Patents

Literature

263 results about "Titanium trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trivalent titanium. In titanium: Compounds …the more important is the trichloride TiCl3, a crystalline form of which is particularly useful as a catalyst in the stereospecific polymerization of propylene to make the commercially valuable polymer polypropylene.

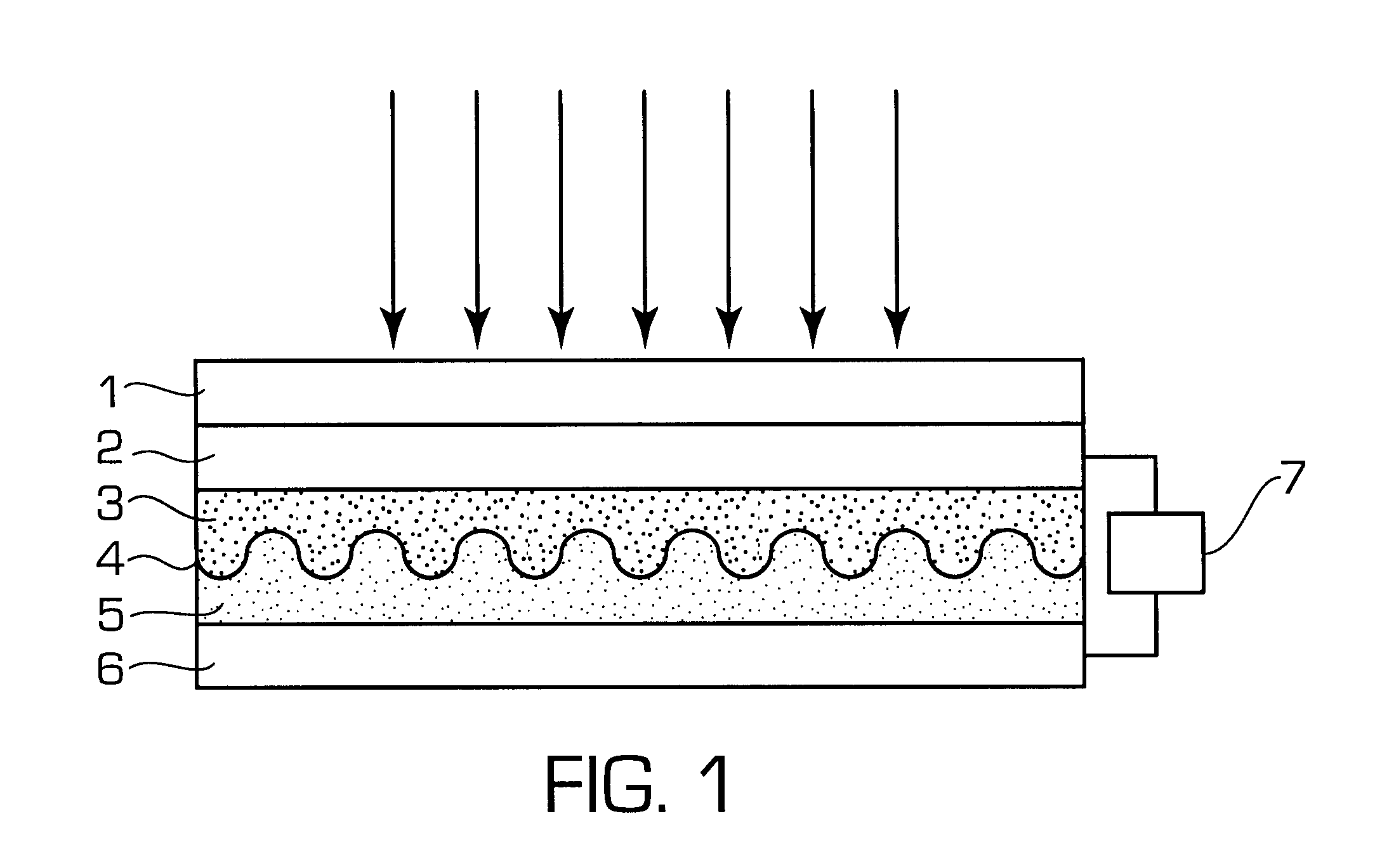

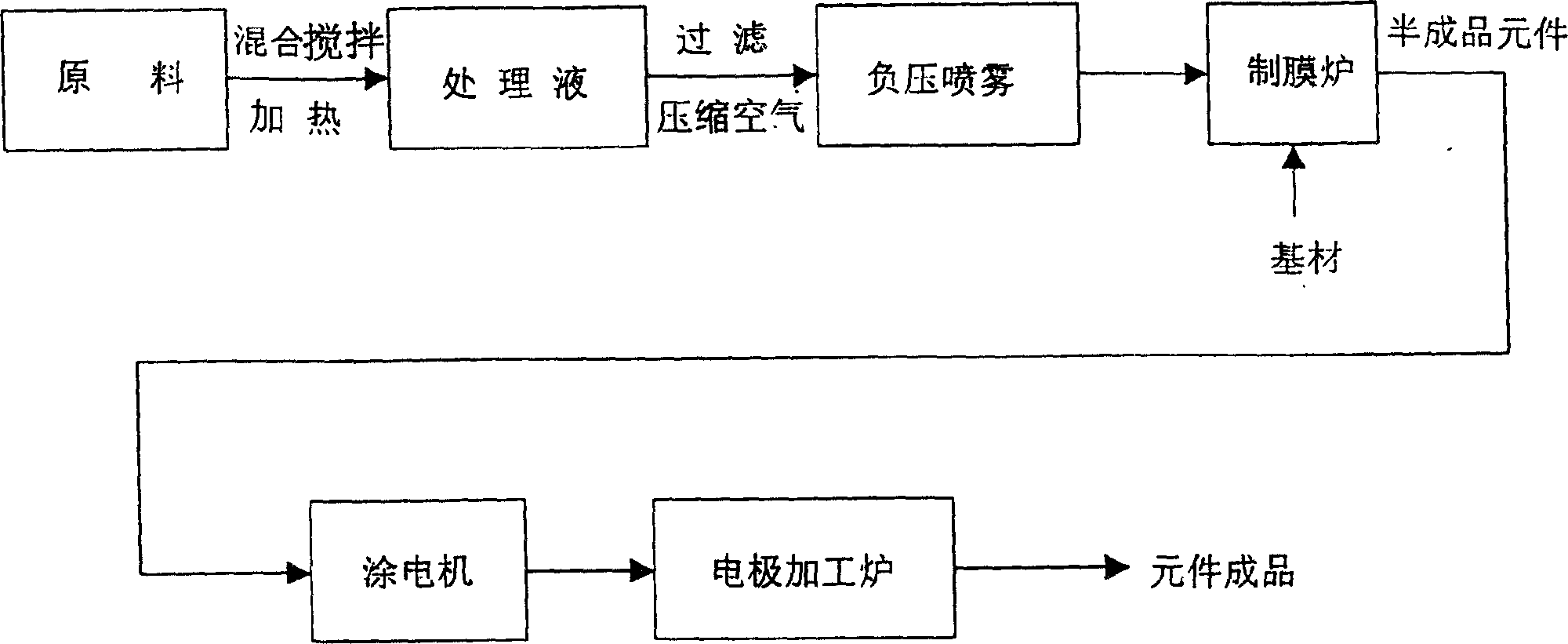

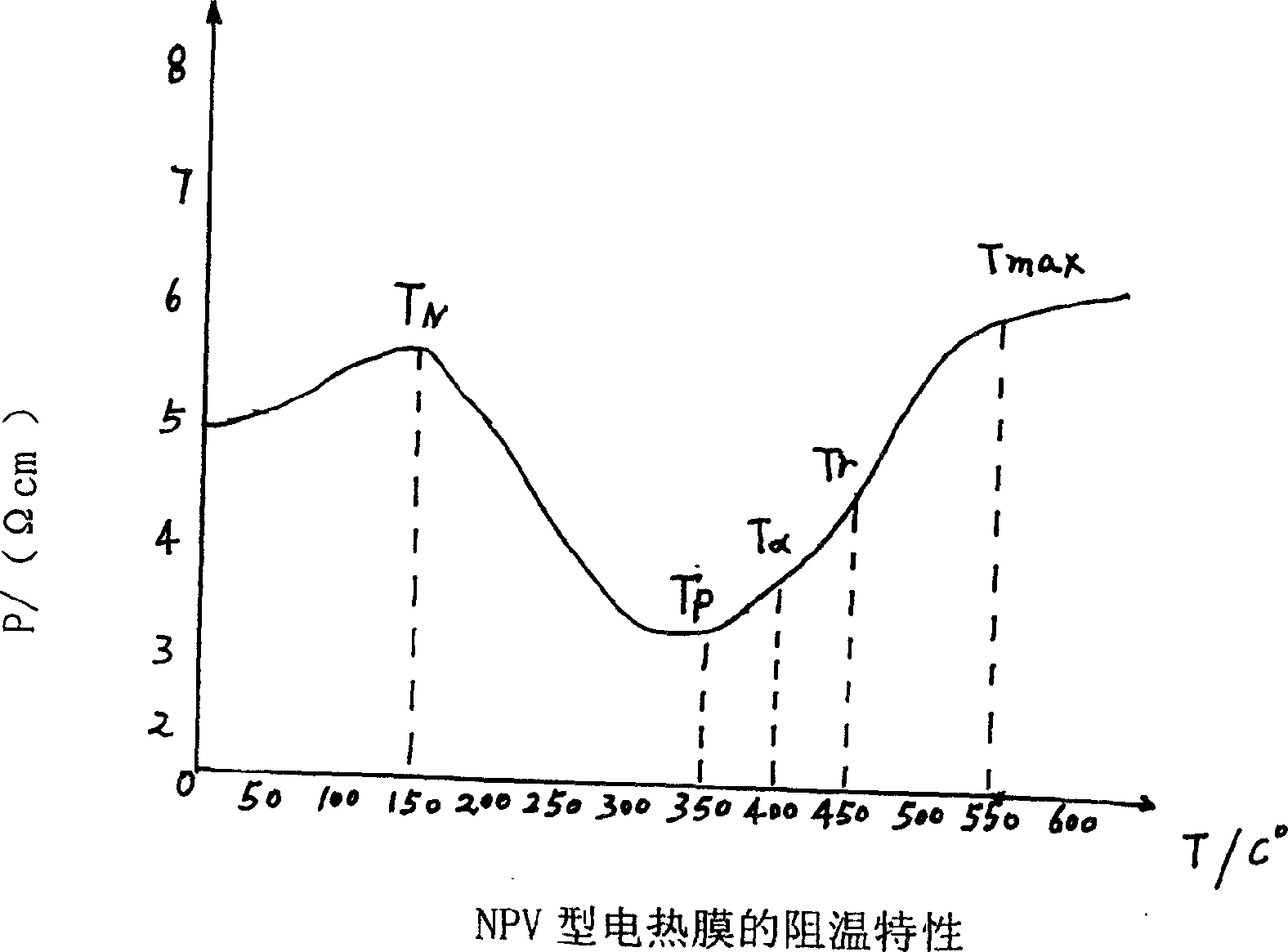

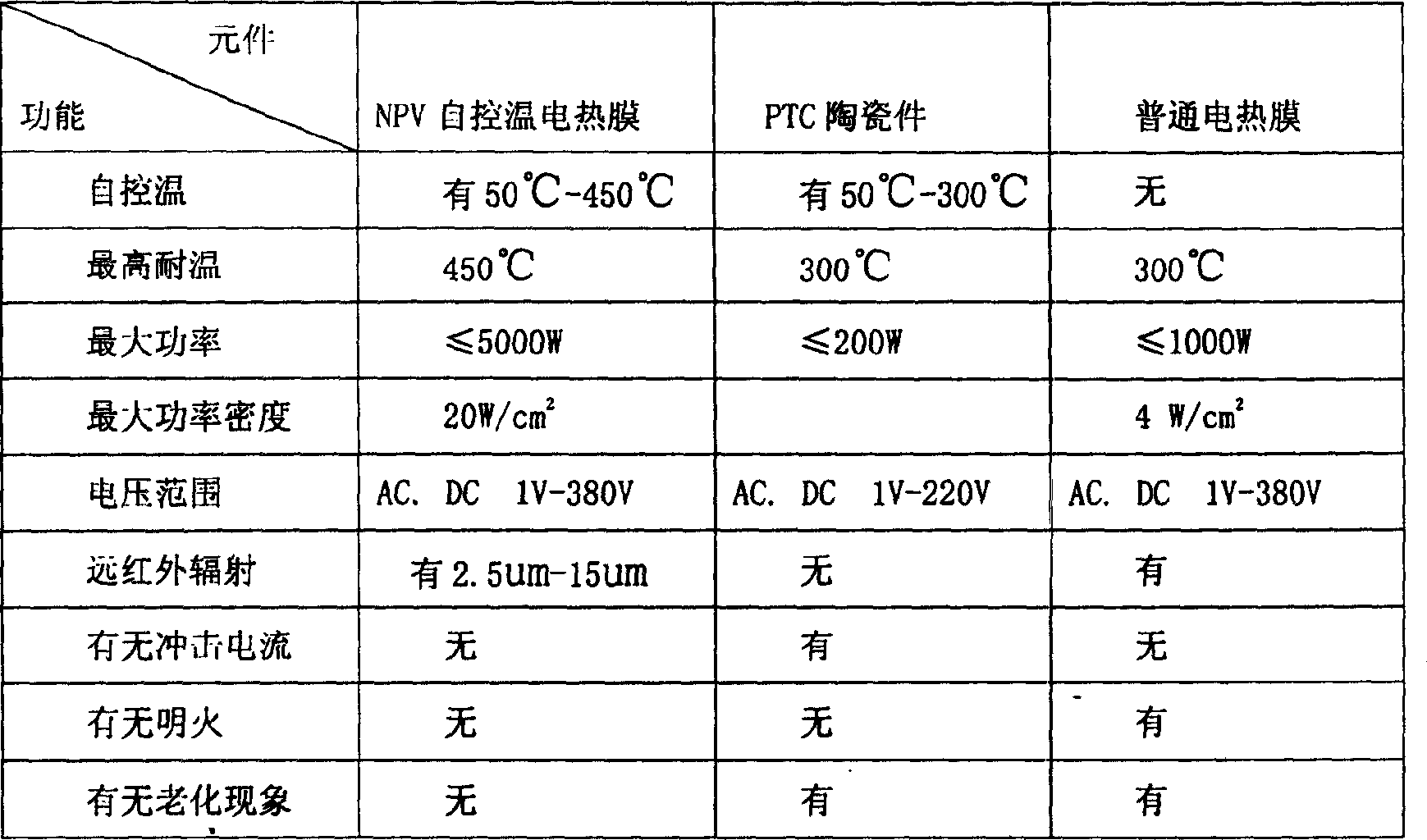

Electrothermal film and manufacturing method thereof

ActiveCN101668359ASimple processEfficient processHeating element materialsResistors adapted for applying terminalsTitanium chlorideMetallurgy

The invention relates to an electrothermal film and a manufacturing method thereof, belonging to the technical field of semiconductor heating. The electrothermal film is mainly prepared by adopting stannic chloride, titanium tetrachloride, stannic chloride, titanium trichloride, ferric chloride, antimony trichloride, calcium chloride, potassium chloride, cadmium chloride, stannic dioxide, stannictetroxide, hydrofluoric acid, boric acid, ethanol, isopropyl alcohol and inorganic water. By adopting the above formula, the mixture is mixed, stirred and heated to prepare into electrothermal film treating fluid, a semi-finished product of the electrothermal film is obtained by spraying the electrothermal film treating fluid at negative pressure on the electrothermal film carrier, and then silveroxide slurry is coated on the semi-finished product of the electrothermal film for baking to form a finished product of the electrothermal film. The electrothermal film has reasonable proportion andsimple manufacturing process, can be manufactured into various electrothermal film heating devices, has a working temperature capable of being up to 500 DEG C, and has wider application range. The electrothermal film of the invention also has the function of far infrared radiation, can play a role of physical therapy and health care to human body, and can help improve the quality and output of agricultural products.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

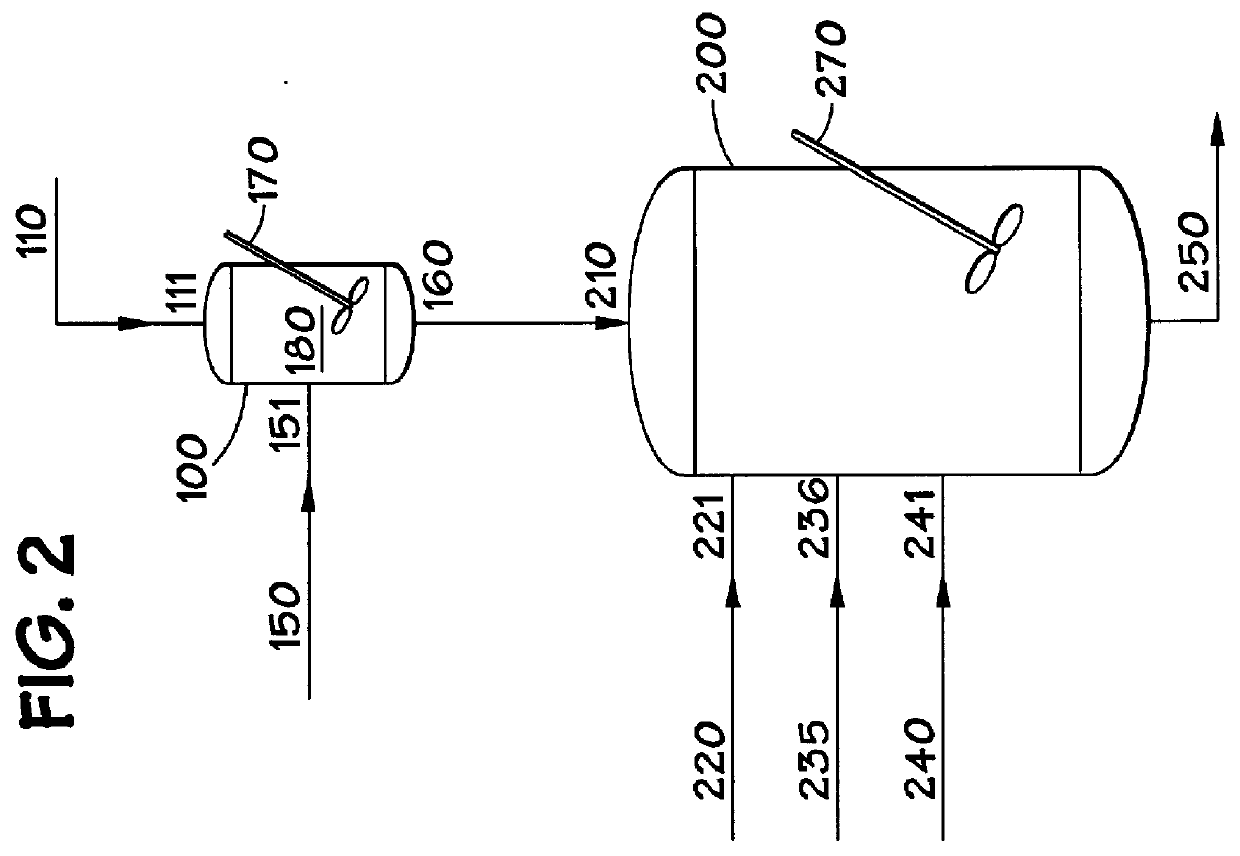

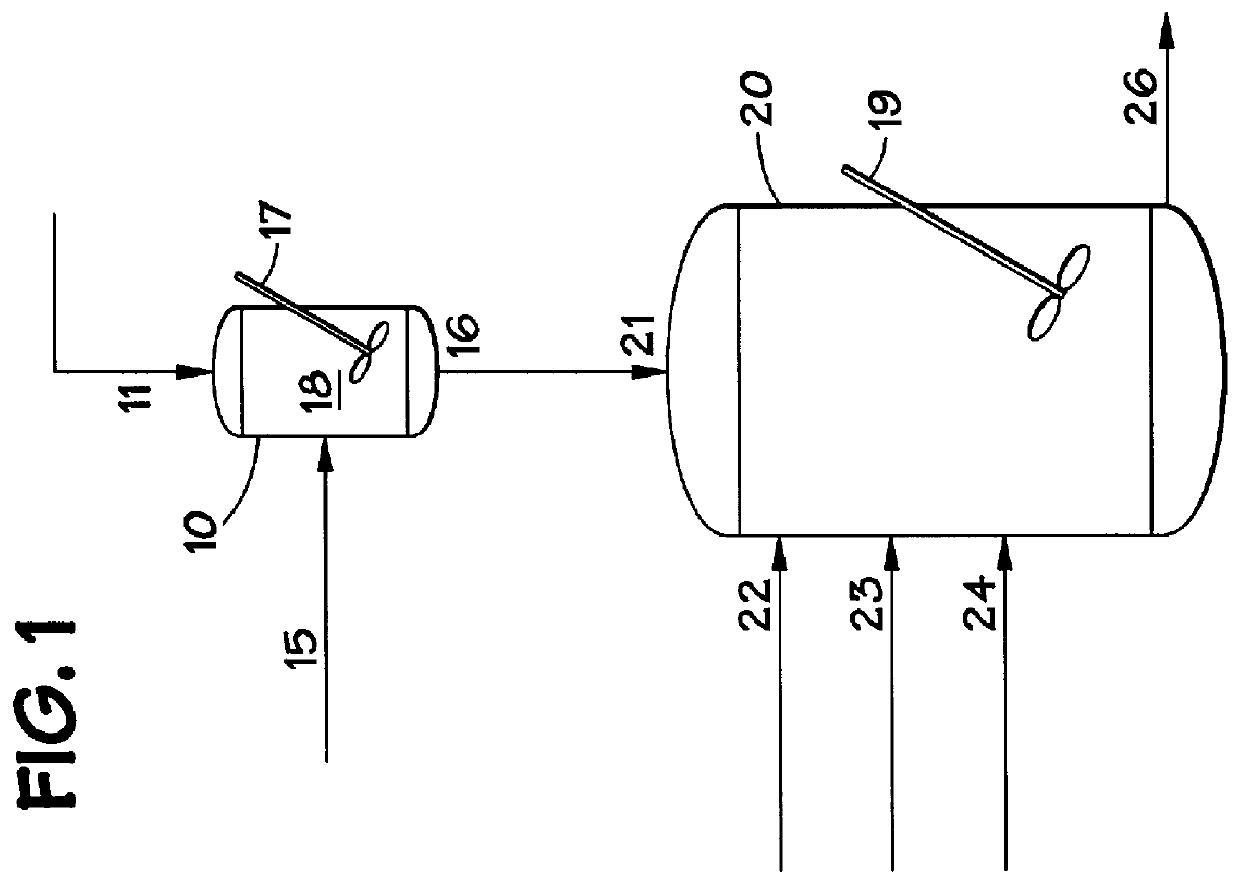

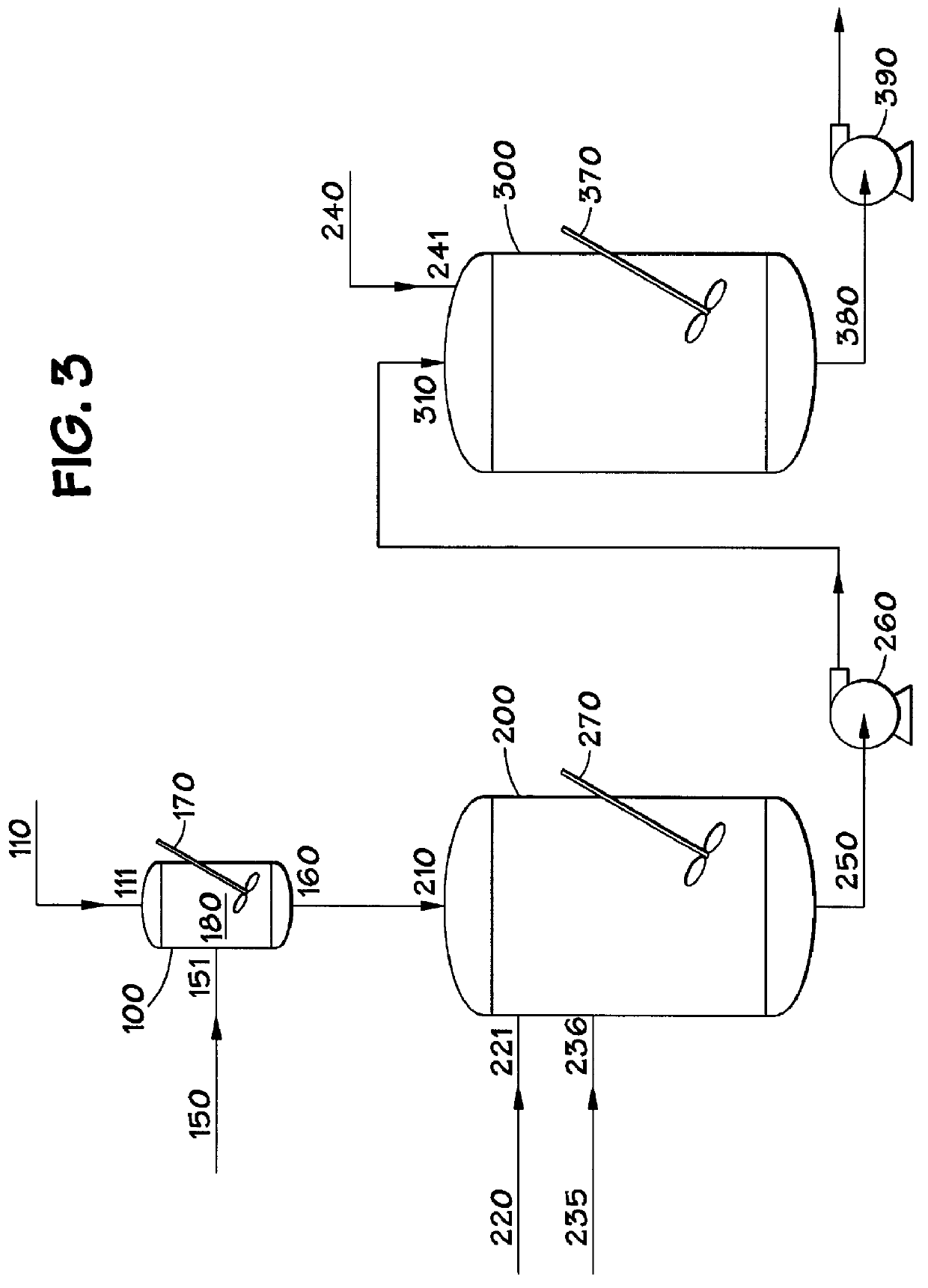

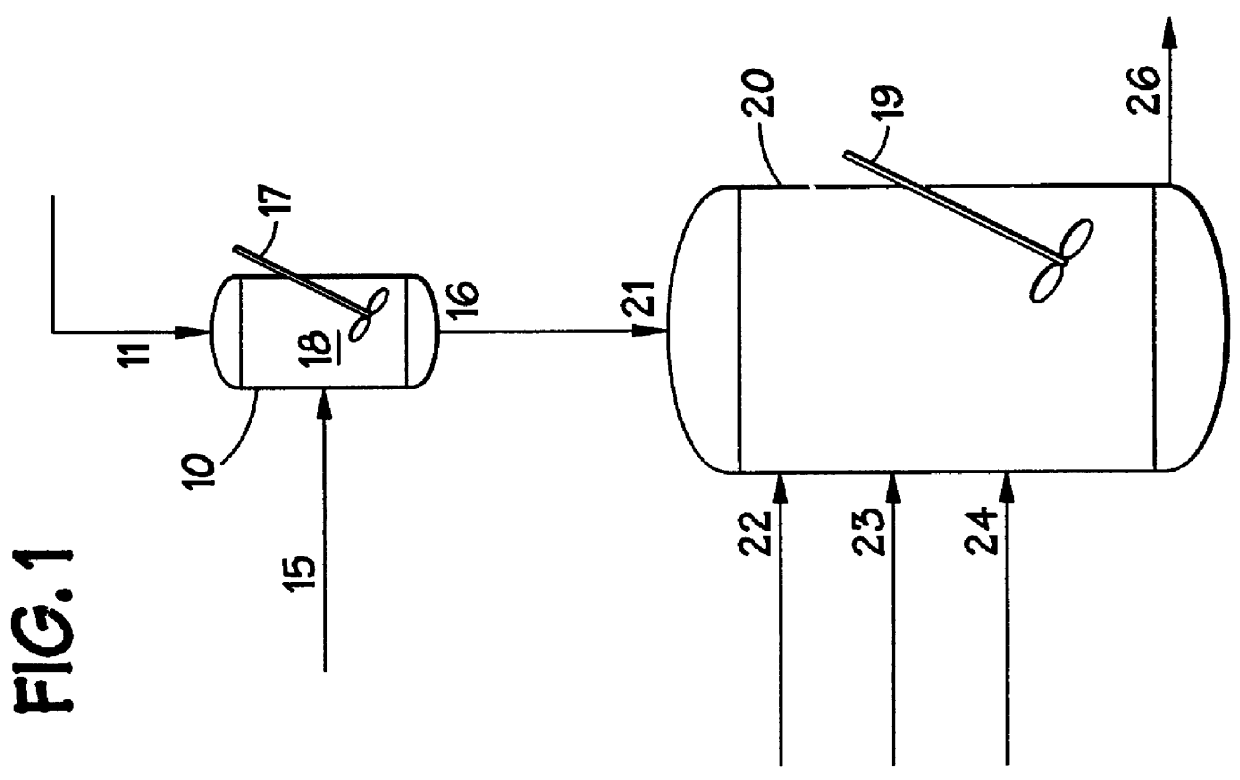

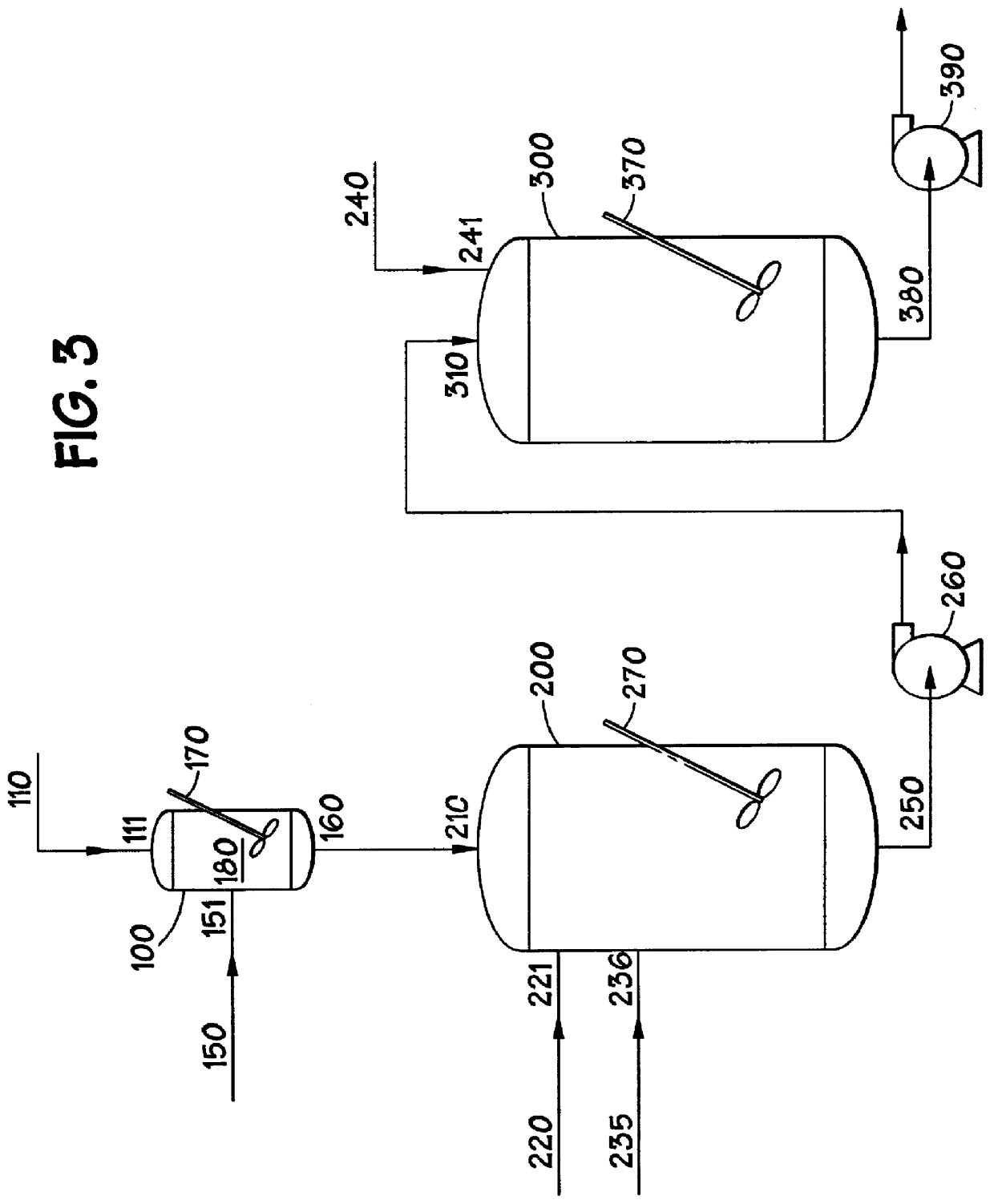

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents

InactiveUS6015779AReduce frictional energy lossHigh molecular weightOther chemical processesLiquid organic insulatorsHalohydrocarbonAlpha-olefin

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

Prepn process of photocatalytic filtering net of foamed metal carrying nano Tio2

InactiveCN1486785AStable chemical propertiesImprove breathabilityCatalyst activation/preparationFiltration separationUltravioletMaterials science

The present invention belongs to the field of chemistry and chemical engineering. The loaded photocatalytic filtering net is prepared with foamed metal sheet as carrier and through preoxidation of the foamed metal sheet, soaking the preoxidized foramed metal sheet in sol with tetrabutyl titanate or titanium trichloride precursor, drying and sintering. Carried TiO2 as active component accounts for 3.0-9.8% of total photocatalytic filtering net weight. The foamed metal of the present invention has stable chemical performance and high air penetration; and the loaded photocatalytic filtering net has great carrying amout, great specific surface area, high combination performance and high photocatalytic activity. When cooperating with ultraviolet ligh source, the loaded photocatalytic filtering net may be used to eliminate organic pollutant effectively.

Owner:SHANGHAI JIAO TONG UNIV

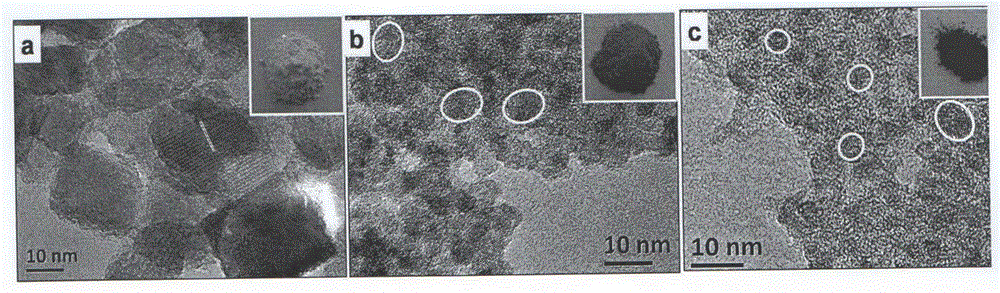

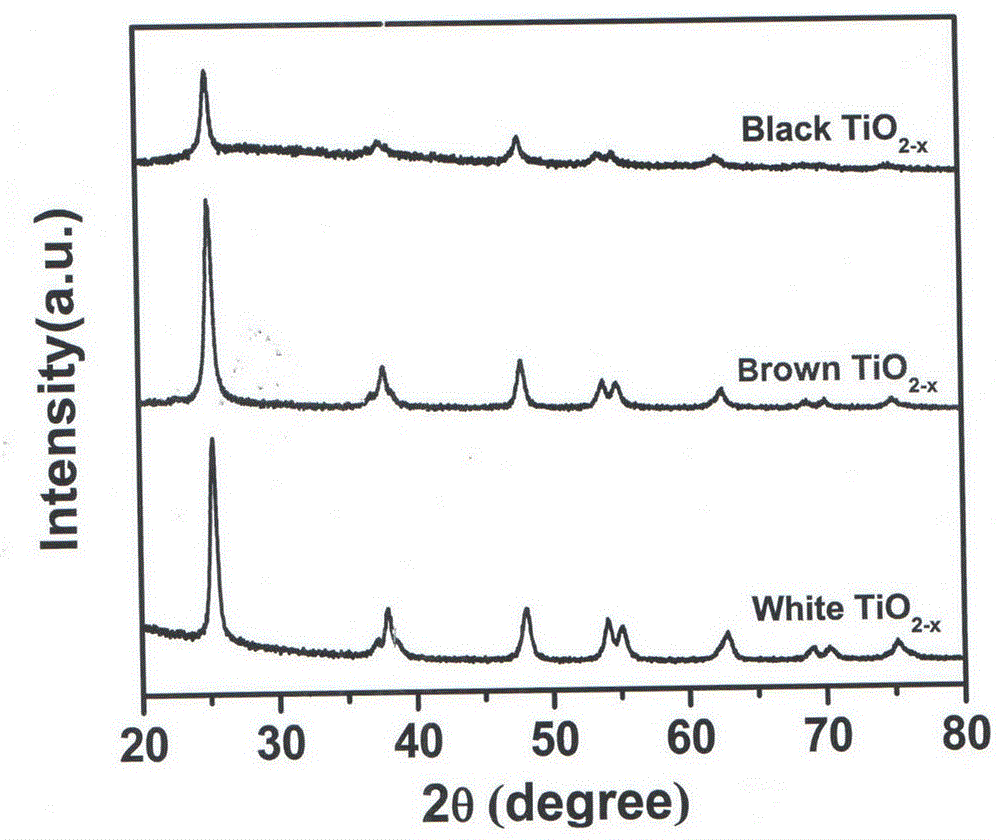

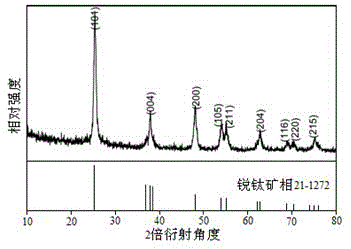

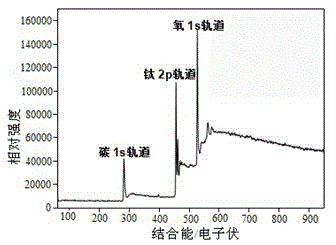

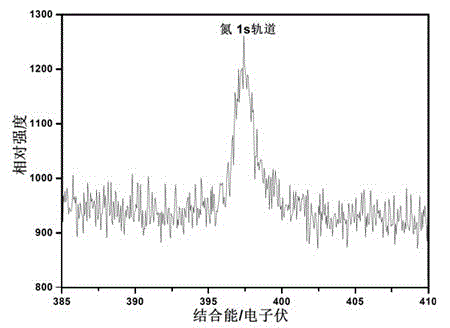

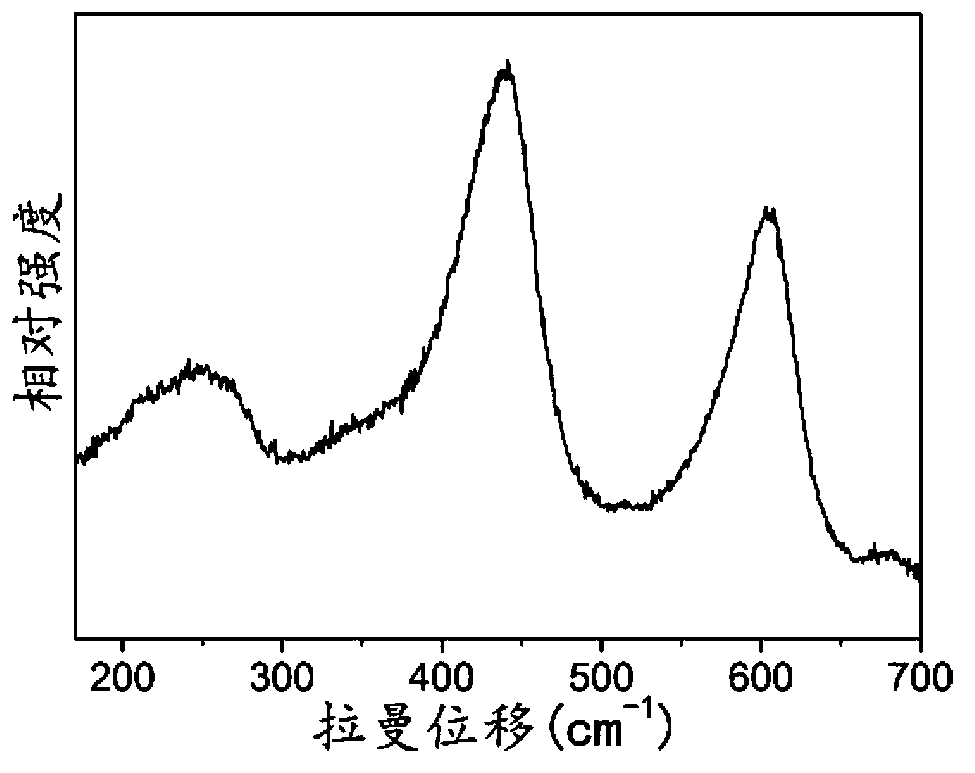

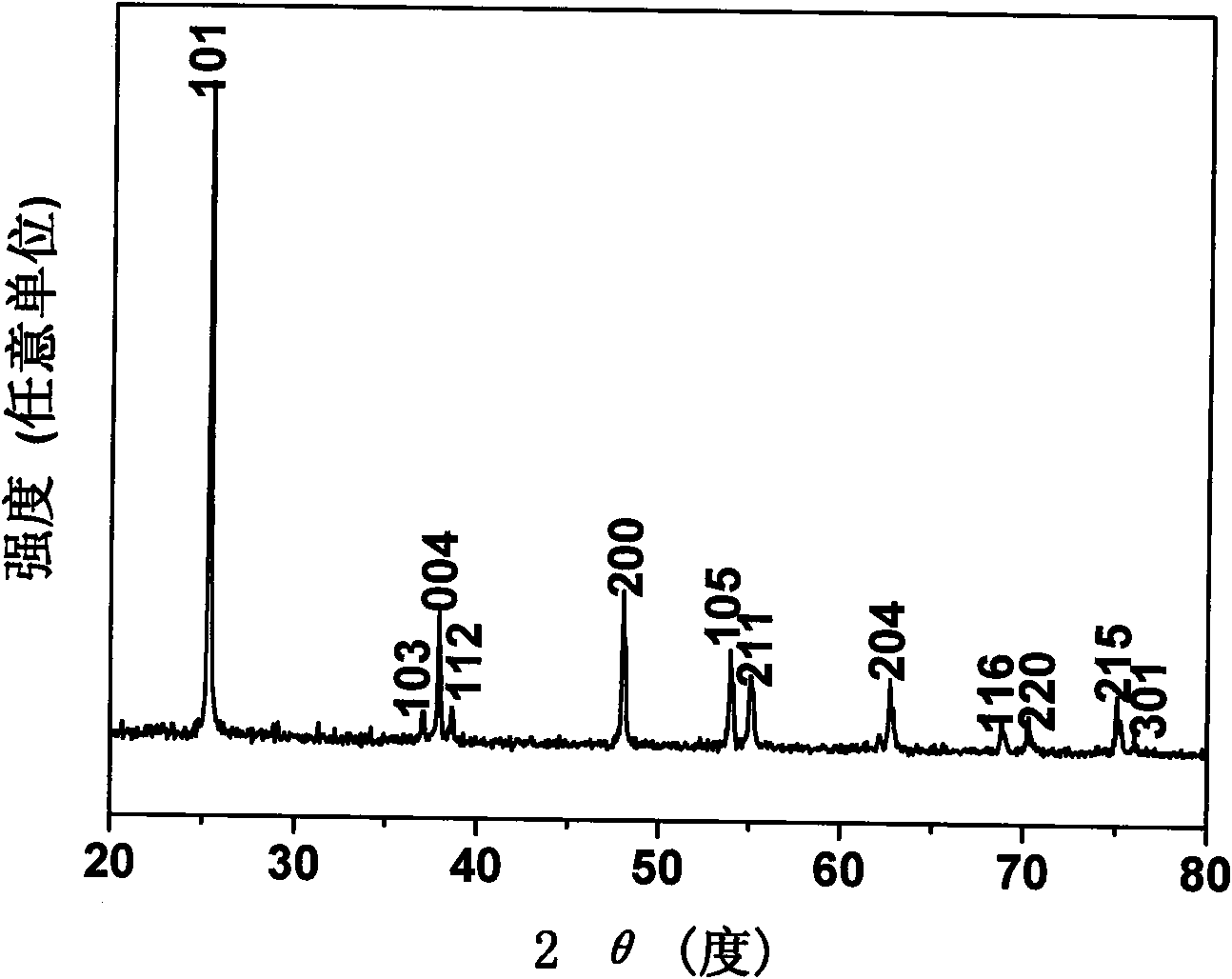

Preparation method for nanometer black titanium dioxide photocatalyst

InactiveCN106076302AStrong absorption capacityPromote absorptionCatalyst activation/preparationOxygen vacancyHydrazine compound

The invention relates to a preparation method for a nanometer black titanium dioxide photocatalyst. The method takes trivalent titanium titanium trichloride and TiOCl as raw materials, takes sodium borohydride, ascorbic acid or hydrazine hydrate as a reducing agent, and employs a hydrothermal synthesis process for preparing the nanometer black titanium dioxide photocatalyst. By introducing Ti<3+> into the titanium dioxide photocatalyst and performing oxygen vacancy, absorption performance of a titanium dioxide material in ultraviolet light region, visible light region and infrared light region is enhanced, and by adjusting the usage amount of the reducing agent, the color of the nanometer titanium dioxide photocatalyst is adjusted.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

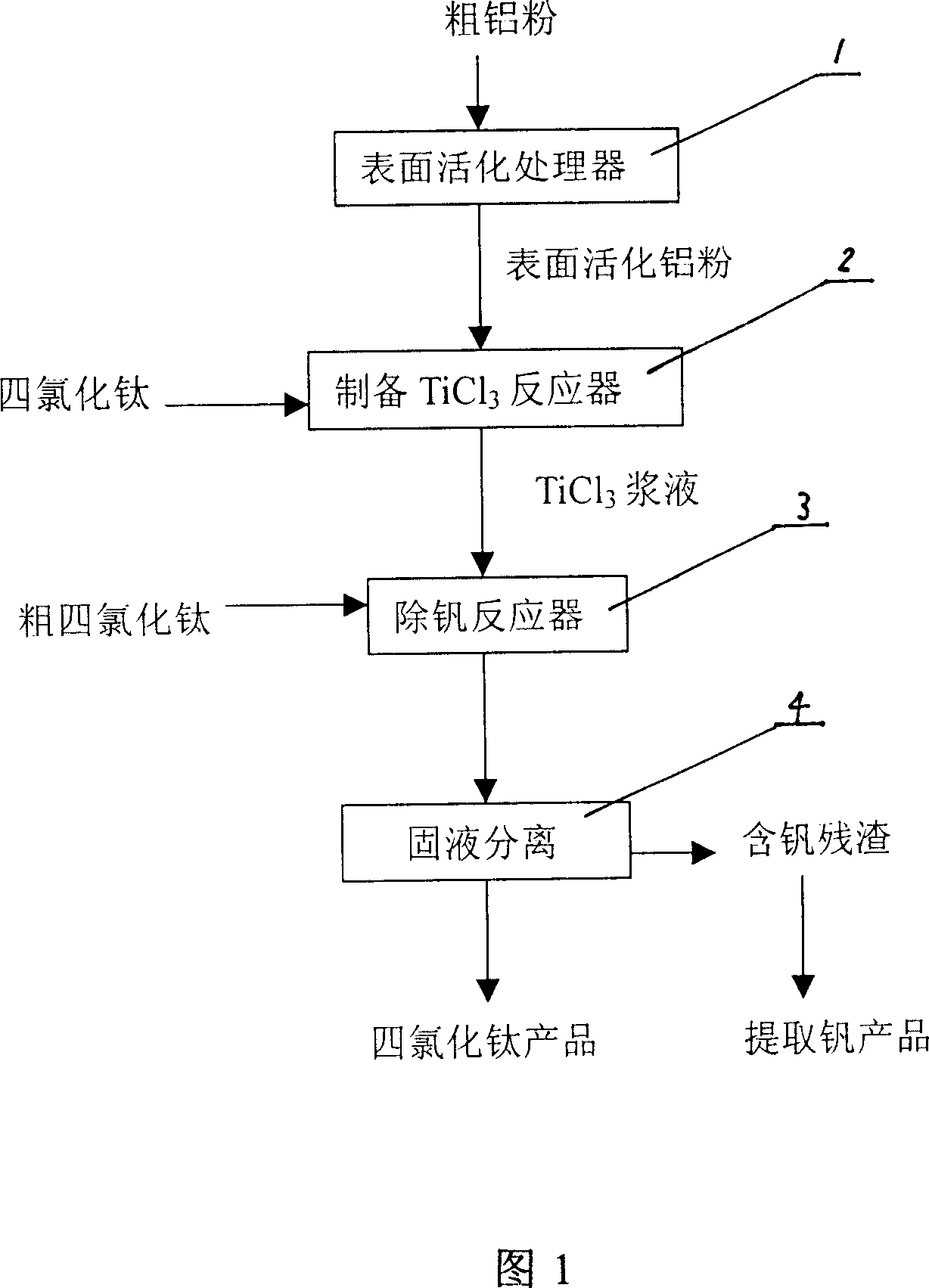

Method for removing vanadium in titanium tetrachloride

InactiveCN101054201ASimple processSimple waste treatmentTitanium halidesTetrachlorideBiological activation

The invention relates to a method for removing vanadium impurity from titanic tetrachloride. The invention prepares titanium trichloride serum by the reaction between the cost aluminum powders with the average grain size no bigger than 150mum after surface activation treatment. TiCl3 in the serum reduces VOCl3 in the titanic tetrachloride to be VOCl2 deposit so as to remove the vanadium. And the titanic tetrachloride after removing the vanadium contains no more than 0.0007% vanadium. The process of vanadium removal can be implemented together with rectification process in order to realize continuous operation. The invention has the advantages of simple in process, low in cost, safe in operation, high in product quality and recovery rate and simple in treating the ''three-waste'' pollution.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

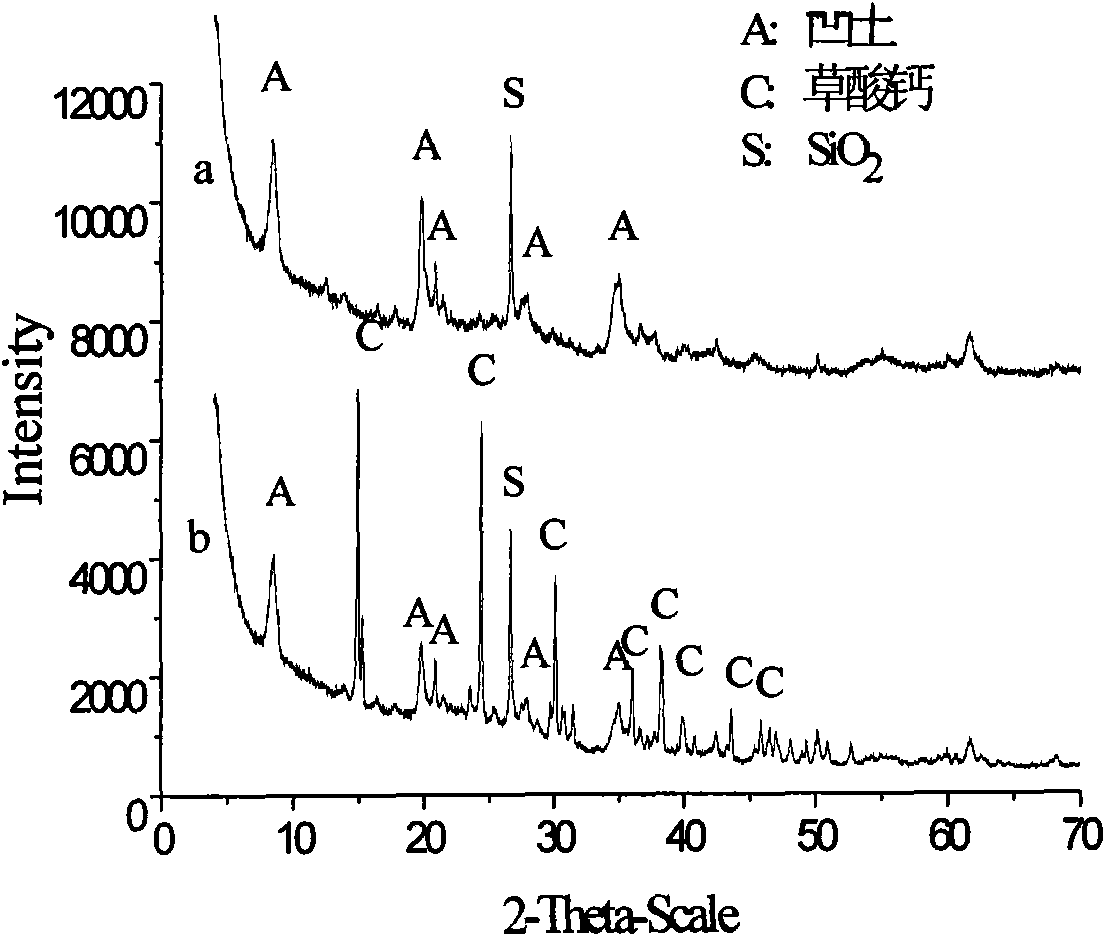

Method for removing iron and whitening for iron-containing attapulgite clay

InactiveCN101818000AEfficient removalIntensified collisionPigment physical treatmentDistilled waterSlurry

The invention relates to a method for removing iron and whitening for iron-containing attapulgite clay, comprising the following steps of: (1) selecting ore the content of attapulgite of which is more than 40%, crashing the attapulgite clay, and screening the attapulgite clay by a 100-mesh sieve, roasting and activating the attapulgite clay for 1 hour at the temperature of 300 to 700 DEG C; (2) acidulating the attapulgite clay after roasting treatment by 3 to 8% sulfuric acid , wherein the mass ratio of the sulfuric acid solution to the attapulgite clay is 8:1; placing the attapulgite clay in the sulfuric acid, stirring and soaking for 4 hours at the temperature of 60 DEG C, then washing for many times by utilizing distilled water, controlling the pH value to be 6.0 to 7.0, drying at the temperature of 105 DEG C, and then grinding, screening by a 80 to 120 mesh sieve; and (3) preparing the attapulgite clay after acidification to 10 to 30% ore slurry, placing the ore slurry into a reaction vessel, adding oxalic acid with the concentration of 0.5 to 1.5 mol / L and 3 to 5% titanium trichloride, heating reaction vessel for 8 to 150 minutes, acidulating for 40 to 50 minutes, and centrifuging, washing and filtering after reaction, and drying at the temperature of 105 DEG C to obtain the white attapulgite clay.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

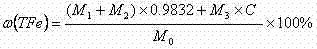

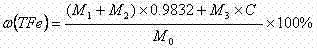

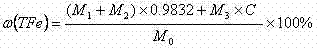

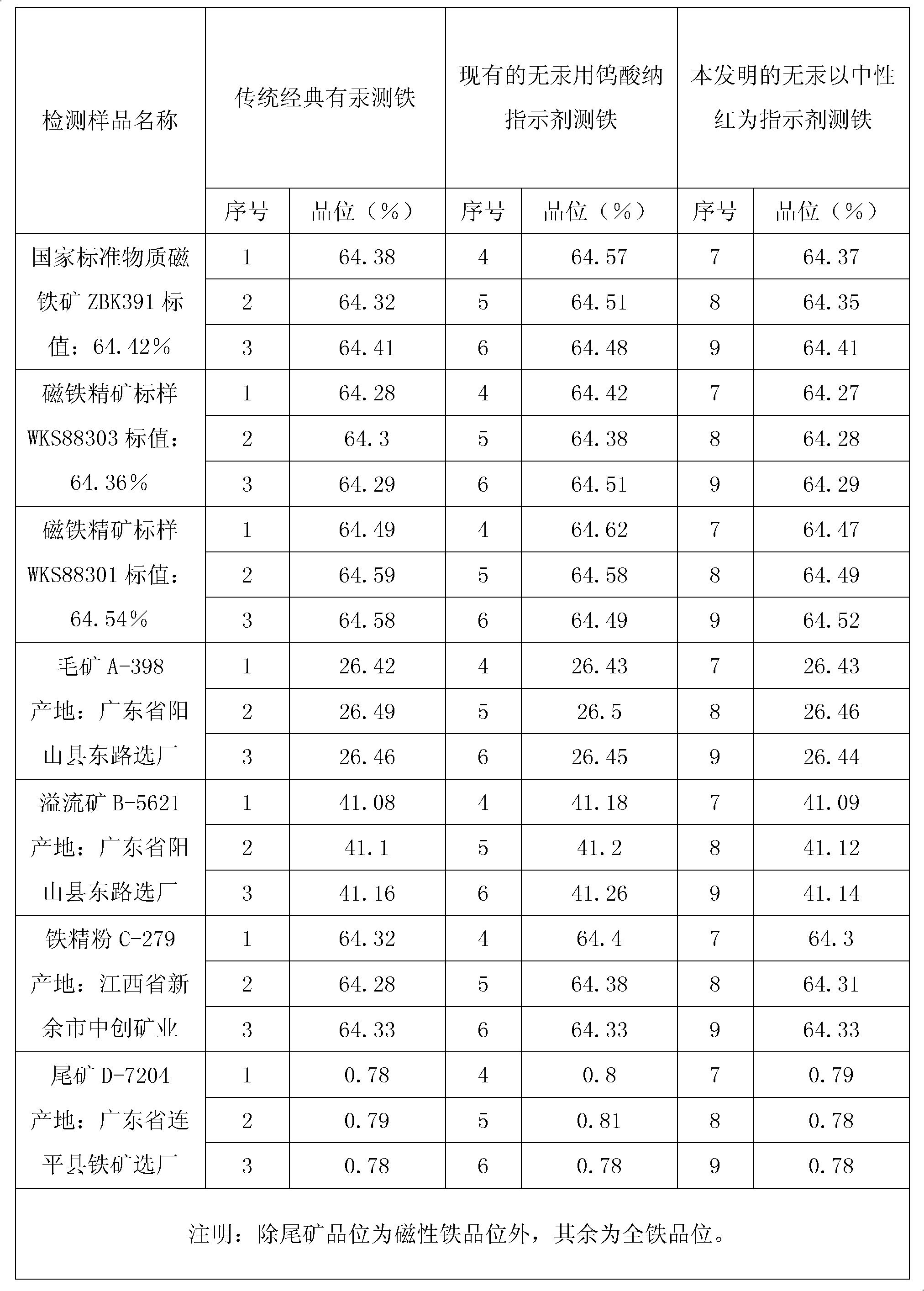

Method for measuring iron content in steel slag

The invention provides a method for measuring iron content in steel slag. The method includes grinding and screening a steel slag sample by multiple times; completely separating granular metal substances from slag in the steel slag sample; measuring the mass of the granular metal substances by a physical process; measuring iron content of the slag by a titanium trichloride and potassium dichromate volumetric process; and computing the full iron content of the steel slag sample via data of the iron content of the slag and the mass of the granular metal substances. The method has the advantages of convenience in operation, high accuracy of the measured iron content and good stability, repeatability and accuracy of a measuring result. Besides, as proved by tests, the method is reliable and practical, and the requirement on measuring iron content in steel slag in daily life can be met.

Owner:WUKUN STEEL

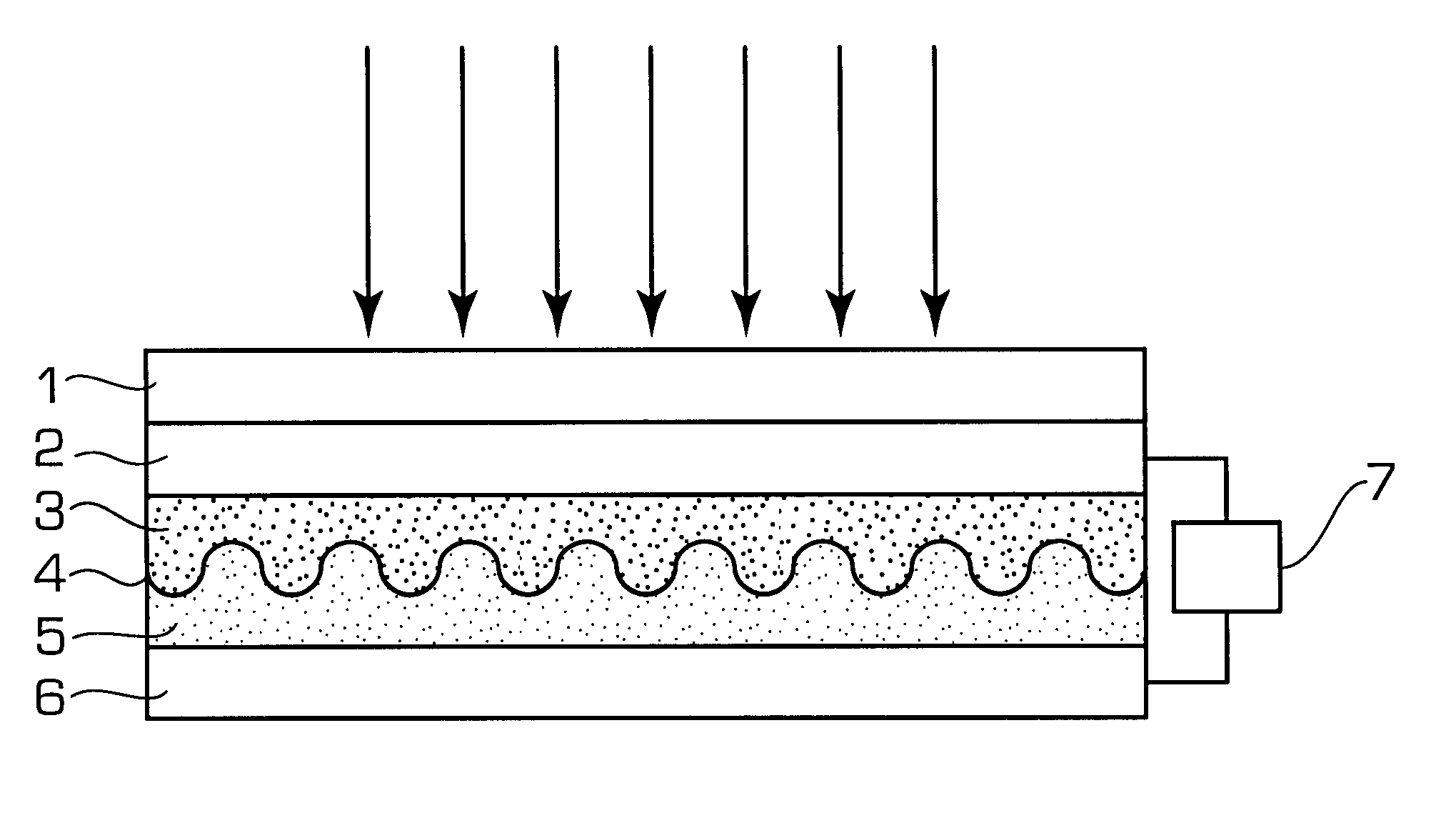

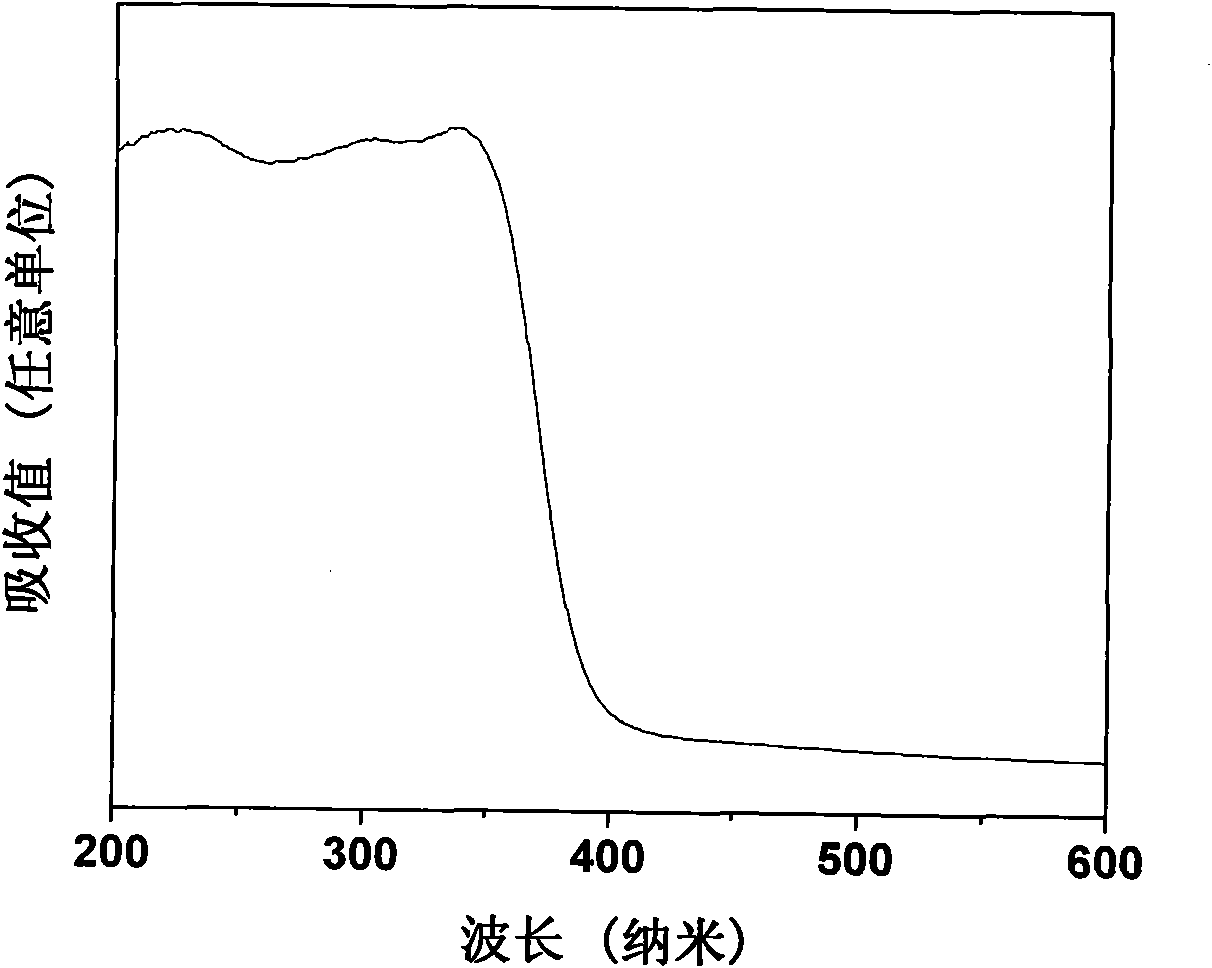

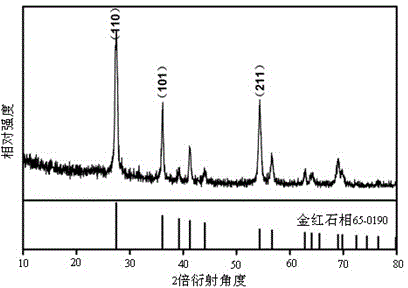

Dye-sensitization-type photoelectric conversion element

InactiveUS6300559B1Improve photoelectric conversion efficiencyLight-sensitive devicesDeferred-action cellsPhotoelectric conversionHYDROSOL

A dye-sensitization-type photoelectric conversion element comprising a semiconductor and a dye adhering onto a surface of the semiconductor, which semiconductor is predominantly comprised of brookite-type titanium oxide. The dye-sensitimation-type photoelectric conversion element is preferably made of a titanium oxide sol predominantly comprising brookite-type titanium oxide, produced by a process comprising a step of hydrolyzing titanium tetrachloride or titanium trichloride.

Owner:SHOWA DENKO KK

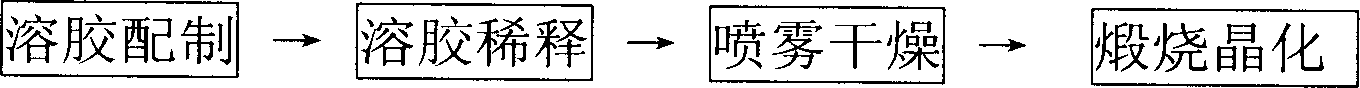

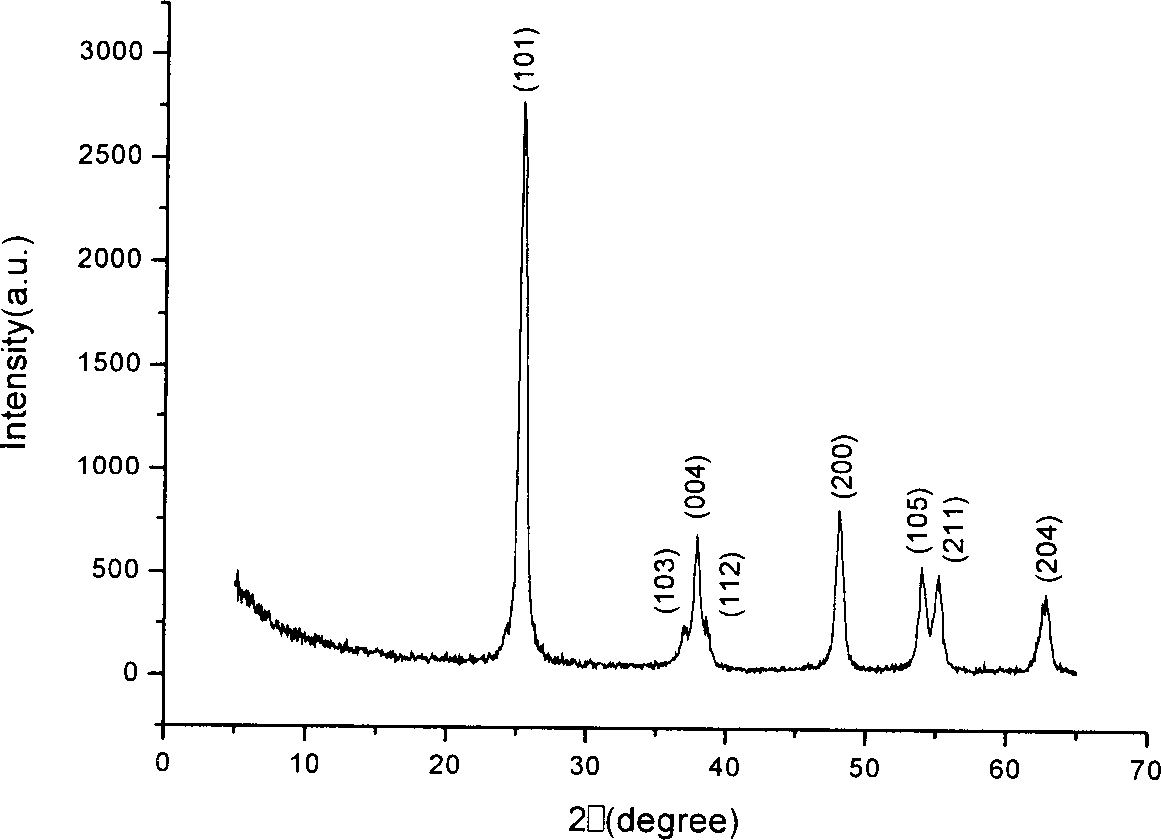

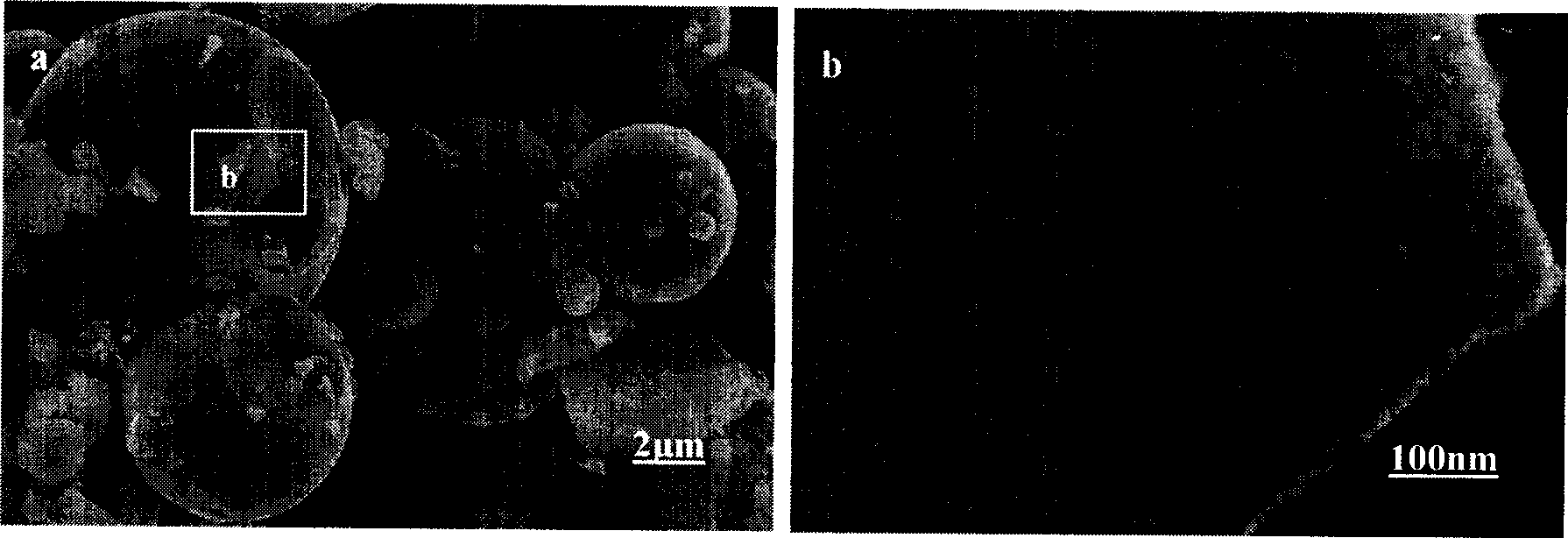

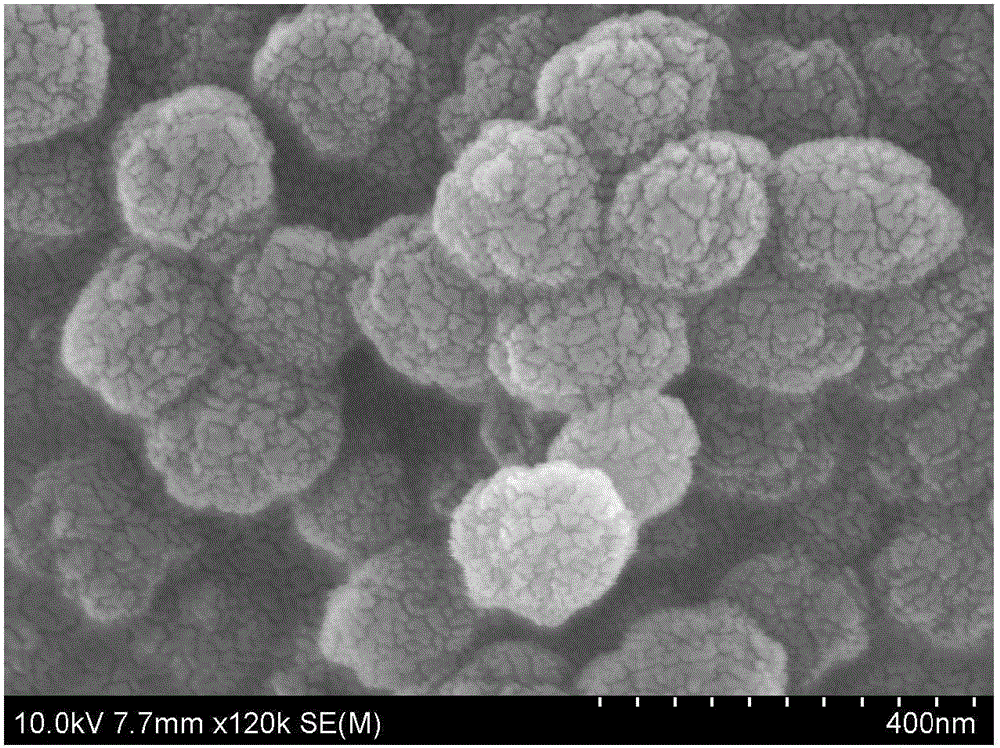

Prepn. process of mesic hole hollow ball-shape titania powder

This invention relates to a method to prepare mezoporous empty-centered titanium dioxide powders, which comprises following steps: titanium chloride is made into hydrosol with pure water, diluted and introduced into a spray dryer for spray drying. The subsequent product is empty-centered ball-shaped powder made up of nanosized titanium dioxide particles and the preceding titanium chloride is titanium tetrachloride or titanium trichloride. The titanium dioxide particles prepared in this invention all have mezoporous empty-centered ball-shaped structure and the empty-centered wall is made up of nanosized titanium dioxide particles and mezopores, on the surface of which titanium atoms possess a fraction of as high as 70%. As only titanium tetrachloride is adopted as precursor and no other reagent is necessary, the product is highly pure and has excellent photocatalytic properties. This method has the advantages of high yield, low cost, easily controlled technique and convenience for magnification experiment. Besides, there are not severe requirements for facilities and this method is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

Electric-heating film and manufacturing method thereof

InactiveCN1529534AWith PTC functionExtended service lifeHeating element materialsWorking temperatureEngineering

Mixing, stirring butter of tin, titanium trichloride, antimonous chloride, calcium dichloride, isopropyl alcohol, ethanol and water evenly makes solid be dissolved; then, cooling the said liquid to normal temperature obtains treating liquid of electric heating film to be used; spraying the said treating liquid on substrate so as to form semiconductor conductance film that is half-finished product of electric heating film. Surfaces of two ends of half-finished product coated by paste of silver oxide are torrefied in electrode furnace so as to produce finished product. Advantages of the invention are: simple technique, large power, high working temperature, PTC and far infrared radiation functions, moisture-proof, acid and alkali proof, no pollution, and service life more than 5000 hr.

Owner:杨金林

Prepn process of nanometer crystal titania aerogel with high photocatalysis activity

InactiveCN1810356ALarger than surfaceSmall grain sizeCatalyst activation/preparationSupercritical dryingMicro structure

The preparation process of aerogel TiO2 with high photocatalysis activity includes the following steps: dissolving non-titanium alkoxide and titanium source in alcohol-water mixture solution through stirring; adding metered epoxide to obtain translucent lumpy alcohol gel of titanium oxide in minutes; ageing, supercritical drying and roasting to obtain nanometer crystal aerogel TiO2 block or powder with adjustable micro structure and specific surface area greater than 100 sq m / g. Where, the titanium source is titanium tetrachloride, titanium trichloride or titanium sulfate; the epoxide is ethylene oxide, propylene oxide, chloropropylene oxide or butylenes oxide; and the organic alcohol solvent is methanol, ethanol, isopropanol or tert-butyl alcohol. When used in degrading nitrobenzene and other sewage treatment, the aerogel TiO2 has photocatalysis activity as high as three times that of commercial P-25 photocatalyst.

Owner:FUDAN UNIV

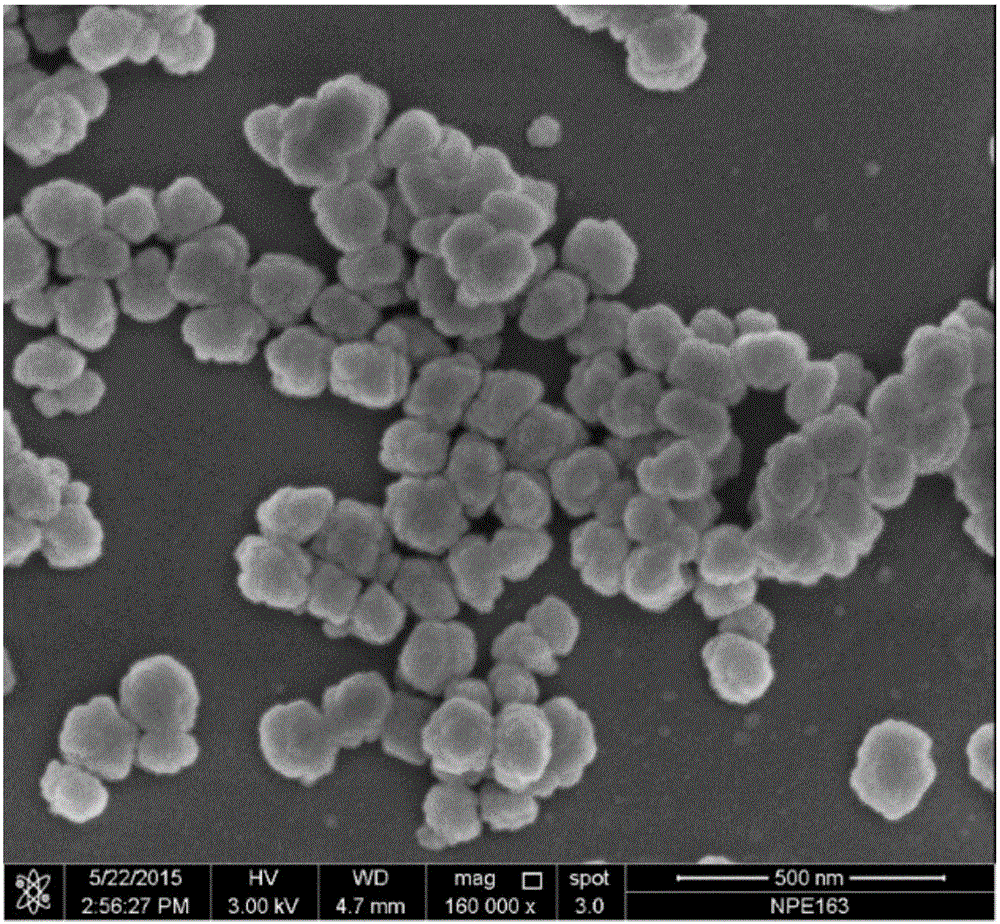

Method for preparing precious metal titanium dioxide core-shell structure

ActiveCN103933972AGood monodispersityGood catalytic hydrogen production effectHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsCore shellNanometre

The invention discloses a method for preparing a precious metal titanium dioxide core-shell structure. The method comprises the following steps: (1) preparing a precious metal nano particle colloidal solution; (2) adjusting the pH value of a titanium trichloride solution by adding alkaline matter; (3) adding the solution prepared in the step (1) to the solution obtained in the step (2) and reacting; (4) carrying out solid-liquid separation so as to obtain a nano material with the precious metal titanium dioxide core-shell structure. The preparation method disclosed by the invention is simple and feasible, and is good in repeatability, the prepared core-shell structure is good in monodispersity, and the thickness of a titanium dioxide shell layer can be controlled by adjusting the pH of the reaction system. Therefore, the core-shell structure can be applied to the field of hydrogen production of photocatalytic decomposition of water.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Manufacturing method of electrothermal film

ActiveCN104080208AImprove stabilityImprove temperature resistanceHeating element materialsNickel sesquioxideManganese

The invention discloses a manufacturing method of an electrothermal film. The manufacturing method comprises the following steps of A, preparing an electrothermal film treatment solution which comprises tin tetrachloride, titanium trichloride, antimony trichloride, calcium chloride, chromic oxide, manganese dioxide, nickel sesquioxide, isopropanol, alcohol and water, B, masking a substrate, C, heating the substrate to be 400-700 DEG C and then spraying the electrothermal film treatment solution on the substrate by a spray gun to form a semifinished electrothermal film, D, annealing the semifinished electrothermal film, and E, coating silver oxide paste on the surfaces of the two ends of the annealed semifinished electrothermal film, loading the semifinished electrothermal film into an electrode oven, baking and fusing the semifinished electrothermal film to form a whole, and obtaining the finished electrothermal film. The manufacturing method has the advantages that the stability of the electrothermal film is improved by adding antimony; the temperature resistance of the electrothermal film is improved by adding titanium; the infrared emitting ability of the electrothermal film is improved by adding nickel and manganese; and an adhesive force between the electrothermal film treatment solution and the substrate is increased by adding isopropanol.

Owner:成都世纪经尧科技有限公司

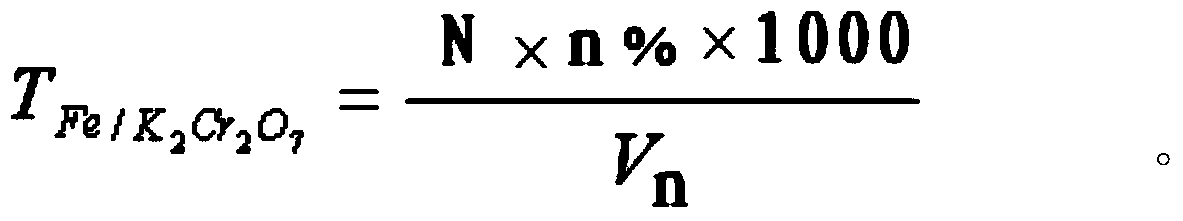

Novel method for measuring iron without mercury

InactiveCN102608112AEliminate pollutionGood reproducibilityMaterial analysis by observing effect on chemical indicatorPhosphoric acidColor changes

The invention relates to a novel method for measuring iron without mercury, which comprises the following steps of: decomposing a test sample through mixed acid of hydrochloric acid, sulfuric acid and phosphoric acid; taking neutral red and sodium diphenylaminesulfonate as indicators; measuring the iron through a SnCl2-TiCl3-K2Cr2O7 volumetric method; reducing Fe<3+> of phi Fe<3+> / Fe<2+>=+0.76V through tin bichloride with phi Sn<4+> / Sn<2+>=+0.16V; adding neutral red reagent when the solution is flavescent, i.e. the solution still contains a small amount of Fe<3+>; taking the color change of the neutral red as an indicator indicating that Fe<3+> is completely reduced to be Fe<2+> according to the principle that the neutral red is reduced to be colorless after the Fe<3+> is reduced completely, and the neutral red reagent is blue in the Fe<3+> solution; dropping titanium trichloride with phi Ti<4+> / Ti <3+>=+0.1V until blue is disappeared; removing excess titanium trichloride through oxidation by a 5.000g. L<-1> sodium diphenylaminesulfonate-potassium dichromate standard solution method; and finally, calculating ion grade of the test sample.

Owner:JIANGXI UNIV OF SCI & TECH

Aluminum product coated with nitrogen-doped graphene/nitrogen-doped TiO2 photo-catalytic material

InactiveCN103949278AImprove adsorption capacityPromote decompositionDispersed particle separationCatalyst activation/preparationDoped grapheneMeth-

The invention provides an aluminum product coated with a nitrogen-doped graphene / nitrogen-doped TiO2 photo-catalytic material. The aluminum product is prepared according to the following steps: preparing graphene oxide by using a method disclosed from the page 4806 to the page 4814 of volume 2010-4 of the journal of Nanometer of the American Chemical Society; adding deionized water, and performing ultrasonic dispersion to obtain graphene oxide dispersion liquid; respectively adding a hexamethylene tetramine solution and a titanium trichloride solution, uniformly mixing, performing hydrothermal reaction, centrifugally washing a precipitate, and drying to obtain the nitrogen-doped graphene / nitrogen-doped TiO2 composite photo-catalytic material; washing and drying an aluminum profile needing to be coated; adding the composite photo-catalytic material into acetonitrile or methyl methacrylate, and performing ultrasonic dispersion; and uniformly spraying the dispersion liquid onto the surface of the aluminum profile, and drying to obtain the aluminum product coated with the nitrogen-doped graphene / nitrogen-doped TiO2 composite photo-catalytic material. According to the aluminum product, photo-catalysis can be generated under the irradiation of indoor light, indoor air is purified, and indoor pollutants are reduced.

Owner:SHANGHAI RONGFU NEW MATERIAL

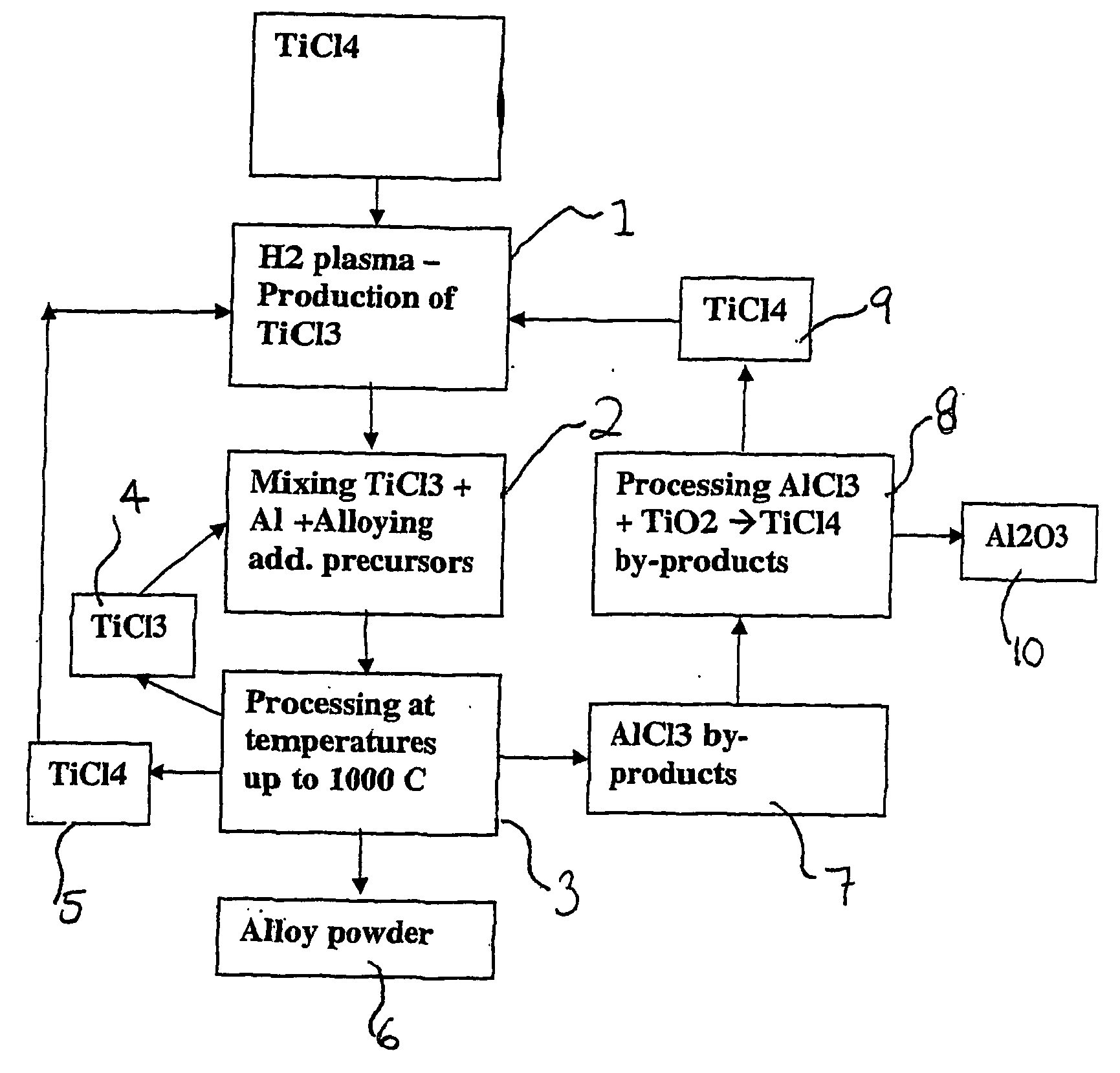

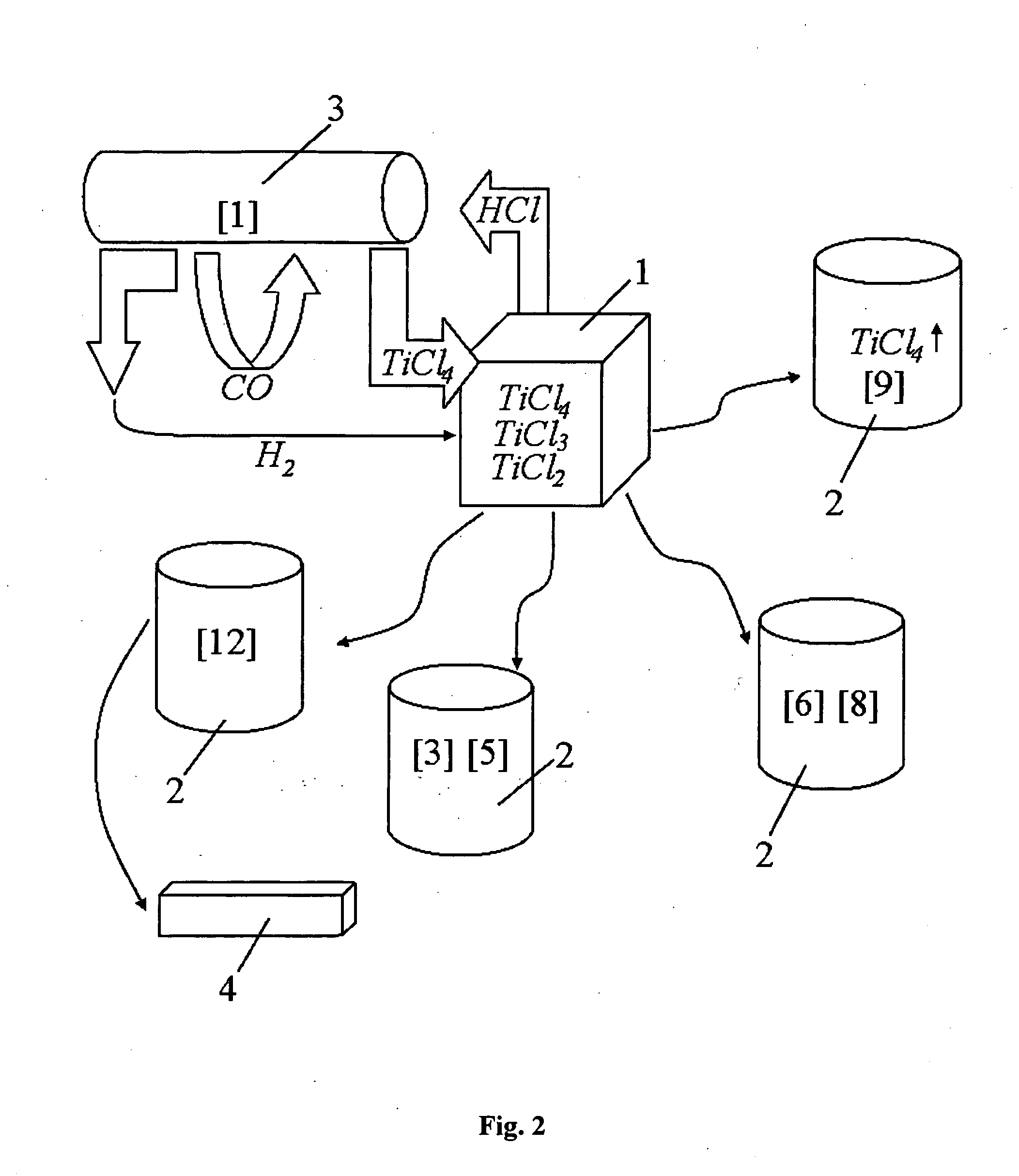

Method and apparatus for the production of metal compounds

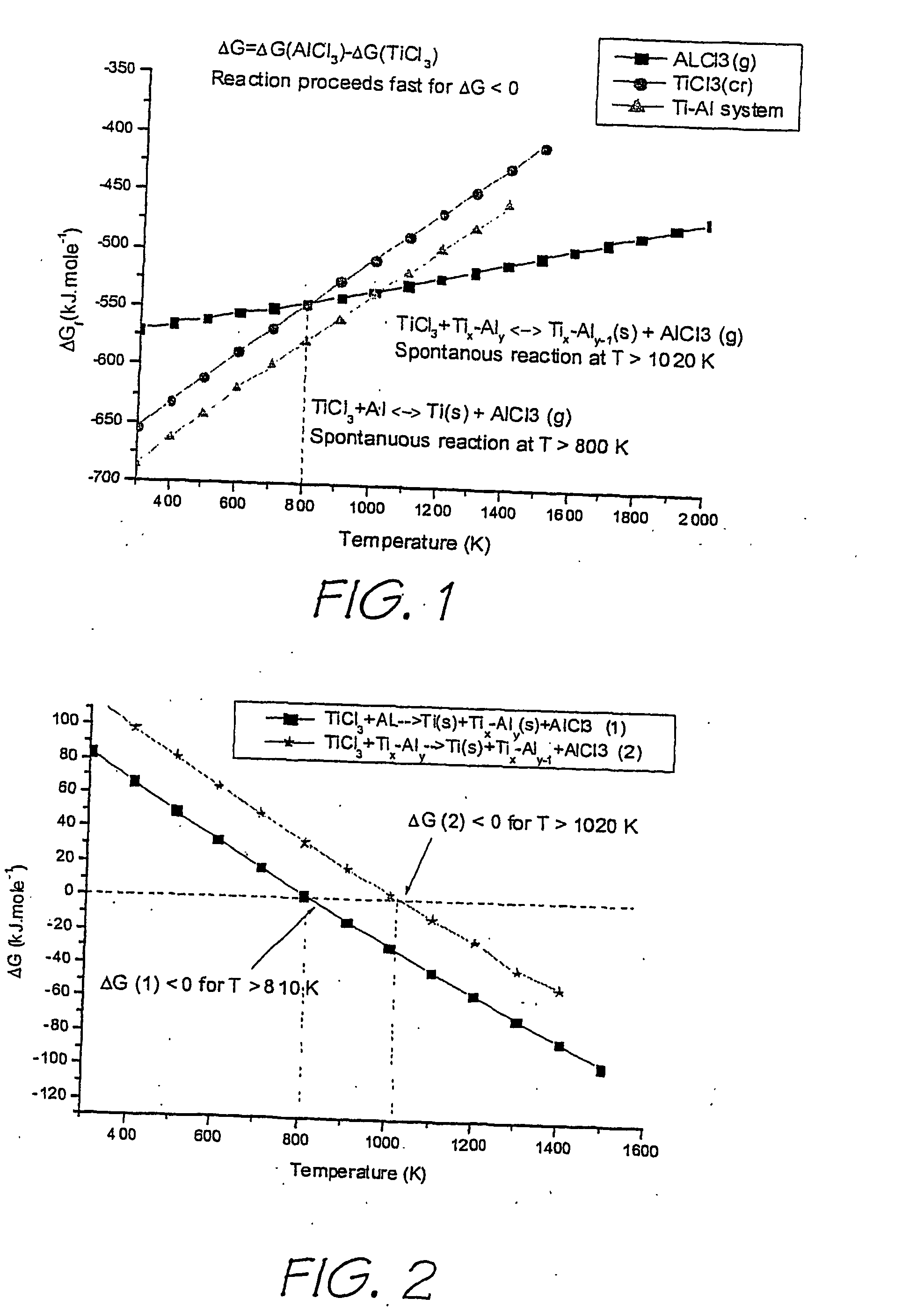

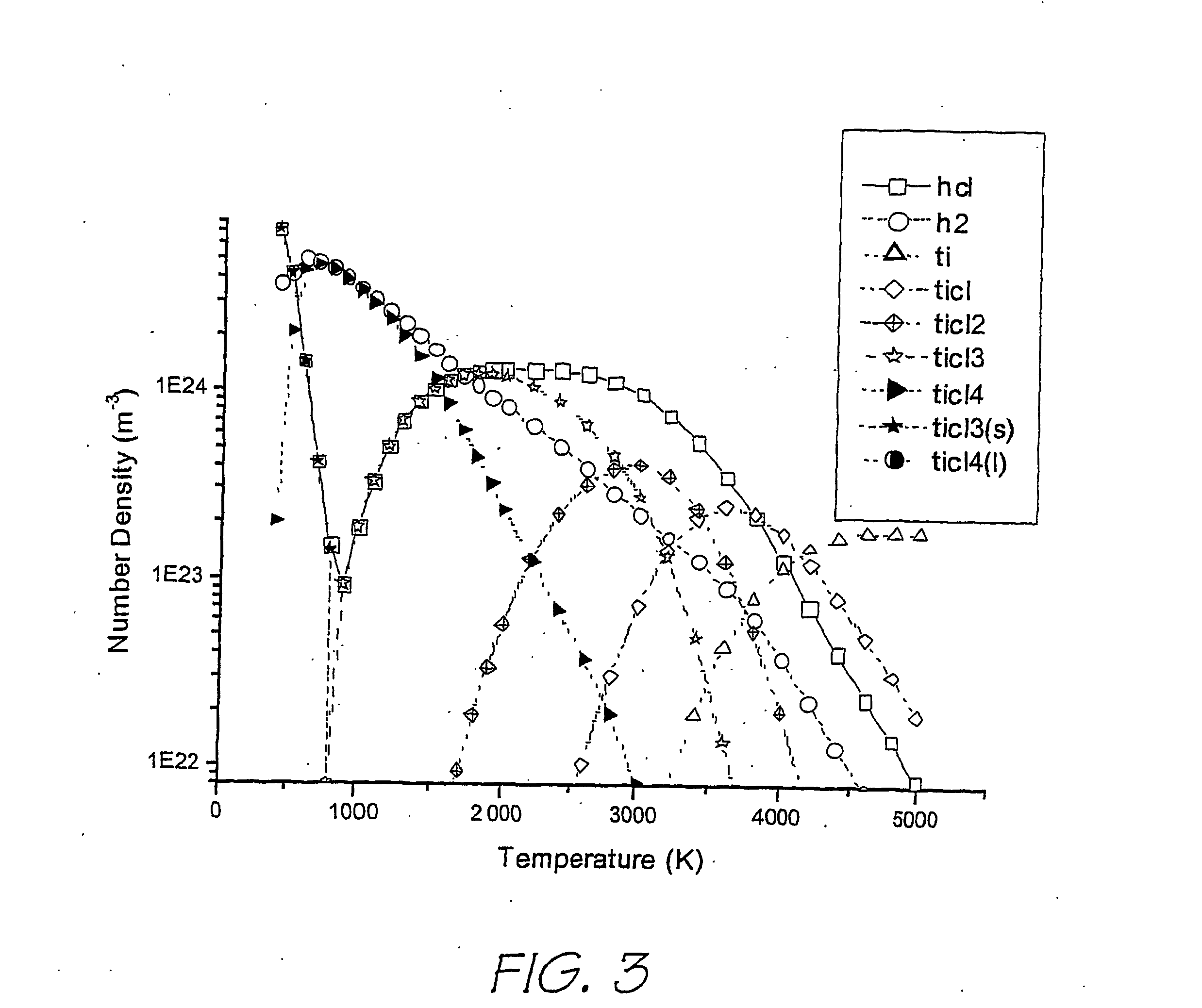

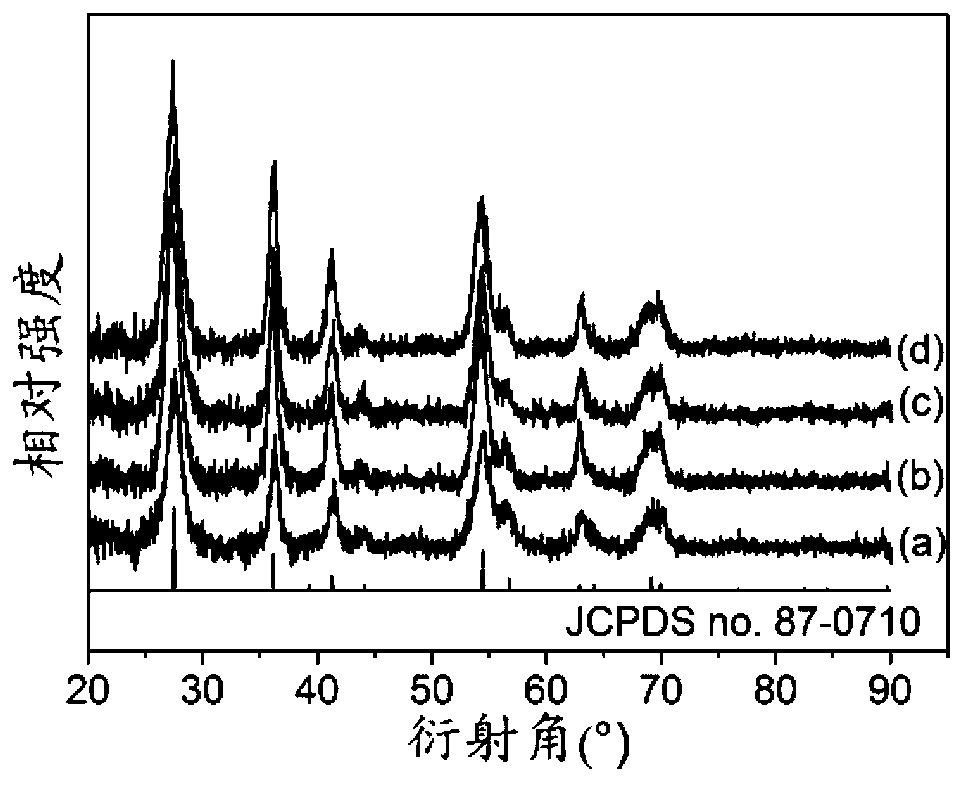

ActiveUS20060191372A1Improve responseTitanium trichlorideTitanium tetrachlorideAluminium chlorideReaction zone

The present invention relates to a method and apparatus for the production of titanium alloys and titanium-aluminium inter-metallic compounds and alloys. Starting from a precursor material including titanium subchloride (titanium trichloride or titanium dichloride), the precursor material is reduced by aluminium to produce titanium-aluminium intermetallic complexes or alloys and aluminium chloride which is driven away from the reaction zone so as to favour the forward reaction and the production of the titanium-aluminium compounds. Starting from a precursor material of titanium subchloride avoids the problems associated with starting from titanium metal (which is expensive to produce) or titanium tetrachloride (a reaction very difficult to control), and results in the production of powdered forms of titanium-aluminium compounds with controllable composition.

Owner:COMMONWEALTH SCI & IND RES ORG

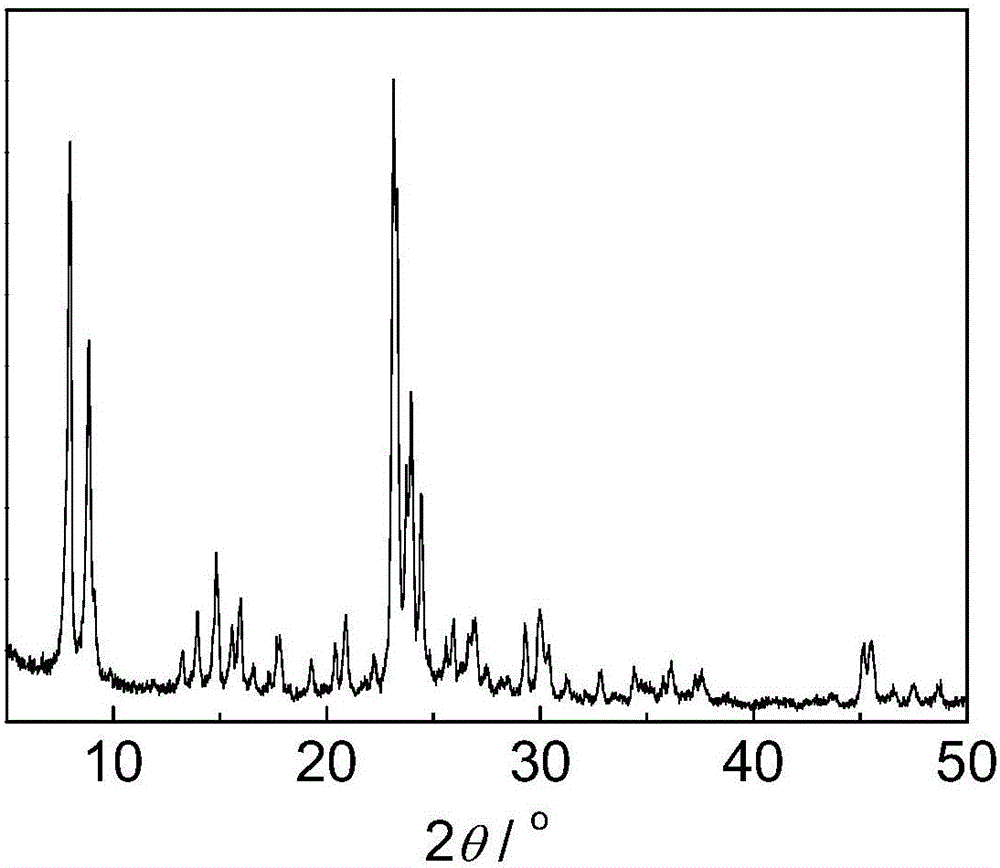

Method for preparing rutile titanium dioxide

The invention relates to a method for preparing rutile titanium dioxide. The method comprises the following steps of: (a) adding titanium tetrachloride or titanium trichloride into a reaction kettle with a polar solvent with stirring to obtain a mixed solution A, sealing the reaction kettle, heating to 50 to 75 DEG C, preserving heat, and reacting for 6 to 24 hours to obtain a reaction solution; and (b) performing solid-liquid separation on the reaction solution obtained in the step (a), recycling liquid, and washing and drying a solid to obtain the rutile titanium dioxide. The pure rutile titanium dioxide is prepared by directly hydrolyzing the titanium tetrachloride or the titanium trichloride in the polar solvent, so that the process is simple; inorganic acid, a crystal form control agent, a chelating agent or a surfactant is not required to be added into a reaction system, so that cost is reduced; and the method is suitable for large-scale industrial production.

Owner:盐城韩资工业园产业发展有限公司

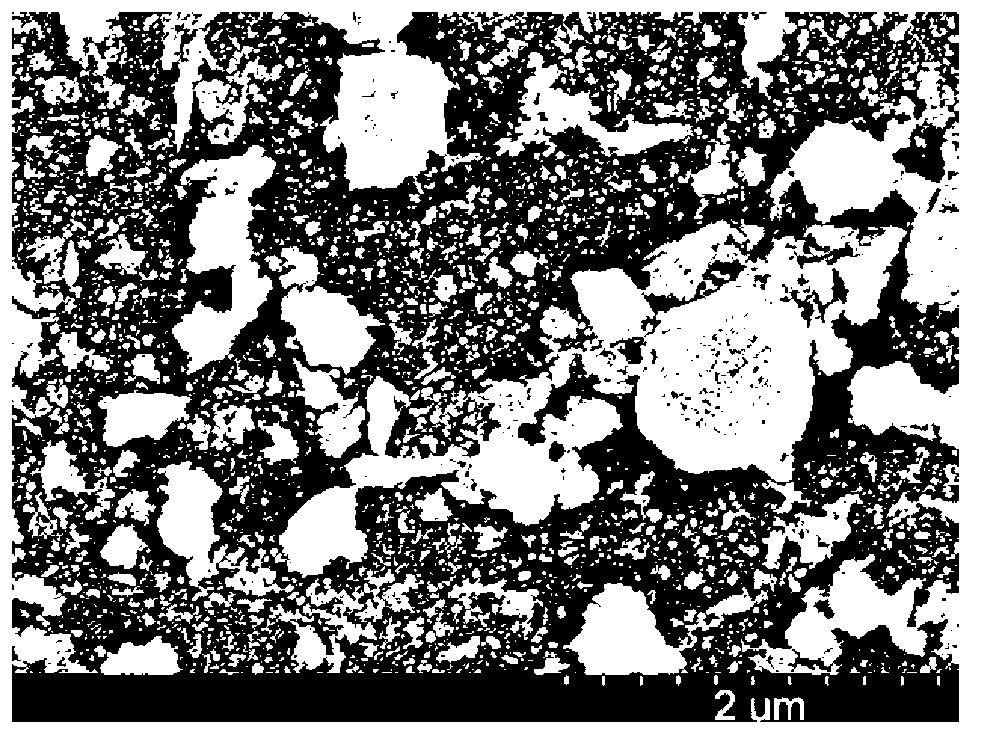

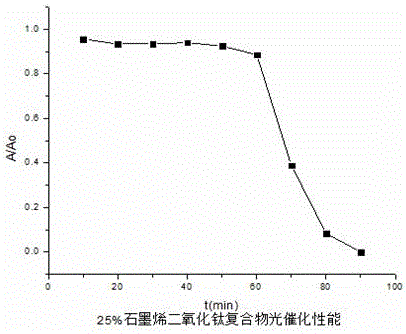

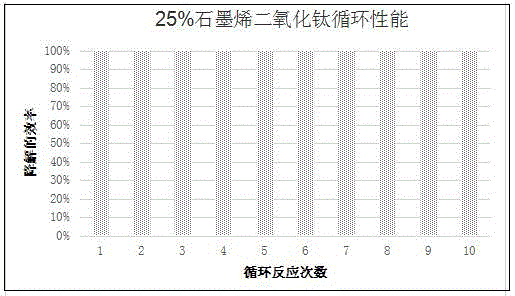

Preparation method of graphene-titanium dioxide compound photocatalyst

InactiveCN105854861AImprove photocatalytic performanceNo secondary pollutionPhysical/chemical process catalystsAmmonium bromideCvd graphene

The invention provides a preparation method of a graphene-titanium dioxide compound photocatalyst. The graphene-titanium dioxide compound photocatalyst is prepared by taking titanium trichloride, n-hexane, n-pentyl alcohol, hexadecyl trimethyl ammonium bromide and graphene oxide as raw materials through a hydrothermal-process reaction. The preparation method is simple in synthesis process, convenient to operate, low in cost and environment-friendly; and a prepared graphene-titanium dioxide compound has a good photocatalytic property and can be repeatedly used for a plurality of times, and the capability of degrading organic pollutants is higher than that of similar photocatalysts.

Owner:NANCHANG HANGKONG UNIVERSITY

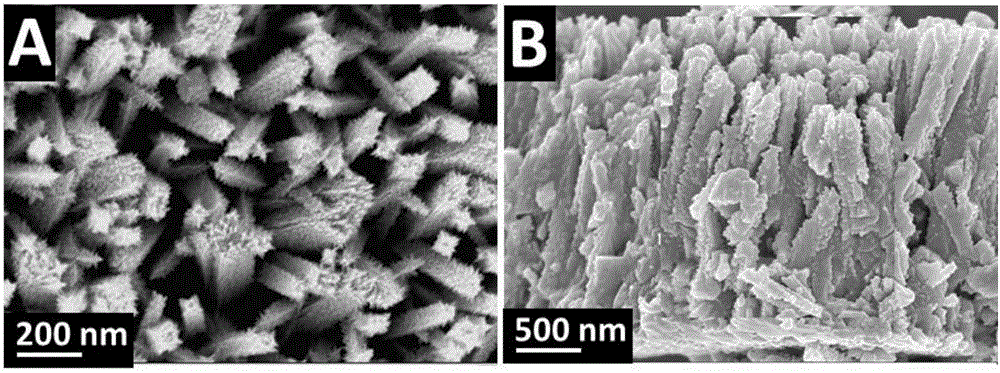

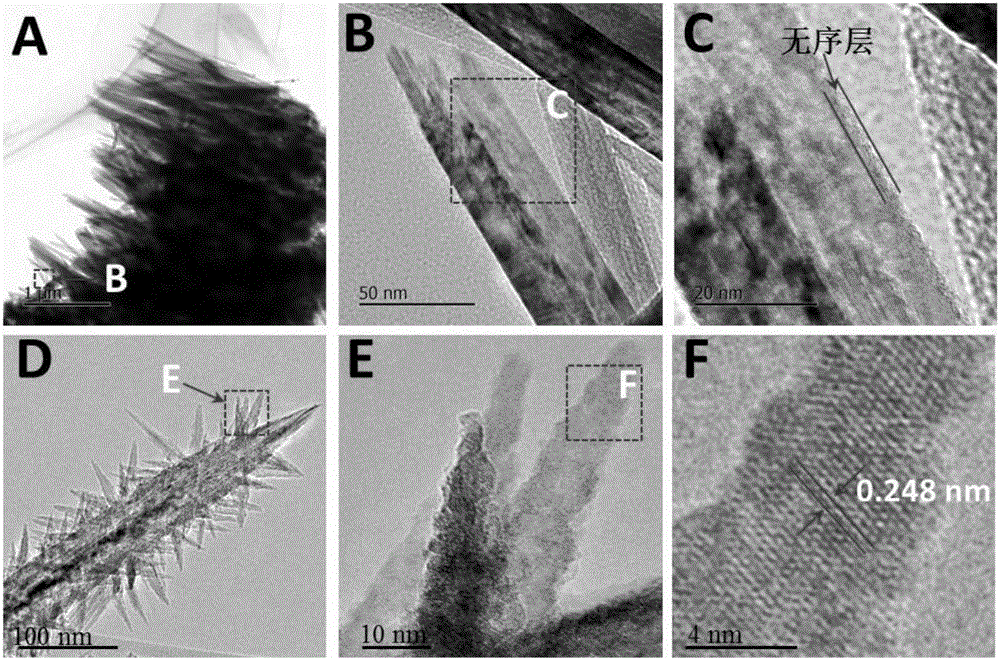

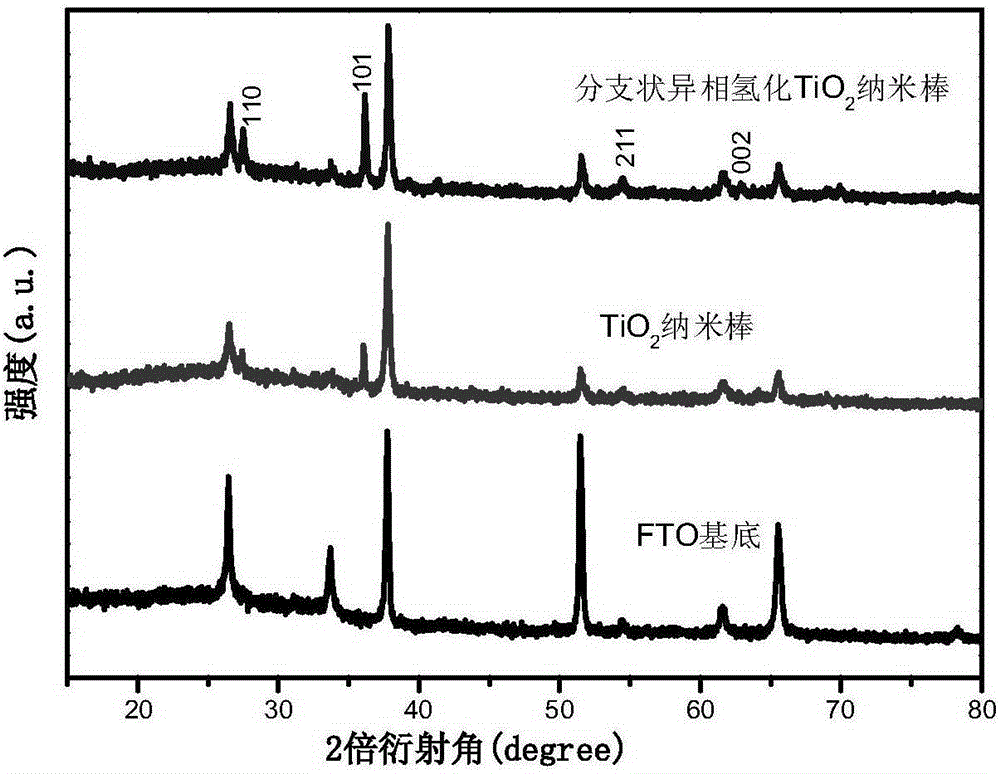

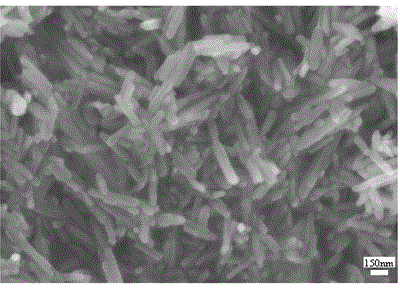

Branched heterogeneous hydrogenated titanium dioxide nanorod array electrode and preparation method thereof

The invention belongs to the technical field of functional materials, and discloses a branched heterogeneous hydrogenated titanium dioxide nanorod array electrode and a preparation method thereof. The preparation method is as below: subjecting FTO conducting glass to ultrasonic pretreatment, placing the conducting glass in a mixed solution of deionized water, hydrochloric acid and tetrabutyl titanate, and conducting water thermal reaction at 150-200 DEG C to prepare the TiO2 nanorod array; then annealing the TiO2 nanorod array in a mixed atmosphere of hydrogen and argon at 300 to 500 DEG C to obtain a hydrogenated TiO2 nanorod array electrode; then putting the electrode into a mixed solution of deionized water, hydrochloric acid and titanium trichloride solution, reacting at 60-100 DEG C for 0.5-3 h to obtain the branched hydrogenated TiO2 nanorod array electrode. The method provided by the invention has the advantages of simple operation, short time, cheap and easily available raw materials, and low preparation cost; and the obtained electrode gains greatly improved photoelectric properties and has good application prospect in the field of hydrogen production from photocatalytic decomposition of water.

Owner:SOUTH CHINA UNIV OF TECH

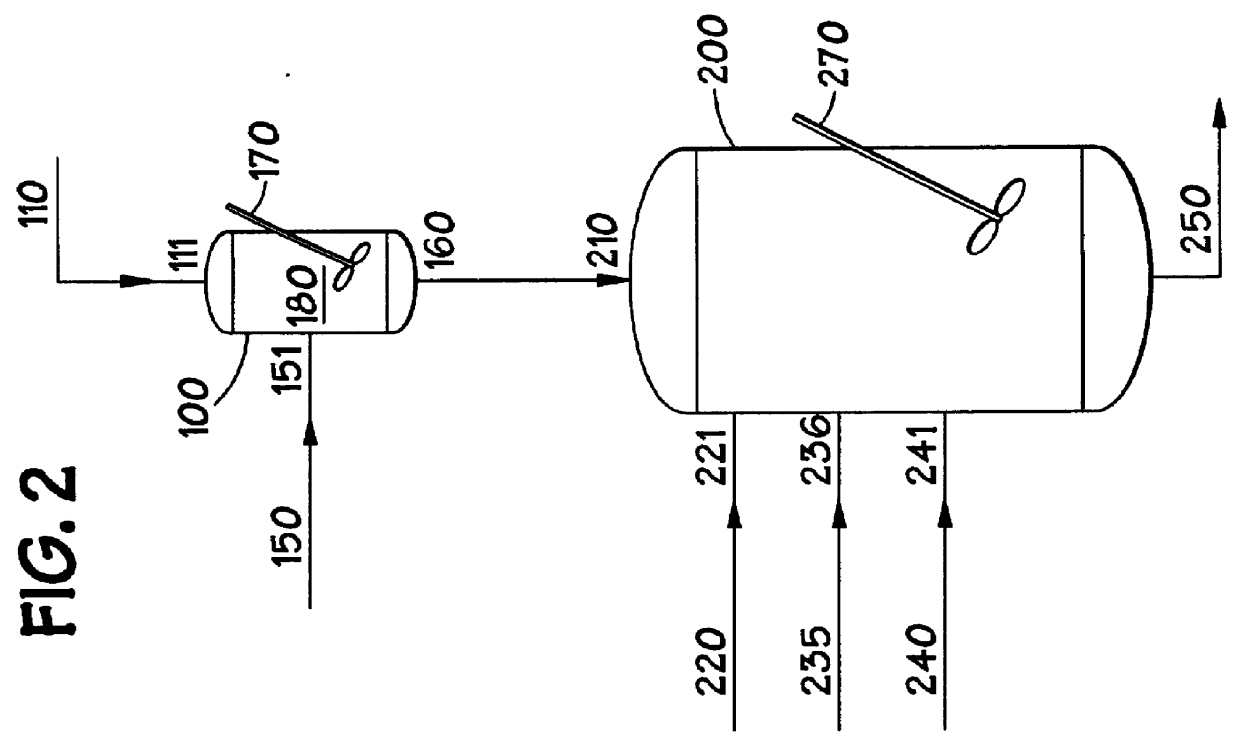

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents using a halohydrocarbon

InactiveUS6162773AGood drag reduction effectInherent viscosityOther chemical processesLiquid organic insulatorsHalohydrocarbonAluminoxane

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

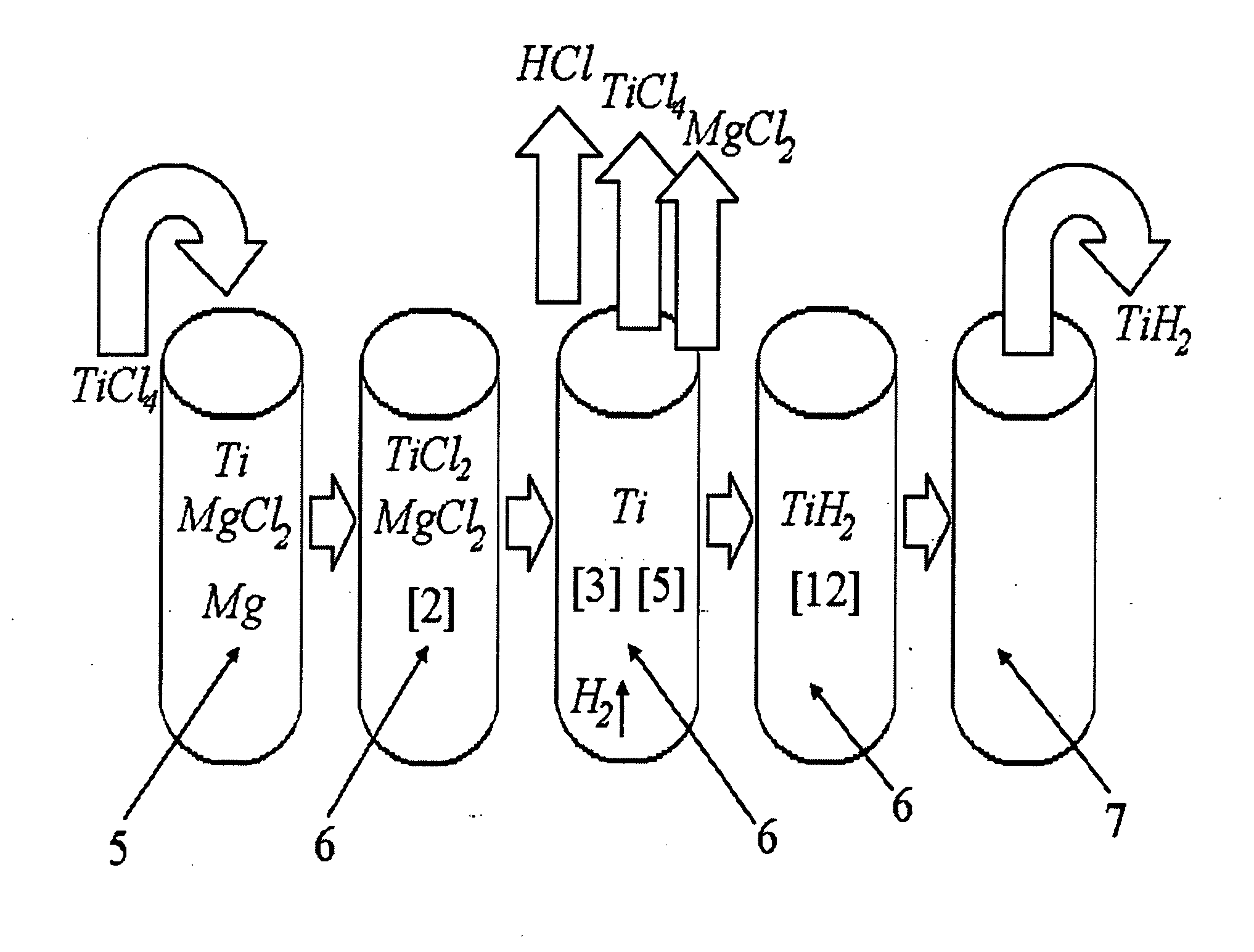

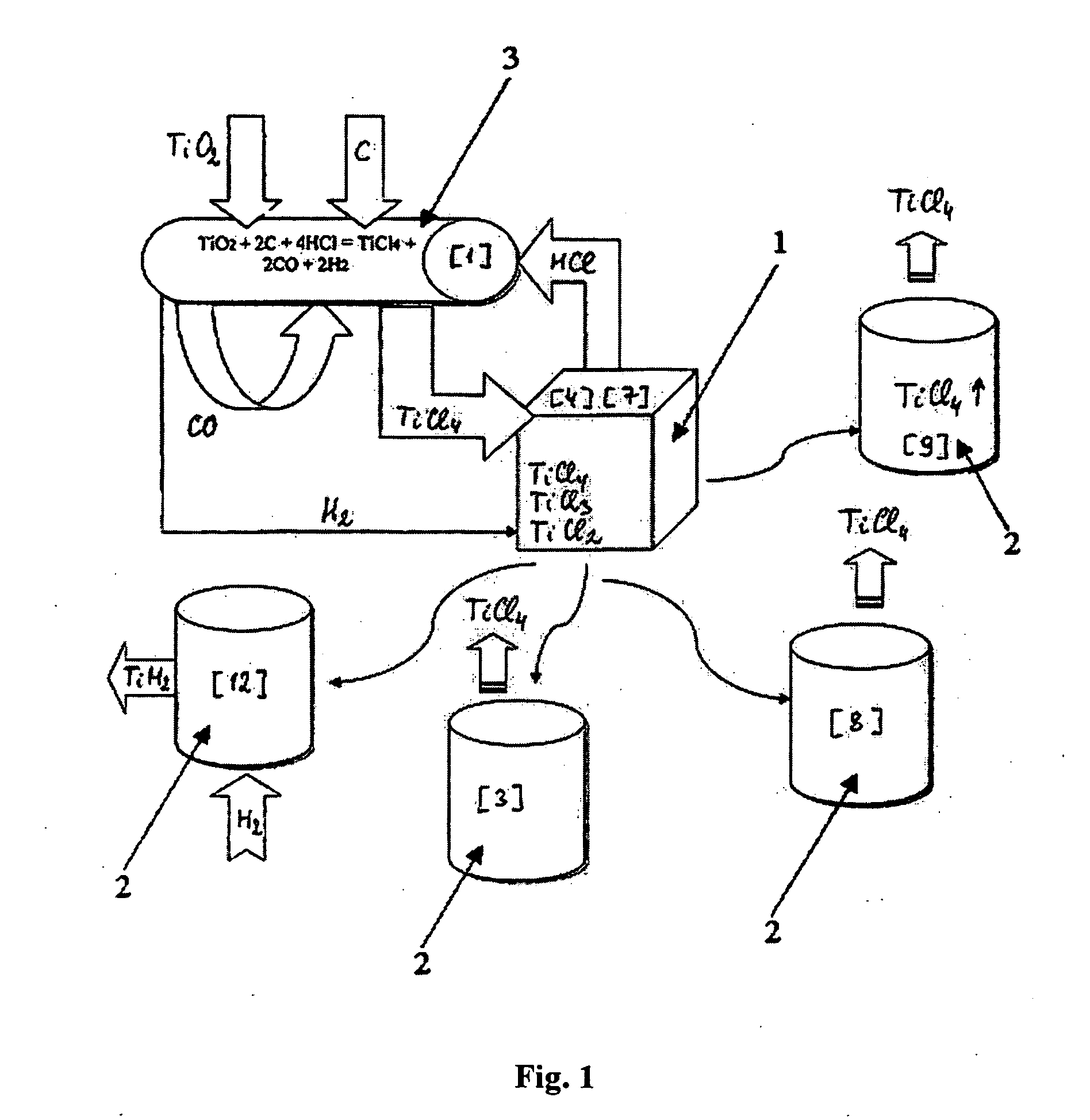

Continuous and semi-continuous process of manufacturing titanium hydride using titanium chlorides of different valency

InactiveUS20110171116A1Reduce manufacturing costCost-effective and highly-productive manufactureTransition element hydridesTitanium chlorideOxygen

The invention relates to the manufacture of titanium hydride powder using continuous or semi-continuous process, and using titanium slag or synthetic rutile as raw materials, while hydrogen, titanium tetrachloride, titanium trichloride, titanium dichloride, and hydrogen chloride are participate as intermediate reaction products. The continuous comprises: (a) reduction of TiCl4 to low titanium chlorides followed by cooling a mixture, (b) separating of residual TiCl4 from solid low chlorides by heating the mixture in argon or vacuum up to 150° C. followed by removing the titanium tetrachloride from the mixture, (c) dissociation of TiCl3 to TiCl2 at 450° C. in vacuum followed by removal of gaseous titanium tetrachloride from the reaction zone, condensation to the liquid, and returning back into the reaction retort, (d) dissociation of TiCl2 in vacuum at 750-850° C. to manufacture fine powder of metallic titanium and titanium tetrachloride, whereby hydrogen heated up to 1000° C. is used to accelerate this reaction, and (e) saturation of the fine titanium powder by hydrogen at 400-640° C. to manufacture final product of titanium hydride powder which is free of oxygen or nitrogen. The semi-continuous process includes the Kroll's process as the very first step.

Owner:ADMA PRODS

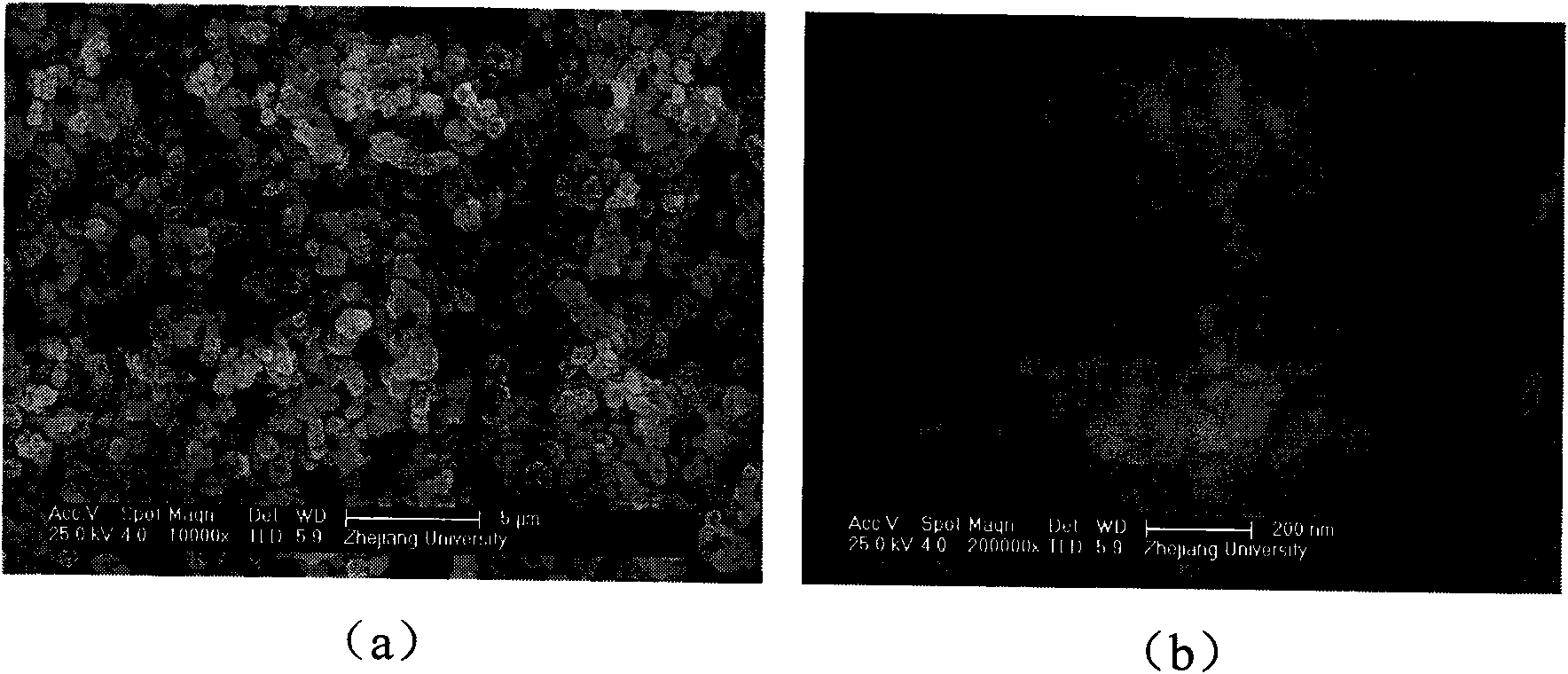

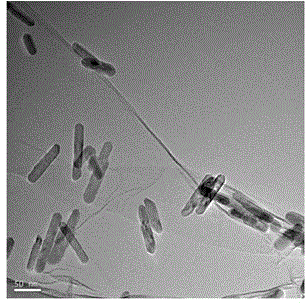

Method for preparing hollow titanium dioxide nano-sphere

InactiveCN101555037ASimple and fast operationLow costNanostructure manufactureTitanium dioxideContinuous mixingPolytetrafluoroethylene

The invention discloses a method for preparing a hollow titanium dioxide nano-sphere, which comprises the steps of dissolving fluoroborate in de-ionized water, adding titanium trichloride and hydrogen peroxide under continuous mixing to obtain clarified solution, putting the clarified solution in a stainless steel reaction kettle with a poly-tetrafluoroethylene internal lining, sealing the solution, putting the solution in a baking oven with the temperature of 160 DEG C to 200 DEG C to preserve temperature for 10 to 16 hours, cooling the solution to room temperature, repeatedly washing and centrifugation-separating the obtained precipitation and de-ionized water, and then obtaining the hollow titanium dioxide nano-sphere by drying for 12 to 24 hours at the temperature of 80 to 100 DEG C. The method has simple process, low cost and friendly environment and is suitable for mass production; the obtained product is expected to be used in files of catalysts, dye-sensitized solar cell materials, lithium-ion electrode materials and the like.

Owner:ZHEJIANG UNIV

High yield rapid synthesis method of titanium-silicon molecular sieve TS-1

ActiveCN105819464AReduce dosageLess total waterCrystalline aluminosilicate zeolitesSynthesis methodsHydrolysis

The invention provides a high yield rapid synthesis method of a titanium-silicon molecular sieve TS-1. The synthesis method comprises the following steps: mixing raw materials namely a silicon source, a titanium source, tetrapropyl ammonium hydroxide and water according to a ratio of SiO2:TiO2:TPAOH:H2O of 1:(0.0501-0.099):(0.0501-0.1499):(0.101-4.999), wherein the silicon source is at least one of n-methyl silicate, n-ethyl silicate, silica sol, and white carbon black; the titanium source is at least one of tetraethyl titanate, tetrabutyl titanate, isopropyl titanate, titanium trichloride, and titanium tetrachloride; carrying out hydrolysis for 0-5 hours at a temperature of 30 to 60 DEG C, performing alcohol removal for 0 to 1 hour at a temperature of 90 DEG C, filling the hydrolysis product into a crystallization kettle, carrying out crystallization for 2 to 10 hours at a temperature of 210 to 250 DEG C; drying, and burning to obtain the titanium-silicon molecular sieve TS-1. The titanium-silicon molecular sieve TS-1 synthesized by the provided method has the advantages of high content of titanium in skeleton, little using amount of template, no generation of wastewater, and high crystallization speed. The particle size of obtained nano level titanium-silicon molecular sieve is about 100 nm. The titanium-silicon molecular sieve has an excellent catalytic performance on alkene epoxidation and aromatic hydrocarbon hydroxylation.

Owner:DALIAN UNIV OF TECH

Preparation method of boron-doped graphene/TiO2 nanorod photocatalytic material

InactiveCN103949234AImprove photocatalytic activityImprove adsorption capacityMaterial nanotechnologyPhysical/chemical process catalystsDoped grapheneChemical adsorption

The invention provides a preparation method of boron-doped graphene / TiO2 nanorod photocatalytic material. The method comprises the following steps of preparing graphene oxide by a method disclosed in pages from 4806 to 4814 in the volume 4 in 2010 of nanometer periodical of the American chemical society; weighing 8-80mg of graphene oxide, feeding 15-25ml of deionized water and carrying out ultrasonic dispersion to obtain graphene oxide dispersion liquid; feeding sodium borohydride and titanium trichloride solution into the graphene oxide dispersion liquid, stirring and then carrying out a hydrothermal reaction to obtain precipitate; and washing the precipitate, carrying out vacuum drying, and grinding the product into uniform powder to obtain the boron-doped graphene / TiO2 nanorod composite photocatalytic material. After the method is adopted, titanium dioxide can be well loaded on boron-doped graphene, the photocatalytic activity of the composite material is improved, harmful gases such as nitrogen oxide and nitrogen dioxide can be chemically adsorbed, and the harmful gases can be well adsorbed and decomposed on the surface of the graphene.

Owner:SHANGHAI RONGFU NEW MATERIAL

Method for preparing ultra hydrophilic coat of titanium dioxide by using titanium trichloride as precursor

InactiveCN1687253AIncrease loadImprove bindingSpecial surfacesCoatingsCoated surfaceHydrophilic coating

The preparation method of titanium dioxide super-hydrophilic coating using titanium trichloride as precursor body includes the following steps: firstly, using titanium trichloride as precursor body, preparing titanium dioxide aqueous colloid with a certain concentration, using surface of metal copper, stainless steel or glass as carrier, adopting impregnation method or brush coating method to apply the titanium dioxide aqueous colloid on the surface of carrier, drying at proper temperature and irradiating by UV-light so as to form powder colloid coating layer with super-hydrophilic property on the carrier surface.

Owner:SHANGHAI JIAO TONG UNIV

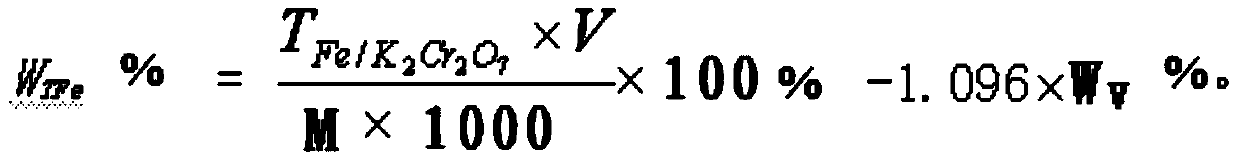

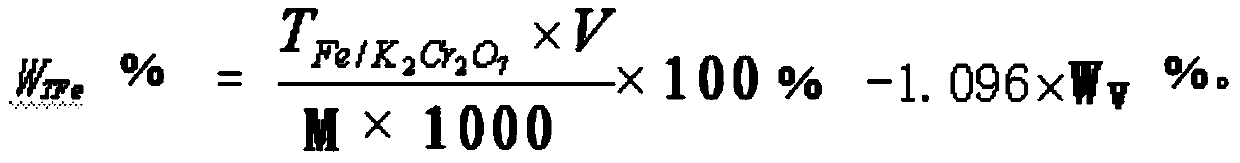

Method for rapidly determining content of total iron in vanadium titano-magnetite

InactiveCN104181272AEasy to operateQuick breakdownMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationMagnetiteRoom temperature

The invention provides a method for rapidly determining the content of total iron in vanadium titano-magnetite. The method comprises the following steps: (1) weighing a to-be-determined vanadium titano-magnetite sample with the weight of M; (2) adding sufficient mineral dissolving solution to dissolve the to-be-determined vanadium titano-magnetite sample in a heating manner; (3) adding dilute hydrochloride acid into a reaction vessel; (4) dropwise adding stannous chloride solution to the reaction vessel until the mixed solution turns pale yellow, reheating the mixed solution to be boiled slightly, and cooling the mixed solution to the room temperature; (5) adding sodium tungstate solution into the reaction vessel, dropwise adding titanium trichloride solution until the mixed solution turns blue, and dropwise adding titanium trichloride solution to be slightly excessive in volume; (6) dropwise adding potassium dichromate solution into the reaction vessel until the mixed solution is colorless, and dropwise adding sodium diphenylaminesulfonate indicator; (7) titrating the mixed solution in the reaction vessel to be purple by adopting potassium dichromate standard titration solution; (8) sampling the solution after being titrated to be purple, and determining the weight percentage of vanadium in the sample; and (9) calculating. The method is easy to operate, high in determination speed, capable of enabling the detection result to be equivalent to that of a national standard method and capable of better meeting the in-situ rapid analysis requirement.

Owner:武汉钢铁有限公司

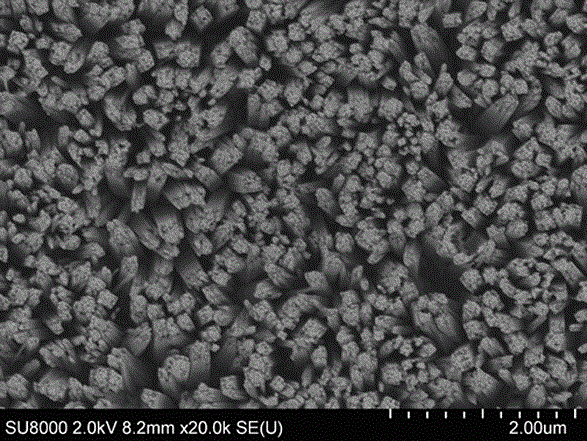

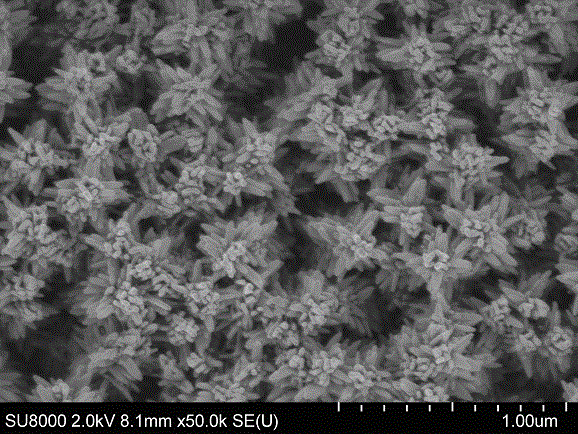

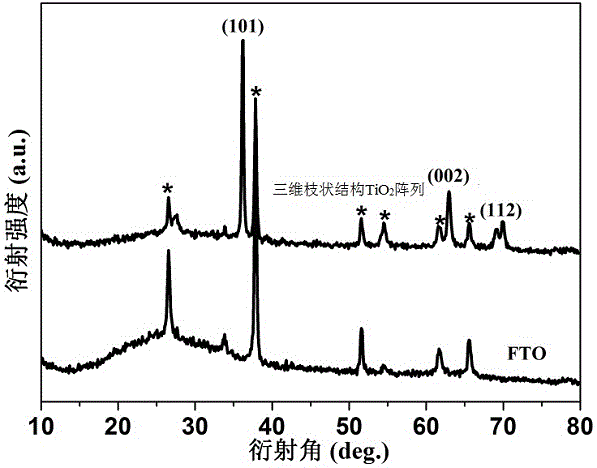

Three-dimensional dendritic structure TiO2 array preparation method

The present invention discloses a three-dimensional dendritic structure TiO2 array preparation method, the specific steps are as follows: (1) hydrolysis of tetrabutyl titanate as a titanium source under acidic conditions, and use of conductive glass as a substrate for hydrothermal reaction to obtain a quartet TiO2 nanorod array; and (2) use of the quartet TiO2 nanorod array as a substrate for secondary hydrothermal reaction to obtain a three-dimensional dendritic structure TiO2 array by use of titanium trichloride as a source of titanium. The resulting three-dimensional dendritic structure TiO2 array has a large specific surface area and collimated electron transport channel, helps capture of incident light and transmission of photogenerated charges, and can be used as a light anode material for solar cells and photoelectrochemical decomposition of water.

Owner:HENAN NORMAL UNIV

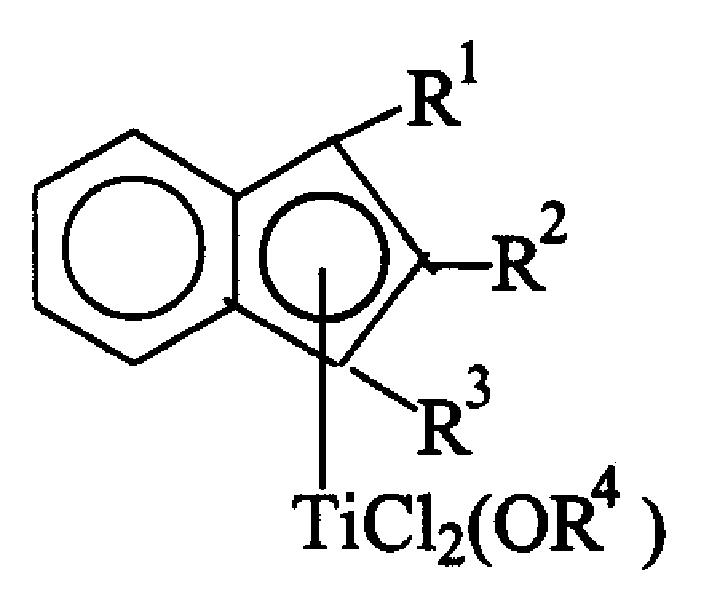

Substituted indenyl metal titanium compound and its preparation method and use

A substituted indenyl metal titanium compound is prepared through reaction of relative alcohol solution with alkyllithium or Grignard reagent, adding relative substituted indenyl titanium trichloride solution, reaction, filter, concentrating and crystallizing. It has high catalytic activity to the syndiotactive polymerization of p-styrene.

Owner:CHINA PETROLEUM & CHEM CORP +2

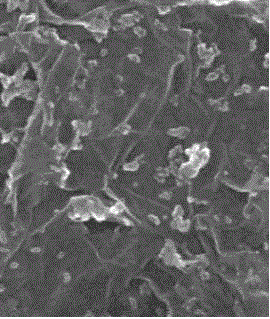

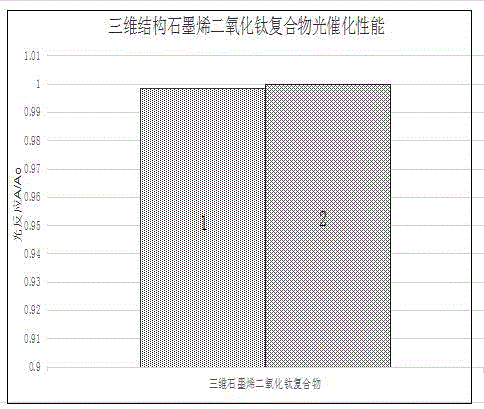

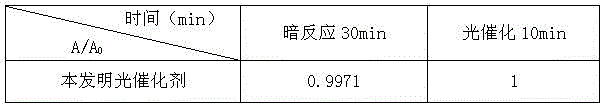

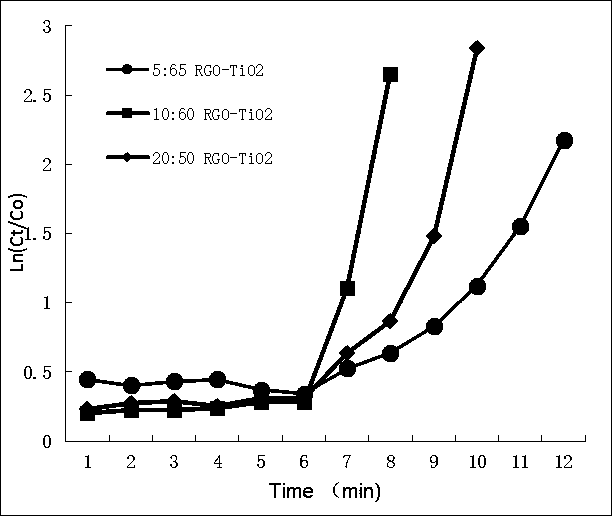

Preparation method of three-dimensional graphene-titanium dioxide compound photocatalyst

InactiveCN105749894AImprove photocatalytic abilityIncrease profitPhysical/chemical process catalystsCerium(IV) oxideLithium-ion battery

The invention relates to a preparation method of a three-dimensional graphene-titanium dioxide compound photocatalyst. A three-dimensional porous-structure graphene-titanium dioxide compound is prepared through a hydrothermal-method reaction of graphene oxide and titanium trichloride. The three-dimensional graphene-titanium dioxide compound provided by the invention has a very good photocatalytic property and can be used for rapidly degrading organic pollutants in wastewater, particularly organic pollutants including pesticides and the like, into pollution-free substances including H2O, CO2 and the like under the conditions of normal temperature, normal pressure and light illumination; and the compound can be repeatedly utilized for a plurality of times and has lasting photocatalytic activity. Furthermore, the three-dimensional graphene-titanium dioxide compound can also be used as a material of a super capacitor, a lithium-ion battery and a fuel cell, and has a wide application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method for graphene/nanometer titanium dioxide composite photocatalyst

InactiveCN107308929AImprove photocatalytic performanceHigh purityPhysical/chemical process catalystsWater/sewage treatment by irradiationGraphiteGraphene

The invention relates to a preparation method for a graphene / nanometer titanium dioxide composite photocatalyst. The graphene / nanometer titanium dioxide composite photocatalyst is prepared from graphite powder, concentrated sulfuric acid, titanium trichloride, n-hexane, n-amyl alcohol and cetyltrimethylammonium bromide through a hydrothermal reaction. The preparation method provided by the invention has the advantages of simple synthesis, convenient operation, low cost and no pollution; and the prepared graphene / nanometer titanium dioxide composite photocatalyst has excellent photocatalytic performance and strong ability of degrading organic pollutants, can be cyclically used and further has the characteristics of adsorption.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com