Method for quickly synthesizing small-crystallite titanium-silicon molecular sieve in cheap system

A titanium-silicon molecular sieve and small-grain technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of severe reaction impact and low selectivity of the main product, simplify the separation process, shorten the synthesis cycle, and accelerate the crystallization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

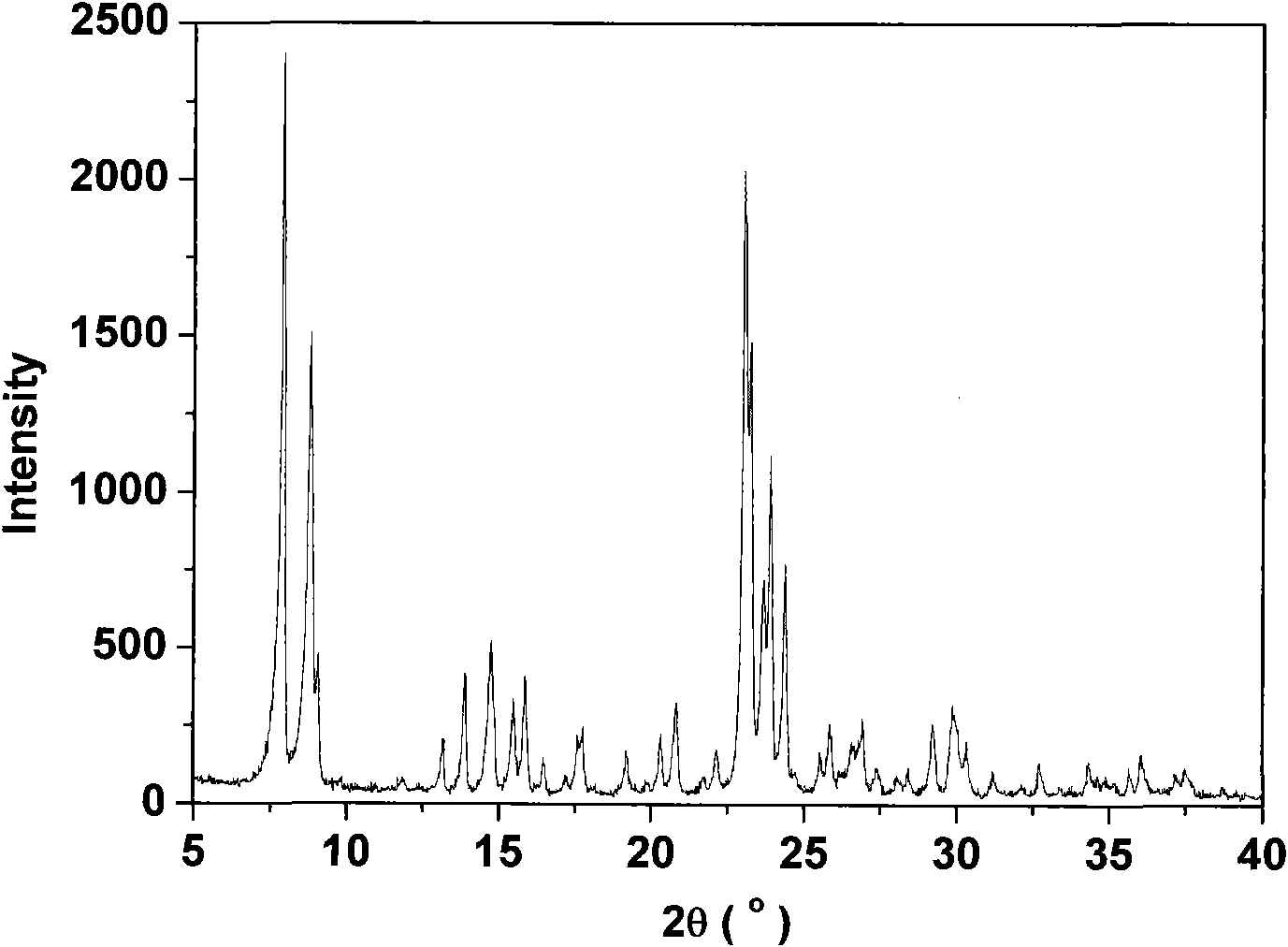

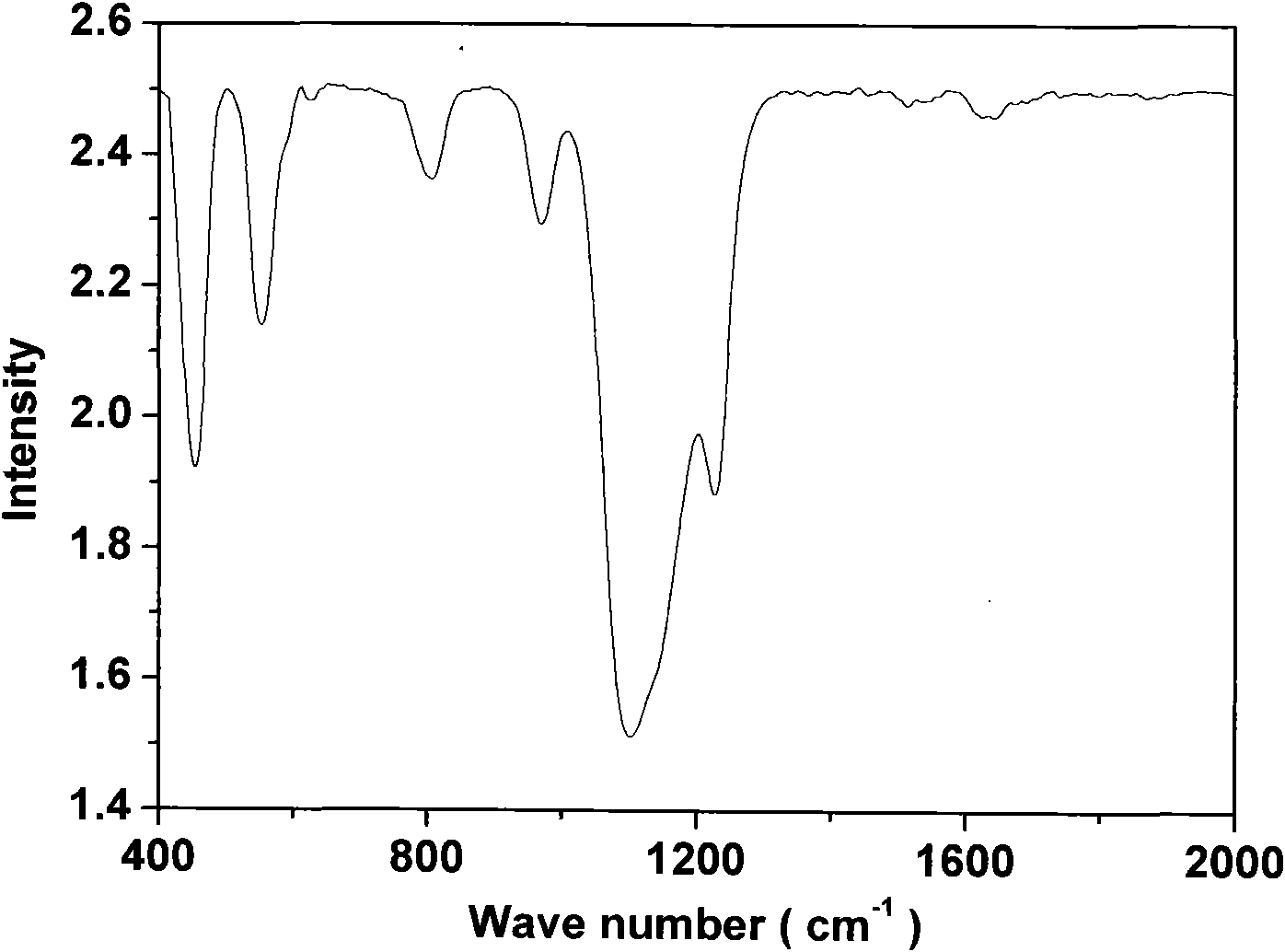

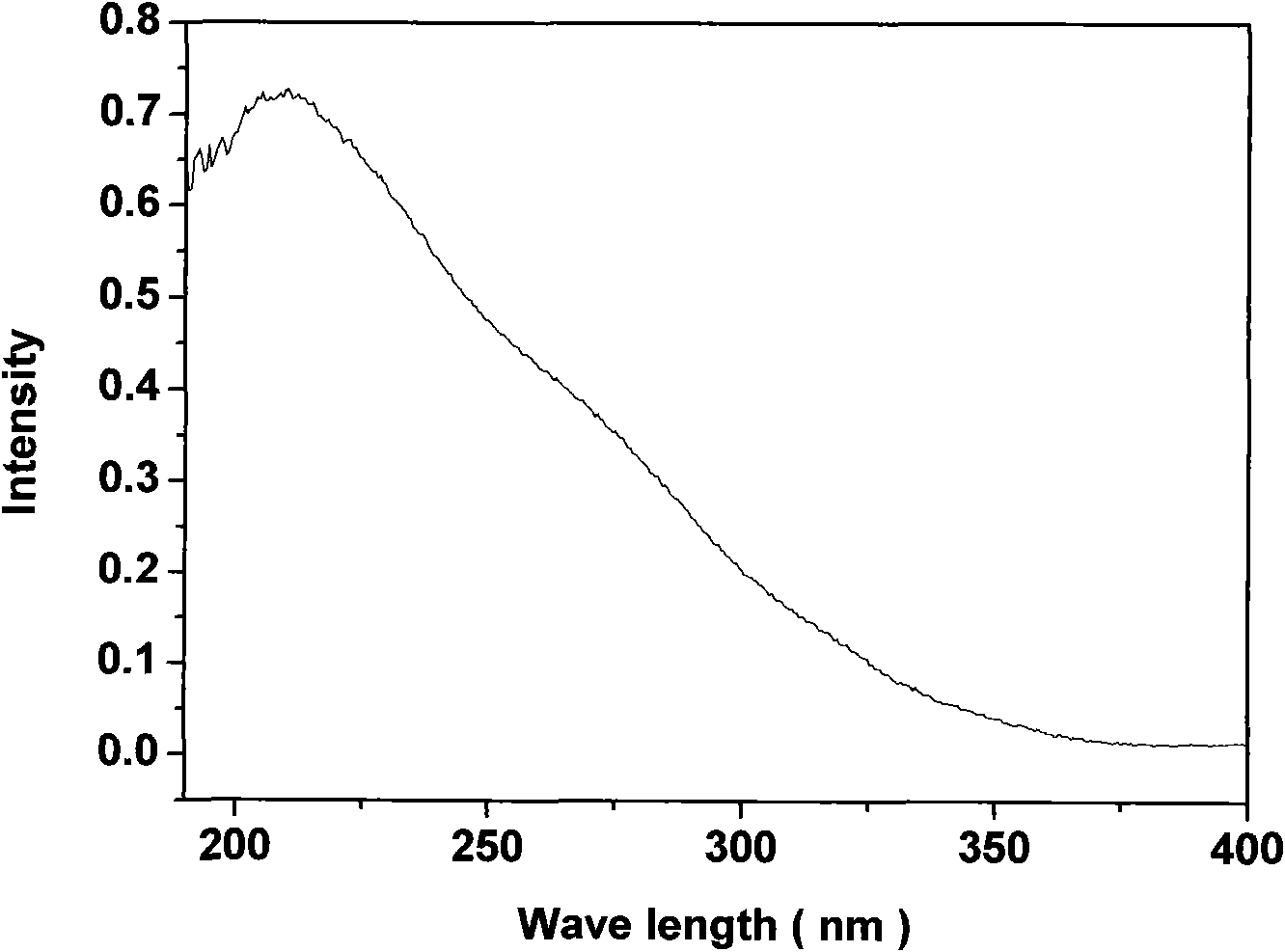

[0036]1.4 mL of titanium tetrachloride was dropped into 12 mL of isopropanol, and stirred until the HCl was completely volatilized to obtain a solution of titanium tetrachloride in isopropanol. Add 81mL of deionized water to 100mL of 30wt% silica sol, stir for 10min, then mix with the alcohol solution of titanium tetrachloride, stir for 30min, then add 24g of tetrapropylammonium bromide, 50mL of 65wt% ethylamine aqueous solution, 12mL Nano-scale titanium-silicon molecular sieve mother liquor, and 78mL deionized water, after stirring for 30 minutes, the glue solution was added to a stainless steel crystallization kettle with a polytetrafluoroethylene liner, crystallized at 170°C for 24h, and the crystallized product was washed and dried. Calcined at 540°C for 6h to obtain TS-1, which is numbered as E. Its X-ray diffraction (XRD) spectrum is as figure 1 As shown, its Fourier transform infrared (FT-IR) spectrum is shown as figure 2 The scanning electron microscope (SEM) pictur...

Embodiment 2

[0038] The composition of all raw materials and the batching operation process are the same as in Example 1, except that the obtained titanium silica gel solution is crystallized at 170°C for 60 hours, and then undergoes the same post-treatment process to obtain TS-1, which is numbered as F, XRD spectrum and figure 1 Similar, but with higher relative crystallinity; IR spectrum and figure 2 Similarly, the titanium content of the framework basically did not change; SEM photos and image 3 Similarly, the grain size did not change significantly.

Embodiment 3

[0040] Since the mother liquor of nano-scale titanium-silicon molecular sieve contains excessive template agent TPAOH, which may have a certain impact on the crystallization process, the seed crystal is changed to nano-scale titanium-silicon molecular sieve powder, and then a certain amount is added to the synthesis of small-grain TS-1 TPAOH, to investigate the cause of the smaller grains of the small grain TS-1. Add 81mL deionized water to 100mL 30wt% silica sol, stir for 10min, then mix with 14mL alcohol solution of titanium tetrachloride, stir for 30min, then add 24g tetrapropylammonium bromide, 50mL65wt% ethylamine aqueous solution, 1g Nanoscale titanium-silicon molecular sieve powder, 25mL 0.12mol / L TPAOH, and 55mL deionized water, after stirring for 30 minutes, add the glue solution into a stainless steel crystallization kettle with PTFE lining, crystallize at 170°C for 36h, and crystallize After the product was washed and dried, it was calcined at 540°C for 6 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com