Method for preparing cadmium selenide/cadmium sulfide /zinc sulfide core-shell quantum dots

A technology of core-shell quantum dots and cadmium chloride, which is applied in the field of II-VI group nano-luminescent materials, can solve the problems of long time and complicated subsequent steps, and achieves the effects of low cost, safe raw materials and simplified operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

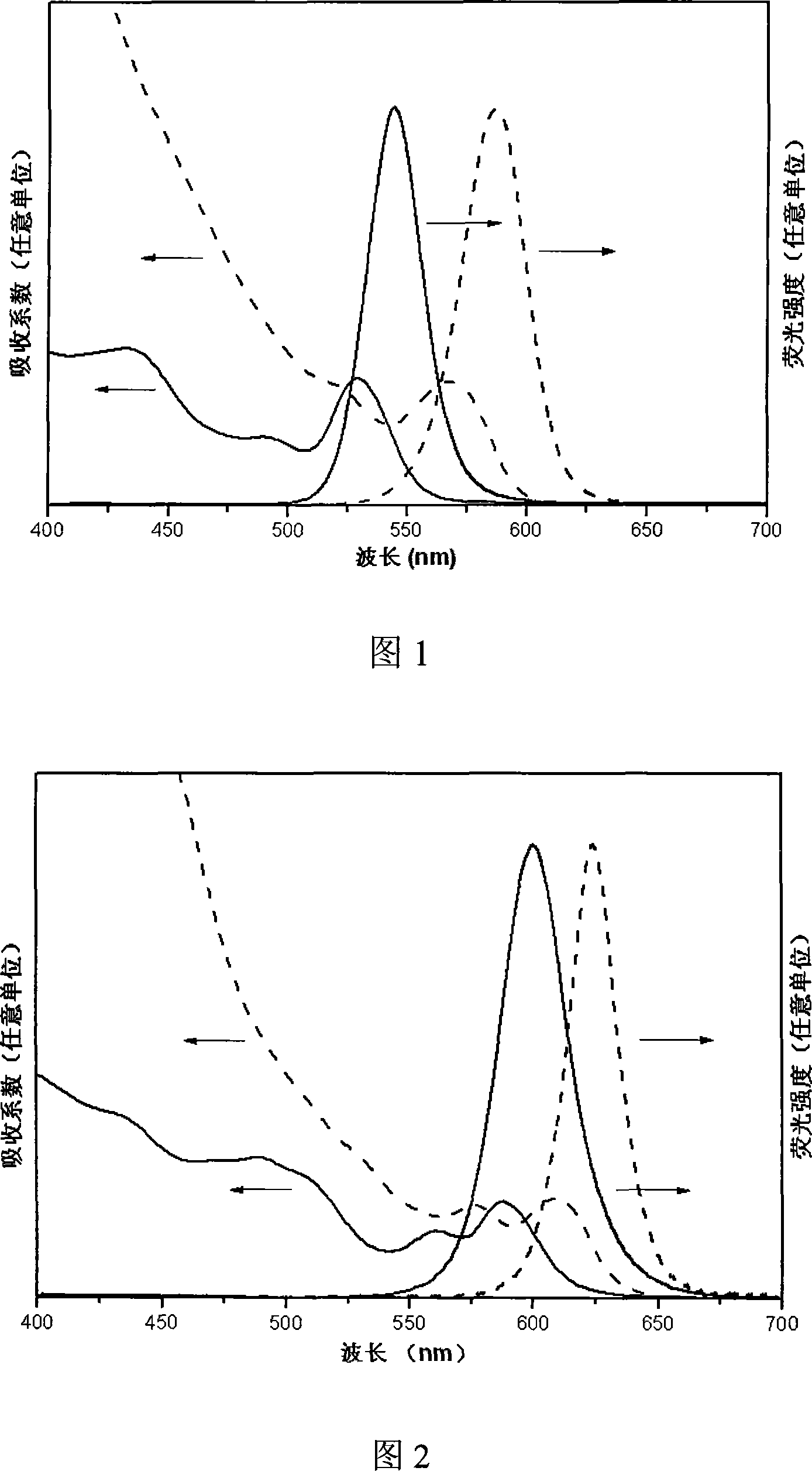

Image

Examples

Embodiment 1

[0019] A. Preparation of CdS precursor solution. Cadmium ethyl xanthate is produced by co-precipitation of cadmium chloride and potassium ethyl xanthate in deionized water; cadmium stearate is produced by co-precipitation of cadmium chloride and potassium stearate in deionized water; All were dehydrated in a vacuum oven. Put cadmium ethyl xanthate, cadmium stearate, oleic acid, and oleylamine into a container, such as a pear-shaped bottle, stir, and store at room temperature. The mass percentages of cadmium ethyl xanthate, cadmium stearate, oleic acid and oleylamine added are 0.8%, 4.6%, 16.5% and 78.1%, respectively.

[0020] B. Preparation of ZnS precursor solution. Zinc ethyl xanthate is produced by co-precipitation of zinc chloride and potassium ethyl xanthate in deionized water, zinc stearate is produced by co-precipitation of zinc chloride and potassium stearate in deionized water, and the latter two All were dehydrated in a vacuum oven. Put zinc ethyl xanthate, zinc...

Embodiment 2

[0027] A. Preparation of CdS layer precursor solution. Cadmium ethyl xanthate is produced by co-precipitation of cadmium chloride and potassium ethyl xanthate in deionized water, and cadmium stearate is produced by co-precipitation of cadmium chloride and potassium stearate in deionized water. All were dehydrated in a vacuum oven. Put cadmium ethyl xanthate, cadmium stearate, oleic acid, and oleylamine into a container, such as a pear-shaped bottle, stir, and store at room temperature. The mass percentages of cadmium ethyl xanthate, cadmium stearate, oleic acid and oleylamine added are 0.8%, 4.6%, 16.5% and 78.1%, respectively.

[0028] B. Preparation of ZnS layer precursor solution. Zinc ethyl xanthate is prepared by co-precipitation of zinc chloride and potassium ethyl xanthate in deionized water, and zinc stearate is prepared by co-precipitation of zinc chloride and potassium stearate in deionized water. All were dehydrated in a vacuum oven. Put zinc ethyl xanthate, zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com