High yield rapid synthesis method of titanium-silicon molecular sieve TS-1

A titanium-silicon molecular sieve, TS-1 technology, applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problem of large molecular sieve particles, low skeleton titanium content, large amount of templates, etc. Problems, to achieve the effect of short synthesis cycle, fast crystallization rate, and increase crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

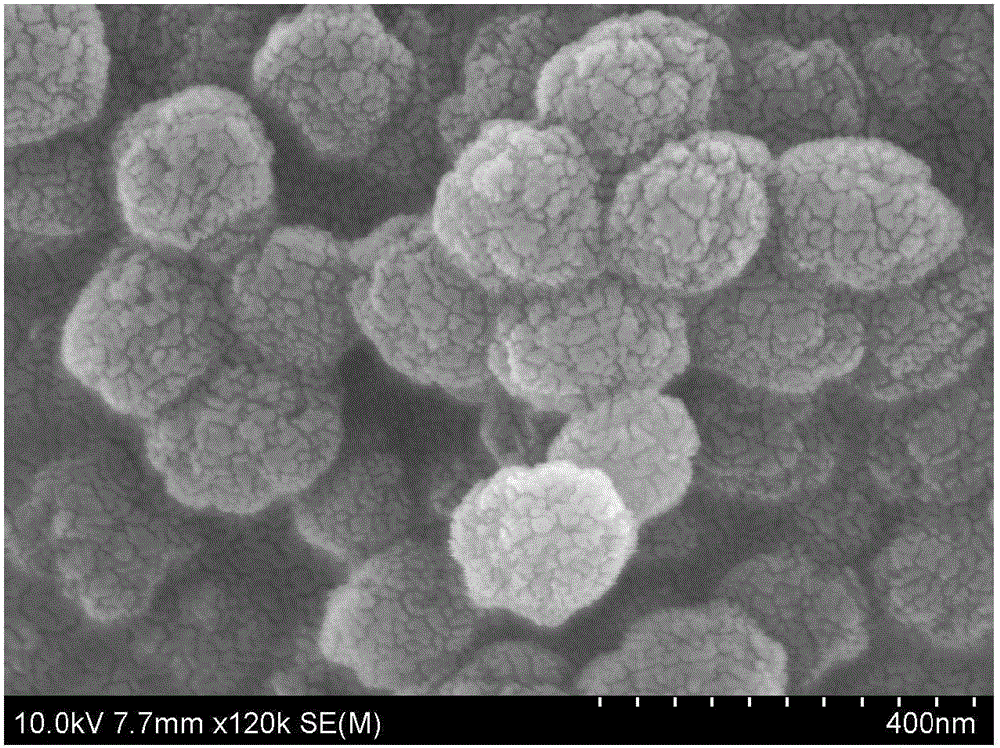

[0054] Add 41.7g of methyl orthosilicate into a jacketed three-necked flask, sequentially add 3.4g of tetraethyl titanate and 15.3g of 40wt% tetrapropylammonium hydroxide solution, immerse the three-necked flask in a 40°C water bath, and hydrolyze for 2.5h . After removing the alcohol at 90°C for 1 hour, the hydrolyzed product was put into a crystallization kettle and crystallized at 230°C for 8 hours. After washing and drying the crystallized product, it was roasted at 540°C for 6 hours to obtain TS-1, which is numbered as TS-1-C.

[0055] TS-1 was synthesized according to the above-mentioned method, the 100mL crystallization tank was filled with 70%, and the mass of the synthesized TS-1 molecular sieve was 24.6g.

Embodiment 2

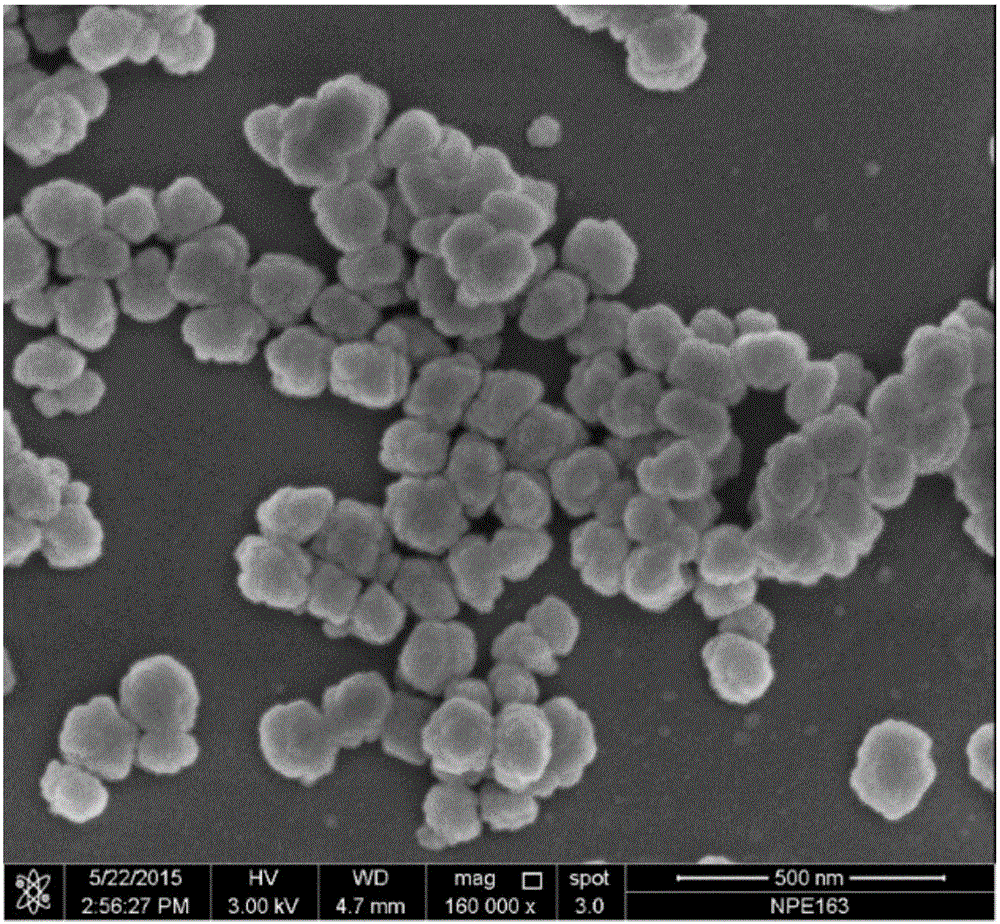

[0057] Add 31.3g of ethyl orthosilicate into a jacketed three-necked flask, sequentially add 2.6g of tetrabutyl titanate and 6.8g of 50wt% tetrapropylammonium hydroxide solution, and immerse the three-necked flask in a 50°C water bath for 1 hour of hydrolysis. After removing the alcohol at 90°C for 0.5h, the hydrolyzed product was put into a crystallization kettle, and crystallized at 240°C for 4h. After washing and drying the crystallized product, it was roasted at 540°C for 5h. The obtained TS-1 was numbered for TS-1-D.

[0058] figure 2 It is a scanning electron microscope photo of titanium silicon molecular sieve TS-1-D; it can be seen from the figure that the particle size of the synthesized TS-1-D sample is about 100nm.

[0059] TS-1 was synthesized according to the above method, the 100mL crystallization tank was filled with 70%, and the mass of TS-1 molecular sieve synthesized was 25.0g.

Embodiment 3

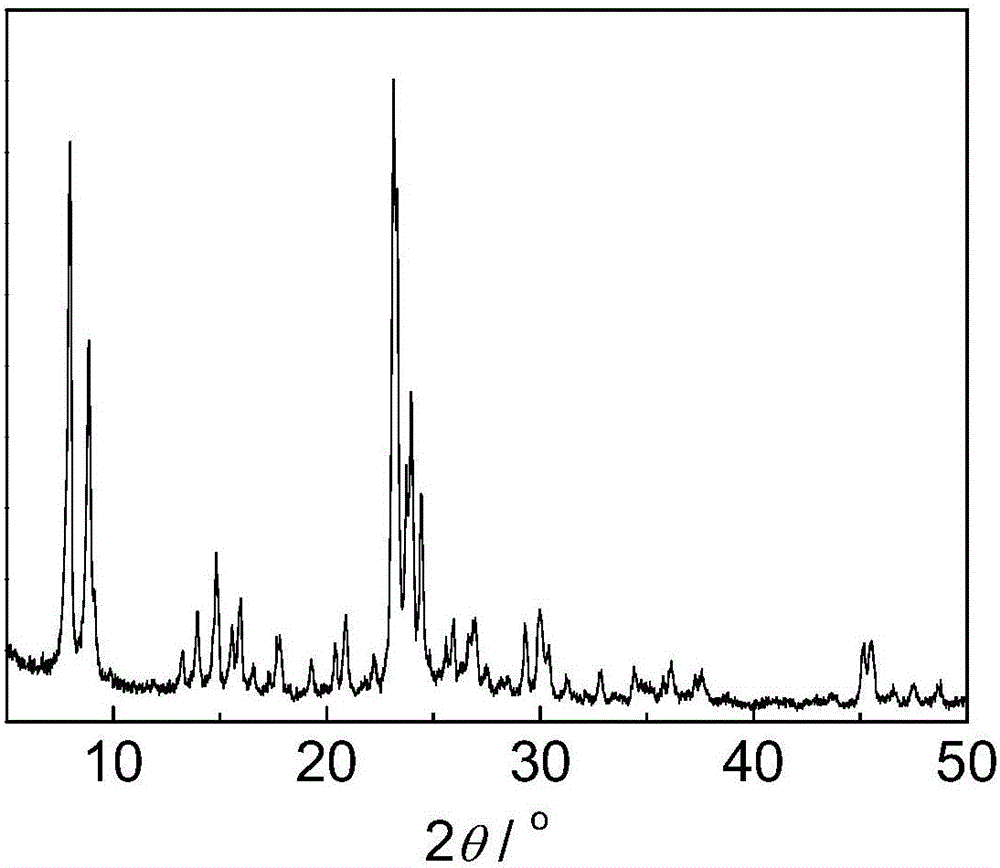

[0061] Add 20.6 g of tetrabutyl titanate and 7.5 g of 40 wt % tetrapropylammonium hydroxide solution in a jacketed three-necked flask, and then immerse the three-necked flask in a 50° C. water bath for 1 hour of hydrolysis. After removing the alcohol at 90°C for 1 hour, the hydrolyzed product was put into a crystallization kettle and crystallized at 250°C for 2 hours. After washing and drying the crystallized product, it was roasted at 540°C for 3 hours to obtain TS-1, which is numbered as TS-1-E.

[0062] image 3 It is the X-ray diffraction spectrum of titanium-silicon molecular sieve TS-1-E; it can be seen from the figure that the synthesized TS-1-E sample has characteristic diffraction peaks of typical MFI structures at 7.8, 8.8, 23.4, 23.9, and 24.4° , and the crystallinity of the sample is very high.

[0063] TS-1 was synthesized according to the above method, the 100mL crystallization tank was filled with 70%, and the mass of TS-1 molecular sieve synthesized was 24.9g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com