Method for preparing precious metal titanium dioxide core-shell structure

A technology of titanium dioxide and core-shell structure is applied in the field of preparation of core-shell structure, which can solve the problems that synthesis is limited by harsh conditions, increase difficulty, and easy to coagulate, and achieves simple preparation method, good repeatability, and monodispersity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 prepares gold rod

[0052] 1) Measure 7.5ml, 100mmol / L cetyltrimethylammonium bromide, 1.65ml water, and 0.25ml, 10mmol / L chloroauric acid into a 20ml serum bottle in a 30°C water bath. After stirring for 5 minutes, add 0.6ml, 10mmol / L newly configured sodium borohydride solution to the serum bottle. After adding sodium borohydride, a brown gold seed solution can be obtained. After stirring for 30 seconds, move it to a water bath at 30°C for 3-5 hours.

[0053] 2) Measure 200ml, 100mmol / L cetyltrimethylammonium bromide solution into a blue cap bottle, add 10ml, 10mmol / L chloroauric acid, 2ml, 10mmol in a water bath at 30°C with vigorous stirring / L silver nitrate, 1.16ml, 1mmol ascorbic acid, after the reaction solution is mixed evenly, add 0.24ml of the seed solution obtained in 1), stir for 1min, put it in a 30°C water bath and let it stand for 12 hours. The aspect ratio of the obtained gold rods can be regulated by adding the volume of silver nitrate. ...

Embodiment 2

[0054] Embodiment 2 prepares platinum nanoparticles

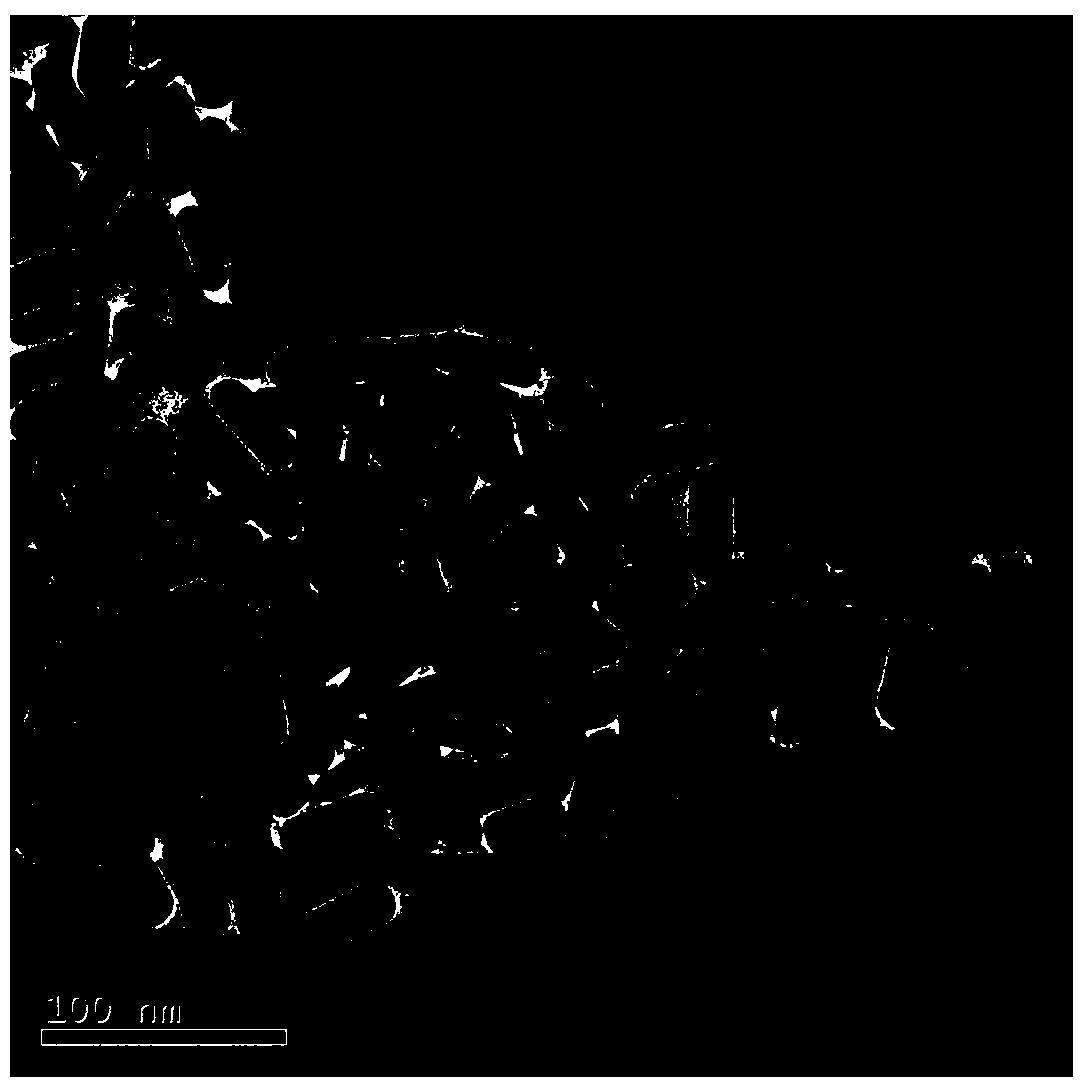

[0055] At 25°C, measure 5ml of water into the serum bottle, then measure 0.2ml, 25mmol / L chloroplatinic acid solution, 1ml, 50mmol / L sodium citrate and 2ml, 30mmol / L ascorbic acid, After stirring evenly, put it into an 80° C. water bath and react for 10 minutes to obtain a colloidal solution of platinum nanoparticles. figure 2 It is a transmission electron microscope picture of platinum nanoparticles prepared in this example.

Embodiment 3

[0056] Example 3 Preparation of Gold Rod Titanium Dioxide Core-Shell Structure

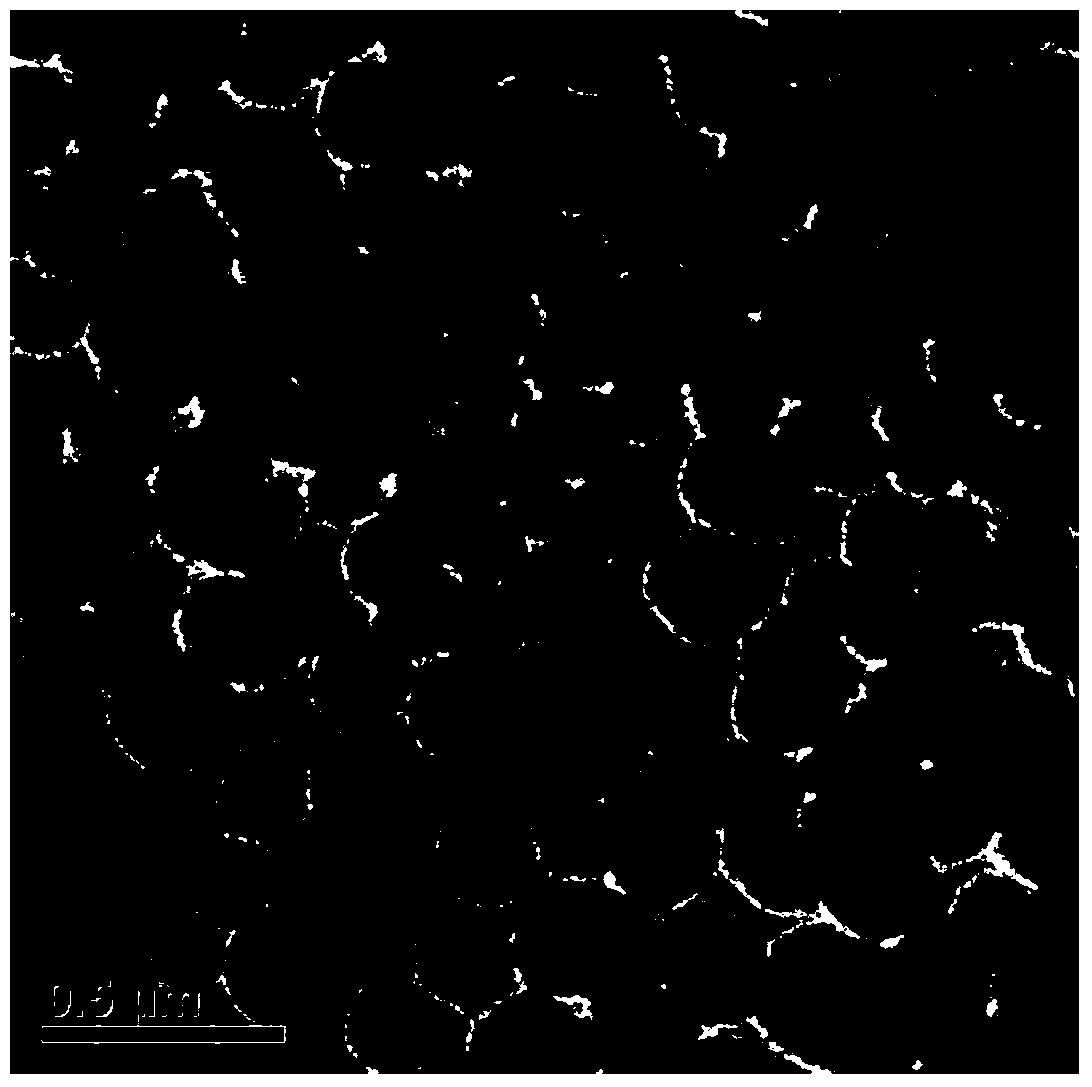

[0057] At 25°C, measure 60ml of water into a serum bottle, then add 2ml of titanium trichloride precursor therein, stir for 2 minutes and mix well. Add 1mol / L, 12ml sodium bicarbonate solution dropwise to the reaction system, bubbles are generated during the reaction, and the pH of the system gradually increases (the pH changes from 1.5 to 5.48 during the dropwise addition). Then add the ligand-exchanged gold rod solution dropwise therein, and the reaction lasts for 10-30 minutes. Finally, the gold rod titania core-shell structure is obtained. After the reaction, the product was centrifuged at 6000r / min for 10 minutes, and the solution in the upper layer was removed to obtain a solid with a core-shell structure. After lyophilization for 12 hours, a solid titanium dioxide core-shell structure was finally obtained. image 3 It is an electron microscope picture of the gold rod titanium dioxide core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com