Patents

Literature

430 results about "Alkene epoxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkene epoxidation is an exciting reaction in which a double bond reacts with a peroxy acid to form an epoxide. This is considered a syn addition since the oxygen is bound to 2 carbon atoms.

Method for the start-up of an epoxidation process and a process for the epoxidation of an olefin

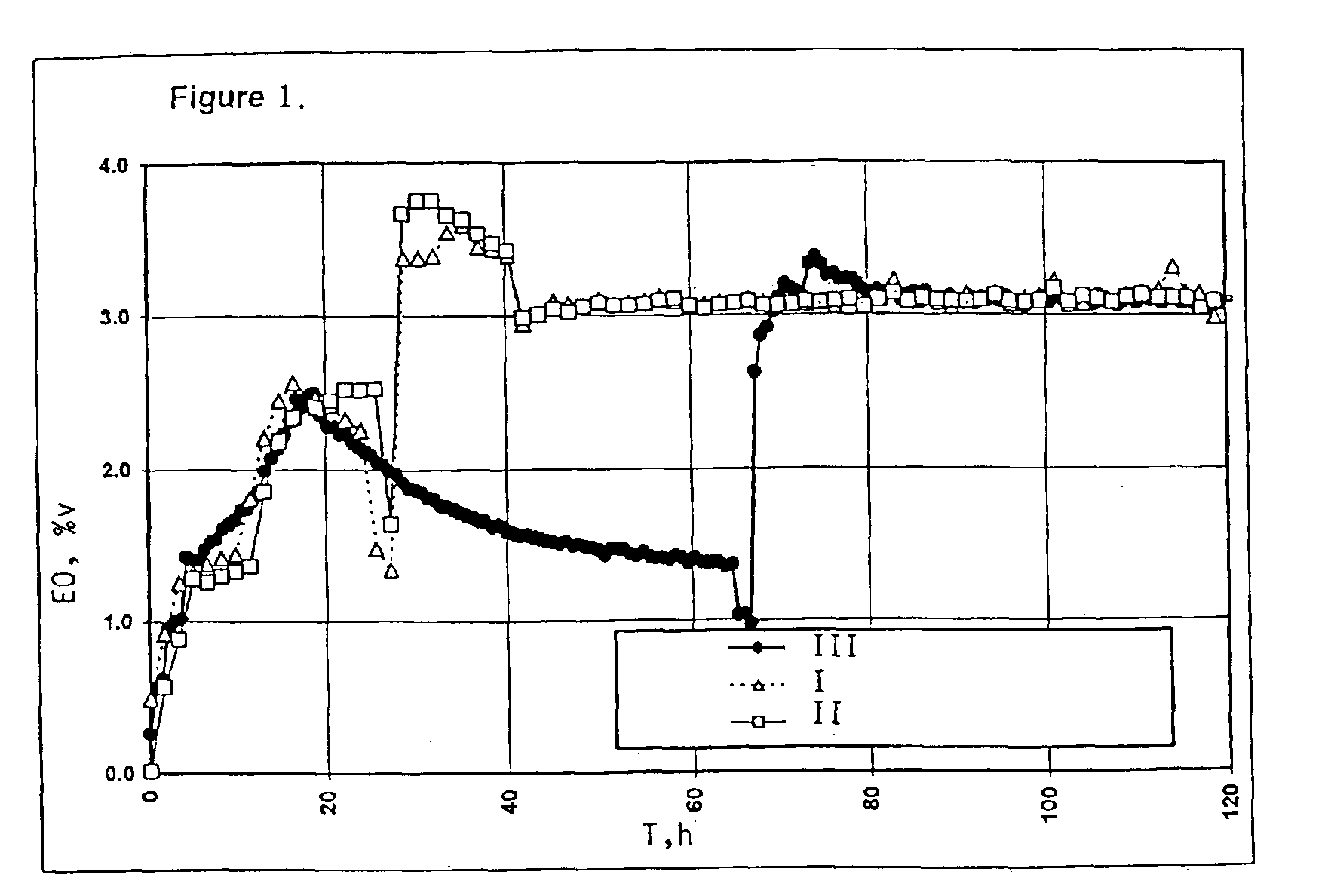

A method for the start-up of a process for the epoxidation of an olefin, which method comprisescontacting a catalyst bed comprising a silver-based highly selective epoxidation catalyst, or a precursor of the catalyst comprising the silver in cationic form, with a feed comprising oxygen at a temperature of the catalyst bed above 260° C. for a period of at most 150 hours, andsubsequently decreasing the temperature of the catalyst bed to a value of at most 260° C., and a process for the epoxidation of an olefin, which process, comprisescontacting a catalyst bed comprising a silver-based highly selective epoxidation catalyst, or a precursor of the catalyst comprising the silver in cationic form, with a feed comprising oxygen at a temperature of the catalyst bed above 260° C. for a period of at most 150 hours, andsubsequently decreasing the-temperature of the catalyst bed to a value of at most 260° C. and contacting the catalyst with the feed comprising the olefin and oxygen.

Owner:SHELL USA INC

Olefin epoxidation catalysts

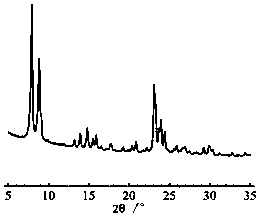

A method of synthesizing an olefin epoxidation catalyst comprises the step of treating a porous crystalline aluminosilicate material having an X-ray diffraction pattern including d-spacing maxima at 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07 Angstrom, such as MCM-22, with a dealuminating agent under conditions effective to remove framework aluminium from the material and produce a dealuminated product. The dealuminated product is then treated with a titanium-containing material under conditions effective to insert titanium into the dealuminated product and produce a titanium-containing, dealuminated catalyst composition. The resultant catalyst is useful in the epoxidation of olefins, such as propylene and cyclohexene, with hydrogen peroxide and organic hydroperoxides.

Owner:MOBIL OIL CORP

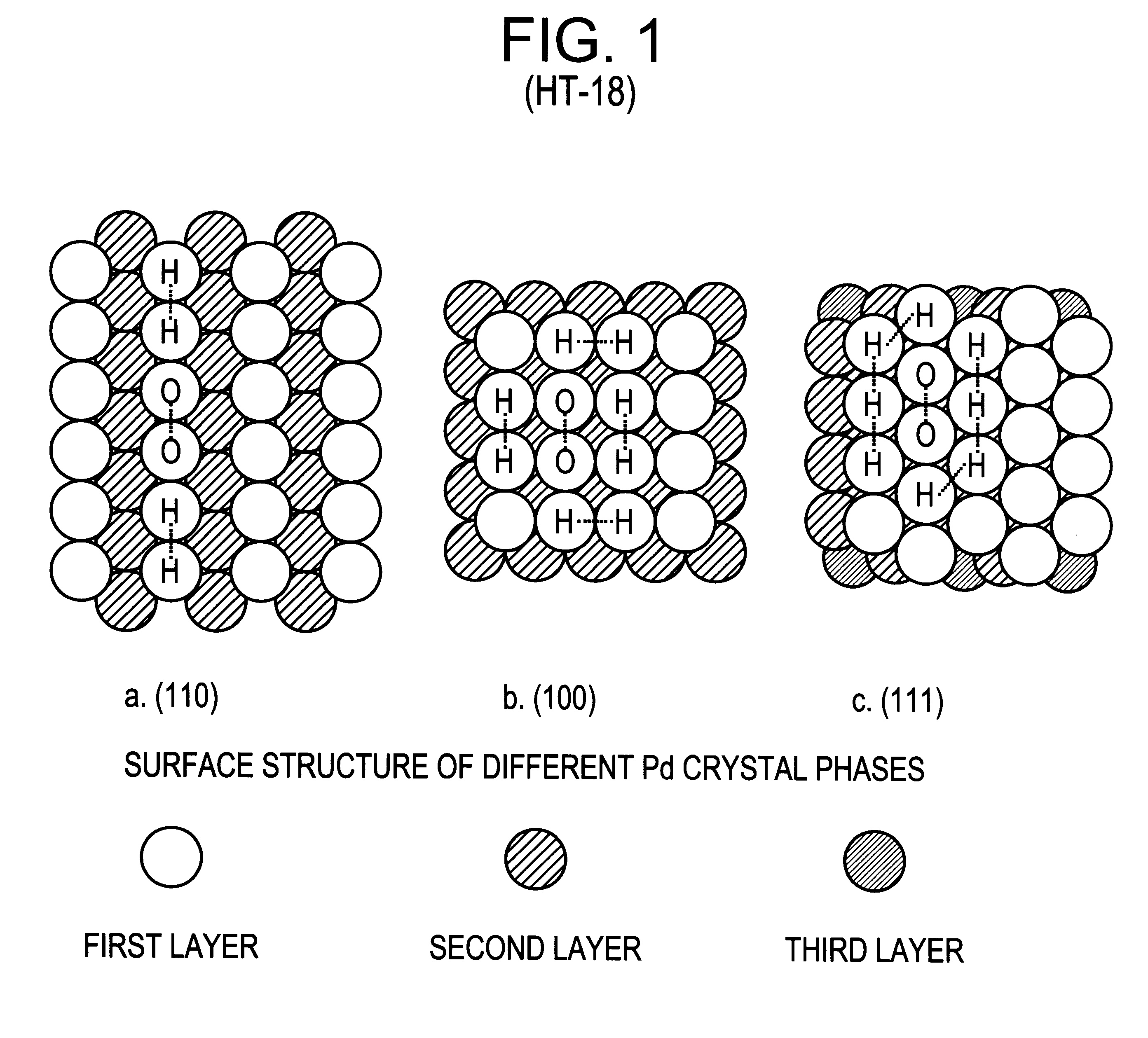

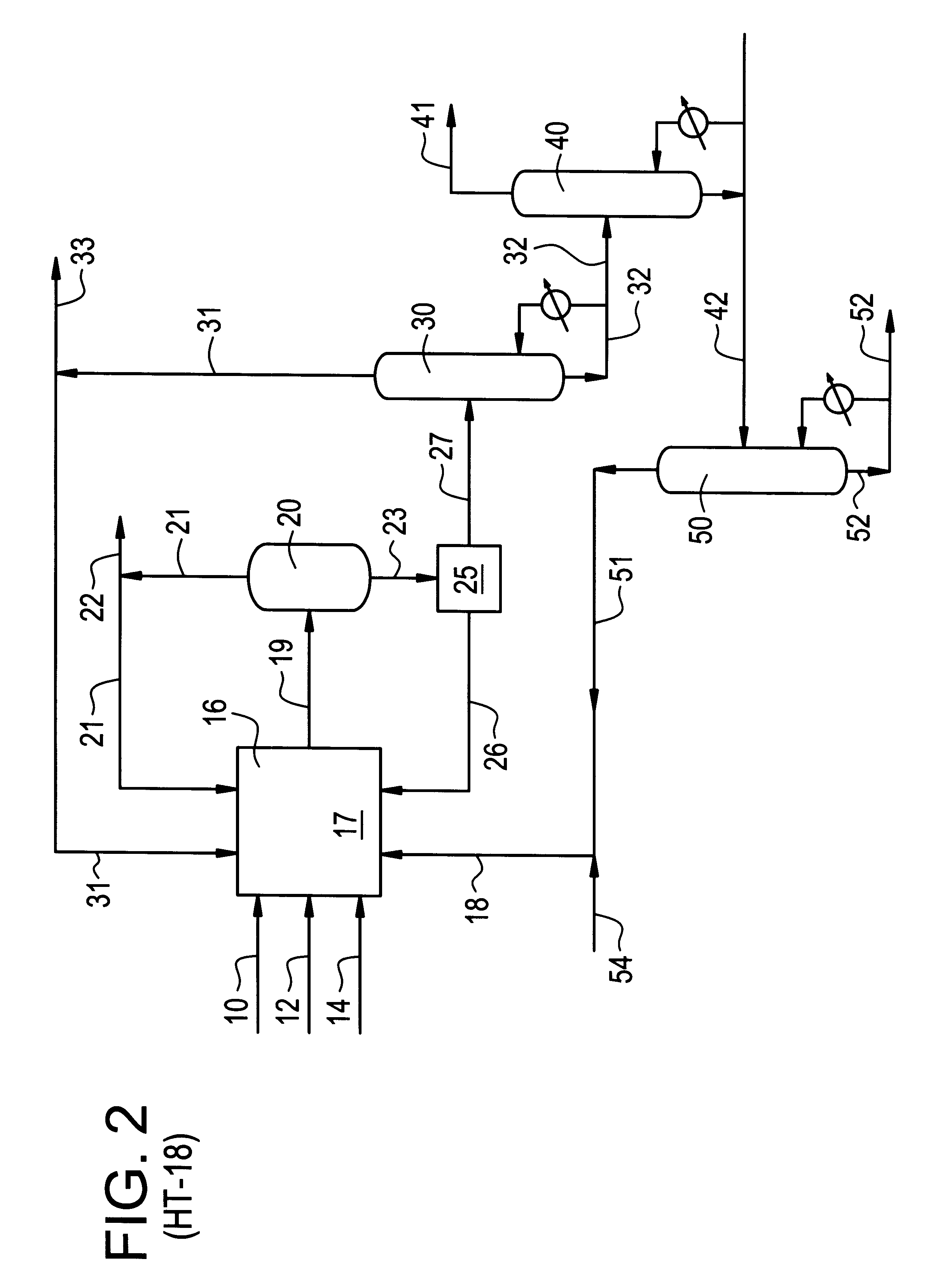

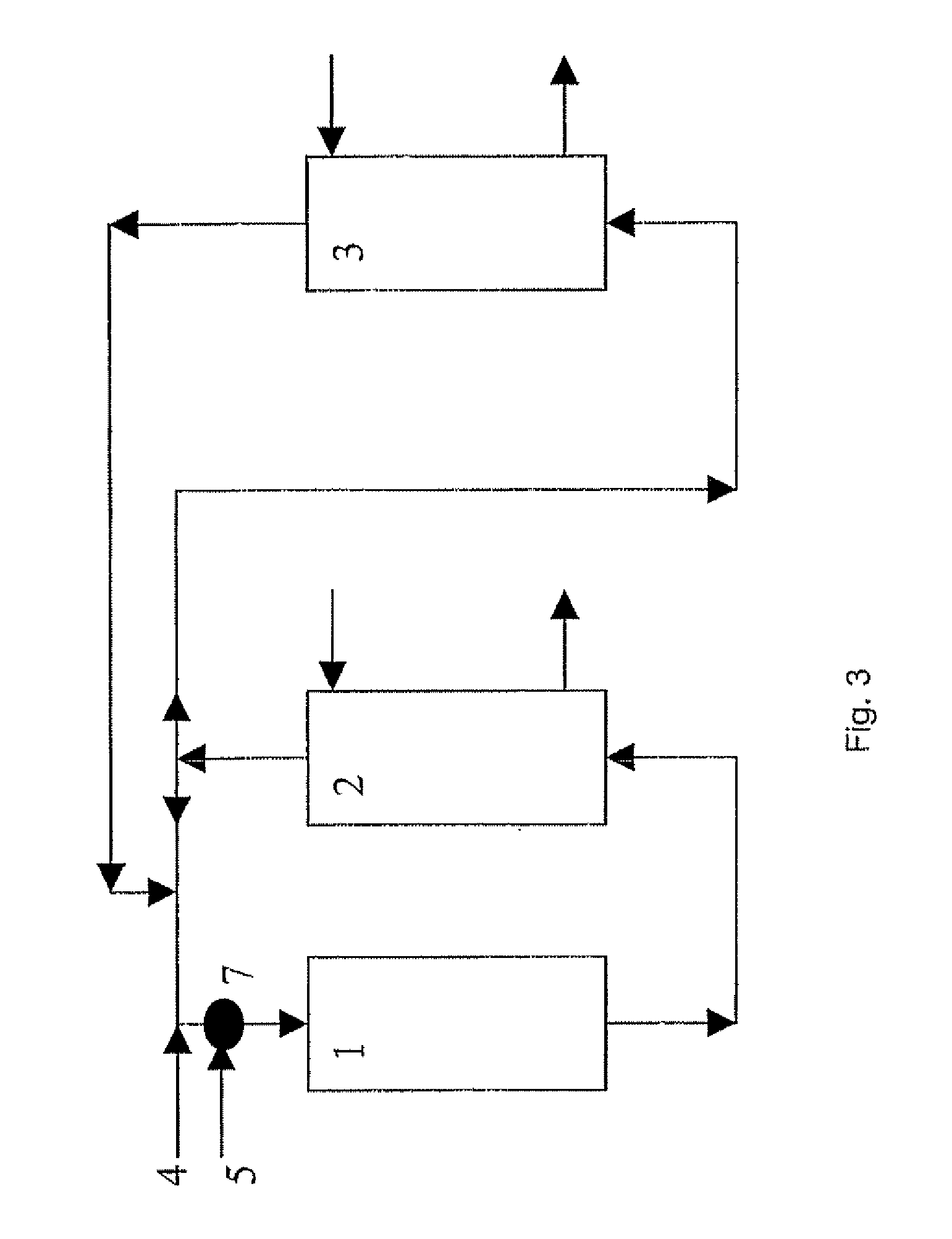

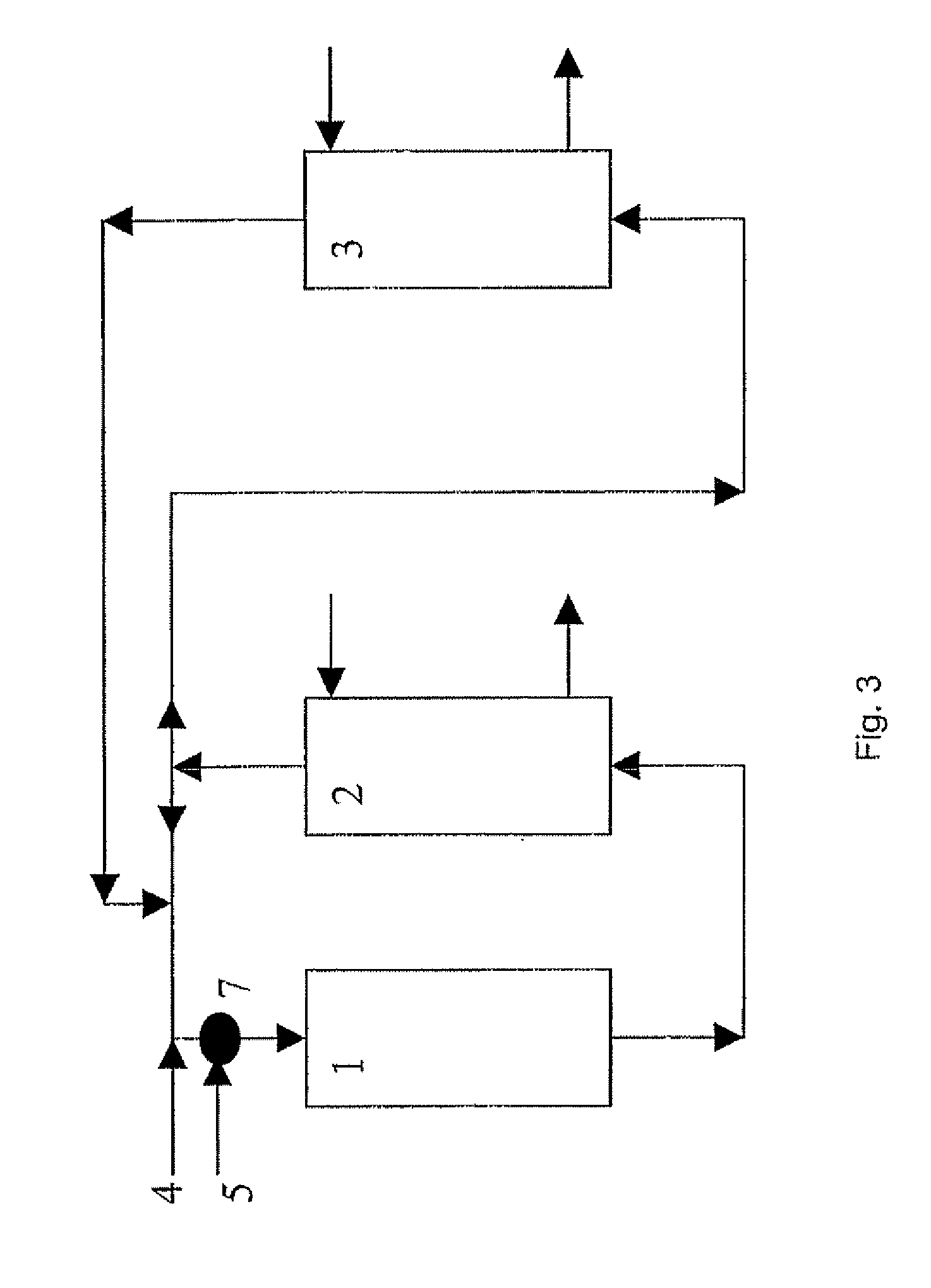

Integrated process and dual-function catalyst for olefin epoxidation

The invention discloses a dual-functional catalyst composition and an integrated process for production of olefin epoxides including propylene oxide by catalytic reaction of hydrogen peroxide from hydrogen and oxygen with olefin feeds such as propylene. The epoxides and hydrogen peroxide are preferably produced simultaneously in situ. The dual-functional catalyst comprises noble metal crystallites with dimensions on the nanometer scale (on the order of <1 nm to 10 nm), specially dispersed on titanium silicalite substrate particles. The dual functional catalyst catalyzes both the direct reaction of hydrogen and oxygen to generate hydrogen peroxide intermediate on the noble metal catalyst surface and the reaction of the hydrogen peroxide intermediate with the propylene feed to generate propylene oxide product. Combining both these functions in a single catalyst provides a very efficient integrated process operable below the flammability limits of hydrogen and highly selective for the production of hydrogen peroxide to produce olefin oxides such as propylene oxide without formation of undesired co-products.

Owner:HEADWATERS TECH INNOVATION GRP

Process and systems for the epoxidation of an olefin

A process for the epoxidation of an olefin, which process comprises reacting a feed comprising the olefin, oxygen and a reaction modifier in the presence of a highly selective silver-based catalyst at a reaction temperature T, and with the reaction modifier being present in a relative quantity Q which is the ratio of an effective molar quantity of active species of the reaction modifier present in the feed to an effective molar quantity of hydrocarbons present in the feed, and which process comprises the steps of:operating at a first operating phase wherein the value of T is T1 and the value of Q is Q1, andsubsequently operating at a second operating phase at a reaction temperature which is different from the reaction temperature employed in the first operating phase, such that the value of T is T2 and the value of Q is substantially Q2, whereby Q2 is determined by calculation and Q2 is defined by the formulaQ2=Q1+B(T2−T1),wherein B denotes a constant factor which is greater than 0; a reaction system suitable for performing the process for the epoxidation of an olefin; a computer program product which comprises a computer readable program recorded on a computer readable medium, suitable for instructing a data processing system of a computer system to execute calculations for the process for the epoxidation of an olefin; and a computer system which comprises the computer program product and a data processing system.

Owner:SHELL OIL CO

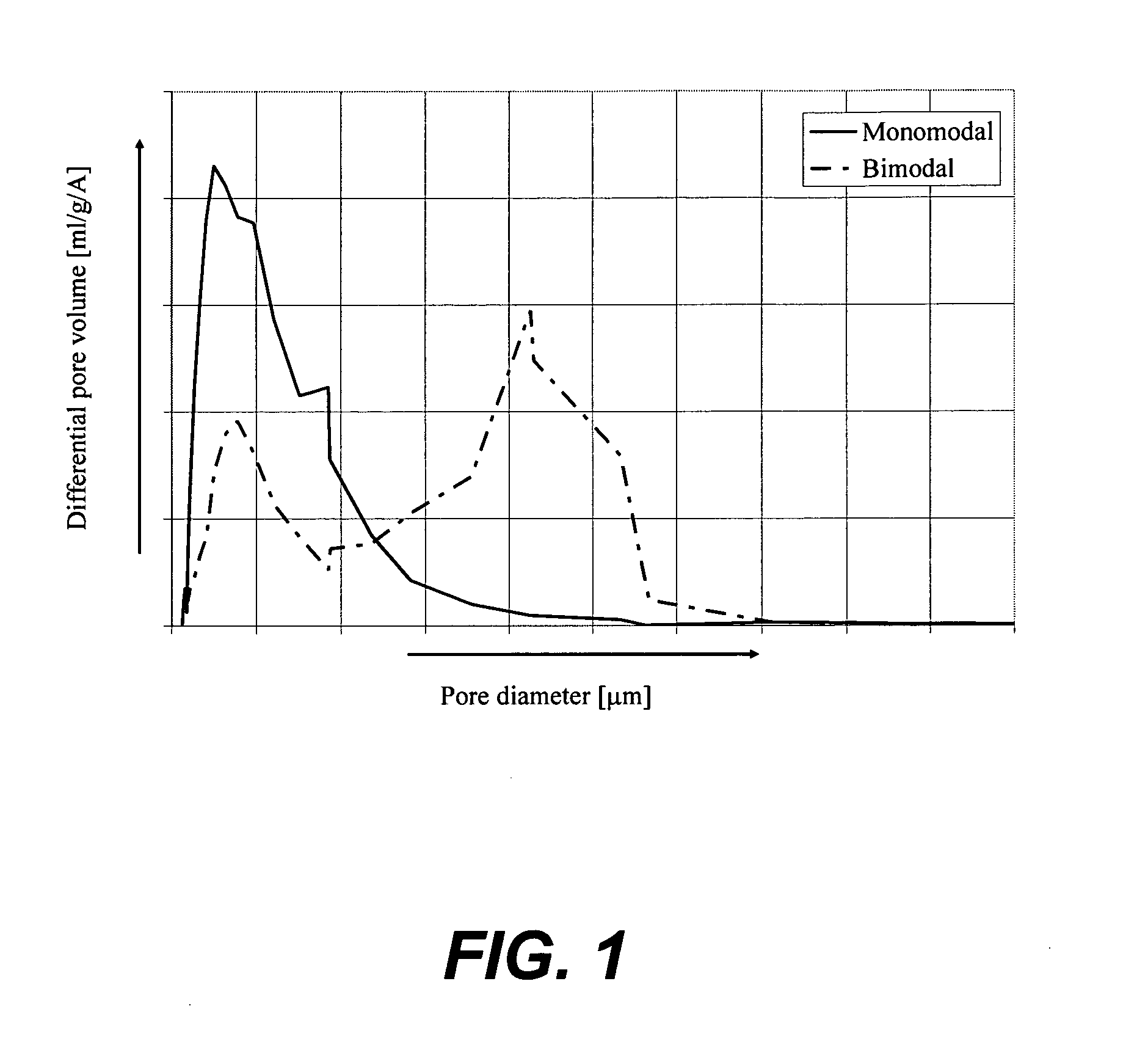

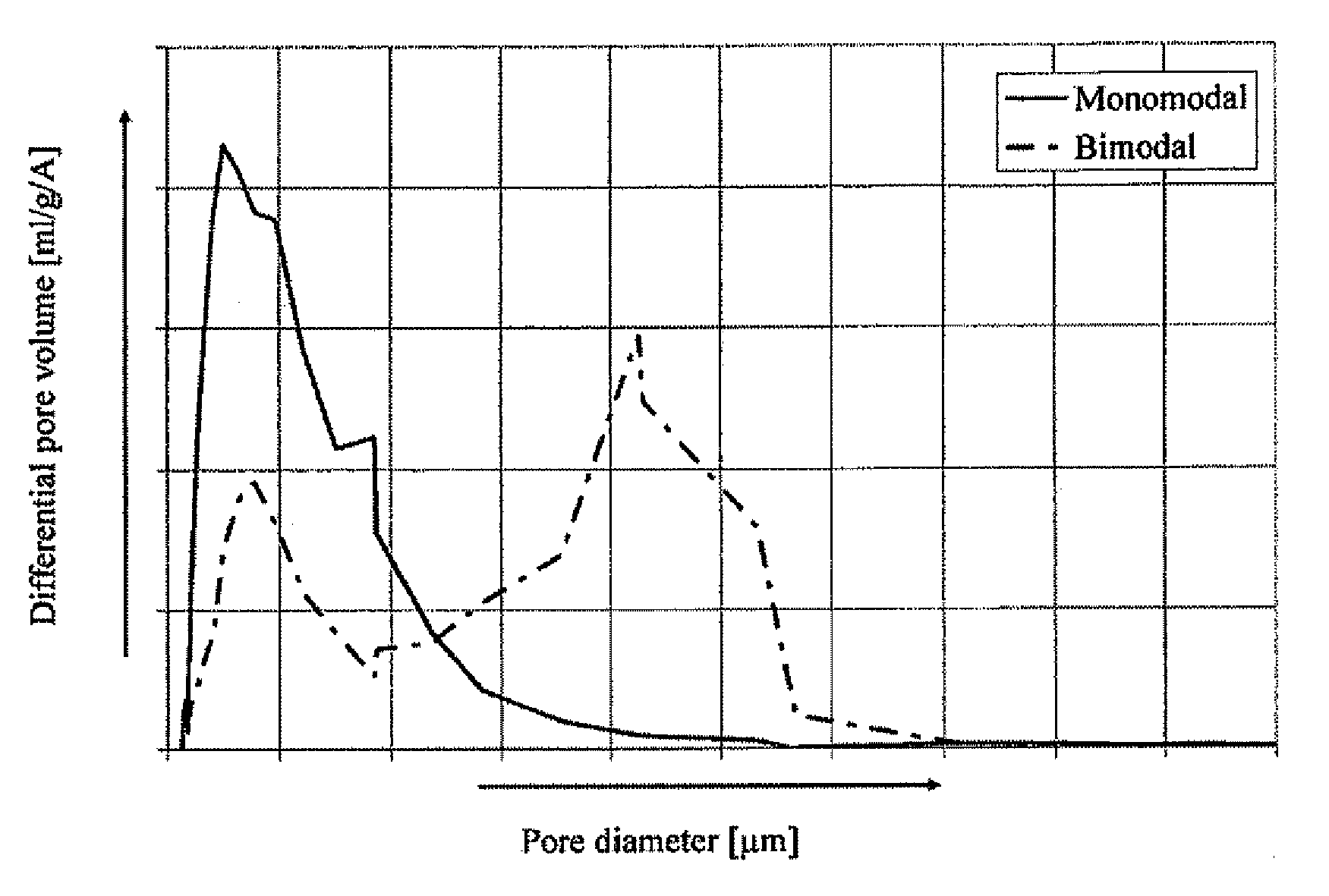

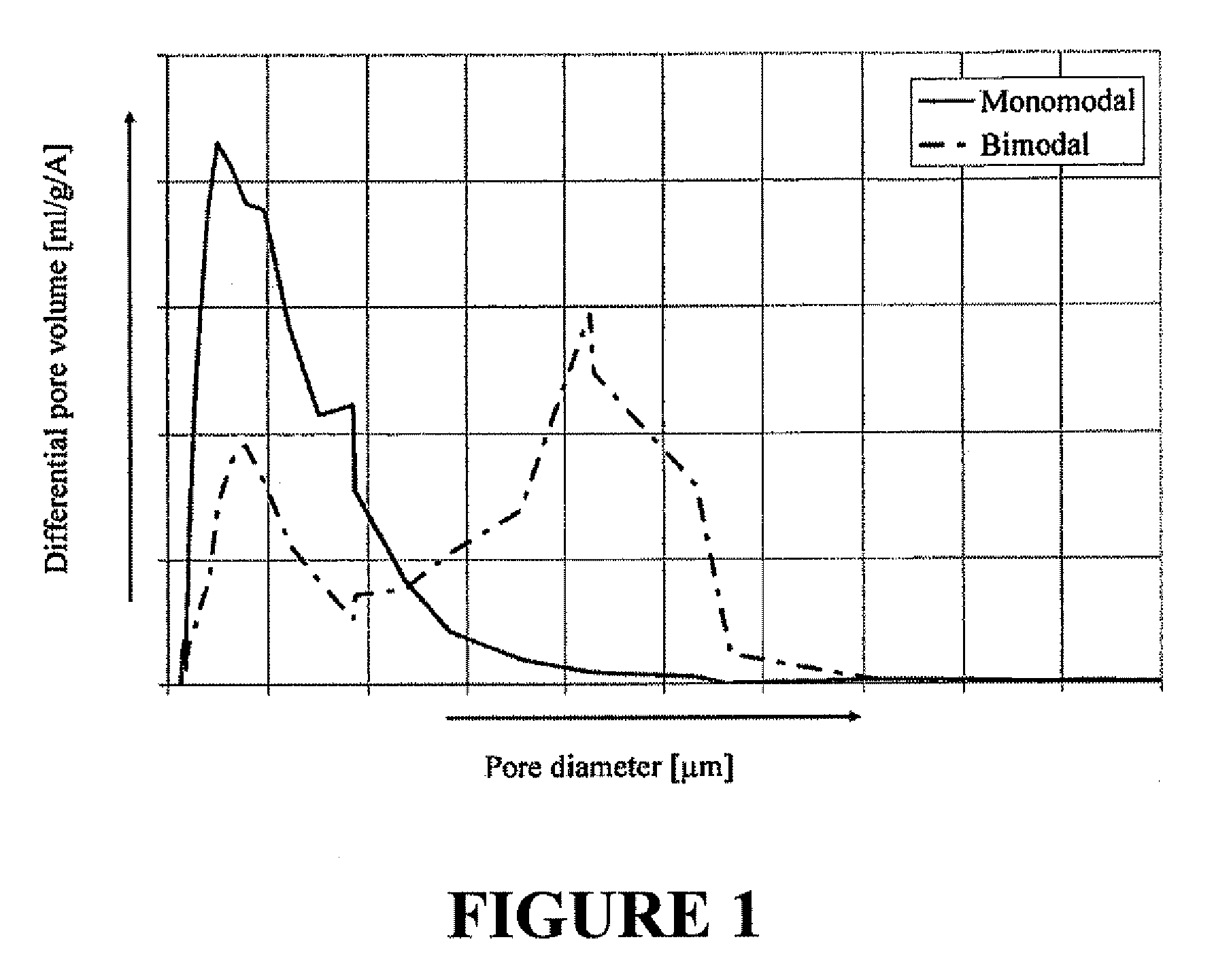

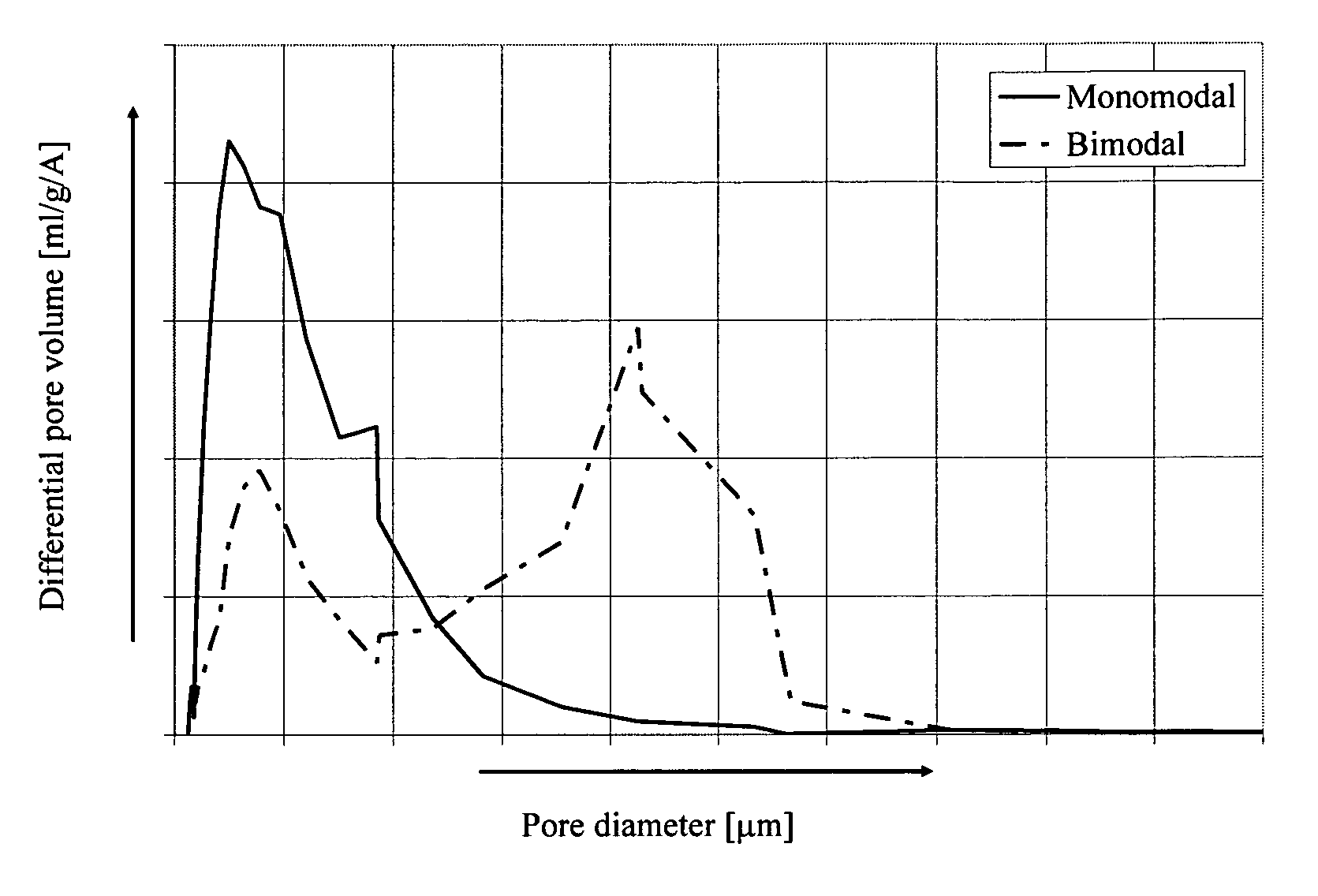

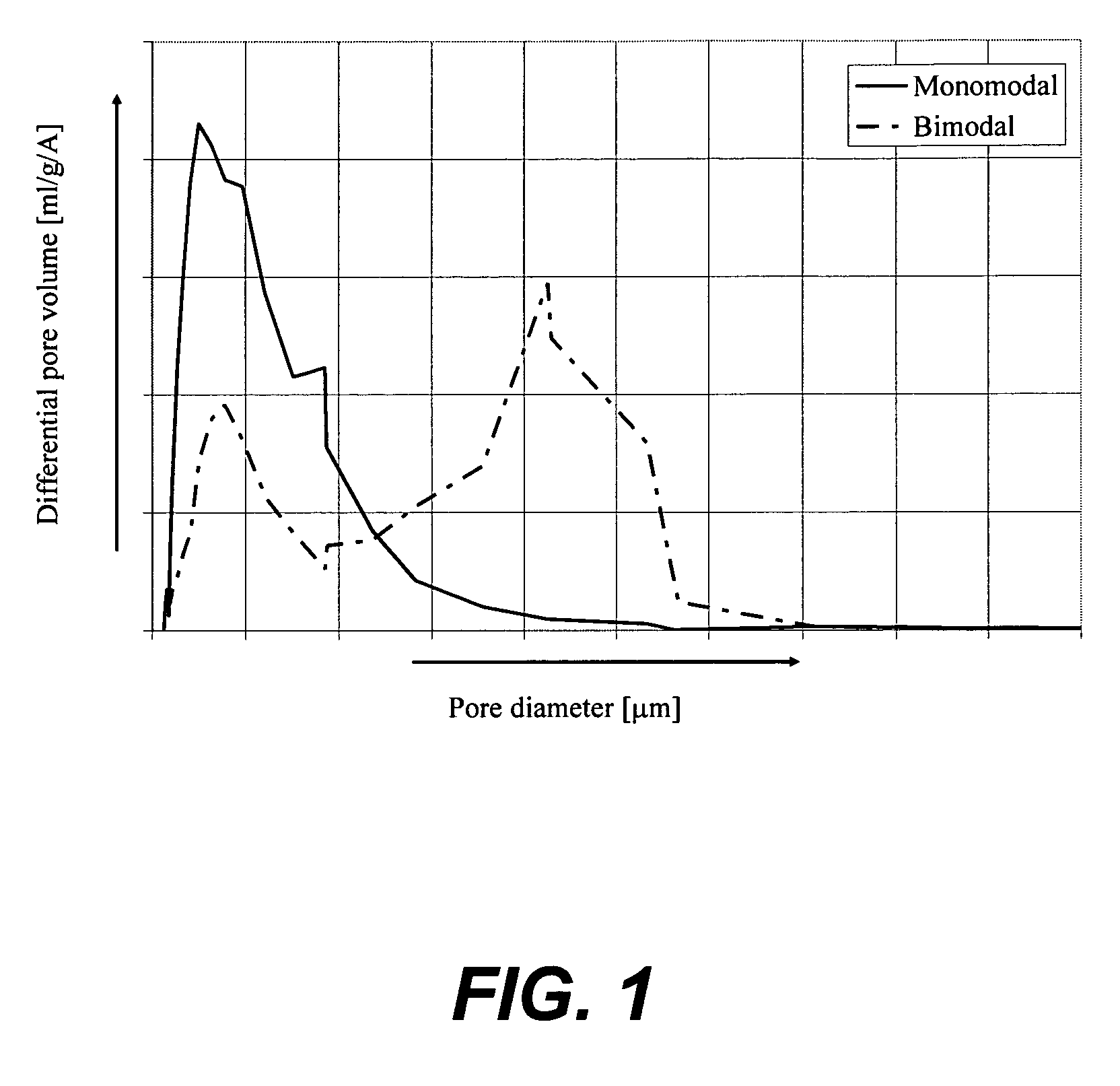

Catalyst with bimodal pore size distribution and the use thereof

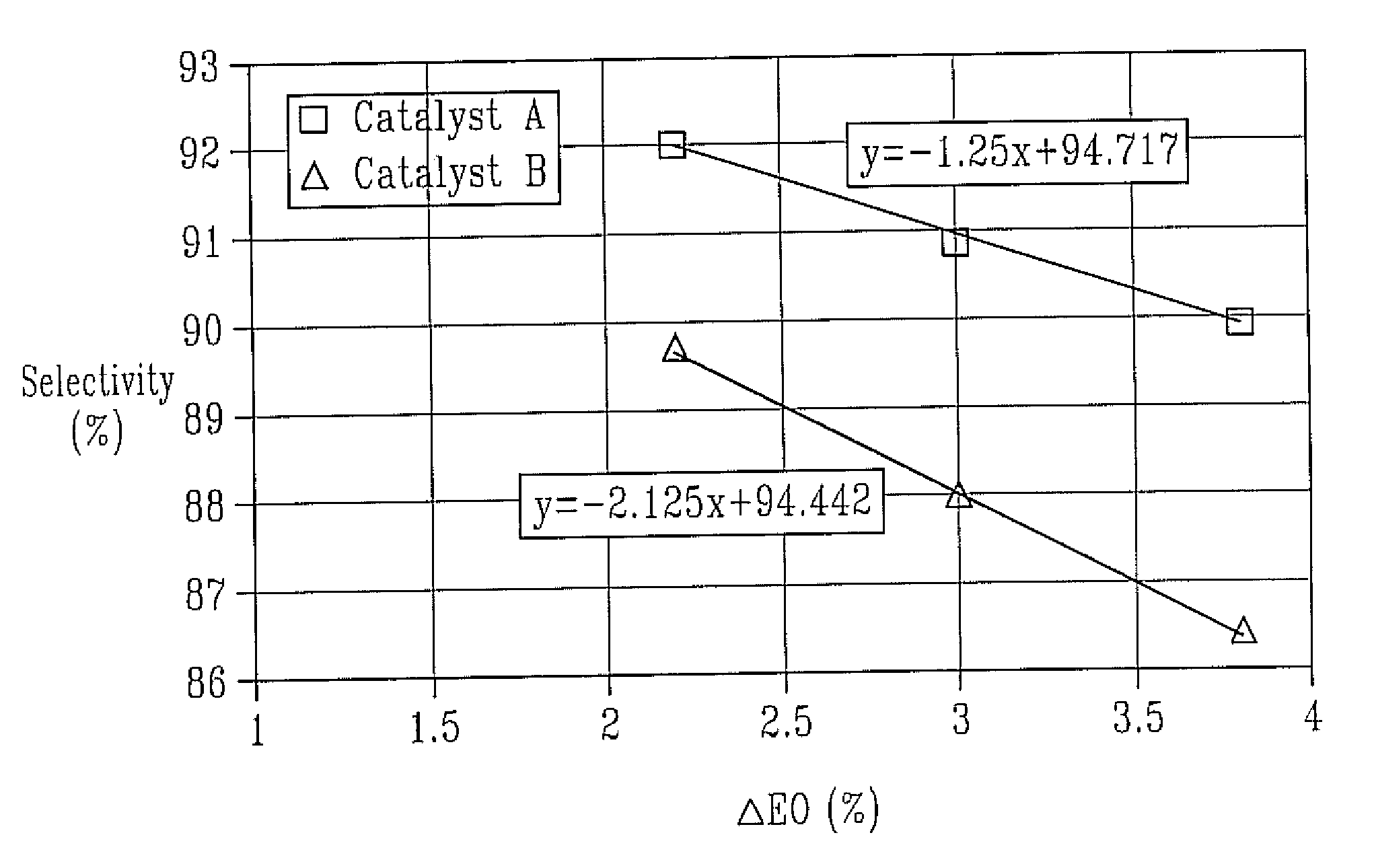

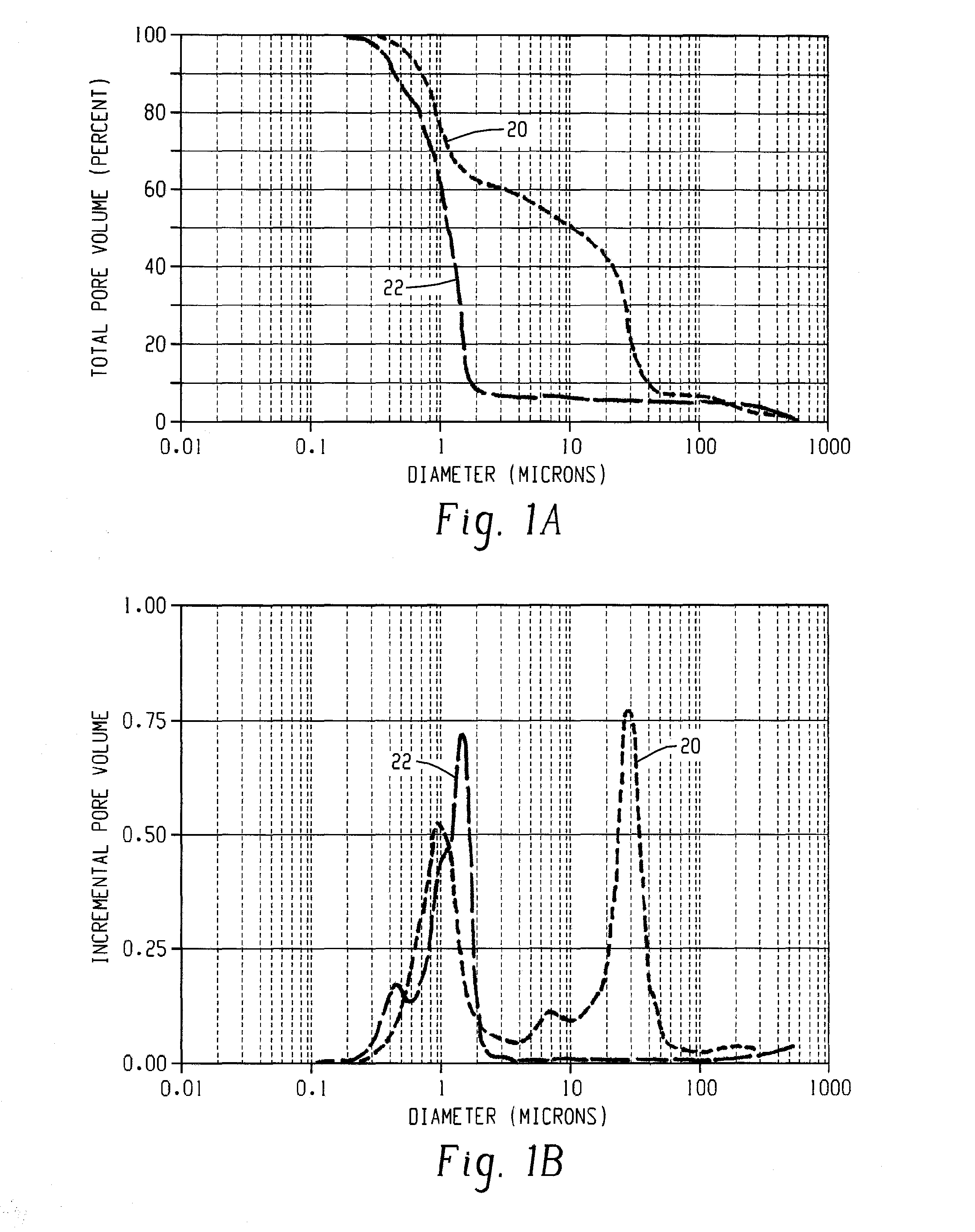

The invention pertains to a catalyst useful for the epoxidation of an olefin. More particularly, the invention pertains to an improved catalyst useful for the epoxidation of ethylene to ethylene oxide. The catalyst has improved selectivity in the epoxidation process. The catalyst comprises a solid support having a surface, which has a first mode of pores which have a diameter ranging from about 0.01 μm to about 5 μm and having a differential pore volume peak in the range of from about 0.01 μm to about 5 μm. The surface then has a second mode of pores, different from the first mode of pores, which second mode of pores have a diameter ranging from about 1 μm to about 20 μm and have a differential pore volume peak in the range of from about 1 μm to about 20 μm. On the bimodal pore surface is a catalytically effective amount of silver or a silver-containing compound, a promoting amount of rhenium or a rhenium-containing compound, and a promoting amount of one or more alkali metals or alkali-metal-containing compounds.

Owner:SD LIZENZVERWGMBH

Method of installing an epoxidation catalyst in a reactor, a method of preparing an epoxidation catalyst, an epoxidation catalyst, a process for the preparation of an olefin oxide or a chemical derivable from an olefin oxide, and a reactor suitables for such a process

InactiveUS20070197801A1Oxygen-containing compound preparationOrganic compound preparationCompound (substance)Alkene

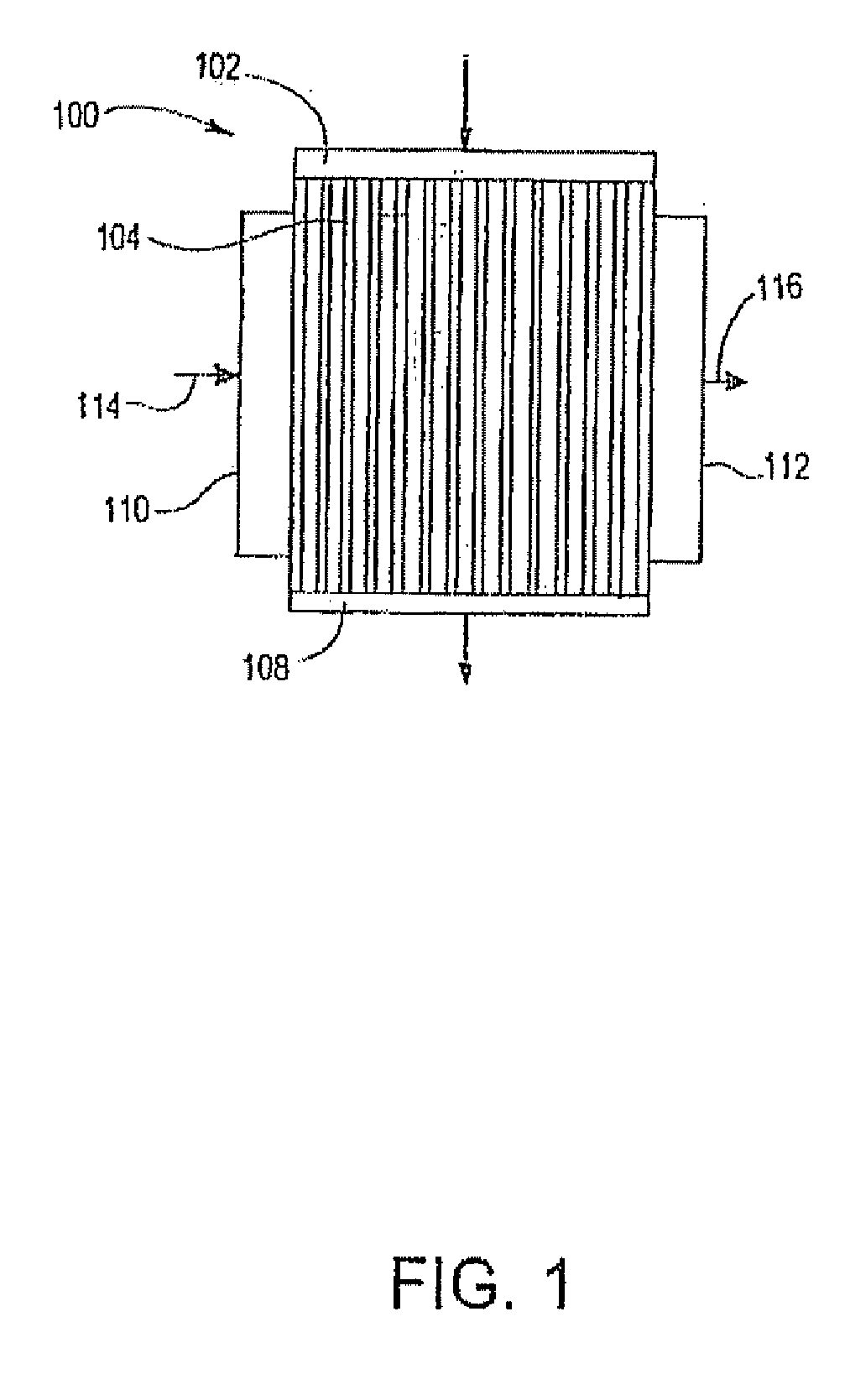

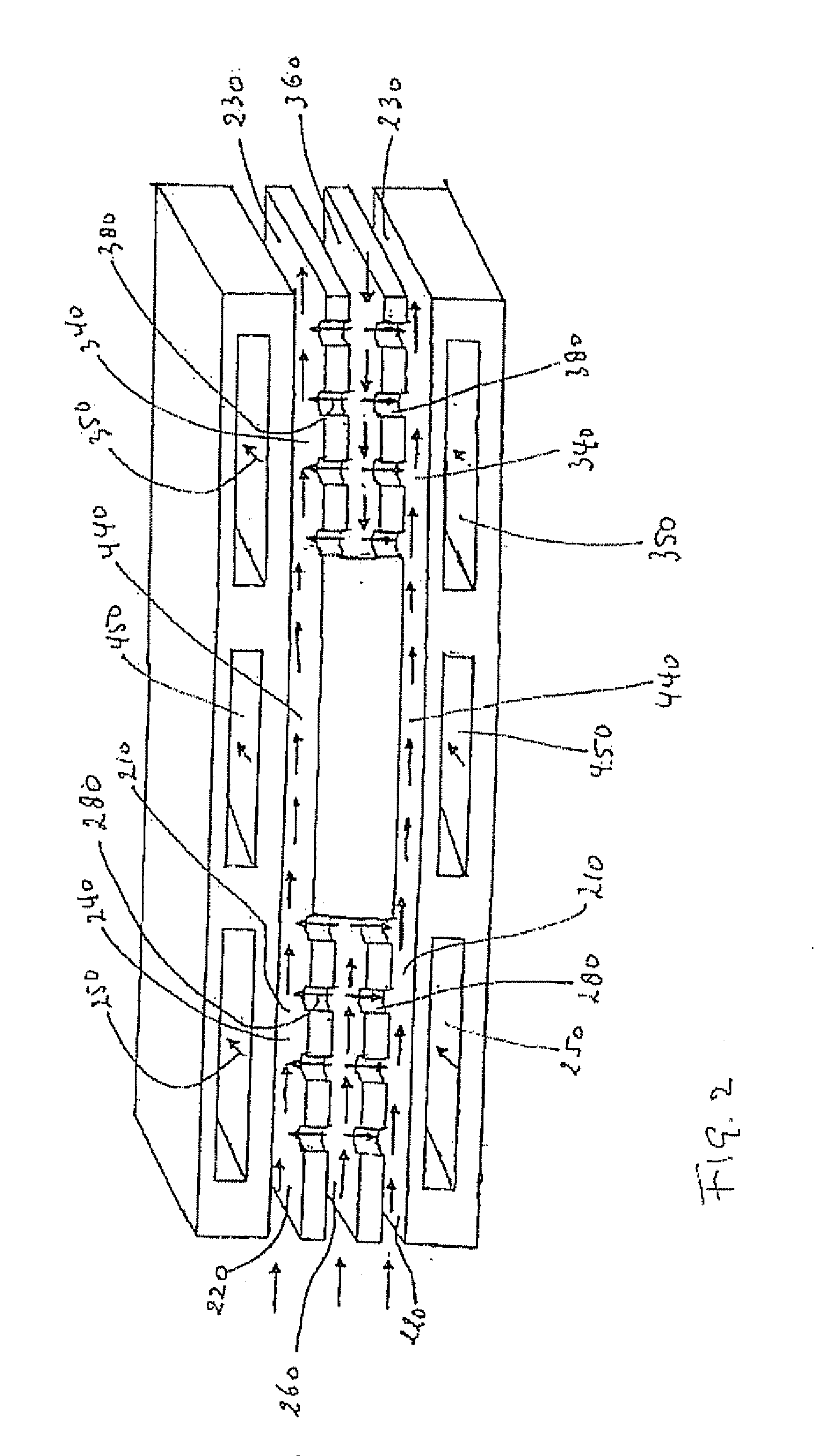

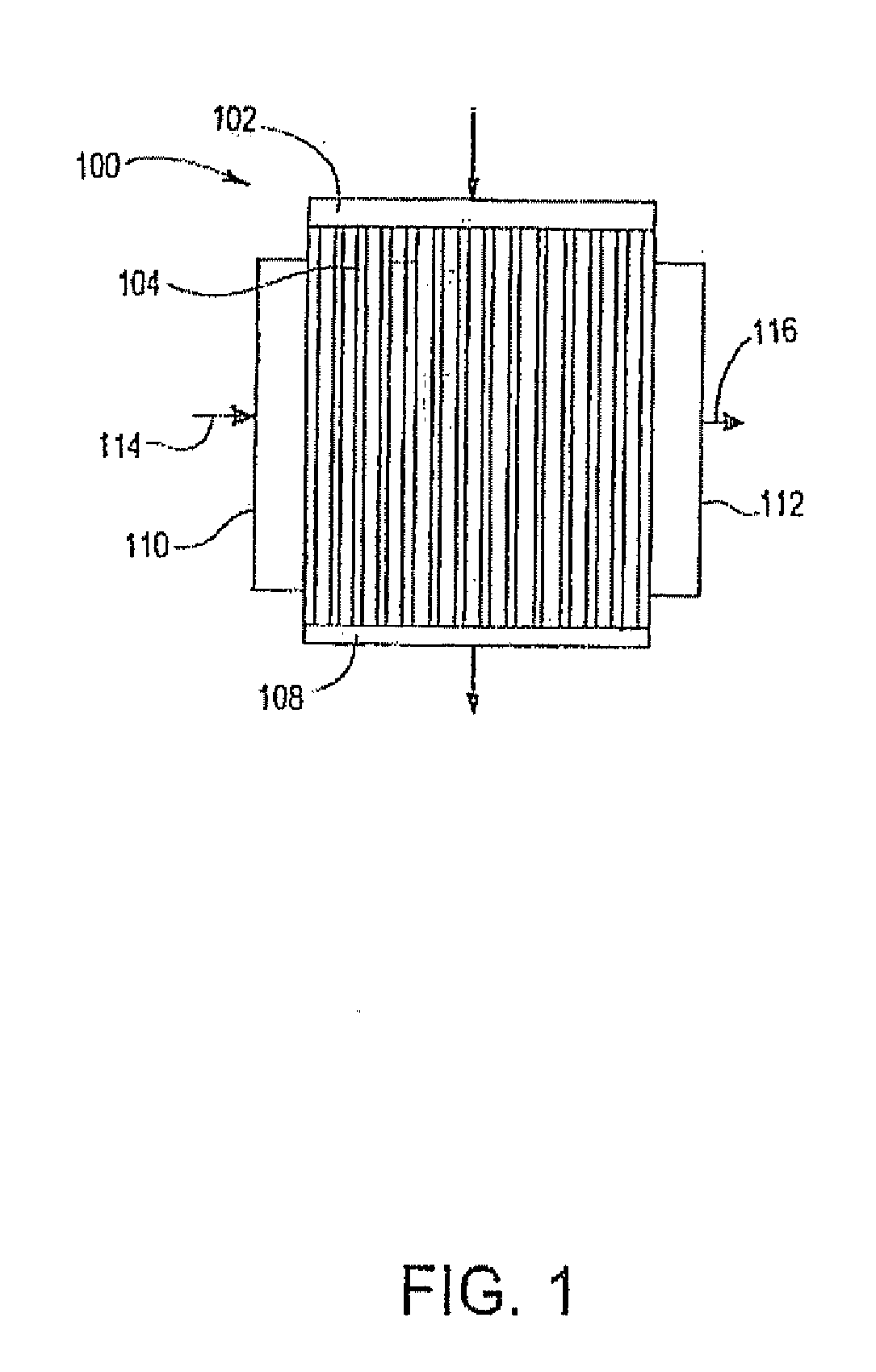

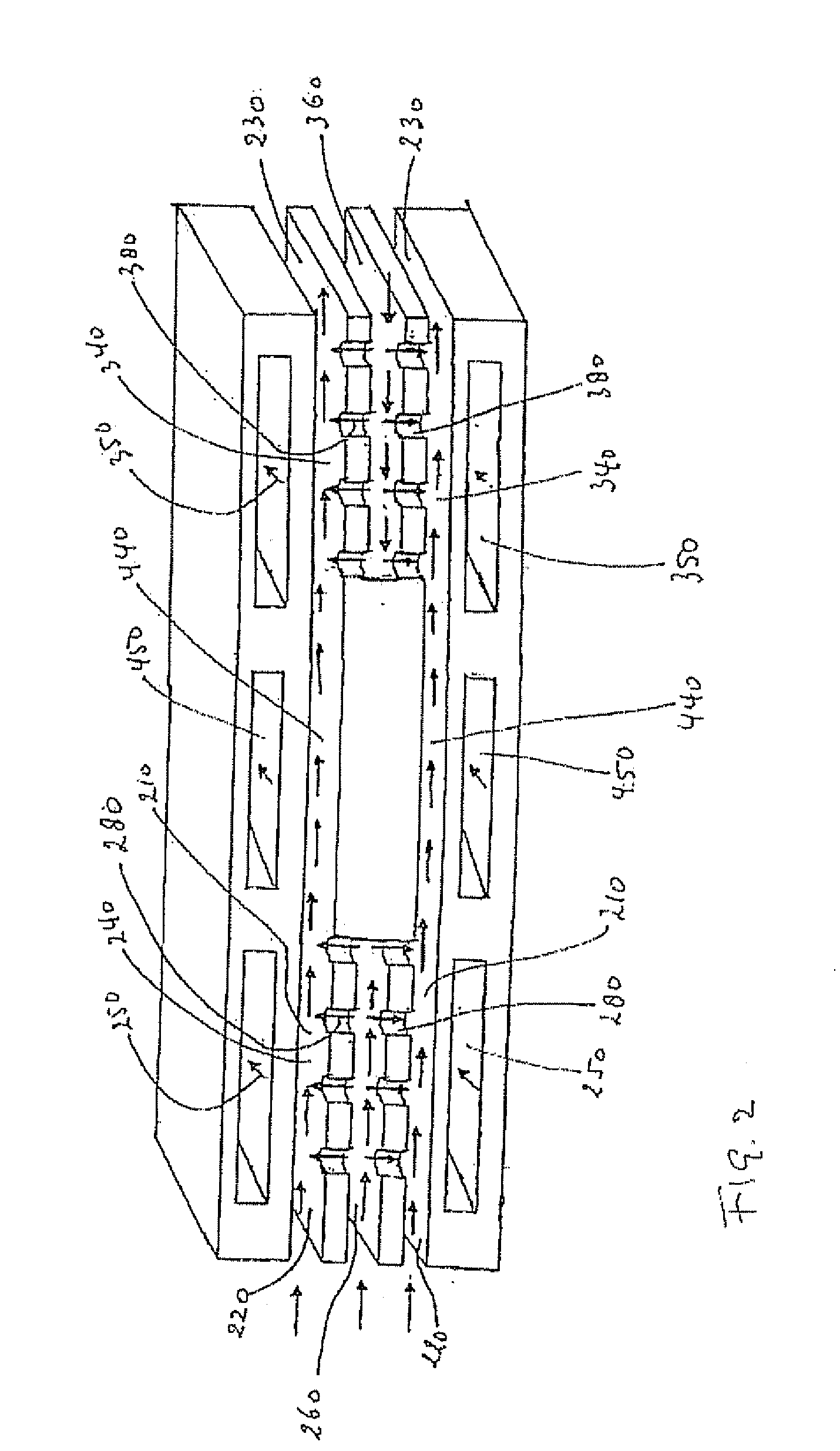

The present invention relates to an improved epoxidation process and an improved epoxidation reactor. The present invention makes use of a reactor which comprises a plurality of microchannels. Such process microchannels may be adapted such that the epoxidation and optionally other processes can take place in the microchannels and that they are in a heat exchange relation with channels adapted to contain a heat exchange fluid. A reactor comprising such process microchannels is referred to as a “microchannel reactor”. The invention also provides a method of installing an epoxidation catalyst in a microchannel reactor. The invention also provides a method of preparing an epoxidation catalyst. The invention also provides an epoxidation catalyst. The invention also provides a certain process for the epoxidation of an olefin and a process for the preparation of a chemical derivable from an olefin oxide. The invention also provides a microchannel reactor.

Owner:SHELL OIL CO

Catalyst carriers

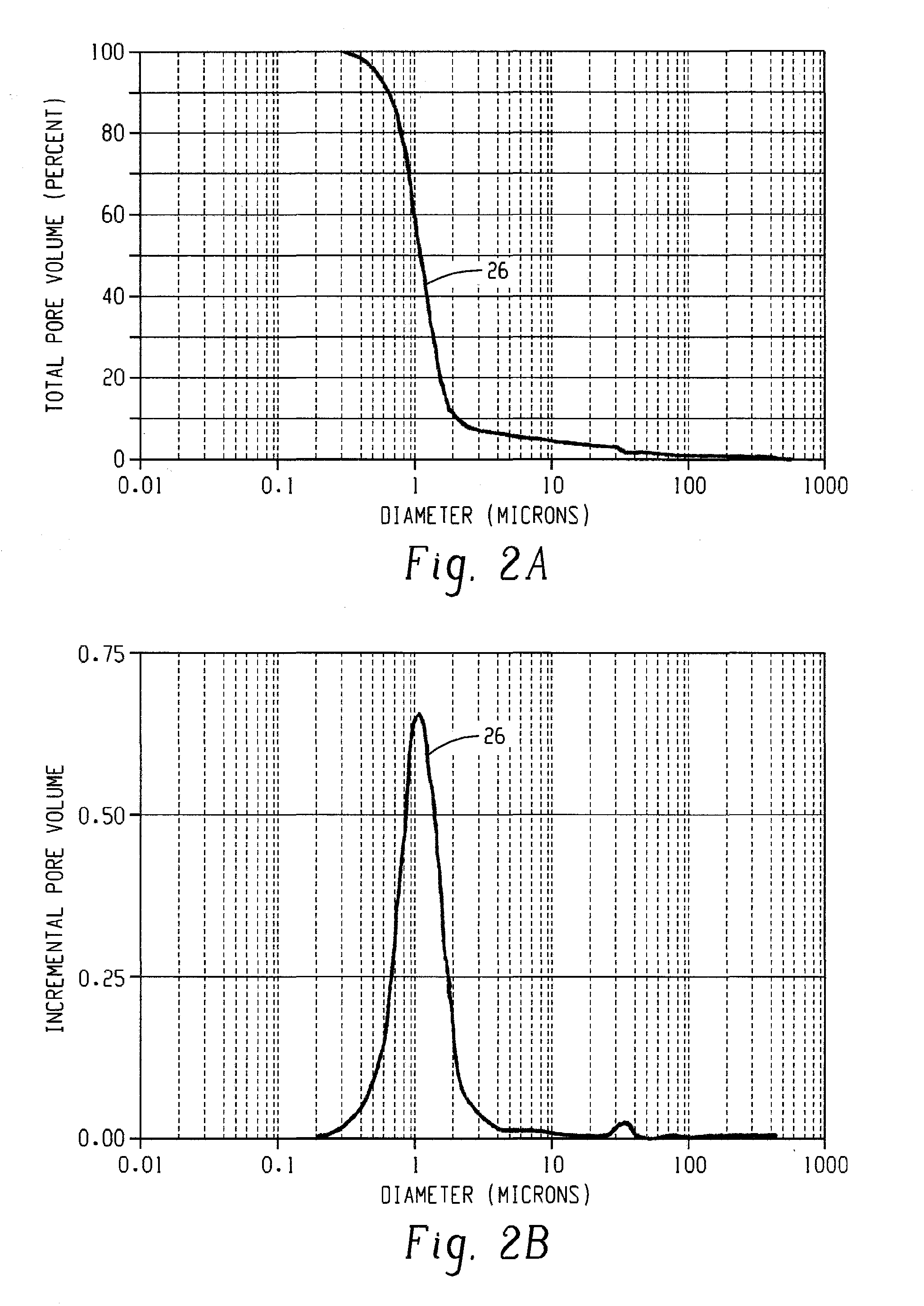

The selectivity and activity of a silver-based olefin epoxidation catalyst is found to be a function of the pore size distribution in the alumina carrier on which it is deposited. Specifically it is found advantageous to provide a carrier which has a minimum of very large pores, (greater than 10 micrometers) and a water absorption of 35 to 55% and a surface area of at least 1.0 m2 / g. A method of making such carriers is also described.

Owner:SAINT-GOBAIN GLASS FRANCE

Method for improving the selectivity of a catalyst and a process for the epoxidation of an olefin

A method for improving the selectivity of a supported highly selective epoxidation catalyst comprising silver in a quantity of at most 0.17 g per m2 surface area of the support, which method comprisescontacting the catalyst, or a precursor of the catalyst comprising the silver in cationic form, with a feed comprising oxygen at a catalyst temperature above 250° C. for a duration of up to 150 hours, andsubsequently decreasing the catalyst temperature to a value of at most 250° C.; anda process for the epoxidation of an olefin, which process comprisescontacting a supported highly selective epoxidation catalyst comprising silver in a quantity of at most 0.17 g per m2 surface area of the support, or a precursor of the catalyst comprising the silver in cationic form, with a feed comprising oxygen at a catalyst temperature above 250° C. for a duration of up to 150 hours, andsubsequently decreasing the catalyst temperature to a value of at most 250° C. and contacting the catalyst with the feed comprising the olefin and oxygen.

Owner:SHELL USA INC

Catalyst with bimodal pore size distribution and the use thereof

ActiveUS20090198076A1Promoting amountExcessive amountMolecular sieve catalystsOther chemical processesRheniumPore diameter

The invention is directed to a catalyst for the epoxidation of an olefin to an olefin oxide, the catalyst comprising a support having at least two pore size distributions, each pore size distribution possessing a different mean pore size and a different pore size of maximum concentration, the catalyst further comprising a catalytically effective amount of silver, a promoting amount of rhenium, and a promoting amount of one or more alkali metals, wherein the at least two pore size distributions are within a pore size range of about 0.01 μm to about 50 μm. The invention is also directed to a process for the oxidation of an olefin to an olefin oxide using the above-described catalyst.

Owner:SCI DESIGN

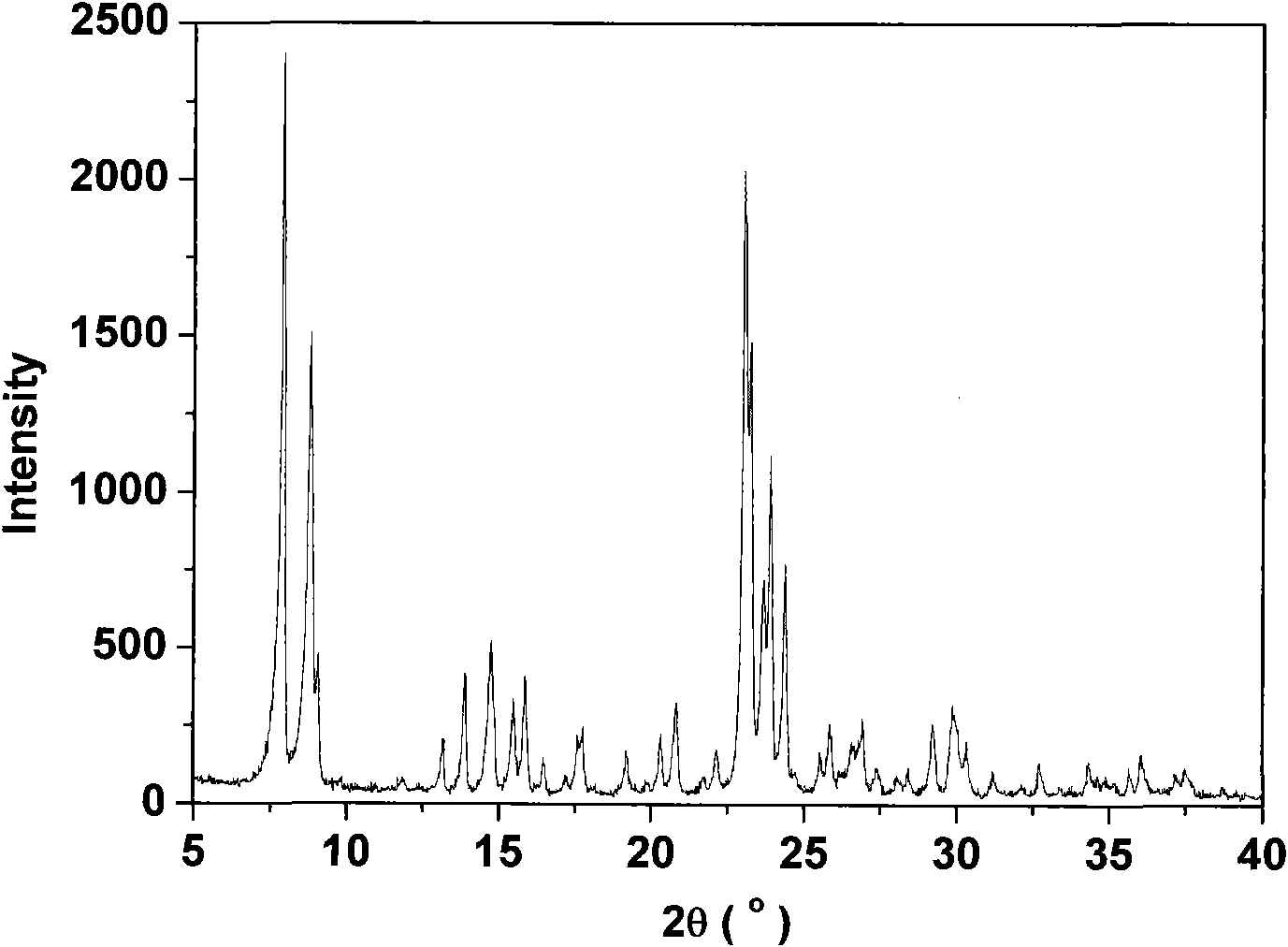

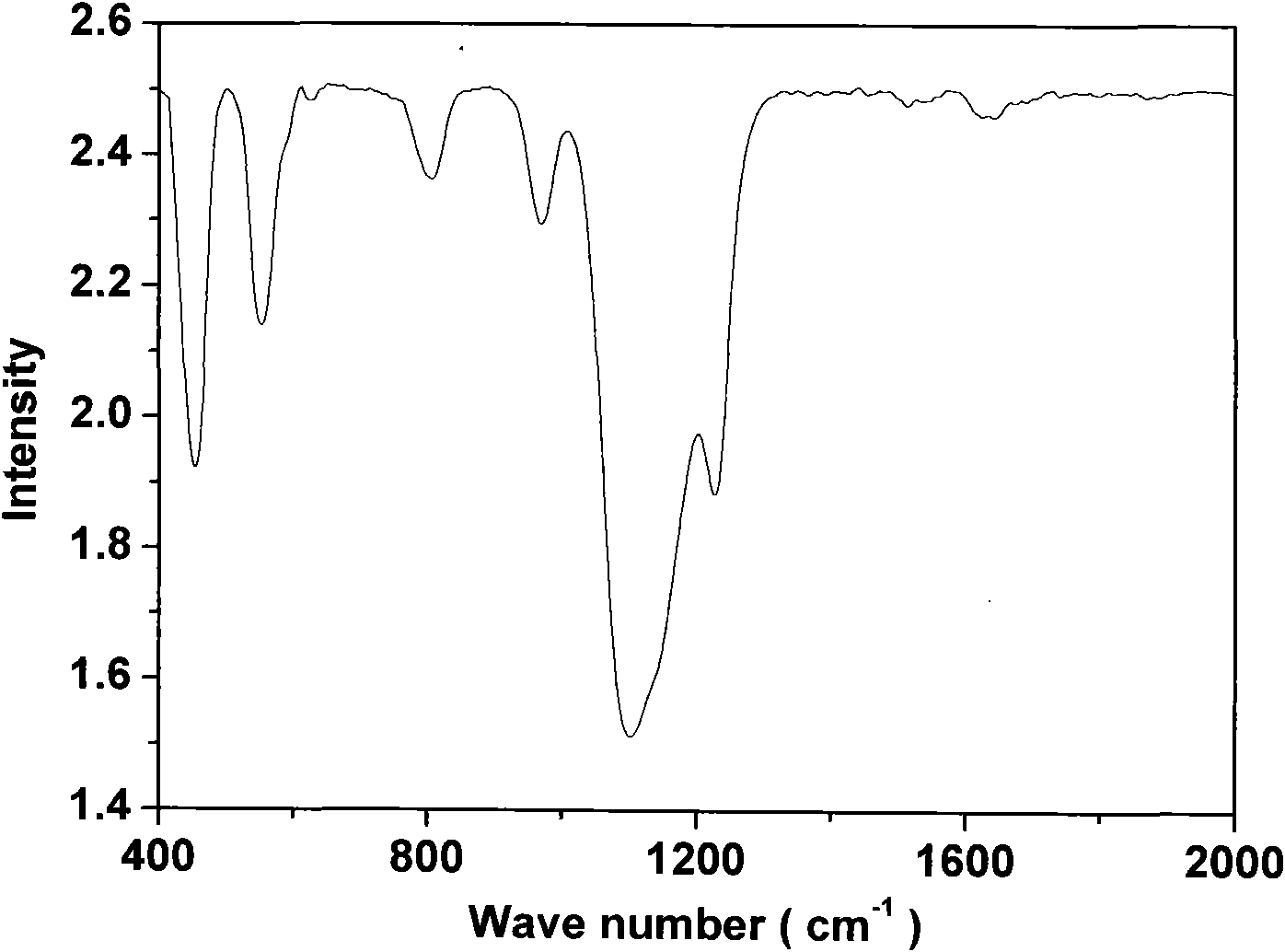

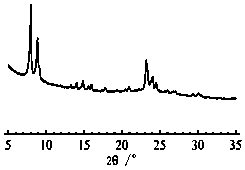

Method for quickly synthesizing small-crystallite titanium-silicon molecular sieve in cheap system

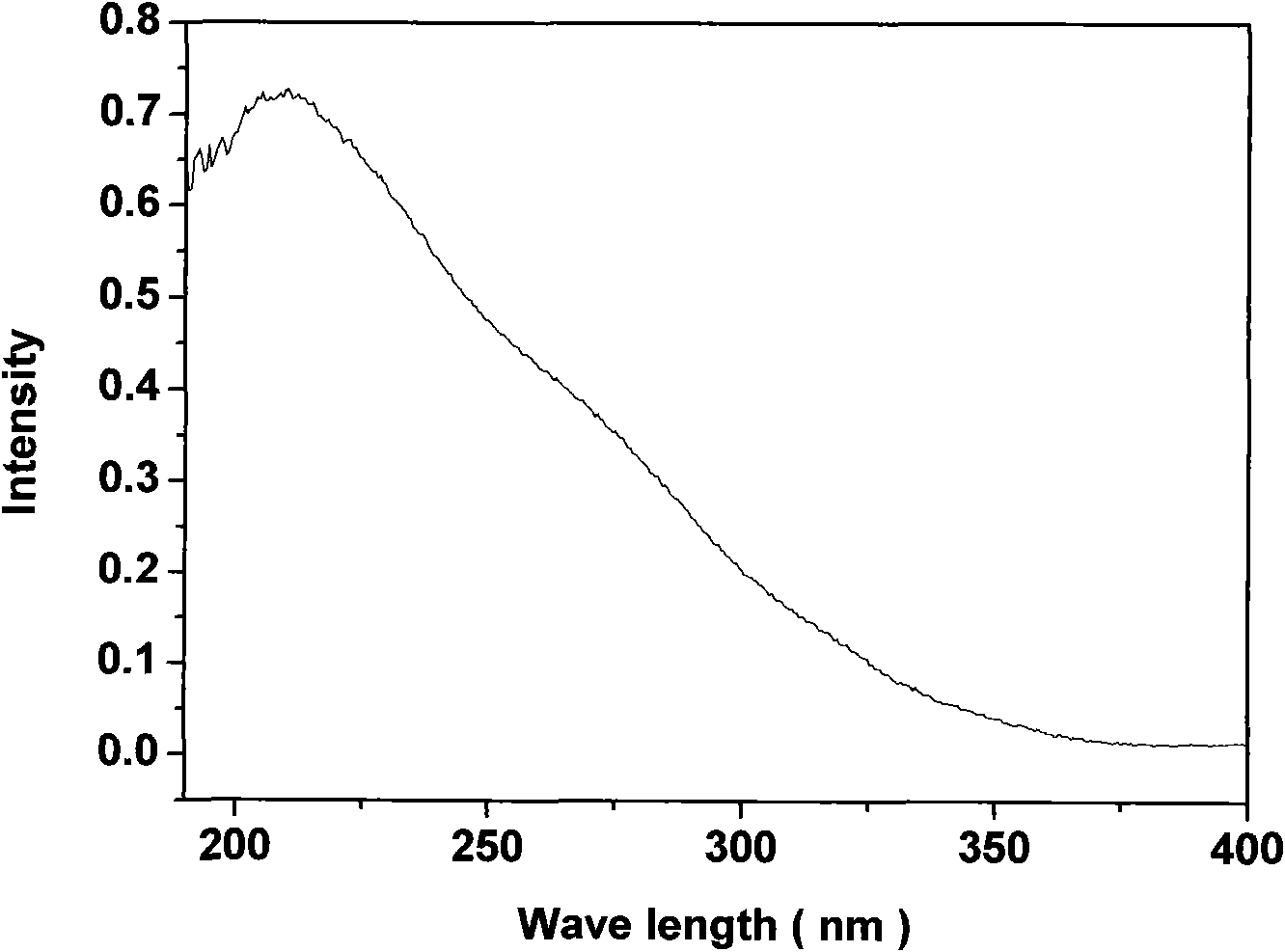

ActiveCN101913620ALower synthesis costFast crystallization rateCrystalline aluminosilicate zeolitesCyclohexanoneHigh activity

The invention provides a method for preparing a small-crystallite titanium-silicon molecular sieve in a cheap system by changing the adding mode of seed crystals and by a hydrothermal process. The titanium-silicon molecular sieve is prepared by using silicon sol as a silicon source, titanium tetrachloride or tetrabutyl titanate as a titanium source, tetrapropylammonium bromide ( TPABr) as a template agent, organic amine as an alkali source and unseparated nanoscale TS-1 mother liquor as seed crystals directly and by the hydrothermal process. The grain size of the titanium-silicon molecular sieve is less than 1 micrometer, and the titanium-silicon molecular sieve has high activity for selective oxidization reactions using hydrogen peroxide as an oxidant, such as epoxidation of olefins, hydroxylation of phenol, ammoxidation of cyclohexanone and the like. The method simplifies the synthesis process of small crystallite TS-1 in the cheap system and reduces synthesis time and cost.

Owner:DALIAN UNIV OF TECH

Method Of Installing An Epoxidation Catalyst In A Reactor, A Method Of Preparing An Epoxidation Catalyst, An Epoxidation Catalyst, A Process For The Preparation Of An Olefin Oxide Or A Chemical Derivable From An Olefin Oxide, And A Reactor Suitable For Such A Process

InactiveUS20070213545A1Speed up the processOxygen-containing compound preparationOrganic compound preparationAlkeneChemical substance

The present invention relates to an improved epoxidation process and an improved epoxidation reactor. The present invention makes use of a reactor which comprises a plurality of microchannels. Such process microchannels may be adapted such that the epoxidation and optionally other processes can take place in the microchannels and that they are in a heat exchange relation with channels adapted to contain a heat exchange fluid. A reactor comprising such process microchannels is referred to as a “microchannel reactor”. The invention also provides a method of installing an epoxidation catalyst in a microchannel reactor. The invention also provides a method of preparing an epoxidation catalyst. The invention also provides an epoxidation catalyst. The invention also provides a certain process for the epoxidation of an olefin and a process for the preparation of a chemical derivable from an olefin oxide. The invention also provides a microchannel reactor.

Owner:SHELL OIL CO

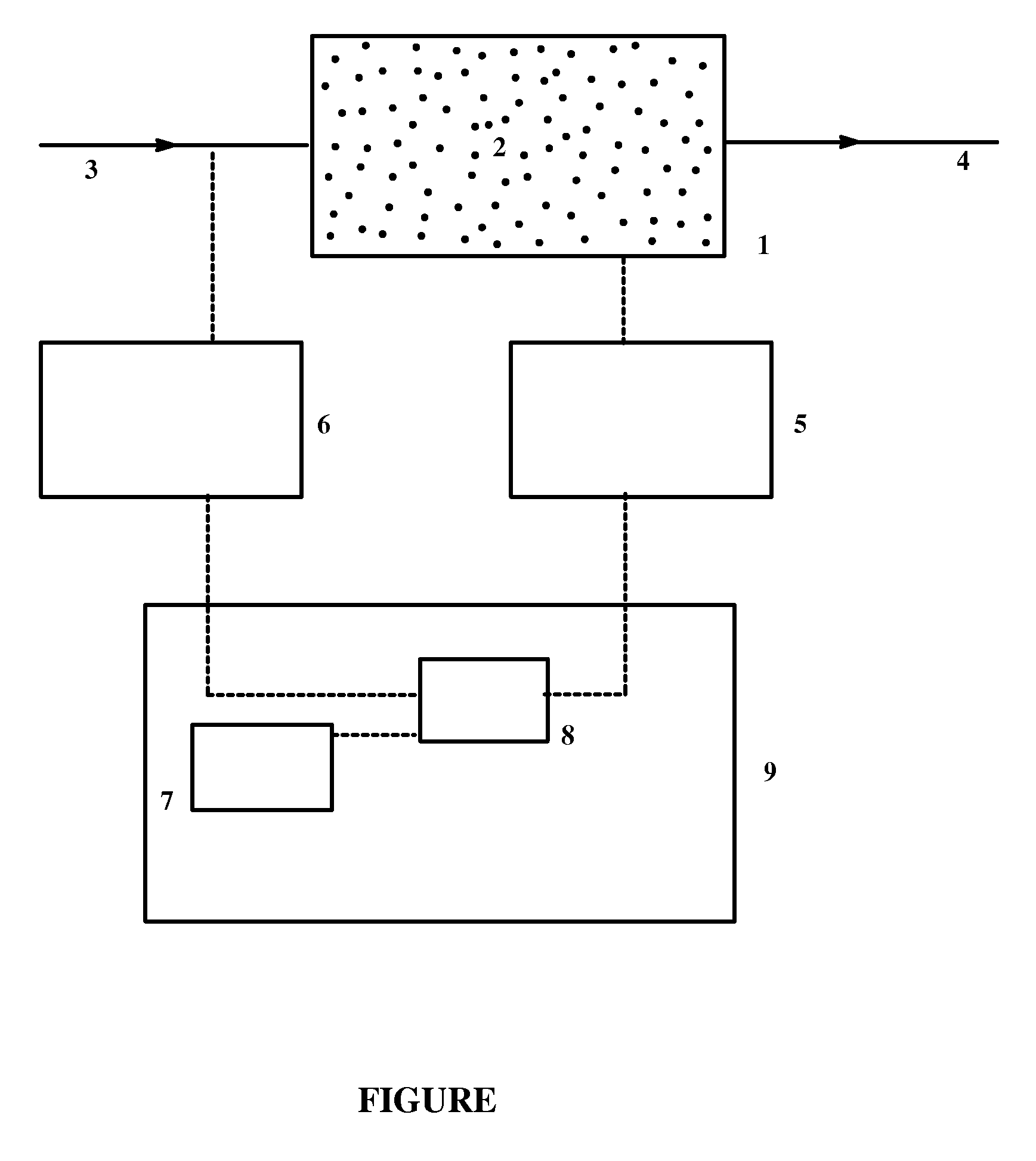

One-step molding method of titanium silicalite molecular sieve

ActiveCN102614911AImprove function and effectImprove adhesionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCyclohexanone

The invention relates to a one-step molding method of a titanium silicalite molecular sieve. The method comprises the following steps of crystallizing the titanium silicalite molecular sieve subjected to hydro-thermal synthesis; directly adding a matrix substance, a binder, a peptizing agent and a pore-enlarging agent without separating, washing and calcining; pulping; performing spray forming; and calcining the formed microspheres to remove a template agent to obtain large formed titanium silicalite molecular sieve particles which can be applied to ammoximation of cyclohexanone and epoxidation of olefin.

Owner:XIANGTAN UNIV

Process and systems for the epoxidation of an olefin

A process for the epoxidation of an olefin, which process comprises reacting a feed comprising the olefin, oxygen and a reaction modifier in the presence of a highly selective silver-based catalyst at a reaction temperature T, and with the reaction modifier being present in a relative quantity Q which is the ratio of an effective molar quantity of active species of the reaction modifier present in the feed to an effective molar quantity of hydrocarbons present in the feed, and which process comprises the steps of: operating at a first operating phase wherein the value of T is T1 and the value of Q is Q1, and subsequently operating at a second operating phase at a reaction temperature which is different from the reaction temperature employed in the first operating phase, such that the value of T is T2 and the value of Q is substantially Q2, whereby Q2 is determined by calculation and Q2 is defined by the formula Q2=Q1+B(T2−T1), wherein B denotes a constant factor which is greater than 0; a reaction system suitable for performing the process for the epoxidation of an olefin; a computer program product which comprises a computer readable program recorded on a computer readable medium, suitable for instructing a data processing system of a computer system to execute calculations for the process for the epoxidation of an olefin; and a computer system which comprises the computer program product and a data processing system.

Owner:SHELL OIL CO

Process for the production of an olefin oxide, a 1,2-diol, a 1,2-diol ether, or an alkanolamine

ActiveUS20060009647A1Improve the level ofLow selectivityOxygen-containing compound preparationOrganic compound preparationDopantPolymer science

A process is provided for the epoxidation of an olefin comprising the steps of: contacting a feed comprising an olefin and oxygen with a catalyst comprising a silver component deposited on a fluoride-mineralized carrier; and producing a product mix comprising an olefin oxide, wherein the partial pressure of olefin oxide in the product mix is greater than about 60 kPa. A process is provided for the epoxidation of an olefin comprising the steps of: contacting a feed comprising an olefin and oxygen with a catalyst comprising a silver component and a high-selectivity dopant deposited on a fluoride-mineralized carrier; and producing a product mix comprising an olefin oxide, wherein the partial pressure of olefin oxide in the product mix is greater than about 20 kPa.

Owner:SHELL OIL CO

Process for production of an olefin oxide

ActiveUS7507845B1Loss in selectivityImprove productivityOrganic chemistryMolecular sieve catalystsRheniumProduction rate

The invention relates to a process for the epoxidation of an olefin, wherein the concentration of the olefin oxide in the outlet is greater than about 2.2% by volume. More particularly, the invention relates to a process for the epoxidation of ethylene by contacting a feed including at least ethylene and oxygen with an improved epoxidation catalyst. The catalyst which has improved selectivity in the epoxidation process at high productivities, includes a solid support having a surface, which has a first mode of pores that have a diameter ranging from about 0.01 μm to about 5 μm and having a differential pore volume peak in the range from about 0.01 μm to about 5 μm. The surface also has a second mode of pores, which is different from the first mode of pores, having a diameter ranging from about 1 μm to about 20 μm and have a differential pore volume peak in the range from about 1 μm to about 20 μm. On the bimodal pore surface is a catalytically effective amount of silver or a silver-containing compound, a promoting amount of rhenium or a rhenium-containing compound, and a promoting amount of one or more alkali metals or alkali-metal-containing compounds.

Owner:SD LIZENZVERWGMBH

Catalyst and catalyst carrier

ActiveUS20140100379A1Organic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAlkene

The carrier of the present invention includes at least 85 wt percent alpha alumina, at least 0.06 wt percent SiO2 and no more than 0.04 wt percent Na2O. The carrier has a water absorption no greater than 0.35 g / g and a ratio of water absorption (g / g) to surface area (m2 / g) no greater than 0.50 g / m2. Another aspect of the invention is a catalyst for the epoxidation of olefins which comprises the above described carrier and silver dispersed thereon, where the carrier has a monomodal, bimodal or multimodal pore distribution and where the quantity of silver is between 5 and 50 wt %, relative to the weight of the catalyst. A reactor to system for the epoxidation of olefins is also disclosed.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Activation of high selectivity ethylene oxide catalyst

The invention describes a process for producing a catalyst useful for the epoxidation of an olefin. More particularly, the invention pertains to a catalyst useful for the oxidation of ethylene to ethylene oxide. The catalyst comprises a solid support such as alpha-alumina, which has a catalytically effective amount of silver or a silver-containing compound, and a promoting amount of rhenium or a rhenium-containing compound, and a promoting amount of one or more alkali metals or alkali metal-containing compounds on the surface of the support. To produce a catalyst precursor. The catalyst precursor is contacted with an atmosphere comprising oxygen and steam, which atmosphere is substantially absent of an olefin, to hasten the attainment of peak selectivity in the process of oxidation of ethylene to ethylene oxide.

Owner:SD LIZENZVERWGMBH

Olefin epoxidation catalyst, preparation method, and method for epoxidation of olefin

ActiveCN102441429AImprove conversion rateHigh selectivityOrganic chemistryMolecular sieve catalystsSolventHydrogen peroxide

The present invention provides an olefin epoxidation catalyst and a preparation method thereof. The catalyst comprises titanium-silicon molecular sieve, a binder and a metal oxide, wherein the binder is amorphous silica, and the metal oxide is an alkaline earth metal oxide. The preparation method comprises: preparing a mixture containing the titanium-silicon molecular sieve, the binder source, the alkaline earth metal oxide and the water; carrying out forming for mixture to obtain a formed body; drying and baking the formed body. The binder source is at least one selected from silica sol, silicane with at least two hydrolyzable groups, and siloxane with at least two hydrolyzable groups. The present invention further provides a method for epoxidation of the olefin. The method comprises that: the olefin contacts hydrogen peroxide in a solvent in the presence of the catalyst of the present invention. According to the present invention, the olefin epoxidation catalyst of the present invention provides high hydrogen peroxide conversion rate and high epoxide selectivity in the olefin epoxidation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +2

Preparation method of perfluorethyl isopropyl ketone

InactiveCN102992986AImprove conversion rateHigh selectivityOrganic compound preparationCarbonyl compound preparationIsomerizationHexafluoropropylene

The invention provides a preparation method of perfluorethyl isopropyl ketone. The preparation method specifically comprises the step of: with a hexafluoropropylene dipolymer mixture and perfluo-4-methyl-2-amylene or perfluo-2-methyl-2-amylene as raw materials, carrying out reaction processes such as olefin epoxidation, structural rearrangement of epoxide to prepare the perfluorethyl isopropyl ketone. An aprotic polar solvent, a catalyst and a phase transfer catalyst are used in a preparation process, high selectivity and high transformation rate of all steps of reactions are realized, and after a reaction mixture is simply separated so that an intermediate and a perfluorethyl isopropyl ketone product with high quality can be obtained. Meanwhile, a one-pot technology of double bond isomerization and epoxidation reaction is established. The preparation method provided by the invention has the characteristics that raw materials are easily available, the cost is low, reaction conditions are mild, operation is safe and simple, reaction selectivity and transformation rate are high, little environment influence is low; therefore, the preparation method is suitable for industrial application.

Owner:CHINESE PEOPLES ARMED POLICE FORCE ACAD

Catalyst, a process for preparing the catalyst and a process for the production of an olefin oxide, a 1,2-diol, a 1,2 diol ether, or an alkanolamine

ActiveUS20090131695A1High selectivityImprove stabilityOrganic compound preparationHydroxy compound preparationParticulatesAlkaline earth metal

A catalyst which comprises a carrier and silver deposited on the carrier, which carrier has a surface area of at least 1.3 m2 / g, a median pore diameter of more than 0.8 μm, and a pore size distribution wherein at least 80% of the total pore volume is contained in pores with diameters in the range of from 0.1 to 10 μm and at least 80% of the pore volume contained in the pores with diameters in the range of from 0.1 to 10 μm is contained in pores with diameters in the range of from 0.3 to 10 μm; process for the preparation of a catalyst which process comprises depositing silver on a carrier, wherein the carrier has been obtained by a method which comprises forming a mixture comprising: a) from 50 to 95 weight percent of a first particulate a-alumina having a median particle size (d50) of from 5 to 100 μm; b) from 5 to 50 weight percent of a second particulate a-alumina having a d50 which is less than the d50 of the first particulate a-alumina and which is in the range of from 1 to 10 μm; and c) an alkaline earth metal silicate bond material; weight percent being based on the total weight of a-alumina in the mixture; and firing the mixture to form the carrier; a process for the epoxidation of an olefin, which process comprises reacting a feed comprising an olefin and oxygen in the presence of a said catalyst; and a process for preparing a 1,2-diol, a 1,2-diol ether or an alkanolamine.

Owner:SHELL USA INC

Catalyst for olefine epoxidation

InactiveCN1418876AReduced activitySolve the separation problemOrganic chemistryMolecular sieve catalystsMolecular sieveAlkali metal oxide

The present invention relates to a catalyst for olefinic epoxidation. Said invention is characterized by that the titanium-silicon molecular sieve synthesized by hydrothermal method can be supported on the aluminium oxide carrier, and the catalyst can be made into the size suitable for industrial application. In the catalyst the alkali metal or / and alkali metal oxide component can be added, so that said catalyst can have higher activity and selectivity, can be used in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for making titanium-MWW zeolite

ActiveUS8124555B2Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsTitaniumBoron

Titanium-MWW zeolite is prepared by heating a gel formed from a titanium compound, a silicon source, a boron source, an MWW-templating agent, and water at a temperature in the range of 35° C. to 75° C. for a period of 8 to 30 hours to form a pre-crystallized gel, and heating the pre-crystallized gel to a temperature in the range of 160° C. to 190° C. for a period of 5 or more days to form the titanium-MWW zeolite. The zeolite, after it is contacted with an acid, is useful in olefin epoxidation with hydrogen peroxide.

Owner:LYONDELL CHEM TECH LP

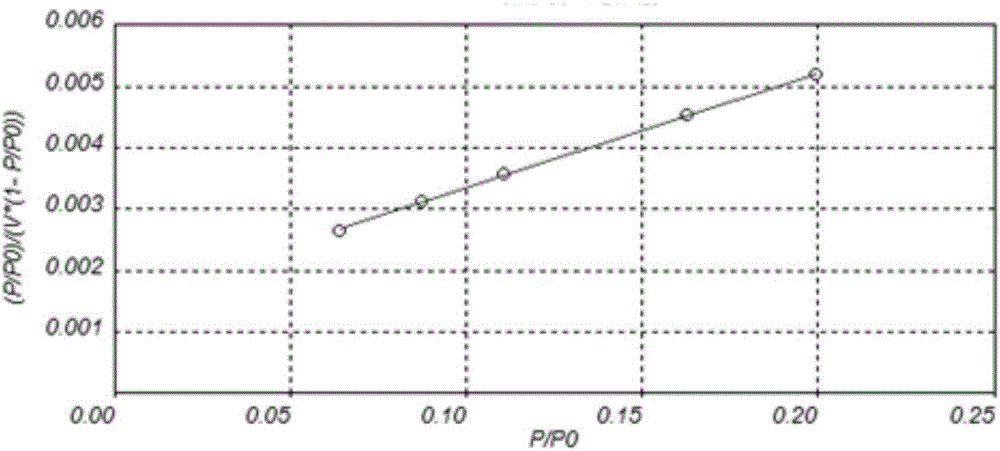

Catalyst for epoxidation of olefin and preparation method thereof

ActiveCN106582809ARaw materials are easy to getLow costMolecular sieve catalystsFiltrationThermal insulation

The present invention relates to a catalyst for epoxidation of an olefin. The catalyst is a modified titanium silica molecular sieve, the pore size is 10-30 nm, the content of TiO is 0.5-10 wt%, the pore volume is 1.0-1.5 mL / g, the aperture distribution rate is >=93.5%, and the specific surface area is 150-500 m<2> / g. A preparation method comprises the following steps: a template agent, a template modifier, water and a solvent are added into a reactor, heating under stirring is conducted, then a silicon source is added, and thermal insulation, suction filtration and drying are conducted to obtain a molecular sieve raw powder; the molecular sieve raw powder, an extrusion aid, an adhesive agent and a glue mixing agent are mixed evenly, an obtained mixture is subjected to extrusion molding, and then drying and roasting are conducted to obtain a molded molecular sieve; a titanium source is added into the molded molecular sieve to prepare the titanium silica molecular sieve, and finally a surface modifier is added for modificationto obtain the catalyst. The catalyst provided by the present invention is suitable for catalyzing the oxidation of propylene with cumyl hydroperoxide. The conversion rate of cumyl hydroperoxide is high, the selectivity of propylene oxide is high and the content of a byproduct, namely phenol is relatively little.

Owner:HONGBAOLI GRP CO LTD +1

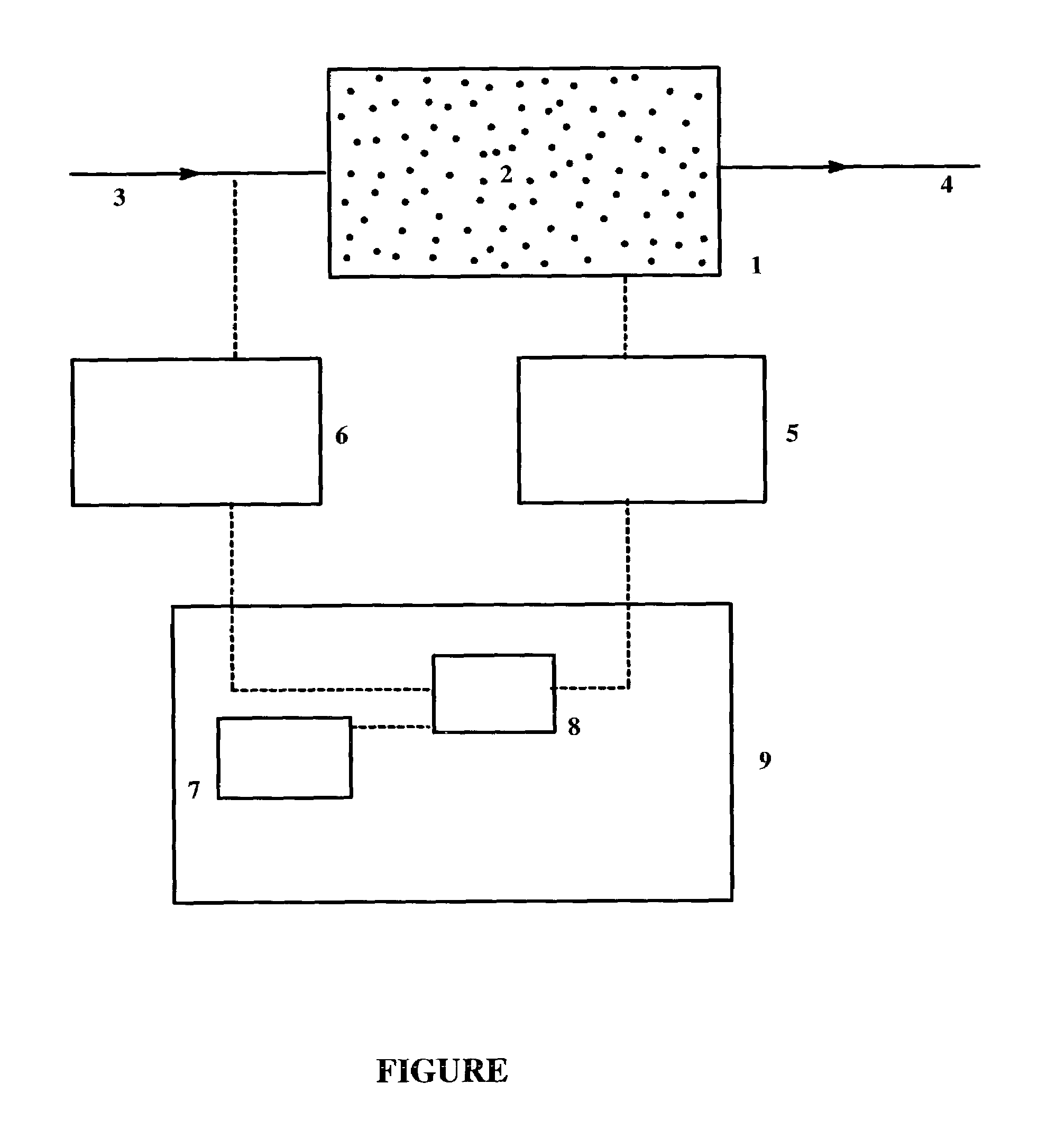

Catalyst and process using the catalyst

InactiveUS20070184973A1High activityHigh selectivityOrganic compound preparationOrganic chemistry methodsParticulatesOxygen

A catalyst which comprises a carrier and silver deposited on the carrier, which carrier has a surface area of at least 1 m2 / g, and a pore size distribution such that pores with diameters in the range of from 0.2 to 10 μm represent at least 70% of the total pore volume and such pores together provide a pore volume of at least 0.27 ml / g, relative to the weight of the carrier; a process for the preparation of a catalyst which process comprises depositing silver on a carrier, wherein the carrier has been obtained by a method which comprises forming a mixture comprising: a) from 50 to 90% w of a first particulate α-alumina having an average particle size (d50) of from more than 10 up to 100 μm; and b) from 10 to 50% w of a second particulate α-alumina having an average particle size (d50) of from 1 to 10 μm; % w being based on the total weight of α-alumina in the mixture; and shaping the mixture into formed bodies and firing the formed bodies to form the carrier, and a process for the epoxidation of an olefin, which process comprises reacting an olefin with oxygen in the presence of a said catalyst.

Owner:SHELL OIL CO

Process for making titanium-MWW zeolite

ActiveUS20110190517A1Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsTitaniumBoron

Titanium-MWW zeolite is prepared by heating a gel formed from a titanium compound, a silicon source, a boron source, an MWW-templating agent, and water at a temperature in the range of 35° C. to 75° C. for a period of 8 to 30 hours to form a pre-crystallized gel, and heating the pre-crystallized gel to a temperature in the range of 160° C. to 190° C. for a period of 5 or more days to form the titanium-MWW zeolite. The zeolite, after it is contacted with an acid, is useful in olefin epoxidation with hydrogen peroxide.

Owner:LYONDELL CHEM TECH LP

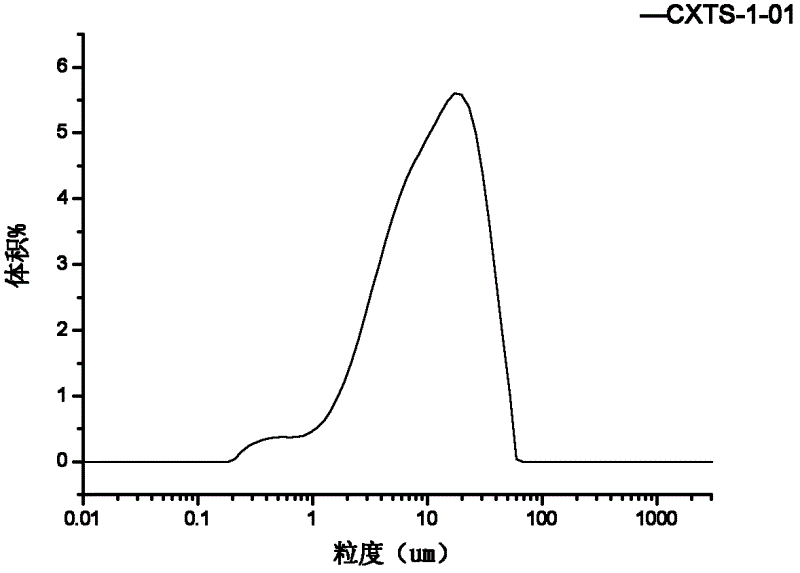

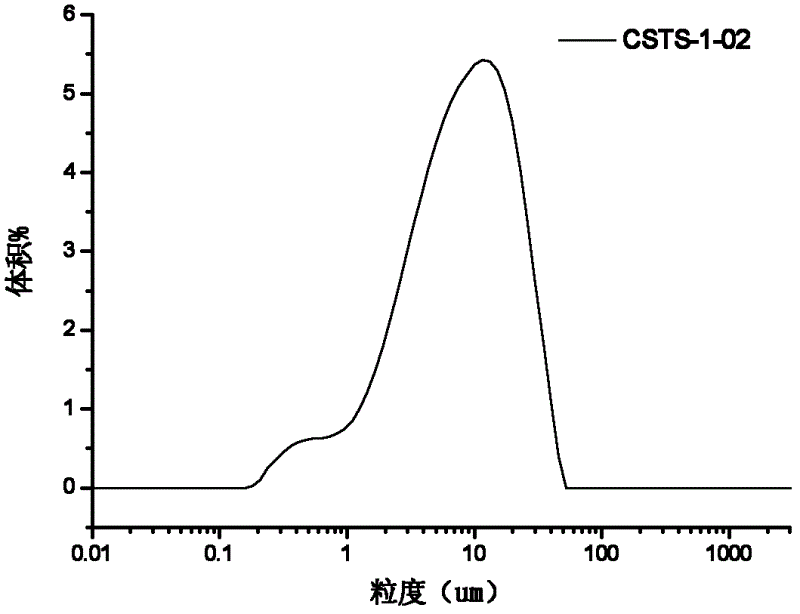

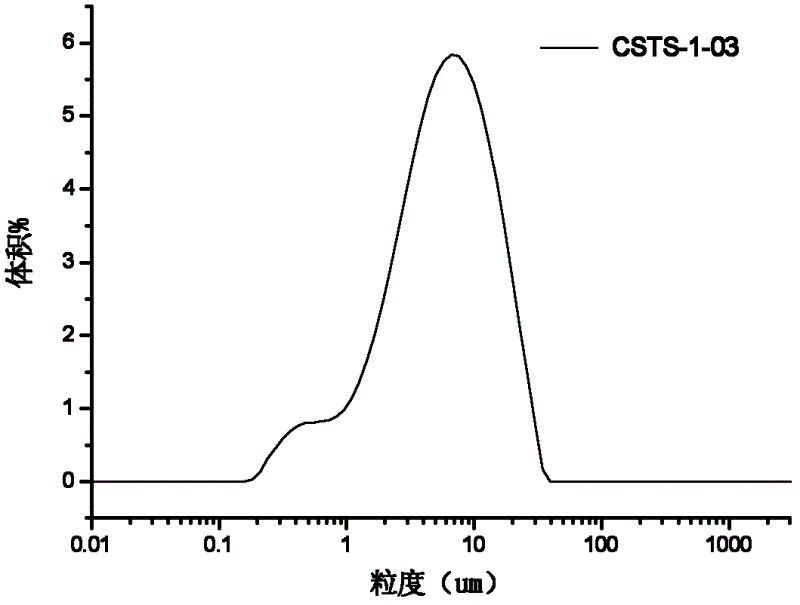

Preparation method of titanium-silicon molecular sieve with controllable grain size

ActiveCN103641134AEffective grain size controlHigh crystallinityMaterial nanotechnologyCrystalline aluminosilicate zeolitesKetoneHigh activity

The invention relates to a preparation method of a titanium-silicon molecular sieve with controllable grain size. The method is as follows: the titanium-silicon molecular sieve with the controllable grain size is synthesized in a hydrothermal system by modulating a nano-scale molecular sieve mother solution as a seed crystal, and the range of the grain size is 50-500nm. The titanium-silicon molecular sieve synthesized by the method provided by the invention has the advantages of small grain size, high degree of crystallization, high content of framework titanium, strong hydrophobicity and very high activity against selective oxidation reaction of olefin epoxidation, hydroxylation of aromatic hydrocarbons, ammonia oxidation of ketones and the like. The method is suitable for a classic or cheap system, and the nano-scale titanium-silicon molecular sieve can be synthesized in the cheap system.

Owner:DALIAN UNIV OF TECH

Titanium-silicon molecular sieve compound catalyst and preparation method thereof

ActiveCN102451763AGood catalyticAchieve direct catalytic conversionOrganic-compounds/hydrides/coordination-complexes catalystsBulk chemical productionHydration reactionFixed bed

The invention discloses a titanium-silicon molecular sieve compound catalyst and a preparation method thereof. The method comprises the following steps of: fully mixing a titanium-silicon molecular sieve, an acid molecular sieve, a polymeric monomer polyene-based compound and a pore forming agent; undergoing a polymerization reaction in the presence of an initiator; smashing an obtained lump solid catalyst; adding into a halogenated hydrocarbon for swelling; and extracting and activating with a solvent to obtain a molded titanium-silicon molecular sieve compound catalyst. Due to the adoption of the catalyst obtained in the invention, a corresponding process for preparing a corresponding diol compound by performing alkene epoxidation and undergoing a one-step hydration reaction can be realized, the problem of difficulty in separating titanium-silicon catalyst powder from a reaction solution can be solved simultaneously, and the reaction efficiency is increased. The catalyst is particularly suitable for catalytic reaction processes for preparation of ethylene glycol from ethylene, preparation of 1,2-propylene glycol from ethylene, alkene epoxidation, preparation of alcohol ether by etherification, and the like with a fixed bed process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst with bimodal pore size distribution and the use thereof

Owner:SD LIZENZVERWGMBH

Direct epoxidation process using modifiers

The invention is a process for epoxidizing an olefin with hydrogen and oxygen in the presence of a noble metal-containing titanium or vanadium zeolite and a modifier selected from the group consisting of carbon monoxide, methylacetylene, and propadiene. The process results in significantly reduced alkane by-product formed by the hydrogenation of olefin compared to processes that do not use the carbon monoxide, methylacetylene, and / or propadiene modifier.

Owner:LYONDELL CHEM TECH LP

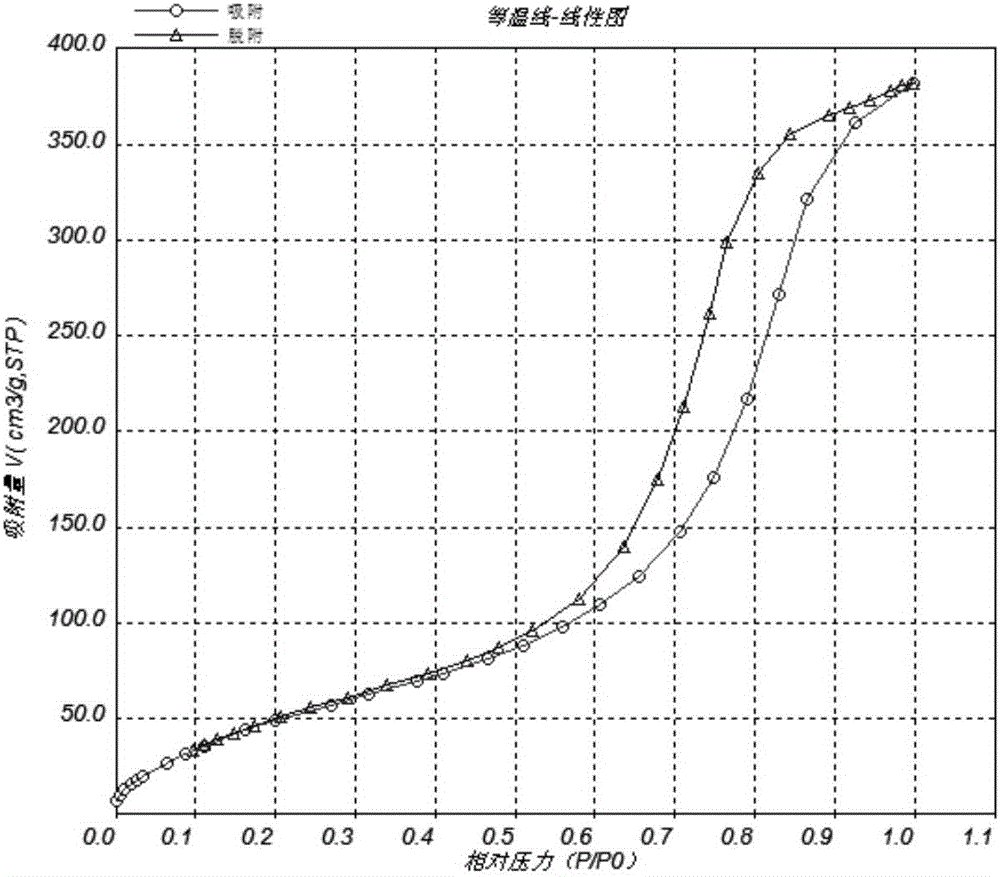

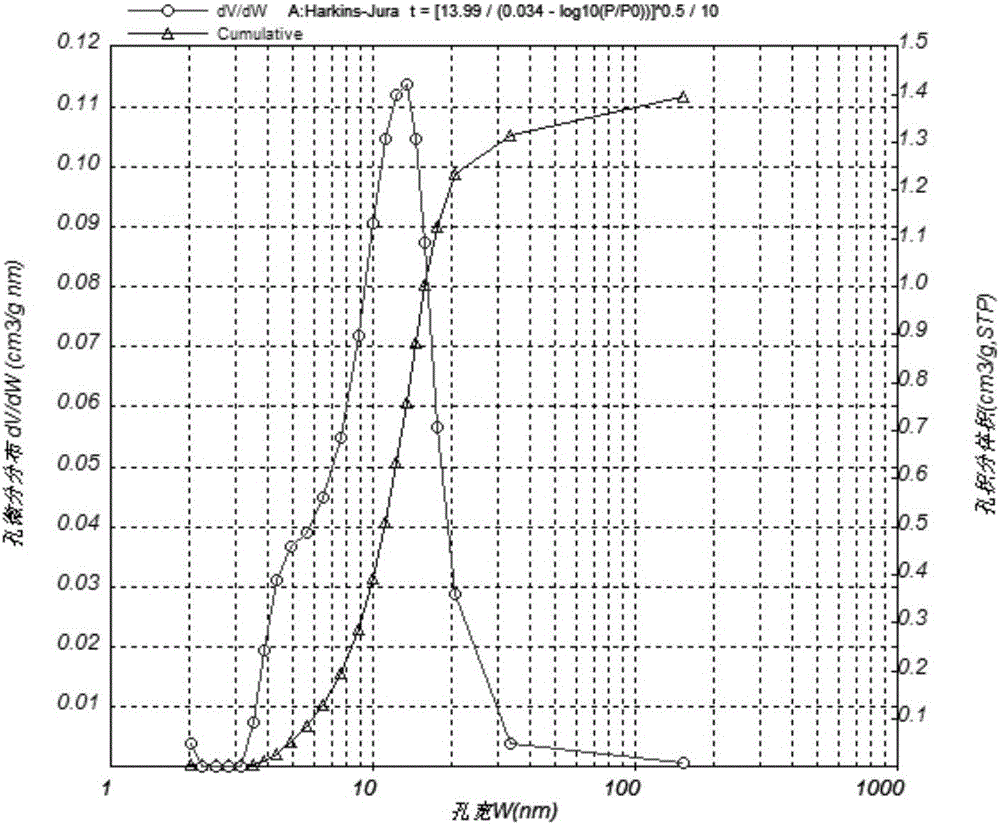

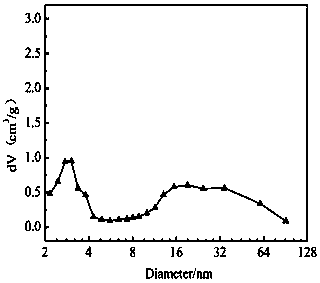

Hierarchical porous titanium-silicon molecular sieve as well as preparation method thereof and olefin epoxidation method

ActiveCN108726528AIncreased mesopore volumeImprove conversion rateOrganic chemistryMolecular sieve catalystsMolecular sievePore diameter

The invention relates to a hierarchical porous titanium-silicon molecular sieve as well as a preparation method thereof and an olefin epoxidation method. The hierarchical porous titanium-silicon molecular sieve has a grain size of 600-700 nm, has relative crystallinity of 55-64%, has a specific surface area of 660-725 m<2> / g, has a total pore volume of 0.55-0.7 cm<3> / g, and has a mesoporous volumeof 0.3-0.5 cm<3> / g; the volumes of pores with the pore diameters of 0.5-2 nm of the hierarchical porous titanium-silicon molecular sieve account for 15-36% of the total pore volume, the volumes of pores with the pore diameters of 2-4 nm account for 1-25% of the total pore volume, and the volumes of the pores with the pore diameters of 4-16 nm account for 20-45% of the total pore volume, and the volumes of the pores with the pore diameters greater than 16 nm account for 20% or lower of the total pore volume. The hierarchical porous titanium-silicon molecular sieve disclosed by the invention isgreater in mesoporous volume, is higher in proportion of the total pore volume, and can remarkably increase an olefin conversion rate and can improve selectivity of alkyleneoxide while used for olefin oxidization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com