Method for preparing hollow titanium dioxide nano-sphere

A technology of titanium dioxide and nanospheres, applied in the direction of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of adverse environmental effects, unfavorable large-scale production, inconvenience, etc., and achieve low cost, easy operation and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

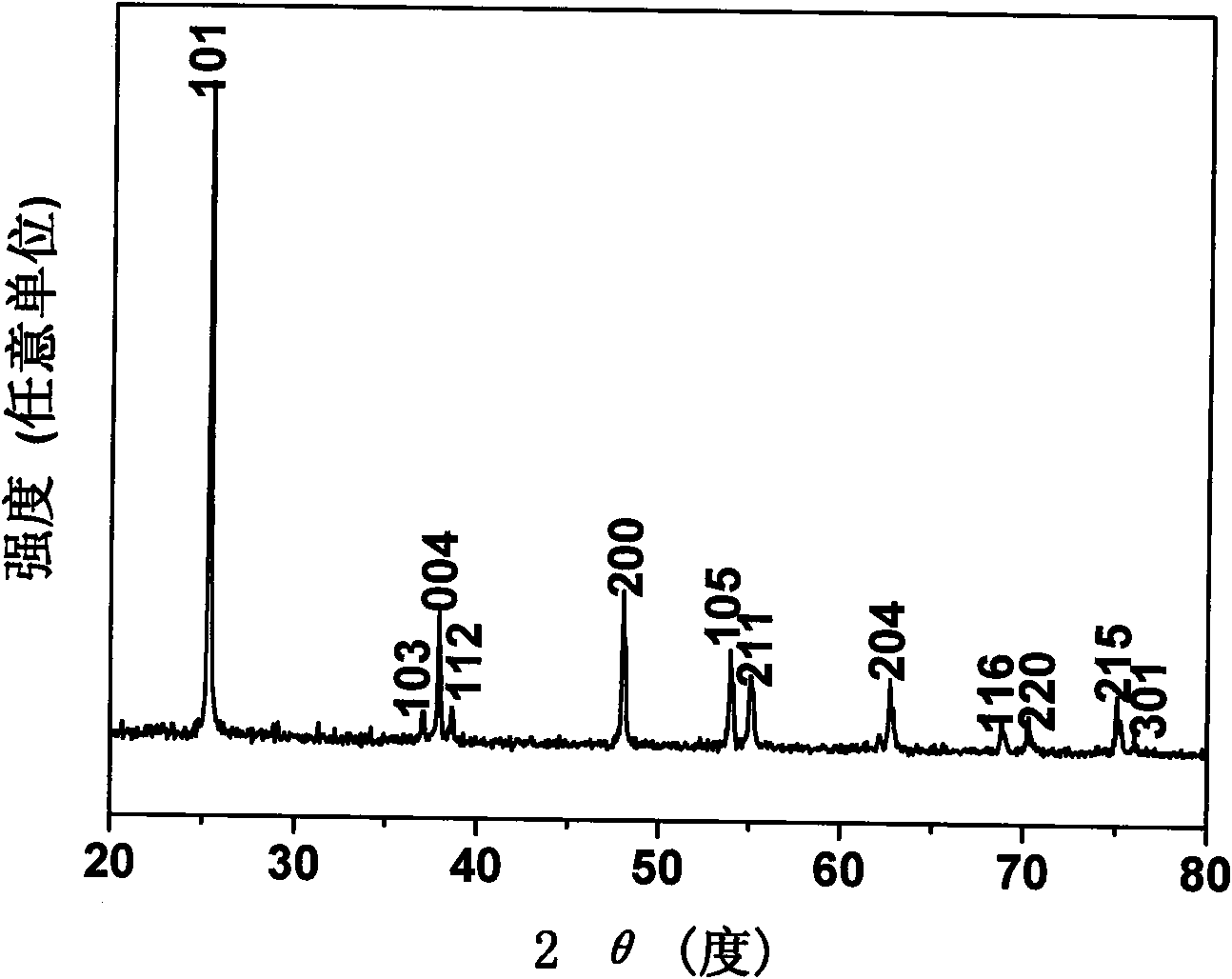

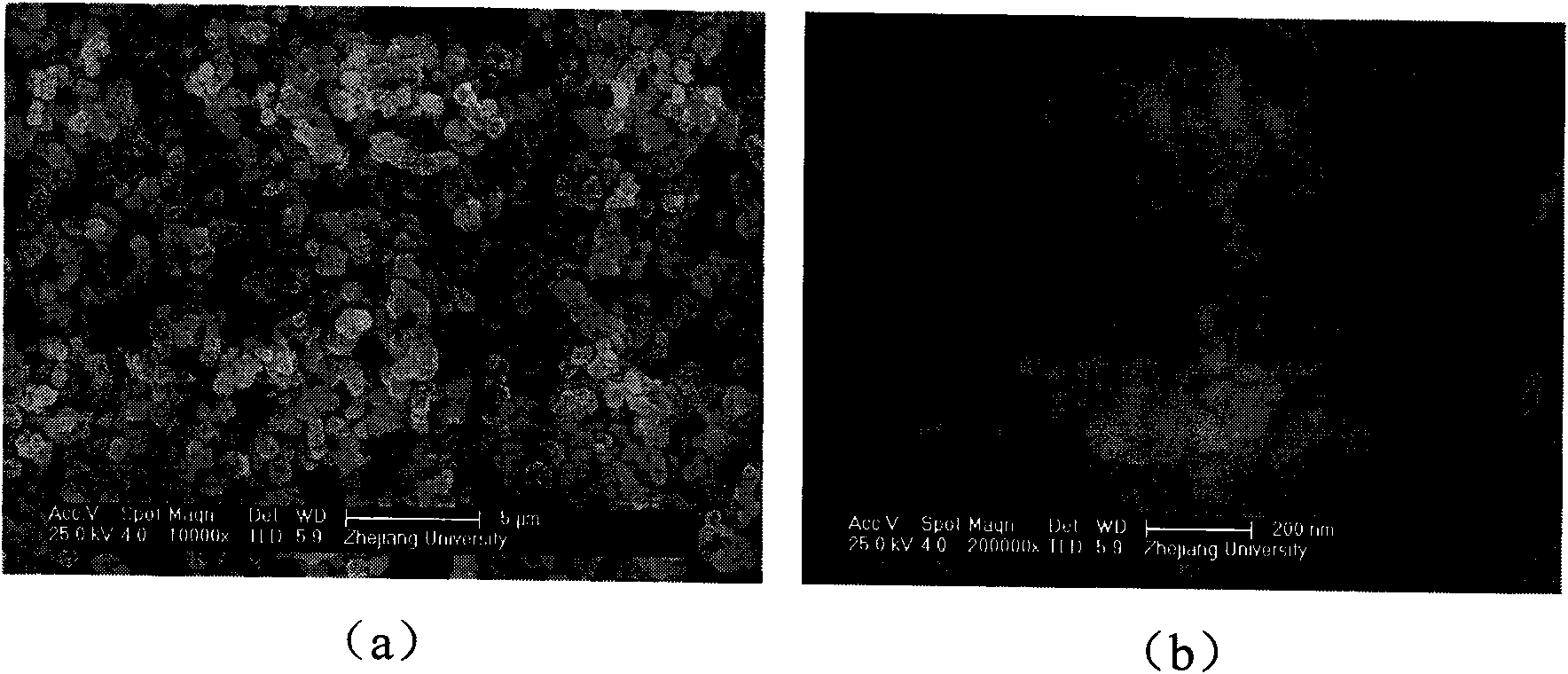

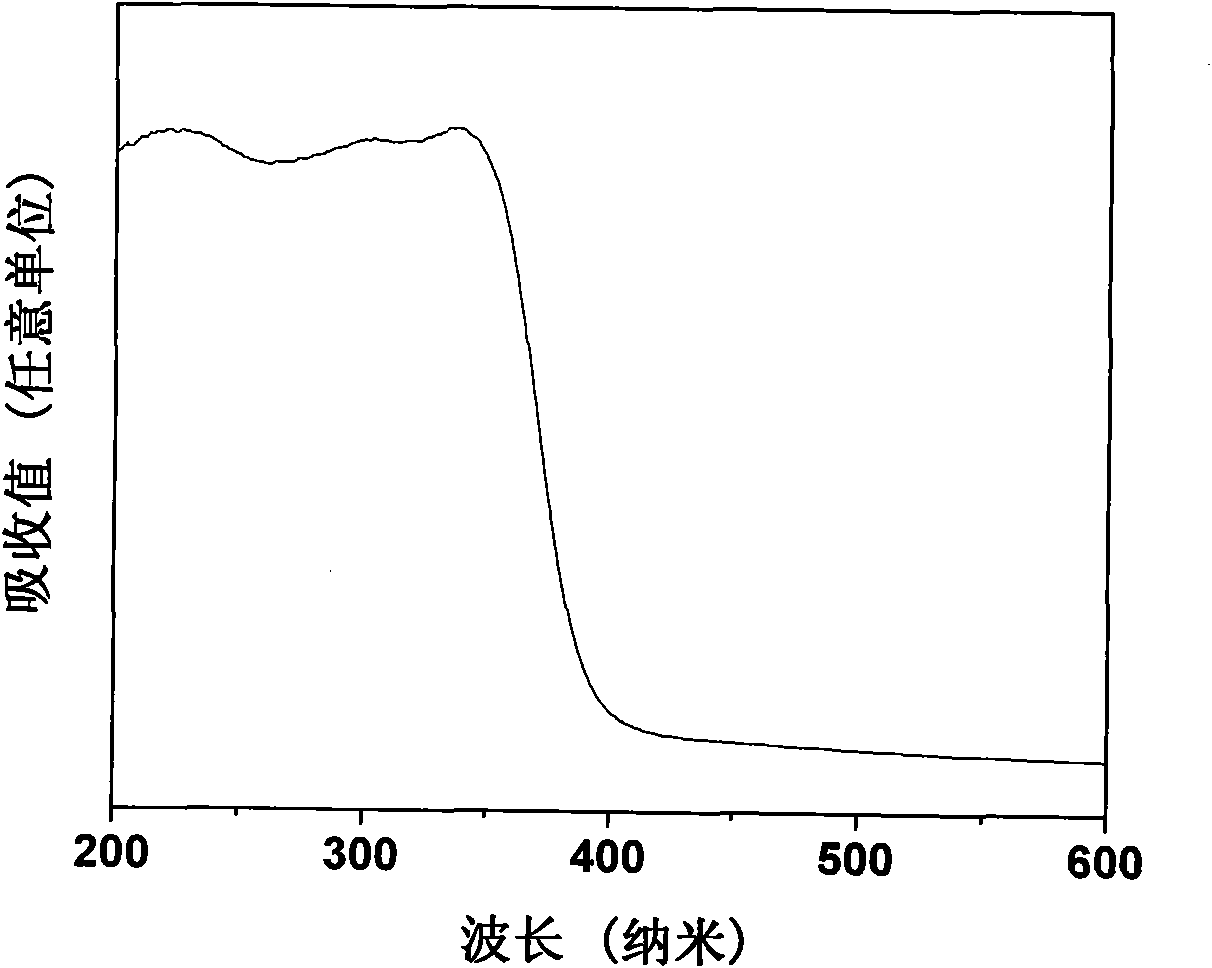

[0014] Dissolve 4mmol potassium fluoroborate in 80mL deionized water, add 8mmol titanium trichloride (16-18% solution) and 20mmol hydrogen peroxide (30% solution) under continuous stirring to obtain a clear solution Put it in a stainless steel reaction kettle with ethylene lining, seal it, put it in an oven at 180°C, keep it warm for 12 hours, cool to room temperature, wash the obtained precipitate repeatedly with deionized water and absolute ethanol, separate it by centrifugation, and dry it at 80°C for 24 hours , to obtain hollow titania nanospheres. figure 1 It is the X-ray diffraction pattern of the prepared hollow titanium dioxide nanosphere, which is consistent with the standard card JCPDS No.21-1272. It is a pure anatase phase, and the product has high crystallinity and purity. figure 2 (a) is a low-magnification field emission scanning electron microscope image of the prepared hollow titania nanospheres. It can be seen that the product is composed of a large number of...

Embodiment 2

[0016] Dissolve 4mmol of sodium fluoroborate in 80mL of deionized water, add 8mmol of titanium trichloride (16-18% solution) and 20mmol of hydrogen peroxide (30% solution) under continuous stirring to obtain a clear solution, and load it with polytetrafluoroethylene Put it in a stainless steel reaction kettle with ethylene lining, seal it, put it in an oven at 180°C, keep it warm for 12 hours, cool to room temperature, wash the obtained precipitate repeatedly with deionized water and absolute ethanol, separate it by centrifugation, and dry it at 80°C for 24 hours , to obtain hollow titania nanospheres. The structure and appearance of the product are the same as in Example 1.

Embodiment 3

[0018] Dissolve 5.3mmol potassium fluoroborate in 80mL deionized water, add 8mmol titanium trichloride (16-18% solution) and 16mmol hydrogen peroxide (30% solution) under continuous stirring to obtain a clear solution Put it in a stainless steel reaction kettle lined with vinyl fluoride, seal it, put it in an oven at 160°C, keep it warm for 16 hours, and cool it to room temperature. Hours, hollow titanium dioxide nanospheres were obtained. The structure and appearance of the product are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com