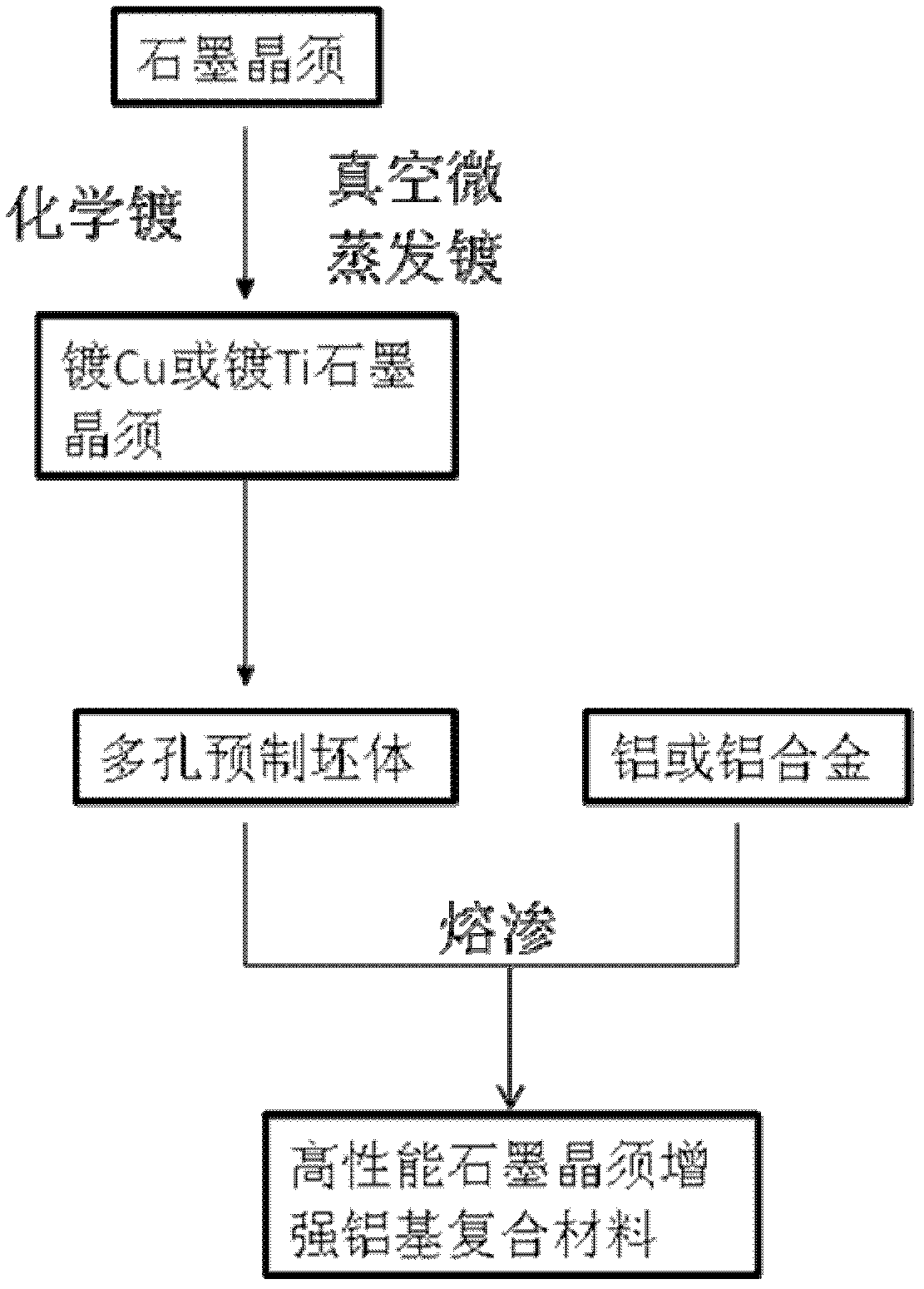

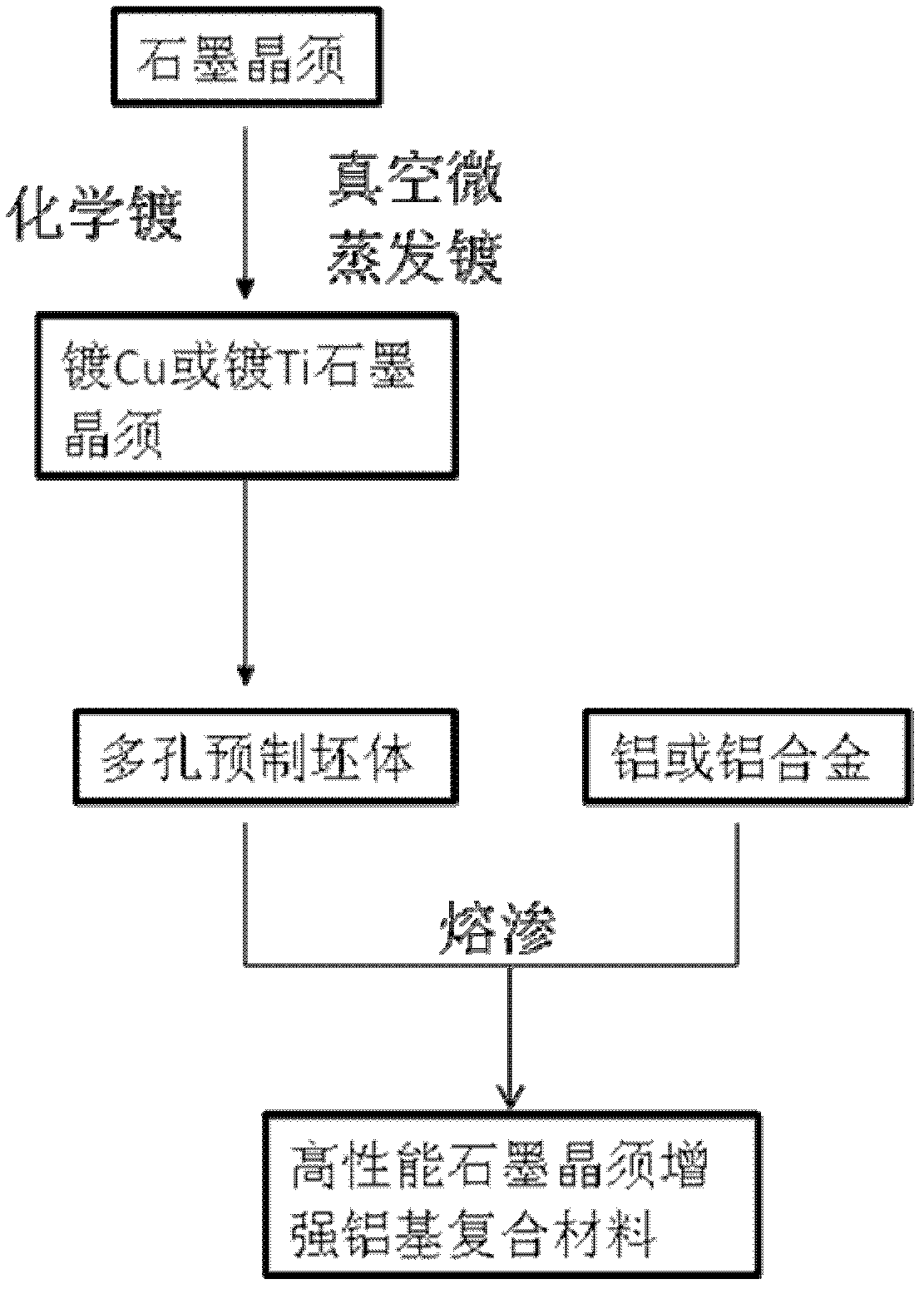

Method for preparing graphite whisker reinforced aluminum matrix composite material

A technology of graphite whisker and composite material, which is applied in the field of high thermal conductivity graphite whisker reinforced aluminum matrix composite material and its preparation, achieves the effects of low thermal expansion coefficient, low production cost and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] First, put graphite whiskers into 20% NaOH solution and boil for 15 minutes to remove surface oil. Then put the treated graphite whiskers into 20% HNO 3 Boil in the solution for 15 min to roughen the surface. Sensitize and activate graphite whiskers that have been roughened after degreasing. The formula of sensitization solution is 20ml / LHCl+20g / LSnCl 2 , the activation solution formula is 20ml / L HCI+0.5g / LPdCl 2 . During the activation and sensitization stage, the solution should be vigorously stirred for 15 minutes.

[0018] Pour the sensitized and activated graphite whiskers into the copper plating solution. The formula of the solution is copper sulfate pentahydrate 15g / L, potassium sodium tartrate 14g / L, EDTA 19.5g / L, bipyridine 0.02g / L, Potassium ferrocyanide 0.01g / L. And add 10ml / L of formaldehyde solution with a mass fraction of 36%, the plating pH is 12, the temperature is 45°C, and the plating time is 3min. After the plating solution is filtered out by v...

Embodiment 2

[0022] A titanium layer with a thickness of 0.2 μm was plated on the surface of graphite whiskers by vacuum micro-evaporation plating. Graphite whiskers after degreasing to a certain extent are mixed with titanium trichloride and titanium cyanide powder according to the mass ratio of graphite whiskers: titanium trichloride: titanium cyanide=100:1:8, placed in a coating container, and Put them into a vacuum chamber together, and the vacuum chamber is pumped to a vacuum degree of 10 -3 Pa, start heating to 700°C, at this time the pressure of the vacuum chamber rises to (1-10Pa), plating for 2 hours, a titanium layer is formed on the surface of the graphite whisker. Then evacuate to high vacuum (10 -3 Pa), get rid of residual reaction gas phase, sieve after cooling and taking out, obtain the graphite whisker with uniform coating.

[0023] The preparation of porous prefabricated body: get a certain amount of titanium-plated graphite whiskers and paraffin wax binder and pour in t...

Embodiment 3

[0026] A titanium layer with a thickness of 0.2 μm was plated on the surface of graphite whiskers by vacuum micro-evaporation plating. Graphite whiskers after degreasing to a certain extent are mixed with titanium trichloride and titanium cyanide powder according to the mass ratio of graphite whiskers: titanium trichloride: titanium cyanide=100:1:8, placed in a coating container, and Put them into a vacuum chamber together, and the vacuum chamber is pumped to a vacuum degree of 10 -3 Pa, start heating to 700°C, at this time the pressure of the vacuum chamber rises to (1-10Pa), plating for 2 hours, a titanium layer is formed on the surface of the graphite whisker. Then evacuate to high vacuum (10 -3 Pa), get rid of residual reaction gas phase, sieve after cooling and taking out, obtain the graphite whisker with uniform coating.

[0027] The preparation of porous prefabricated body: get a certain amount of titanium-plated graphite whiskers and paraffin wax binder and pour in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com