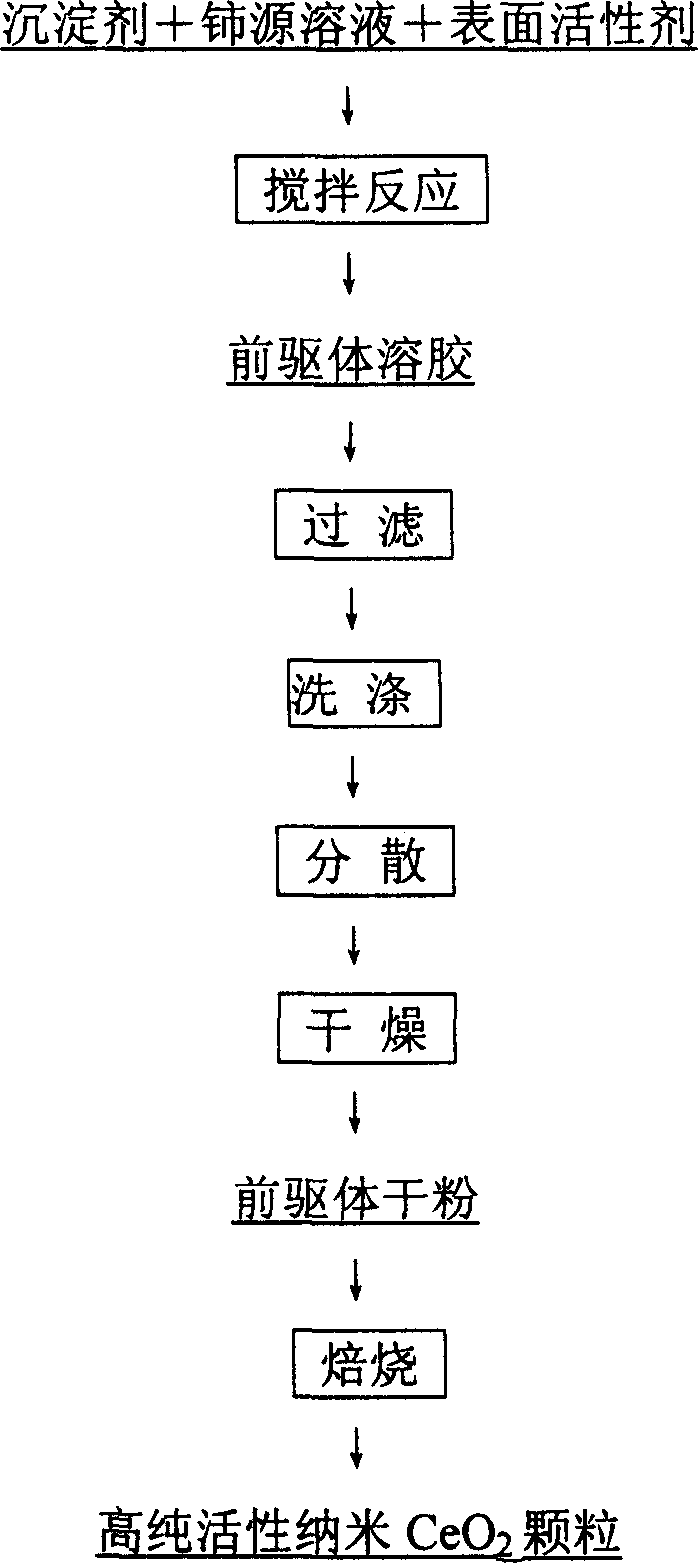

Process for preparing high purity active nano ceria

A nano-ceria, active technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve problems such as poor product performance, harsh reaction conditions, complex production processes, etc., and achieve a simple and easy control process. , Simple equipment, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

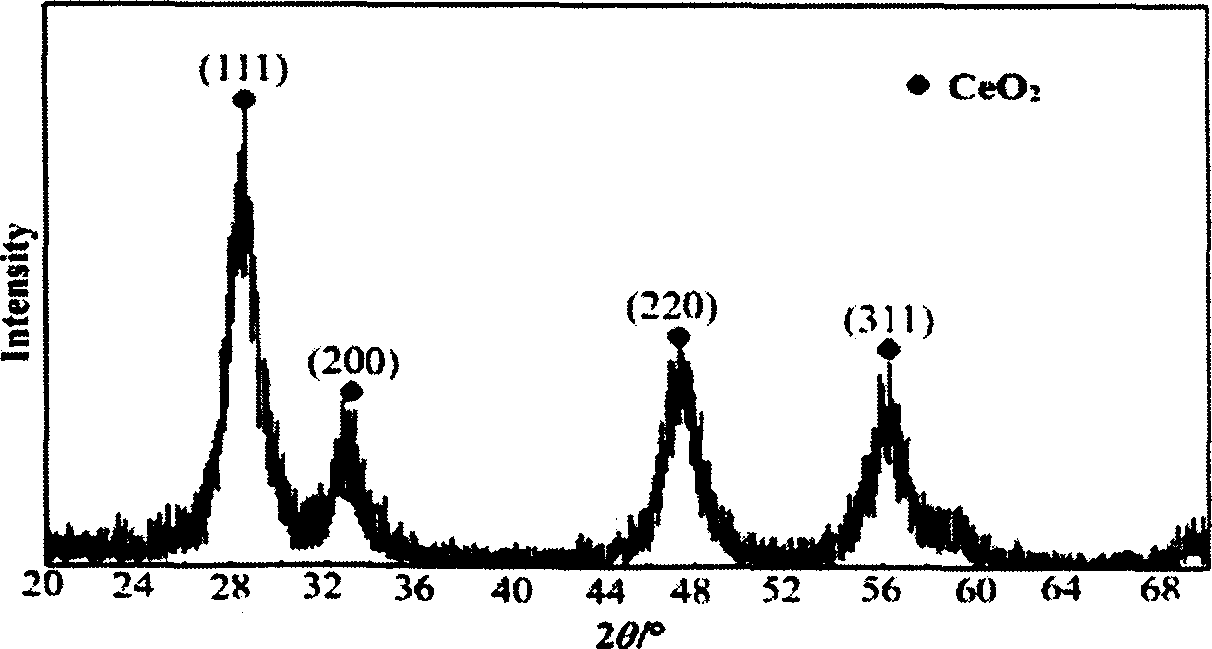

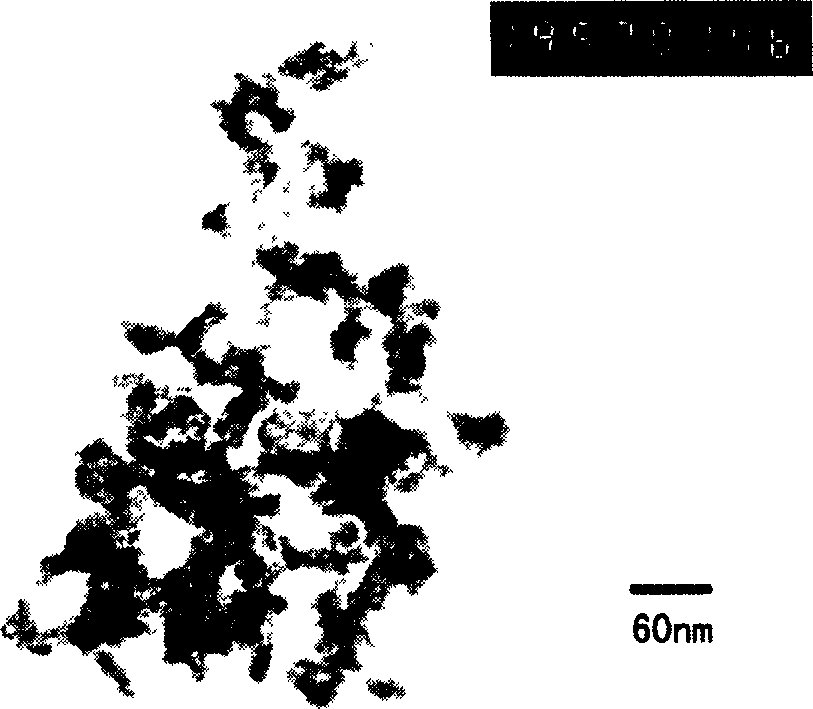

[0020] Example 1 Weighing Ce(NO 3 ) 3 ·6H 2 O 8.68g, be made into 0.1mol / L solution of 100ml, and add 1gPEG4000 wherein; Weigh (NH 4 ) 2 CO 3 ·H 2 O 5.13g, made into 150ml of 0.1mol / L solution. The prepared two solutions were placed in a water bath, preheated at 40°C for 10 min, and then (NH 4 ) 2 CO 3 ·H 2 The O solution was quickly poured into the Ce(NO 3 ) 3 ·6H 2 O mixed solution, under 800r / min rotating speed electric mechanical stirring reaction 10min, the obtained precursor Ce 2 (CO 3 ) 3 ·H 2 O sol was washed twice with deionized water during the vacuum filtration process, and the filtered product was dispersed in absolute alcohol for 10 minutes by ultrasonic waves, vacuum filtration, repeated twice, and then vacuum-dried at 70°C to obtain the precursor The dry powder is put into a muffle furnace and calcined in the air at 300°C for 1 hour to obtain light yellow high-purity active nano-CeO 2 product, its XRD pattern is as follows figure 2 As shown, t...

Embodiment 2

[0021] Example 2 Weighing Ce(NO 3 ) 3 ·6H 2 O 8.68g, be made into 0.1mol / L solution of 100ml, and add 1gPEG4000 wherein; Weigh (NH 4 ) 2 CO 3 ·H 2 O 5.13g, made into 150ml of 0.1mol / L solution. At 40°C, the (NH 4 ) 2 CO 3 ·H 2 The O solution was quickly poured into the Ce(NO 3 ) 3 ·6H 2 O mixed solution, mechanical stirring reaction at 800rpm for 10min, the obtained precursor sol was washed twice with distilled water in the vacuum filtration process, the filtered product was put into absolute alcohol and dispersed by ultrasonic wave for 10min, vacuum filtration, repeated two times and then dried at 70°C, the resulting precursor gel powder was calcined in a muffle furnace at 700°C for 3 hours to obtain yellow high-purity active nano-CeO 2 The product has a grain size of 15.26nm and a BET specific surface area of 69.78m 2 / g, the purity is greater than 99.5%.

[0022] La

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com