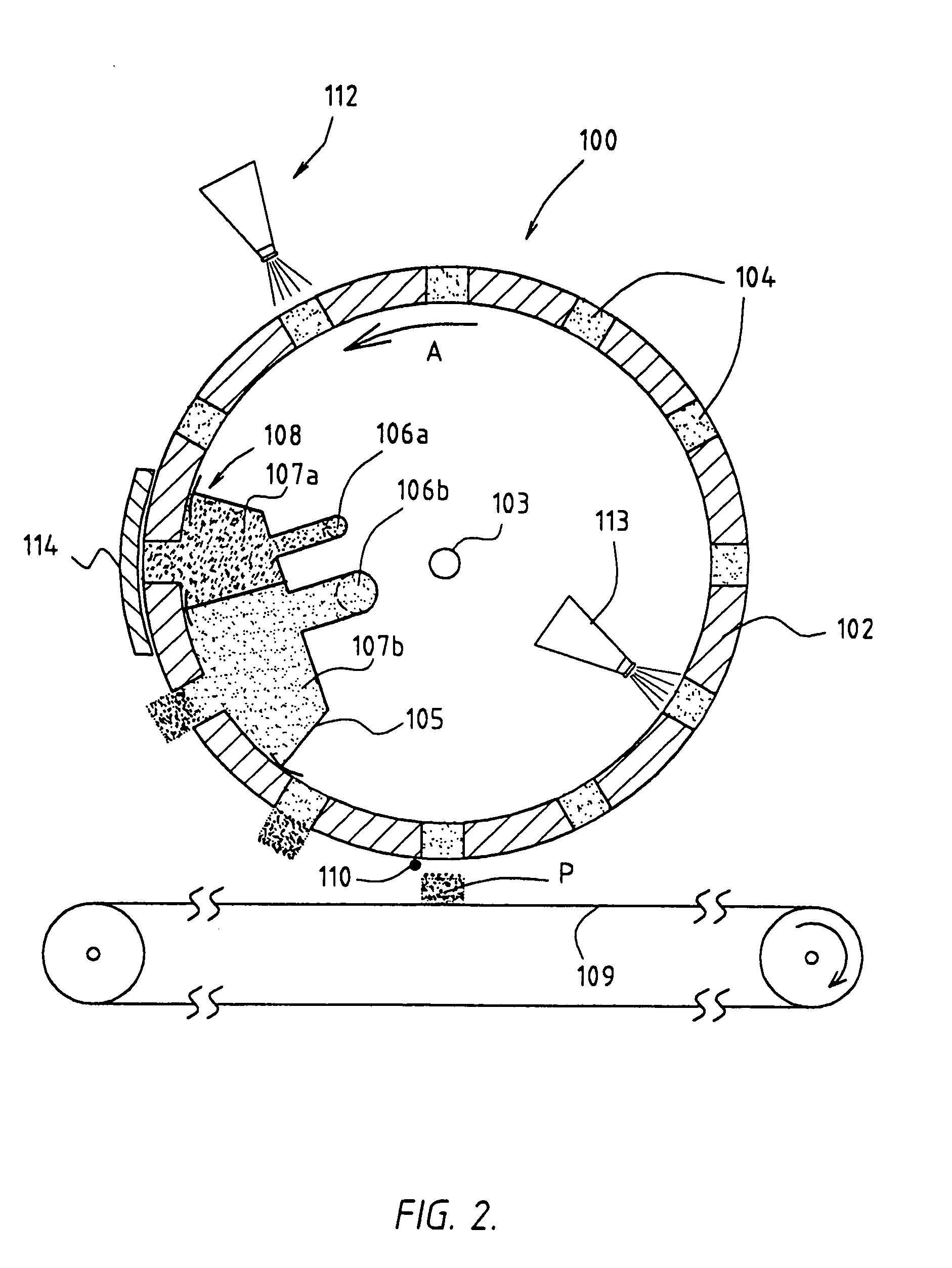

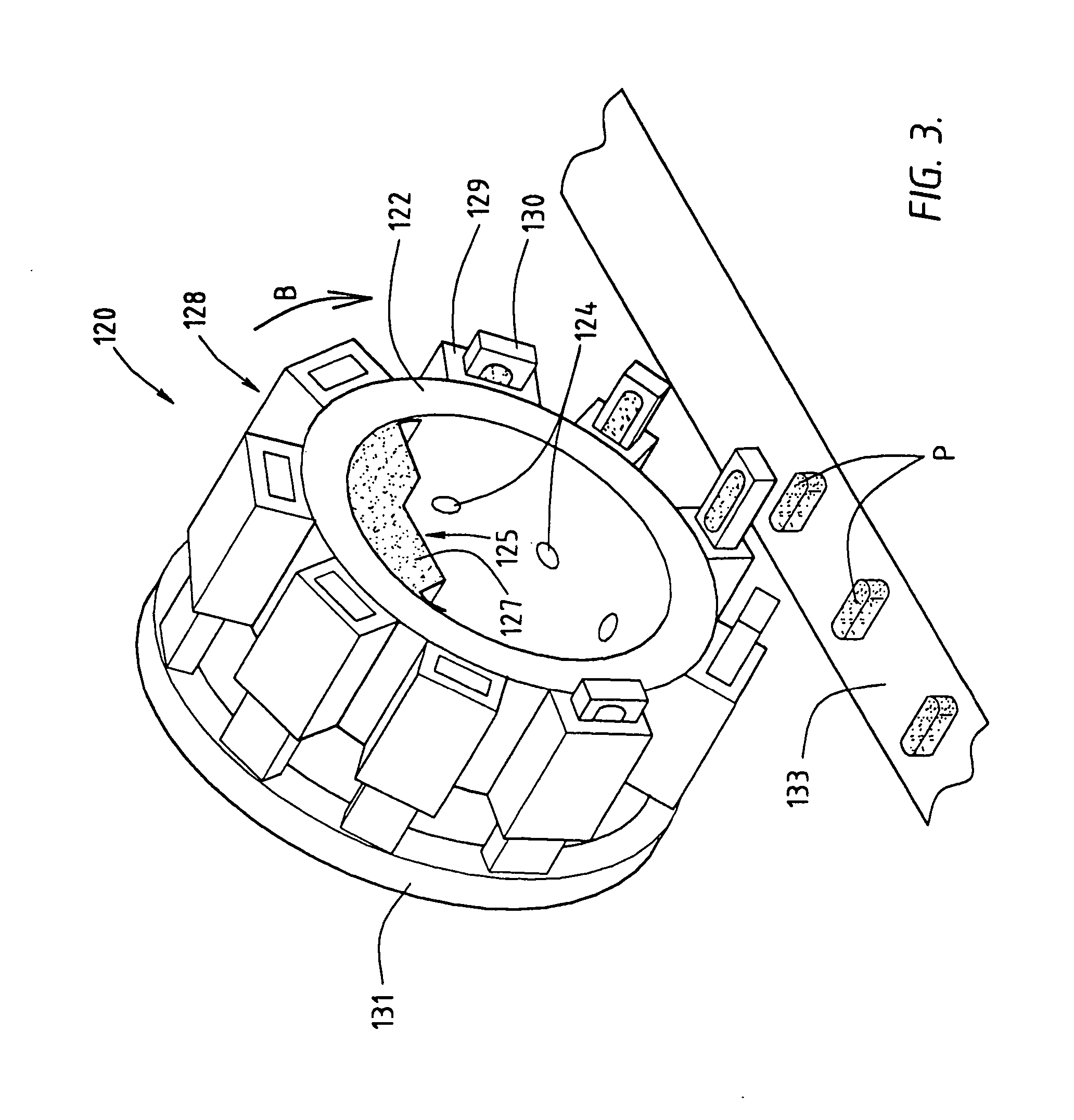

Moulding

InactiveUS20050003062A1Efficient packagingHigh priceConfectionerySweetmeatsPartial fillingMaterials science

The invention provides methods and moulding devices for moulding three-dimensional products from a mass of foodstuff which is suitable for human consumption, in particular from a mass of meat, in particular chicken. The method comprises filling a mould cavity with a portion of the mass under the influence of a filling pressure exerted on the mass and for a filling period via a filling opening associated with the mould cavity, closing the filling opening of the mould cavity and holding the mass in the mould cavity for a fixing period. Then, the mould cavity is opened and the moulded product is removed from the mould cavity. The method uses fixing-pressure-exerting means which are designed to exert a fixing pressure which acts on the mass in the mould cavity after the filled mould cavity has been closed.

Owner:STORK PMT

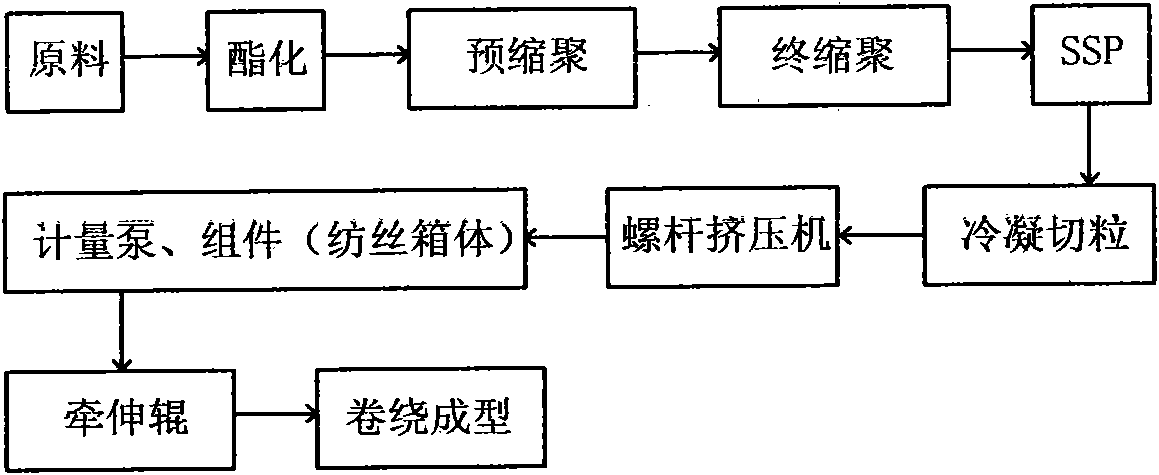

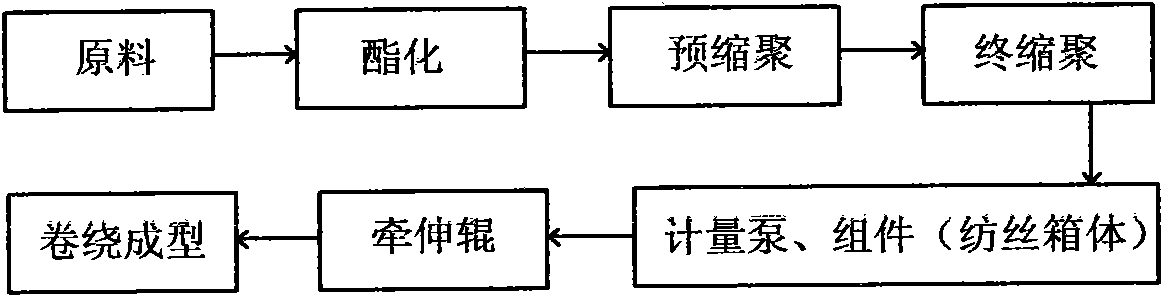

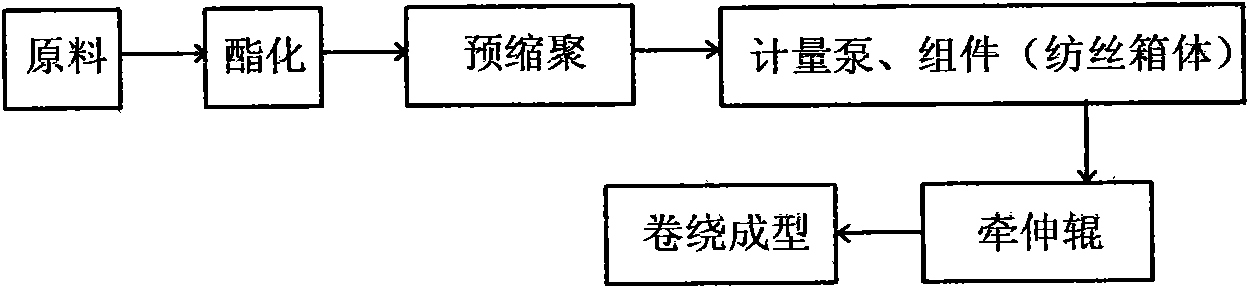

Technology for producing direct spinning terylene industrial filaments after liquid state polycondensation of prepolymer

ActiveCN101914820AShort processReduce energy costsSpinning head liquid feederMelt spinning methodsPolyesterLiquid state

The invention discloses technology for producing direct spinning terylene industrial filaments after liquid state polycondensation of prepolymer and belongs to the technical field of spinning. The technology comprises the processes of esterification, prepolycondensation, liquid state polycondensation, and spinning, and is characterized by comprising the following steps of: performing prepolycondensation reaction on esterified ethylene glycol and phthalic acid to prepare a melt with the viscosity of 0.3 to 0.4dl / g, and conveying the melt to a liquid state polycondensation kettle for liquid state polycondensation by using a booster pump; and conveying the melt to a spinning beam for spinning through a gear pump, wherein the inherent viscosity of the polyester melt after liquid state polycondensation is 0.85 to 1.05dl / g. By directly conveying the melt into the liquid state polycondensation kettle for polycondensation and performing the production technology of directly spinning the melt, the production technology for producing the direct spinning terylene industrial filaments after the liquid state polycondensation of the prepolymer shortens the process flow, reduces the production energy consumption and production cost, and solves the technical problem of difficulty in conveying the melt simultaneously.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

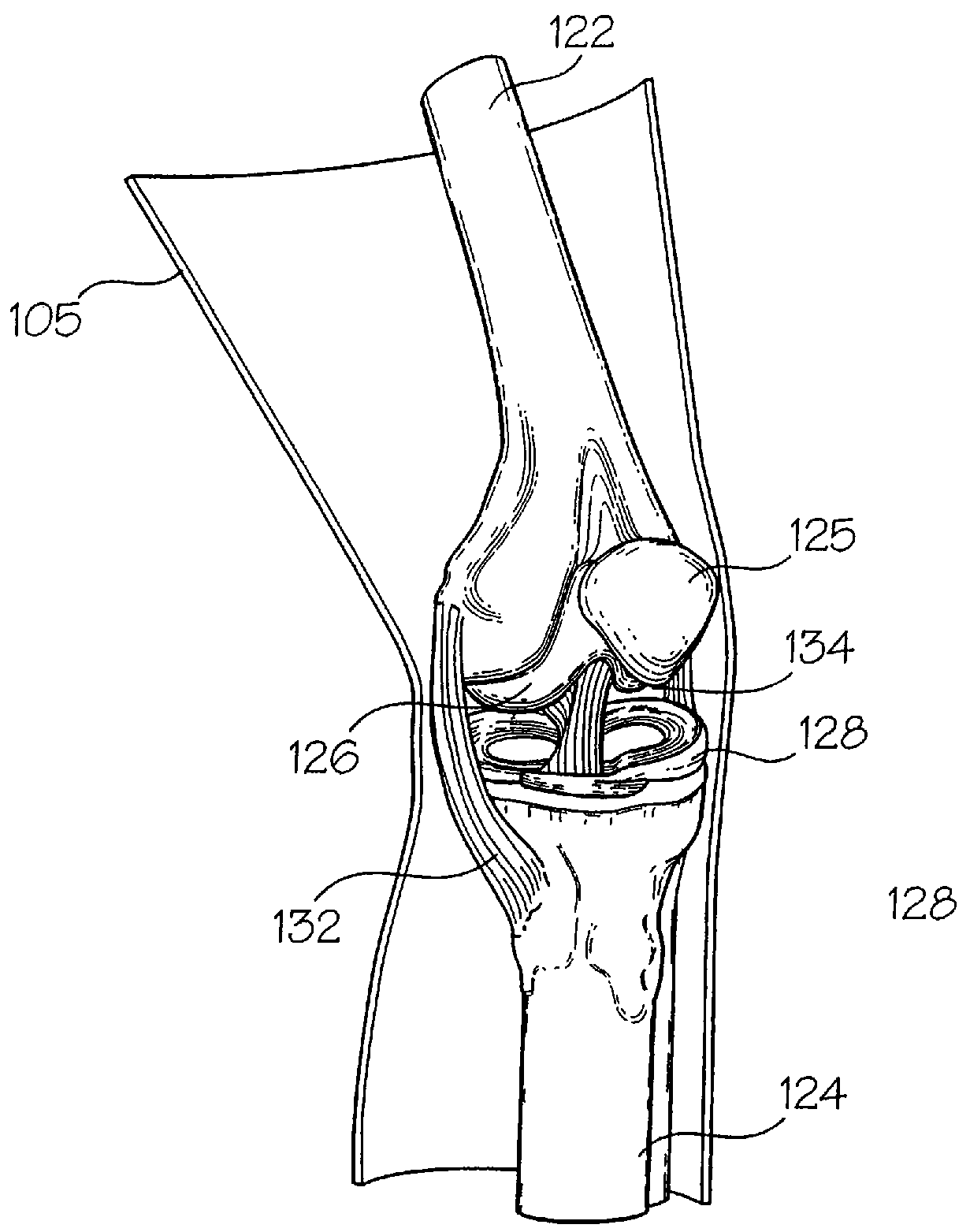

Joint replica models and methods of using same for testing medical devices

ActiveUS7699615B2Avoid product qualityImprove timelinessAdditive manufacturing apparatusEducational modelsAnatomical structuresMedical device

Disclosed herein are joint replica models that are designed to enable simulated use testing by medical device companies, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

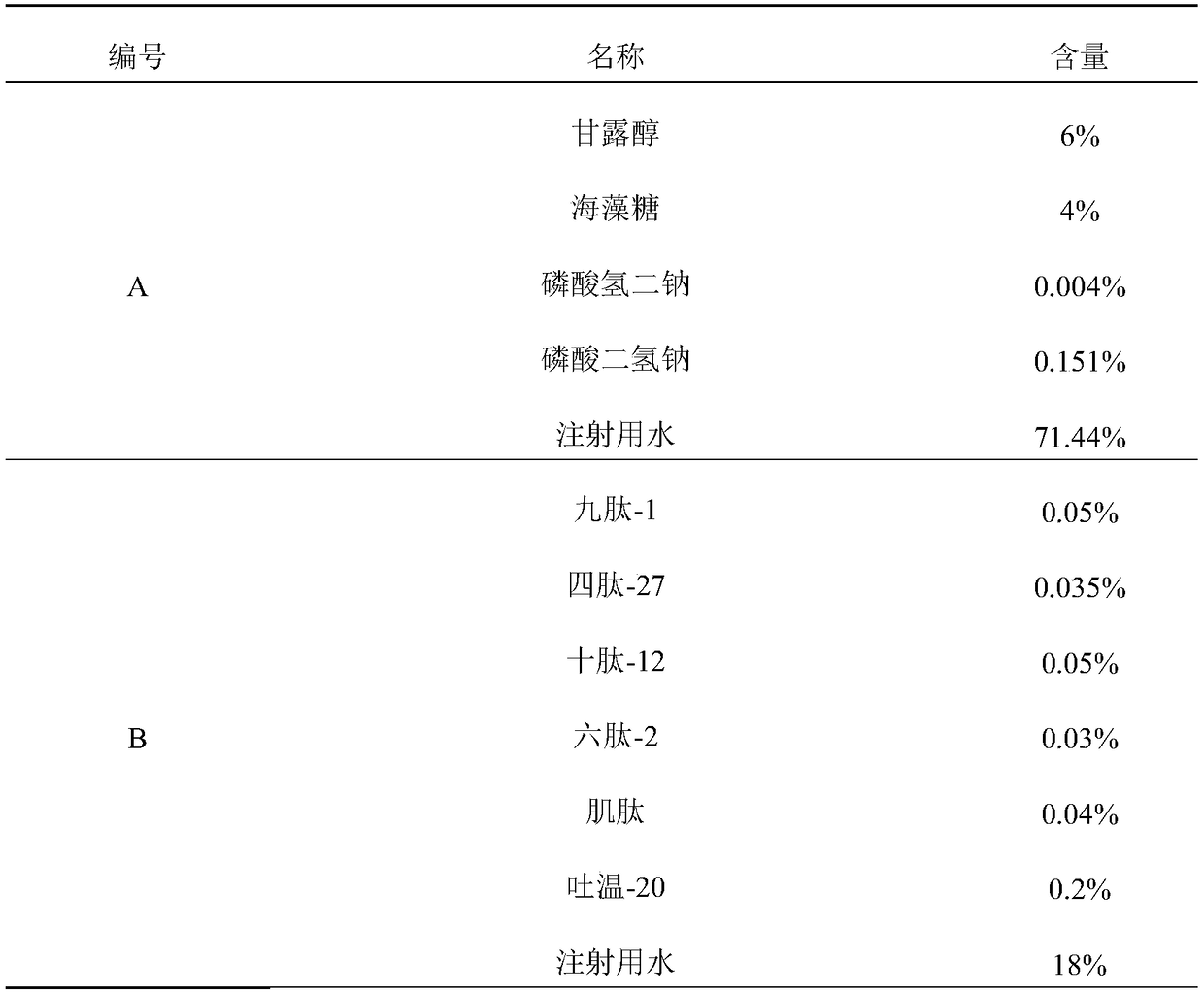

Polypeptide freeze-drying composition with skin activity and preparation method thereof

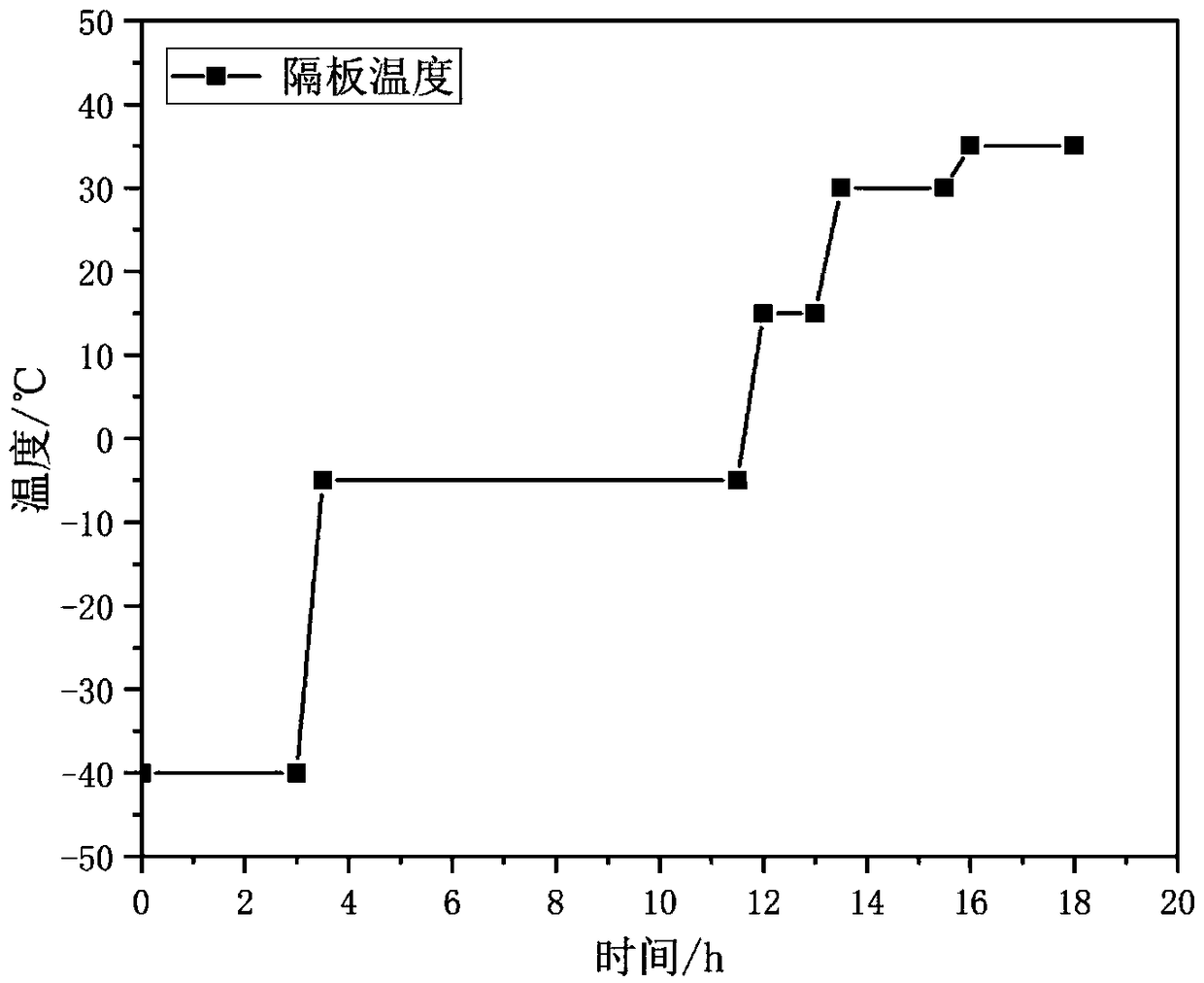

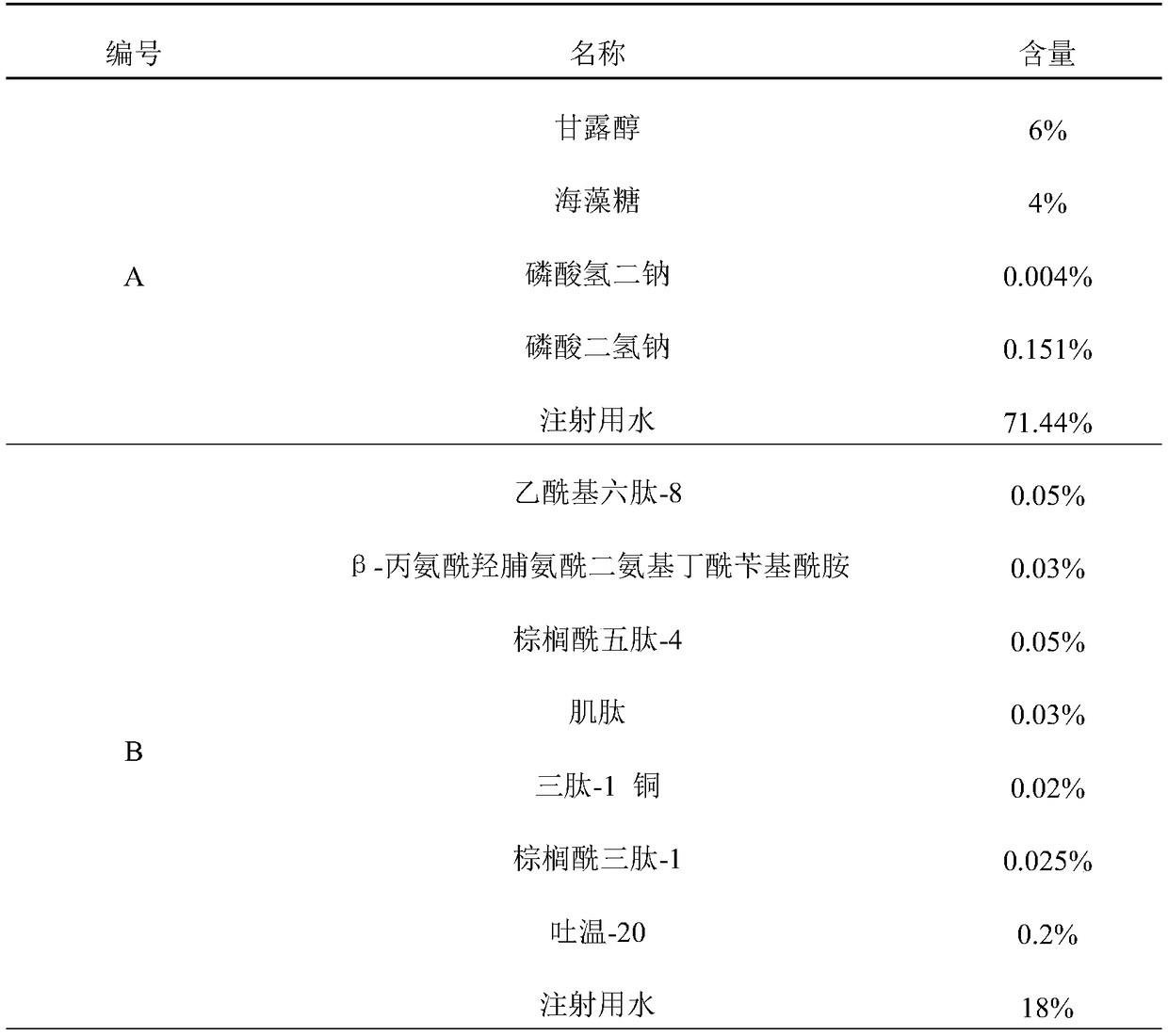

PendingCN109431849AFix stability issuesInhibit growthCosmetic preparationsHair cosmeticsWrinkle skinFreeze-drying

The invention discloses a polypeptide freeze-drying composition with skin activity and a preparation method thereof and belongs to the technical field of beauty polypeptide. The composition is prepared from polypeptide with skin activity, an excipient, a solubilizer and a pH buffer agent. The preparation method of the composition disclosed by the invention comprises the following steps: dissolving, mixing, filtering, sterilizing and filling all the ingredients; setting freeze drying according to a freeze-dry curve to obtain the polypeptide freeze-drying composition with the skin activity. Thepreparation method has the advantages of simple operation and mature and controllable technologies; furthermore, freeze drying is finished within 18h, so that the product quality is ensured; simultaneously, the production energy consumption is reduced, and the production cost is reduced. The polypeptide freeze-drying composition with skin activity prepared by the method has the advantages of goodstability, easiness in storage and no preservative addition. The composition disclosed by the invention is mainly applied to removing wrinkles, resisting senility, whitening the skin, removing freckles, relieving and resisting allergy, removing eye bags, developing hair and fixing hair, so that varieties of skin problems can be improved.

Owner:宇肽生物(东莞)有限公司

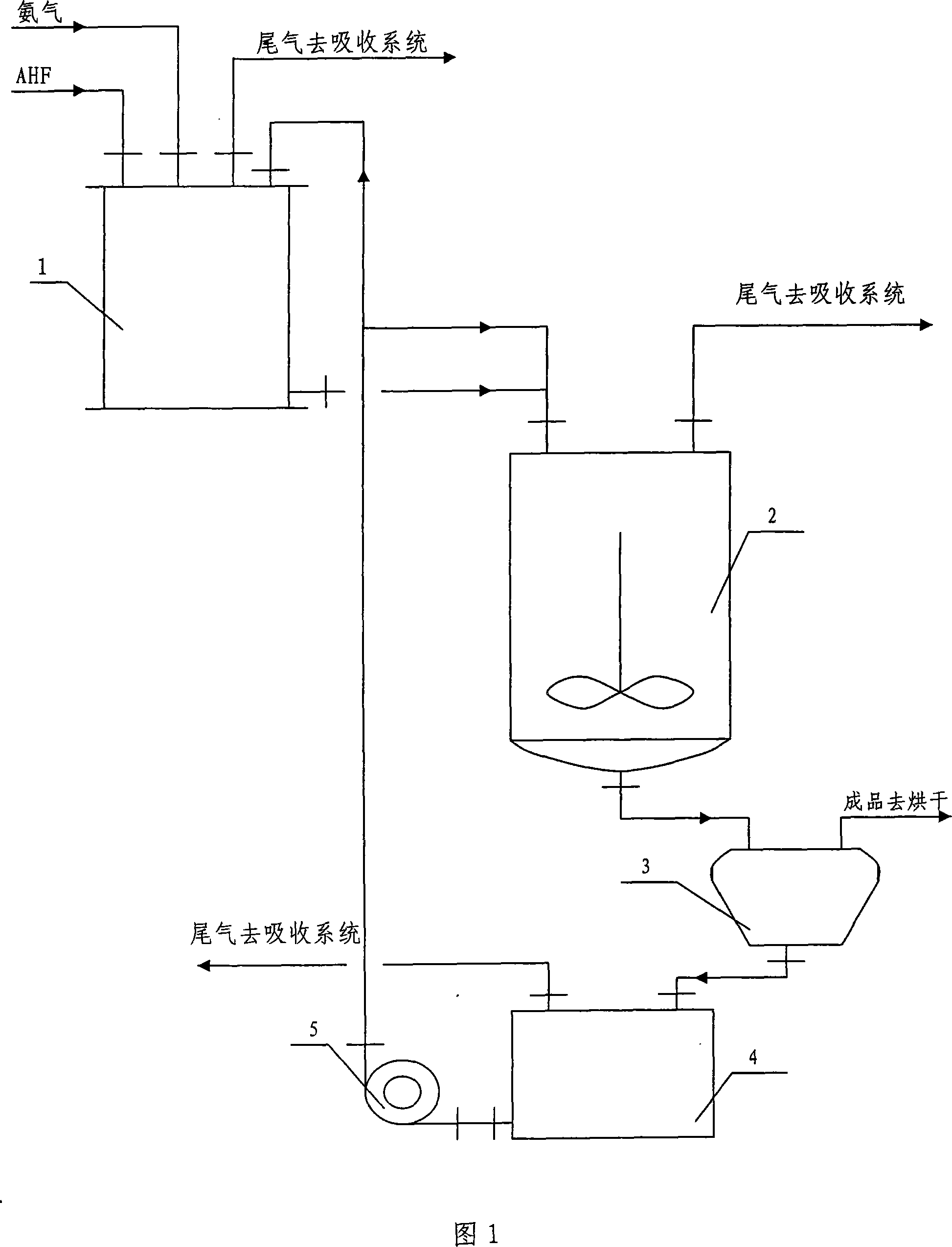

Improved wet process and apparatus for producing ammonium bifluoride

The present invention discloses improved wet process and apparatus for producing ammonium bifluoride. The process includes the following steps: reacting certain amount of mother liquid, ammonia and anhydrous hydrogen fluoride in a plastic reactor with cooling coil; preheating certain amount of mother liquid in a crystalline kettle, adding the resultant while stirring, and slowly cooling to crystallize; dewatering the crystallized product in a centrifuge and stoving to obtain the product, and absorbing the tail gas with mother liquid. The process has simple operation, high yield, high product quality, low power consumption, less pollution and other advantages.

Owner:ZHEJIANG SANMEI CHEM IND

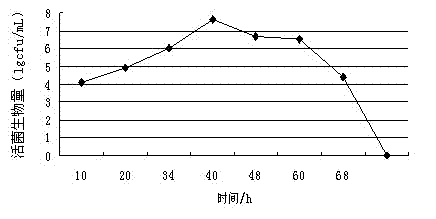

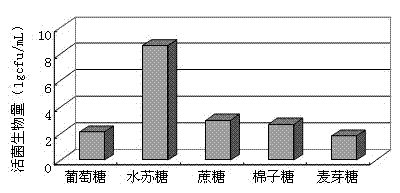

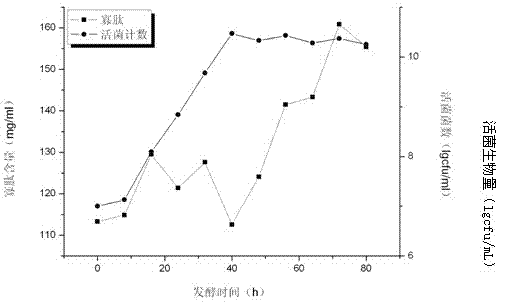

Preparation method of spirulina extract

The invention discloses an extraction method of a spirulina organism, which comprises the following three steps: a fermentation preprocessing step: super macro pulverizing spirulina fine powders, and adding a complex medium to carry out fermentation to prepare fermentation basic solution; a fermentation step: inoculating eosinophilic spirulina bifidobacterium with the fermentation basic solution, and carrying out fermentation to prepare fermentation liquor; and a fermentation postprocessing step: carrying out thallus removal and enzyme inactivation on the fermentation liquor, concentrating, and drying to prepare a spirulina main chemical componet extract. According to the invention, a process combining a super macro pulverization physical method and a bifidobacterium fermentation biological method is adopted for processing spirulina fine powder, so that the unpleasant fishy smell of the spirulina can be effective removed, and the taste of an end product is improved; an eucaryotic cell structure of the spirulina can be effectively damaged, and the contained protein is disassociated, so that the extraction rate of the protein is improved; the high protein can be completely resolved to translate into oligopeptides, and the content of the oligopeptides is improved, so that the end product is easy to absorb and utilize; and the method is simple and convenient to operate, has low cost and little environment pollution.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Efficient biochemical fulvic acid preparing process

The efficient biochemical fulvic acid preparing process is to utilize, enrich and culture humic acid producing bacteria and auxiliary bacteria existing in nature to form specific fulvic acid producing bacteria. The fermented material includes crop stalks, saw dust and other agricultural and forest waste and some inorganic nutrient components as well as fulvic acid producing bacteria, and through controlling nutrients compounding ratio, water content, temperature, humidity and other technological parameters, fulvic acid is produced through directional fermentation. The present invention has the advantages of short fermentation period, low cost, high fulvic acid content, high product quality and easy control of the production process. The fermented product contains great amount of fulvic acid, amino acid, nucleic acid and other matters, and may be used widely in plantation, stockbreeding, aquiculture, industrial fermentation, medicine, pesticide and other industry.

Owner:郭伟光

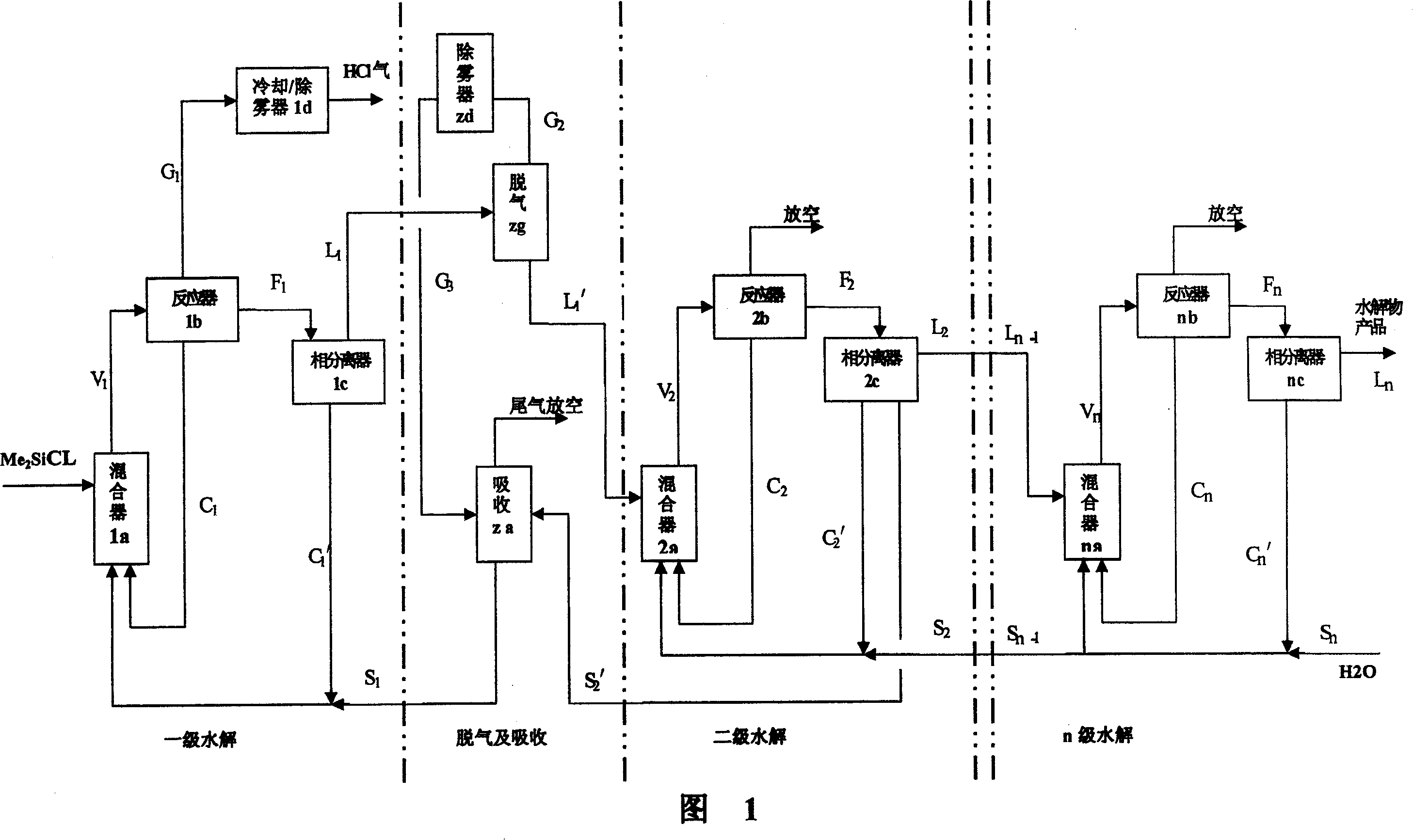

Method for preparing polyorganosiloxane and gas phase hydrogen chloride by multi-stage continuously hydrolyzing dichlorosilane

InactiveCN101148510AReduce pollutionReduce manufacturing costChlorine/hydrogen-chlorideDegasserGas phase

The present invention relates to continuous multistage organic dichlorosilane hydrolyzing process for preparing organic siloxane polymer and gaseous hydrogen chloride. Organic dichlorosilane is hydrolyzed continuously in a circulating hydrolysis reaction system with at least thee stages, each of which includes one inner circulating unit and one outer circulating unit. In the relatively independent hydrolysis reaction stages, the hydrolyzed organic siloxane polymer is fed continuously from the upper stage to the lower stage through one degasser to eliminate great amount of free hydrogen chloride, while hydrolyzed hydrochloric acid is replenished from the lower stage to the upper stage. The present invention has low gaseous hydrogen chloride content in each hydrolysis reaction stage, easy operation, stable product quality, high yield and stable pressure of anhydrous gaseous hydrogen chloride.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Composite material nylon material for polymer lithium ion battery

The invention which provides a nylon film material for a polymer lithium ion battery, which aims at providing a nylon of stable thermal property, superior longitudinal and transverse mechanical property, good compatibility of multilayer compositing, synchronous flow and consistent extension, and a manufacturing method of the nylon. The infill of nylon resin comprises enhanced graft POE or EPDM thermal-plastic elastomer and graft copolymer K-MAH, wherein the additive amount of the enhanced graft POE or the EPDM thermalplastic elastomer and the graft copolymer K-MAH at least accounts for 8-12 wt% of the total amount. The infill of nylon resin also comprises Kresin epoxy resin, N-butyl benzsulfamide, silane surface treating agent, silane-treated nano calcium carbonate and glass fiber. The additive amount of the glass fiber accounts for 30-35 wt% of the total amount. The copolymer (EVA) of ethylene-vinyl acetate is also added, wherein the additive amount of the EVA accounts for 10-16 wt% of the total amount. The problems of the excessive extension of BOPA (biaxially oriented polyamide) in the molding process, and layering, and bubbles appearing at the corners and folded edges in heat-sealing layer contraction when the contraction force is greater than the bonding intensity between a BOPA layer and a Al layer can be mainly solved.

Owner:刘继福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com